Liquefied gas treatment system

a technology of liquefied gas and treatment system, which is applied in the direction of machines/engines, machine/engine discharging methods, lighting and heating apparatus, etc., can solve the problems of different temperature and pressure of liquefied gas required by a source of demand, such as an engine, and achieve the effect of improving liquefaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

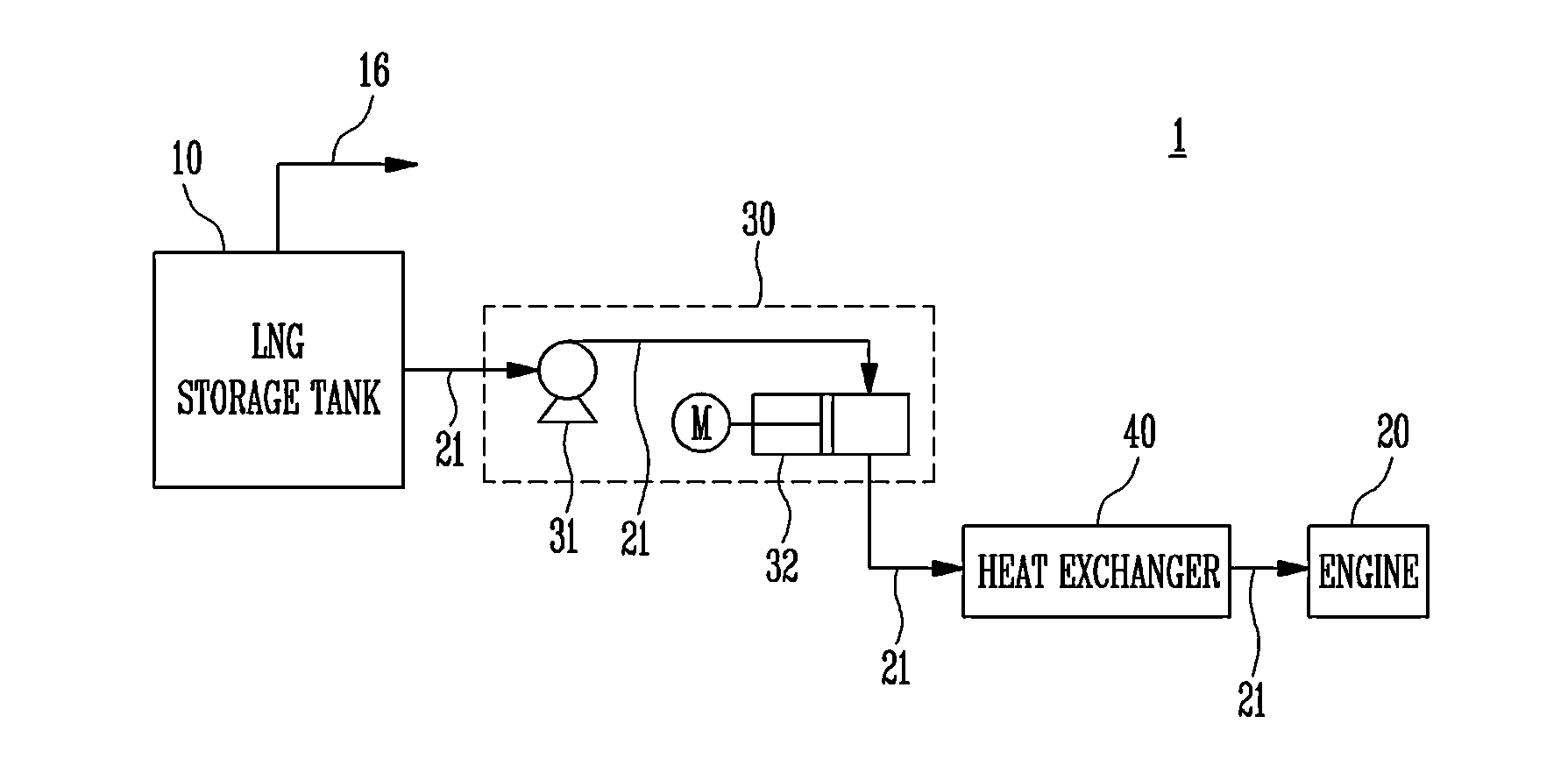

first embodiment

[0043]As described above, according to the present invention, since the pressure tank type liquefied gas storage tank 10 that includes the vacuum insulation unit 13 between the outdoor tank 11 and the indoor tank 12 is used, generation of boil-off gas may be reduced, and the liquefied gas storage tank 10 may be prevented from being damaged despite increase in internal pressure.

[0044]According to a first embodiment of the present invention, boil-off gas, generated from the liquefied gas storage tank 10, may be efficiently used by supplying the boil-off gas to the boil-off gas compressor 50 to heat the boil-off gas or by pressurizing and supplying the boil-off gas as fuel to the liquefied gas-consuming unit 20.

