Patents

Literature

187 results about "Flash-gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

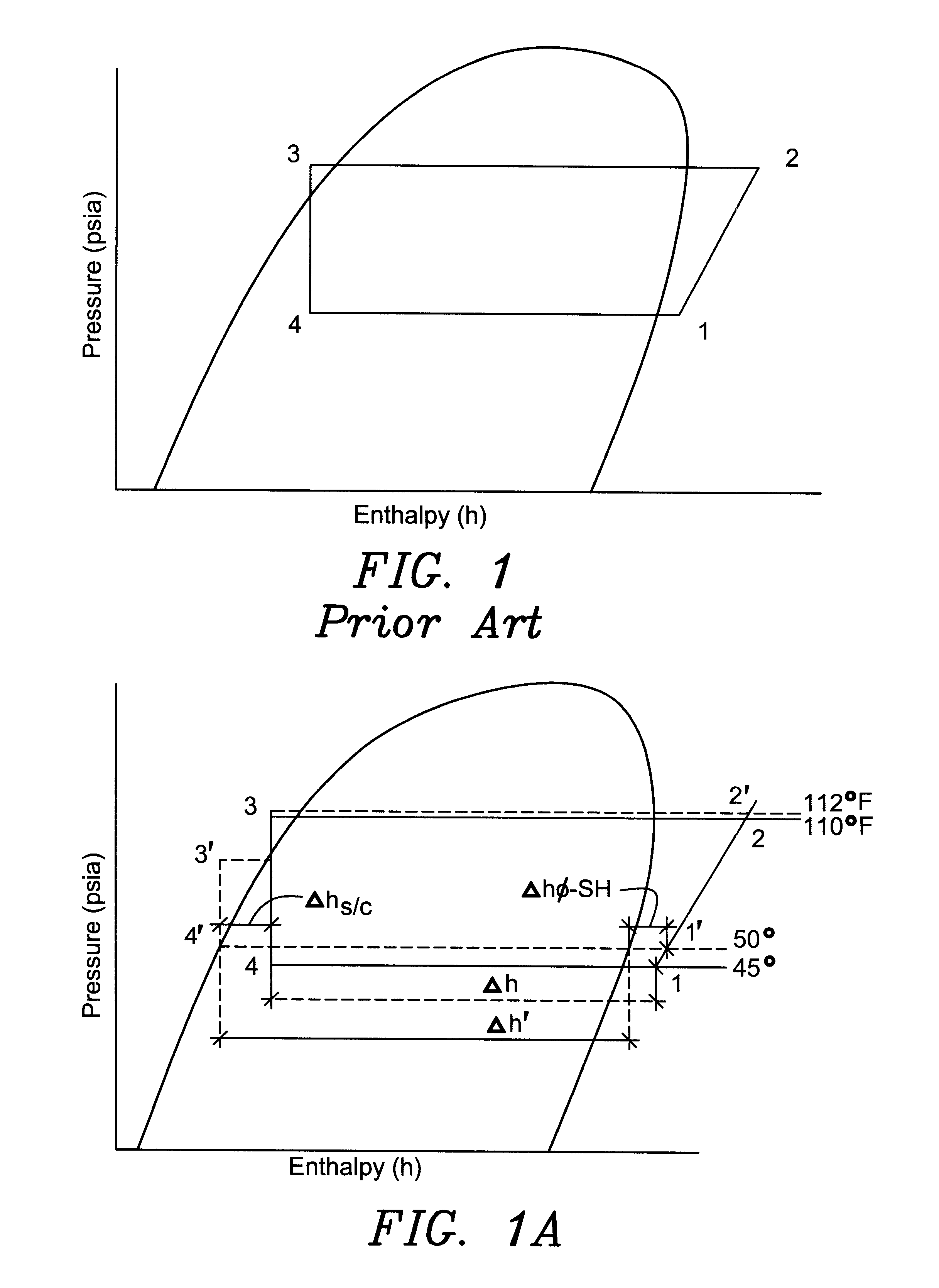

In refrigeration, flash-gas is refrigerant in gas form produced spontaneously when the condensed liquid is subjected to boiling. The presence of flash-gas in the liquid lines reduces the efficiency of the refrigeration cycle. It can also lead several expansion systems to work improperly, and increase superheating at the evaporator. This is normally perceived as an unwanted condition caused by dissociation between the volume of the system, and the pressures and temperatures that allow the refrigerant to be liquid. Flash-gas must not be confused with lack of condensation, but special gear such as receivers, internal heat exchangers, insulation, and refrigeration cycle optimizers may improve condensation and avoid gas in the liquid lines.

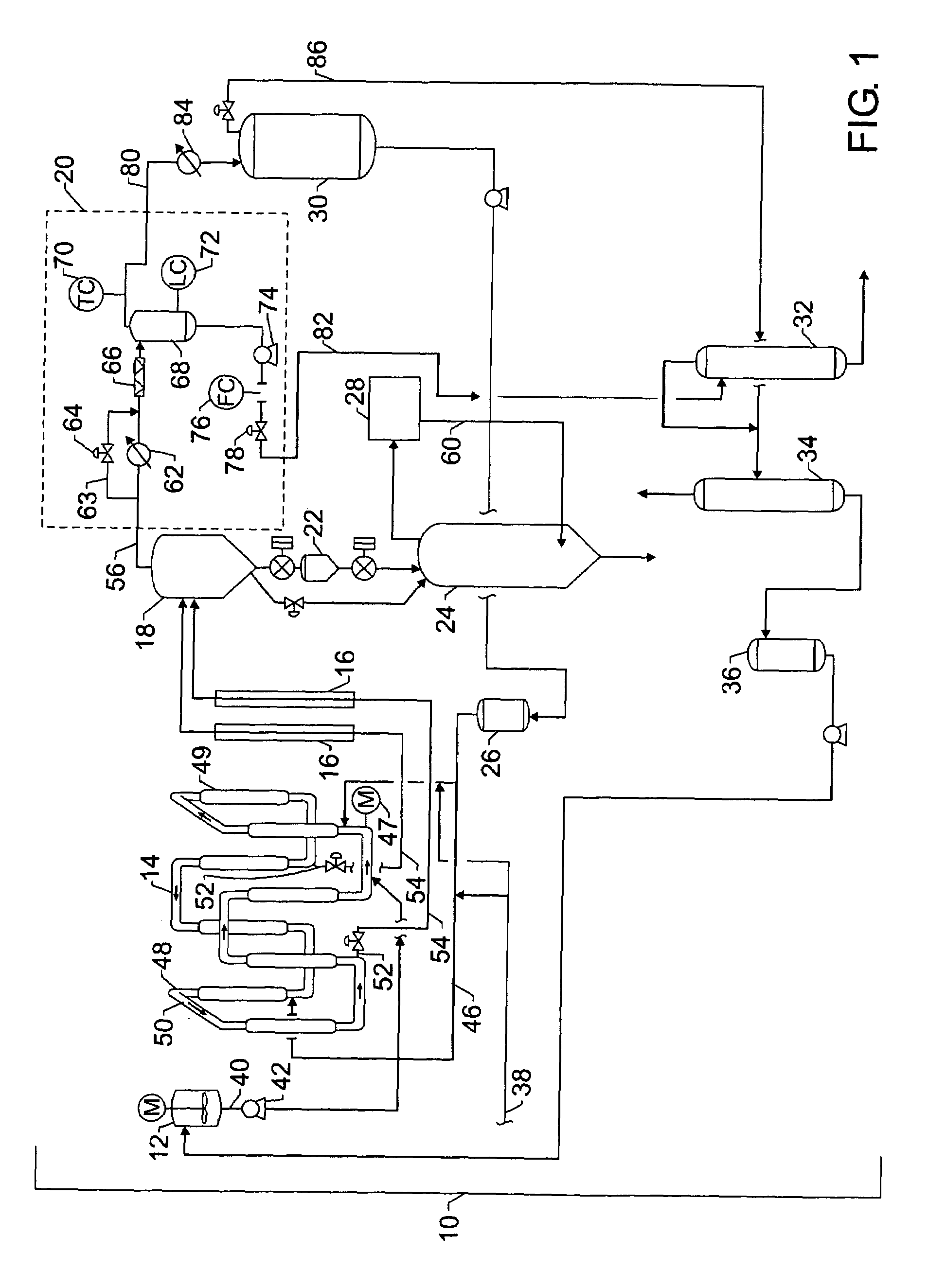

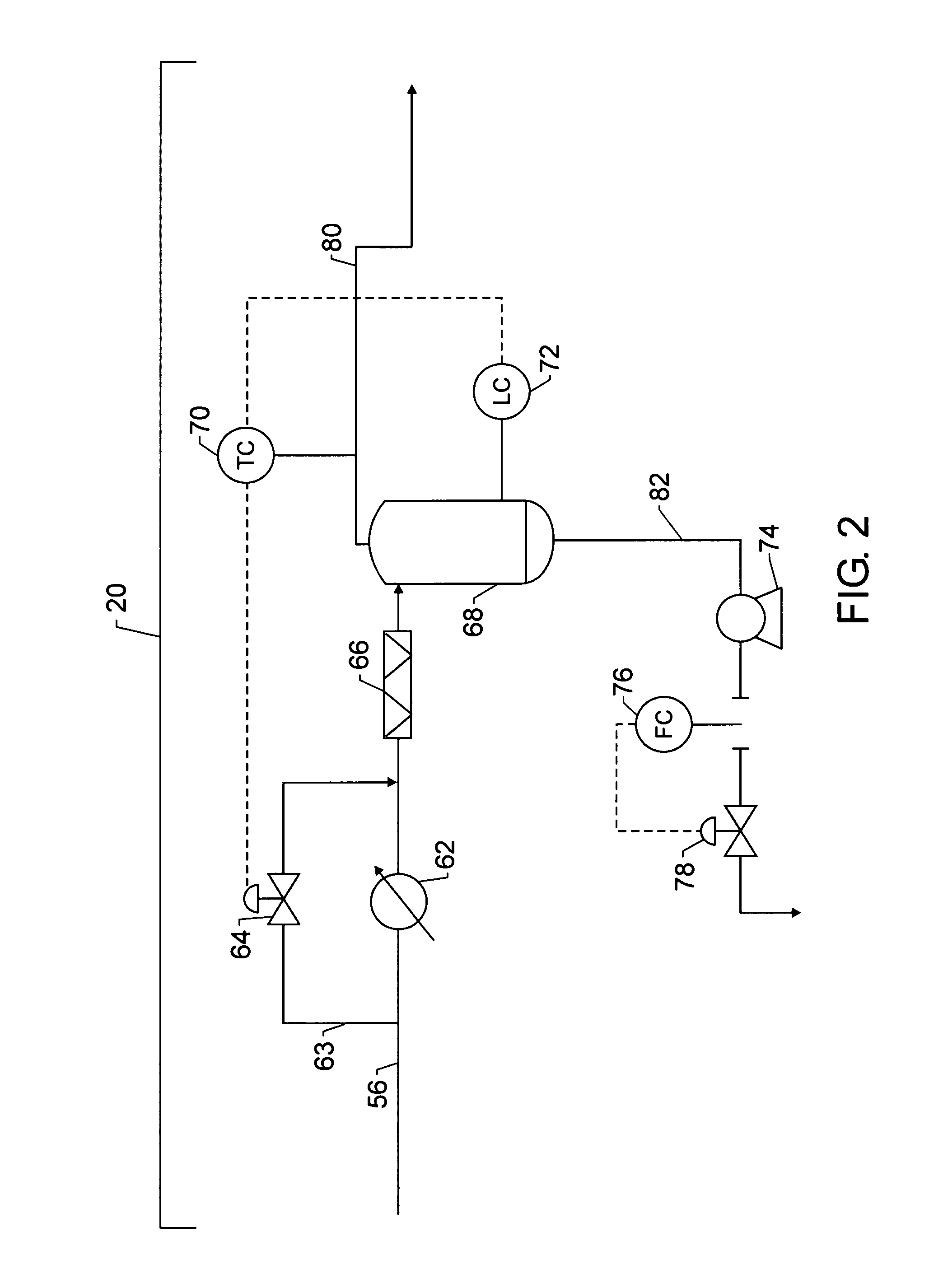

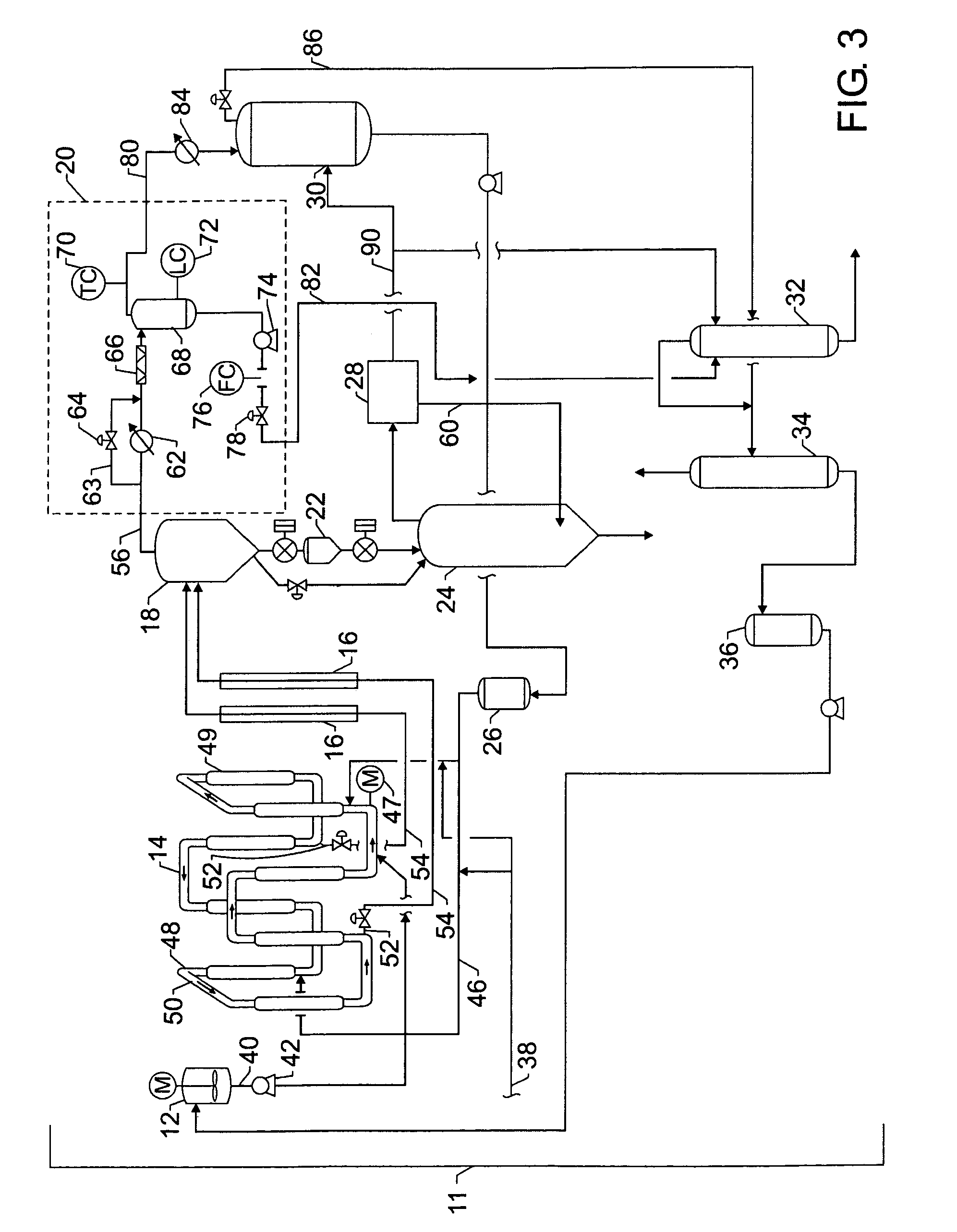

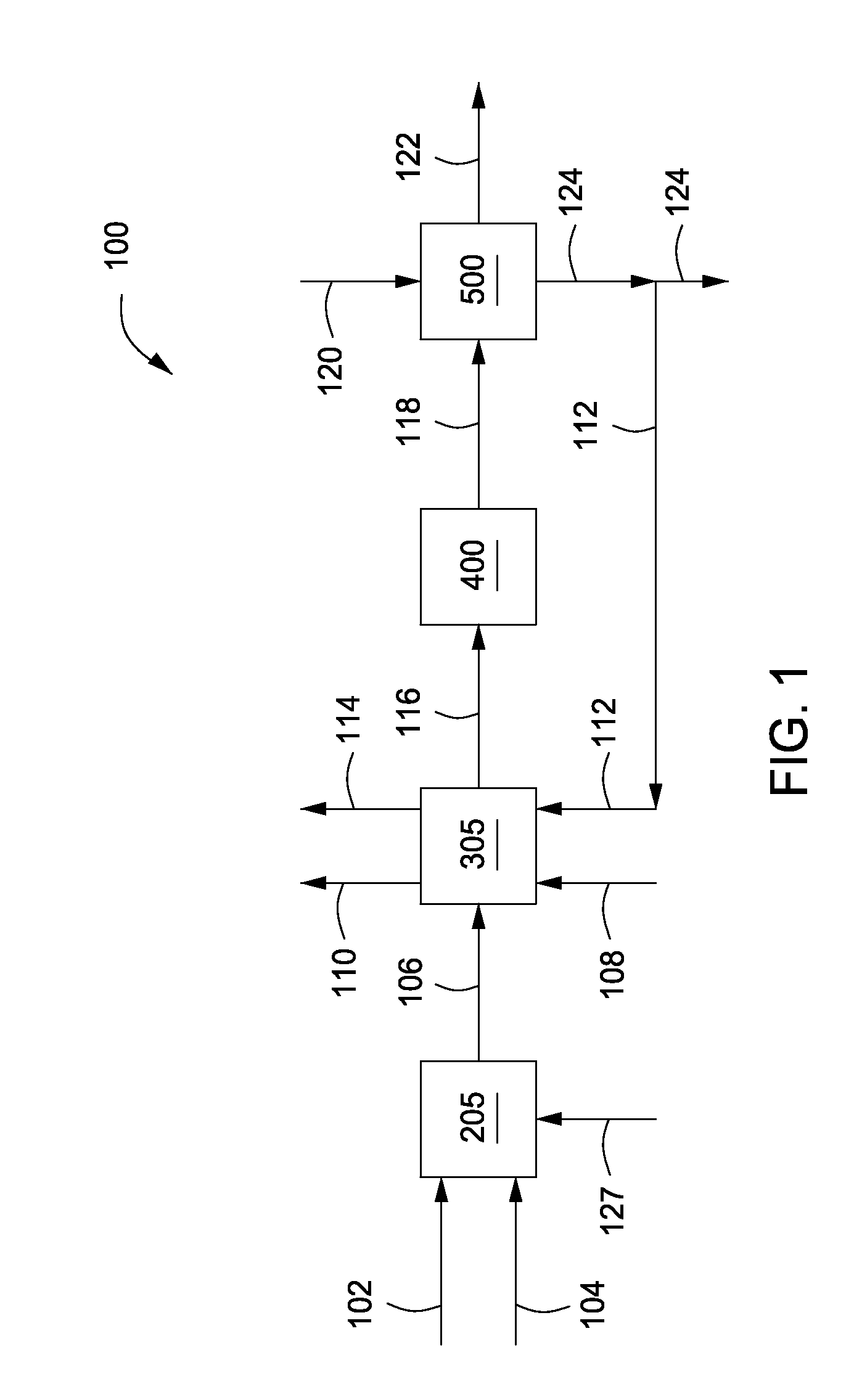

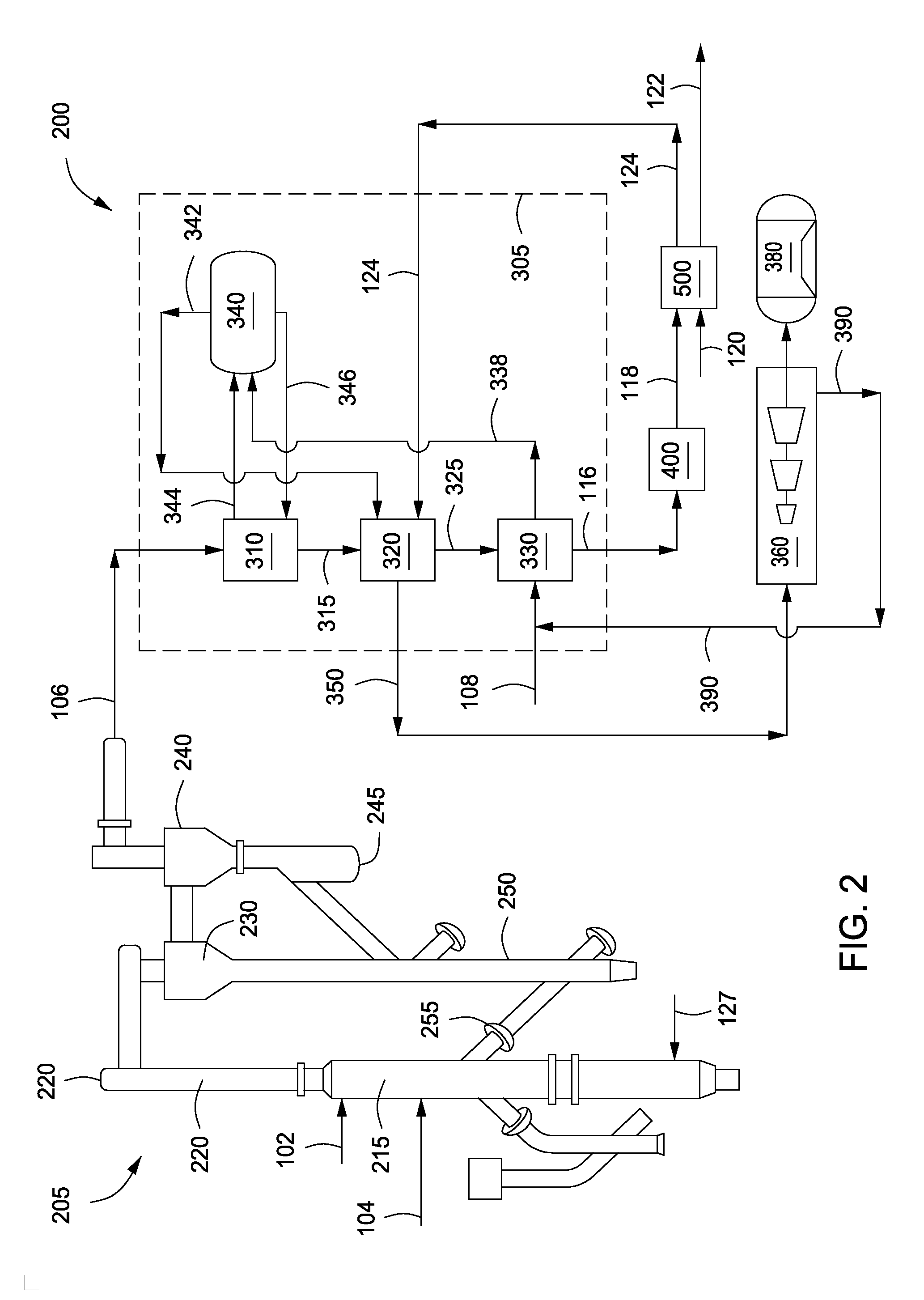

Closed loop single mixed refrigerant process

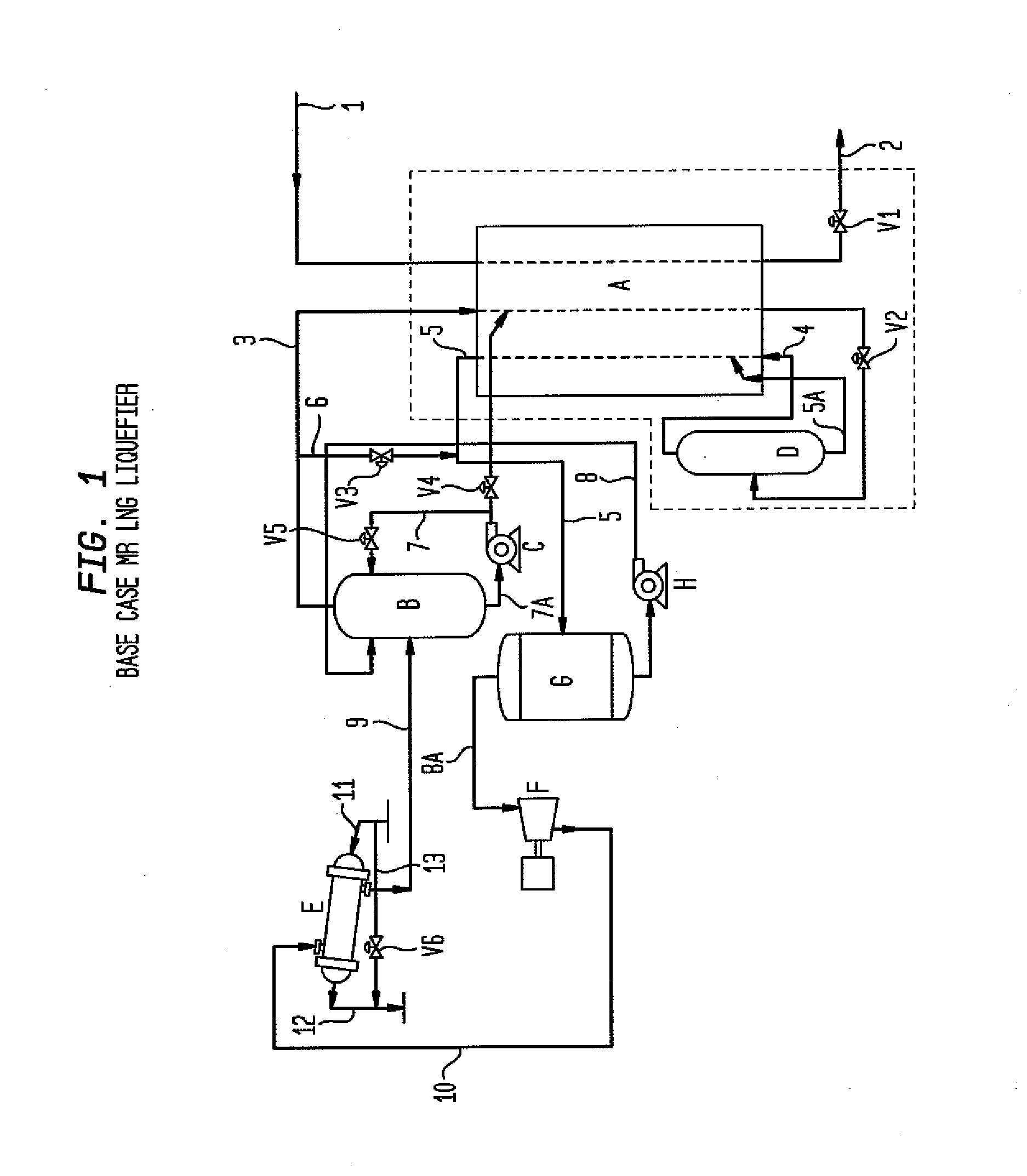

InactiveUS6295833B1Improve efficiencyIncrease flexibilitySolidificationLiquefactionFlash-gasClosed loop

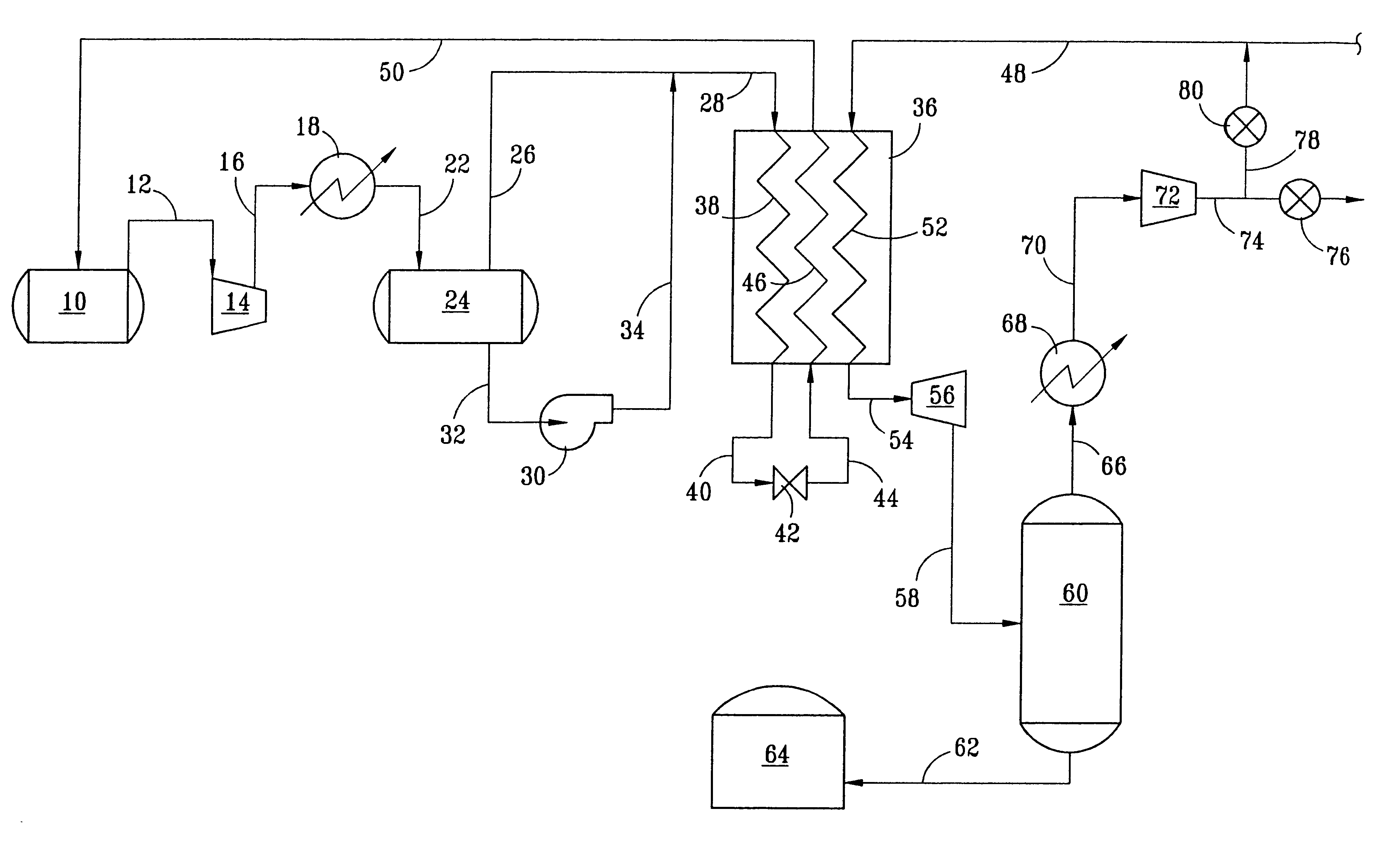

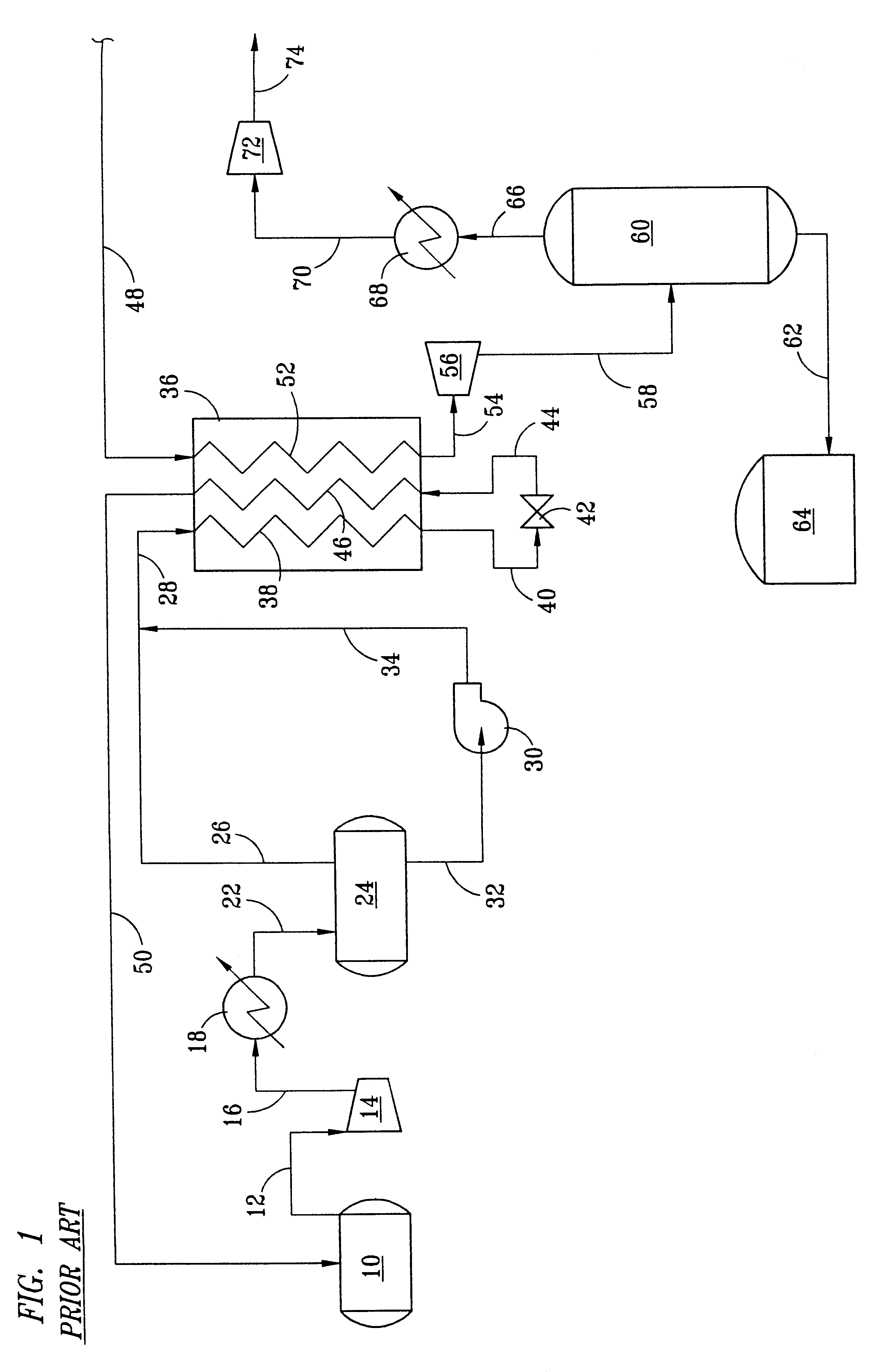

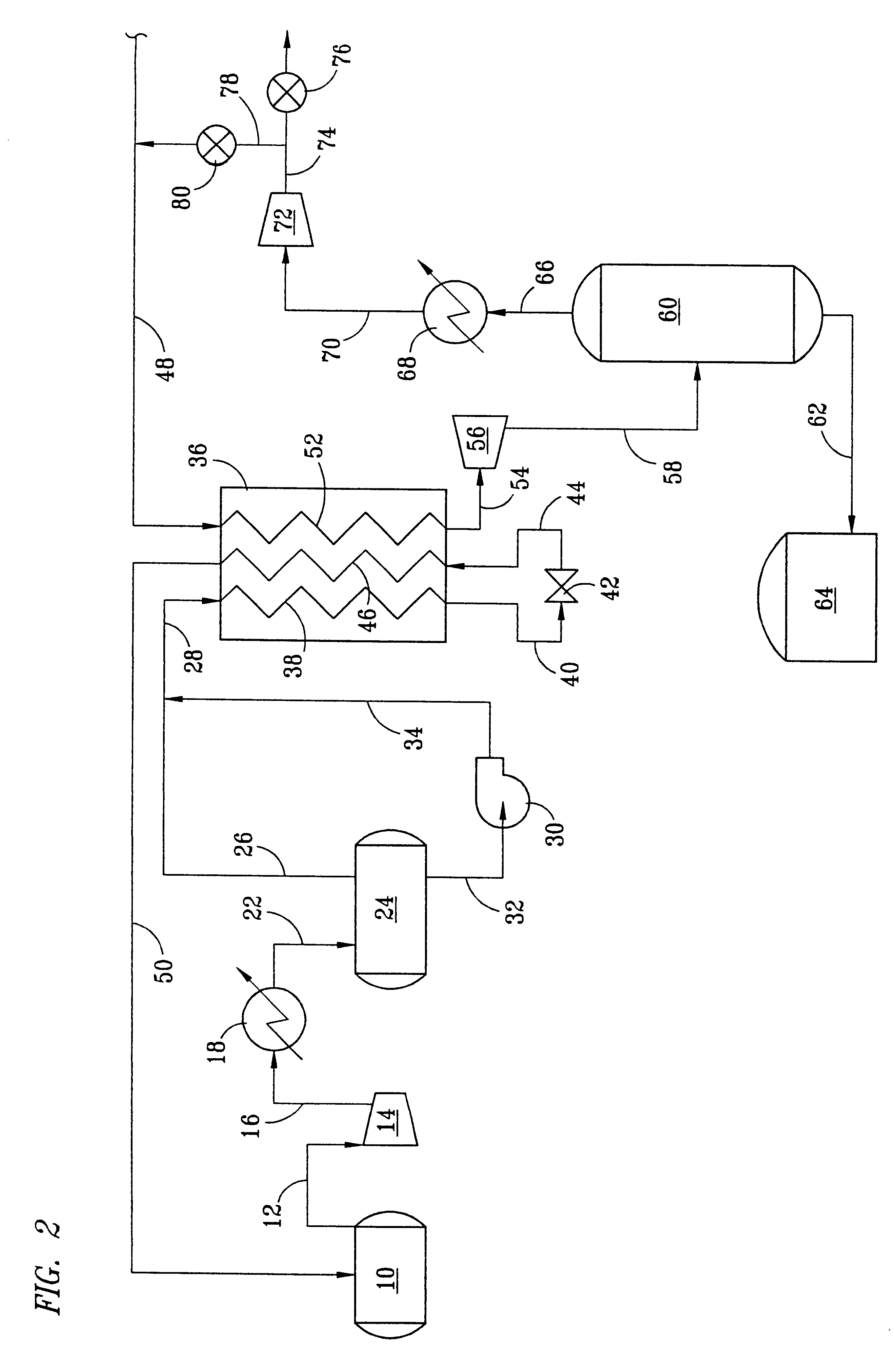

A closed loop single mixed refrigerant process and system wherein the process efficiency is increased by increasing the temperature of liquefied material produced in a heat exchange refrigeration zone and thereafter cooling the liquefied material by flashing a portion of the liquefied material to produce a cooler liquefied material and a flash gas a portion of which is recycled to the heat exchange refrigerator. The process and system provide increased process efficiency and flexibility.

