Patents

Literature

250results about How to "Addressing Purity Issues" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

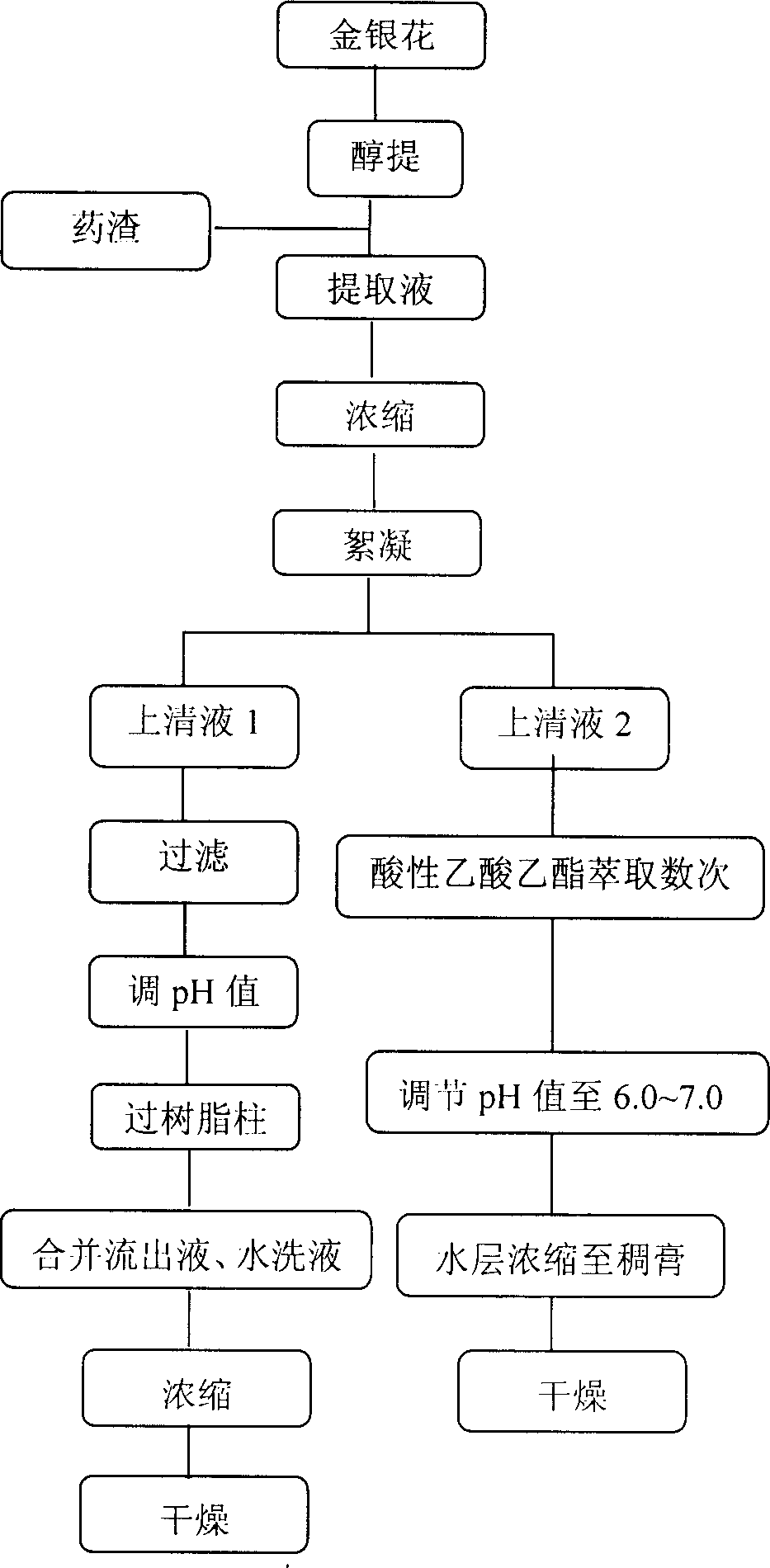

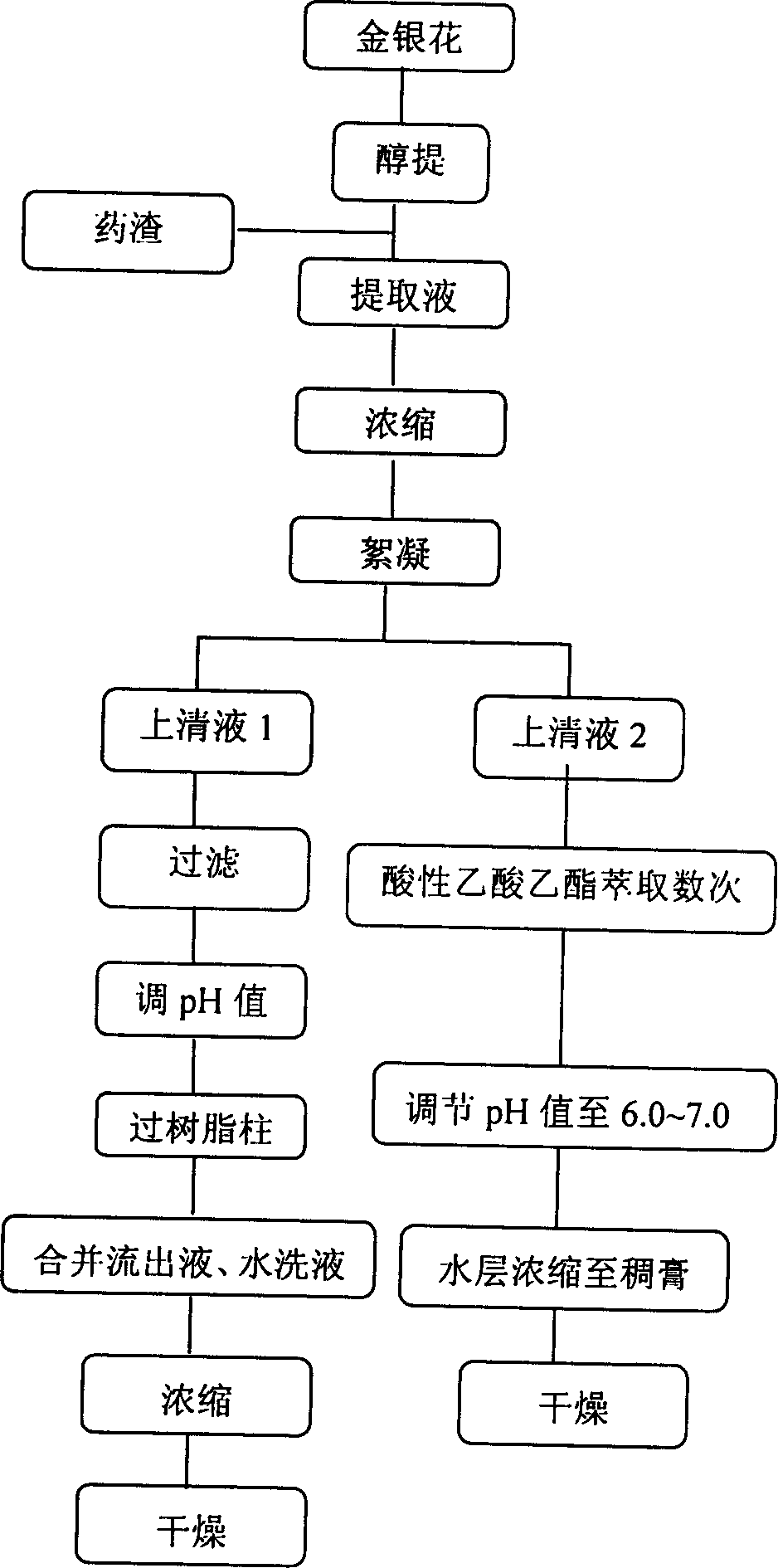

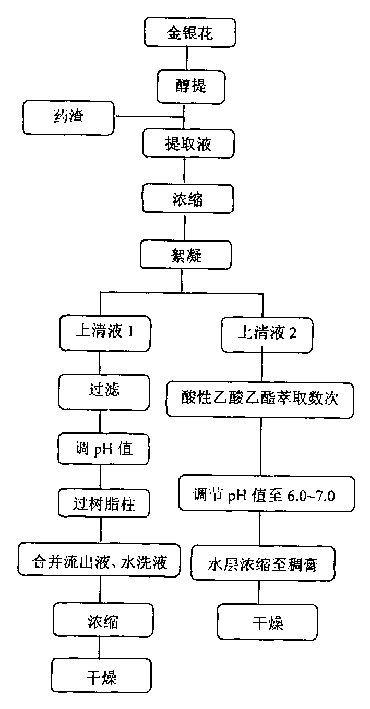

Extracting and purifying method for chlorogenic acid in honeysuckle

InactiveCN1425643AAddressing Purity IssuesOrganic compound preparationCarboxylic acid esters preparationReflux extractionChlorogenic acid

The present invention relates to extraction and purification of functional components in Chinese herbal medicine and aims at provindg extraction and purification process of chlorogenic acid in honeysuckle in relatively high yield and purity. The techonlogical scheme includes twice reflux extraction of honeysuckle cut into sections with dilute alcohol, concentrating the extractive, flocculating for initial purification and final purification through macroporous resin or ethyl acetate extraction. The said process is simple and practical and has less loss of chlorogenic acid and high product yield and purity.

Owner:CHINA AGRI UNIV

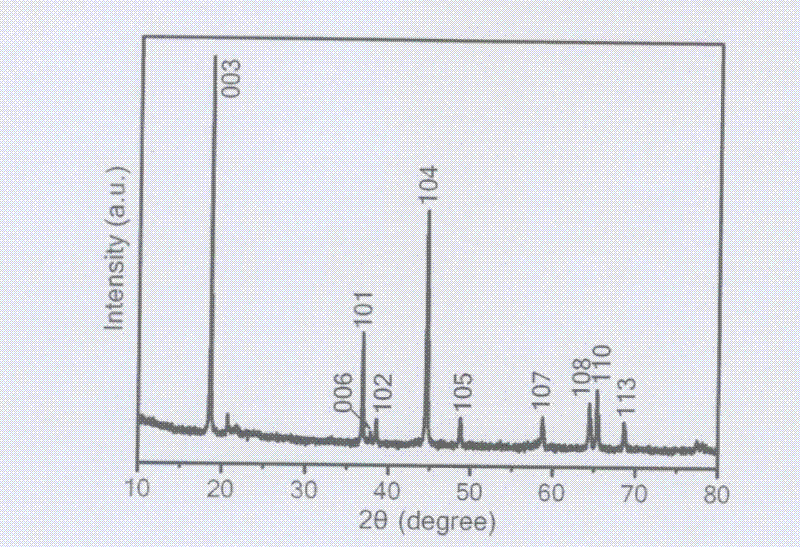

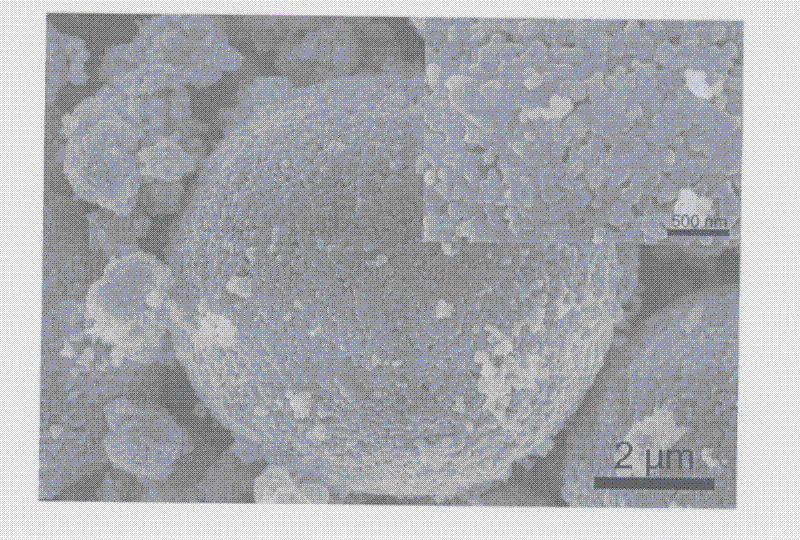

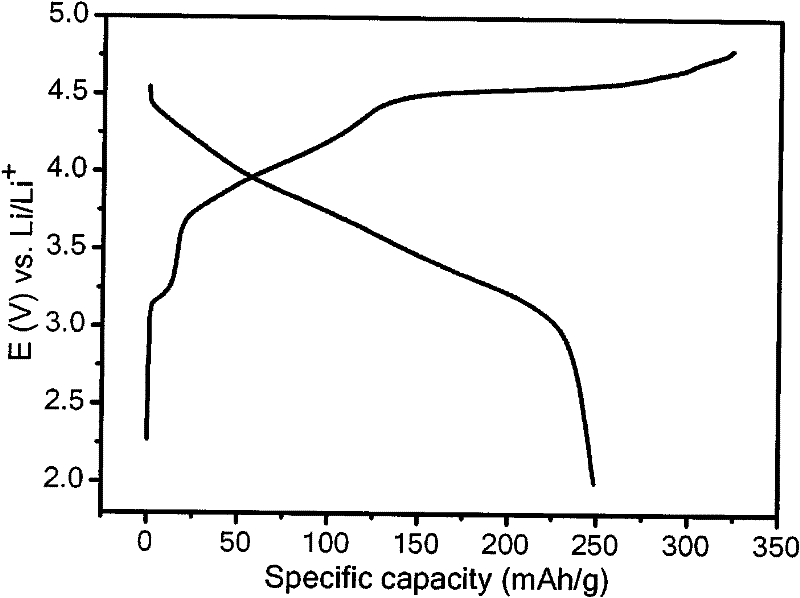

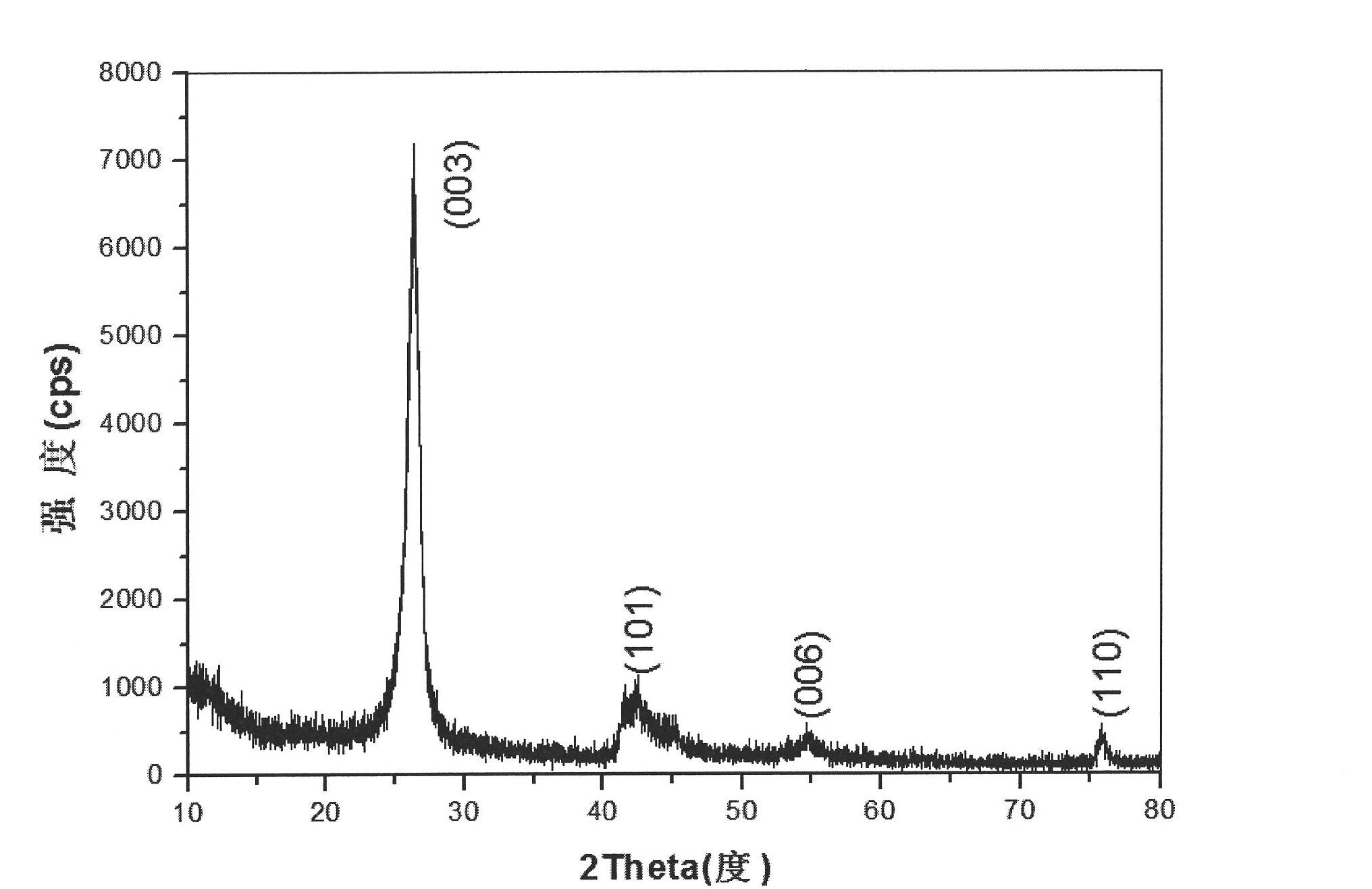

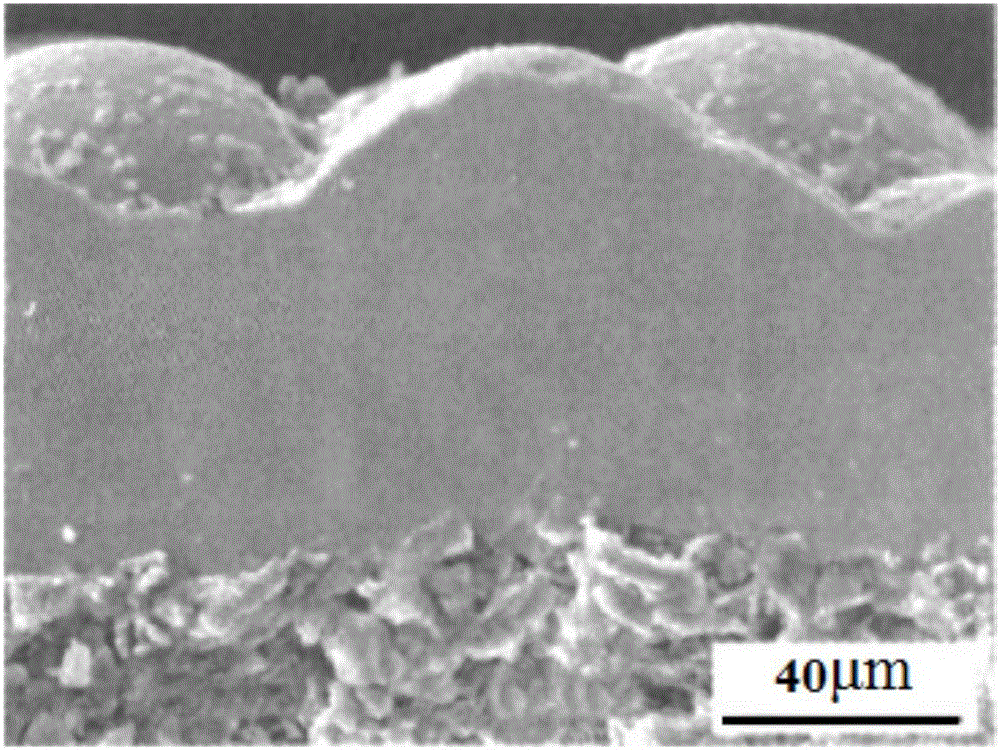

Preparation method of layered lithium-rich manganese base oxide of positive material of lithium ion battery

InactiveCN102683645AImprove electrochemical performanceReduce energy consumptionCell electrodesManganeseSodium-ion battery

The invention discloses a preparation method of a layered lithium-rich manganese base oxide of a positive material of a lithium ion battery. The preparation method comprises the following steps of: slowly adding transition metal brine solution, alkali liquor and ammonia water which conform to a stoichiometric ratio into a stirring reactor respectively; stirring and heating; aging, filtering, washing and drying the obtained precipitate to obtain a nickel cobalt and manganese composite precursor; proportioning and mixing with a lithium source according to the stoichiometric ratio; adding a fluxing agent of a certain proportion and uniformly mixing in a mechanical mode; placing mixed powder in a furnace for sintering; cooling to room temperature; fully washing with water; and removing remaining fluxing agent to obtain the layered lithium-rich manganese base oxide Li1+xNialphaCobetaMngammaO2 (wherein x is greater than 0 and is less than or equal to 0.33, alpha is greater than or equal to 0 and is less than 1, beta is greater than or equal to 1 and is less than 1, gamma is greater than 0 and is less than 1, and alpha and beta are not zero simultaneously.). According to the preparation method, the heating efficiency is greatly increased, the energy consumption is reduced, and meanwhile, the electrochemical performance of the material is improved; the prepared spherical layered lithium-rich manganese base oxide has no doped phase; and a product has a uniform average particle diameter and superior circulation performance.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Manufacturing method of high-purity nickel strap

ActiveCN102672447AQuality improvementImprove consistencyMetal working apparatusMetal rolling arrangementsWork in processEnergy consumption

The invention discloses a manufacturing method of a high-purity nickel strap. The method comprises the steps of hot rolling and cogging an un-smelted nickel plate, then processing the cogged semi-finished product into a nickel strap with desired thickness through at least one annealing process and at least one cold rolling process. According to the manufacturing method, not only can the high purity of the material be guaranteed, the energy consumption and the nickel loss are reduced, the delamination defect in an electrolytic nickel raw material plate can be repaired effectively; the pass percent is high by adopting the electrolytic nickel raw material plate provided by a plurality of existing electrolytic nickel plate manufacturers, and the produced nickel strap has good consistency; and meanwhile, due to the method, the production efficiency is high, the energy consumption is low, and rolling mill component loss is small.

