Patents

Literature

43results about How to "Accurate dimensional accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

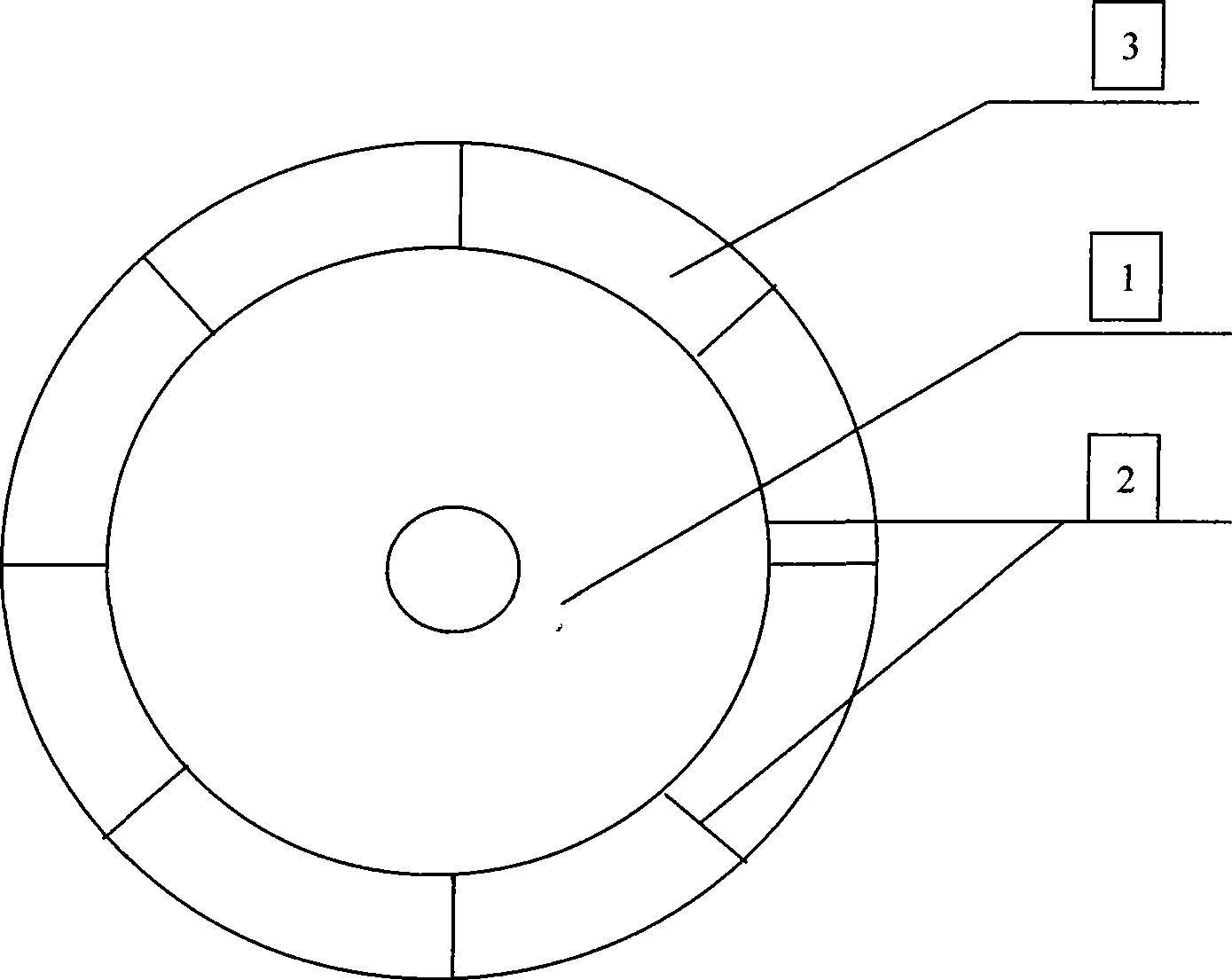

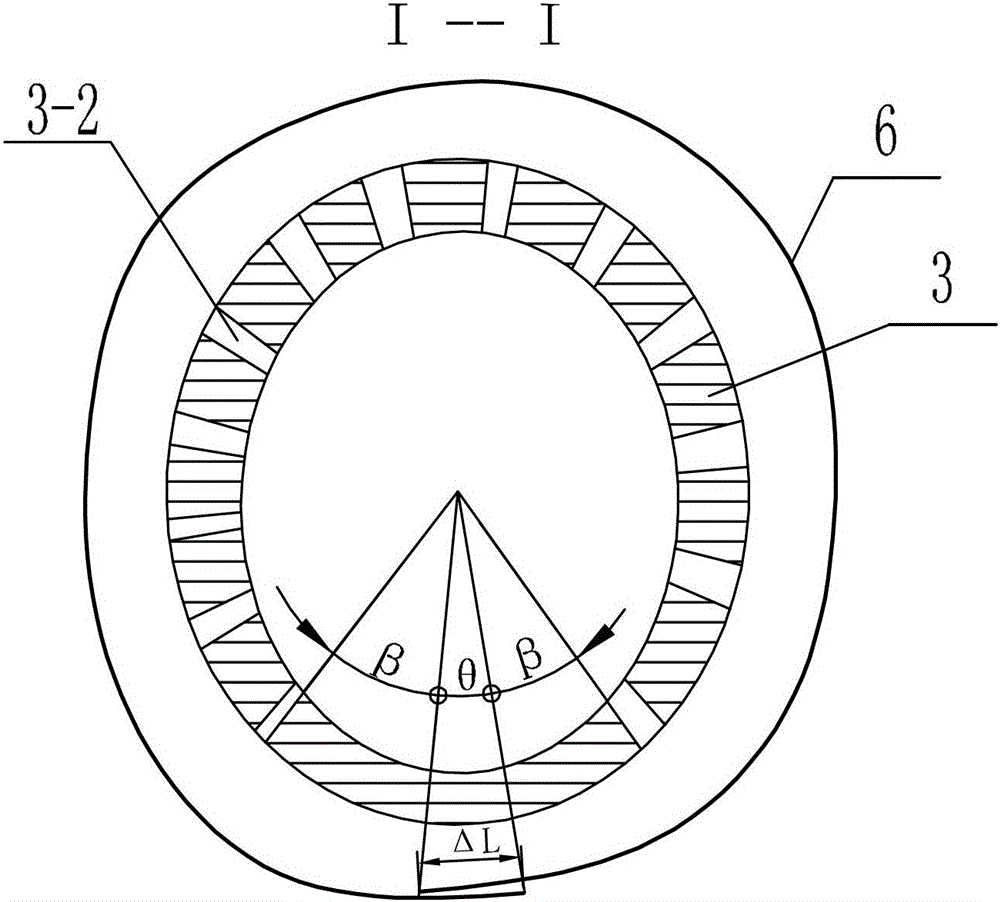

Low-temperature high-strength devitrified glass ceramics bond cubic boron nitride grinding wheel

InactiveCN101362316AHigh hardnessImprove grinding abilityBonded abrasive wheelsNumerical controlBoron nitride

The invention discloses a cubic boron nitride grinding wheel with low-temperature and high-strength microcrystalline glass ceramic binder. The cubic boron nitride grinding wheel consists of a matrix, a binding course and a grinding wheel block. The grinding wheel block is a cubic boron nitride grinding wheel block, and adopts the following raw materials (according to the weight percentage of the content): 45 to 80 percent of cubic boron nitride abrasive, 0 to 20 percent of corundum, and 20 to 35 percent of ceramic binder; the ceramic binder is the microcrystalline glass ceramic binder, and the raw material composition and the weight percentage content is as follows: 40 to 70 percent of SiO2, 5 to 25 percent of B2O3, 2 to 5 percent of Al2O3, 2 to 15 percent of Na2O, 2 to 5 percent of K2O, 2 to 4 percent of MgO, 2 to 4 percent of CaO, 1 to10 percent of Li2O, 2 to 5 percent of ZrO2 and 2 to 5 percent of Sb2O3. The invention provides a high efficiency grinding tool which has the advantages that the using linear speed of the grinding wheel can be 160 m / s, the process precision is high, the service life is long, the environment pollution is avoided, and the high efficiency grinding tool can be matched with a high speed high efficiency numerical control crankshaft grinder and is mainly used in the grinding machining of car crank shafts and various numerical control.

