Preparation method of layered lithium-rich manganese base oxide of positive material of lithium ion battery

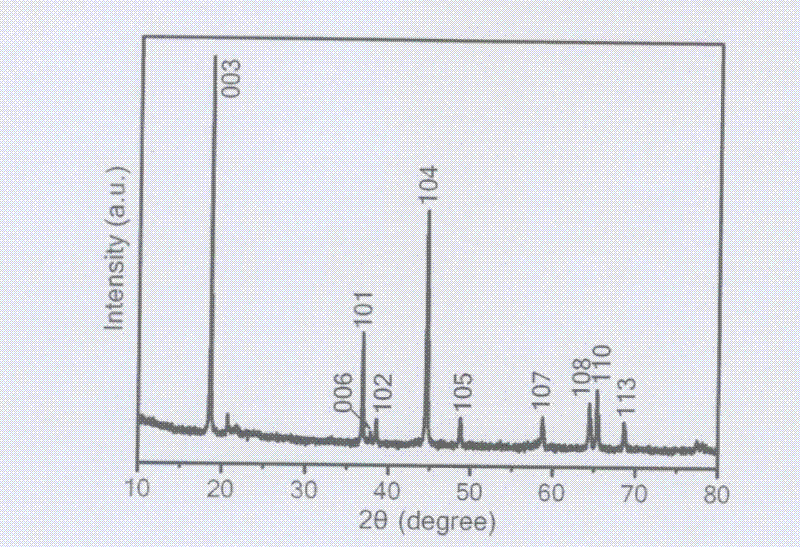

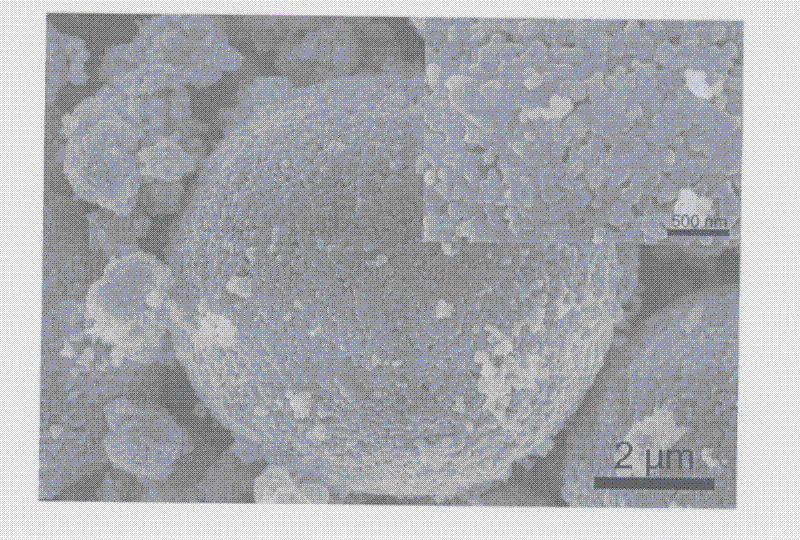

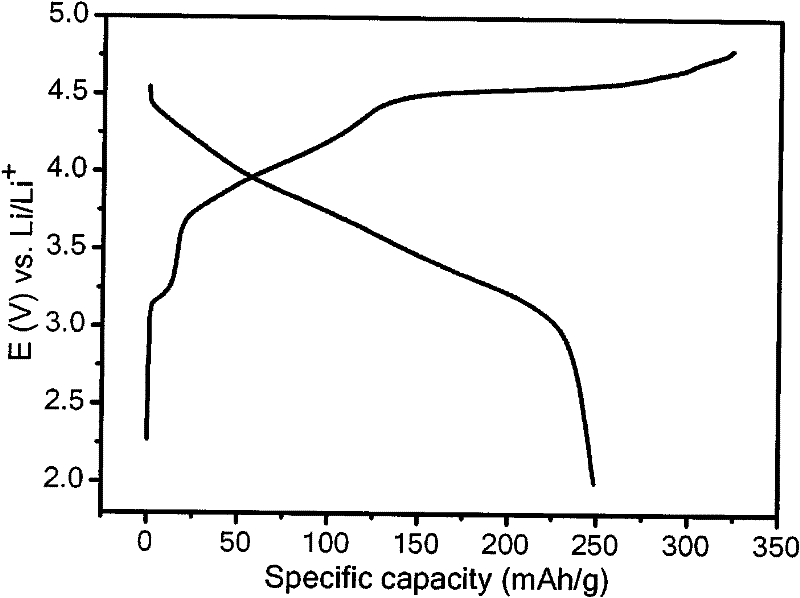

A cathode material layer, lithium-ion battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as uneven heating, and achieve the effects of improving heating efficiency, improving electrochemical performance, and excellent cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Mix nickel sulfate and manganese sulfate with a molar ratio of 1:3, add deionized water to prepare a 2mol / L mixed solution, use 2mol / L sodium carbonate solution as a precipitant, and 0.2mol / L ammonia water as a complex The reagent was added dropwise into the continuously stirred reactor at the same time, and the pH value of the reaction system was controlled to be 8, and the mixture was heated at a constant temperature of 60°C for 10h. The resulting precipitate was aged, filtered, washed, and dried to obtain the nickel-manganese carbonate precursor (Ni 0.25 mn 0.75 )CO 3 . Will (Ni 0.25 mn 0.75 )CO 3 Placed in an air atmosphere furnace at 500°C for constant temperature calcination for 5 hours to obtain the nickel manganese oxide precursor (Ni 0.25 mn 0.75 ) 3 o 4 .

[0022] Mix the obtained nickel-manganese oxide precursor, lithium carbonate and potassium chloride uniformly in a certain proportion, wherein the mass of potassium chloride is 5 times the total ma...

Embodiment 2

[0024] Mix nickel sulfate, cobalt sulfate and manganese sulfate in a molar ratio of 1:1:4, add deionized water to prepare a 2mol / L mixed solution, use 2mol / L sodium carbonate solution as a precipitant, 0.2mol / L Ammonia water was used as a complexing agent, and was added