Patents

Literature

50results about How to "Reduce charring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

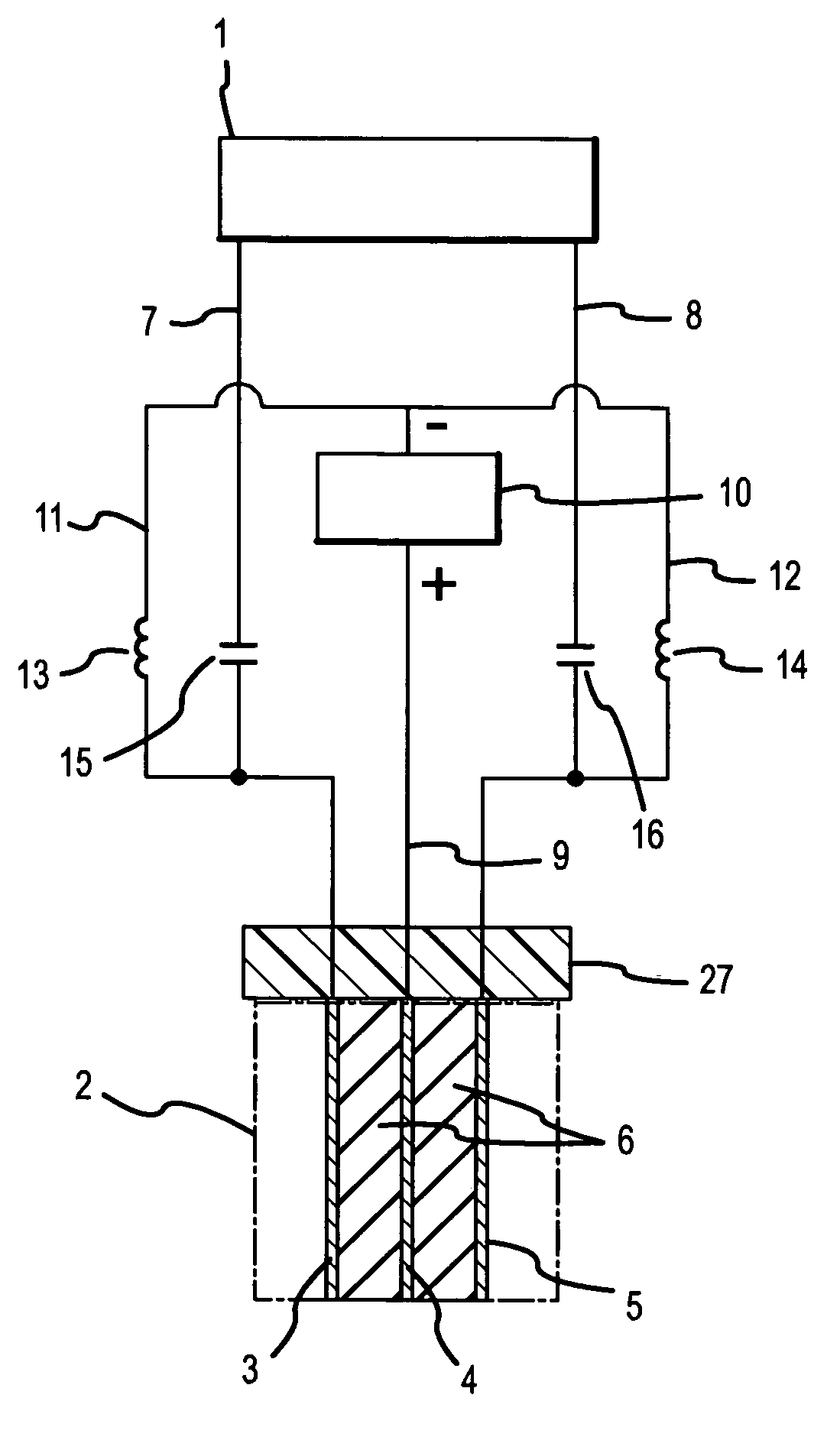

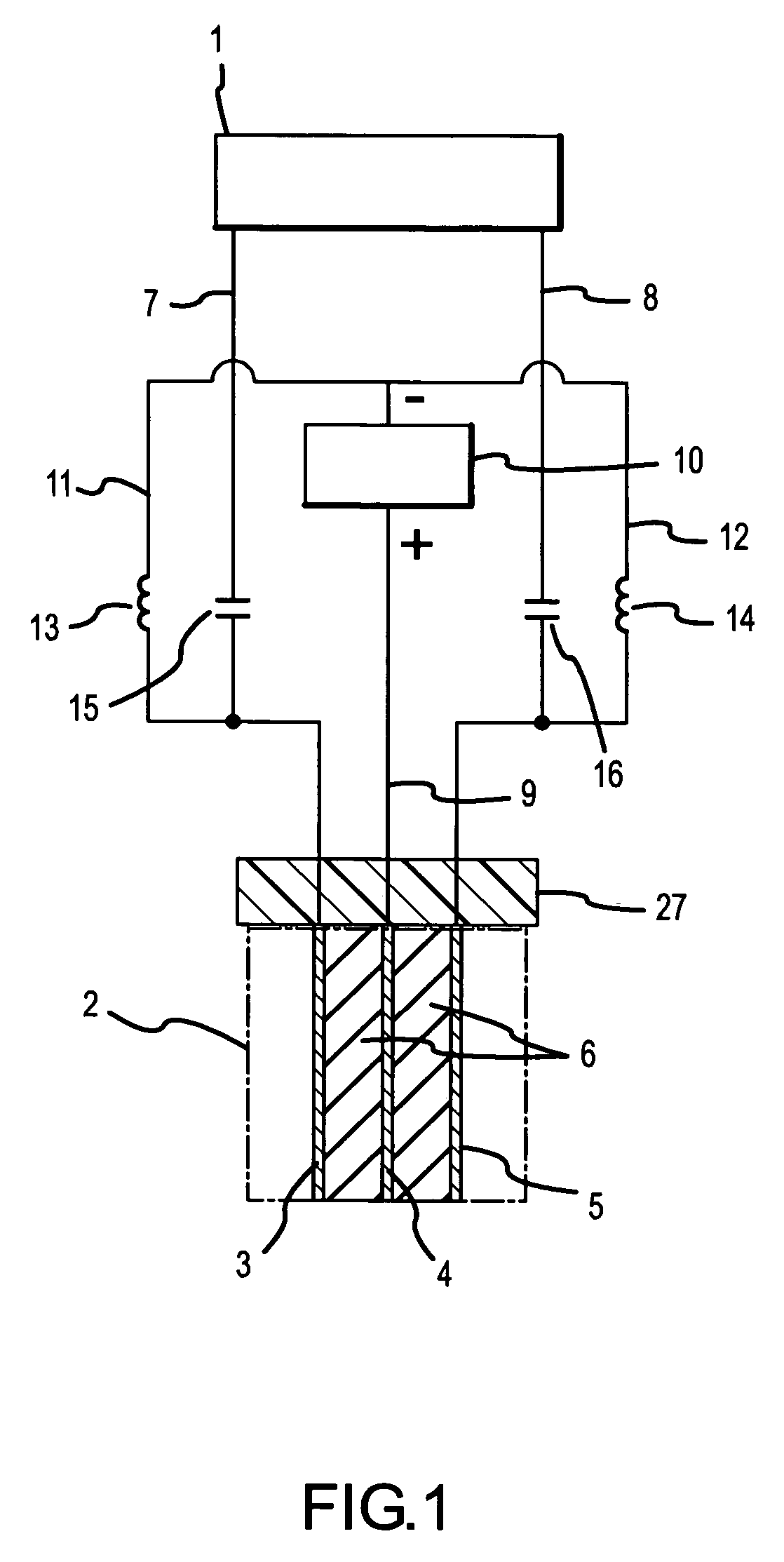

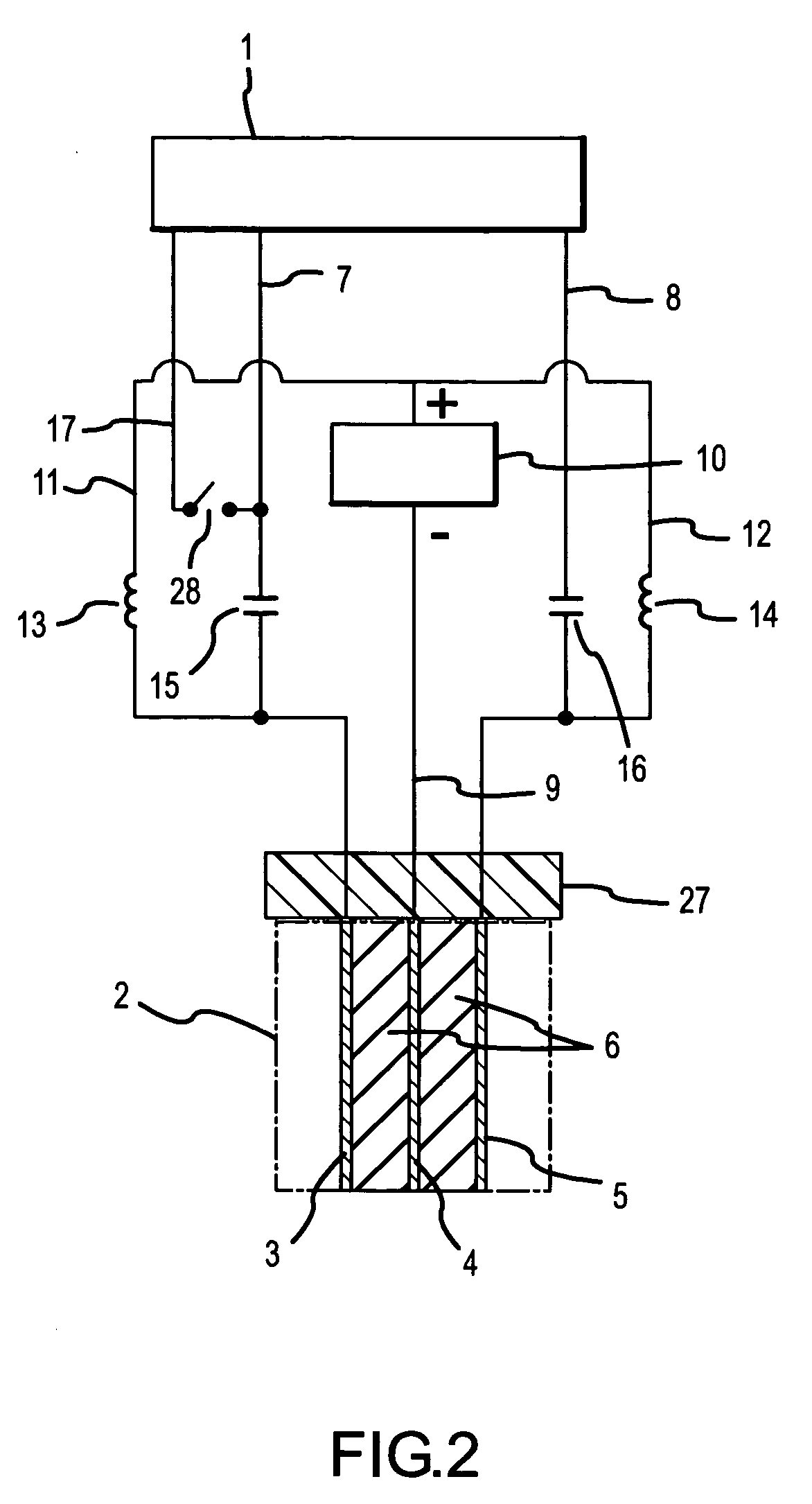

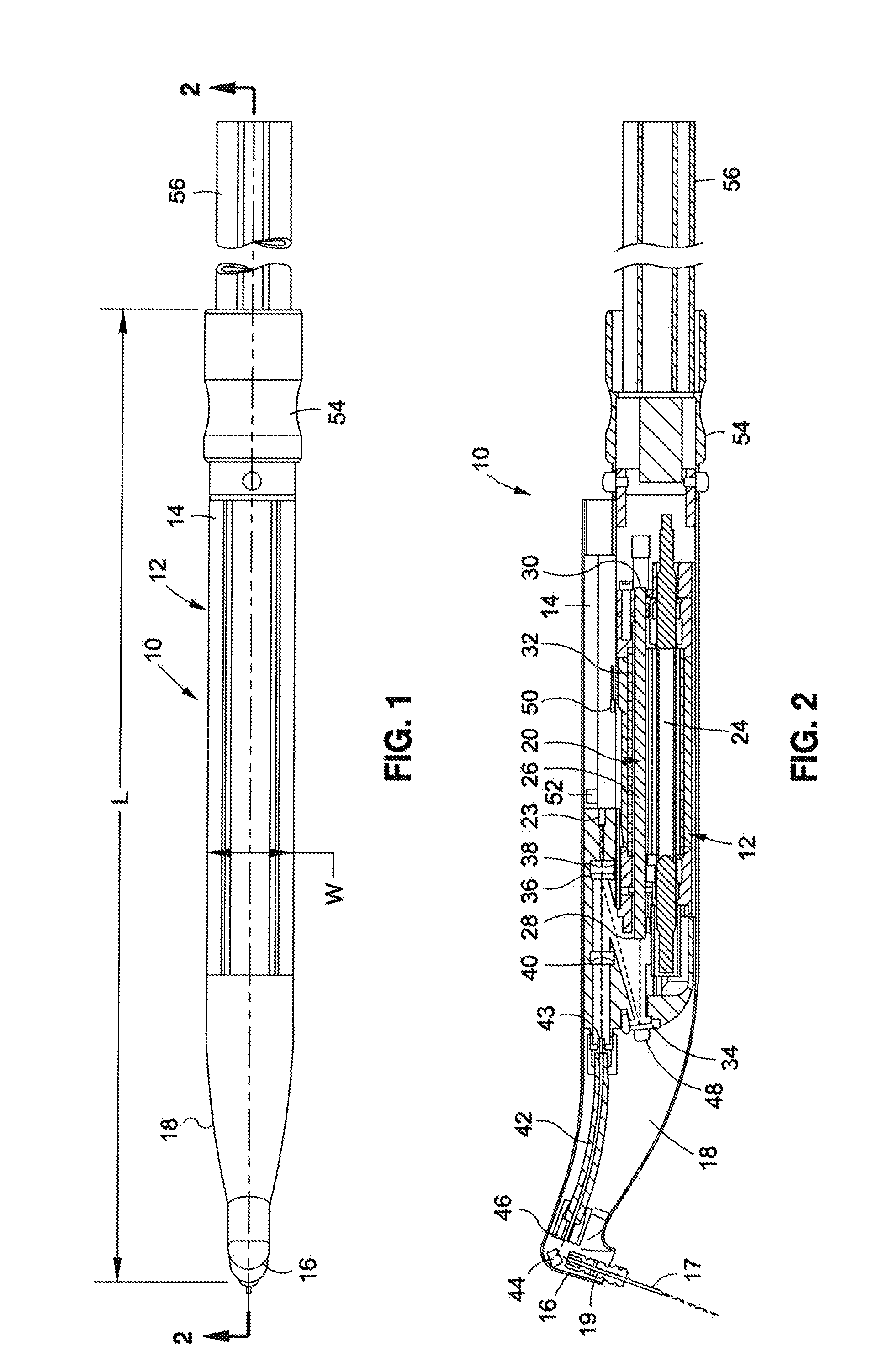

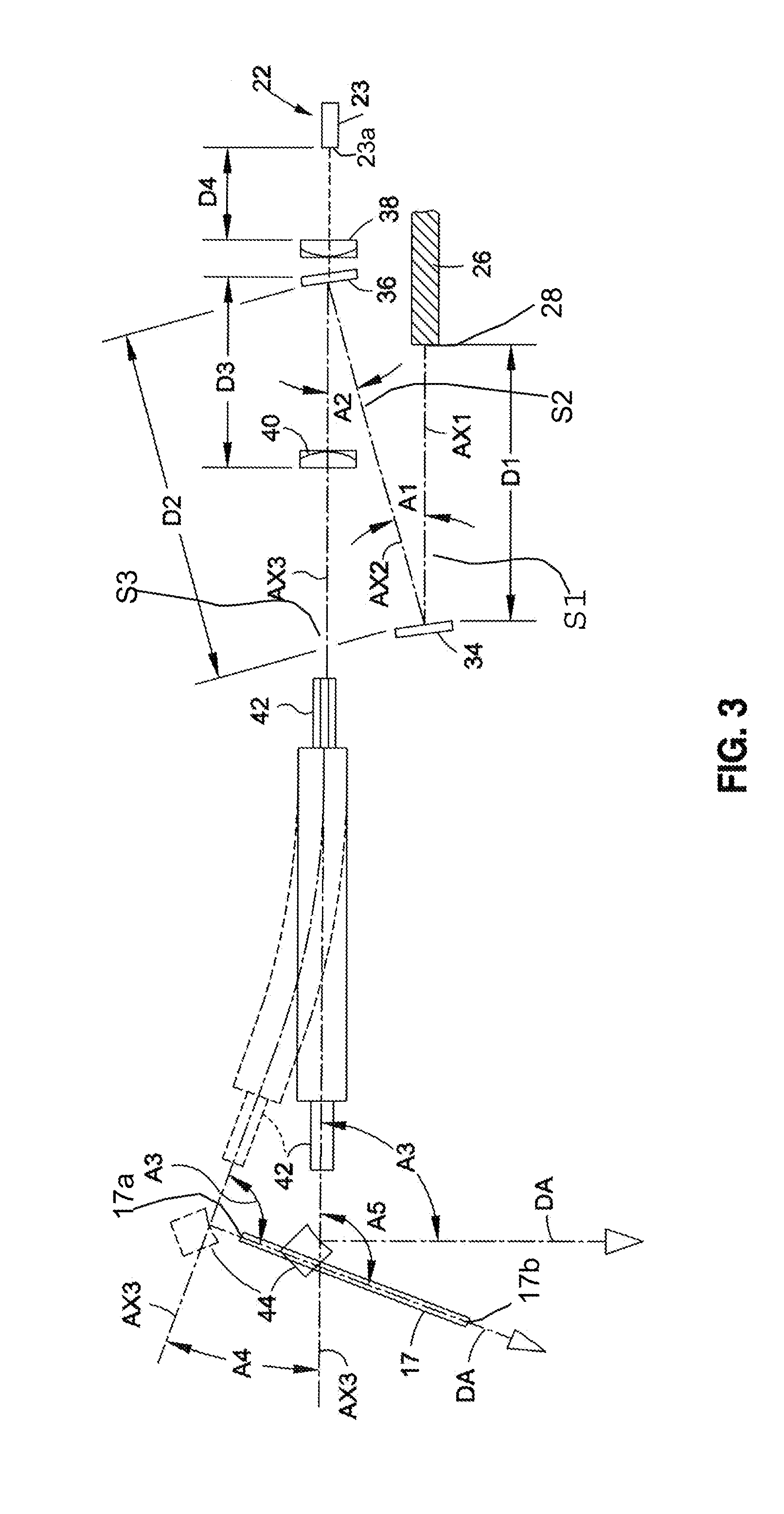

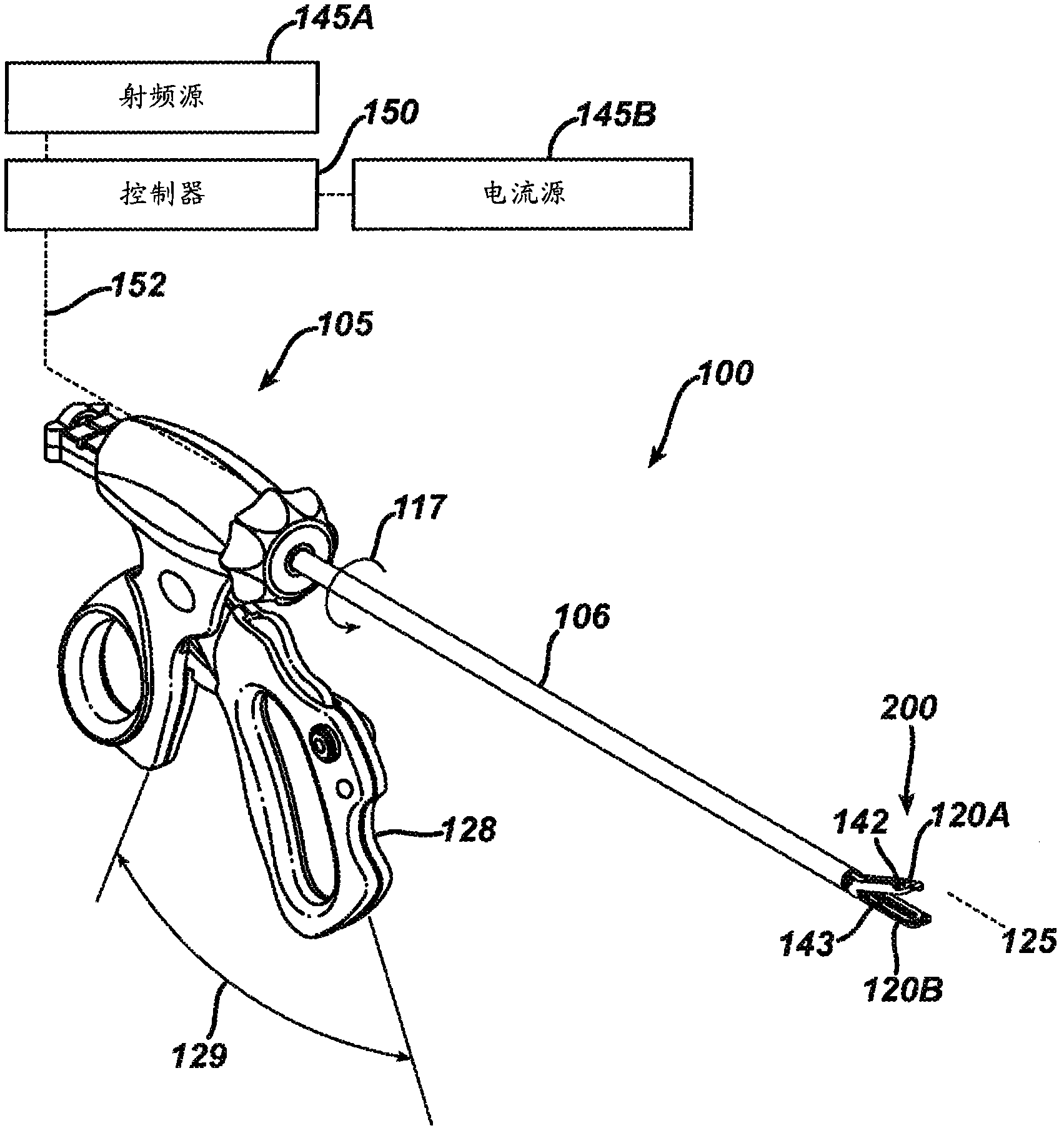

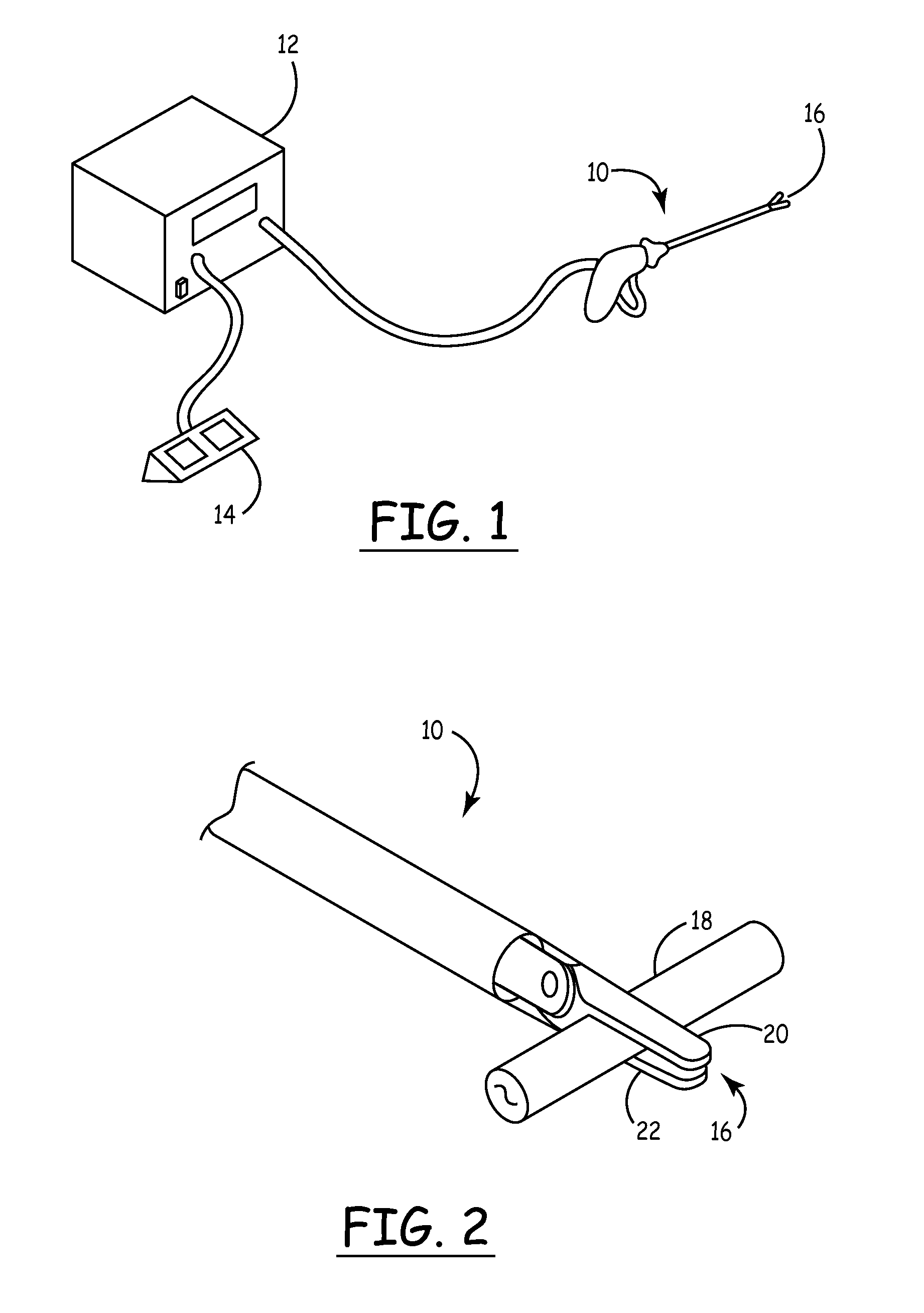

Multielectrode electrosurgical instrument

InactiveUS20060025757A1Prevent short-circuitingReliable contactSurgical instruments for heatingElectricityElectrolysis

An improved electrosurgical instrument and method is disclosed for simplifying making incisions and other treatments using electrosurgery. The electrosurgical instrument comprises a body having more than two electrodes with at least two electrodes having alternating current power supplied to them such that they comprise a bipolar alternating current configuration and employ a means other than electrode spacing, composition, or geometry for reducing or preventing accumulation of eschar that would otherwise form a short circuit current path and interfere with obtaining a predetermined surgical effect. In one aspect, such means for reducing or preventing eschar accumulation consists of at least one other electrode having a direct current voltage between it and at least one of the two electrodes forming the alternating current bipolar configuration. In another aspect of the invention two or more pairs of alternating current electrodes comprising bipolar electrodes are powered with alternating current having a nonzero RMS voltage sufficient to at least reduce eschar accumulations on one electrode or induce electrolysis of at least one component of a medium surrounding at least one pair of bipolar electrodes. The electrodes are separated from each other using electrically insulating materials such that electric current does not flow between at least two of the bipolar alternating current electrodes unless they contact at least one other electrically conductive medium, such as patient tissue or a medium comprising at least in part a solid, liquid, gas, or ionized component that allows electric current to flow between electrodes. In the aspect where at least one electrode is powered by direct current the electrodes are configured such that electrical current does not flow between at least one of the bipolar alternating current electrodes and at least one of the direct current electrodes unless one or more media, such as patient tissue or a medium comprising at least in part a solid, liquid, gas, or ionized component that allows electric current to flow between electrodes, are contacting or adjacent to the electrodes having a direct current voltage difference between them. The assembly comprised of the electrodes and the separating insulating materials may also employ one or more means to reduce the current flowing between them that does not produce a desired predetermined surgical effect with one aspect of such means being using an outer insulating coating configured such that one or more portions of at least one of the bipolar alternating current electrodes are insulated while leaving exposed other portions of such insulated electrodes so that they are capable of being in electrical communication with tissue or at least one material in electrical communication with tissue.

