A ternary lithium battery material, its preparation method and lithium ion battery

A lithium battery and lithium source technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as affecting the cycle performance, aggravation, and large stress of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

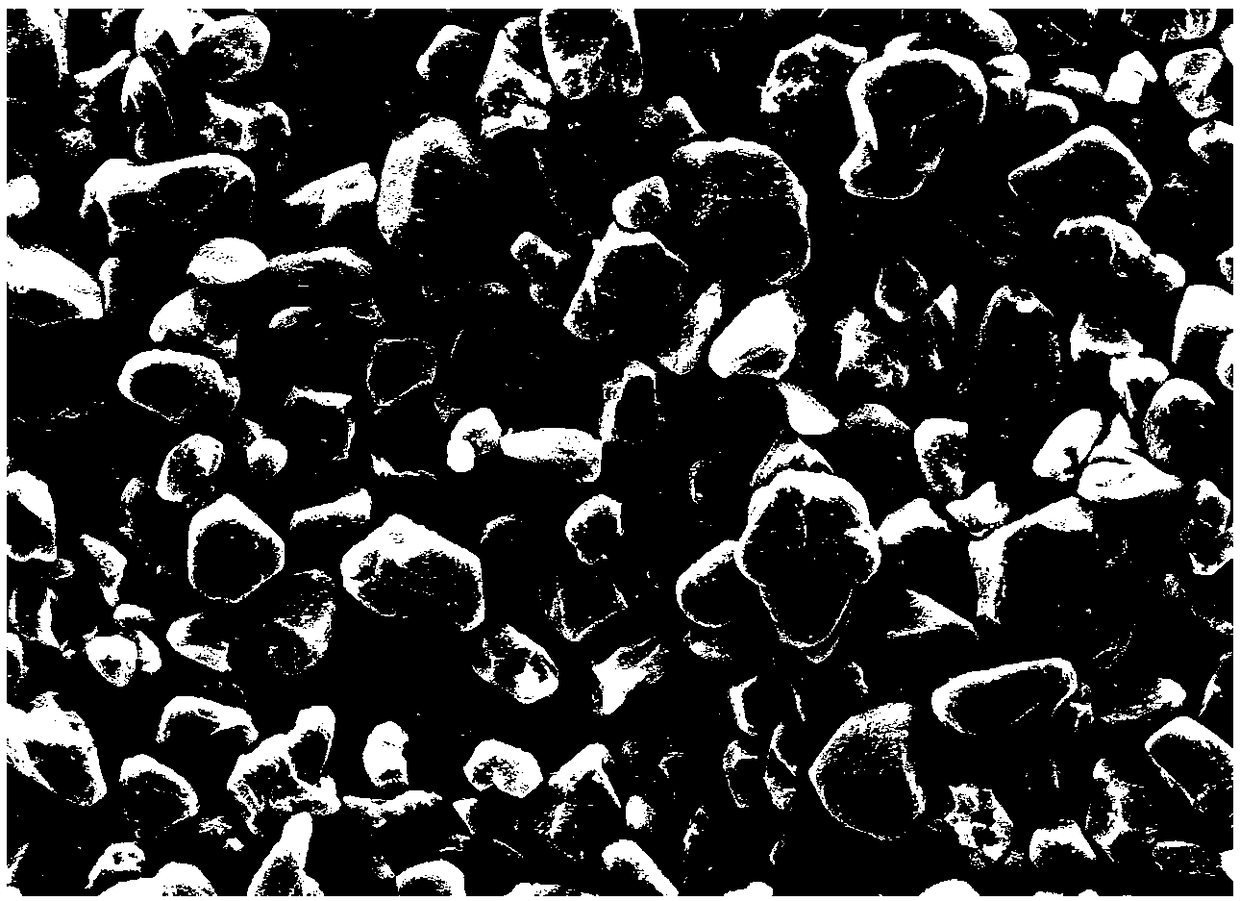

[0035] Aiming at the problem in the prior art that the particle size of the ternary positive electrode material is small, and it is easy to produce micropowder to affect the cycle stability and safety of the battery, the present invention provides a method for preparing a ternary lithium battery material. The ternary lithium battery material particles prepared by the method are The diameter is large, and the distribution is uniform without fine powder. The material has a complete structure and good processing performance. As a positive electrode material, there will be no particle fragmentation during the cycle, which effectively prevents the direct contact between the surface of the material and the electrolyte, especially with The contact of HF in the electrolyte prevents the occurrence of side reactions and stabilizes the crystal structure of the material. When applied to lithium-ion batteries, especially high-voltage power lithium-ion batteries, it can effectively improve th...

Embodiment 1

[0059] (1) Weigh high-purity nickelous oxide, high-purity cobalt carbonate, and high-purity manganese carbonate by Ni: Co: Mn stoichiometric ratio 5:2:3 and place them in a ball mill, wherein the high-purity nickelous oxide material D50=3 μm, High-purity cobalt carbonate material D50 = 8 μm, high-purity manganese carbonate material D50 = 3 μm, ball milling and activation at 150 r / min for 1 hour to obtain D50 = about 6 μm nickel-cobalt-manganese mixture A1;

[0060] (2) Mix the materials A1, Li 2 CO 3 、Al 2 o 3 , mix according to the molar ratio of Li:Al:(Ni+Co+Mn)=1.05:0.01:0.99, add polyethylene glycol whose quality is 0.95% of the total mass of nickel-cobalt-manganese, add polyethylene glycol with a mass concentration of 10% Alcoholic aqueous solution, the mass of the aqueous solution is 15% of the total mass of nickel, cobalt and manganese, mixed and dispersed in the water system for 3 hours, spray dried, and pressed into block B1;

[0061] (3) Place the above-mentioned...

Embodiment 2

[0066] (1) Take high-purity nickel sesquioxide, high-purity tricobalt tetroxide, and high-purity manganese dioxide by Ni: Co: Mn stoichiometric ratio 6:2:2 and place them in a ball mill, wherein the high-purity nickel sesquioxide material D50= 5 μm, high-purity cobalt tetroxide material D50 = 10 μm, high-purity manganese dioxide material D50 = 8 μm, and ball milling at 300 r / min for 1.5 hours to obtain D50 = about 7 μm nickel-cobalt-manganese mixture A2;

[0067] (2) Add tetrabutyl titanate to isopropanol to prepare a tetrabutyl titanate solution with a molar concentration of 1%. After stirring for 10 minutes, a solution containing titanium element is obtained for use; mix materials A2, LiOH, titanium Acid tetrabutyl ester solution, mix according to the molar ratio of Li:Ti:(Ni+Co+Mn)=1.08:0.015:0.985, add Li 3 BO 3 Its mass is 0.15% of the total mass of nickel-cobalt-manganese, adding a polyvinyl alcohol aqueous solution with a mass concentration of 10%, the aqueous solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com