Explosion method capable of enhancing bar shaped explosive explosion energy utilization rate

A blasting energy and utilization rate technology, applied in the field of blasting, can solve problems such as increased engineering costs, instability and low intensity of industrial explosives, and unsatisfactory improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

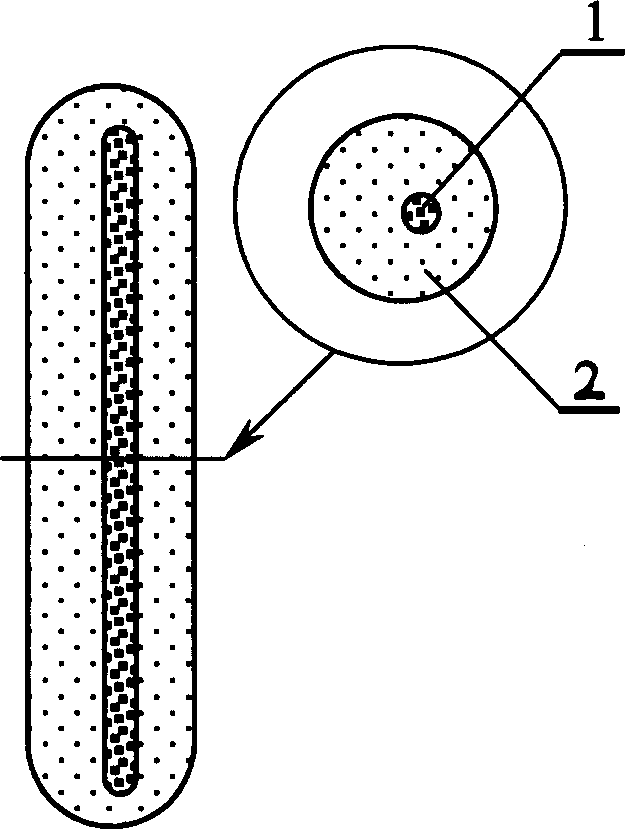

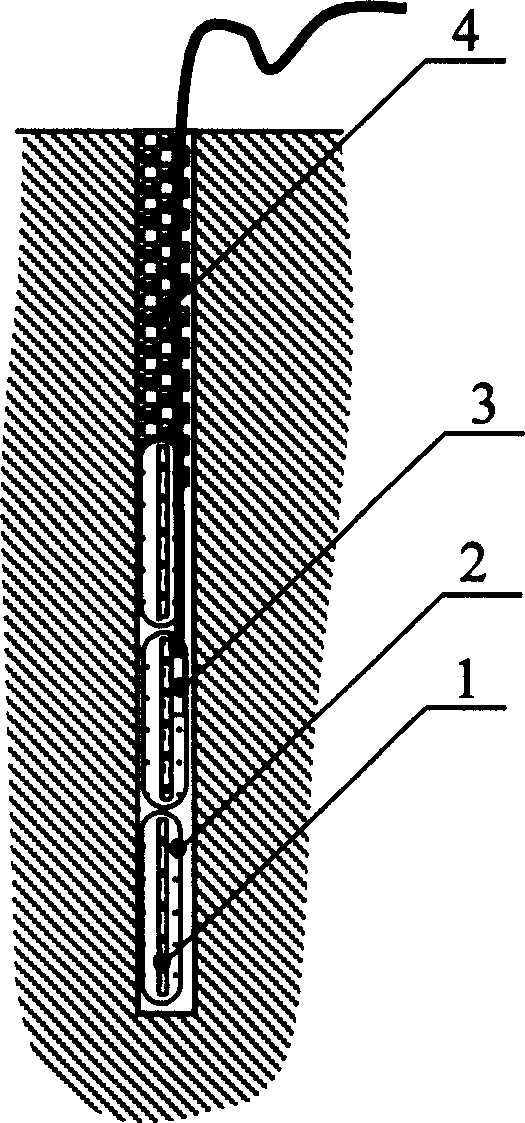

[0034] according to figure 1 Manufacture prefabricated emulsified charge, use 500mm long and 20mm diameter colloidal explosive roll as the priming charge 1, and the detonation velocity is greater than 6.5mm·μs -1 , the detonation velocity is 4.5mm·μs -1 The emulsified ammonium oil explosive is the main explosive 2, made into a roll with a length of 500 mm and a diameter of 90 mm. figure 2 The way is to put it in the Φ100mm hole to implement water hole or underwater blasting.

Embodiment 2

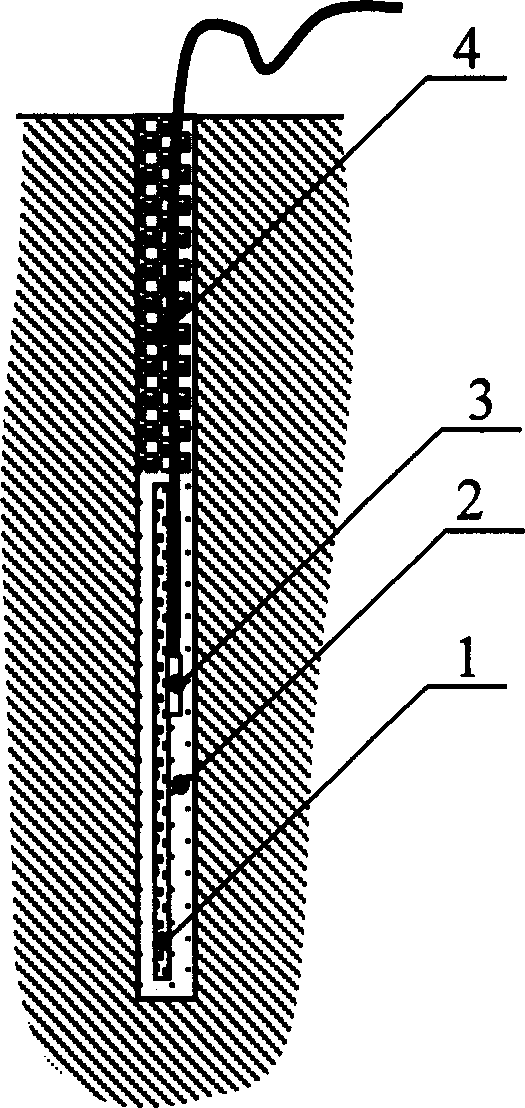

[0036] according to image 3 Charged in the same way, the detonation velocity is greater than 6.9mm·μs -1 The detonating cord is the detonating charge 1, and the 8 # The detonator 3 is tied to the detonating cord, placed in a Φ140mm hole, and the injection detonation velocity is 3.5mm·μs -1 Powdered ammonium oil explosives are used as the main explosive 2, and the blasting effect is good, and there is no yellow smoke in the 14m deep hole blasting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com