Patents

Literature

66results about How to "Prevent purity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

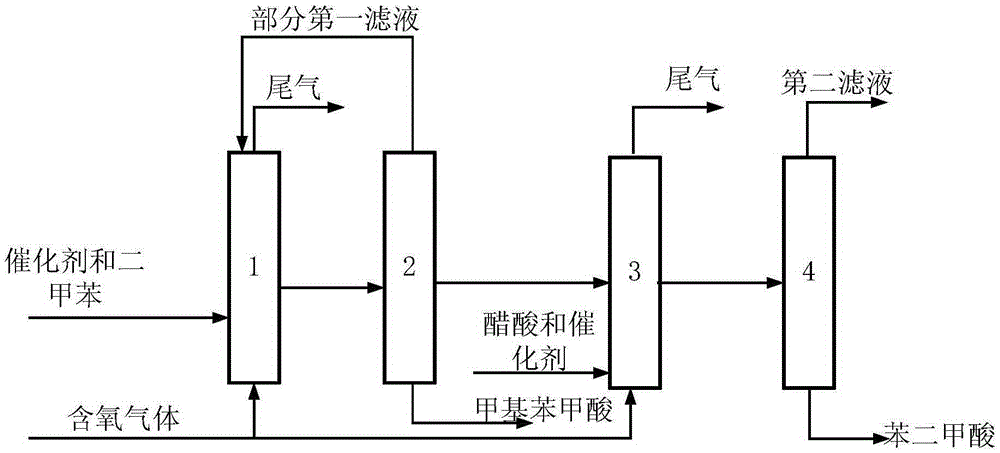

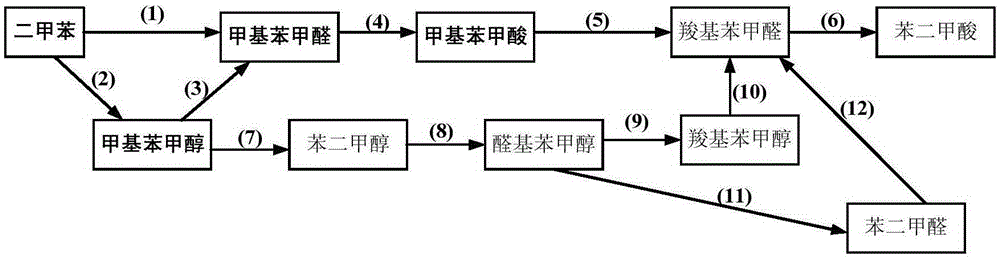

Co-production method for methyl benzoic acid and phthalic acid

ActiveCN105348067AHigh activityRealize online in-situ generationOrganic compound preparationCarboxylic compound preparationBenzoic acidAcetic acid

The invention discloses a co-production method for methyl benzoic acid and phthalic acid. The co-production method comprises the following steps: (1) continuously introducing fresh dimethylbenzene, a catalyst and oxygen-containing gas into a primary oxidation reactor for a reaction to obtain a primary oxidation reaction solution containing methyl benzoic acid and an eight-carbon oxygen-contained compound; (2) carrying out continuous cooling, crystallization and filtration on the primary oxidation reaction solution to obtain filter liquor and filter cake, circulating 1-98% of the filter liquor back the primary oxidation reactor continuously, and continuous rectifying the filter cake continuously, to obtain a low-boiling point front cut fraction, distillation raffinate and a methyl benzoic acid product separately; (3) adding the remaining filter liquor in the step (2) and the obtained front cut fraction and distillation raffinate in the step (2) into a secondary oxidation reactor continuously, and meanwhile continuously introducing a Co / Mn / Br catalyst, acetic acid and oxygen-containing gas into the secondary oxidation reactor for an oxidation reaction to obtain a secondary oxidation reaction mixture; and (4) continuously cooling, crystallizing and filtrating the secondary oxidation reaction mixture to obtain a filter liquor and a phthalic acid product. The co-production method has advantages of a simple process, a low cost, a high yield, good selectivity, good economic benefits, and environmental protection.

Owner:山东友道化学有限公司

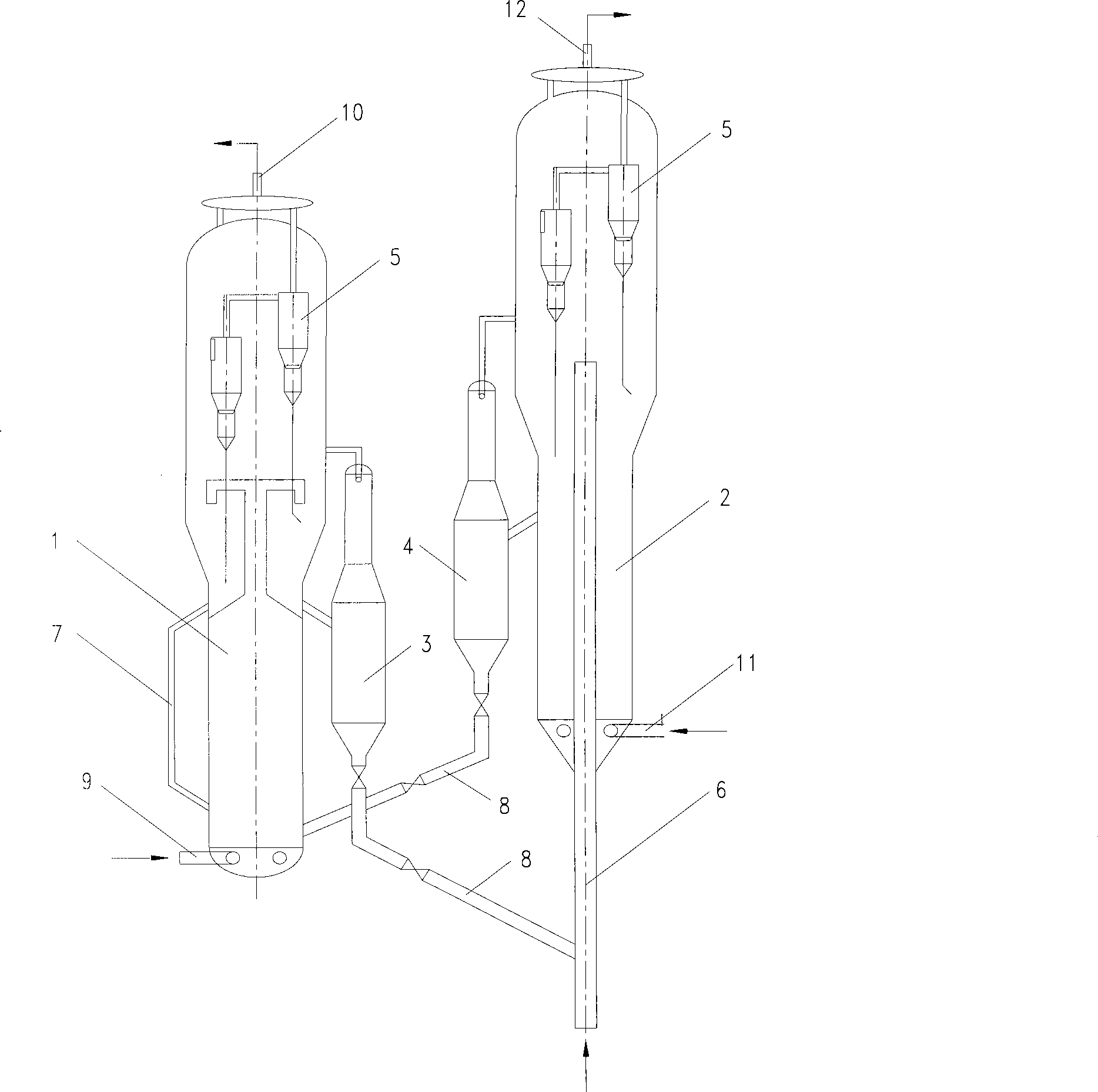

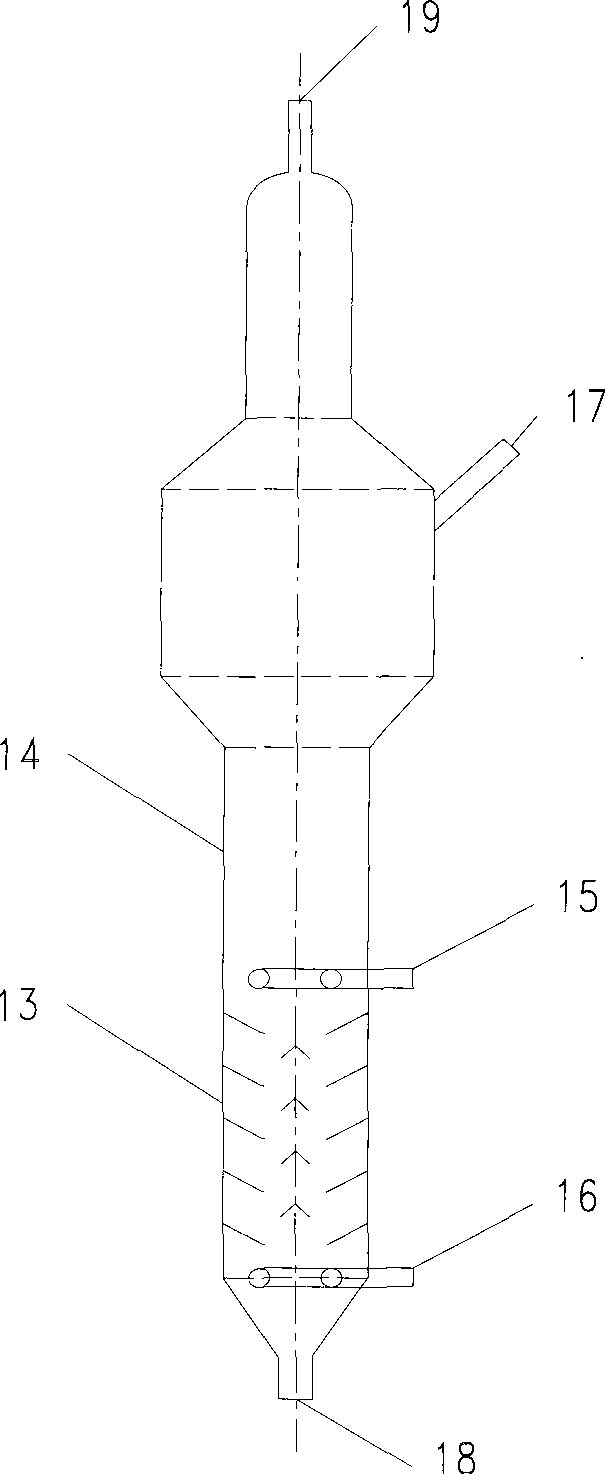

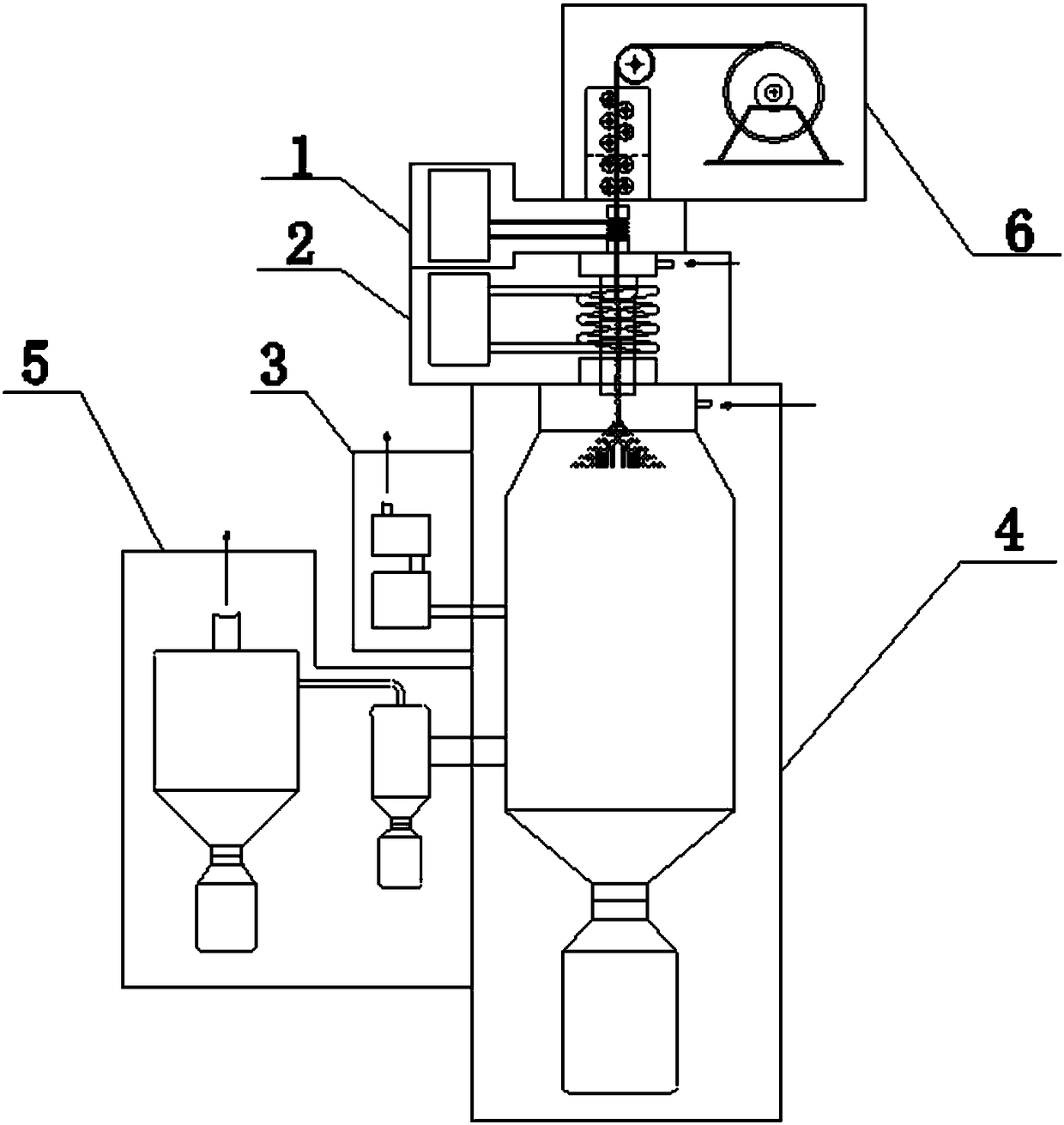

Powder preparation method for induction heating and radio frequency plasma combined atomizing powder system

ActiveCN108161019AHigh purityPrevent purityAdditive manufacturing apparatusHigh pressureRadio frequency

The invention relates to a powder preparation method for an induction heating and radio frequency plasma combined atomizing powder system. The powder preparation method comprises the following steps that (1), raw materials are prepared and processed; (2), the system is pre-vacuumed and a protective atmosphere is established; (3), wire materials are straightened and conveyed; (4), high-frequency induction preheating is carried out; (5), radio frequency plasma melting is carried out; (6), powders are prepared by atomizing; (7), separation and dust removal are carried out; and (8), the powder size is graded. The powder preparation method for the induction heating and radiofrequency plasma combined atomizing powder system uses high purity metal wire material instead of the powders as the raw materials, so that the carrying of raw materials to adsorb gas and water is reduced; a technology of the high frequency induction heating combined with the radio frequency plasma smelting and gas atomization is adopted, during the whole process of heating, melting, and the gas atomization is free of pollution and impurities in the protective atmosphere, and the degree of superheat of liquid flow ordroplets is increased during the process of radio frequency plasma smelting; and high quality spherical powders can be obtained by adopting high pressure atomizing nozzles atomizing, and the yield ofmetal powders per unit time is increased.