Owner:YULIN NORMAL UNIVERSITY

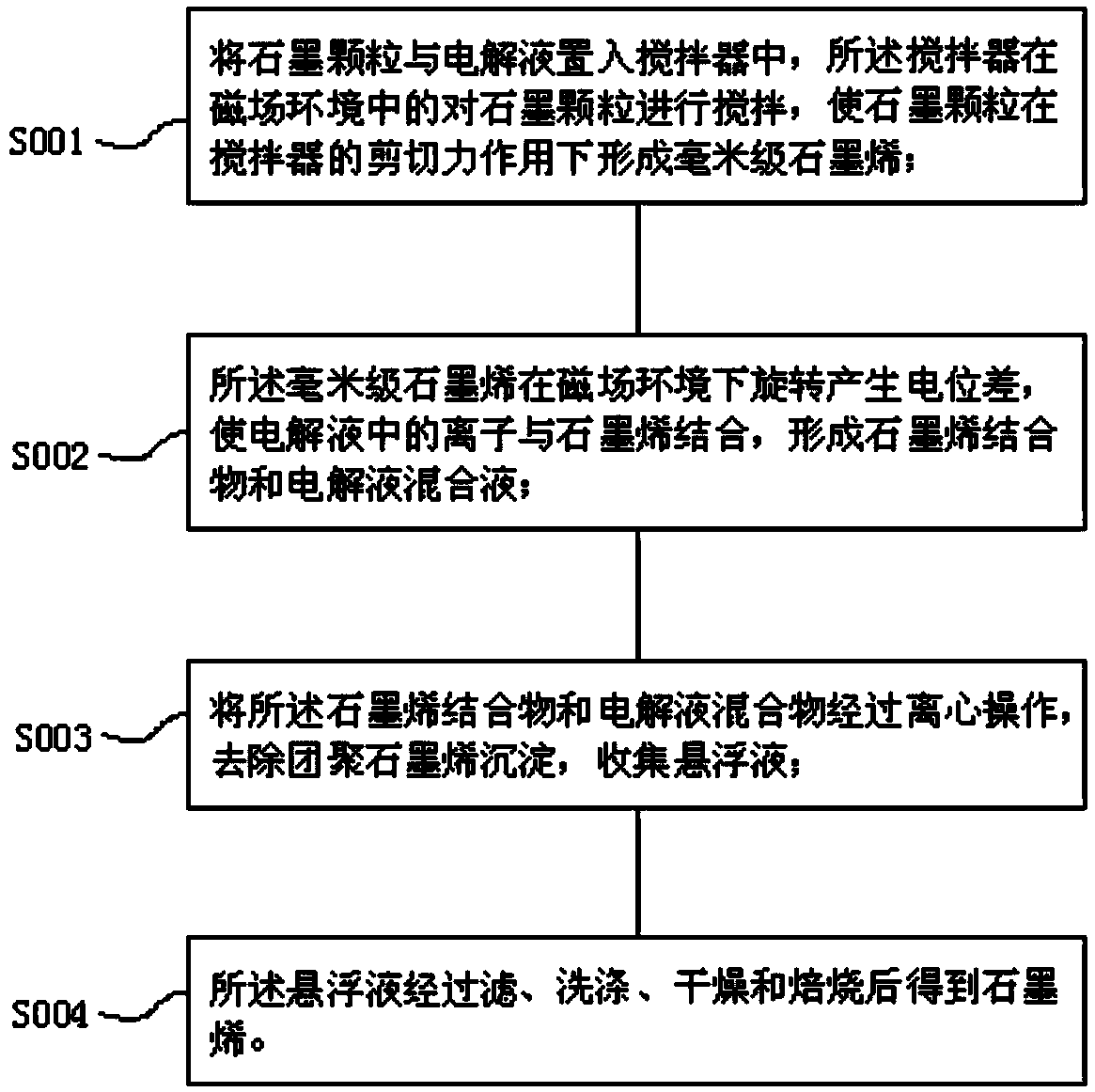

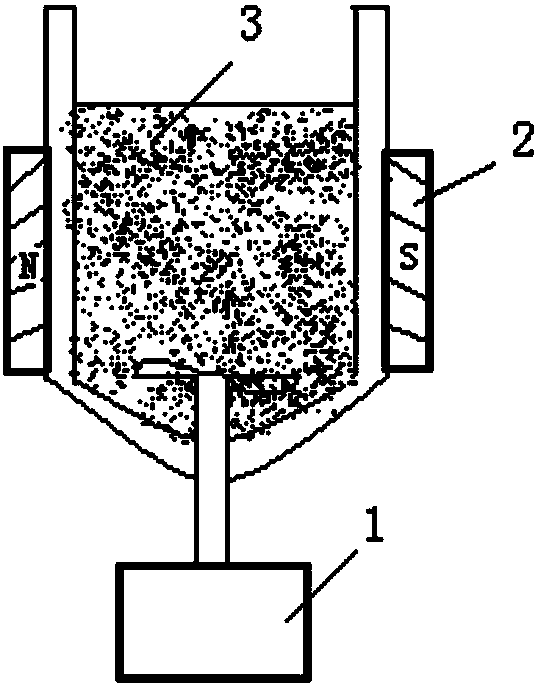

Novel graphene preparation technique

The invention relates to a novel graphene preparation technique which at least comprises the following steps: S001: adding graphite particles and an electrolyte into a stirrer, and stirring the graphite particles in a magnetic field environment by the stirrer so that the graphite particles form millimeter-grade graphene under the action of the shearing force of the stirrer; S002: rotating the millimeter-grade graphene in the magnetic field environment to generate potential difference so that the ions in the electrolyte are combined with the graphene to form a graphene conjugate-electrolyte mixture; S003: centrifuging the graphene conjugate-electrolyte mixture to remove the aggregated graphene precipitate, and collecting the suspension; and S004: filtering the suspension, washing, drying and roasting to obtain the graphene. The graphene preparation provided by the invention is simple, has high operability, is suitable for industrial production, improves the high area ratio and purity of the graphene, enhances the graphene production efficiency and lowers the production cost.

Owner:张泽宇

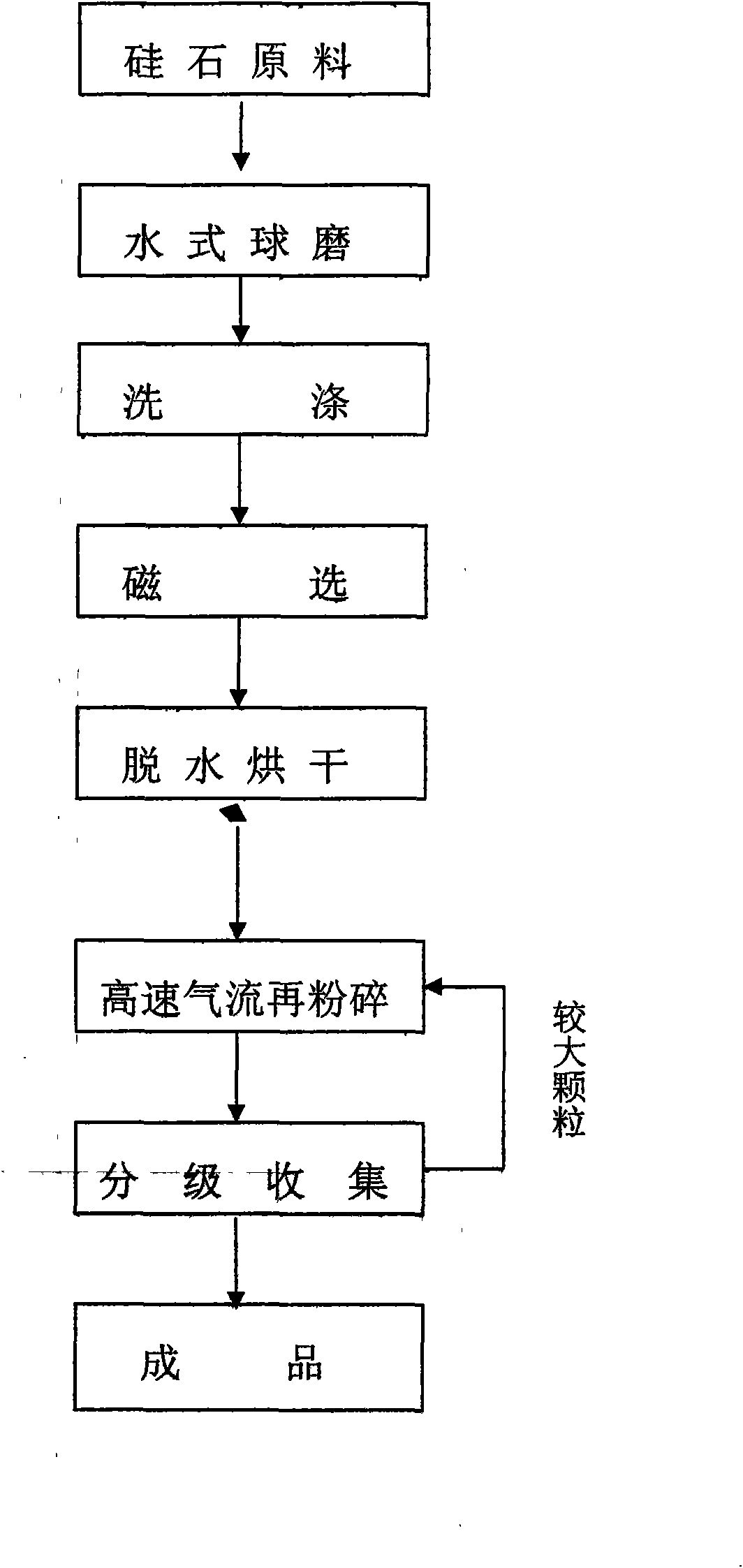

Production method of silicon dioxide ultrafine powder

InactiveCN102145898AAddressing Purity IssuesNo pollution in the processSilicaAcid washingSilicon dioxide

The invention discloses a production method of silicon dioxide ultrafine powder. The production method comprises the following steps of: performing water ball milling and grinding on a high-quality silica raw material; performing water washing, acid washing, magnetic dressing and centrifugal dehydration; performing ultrafine grinding by using a supersonic air current grinder; separating micro powder out by using a high-speed grading machine; and collecting silicon dioxide micro powder by using a cyclone collector. Key points of the production method are that: the entire process is divided into two parts, wherein the first part is used for removing impurities from the material by performing primary grinding and water washing; and the second part is used for preparing ultrafine silicon powder which is accordant with requirement by performing ultrafine grinding. By adopting the production method, the problems of purity and fineness in the production of the silicon dioxide ultrafine powder are solved. In a previous impurity removing process, water type production is adopted, used waste water can be recycled by secondary treatment and valuable byproducts including ferroferric oxide and the like can be recycled from the waste water. In a next selection process, dry enclosed production is adopted, no waste is discharged, the noise is within the national control standard and the entire process is environmentally-friendly.

Owner:张冬玲

Process method for separating quartz sand, arkosic sand and iron powder from river yellow sand

The invention provides a process method for separating quartz sand, arkosic sand and iron powder from river yellow sand. The method mainly comprises the following process steps of (1), performing desliming, grading and sheet mica removing; (2), removing iron through magnetic separation and gravity separation; (3), removing an oxidized skin through alkaline wash; (4) performing acid neutralization and removing the iron; (5) separating the quartz sand from the arkosic sand through flotation separation; (6) removing the iron through water wash, the magnetic separation and the gravity separation; (7) removing variegated pellets through photoelectric separation; (8) recycling fine iron powder made of iron. The quartz sand produced by the process method is high in purity, wherein the content of SiO2 is 98.0-99.0%, and the content of Fe2O3 is 0.009-0.015%. The produced arkosic sand can serve as materials of ordinary glass and ordinary ceramics. Metallics obtained through the magnetic separation and the gravity separation can produce the fine iron powder with the grade larger than or equal to 66%. By means of the process method, yellow sand resources are fully utilized without any waste, and the whole production process does not discharge waste alkali and waste acid. Therefore, the process method is friendly to the environment.

Owner:田辉明

Method for extracting cyclic adenosine monophosphate (cAMP) from red jujubes

InactiveCN101525363AThe process consumes less energySimple processSugar derivativesUltrafiltrationFood additiveFiltration membrane

The invention relates to a method for extracting cyclic adenosine monophosphate (cAMP) from red jujubes, which comprises the steps of cleaning of the red jujubes, soaking of the red jujubes at normal temperature, precooking and pulping, zymohydrolysis on pectin mixed enzyme, filter pressing, anion resin combination, formic acid elution, nano-filtration and interception of formic acid with nano-filtration membrane, and purification, thus obtaining a finished product. The method solves the problems of complex current process, long period, low product purity and the like, and has the advantages of rich raw material sources, simple process, large processing amount, high extraction rate, high product purity and the like; the product is a natural non-toxic product; the finished product cAMP can be used for medical raw materials or used as food additive; the extracted byproduct red jujube juice can be continuously and deeply processed to promote the industrial chain of comprehensive development and achieve pollution-free production; the modern nano-filtration technology is applied to industrial production, therefore, not only the cost is reduced, but also a better path for deeply processing the red jujube raw material is provided, and the consumption of energy is greatly reduced; and the method not only has important economic benefit, but also has remarkable social benefits.

Owner:TIANJIN UNIV OF SCI & TECH

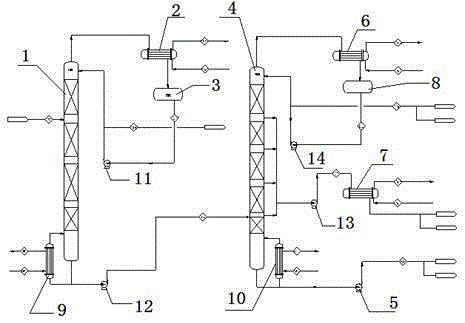

Refining purifying device and method used for continuously producing battery grade dimethyl carbonate

ActiveCN105384639AAddressing Purity IssuesSettlement yieldCarbonic/haloformic acid esters purification/separationHigh energyReboiler

The invention relates to a refining purifying device and method used for continuously producing battery grade dimethyl carbonate. The device is characterized in that the top of a light component removal column is connected with an overhead condenser; the overhead condenser is connected with the light component removal column by a first reflux drum and a first reflux pump and is connected with a light component removal outlet; the bottom of the light component removal column is connected with a first reboiler; the first reboiler is used for conveying raw materials subjected to light component removal to a rectifying column via a column reactor pump; the rectifying column is connected with a second reflux drum by a rectifying column condenser; the second reflux drum is connected with the rectifying column by a second reflux pump; the bottom of the separate column reactor is connected with a second column reactor pump by a second reboiler; the middle part of the separate column reactor is connected with a side condenser by a side withdrawing pump. The device and the method have the beneficial effects that the problems of low product purity, low yield, high energy consumption and generation of solid waste pollutants in traditional production processes are solved; the purity of the dimethyl carbonate product is improved 99.99% or more after removing light components by the light component removal column and then carrying out purifying refining by the rectifying column.

Owner:DONGYING HI TECH SPRING CHEM IND

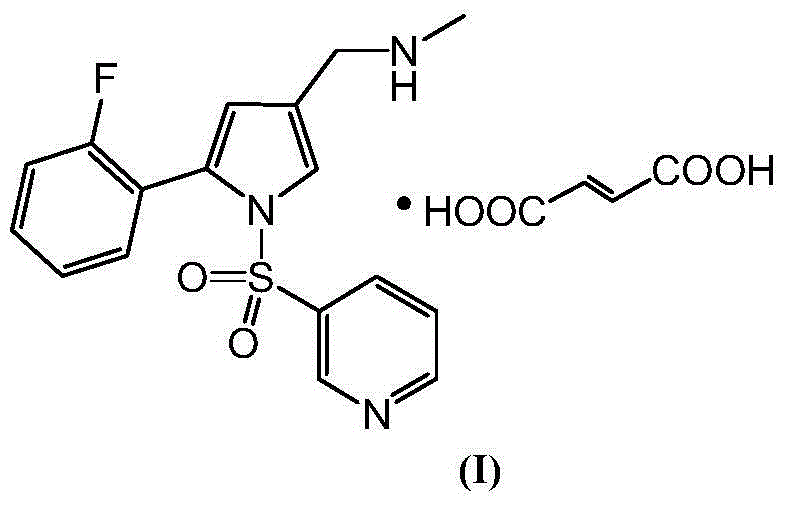

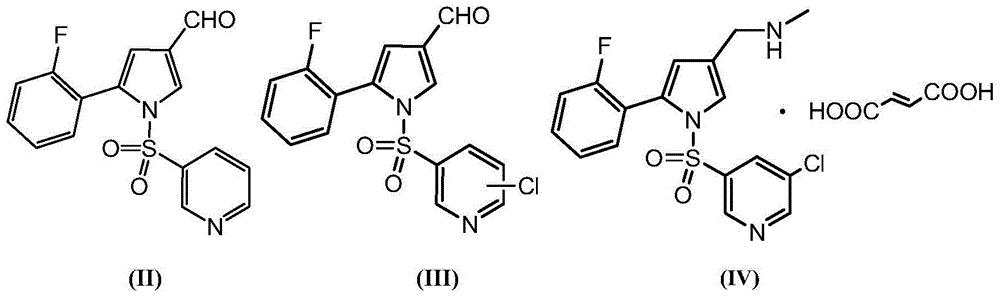

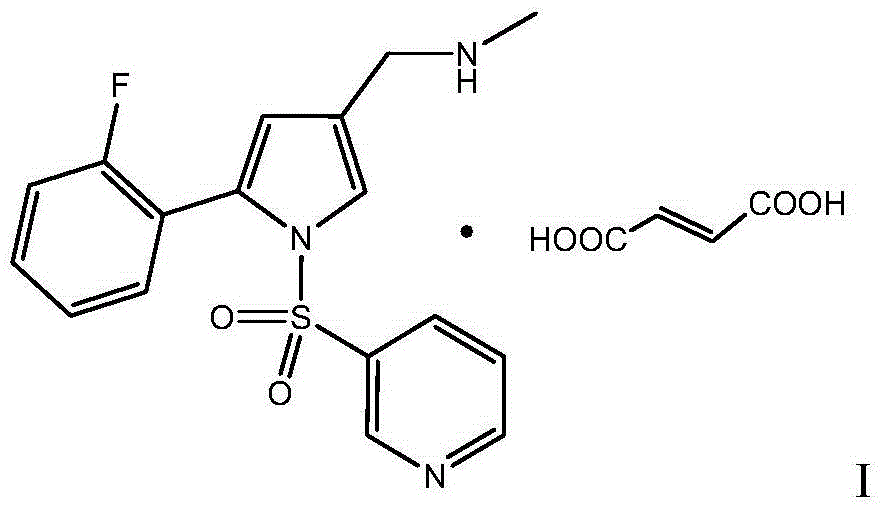

High-purity Vonoprazan Fumarate compound, intermediate and impurity thereof and preparation methods of high-purity Vonoprazan Fumarate compound, intermediate and impurity

ActiveCN104926790AAddressing Purity IssuesHigh purityOrganic chemistryCombinatorial chemistryStructural formula

The invention provides a high-purity Vonoprazan Fumarate compound and a preparation method thereof. The purity of the Vonoprazan Fumarate compound shown in structural formula I is higher than 99.6%, and the content of an impurity compound shown in formula IV is lower than 0.1%. The invention further provides an intermediate of the high-purity Vonoprazan Fumarate compound, a preparation method of the intermediate, the Vonoprazan Fumarate impurity compound and a preparation method thereof. Vonoprazan Fumarate products are high in purity and little in impurity content, and the preparation methods are simple and easy to operate, low in cost and little in energy consumption and are of great significance to industrial production.