Owner:COLORADO FUND I L P ON ITS OWN BEHALF & AS OF BOTH AGENT FOR AND COLLATERAL AGENT FOR SERIES A 1 STOCKHOLDERS & AWEIDA VENTURE PARTNERS

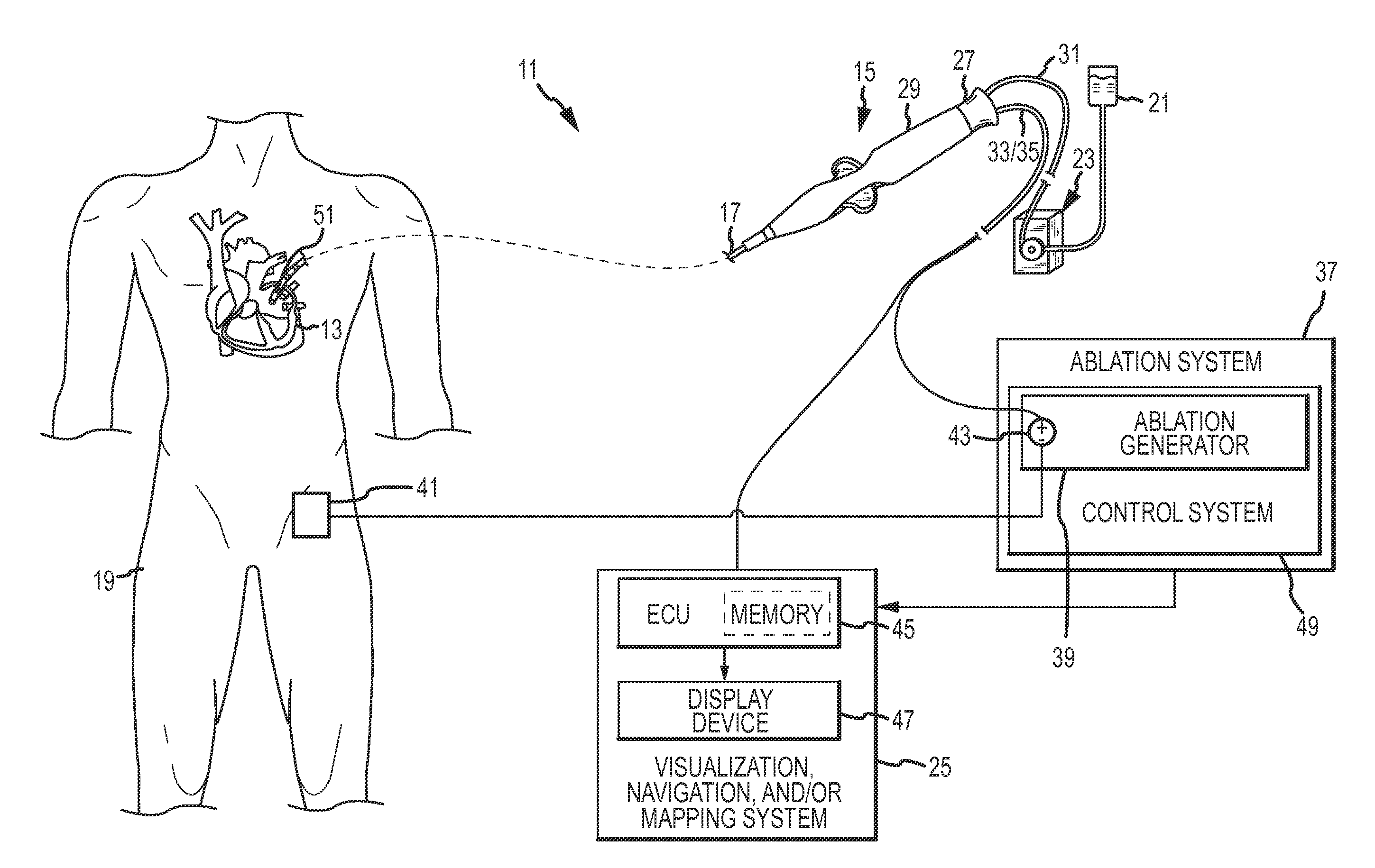

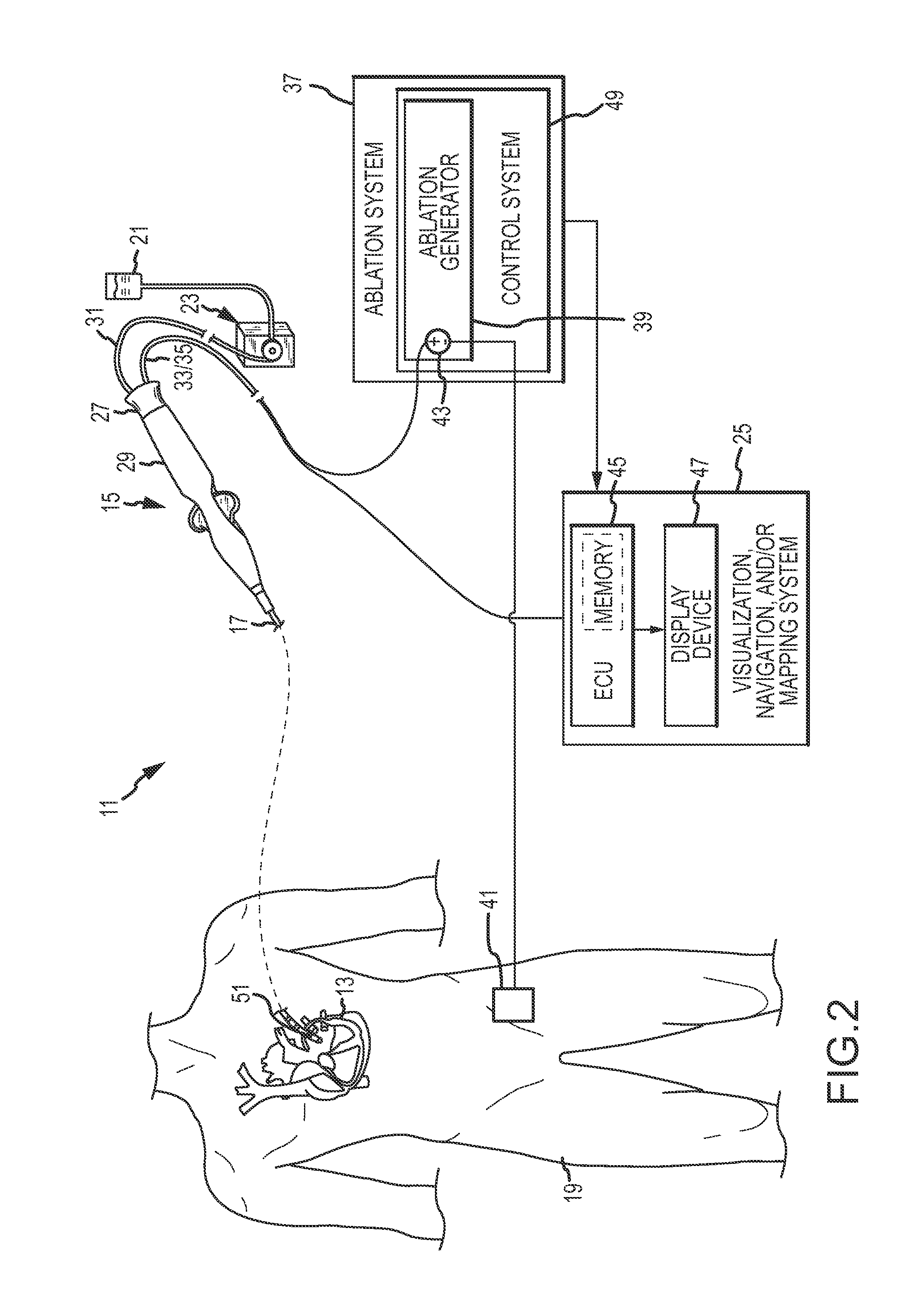

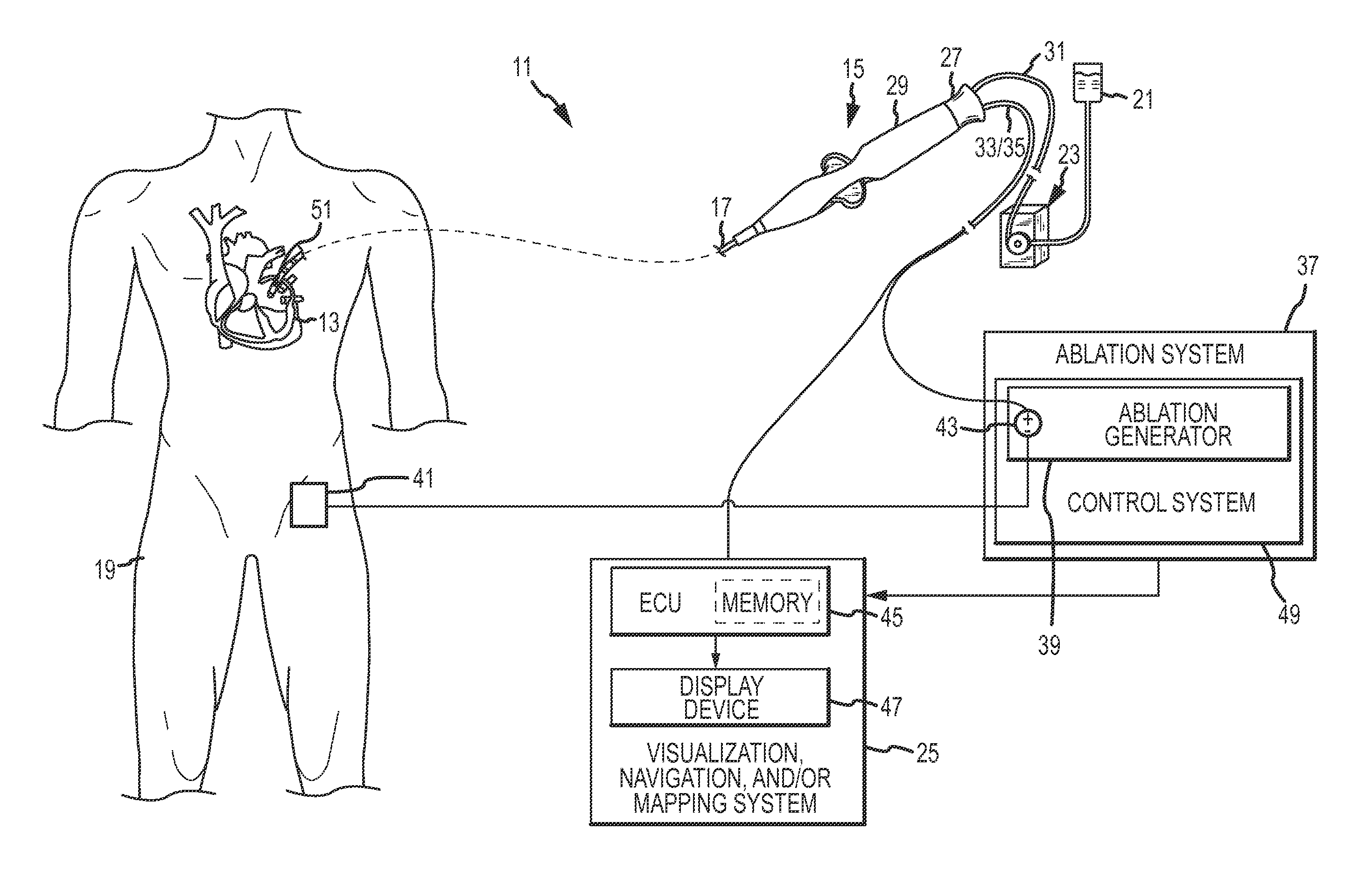

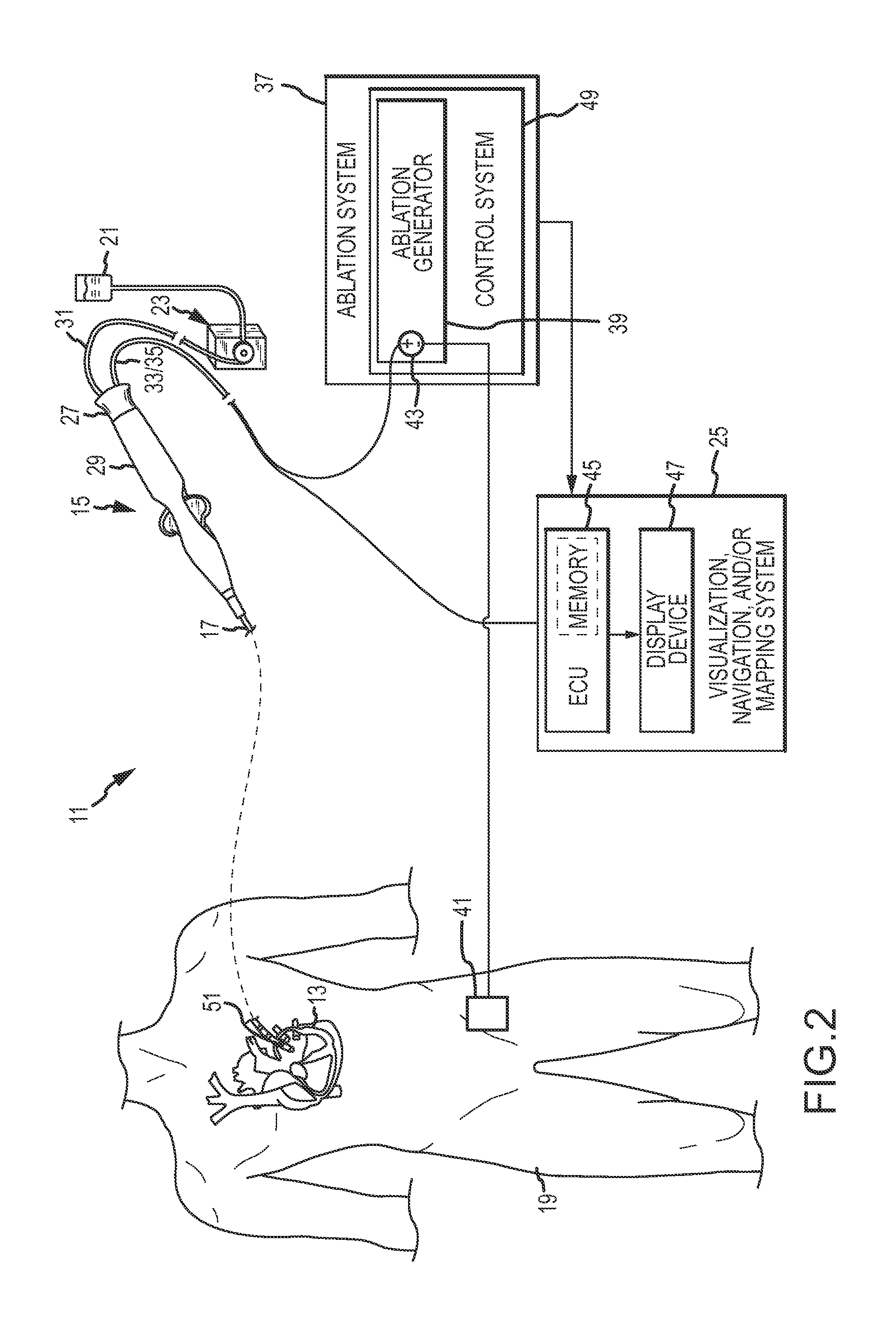

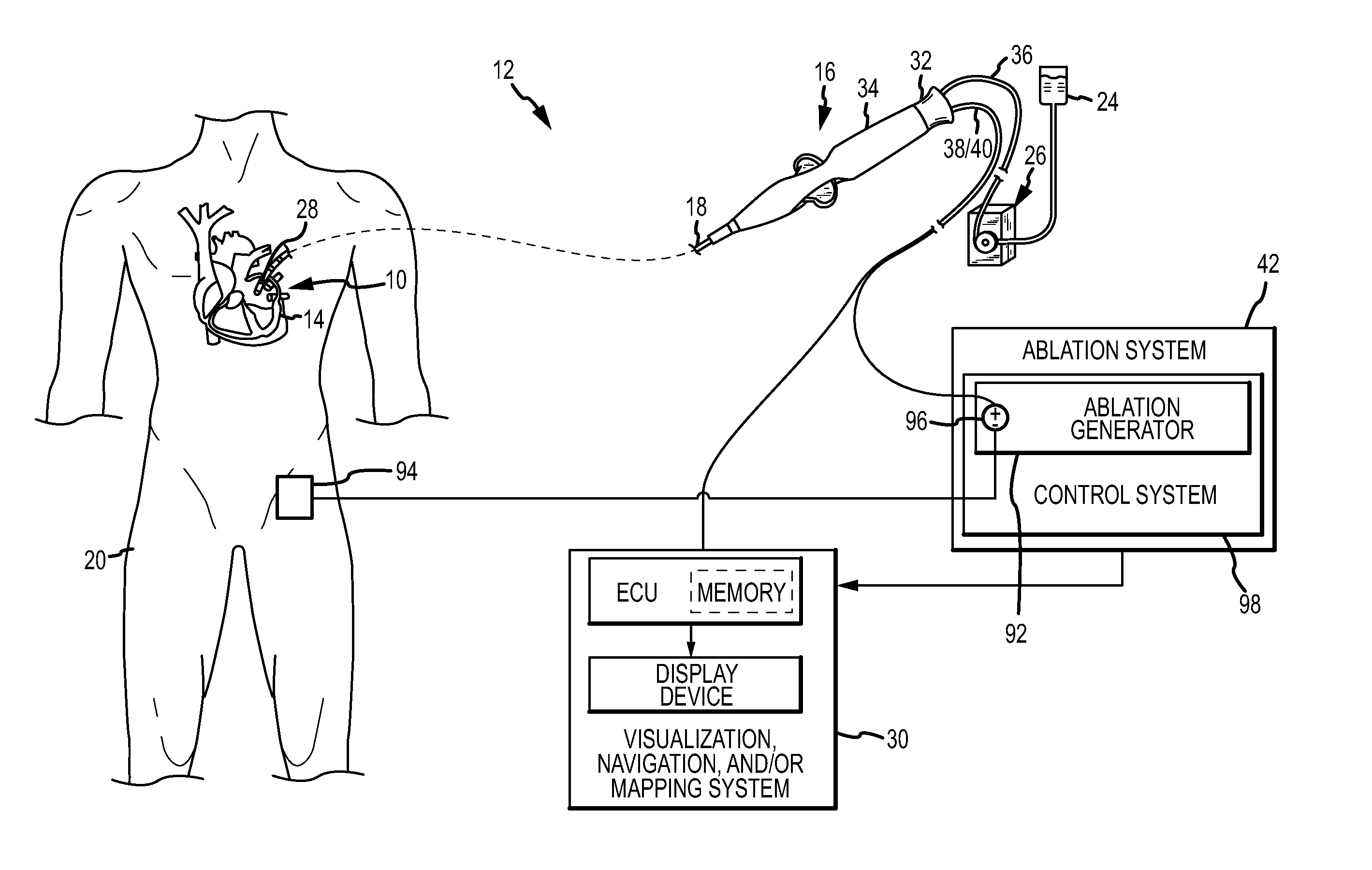

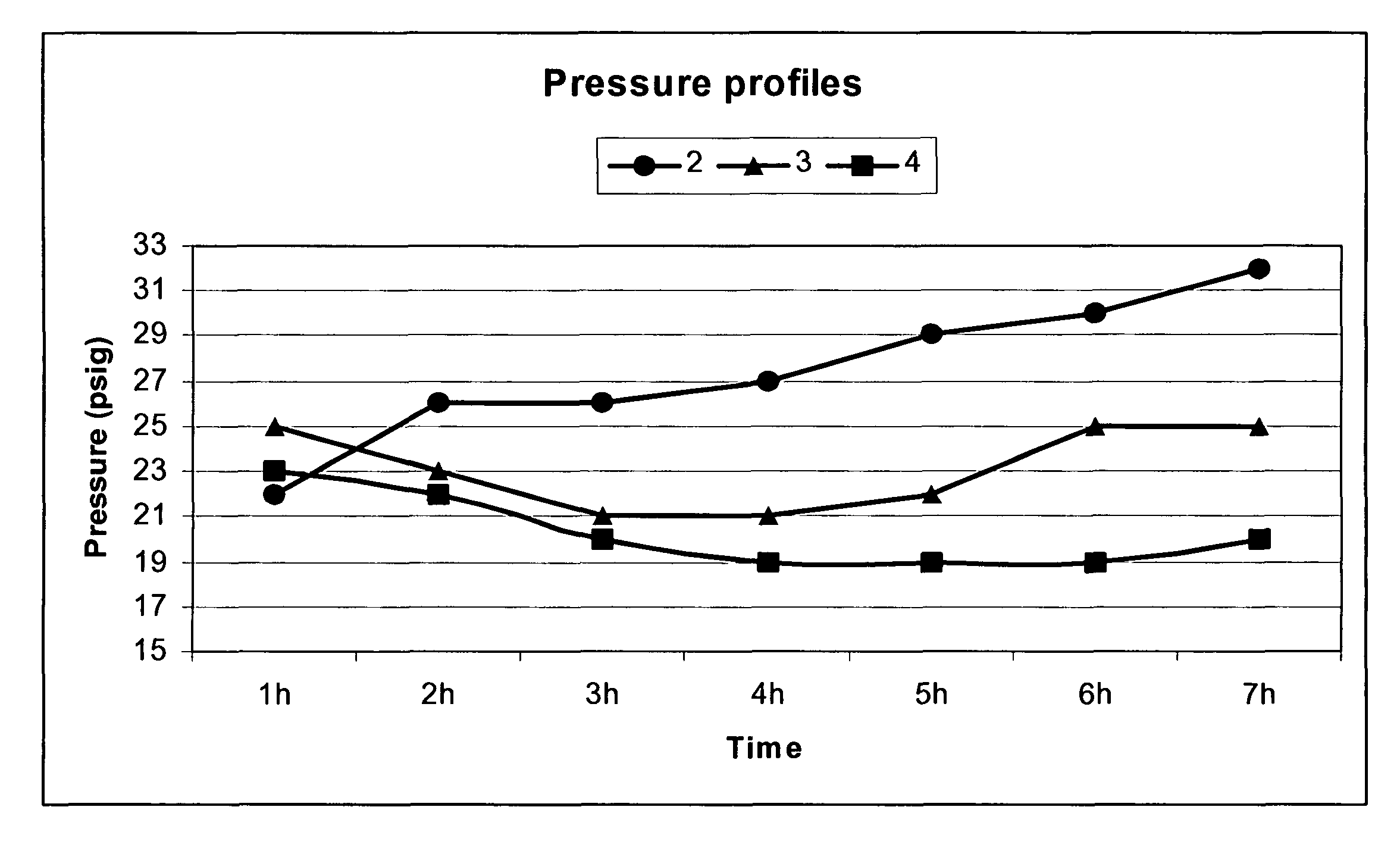

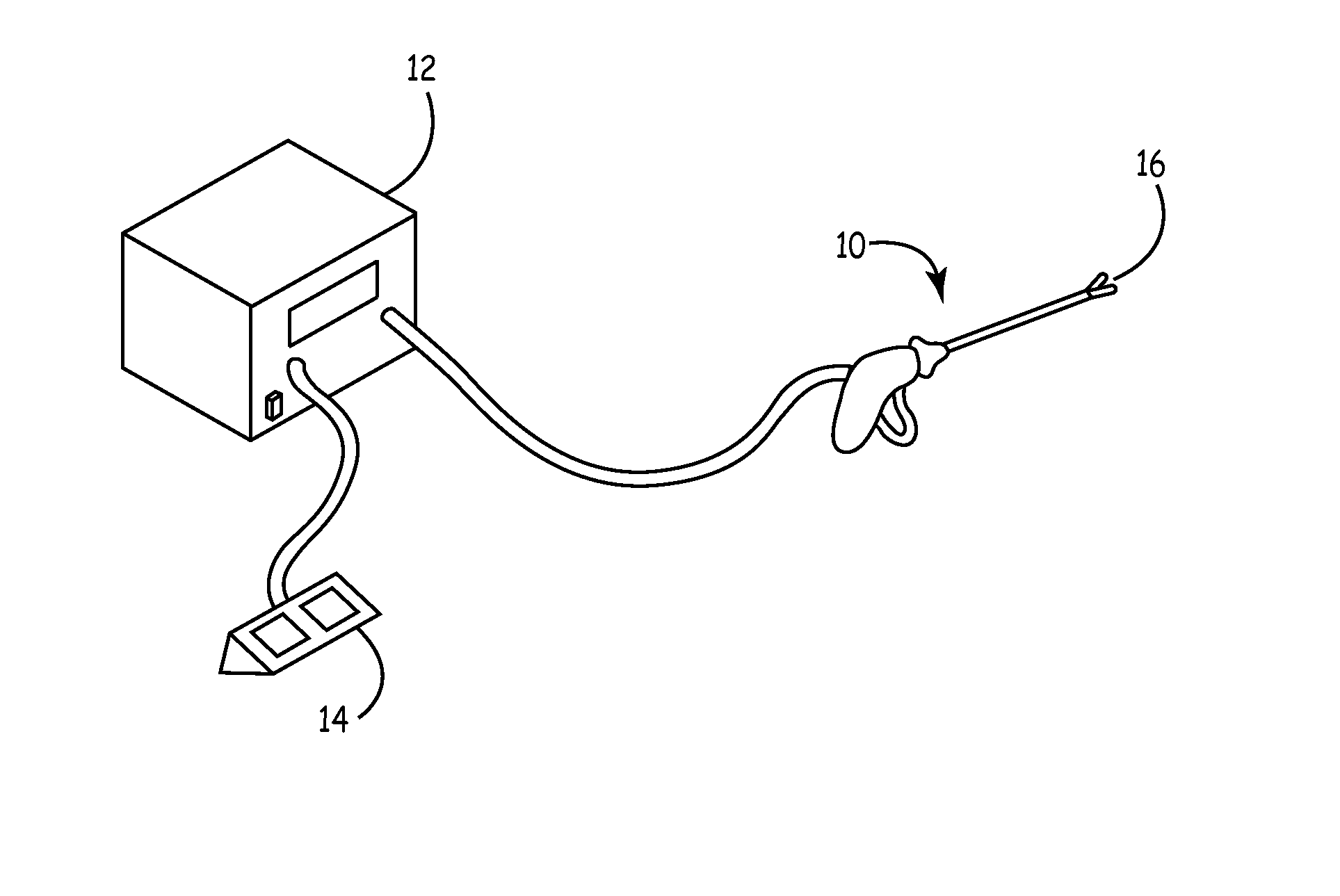

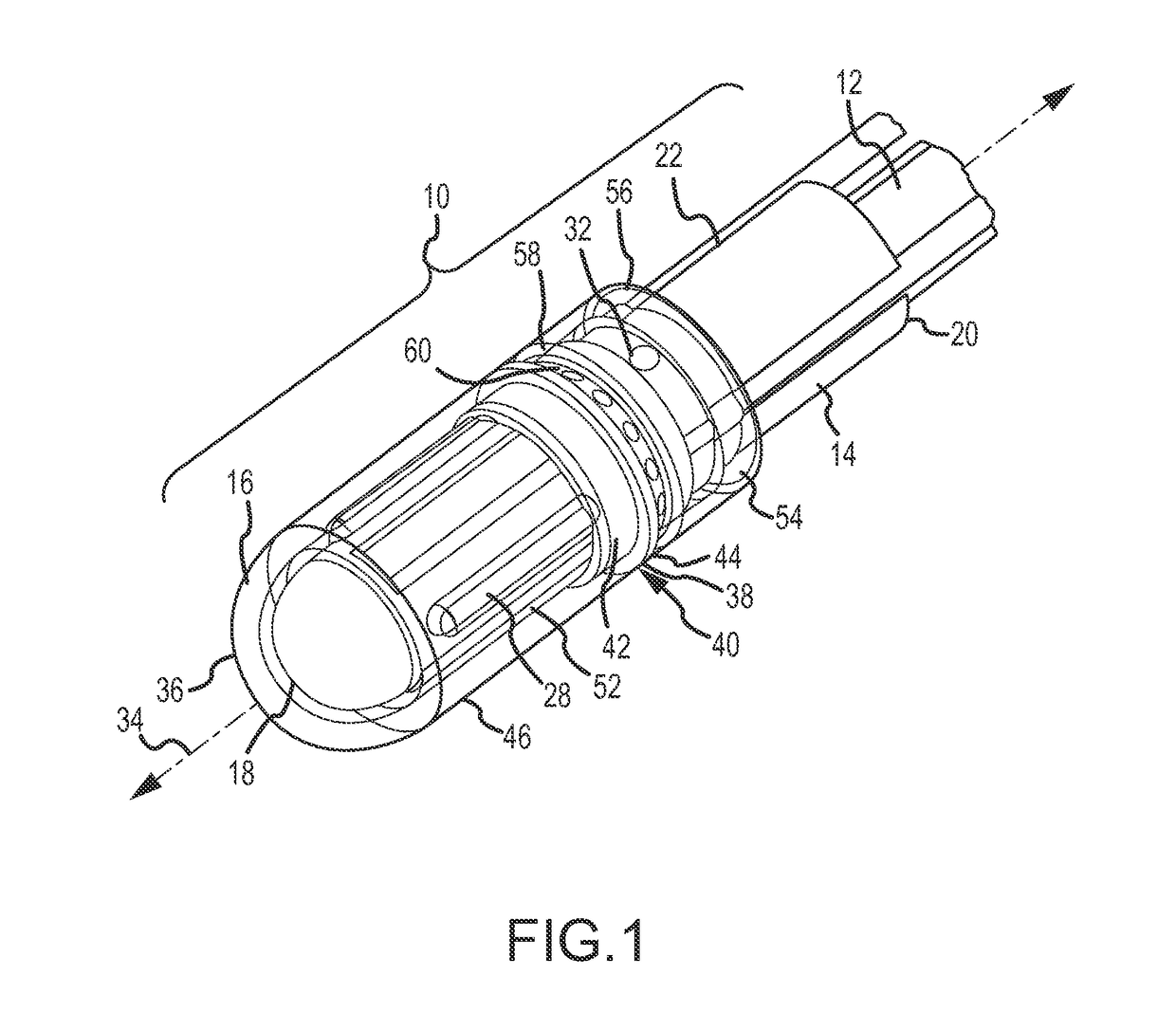

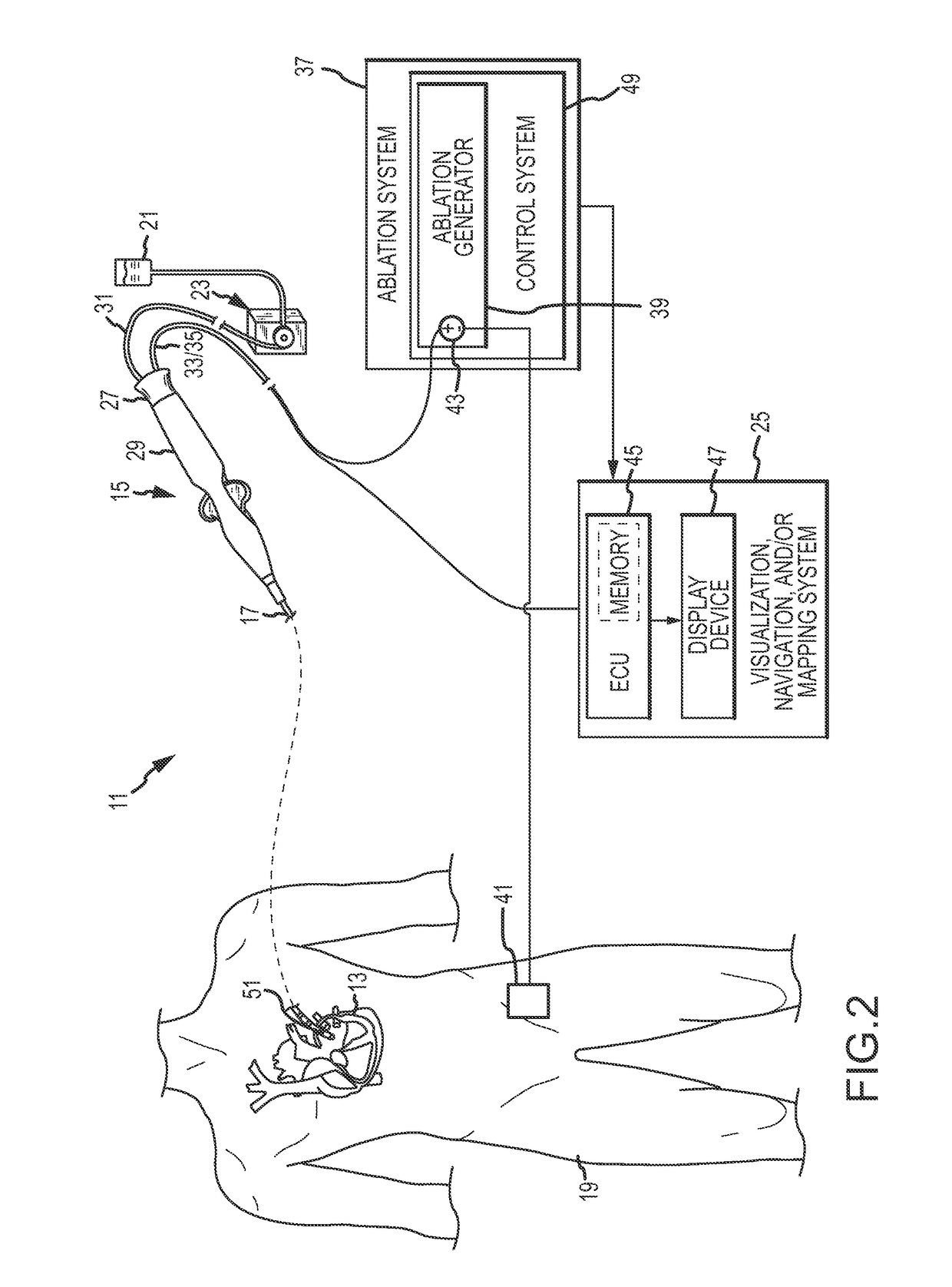

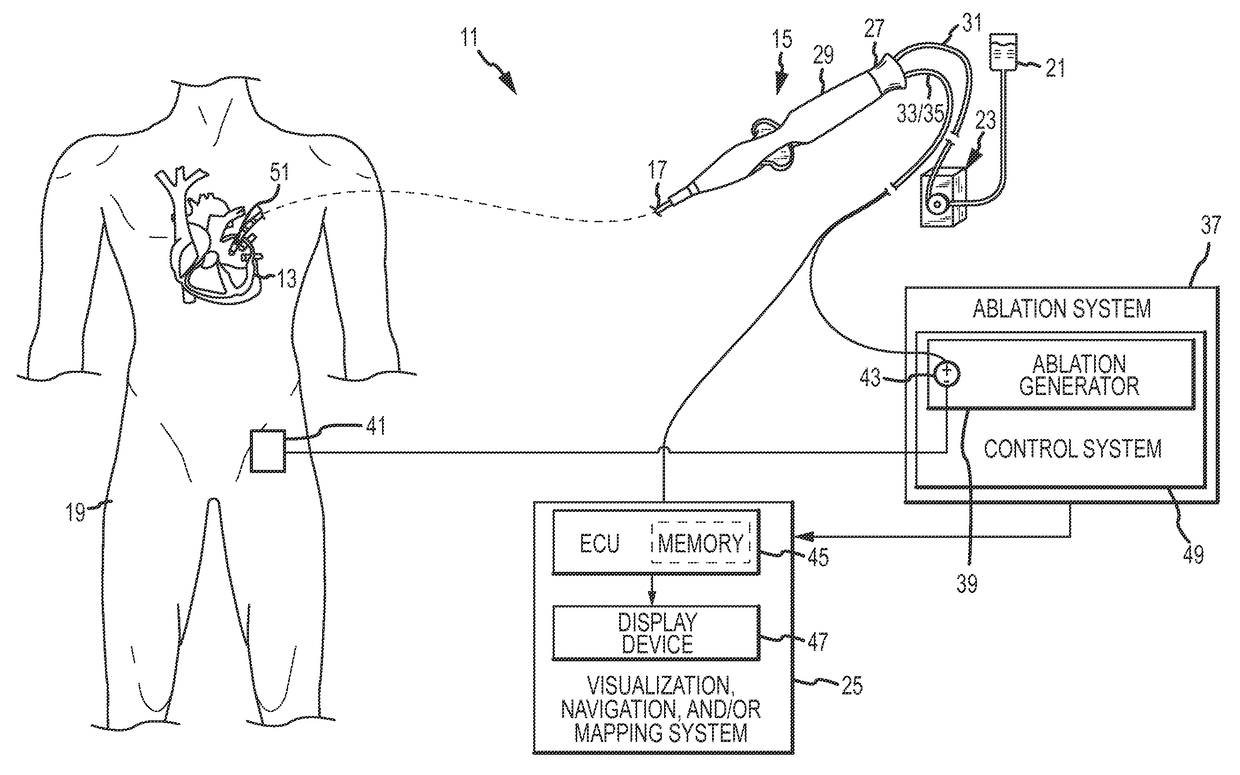

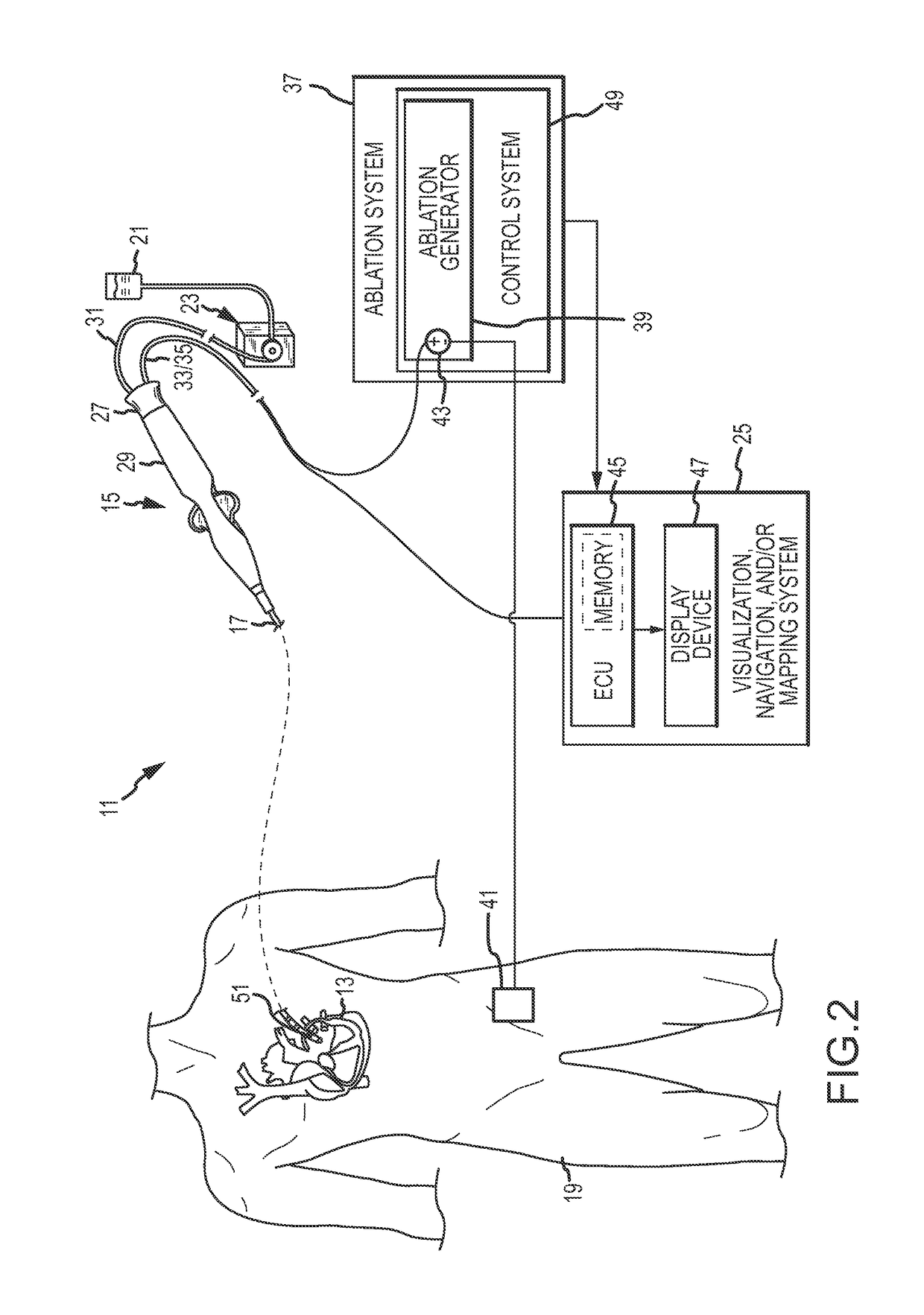

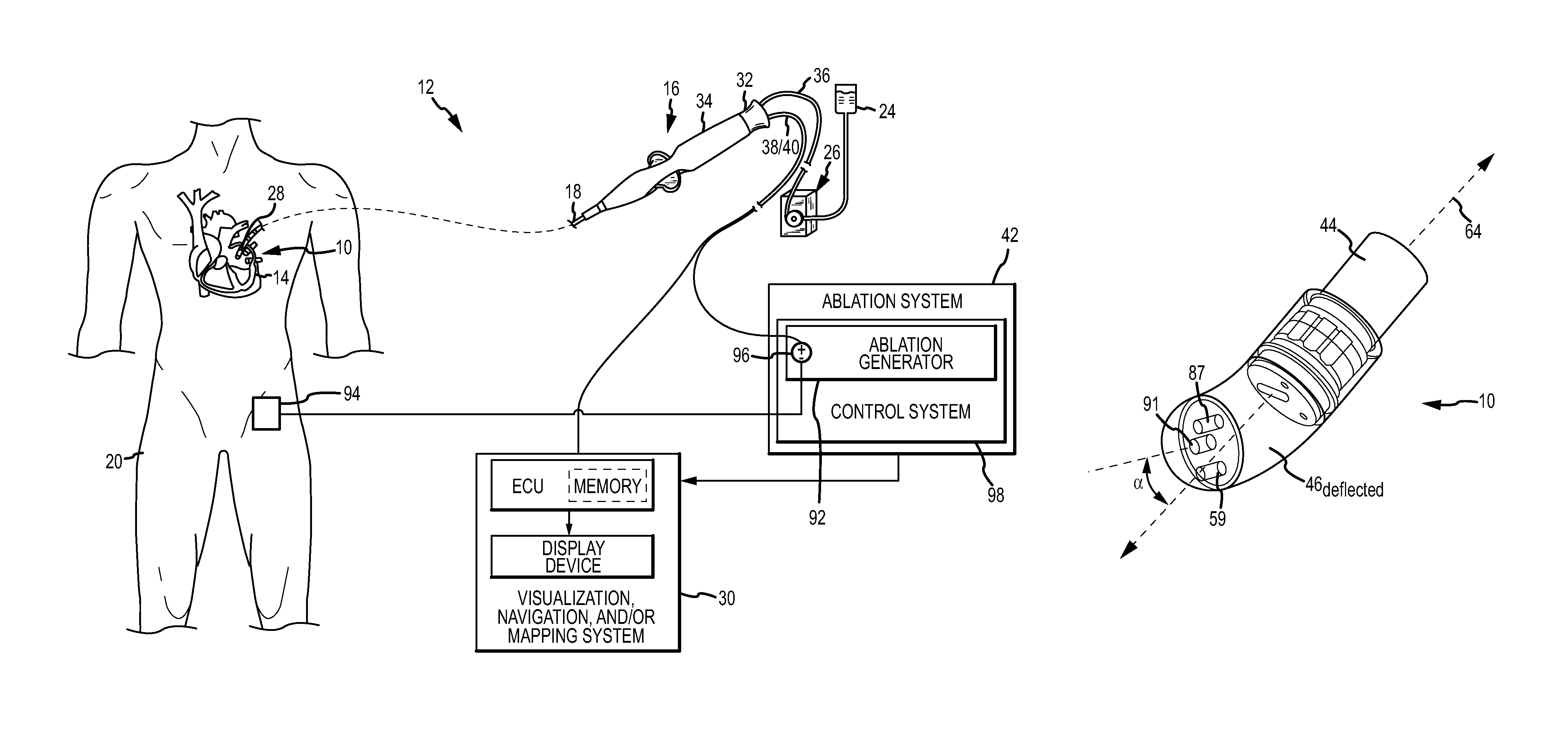

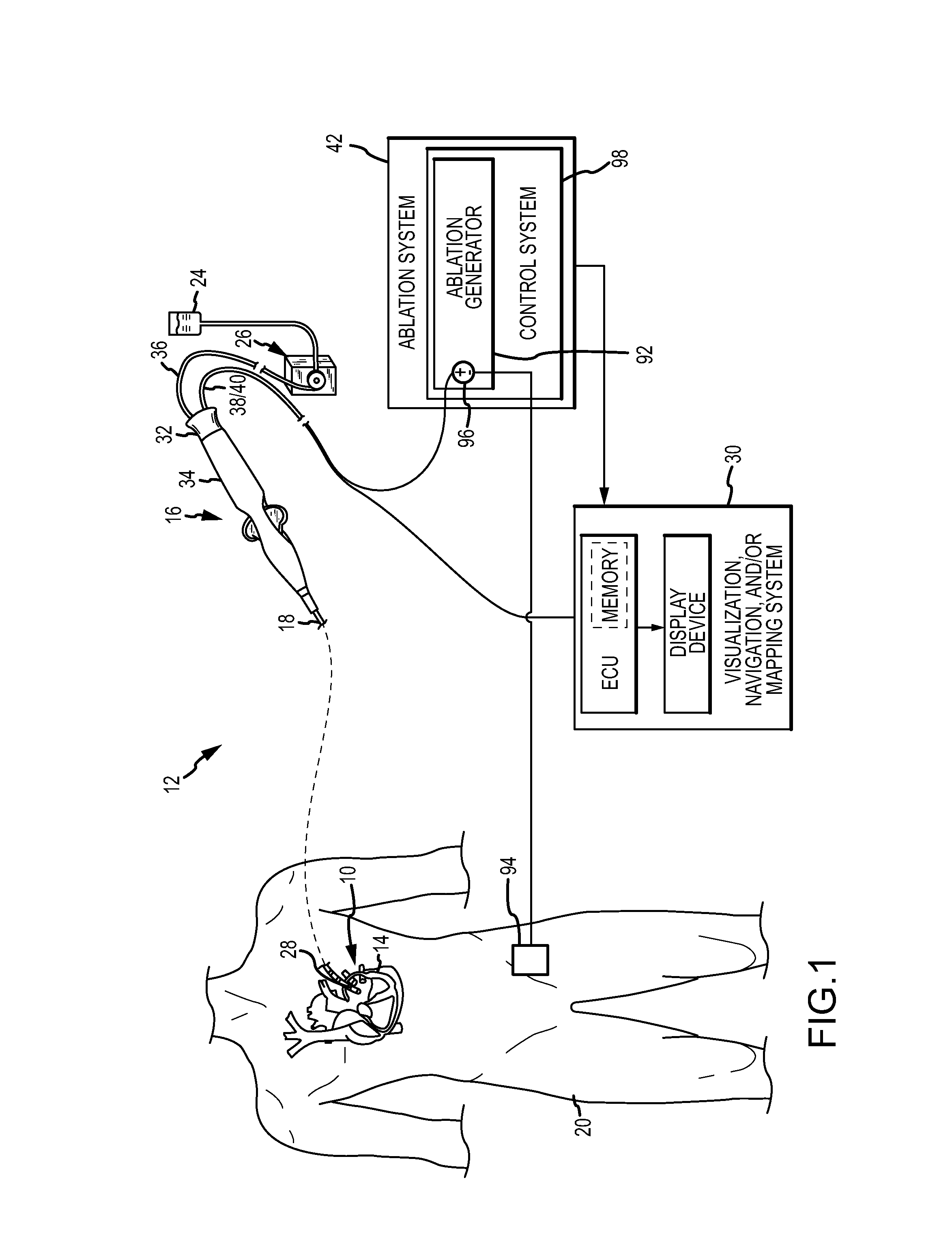

Multi-rate fluid flow and variable power deliverty for ablation electrode assemblies used in catheter ablation procedures

ActiveUS20120165812A1Improve abilitiesImproved temperature correlationCatheterMachines/enginesControl systemEngineering

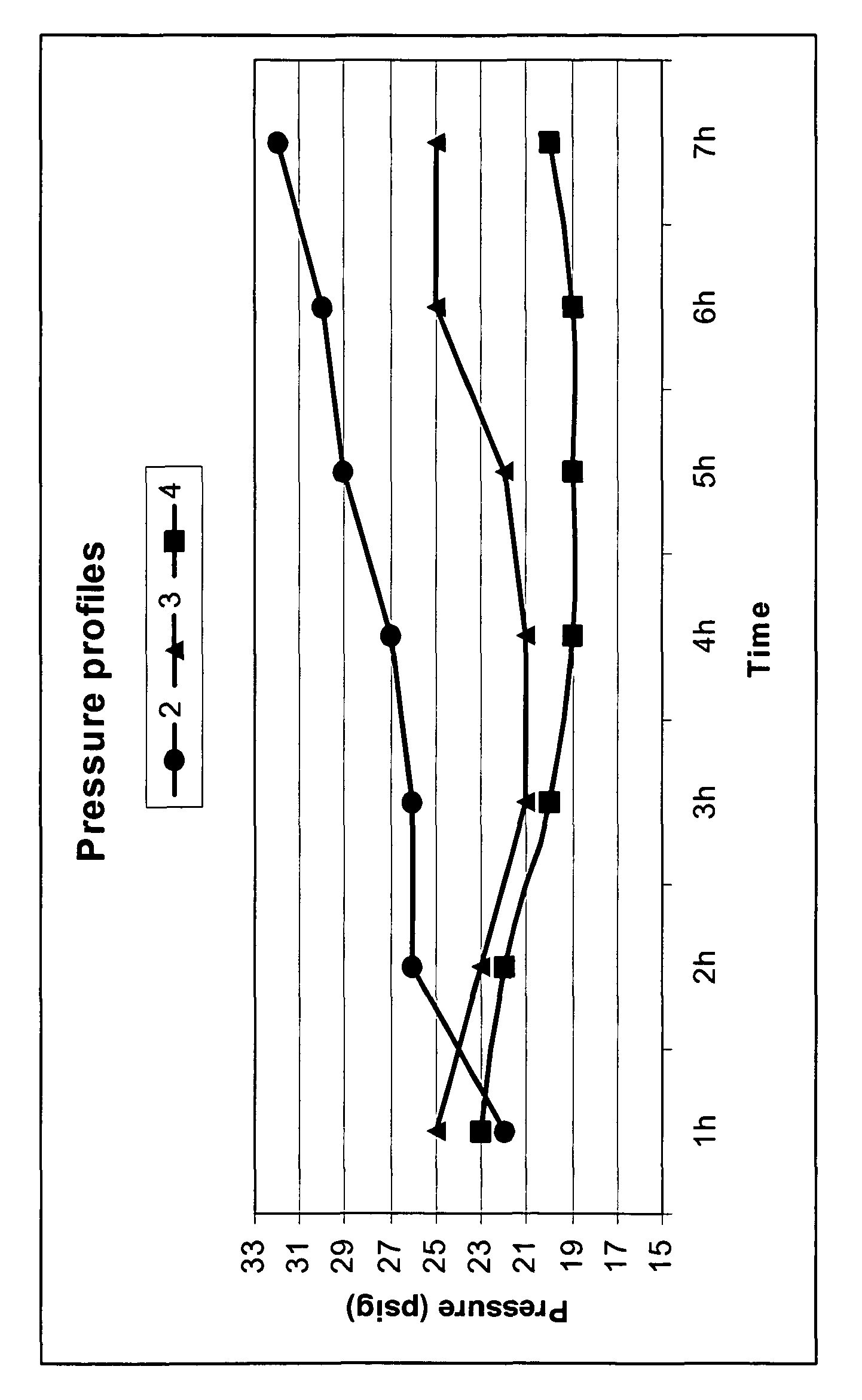

A system for providing irrigation fluid during ablation of tissue includes a catheter, an electrode assembly, at least one thermal sensor adapted to be connected to the catheter, and a control system. The electrode assembly is adapted to be connected to an ablation generator. The thermal sensor is adapted to be operatively connected to an electronic control unit (ECU). The ECU receives as an input temperature measurement data from the thermal sensor; determines a power delivery rate value for the ablation generator responsive to the temperature measurement data; and outputs the power delivery rate value. The control system also delivers irrigation fluid to the irrigated catheter at a first flow rate in a first time period and at a second flow rate in a second time period that is temporally after the first time period. The second flow rate is at least half of the first flow rate.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

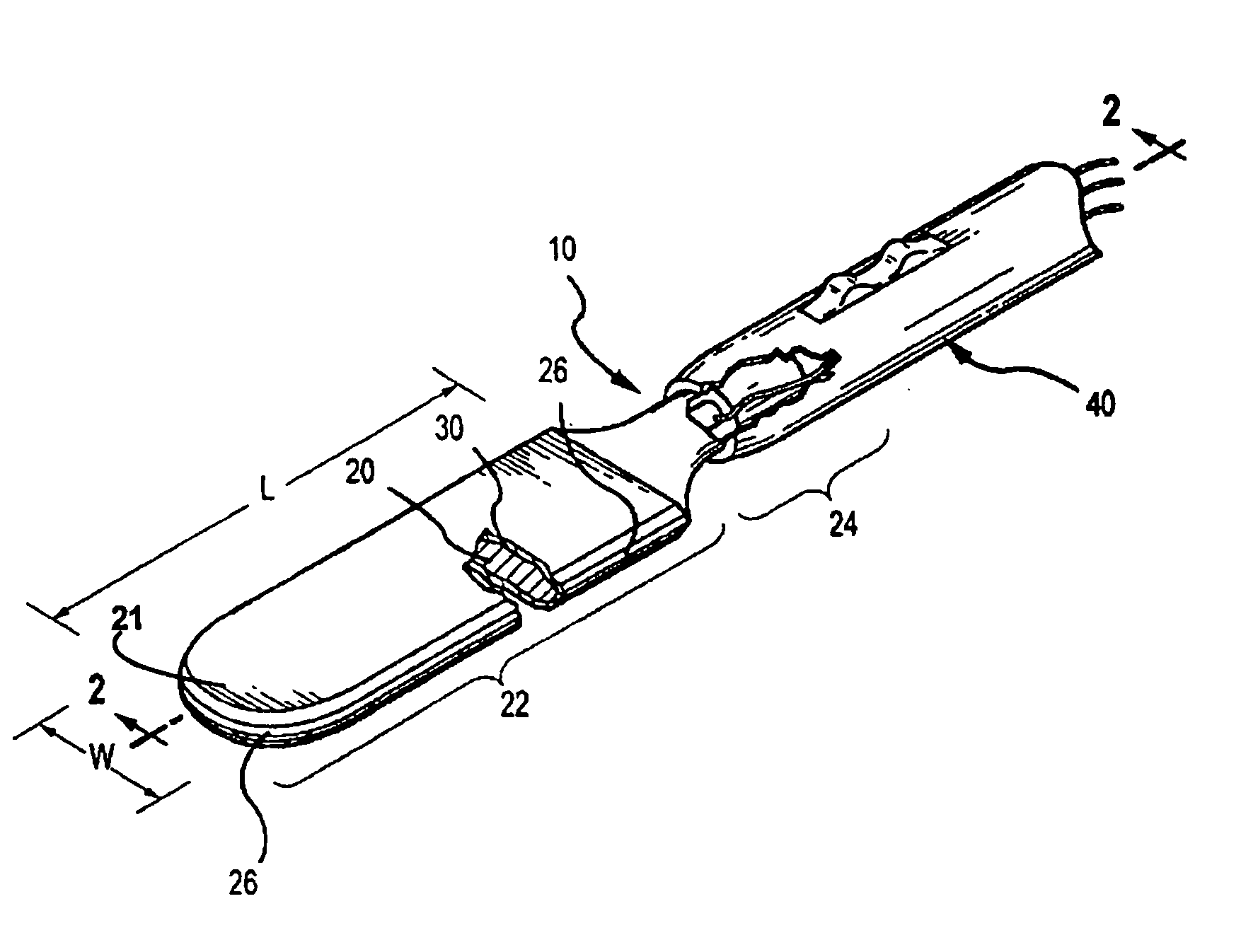

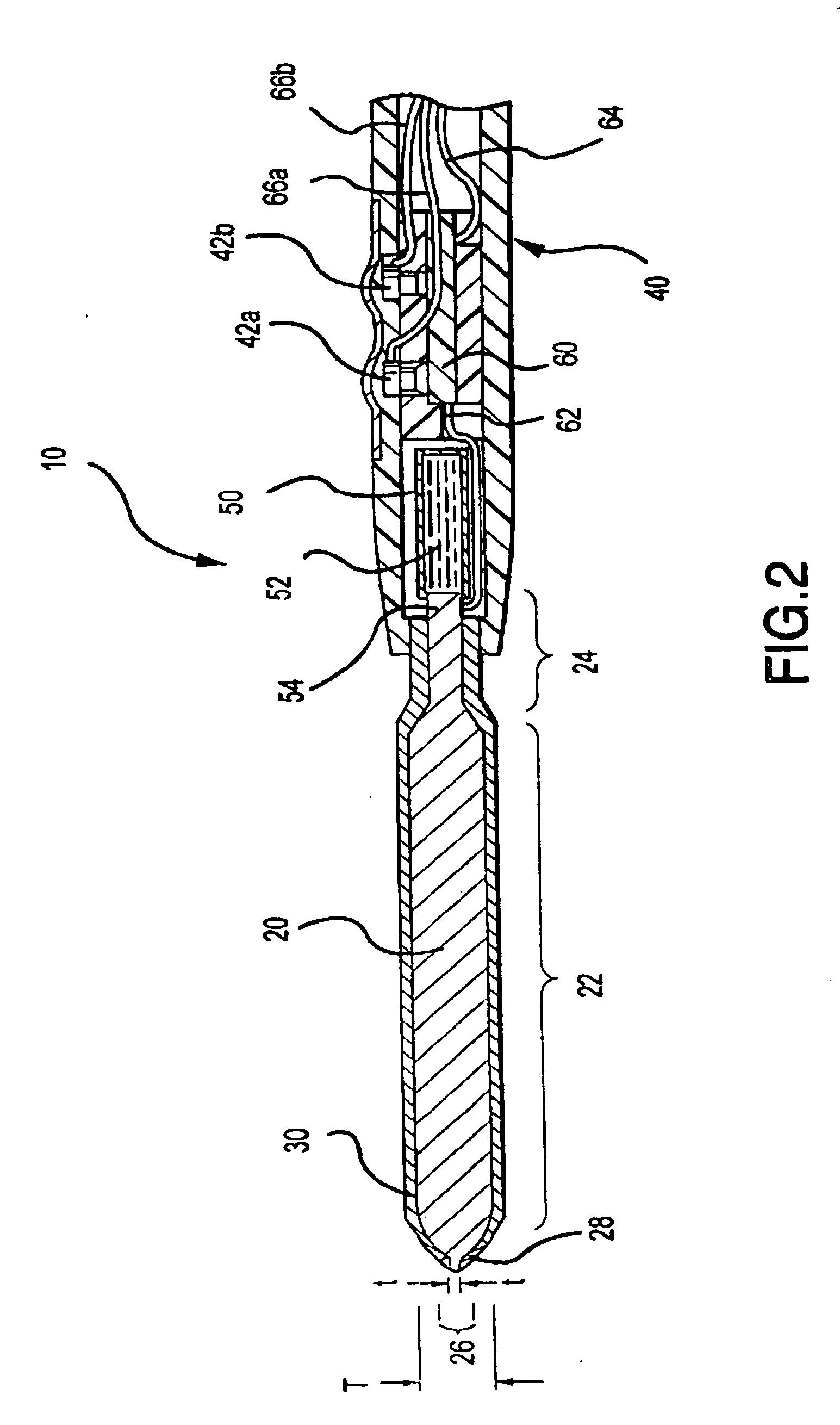

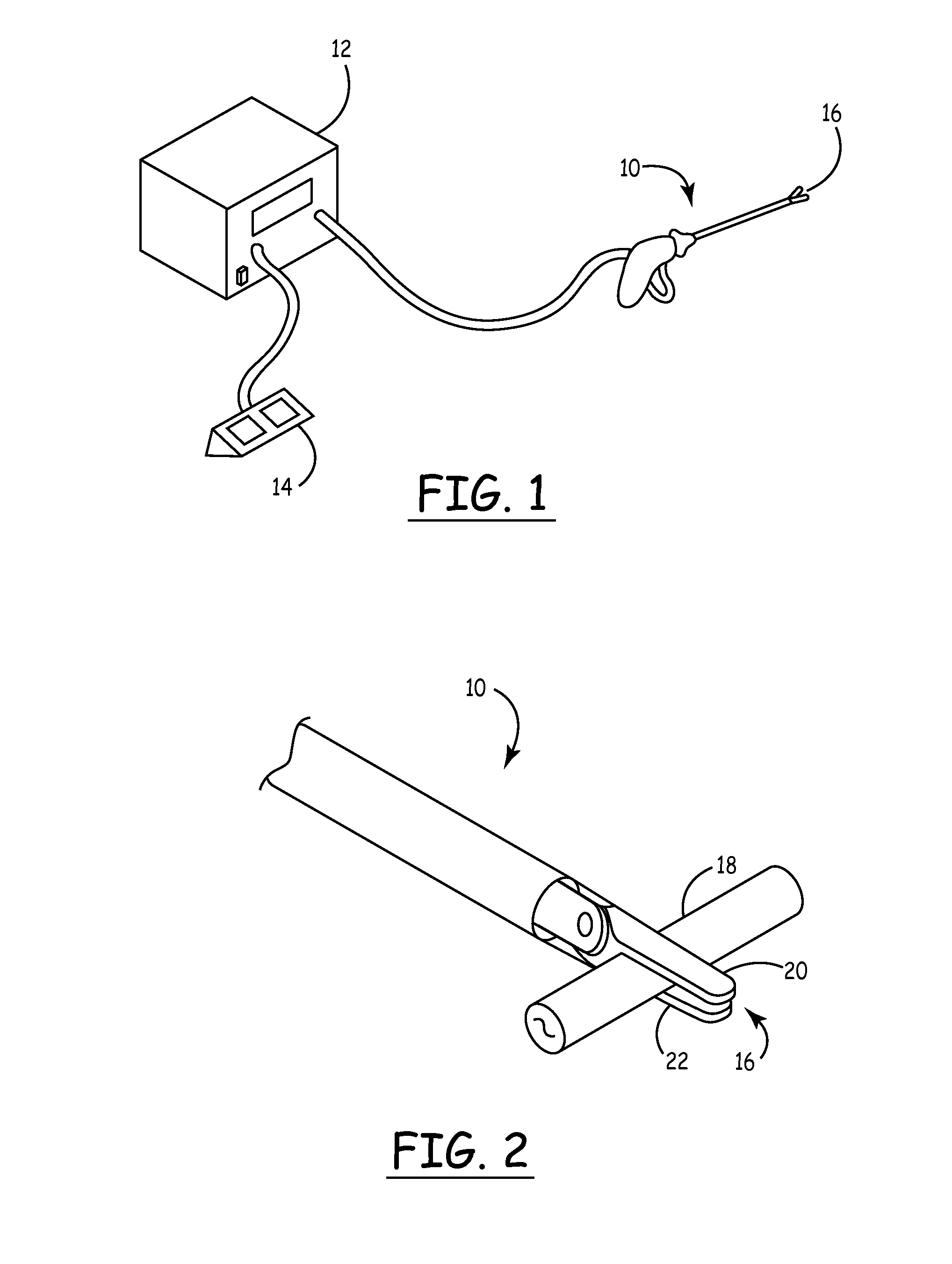

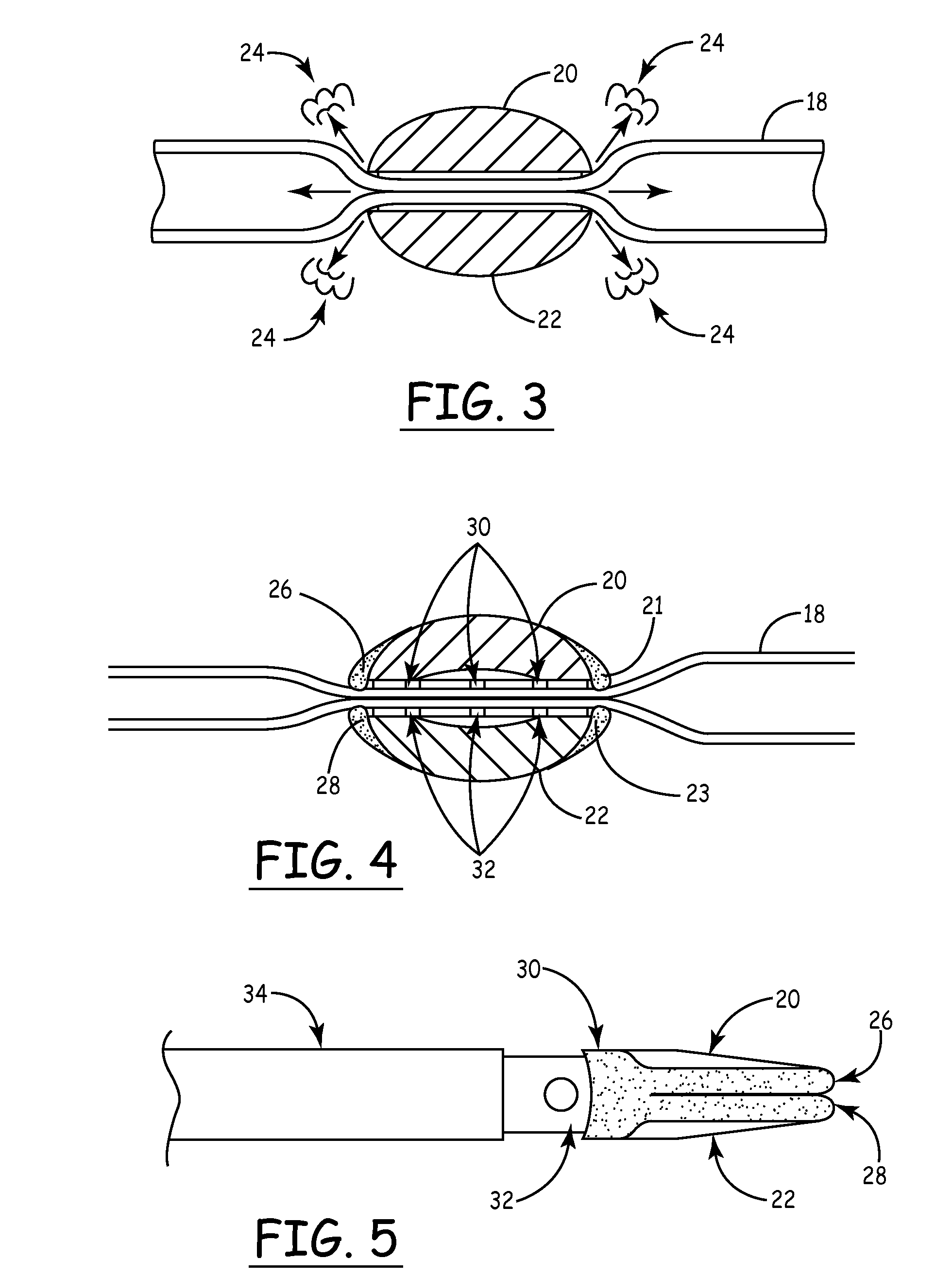