Owner:BLACK & VEATCH HLDG

Flash gas and superheat eliminator for evaporators and method therefor

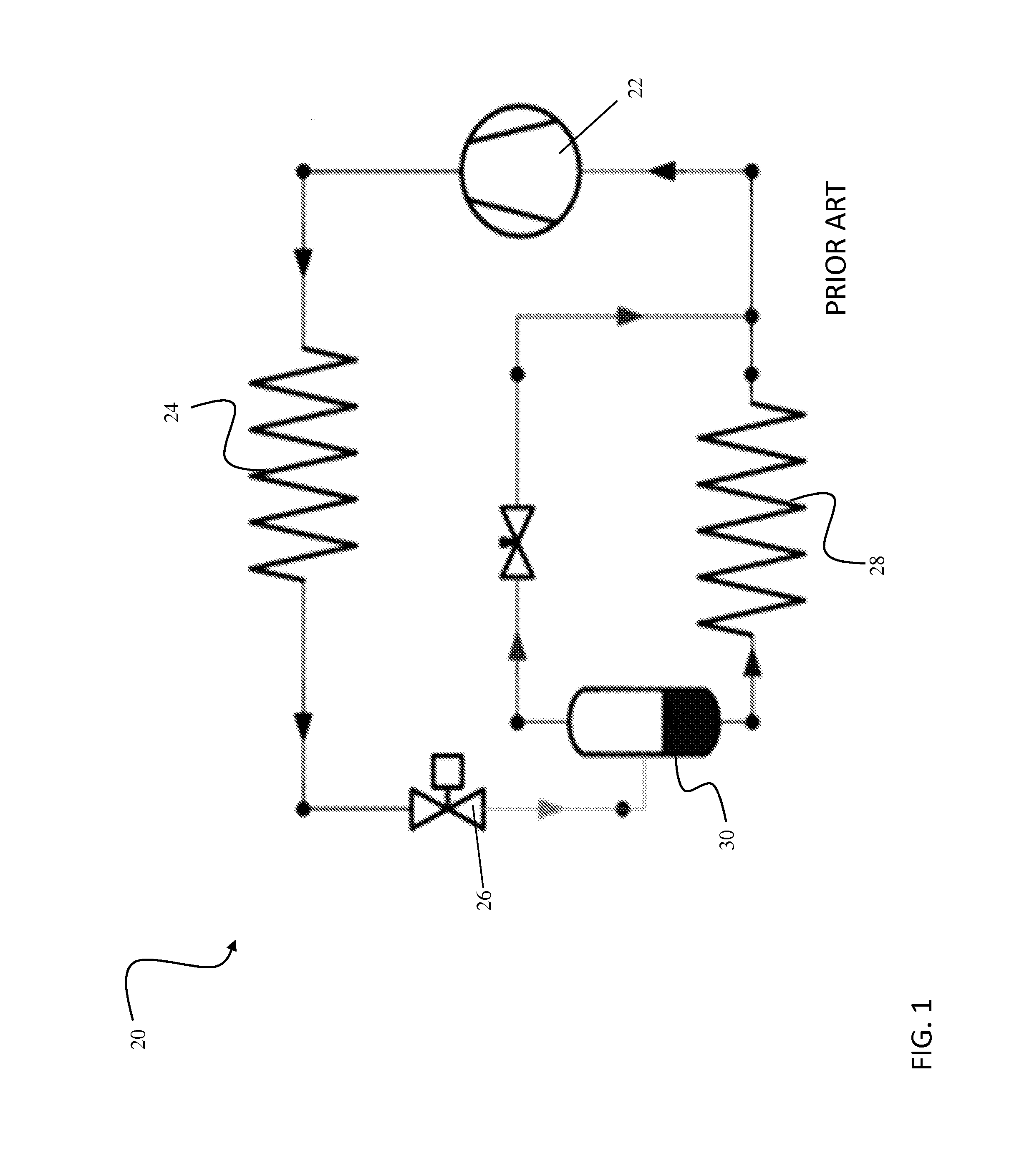

InactiveUS6460358B1Comprehensive understandingImprove cooling effectMechanical apparatusFluid circulation arrangementHeat rejectionFlash-gas

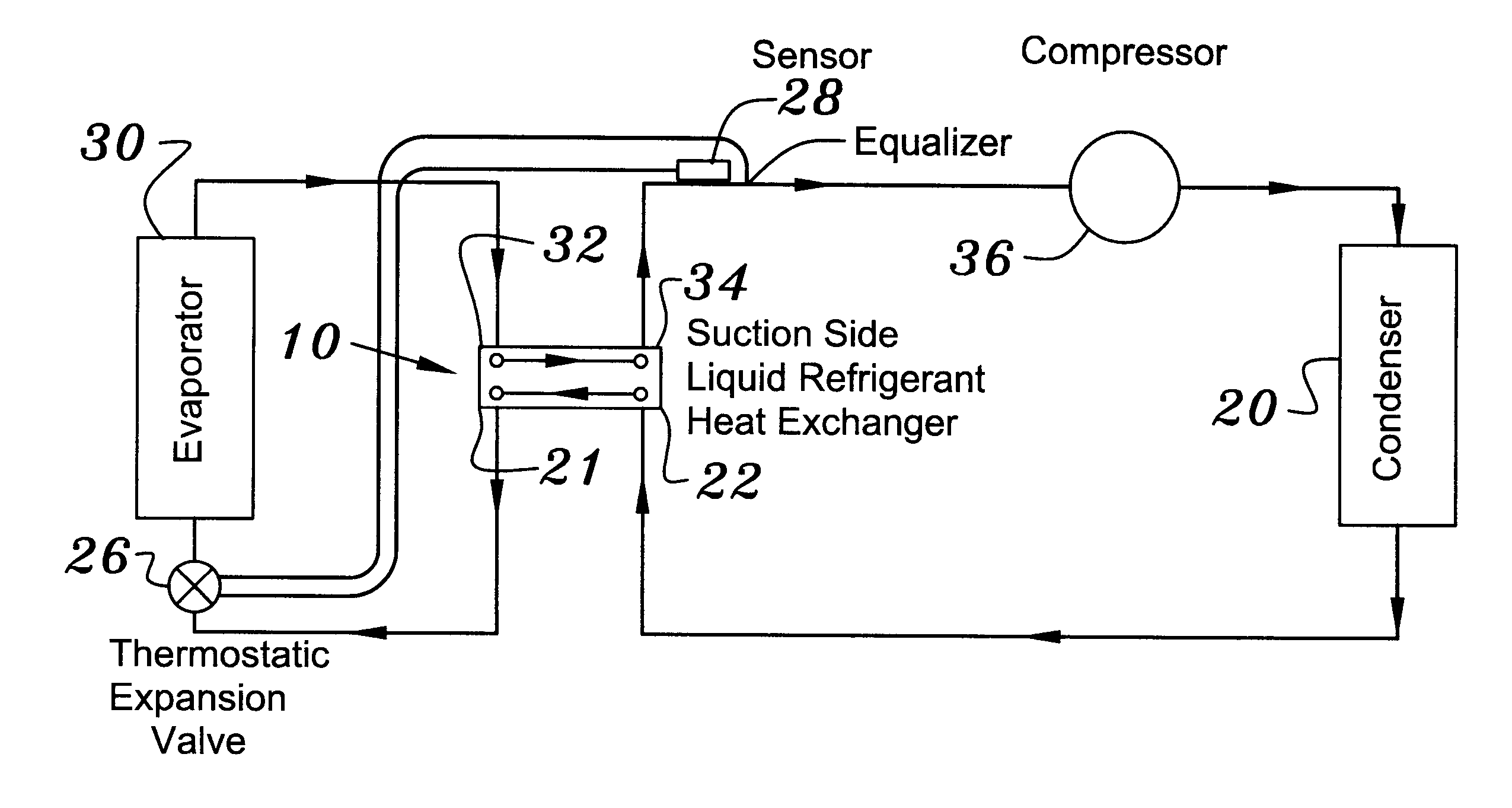

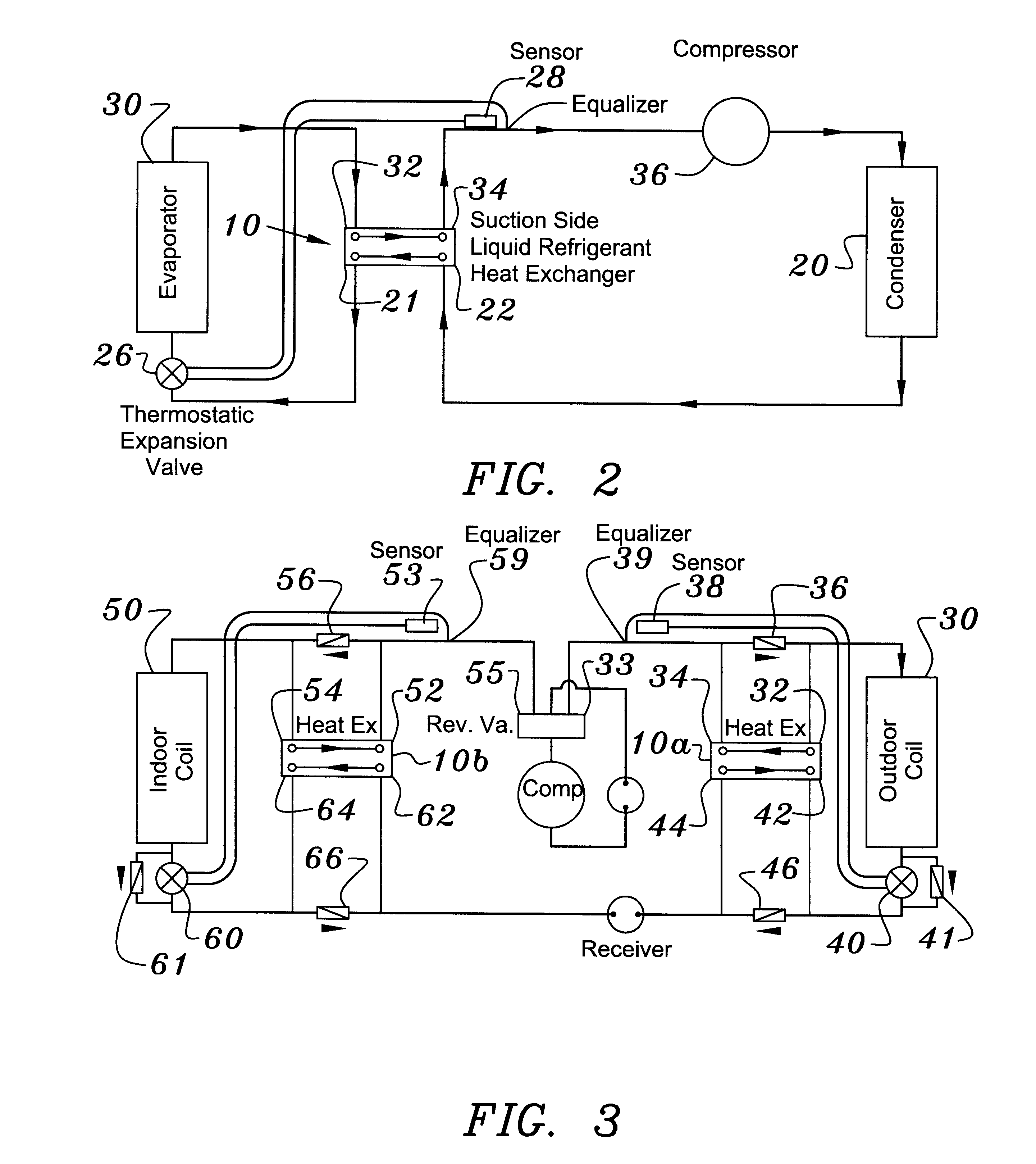

A low pressure suction side refrigerant to liquid refrigerant heat exchanger, located in the refrigeration circuit in such a way that the sensor (and external equalizer tube, if applicable) is located downstream of the low pressure refrigerant outlet of the heat exchanger, provides for effectively eliminating both the superheat and flash gas loss regions of the evaporator which in turn increases the mass flow through the evaporator and increases the refrigerating capacity of the evaporator at very little increase in compressor power thereby providing for increased system efficiency for refrigerating or cooling purposes. On the heating side, heat rejection capacity of a heat pump is increased even more dramatically because of the heat reclaim of the flash gas loss heat, which provides for even greater efficiency increases for heating applications.

Owner:OLIVE TREE PATENTS 1 +1

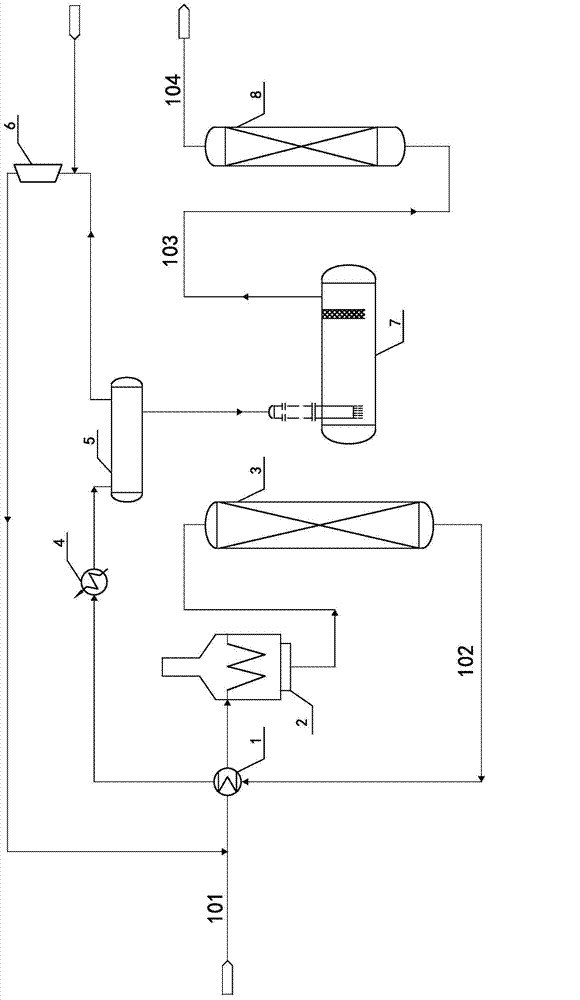

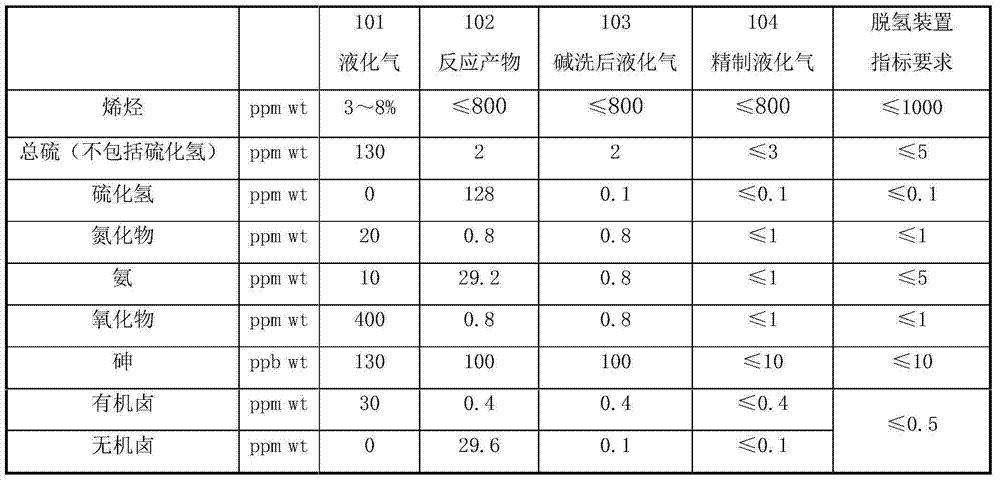

High-temperature hydrogenation and purification process for liquefied gas materials

The invention relates to a purification process of liquefied gas and particularly provides a high-temperature hydrogenation and purification process for liquefied gas materials. The high-temperature hydrogenation and purification process is characterized by comprising the following steps: (1) carrying out heat exchange on raw material liquefied gas and a reactor outlet product in a heat exchanger, heating by a heating furnace to a reaction temperature, then feeding the material into a reactor from the top, carrying out saturation hydrogenation on olefin in the material to obtain alkane, and respectively hydrogenating and converting sulfide, oxide, nitride and halide into hydrogen sulfide, water, ammonia and hydrogen halide; (2) carrying out sufficient heat exchange on the reactor outlet product and the raw material by an efficient heat exchanger, carrying out water cooling by a water cooler and enabling the material to enter a gas-liquid separation tank, compressing a flashing gas phase and fresh hydrogen by a compressor and circulating to the raw material liquefied gas; (3) enabling the flashing liquid phase to enter an alkali washing deposition tank and carrying out fiber membrane alkali washing to remove hydrogen sulfide, ammonia and hydrogen halide; (4) enabling the material which is subjected to the alkali washing to enter a dearsenicator, and removing arsenic and metal to obtain refined liquefied gas. The high-temperature hydrogenation and purification process mainly aims at a project which is very strict in requirement on the impurity content of a catalyst, and is short in flow, small in investment, low in cost and less in solid wastes.

Owner:山东海成石化工程设计有限公司

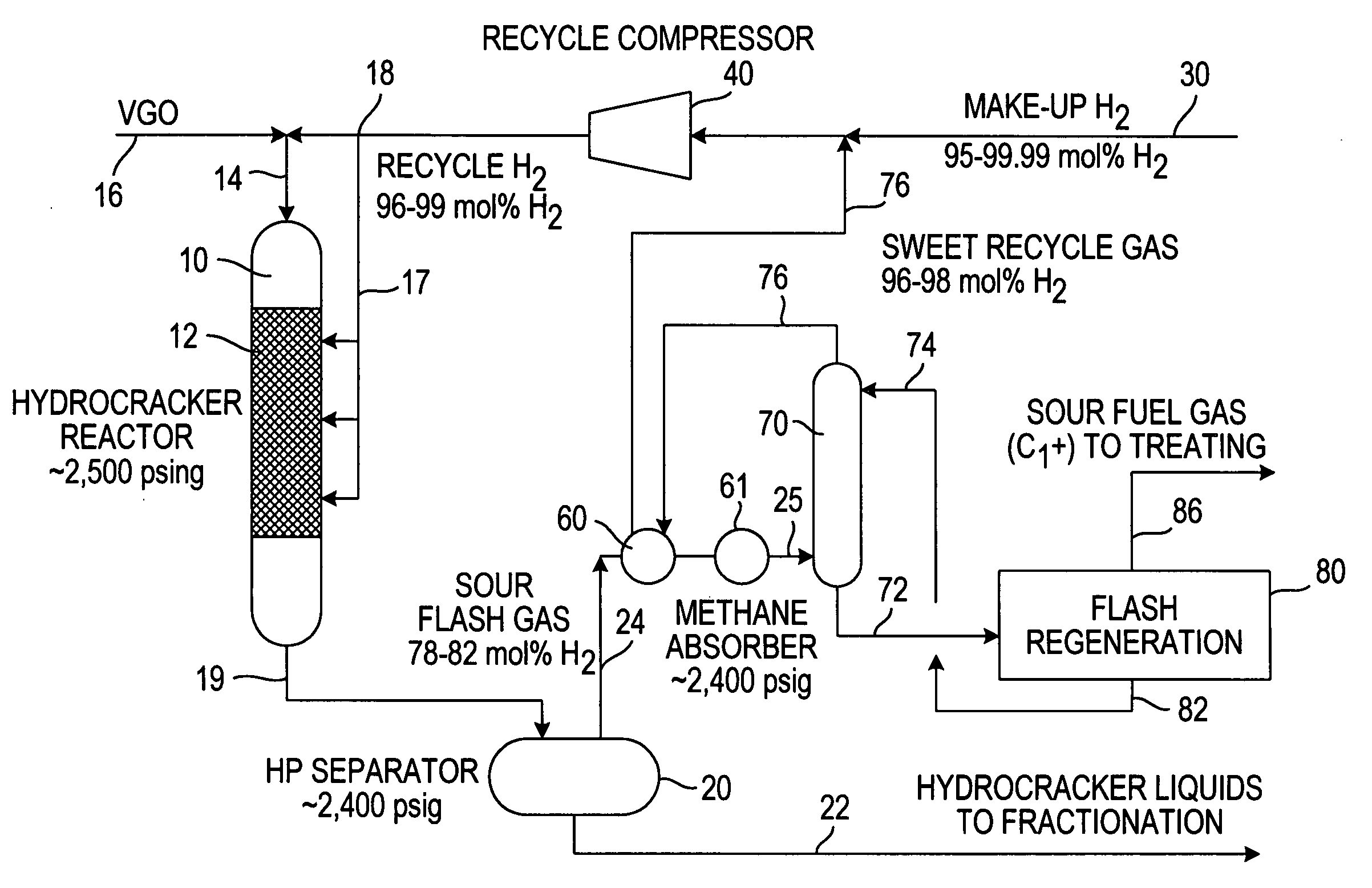

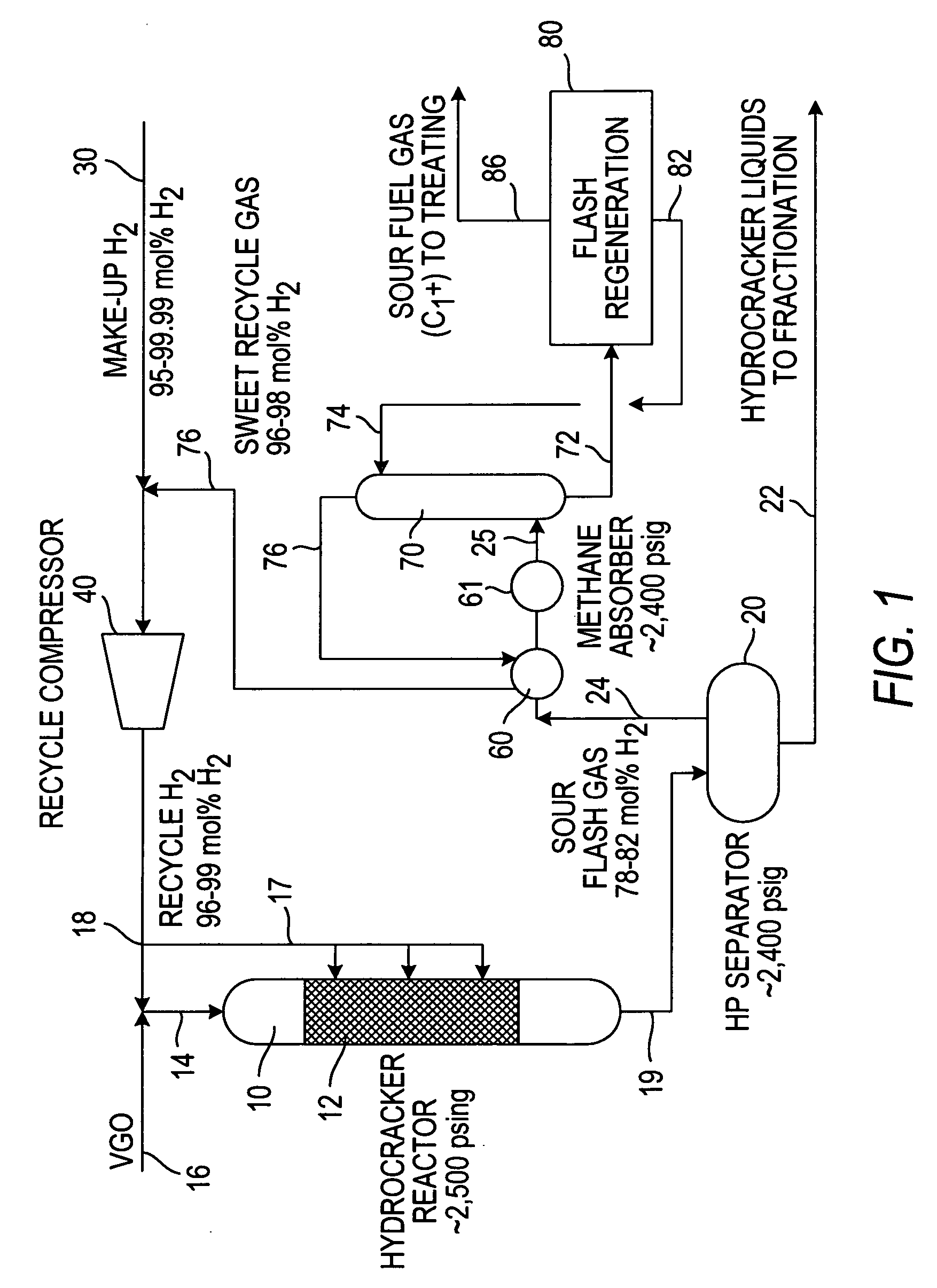

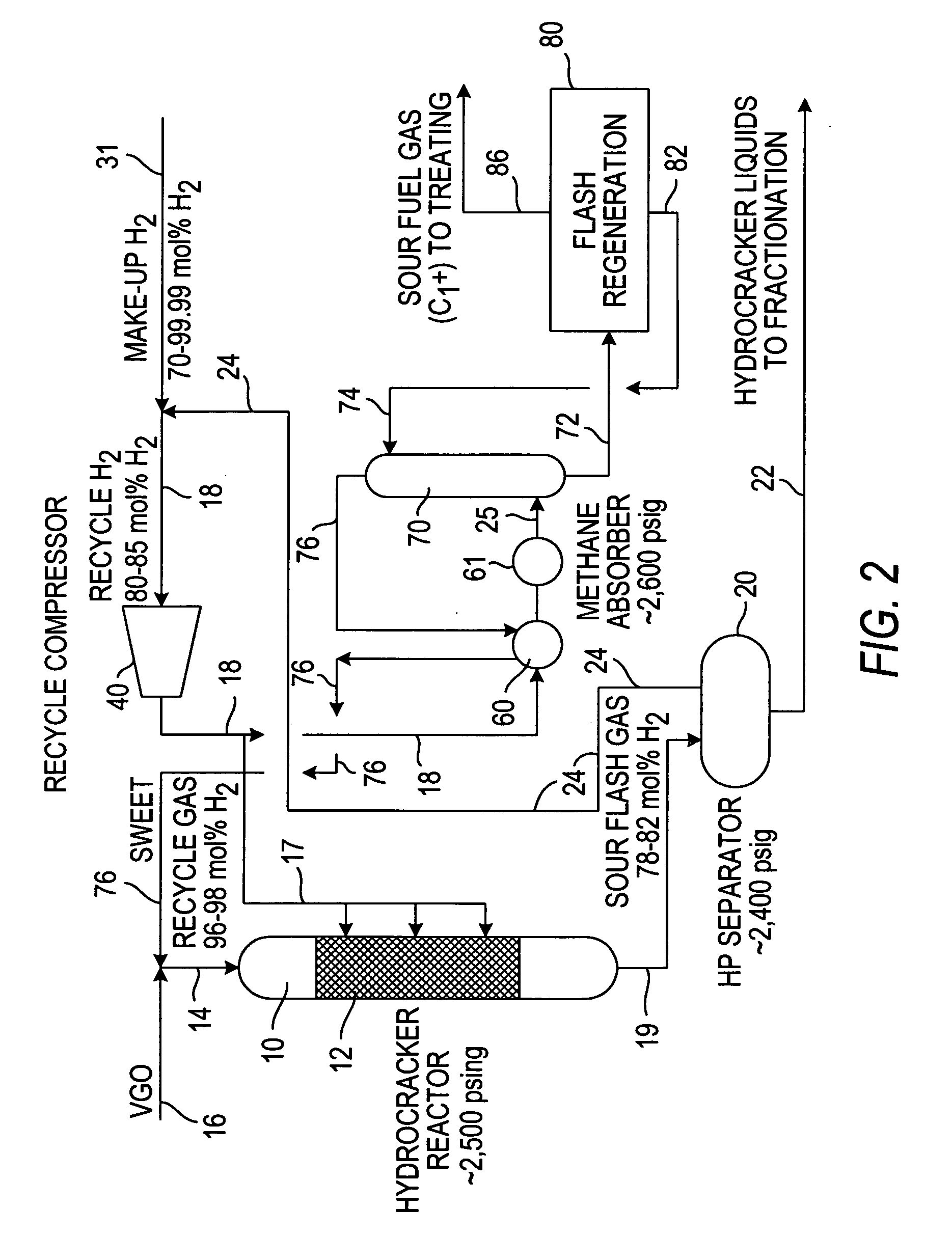

Hydrogen purification for make-up gas in hydroprocessing processes

InactiveUS20070017851A1Minimize changesHigh levelHydrocarbon oil crackingTreatment with hydrotreatment processesGas compressorFlash-gas

The recycle gas stream containing hydrogen that is part of the feedstream to a hydroprocessing reactor is mixed with the low purity make-up hydrogen and the sour flash gases upstream of the recycle gas compressor and compressed by the recycle gas compressor. The compressed gases pass through a methane and higher (C1+) absorber to produce a sweet hydrogen recycle gas stream that is delivered to the hydroprocessing reactor at 96-98 mol % hydrogen. The process can be used to advantage in existing process facilities to increase the hydrogen partial pressure in the feedstream to the hydroprocessor where the existing recycle gas compressor is not designed for compressing the high purity hydrogen.

Owner:SAUDI ARABIAN OIL CO

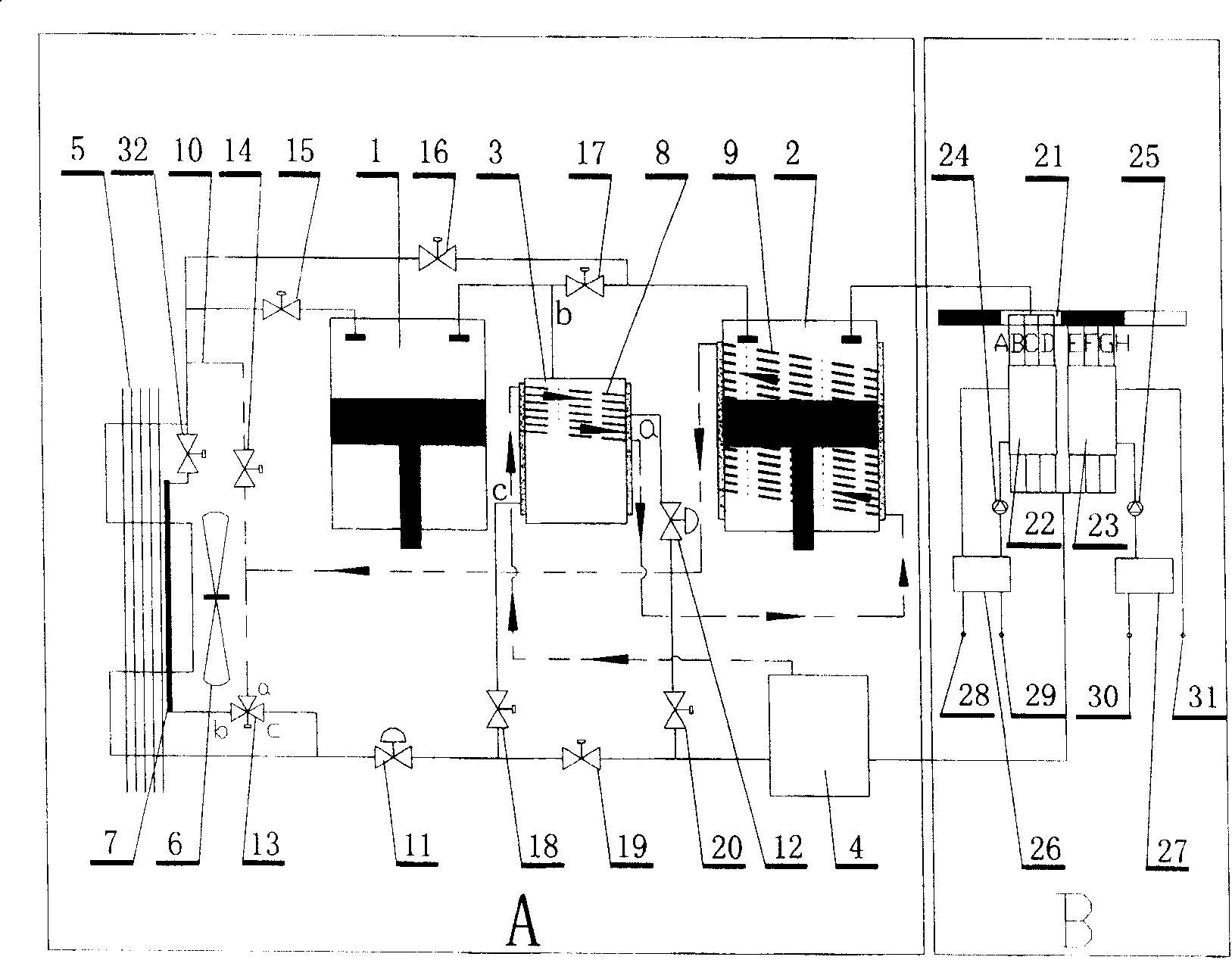

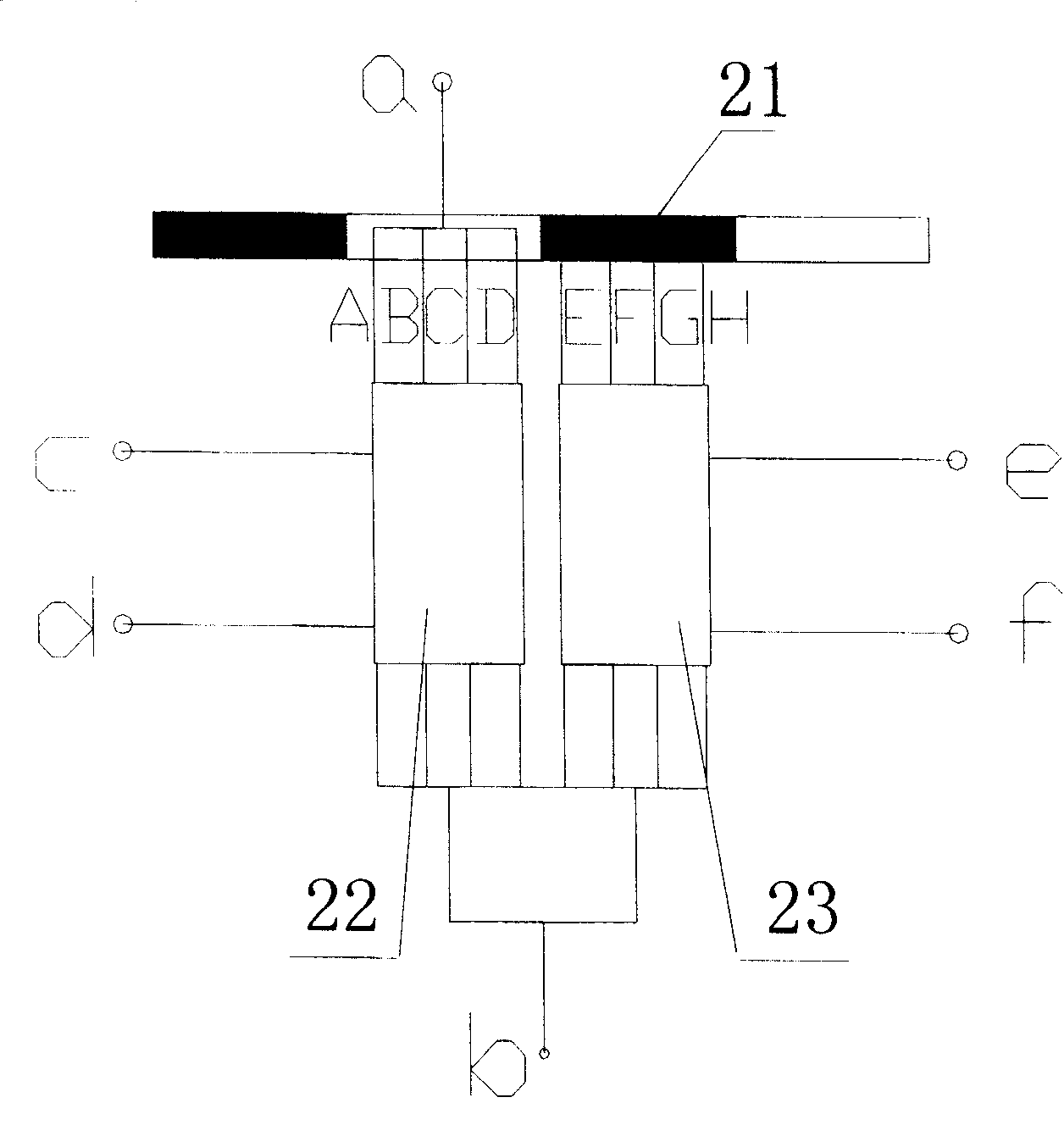

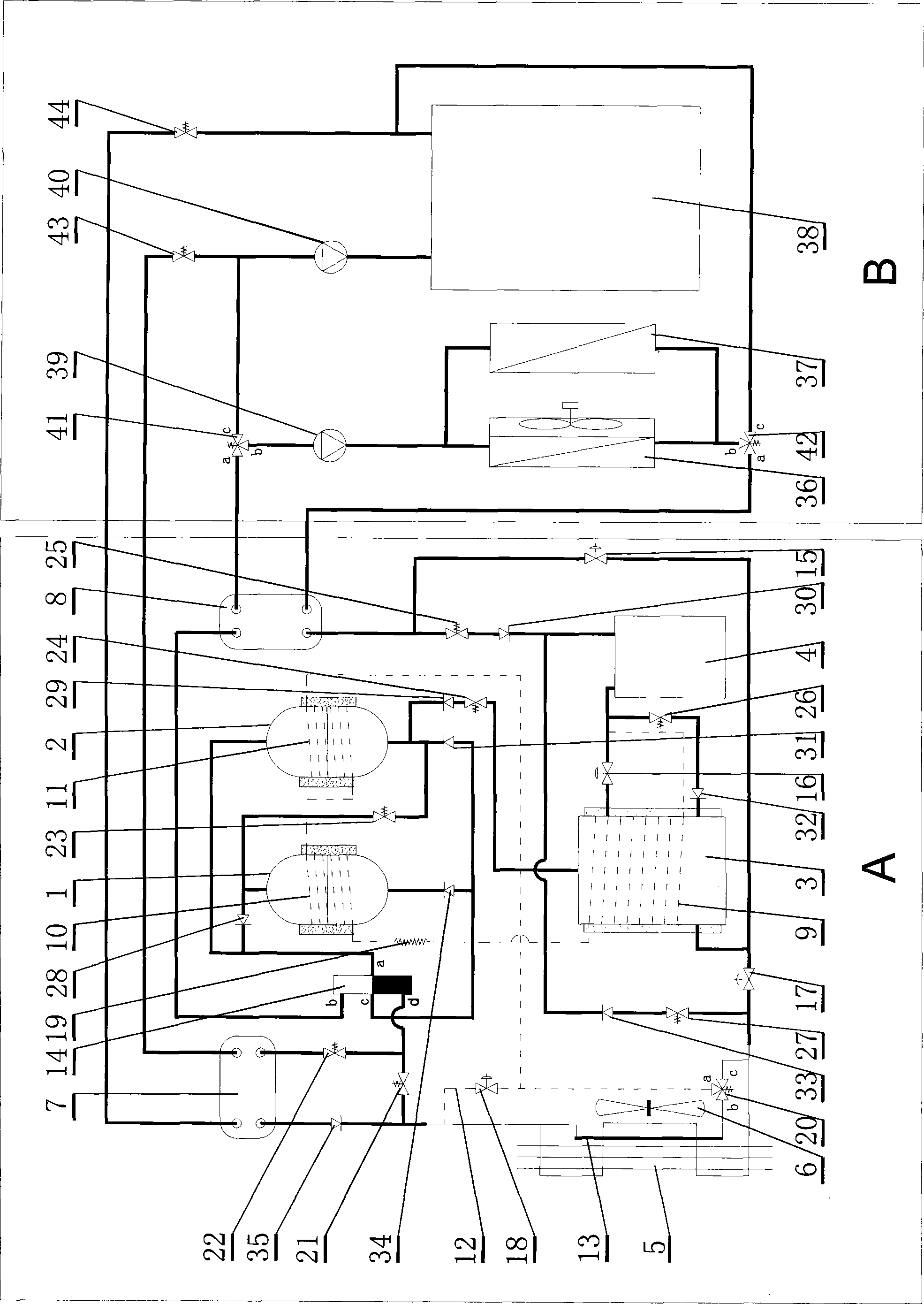

Domestic air source heat pump heating system and apparatus for coldness area

InactiveCN101457949ALower oil temperatureReduce exhaust temperatureHeat pumpsEnergy efficient heating/coolingBusiness efficiencyFlash-gas

