Patents

Literature

535results about How to "Improve blasting effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

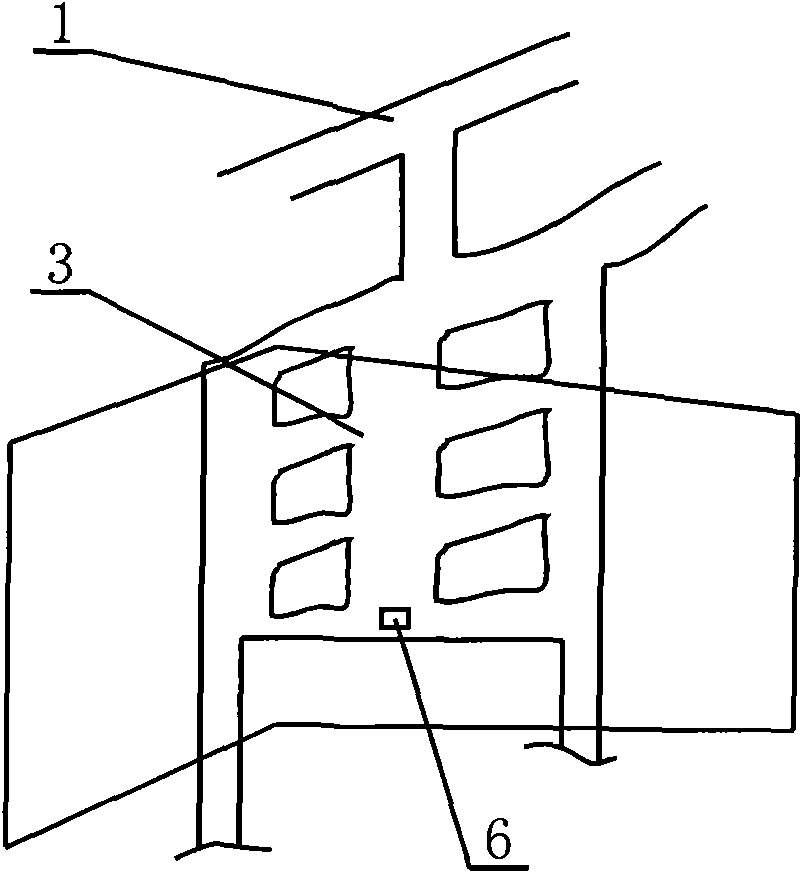

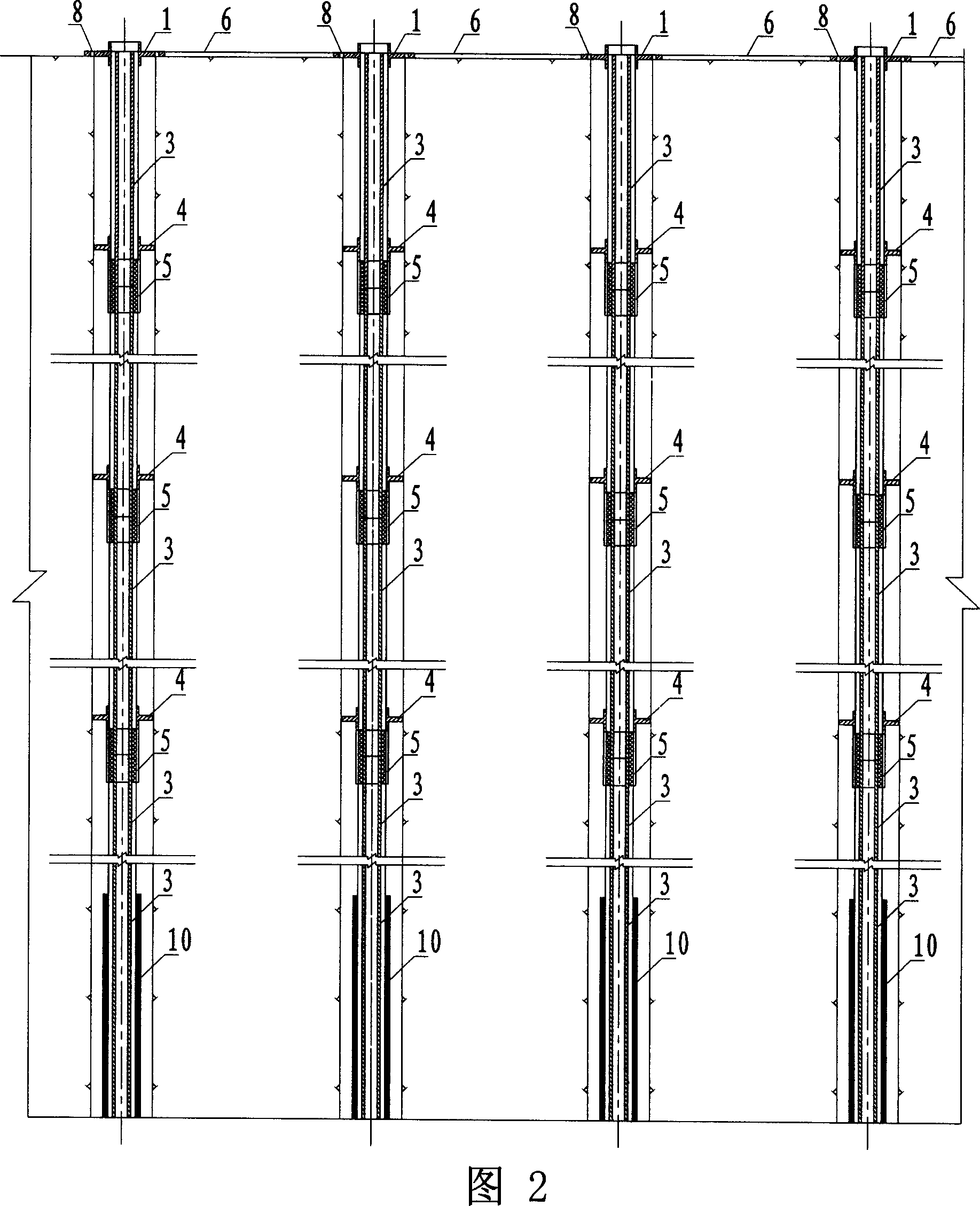

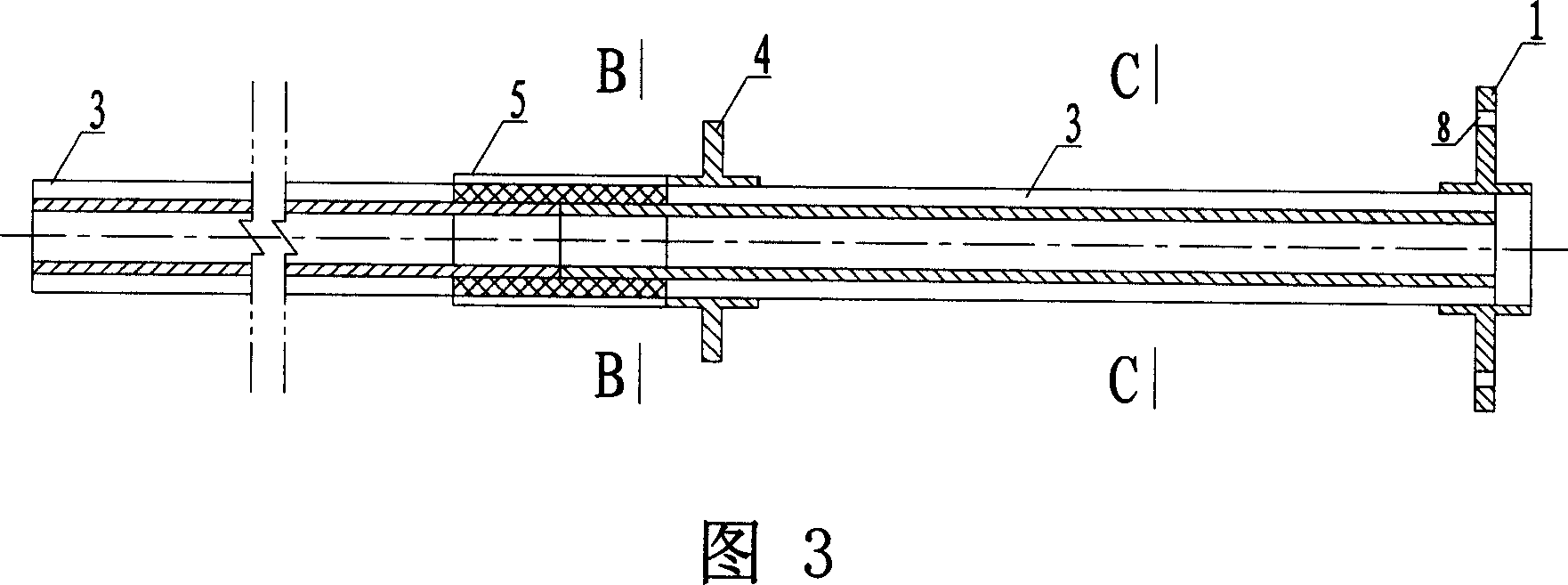

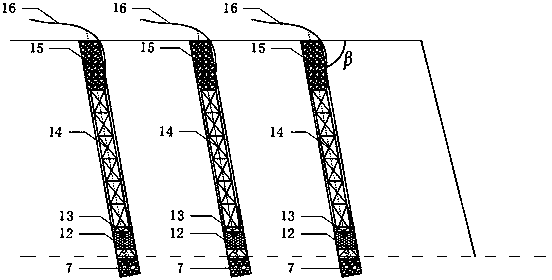

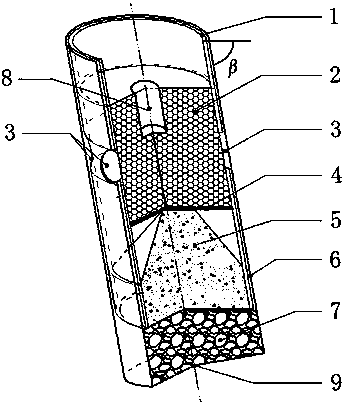

Efficient mining method for thick metal ore body in slanting

InactiveCN102182461ARealize continuous productionImprove mining efficiencyUnderground miningSurface miningEngineeringMetal

The invention relates to an efficient mining method for a thick metal ore body in slanting, comprising the following mining steps: constructing a transportation roadway outside a dike, constructing flat roadways for rock drilling by sections, constructing a cutting roadway, constructing a cutting well, constructing a cutting groove and reserving a temporary triangular ore pillar, constructing a trench, constructing a sector medium-deep hole and implementing blasting and ore removal, and recovering residual ore. The method realizes safe and efficient recovering of metal ore bodies with the inclination of 30 to 55 degrees and the average thickness of 4 to 15m by adopting a medium-deep hole blasting ore dropping valve under the circumstance without a filling condition, thereby further improving the mining recovery rate and the mining efficiency.

Owner:SHANDONG GOLD MINING LINGLONG

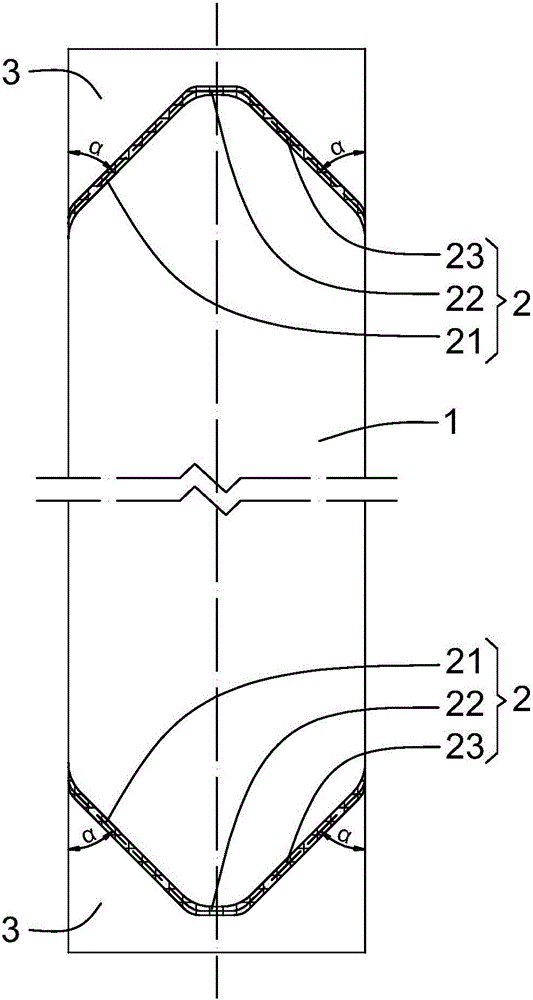

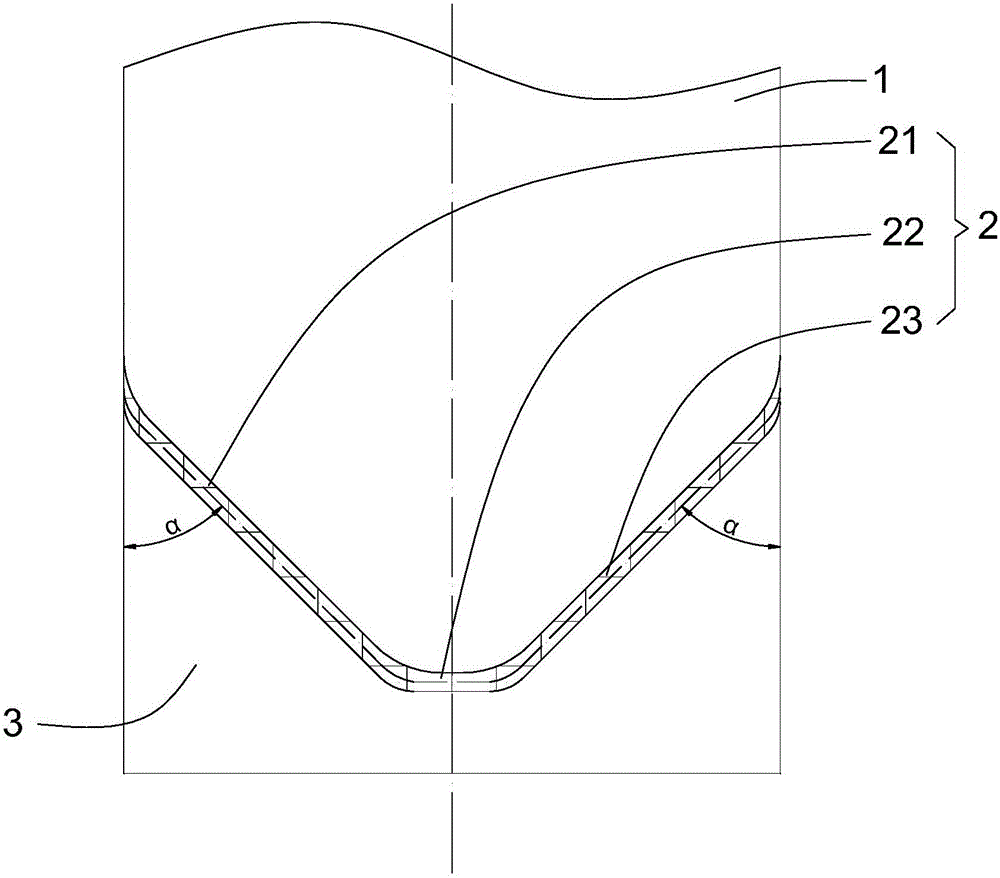

Method of energy cumulative presplitting and smoothsurface blasting and special device therof

ActiveCN101033932AIncrease profitEnhance blasting forceBlasting cartridgesBlastingBinding energyDetonator

It is a special-purpose device used for two-directional energy-focusing and smooth blasting, post standard knot of multisection energy-gathering pipe which is in the double ''V'' shaped energy-accumulating groove which is set on the pipewall full of detonator, each post standard knot is linked with connection casing on which there is energy-accumulating groove, centering ring in the hole is noosed on the standard joint of the binding energy tube so that the center lines of the upper and the lower energy-gathering groove like V shape are in the same surface in the blasthole. Orifice centering rings of the two V- shaped central whose orientation is the same with V- shaped energy-gathering groove are set on the noose annulus wall at the ground end of energy -gathering pipe at orifice of blasthole, which makes the center line of each energy-gathering groove like a V shape forms a surface of centering and coinciding with blasting surface in each blasthole and among. After detonating explosive, make shaped charge jet spark along initial small crack that forms while the crack begins to form, then forms presplitting or smooth blasting surface, and finish energy-gathering presplitting and smooth blasting. The invention can enhance utilization ratio of demolishing energy and debase quantity of drilled holes, the influence of destroying rock mass kept down is little and the blasting surface is more level.

Owner:SINOHYDRO BUREAU 8 CO LTD

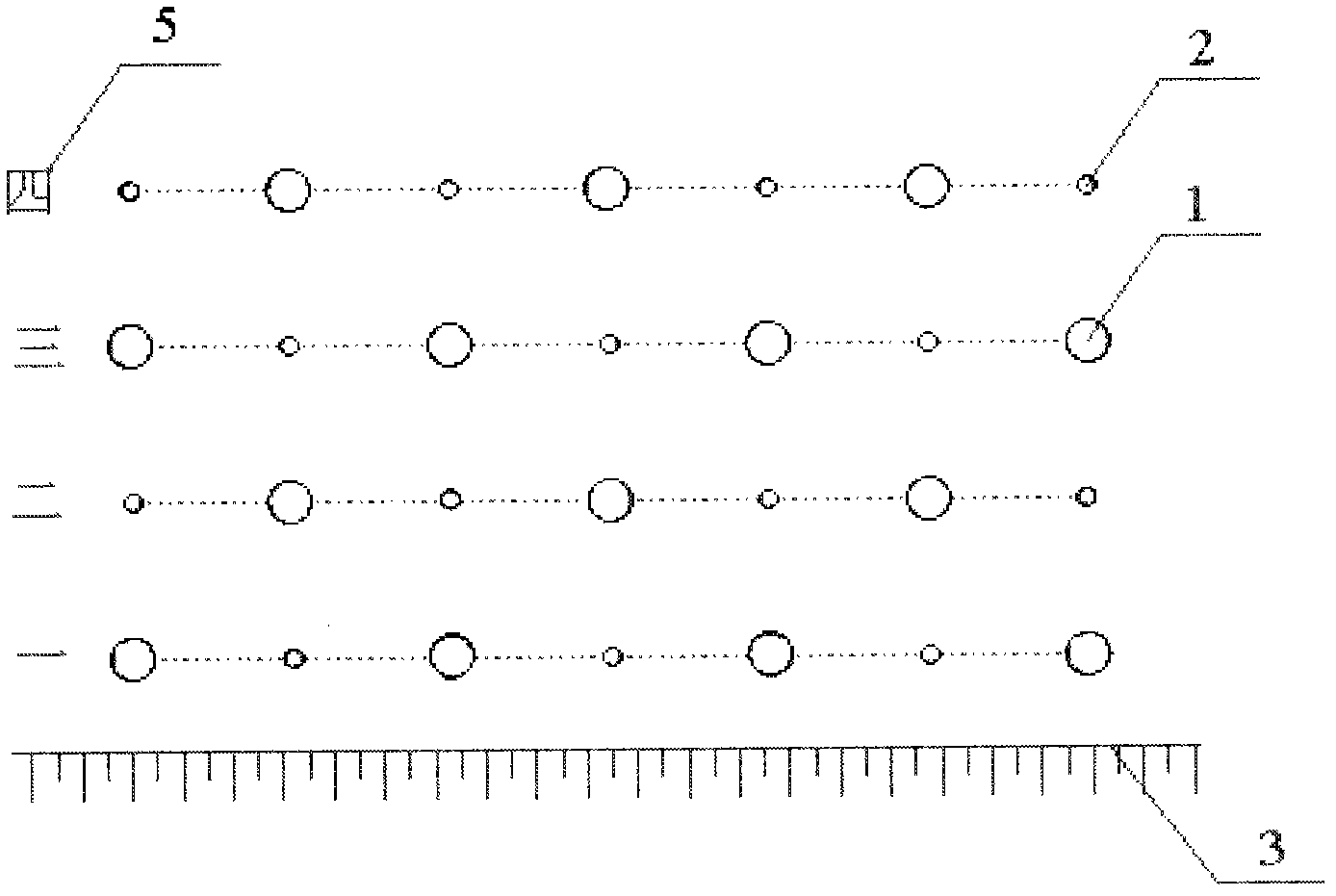

Multi-row micro-differential roadbed deep hole blasting construction method

The invention relates to a multi-row micro-differential roadbed deep hole blasting construction method, which comprises the following steps of: (1) selecting blasting parameters; (2) calculating security; (3) arranging a stair and a free face; (4) distributing holes and drilling holes; and (5) blasting. The blasting method is a multi-row deep hole millisecond micro-differential blasting method; and the blasting is performed by pull trough blasting and side slope blasting in a roadbed sequentially, wherein the pull trough blasting is loose blasting and the side slope blasting is precraking blasting. In the method, a shock conducting tube non-electric priming system micro-differential control blasting technology, a comprehensive blasting construction scheme of loose blasting, the deep hole millisecond micro-differential blasting technology and the roadbed side slope precraking blasting technology, and a wide-pitch and low-resistance hole distribution mode are adopted, so that explosivesand detonators are saved, the drilling mechanization degree is enhanced, the labor cost is reduced, the blasting effect is enhanced, the large rate of blast rocks is reduced, the material abandoning rate is reduced and harms of blasting vibration, impact waves, flying stones and the like are reduced; furthermore, when the blasting effect is enhanced and the stability of the blast roadbed side slope rocks is guaranteed, the absolute safety of blasting can be guaranteed.