Electrosurgical instrument

ActiveUS20050154385A1Reduce smoke productionAvoid excessive accumulationDisinfectionSurgical instruments for heatingThermal energySurgical site

An improved means for insulating electrosurgical instruments and its use for electrosurgical instruments for reducing smoke generation at a surgical site is disclosed. An insulating layer is employed that may include a ceramic material that is substantially sealed with a coating comprising substantially of a material based on polydiorganosiloxanes or derivatives thereof that have been cured, preferably with the aid of temperatures in excess of about 150° F. In one aspect of the invention, an insulating layer having a thermal conductance of about 1.2 W / cm2° K. and a dielectric withstand strength of at least about 50 volts is employed. Such insulating layer may advantageously comprise one or more insulating materials with pores that have been sealed so as to prevent biological materials from entering the pores with such sealing material preferably containing one or more of silicate materials or materials that form silicates. In another aspect of the invention, the metal body is provided to have a thermal conductivity of at least about 0.35 W / cm° K., and may advantageously comprise a metal selected from the group: gold, silver, aluminum, copper tantalum, tungsten, columbium and molybdenum. In yet a further aspect, the metal body may include an intermediate layer that defines a peripheral edge portion of reduced cross-section (e.g., about 0.001 inches thick or less) for electrosurgical signal transmission. Such intermediate layer may comprise a metal having a melting point of at least about 2600° F. Heat sink means may be included in various embodiments to establish a thermal gradient away from functional portions of the instrument (i.e., by removing heat from the metal body). In one embodiment, the heat sink means may comprise a phase change material that changes from a first phase to a second phase upon absorption of thermal energy from the metal body.

