Patents

Literature

72results about How to "Flat end" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

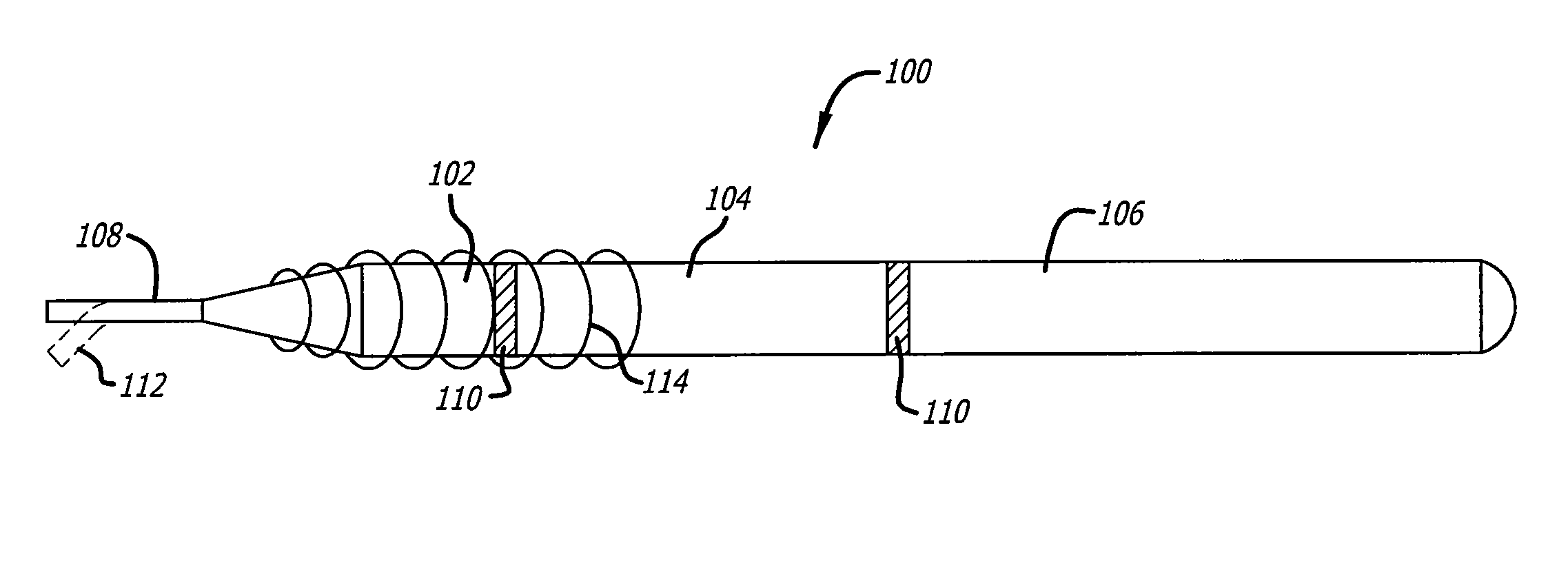

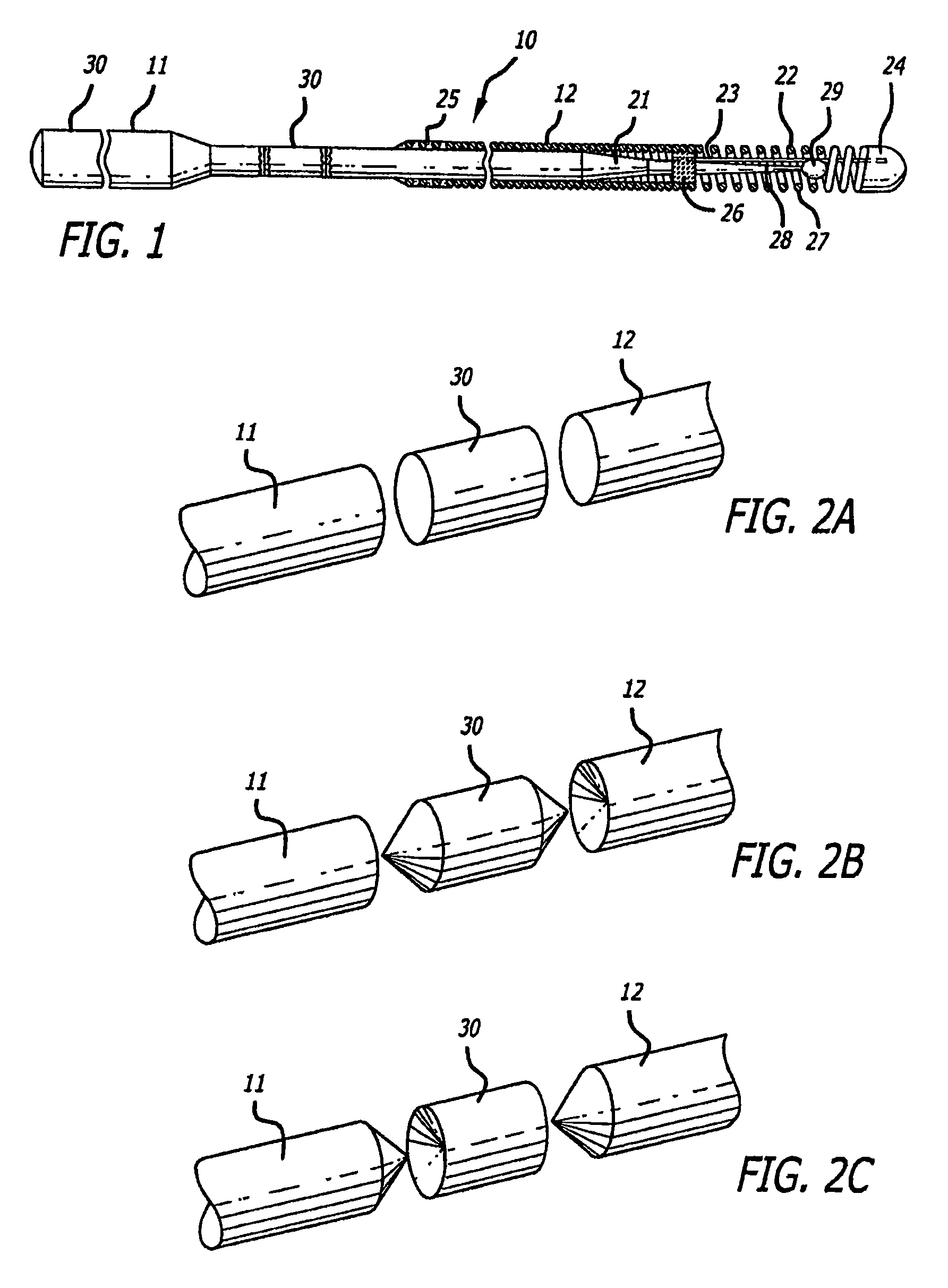

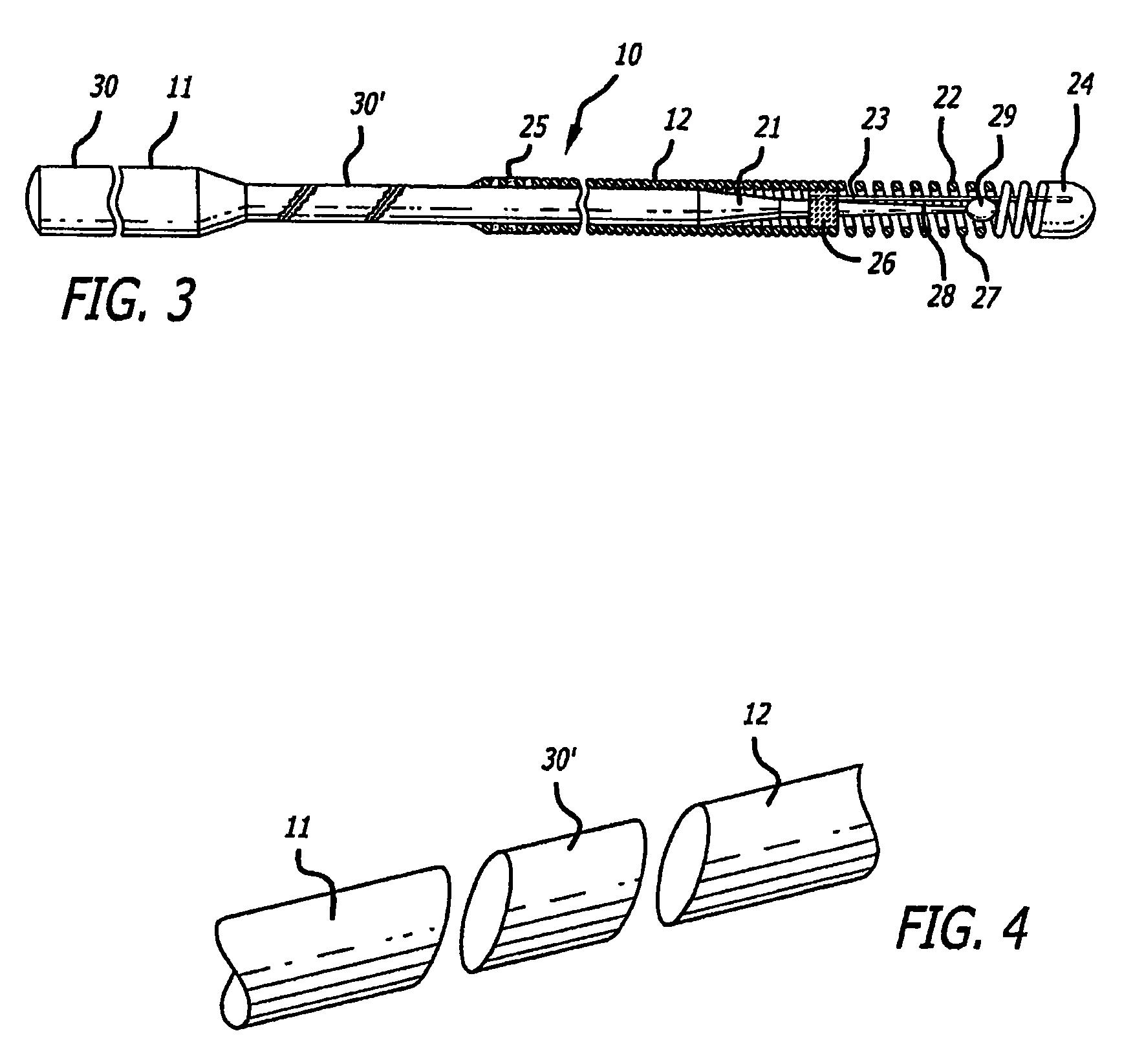

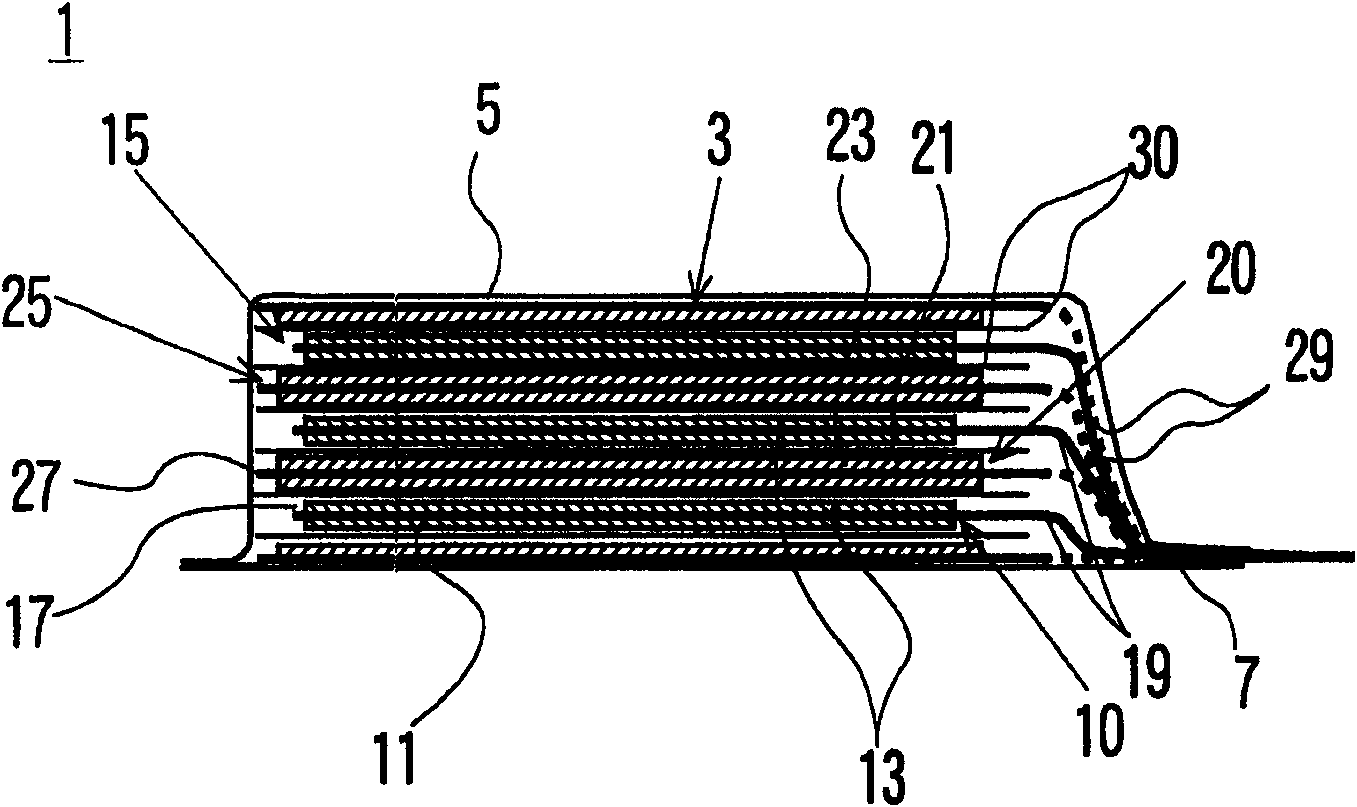

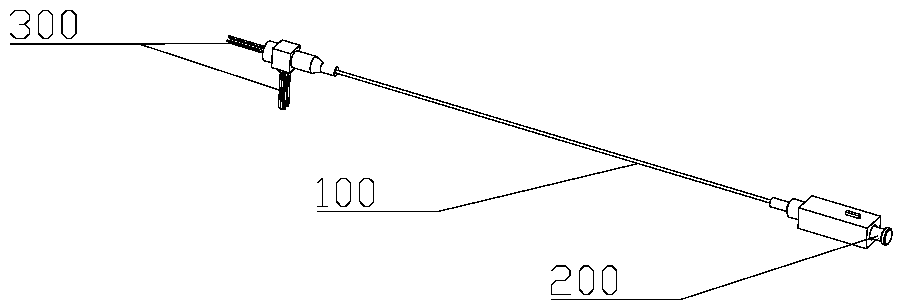

Guide wire with core having welded wire segments

InactiveUS7998090B2Enhanced compressive and tension and torsion strengthDifferent advantagesGuide wiresDiagnostic recording/measuringFriction weldingMetal alloy

An intravascular guide wire having two core materials joined together without the use of a connector tube or sleeve, the core materials being stainless steel and pseudoelastic metal alloy, nitinol. The core materials are joined to each other through an intermediate transition piece made essentially of nickel, which is welded on either side to the two core materials. In a multi-segment intravascular guide wire, discrete, high modulus and medium modulus core portions of different materials are welded to a shapeable, low modulus distal core portion made of a third material having a flattened, shapeable section at a most distal end that is not welded to but made from the distal core portion, so the flattened, shapeable section can be deformed to create a steerable tip. Processes such as simultaneous resistance and friction welding can be used to join the core portions.

Owner:ABBOTT CARDIOVASCULAR

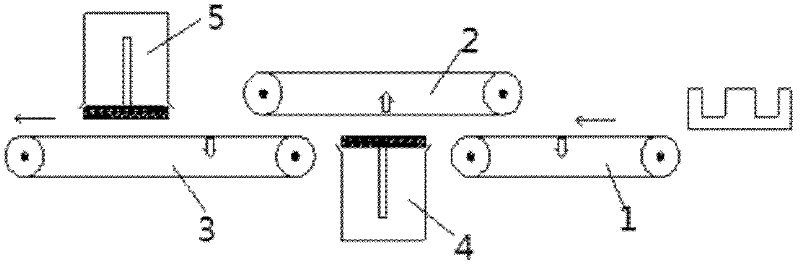

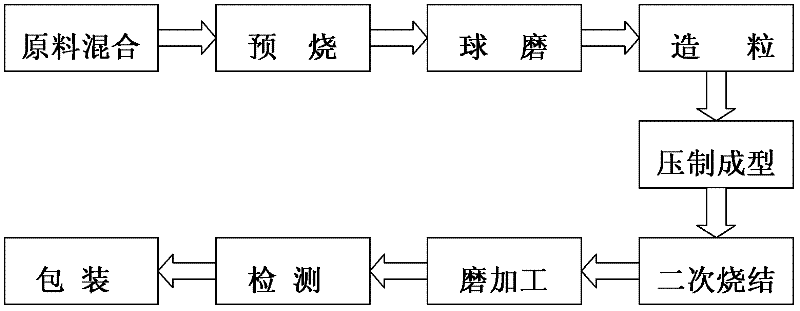

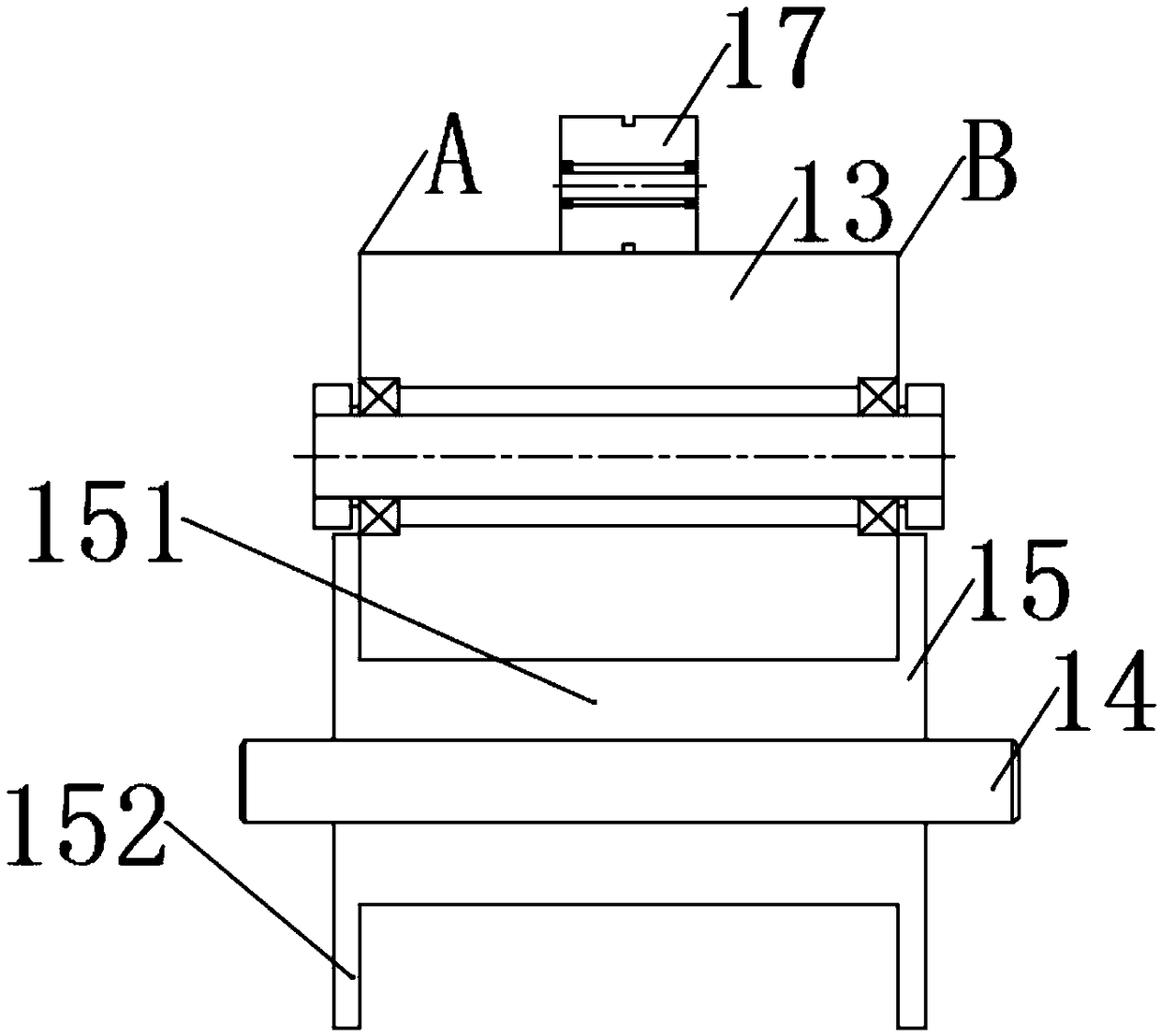

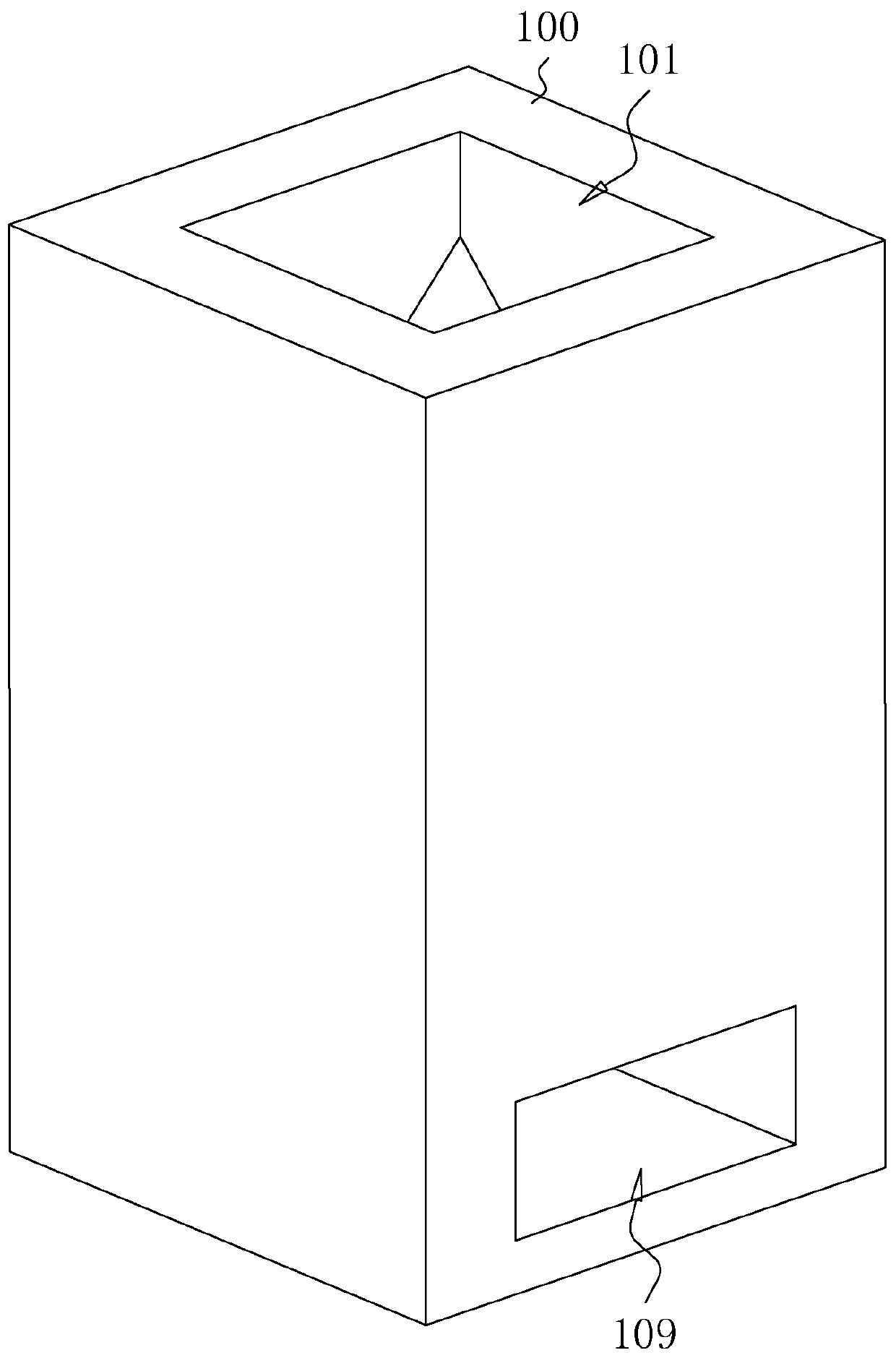

Method for producing soft magnetic ferrite core

InactiveCN102643083AImprove permeabilityLow dissipation factorEdge grinding machinesPolishing machinesInitial permeabilitySoft magnet

The invention discloses a method for producing a soft magnetic ferrite core. The method comprises the following steps of: mixing of raw materials, pre-sintering, ball milling, compression moulding, secondary sintering, grinding and detection, wherein an integral magnetic-attraction double-sided grinding machine is adopted in the grinding process. The magnetic core produced by the method has high magnetic conductivity and low loss factor, and energy sources can be saved; the magnetic core has uniform color, flat end surface and bright and clean surface; the ball milling as well as the uniformity and sphericity of the mixed material are improved; a low-temperature sintering technology is adopted, the heating rate and cooling rate of each stage are adjusted, the ferrite transformation of the material is promoted, and the grain size can be effectively controlled; and the initial permeability and temperature characteristic are improved.

