Patents

Literature

256 results about "Cnc grinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Asymmetric shaver and methods for making same

InactiveUS20050065538A1Improve resection efficiencyImprove efficiencyCannulasSawing tools dressing arrangementsCnc grindingEngineering

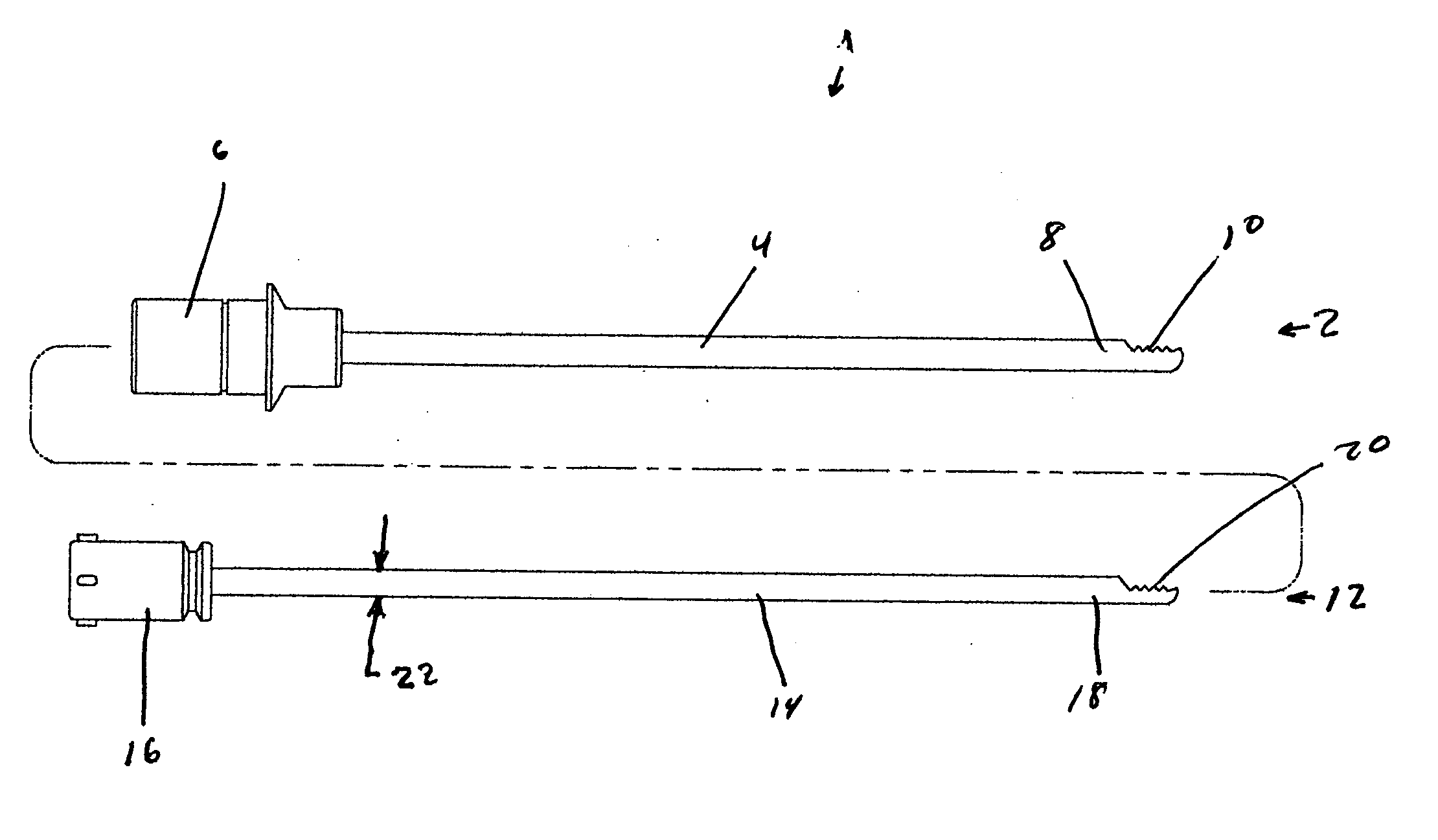

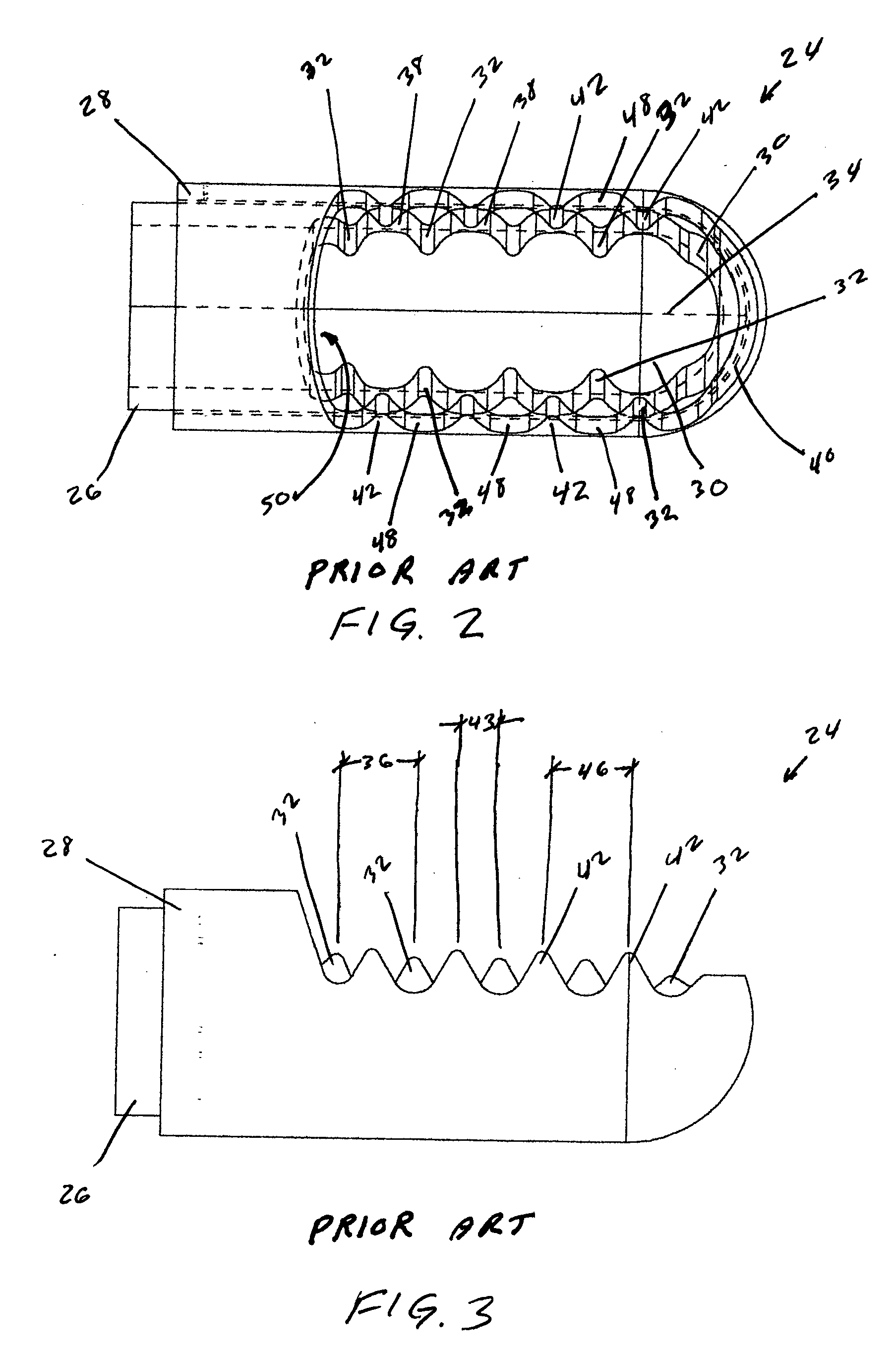

A surgical shaver blade is provided with a stationary elongated outer tube, having a cutting window at its distal tip and a rotatable elongated inner tube having a cutting window at its distal tip. Each cutting window is not symmetrical about any line in a sectional view through the window normal to the tube axis. In a preferred embodiment the cutting edges of each window have a plurality of teeth, the teeth of one lateral cutting edge being offset axially from the teeth of the other lateral edge so that the teeth of one edge align axially with the valleys between teeth on the opposite edge. When the shaver is used in oscillate mode, the teeth of one direction of rotation align with tissue that was between teeth during the previous opposite direction rotation thereby enhancing the ability of the teeth to penetrate the tissue and prevent its ejection from the cutting window as the cutting edges approach. In another embodiment the outer window is asymmetric without teeth and the inner window is asymmetric with teeth. In yet another embodiment only the inner cutting edges are asymmetric. The cutting edges are formed in a single grinding operation or multiple grinding operations using a multi-axis CNC grinding machine, or electrochemically.

Owner:ASYMMETRICS

Processing method of aspherical optical element of optical glass and silicon monocrystal

InactiveCN1846937AImprove surface qualityIncrease productivityOptical surface grinding machinesSingle crystalEngineering

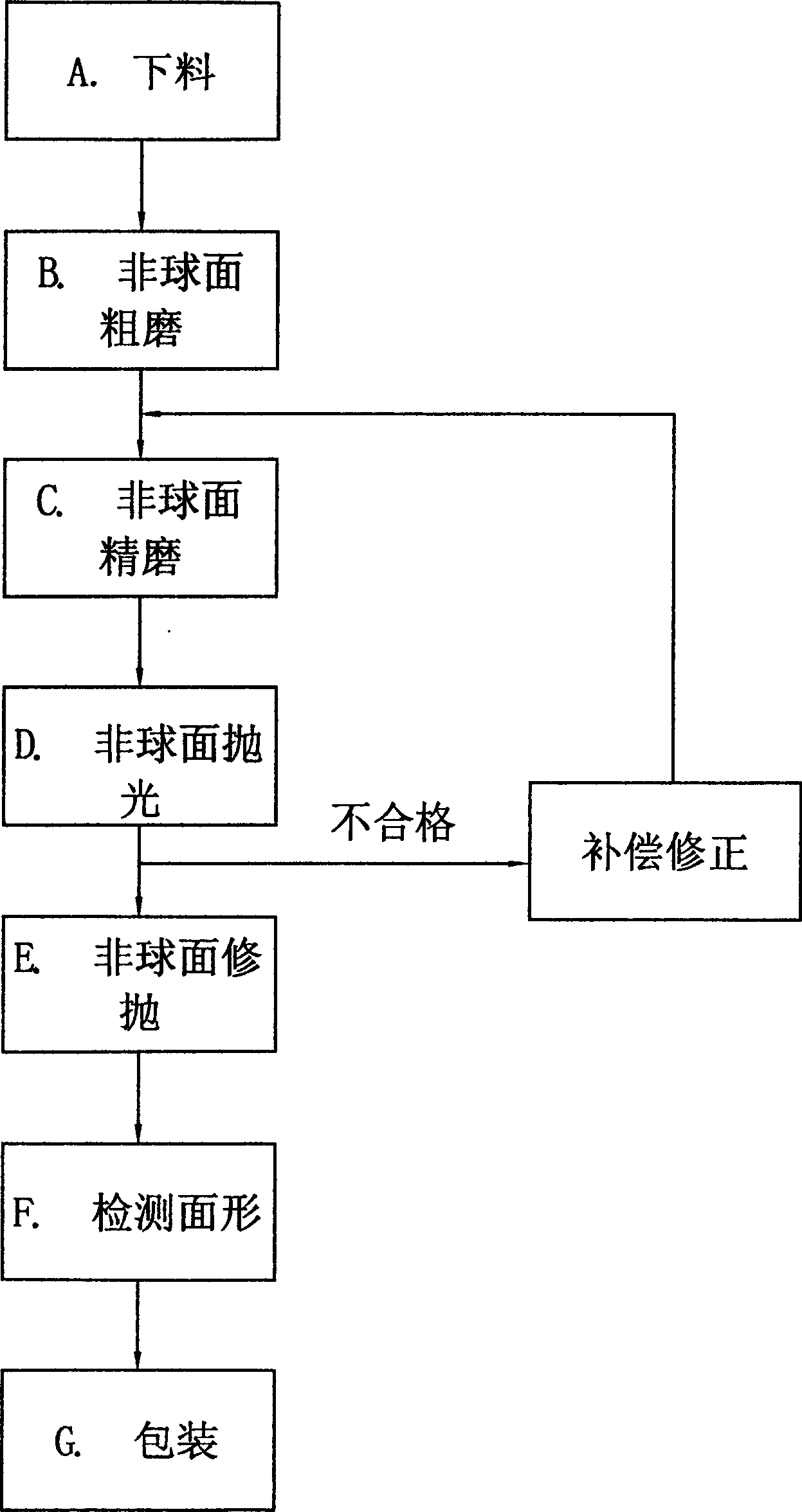

The present invention discloses optical element processing technology, and is especially processing method of aspherical optical element of optical glass and silicon monocrystal. The present invention features that optical glass and silicon monocrystal is processed in computerized numerically controlled grinder and computerized numerically controlled polishing machine through a new technological process including the steps of fine grinding of aspherical, polishing of aspherical, trim polishing of aspherical, profile detection, etc. The present invention is superior to traditional method, and has low production cost, stable quality and high efficiency.

Owner:云南北方光学电子集团有限公司

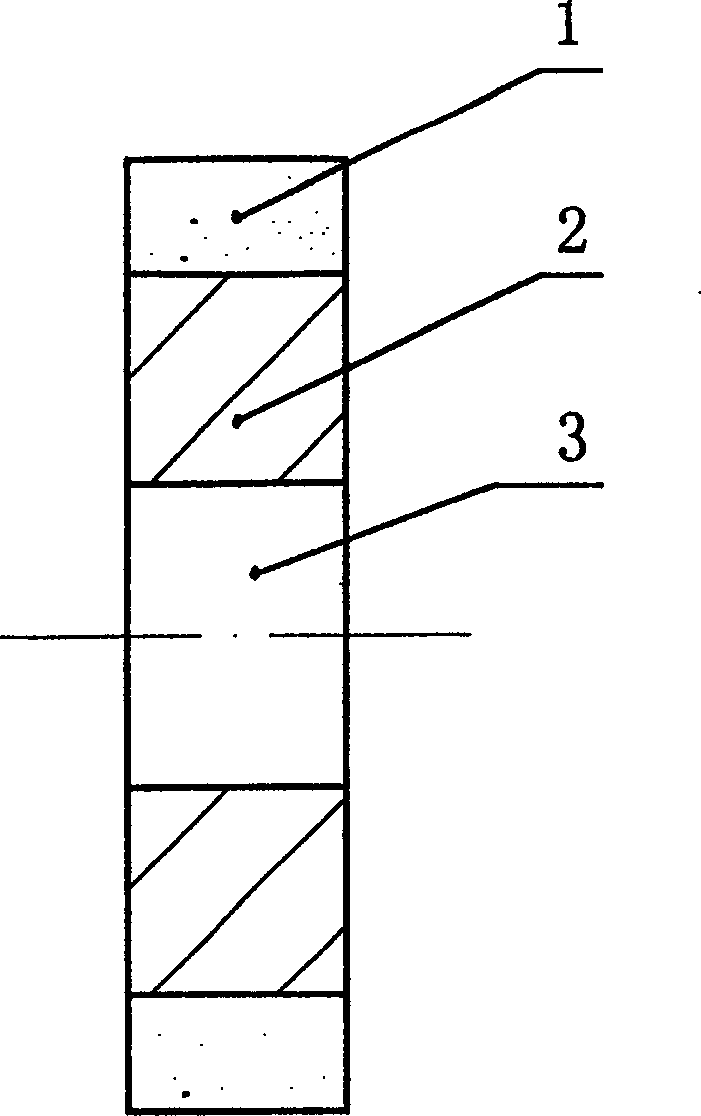

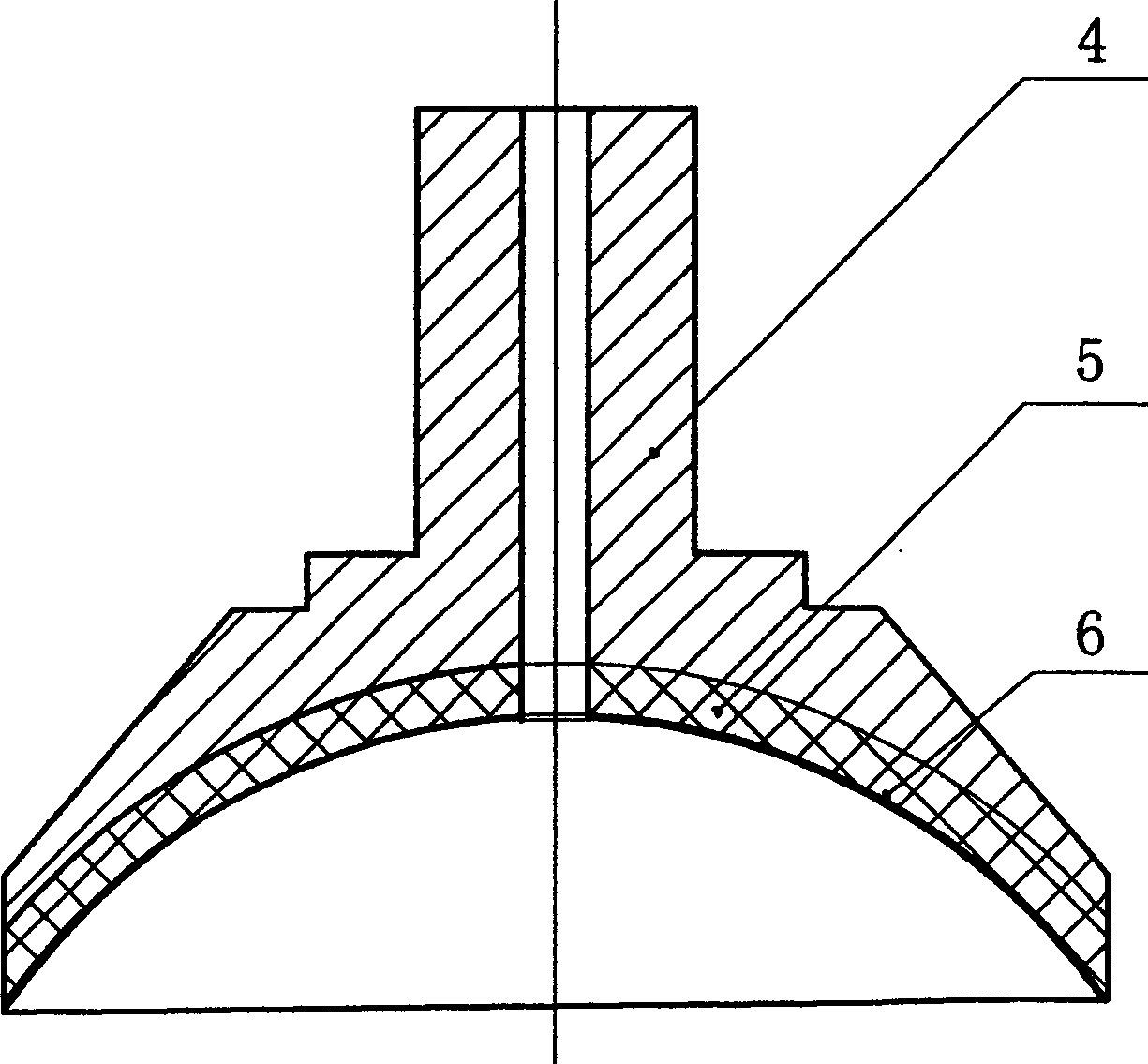

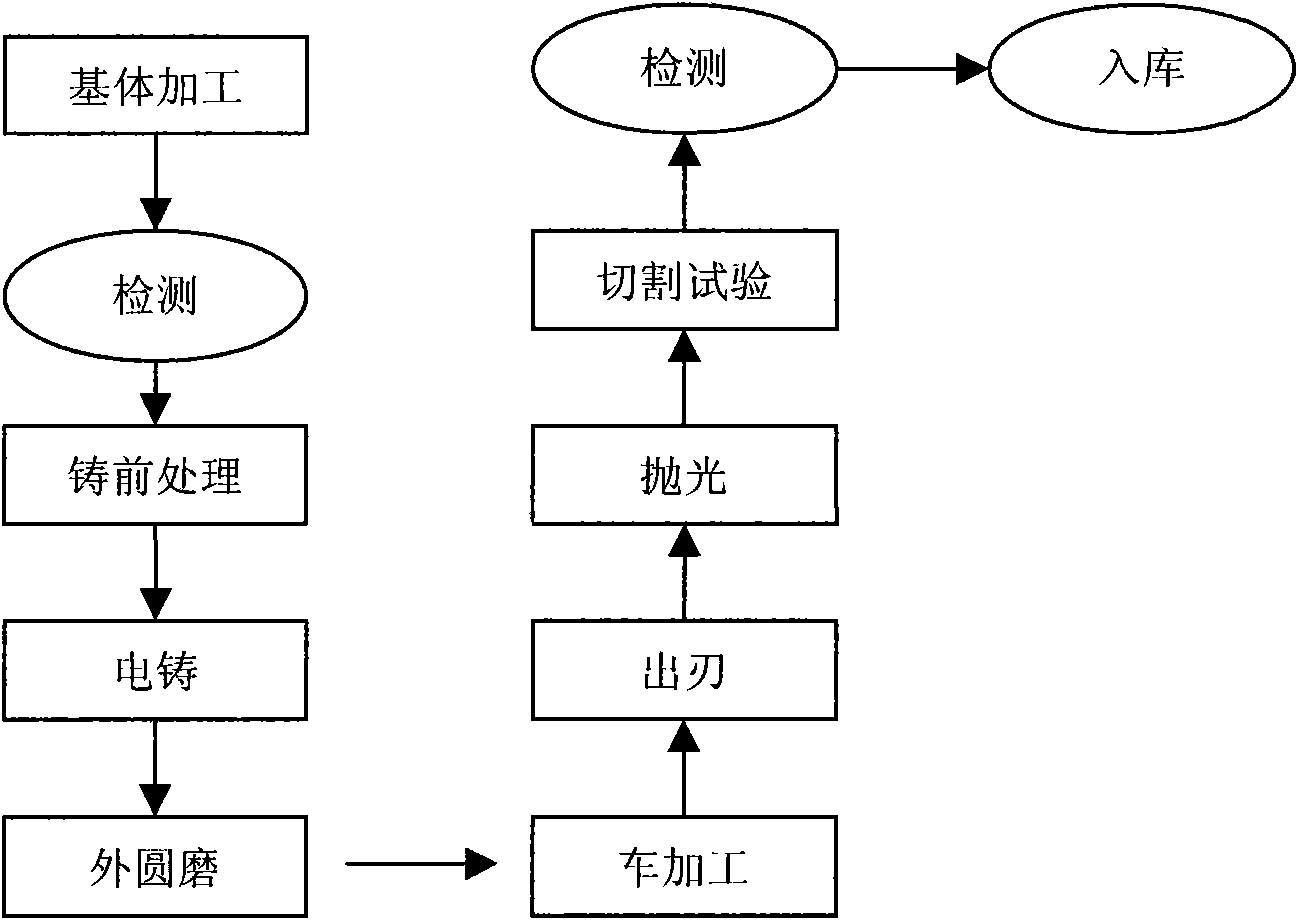

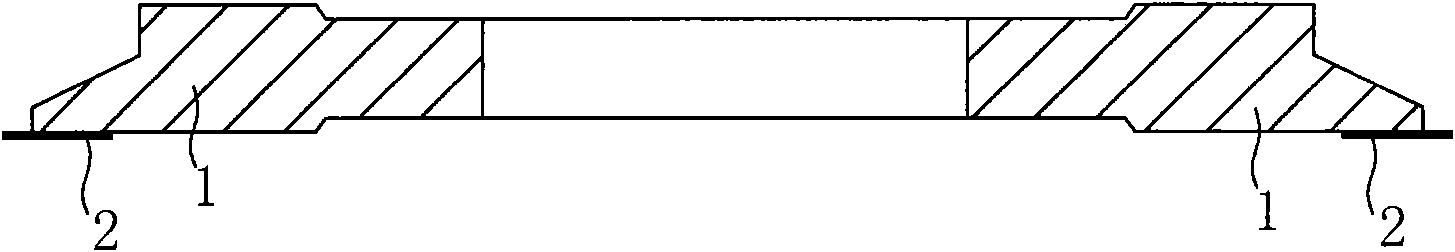

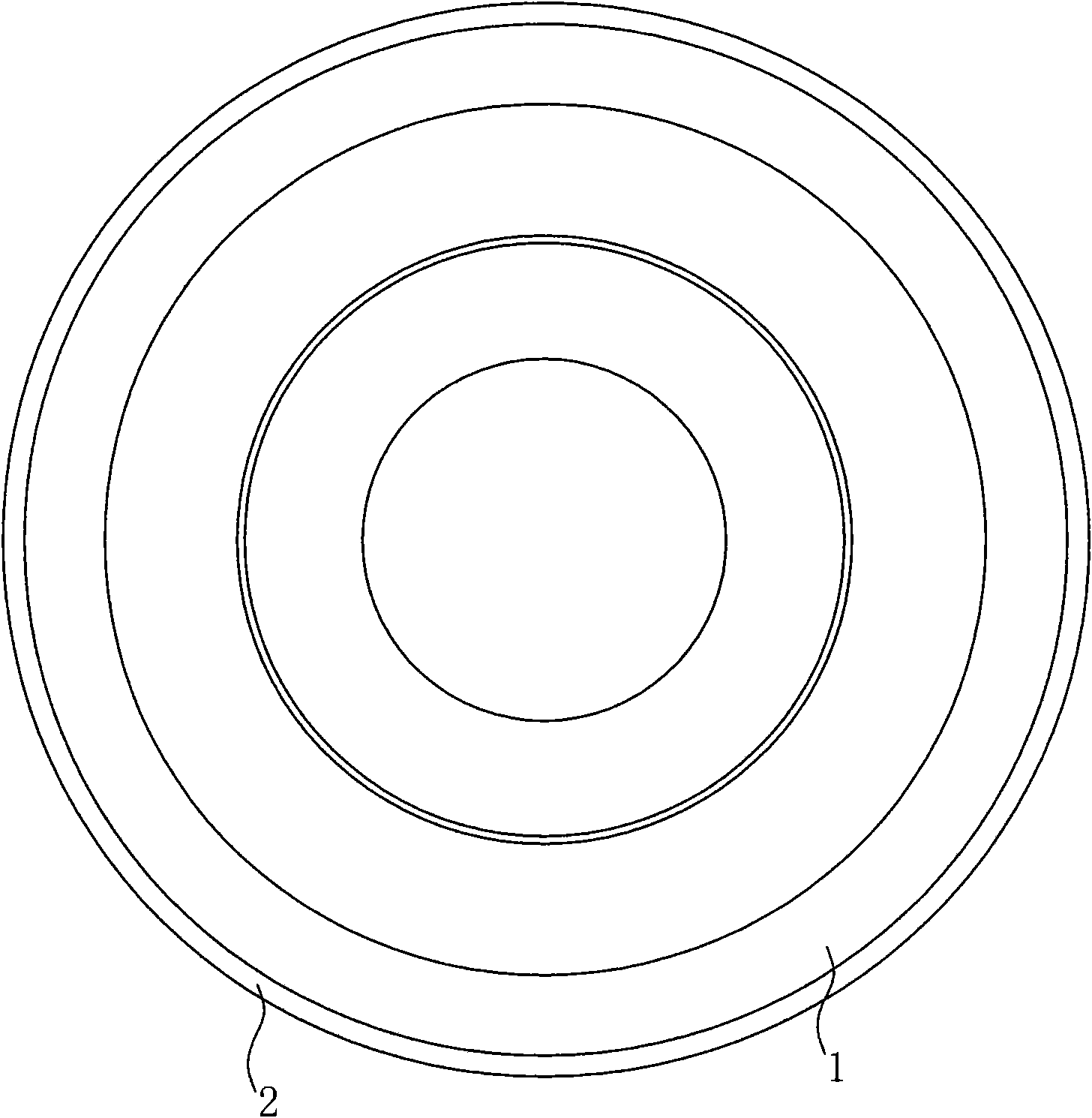

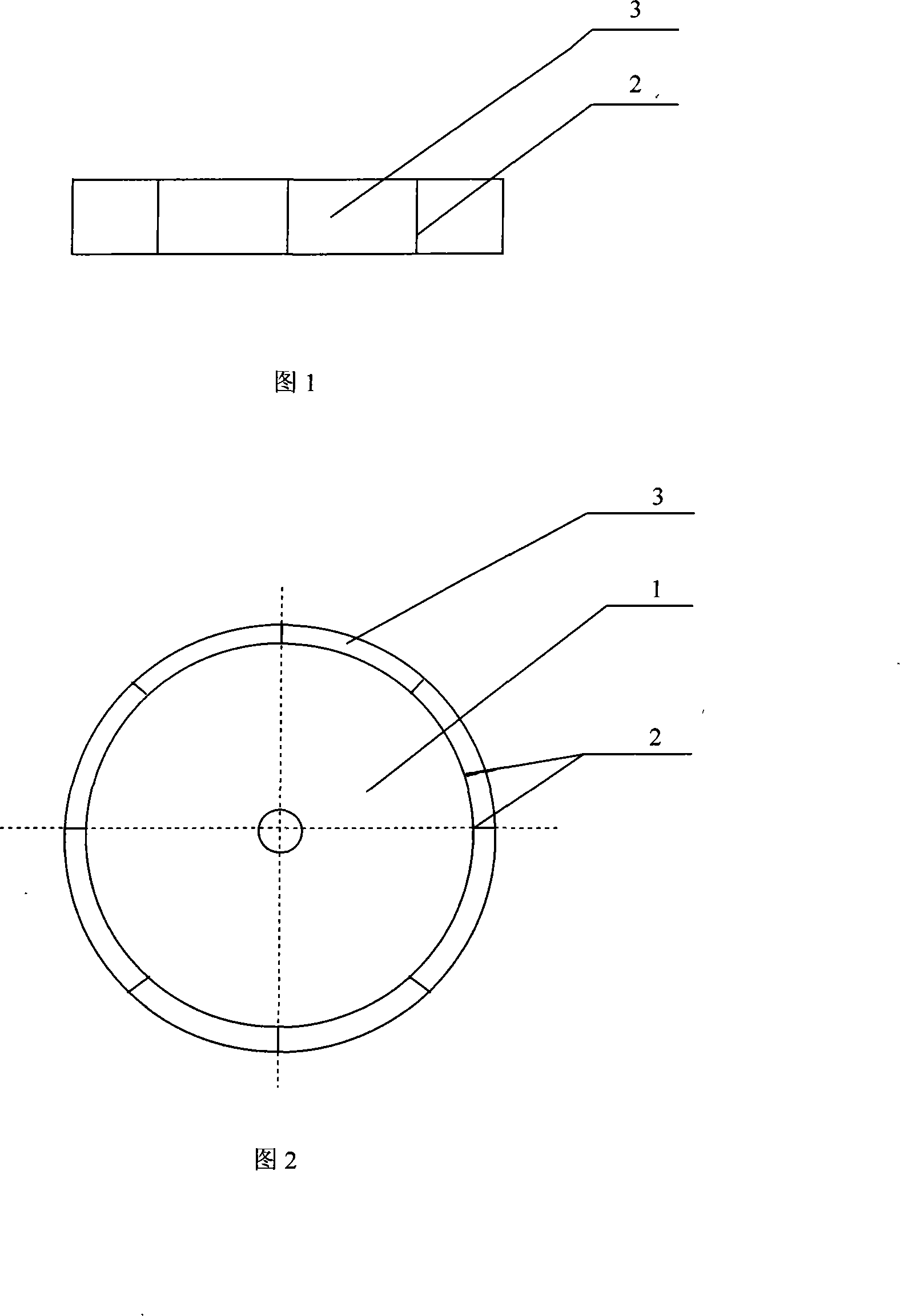

Diamond grinding wheel for cutting silicon crystal circle and preparation method thereof

