Novel method for preparing medicinal despun hydroxyl methionine calcium

A technology of racemic calcium hydroxymethionine and liquid methionine, which is applied in the field of chemical synthesis of racemic calcium hydroxymethionine, can solve the problem of increasing operation steps and difficulty, not considering the existence of dimers and trimers, polyesterification operation and refining. Distillation purification operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

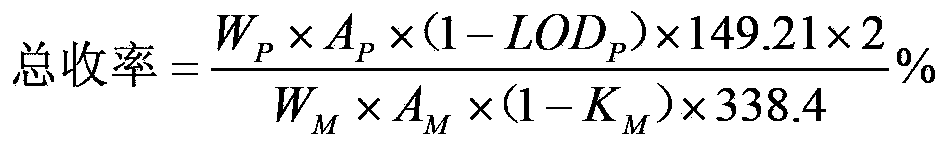

Image

Examples

Embodiment 1

[0026] Add 70kg of liquid methionine, 210kg of pure water, and 2.45kg of sulfuric acid to the reactor in sequence, and heat up to reflux (98-105°C) for 10.0 hours. Cool down to room temperature, add calcium hydroxide to pH 2.5~3.5, add 300kg tetrahydrofuran dropwise at 10~20°C, keep warm for 20~30 minutes after the dropwise addition, press filter, add 120kg pure water to the filtrate, and concentrate the reaction solution under reduced pressure to 350kg (for standby), cool down to below 43°C, weigh, add pure water until the total reaction liquid weighs 420kg. Raise the temperature to 60°C, add calcium hydroxide in batches until the pH is 4.5-5.5, add 1.0 kg of activated carbon, decolorize at 70-80°C for 20-30 minutes, and press filter. The tetrahydrofuran-water mixture obtained by concentration under reduced pressure was slowly added dropwise at 60-64°C. After dripping, the temperature was naturally cooled to room temperature, and the crystal was incubated for 2 hours, and ce...

Embodiment 2

[0029]Add 70kg of liquid methionine, 210kg of pure water, and 3.15kg of sulfuric acid to the reactor in sequence, and heat up to reflux (98-105°C) for 7.0 hours. Cool down to room temperature, add calcium hydroxide to pH 2.5-3.5, add 300kg methanol dropwise at 10-20°C, keep warm for 20-30 minutes after the dropwise addition, press filter, add 120kg pure water to the filtrate, and concentrate the reaction solution under reduced pressure to 320kg (for standby), cool down to below 43°C, weigh, add pure water until the total reaction liquid weighs 480kg. Raise the temperature to 60°C, add calcium hydroxide in batches until the pH is 4.5-5.5, add 1.0 kg of activated carbon, decolorize at 70-80°C for 20-30 minutes, and press filter. The methanol-water mixed solution obtained by concentrating under reduced pressure was slowly added dropwise at 60-64°C. After dripping, the temperature was naturally cooled to room temperature, and the crystal was incubated for 2 hours, and centrifuged...

Embodiment 3

[0032] The difference between this example and Example 2 is that 350kg of acetone is used instead of methanol as the solvent to obtain 68.0kg of refined product, with a loss on drying of 28.0%, a content of 99.5% (area normalization method), and a total yield of 70.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com