Owner:ANHUI TAIDE ELECTRONICS TECH

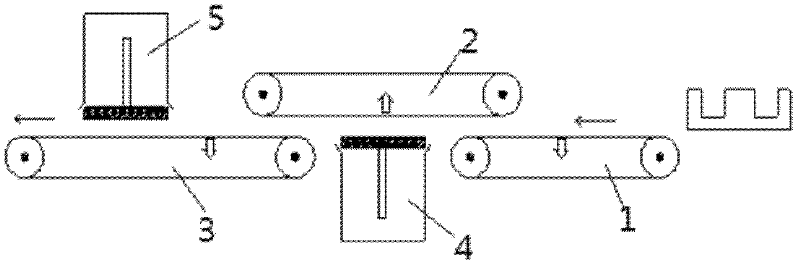

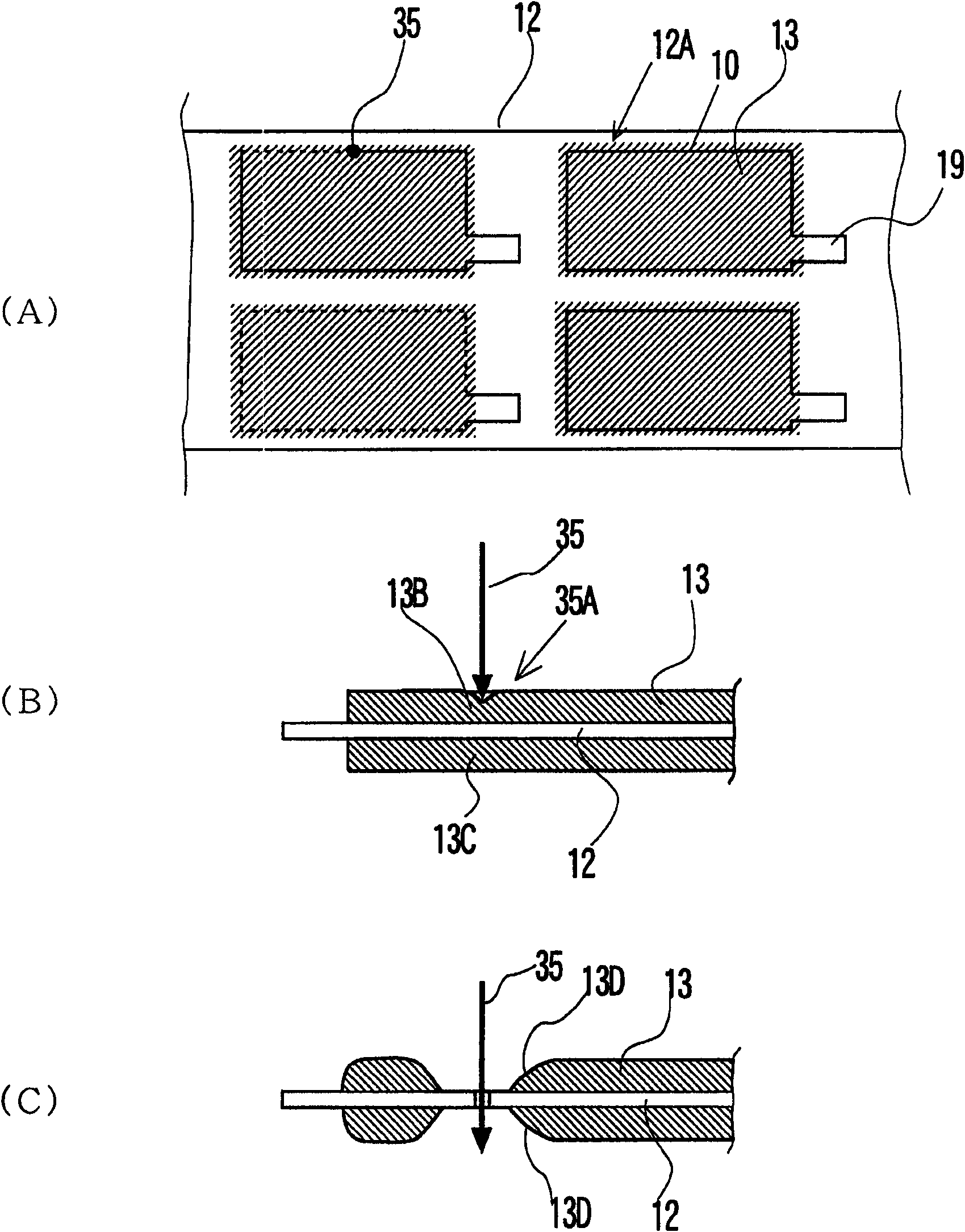

Stacked secondary battery and method of manufacturing the same

InactiveCN101640280AImprove adhesion strengthExcellent charge and discharge characteristicsElectrode manufacturing processesLarge-sized flat cells/batteriesSlurryBiomedical engineering

A stacked secondary battery is formed by laying plate-shaped positive electrodes and plate-shaped negative electrodes one on the other by way of separators, wherein a collector is disposed at the front end of the end facet of each of the positive electrodes or the negative electrodes as viewed in a direction orthogonal relative to the stacking direction and has an active substance layer formed onthe collector by applying slurry of particles of an active substance with a gap separating it from the front end or the electrode active substance layer is made to show a thickness varying from the front end toward the inside.

