Starting clutch

a clutch and clutch technology, applied in the direction of fluid-actuated clutches, clutches, non-mechanical actuated clutches, etc., can solve the problems of increasing the amount, affecting the efficiency, and the supply of the pump capacity of the oil pump, so as to achieve sufficient cooling operation and efficiently cool down

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

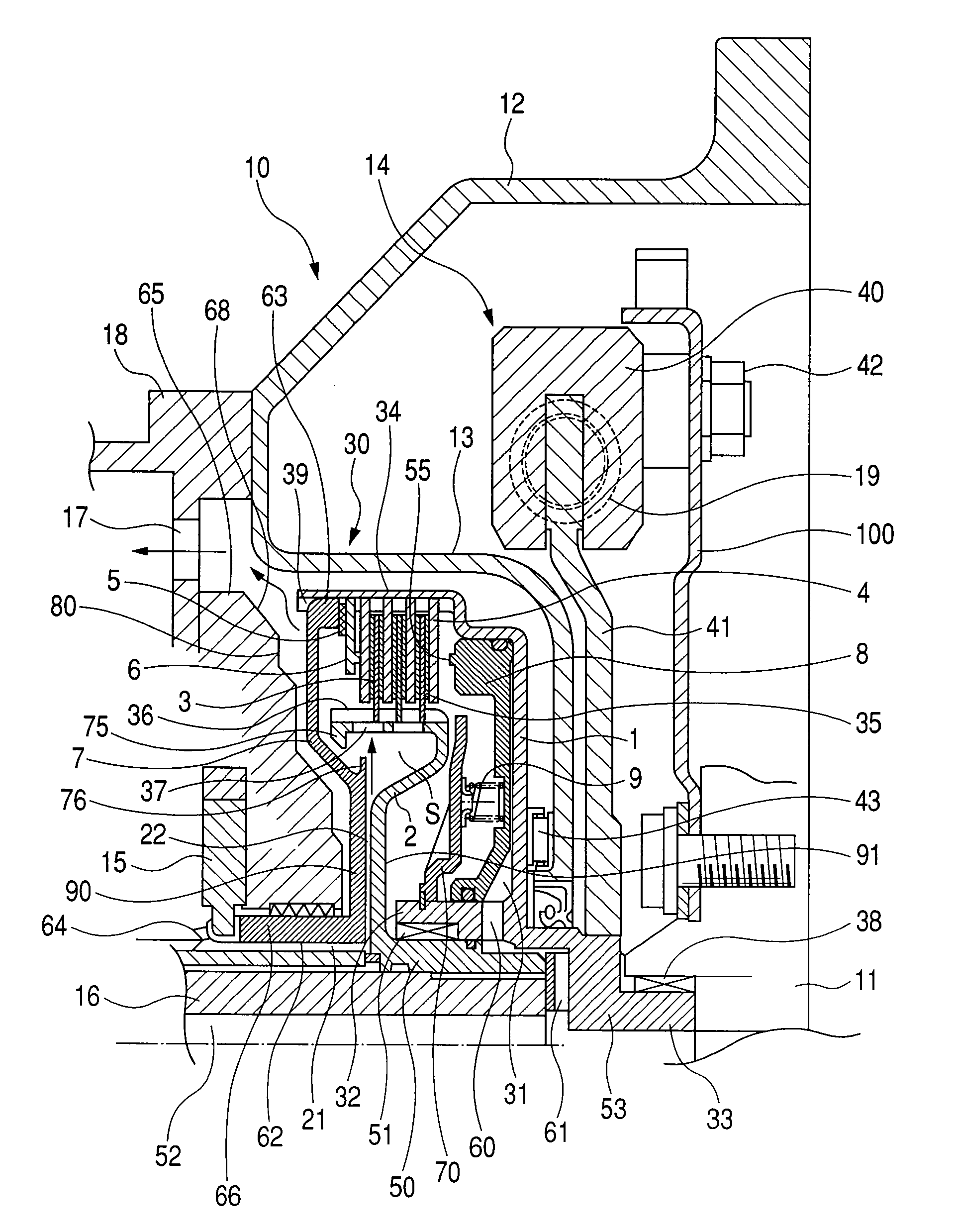

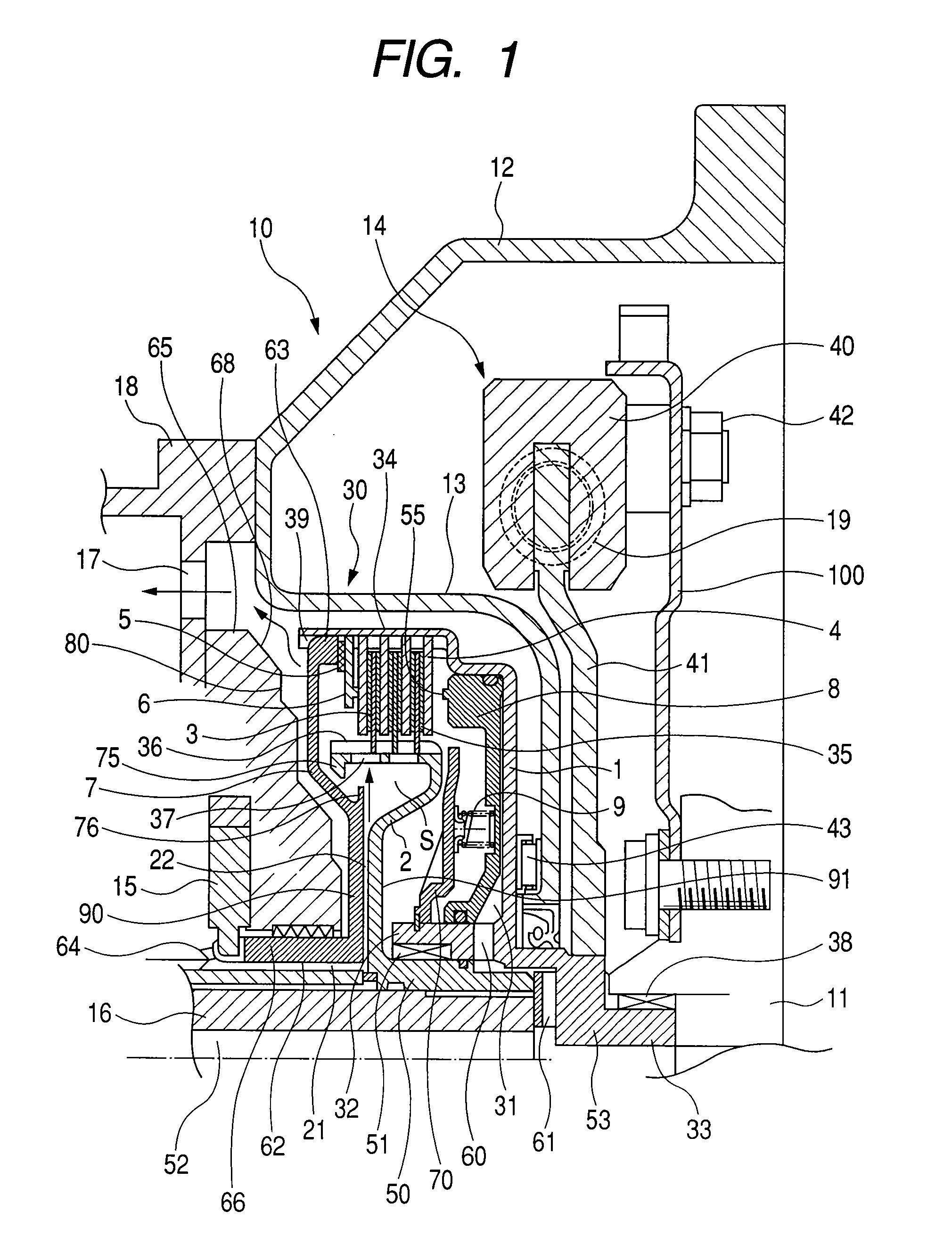

[0023]FIG. 1 is an axial sectional view showing a starting clutch according to a first embodiment of the present invention. The starting clutch 10 includes a clutch drum 1 and a wet type multi-plate clutch 30 housed within the clutch drum. The wet type multi-plate clutch 30 comprises substantially annular friction plates (internally-toothed plates) 3 as friction engaging elements at an output side and substantially annular separator plates (externally-toothed plates) 4 as friction engaging elements at an input side, which plates are arranged alternately along an axial direction within the clutch drum 1. Within one axial end (open end) of the clutch drum 1, a substantially annular backing plate 6 is fixedly supported by a substantially annular stop ring 5 in the axial direction, thereby holding the separator plates 4.

[0024]The annular clutch drum 1 is provided at its inner periphery with a central cylindrical portion 32 and is also provided at its outer periphery with an outer diamet...