Owner:TIANJIN UNIV

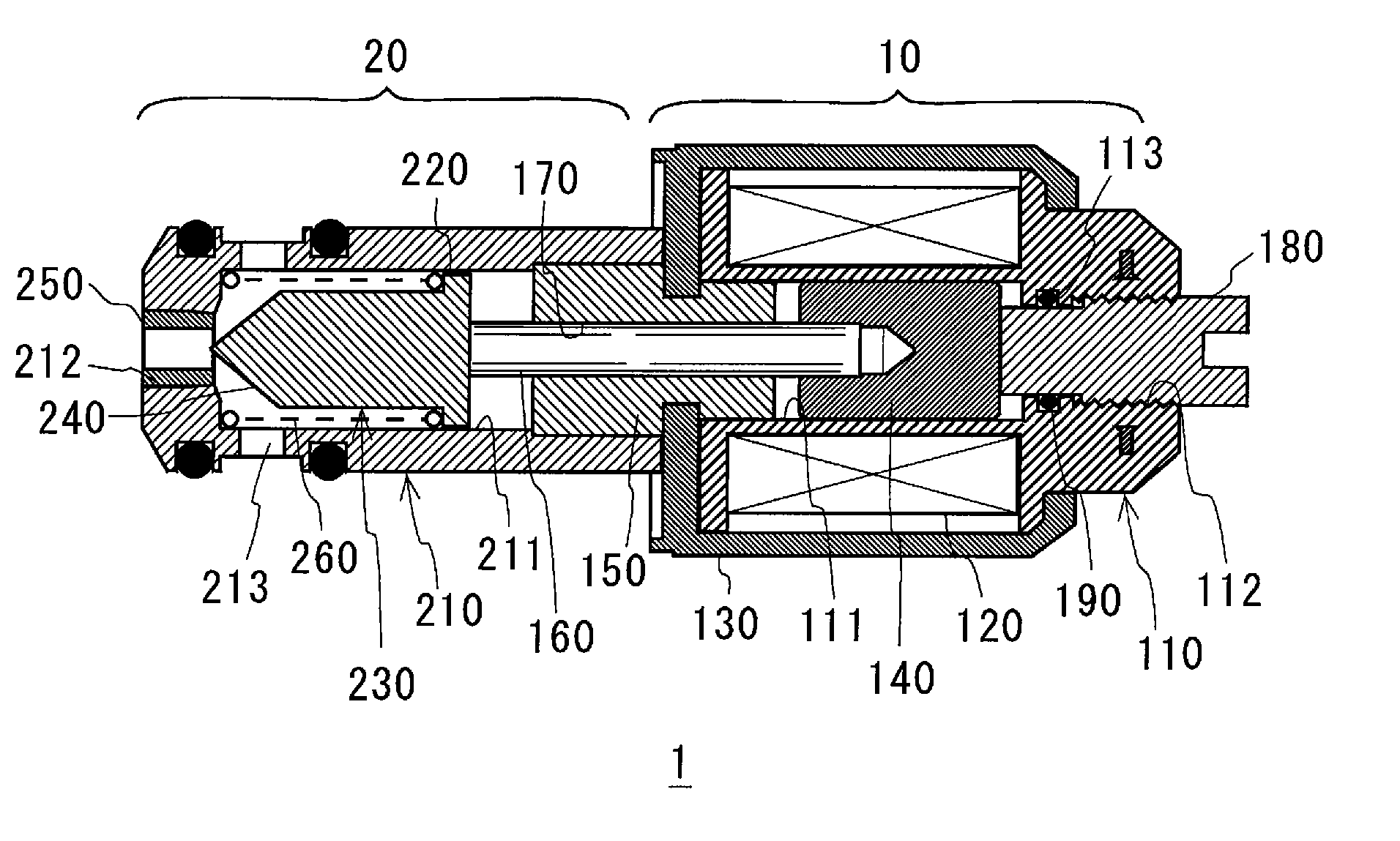

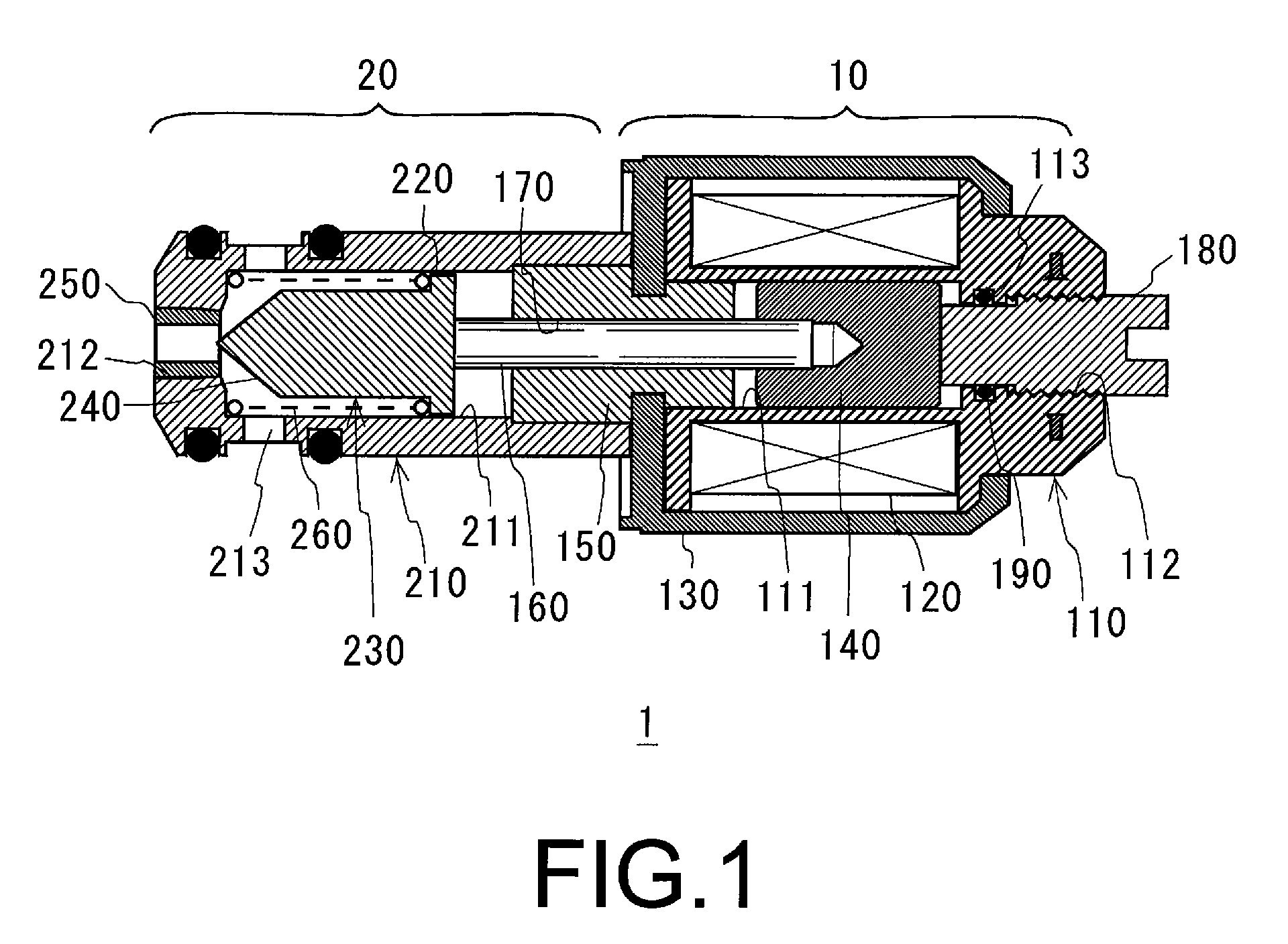

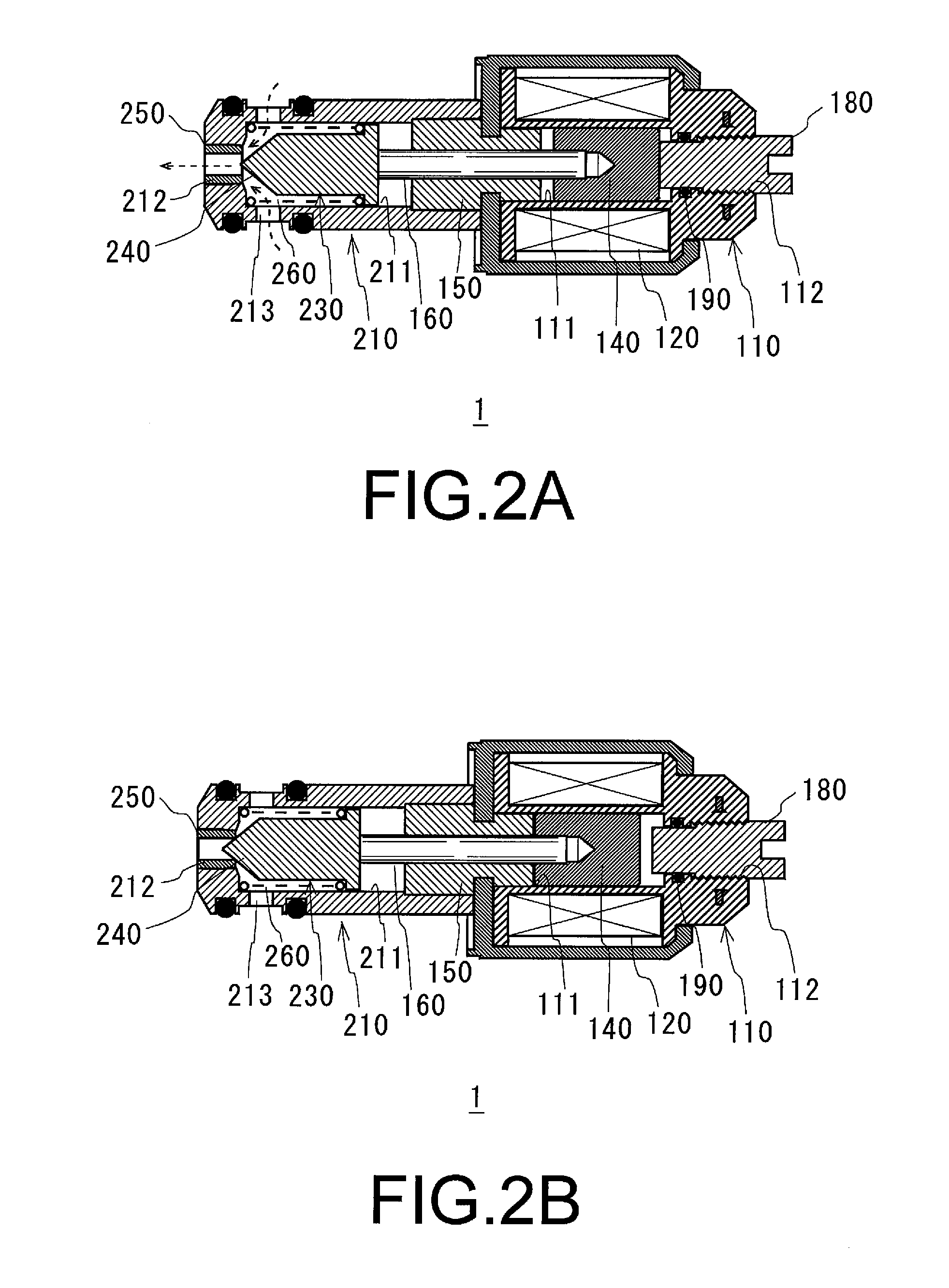

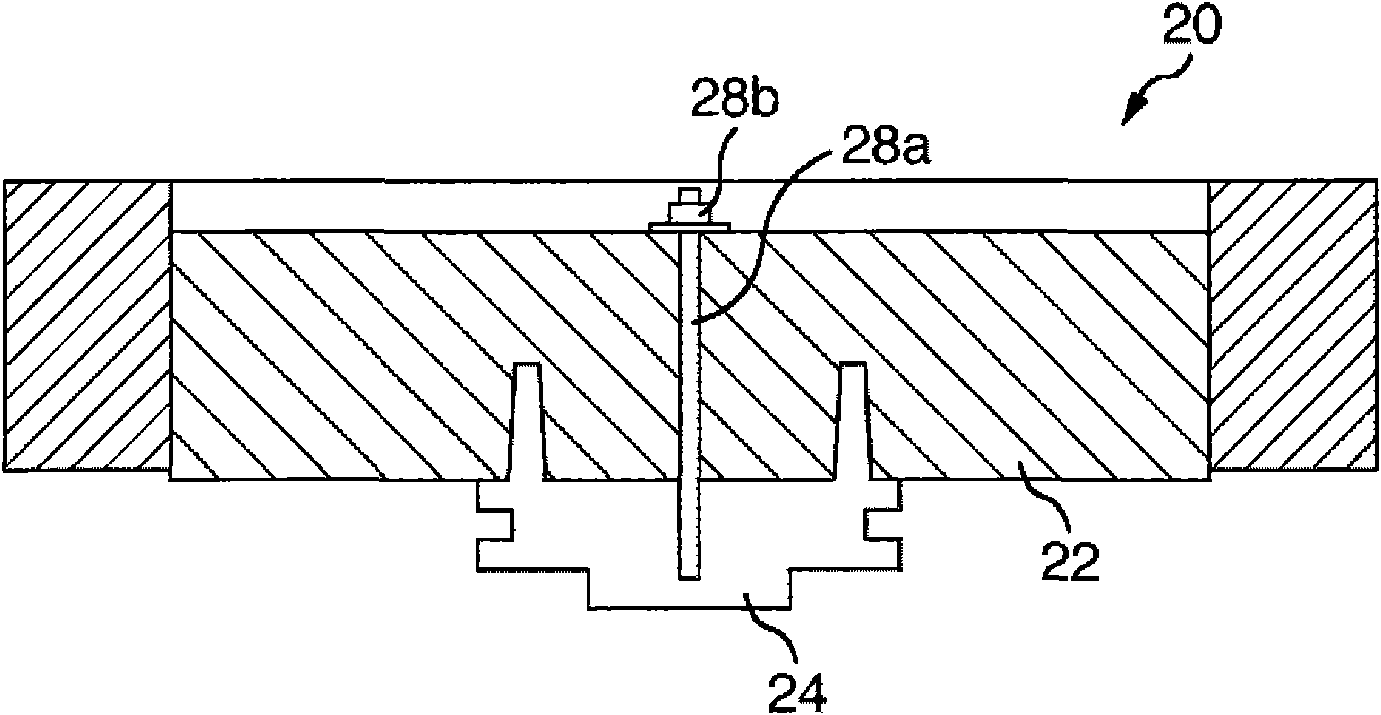

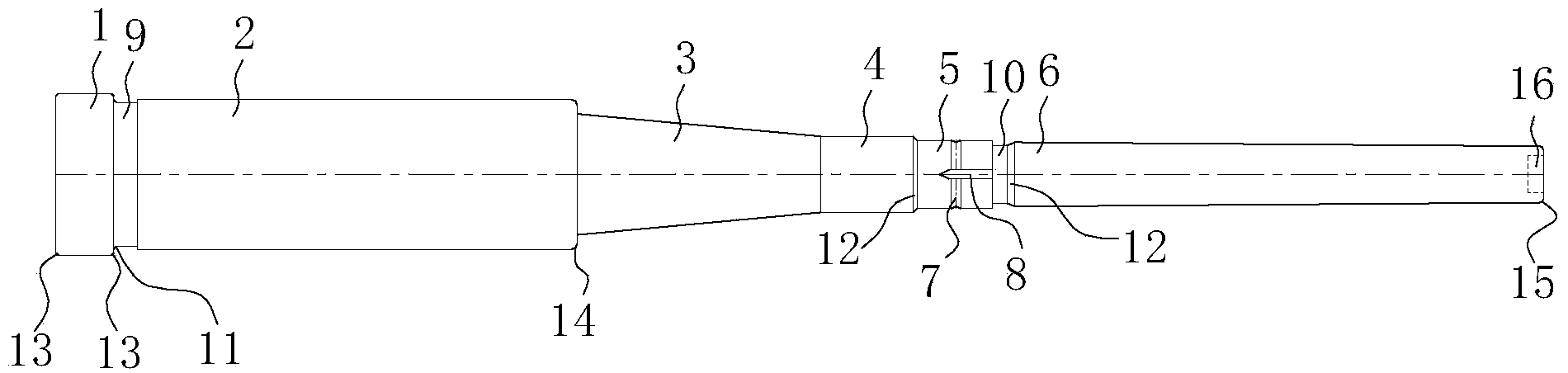

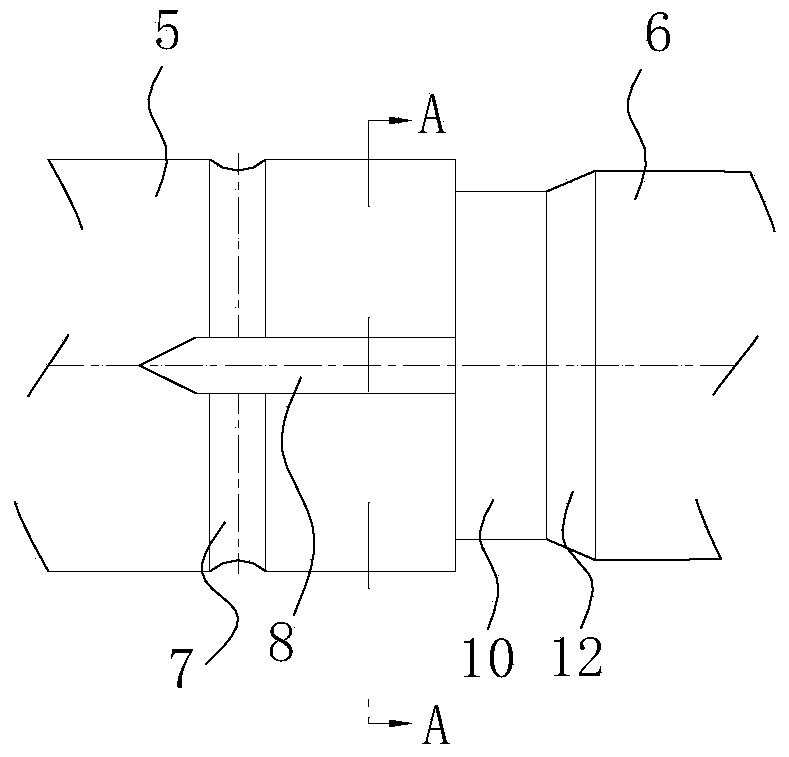

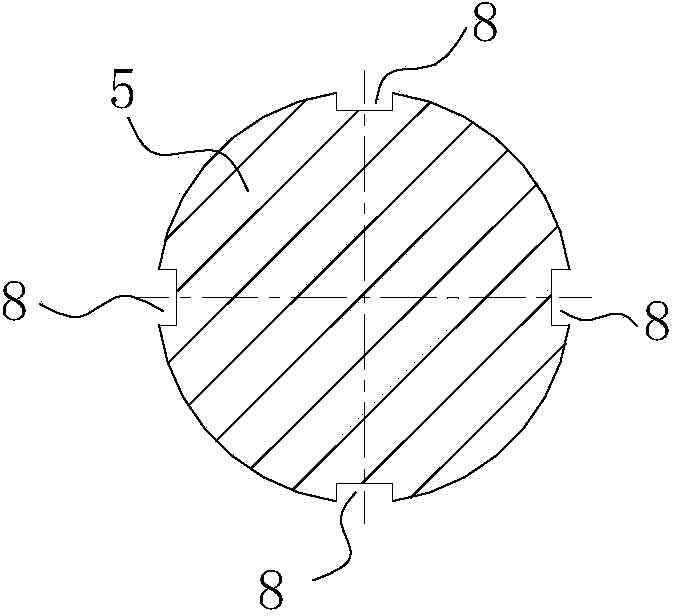

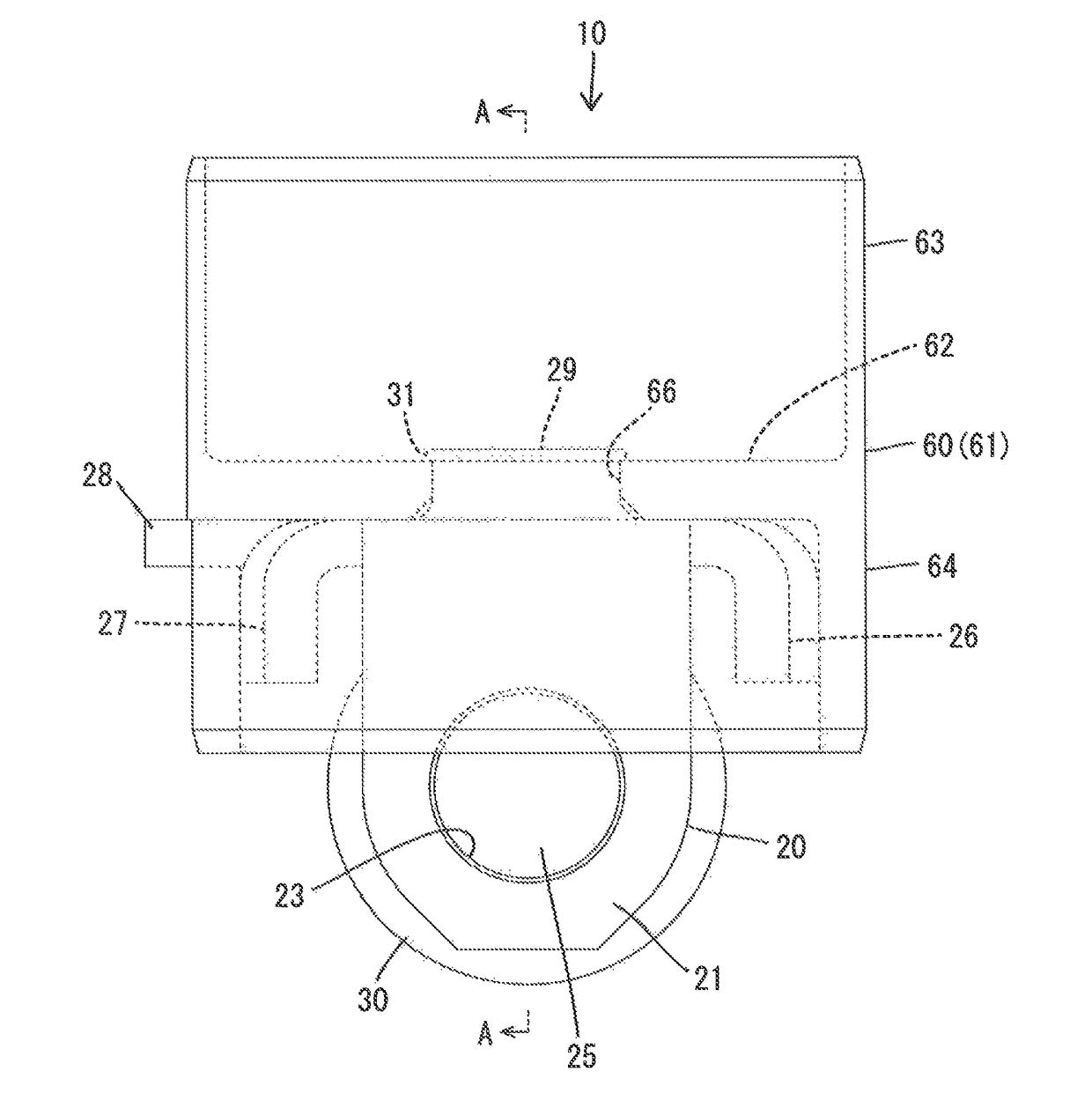

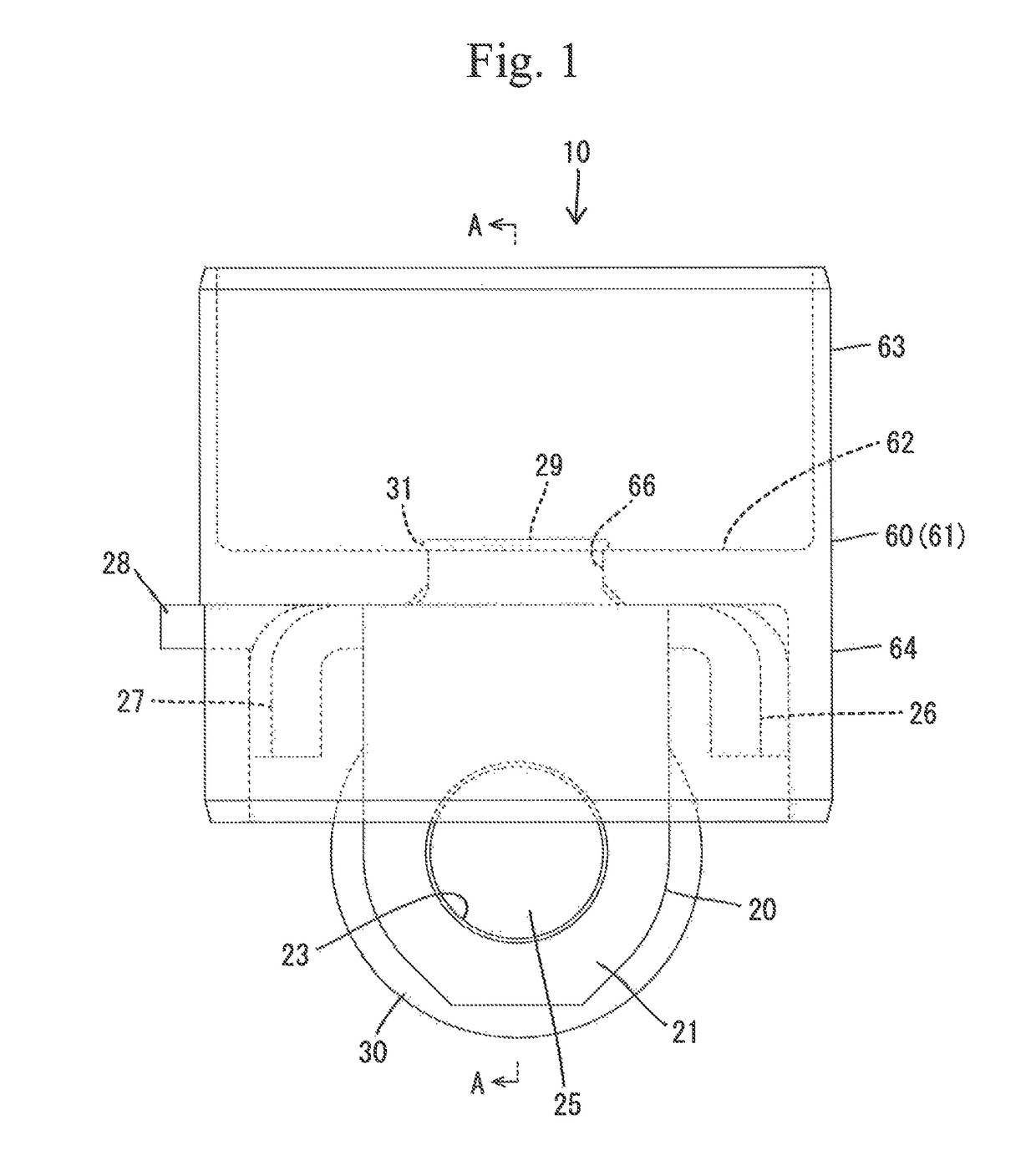

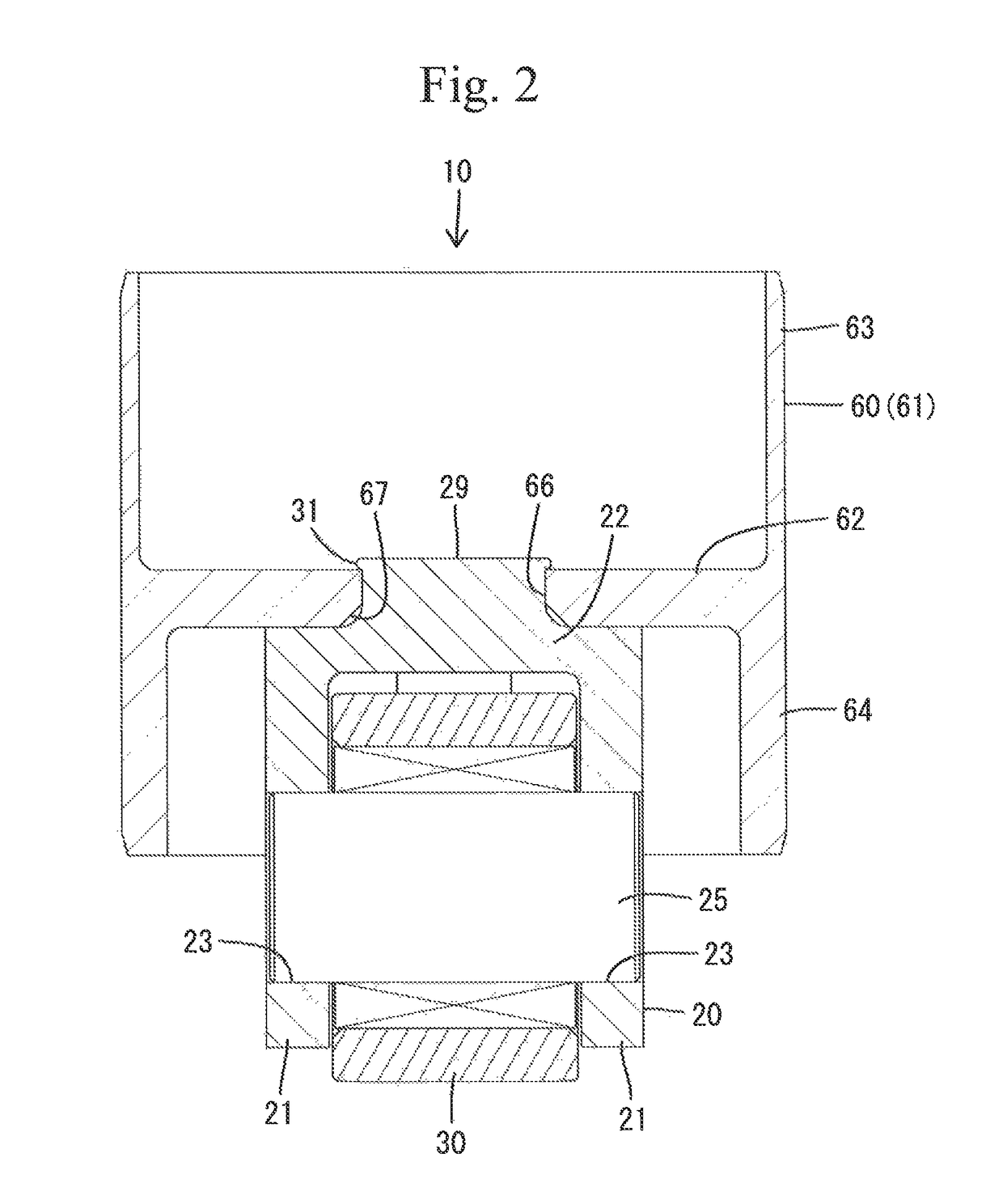

Solenoid Valves

InactiveUS20060169936A1Accurate dimensional accuracyCalibration accuracyOperating means/releasing devices for valvesBobbinSolenoid valve

In a solenoid valve, a desire valve stroke width may be set, and a flow rate may be returned to an original flow rate even when that the flow rate is changed. A solenoid valve includes a drive portion having a bobbin including a slidable hole formed there through, a fixed iron core disposed with in the bobbin and a movable iron core disposed to be slidable within the slidable hole, and a valve function portion having a valve body extending from the movable iron core and disposed in a leading end of a valve shaft passing through the fixed iron core and a valve seat with which the valve body is brought into close contact and from which the valve body is separated. In the solenoid valve, a predetermined gap width is formed between the valve body and the valve seat, when the solenoid valve is not energized, to open the valve, and the movable iron core is drawn to the fixed iron core when the solenoid valve is energized to close the valve. A valve stroke width may be adjusted by screwing a flow rate adjusting screw from an outer side in a rear end of the solenoid valve to bring the leading end into contact with a rear end surface of the movable iron core when the valve is opened, thereby adjusting a protrusion amount of the screw in the leading end of the slidable hole.

Owner:NONAKA TAKUMI +2

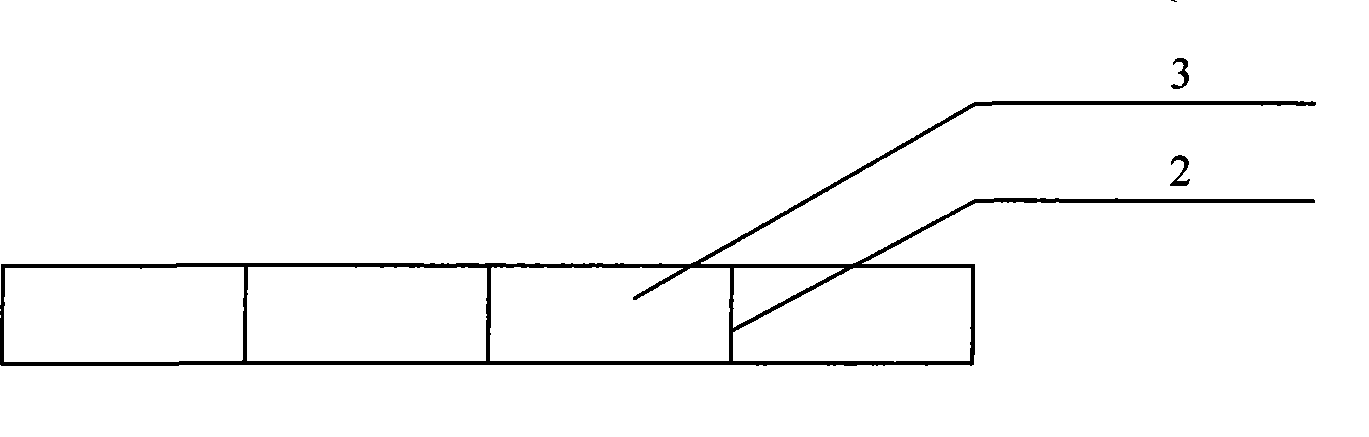

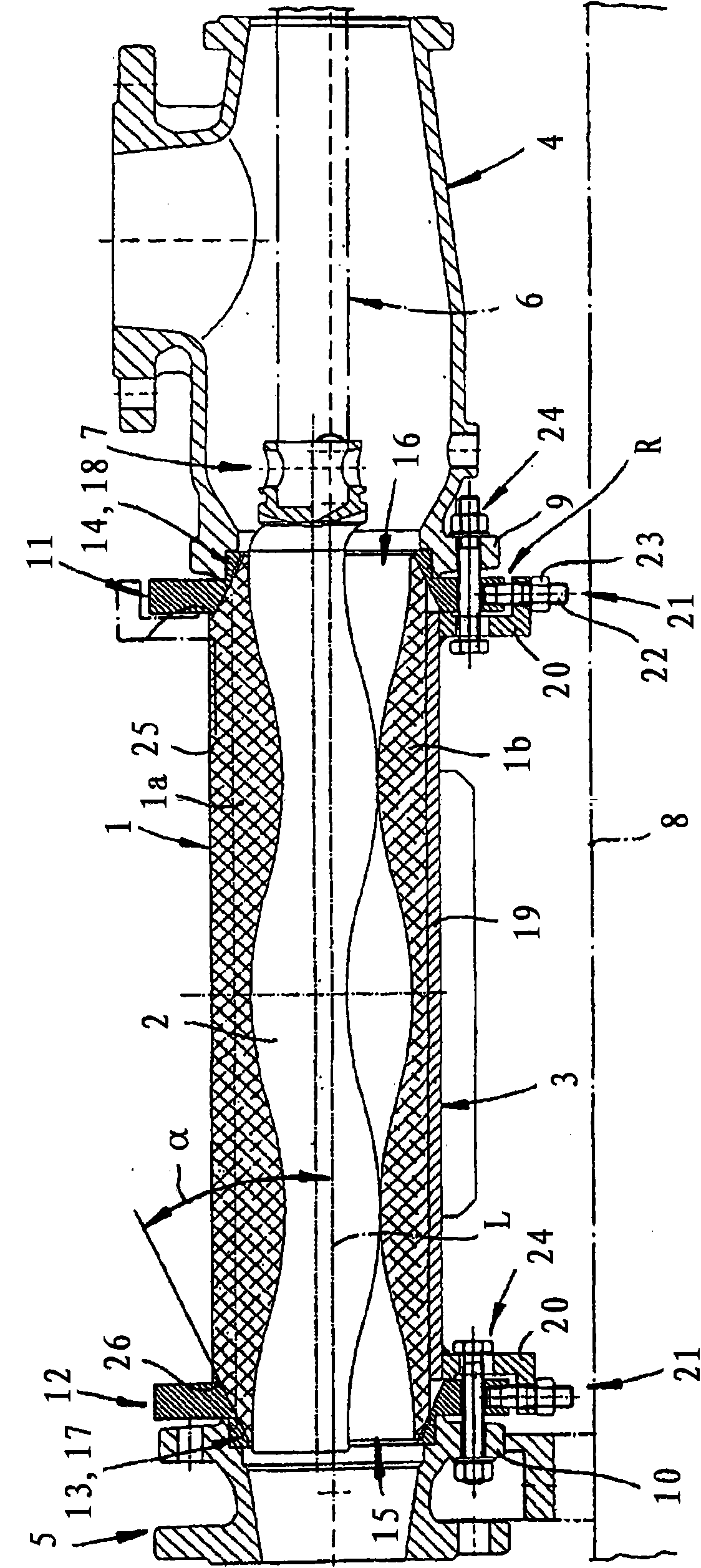

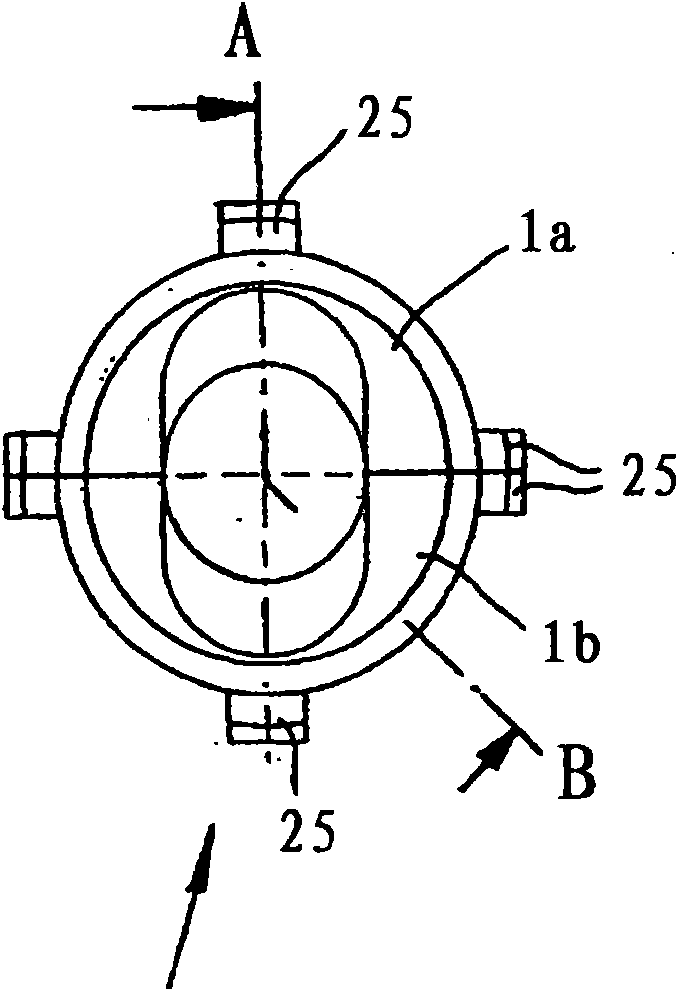

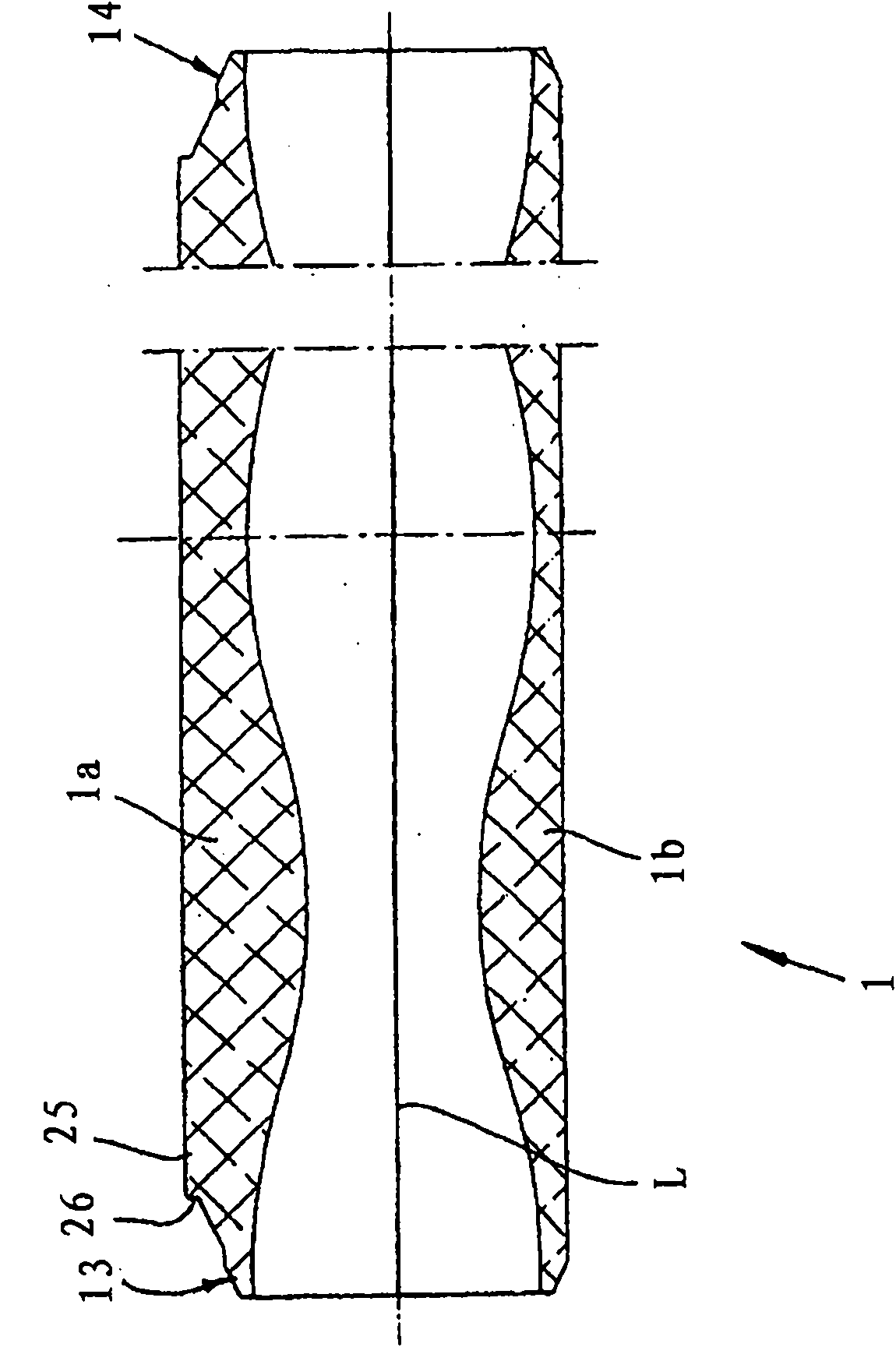

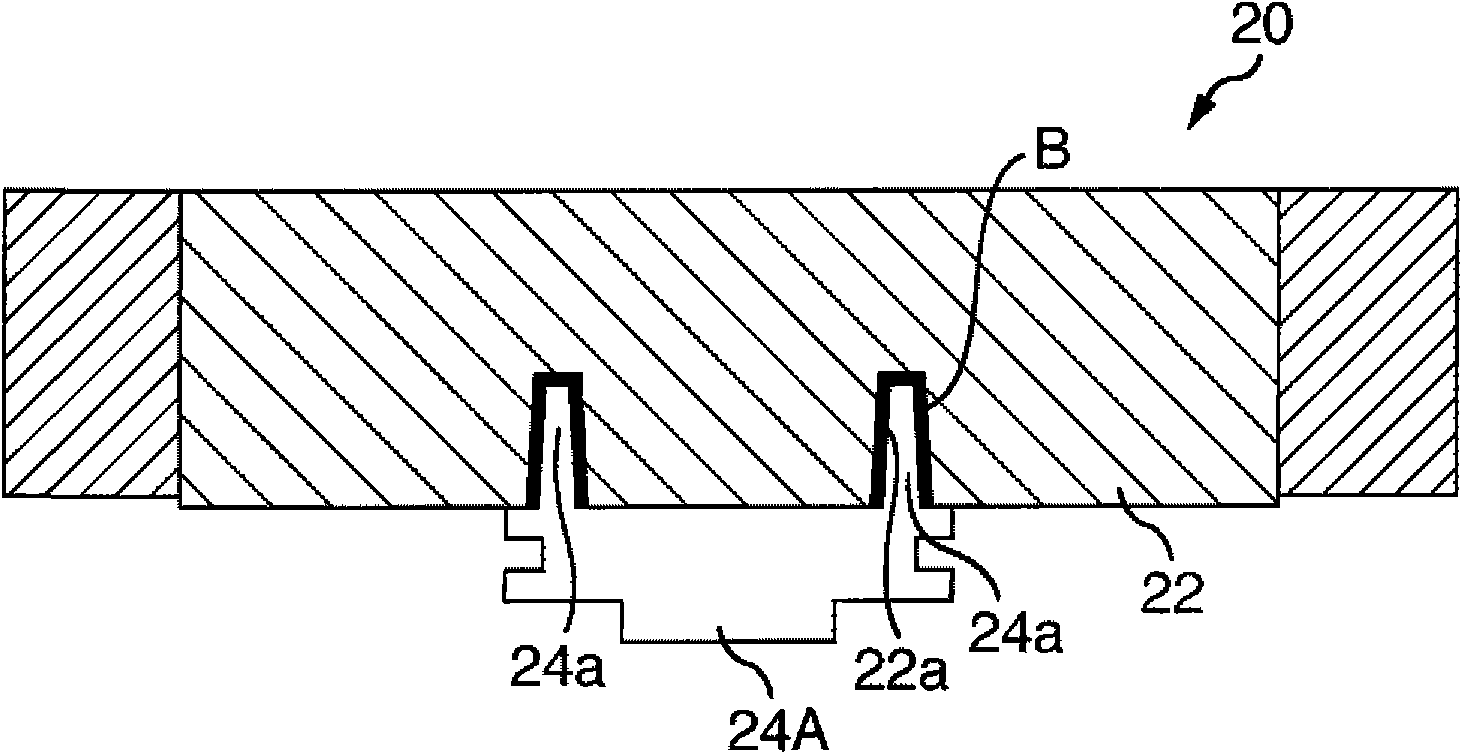

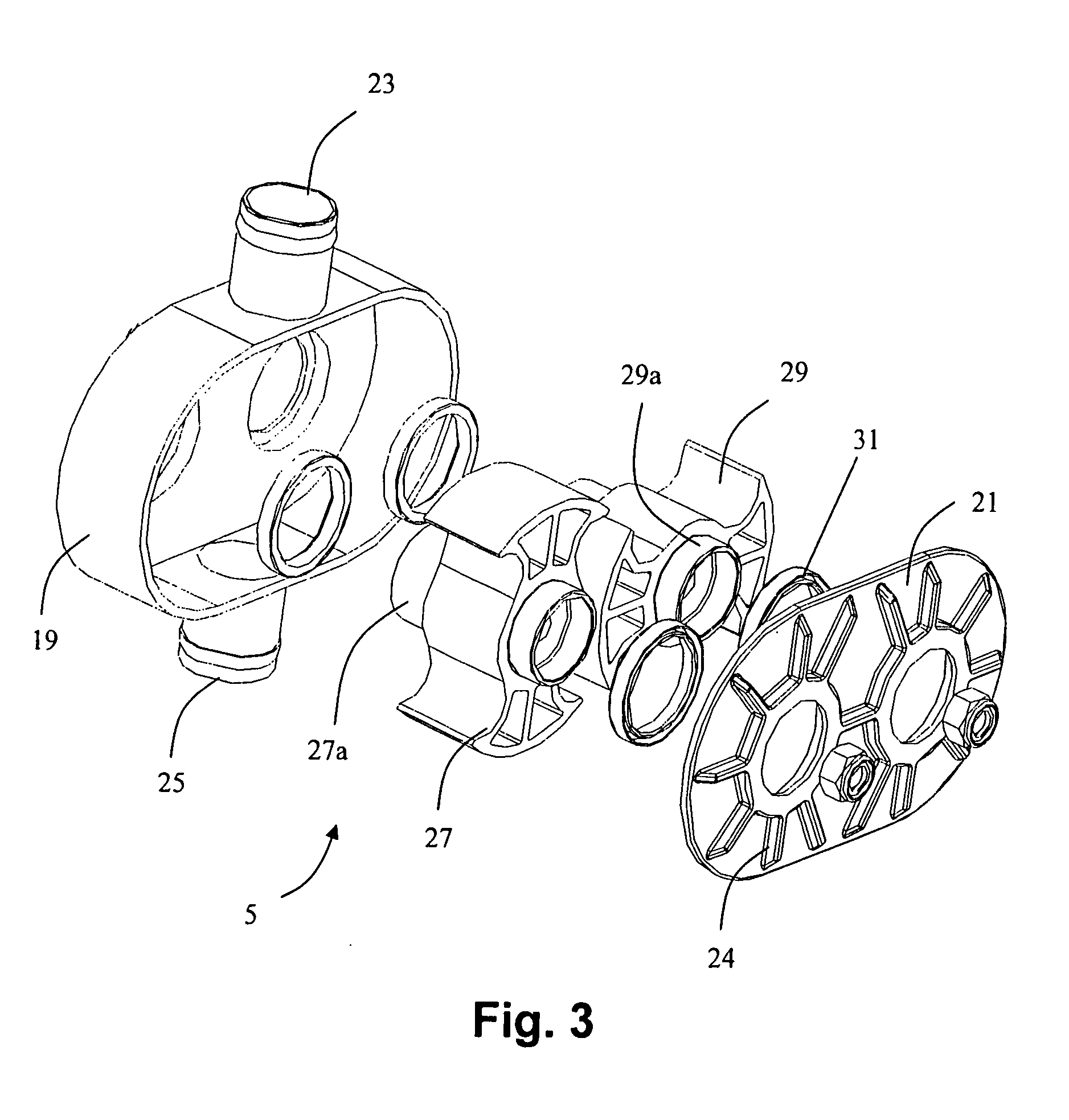

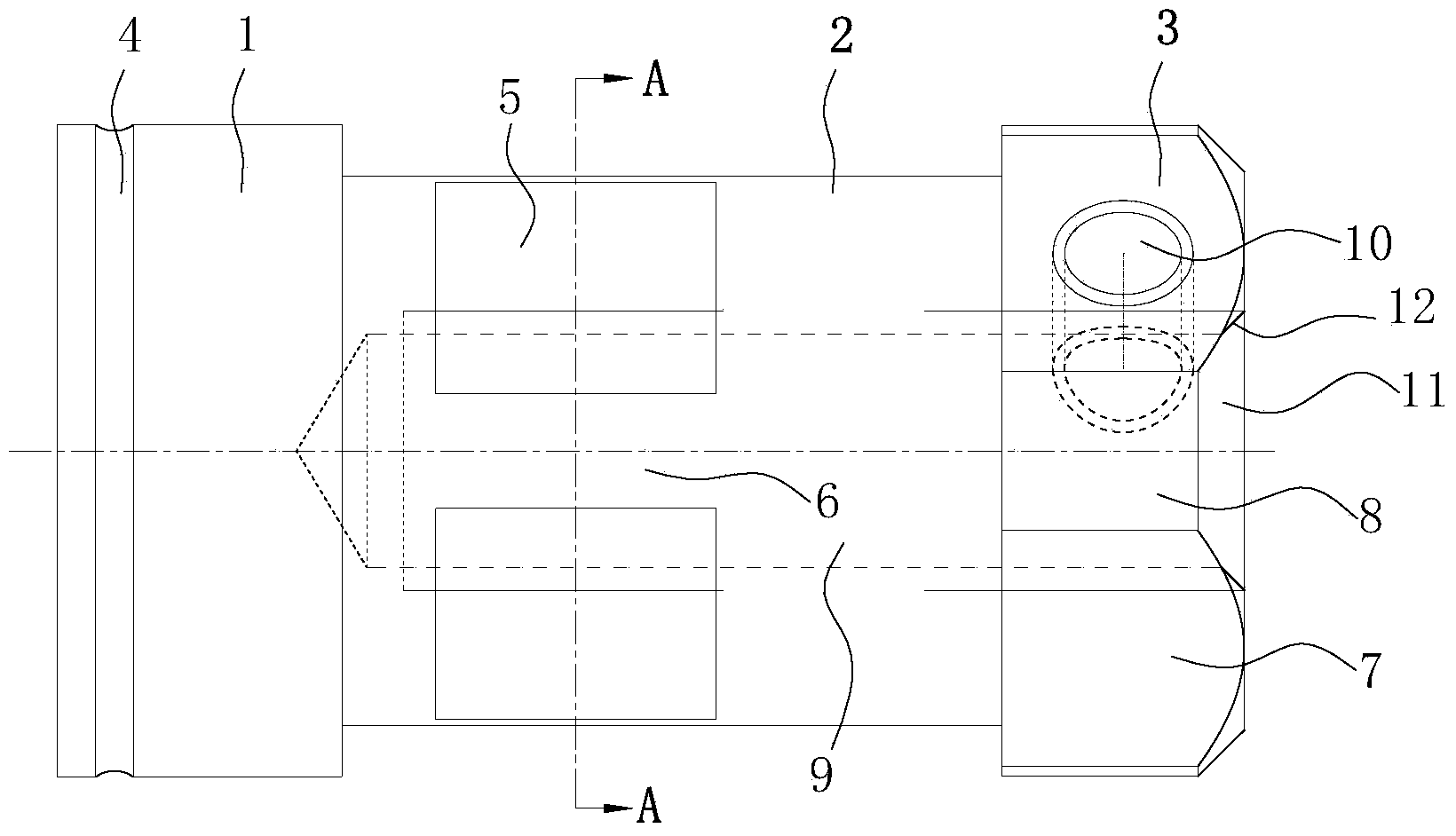

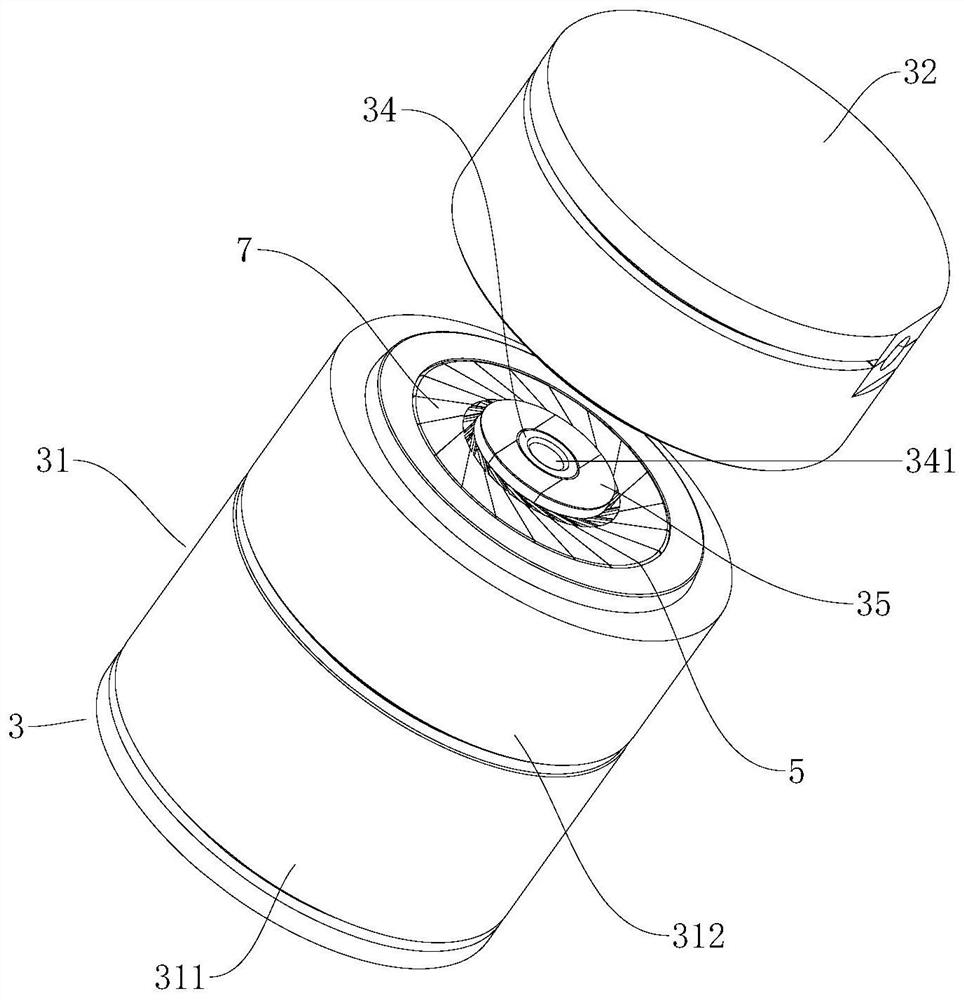

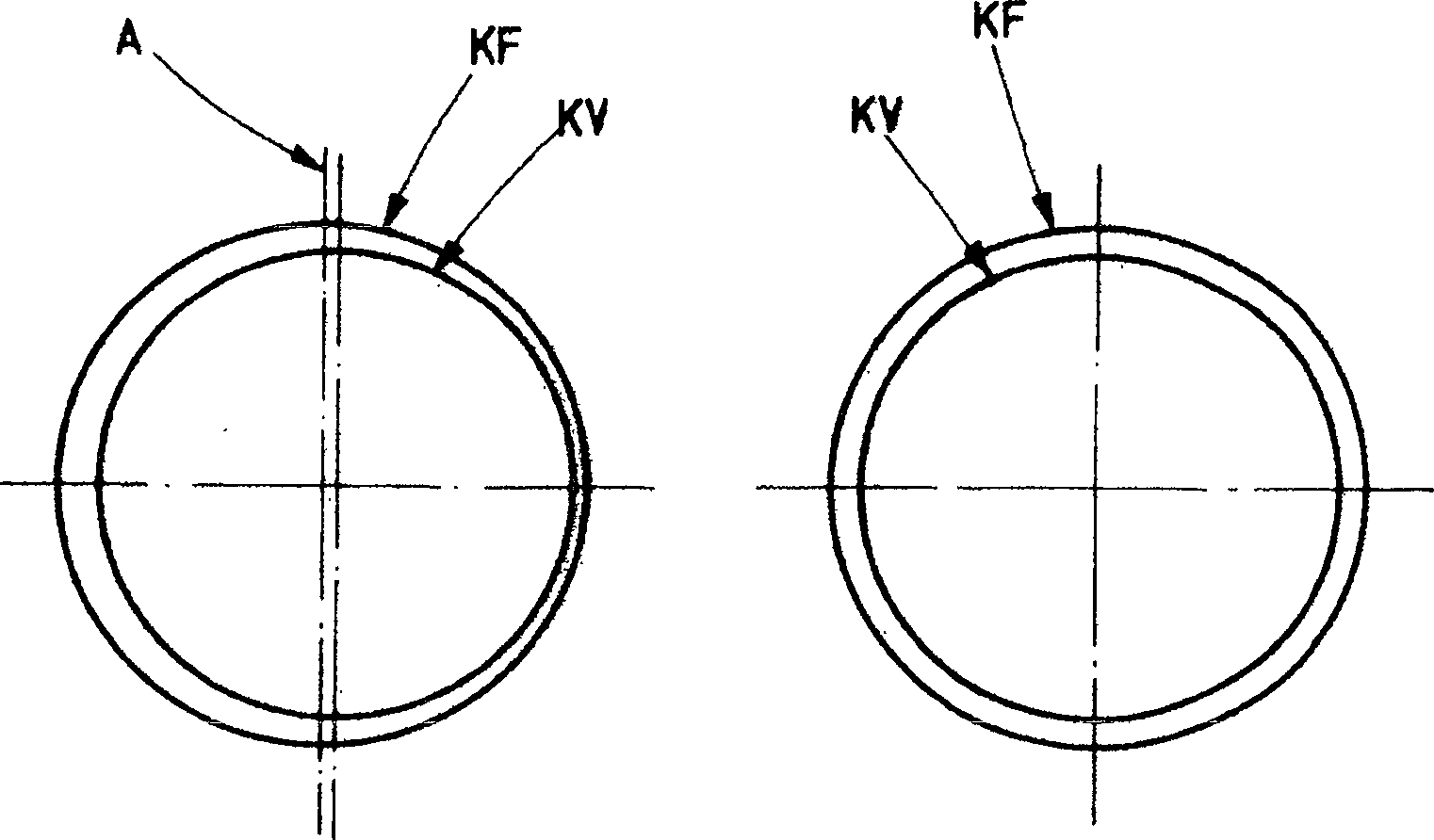

Eccentric worm pump with split stator

ActiveCN101796301AGuaranteed reusabilityEasy to installRotary piston pumpsRotary piston liquid enginesPhysicsStator

Eccentric worm pump with at least one stator (1) composed of an elastic material and a rotor (2) which is mounted in the stator (1), wherein the stator (1) is surrounded at least in certain areas by a stator casing (3), characterized in that the stator (1) is in the form of a longitudinally split stator which is composed of at least two stator component shells (1a, 1b).