ActiveCN101633158AHigh strengthImprove rigidityGrinding devicesGrinding machinesNumerical controlCobalt sulphate

The invention discloses a diamond grinding wheel for cutting a silicon crystal circle and a preparation method thereof. The method comprises the following steps: (1) preprocessing an aluminum alloy basal body; (2) configuring electroforming liquid: configuring the electroforming liquid according to the weight ratio of (38-43):(15-20):(43-57):(50-180):(4-8) of nickel sulphate, cobalt sulphate, deionized water, a diamond grinding material and a suspending agent; fully stirring evenly and obtaining the electroforming liquid; (3) carrying out insulation processing on the aluminum alloy basal body obtained in the step (1), putting the aluminum alloy basal body into the electroforming liquid, electroforming in an ultrasonic field, evenly precipitating the diamond grinding material in the electroforming liquid and metal on the basal body together and obtaining a grinding wheel blank body with a compound electroforming layer; and (4) taking out the grinding wheel blank body completing electroforming, and carrying out accurate processing on the grinding wheel blank body on a numerical control grinder and a numerical control lathe respectively according to the accuracy requirements of the required basal body and the required cutting edge. The diamond grinding wheel obtained by the invention meets the ultrathin and superfine technical conditions and also has favorable strength and rigidity.

Owner:赛尔科技(如东)有限公司

Ceramic bonding agent cubic boron nitride grinding wheel applied for camshaft grinding processing

InactiveCN101168244ACreate pollutionAccurate dimensional accuracyBonded abrasive wheelsCnc grindingHardness

The invention discloses a vitrified bonded cubic boron nitride grinding wheel for camshaft grinding, which consists of a substrate, a bonding layer and a grinding wheel block, the grinding wheel block is a cubic boron nitride grinding wheel block, cubic borax nitride The raw material components and weight percentage content of the wheel block are: 45-75% cubic boron nitride abrasive, 5-20% corundum, 20-35% vitrified bond; the raw material component and weight percentage content of the vitrified bond are : 50-60% SiO2, 20-30% B2O3, 2-5% Al2O3, 4-15% Na2O, 4-10% K2O. The invention provides a high-efficiency grinding tool with high hardness, high processing precision, long service life, no pollution to the environment, and can be matched with a numerical control grinding machine. Sharp, simple preparation process.