Owner:NEC ENERGY DEVICES LTD

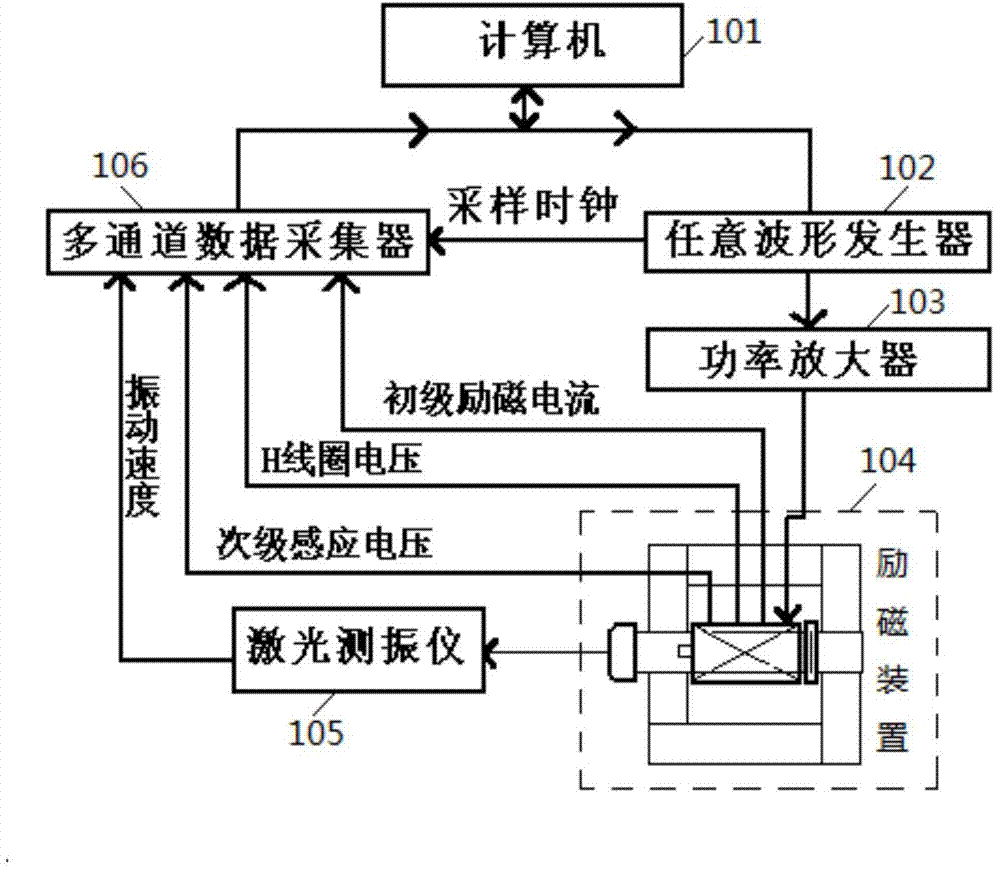

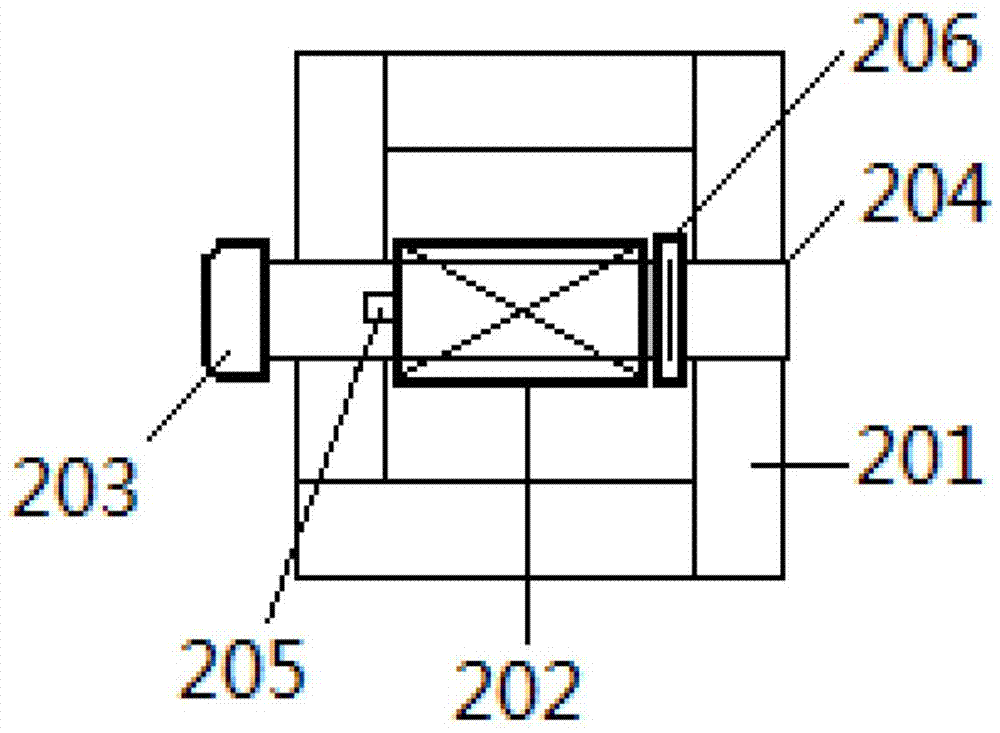

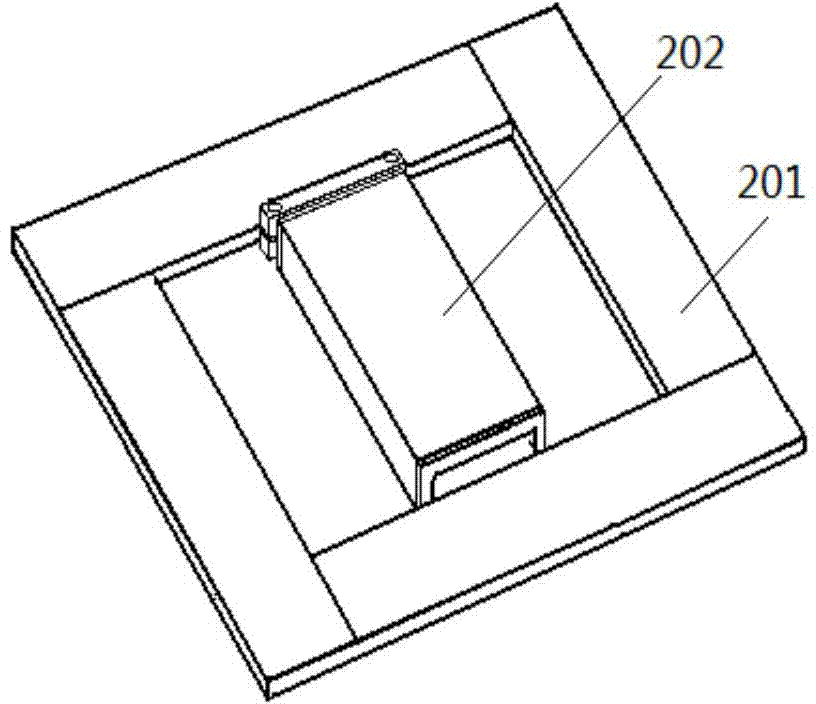

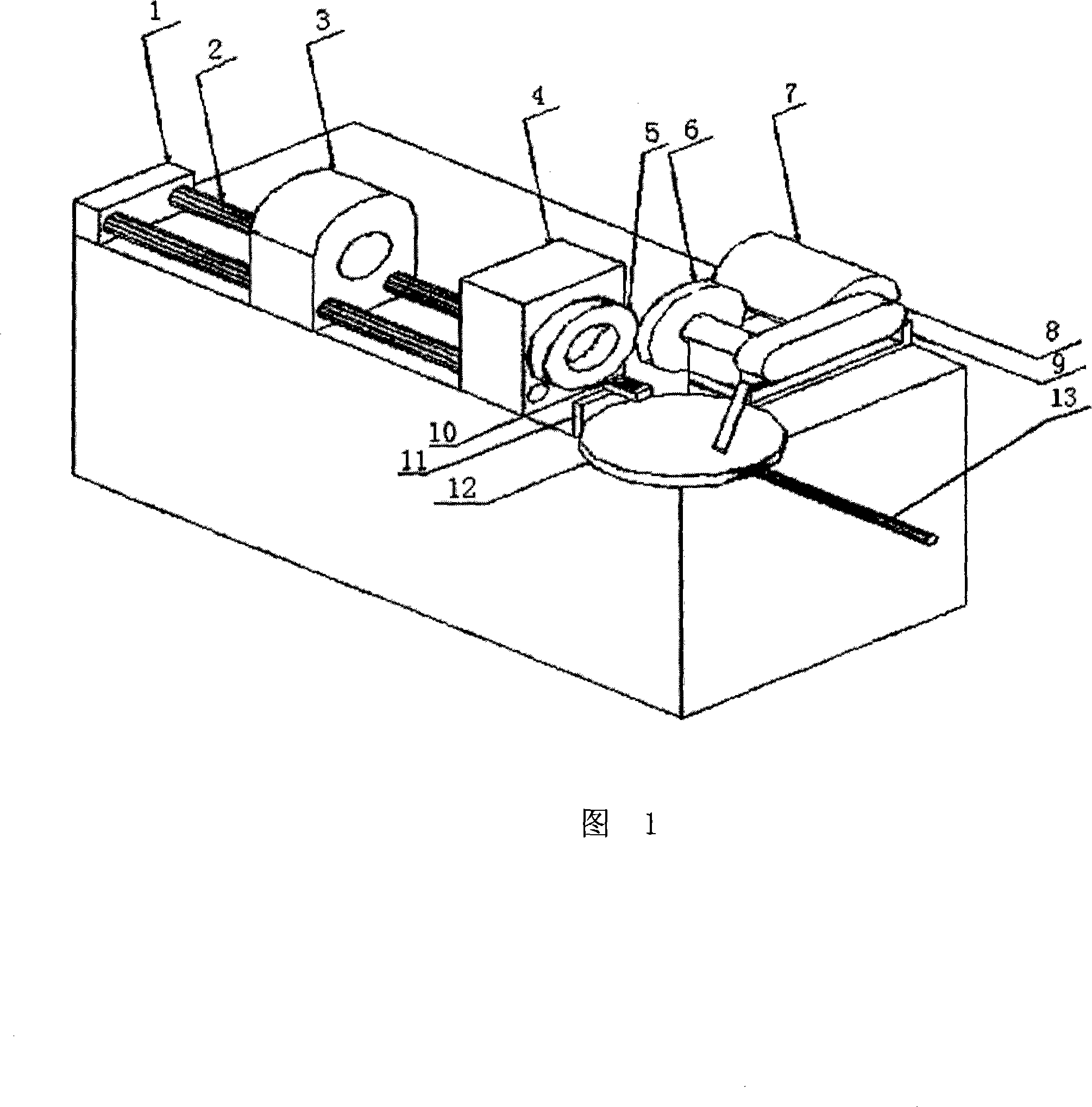

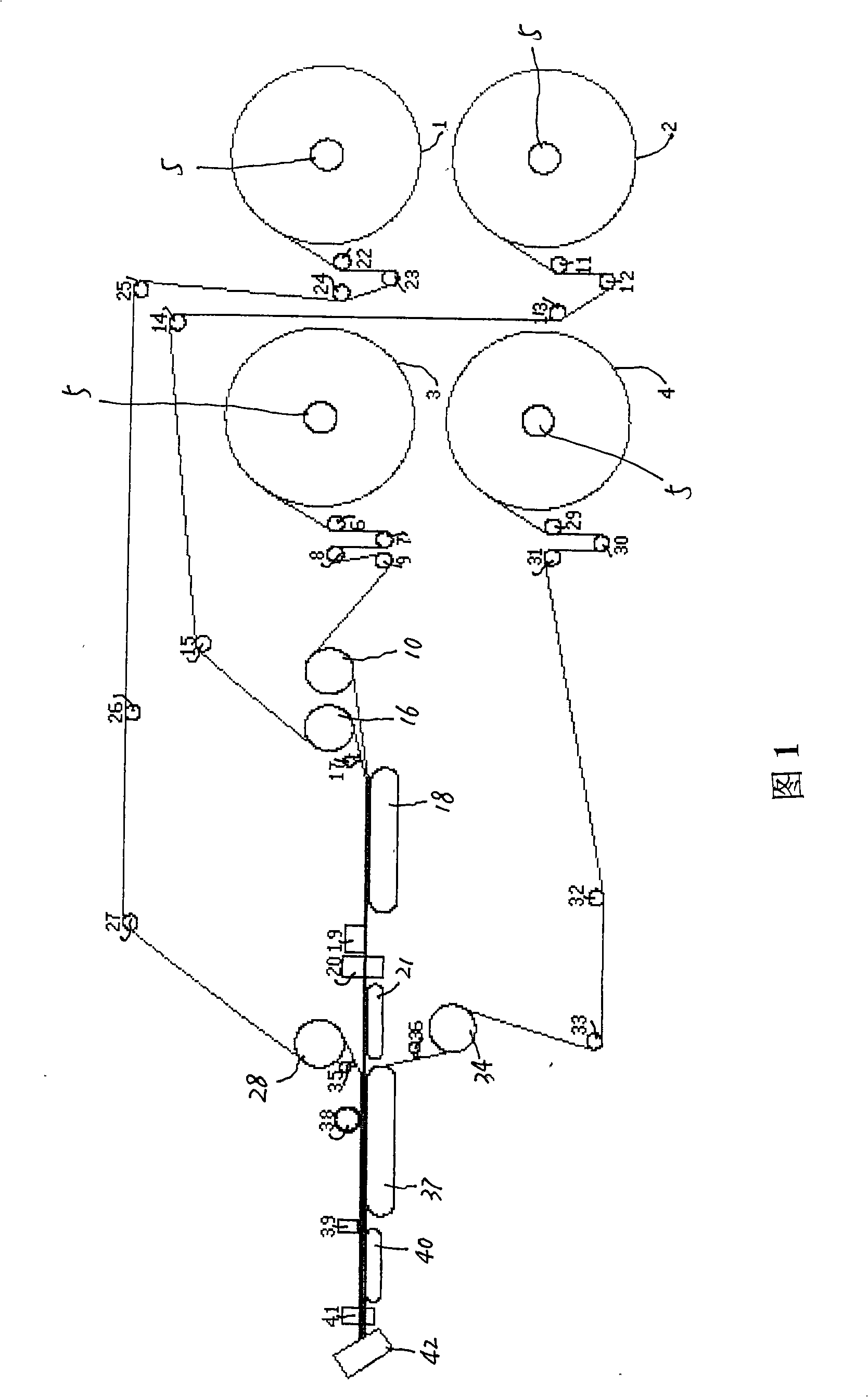

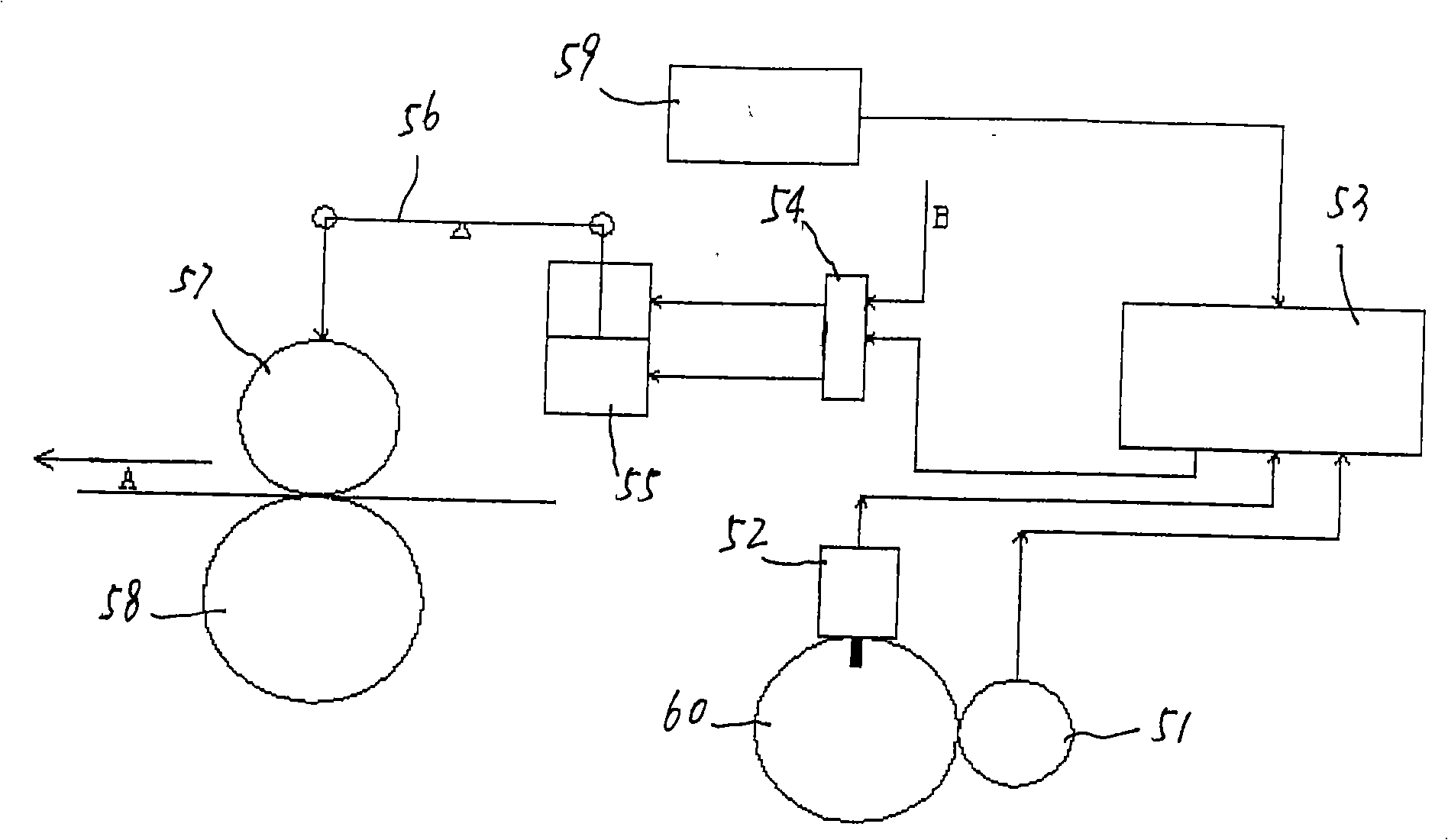

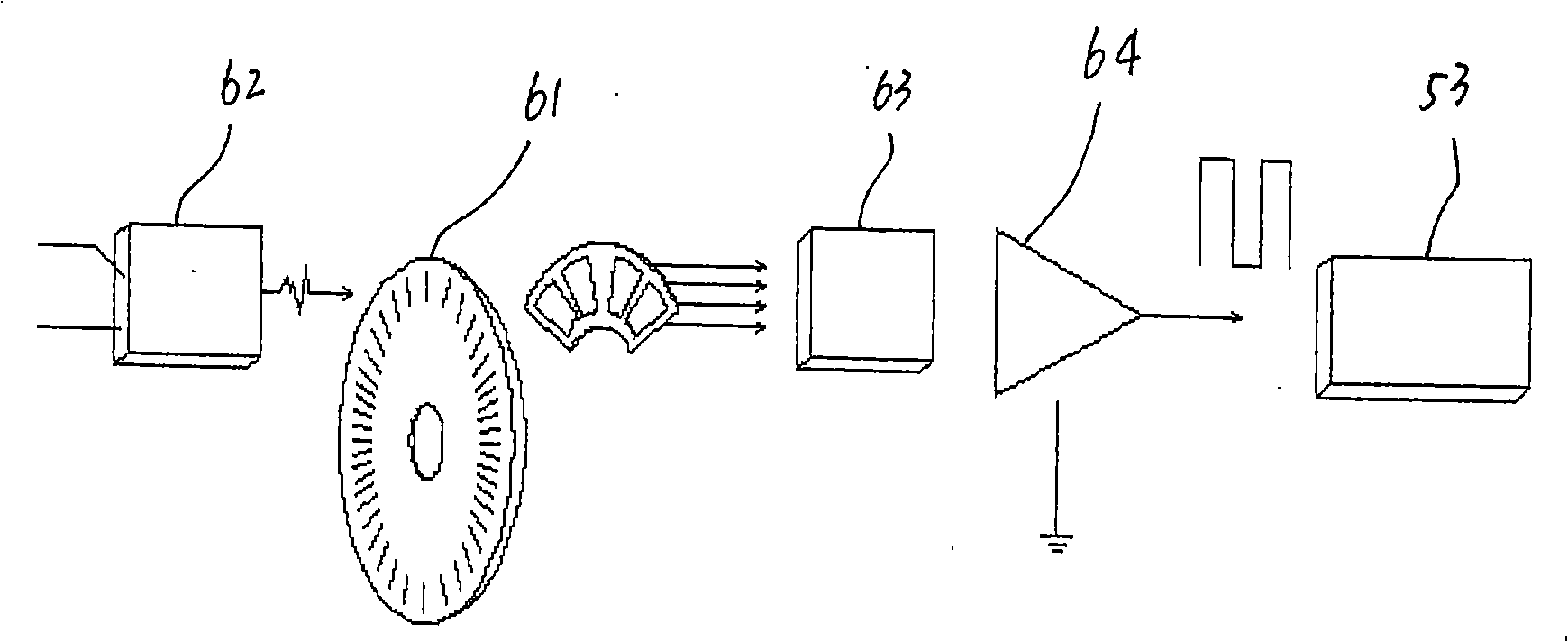

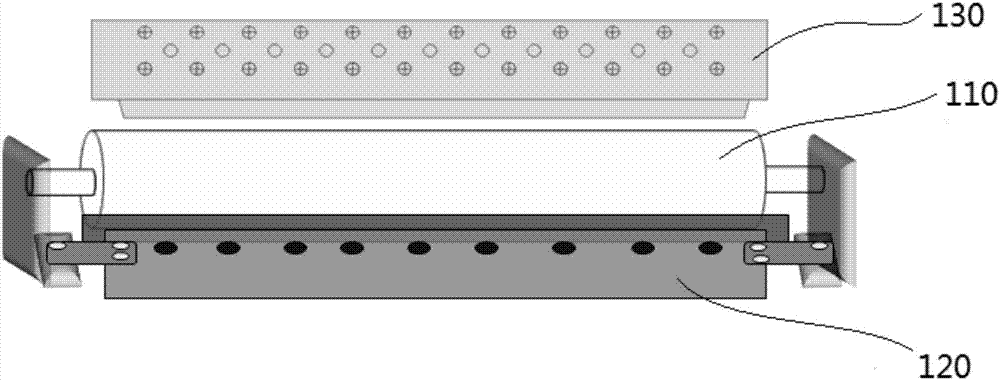

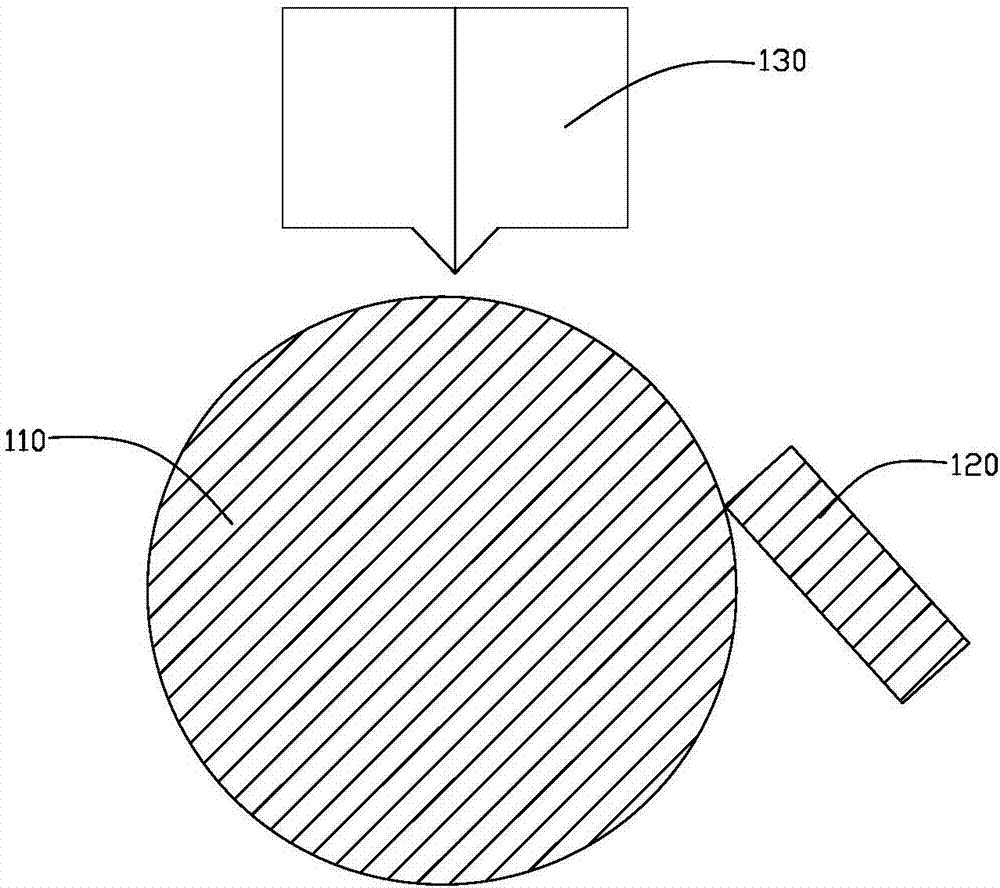

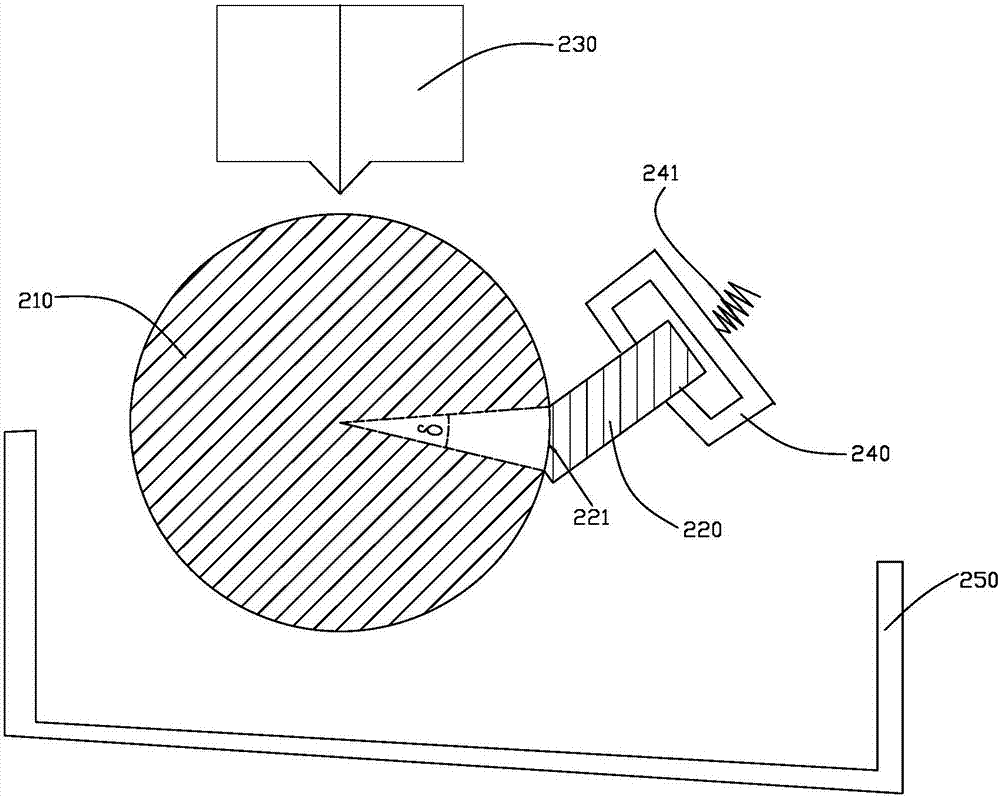

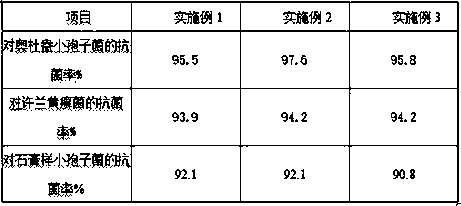

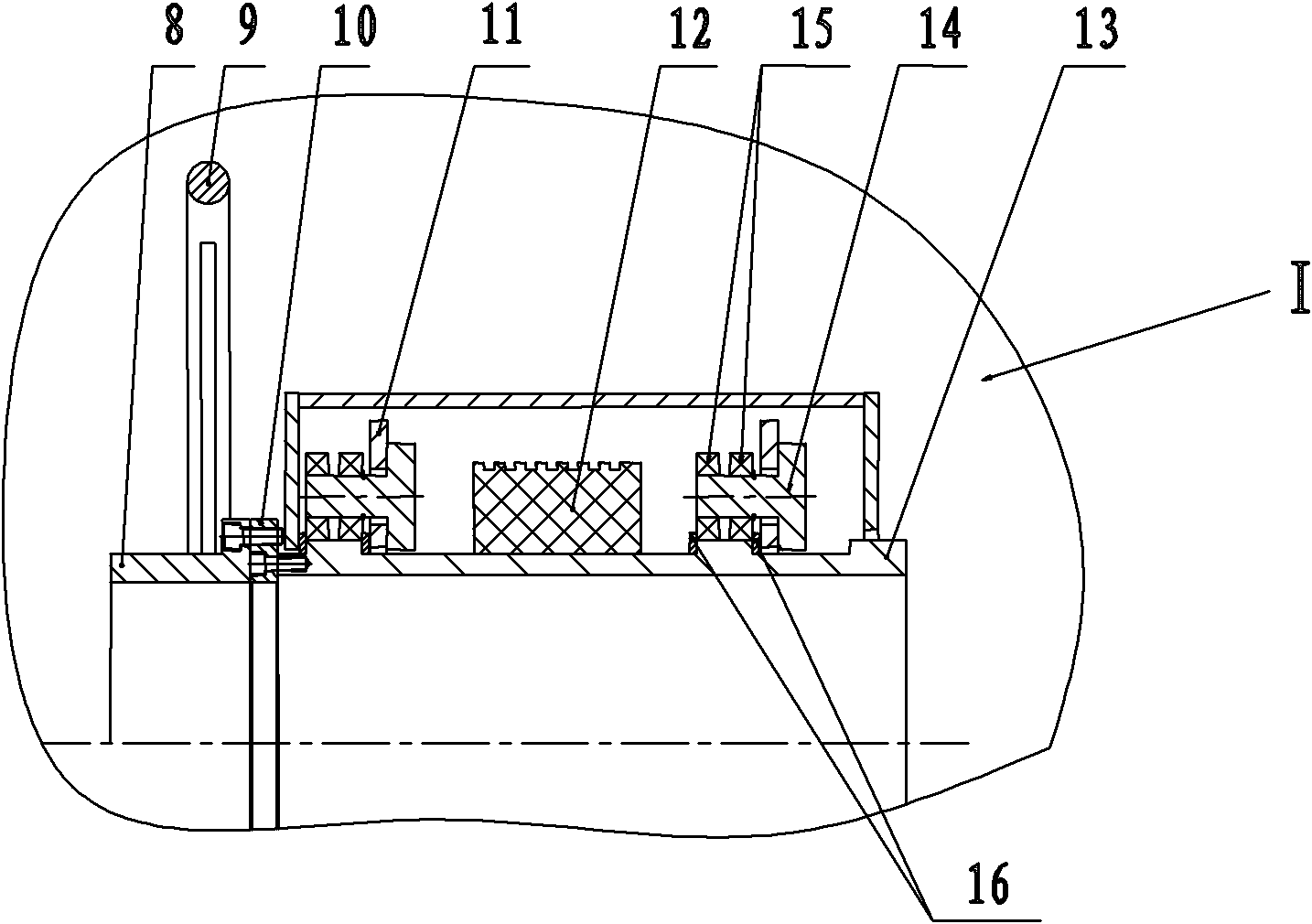

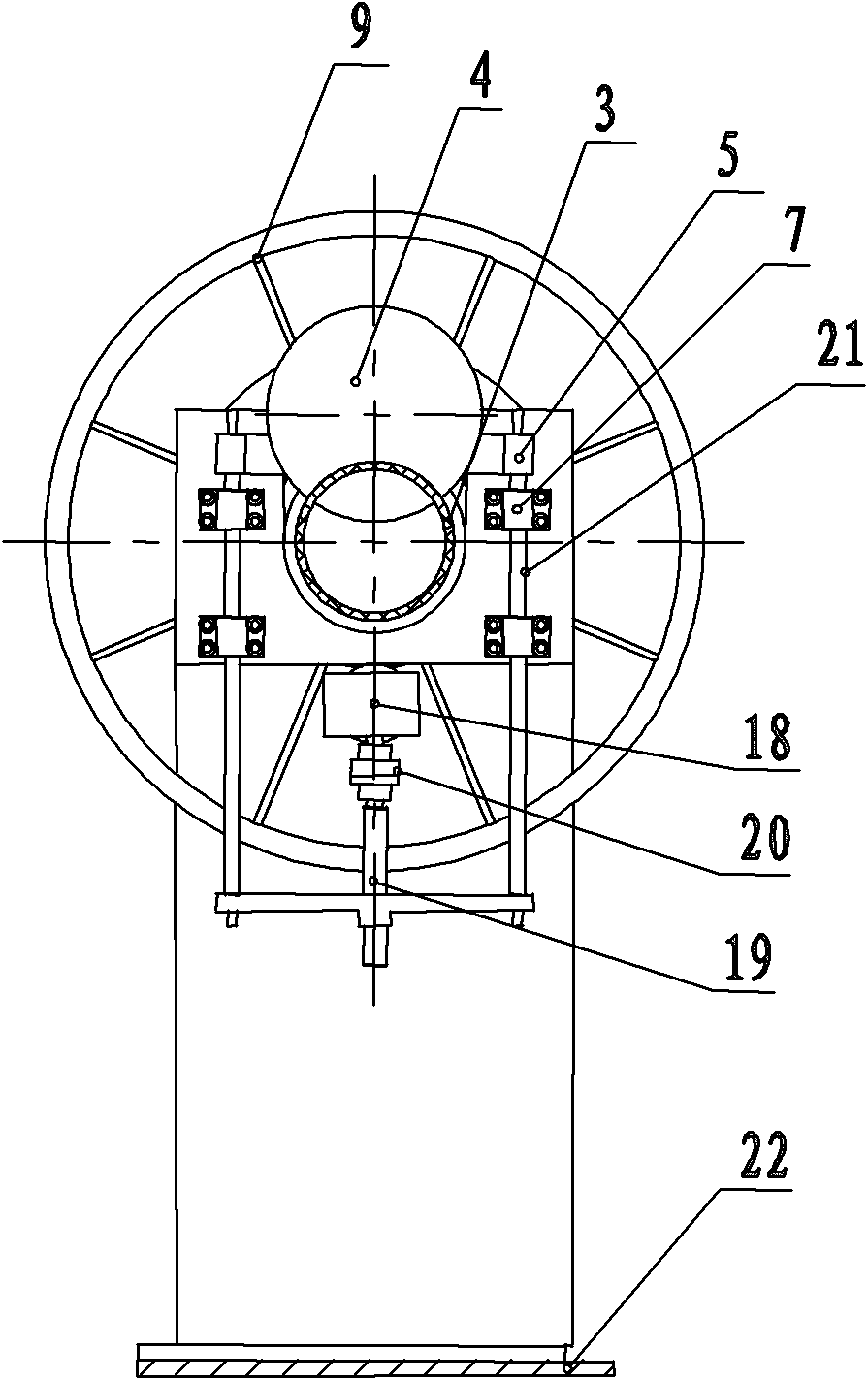

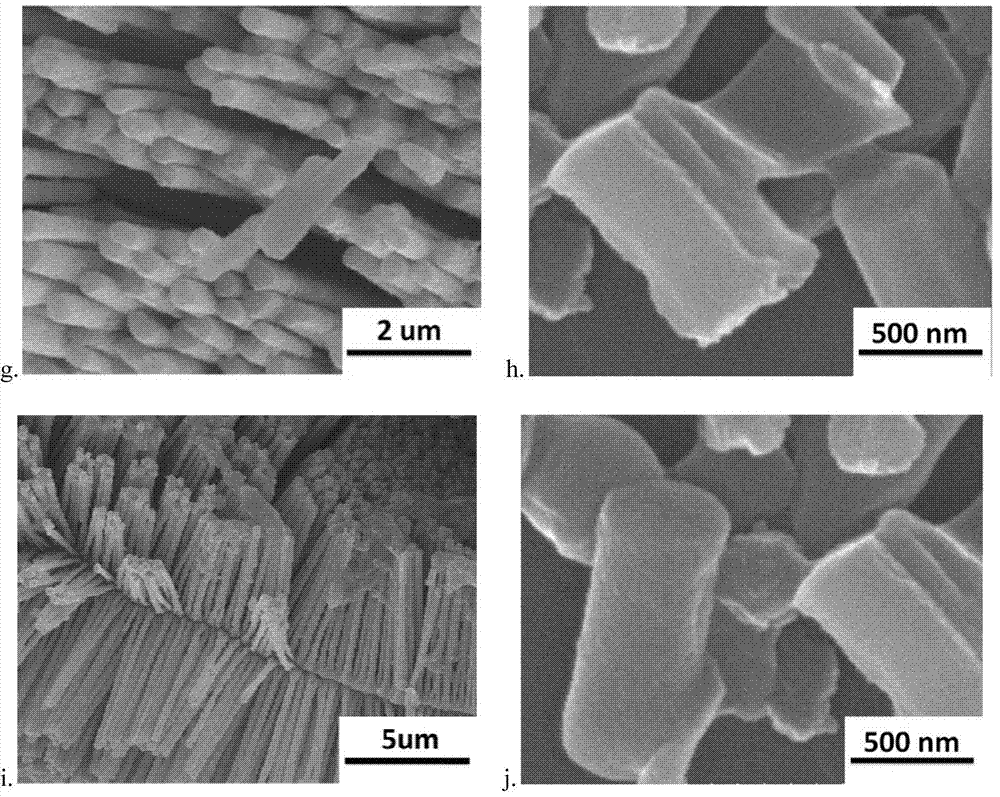

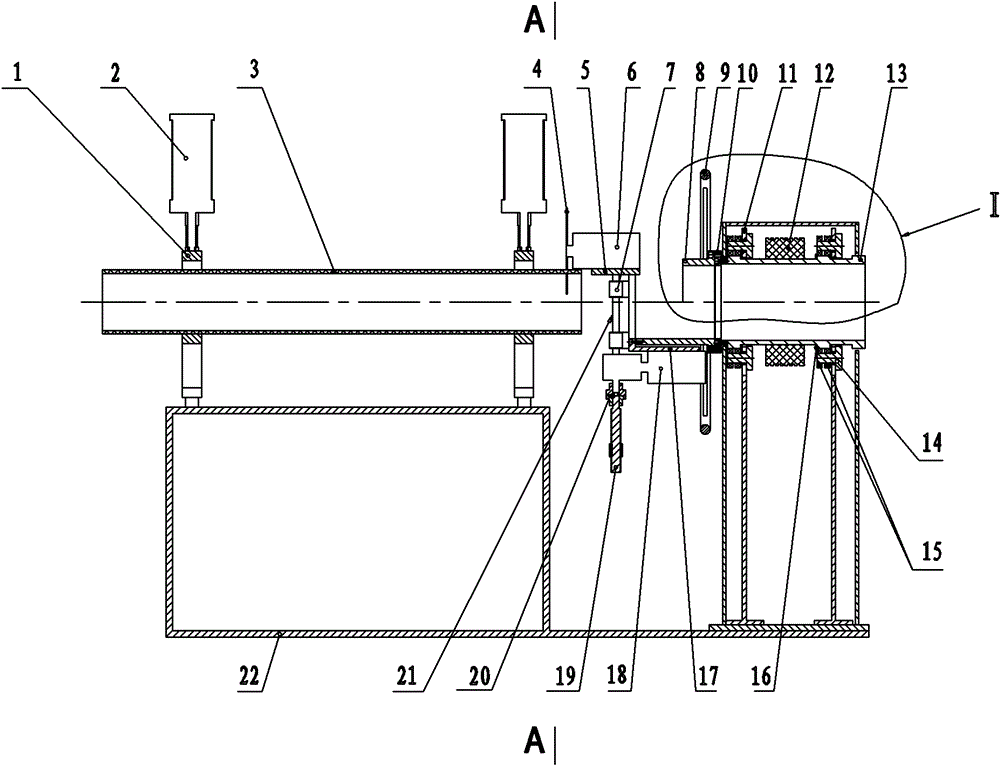

Electrical sheet steel magnetostriction measurement system and method

InactiveCN104122516AImprove measurement accuracyGood repeatabilityMagnetostrictive property measurementsMagnetizationData acquisition

The invention relates to an electrical sheet steel magnetostriction measurement system and method. A computer controls an arbitrary waveform generator to produce waveforms, the arbitrary waveform generator is controlled to change the waveforms according to data uploaded by a multi-channel data acquisition unit, an iterative algorithm is utilized to obtain expected waveforms of magnetic polarization intensity induced voltage, and a magnetostriction loop line of a measured sample is further calculated. A power amplifier performs amplification processing on a received signal, and an excitation device fixes the measured sample to enable the measured sample to work in the closed magnetic circuit condition and exerts stress in the magnetization direction. A laser vibration measurement instrument is used for measuring the vibration speed. The multi-channel data acquisition unit is used for acquiring voltage, current and the vibration speed. The electrical sheet steel magnetostriction measurement system and method achieves measurement of the electrical sheet steel magnetostriction loop line under the conditions of the closed magnetic circuit and the stress, meets a general using environment of an electrical sheet steel, utilizes the iteration method to enable the magnetic polarization intensity induced voltage waveforms to be sine waves, replaces a traditional analog feedback loop and has the advantages of being not prone to oscillation, wide in frequency range and the like.

Owner:NAT INST OF METROLOGY CHINA

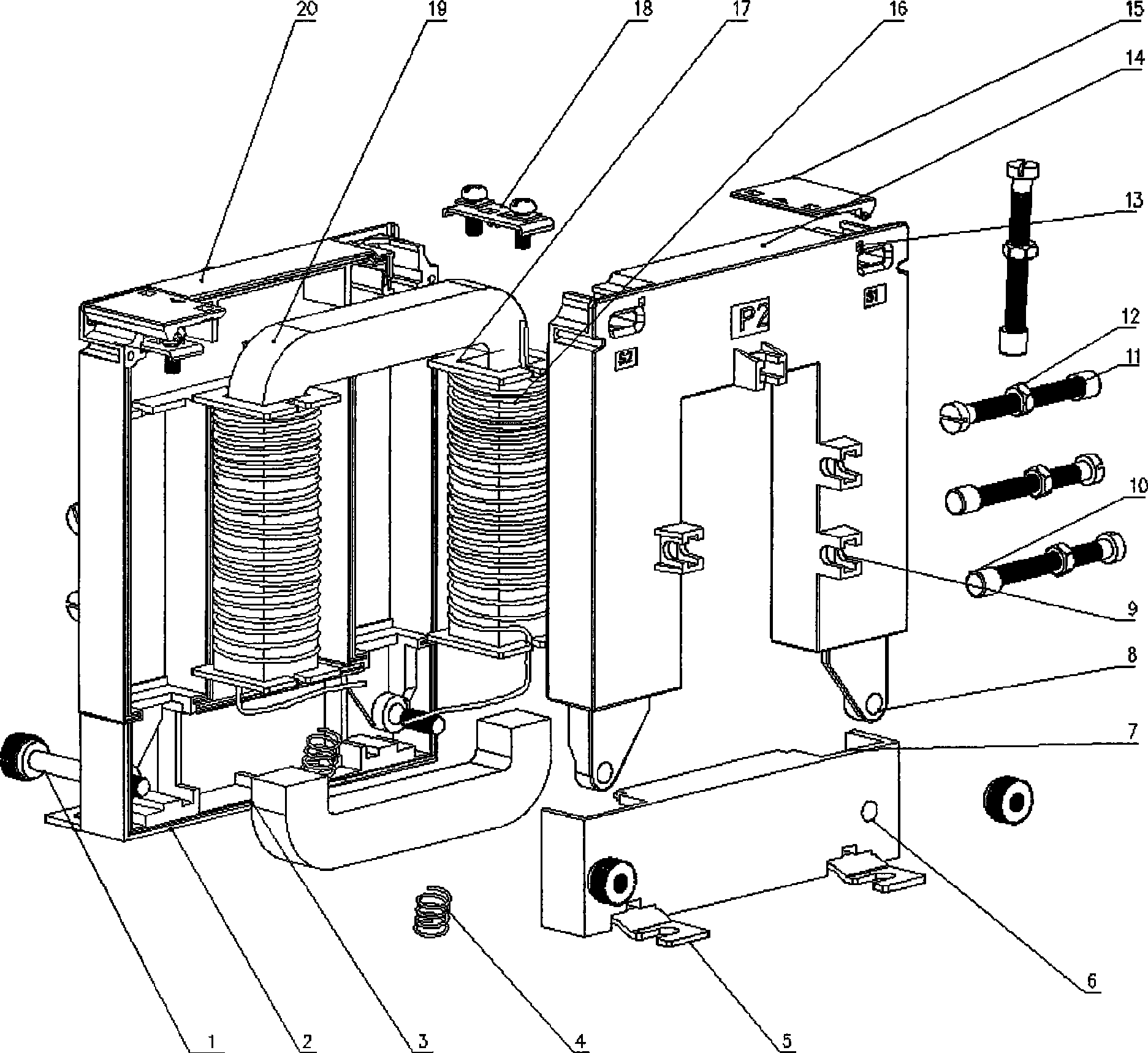

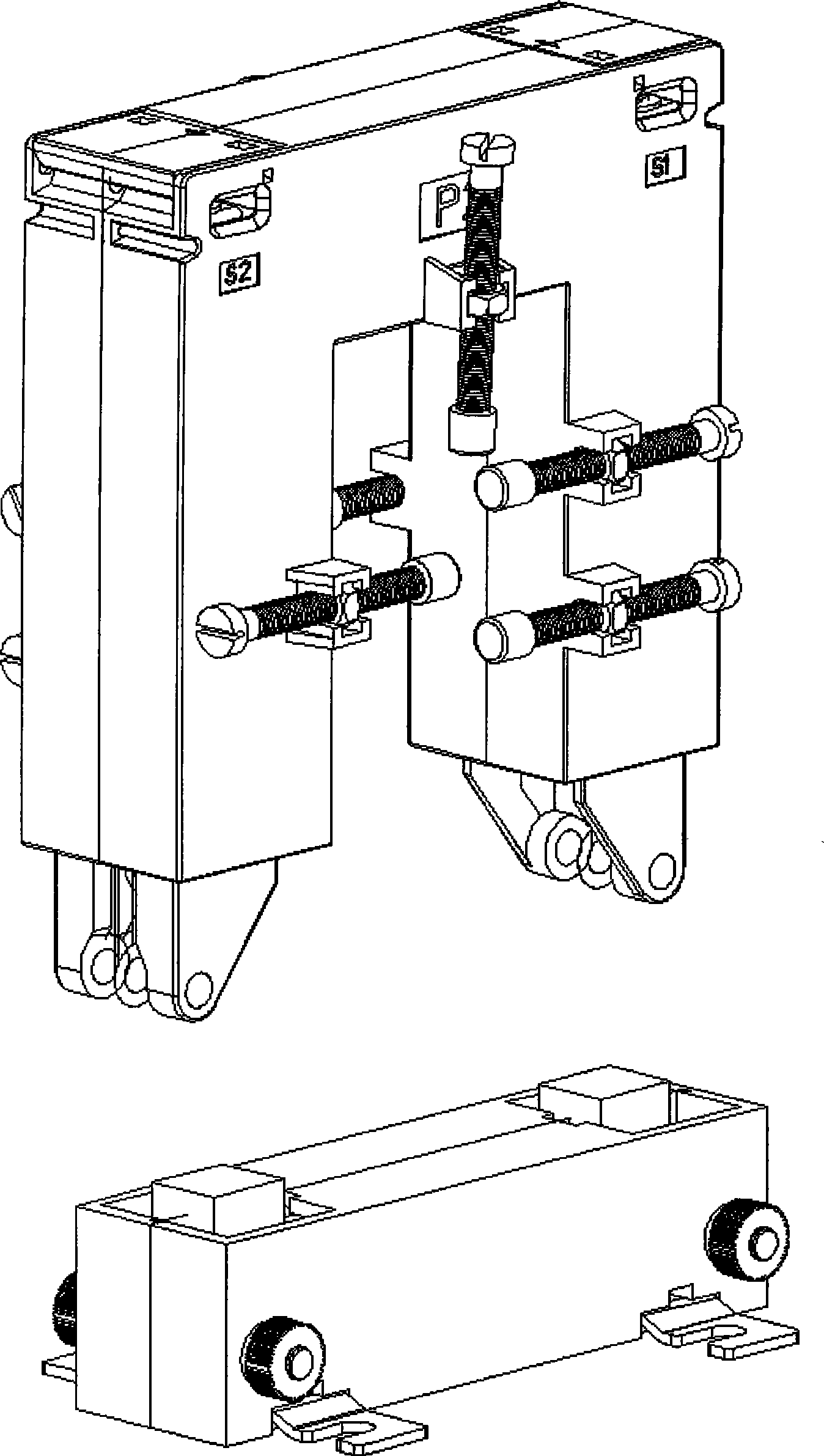

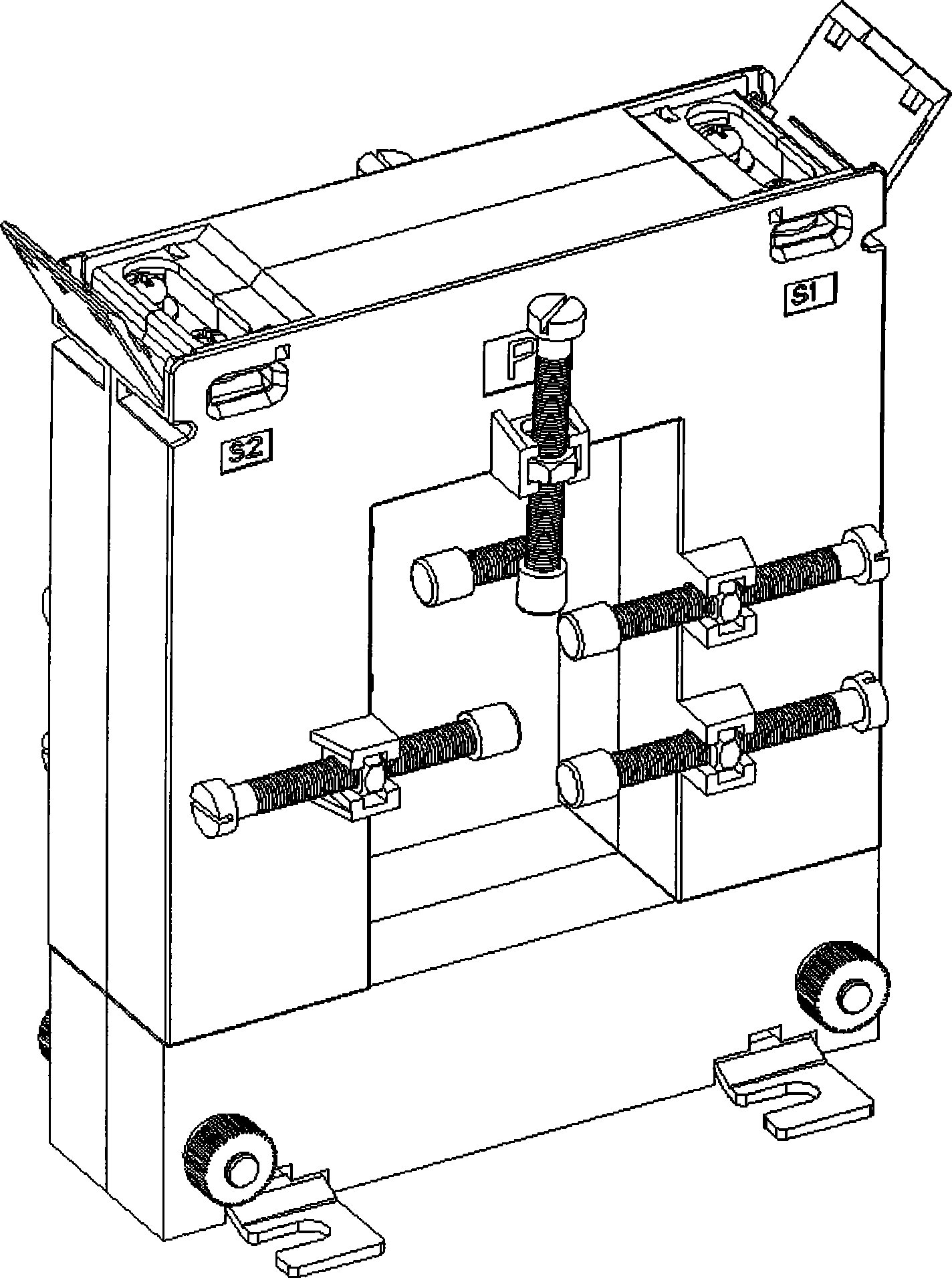

Open-close type current transformer

ActiveCN101447328AEasy to disassembleImprove work efficiencyTransformersVoltage/current isolationEngineeringInstrument transformer

The invention discloses an open-close type current transformer, comprising a shell, an iron core, a coil and a connecting terminal. The iron core consists of two iron cores which can be assembled into a square ring shape; the shell is a hollow square shell and consists of an upper shell and a rectangular lower shell; the front surface and the rear surface of the shell are inverted concave shape; the inner part of the upper shell is encapsulated with a big iron core; the inner part of the lower shell is encapsulated with a small iron core; and the upper shell and the lower shell are fixed by a connecting pawl and screws which are convenient to be disassembled. The transformer does not disassemble a circuit to be measured when in maintenance and exchanging, has convenient disassembling and high working efficiency and simultaneously has the protecting function of preventing electrical larceny, easy manufacture, low cost and wide market prospect.