Owner:HUITONG ROAD & BRIDGE CONSTR GROUP

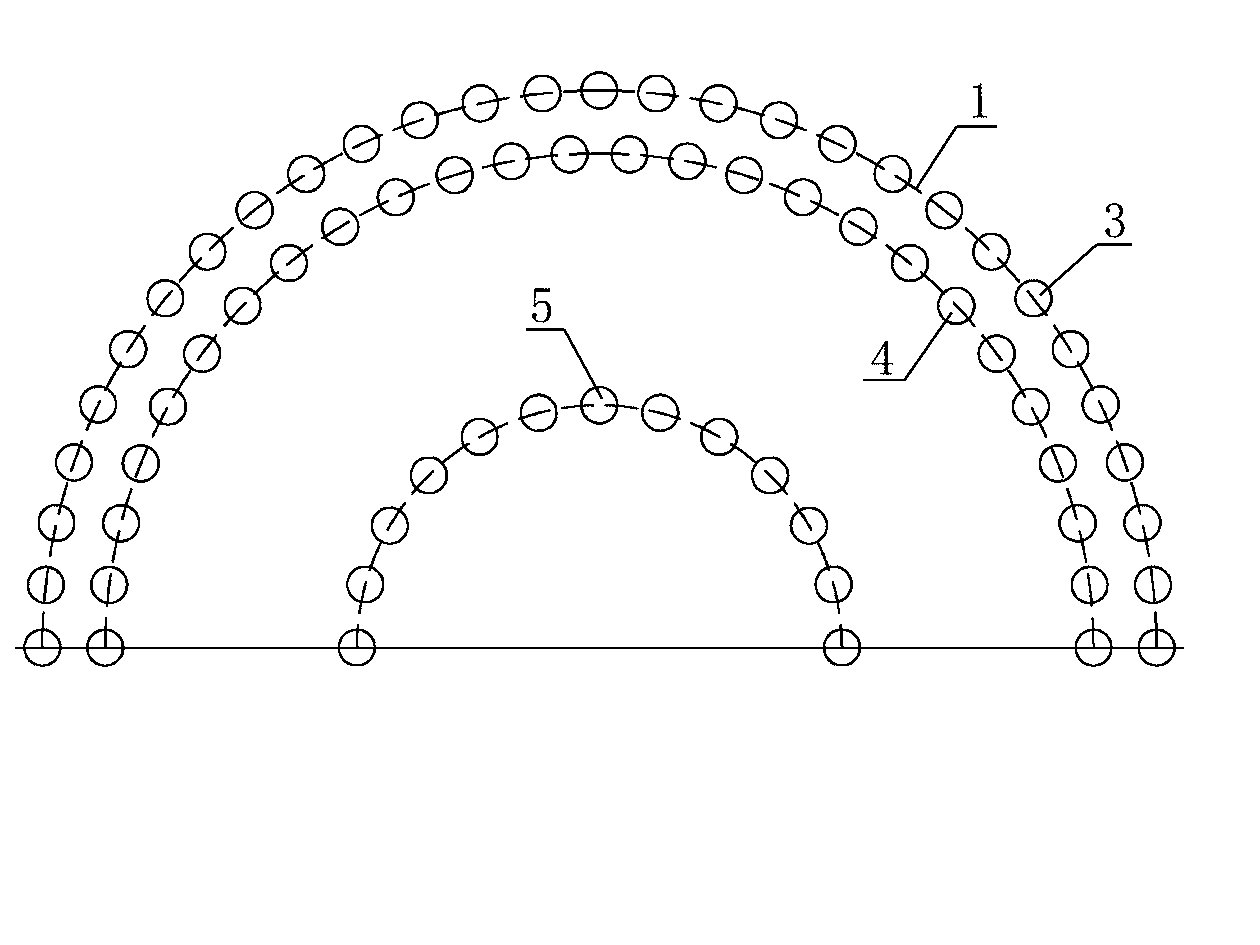

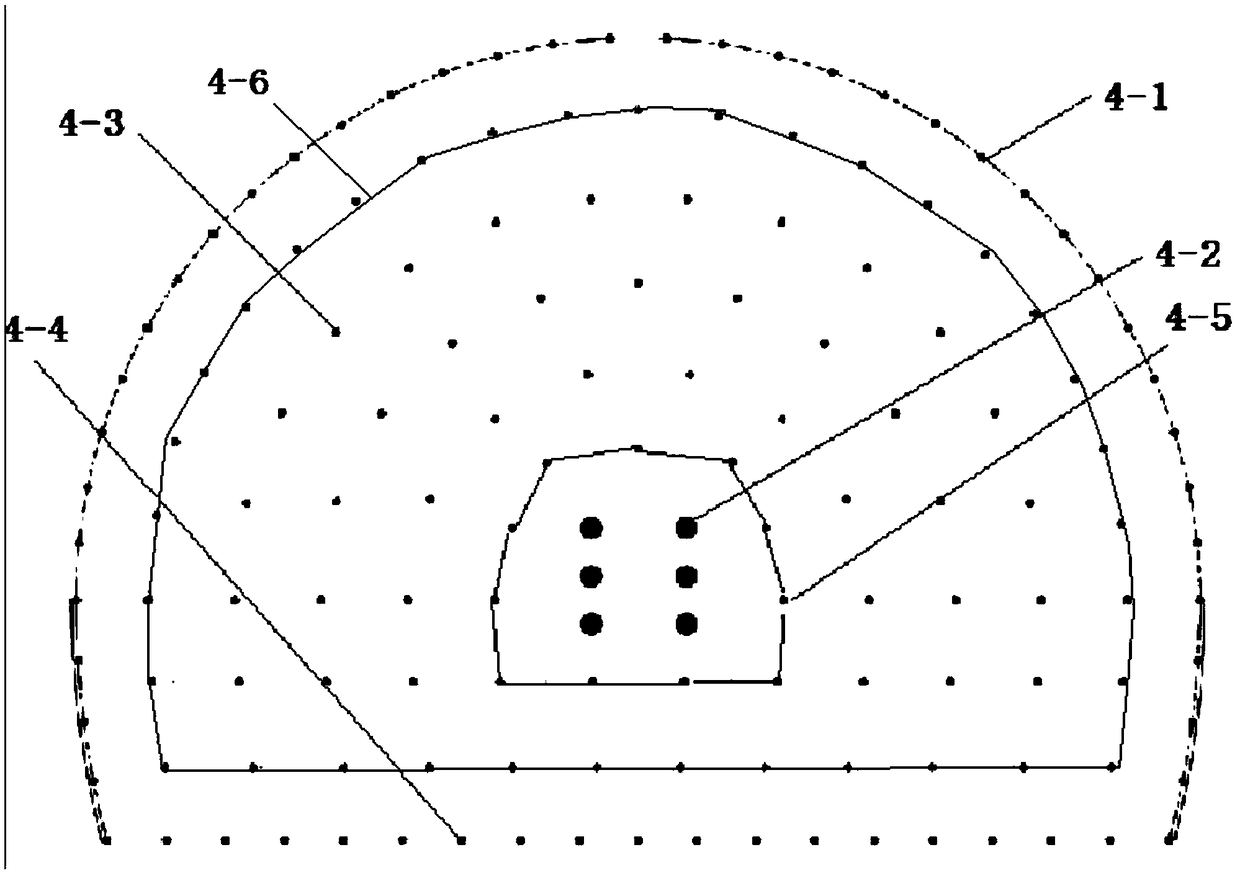

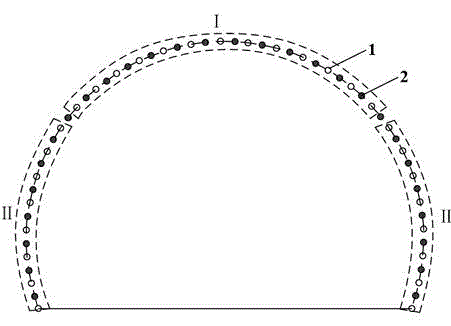

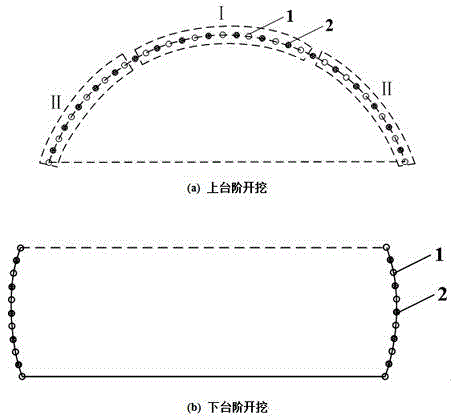

Construction method of tunnel shock relieve hole controlling blasting

ActiveCN103175451AReduce blasting vibration velocityAvoid damageBlastingBlasting vibrationBuilding construction

The invention relates to a construction method of a tunnel shock relieve hole controlling blasting. Shock relieve holes are circumferentially distributed in the peripheries of an upper step arch part and a slotting zone, and a row of inner shock relieve holes and a row of outer shock relieve holes are especially formed in periphery hole zone of the upper step arch part, presplitting belt width of the periphery holes after blasting is increased, presplitting effect is strengthened, meanwhile through separating and cutting function of the shock relieve holes, explosive load is lowered, earthquake stress is reduced, and thus the target of reducing blasting vibration velocity is achieved. The construction method of a tunnel shock relieve hole controlling blasting can be widely applied to blasting construction in a tunnel mining construction, and especially to a city flourishing area and an area with a plurality of pipelines.

Owner:中国建筑土木建设有限公司

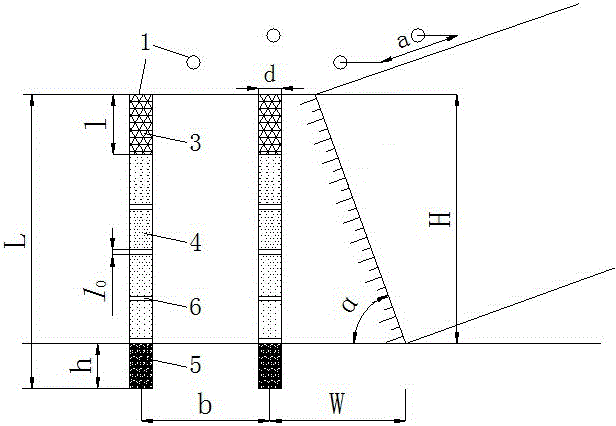

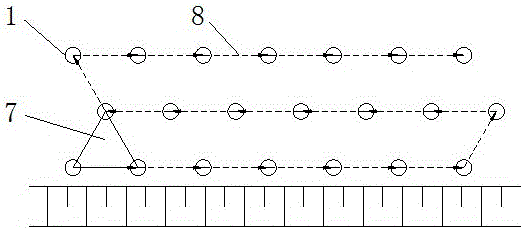

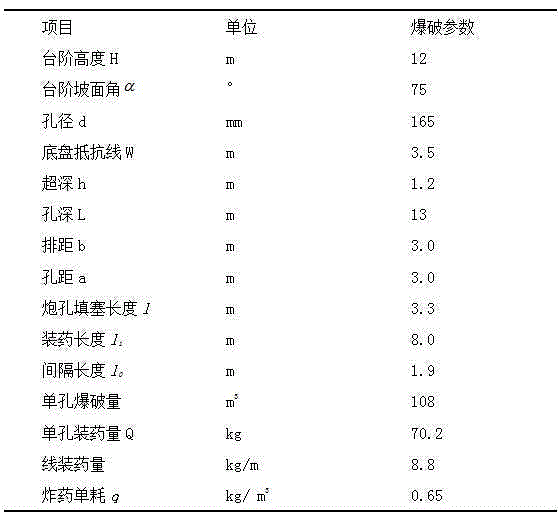

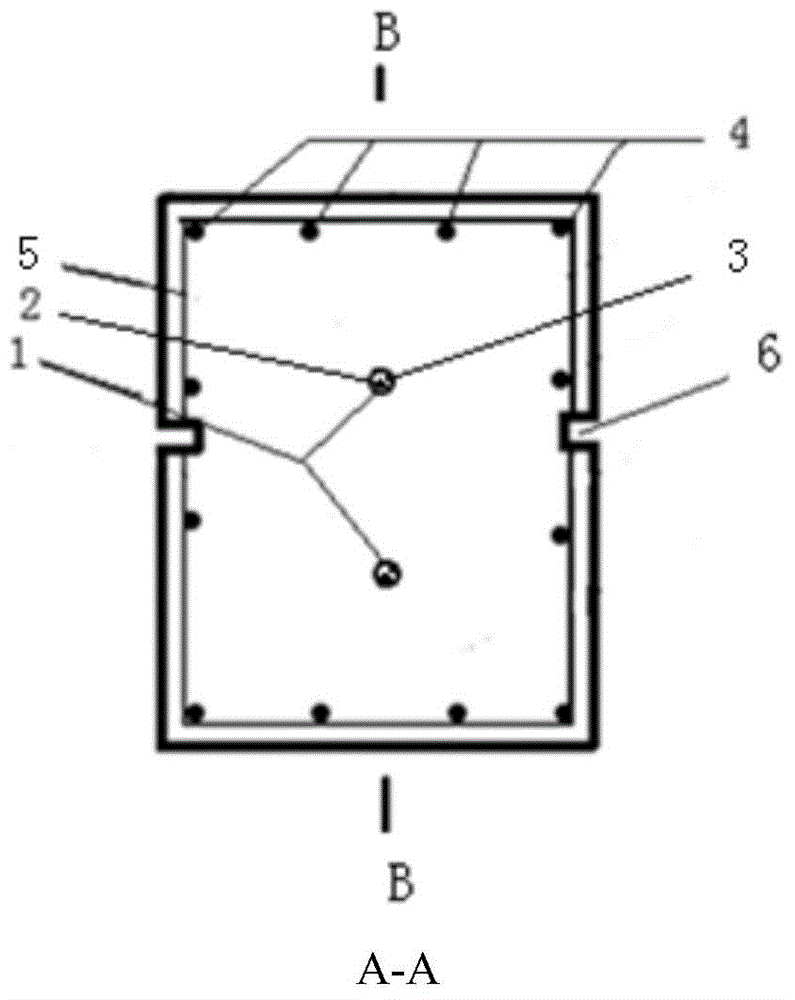

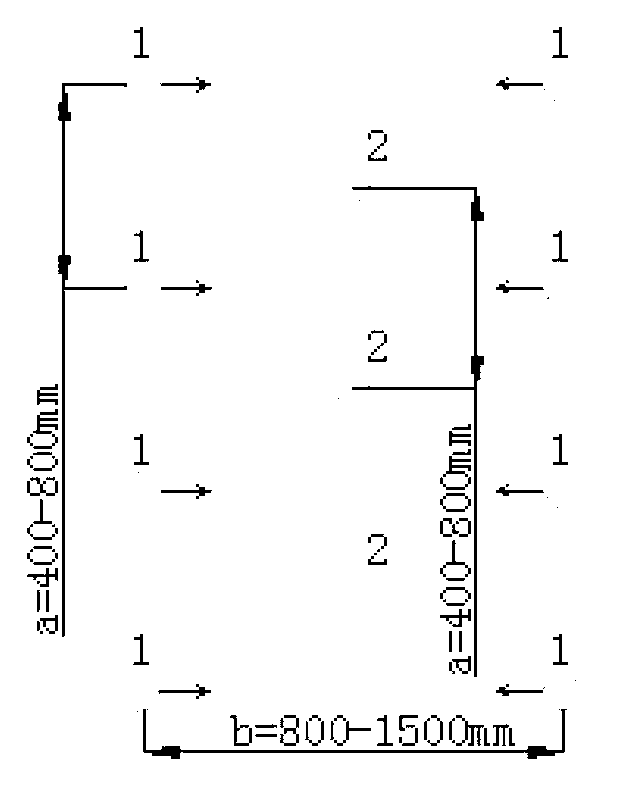

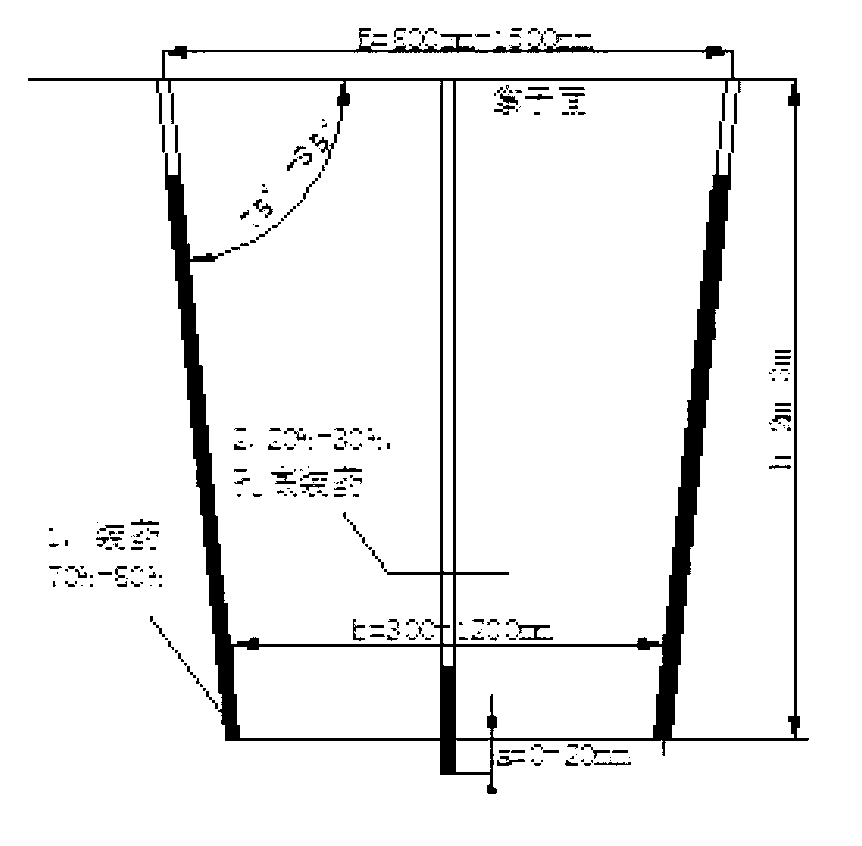

Method for improving bench blasting quality of deep-hole of super-hard rocks

The invention discloses a method for improving the bench blasting quality of a deep-hole of super-hard rocks. The method includes the following steps that blast holes are formed in a step of a blast area, hole mesh parameters are determined, and perpendicular drilling is conducted; explosive loading structures are determined, and the explosive loading structures for segmented explosive loading and mixed explosive loading are adopted in the blast holes at the same time; explosives are determined, wherein the explosives are selected according to according to matching coefficients of explosive wave impedance and rock wave impedance; blasting parameters are determined and include the length W of a resistance line of a base plate, the hole pitch a, the row distance b, the super depth h and the blast hole filling length l; and blasting is conducted, wherein the explosives are loaded, the blast holes are filled with stemming on the tops of the blast holes, reverse blasting is conducted from the bottoms of the blast holes, and blasting is conducted in an inter-hole elementary error sequence. According to the method for improving the bench blasting quality of the deep-hole of super-hard rocks, due to the fact that the hole mesh parameters, the explosive loading structures, the explosives, the blasting parameters, the blasting position and the blasting sequence are reasonably selected, multi-way comprehensive functions are achieved, the performance of the explosives is fully achieved, the sufficient reaction of the explosives is ensured, the utilization rate of the blast holes is increased, and the boulder frequency and bedrocks of rock blasting are reduced.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Axial embedded blast hole of reinforced concrete beam and blasting demolition method

The invention provides an axial embedded blast hole of a reinforced concrete beam and a blasting demolition method. The blast hole is formed in the mode that a pipe is embedded in the beam in the axial direction, continuous or discontinuous charging is adopted in the blast hole, a detonating fuse is arranged in the blast hole in an overall-length mode, a stirrup is cut off, and other technical means are taken. In this way, drilling operation is avoided, the number of blast holes and the number of detonators are reduced, consumption of explosive and the detonators is reduced, the smashing effect on reinforced concrete is improved, and the damage of explosion to the environment is reduced. The axial embedded blast hole of the reinforced concrete beam and the blasting demolition method can bring remarkable economic and social benefits.

Owner:HUBEI UNIV OF TECH +1

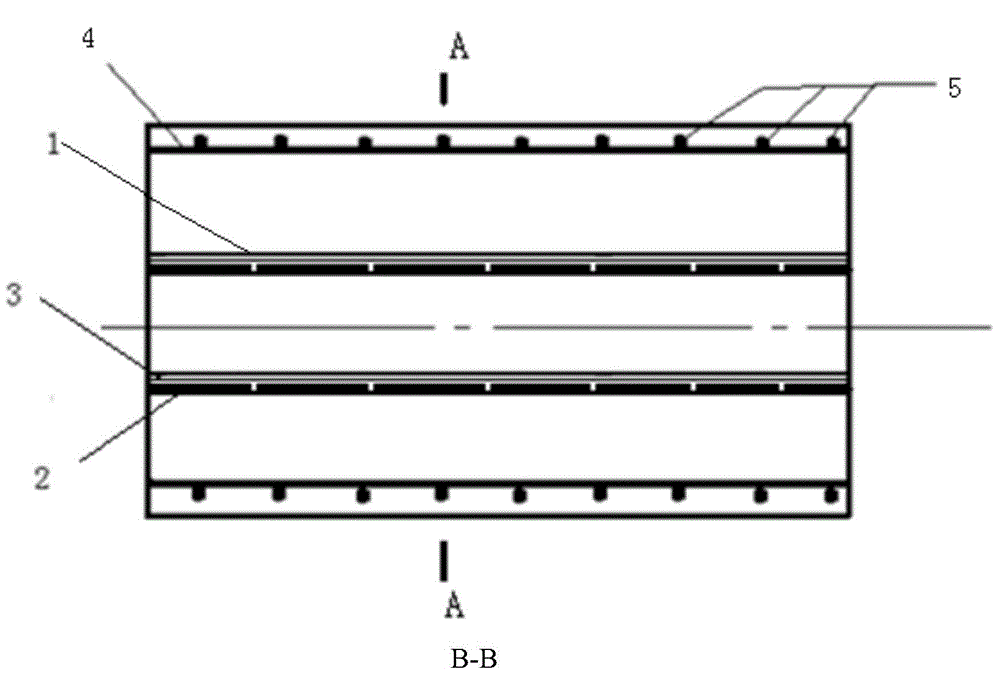

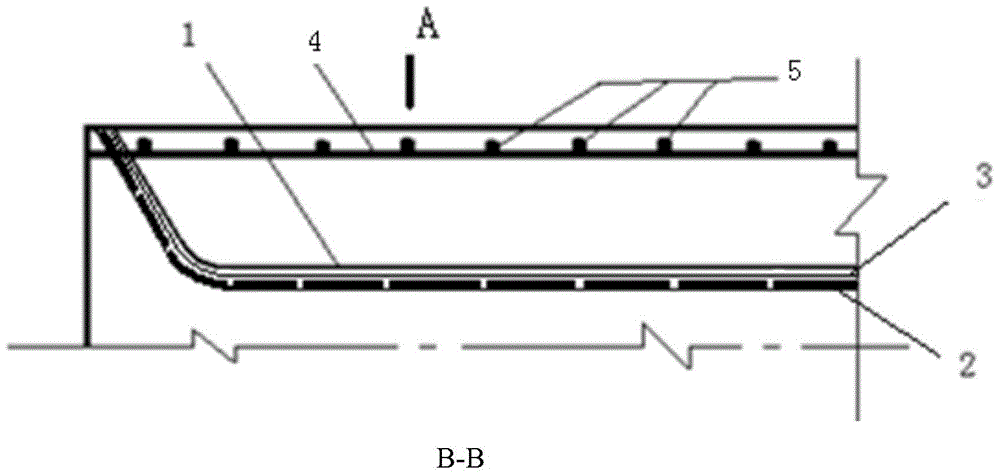

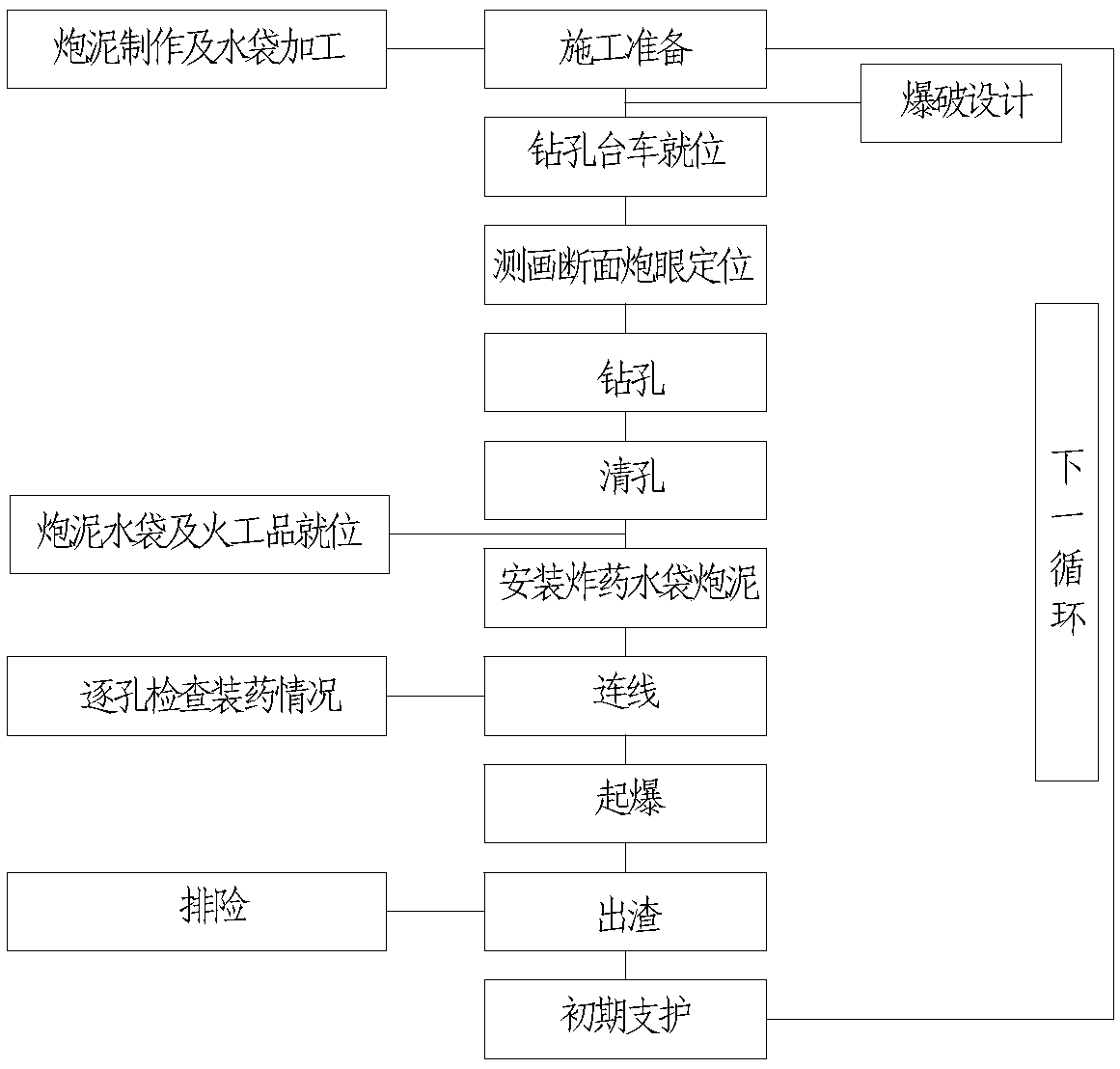

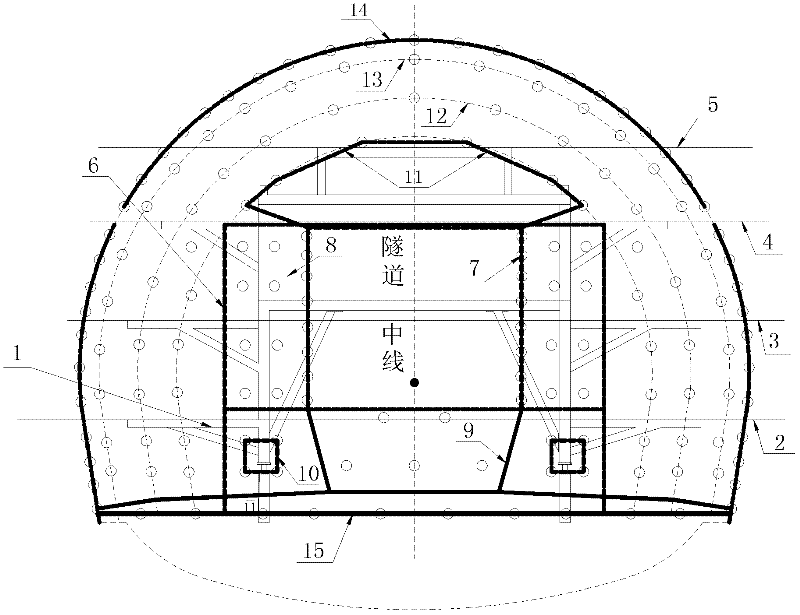

Tunnel excavation water pressure blasting construction method

InactiveCN109373840AImprove the construction environmentIncrease profitBlastingTunnelsGeomorphologyDetonation

The invention discloses a tunnel excavation water pressure blasting construction method. The tunnel excavation water pressure blasting construction method comprises the following steps of (1) arranging a trolley in place and conducting danger elimination; (2) measuring, distributing and drilling holes; (3) installing explosives, water bags and stemming, wherein the peripheral holes are excavated on the arc edge of the tunnel face of a tunnel, and the explosives, the water bags and stemming are installed in the following manners of air spacing, decoupling charge and the explosive quantity at hole bottoms more than that of other parts; cut holes are drilled in an inclined mode, and the included angle between the cut holes and the excavation face is 65 degrees-75 degrees; the continuous coupling charge method is adopted for loosening holes, relief holes, inner ring holes and bottom plate holes, blasting caps are buried into hole bottom cartridges, and energy gathering holes face orifices;the water bags are arranged at the hole bottoms of shot holes, and the water bags are arranged again after completion of explosive charging, and the holes are blocked through the stemming; (4) detonating a detonating network; (5) conducting after-detonation check and misfire processing; and (6) withdrawing the explosives to the warehouse. Through the tunnel excavation water pressure blasting construction method, the energy of explosives can be made full use of, environmental pollution can be reduced, and the cost can be saved.

