Patents

Literature

41results about How to "Short forming time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

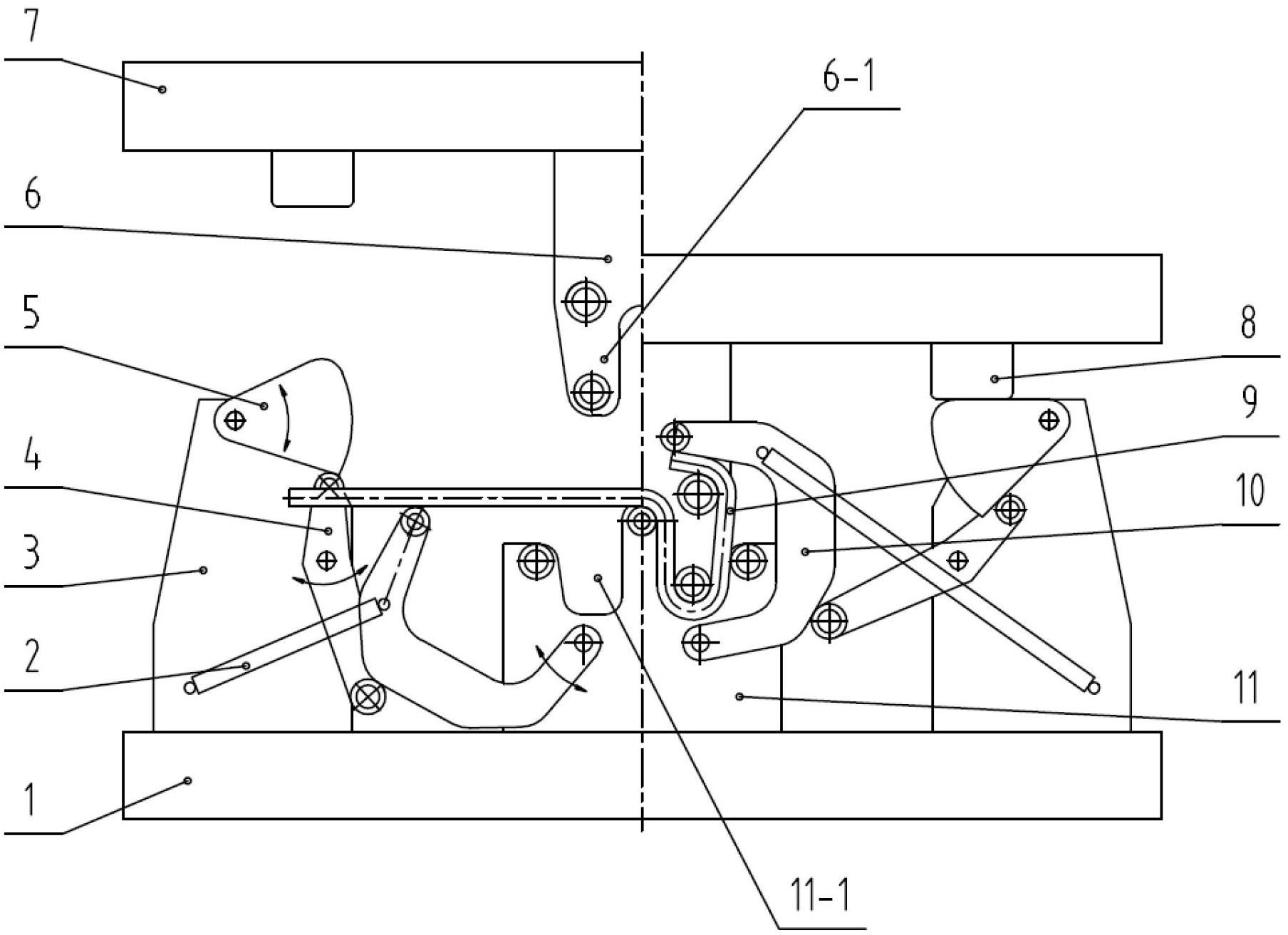

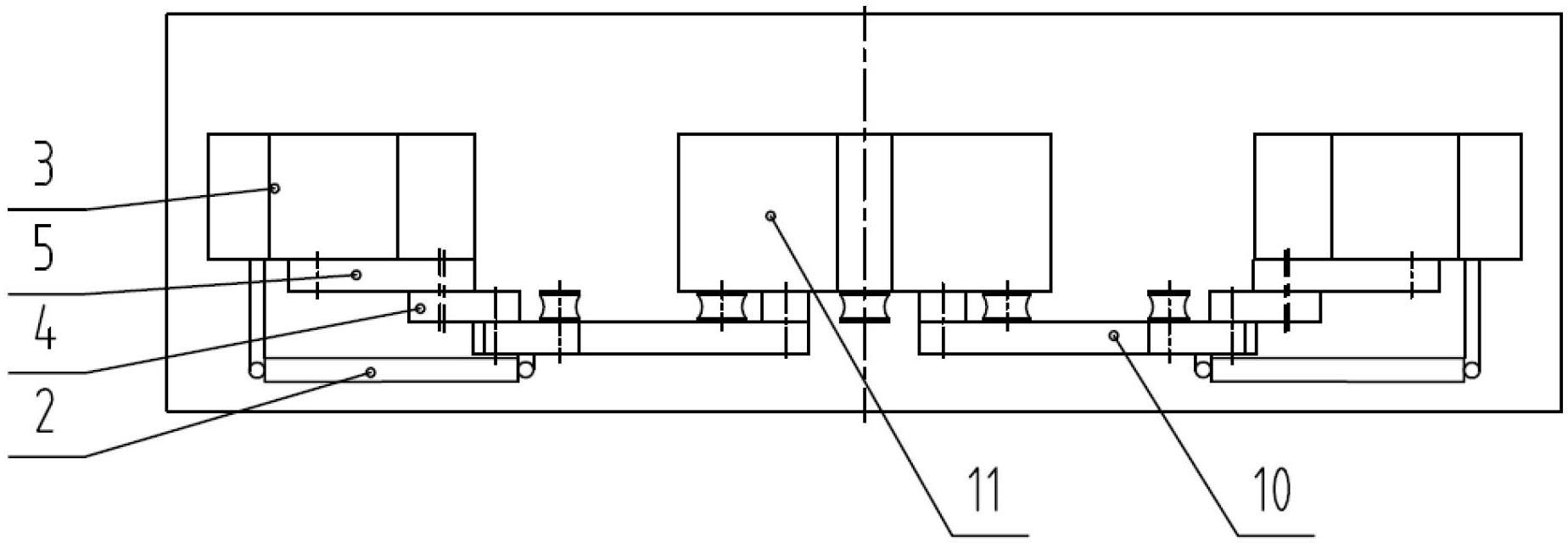

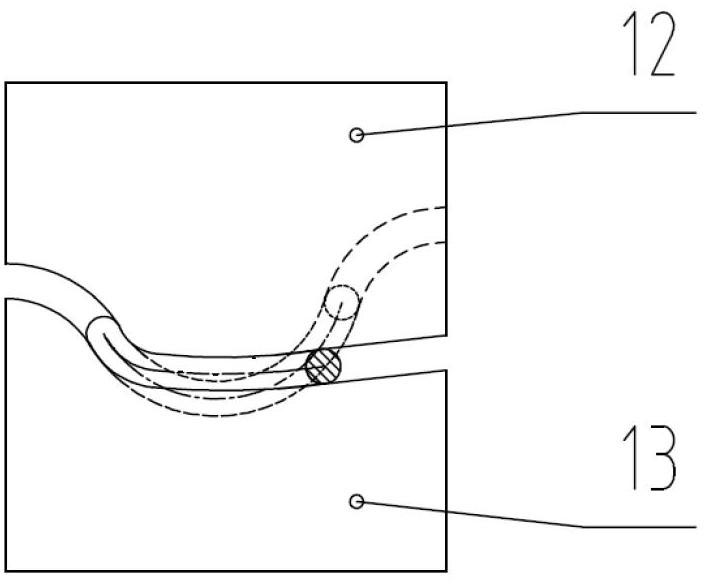

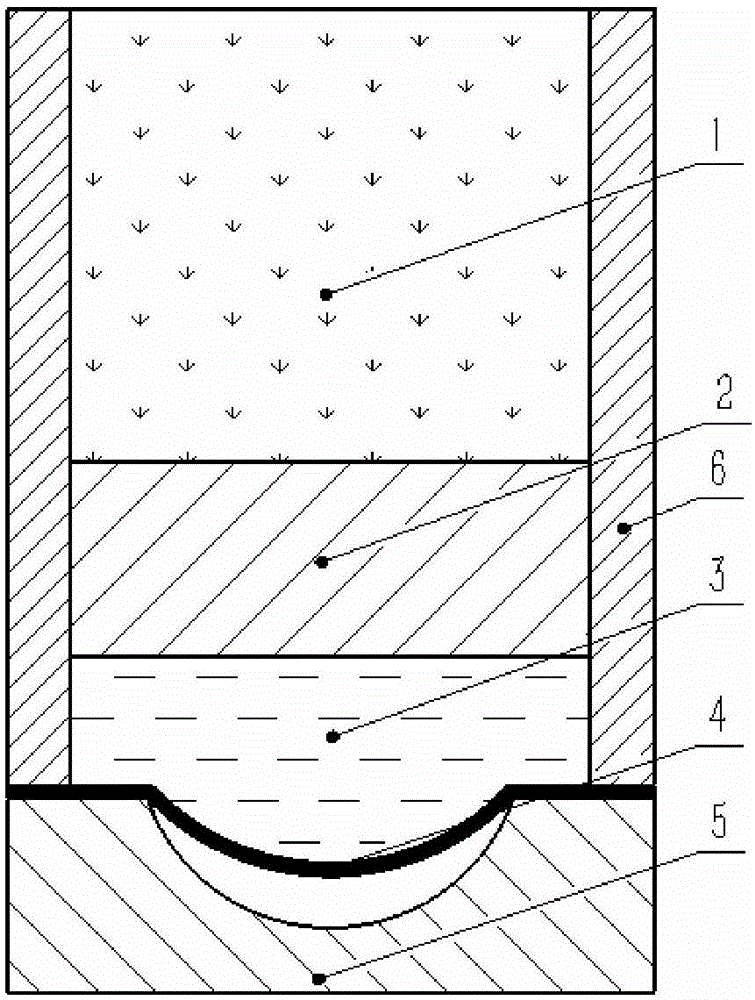

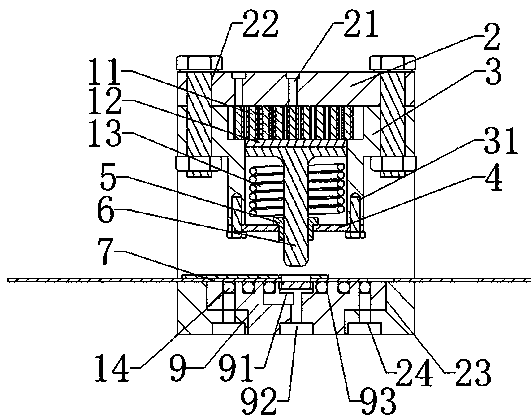

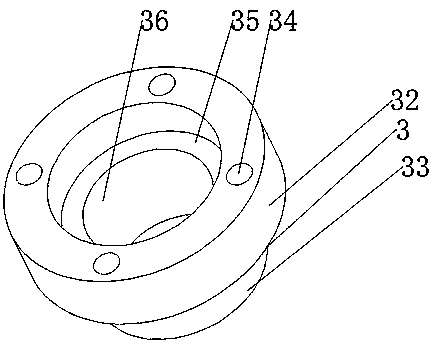

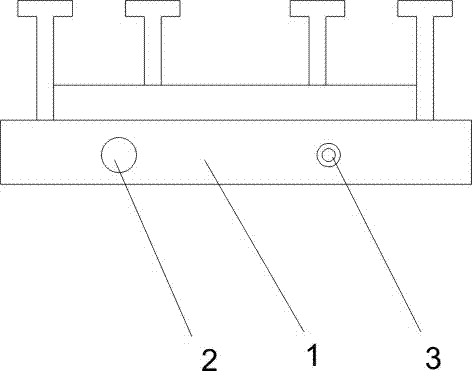

Railway fastener elastic strip forming die and forming method

The invention discloses a railway fastener elastic strip forming die and a forming method. The forming die comprises a base, racks and an upper template, wherein the base is fixedly provided with a lower roller carrier with an omega-shaped groove, the upper template is provided with an upper roller carrier which is provided with a press head adaptive to the omega-shaped groove of the lower roller carrier, the lower roller carrier is also symmetrically connected with two bent oscillating bars, one end of each bent oscillating bar is pivoted with the lower roller carrier, the racks are arranged at two sides of the lower roller carrier, and the racks are hinged with a lever which is used for bending two ends of the elastic strip. The railway fastener elastic strip forming die has the main beneficial effects that the appearance of the elastic strip is manufactured by adopting a two-step molding manner, so that the defects of the three-step molding manner are improved to some extent, and compared with the one-step molding elastic trip machine, the railway fastener elastic strip forming die has the advantages that the molded module has a simple structure, and low cost.

Owner:CRRC QISHUYAN INSTITUTE CO LTD +1

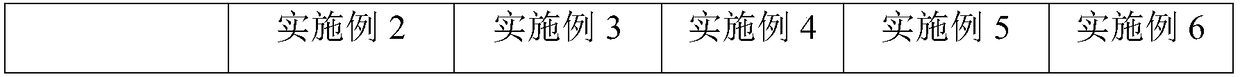

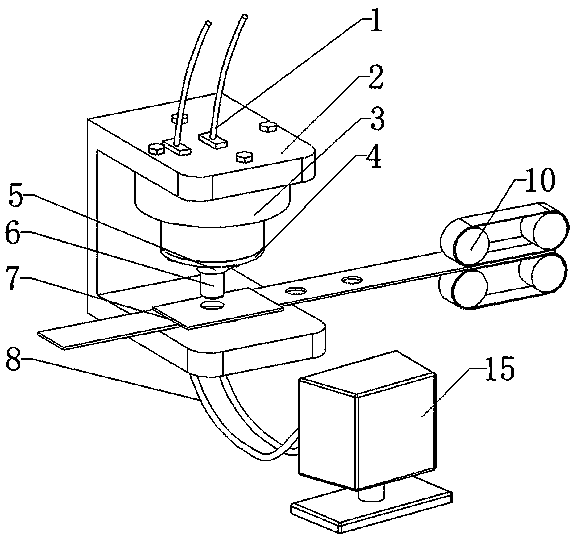

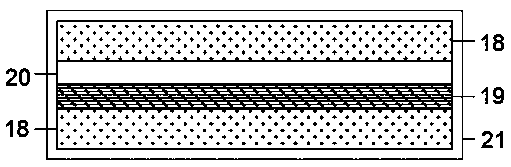

Method for preparing 316 stainless steel complex thin-wall pipeline through selective laser melting forming technology

InactiveCN106493365ARapid responseShort forming timeAdditive manufacturing apparatusIncreasing energy efficiencyThin walledSoftware

The invention provides a method for preparing a 316 stainless steel complex thin-wall pipeline through the selective laser melting forming technology. The method comprises the steps that firstly, a three-dimensional digital model of the complex thin-wall pipeline is constructed; secondly, the three-dimensional digital model is repaired through three-dimensional repairing software; and thirdly, the repaired three-dimensional digital model is sliced through slicing software and converted into two-dimensional slice information, and a machining program file is generated. The method has the beneficial effects that firstly, the time for forming the complex thin-wall pipeline is short through the selective laser melting forming technology, procedures are reduced, and the manufacturing period is shortened; secondly, the quality of the complex thin-wall pipeline formed through the selective laser melting forming technology is high, consistency between the complex thin-wall pipeline and the digital model is good, and the qualification rate is high; and thirdly, the 316 stainless steel complex thin-wall pipeline formed through the method is uniform in inner structure, good in surface quality and excellent in mechanical performance.

