A Stress Relief Blasting Method Based on Face Grooving

A technology of stress relief and face surface, applied in the field of geotechnical engineering, to achieve the effect of broad application prospects, lifting effect, and increasing energy release rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment takes a certain circular palm face as an example.

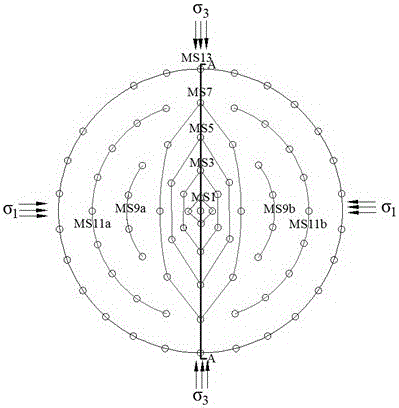

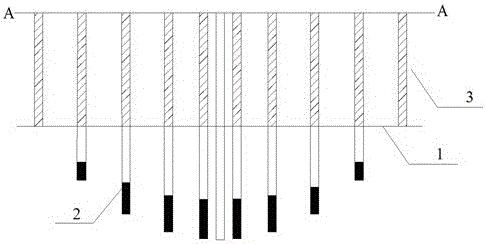

[0028] Firstly, the major principal stress σ of the tunnel cross section is obtained through exploration and geological data 1 direction and minor principal stress σ 3 According to the magnitude and direction of the ground stress, the original blasting sequence of the excavation blasting network is rearranged, so that the blasting network forms a grooving form approximately perpendicular to the direction of the major principal stress. Such as figure 1 In the middle MS5 section, the connection line of the blastholes in this section is approximately perpendicular to the direction of the major principal stress, and the strain energy can be released more fully during blasting. In addition, the holes are drilled according to the process of gradually decreasing blast hole depth from the inside to the outside, that is, from the cut hole to the light blast hole, such as figure 2 The middle is the A-A profil...

Embodiment 2

[0032] In this embodiment, the tunnel face of a city gate is taken as an example.

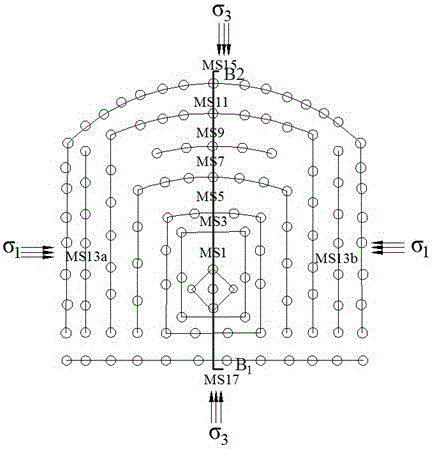

[0033] Firstly, the major principal stress σ of the tunnel cross section is obtained through exploration and geological data 1 direction and minor principal stress σ 3 According to the magnitude and direction of the ground stress, the order of the excavation and blasting network is rearranged, so that the blasting network forms a grooving form approximately perpendicular to the direction of the major principal stress. Such as image 3 In the middle MS5 section, the connection line of the blastholes in this section is approximately perpendicular to the direction of the major principal stress, and the strain energy can be released more fully during blasting. In addition, the holes are drilled according to the process of gradually decreasing blast hole depth from the inside to the outside, that is, from the cut hole to the light blast hole, such as Figure 4 The middle is the blast hole B perpe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com