Patents

Literature

1283results about How to "Improve distribution uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

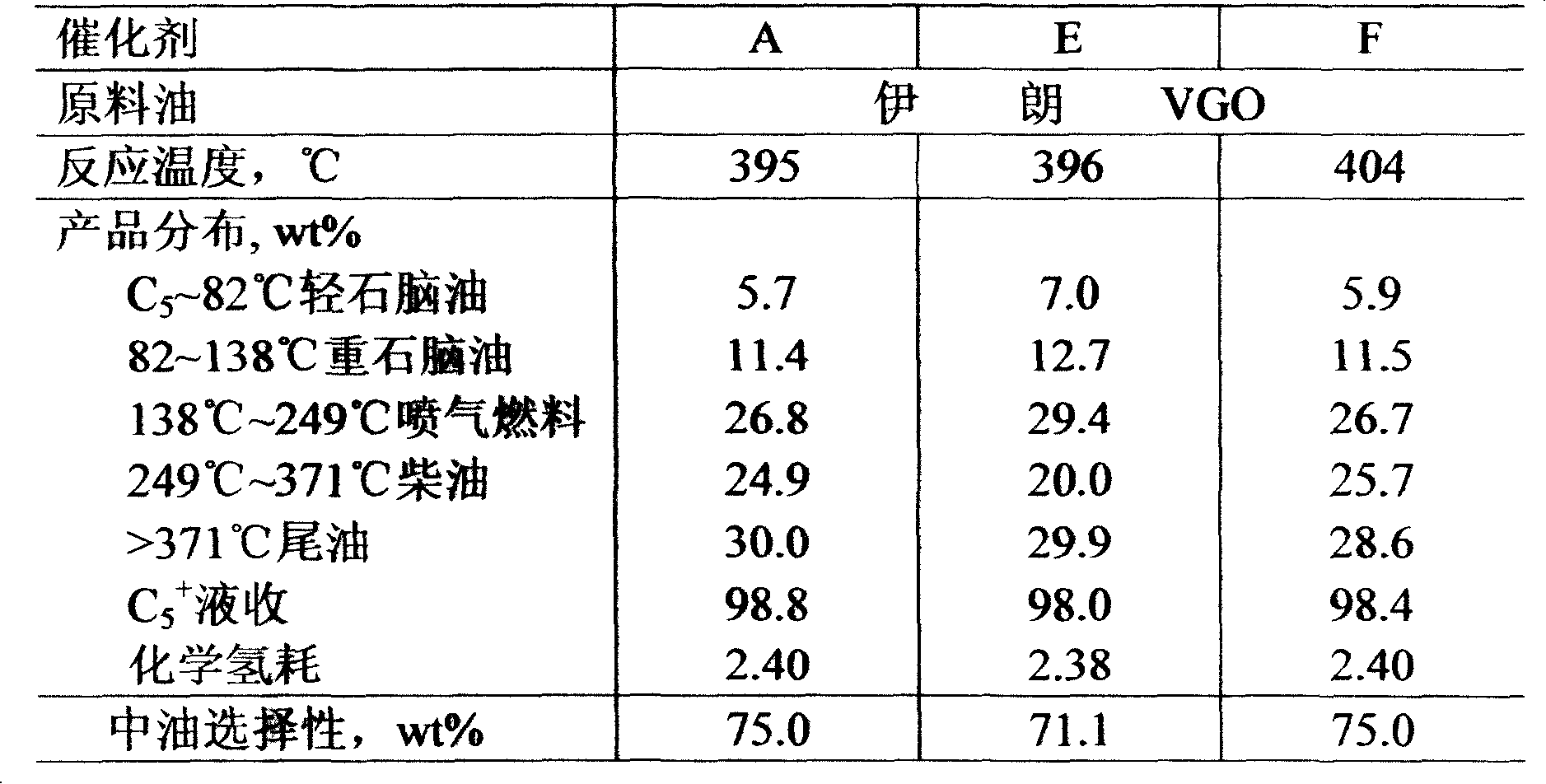

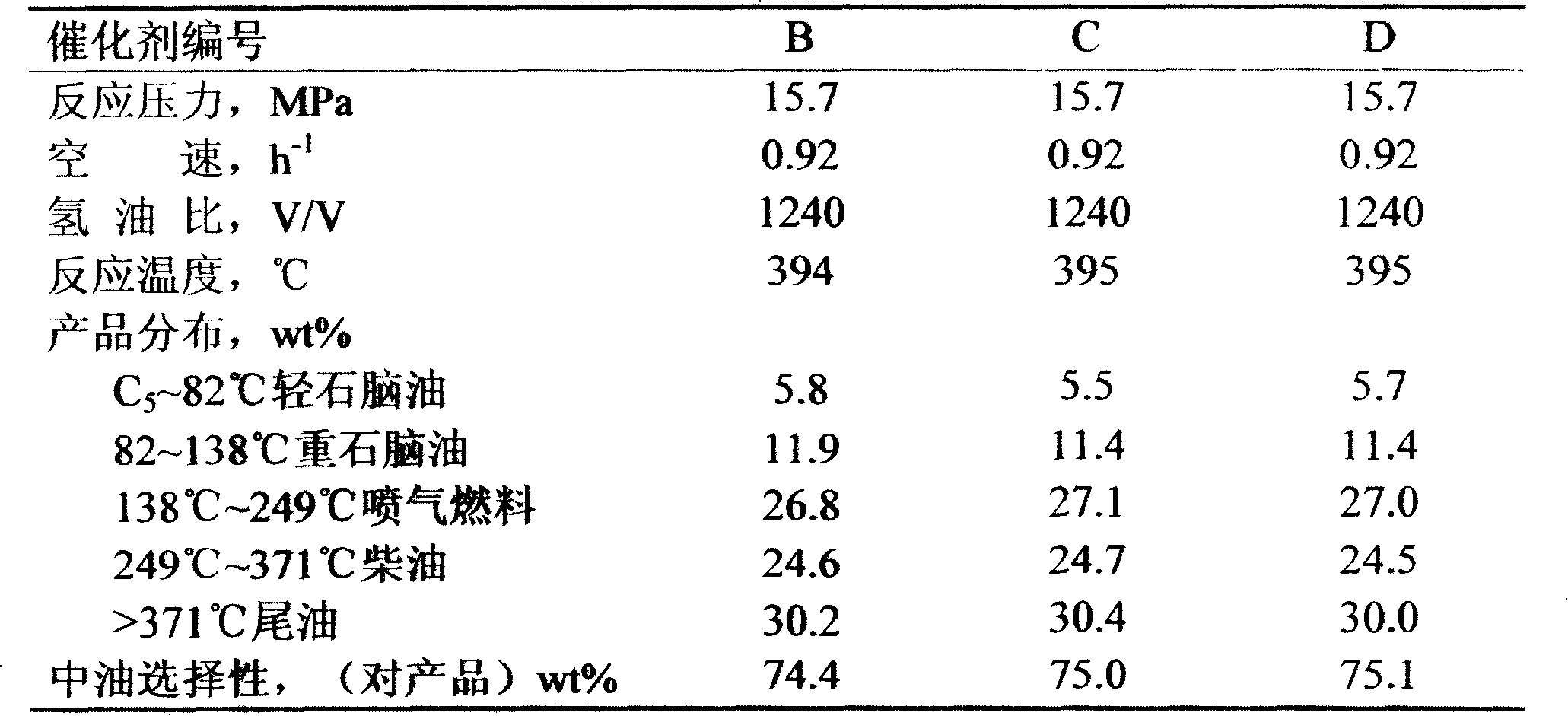

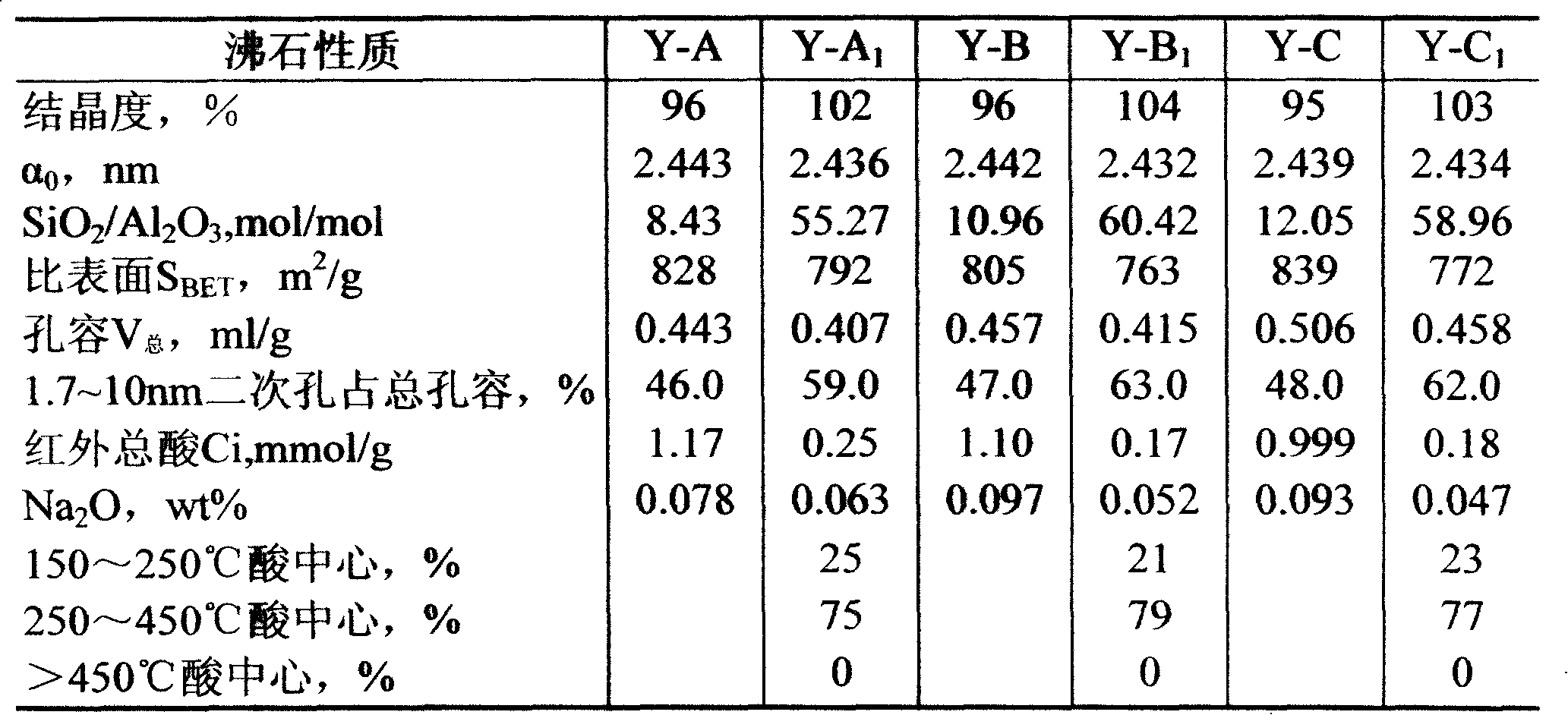

High active high medium oil selective hydrocracking catalyst and preparation thereof

ActiveCN101239324AHigh crystallinityLow cell parametersMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveSingle stage

The present invention provides a hydrocracking catalyst having high activity, high medium oil selectivity, catalyst constitute uses amorphous silica-alumina as a carrier, Y type molecular sieve processed by special modification is an acidity component, the molecular sieve has a high crystallinity and a lower cell parameter, a plenty quadric hole, larger surface, in addition, has a small acid center, even distribution, no strong acid center, 70-80% is moderate intensity acid center, 20-30% is weak acid center, and the molecular sieve also has a strong anti-nitrogen ability and better damaging ability, the hydrocracking catalyst using the molecular sieve has a better hydrocracking activity, and a higher medium oil selectivity, and a strong anti-nitrogen ability at the same time. The invention uses heavy hydrocarbon single stage or single stage serial hydrocracking process generate midbarrel oil product, and has better activity and medium oil selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

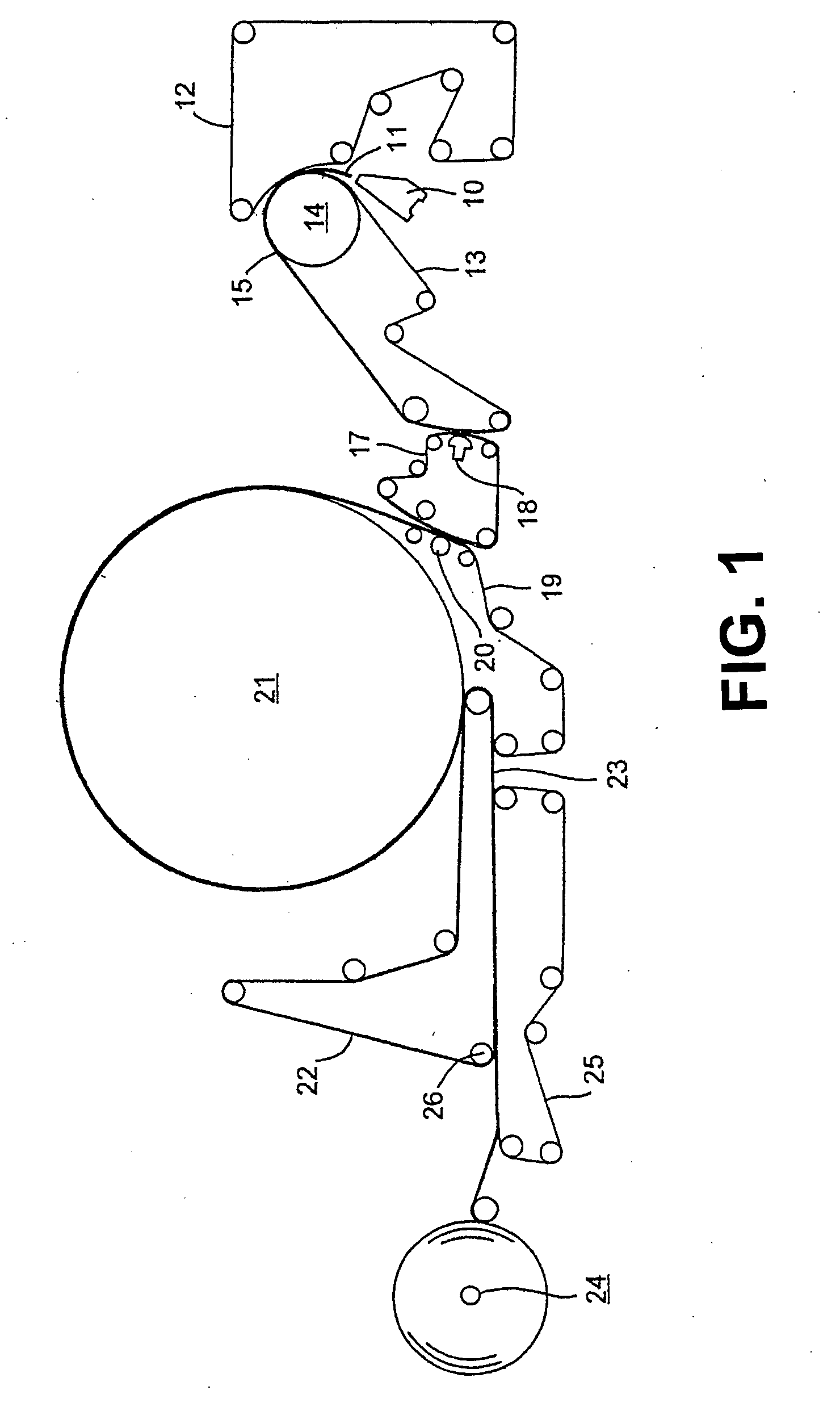

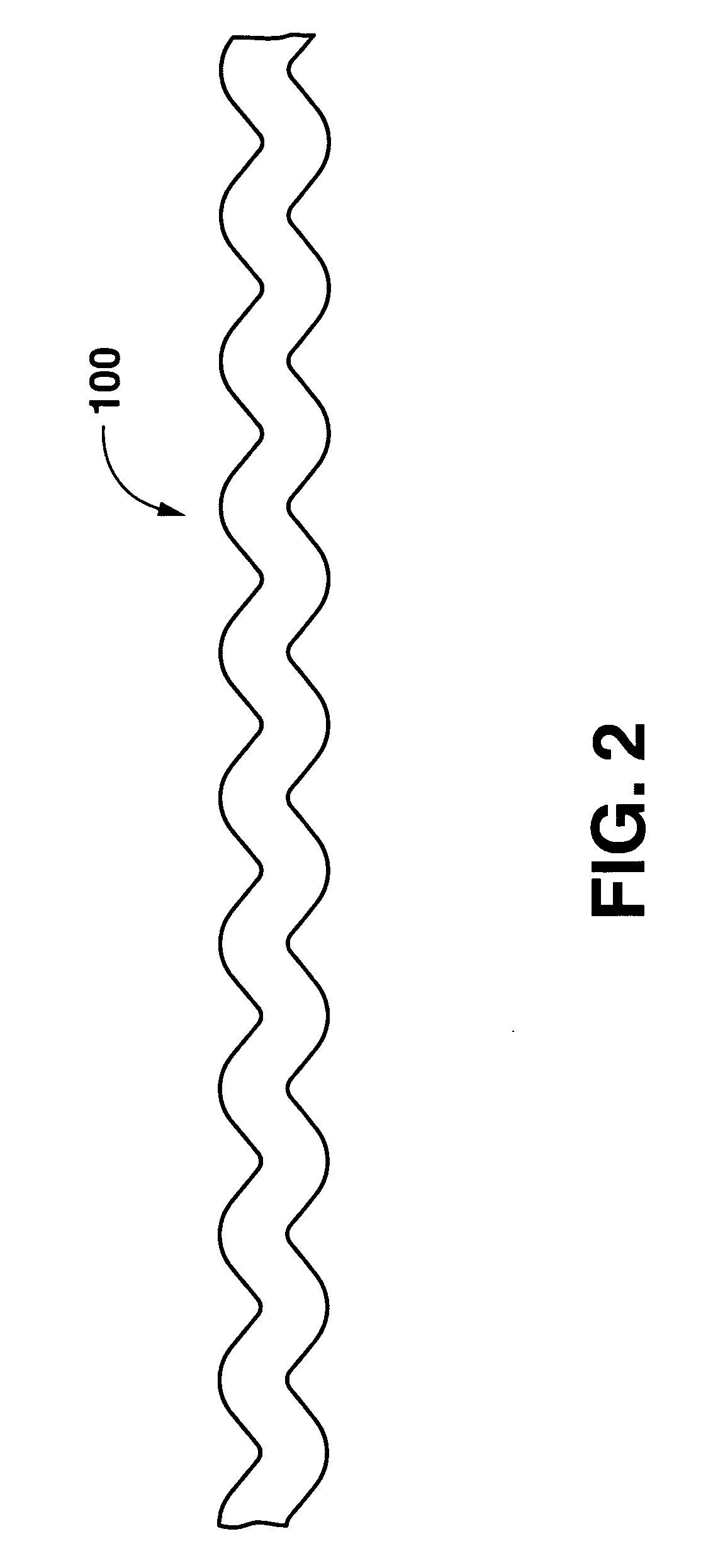

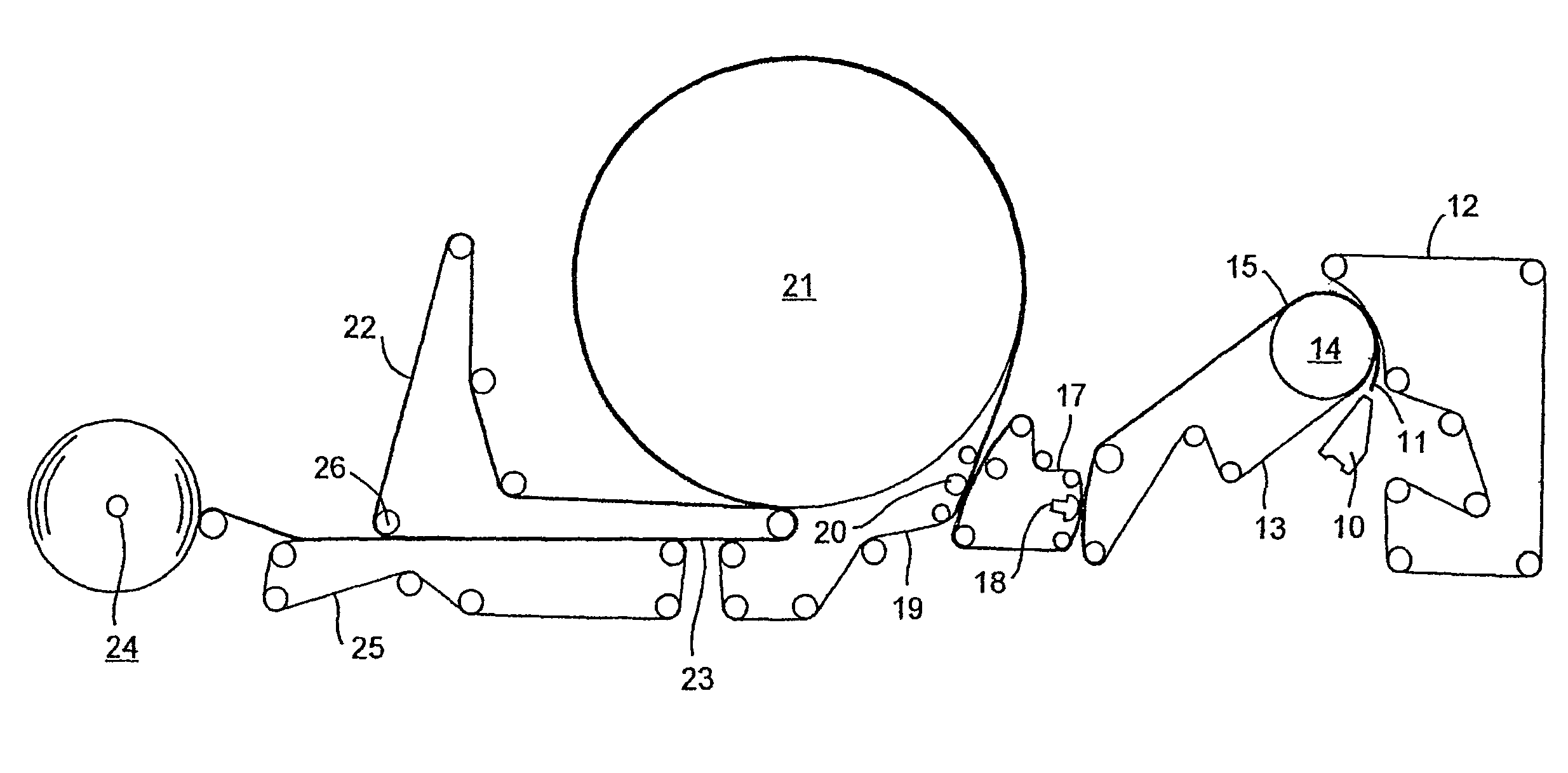

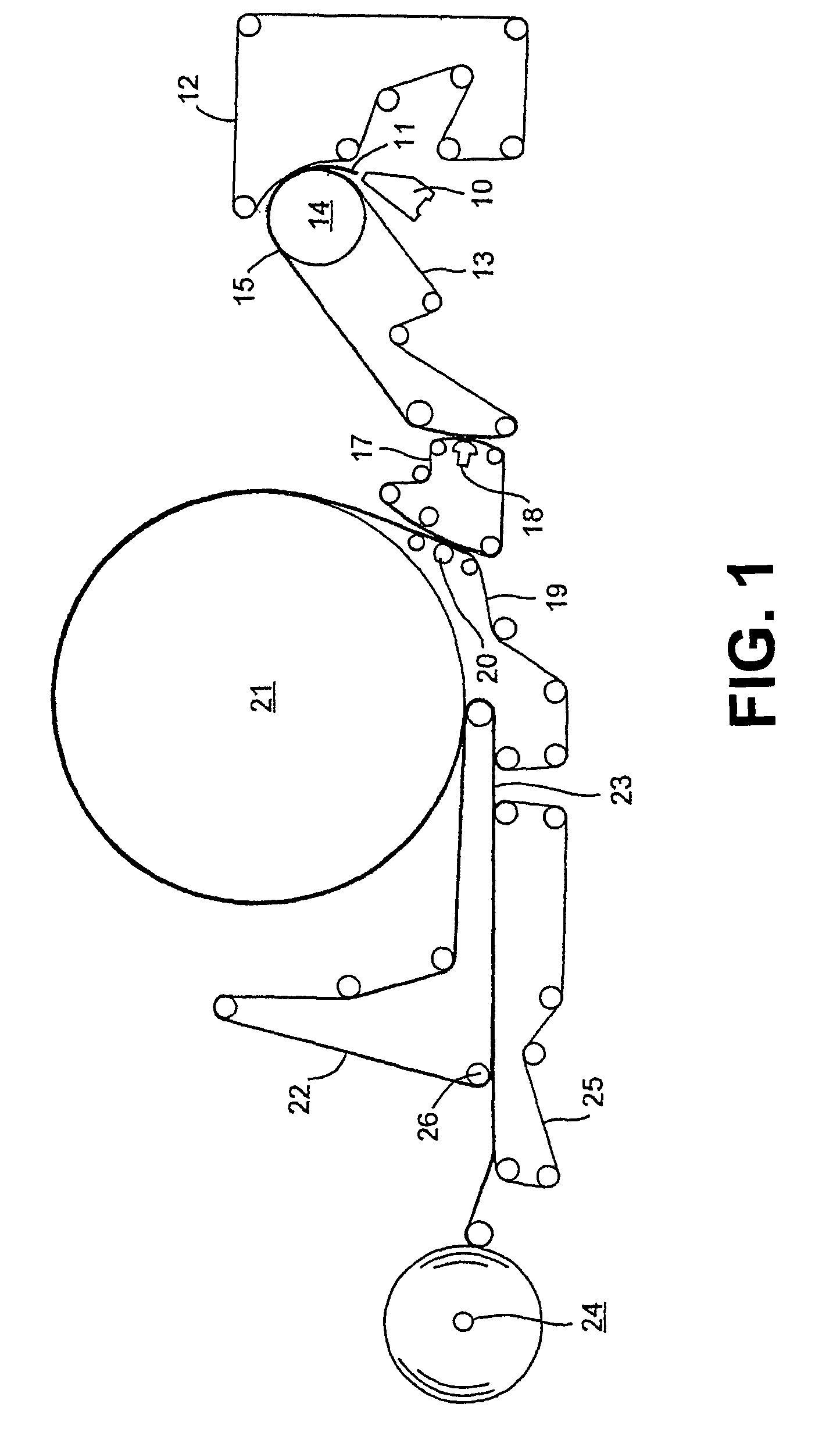

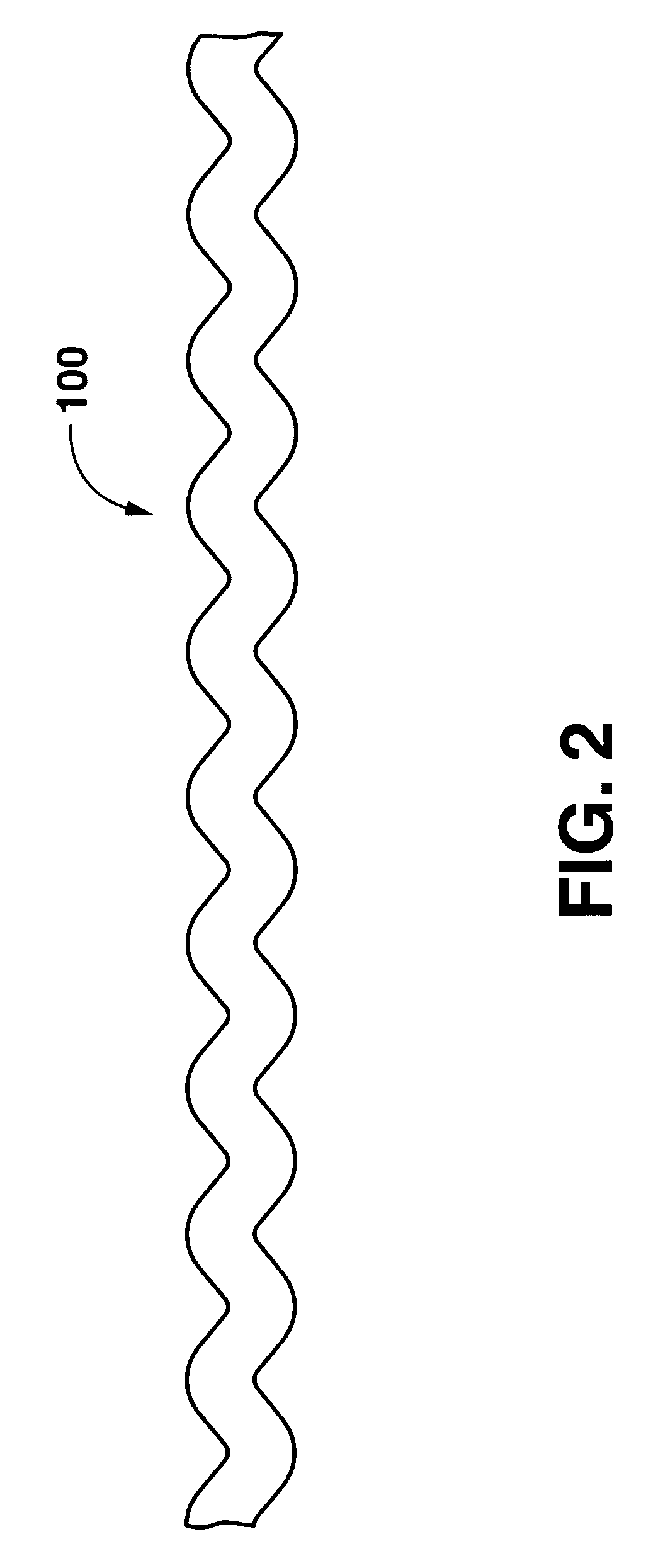

Tissue products having enhanced cross-machine directional properties

ActiveUS20070131366A1Enhanced cross-machine directional propertyHigh peak stretchNon-fibrous pulp additionNatural cellulose pulp/paperMedicineUltimate tensile strength

Tissue products are disclosed having desirable strength, stretch and softness properties. In particular, the tissue products exhibit relatively high strength while still having a relatively low stiffness and a significant amount of stretch. The tissue webs generally comprise uncreped through-air dried webs. In accordance with the present disclosure, the webs are formed in a through-air drying process in which the transfer fabric and the through-air drying fabric are both textured fabrics having a substantially uniform high strain distribution in the cross-machine direction. Various improvements in properties in the cross-machine direction are exhibited by deforming or molding a tissue web against one or more of the fabrics during the tissue making process.

