An energetic thin film of aluminum-copper oxide-graphene oxide ternary composite material and its preparation method

A composite material and graphene technology, used in electrolytic coatings, coatings, electrophoretic plating, etc., can solve the problems of restraint of thermite reaction propagation, slow energy release rate, and limit thermite, etc., to improve flatness, operation Simple, mild effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

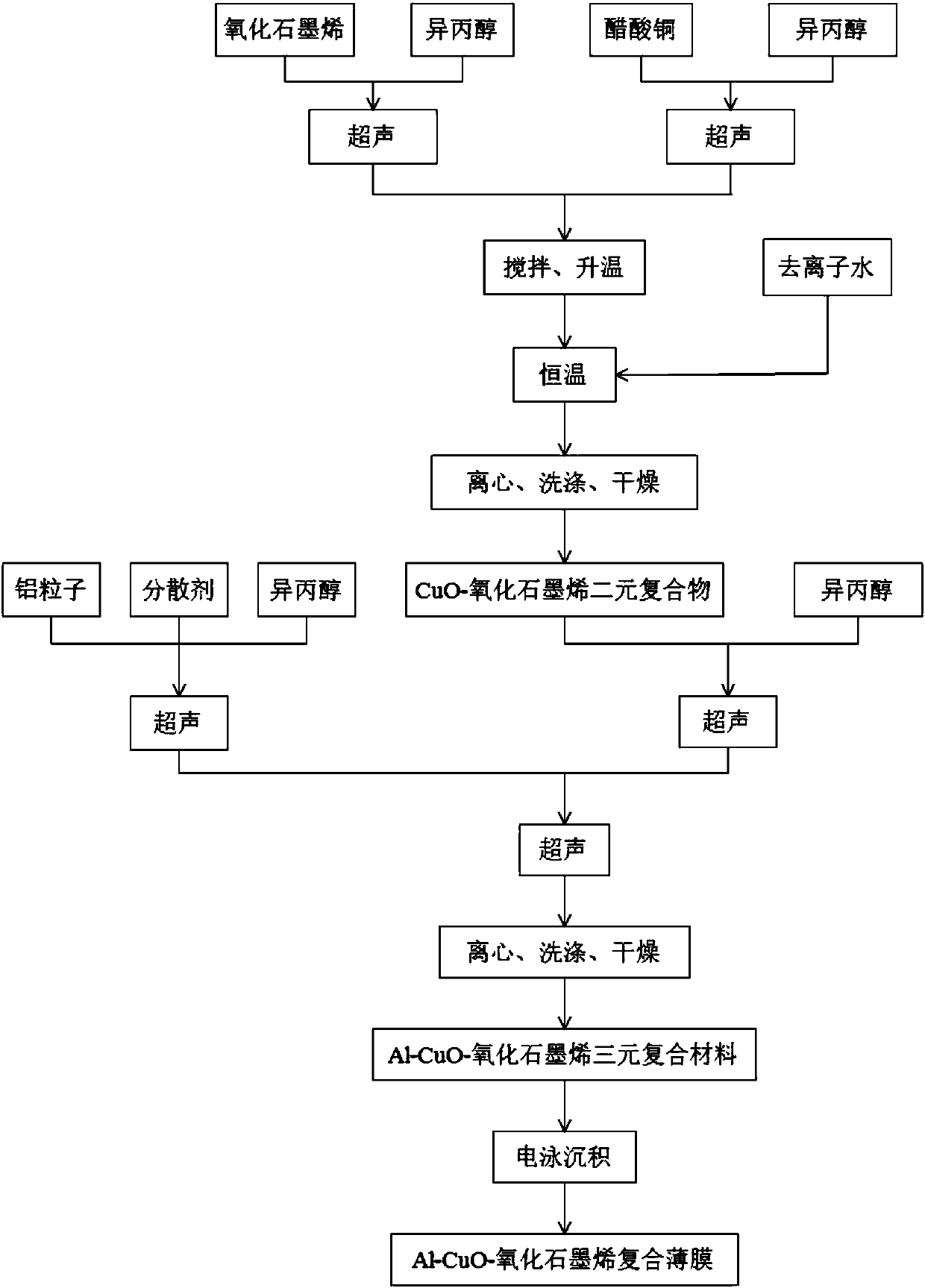

[0027] combine figure 1 , the present invention is an aluminum-copper oxide-graphene oxide ternary composite energetic film and a preparation method thereof, specifically comprising the following steps:

[0028] Step 1: ultrasonically disperse graphene oxide in isopropanol; the ultrasonic time is 0.5-3h, and the concentration of graphene oxide dispersion is 1-2mg / mL;

[0029] Step 2: ultrasonically dissolve copper acetate in isopropanol, and then dropwise add it to the solution in step 1; the ultrasonic time is 0.5-3h, and the mass ratio of CuO to graphene oxide obtained is 1:3;

[0030] Step 3: Heat the mixed solution in Step 2 to 83° C. under vigorous stirring for 0.5 h of constant temperature reflux reaction;

[0031] Step 4: Add deionized water to the above reaction solution, and then reflux at a constant temperature of 83°C; the volume ratio of the added deionized water to the original reaction solution is 1:10-1:5, and the constant reaction time of this process is 0.5-...

Embodiment 1

[0040] Step 1: ultrasonically disperse 0.05g of graphene oxide in 50mL of isopropanol, and ultrasonicate for 0.5h;

[0041] Step 2: Dissolve 0.13g of copper acetate in 10mL of isopropanol, sonicate for 0.5h, and drop the copper acetate solution into the graphene oxide dispersion;

[0042] Step 3: Heat the mixed solution in Step 2 to 83° C. under vigorous stirring for 0.5 h of constant temperature reflux reaction;

[0043] Step 4: Add 5 mL of deionized water to the above reaction solution, and then continue the constant temperature reaction at 83°C for 1 hour;

[0044] Step 5: centrifuging, washing, and drying the product obtained in step 4 to obtain a graphene oxide-loaded nano-CuO composite material;

[0045] Step 6: ultrasonically disperse 0.05 g of the CuO-graphene oxide binary compound obtained in step 5 in 50 mL of isopropanol, and ultrasonically 0.5 h;

[0046] Step 7: Add 0.05g of aluminum particles (about 50nm) and a small amount of PEG-600 into 10mL of isopropanol, ...

Embodiment 2

[0052] Step 1: ultrasonically disperse 0.075g of graphene oxide in 50mL of isopropanol, and sonicate for 1h;

[0053] Step 2: Dissolve 0.20 g of copper acetate in 10 mL of isopropanol, sonicate for 1 hour, and drop the copper acetate solution into the graphene oxide dispersion;

[0054] Step 3: Heat the mixed solution in Step 2 to 83° C. under vigorous stirring for 0.5 h of constant temperature reflux reaction;

[0055] Step 4: Add 5 mL of deionized water to the above reaction solution, and then continue the constant temperature reaction at 83°C for 1 hour;

[0056] Step 5: centrifuging, washing, and drying the product obtained in step 4 to obtain a graphene oxide-loaded nano-CuO composite material;

[0057] Step 6: ultrasonically disperse 0.075 g of the CuO-graphene oxide binary compound obtained in step 5 in 50 mL of isopropanol, and ultrasonically disperse for 1 h;

[0058] Step 7: Add 0.015g of aluminum particles (about 50nm) and a small amount of PEG-200 into 10mL of is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com