The invention discloses a household air source heat pump heating system in cold area and a device thereof, and relates to a heat pump system which uses the air source for running steadily under the low-temperature environment and supplying the interior with the needed heat and healthy hot water and a device thereof. The device comprises parts such as a low pressure frequency compressor, a high pressure compressor, an outdoor heat exchanger, a flash evaporator, a reservoir, a defrosting coil, a flash gas overheating coil, a compressor heat radiating recovery coil, a low pressure air supply pressurization line, a sub-thermal converter, a multi-head efficient spiral heat exchanger, a thermal expansion valve, and the like, which are connected by a pipeline. The invention is characterized in that the system comprises a flash evaporator component, a flash gas overheating coil, a compressor heat radiating recovery coil, and a low pressure air supply pressurization line. When in heat operation under low-temperature working condition, based on the two-stage compression cycle which is incompletely cooled between two stages of throttles, the invention uses the flash gas overheating coil, the compressor heat radiating recovery coil, and the low pressure air supply pressurization line for recovering the heat radiating capacity of a compressor, realizes the overheating of the flash gaseous working substance, enhances the gas transmission capacity of the compressor, and further improves the heat and the energy efficiency ratio of a heat pump system. Meanwhile, the defrosting coil is added to the bottom part of the heat exchanger device, so the frosting problem of the outdoor heat exchanger of the heat pump is solved. The invention can realize the mutual switch among a single heating operating mode in winter, a heating and healthy hot water united operating mode in winter, and a healthy hot water single operating mode during a non-heating period.

Owner:DALIAN ZHONGXING TECH DEV

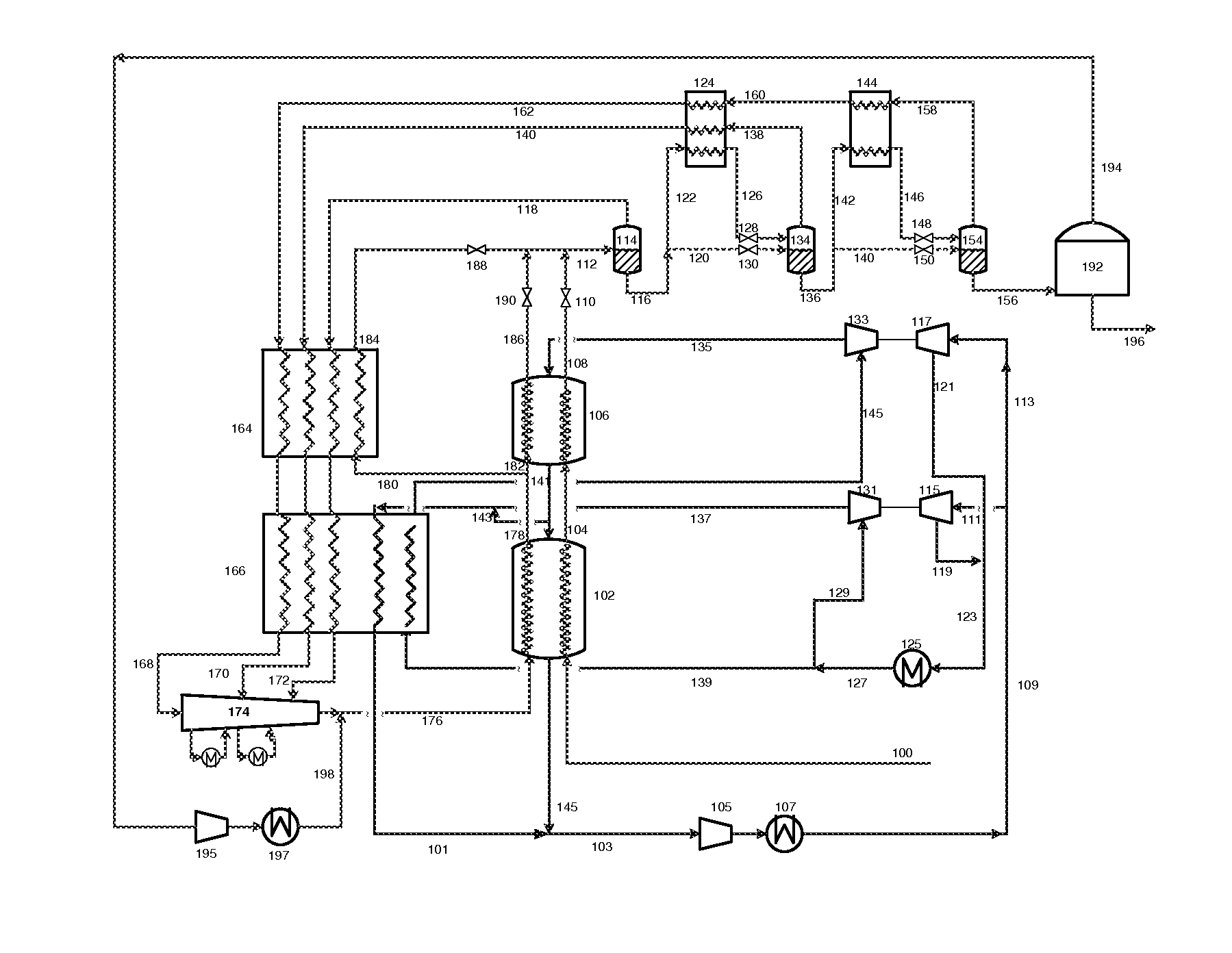

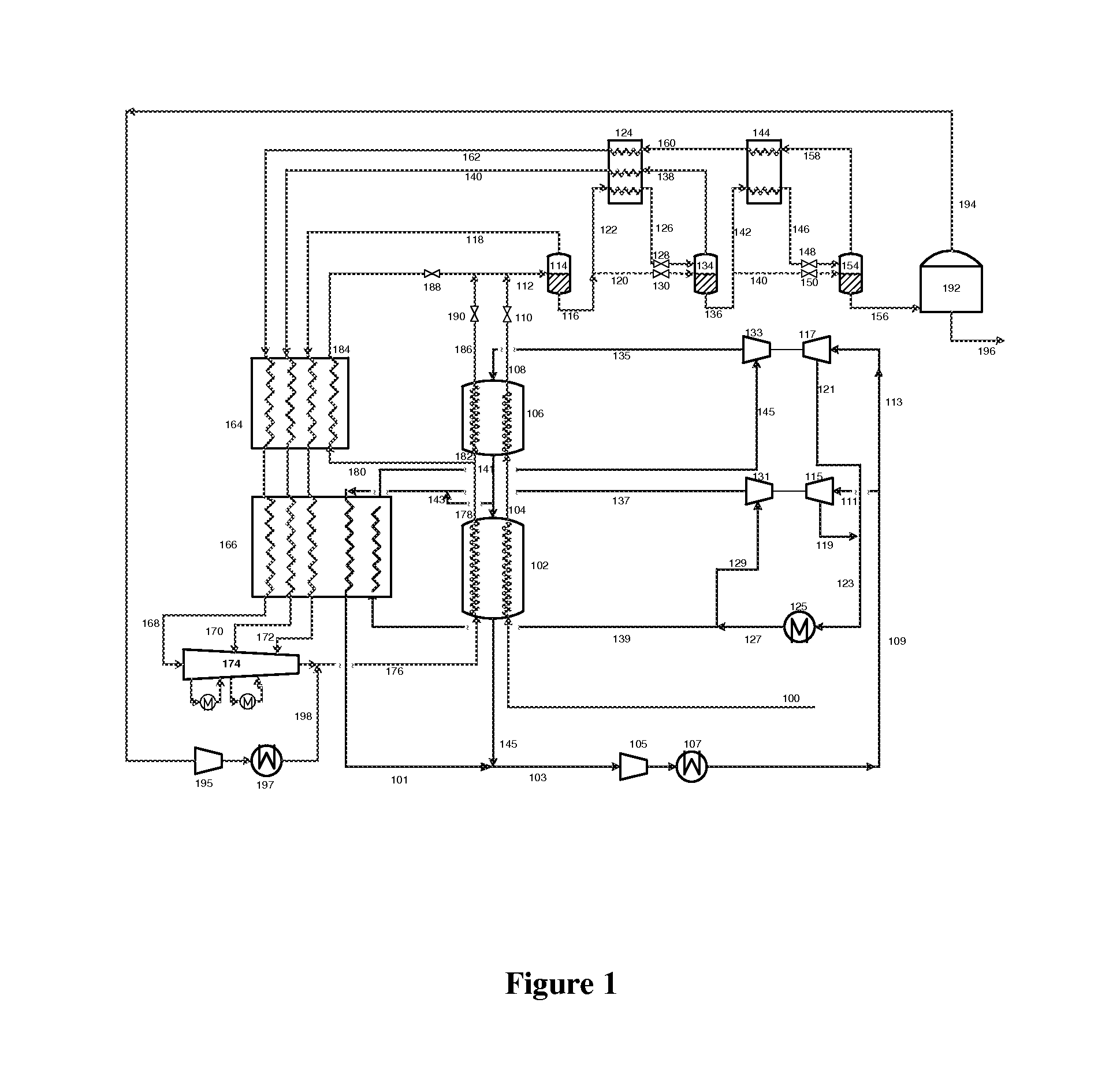

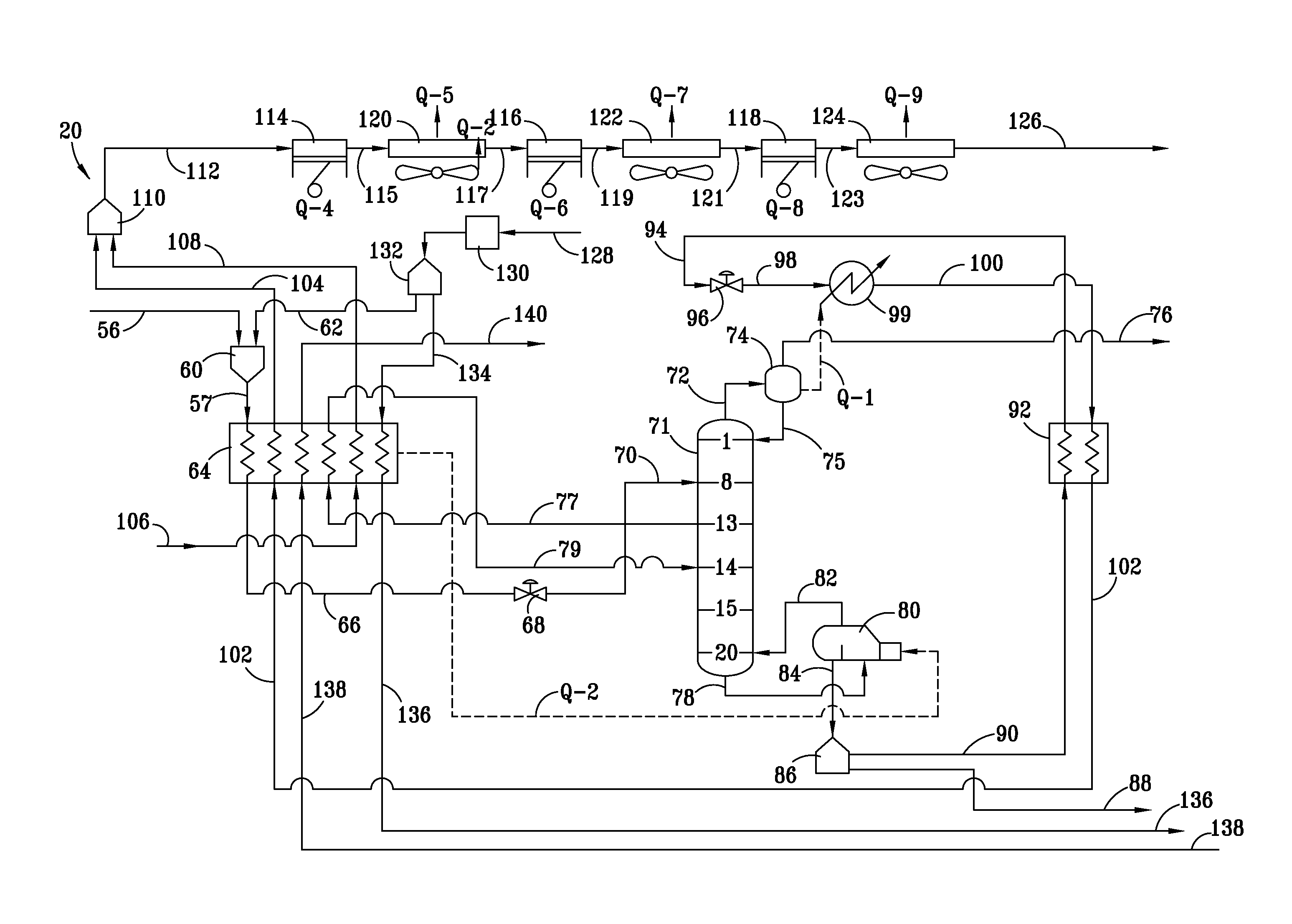

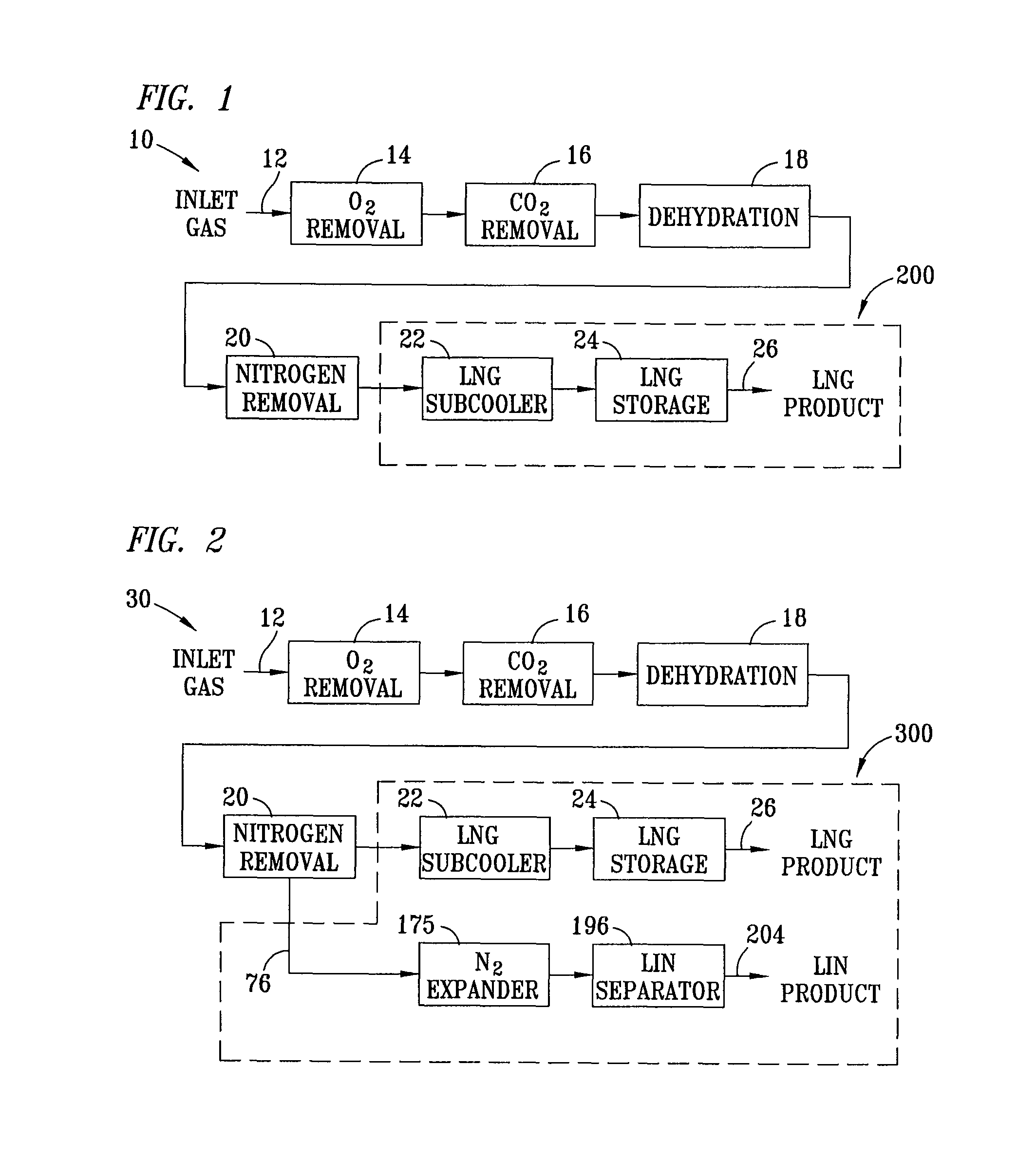

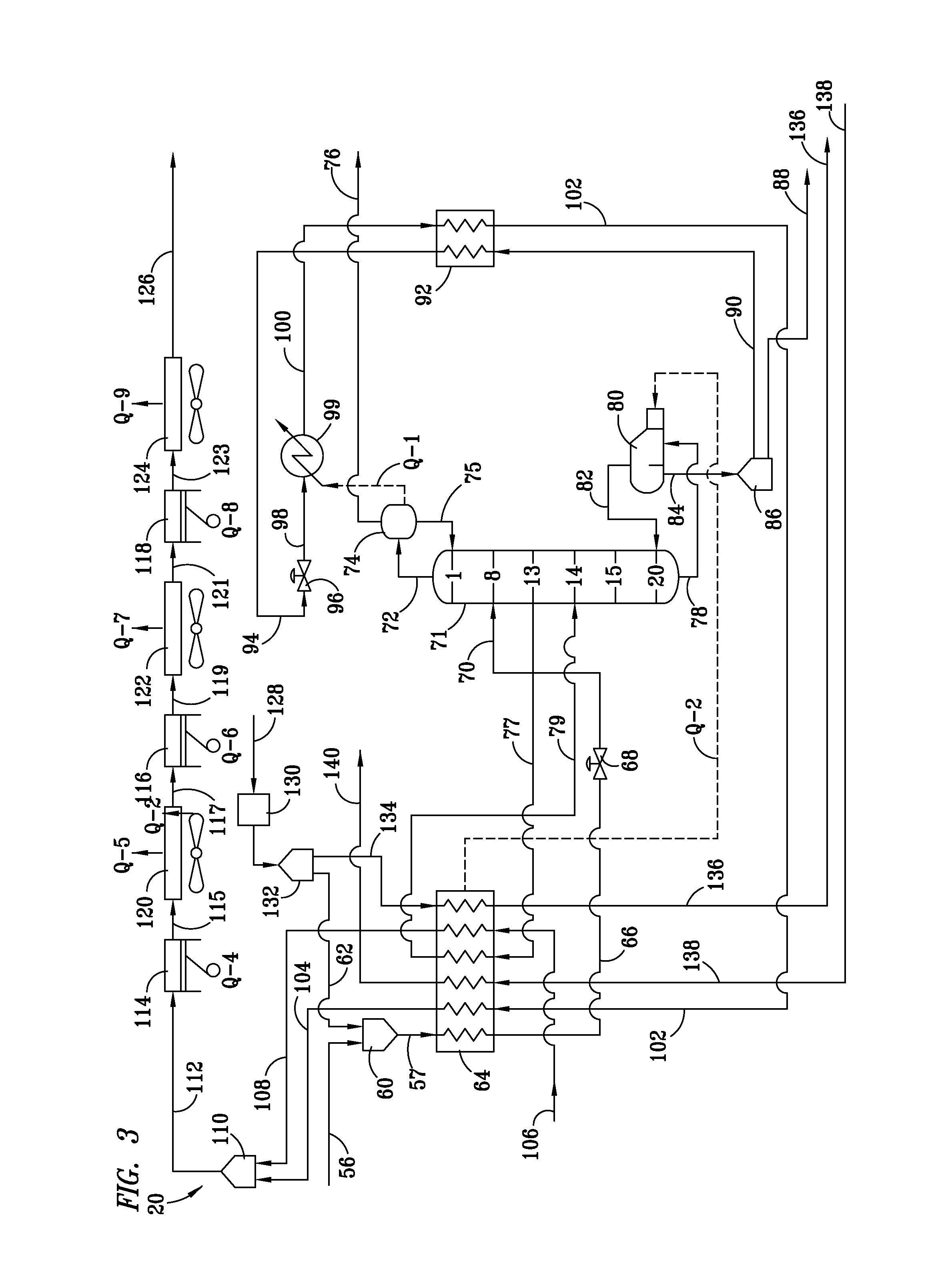

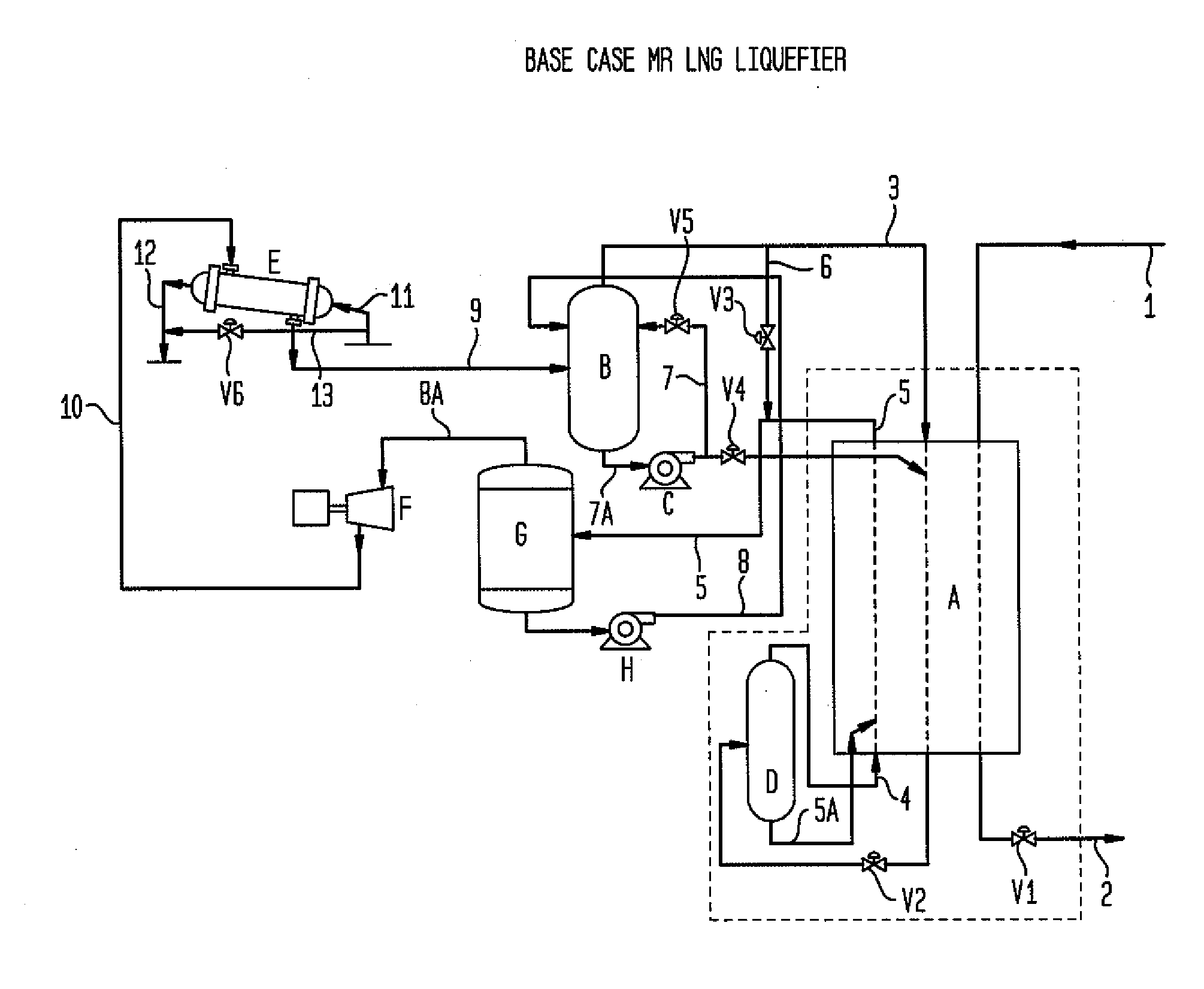

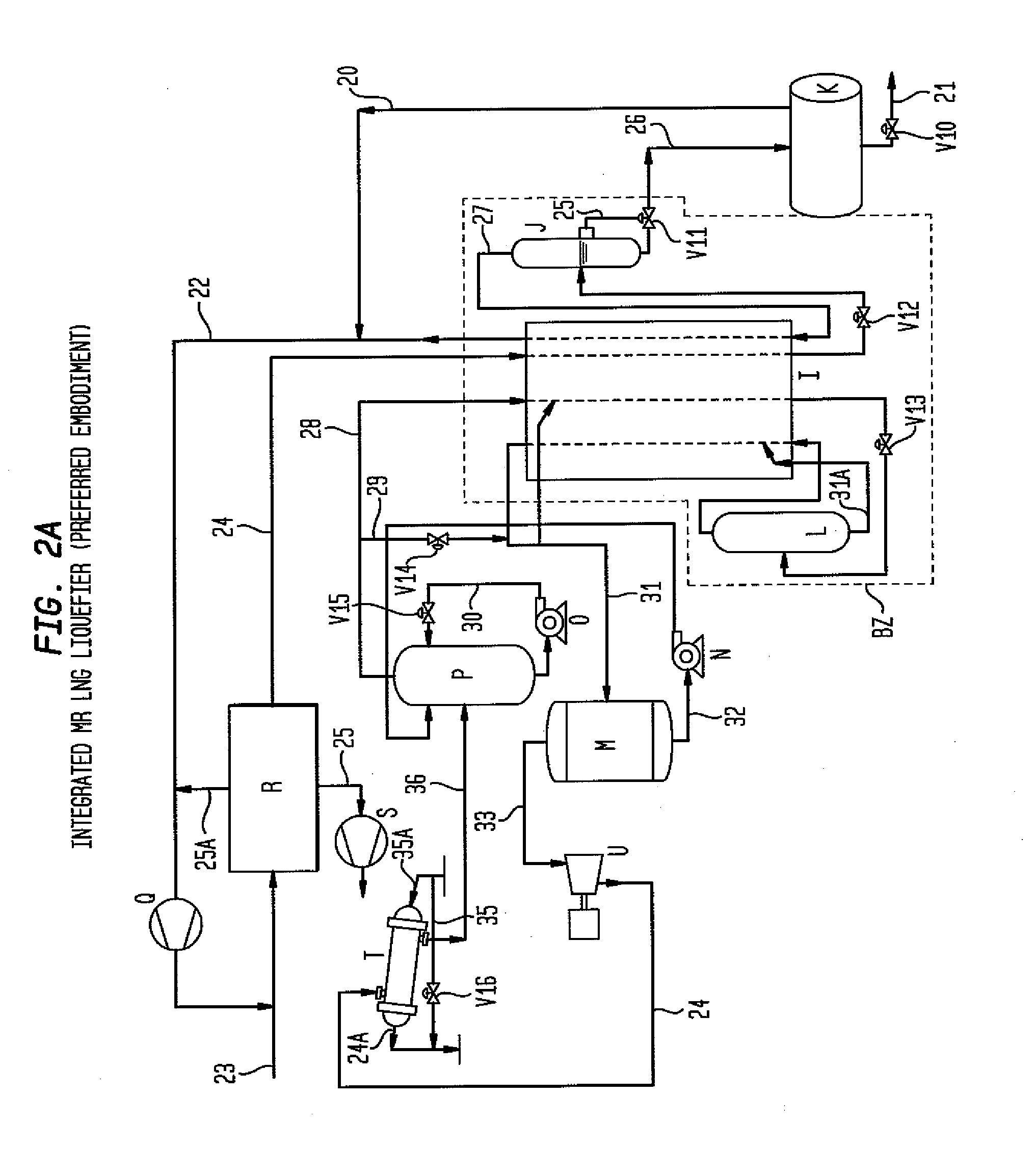

Integrated Methane Refrigeration System for Liquefying Natural Gas

Described herein is a method and system for liquefying a natural gas feed stream to produce an LNG product. The natural gas feed stream is liquefied, by indirect heat exchange with a gaseous methane or natural gas refrigerant circulating in a gaseous expander cycle, to produce a first LNG stream. The first LNG stream is expanded, and the resulting vapor and liquid phases are separated to produce a first flash gas stream and a second LNG stream. The second LNG stream is then expanded, with the resulting vapor and liquid phases being separated to produce the second flash gas stream and a third LNG stream, all or a portion of which forms the LNG product. Refrigeration is recovered from the second flash gas by using said stream to sub-cool the second LNG stream or a supplementary LNG stream.