Owner:JIANGSU AOSAIKANG PHARMA CO LTD

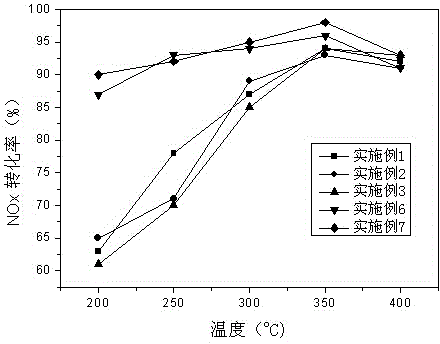

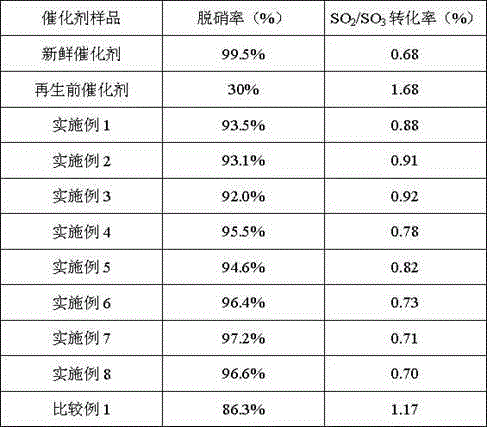

Regeneration method of SCR denitration catalyst

ActiveCN105709861ARestore activityReduce adverse effectsCatalyst regeneration/reactivationRoom temperatureSodium tungstate dihydrate

The invention discloses a regeneration method of an SCR denitration catalyst. The regeneration method includes: (1), performing ash blowing, cleaning and drying on the SCR denitration catalyst which is waste and deactivated; (2), smashing the waste SCR denitration catalyst which is dried well, adding a strong base solution of 10 wt%-40 wt% in mass concentration, and reacting for 3-8 h at temperature of 150-200 DEG C; (3), adjusting pH value of reaction liquid in the step (2) to 9-10, filtering and separating to obtain recovery liquid containing sodium tungstate and sodium vanadate, and adjusting concentration of vanadium in regeneration liquid to 2-10 g / L; (4), soaking the deactivated SCR denitration catalyst dried well in the step (1) in the regeneration liquid with concentration fixed well in the step (3) at room temperature for regeneration, and taking out before placing for 60 min at room temperature; (5), drying, roasting and cooling a catalyst in the step (4) to obtain a regenerated SCR denitration catalyst. The regeneration method has the advantages of good regeneration effect, low SO2 / SO3 conversion rate and low regeneration cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

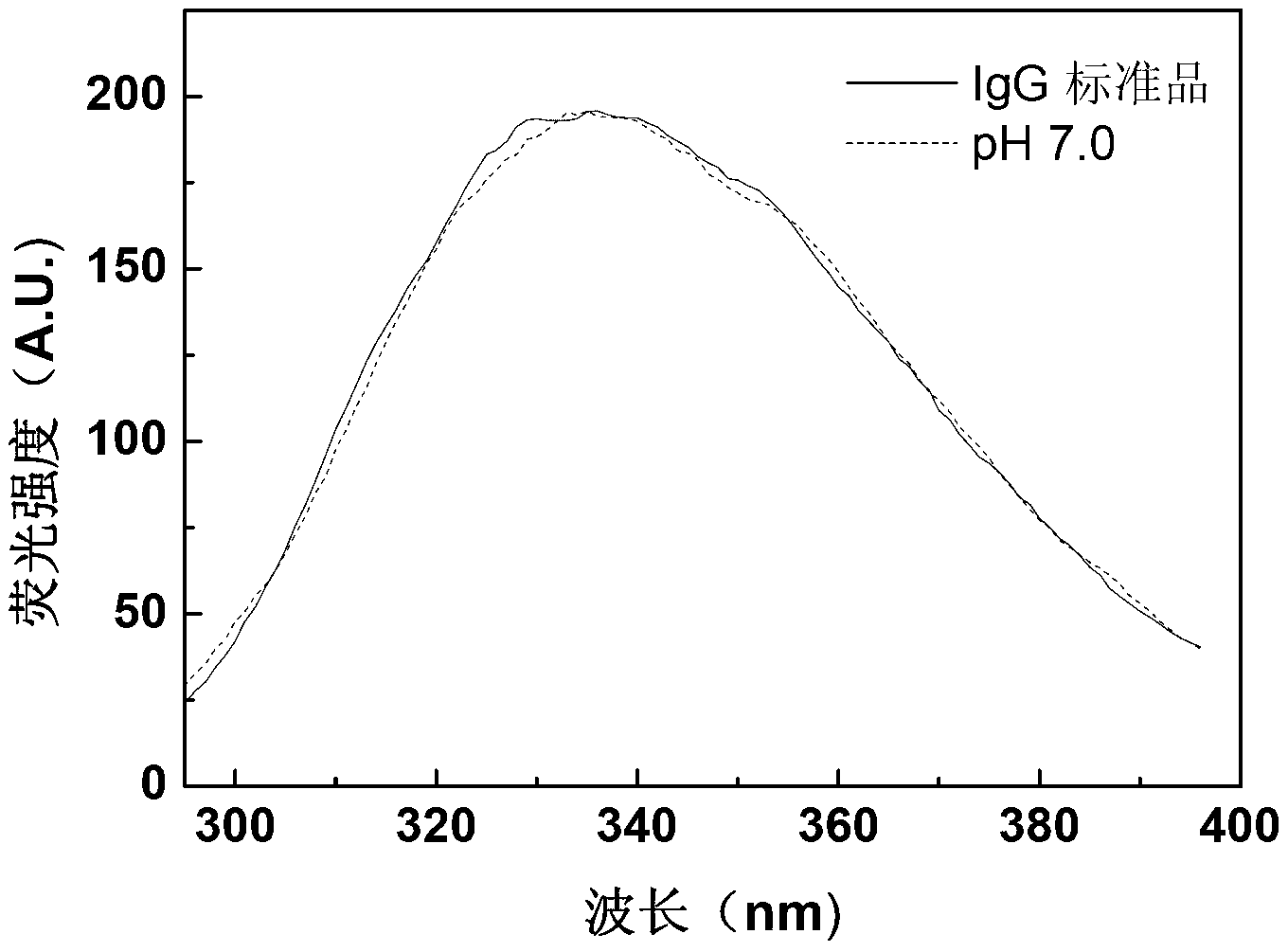

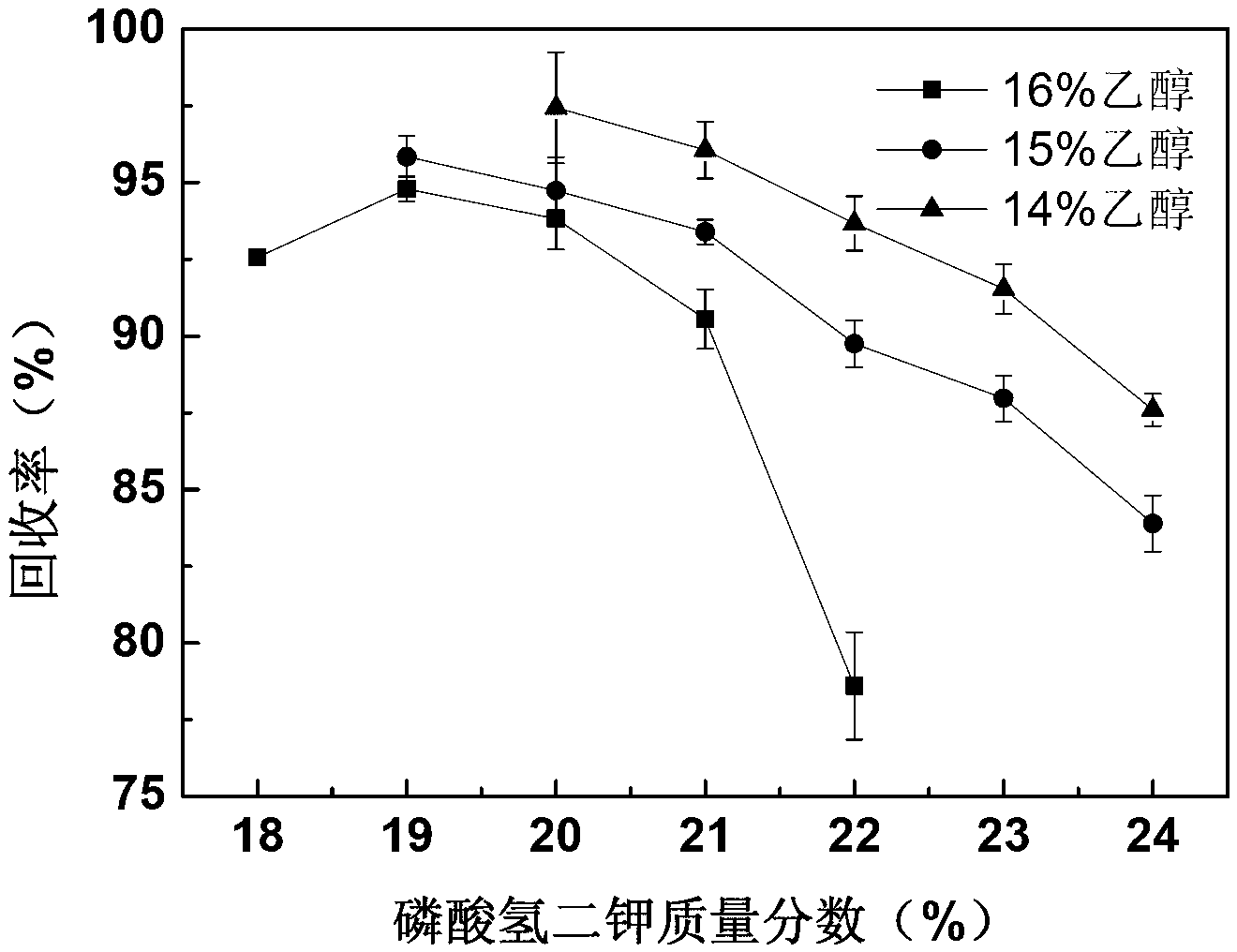

Method for separating and purifying functional protein in plasma

ActiveCN103288953AImprove extraction efficiencyHigh puritySerum immunoglobulinsSerum albuminIon exchangeBlood plasma

The invention provides a method for separating and purifying functional protein in plasma, which comprises the following steps of: adding soluble inorganic salt and a hydrophilic organic solvent into a plasma solution to form a two-aqueous phase extraction system, and obtaining the upper-phase extraction liquid rich in plasma functional protein; and performing further separation and purification of the extraction liquid through hydrophobic chromatography and ion exchange chromatography to obtain the plasma functional protein of which the electrophoresis purity is higher than 95%. The method provided by the invention simplifies the purifying steps of the plasma functional protein; the organic solvent / salt two-aqueous phase extraction has the advantages of convenience in solvent recovery, low cost and short phase separating time, does not need back-extraction operation and can selectively remove glucose and partial protein in the plasma; and the extraction liquid is directly separated and purified by hydrophobic chromatography and ion exchange chromatography, the complicated steps of desalination are avoided, and the separation and purification effects of the plasma functional protein are remarkably improved. The method provided by the invention solves the problems of complicated separation steps, high cost, low purity and the like in the separation and purification of functional protein in the plasma protein.

Owner:DALIAN UNIV OF TECH

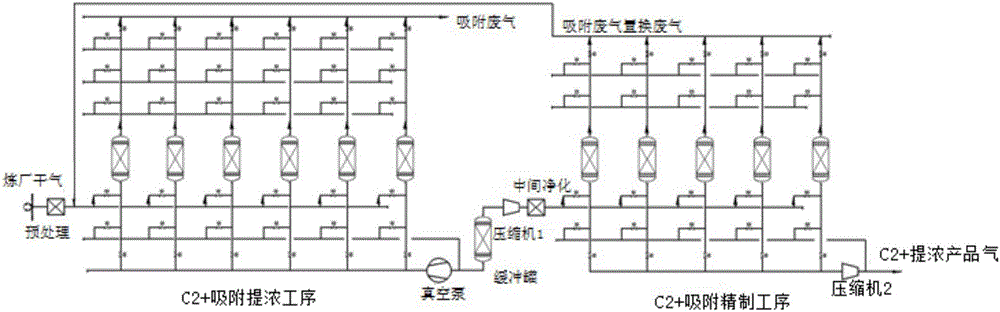

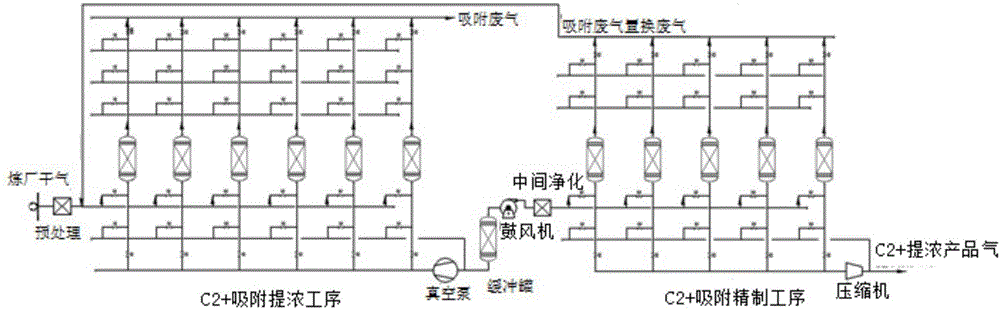

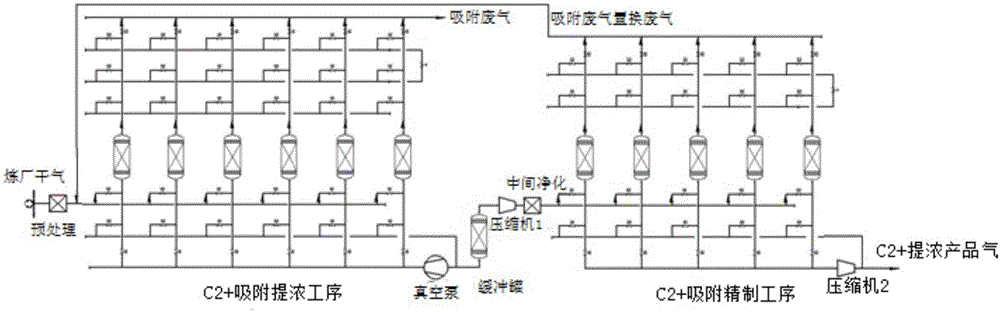

Two-stage PSA method for recovering C2+ from refinery dry gas according to concentration

ActiveCN107433107ABreak adsorption equilibriumReduce methane contentProductsGas treatmentHydrogenPetrochemical

The invention discloses a two-stage PSA method for recovering C2+ from refinery dry gas according to concentration, which relates to the technical field of separating and recovery of in valuable substances in petrochemical tail gas. The method comprises a pretreatment process, a C2+ adsorption concentration process, an intermediate purifying process, and a C2+ adsorption refining process, wherein, the pre-treated refinery mixed dry gas is introduced into the CO2+ adsorption concentration process, then flowed non-adsorption phase gas is the adsorption exhaust gas, or directly taken as hydrogen (H2) product gas, or taken as fuel gas, or taken as raw material gas for extraction of hydrogen for output; the flowed adsorption phase gas forms the intermediate gas through the intermediate purifying process, and then is introduced into the C2+ adsorption refining process for refining, the flowed non-adsorption phase gas is taken as the raw material gas for mixing with the refinery mixed dry gas, a mixture is returned to the C2+ adsorption concentration process; the flowed adsorption phase gas has the C2+ concentration being more than 90-95% (a volume ratio), wherein the methane impurity concentration is less than 4%, the flowed adsorption phase gas is taken as the C2+ concentrate product gas for output, and the yield of C2+ is more than 90-95%.

Owner:SICHUAN TECHAIRS

Preparation method of boron nitride nano-tube

The invention relates to a preparation method of a boron nitride nano-tube, comprising the steps of: leading inorganic porous ceramic material and ammonia to have ammoniation reaction for 5-24h at 800-1200 DEG C, and obtaining crude product of the boron nitride nano-tube, wherein the element mole ratio in the inorganic porous ceramic material is Mg: Fe: B: O= 1: (0.10-1.65): (0.33-1.95): (0.5-5); and separating and purifying the obtained crude product, and obtaining the boron nitride nano-tube. The preparation method has the advantages that (1) batch preparation of the boron nitride nano-tube product can be realized, the yield is more than 80%, and the purity is about 85%; the preparation technique is simple, the power consumption is lower, and the method is suitable for industrial batch production; and (2) the adopted inorganic porous ceramic material has good mechanical strength at higher temperature and can be taken as filler, and compared with other powder or block raw material, the inorganic porous ceramic material is more beneficial to preparing the boron nitride nano-tube by gas-solid phase reaction.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