Owner:ZHEJIANG DIXSEN ELECTRICAL

Fast copper bar cut-off machine

InactiveCN101209503AIncrease usageImprove cutting efficiencyMetal sawing devicesRotational axisGear wheel

The invention discloses a fast copper rod cutting machine, comprising a base which is provided with a chuck fixed seat and a slitting disc motor seat. The invention is characterized in that the chuck fixed seat is a mainshaft box which is provided with a chuck which is fixedly connected with a rotary shaft in the mainshaft box; the invention is also provided with a rotary motor and a driving gear group; the rotary shaft is connected with the driving gear group; the rotary axis line of the slitting disc in the slitting disc motor seat is parallel to the rotary shaft. The invention has the advantages of improving the cutting efficiency more than 10 times, improving the utilization ratio of the saw bit, saving the cost, smoothening the end surface in the cutting process, saving raw material, and improving the efficiency of post-process in disguised form.

Owner:东莞市瑞为电器配件有限公司

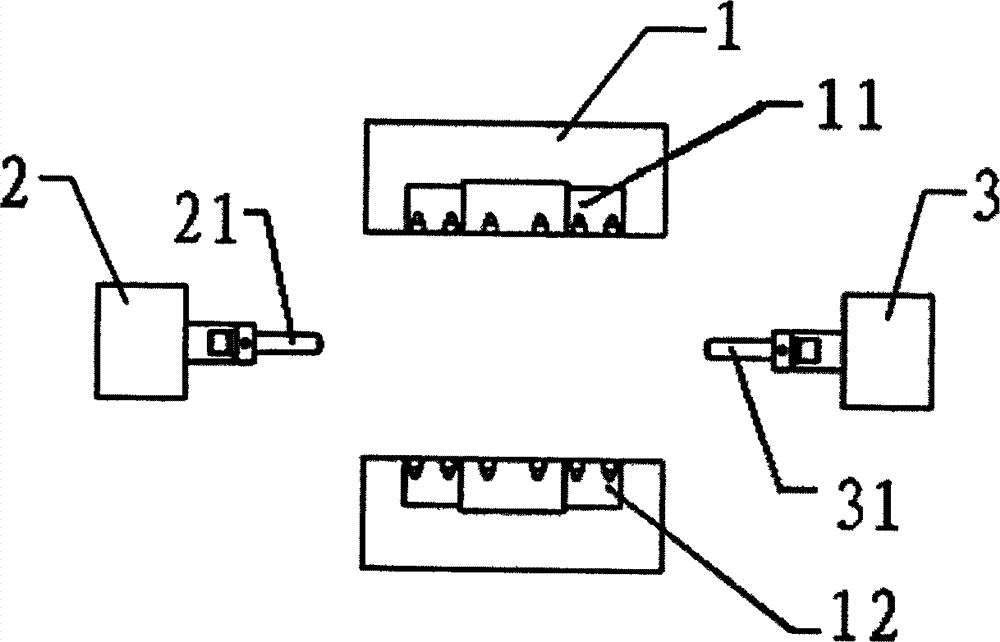

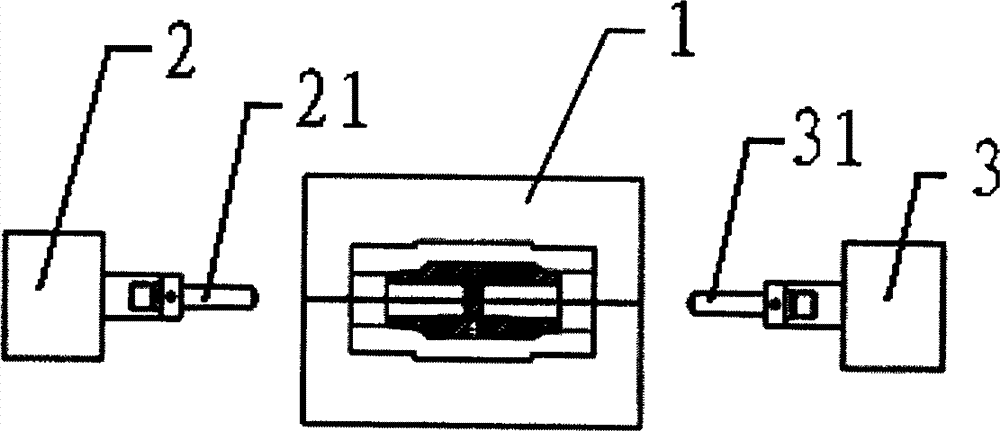

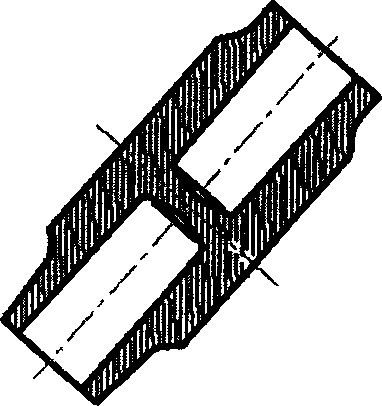

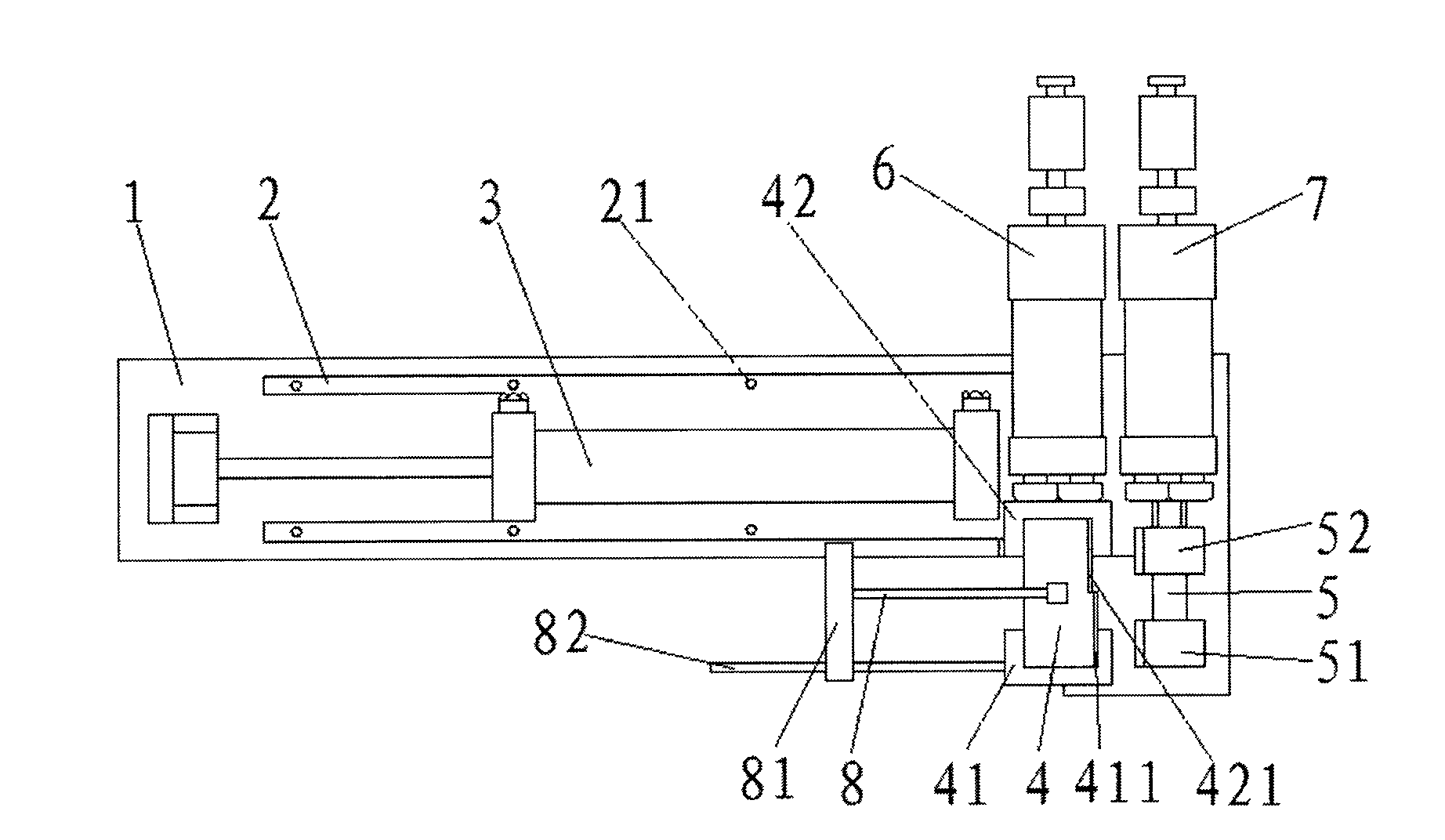

Totally-closed multi-direction horizontal type die forging technology special for oil drill rod joint

The invention discloses a totally-closed multi-direction horizontal type die forging technology special for an oil drill rod joint. The technology comprises the steps that (1) billets are placed into a lower die cavity; (2) a main position pressing machine carries out die assembly, reaches preset pressure, and maintains the pressure; (3) a left side position pressing machine and a right side position pressing machine extrude inwards at the same time to form a left side position inner hole and a right side position inner hole; (4) hydraulic systems of the main position pressing machine, the left side position pressing machine and the right side position pressing machine are communicated, the left side position pressing machine and the right side position pressing machine apply force at the same, and workpieces are extruded in all directions in a totally-closed mode; (5) the main position pressing machine is still in the pressure maintenance state, and the left side position pressing machine and the right side position pressing machine are reset at the same time; (6) the main position pressing machine is reset, and multi-direction forging forming is achieved. According to the totally-closed multi-direction horizontal type die forging technology special for the oil drill rod joint, whole oil drill rod joint structure forging can be achieved through one-heat forging, excess material trimming is not needed, ends are flat, metal full-fiber forging forming is achieved, the raw material utilization rate is improved, machining efficiency is improved, the rate of finished forged pieces is improved, and the general mechanical performance of products is improved.

Owner:JIANGSU LONGSHENG DRILLING MACHINERY MFG

Automatic quick cable-stripping machine

InactiveCN102163787AAutomatic stripping and cutting labor savingAutomatic peeling and cutting saves time and effortLine/current collector detailsApparatus for removing/armouring cablesEngineeringMechanical engineering

The invention relates to the field of machining equipment, in particular to an automatic quick cable-stripping machine which comprises a machine seat; a sliding seat fixed through a screw is arranged on the machine seat; a first air cylinder is arranged on the sliding seat; an upper guide rail and a lower guide rail are respectively and parallelly fixed at one end of the machine seat; a left slide block and a right slide block are arranged on the upper guide rail; the right slide block is connected to a second air cylinder; a left cutter blade is arranged on the left slide block; a right cutter blade is arranged on the right slide block; a left clamping block and a right clamping block are arranged on the lower guide rail; the right clamping block is connected to a third air cylinder; a cable blocking rod is fixed on the machine seat by a fixed block; the fixed block is connected to the upper guide rail by a support rod; and both the left cutter blade and the right cutter blade adopt an arc angel cutter blade. The automatic quick cable-stripping machine operates under driven of power and can be used for automatically and quickly stripping off a corrugated pipe.

Owner:浙江亿诚电器有限公司

Process method for producing tool through caulking groove substrate

The invention discloses a process method for producing a tool through a caulking groove substrate. The process method comprises the following steps of (1) substrate preparing, (2) substrate cleaning,(3) high-speed steel bar embedding, (4) vacuum welding, (5) tempering, (6) straightening, (7) accurate grinding, (8) blade planing, (9) long blank cutting, (10) blade accurate grinding, (11) tool cutting, (12), perforating, (13), straightening and (14) cleaning, rust prevention and finished product packaging. By means of the process, the machining steps and process are shortened, the machining difficulty is reduced, the machining efficiency is improved, the machining cost is saved, and the machining yield and the stability of quality and performance are improved.

Owner:DONGE LIYUAN MACHINERY KNIFE

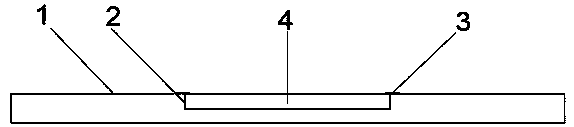

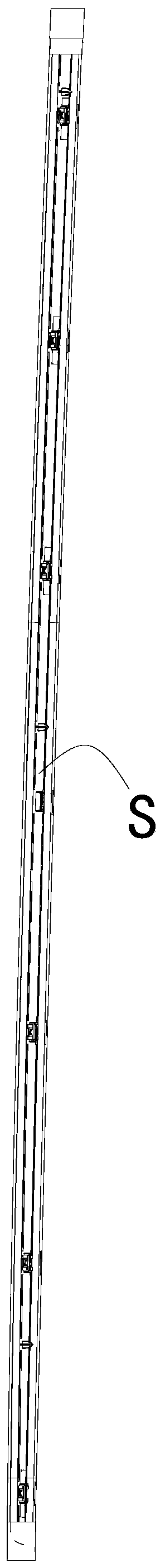

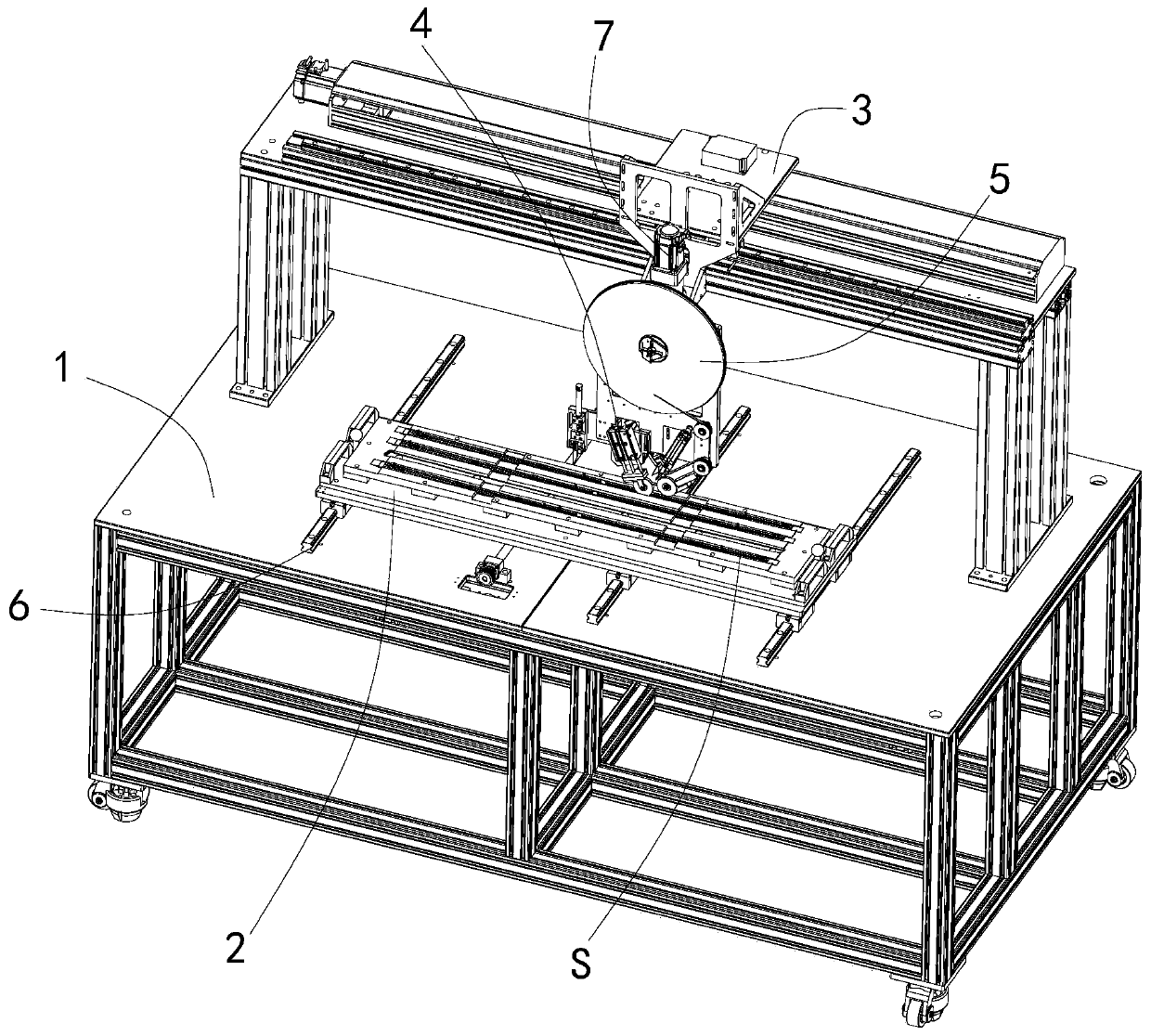

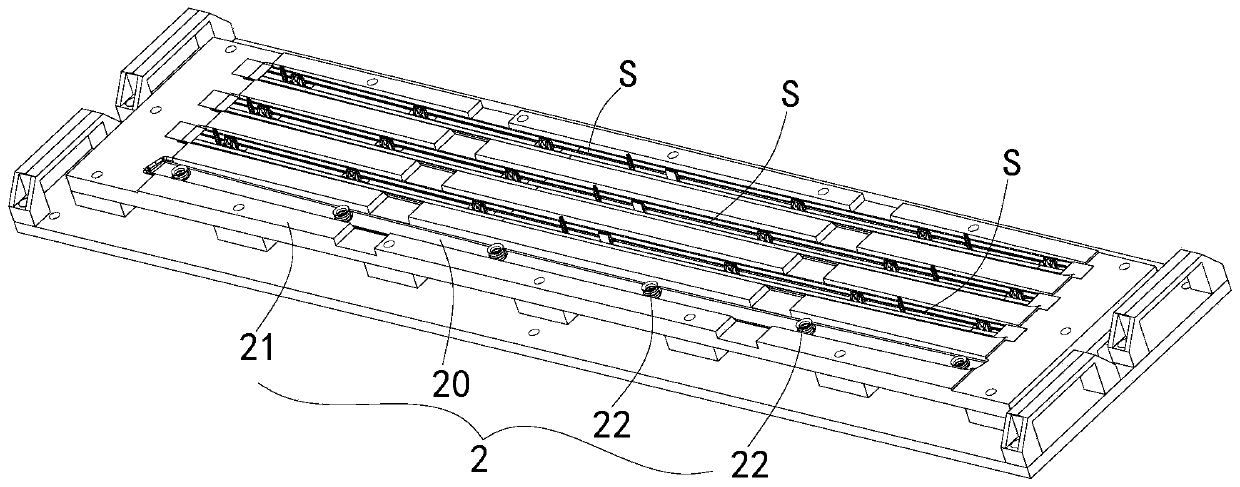

Device for pasting 3M adhesive tape on automobile decoration strip

The invention provides a device for pasting 3M adhesive tape on an automobile decoration strip. A pressing roller is arranged behind an adhesive pasting roller, on one hand, the decoration strip can be pressed and prevented from being warped, and in addition, the adhesive tape on the adhesive pasting roller is subjected to rolling, so that the bonding strength is improved; a shearing mechanism isarranged between the adhesive pasting roller and the pressing roller, when the pressing roller runs to the end of the adhesive tape, the adhesive tape is cut off, and then the cut adhesive tape is subjected to rolling and pasting through the pressing roller, so that the problems of infirm bonding, easiness in warping, falling off, ash sticking and the like caused by uneven section of the cut can be prevented; a cutting mechanism is arranged behind the pressing roller, the redundant adhesive tape is broken, the end face is flush, the redundant adhesive tape is prevented from being exposed out,and the appearance of the product is more attractive; and a decoration strip fixing seat comprising a vacuum sucker is arranged, and the decoration strip can be quickly fixed.