Owner:北京金物科技发展有限公司

Production of Mn-zn ferrite from waste magnesium dioxide batteries

InactiveCN1645657ARealize recyclingEasy to prepareReclaiming serviceable partsWaste accumulators reclaimingIron powderManganese

The method includes liquid extraction and filter processes. Iron powder being more than mercury content is added into the above extracted and filtered solution. The mercury is removed and an amount of Fe(NO3)3, Fe(NO2)3, Zn(NO3)2, Mn(NO3)2 are added. The total metal ionic concentration is made to be 1mol / L. MnO: ZnO: FeO=0.6:0.4:1.0 (mol ratio).After the above solution is heated, the citric acid is added. After evaporation the sol is obtained. After drying the sol the xerogel is obtained. After xerogel is calcinated, the manganese-zinc ferrite is obtained.

Owner:HENAN NORMAL UNIV

Preparation method for dialkyl phosphinates

ActiveCN102924508AAvoid residueReduce solubilityGroup 5/15 element organic compoundsOrganic solventReaction temperature

The invention relates to a preparation method for dialkyl phosphinates, and belongs to the field of green and environment-friendly fire retardant. The preparation method for dialkyl phosphinates comprises the following technical steps: (1) preparing dialkyl phosphinic acid and / or alkali metal salt of dialkyl phosphinic acid; and (2) preparing dialkyl phosphinates. The preparation method adopts the water as the reaction solvent, so that the organic solvent residual in a product can be avoided, and the generation of telomere can be obviously reduced and even avoided, and as a result, the purity of the product can be ensured. Special assistant is added in the preparation method, so that the reaction temperature is reduced, the reaction time is reduced, and the energy consumption is also reduced while the yield and purity of dialkyl phosphinic acid and / or the alkali metal salt of dialkyl phosphinic acid are ensured.

Owner:ZHEJIANG XINHUA CHEM

Preparing method for high-purity sanshoamides

ActiveCN104026538AReduce difficultyReduce complexityNatural extract food ingredientsFood preparationDistillationEvaporation

The invention discloses a preparing method for high-purity sanshoamides. The preparation method comprises the following steps: a supercritical carbon dioxide extraction technology and a molecular distillation technology are combined, zanthoxylum oil resin which is obtained through supercritical extraction is used as a raw material, pre-treatment, and evaporation and molecular distillation are performed on the raw material to prepare the sanshoamides. The utilization rate of the raw material in the preparation method is high, the content of the sanshoamides in the obtained sanshoamides products is 720mg / g-850mg / g, and the purity of the products is high.

Owner:南阳雪麦龙生物科技有限公司

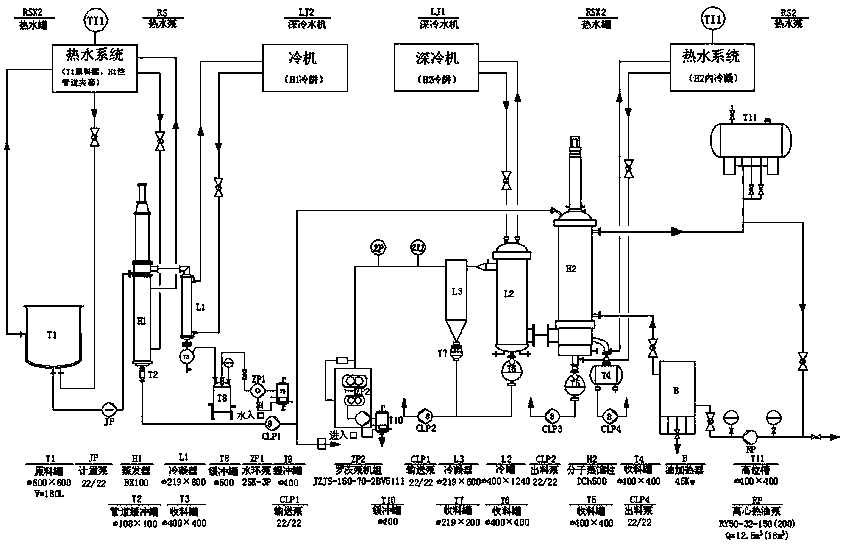

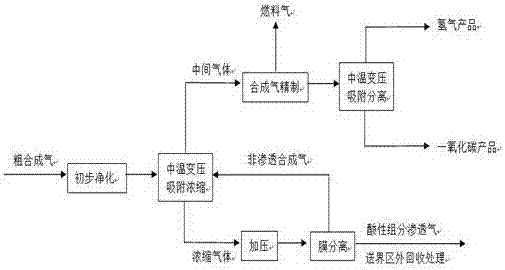

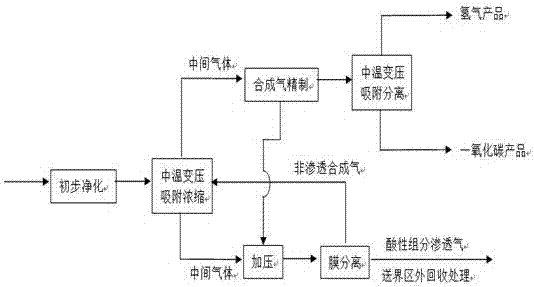

Purification and separation method of syngas by full temperature range-pressure swing adsorption (FTrPSA)

ActiveCN107285279ASave the cooling capacity required for the operating temperature of -75~-34°CSave coolingHydrogen separation using solid contactHydrogen/synthetic gas productionSeparation technologyImpurity

The invention discloses a purification and separation method of a syngas by FTrPSA, and relates to the technical field of H2 production, CO production and purification and separation for a PSA gas. Compared with the prior art, the purification and separation method of the syngas by FTrPSA disclosed by the invention separates coarse removal and refined removal of impurities of acidic components and the like in the syngas purification process, an intermediate gas is refined by the syngas and subjected to an intermediate temperature PSA separation process to obtain a qualified syngas product or H2 and CO products, the operating temperature and operating pressure are the same as those of an intermediate temperature PSA concentration process, so that the load and energy consumption of the syngas in the refining and intermediate temperature PSA separation are reduced, the integration degree of purification and separation process and the purity of the produces are improved, furthermore, a concentrated gas is subjected to a membrane separation process to obtain further recycled syngas and remove the acidic components, so that the load of the membrane separation process is reduced and the yield of the products is improved.

Owner:SICHUAN TECHAIRS

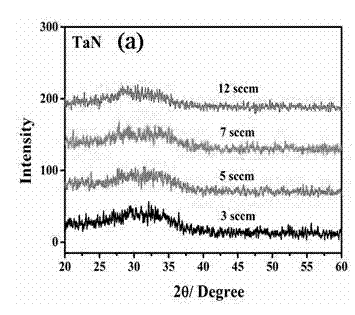

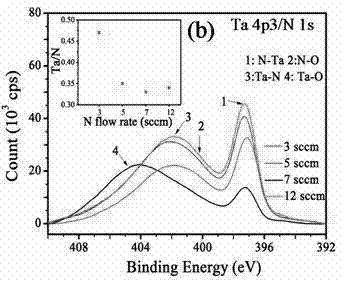

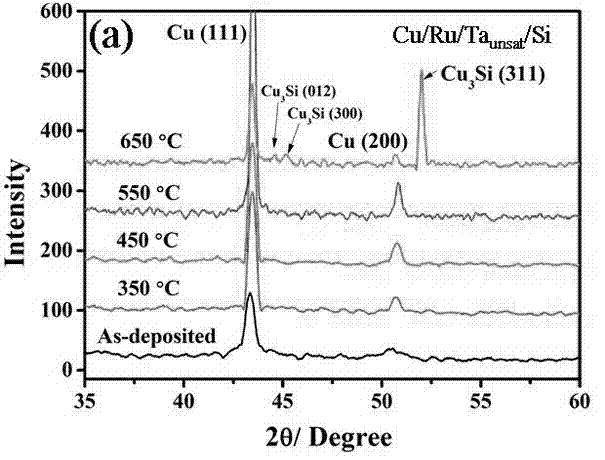

Method for preparing high thermal stability double layer diffusion impervious layer material

InactiveCN102392216APrevent purityAvoid pollutionVacuum evaporation coatingSputtering coatingDiffusionElectrical performance

The invention provides a method for preparing a high thermal stability double layer diffusion impervious layer material. The method is characterized in that a direct current magnetron sputtering process is employed, accurate control of N content in an amorphous TaN film is realized by regulating N air flow rate, a high performance double layer Ru / TaN diffusion impervious layer structure with different N content is prepared, the effective work is stably as high as 650 DEG C. N atoms in gap of the TaN film are diffused during the annealing process and then raise the diffusion impervious performance of the Ru / TaN bilaminar membrane. The thermal stability double layer diffusion impervious layer material can be obtained by accurately controlling the N content, and is capable of keeping excellent electrical performance and better ensuring its practical application. The invention has the advantages of simple operation, good repeatability and good realization effect.

Owner:NANJING UNIV

Method for preparing manganese-zinc ferrite using waste alkaline manganese bioxide battery

InactiveCN1880273AWide range of usesIncrease dosageWaste processingSolid waste disposalManganeseEngineering

The invention discloses a preparing method of manganese-zinc ferrite by using waste alkaline manganese dioxide battery belonging to the preparing method of magnetic material. The technology problem resolved in the invention is producing manganese-zinc ferrite directly by the metal in waste alkaline manganese dioxide battery, to realize the renewable resources of waste battery with simple preparing method, low consumption energy, low cost, high additive value. The technical project of the invention is sol-gal process including liquid leaching, filtering for removing insoluble matter, adjusting solution components, making sol-gel, burning xerogel in the temperature of 600-650 degree centigrade or burning xerogel for manganese-zinc ferrite product. The invention is used for producing manganese-zinc ferrite by waste alkaline manganese dioxide battery.

Owner:HENAN NORMAL UNIV

Novel method for preparing medicinal despun hydroxyl methionine calcium

ActiveCN103420881AImprove qualityIncrease profitOrganic compound preparationSulfide preparationSolventCaking

The invention discloses a novel method for preparing medicinal despun hydroxyl methionine calcium. Pure water and acid are added to feed grade liquid methionine to carry out warming and backflow, after cooling, calcium hydroxide is added to the mixture to regulate the pH value, an organic solvent is added to the mixture, a small amount of solid impurities are filtered, vacuum concentration is carried out after adding pure water into the filter liquor, purified water is added, calcium hydroxide is added to the mixture to regulate the pH value after warming, the organic solvent is added to the mixture dropwise after activated carbon decoloration, cooling and centrifugation are carried out after dropwise adding is completed, crude products of the despun hydroxyl methionine calcium are obtained, and the crude products of the despun hydroxyl methionine calcium are refined in a mixed solvent of pure water and the organic solvent to obtain the refined products of the despun hydroxyl methionine calcium. According to the technology, raw materials are easy to obtain, the technology is simple, used solvents can be recycled to use, the content and purity of obtained products are quite high, the crystalline form is quite good, stirring of high rotating speed is not needed, materials are easy to separate and dry, the phenomena of caking and hardening in material drying will not be generated, course products in a mother solution can also be recycled, and the novel method for preparing the medicinal despun hydroxyl methionine calcium is suitable for industrial mass production.

Owner:SHAOXING MINSHENG PHARMA

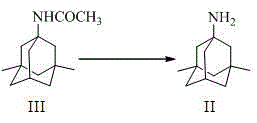

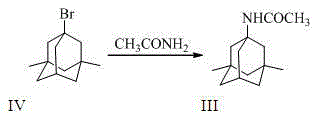

Method for preparing memantine hydrochloride

ActiveCN104557567ARaw materials are easy to obtainEasy to operateOrganic compound preparationCarboxylic acid amides preparationKetone solventsMemantine hcl

The invention discloses a method for preparing memantine hydrochloride. The method is characterized in that the method provided by the invention uses 1-bromo-3,5-dimethyladamantane (represented by a general formula IV in the description) as a starting material which is subjected to an amination reaction with acetamine to obtain a key intermediate 1-actamido-3,5-dimethyladmantane (represented by a general formula III in the description); the compound represented by the general formula III is subjected to alcoholysis in a mixture system of inorganic base and n-butyl alcohol for deacetylated to obtain memantine; memantine is treated using hydrochloric acid in a ketone solvent to obtain memantine hydrochloride. The method provided by the invention overcomes deficiencies in the prior art and has the advantages that the raw materials are simple and readily available, the reaction steps are simple and short, and the operations are convenient and fast, therefore, the method is suitable for industrial production.