Owner:MICROLINE SURGICAL INC

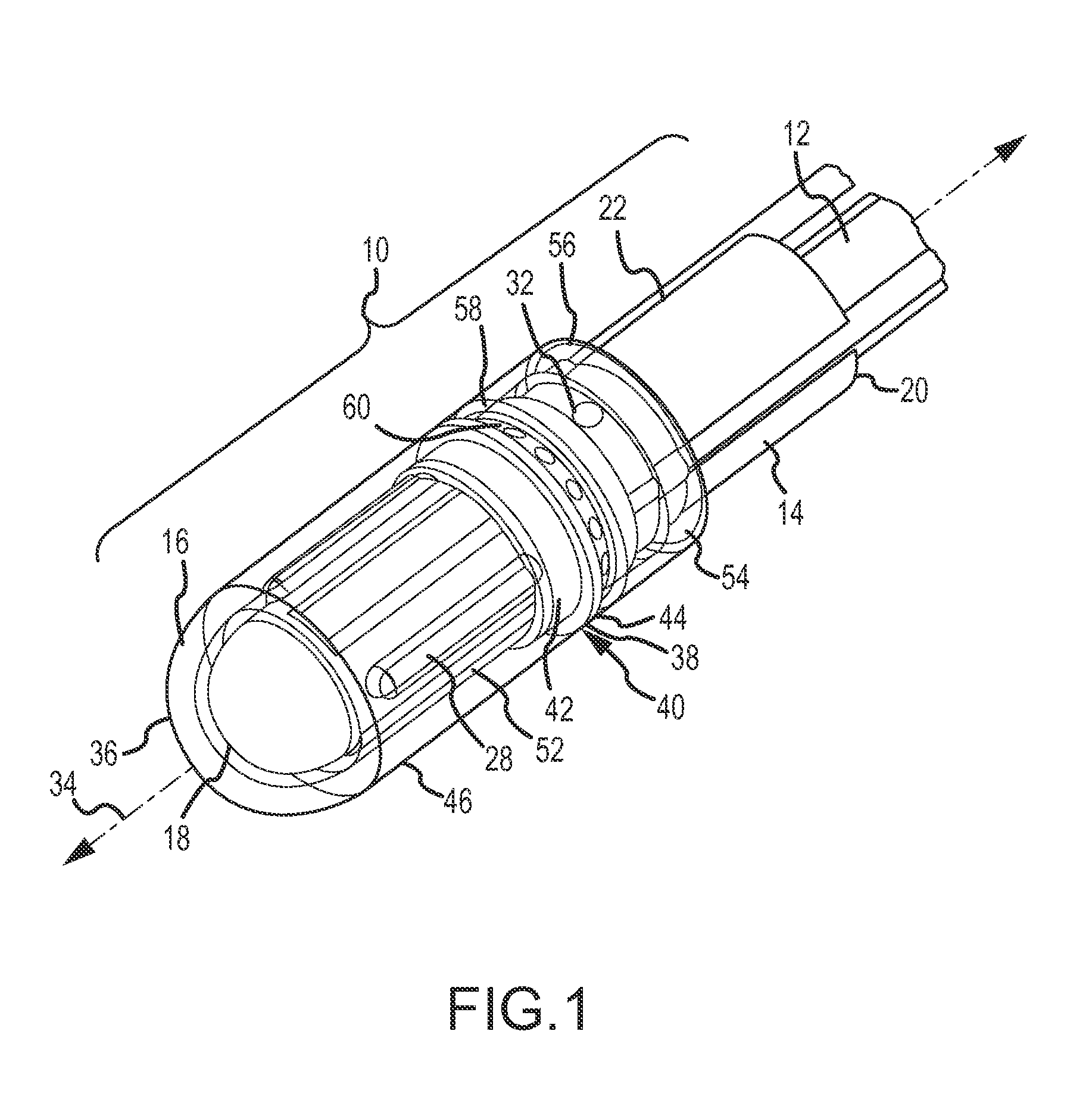

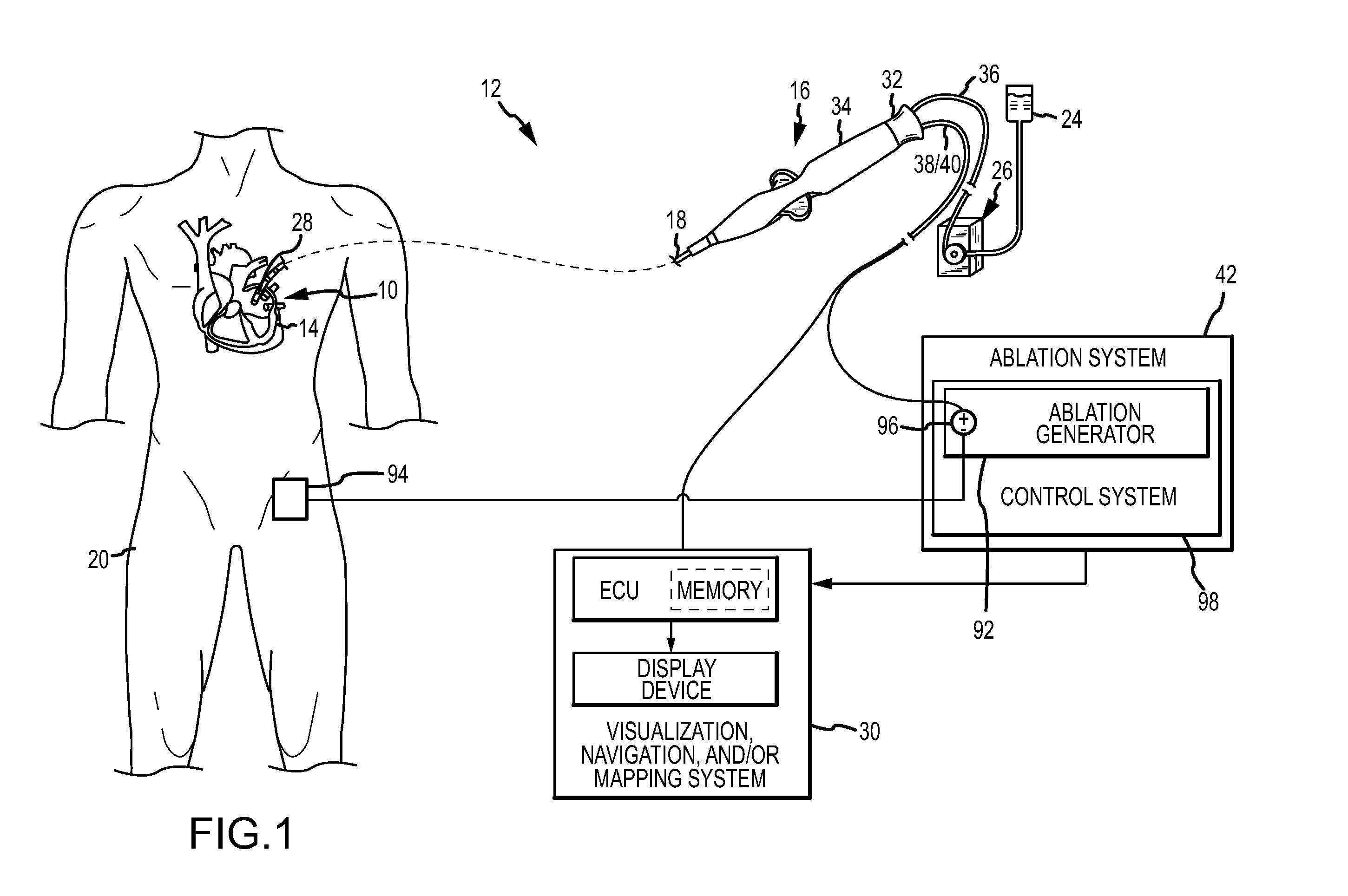

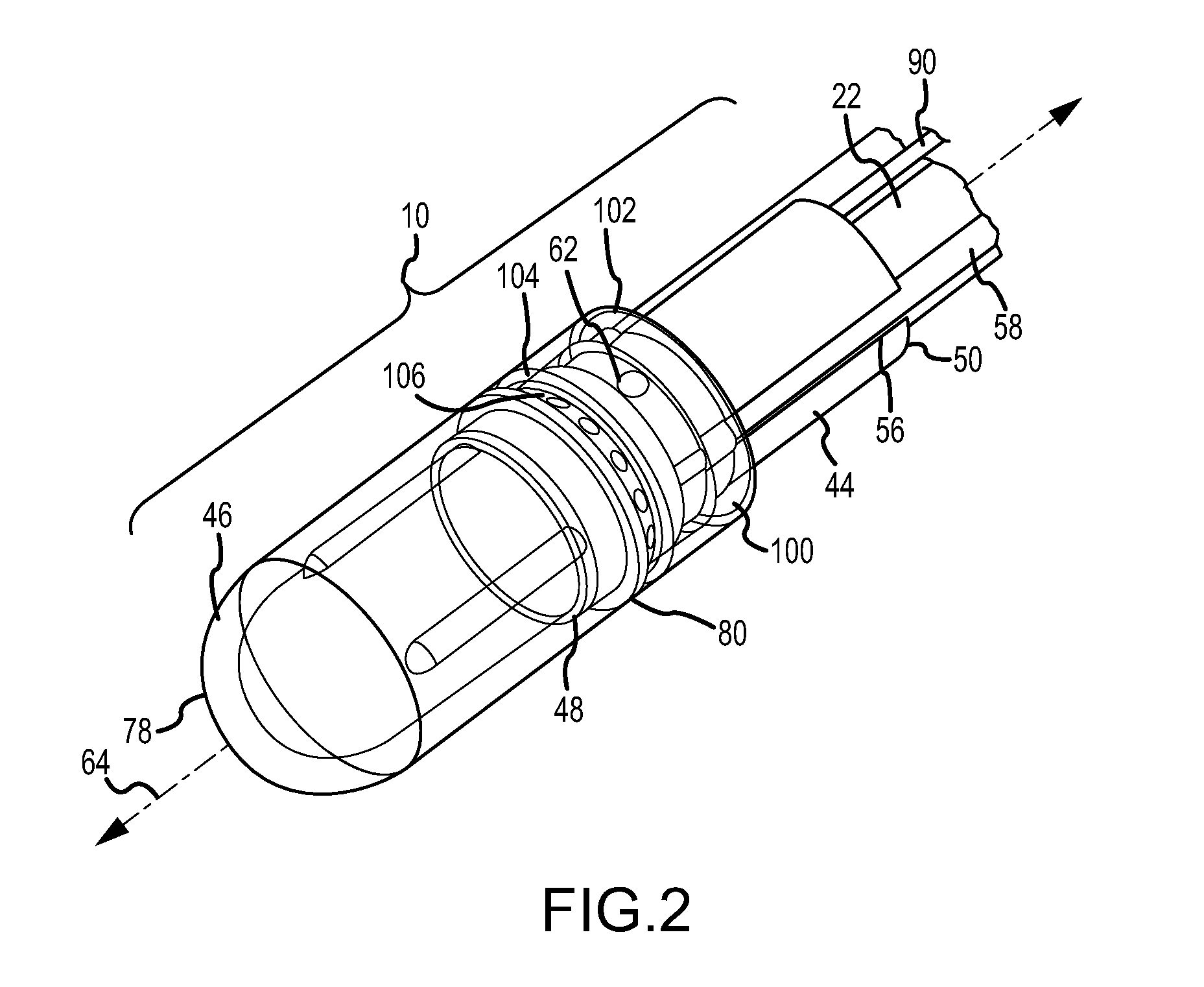

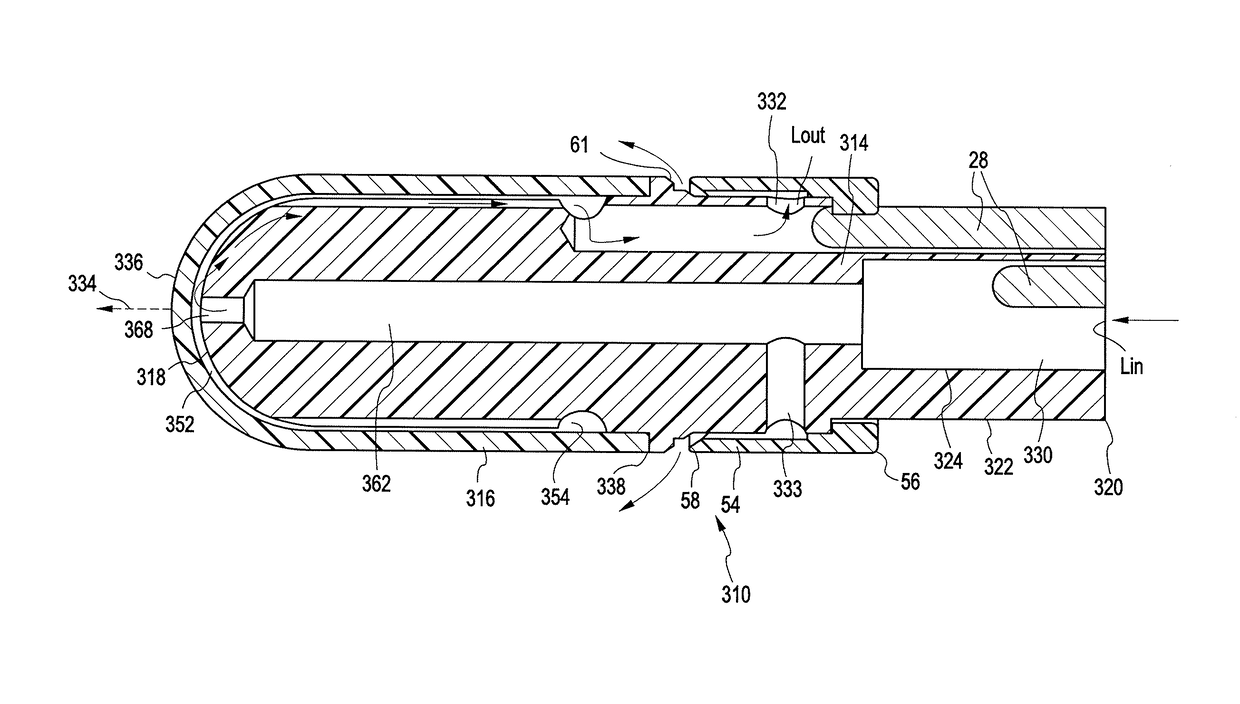

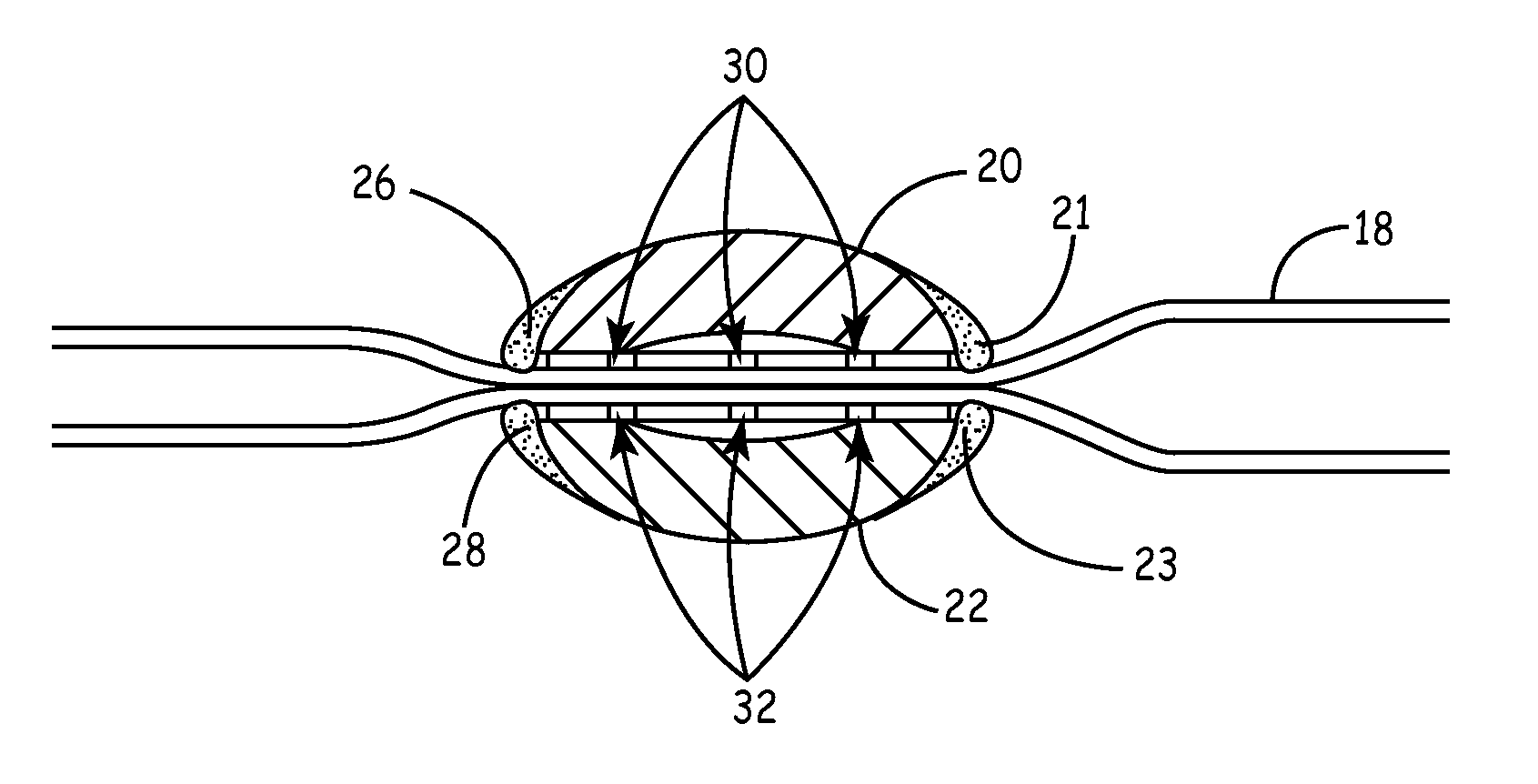

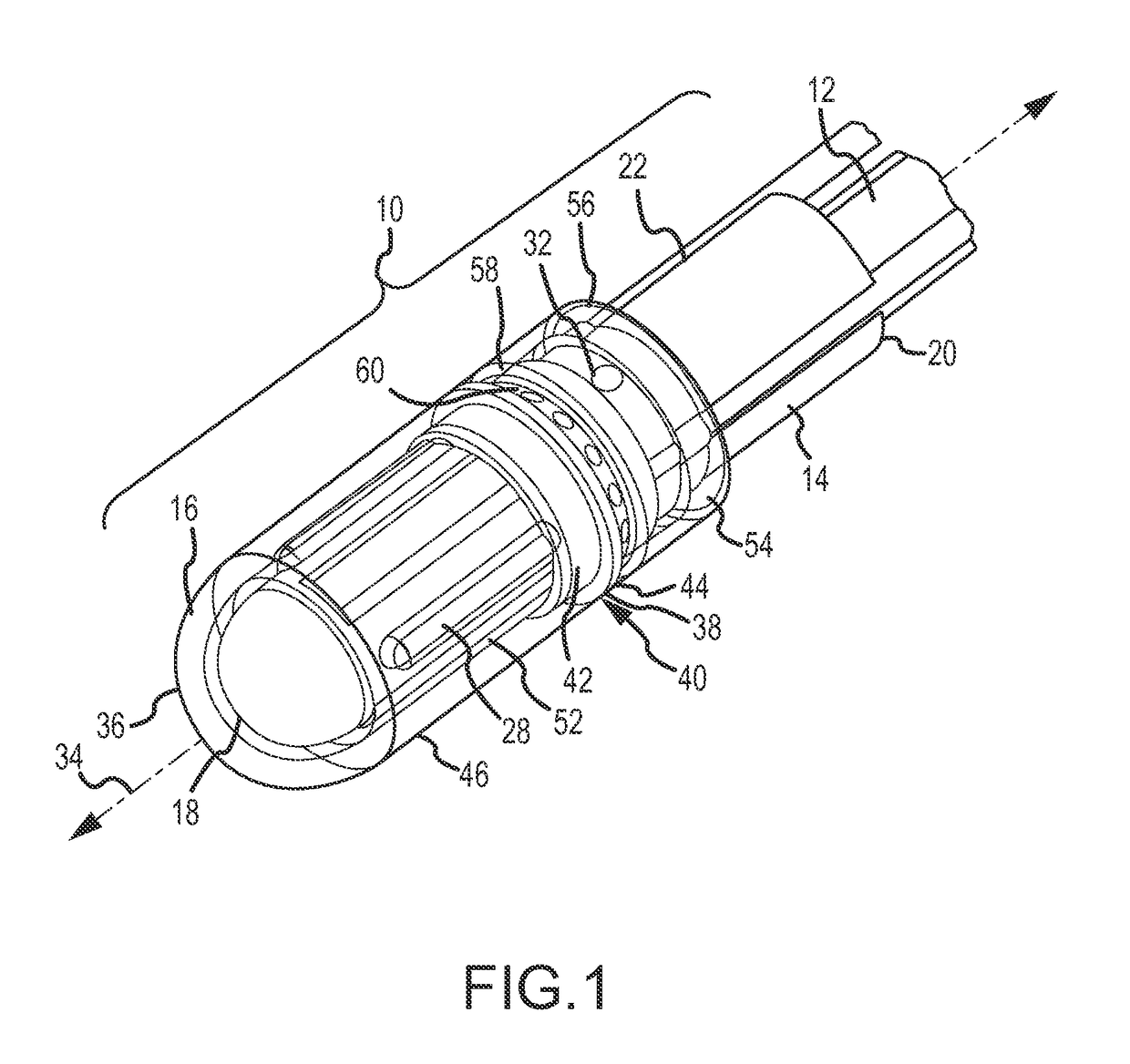

Ablation electrode assemblies and methods for using same

ActiveUS20120165809A1Mitigate effect of orientationImprove abilitiesSurgical instruments for heatingTemperature sensorsCardiac AblationPulsatile flow

Ablation electrode assemblies include an inner core member and an outer shell surrounding the inner core member. The inner core member and the outer shell define a space or separation region therebetween. The inner core member is constructed from a thermally insulative material having a reduced thermal conductivity. In an embodiment, the space is a sealed or evacuated region. In other embodiments, irrigation fluid flows within the space. The ablation electrode assembly further includes at least one thermal sensor in some embodiments. Methods for providing irrigation fluid during cardiac ablation of targeted tissue are disclosed that include calculating the energy delivered to irrigation fluid as it flows within the ablation electrode assembly through temperature measurement of the irrigation fluid. Pulsatile flow of irrigation fluid can be utilized in some embodiments of the disclosure.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

Isocyanate-based polymer foams with nano-scale materials

Isocyante-based polymer foams containing functionalized nano-scale materials in which the functional groups are OH, NH2, COOH or NCO groups. The incorporation of such functionalized nano-scale materials into the isocyanate-based polymer foams provides foams with improved properties such as insulation values, mechanical properties and flame retardancy performance properties, including but not limited to k-factor and dimensional stability.