Owner:武汉振佳宇恒机器人科技有限公司

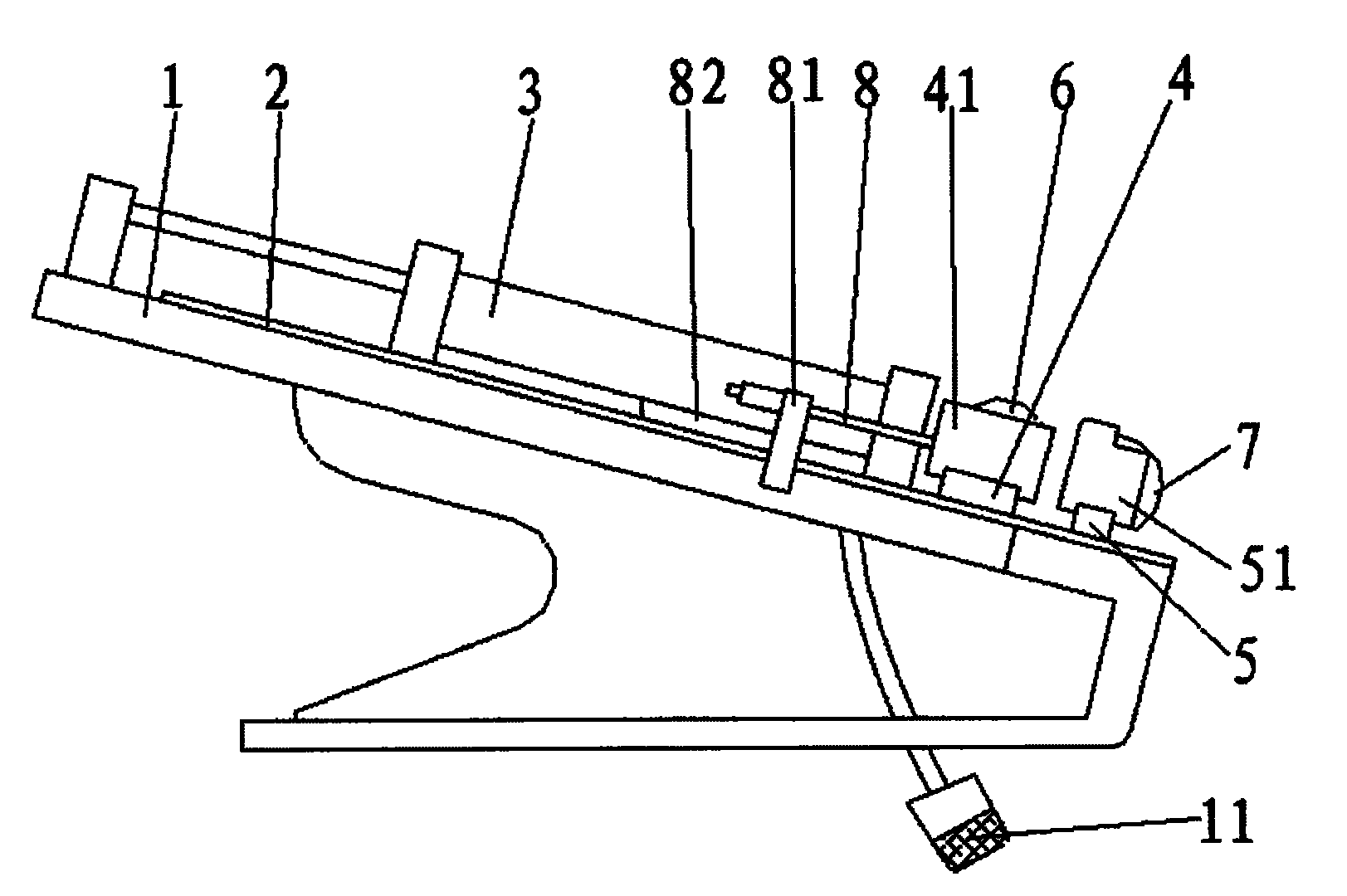

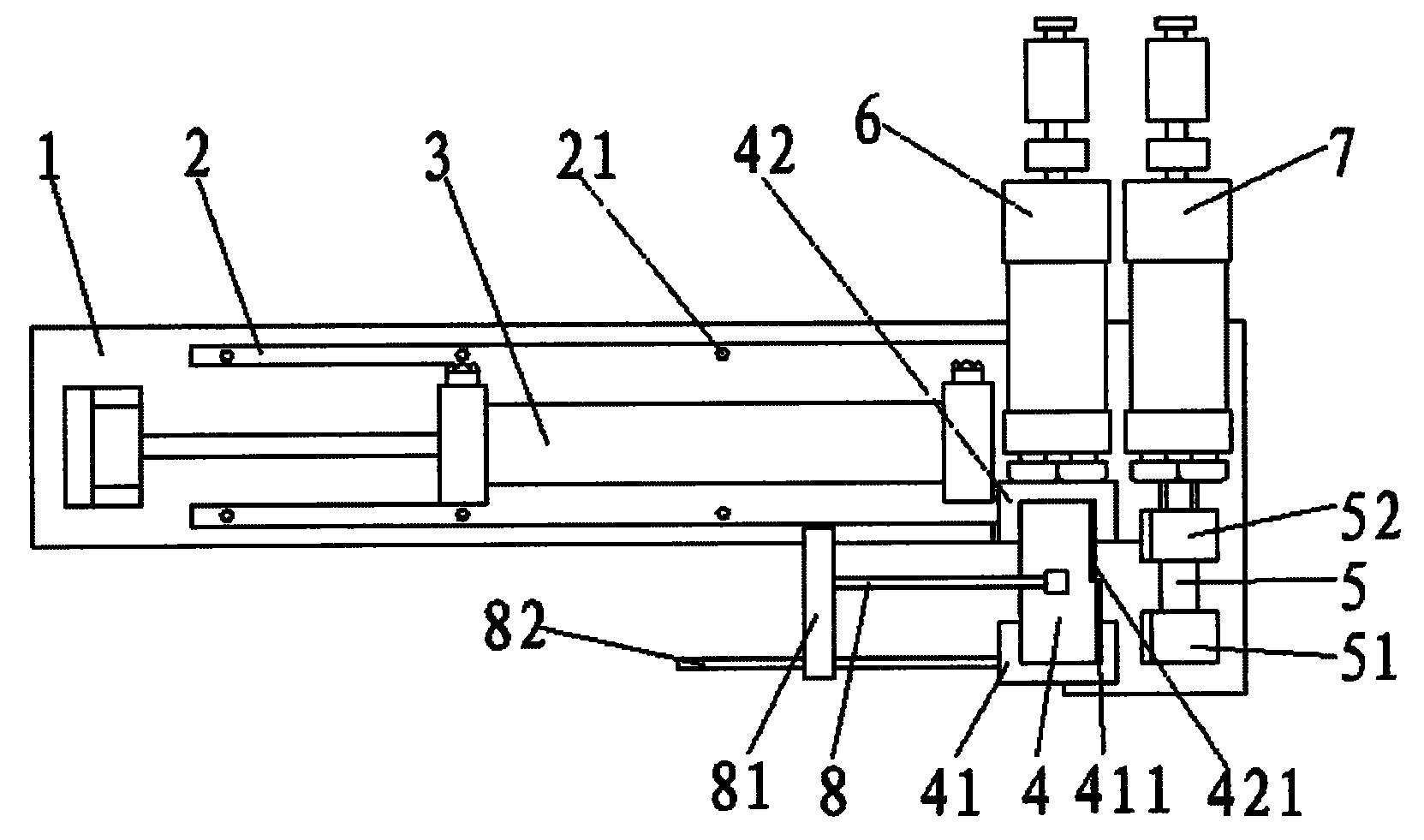

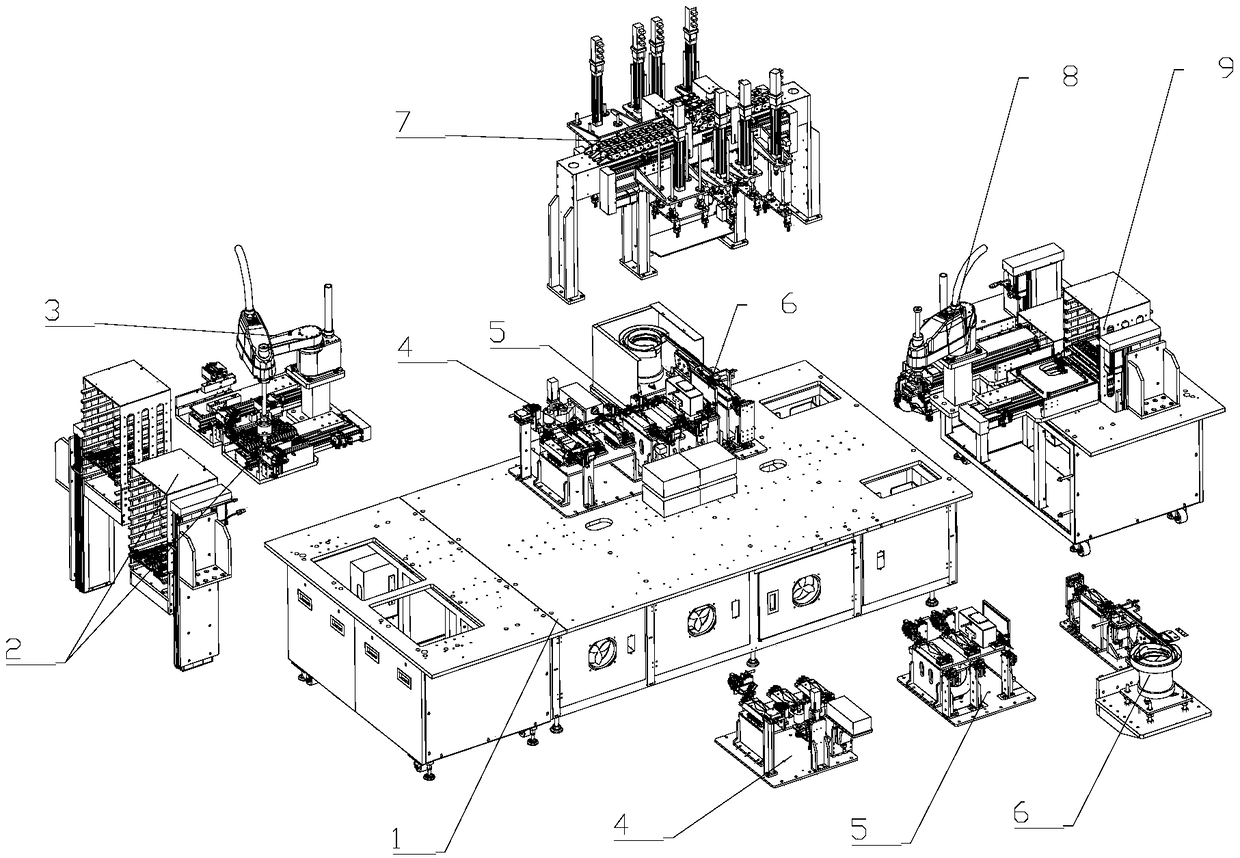

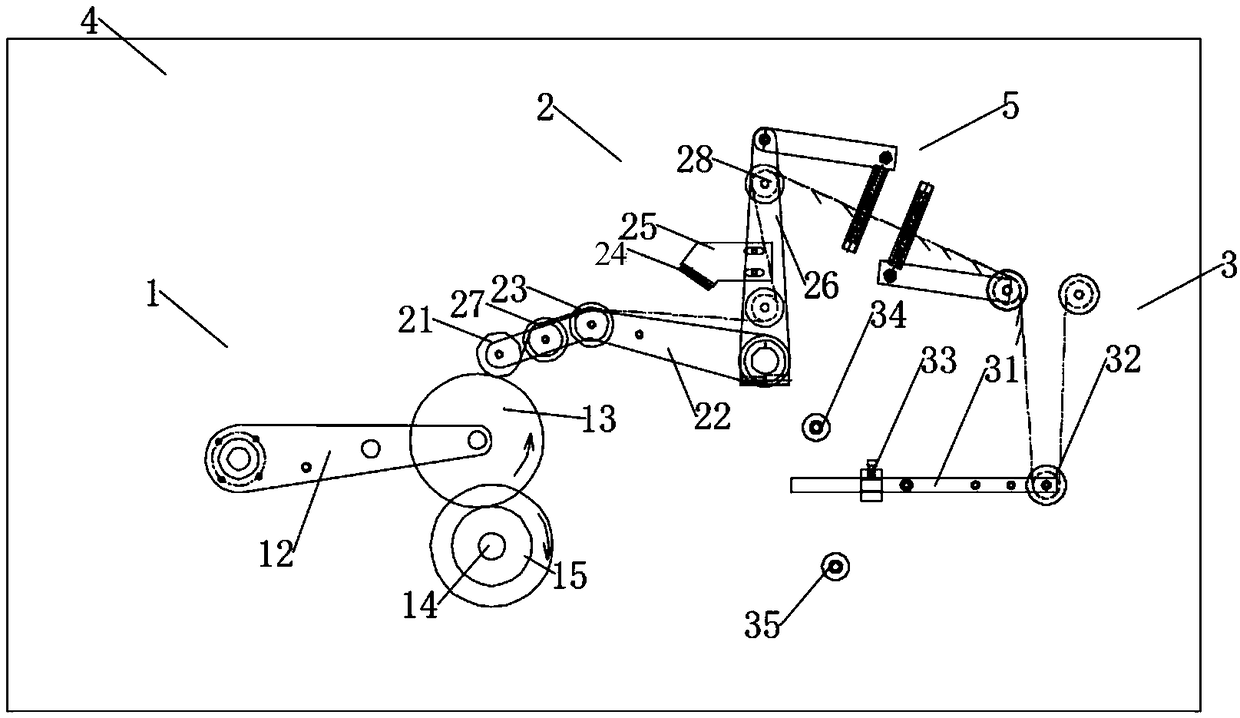

Optical fiber device test equipment

ActiveCN109186952AAvoid interferenceEasy to carryTesting fibre optics/optical waveguide devicesEngineeringManipulator

The invention relates to the technical field of the communication. Optical fiber device detection equipment comprises a rack and a feeding device, a feeding manipulator device, a before-detection analysis module, an optical fiber device performance detection module, a protective cap mounting device, a stepping conveying device, a foldable manipulator placing device and a blanking device which arearranged on the rack; the feeding device is joined with the before-detection analysis module through the feeding manipulator device; the before-detection analysis module, the optical fiber device performance detection module and the protective cap mounting device are orderly joined; the location of the stepping conveying device is corresponding to the before-detection analysis module, the opticalfiber device performance detection module and the protective cap mounting device; and the protective cap mounting device is joined with the blanking device through the foldable manipulator placing device. The optical fiber device detection equipment has the advantages of being high in automation degree, high in working efficiency, high in finished product yield and extensive in testing range.

Owner:SHANDONG JIANBO TELECOMM EQUIP

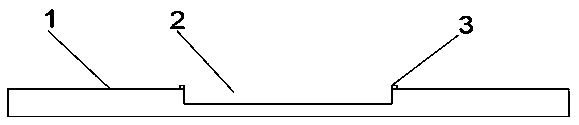

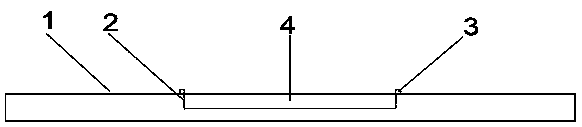

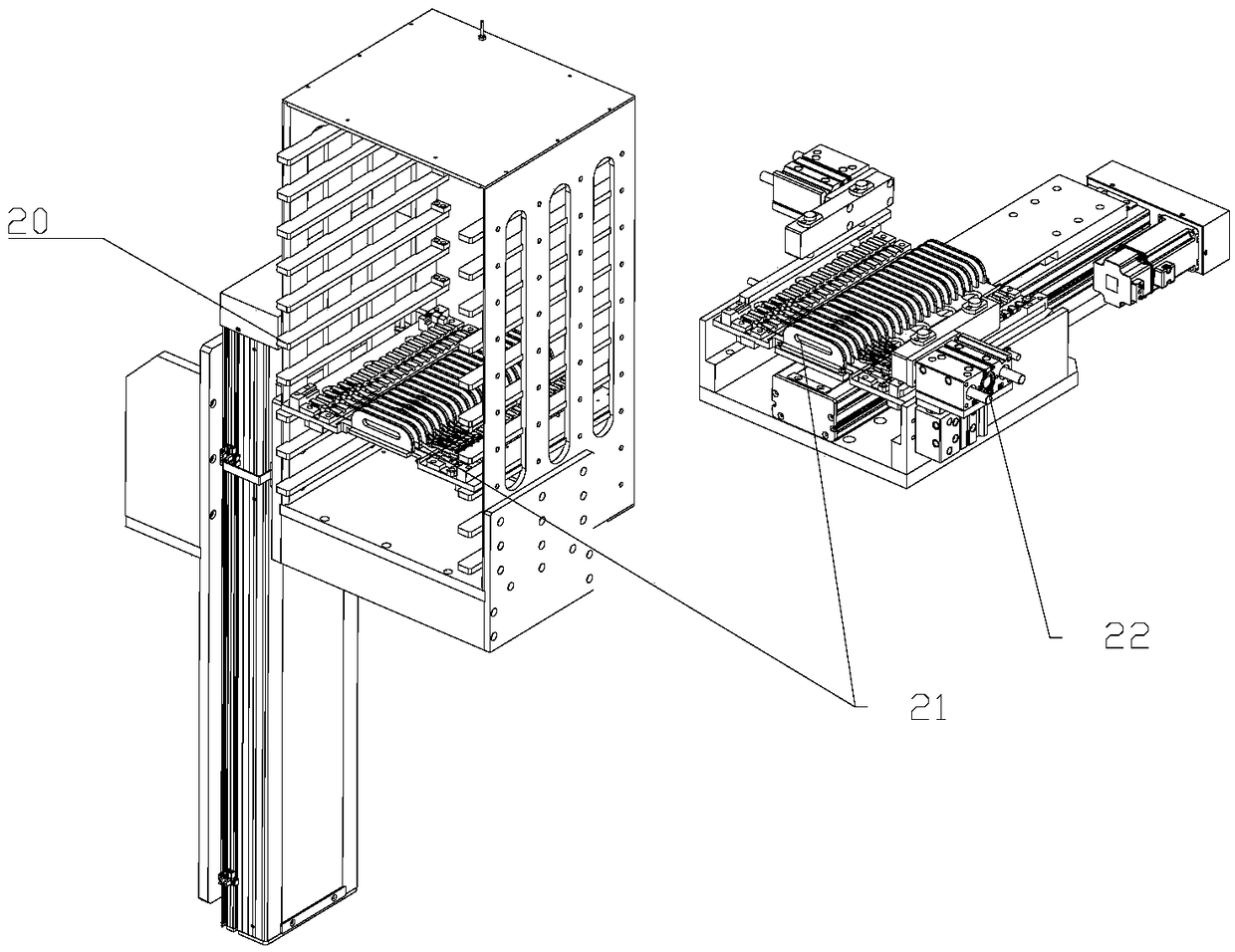

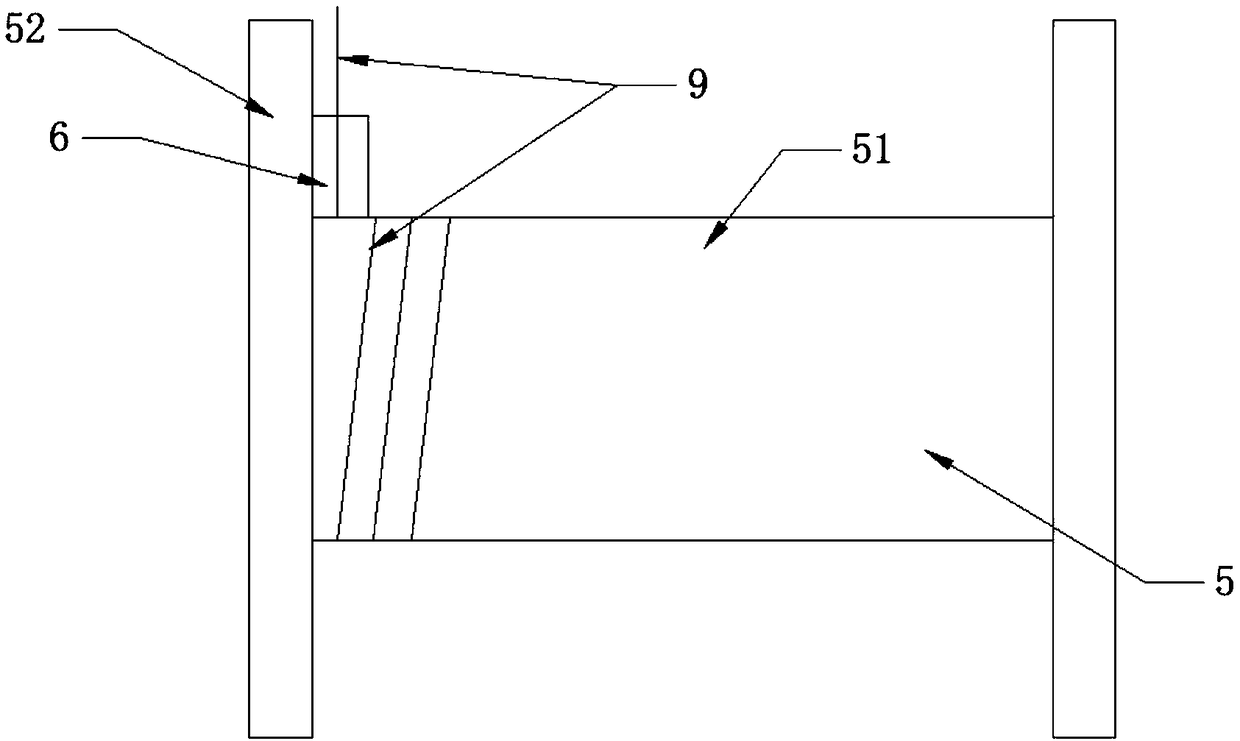

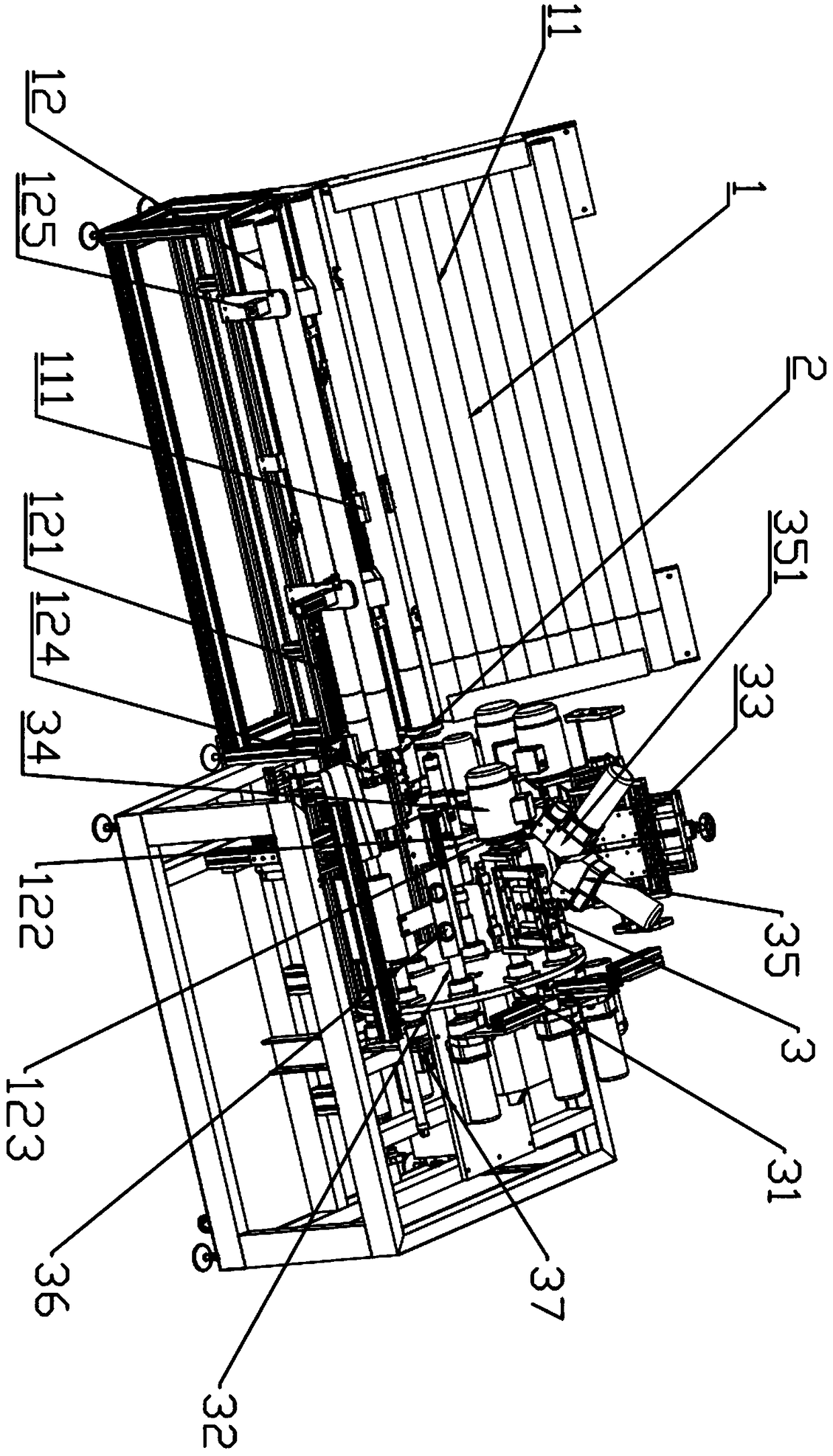

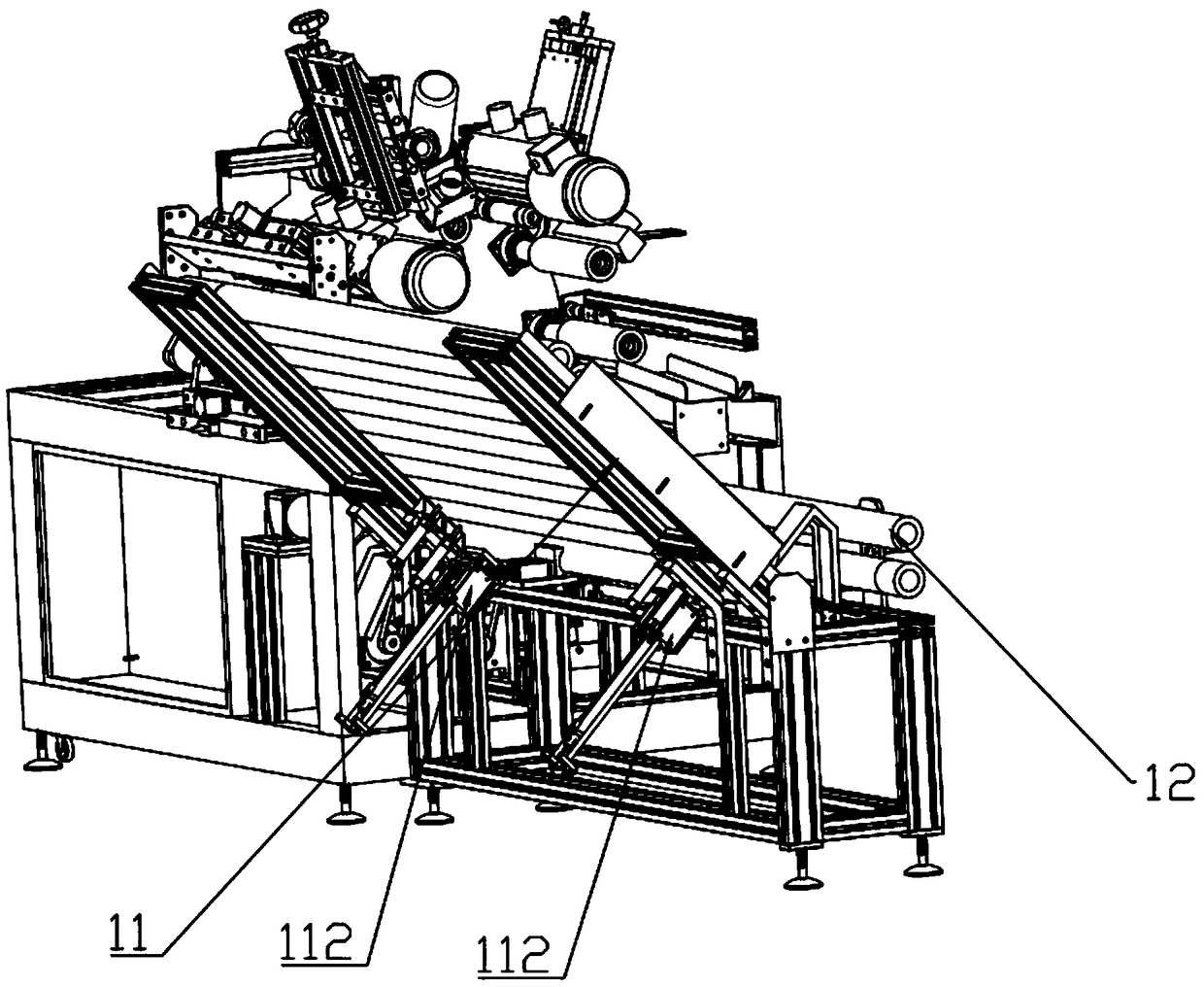

Surface-sizing die-cutting folding type assembling machine of multi-layer wound roll

The invention discloses a multi-layer coiling block die-cutting folding sheet-collating machine. Firstly, two-layer paper is collated once and is collated again with other collated two-layer paper after being collated, and so on; finally the collated paper is sent to a transverse pressing line to carry through pressing and folding. The sheet-collating machine has the advantages that every two sheets of the sheet-collating-forming product is compact in every two sheets, flat in end surface, high precision in alignment of every two layers; equipment has a high degree of automation, the production and quality of various multi-chain printing paper, computer print envelopes and parcel detail lists can be ensured, the use is wide, and the social benefit is obvious.

Owner:上海丹鹏金属机械有限公司

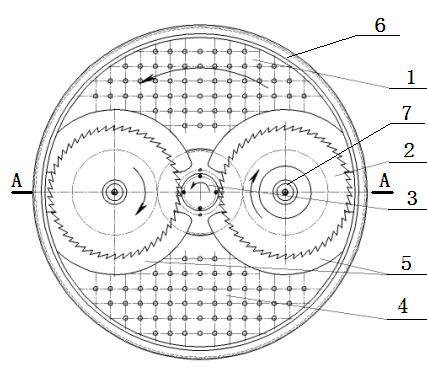

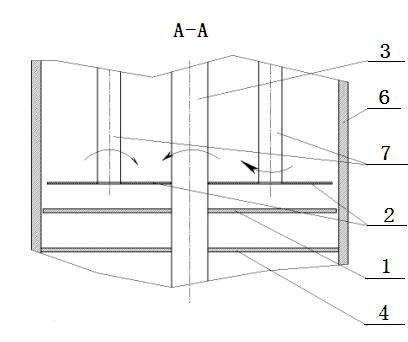

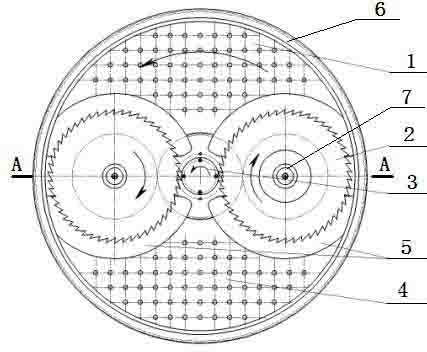

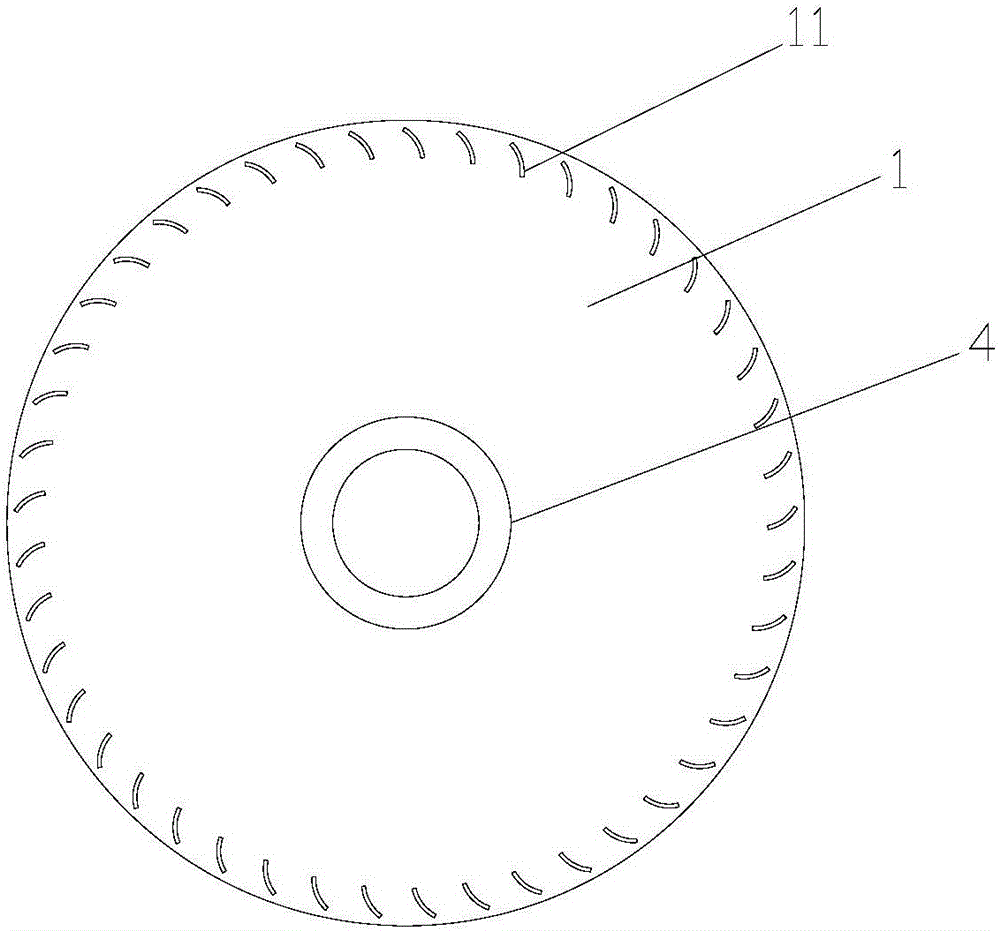

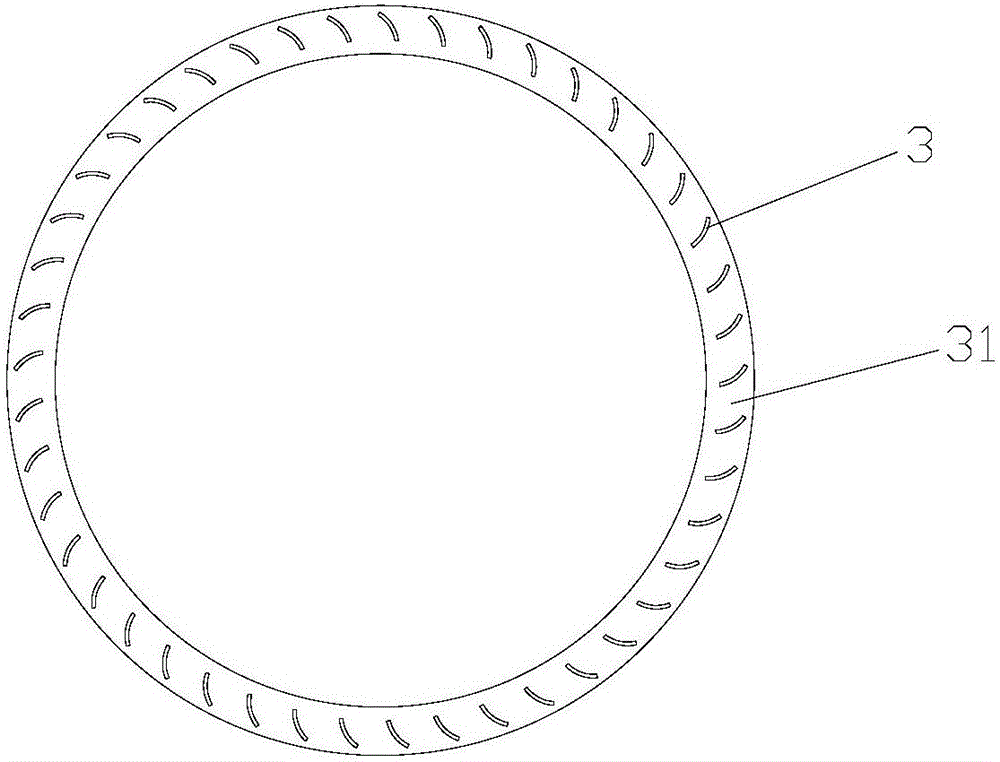

Shell ice cutting device

InactiveCN102183111AFlat endEasy to useLighting and heating apparatusIce storing/distributionEngineeringRefrigerated temperature

The invention relates to a refrigerator, refrigerating equipment or the system category, in particular to a shell ice cutting device. The technical scheme is that: the shell ice cutting device comprises an ice cutting turntable (1), an ice stopping disk (4), an ice outlet (5) and an ice maker outer barrel (6), and is characterized in that: a rotating shaft (3) is connected with a round saw bit (2) through a saw bit rotating shaft (7) above the ice cutting turntable (1); and the rotating direction of the round saw bit (2) is opposite to that of the ice cutting turntable (1). The shell ice cutting device has the advantages that: by adoption of a mode that two saw bits rotate in a high speed, a falling shell ice can be sawed off as required; therefore, the lengths of the sawed-off shell ices are consistent with one another, the end faces of the sawed-off shell ices are flat and neat, and the sawed-off shell ices are attractive in appearance and convenient in use.

