Viscous porous granulated ammonium nitrate fuel oil explosive and preparation method thereof

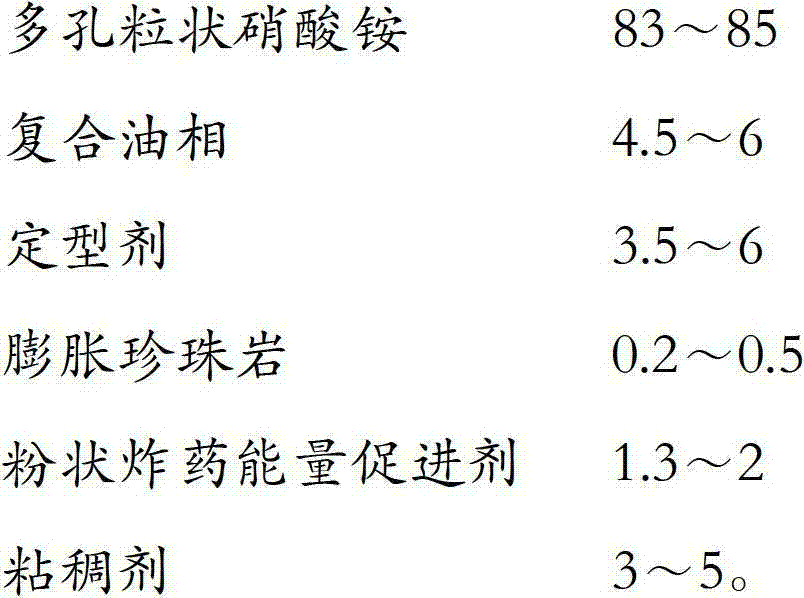

An ammonium explosive, granular technology, used in explosives and other directions, can solve the problems of high toxicity, poor conductors, and large amount of toxic gas in the human body, and achieve stable quality performance indicators, slow attenuation, and good effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

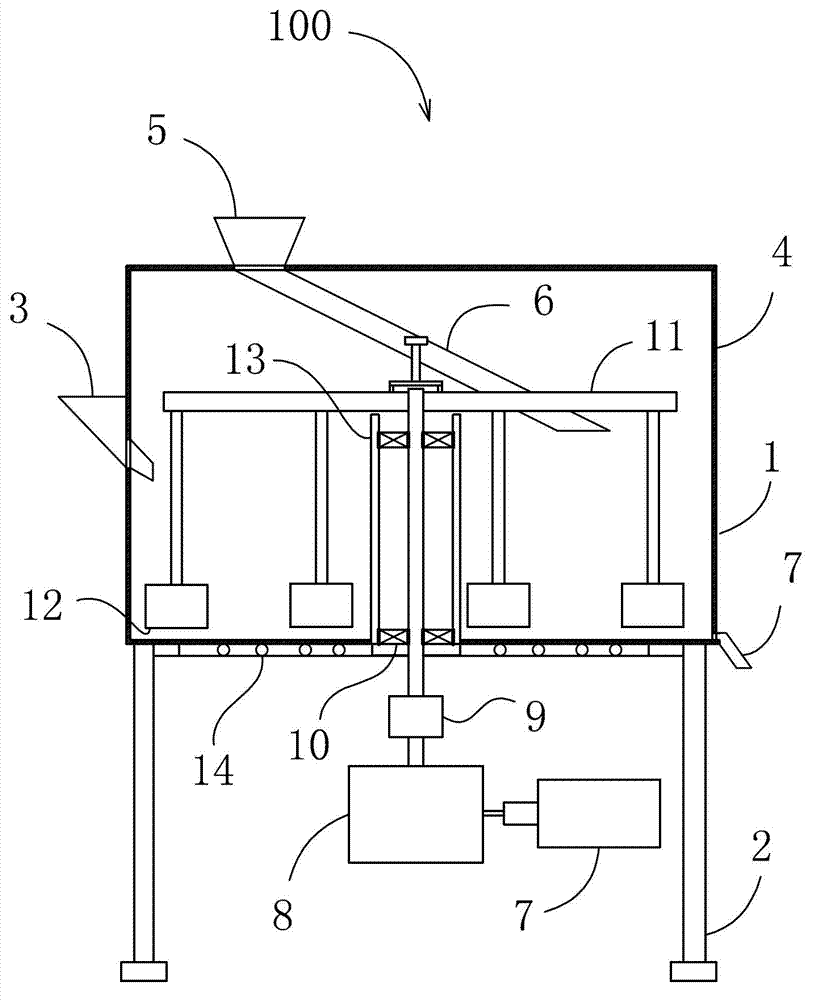

Image

Examples

Embodiment Construction

[0032] The following examples are further explanations and illustrations of the present invention, and do not constitute any limitation to the present invention.

[0033] 1. Preparation of composite oil phase

[0034] 75% diesel oil, 23.5% base oil and 1.5% emulsifier [C 8 h 17 C 6 h 4 O(CH 2 CH 2 )] at a temperature of 55° C. into a mixing and melting tank for mixing to form a composite oil phase.

[0035] 2. Preparation of viscous agent

[0036] 94.5% water, 0.75% polyvinyl alcohol [(C 2 h 4 O) n], 2.5% polyacrylamide [(CH 2 CHCONH 2 ) 2 ], 1.5% polyethylene oxide (CH2CH2O), 0.75% urea [CO (NH 2 ) 2 ] phase mixing, the specific steps are: heat the water of the stated proportion to 92°C in a stirred tank, then add the polyvinyl alcohol of the stated proportion and stir to dissolve, and then add polyacrylamide, polyvinyl alcohol after the temperature drops below 60°C Ethylene oxide and urea are stirred and dissolved to form a viscous agent.

[0037] 3. Preparati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| relative humidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com