Image-processing-based robot polishing production method and production system applying same

A technology of image processing and production methods, which is applied in the direction of manipulators, program control manipulators, manufacturing tools, etc., and can solve problems such as difficulty in guaranteeing grinding strength, affecting production efficiency, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

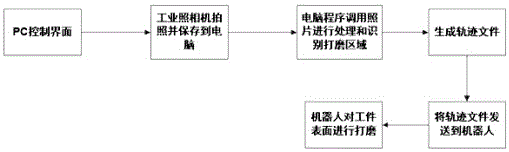

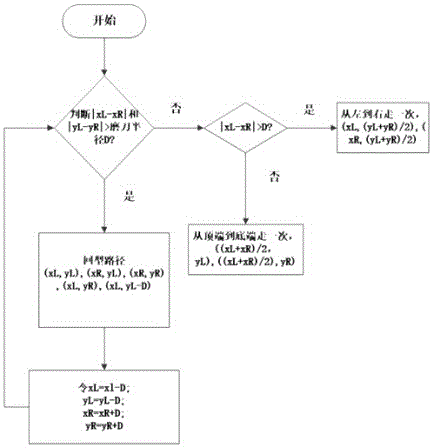

[0034] The robot grinding production method based on image processing is applied to the CNC grinding robot, such as Figure 1-3 Shown, described production method comprises the steps:

[0035] (1) Workpiece image acquisition: The computer triggers and controls the industrial camera to take pictures of the surface of the polished workpiece through software, and saves it to the computer disk for later program calling; the specific steps are as follows:

[0036] a. Image processing: binarize, corrode and dilate the image;

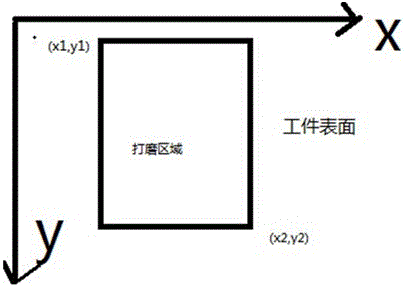

[0037] b. Image recognition: recognize the coordinates of the pixels of the boundary of the polished area.

[0038] (2) Workpiece image processing and recognition: Call the machine vision program to process the image and identify the grinding area in the image; specifically, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com