Owner:AIR PROD & CHEM INC

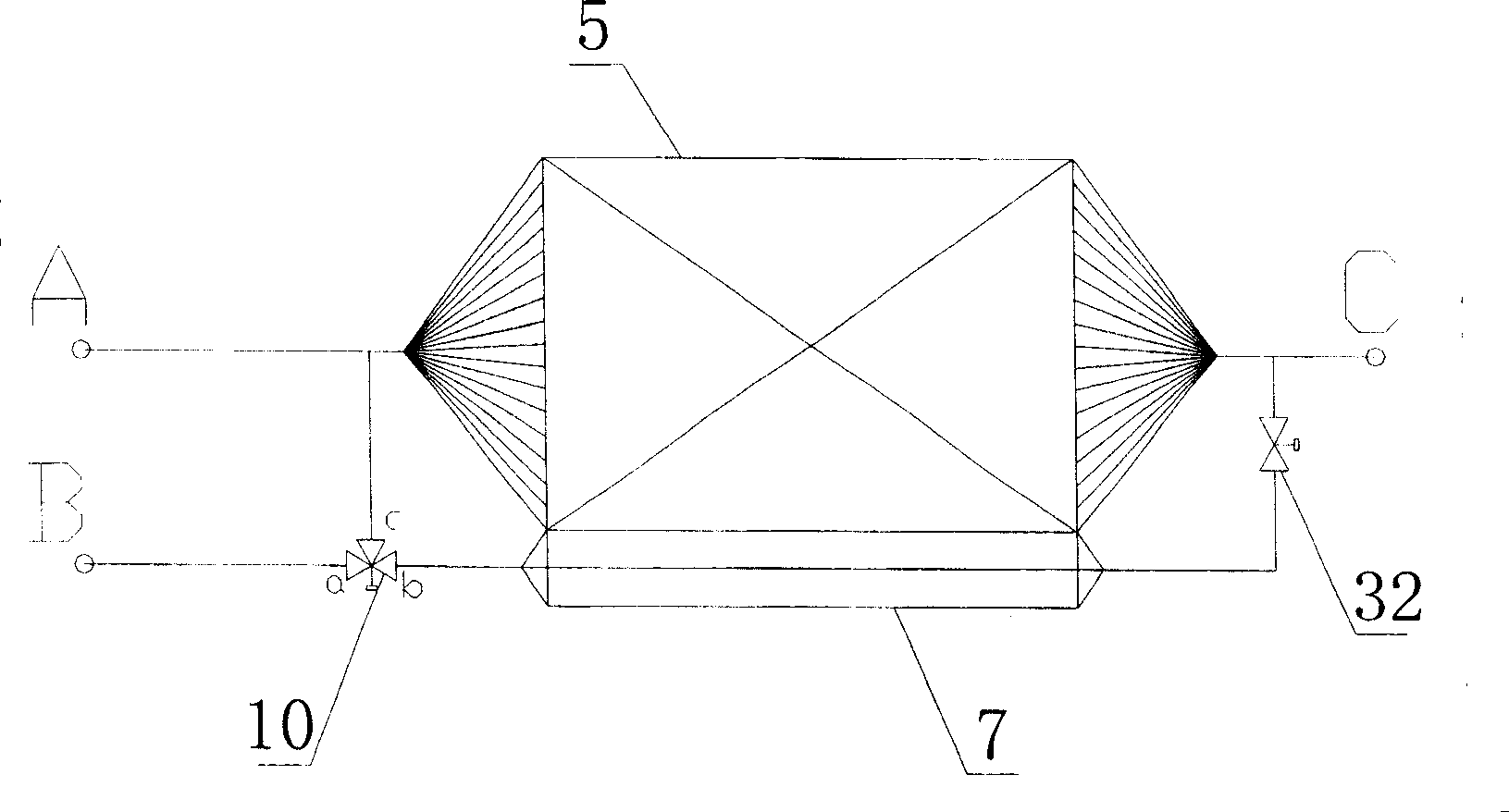

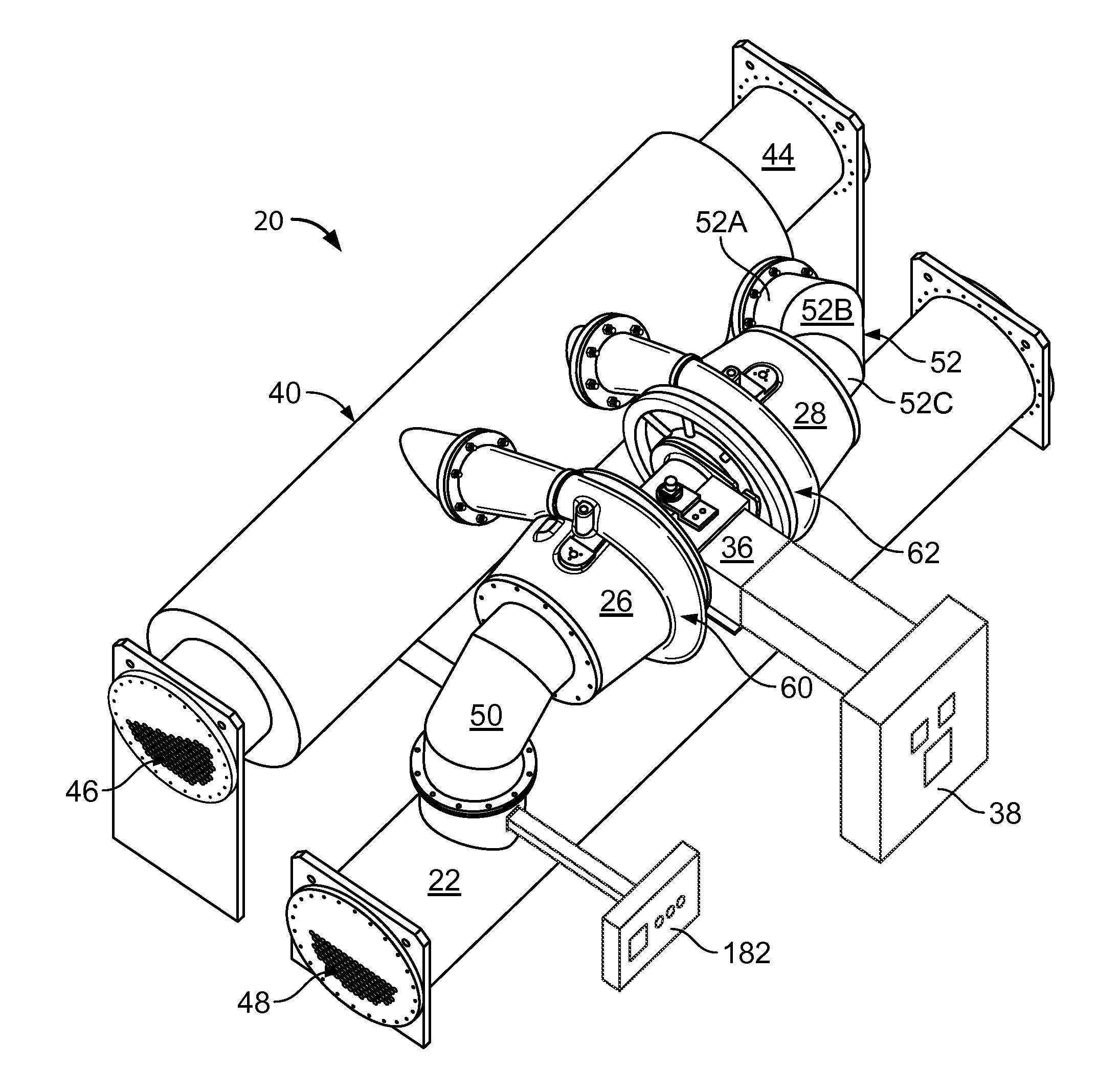

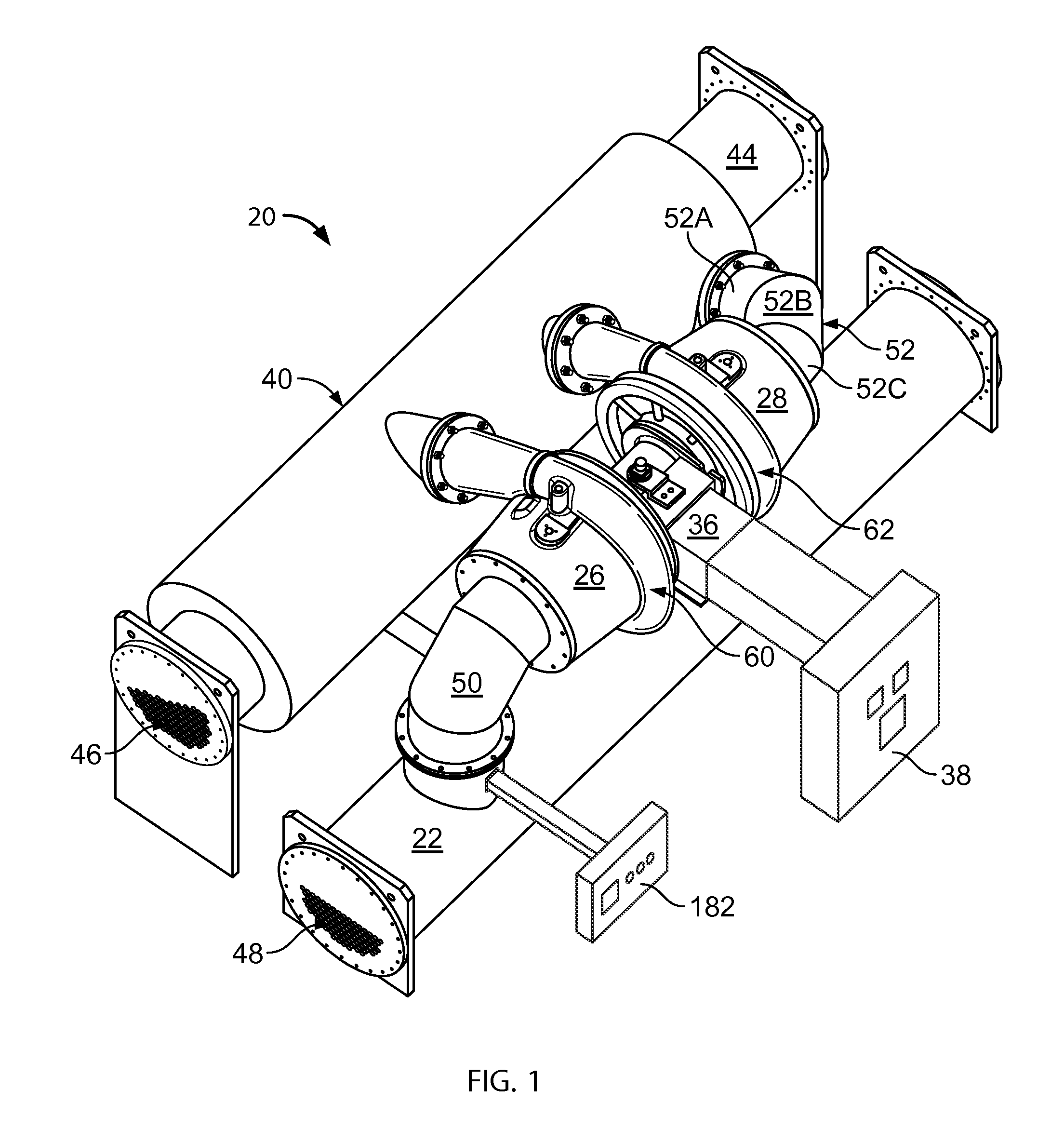

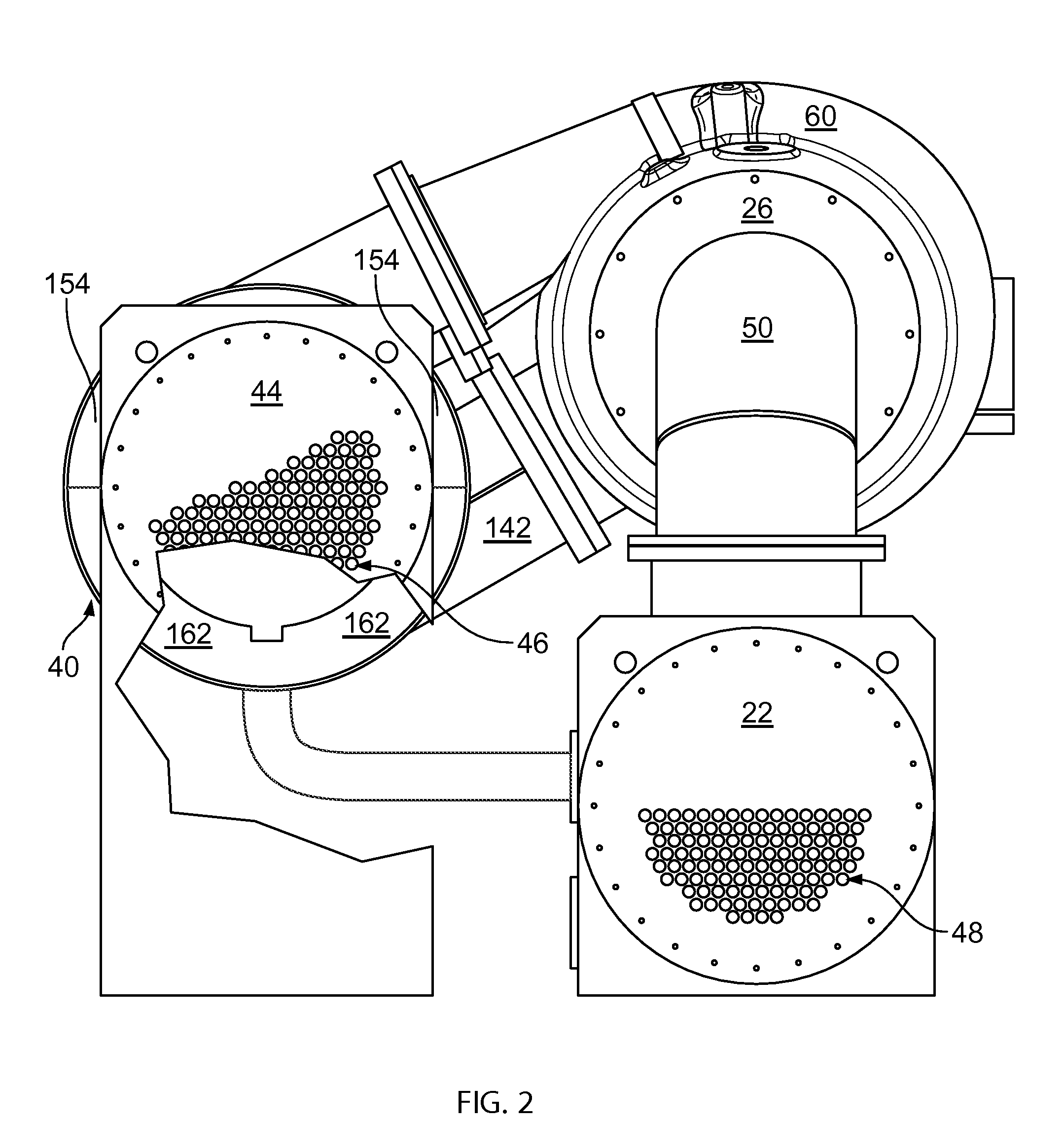

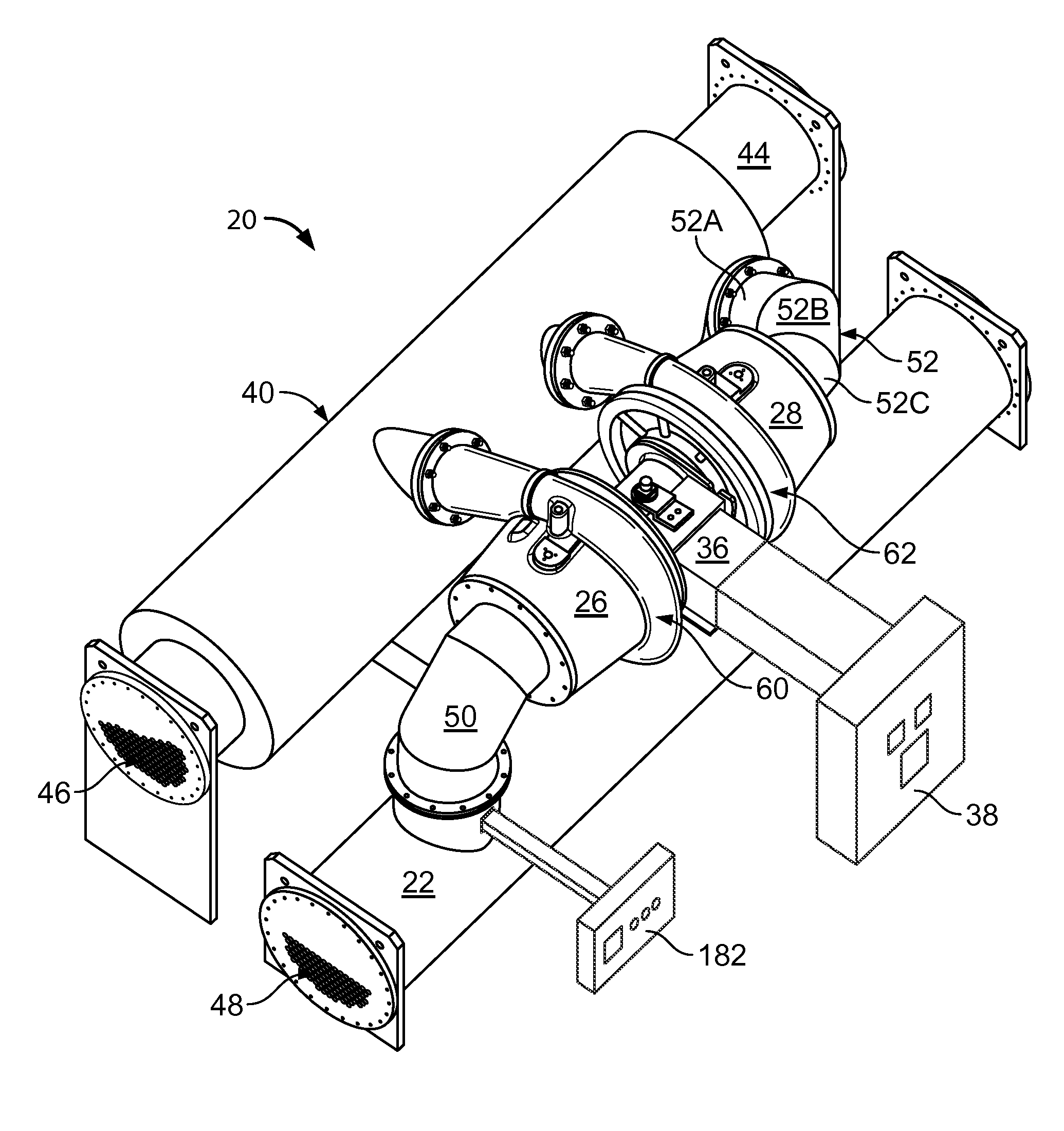

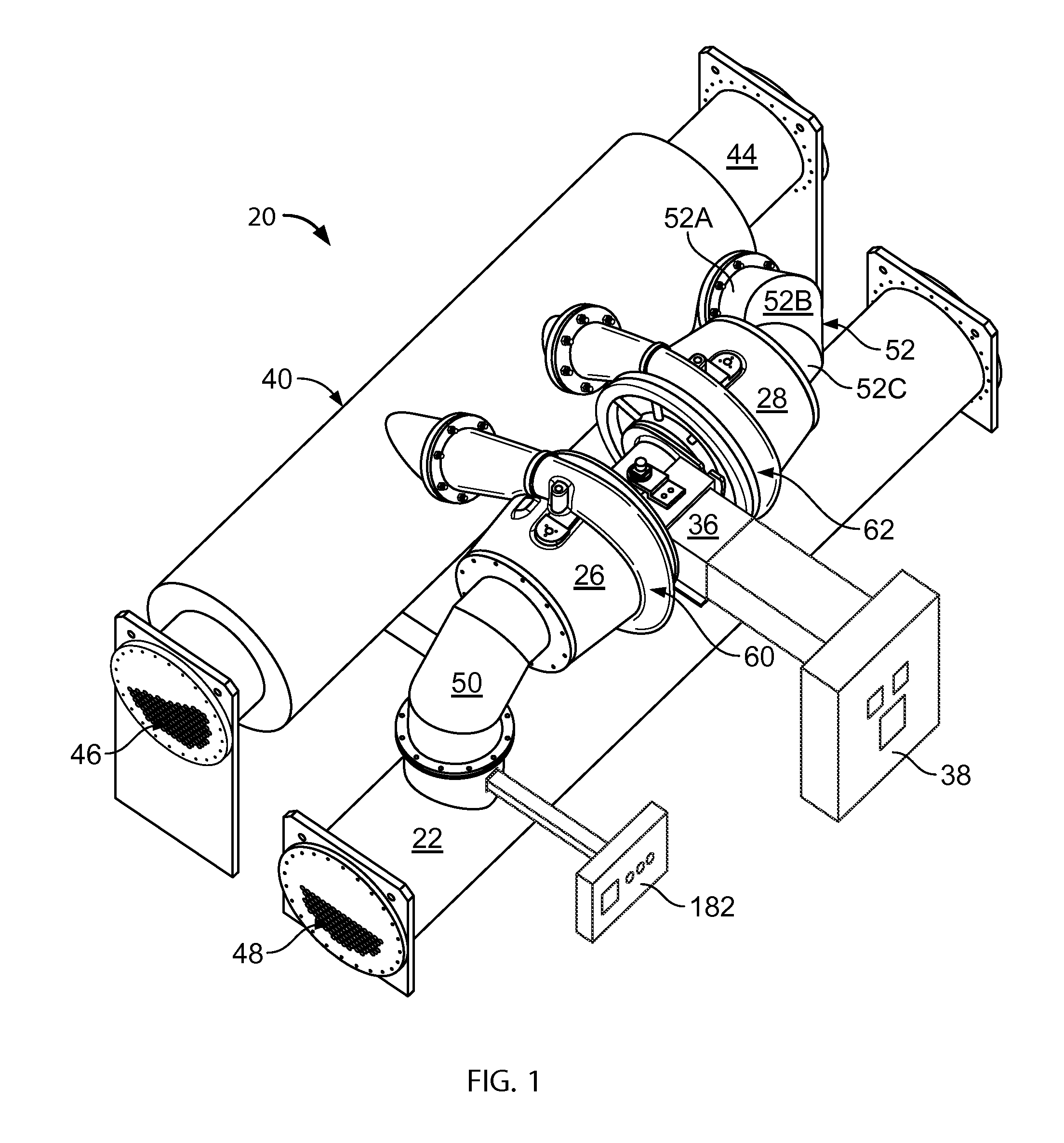

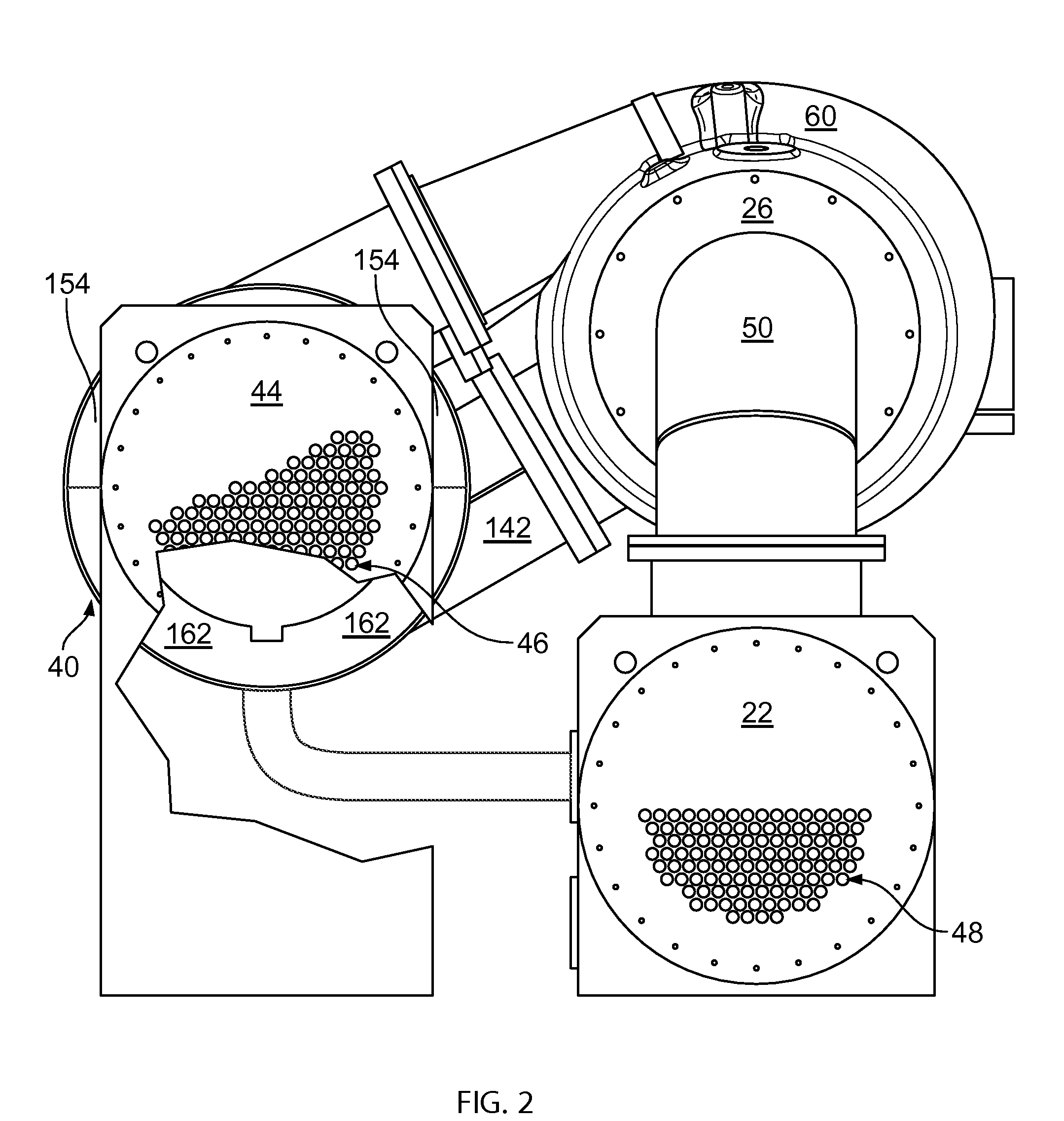

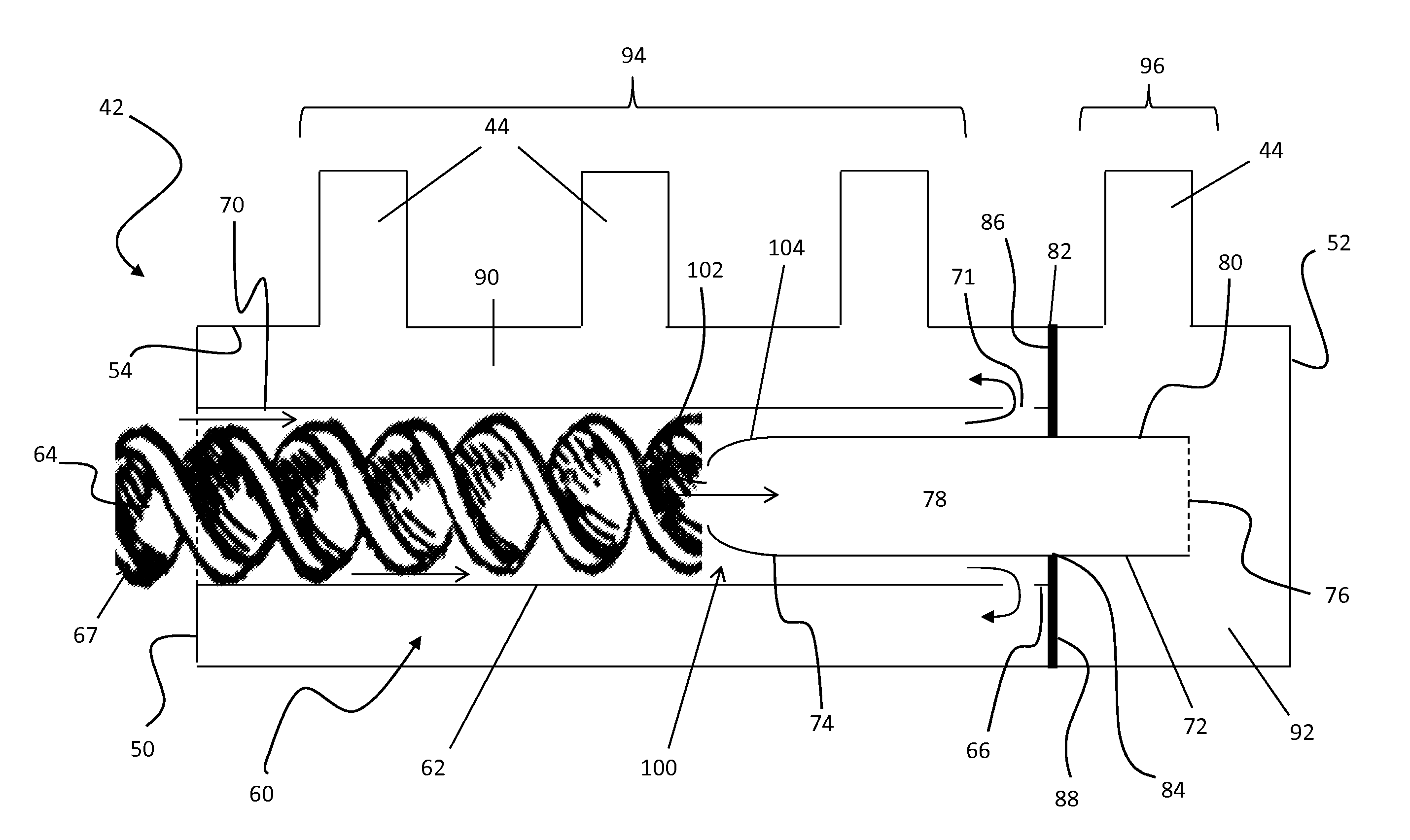

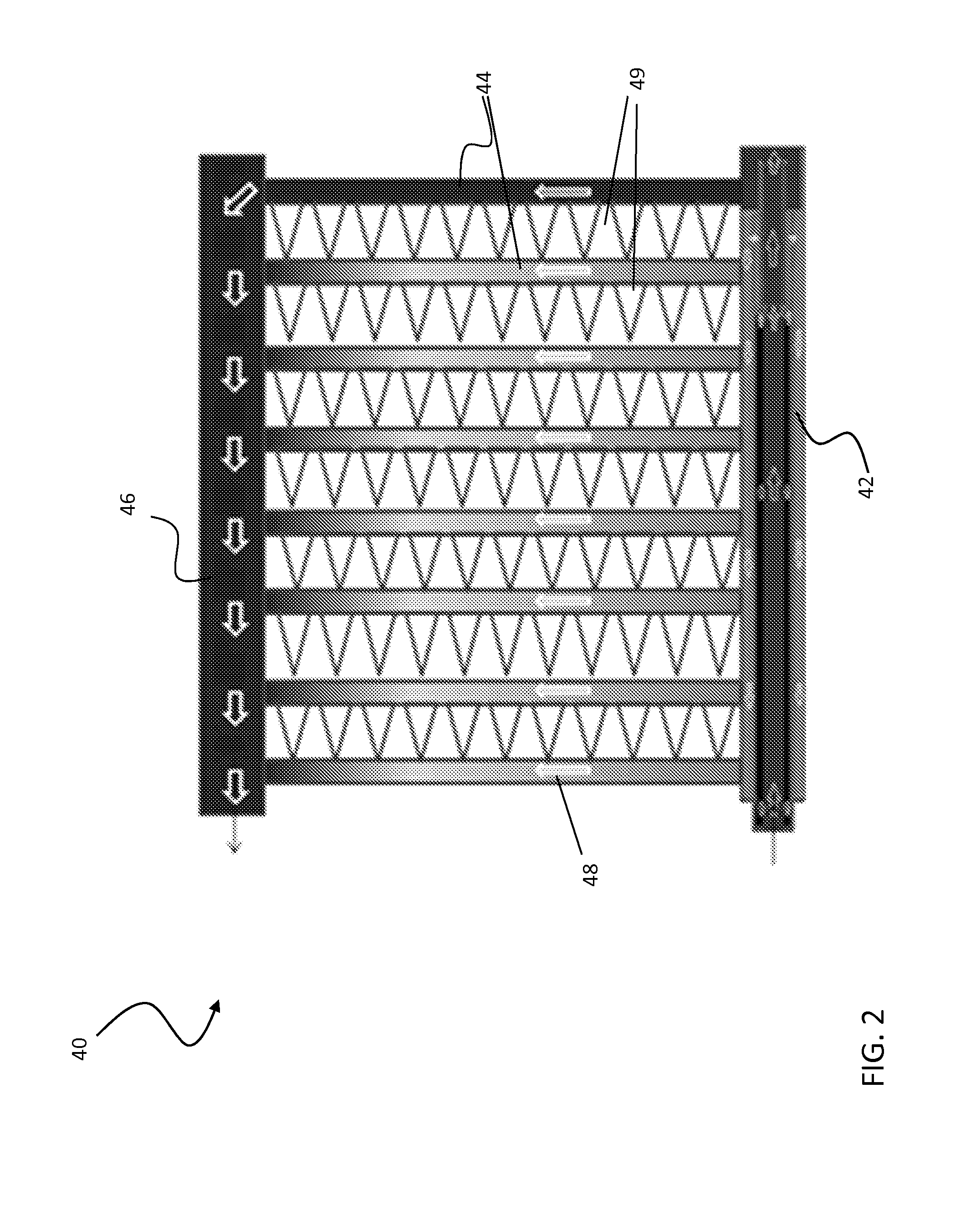

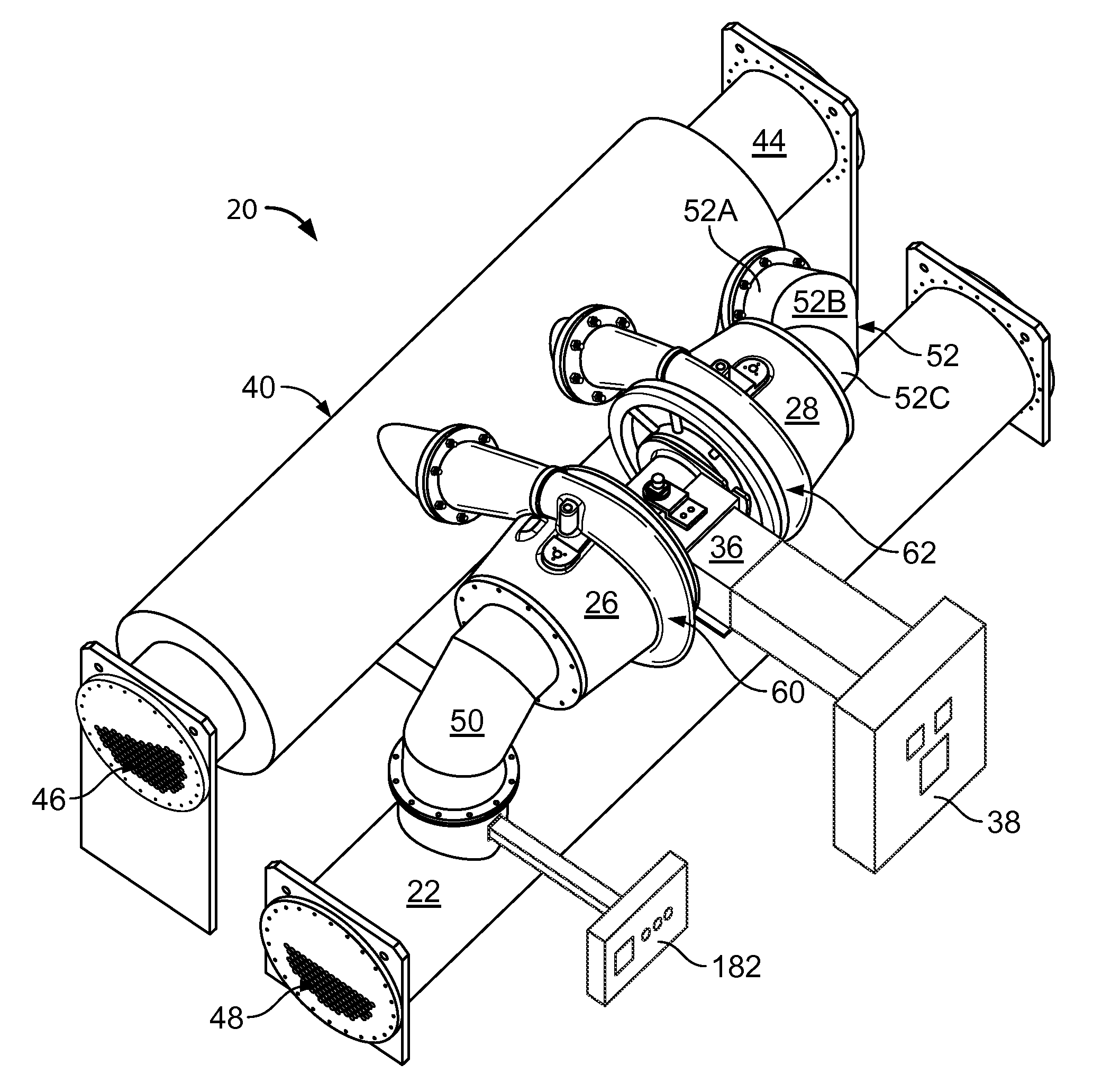

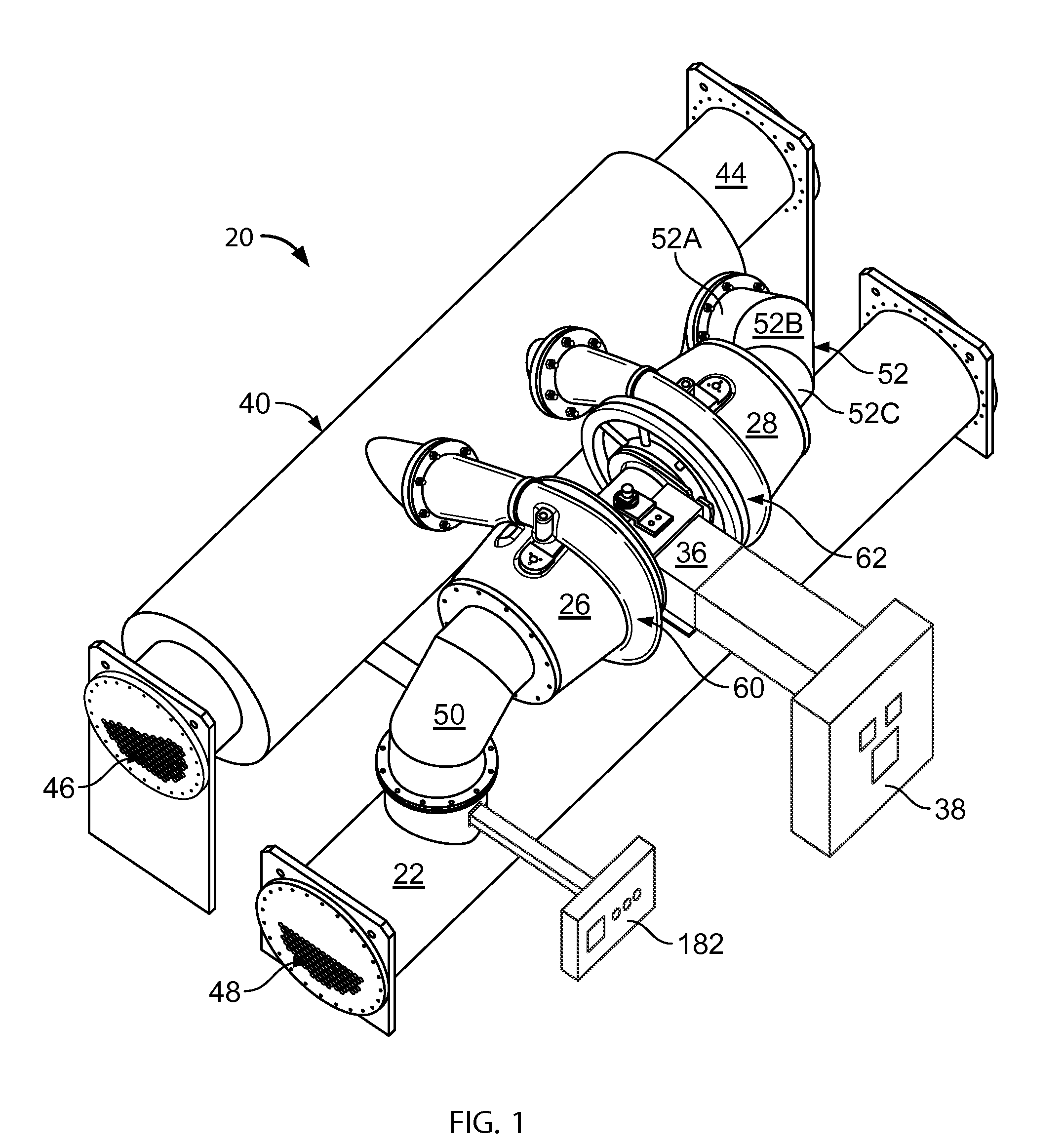

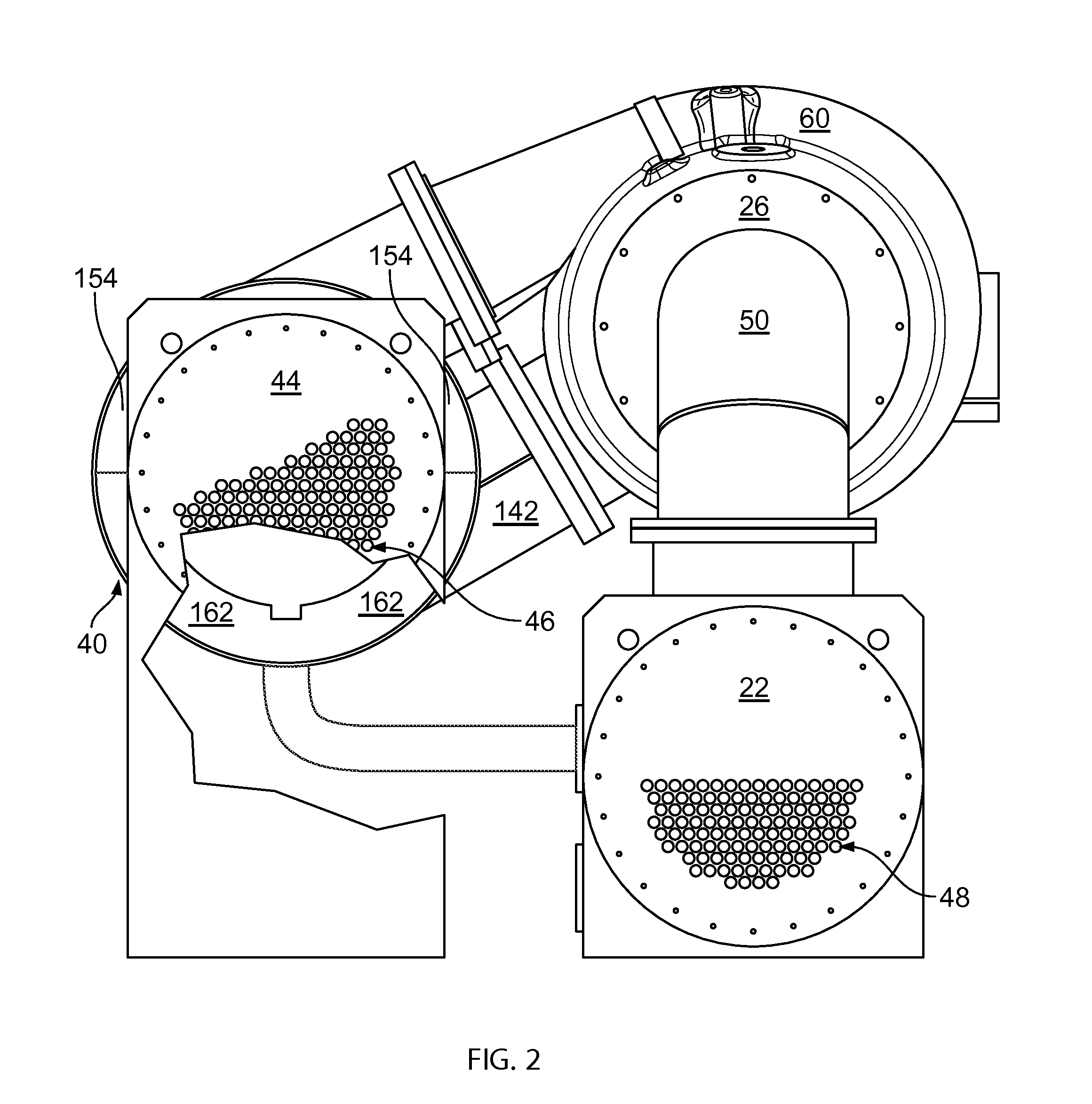

Coaxial economizer assembly and method

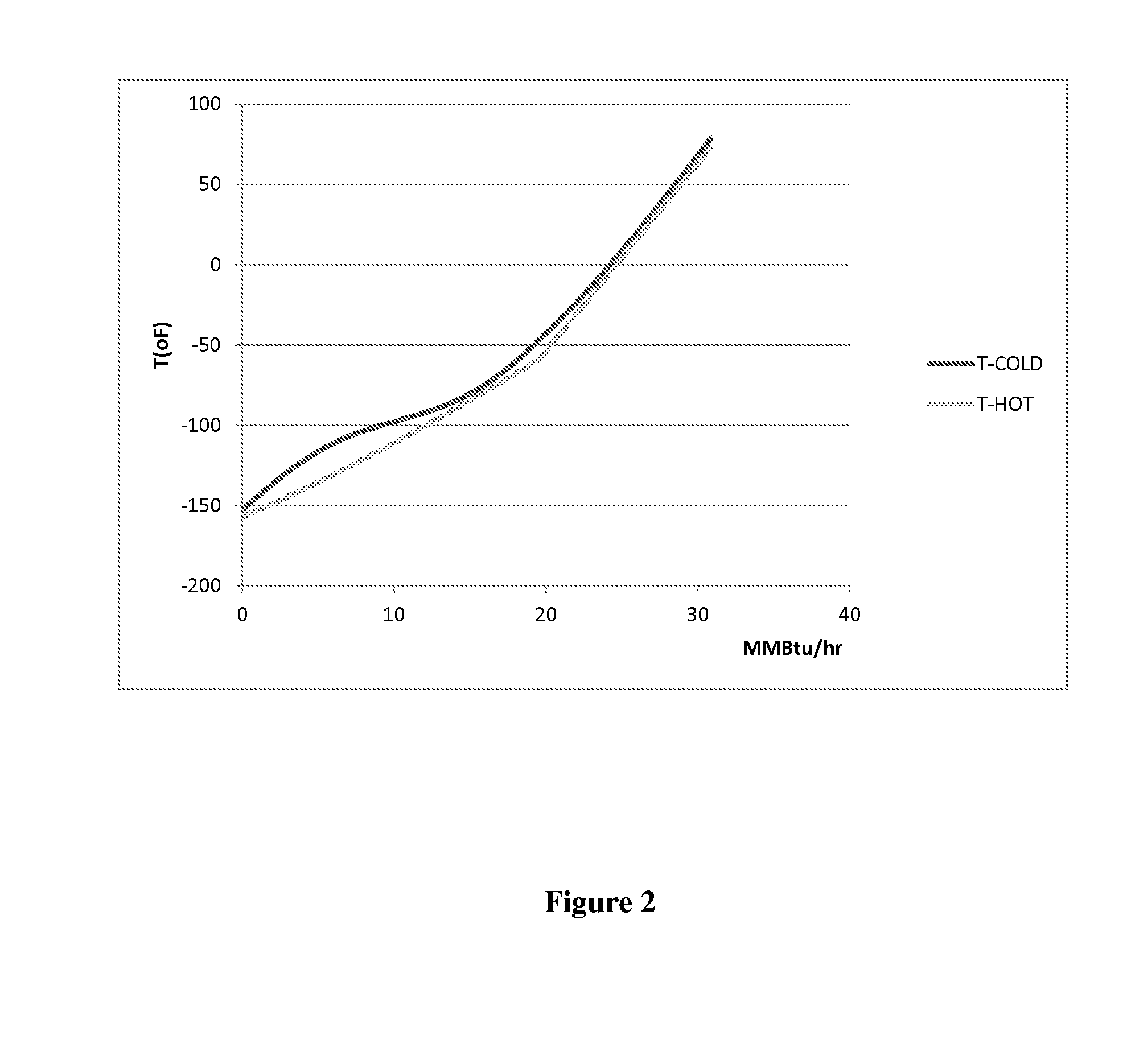

ActiveUS20090205361A1Improve fluid flowImprove performanceCompressorMechanical apparatusLiquid stateFlash-gas

A coaxial economizer for use in a chiller system comprising an inner housing and an outer housing having a common longitudinal axis. The outer housing has an inlet for receiving a fluid from a upstream compressor stage of a multistage compressor and an outlet for conveying a fluid to a downstream compressor stage of a multistage compressor. A flow chamber forms a fluid flow path about the inner housing. A flash chamber is coterminous with the flow chamber and flashes fluid in a liquid state to a gas state. A flow passage between said flash chamber and the flow chamber for conveying a flashed gas from the flash chamber to the flow chamber; wherein the flashed gas conveyed from the flash chamber and the fluid received from the inlet of the outer housing mix along the fluid flow path toward the outlet of the outer housing.

Owner:TRANE INT INC

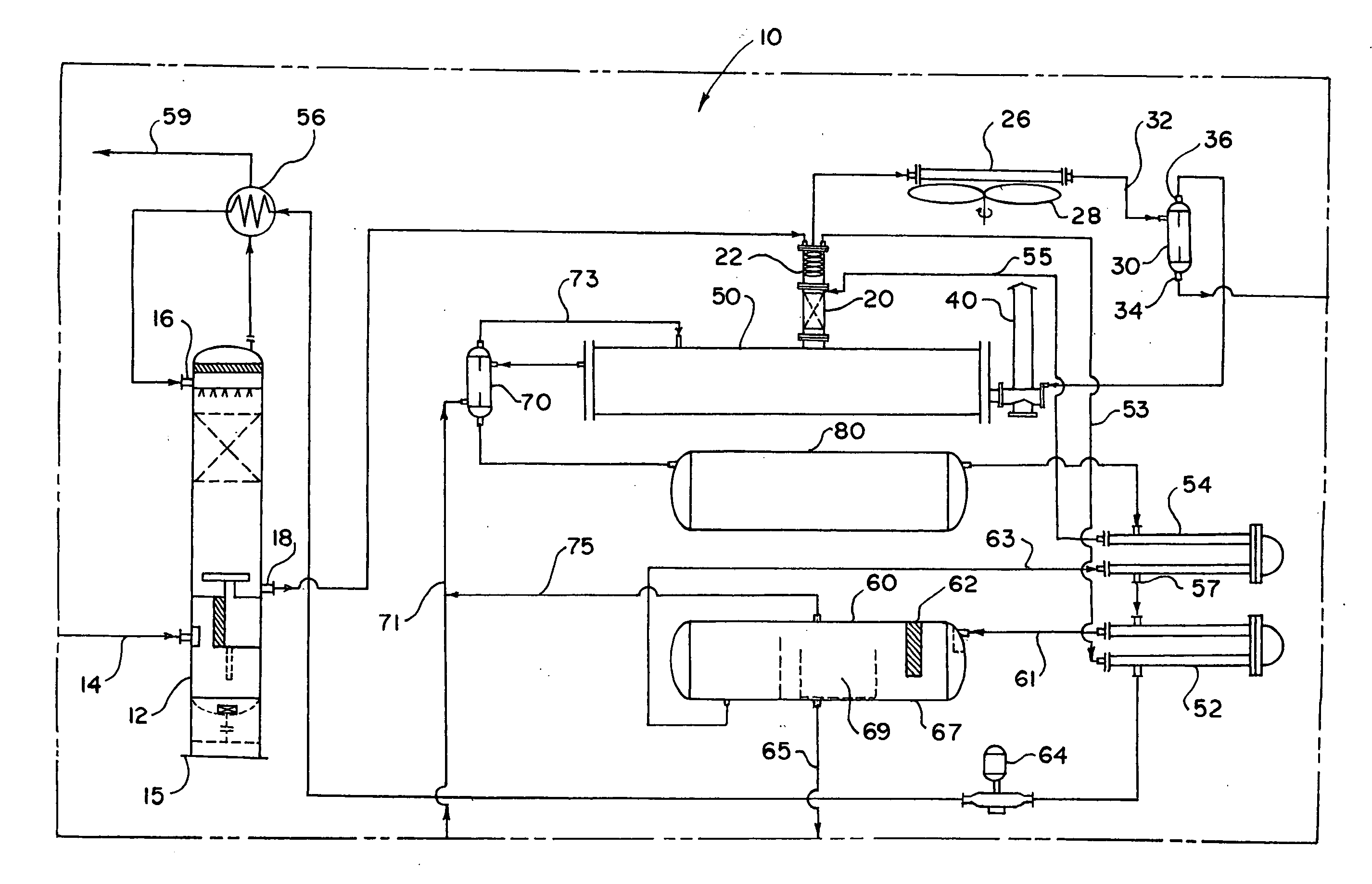

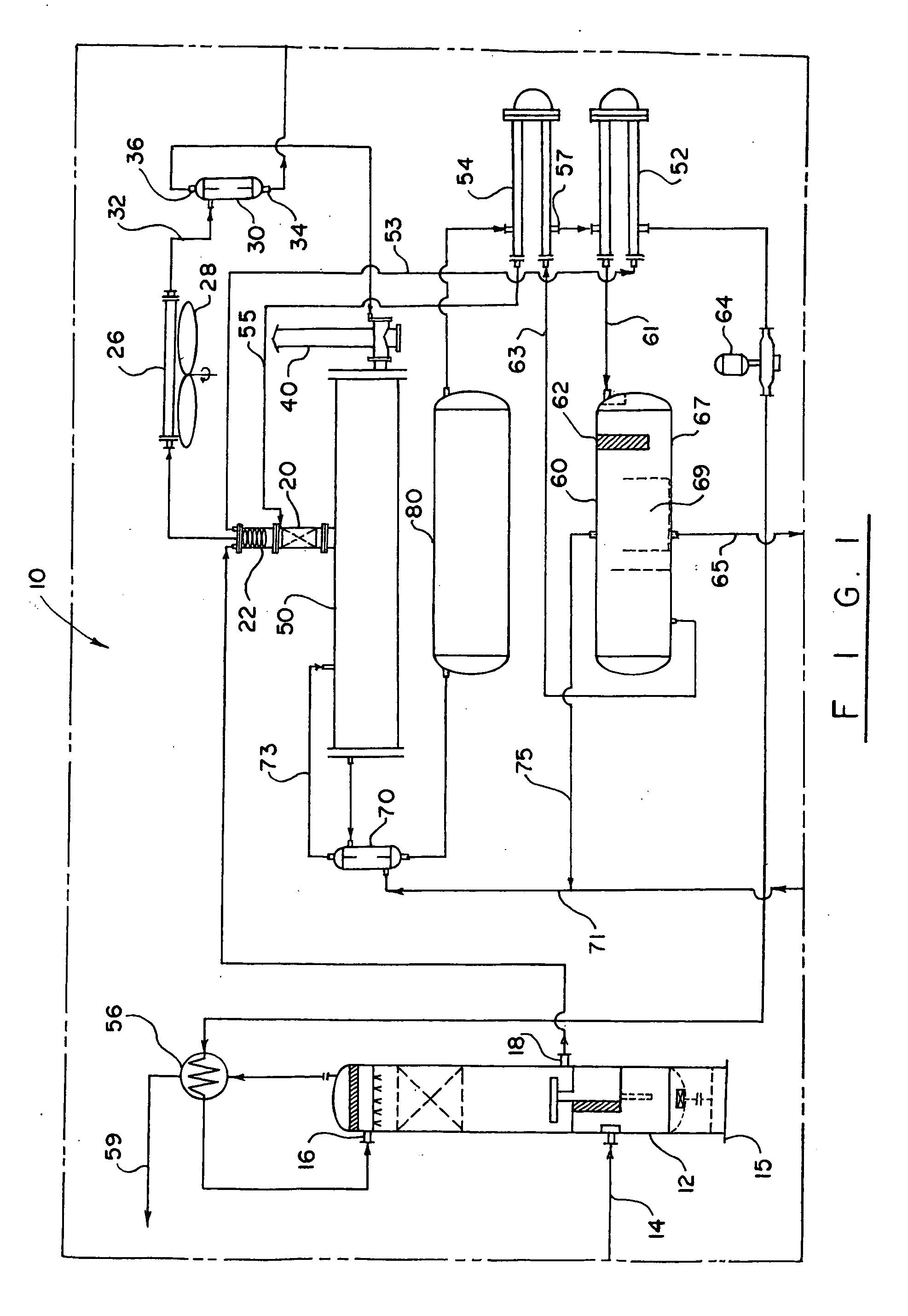

System and method for producing LNG from contaminated gas streams

A system and method for removing nitrogen and producing liquefied natural gas (“LNG”) from methane without the need for external refrigeration. The invention also relates to a system and method for removing nitrogen from methane and for producing liquefied nitrogen in addition to LNG. The system and method of the invention are particularly suitable for use in recovering and processing comparatively small volumes of methane from coal mines or from flash gas captured at an LNG loading site.

Owner:BCCK HLDG CO

Cold-warmer bath integrated air source heat pump at cold region

InactiveCN101387456AGuaranteed stabilityAvoid the problem of large indoor temperature fluctuationsHeat pumpsCompression machines with reversible cycleFlash-gasEngineering

The invention discloses an air-source heat pump device integrating cool and warm air conditioning and water heating in the cold area, which belongs to the technical field of refrigeration air conditioner. The device consists of two high and low pressure compressors, a flash evaporator, a defrosting coil pipe, a flash gas superheated coil pipe, a compressor heat recovery coil pipe, a low pressure gas supply pressure pipeline and other parts which are connected through pipelines. The device is characterized in that the two high and low pressure compressors in the system have three modes of separate operation, parallel operation, and two-stage compression combined operation; and the two compressors are matched with a four-way electromagnetic directional valve, a three-way electromagnetic valve and an electromagnetic valve to form a refrigeration mode, a heating mode, a hygienic hot water mode and a refrigeration and hygienic hot water combined operation mold. The air-source heat pump device has the advantages that the device not only can refrigerate and produce hygienic hot water while refrigerating in summer; and under the microthermal climate in winter, the device can run stably to provide the heat needed by indoor heating and hygienic hot water, thereby realizing the integrated cool and warm air conditioning and water heating. The device which is used in a house in the cold area has wide popularization and application space and energy-saving significance.

Owner:DALIAN UNIV OF TECH +1

Coaxial economizer assembly and method

ActiveUS7975506B2Improve fluid flowImprove performanceCompressorMechanical apparatusLiquid stateFlash-gas

Owner:TRANE INT INC

Energy-saving gas washing process

ActiveCN105920978AReduce concentrationReduce energy consumptionDispersed particle separationSulfurGas phase