[0045]A forcing vaporizer 19 may be provided downstream of the liquefied gas storage tank 10. When the mass flow of the boil-off gas is insufficient, the forcing vaporizer 19 may operate to increase the mass flow of the boil-off gas supplied to the liquefied gas-consuming unit 2...

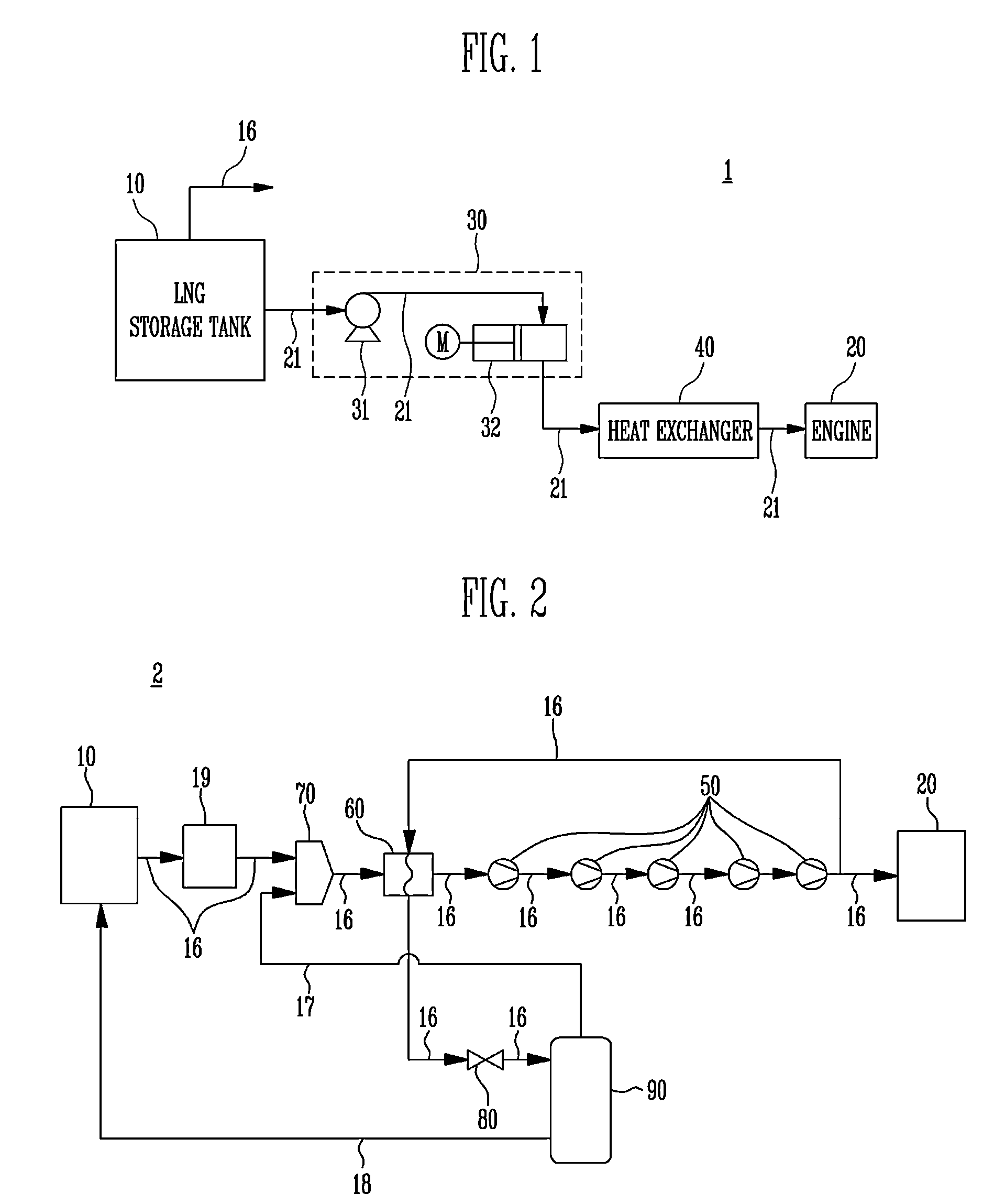

second embodiment

[0091]As described above, according to the present invention, since the pressure tank type liquefied gas storage tank 10 that includes the vacuum insulation unit 13 between the outdoor tank 11 and the indoor tank 12 is used, generation of boil-off gas may be reduced, and the liquefied gas storage tank 10 may be prevented from being damaged despite increase in internal pressure.

[0092]According to a second embodiment of the present invention, boil-off gas, generated from the liquefied gas storage tank 10, may be efficiently used by supplying the boil-off gas to the boil-off gas compressor 50 to heat the boil-off gas or by pressurizing the boil-off gas to supply the pressurized boil-off gas as fuel to the liquefied gas-consuming unit 20.