Owner:GUANGXI ROAD & BRIDGE ENG GRP CO LTD

Blasting method of driving, mining and cutting drift under ultrahard fault

InactiveCN101846484AReduce blasting resistanceImprove blasting effectBlastingSmooth surfaceEngineering

The invention discloses a blasting method of a driving, mining and cutting drift under an ultrahard fault and is characterized in that the method can be used to increase the blasting effect. The blasting method comprises the following steps: 1) drilling detonating cave blastholes on both sides of a fault plane 2) placing detonators and explosive in the detonating cave blastholes; 3) shooting the detonators and explosive in the detonating cave blastholes to obtain detonating caves; 4) drilling auxiliary blastholes around the detonating caves, drilling peripheral blastholes around the auxiliary blastholes; 5) placing detonators and explosive in the auxiliary blastholes and the peripheral blastholes; and 6) shooting the detonators and explosive in the auxiliary blastholes and the peripheral blastholes. During the blasting process of the mining and cutting drift, primary blasting is firstly performed to obtain free space for secondary blasting so that the mechanical property of country rocks can be changed and the mining and cutting drift with better smooth surface effect can be obtained after the next blasting; and the method is especially suitable to be used in the projects such as drift driving and mining approach road driving under special geological conditions.

Owner:PANGANG GRP ENG TECH +1

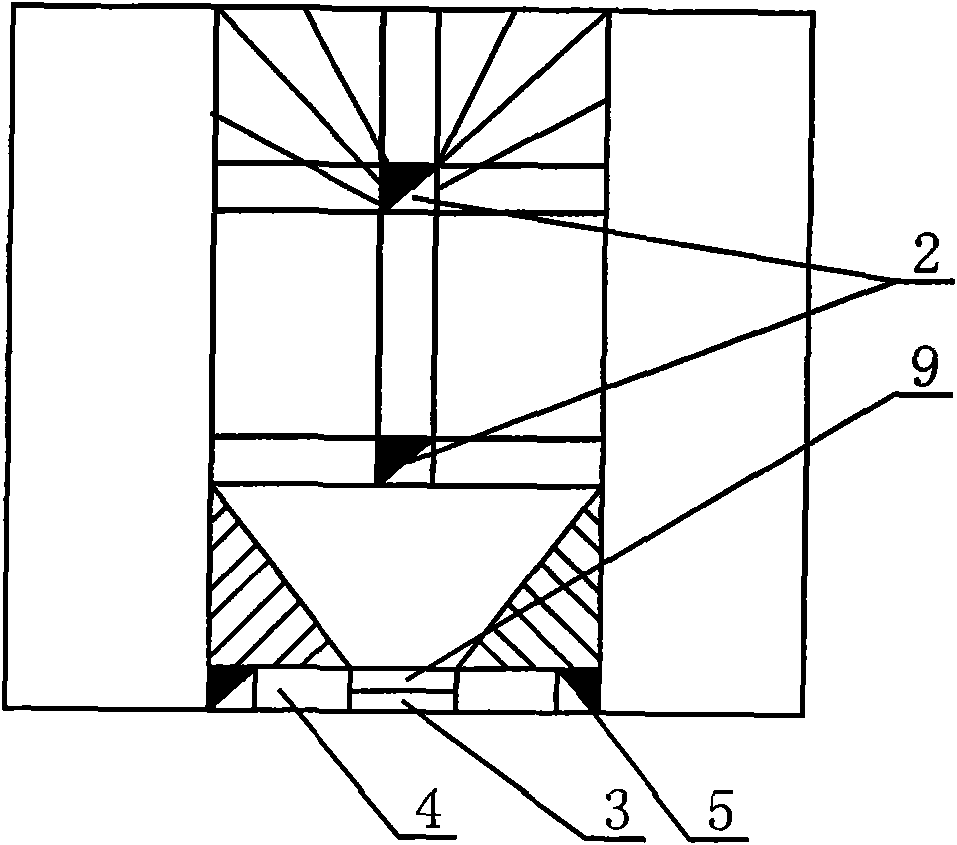

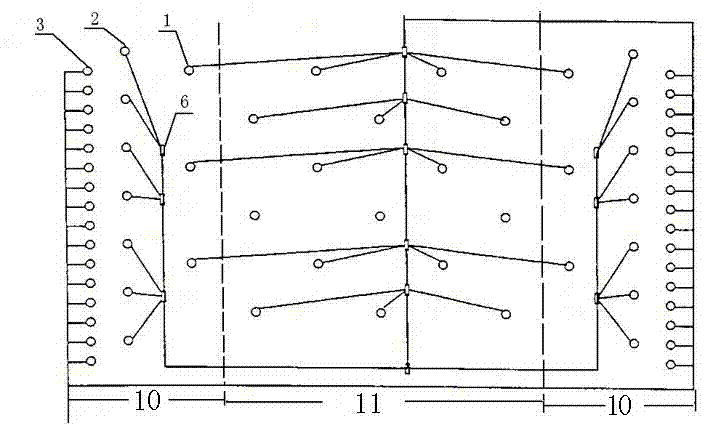

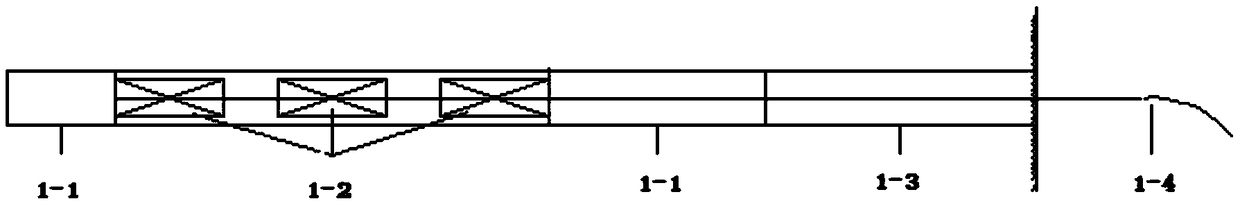

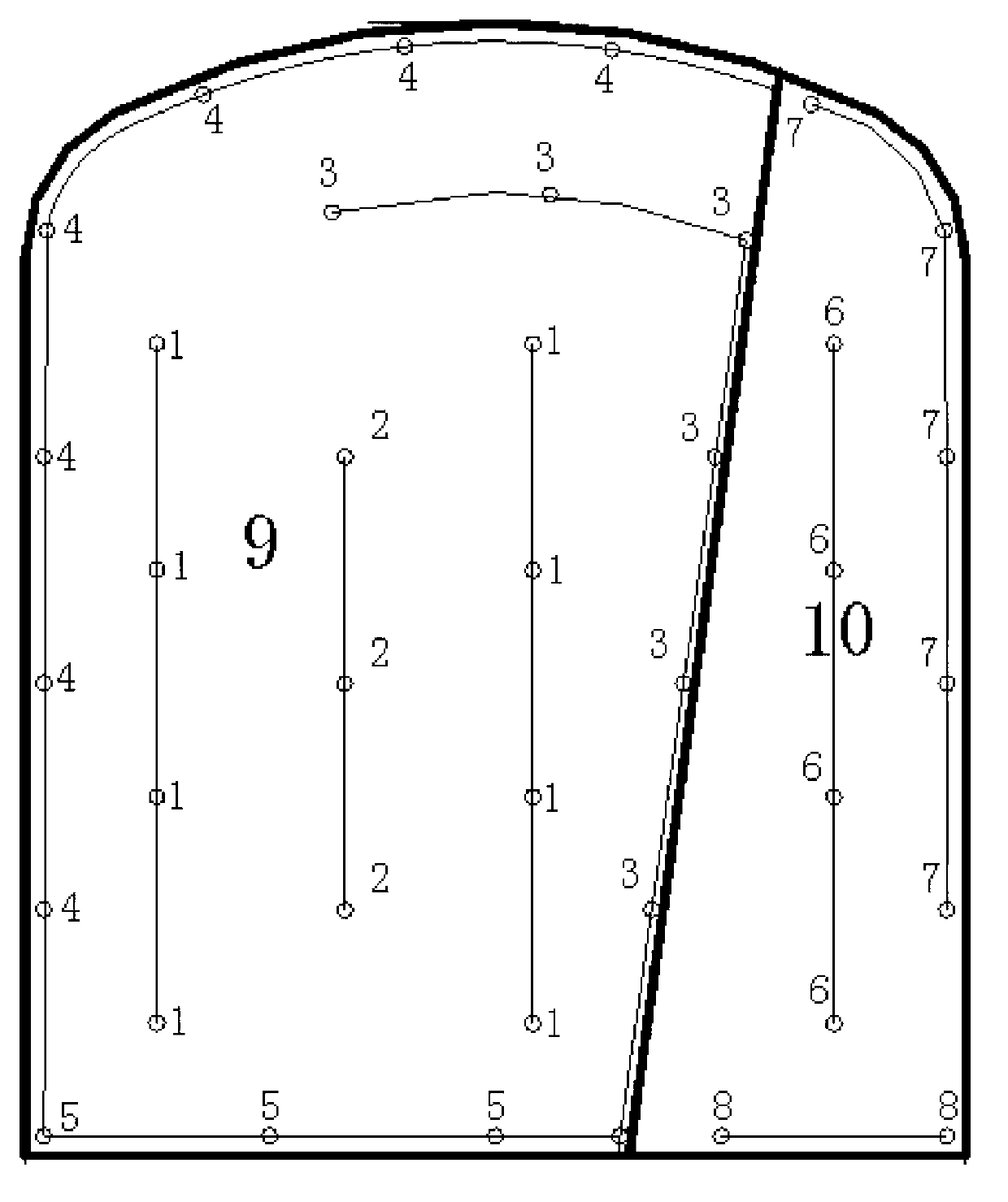

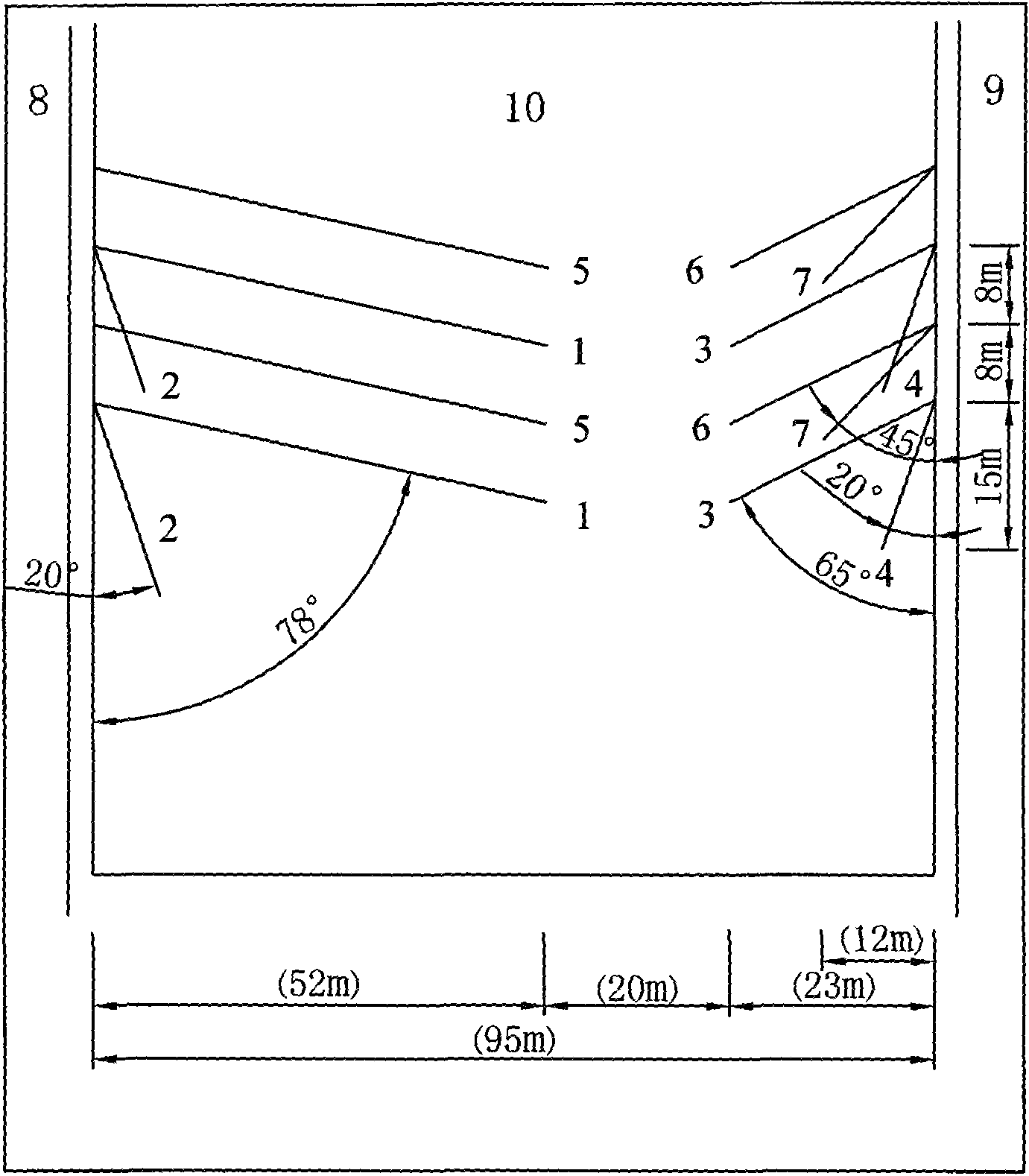

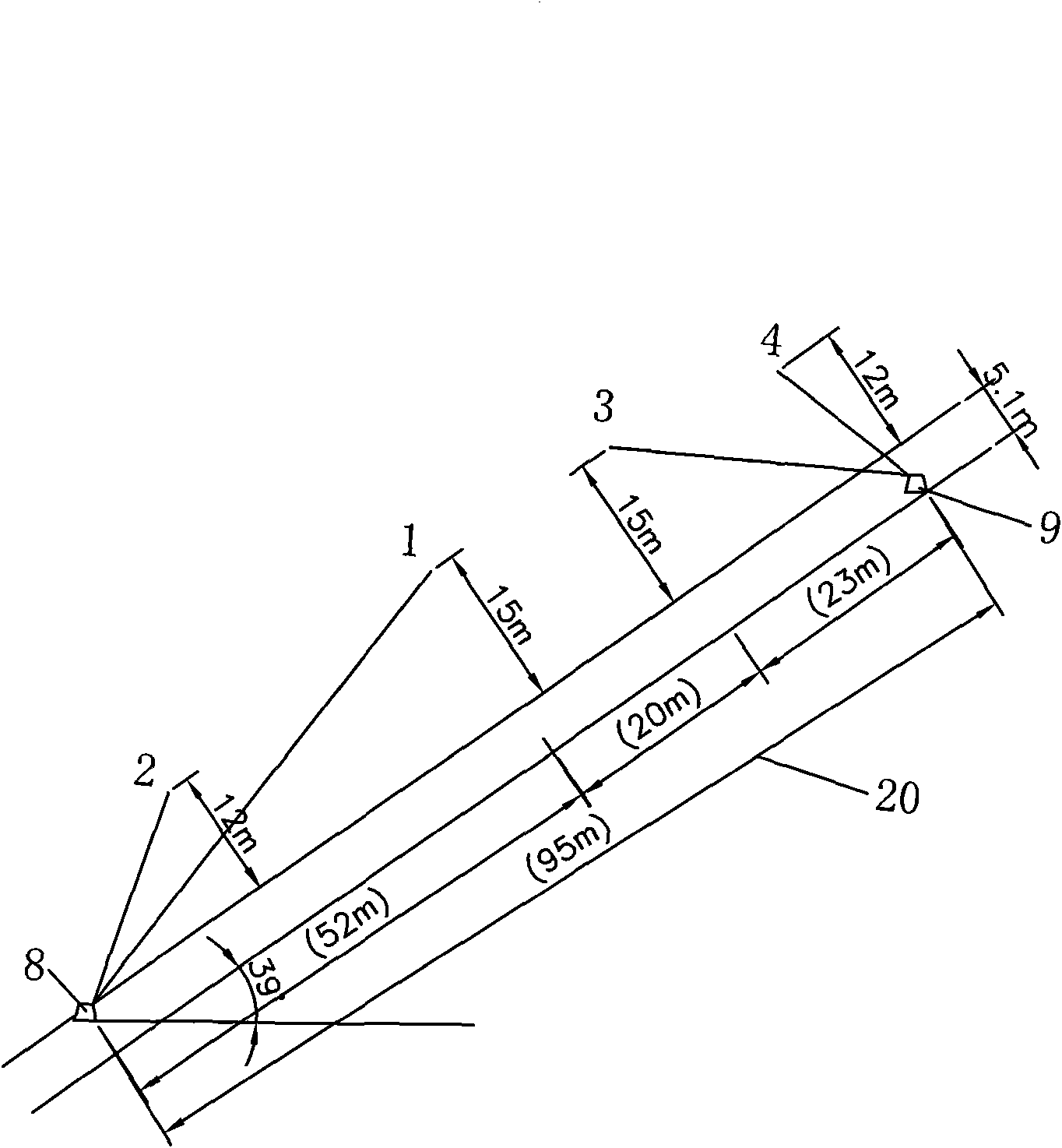

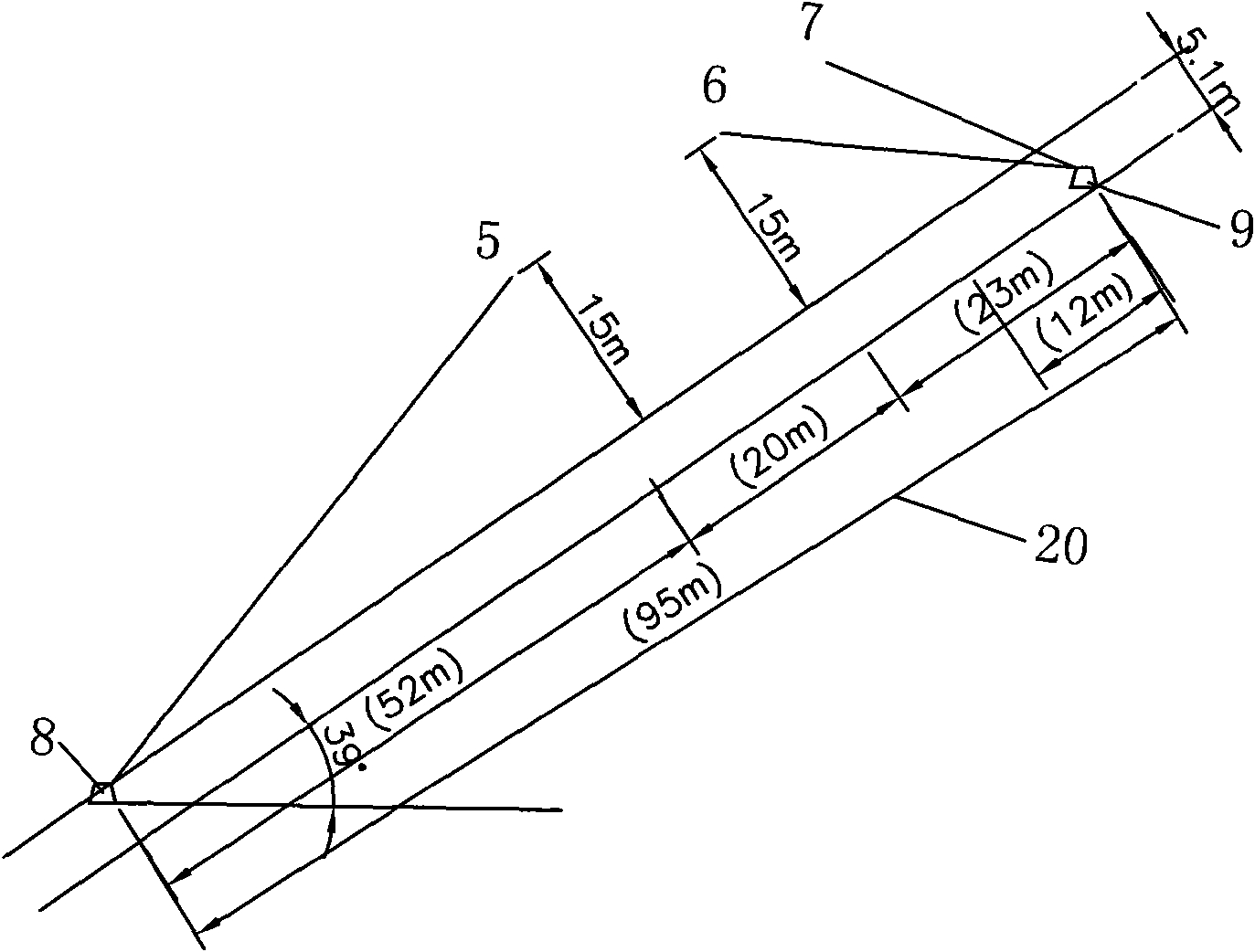

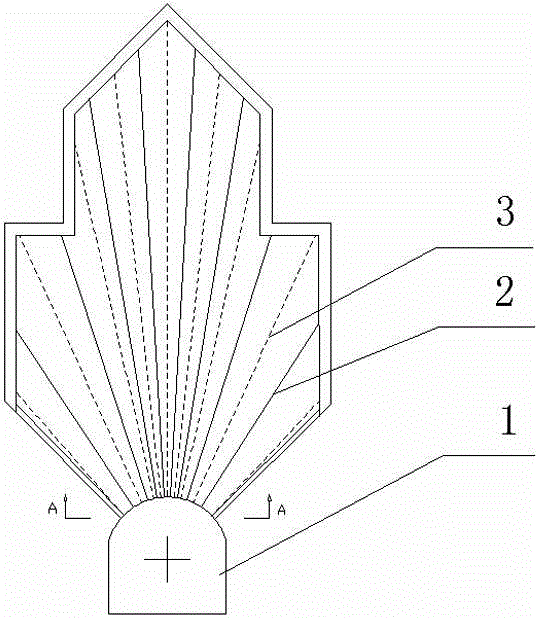

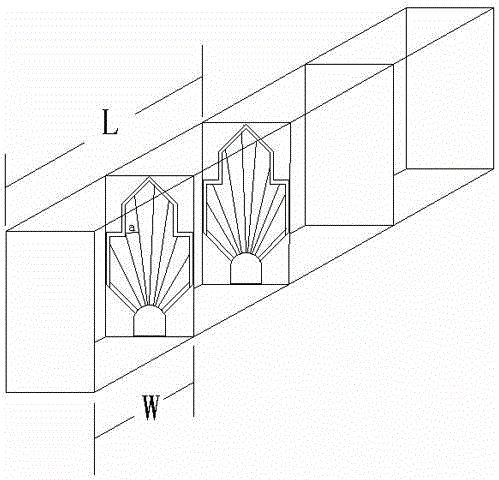

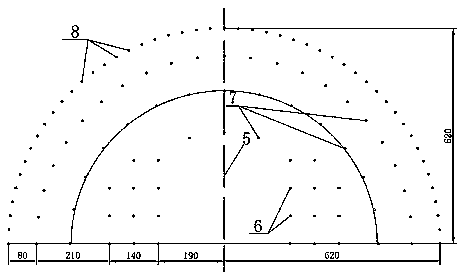

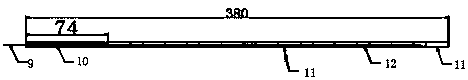

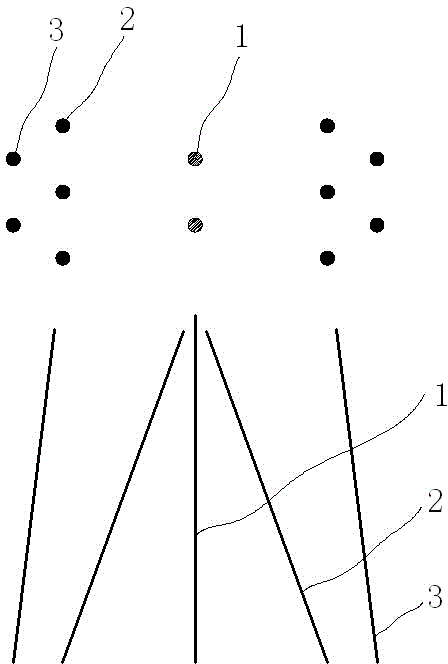

Method for blasting inclined thin ore body by dividing ores and rocks in area in drift driving

The invention provides a technology for blasting an inclined thin ore body by dividing ores and rocks in area in drift driving, belonging to the field of mining engineering. A design process comprises the steps of: 1, dividing a waste rock area (9) and an ore area (10) according to an ore body and a rock distribution condition of a tunnel cross section; 2, arranging a main easer (1) and a secondary easer (2) at the lower part in the waste rock area; 3, arranging an auxiliary hole (3) in the waste rock area according to the size of the cross section; 4, arranging a breaking hole (6) in the ore area according to an inclination angle of the ore body and the size of the cross section; 5, arranging rim holes (4 and 7) and bottom holes (5 and 8) in the circumference edge and the bottom edge of a tunnel; 6, charging each blast hole; 7, sequentially initiating the blast holes; and 8, clearing slag after blasting, and respectively transporting the ores and the waste rocks. With the adoption of the technology provided by the invention, the quantity of the blast holes can be reduced, the use ratio of the blast holes can be improved, a blast effect can be enhanced, the driving efficiency and the ore and rock transportation efficiency can be improved, the dilution rate of the byproduct ores and the engineering cost can be reduced, and the economical benefits of a mine can be improved.

Owner:QINGHAI SHANJIN MINING

Tunnel medium-length hole smooth blasting method

InactiveCN101738148AImprove blasting effectEasy to operate downholeBlastingEngineeringOblique cutting

