Complex environment foundation pit excavation hole-by-hole blasting method

A technology of complex environment and detonation method, which is applied in excavation, blasting, infrastructure engineering, etc., can solve the problems of slow forming cycle of foundation pit excavation, high cost of foundation pit excavation, vibration, etc., so as to improve the blasting effect and reserve The effect of small disturbance of rock mass and high average vibration reduction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

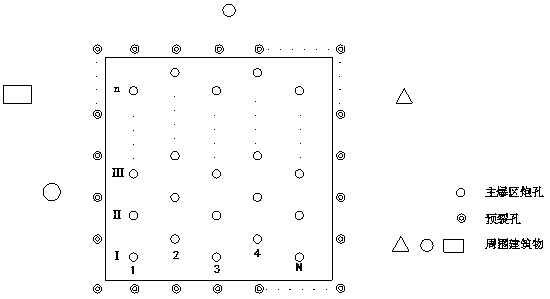

[0032] Embodiment 1: The complex environment schematic diagram of this embodiment is as follows Figure 8 As shown, the rock properties are medium-hard rocks, the rock-soil properties are stable, and the joints and fissures are not developed;

[0033] Such as Figure 1~8 As shown, a hole-by-hole detonation method for foundation pit excavation in complex environment, the specific steps are as follows:

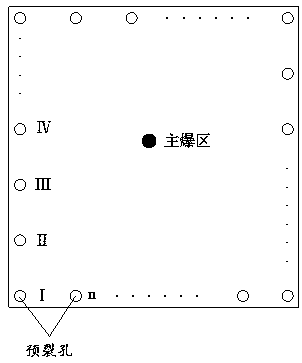

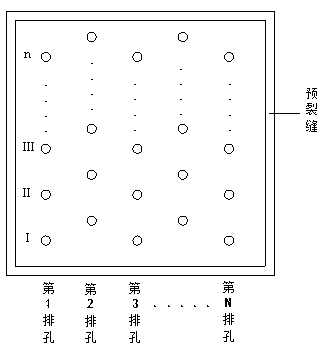

[0034] (1) Pre-splitting holes are evenly arranged on the excavation contour line of the foundation pit in a complex design environment, and a radial non-coupling charge device is installed in the pre-splitting hole, and the non-coupling charge in the pre-splitting hole is controlled by a digital electronic detonator and detonated hole by hole;

[0035] (2) Clean up the pre-splitting blasting pile, arrange several rows of staggered main blasting holes in the main blasting area of the excavation surface of the foundation pit, the row spacing of the main blasting holes is equal...

Embodiment 2

[0049] Embodiment 2: The complex environment is that there are residential areas and large-scale breeding farms within 100m of the edge of the blasting area; the rock properties are soft rocks with drillability, and joints and fissures are developed;

[0050] The hole-by-hole detonation method for foundation pit excavation in complex environment in this embodiment is basically the same as that in Embodiment 1, except that:

[0051] The hole spacing of the pre-splitting hole is 10 times the diameter of the pre-splitting hole, and the delay time of the digital electronic detonator of the pre-splitting hole is 16ms;

[0052] The delay time between the main blast hole holes and the delay time between the main blast hole rows in the main blast area is determined according to the ore rock properties in the main blast area. The row spacing of the gun holes is 0.85 times the hole spacing of the main gun holes, the delay time between the digital electronic detonators of the main gun hole...

Embodiment 3

[0054] Embodiment 3: The complex environment is that there are ancient buildings to be protected within 100m of the edge of the blasting area; the rock properties are hard and compact rocks with drillability, and the joints and fissures are not developed;

[0055] The hole-by-hole detonation method for foundation pit excavation in complex environment in this embodiment is basically the same as that in Embodiment 1, except that:

[0056] The hole spacing of the pre-splitting hole is 8 times the diameter of the pre-splitting hole, and the delay time of the digital electronic detonator of the pre-splitting hole is 22ms;

[0057] The delay time between the main blast hole holes and the delay time between the main blast hole rows in the main blast area is determined according to the ore rock properties in the main blast area. The row spacing of the gun holes is 0.9 times the hole spacing of the main gun holes, the delay time between the digital electronic detonators of the main gun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com