Owner:KIMBERLY-CLARK WORLDWIDE INC

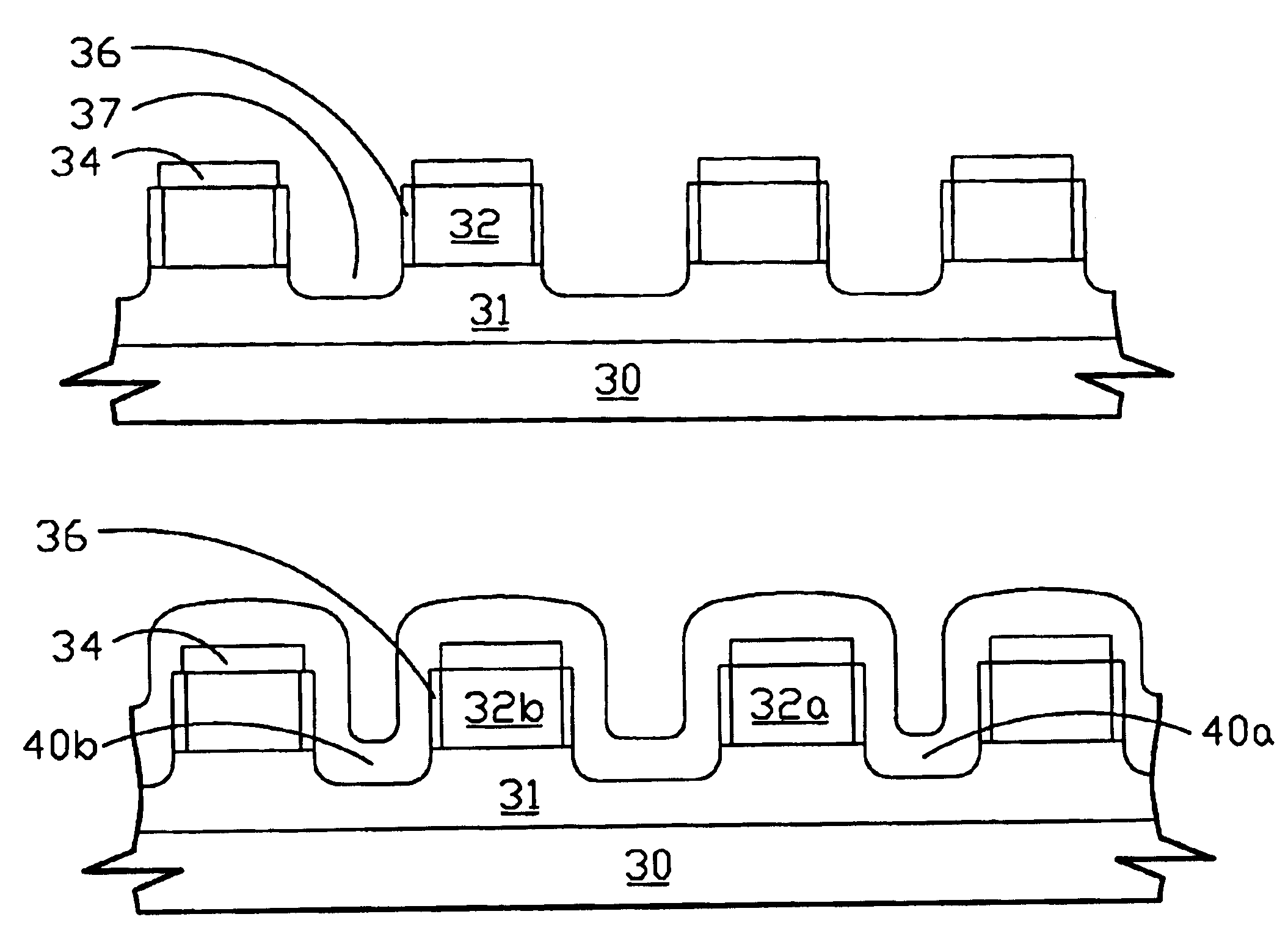

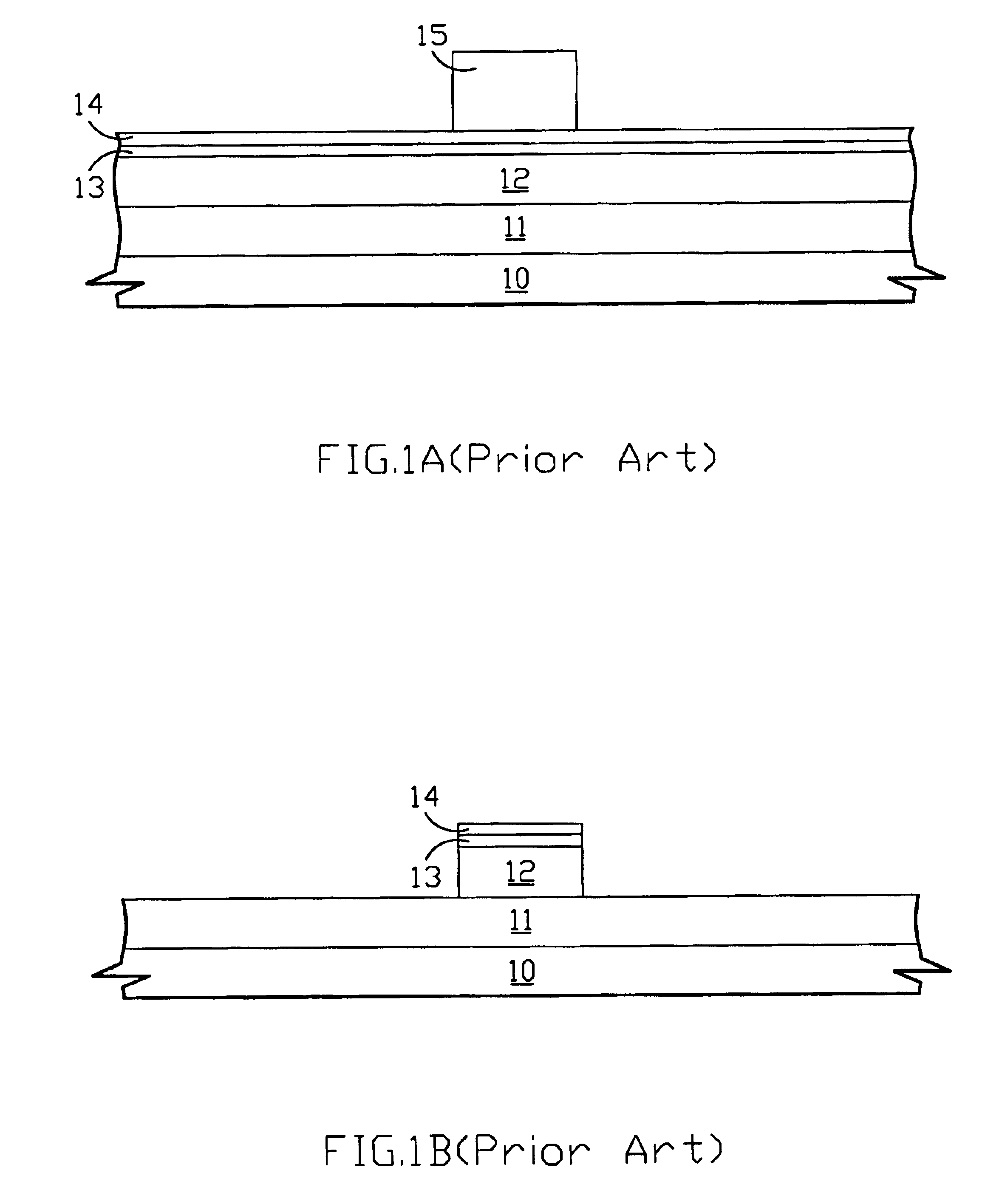

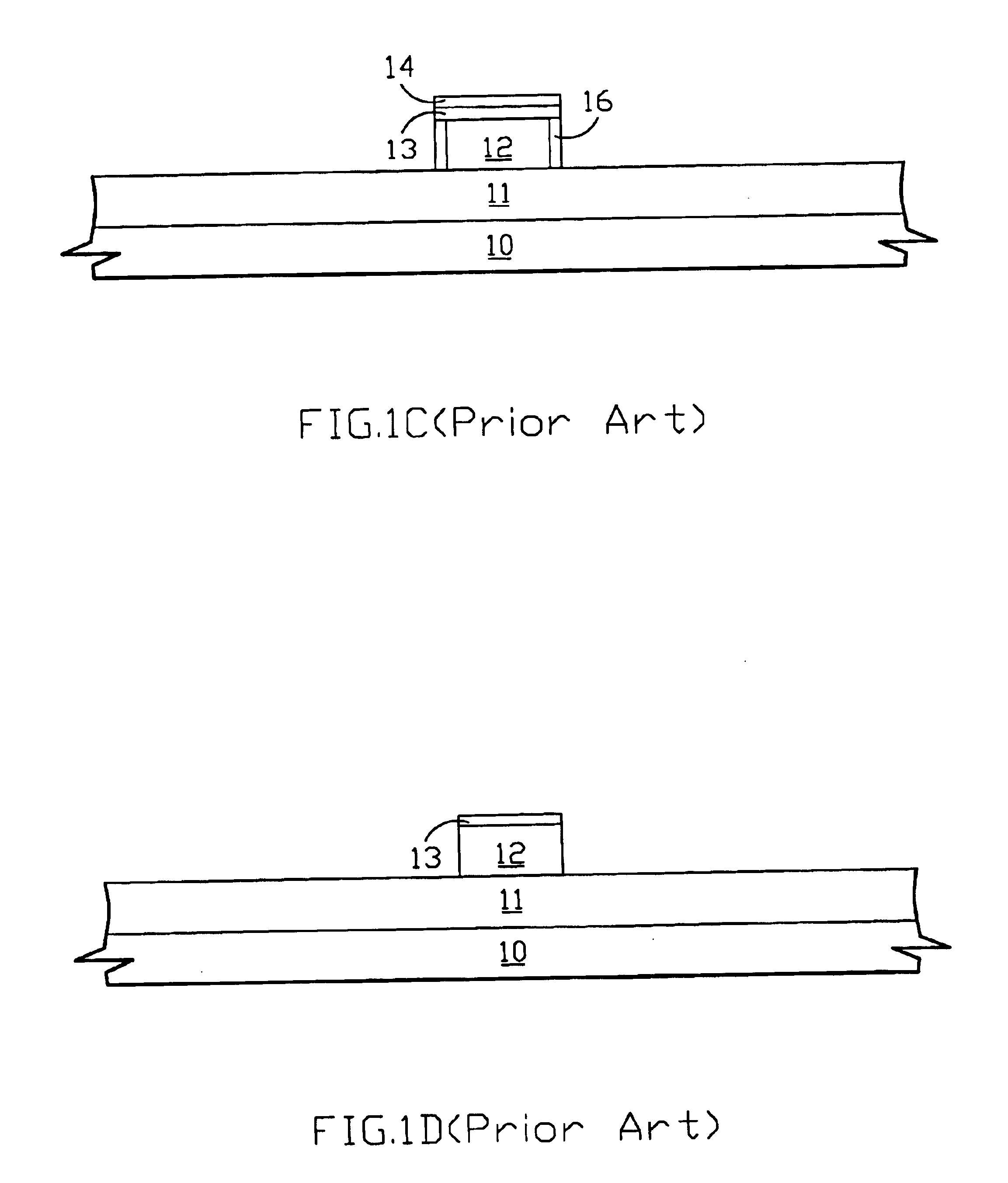

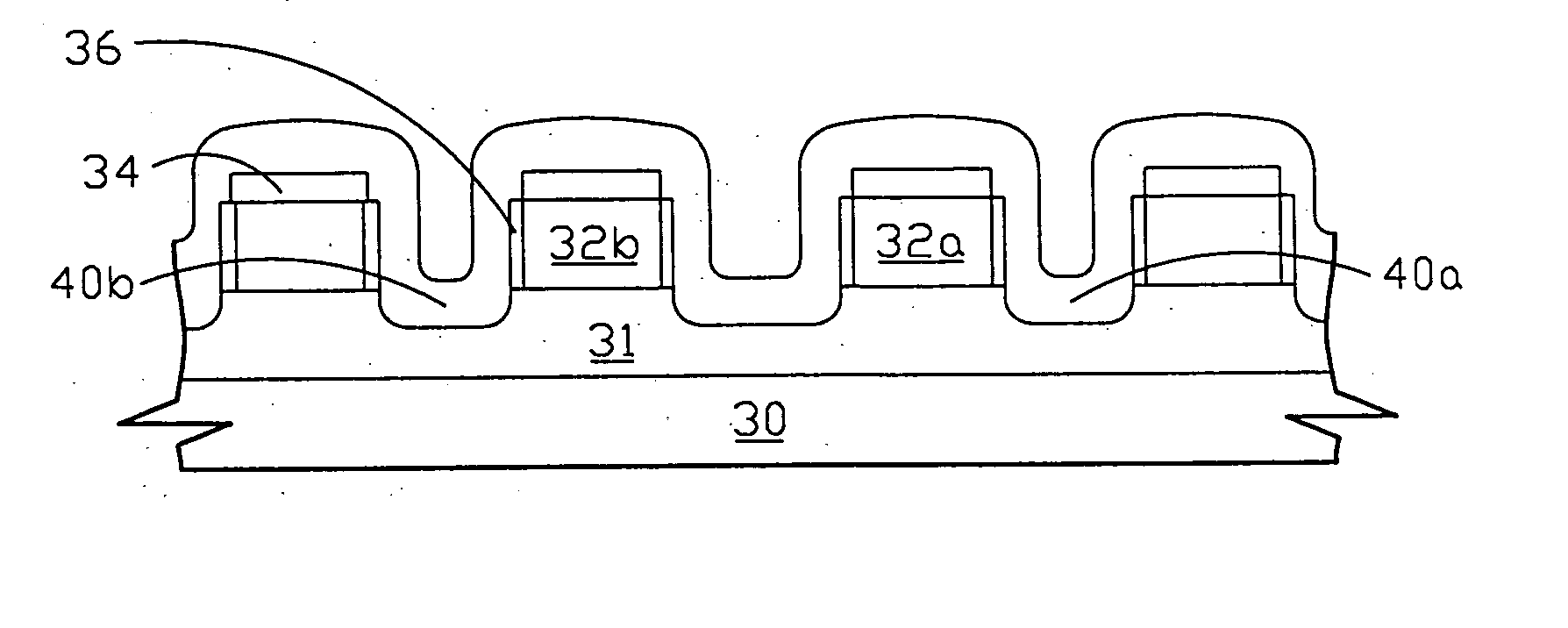

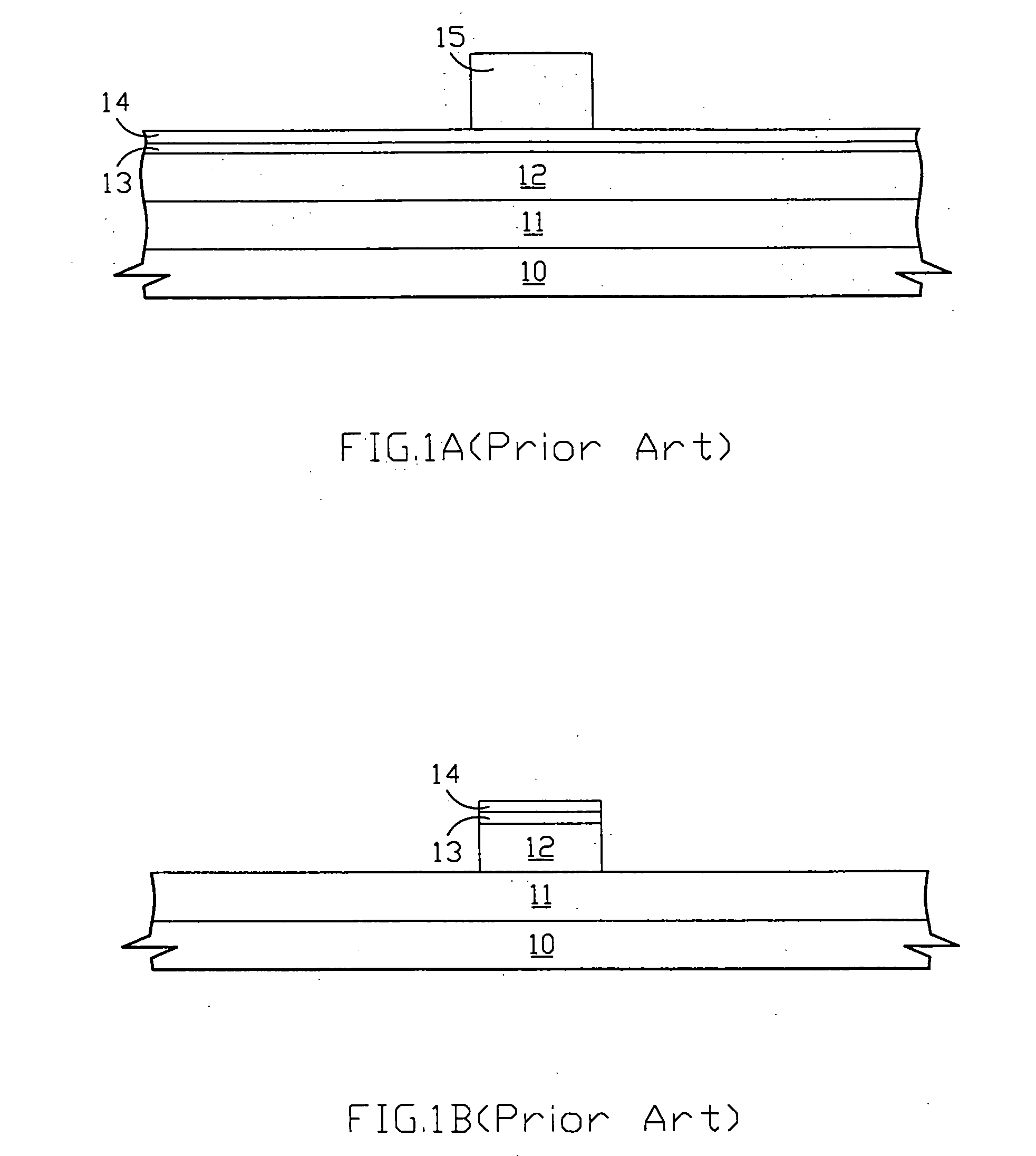

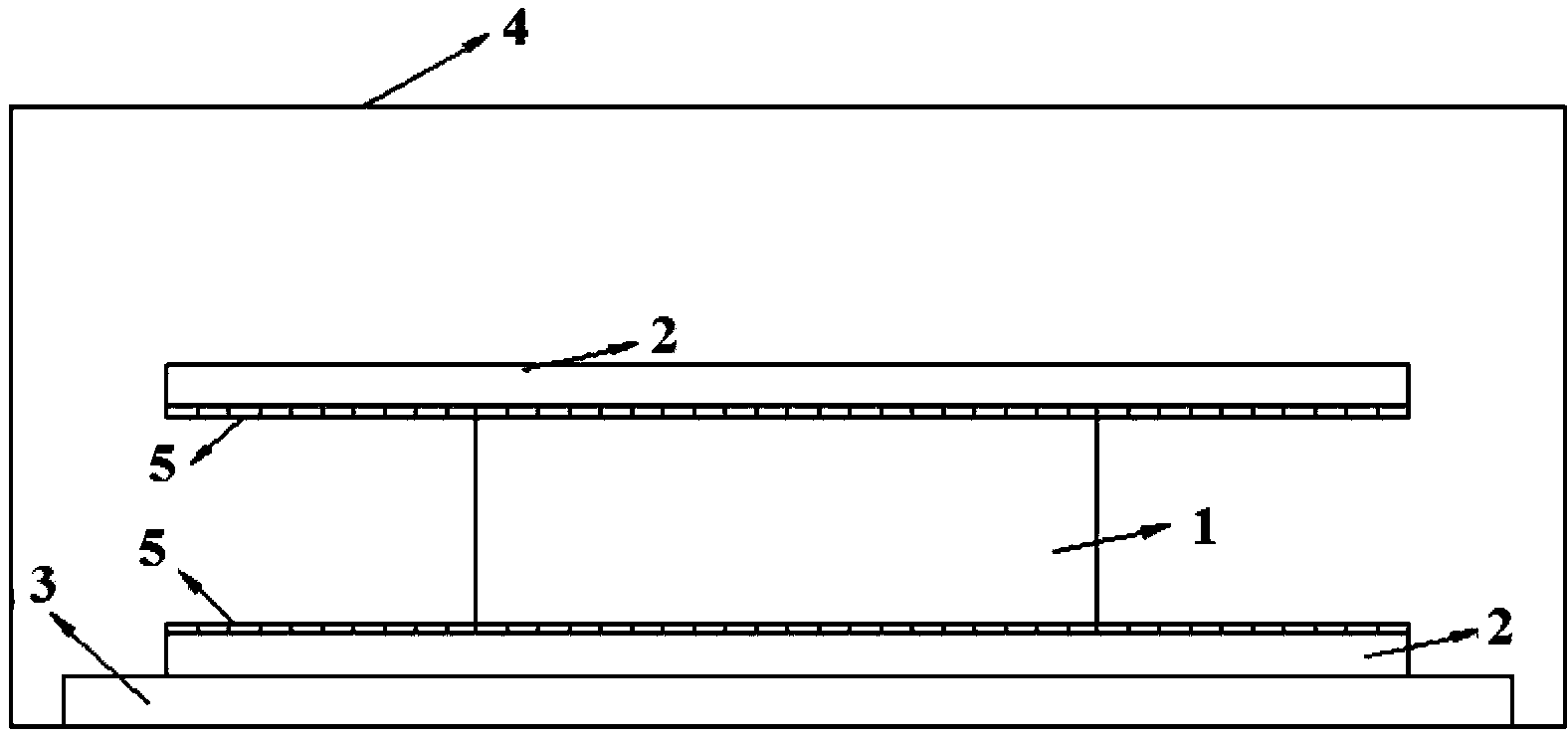

Method of fabricating a double gate MOSFET device

ActiveUS6855588B1Excellent short channel behaviorBetter gate controlTransistorSemiconductor/solid-state device manufacturingDriving currentDouble gate

A method of fabricating a double gate MOSFET device is provided. The present invention overetches a silicon layer overlying a buried oxide layer using a hard mask of cap oxide on the silicon layer as an etching mask. As a result, source, drain and channel regions are formed extending from the buried oxide layer, and a pair of recesses are formed under the channel regions in the buried oxide layer. The channel is a fin structure with a top surface and two opposing parallelly sidewalls. The bottom recess is formed under each opposing sidewall of the fin structure. A conductive gate layer is formed straddling the fin structures. The topography of the conductive gate layer significantly deviates from the conventional plainer profile due to the bottom recess structures under the channel regions, and a more uniformly distributed doped conductive gate layer can be obtained. Hence, the depletion effect of the conductive polysilicon gate while operating the device can be suppressed and the device drive-on currents can be further enhanced.

Owner:UNITED MICROELECTRONICS CORP

Tissue products having enhanced cross-machine directional properties

ActiveUS7972474B2Enhanced cross-machine directional propertyHigh peak stretchNon-fibrous pulp additionNatural cellulose pulp/paperMedicineHardness

Tissue products are disclosed having desirable strength, stretch and softness properties. In particular, the tissue products exhibit relatively high strength while still having a relatively low stiffness and a significant amount of stretch. The tissue webs generally comprise uncreped through-air dried webs. In accordance with the present disclosure, the webs are formed in a through-air drying process in which the transfer fabric and the through-air drying fabric are both textured fabrics having a substantially uniform high strain distribution in the cross-machine direction. Various improvements in properties in the cross-machine direction are exhibited by deforming or molding a tissue web against one or more of the fabrics during the tissue making process.