Owner:HONEYWELL INT INC

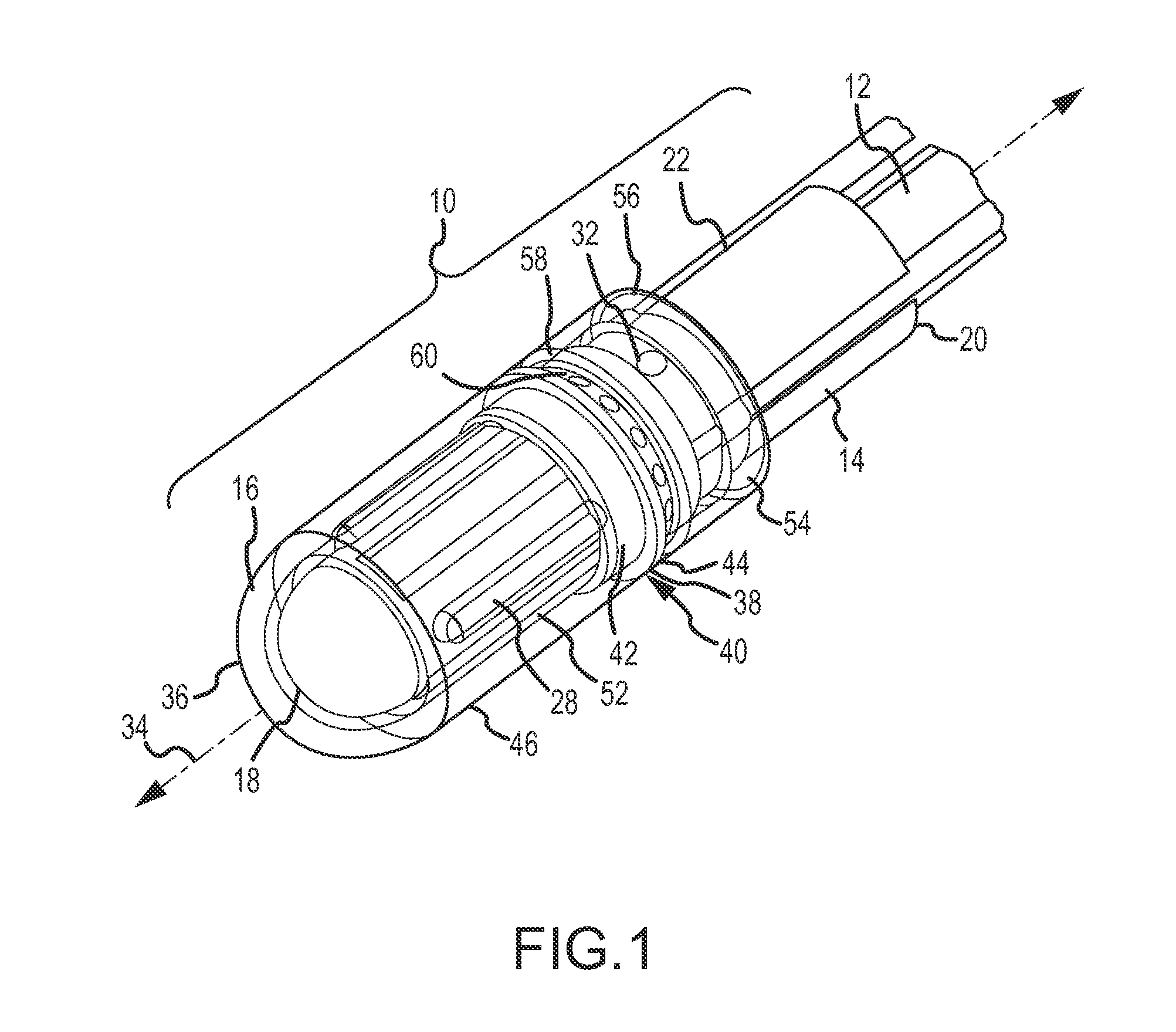

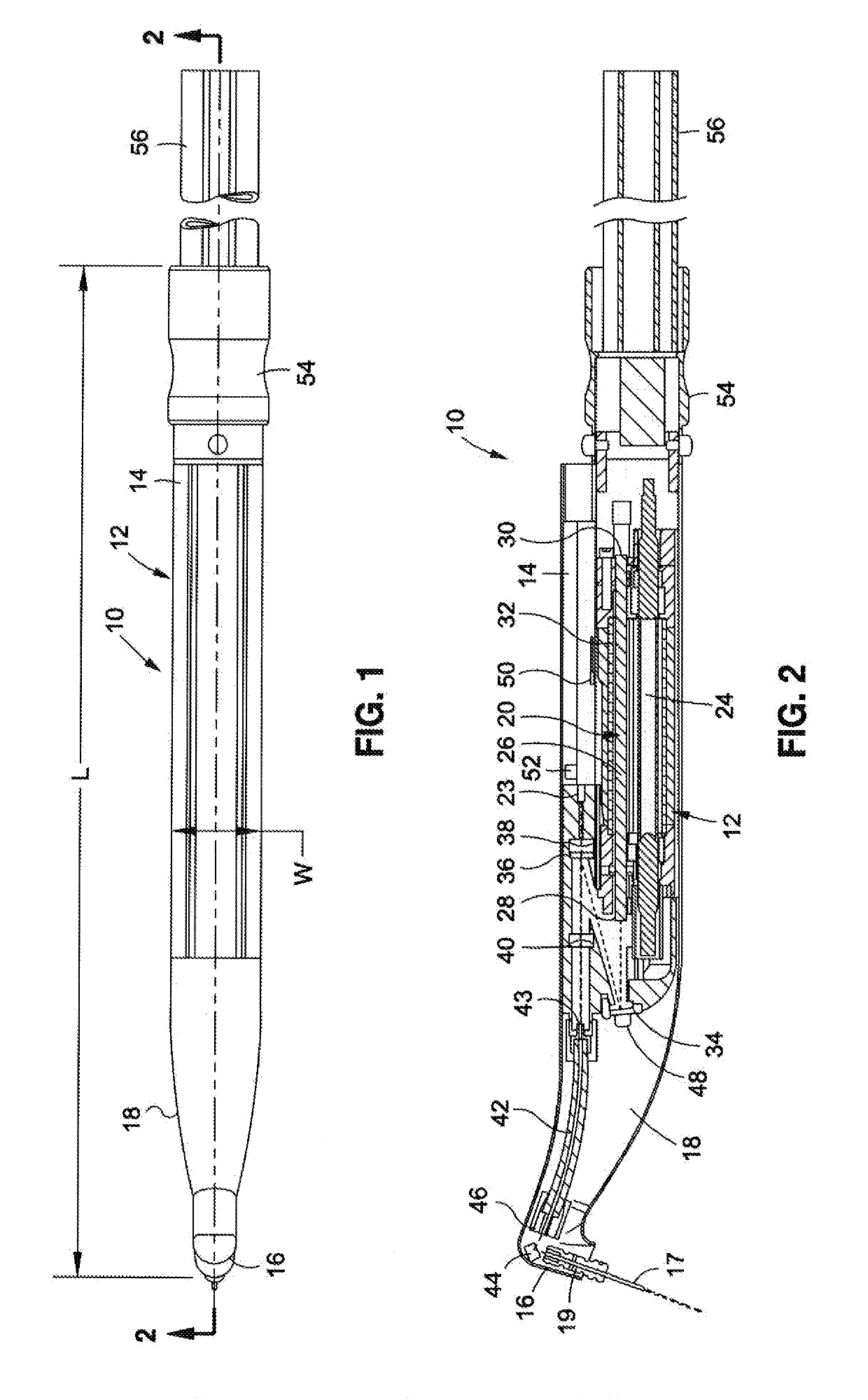

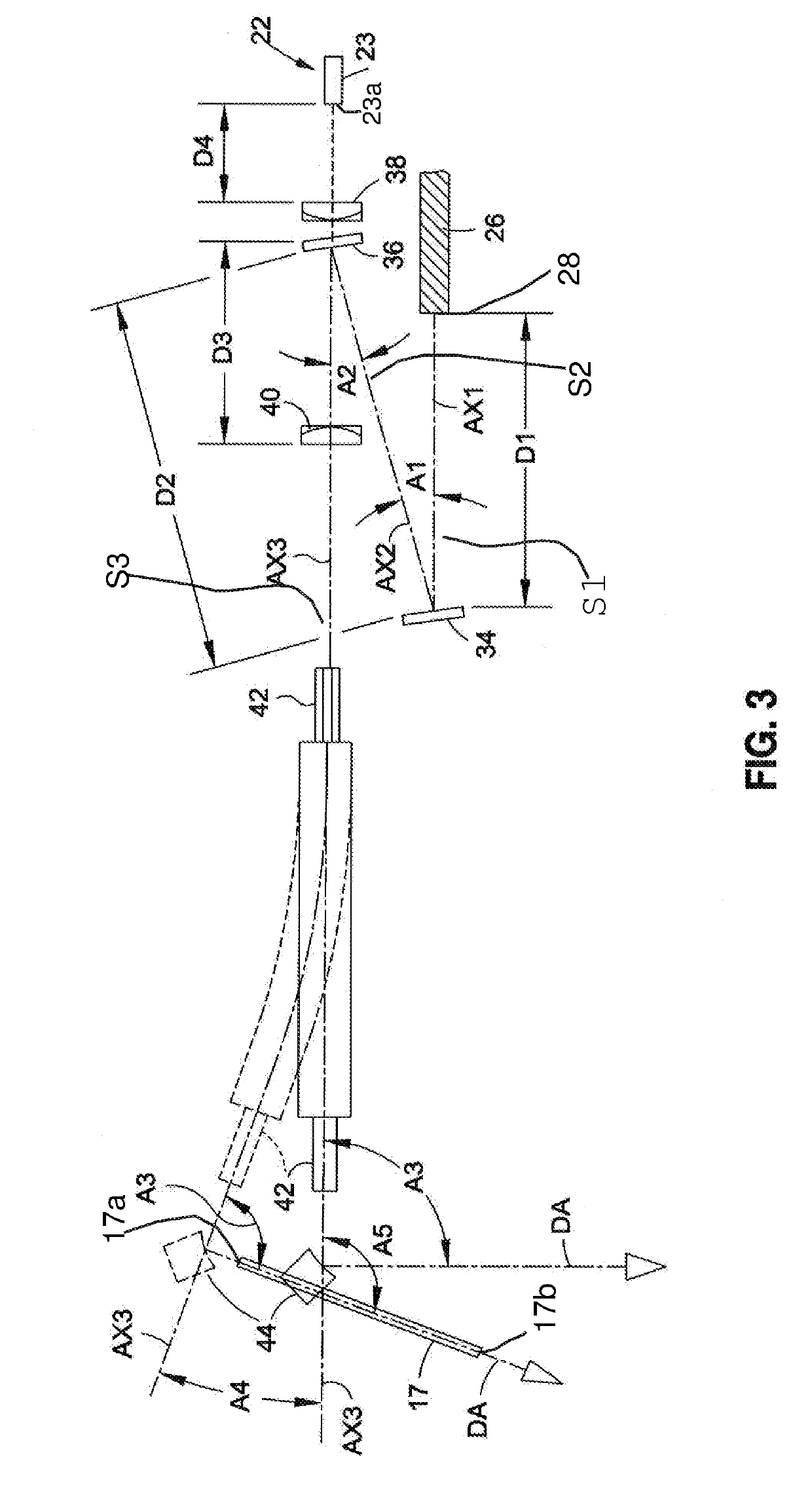

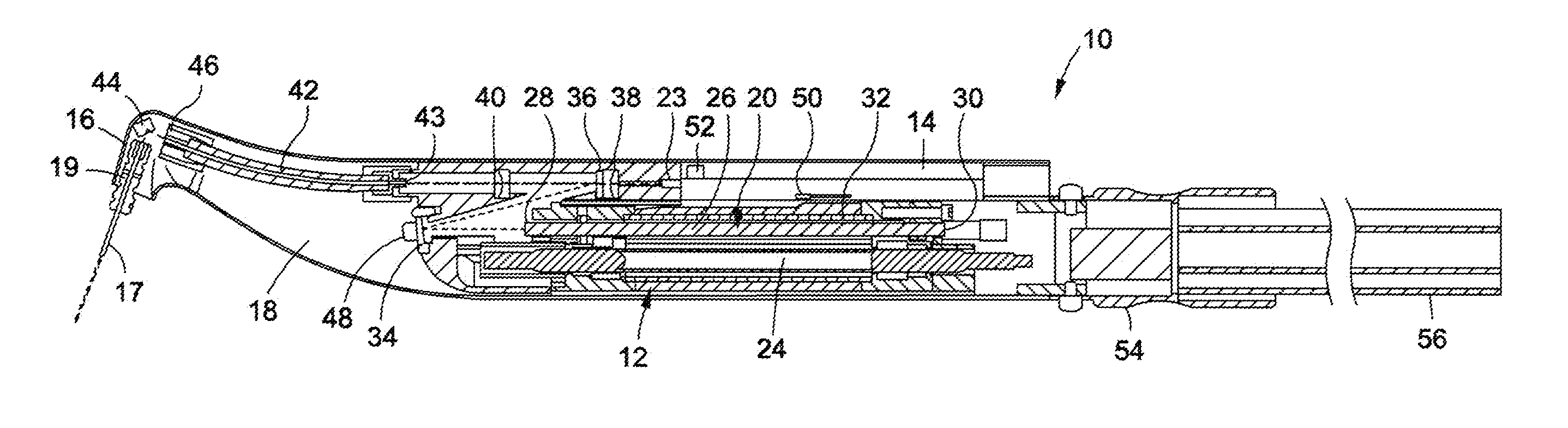

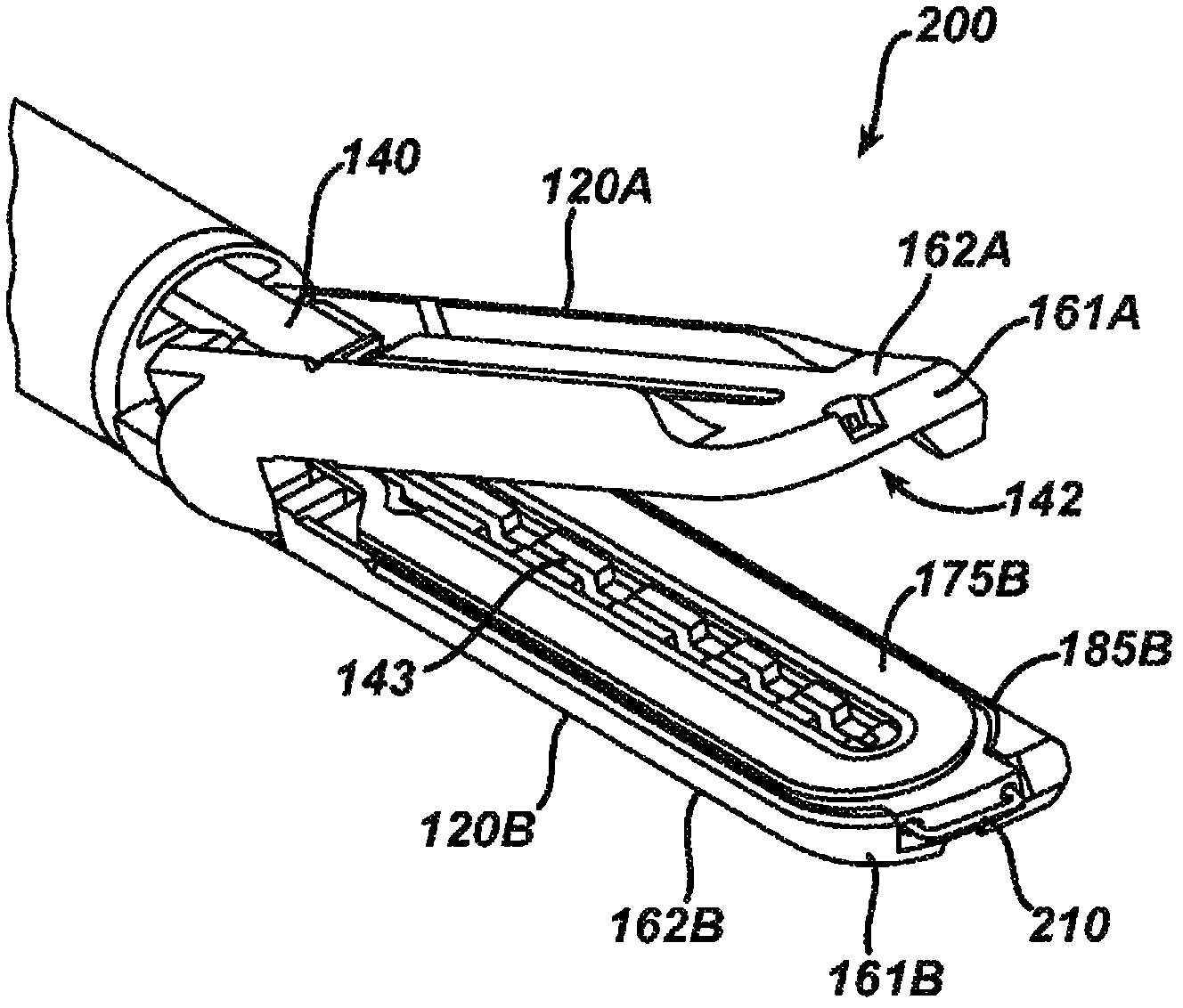

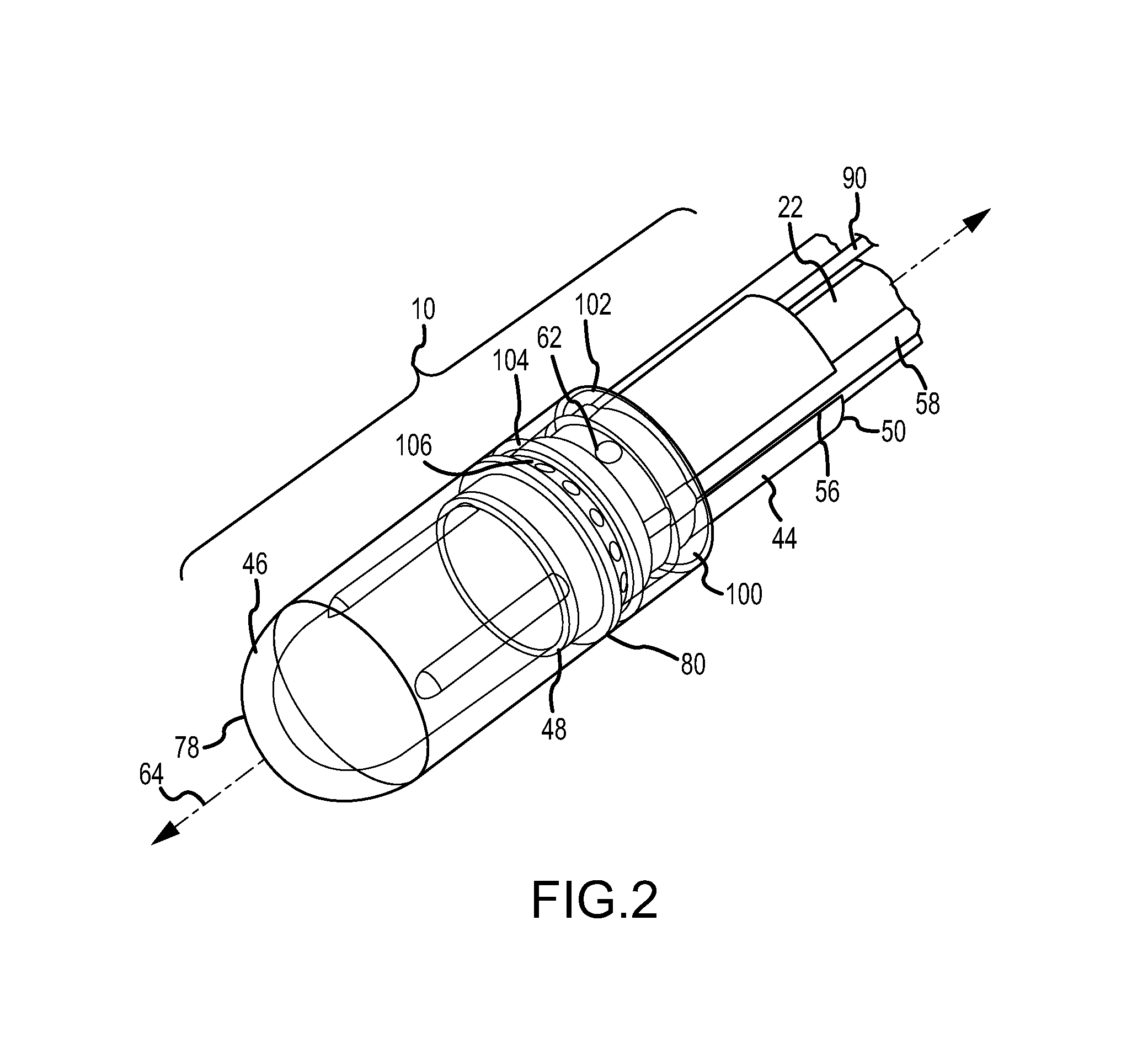

Irrigant distribution system for flexible electrodes

ActiveUS20120157991A1Improved temperature correlationReduce charringUltrasound therapySurgical instruments for heatingDistribution systemEngineering

Ablation electrode assemblies having a longitudinal axis include an electrode core member; an electrode shell; and an irrigant distribution element. The electrode core member comprises a thermal insulator and has a first end; a second end; and at least one irrigation passageway. The electrode shell comprises an electrically conductive material, defines an inner volume, and has a first end; and a second end. The second end of the electrode shell is configured for connection to the first end of the electrode core member. The electrode shell is sufficiently flexible for deflection of the distal end of the electrode shell relative to the longitudinal axis of the ablation electrode assembly. The irrigant distribution assembly comprises a first end; and a second end, wherein the second end of the irrigant distribution element defines a circumferential irrigation port between the irrigant distribution element and the electrode core member.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

Process for reacting an α, β-unsaturated dicarboxylic acid compound with an ethylenically unsaturated hydrocarbon

ActiveUS8242287B2Reduce degradationReduce charringOrganic compound preparationCarboxylic compound preparationAntioxidantChar

The invention provides an improved method of synthesizing chemicals according to the ene reaction. The method addresses two problems that previously could not be addressed simultaneously, preventing charring of the reaction, and preventing gaseous degradation of the reagents. The method involves adding a boron bearing compound and an aromatic / antioxidant compound to the ene reaction. Combining these two compounds together inhibits charring and also causes an effect that neither compound can accomplish alone. The addition of these two compounds together also more effectively prevents either of the reagents from degrading than when either reagent is added alone. As a result the method reduces costs by reducing the amount of reagents needed for a synthesis and further reduces costs by eliminating the need to filter out char from the end products of the ene reaction. The method is particularly useful in the ene reaction synthesis of ASA from olefins and maleic anhydride.

Owner:ECOLAB USA INC

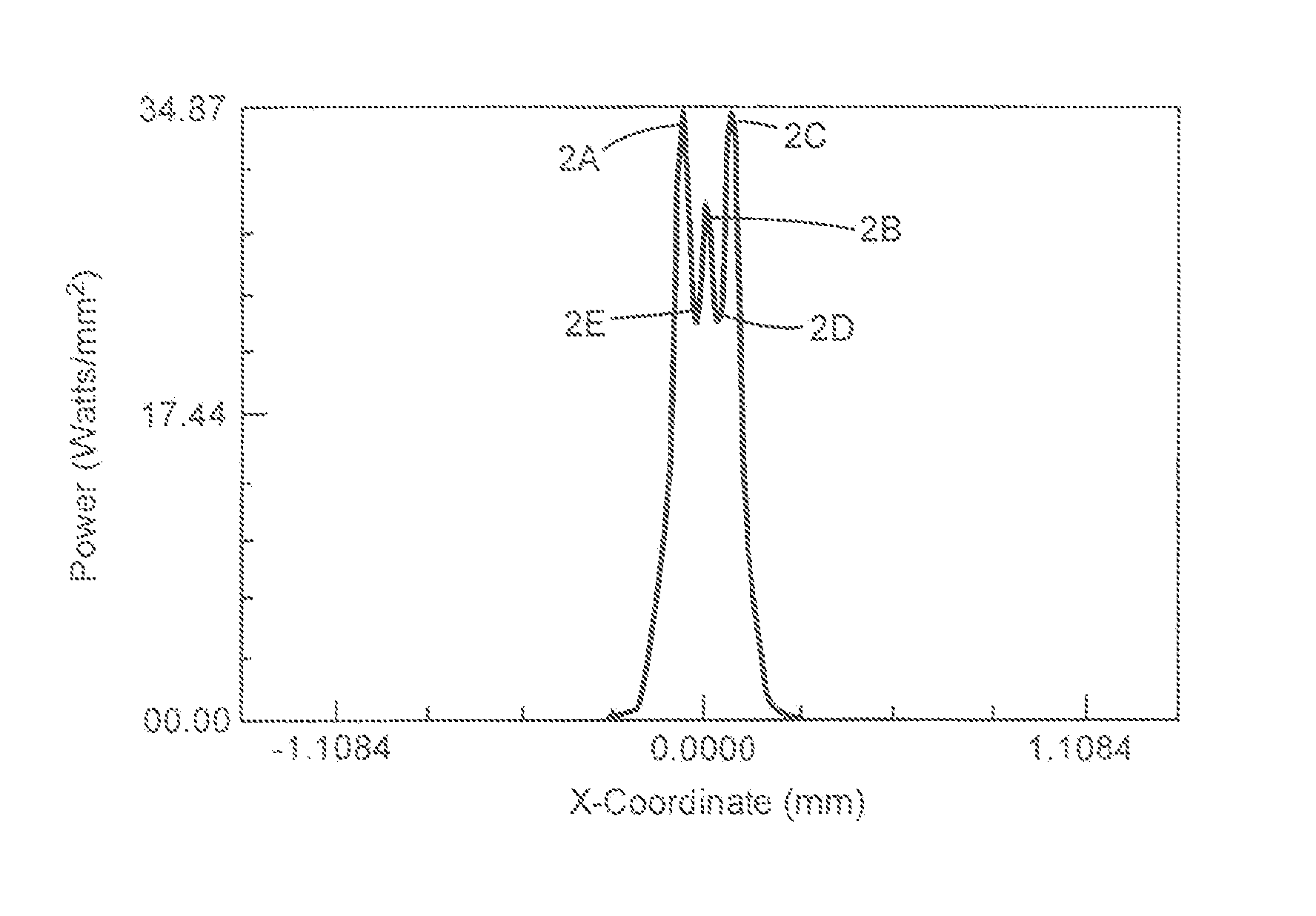

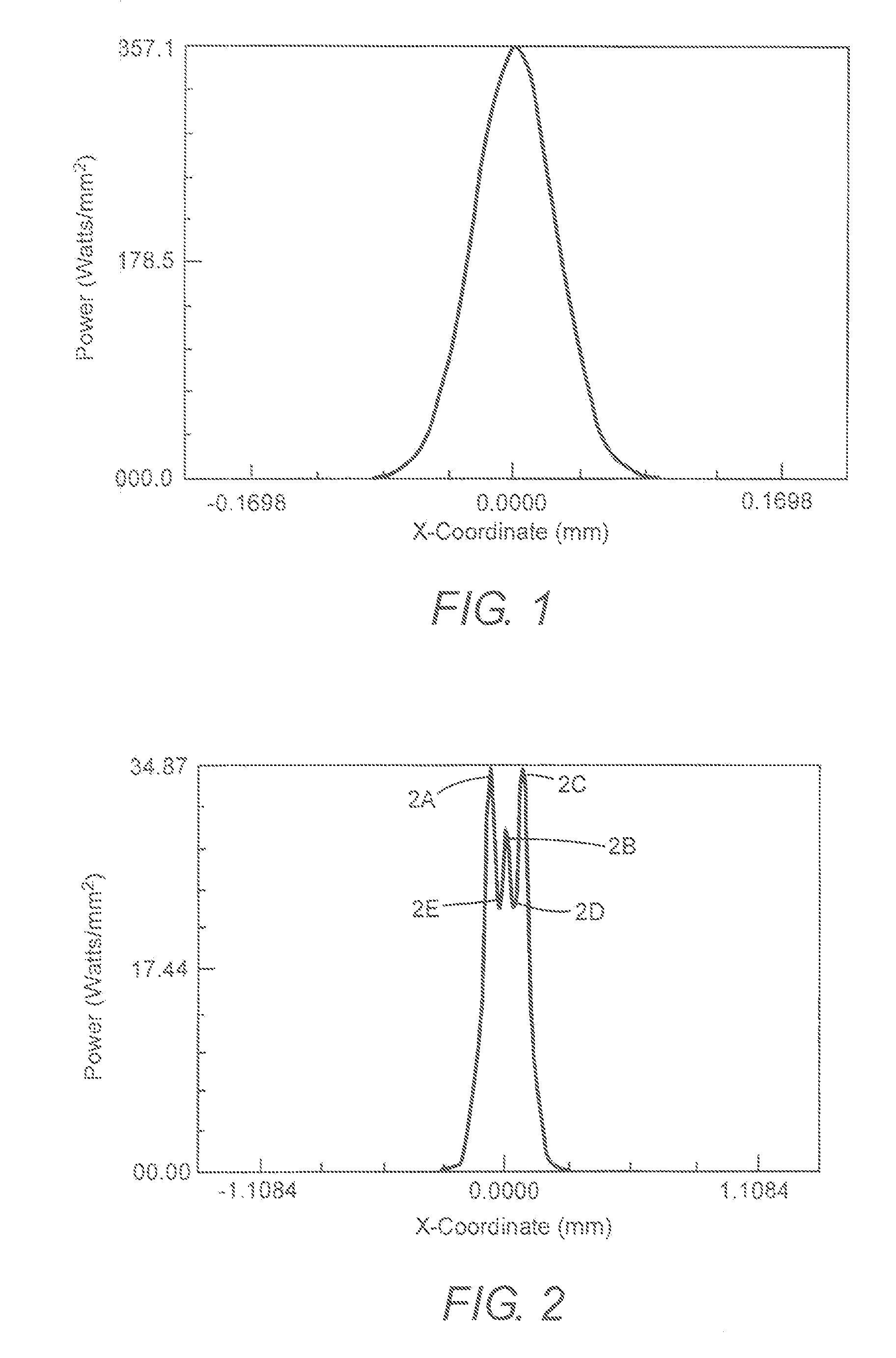

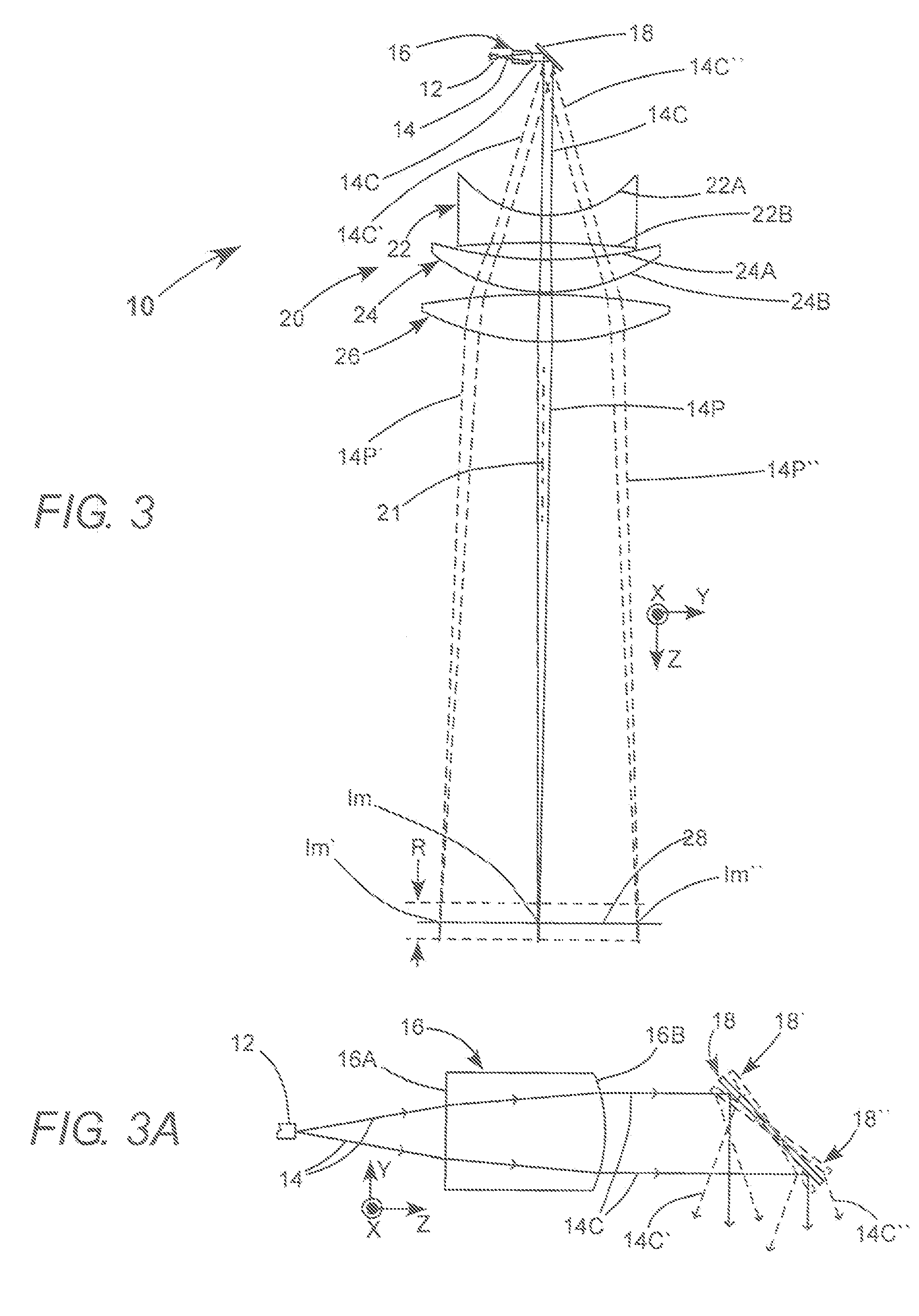

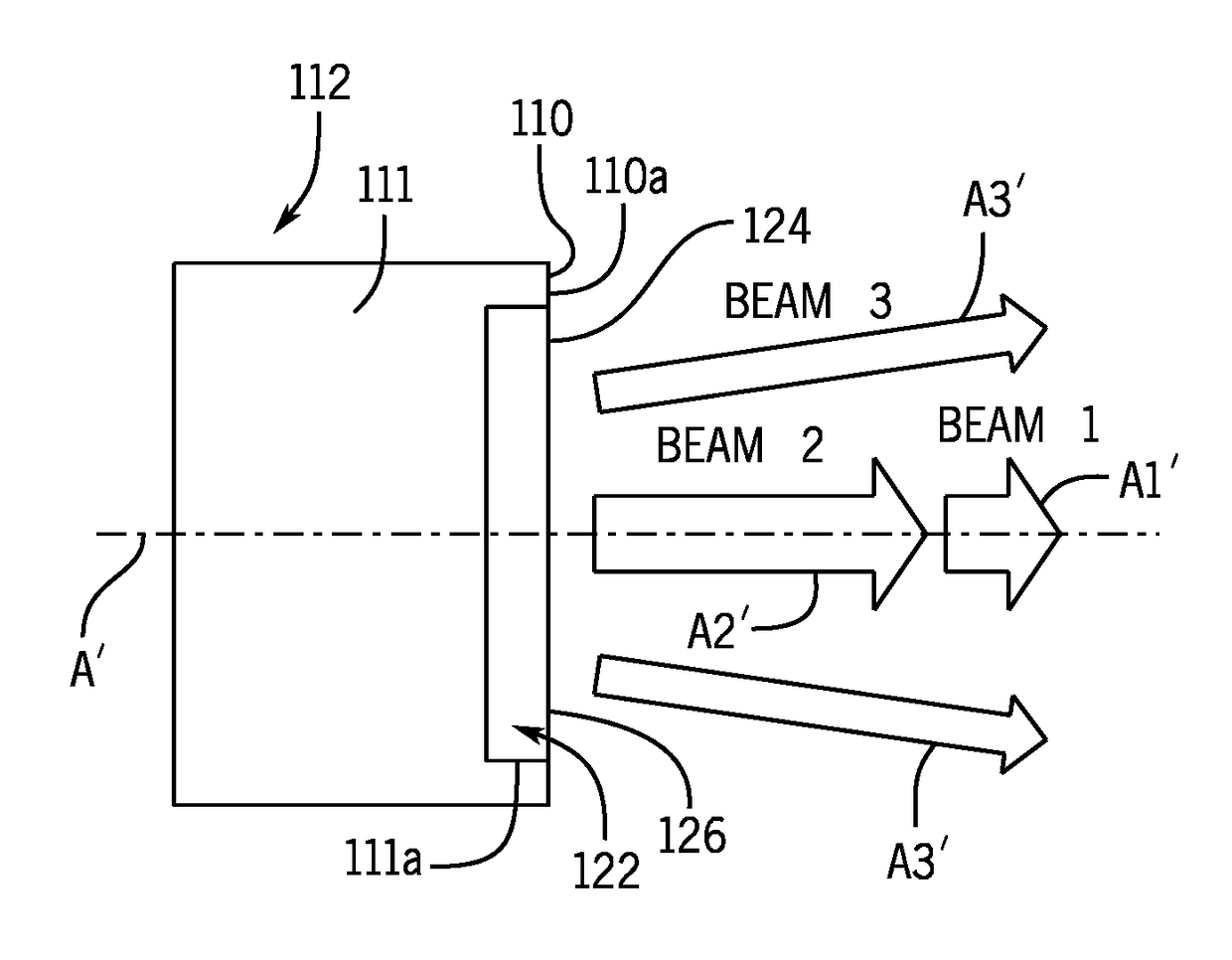

Optical System Having Aberrations for Transforming a Gaussian Laser-Beam Intensity Profile to a Quasi-Flat-Topped Intensity Profile in a Focal Region of the Optical System

ActiveUS20070140092A1Enhanced interactionReduce charringLaser detailsRecord information storageLight beamOptical aberration

An optical system is configured for projecting an image having a quasi-flat-topped intensity profile from a laser-beam having a Gaussian intensity profile. The optical system includes a diffraction limited lens for focusing the laser beam and one or more optical elements that introduce aberration into the beam before the beam is focused. The aberration introduced causes the Gaussian intensity profile to be changed to the quasi-flat-topped intensity profile at some position in a focal region of the diffraction-limited lens.