Owner:TIANJIN UNIV

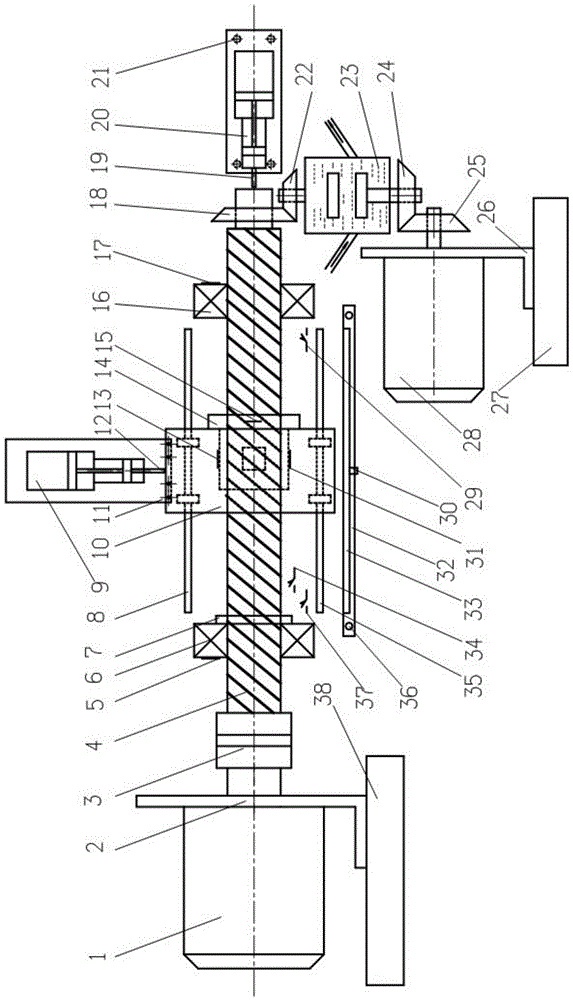

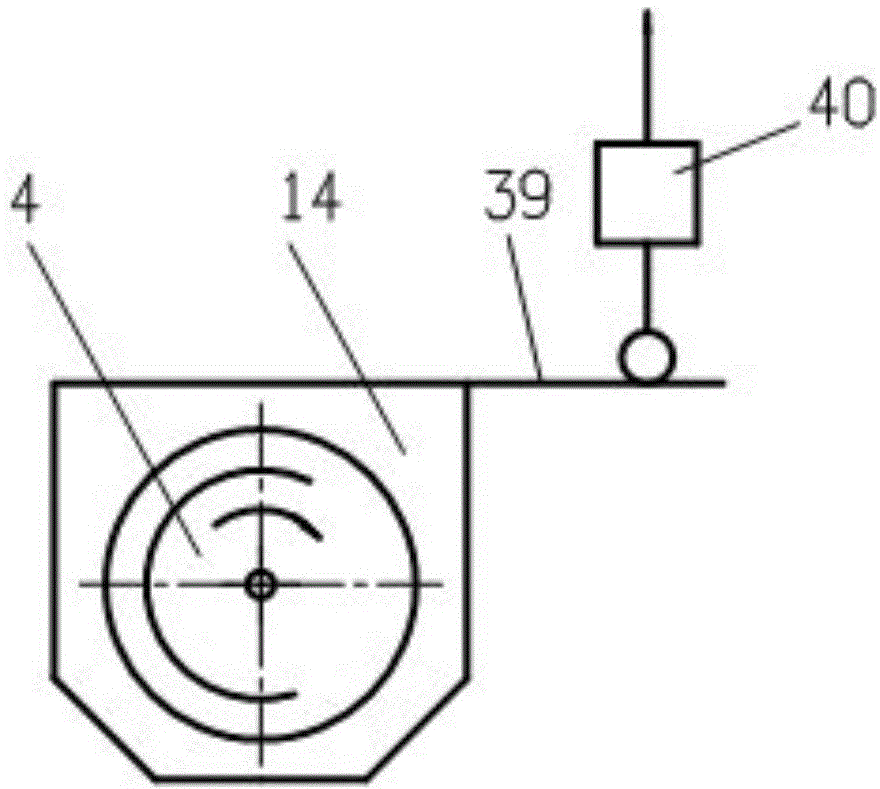

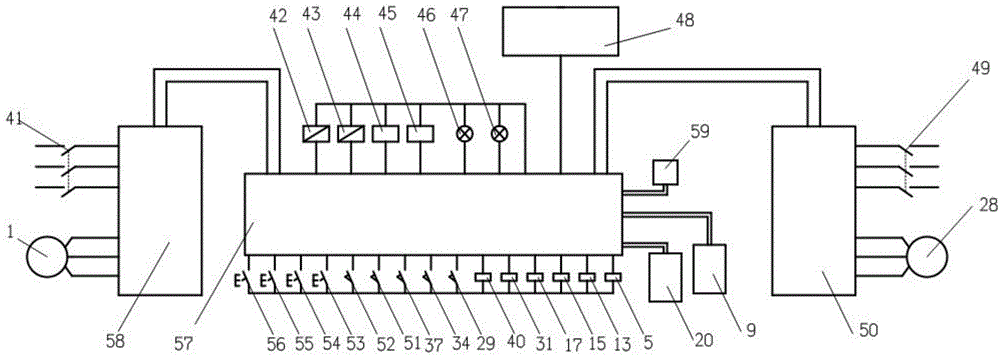

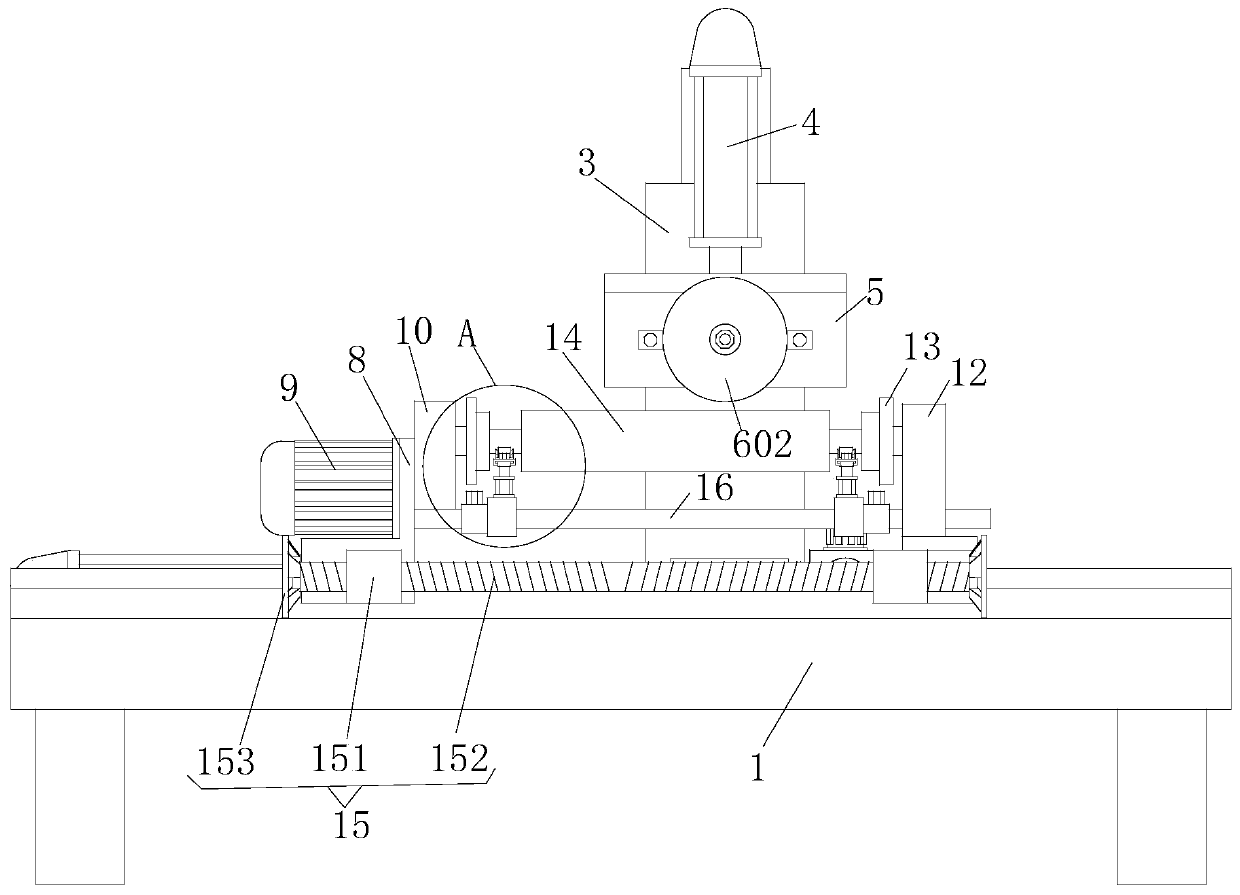

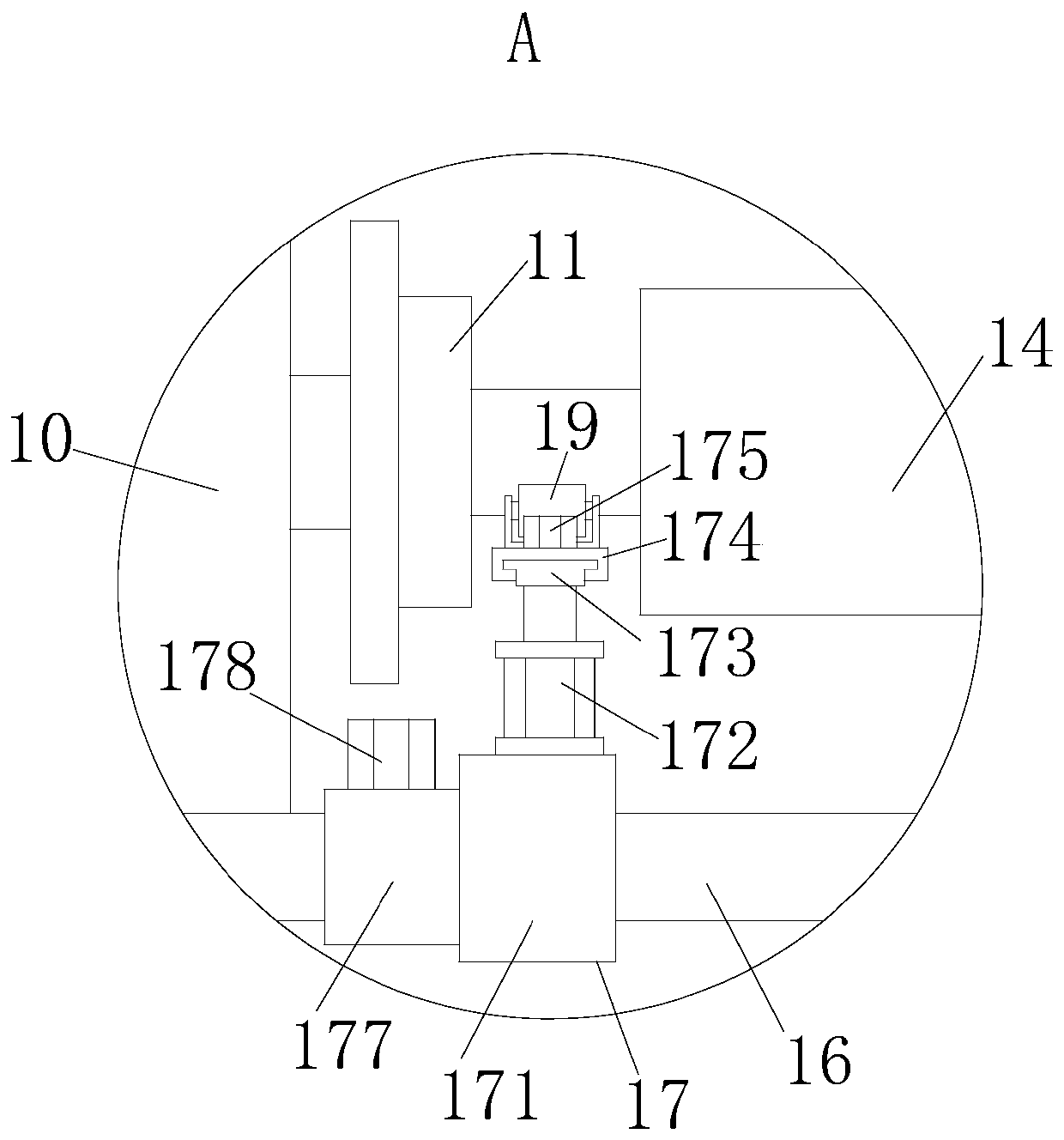

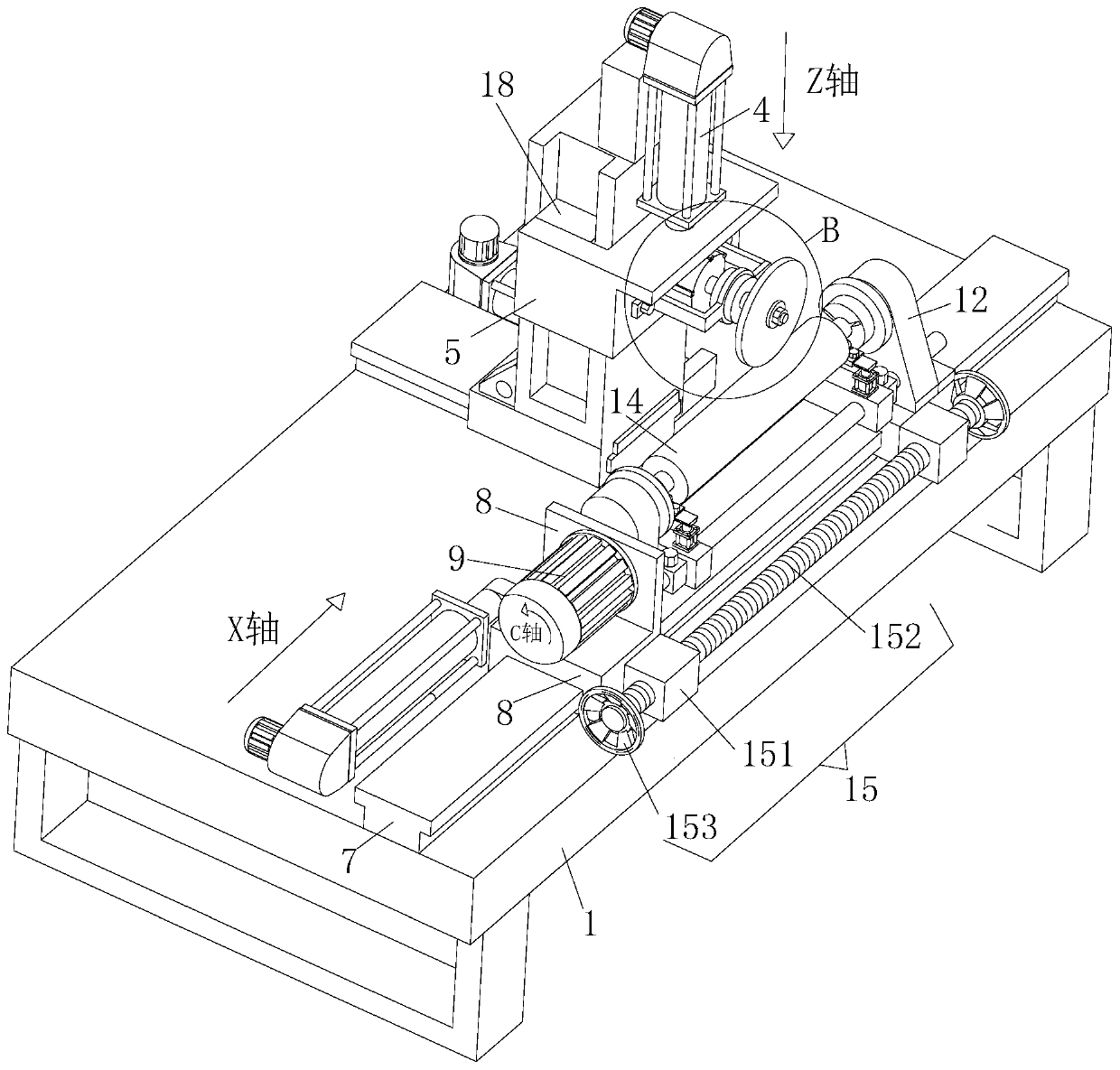

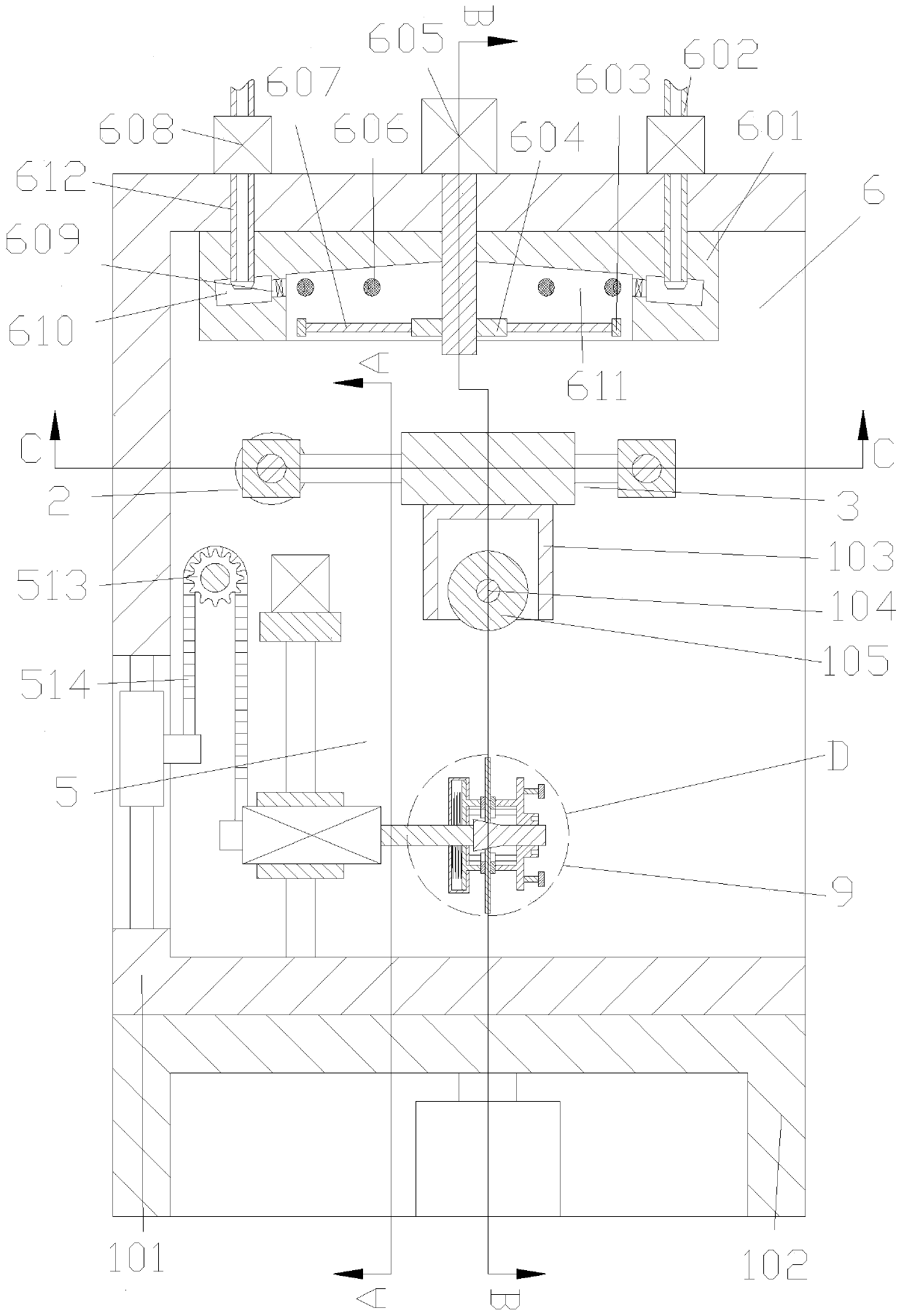

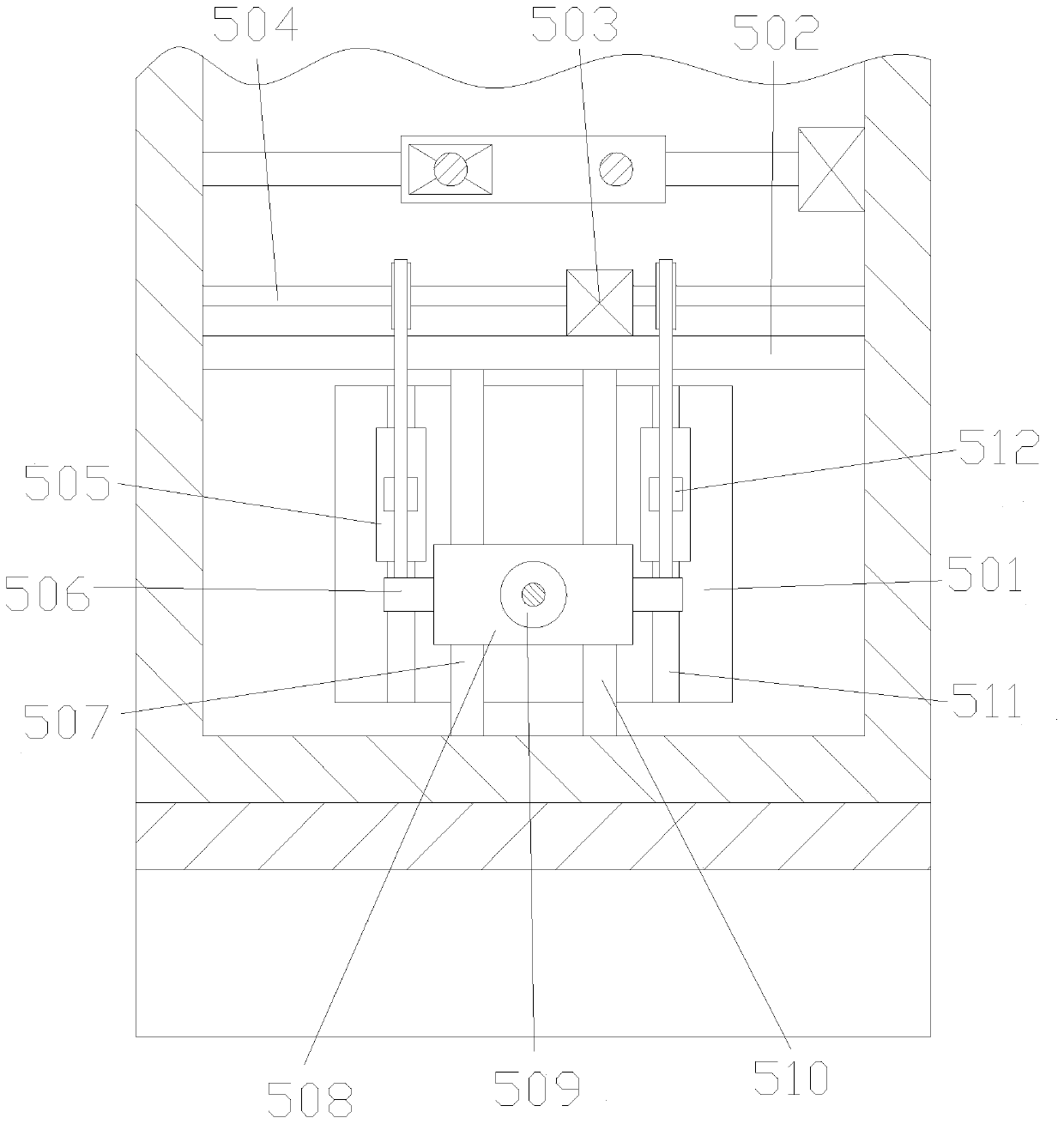

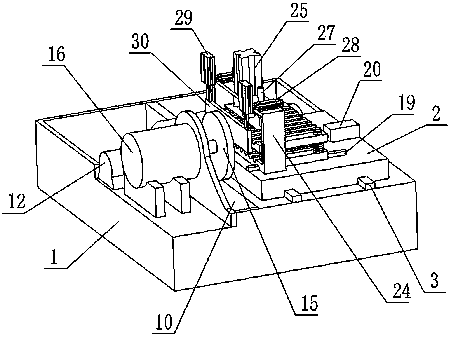

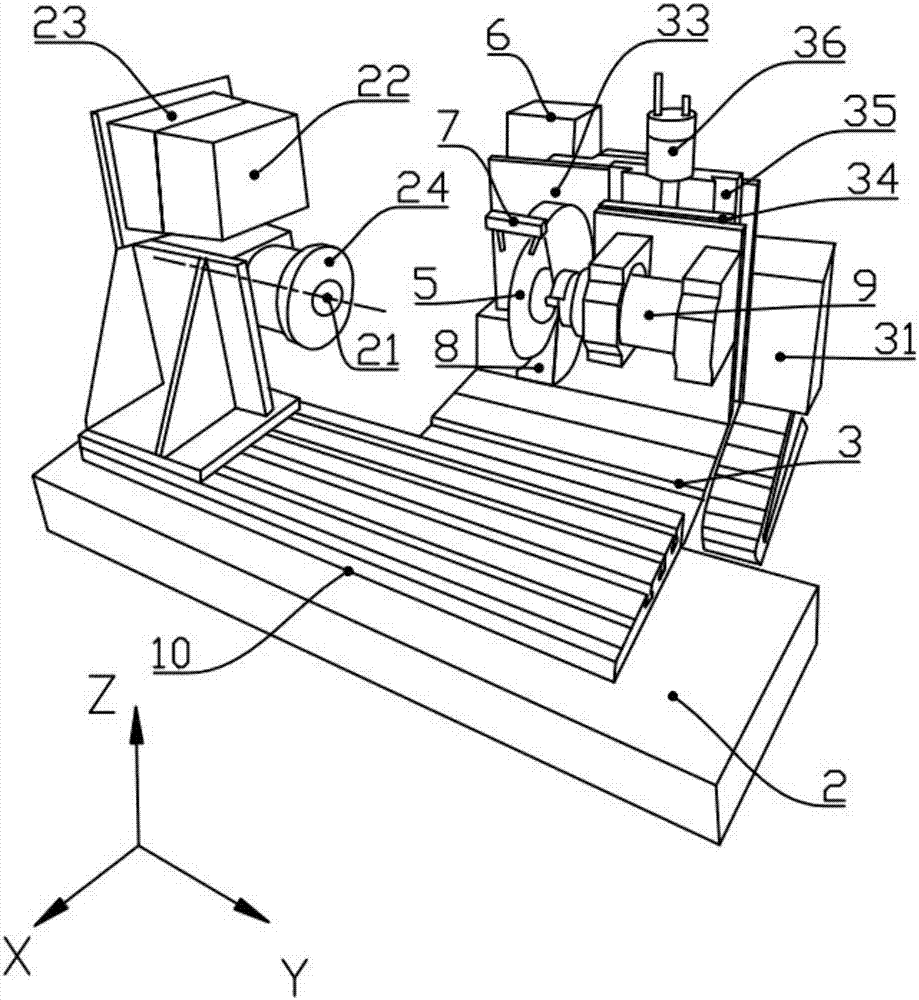

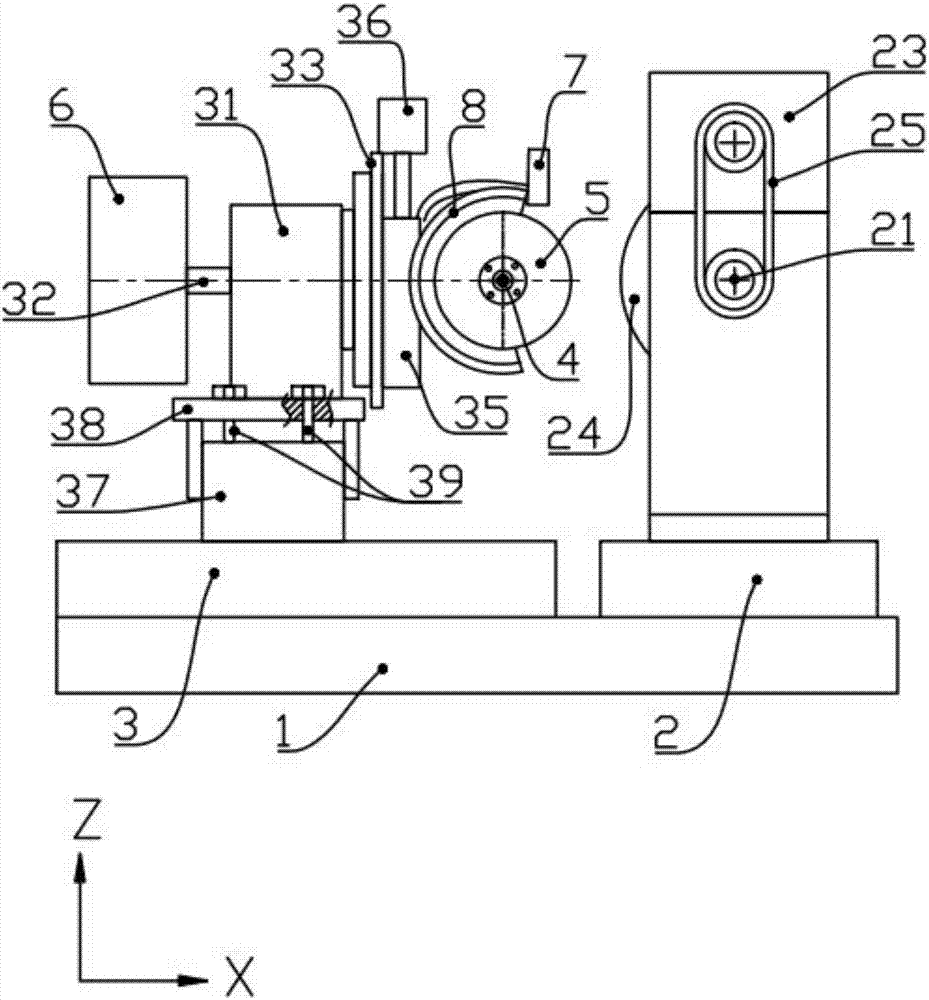

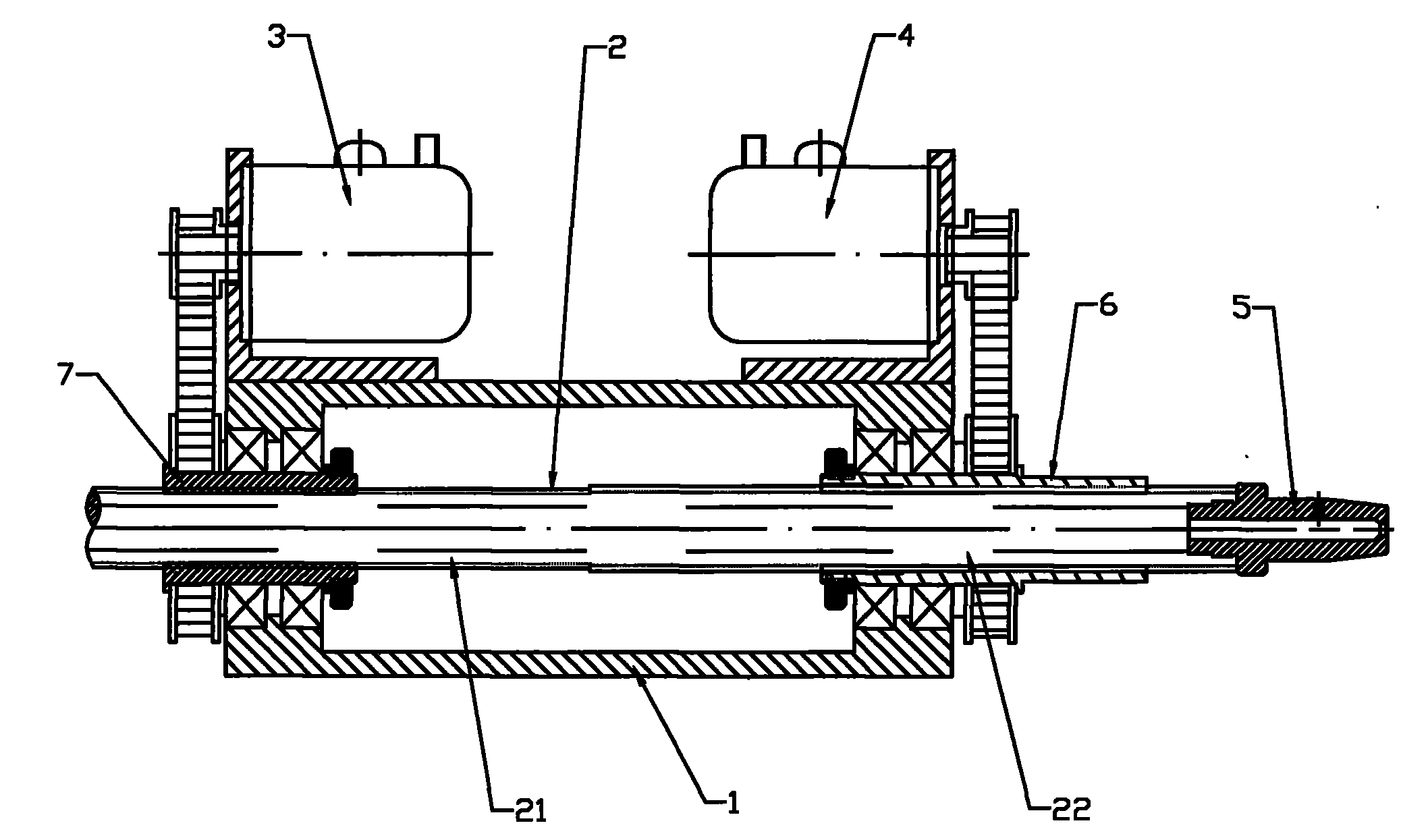

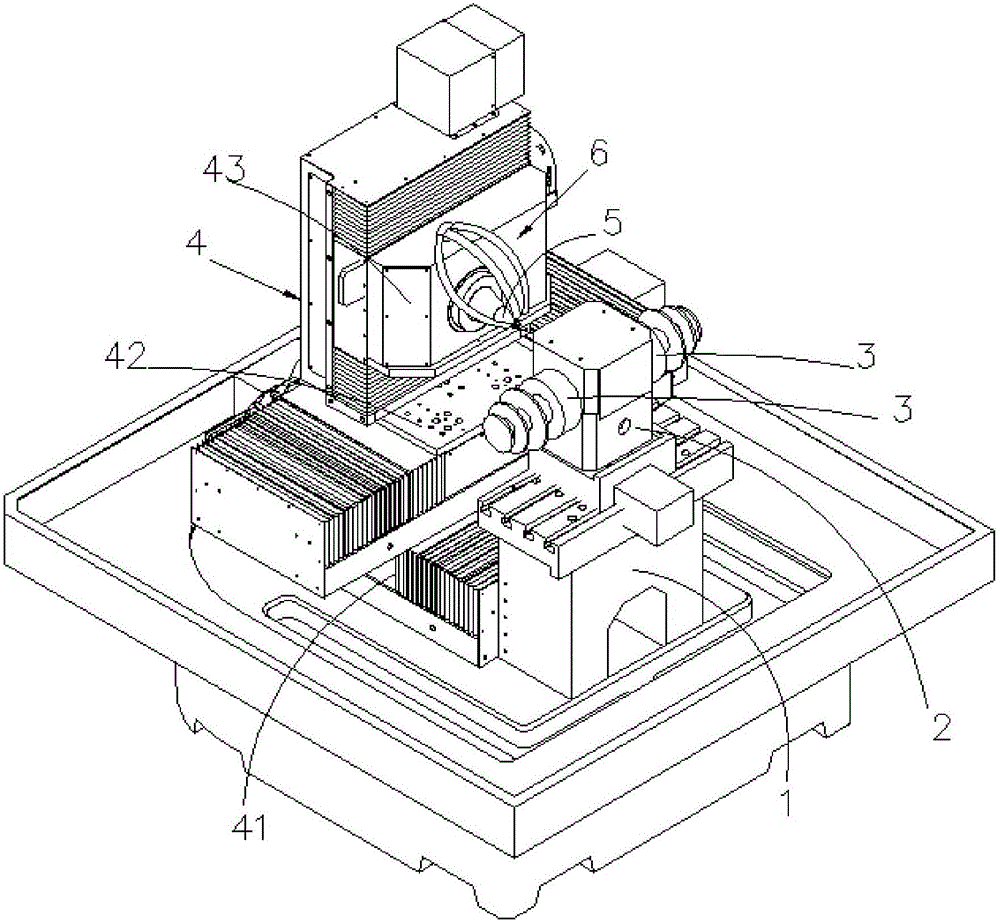

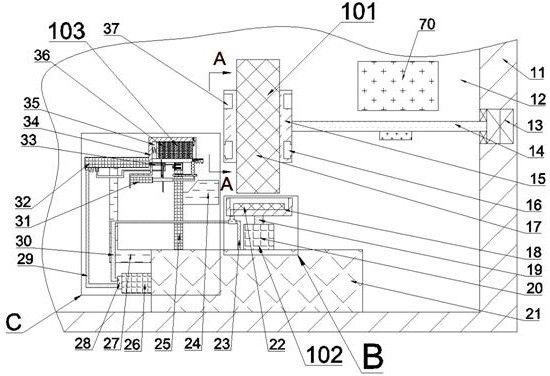

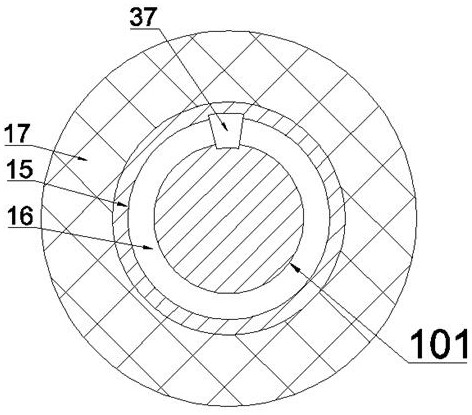

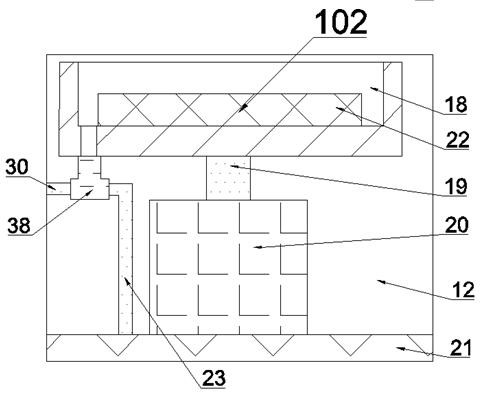

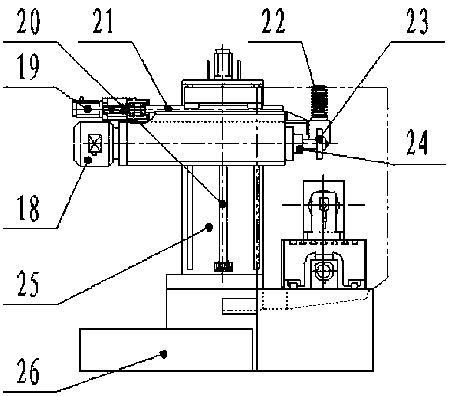

Reliability test device for CNC (Computer Numerical Control) grinding machine

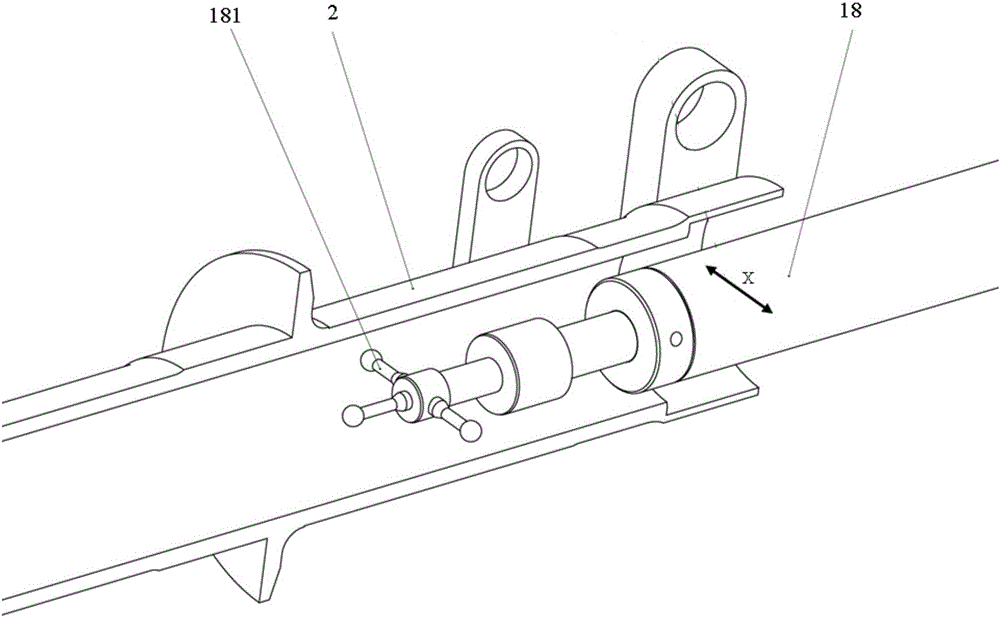

The invention discloses a reliability test device for a CNC (Computer Numerical Control) grinding machine. The integral test device is controlled by a PLC (Programmable Logic Controller); axial grinding force is loaded at one end of a screw of a hydraulic cylinder extension cylinder; the axial grinding force is loaded at one end of the screw due to the fact that a servo motor drives a hydraulic coupler; loading of radial feed force is achieved due to the fact that the hydraulic cylinder extension cylinder acts on a workbench; the positioning accuracy of a feed unit is measured through element devices such as a high-accuracy encoder and an optical grating; friction moment of the screw is indirectly achieved due to the fact that a force transducer measures the bearing force of a force measuring rod which is installed on a nut; the temperature is measured through temperature sensors which are installed on a front bearing seat, a rear bearing seat and a screw nut; the vibration acceleration is measured through an acceleration sensor which is installed on the screw nut. The reliability test device for the CNC grinding machine can simulate working conditions of a feed system of the CNC grinding machine and collect reliability data of the feed system of the CNC grinding system to calculate the reliability level of the feed system of the CNC grinding machine.

Owner:BEIJING UNIV OF TECH

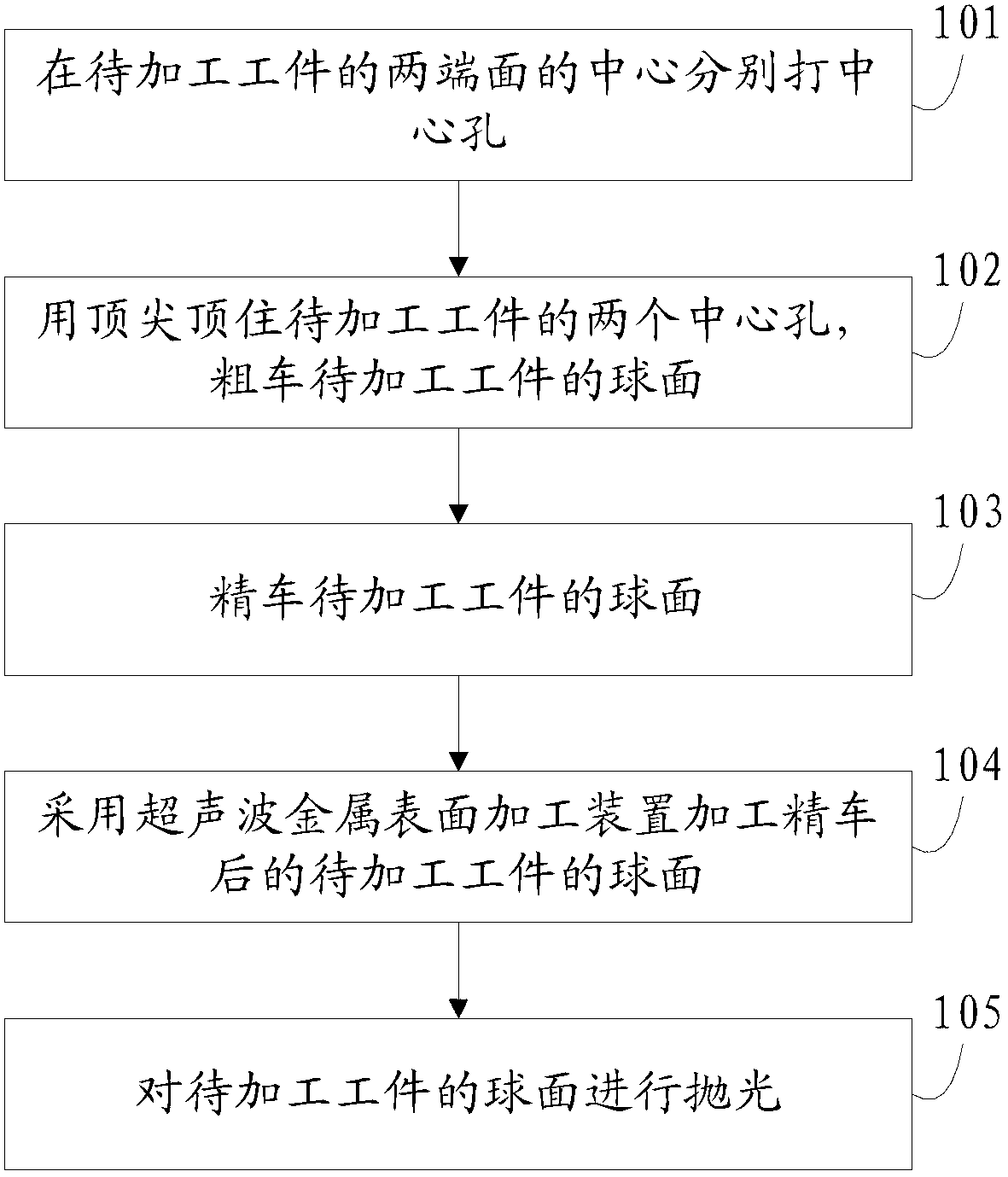

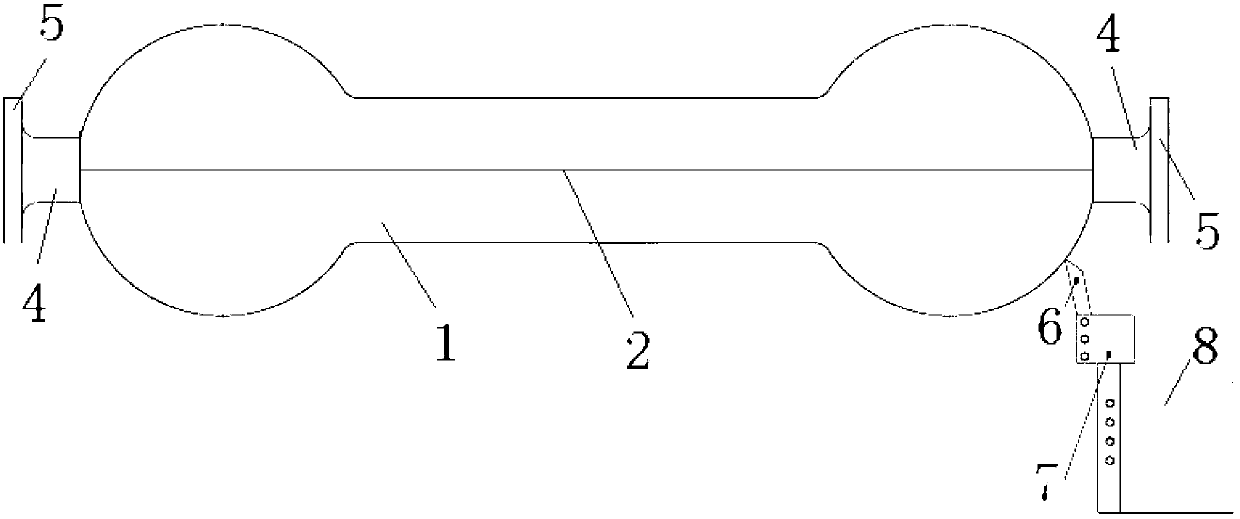

Spherical surface machining method

ActiveCN102990304AGuaranteed spherical accuracyGuaranteed smoothnessMachine partsMechanical components

The invention discloses a spherical surface machining method belonging to the technical field of machine part machining. The method comprises the following steps of sequentially carrying out rough turning, finish turning, grinding and polishing on a spherical surface of a workpiece to be machined by using a numerical control machine tool, wherein the grinding step is implemented as follows: the finish-turned spherical surface of the workpiece to be machined is machined by using an ultrasonic metal surface machining device which is arranged on the numerical control machine tool. According to the spherical surface machining method, the finished-turned spherical surface of the workpiece to be machined is machined by using the ultrasonic metal surface machining device which replaces a numerical control grinder in the prior art, and therefore, the precision and the smooth finish of the spherical surface of the workpiece to be machined are ensured, and meanwhile, the machining process is simplified, the used equipment is reduced, the machining efficiency is improved, and the machining cost is lowered.

