Patents

Literature

512results about How to "Uniform pressure distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

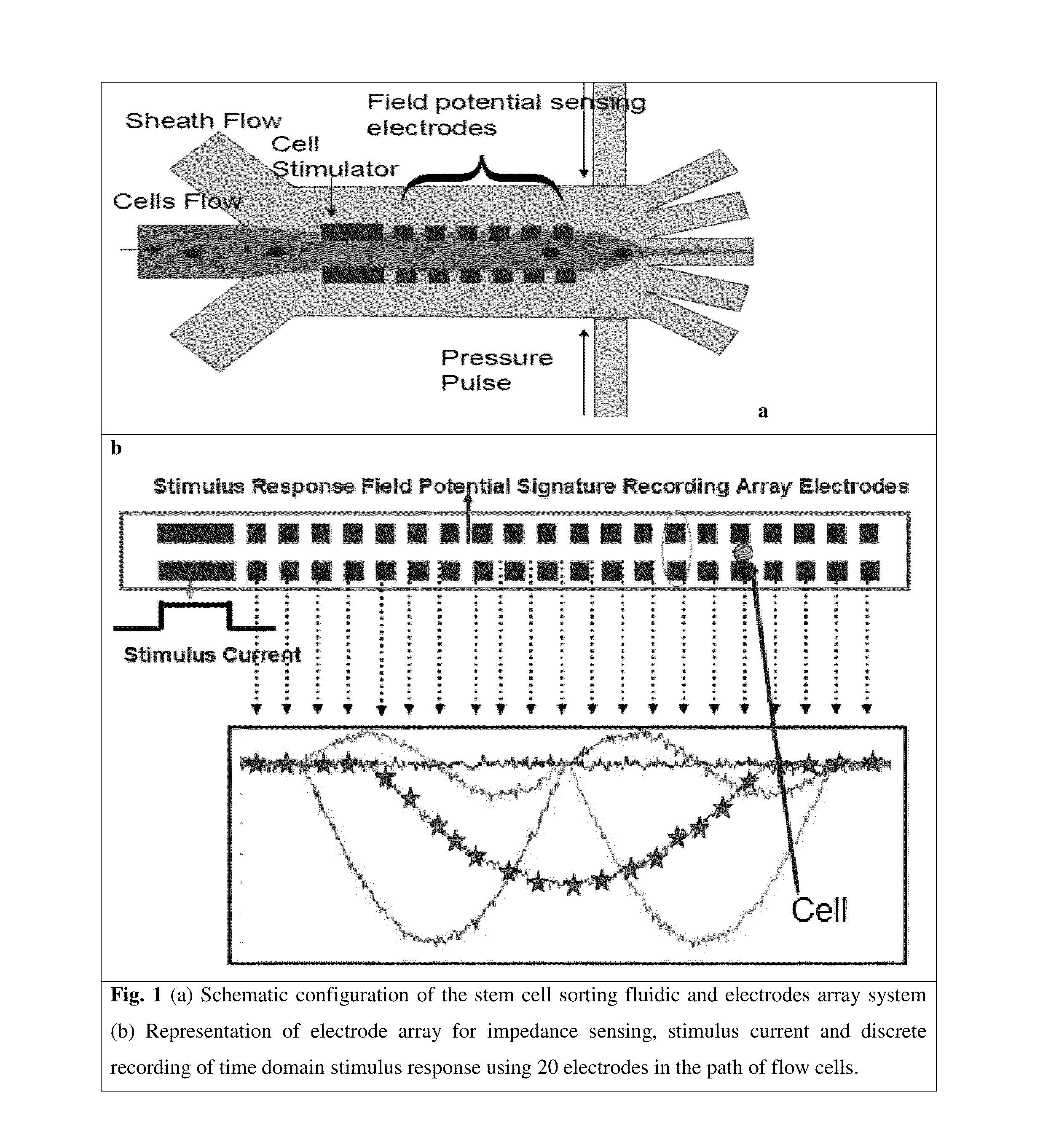

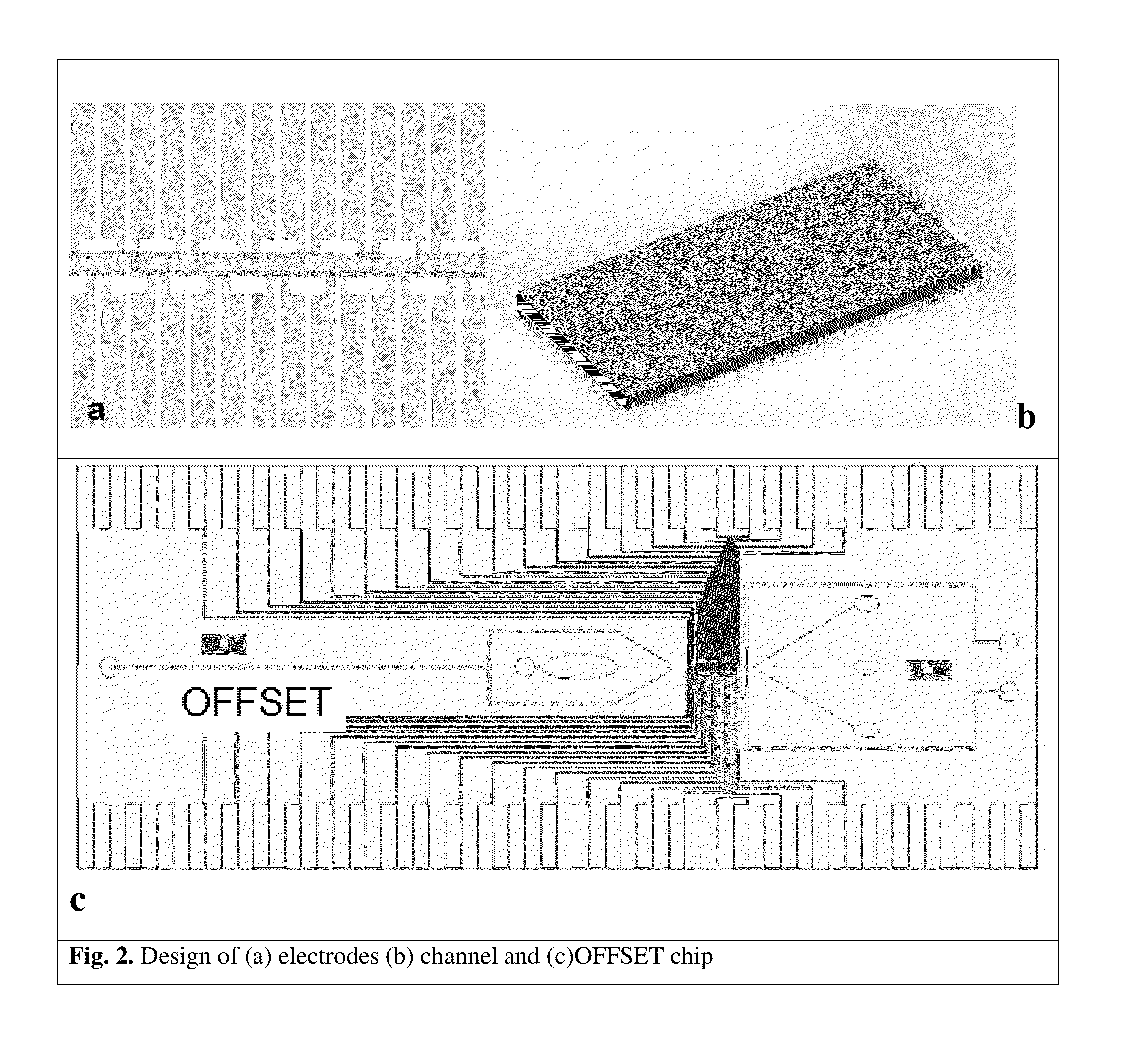

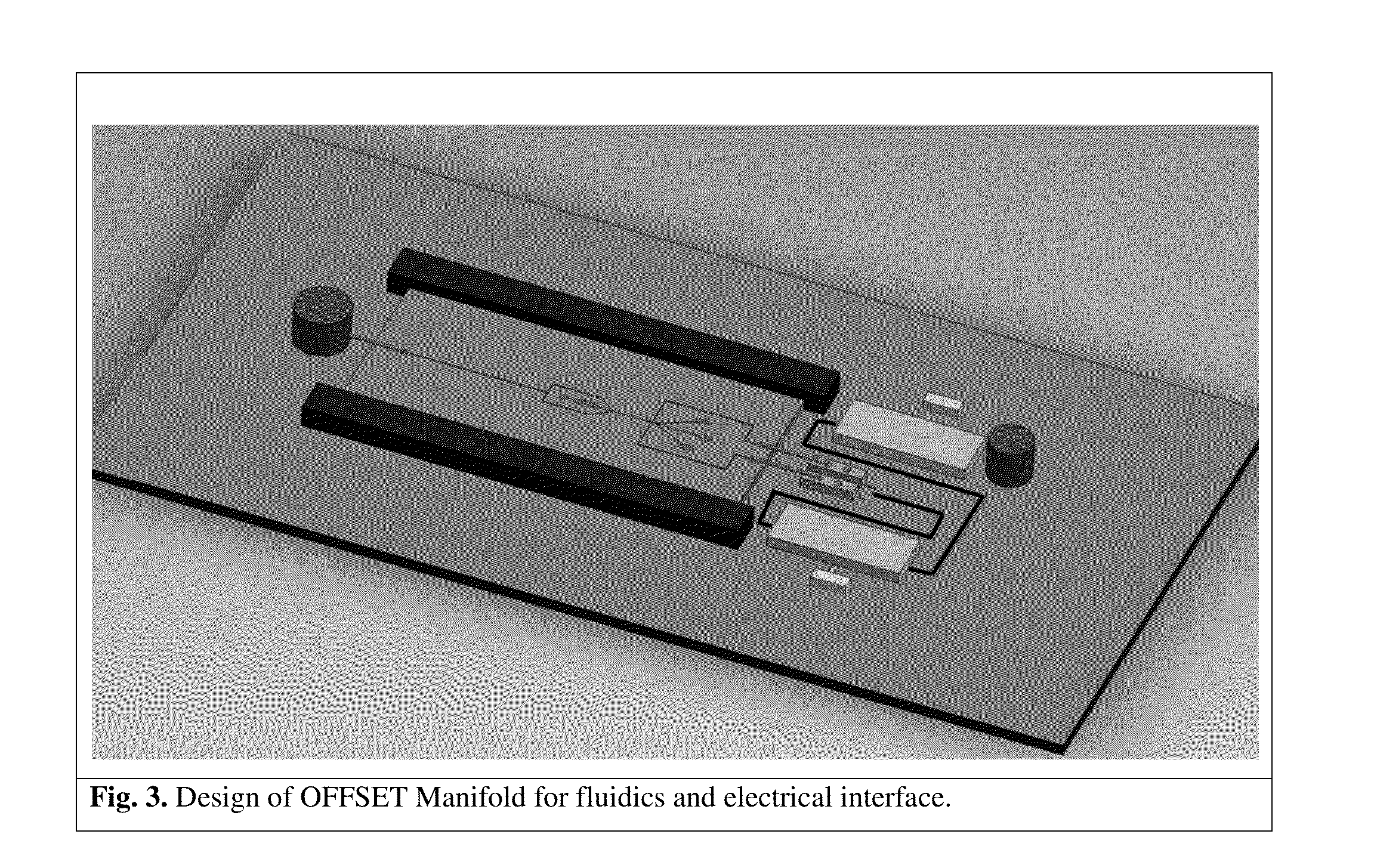

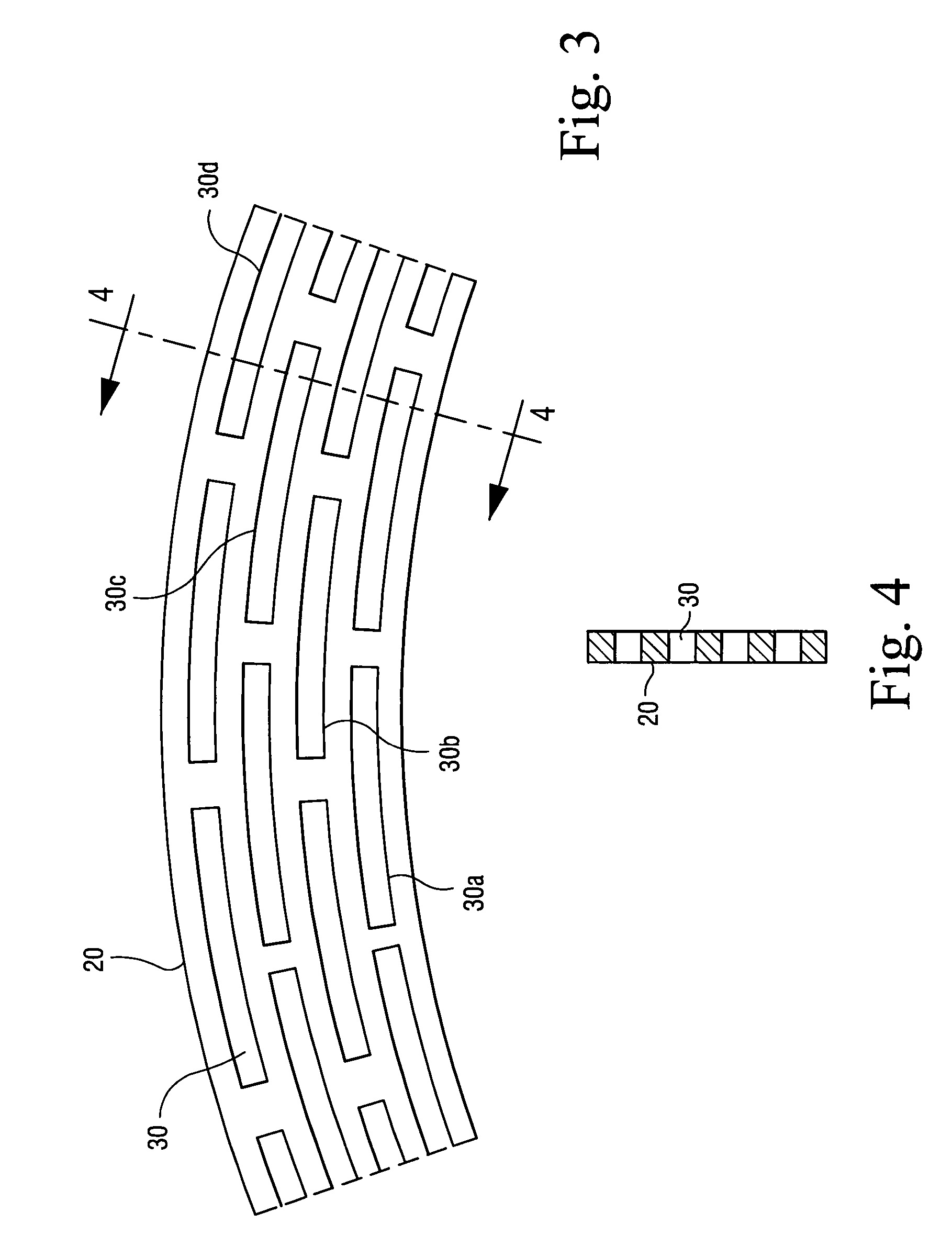

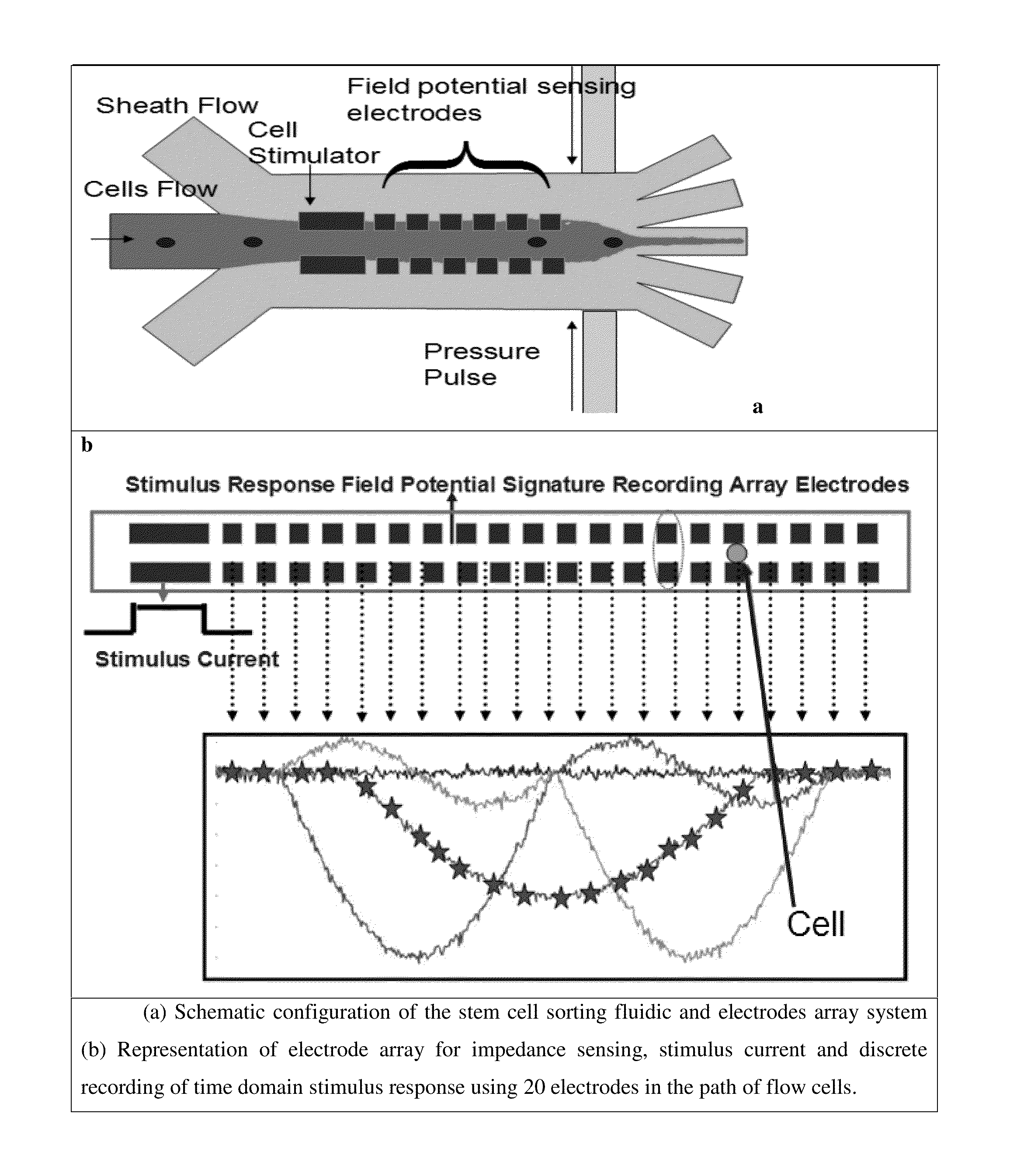

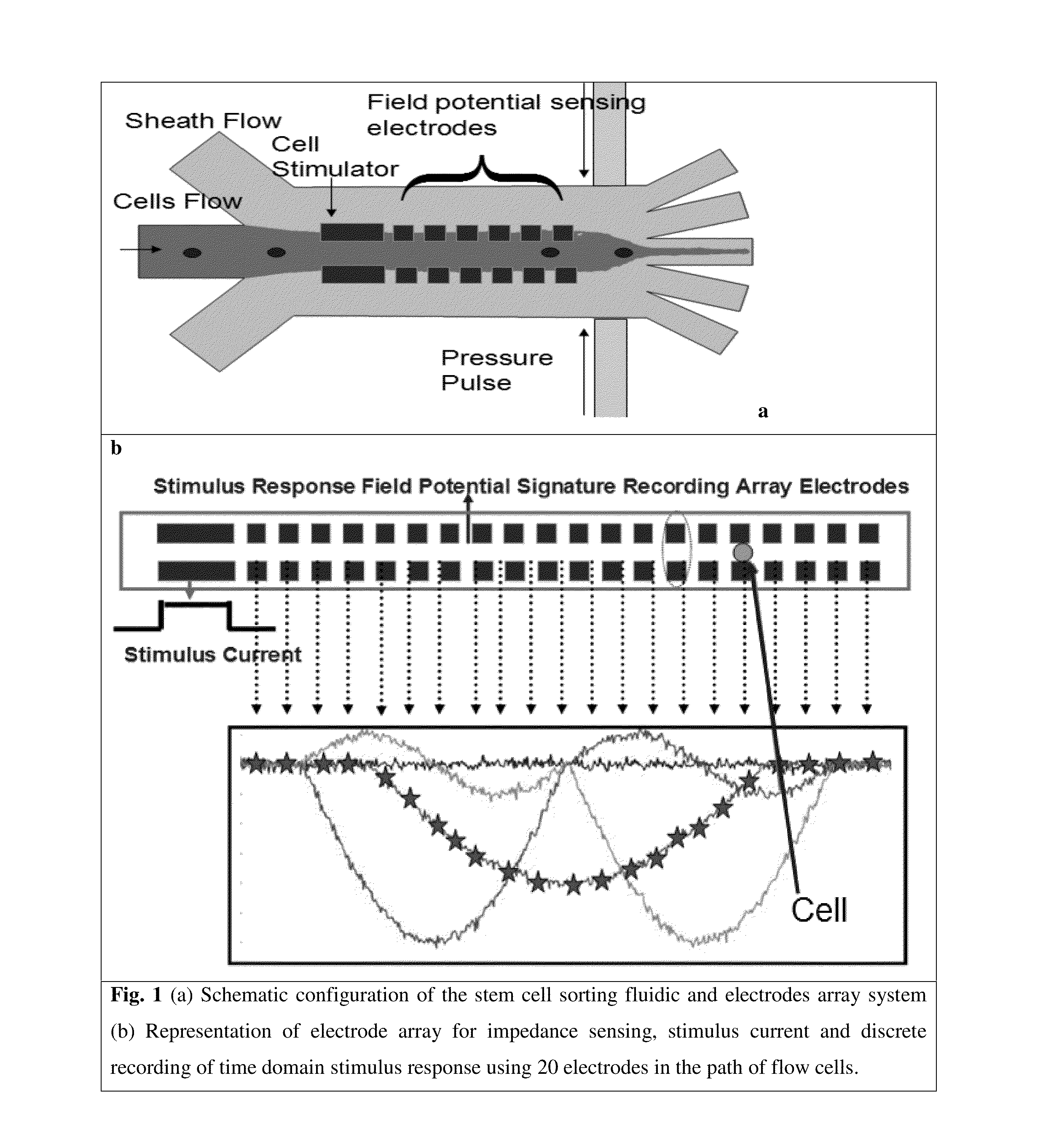

Microfluidic devices and methods for cell sorting, cell culture and cells based diagnostics and therapeutics

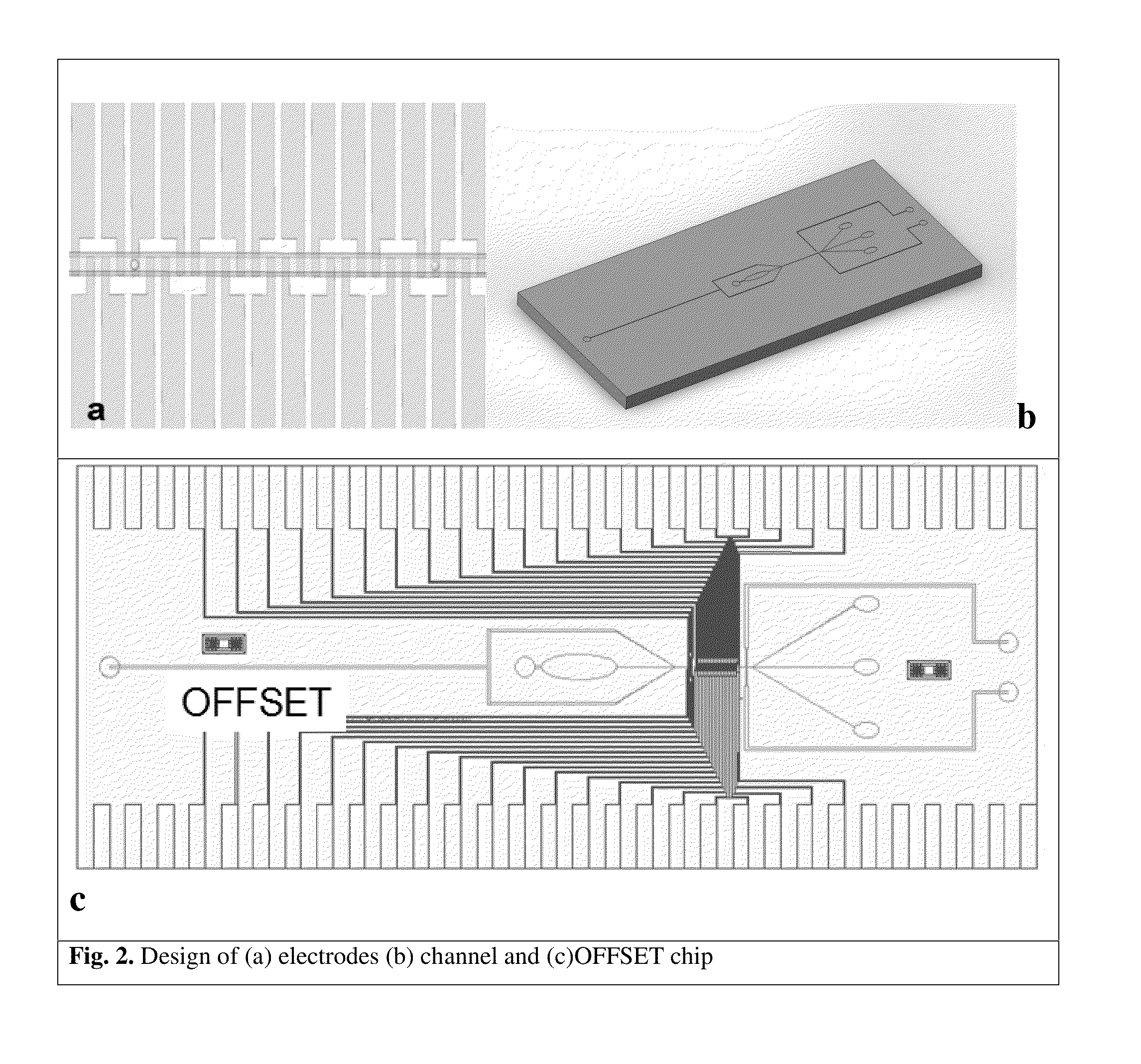

ActiveUS20140248621A1Uniform pressure distributionReduce widthHeating or cooling apparatusMicrobiological testing/measurement3D cell cultureTumor cells

Microfluidic devices and methods that use cells such as cancer cells, stem cells, blood cells for preprocessing, sorting for various biodiagnostics or therapeutical applications are described. Microfluidics electrical sensing such as measurement of field potential or current and phenomena such as immiscible fluidics, inertial fluidics are used as the basis for cell and molecular processing (e.g., characterizing, sorting, isolation, processing, amplification) of different particles, chemical compositions or biospecies (e.g., different cells, cells containing different substances, different particles, different biochemical compositions, proteins, enzymes etc.). Specifically this invention discloses a few sorting schemes for stem cells, whole blood and circulating tumor cells and also extracting serum from whole blood. Further medical diagnostics technology utilizing high throughput single cell PCR is described using immiscible fluidics couple with single or multi cells trapping technology.