Owner:SOLTA MEDICAL

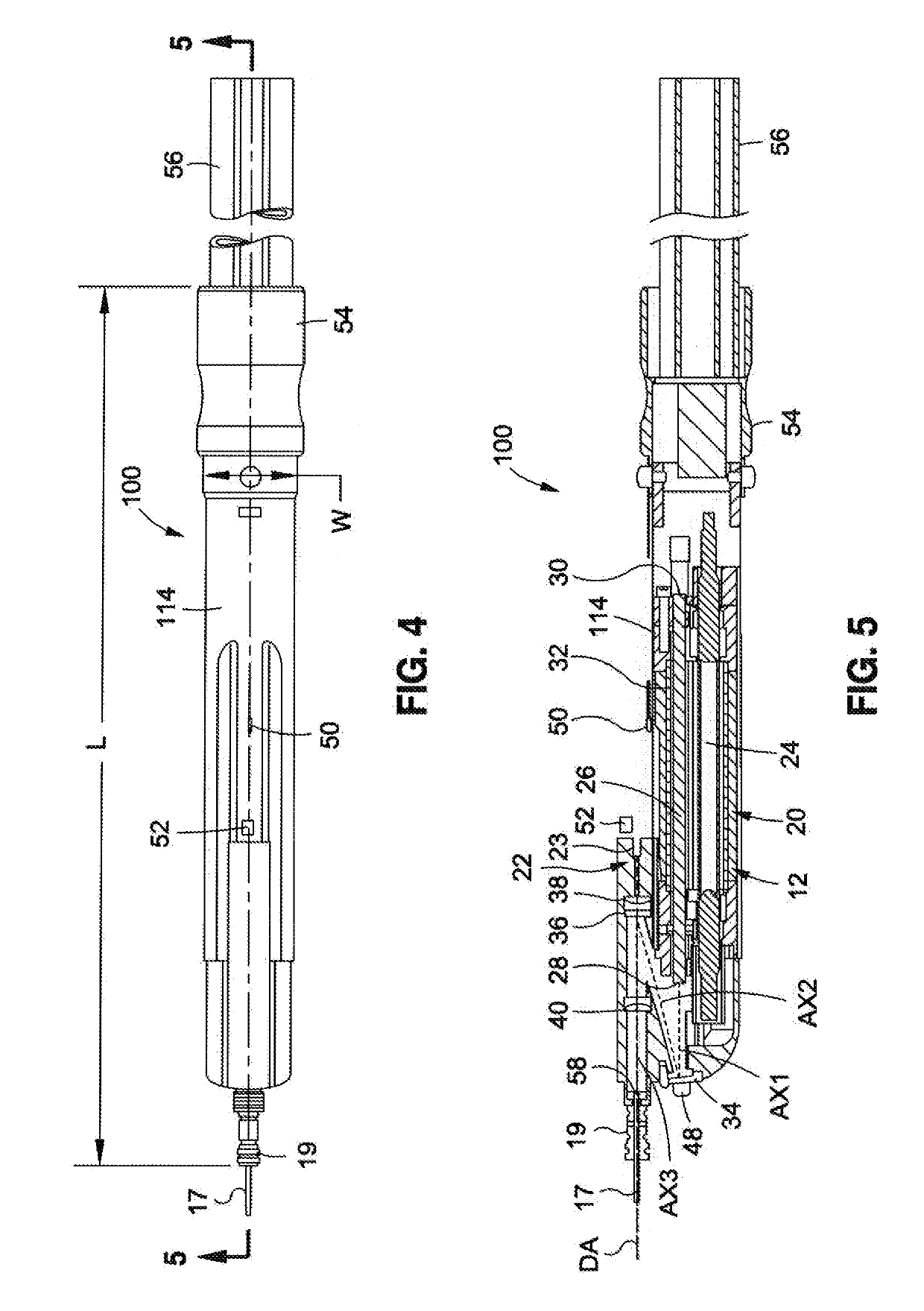

Dual wavelength laser treatment device

InactiveUS20190142516A1Improve treatmentGood curative effectSurgical instrument detailsLight therapyHand heldTherapeutic effect

Embodiments of the invention include a compact, lightweight, hand-held laser treatment device that combines the emissions of two separate laser energy sources into a common optical pathway for improved therapeutic effect. In some embodiments, the device includes a housing having separate first and second laser sources disposed within the interior thereof. In some embodiments, the laser energy emissions from the two internal laser sources can be individually or concurrently transmitted to a delivery tip of the device via a laser transmission path also defined within the interior of the housing. In some embodiments, the structural and functional features of the first and second laser sources, in concert with the unique architecture of the laser transmission path, can be configured to provide efficacy and efficiency in the operation of the device within the spatial constraints of the lightweight, hand-held housing thereof.

Owner:BIOLASE INC

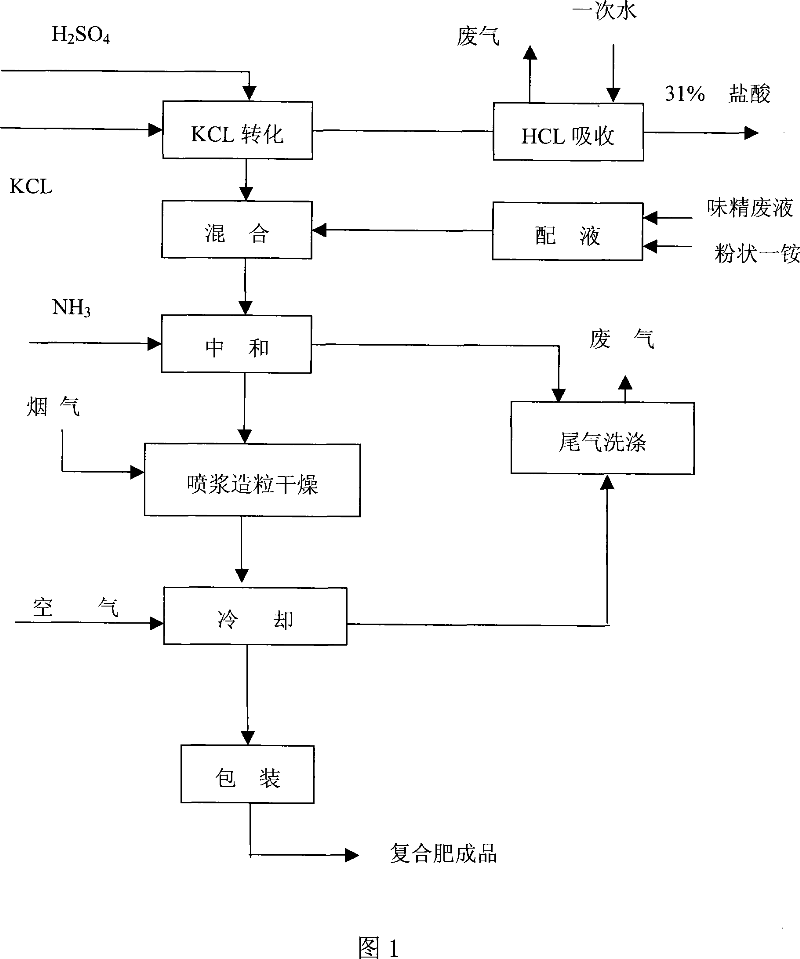

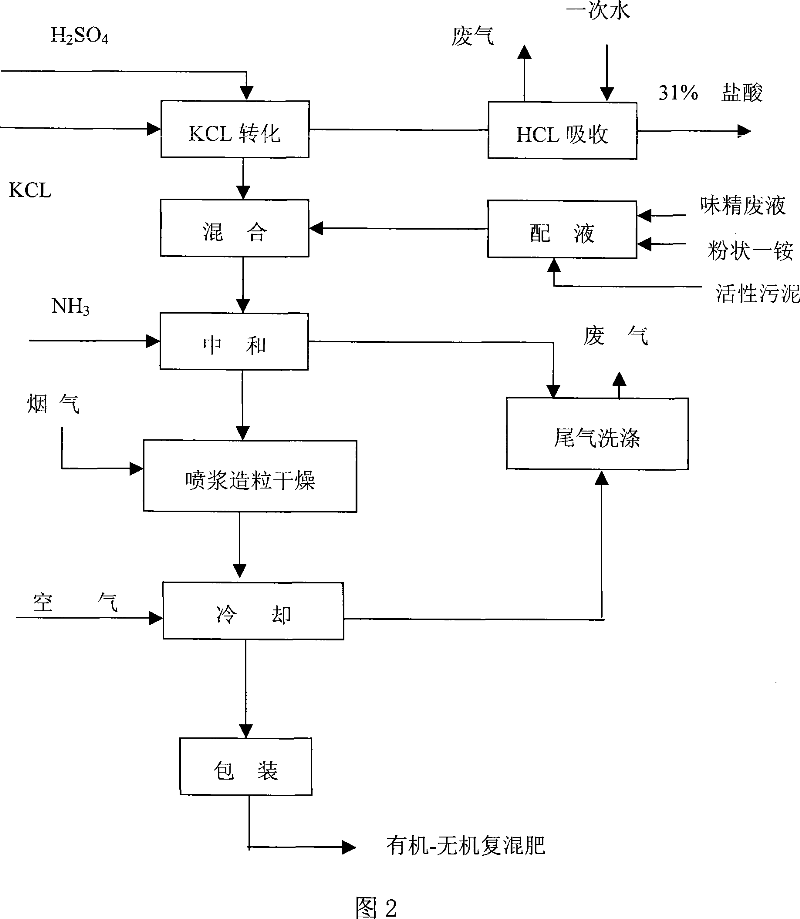

Method for producing agricultural fertilizer by using waste liquid of monosodium glutamate

InactiveCN101037353AReduce consumptionIncrease profitSuperphosphatesClimate change adaptationMonosodium glutamateHigh concentration

The invention discloses a method for producing farm fertilizer by monosodium glutamate tail washings with a primary raw materials: monosodium glutamate tail washings containing a solid content of 8-50%, active sludge with an organic matter content more than 50%, sulphuric acid with a concentration of 90-98%, potassium chloride with a pureness of 95-98%, powdered monoammonium phosphate with a total nutrition of 55-60%, liquid ammonia. The potasium bisulfate is got by a reaction of potassium chloride and concentrated sulfuric acid. A mixing ammonium liquid is obtained by introducing the powdered monoammonium phosphate and active sludge into the monosodium glutamate tail washings. The mixing ammonium liquid mixes with the potasium bisulfate to form mixed acid. Slurry is produced by feeding the gas ammonia into the mixed acid for a neutralization reaction. The slurry produces the compound fertilizer of potassium sulfate style and organic-mineral compound fertilizers by spouting of stock, prilling and drying. The method can make the material fully mix and get an even slurry liquid with an excellent flowability which fits for the spouting of stock and prilling. Therefore, it may produce standard compound fertilizer containing organic matters and organic-mineral compound fertilizers in potassium sulfate style with a low, medium, high concentration.

Owner:梅花生物科技集团股份有限公司

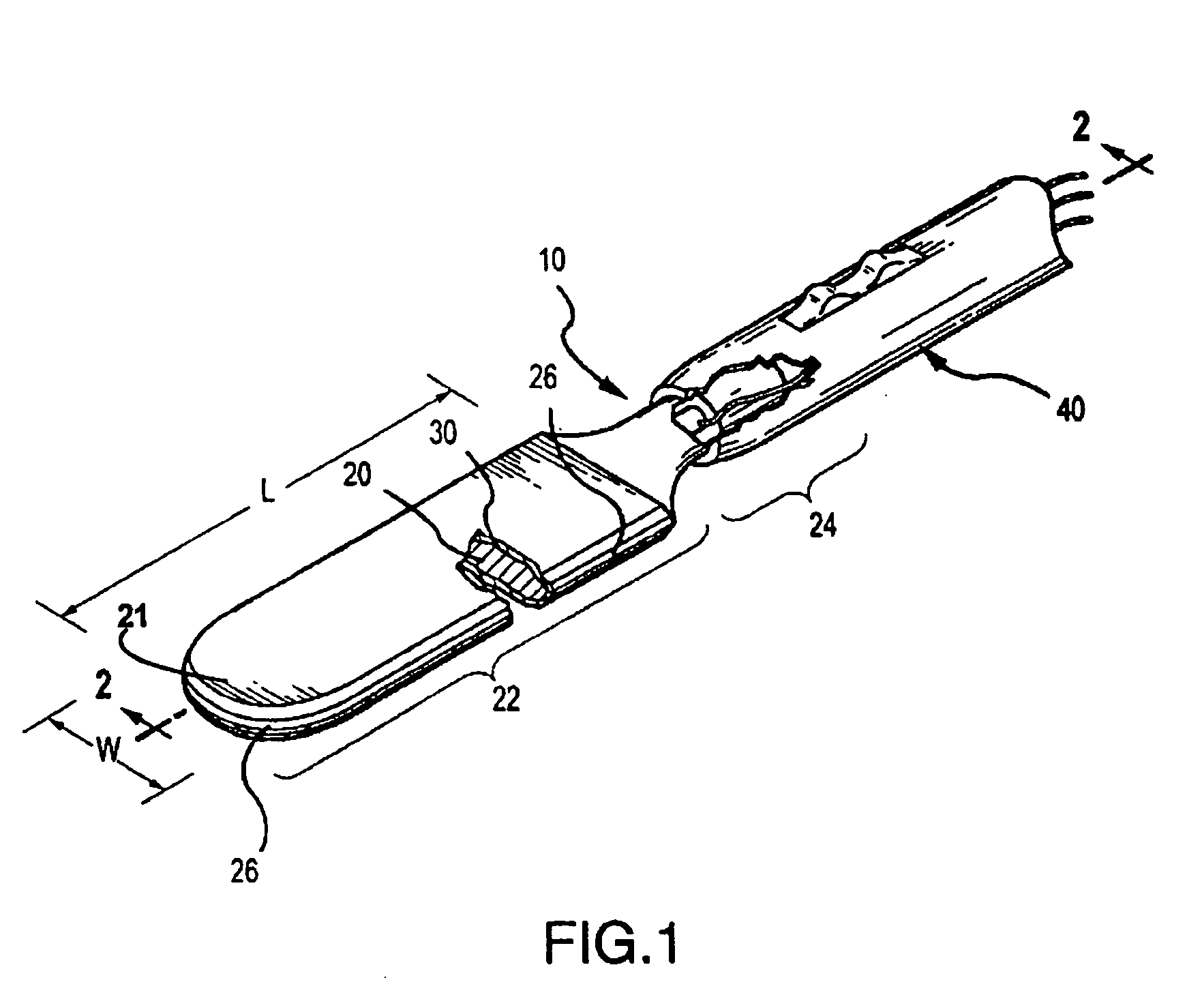

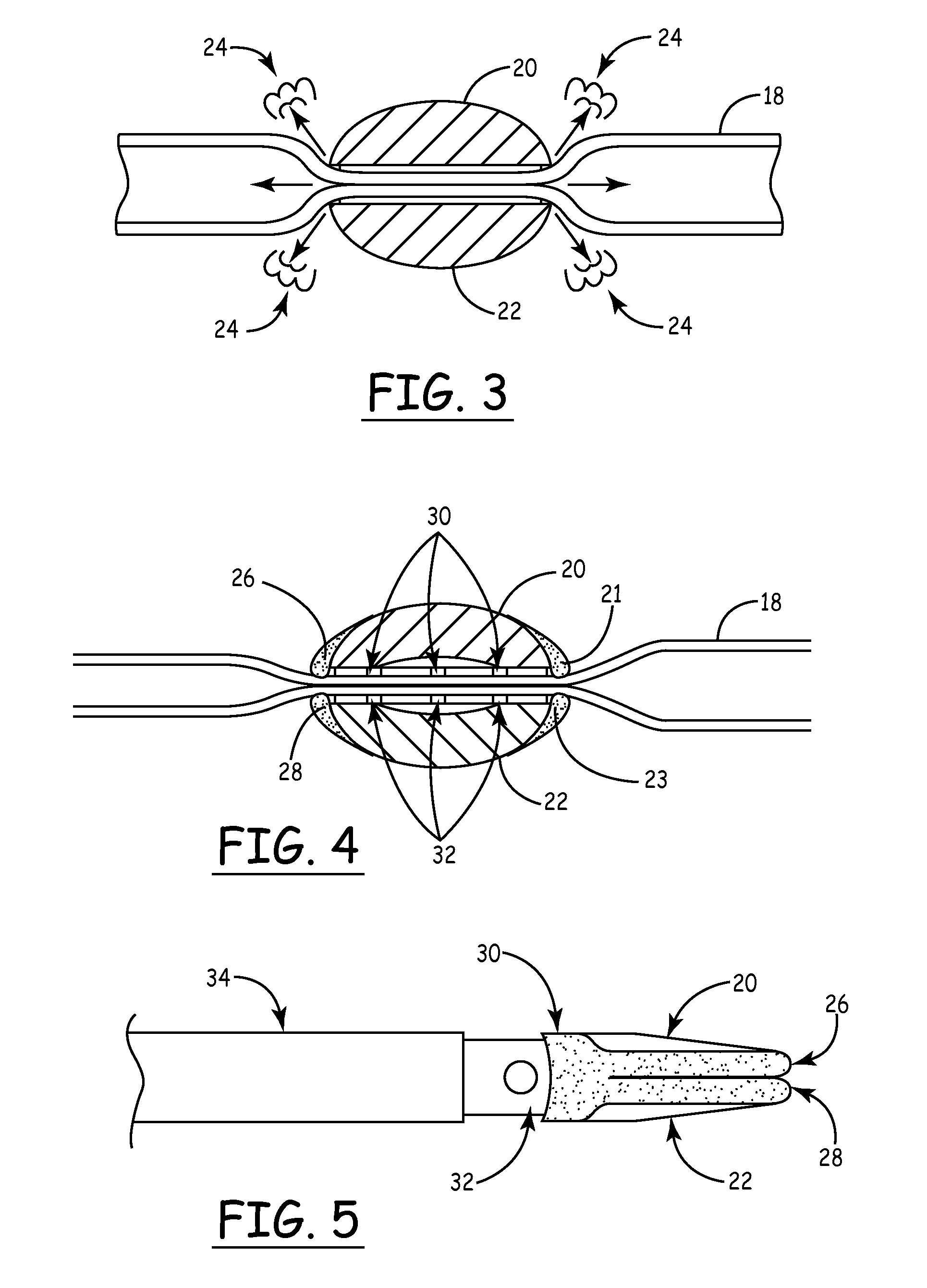

Tissue sealing method

InactiveUS20140221998A1Easy to controlEasy to useDiagnosticsSurgical instrument detailsVessel sealingImproved method

An improved method and equipment for tissue / vessel sealing is disclosed for the sealing, coagulation and transection of tissue during surgical procedures. The improvement is accomplished through better management of heat and moisture present during tissue treatment by having tissue grasping surfaces comprised of an outer non-conducting region and an inner conductive region, and including channels in the jaw assembly to direct steam and moisture away from surrounding tissue. The outer region follows the perimeter each jaw, isolating the treatment zone and preventing steam and excess heat from leaving the tissue treatment zone, reducing thermal margins and unintended patient burns. The outer region also prevents surrounding moisture from affecting the treatment zone and allowing more consistent results.