Owner:FUJIAN SNOWMAN

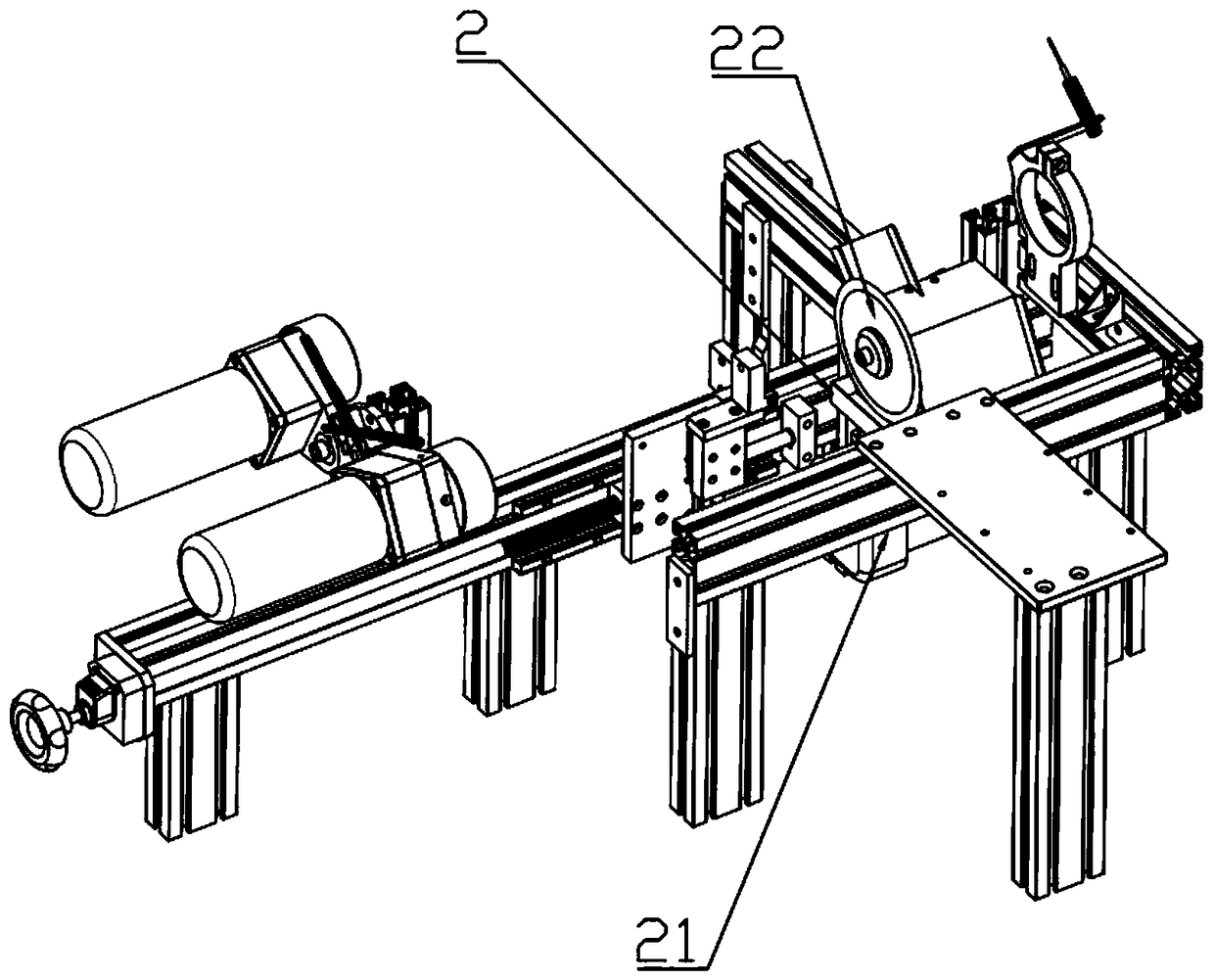

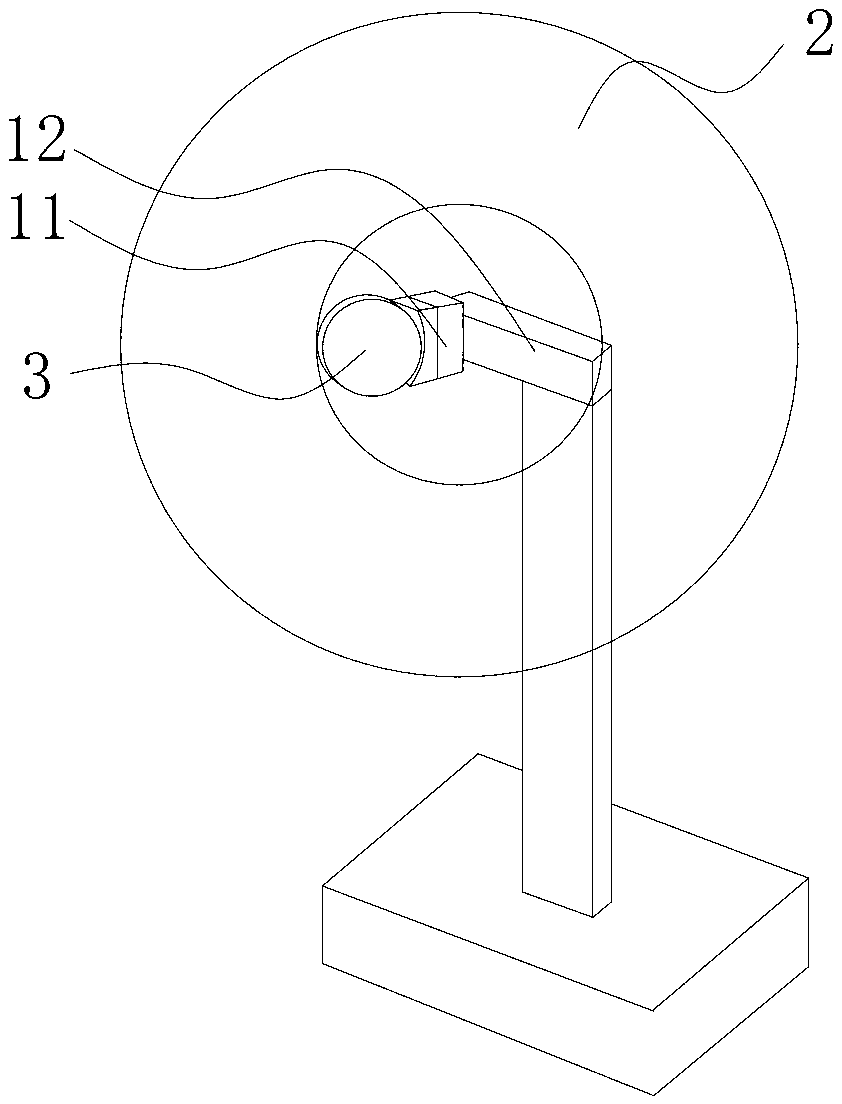

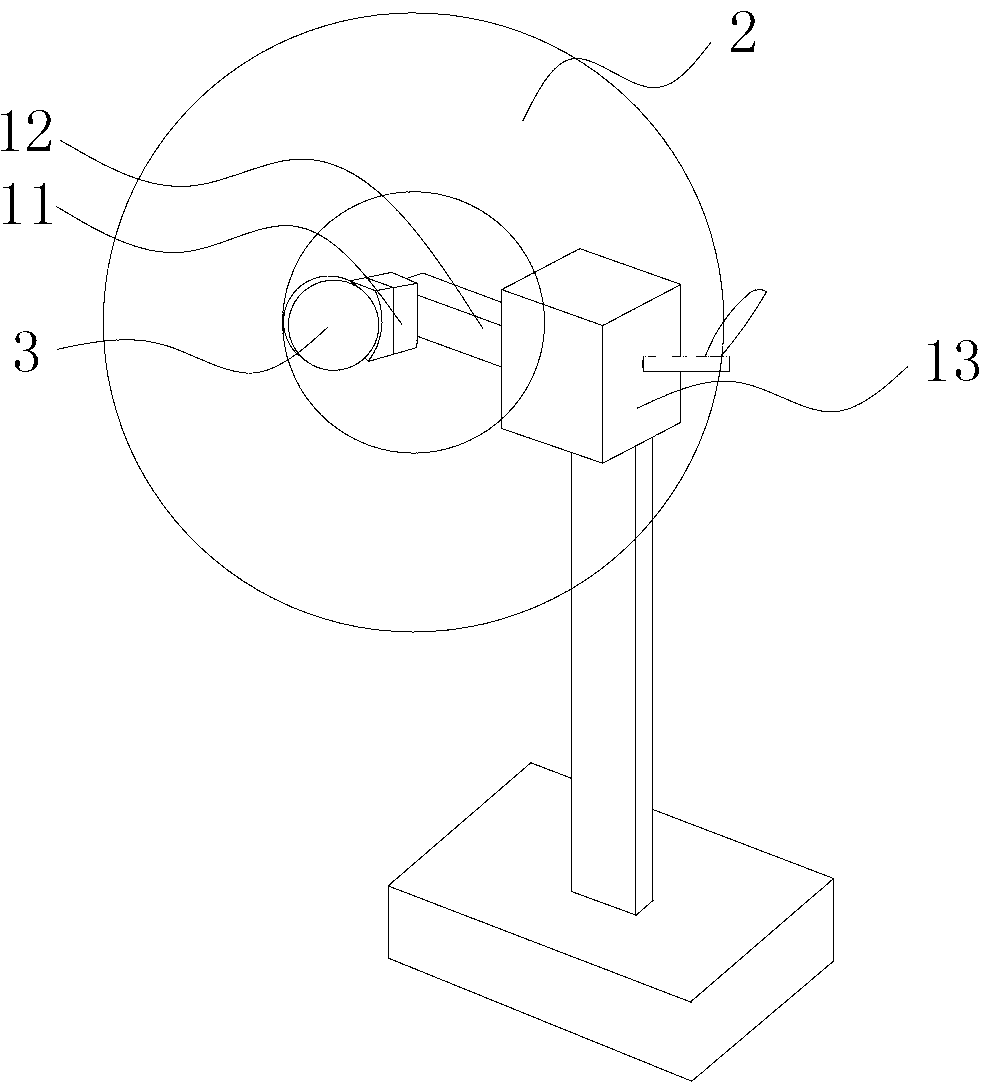

Winding device

ActiveCN108975055AIncrease wrap angleIncrease contact areaFilament handlingWebs handlingEngineeringAxial distance

The invention discloses a winding device. The winding device includes a roll-up device, a pressing wheel device, a tension adjusting device and a machine table; the roll-up device, the pressing wheeldevice and the tension adjusting device are sequentially arranged on the machine table, andafter passing through the tension adjusting device and then passing through the pressing wheel device, a wound wire is wound through the roll-up device; a large pressing wheel is arranged between a small pressing wheel and a roll-up disc to play a role of transition, therefore, the small pressing wheel getsaway from limit of the roll-up disc, the small pressing wheel does reciprocating movement on the surface of the large pressing wheel and can move to the very edge of the large pressing wheel, meanwhile, the axial distance of the large pressing wheel is the same as that of thecore of the roll-up disc so that the wound wire can be directly guided to the edge of the roll-up disc through cooperation of the small pressing wheel and the large pressing wheel, the problem of edge wire winding is solved, the end face is flat, the wound wire has the sense of layering, the accuracy of products is greatlyimproved, and the qualification rate of the products is greatly increased.

Owner:TAICANG HONGHAI PRECISION MACHINERY CO LTD

Roller cutting machining equipment

The invention provides roller cutting machining equipment. The problems that existing equipment is large in structure and occupies space are solved. The roller cutting machining equipment comprises afeeding rack, an excessive material cutting mechanism and a circumferential machining mechanism. The circumferential machining mechanism comprises a rotating disc driven by a motor to rotate. Multiplerotating shafts driven by the motor are arranged in the circumferential direction of the rotating disc and used for sleeving rollers. A carding mechanism, a shearing mechanism and a chamfering mechanism are mounted beside the multiple rotating shafts. The feeding rack comprises a first feeding groove and a second feeding groove. A pushing air cylinder is further arranged on the first feeding groove and used for pushing the rollers into the second feeding groove from the first feeding groove. The excessive material cutting mechanism is arranged at the tail end of the first feeding groove. According to the roller cutting machining equipment, excessive material cutting is carried out, and the end faces of finished rollers can be level; disc type machining is achieved, the structure is compact, and the occupied space is small; and the first feeding groove and the second feeding groove are arranged and used for material preparing and feeding, and the material preparing time is shortened.

Owner:李卫

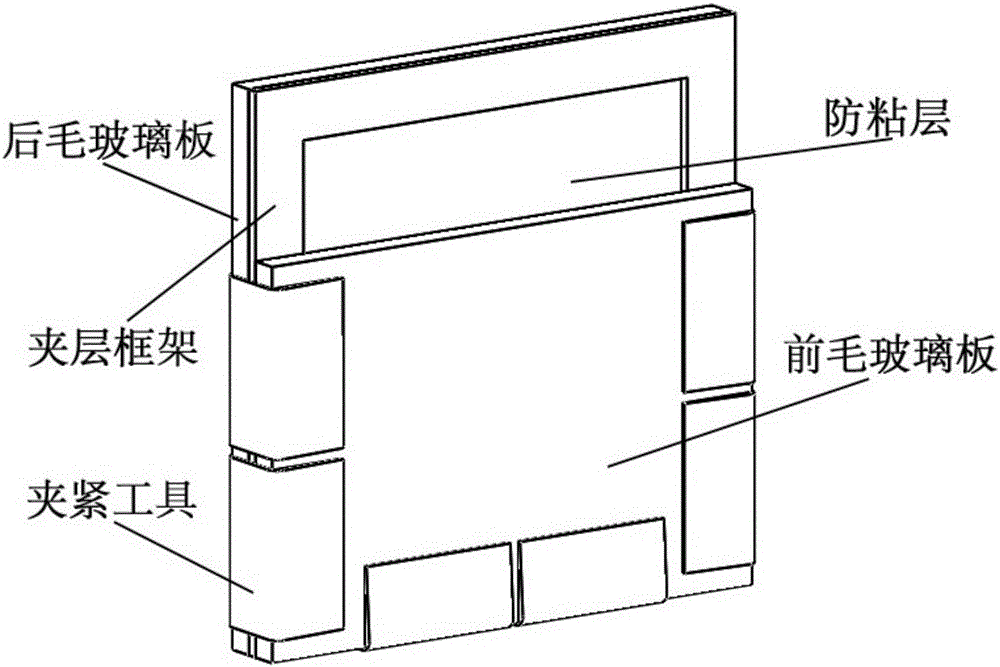

Device and method for preparing small-size round gelatin sheet sample

PendingCN106482996ARegular shapeImprove consistencyPreparing sample for investigationEngineeringGelatin

The invention discloses a device and a method for preparing a small-size round gelatin sheet sample. The device comprises a preparation die and a punch, wherein the preparation die is used for preparing a rectangular gelatin sheet comprising a front frosted glass plate, a rear frosted glass plate, a sandwich framework and a clamping tool; the front and rear frosted glass plates are of rectangular structures with same width; the sandwich layer framework is a hollow square-shaped framework which is arranged between the front frosted glass plate and the rear frosted glass plate; the front frosted glass plate, the sandwich framework and the rear frosted glass plate are clamped and sealed through the clamping tool; inner walls of the front and rear frosted glass plates are each provided with an anti-sticking layer; the height of the front frosted glass plate is smaller than the height of the rear frosted glass plate; a gap used for injecting a gelatin solution is formed between the front frosted glass plate and an upper frame of the sandwich framework; the punch is of a tubular structure, and a taper for cutting the rectangular gelatin sheet prepared by the preparation die is arranged at the head part of the punch. A gelatin sample prepared by the device disclosed by the invention is regular in shape, uniform in thickness and smooth in end surface, and the efficiency for preparing the small-size round gelatin sheet sample is greatly increased.

Owner:NANJING UNIV OF SCI & TECH

Light blocking object nozzle maintaining device and light blocking object coating device

InactiveCN107463068AFlat endImprove the problem of startmuraPhotomechanical coating apparatusSpray nozzleEngineering

The embodiment of the invention discloses a light blocking object nozzle maintaining device. The light blocking object nozzle maintaining device comprises a roller and a scraping knife, wherein the roller can rotate and is used for maintaining a nozzle; the scraping knife is arranged by attaching to the outer surface of the roller; the scraping knife is in surface contact with the outer surface of the roller, and the roller rotates to drive the scraping knife to clear light blocking objects on the surface of the roller. The embodiment of the invention also discloses a light blocking object coating device. The light blocking object coating device has the advantages of improving the poor front-stage spraying uniformity and consistency of light blocking.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

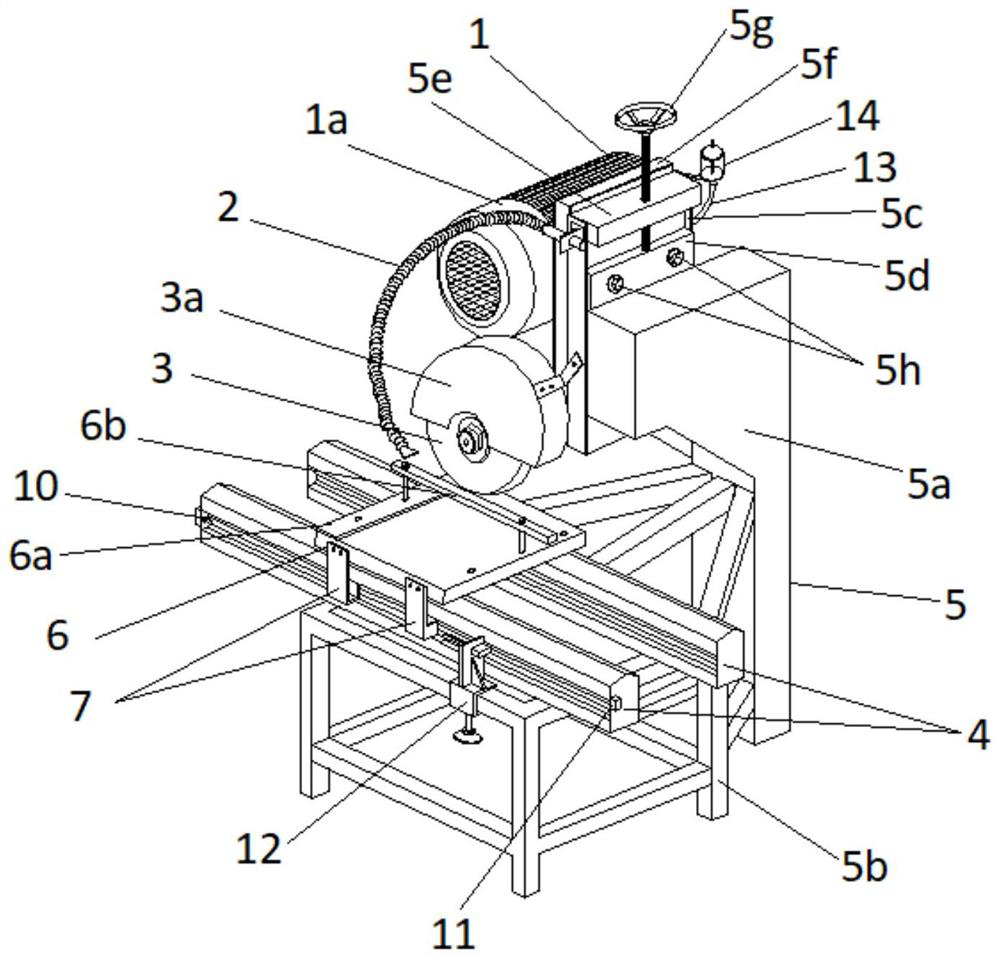

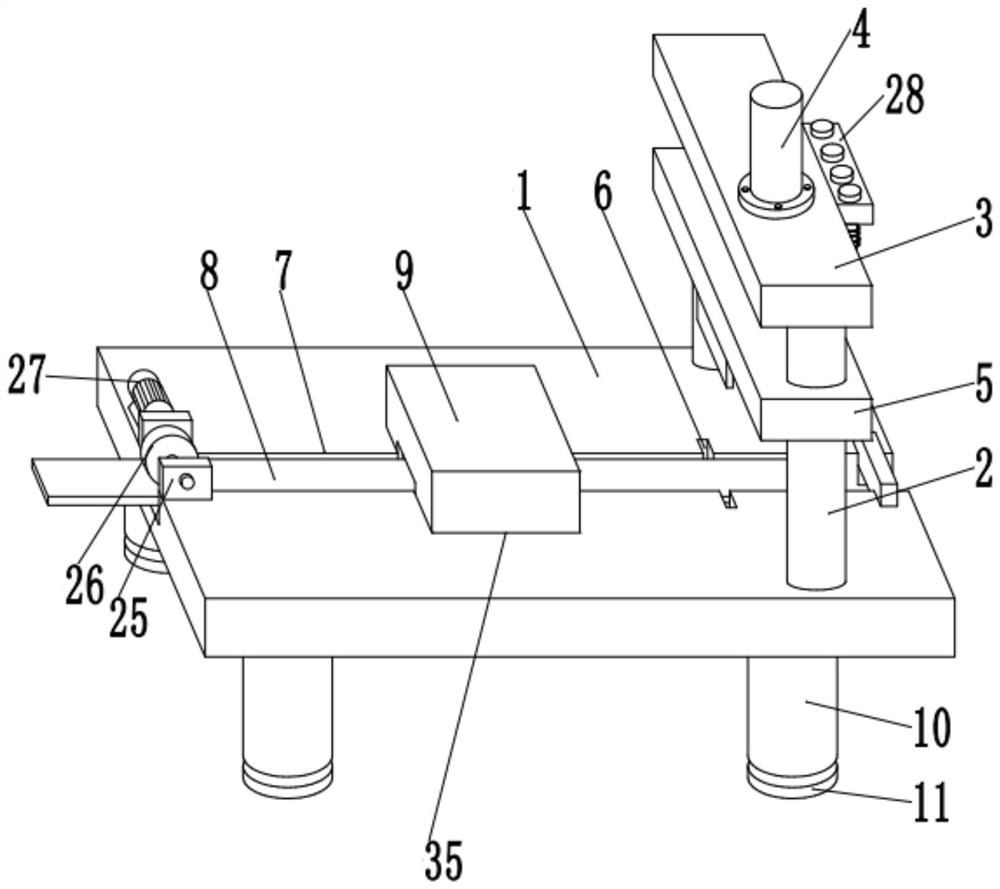

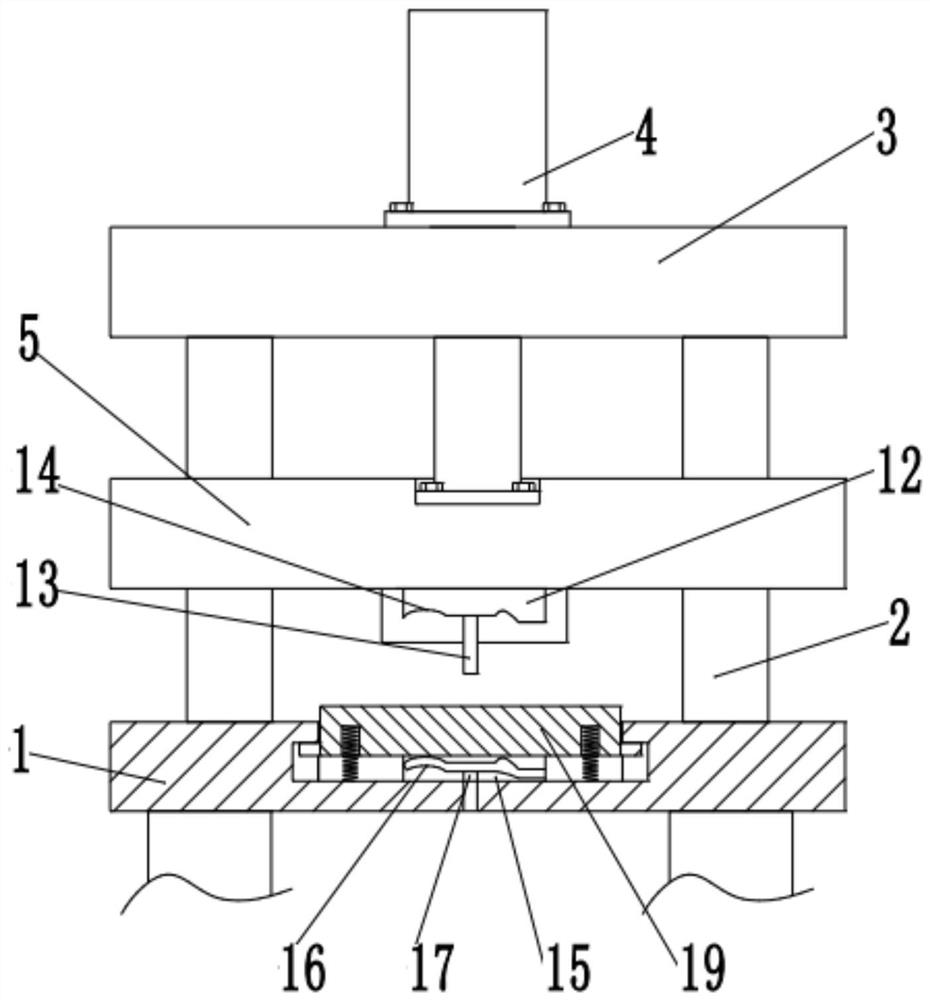

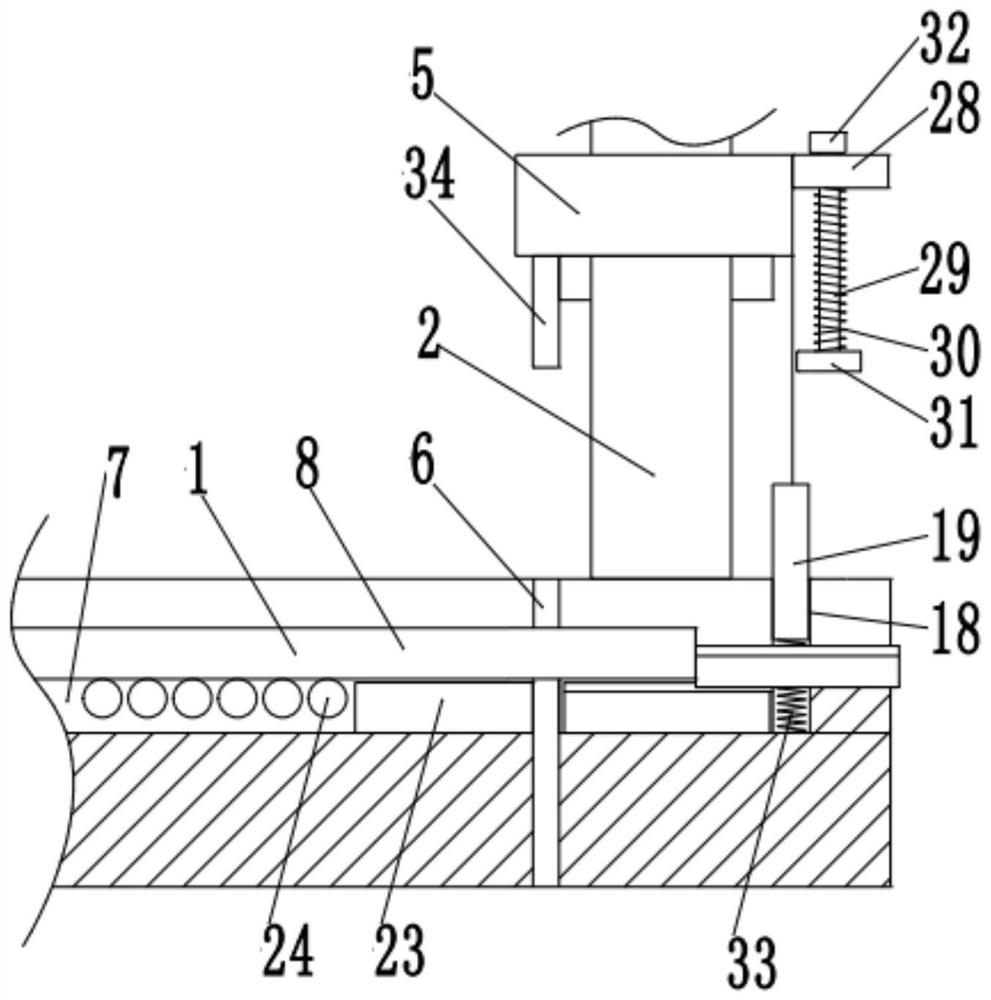

Double-cutter asphalt concrete test piece cutting machine

PendingCN112706307ASimple structureNovel and reasonable designWorking accessoriesStone-like material working toolsSupporting systemControl system