Owner:NANTONG JINYUAN INTELLIGENT TECH CO LTD

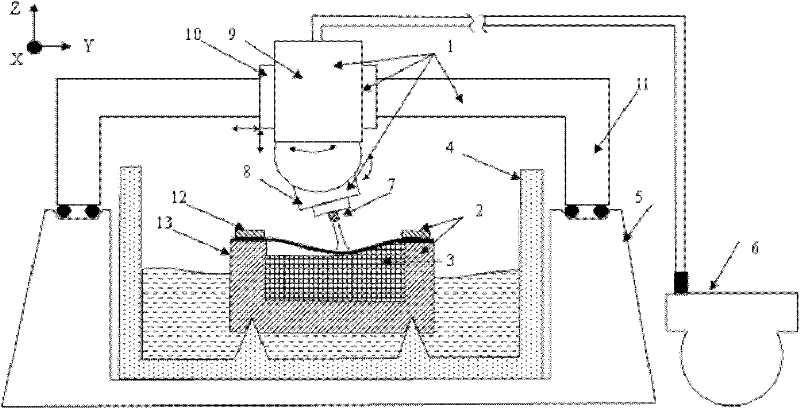

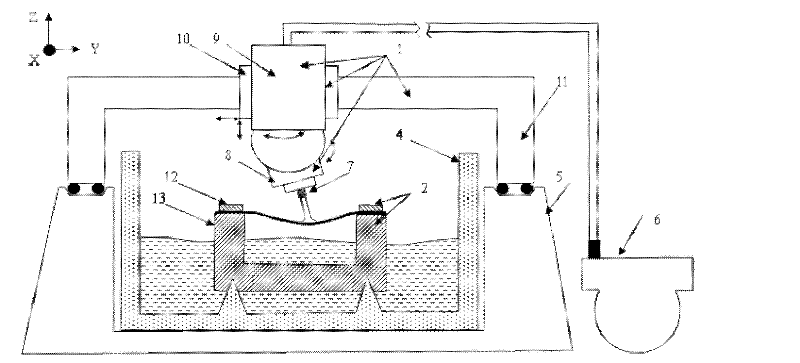

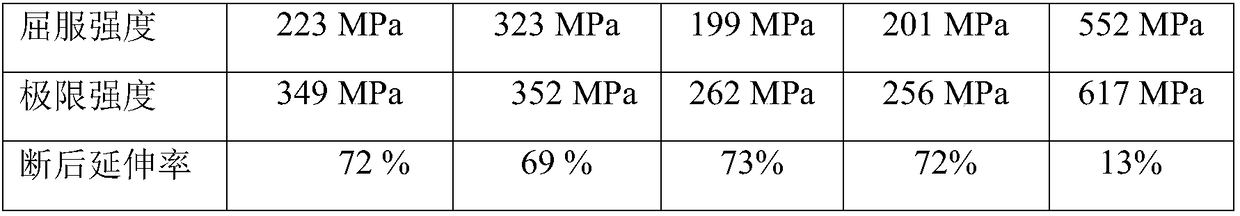

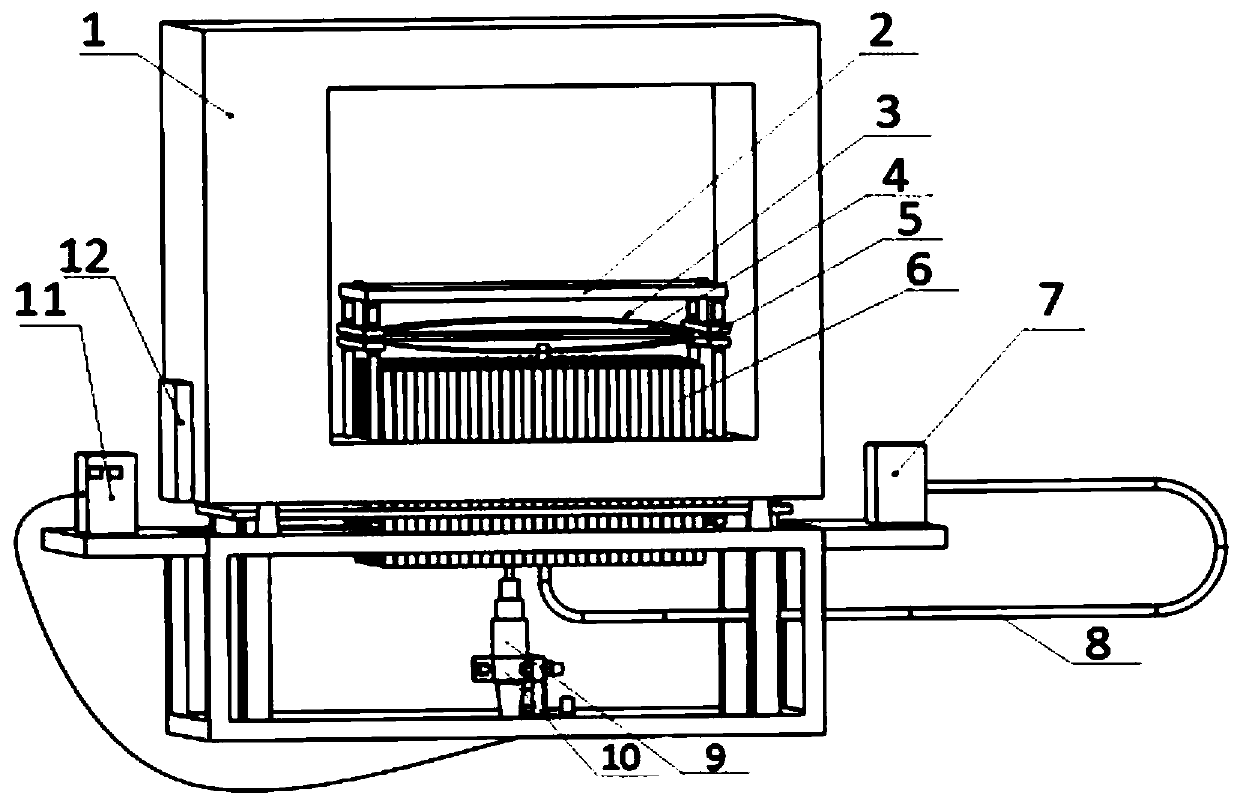

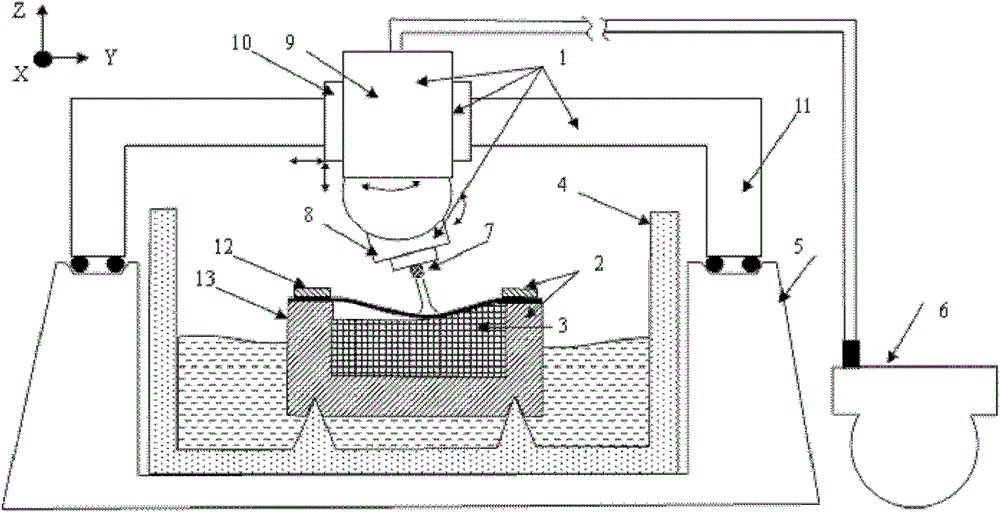

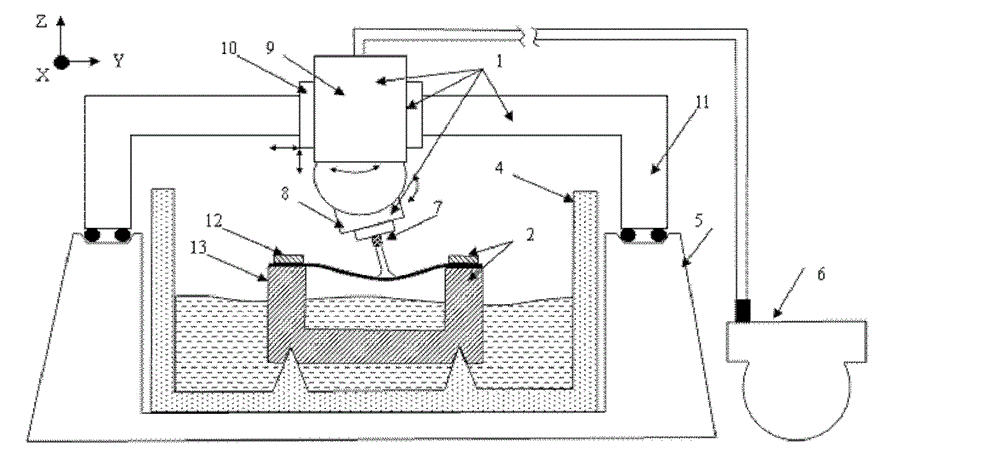

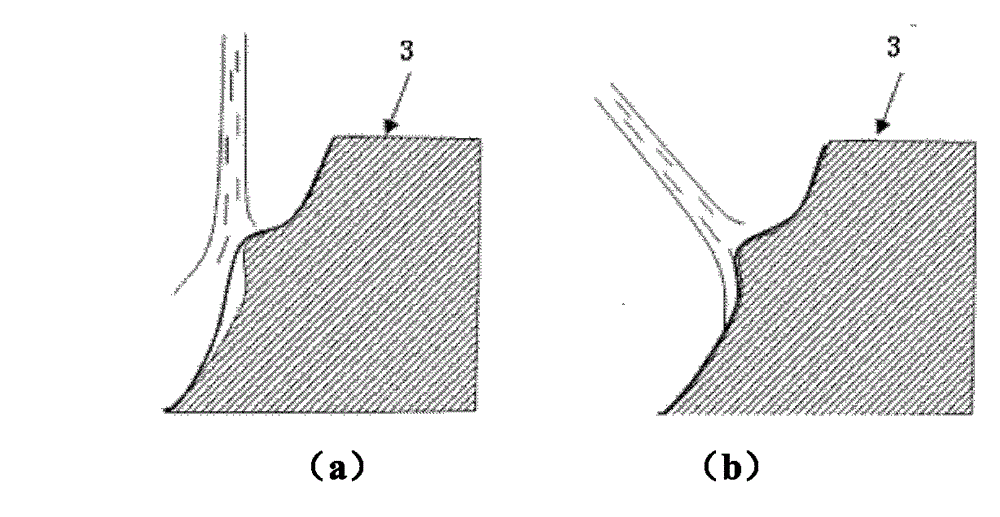

High-pressure water jet plate incremental forming and cutting device

ActiveCN102218706AIncrease movement speedUniform thicknessAbrasive blasting machinesJet flowUltra high pressure

The invention discloses a high-pressure water jet plate incremental forming and cutting device, which comprises a five shaft forming unit, a plate material fixture, a lower support mold, a trough, a base, an ultrahigh pressure water pump and a high pressure water nozzle, wherein the five shaft forming unit is mounted above the base; the plate material fixture is mounted in the trough; the lower support mold is mounted in the plate material fixture and is connected with the trough; the trough is fixed on the base; and the high pressure water nozzle is mounted at the tail end of the forming armof the five shaft forming unit and is connected with the ultrahigh pressure water pump through a high pressure pipe. In the utility model, the powerful impact force of water jet is used for carrying out incremental forming on the plate; moreover, the fine features of the plate can be formed and cut by controlling the pressure of the water jet and the thickness of the water jet; and the forming efficiency and quality are far higher than the forming efficiency and quality of the current incremental forming method. Besides, the incremental forming way does not need lubricant and does not cause pollution to the environment, thus being a clean plate forming way.

Owner:SHANGHAI JIAO TONG UNIV

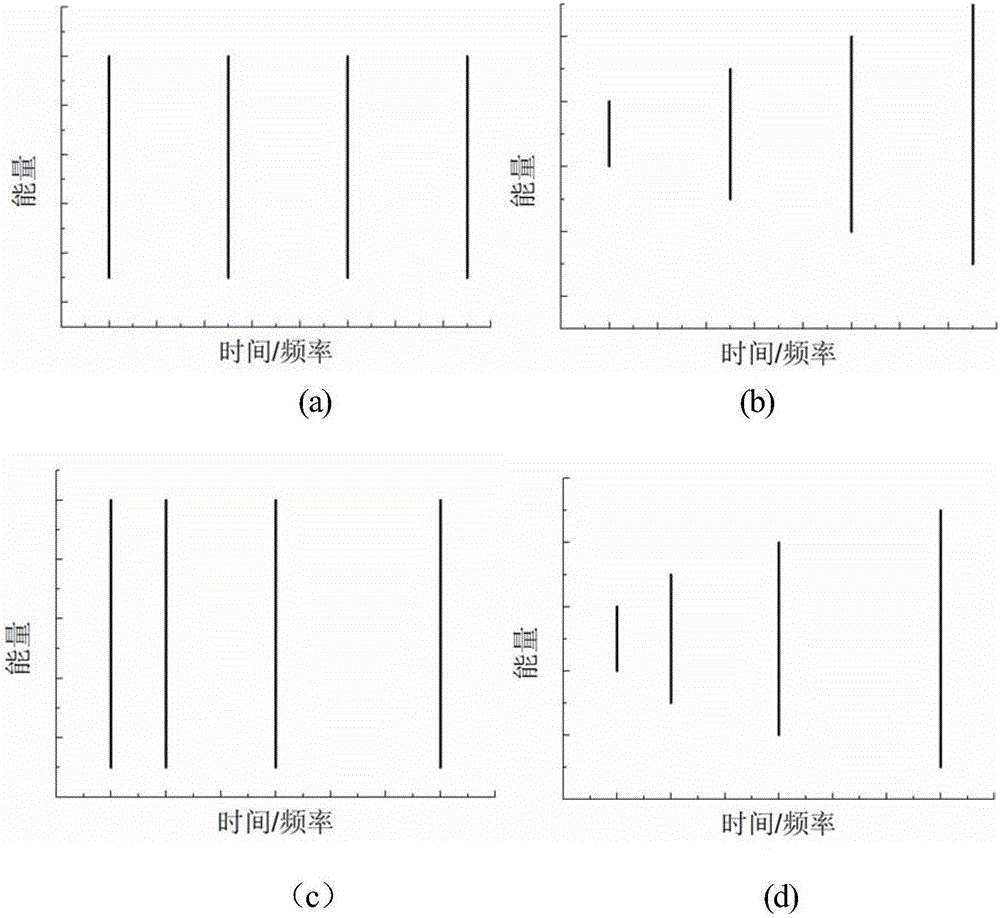

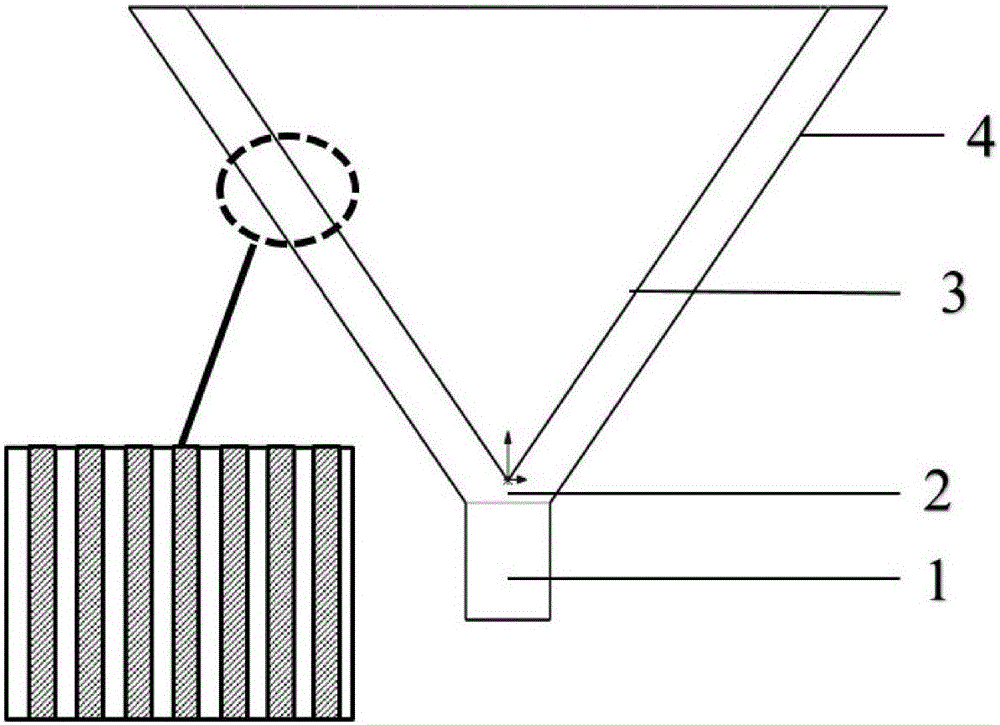

High-energy-rate pulse impact hydraulic-forming method

The invention discloses a high-energy-rate pulse impact hydraulic-forming method and belongs to the field of high-speed formation of materials. According to the high-energy-rate pulse impact hydraulic-forming method, the advantages of high-speed impact forming and the advantages of pulse hydraulic forming are combined, and an impact body which moves at a high speed impacts liquid media repeatedly to complete incremental forming of a part. According to the process of each time of impacting, an impact power source drives the impact body to move at a high speed, the impact body which moves at a high speed impacts the liquid media, the kinetic energy of the impact body is instantly converted into the pressure energy of the liquid media, and thus rapid deformation of a workpiece is completed. According to the method, the overall output energy can be controlled accurately, so that the energy transmission rate, namely energy used for workpiece forming, is controlled accurately, and the required part shape is obtained through multiple times of pulse impact; the deformation of each pass can be controlled accurately, the forming time is short, the strain rate of materials is high (10<3>s<1->-10<4>s<-1>), the forming limit of the materials can be increased, and the mold attaching effect is good; and the high-energy-rate pulse impact hydraulic-forming method can be used for precise formation of magnesium alloy, aluminum alloy, titanium alloy and other alloys difficult to deform.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