Owner:SEEPEX GMBH

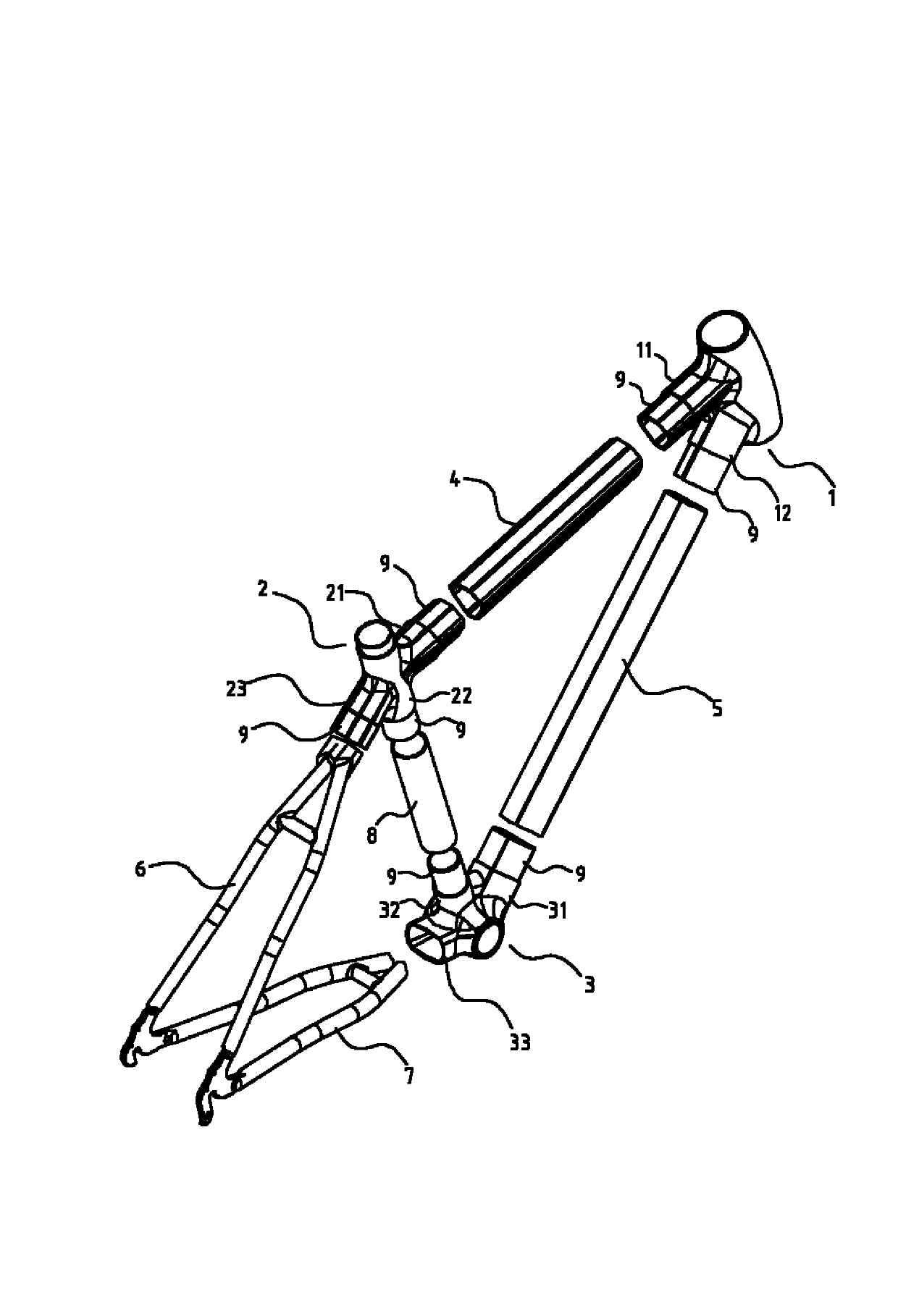

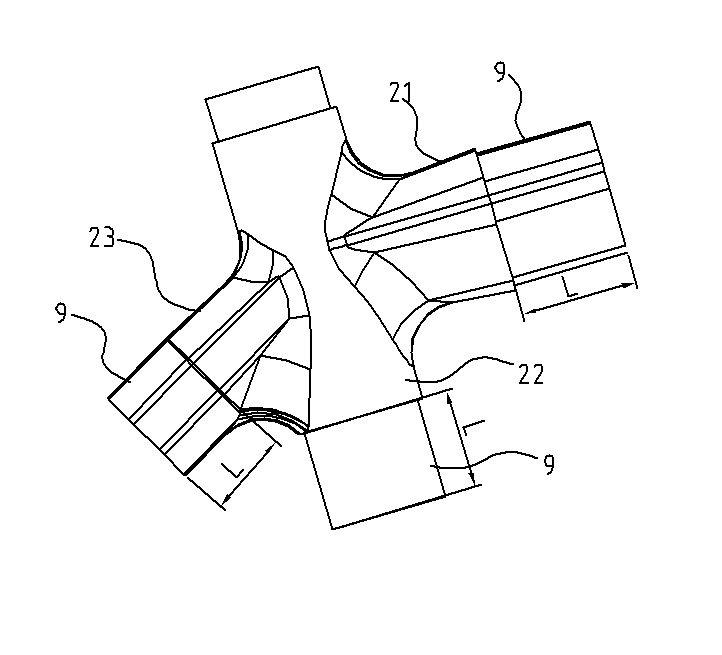

Method for manufacturing frame of combined bicycle

The invention provides a method for manufacturing a frame of a bicycle. The method comprises the following steps of: (1) manufacturing frame fittings, wherein the frame fittings comprise frame pipes and joints, the frame pipes comprise an upper pipe, a back upper fork, a back lower fork, a lower pipe and a middle pipe which are all made of aluminum alloy, and the joints comprise a head pipe joint, a middle pipe joint and a five-way joint which are all made of magnesium alloy; (2) processing surfaces of the frame fittings; (3) molding the frame pipes and the joints by gluing; (4) grinding and polishing the frame; and (5) performing baking finish on the surface of the frame. The whole frame utilizes the gluing molding technology so that the frame has beautiful appearance, better streamline form, and higher size precision; furthermore, the deformation and stress concentration caused by welding in the traditional manufacturing method are eliminated.

Owner:GUANGZHOU LEONIS MACHINERY

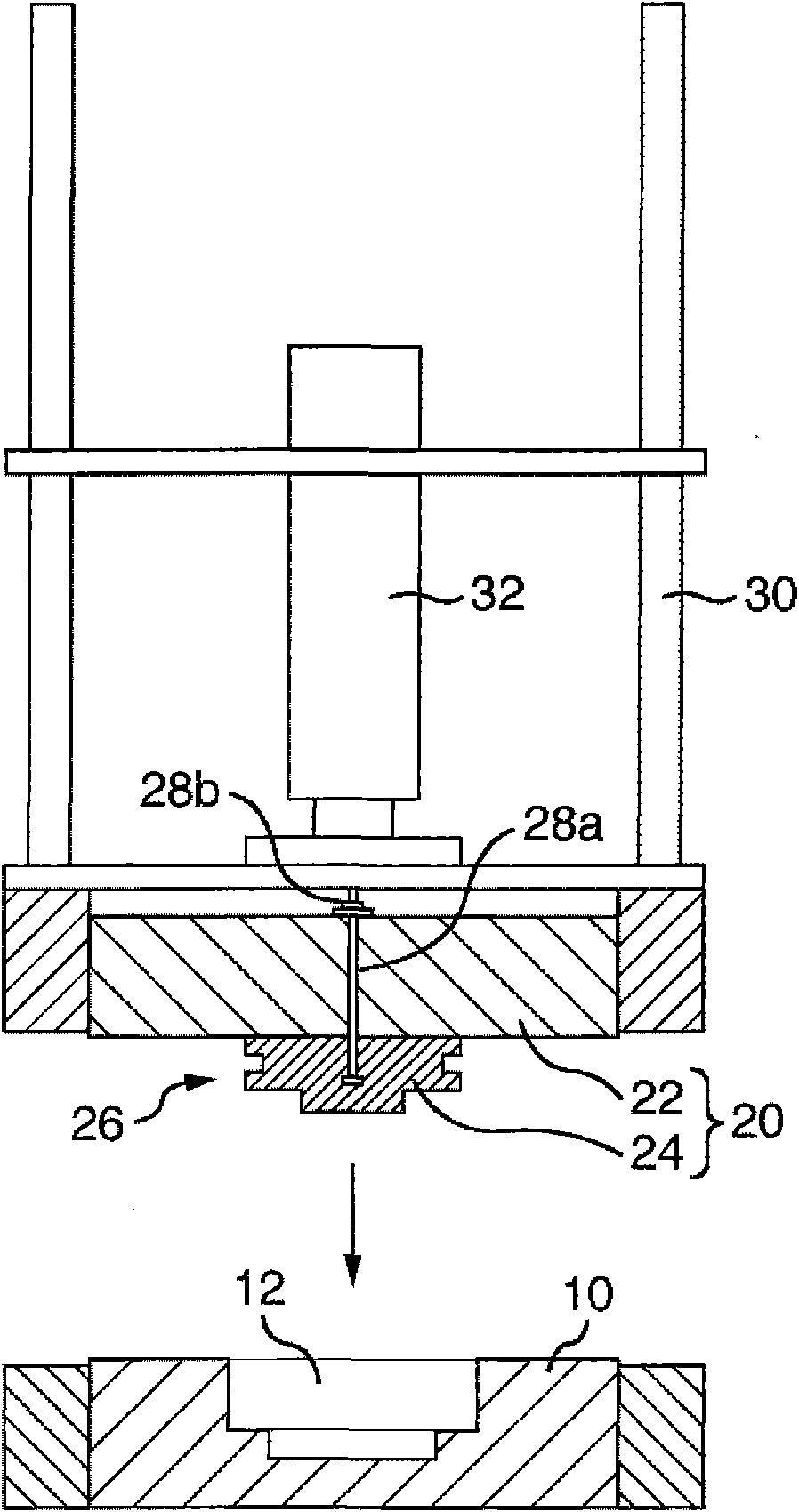

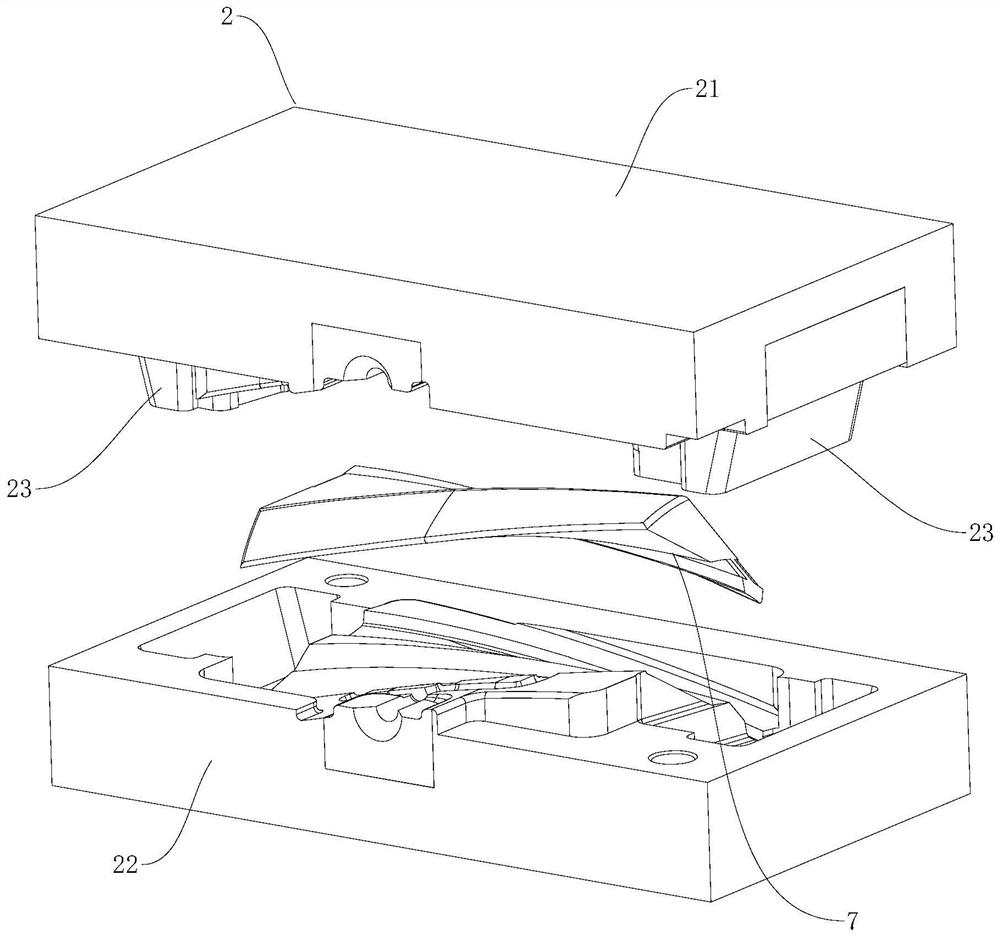

Casting method, upper mold assembly, and method for fixing core to the upper mold

This invention provides a casting method characterized by comprising the step of fixing a core to an upper mold to provide an upper mold assembly, the step of pouring a minimized amount of molten metal necessary for providing a cast product into a concave in a lower mold, the step of moving the upper mold assembly at a predetermined first speed and lowering the upper mold assembly to a predetermined height just above the surface of the molten metal in the concave, the step of varying the lowering speed of the upper mold assembly from the first speed to the predetermined second speed to further lowering the upper mold assembly from the predetermined height, the step of detecting information about the state of the upper mold assembly in such a state that the upper mold assembly has been superimposed on or lowered toward the lower mold, and the step of stopping of the lowering of the upper mold assembly after the detection that the state information has reached predetermined state information. The core is fixed to the upper mold depending upon a frictional fitting relationship between mechanical means, an adhesive, and a core-side fitting protrusion and the concave fitting part, or the engagement relationship between a core-side engaging projection and molding sand to be tamped down.