The invention provides a tunnel blasting method, in particular to a medium-length hole smooth blasting method. The method can not only realize good medium-length hole smooth blasting effect and facilitate the downhole operation of a coal mine, but also realize the more extensive applicability. The portable energy directional smooth blasting technology and the combined cutting blasting technology are adopted in the method. The tunnel blasting method mainly solves the two key technologies of the smooth blasting technology and the cutting blasting technology, and the full-section blasting process and the parameters are set on the basis of the two key technologies, thereby achieving the medium-length hole smooth blasting effect that the desired hole depth is not more than 3m. To this end, theportable energy directional smooth blasting technology is adopted, thereby realizing the good smooth blasting effect under the conditions of simple operation and low cost; and the combined cutting blasting technology with combined oblique cut and shatter cut is adopted, thereby achieving the good medium-length hole smooth blasting effect in middle explosive and difficult explosive rock bodies.

Owner:NANJING INST GENERAL INST OF COAL SCI +1

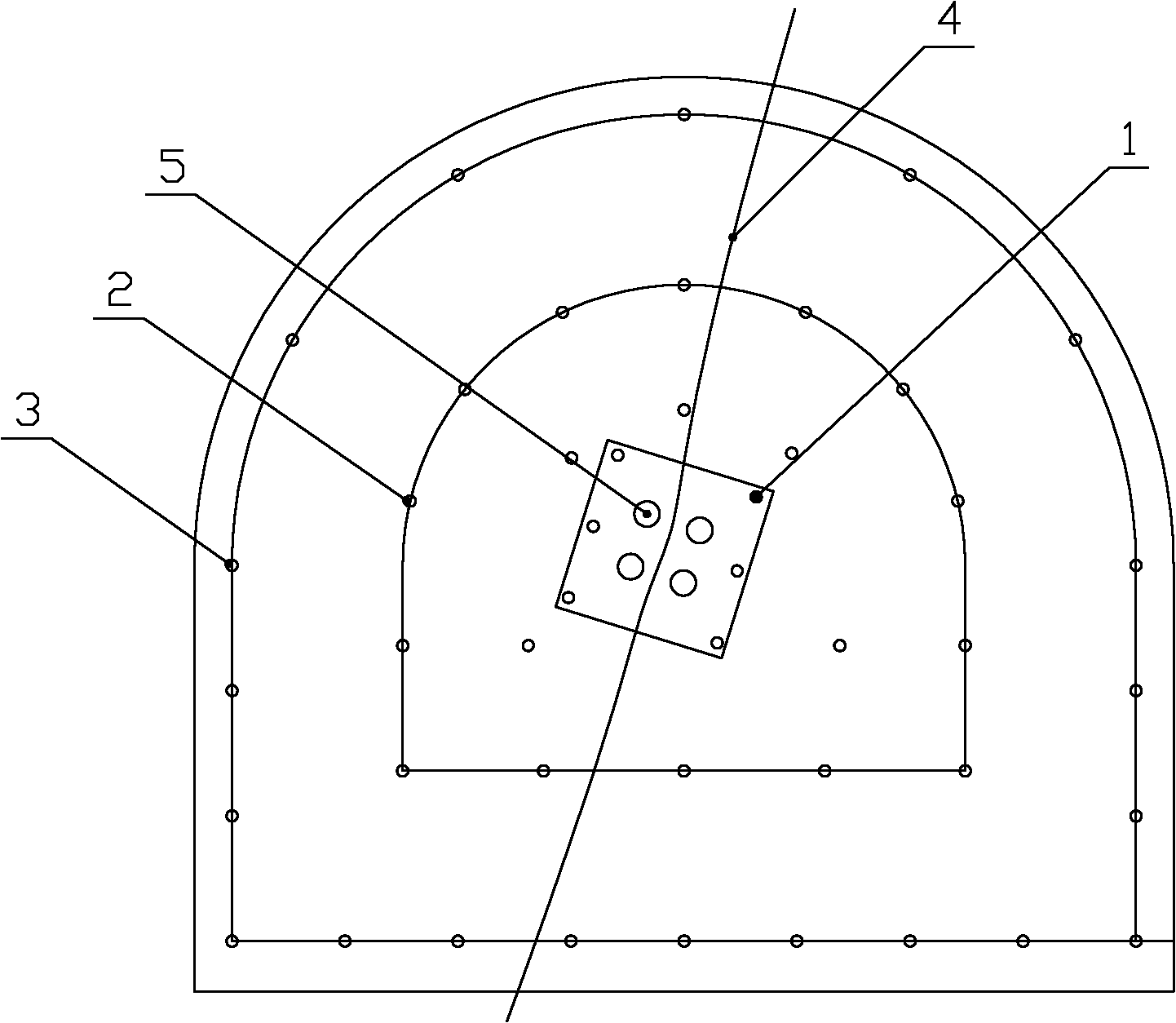

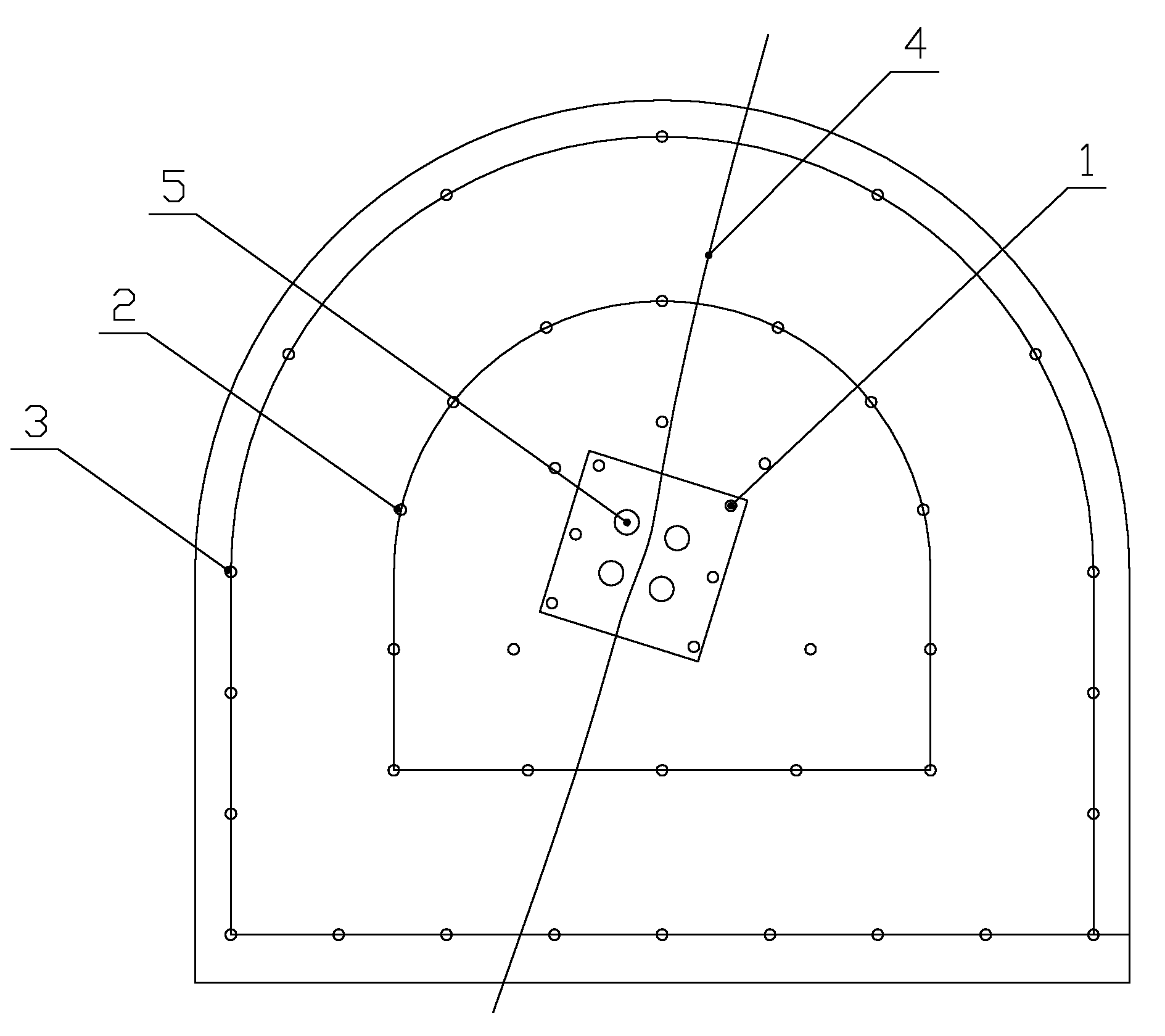

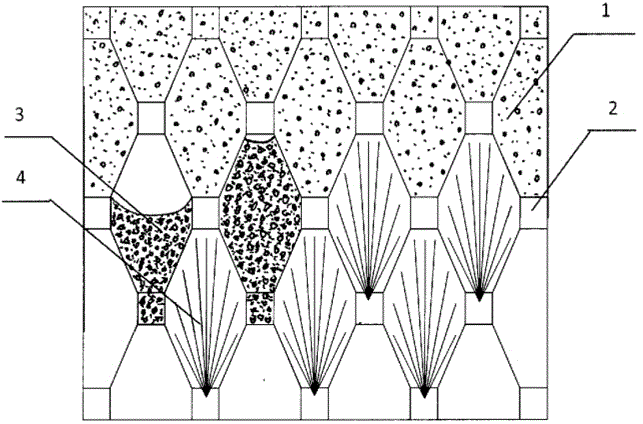

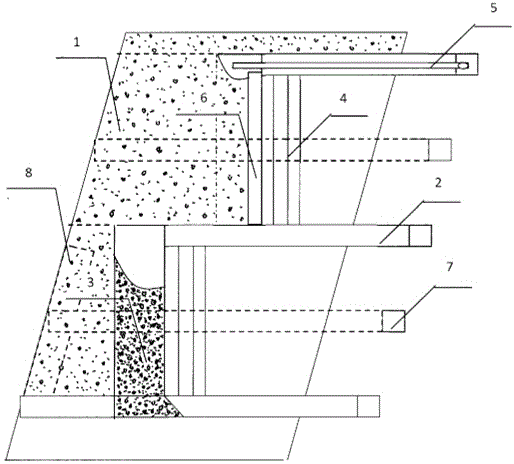

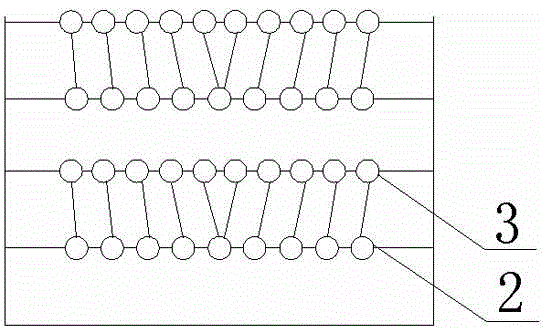

Non-pillar sublevel mining cemented filling mining method

InactiveCN105909247AImprove mining efficiency and mining equipment efficiencyReduce mining costsUnderground miningSurface miningCushionMineralogy

The invention discloses a non-pillar sublevel mining cemented filling mining method. The method is characterized in that sublevels are used as stoping units; stoping drifts are arranged in a staggered way in upper and lower sublevels; rhombic components are stoped in a sublevel mining way; the paces are the basic stoping units; deep hole breakdown is performed in upward fan shapes; multi-row hole short-delay blasting is performed; ore removal is performed under the barnyard condition; after the mining, the cemented filling is performed in time; and rhombic cushions capable of being cyclically used for filling partition wall reserved blasting compensation spaces, blasting free surfaces and the like of the partition wall are used, so that a series of problems of complicated and expatiatory production process, low mining efficiency, high mining cost and the like of the existing top slicing horizontal stoping drift cemented filling mining method can be solved under the condition of steeply-inclined large and thick ore bodies.

Owner:SOUTHWEAT UNIV OF SCI & TECH

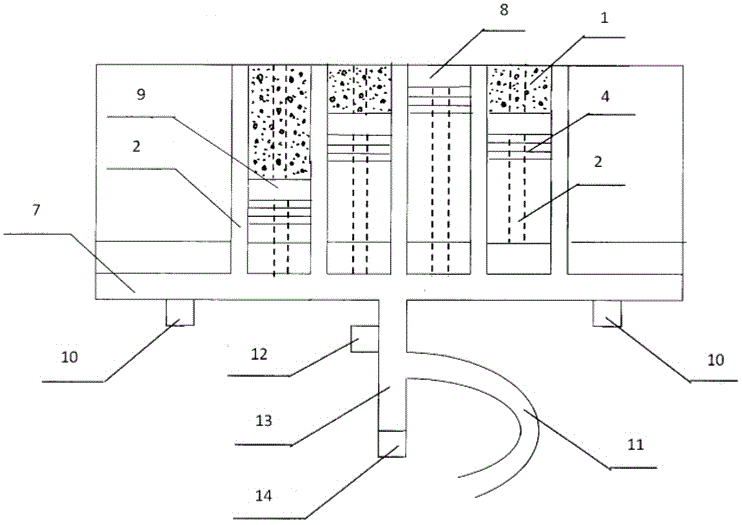

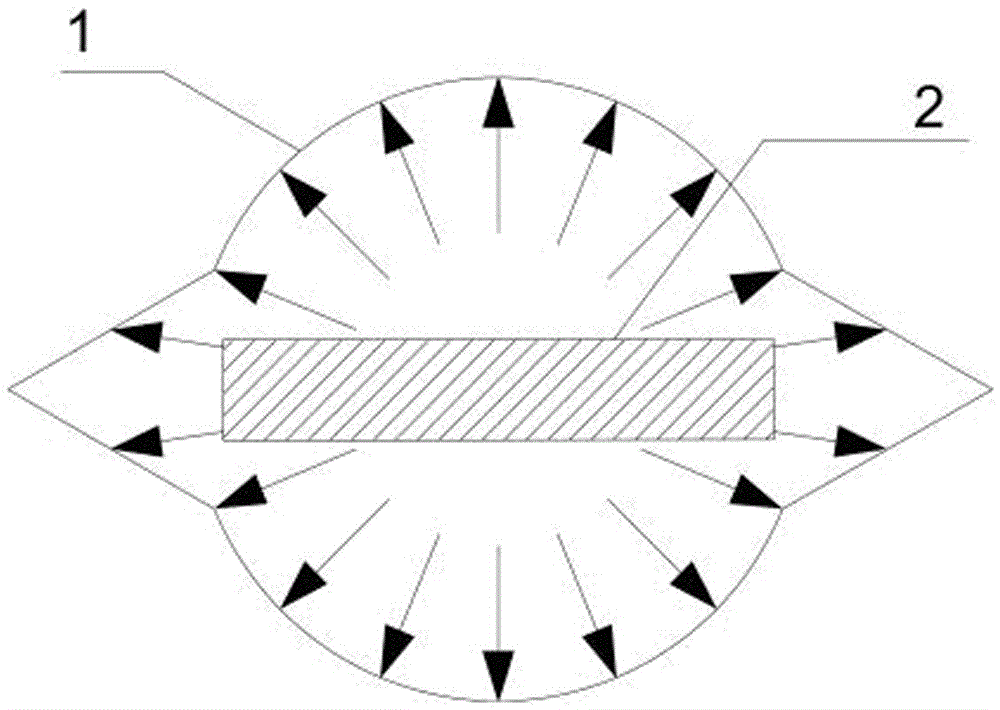

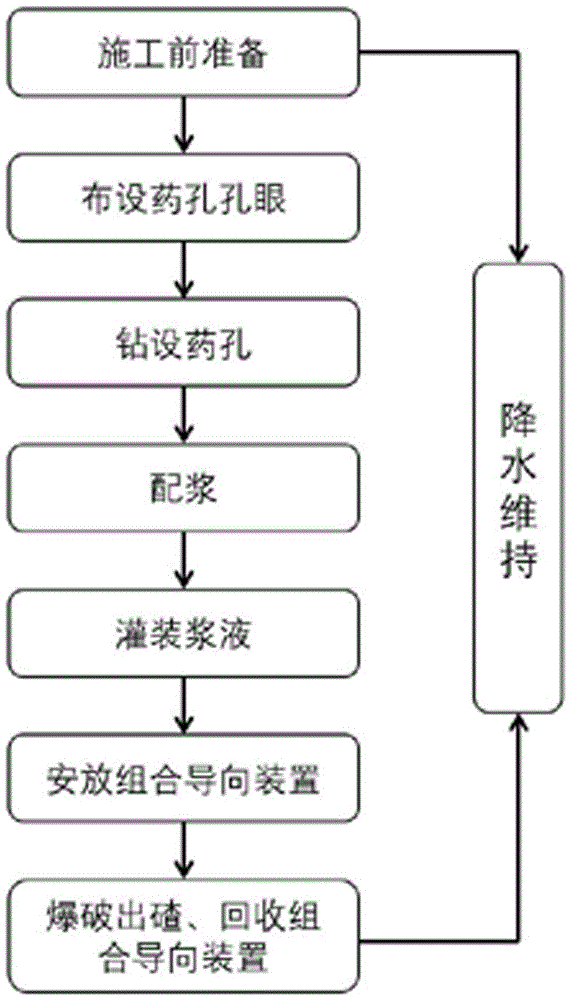

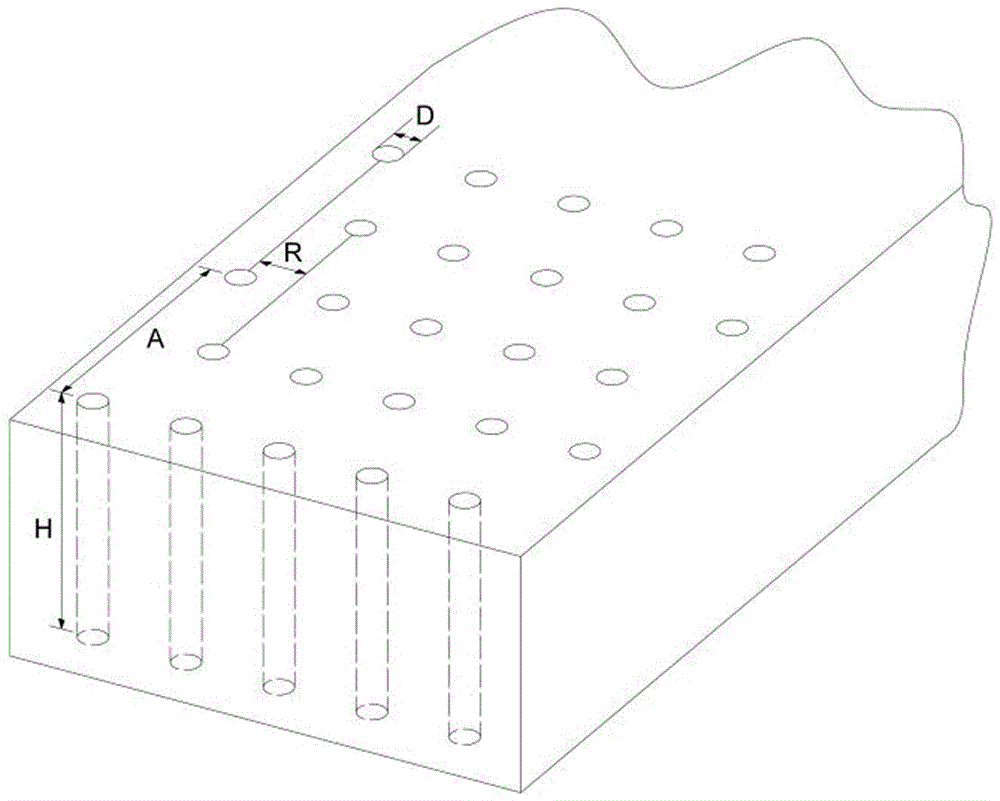

Directional static blasting construction method for foundation pit stratum and combined guiding device for directional static blasting construction method

The invention discloses a directional static blasting construction method for a foundation pit stratum and a combined guiding device for the directional static blasting construction method. The directional static blasting construction method for the foundation pit stratum comprises the first step of field testing, the second step of chemical hole opening arranging, the third step of chemical hole drilling, the fourth step of grout preparing, the fifth step of grout filling, the sixth step of combined guiding device arranging, the seventh step of blasting, slag discharging and combined guiding device recycling and the eighth step of dewatering maintaining. The combined guiding device for directional static blasting is formed by combining long-strip steel sheets and a metal square pipe with guiding square holes for the long-strip steel sheets to penetrate. The long-strip guiding steel sheets are placed in static blasting chemical holes, and consequently penetrating main cracks are generated by a rock mass in the width direction of the long-strip steel sheets. Meanwhile, compared with a conventional static blasting method, the distance of the chemical holes is increased by 1.3-1.5 times in the method, the effect of directional rock mass fracturing is achieved, and meanwhile the blasting efficiency is improved.