Owner:BIOPICO SYST

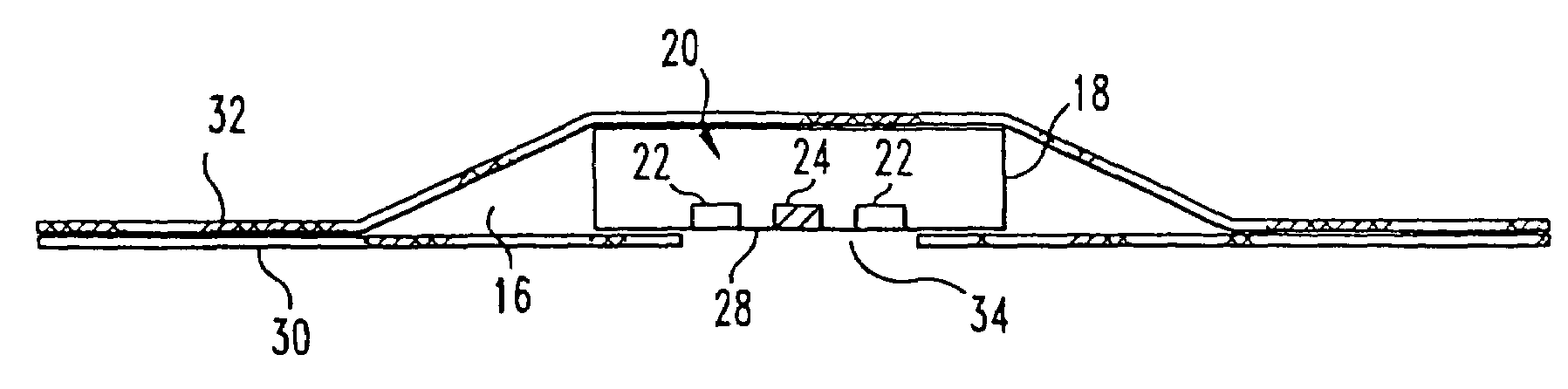

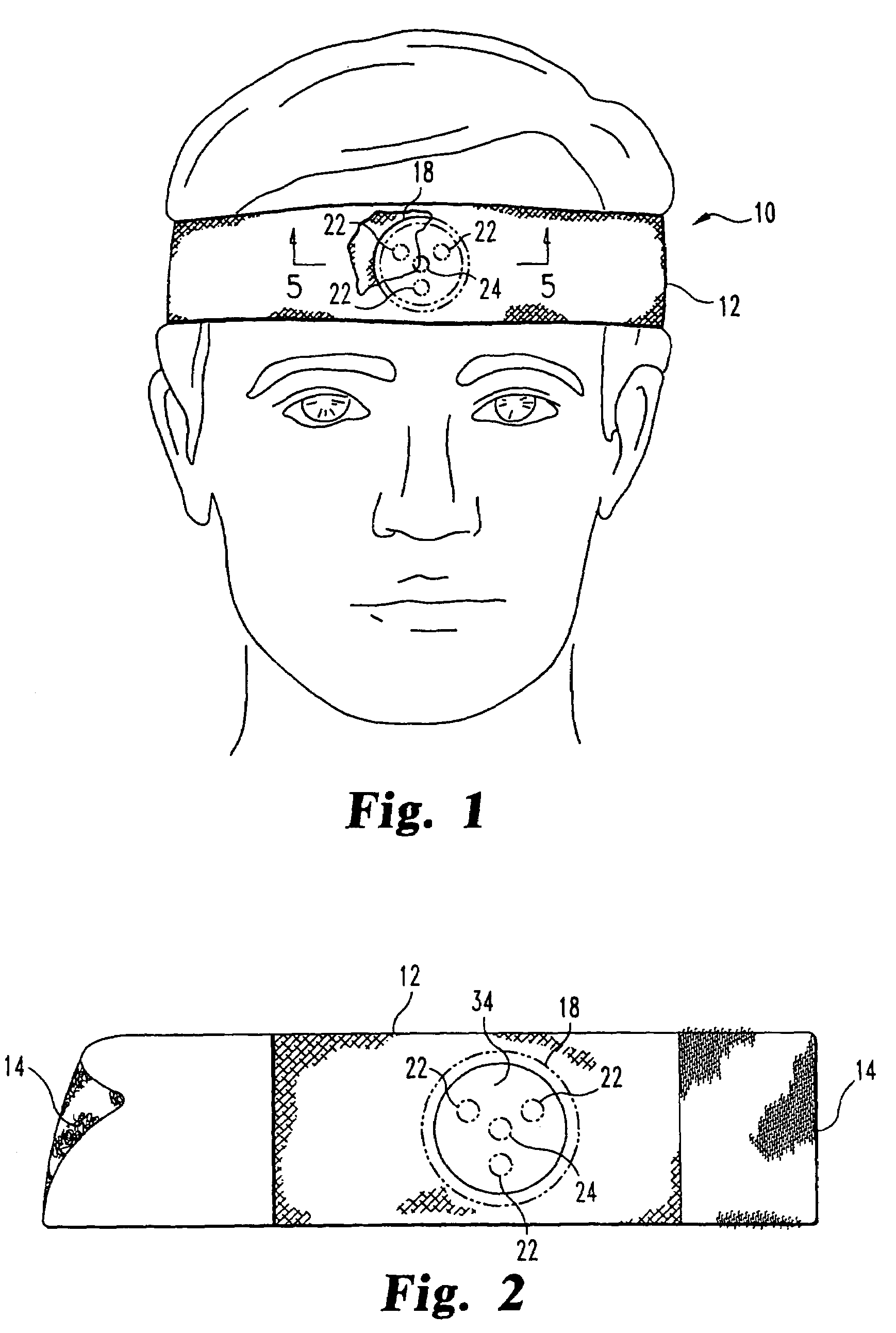

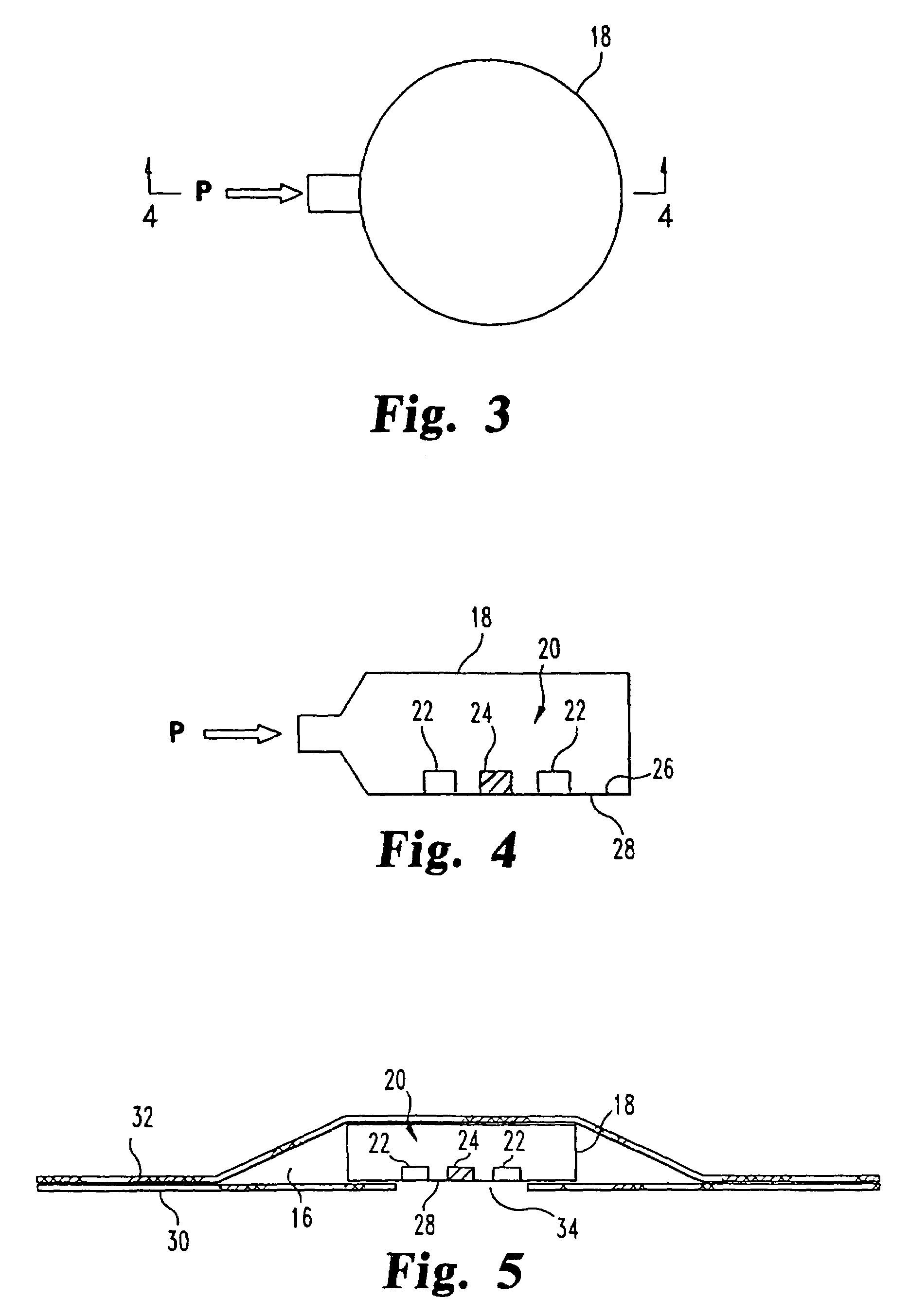

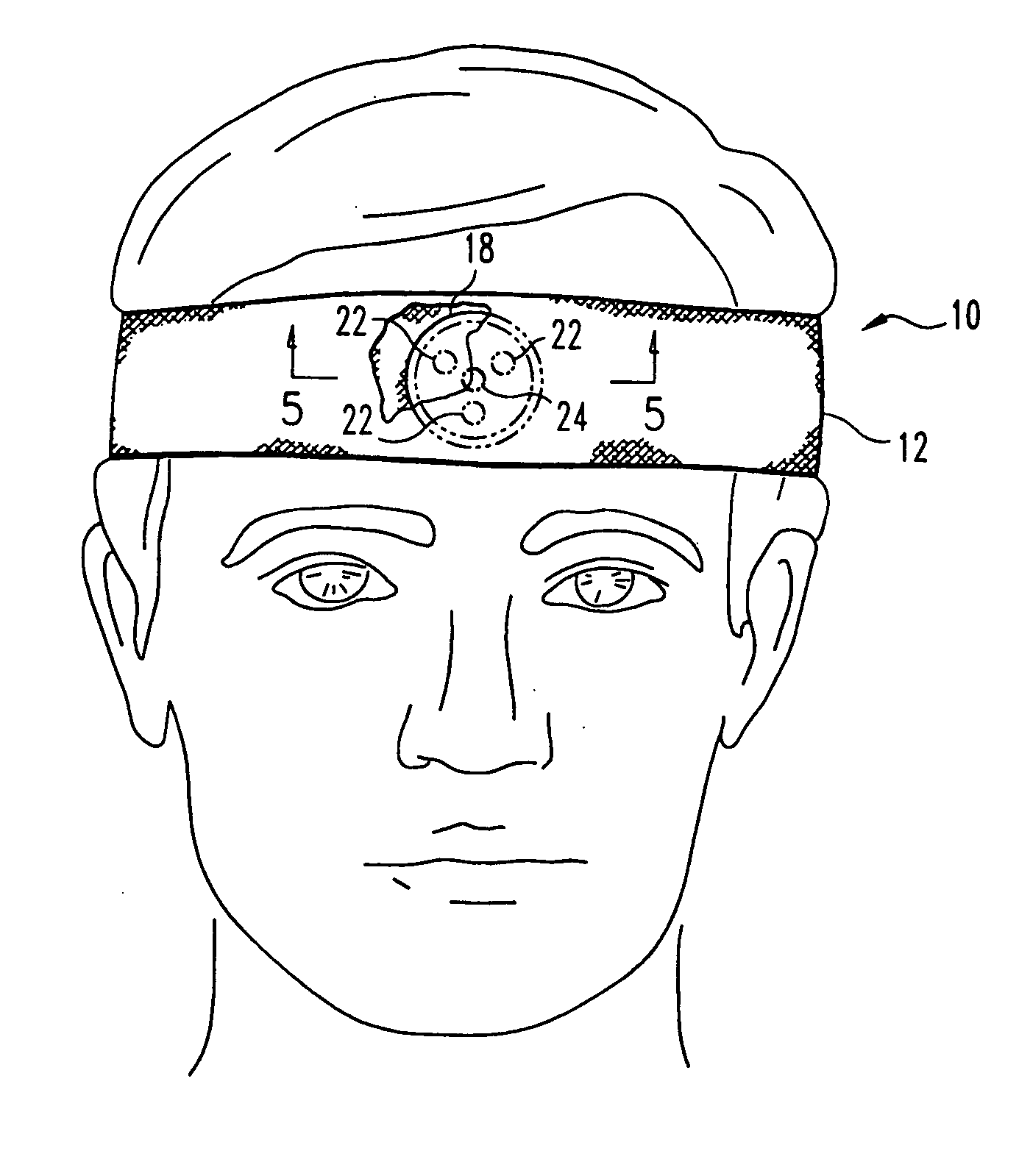

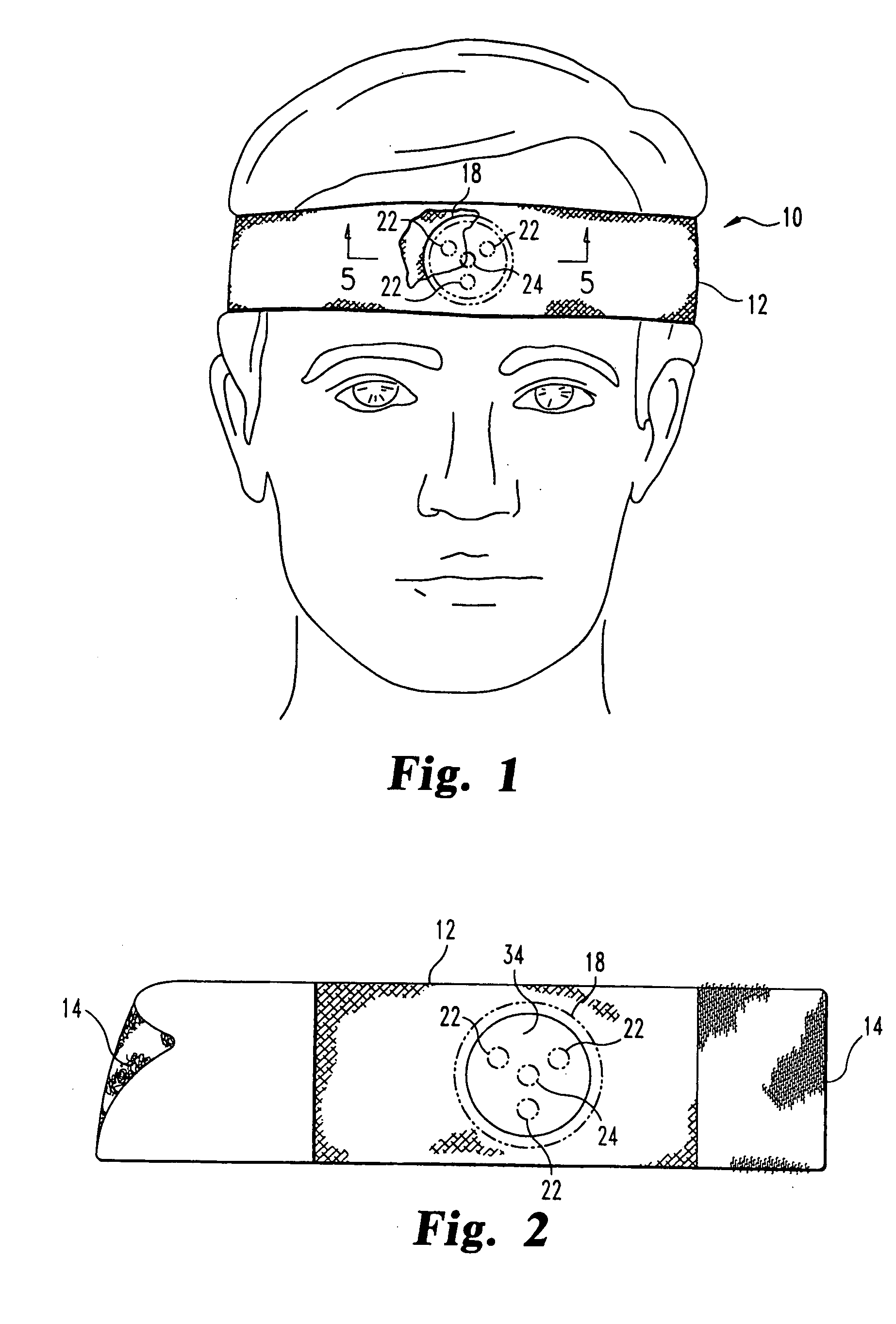

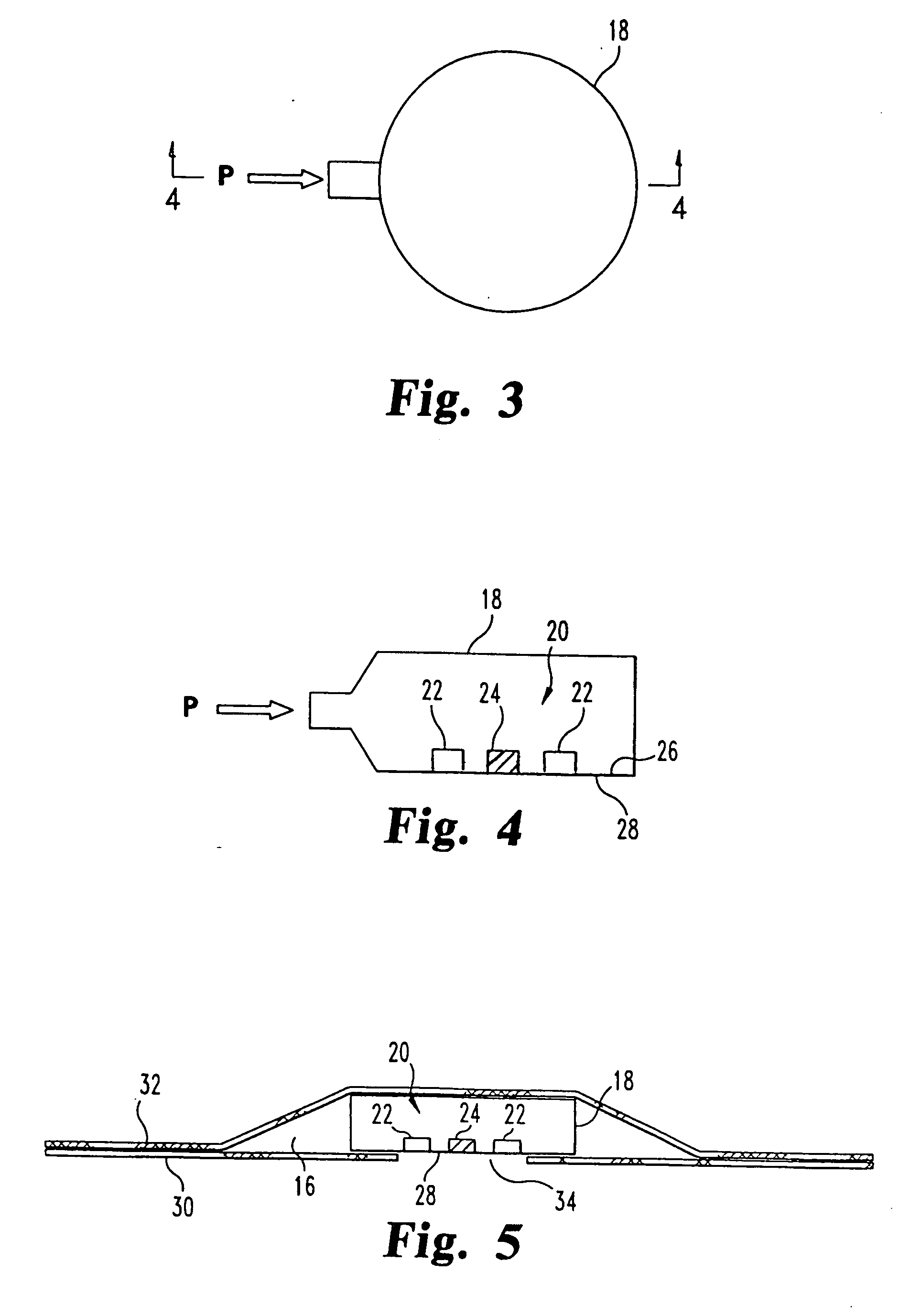

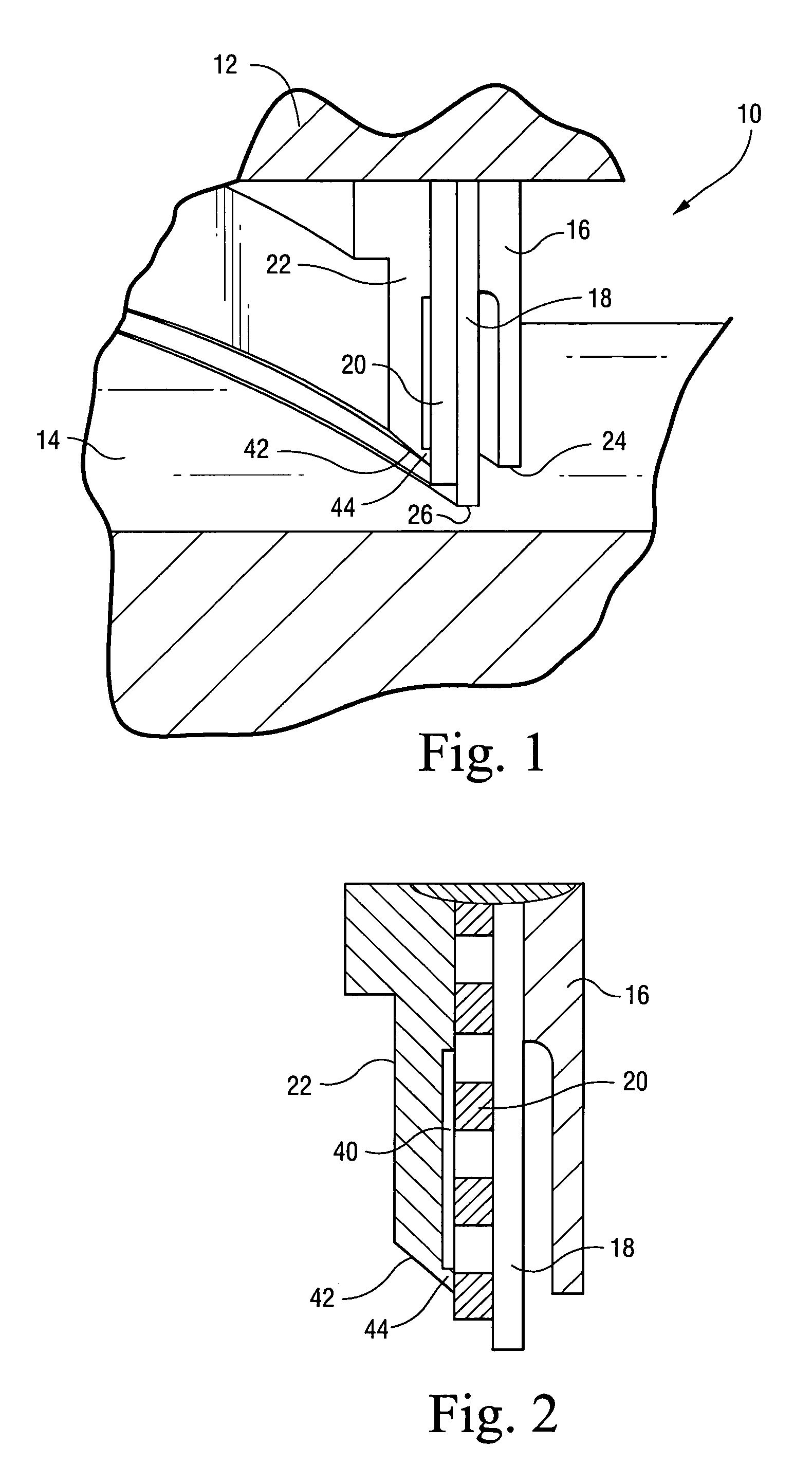

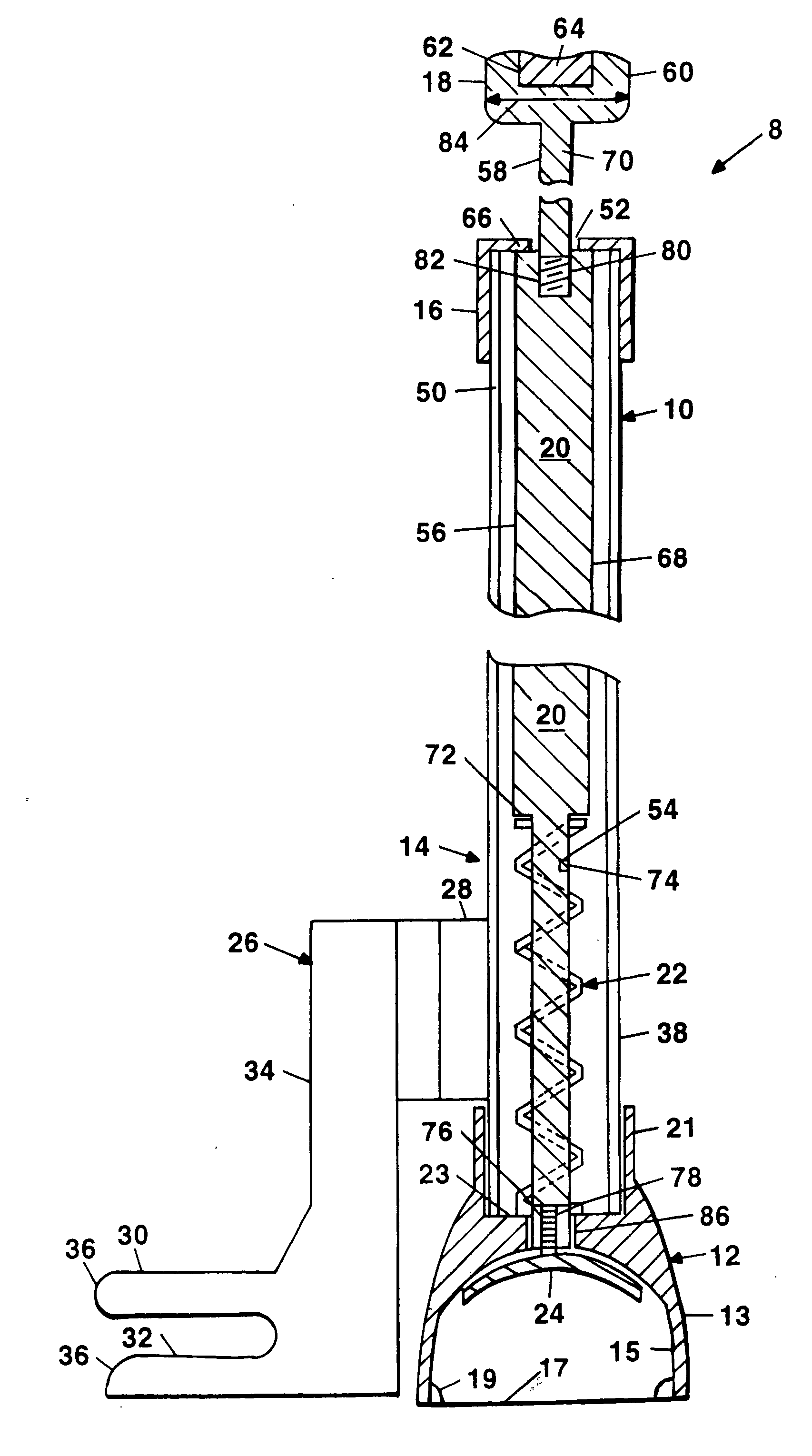

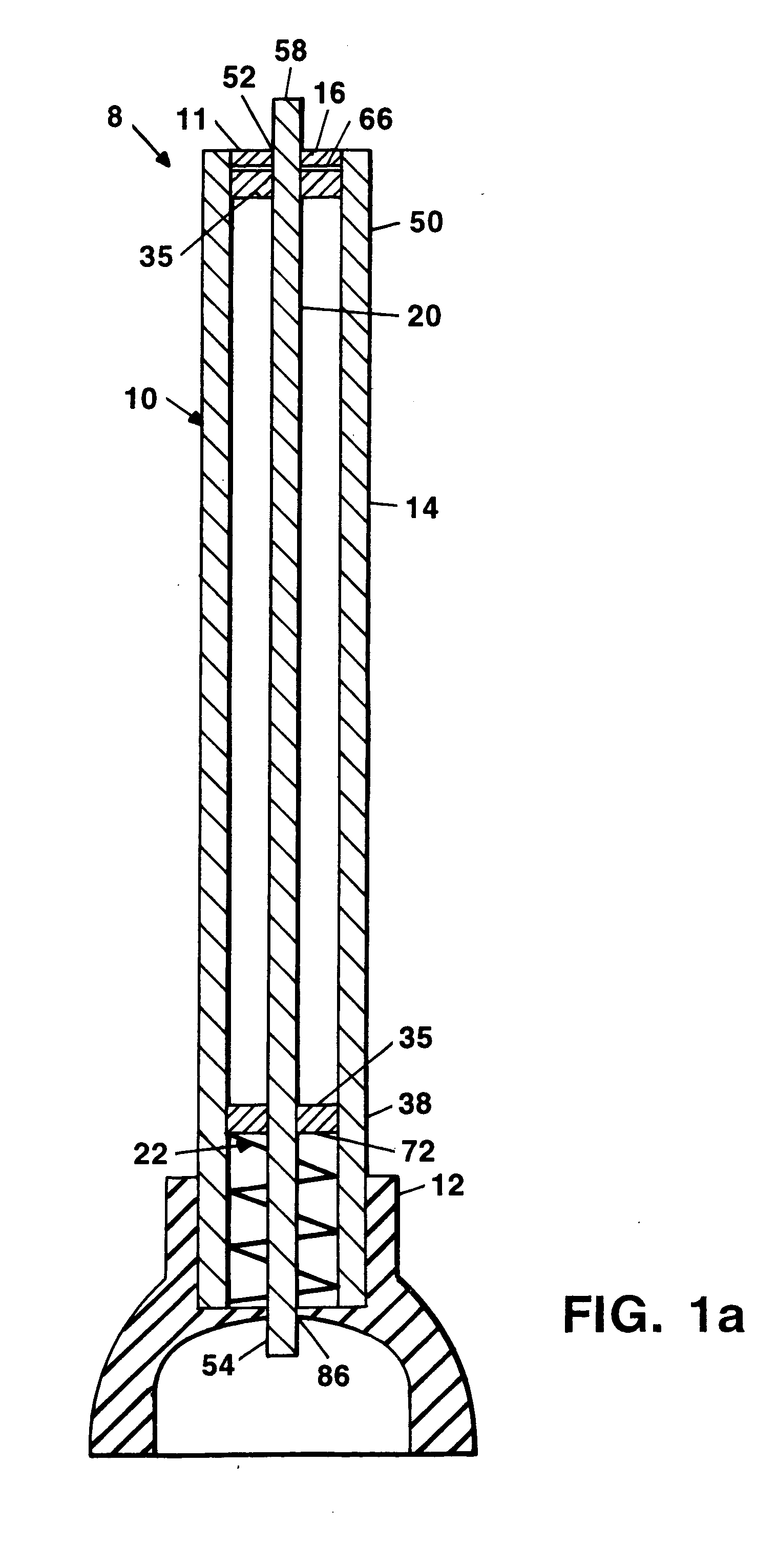

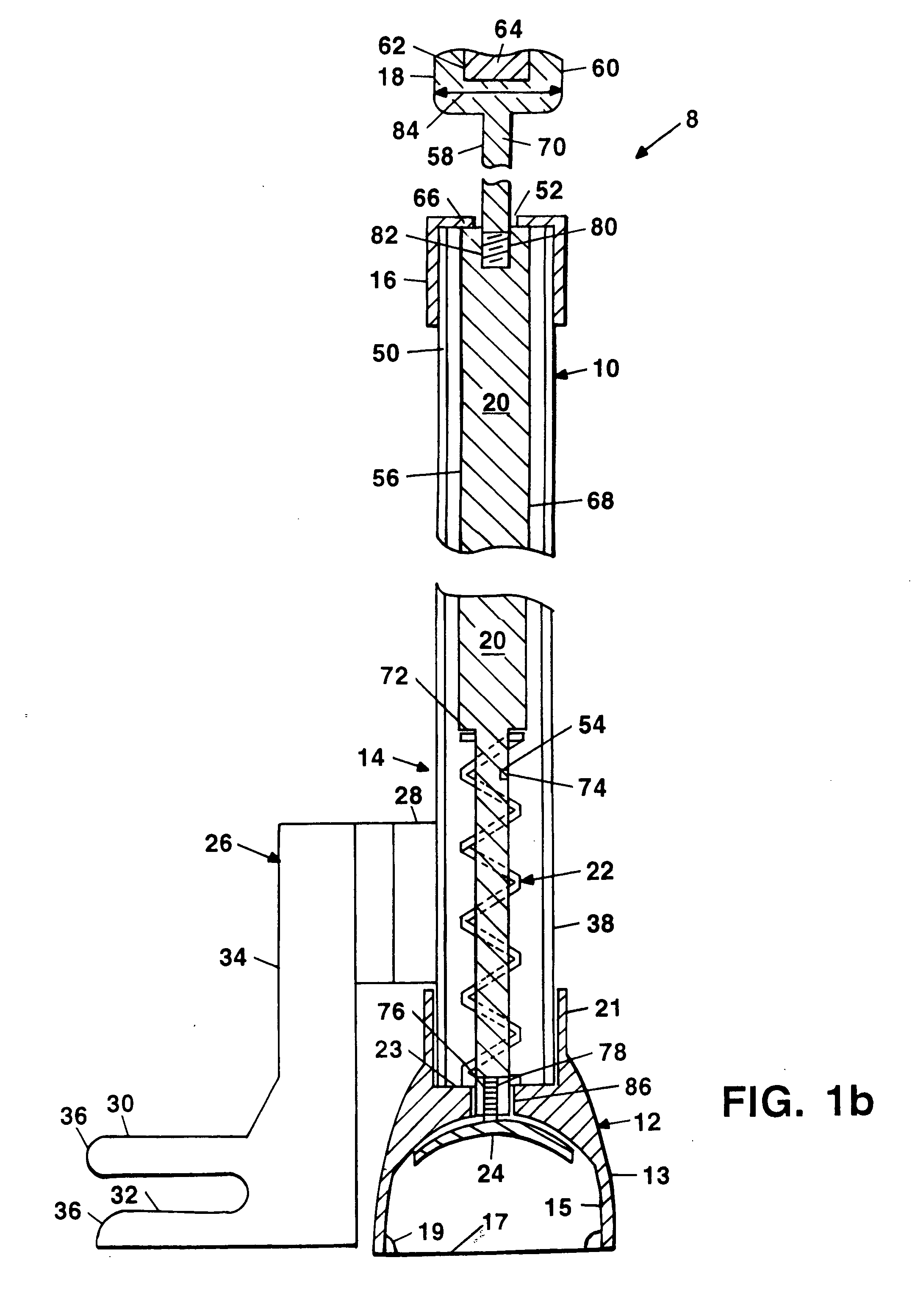

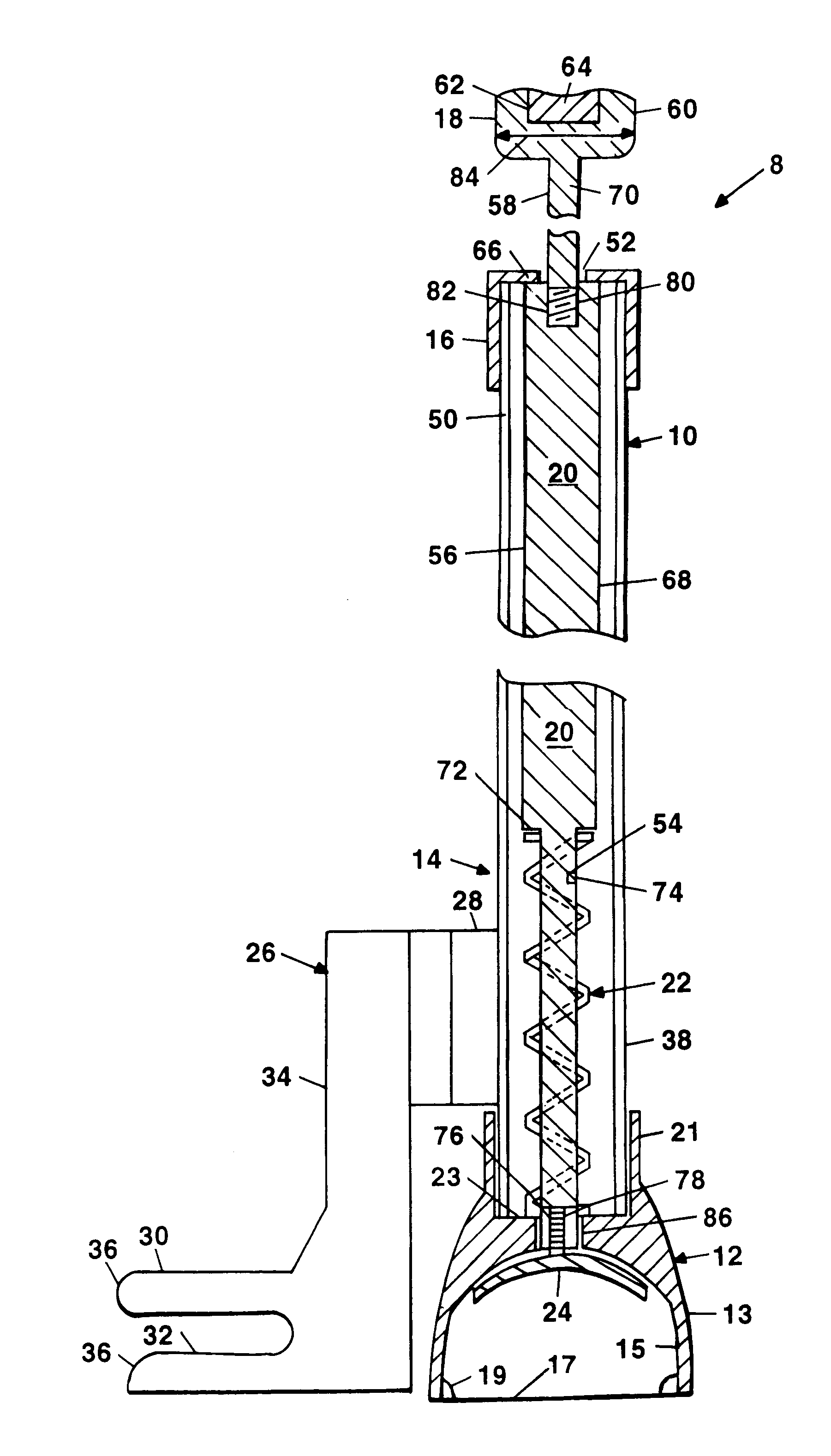

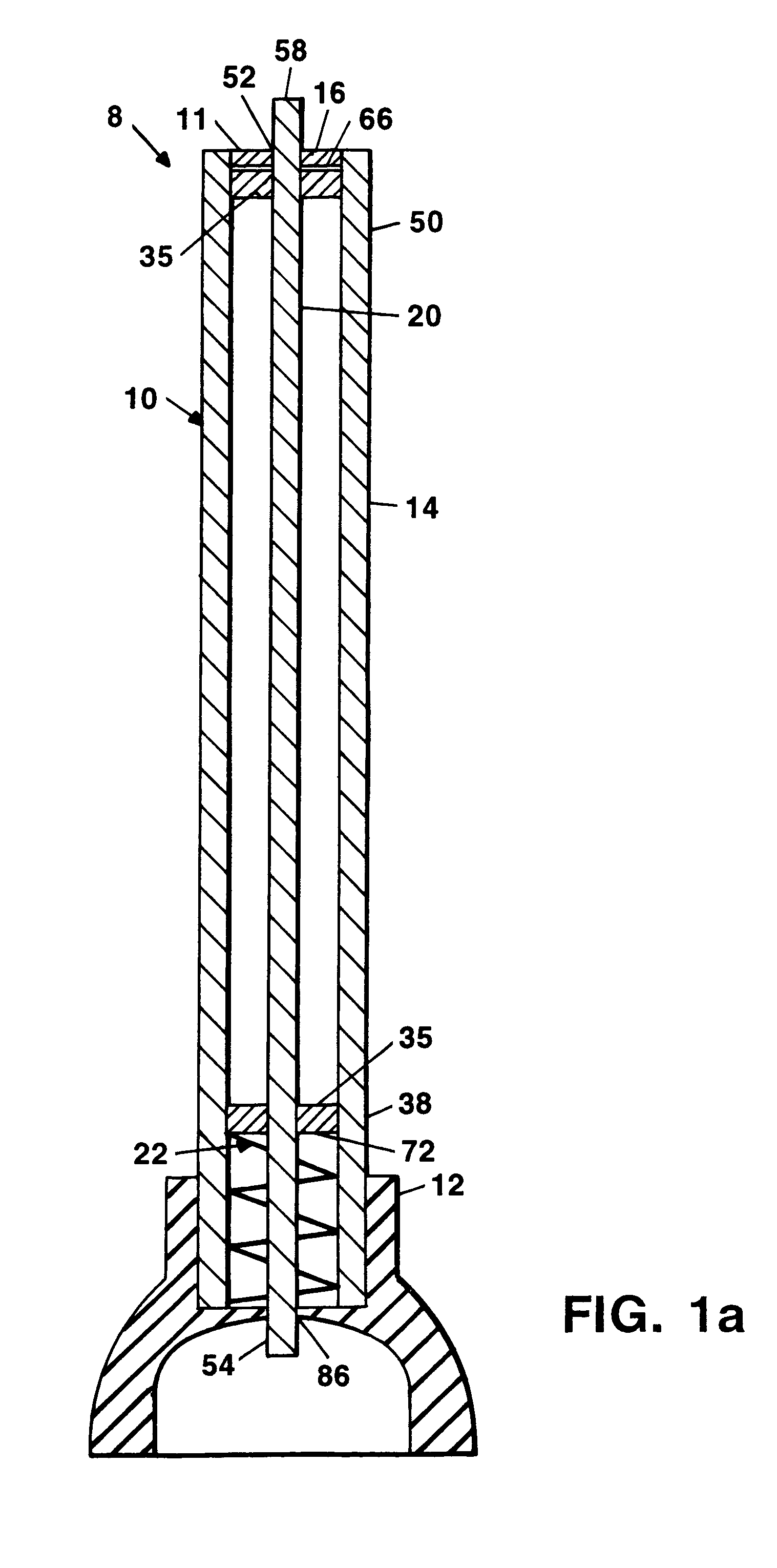

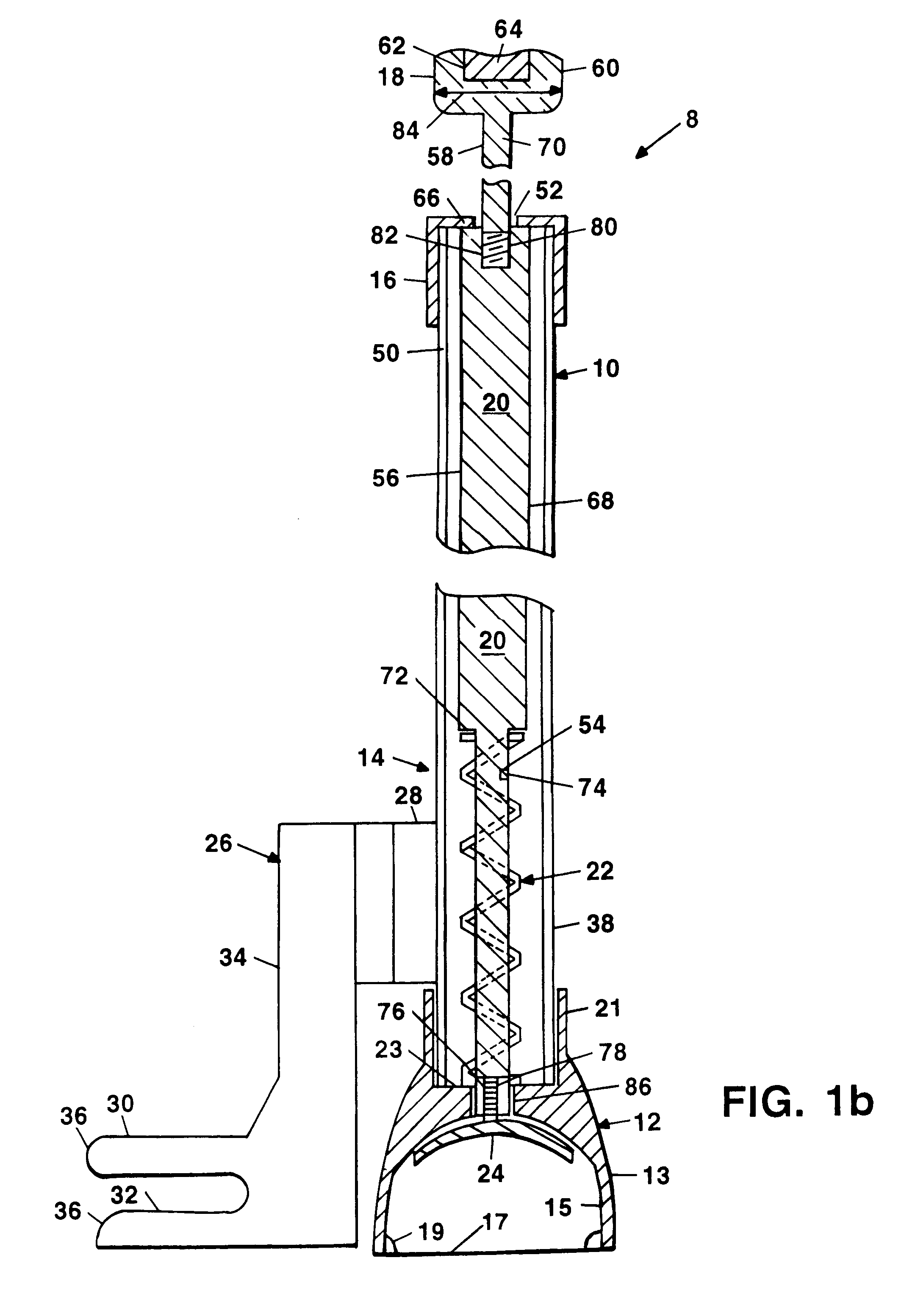

Optical noninvasive vital sign monitor

ActiveUS7164938B2Uniform pressure distributionEven contactDiagnostics using lightEvaluation of blood vesselsPhotovoltaic detectorsPhotodetector

An optical noninvasive vital sign monitor comprising a reflectance-type optical sensor within a pressurizable capsule retained by a headband, the capsule having an optically transparent or translucent inner wall adapted for placement against a subject's forehead. The optical sensor is mounted on the inside surface of the pressurizable capsule's inner wall, which contacts the subject's forehead during use, and includes a light source and a photodetector aimed toward the inside surface of the inner capsule wall. One embodiment of the vital sign monitor includes optical oscillometric circuit means responsive to an output signal from the optical sensor for determining systolic pressure, mean pressure and diastolic pressure during a transition in capsule pressure between a pressure greater than normal systolic pressure and a pressure less than normal diastolic pressure.