Owner:SINTOKOGIO LTD +1

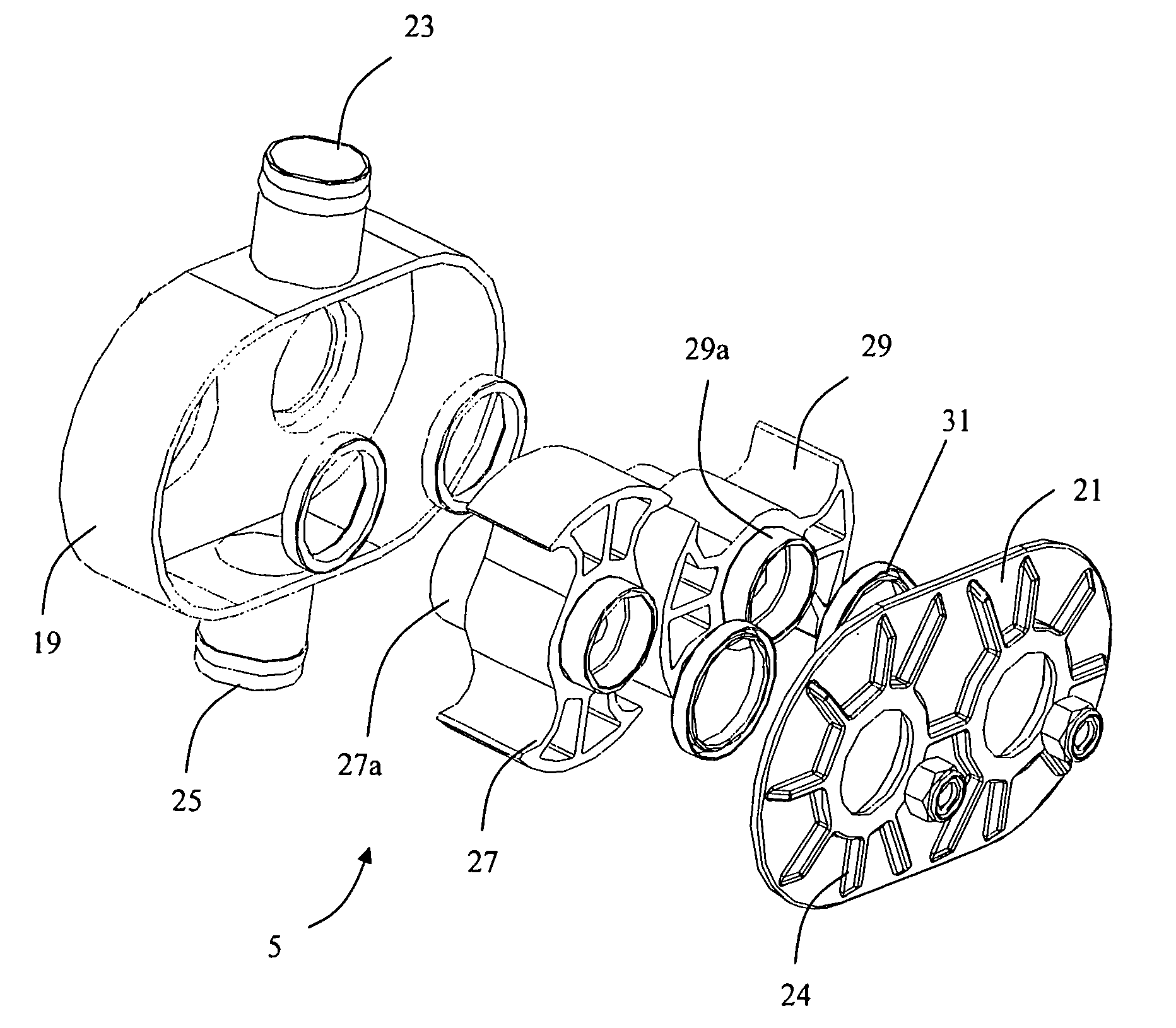

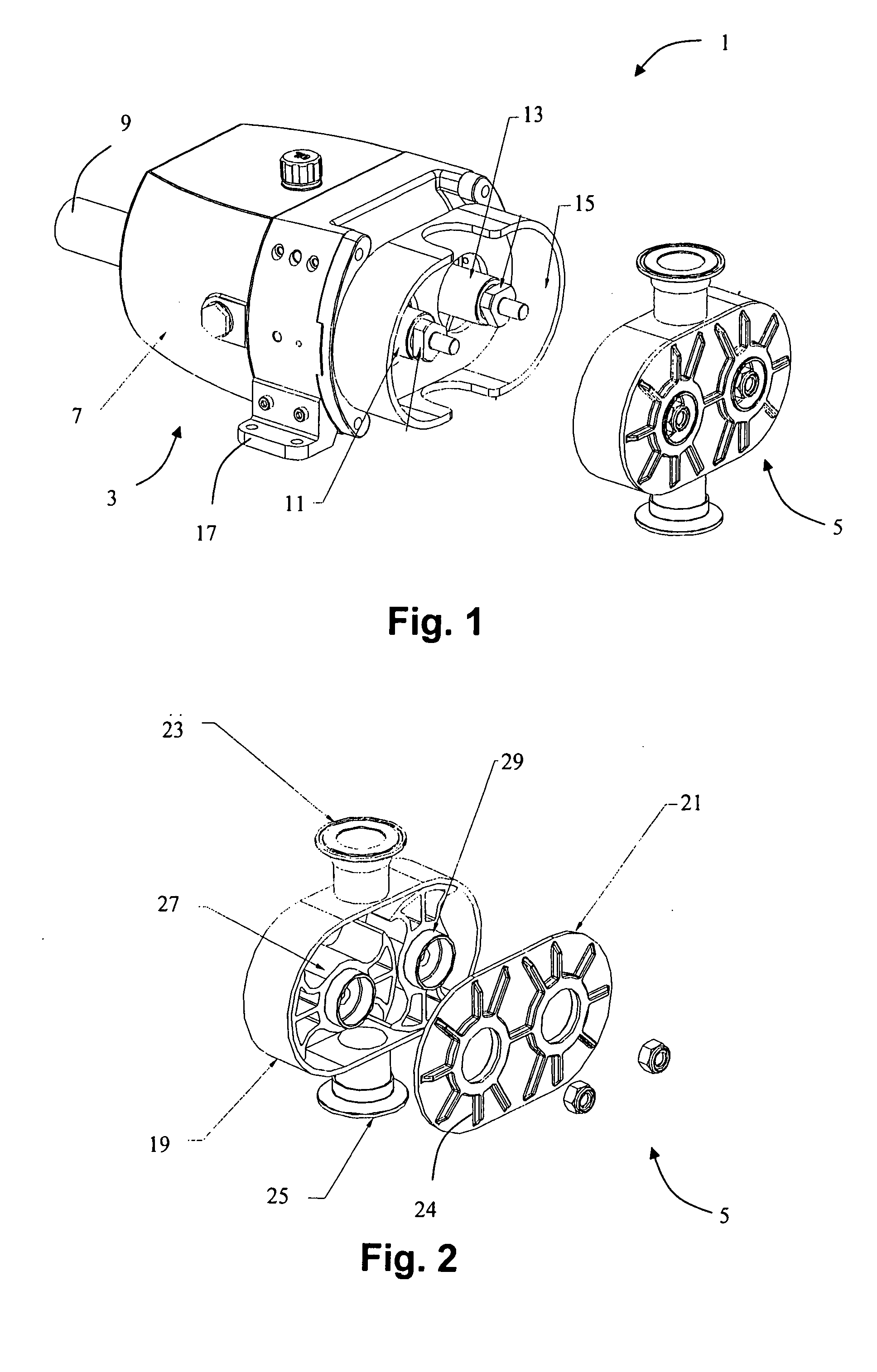

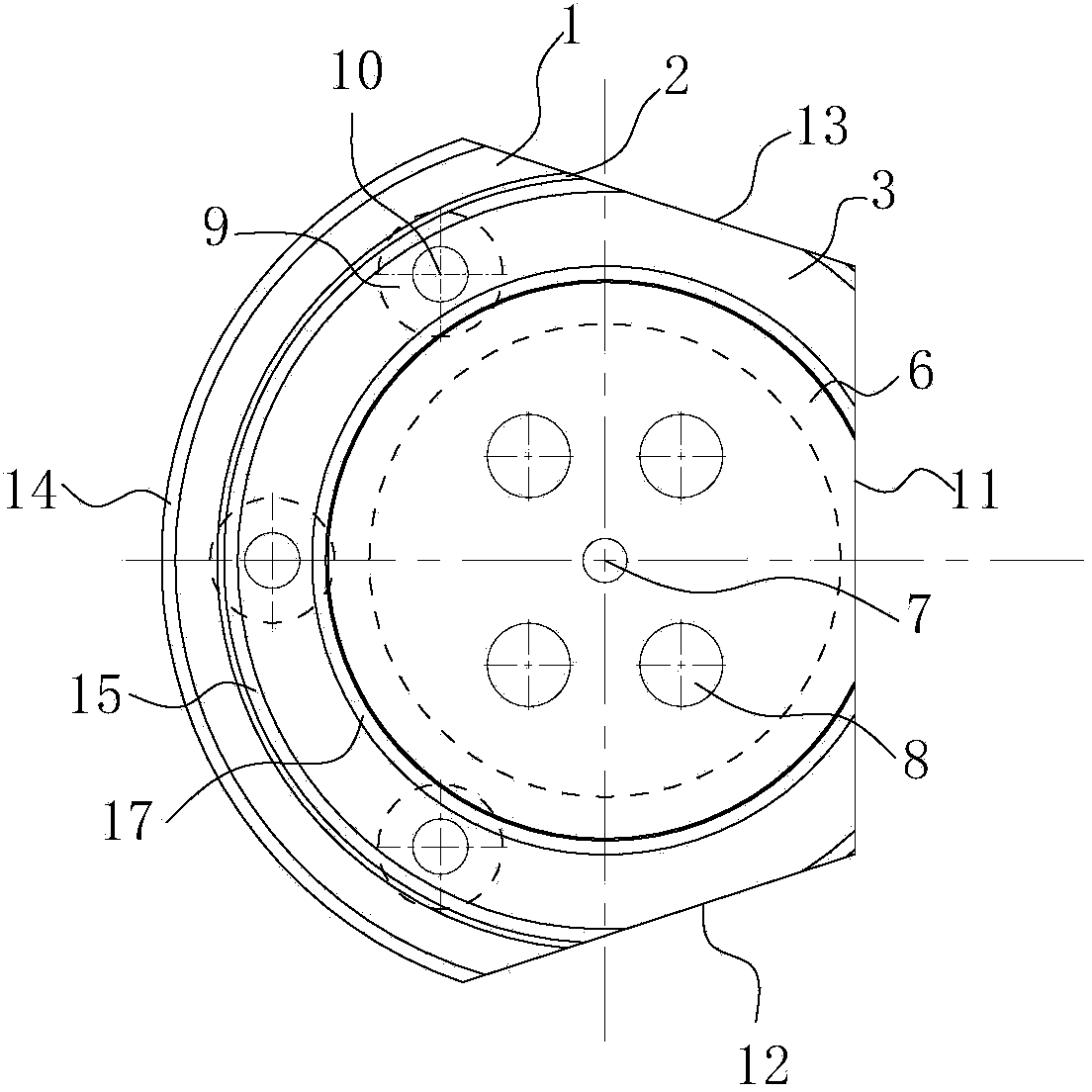

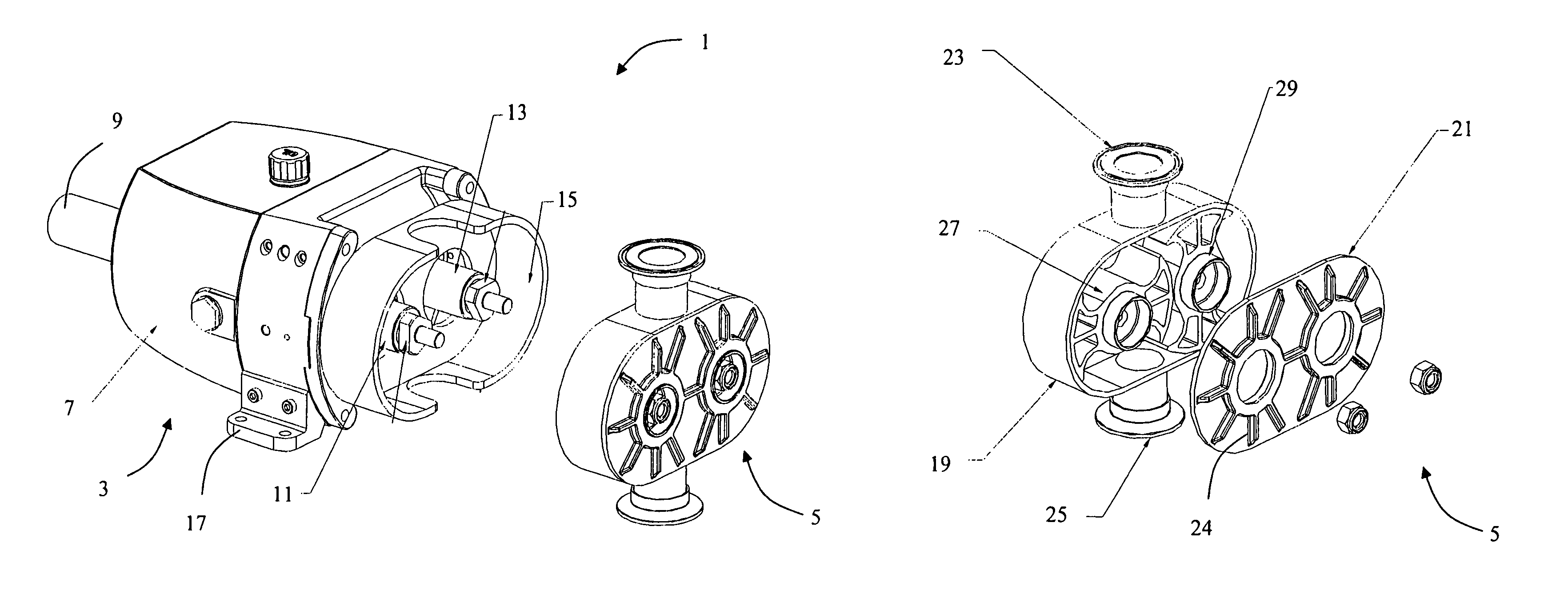

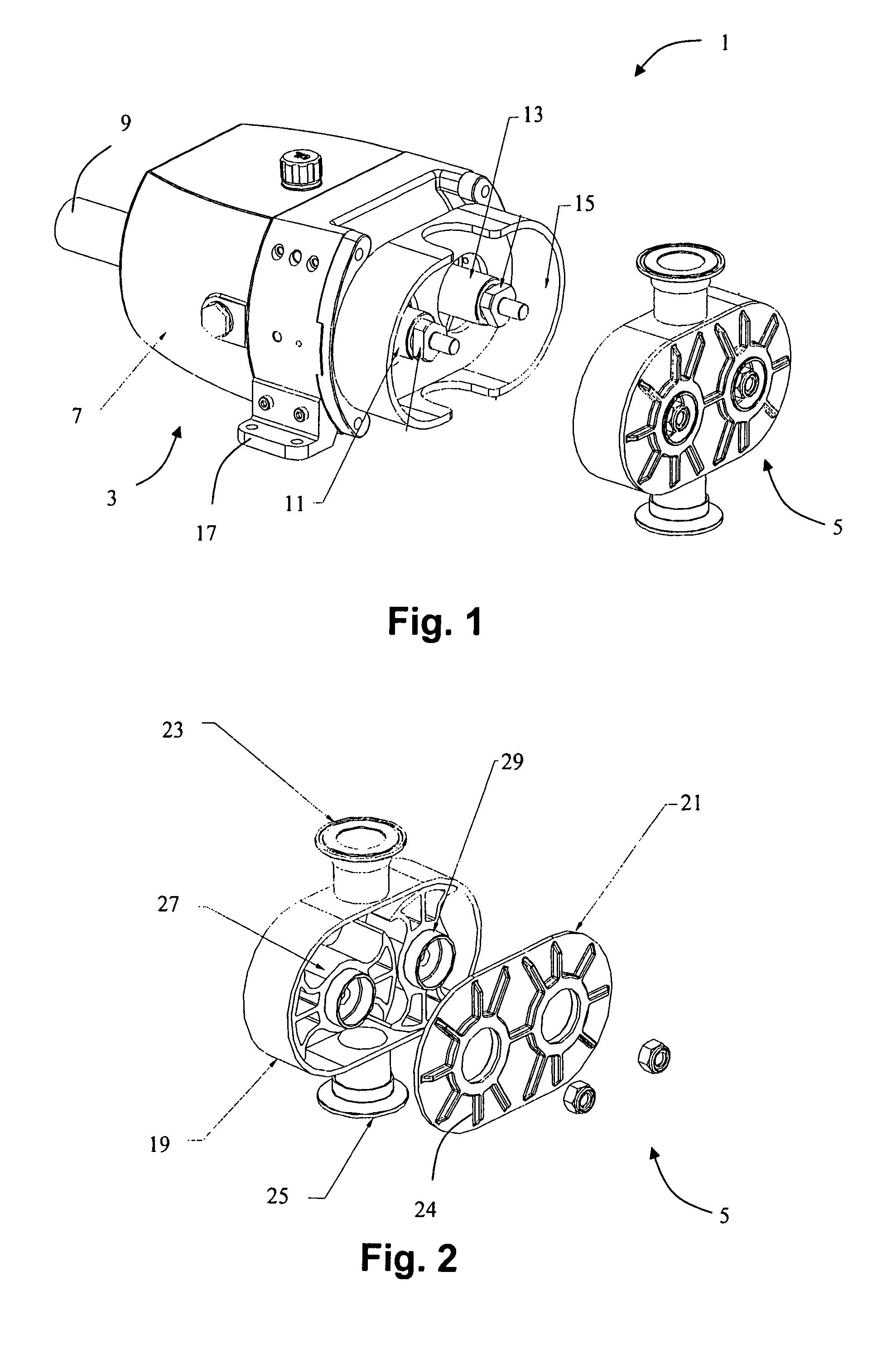

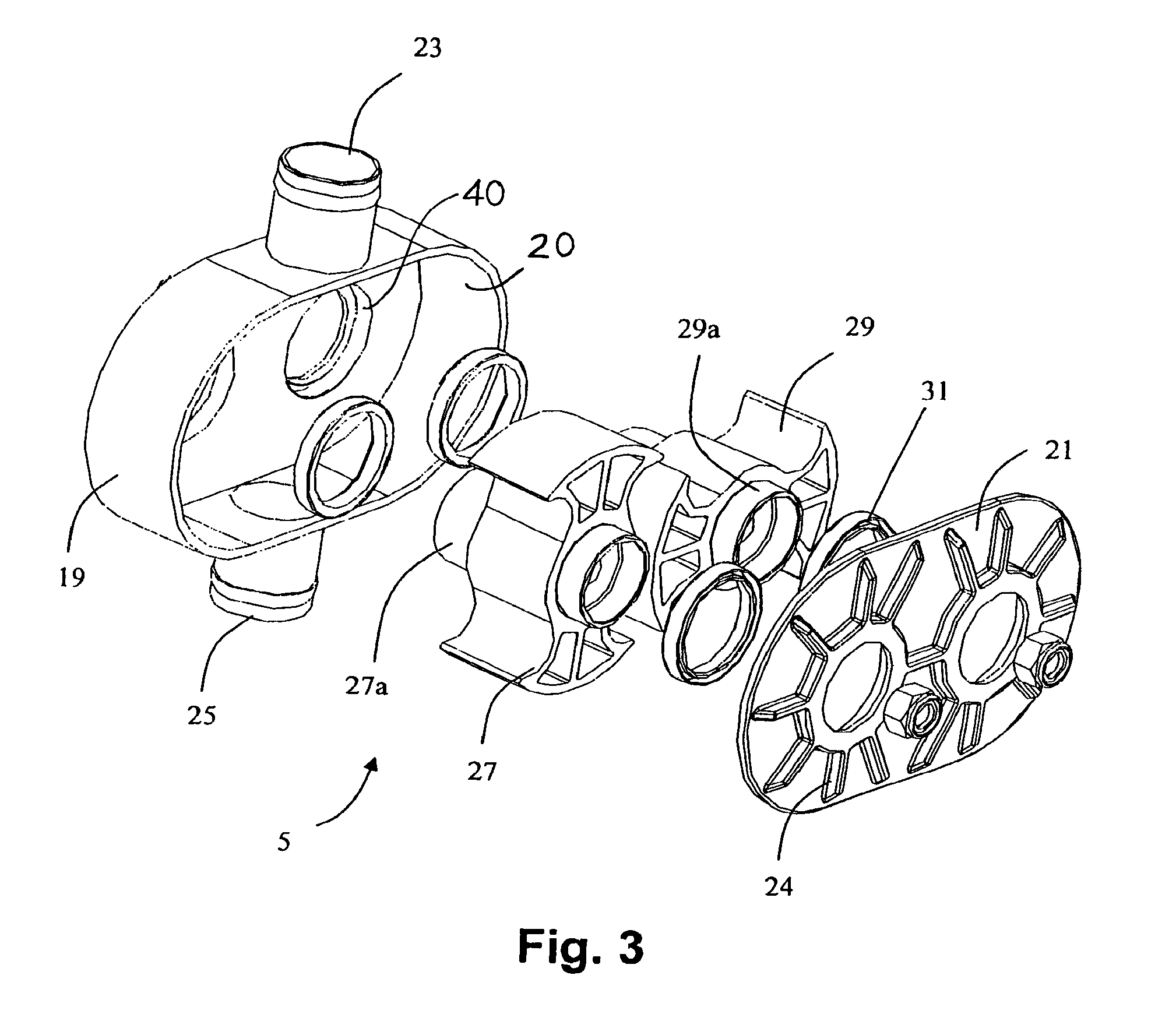

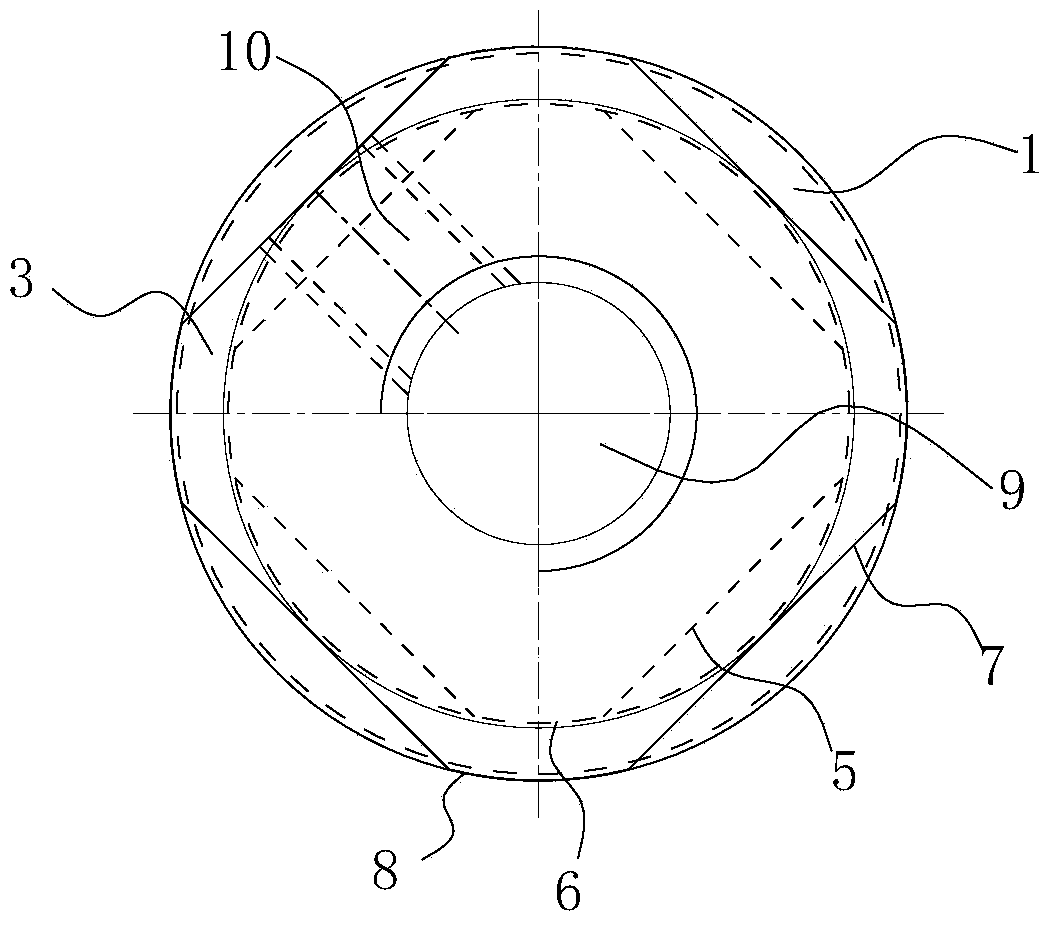

Rotary lobe pump

ActiveUS20080038138A1Seal performance be improveSimplify moldingOscillating piston enginesEngine of counter-engagement typeLobe pumpPlastic materials

A rotary lobe pump comprises a pump body having a driving means and an outer casing, and an insert that can be replaced. The replaceable insert comprises a housing formed of a plastic material and having an inlet port, an outlet port and internal surfaces defining a pumping chamber. The replaceable insert also includes a pair of lobed rotors arranged for rotation within the pumping chamber. The housing includes apertures through which the lobed rotors may be rotationally driven, so that the lobed rotors mesh together for pumping a fluid from the inlet port to the outlet port.

Owner:ITT MFG ENTERPRISES LLC

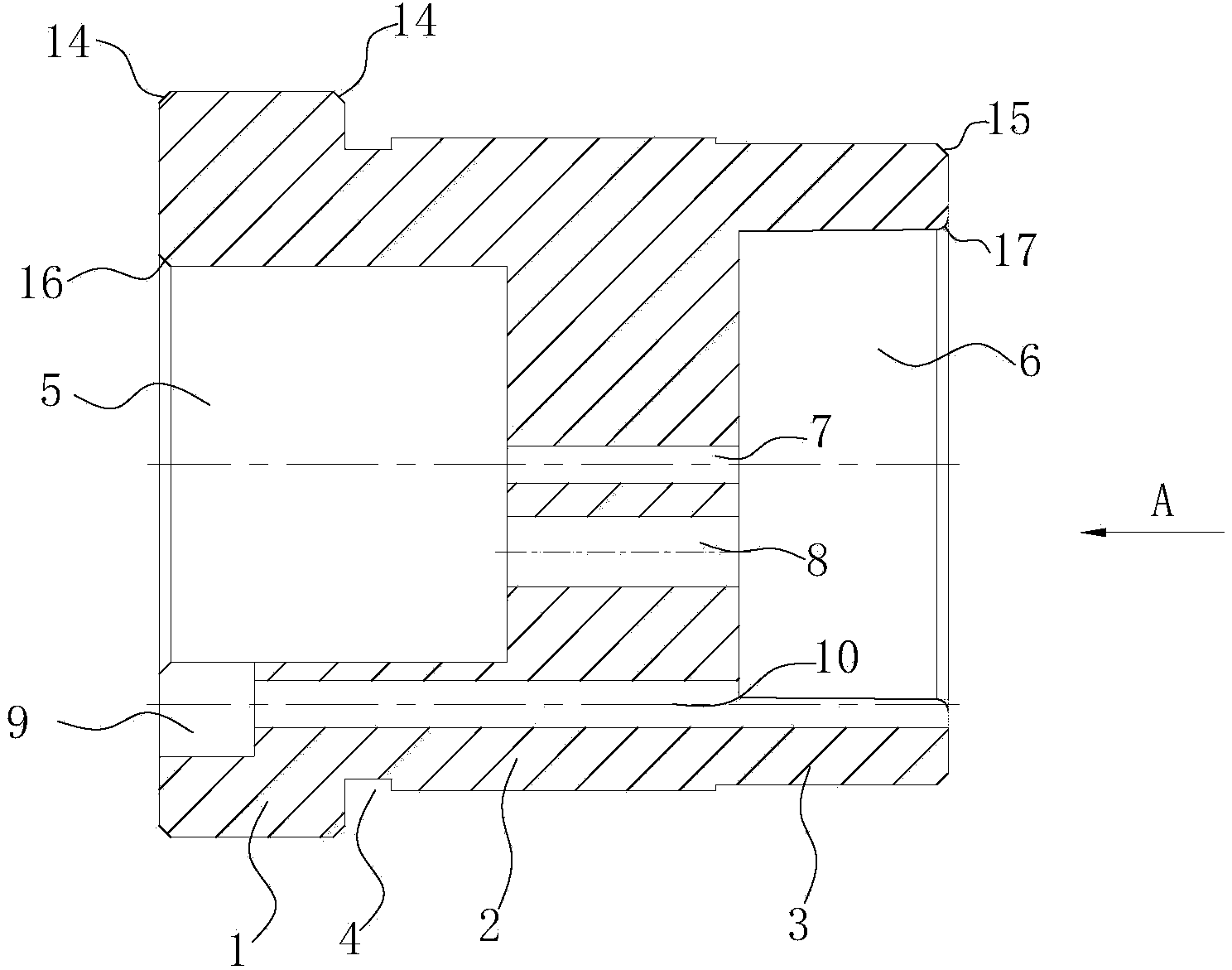

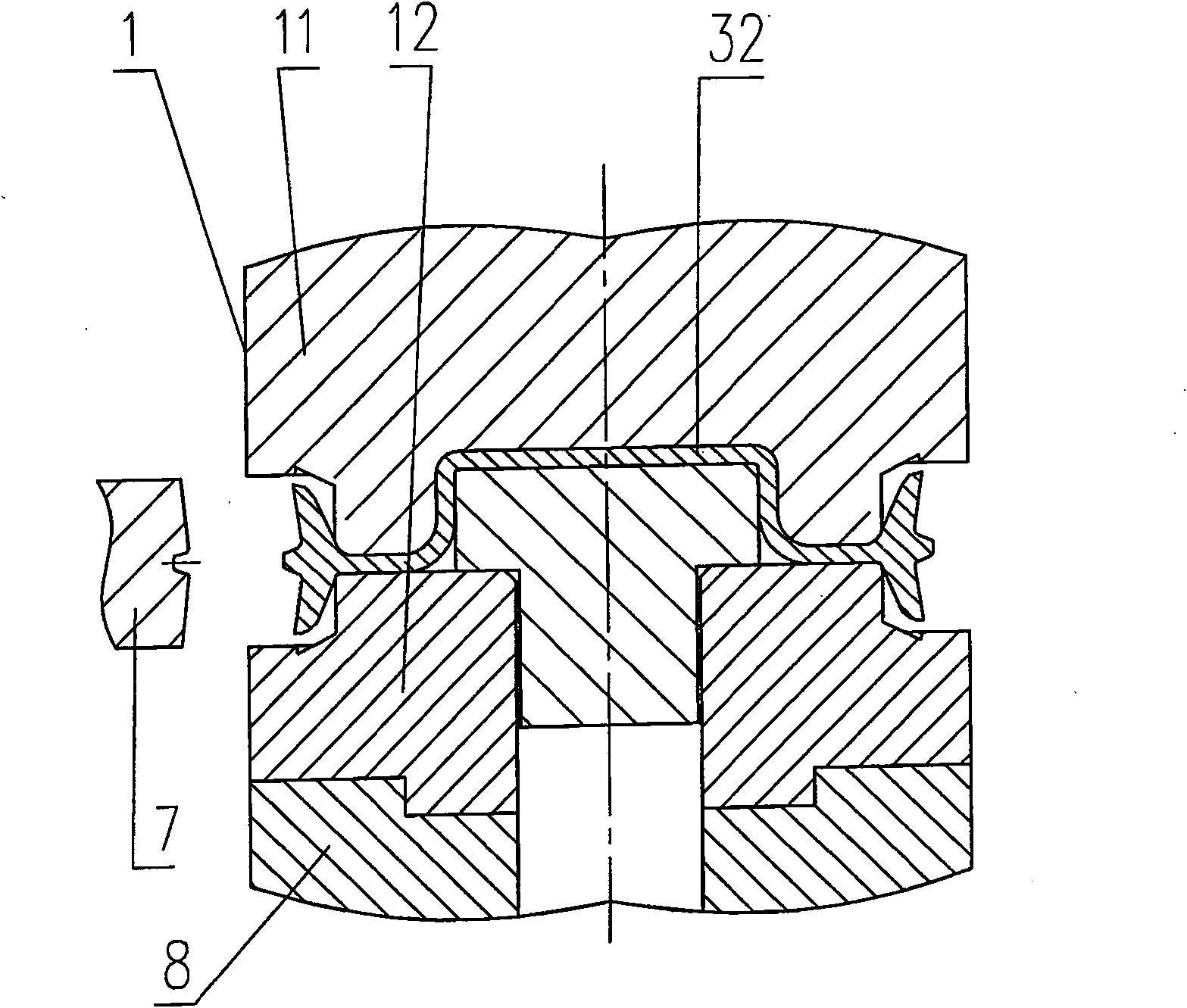

Female die for stamping of automobile parts and machining method thereof

InactiveCN103521621AAccurate dimensional accuracyReduce product scrap rateShaping toolsEngineeringDimensional precision

The invention discloses a female die for stamping of automobile parts. The female die comprises a female die body. The female die body comprises a female die first part, a female die second part and a female die third part, wherein the female die first part, the female die second part and the female die third part are coaxially arranged in sequence from left to right. The outer diameter of the female die first part is larger than that of the female die second part, and the outer diameter of the female die second part is larger than that of the female die third part. A first middle hole is formed in the center of the female die first part, and the depth of the first middle hole is larger than the axial thickness of the female die first part. A second middle hole which is coaxial with the first middle hole and communicated with the first middle hole is formed in the center of the female die third part, and the diameter of the first middle hole is larger that that of the second middle hole. The female die has high dimensional precision, and can be used repeatedly and guarantee manufacturing precision and assembly precision of the automobile parts which are manufactured through the female die. The invention further discloses a machining method of the female die. By means of the machining method, the dimensional precision of the female die in a stamping die is high, the female die can be qualified at a time through the production process, and the product rejection rate is low.

Owner:昆山精创模具有限公司

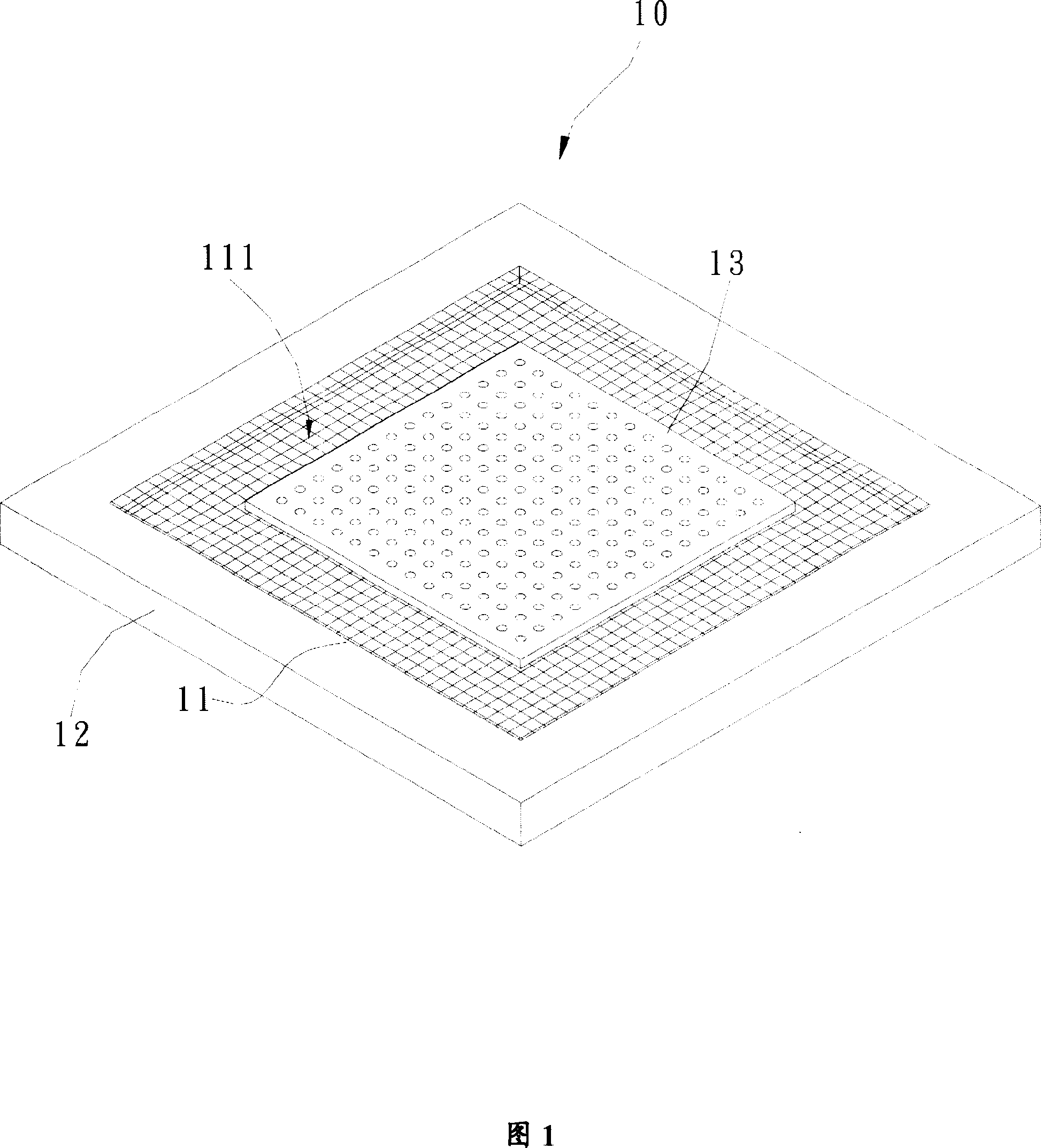

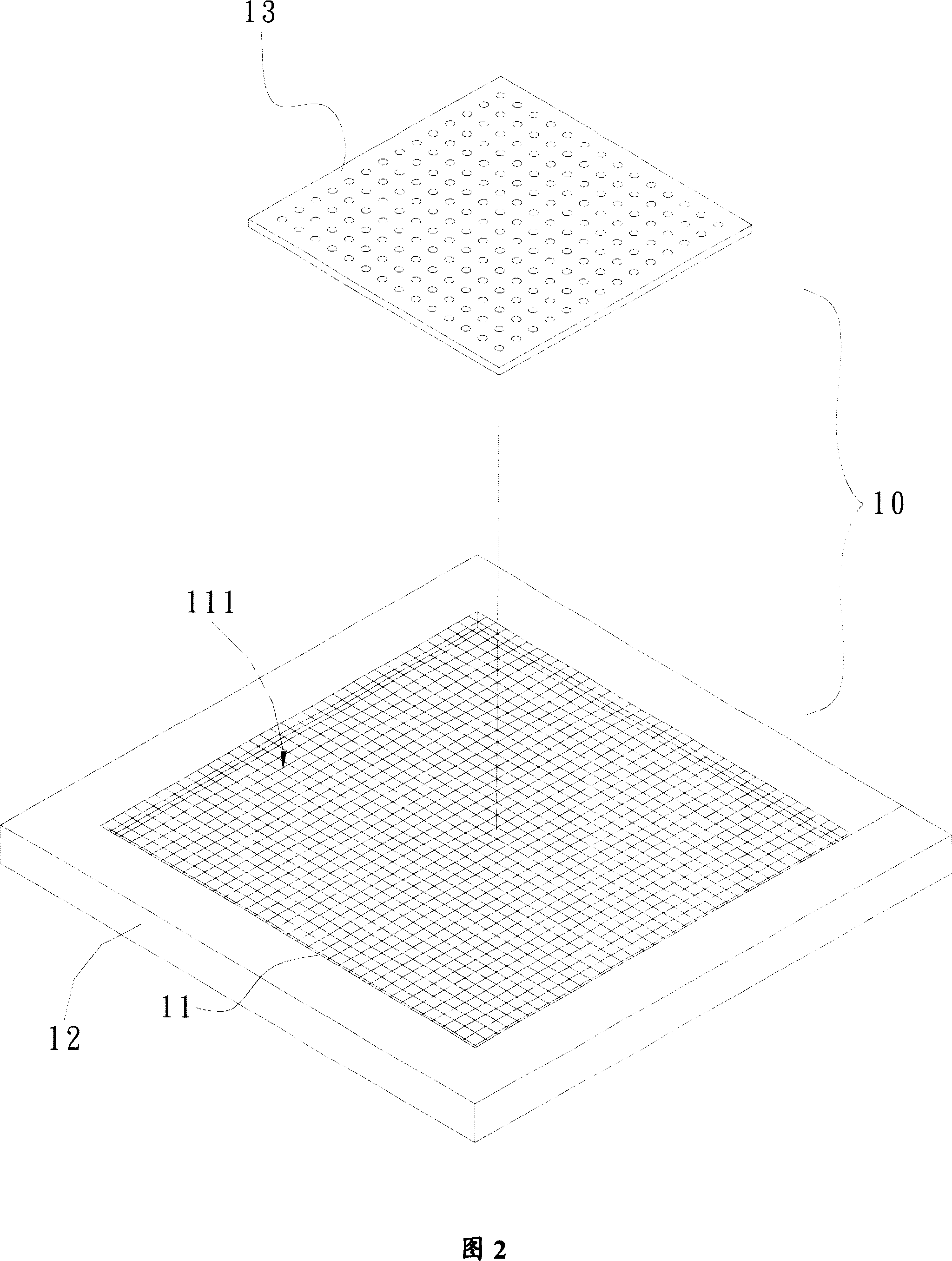

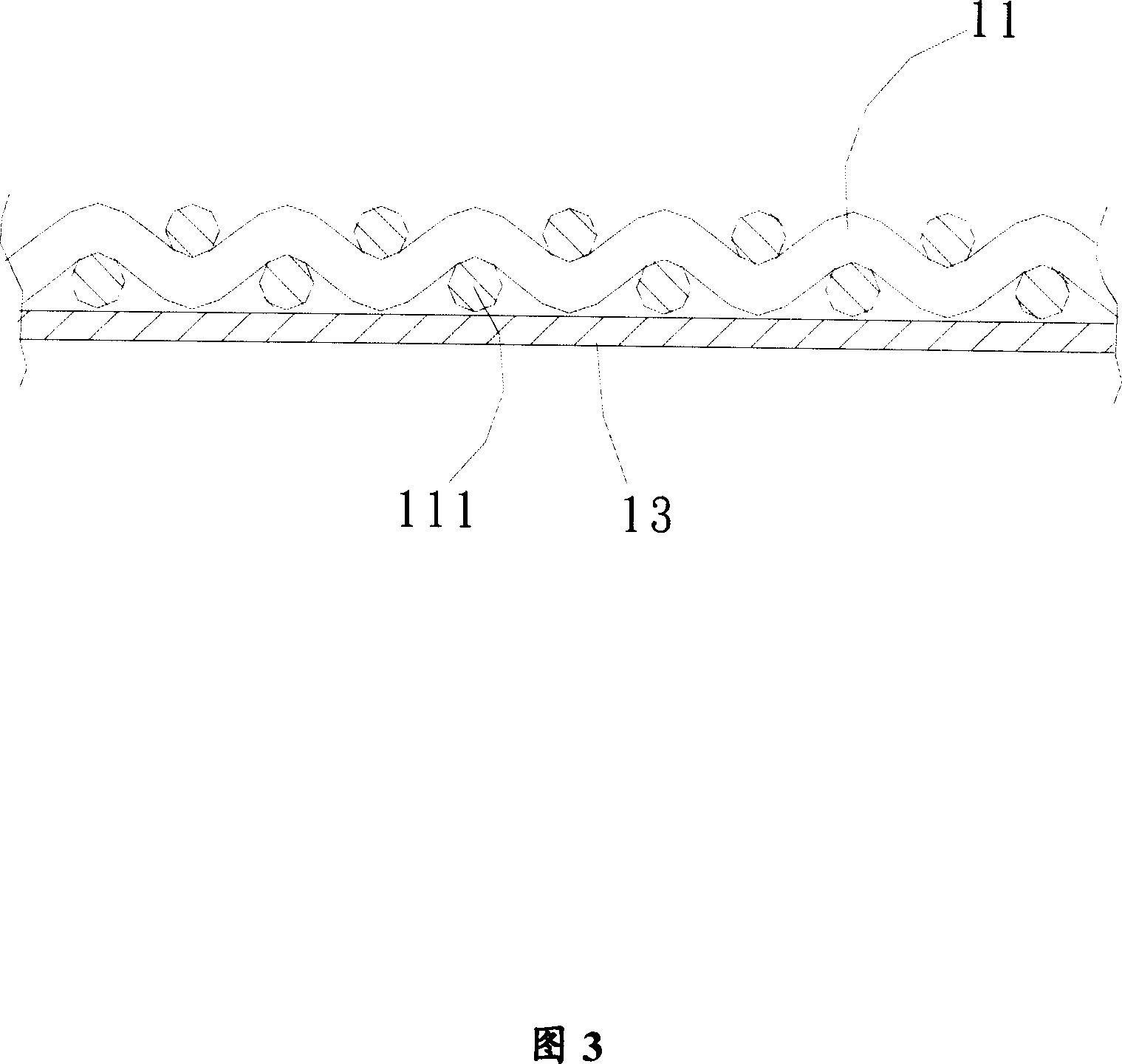

Electroforming foiled film screen-board

InactiveCN101100128AHigh precisionImprove printing qualityScreen printersPrinting pre-treatmentMetal foilMetal

The electroformed foiled screen plate includes one metal screen, one metal foil layer combined to the metal screen and one metal frame, and the metal foil layer is formed onto the metal screen through an electroforming process. The electroformed foiled screen plate has high strength and high printing density and quality.

Owner:FAITHFUL PRINTING EQUIP & SUPPLY

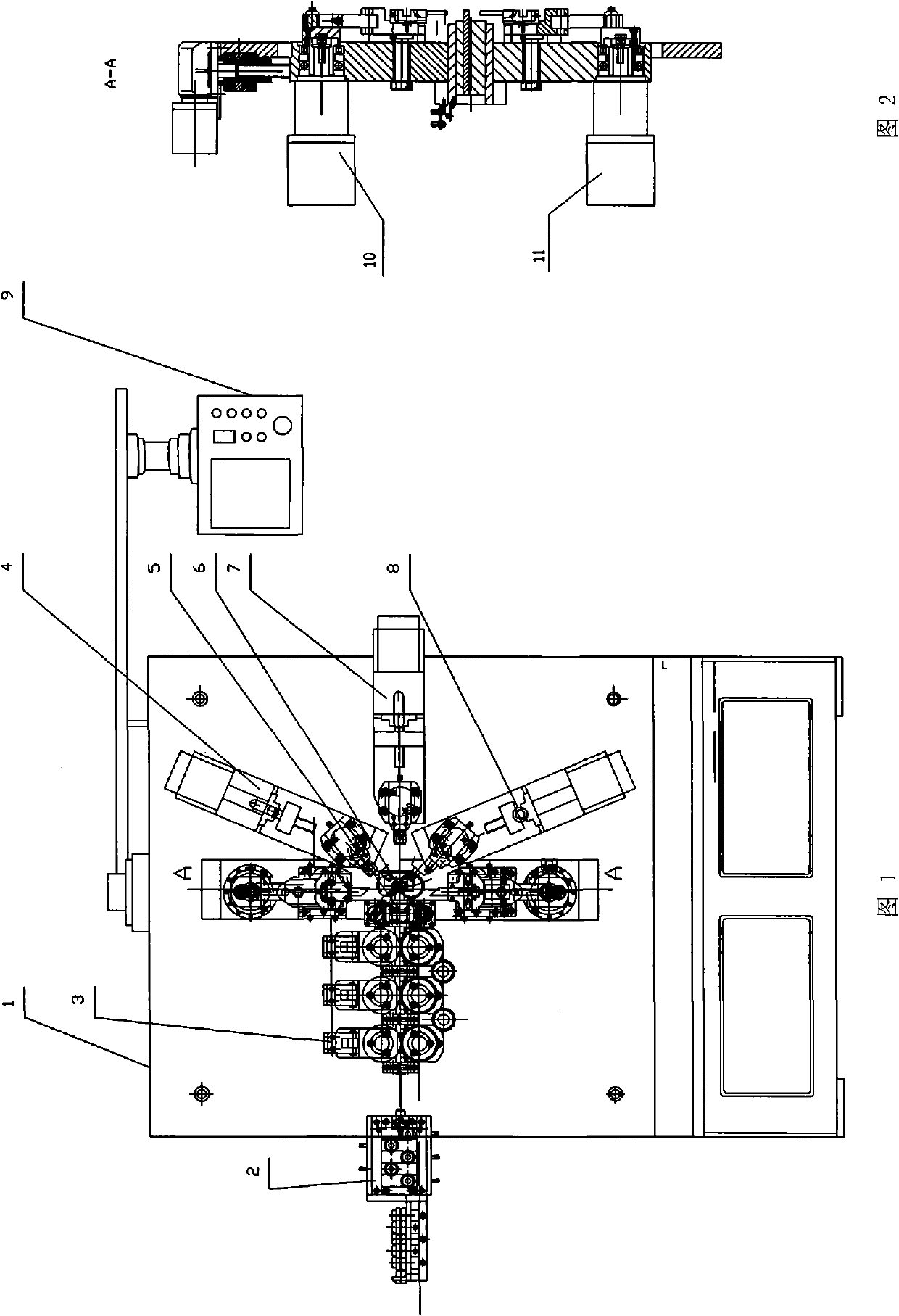

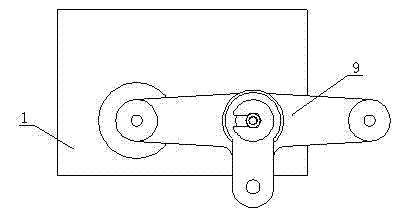

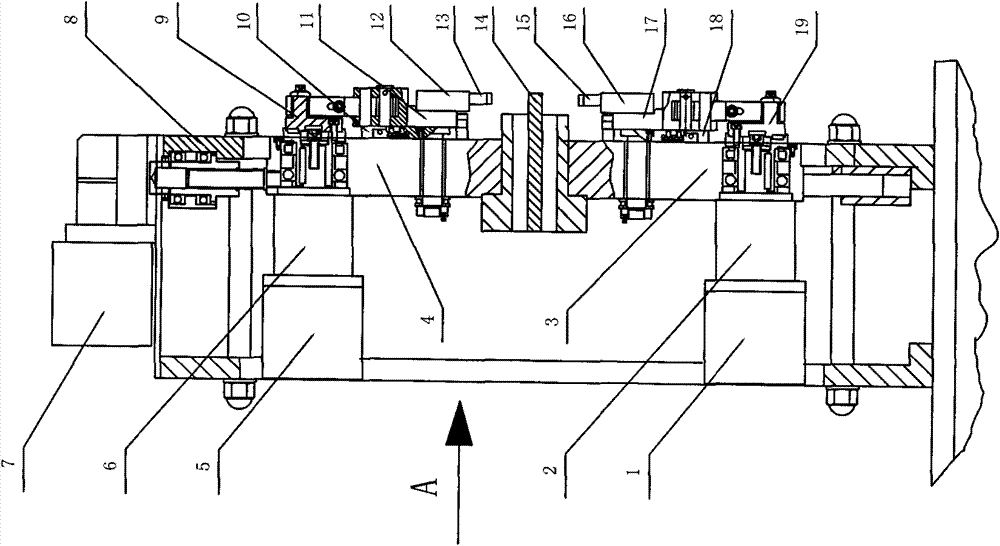

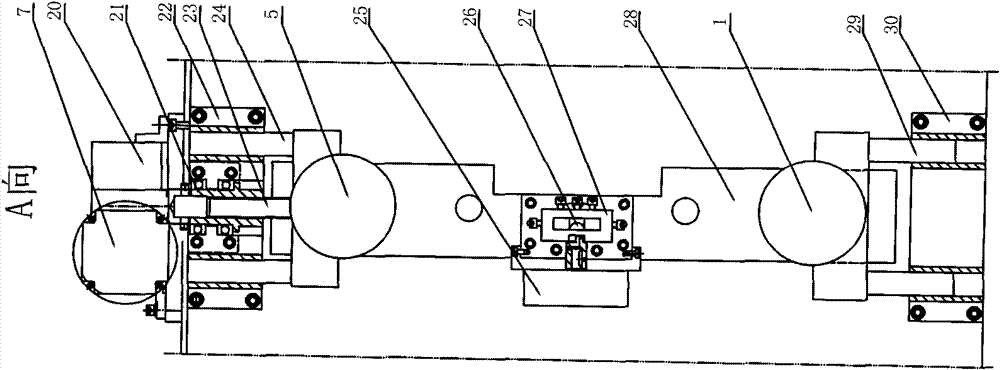

High-accuracy numerical control eight-axle helical compression spring former

The invention provides a high-accuracy numerical control eight-axle helical compression spring former. The former comprises a machine tool body, an alignment mechanism, a press feeding mechanism, an upper reducing mechanism, a pitch mechanism, a mandril, a middle reducing mechanism, a lower reducing mechanism, a computer control box, an upper cut mechanism and a lower cut mechanism. The former isdesigned by combining machinery, the computer closed ring technology and pneumatic technology, the whole machine tool realizes intelligent operation, and eight-axle data control is realized, so that the performance and reliability of the former are improved along with high sensitivity, quick response and accurate dimension accuracy, the manual operation amount is reduced, the working efficiency is improved, the operation is safe and convenient, and energy consumption is saved. In the former, 'mandril-cut' integration is realize to ensure that no tail hook exists in cutting, and a three-axle design is adopted for the reducing mechanism to ensure that the product has high processing accuracy, and the product quality and production efficiency are improved.