Owner:KIMBERLY-CLARK WORLDWIDE INC

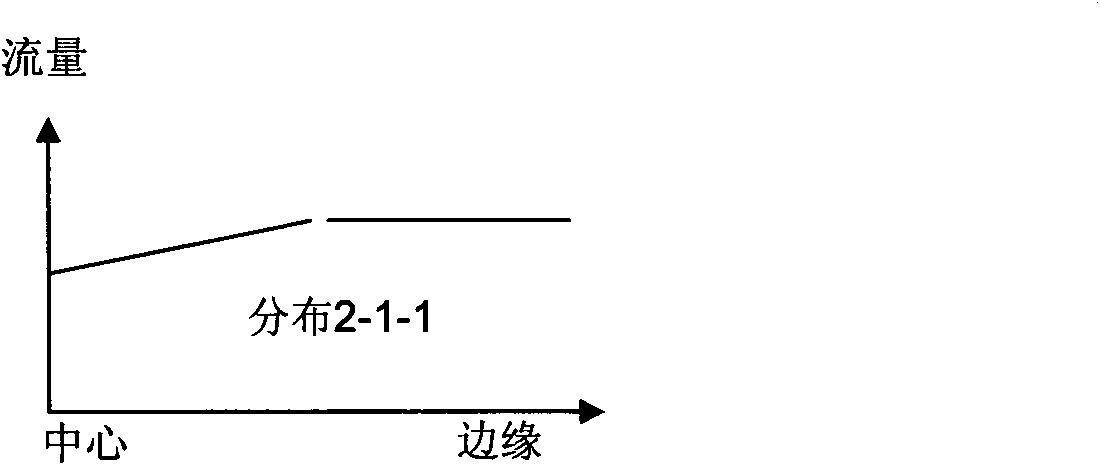

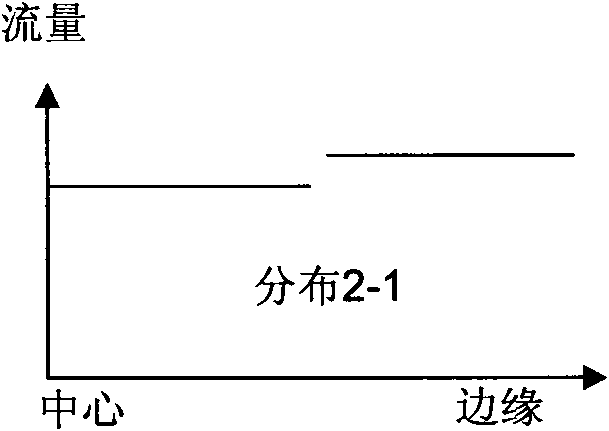

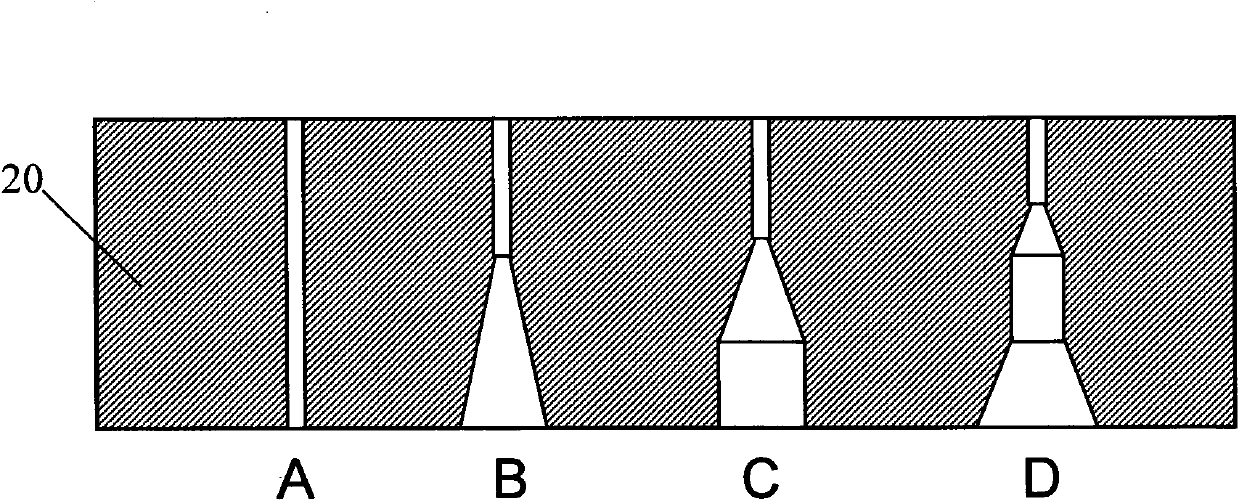

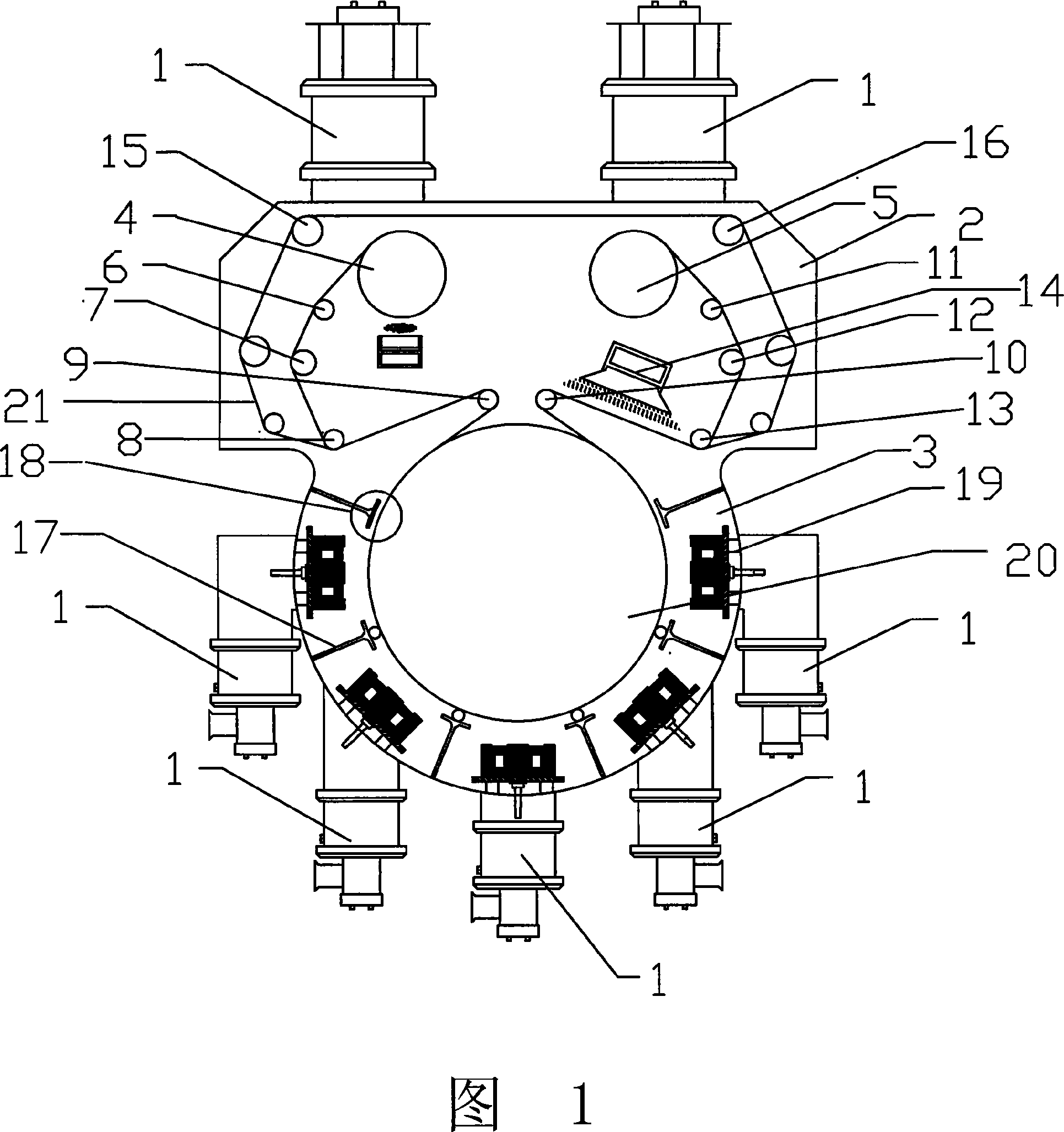

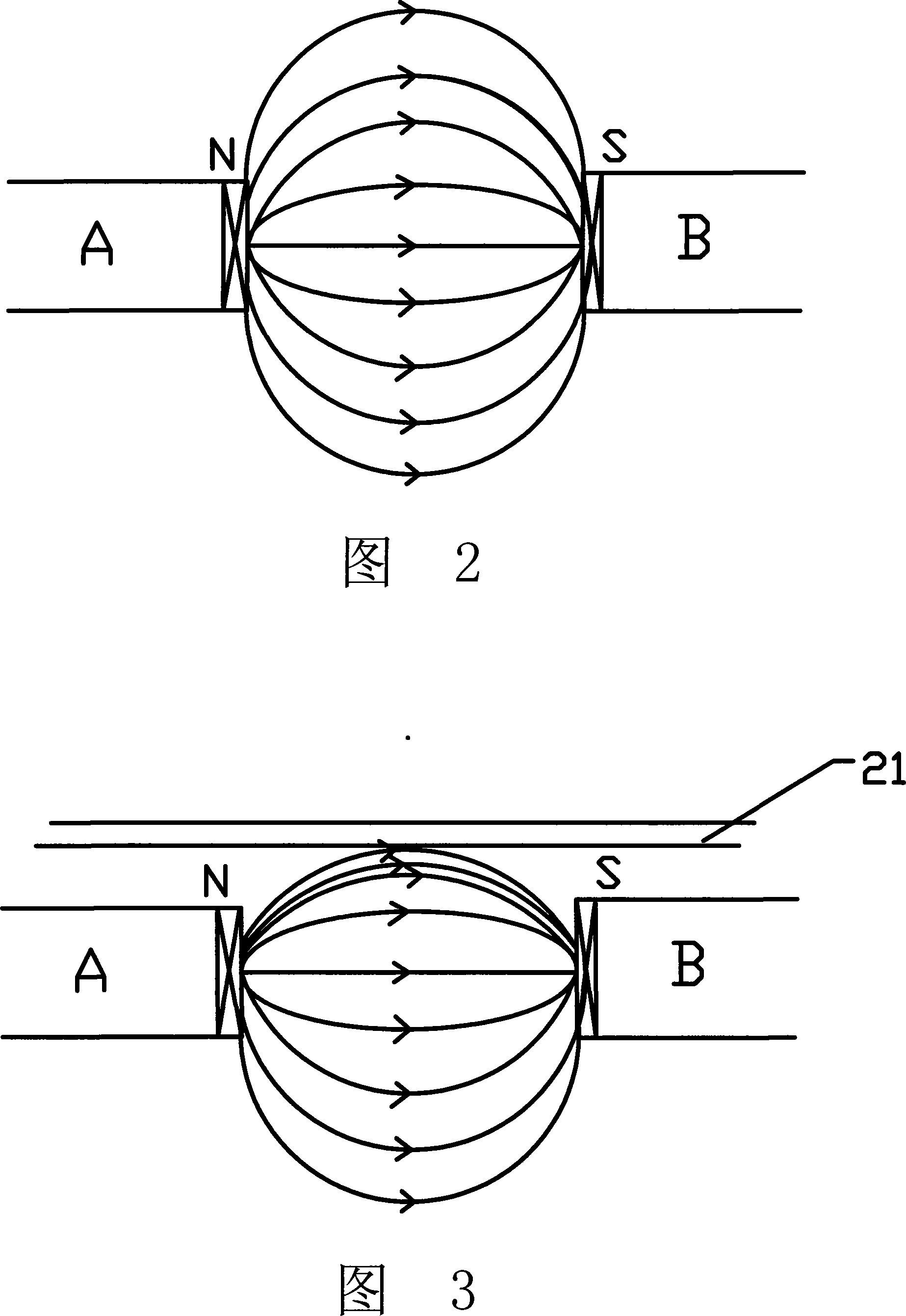

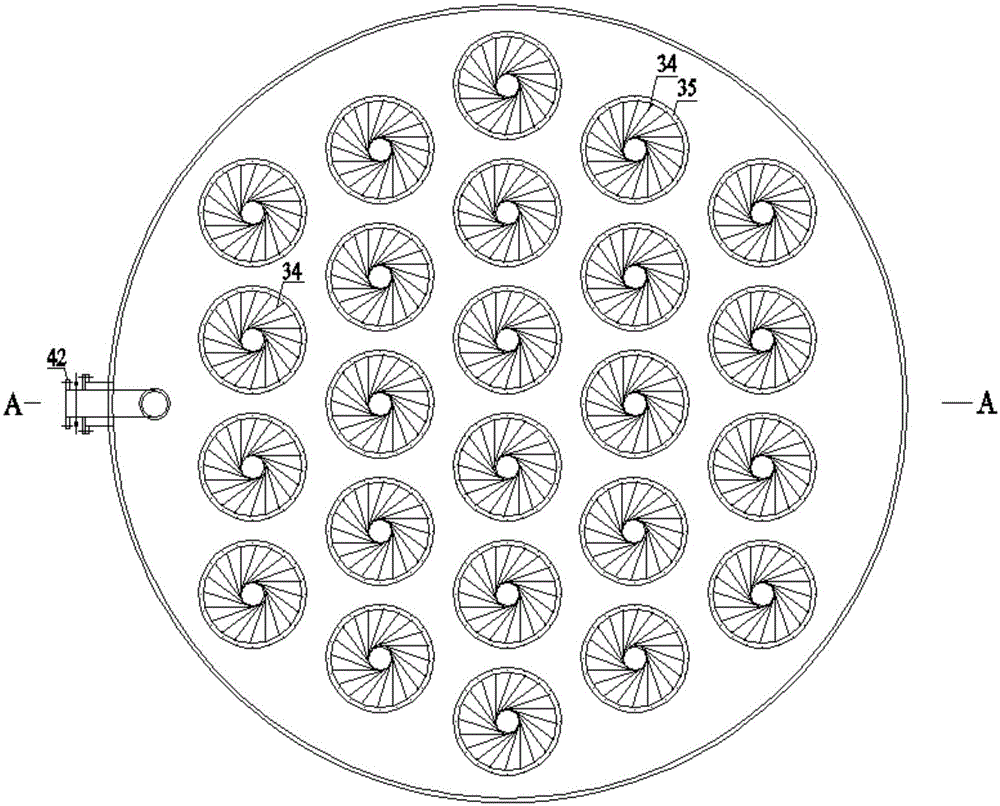

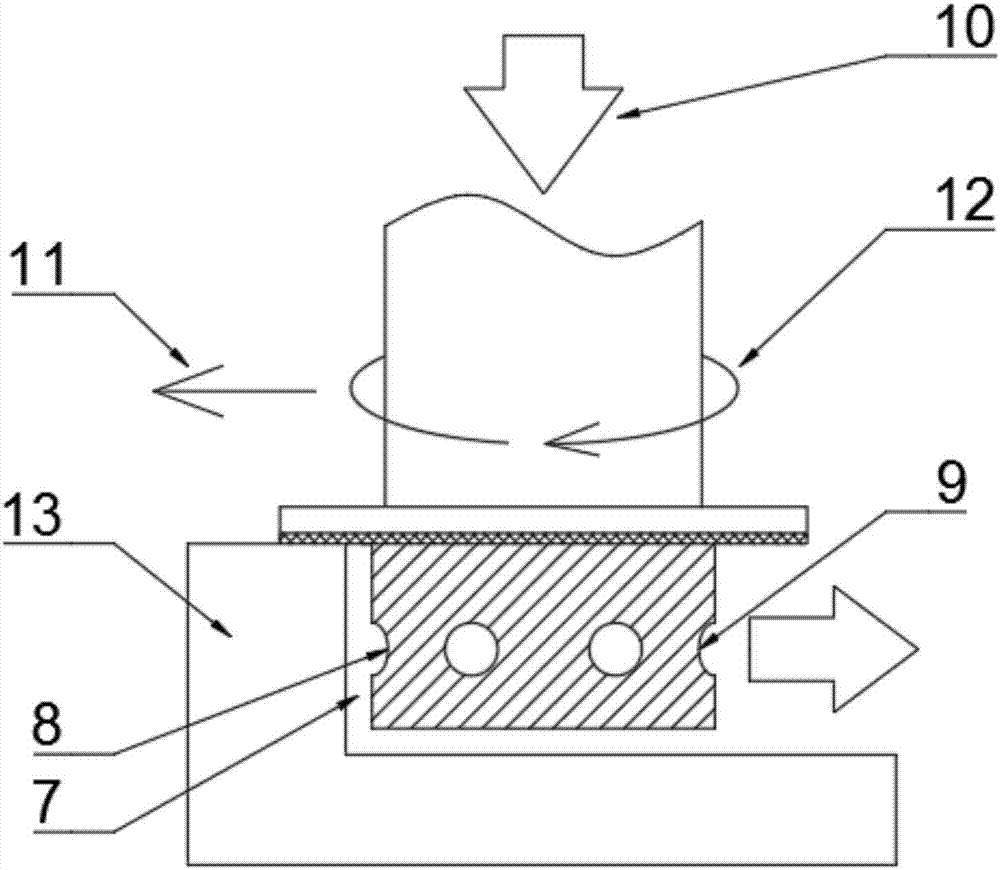

Device for controlling delivery and uniform distribution of reaction gases in MOCVD reaction chamber

ActiveCN101914761AReduce manufacturing costControl consumptionChemical vapor deposition coatingSystem capacityEngineering

The invention discloses a device for controlling the delivery and the uniform distribution of reaction gas in a MOCVD reaction chamber. By respectively controlling the flow of gas passages non-uniformly distributed radially on a front gas homogenizing plate and input passages at different positions, at least two reaction gases are respectively introduced into two paths which are radially and axially crossed on a spray header, and can be secondarily distributed by nozzles in different shapes, so the uniformly distributed boundary layer concentration, speed and temperature required are achieved on the surface of a rotary epitaxial wafer, the quality of massively produced epitaxial films and the finished product ratio of massively produced epitaxial wafers are improved, the consumption of expensive reaction gases can be effectively controlled and the epitaxial production cost is reduced. By properly increasing the distance between the surface of the spray header and the epitaxial wafer, deposits generated on the surface of the spray header and the nozzles in the epitaxial growth are reduced, the cleaning period is prolonged, and the production efficiency and system capacity are improved. The device also can reduce the processing difficulty and manufacturing cost of the nozzles of the spray header and cooling medium passages.

Owner:JIANGSU ZHONGSHENG SEMICON EQUIP

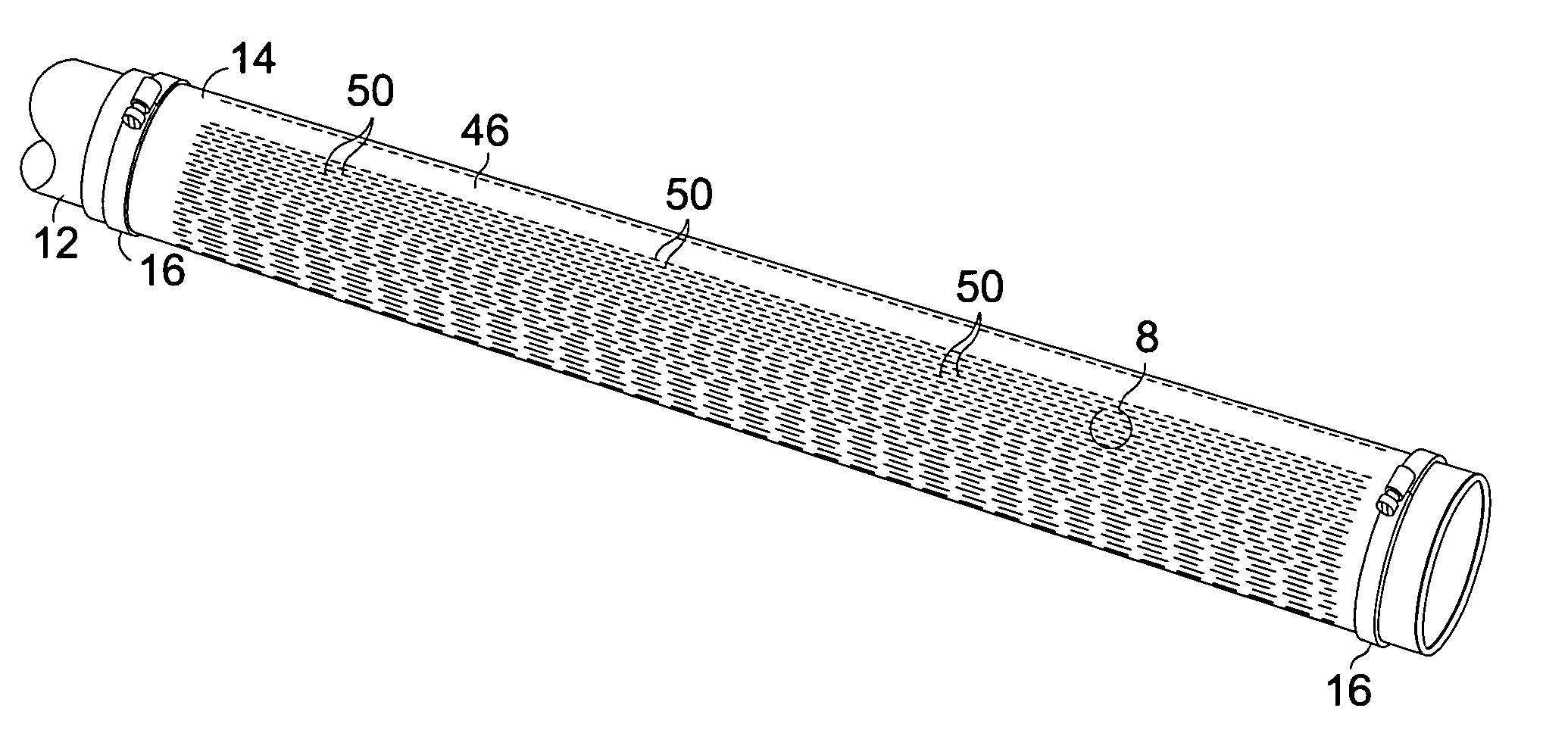

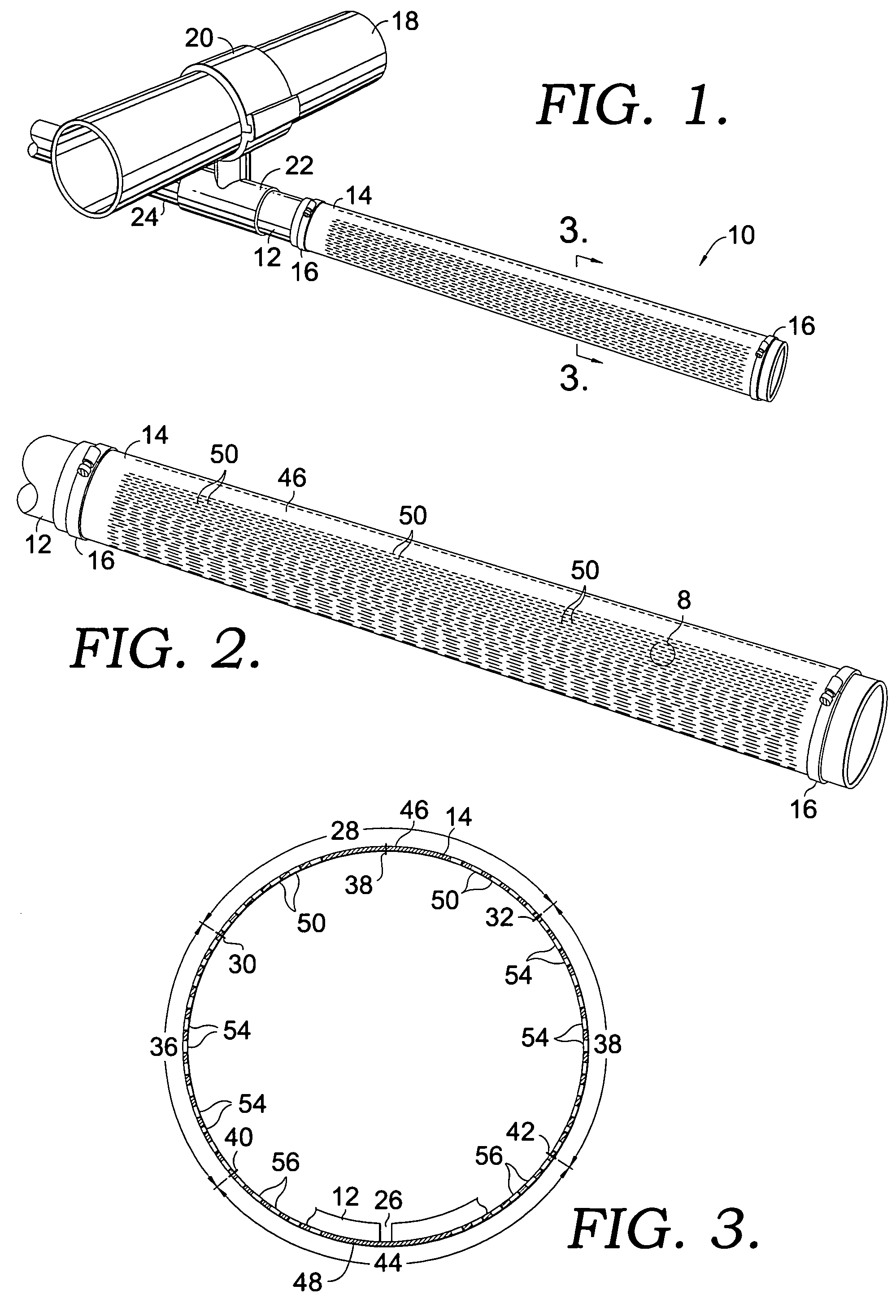

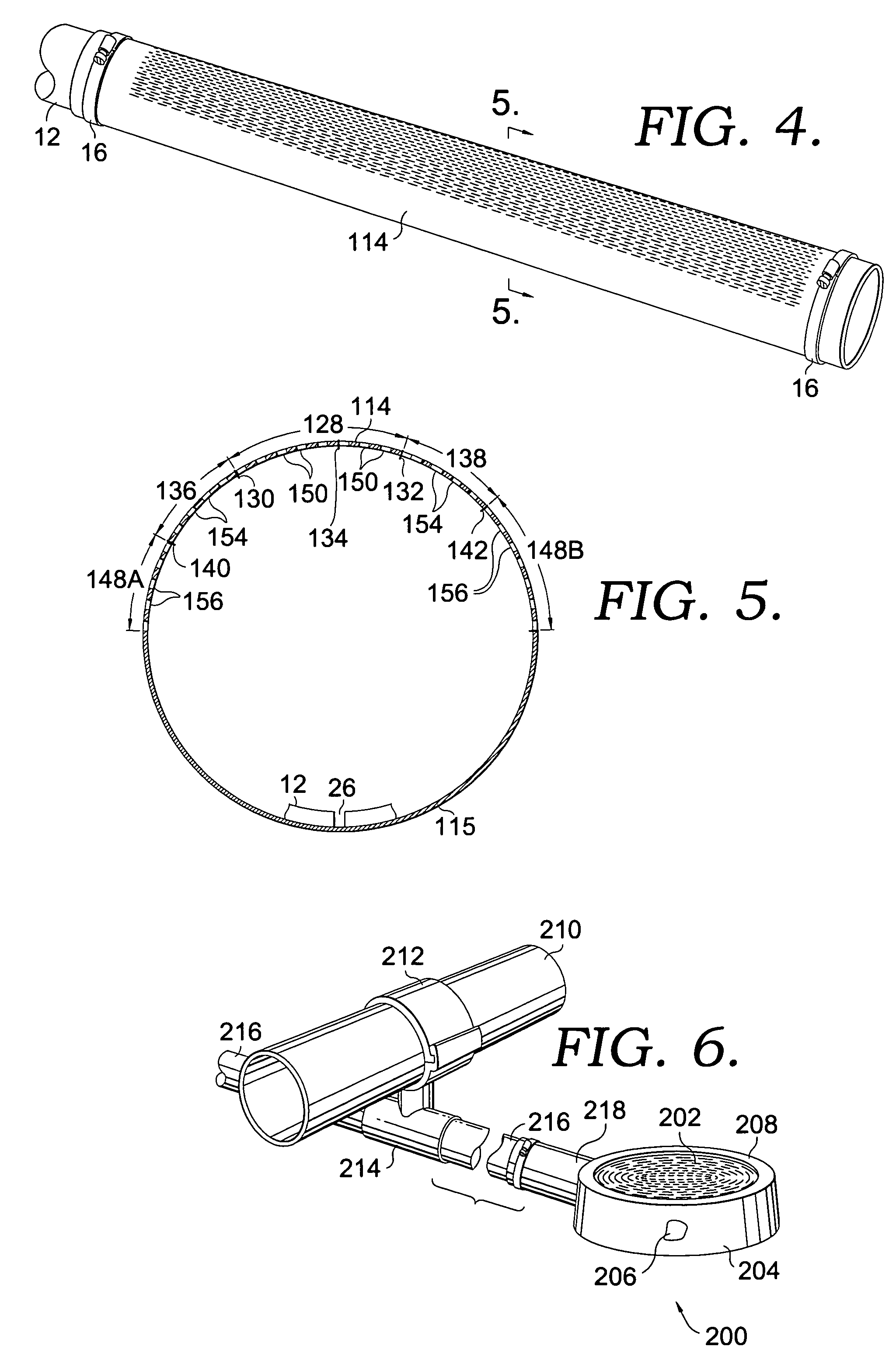

Membrane diffuser with uniform gas distribution

InactiveUS7044453B2Improve distribution uniformityImprove transmission efficiencyCarburetting airTransportation and packagingMembrane surfaceMaterial Perforation

A flexible diffuser membrane is provided with a unique system of perforations arranged to result in uniform distribution of gas even though the membrane deflects to different extents or the submergence varies in different parts of the membrane. The perforations are arranged to provide less perforation area per unit of perforated membrane surface area in the membrane parts that deflect the most or are submerged least and greater perforation area in membrane parts that deflect the least or are submerged most. The perforations can be slits arranged in parallel rows on a tubular membrane, in concentric circles or another pattern on a disk membrane, or in still a different pattern on a flat panel diffuser membrane. The slit length or separation can be varied between different zones on the membrane surface or the spacing between rows or circles can be varied.