Owner:PURDUE RES FOUND INC

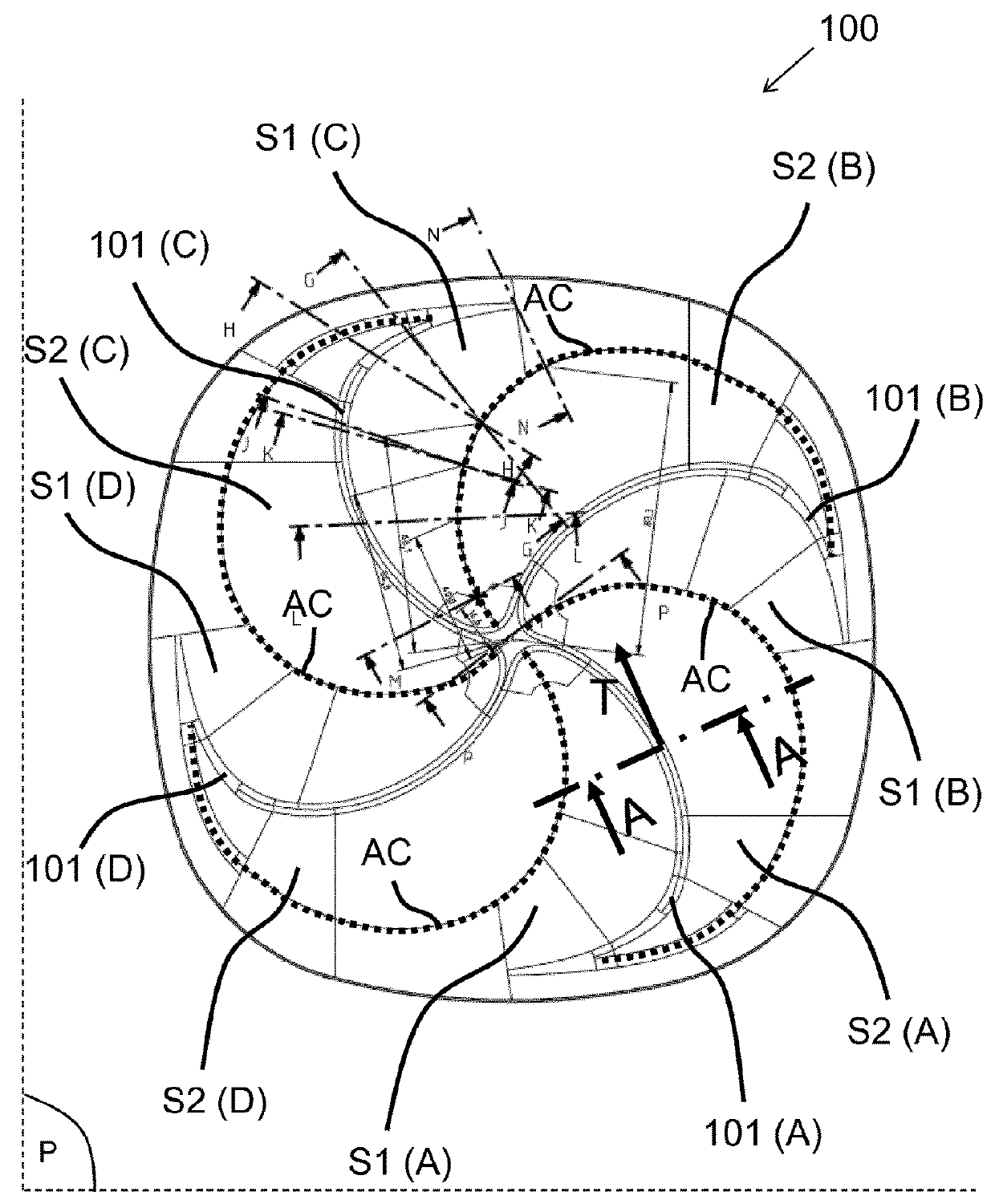

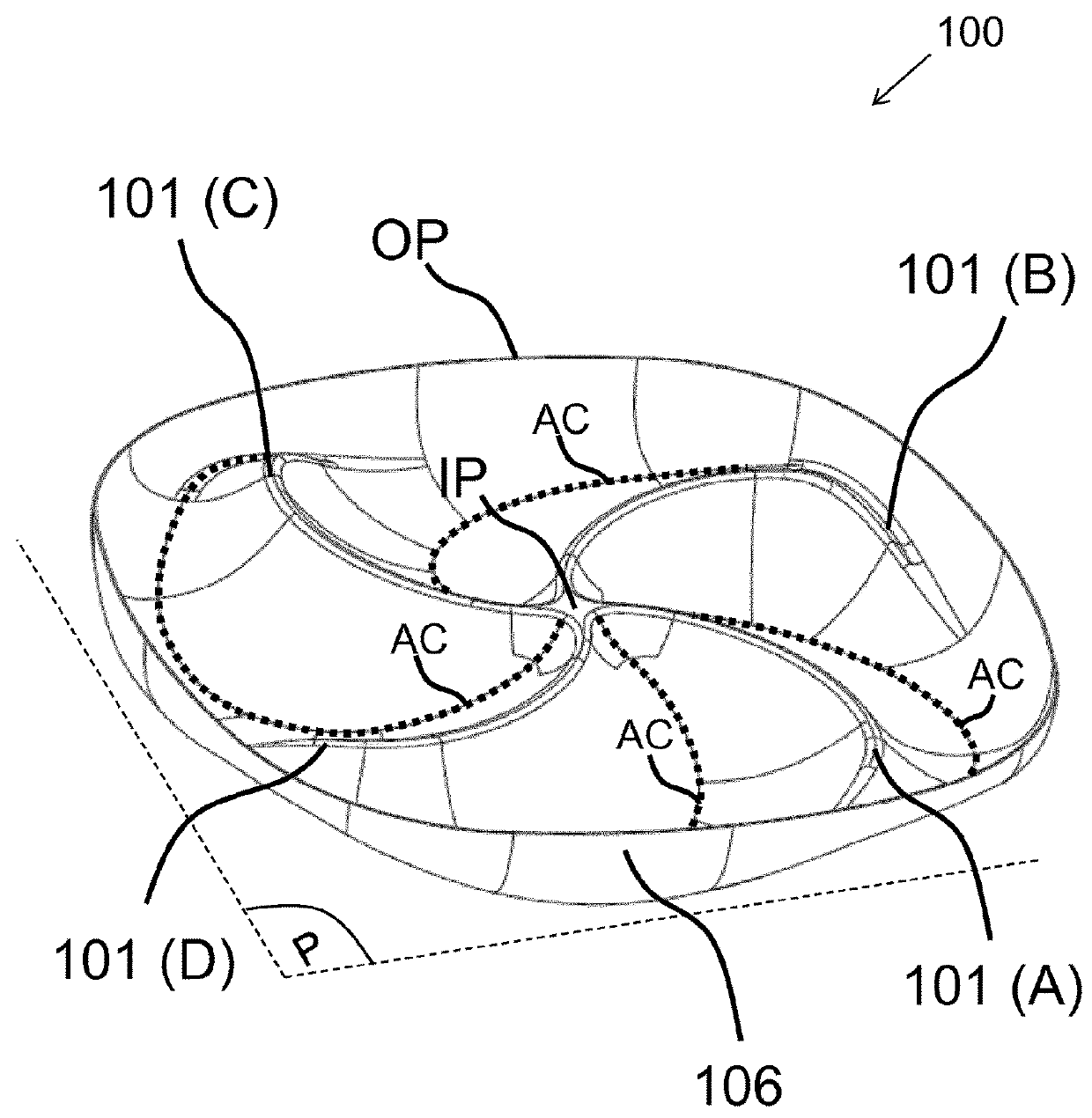

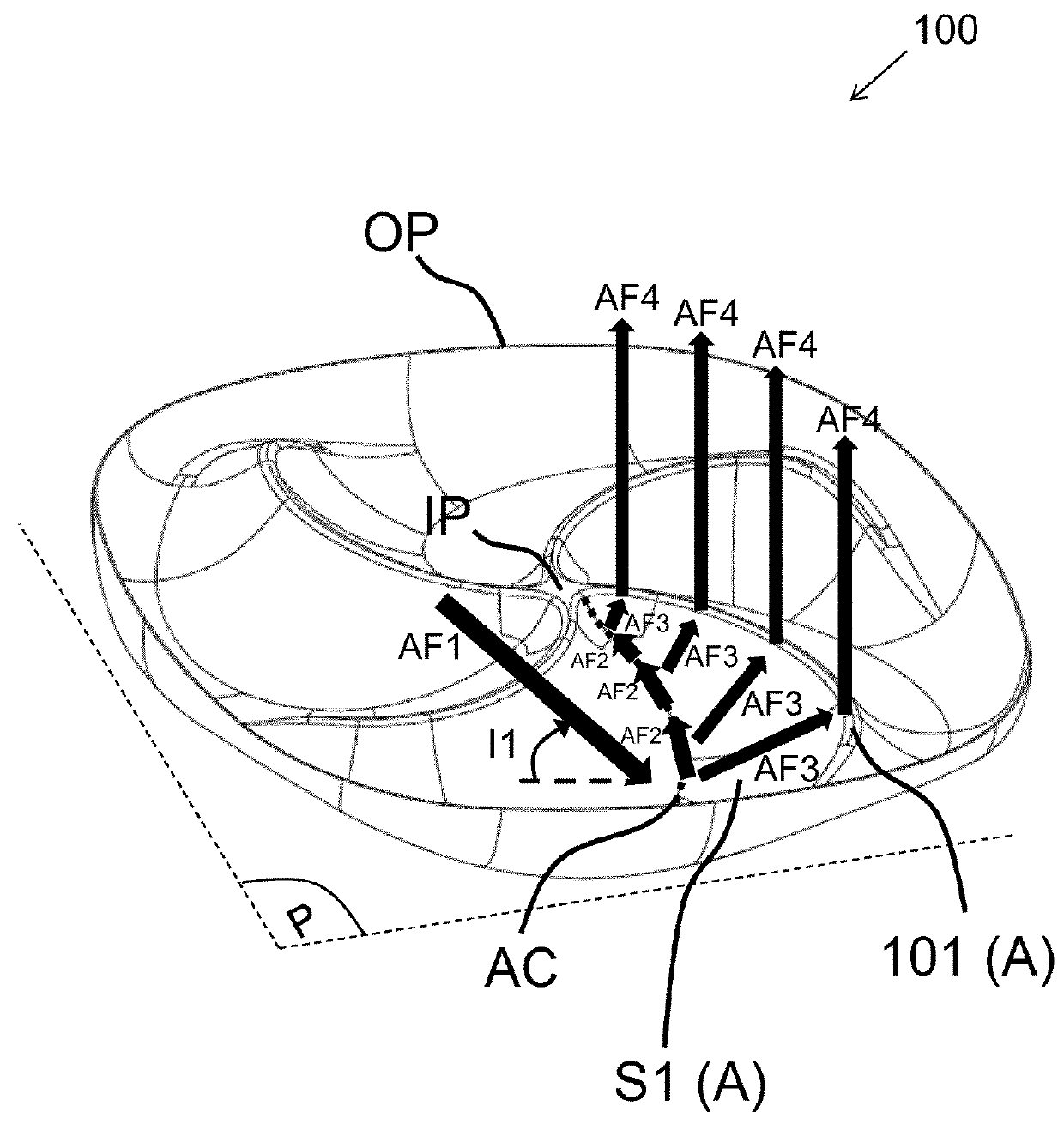

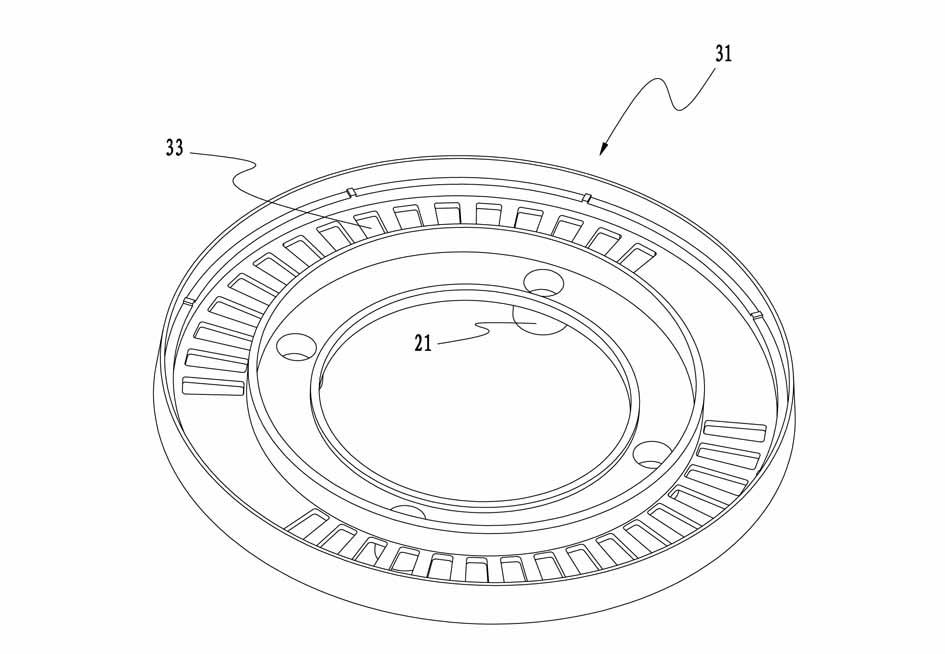

Air-guide member for an apparatus using air flow to prepare food ingredients

ActiveUS20180271323A1Uniform pressure distributionEqually distributedRoasters/grillsWarming devicesAdditive ingredientEngineering

The invention relates to an air-guide member (100) for guiding an air flow (AF) in the food preparation chamber of an apparatus using the air flow (AF) to prepare food ingredients. The air-guide member (100) comprises a plurality of air-deflecting arms (101) arranged symmetrically and extending in a horizontal plane (P) between an inner part (IP) and an outer part (OP) of the air-guide member (100). The air-deflecting arms (101) comprises a first surface (S1) being inclined with a positive angle compared to the horizontal plane (P), and a second surface (S2) being inclined with a negative angle compared to the horizontal plane (P). The air-deflecting arms (101) is such that the second surface (S2) of a given air-deflecting arms (101) and the first surface (SI) of an air-deflecting arms (101) consecutive to the given air-deflecting arms (101) intersect to form a concave air channel (AC) extending between the outer part (OP) and the inner part (IP). This allows directing the air flow upwards and more evenly between the outer part and the inner part of the air-guide. The food ingredients can thus receive a flow of hot air having a more uniform air pressure distribution, which results in a more even cooking of the food ingredients.

Owner:VERSUNI HLDG BV

Optical noninvasive vital sign monitor

ActiveUS20050283082A1Uniform pressure distributionEven contactDiagnostics using lightEvaluation of blood vesselsPhotovoltaic detectorsPhotodetector

An optical noninvasive vital sign monitor comprising a reflectance-type optical sensor within a pressurizable capsule retained by a headband, the capsule having an optically transparent or translucent inner wall adapted for placement against a subject's forehead. The optical sensor is mounted on the inside surface of the pressurizable capsule's inner wall, which contacts the subject's forehead during use, and includes a light source and a photodetector aimed toward the inside surface of the inner capsule wall. One embodiment of the vital sign monitor includes optical oscillometric circuit means responsive to an output signal from the optical sensor for determining systolic pressure, mean pressure and diastolic pressure during a transition in capsule pressure between a pressure greater than normal systolic pressure and a pressure less than normal diastolic pressure.

Owner:PURDUE RES FOUND INC

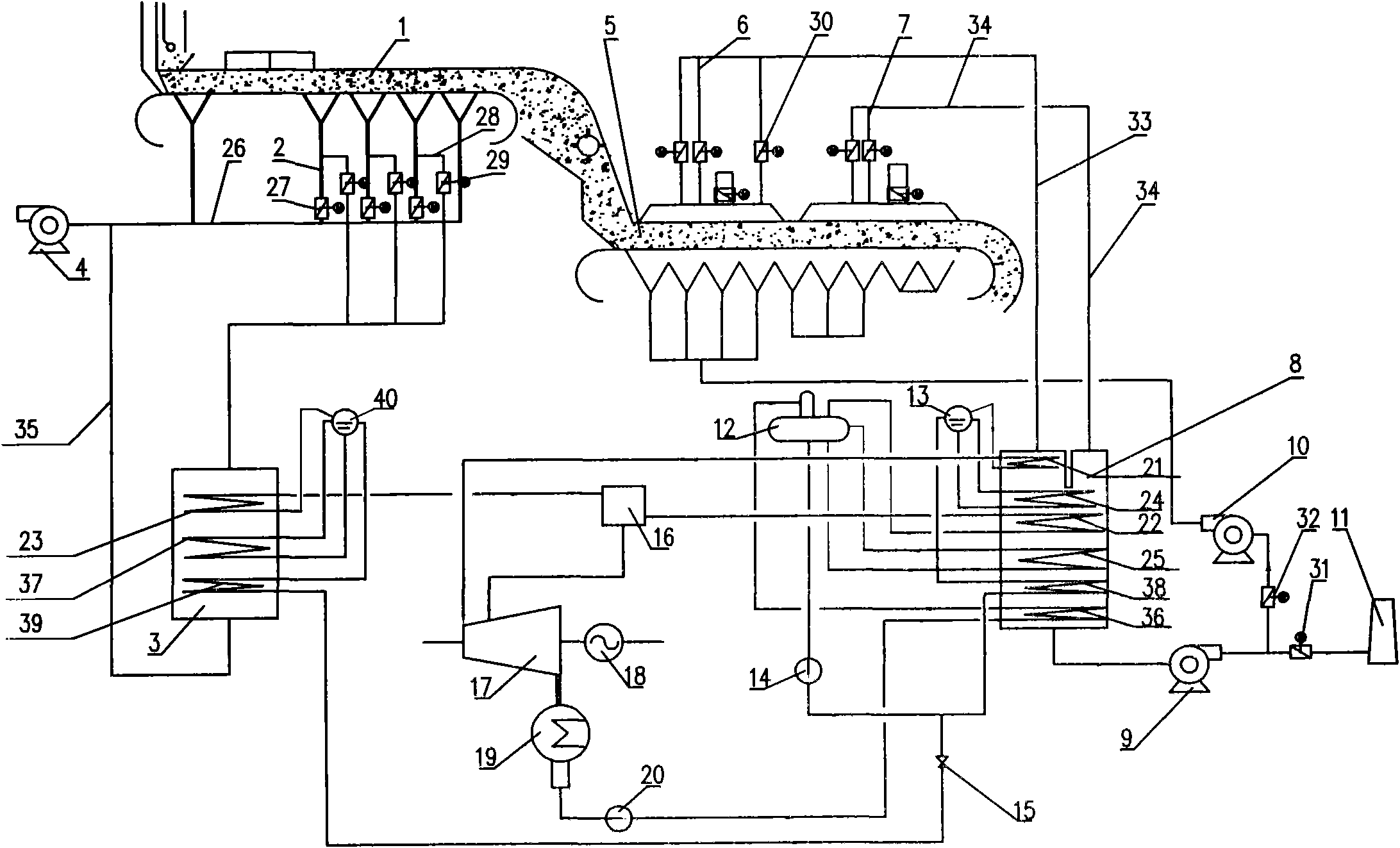

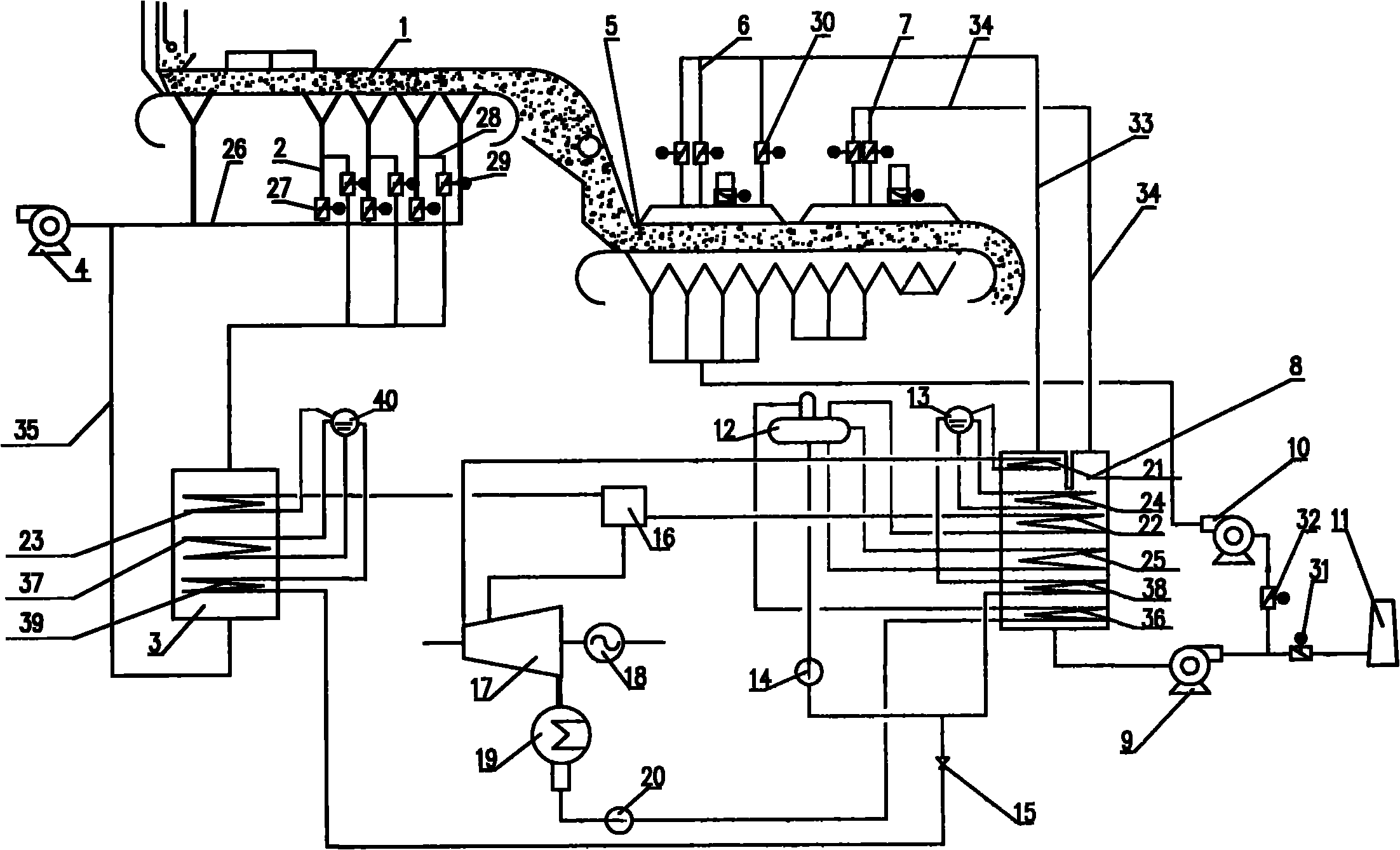

System and method for using sintering waste heat to generate electricity

InactiveCN101806230AImprove utilization efficiencyIncrease waste heat power generationIncreasing energy efficiencySteam engine plantsElectricityExhaust fumes

The invention discloses a system and a method for using sintering waste heat to generate electricity and belongs to the technical field of sintering waste heat electricity generation of the steel works. The system comprises a sintering machine, a hot gas outlet pipe, a gas waste heat boiler, a main exhaust fan, a ring cooling machine, a first and second stage heat waste gas collecting pipe, a waste gas heat boiler, a draught fan, a circulating fan, a chimney, a low pressure steam drum, a middle pressure steam drum, a feed pump, a pressure reducing valve, a collecting header, a steam turbine, a generator, a condenser and a condensate pump. The invention realizes utilizing the waste heat of the non-desulfurization flue header of the sintering machine without arranging an inducing fan by reasonably designing the hot gas connecting mode of the air box at the tail part of the sintering machine and the gas resistance of the waste gas heat boiler. First and second stage sealing covers of the ring cooling machine are uniformly provided with a plurality of waste gas branch pipes so as to realize uniform distribution of the waste gas pressure in the sealing covers and reduce air leakage. Part of waste gas is adopted to circulate to improve the temperature of the waste gas. Compared with the existing system for using sintering waste heat to generate electricity, the system of the invention sufficiently uses the waste heat of the sintering system, improves the waste heat generated energy and reduces the operation cost.

Owner:湖南永清环境科技产业集团有限公司

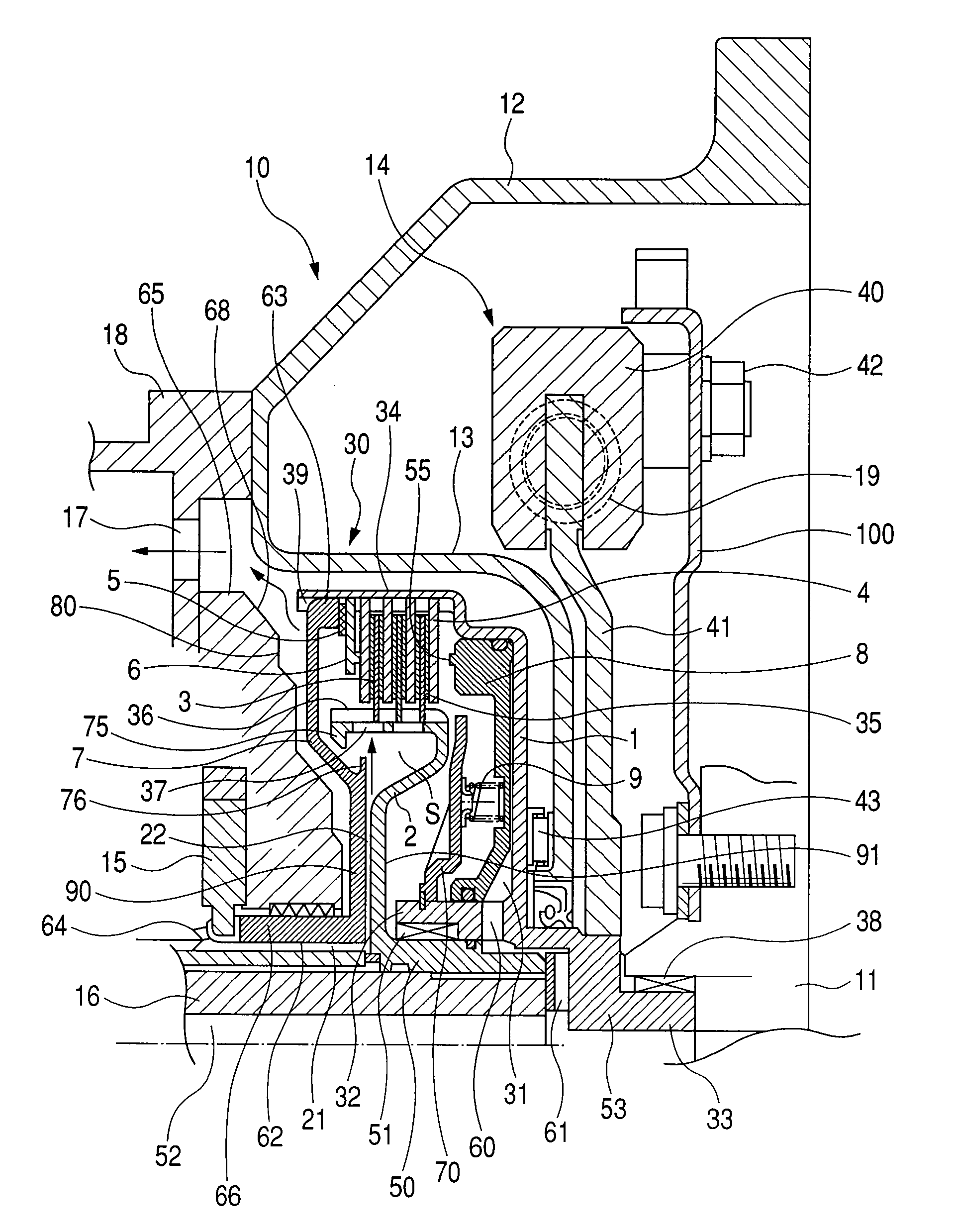

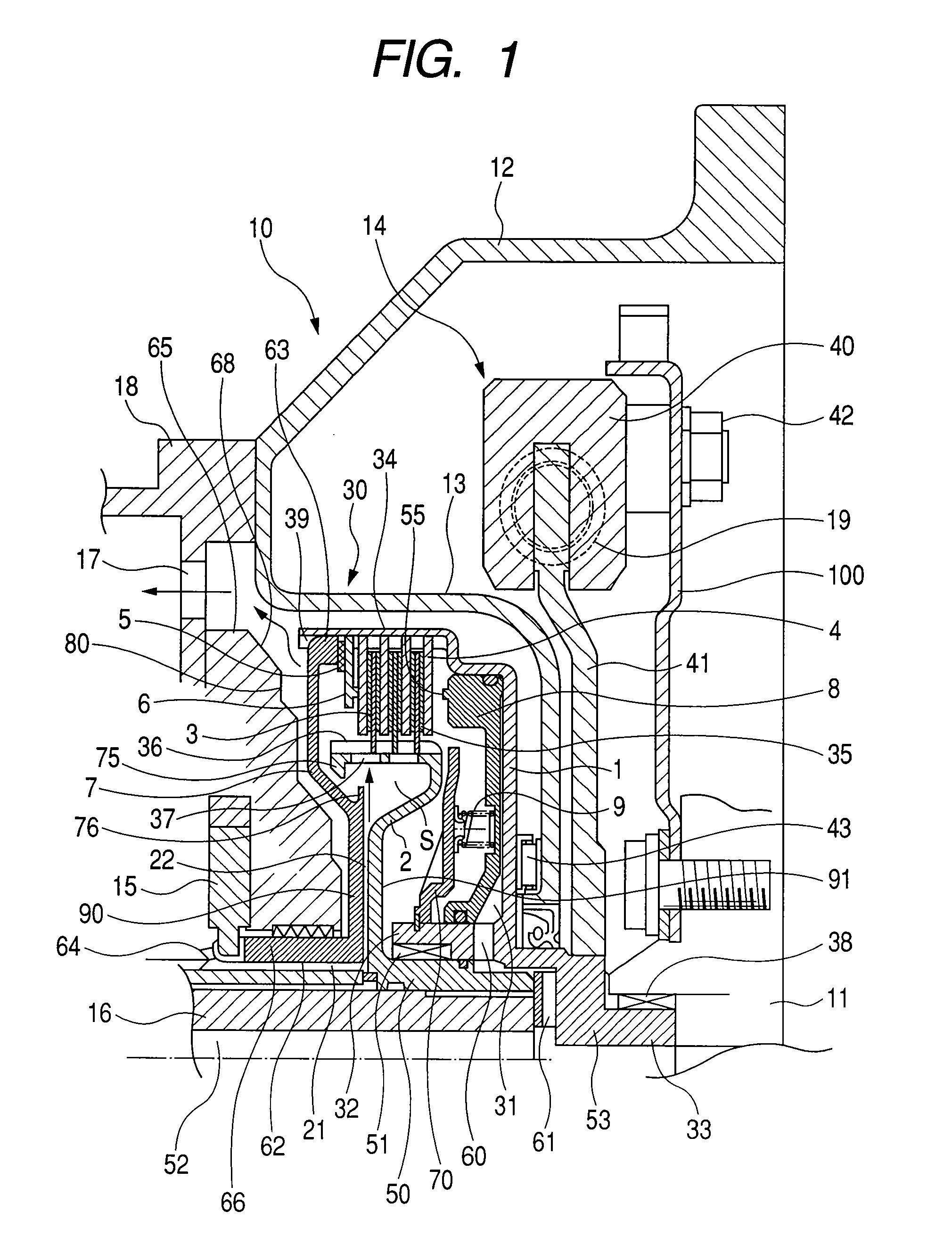

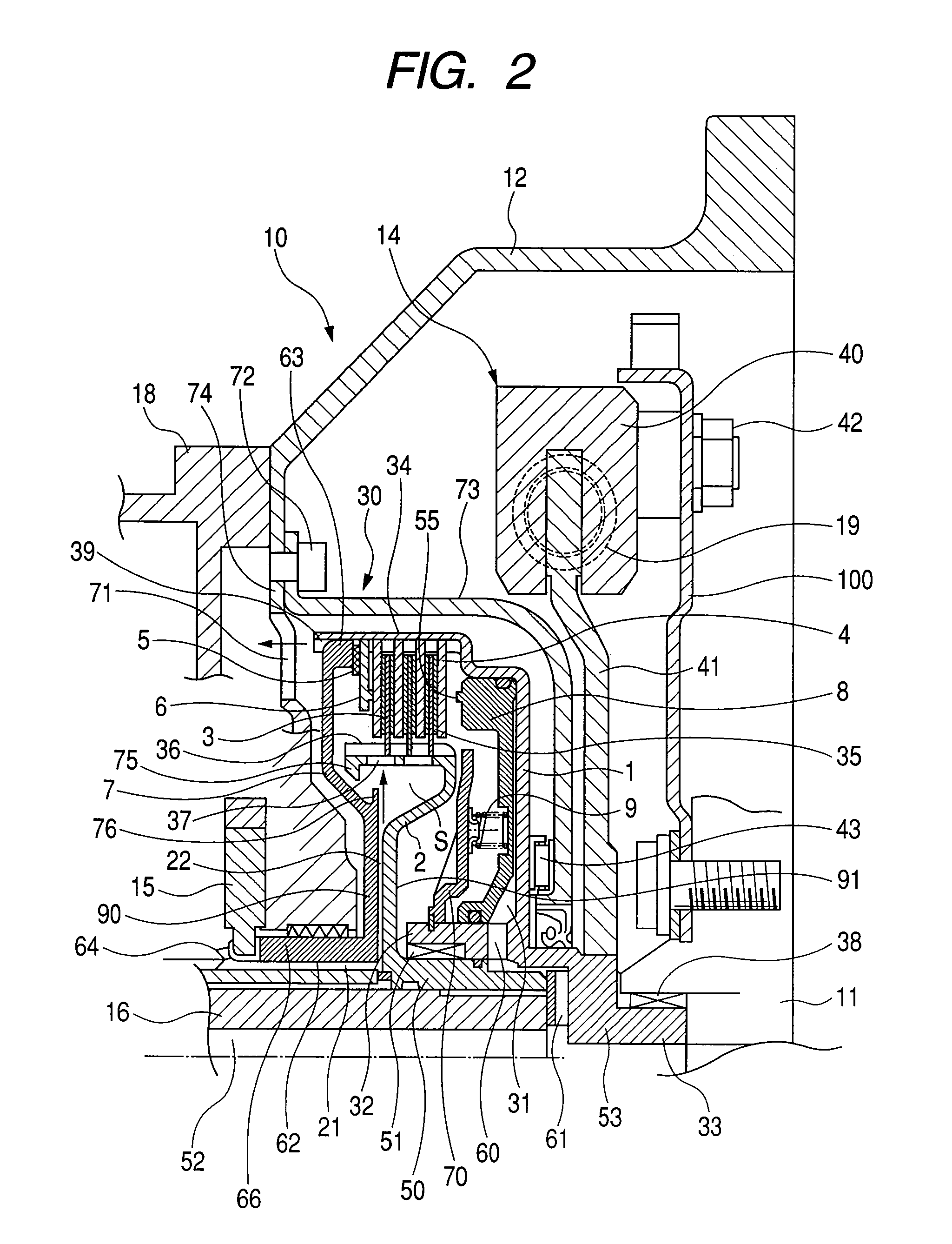

Starting clutch

InactiveUS20080142331A1Improve cooling effectSufficient operationFluid actuated clutchesFriction clutchesEngineeringPiston

The present invention provides a starting clutch disposed between a transmission and an engine and having a wet type multi-plate clutch for transmitting a power, in which the wet type multi-plate clutch includes a plurality of friction plates housed for an axial sliding movement, a clutch drum for housing the friction plates, and a piston for urging a radial central region or therearound of the friction plate to engage the friction plates, and oil which has lubricated the wet type multi-plate clutch is temporarily trapped within the clutch drum and then is discharged.