Owner:盐城海旭数控装备有限公司

Rotary lobe pump

ActiveUS7857607B2Accurate dimensional accuracyReduce frictionOscillating piston enginesEngine of counter-engagement typePlastic materialsPump chamber

A rotary lobe pump comprises a pump body having a driving means and an outer casing, and an insert that can be replaced. The replaceable insert comprises a housing formed of a plastic material and having an inlet port, an outlet port and internal surfaces defining a pumping chamber. The replaceable insert also includes a pair of lobed rotors arranged for rotation within the pumping chamber. The housing includes apertures through which the lobed rotors may be rotationally driven, so that the lobed rotors mesh together for pumping a fluid from the inlet port to the outlet port.

Owner:ITT MFG ENTERPRISES LLC

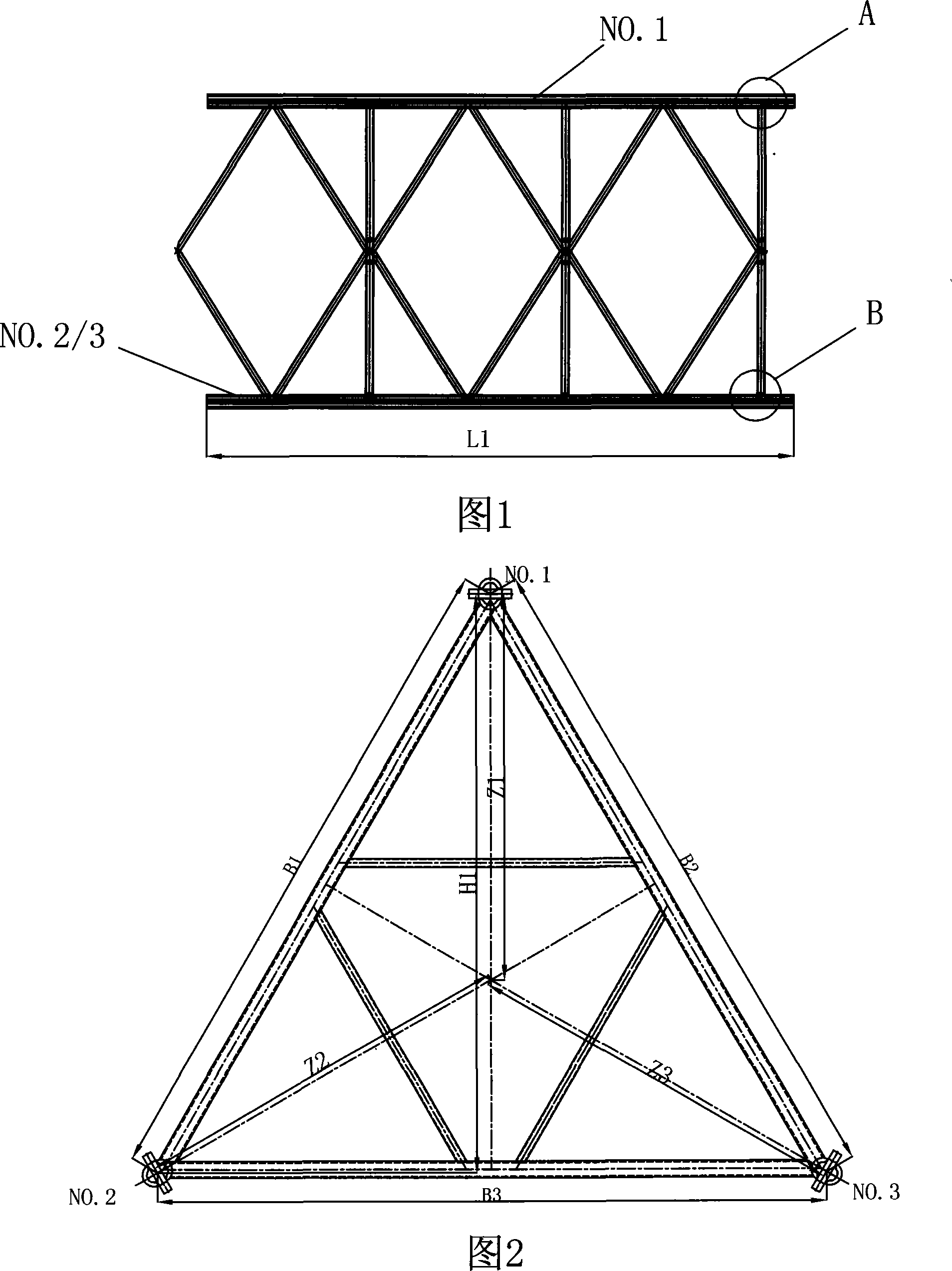

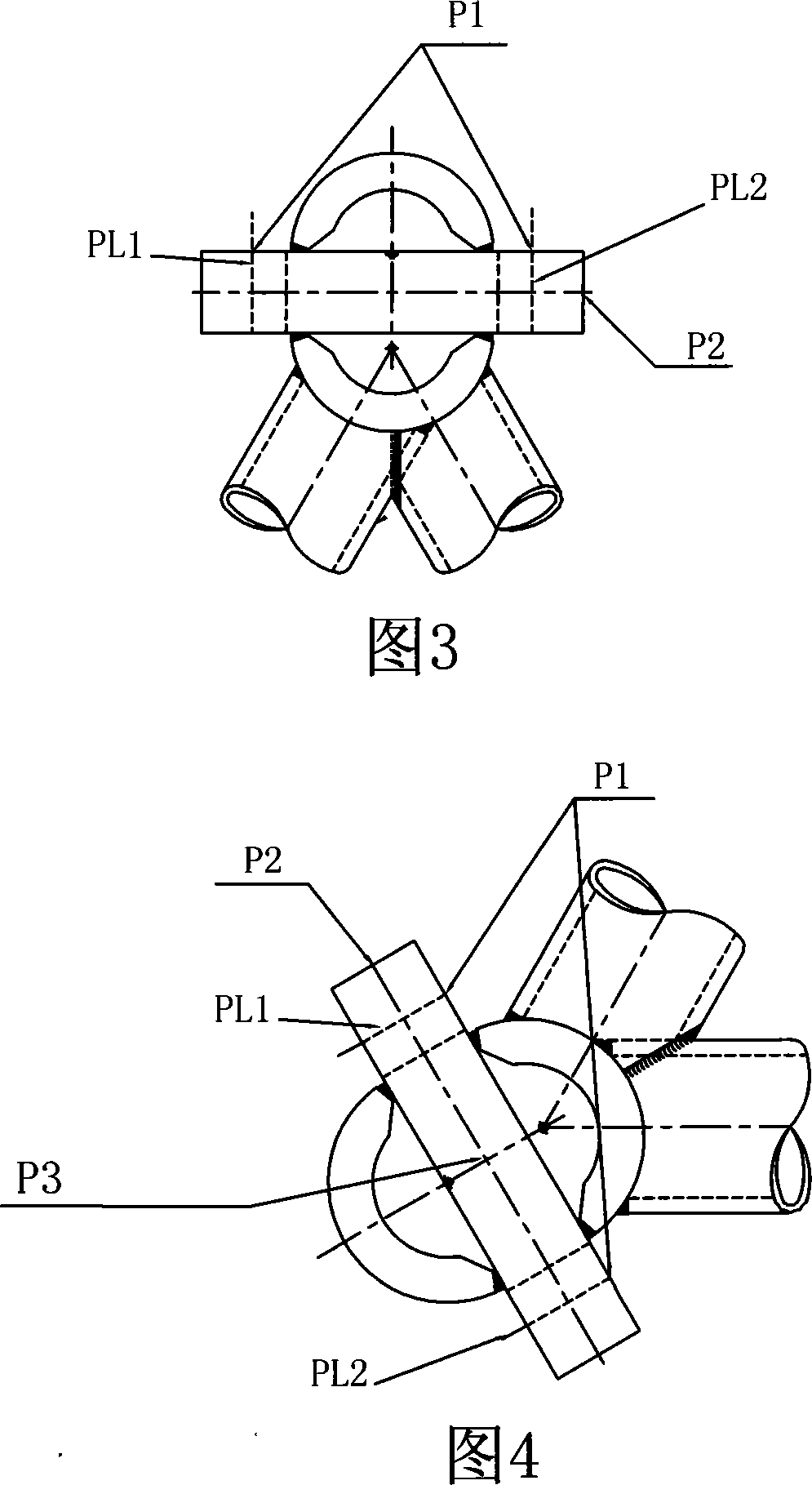

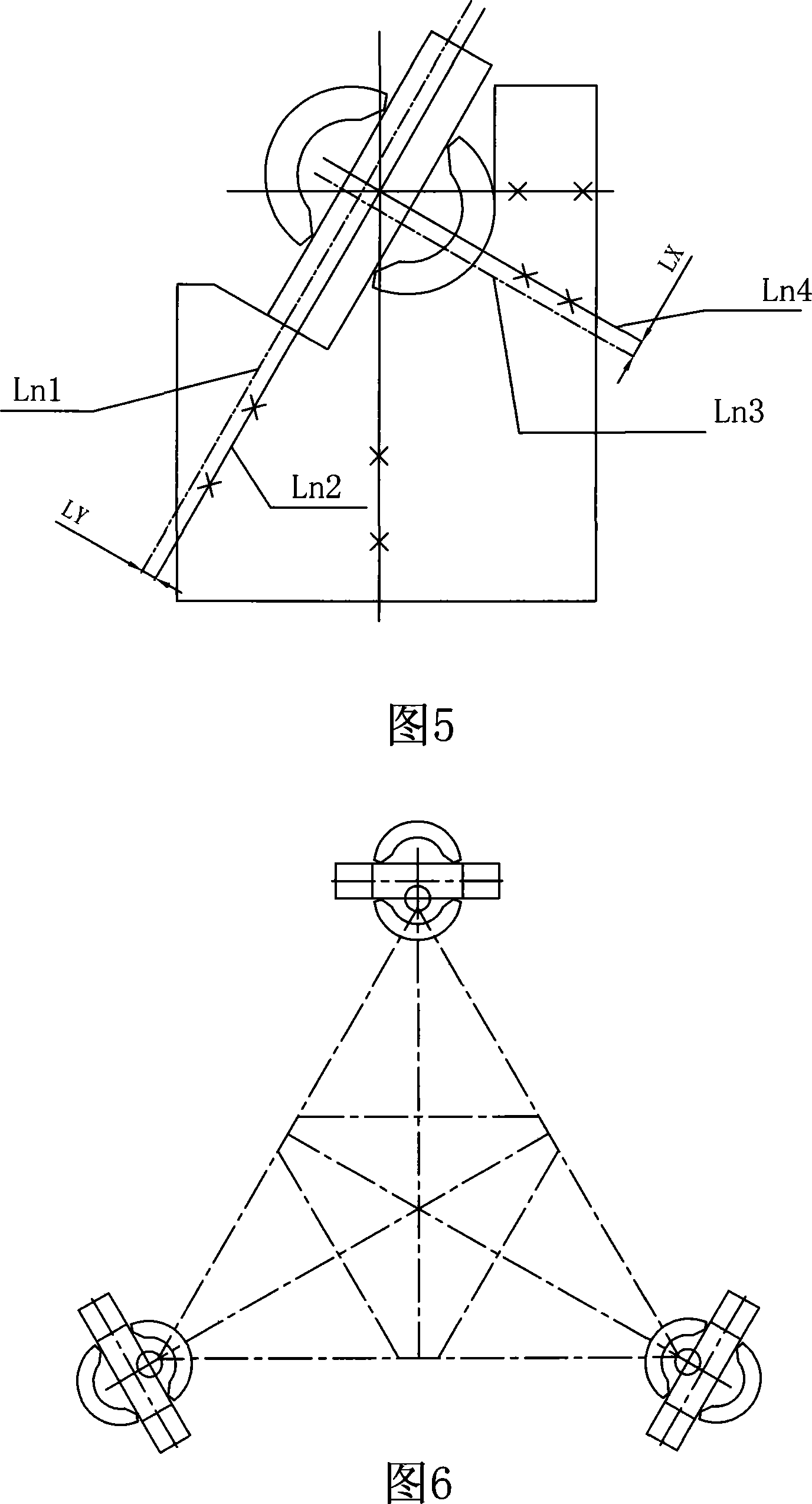

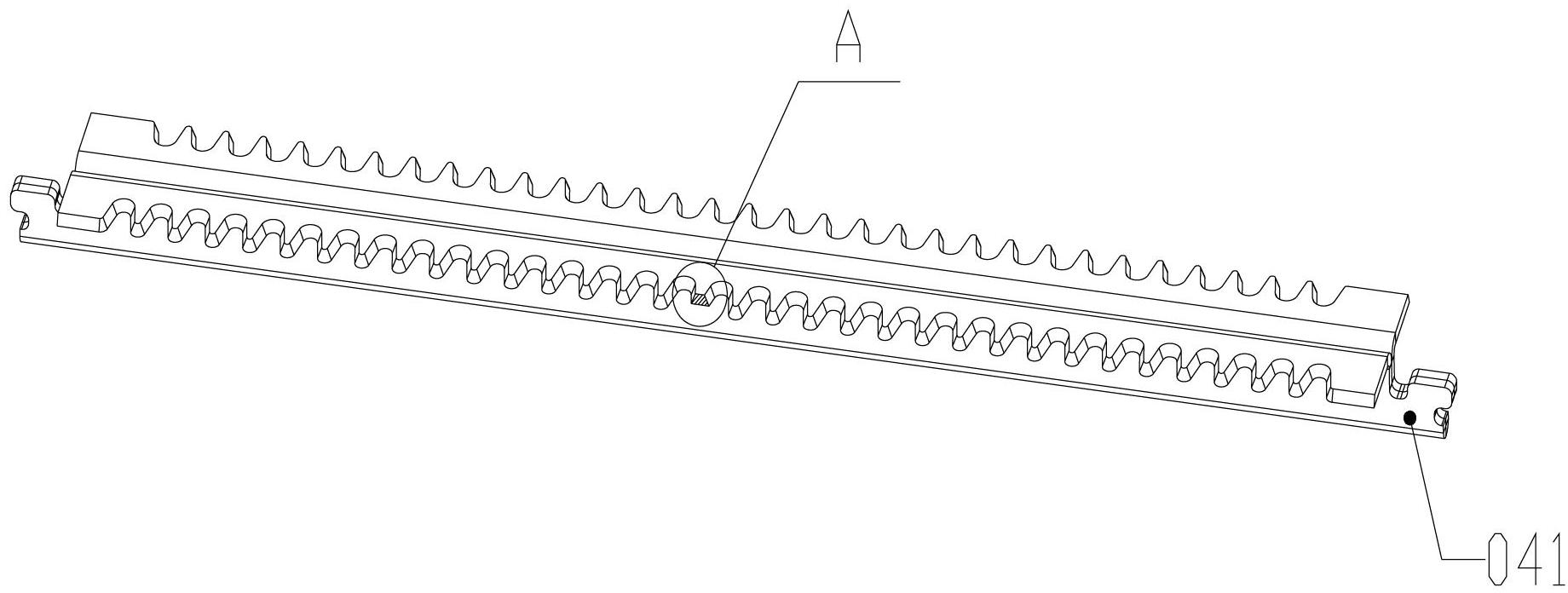

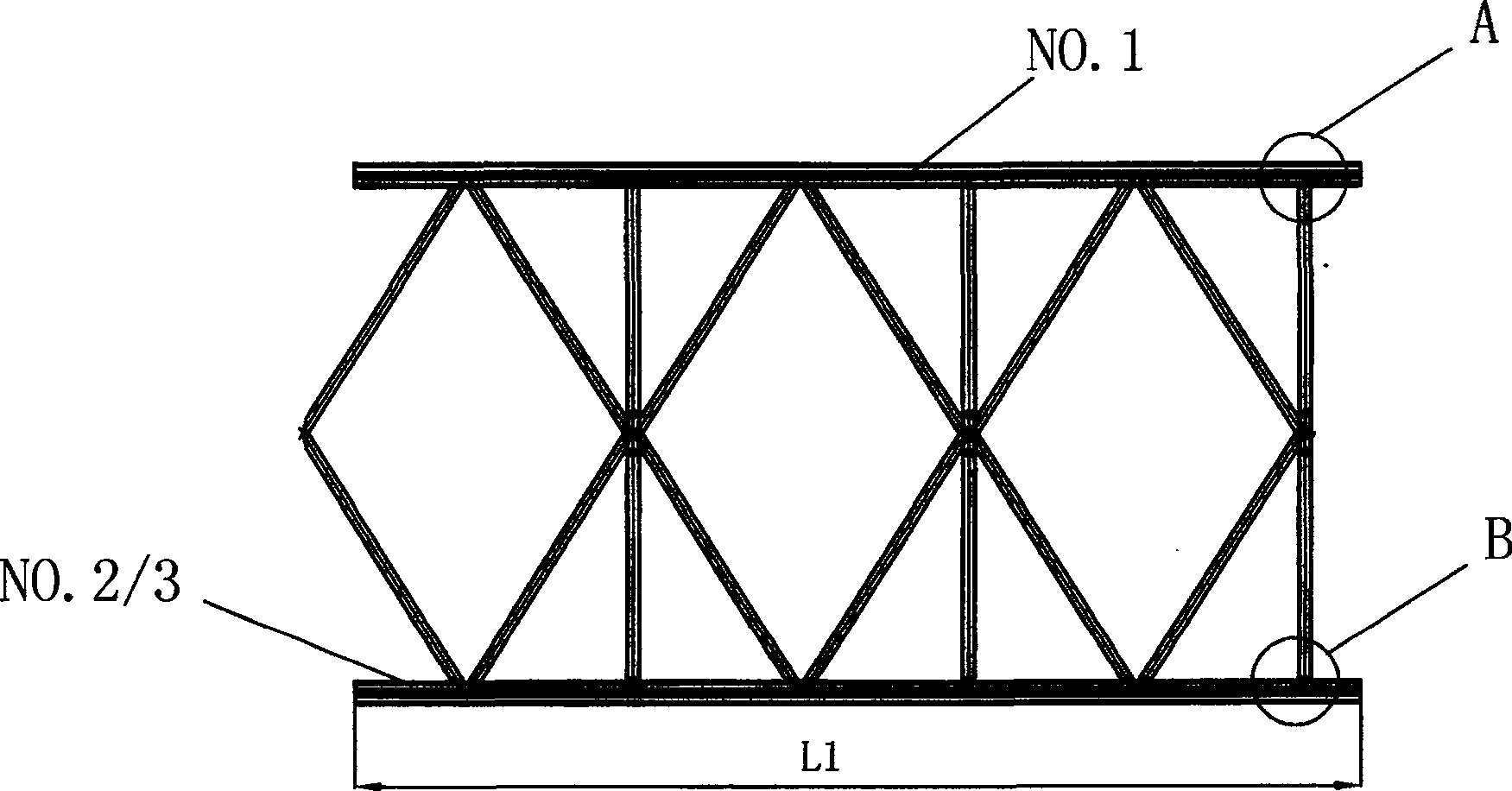

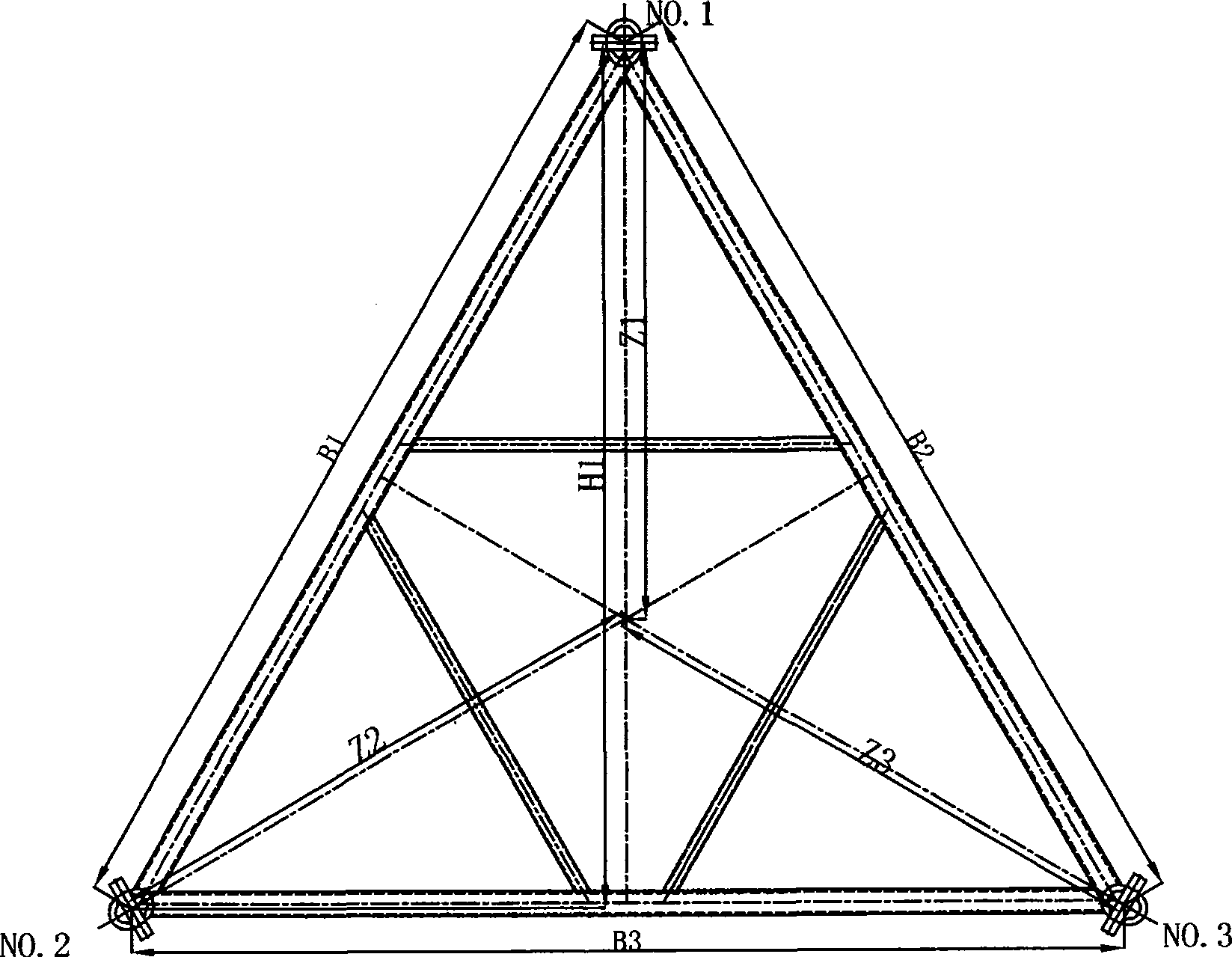

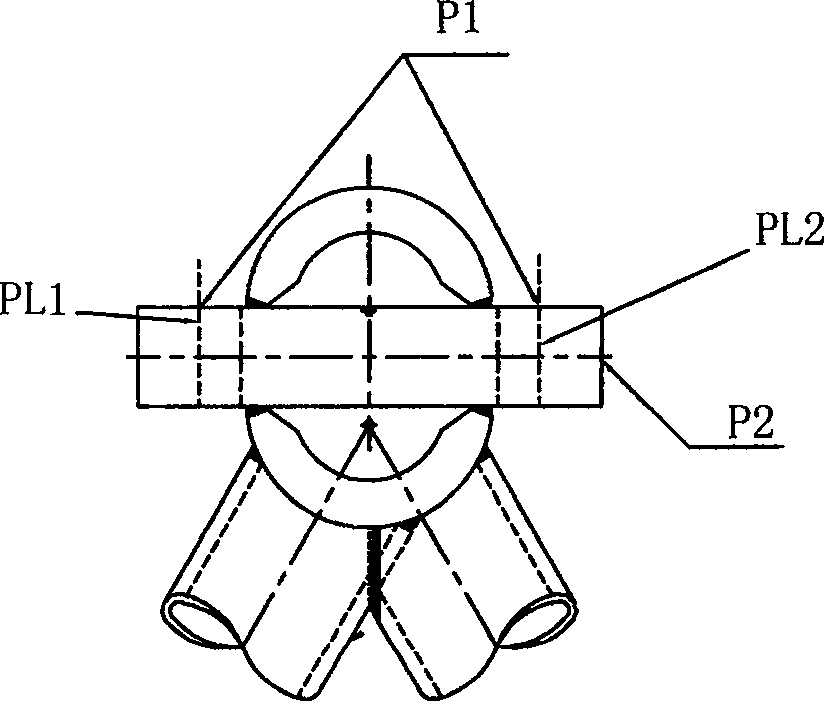

Large-scale truss type stake leg segmentation data detection method

ActiveCN101144713AQuality assuranceReduce the likelihood of damageArtificial islandsMeasurement devicesComputer scienceData detection

The invention discloses a method for performing a measurement to the size of the triangle truss type spud leg and the local precision during the process of constructing a jack up drilling platform, wherein, the large scale truss type spud leg segmenting data detecting method of the invention comprises the detecting procedures that: the main size of the spud leg is detected; the main size of the spud leg comprises a spud leg segmenting length (L1), a spud leg segmenting height (H1), a distance from a gear rack plate to a spud leg (Z1, Z2 and Z3), and a gear rack plate space (B1, B2, B3); the levelness of the gear rack plate and the crown of the gear rack plate end face are detected; the middle point (P5) of an end part gear rack central line is fetched to detect the same face degree of the gear rack plate. The invention has the advantages that the invention is convenient and advisable and has high detection precision, under the support of a high precision instrument, the exact dimensional accuracy, a tolerance and a derivation can be obtained, thereby guiding a construction process, guaranteeing the quality of the final drilling platform, reducing the possibility of the platform damage, and ensuring the safety of an offshore operation.

Owner:DALIAN SHIPBUILDING IND

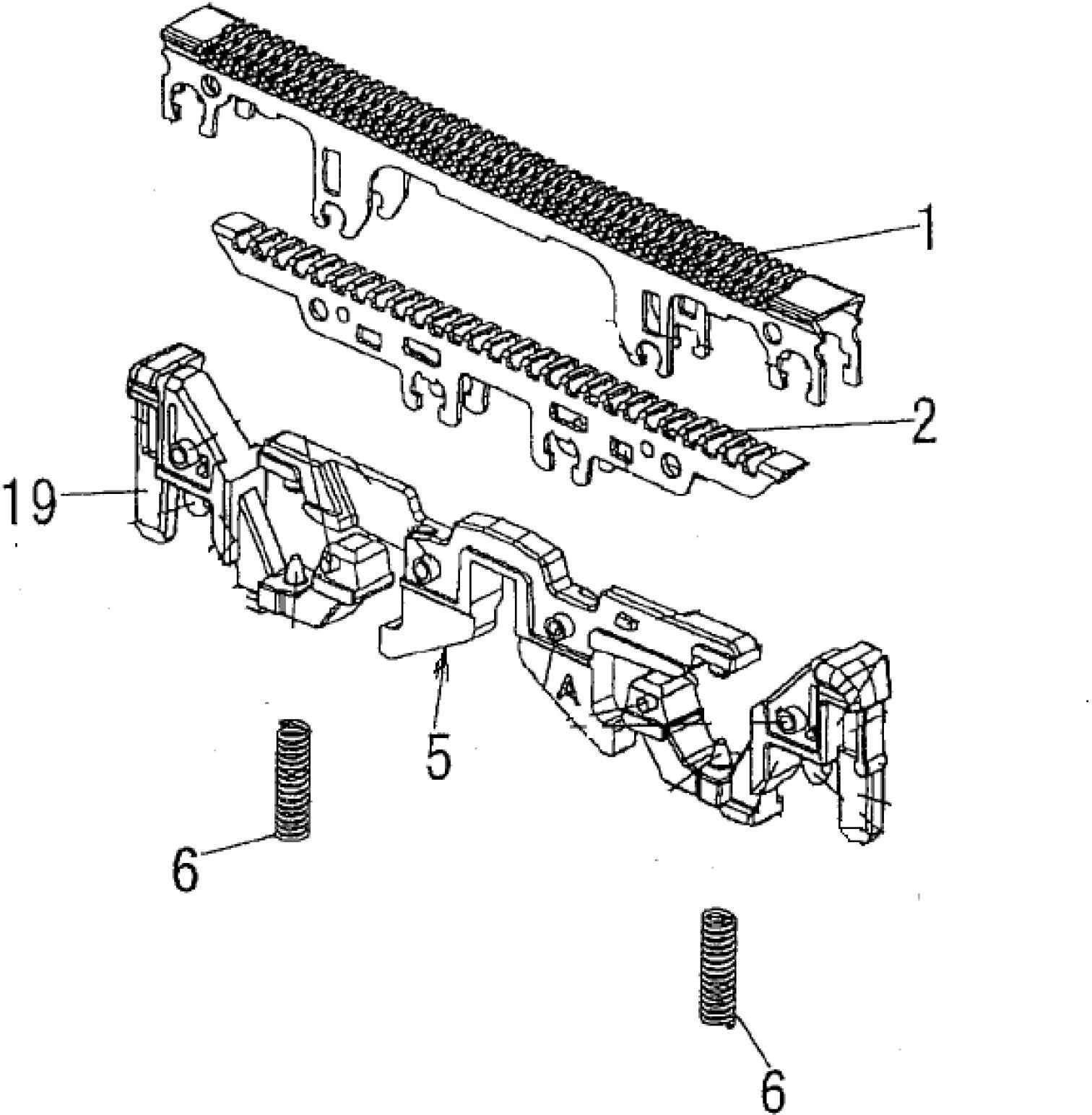

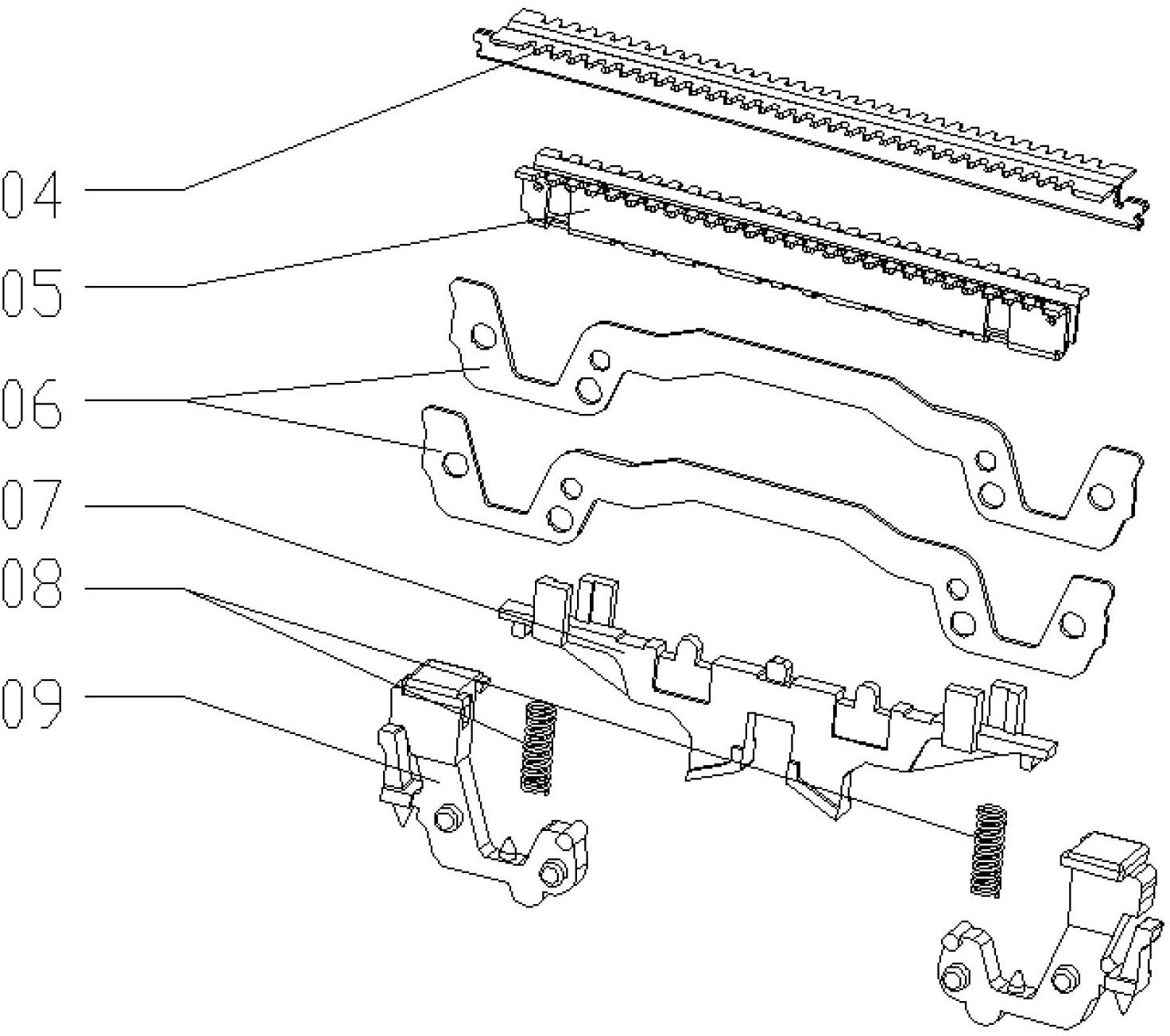

Shaver and reciprocating-type T-shaped cutting head

ActiveCN102689318AStable dimensional accuracyAccurate dimensional accuracyMetal working apparatusEngineeringRazor Blade

The invention discloses a reciprocating-type T-shaped cutting head, comprising a T-shaped fixed cutting head, a T-shaped movable cutting head and a drive block for driving the T-shaped movable cutting head. Both the T-shaped fixed cutting head and the T-shaped movable cutting head are provided with two rows of cutting gears; the T-shaped fixed cutting head is provided with a positioning raised line; and the T-shaped movable cutting head is provided with a positioning chute adapted to the positioning raised line. The cutting head provided by the invention operates reliably, can shave long beard effectively and is beneficial for shaving short beard from the root by other cutting heads, thereby improving the shaving efficiency and saving the shaving time for users.