second embodiment

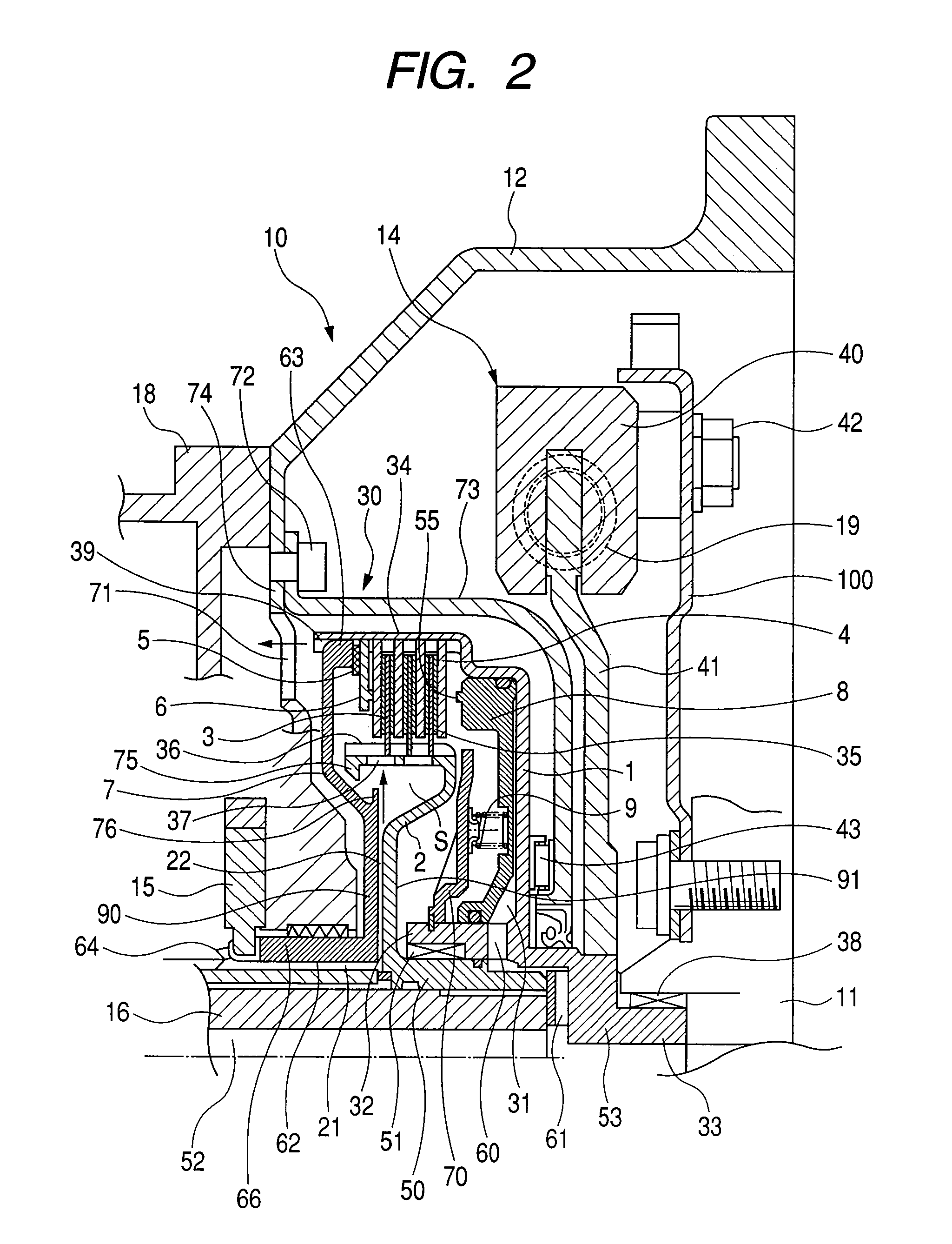

[0044]FIG. 2 is an axial sectional view showing a starting clutch according to a second embodiment of the present invention. Since a fundamental arrangement of the second embodiment is the same as that of the first embodiment, the detailed explanation thereof will be omitted.

[0045]The second embodiment differs from the first embodiment regarding a construction of a clutch cover and a lubricating oil discharging path. A clutch cover 73 covering the clutch portion 30 is provided independently from the housing 12. Although the connection to the clutch drum 1 is similar to that in the first embodiment, the clutch cover 73 is secured to a side wall of the housing 12 at the transmission side by bolts 72.

[0046]The side wall 74 is provided with a through hole 71 through which the lubricating oil which has lubricated the clutch portion 30 is discharged toward the transmission. The lubricating oil from the clutch portion 30 passes through the through hole 71 and flows toward the transmission....

third embodiment

[0050]FIG. 3 is an axial sectional view of a starting clutch according to a third embodiment of the present invention. The starting clutch 10 includes a clutch drum 1 and a wet type multi-plate clutch 30 housed in the clutch drum. The wet type multi-plate clutch 30 comprises substantially annular friction plates (internally-toothed plates) 3 as friction engaging elements at an output side and substantially annular separator plates (externally-toothed plates) 4 as friction engaging elements at an input side, which plates are arranged alternately along an axial direction within the clutch drum 1. Within one axial end (open end) of the clutch drum 1, a substantially annular backing plate 79 is fixedly supported by a substantially annular stop ring 5 in the axial direction, thereby holding the separator plates 4. The backing plate 79 is provided at it tip end with a curved portion 79a protruding toward the clutch portion.

[0051]The annular clutch drum 1 is provided at its inner periphery...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com