The invention discloses a double-cutter asphalt concrete test piece cutting machine. The double-cutter asphalt concrete test piece cutting machine comprises a supporting system, a cutting system and a control system. The height-adjustable cutting system is arranged on the supporting system and is used for cutting an asphalt concrete test piece. A sample conveying system capable of moving horizontally is further arranged on the supporting system, is positioned below the cutting system and is used for pushing an asphalt concrete sample to be cut to the cutting system. The control system is used for controlling the cutting work of the cutting system to start or stop and controlling the position of the sample conveying system to move or stop. The double-cutter asphalt concrete test piece cutting machine is simple in structure, novel and reasonable in design and convenient to operate, the whole cutting process is high in automation degree, the sample conveying process is uniform in speed, errors are reduced, and the quality of the asphalt concrete test piece is improved; the speed of adjusting the distance between cutter heads is high, and the working efficiency is improved; and various types of asphalt concrete samples can be clamped, the application range is wide, and the double-cutter asphalt concrete test piece cutting machine is suitable for general popularization.

Owner:SINOHYRDO ENG BUREAU 3 CO LTD

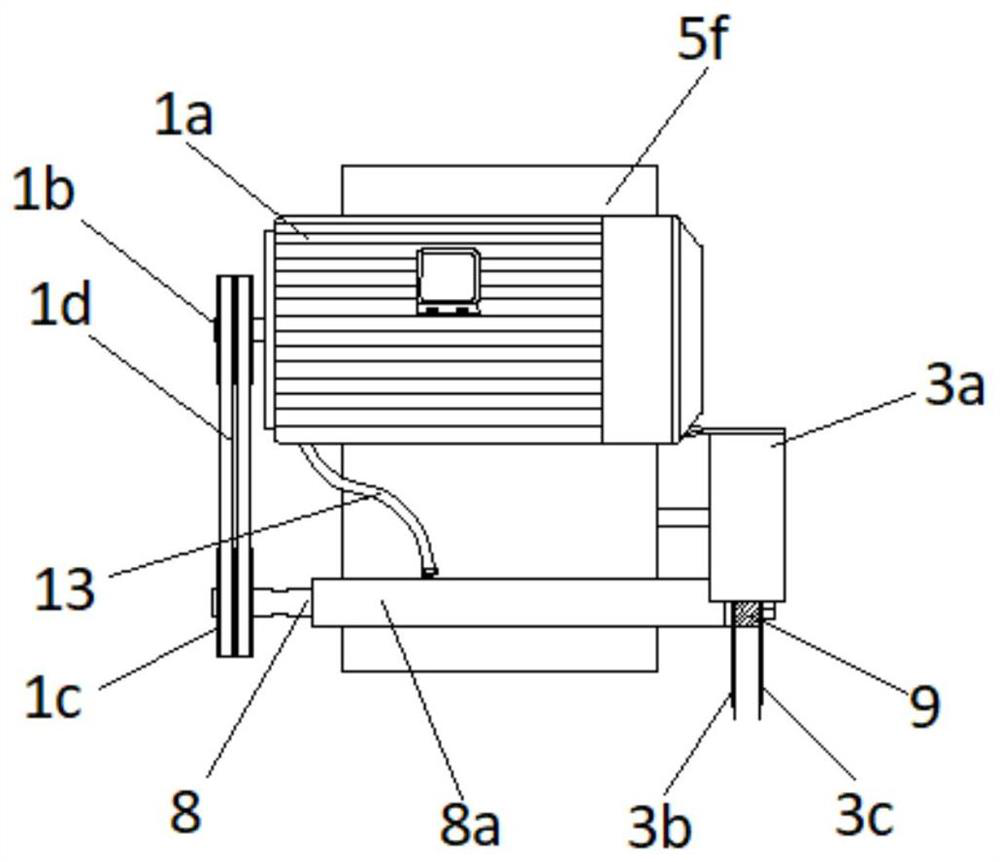

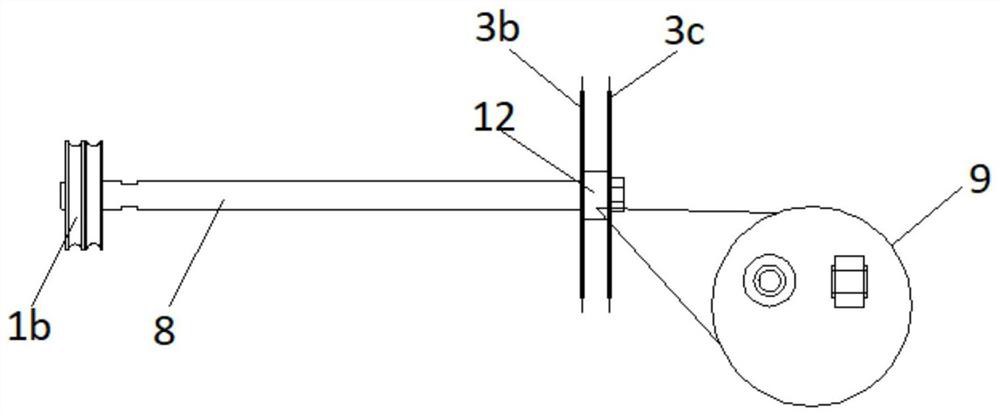

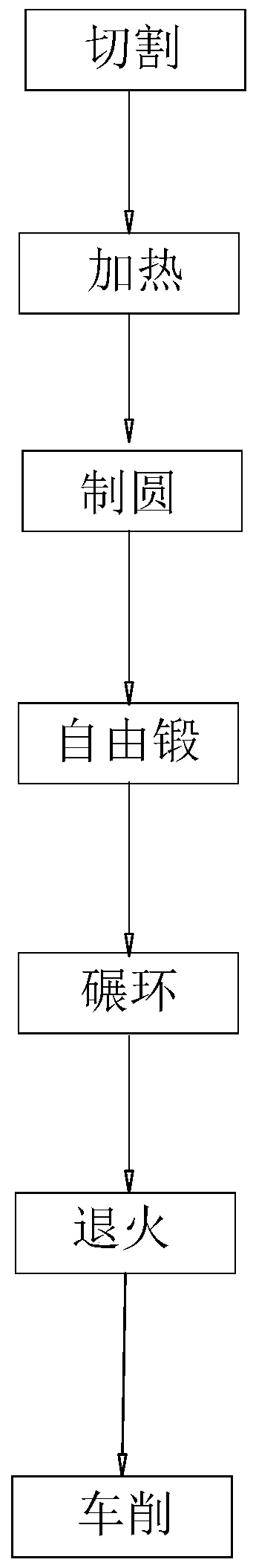

Flange forging technology

ActiveCN110814264AReduce thicknessReduce weightWheelsMetal rollingSquare cross sectionHeating furnace

The invention discloses a flange forging technology and belongs to the technical field of flange production. The technology comprises the following steps of step S1, cutting, wherein a long-strip-shaped blank with a square cross section is cut into multiple square billets; step S2, heating, wherein the square billets are placed in a heating furnace for heating, so that the temperature of the square billets is greater than that of the recrystallization temperature and smaller than that of a solid phase line; step S3, rounding, wherein the square billets are placed in a rounding mold and forgedinto cylindrical billets; step S4, free end finishing, wherein a pressure machine is used for upsetting the heated billets, and a puncher pin is used for punching the billets; step S5, ring grinding,wherein the billets are installed on a ring grinding machine for ring grinding, and center holes of the billets are enlarged; step S6, annealing, wherein the billets are placed in a resistance furnacefor annealing; step S7, turning, wherein a turning lathe is used for turning a flange. The flange forging technology has the advantage of improving the forging efficiency.

Owner:济南泰康锻造股份有限公司

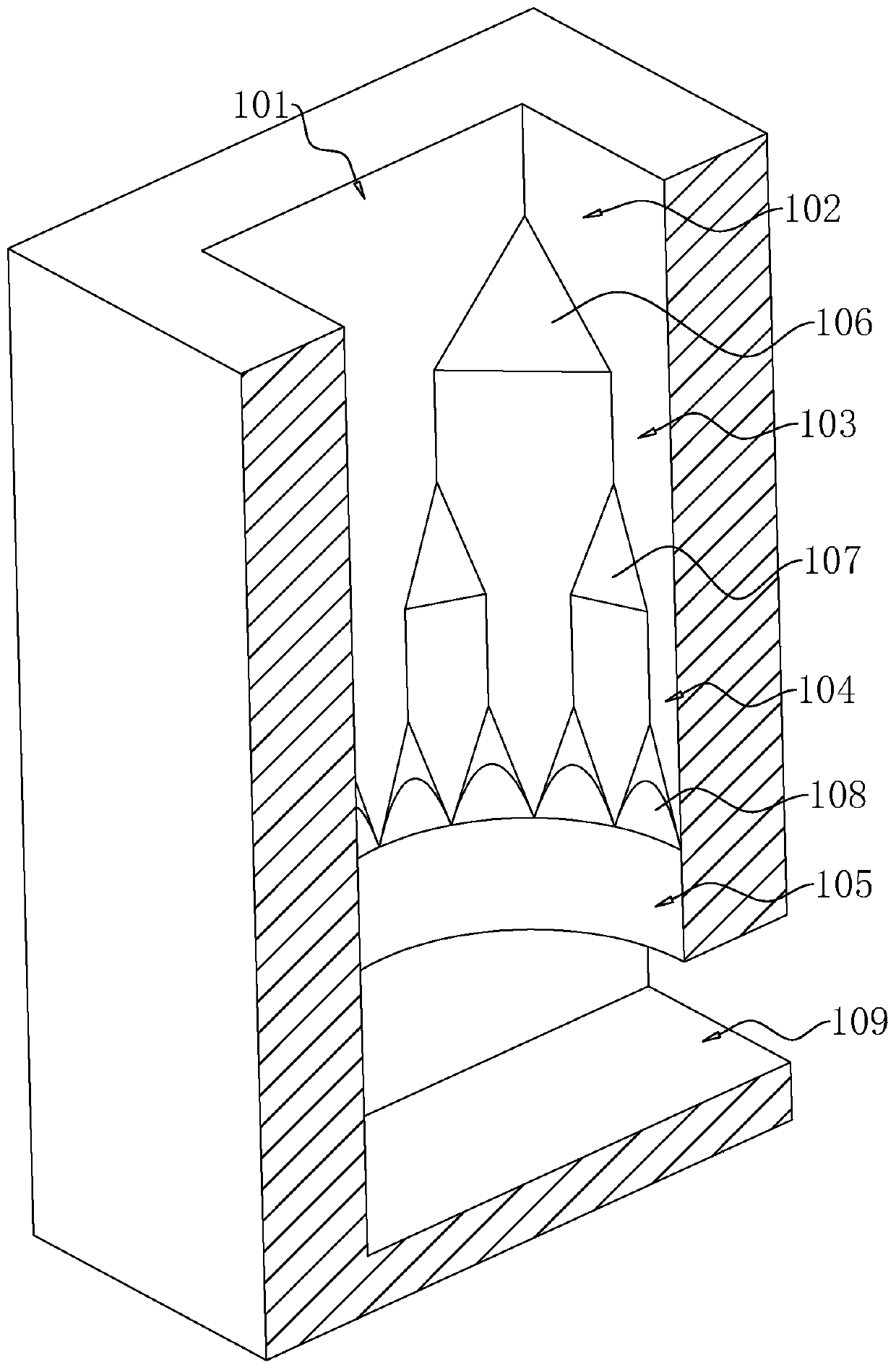

Semen cassiae composite fiber of polyester carrier and preparing method of fiber

InactiveCN110106577AKeep aliveReduce churnMelt spinning methodsMonocomponent polyesters artificial filamentFiberPolyester

The invention provides a preparing method of a semen cassiae composite fiber of a polyester carrier. The method includes the steps of preprocessing semen cassiae extracts, preparing a wall material, preparing a microcapsule and conducting spinning. The semen cassiae composite fiber of the polyester carrier is high in tow evenness, slippery in silk layer and good in package forming and has the antibacterial rate of 95.5-97.6% for microsporum odouins, the antibacterial rate of 93.9-94.2% for trichophyton schoenleini, the antibacterial rate of 90.8-92.1% for microsporum gypseum, the total anthraquinone wastage rate of 16.36-23.33% and the chrysophanol wastage rate of 6.38-15.79%. The semen cassiae composite fiber has the advantages of keeping the activity of the semen cassiae extracts and reducing the wastage rate and solves the charring problem in the high-temperature fusion spinning process of the semen cassiae extracts and polyester chips.

Owner:ZHONGKE TEXTILE RES INST QINGDAO CO LTD

Plastic composite tubular product sample cutting machine for steel wire gauze framework

ActiveCN102133659AWill not shiftImprove efficiencyMetal sawing devicesMetal sawing toolsWire gauzeCoupling

The invention discloses a plastic composite tubular product sample cutting machine for a steel wire gauze framework. A frame is provided with a fixture for clamping a plastic composite pipe of the steel wire gauze framework; a large wheel has a hollow cylindrical structure, is fixed on the frame through two groups of bearing devices, and is positioned at one side of the plastic composite pipe of the steel wire gauze framework; the central axis of the plastic composite pipe of the steel wire gauze framework is coincided with the central axis of the large wheel; a connecting part is connected with the large wheel into a whole through a connecting flange; a reducing motor is fixed on the large wheel or the connecting part, and is connected with a screw rod through a shaft coupling; the screw rod is fixedly connected with a guide post; a cutting motor is fixed on a cutting motor fixing plate; and a high-speed resin saw blade is connected with the cutting motor. The high-speed resin saw blade is taken as a cutting tool, so that cutting and grinding are completed synchronously, the efficiency is high; a steel wire is prevented from being broken by hooking, a steel wire in a sample is fixed, and the end face is smooth and even; and the entire set of equipment has low manufacturing cost and is easy to accept by small and medium-sized enterprises.

Owner:广东致顺化工环保设备有限公司

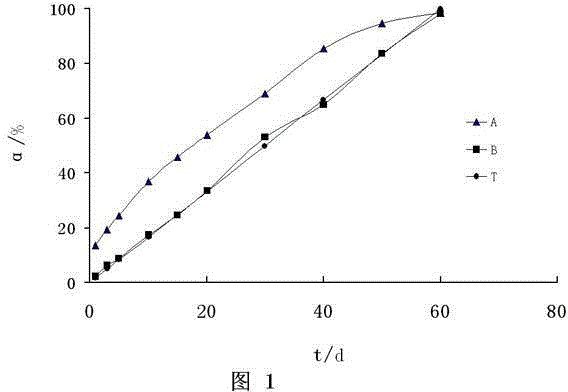

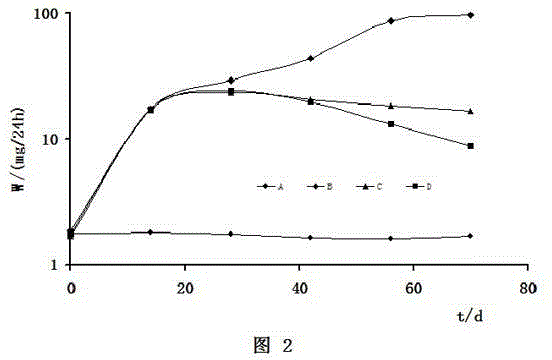

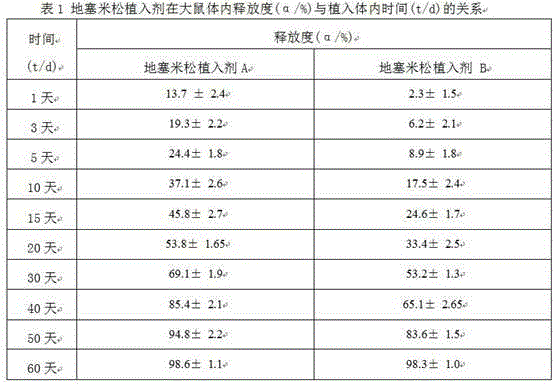

Preparation method of dexamethasone implant for kidney

ActiveCN105560161APromote meltingEasy extrusionOrganic active ingredientsPharmaceutical delivery mechanismDexamethasone acetateEngineering

The present invention relates to a preparation method, uses and a use method of a dexamethasone implant for kidney, wherein the dexamethasone implant comprises dexamethasone or dexamethasone acetate, a degradable polymer material, and a water soluble auxiliary material. The preparation method comprises: crushing various materials, mixing, carrying out micro-spheroidization, carrying out mold pressing molding, and heating for a certain time at a proper temperature to prepare the cylindrical implant with a diameter of 0.2-0.9 mm and a length of 0.8-4 mm. According to the present invention, the implant has characteristics of smooth surface and uniform drug release in vivo, wherein the time for releasing 90% of the drug is 1 month to 1 year; and the implant can be implanted into the renal sac through a drug implanting needle so as to treat nephrotic syndrome, nephritis and other chronic kidney diseases.

Owner:ANHUI ZHONGREN TECH +2

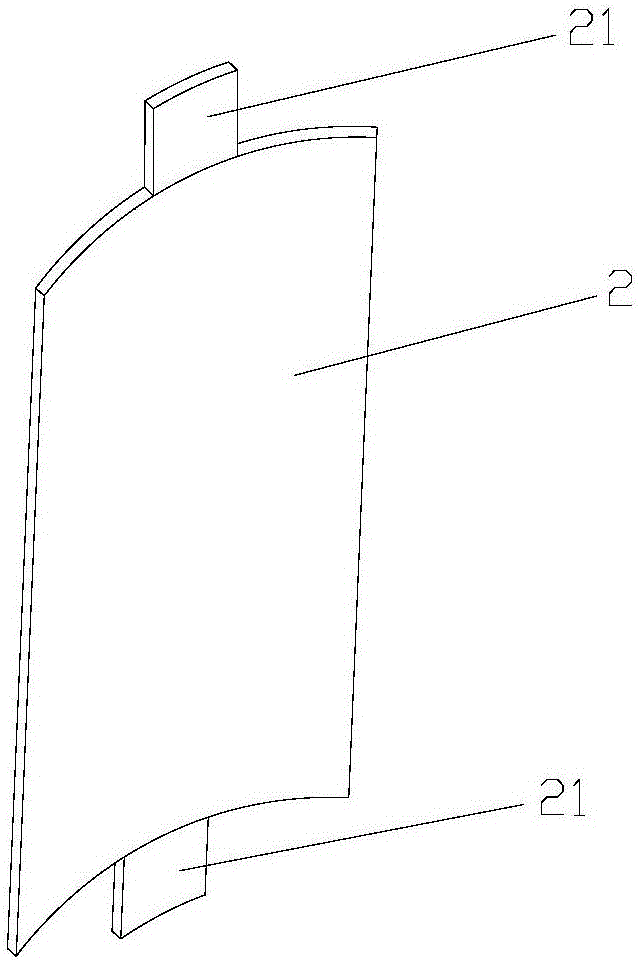

Production method of mortised and riveted impeller

InactiveCN107524632AStable structureReduce production processPump componentsPumpsMaterials preparationImpeller

The invention belongs to the technical field of a motor impeller, in particular to a production method of a mortised and riveted impeller. The production method comprises the steps: step 1, material preparation: preparing a lower impeller tray, blades and an upper impeller tray as required, cutting lower tray mortises in the lower impeller tray, cutting upper tray mortises in the upper impeller tray, and processing tenons on the two ends of each blade; step 2, assembly: mounting a plurality of blades on the lower impeller tray and the upper impeller tray one by one, inserting the blade tenons on one side of the lower impeller tray into the lower tray mortises or tongue-and-grooves in the corresponding positions of the lower impeller tray, inserting the blade tenons on one side of the upper impeller tray into the upper tray mortises or tongue-and-grooves in the corresponding positions of the upper impeller tray, and thus obtaining an impeller packaging body; step 3, rivet-pressing: rivet-pressing the blade tenons of the impeller packaging body obtained in the step 2 and the insertion positions of the upper tray mortises or tongue-and-grooves and the lower tray mortises or tongue-and-grooves by using rivet-pressing equipment, riveting the blade tenons with the upper tray mortises or tongue-and-grooves and the lower tray mortises or tongue-and-grooves, and thus obtaining an impeller assembly. The production method has the advantages of less procedure, high production efficiency and stable impeller structure.