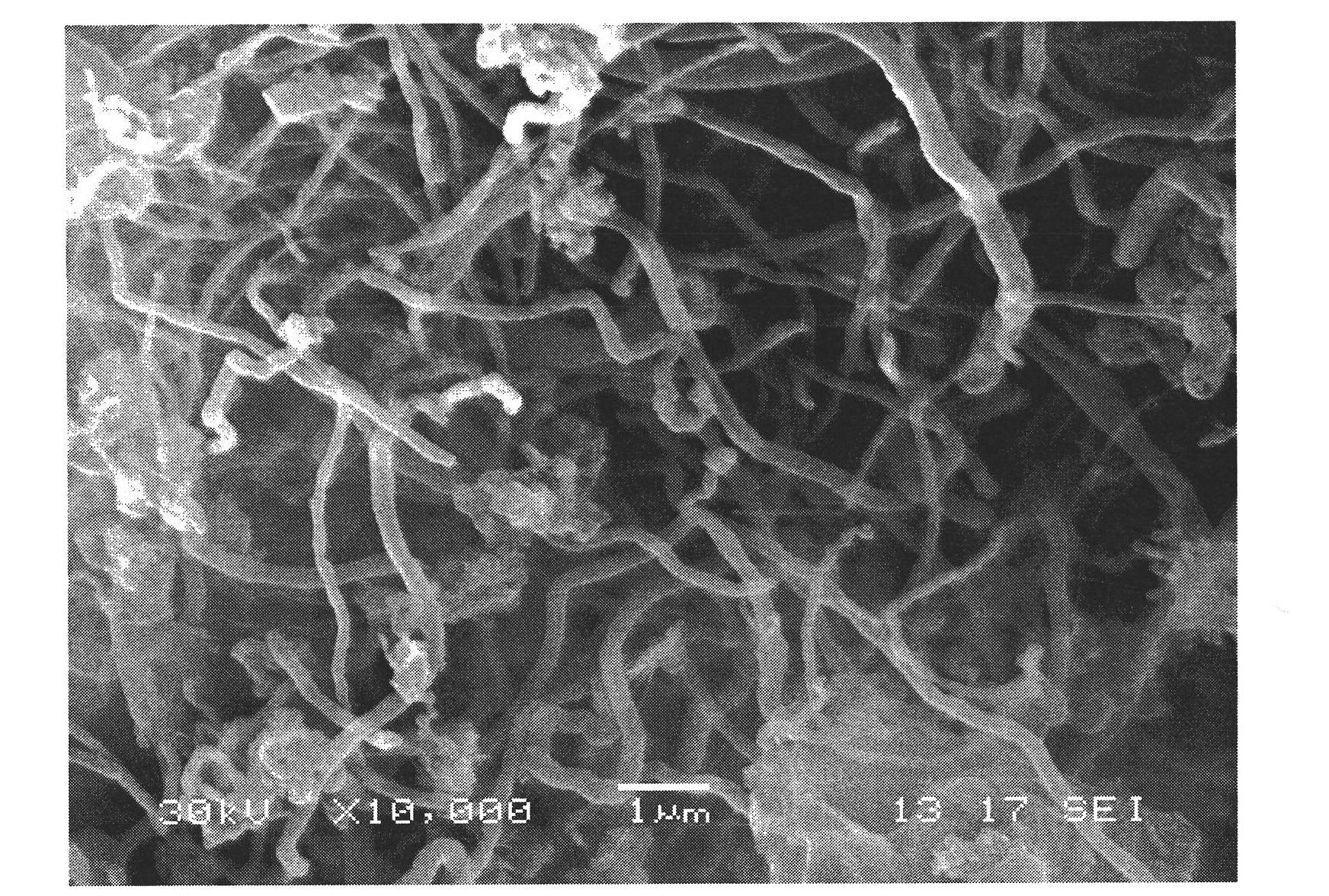

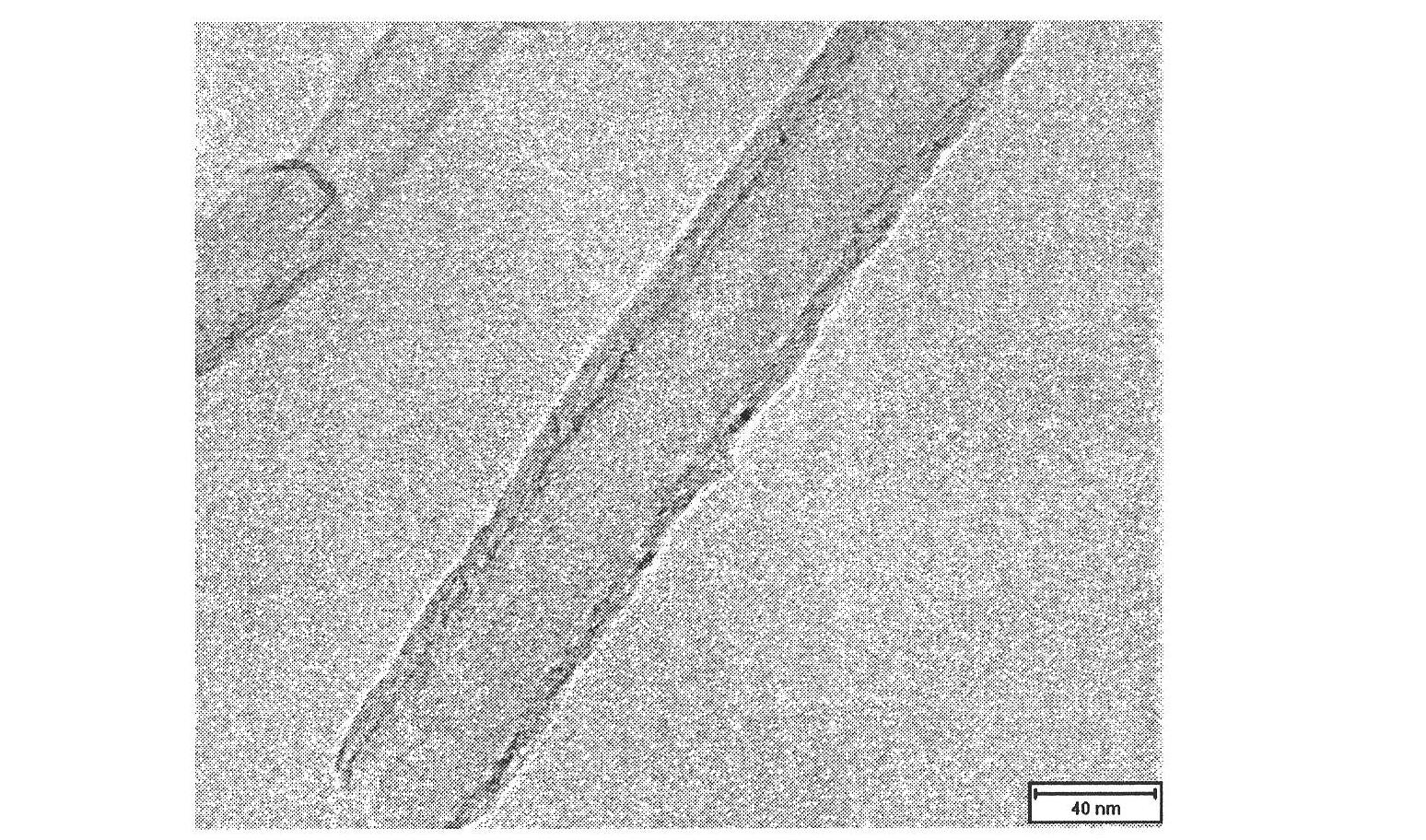

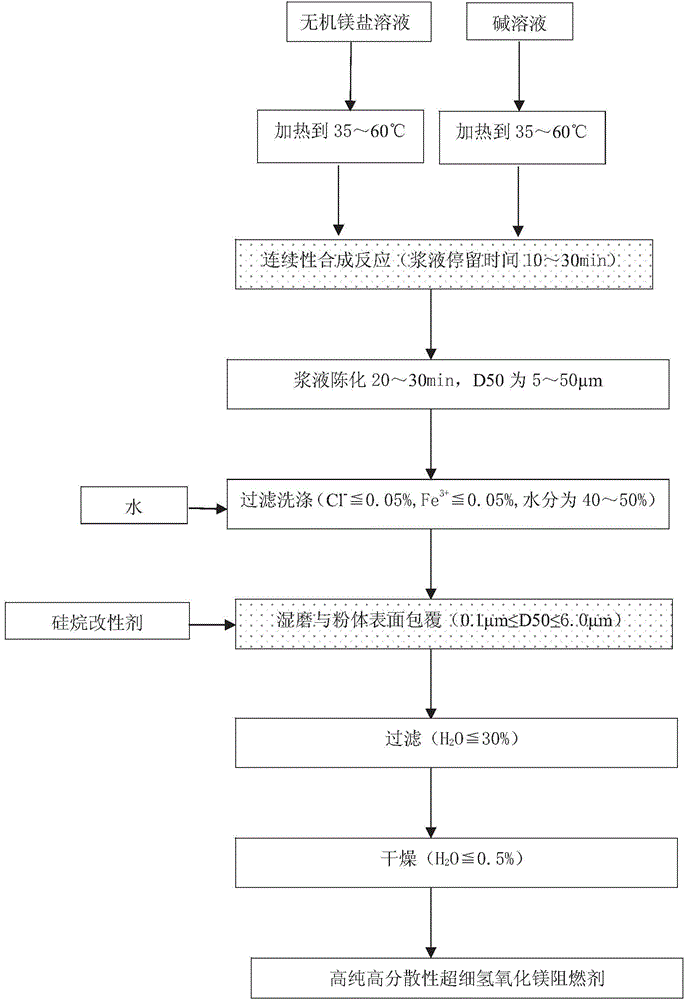

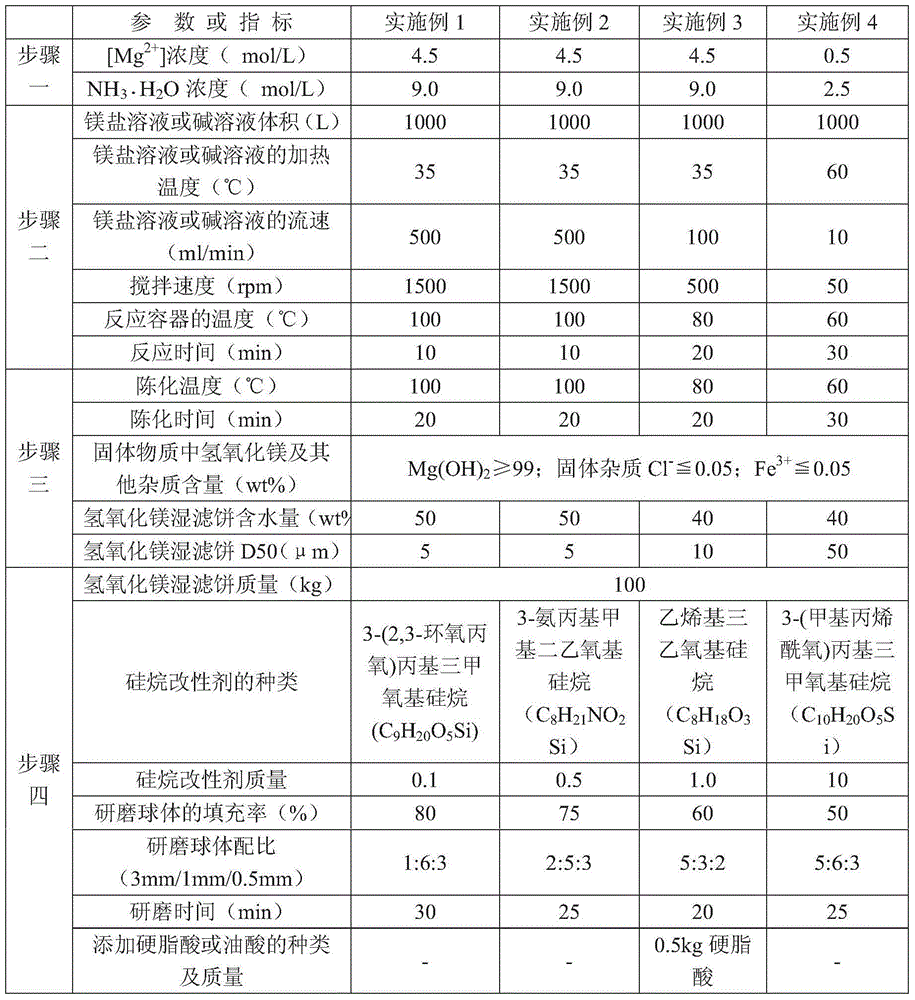

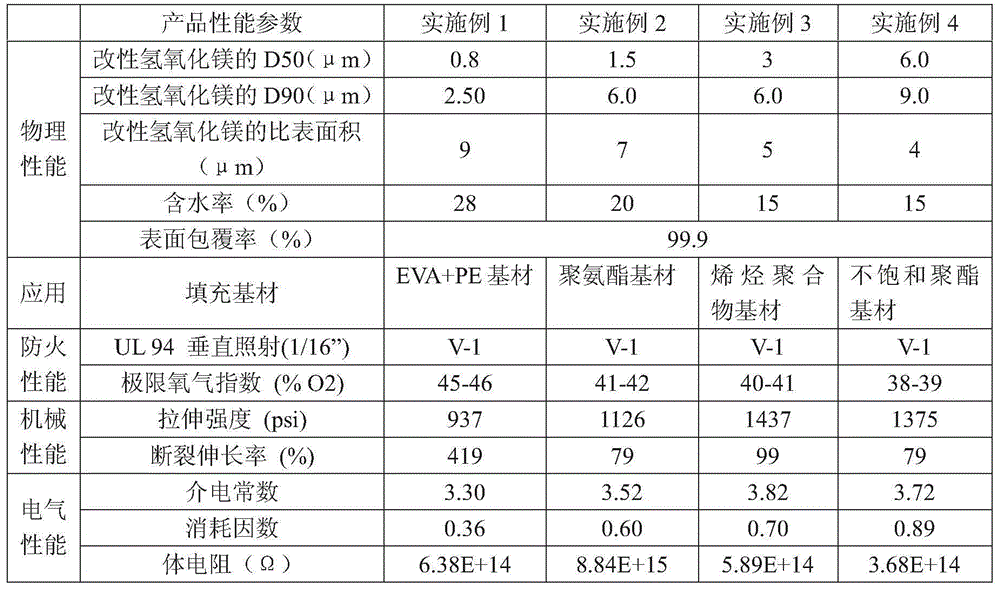

Method for preparing magnesium hydrate flame retardant

ActiveCN104592789AAddressing Purity IssuesSolve for uniformityPigment treatment with organosilicon compoundsPigment physical treatmentDispersityWet grinding

The invention discloses a method for integrally preparing a high-dispersity ultrafine magnesium hydroxide flame retardant, which comprises the following steps: continuously synthesizing high-purity magnesium hydroxide; and carrying out single cycle wet grinding and surface modification on magnesium hydroxide and integrally implementing particle size control and surface processing of the magnesium hydroxide flame retardant. According to the invention, the technical difficulties of control on purity, slurry viscosity, particle size, particle size distribution and specific surface area of the magnesium hydroxide flame retardant, the existence of the phenomena of secondary coagulation and bonding during the drying process and the like; a hydrophilic surface of magnesium hydroxide flame retardant powder is modified into a lipophilic surface, so that the intermiscibility and dispersity of the powder in a macromolecule polymeric material are improved, the influence of the high-dispersity ultrafine magnesium hydroxide flame retardant on the processing performance and the mechanical performance of a polymer product is reduced, and the comprehensive properties of the macromolecule polymer, such as flame retardance, processing, mechanics, electrics, are optimized.

Owner:江苏艾特克阻燃材料有限公司

Method for co-producing high-concentration xylose and xylooligosaccharide by utilizing wood fiber raw materials

The invention discloses a method for co-producing high-concentration xylose and xylooligosaccharide by utilizing wood fiber raw materials. The method comprises the following steps: crushing wood fiber biomass and directly adding the crushed wood fiber biomass into a high-pressure reaction kettle, adding a furaldehyde / water mixed liquor with volume concentration being 10%-90%, carrying out solid-liquid separation on a reacted product, taking a supernatant water phase to further refine to obtain xylose and xylooligosaccharide; and distilling a non-water-phase part under reduced pressure for recycling furfural for cycle use. According to the method, by virtue of inhibiting and extracting effects of furaldehyde, wood fiber raw materials are hydrolyzed in a furfural two-phase system to prepare hemicellulose derived carbohydrate such as xylose and xylooligosaccharide, so that the concentration and the purity of the hemicellulose derived carbohydrate such as xylose and xylooligosaccharide are improved, and the problems of low concentration and low purity of hemicellulose derived carbohydrate such as xylose and xylooligosaccharide due to the fact that byproducts such as furaldehyde and formic acid are generated by excessively decomposing xylan by a hemicelluloses direct hydrolysis method are solved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

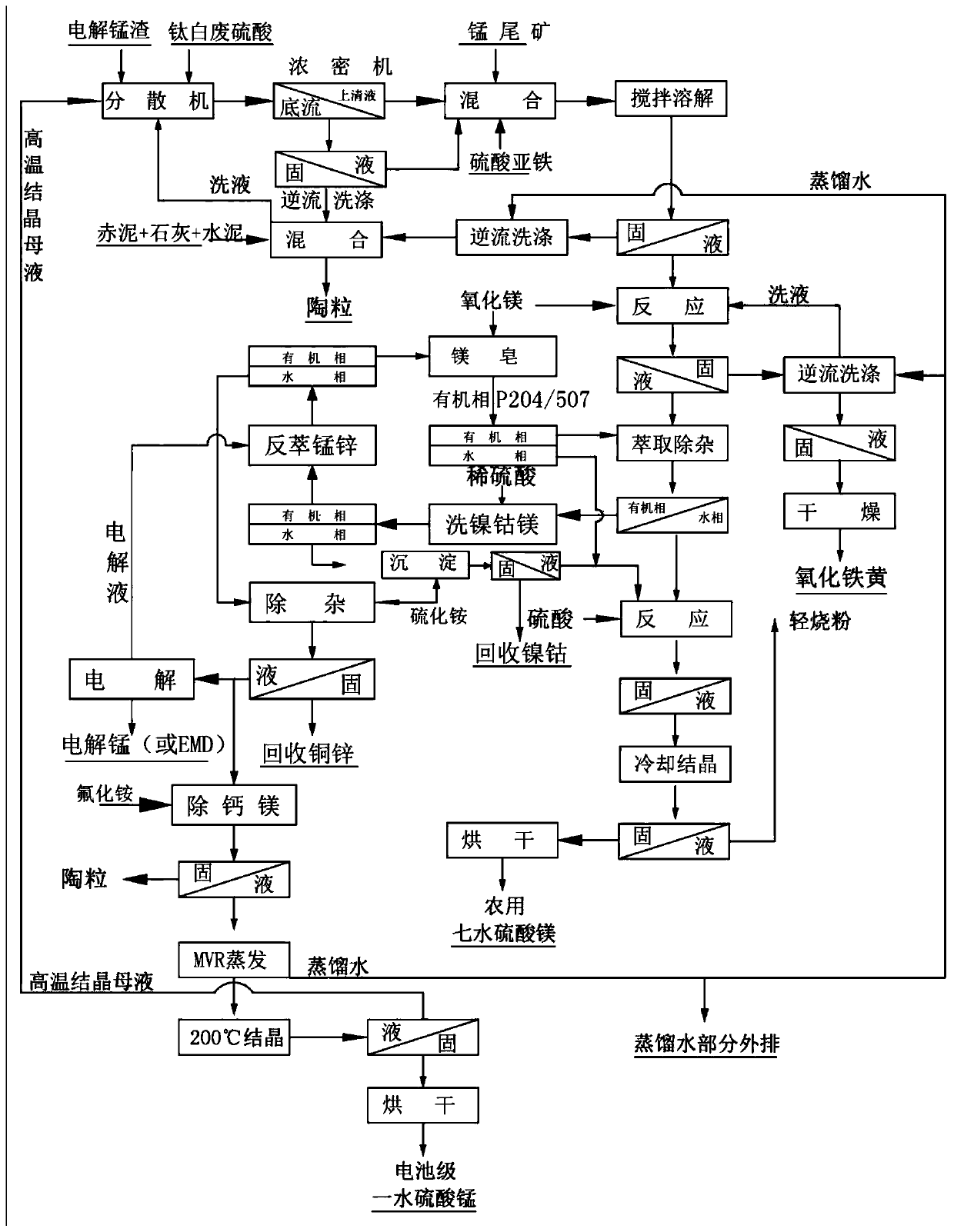

Process for comprehensively recycling electrolytic manganese residues and manganese tailings

InactiveCN110157911ASolve pollutionAddressing Purity IssuesProcess efficiency improvementElectrolysisManganese

The invention discloses a process for comprehensively recycling electrolytic manganese residues and manganese tailings. The process for comprehensively recycling the electrolytic manganese residues and the manganese tailings specifically comprises the following steps that liquid-phase crushing is performed on the electrolytic manganese residues by adopting a dispersion machine so as to obtain leached residues and leachate; a qualified de-ironed precursor solution without solid particles is obtained through filter pressing, and hydration pulping is performed on the magnesium oxide through the dispersion machine. The process for comprehensively recycling the electrolytic manganese residues and the manganese tailings has the advantages that as long as the manganese content of the electrolyticmanganese residues and the manganese tailings is greater than 1%, the manganese can be enriched and recovered, so that a new profitable industrial way is developed for resource comprehensive recoveryof the manganese tailings, the problems that when electrolytic manganese is produced through a traditional process, pollution is caused due to the fact that sodium jarosite and goethite which are generated through purification iron removal cannot be recovered, the purity of the electrolytic manganese is low due to the fact that the leaching solution is not purely purified and the like are solved,and the process is simple, stable and strong in operability.