Owner:CHONGQING PHARMA RES INST

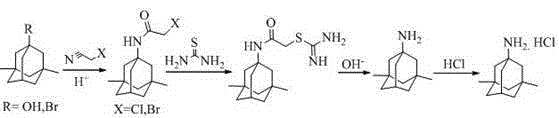

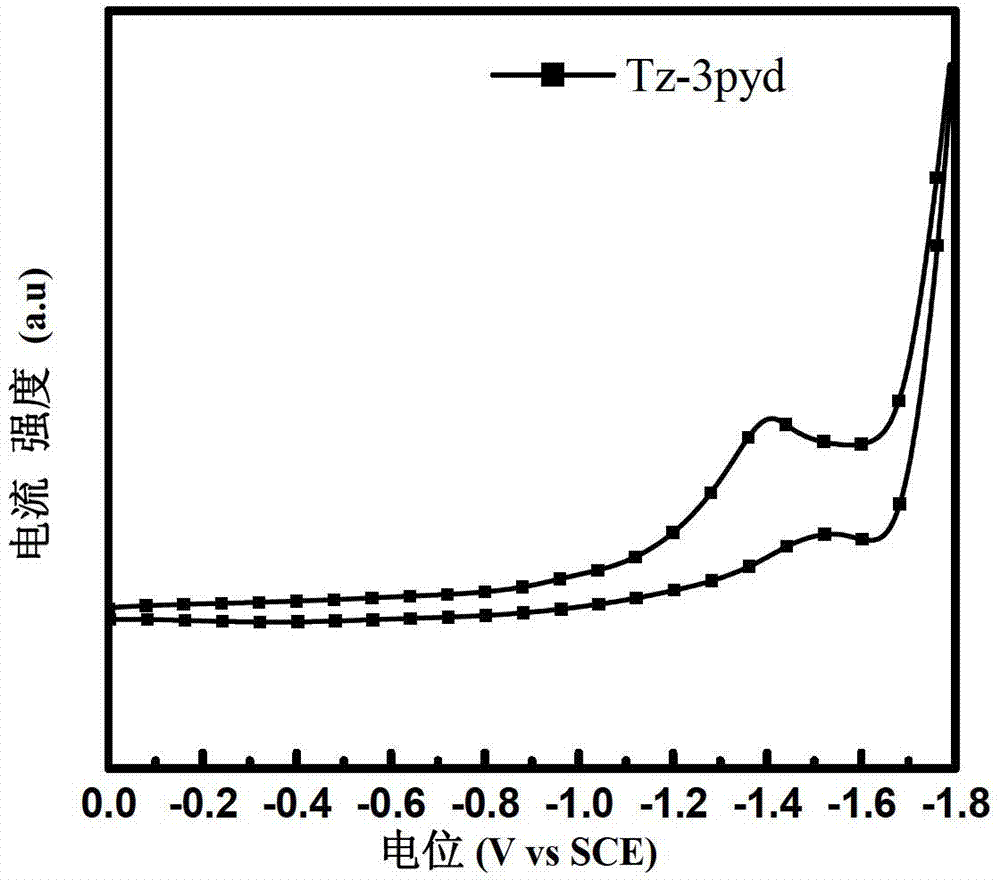

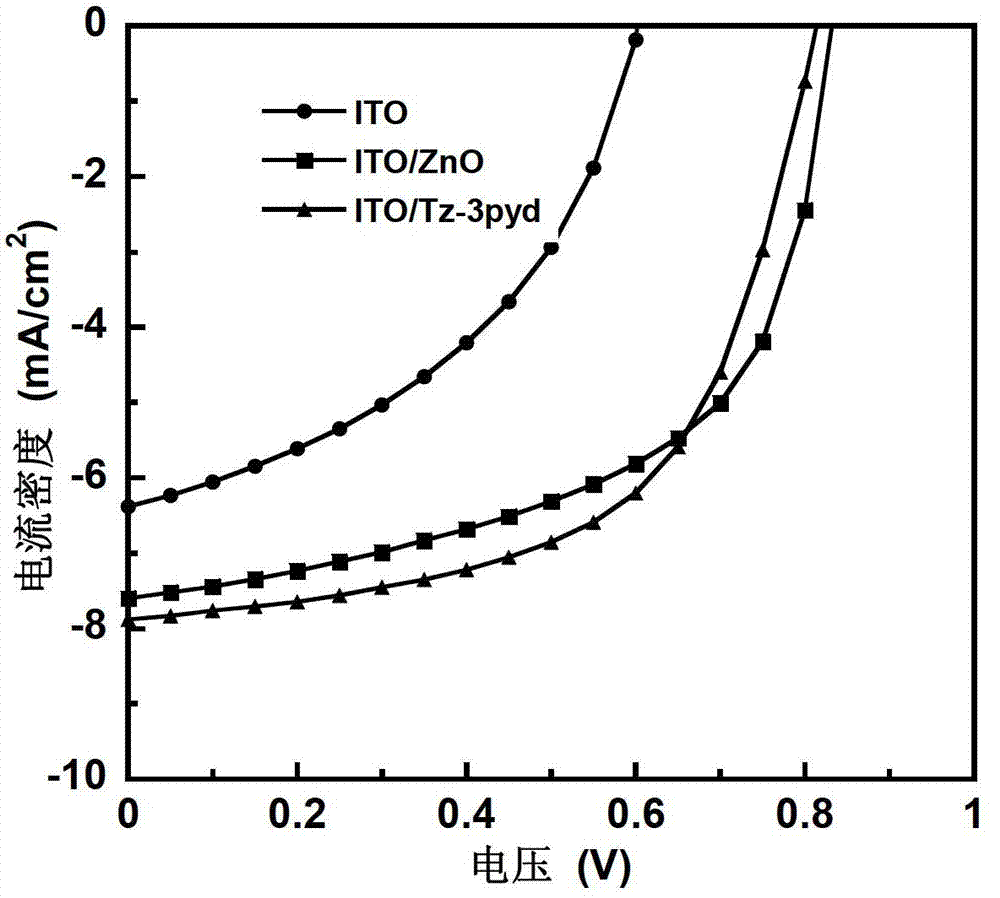

Water-soluble small molecule pyridinium photoelectric material and preparation method and application thereof

InactiveCN103193764AEasy to purifyImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingSolubilityElectron injection

The invention discloses a preparation method of a water-soluble small molecule pyridinium photoelectric material. The method comprises the following steps of: adding pyridine and acetonitrile into a reaction container, heating and stirring the materials, adding a bromomethyl or chloromethylated aromatic heterocyclic compound to the reaction container, cooling the materials to room temperature after the reaction is finished, and removing the solvent under a pressure reduced condition, thus obtaining a coarse product; dissolving the coarse product through methanol, precipitating and filtering the dissolved product for multiple times, and performing vacuum drying on the product to obtain the final product; or dissolving the coarse product through methanol, adding a sodium salt solution containing an anion group to the product, stirring the solution and the product for two days, removing the solvent under a pressure reduced condition, washing and drying the mixture for multiple times, and performing vacuum drying on the dried mixture to obtain the final product. The water-soluble small molecule pyridinium photoelectric material is determinate in structure and molecular weight and is easily purified, avoids the problem that the batch of a polymer interface material is instable, and has the advantages of high water solubility, film-forming property, film morphology stability, high eletrophilicity, deep lowest unoccupied molecular orbital (LUMO) energy level and low electron injection / extracting energy barrier.

Owner:SOUTH CHINA UNIV OF TECH

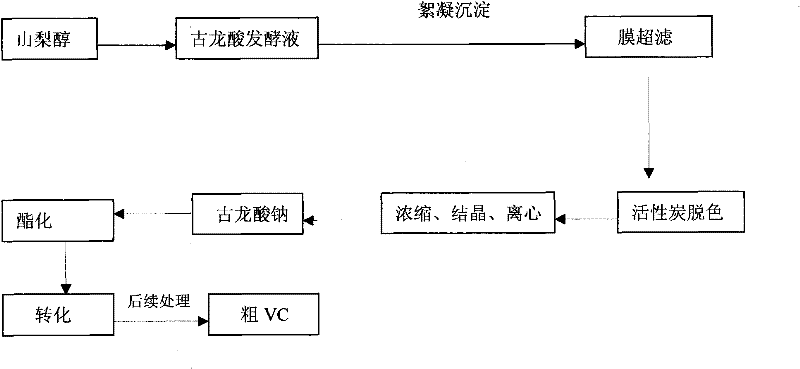

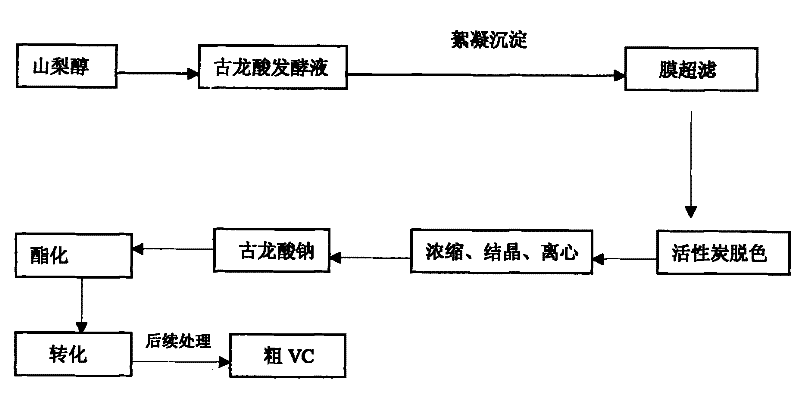

Method for preparing vitamin C with low consumption

The invention discloses a method for preparing vitamin C with low consumption, which comprises the following steps: (a) preparing fermented liquor produced by the vitamin C through a two-step fermentation method, and adding a flocculating agent into the fermented liquor to perform sediment; (b) adding strong alkali into the fermented liquor to adjust the pH value; (c) performing member ultra-filtration and decolorizing treatment on the fermented liquor to obtain sodium gulonate crystal; and (d) performing esterification reaction, conversion reaction and acidification reaction on the sodium gulonate crystal, and filtering the reaction product to obtain coarse Vc. The method further improves the quality and increases the yield of the vitamin C, simplifies the production process and reduces the production and manufacturing costs.

Owner:HEBEI WELCOME PHARMACEUTICAL CO LTD +1

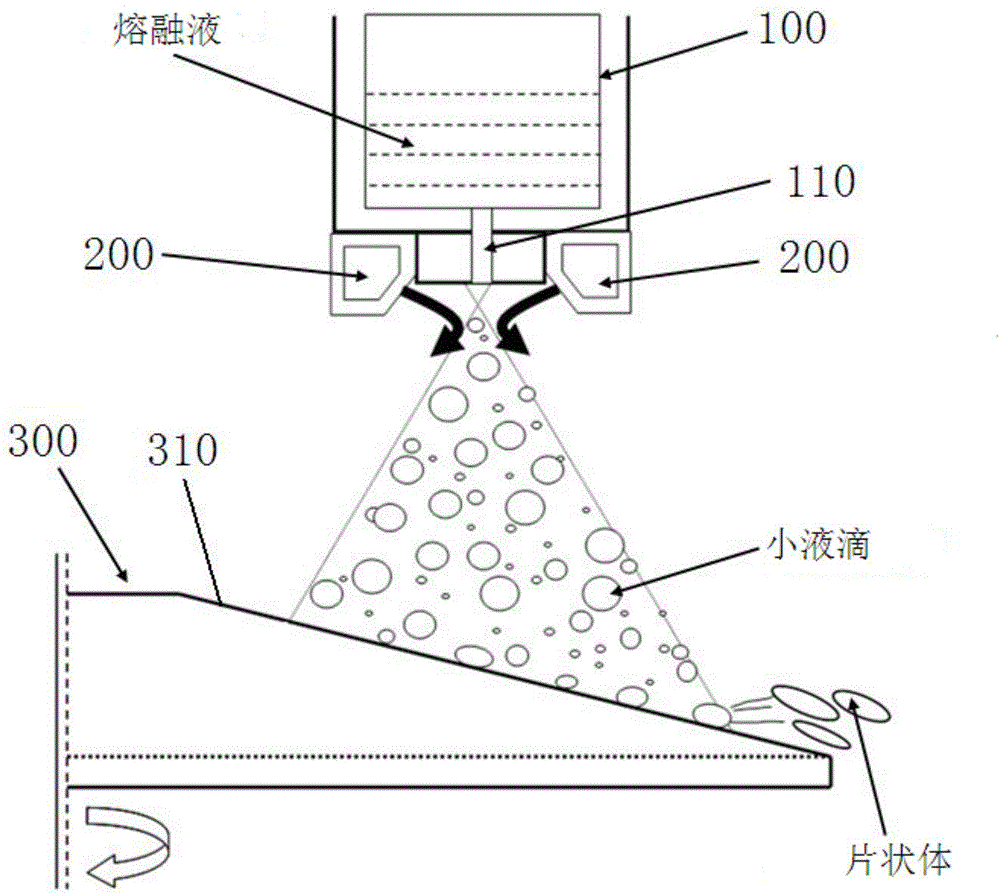

Preparation device and method for flaky powder

The present invention provides a device and method for preparing flake powder, wherein the device includes a melting device, and a nozzle is arranged on the melting device; a gas atomizing device, the gas atomizing device is arranged below the nozzle; A turntable, the turntable is arranged below the gas atomizing device, and the surface of the turntable close to the gas atomizing device is an inclined plane, and the turntable rotates at a certain speed; and a discharge collecting device , the discharging and collecting device is arranged below the rotary disc. The flake powder preparation device of the invention has the advantages of simple structure, low cost, low energy consumption, convenient operation and no pollution, and can be applied to continuous industrial production for preparing flake metal powder, flake amorphous and flake quasicrystal. and flaky microcrystalline powder.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Preparation method of dialkyl phosphinate

ActiveCN103319525AAvoid residueReduce generationGroup 5/15 element organic compoundsChemical synthesisPhosphoric acid

The invention discloses a chemical synthetic method, and specifically relates to a preparation method of dialkyl phosphinate. The preparation method comprises the following steps of: adding a small amount of a reaction auxiliary agent into reaction raw materials including hypophosphorous acid and / or an alkali metal salt of hypophosphorous acid, and dissolving the mixture into water; then transferring the mixture into a pressure kettle; performing nitrogen replacement, and then heating to raise the temperature; introducing alkene, and then adding an initiating agent to react so as to obtain dialkyl phosphinic acid and / or an alkali metal salt of the dialkyl phosphinic acid; and then transferring the dialkyl phosphinic acid and / or the alkali metal salt of the dialkyl phosphinic acid into a reactor, heating to a certain temperature, slowly dropping a solution of a metal salt to obtain a corresponding dialkyl phosphinate deposit, and then filtering, washing and drying to obtain a dialkyl phosphinate product. The preparation method has the advantages that water is used as a reaction solvent system, a specific reaction auxiliary agent is added, and the way of feeding the initiating agent is changed, so that the reaction temperature is lowered, the reaction time is shortened, the product yield and the product quality are improved, and the cost is saved.

Owner:ZHEJIANG XINHUA CHEM

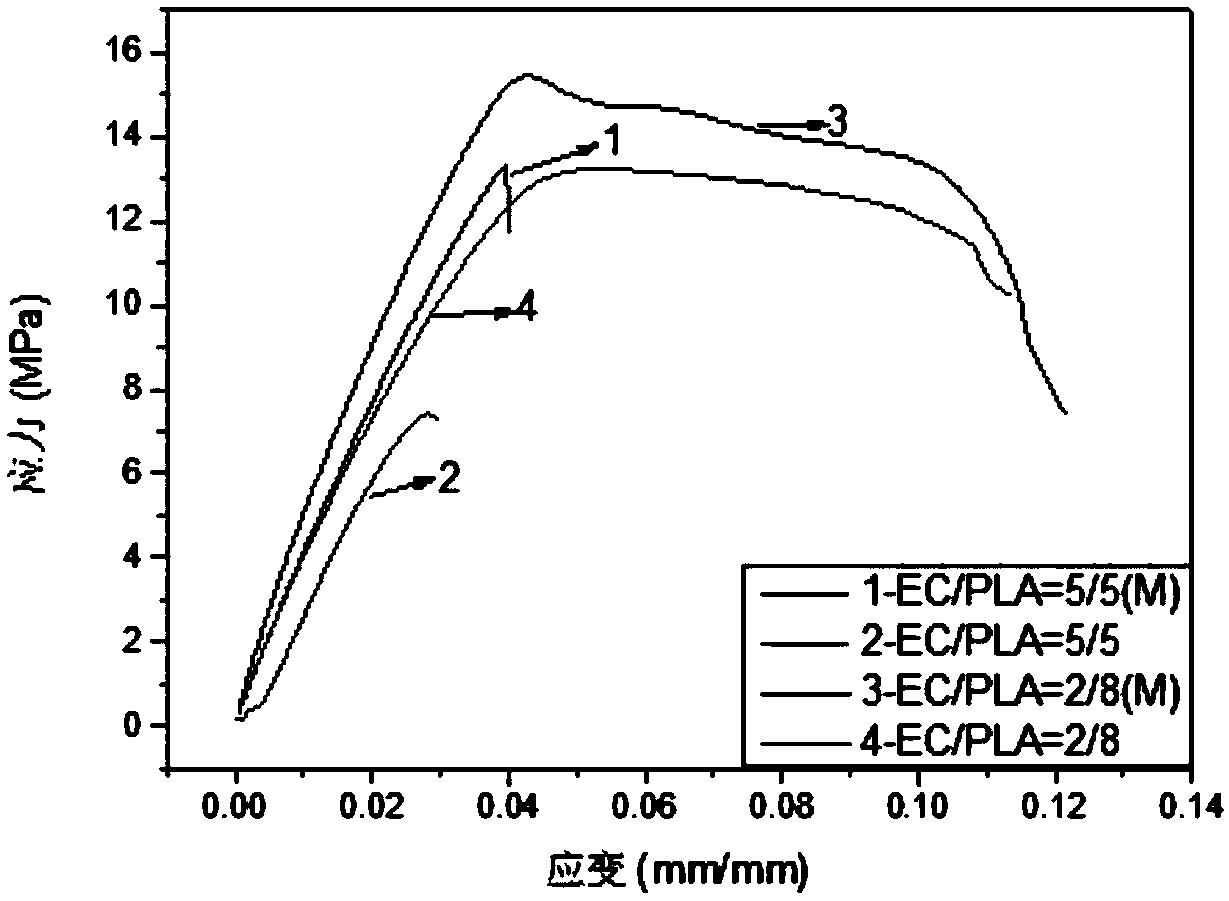

Preparation and application methods of cellulose derivative-grafted polylactic acid

