Process for separating and extracting 98% quercetin from aboveground part of pubescent holly root

A technology of aerial parts and hairy holly, which is applied in the field of separation and extraction of plant active ingredients, can solve the problems of reducing the extraction rate of rutin, making no profit for production enterprises, and different production costs, so as to improve market competitiveness and reduce production costs. cost, and the effect of increasing corporate profits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

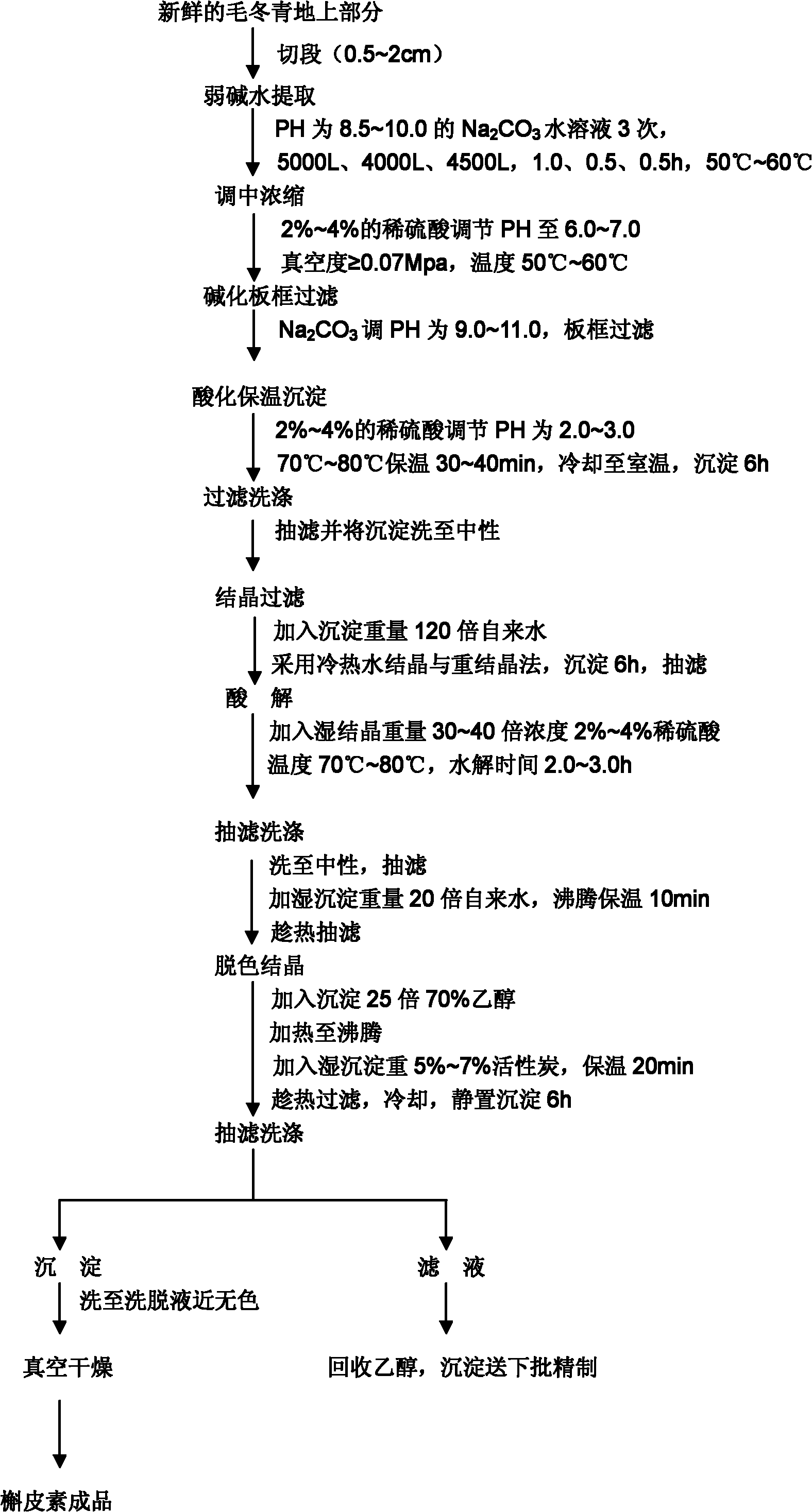

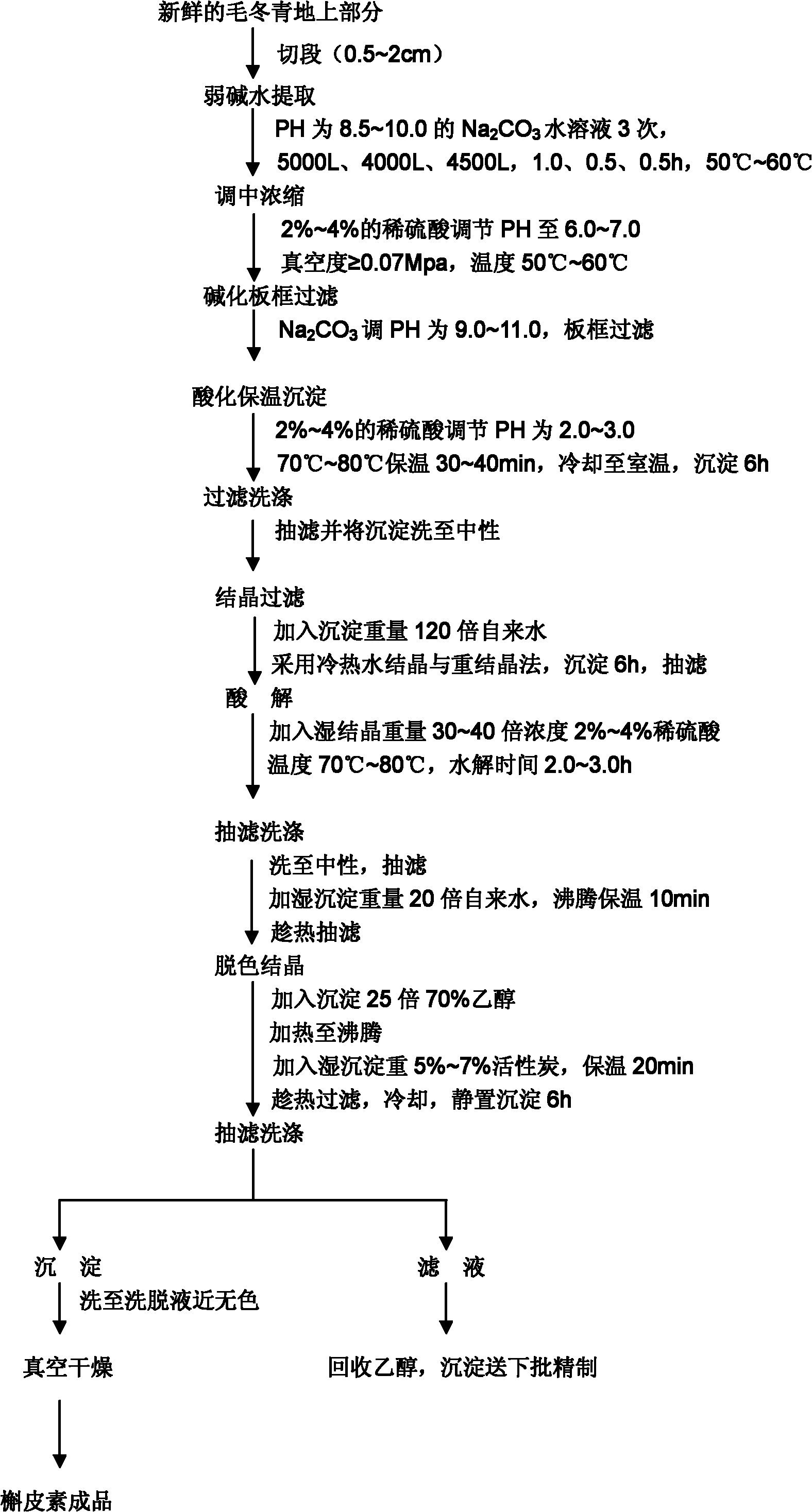

[0029] With reference to Fig. 1, the present invention separates and extracts the technique of 98% quercetin from the aerial part of Ilex pubescens, comprises the steps:

[0030] (1) Cutting into sections: Take 1000kg of the above-ground part of fresh holly, and cut into sections of 0.5-2cm;

[0031] (2) Weak alkaline water extraction: Put a small piece of medicinal material into 6cm 3 In the extraction tank, use Na with a pH of 8.5 2 CO 3 The aqueous solution was extracted 3 times, the amount of the added extract: the first time was 5000L, the second time was 4000L, the third time was 4500L, the extraction time was 1.0, 0.5, 0.5h, and the extraction temperature was 50℃~60℃. Filtrate, combine the first 2 filtrates, and extract the third filtrate as the first extract of the next batch of materials. residue discarded;

[0032] (3) Adjusting and concentrating: Use dilute sulfuric acid with a concentration of 2% to adjust the pH of the first two combined filtrates to 6.0~7.0, ...

Embodiment 2

[0046] Carry out embodiment 1 repeatedly by the same step as described, but: step (2) is 10 Na with pH 2 CO 3 The aqueous solution was extracted 3 times; step (3) adjusted the pH of the first two combined filtrates to neutral with 4% dilute sulfuric acid; step (5) adjusted the pH value of the filtrate with 4% dilute sulfuric acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com