Owner:湖南航天建筑工程有限公司

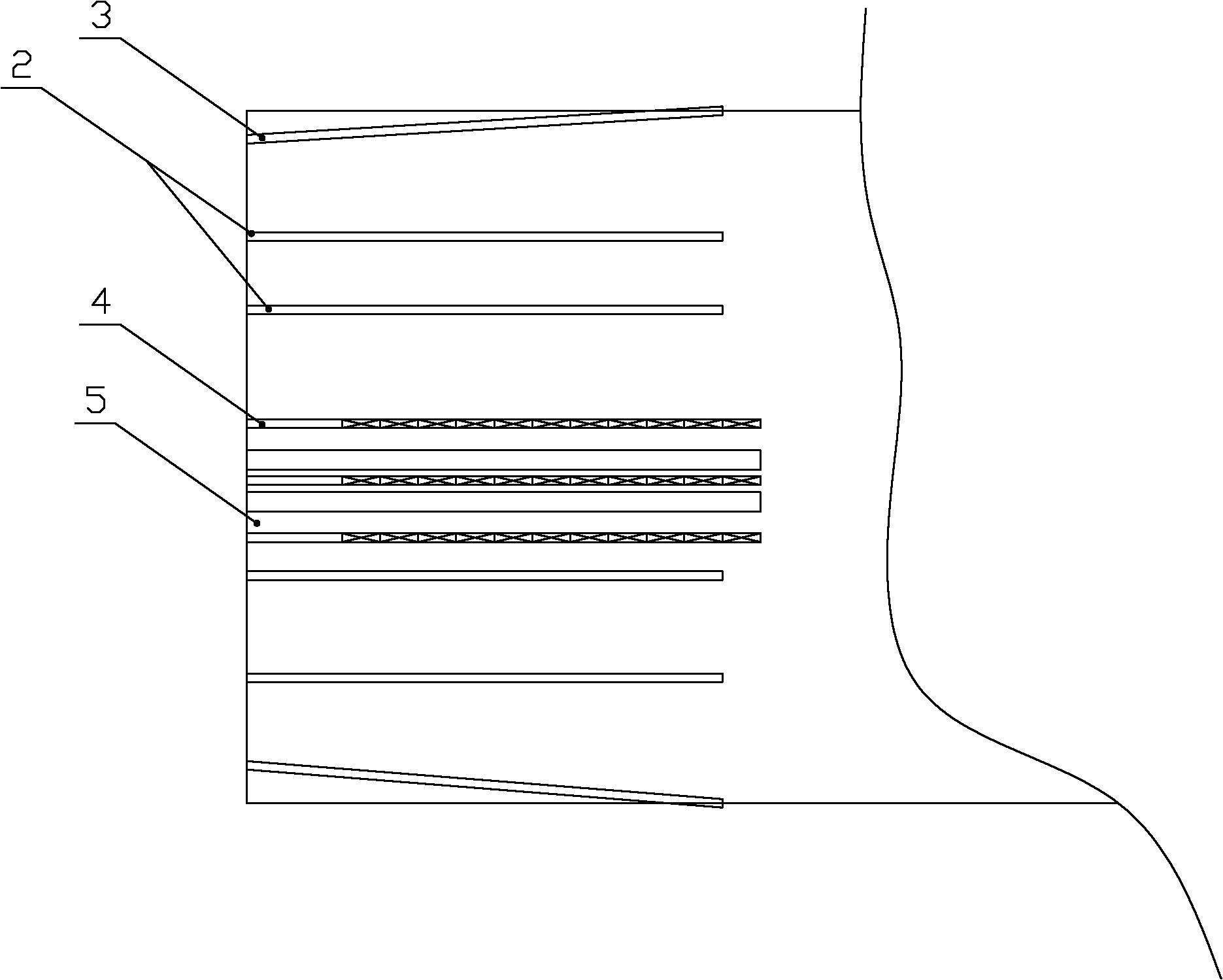

Segment pre-blasting technology for steeply dipping hard coal seam roof

InactiveCN101876520ADecrease the caving stepReduce cavingBlastingMine roof capsEngineeringMechanical engineering

The invention discloses a segment pre-blasting technology for a steeply dipping hard coal seam roof. Blast holes with different angles and length are distributed in gate roads of air return and transportation roadways in front of a working surface towards a roof rock in front of the working surface; and the blast holes are charged in an uneven way with large charge mass, which has controlled fracturing action on the hard roof.

Owner:BAOSTEEL GROUP XINJIANG BAYI IRON & STEEL

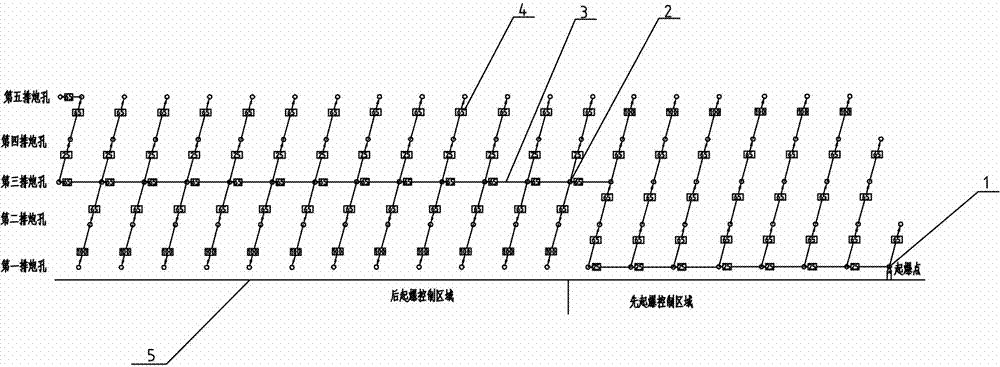

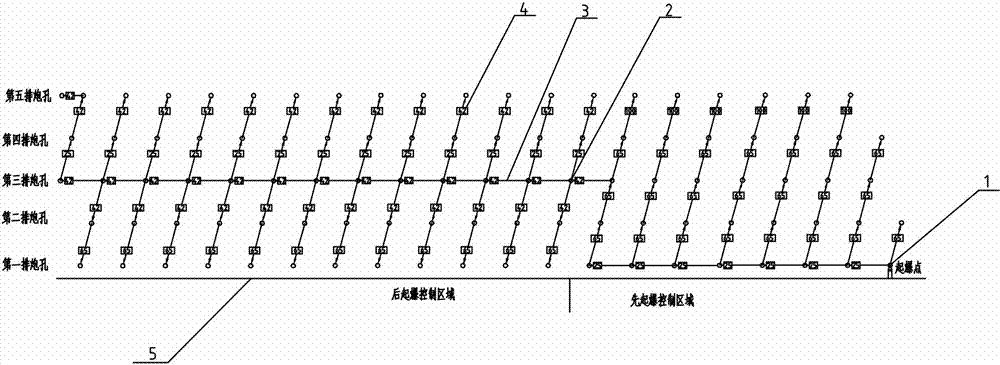

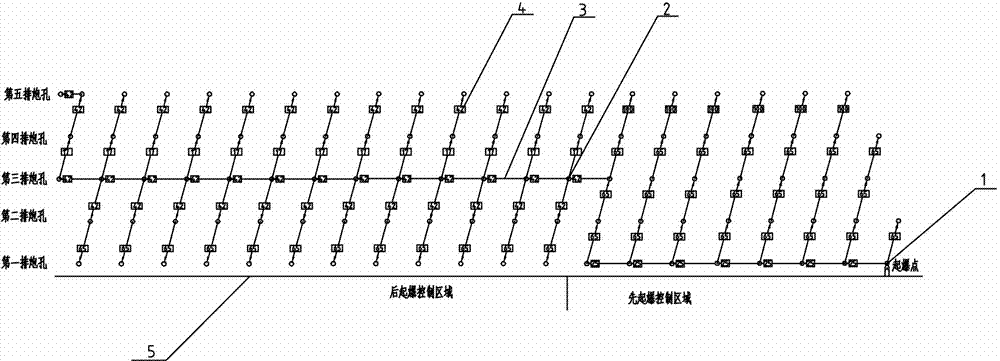

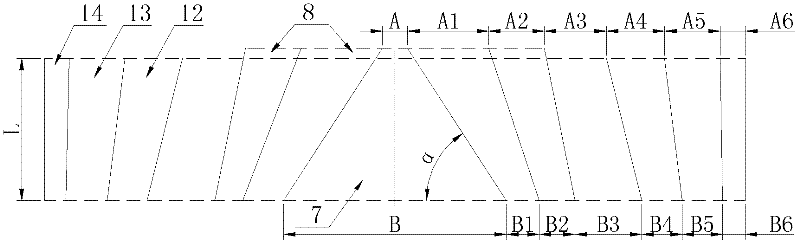

Open-bench blasting method capable of controlling forward stroke of blasting muck pile

An open-bench blasting method capable of controlling a forward stroke of a blasting muck pile comprises the steps of conducting deep hole arrangement, conducting drilling construction, arranging initiation bombs and detonators in deep holes, mounting explosives in the deep holes, conducting detonator delayed initiation design on an earth surface network in the same blasting area, connecting the detonators in the blast holes with detonators of the earth surface network, and initiating the detonators. The method is characterized in that the detonator delayed initiation design of the earth surface network in the same blasting area is that the blasting area is divided into an earlier initiation control area and a later initiation control area which are initiated in sequence, and blasting occurs in the two initiation areas at one time. According to the method, as the blasting area is divided into the two initiation areas, the earlier initiation control area is initiated to provide the later initiation control area with a moving space for containing goods supply and create a free face space condition for the blasting of the later initiation control area. The forward stroke of the blasting muck pile can be controlled precisely and effectively. The safety of the mining operation is ensured, the assistant workload of an electric shovel is reduced, the production efficiency is improved, and the damage and loss caused by the blasting can be reduced.

Owner:ANSTEEL GRP MINING CO LTD

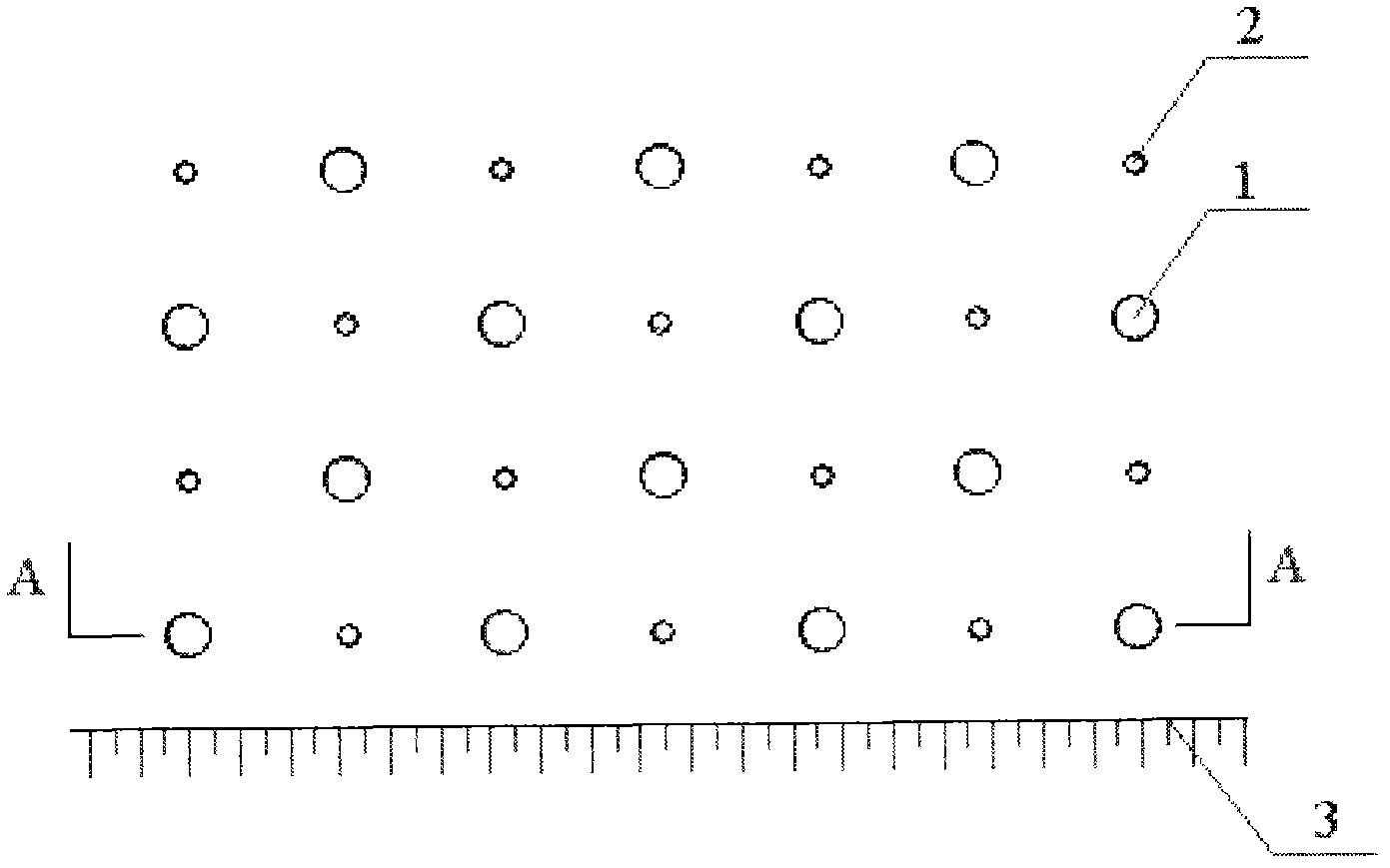

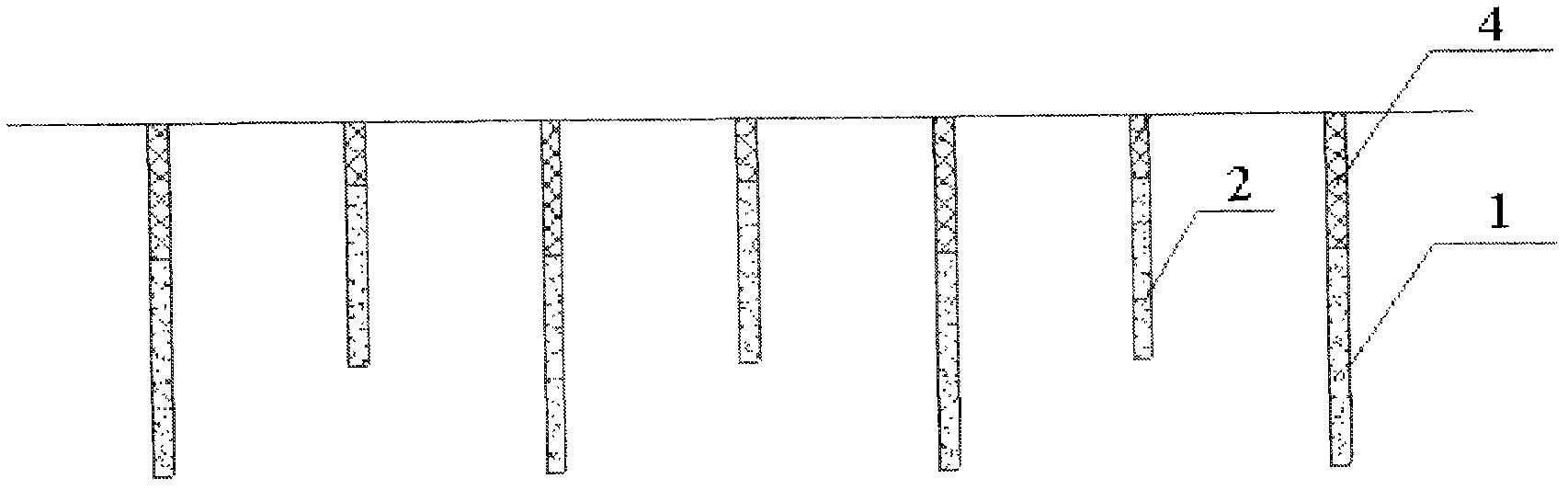

Deep-hole and shallow-hole combined bench blasting method capable of reducing blasting boulder rate

InactiveCN102506623AAvoid uniformityAvoid problems that are mainly concentrated in the bottom of the blast zoneBlastingQuincunxDeep hole

The invention relates to a deep-hole and shallow-hole combined bench blasting method capable of reducing blasting boulder rate. The method comprises the following steps of: 1) drilling boreholes on the bench of a blasting area through a triangular or quincunx-shaped hole arrangement method according to open deep-hole bench blasting design and requirements to obtain deep holes; 2) drilling a shallow borehole with hole diameter being less than or equal to 50mm in the middle between every two deep holes in the same row to obtain shallow holes; 3) respectively charging the deep holes and the shallow holes, laying initiating explosive cartridges and blocking the mouths of the deep holes and the shallow holes; and 4) conducting row-to-row sequential short-delay initiation according to initiation sequence in design requirements and blasting in one step. The deep-hole and shallow-hole combined bench blasting method capable of reducing blasting boulder rate has the advantages that the problem of high boulder rate of blocked sections in a deep-hole bench blasting method is solved, the blasting effect is improved, the subsequent excavating and loading efficiency is improved, the engineering progress is accelerated and the engineering cost is reduced.

Owner:LANZHOU UNIVERSITY

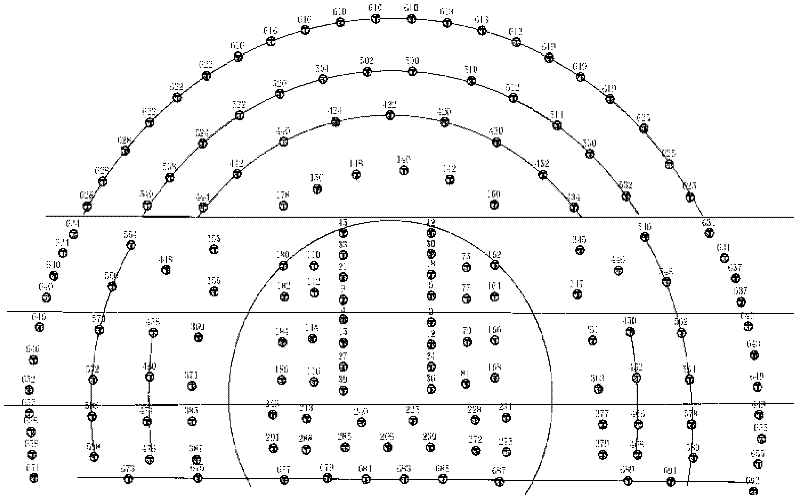

Medium-length hole blasting method used for underground mining

The invention belongs to the technical field of mining, and particularly relates to a medium-length hole blasting method used for underground mining. According to the method, blast holes are distributed in a fan shape, detonators are simultaneously buried in the middles and at the bottoms of the blast holes, the mode that delayed blasting is carried out from the middle to two sides simultaneously and every two rows of blast holes are taken as one group and are sequentially blasted is adopted in the blasting method, the blasting effect is obviously improved, the block rate is substantially reduced, and the ore removal efficiency is obviously improved. Compared with a traditional blasting method, the blasting method reduces the block rate from 27.6% to 6%, the ore removal efficiency of an ore removal equipment scraper is raised from 58 tons per machine team to 122 tons per machine team, the ore removal cost is reduced from 13.63 RMB per ton to 11.53 RMB per ton, recrushing times are substantially reduced and operation safety is guaranteed.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Permafrost region road tunnel peripheral hole blasting construction method

InactiveCN103983147APrevent thermal melt landslidesBlock free radical reactionBlastingDetonatorDynamite

The invention relates to the field of tunnel construction, in particular to a permafrost region road tunnel peripheral hole blasting construction method. The method comprises the following steps of step 1, according to the grade of a tunnel peripheral rock, determining a digging way and the single-circulation advanced depth; step 2, according to the position of the designed digging outline of a tunnel, drilling holes in the periphery at set intervals; step 3, after drilling the holes, cleaning the holes; step 4, filling dynamite into each blast hole, and connecting a percussion cap and a detonating cord; step 5, filling NaCl solution into each blast hole and each shock-absorbing hole, wherein each hole opening is blocked by stemming; step 6, using a blasting way to arrange a blasting network by using area-by-area blasting, blasting the peripheral holes in hole wall position areas, and then blasting the peripheral holes in the arch top. When the tunnel peripheral holes are designed, an un-coupled dynamite filling structure is adopted, and a section-to-section blasting way, a millisecond blasting way and a shock-absorbing design are adopted, so that the blasting heat is reduced, the blasting temperature of the peripheral rock is reduced, the stability of the permafrost is guaranteed, the construction cost is reduced, and construction is simply, conveniently and quickly performed.