Owner:WUHAN MARINE MACHINERY PLANT

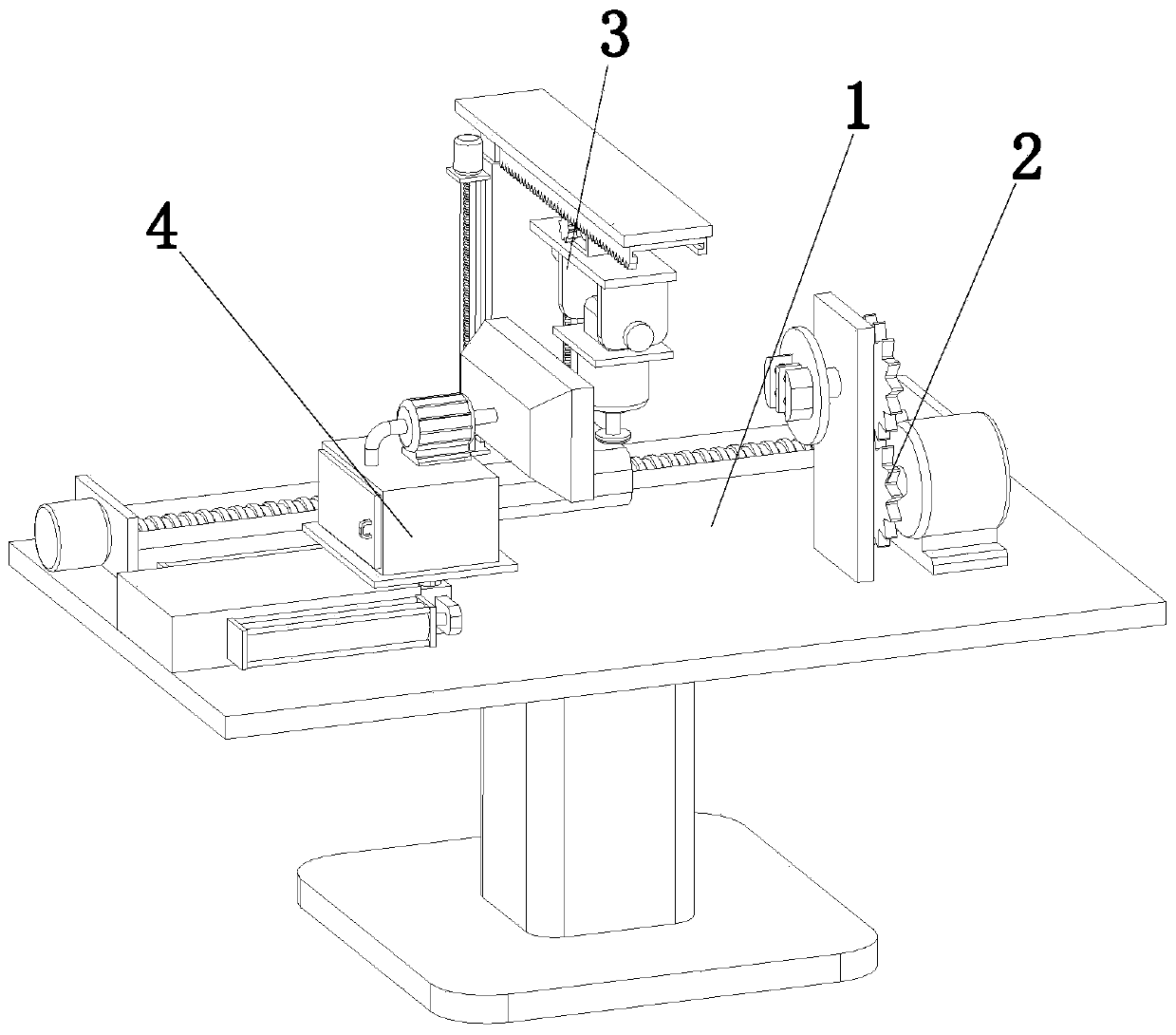

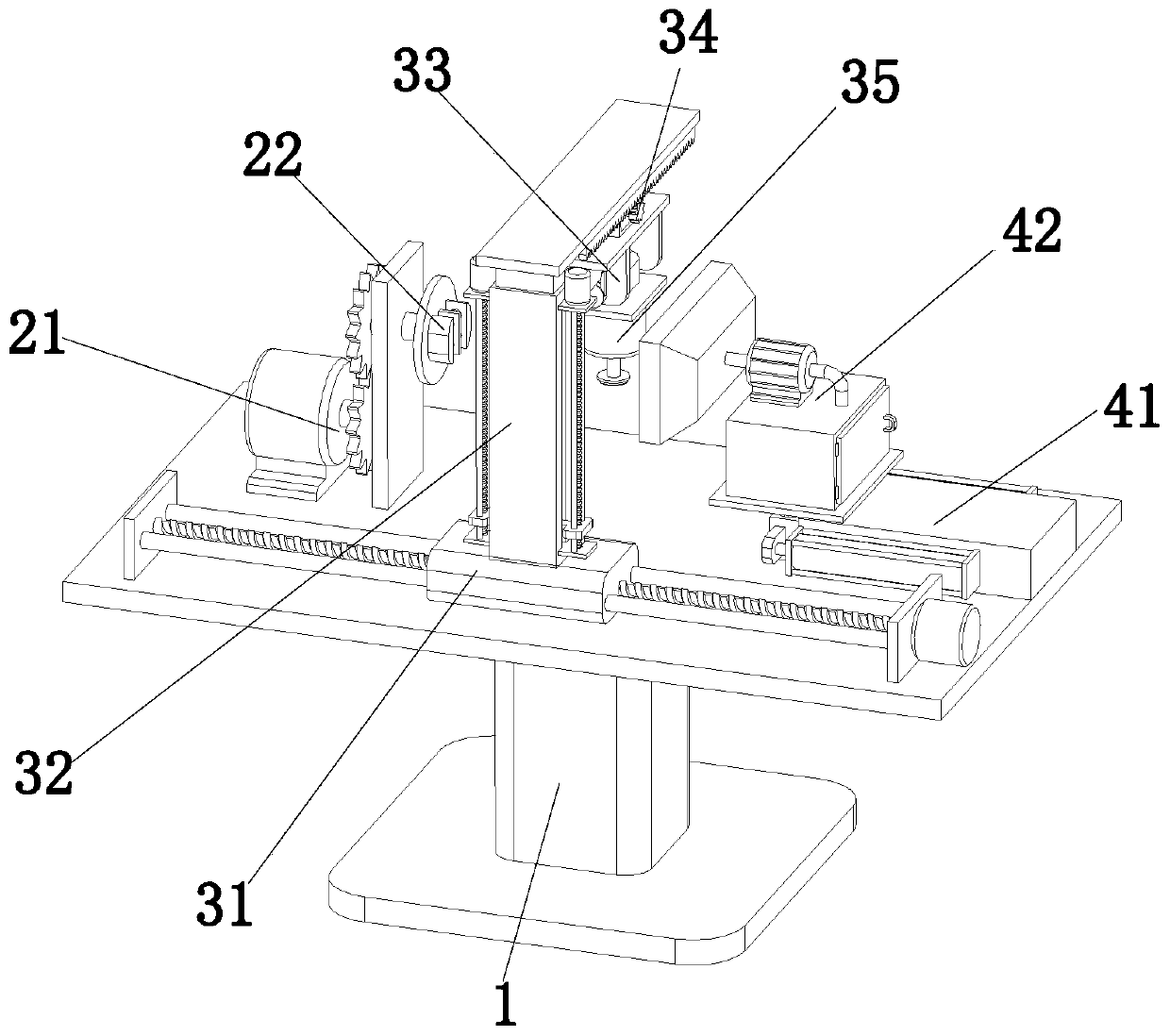

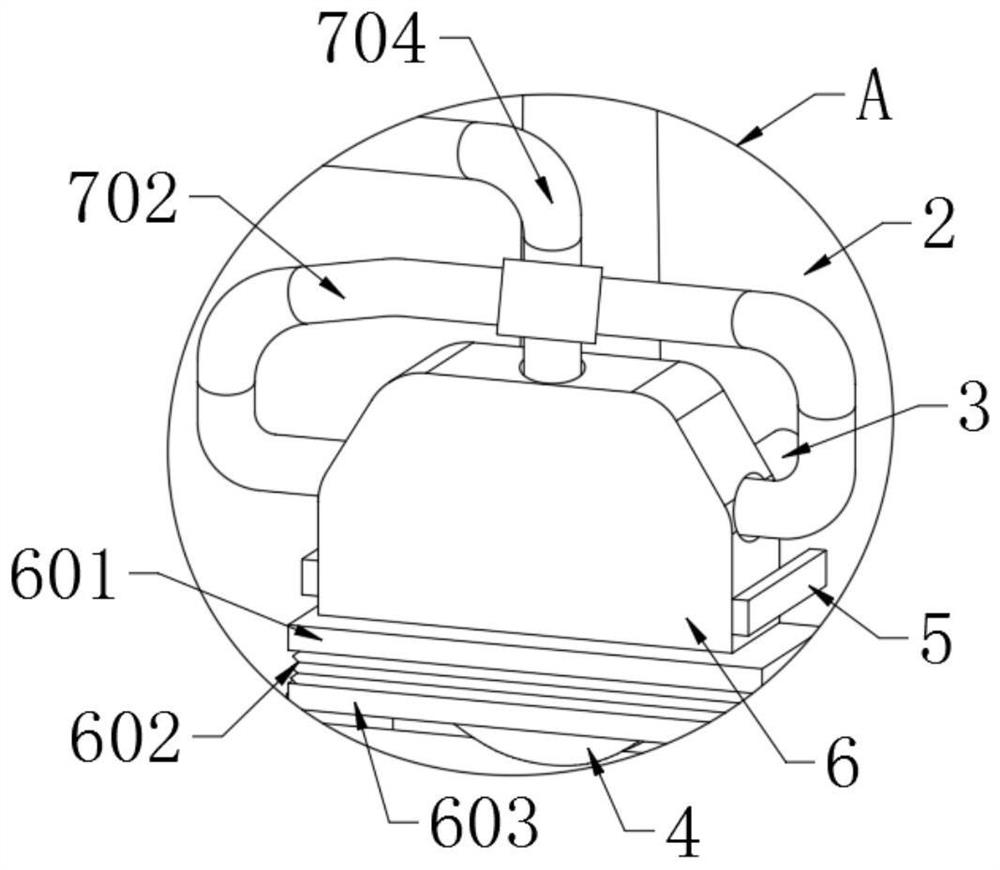

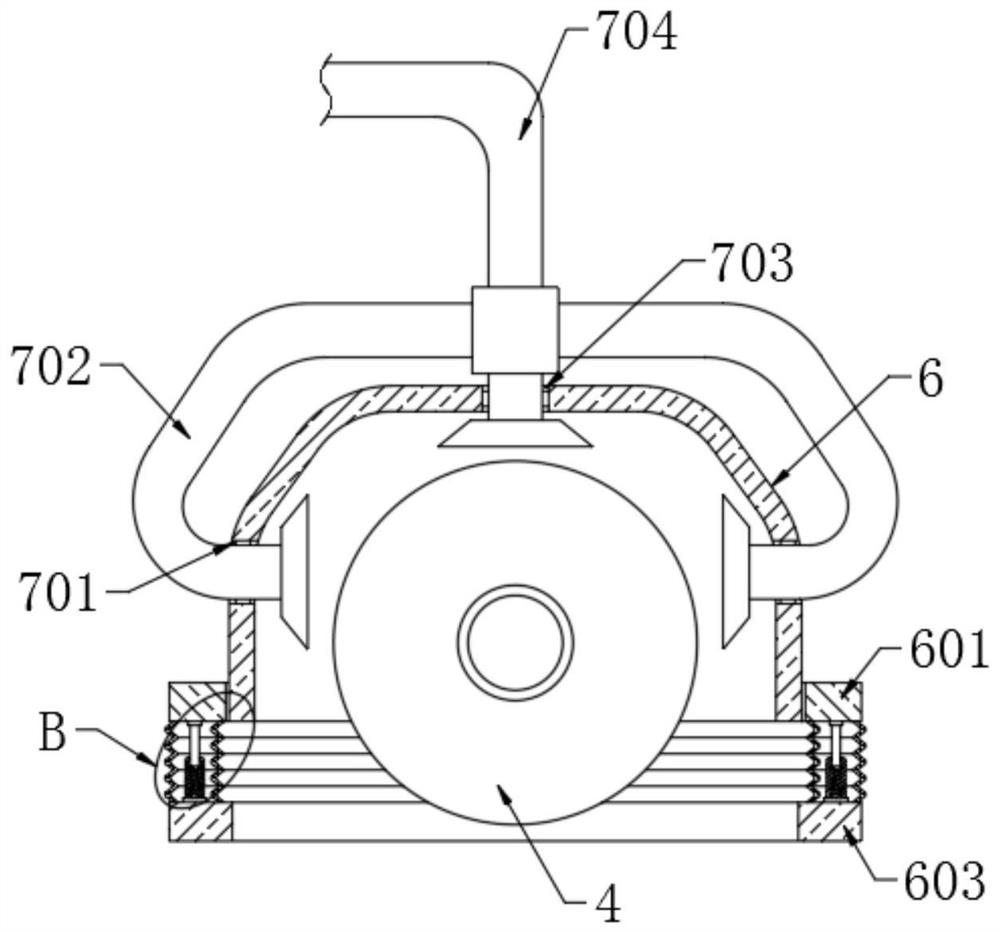

Large-cone-angle thrust tapered roller bearing outer ring large-angle machining numerical control grinding machine

InactiveCN111451859AAvoid offsetEasy to GrindGrinding drivesGrinding work supportsCnc grindingEngineering

The invention discloses a large-cone-angle thrust tapered roller bearing outer ring large-angle machining numerical control grinding machine, and relates to the technical field of bearing machining. The grinding machine comprises a grinding machine body, a limiting mechanism, a grinding mechanism and a cleaning mechanism, wherein the limiting mechanism comprises a rotating assembly and a limitingassembly, the grinding mechanism comprises a moving assembly, a lifting assembly, a first adjusting assembly, a second adjusting assembly and a grinder, the moving assembly is fixedly arranged on oneside of the grinding machine body, the lifting assembly is fixedly arranged on the moving assembly, the first adjusting assembly is fixedly arranged on the lifting assembly, the second adjusting assembly is fixedly arranged on the first adjusting assembly, the grinder is fixedly arranged on the second adjusting assembly, and the cleaning mechanism comprises a pushing assembly and a cleaning assembly. According to the grinding machine, full-automatic grinding of a tapered roller bearing outer ring and cleaning operation of chippings in grinding process are completed through cooperative work ofall assemblies, manual operation is not needed, and the working efficiency is improved.

Owner:陈习

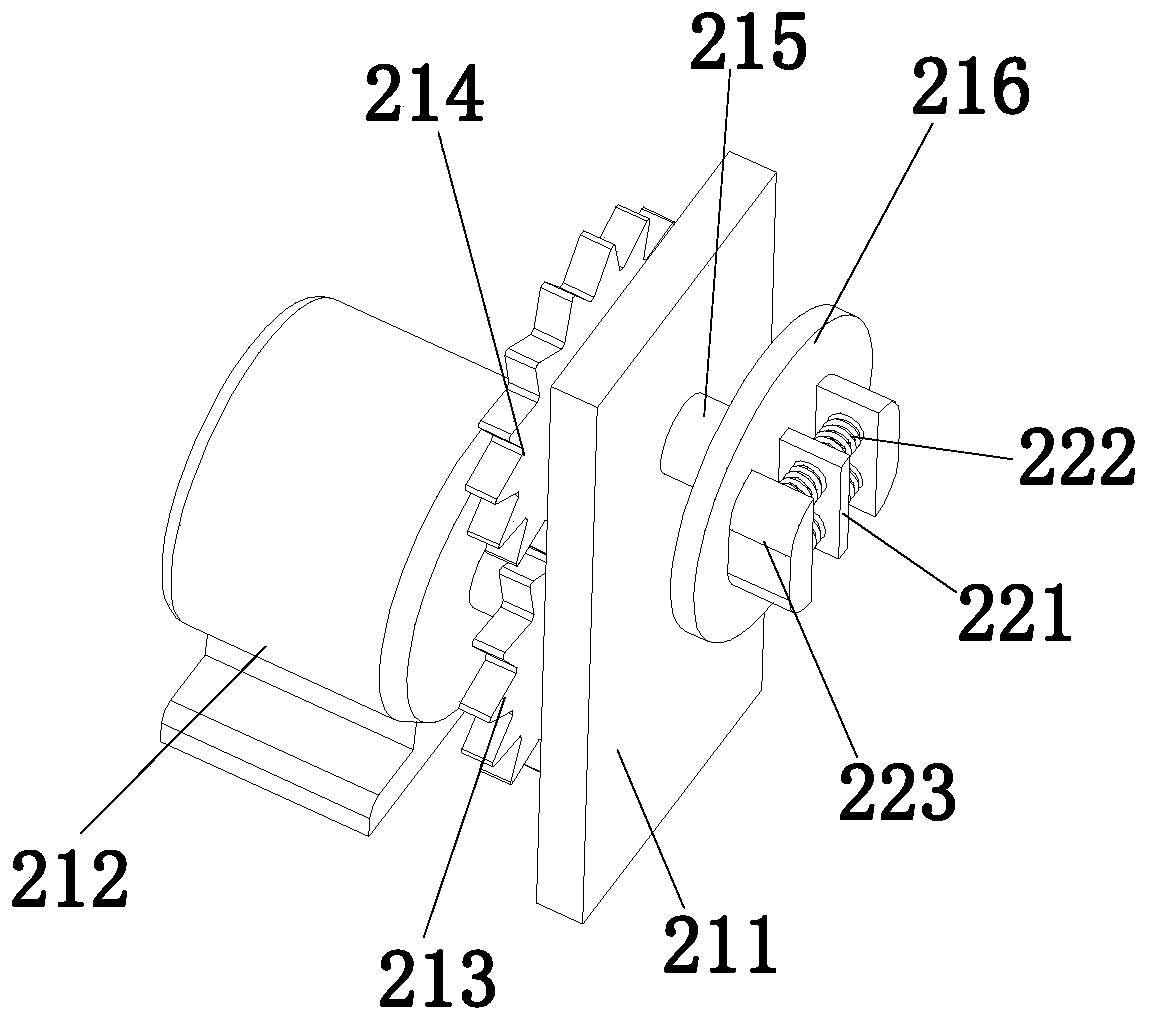

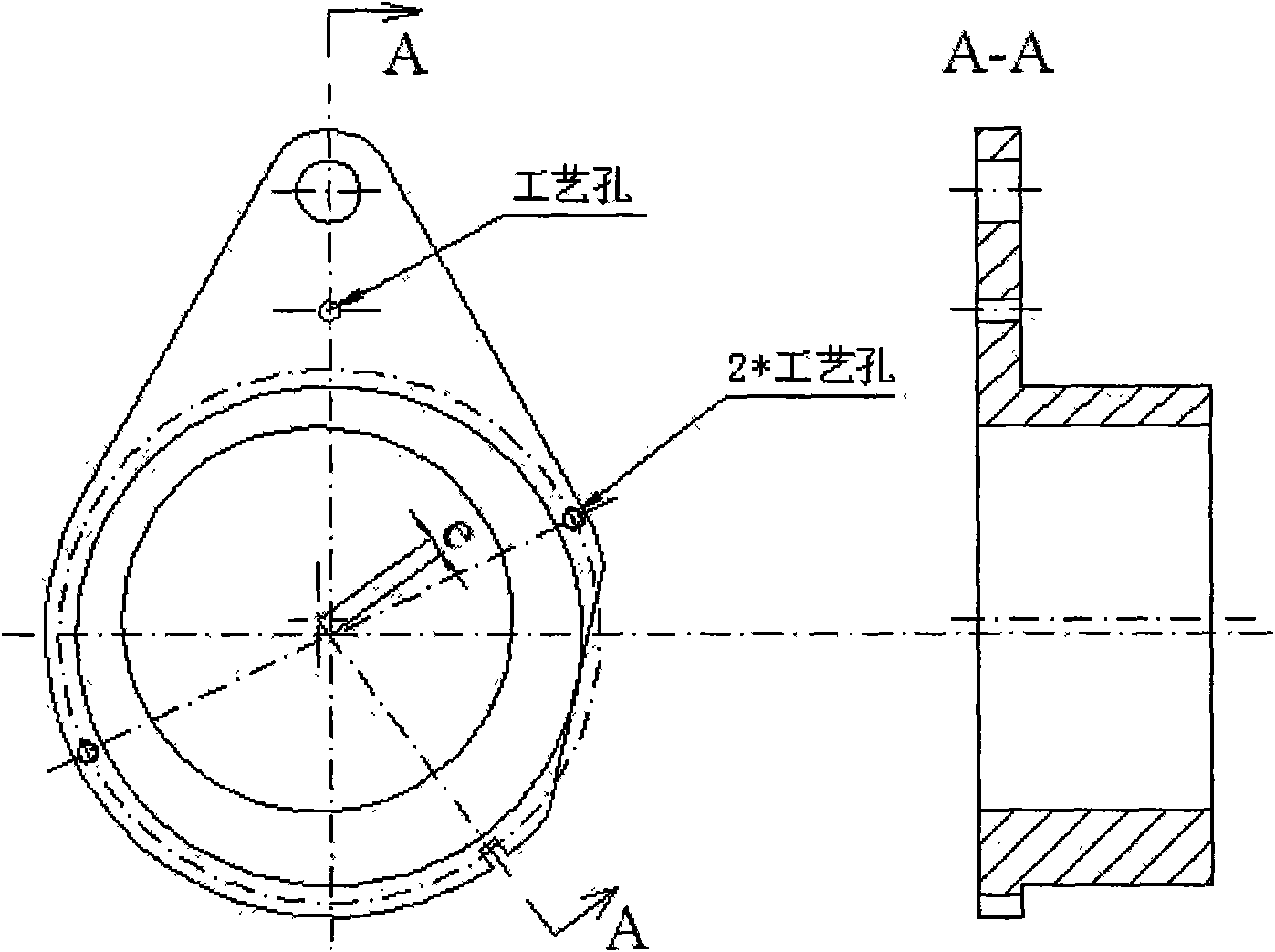

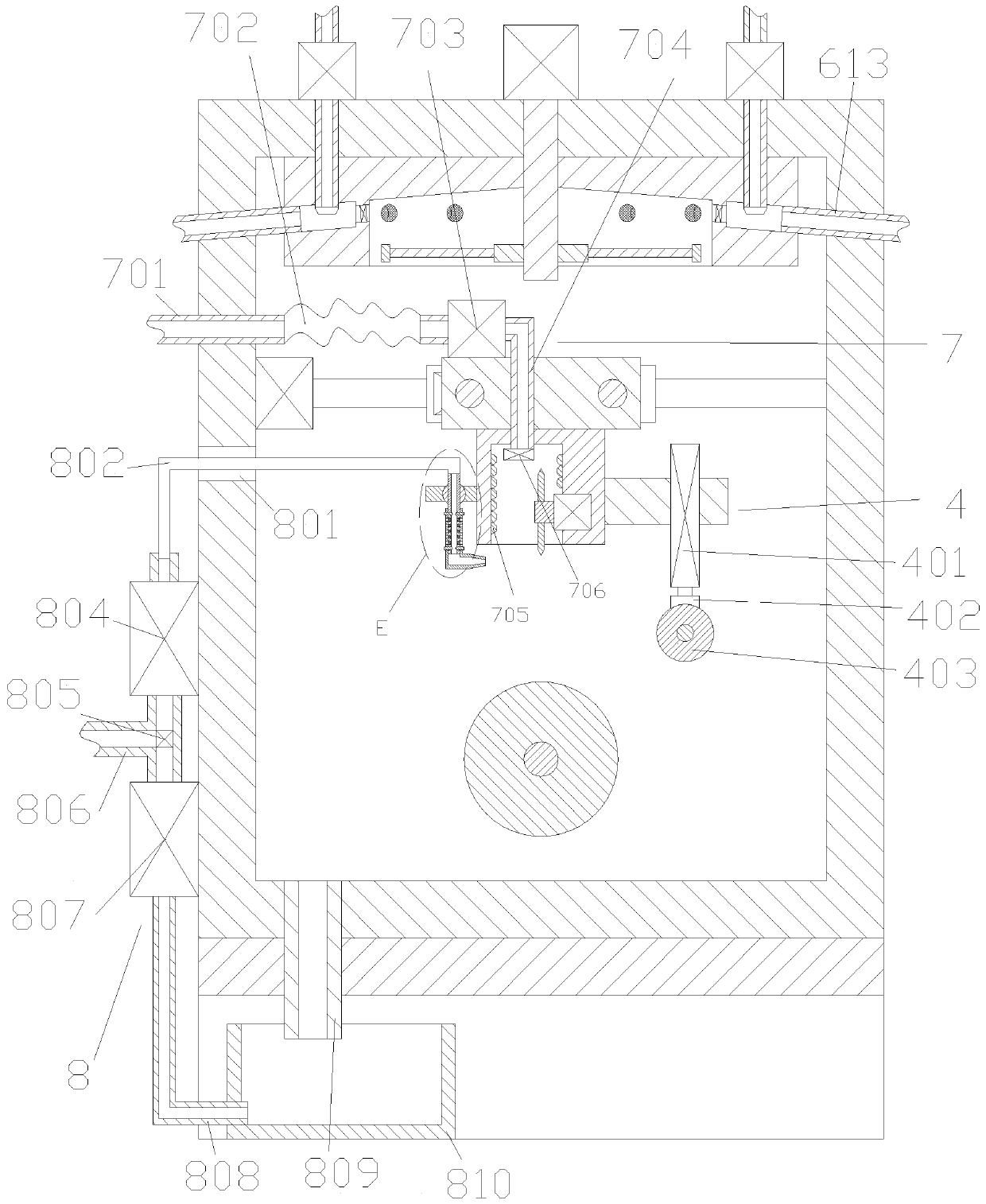

Eccentricity adjusting method and device for vertical numerically controlled grinder to process eccentric orifice

InactiveCN101585156ARealize positive and negative rotationRealize clamping and unclampingRevolution surface grinding machinesControl theoryServo control

The invention relates to an eccentricity adjusting method and device for vertical numerically controlled grinder to process eccentric orifice. When the vertical numerically controlled grinder processes an eccentric orifice, the invention uses numerical servo control to realize method of precisely adjusting eccentricity of eccentric orifices of various specifications. The method comprises steps of adding a servo assistant shaft on the vertical numerically controlled grinder, driving the shaft through numerical servo to drag a worktable so as to making center of the eccentric orifice and rotatory center of a rotatory pedestal overlapped, thus realizing numerical servo control of eccentricity adjustment. The method makes adjustment precision of the eccentricity not dependent on precision of a clamp any more, makes adjustment range not limited to structure of the clamp and is especially applied to large-eccentricity workpiece. The invention simplifies process of clamping the workpiece, decreases human intervention degree and work intensity, can finish grinding an outer circle and a eccentric orifice during process of one-time clamping, improves processing efficiency and guarantees stability of processing precision.