Owner:ENVIRONMENTAL DYNAMICS INC

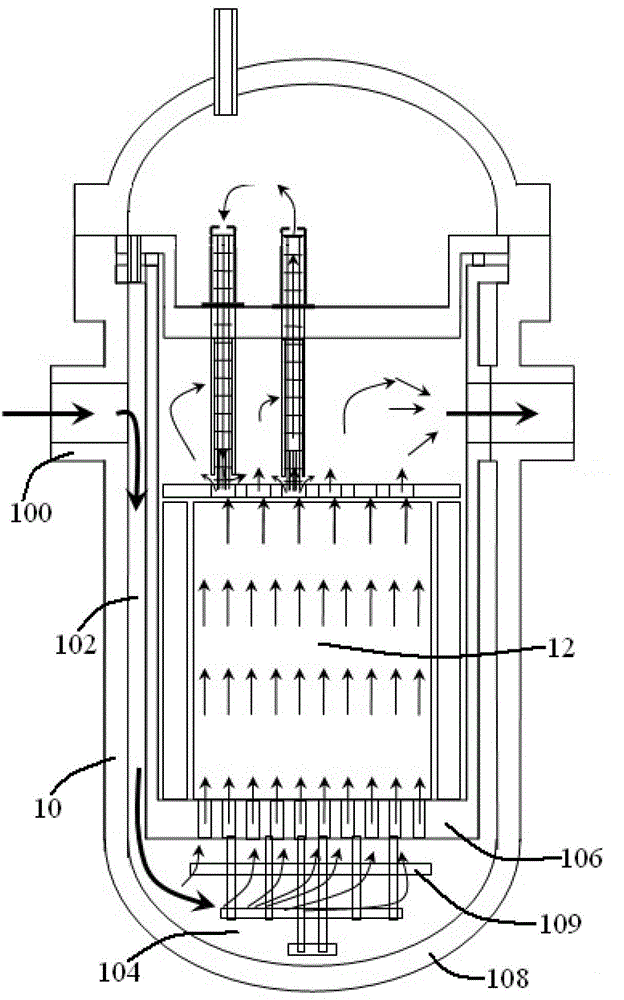

Flow distribution structure of reactor of nuclear power station

ActiveCN102800371AImprove flow field characteristicsAvoid vortex sheddingNuclear energy generationReactor fuel elementsNuclear engineeringNuclear power plant

The invention discloses a flow distribution structure of a reactor of a nuclear power station. The flow distribution structure is used for distributing the flow of coolant of a cooled reactor core and comprises a reactor core lower supporting plate and an end-socket-shaped structure fixed on the reactor core lower supporting plate; and the end-socket-shaped structure comprises an end socket with drain holes. Compared with the prior art, the flow distribution structure of the reactor of the nuclear power station has the advantages that the shape of a coolant channel is changed through the end socket, so that characteristics of a flow field of a lower cavity are improved effectively, vertex shedding of reactor internals in the lower cavity is avoided, the flow of the coolant is distributed through the drain holes of the end socket, and uniformity of flow distribution of fuel assemblies entering the reactor core is perfect.

Owner:中广核工程有限公司 +1

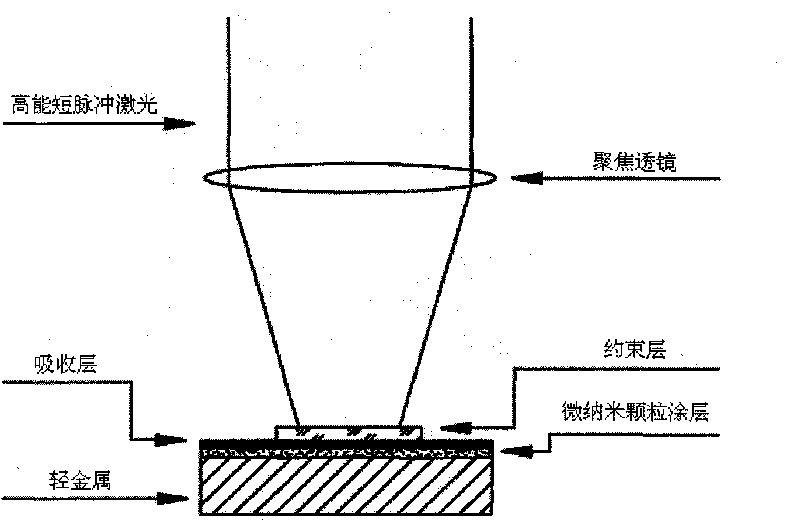

Light metal surface laser impact micronano particle injection reinforcing method

The invention relates to a light metal surface laser impact micronano particles injection reinforcing method, comprising the following steps: 1) removing the oxide layer probably existing on the surface of the light metal by a mechanical polishing or chemical corrosion method, then grinding and polishing with sand paper, and finally cleaning the surface of the light metal alloy with acetone or alcohol; 2) precoating the micronano particles on the surface of the light metal with inorganic bonding agent, recoating a layer of black paint on the surface of the micronano particle coating layer to serve as the absorption layer of laser impact after drying, and drying naturally; 3) impacting the absorption layer and the micronano particle layer with high-energy short pulse laser, and utilizing K9 glass or running water as a restriction layer during laser impact; and 4) soaking the micronano particle coating layer processed by acetone, and then removing the absorption layer through washing with running water or ultrasonic washing to obtain the micronano particle injection reinforcing layer. The invention integrates the actions of laser impact reinforcement, nano particle reinforcement and nano particle reinforcement, can dramatically improve hardness, abrasion resistance and fatigue resistance property of light metal surface layer, and has wide application prospect.

Owner:TSINGHUA UNIV

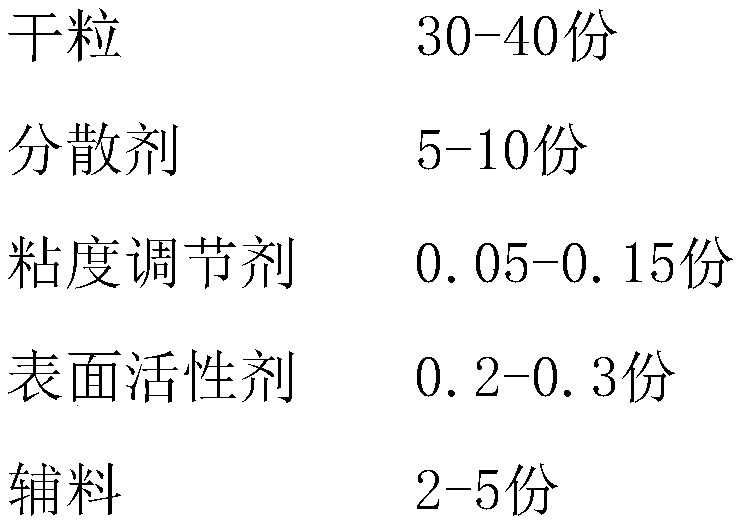

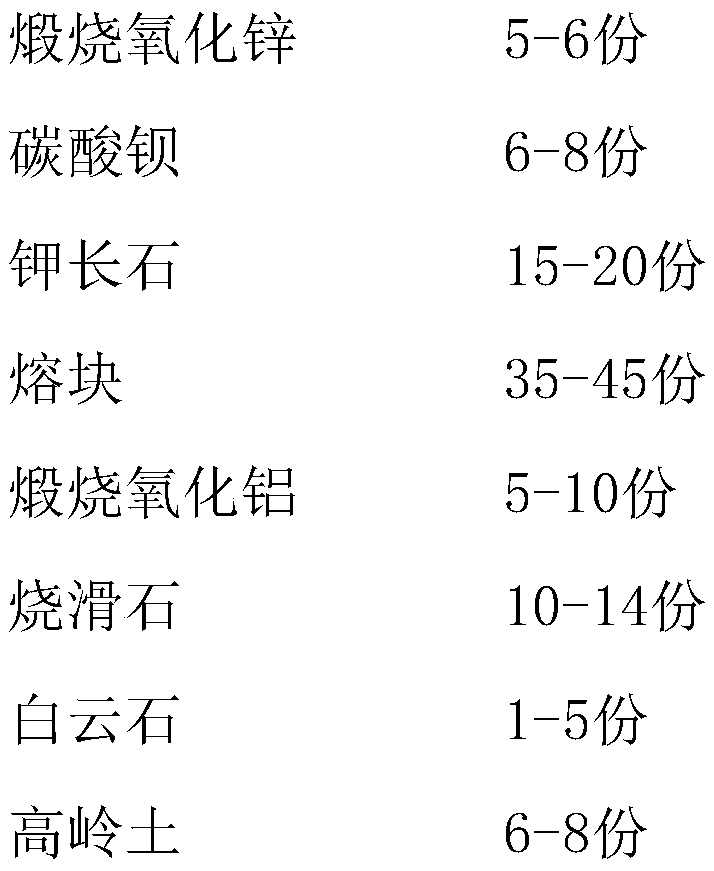

Ink-jet dry granular decorative ceramic tile and manufacturing method thereof

The invention relates to the technical field of ceramic tiles, in particular to an ink-jet dry granular decorative ceramic tile and a manufacturing method thereof. The manufacturing method includes the following steps: A. bottom glaze decoration; B. pattern decoration; C. drying for the first time; D. dry granular decoration; E. spraying a protective glaze; and F. calcining to obtain the product.The method for preparing the dry granular decorative ceramic tile has the advantages of simple operation steps, convenient control, simplified process flow, improved production efficiency, reduced production difficulty and production cost, so that the method is suitable for industrial large-scale production; by spraying with dry granular ink, spray printing can be carried out on a designated position on the surface of a blank body, so as to enable a spray printed texture to be accurately correspond to a pattern decorative texture, and thus the distribution uniformity and adhesion of dry granules on the surface of the blank body are improved, and the prepared ceramic tile product has clear and distinct patterns, low glaze gloss, good anti-skid effect, obvious dry granular feeling, strong stereoscopic impression, rich colors, stable physicochemical properties and wide temperature adaptation range.

Owner:JIANGXI HEMEI CERAMICS +3

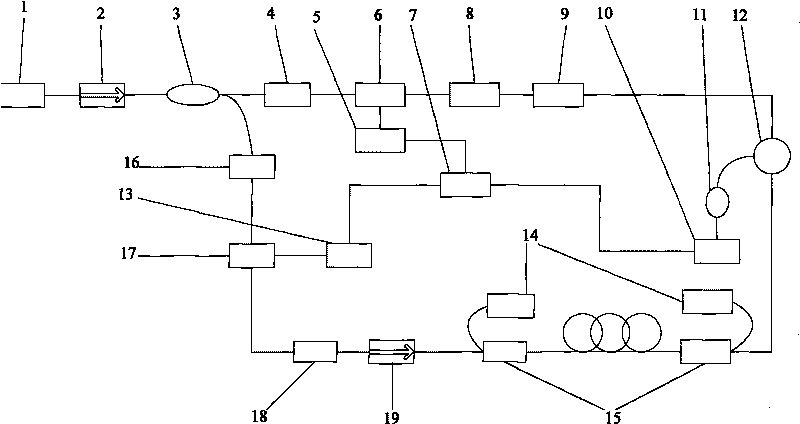

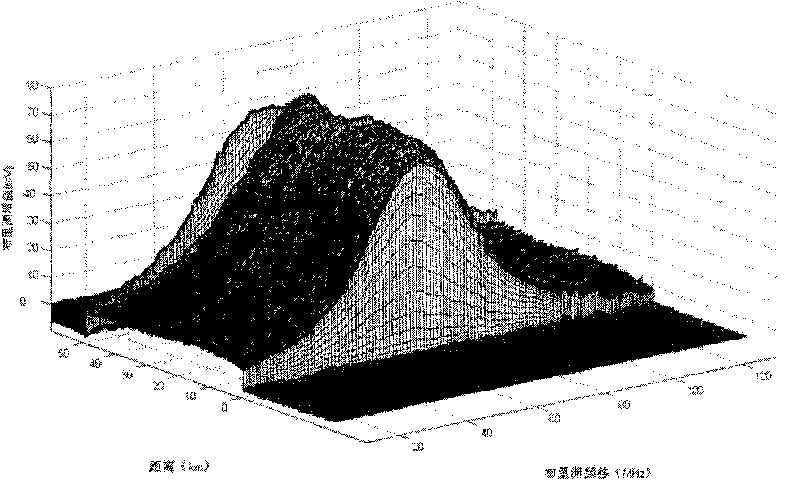

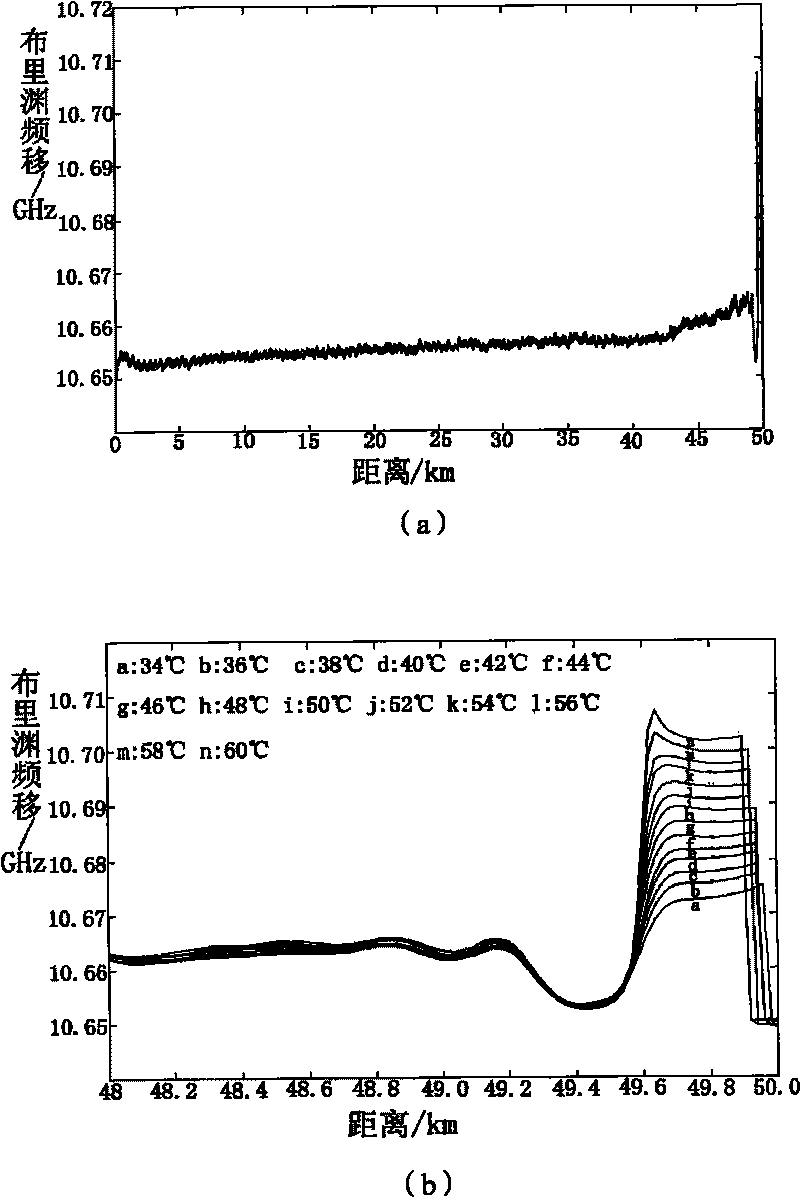

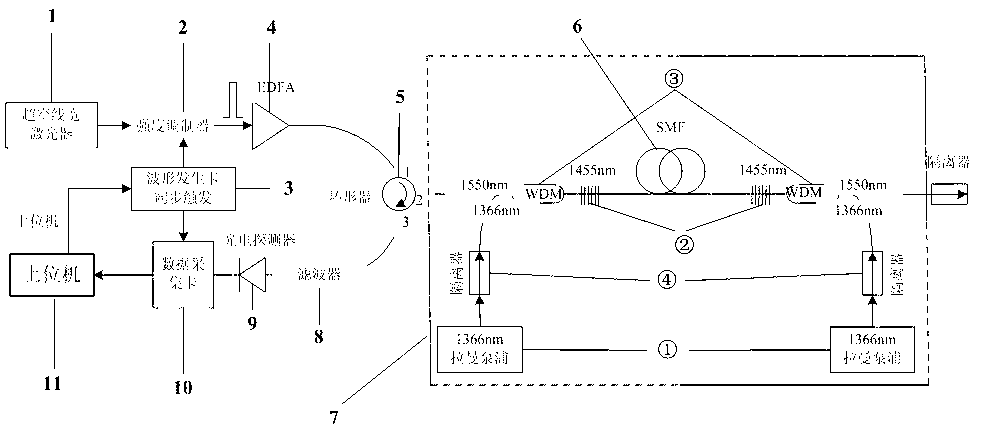

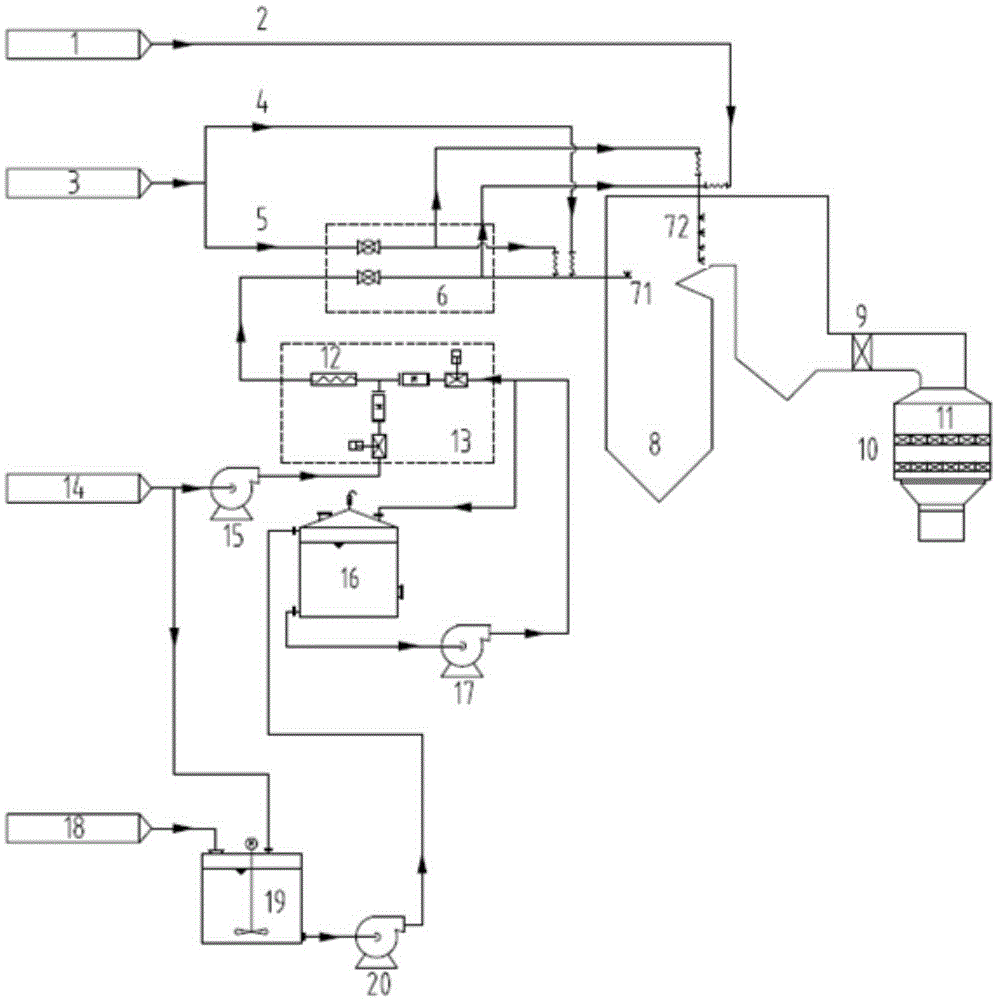

Distributed Raman amplification-based Brillouin optical time domain analysis system

InactiveCN101762290AImprove distribution uniformityGuaranteed temperature/strain resolutionNon-linear opticsConverting sensor output opticallyTime domainErbium doped fiber amplifier

The invention discloses a bidirectional distributed Raman amplification-based Brillouin optical time domain analysis system. The system comprises a laser 1, a coupler 3, a first electro-optical modulator 6, a second electro-optical modulator 17, a polarization scrambler 8, a first erbium-doped fiber amplifier 9, a second erbium-doped fiber amplifier 18, an optical circulator 12, a tunable filter 11, a detector 10, a data acquisition processing system 7 and a Raman amplification system. In the system, the bidirectional distributed Raman amplification technology is applied in the Brillouin optical time domain analysis system to improve the distribution evenness of Brillouin detection signal gain on a whole section of a sensing fiber, so that the temperature / strain resolution of the whole section of the sensing fiber can be ensured, and long distance distribution sensing in true sense can be realized.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

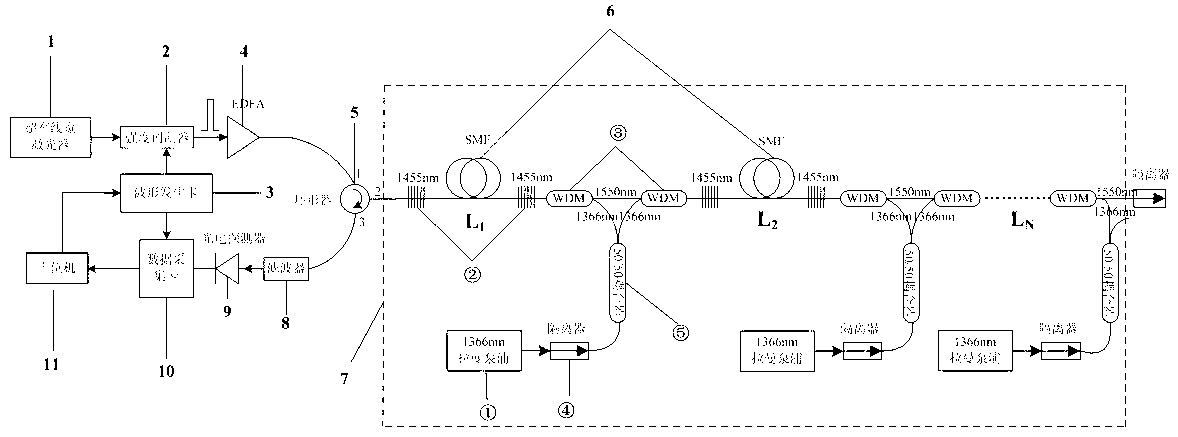

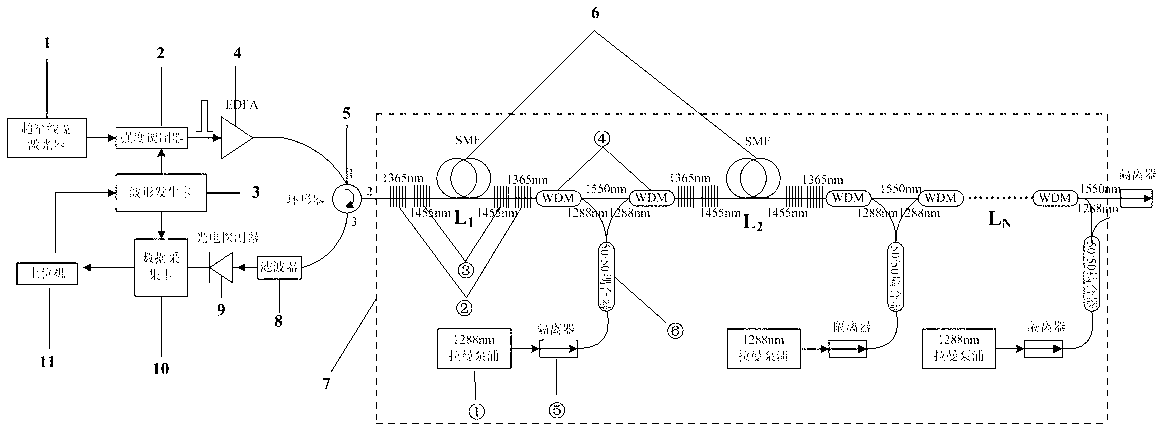

Super-long distance phase-sensitive optical time domain reflectometer (Phi-OTDR) system

InactiveCN102706437AHigh strengthImprove distribution uniformitySubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansRayleigh scatteringSignal on

The invention discloses a super-long distance phase-sensitive optical time domain reflectometer (Phi-OTDR) system, which comprises a Phi-OTDR demodulating system and detecting optical fiber, wherein a forward amplifying unit and a backward amplifying unit are respectively arranged at the front end and the back end of the detecting optical fiber. Detecting signal light of the Phi-OTDR system is amplified in a distributed manner by utilizing a bidirectional second-order or bidirectional multi-order Raman amplifying method, so that the uniformity of the intensity and the distribution of Rayleigh scattering signals on the whole optical fiber is further improved, the problem of the prior amplifying method of the Phi-OTDR system is effectively overcome, and the sensing distance of a single segment of detecting optical fiber of the Phi-OTDR system is further prolonged; and meanwhile, by utilizing bidirectional Raman amplifying multi-segment cascade connection, the super-long distance Phi-OTDR system which requires a low cost and has high performance can be realized. The method of the super-long distance Phi-OTDR system is helpful to improvements on the whole performance and the performance price ratio of the Phi-OTDR system during the application to long-distance safety monitoring of oil and gas transmitting pipelines, large-range peripheries, large-scale civil engineering structures, and the like.

Owner:SICHUAN GUANGSHENG IOT TECH CO LTD

Method for fabricating a double gate MOSFET device

InactiveUS20050087811A1Prevent depletion of polysiliconImprove distribution uniformityTransistorSemiconductor/solid-state device manufacturingDriving currentEngineering

A method of fabricating a double gate MOSFET device is provided. The present invention overetches a silicon layer overlying a buried oxide layer using a hard mask of cap oxide on the silicon layer as an etching mask. As a result, source, drain and channel regions are formed extending from the buried oxide layer, and a pair of recesses are formed under the channel regions in the buried oxide layer. The channel is a fin structure with a top surface and two opposing parallelly sidewalls. The bottom recess is formed under each opposing sidewall of the fin structure. A conductive gate layer is formed straddling the fin structures. The topography of the conductive gate layer significantly deviates from the conventional plainer profile due to the bottom recess structures under the channel regions, and a more uniformly distributed doped conductive gate layer can be obtained. Hence, the depletion effect of the conductive polysilicon gate while operating the device can be suppressed and the device drive-on currents can be further enhanced.