dropwise into a continuously stirred reactor at the same time, and the pH of the reaction system was controlled to be 8, and heated at a constant temperature of 60° C. for 12 hours. The resulting precipitate was aged, filtered, washed, and dried to obtain the nickel-cobalt-manganese carbonate precursor (Ni 1 / 6 co 1 / 6 mn 4 / 6 )CO 3 .

[0025] Mix the obtained nickel-cobalt-manganese carbonate precursor, lithium carbonate and sodium chloride uniformly in a certain proportion, wherein the quality of sodium chloride is 10 times of the total mass of the nickel-cobalt-manganese carbonate precursor and lithium carbonate, at 5°C Raise the temperature at a rate of 1 / min, then place the obtained powder in an air atmos...

Embodiment 3

[0027]Mix nickel sulfate, cobalt sulfate and manganese sulfate in a molar ratio of 2:1:7, add deionized water to prepare a 2mol / L mixed solution, use 2mol / L sodium carbonate solution as a precipitant, and 2mol / L Ammonia water was used as a complexing agent, and was added dropwise into a continuously stirred reactor at the same time, and the pH of the reaction system was controlled to be 8, and heated at a constant temperature of 60° C. for 8 hours. The resulting precipitate was aged, filtered, washed, and dried to obtain the nickel-cobalt-manganese carbonate precursor (Ni 0.2 co 0.1 mn 0.7 )CO 3 .

[0028] Mix the obtained nickel-cobalt-manganese carbonate precursor, lithium carbonate and potassium chloride uniformly in a certain proportion, wherein the quality of potassium chloride is 5 times the total mass of the nickel-cobalt-manganese carbonate precursor and lithium carbonate. Raise the temperature at a rate of 1 / min, then place the obtained powder in an air atmosphere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com