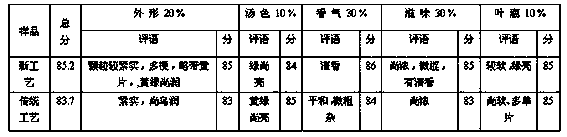

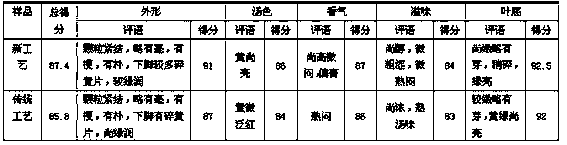

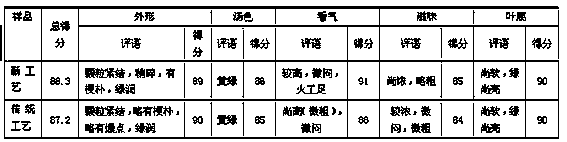

Granular green tea processing method through combination of microwave drying of first-step roasting leaves and double-pot tea curling machine shaping

The invention relates to a granular green tea processing method through the combination of microwave drying of first-step roasting leaves and double-pot tea curling machine shaping, and belongs to the technical field of tea processing. The granular green tea processing method comprises the following processing steps: spreading of fresh tea leaves; deactivation; spreading for cooling; rolling; drying of first-step roasting leaves; shaping; spreading for cooling; drying; fragrance extraction. According to the granular green tea processing method through the combination of microwave drying of the first-step roasting leaves and double-pot tea curling machine shaping, the design is reasonable, and a good foundation is provided for the subsequent steps of drying of the first-step roasting leaves and shaping by reasonably restricting the conditions of spreading, deactivating, spreading for cooling and rolling; microwave heating is utilized for completing the working procedure of drying of the first-step roasting leaves, so that the water content of first-step roasting leaves is easily adjusted and controlled, the color is relatively green, and cooling treatment is not needed, so that the shaping can be directly performed; a double-pot tea curling machine is utilized for shaping, so that the shaping time is short, and the quality of a final tea product is excellent. Experiment results show that leaves collected by machines are suitable for being processed into granular green tea by adopting the granular green tea processing method provided by the invention, and the granular green tea is attractive in appearance, fresh in fragrance and pure in mouthfeel, and is popular among green tea consumers.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI

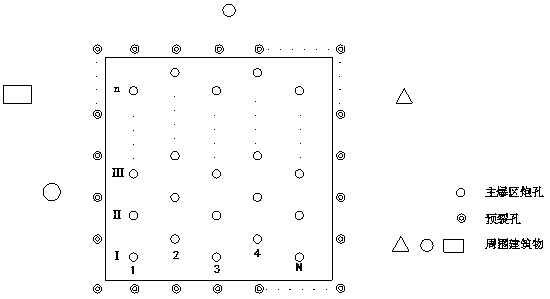

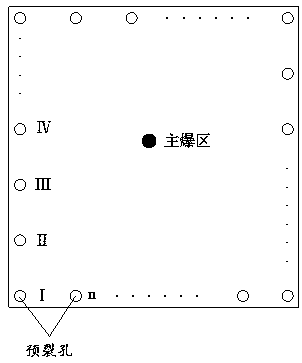

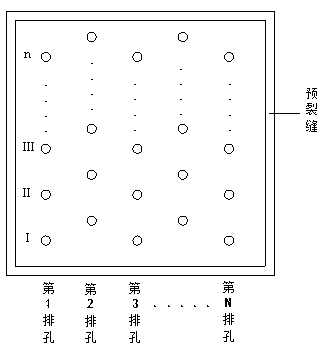

Complex environment foundation pit excavation hole-by-hole blasting method

InactiveCN110657722AShort forming timeRealize hole-by-hole detonationBlastingExcavationsDetonatorArchitectural engineering

The invention relates to a complex environment foundation pit excavation hole-by-hole blasting method and belongs to the technical field of blasting. The complex environment foundation pit excavationhole-by-hole blasting method comprises the steps of uniformly arranging presplitting holes in a designed complex environment foundation pit excavation contour line, arranging uncoupling explosive charging devices in the presplitting holes, and controlling the uncoupling explosive charging devices in the presplitting holes to conduct accurate delay hole-by-hole blasting through digital electronic detonators; and cleaning presplitting blasting muck piles, and arranging a plurality of staggered main blasting holes in a main blasting region of a foundation pit excavation face, wherein the row pitches of the main blasting holes are equal, and the hole distances of the main blasting holes are equal. The uncoupling explosive charging devices are arranged in the presplitting holes. The uncouplingexplosive charging devices in the main blasting holes control accurate delay row-by-row hole-by-hole blasting through the digital electronic detonators, and then the blasting muck piles in the main blasting region are cleaned. Through the complex environment foundation pit excavation hole-by-hole blasting method, the foundation pit forming time is quick. Compared with the presplitting hole simultaneous blasting method, the presplitting hole hole-by-hole blasting method has the advantages that the average vibration reduction rate is high, vibration generated during main blasting region hole-by-hole blasting is greatly reduced, meanwhile, the presplitting holes are detonated to form a new free face first, and the blasting effect is greatly improved.

Owner:KUNMING UNIV OF SCI & TECH +1

Ceramic-base compound material and forming technique

The invention relates to a technology for shaping a ceramic-based composite material, which is integrated with principles of pressure injection, gel-casting and impregnating for preparing the ceramic-based composite material blank in complicated shape, even density of structure compositions and high strength so as to obtain a high-tenacity ceramic-based composite material product through sintering. The technology provided by the invention is a novel technology for shaping the ceramic-based composite material with high performance, complicated shape and fiber reinforcement, low cost and approximate net dimension. Compared with the prior art for shaping the fiber-reinforced ceramic-based composited material, the technology has the advantages of obvious superiority, short shaping time and high production efficiency.

Owner:肖青

Modeling method for plant building

The invention belongs to the technical field of garden modeling and discloses a modeling method for a plant building. The modeling method includes step S1 of manufacturing and fixing a framework die;step S2 of selecting and planting suitable plants; step S3 of cutting off the plants, treating the cross sections, and screening and shearing off tender shoots that grow in the cross sections; step S4of repeating step S3, so that a plurality of thin branches with uniform thicknesses are formed on the cross sections; and step S5 of weaving and binding the thin branches of the adjacent plants alongthe framework die so that the modeling of the plant building is made perfect. The modeling method makes the overall forming time short, is high in commercialization degree, facilitates rapid batch cultivation, transportation and cultivation, avoids the damage during transportation, and avoids the scraping of the whole building caused by the death of one plant, and is economical and practical andsuitable for promotion.

Owner:成都千蜀农业发展有限公司

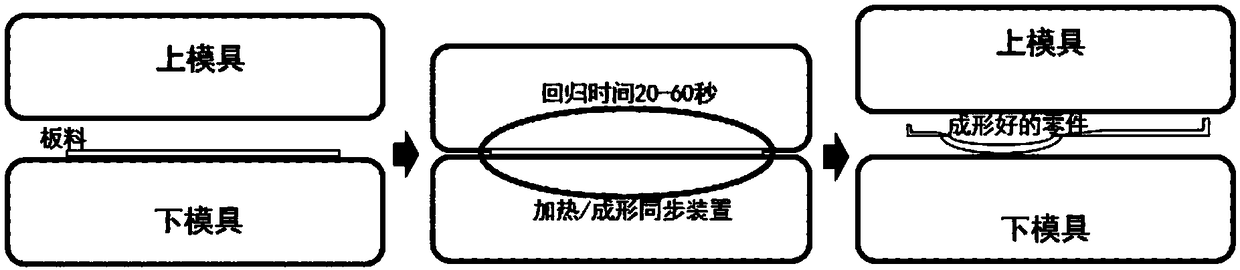

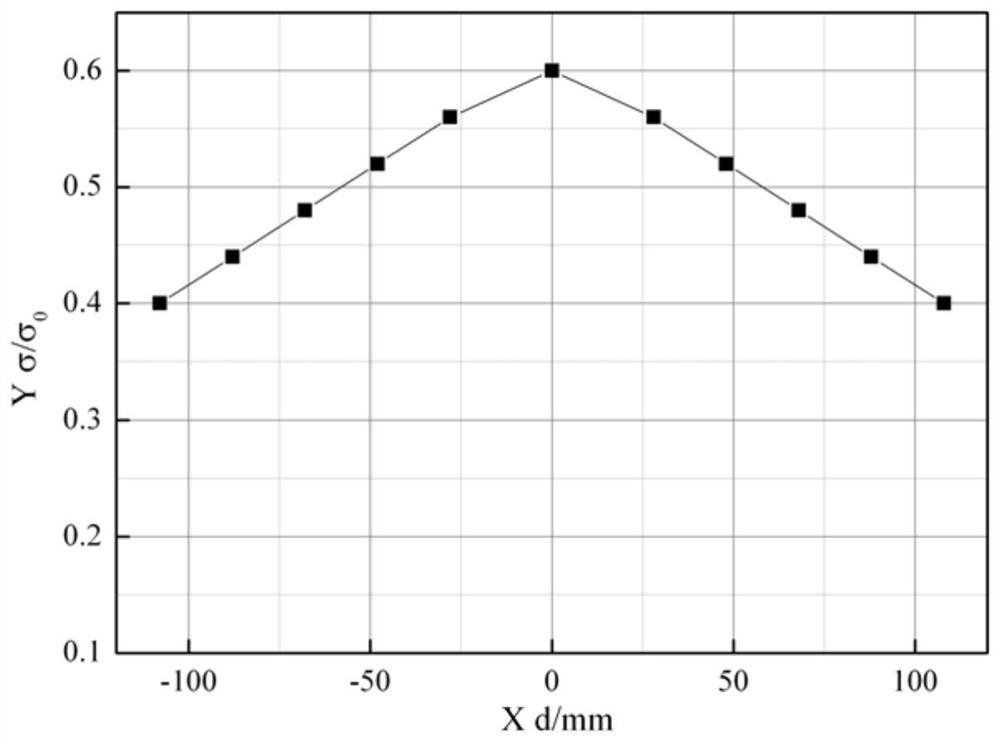

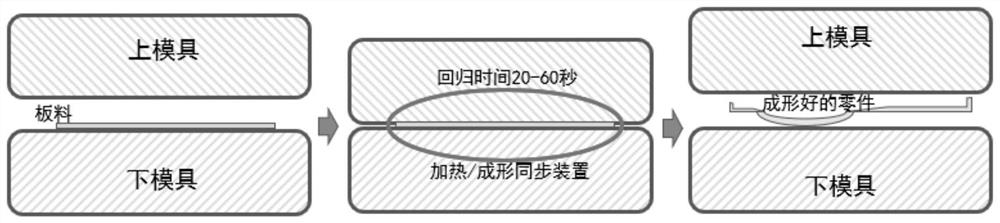

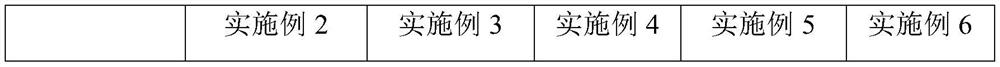

Artificial aging-state high-strength aluminum alloy retrogression forming synchronous process

ActiveCN109487184AImprove forming efficiencyReduce energy consumptionElectromagnetic inductionHolding time

The invention provides an artificial aging-state high-strength aluminum alloy retrogression forming synchronous process. Firstly, a stamping forming die is cleaned, and an artificial aging-state aluminum alloy is placed on the die; a sheet is rapidly heated to a temperature higher than an artificial aging temperature by 120-160 DEG C by means of electromagnetic induction or electric conduction heating; the heat preservation is carried out for a certain time period, wherein the heat preservation time is controlled to be 20-60 seconds or within; the stamping and the forming are carried out in the process, and a formed component is air-cooled to the room temperature; and the artificial aging strengthening treatment can be continuously carried out at a later stage according to the requirements. According to the process, the alloy stamping formability can be remarkably improved at a lower temperature, and specifically, the formability efficiency of the high-strength aluminum alloy is improved while the material performance of the high-strength aluminum alloy is ensured; and the synchronous process is beneficial to the cooperative control of the shape and performance of the high-strengthalloy, and can be used for manufacturing parts of automobiles, aerospace, ships and the like.

Owner:CENT SOUTH UNIV

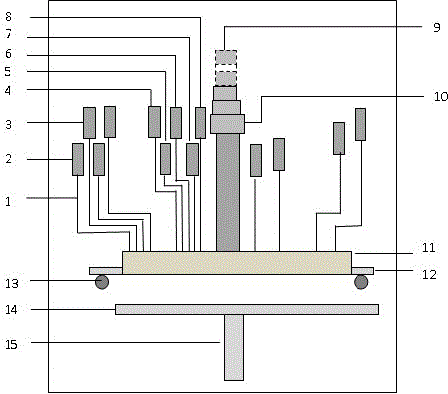

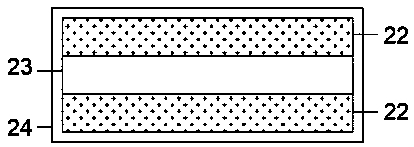

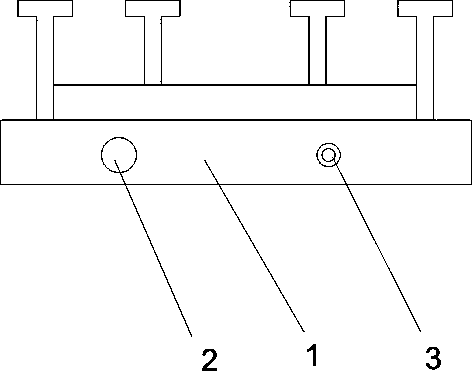

Full-area three-dimensional molding system

The invention discloses a full-area three-dimensional molding manufacturing system. According to the system, finite element analysis is firstly carried out on a three-dimensional model, and then parallel continuous molding of multiple materials is carried out through the full-area three-dimensional molding manufacturing system. Through the automatic material selecting and combining function of the molding manufacturing system, any multiple printing molding materials are freely combined, and wide materials are provided for the three-dimensional molding system. According to the full-area three-dimensional molding system, multiple materials of the model can be printed at the same time, any multiple materials can be freely and adjacently connected, molding time is short, and molding precision is high. Therefore, the mold has a few material compositions and is high in strength, and the functional or semi-functional model requirement can be met.

Owner:张亮 +1

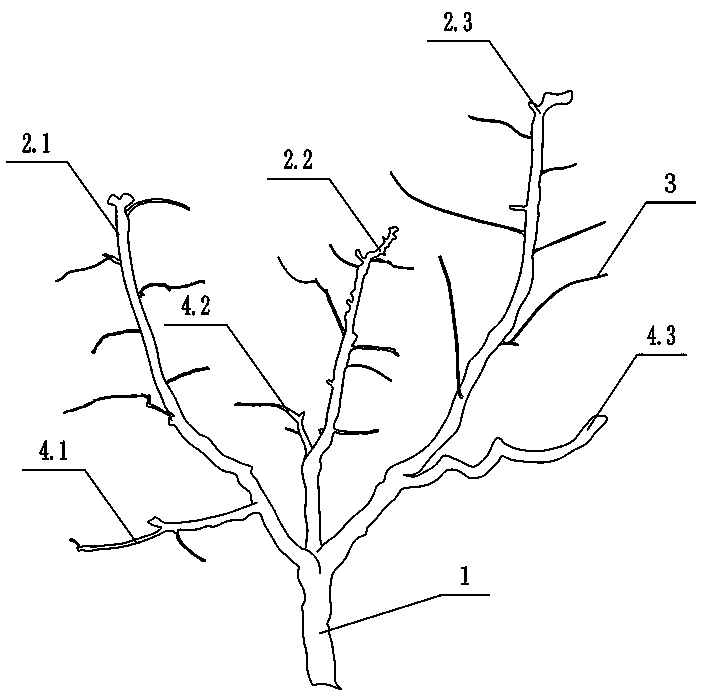

Tree shape and pruning method of three-main branch peach tree

ActiveCN109220304AShort forming timeHigh light efficiencyCultivating equipmentsHorticulture methodsMain branchTree shaped

The invention discloses a tree shape and pruning method of a three-main branch peach tree. The tree is 2.4-2.6m high and the trunk is 30-40cm high; three uniformly distributed main branches are left in the trunk outside the south; the angle between the adjacent main branches is 110-130 degrees, and the angle between each main branch and the trunk is 50-55 degrees; the base of each main branch is respectively provided with a permanent branch, and each main branch is provided with a bearing branch. The tree shape of the invention has the advantages of short forming time, high light efficiency, premature delivery, high yield and stable yield. Due to the sufficient illumination of fruits, the tree body is robust, the flower bud is full, the yield is stable and the fruit quality is good. Sincethe main branches grow with small inclination and the overall height is not high, people is convenient to stand on the ground to perform pruning and fruit picking, and inter-row mechanical operation can also be achieved. Meanwhile, the pruning method is simple to operate, easy to master, and can be quickly popularized.