The invention relates to an energy-saving gas washing process, comprising the following steps: subjecting raw gas to countercurrent contact with methanol in an absorbing column, and washing out acidic gas from the raw gas; delivering obtained carbon-rich methanol to the upper portion of a medium-pressure flashing column, and delivering rich methanol to the lower segment of the medium-pressure flashing column; delivering via an ejector, liquid carbon-rich methanol in the medium-pressure flashing column to the upper part of a re-absorbing column, and delivering sulfur-rich methanol at the bottom of the medium-pressure flashing column to the lower part of the re-absorbing column for flashing; returning two parts of liquid flashed from the upper part of the re-absorbing column respectively to the re-absorbing column and a negative-pressure flashing column; using flashed liquid rich methanol as main washing methanol, delivering flashed gas to a suction ejector, and delivering flashed sulfur-rich methanol to a subsequent heat regeneration system.

Owner:SINOPEC NINGBO ENG +2

Improved method for producing food grade liquid carbon dioxide product and distillation and purification tower

The invention relates to a method for producing carbon dioxide and in particular discloses a method for producing a food grade liquid carbon dioxide product. The method comprises the following steps of: (1) compressing; (2) dealkylating; (3) purifying; (4) liquefying; and (5) performing distillation and purification, wherein flashing gas rises and passes through structured packing of a lower corrugated plate, structured packing of an upper corrugated plate, tube pass of a lower heat exchanger and tube pass of an upper heat exchanger, and finally, the flashing gas becomes a gas mixture containing a little uncooled carbon dioxide gas and lots of methane, ethylene and oxygen and is exhausted from the top of the distillation and purification tower. By the method, the yield of the food grade liquid carbon dioxide product is improved.

Owner:HUNAN KAIMEITE GASES

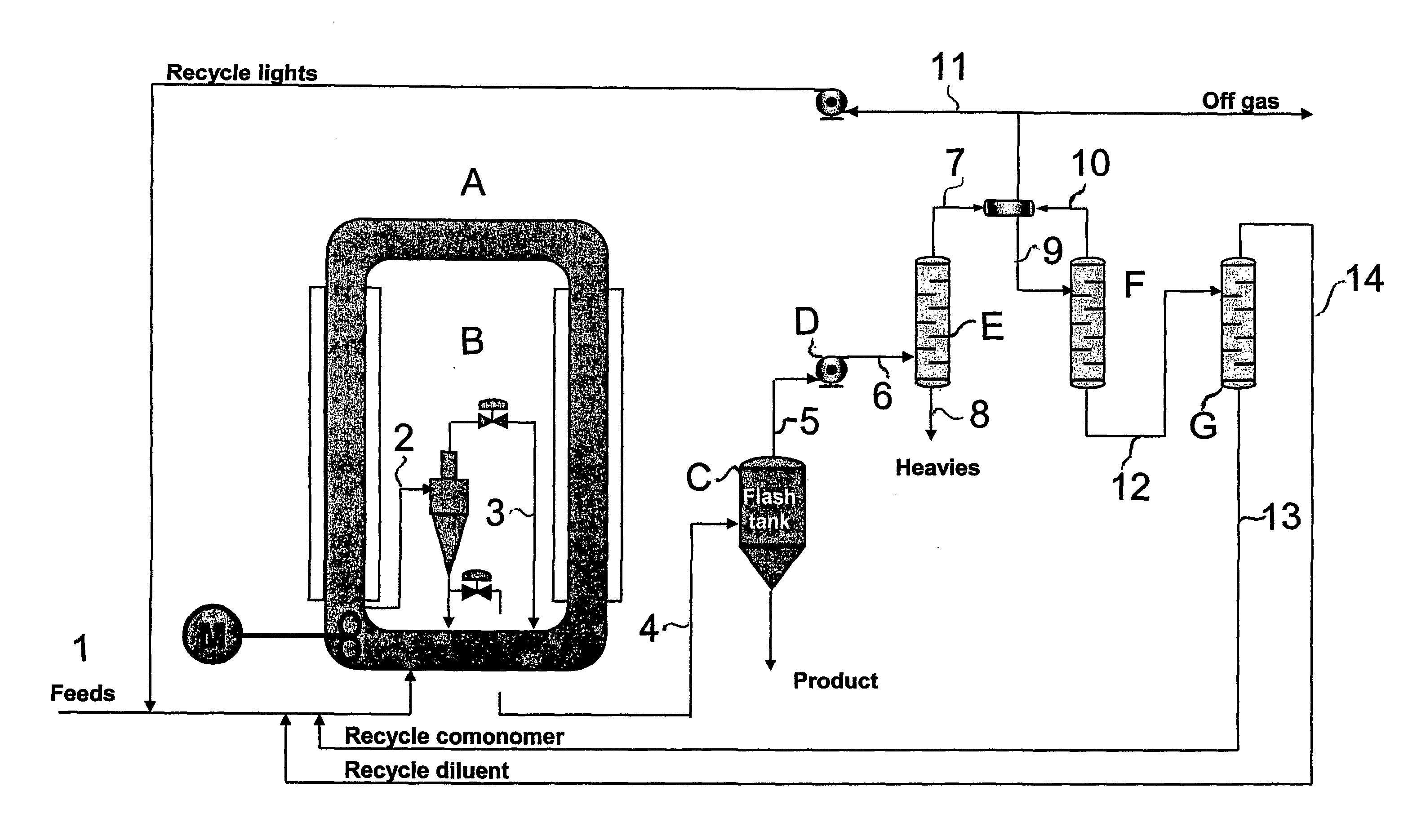

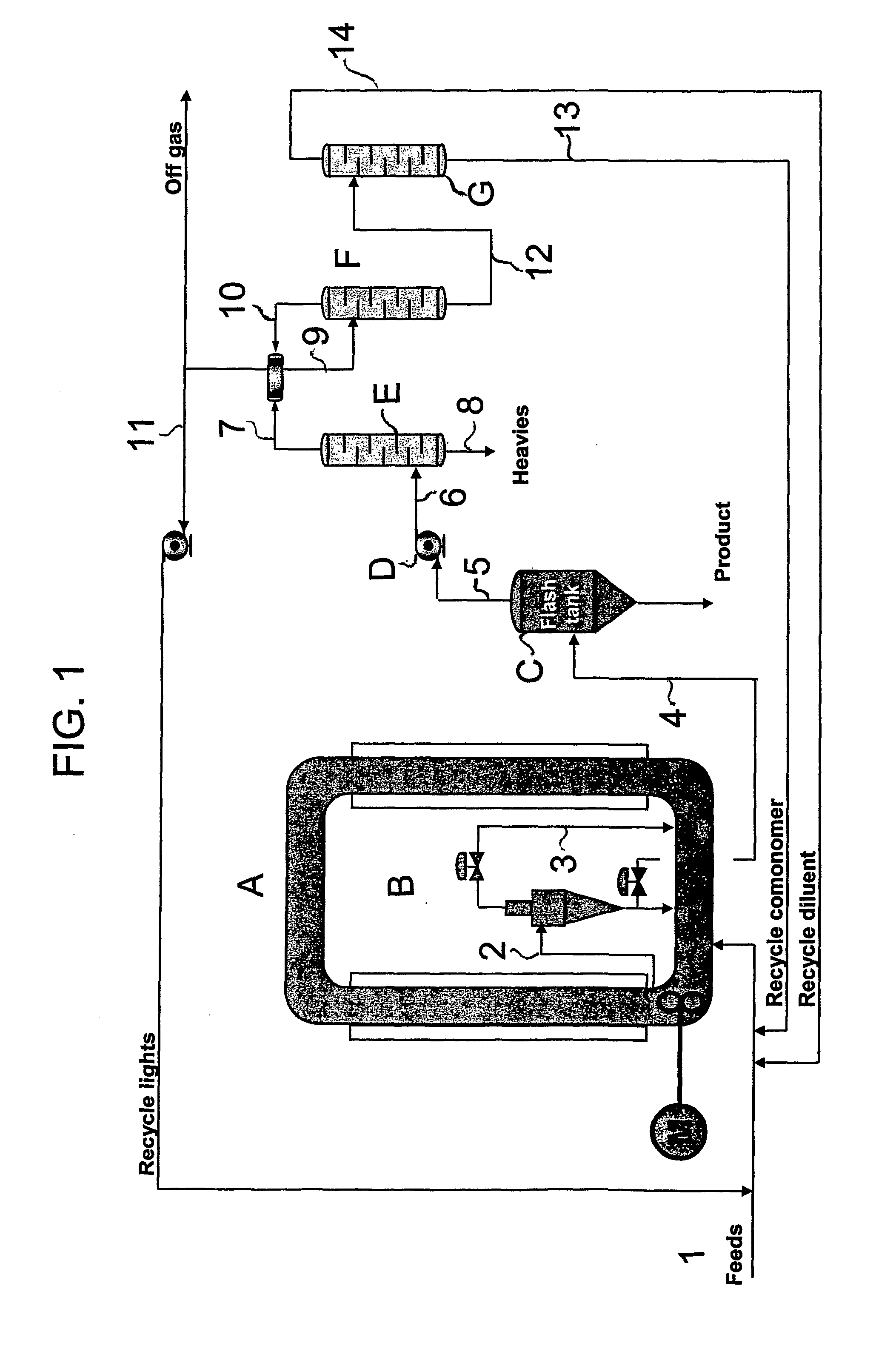

Process and system for removing heavies from diluent recycled to a slurry polymerization reactor

A recycling and recovery system and process comprising a flash gas separator that receives a slurry comprising liquid medium and solid polymer particles. The flash gas separator separates the diluent from the solid polymer particles as a vapor stream comprising at least diluent and heavies. A line receives the vapor stream from the flash gas separator. The line leads to a heavies removal system that yields a liquid that is relatively concentrated in heavies and a diluent vapor that is relatively free of heavies. The liquid is passed to a heavies column while the diluent vapor is passed to a diluent recycle chamber and then recycled to a slurry polymerization reactor without additional treatment to remove heavies.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Nitrogen rejection and liquifier system for liquified natural gas production

InactiveUS20120067079A1Maximize productionLoss of productionSolidificationLiquefactionNitrogen rejection unitFlash-gas

A method for recovering liquefied natural gas from a gas mixture containing natural gas and impurities by subjecting the natural gas to a series of steps beginning with feeding a natural gas stream containing impurities to a nitrogen rejection unit; feeding the purified natural gas stream to a liquefier heat exchanger; expanding the liquefied natural gas and feeding the expanded liquefied natural gas to a flash vessel; flashing the liquid natural gas and separating the liquefied natural gas from the flash gas; and feeding the liquefied natural gas to storage and the flash gas to the nitrogen rejection unit.

Owner:LINDE AG

Separation method of dimethyl ether prepared with synthetic gas through one-step process

The separation method of dimethyl ether prepared with synthetic gas through one-step process includes condensing the reacted gas in condensator, absorbing un-condensed gas with soft water in the bottom part of the absorbing tower, and making the tower top product tail gas enter to the gas storage tank. The present invention features that dimethyl ether solution as the bottom flow product from the condensator and / or ether aqua as the bottom flow product from the absorbing tower are made to enter the flashing tank, flashed gas is made to enter the bottom of the absorbing tower; and ether solution as the bottom flow product of the flashing tank is made to enter the dimethyl ether rectifying tower to obtain refined dimethyl ether in the tower top and coarse methanol solution in the bottom flow. The present invention has dimethyl ether product purity as high as 98 % and recovering rate as high as 98 %.

