Regeneration process for washing and spraying methanol by low-temperature methanol

A low-temperature methanol washing, methanol technology, applied in the preparation of organic compounds, organic chemistry, chemical instruments and methods, etc., can solve the problems of reducing concentration, increasing material consumption and energy consumption in acid gas treatment process, and reducing operation and design pressure. , The effect of reducing equipment investment and consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

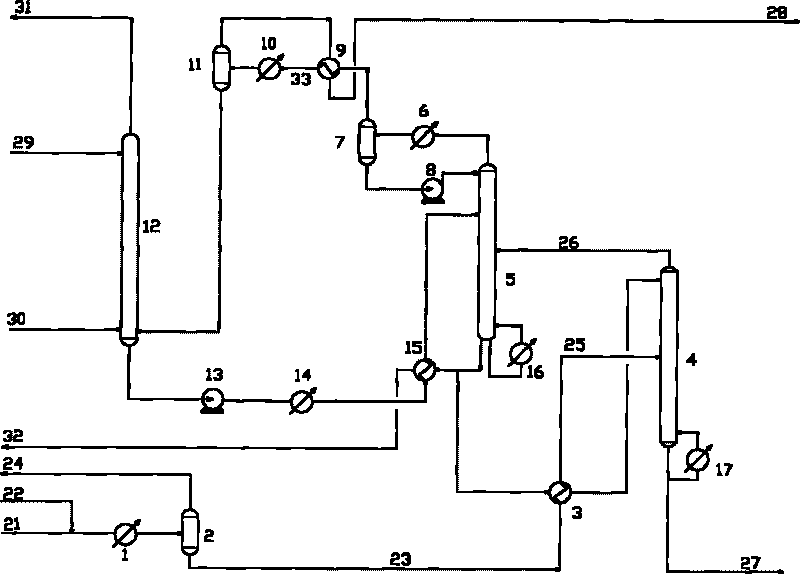

[0031] A low-temperature methanol washing and spraying methanol regeneration process adopts single-tower absorption, such as image 3 As shown, the logistics data are all the simulation calculation results of the 900,000 tons / year coal gasification methanol scale plant process.

[0032] Raw gas 21 (390000Nm 3 / h, 313.0K, 5.60MPaA, gas composition H 2 : 46.00%, CO: 21.55%, CO 2 : 31.56%, H 2 S: 0.24%, H 2 O: 0.23%, other 0.42%), spray into methanol 22 (1770Kg / h, 313.0K) and then enter the raw material gas cooler 1, after the raw material gas is cooled, it is sent into the spray methanol and hydrocondensate separation tank 2, after separation The raw material gas 24 (261.0K, 5.56MPaA) is sent to the absorption tower, and the spray methanol and the hydrocondensate 23 (2630Kg / h, 261.0K, 5.56MPaA) are introduced into the flash tank 18, and the flash steam 35 (113Nm 3 / h, 252.3K, 0.8MPaA) into H 2 S concentration tower 12, condensate 34 (2421kg, 252.3K, 0.8MPaA) in methanol an...