Owner:濮阳市林业科学院

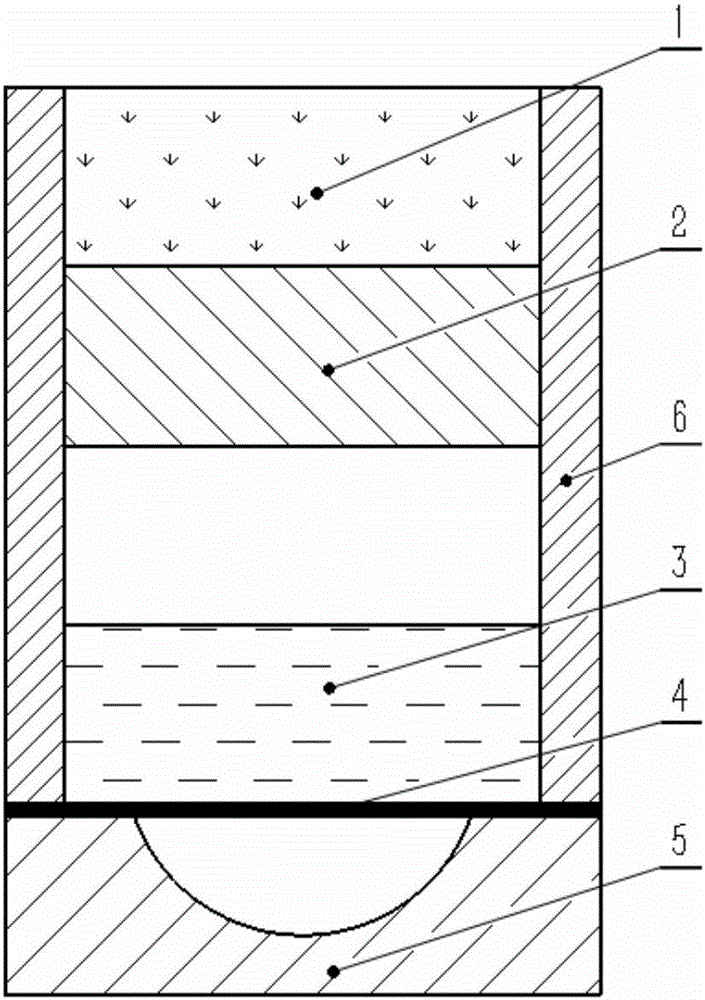

Copper conic liner and preparation method thereof

ActiveCN106694877ASame orientationImprove plasticityAmmunition projectilesFluid removalMelting tankStructure property

The invention discloses a copper conic liner and a preparation method thereof. The copper conic liner comprises a supporting column body, a liner top, an inner wall surface and an outer wall surface, wherein the supporting column body is connected with the liner top. The preparation method is characterized in that a laser fusion covering type rapid forming method is adopted; the temperature gradient of a bath formed by laser beams is utilized, and the hot flow dispersing direction is controlled through a water cooling system, on that basis, small columnar dendrite grains in a fusion covering layer can directionally grow in the axis direction of the liner, and thus the liner of which each part has the directional solidifying structure property can be prepared. The copper conic liner prepared by the method is outstanding in stretching performance in the axis direction, so that the metal jet extending performance can be effectively improved, the jet breakup time can be prolonged, and as a result, the penetration performance can be improved; in addition, the preparation method has the advantages of being short in formation time, high in size accuracy, and high in material utilization rate.

Owner:NANJING UNIV OF SCI & TECH

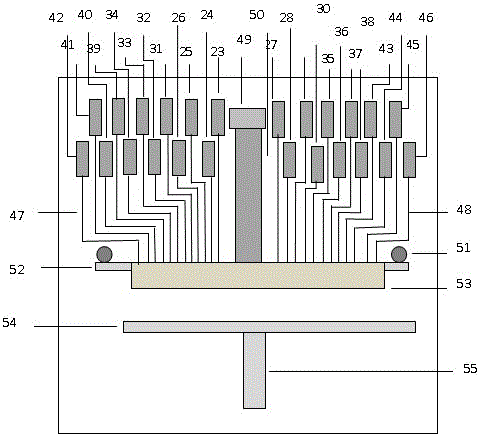

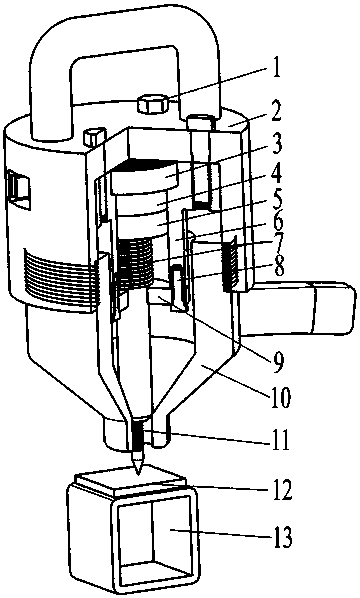

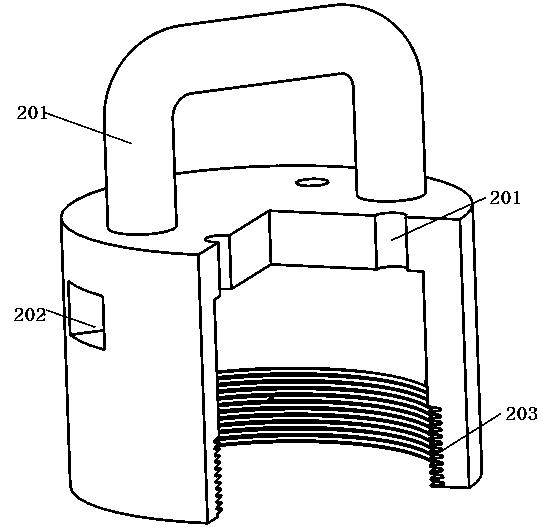

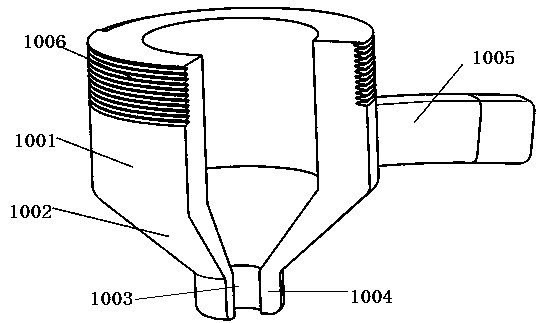

Heating type electromagnetic rivet-free connecting device and working method

The invention provides a heating type electromagnetic rivet-free connecting device and a working method. The connecting device comprises a fixed frame. A puncher pin drive device is arranged on the upper portion of the fixed frame, and a rivet mold is arranged on the lower portion of the fixed frame. An induction heating coil capable of heating to-be-connected workpieces through the eddy current effect is arranged on the rivet mold. The puncher pin drive device comprises an electromagnetic induction coil and a driver connected with a puncher pin and provided with a metal structure. The electromagnetic induction coil is adjacent to or connected with the metal structure of the driver. When the electromagnetic induction coil works, the induced current capable of forming a mutual exclusion magnetic field is induced by an alternating magnetic field formed by powering on the electromagnetic induction coil on the metal structure of the driver, the electromagnetic induction coil pushes the driver to move downwards through electromagnetic repulsive force, and the puncher pin is driven to impact on the two heated to-be-connected metal workpieces on the rivet mold so that the to-be-connectedmetal workpieces can be connected. Through the principle of electromagnetic induction heating, preheating of two kinds of to-be-connected metal is achieved, electromagnetic force is used as drive forso that the two kinds of to-be-connected metal workpieces can generate deformation to achieve one-time punching forming, and the forming effect is improved.

Owner:FUZHOU UNIV

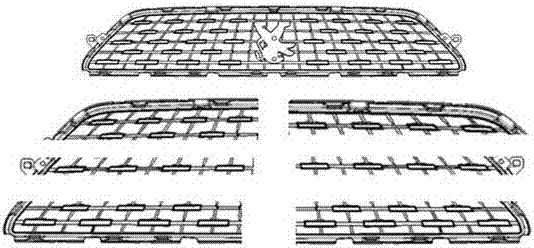

Car grille hot stamping technology

ActiveCN106853724AImprove qualityShort forming timeDuplicating/marking methodsOther printing apparatusHot stampingStamping process

The invention provides a car grille hot stamping technology. The technology comprises the following steps: 1, making a hot stamped film which sequentially comprises a carrier, a stripping layer, a protection layer, a metal layer and a sticking layer from top to bottom; 2, selecting a stamping clamp: arranging a direction adjusting mechanism below the stamping clamp, wherein the direction adjusting mechanism can realize the adjustment of the X direction, the Y direction and the Z direction in the space; 3, heating silica gel of an upper die in the stamping process, pressing the silica gel to make the silica gel touch the hot stamped film in order to press the hot stamped film and compact the hot stamped film on the stamped surface of a grille component on the surface of a lower die; and 4, separating a stamped surface area and a non-stamped surface area, arranging the stamped surface to be a projecting structure, and dividing the whole grille component into a plurality of parts, and stamping the grille component. The hot stamping technology adapts to multiple form styles, has the advantages of short shaping time, provision of a bright surface effect, avoiding of toxic gases or wastewater generated in the electroplating process, energy saving, and environmental protection; and a stamping device has the advantages of small occupied space, small energy consumption and low development cost.

Owner:WUHAN LIAOYUAN MOLDING

Cultivation method for fan-shaped artistic modeling of lagerstroemia plants

InactiveCN105028088AEasy to viewImprove product valueGraftingCultivating equipmentsLagerstroemiaNitzschia

The invention discloses a cultivation method for fan-shaped artistic modeling of lagerstroemia plants. The cultivation method comprises the following steps of firstly, structural analysis of folding fans; secondly, modeling design of fan-shaped trunks; thirdly, modeling design map production of single plant; fourthly, manufacturing and mounting of a single trunk breeding mold base; fifthly, single trunk breeding; sixthly, manufacturing of a fan-shaped trunk inarching supporting frame; seventhly, planting and inarching of the fan-shaped trunks; eighthly, maintenance management after inarching; ninthly, high grafting and head changing. The cultivation method disclosed by the invention has the advantages that the forming time is short, the service life is long, and the formed modeling can be viewed all the year round and for multiple years; standard and scale production can be realized; the artistic effect of the fan-shaped modeling is obtained, and the ornamental value and the commodity value of nursery stock are obviously improved.

Owner:TONGREN MANTANGHONG AGRI TECH

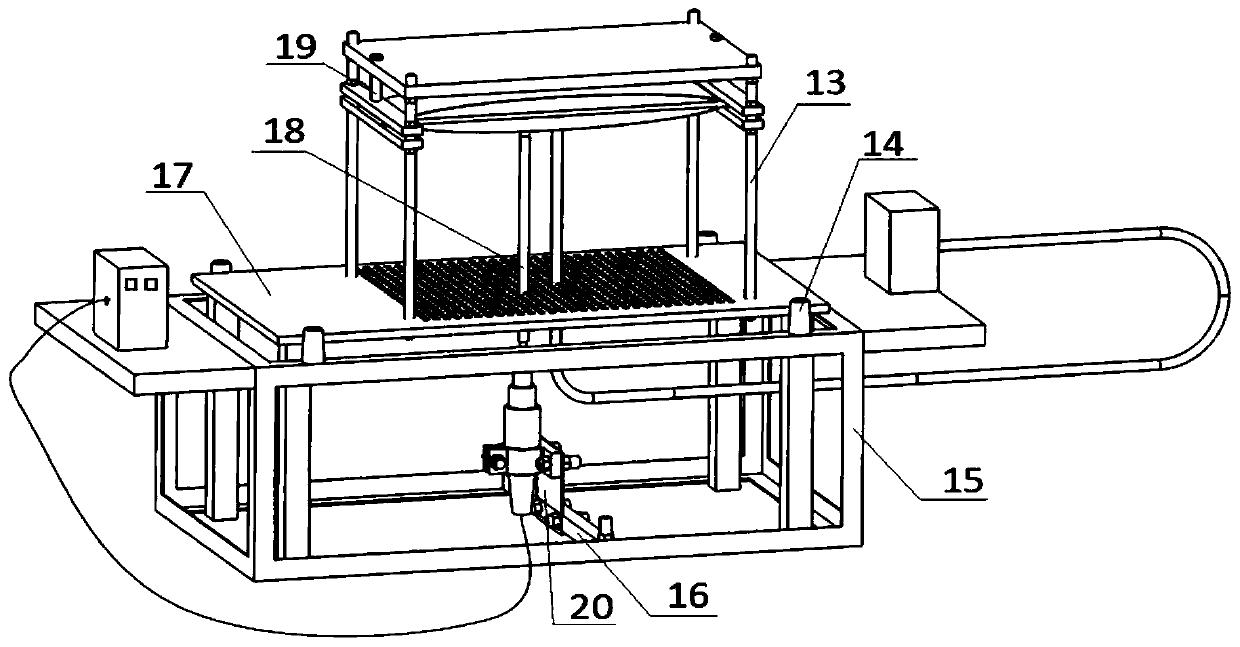

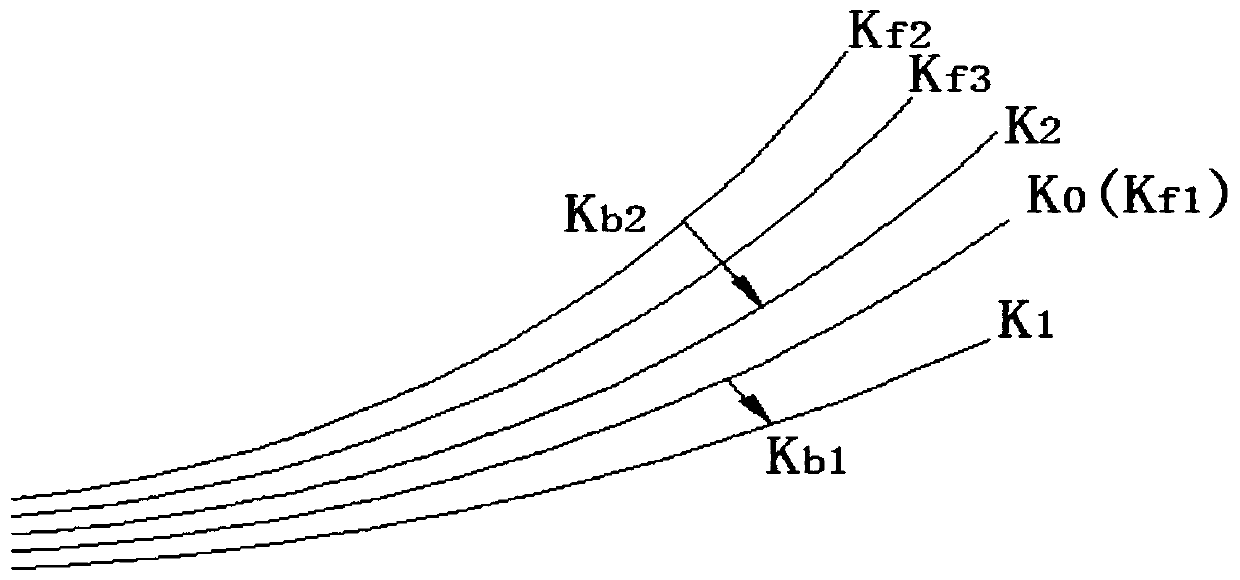

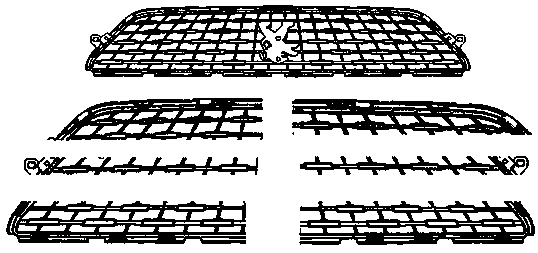

Air pressure loading based vibration creep combined incremental age forming method and device

The invention discloses an air pressure loading based vibration creep combined incremental age forming method and device. The method is characterized in that a die surface is constructed in real timethrough an adjustable height multi-point type tool head based on the optimized incremental forming route, and the air source is adjusted to change the air pressure, so that a rib sheet can be clung tothe constructed die surface in each time; a special temperature control box is used for performing vibration creep combined incremental age forming on the rib sheet after being clung each other, andthe forming is finished after the rebound rate delta K / H of the forming surface is not beyond epsilon, and the forming surface is finally obtained. According to the method, a deformable curved surface is constructed in real time, and low-frequency vibration is caused so as to realize incremental forming and shape property adjusting and controlling of the rib sheet in age forming, thus multi-die processing, mounting and debugging processes can be avoided; the inner dislocation quantity of the material is increased and the crystal grains are enhanced while inner stress in formation is released,and as a result, the purposes of reducing the age time, decreasing the rebound rate, improving the crystal grain distribution uniformity and improving the size stability of the rib sheet can be achieved.