Owner:SINOPEC NINGBO ENG

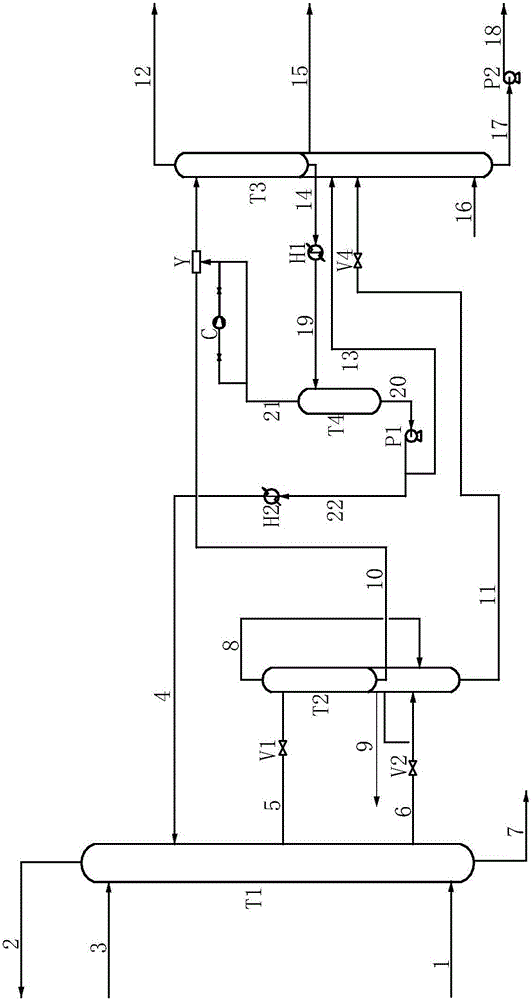

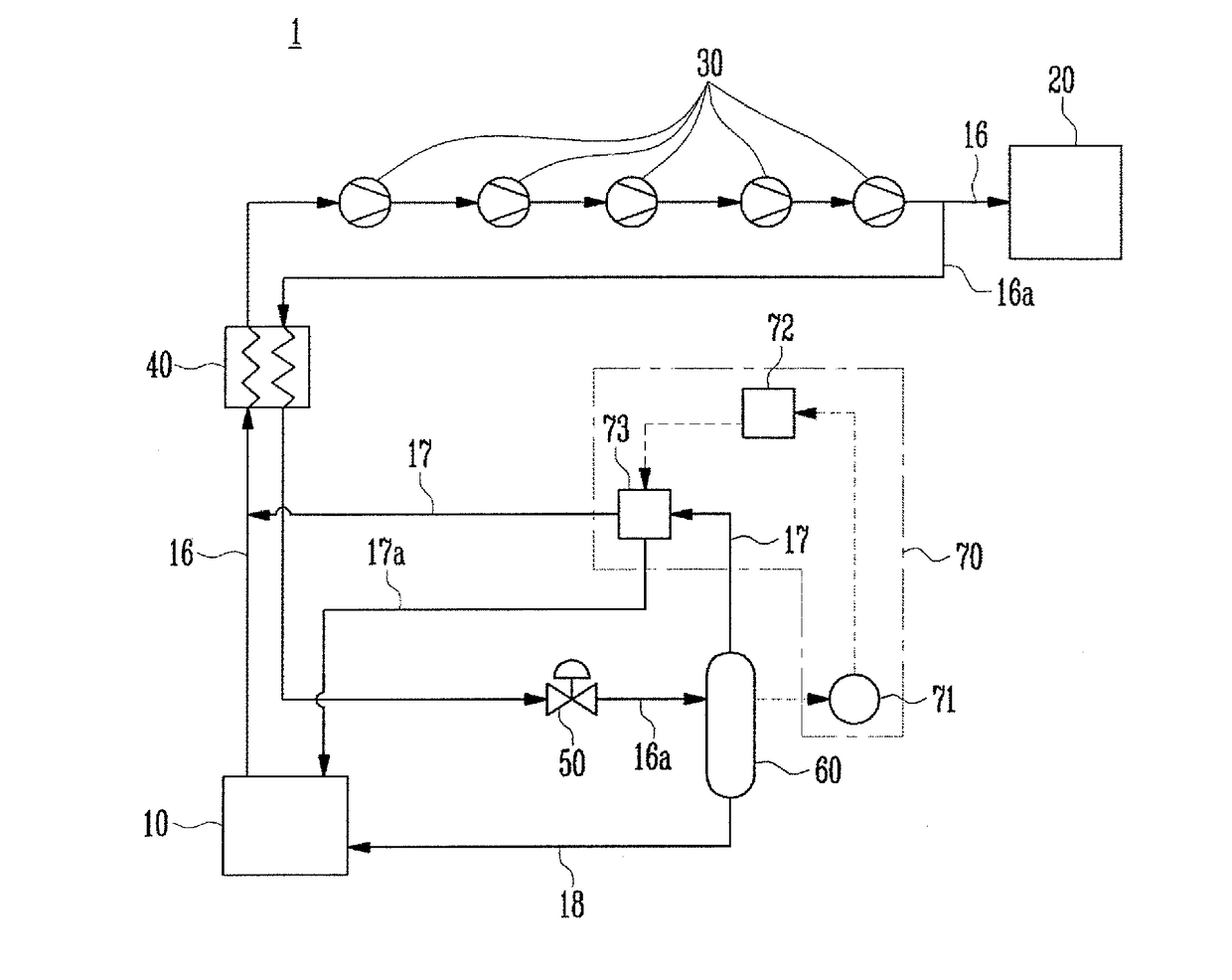

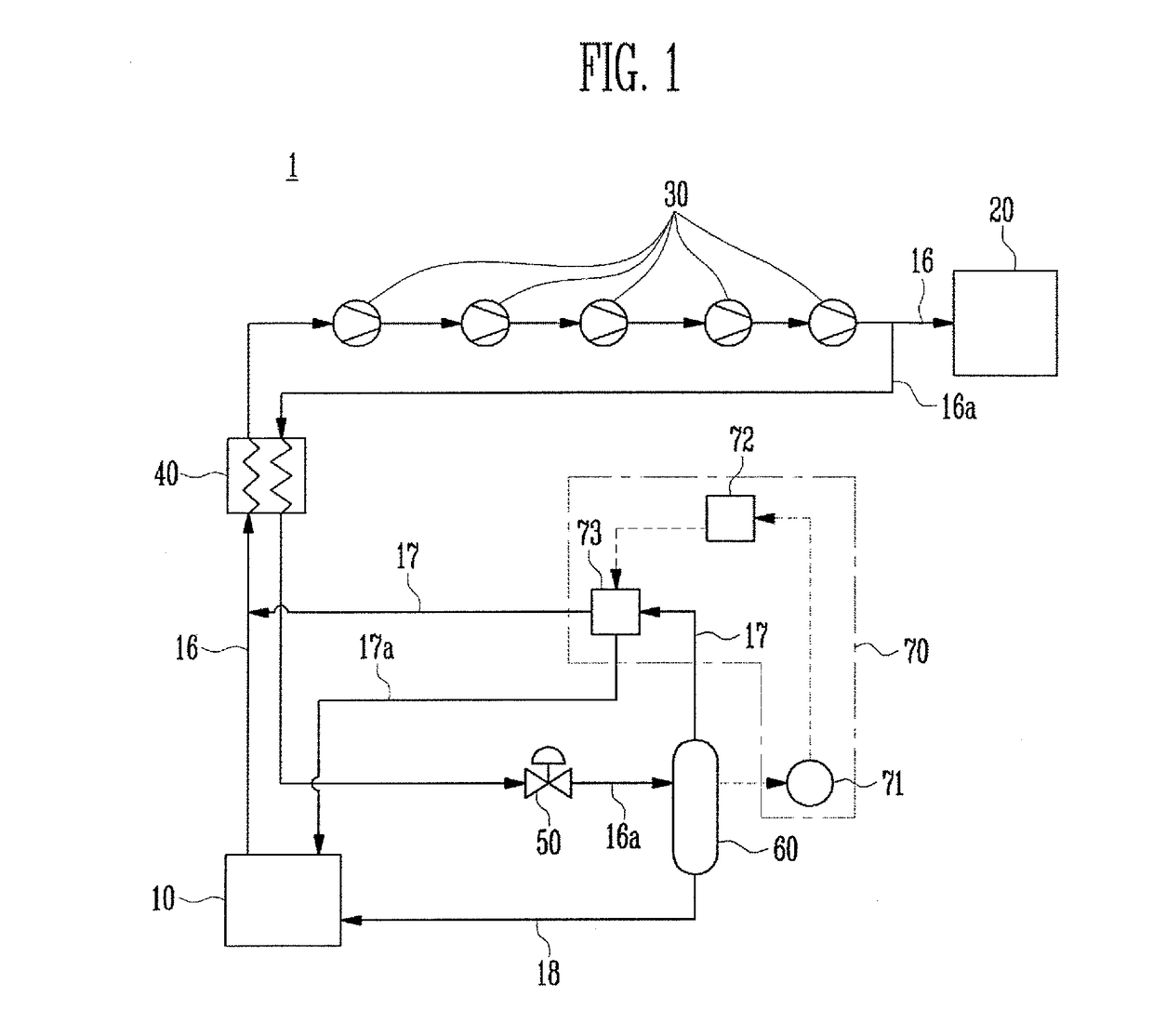

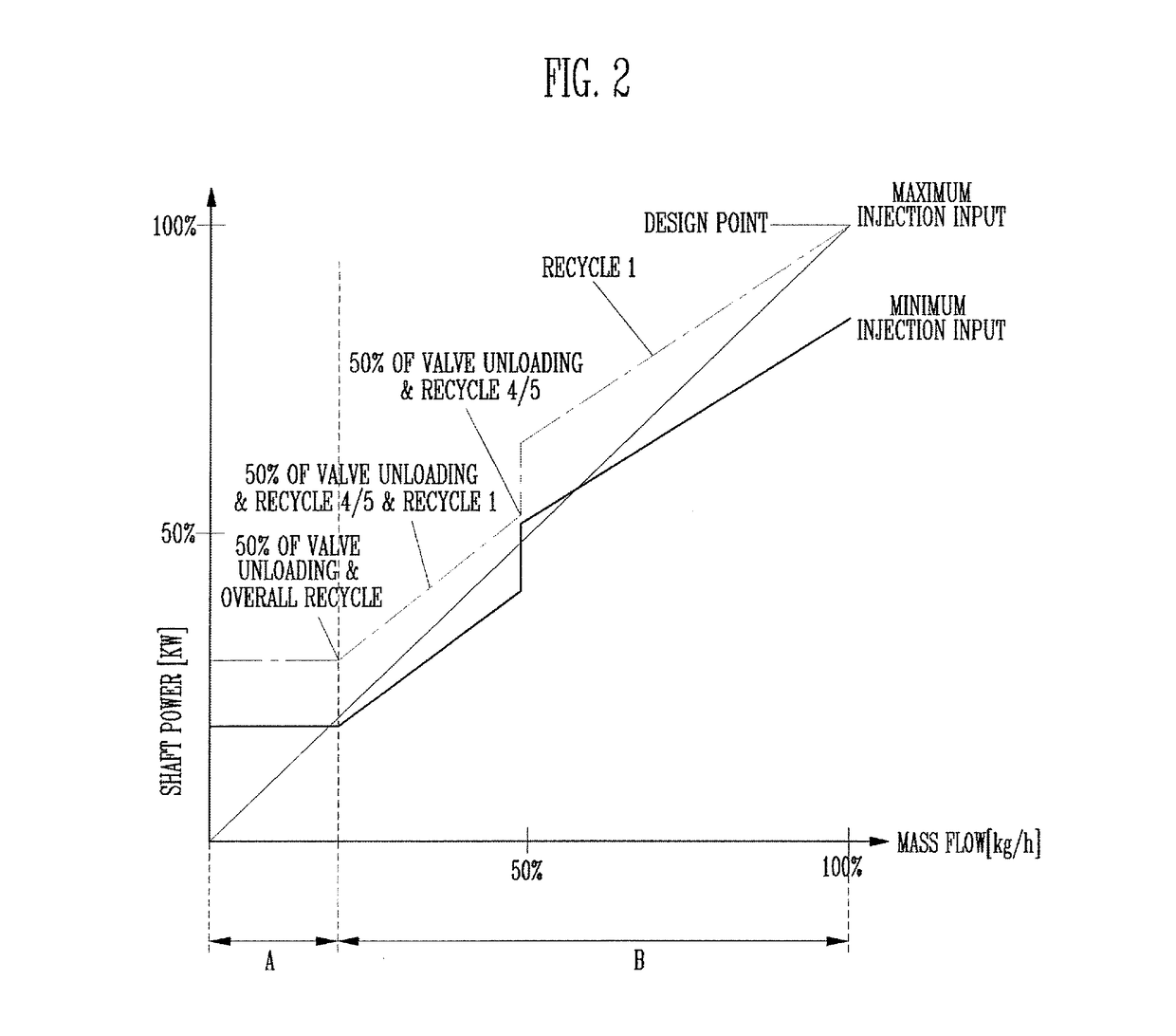

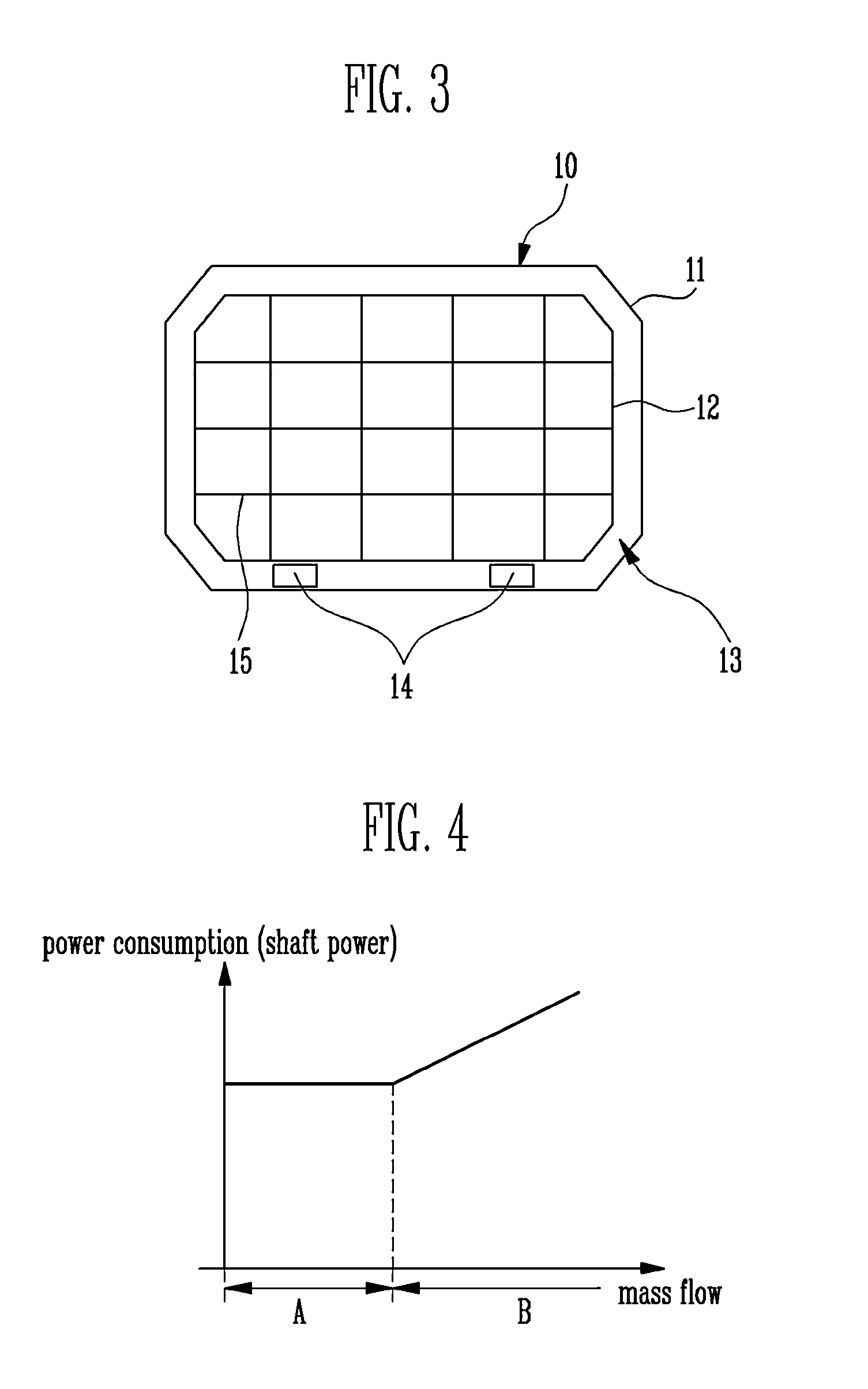

Liquefied gas treatment system

InactiveUS20170114960A1Improve efficiencyAvoid wastingSolidificationLiquefactionGas compressorNitrogen

The present invention relates to a liquefied gas treatment system in which a nitrogen control unit controls a content of nitrogen in a boil-off gas or a flash gas when a ratio of a nitrogen component of the flash gas is equal to or greater than a preset value. The efficiency of a boil-off gas compressor can be improved and the system can be stabilized by means of the nitrogen control unit.

Owner:HYUNDAI HEAVY IND CO LTD

Method and a device for detecting flash gas

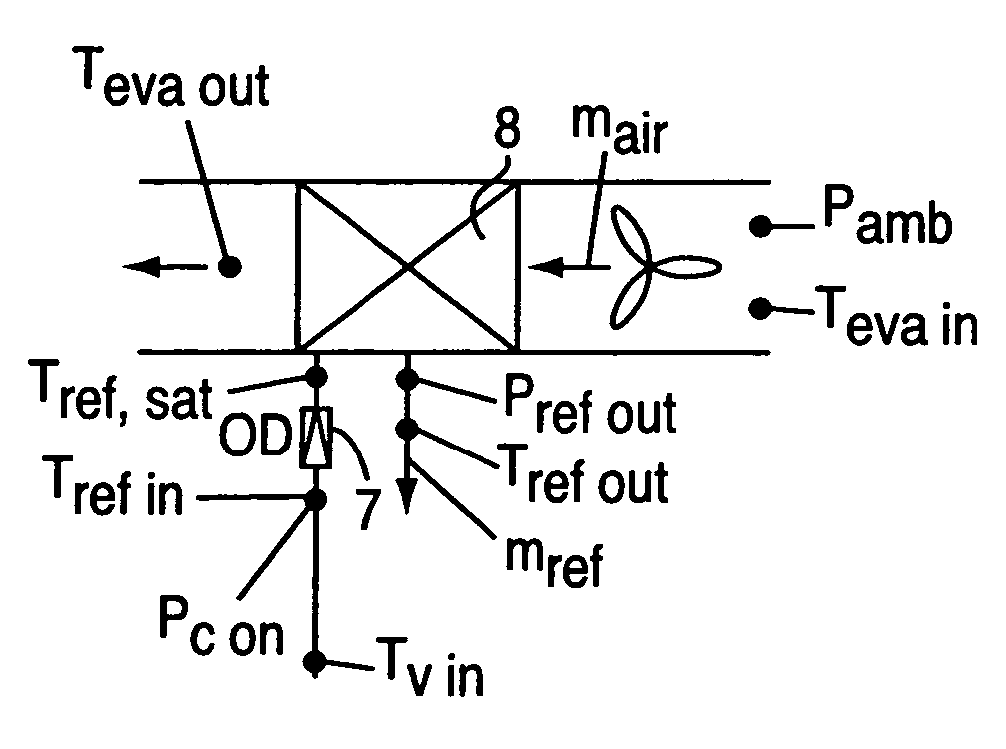

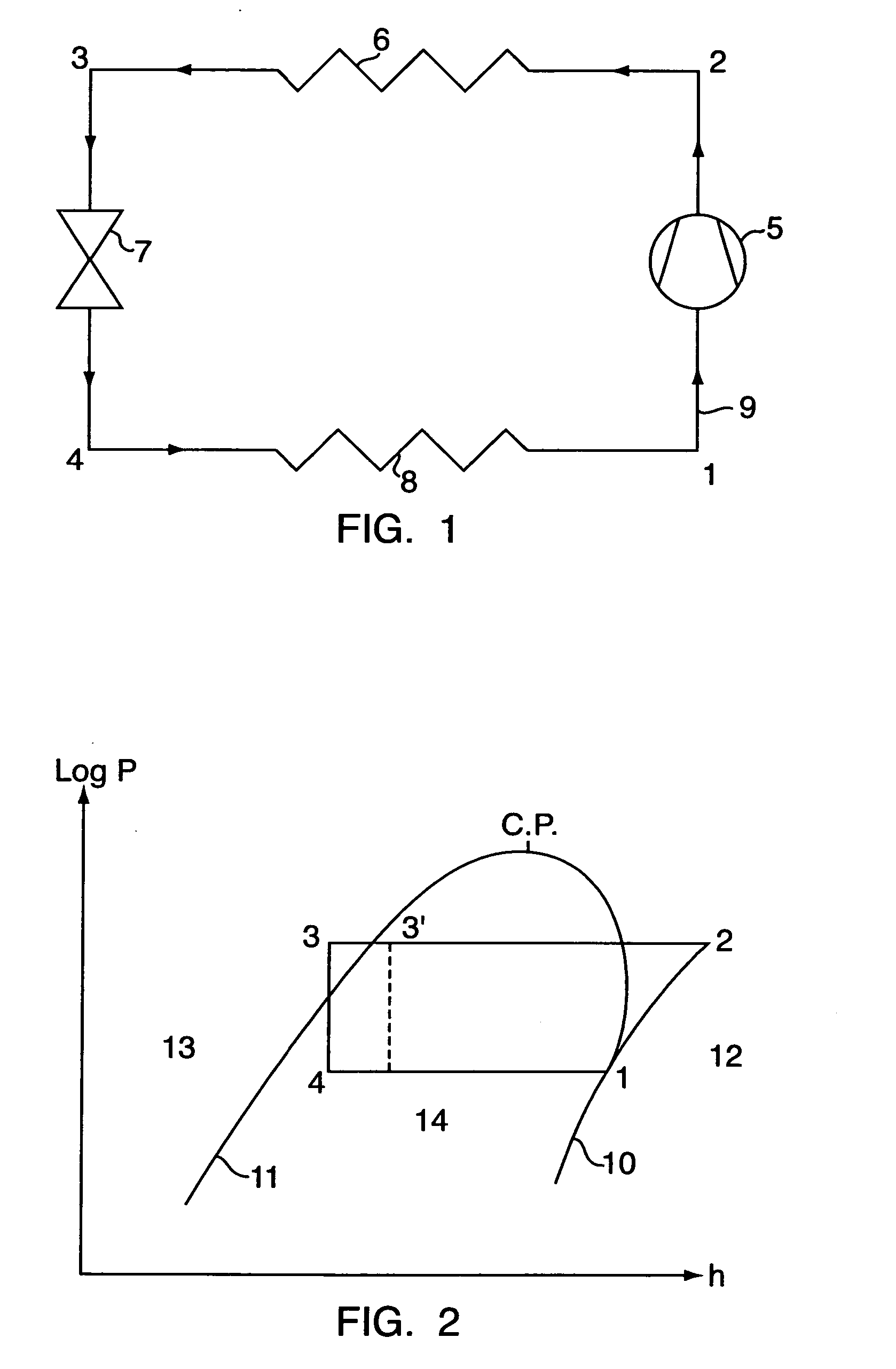

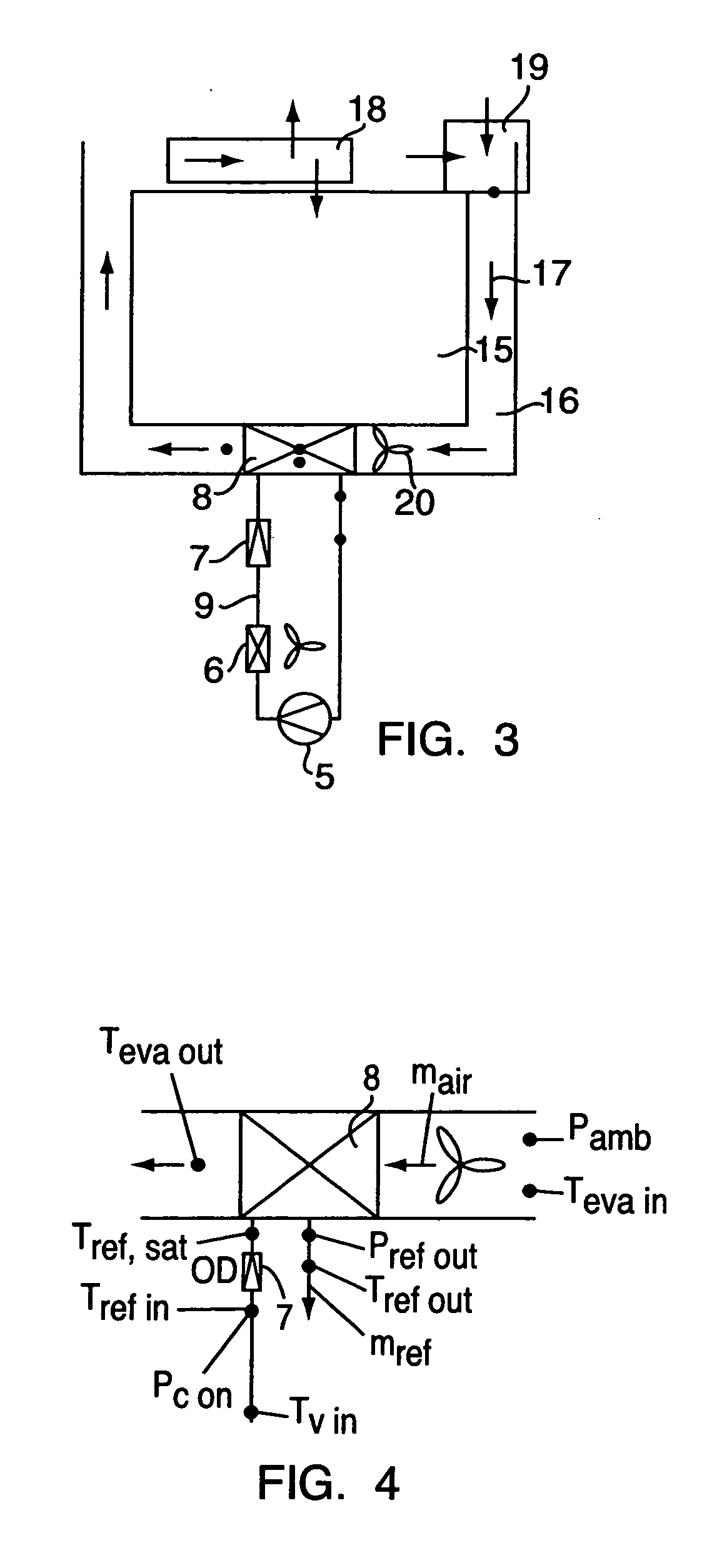

InactiveUS20050166609A1Minimal numberThermometer applicationsRefrigeration safety arrangementEnergy balancingHeat flow

A method and a device for detecting flash gas in a vapour-compression refrigeration or heat pump system comprising a compressor, a condenser, an expansion device, and an evaporator interconnected by conduits providing a flow path for a refrigerant, by determining a first rate of heat flow of a heat exchange fluid flow across a heat exchanger of the system and a second rate of heat flow of the refrigerant across the heat exchanger, and using the rates of heat flow for establishing an energy balance from which a parameter for monitoring the refrigerant flow is derived, to thereby provide early detection of flash gas with a minimum number of false alarms.

Owner:DANFOSS AS

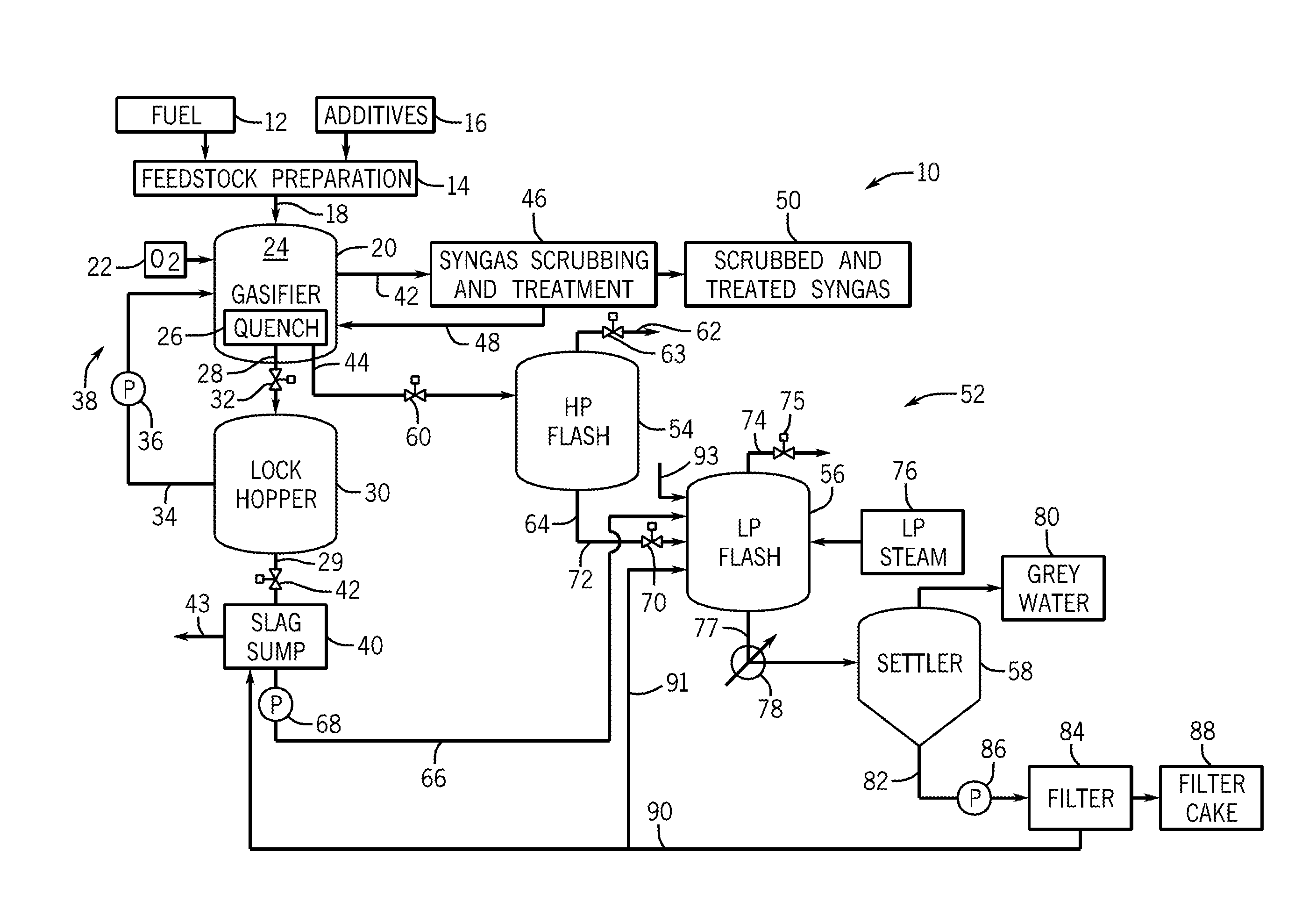

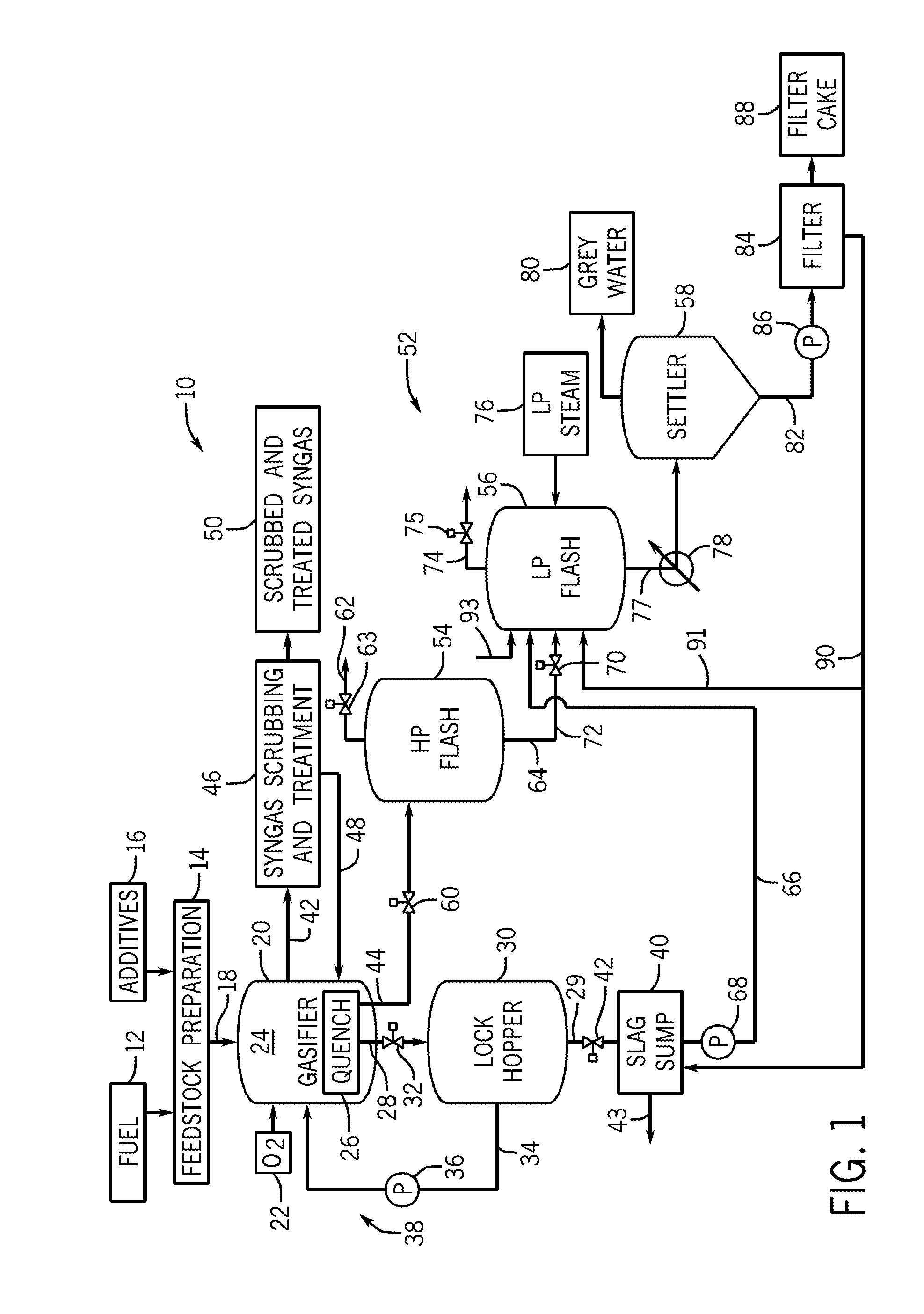

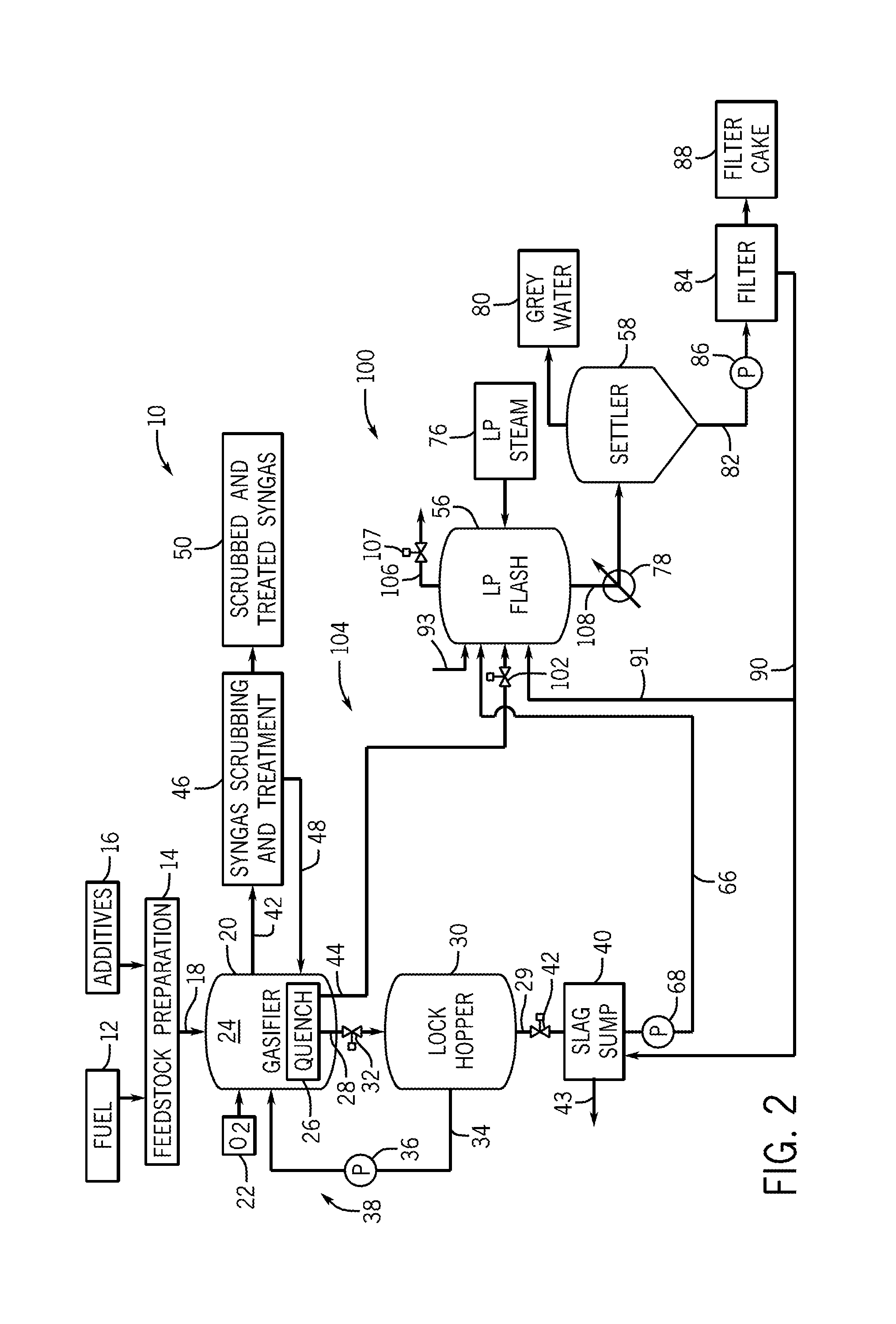

System for deaeration in a flash vessel

ActiveUS20130183204A1Gasification processes detailsWaste water treatment from gaseous effluentsSlagWater flow

The disclosed embodiments relate to systems for deaerating a stream of slag sump water produced by a gasifier. For example, in one embodiment, a system includes a flash vessel having a first inlet configured to introduce a first fluid into the flash vessel, wherein the flash vessel is configured to flash the first fluid to produce a first flash gas, a second inlet configured to introduce a stream from slag sump into the flash vessel, wherein the stream from slag sump comprises a mixture of a gasification fine slag, dissolved oxygen (O2), and water. A gas-liquid contactor in the flash vessel is configured to contact the stream from slag sump with the first flash gas to enable the first flash gas to deaerate the stream from slag sump. A first outlet of the vessel is configured to output an overhead discharge comprising the first flash gas and oxygen from the stream from slag sump.

Owner:AIR PROD & CHEM INC

Method for recovering tank car unloading gas and storage tank flash stream of LNG (liquefied natural gas) automobile gas station

InactiveCN104456070ATake advantage ofStable and continuous gas sourceContainer filling methodsPipeline systemsWater bathsBuffer tank

The invention provides a method for recovering unloading gas of a natural gas tank car and flash stream of a natural gas storage tank. The method comprises the following steps: when the gas phase pressure of an LNG (liquefied natural gas) tank car is 0.6-0.8 MPa, a pressure regulating valve is opened; unloading gas utilizes the self pressure to enter an air heater or a water-bath type electric heater; the unloading gas heated by the heater sequentially enters a buffer tank and a gas storage tank; after the pressure of the unloading gas is reduced by a secondary dropping valve to be a pressure required by a user, the pressure of the unloading gas is metered by a meter; finally, an odorizing device odorizes the unloading gas and then feeds the unloading gas to a station; when the gas phase pressure of the LNG tank car is reduced to 0.3 MPa, the pressure regulating valve is closed. The method for recovering the unloading gas of the natural gas tank car and the flash stream of the natural gas storage tank has the advantages of no waste of natural gas, safety and convenience.

Owner:SEDIN ENG

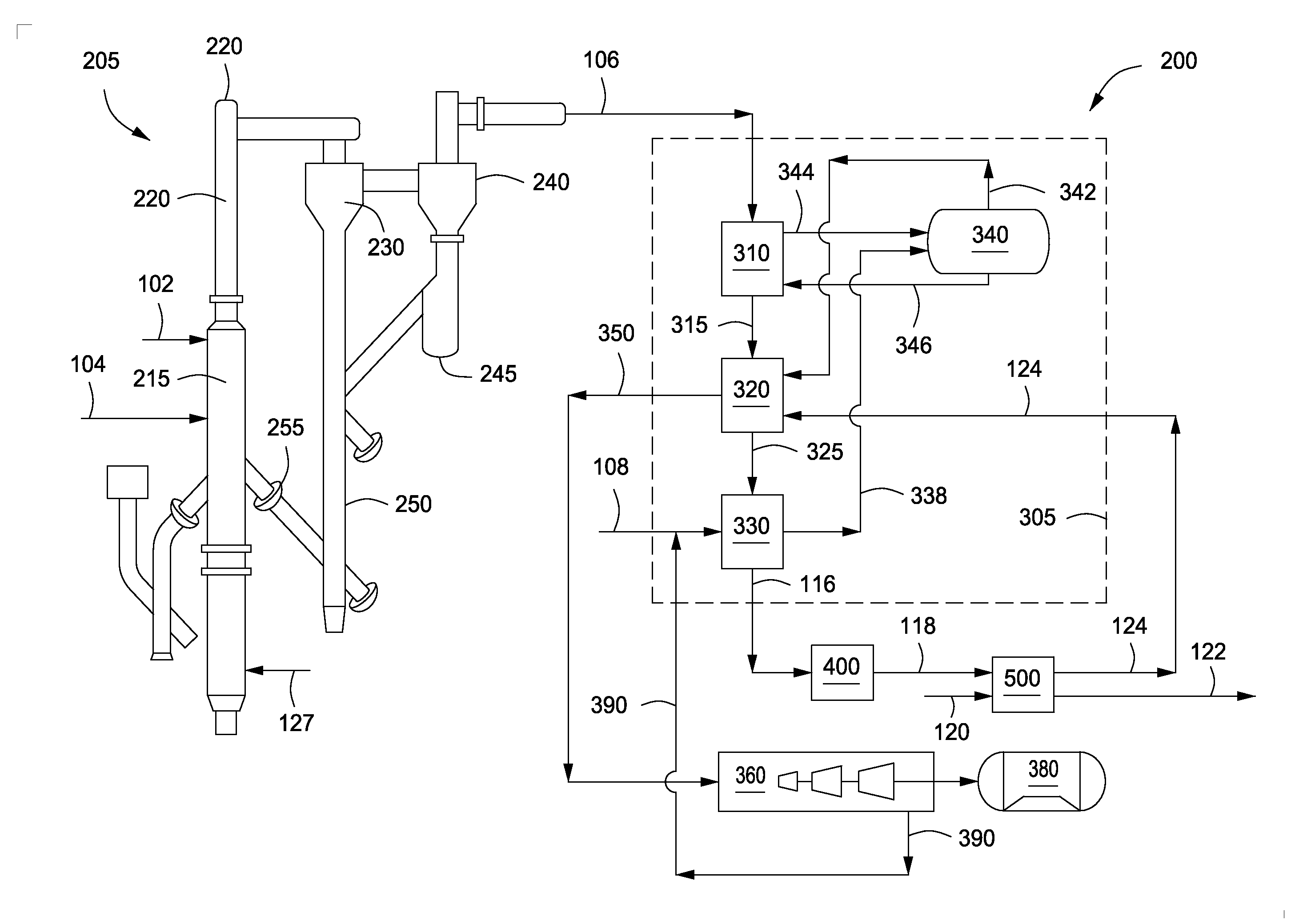

Systems and methods for producing substitute natural gas

ActiveUS20120101323A1Combustible gas catalytic treatmentHydrocarbon purification/separationMethanationFlash-gas

Systems and methods for producing synthetic natural gas are provided. The method can include gasifying a carbonaceous feedstock within a gasifier to provide a raw syngas. The raw syngas can be cooled to provide a cooled raw syngas. The cooled raw syngas can be processed in a purification system to provide treated syngas. The purification system can include a flash gas separator in fluid communication with the gasifier and a saturator. The treated syngas can be converted to synthetic natural gas to provide steam, a methanation condensate, and a synthetic natural gas. The methanation condensate can be introduced to the flash gas separator.