The invention relates to preparation and application methods of a cellulose derivative-grafted polylactic acid. The preparation method of the cellulose derivative-grafted polylactic acid comprises thefollowing steps of dissolving cellulose derivatives into solvent, then completely stirring and dissolving in polylactic acid; adding in catalysts and increasing the temperature for reaction; performing vacuum drying to obtain the cellulose derivative-grafted polylactic acid. The prepared cellulose derivative-grafted polylactic acid is applied to fully biodegradable films to improve two-phase interface compatibility, mechanical performance and transparency of a polylactic acid-cellulose composite film. According to the preparation method the cellulose derivative-grafted polylactic acid, the applied polylactic acid is commercial polylactic acid and reacts with the cellulose derivative through transesterification to prepare the cellulose derivative-grafted polylactic acid, which can serve asan interfacial solubilizer for polylactic acid / cellulose composite materials to improve the mechanical performance of the polylactic acid / cellulose composite materials. The preparation method of thecellulose derivative-grafted polylactic acid avoids the problems of high reaction requirements and expensive catalysts of ring-opening polymerization of high-purity lactide monomers and is easy to industrialize.

Owner:HUBEI GUANCHENG BIODEGRADABLE PLASTIC PRODS

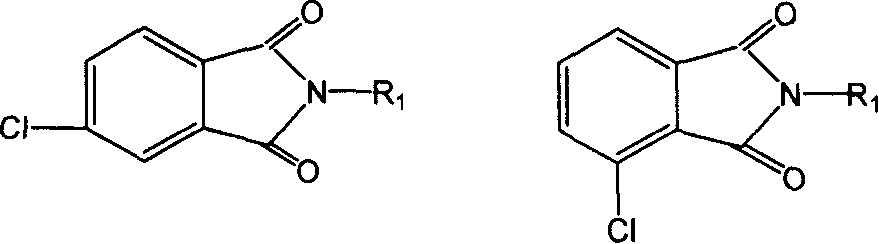

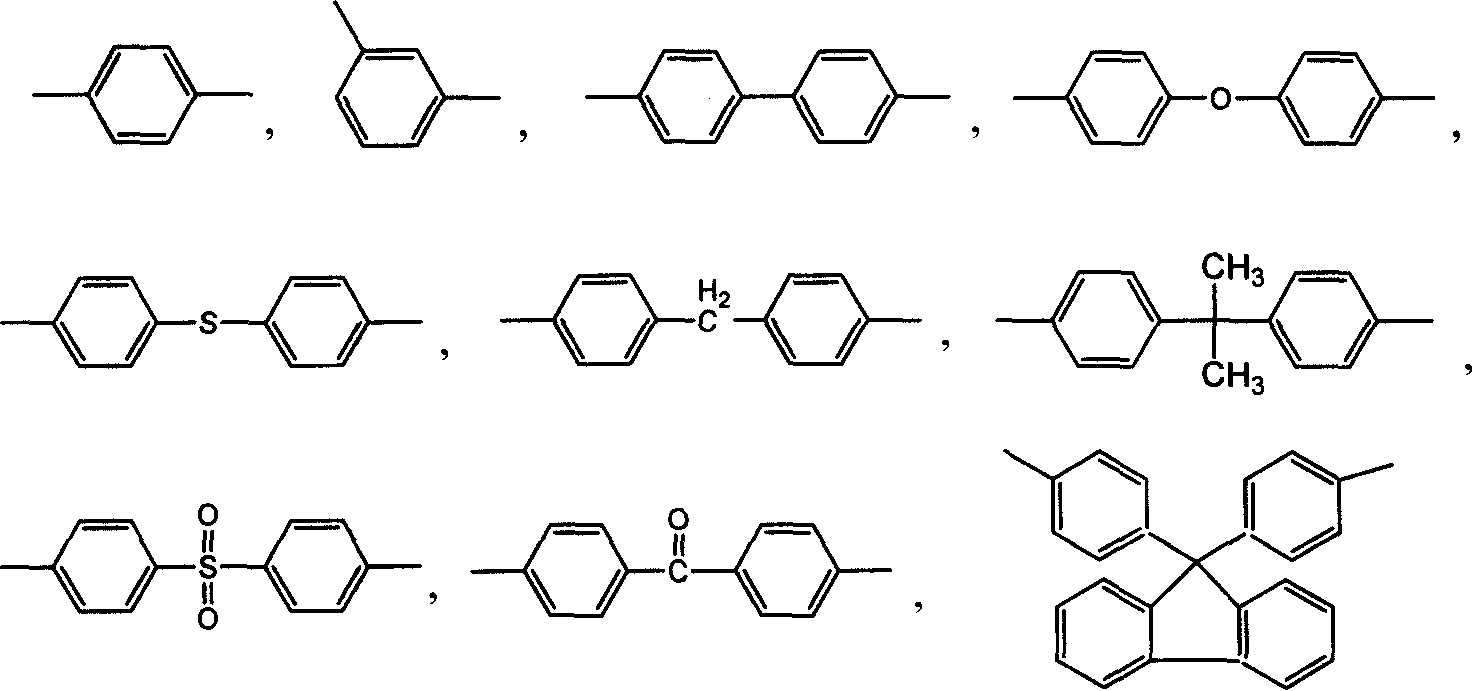

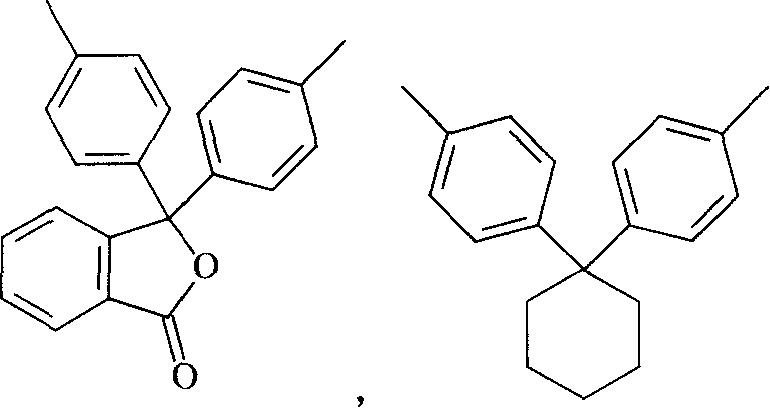

Method for preparing diether type tetraacid dianhydride isomer

This invention relates to bi aether style tetracid bi anhydride isomer prepeartion method. N-substitution-4-chlorine phthalic imidine or / and N-substitution-3- chlorine phthalic imidine, bisphenoland anhydrous potassium carbonate are used to generate N,N'-bi substitution bi aether style tetracid bi anhydride different isomer, then the quadric acid imide is hydrolyzed and acidified, and different bi aether style tetracid bi anhydride isomers are got after dewatering. Chlorine benzene anhydride isomer that cheap and easy get is used in this invention, initial material is N-substitution chlorine phthalic imidine made by the chlorine benzene anhydride isomer, so the environmental pollution brought by using materials of nitro substitution acid imide or nitro substitution benzene dinitrile is avoided, and problem of product deep color and low purity is also avoided. The reaction is happened in one tank, so its operation is simple and procedures are saved. Bi aether style tetracid bi anhydride isomer is synthesized first time, especially 3, 4'-bit isomer.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

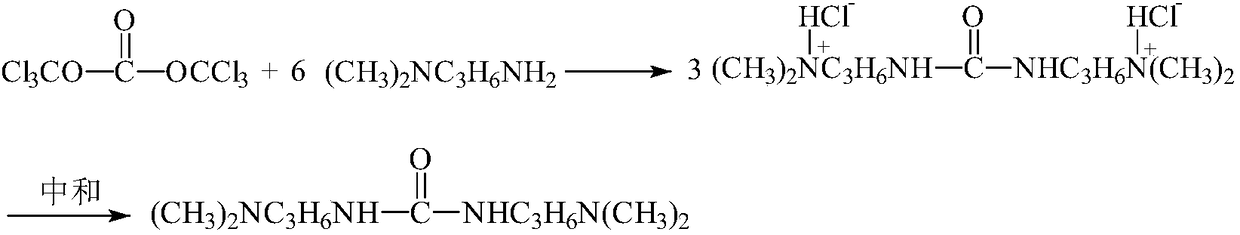

Synthetic process for N,N'-bi(3-dimethylaminopropyl)urea

ActiveCN108299245AAvoid pollutionAvoid polluting the environmentUrea derivatives preparationOrganic compound preparationOrganic solventDistillation

The invention discloses a synthetic process for N,N'-bi(3-dimethylaminopropyl)urea. The synthetic process comprises the following steps: firstly dissolving N,N'-dimethyl-1,3-diaminopropane in an organic solvent, reacting with bi(trichloromethyl)carbonate to obtain hydrochloride of the N,N'-bi(3-dimethylaminopropyl)urea; and adding alkaline liquor for neutralizing, so as to obtain an N,N'-bi(3-dimethylaminopropyl)urea water solution, and removing the solvent through azeotropic water separation, filtration desalination and distillation, so as to obtain a target product of the N,N'-bi(3-dimethylaminopropyl)urea. The synthetic process is high in product yield, high in purity, simple and convenient in operation, and less in three wastes, and suitable for industrial application.