Owner:TONGJI UNIV

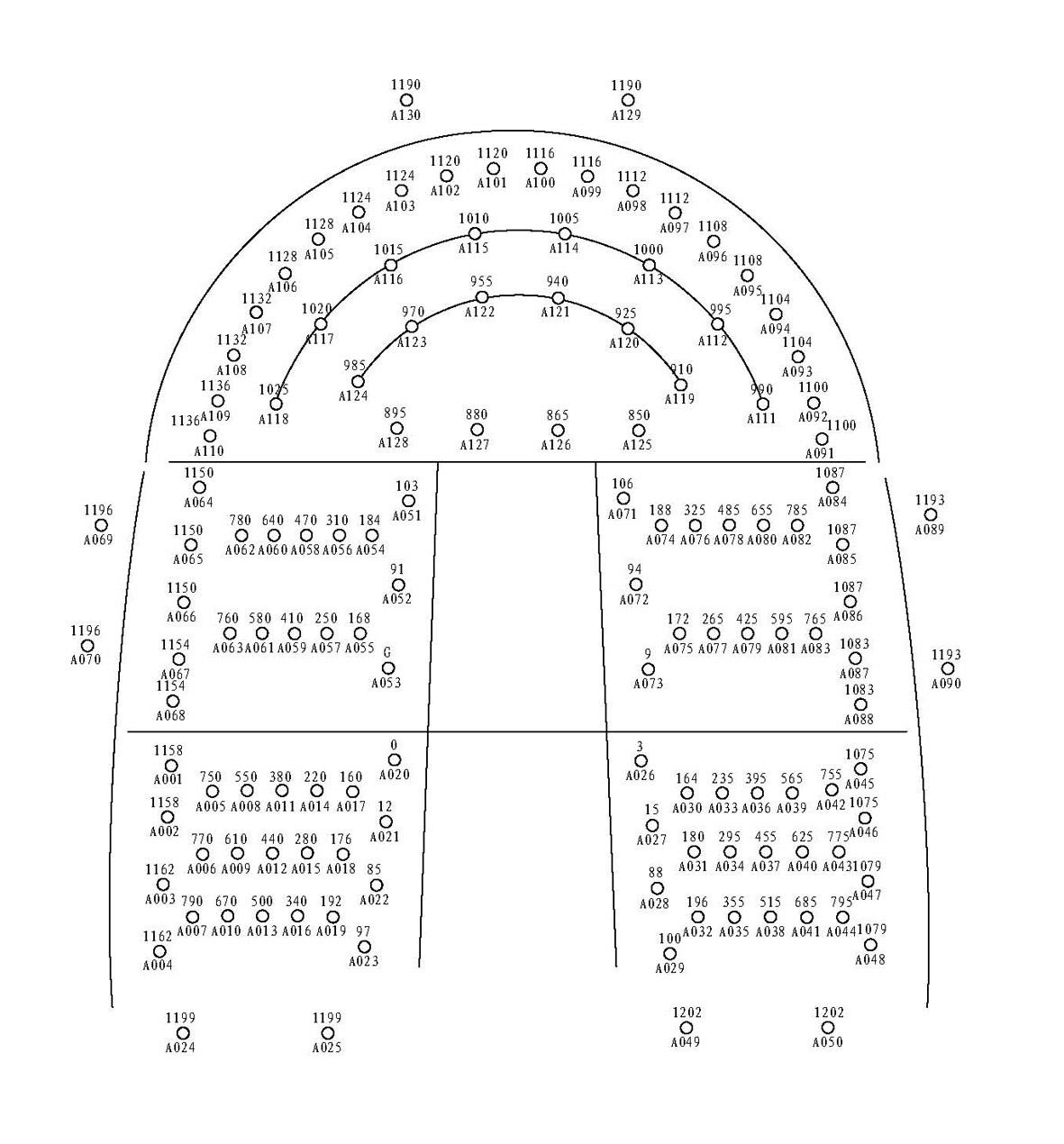

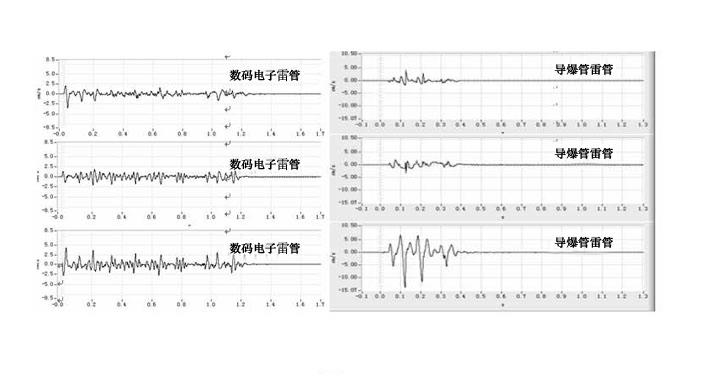

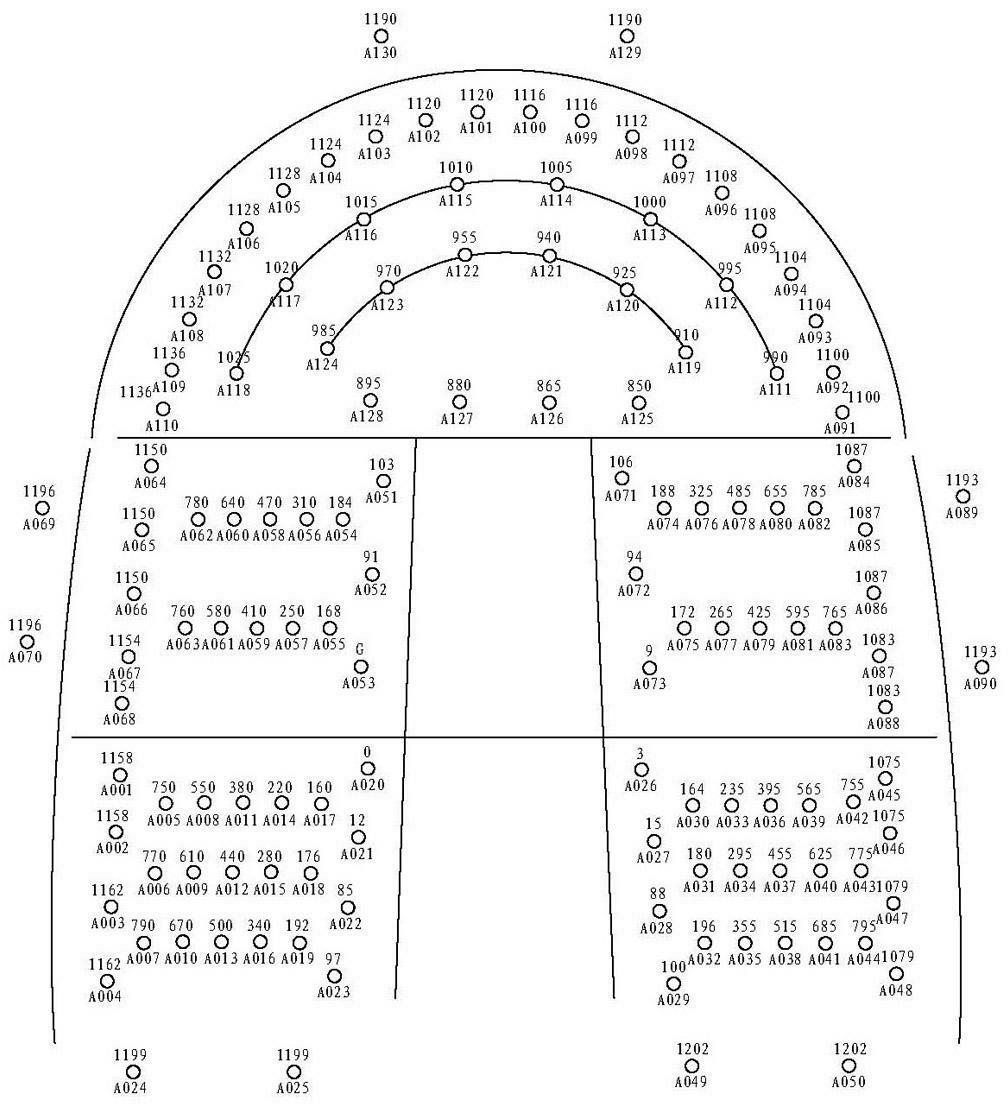

Full-face blasting vibration control construction method for tunnel electronic millisecond electric detonator

ActiveCN102506622AGuaranteed shock absorptionIncrease Single Cycle FootageBlastingDetonatorTime delays

The invention discloses a full-face blasting vibration control construction method for a tunnel electronic millisecond electric detonator, relating to the blasting vibration control technology. The method comprises the following step of: performing a full-face blasting damping control drilling-blasting design by combining blasting vibration requirements according to a tunnel engineering geological condition, an excavated section, an excavating method, a tunneling circulation footage, drilling machine tools and blasting equipment, wherein the drilling-blasting design is as follows: in order to realize the single blasting of cutting holes, auxiliary holes and base plate holes, peripheral holes which are blasted simultaneously are grouped, and the detonator time delay of each shot hole is set, so that the misphase blasting damping is realized; a use flow of the electronic millisecond electric detonator is designed, and the electronic millisecond electric detonator is used according to the flow; an analysis is carried out in the construction process according to the blasting effect and the vibration waveform obtained by blasting monitoring, information is fed back to guide the construction, and blasting parameters are adjusted continuously. The blasting construction method has the advantage of capability of obviously reducing the full-face blasting vibration.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

Back break control method for tunnel

ActiveCN110132084AImprove blasting qualityImprove blasting effectBlastingTunnelsStructure of the EarthEngineering

The invention provides a back break control method for a tunnel. The method comprises the following steps: first, further optimizing original blasting parameters according to a surrounding rock condition determined by advance geology forecast and construction site investigation; then letting out a hole distributing position accurately according to the optimized blasting parameters; and finally, drilling, cleaning the hole, and charging an explosive, and connecting a detonating network to blast. The blasting parameters of an excavated smooth face of a conventional stone tunnel is optimized according to the type of the surrounding rock determined jointly by advance geology forecast combined with construction site investigation around by finely adjusting the drilling parameter and the charging structure by means of existing common materials such as a fire work material and a water bag, so that the blasting quality of full face excavation of the tunnel is improved, a back break phenomenonin conventional full face blasting of the tunnel is reduced to the maximum extent, and targets that the blasting effect is good, the quality safety is guaranteed, the construction cost is controlled effectively and the steps are circular and convenient in sandy slate tunnel excavation penetrating a belt of folded strata are achieved.

Owner:陕西路桥集团有限公司

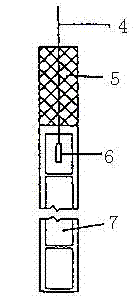

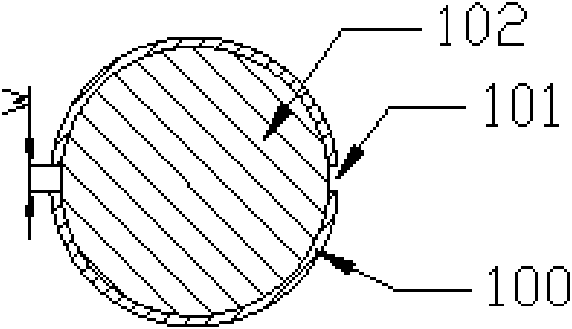

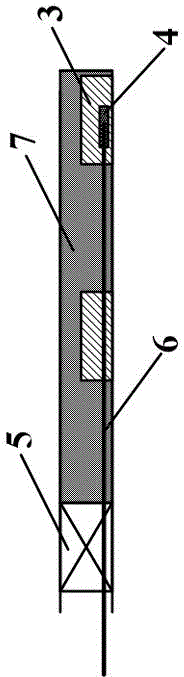

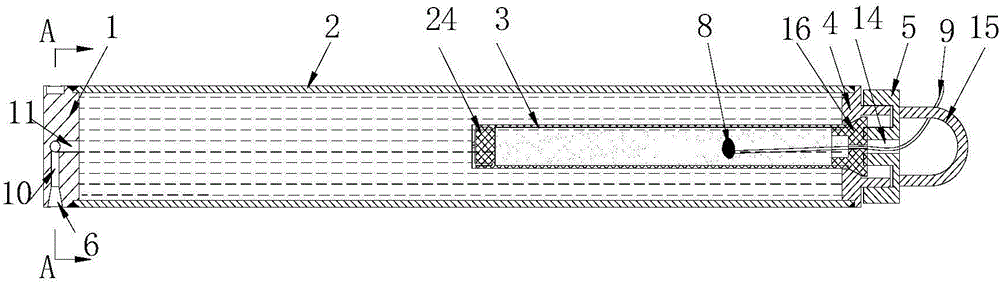

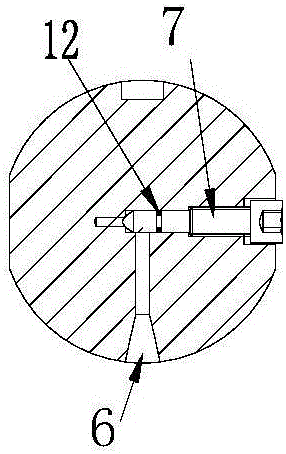

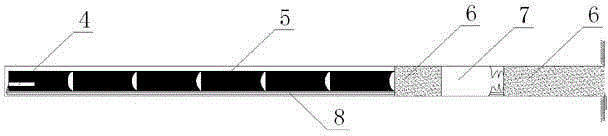

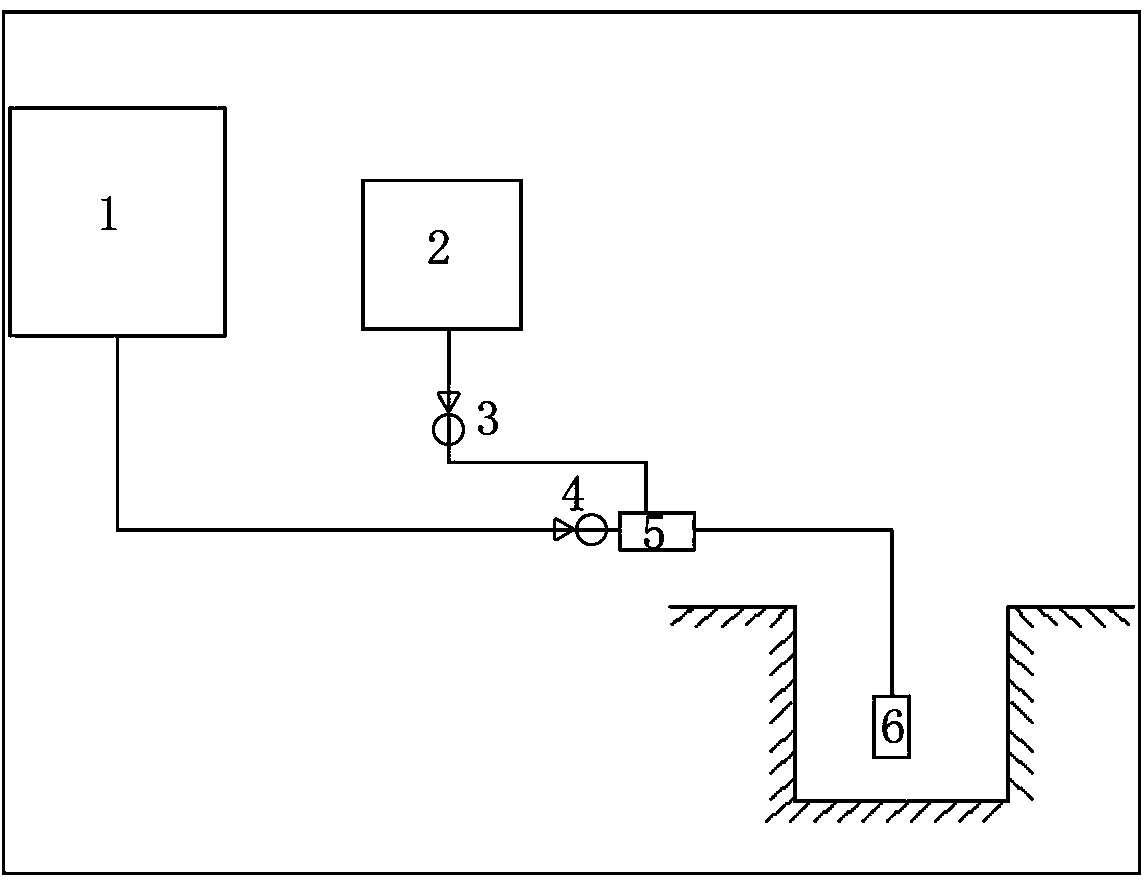

Disposable carbon dioxide cracking device and manufacturing method thereof

ActiveCN105863637AReduce consumptionLarge capacityDisloding machinesSlide valveMaterial consumptionEngineering

The invention discloses a disposable carbon dioxide cracking device and a manufacturing method thereof, and belongs to the field of carbon dioxide cracking devices and the manufacturing methods of the carbon dioxide cracking devices. The disposable carbon dioxide cracking device comprises an expansion pipe, an activator, an upper plug and a locking device, wherein the expansion pipe and the upper plug form a closed container, and the activator is located in the closed container; a mounting opening for mounting the activator is formed in the upper plug, and the locking device is used for sealing the mounting opening; a liquid filling hole is formed in the expansion pipe or the upper plug; a locking valve for controlling the on-off of liquid filling is arranged at the liquid filling hole; the expansion pipe mainly comprises a pipe body and a lower end cover, and when the liquid filling hole is formed in the expansion pipe, the liquid filling hole is formed in the lower end cover of the expansion pipe. According to the invention, a cut long groove is formed in the expansion pipe and a constant pressure energy relief sheet is removed to reduce the material consumption; tedious recycling is reduced, and the material cost is low.

Owner:湖南烈岩科技有限公司

Aqueous medium energy transition blasting method and charging cavity

ActiveCN105674819ASolve the problem of insufficient effective utilization of energyAir Shock MitigationBlastingHydrogenMass ratio

The invention discloses an aqueous medium energy transition blasting method and charging cavity. The aqueous medium energy transition blasting method comprises the steps that firstly, an aqueous medium and explosives with the mass ratio larger than or equal to an optimal value are mounted in the explosive charging cavity of a blasting medium, and the explosives and the aqueous medium are isolated from each other; and then the explosives mounted in the explosive charging cavity are detonated. The aqueous medium and the explosives with the mass ratio larger than or equal to the optimal value M are mounted in the charging cavity, the explosives and the aqueous medium are isolated from each other, and the optimal value M is the ratio of explosion heat of the explosives adopted in the blasting process to heat energy released when water is synthesized by hydrogen and oxygen. The aqueous medium energy transition blasting method and charging cavity have the beneficial effects that the effective utilization rate of energy of the explosives can be increased, the blasting effect of the explosives on the blasting medium can be improved, blasting damage can be reduced, and blasting smoke is less.

Owner:秦健飞

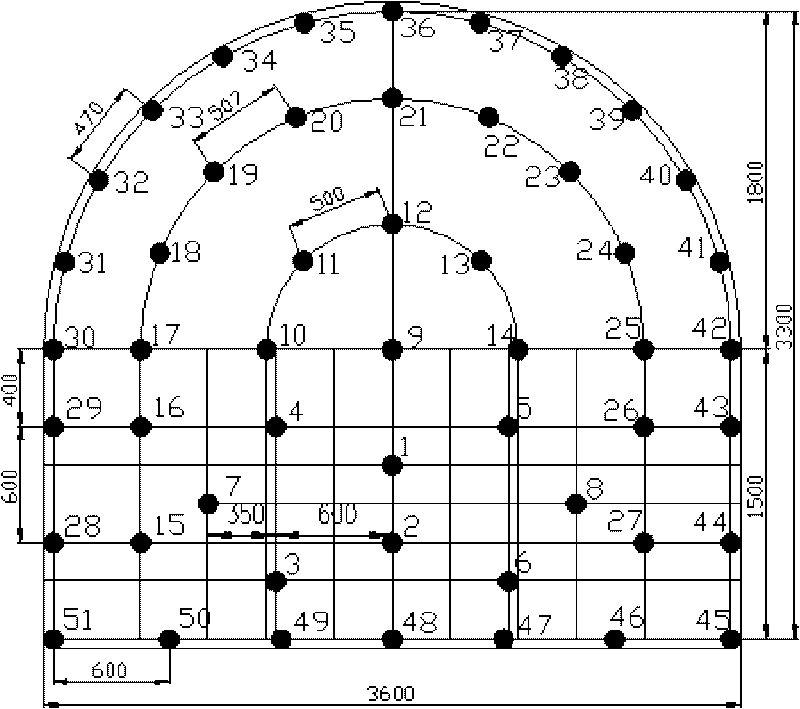

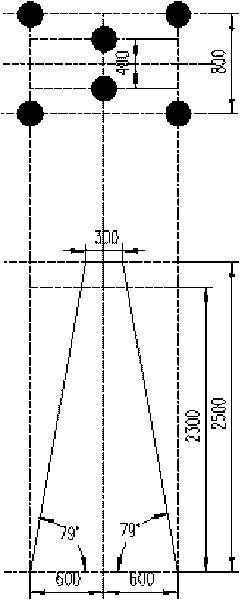

Hard stone drift composite reinforcing vertical wedge cutting method

InactiveCN104864782AGood blasting effectImprove the progress of excavation constructionBlastingDetonatorDetonation

The invention discloses a hard stone drift composite reinforcing vertical wedge cutting method. Two center eyes are formed at a center point of a tunneling roadway center line groove cavity. Three pairs of main cutting eyes and two pairs of auxiliary cutting eyes are symmetrically formed in the two sides of the center eyes. The hole space distance between the center eyes is 400 mm. The vertical hole distance between two adjacent eye holes of the main cutting eyes is 400 mm. The horizontal angle is 70 degrees. The hole distance between two adjacent eye holes of the auxiliary cutting eyes is 400 mm. The horizontal angle is 83 degrees. The main cutting eyes are subjected to detonation through a section of a detonator. The auxiliary cutting eyes and the center eyes are subjected to detonation through two sections of detonators. Center eye blast hole diameter is 42 mm. Large cartridges with the diameter of 40 mm are used for normal charging. Main cutting eye and auxiliary cutting eye blasting hole diameter is 42 mm. Large cartridges with the diameter of 40 mm are used for reverse charging. Normal cartridges are used for forward charging for other blasting holes. At morning shift, a medium-deep hole is used for one-cycle detonation; at noon shift and night shift, two cycles are carried out; detonation depth at each cycle is 1.6-1.7 m.