Owner:NSK WARNER

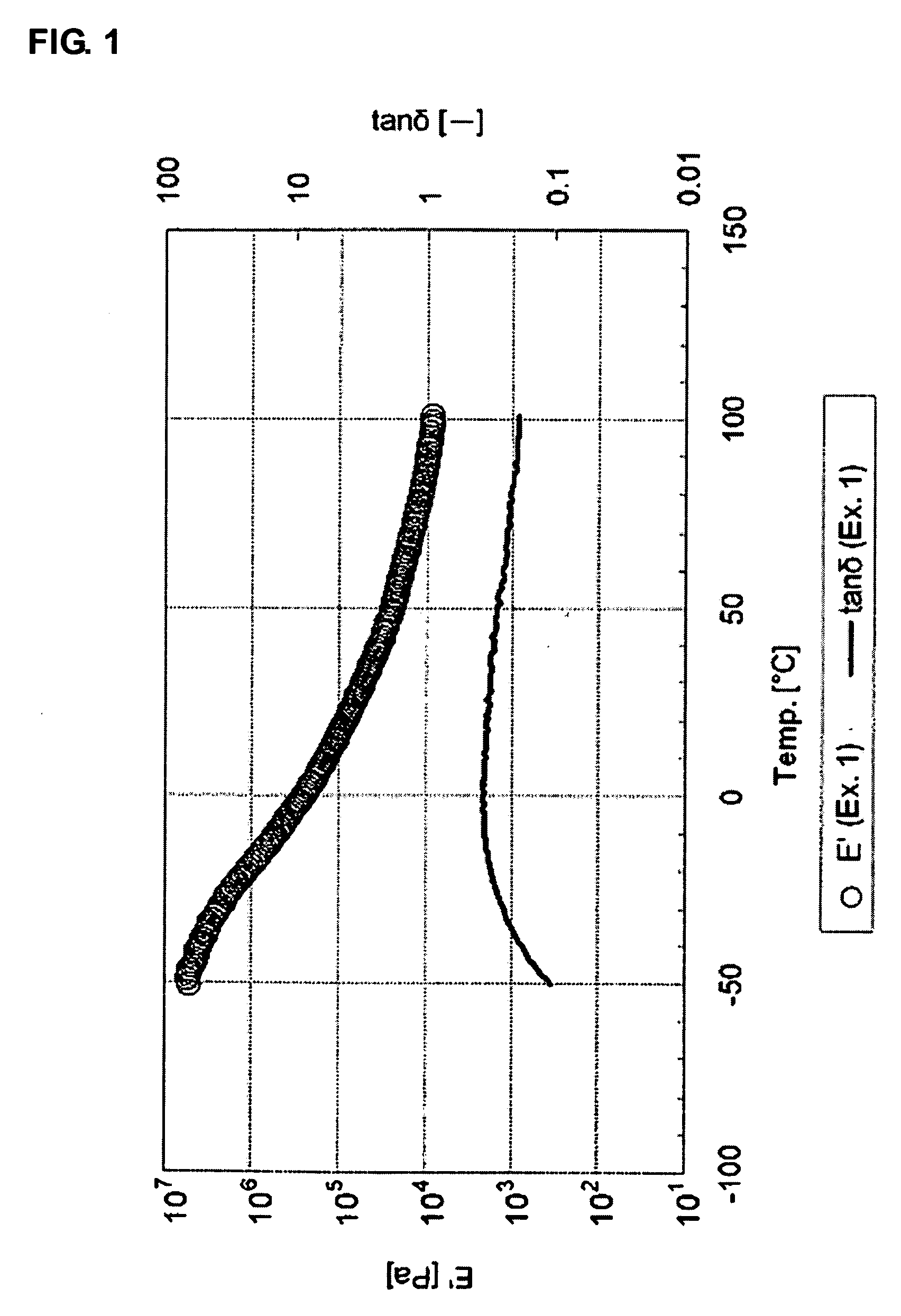

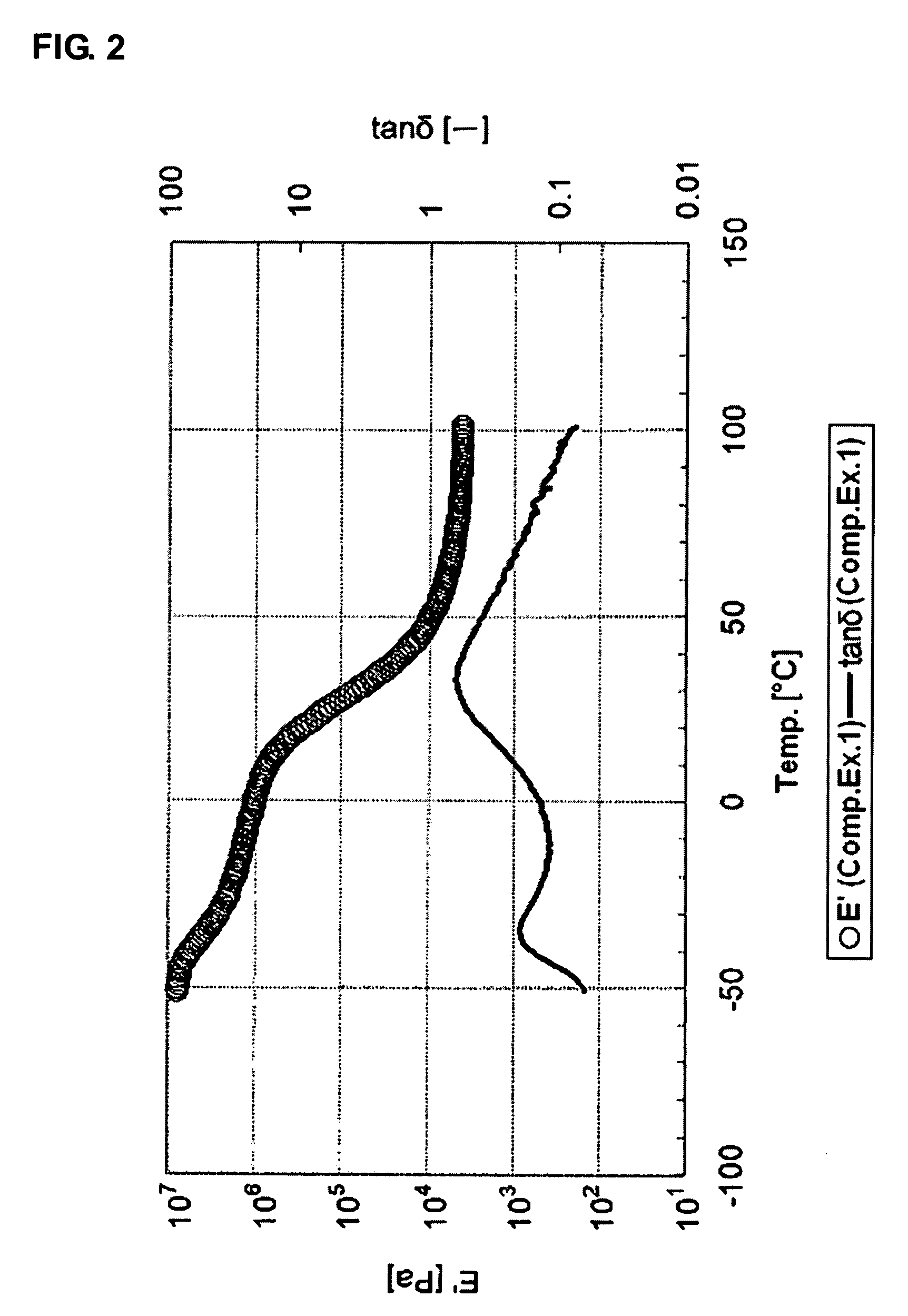

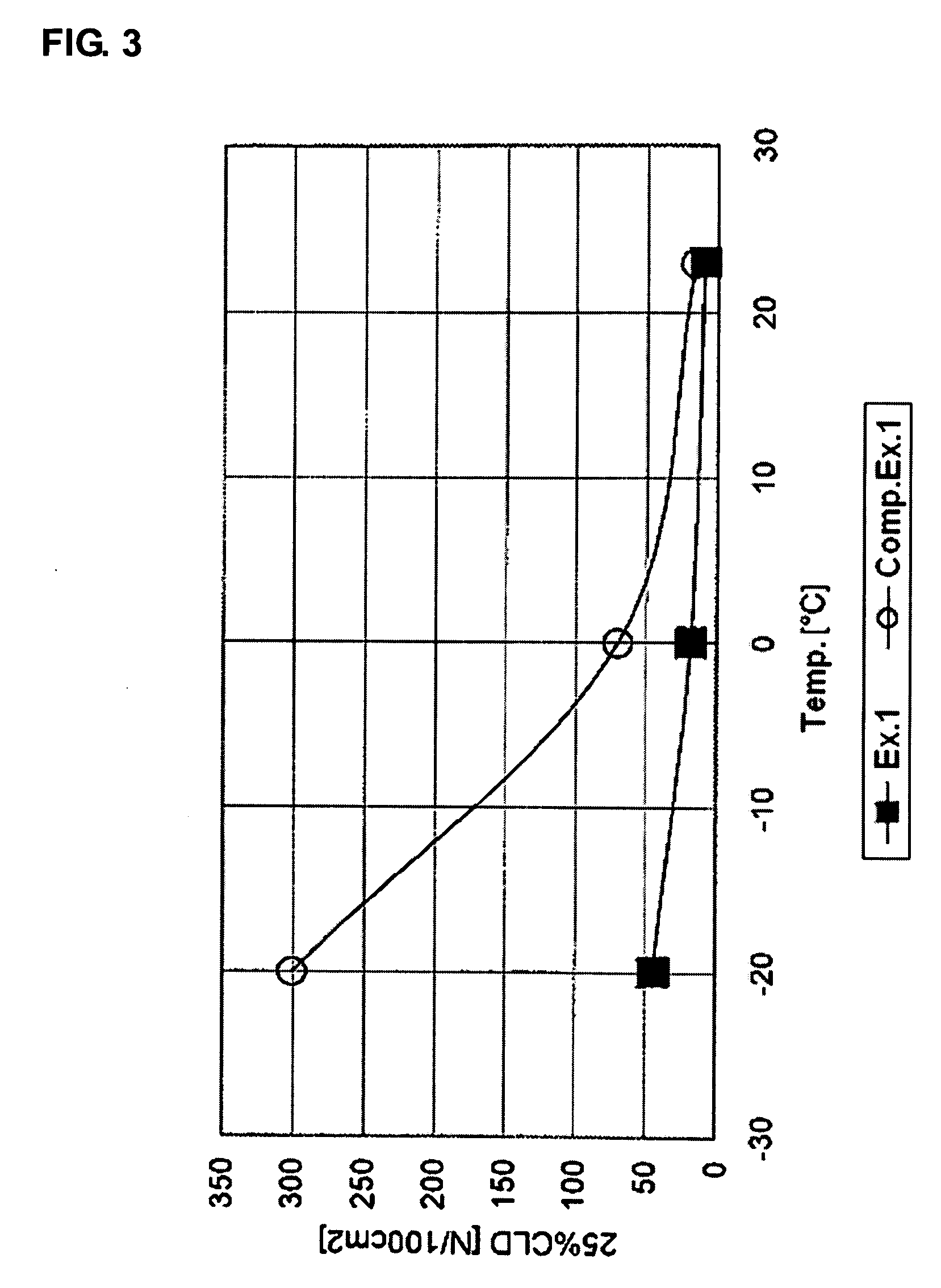

Composition for Polyurethane Foam, Polyurethane Foam Obtained From the Composition, and Use Thereof

InactiveUS20090143495A1Excellent low rebound propertyReduce decreaseOrganic chemistryFoaming agentSide chain

The polyurethane foam composition of the present invention comprises a polyol, a catalyst, a surfactant, a foaming agent and a polyisocyanate, wherein the polyol contains, at least, (A) a polyol that is produced by using a raw material obtained from plant-derived oil, contains more than three side chains per molecule, each side chain comprising a hydrocarbon chain having 4 or more carbon atoms, and has an average number of functional groups of 1.5 to 4.5 and a hydroxyl value of 80 to 140 mgKOH / g. The polyurethane foam of the present invention is produced by foaming the above polyurethane foam composition. The polyurethane foam contributes to reducing environmental burdens, and has excellent low rebound property, particularly a characteristic that the increase in hardness at low temperatures is suppressed.

Owner:MITSUI CHEMICALS POLYURETHANES INC

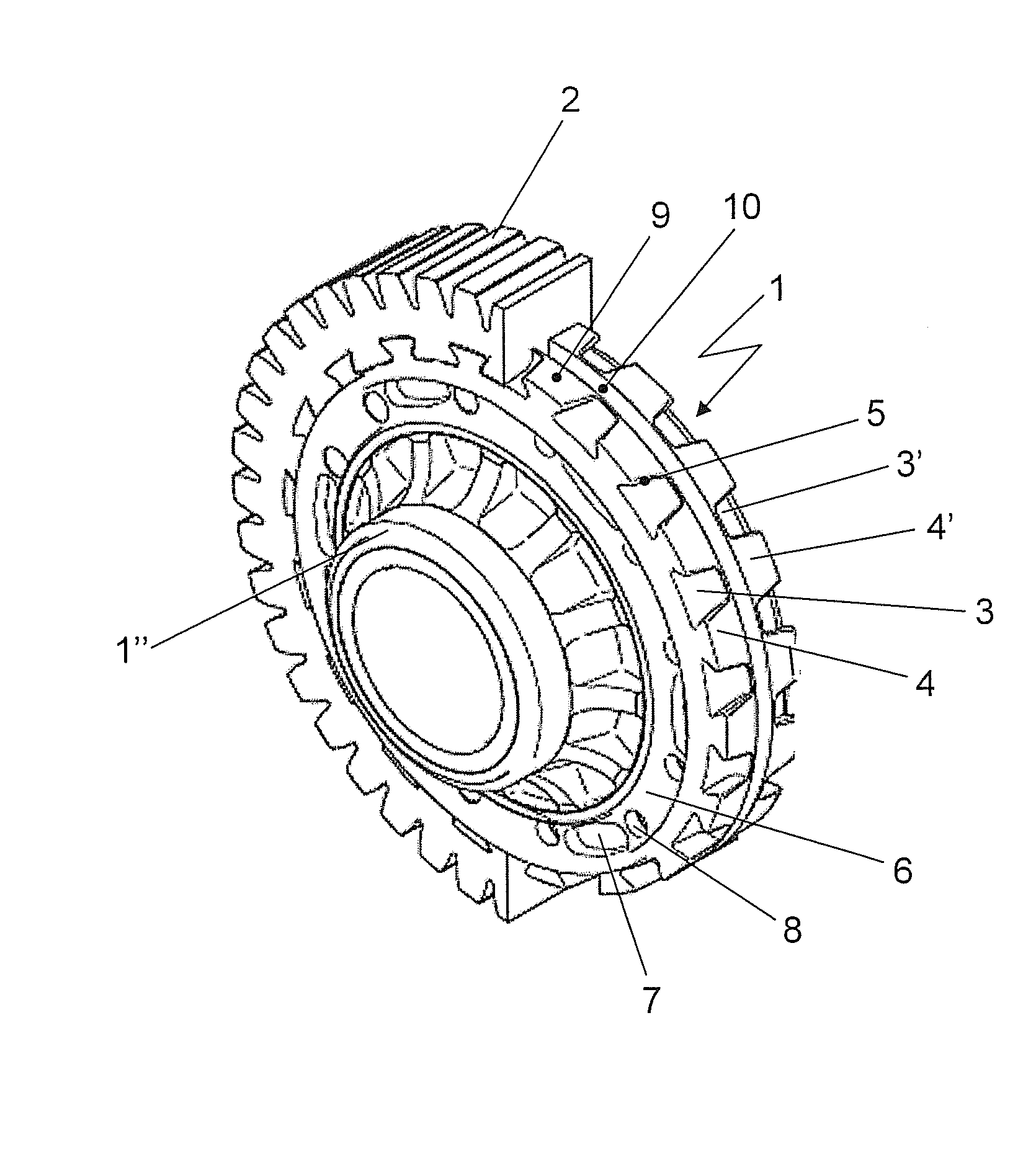

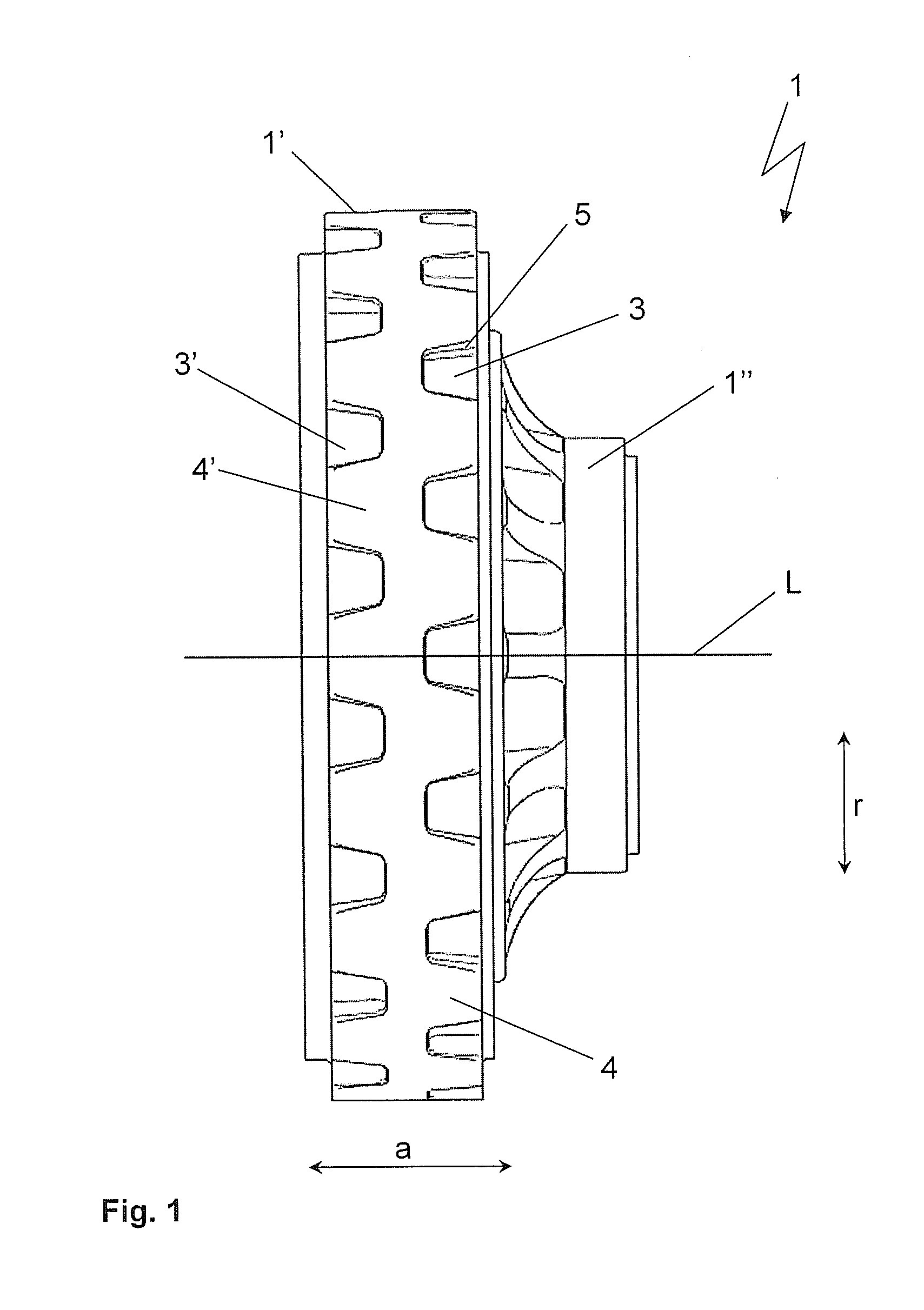

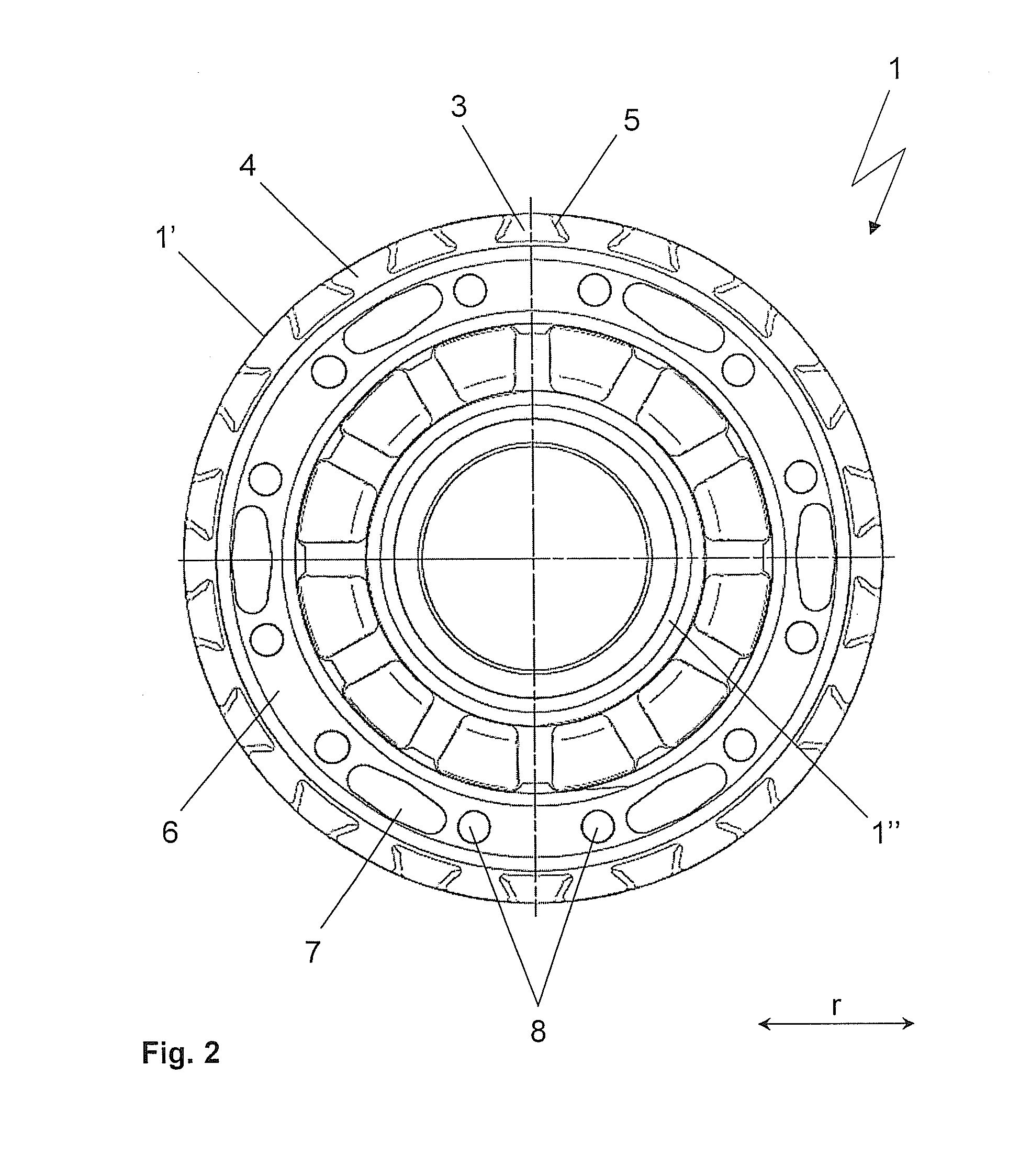

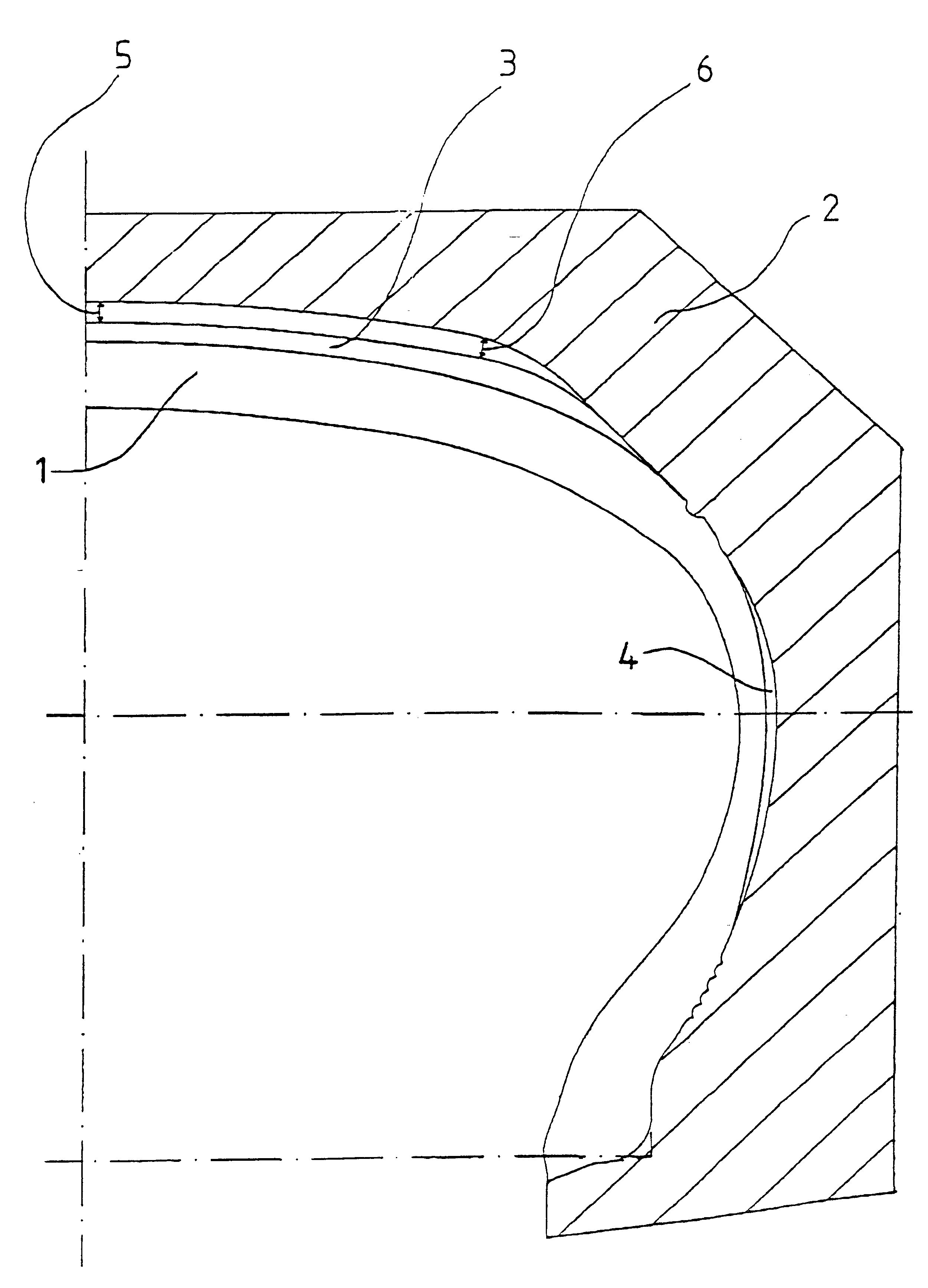

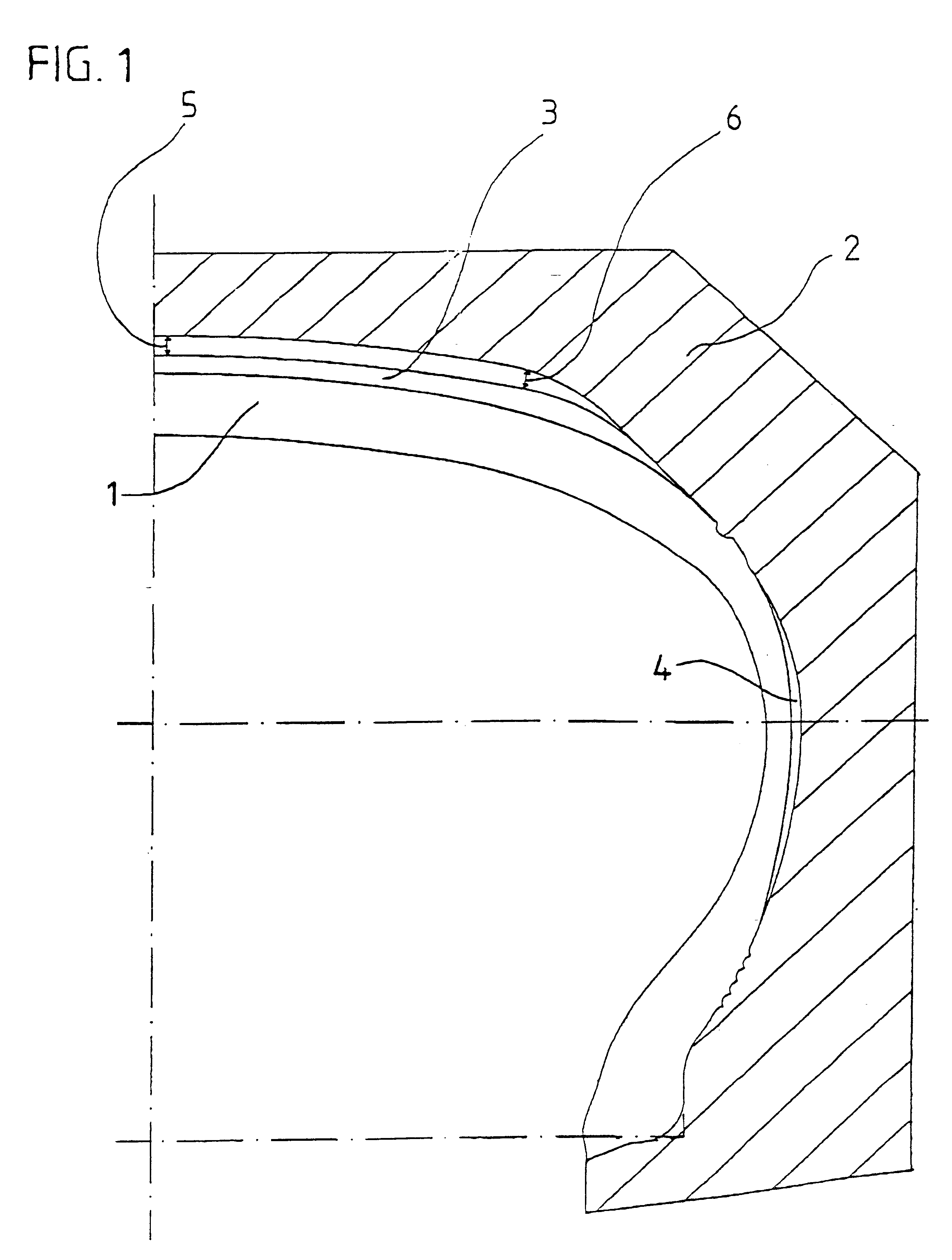

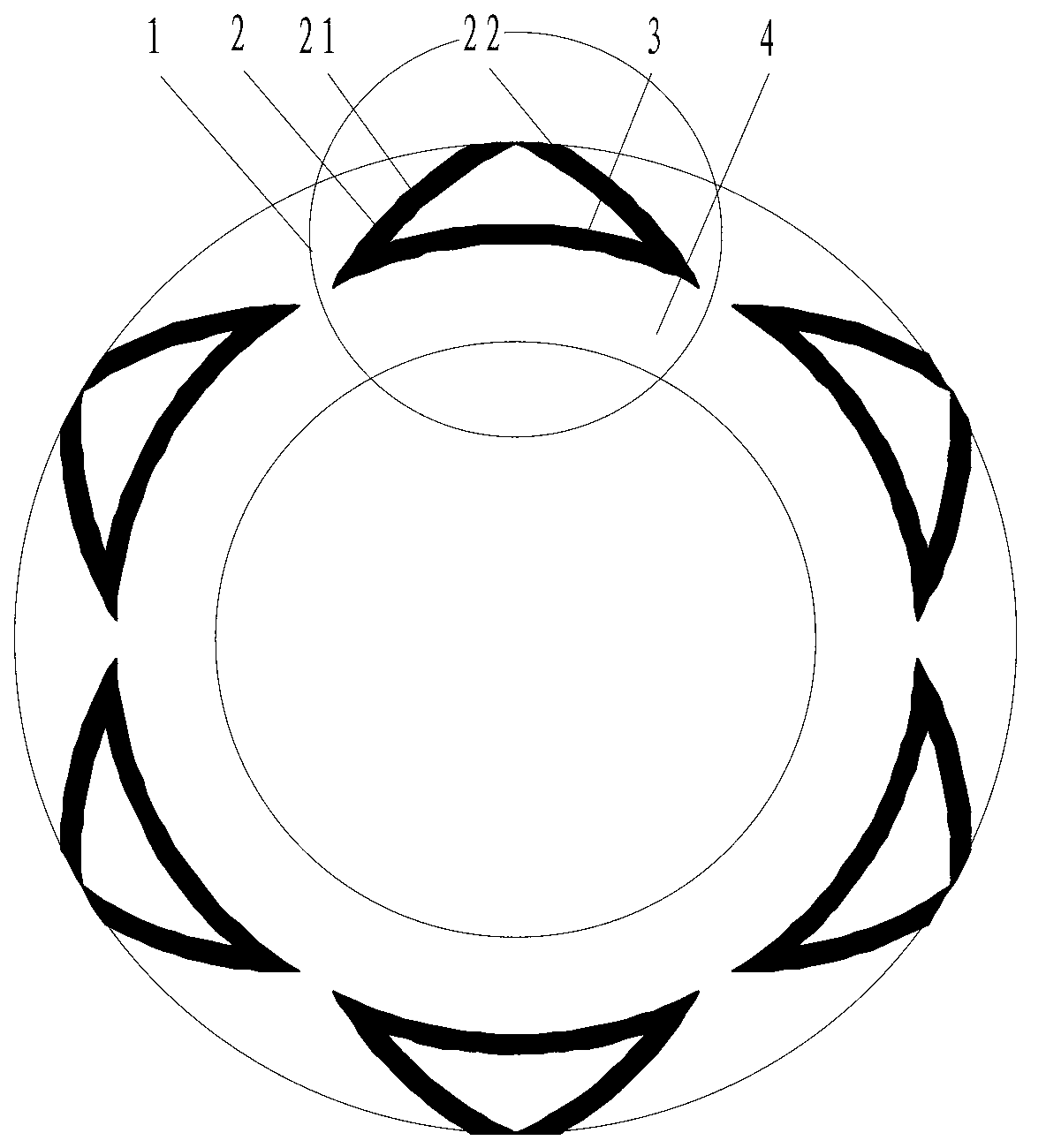

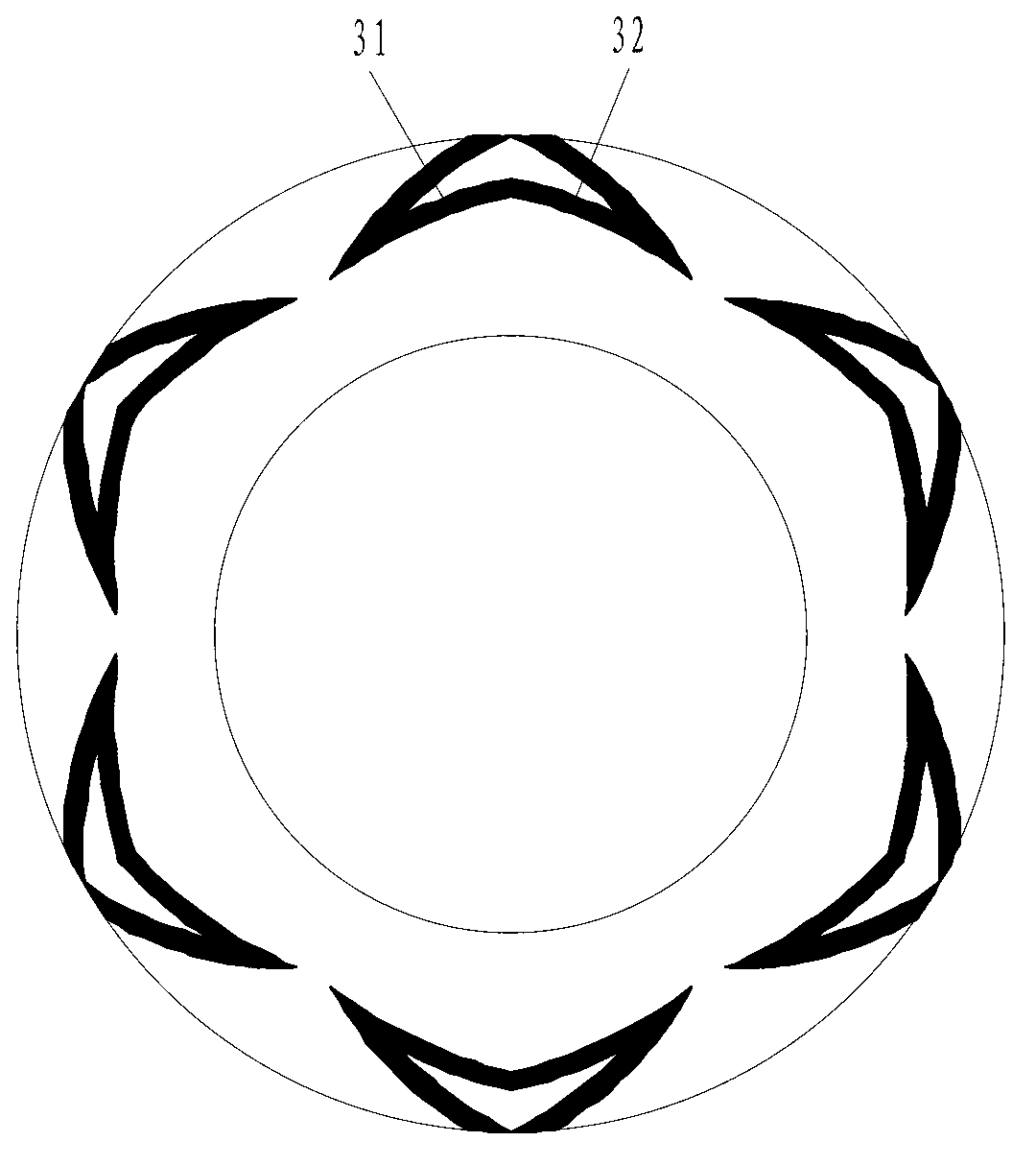

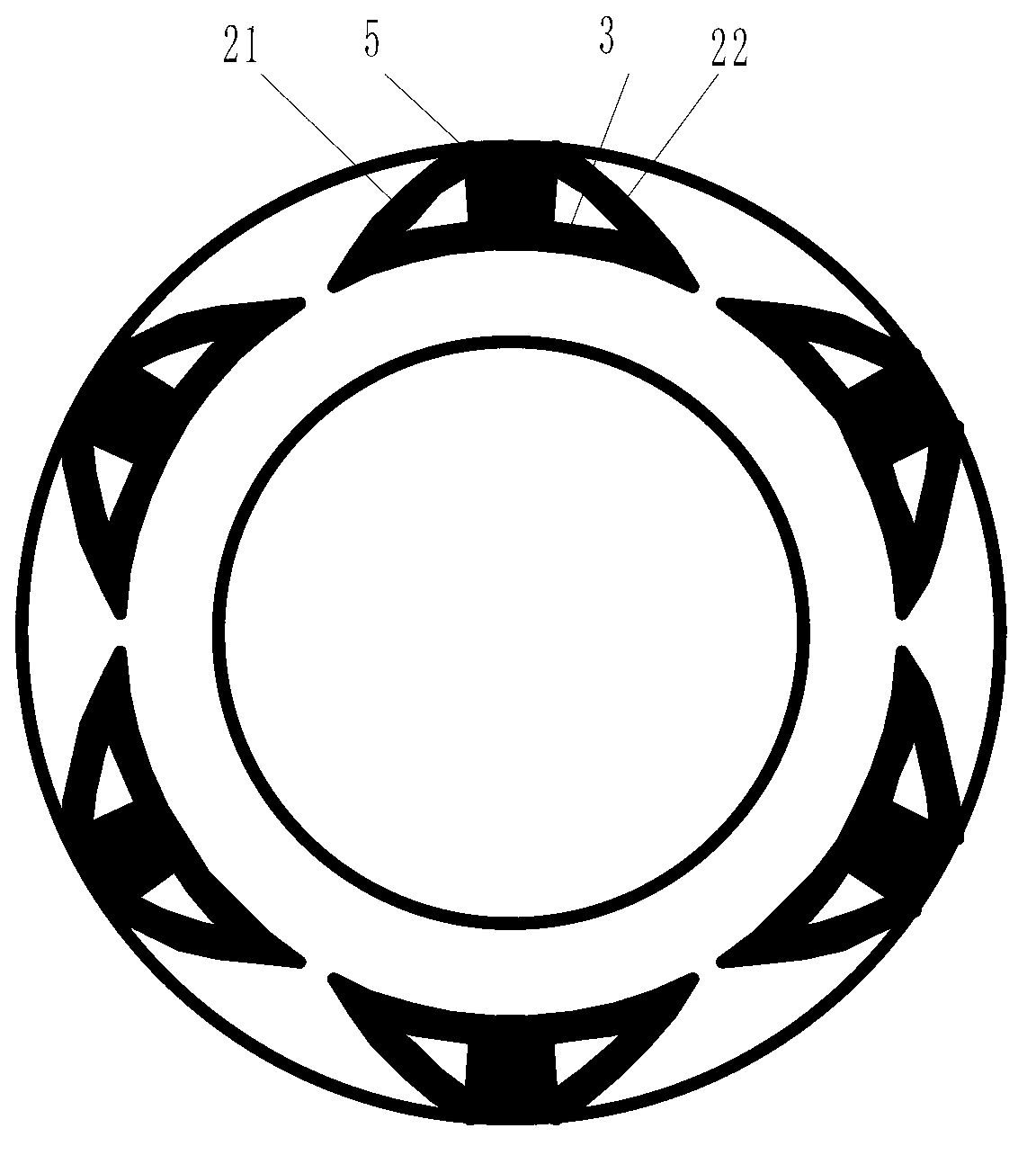

Spiral-toothed gear

InactiveUS20090282939A1Evenly distributedRaise the possibilityPortable liftingToothed gearingsEngineeringHigh torque