Owner:SPINNAKER MEDICAL

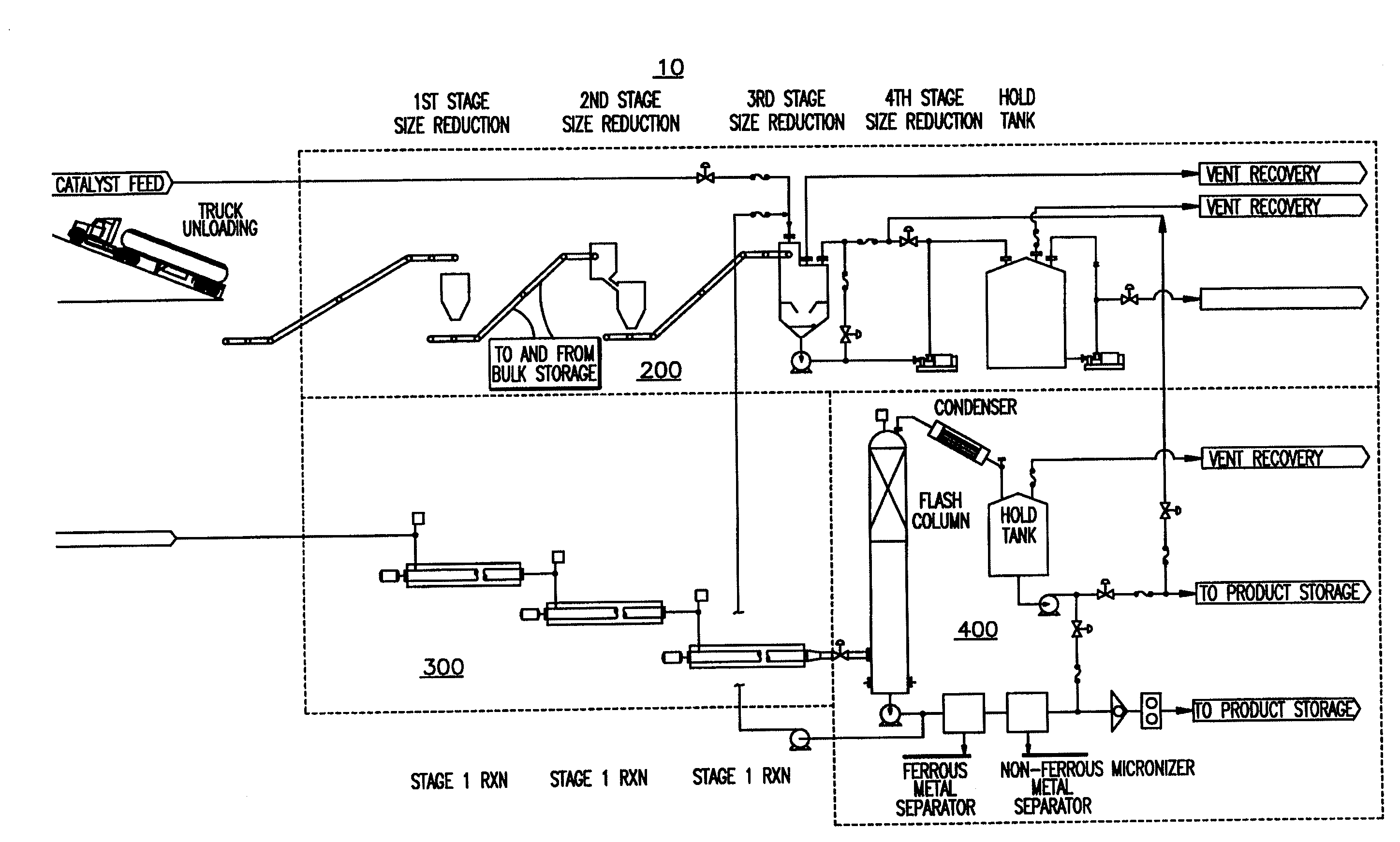

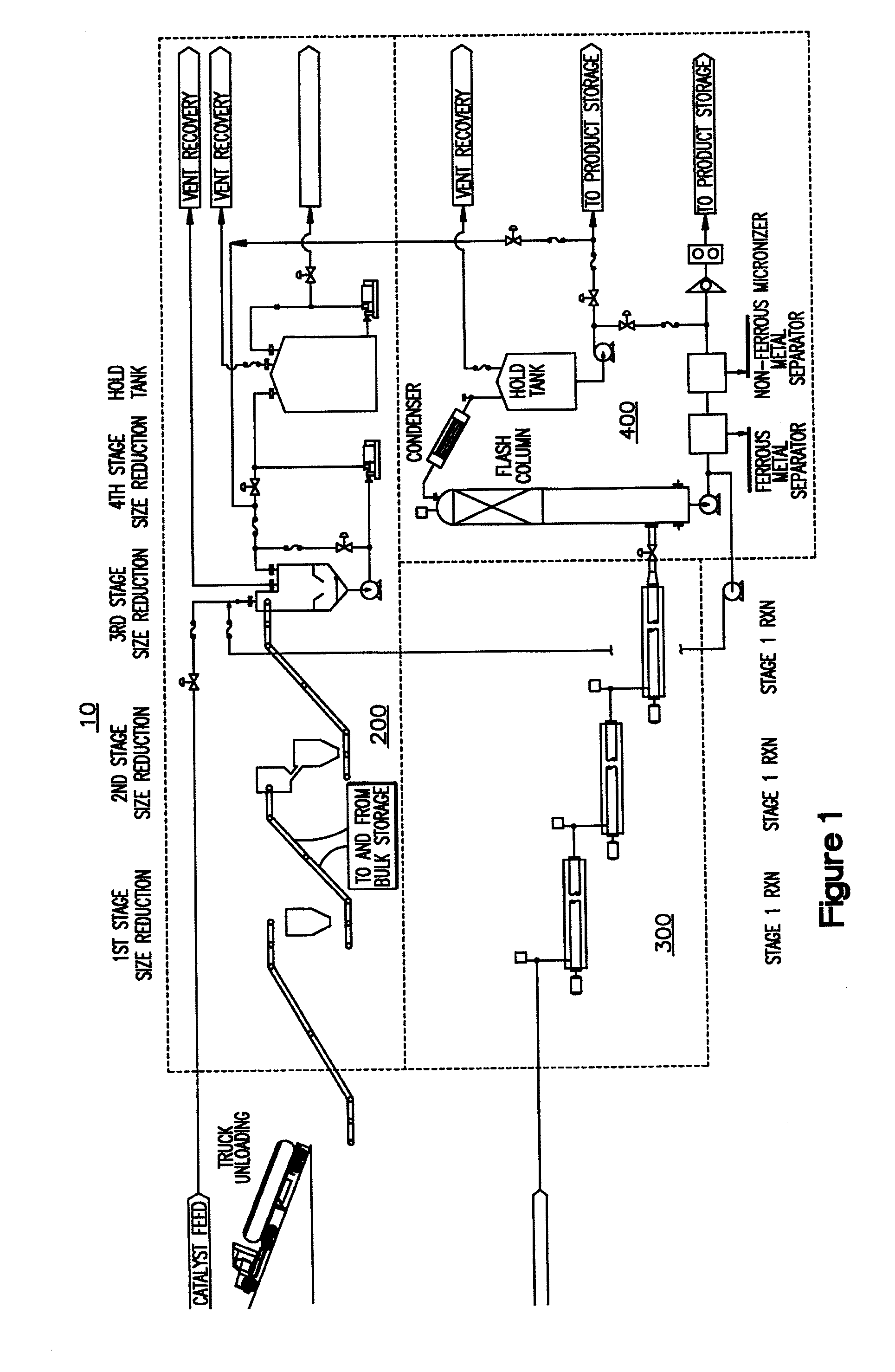

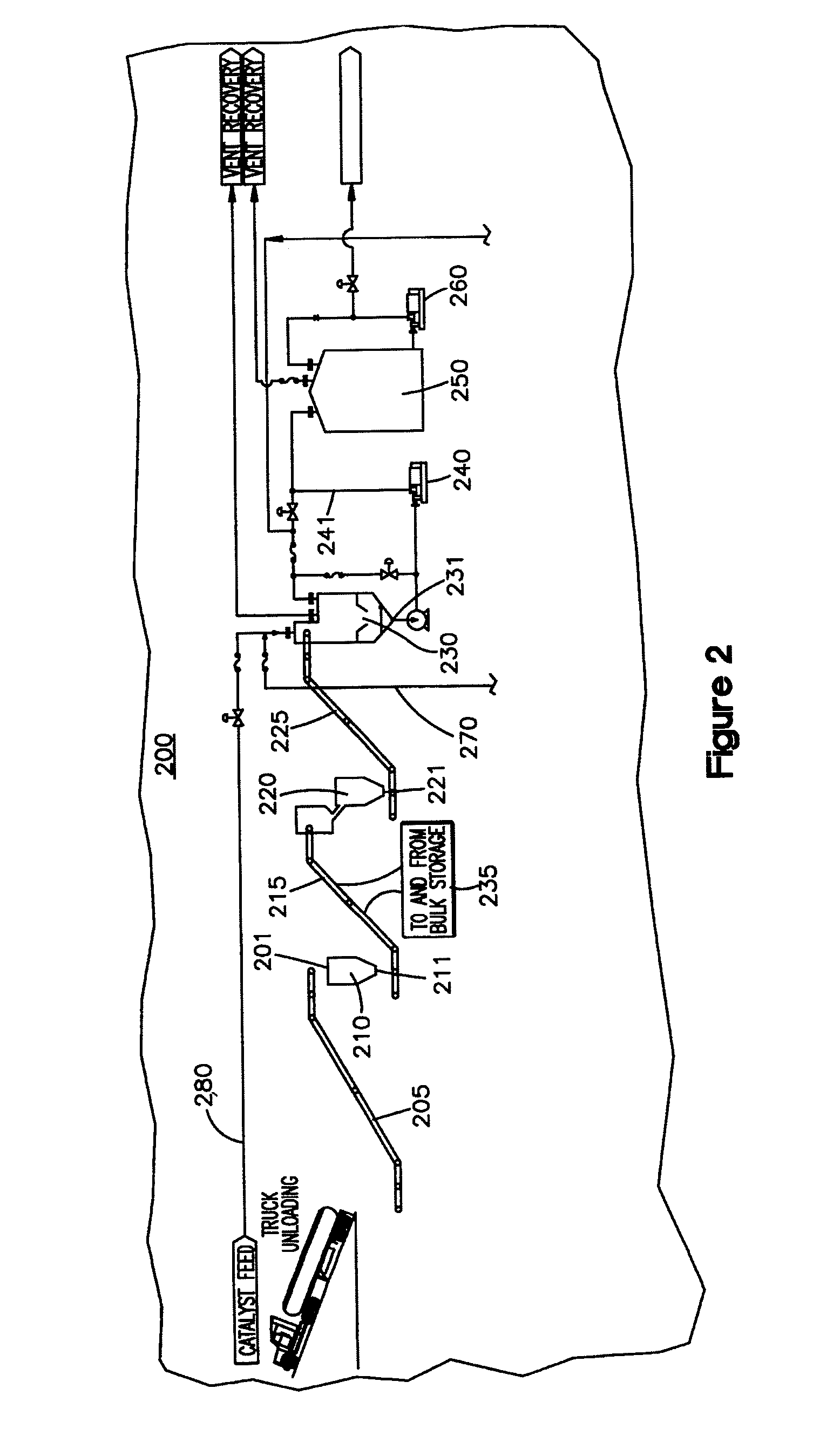

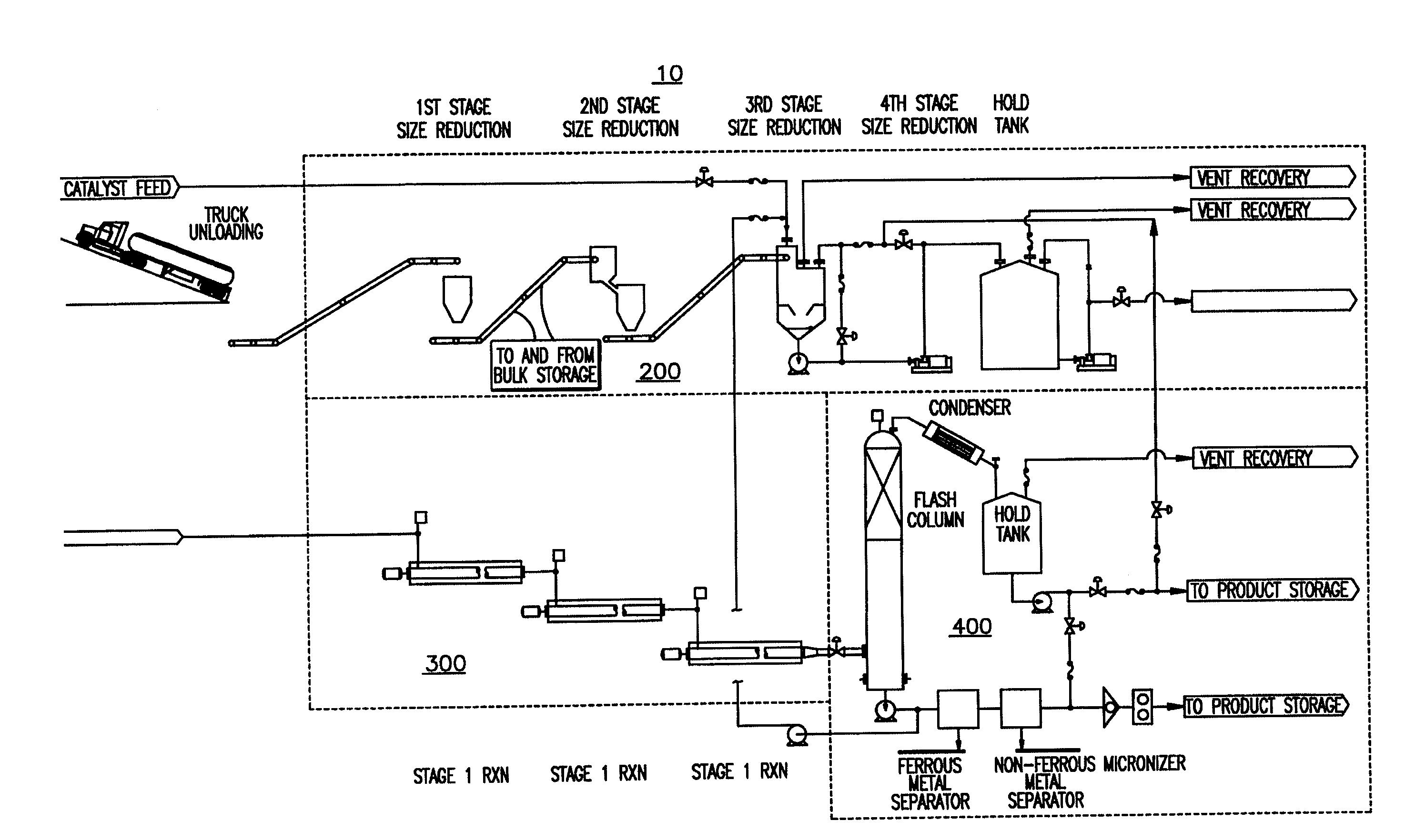

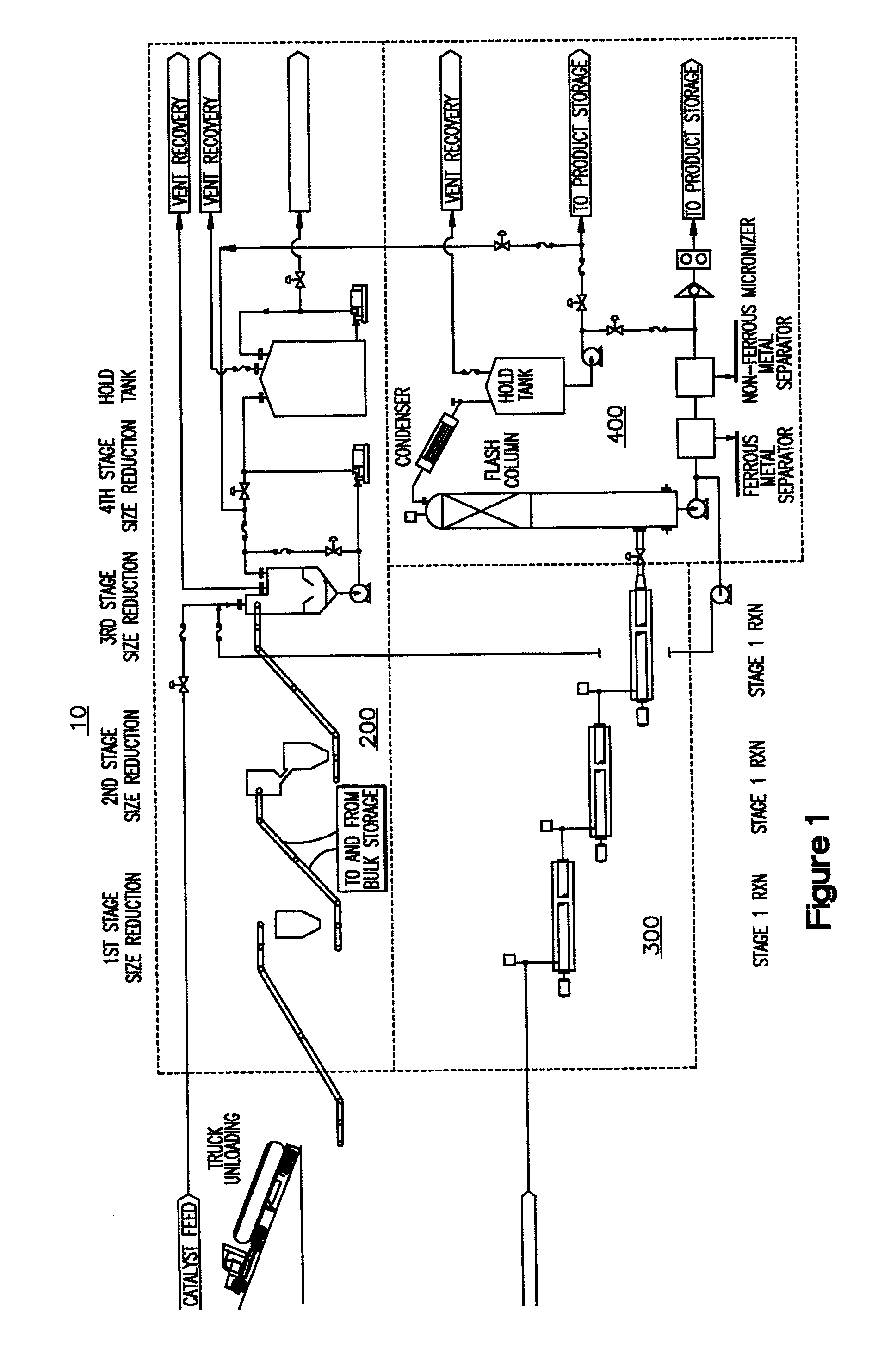

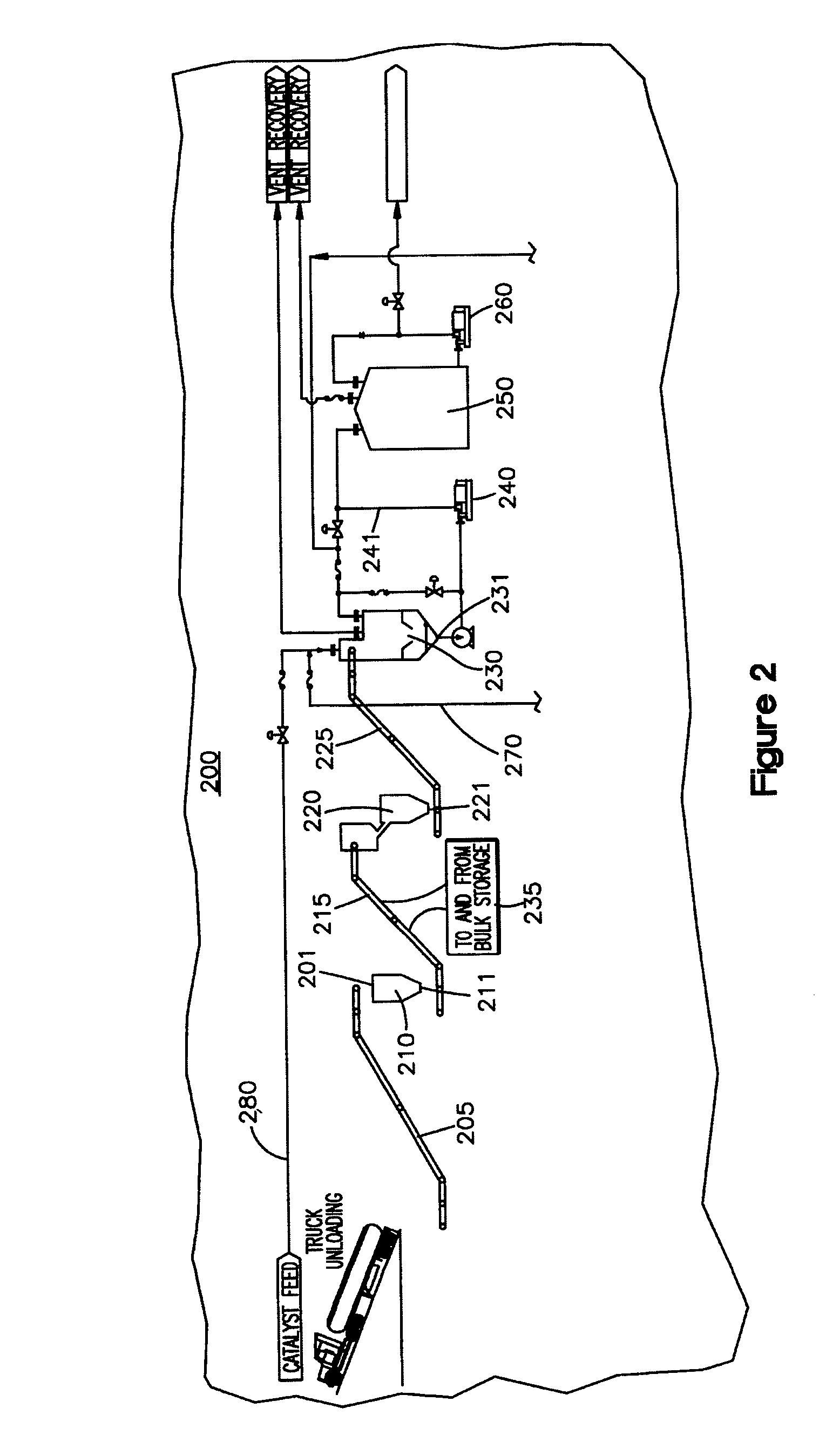

System for the production of synthetic fuels

InactiveUS20080299021A1Assist in downsizingReduce charringLiquid carbonaceous fuelsLiquid hydrocarbon mixture productionParticulatesMetal particle

A system and method for producing synthetic fuels are disclosed in which a slurry comprised of a particulate solid portion dispersed in a carrier liquid portion is provided. The solid portion comprises (i) a feedstock of carbon-containing polymeric materials that are substantially free of each of halogen, sulfur and nitrogen atoms, and contain about 5 to about 25 percent by weight water, and (ii) a catalytic amount of metal particles. The carrier liquid portion is a hydrocarbon / oxyhydrocarbon composition. The feedstock constitutes about 10 to about 60 weight percent of the slurry. The slurry is heated anaerobically to provide an elevated temperature of about 250° to about 455° C. and a pressure of about 20 to about 50 atmospheres that are maintained for a time period sufficient to provide a combustible liquid fuel at least 80 percent of which contains about 6 to about 21 carbon atoms per molecule.

Owner:CELLO ENERGY

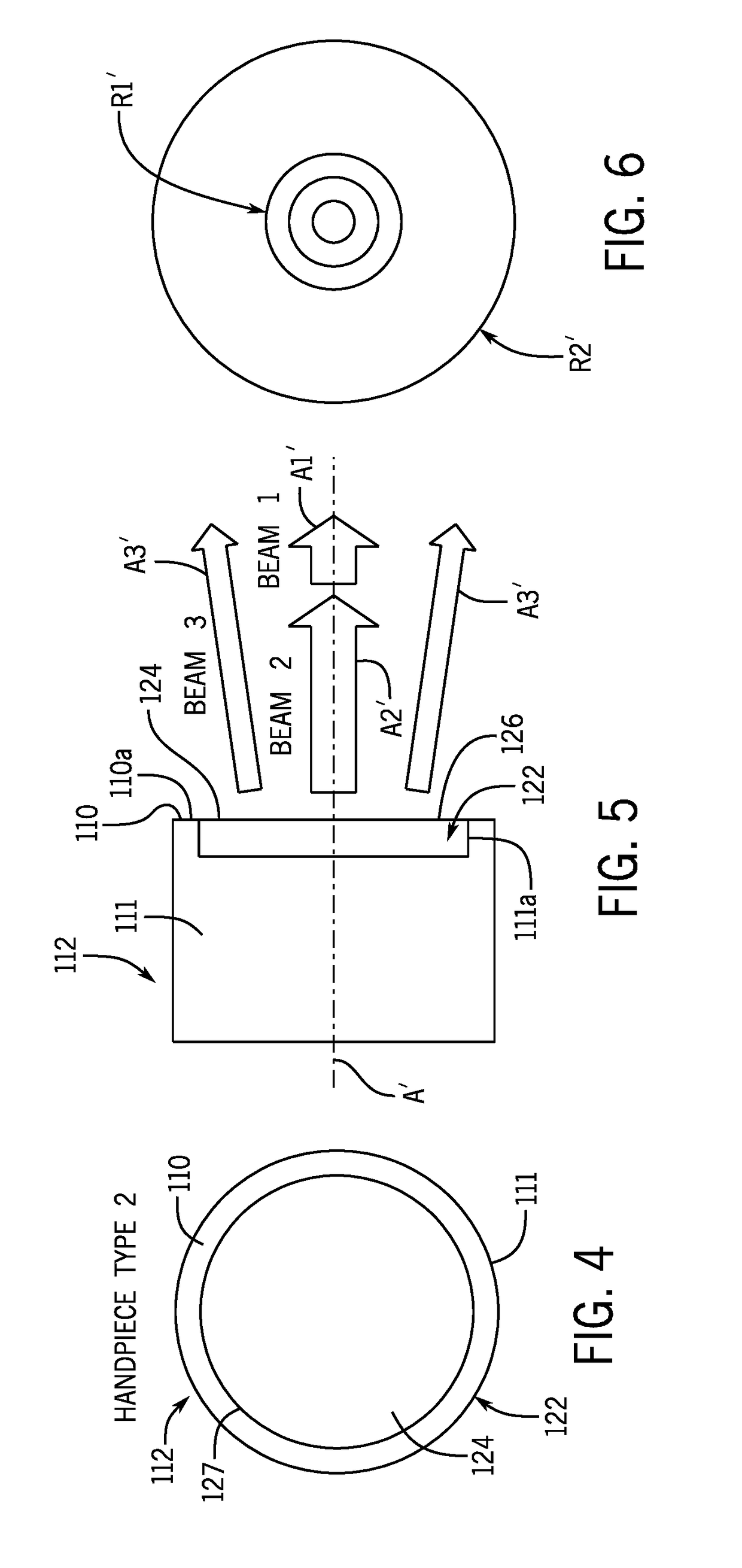

Dual wavelength laser treatment device

InactiveUS20150182283A1Reduce the impactImprove treatmentSurgical instrument detailsLight therapyTreatment effectHand held

Embodiments of the invention include a compact, lightweight, hand-held laser treatment device that combines the emissions of two separate laser energy sources into a common optical pathway for improved therapeutic effect. In some embodiments, the device includes a housing having separate first and second laser sources disposed within the interior thereof. In some embodiments, the laser energy emissions from the two internal laser sources can be individually or concurrently transmitted to a delivery tip of the device via a laser transmission path also defined within the interior of the housing. In some embodiments, the structural and functional features of the first and second laser sources, in concert with the unique architecture of the laser transmission path, can be configured to provide efficacy and efficiency in the operation of the device within the spatial constraints of the lightweight, hand-held housing thereof.

Owner:BIOLASE TECH INC

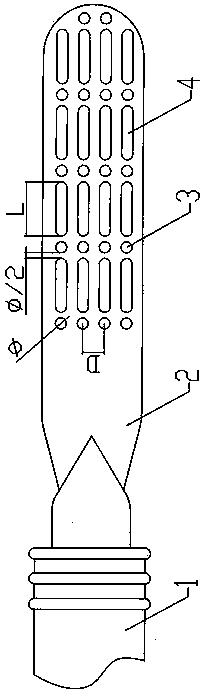

Bionic anti-sticking high-frequency electrotome bit

ActiveCN103892905AReduces tissue charring and adhesionGood for heat dissipationSurgical instruments for heatingMicrometerEngineering

The invention discloses a bionic anti-sticking high-frequency electrotome bit, and belongs to the technical field of energy-carrying minimally invasive medical instruments. The bionic anti-sticking high-frequency electrotome bit takes a plant leaf with anti-sticking and desorption functions as a prototype, a bionic surface form with round grooves and strip-shaped grooves distributed in a compound mode is machined in the surface of a high-frequency electric-conduction blade by simulating the surface form of the plant leaf, the round grooves and the strip-shaped grooves are distributed in the length direction of the blade alternatively, and the interval between the two types of forms is equal to the radius of the circle; the round grooves and the strip-shaped grooves are respectively distributed in the width direction of the blade at equal intervals, and the center distance is 460-700 micrometers; the diameter of each round groove is equal to the width of each strip-shaped groove and is 180-300 micrometers; the length of each strip-shaped groove is 800-1400 micrometers; the depth of each round groove and the depth of each strip-shaped groove are the same and are both 60-100 micrometers. The bionic anti-sticking high-frequency electrotome bit effectively reduces the carbonization and sticking phenomena of the tissue when the electrotome works at a high temperature, and is favorable for heat radiation, and the minimum sticking quality is reduced by about 39% compared with a smooth electrotome bit.

Owner:JILIN UNIV

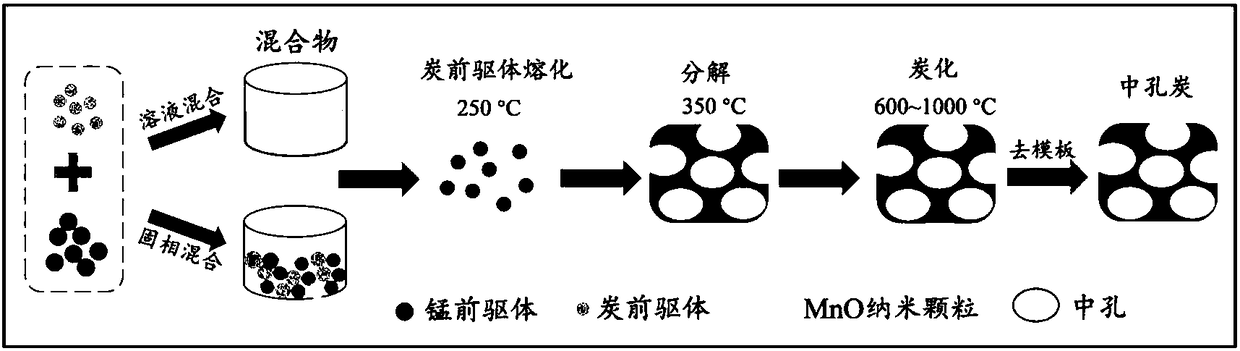

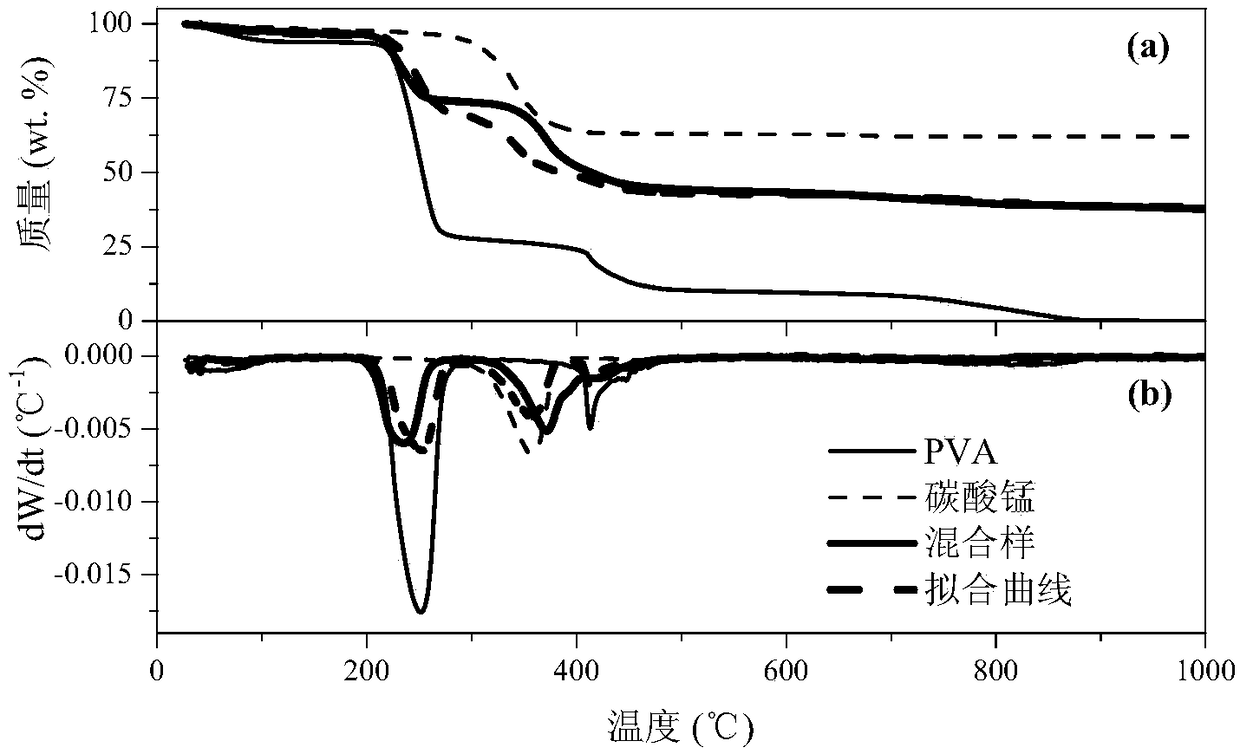

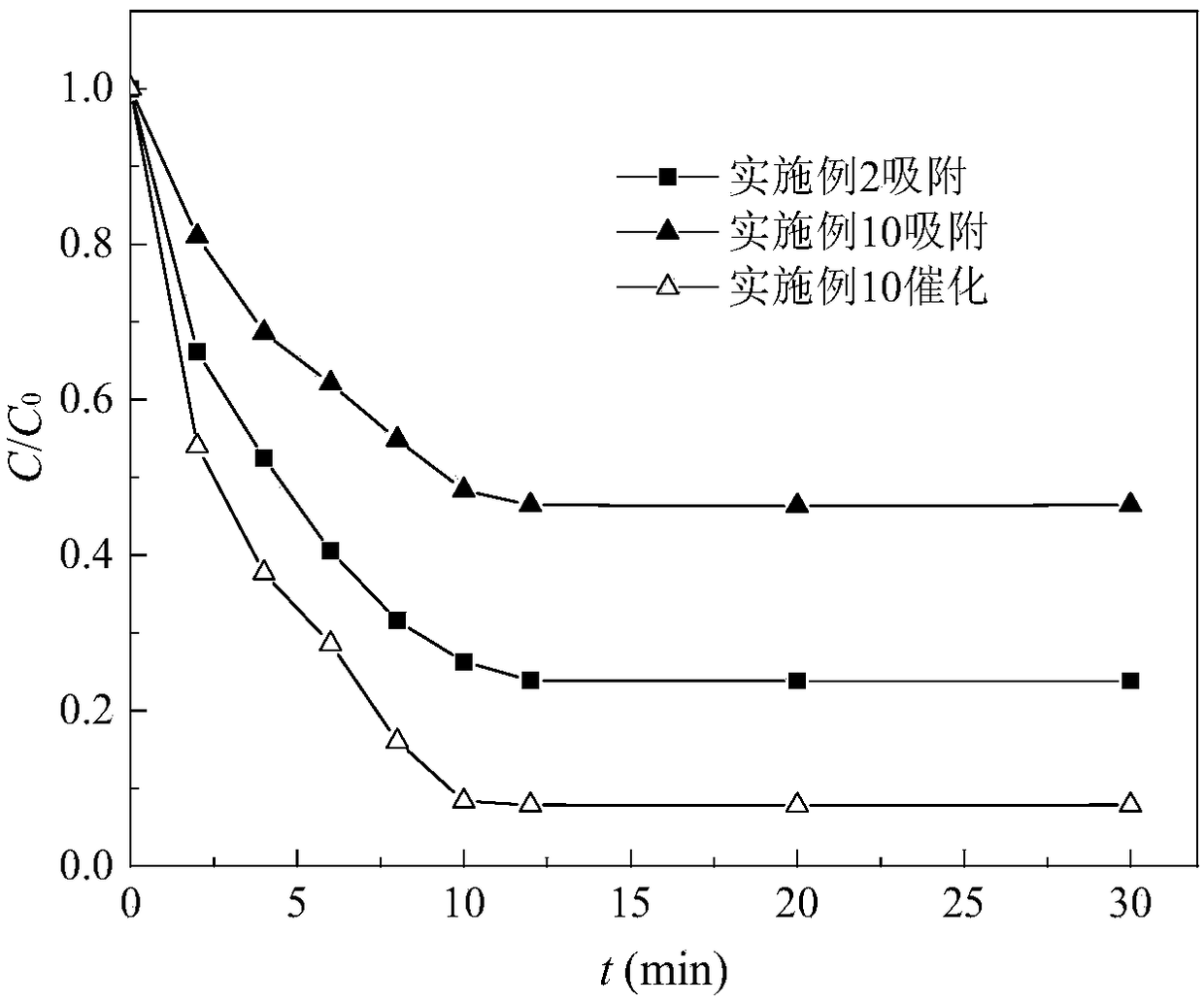

Mesoporous carbon prepared by using manganese compound, and preparation method thereof

ActiveCN109110742AAchieve recyclingLarge specific surface areaMaterial nanotechnologyCatalyst carriersNanoparticle coatingChemical compound

The invention discloses mesoporous carbon prepared by using a manganese compound, and a preparation method thereof. According to the method, manganese oxide crystal nanoparticles formed by decomposinga manganese compound during pyrolysis carbonization of a carbon precursor have mesoporous size characteristic, the manganese compound can catalyze the carbon precursor to form carbon, and the manganese compound is used as a template agent precursor so as to prepare mesoporous carbon. The method specifically comprises: 1, uniformly mixing a thermoplastic carbon precursor and a manganese compound through solid phase powder or a liquid phase solution; 2, carrying out high-temperature carbonizing on the mixture in an inert atmosphere to obtain a MnO-nanoparticle-coating carbide; and 3, uniformlymixing the carbide and a dilute acid solution, and removing MnO to obtain mesoporous carbon. According to the present invention, the prepared mesoporous carbon has characteristics of high specific surface area, high mesoporosity, large mesopore volume, easily-controlled pore structure and easily-controlled pore size distribution, can greatly reduce the carbonization temperature of the carbon precursor, and can be widely used in the fields of adsorption, catalysis and separation.

Owner:SICHUAN UNIV

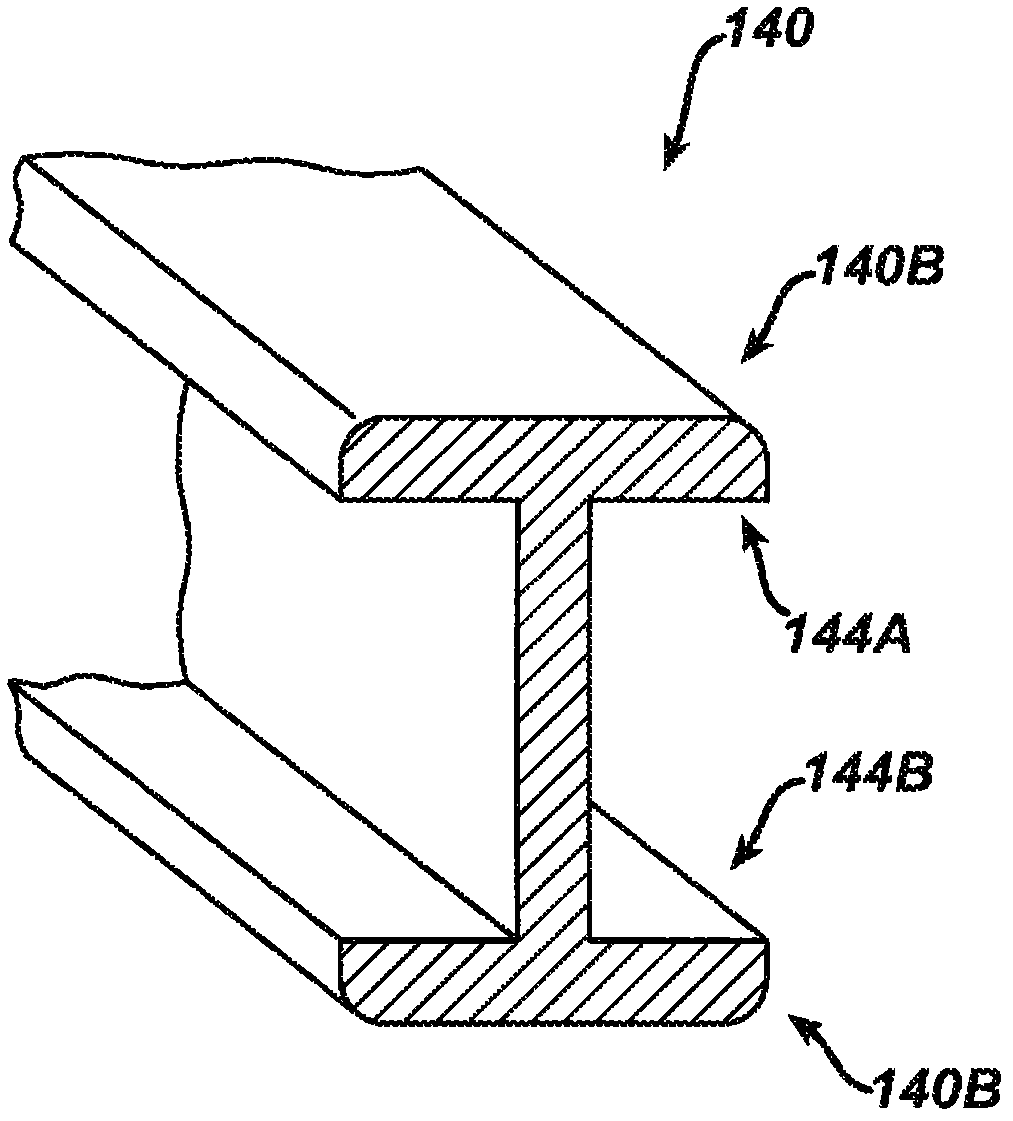

Electrosurgical instrument jaw structure with cutting tip

InactiveCN102119010AReduce dehydrationReduce charringSurgical instruments for heatingSurgical forcepsBiomedical engineeringElectrode

Owner:SURGRX

Method for preparing cyclopentanone from adipic acid

ActiveCN103044226AReduce unit consumptionSave cleaning timeCarbonyl compound preparation by condensationSodium bicarbonateCarbonization

The invention discloses a method for preparing cyclopentanone from adipic acid. The method comprises the following steps: (1) filling heat conduction oil in a reaction kettle, stirring, slowly adding a composite catalyst after heating to 100 DEG C, continuously dropping melted adipic acid after continuously heating to 250 DEG C, and controlling the reaction temperature to be 250 to 260 DEG C during the dropping process; (2) after condensing cyclopentanone generated during the reaction and water, collecting the condensed matter as hydrated ketone, and exhausting CO2 gas generated during the reaction from high altitude after being condensed; and (3) rectifying hydrated ketone obtained in the step (2) at normal pressure after being neutralized and salted out through sodium bicarbonate and sodium chloride to obtain a cyclopentanone finished product. The composite catalyst is prepared by mixing stannous oxide, borax, strontium carbonate and sodium dodecyl benzene sulfonate according to the mass ratio of 1:2:(6-8):0.05. According to the invention, the composite catalyst is adopted, so that the yield of cyclopentanone is improved, the polymerization and the carbonization of organic matters such as cyclopentanone and the like are reduced, produced hydrated ketone can reach more than 98%, and the unit consumption of adipic acid is low.