Owner:浙江海顺电工有限公司

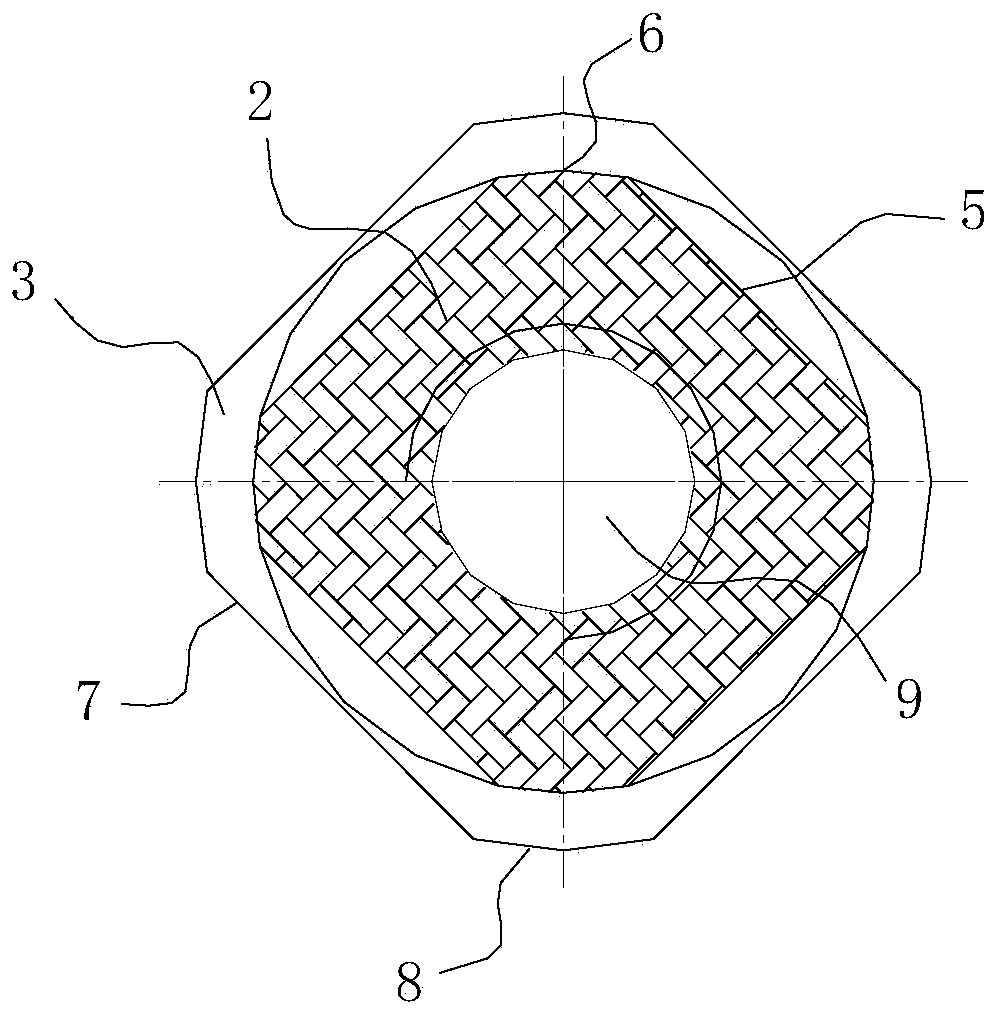

Sleeve protecting core and processing method thereof

ActiveCN103552190AHigh dimensional accuracyAccurate dimensional accuracyStructural engineeringRejection rate

The invention discloses a sleeve protecting core. The sleeve protecting core comprises a core body, wherein the core body is successively and coaxially provided with a core first part, a core second part, a core third part, a core forth part, a core fifth part and a core sixth part from left to right, wherein the periphery of the core fifth part is provided with a first groove in an annular manner, and four second grooves are uniformly distributed in the periphery of the core fifth part; the length directions of the second grooves are parallel to an axis of the core body, the second grooves are formed in a way that one end, which is close to the core sixth part, of the core fifth part extends towards the core forth part and can not run through the core fifth part. The sleeve protecting core has high dimensional precision and can be used for many times. The invention also discloses a processing method of the sleeve protecting core, the processing method can enable the sleeve protecting core in a stamping mould to be accurate in precision, the productive process is qualified once, and the product rejection rate is low.

Owner:昆山精创模具有限公司

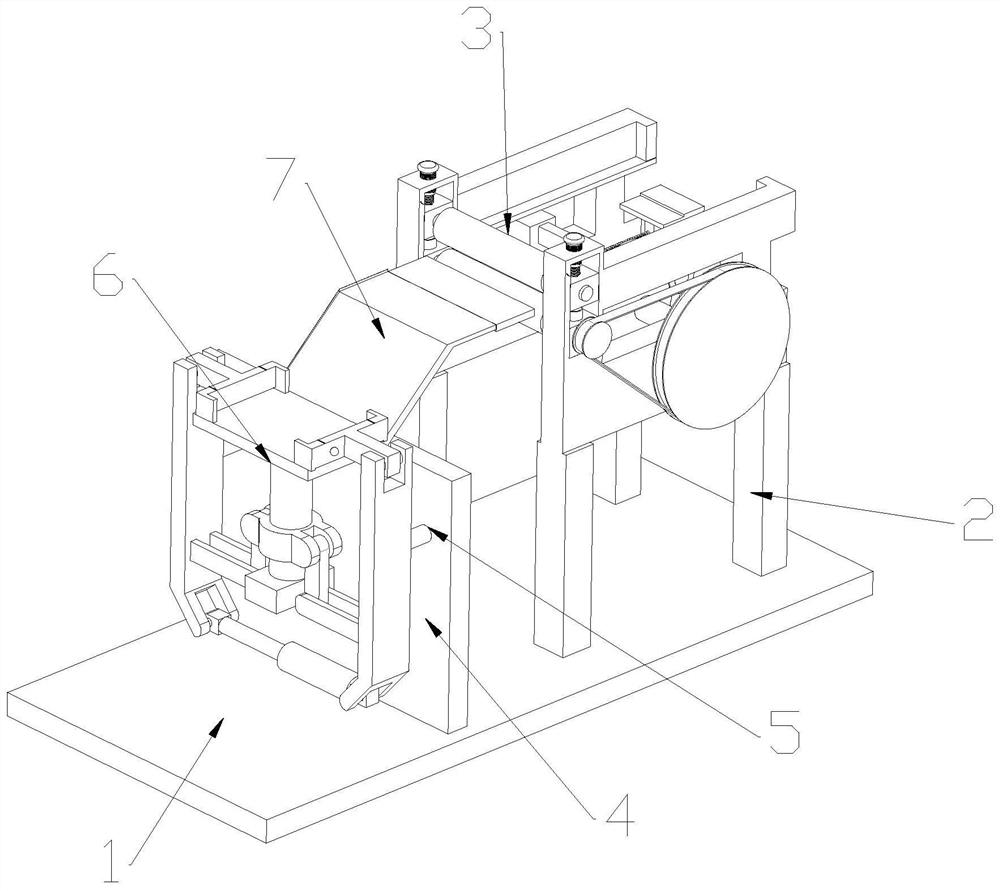

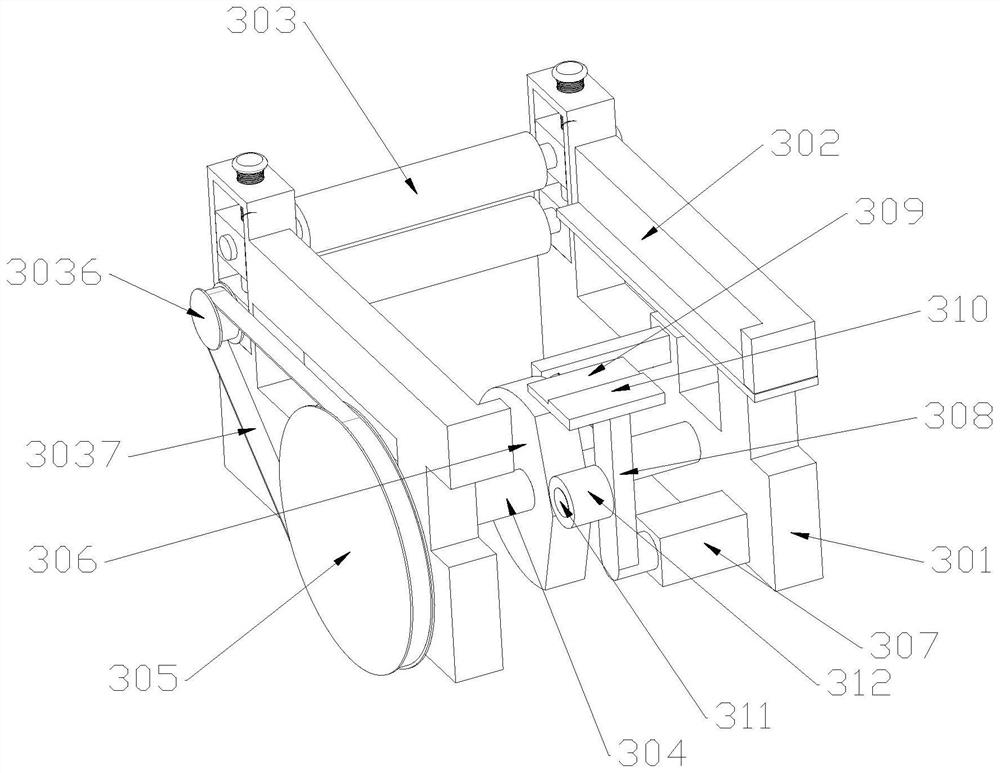

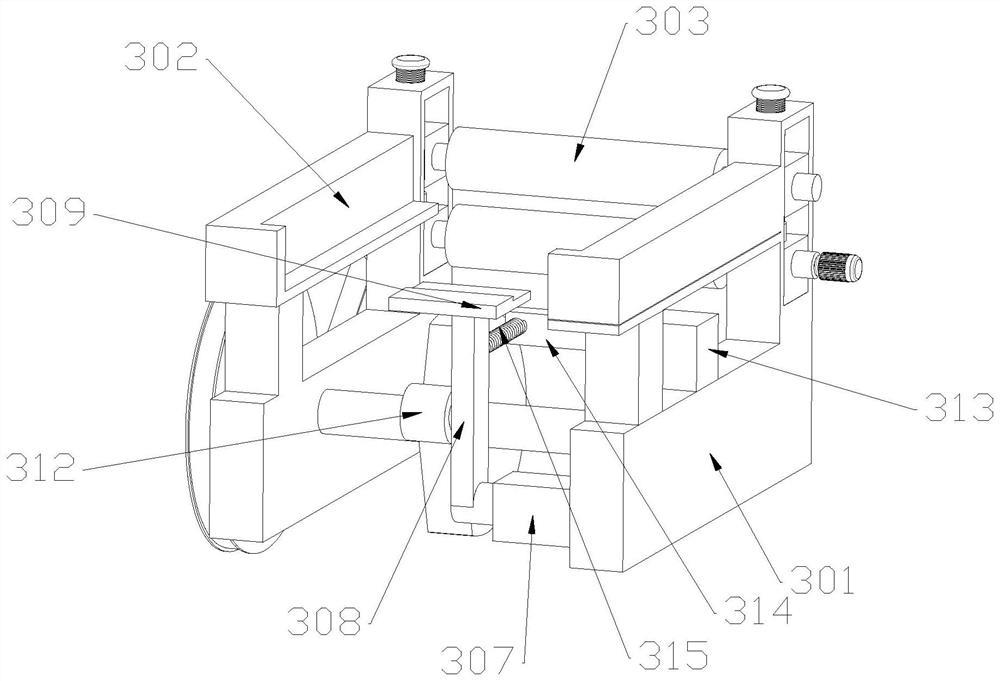

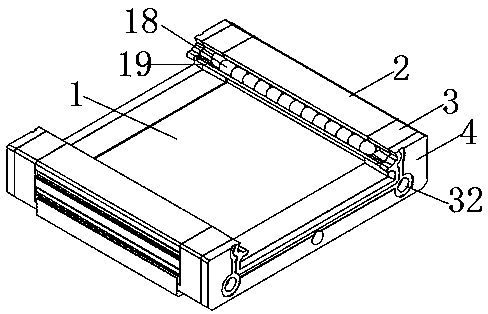

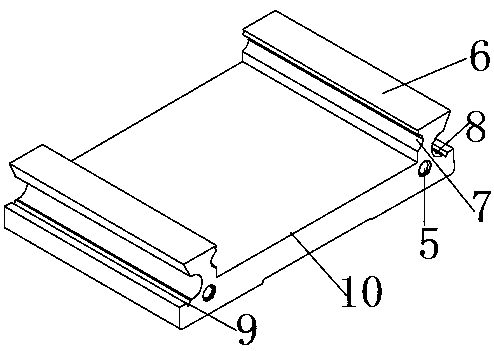

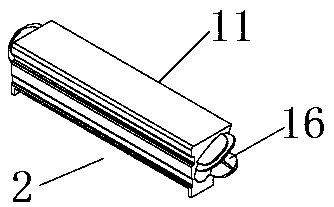

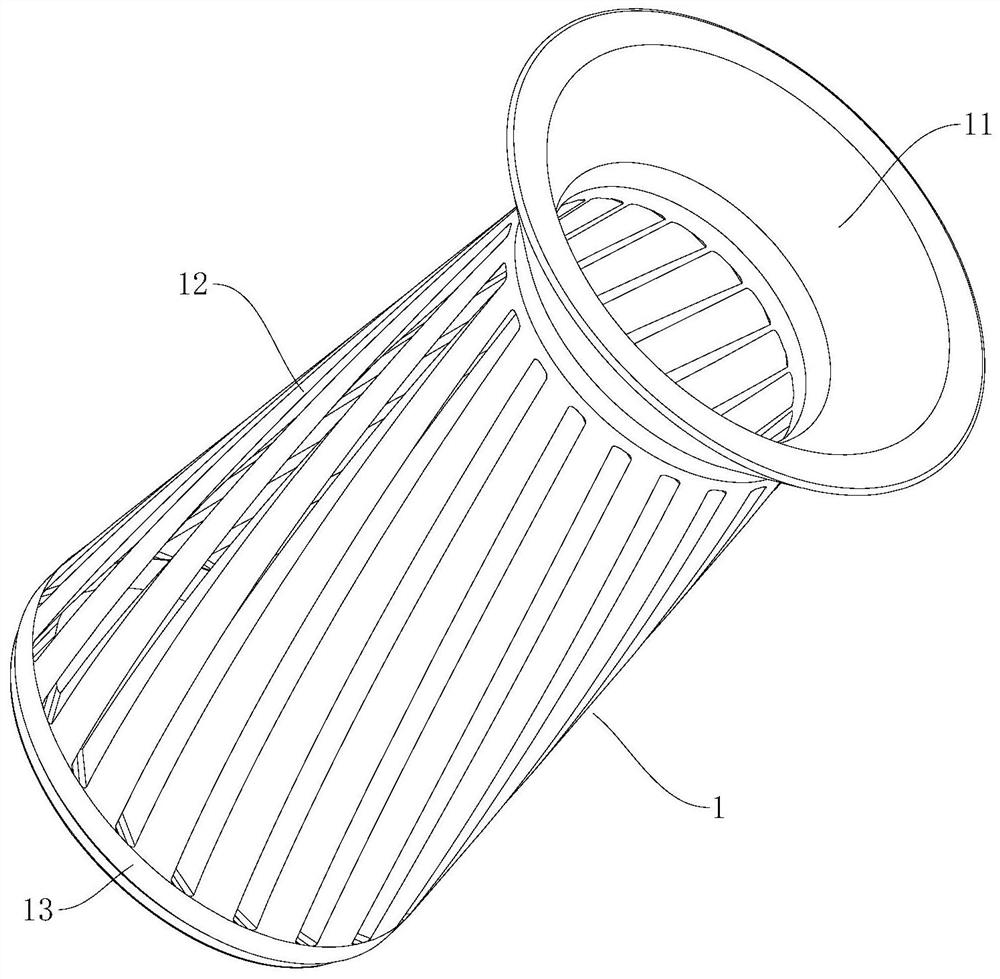

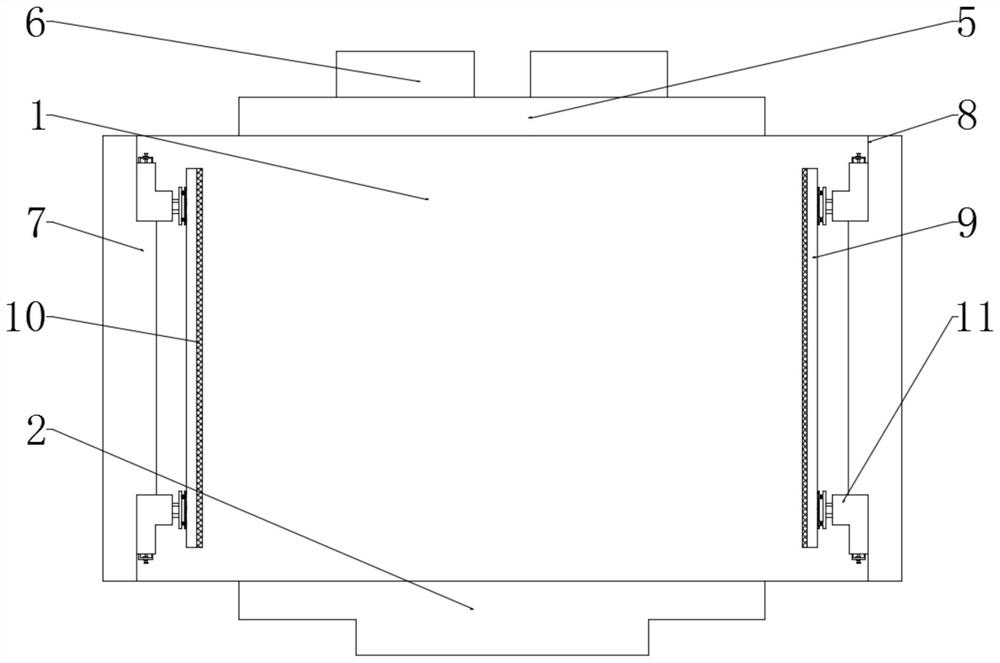

Wooden door precise regulation and control intelligent complete machining method and device

ActiveCN114393458AAccurate dimensional accuracyEasy to operateGrinding drivesWood working apparatusPolishingWood plank

The invention discloses a wooden door precise regulation and control intelligent complete machining method and device, and belongs to the technical field of wooden door machining.The wooden door precise regulation and control intelligent complete machining device comprises a base, a supporting frame is arranged on the base, a grinding mechanism for conducting secondary grinding on a wooden plate is arranged above the supporting frame, a mounting plate is arranged at the front end of the supporting frame, and two first fixing shafts are arranged at the side end of the mounting plate; a limiting mechanism used for fixing a wood board during cutting is rotationally arranged on the first fixing shaft, an inclined plate is arranged at the top end of the mounting plate, and the grinding mechanism is connected with the limiting mechanism through the inclined plate. The wood board polishing device is easy to operate, wood boards can be automatically polished, two polishing rollers on the polishing assembly can be adjusted through adjusting columns, so that the two sides of the wood boards with different thicknesses can be polished at the same time, and a rotating disc arranged on the polishing mechanism is matched with a rotating column, so that a push plate can be driven to intermittently move; and the wood board can be automatically fed into the polishing assembly to be polished, operation and use are convenient, and the labor cost is saved.

Owner:广东联塑日利门业有限公司

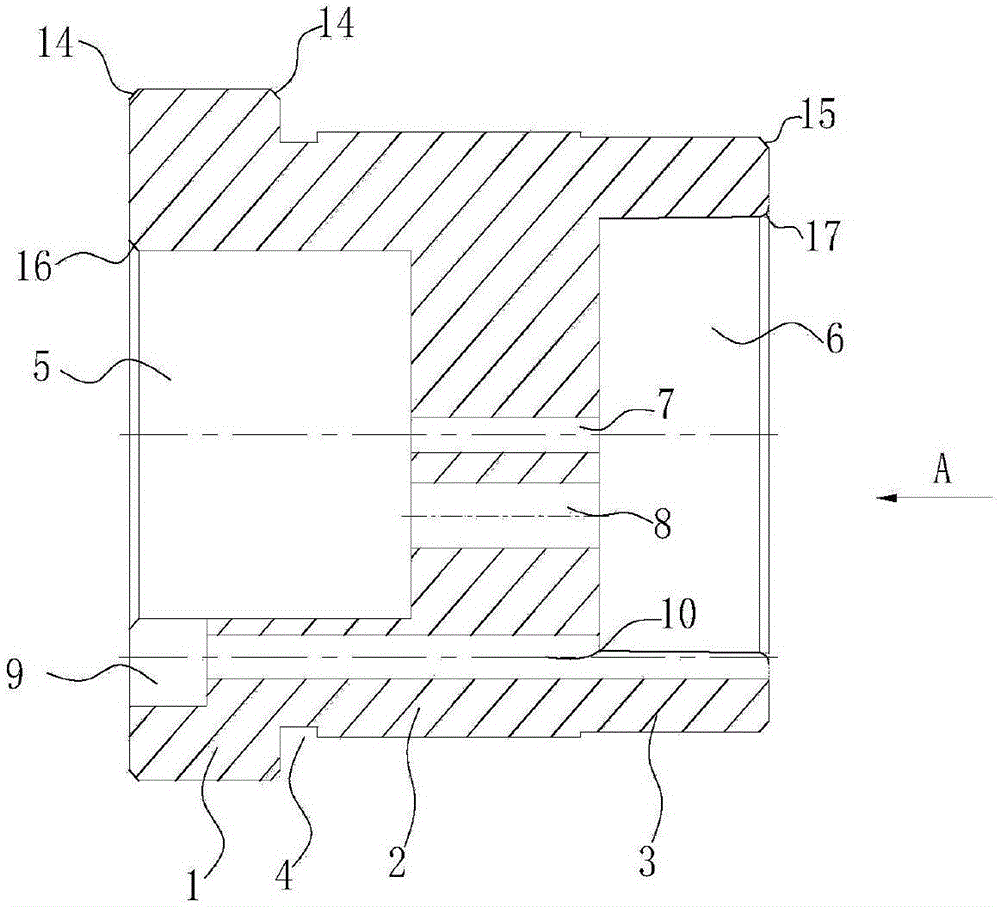

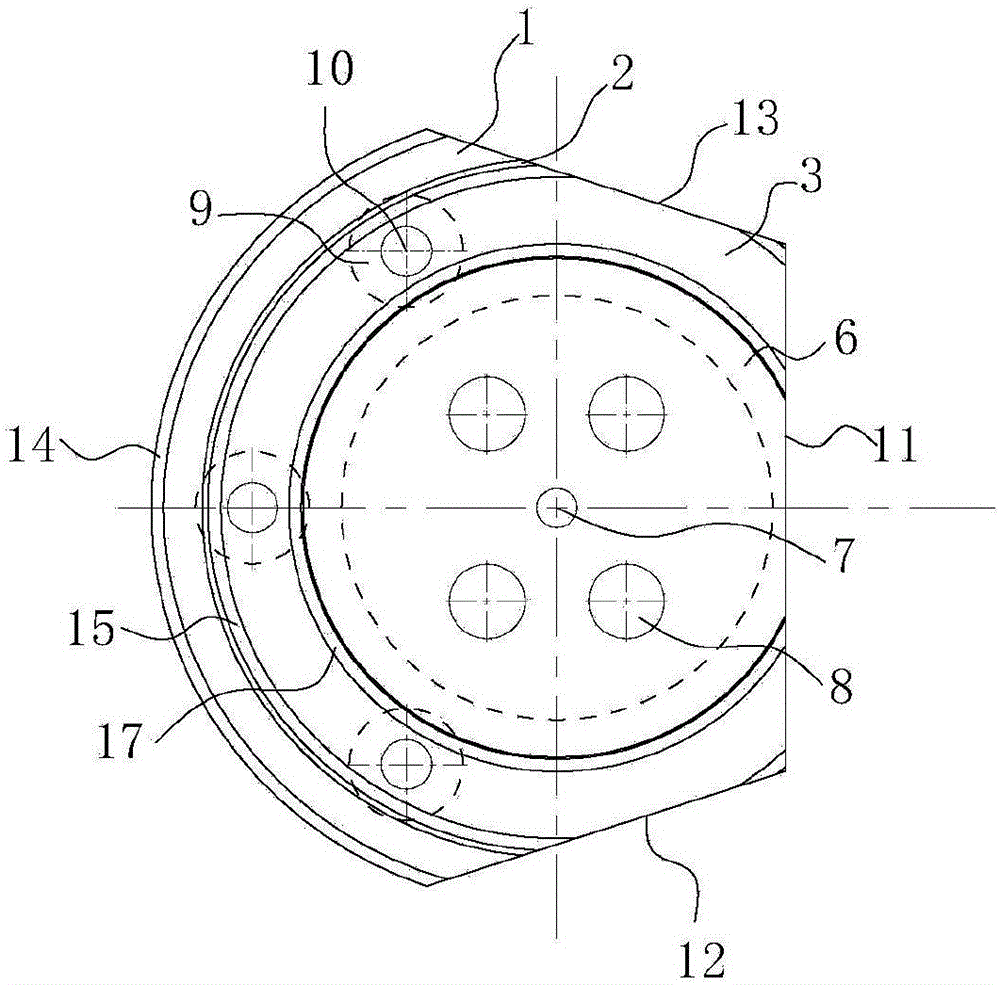

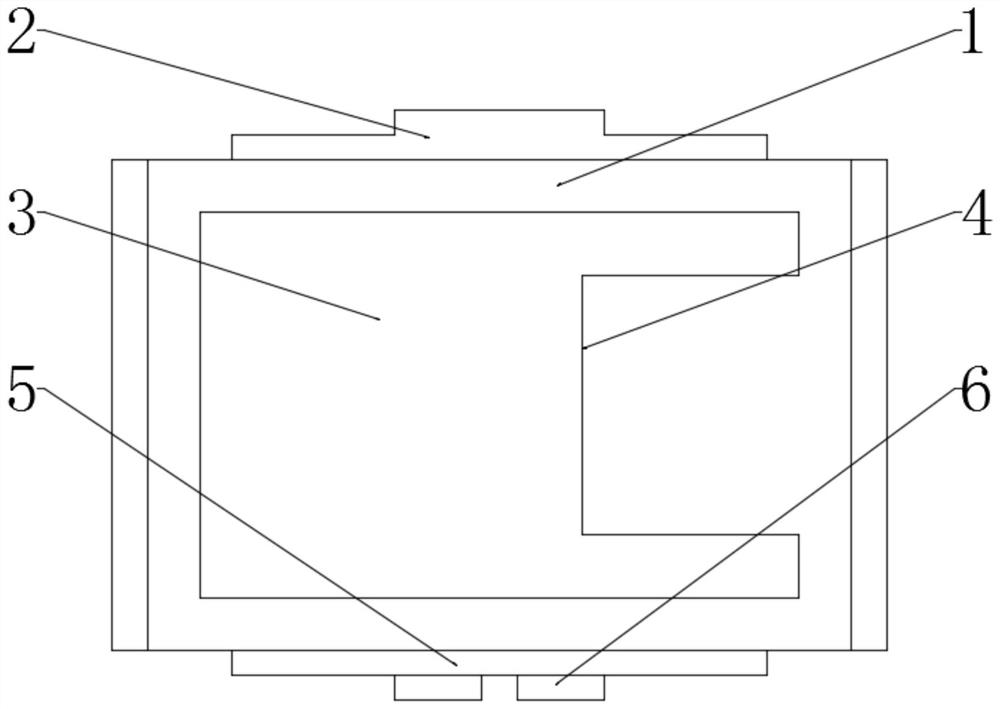

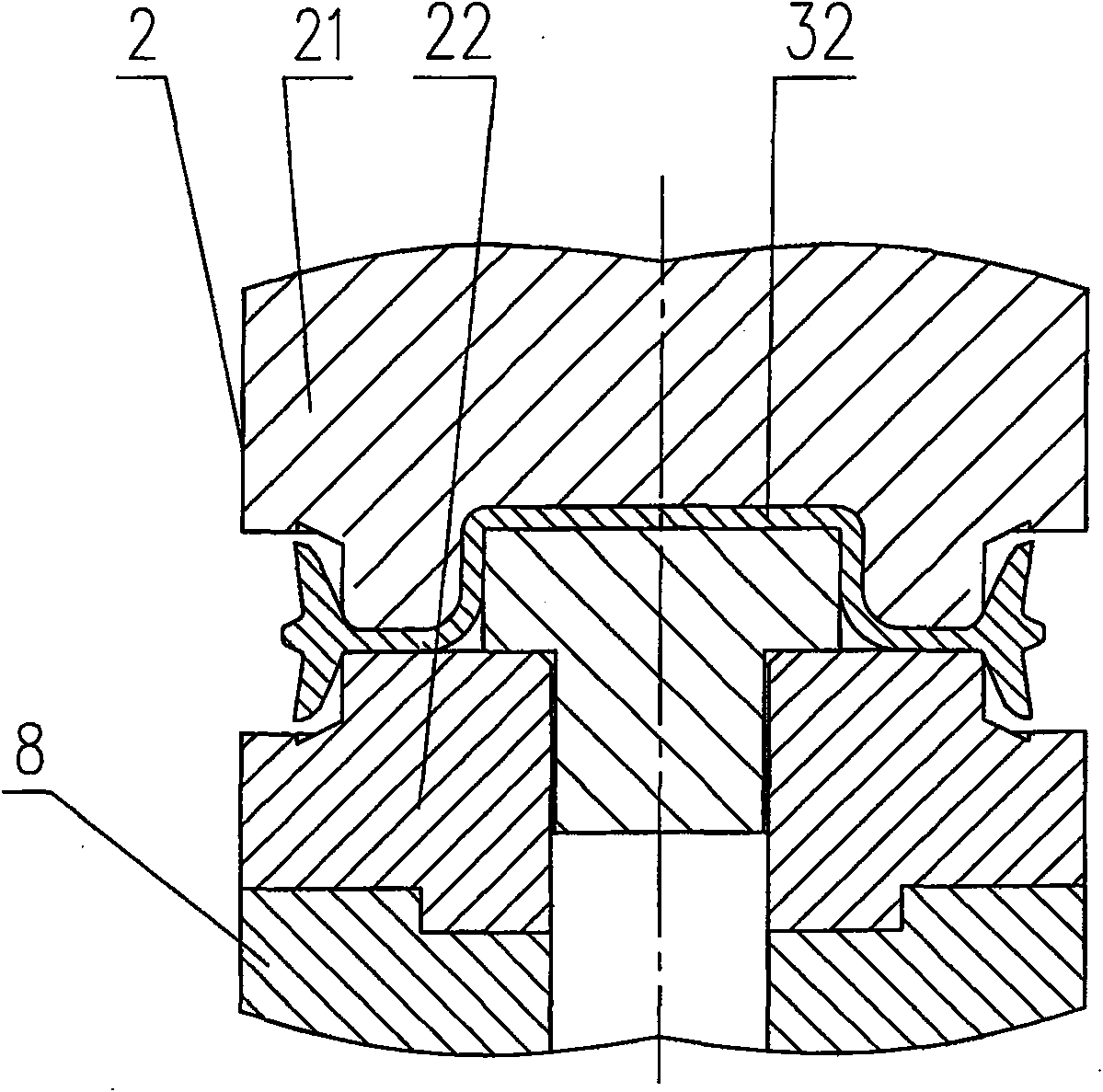

Stamping cavity die for automotive components and processing method thereof

InactiveCN106311905AHigh dimensional accuracyAccurate dimensional accuracyShaping toolsVehicle componentsRejection rateIndustrial engineering

The invention discloses a stamping cavity die for automotive components, comprising a die main body which comprises coaxially set first die part (1), a second die part (2) and a third die part (3) from the left side to the right side, wherein the outer diameter of the first die part (1) is greater than that of the second die part (2), the outer diameter of the second die part (2) is greater than that of the third die part (3), a first middle hole is arranged in the center of the first die part 91), the depth of the first middle hole is greater than the axial thickness of the first die part(1), the centre of the third die part (3) is provided with a second middle hole coaxial and communicating with the first middle hole; and the diameter of the first middle hole is greater than that of the second middle hole. With higher size precision, the die can be used repeatedly; and the manufacturing precision and assembly precision of the automotive components manufactured by the die can be ensured. The invention further discloses a die processing method, the sizeof the die of the stamping die is accurate and precise by the processing method.The production process is qualified and has low product rejection rate.