Owner:张响 +2

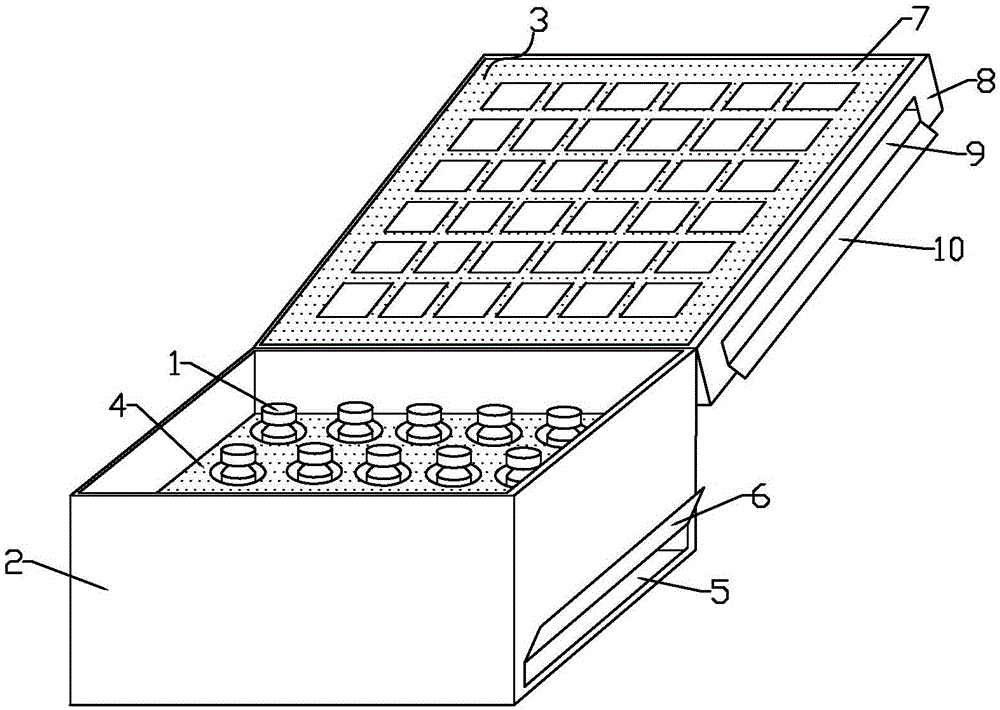

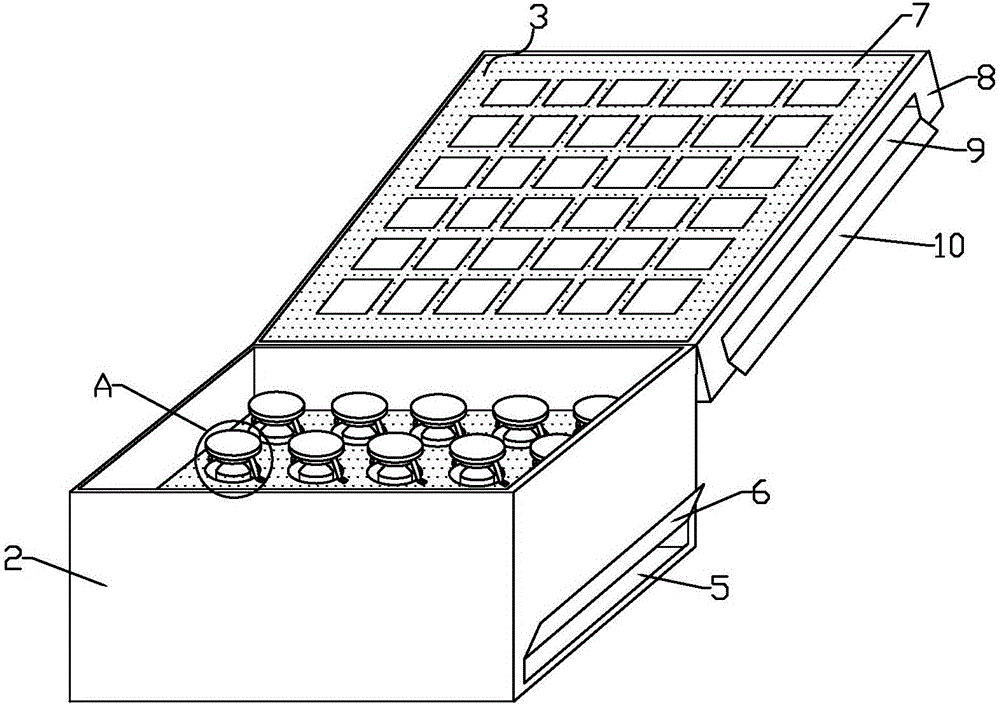

Kit for culture of adipose-derived stem cells and culture method

ActiveCN106047702AResolve separabilityAddressing Purity IssuesCulture processDead animal preservationNutrientDecomposition

The invention provides a kit for culture of adipose-derived stem cells, wherein the kit includes a kit body, a plurality of reagent bottles and a plurality of ice bags; the plurality of reagent bottles are internally filled with a tissue preservation liquid, a basal culture medium, a culture medium additive, a growth factor I, a growth factor II, a tissue decomposition liquid, a cell digestion liquid, a washing liquid and a frozen stock liquid respectively. The kit provided by the invention can separate the adipose-derived stem cells from adipose tissues, and cultures and preserves the adipose-derived stem cells, solves the problems of small separation number and low purity of the adipose-derived stem cells, low culture survival rate, low culture efficiency, nonideal frozen resurrection rate and the like, makes the adipose-derived stem cells subjected to multi-generation amplification and not generate differentiation in an ideal nutrient equilibrium state, provides a rich source for further experimental research with use of the adipose-derived stem cells, and is quite suitable for culture of the adipose-derived stem cells.

Owner:BEIJING YULONG SHENGSHI BIOTECH CO LTD

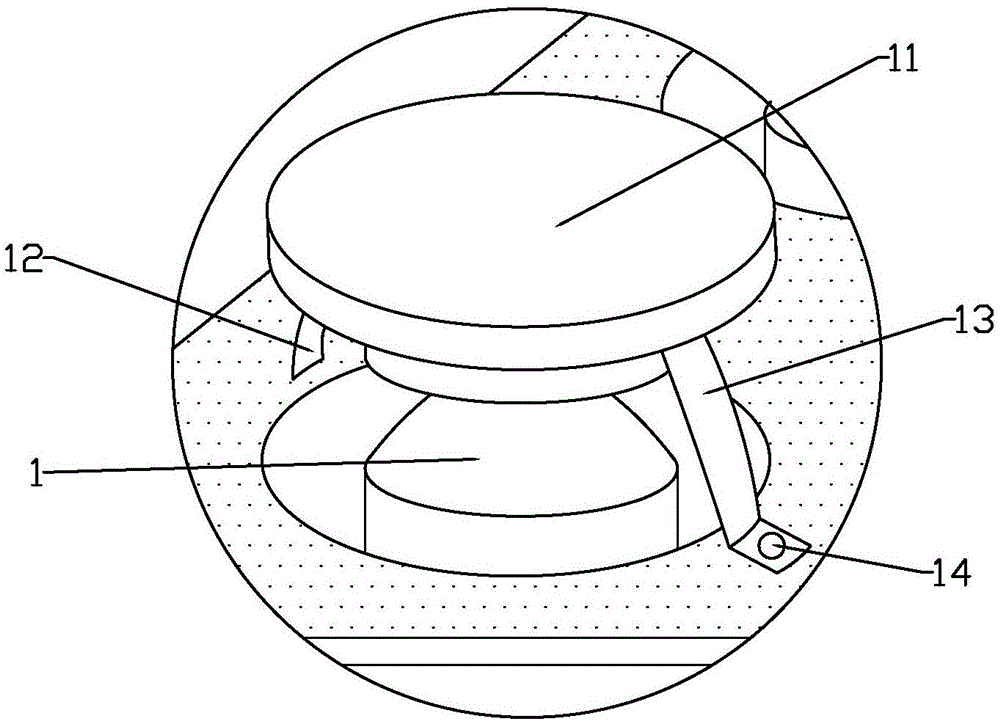

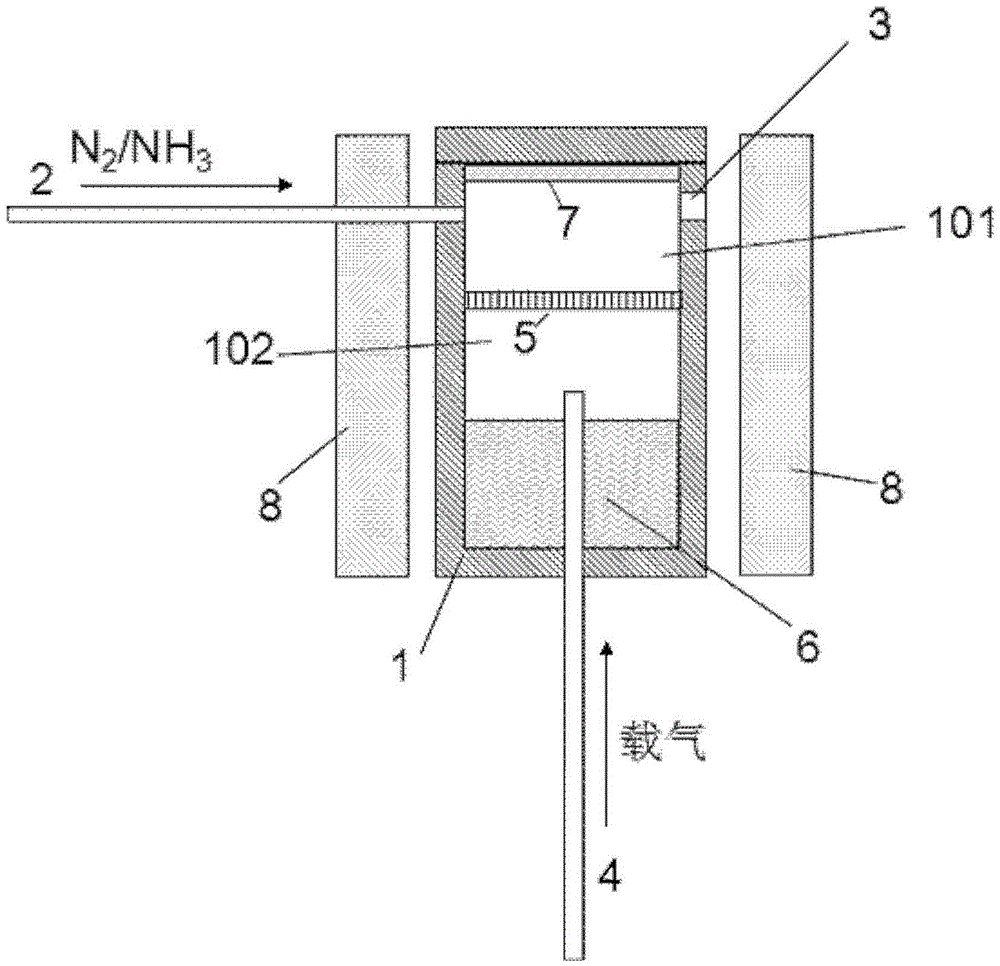

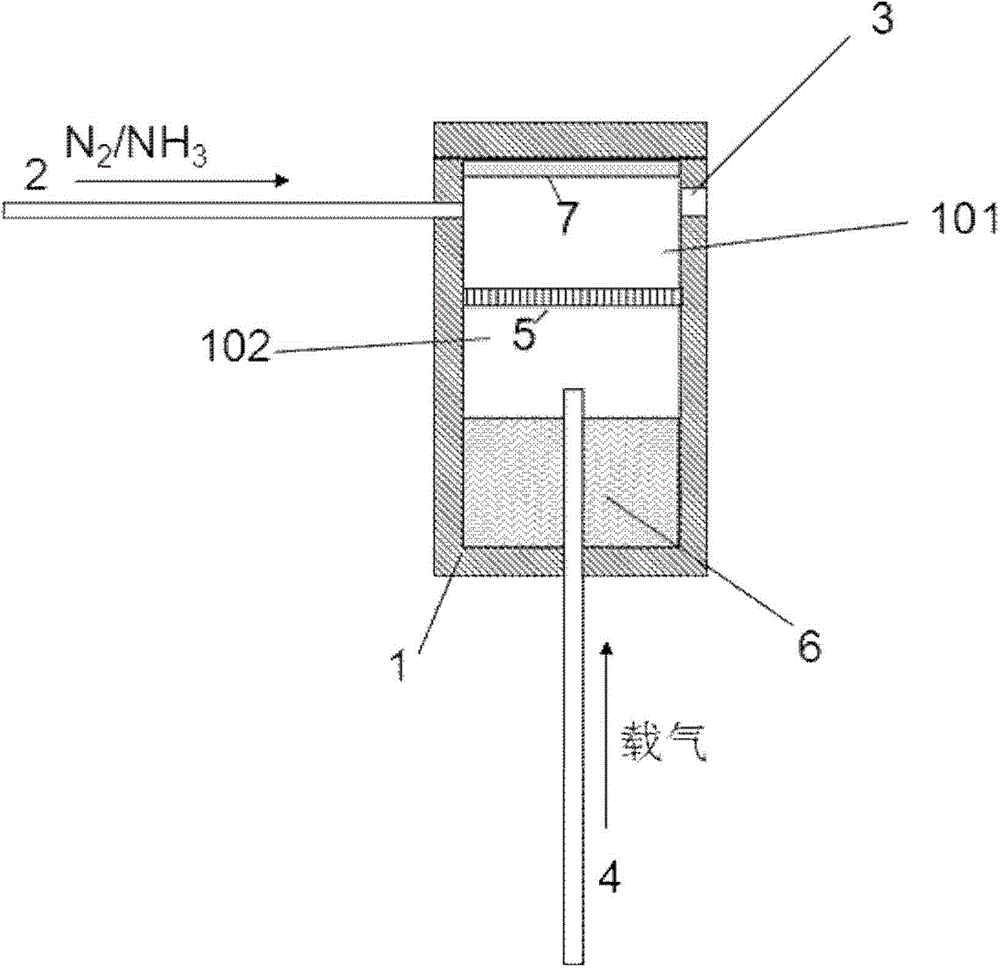

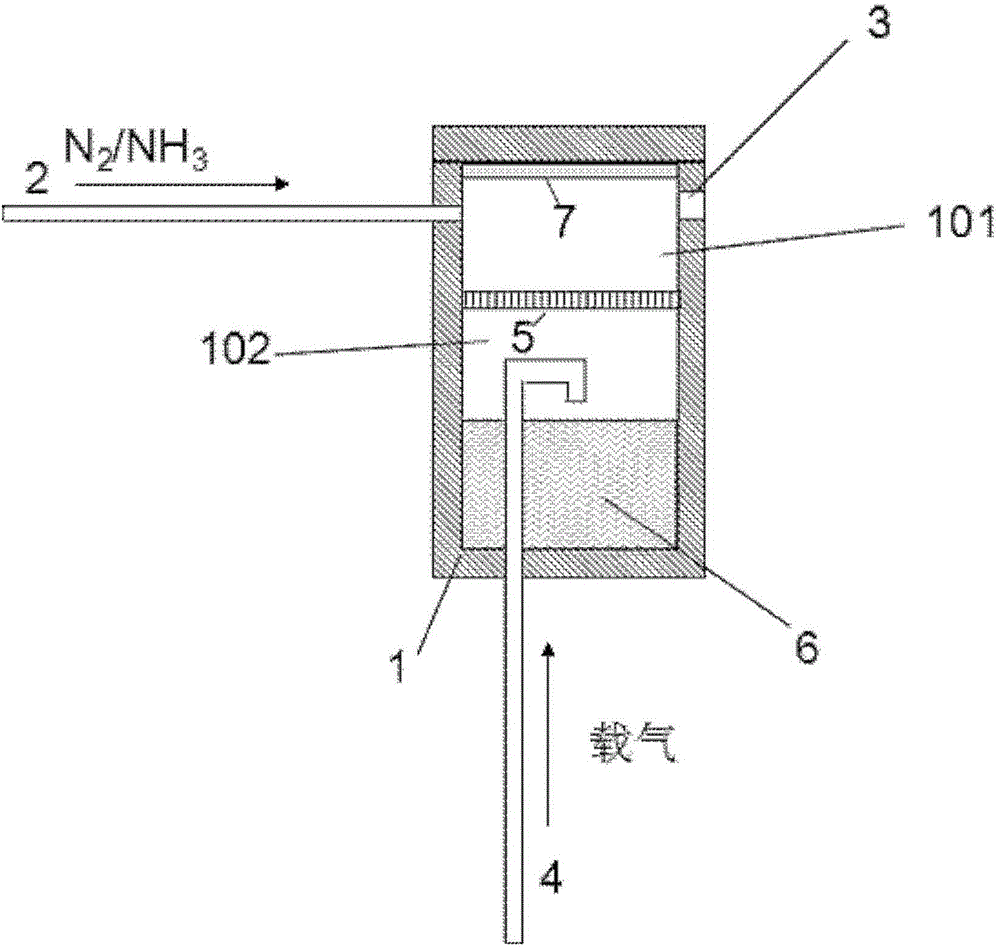

AlN single crystal substrate production apparatus and application method thereof

InactiveCN104878450AAddressing Purity IssuesLess impuritiesPolycrystalline material growthFrom chemically reactive gasesNitrogen gasSeed crystal

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Application by using carbon nanotube/urea formaldehyde resin carbon-coated spherical microcrystalline graphite as negative electrode material of lithium ion battery

InactiveCN107959028AImprove processing efficiencyImprove crushing precisionCell electrodesArgon atmosphereCarbon nanotube

The invention relates to application by using carbon nanotube / urea formaldehyde resin carbon-coated spherical microcrystalline graphite as negative electrode material of a lithium ion battery. Spherical microcrystalline graphite material is adopted as the lithium ion negative-electrode material to prepare the lithium ion battery, wherein the weight ratio of the negative electrode material, SBR (50% of solid content), CMC to Super-p is 97.5: 1.5: 2: 1, then moderate deionized water is added to mix to be syrup-like liquid, copper foil is coated with the liquid and dried in a vacuum drying oven for 12 h to prepare a negative electrode plate, an electrolyte of the lithium ion battery adopts 1MLiPF6 / EC+DEC+DMC=1: 1: 1, a separator is microporous polypropylene membrane, a counter electrode is alithium tablet, and the battery is assembled in a glove box with an airtight argon atmosphere. When the lithium ion battery is charged and discharged at the ratio of 0.1 C, a first charging and discharging cycle charging capacity is 390 mAh / g, and when the lithium ion battery is charged and discharged at the ratio of 5 C, after 500 times of cycles, the capacity retention ratio is 97.2%.