Owner:KELLOGG BROWN & ROOT LLC

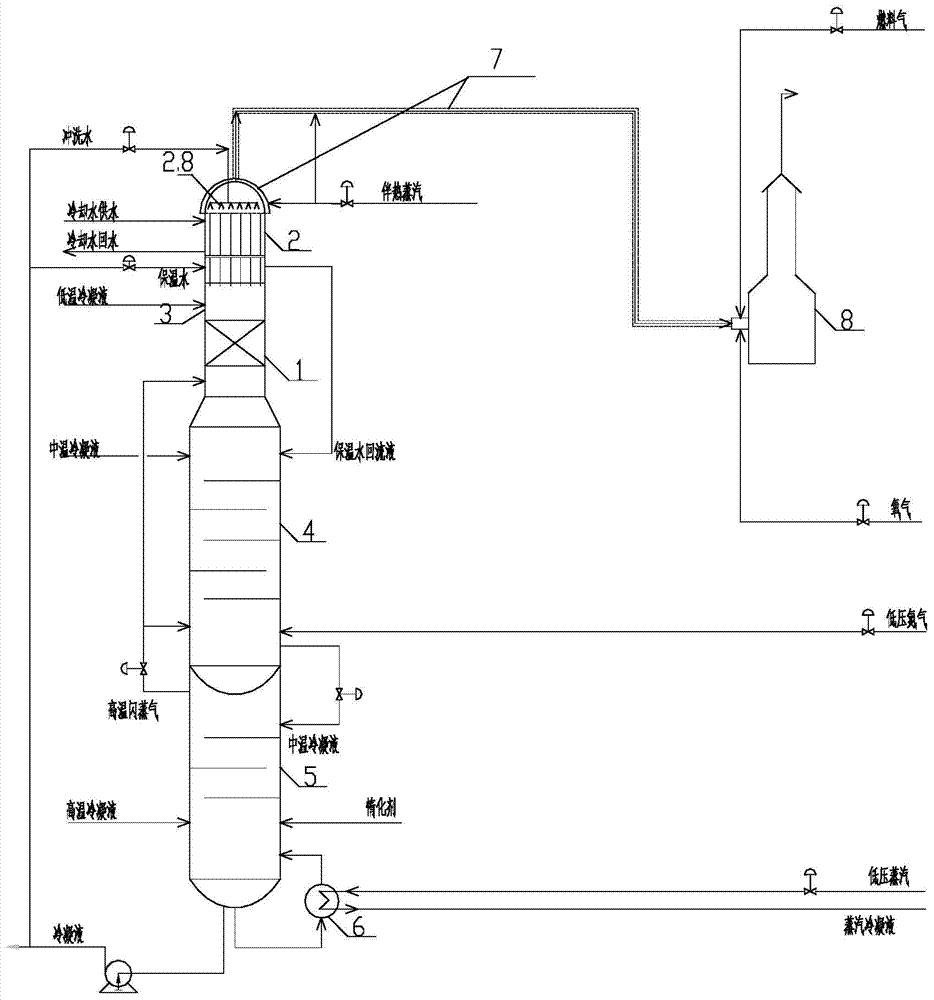

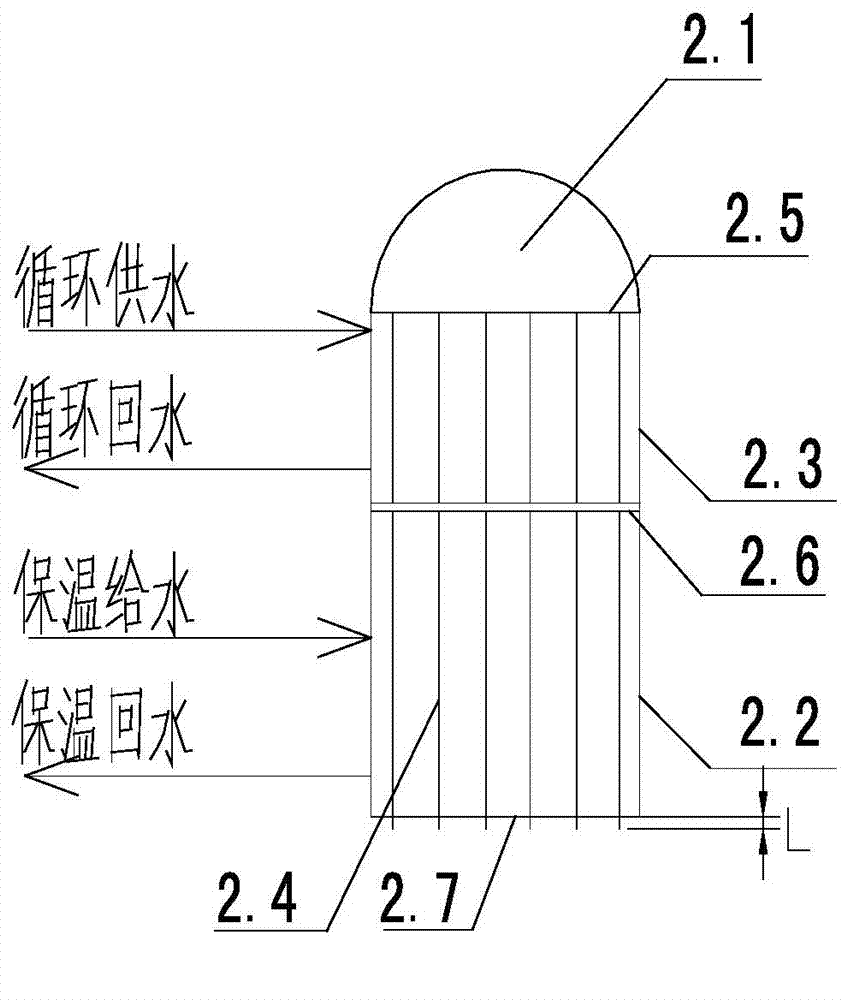

Amino acid-containing condensate steam stripping system and tail gas treatment method

ActiveCN103785193AReasonable process configurationReduce energy consumptionDistillation regulation/controlSteam distillationReboilerFlash-gas

The invention discloses an amino acid-containing condensate steam stripping system and a tail gas treatment method for solving the problems of an existing steam stripping system that a treatment method is complex, system energy consumption is high, corrosion to pipe plates and pipelines is serious and equipment investment is high. The method comprises the steps of correspondingly feeding high temperature condensate, medium temperature condensate and low temperature condensate to a high temperature condensate stripping section, a medium temperature condensate stripping section and a low temperature condensate stripping section of a stripping tower, respectively, reducing the temperature of stripping gas at a stripping tower top to be 85-90 DEG C through an overhead condenser, and feeding into an incineration furnace, wherein the high temperature condensate stripping section is provided with a reboiler, low-pressure steam used as a heat source is used for carrying out steam stripping to the condensate, the medium temperature condensate stripping section and the low temperature condensate stripping section adopt high temperature flash gas generated by the high temperature condensate stripping section as the heat source, and low-pressure nitrogen gas is introduced for gas stripping. The process is simple, the operation can be controlled flexibly, the system stability is good, energy is saved, the consumption is reduced, the corrosion of the steam stripping system can be reduced to the maximum extent and the service life of the equipment can be prolonged.

Owner:湖北华庆石化设备有限公司

Polyethyleneglycol dimethyl ether desulfurizing system optimization extracting and concentrating technology

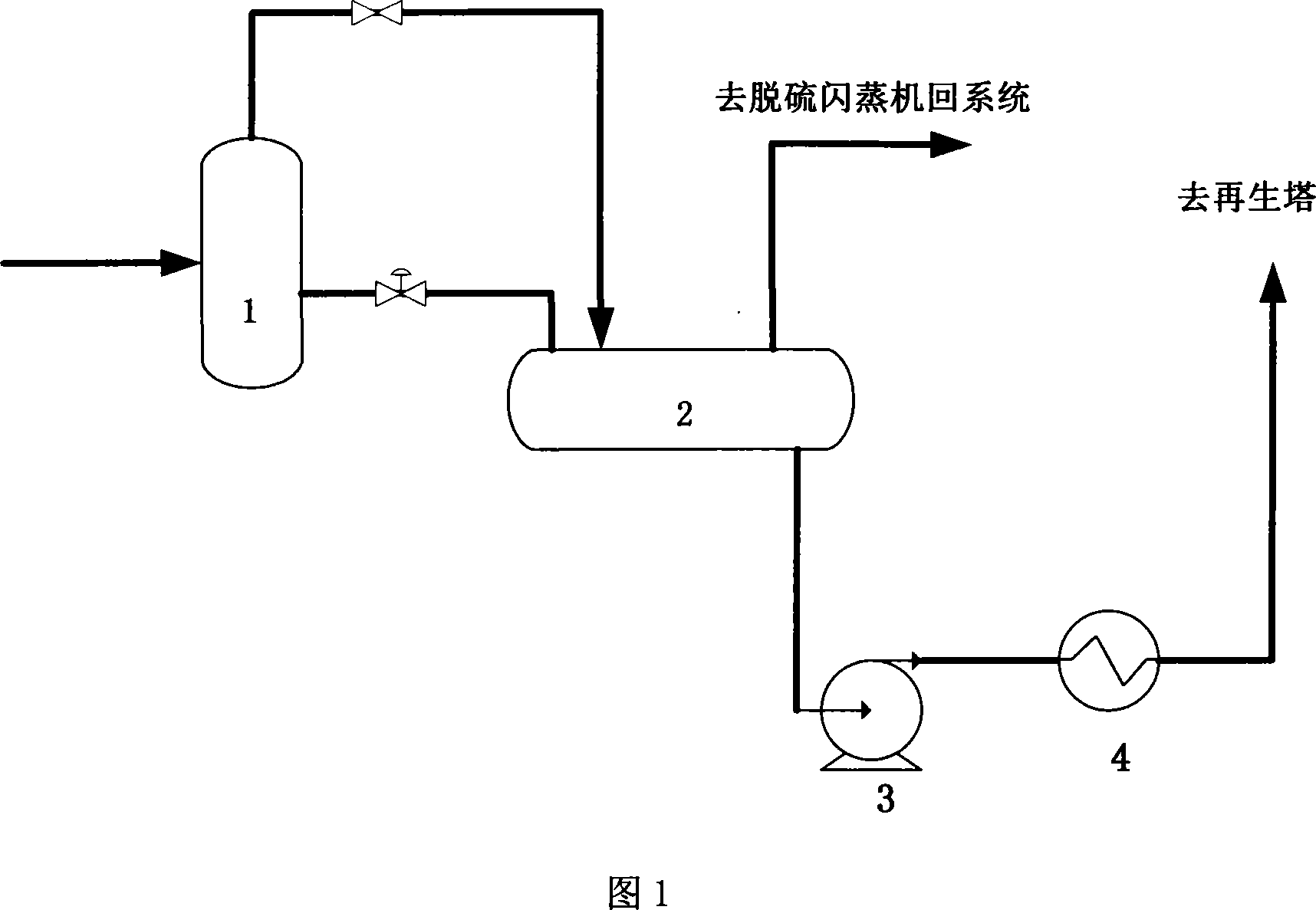

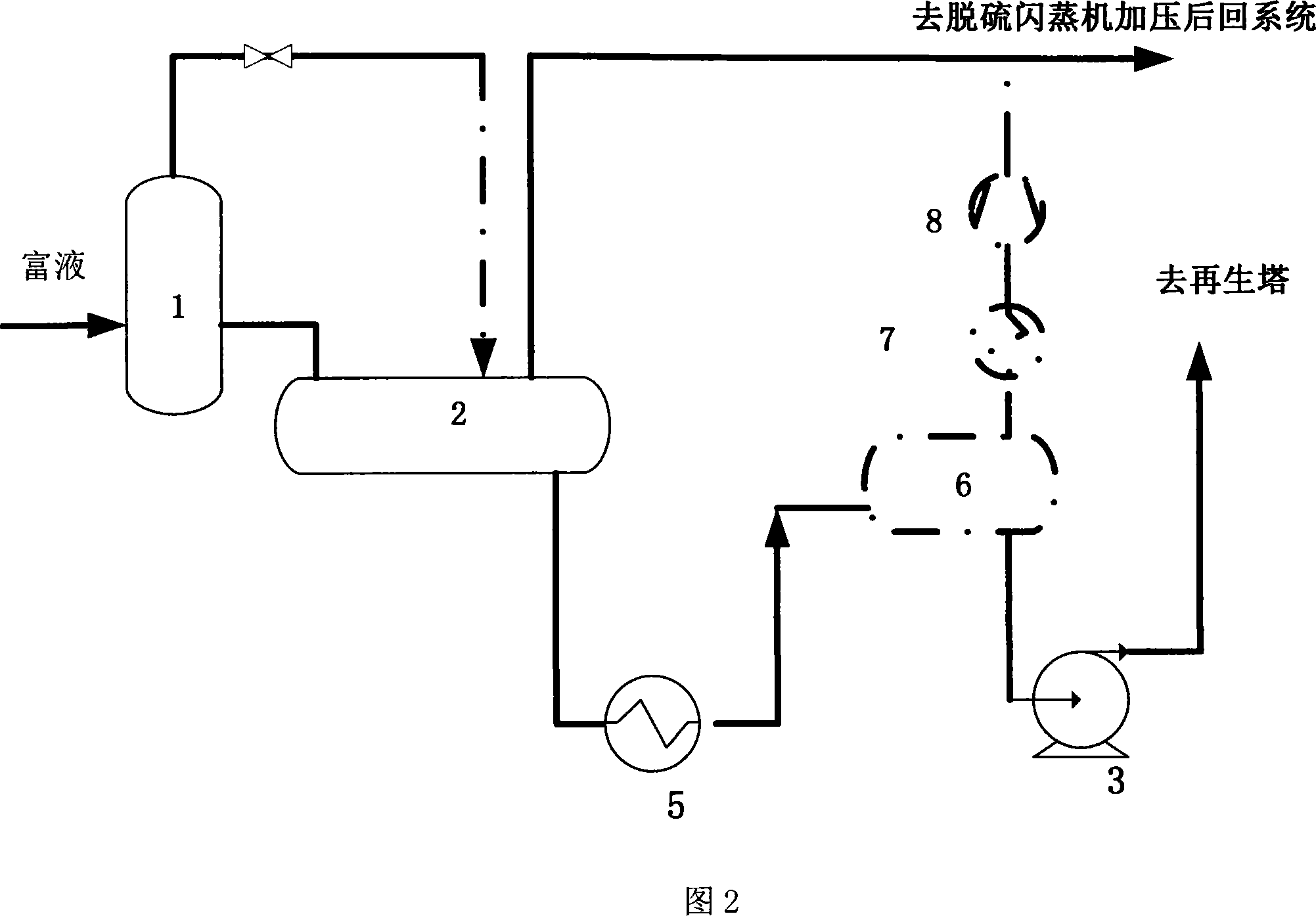

InactiveCN101077467AIncrease temperatureEfficient use ofHydrogen sulfidesDispersed particle separationPoly(ethylene glycol) dimethyl etherGas phase

The present invention discloses optimized concentration process of NHD desulfurization system, and has the advantages of environment friendship, high S recovering rate, reuse of recovered material, etc. The optimized concentration process includes: 1. feeding the rich NHD solution with absorbed hydrogen sulfide to the flash tank I; 2. connecting the flash tank I to the flashed gas pipeline in the gas phase outlet side of the flash tank II; 3. heating the rich solution from the flash tank II to 90-130 deg.c in a heat exchanger and high temperature decompression regenerating the rich solution in a low pressure flash tank at pressure lower than 30 KPa; 4. water cooling and separating flash gas from the low pressure flash tank, pressurizing to 50-150 KPa, mixing with flash gas from the flash tank II, pressurizing the gas mixture in desulfurizing flash machine, and returning to the concentrating tower system; and 5. regenerating the rich solution from the low pressure flash tank in a regenerating tower.

Owner:YANKUANG LUNAN CHEM FERTILIZER PLANT

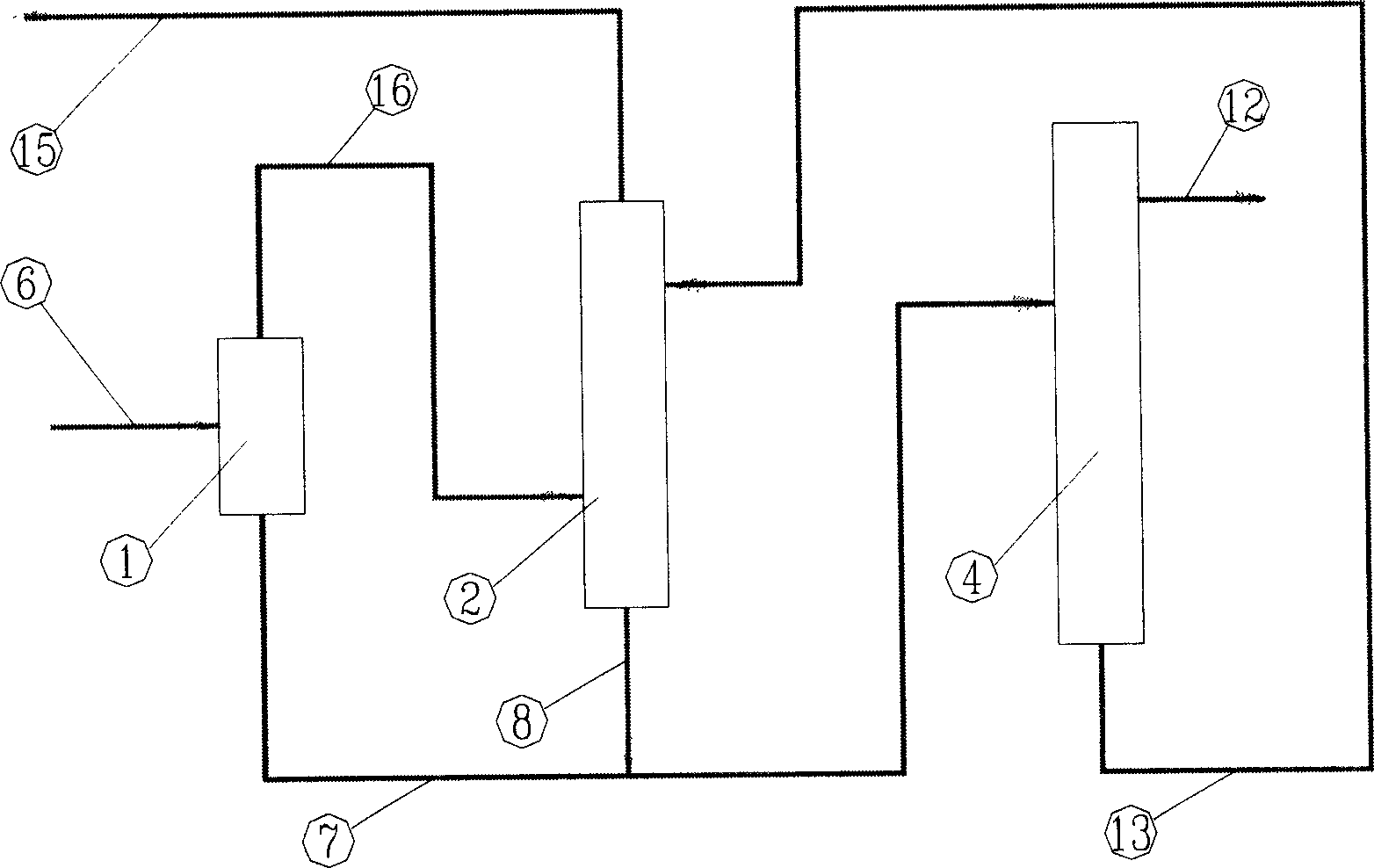

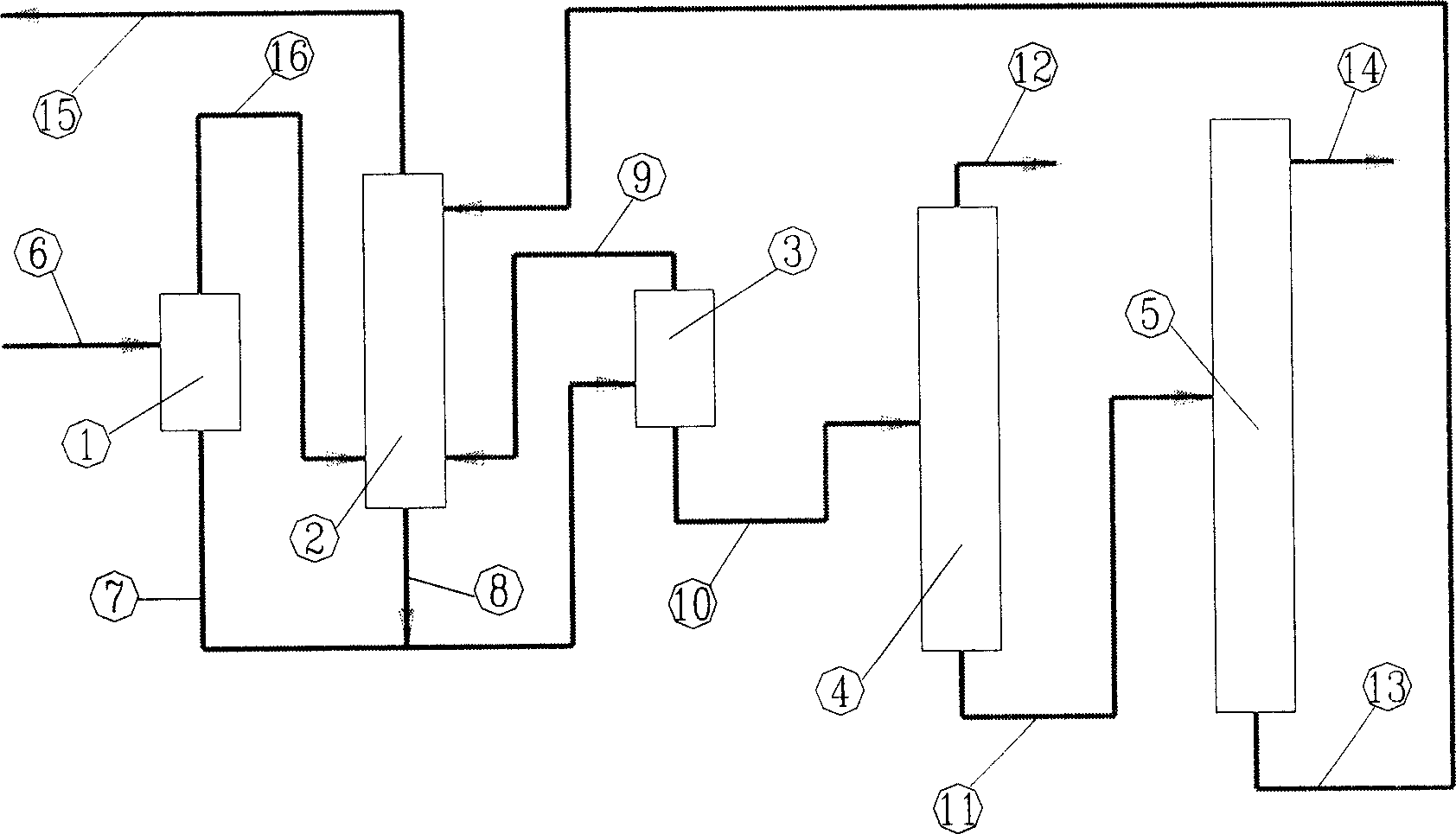

Flash gas bypass evaporator

A heat exchanger includes a fluid distribution manifold, a fluid collection manifold, and a plurality of tubes extending there between. A separator within the fluid distribution manifold includes a first fluid conduit and a second fluid conduit. The first fluid conduit extends through an inlet end and over at least a portion of the length of the fluid distribution manifold. A plurality of openings in the first fluid conduit fluidly couples the first fluid conduit to at least a first portion of the plurality of tubes. A first end of a second fluid conduit is arranged generally centrally within and parallel to the first fluid conduit. Refrigerant vapor is configured to flow through the second fluid conduit. Liquid refrigerant is configured to flow between the first fluid conduit and the second fluid conduit to at least the first portion of the plurality of tubes.

Owner:CARRIER CORP

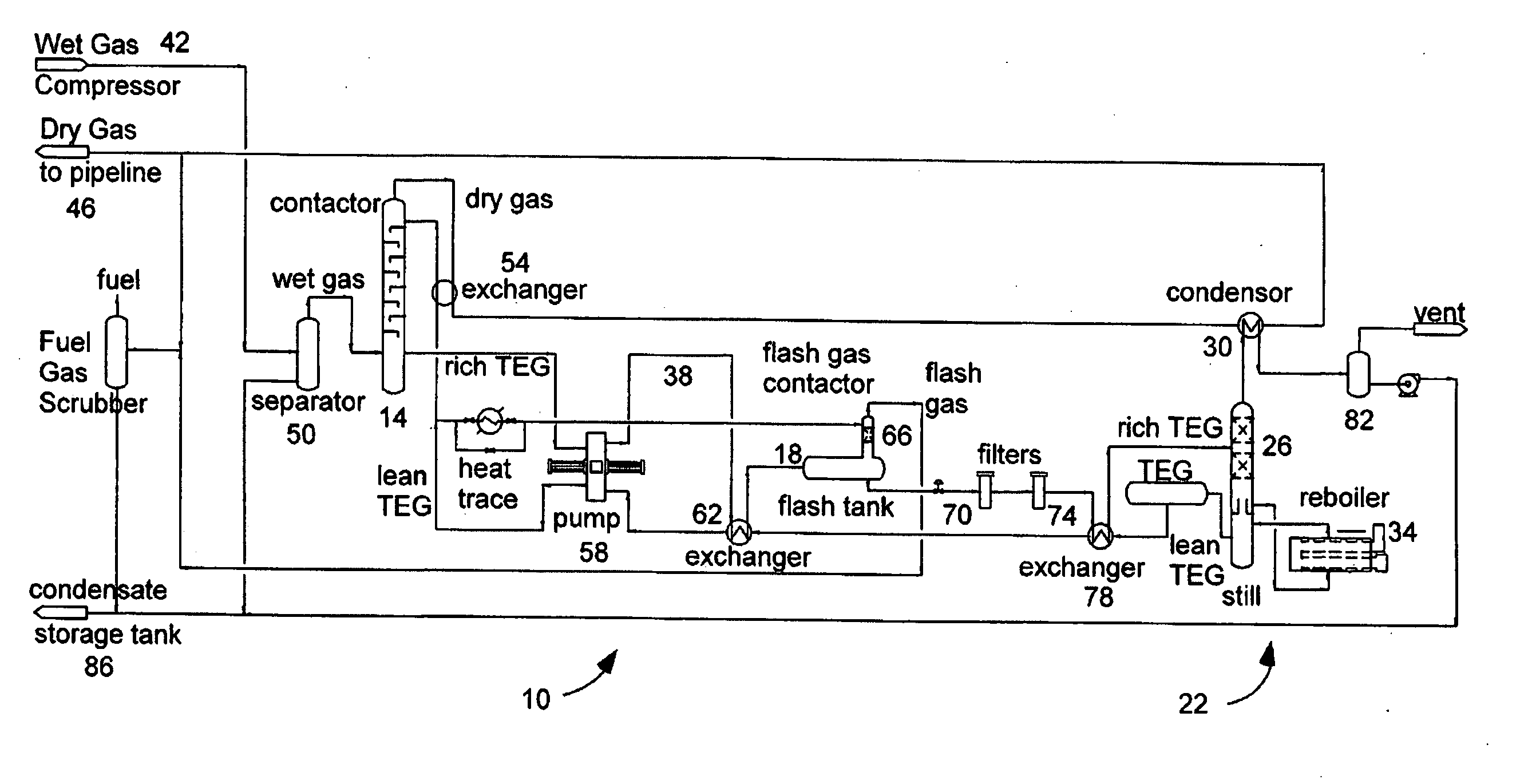

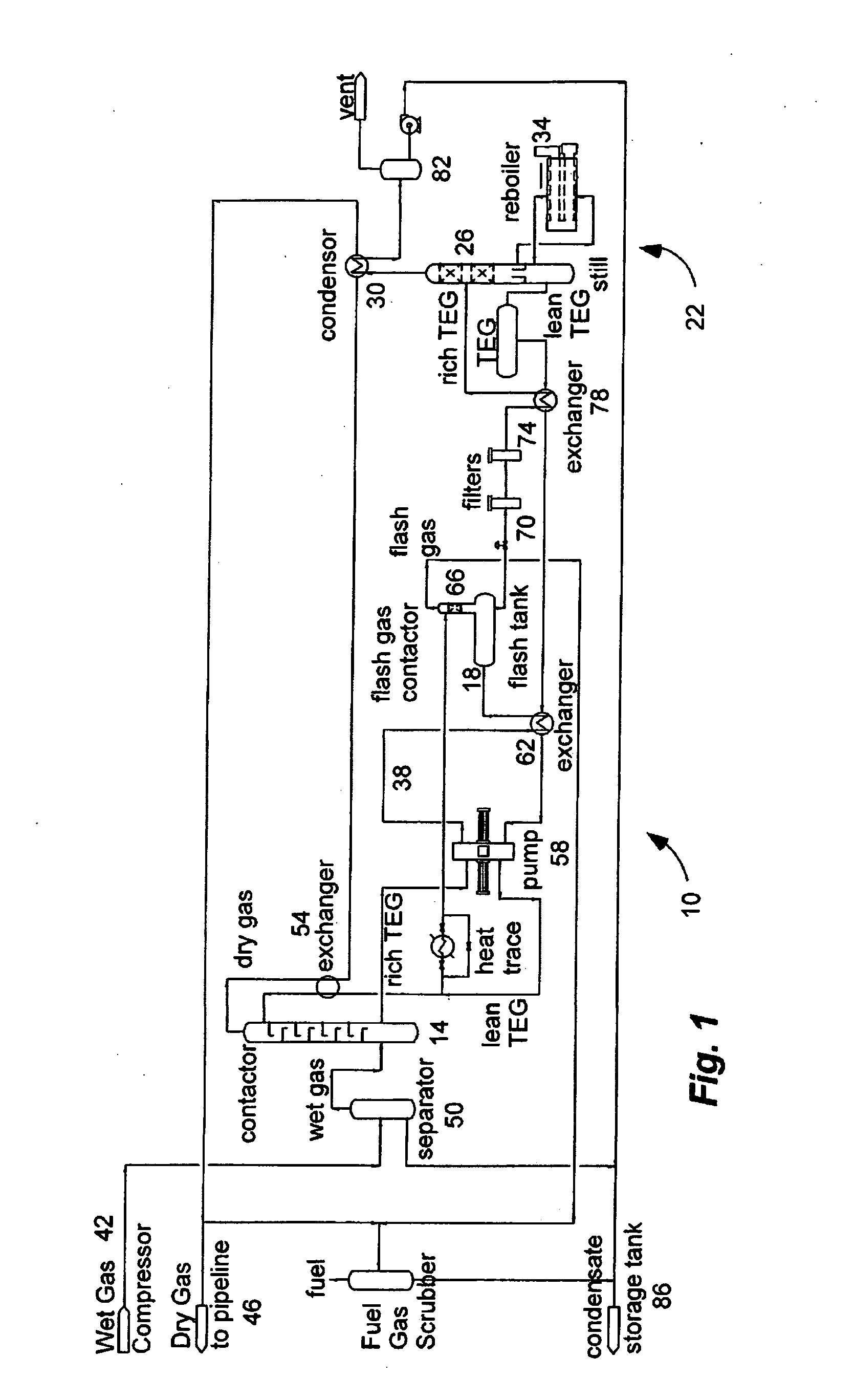

System for dehydrating natural gas

InactiveUS20100281775A1Low costReduce the amount requiredGas treatmentHydrogen separationReboilerNatural gas dehydration

An apparatus and process for dehydrating a wet natural gas while removing volatile organic compounds (VOC). The well-produced natural gas is contacted with a dehydrating agent, such as glycol, which absorbs water from the natural gas. The mixture of dehydrating agent / water and heavy hydrocarbons is conveyed through a heat exchanger, separator and reboiler for removing VOC and recovering the dehydrating agent for recirculation. A stripping column is coupled to an outlet of the reboiler for stripping the dehydrating agent of any traces of water that is flashed out in the reboiler. Light hydrocarbons removed from the mixture are re-circulated as flash gas in the reboiler, thereby reducing the amount of make-up fuel necessary in the heating process.

Owner:GLY TECH SERVICES

Process And Apparatus For Producing Olefin Polymers

ActiveUS20080039597A1Eliminate disadvantagesReduce capacityChemical/physical/physico-chemical stationary reactorsFluid phaseDistillation

The present invention concerns a process and an apparatus for continuous polymerisation of olefin monomers. In particular, the present invention concerns a process and an apparatus for continuous polymerisation olefin monomers like ethylene and other monomers, wherein an olefin monomer is polymerised in slurry phase in an inert hydrocarbon diluent in at least one loop reactor. According to the invention, a polymer slurry is continuously withdrawn from the loop reactor and concentrated. The concentrated slurry is conducted to a flash unit in order to remove the remaining fluid phase, and gas obtained is compressed in a flash gas compressor before it is being fed to a distillation section. By means of the present invention it is possible reduce the size of the flash gas compressor and the capacity of the distillation sections. This significantly reduces investment cost for a continuously operated polymerization apparatus.

Owner:BOREALIS TECH OY

Ultra-low emission natural gas dehydration unit with continuously fired reboiler

InactiveUS20110247489A1Prevent freezingEffective destructionDispersed particle filtrationGaseous fuelsReboilerDesiccant

A natural gas dehydration system and method includes a contactor, a flash tank, and a still interconnected by a desiccant circulation system. A continuously fired reboiler is coupled to the still and the flash tank to bum the flash gas from the flash tank and heat the desiccant.