Owner:CHONGQING QINGYI MOLD MFG

Tungsten steel push rod and machining method thereof

The invention discloses a tungsten steel push rod. The tungsten steel push rod comprises a cylindrical push rod body, wherein the push rod body comprises a first push rod part, a second push rod part and a third push rod part which are arranged coaxially from left to right; a groove is annularly formed around the axis of the push rod body outside the first push rod part; four first planes are uniformly distributed on the periphery of the second push rod part in an annular form; four second planes are uniformly distributed on the periphery of the third push rod part in an annular form; a first threaded hole is formed in the center, far away from the second push rod part, of the third push rod part, and extends into the first push rod part from the third push rod part, but does not penetrate through the first push rod part; a second threaded hole is formed in one of second arc surfaces along the axial direction which is perpendicular to the push rod body, and extends into the first threaded hole. The invention also discloses a machining method for the tungsten steel push rod. By the machining method, the size precision of the tungsten steel push rod is accurate, the production process is qualified at one time, and product obsolescence rate is low.

Owner:昆山精创模具有限公司

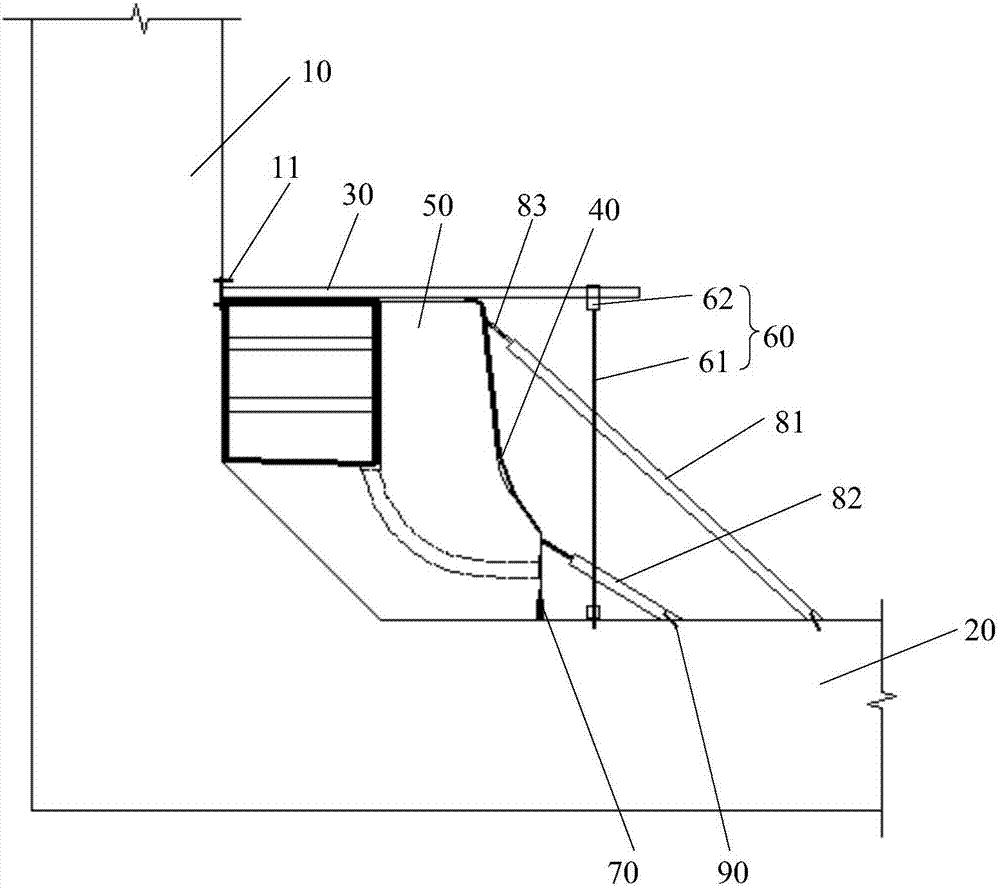

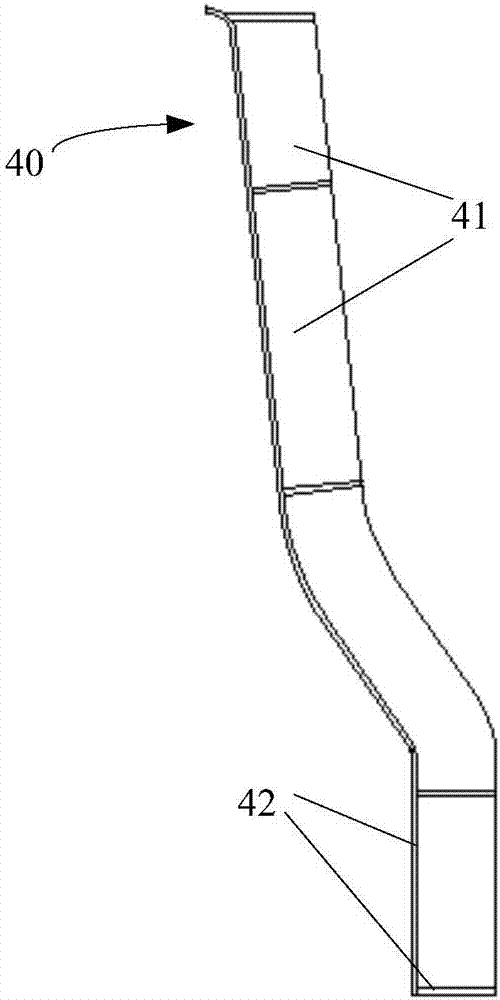

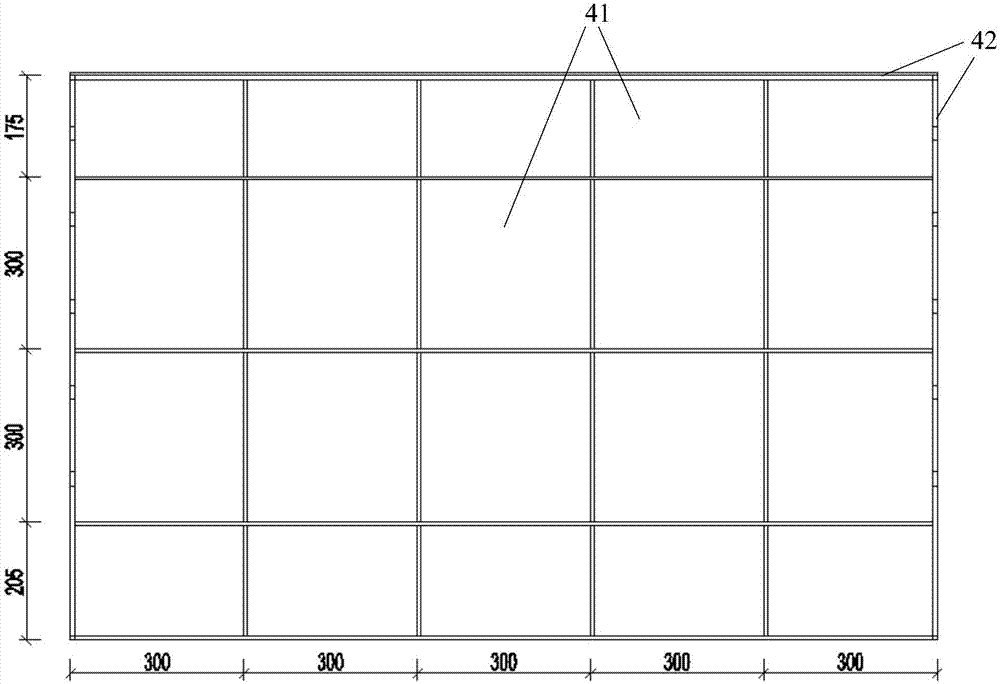

Tunnel anti-collision wall formwork strengthening system and construction method

PendingCN108004986AIncrease stiffnessAccurate dimensional accuracyUnderground chambersTunnel liningMaterial consumptionEngineering

The invention discloses a tunnel anti-collision wall formwork strengthening system and a construction method. The tunnel anti-collision wall formwork strengthening system includes a plurality of horizontal square steel pipes of which one ends are fixed to a side wall, a plurality of steel templates of which the top ends abut against the lower bottom surfaces of the horizontal square steel pipes and the bottom ends are fixed to a structural base plate, a plurality of steel pipe inclined struts which are installed between the outer sides of the steel templates and the structural base plate and aflower basket structure of which the upper and the lower ends are separately connected with the horizontal square steel pipes and the structural base plate, and the steel templates are of a hook facestructure which is suitably matched with anti-collision side stones. The horizontal square steel pipes are fixed to the side wall to perform coping to the steel templates, the horizontal square steelpipes are high in rigidity and accurate in dimensional precision, are not prone to deforming, the contact area with the steel templates is large, and the entire stability of a strengthening system isimproved; the steel templates are machined and produced adopting uniform canalization, the specification is uniform, the installation and the disassembly are convenient, the construction efficiency is improved, and the material consumption is decreased; and the structure size and the appearance quality of the shaped anti-collision side stone are better, the performance of actual measurement is improved, and the subsequent decoration cost is reduced.

Owner:NO 2 CONSTR GRP CO LTD OF SHANGHAI CONSTR GRP

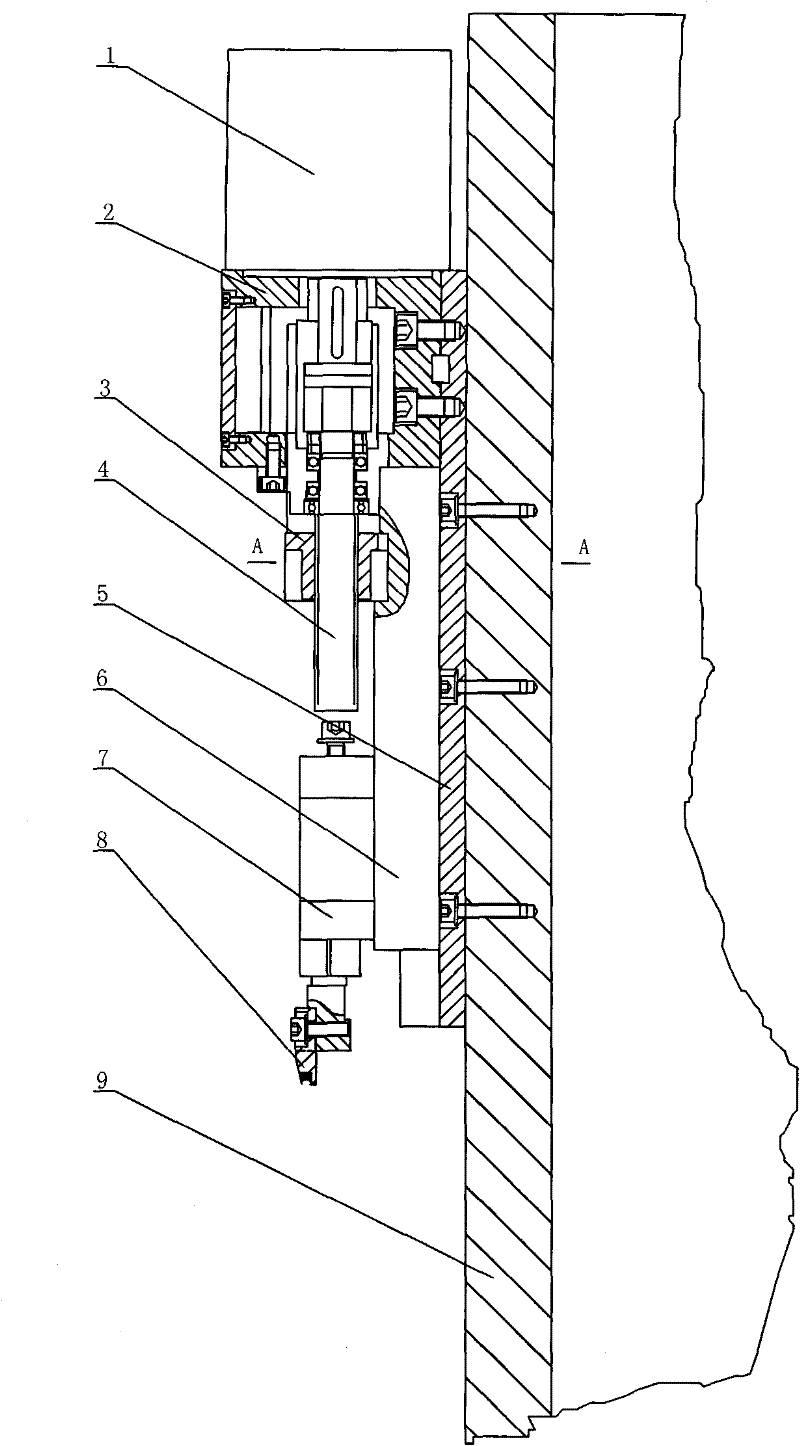

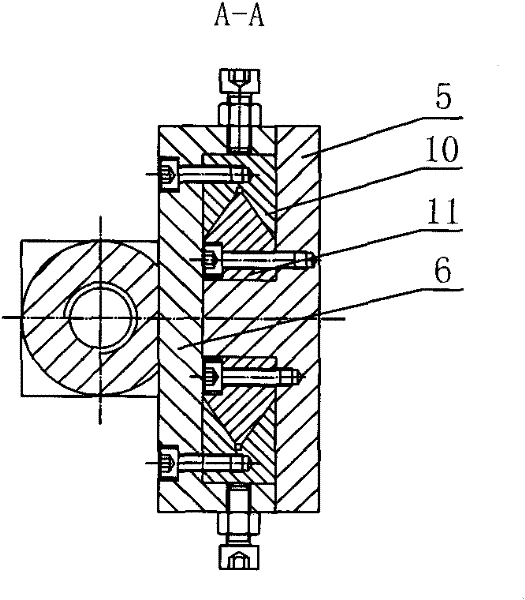

Roller lifter

InactiveUS10047641B2Accurate dimensional accuracyValve arrangementsMachines/enginesReciprocating motionEngineering

Owner:OTICS CORP

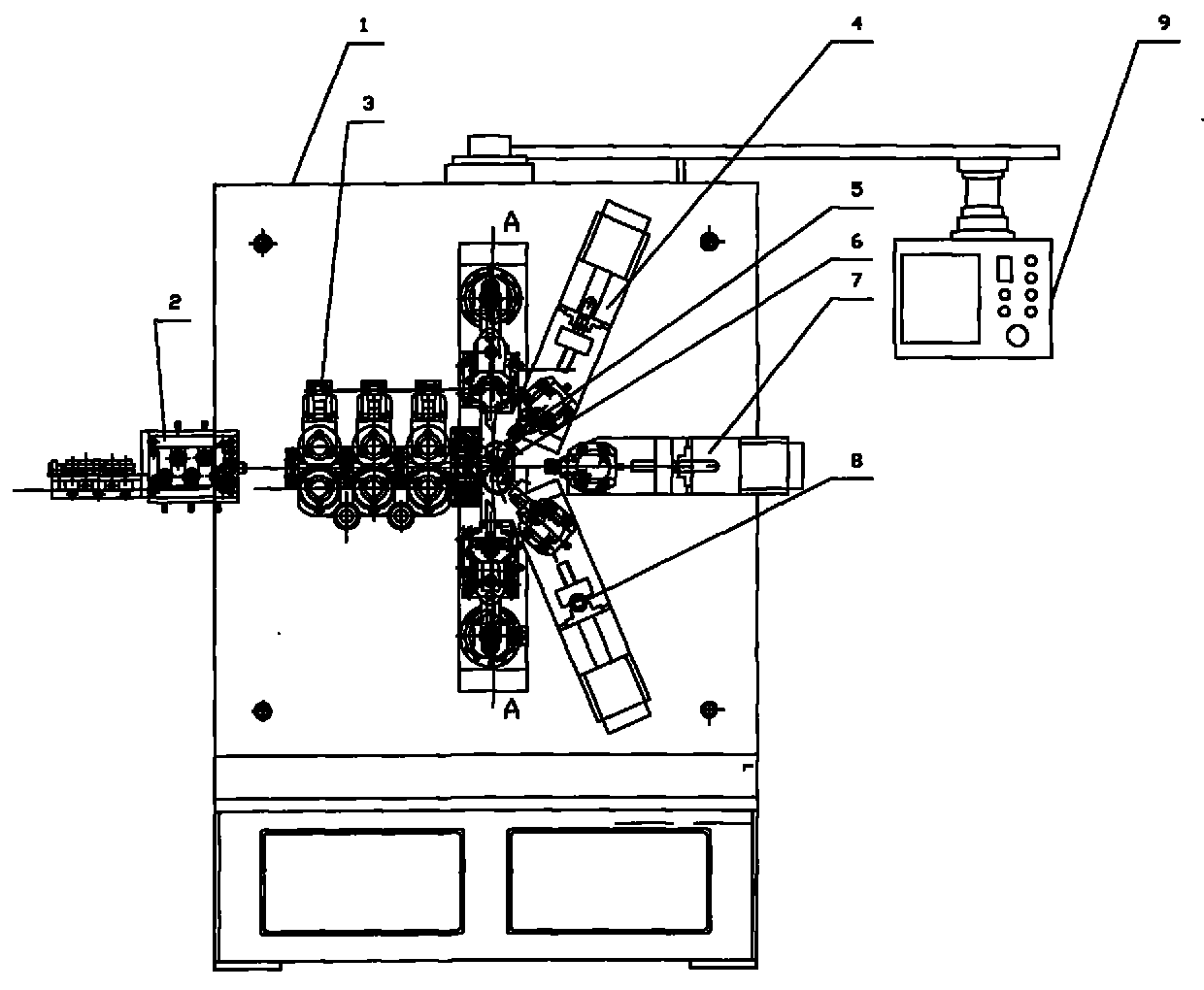

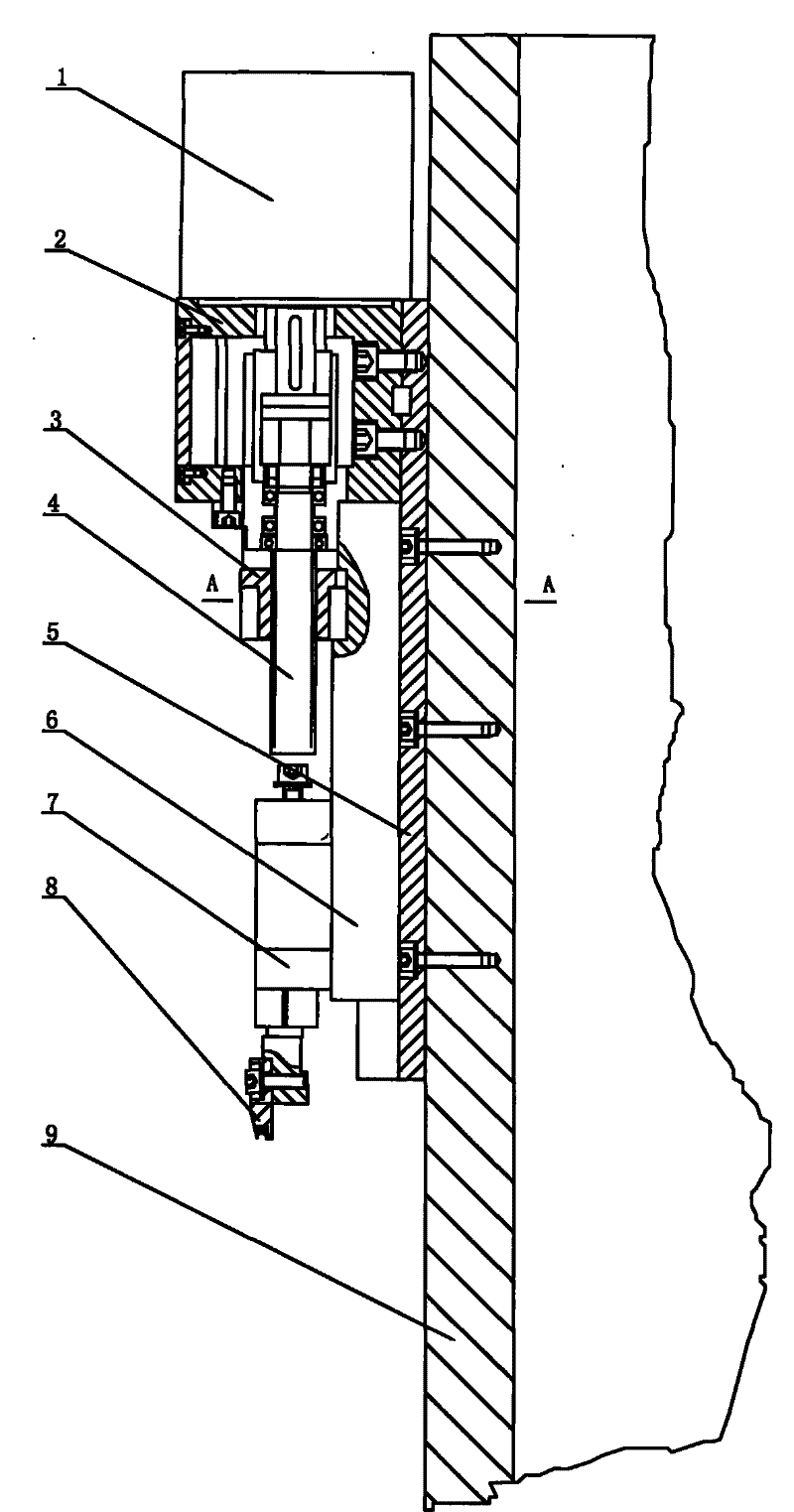

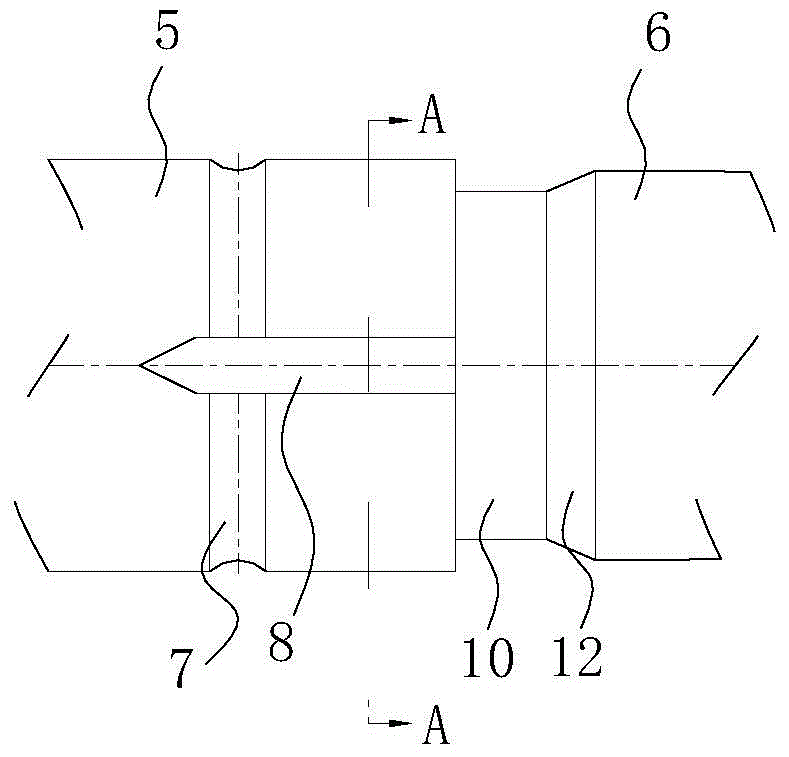

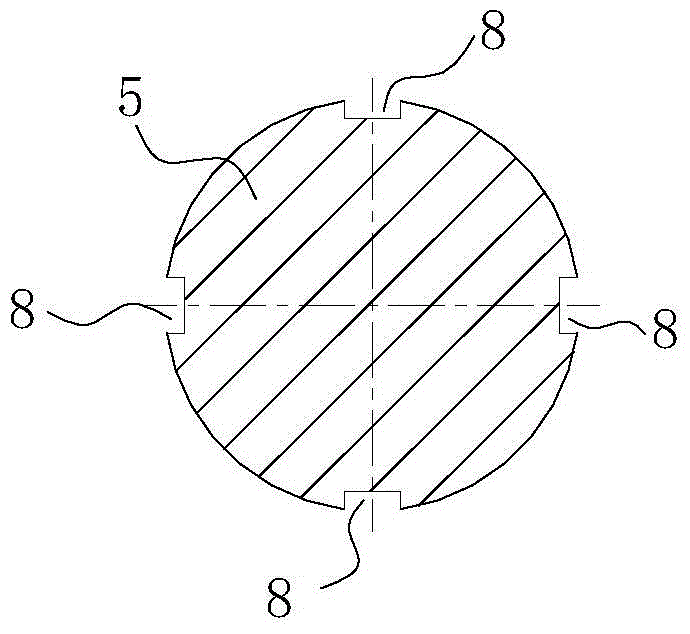

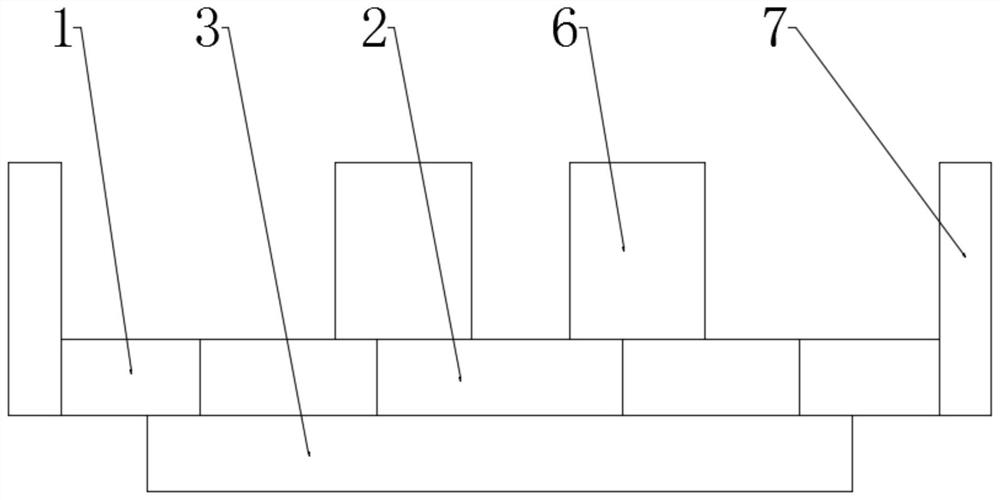

Reducing mechanisms for eight-axis spring forming machine

The invention provides reducing mechanisms for an eight-axis spring forming machine, and belongs to springing machining mechanical equipment. Each reducing mechanism comprises a servo motor, a support, a nut, a ball screw, a sliding block base, a sliding block, a reducing cutter holder, a reducing cutter, a front wallboard, concave V-blocks and convex V-blocks. In the invention, the reducing mechanisms are designed by combining a computer closed-loop technology with a reducing three-axis design; machining procedures of the reducing mechanisms for the spring forming machine are controlled by computer programs, thus realizing intelligent operation, improving performance and reliability of the machine, achieving high sensitivity and fast response speed as well as accurate dimensional accuracy, reducing manual operation amount, improving operating efficiency, ensuring safety and convenience in operation and saving energy consumption; combinations of the convex V-blocks and the concave V-blocks at 70 degrees are respectively utilized as guide rails of the sliding block and the sliding block base, which reliably and stably ensures dimensional accuracy of external diameter and shape accuracy of the spring to be machined; and by utilizing the three-axis design, the machining accuracy of the product is high, thus the product quality and production efficiency are improved.

Owner:盐城海旭数控装备有限公司

Lever arm detection platform

InactiveCN102829689AAccurate dimensional accuracyMeasuring Dimensional AccuracyMechanical measuring arrangementsEngineering

Owner:无锡市华润环保设备有限公司

Weaving Welding Forming Method of Large Circulation Pump Impeller

ActiveCN103394880BAccuracy of surfaceImprove surface roughnessWelding apparatusImpellerStructural engineering

The invention relates to a large-sized circulating pump impeller forming method through swing welding. The method comprises the following steps: the geometry of an impeller is disintegrated into blades, a front cover plates and rear cover plates; inverted grooves are formed in the front cover plates and the rear cover plates of the blades; a flow passing surface of each front cover plate and each rear cover plate are connected with each other by adopting a welding method through the blades. According to the large-sized circulating pump impeller forming method through swing welding, the surface of a flow passing part of the impeller is smooth and clean, the water power size is accurate, a dynamic balance test and a static balance test of the impeller are accurate, the water pump efficiency is high, the product quality is excellent, the impeller is welded according to a welding technology during welding, the deformation of the impeller is small after welding, dimensional requirements of drawings can be met, the welding quality is high without defects, and national flaw detection quality standard requirements can be met.

Owner:SHENYANG SANKE HYDRAULIC MACHINERY MANUFACTORY

Sheath core and processing method thereof

ActiveCN103552190BHigh dimensional accuracyAccurate dimensional accuracyStructural engineeringRejection rate

The invention discloses a sleeve protecting core. The sleeve protecting core comprises a core body, wherein the core body is successively and coaxially provided with a core first part, a core second part, a core third part, a core forth part, a core fifth part and a core sixth part from left to right, wherein the periphery of the core fifth part is provided with a first groove in an annular manner, and four second grooves are uniformly distributed in the periphery of the core fifth part; the length directions of the second grooves are parallel to an axis of the core body, the second grooves are formed in a way that one end, which is close to the core sixth part, of the core fifth part extends towards the core forth part and can not run through the core fifth part. The sleeve protecting core has high dimensional precision and can be used for many times. The invention also discloses a processing method of the sleeve protecting core, the processing method can enable the sleeve protecting core in a stamping mould to be accurate in precision, the productive process is qualified once, and the product rejection rate is low.

Owner:昆山精创模具有限公司

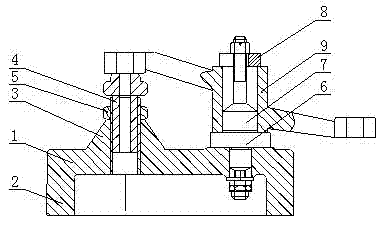

Central shaft cutting-off mechanism for eight-shaft spring forming machine

The invention discloses a central shaft cutting-off mechanism for an eight-shaft spring forming machine, which belongs to spring machining mechanical equipment. The mechanism is formed by combining a computer closed loop technology with a central shaft and cutting-off integrated design; all machining processes of a central shaft mechanism and a cutting-off mechanism of the spring forming machine are controlled by computer programs; parameters corresponding to springs of different models are set in a computer; and when a spring of a certain size is required to be machined, intelligent operation and data control can be realized only by inputting a corresponding parameter. The mechanism improves the performance and the reliability of a machine, has high sensitivity, quick response and high dimensional accuracy, reduces manual operation capacity, improves working efficiency, is safely and conveniently operated, and reduces energy source consumption. In the mechanism, central shaft and cutting-off integration is realized, so that a spring steel wire is not provided with a tail hook after being cut off; therefore, the mechanism has high product machining accuracy, and improves product quality and production efficiency.

Owner:盐城海旭数控装备有限公司

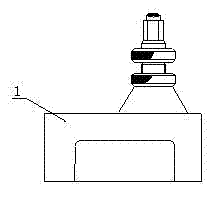

Mini-type sliding block

The invention discloses a mini-type sliding block. The mini-type sliding block comprises a fixing mechanism, returning mechanisms, sealing mechanisms and separation mechanisms, wherein the returning mechanisms are clamped at two sides of the fixing mechanism; the sealing mechanisms are fixedly connected with two ends of the returning mechanisms; the separation mechanisms are fixedly connected withone side, far away from the corresponding returning mechanism, of the sealing mechanisms; the fixing mechanism is composed of a first connection hole, a mounting frame, a first roller path, a connection clamping groove, a guide rail groove and a fixed plate. The mini-type sliding block is compact in structure, and convenient and simpler to process; a grinding technology adopts a special tool jigto clamp, so that the precision and perpendicularity of the sliding block are improved; the size precision of a product is more accurate and the product is very smoothly matched with a plastic part; automation can be realized on a mounting part, so that a lot of manpower and material resources are save and the labor cost is reduced; a steel ball is changed into a nylon material from a previous metal roller path; nylon has a self-lubrication condition so that the collision and friction between the steel ball and a metal wall is reduced, the service life of the product is relatively increased and the utilization cycle of a user is prolonged; the production cost is reduced.