Owner:林荣铨

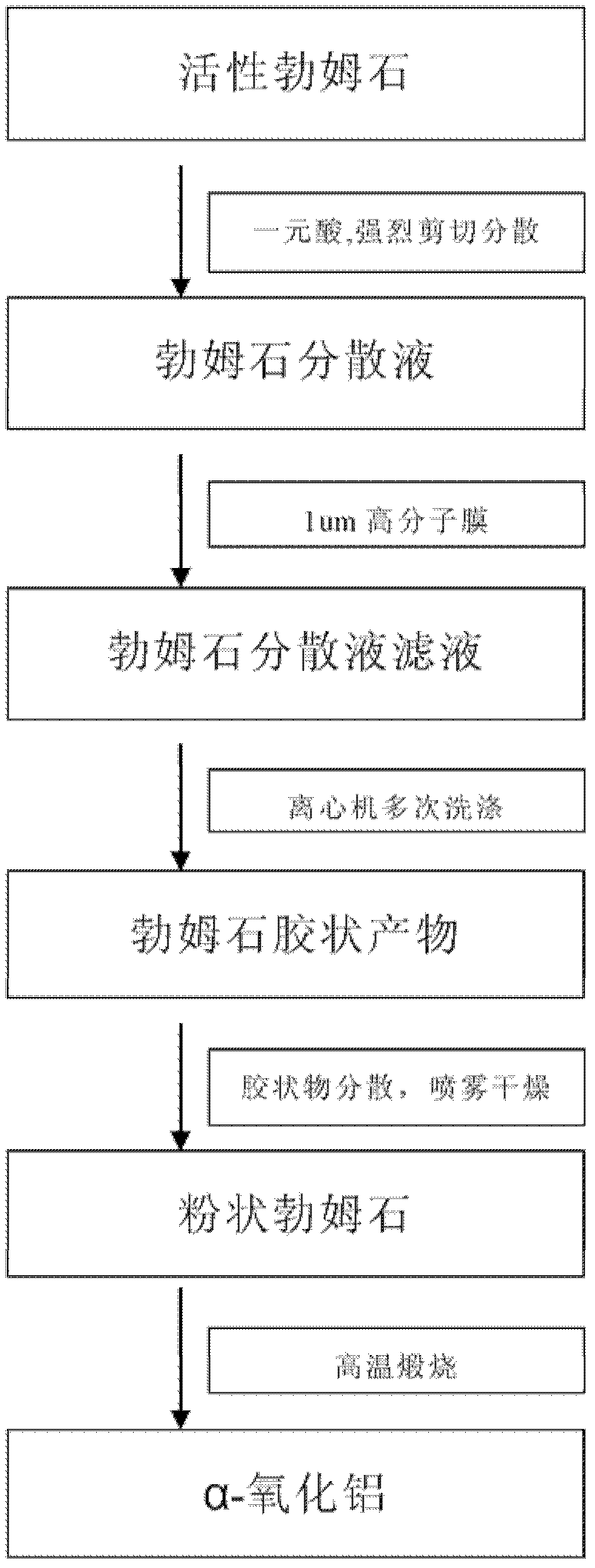

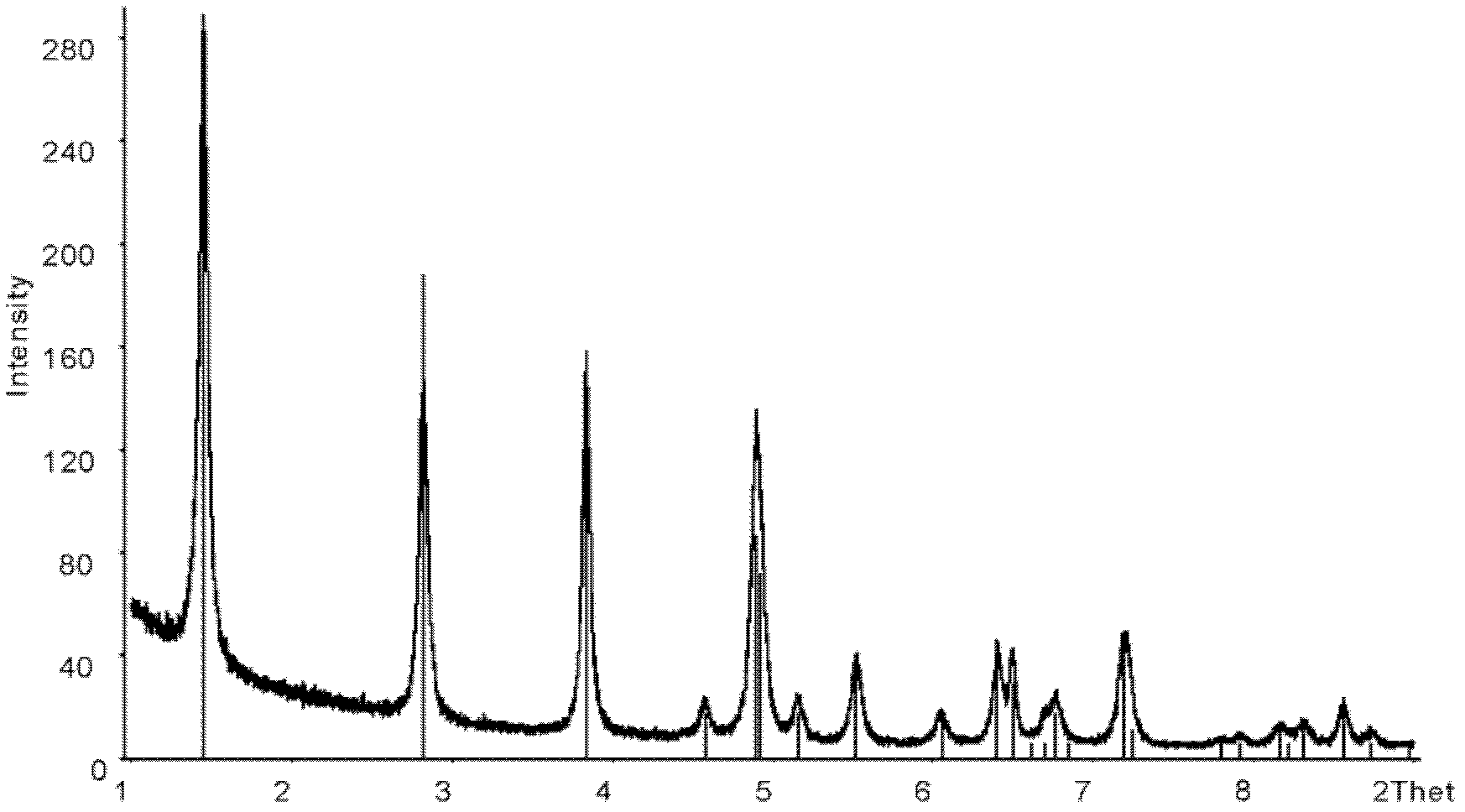

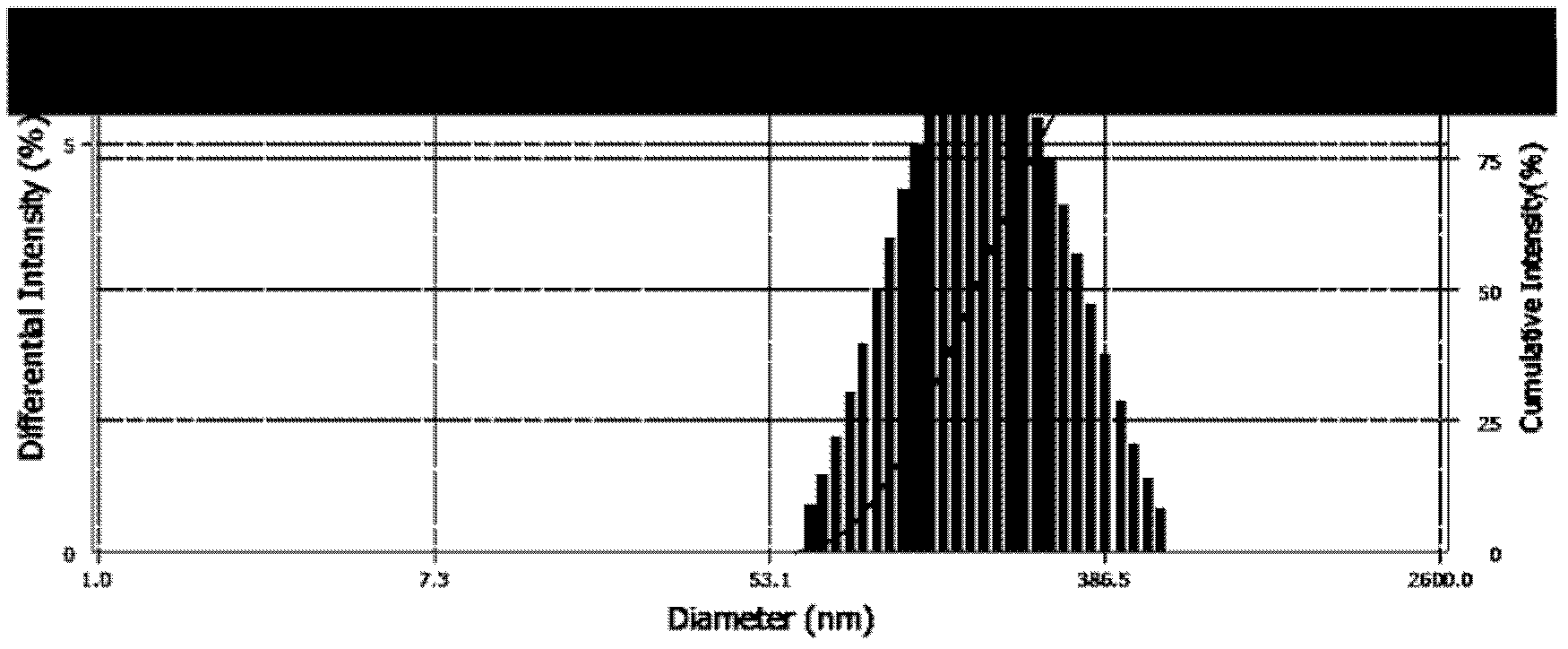

Industrial production method for superfine high-purity alpha-alumina

ActiveCN102583469AGuaranteed purityGuaranteed Particle SizeAluminium oxides/hydroxidesOrganic acidGranularity

The invention discloses an industrial production method for preparing superfine high-purity alpha-alumina. The industrial production method comprises the following steps that: (1) boehmite is dispersed in unitary organic acid; (2) an obtained dispersing agent of the boehmite is filtered; (3) the dispersing agent of the boehmite is subjected to solid-liquid separation, washing and redispersion; (4) the dispersing agent with impurities being removed is subjected to spray drying; and (5) the dried boehmite obtained in the step (4) is subjected to high-temperature calcination. According to the invention, the purity and the grain size of the produced alpha-alumina are well guaranteed, and the purity and the grain size of a final product can reach the using requirements in a high-end electronic industry.

Owner:GUANGZHOU HUMAN CHEM

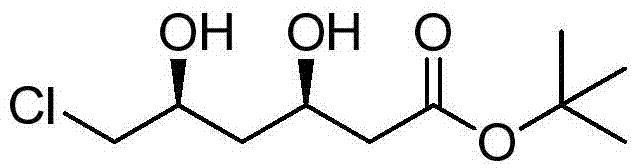

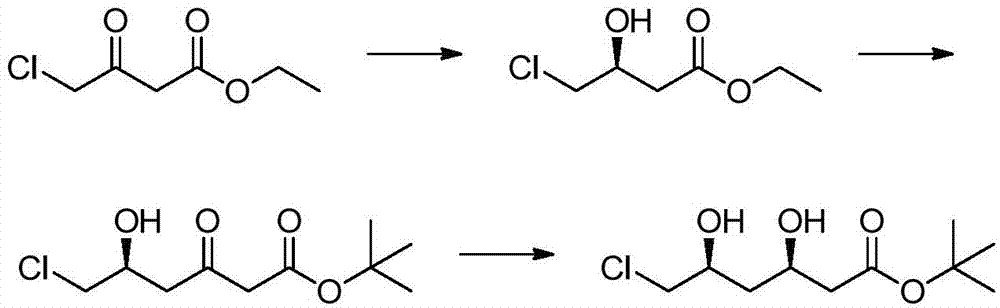

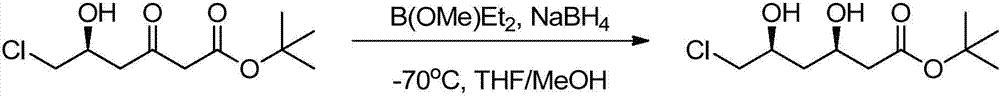

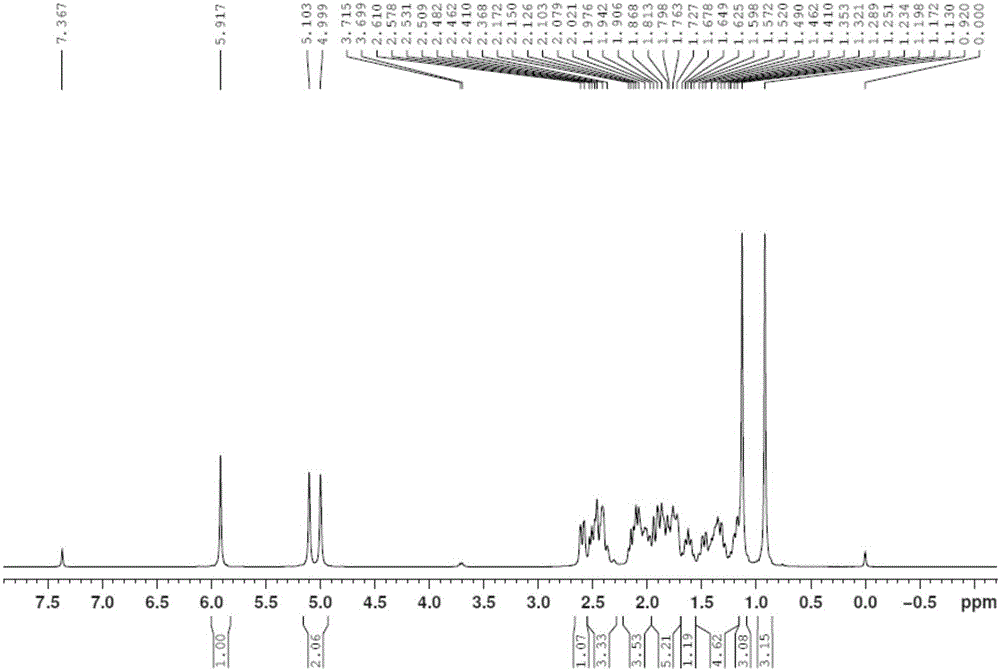

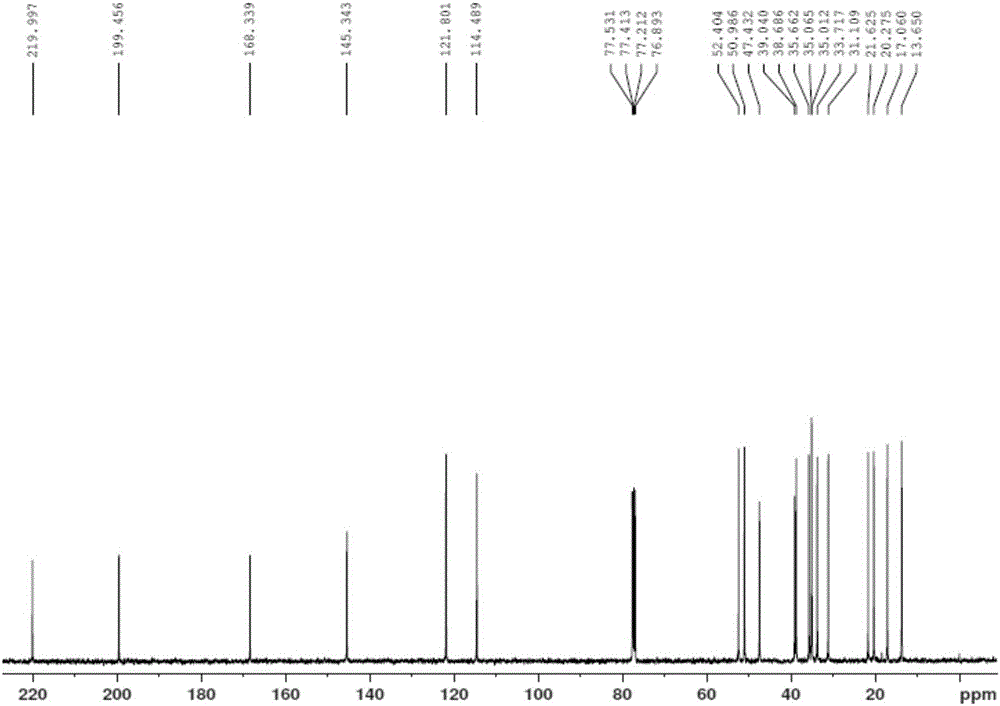

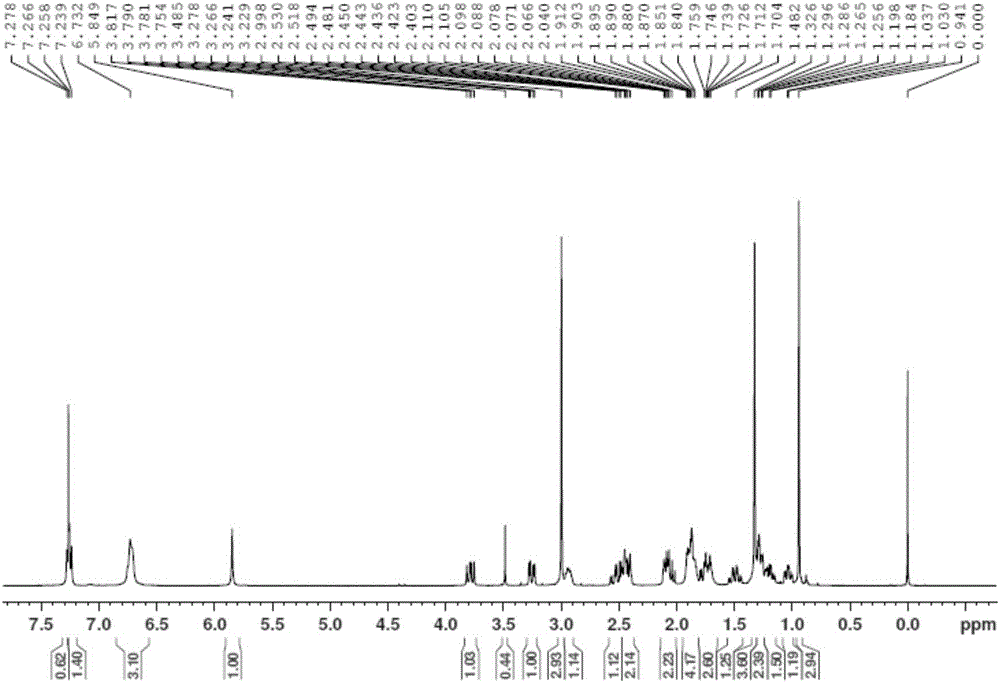

Preparation method of tert-butyl (3R,5S)-6-chloro-3,5-dihydroxyhexanoate

The invention relates to a preparation method of tert-butyl (3R,5S)-6-chloro-3,5-dihydroxyhexanoate. The preparation method is characterized in that tert-butyl (S)-6-chloro-5-hydroxy-3-carbonylhexanoate is taken as a substrate and the substrate is subjected to reduction reaction in the presence of a biocatalyst, a coenzyme and coenzyme regeneration systems to generate tert-butyl (3R,5S)-6-chloro-3,5-dihydroxyhexanoate; the biocatalyst is ketoreductase; the coenzyme is NADP (nicotinamide adenine dinucleotide phosphate); the coenzyme regeneration systems are glucose and glucose dehydrogenase; the reduction reaction is carried out in a phosphate buffer solution at 25-30 DEG C in the presence of an enzyme protection reagent; the pH value of a reaction system is controlled to be 6.0-8.0 by adding a sodium carbonate solution. The preparation method has the effects of substantially increasing the concentration of the substrate and reducing the usage amount of the enzyme, so that the product has good production environment friendliness and the commercial value of industrialization is prominent.

Owner:ENZYMEWORKS

Extracting and purifying method for chlorogenic acid in honeysuckle

InactiveCN1181042CAddressing Purity IssuesOrganic compound preparationCarboxylic acid esters preparationReflux extractionChlorogenic acid

The present invention relates to extraction and purification of functional components in Chinese herbal medicine and aims at provindg extraction and purification process of chlorogenic acid in honeysuckle in relatively high yield and purity. The techonlogical scheme includes twice reflux extraction of honeysuckle cut into sections with dilute alcohol, concentrating the extractive, flocculating for initial purification and final purification through macroporous resin or ethyl acetate extraction. The said process is simple and practical and has less loss of chlorogenic acid and high product yield and purity.