A spiral-toothed gear is provided with a toothed ring (2) formed by extrusion coating a basic body (1) with a plastic. The spiral-toothed gear provides a connection between the basic body (1) and the toothed ring (2), whose strength makes possible the transmission of high torques in a reliable manner. The basic body (1) of the spiral-toothed gear has a flange with a disk-shaped area (1′) that is extrusion coated with the plastic toothed ring (2). The area (1″) of reduced diameter adjoining area (1′) forms a hub for mounting the spiral-toothed gear on a shaft in such a way that it rotates in unison. The area (1′) of the flange has, axially on both sides, a plurality of recesses (3, 3′) each, which are arranged distributed on its circumference, extend primarily in the axial direction but do not pass through area (1′). The recesses (3, 3′) are of a dovetail design, so that sections (4, 4′) of the outer circumference of area (1′), which are left in place between them, are undercut by the edges of the recesses (3, 3′), which said edges extend in the axial direction.

Owner:ZF FRIEDRICHSHAFEN AG

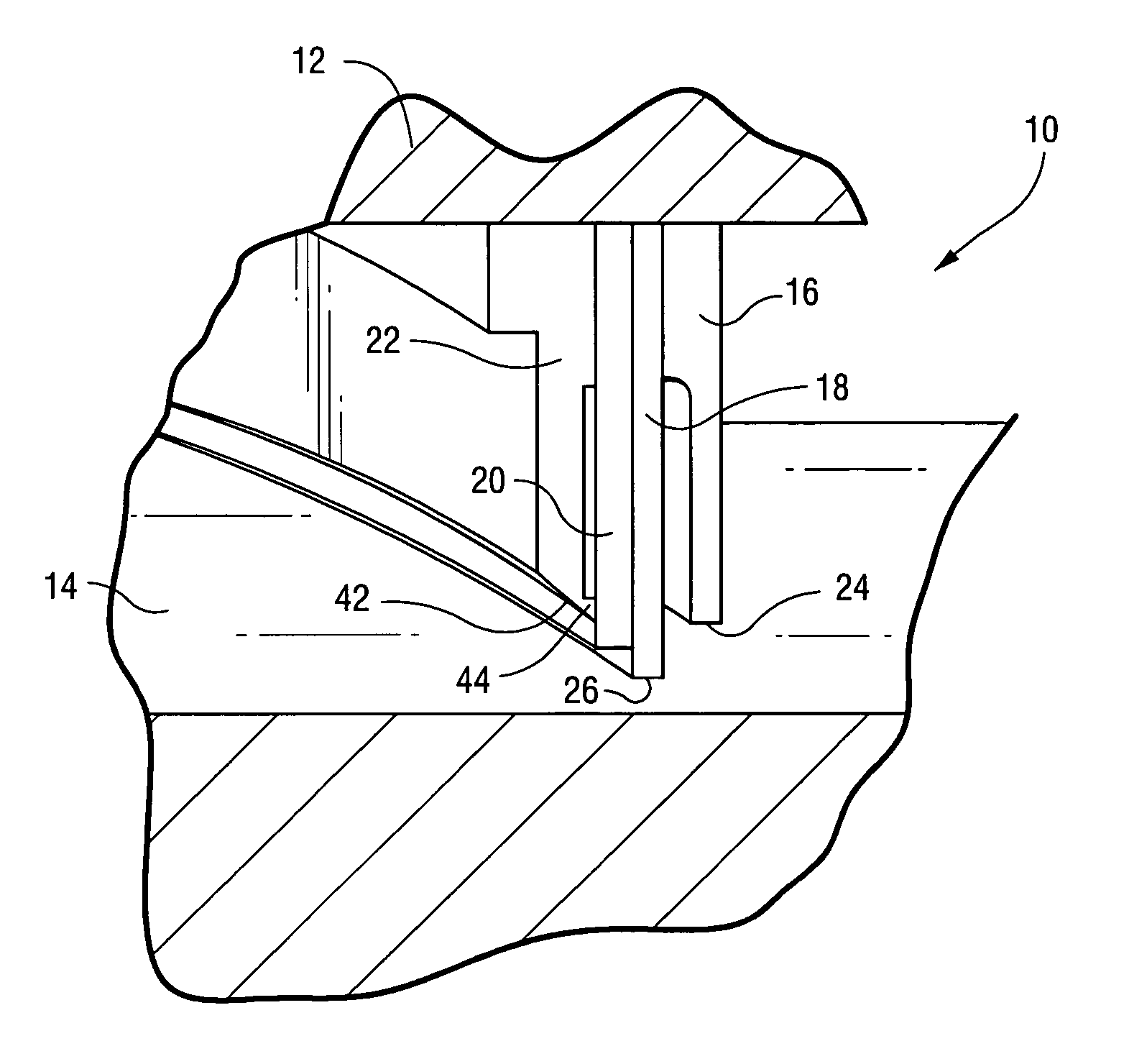

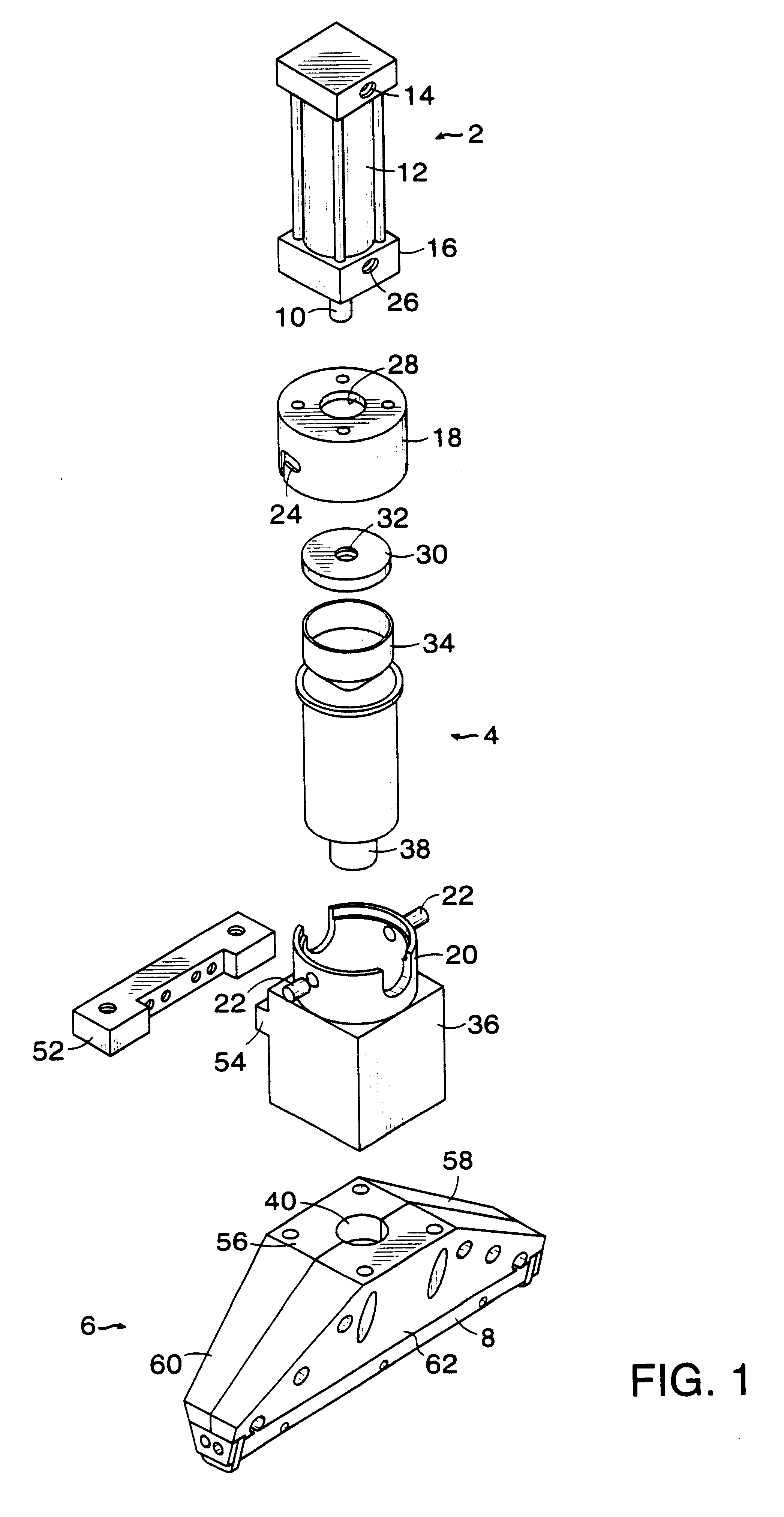

Pressure balanced brush seal

A brush seal extends between static and rotary components. The brush seal includes a fence on the high pressure side, a bristle pack behind the fence, a bristle pack backing plate and a pressure plate. The backing plate includes a plurality of circumferentially and radially spaced arcuate slots arrayed in staggered relation about the brush seal segment. The pressure plate includes radially extending grooves opening toward the backing plate and intersecting each of the slots along that radius to afford a substantially uniform distribution of pressure on the downstream side of the bristle backing plate. In another embodiment, the grooves extend along the downstream faces of the bristle backing plate.

Owner:GENERAL ELECTRIC CO

Top-intake burner of gas cooker

InactiveCN102661606AImprove combustion performanceImprove combustion thermal efficiencyDomestic stoves or rangesStoves/ranges topsFuel gasGas stoves

The invention relates to a top-intake burner of a gas cooker. The top-intake burner comprises a burner support, a fire distribution seat and fire caps. The top-intake burner is characterized in that the burner support is combined by an lower support and an upper cover, at least two Venturi ejector pipes are formed, the openings of the Venturi ejector pipes are correspondingly communicated with primary air inlets with an upward opening, a single gas nozzle is mounted in the primary air correspondingly and is disposed right against the center of one of the the Venturi ejector pipes, the other end of the gas nozzle is communicated with a gas inlet pipe, one Venturi ejector pipe is communicated with a fire distribution chamber of the fire distribution seat through one gas guide pipe or multiple gas guide pipes, and an air passage is reserved between the upper cover of the burner support and the fire distribution seat. The top-intake burner is reasonable in structural design, efficient and energy saving, is capable of realizing precision supply of primary and secondary air and complete and stable burning of the gas, and is especially suitable for embedded household gas stoves.

Owner:HUNAN XUNDA JI TUAN YOU XIAN GONG SI +1

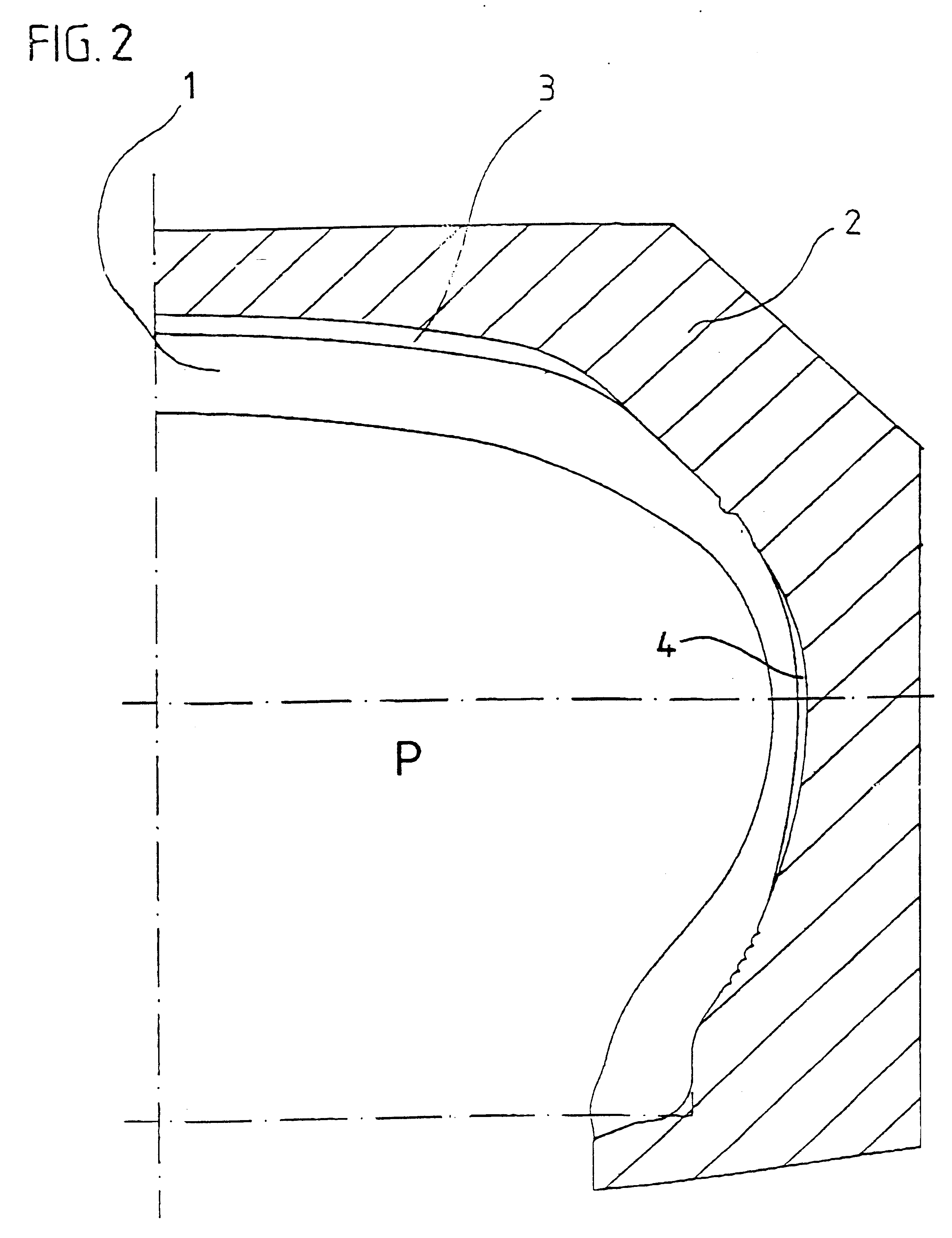

Process for producing a pneumatic tire

InactiveUS6406575B1Reducing cord forceGood effectTyresTyre tread bands/patternsInternal pressureVulcanization

Process for producing a pneumatic tire that includes an inner liner of a layer that is as air-impermeable as possible, at least one carcass ply provided with strength supports, horn profiles, bead cores, sidewalls, a belt assembly, and a tread. The process includes building-up a partial tire in a production part A, where the partial tire includes at least a carcass body that includes the at least one carcass ply provided with the strength supports, bead reinforcements and cores, core fillers and horn profiles, and an undertread, and shaping and at least partially vulcanizing the partial tire under an internal pressure in a vulcanization mold in a first vulcanization procedure. The process also includes determining a cross-sectional contour for a completed tire and an amount of surface and strength supports to be added to the partial tire prior to a production part B, and building-up the partial tire in the production part B by adding remaining tire components to produce a complete tire. Further, the process includes vulcanizing the complete tire in the vulcanization mold, thereby bonding the partial tire to the remaining tire components. While vulcanizing the complete tire, a residual elevation produced by internal pressure is applied, whereby the complete tire is molded to its final contour. The residual elevation in shoulder areas of the completed tire is greater than or equal to the residual elevation in a zenith area.

Owner:CONTINENTAL AG

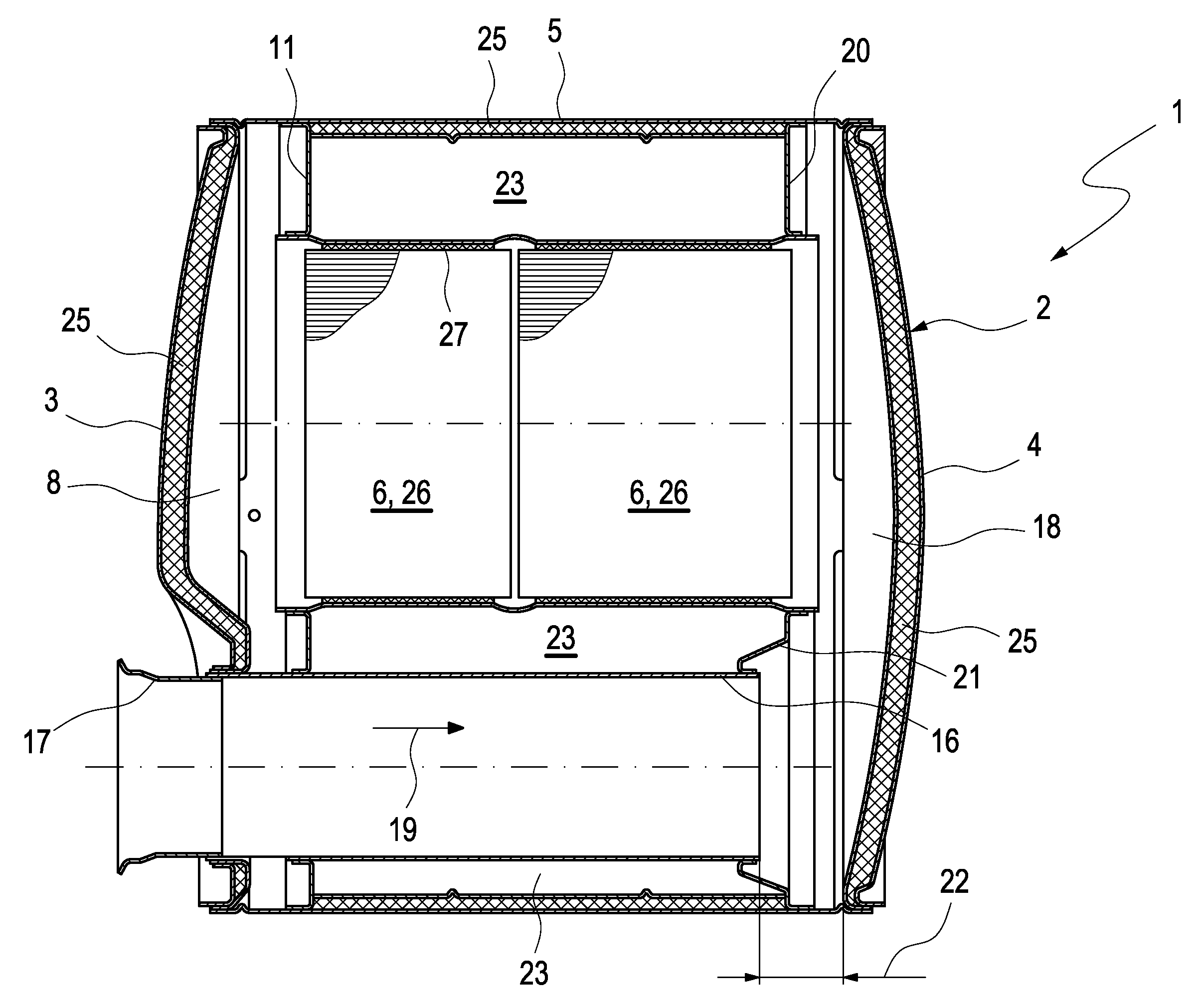

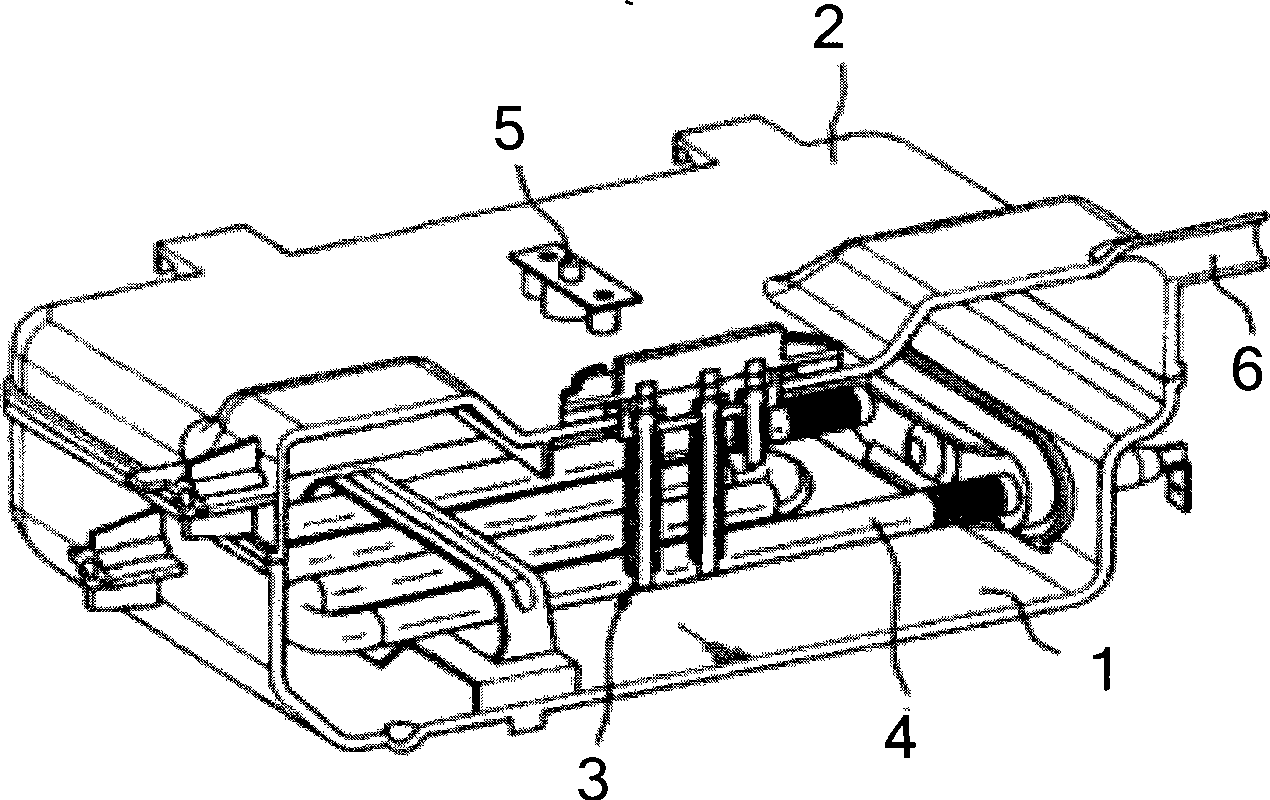

Exhaust gas treatment unit

ActiveUS20090272106A1Compact and rigid constructionSimple designInternal combustion piston enginesExhaust apparatusCombustionExhaust fumes

The present invention relates to an exhaust gas treatment unit for an exhaust system of a combustion engine, in particular of a motor vehicle, includes a housing, a plurality of exhaust gas treatment elements, which are arranged in the housing and through which a parallel flow is possible. The unit further includes an outlet nozzle, which penetrates a side face of the housing, and an outlet space disposed in the housing, whereby the outlet of at least one of the exhaust gas treatment elements opens into the outlet space. The rigidity and / or effectiveness of the exhaust gas treatment unit can be improved by means of a funnel body disposed in the outlet space, and comprising a funnel surface which is permeable to exhaust gas. The funnel body connects an outlet end of one of the exhaust gas treatment elements with the outlet nozzle.