Owner:常州恒益电机有限公司

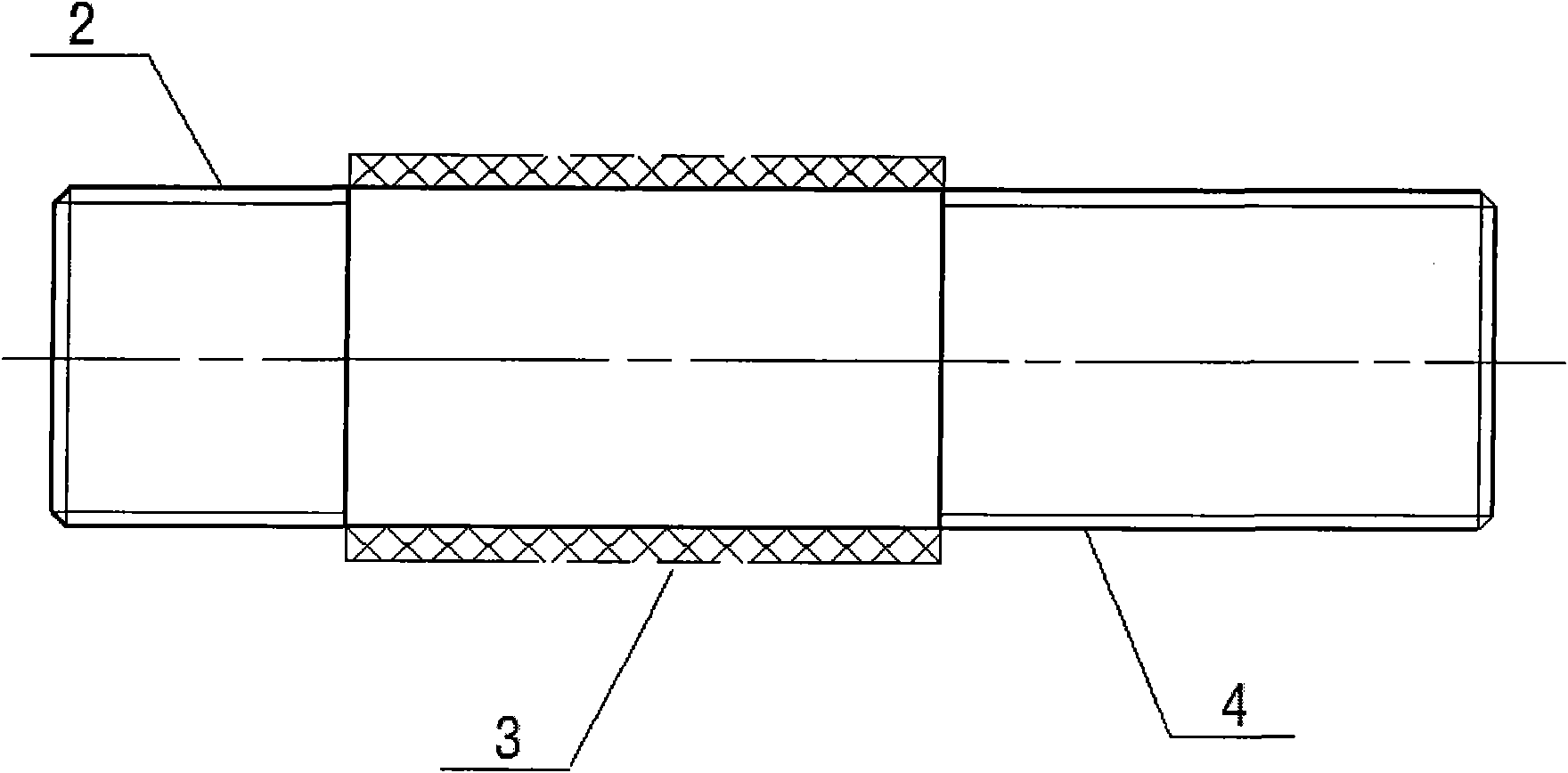

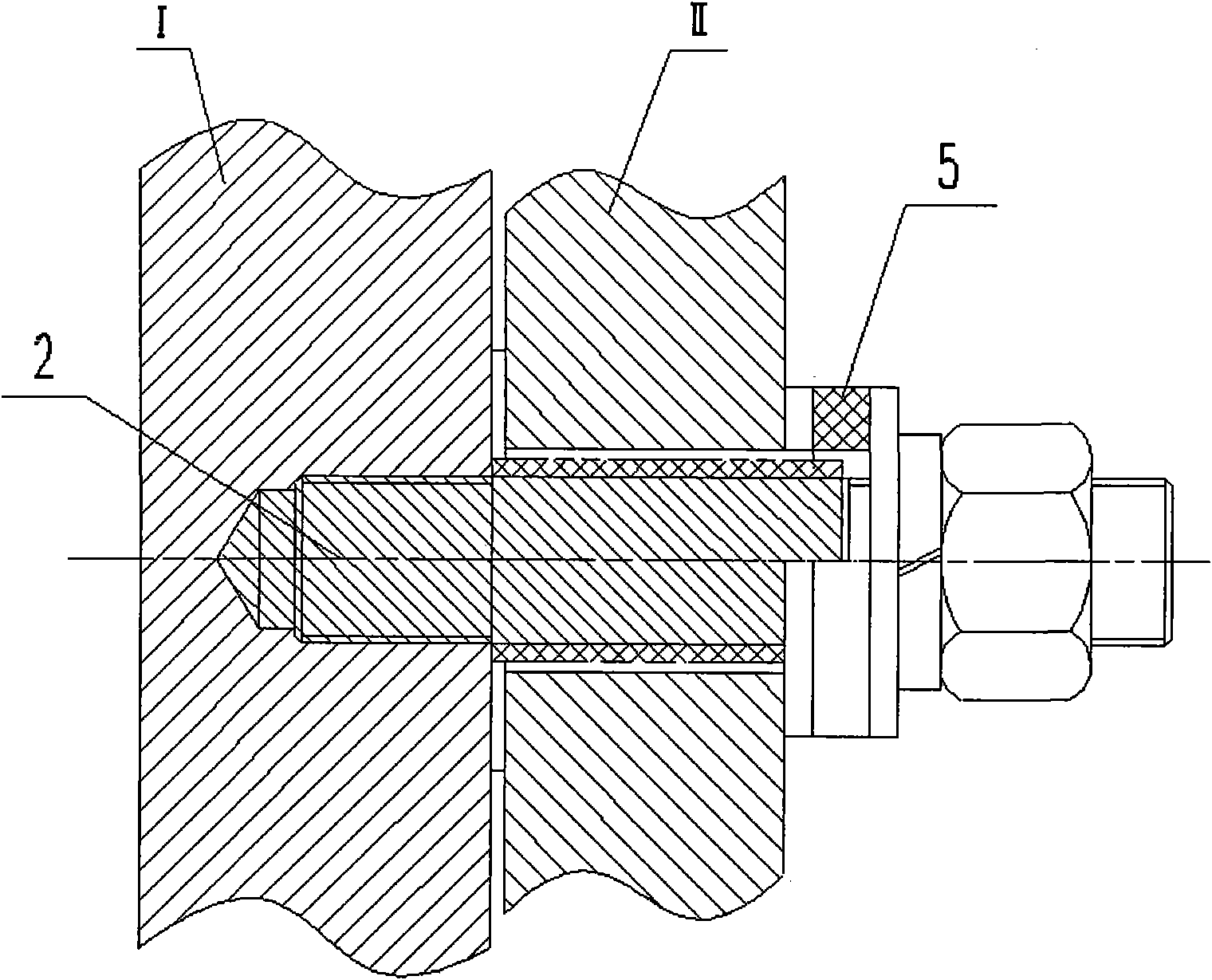

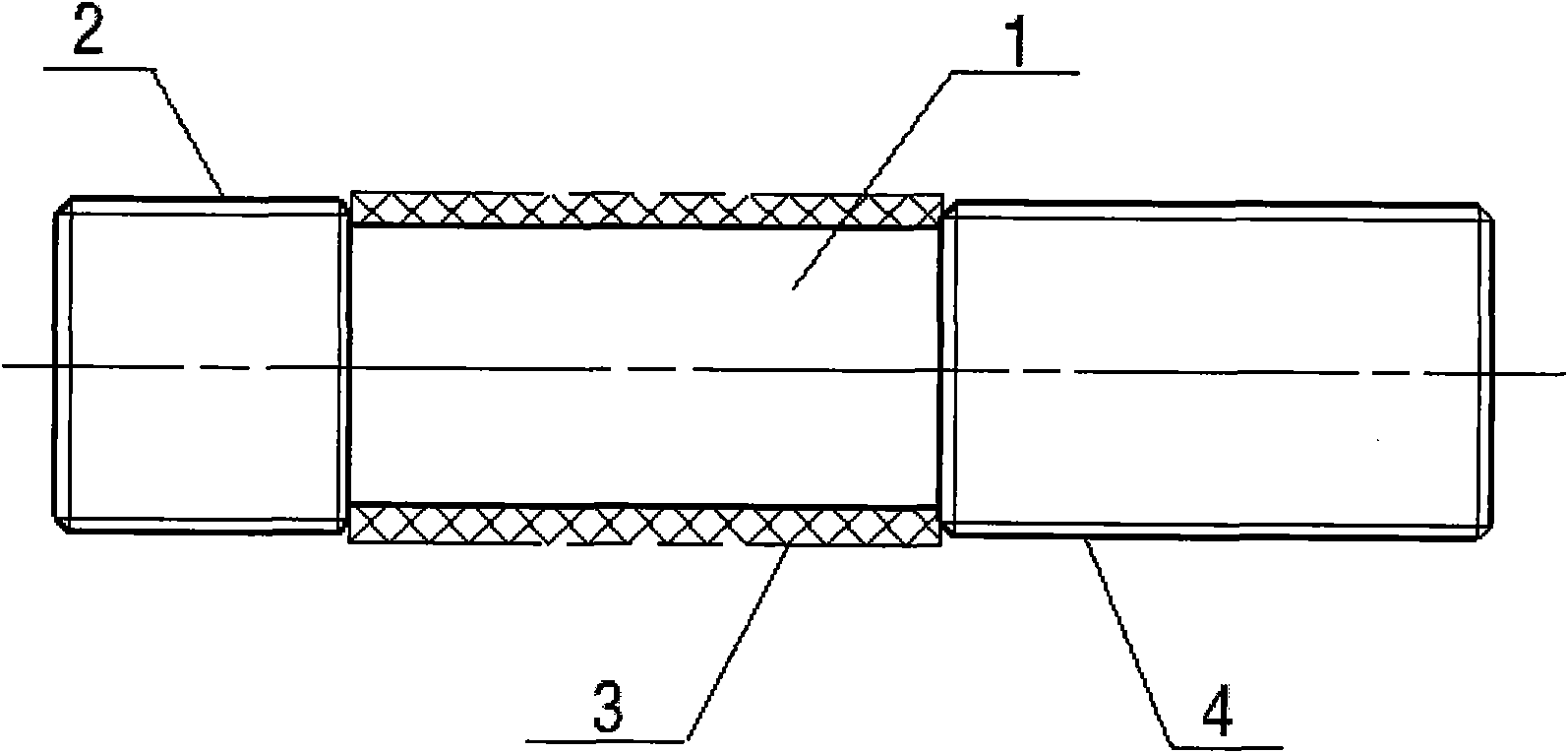

Insulation method for preventing metal screw or bolt from generating magnetic flux leakage linkage circulation

ActiveCN101552109AThe effect of the method is obviousGood effectTransformers/inductances coils/windings/connectionsInductances/transformers/magnets manufactureInsulation layerEngineering

The invention discloses an insulation method for preventing a metal screw or a bolt from generating magnetic flux leakage linkage circulation; the insulation method is characterized by comprising the following steps of wrapping the middle of the screw or the bolt by weft-free glass filaments with thickness of 1-4mm, using thermosetting insulation resin for infiltrating the glass filaments to form an insulation layer, and processing the surface after the insulation layer is solidified so as to lead the surface to be smooth and lead the outer diameter size of the screw or the bolt insulated by wrapping to be capable of extending into the hole of a structure part flange; and the insulation layer separates the structure part from one section of the middle part of the screw.

Owner:CHINA XD ELECTRIC CO LTD

Preparation method of zinc oxide lightning arrester valve plate

The invention provides a preparation method of a zinc oxide lightning arrester valve plate. The preparation method comprises the following steps: performing grinding, granulating, forming, glue discharging, high-resistance layer coating, sintering and glazing procedures on a zinc oxide raw material to form a zinc oxide magnet, and the preparation method further comprises a cutting step for correcting the smoothness and the shape of the end face of the zinc oxide magnet in ahead of an aluminum spraying procedure. The cutting step comprises the sub-steps: mounting and fastening the zinc oxide magnet on a cutting machine worktable through a tool fixture; adjusting the tension of a cutting machine blade, setting the cutting depth, aligning the blade to the radial angle of the end face of the zinc oxide magnet, starting a cutting machine for cutting, and simultaneously spraying cooling liquid; shutting down to set the cutting width and cutting times, and continuously and automatically cutting after the setting operation, wherein the cut end face is used as a benchmark surface,; taking off the cut zinc oxide magnet and rim charge after the cutting operation. By adopting the preparation method provided by the invention, the end face of a zinc oxide lightning arrester electromagnet is smooth, and the technical effects of environment protection, high efficiency, low energy consumption and energy conservation are realized.

Owner:SUCCESS ELECTRONICS HUIZHOU

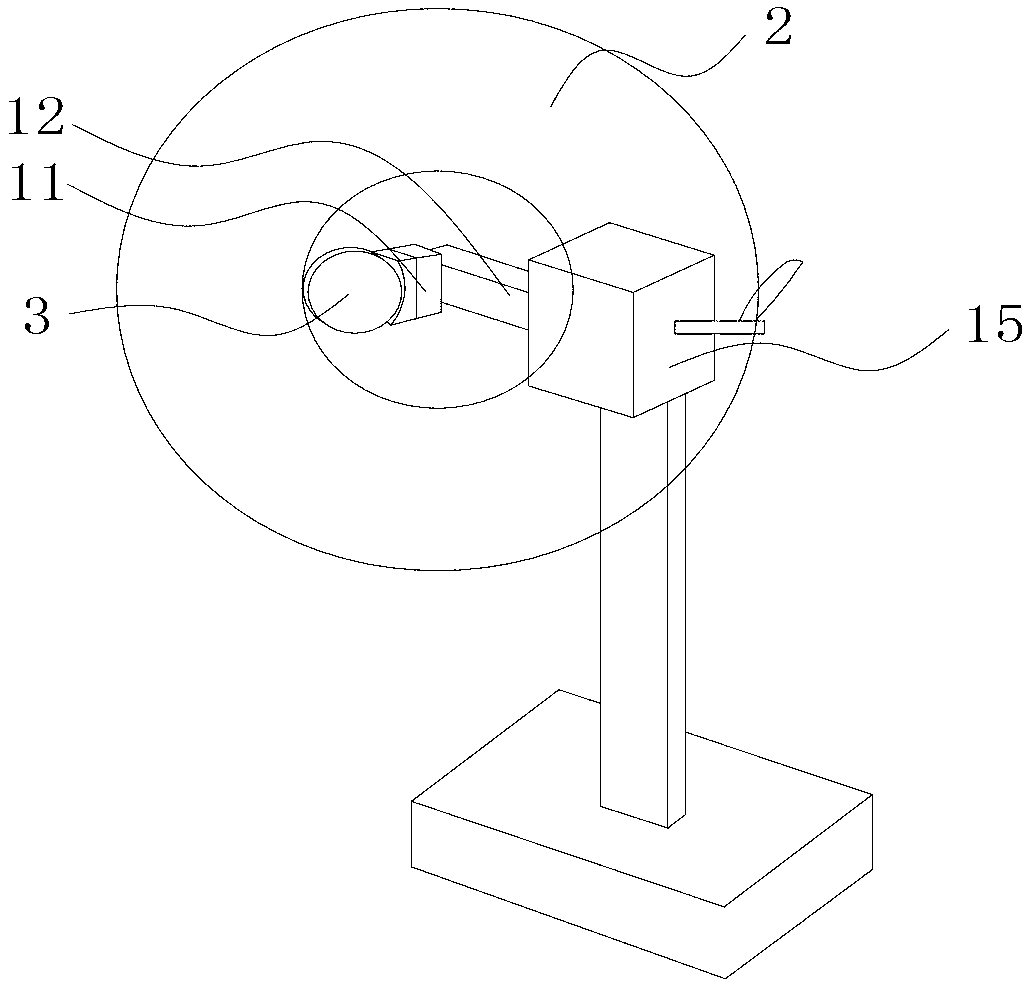

Connecting tube of end of water system of central air conditioner and manufacture process thereof

InactiveCN101684874ASimple preparation processSimple manufacturing processFlexible pipesHose connectionsEngineeringInjection moulding

The invention discloses a connecting tube of the end of a water system of a central air conditioner and a manufacture process thereof. The connecting tube consists of a stainless steel corrugated tube. Both ends of the corrugated tube are provided with convex ribs; a fixed seal ring of once injection moulding is respectively arranged on the convex ribs; the fixed seal ring of once injection moulding is also provided with a joint nut; the joint nut is rotatably connected with a joint; and the convex ribs, the fixed seal ring of once injection moulding and the joint are compressed by the joint nut, thereby achieving the effect of seal connection. The invention has the manufacture process: due to the fact that the convex ribs are arranged near both end openings of the corrugated tube, the convex ribs arranged near both end openings are also molded at one time while the corrugated tube is manufactured; the convex ribs on the corrugated tube are put in a plastic injection machine; and the fixed seal ring is cast on the peripheries of the convex ribs. The invention is suitable for connecting the ends of water-system air conditioners.

Owner:何永水

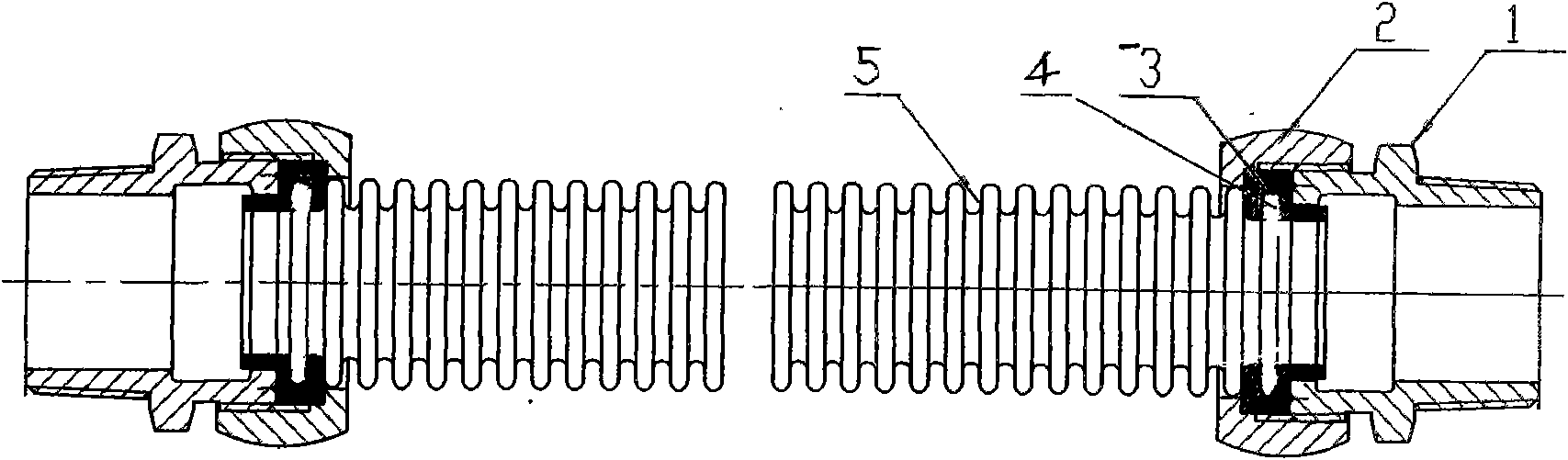

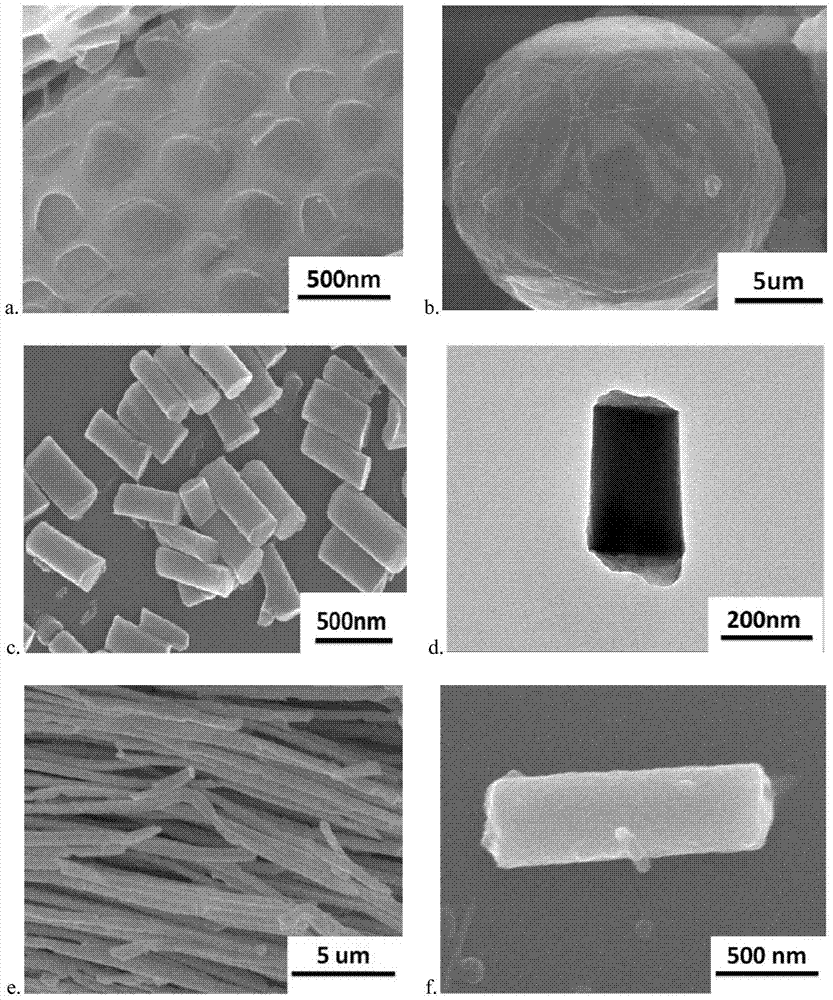

Rod-shaped material with surface having multiple properties and manufacturing method and application of Pickering emulsion thereof

InactiveCN103935955AThe method steps are simpleMild reaction conditionsMaterial nanotechnologyIndividual molecule manipulationFiberPickering emulsion

The invention discloses a rod-shaped material with a surface having multiple properties and a manufacturing method and application of Pickering emulsion of the material. The material is composed of a nanorod and discs at the two ends of the nanorod, wherein the diameter of each disc is equal to the diameter of the two end faces of the nanorod, the material forming the nanorod is marked as the material B, the materials forming the discs at the two ends of the nanorod are different and are marked as the material A1 and the material A2 respectively, the material B is selected from at least one of an inorganic material and a metal material, and the material A1 and the material A2 are made of polymer. According to the rod-shaped material, a fiber array manufactured through a die plate method passes through an ultrathin section to obtain rod-shaped nano materials with the uniform size, and then the nano materials are combined with a Pickering emulsion protection-deprotection method to form the rod-shaped material. According to the method, the manufactured number of rod-shaped nano materials can be obviously increased, and the rod-shaped materials have the great potential in biological applications such as a superstructure with the functional surface and the complex assembly and amphiphilic molecular simulation.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Plastic composite tubular product sample cutting machine for steel wire gauze framework

ActiveCN102133659BWill not shiftImprove efficiencyMetal sawing devicesMetal sawing toolsWire gauzeCoupling

The invention discloses a plastic composite tubular product sample cutting machine for a steel wire gauze framework. A frame is provided with a fixture for clamping a plastic composite pipe of the steel wire gauze framework; a large wheel has a hollow cylindrical structure, is fixed on the frame through two groups of bearing devices, and is positioned at one side of the plastic composite pipe of the steel wire gauze framework; the central axis of the plastic composite pipe of the steel wire gauze framework is coincided with the central axis of the large wheel; a connecting part is connected with the large wheel into a whole through a connecting flange; a reducing motor is fixed on the large wheel or the connecting part, and is connected with a screw rod through a shaft coupling; the screwrod is fixedly connected with a guide post; a cutting motor is fixed on a cutting motor fixing plate; and a high-speed resin saw blade is connected with the cutting motor. The high-speed resin saw blade is taken as a cutting tool, so that cutting and grinding are completed synchronously, the efficiency is high; a steel wire is prevented from being broken by hooking, a steel wire in a sample is fixed, and the end face is smooth and even; and the entire set of equipment has low manufacturing cost and is easy to accept by small and medium-sized enterprises.

Owner:广东致顺化工环保设备有限公司

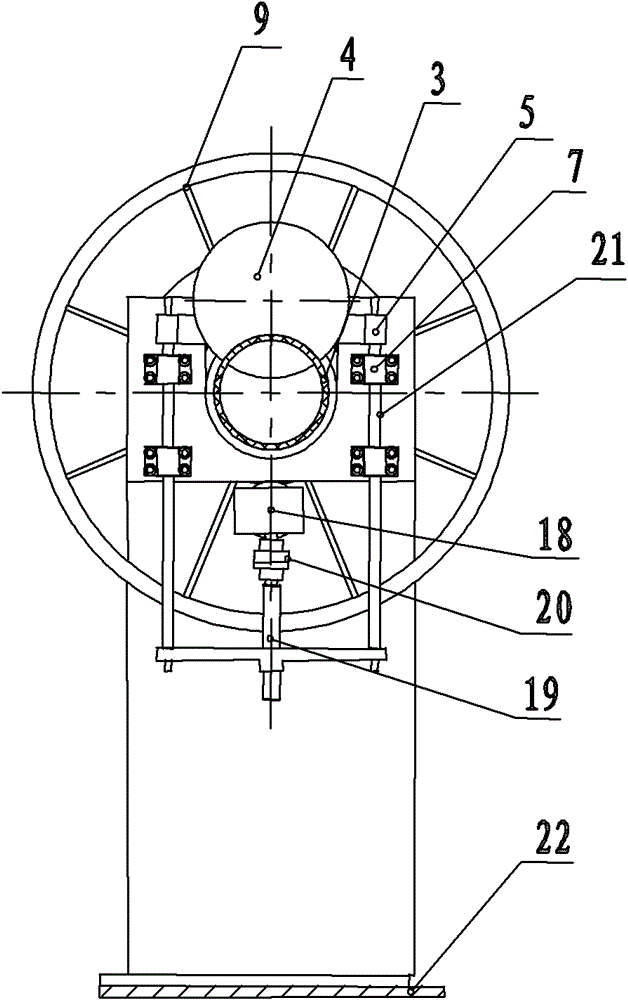

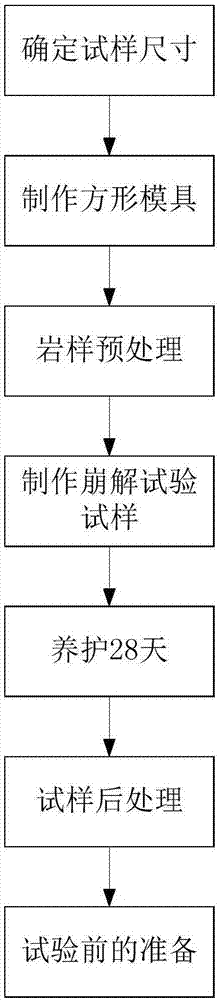

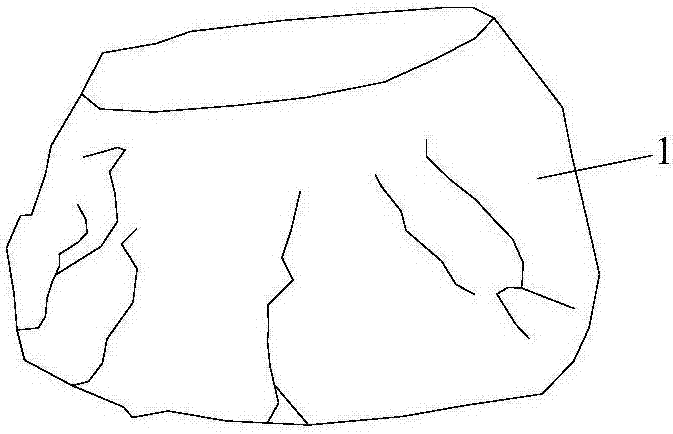

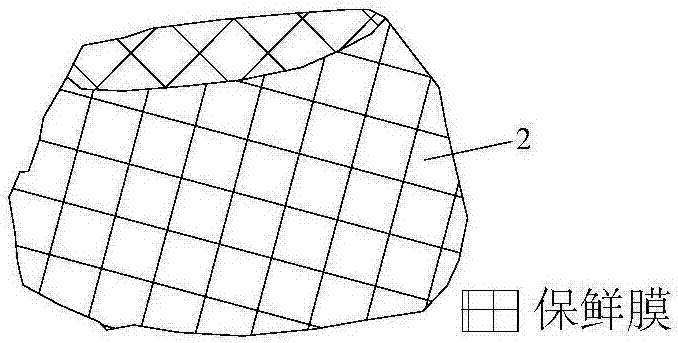

Making method of soft rock disintegration test sample under joint action of wet-dry alternation and stress

ActiveCN106989967AChange intensityEven by forcePreparing sample for investigationTest sampleRock cutting

The invention relates to a making method of a soft rock disintegration test sample under joint action of wet-dry alternation and stress. The making method includes steps: (1), determining size of the test sample; (2), making a square die; (3), pre-treating an original rock sample; (4), making cement mortar; (5), wrapping rock with the cement mortar in the die to form a cuboid disintegration test sample; (6), maintaining the sample for 28 days, and demounting the die; (7), after-treating the disintegration test sample; (8), preparing before a disintegration test. When the disintegration test sample is made under the joint action of wet-dry alternation and stress, conventional rock cutting methods cannot process soft rock into regular cuboid samples due to the fact that the soft rock is soft in texture and are low in sample making success rate. Aiming at the problem, the method can make the original sample into a regular cuboid needed for the test and is simple in process, low in cost and high in success rate. The sample made by the method can be used for simulating the soft rock disintegration test under the joint action of wet-dry alternation and stress.

Owner:HEFEI UNIV OF TECH

Rail vehicle part stamping machine

ActiveCN111702092AAvoid deformationImprove pass rateShaping toolsPerforating toolsHydraulic cylinderMachine

The invention relates to the technical field of rail vehicles, in particular to a rail vehicle part stamping machine which comprises a table top. The outer wall of the top of the table top is connected with two guide posts through bolts, the tops of the guide posts are connected with a top plate through bolts, the outer walls of the guide posts are slidably connected with an upper die holder, theouter wall of the top of the top plate is connected with a hydraulic cylinder through bolts, the bottom of the hydraulic cylinder is connected with the upper die holder through bolts, a rail groove isformed in the outer wall of the top of the table top, a plate is arranged inside the rail groove, the outer wall of the bottom of the upper die holder is connected with an upper die core through a bolt, the inner wall of the bottom of the rail groove at the bottom of the upper die core is connected with a lower die core through a bolt, a sliding groove is formed in the outer wall of the top of the table top, and a baffle is connected in the sliding groove in a sliding manner. Through the arranged upper die core, equidistant cutting is firstly carried out by a cutting knife, and then the plateis formed through pressing by the upper die core and the lower die core, so that the problem of deformation of the special-shaped end face is avoided, and the effect of improving the qualified rate of manufactured gauge aprons is realized.

Owner:南京天普机电产品制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com