Owner:WITHERSPOON JOSEPH A

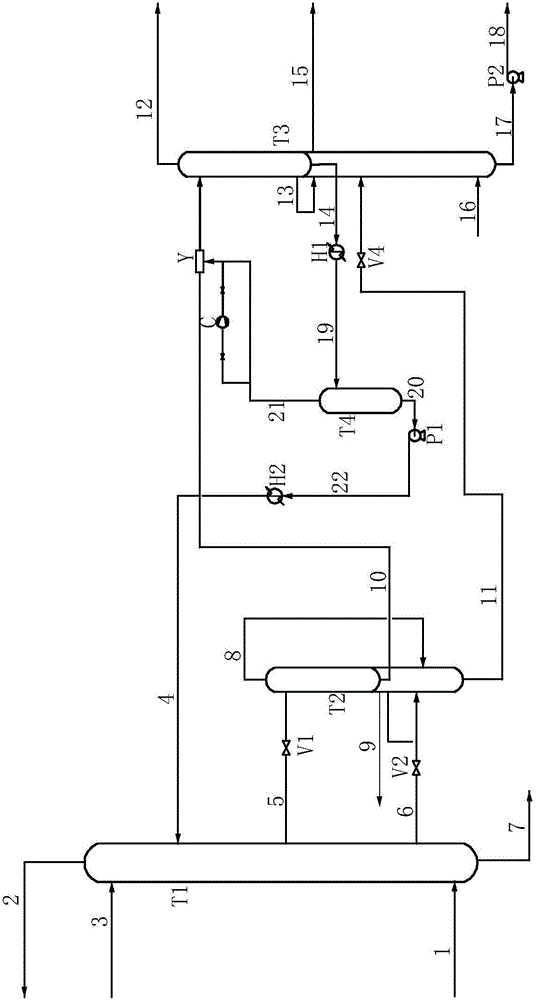

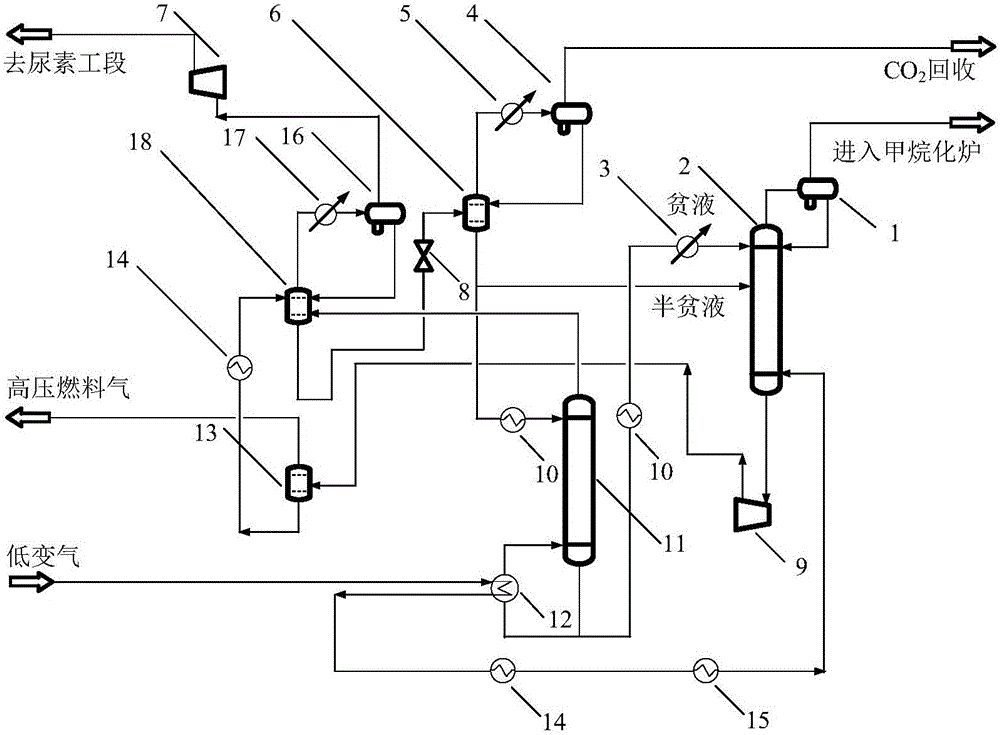

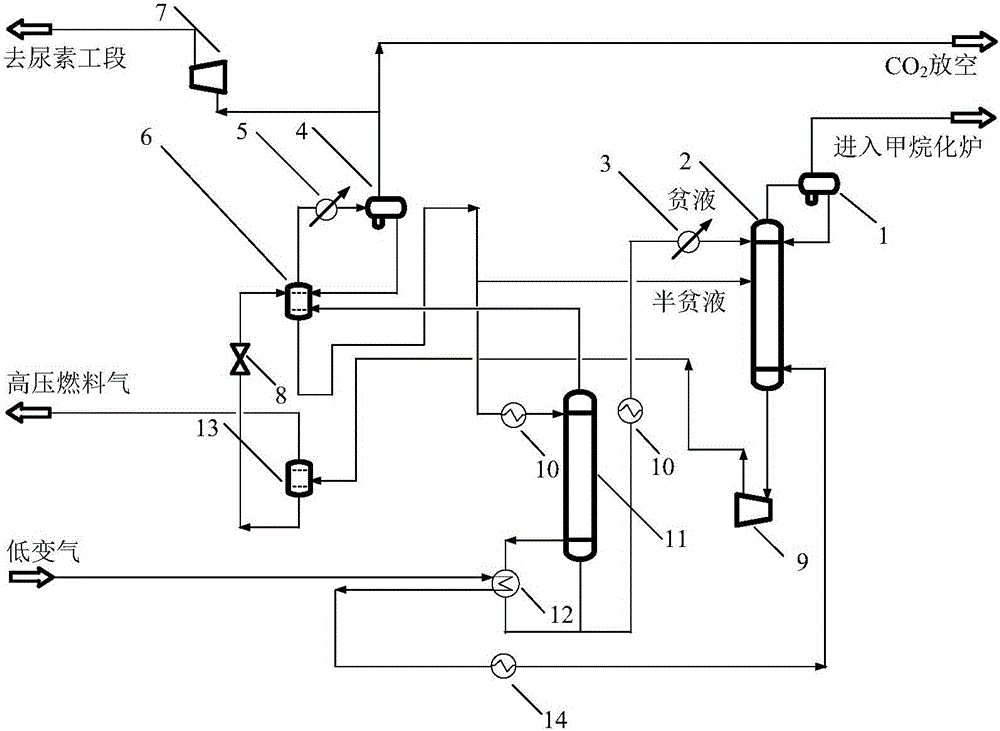

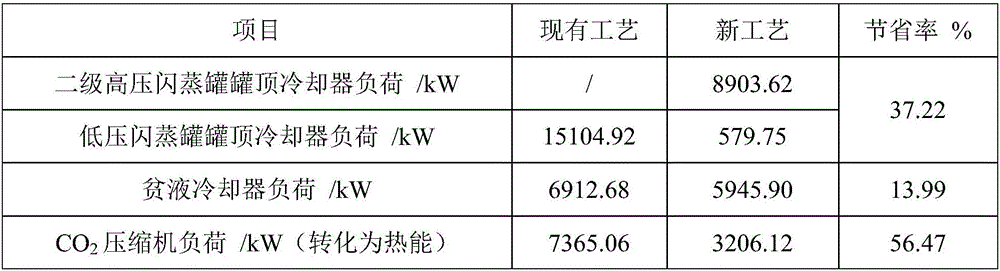

Device and method for performing multistage flash, resolution and separation on synthetic ammonia decarburization absorption tower bottom pregnant solution

ActiveCN106000000ATake advantage ofReduce consumptionDispersed particle separationGas phaseMethanation

The invention discloses a device and a method for performing multistage flash, resolution and separation on a synthetic ammonia decarburization absorption tower bottom pregnant solution. The absorption tower bottom pregnant solution enters into a primary high-pressure flash tank after being decompressed; a flashing gas phase is used as a fuel gas, and a flashing liquid phase enters into a secondary high-pressure flash tank after being subjected to heat exchange; after being cooled and separated, a gas phase of the secondary high-pressure flash tank enters into a CO2 compressor so as to be conveyed to a urea workshop section, and a separated liquid phase flows back to the secondary high-pressure flash tank, and a flashing liquid phase enters into a low-pressure flash tank after being decompressed; after being cooled and separated, the gas phase of the low-pressure flash tank enters into a CO2 recovery device, a separated liquid phase flows back to the low-pressure flash tank, the flashing liquid phase partially enters into a resolution tower after being subjected to heat exchange, and the residual part enters into an absorption tower; resolution tower overhead gas enters into a secondary high-pressure flash tank, the tower bottom solution partially returns to the tower after exchanging heat with low-change gas, the residual part enters the absorption tower after being cooled, and the absorption tower overhead gas is fed into a methanation furnace through a separator. A multistage flash evaporation and resolution process is adopted, so that the CO2 yield is improved and the energy consumption of an absorption tower bottom pregnant solution resolving process is reduced.

Owner:SUN YAT SEN UNIV

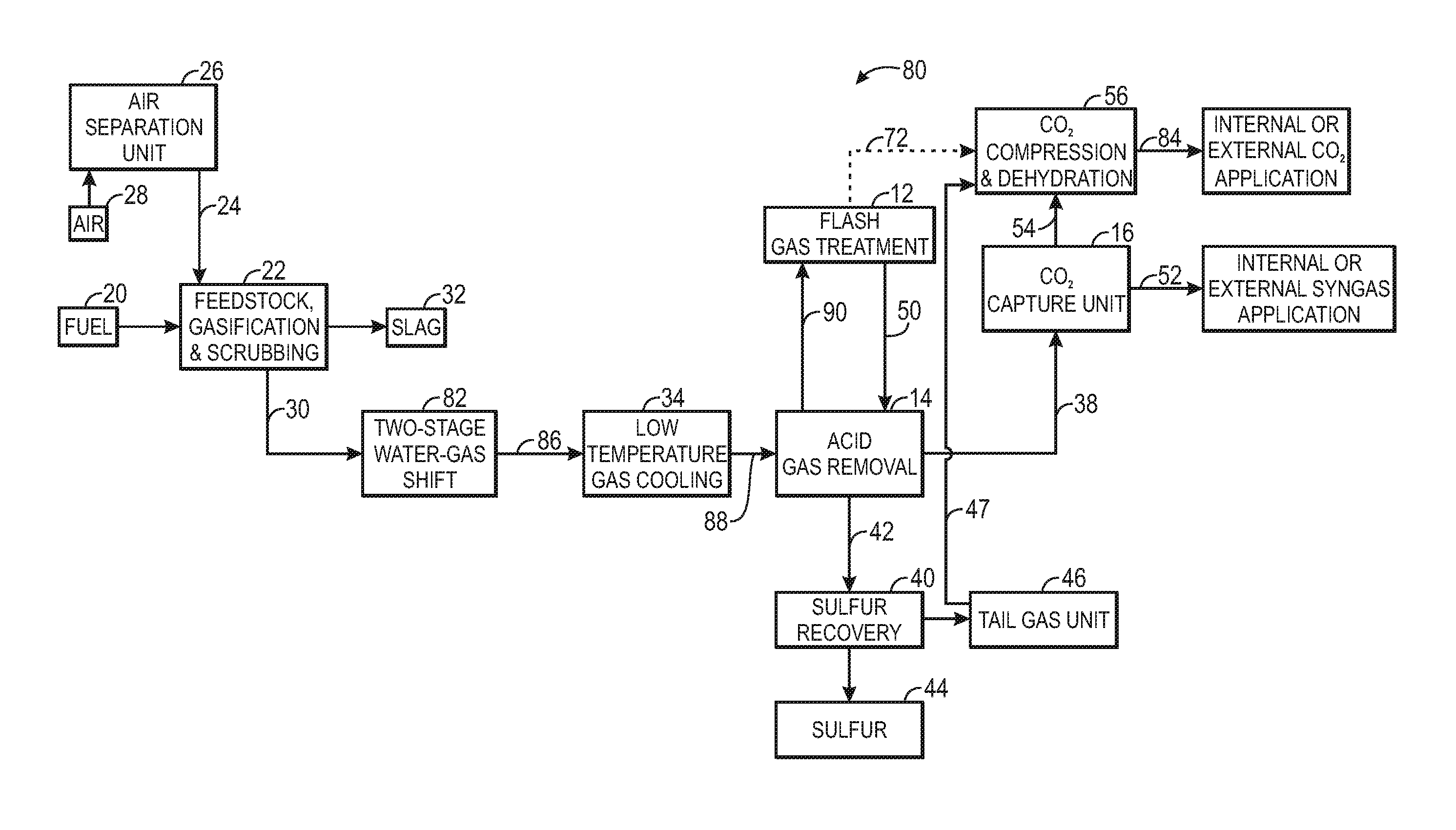

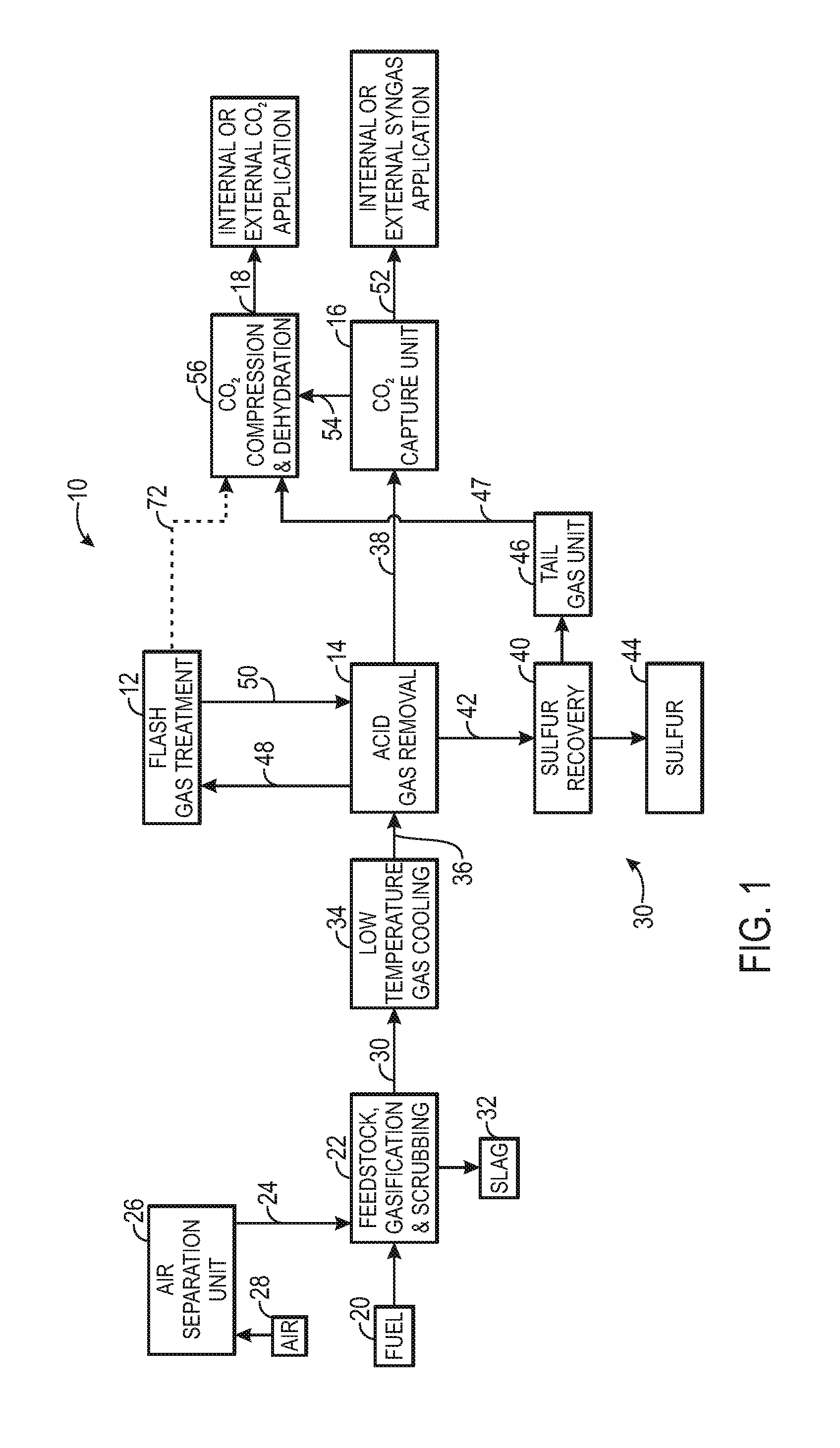

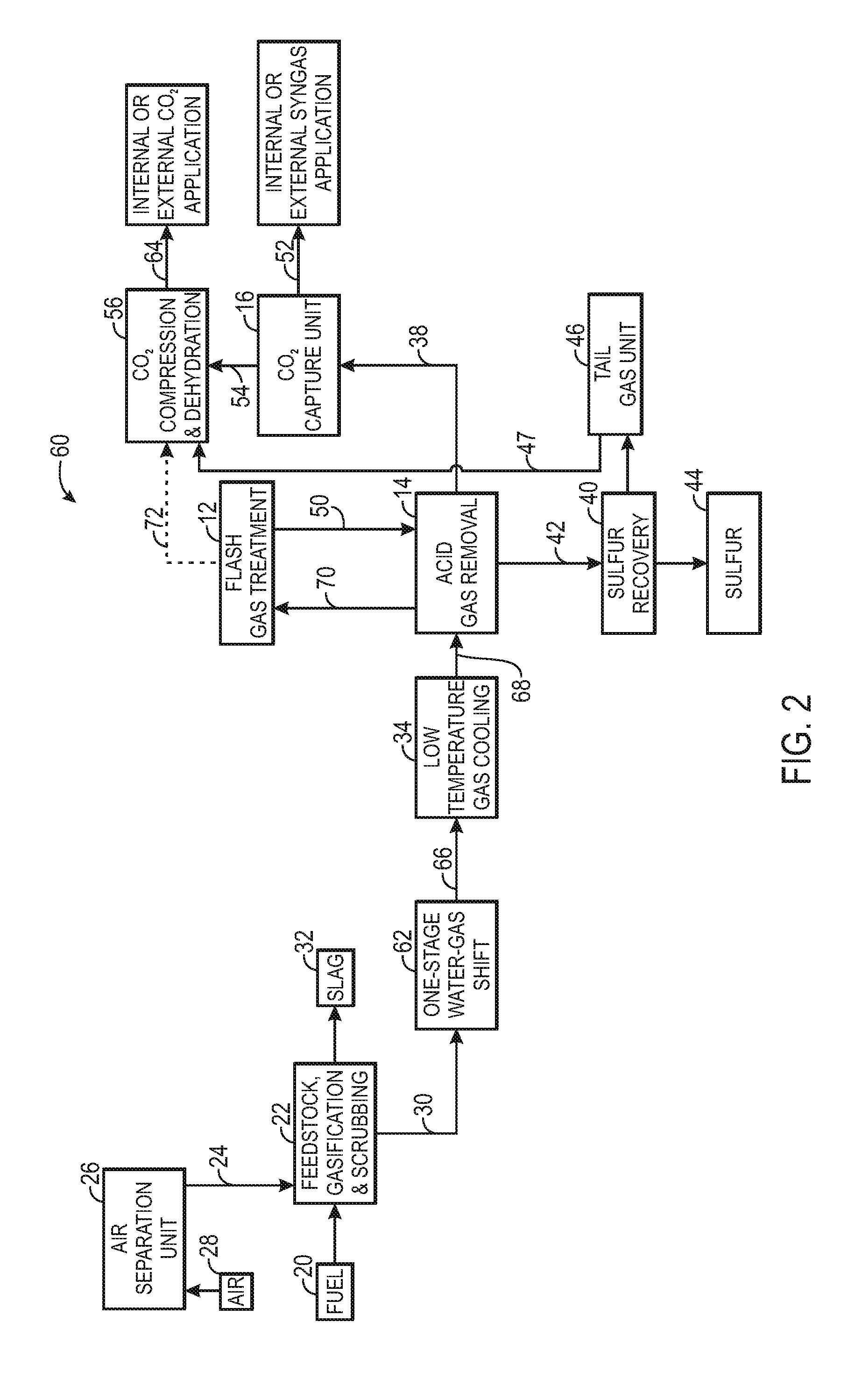

System for Integrating Acid Gas Removal and Carbon Capture

In one embodiment, a system includes a hydrogen sulfide (H2S) absorber, a first flash tank, a flash gas treatment column, and a CO2 absorber. The system also includes a first fluid path extending sequentially through the H2S absorber, the first flash tank, the flash gas treatment column, the H2S absorber, and the CO2 absorber.

Owner:AIR PROD & CHEM INC

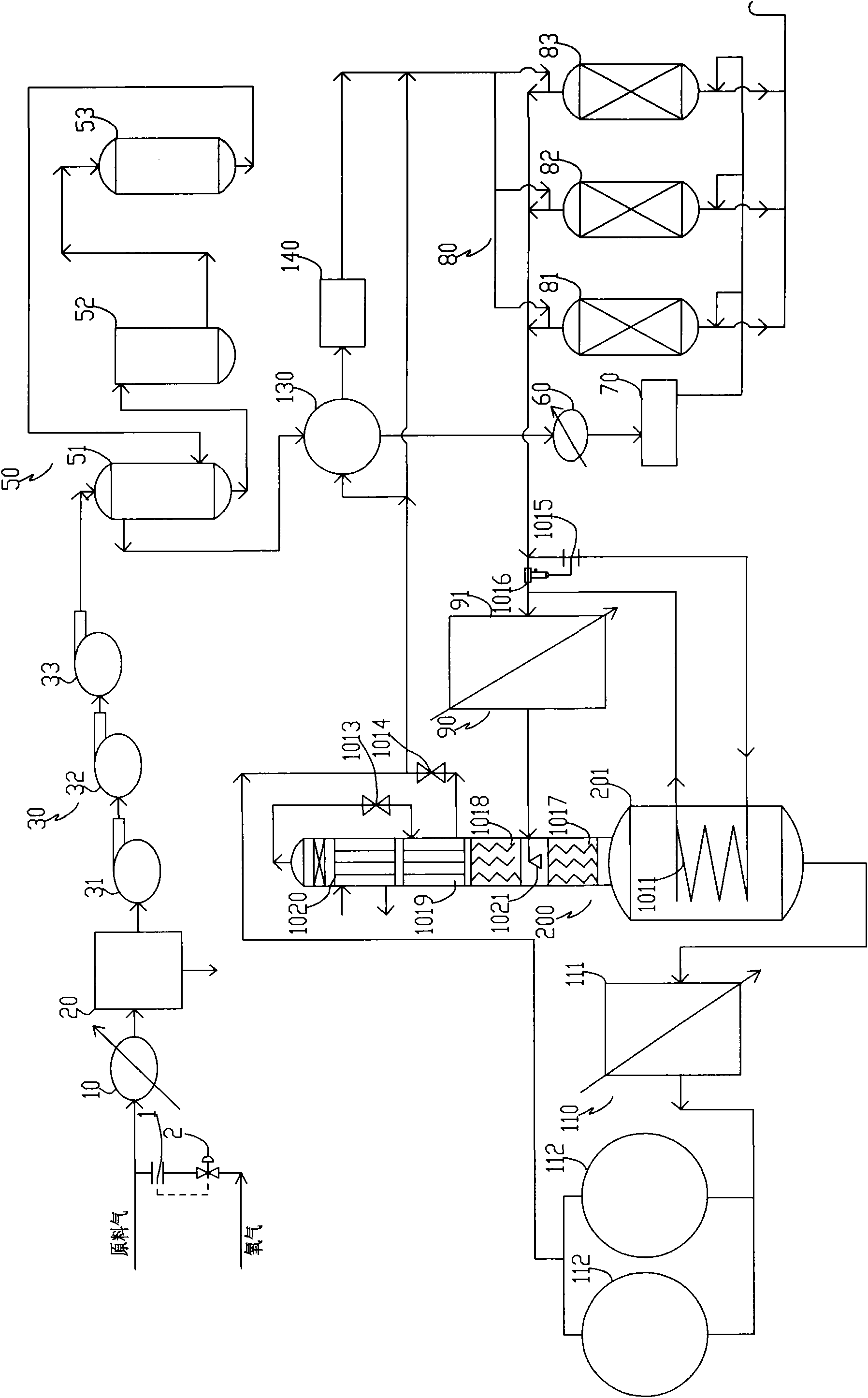

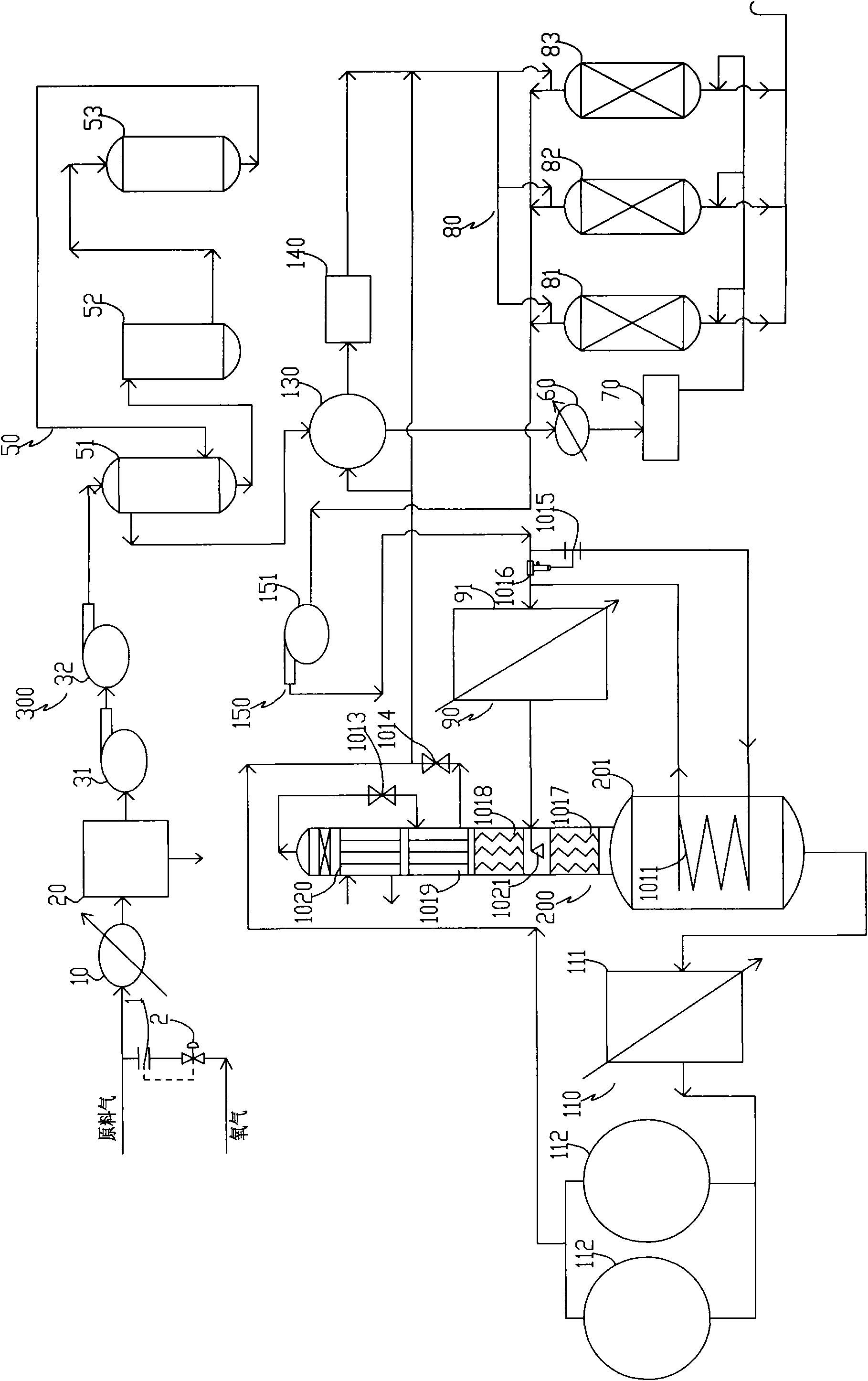

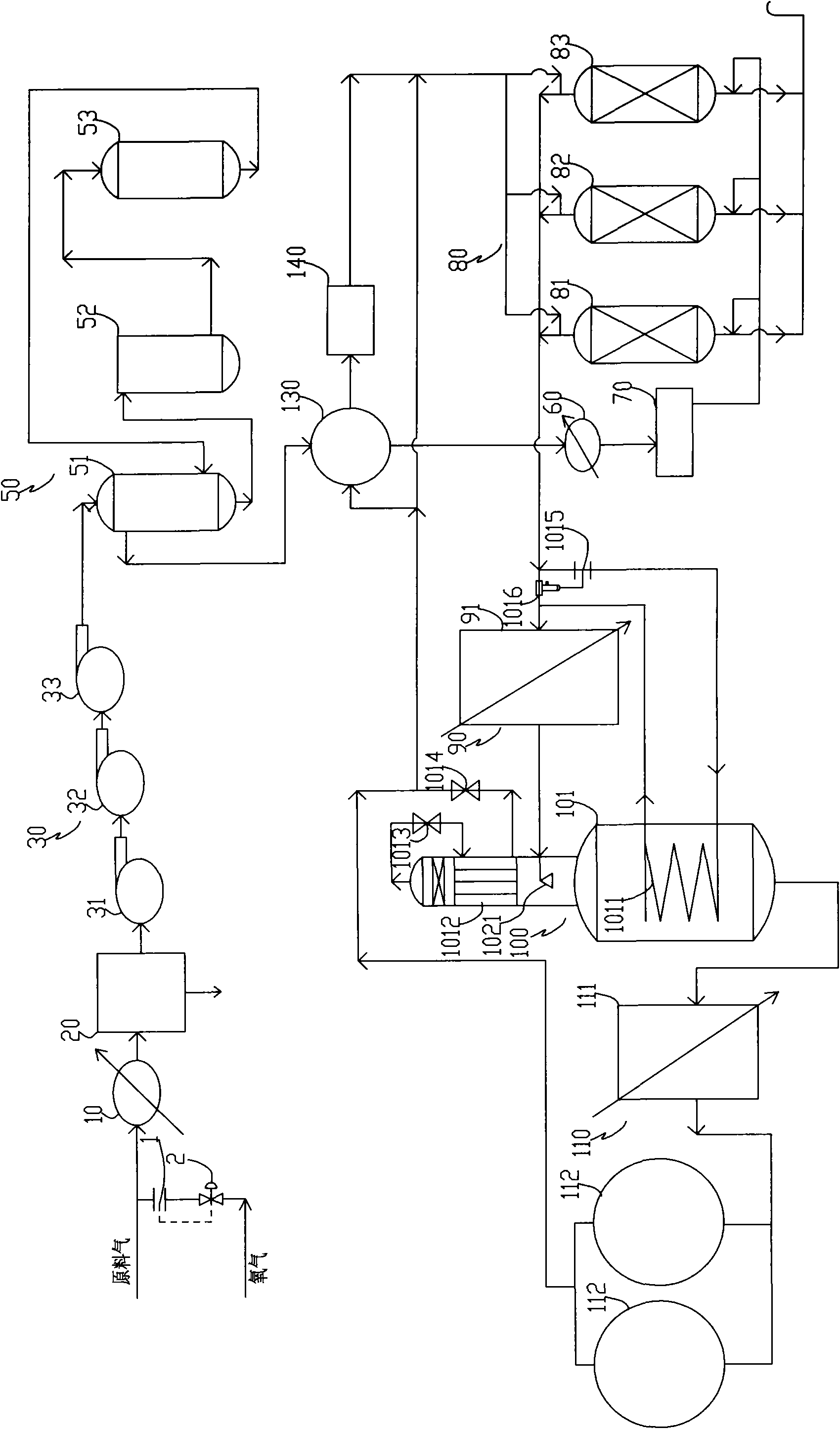

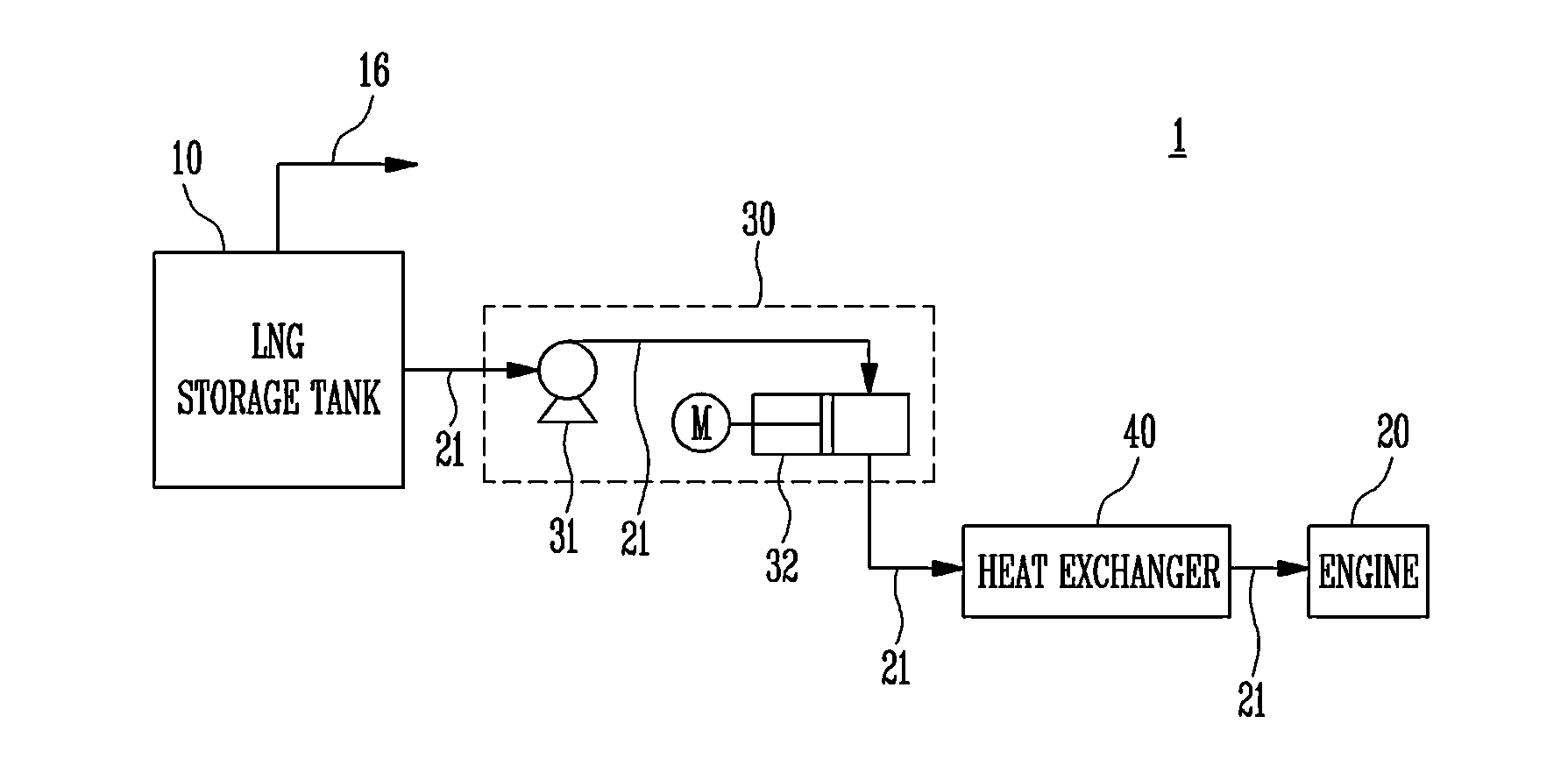

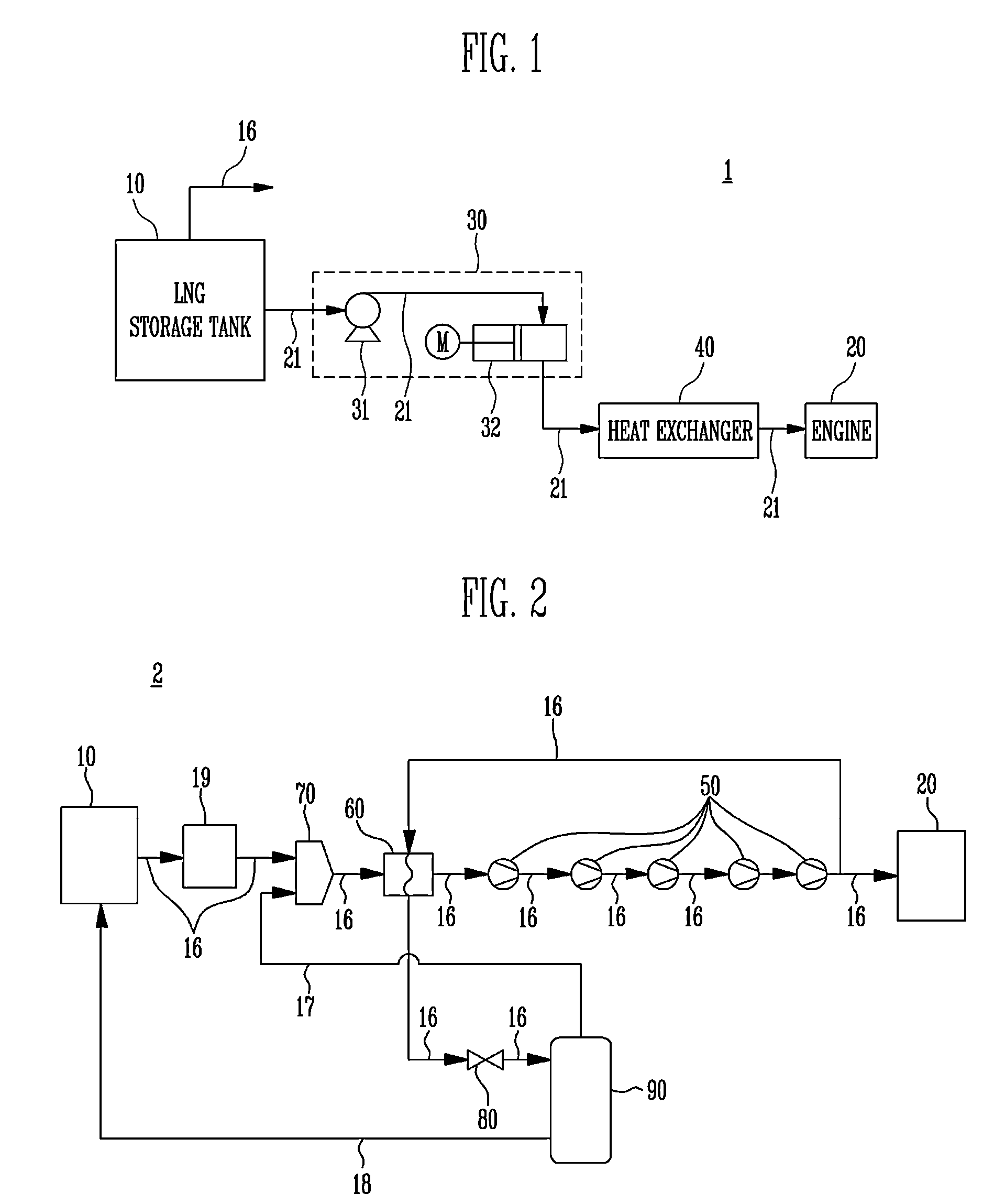

Liquefied gas treatment system

InactiveUS20140352330A1Conducive to liquefactionImproving reliquefaction efficiencySolidificationLiquefactionGas compressorFlash-gas

A liquefied gas treatment system according to an embodiment of the present invention includes a boil-off gas heat exchanger exchanging heat between boil-off gas, pressurized by a boil-off gas compressor and recovered along a boil-off gas supply line branching off upstream of a liquefied gas-consuming unit, and the boil-off gas supplied from a liquefied gas storage tank, wherein the boil-off gas heat exchanger cools the boil-off gas, recovered along the boil-off gas supply line, with the boil-off gas, supplied from the liquefied gas storage tank, or flash gas, supplied through a vapor recovery line.

Owner:HYUNDAI HEAVY IND CO LTD

Coaxial economizer assembly and method

ActiveUS20110296859A1Improve fluid flowImprove performanceCompressorMechanical apparatusLiquid stateFlash-gas

A coaxial economizer for use in a chiller system comprising an inner housing and an outer housing having a common longitudinal axis. The outer housing has an inlet for receiving a fluid from a upstream compressor stage of a multistage compressor and an outlet for conveying a fluid to a downstream compressor stage of a multistage compressor. A flow chamber forms a fluid flow path about the inner housing. A flash chamber is coterminous with the flow chamber and flashes fluid in a liquid state to a gas state. A flow passage between said flash chamber and the flow chamber for conveying a flashed gas from the flash chamber to the flow chamber; wherein the flashed gas conveyed from the flash chamber and the fluid received from the inlet of the outer housing mix along the fluid flow path toward the outlet of the outer housing.

Owner:TRANE INT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com