Owner:CHONGQING THREE GORGES UNIV

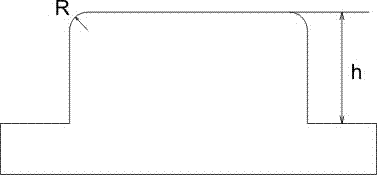

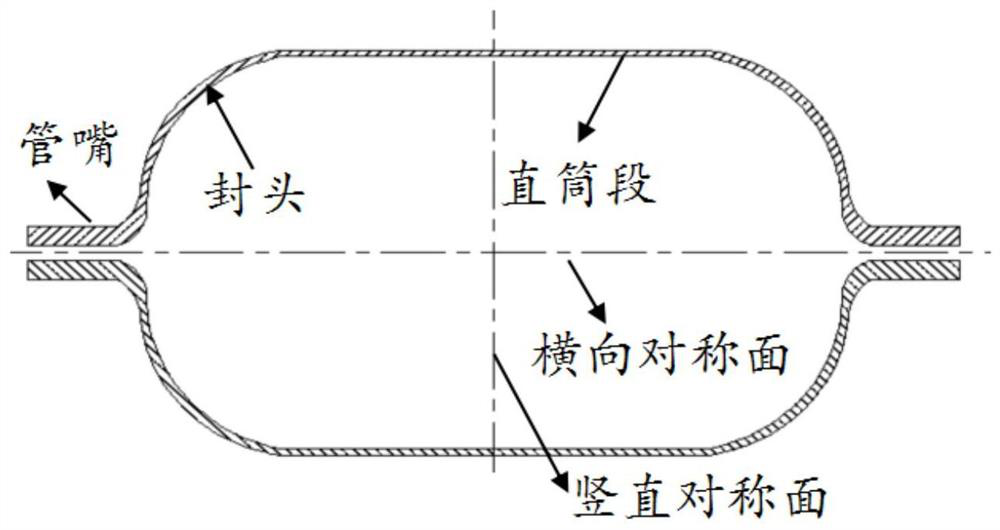

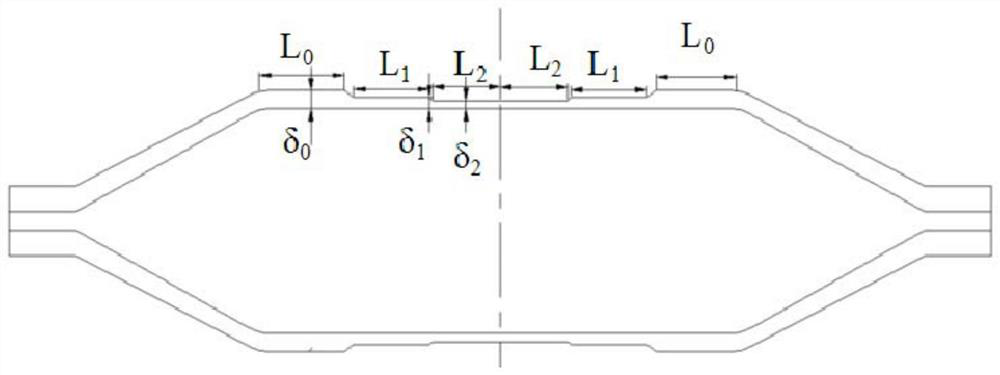

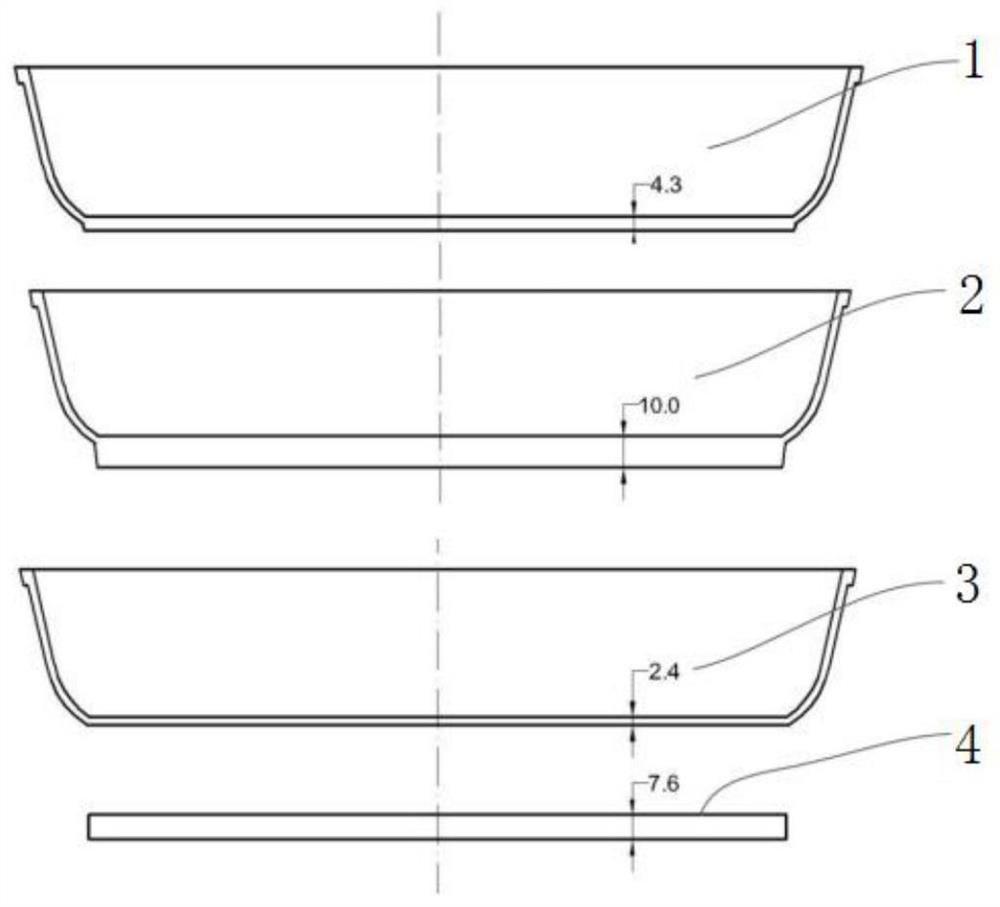

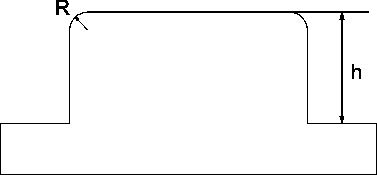

Titanium alloy thin-wall seamless lining straight cylinder section superplastic forming wall thickness uniformity control method

ActiveCN112974614AGuaranteed accuracyControl wall thicknessShaping toolsHydro energy generationSpinningTitanium alloy

The invention discloses a titanium alloy thin-wall seamless lining straight cylinder section superplastic forming wall thickness uniformity control method, and belongs to the technical field of plastic processing. According to the method, a small-caliber lining spinning part with the variable wall thickness is adopted for conducting superplastic bulging, firstly, a thinning area is machined on a straight cylinder section of the lining spinning part, an original equal-thickness straight cylinder section is machined into a variable-wall-thickness pipe with the same annular direction and axial gradient distribution, and then superplastic bulging is conducted. According to the method of the invention, through the special wall thickness gradient design, the wall thickness distribution of the straight cylinder section of the bulged titanium alloy lining can be adjusted, a large-diameter lining blank with the thickness of the straight cylinder section being evenly distributed is obtained, the requirement for subsequent machining thinning wall thickness tolerance is met, meanwhile, control measures are taken for cooling of the lining blank, and the dimensional stability of the formed titanium alloy lining is ensured. The method is suitable for titanium alloy thin-wall seamless linings with various diameters, which are integrally formed by spinning / superplastic.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

A Simultaneous Regression Forming Process of Artificially Aged High-Strength Aluminum Alloy

ActiveCN109487184BTo achieve the effect of precipitation strengtheningInhibition of the effect of aging treatment enhancementAerospaceAluminium alloy

The invention provides an artificial aging-state high-strength aluminum alloy retrogression forming synchronous process. Firstly, a stamping forming die is cleaned, and an artificial aging-state aluminum alloy is placed on the die; a sheet is rapidly heated to a temperature higher than an artificial aging temperature by 120-160 DEG C by means of electromagnetic induction or electric conduction heating; the heat preservation is carried out for a certain time period, wherein the heat preservation time is controlled to be 20-60 seconds or within; the stamping and the forming are carried out in the process, and a formed component is air-cooled to the room temperature; and the artificial aging strengthening treatment can be continuously carried out at a later stage according to the requirements. According to the process, the alloy stamping formability can be remarkably improved at a lower temperature, and specifically, the formability efficiency of the high-strength aluminum alloy is improved while the material performance of the high-strength aluminum alloy is ensured; and the synchronous process is beneficial to the cooperative control of the shape and performance of the high-strengthalloy, and can be used for manufacturing parts of automobiles, aerospace, ships and the like.

Owner:CENT SOUTH UNIV

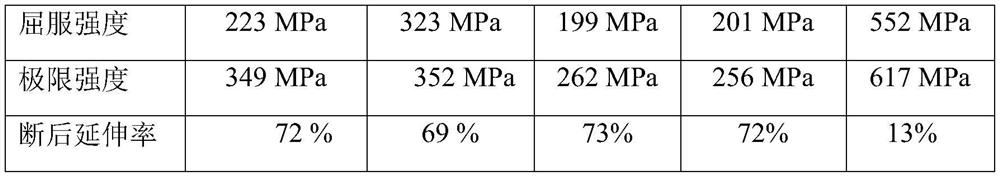

Mold heating device

The invention discloses a mold heating device, which comprises a device body. A heat preservation layer is arranged on the inner side of the device body, and a heating cavity is formed in the device body and communicates with a charging opening in the left side of the device body through a feeding pipeline; a heat dissipation opening is formed in the top of the device body, and a heat dissipationfan is arranged at the heat dissipation opening; a plurality of silicon molybdenum bars are arranged on the periphery and at the bottom of the heating cavity, and a thermocouple is arranged on one side of the heating cavity and connected with a temperature control meter which is arranged on the device body; the device body is externally connected with a control cabinet, and universal wheels are arranged at the bottom of the device body; the bottom in the heating cavity is connected with a tray through a rotating shaft, and the tray is in a hollowed-out shape; the rotating shaft is connected with a rotating motor, and the rotating motor is mounted at the bottom of the device body; heat conducting pipes are arranged on the two sides outside the heating cavity and are each in a U shape, and the heat conducting pipes on the two sides are connected with the heat dissipation opening and provided with heat insulation layers; and heat dissipation sheets are arranged on the heat insulation layers, and a discharging outlet is formed in the other side of the heating cavity. Heating distribution in the heating cavity is uniform, mold heating is full and uniform, water vapor can be effectivelyremoved, and the heating efficiency is improved.

Owner:MAANSHAN NIUZE TECH SERVICE

Production process for bottoms of light-emitting diode (LED) landscape tree lights

The invention discloses a production process for bottoms of light-emitting diode (LED) landscape tree lights. The production process is characterized by comprising the following steps of: 1, coating a silicon rubber mould provided with a cavity on the bottom of a trunk of a landscape tree; 2, accurately weighing polyether or polyester polyol (a white material), polyisocyanate (a black material), water, a catalyst, a surfactant and a foaming agent, adding into a container by one step, and mixing under high speed stirring condition; 3, pouring the raw materials into the silicon rubber mould; 4, fully foaming and cooling the raw materials in the silicon rubber mould, and opening the silicon rubber mould; and 5, coating a polyurethane (PU) elastomer layer outside a foam body. The production process has the advantages of simple production process, high production efficiency, low cost and the like.

Owner:张宏伟

High-pressure water jet plate incremental forming and cutting device

ActiveCN102218706BIncrease movement speedUniform thicknessAbrasive blasting machinesJet flowUltra high pressure

The invention discloses a high-pressure water jet plate incremental forming and cutting device, which comprises a five shaft forming unit, a plate material fixture, a lower support mold, a trough, a base, an ultrahigh pressure water pump and a high pressure water nozzle, wherein the five shaft forming unit is mounted above the base; the plate material fixture is mounted in the trough; the lower support mold is mounted in the plate material fixture and is connected with the trough; the trough is fixed on the base; and the high pressure water nozzle is mounted at the tail end of the forming armof the five shaft forming unit and is connected with the ultrahigh pressure water pump through a high pressure pipe. In the utility model, the powerful impact force of water jet is used for carrying out incremental forming on the plate; moreover, the fine features of the plate can be formed and cut by controlling the pressure of the water jet and the thickness of the water jet; and the forming efficiency and quality are far higher than the forming efficiency and quality of the current incremental forming method. Besides, the incremental forming way does not need lubricant and does not cause pollution to the environment, thus being a clean plate forming way.