Owner:SHANGHAI UNIV

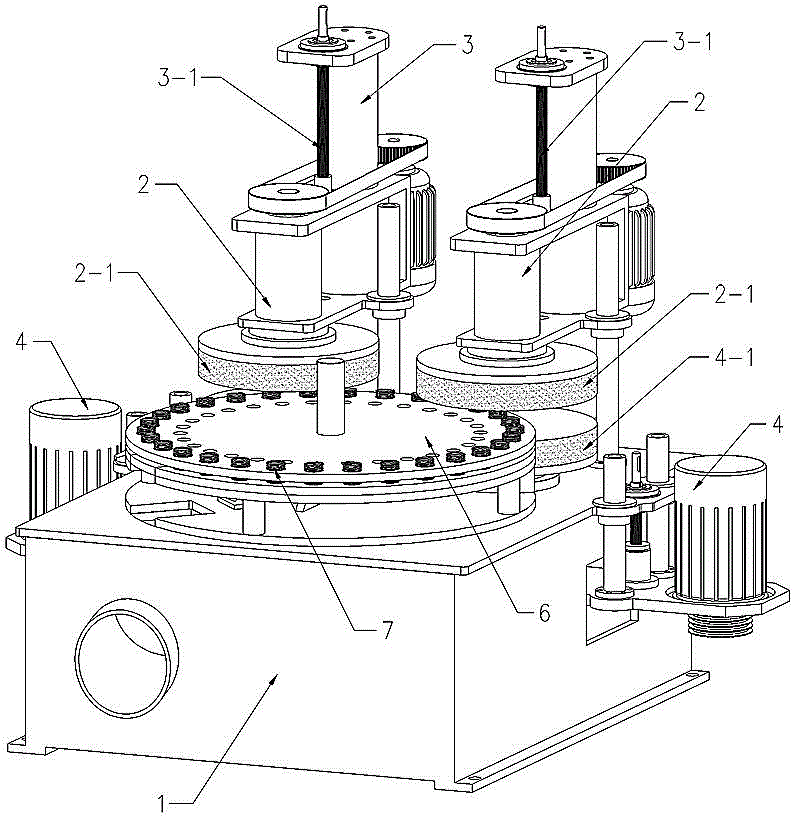

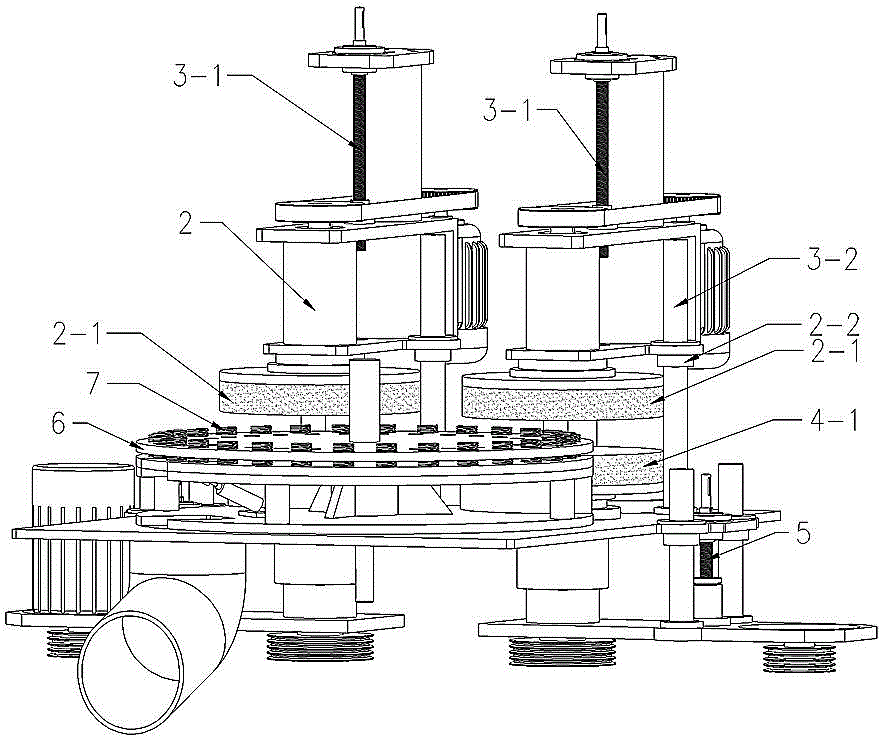

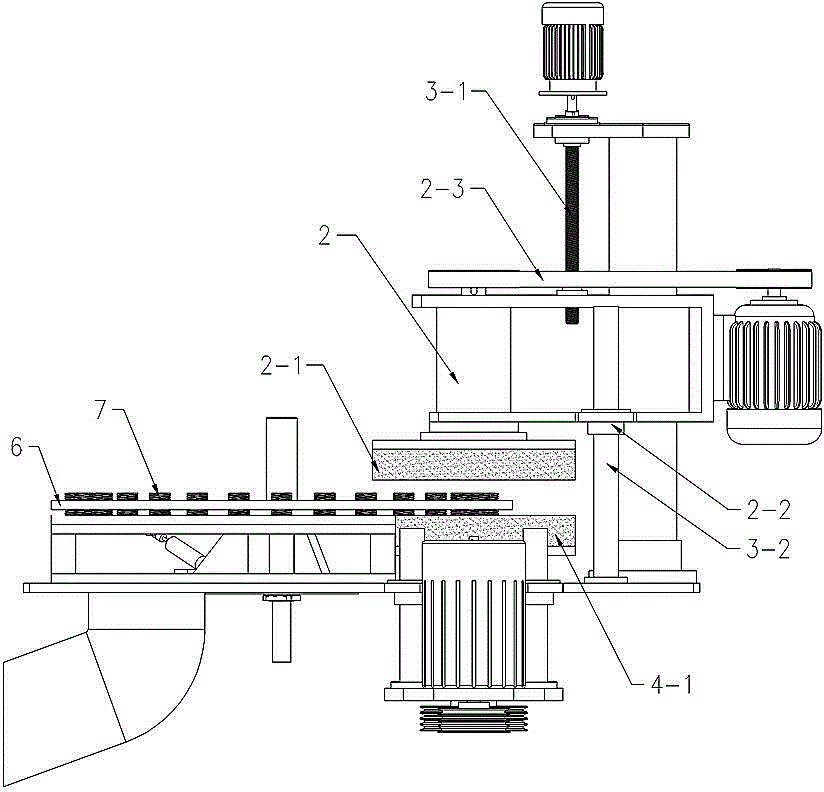

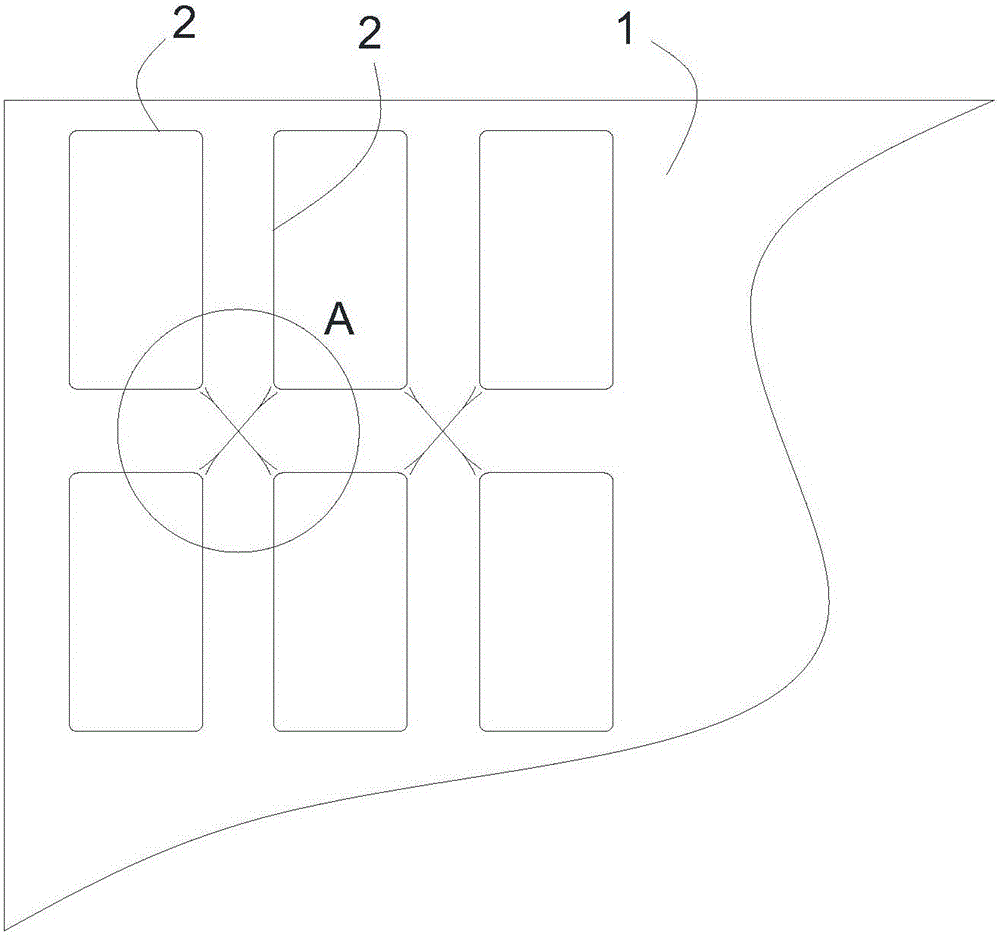

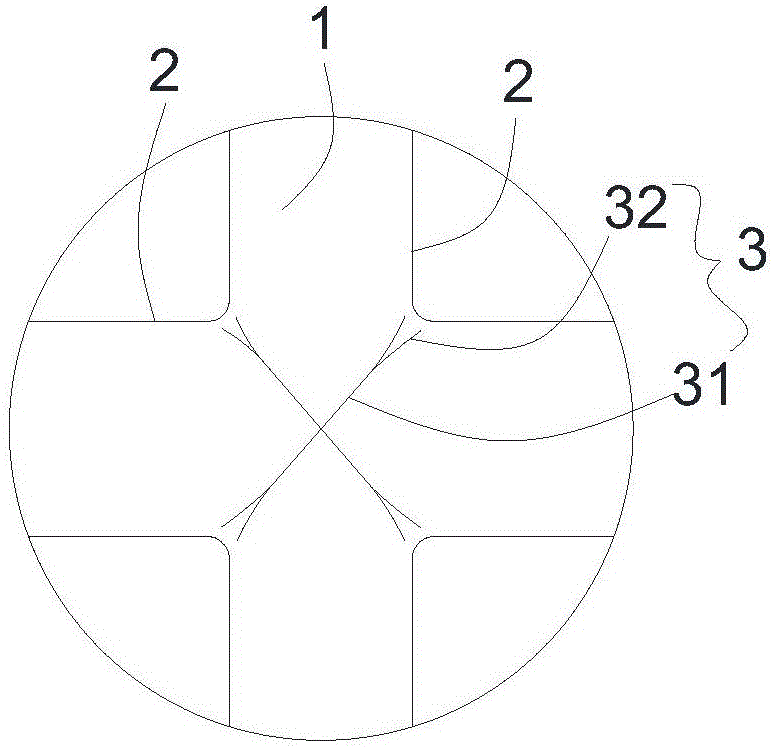

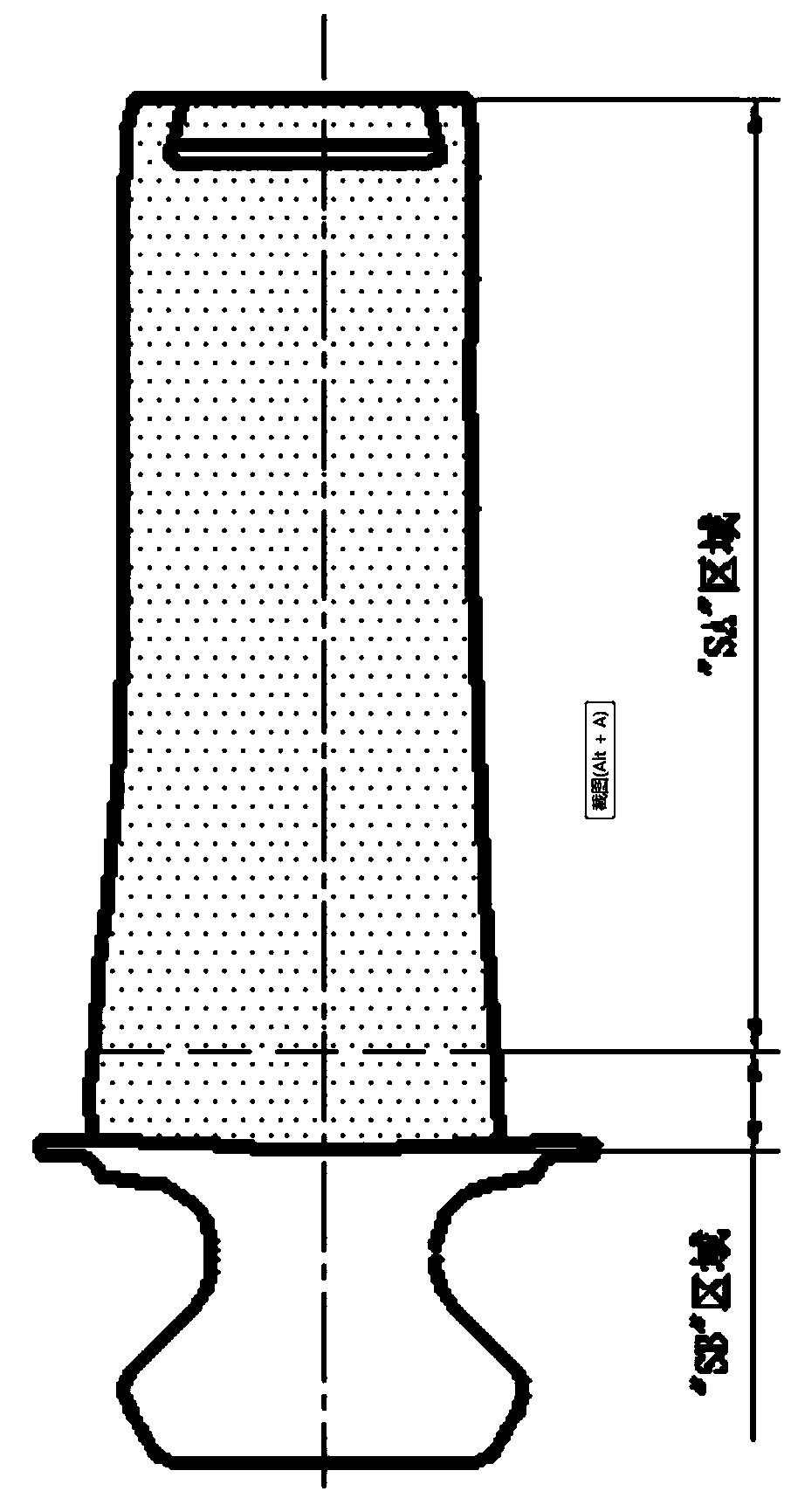

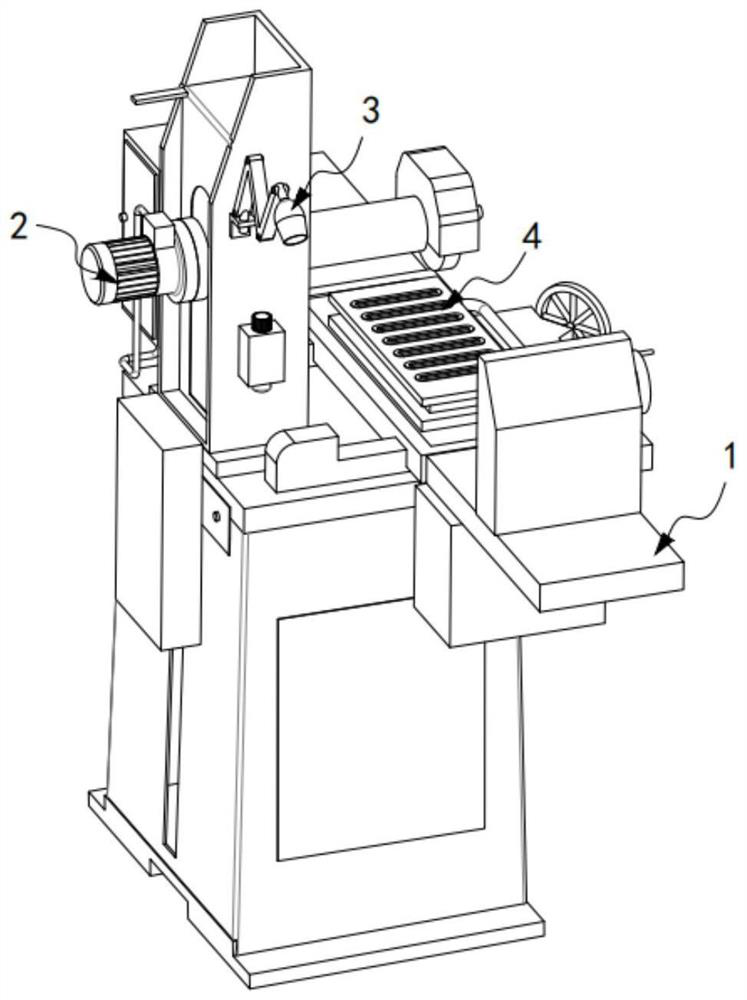

Vertical numerical control spring grinding machine

InactiveCN103551947AGuaranteed accuracyGuaranteed smoothnessPlane surface grinding machinesThermodynamicsCnc grinding

The invention discloses a vertical numerical control spring grinding machine which comprises a rack, a grinding table, grinding wheel rotating mechanisms and a grinding wheel elevating mechanism, wherein die holes for placing springs are annually arrayed in the grinding table; a grinding wheel is arranged at the top end of each grinding wheel rotating mechanism and is drawn by the grinding wheel elevating mechanism to vertically lift. The vertical numerical control spring grinding machine is characterized in that the number of the grinding wheels used by the device is not less than four and the grinding wheels are different in granularity; a plurality of groups of upper and lower grinding wheels are arranged above and below the die holes which are annularly arranged in the grinding table in pairs; the granularities of the two grinding wheels which vertically correspond to each other in each group are identical but the granularities of the grinding wheels in each group are different from the granularities of the grinding wheels in other groups; from the view of the rotating direction of the grinding table, the granularities of the grinding wheels in one group, which are contacted with the springs firstly, are coarser, the granularities of the grinding wheels in a sequent group are slightly finer and the granularities of the sequent grinding wheels are finer. From the view of the vertical heights of the upper grinding wheels, the positions of the grinding wheels with the coarse granularities are highest, the positions of the grinding wheels with the fine granularities are slightly lower and the positions of the grinding wheels with the finest granularities are lowest. The vertical numerical control spring grinding machine disclosed by the invention has the beneficial effects that multiple paths of thick and thin grindings are combined to one machine for finishing the machining at one time; in addition, the precision and the smoothness can be ensured and high quality and high yield are obtained.

Owner:浙江创宇机械科技有限公司

Five-axis numerical control grinding machine

ActiveCN111451882AEasy to useTo achieve the effect of adjusting the distanceGrinding drivesGrinding machinesCnc grindingEngineering

The invention belongs to the technical field of hard alloy grinding machines, and particularly relates to a five-axis numerical control grinding machine. The five-axis numerical control grinding machine comprises an operation table. A longitudinal supporting plate is in sliding connection with the back side of the top of the operation table through a track mechanism. A second electric cylinder isfixedly connected to the top of the longitudinal supporting plate. An installing frame is fixedly connected to the bottom of an output rod of the second electric cylinder. A sliding groove is formed in the back face of the installing frame. The inner wall of the sliding groove is in sliding connection with the surface of the longitudinal supporting plate. A grinding mechanism is fixedly installedon the front face of the installing frame. By rotating a two-way screw, two reverse threads of the two-way screw can drive a first sliding block and a second sliding block to move synchronously in a face-to-face mode, and therefore the effect of adjusting the interval is achieved, and the requirement of grinding pieces of different lengths is met. The surface of a supporting roller makes contact with the surface of a grinding piece, supporting is performed, the bottom of the grinding piece is stably supported, vibration is lowered, and the problem that the grinding quality is affected by vibration is avoided.

Owner:浙江晨日智能科技有限公司

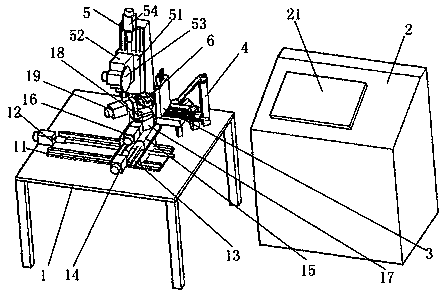

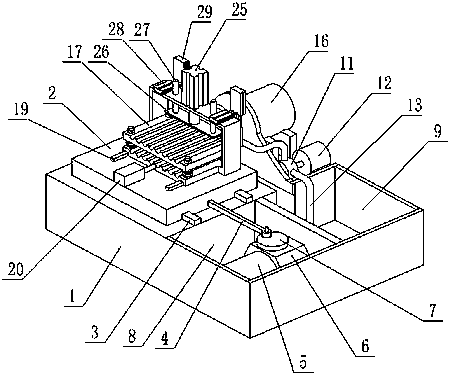

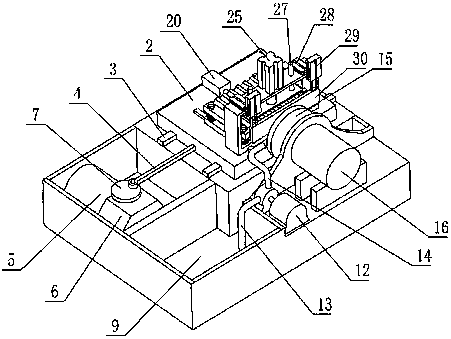

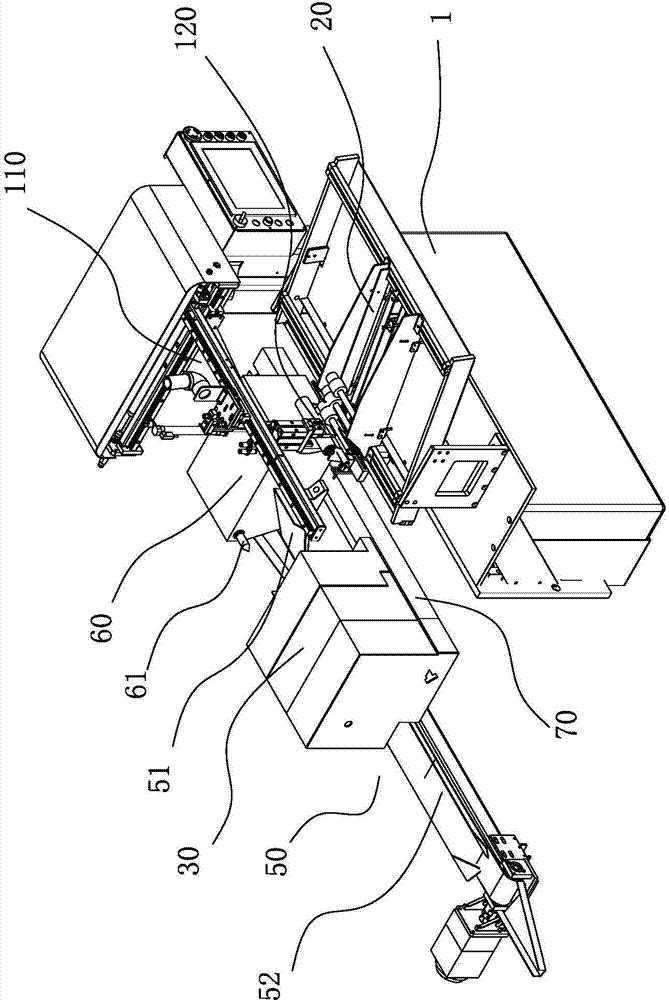

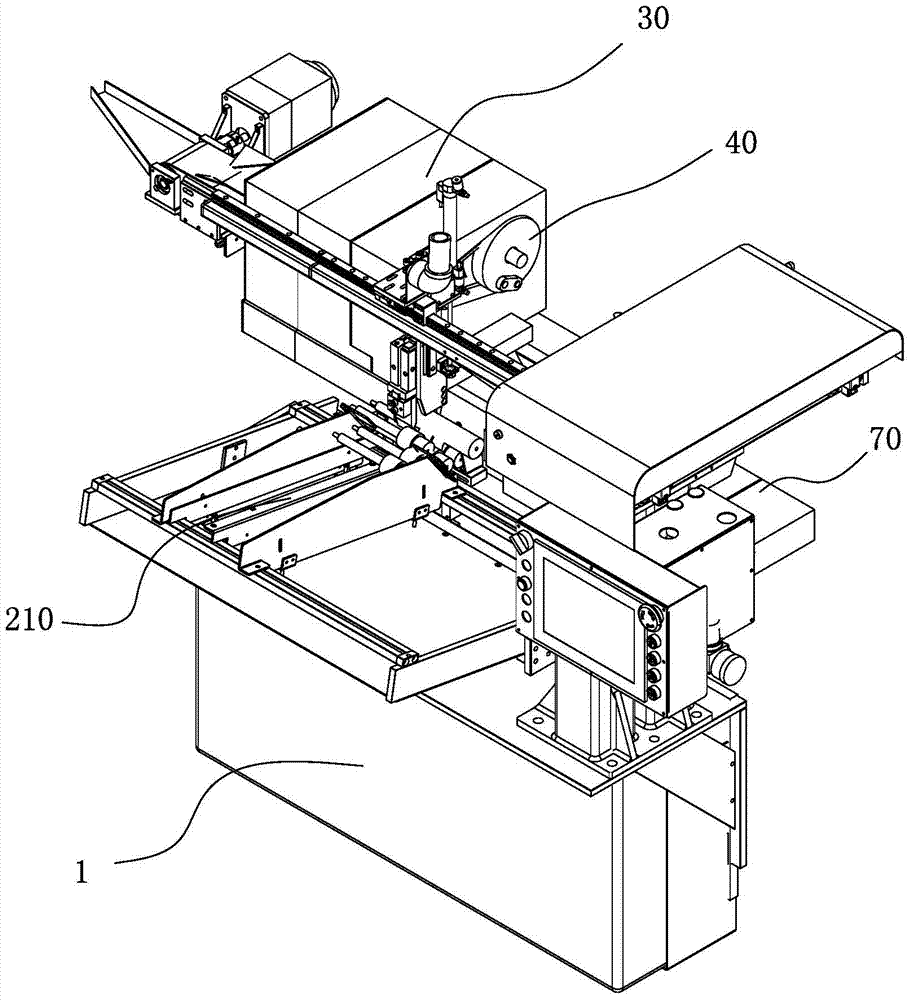

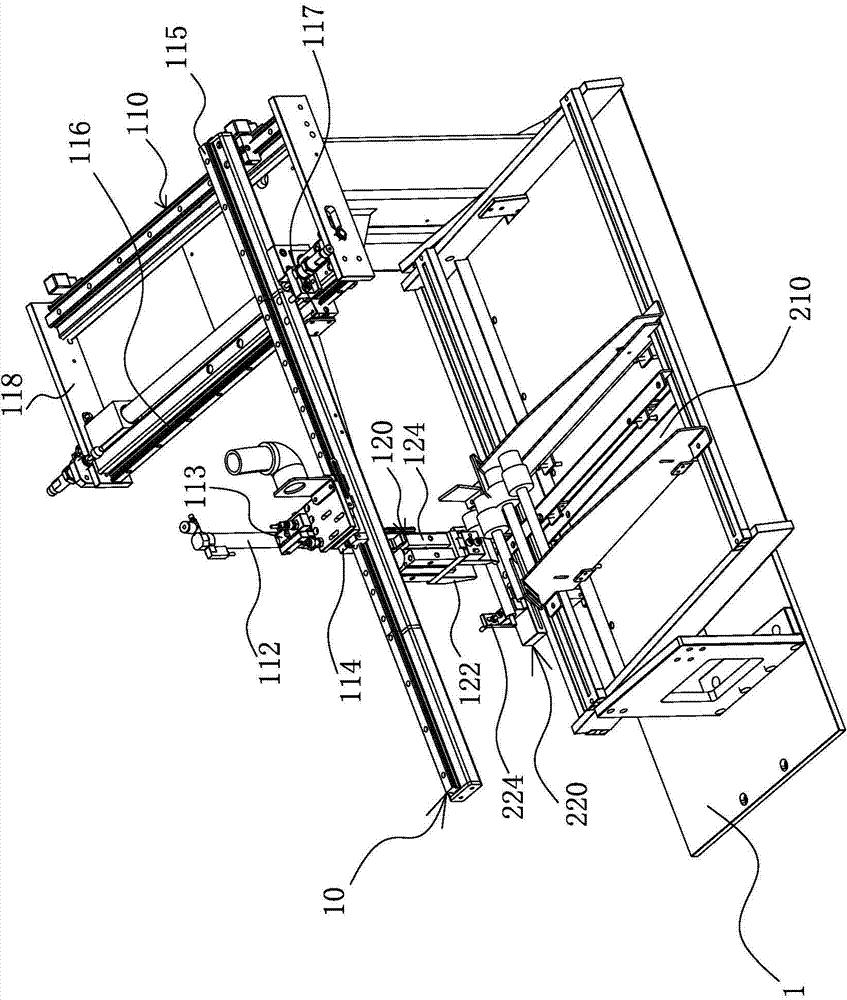

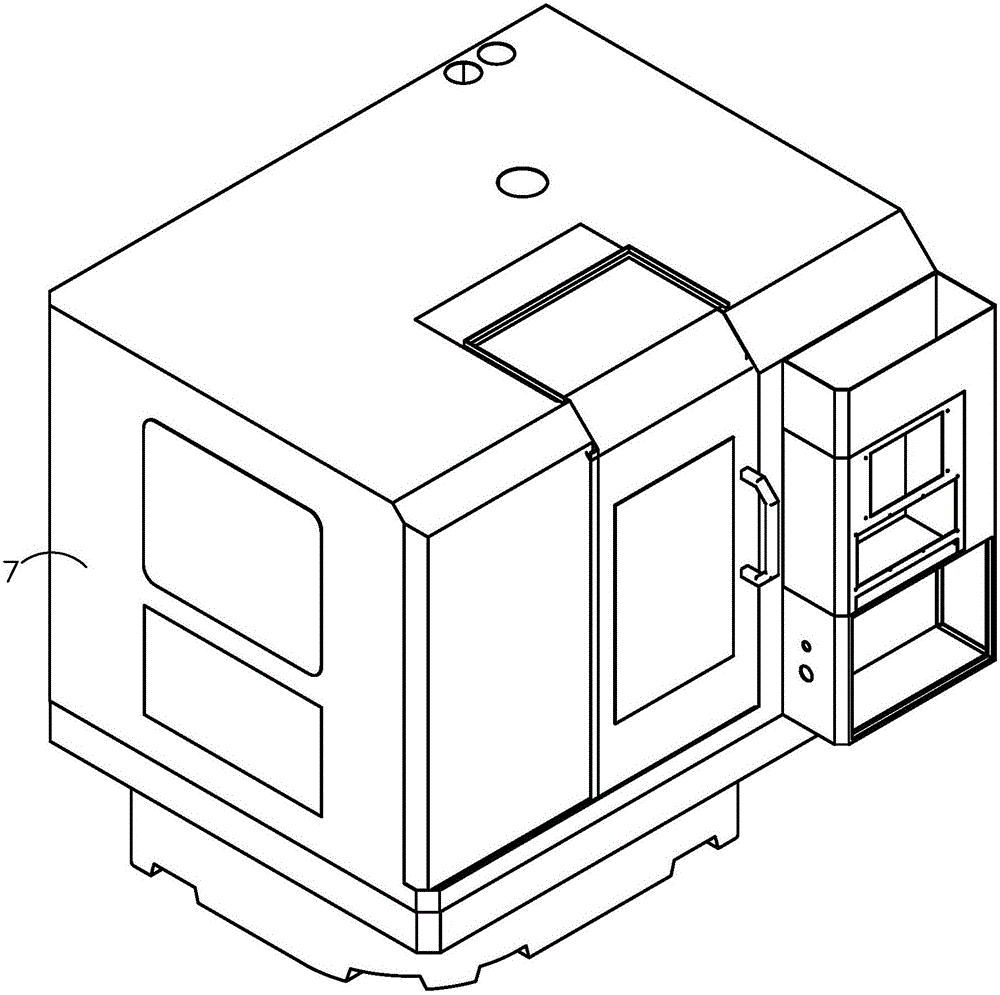

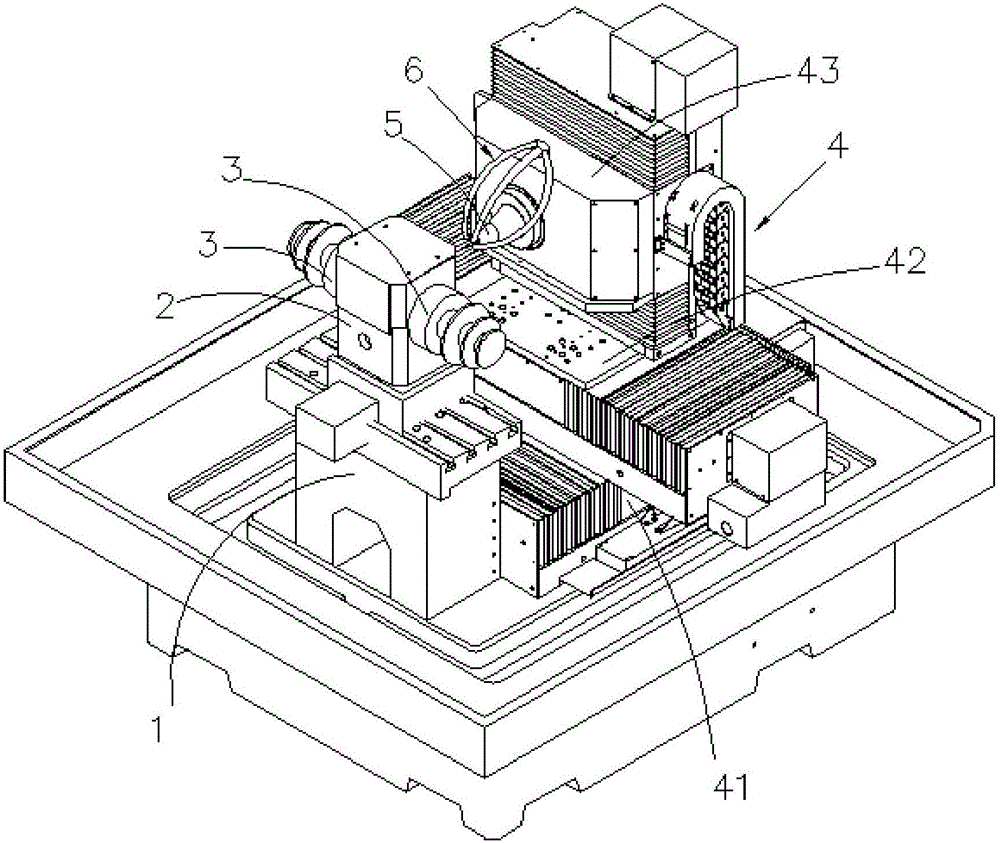

A fully automatic CNC knife grinder

ActiveCN105397579BImprove securityHigh degree of automationOther manufacturing equipments/toolsAutomatic grinding controlCnc grindingEngineering

The invention discloses a full-automatic numerical control knife grinder. The full-automatic numerical control knife grinder comprises a worktable and a control box. A first horizontal guide rail, a knife grinding rack, a feeding device and a discharging device are arranged on the worktable. The discharging device and the knife grinding rack are arranged on the same side of the first horizontal guide rail. The feeding device is arranged above the tail end of the first horizontal guide rail, and a second horizontal guide rail perpendicularly intersecting with the first horizontal guide rail is arranged above the first horizontal guide rail. A sliding seat is arranged above the second horizontal guide rail. A rotation table is arranged on the sliding seat. An L-shaped bent plate is connected with the output end of the top of the rotation table. A blade clamping device is arranged on the inner side of the L-shaped bent plate, and a numerical control device is arranged in the control box. By means of the full-automatic numerical control knife grinder with the manner, visual parameter adjustment and operation can be conducted through the numerical control device, the automation degree is high, manual clamping and discharging are not needed, safety is good, and working efficiency is high.

