Semen cassiae composite fiber of polyester carrier and preparing method of fiber

A composite material fiber and cassia seed technology, which is applied to polyester carrier cassia seed composite material fiber and its preparation, in the field of composite material fiber, can solve problems such as fiber strength decline, solve the problem of carbonization, reduce the loss rate, and have no unevenness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

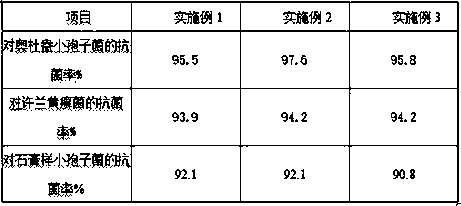

Examples

Embodiment 1

[0038] Embodiment 1 A kind of cassia seed composite material fiber of polyester carrier and its preparation method

[0039] The preparation method of the cassia seed composite material fiber of a kind of polyester carrier of the present embodiment, specifically comprises:

[0040] Step 1: Pretreatment of Cassia Seed Extract

[0041] (1) Selection of raw materials

[0042] The raw material is cassia seed extract;

[0043] The cassia seed extract has a yellow-brown powder shape, 99.5% of which pass through a 10,000-mesh sieve, a moisture content of 2.5%, a heavy metal content of ≤10ppm, a total anthraquinone content of 1.2%, and a chrysophanol content of 0.47%. Specifications: 1 kg / Bag or cardboard drum (25kg / drum), with a shelf life of 2 years.

[0044] (2) Vacuum dipping

[0045] Mix the above-mentioned cassia seed extract according to the ratio of extract: deionized water of 1:20, stir evenly, place in a vacuum-tight container with a vacuum of 20-25 inches of mercury for...

Embodiment 2

[0060] Embodiment 2 A kind of cassia seed composite material fiber of polyester carrier and its preparation method

[0061] The preparation method of the cassia seed composite material fiber of a kind of polyester carrier of the present embodiment, specifically comprises:

[0062] Step 1: Pretreatment of Cassia Seed Extract

[0063] (1) Selection of raw materials

[0064] The raw material is cassia seed extract;

[0065] The cassia seed extract has a yellow-brown powder shape, 99.5% of which pass through a 10,000-mesh sieve, a moisture content of 2.5%, a heavy metal content of ≤10ppm, a total anthraquinone content of 1.1%, and a chrysophanol content of 0.38%. Specifications: 1 kg / Bag or cardboard drum (25kg / drum), with a shelf life of 2 years.

[0066] (2) Vacuum dipping

[0067] Mix the above cassia seed extract according to the ratio of extract: deionized water of 1:22, stir evenly, place in a vacuum airtight container with a vacuum degree of 23 inches of mercury for di...

Embodiment 3

[0082] Embodiment 3 A kind of cassia seed composite material fiber of polyester carrier and its preparation method

[0083] The preparation method of the cassia seed composite material fiber of a kind of polyester carrier of the present embodiment, specifically comprises:

[0084] Step 1: Pretreatment of Cassia Seed Extract

[0085] (1) Selection of raw materials

[0086] The raw material is cassia seed extract;

[0087] The cassia seed extract has a yellow-brown powder shape, 99.5% of which pass through a 10,000-mesh sieve, a moisture content of 3.5%, a heavy metal content of ≤10ppm, a total anthraquinone content of 1.2%, and a chrysophanol content of 0.47%. Specifications: 1 kg / Bag or cardboard drum (25kg / drum), with a shelf life of 2 years.

[0088] (2) Vacuum dipping

[0089] Mix the above cassia seed extract according to the ratio of extract: deionized water of 1:30, stir evenly, place in a vacuum airtight container with a vacuum of 25 inches of mercury for dipping t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com