Owner:ANHUI UNIVERSITY

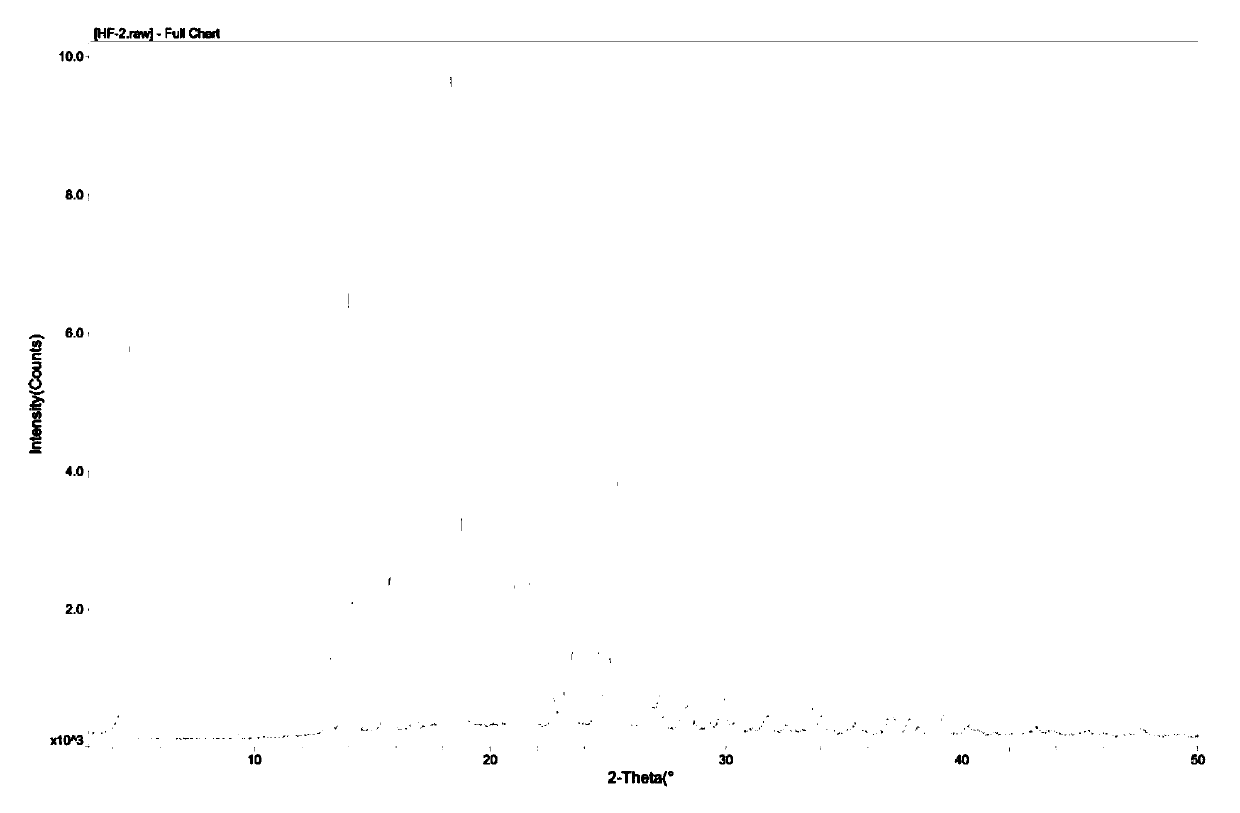

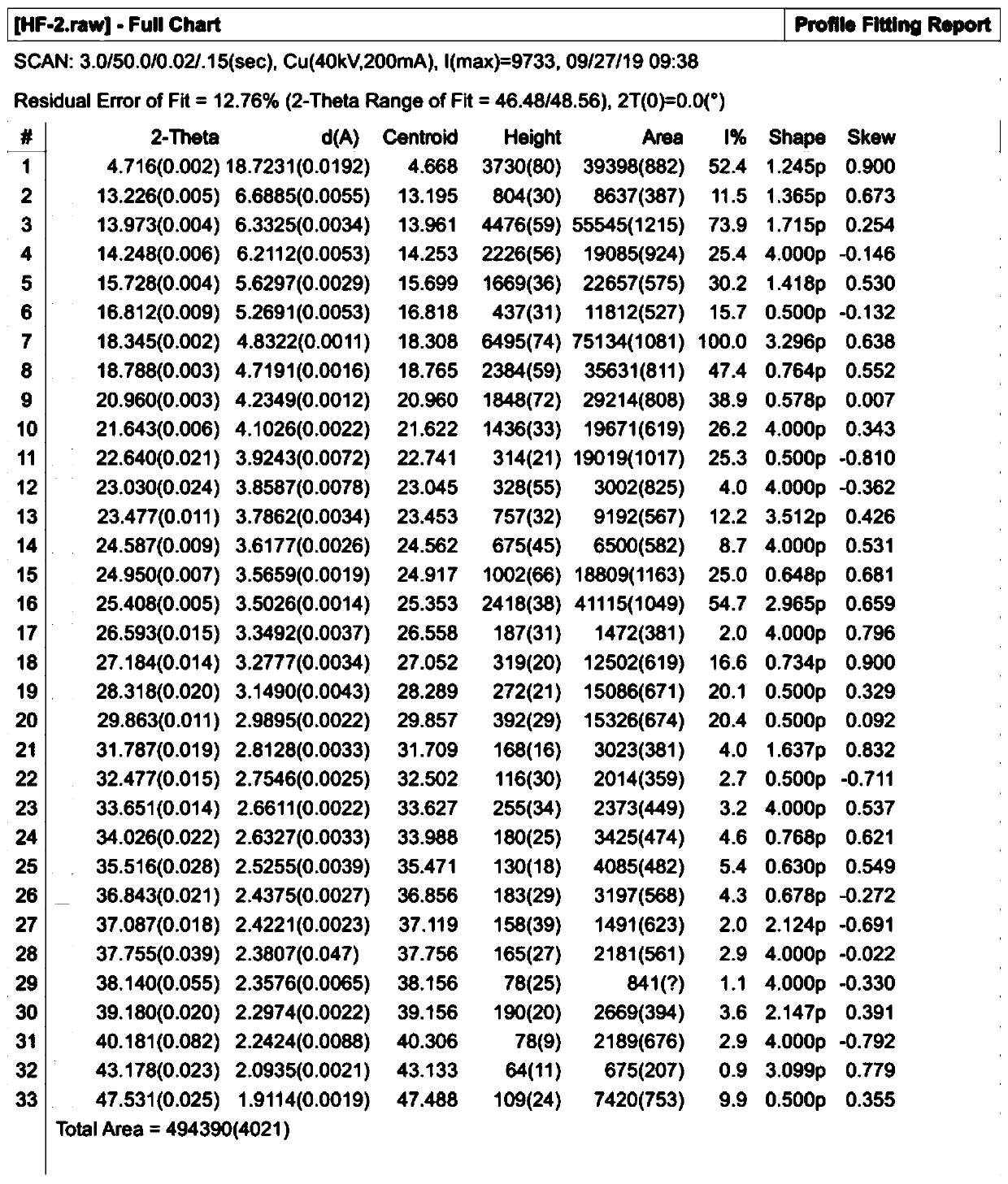

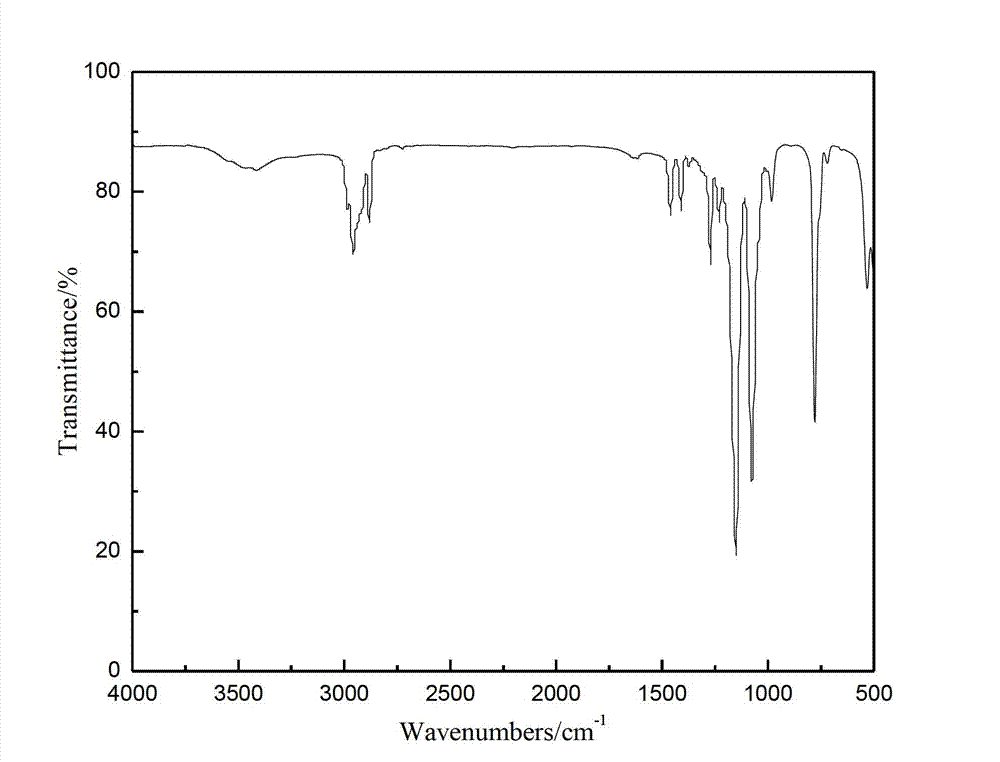

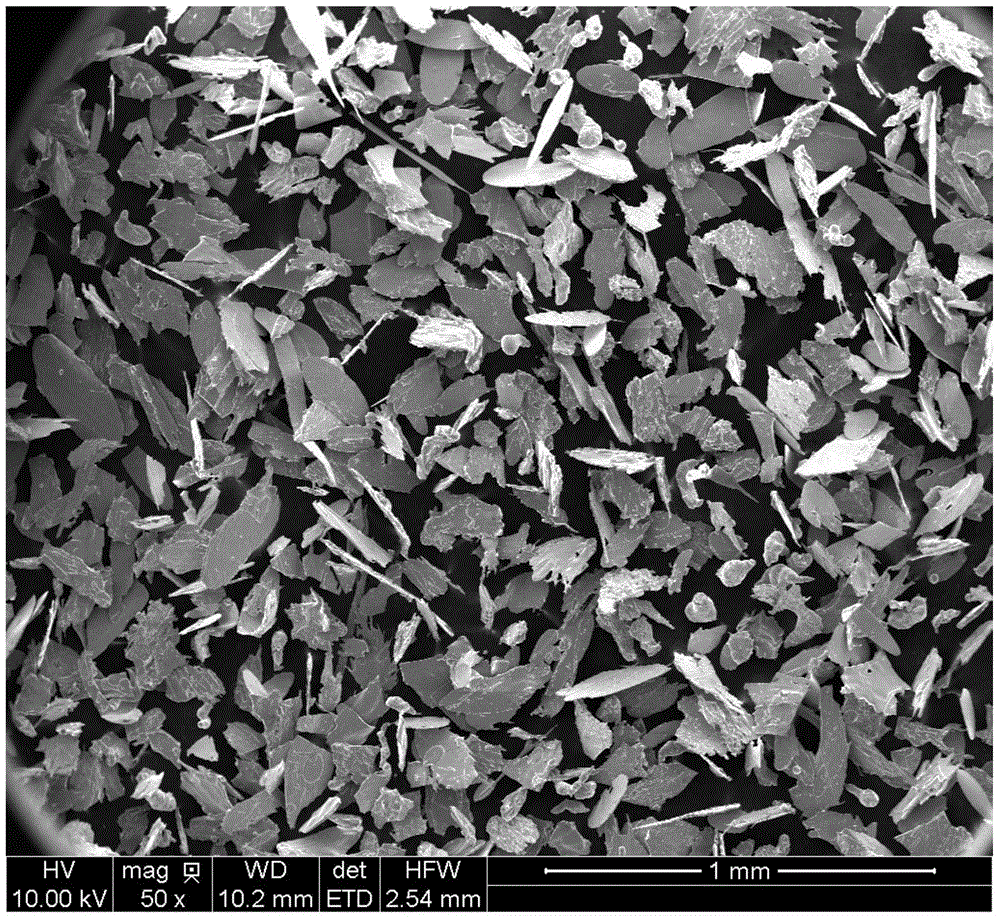

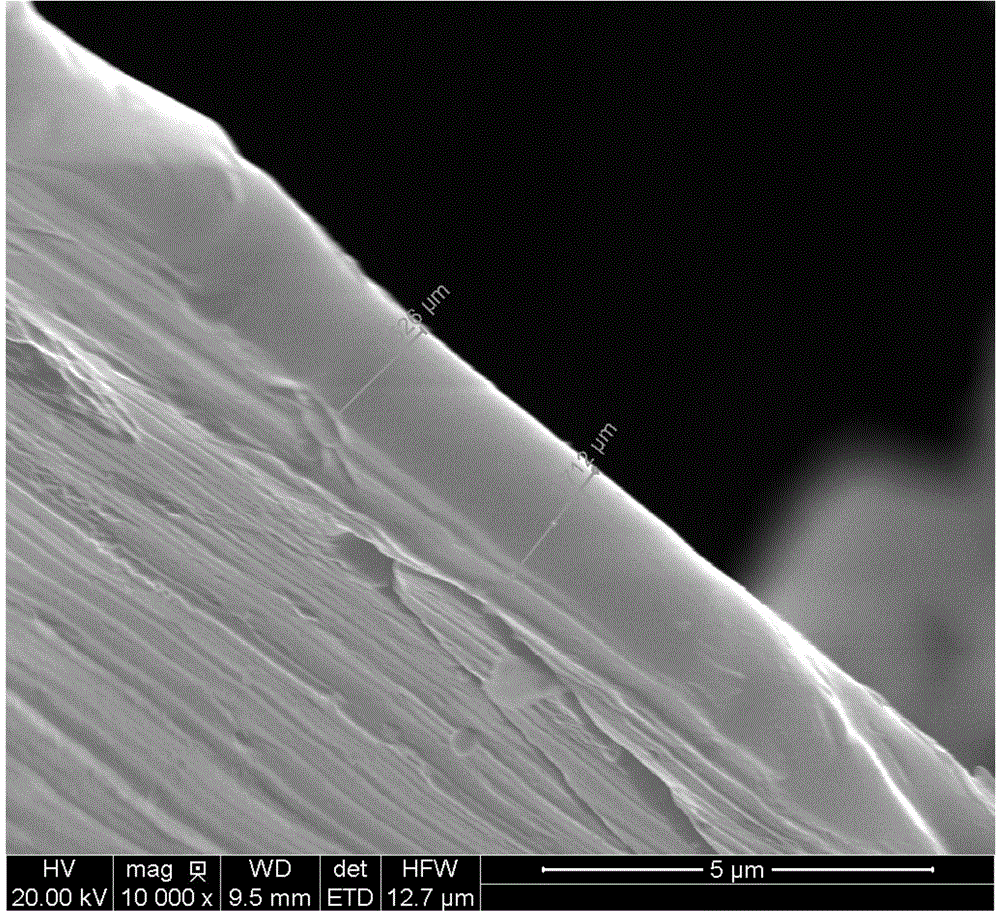

Preparation method of rod-shaped [alpha]-calcium sulfate hemihydrate whiskers

ActiveCN110129888AHigh purityShape rules are controllablePolycrystalline material growthFrom normal temperature solutionsMaterials preparationWhiskers

The invention relates to the technical field of gypsum material preparation, in particular to a preparation method of rod-shaped [alpha]-calcium sulfate hemihydrate whiskers. The method comprises thefollowing steps: 1) adding an organic crystal form control agent into a sodium sulfate aqueous solution, heating and stirring the solution, adding an inorganic calcium salt, and continuously stirringand reacting the mixture; and 2) after the reaction in the step 1) is finished, standing and aging the reaction product to obtain a rod-shaped [alpha]-calcium sulfate hemihydrate whisker crude product, and washing and drying the crude product to obtain the rod-shaped [alpha]-calcium sulfate hemihydrate whisker. The preparation method has the advantages of advanced method, low synthesis temperature, low raw material price, green and pollution-free preparation process and good repeatability. The [alpha]-calcium sulfate hemihydrate whisker is in a short rod shape, and the morphology is regular and controllable.

Owner:河南博海化工有限公司 +1

Method for purifying N-phenylmaleimide

The invention discloses a method for purifying N-phenylmaleimide. The method utilizes an N-phenylmaleimide crude product as a raw material and comprises selecting a distillation kettle with an inner copper block, transferring the N-phenylmaleimide crude product into the distillation kettle, setting kettle pressure of less than or equal to 1.5kPa, heating the N-phenylmaleimide crude product to 90-110 DEG C, carrying out primary vacuum distillation to obtain a front fraction, replacing a receiving bottle when there is no liquid reflux in the distillation kettle under the primary vacuum distillation condition, carrying out heating to 110-130 DEG C, carrying out secondary vacuum distillation to obtain an N-phenylmaleimide fraction, and stopping distillation when there is no liquid reflux in the distillation kettle under the secondary vacuum distillation. The method is free of additives, prevents new impurities, produces a high purity product and has a high yield.