Owner:CHINA AGRI UNIV

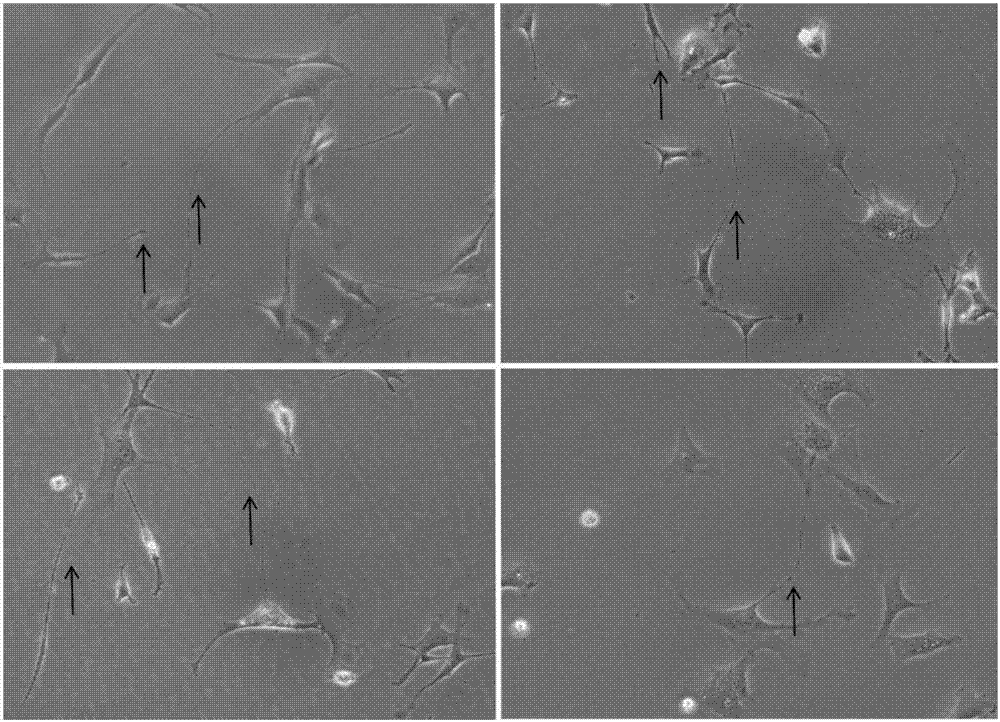

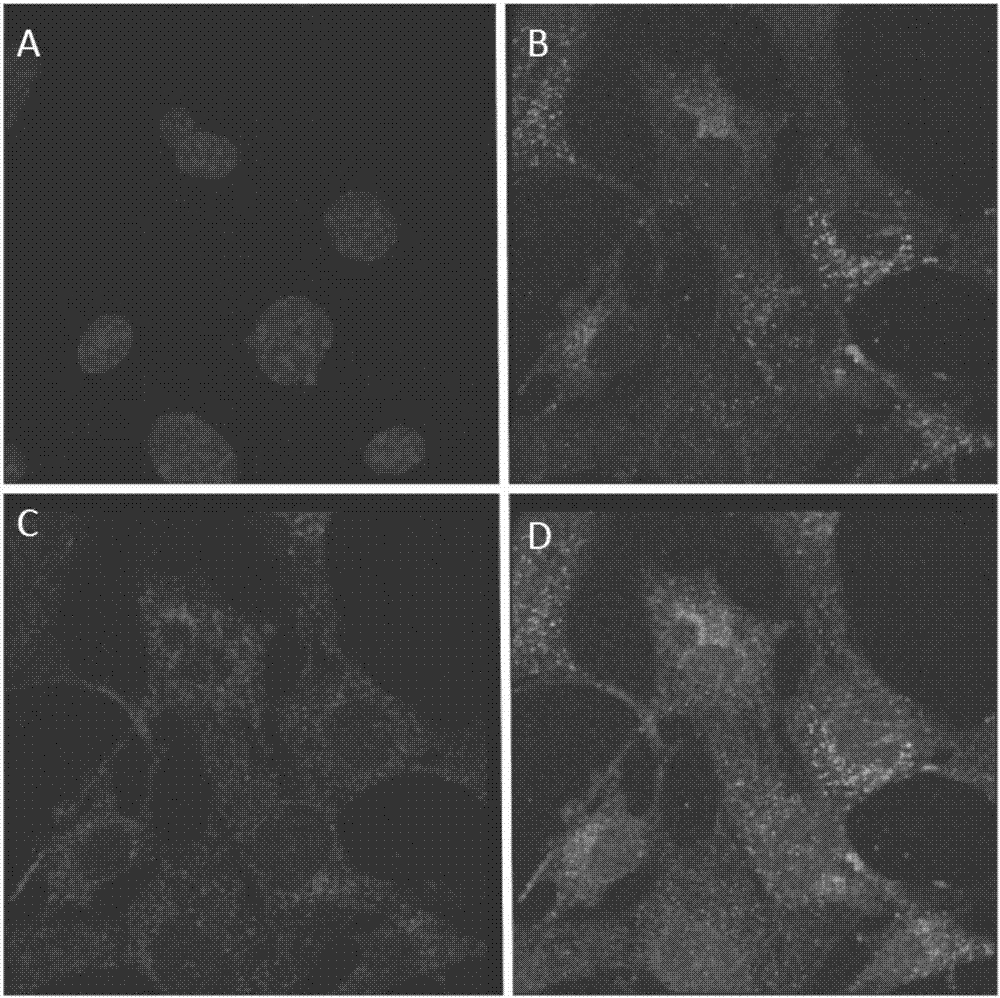

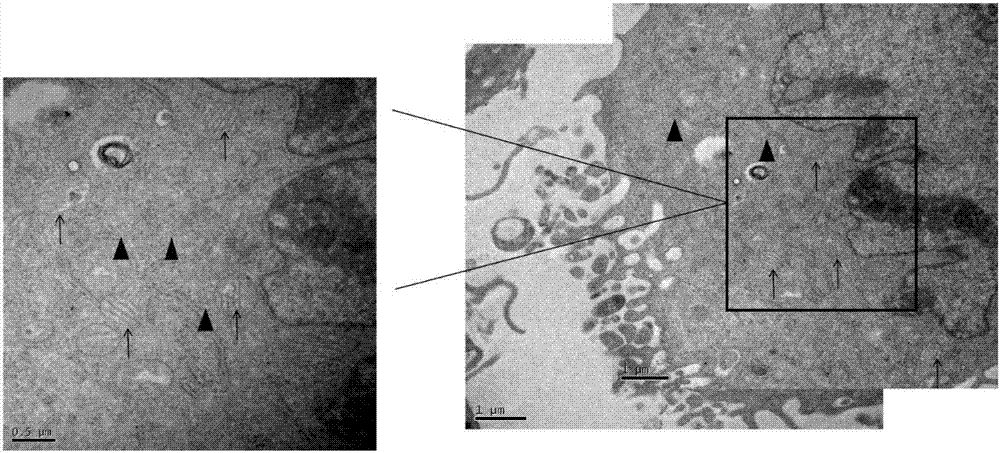

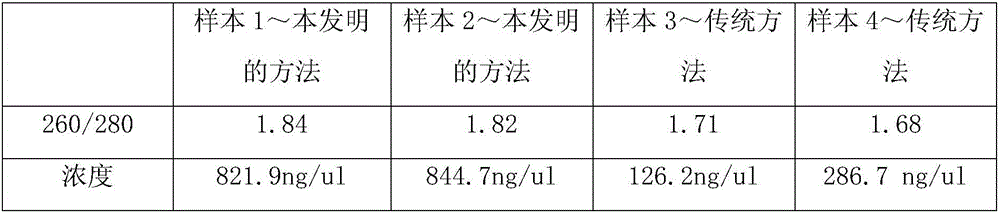

Immortalized telocytes system and construction method thereof

ActiveCN107034238AResolve separabilityAddressing Purity IssuesGenetically modified cellsVirus peptidesAntigenCulture mediums

The invention relates to a construction method of an immortalized telocytes system. The construction method comprises the following steps: (1) digesting shorn off mouse lung tissue block in type-II collagenase, carrying out filtering and centrifuging, collecting cyte precipitate, culturing the cyte precipitate in a culture medium, after fibrocytes are attached to a wall, transferring supernate to another culture dish, culturing for 12 hours, then changing liquid, and continuing culturing for 3-5 days; (2) taking a trace spearhead as a cyte scraper to scrape off the fibrocytes, and after scraping off the fibrocytes repeatedly, observing a specificity structure telopode and identifying telocytes by an immune marker; and (3) taking the telocytes as host cells, infecting the host cells by using a retroviral vector which contains SV-40-large tumor antigen, and carrying out passage, screening and identifying. Even if the immortalized telocytes system is cultured to the 50th generation, the state is still stable, and therefore, the problem that the purity and the stability of the telocytes cannot be guaranteed by repeated separation and extraction in the prior art.

Owner:ZHONGSHAN HOSPITAL FUDAN UNIV

Method for rapidly extracting fecal bacterial genome DNA and virus RNA through paramagnetic particle method

InactiveCN105950610AHigh speedEasy extractionMicrobiological testing/measurementDNA preparationWater bathsFeces

The invention discloses a method for rapidly extracting fecal bacterial genome DNA and virus RNA through a paramagnetic particle method. The method comprises the steps that 1, faeces is taken and put into a centrifuge tube, a buffer A is added, crushing and standing are conducted, and supernatant is taken and put into a new centrifuge tube; 2, a buffer B and a buffer C are added into the supernatant in sequence, and water-bath heating is conducted; 3, adsorption of DAN and RNA is conducted, wherein after decomposition is completed, a buffer D and a buffer E are added in sequence, vortex oscillation, standing and magnetic separation are conducted, and solid substances are left; 4, a buffer F and a buffer G are added into a centrifuge tube with left solid substances in sequence, vortex oscillation and magnetic separation are conducted; 5, a buffer H is added into the centrifuge tube subjected to treatment in the fourth step, vortex oscillation and water-bath heating are conducted, vortex oscillation is conducted again, cooling and magnetic separation are conducted, and the supernatant is moved to a new centrifuge tube for use.

Owner:杭州卓立纳米科技有限公司

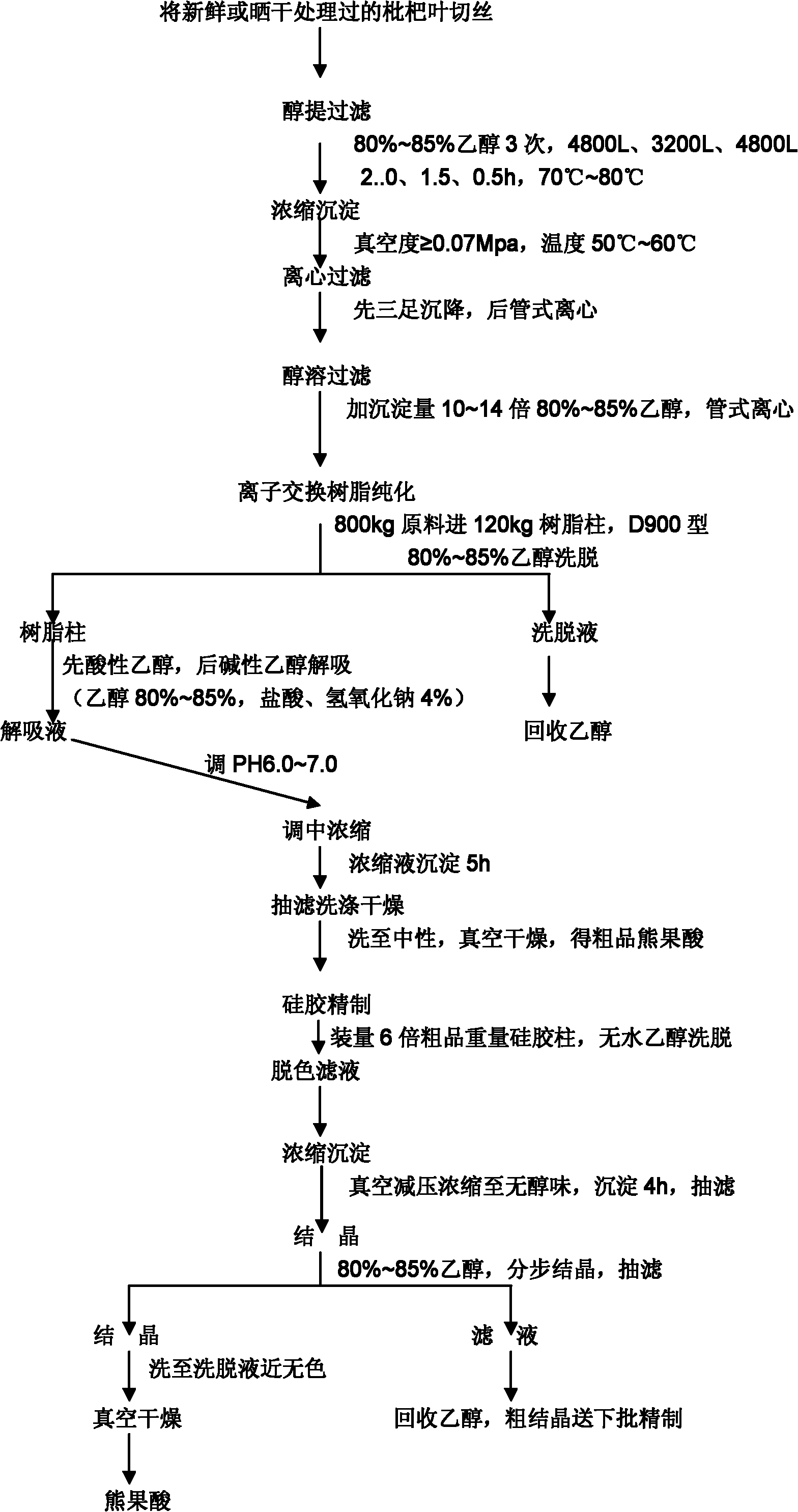

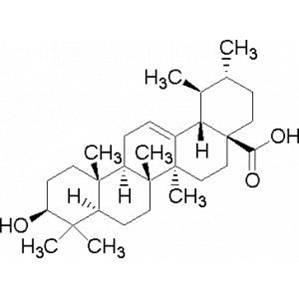

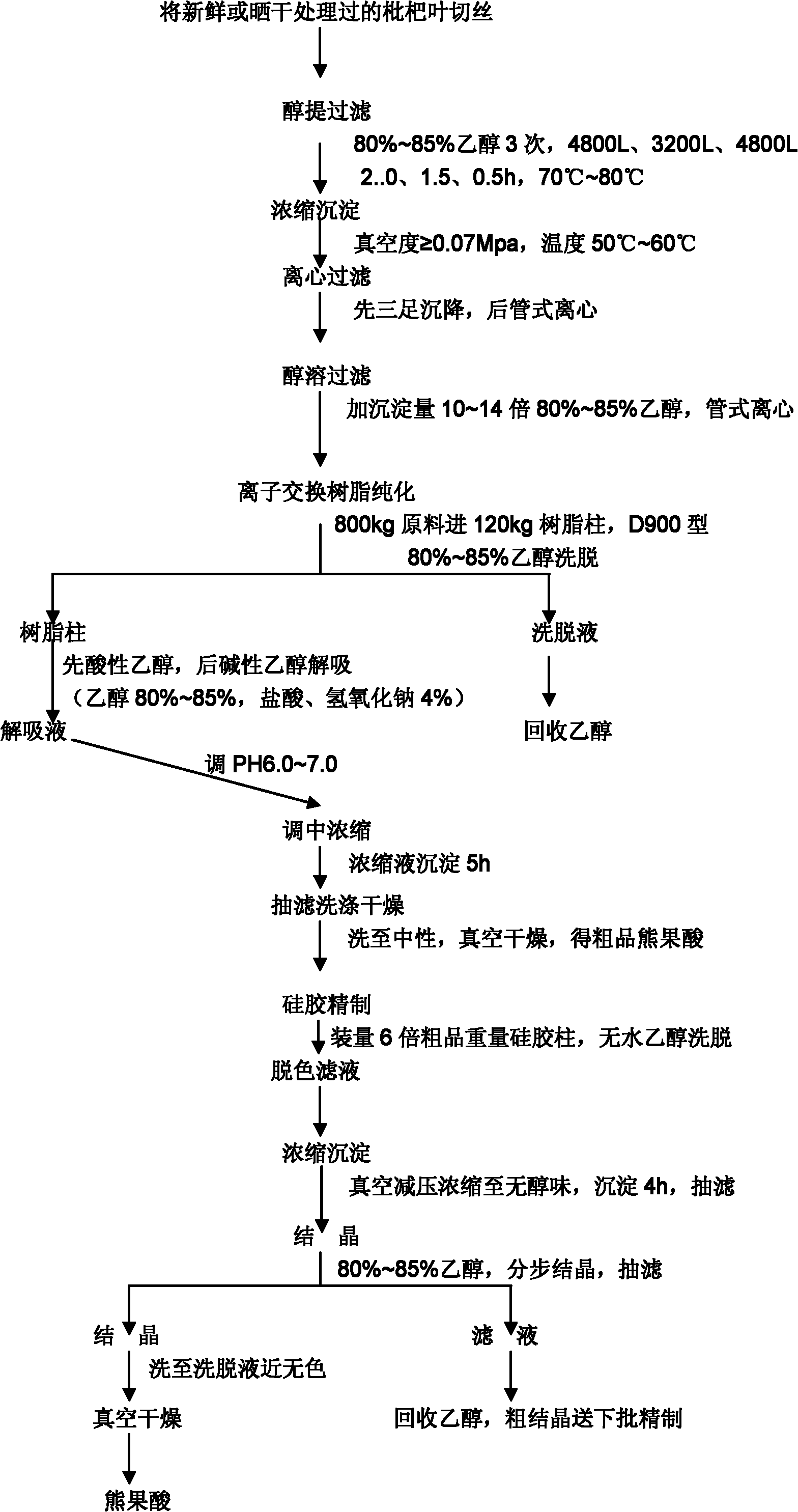

Process for extracting greater than or equal to 98% of ursolic acid from loquat leaf

The invention discloses a process for extracting greater than or equal to 98% of ursolic acid from loquat leaf, which is characterized by the following steps: taking fresh loquat leaves or loquat leaves dried in the sun as a raw material, slicing, extracting with alcohol and filtering, concentrating and precipitating, centrifuging and filtering, dissolving in alcohol and filtering, purifying by ion exchange resin, neutralizing and concentrating, washing and drying, refining by silica gel, discoloring and filtering, concentrating and precipitating, crystallizing and vacuum drying. The invention has the advantages: (1) establishing a standard production line and associated equipment for industrial production of the ursolic acid, searching for a feasible process route, and realizing mass production of high-quality ursolic acid products; (2) solving the problem of purity of the current ursolic acid, wherein the content of the ursolic acid achieves greater than 98% of an HPLC level by analysis and detection; and (3) improving the added value of the loquat leaf and changing wastes into valuables.