Embodiment 2

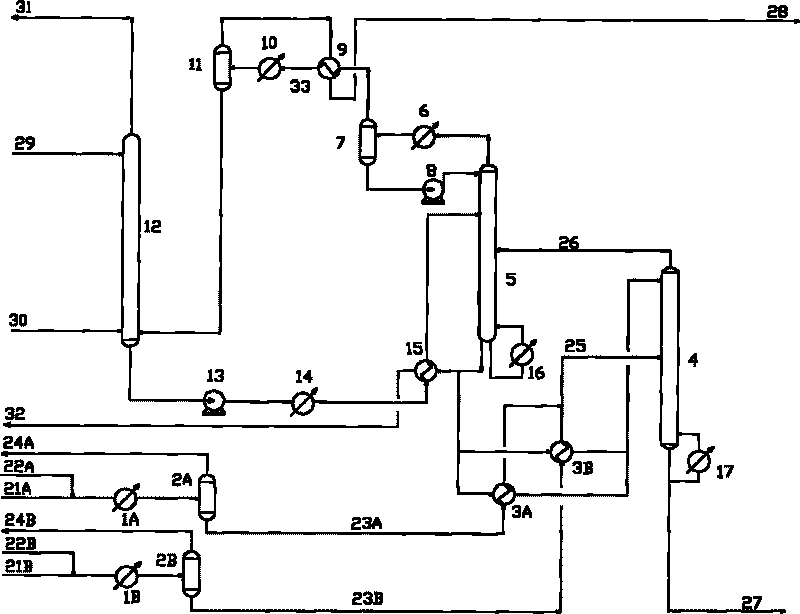

[0041] A low-temperature methanol washing and spraying methanol regeneration process, using double-tower absorption, such as Figure 4 As shown, the method includes the following steps:

[0042] Methanol 22A and 22B are sprayed into the feed gas 21A and 21B, and then enter the feed gas cooler 1A and 1B. After the feed gas is cooled, it is sent to the spray methanol and hydraulic fluid separation tanks 2A and 2B, and the separated feed gas 24A and 24B are sent to the absorption tower, spray methanol and hydrocondensate 23A and 23B are introduced into the flash tank 18, and the flash gas 35 is sent into the H 2 S concentration tower 12, condensate 34 in methanol and water condensate / H 2 S gas heat exchanger 19 with H 2 H at the outlet of S fraction heat exchanger 9 2 S gas 33 heat exchange, after reheating, the condensate 36 enters the methanol-water separation tower 4, the water in the condensate is output from the bottom of the tower 4, and is treated as the waste liquid 27...

Embodiment 3

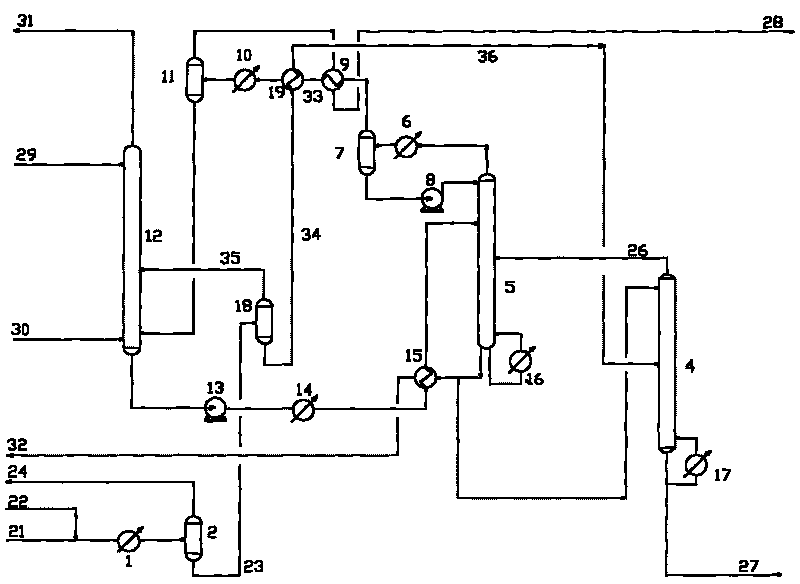

[0044] A low-temperature methanol washing and spraying methanol regeneration process, the process includes raw material gas spraying methanol, raw material gas cooling, raw material gas gas-liquid separation, methanol and hydrocondensate flash evaporation, methanol and hydrocondensate reheating, methanol rectification and regeneration , the specific steps of the process are as follows: a stream of raw material gas is sprayed with methanol and condensate, the pressure is 3.0MPa, the temperature is 243K, flashed through the flash tank, the operating pressure of the flash tank is controlled at 0.6MPa, and the condensate is obtained The flash steam temperature is 233K, and the condensate flash steam is sent to a H 2 S concentrating tower, and finally into the tail gas, H 2 The operating temperature of the S concentration tower is controlled at 203-238K, and the temperature of the methanol and water condensate after decompression is 233K, and the H 2 H at the outlet of S fraction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com