Making method of soft rock disintegration test sample under joint action of wet-dry alternation and stress

A technology of combined action and production method, applied in the field of soft rock disintegration, can solve the problems of low success rate of sample preparation, etc., and achieve the effect of low cost, high success rate, and simple sample preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

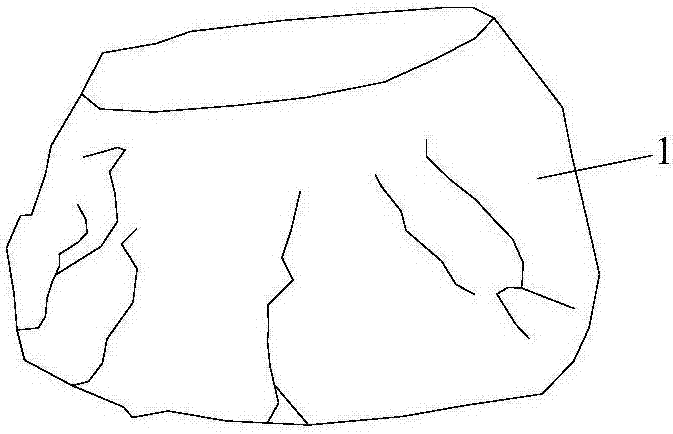

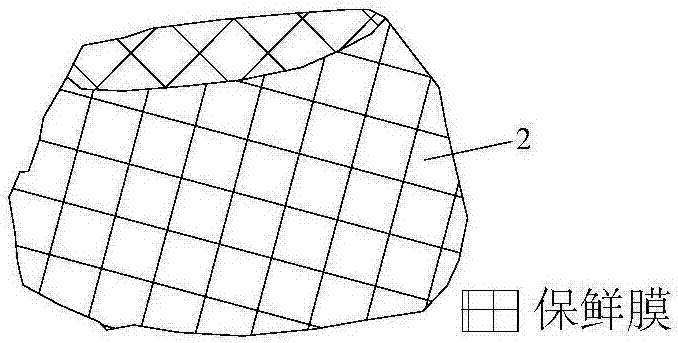

[0044] The structural features of the present invention will now be described in detail in conjunction with the accompanying drawings.

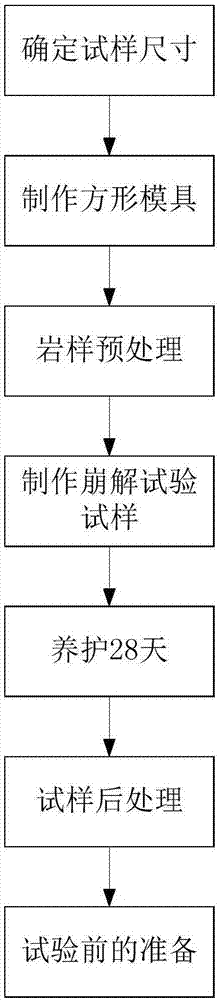

[0045] see figure 1 , the preparation method of the soft rock disintegration test sample under the joint action of wet-dry alternation and stress, the steps are as follows:

[0046] Step 1: Determine the size of the cuboid sample to be prepared:

[0047] According to the disintegration test requirements and the characteristics of the test device, determine the specific size of the disintegration test sample. For example, when using a disintegration test device under the combined action of wet-dry alternation and stress, if the net size of the cuboid sample box in the device is 200×200×100mm, then the disintegration sample is a cuboid and its size is 200×200×100mm.

[0048] Step 2: Make a cuboid (including cube) mold 3; the mold 3 is used to make a cuboid (including cube) sample; determine the internal size of the mold 3 according to the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com