Purification and separation method of syngas by full temperature range-pressure swing adsorption (FTrPSA)

A synthesis gas purification and pressure swing adsorption technology, applied in hydrogen/syngas production, chemical instruments and methods, using solid contact hydrogen separation, etc., can solve the problem of increased energy consumption, low purity and yield, and expensive membrane materials, etc. problems, to achieve the effect of reducing load and energy consumption, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

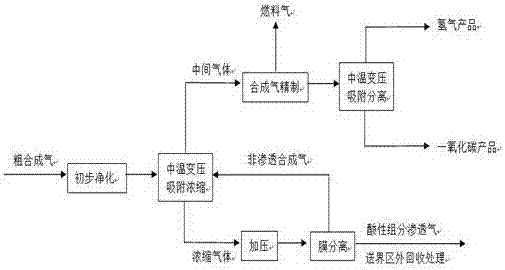

[0043] Such as figure 1 As shown, a synthesis gas purification and separation method using full-temperature pressure swing adsorption, the following operations are performed in sequence:

[0044] (1) Initial purification:

[0045] The crude synthesis gas produced from coal gasification or natural gas or coke oven gas, with a temperature of 400~1,600℃ and a pressure of 0.01~7.0MPa, enters the preliminary purification process consisting of chilling, water washing mixer, cyclone separator and washing tower. The temperature of the crude synthesis gas produced by gasification is reduced from 400-1600°C to 50-150°C, and the ash, gray water, black water, and some high-hydrocarbon organic matter and oil residue in the crude synthesis gas are removed. Dust content ≤ 1mg / m3, hydrocarbon organic matter ≤ 100~300ppm.

[0046] (2) Medium temperature pressure swing adsorption concentration process:

[0047] Alternate cycle operation is carried out in the medium temperature pressure swing...

Embodiment 2

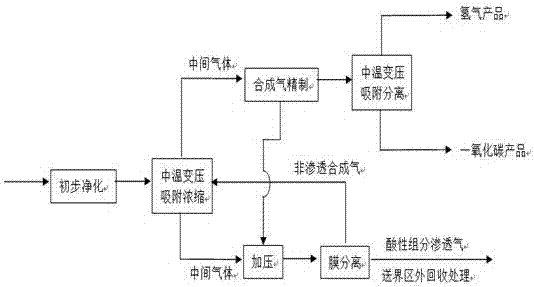

[0062] Such as figure 2As shown, a synthesis gas purification and separation method using full-temperature pressure swing adsorption, the following operations are performed in sequence: the temperature of the high-temperature crude synthesis gas after preliminary purification is 50-70 ° C, the pressure is 1.2-2.0 MPa, and the dust After the removal of dust, gray water, oil and high hydrocarbon impurities, enter the medium temperature pressure swing adsorption concentration process under the same operating conditions for adsorption and concentration to remove acidic components and hydrocarbon impurities. At this time, the intermediate gas flows out from the top of the adsorption tower, and the acidic components and hydrocarbon impurities contained in it are reduced to less than 0.1~1%, and the intermediate gas is subjected to the next refining treatment; desorption and regeneration obtain the concentration of acidic components and hydrocarbon impurities About 15~25% concentrat...

Embodiment 3

[0064] Such as figure 1 As shown, a synthesis gas purification and separation method using full-temperature pressure swing adsorption, the following operations are performed in sequence: the temperature of the high-temperature crude synthesis gas after preliminary purification is 120-150 ° C, the pressure is 0.03-0.6 MPa, and the dust After the removal of dust, gray water, oil and high hydrocarbon impurities, enter the medium temperature pressure swing adsorption concentration process under the same operating conditions for adsorption and concentration to remove acidic components and hydrocarbon impurities. The medium temperature pressure swing adsorption concentration process is operated by 6 towers in parallel and alternately, one tower is in the adsorption stage, and the other 5 towers are in the desorption regeneration stage. At this time, the intermediate gas flows out from the top of the adsorption tower, and the acidic components and hydrocarbons contained in it are Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com