Owner:陈国全

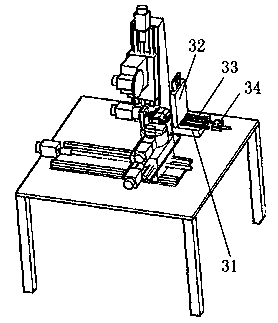

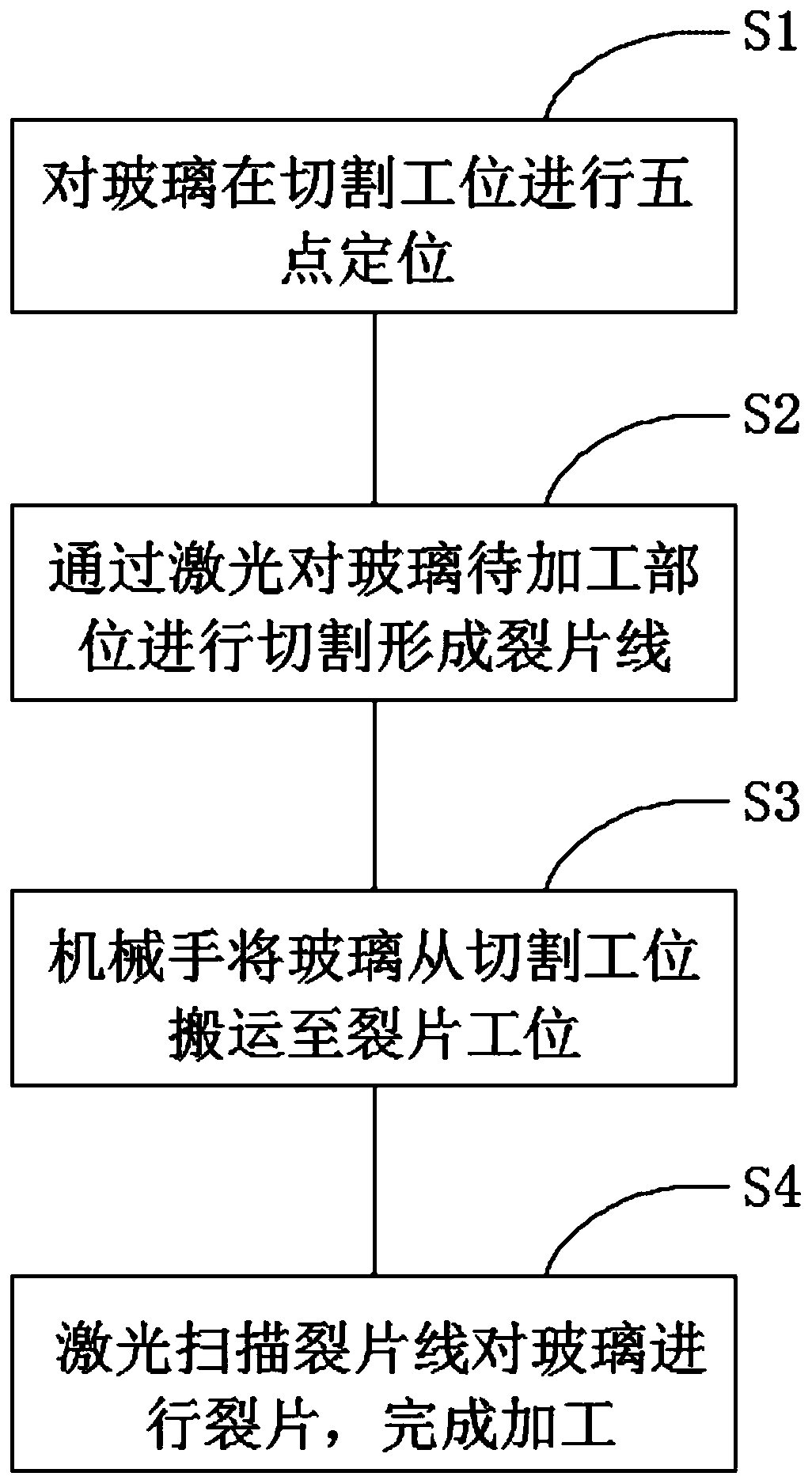

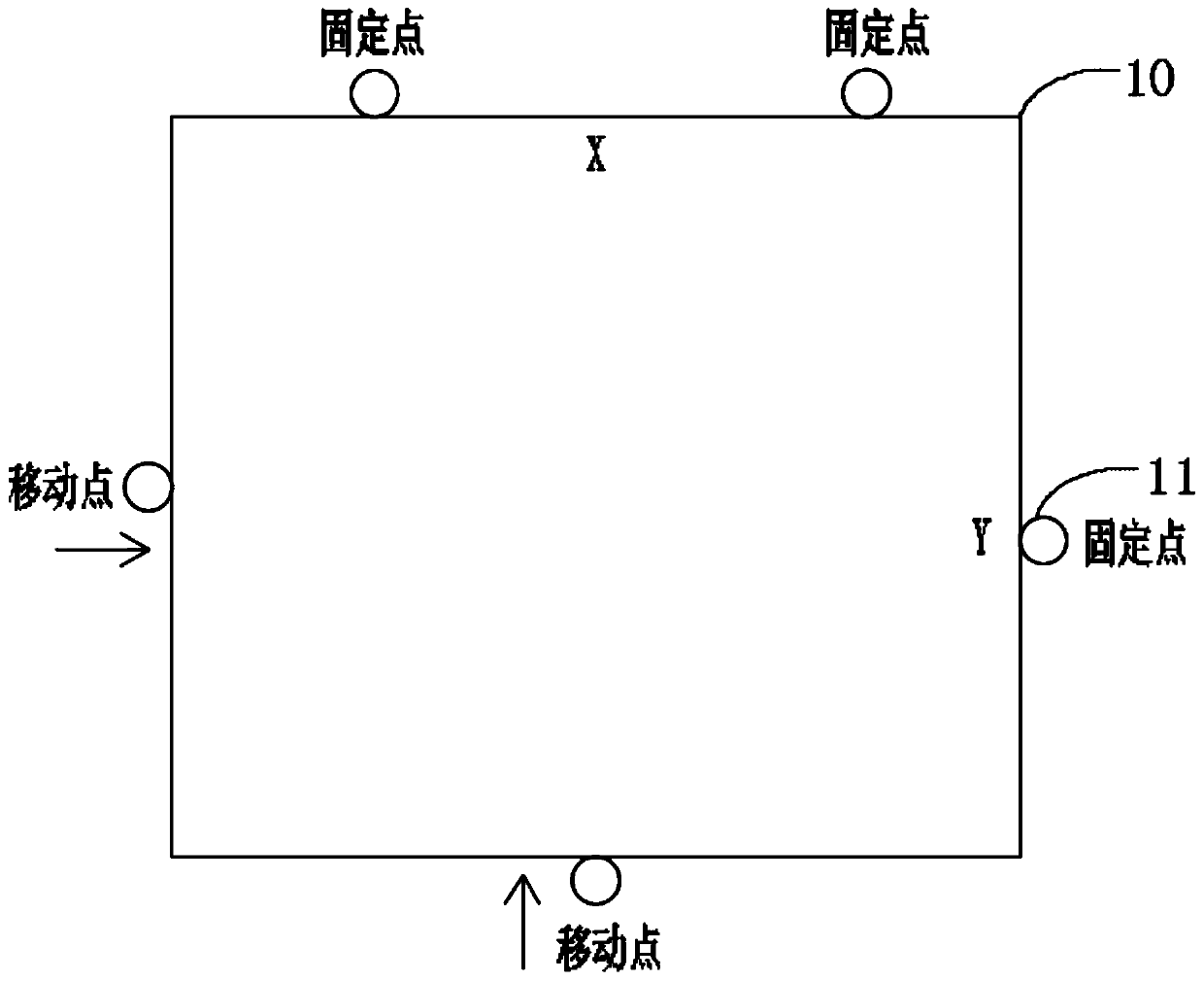

Glass cutting and splitting processing method and device

InactiveCN111393019AIncrease profitReduce labor costsGlass severing apparatusGlass productionLaser processingWatch glass

The invention relates to the technical field of laser processing, and discloses a glass cutting and splitting processing method and device, which are applied to watch glass laser cutting and splitting, and the method comprises the following steps: carrying out five-point positioning on watch cover glass at a cutting station; cutting and scribing the watch cover glass according to a set track to obtain a cutting line; using a transplanting manipulator for transplanting the watch cover glass from the cutting station to a splitting station; and generating laser thermal stress at the watch cover glass cutting line according to the set track so as to split the cut watch cover glass under the action of the laser thermal stress. According to the glass cutting and splitting machining method and device, watch cover glass cutting and splitting machining is integrated into circle cutting machining, only manual feeding and discharging are needed in the production process, the rest of cutting, splitting and carrying are all full-automatic machining, and the labor cost is reduced; compared with a traditional mode that a cutter wheel cuts square blocks and then CNC grinding is conducted to form circles, production efficiency is improved, machining processes are reduced, and the glass product utilization rate is increased.