Owner:HUAIAN WAN BANG SPICE IND CO LTD

Ablation electrode assemblies and methods for using same

ActiveUS9788891B2Improve abilitiesImproved temperature correlationTemperature sensorsSurgical instruments for heatingEngineeringCardiac Ablation

Ablation electrode assemblies include an inner core member and an outer shell surrounding the inner core member. The inner core member and the outer shell define a space or separation region therebetween. The inner core member is constructed from a thermally insulative material having a reduced thermal conductivity. In an embodiment, the space is a sealed or evacuated region. In other embodiments, irrigation fluid flows within the space. The ablation electrode assembly further includes at least one thermal sensor in some embodiments. Methods for providing irrigation fluid during cardiac ablation of targeted tissue are disclosed that include calculating the energy delivered to irrigation fluid as it flows within the ablation electrode assembly through temperature measurement of the irrigation fluid. Pulsatile flow of irrigation fluid can be utilized in some embodiments of the disclosure.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

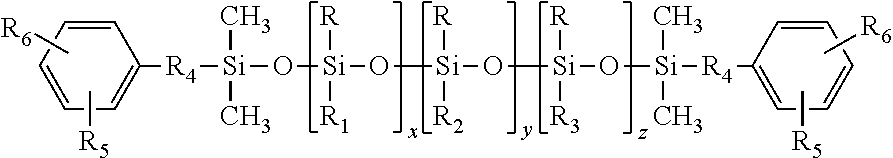

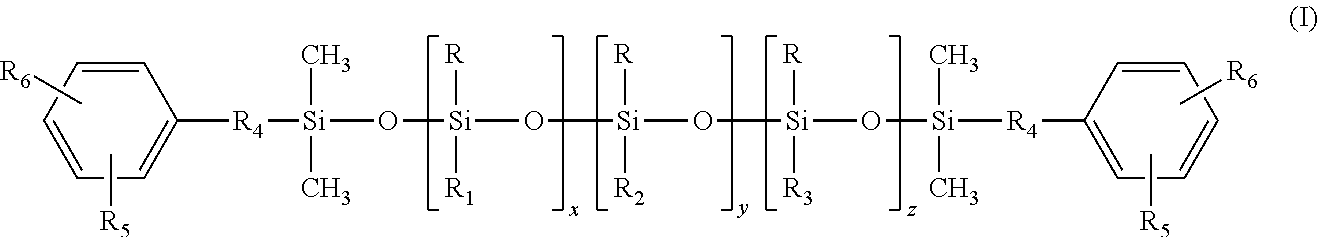

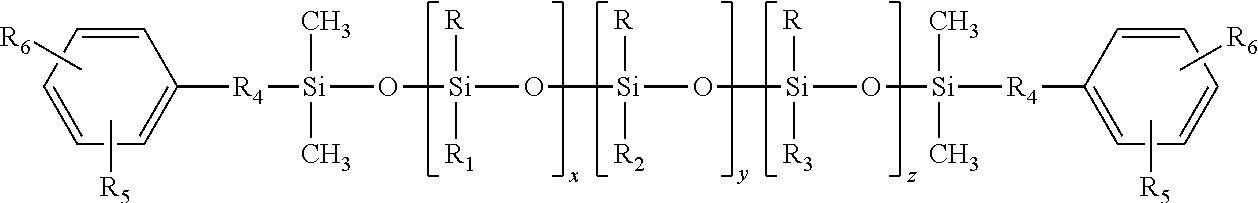

Polysiloxane co- or terpolymers and polymers made therefrom

Thermoplastic resin polymer compositions having a block of random polysiloxane co- or terpolymer structure, such as substituted phenyl-terminated polysiloxane co- or terpolymers having the general structure:provide improved flame resistance, optical clarity, and better low-temperature impact strength compared to conventional blends, additives, and copolymers. The substituted phenyl terminated polysiloxanes may be used to make various polysiloxane-thermoplastic resin polymer and polymer blends, as well as articles including such polysiloxane-thermoplastic resin polymer and blends.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

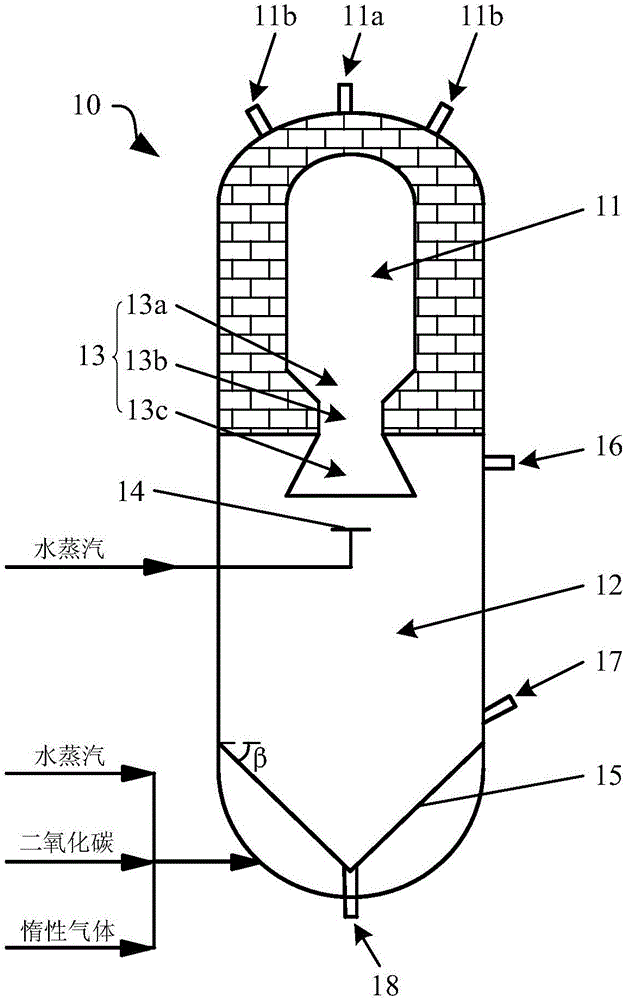

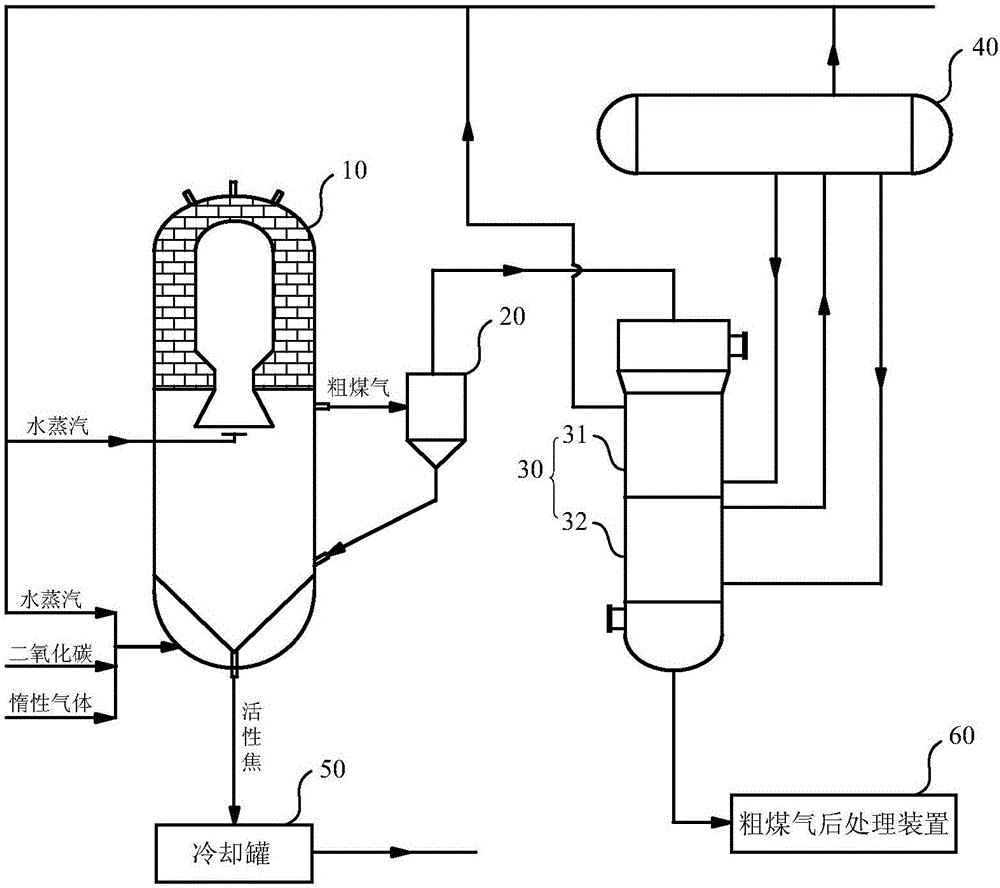

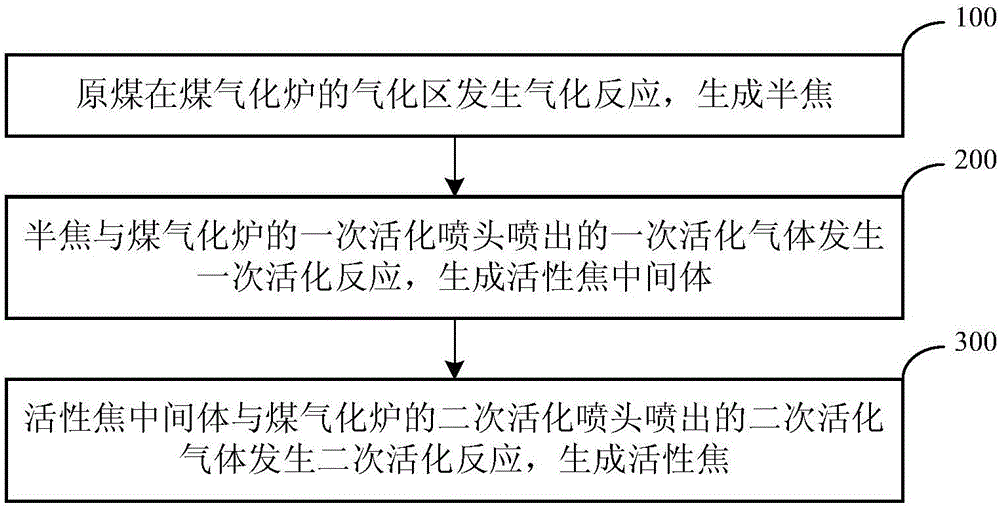

Coal gasification furnace, coal gasification system and preparation method of active coke

ActiveCN106190317AReduce millingReduce moldingGasification processes detailsGasification apparatus detailsEngineeringProduct gas

The invention discloses a coal gasification furnace, a coal gasification system and a preparation method of active coke and relates to the technical field of coal gasification. The invention aims at solving the problem of tedious and complex preparation process of the active coke in the prior art. The coal gasification furnace comprises a gasification area, an activation area and a communication channel, wherein the activation area is positioned under the gasification area; the communication channel is communicated with the gasification area and the activation area; the activation area is internally provided with a primary activation spraying nozzle and a secondary activation spraying nozzle; the secondary activation spraying nozzle is positioned under the primary activation spraying nozzle; semicoke and crude coal gas generated from gasification reaction of raw coal in the gasification area are introduced into the activation area through the communication channel; active coke intermediates are generated by primary activation reaction between the semicoke and primary activation gas sprayed from the primary activation spraying nozzle; the active coke is generated by secondary activation between the active coke intermediates and secondary activation gas sprayed from the secondary activation spraying nozzle.

Owner:ENN SCI & TECH DEV

Tissue sealing method

InactiveUS8636687B1Improve sealingEasy to controlEnemata/irrigatorsDiagnosticsVessel sealingImproved method

An improved method and equipment for tissue / vessel sealing is disclosed for the sealing, coagulation and transection of tissue during surgical procedures. The improvement is accomplished through better management of heat and moisture present during tissue treatment by having tissue grasping surfaces comprised of an outer non-conducting region and an inner conductive region, and including channels in the jaw assembly to direct steam and moisture away from surrounding tissue. The outer region follows the perimeter each jaw, isolating the treatment zone and preventing steam and excess heat from leaving the tissue treatment zone, reducing thermal margins and unintended patient burns. The outer region also prevents surrounding moisture from affecting the treatment zone and allowing more consistent results.

Owner:SPINNAKER MEDICAL

System for the production of synthetic fuels

InactiveUS20080295390A1Assist in downsizingReduce charringLiquid hydrocarbon mixtures productionLiquid carbonaceous fuelsParticulatesLiquid fuel

A system and method for producing synthetic fuels are disclosed in which a slurry comprised of a particulate solid portion and a carrier liquid portion is provided. The solid portion comprises (i) a feedstock of carbon-containing polymeric materials that are substantially free of each of halogen, sulfur and nitrogen atoms, and contain about 5 to about 25 percent by weight water, and (ii) a catalytic amount of metal particles. The carrier liquid portion is a hydrocarbon / oxyhydrocarbon composition. The feedstock constitutes about 10 to about 60 weight percent of the slurry. The slurry is heated anaerobically to provide an elevated temperature of about 250° to about 455° C. and a pressure of about 20 to about 50 atmospheres that are maintained for a time period sufficient to provide a combustible liquid fuel at least 80 percent of which contains about 6 to about 21 carbon atoms per molecule.

Owner:CELLO ENERGY

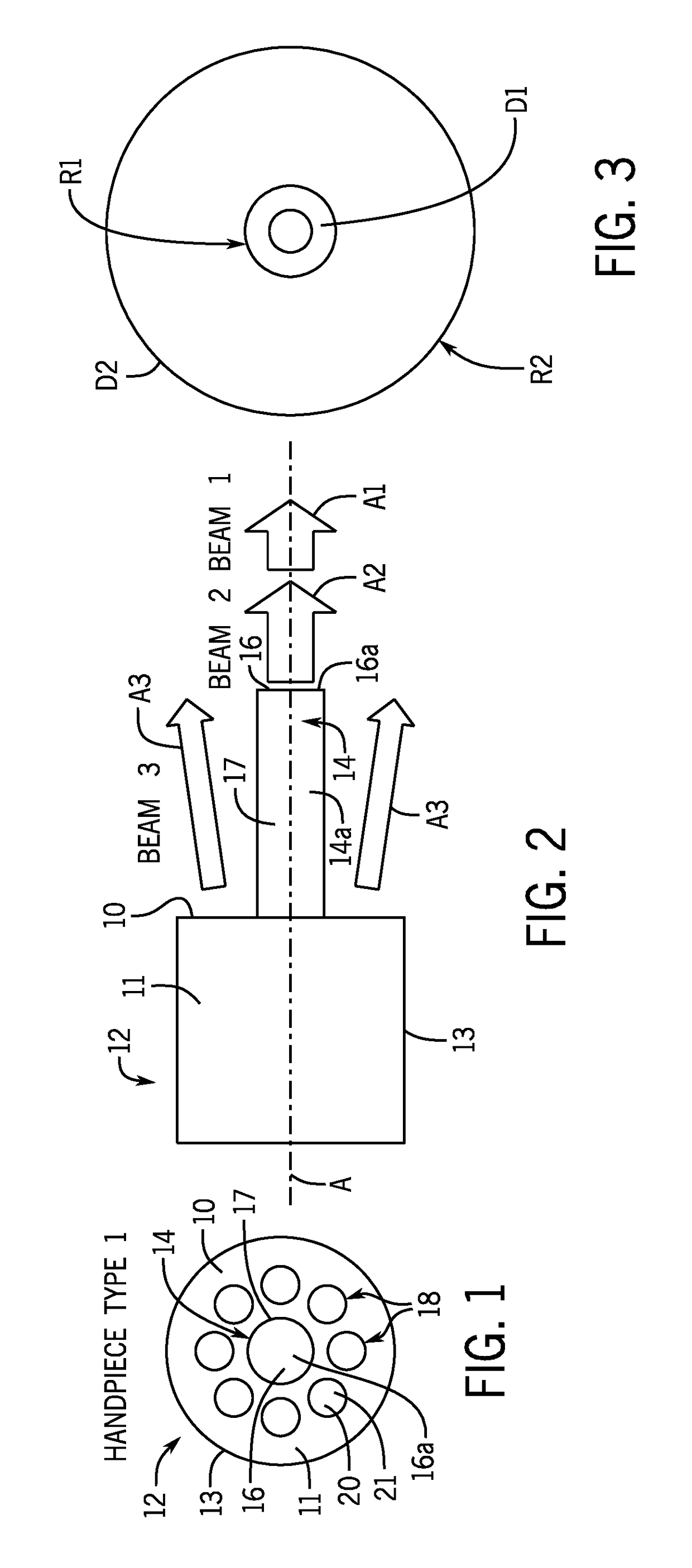

Multiple beam laser treatment device

ActiveUS10130424B2Improve treatmentGood curative effectSurgical instrument detailsLight therapyWound healingLight beam

Embodiments of the invention include a treatment device and corresponding treatment method for laser wound healing, the device and method making use of the simultaneous action of multiple laser types and laser wavelengths which are applied at human tissue. The treatment device generally includes a laser system and a hand-piece which is coupled to the laser system. The hand-piece is designed so that one or multiple laser beams are applied at relatively small spot and at a relatively high power level, and are surrounded by a relatively large spot of another laser beam with a relatively low power level. In a preferred implementation, the hand-piece is adapted to facilitate the emission of first and second laser beams together with a third laser beam which is delivered at a different spatial profile in comparison to the first and second laser beams.

Owner:BIOLASE INC

DNA immunoadsorbent, and preparation method thereof

ActiveCN108246264AHigh strengthReduce sheddingOther blood circulation devicesOther chemical processesImmunosorbentsPolystyrene

The invention discloses a DNA immunoadsorbent and a preparation method thereof. The preparation method comprises the following steps: 1) preparation of polystyrene-based macroporous adsorption resin containing aldehyde groups; and 2) grafting and immobilization of DNA ligand. The DNA immunosorbent prepared by using the method directly adopts the macroporous adsorption resin as a carrier and replaces activated carbon or carbonized resin with the macroporous adsorption resin; and the toughness of a resin skeleton is retained and the risk of falling of particles is greatly reduced due to the omitting of carbonization and activation procedures during production. In addition, a chemical grafting method is employed to directly immobilize the DNA ligand to the macroporous adsorption resin, and the DNA ligand linked by a chemical bond is firmly immobilized and hardly falls off; moreover, without embedding and covering of coating materials like collodion, DNAs immobilized on the surface of theresin and inside the pores of the resin can exert maximum adsorption effect.

Owner:JAFRON BIOMEDICAL

Multi-rate fluid flow and variable power delivery for ablation electrode assemblies used in catheter ablation procedures

ActiveUS9855094B2Improve abilitiesImproved temperature correlationSurgical navigation systemsCatheterControl systemEngineering

A system for providing irrigation fluid during ablation of tissue includes a catheter, an electrode assembly, at least one thermal sensor adapted to be connected to the catheter, and a control system. The electrode assembly is adapted to be connected to an ablation generator. The thermal sensor is adapted to be operatively connected to an electronic control unit (ECU). The ECU receives as an input temperature measurement data from the thermal sensor; determines a power delivery rate value for the ablation generator responsive to the temperature measurement data; and outputs the power delivery rate value. The control system also delivers irrigation fluid to the irrigated catheter at a first flow rate in a first time period and at a second flow rate in a second time period that is temporally after the first time period. The second flow rate is at least half of the first flow rate.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

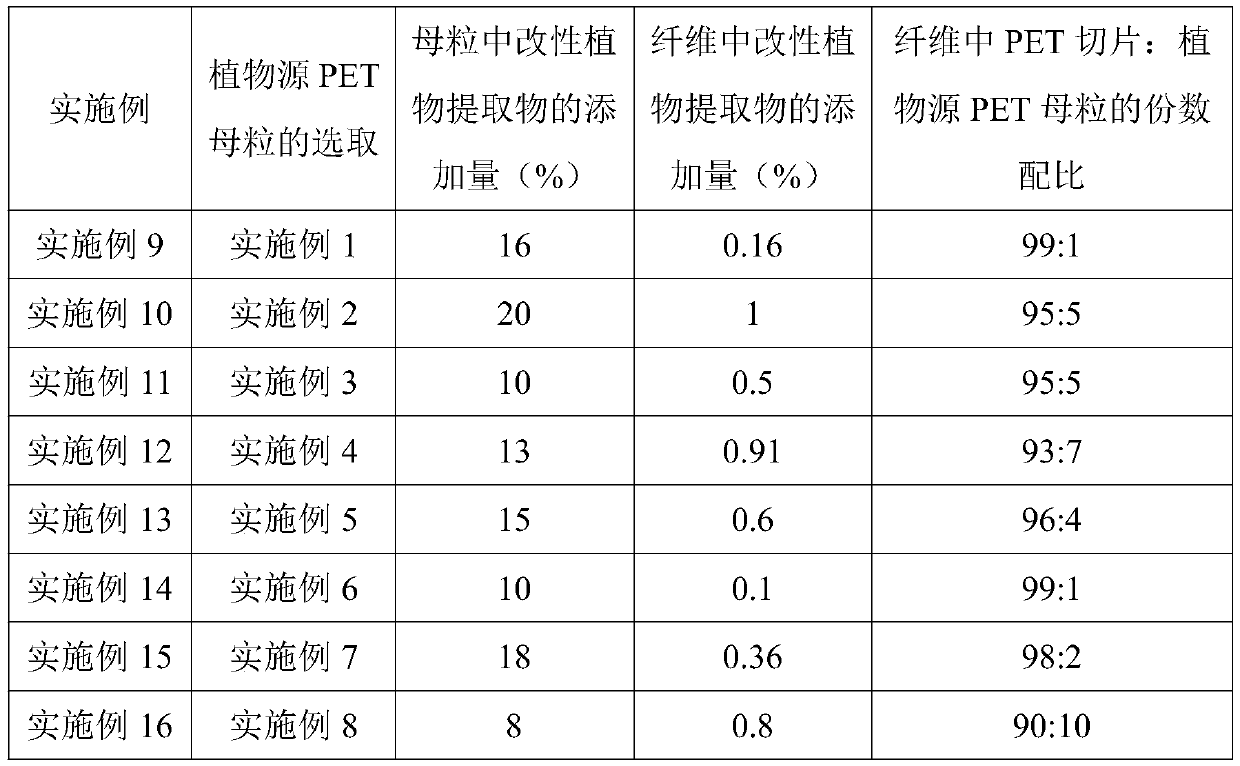

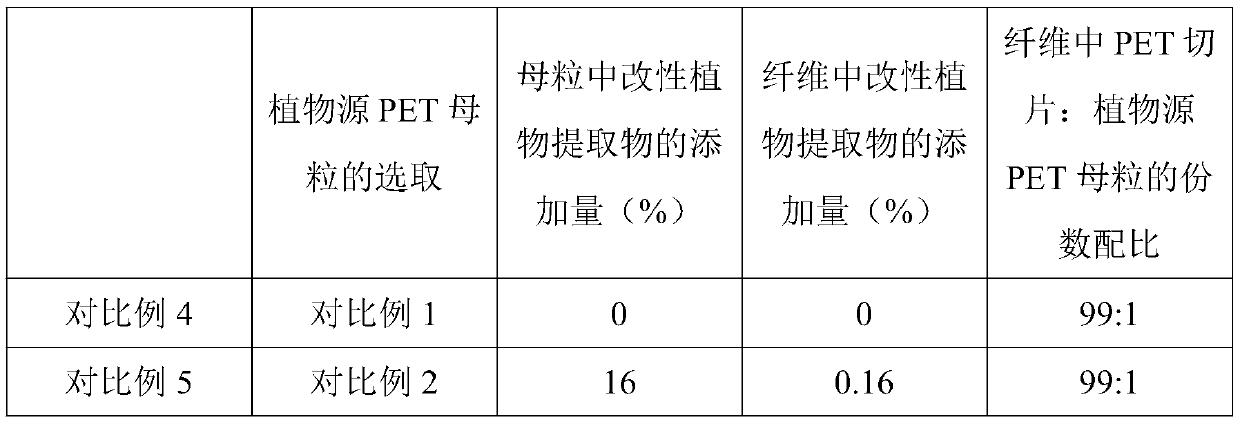

Plant-derived PET master batch, preparation method and application thereof

The invention relates to a plant-derived PET master batch and a product prepared from the same. According to the invention, anti-carbonization additives including chitin and starch are added into a plant extract, and a modified plant extract is obtained after internal mixing of an internal mixer, so that carbonization in a high-temperature melting process is reduced, and the components of the plant extract are not lost; PET slices and the modified plant extract are blended and melted to prepare plant-derived PET master batch, wherein the master batch is uniform in particle size; and after fiber spinning, film making, bottle blowing or plastic making, the product has fragrance, is helpful for releasing negative ions, and has antibacterial performance, and the moisture regain of fibers is improved.

Owner:BESTEE MATERIAL (TSINGTAO) CO LTD +2

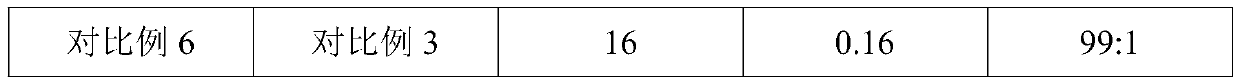

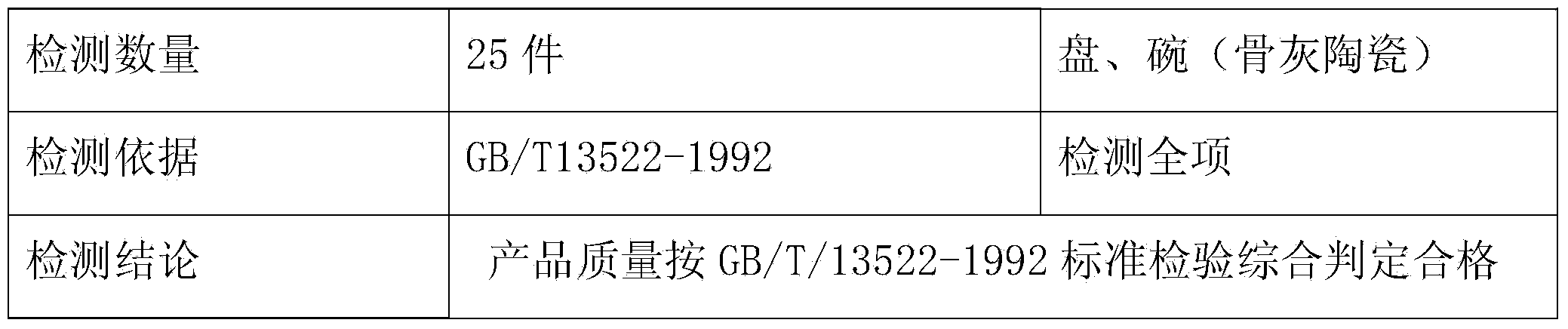

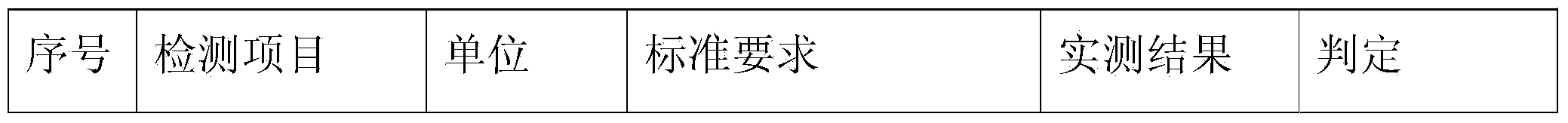

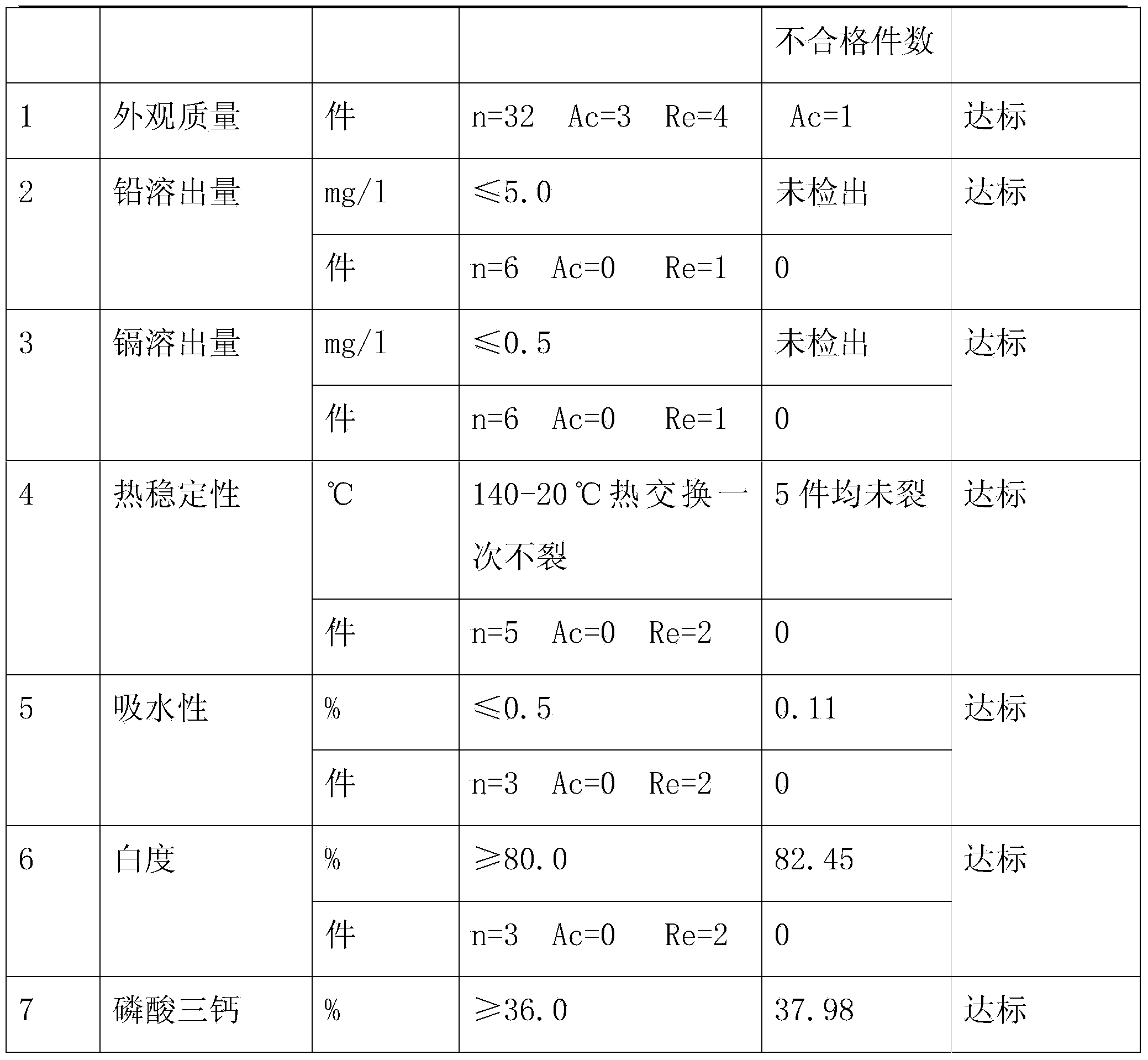

Preparation method for bone-ash ceramic

A preparation method for bone-ash ceramic comprises the following steps: preparing raw materials, specifically performing mechanical beating on raw materials, sieving with a 200 mesh sieve for usage; performing mixing pulping on the prepared raw materials for usage; utilizing pressure to form a green body; drying at 500-600 DEG C; after drying is performed, placing at 0-5 DEG C for 1-2 h; glazing at normal temperature; and putting in a kiln and sintering for forming. According to the preparation technology, roasting for obtaining a green body can be finished at a relatively low temperature, and the prepared bone-ash ceramic has excellent heat stability, high qualified rate and low production cost.

Owner:上海景潮酒店用品有限公司

Wood-plastic composite material and preparation method thereof

The invention discloses a wood-plastic composite material which is prepared from the following raw materials in parts by weight: 0.1-5 parts of cellulose nano fiber, 5-30 parts of plant fiber powder,30-90 parts of polyvinyl chloride particles, 25-80 parts of nano calcium carbonate, 0.5-2 parts of nano zinc oxide, 1-5 parts of an AC foaming agent, 0.5-2 parts of a coupling agent and 0.5-3 parts ofa lubricant. In the wood-plastic composite material disclosed by the invention, the cellulose nano fiber is added, which is nanoscale fiber obtained by defibrillation of natural plant fiber and has the properties of great length-diameter ratio, large specific surface area and low thermal expansion and can effectively improve the toughness and impact strength of the wood-plastic composite material. Moreover, the cellulose nano fiber can serve as a foaming nucleation point in the composite material foaming process, and under the action of the foaming agent, is helpful in forming microporous bubbles of the composite material, reducing the bubble size and improving the uniformity of the bubble structure, wherein the microporous structure can make the material light and also can adsorb organicvolatile gases or allergic matters such as formaldehyde generated indoors.

Owner:HUNAN ACAD OF FORESTRY

Irrigant distribution system for flexible electrodes

ActiveUS8979840B2Improved temperature correlationInhibition formationUltrasound therapySurgical instruments for heatingDistribution systemEngineering

Ablation electrode assemblies having a longitudinal axis include an electrode core member; an electrode shell; and an irrigant distribution element. The electrode core member comprises a thermal insulator and has a first end; a second end; and at least one irrigation passageway. The electrode shell comprises an electrically conductive material, defines an inner volume, and has a first end; and a second end. The second end of the electrode shell is configured for connection to the first end of the electrode core member. The electrode shell is sufficiently flexible for deflection of the distal end of the electrode shell relative to the longitudinal axis of the ablation electrode assembly. The irrigant distribution assembly comprises a first end; and a second end, wherein the second end of the irrigant distribution element defines a circumferential irrigation port between the irrigant distribution element and the electrode core member.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

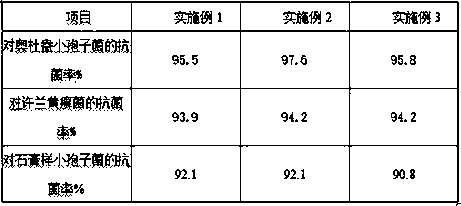

Semen cassiae composite fiber of polyester carrier and preparing method of fiber

InactiveCN110106577AKeep aliveReduce churnMelt spinning methodsMonocomponent polyesters artificial filamentFiberPolyester

The invention provides a preparing method of a semen cassiae composite fiber of a polyester carrier. The method includes the steps of preprocessing semen cassiae extracts, preparing a wall material, preparing a microcapsule and conducting spinning. The semen cassiae composite fiber of the polyester carrier is high in tow evenness, slippery in silk layer and good in package forming and has the antibacterial rate of 95.5-97.6% for microsporum odouins, the antibacterial rate of 93.9-94.2% for trichophyton schoenleini, the antibacterial rate of 90.8-92.1% for microsporum gypseum, the total anthraquinone wastage rate of 16.36-23.33% and the chrysophanol wastage rate of 6.38-15.79%. The semen cassiae composite fiber has the advantages of keeping the activity of the semen cassiae extracts and reducing the wastage rate and solves the charring problem in the high-temperature fusion spinning process of the semen cassiae extracts and polyester chips.

Owner:ZHONGKE TEXTILE RES INST QINGDAO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com