Owner:UNITED MICROELECTRONICS CORP

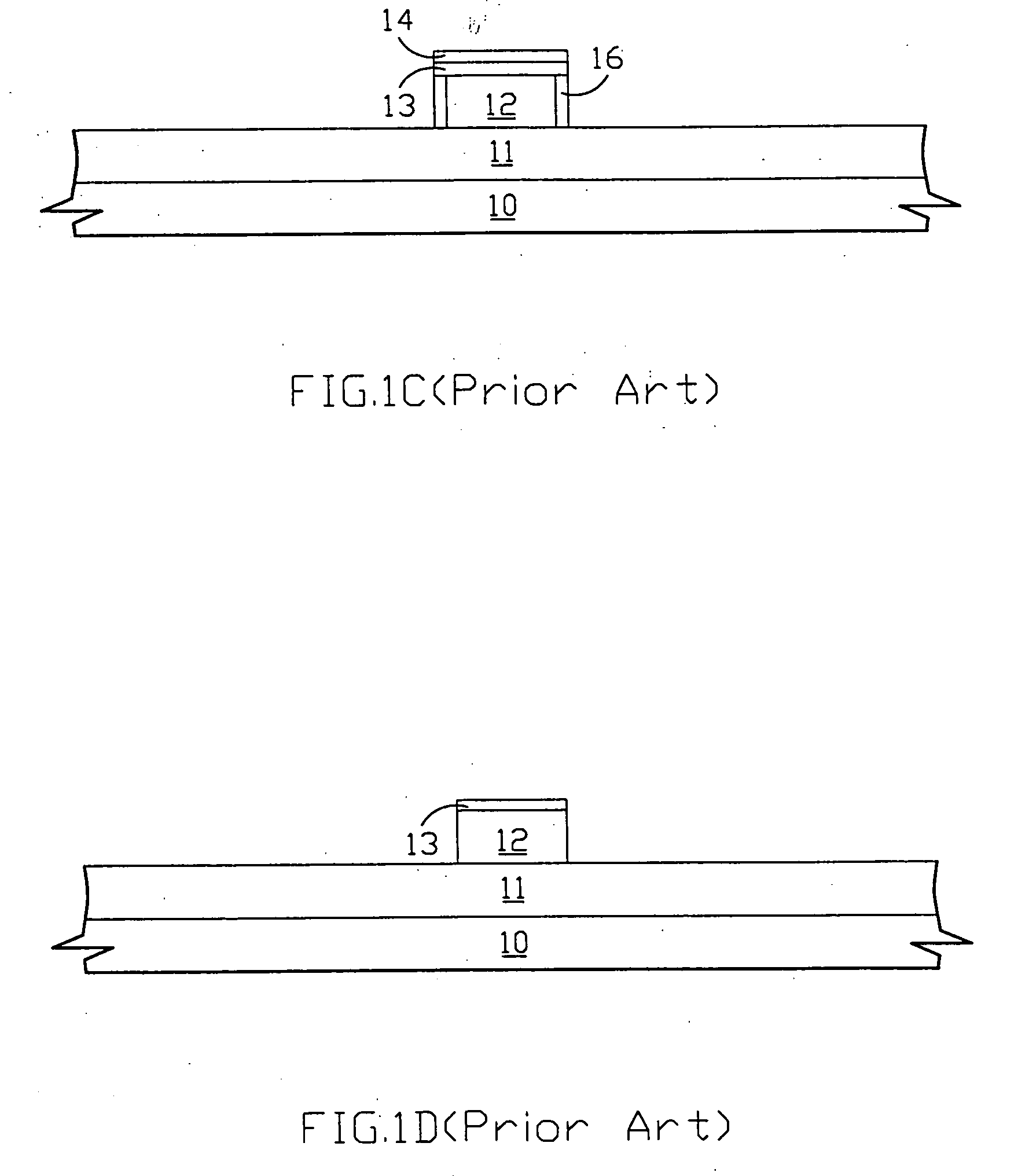

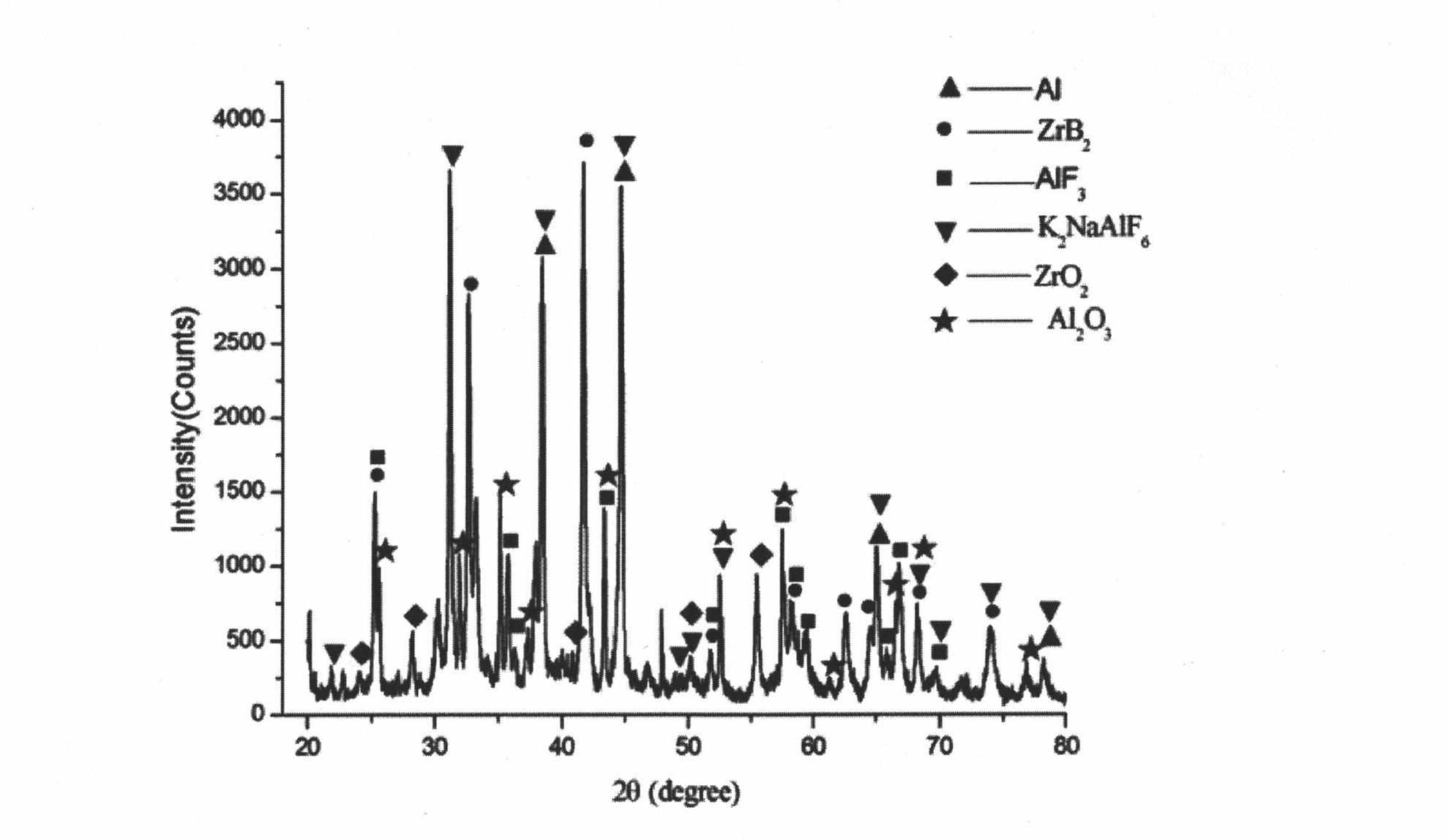

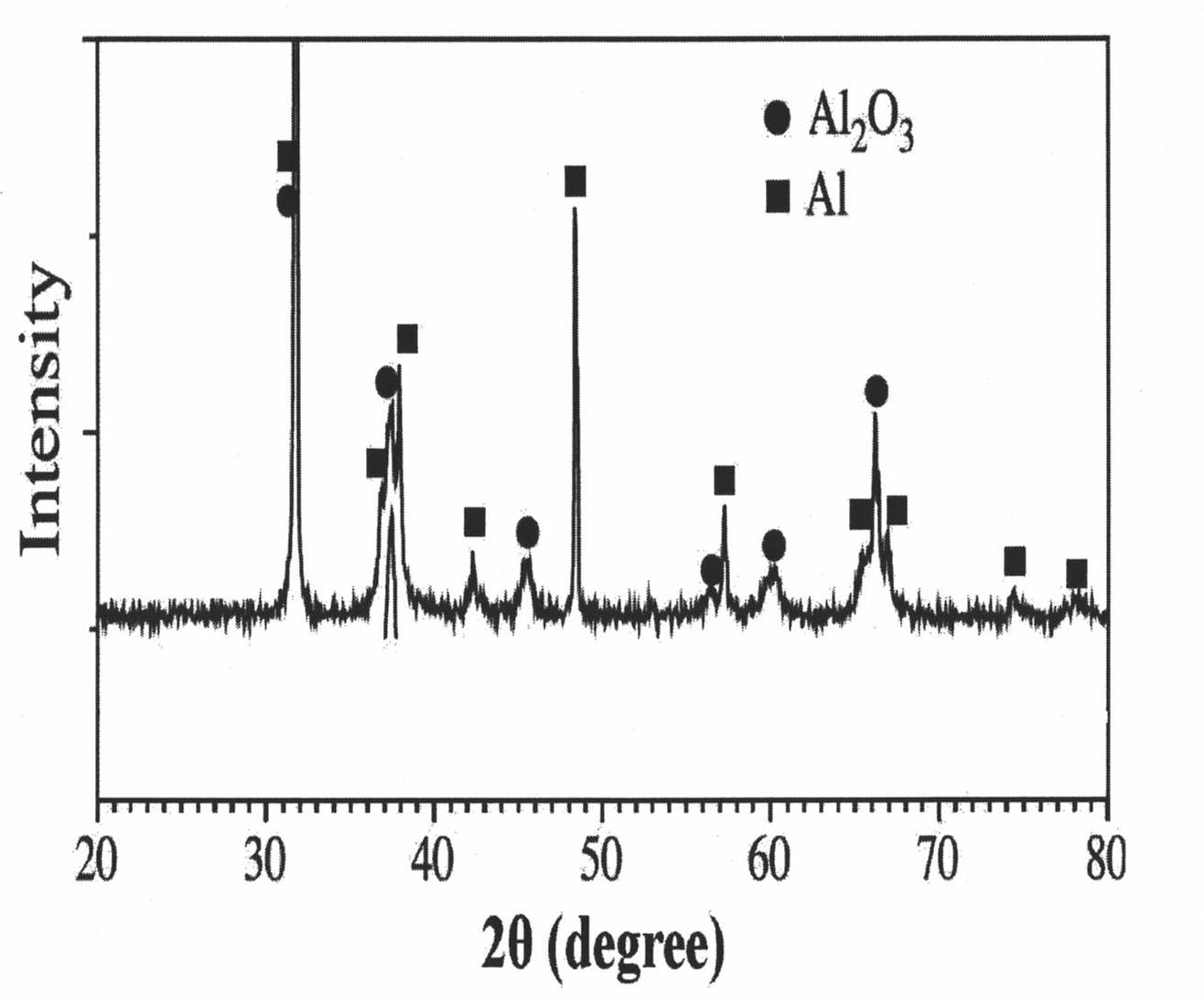

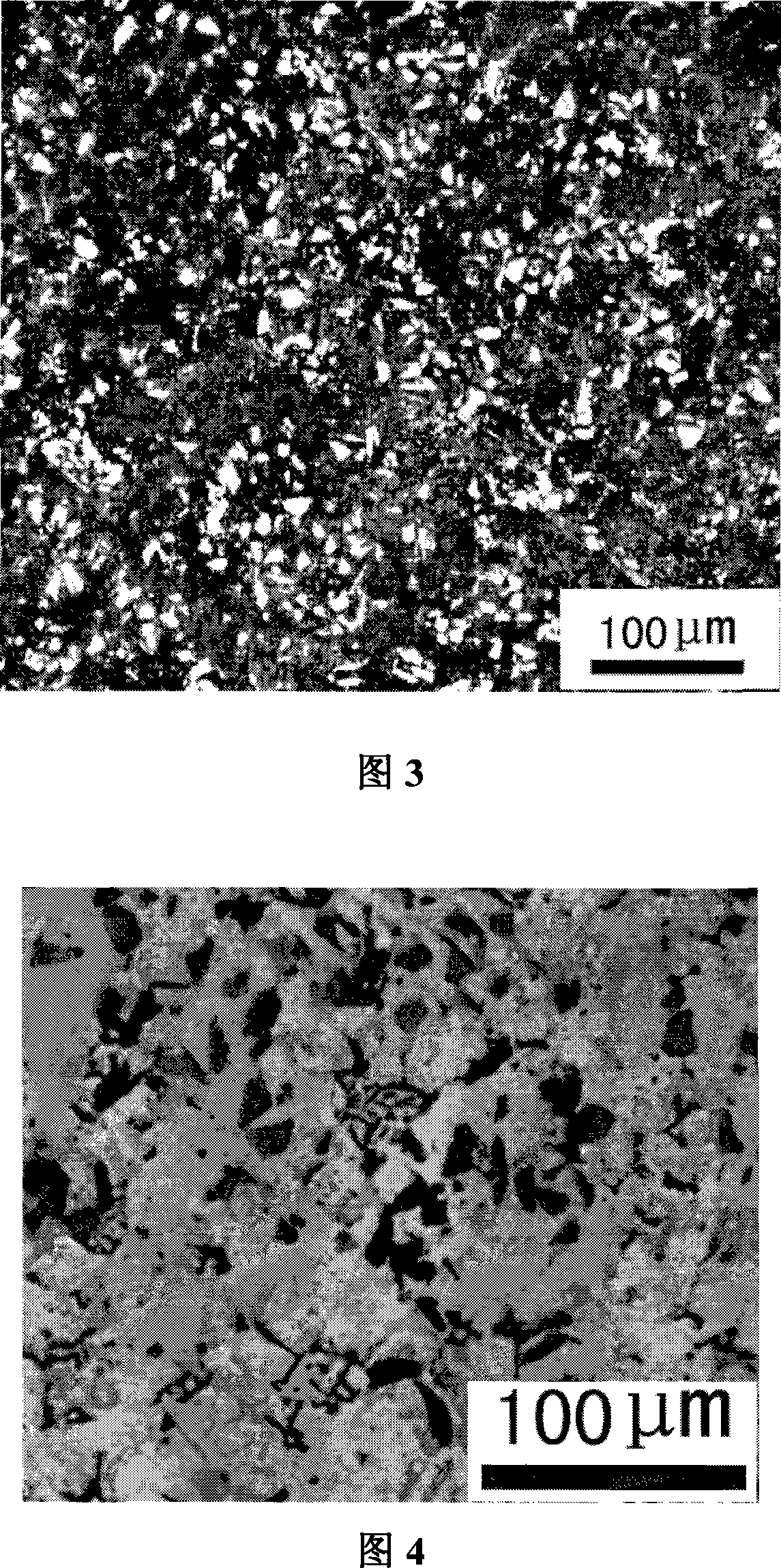

Preparation method of Al2O3 nanoparticle reinforced aluminum-based composite material

The invention provides a preparation method of a Al2O3 nanoparticle reinforced aluminum-based composite material, belonging to the technical field of the aluminum-based composite material. The method uses sodium borate (Na2B4O7.10H2O) type boride and K2ZrF6 type fluoride powder as the reaction mixed salt and adopts the direct reaction of molten metal to directly synthetize the nano-Al2O3 particlereinforced aluminum-based composite material in molten aluminum. The invention mainly has the following advantages: the reaction system can effectively control the growth of Al2O3 particles and ensure that the size of the reinforcement phase is controlled to the nanoscale; and the synthesis temperature of the reaction system is 800-850 DEG C, and the defects of the traditional method which uses oxide to prepare the Al2O3 particle reinforced aluminum-based composite material can be overcome, wherein the defects are that the particles are easy to grow, the size can not be controlled and the reaction temperature is high. In addition, with the increase of the addition amount of the reaction mixed salt in the reaction system, the reinforcing particles have smaller size and more uniform distribution; the interface binding of the particles and the substrate is good, no pollution is caused; and the preparation method is an effective method which is suitable for preparing the high-performance nanoparticle reinforced composite material at a low temperature.

Owner:JIANGSU UNIV

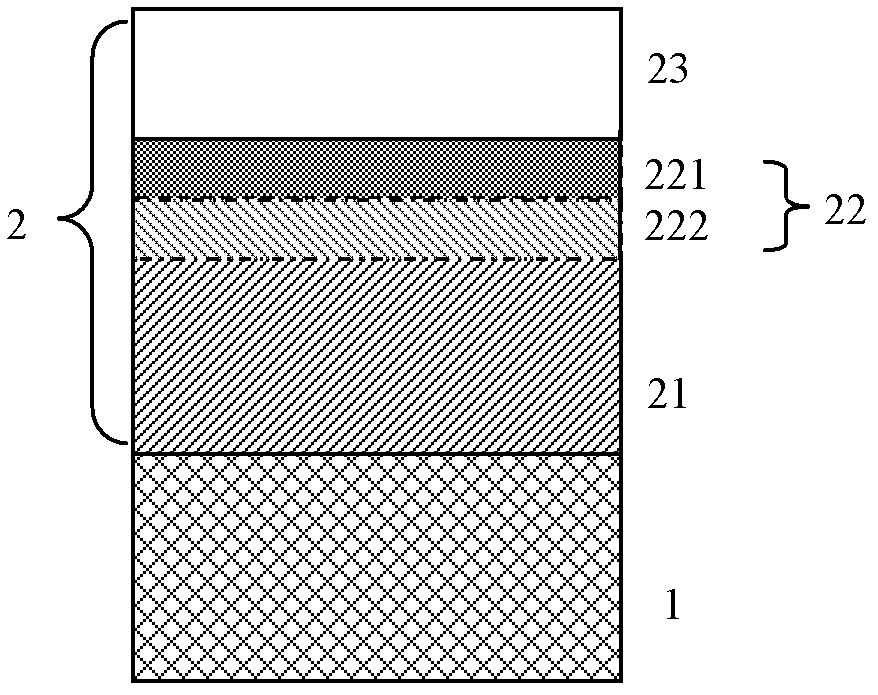

Novel lithium-pre-intercalated negative plate and preparation method thereof

ActiveCN105244472AExcellent charge and discharge characteristicsLarge amount of pre-intercalated lithiumCell electrodesComposite filmGraphite

The invention discloses a novel lithium-pre-intercalated negative plate and a preparation method thereof. The novel lithium-pre-intercalated negative plate comprises a porous current collector, an active material layer and a lithium pre-intercalation layer, wherein the lithium pre-intercalation layer is attached to the active material layer; the active material layer is prepared from the following components represented by mass percentage: 75%-90% of an active material, 5%-20% of a conductive agent and 5%-10% of a binder; the active material is a lithium-intercalated carbon material; the lithium pre-intercalation layer is a dense and uniform composite thin-film layer of which the thickness is 5-30 microns; the lithium pre-intercalation layer is prepared from the following components represented by mass percentage: 50%-70% of graphite and 30%-50% of a lithium salt; and the lithium pre-intercalation layer is obtained by magnetron sputtering coating on the active material layer. The novel lithium-pre-intercalated negative plate disclosed by the invention is high in lithium-pre-intercalated quantity, high in adhesion to the active material layer and uniform in lithium intercalation, is achieved through magnetron sputtering coating, and is safe and time-saving; and the lithium-pre-intercalated quantity can be controlled.

Owner:江西展枭新能源科技有限公司

Preparing method of high-thermal-conductivity graphite/aluminum composite

InactiveCN106916985AEnhanced interface bindingImprove performanceTransportation and packagingMetal-working apparatusHeat managementTitanium

The invention relates to a preparing method of a high-thermal-conductivity graphite / aluminum composite and belongs to the technical fields of high-thermal-conductivity electronic packaging material preparing technologies and heat management materials. The method comprises the following steps: plating graphite powder with titanium; rolling aluminum and / or aluminum alloy powder into a flake; carrying out ball milling and mixing on the titanium-plated graphite powder and the flaky aluminum and / or aluminum alloy powder according to a ratio so as to obtain composite powder; then, filling a graphite die with the uniformly mixed graphite / aluminum powder, and adopting powder metallurgy hot-pressing; and after cooling the composite powder with the die, carrying out demoulding to obtain the high-thermal-conductivity graphite / aluminum composite. The method solves the problem that the thermal conductivity of the existing graphite / aluminum composite is low, improves the thermal conductivity of the graphite / aluminum composite, and is simple in technology, high in efficiency and low in cost.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Production method of multi-element aluminum alloy standard sample

ActiveCN101294875AHigh yieldImprove distribution uniformityPreparing sample for investigationColor/spectral properties measurementsMulti elementStandard samples

The invention relates to a method for preparing a standard multi-element aluminum alloy sample. The method comprises the steps of proportioning materials, melting, casting, homogenization processing, extruding and post-processing, and is characterized in that the standard sample contains the following 20 chemical elements in pure aluminum: Si, Fe, Cu, Mg, Mn, Zn, Sn, Pb, Ni, Ti, Cr, Sr, Ca, V, Ga, Zr, Cd, Be, B and P. The standard sample is manufactured sequentially through proportioning materials, melting, casting, homogenization processing, extruding and post-processing, and finally, standard samples are prepared according to the requirements for the standard samples. By adopting the preparation method, the multi-element aluminum alloy sample with uniform composition and good stability can be obtained.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

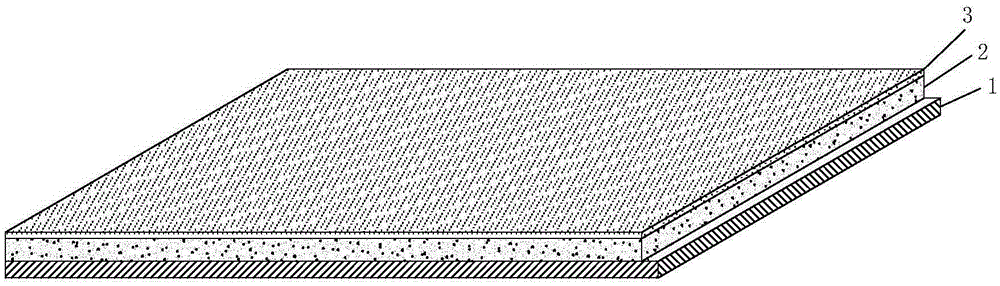

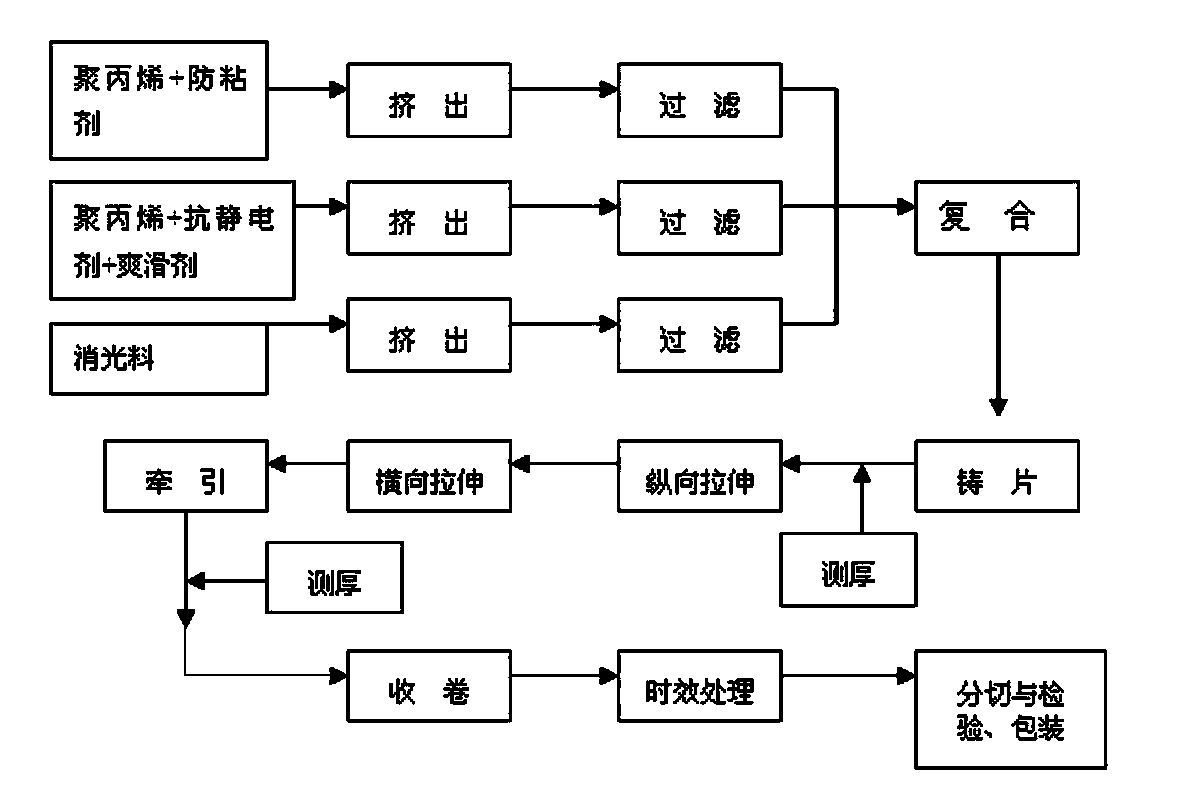

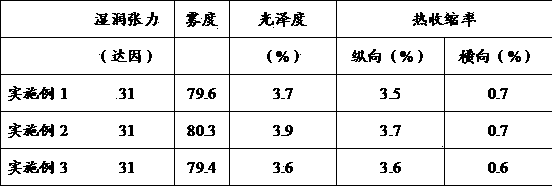

Matte BOPP (Biaxially-oriented Polypropylene) film for leather transferring and preparation method thereof

ActiveCN103709517AImprove rigidityIncrease the stretch ratioSynthetic resin layered productsCoatingsAnti adhesivePolypropylene

The invention relates to a matte BOPP (Biaxially-oriented Polypropylene) film for leather transferring and a preparation method thereof. The matte BOPP film consists of an inner surface layer, a core layer and an outer surface layer, and is prepared by coextrusion and two-way stretching of the inner surface layer, the core layer and the outer surface, wherein the inner surface layer comprises the following components in percentage by weight: 97.5-98.5% of polypropylene and 1.5-2.5% of adhesive; the core layer comprises the following components in percentage by weight: 98.0-98.4% of polypropylene, 1.0-1.2% of antistatic agent and 0.4-1.0% of slipping agent; the outer surface layer adopts a delustering material which comprises the following components in percentage by weight: 54-56% of polyethylene, 43.7-45.7% of high-density polyethylene and 0.3% of antioxidant. The matte BOPP film and the preparation method have the advantages that the selection and matching of the materials are reasonable, the selected polypropylene material is good in processing performance and high in mechanical strength; the prepared BOPP film is large in elastic modulus and low in heat shrinkage rate; the performance indexes such as haze and glossiness of the outer surface layer are excellent.