Owner:SHANGHAI JIAOTONG UNIV

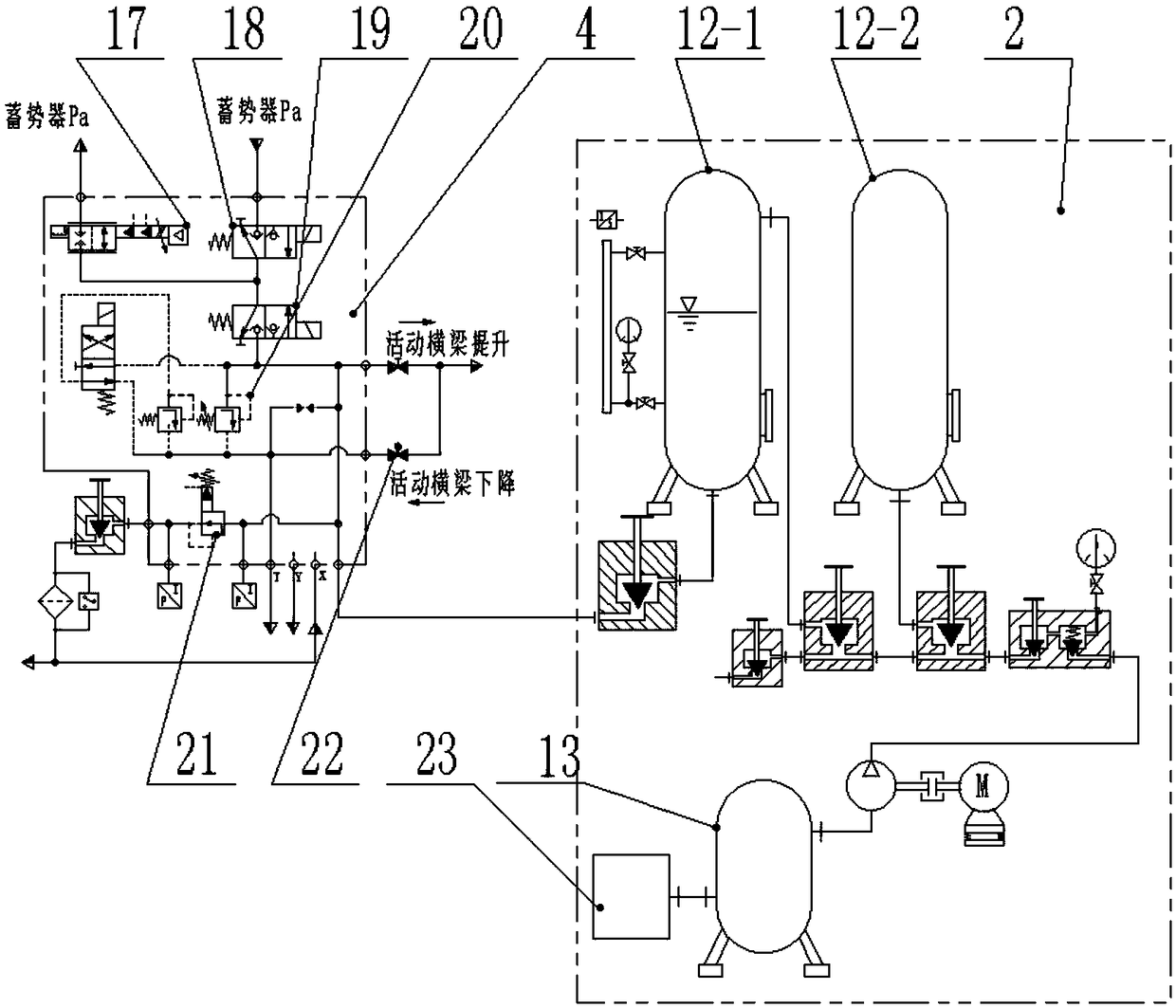

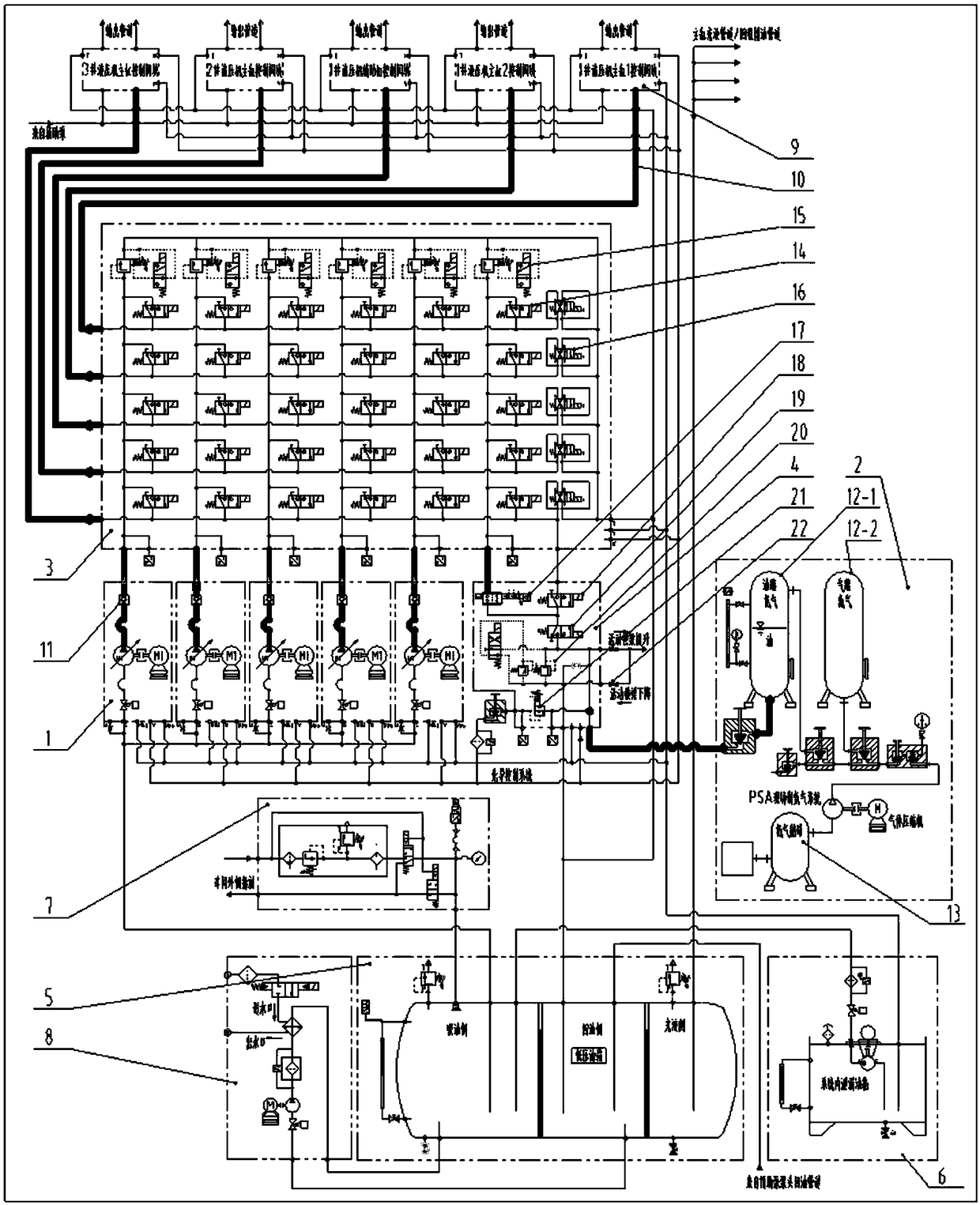

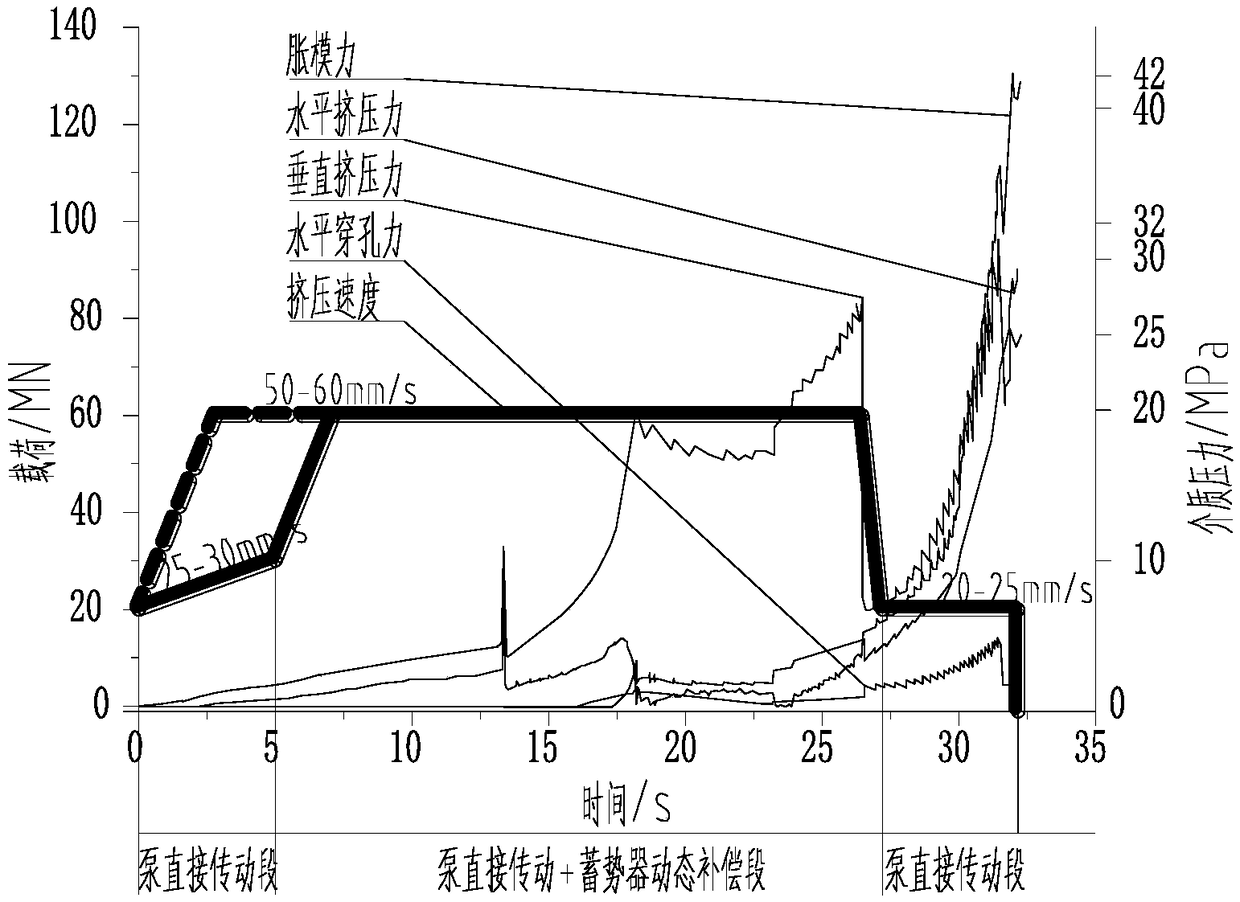

Dynamic compensation control system for flow and pressure of accumulators

PendingCN109248981AReduce the total installed powerReduce purchasing costsForging press drivesLow voltageHigh pressure

The invention discloses a dynamic compensation control system for flow and pressure of accumulators. The dynamic compensation control system for flow and pressure of the accumulator comprises a plurality of medium and high pressure accumulators and accumulator control valve blocks, each medium and high pressure accumulator comprises a plurality of oil tanks and gas tanks, a pipe of an outlet of each oil tank is connected with an accumulator control valve block, and the accumulator control valve blocks control compensation flow of output of the oil tanks. By the accumulators and the accumulatorcontrol valve blocks, output of maneuvering flow of the oil tanks can be controlled through a high frequency response proportional valve according to a process load curve of a hydraulic machine, in acycle period, power stored by the accumulators dynamically compensate flow required for a direct transmission system of an oil pump in a medium and low voltage load stage, thus, a main cylinder meetsthe requirement for specified working speed, and the main cylinder can serve as a pilot control oil source of a whole hydraulic system. By the dynamic compensation control system for flow and pressure of accumulators, installing total power required for establishment of an independent pump station of each hydraulic machine can be greatly reduced, idle or less power consumption of the accumulatorsis reduced effectively, the running efficiency is improved, the purchasing cost of the hydraulic system can be reduced remarkably, and project investment and production and running costs are reduced.

Owner:NANJING DEV ADVANCED MFG

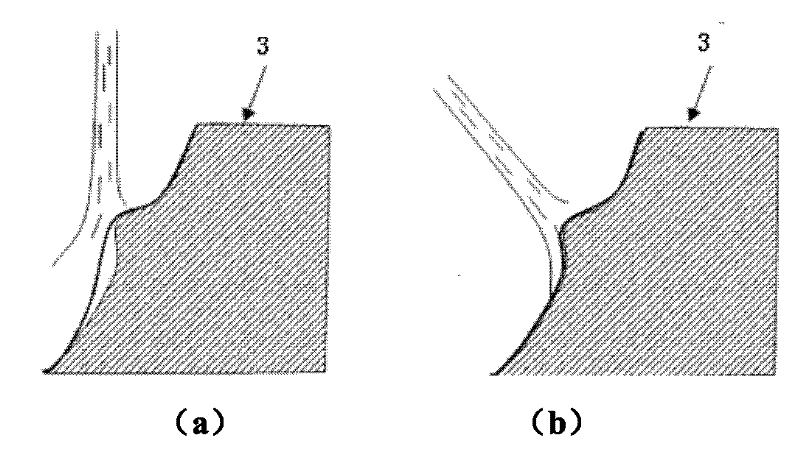

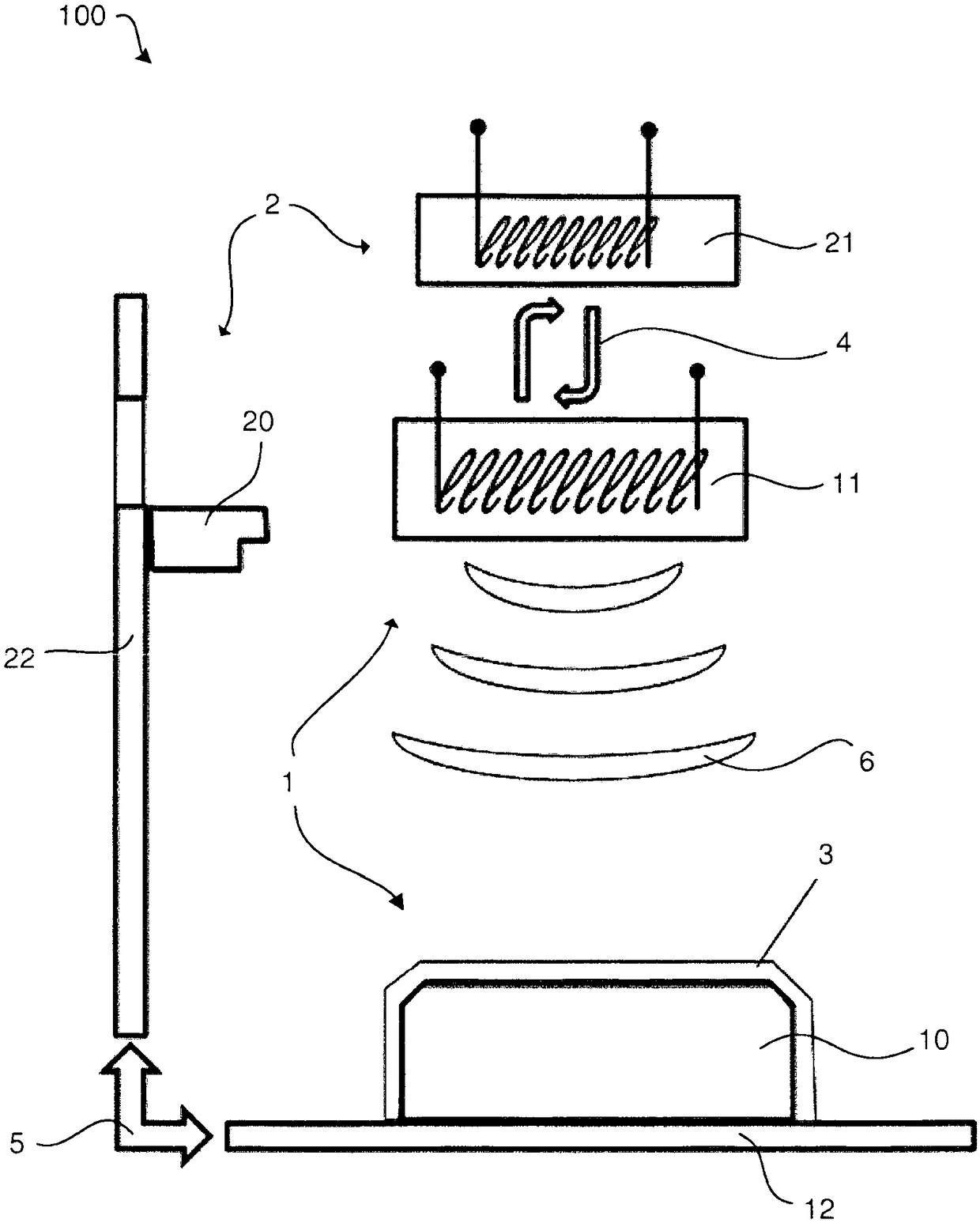

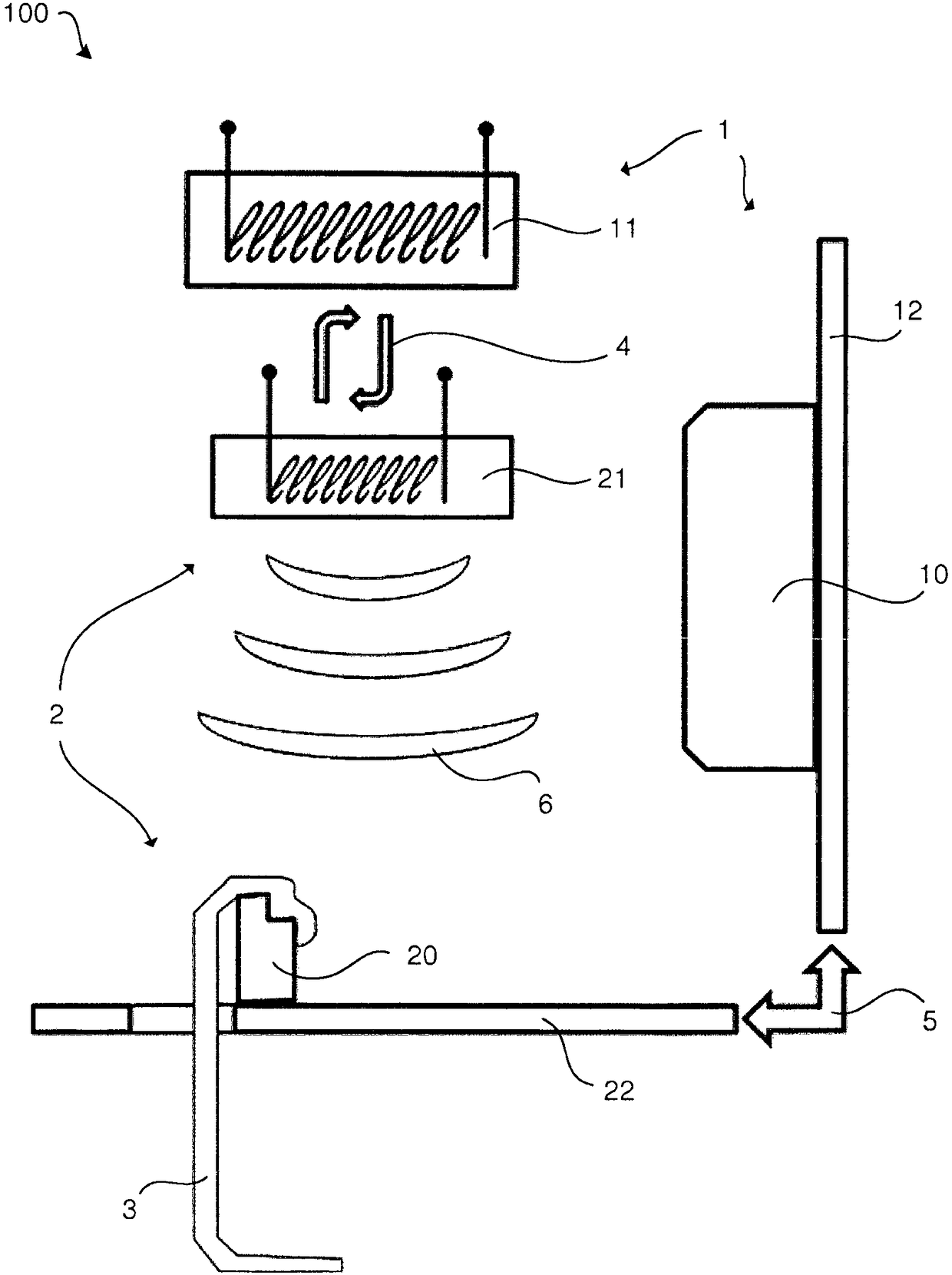

Device and method for shaping workpieces by means of magnetic pulse forming

ActiveCN108495725AReduce consumptionShort forming timeInductances/transformers/magnets manufacturePress ramEngineeringMetal

The invention relates to a device (100) for shaping workpieces, in particular for shaping body sheet-metal parts. The device (100) has a first magnetic forming apparatus (1), which comprises at leastone first forming tool (10) and at least one first magnetic tool (11), and a second magnetic forming apparatus (2), which comprises at least one second forming tool (20) and at least one second magnetic tool (21). The first magnetic forming apparatus (1) is designed to shape a workpiece (3) in a first magnetic forming process, and the second magnetic forming apparatus (2) is designed to further shape the workpiece (3) in a second magnetic forming process following the first magnetic forming process. The invention further relates to a method for shaping a workpiece (3).