Owner:PUREM GMBH

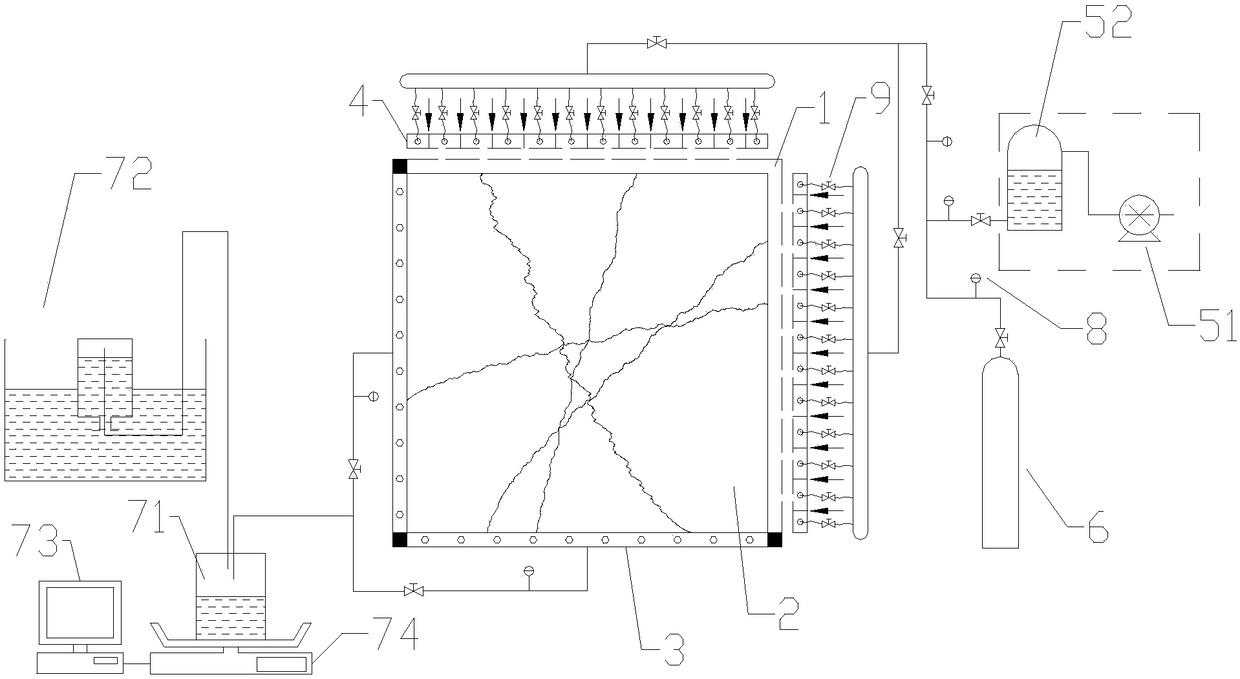

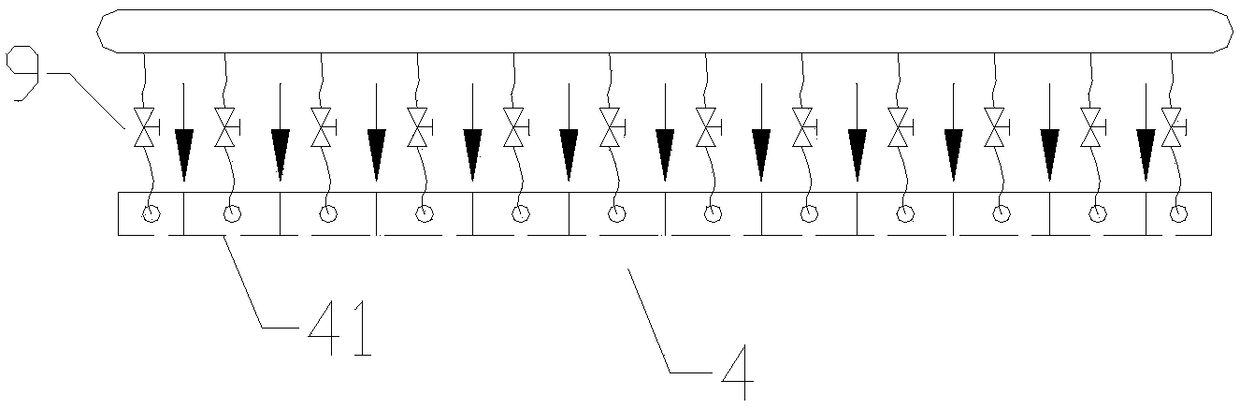

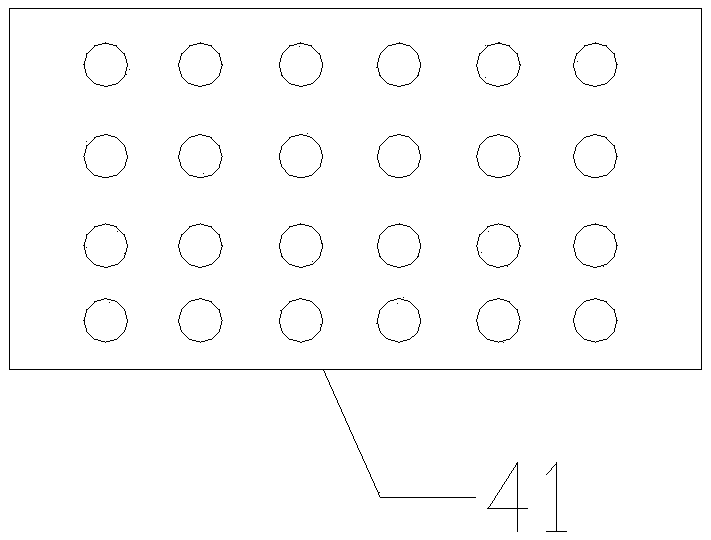

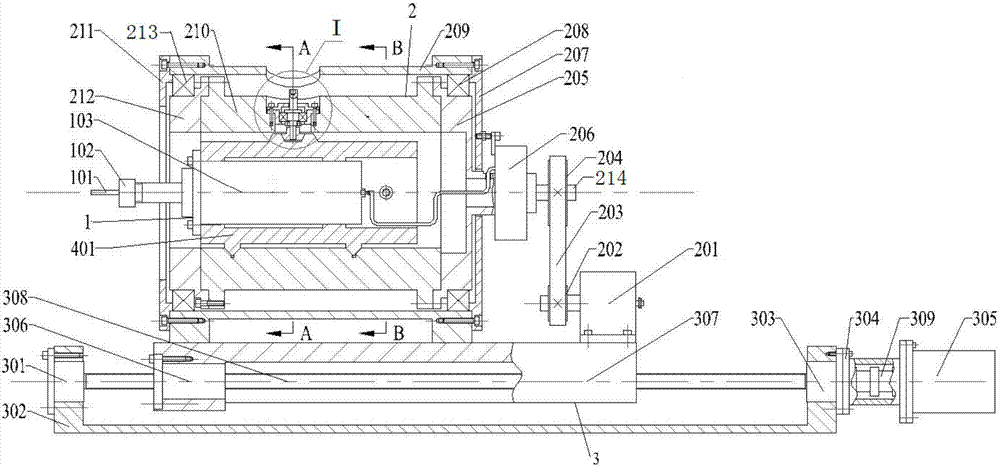

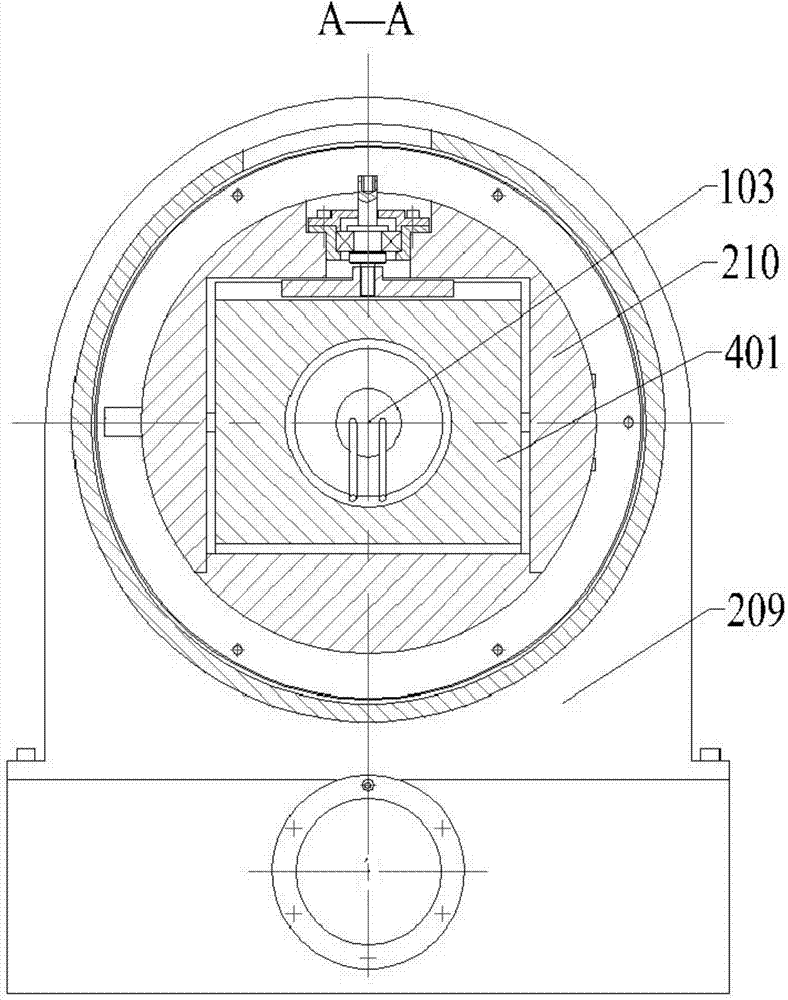

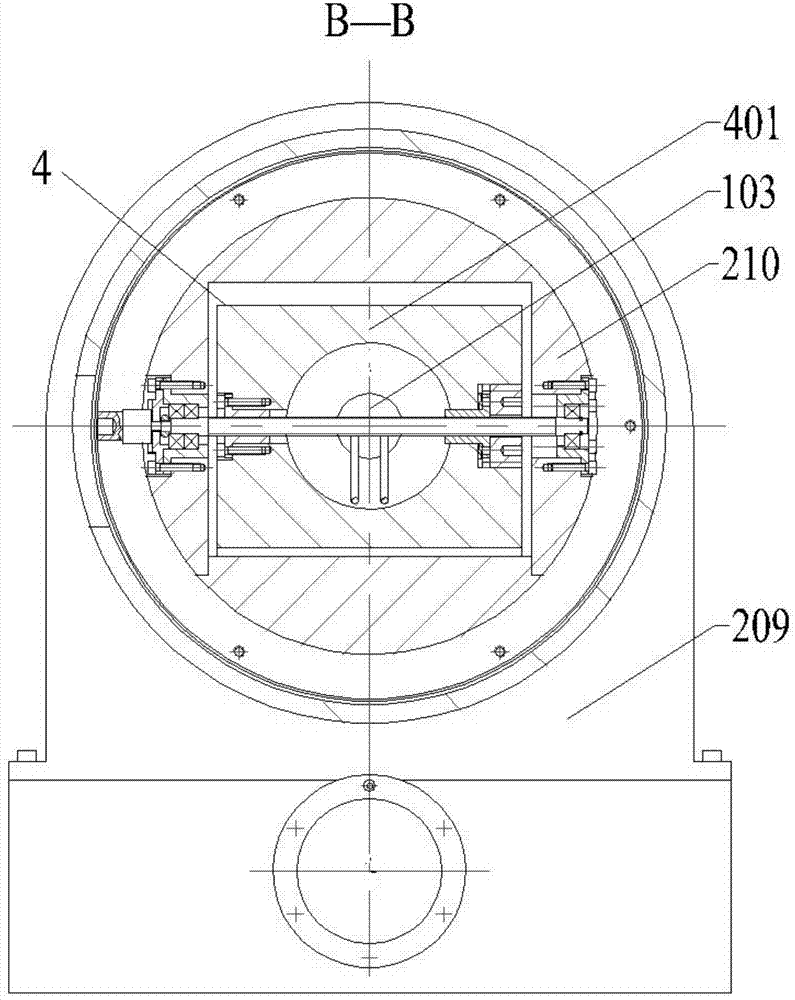

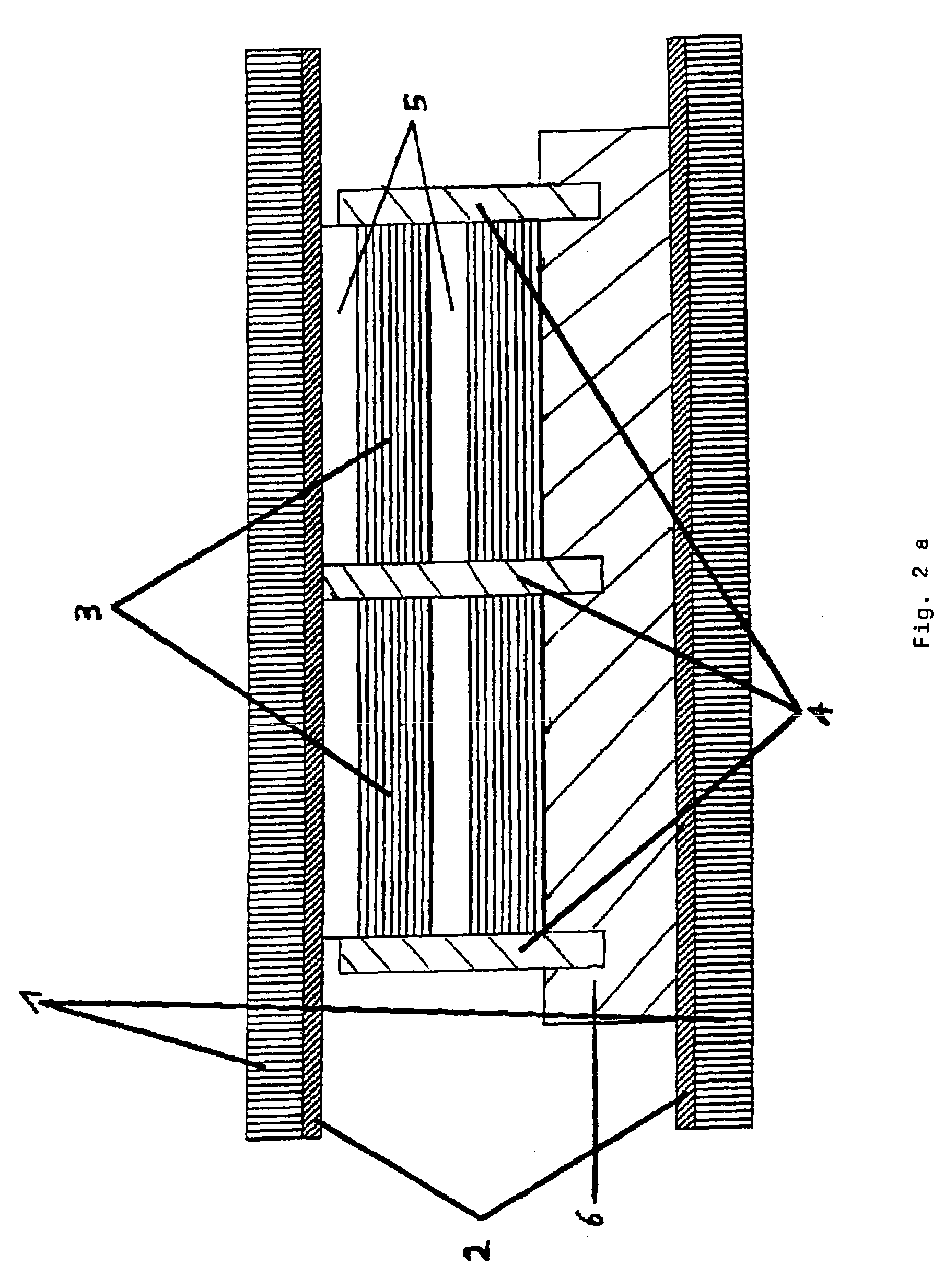

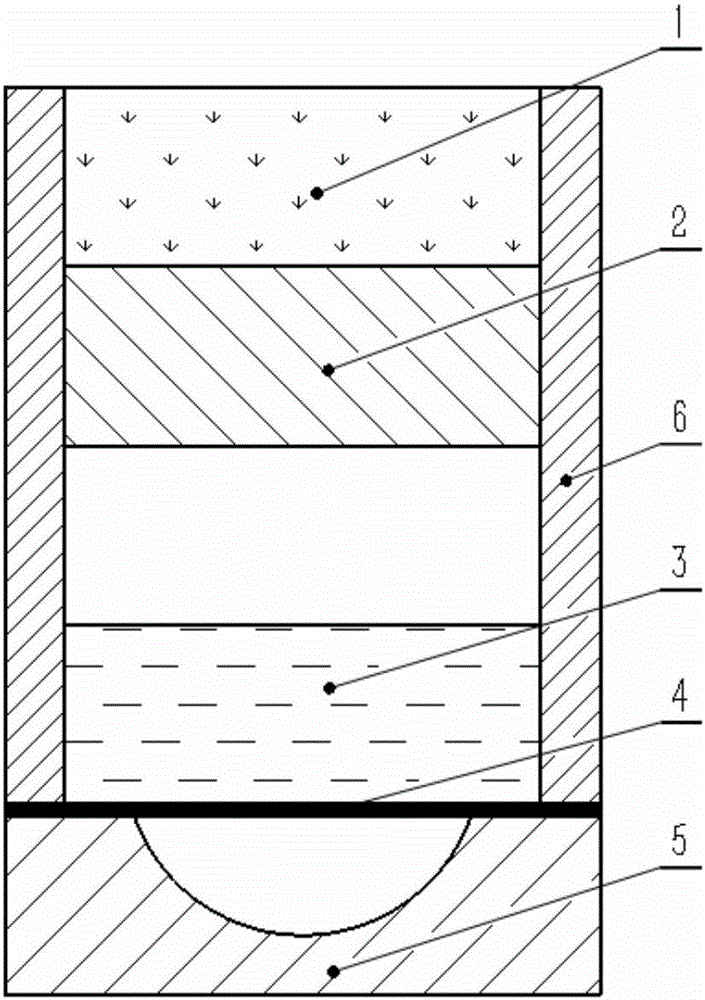

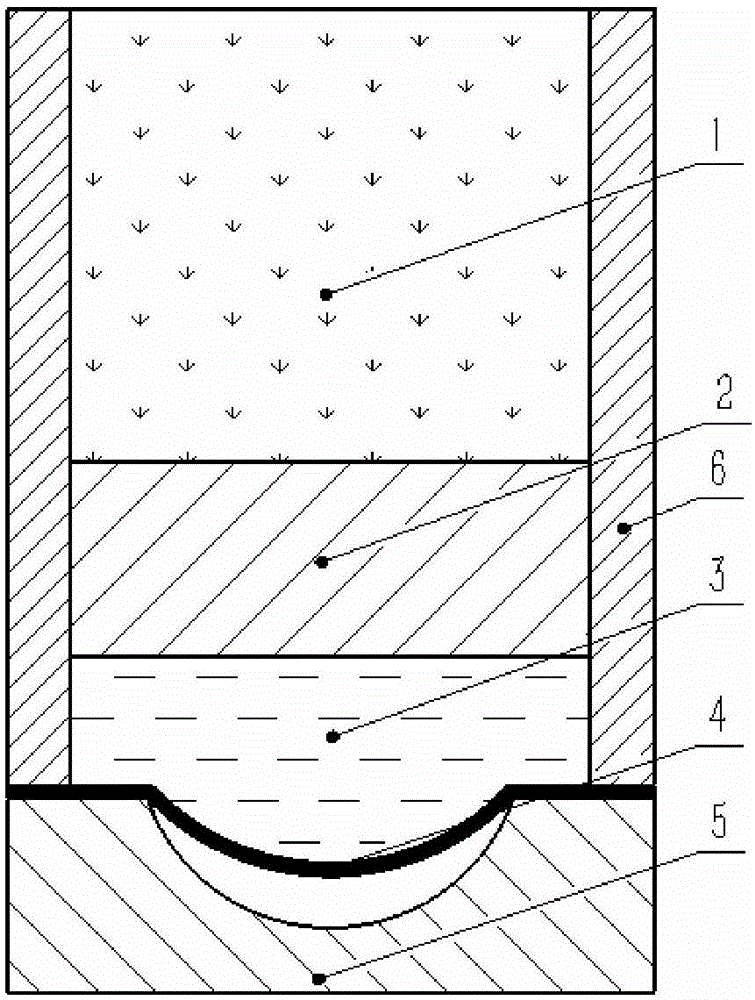

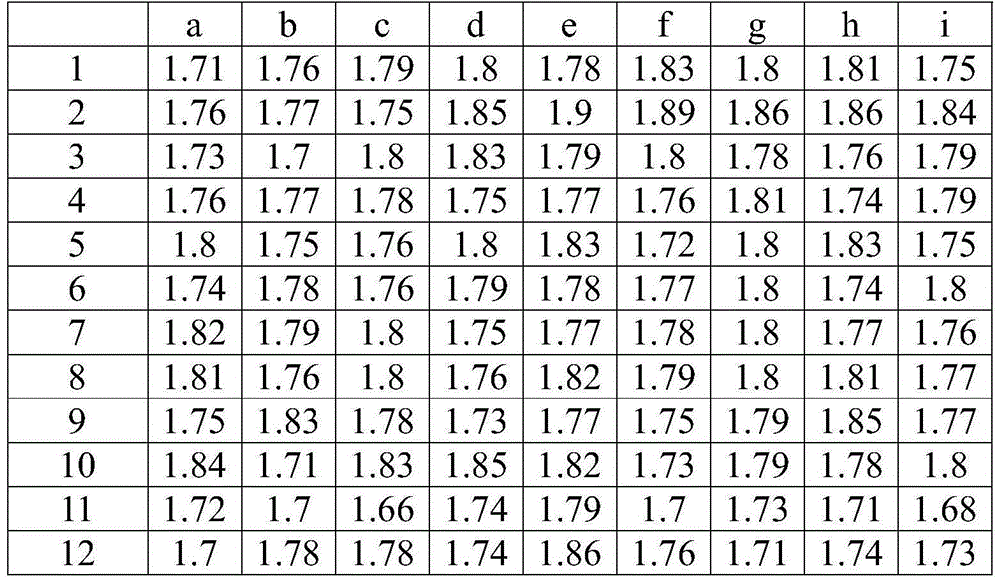

3D (Three-Dimensional) fractured network rock mass two-phase medium seepage test device under stress action

InactiveCN108333093AControl infiltration pressureUniform pressure distributionPermeability/surface area analysisTest sampleEngineering

The invention discloses a 3D (Three-Dimensional) fractured network rock mass two-phase medium seepage test device under stress action. The 3D fractured network rock mass two-phase medium seepage testdevice comprises a test platform, a liquid-gas loading device and a liquid-gas separating and collecting device, wherein a fixed boundary and a movable loading boundary are arranged at the edges of the test platform; a plurality of small holes are formed in one side surface, which is fitted with a 3D fractured rock test sample, of the movable loading boundary, and the other side surface of the movable loading boundary is connected with the liquid-gas loading device; a strip-shaped hole is formed in one side surface, which is fitted with the 3D fractured rock test sample, of the fixed boundary,and the other side surface of the fixed boundary is connected with the liquid-gas separating and collecting device; high-strength transparent glass is arranged above the 3D fractured rock test sample; sealing space is formed by the high-strength transparent glass, a limiting frame and the test platform; a 3D camera is arranged above the high-strength transparent glass. The 3D fractured network rock mass two-phase medium seepage test device disclosed by the invention has the characteristics of simpleness and convenience in operation, low cost, visualization, high accuracy degree and the like,and has a wide application prospect in a fractured rock mass multi-phase medium seepage test research.

Owner:CHINA UNIV OF MINING & TECH

Microfluidic devices and methods for cell sorting, cell culture and cells based diagnostics and therapeutics

InactiveUS9149806B2Reduce widthImprove efficiencyHeating or cooling apparatusLaboratory glasswares3D cell cultureTumor cells

Microfluidic devices and methods that use cells such as cancer cells, stem cells, blood cells for preprocessing, sorting for various biodiagnostics or therapeutical applications are described. Microfluidics electrical sensing such as measurement of field potential or current and phenomena such as immiscible fluidics, inertial fluidics are used as the basis for cell and molecular processing (e.g., characterizing, sorting, isolation, processing, amplification) of different particles, chemical compositions or biospecies (e.g., different cells, cells containing different substances, different particles, different biochemical compositions, proteins, enzymes etc.). Specifically this invention discloses a few sorting schemes for stem cells, whole blood and circulating tumor cells and also extracting serum from whole blood. Further medical diagnostics technology utilizing high throughput single cell PCR is described using immiscible fluidics couple with single or multi cells trapping technology.

Owner:BIOPICO SYST

Spiral hole milling device

ActiveCN104117719AHigh adjustment accuracyIncrease adjustment errorFeeding apparatusMilling equipment detailsMilling cutterPulley

The invention discloses a spiral hole milling device. The spiral hole milling device comprises an rotationsystem, a revolution system, a feeding system and an eccentricity adjusting system. An electric main shaft in the rotation system drives a milling cutter to rotate through a spring collet arranged on an output shaft of the electric main shaft. A revolution motor in the revolution system drives an inner sleeve to perform revolution relative to the axis of an outer sleeve through a small synchronous pulley, a synchronous belt and a large synchronous pulley. A feeding motor in the feeding system drives a feeding lead screw to enable a feeding nut to move so as to achieve feeding. An eccentricity adjusting mechanism in the eccentricity adjusting system controls motion of a shifting sliding block, a fixed anti-backlash nut and a movable anti-backlash nut remove the backlash of the eccentricity adjusting system, and therefore high-precision adjustment of the eccentricity can be achieved. A holding mechanism arranged on the inner sleeve achieves the aim that the shifting sliding block is held on the inner sleeve after the eccentricity adjustment is completed. The spiral hole milling device can be applied to integral, high-quality and high-efficiency hole forming of difficultly-machined materials in the aerospace field.

Owner:DALIAN JIAOTONG UNIVERSITY

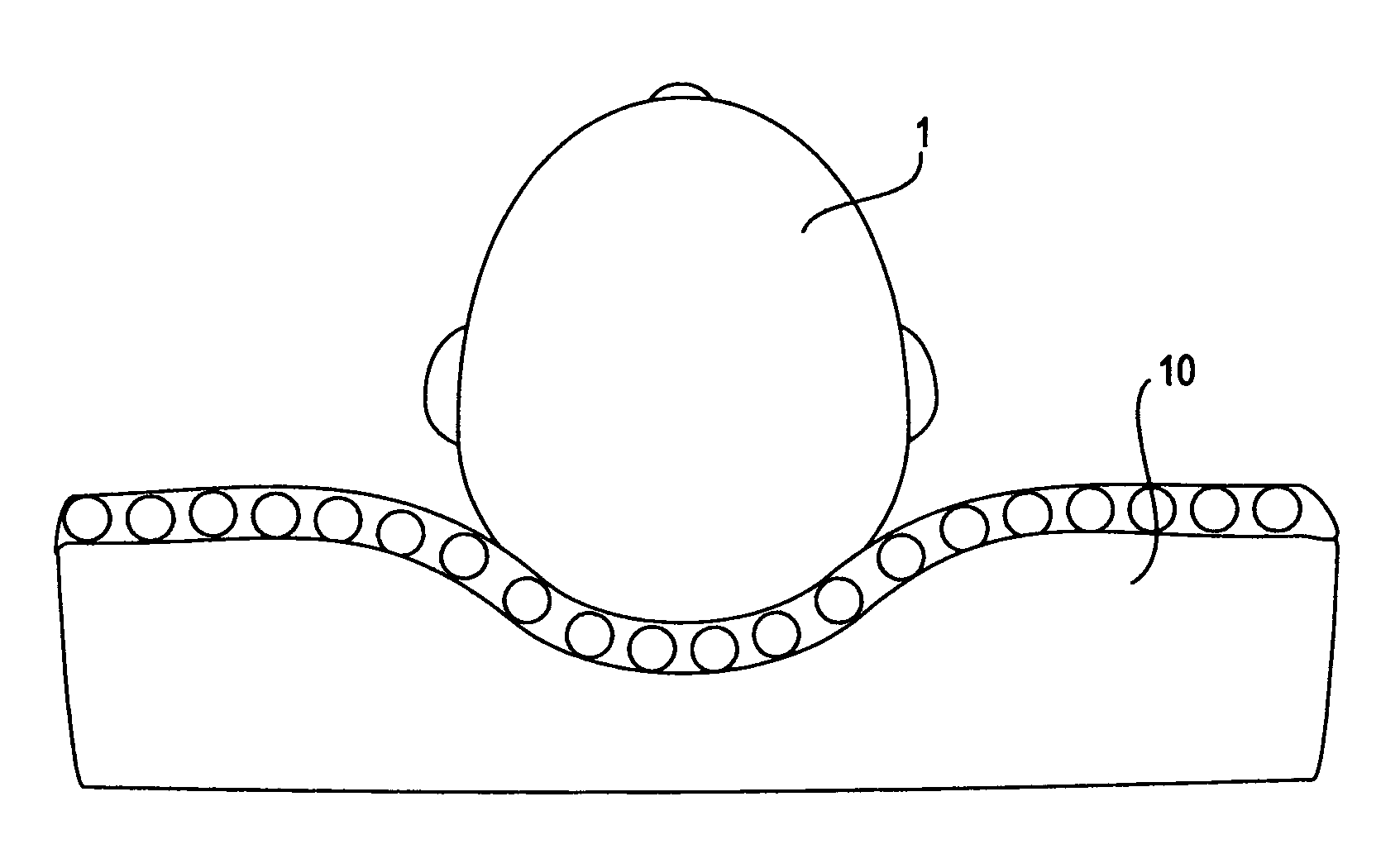

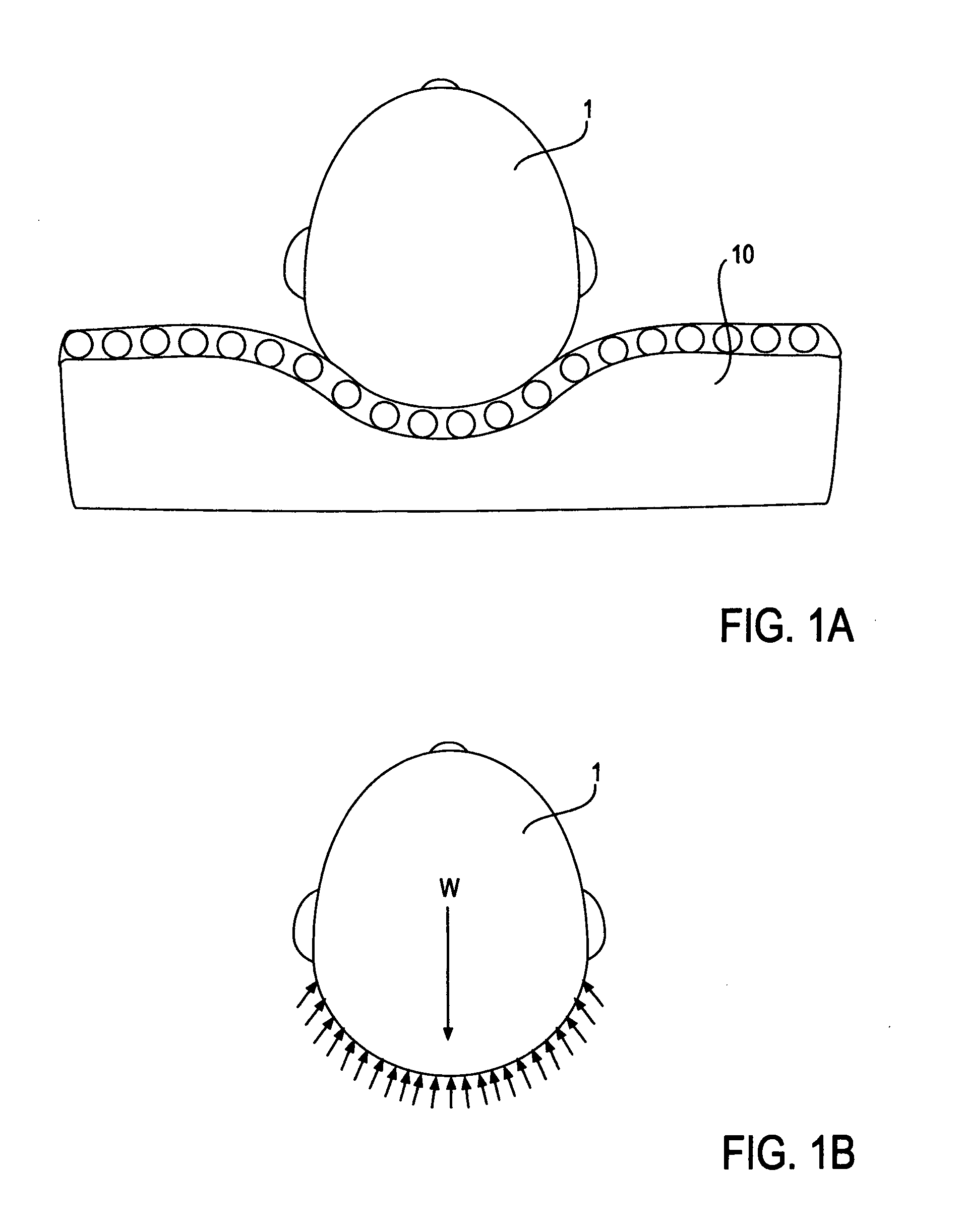

Personal support device that provides uniform distribution of pressure on a body portion

InactiveUS20110239372A1Uniform pressure distributionTreatment or prevention of brachycephaly or plagiocephalySofasFluid mattressesPopulationBiomedical engineering

Embodiments of the technology provide a personal support device for provision of therapeutic support to a portion of a body resting thereon and methods associated with the device. Device embodiments include a substrate having an array of pressure-distributing element host sites, and a population of volumetrically-incompressible pressure-distributing elements at the host sites to form an array of pressure-distributing elements. A therapeutic surface overlays the pressure-distributing elements, and provides an interface between the array of pressure-distributing elements and an aspect of the body portion in contact with the therapeutic surface. The device is configured to form a supportive site within the therapeutic surface that is conformative to the aspect of the body portion in contact with the therapeutic surface when the body part is lying thereon. The supportive site is further configured to apply a substantially uniform distribution of pressure against the aspect of the body part in contact with the supportive site.

Owner:PRS MEDICAL TECH

Preparation method of high-strength corrosion-resistant copper pipe for heat exchanger

The invention discloses a preparation method of a high-strength corrosion-resistant copper pipe for a heat exchanger. The high-strength corrosion-resistant copper pipe comprises a copper matrix and alloy metals. The alloy metals comprise, by weight, 0.5-0.6% of magnesium, 0.08-0.09% of silver, 0.2-0.4% of tin. 0.012-0.014% of zirconium, 0.012-0.014% of niobium, 0.05-0.06% of nickel, 0.005-0.008% of titanium and 0.02-0.04% of mischmetal. The mischmetal comprises yttrium, berkelium and lanthanum according to a mass ratio of 1: (0.15-0.2): (0.4-0.5). The preparation method utilizes upward continuous casting, rolling and drawing processes to replace casting, sawing, heating, extrusion and pickling processes of the traditional preparation method so that processes are greatly simplified, continuous production is realized, a period is short, and efficiency is high. A copper pipe prepared by the preparation method has oxygen content satisfying the oxygen-free copper level standard, has fine grains, and has mechanical strength, high temperature resistance, corrosion resistance and wear resistance obviously superior to the same performances of the existing copper pipe.

Owner:山东兴鲁有色金属集团有限公司

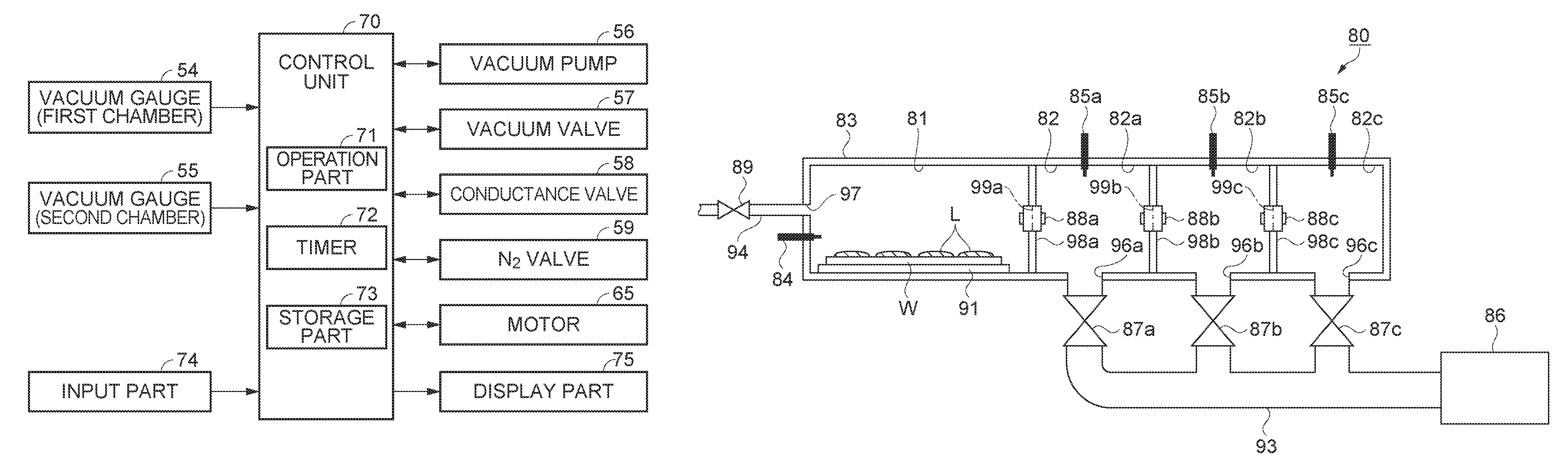

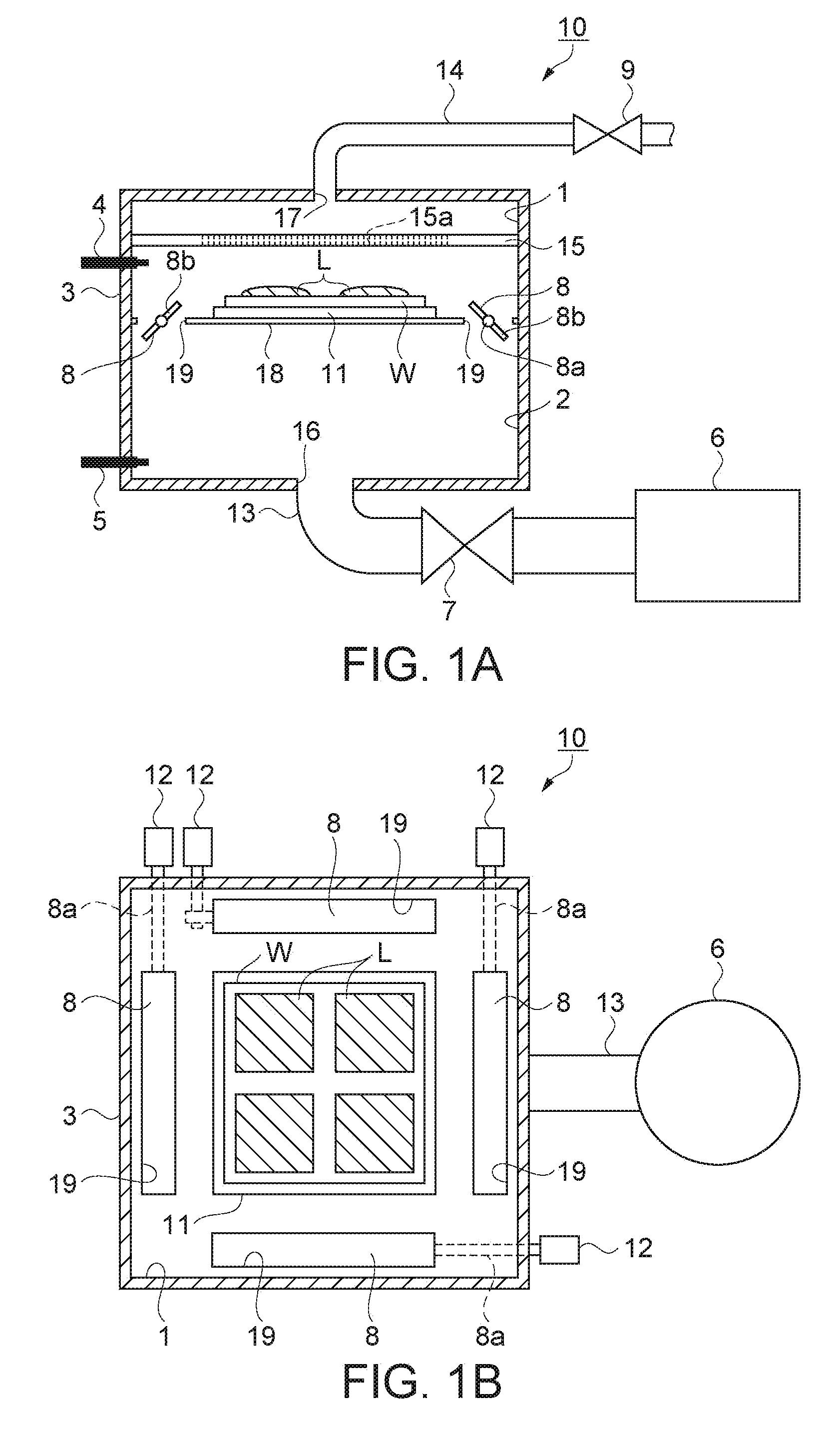

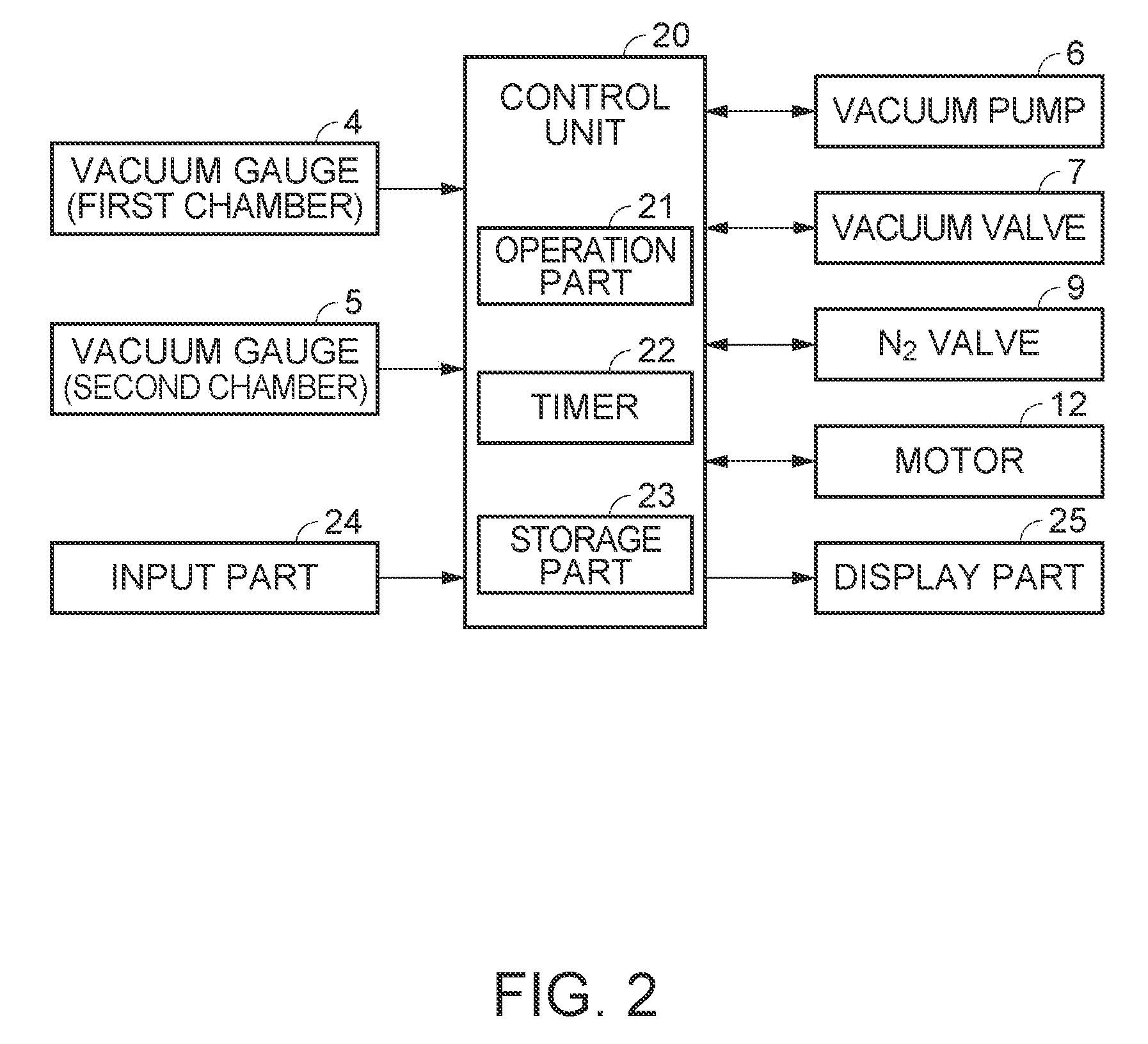

Reduced-pressure drying apparatus

InactiveUS7493705B2Reduce pressureEvenly distributedDrying solid materials with heatDrying solid materials without heatEvaporationSolvent

A reduced-pressure drying apparatus for drying a solvent in a liquid under a reduced pressure by evaporation of the solvent, includes a chamber including a first chamber and a second chamber, the first chamber accommodating work to which a liquid containing a film forming material is applied, the second chamber being coupled to the first chamber through a communicating part; a depressurizing unit depressurizing at least the second chamber; a communicating valve opening and closing the communicating part; and a control unit controlling a reduced pressure state at least of the second chamber by driving the depressurizing unit, the control unit also controlling an opening and closing state of the communicating part by driving the communicating valve.