Owner:ZHEJIANG KINLEAD PACKAGING MATERIAL

Cutting tool for improving coating structure and preparation method thereof

ActiveCN103173761AExcellent oxidation and crater wear resistanceImprove uniformityTurning toolsSuperimposed coating processSingle phaseCast iron

The invention discloses a cutting tool for improving a coating structure. The cutting tool comprises a matrix and a coating covering the matrix. The coating comprises an inner layer B, a transitional layer C and an outer layer D from inside to outside. The inner layer B consists of transitional elements and nonmetal compounds. The transitional layer C comprises a transitional layer C1 and / or a transitional layer C2. The transitional layer C1 and C2 are mainly formed by carbon oxynitride with titanium. The outer layer D has a single phase alpha-Al2O3 structure. The thickness d of the outer layer D is 0.5-4 mu m. The mean grain size S is greater than or equal to 0.2 mu m but less than or equal to 0.5 mu m. The preparation method comprises the following steps of: first, preparing the tool matrix; then, sequentially depositing the inner layer B, the transitional layer C2, the transitional layer C1 and the outer layer D in a same coating period; and then, performing surface treatment to manufacture the cutting tool. The cutting tool provided by the invention is high in hardness and good in wear resistance, and has excellent cutting performance in cutting materials such as steel, stainless steel and cast iron.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

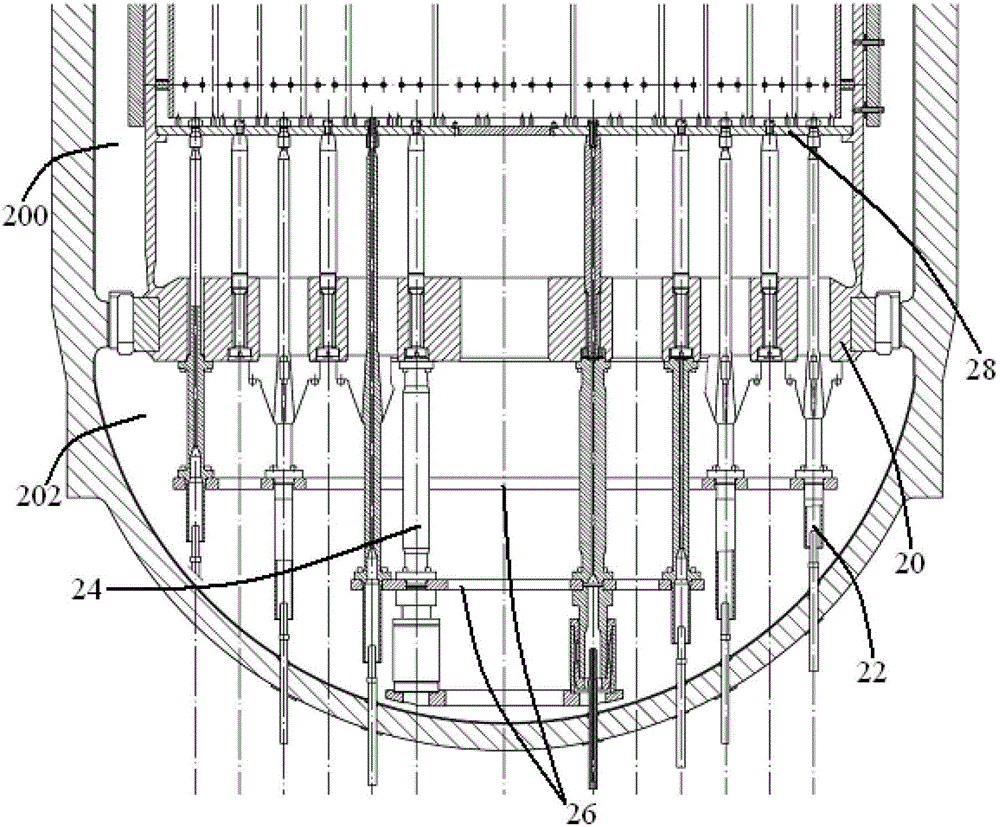

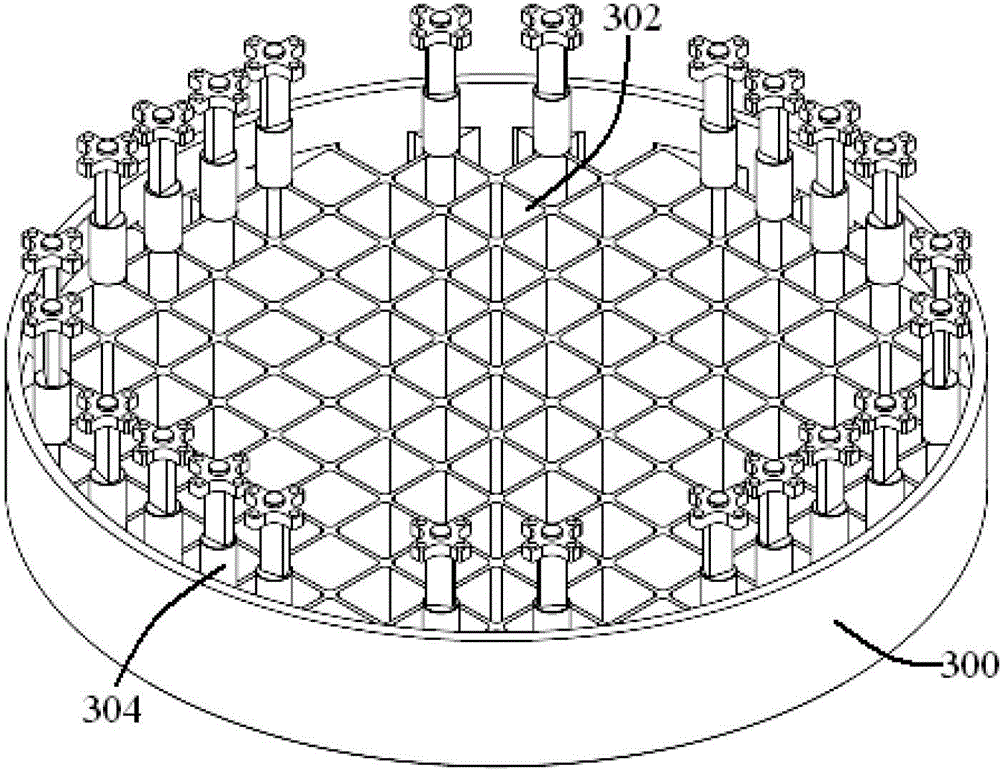

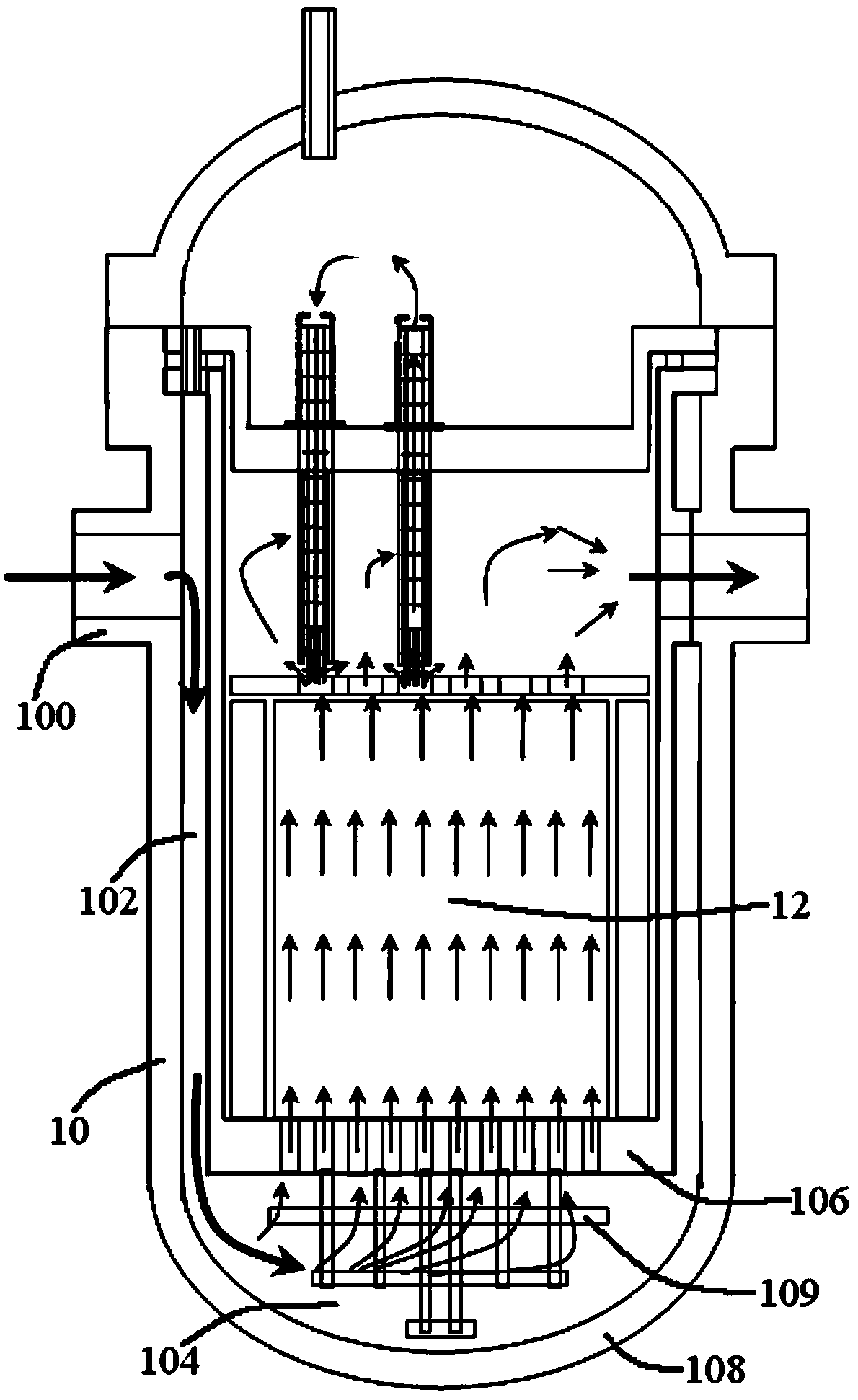

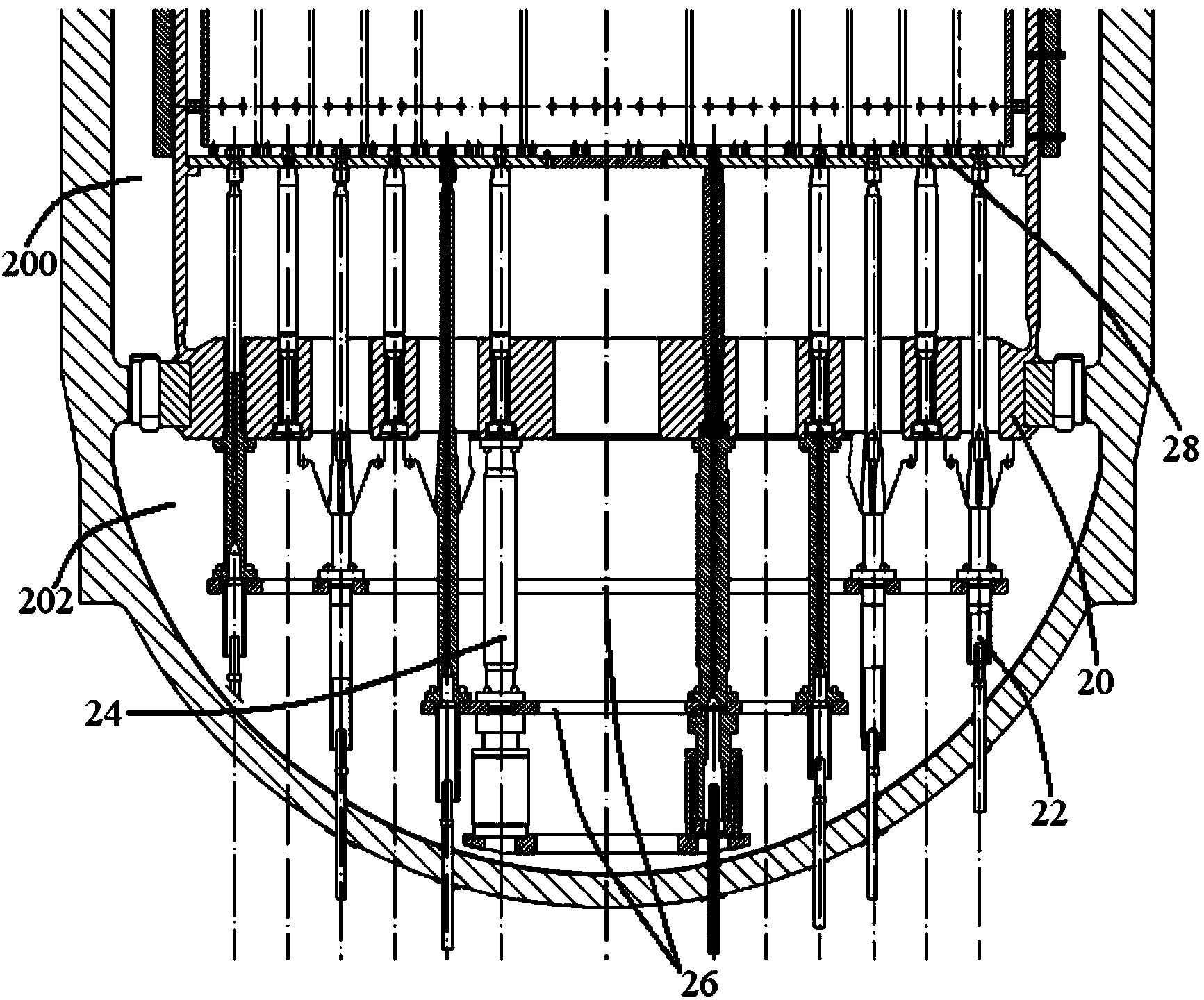

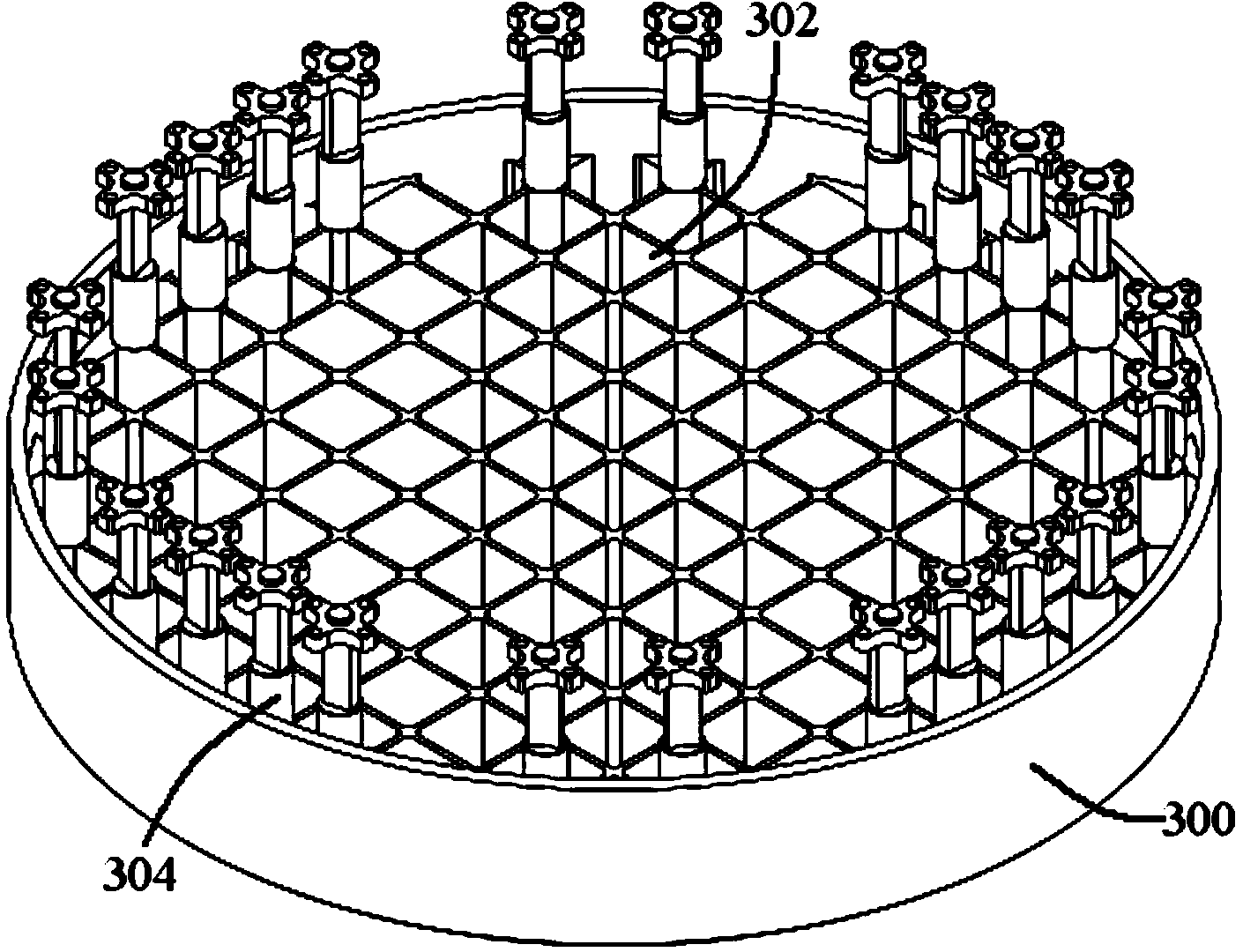

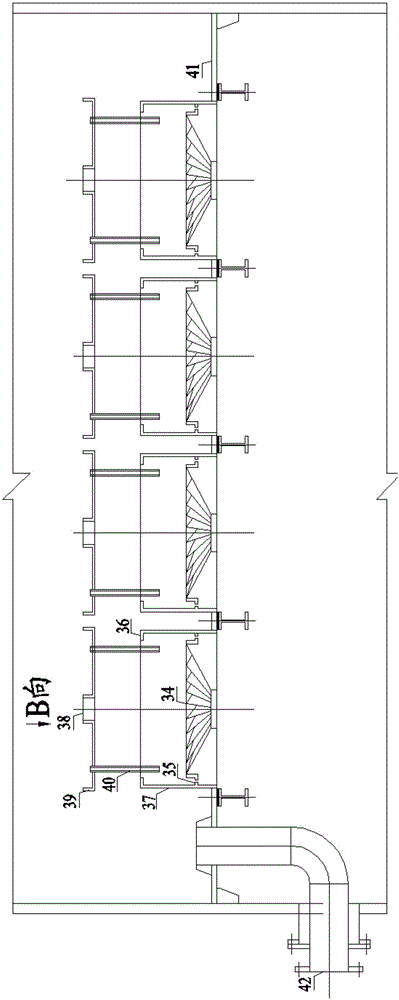

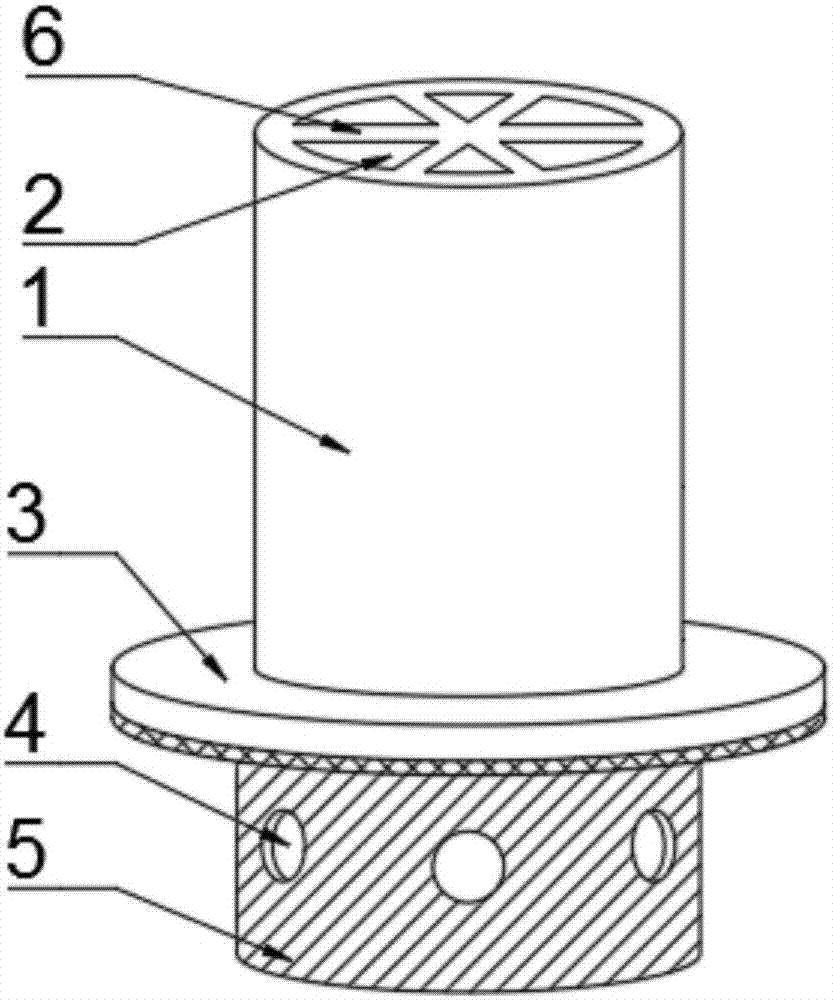

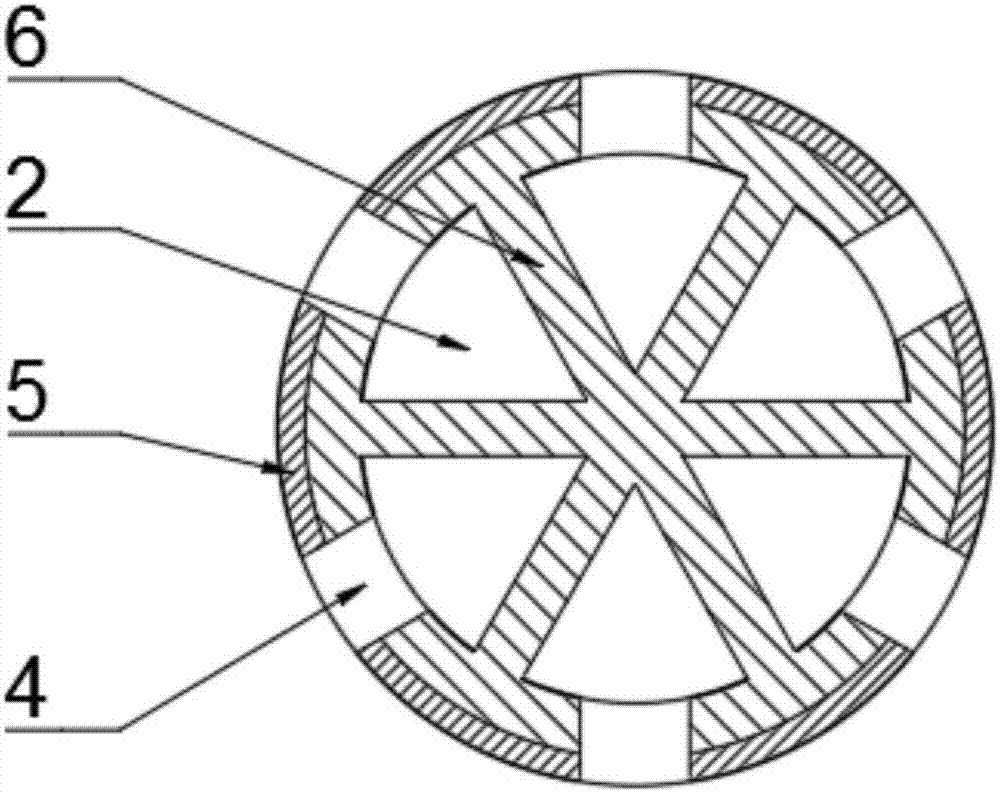

In-pile flow distribution device of reactor of nuclear power station

InactiveCN103971763ASimple structureImprove distribution uniformityNuclear energy generationShieldingNuclear powerNuclear engineering

The invention discloses an in-pile flow distribution device of a reactor of a nuclear power station. The device is used for distributing flow of a reactor core coolant; the flow distribution device comprises a lower reactor core support plate, a surrounding basket-shaped structure and vertical columns, wherein the surrounding basket-shaped structure is fixed below the lower reactor core support plate and comprises a porous surrounding basket and an eddy-current confinement plate positioned at the bottom of the porous surrounding basket; a plurality of flowing holes are respectively formed in the porous surrounding basket and the eddy-current confinement plate; the vertical plates are vertically arranged between the eddy-current confinement plate and the lower reactor core support plate. The in-pile flow distribution device of the reactor of the nuclear power station is relatively simple in structure, and by stirring and mixing the coolant through the eddy-current confinement plate and the vertical columns, eddy-current of a lower chamber is effectively inhibited, and the structure of the lower chamber is prevented from vortex shedding. The coolant is subjected to twice flow distribution through the surrounding basket-shaped structure and the lower reactor core support plate, so that the distribution effect is better, and the flow distribution uniformity in a reactor core fuel component is better.

Owner:中广核工程有限公司 +1

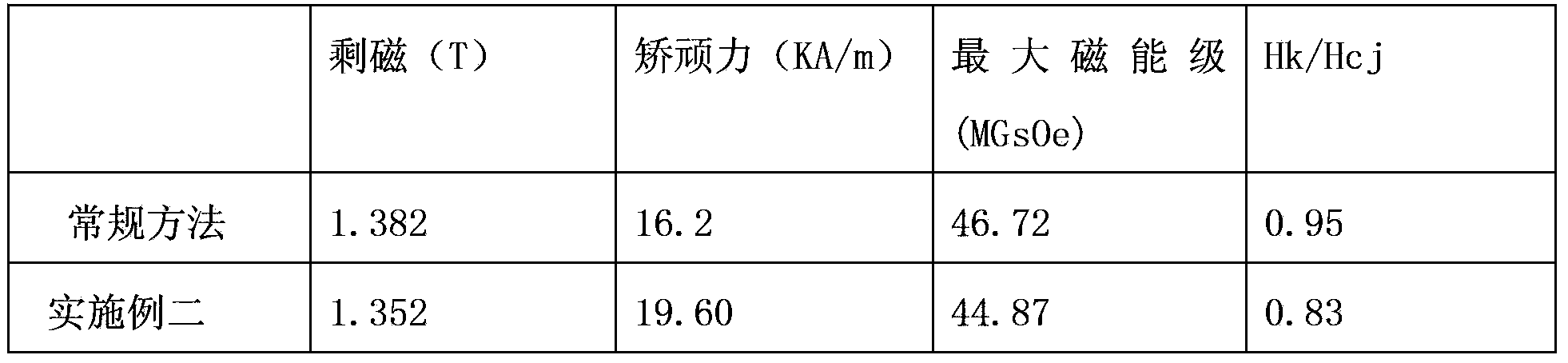

Method for depositing magnetic film on flexible substrate

InactiveCN101100742AReduce lossImprove efficiencyVacuum evaporation coatingSputtering coatingMagnetic anisotropyDeposition process

Vacuum winding-electroplating magnetic film on flexible substrates by deposition process is carried out by: assembling magnetic mask plates in vacuum winding electroplating apparatus to move in a direction same as the substrates do synchronously, installing magnets on top of target cabin of film plating chamber to form magnetic path between the magnets and magnetic mask plates, and electroplating film on the flexible substrates by sputtering or evaporating process. It effectively makes continuous 2D pattern on a large area of substrates with controlled magneto-anisotropy, and without environment pollution.