Owner:BAYERISCHE MOTOREN WERKE AG

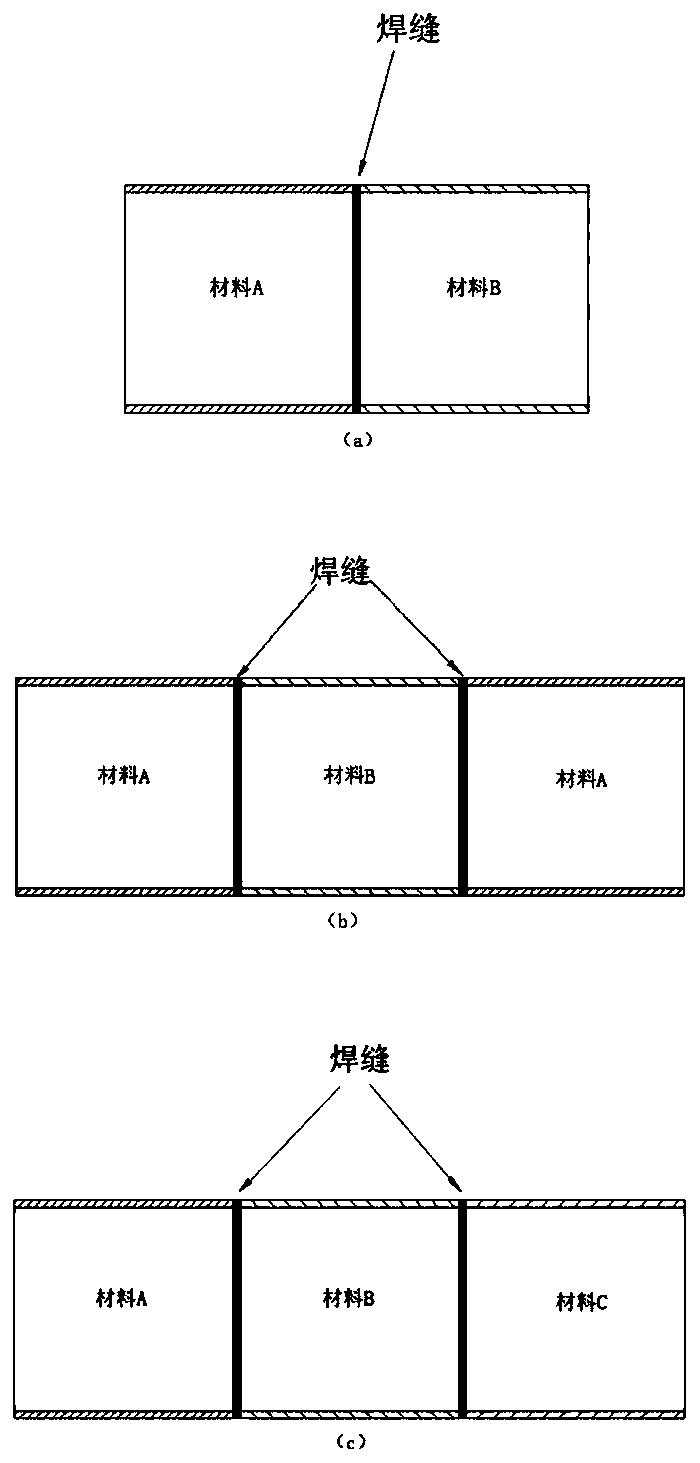

A Warm and Hot Forming Method of Magnesium Alloy Parts Based on Diffusion Bonding

ActiveCN110802190BIncrease profitReduce deformation resistanceMetal-working apparatusHeat conservationMagnesium alloy

The invention provides a magnesium alloy component warm heating forming method based on diffusion bonding, and belongs to the technical field of stamp forging forming. A magnesium alloy component is formed sequentially through preheating, compressing and heat preservation treatment after composition components are spliced. The preheating temperature is 350-400 DEG C, and the compressing temperature is consistent to the preheating temperature. The forming method can solve the problem that forming of magnesium alloy components with local small characters, special shapes and uneven wall thicknesses is difficult; and meanwhile, through the forming method, the production cost can be reduced, and the product quality and the production efficiency are improved.

Owner:SHANGHAI FUTING TECH CO LTD

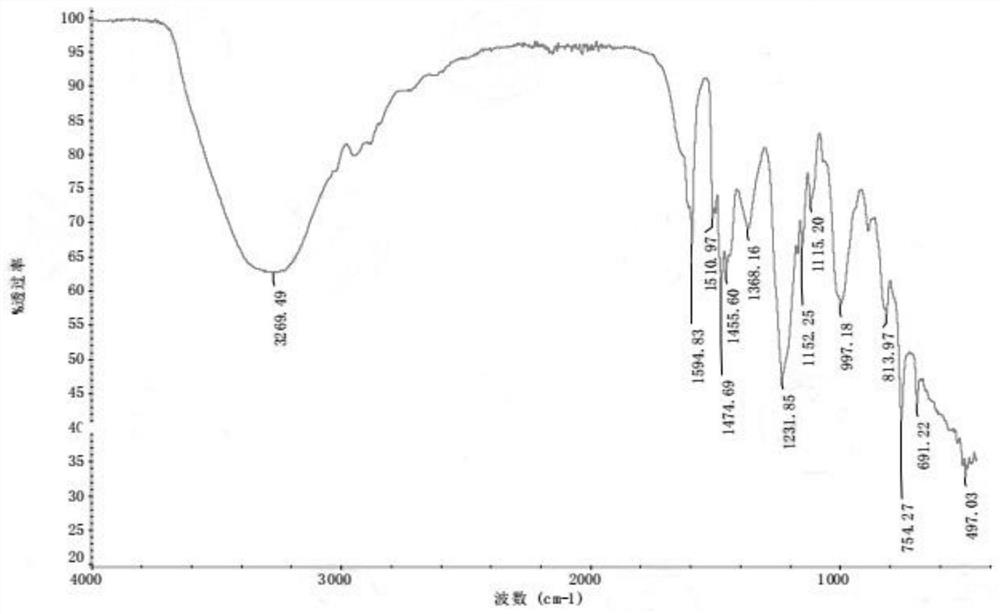

Environmentally friendly water-based phenolic resin for speaker springs

The invention discloses an environmentally friendly water-based phenolic resin used for loudspeaker elastic waves, which is characterized in that the weight ratio of raw materials is as follows: 73.8-75% of phenolic resin, 1-5% of phenol, 0.5-1.5% of m-hydroxybenzyl alcohol, Oleic acid 0.5-1.5%, water 18.7-20%, sodium hydroxide 0.5-1.5%. The optimal formula of the above raw materials is 73.8% of phenolic resin, 3.6% of phenol, 1.4% of m-hydroxybenzyl alcohol, 1.3% of oleic acid, 18.7% of water and 1.2% of sodium hydroxide. The invention has the advantages of high strength, good temperature resistance, improved elastic wave performance index, no volatile harmful substances, environmental protection and no volatile odor.

Owner:陈志豪 +1

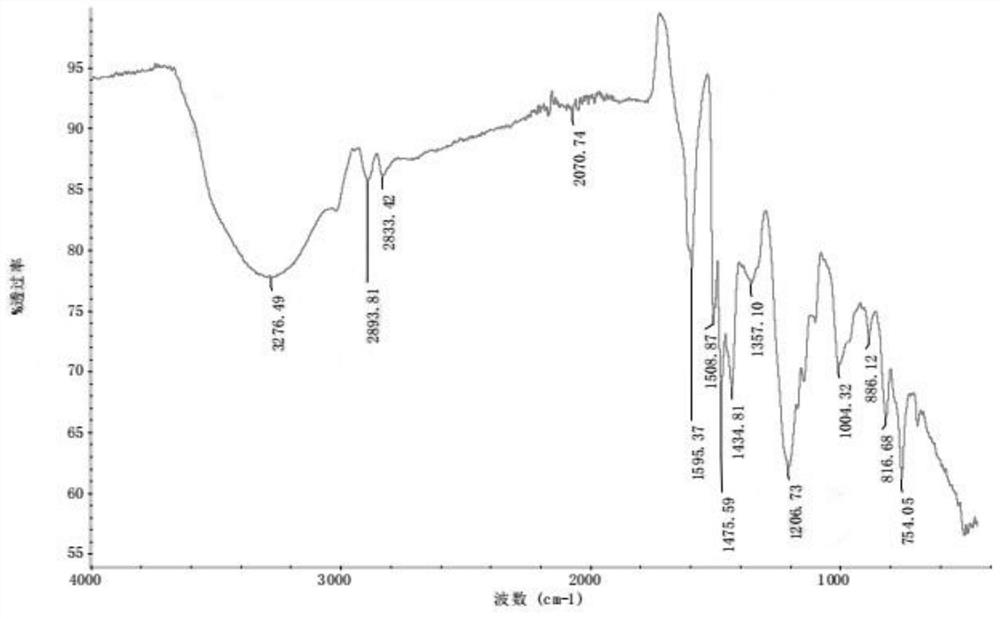

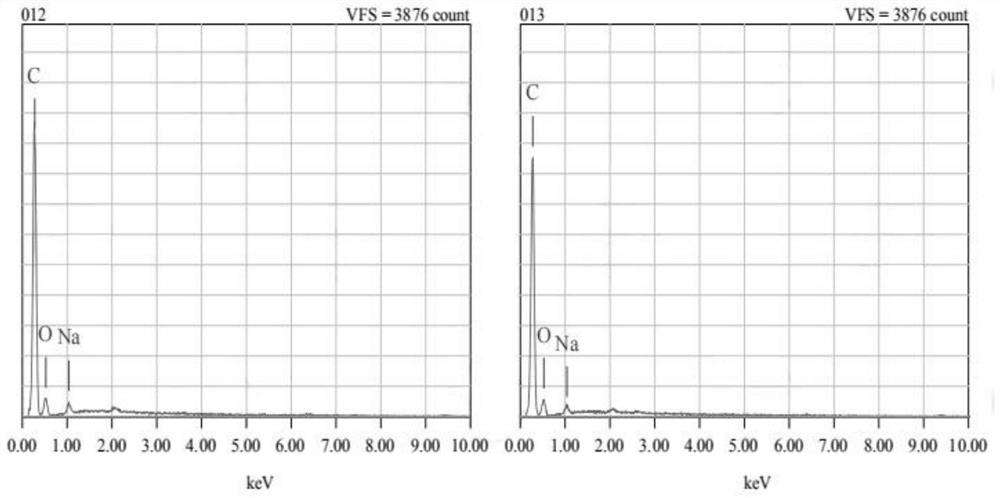

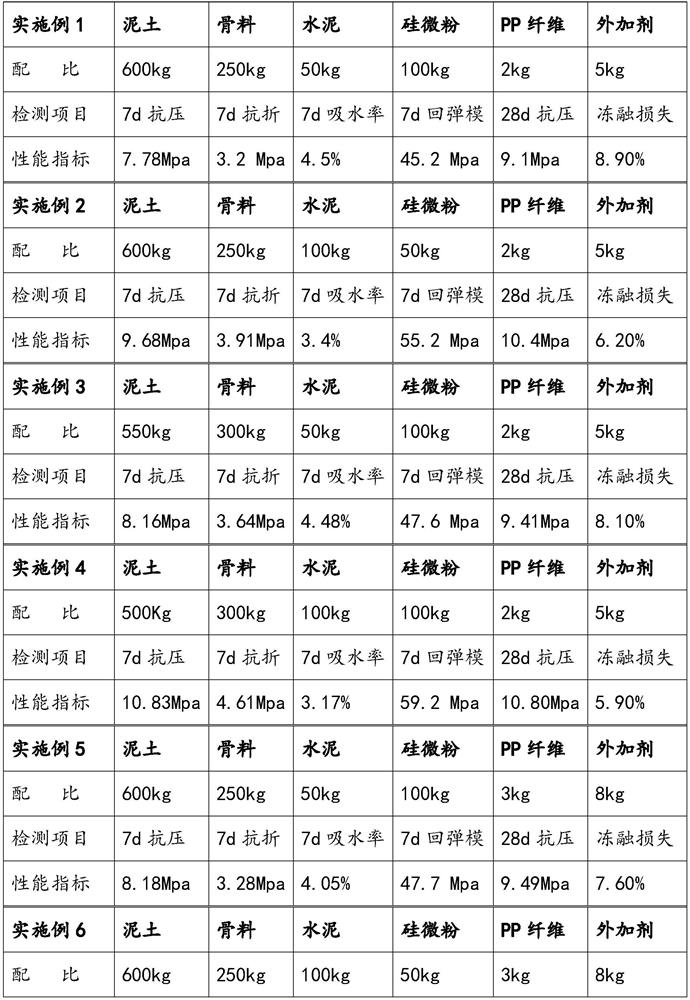

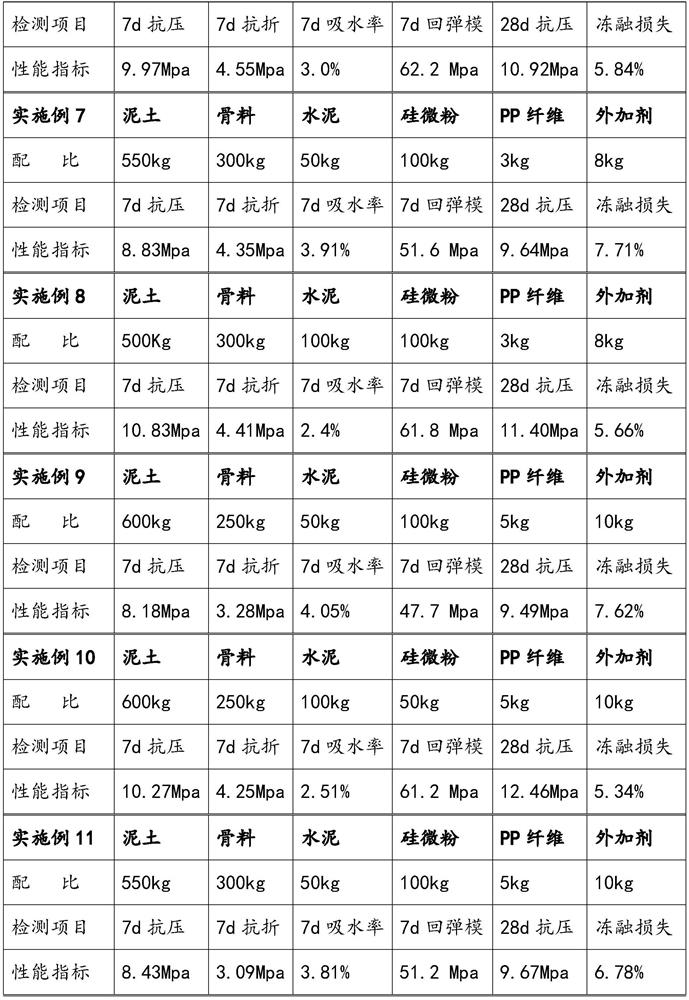

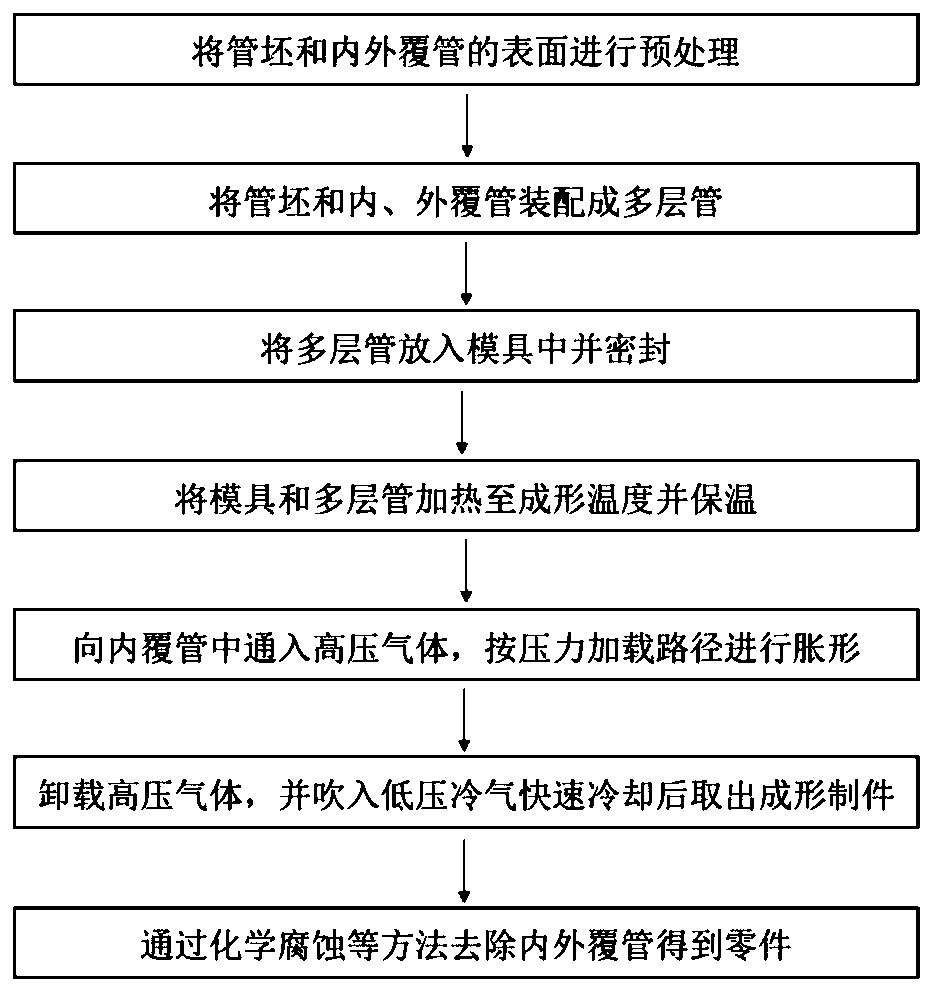

Tabia as well as preparation method and use method thereof

InactiveCN113213849ARaise the ratioRaw materials are easy to getIn situ pavingsBuilding material handlingFiberEngineering

The invention is applicable to the related fields of cultural relic protection and repair, and provides tabia and a preparation method and a use method thereof, and the tabia comprises a mixture, anti-crack fibers and an additive diluent; the mixture comprises the following raw materials in percentage by mass: 50-65% of soil, 20-30% of aggregate, 5-10% of cement and 5-10% of silica powder; the weight of the anti-crack fibers is 0.2-0.5% of the weight of the mixture; and the admixture diluent comprises an admixture and water, the weight of the admixture is 0.5-1% of the weight of the mixture, and the water amount is equal to the sum of the optimal water content- the onsite water content + 3%. According to the tabia, the preparation method of the tabia and the use method of the tabia provided by the embodiment of the invention, the proportion of the tabia is simple, the raw materials are easy to obtain, the cost is low, the water resistance is good, the frost resistance is good, the strength is high, the wear resistance is good, the preparation mode is rapid and simple, the technical construction is simple and convenient, the molding time is short, and the tabia can be suitable for various application scenes.

