Surface-sizing die-cutting folding type assembling machine of multi-layer wound roll

A folding and collating machine technology, applied in the direction of sending objects, thin material processing, transportation and packaging, etc., can solve the problems of inaccurate paper feeding, poor hole spacing correction ability, slow speed, etc., and achieve high alignment accuracy, The effect of high degree of automation and smooth end surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

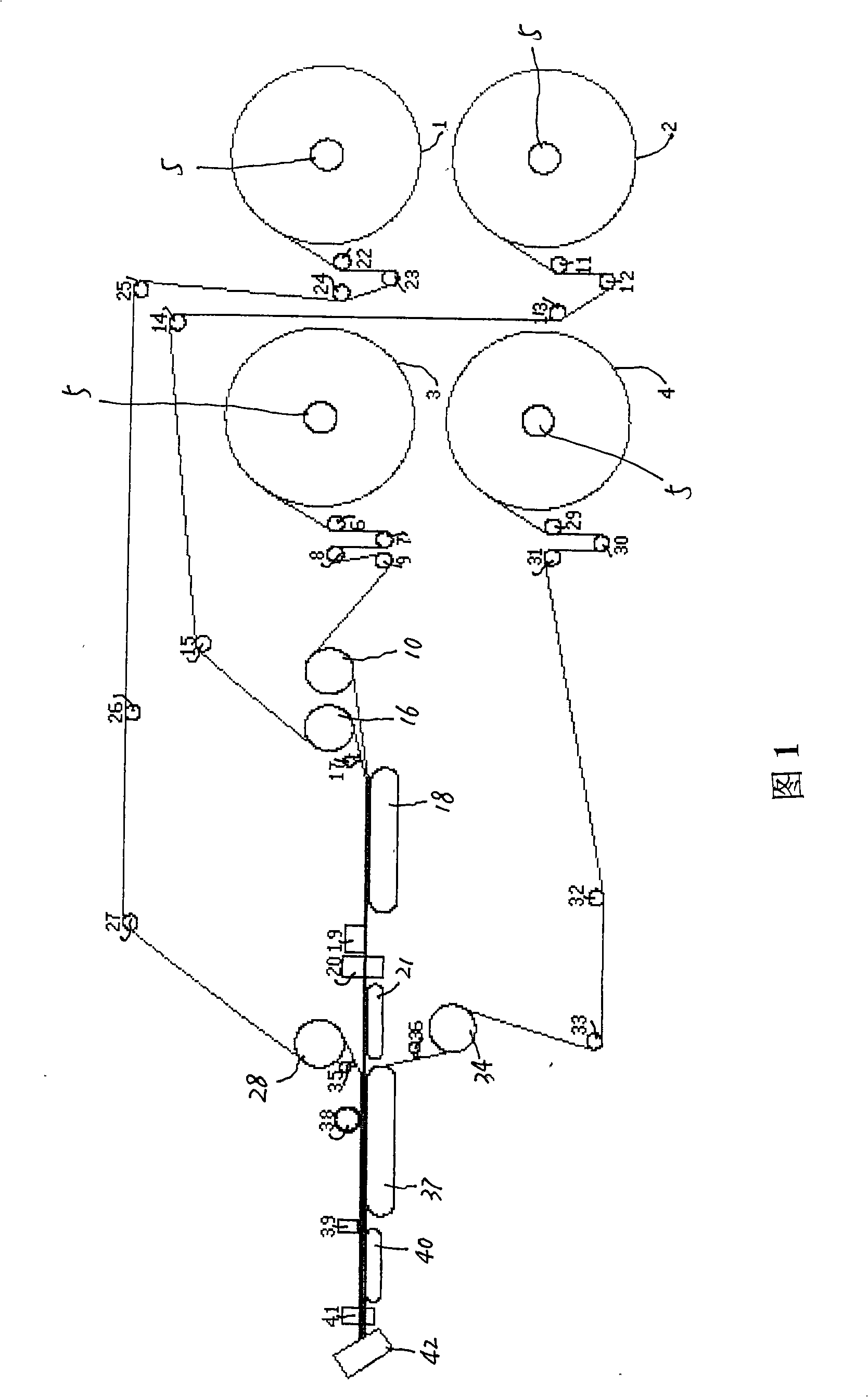