Owner:CHINA BANKNOTE PRINTING & MINTING

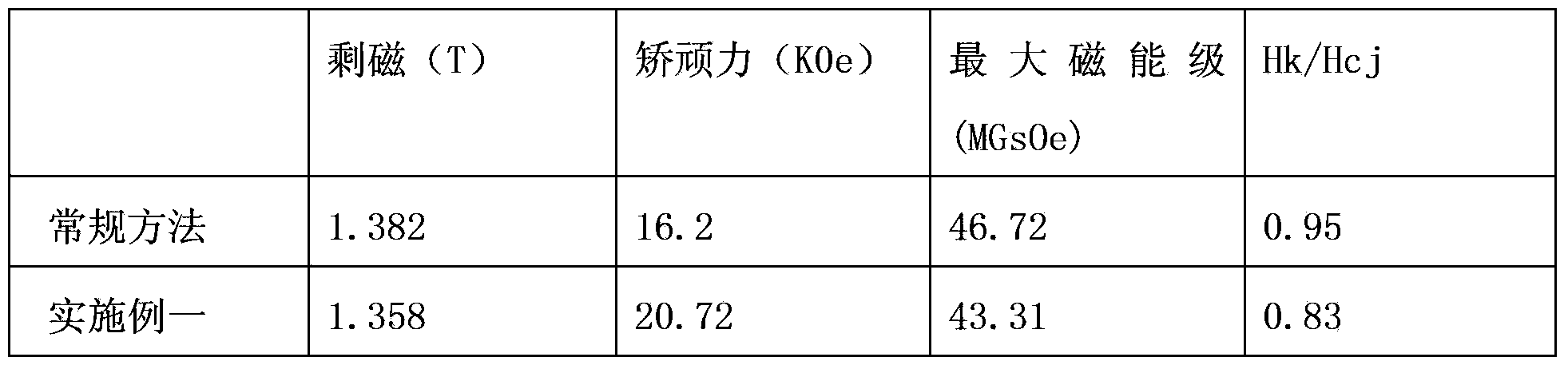

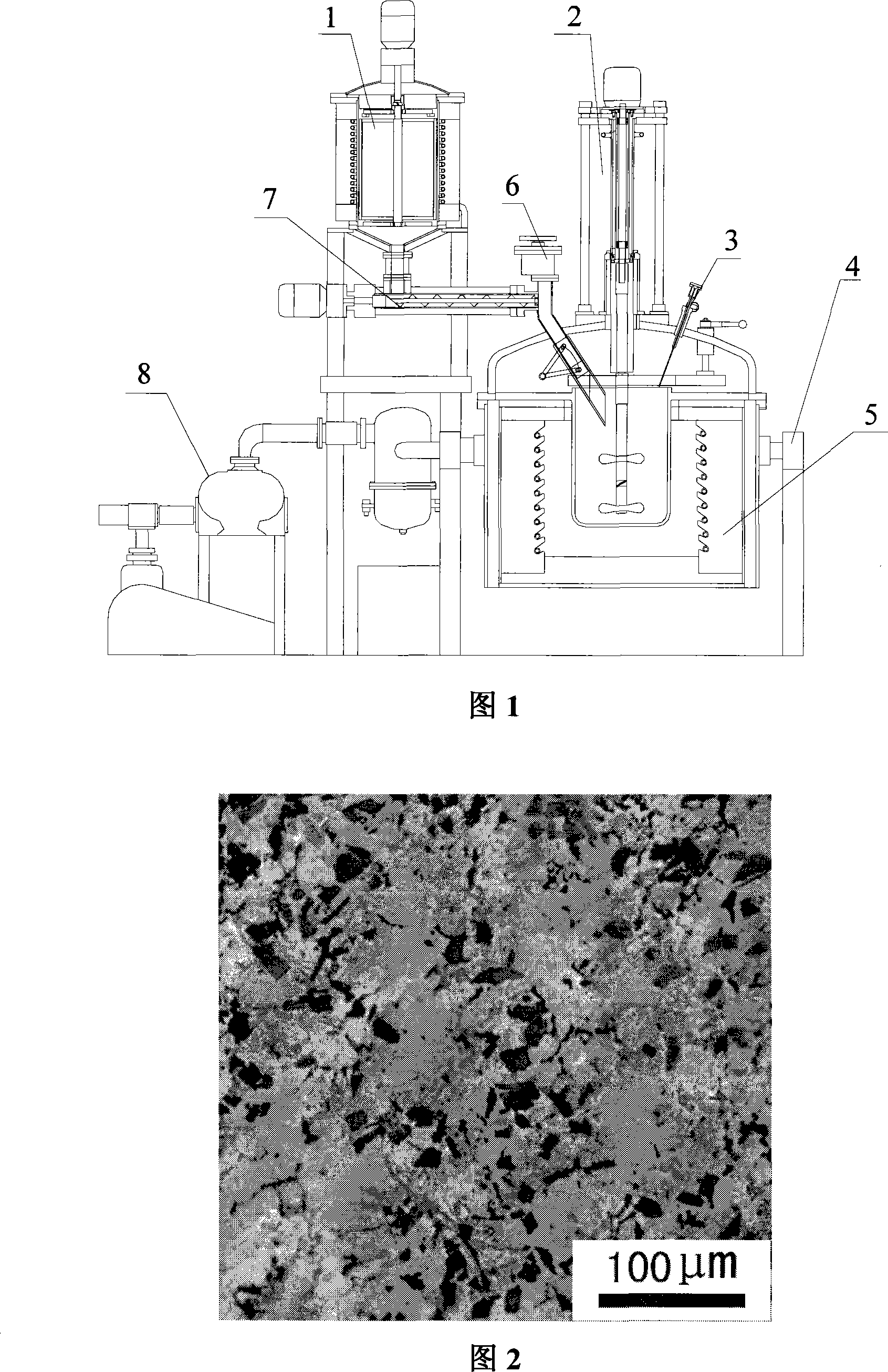

Method for improving performance of sintered neodymium-iron-boron magnet

ActiveCN103366944AImprove coercive forceWide range of applicationsInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementCrystallite

The invention discloses a method for improving the performance of a sintered neodymium-iron-boron magnet. Two pieces of heavy rare earth, a sintered neodymium-iron-boron magnet green body and two separation nets are arranged on a separation board in an evaporation diffusion box one above another; the sintered neodymium-iron-boron magnet green body is positioned between the two pieces of heavy rare earth; the two pieces of heavy rare earth cover the upper surface and the lower surface of the sintered neodymium-iron-boron magnet green body; and when the sintered neodymium-iron-boron magnet green body is subjected to vacuum sintering under the condition that the vacuum degree is less than 1*10<-2>Pa, the two pieces of heavy rare earth are evaporated and diffused in an enclosed space, and heavy rare earth elements are diffused into the sintered neodymium-iron-boron magnet green body and are better distributed in the grain boundary and on the crystalline grain edge of the sintered neodymium-iron-boron magnet green body. The method has the advantages that specific to the sintered neodymium-iron-boron magnet of which the thickness surpasses 3 millimeters, the coercive force can be increased on the basis of ensuring that the residual magnetism does not fall basically; and the method is suitable for sintered neodymium-iron-boron magnets of which the thicknesses do not surpass 3 millimeters as well as sintered neodymium-iron-boron magnets of which the thicknesses surpass 3 millimeters, and has a wide application range.

Owner:NINGBO YUNSHENG +5

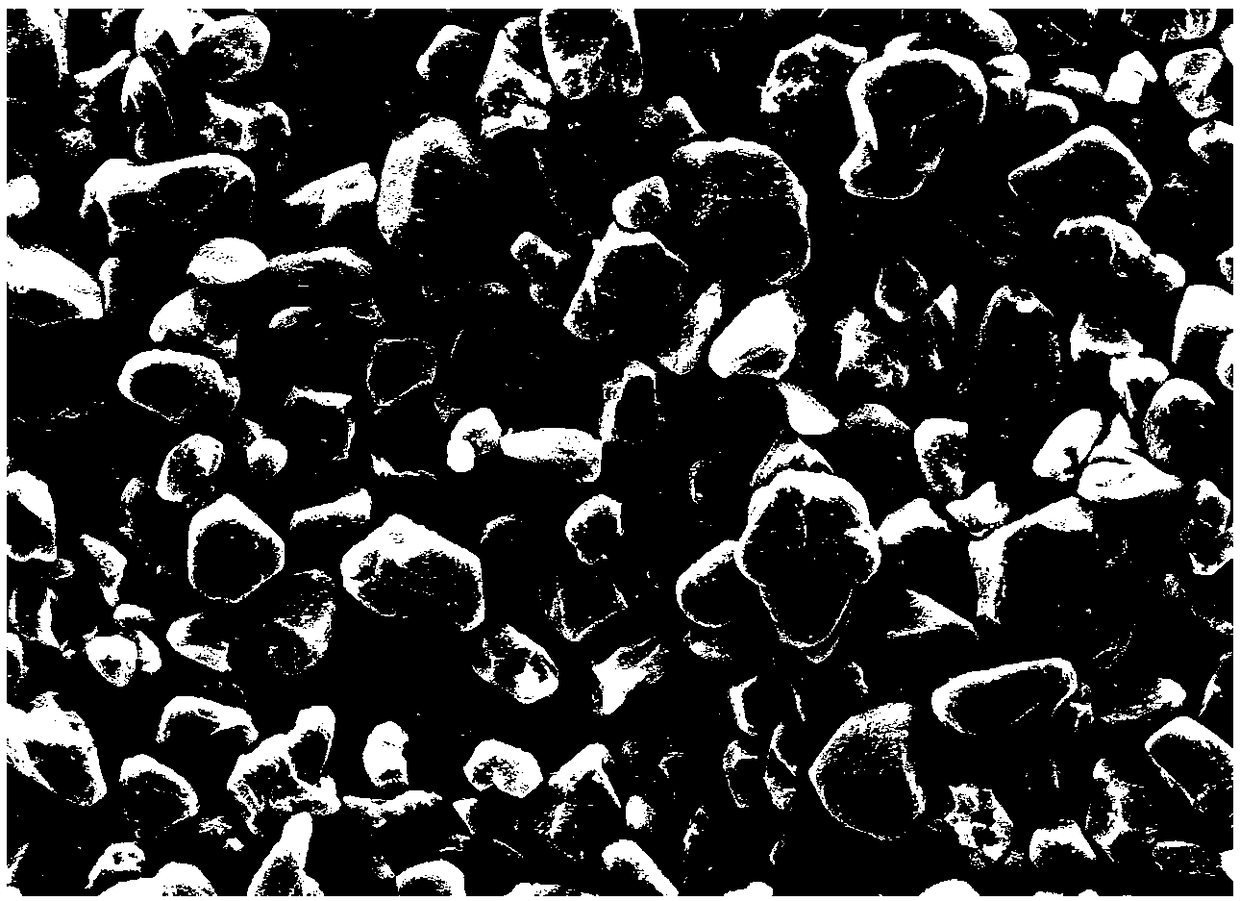

Vacuum stirring composite granule reinforcing aluminium-based composite material and preparation technique thereof

The invention relates to a composite material of vacuum churning composite granule enhanced aluminum matrix and a preparation technique, which comprises: Si 0-15Wt%, Mg 0-1.5Wt%, Cu 0-2.0Wt%, Mn 0-1.0Wt%, Cr 0-0.4Wt%, Ti 0-0.2Wt%, SiC 0.1-20% (volume proportion). Firstly base alloy is smelted, slag is removed, and refined, churned slowly in vacuum to complete degassing procedure for base melt, the pre-treated enhanced granule is continuously added into the aluminum base melt, mechanical churning to roll the granule into the melt, after the granule is completely rolled in the melt, strong churning and slow churning in reverse direction are conducted so as to disperse the granule evenly in the base; the temperature raises, modifier and refiner are added; the vacuum is dismounted, and placed in static, the floating slag is removed above the melt, and cast. The composition between the granule and the base is realized via vacuum mechanical churning, the joining interface is good, the enhanced granule is evenly dispersed in the base, the prepared composite material has low porosity rate, which is easy to realize industrial mass production.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND +1

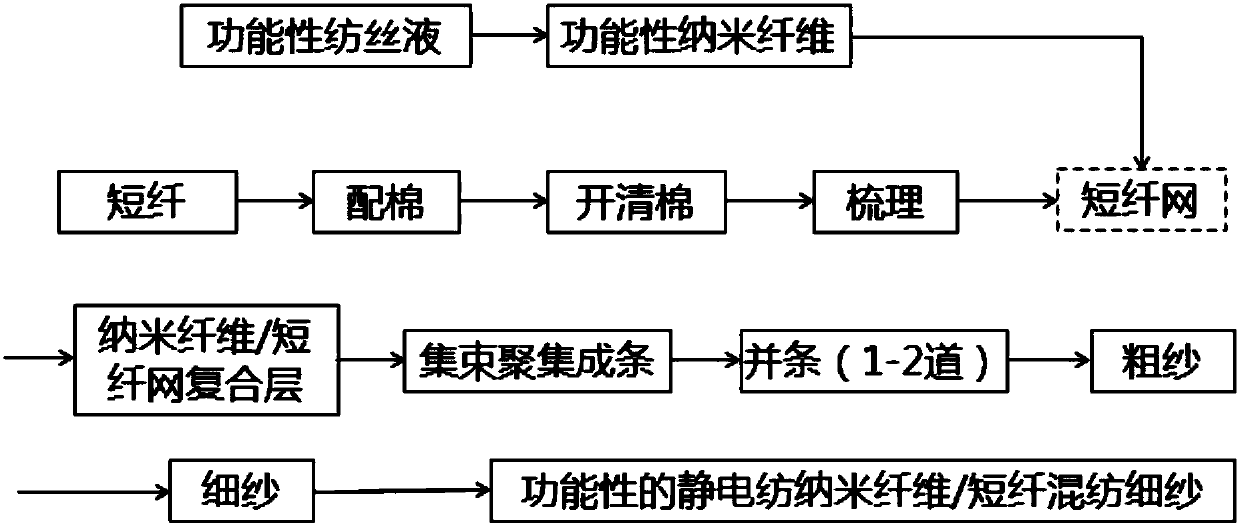

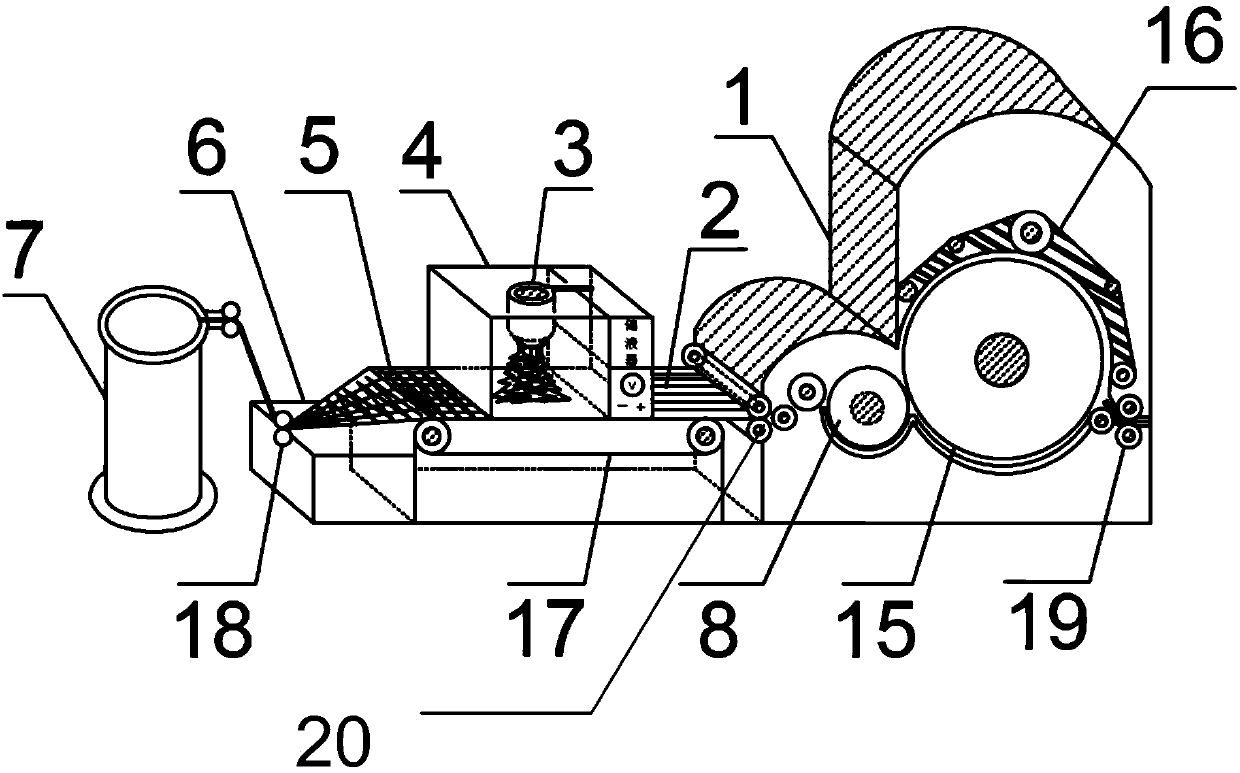

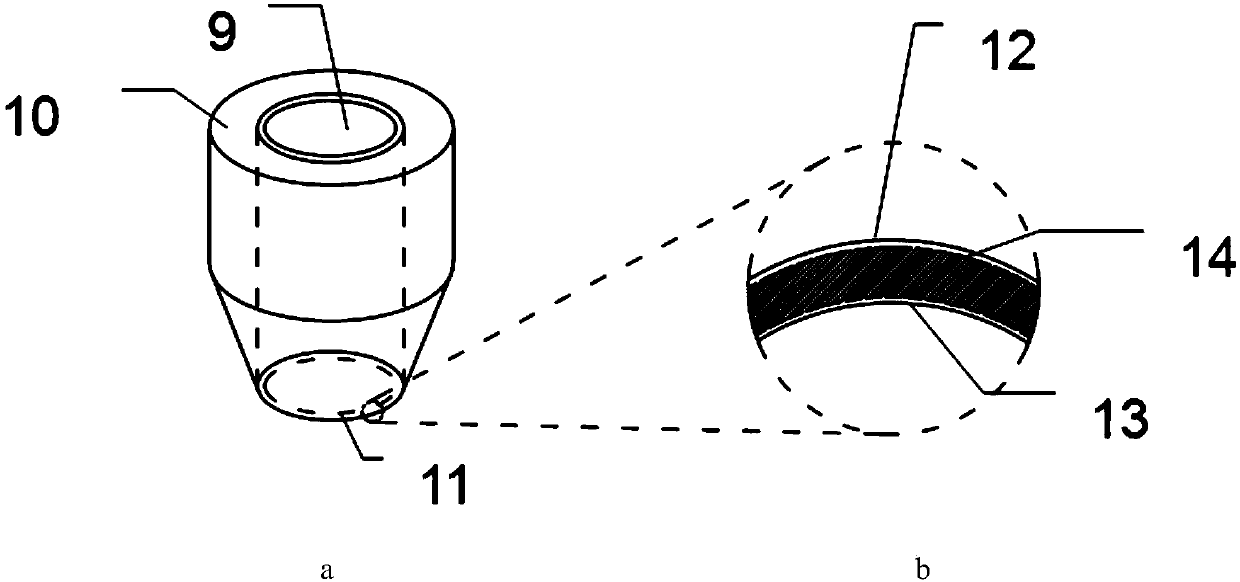

Device and method for batch preparation of blended yarn with electrostatic spinning nanofiber composite short fiber network

The invention relates to a device and a method for batch preparation of blended yarn with an electrostatic spinning nanofiber composite short fiber network. The device is that a conveyor belt (17) isarranged on one side of a carding machine (1), an electrostatic spinning device (4) is arranged on the conveying belt (17), a bell mouth fixing device (6) is arranged on the other side of the conveying belt (17), a bell mouth (18) is arranged on the bell fixing device (6), a cylinder (7) is arranged on the other side of the bell fixing device (6). The method comprises preparation of functional spinning solution, preparation of functional nanofibers, preparation of a composite layer of nanofiber / short fiber network and preparation of electrostatic spinning nanofiber / short fiber blended yarn.The device is simple in processing, the operation is feasible, the prepared nanofibers / short fiber blended yarn has better functionality and nanofiber distribution uniformity, the grades and added value of traditional textiles are significantly improved, and the device and the method have a good application prospect of industrialization.

Owner:DONGHUA UNIV

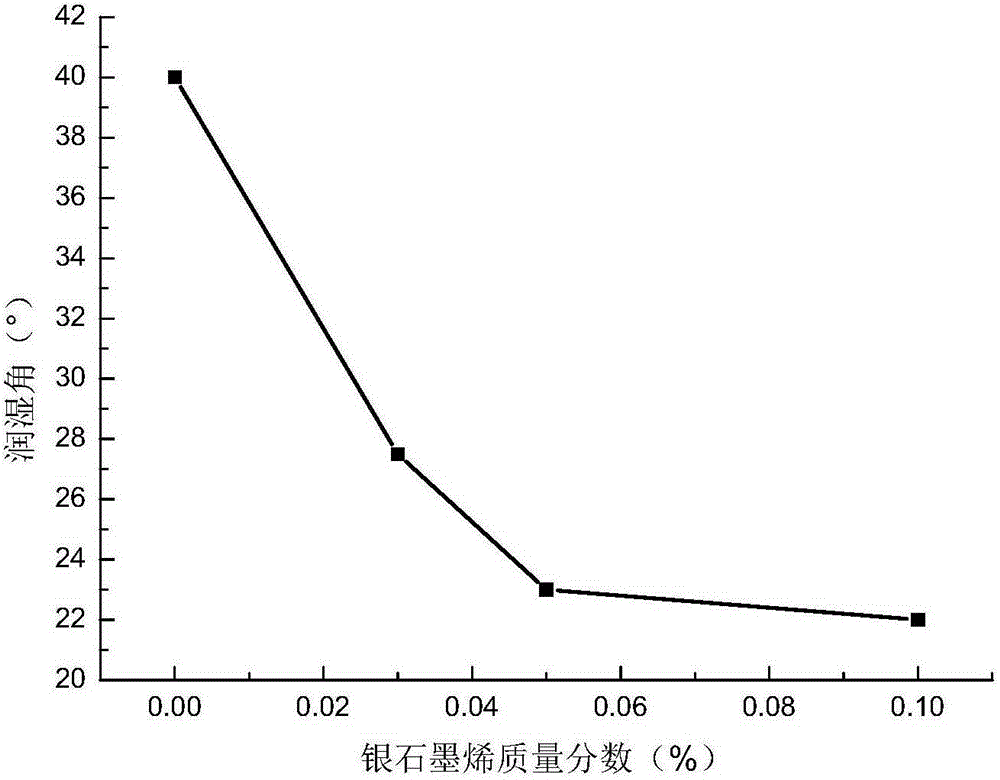

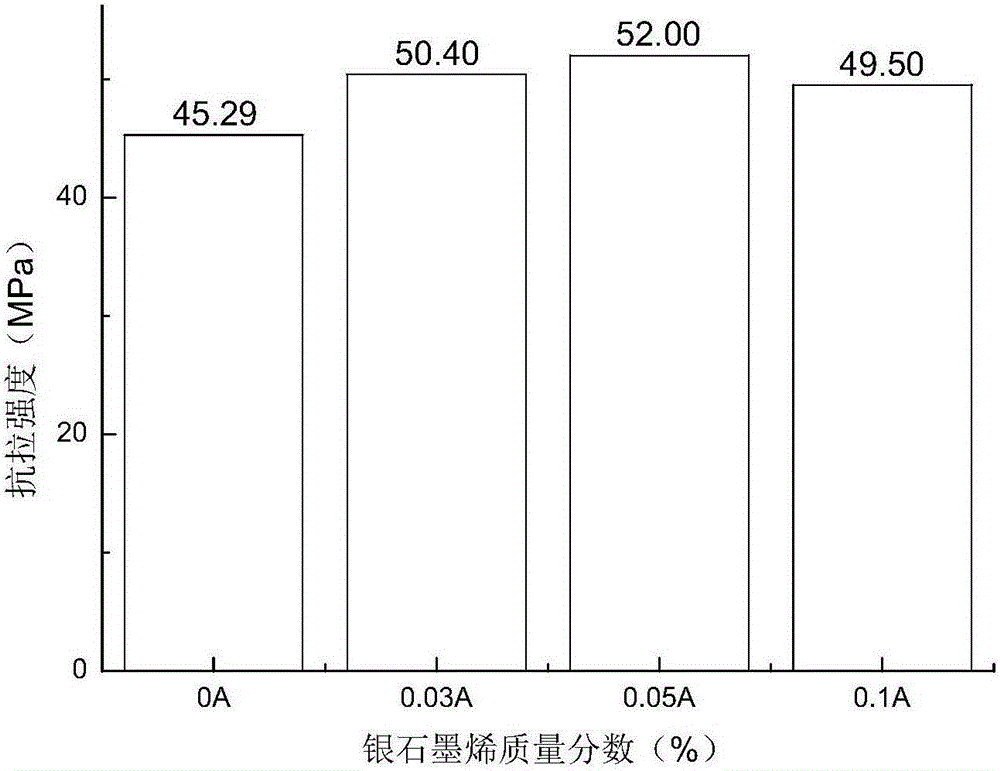

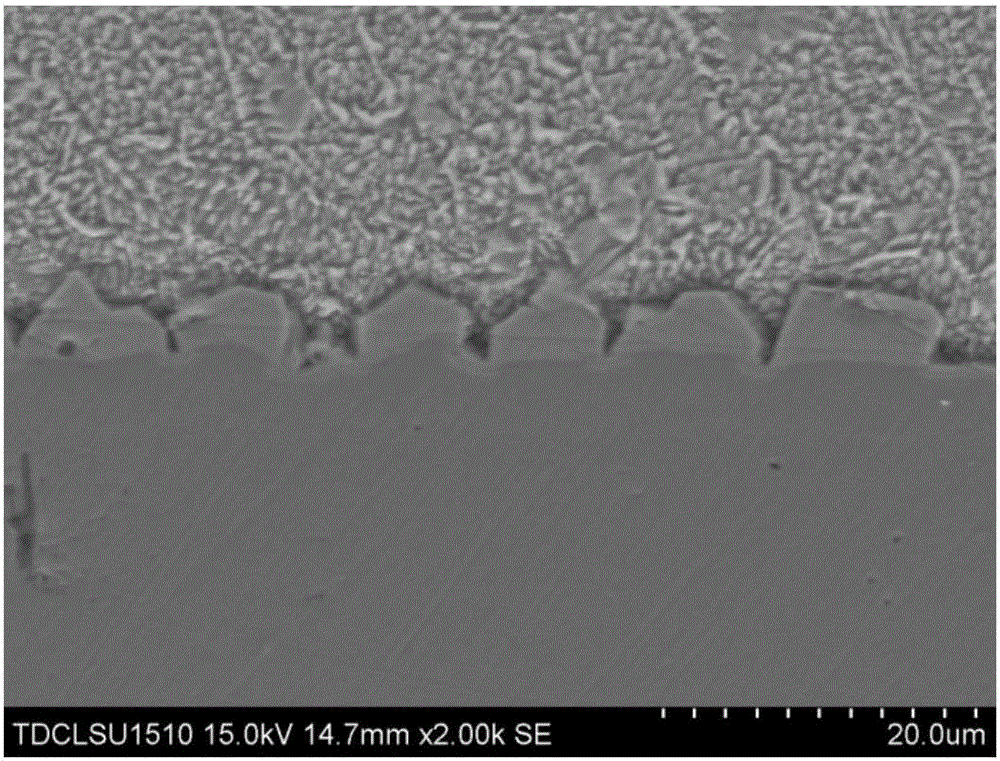

Preparation method of tin-based silver graphene lead-free composite solder

InactiveCN105171277AImprove distribution uniformityUniform compositionTransportation and packagingWelding/cutting media/materialsSolder matrixRoom temperature

The invention discloses a preparation method of tin-based silver graphene lead-free composite solder. The method comprises the steps that a certain amount of graphene and lauryl sodium sulfate are mixed, then a certain amount of dimethylformamide is added, ultrasonic treatment is performed for 2 h, a certain amount of silver nitrate is added into a mixed solution, ultrasonic treatment is performed continuously, and finally a self-made silver graphene nanosheets are obtained; and required solder matrix powder is weighed according to different graphene mass fractions and poured into a ball milling tank for ball milling for 5 h, the powder is placed into a stainless steel mold after being dried and placed under a hydraulic machine to be pressed and molded at the pressure of 500 Mpa, and then a cylinder obtained through cold pressing is placed into a high-vacuum tubular resistance furnace for vacuum sintering for 2 h at the temperature of 175 DEG C and placed under the hydraulic machine after being cooled to the room temperature to obtain a cylinder through impact extrusion. According to the preparation method, Ag-particle-modified graphene is selected as a strengthening material so as to improve load transmitting between the nano-silver-modified graphene and a Sn matrix, and therefore the better strengthening effect is achieved.