Owner:深圳市青虹激光科技有限公司

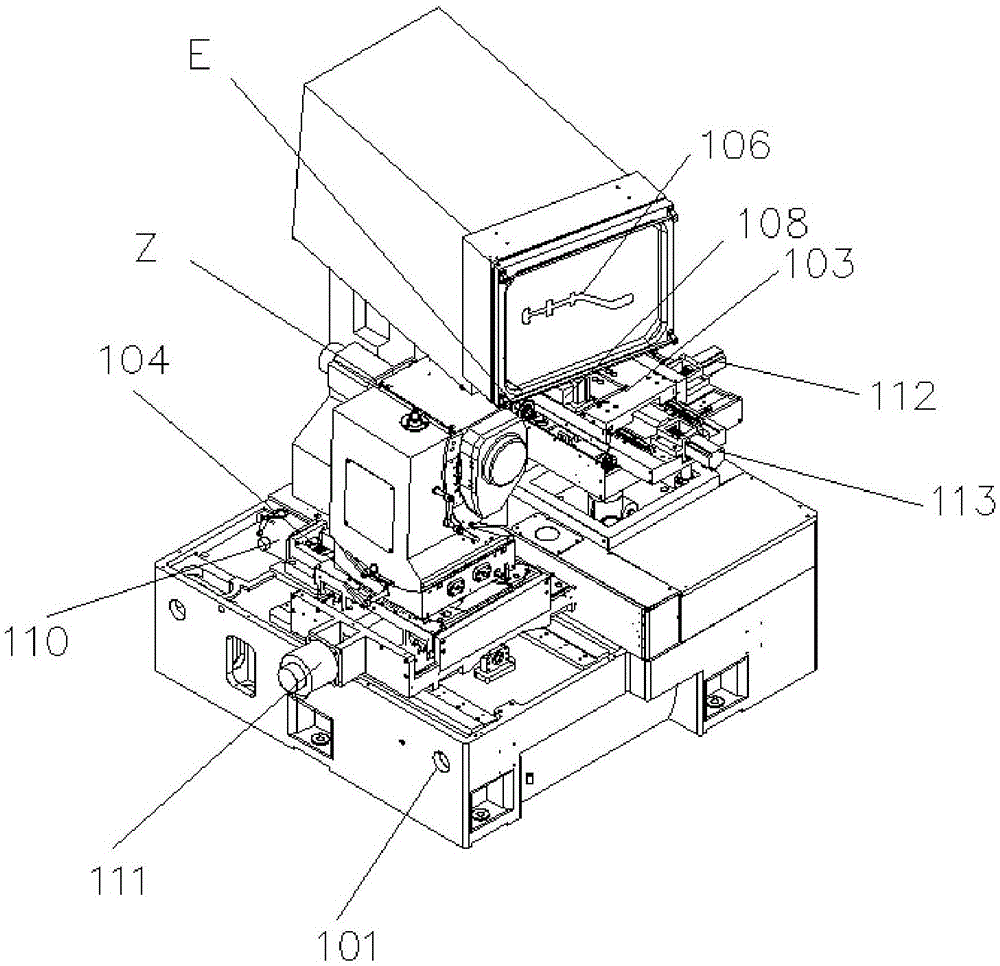

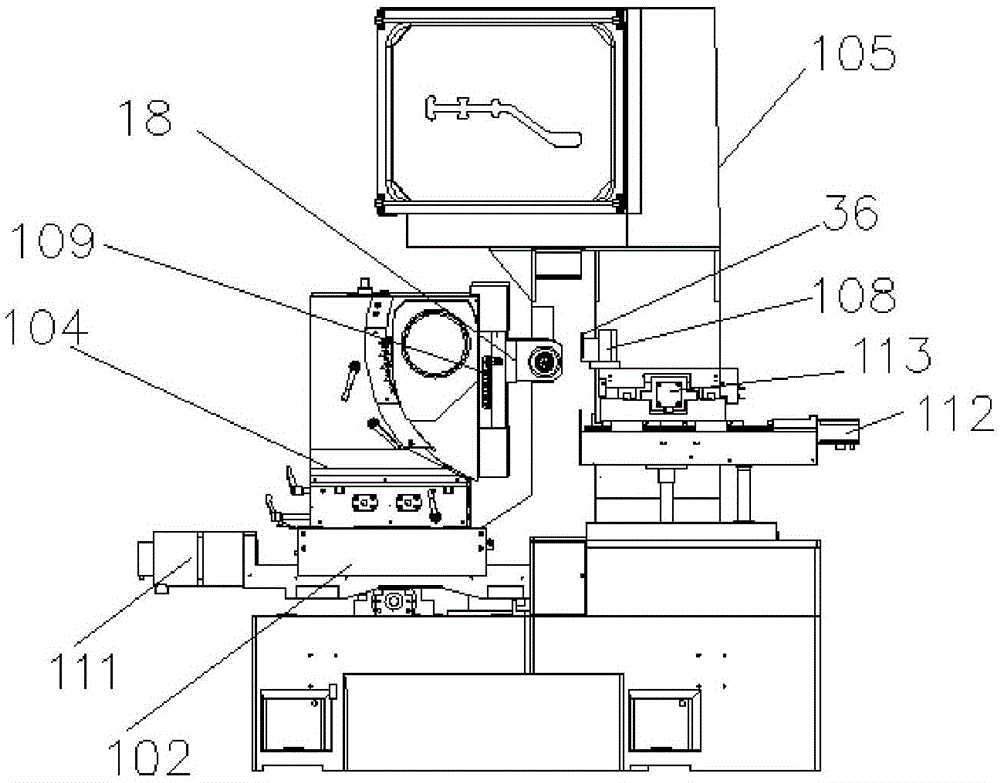

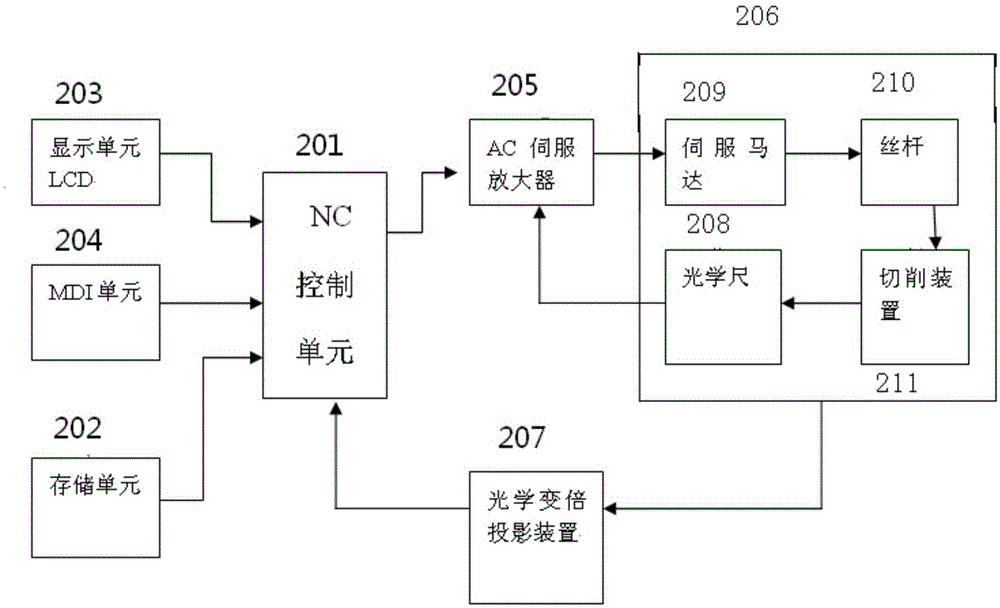

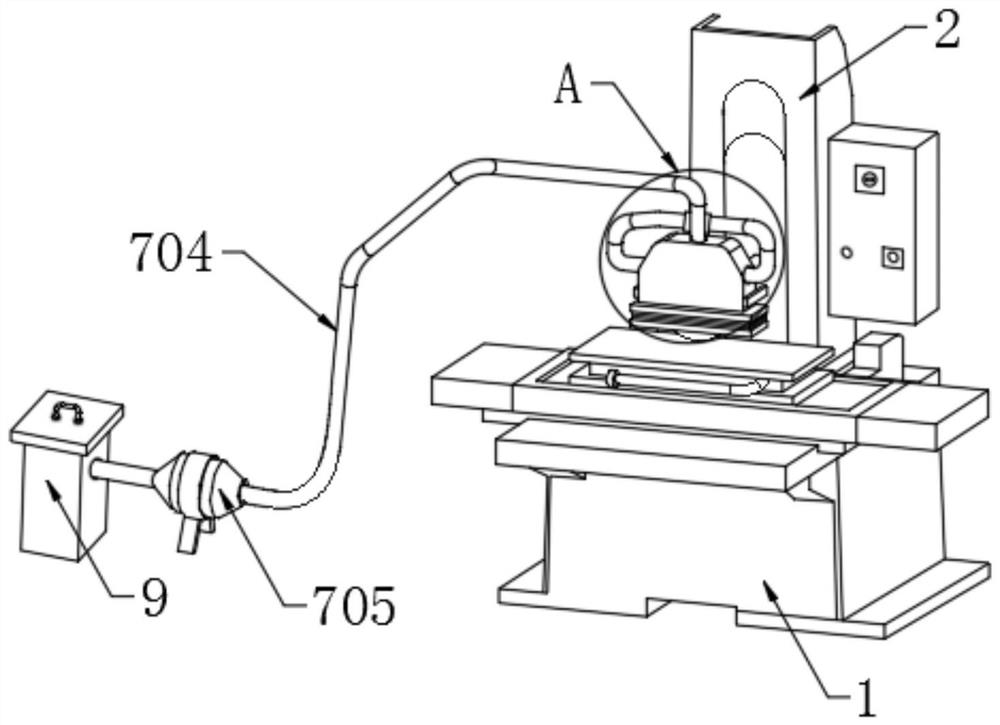

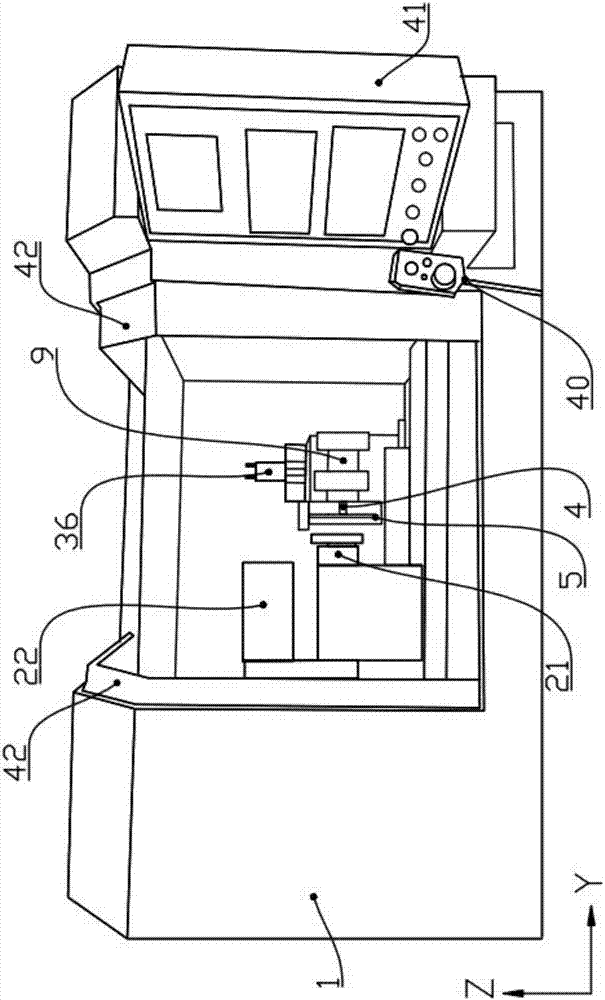

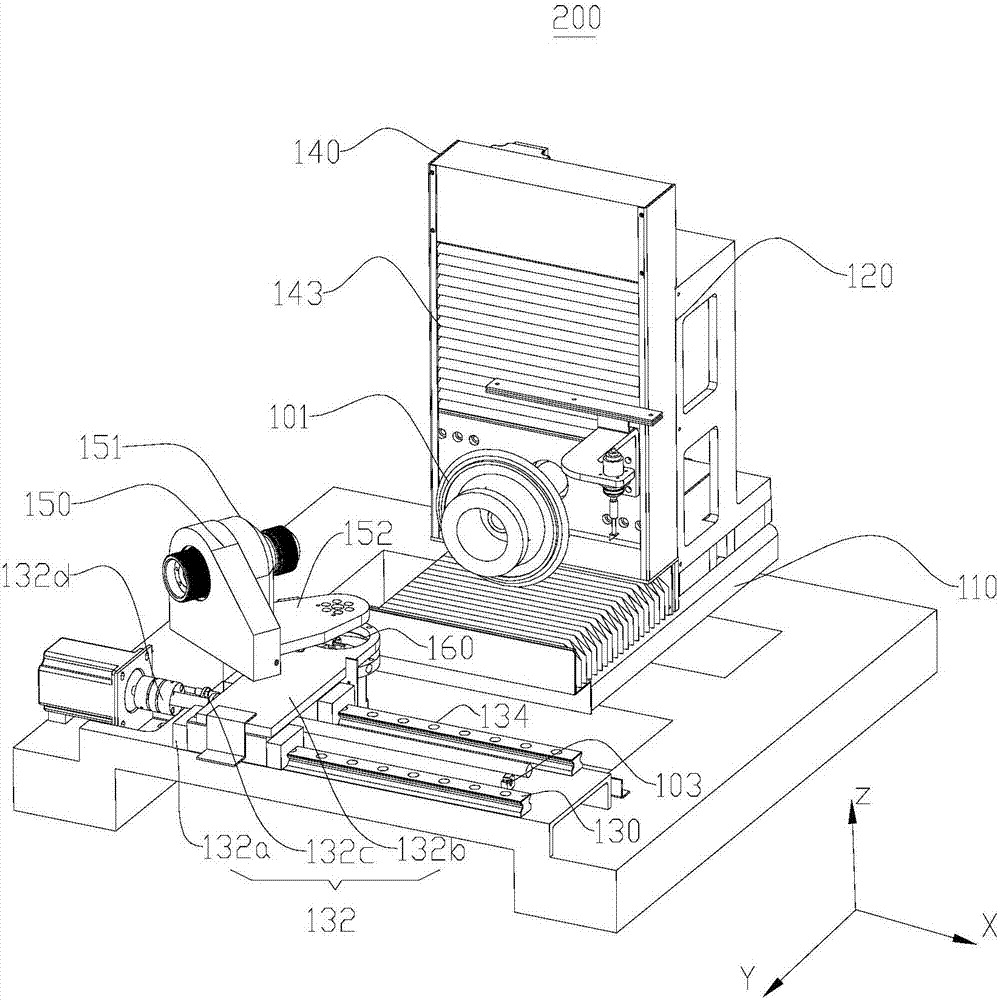

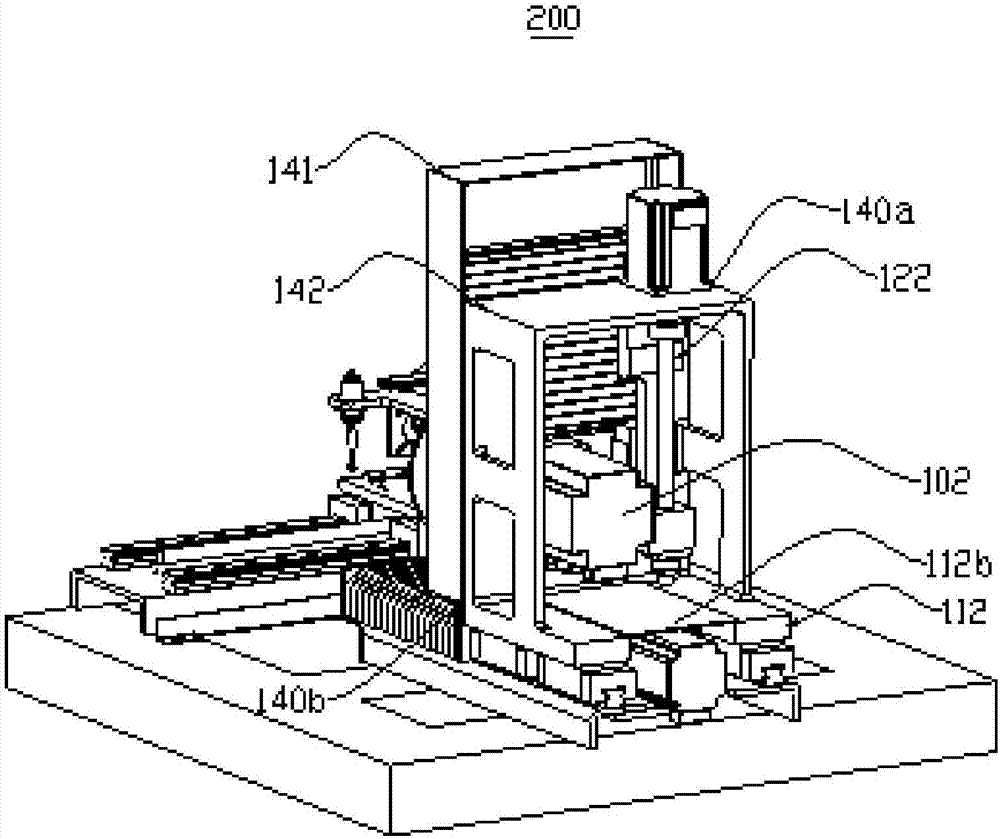

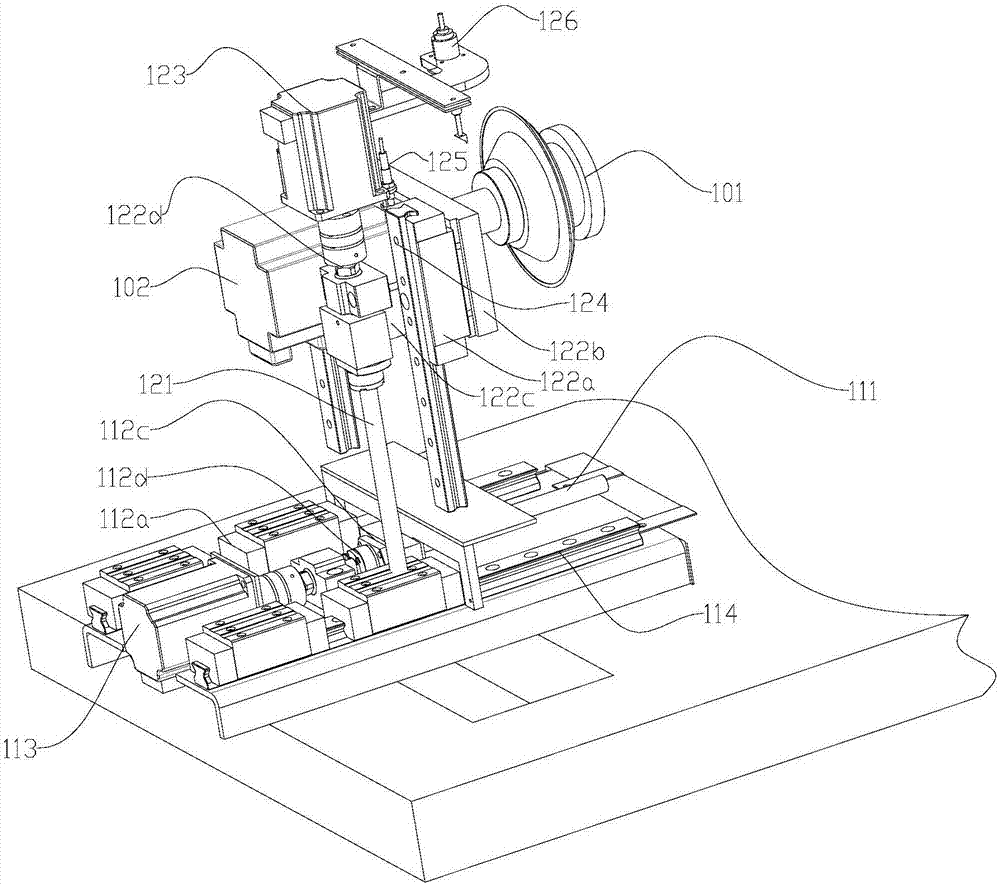

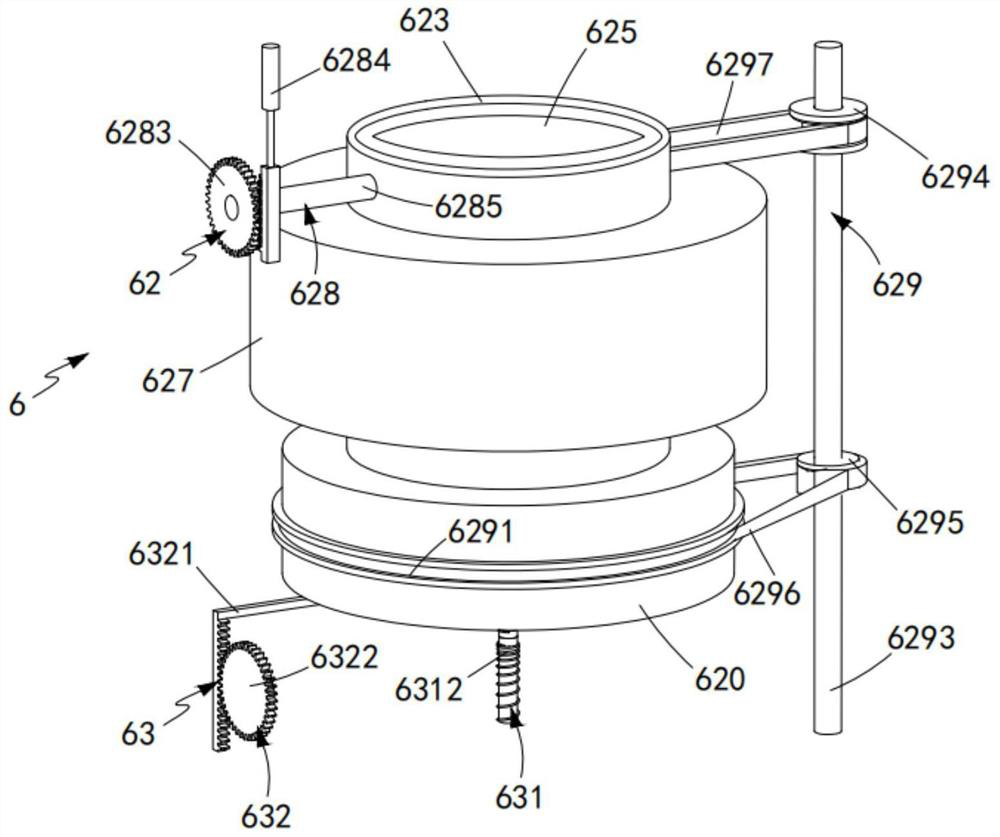

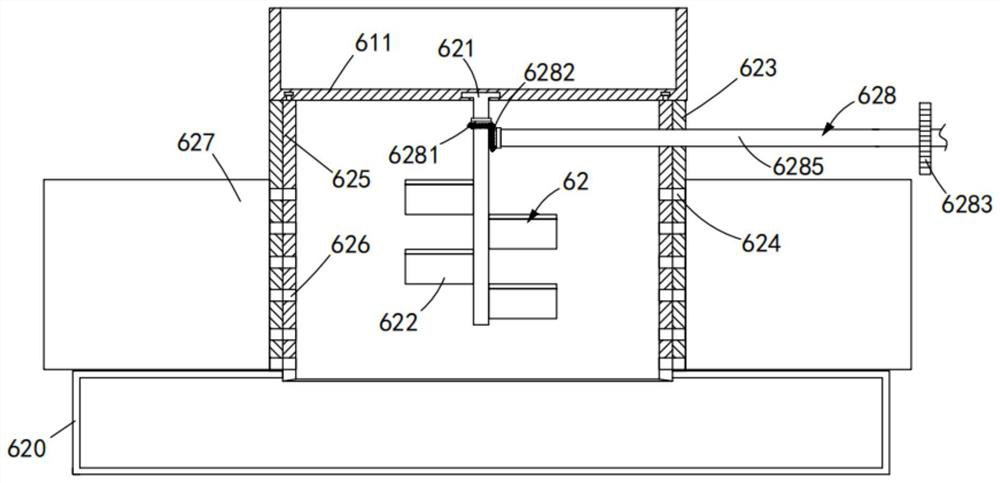

Optic zooming CNC grinding machine, control system and control method

ActiveCN105081924AEasy to assemble and disassembleNo need to moveOptical surface grinding machinesGrinding drivesControl systemCnc grinding

The invention discloses an optic zooming CNC grinding machine, comprising a machining cabinet. The machining cabinet is provided with an XY axis regulation platform and an UV worktable for clamping a workpiece. The XY axis regulation platform is provided with a three-direction angle regulation device capable of regulating front and back and left and right positions. A rear bracket is arranged at the rear side of the machining cabinet. The rear bracket is provided with an optic zooming projection device with variable magnification times. A transmission light source is arranged at a position, exacting facing the optic zooming projection device, below the machining cabinet. The UV worktable is provided with a permanent magnetic table. The permanent magnetic table is positioned between the optic zooming projection device and the transmission light source, and the three-direction angle regulation device is provided with a cutting device. The optic zooming CNC grinding machine is high in grinding precision, convenient to adjust and has variable magnification times.

Owner:DONGGUAN JOERG MACHINERY TECH

Method for cutting ultra-thin tempered glass by laser

InactiveCN106316090AHigh end face cutting qualityAvoid defects such as chipping and crackingGlass severing apparatusGlass productionHigh volume manufacturingGalvanometer

The invention provides a method for cutting an ultra-thin tempered glass by laser. Compared with the existed mechanical CNC (computer numerical control) grinding on the market, energy of a laser beam cuts a glass by a non-contact way, and the method avoids the shortcoming of edge breakage caused by mechanical contact; meanwhile, for the heating action zone of the laser is small, the end face cutting quality is higher; as for the ultra-thin tempered glass, laser can reach good cutting but CNC grinding cannot achieve; compared with laser ablation technology of picosecond galvanometer, taper of the glass end face is eliminated for the light beam scans the glass sample surface vertically after focusing, and thus the radial loading capacity of a sample is promoted; cutting process is one-time molding, the roughness of the sample end face is largely reduced and the sample quality is further promoted; moreover, the processing speed is better than the galvanometer scanning way; the method is applicable to the large-batch production and further promotes the product yield, and is good for industrial application.

Owner:武汉市楚源光电有限公司

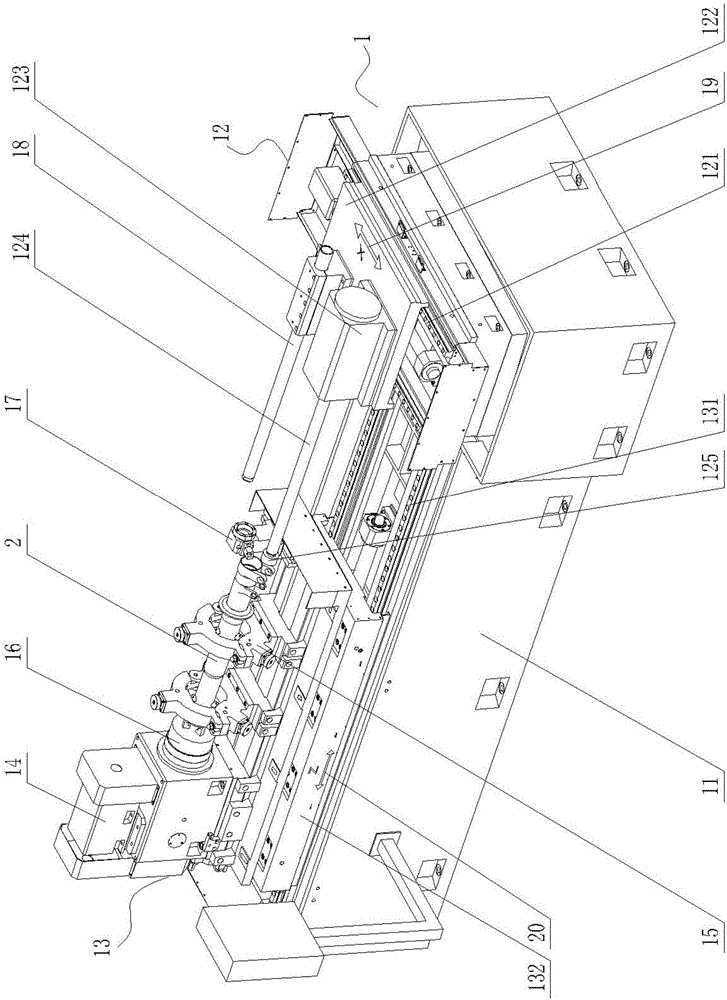

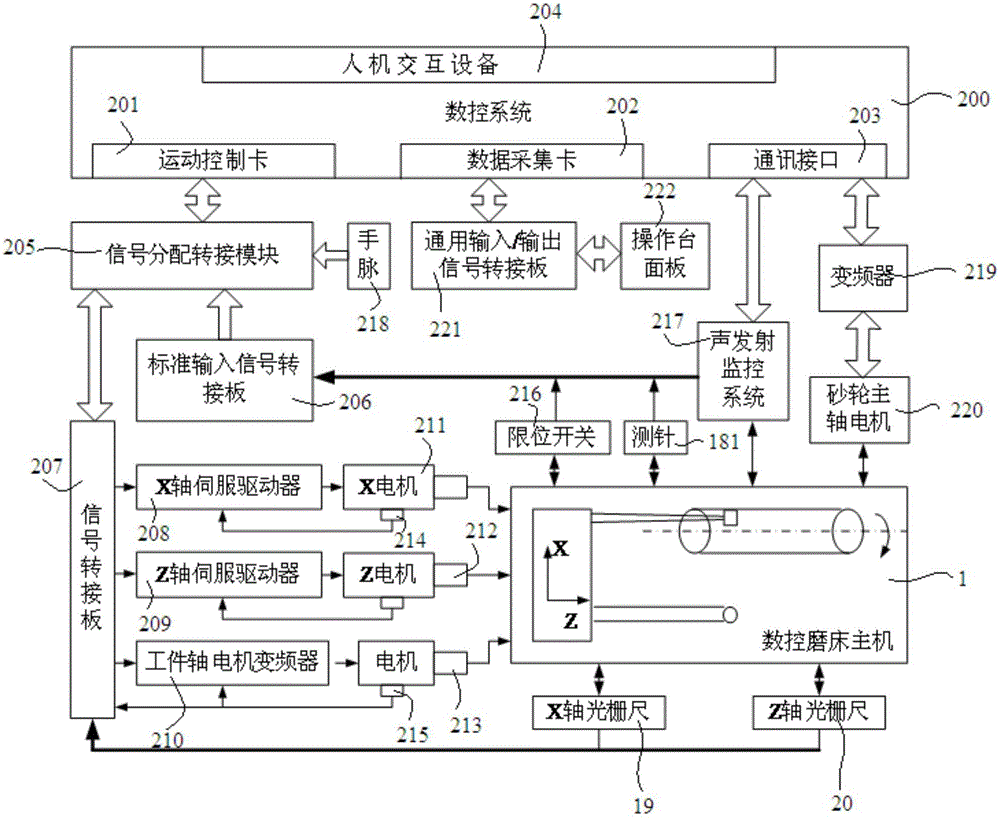

Measuring, monitoring and machining integrated device of numerical control deep hole inner circle grinding machine and control system

InactiveCN106112713AGuaranteed accuracy and poor reliabilityImprove processing efficiency and controllability of processing engineeringGrinding carriagesRevolution surface grinding machinesMeasurement deviceMachining process

The invention relates to a measuring, monitoring and machining integrated device of a numerical control deep hole inner circle grinding machine and a control system. The device is characterized by comprising a numerical control grinding machine host machine, and a deep hole size and shape in-place measuring device; an X-axle feeding system and a Z-axle feeding system are arranged on a machine body of the numerical control grinding machine host machine; the Z-axle feeding mechanism includes a Z-axle guide rail, a worktable slidingly arranged on the Z-axle guide rail, and a Z-axle driving device; the X-axle feeding system includes an X-axle guide rail, a main shaft box mounting base slidingly arranged on the X-axle guide rail, and an X-axle driving device; a grinding wheel main shaft box is mounted on the main shaft box mounting base; and a power output end of the grinding wheel main shaft box is connected with a grinding rod. The deep hole size and shape in-place measuring device includes a measuring rod, an X-axle grating ruler and a Z-axle grating ruler; the measuring rod is mounted on the main shaft box mounting base; and a measuring needle is arranged at the head part of the measuring rod. The device combines precise machining with online measuring control of a machine tool to replace one part of three-coordinate detecting functions, and improves the deep hole measuring, machining efficiency and machining process controllability.

Owner:无锡市明鑫数控磨床有限公司

Safety protective device used for numerical-control grinding machine

InactiveCN111774992AThere will be no flyingEnsure safetyGrinding drivesGrinding machinesCnc grindingElectric machinery

The invention belongs to the technical field of safety protection of numerical-control grinding machines, and particularly relates to a safety protective device used for a numerical-control grinding machine. The safety protective device comprises a table rack, wherein the top of the table rack is fixedly equipped with a supporting frame; one side of the supporting frame is fixedly equipped with amotor; a grinding wheel is fixedly mounted on the output shaft of the motor; one side, close to the grinding wheel, of the supporting frame is fixedly equipped with two connecting rods; sides, close to each other, of the two connecting rods are fixedly equipped with the same protective cover; a through hole is formed in the inner wall of one side, close to the supporting frame, of the protective cover; the output shaft of the motor penetrates through the through hole and is rotatably connected to the inner wall of the through hole; the grinding wheel is positioned in the protective cover; first mounting holes are formed in inner walls of two sides of the protective cover; and first guide tubes are fixedly mounted in the two first mounting holes. The safety protective device can effectivelyavoid a condition that workpiece fragments transversely fly while the grinding machine works, guarantees safety of an operator, and also guarantees an operation environment to be clean.

Owner:陈习

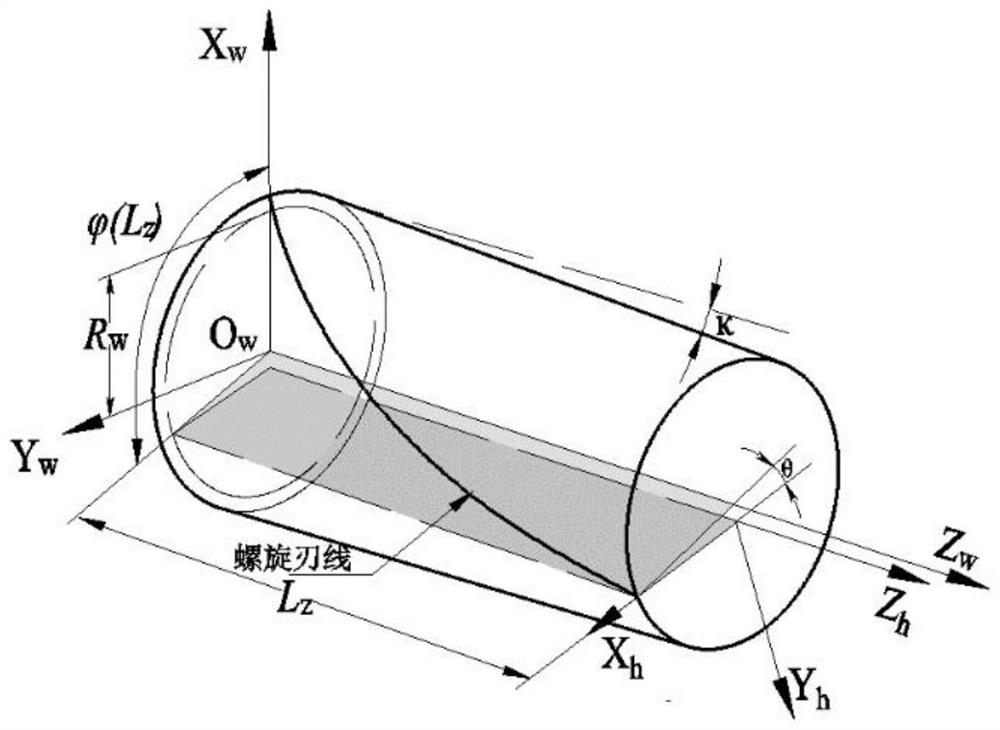

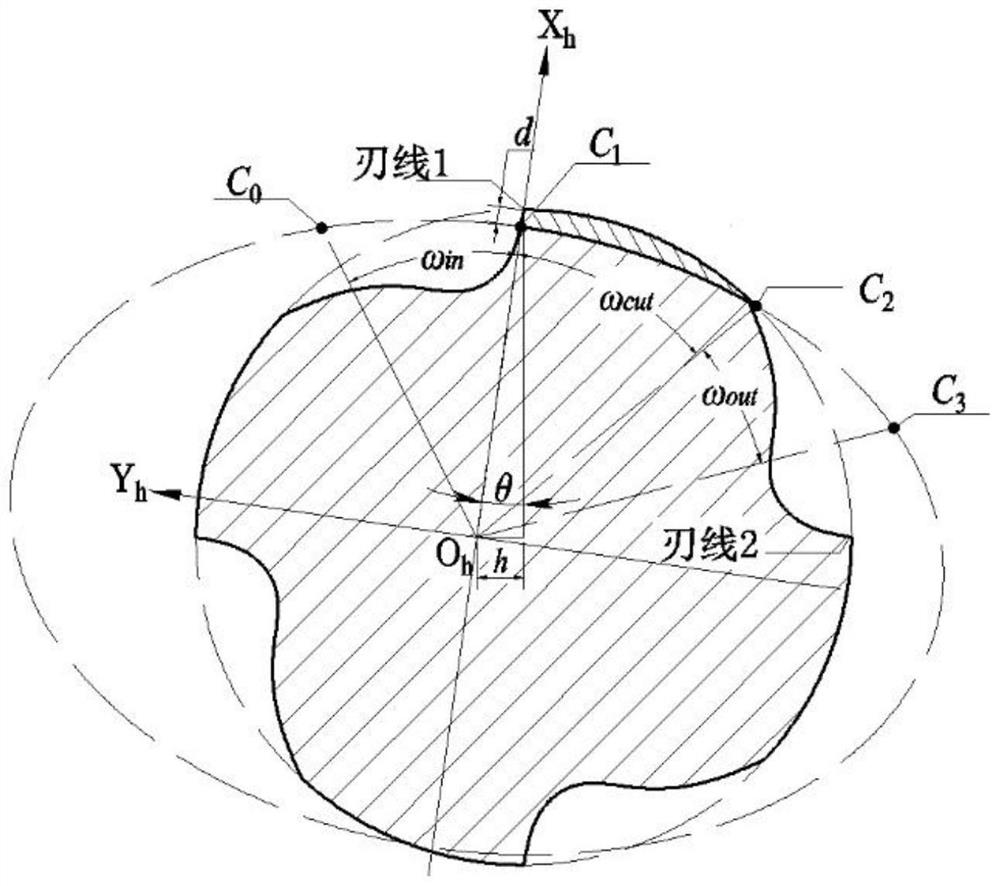

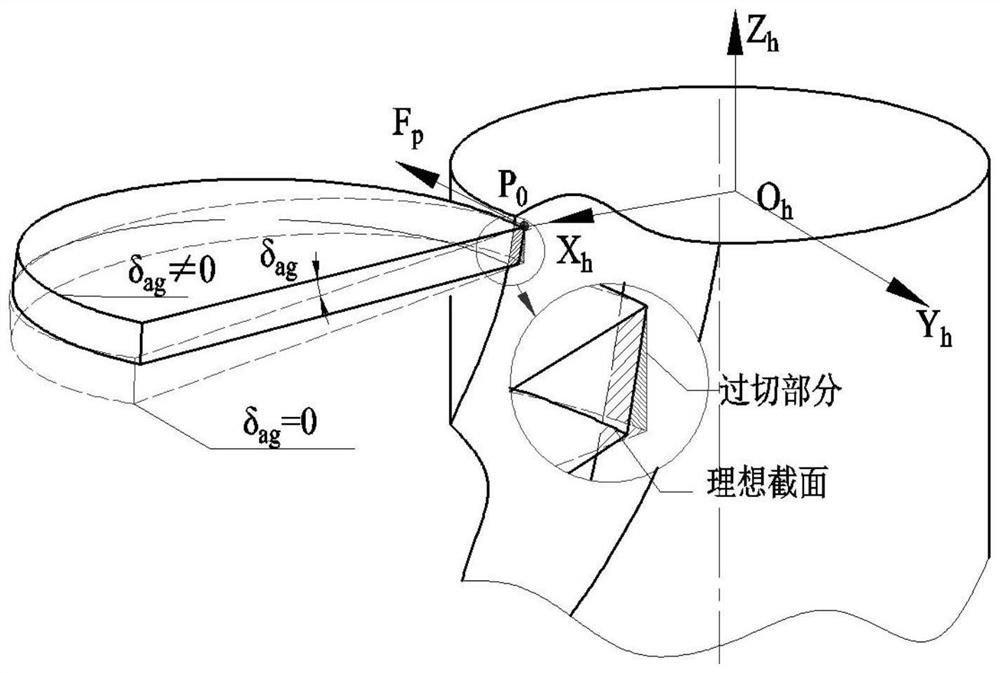

Numerical control grinding track calculation method for peripheral tooth chip separating groove of rough milling cutter

ActiveCN113927378AImprove calculation accuracyIncrease flexibilityMilling cuttersTotal factory controlKinematic theoryMilling cutter

The invention discloses a numerical control grinding track calculation method for a peripheral tooth chip separating groove of a rough milling cutter. The numerical control grinding track calculation method specifically comprises the following steps: firstly, defining structural parameters of the peripheral tooth chip separating groove of the rough milling cutter, and establishing a machining coordinate system and a cutting depth guide curve equation; and secondly, by means of the kinematics theory, providing a calculation method for the grinding wheel grinding posture and the grinding wheel grinding track. A chip flute structure is flexibly machined by controlling the moving posture of a grinding wheel, and good cutter structure expansibility and machining precision are achieved.

Owner:SOUTHWEST JIAOTONG UNIV +1

Numerical control tooth grinding machine with slotting function

InactiveCN110788400AUniform sizeFast absorptionSawing tools dressing arrangementsCnc grindingMachine

The invention discloses a numerical control tooth grinding machine with a slotting function. The numerical control tooth grinding machine comprises a box body, a concave base is fixedly installed at the bottom of the box body, a translation mechanism is installed inside the box body, and an abrasion wheel box of which the bottom is communicated with the outside is installed on the translation mechanism. The numerical control tooth grinding machine has the advantages of being simple in structure and easy to operate, saw webs can move up and down, thus errors generated in the traditional machining mode are reduced to guarantee the uniformity of the size of sawteeth, the tooth bottoms of the saw webs can be immediately slotted after tooth grinding on the saw webs is finished, extra detachmentis omitted, the working efficiency is improved, and the cost is reduced; the jetting angle and the jetting position of cooling liquid can be adjusted, and machining of the saw webs with different models can be better adapted to; and moreover, the cooling liquid can be recycled, extra cost is reduced, during machining, smoke can be quickly and timely absorbed and discharged after being diluted, subsequent treatment is facilitated, blockage on the device caused by the oil is also avoided, and the numerical control tooth grinding machine is simple, efficient, rapid and convenient.

Owner:缙云县先锋工具有限公司

Horizontal single-sided numerical control grinding spring machine

PendingCN107738184AReasonable structural designEasy to useGrinding carriagesGrinding drivesMotor driveCnc grinding

The invention relates to the technical field of mechanical equipment, in particular to a horizontal single-sided numerical control grinding spring machine. A plurality of springs to be ground can be put in a plurality of spring placement grooves in a lower spring placement plate and an upper spring placement plate, and a positioning plate can make the front ends of the springs flush; the springs are compressed by a compression cylinder, and a grinding wheel driving motor drives a grinding wheel to grind the ends of the springs; in the grinding process, a water outlet pipe of a water pump coolsthe grinding wheel, a sliding plate driving motor and a servo motor can drive the springs to move and finally one end of each of the springs are ground flush. The device is used, so as to reduce thelabor intensity of workers and improve the labor efficiency, so that the quality of the ground springs is stable and uniform. In short, the horizontal single-sided numerical control grinding spring machine has the advantages of reasonable structure design, convenience in use, effective improvement on the grinding quality of springs, and is suitable to be popularized and used.

Owner:苏州市相城区北桥镇轻工机械厂

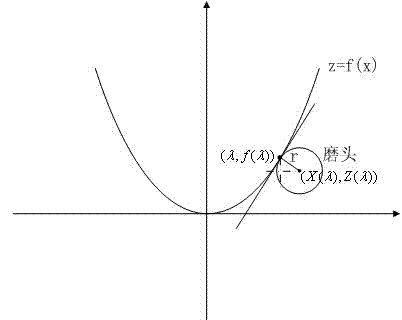

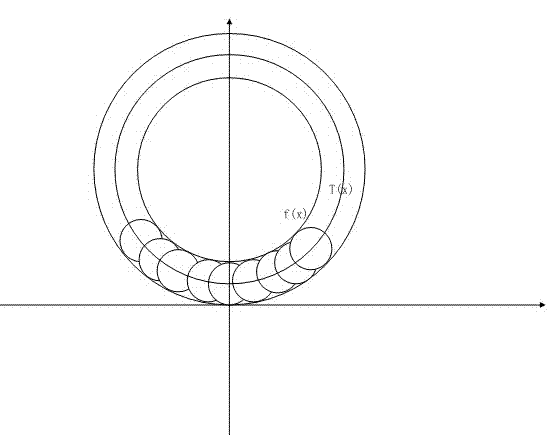

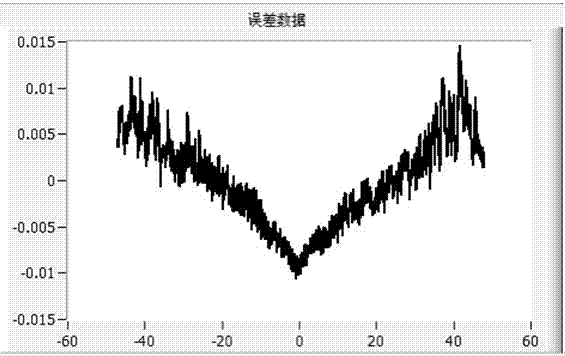

Method for measuring machine main shaft zero point and grinding head radius of computerized numerical control (CNC) grinding machine

InactiveCN102303284AEasy to analyzeImprove machining accuracyGrinding feed controlObservational errorPlane mirror

The invention discloses a method for measuring a machine main shaft zero point and a grinding head radius of a computerized numerical control (CNC) grinding machine. The method comprises the following steps of: (1) controlling the CNC grinding machine to grind a plane mirror, measuring the profile error data curve of the plane mirror, and making a reference compensation file of a guide rail according to measured error data; (2) compiling CNC codes aiming at a workpiece to be machined according to the zero point coordinate of a machine main shaft and data about the grinding head radius which are provided by a manufacturer, and the reference compensation file obtained in the step (1), and controlling the CNC grinding machine to machine and obtaining the rough-machined workpiece; (3) measuring the bus profile of the rough-machined workpiece by using a profile meter; and (4) analyzing the position of the zero point coordinate of the machine main shaft and the deviation of the grinding head radius by using data processing program which is compiled based on a data analysis model, according to the data about the bus profile obtained in the step (3) and the curve equation of the workpieceto the machined. According to the invention, the optimal values of the machine zero point and the grinding head radius of the CNC machine can be conveniently analyzed according to measured data of a machining workpiece, thus the machining accuracy is enhanced.