Owner:Z RIVER GRP LTD

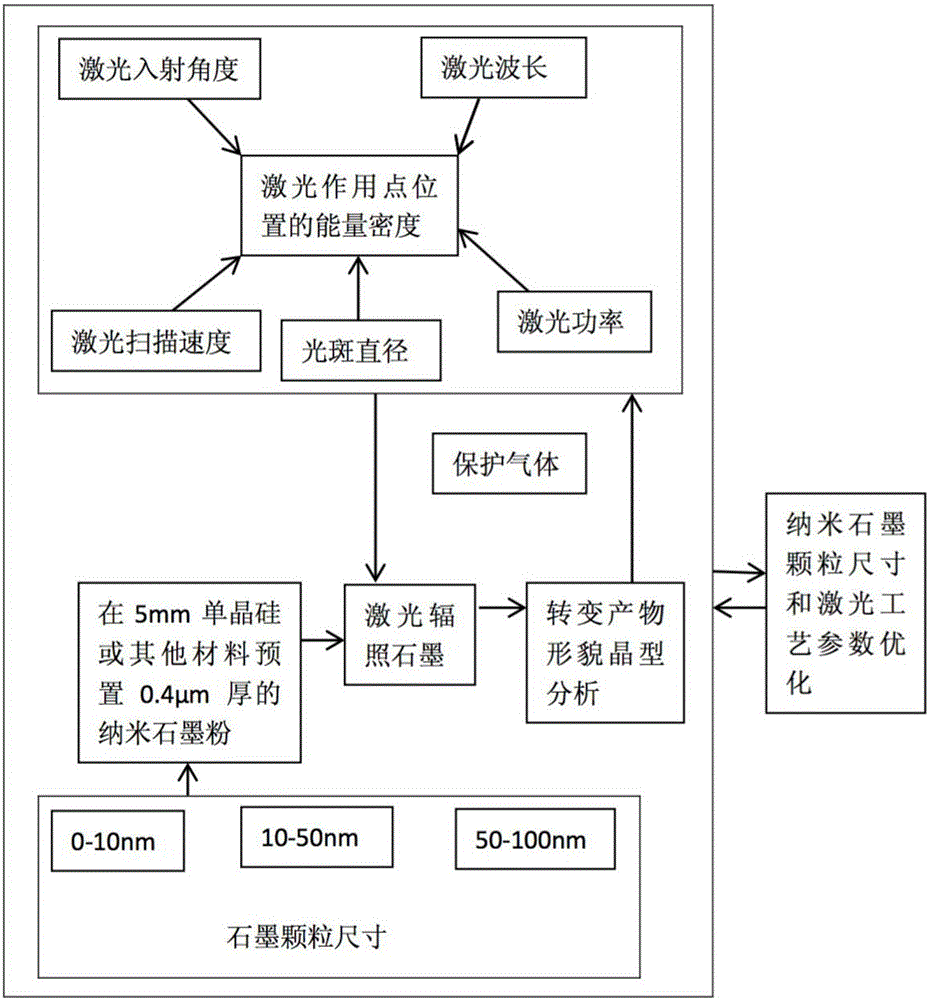

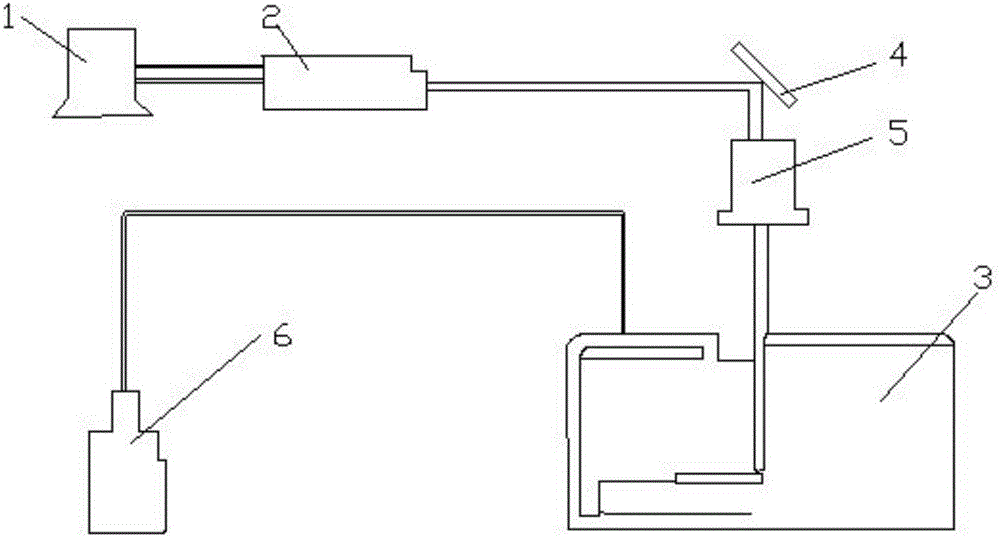

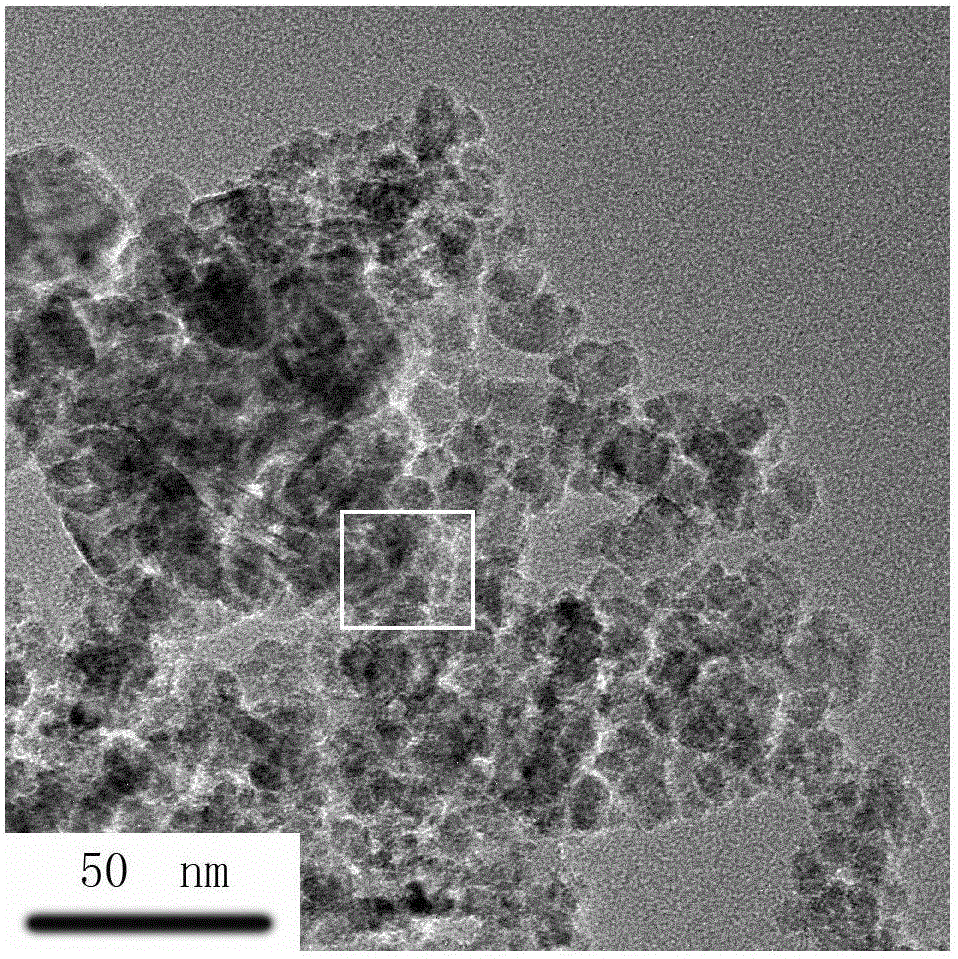

Method for converting nano graphite into one-dimensional carbon nano fiber by laser irradiation

InactiveCN106048782AAvoid polluting the environmentAvoid controllabilityFibre chemical featuresFiberCarbon fibers

The invention discloses a method for converting nano graphite into one-dimensional carbon nano fiber by laser irradiation, comprising the following steps: 1), selecting a laser energy density reference value according to conversion physical parameters of nano graphite, selecting a laser through the laser energy density reference value, and setting laser process parameters; 2), using the data of step 1) to acquire an optimal laser energy density set value of a one-dimensional carbon nano wire, selecting reasonable laser process parameters by using the optimal laser energy density set value, and using a protective gas to prevent graphite oxidation so as to produce one-dimensional nano carbon fiber; the carbon nano fiber is controllably industrialized; the defects due to chemical methods and other methods are avoided; no waste is caused ,and manpower and material resources are saved.

Owner:ZHEJIANG COLLEGE OF ZHEJIANG UNIV OF TECHOLOGY

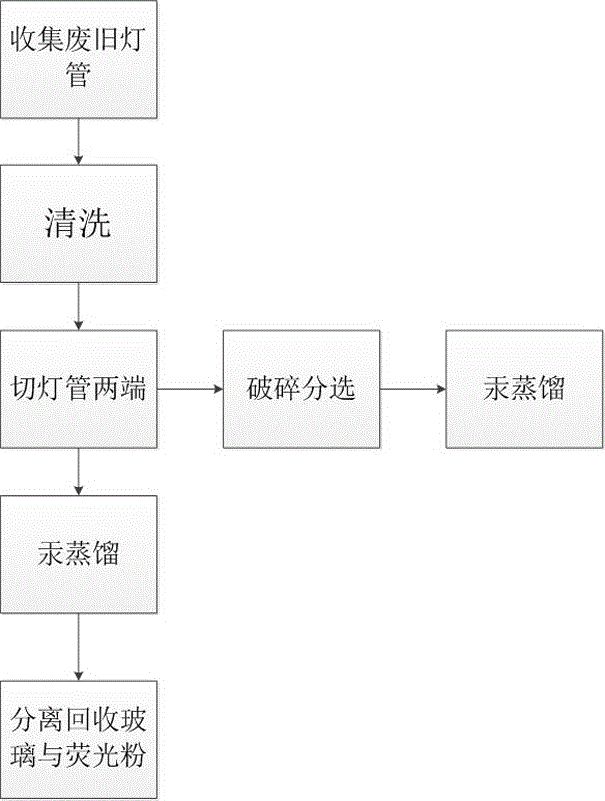

LED lamp reuse process

The invention discloses an LED lamp reuse process. The LED lamp reuse process comprises the following steps: (A) a waste fluorescent lamp recovery box is used for recovering and transferring into a cleaning machine for cleaning; (B) two ends of fluorescent lamps are cut by a cutter, and are smashed; metal chips and plastic chips are respectively conveyed into a metal recoverer and a plastic recoverer; and the metal recoverer and the plastic recoverer are heated; (C) lamp tubes with two cut ends are heated; and (D) the lamp tubes are put in a ultrasonic pool for ultrasonic processing, and are fed in a lamp tube cleaning pool for cleaning the inner walls of the lamp tubes; and finally, ultrasonic processing powder-contained liquid is mixed with lamp tube cleaning pool powder-contained liquid for filtering. The LED lamp reuse process separates and recover fluorescent powder under the condition of not smashing glass, and guarantees the glass recovery quality and the purity of the fluorescent powder.

Owner:河北君业科技股份有限公司 +1

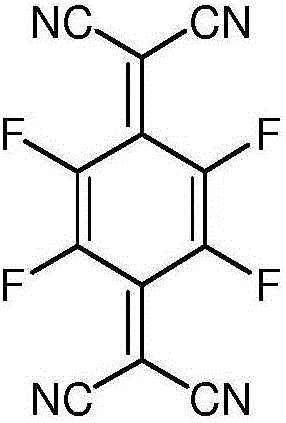

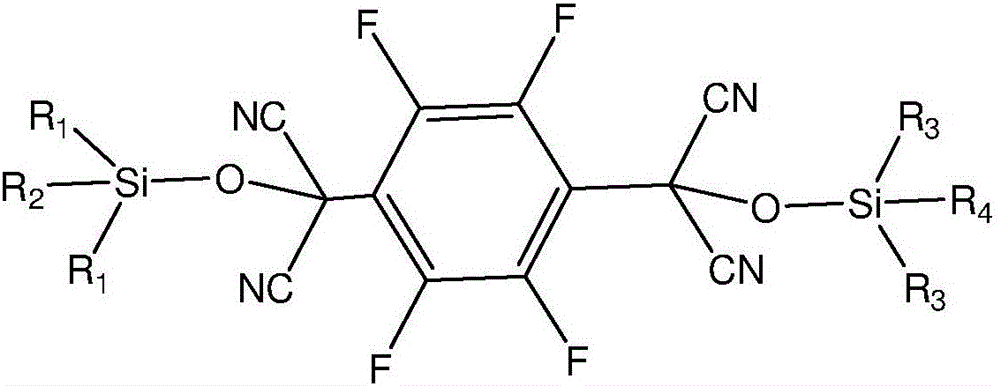

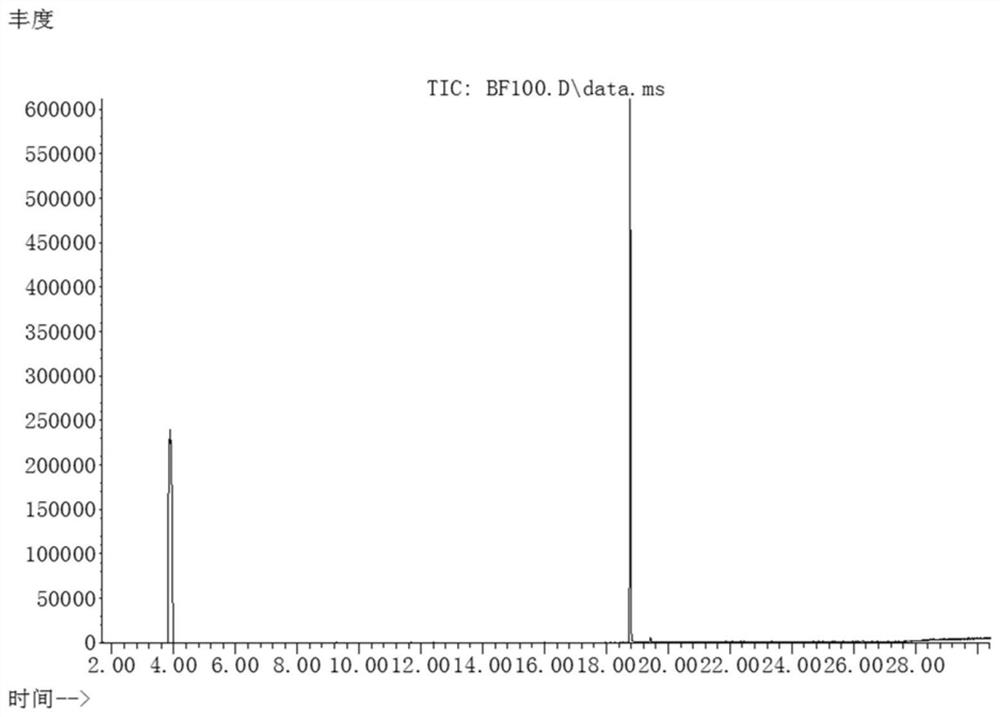

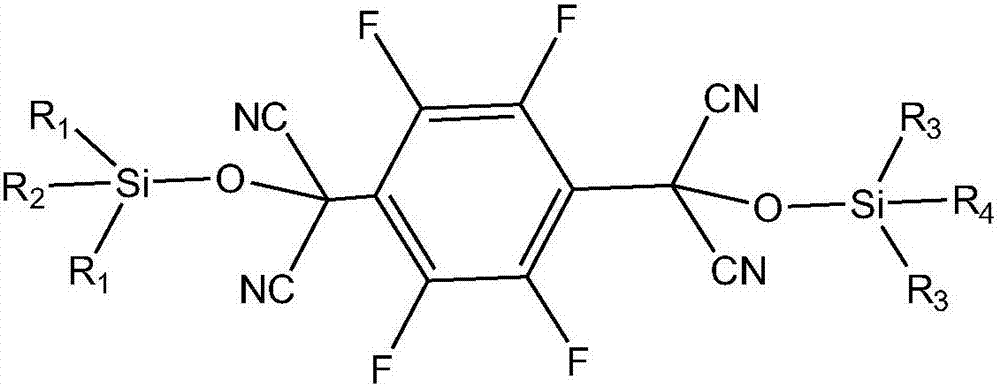

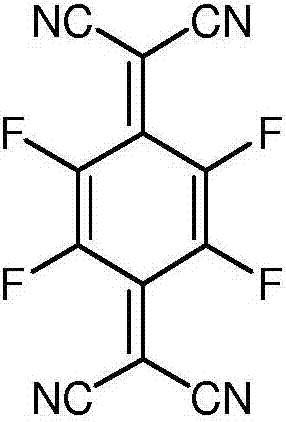

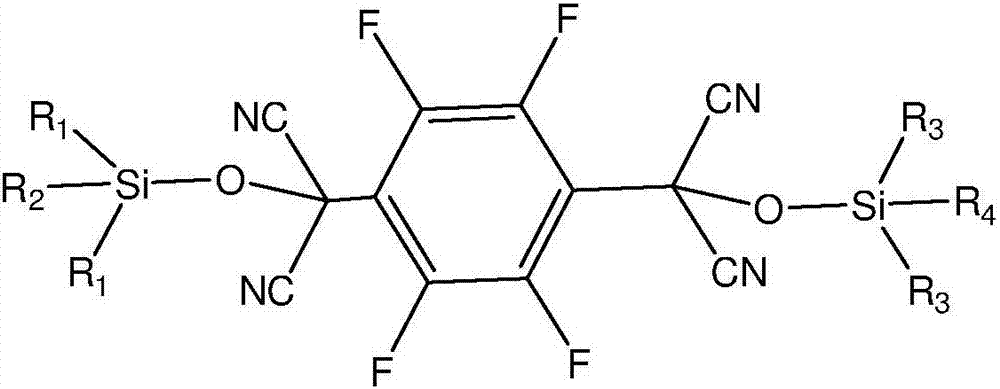

Synthesis method of 2,3,5,6-tetrafluoro-7,7,8,8-tetracyanoquinodimethane

ActiveCN106083652AGood stabilityLow environmental requirementsCarboxylic acid nitrile preparationOrganic compound preparationTetracyanoquinodimethaneChloride

The invention discloses a synthesis method of 2,3,5,6-tetrafluoro-7,7,8,8-tetracyanoquinodimethane and relates to the technical field of organic electroluminescent materials. On the basis of simplifying the synthesis method, wastewater generated by post-treatment is reduced, and the safety of a synthesis process is improved, so that the synthesis method is applicable to industrial production. The synthesis method comprises the following steps: firstly, carrying out a condensation reaction by taking 2,3,5,6-tetrafluoroterephthaloyl chloride andtrialkylsilyl cyanide as raw materials under an oxygen-free and dry environment to obtain an intermediate; and then, removing trialkylsiloxy in the intermediate to obtain F4-TCNQ. The synthesis method of the 2,3,5,6-tetrafluoro-7,7,8,8-tetracyanoquinodimethane, disclosed by the invention, is used for synthesizing organic electroluminescent materials.