Owner:SEIKO EPSON CORP

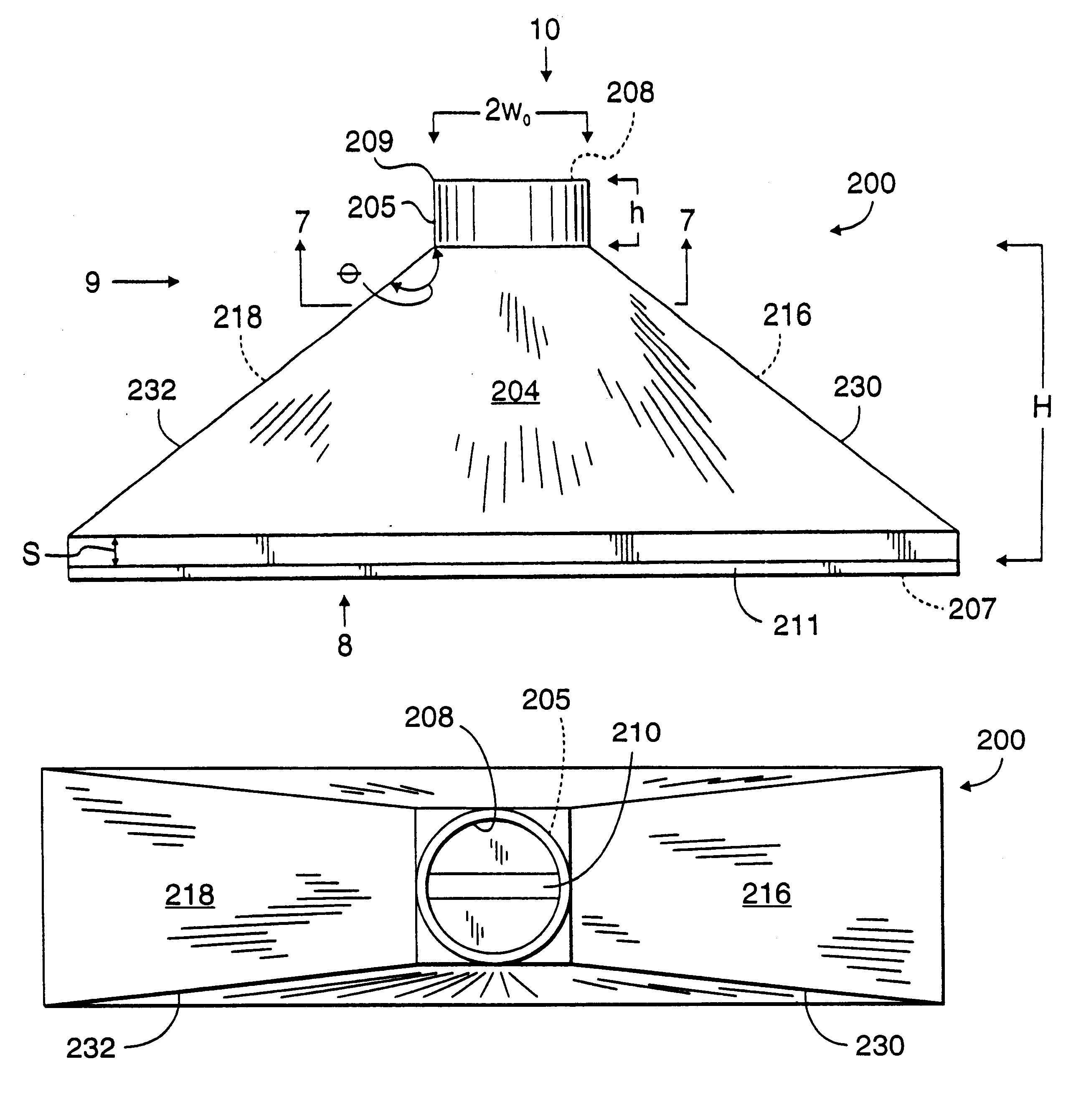

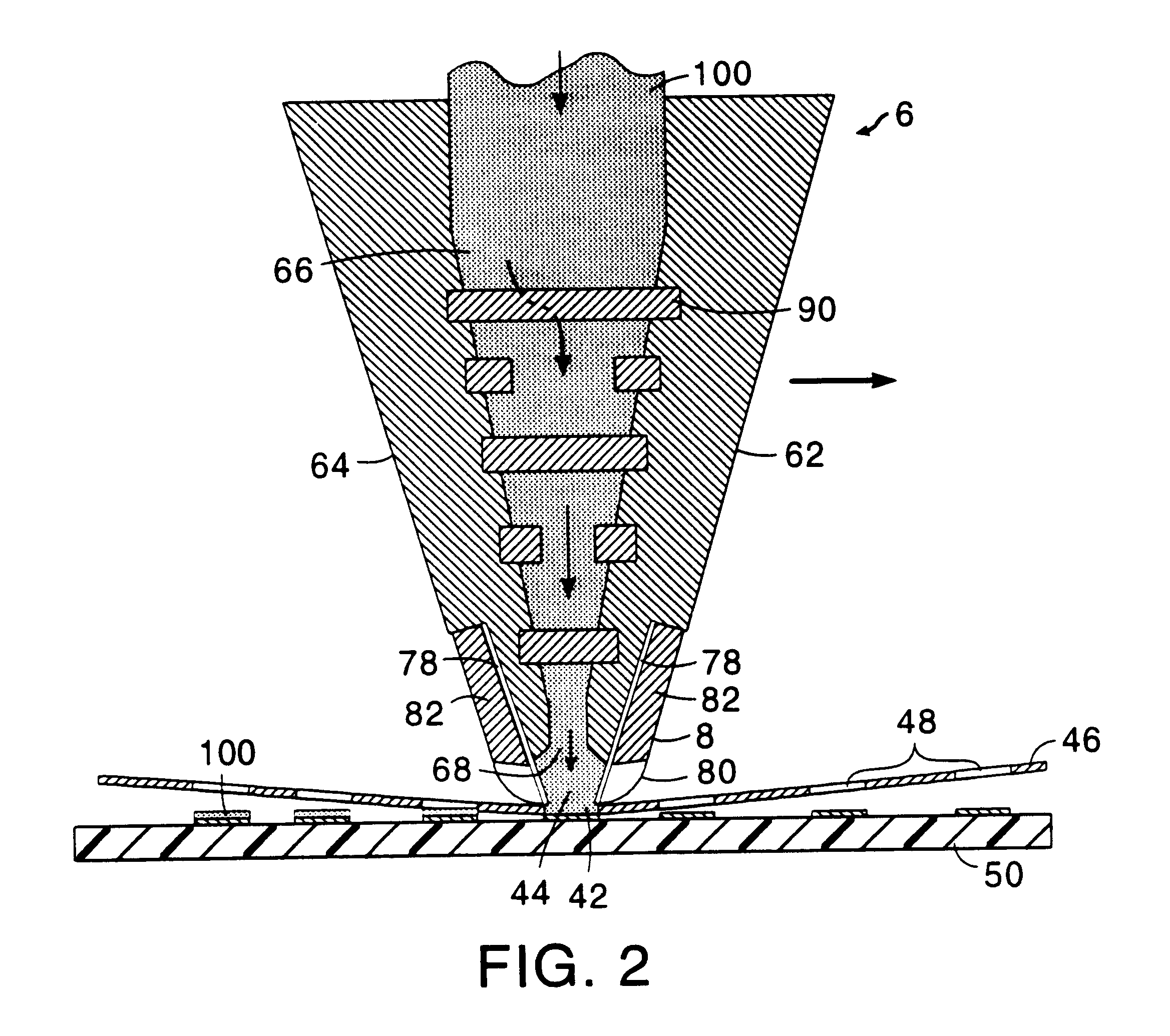

Method and apparatus for dispensing viscous material

InactiveUS6395087B1Uniform velocity profileUniform pressure distributionLiquid surface applicatorsScreen printersEngineeringViscous material

A novel apparatus for compressing viscous material through openings in a stencil is disclosed. The novel apparatus has a compress on head cap which provides a contained environment to direct and to aid the flow of pressurized viscous material through the openings in the stencil. In another embodiment of the invention, the compression head includes a viscous material reception chamber which has a certain shape which is effective to cause said received viscous material to be selectively dispensed while having a substantially uniform velocity profile and which further provides for the creation of a substantially uniform pressure profile.

Owner:VISTEON GLOBAL TECH INC

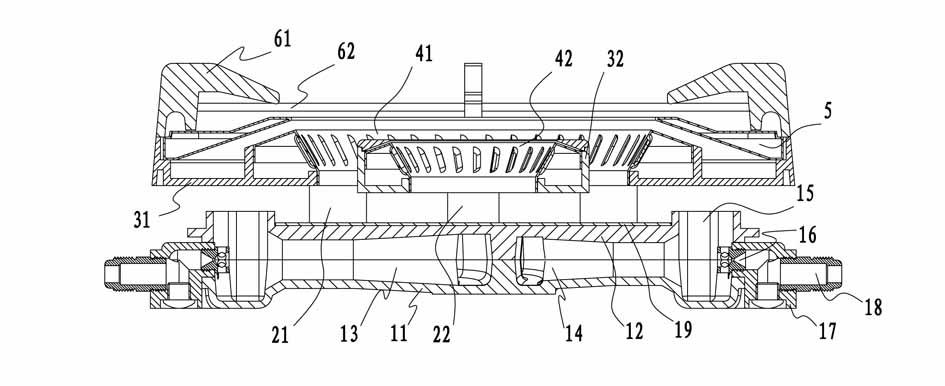

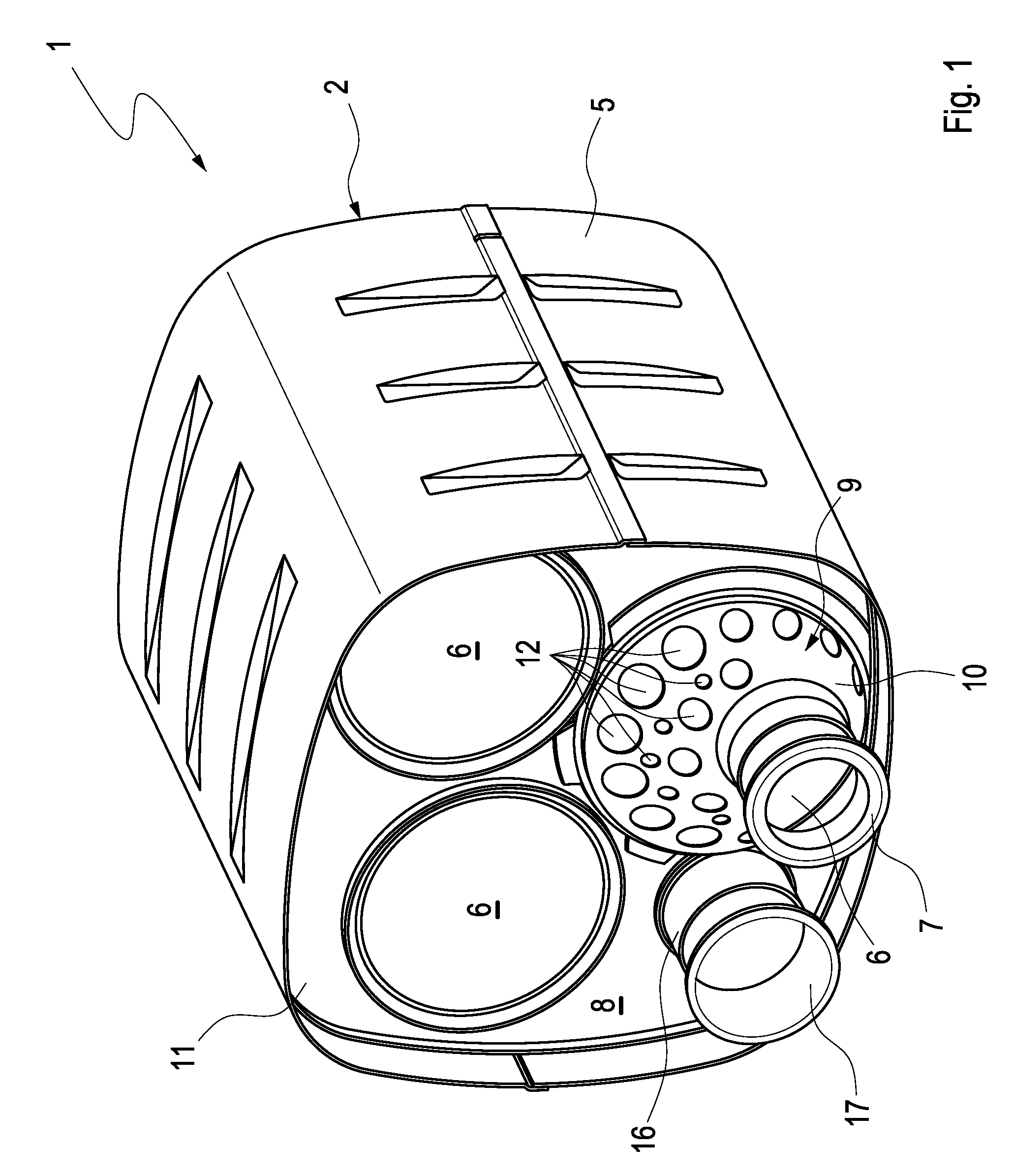

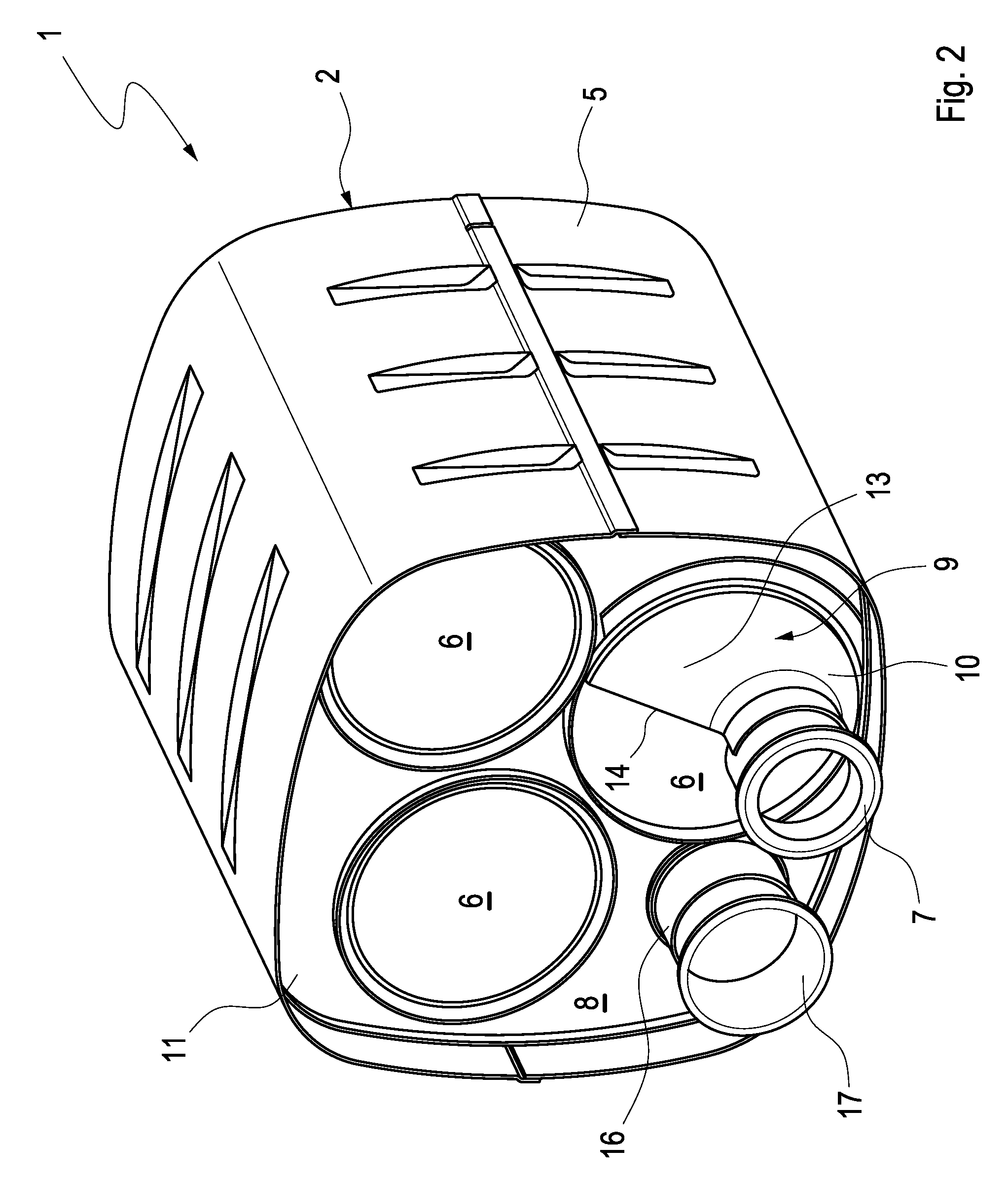

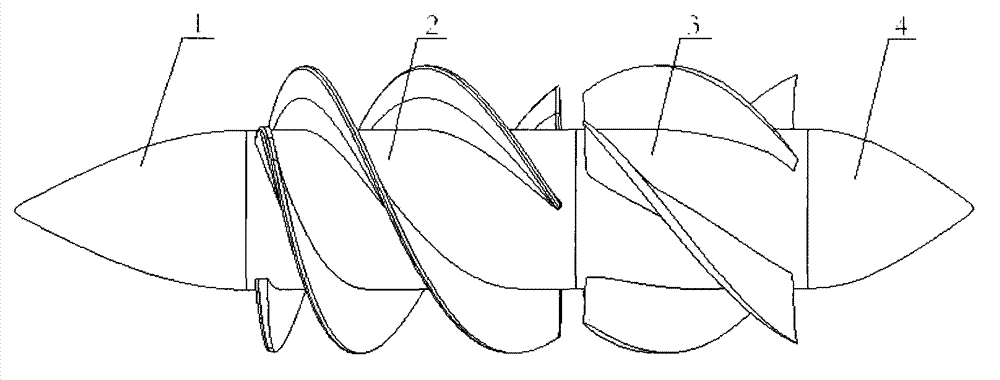

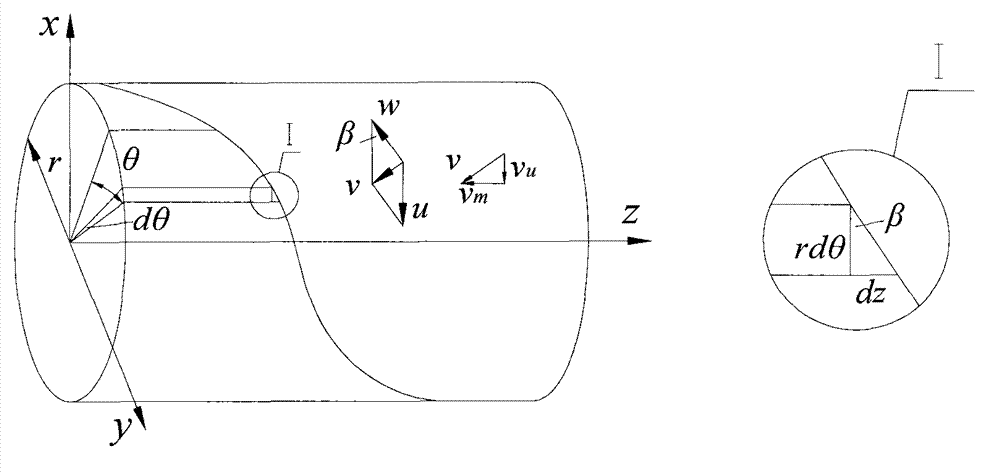

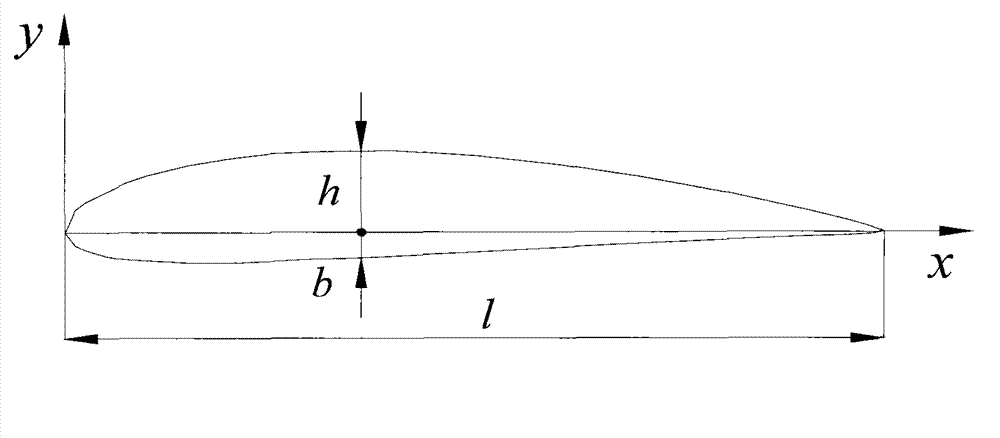

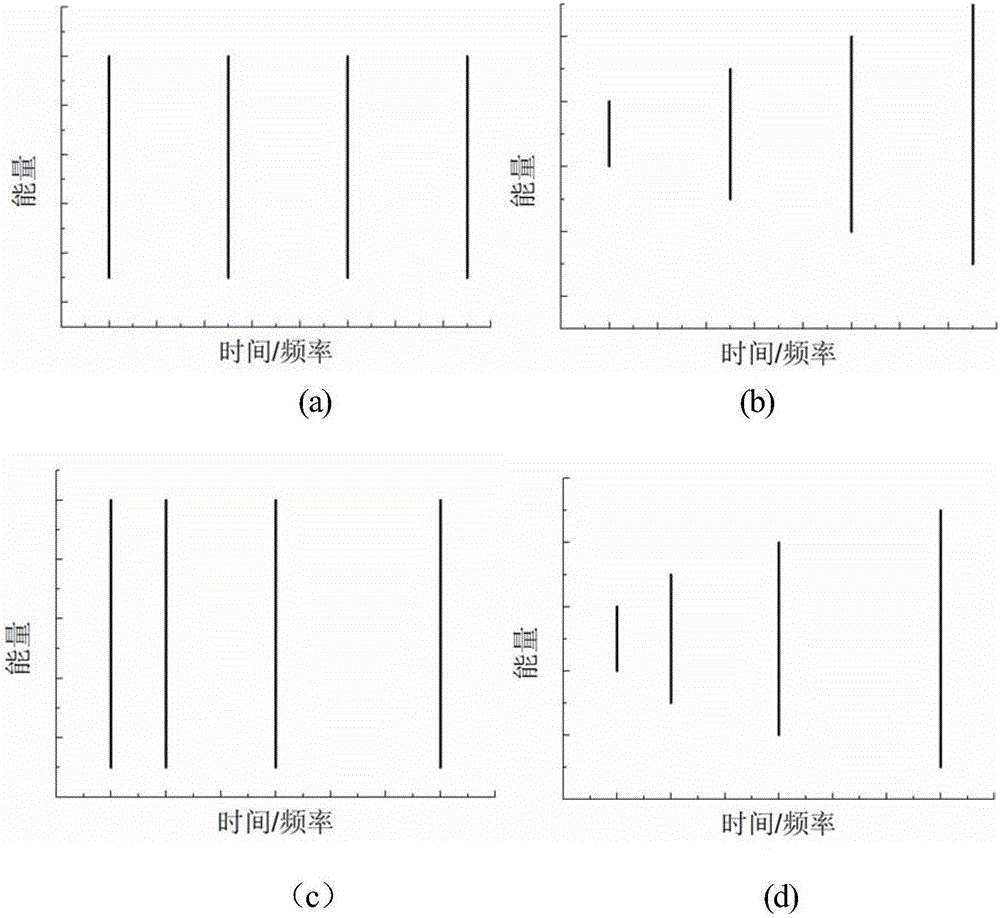

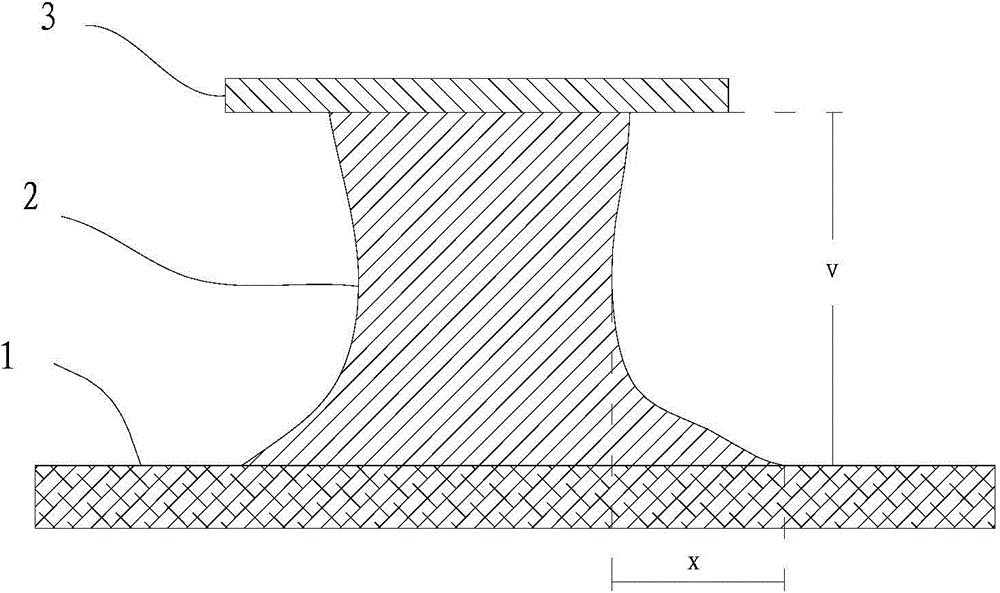

Embeddable two-stage axial flow blood pump rotor structure

InactiveCN103206402AGood thrombus performanceImprove efficiencyPump componentsAxial flow pumpsImpellerBlood pump

The invention relates to an embeddable two-stage axial flow blood pump rotor structure. The embeddable two-stage axial flow blood pump rotor structure comprises a rotor head part, a rotor tail part and an impeller part, wherein the impeller part which adopts a two-stage structure design comprises a front-stage impeller and a back-stage impeller; the front-stage impeller (2) in a spiral structure has three blades; the back-stage impeller (3) is in a traditional axial flow structure; an axial distance is arranged between the front-stage impeller and the back-stage impeller; the surface curve equation of the heat part of the rotor is as follows: Formula, wherein the x is an axial distance of a hub; the y is a radial distance of the hub; and the original point is an intersection point of the surface curve of the head part of the rotor and the axial line of the hub. The embeddable two-stage axial flow blood pump rotor structure can enable the blood pump rotor to satisfy with a lift requirement at a relatively low rotating speed under the precondition that the axial size is as small as possible, thereby decreasing formation of hemolysis and reducing power consumption efficiently, and can reduce irregular flow resulted from the more complex blood pump rotor structure as the transition between the front and back impellers is corrected.

Owner:WUHAN UNIV OF SCI & TECH

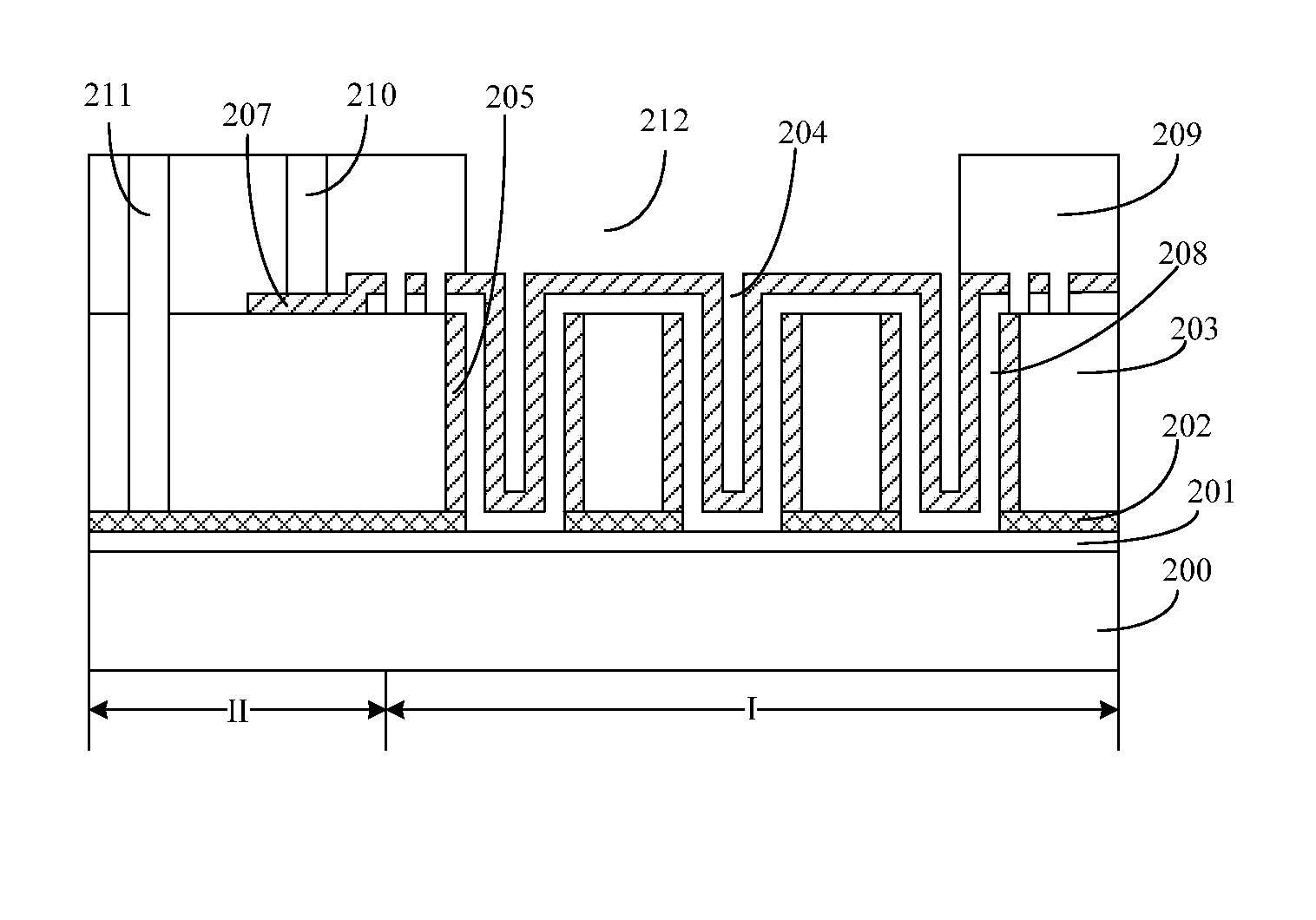

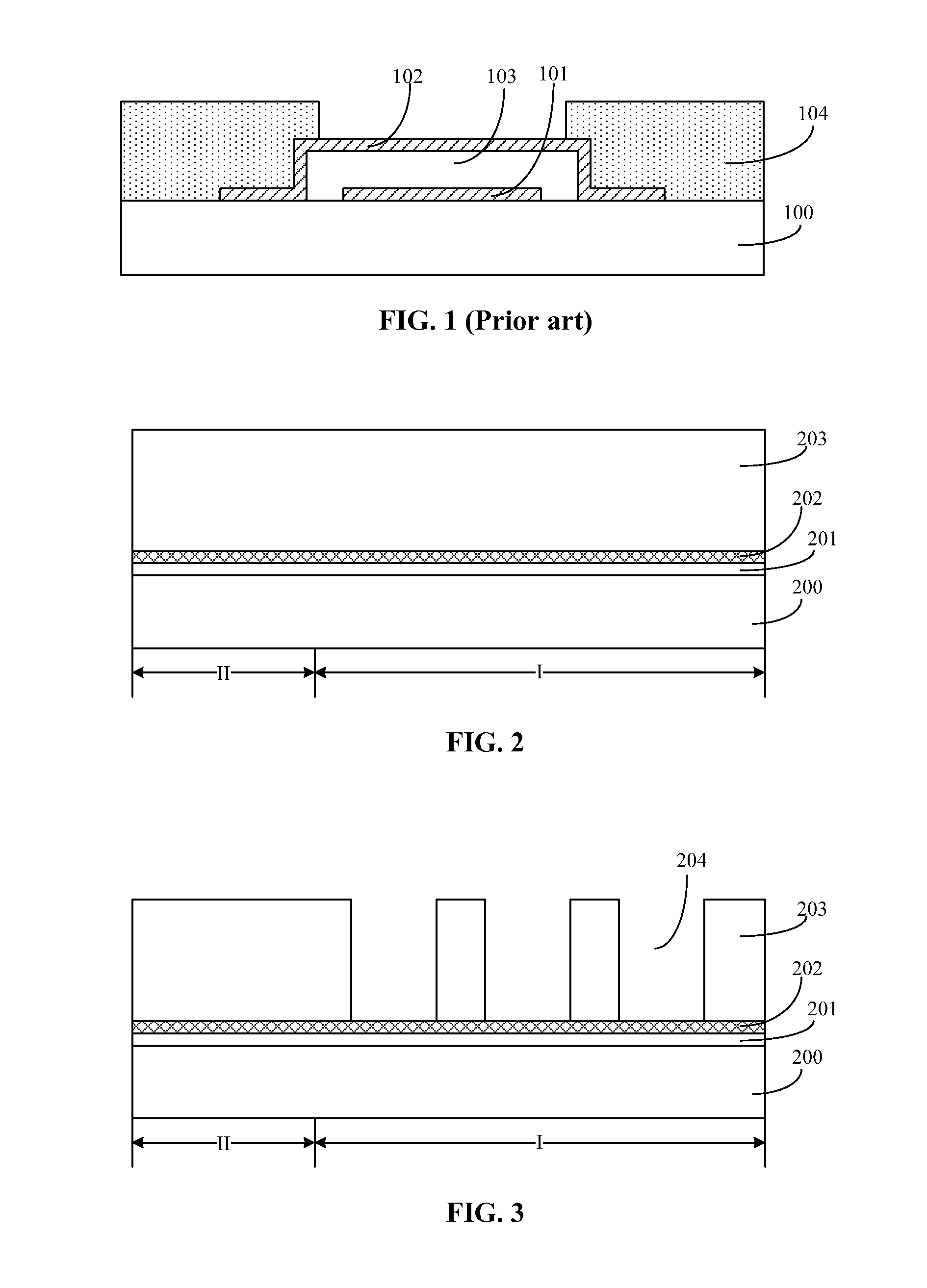

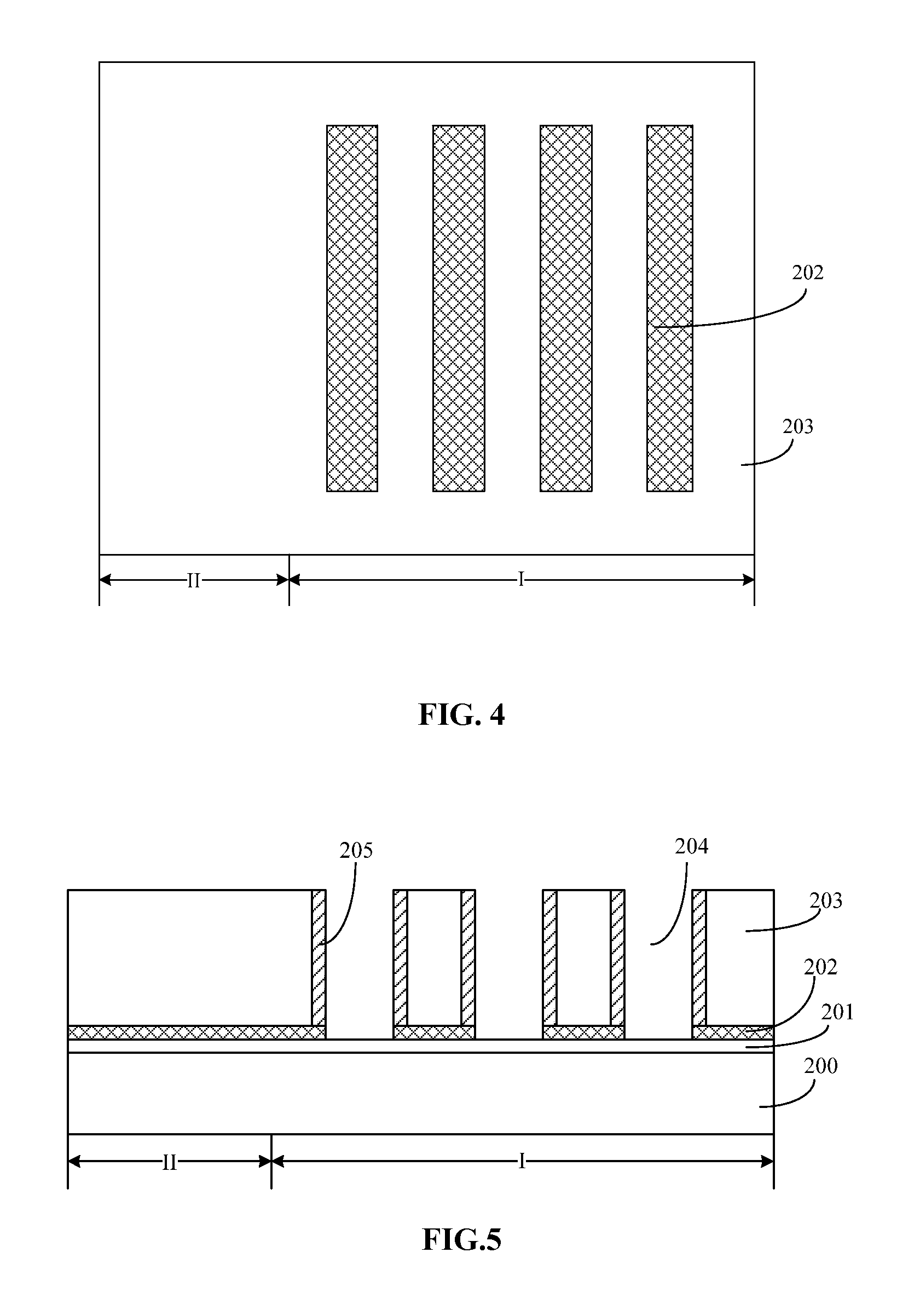

MEMS pressure sensors and fabrication method thereof

ActiveUS20150008541A1Large deformationSignificant changeDecorative surface effectsFluid pressure measurement by electric/magnetic elementsCapacitive pressure sensorMems pressure sensor

A MEMS capacitive pressure sensor is provided. The pressure sensor includes a substrate having a first region and a second region, and a first dielectric layer formed on the substrate. The pressure sensor also includes a first electrode layer formed on the first dielectric layer, and a second dielectric layer having first openings formed on the first electrode layer. Further, the pressure sensor includes conductive sidewalls connecting with the first electrode layer formed on sidewalls of the first openings, and a second electrode layer with a portion formed on the second dielectric layer in the second region and the rest suspended over the conductive sidewalls in the first region. Further, the pressure sensor also includes a chamber between the conductive sidewalls and the second electrode layer; and a third dielectric layer formed on the second electrode layer exposing a portion of the second electrode layer in the first region.