[0093]A forcing vaporizer (not illustrated) may be provided downstream of the liquefied gas storage tank 10. When a mass flow of the boil-off gas is insufficient, the forcing vaporizer may operate to increase the mass flow of the boil-off gas supplied t...

third embodiment

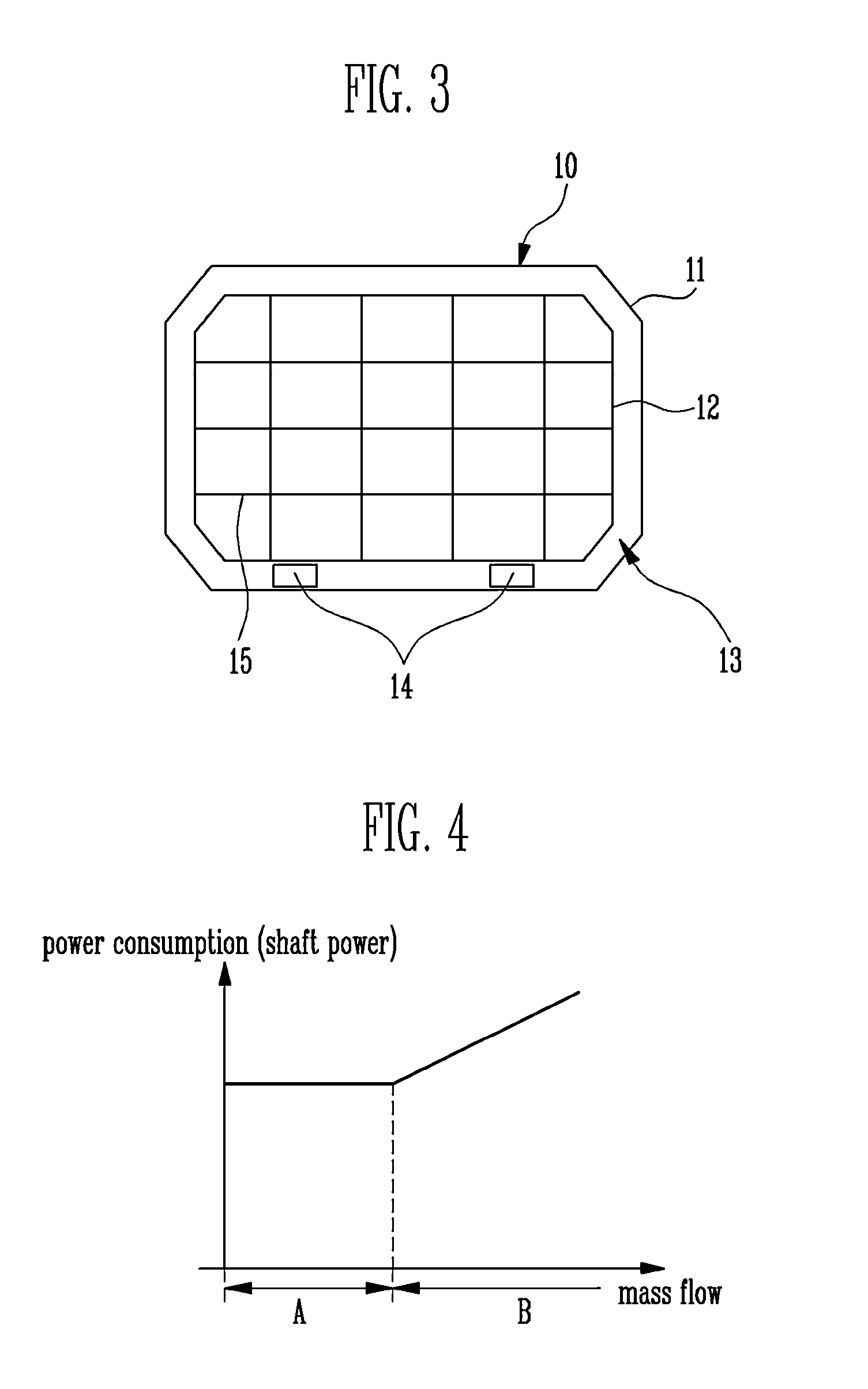

[0123]FIG. 7 is a conceptual view of a liquefied gas treatment system according to the invention. FIG. 8 is a graph illustrating power consumption with respect to mass flow of a boil-off gas compressor in a general liquefied gas treatment system.

[0124]A liquefied gas treatment system 3 is described with reference to FIG. 7. The liquefied gas treatment system 3 may be equal to the liquefied gas treatment system 2, except for a mixer 70 and a flash gas recovery line 18A. The same reference numerals or the same reference designators may denote the same or corresponding elements of the earlier described embodiment, and a detailed description thereof will be omitted.

[0125]According to a third embodiment of the present invention, the flash gas, which is supplied from the vapor-liquid separator 90 and heat-exchanged by the boil-off gas heat exchanger 60, may not be exhausted to the outside but may be recovered for use. According to a third embodiment of the present invention, the flash gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com