Owner:TIANJIN UNIV

A ternary lithium battery material, its preparation method and lithium ion battery

ActiveCN109216688ALarge particle sizeImprove distribution uniformitySecondary cellsPositive electrodesHigh temperature storagePolyvinyl alcohol

The invention provides a preparation method of ternary lithium battery material, comprising the following steps: A) ball milling and activating a nickel source, a cobalt source and a manganese sourceto obtain a mixed material; B) mix that mixed material, the lithium source, the flux, the compound of M and the polyvinyl alcohol, spray dry and pressing to obtain a block; C) grin that mass aft calcination to obtain a quasi-monocrystalline ternary material; D) grin that monocrystalline ternary material and the cladding material source and roast to obtain ternary lithium electric material; The coating source is one of LiCO3 and LiOH. H2O and one or more of Al2O3, ZrO2 and TiO2. The present application also provides the ternary lithium electric material and a lithium ion battery. The preparation method of the ternary lithium battery material provided by the present application synthesizes a monocrystalline ternary cathode material at one time by self-fusion of raw materials, has large particle size and uniform distribution, and is excellent in high-temperature storage performance and high-temperature cycling performance as the cathode material.

Owner:SOUNDON NEW ENERGY TECH CO LTD

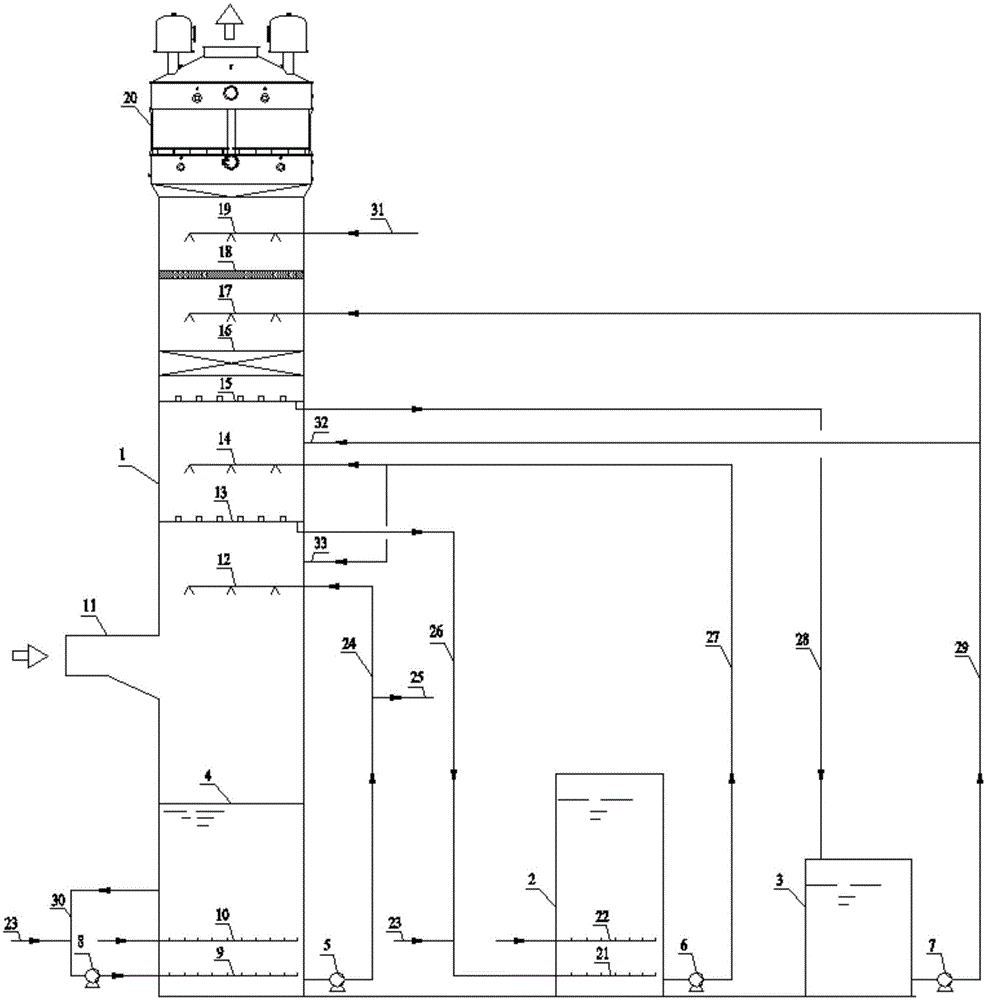

Multi-stage absorbing desulfurizing device by adopting ammonia-ammonium sulfate method

ActiveCN105148712AImprove ammonia utilizationImprove oxidation efficiencyCombination devicesCycloneFlue gas

The invention discloses a multi-stage absorbing desulfurizing device by adopting an ammonia-ammonium sulfate method. The absorbing desulfurizing device comprises a flue gas desulfurizing absorption tower, an absorption liquid circulating tank, a thin slurry circulating tank and a wet-type electric dust remover, wherein the flue gas desulfurizing absorption tower comprises a concentrated slurry circulating tank, a concentration pre-absorption section, an absorption section, a thin slurry washing section and a defogging section that are arranged in a vertical manner; the concentration pre-absorption section comprises at least a layer of concentrated slurry spraying layer; the absorption section comprises an absorption liquid cyclone defogging liquid collector and at least a layer of absorption liquid spraying layer; the thin slurry washing section comprises a thin slurry cyclone defogging liquid collector and a thin slurry spraying layer; the defogging section comprises a defogger and a defogger washing spraying layer. According to the multi-stage absorbing desulfurizing device by adopting the ammonia-ammonium sulfate method, provided by the invention, flue gas cooling, multi-stage defogging absorption and multi-section oxidization are completed in the desulfurizing absorption tower, the utilization rate of ammonia is increased by regulating the ammonia adding positions, and the problems that the concentration of slurry in multiple sections is controlled unsatisfactorily, and the content of aerosol in flue gas after desulfurization is too high are solved, wherein the problems are caused due to the fact that although the conventional desulfurizing absorption tower is divided into multiple sections, slurry in the multiple sections are carried with gases heavily.

Owner:SINOPEC NANJING ENG & CONSTR +1

Multi-cavity baffle type electrolytic milling and grinding complicated machining tool cathode and method

The invention relates to a multi-cavity baffle type electrolytic milling and grinding complicated machining tool cathode and a method and belongs to the field of electrolytic milling and grinding complicated machining. According to the multi-cavity baffle type electrolytic milling and grinding complicated machining tool cathode and the method, by arranging a plurality of sector-shaped blind hole cavities in the tool cathode, and arranging an annular baffle above a cathode diamond abrasive particle layer, the defect that supplied liquid in a machining gap is not sufficient is overcome, the flow field uniformity is improved, and the stability and the machining precision of electrolytic milling and grinding complicated machining are effectively improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

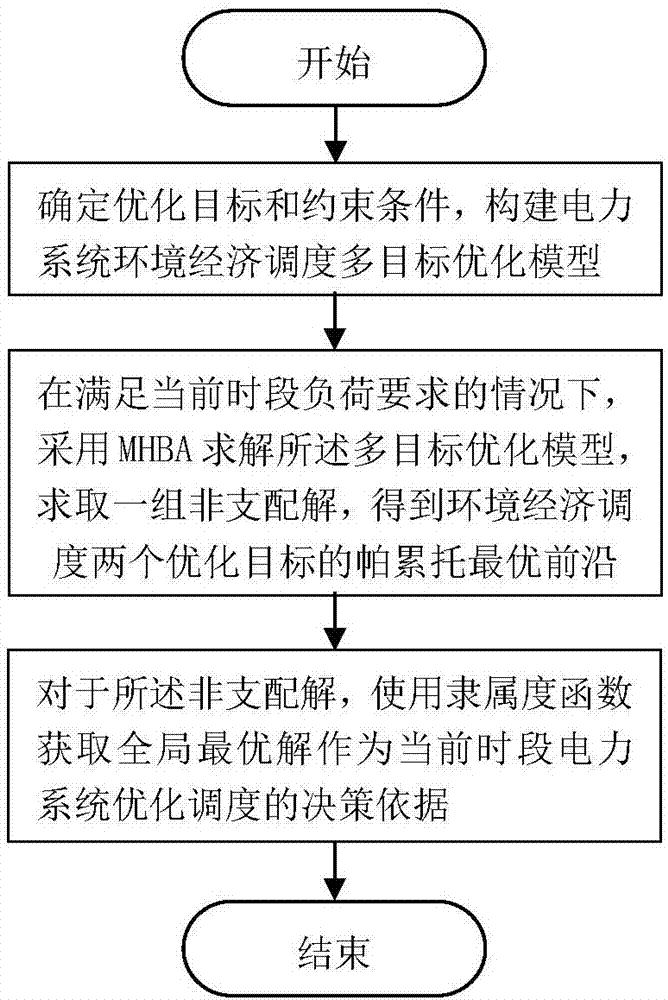

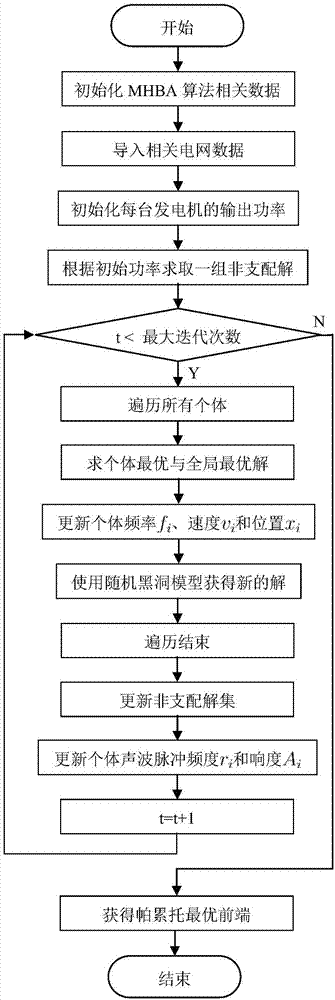

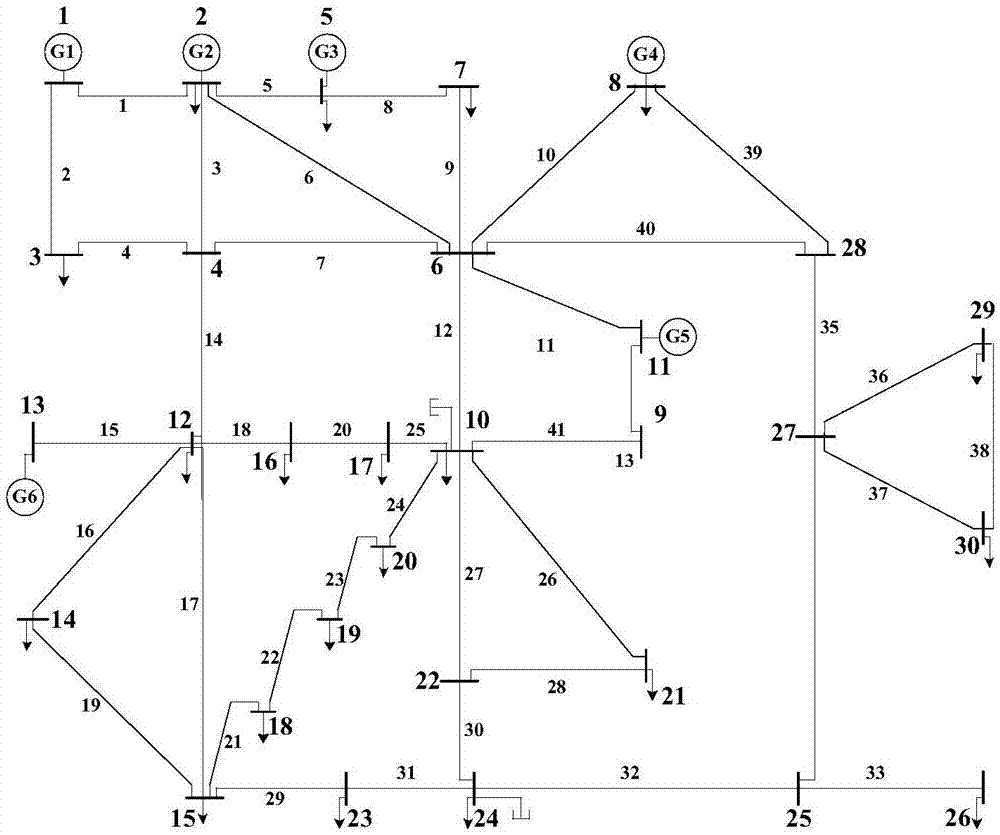

Method and device of environment and economic dispatching based on MHBA for power system

ActiveCN107579518AMinimize the cost of power generationMinimize emissionsEnergy industryAc network circuit arrangementsFossil fuelBat algorithm

The invention discloses a method and device of environment and economic dispatching based on a multi-objective hybrid bat algorithm for a power system. The method includes the steps of determining anoptimization target and constraint conditions, and constructing a multi-objective optimization model of the environment and economic dispatching for the power system; solving the multi-objective optimization model using the multi-objective hybrid bat algorithm under the condition that load requirement of current period is met, obtaining a group of non-dominant solutions, and forming a Pareto optimal frontier for the two optimization targets of the environment and economic dispatching; obtaining a global optimal solution as the basis for an optimal dispatching of the power system during the current period using a membership function for the non-dominant solutions. Under the precondition of satisfying electricity load, the method minimizes generation cost of a generating set and minimizes emissions of polluted gas, minimizes use of fossil fuels to a large extent, and provides intelligent decisions for energy saving and synergy of power enterprises.

Owner:SHANDONG UNIV

Coal-fired boiler SNCR and SCR combined denitration system and method thereof

ActiveCN105289233AImprove mixing uniformityImprove distribution uniformityLighting and heating apparatusDispersed particle separationBoiler furnaceProcess engineering

The invention relates to a coal-fired boiler SNCR and SCR combined denitration system. The denitration system comprises a boiler SNCR reaction system and a SCR reactor; the boiler SNCR reaction system comprises the boiler, an urea solution distribution module and a metering module, and an urea injection system and an urea supply system which are connected with the urea solution distribution module and the metering module; the urea injection system comprises multilayer-designed short spray guns with upper elevation in a 25m to 40m scope in a boiler furnace combustion zone, and multilayer-designed porous long spray guns having an furnace arch with the boiler, wherein, in each layer, at least one porous long spray gun vertically stretches into the boiler, and extends and passes through the cross section; the SCR reactor is connected with a boiler tail through a flue gas mixer; in the SCR reactor, the multilayer cellular catalyst can be arranged at a space between a coal economizer and an air preheater. According to the method, a mol ratio of ammonia nitrogen in an inlet cross section of the SCR catalyst is uniformly distributed, and denitration efficiency of the SCR reactor is enhanced.

Owner:CHINA HUANENG GRP CO LTD +1

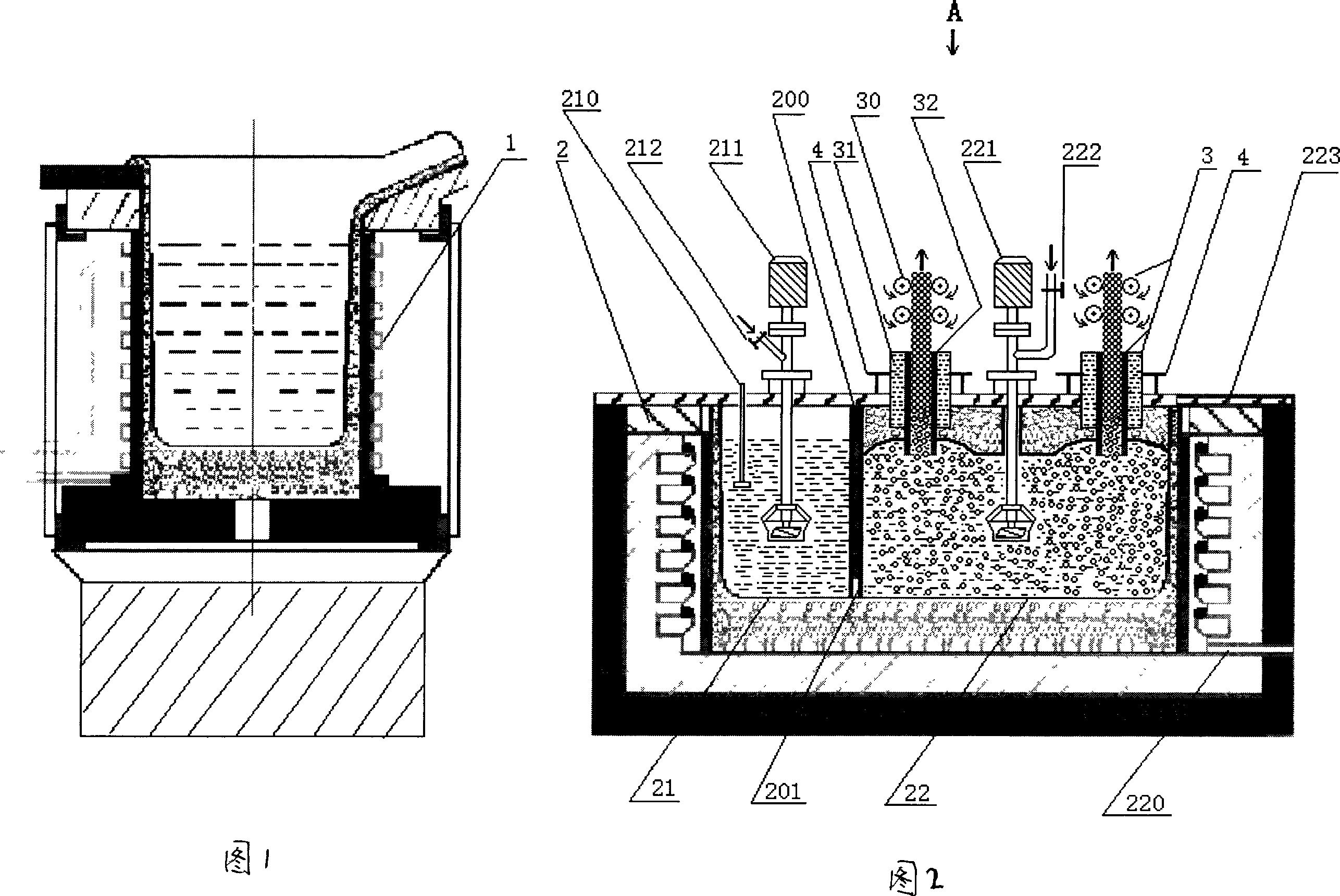

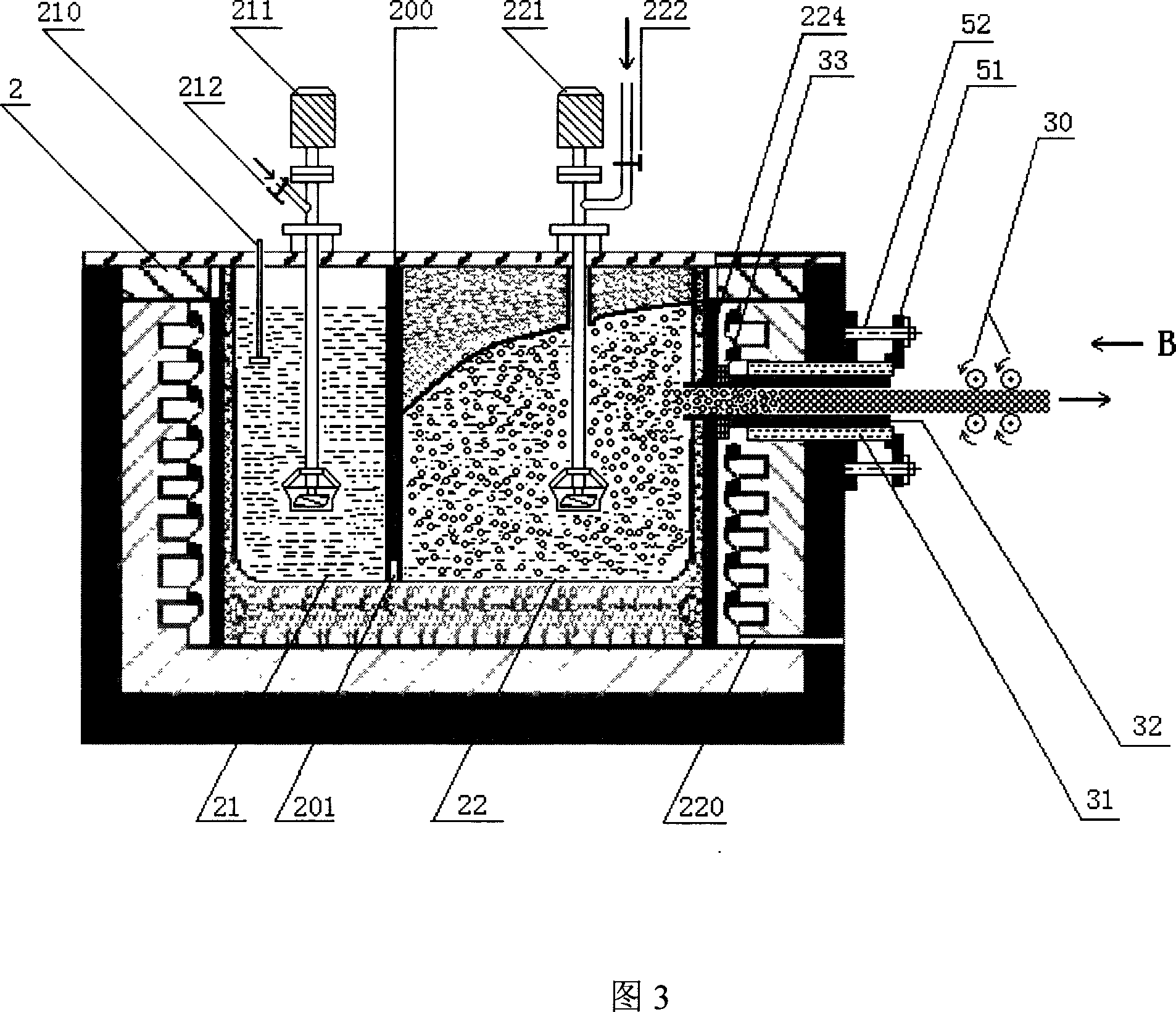

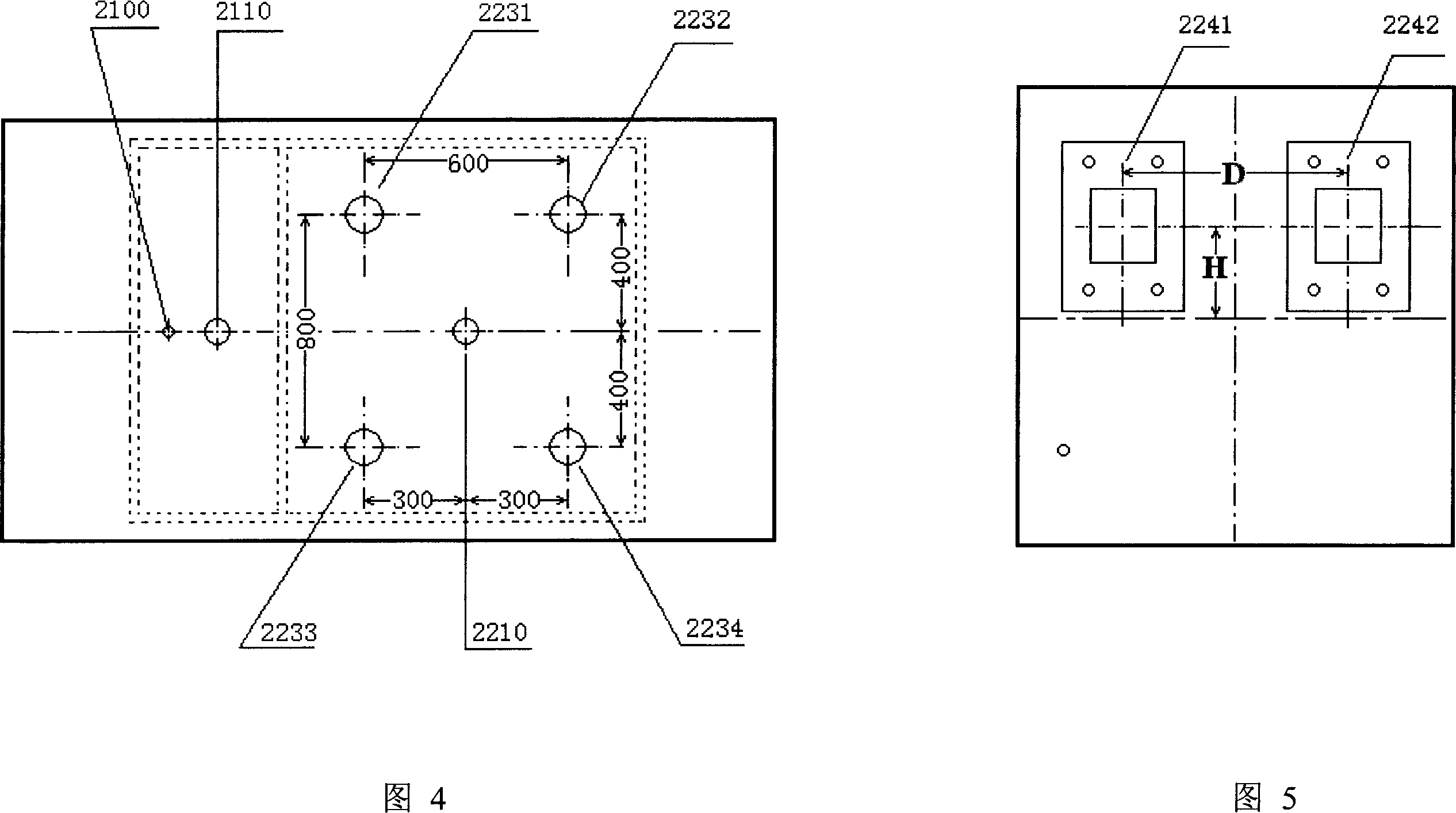

Foamed aluminium or foamed aluminium alloy continuous casting system and continuous casting process

InactiveCN1994620AImprove distribution uniformityImprove uniformityFoaming agentVolumetric Mass Density

The invention relates to a system used to continuously cast foam aluminum or foam aluminum alloy, and relative technique, wherein said system is formed by smelter, foaming furnace with viscosifier room and foaming room, the casting device with drawer and crystallizer. And the continuous casting process comprises that: smelting, viscosifying, foaming, and continuously casting. The viscosifying process is that mixer with vacuum adsorption function adsorbs viscosifier; the foaming process is that the mixer adsorbs foaming agent or foaming gas. The invention can product the foam aluminum with different sections, densities and kinds, with low cost.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com