Owner:SUZHOU UNIV

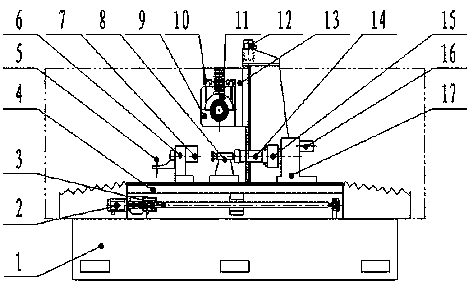

Five-axis linkage numerical control grinding knife machine tool

PendingCN107160243AOutstanding and Beneficial Technical EffectsRealize processingGrinding carriagesGrinding feed controlCnc grindingEngineering

The invention belongs to the technical field of grinding knife machine tools and particularly relates to a five-axis linkage numerical control grinding knife machine tool. The five-axis linkage numerical control grinding knife machine tool comprises a rack, and the rack is provided with a workbench and a main shaft table, wherein the movement directions of the workbench and the main shaft table are perpendicular to each other; the main shaft table is provided with a steering device, the steering device comprises a index plate, the index plate is internally provided with a steering shaft, the axis of the steering shaft and the axis of a workpiece shaft are perpendicular to each other and are arranged on the same horizontal face, the front end of the steering shaft is fixedly provided with a steering plate, and the steering plate is rotatably arranged on the front end portion of the index plate; the steering plate is provided with a lifting device, the lifting device comprises a lifting table, the lifting table is provided with a main shaft drive device, the main shaft drive device comprises a main shaft, the end portion of the main shaft is provided with a grinding wheel, and the axis of the main shaft and the axis of the steering shaft are perpendicular to each other; and the axis of the steering shaft and the work face of the grinding wheel are jointly arranged in the same plane. By means of the five-axis linkage numerical control grinding knife machine tool, woodworking tool cutters, valve cutters, threading dies, screw taps and other cutters with complex knife edge shapes can be machined automatically.

Owner:郑金焕

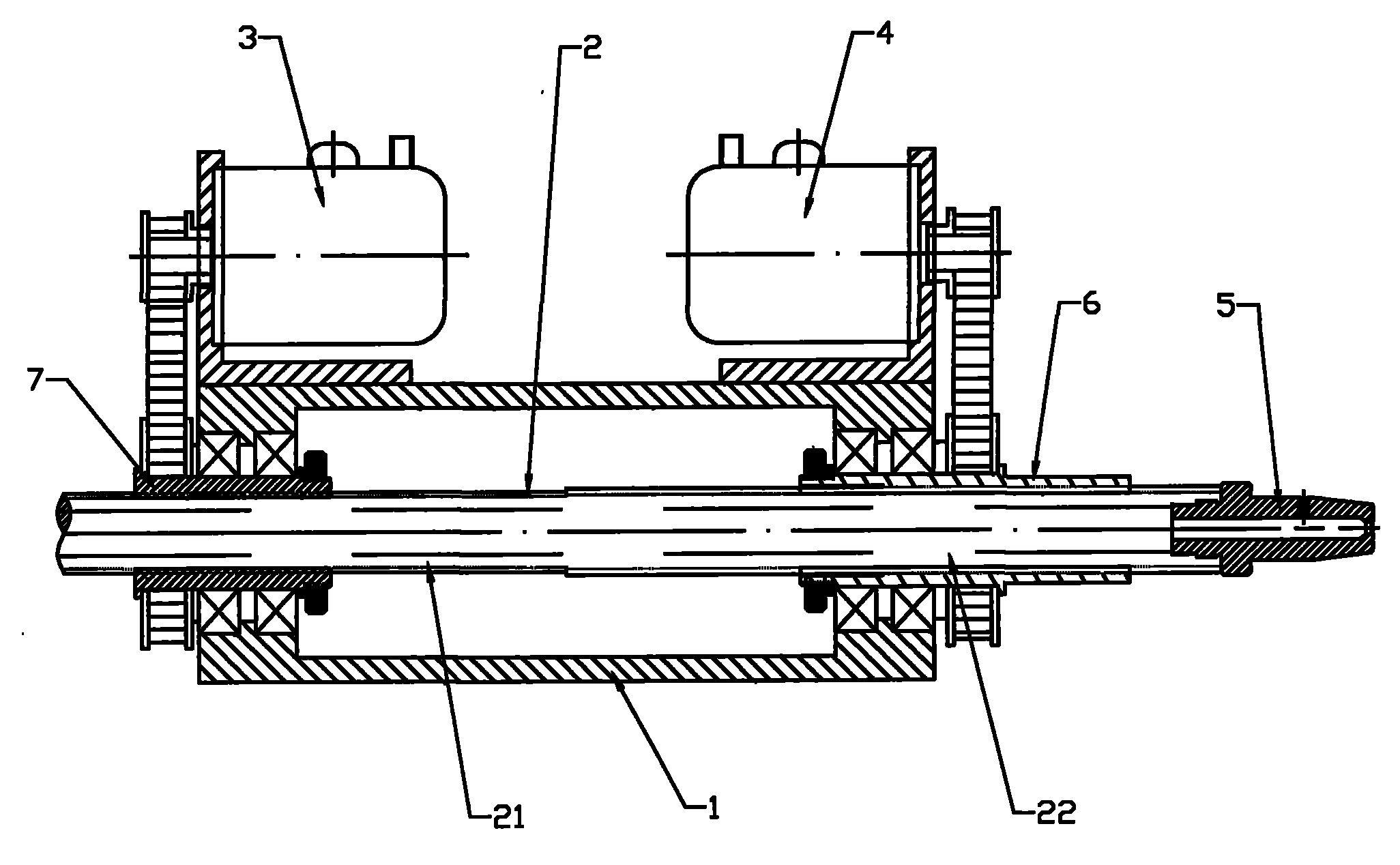

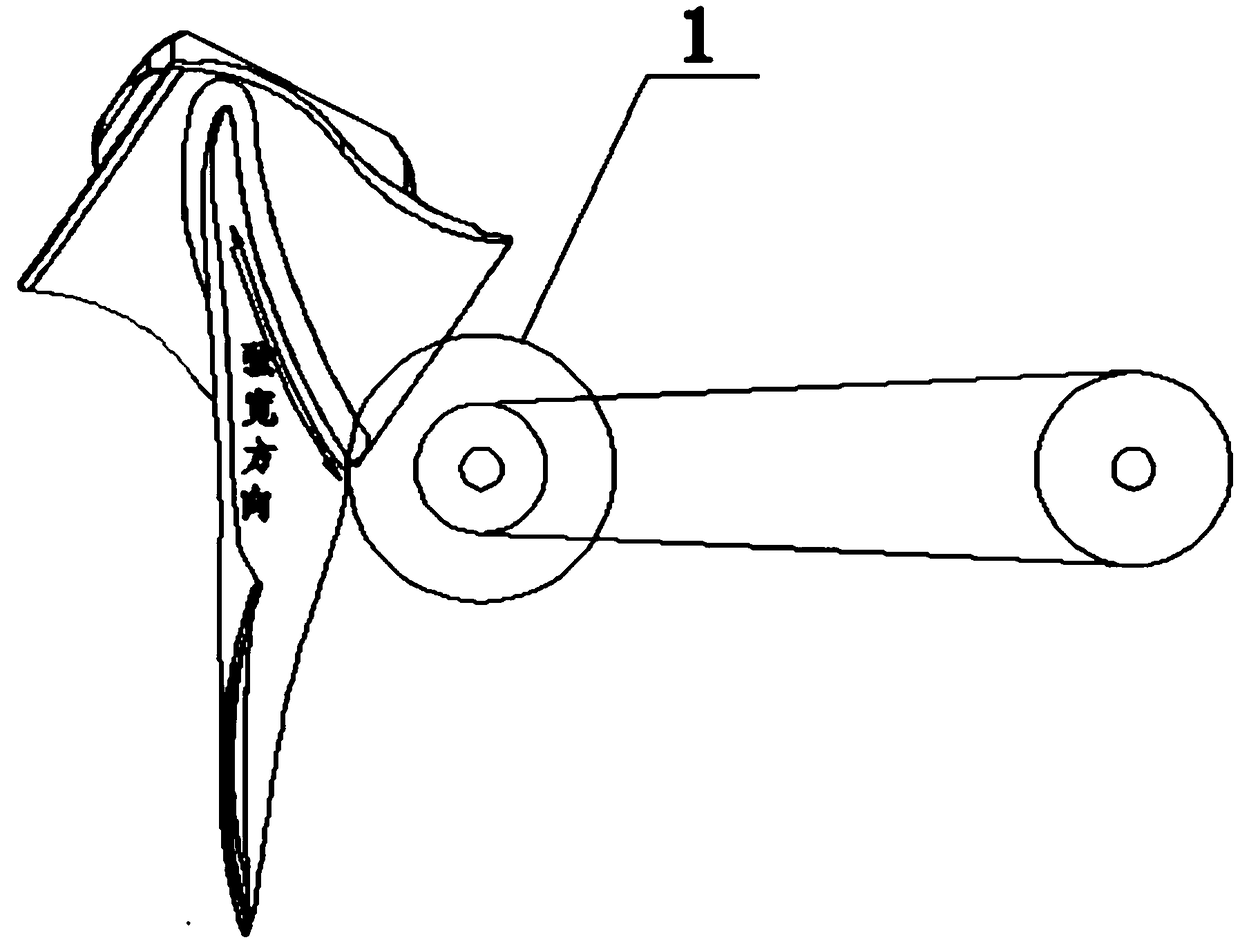

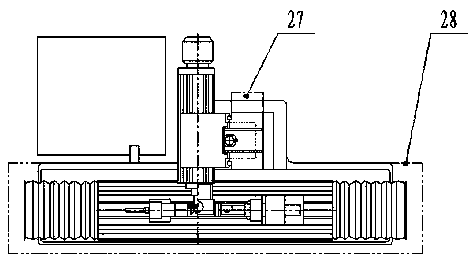

Spindle transmission component of CNC grinding (milling) groove machine tool

ActiveCN101786250AReduce in quantityEasy to manufactureFeeding apparatusDriving apparatusMilling cutterCnc grinding

The invention relates to a machine tool for processing machining tools such as drill bits, screw taps and milling cutters, in particular to a spindle transmission component of a CNC grinding (milling) groove machine tool. The component comprises a fixed tank, a spindle, a linear feed CNC motor and a rotary indexing CNC motor, wherein a collet used for clamping a work piece is arranged at the front end of the spindle; the spindle is divided into a front section and a rear section which are coaxial with each other; the front section of the spindle is a section of spline shaft outside which a spline sleeve is sleeved; the spindle can rotate along with the spindle sleeve and slide forward and backward relative to the spline sleeve; the spline sleeve is arranged on the fixed tank through a bearing and can be driven by the rotary indexing CNC motor; the rear section of the spindle is a section of screw rod matched with a screw rod pair; the spindle can be driven to move forward and backward by the screw rod pair; and the screw rod pair is arranged on the fixed tank through the bearing and is driven by the rotary indexing CNC motor. The spindle transmission component has the advantages of simple structure, small size, convenient manufacturing and installation and high processing accuracy.

Owner:丹阳市盛力机械有限公司

Numerical control grinding and finishing method for blade shot peening surface

ActiveCN108972354AAvoid overall overheatingImprove grinding efficiencyAbrasive machine appurtenancesNumerical controlMaterial removal

The invention relates to a numerical control grinding and finishing method for a blade shot peening surface. The numerical control grinding and finishing method for the blade shot peening surface comprises the following steps: finishing a blade root round corner transition zone, coarsely grinding a blade body profile surface, and finely grinding the blade body profile surface. At the same time, aiming at the situation that the blade profile surface is a free-form surface, the curvature changes greatly, and the difference of the sizes and shapes of different blades is large, the numerical control abrasive belt grinding produces the problem of local grinding unevenness. The numerical control grinding and finishing method for the blade shot peening surface provided by the invention optimizesa contact wheel. And for the problem of local less polishing or over polishing, the local treatment is performed through a program. The numerical control grinding and finishing method for the blade shot peening surface provided by the invention has the advantages of uniformly covering a crater on the blade shot peening surface and having small amount of material removal under the premise of ensuring that the roughness meets the quality requirement, and ensuring that the stress and influence depth of a shot peening residual compressive stress layer meet the design requirement.

Owner:AECC AERO SCI & TECH CO LTD

Workbench of numerical control knife grinder and numerical control knife grinder

PendingCN107283228AImprove efficiencyEasy to useGrinding carriagesGrinding drivesCnc grindingEngineering

The invention provides a workbench of a numerical control knife grinder and the numerical control knife grinder and relates to the technical field of knife grinders. The workbench of the numerical control knife grinder comprises a horizontal motion assembly and a vertical motion assembly driven by a first acting part. The horizontal motion assembly comprises a first lead screw and the first acting part matched with the first lead screw. The first lead screw is transversely arranged. The vertical motion assembly and the first acting part move synchronously. The vertical motion assembly comprises a second lead screw and a second acting part matched with the second lead screw. The second lead screw is vertically arranged, and the second acting part is connected with a grinding wheel. The working efficiency of the workbench is high. The numerical control knife grinder comprises the workbench. The numerical control knife grinder is convenient to use and high in working efficiency and knife grinding precision.

Owner:苏州赛帕埃惜精机有限公司

CNC (computer numerical control) grinding machine

InactiveCN104493677ADoes not affect workHigh degree of automationGrinding machinesGrinding feedersReciprocating motionCnc grinding

The invention provides a CNC (computer numerical control) grinding machine and belongs to the technical field of machinery. The CNC grinding machine comprises a frame, a grinding tool and a bench movably mounted on the frame. The frame includes a conveying area and a processing area sequentially from front to rear. An incoming mechanism and a conveying mechanism are disposed in the conveying area. A spindle box and a discharging mechanism are disposed in the processing area. The discharging mechanism and the incoming mechanism are disposed on two sides of the spindle box. The conveying mechanism is disposed over the incoming mechanism and can linearly reciprocate between the incoming mechanism and the spindle box. A floating chuck is mounted on the spindle box. The frame is provided with an ejector base arranged right in front of the spindle box. The grinding tool is movably mounted right in rear of the spindle box. The spindle box is fixedly connected with the bench. The ejector base is disposed over the bench. The frame is further provided with a first drive motor and a second drive motor; the first drive motor can control the grinding tool to linearly move in the horizontal direction; the second drive motor can control the bench to linearly slide. The CNC grinding machine has the advantages of high automation level and operational convenience.

Owner:NINGBO MEIDE ROBOT

Five-axis CNC grinding robot

InactiveCN105881167ANot easy to looseImprove rigidityGrinding carriagesGrinding machinesCnc grindingThermal deformation

A five-axis CNC grinding robot comprises a base, a machining base rotationally connected to the base along a vertical axis, machining spindle heads rotationally connected to the machining base and with the axis line extending in the horizontal direction, a machined workpiece transferring mechanism arranged on the base, a machined workpiece loading portion arranged on the machined workpiece transferring mechanism, and a program control mechanism, wherein the base is made of marble. The base is made of marble, is good in rigidity and does not have thermal deformation, so that the space between the base and the machining base is not prone to loosening, stability is good, and high precision of machined products is kept.

Owner:KUANI PRECISION IND KUNSHAN CO LTD

Numerical control grinding machine capable of quickly removing cooling liquid for machining

InactiveCN112536682AGood effect of removing impuritiesImprove the quality of useGrinding carriagesGrinding machinesCooling effectCnc grinding

The invention relates to a numerical control grinding machine capable of quickly removing cooling liquid for machining. The numerical control grinding machine comprises a grinding machine, a grindingmechanism, a cooling mechanism, a bearing mechanism, an adsorption mechanism and a screening mechanism; the screening mechanism comprises a scrap iron collecting assembly, a clear water output assembly arranged below the scrap iron collecting assembly, a grinding stone particle collecting assembly arranged below the clear water output assembly and cooperates with the clear water output assembly tocomplete clear water throwing-out work, and a circulating assembly of which one end of communicates with the grinding stone particle collecting assembly and the other end communicates with the cooling mechanism; and the adsorption mechanism and the grinding mechanism work in a synchronous transmission mode through a first transmission mechanism. The technical problems that when water cools the grinding mechanism, the temperature of the water rises, the water cannot be quickly cooled in the recycling process, and then the cooling effect on the grinding mechanism is affected when circulating water conducts cooling work again are solved.

Owner:张达宇

Novel machining technology for grinding plunger

The invention relates to a novel machining technology for grinding a plunger. The novel machining technology comprises the following operation steps of step one, machining the outer circle of the plunger; preparing workblank, roughly grinding the outer circle of the workblank, buffing the roughly-ground outer circle, and finally, finely grinding the outer circle; step two, carrying thermal treatment on the plunger of which the outer circle is machined; step three, machining a straight channel in the plunger on which the thermal treatment is carried out by adopting a CNC (Computer Numerical Control) grinding machine; step four, machining a chute in the plunger by adopting the CNC grinding machine after straight channel machining is completed, carrying out one-step clamping, and automatically overturning one surface which is already machined to machine the other surface. The novel machining technology disclosed by the invention is low in production cost and excellent in product quality.

Owner:无锡威孚马山油泵油嘴有限公司

Numerical control grinding machine with grinding wheel dynamic balance calibration function and using method thereof

ActiveCN113001336AReduce dynamic balance calibration timeFast adjustment processGrinding feed controlAbrasive surface conditioning devicesControl engineeringCnc grinding

The invention discloses a numerical control grinding machine with a grinding wheel dynamic balance calibration function and a using method thereof. The numerical control grinding machine comprises a numerical control grinding machine body, a numerical control grinding machine inner cavity is formed in the numerical control grinding machine body, a waste box is fixedly connected to the inner wall of the lower side of the numerical control grinding machine inner cavity, and a grinding wheel spindle mechanism is arranged in the numerical control grinding machine inner cavity. The grinding wheel spindle mechanism can carry out dynamic balance detection on a grinding wheel, a grinding wheel dressing mechanism located at the lower side of the grinding wheel spindle mechanism is arranged in the numerical control grinding machine inner cavity, and the grinding wheel dressing mechanism is used for dressing the grinding wheel. A grinding wheel dynamic balance adjusting mechanism located at the left side of the grinding wheel spindle mechanism is arranged in the numerical control grinding machine inner cavity. According to the numerical control grinding machine, different numbers of balance blocks can be selected according to dynamic balance detection results, the balance blocks with different masses do not need to be replaced and found, therefore, the dynamic balance calibration time is shortened, the installation position is mechanically positioned, the adjusting process is fast, and the dynamic balance calibration precision is high.

Owner:浙江宸嘉液压科技有限公司

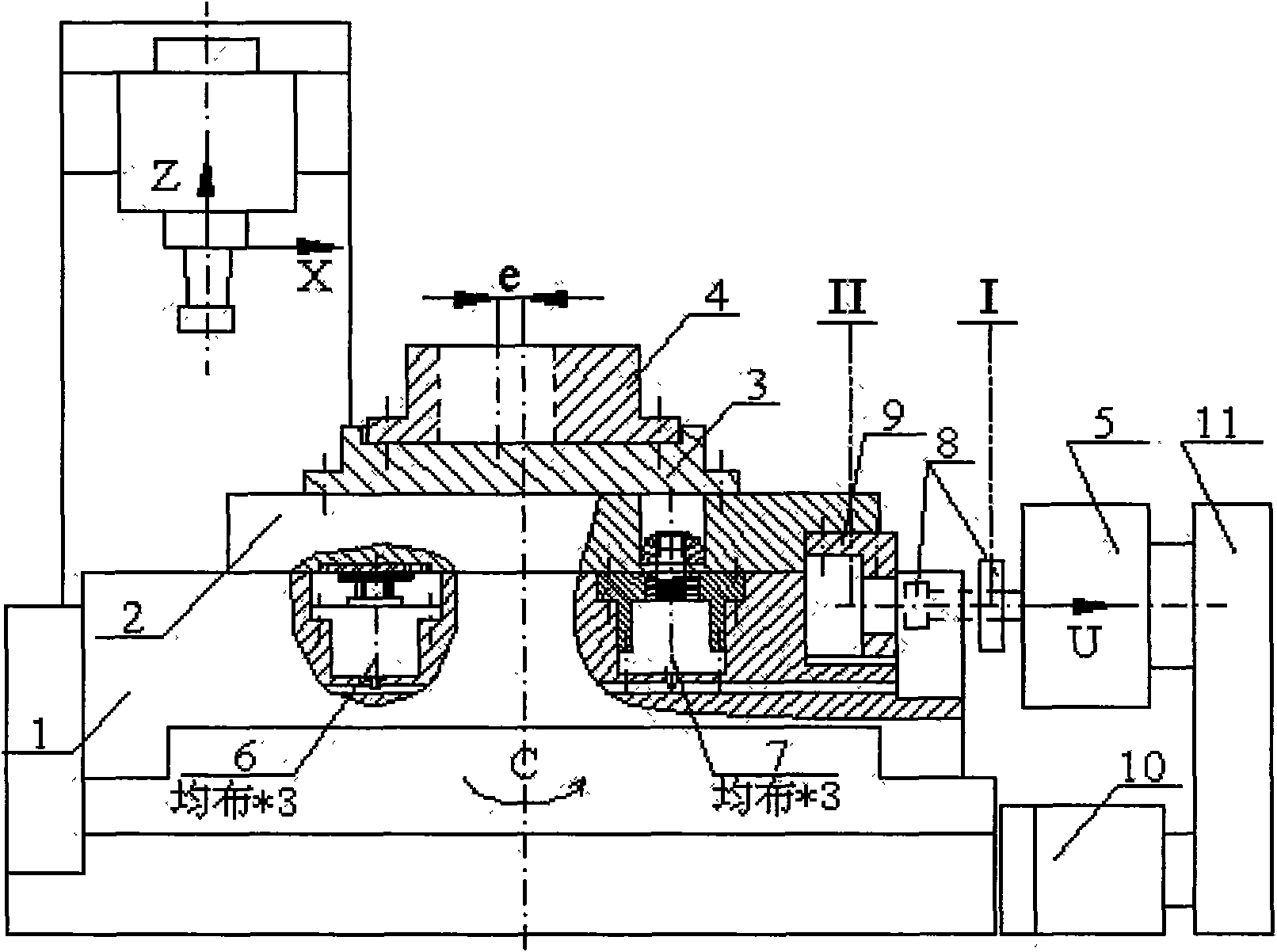

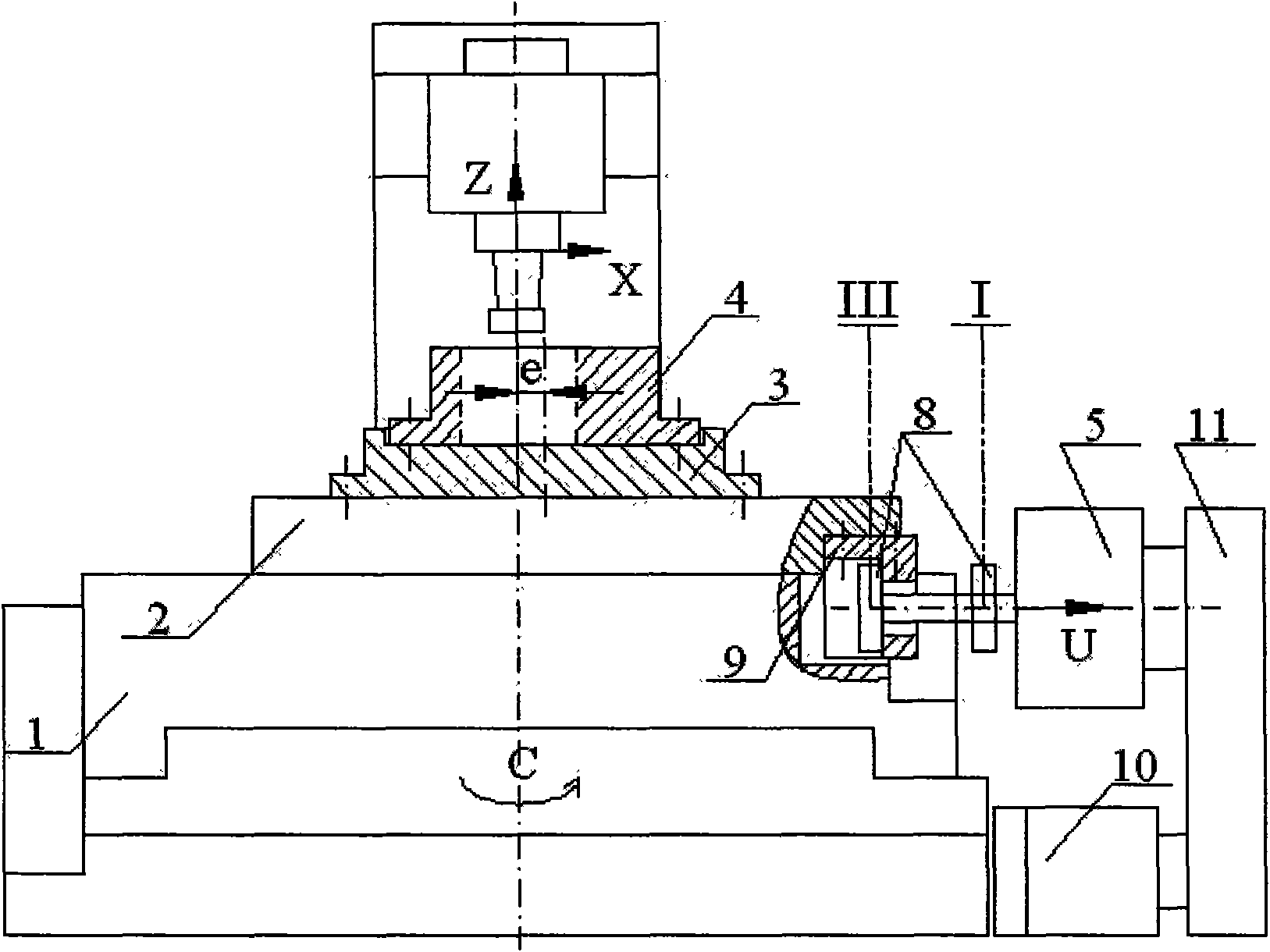

Numerical control grinding machine

InactiveCN107756188AGuaranteed flexibilityGuaranteed accuracy requirementsGrinding carriagesGrinding drivesGrinding wheelAxial rotation

The utility model relates to a numerical control grinding machine, which is used for forming and grinding the groove of the intermediate shaft of the ball cage coupling. The CNC system is respectively connected with the servo motor and the stepping motor. Servo motors 1, 2, and 3 are respectively installed on the grinding head frame, column, and bed base to realize the Z, Y, and X-direction linear motion of the CNC system. Servo motor 4 It is connected with the indexing mechanism to realize the numerical control indexing or axial rotation of the workpiece; the stepper motor is connected with the dresser to realize the rotary motion of the diamond pen; the grinding wheel shaft is driven by the grinding head motor to provide the main grinding movement; the machine tool has a semi-closed cover, Air extraction, dust removal and cooling circulation system; the servo motor is driven by a four-axis linkage numerical control system, and the stepping motor and the four-axis linkage numerical control system are controlled by a program controller; the invention is widely used in grinding various curved surfaces of metal parts. The movement and positioning of each part can be controlled by numerical control, with high degree of automation, high precision of grinding wheel dressing, smooth working surface and accurate indexing precision of workpieces, which can effectively improve the working environment and reduce the labor intensity of workers.

Owner:钟泽

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com