Owner:湖南乐德建筑科技有限公司

Device for quickly winding coverage strips

InactiveCN108783709AShort forming timeNot easy to looseClothes making applicancesEngineeringWire drawing

The invention discloses a device for quickly winding coverage strips. The device comprises a rotary head and an end cover, wire holes are formed in the rotary head and the end cover, and coverage strip inlets are formed in the left and right sides of the rotary head; a hole groove with a U-shaped section is formed in the end face of the front end of the rotary head, a pressing block is arranged inthe hole groove, the front end of the pressing block is located at an arc part of the bottom of the hole groove, a pressing ring is arranged between the end face of the front end of the pressing block and the bottom face of the hole groove, and through holes corresponding to wire holes are formed in the portion, in the length direction of the pressing block, of the middle of the pressing block. Compared with the prior art, the coverage strips can quickly cover a wire core simply by inserting the left and right coverage strips into the coverage strip inlets in sequence through the rotation ofthe rotary head and uniform-speed drawing by a wire drawing machine. The forming time is short; meanwhile, formed belts are solid and durable and do not easily get loose.

Owner:自贡市袋友皮具有限公司

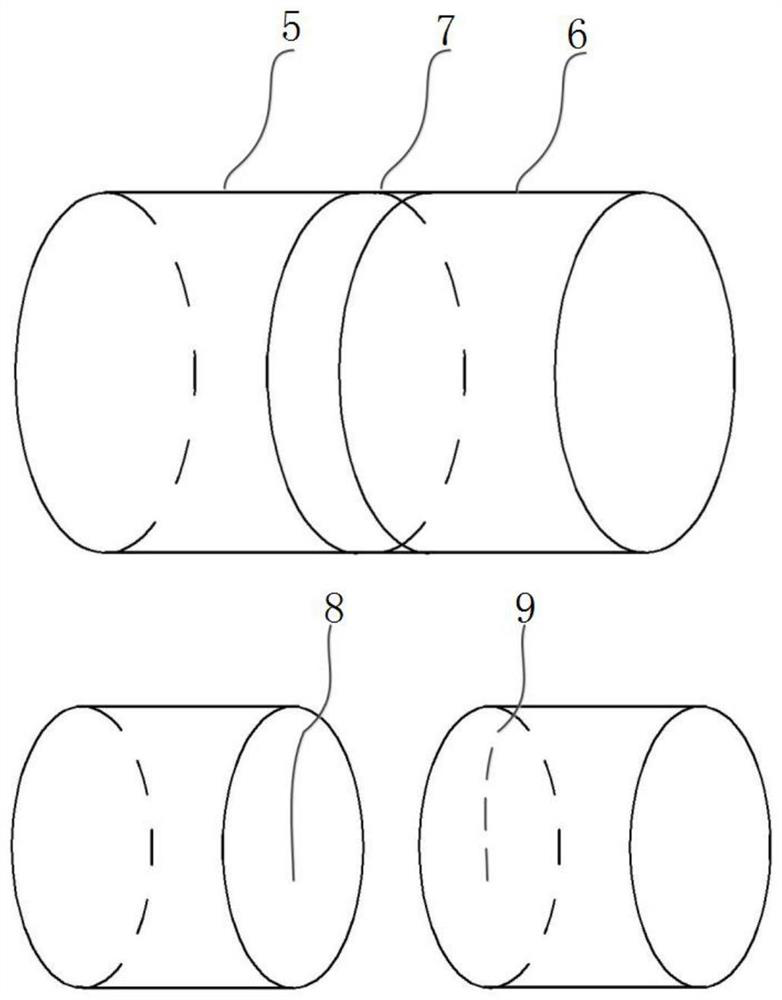

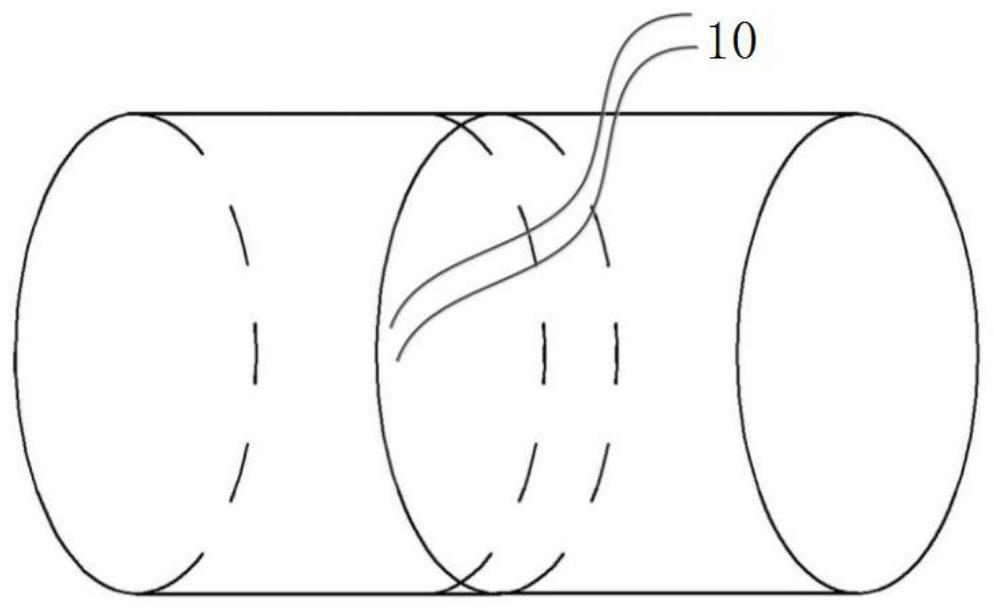

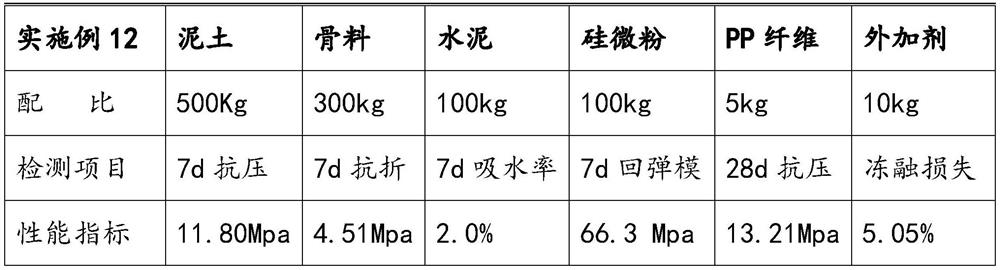

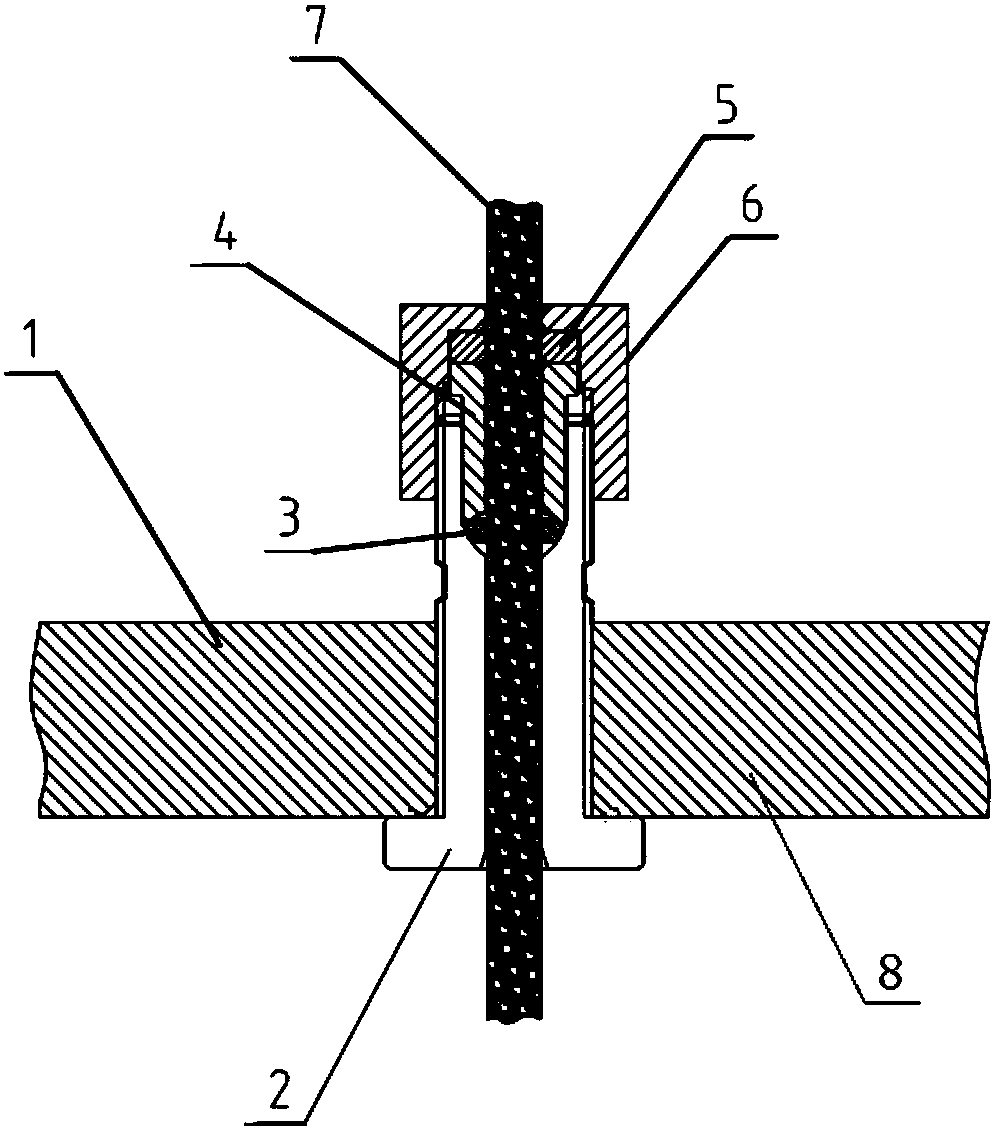

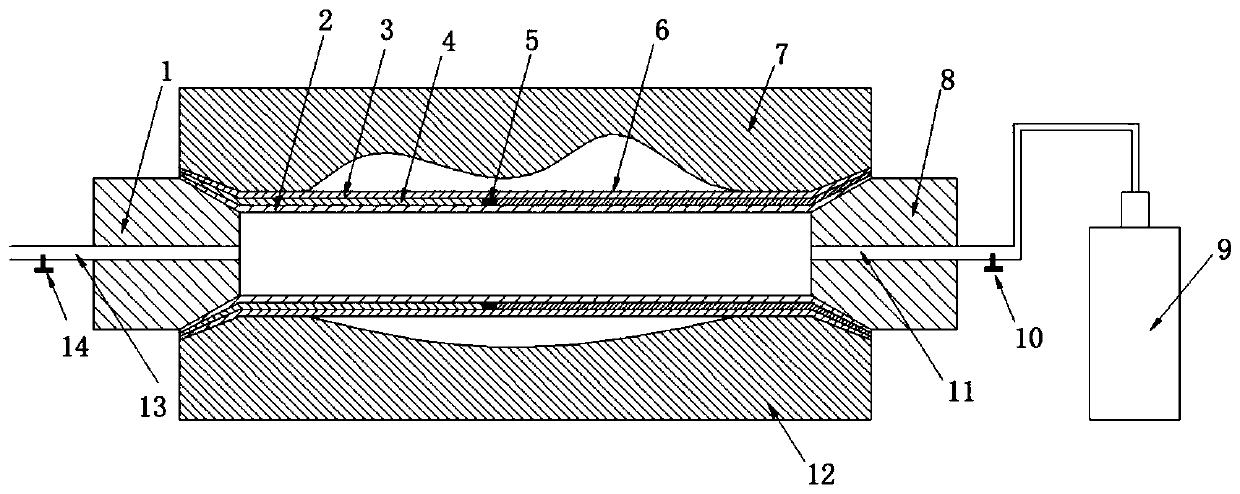

Multi-layer tube assisted rapid inflation device and method for curved pipe fittings made of dissimilar materials

The invention belongs to the field of metal plate or pipe, rod or profile machining treatment, discloses a multilayer pipe assisted rapid air expansion device for a curved surface pipe fitting made ofheterogeneous materials, and further provides a forming method utilizing the device. The interior and the exterior of a pipe blank made of the heterogeneous materials are each additionally provided with a layer of coating pipe, wherein the inner coating pipe is used for promoting material forming on the side, with the larger strength, of the pipe blank, and the outer coating pipe is used for limiting material forming on the side, with the smaller strength, of the pipe blank. High-pressure gas is pumped into an inner cavity of the inner coating pipe to achieve multilayer pipe assisted high-temperature rapid air expansion forming. The forming method is used for efficiently and rapidly preparing the pipe fitting formed by butt welding of the large-size heterogeneous materials and having thecomplex curvature and the special-shaped section, the method can effectively avoid the problems such as uncoordinated deformation, curvature mutation and even rupture defects around weld joints due tothe material difference during expansion, the dimensional accuracy of formed parts is controlled, and the formed pipe fitting is excellent in performance and stable in quality. The method can also beused for post-weld shape righting of the complex pipe fitting.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Automobile grill hot stamping process

ActiveCN106853724BImprove qualityShort forming timeDuplicating/marking methodsOther printing apparatusHot stampingToxic gas

The invention provides a car grille hot stamping technology. The technology comprises the following steps: 1, making a hot stamped film which sequentially comprises a carrier, a stripping layer, a protection layer, a metal layer and a sticking layer from top to bottom; 2, selecting a stamping clamp: arranging a direction adjusting mechanism below the stamping clamp, wherein the direction adjusting mechanism can realize the adjustment of the X direction, the Y direction and the Z direction in the space; 3, heating silica gel of an upper die in the stamping process, pressing the silica gel to make the silica gel touch the hot stamped film in order to press the hot stamped film and compact the hot stamped film on the stamped surface of a grille component on the surface of a lower die; and 4, separating a stamped surface area and a non-stamped surface area, arranging the stamped surface to be a projecting structure, and dividing the whole grille component into a plurality of parts, and stamping the grille component. The hot stamping technology adapts to multiple form styles, has the advantages of short shaping time, provision of a bright surface effect, avoiding of toxic gases or wastewater generated in the electroplating process, energy saving, and environmental protection; and a stamping device has the advantages of small occupied space, small energy consumption and low development cost.

Owner:WUHAN LIAOYUAN MOLDING

High-speed nail shooting connecting device and connecting method

The invention relates to a high-speed nail shooting connecting device and a connecting method. The high-speed nail shooting connecting device comprises a shell and a barrel body arranged in the shell;the barrel body is vertically disposed; the upper end of the barrel body is connected with the inner top of the shell; a coil, a driving sheet and a puncher pin are arranged in the barrel body in sequence from top to bottom; the lower end of the coil is closely fitted to the driving sheet; the puncher pin comprises a punch rod; the upper end of the punch rod is provided with a circular table coaxial with the punch rod; the circular table presses against the driving sheet; the lower end of the punch rod passes through the middle part of the lower end of the barrel body; a magnetic medium is arranged on the lower end face of the punch rod; a punch hole for enabling the lower end of the punch rod to pass through is formed in the lower part of the shell; a spring is arranged on the punch rodin a sleeving manner; the upper end of the spring presses against the circular table; and the lower end of the spring presses against the barrel body. By adoption of an electromagnetic force driving mode, the device is short in forming time; a connecting force and connecting energy can be precisely controlled through single-parameter adjustment, and realizes self-piercing riveting under differentconditions; the process is simple; and automatic production is easy to implement.

Owner:FUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com