Owner:周忠国

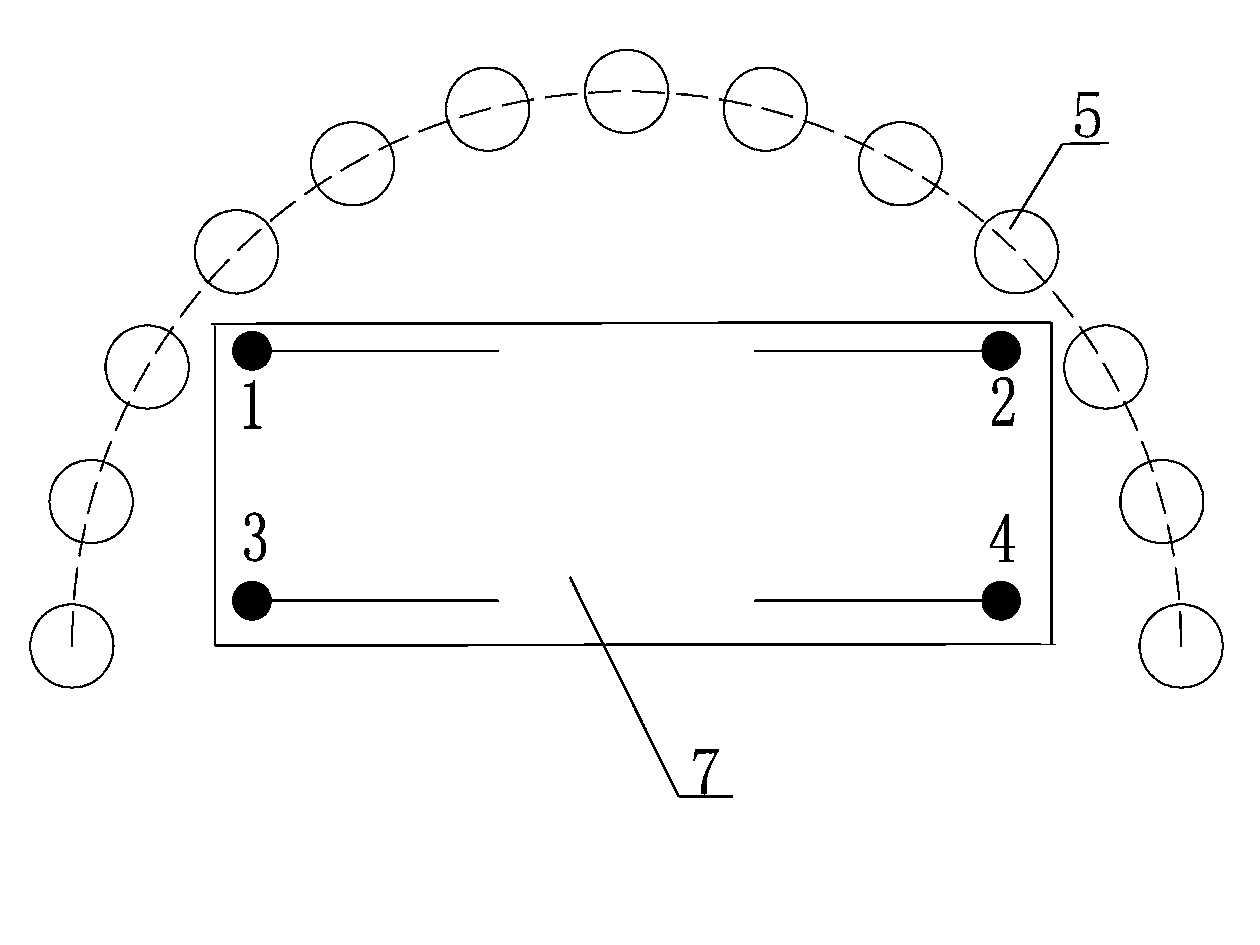

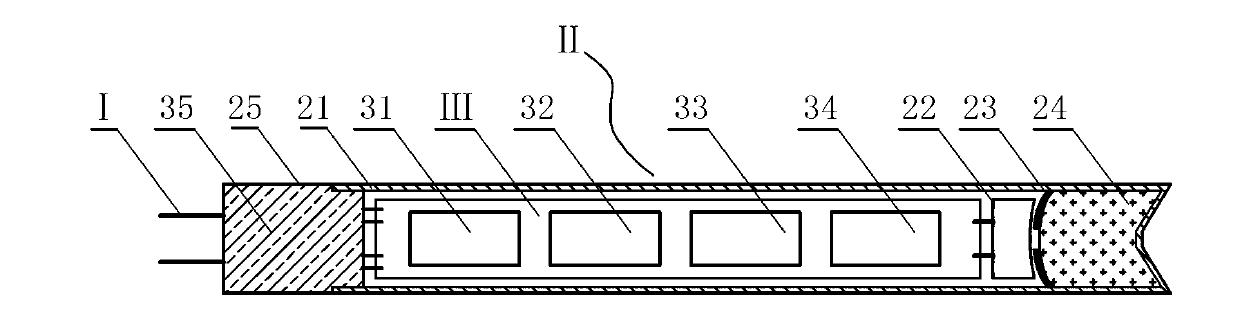

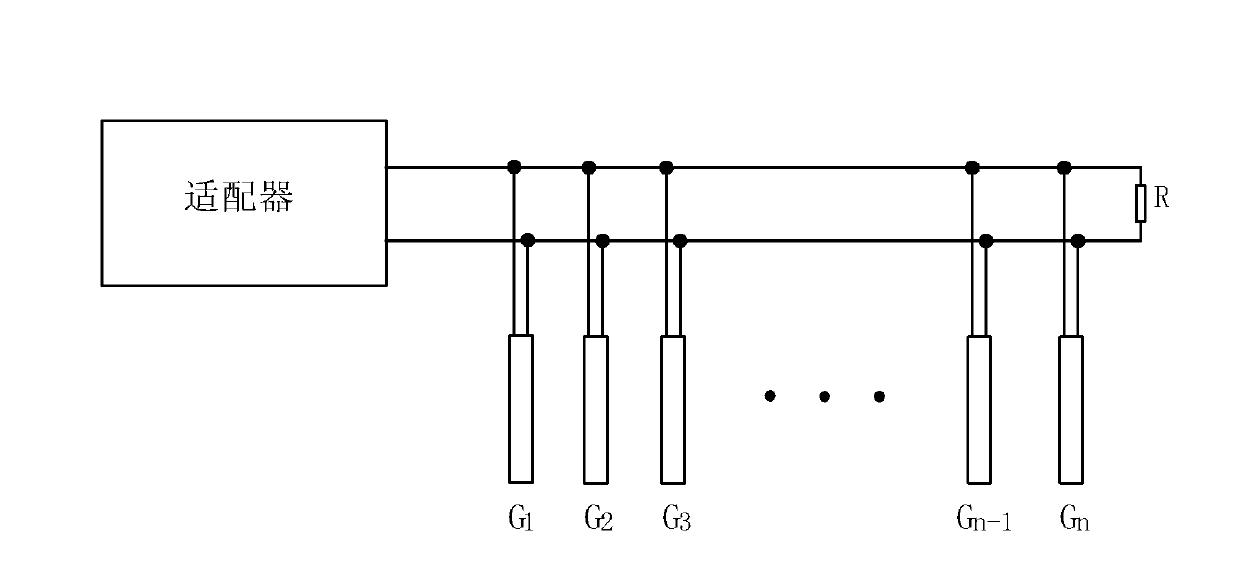

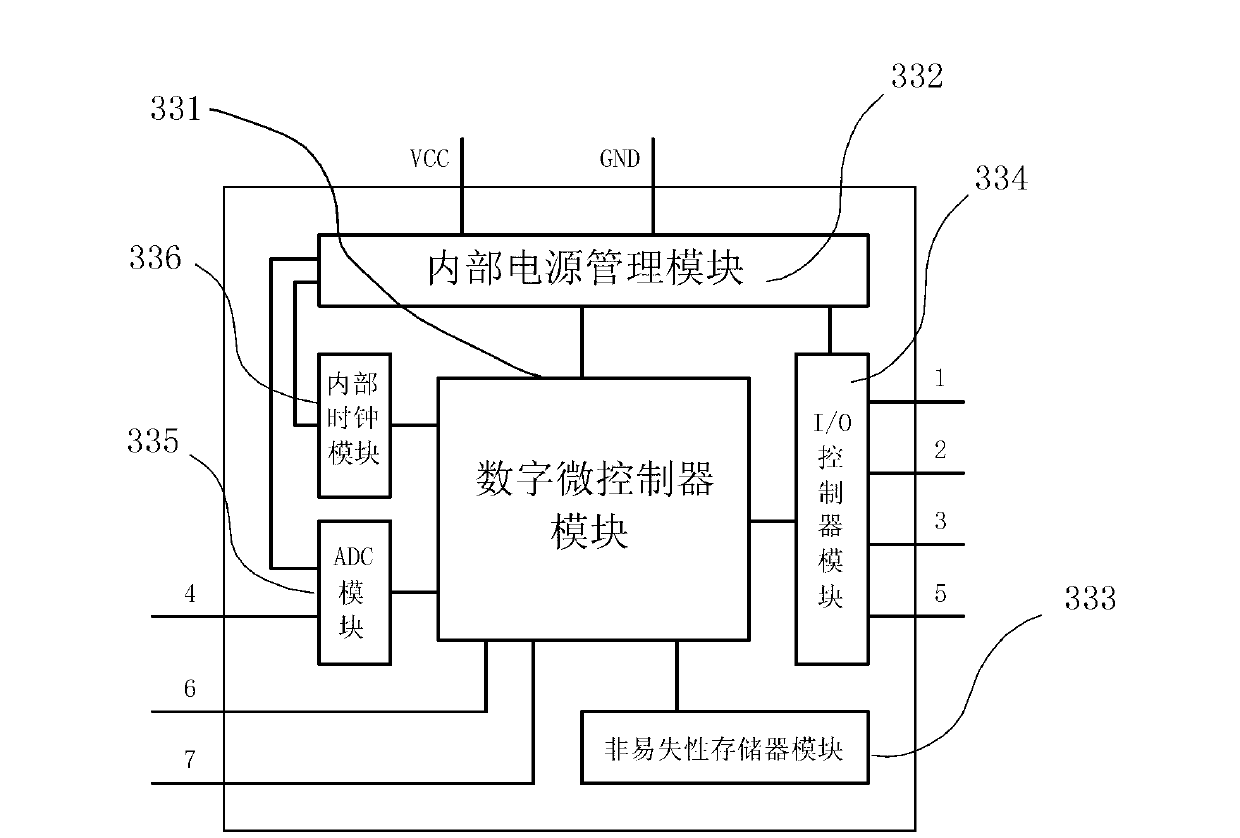

Nonpolar double-wire communication digital electronic detonator capable of self-delaying and detonation method thereof

ActiveCN103217079AHigh authority securityImprove controllabilityBlasting cartridgesElectric fuzesDetonatorDetonation

A nonpolar double-wire communication digital electronic detonator capable of self-delaying, comprises a leg wire and a pipe body, wherein the pipe body comprises a pipe casing, and an ignition device, a detonator charging and tail plugging device, a control circuit and an ignition energy storage device, which are installed in the pipe casing. The control circuit comprises a power supply module, a communication module, a core control module and an ignition loop module, which are orderly electrically connected; input terminals A and B of the power supply module are connected to the leg wire, the ignition loop module is electrically connected with the ignition device and the ignition energy storage device; and a detonation method comprises: (1) detonator configuration, (2) networking, and (3) detonation operation. The nonpolar double-wire communication digital electronic detonator has a UID code and detonation authorization code verifying function, has advantages of controllable itself, high authority security, convenient self-delay, on-site laying, accuracy detonation control, good explosion effect, no need to distinguish polarities of the leg wire, convenient usage and low human error rate, and can obtain higher delay precision by using an internal clock module or an external clock module.

Owner:LIUZHOU CHANGHONG MACHINE MFG +1

Tunneling electron detonator blasting construction method

InactiveCN102095338AHigh delay accuracyMeet the design requirements of vibration reductionBlastingDetonatorEngineering

The invention discloses a novel blasting construction method. In the method, an electron detonator is used for blasting. The method also comprises the following steps of: designing a detonator arrangement diagram; detonating at least one detonator; analyzing a generated blasting vibration waveform; detonating a special detonator; and eliminating the blasting vibration to the maximum extent by a phase-stagger vibration damping technology. By the technology of the method, the blasting vibration is obviously reduced, full cross section blasting can be performed, circulating drilling footage is increased, blasting residues are well crushed and an obvious polished surface effect is achieved.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD +1

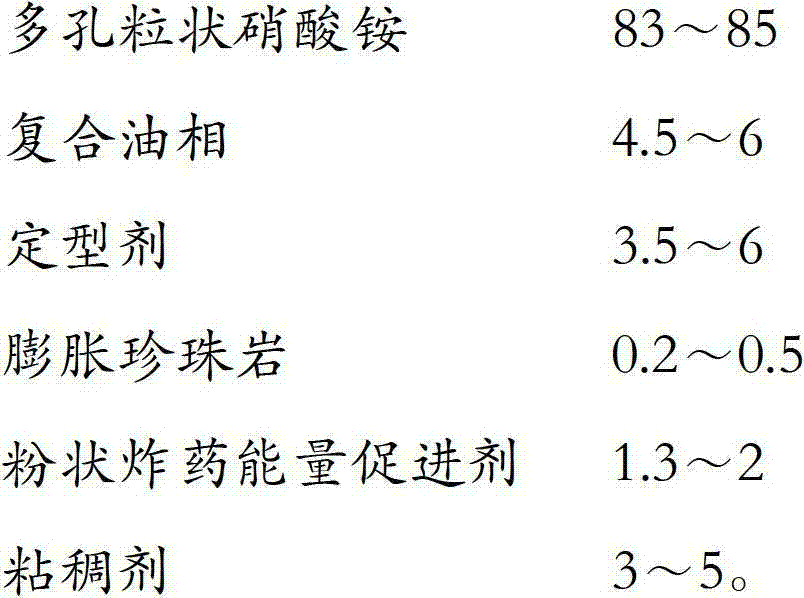

Viscous porous granulated ammonium nitrate fuel oil explosive and preparation method thereof

InactiveCN102924195AHigh detonation velocityImprove working abilityExplosivesEnvironmental resistanceFuel oil

The invention discloses viscous porous granulated ammonium nitrate fuel oil explosive and a preparation method thereof. The ammonium nitrate fuel oil explosive comprises the following constituents in weight percent: 83 to 85 percent of porous granulated ammonium nitrate, 4.5 to 6 percent of compound oil phase, 3.5 to 6 percent of tackifier, 0.2 to 0.5 percent of expanded perlite, 1.3 to 2 percent of powder type explosive energy accelerant, and 3 to 5 percent of thickener. The method comprises the following steps: a, adding the porous granulated ammonium nitrate into a viscous porous granulated ammonium nitrate fuel oil explosive mixer, then adding the compound oil phase, stirring for 2 to 4 minutes at normal temperature, mixing the porous granulated ammonium nitrate and the compound oil phase to be uniform, so as to form mixture A; b, adding the tackifier, the powder type explosive energy accelerant and the expanded perlite into the mixture A, stirring for 1 to 2 munities at normal temperature, mixing the mixture A, the tackifier, the powder type explosive energy accelerant and the expanded perlite to be uniform, so as to form mixture B; and c, adding the thickener into the mixture B, stirring for 1 to 2 munities at normal temperature, and mixing the mixture B and the thickener to be uniform, so as to form the viscous porous granulated ammonium nitrate fuel oil explosive, and then packaging the viscous porous granulated ammonium nitrate fuel oil explosive. The viscous porous granulated ammonium nitrate fuel oil explosive and the method have the advantages that preparation and storage processes are safe and controllable, the power capability is high, the storage period is long, and the explosive is efficient and environmentally friendly.

Owner:肖代军 +2

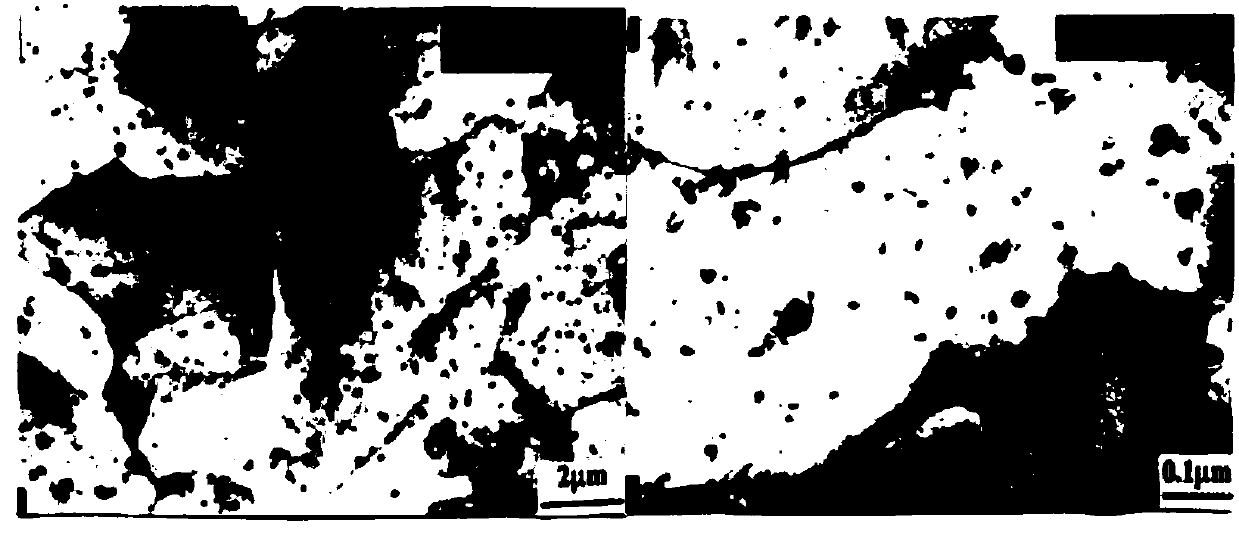

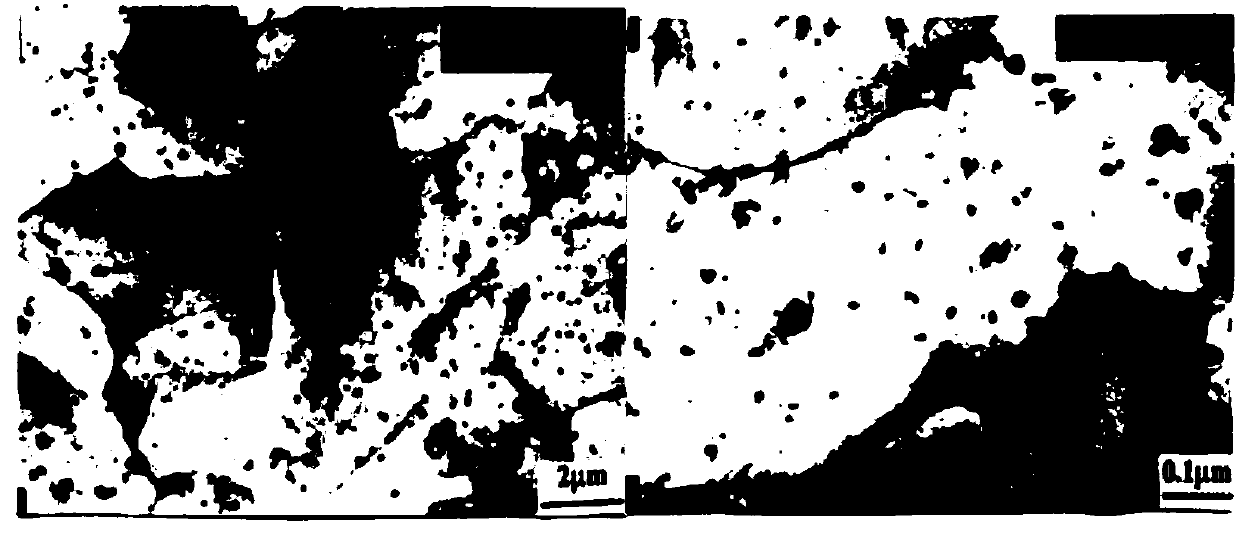

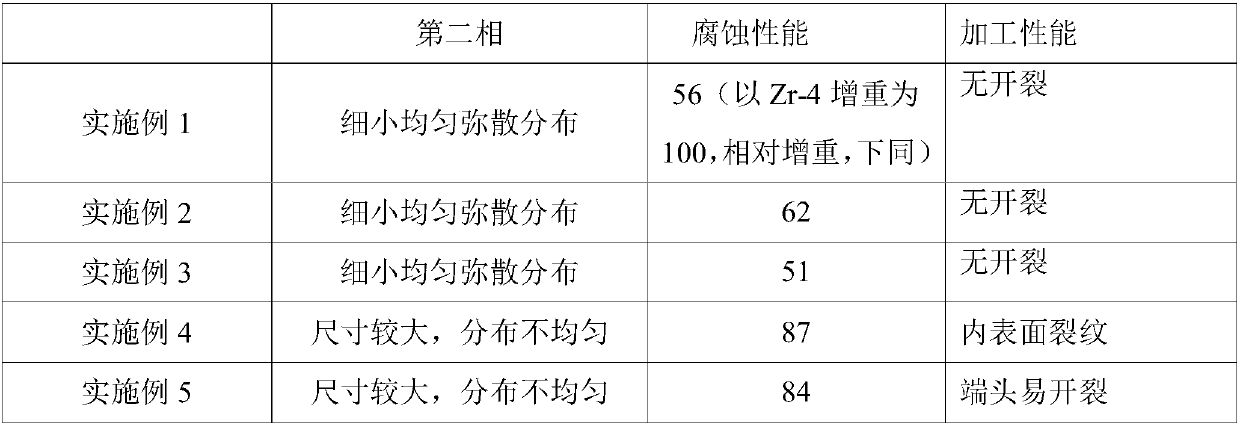

Manufacturing technology of zirconium alloy cladding tubular product

ActiveCN107116339AImprove performanceImprove processing stabilityManufacturing technologyStress relief

The invention discloses a manufacturing technology of a zirconium alloy cladding tubular product. The manufacturing technology of the zirconium alloy cladding tubular product solves the problem that in the prior art, a manufacturing technology suitable for an N36 zirconium alloy finished-product cladding tubular product is not provided. The manufacturing technology of the zirconium alloy cladding tubular product comprises the steps that (1) N36 zirconium alloy is made into an extrusion ingot after smelting, forging and quenching; (2) the extrusion ingot is made into a tube blank with the outer diameter being 71-79 mm and the inner diameter being 40-50 mm through thermal extrusion; (3) the tube blank is rolled into a tube blank with the outer diameter being 50-60 mm and the wall thickness being 10-11.5 mm through the first pass, and annealing is conducted after rolling; (4) cold rolling is conducted for 3-4 passes, finally the cladding tubular product is manufactured, and intermediate annealing is conducted between two adjacent passes of cold rolling; and (5) after final stress relief annealing or final recrystallization annealing is conducted, the cladding tubular product is made into the finished-product tubular product. The manufacturing technology of the zirconium alloy cladding tubular product has the advantages of being stable in technology, high in finished product rate and the like. Besides, the manufactured tubular product has the advantages of being quite excellent in corrosion resistance, tensile property, bursting property, texture, CSR and the like.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

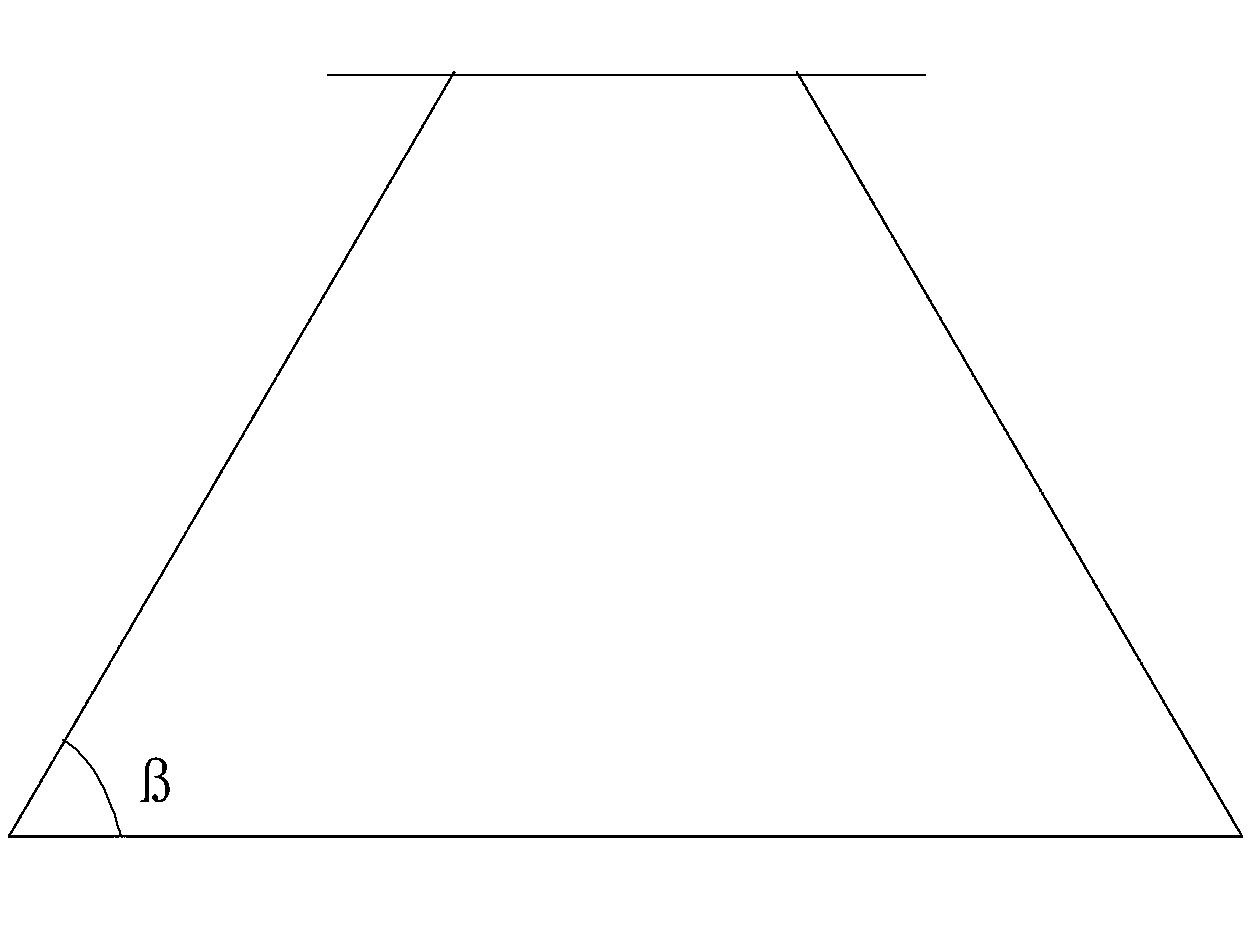

Method for smooth blasting construction with pre-eccentric uncoupling charging

ActiveCN101545746AAvoid cloggingPrevent plugging of blast holesAmmunitionBlastingEngineeringSize ratio

The invention discloses a method for smooth blasting construction, and in particular relates to a method for smooth blasting construction with pre-eccentric uncoupling charging. The invention aims to provide the method for the smooth blasting construction with pre-eccentric uncoupling charging, which can improve the side slope smooth blasting effect. The technical proposal comprises that the method for the smooth blasting construction with pre-eccentric uncoupling charging comprises the following steps: (1) drilling a hole according to design requirement, cleaning up sundries in the hole and beside the hole after drilling the hole to prevent the blasting hole from being blocked by the sundries; (2) processing an ammunition string: processing the ammunition string outside the hole according to the design, wherein the size ratio of the diameter of the charging hole to the diameter of the ammunition string or the uncoupling coefficient is between 3.0 and 4.0; (3) mounting well-processed brackets on the ammunition string at intervals according to construction requirements; (4) putting the ammunition string into the blasting hole slowly by pressing close to the upper hole wall, namely one side of a light blasting body and blocking the blasting hole; and (5) initiating the blasting. The method is mainly applicable for engineering blasting.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