Owner:FUYANG XINYIHUA MATERIAL TECH

Regeneration utilization method of rare earth permanent magnet material

InactiveCN108372179AHigh purityImprove magnetismTransportation and packagingSolid waste disposalScrapMagnetic powder

Owner:龙南市中利再生资源开发有限公司

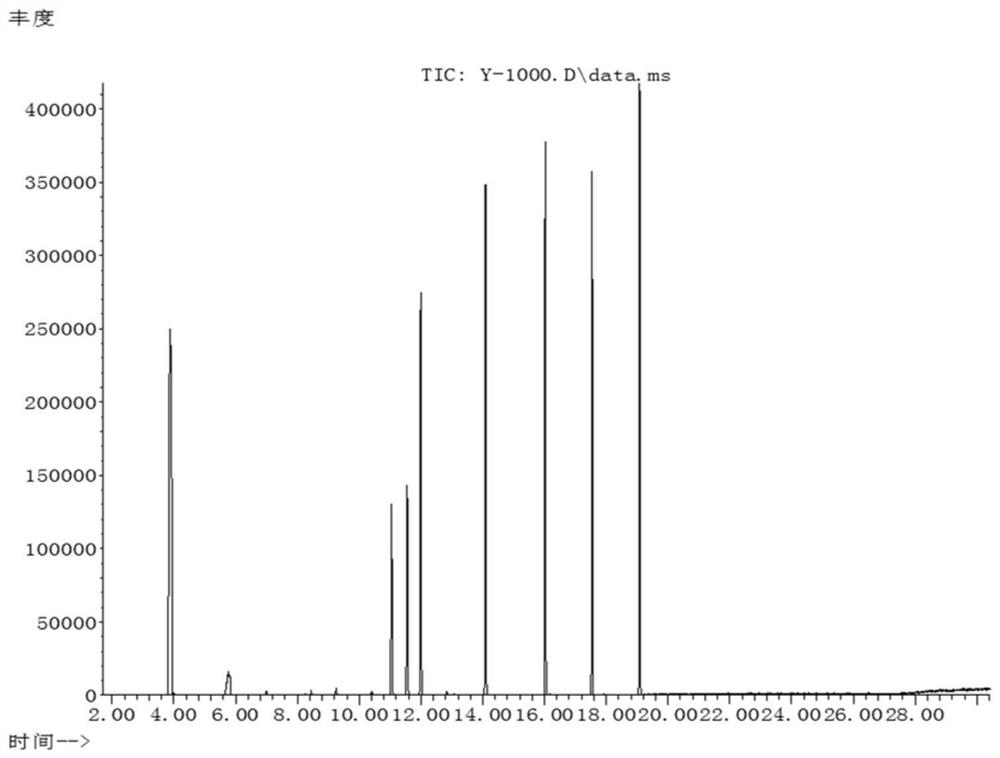

Method for rapidly determining content of phenol in wastewater through purge and trap-gas chromatography-mass spectrometry

PendingCN114216973APrevent purityAvoid askingComponent separationO-Phosphoric AcidIndustrial waste water

The invention relates to a method for rapidly determining the content of phenol in wastewater by purge and trap-gas chromatography-mass spectrometry, which comprises the following steps: 1) collecting a wastewater sample, adding phosphoric acid, and adjusting the pH value of the wastewater sample to weak acidity; (2) purging phenol in the wastewater sample by using a purging and trapping sample injector, trapping the phenol by using a trapping trap, and then analyzing the phenol to enter a gas chromatograph-mass spectrometer; and (3) carrying out qualitative and quantitative analysis on the phenol trapped by the trapping trap by using a gas chromatograph-mass spectrometer. Compared with the prior art, the method for measuring the phenol content in the industrial wastewater is simple, rapid, efficient and accurate, the wastewater with complex components and high organic matter concentration can be directly purged, the pretreatment processes such as separation and purification are omitted, an organic solvent is not needed for extraction, the detection cost is reduced, and the method is suitable for large-scale popularization and application. The time for detecting a group of water samples is shortened from two hours to about 30 minutes, and the detection limit is 0.01-1 mg / L.

Owner:SHANGHAI INST OF TECH +1

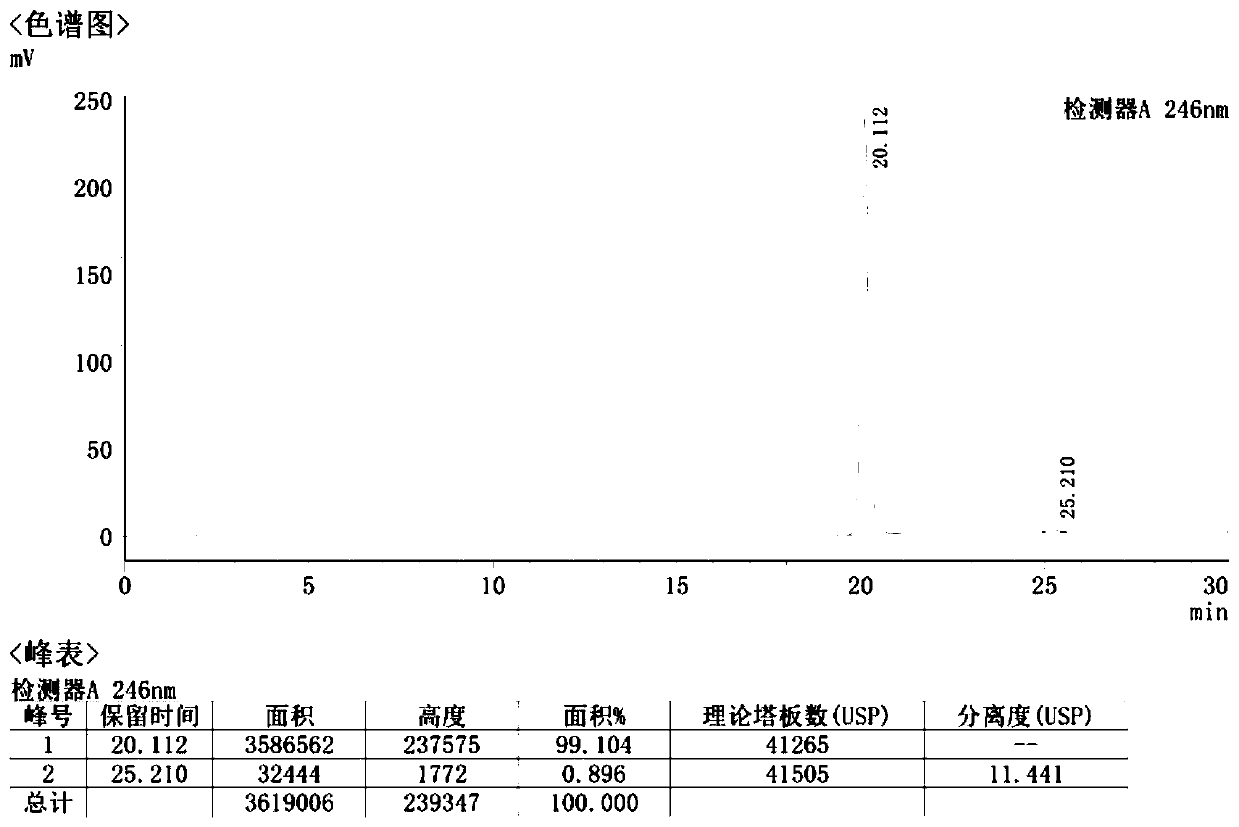

Propacetamol crystal form and preparation method thereof

PendingCN111039814AAvoid Yield ProblemsPrevent purityOrganic compound preparationOrganic chemistry methodsAcetyl chlorideOrganic synthesis

The invention discloses a propacetamol crystal form and a preparation method thereof, and relates to the technical field of chemical organic synthesis. Acetaminophen and chloroacetyl chloride are usedas starting materials, the propacetamol crystal form is prepared through a chloroacetylation reaction and an ammoniation reaction, and the propacetamol crystal form is not reported in the prior art Propacetamol solid is prepared by utilizing the preparation method, and therefore, the feeding amount can be accurately controlled when the propacetamol hydrochloride is prepared through a subsequent salt forming reaction, the situation that the dosage of hydrochloric acid is too large or too small is avoided, and the problem that in the prior art, the yield and purity of the product propacetamol hydrochloride are seriously affected when the propacetamol hydrochloride is prepared through a propacetamol oily matter is solved.

Owner:HEFEI HUAFANG PHARMA SCI & TECH

Production method of Mn-zn ferrite from waste magnesium dioxide batteries

InactiveCN1266794CRealize recyclingWide range of usesReclaiming serviceable partsWaste accumulators reclaimingIron powderManganese

The method includes liquid extraction and filter processes. Iron powder being more than mercury content is added into the above extracted and filtered solution. The mercury is removed and an amount of Fe(NO3)3, Fe(NO2)3, Zn(NO3)2, Mn(NO3)2 are added. The total metal ionic concentration is made to be 1mol / L. MnO: ZnO: FeO=0.6:0.4:1.0 (mol ratio).After the above solution is heated, the citric acid is added. After evaporation the sol is obtained. After drying the sol the xerogel is obtained. After xerogel is calcinated, the manganese-zinc ferrite is obtained.

Owner:HENAN NORMAL UNIV

A kind of synthetic method of 2,3,5,6-tetrafluoro-7,7',8,8'-tetracyanodimethyl-p-benzoquinone

ActiveCN106083652BReduce usageAvoid it happening againCarboxylic acid nitrile preparationOrganic compound preparationCyanideTetracyanoquinodimethane

The invention discloses a synthesis method of 2,3,5,6-tetrafluoro-7,7,8,8-tetracyanoquinodimethane and relates to the technical field of organic electroluminescent materials. On the basis of simplifying the synthesis method, wastewater generated by post-treatment is reduced, and the safety of a synthesis process is improved, so that the synthesis method is applicable to industrial production. The synthesis method comprises the following steps: firstly, carrying out a condensation reaction by taking 2,3,5,6-tetrafluoroterephthaloyl chloride andtrialkylsilyl cyanide as raw materials under an oxygen-free and dry environment to obtain an intermediate; and then, removing trialkylsiloxy in the intermediate to obtain F4-TCNQ. The synthesis method of the 2,3,5,6-tetrafluoro-7,7,8,8-tetracyanoquinodimethane, disclosed by the invention, is used for synthesizing organic electroluminescent materials.

Owner:FUYANG XINYIHUA MATERIAL TECH

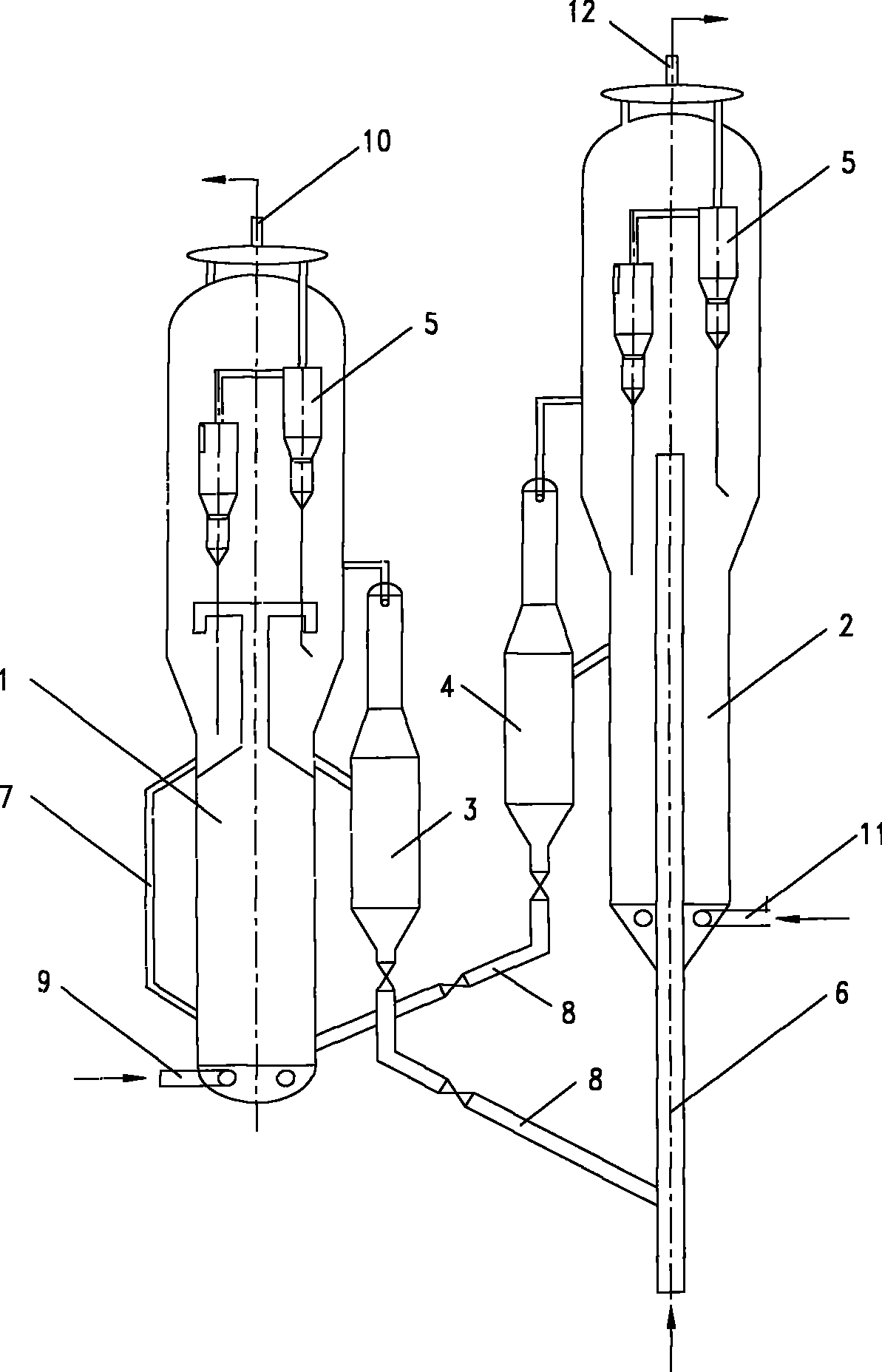

Method for preparing low-carbon olefin hydrocarbon with oxocompound

ActiveCN101279872BPrevent purityGuaranteed continuityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsPtru catalystFluidized bed

The invention relates to a method for producing a low carbon olefin by an oxycompound, which mainly solves the problem that a regenerated catalyst carrying partial N2, O2, CO(X), NO(X) impurities to a reactor brings difficulties and even causes great harm to the product separation in the process of low carbon olefin production by oxycompound. The invention well solves the problem by adopting the technical proposal that the regenerated catalyst firstly passes a degassing tank to remove impurities and then returned to a fluidized bed reactor circularly, and the method can be used for the industrial production of producing the low carbon olefin by oxycompound.