Owner:桂林安和药业有限公司

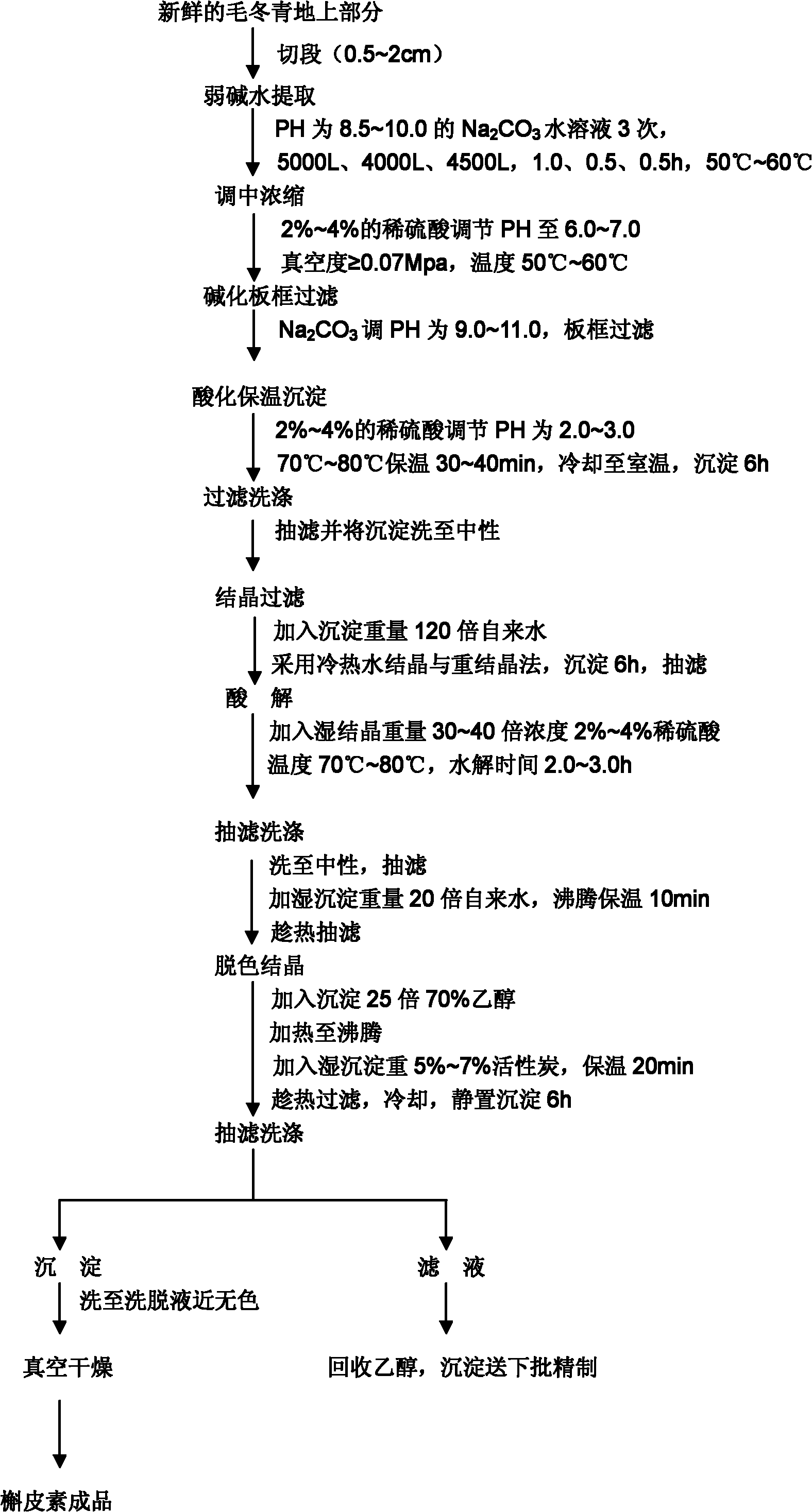

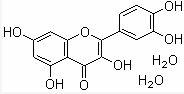

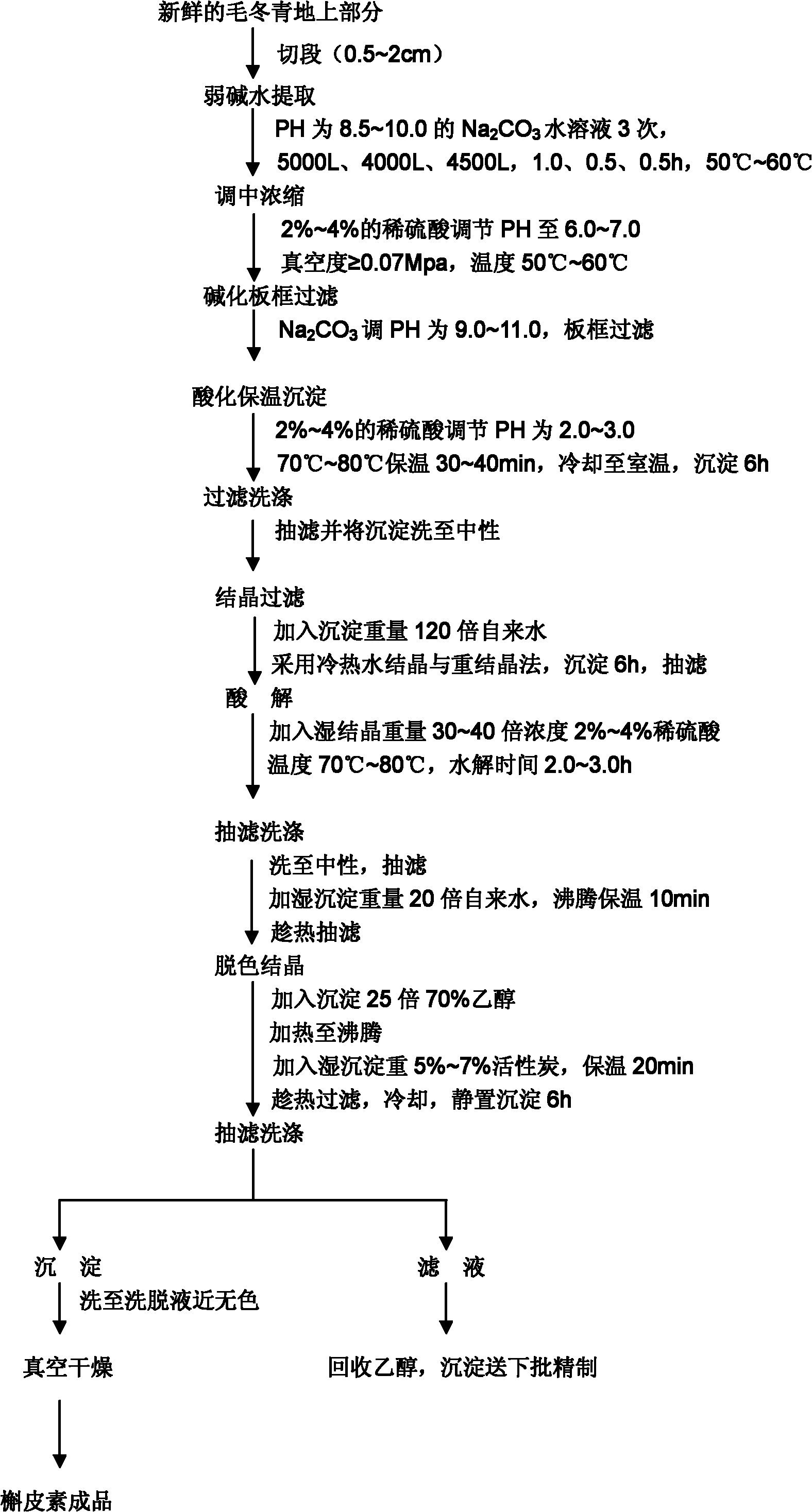

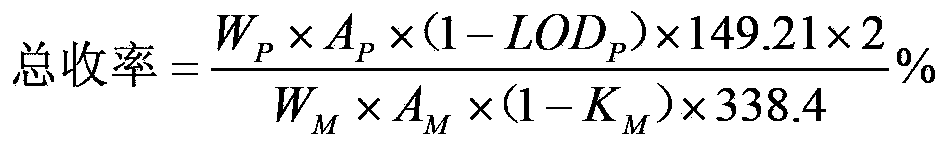

Process for separating and extracting 98% quercetin from aboveground part of pubescent holly root

ActiveCN101985439AReduce manufacturing costIncrease profitOrganic chemistryAlkaline waterProduction line

The invention discloses a process for separating and extracting 98% quercetin from the aboveground part of the pubescent holly root, which is characterized by comprising the following steps: slicing the aboveground part of the pubescent holly root which is taken as a raw material; extracting by weak alkaline water; neutralizing and concentrating; filtering by an alkalified plate frame; acidifying, insulating and depositing; filtering and washing; crystallizing and filtering; carrying out acid hydrolysis; carrying out suction filtration, and washing; discoloring and crystallizing; carrying out suction filtration, and washing; and carrying out vacuum drying to obtain a finished product. The invention has the advantages that (1) the new raw material (the aboveground part of pubescent holly root) for extracting the quercetin are found; (2) the production cost of the quercetin is reduced, the profit of enterprises is increased, energy saving and emission reduction are realized, and the market competitiveness of products is improved; (3) standard production lines and associated equipment for industrially producing the quercetin are established, thereby establishing a basis for industrial production; and (4) the problem of the quercetin purity in the prior art is solved, the content of the quercetin can reach more than 98% at an HPLC (high performance liquid chromatography) grade.

Owner:GUILIN SANLENG BIOTECH

Novel method for preparing medicinal despun hydroxyl methionine calcium

ActiveCN103420881AImprove qualityIncrease profitOrganic compound preparationSulfide preparationSolventCaking

The invention discloses a novel method for preparing medicinal despun hydroxyl methionine calcium. Pure water and acid are added to feed grade liquid methionine to carry out warming and backflow, after cooling, calcium hydroxide is added to the mixture to regulate the pH value, an organic solvent is added to the mixture, a small amount of solid impurities are filtered, vacuum concentration is carried out after adding pure water into the filter liquor, purified water is added, calcium hydroxide is added to the mixture to regulate the pH value after warming, the organic solvent is added to the mixture dropwise after activated carbon decoloration, cooling and centrifugation are carried out after dropwise adding is completed, crude products of the despun hydroxyl methionine calcium are obtained, and the crude products of the despun hydroxyl methionine calcium are refined in a mixed solvent of pure water and the organic solvent to obtain the refined products of the despun hydroxyl methionine calcium. According to the technology, raw materials are easy to obtain, the technology is simple, used solvents can be recycled to use, the content and purity of obtained products are quite high, the crystalline form is quite good, stirring of high rotating speed is not needed, materials are easy to separate and dry, the phenomena of caking and hardening in material drying will not be generated, course products in a mother solution can also be recycled, and the novel method for preparing the medicinal despun hydroxyl methionine calcium is suitable for industrial mass production.

Owner:SHAOXING MINSHENG PHARMA

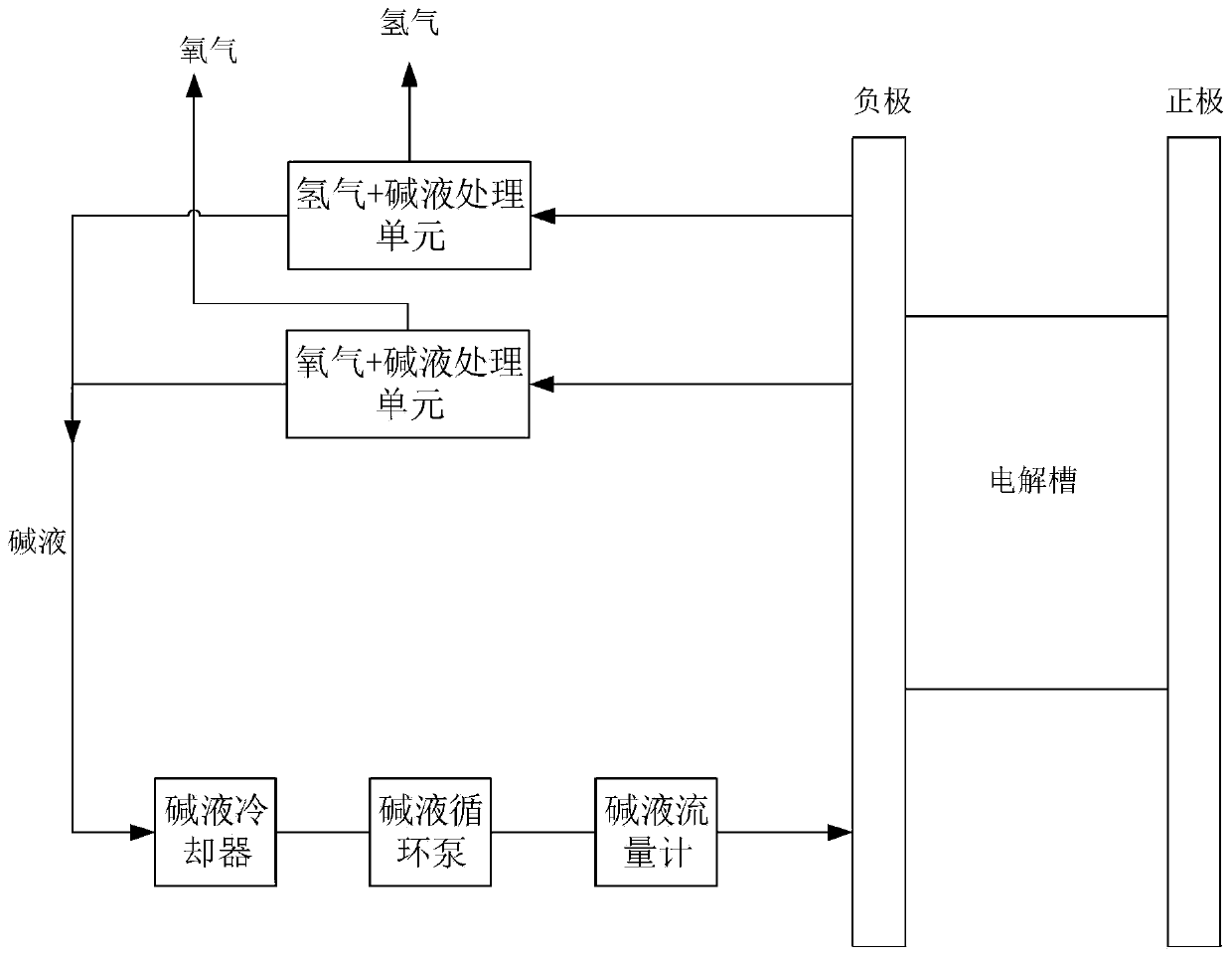

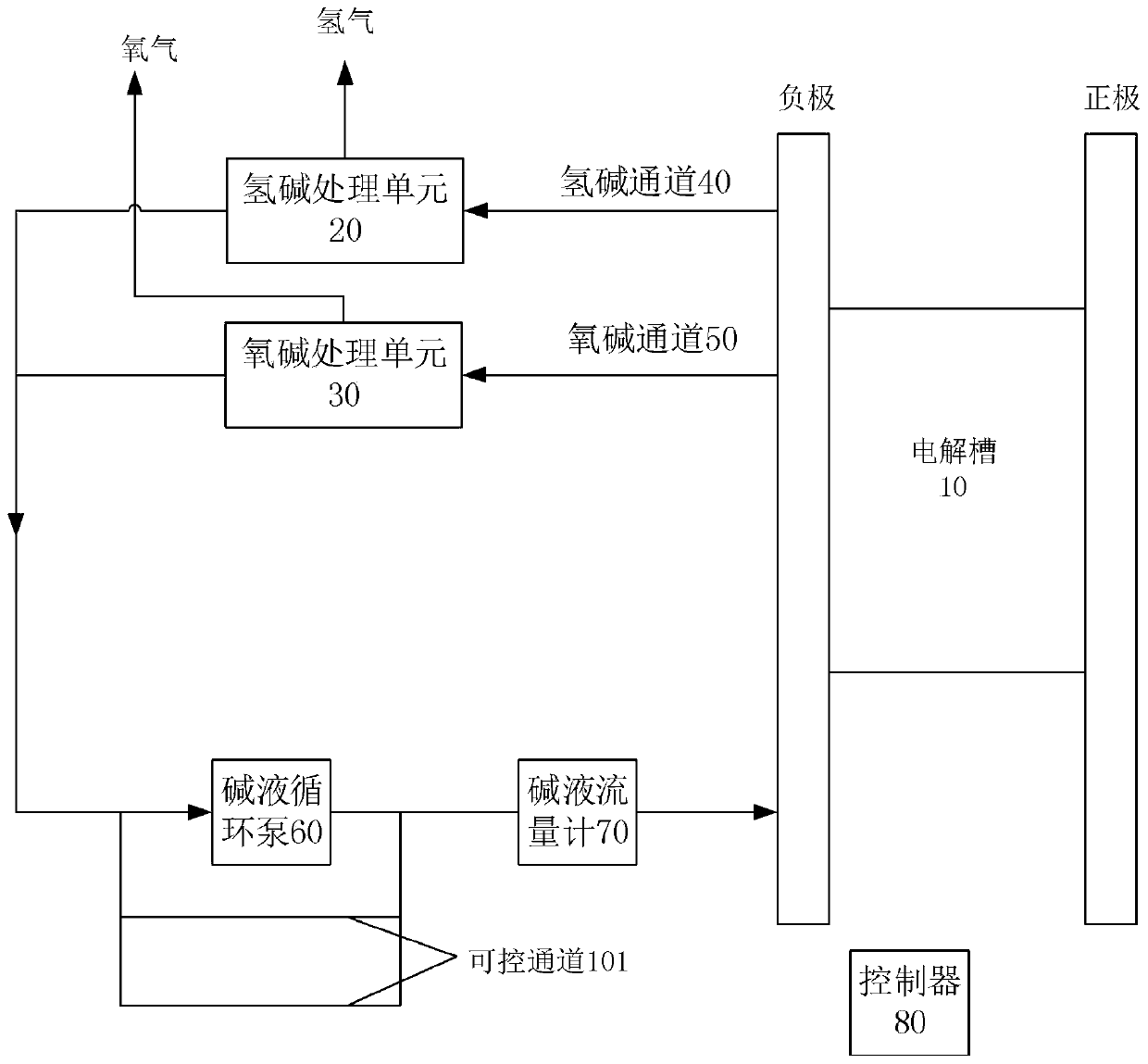

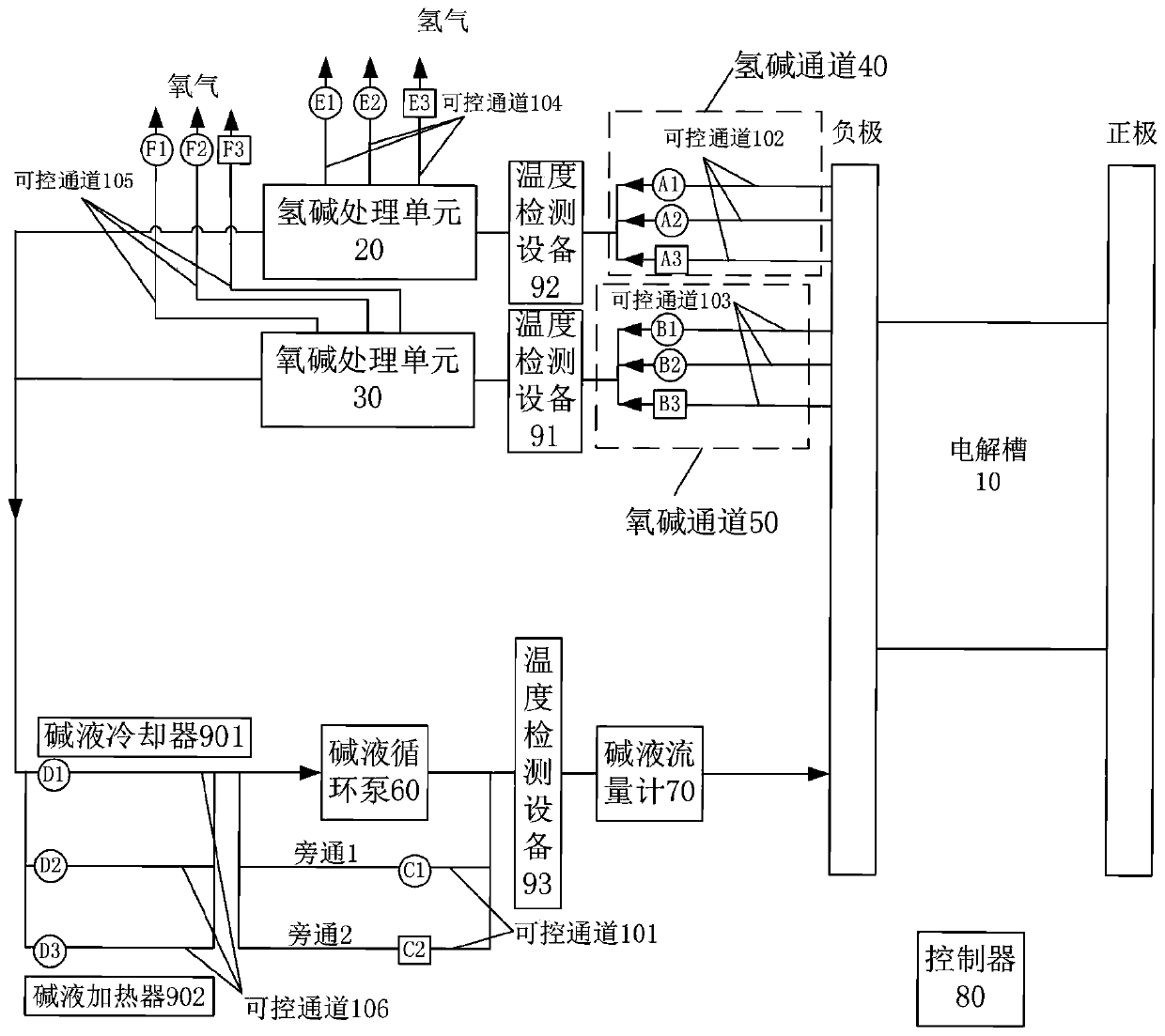

Multi-channel alkaline hydrogen production system

ActiveCN111364053AKeep running at full capacityChange gas purityCellsEnergy inputProcess engineeringChemical engineering

The invention provides a multi-channel alkaline hydrogen production system. Through liquid outlets of a hydrogen alkali processing unit and an oxygen alkali processing unit, a circulating alkali liquor is outputted to an alkali liquor circulating pump and at least one controllable channel that is parallelly arranged relative to the alkali liquor circulating pump; then the circulating alkali liquoris returned to the negative pole of an electrolytic tank; thus a controller can control the amount of produced hydrogen according to the detected current of the electrolytic tank; then based on the amount of produced hydrogen, a corresponding reference value of alkali liquor circulation amount can be calculated; based on the reference value of alkali liquor circulation amount, the work state of the controllable channel on two ends of the alkali liquor circulating pump is controlled, the alkali liquor circulation amount of the multi-channel alkaline hydrogen production system is adjusted, andthe gas purity of the multi-channel alkaline hydrogen production system is changed. Solved are the problems that the electrolytic tank is powered by a renewable power supply system, when the renewablepower supply system operates in a low period, the produced hydrogen purity is low, or even the hydrogen production is stopped. The electrolytic tank can be always in a full-load state, is not limitedin a specific load range, and is suitable for a hydrogen production system powered by a renewable power supply system.

Owner:阳光氢能科技有限公司

Graphite/silicon carbide compact composite material preparation method

The invention discloses a graphite / silicon carbide compact composite material preparation method, comprising the steps of before the sediments of the silicon carbide on the surface of a graphite article, applying a layer of silicon carbide particles on the graphite article as a transition layer, then applying CVD sediments for the coated silicon carbide layer. The method works through applying a layer of silicon carbide particles on the graphite article as the transition layer, and then applying CVD sediments for the coated silicon carbide layer, since the silicon carbide particles transition layer has small holes, the sediments of the silicon carbide on the surface of the transition layer penetrates into the holes, enabling a more compact combination of the coated layer and the base body; at the same while, the method works at short cycles, at low electricity consumption, to effectively solve the question mark of the pureness measure of the graphite article and the binding force of the coated layer, and to prevent from introducing impurities to the section of follow-up work.

Owner:江苏协鑫特种材料科技有限公司

Exemestane intermediate and preparation method therefor and application thereof

InactiveCN105017370AClear structureClear physical and chemical propertiesSteroidsStructural formulaMethyl group

The invention relates to an exemestane intermediate, particularly 6-(N-methyl-N-phenyl)-amine methyl-4-ene-3,17-androstanedione and a preparation method therefor and application thereof. The structural formula of the exemestane intermediate is a formula shown in the description. The 6-(N-methyl-N-phenyl)-amine methyl-4-ene-3,17-androstanedione prepared by the method provided by the invention can be used for preparing 6-methylene-4-ene-3,17-androstanedione through elimination reaction and the 6-methylene-4-ene-3,17-androstanedione is further oxidized to prepare exemestane. By using the intermediate provided by the invention to prepare exemestane, the purity and yield of exemestane are remarkably improved, the long-term troubled problem on the yield and purity of synthesized exemestane in the field is solved, and industrial practices verify that the exemestane intermediate has extreme value.

Owner:ZHEJIANG MEDICINE CO LTD XINCHANG PHAMACEUTICAL FACTORY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com