Owner:无锡泓砺精工科技有限公司

Spiral upper cone casting mold and process

ActiveCN112589048ASmall amount of deformationAccurate dimensional accuracyFoundry moulding apparatusCasting moldMechanical engineering

The invention provides a spiral upper cone casting mold and process, and belongs to the technical field of casting. The spiral upper cone casting mold comprises a mold core forming portion used for manufacturing blade mold cores, and a wax mold forming portion used for accommodating a plurality of wax cores and used for manufacturing a spiral upper cone wax mold. According to the spiral upper conecasting mold, the spiral upper cone wax mold is divided into a plurality of equal portions, then the blade mold cores with the upper portions provided with forming grooves matched with spiral upper cone blades in shape are manufactured through the mold core forming portion, the blade mold cores are placed in the wax mold forming portion according to the shape of a spiral upper cone, then wax liquid is injected into the wax mold forming portion, and the spiral upper cone wax mold is formed through one-time injection molding. The circumstance that the spiral upper cone is divided into multipleportions, and then all portions of the wax mold are spliced to form a complete spiral upper cone wax mold is avoided, the size precision between all the portions of the spiral upper cone is more accurate, and meanwhile, the deformation amount of the wax mold is reduced.

Owner:FENGFAN

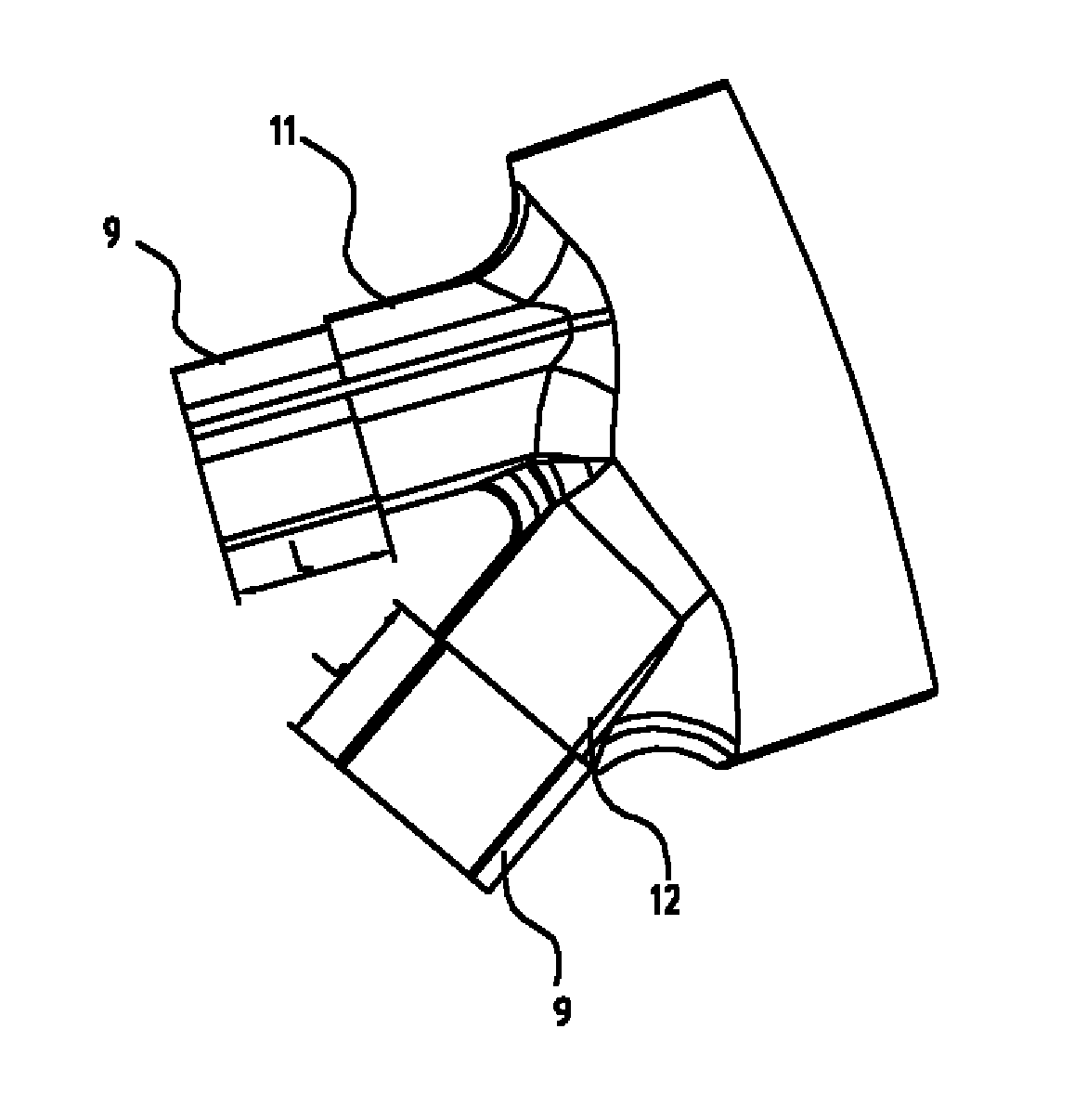

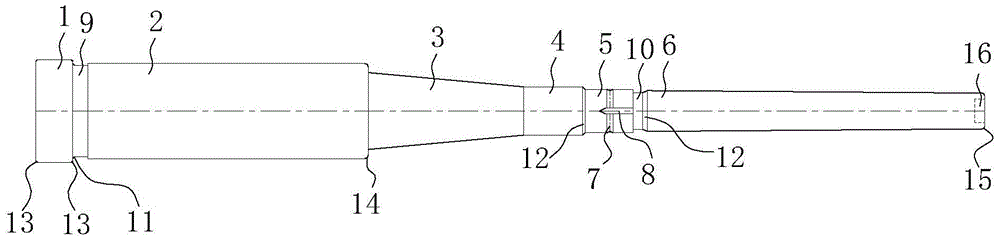

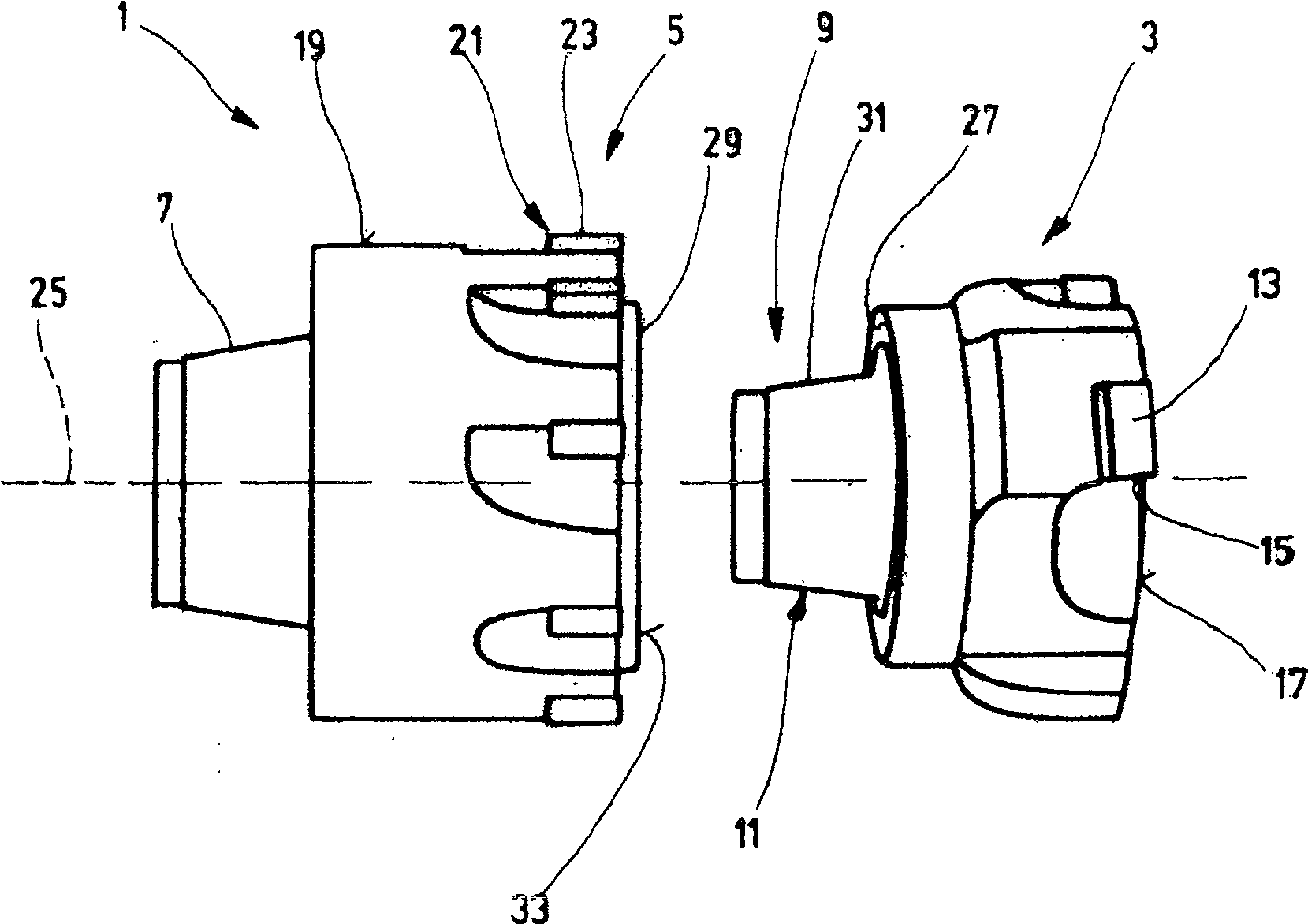

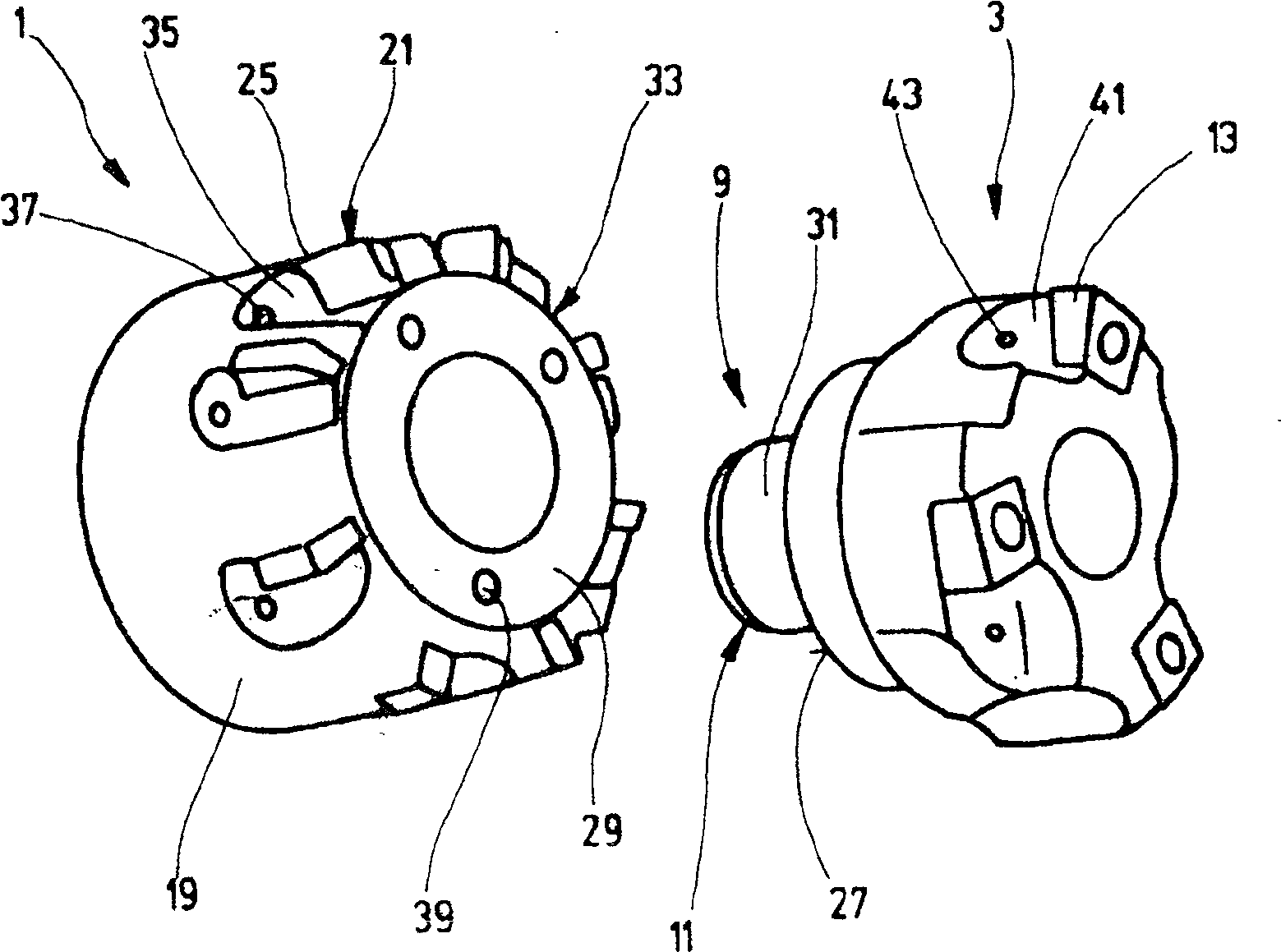

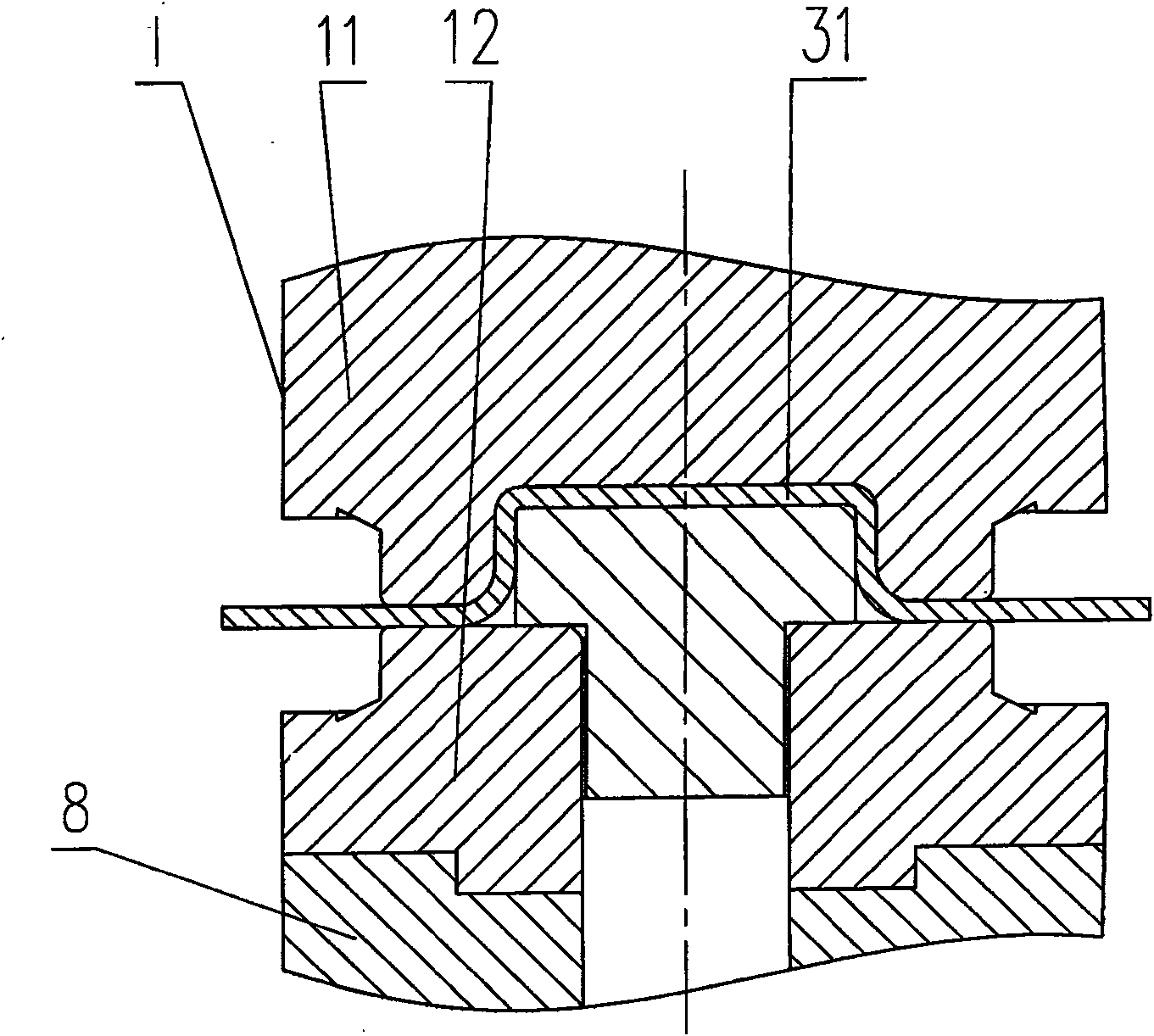

Tool and method for fine machining of workpieces

InactiveCN100519020CImprove Manufacturing AccuracyPrecisely interconnectedLathesTurning machine accessoriesEngineeringMachining

The invention relates to a cutting tool for finishing workpieces, comprising at least one insert (13) for preliminary machining with a geometrically defined cutting edge (15) and at least one insert (13) for final machining with a geometrically defined Define the cutting edge (23) of the blade (21). The tool is characterized in that the insert (13) for preliminary machining is a part of a preliminary machining stage (3) and the insert (21) for final machining is a part of a final machining stage (5), and a The interface (9) provided between the processing stage (3) and the final processing stage (5) is provided with a first planar surface (27) and a second planar surface (29), which are respectively arranged on the preliminary processing stage (3) and the final processing stage (5), and has a device (11) to ensure the coaxiality between the preliminary processing stage (3) and the final processing stage (5).

Owner:MAPAL FAB FUR PRAZIONSWERKZEUGE DR KRESS KG

A large-scale truss type stake leg segmenting data detecting method

ActiveCN100465578CQuality assuranceReduce the likelihood of damageArtificial islandsMeasurement devicesComputer scienceData detection

The invention discloses a method for performing a measurement to the size of the triangle truss type spud leg and the local precision during the process of constructing a jack up drilling platform, wherein, the large scale truss type spud leg segmenting data detecting method of the invention comprises the detecting procedures that: the main size of the spud leg is detected; the main size of the spud leg comprises a spud leg segmenting length (L1), a spud leg segmenting height (H1), a distance from a gear rack plate to a spud leg (Z1, Z2 and Z3), and a gear rack plate space (B1, B2, B3); the levelness of the gear rack plate and the crown of the gear rack plate end face are detected; the middle point (P5) of an end part gear rack central line is fetched to detect the same face degree of the gear rack plate. The invention has the advantages that the invention is convenient and advisable and has high detection precision, under the support of a high precision instrument, the exact dimensional accuracy, a tolerance and a derivation can be obtained, thereby guiding a construction process, guaranteeing the quality of the final drilling platform, reducing the possibility of the platform damage, and ensuring the safety of an offshore operation.

Owner:DALIAN SHIPBUILDING IND

A motor mover assembly welding mold

ActiveCN110948161BSimple structureEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesWire cuttingDimensional precision

Owner:HEILONGJIANG HENGYI ELECTRICAL SHARE CO LTD

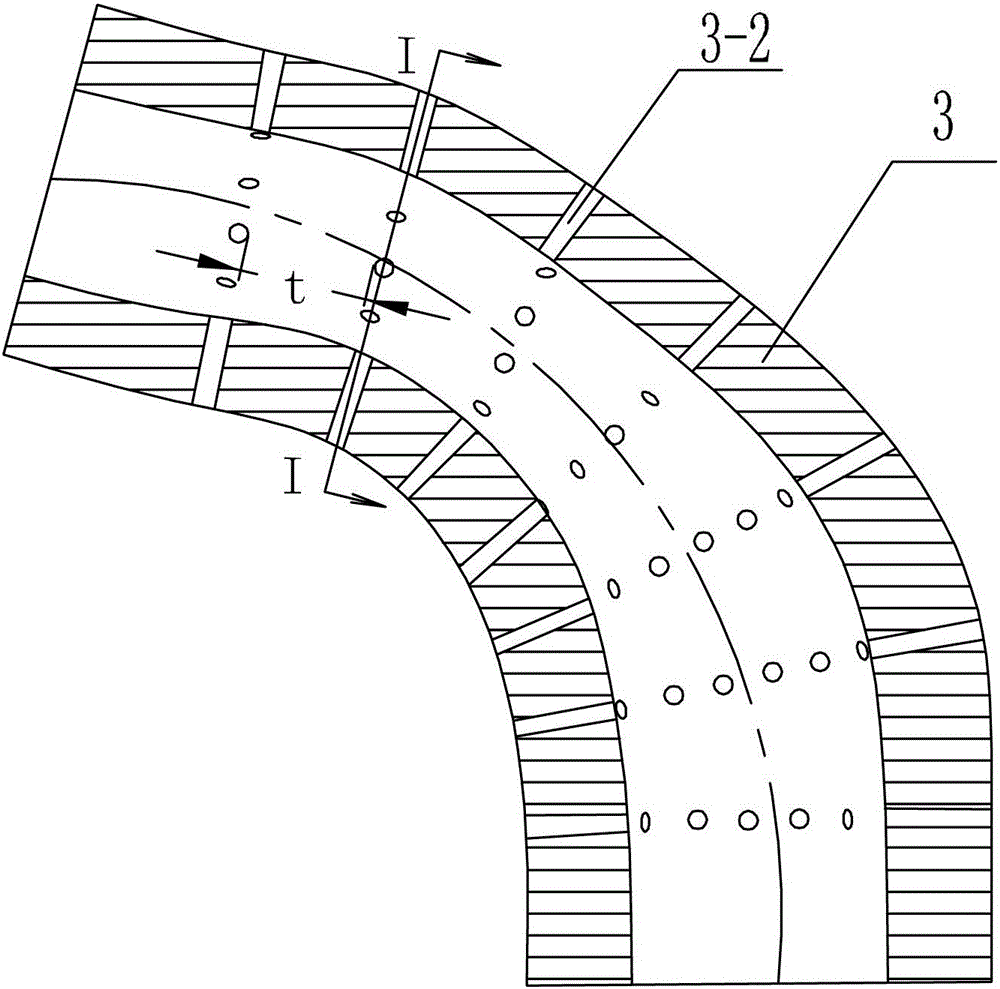

Continuous flow forming molding method different-radii metal plate manufactured flow forming belt pulley

ActiveCN100589896CImprove product qualityAccurate dimensional accuracyShaping toolsPortable liftingEngineeringContinuous flow

The present invention relates to a continuous rotary extrusion forming method for a waney metal-plate rotary extrusion belt pulley with the outer wheel circle being provided with a V-shaped groove, and comprises the procedures of feeding, extension, shape correction, perforation, edge cutting, distribution and rotary extrusion forming; at the rotary extrusion forming procedure, a pre-forming wheelwith a small-diameter U-shaped groove and a large-diameter U-shaped groove is used to perform the rotary extrusion on the Y-shaped cup-shaped belt pulley roughcast of an edge belt after the distribution procedure, and then a forming wheel with a small-diameter V-shaped groove and a large-diameter V-shaped groove is used to perform the forming rotary extrusion so as to be made into a formed wheelof a waney metal-plate rotary extrusion belt pulley; the value range of M and N is: M is more than or equal to 1 and is less than or equal to 10, and N is more than or equal to 1 and less than or equal to 10. The belt pulley that is produced with the forming method hereinabove has good dynamic and static balancing performance, and guarantees the size requirements when simultaneously driving two elements; the jumping consistence of the circle of the V-shaped groove surface is good; at the same time, the processing method also has the advantages of long service life of the distributing wheel andthe forming wheel, simple processing procedures and short processing period.

Owner:柳州市龙杰汽车配件有限责任公司

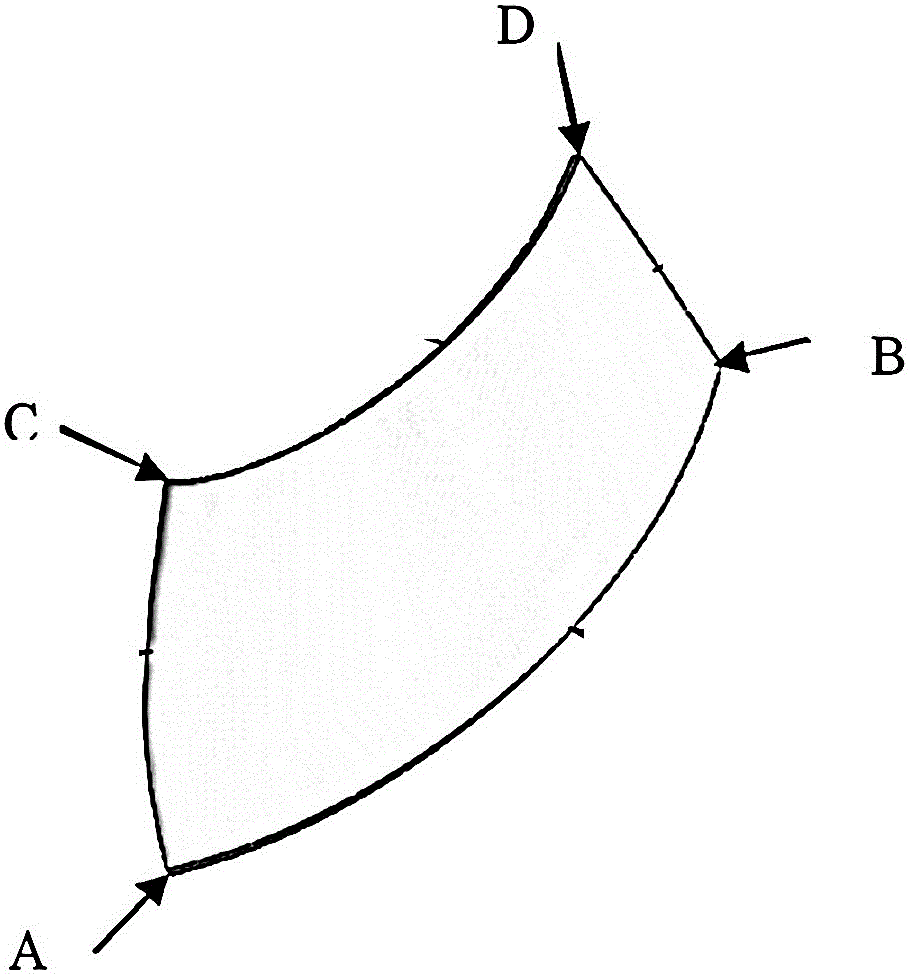

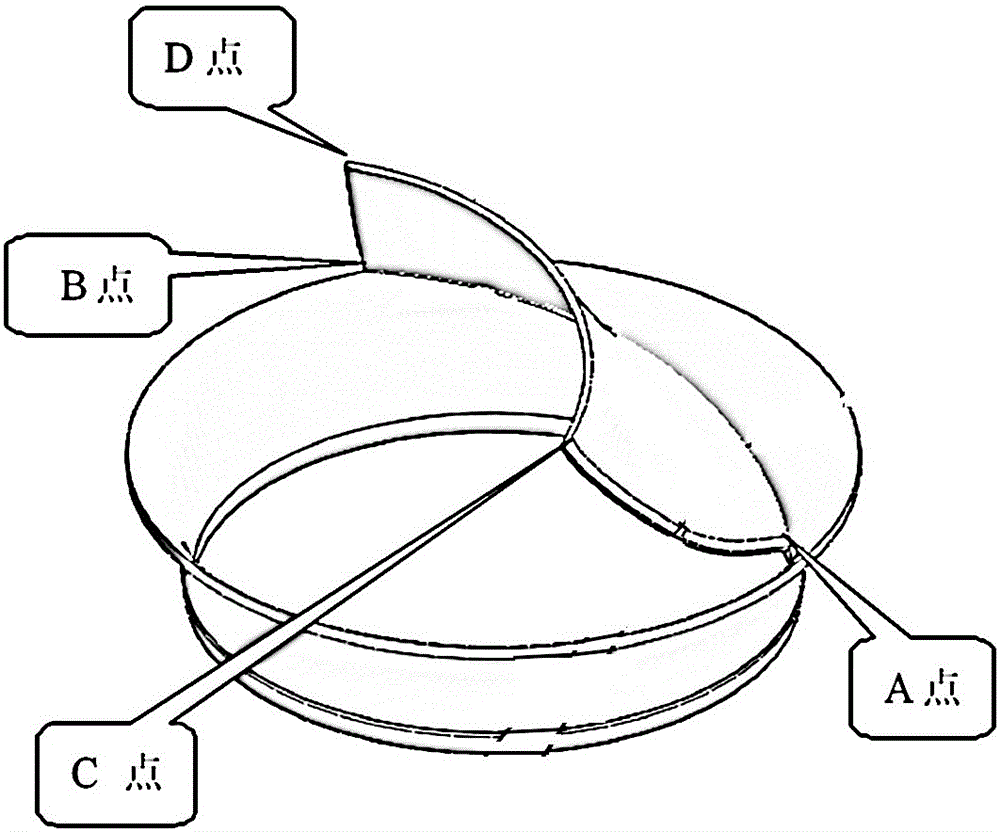

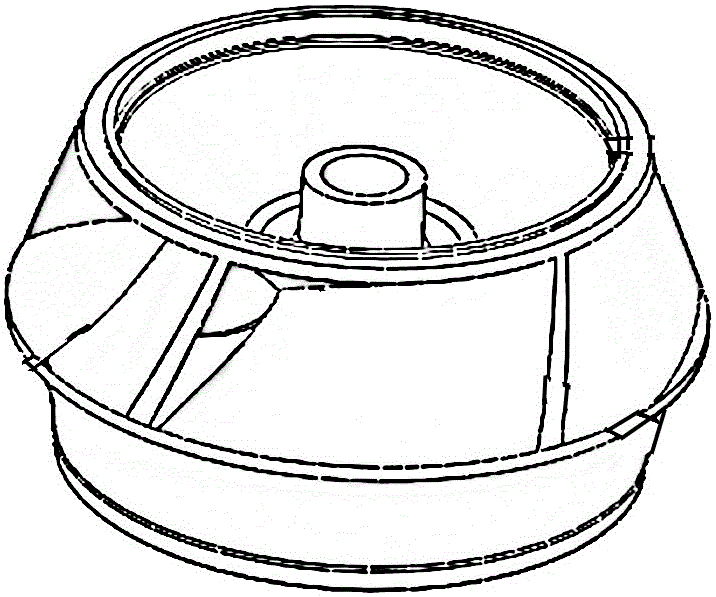

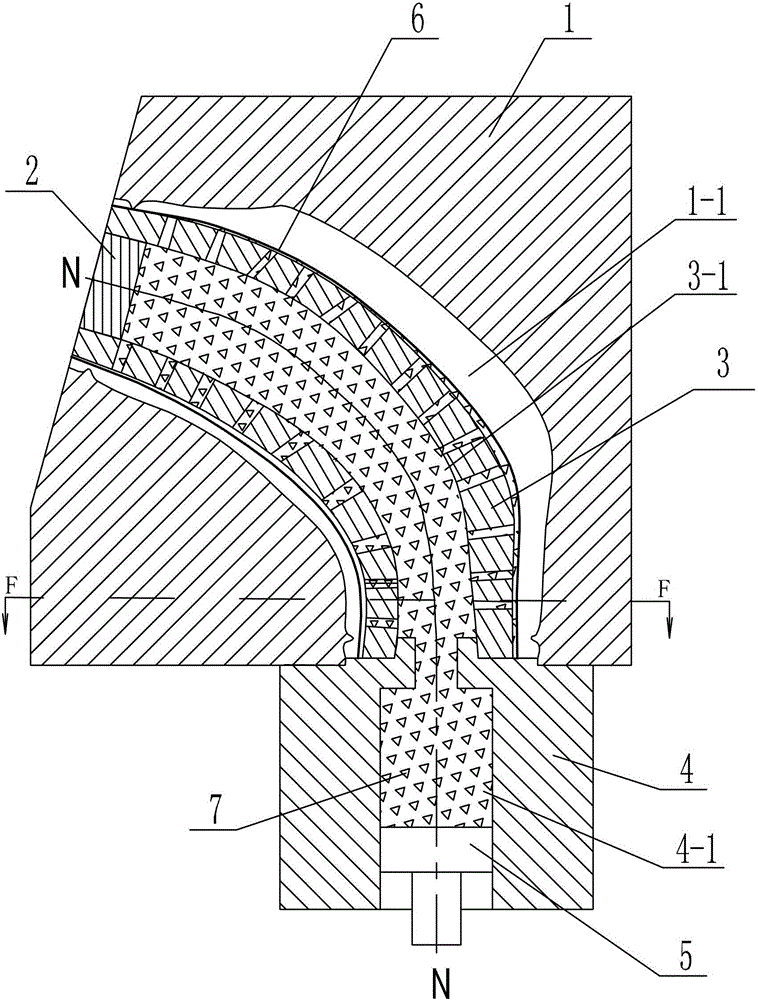

A Circumferential Flow Forming Method for Thin-walled Parts with Variable Curvature

The invention provides a variable camber thin-walled part hoop flow forming device and method, and relates to the forming device and method of a variable camber thin-walled part with the axis as a space curve. The forming device and method solve the problem that a split forming method and a combined welding method are used for forming the variable camber thin-walled part with the axis as the space curve. According to the forming device, the shape of a mold cavity is a variable cross-section channel with the mold cavity axis as a space curve, the shapes of the cross sections of a section mold cavity from the inlet end to the closed end are sequentially a circular shape, a wide and short axis oval shape, a narrow and short axis oval shape, a kidney shape and a crescent moon shape, a core mold is arranged in the section mold cavity, a plurality of load injecting holes are formed in the side wall of the core mold, and a plunger is arranged in a soft mold cavity. The forming method comprises the steps that first, landing edge design is conducted on plate blank; second, the positions of the load injecting holes are designed; third, tubular plate blank is arranged between the core mold and a section mold; fourth, a visco-elastic plastic soft mold is injected into the soft mold cavity; fifth, the plunger is pushed to inject the visco-elastic plastic soft mold into the core mold cavity; sixth, the variable camber thin-walled part is taken out. The variable camber thin-walled part hoop flow forming device and method are used for forming the variable camber thin-walled part.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com