Owner:SEMICON MFG INT (SHANGHAI) CORP

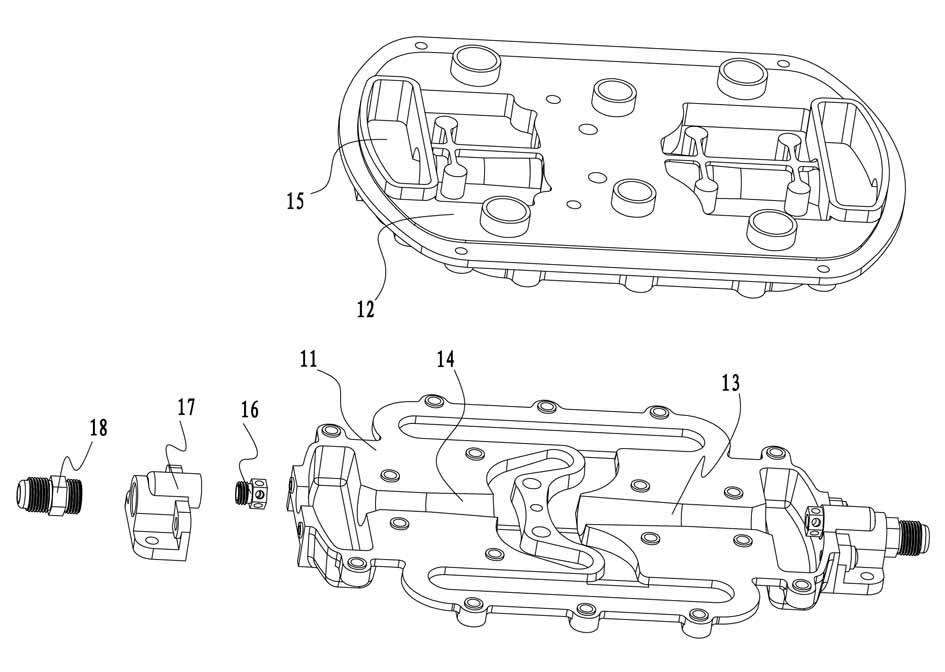

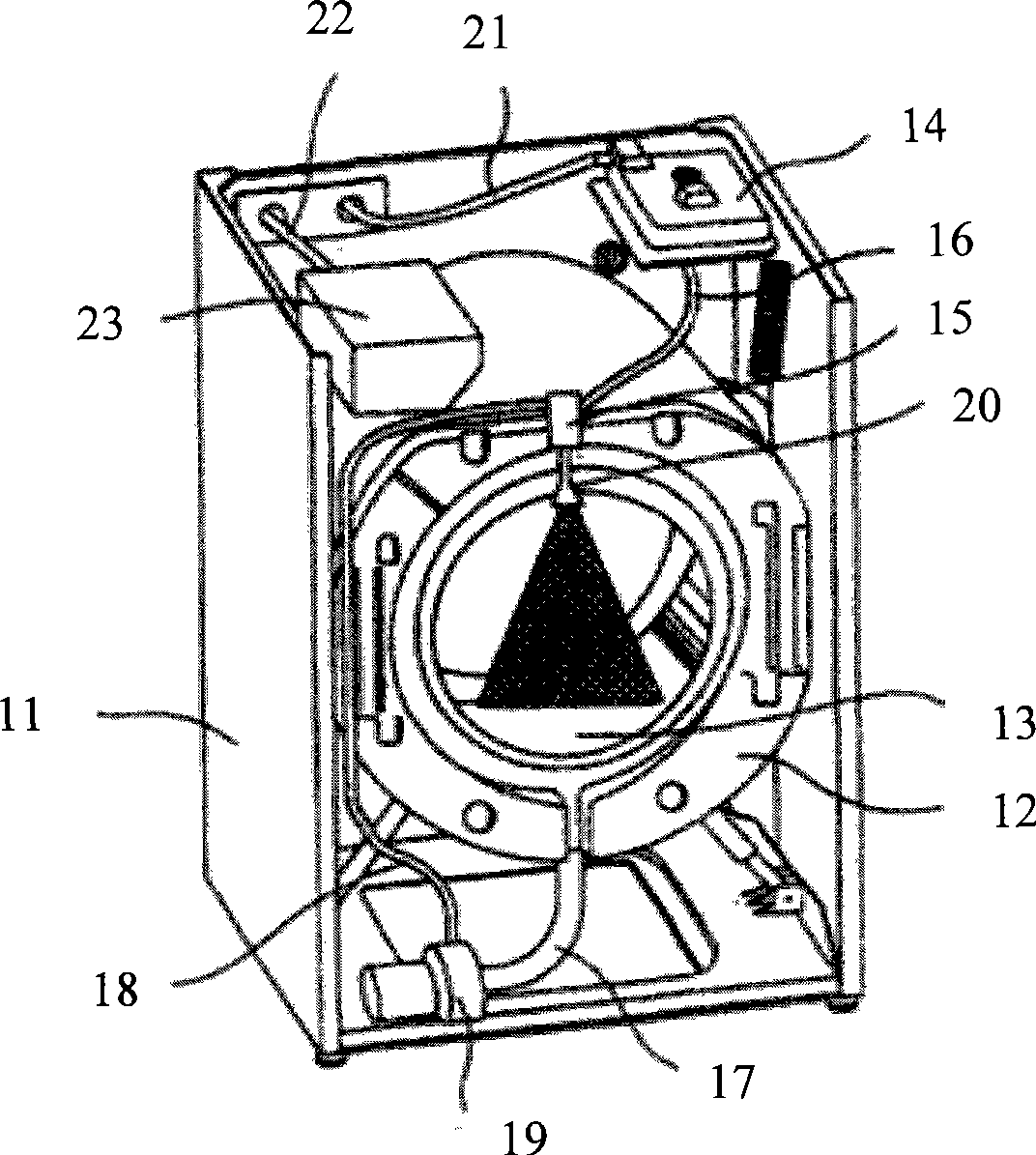

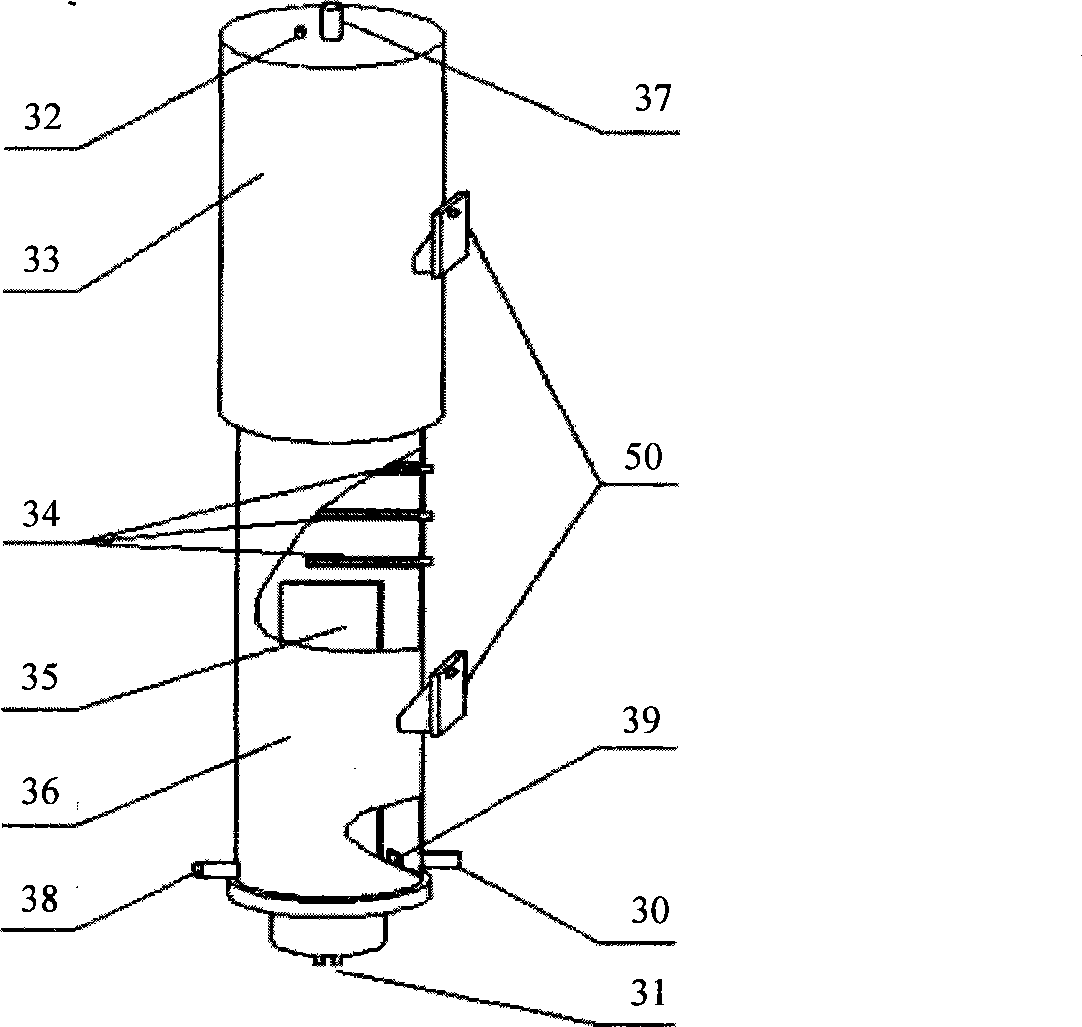

Steam generator of washing machine and wave wheel washing machine equipped with the same

ActiveCN101498092ALow costReduce thicknessOther washing machinesSteam generation plantsThermodynamicsLaundry washing machine

The invention discloses a steam generator of a washing machine and a rotary drum washing machine with the steam generator. The steam generator is of a long column drum structure, a water space capable of storing water is arranged at the lower part of the long column drum structure, and a steam space capable of storing steam is arranged at the upper part of the long column drum structure and is communicated with the water space. The steam generator of the long column drum structure is mounted between the side wall of a casing and the side wall of an outer drum of the rotary drum washing machine. The steam generator structure effectively utilizes the space of the rotary drum washing machine, can mount the steam generator under the condition that an original structure of the rotary drum washing machine is not changed so as to add the steam generation function for the rotary drum washing, and has simple structure and low cost.

Owner:HAIER GRP CORP +1

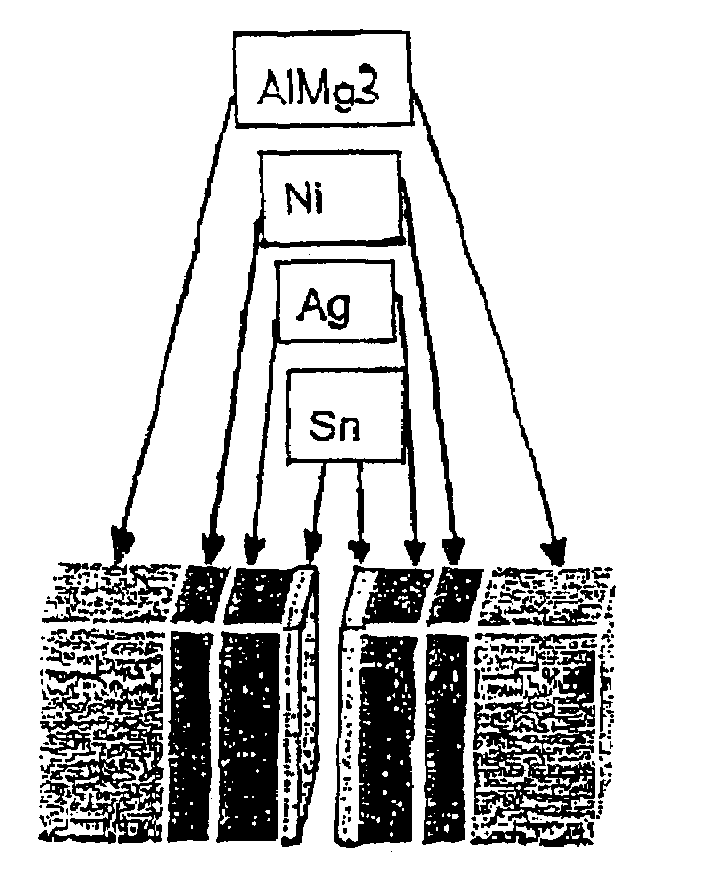

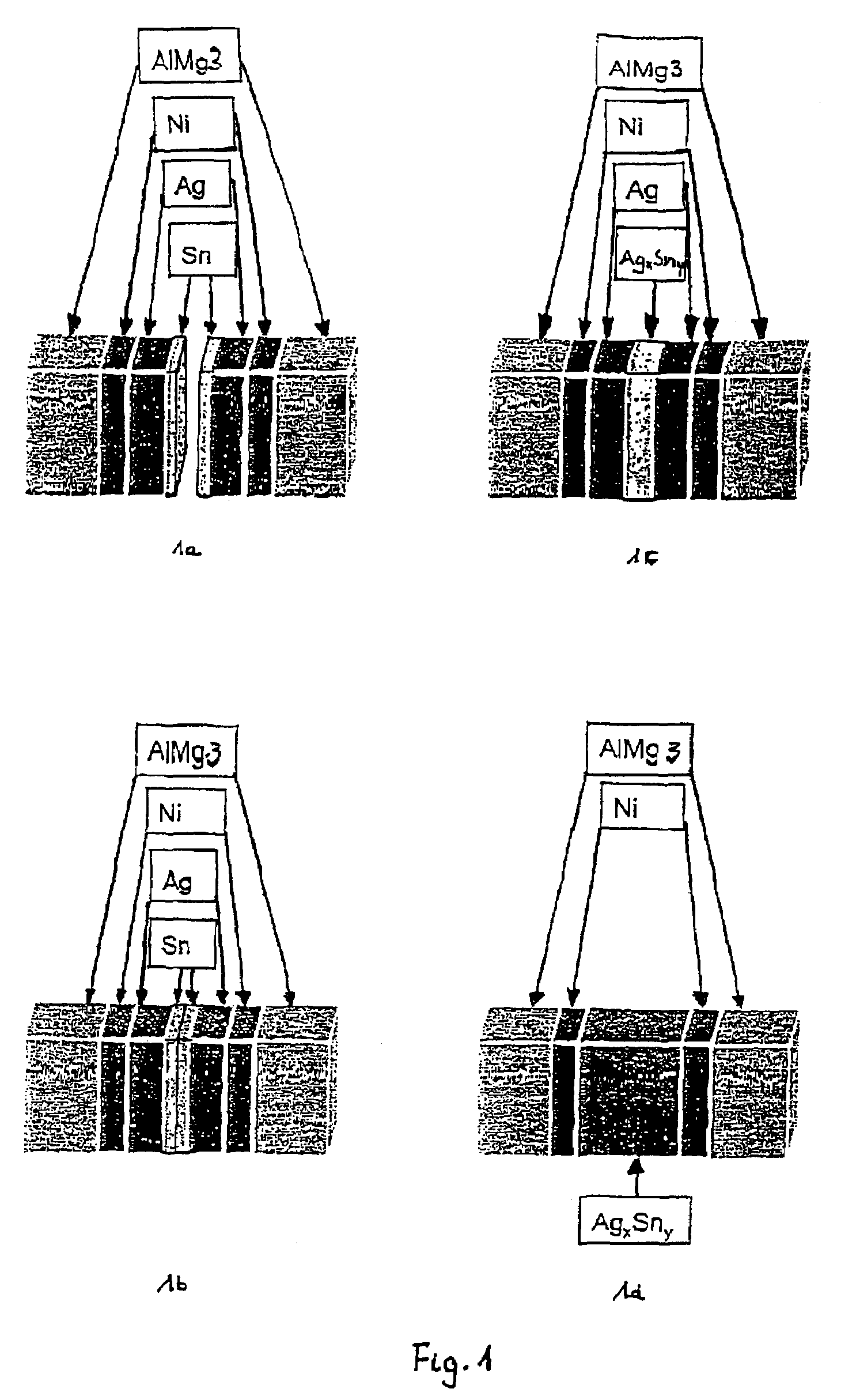

Method of connecting module layers suitable for the production of microstructure modules and a microstructure module

InactiveUS7380698B2Sufficient flectional strengthImproved pressure stabilityDecorative surface effectsWelding/cutting media/materialsMelting temperatureCopper alloy

A method for joining microstructured component layers and a method for manufacturing microstructure component layers and the microstructure component layer is provided. At least one multifunctional barrier coating is applied to the joining surfaces of a base material layer for the microstructured component layers. The layers are made of aluminum / aluminum alloys and / or copper / copper alloys, and / or noble steels. At least one solder / brazing coating is applied to each barrier coating. The coated base material layers comprising the component layers are stacked. The stacked component layers are joined by solder / brazing using heat. The melting temperature of the solder / brazing coating is higher after the heat joining than before same.

Owner:ATOTECH DEUT GMBH

Technological method for upwardly continuously casting, rolling, drawing and producing copper alloy tubes

The invention provides a technological method for upwardly and continuously casting, rolling, drawing and producing copper alloy tubes. The technological method comprises the following steps: melting copper alloy raw materials according to a content proportion; further homogenizing the contents of an undercurrent passing by a standing chamber; keeping the temperature of the undercurrent by a maintaining furnace; cooling the undercurrent by a crystallizer to enter a tractor; upwardly drawing and continuously casting copper alloy tube blanks; then rolling the copper alloy tube blanks by a rolling mill; and drawing finished products of copper alloy tubes by a drawing mill. The technological method simplifies a traditional technological process in a new once-forming technology and has little investment, small occupation of land, low energy consumption, high efficiency, high rolling yield, little pollution and low cost, thereby being an advanced technological method with a certain market competitiveness.

Owner:高玉树

Device to retrieve and position a golf article

InactiveUS20050181886A1Easy to controlEqually distributedBall sportsShop accessoriesEngineeringGolf Ball

A device for retrieving and positioning of golfing articles, such as a golf ball and tee, to eliminate the repeated bending down of the golfer. One embodiment of the device includes a rigid tube with a closed end, a resilient cup-like element, and a biased elongated member. The closed end of the tube can be either integral to the tube, such as being molded during the manufacturing process, or an end cap that is fitted to one end of the tube.

Owner:ZMETRA WILLIAM J

Bilaterally rotatable end surface mechanical sealing structure with dovetail grooves

ActiveCN103133697AImprove compression performanceImprove carrying capacityEngine sealsEngineeringHigh pressure

Owner:ZHEJIANG UNIV OF TECH

High-energy-rate pulse impact hydraulic-forming method

The invention discloses a high-energy-rate pulse impact hydraulic-forming method and belongs to the field of high-speed formation of materials. According to the high-energy-rate pulse impact hydraulic-forming method, the advantages of high-speed impact forming and the advantages of pulse hydraulic forming are combined, and an impact body which moves at a high speed impacts liquid media repeatedly to complete incremental forming of a part. According to the process of each time of impacting, an impact power source drives the impact body to move at a high speed, the impact body which moves at a high speed impacts the liquid media, the kinetic energy of the impact body is instantly converted into the pressure energy of the liquid media, and thus rapid deformation of a workpiece is completed. According to the method, the overall output energy can be controlled accurately, so that the energy transmission rate, namely energy used for workpiece forming, is controlled accurately, and the required part shape is obtained through multiple times of pulse impact; the deformation of each pass can be controlled accurately, the forming time is short, the strain rate of materials is high (10<3>s<1->-10<4>s<-1>), the forming limit of the materials can be increased, and the mold attaching effect is good; and the high-energy-rate pulse impact hydraulic-forming method can be used for precise formation of magnesium alloy, aluminum alloy, titanium alloy and other alloys difficult to deform.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

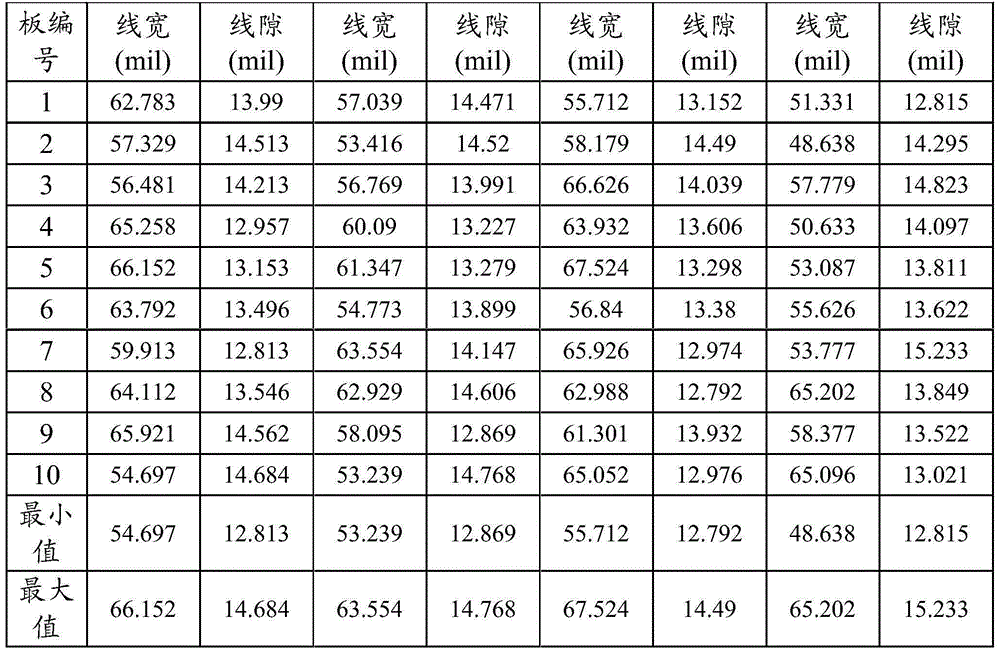

Inner and outer layer copper thickness-differentiated thick copper circuit board and preparation method thereof

ActiveCN104486914AEvenly filledUniform pressure distributionConductive material chemical/electrolytical removalMultilayer circuit manufactureProcess engineeringMechanical engineering

The invention discloses an inner and outer layer copper thickness-differentiated thick copper circuit board and a preparation method thereof and belongs to the PCB technical field. The method includes the steps of board pressing process, drilling process and etching process. According to the board pressing process, a prepreg of which the resin content is equal to or larger than 65% is selected; hot pressing process and cold pressing process are sequentially adopted to perform board pressing; the parameter conditions of the hot pressing process are as follows: pressure ranges from 250 to 450 PSI, temperature ranges from 175 to 220 DEG C, vacuum degree ranges from 0 to 68 cm Hg, and time ranges from 90 to 150 min; and the parameter conditions of the cold pressing process are as follows: pressure ranges from 50 to 450 PSI, temperature ranges from 165 to 220 DEG C, and time ranges from 130 to 230 min. According to the preparation method, a laminated structure and a board lamination mode are adopted, and temperature rising and pressurization control are utilized in cooperation, and therefore, the filling of flowing resin can be uniform, and pressure distribution is uniform when board pressing is performed, and an excellent filling effect can be realized, and air bubble generation can be avoided, and press fit can be excellently realized.

Owner:KALEX MULTI LAYER CIRCUIT BOARD (ZHONGSHAN) CO LTD

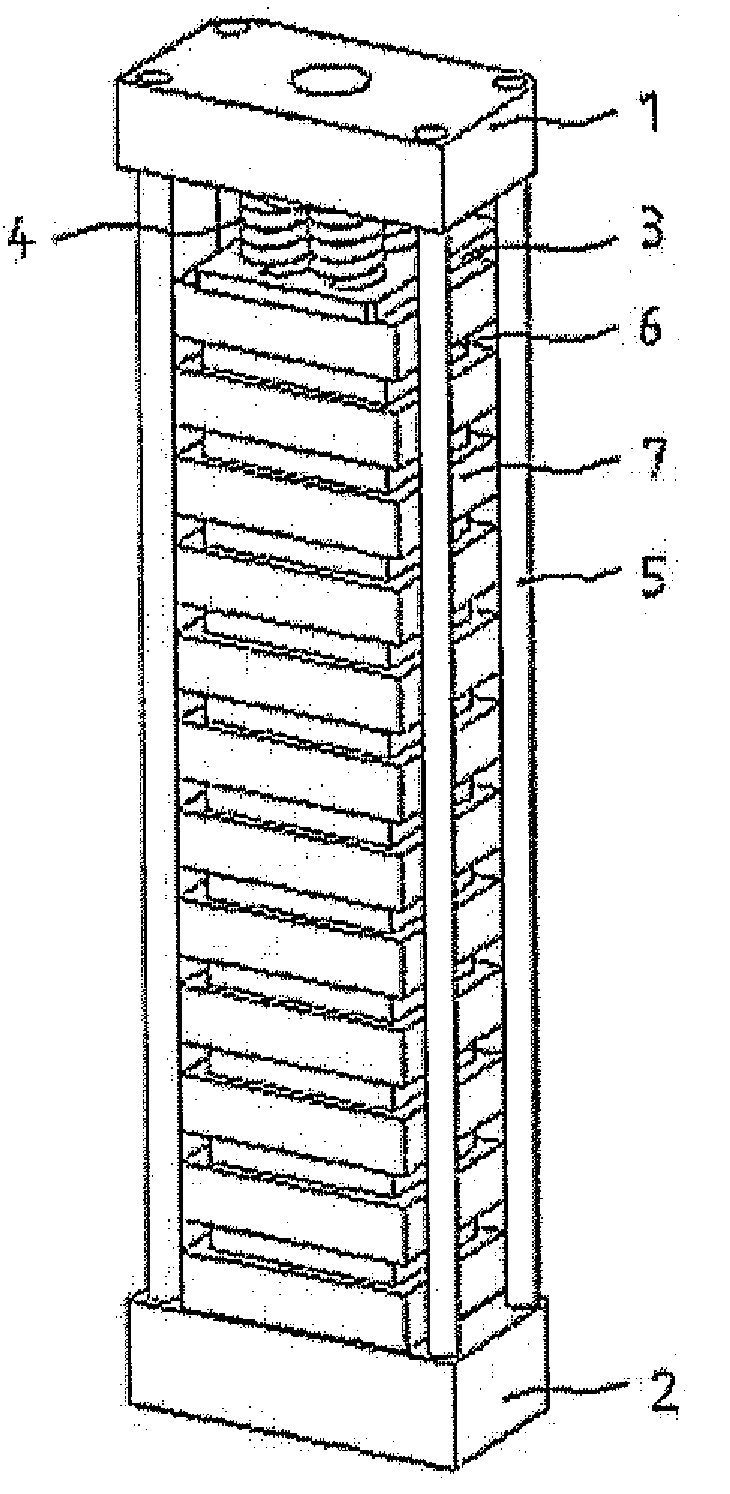

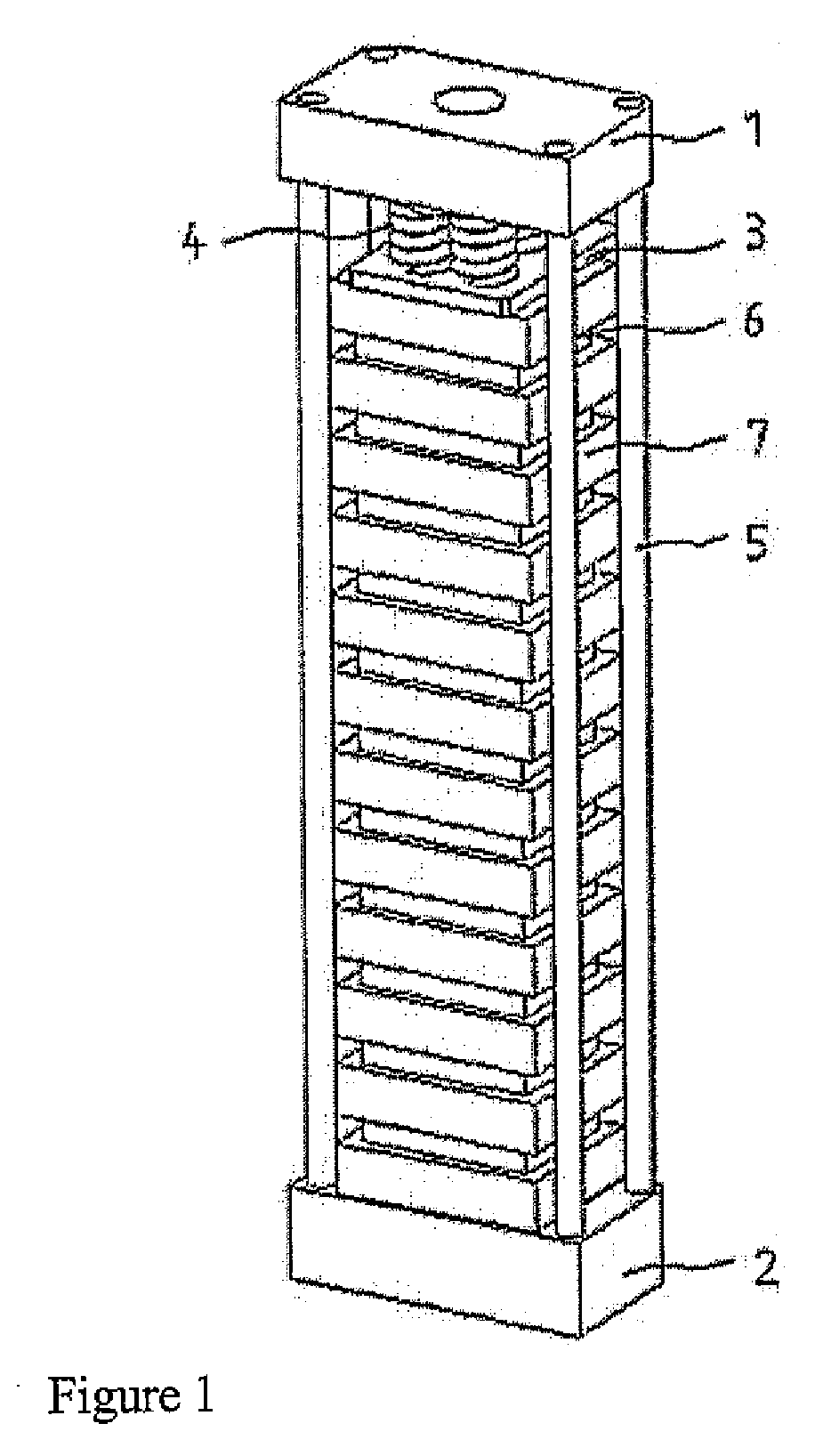

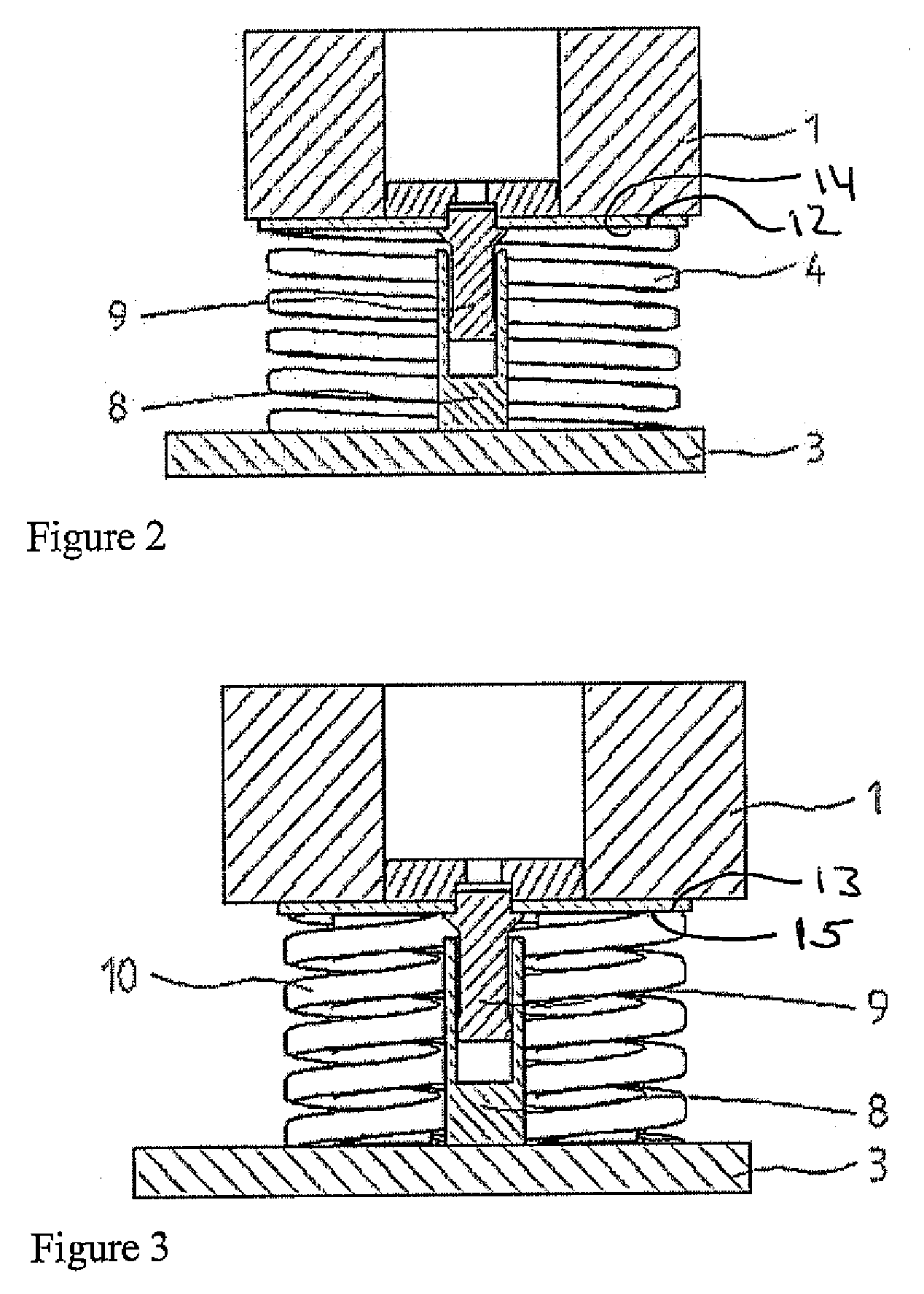

A power semiconductor arrangement and a semiconductor valve provided therewith

InactiveUS20100133676A1Uniform pressure distributionIncrease clamping forceSemiconductor/solid-state device detailsSolid-state devicesCoil springSupport surface

A power semiconductor arrangement including a clamping device including a first clamping element and a second clamping element. A plurality of power semiconductor elements are stacked on each other between the first and second clamping elements of the clamping device. The first clamping element receives a clamping force in an axial direction of the stack of the power semiconductor elements. At least one spring element is arranged between the first clamping element and the power semiconductor elements. The at least one spring element presents at least one support surface with which the at least one spring element bears against at least one corresponding support surface of an adjacent element. The at least one spring element includes a helical spring. A center axis of the at least one spring element coincides with a center of the clamping force, or the at least one spring element includes a plurality of helical springs arranged in parallel with each other, which are arranged symmetrically in relation to a point in which a center of the clamping force is introduced into the first clamping element.

Owner:ABB TECH AG

Device to retrieve and position a golf article

InactiveUS7086971B2Easy to controlEqually distributedBall sportsShop accessoriesEngineeringGolf Ball

A device for retrieving and positioning of golfing articles, such as a golf ball and tee, to eliminate the repeated bending down of the golfer. One embodiment of the device includes a rigid tube with a closed end, a resilient cup-like element, and a biased elongated member. The closed end of the tube can be either integral to the tube, such as being molded during the manufacturing process, or an end cap that is fitted to one end of the tube.

Owner:ZMETRA WILLIAM J

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com