A Circumferential Flow Forming Method for Thin-walled Parts with Variable Curvature

A technology of thin-walled parts and flow forming, which is applied in the field of forming thin-walled parts with variable cross-section, can solve problems such as inability to form integrally, and achieve the effects of improved dimensional accuracy, easy sealing, and simple mold structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

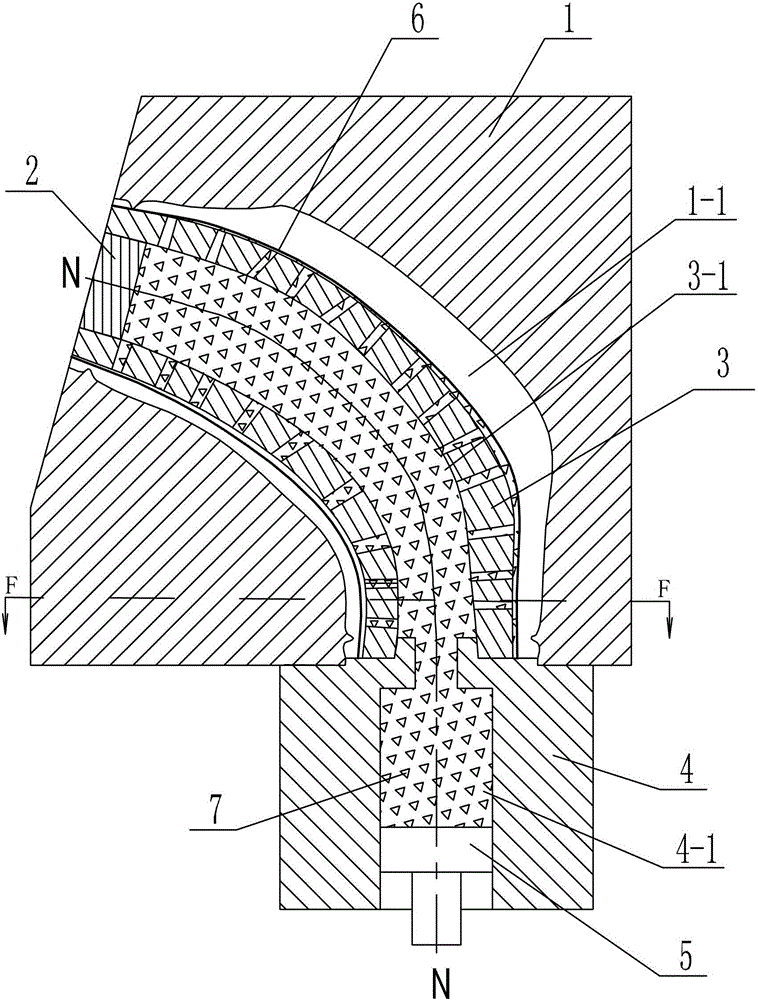

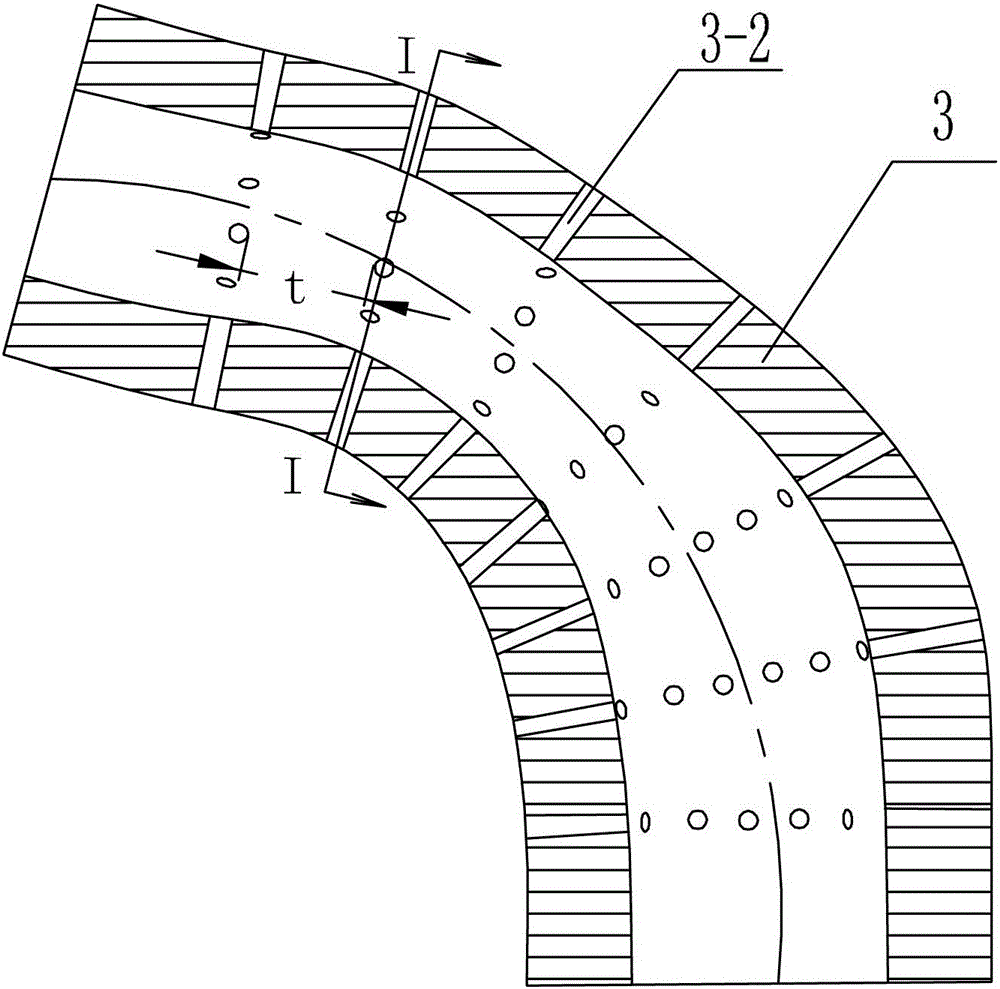

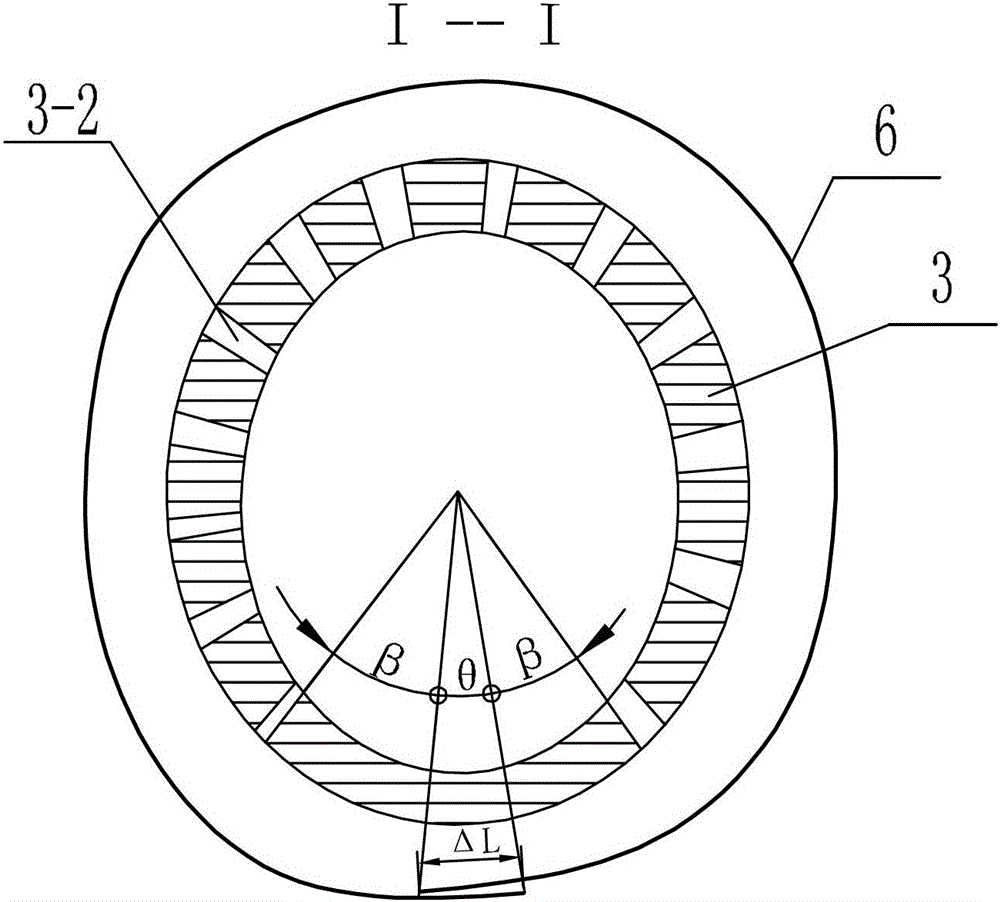

[0021] Specific implementation mode one: combine Figure 1 to Figure 11 Describe this embodiment, this embodiment comprises mold 1, plug 2, mandrel 3, medium storehouse 4 and plunger 5, the inside of mold 1 is provided with mold cavity 1-1, the mold cavity 1-1 The inlet end is located at the bottom of the mold 1, and the closed end of the mold cavity 1-1 is located at the side of the mold 1. The shape of the mold cavity 1-1 is a variable-section channel whose axis N-N of the mold cavity is a space curve, and the mold cavity 1 -1 The cross-sectional shape along the axial direction from the inlet end to the closed end successively transitions to a circle 1-3, a wide-short-axis ellipse 1-4, a narrow-short-axis ellipse 1-5, a waist shape 1-6, and a crescent shape 1-7 , the width minor axis b is greater than the narrow minor axis a, the two ends of the mold cavity 1-1 are provided with ring-shaped protrusions, the ring-shaped protrusions ensure that the annular non-closed blank 5 d...

specific Embodiment approach 2

[0022] Specific implementation mode two: combination Figure 6 The present embodiment will be described. The diameter of the circular 1-3 section in the present embodiment is 280 mm to 320 mm. This range can meet the design requirements of formed parts. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0023] Specific implementation mode three: combination Figure 7 Describe this embodiment, the cross-sectional dimensions of the wide and short axis ellipse 1-4 in this embodiment are: the width and major axis a on the wide and short axis ellipse 1-4 is 300 mm to 320 mm, and the width and short axis a on the wide and short axis ellipse 1-4 Axis b is 220 mm to 300 mm. This range can meet the design requirements of formed parts. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com