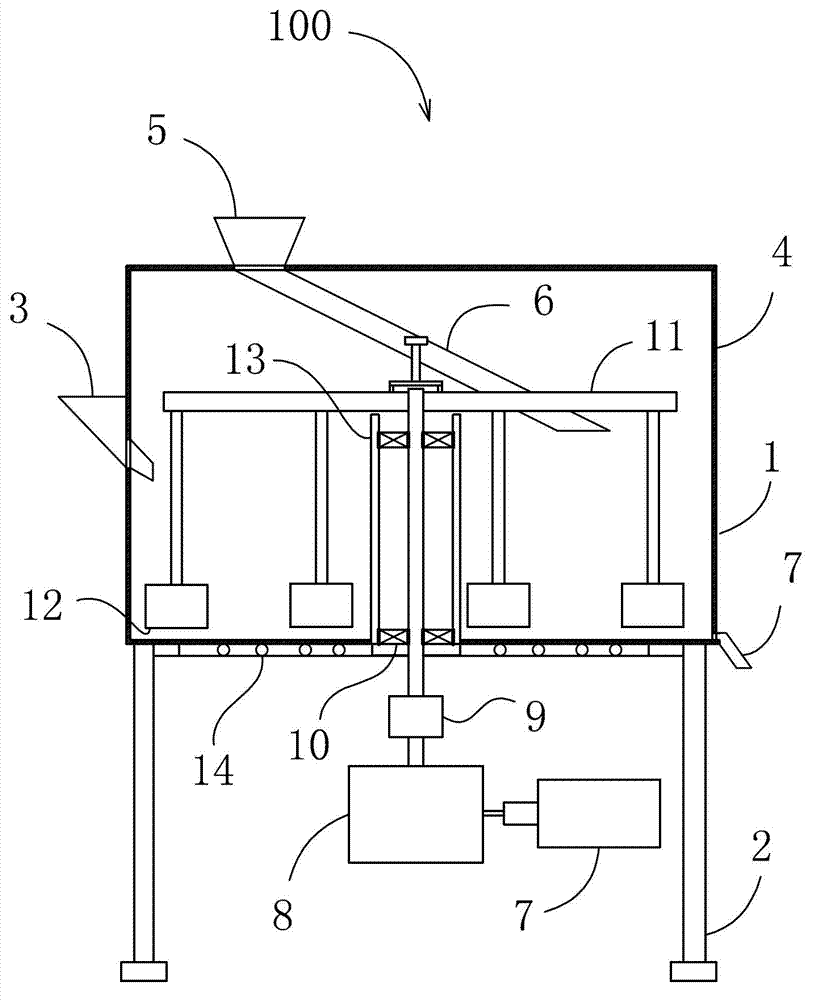

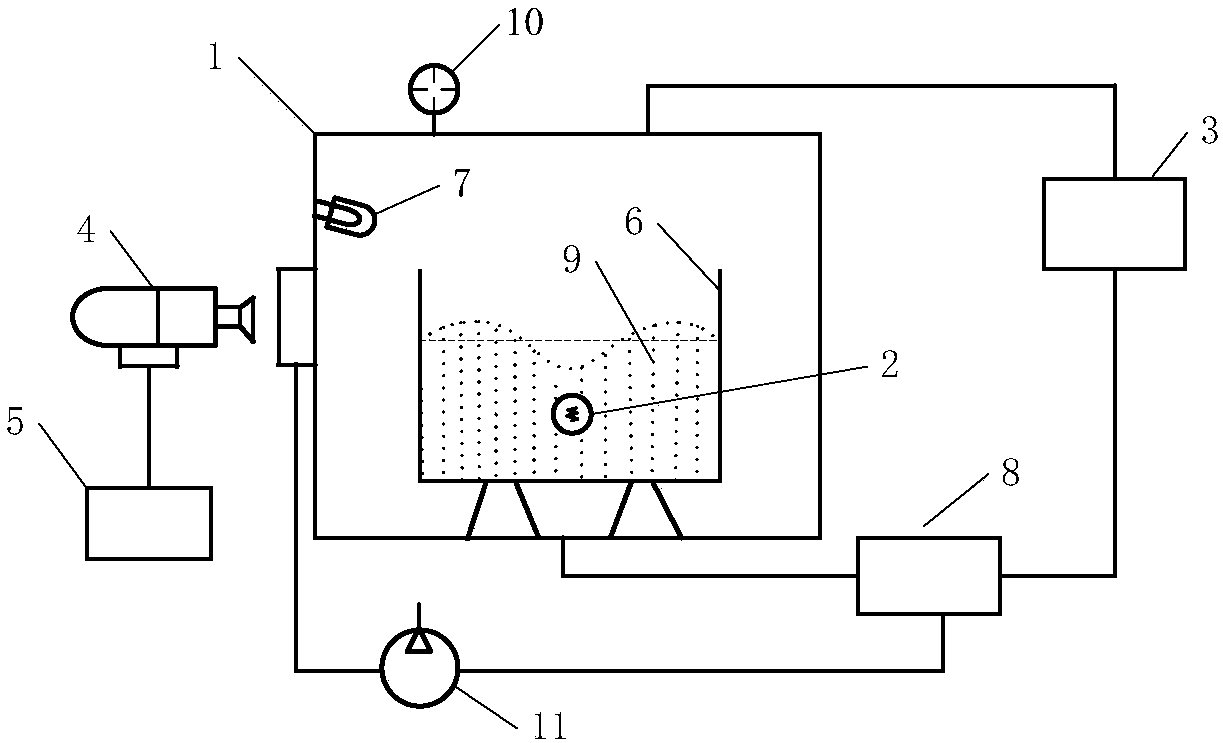

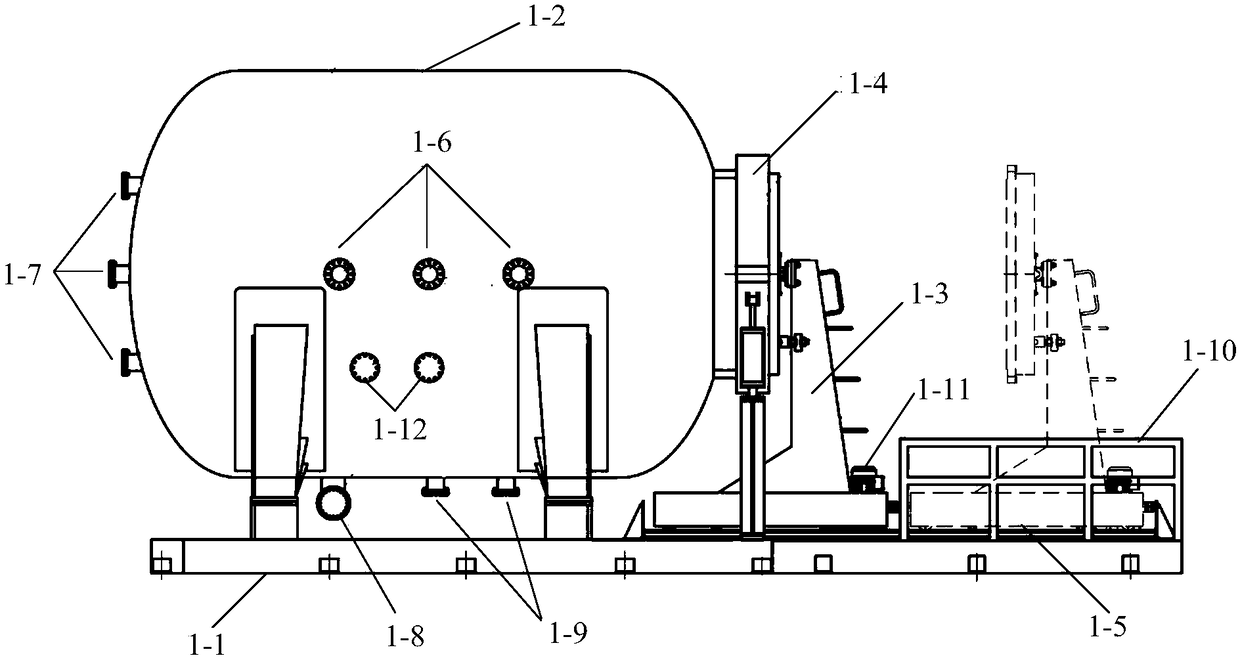

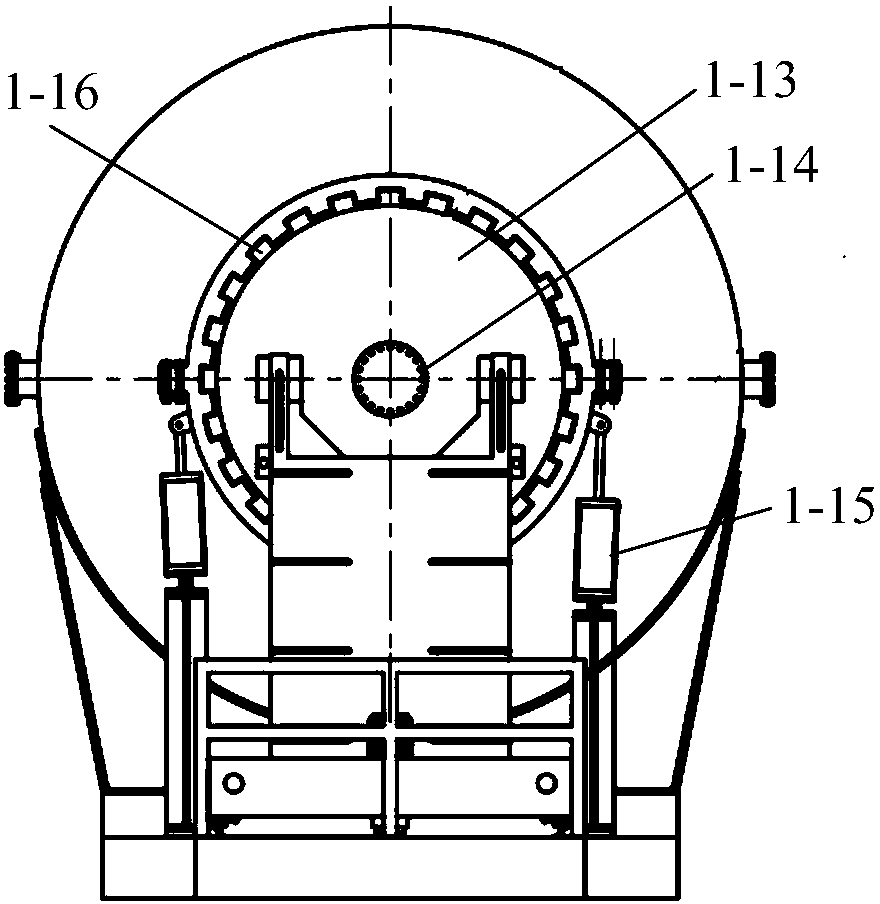

Large-equivalent-weight underground shallow-buried explosion effect simulating device

PendingCN108801816AGood sealing performance under pressureEasy to operateShock testingStrength propertiesSteel tubeDetonator

The invention discloses a large-equivalent-weight underground shallow-buried explosion effect simulating device. The large-equivalent-weight underground shallow-buried explosion effect simulating device comprises a base, a container tank, a first vacuumizing device and an explosion source device, wherein the explosion source device comprises a glass cover, a detonating cord, a steel tube, a sealing plug, an electric detonator, an exploder and an air pressure adjusting device; the base serves as a supporting component of the whole simulating device, and is mounted at the bottommost end of the whole device; the container tank is mounted at one end of the base; the first vacuumizing device is connected with the container tank through a pipe; the glass cover and the electric detonator are positioned in the container tank; the bottom end of the glass cover is sealed through the sealing plug; the detonating cord is positioned in the glass cover, penetrates out of the sealing plug through a steel tube, and is connected with a conical end of the electric detonator; the other end of the electric detonator is connected with the exploder of the outside of the container tank; and the bottom end of the glass cover is connected with the air pressure adjusting device. By the simulating device, a large-scale throwing explosion effect simulating test under different parameter conditions can berepeatedly developed; and the simulating device is simple to operate and low in cost.

Owner:PLA UNIV OF SCI & TECH

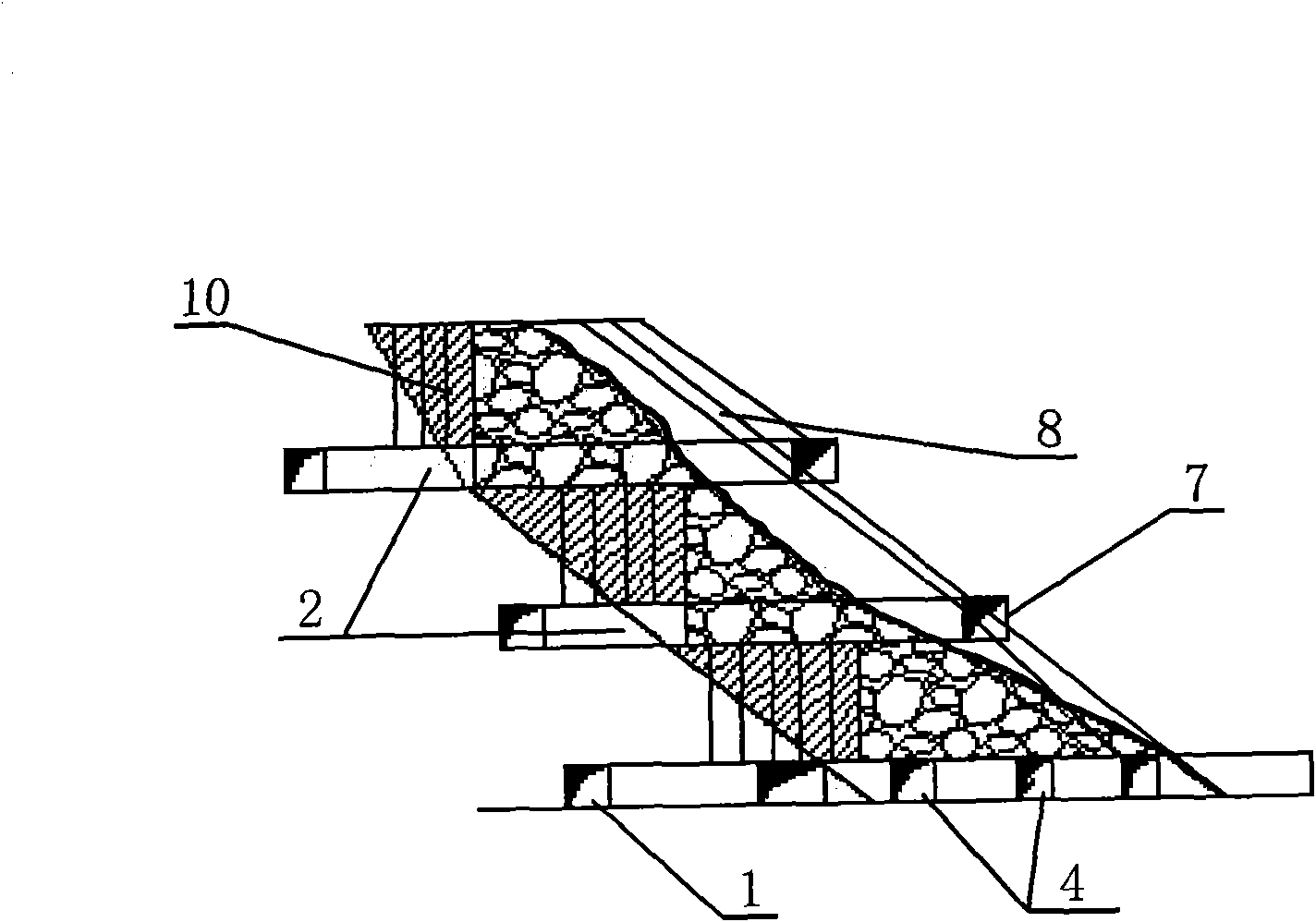

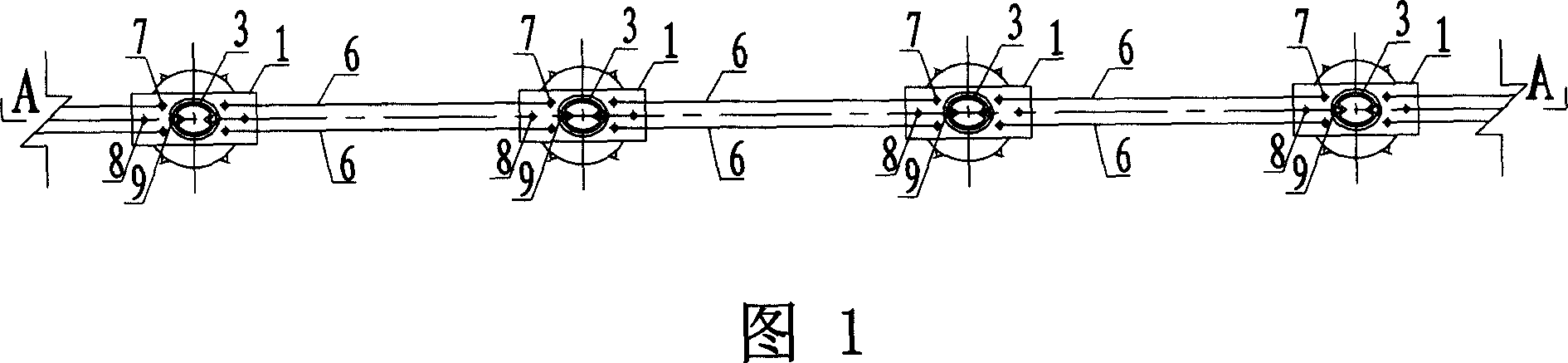

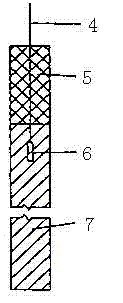

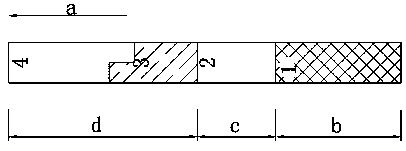

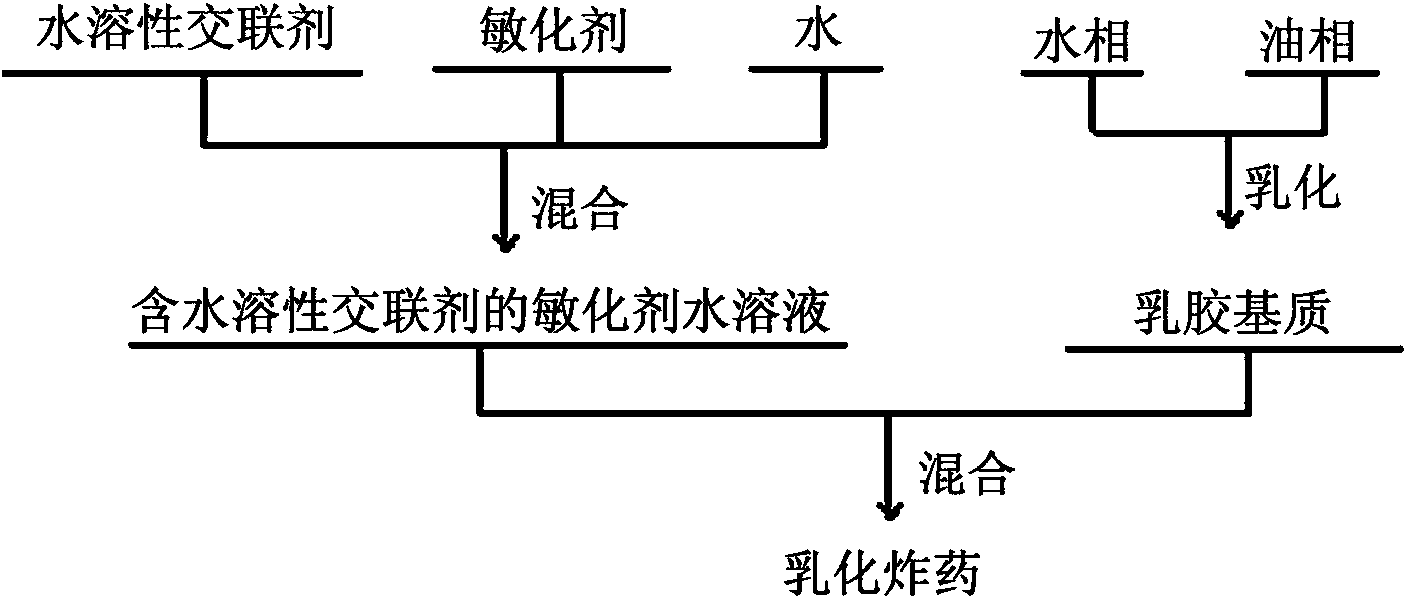

Hole bottom energy gathering and dissipating device suitable for inclined blast hole and capable of improving blasting excavation flatness of foundation surface

A hole bottom energy gathering and dissipating device suitable for an inclined blast hole and capable of improving the blasting excavation flatness of a foundation surface. The hole bottom energy gathering and dissipating device comprises a polyvinyl chloride pipe (1). A gravel layer (7), an energy gathering and dissipating base (5), a kraft paper pad (4) and an energy gathering explosive layer (2) are arranged in the polyvinyl chloride pipe (1) in sequence from bottom to top. The pipe wall of the polyvinyl chloride pipe (1) is provided with energy gathering holes (3). A columnar groove (8) is formed in the center of the energy gathering explosive layer (2). The hole bottom energy gathering and dissipating device has the advantages that the device is arranged in the inclined blast hole, so that operation is fast and convenient, and a good blasting effect is guaranteed; since the advantages of energy gathering explosives and the advantages of the energy gathering and dissipating base are combined, the breaking effect on the bottom of the hole in the horizontal direction is better, damage to the bottom of the hole in the vertical direction is smaller, and the excavated foundation surface is smoother; all the structures are assembled into a whole through the polyvinyl chloride pipe with the energy gathering holes, so that transportation, arrangement during construction and batch production are facilitated, and the efficiency of blasting operation is improved; the excavated foundation surface is small in fluctuation, and the workload of manual excavation in a later period is reduced or even omitted.

Owner:WUHAN UNIV

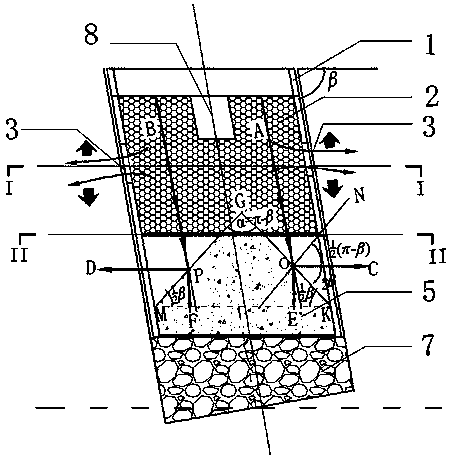

Manufacturing method of on-site mixed emulsion explosive

ActiveCN104109058ANo hanging phenomenonImprove delivery efficiencyExplosive working-up apparatusEmulsion explosiveWater soluble

The invention discloses a manufacturing method of an on-site mixed emulsion explosive. The method comprises the following steps: mixing a latex matrix with a sensitizer water solution containing a water-soluble crosslinking agent, so as to obtain a mixer, then filling the mixture into boreholes so as to enable the latex matrix can have crosslinking reaction and sensitizing reaction in the boreholes, thereby forming an emulsion explosive, wherein the latex matrix is prepared from the following raw materials in percentage by weight: 59%-82% of oxidant, 13%-30% of water, 0-1% of acid, 1%-3% of emulsifier and 4%-7% of oil-soluble substances, at least one of the emulsifier and oil-soluble substances is a compound containing at least one of hydroxyl, carboxyl and anhydride groups; the water-soluble crosslinking agent is one of inorganic weak acid, base and metal salts. According to the manufacturing method, the viscosity of the latex matrix is not increased, so that the hanging problem of the latex matrix in a latex matrix storage tank of filling equipment can be solved, and further the treatment cost can be lowered.

Owner:BEIJING BGRIMM YIBO TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com