Owner:SHANGHAI RES INST OF PETROCHEMICAL TECH SINOPEC

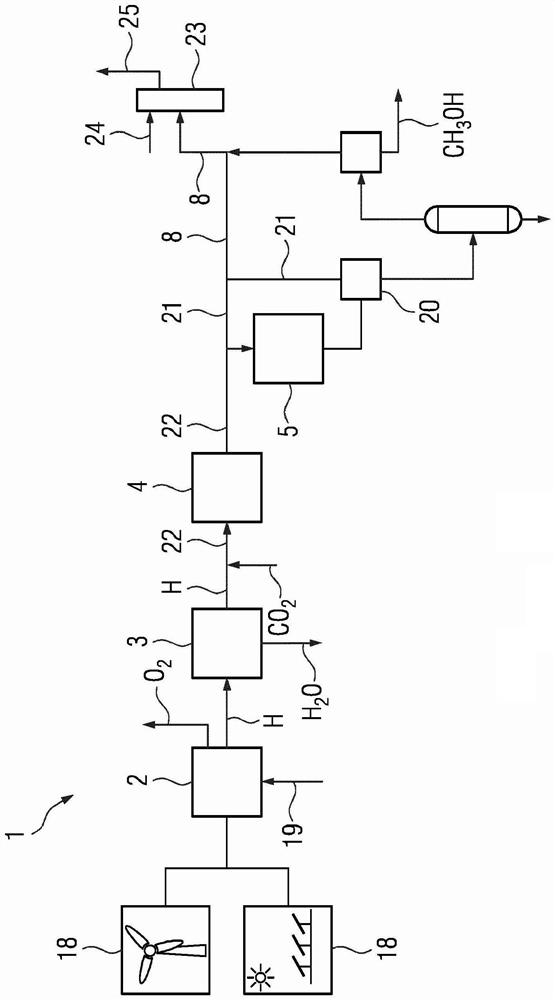

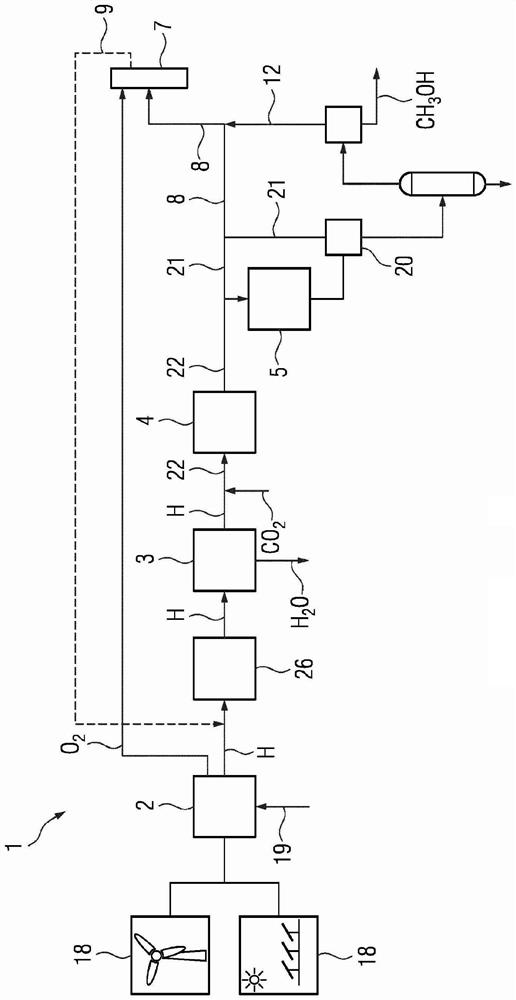

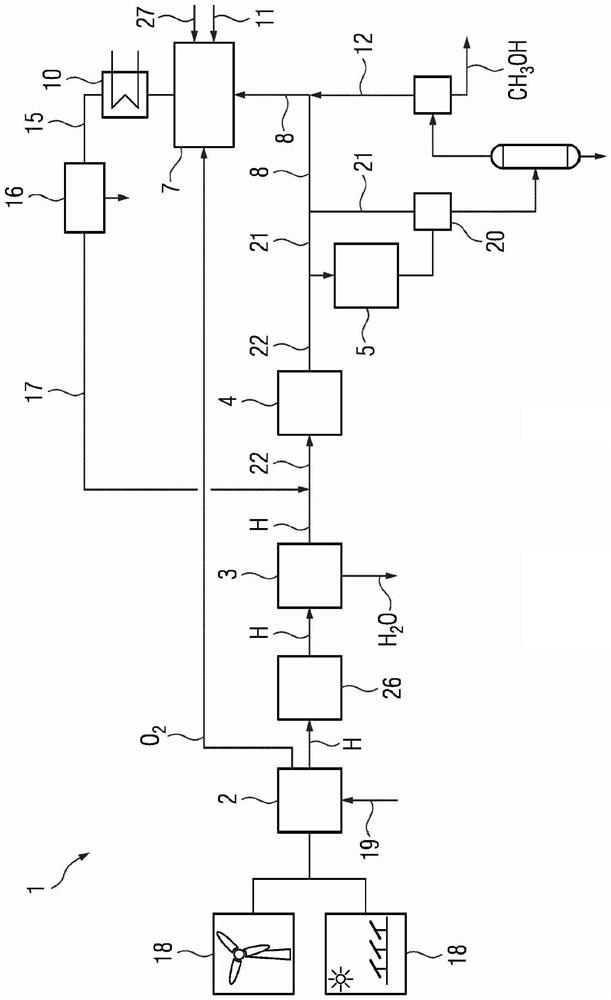

Apparatus and method for utilizing exhaust gas from an electric

PendingCN114867966APrevent purityCellsHydrogen separation at low temperatureCombustion systemElectrolysis

The invention relates to an electric power multi-conversion facility (1) using exhaust gas, comprising: an electrolyser (2) for generating hydrogen H2 and oxygen O2; a facility (3) connected to the electrolyser (2) for treating hydrogen H2 to separate remaining oxygen O2 and water H2O from the produced hydrogen H2 stream; a compressor (4) connected to the facility (3) for processing hydrogen H2 for compressing hydrogen H2; and a chemical reactor (5) connected to the compressor (4) for producing synthesis gas (6) from hydrogen H2 and deliverable carbon dioxide CO2. According to the invention, an oxyfuel combustion system (7) can be fed with non-condensable exhaust gases (8) from the chemical reactor (5) and with oxygen O2 from the electrolyser (2), and the carbon dioxide CO2 generated in the oxyfuel combustion plant (7) by burning the waste body (8) can be returned to the hydrogen H2 stream downstream of the electrolyser (2) via a return line (9).

Owner:西门子能源全球有限两合公司

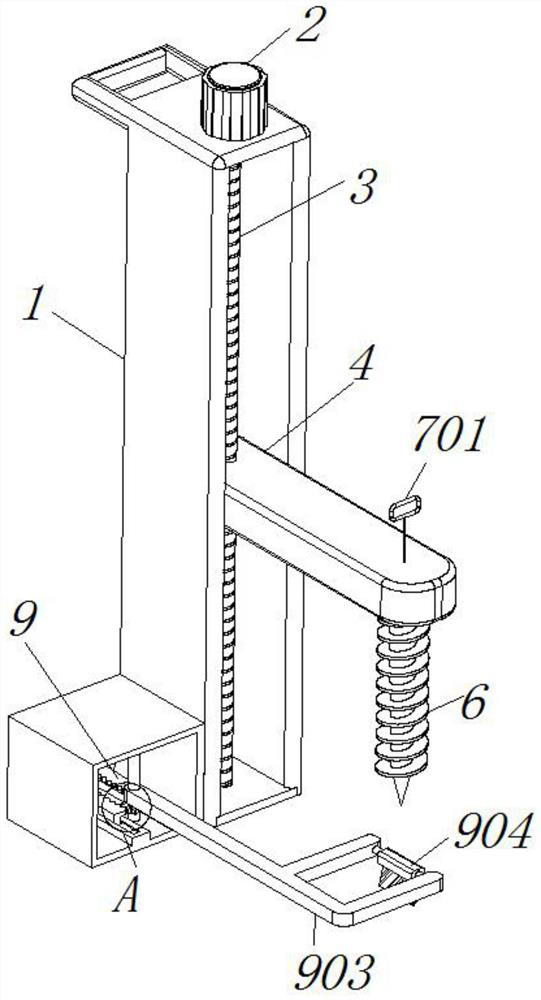

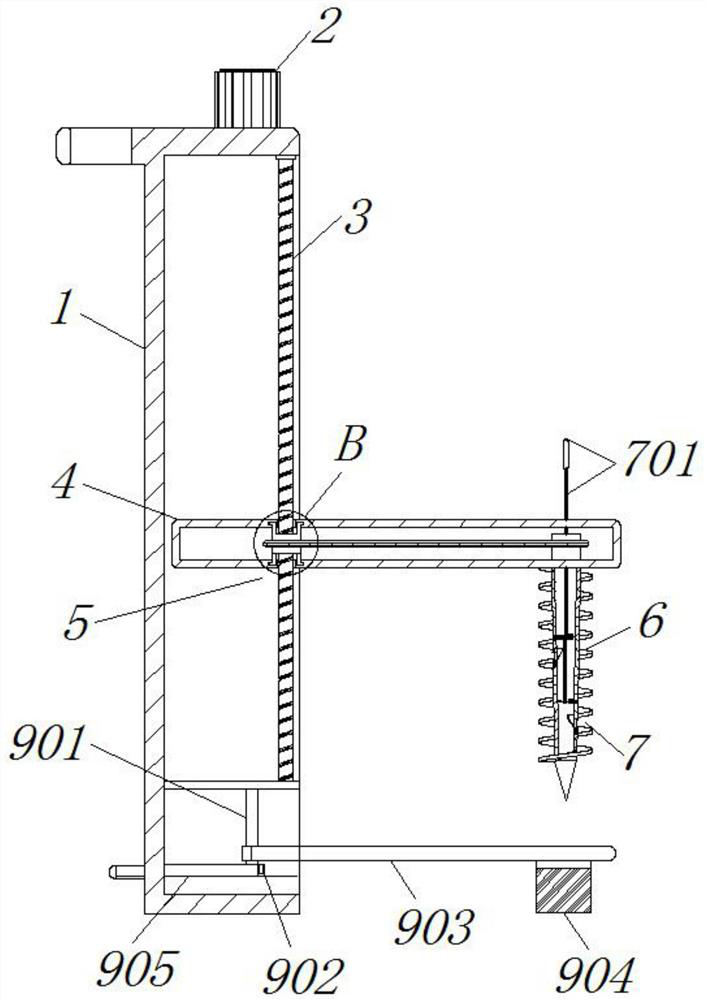

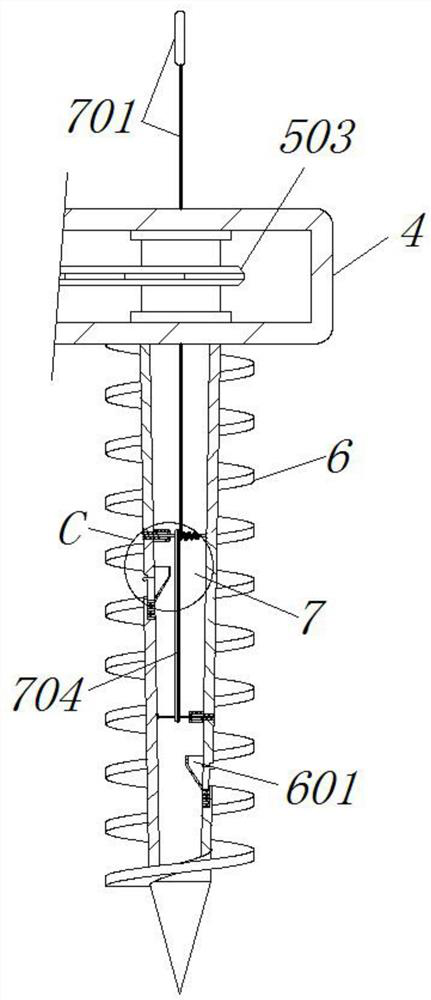

Sampling device for soil detection

InactiveCN113758747AEfficient removalPrevent purityWithdrawing sample devicesAgricultural engineeringStructural engineering

The invention discloses a sampling device for soil detection, and the device comprises a shell support; a servo motor is installed at the top of the shell support, a lifting shell is in threaded connection with the outer side of a spiral shaft, a lifting rotating mechanism is arranged on the inner side of the lifting shell, and a drill bit is connected to the lower portion of the right side of the lifting shell through a bearing; sampling mechanisms capable of sampling soil with different depths at the same time are arranged on the left and right inner sides of the drill bit, and sampling mechanisms capable of taking out all the soil sampled on the inner side of the drill bit are mounted on the left and right outer sides of the drill bit; and a weeding mechanism capable of removing weeds on the surface of the soil sampling area is arranged on the lower portion of the left side of the shell support. According to the invention, the lifting rotating mechanism and the sampling mechanism are arranged, so soil at different depths can be effectively sampled, and the manual labor force is greatly reduced; meanwhile, the whole soil detection sampling efficiency is improved, and the overall practicability and convenience are improved.

Owner:九江市美景水处理科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Preparation method of rod-shaped [alpha]-calcium sulfate hemihydrate whiskers Preparation method of rod-shaped [alpha]-calcium sulfate hemihydrate whiskers](https://images-eureka.patsnap.com/patent_img/fbb9fea9-5c6d-4135-8977-deddc6653837/HSA0000183923390000011.png)

![Preparation method of rod-shaped [alpha]-calcium sulfate hemihydrate whiskers Preparation method of rod-shaped [alpha]-calcium sulfate hemihydrate whiskers](https://images-eureka.patsnap.com/patent_img/fbb9fea9-5c6d-4135-8977-deddc6653837/HSA0000183923390000012.png)

![Preparation method of rod-shaped [alpha]-calcium sulfate hemihydrate whiskers Preparation method of rod-shaped [alpha]-calcium sulfate hemihydrate whiskers](https://images-eureka.patsnap.com/patent_img/fbb9fea9-5c6d-4135-8977-deddc6653837/HSA0000183923390000021.png)