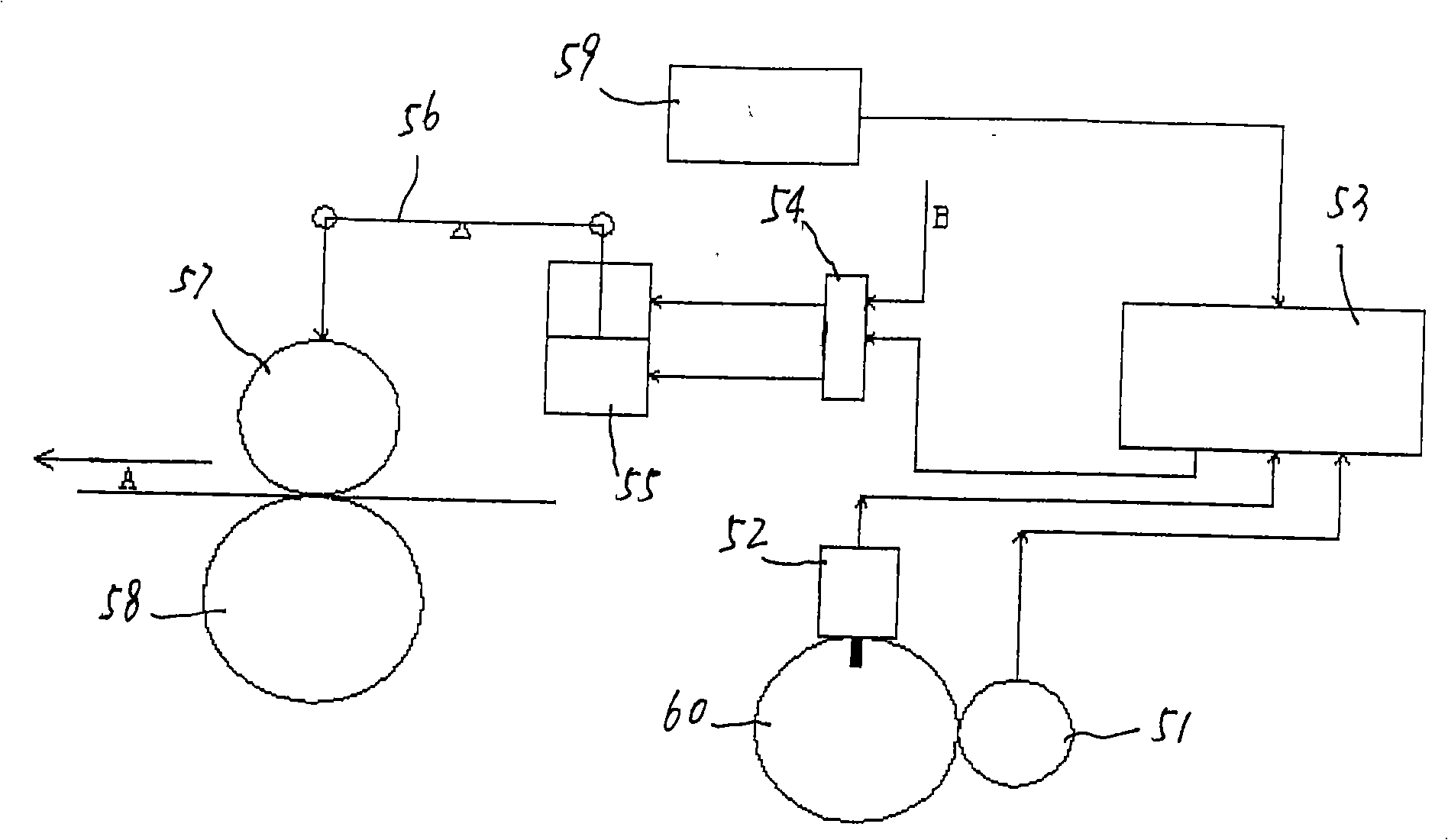

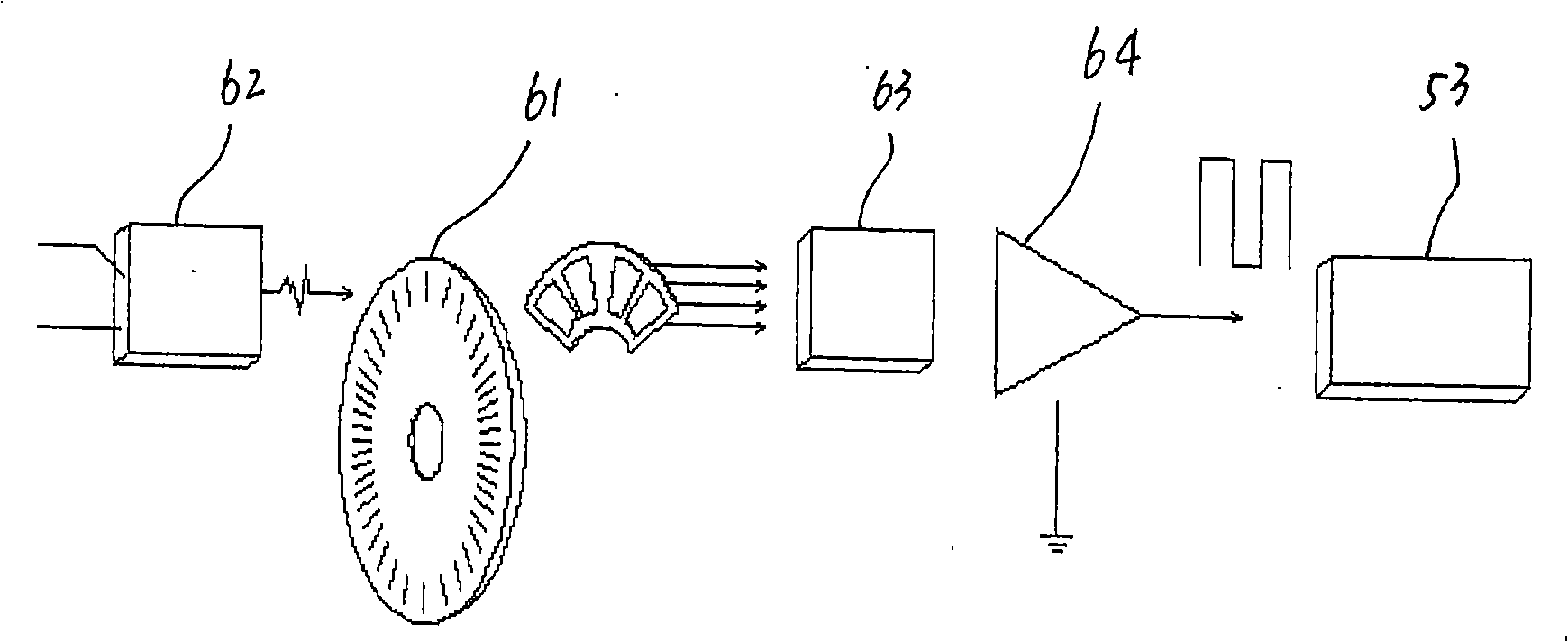

[0029] Figure 1, figure 2 and image 3 As shown, a multi-layer reel gluing die-cutting and folding collating machine, the two-layer web 2, 3 are collated once, and the web 2, 3 is collated and the other two-layer reel is collated Papers 1 and 4 are collated for the second time, then collated with the paper that has been collated for the third time, and so on, and finally sent to the horizontal crimping line to crimp and fold the collated paper. According to the specifications required by the product, the horizontal pressing line can press out various sizes of horizontal pressing lines by changing the gears, and at the same time, the packaging specifications required by the product can be adjusted by controlling the spiral folding mechanism.

[0030] The paper feeding of the two rolls of paper for the first collating is that one roll of roll paper 3 passes through the guide roller 6, the automatic brake device 7 and the guide rollers 8 and 9 respectively, and passes through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com