Patents

Literature

215results about How to "Fully mixed reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

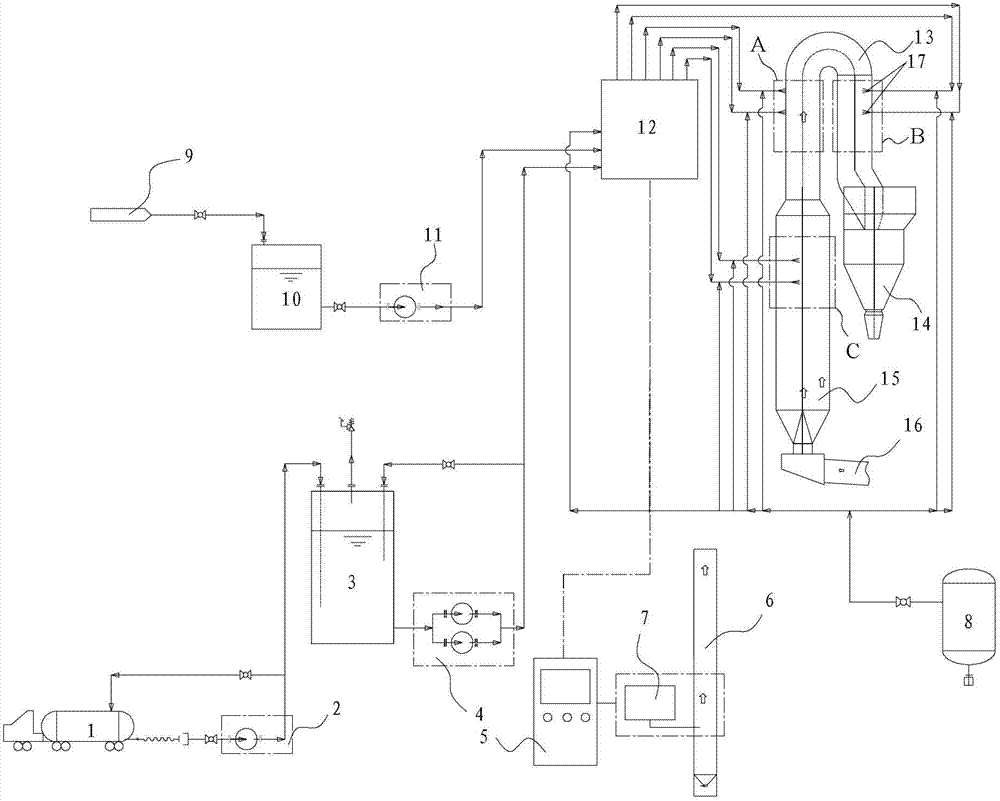

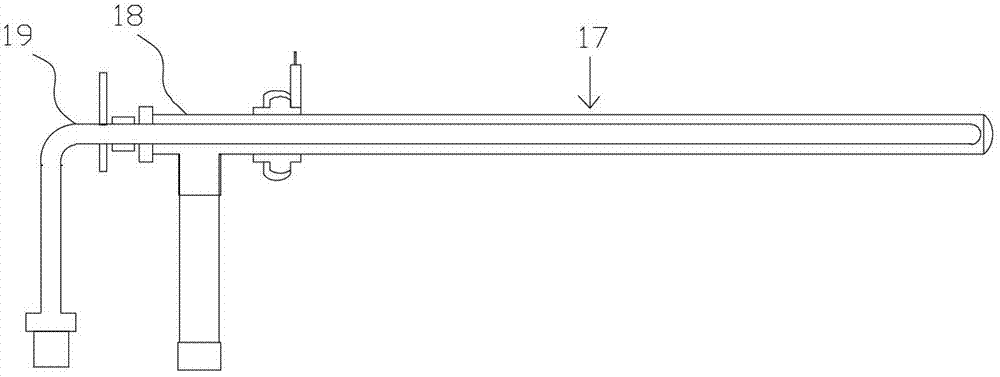

Method and device for controlling NOx concentration in smoke gas of cement kiln

ActiveCN102921284AIncrease profitReduce consumptionDispersed particle separationMulti siteMonitoring system

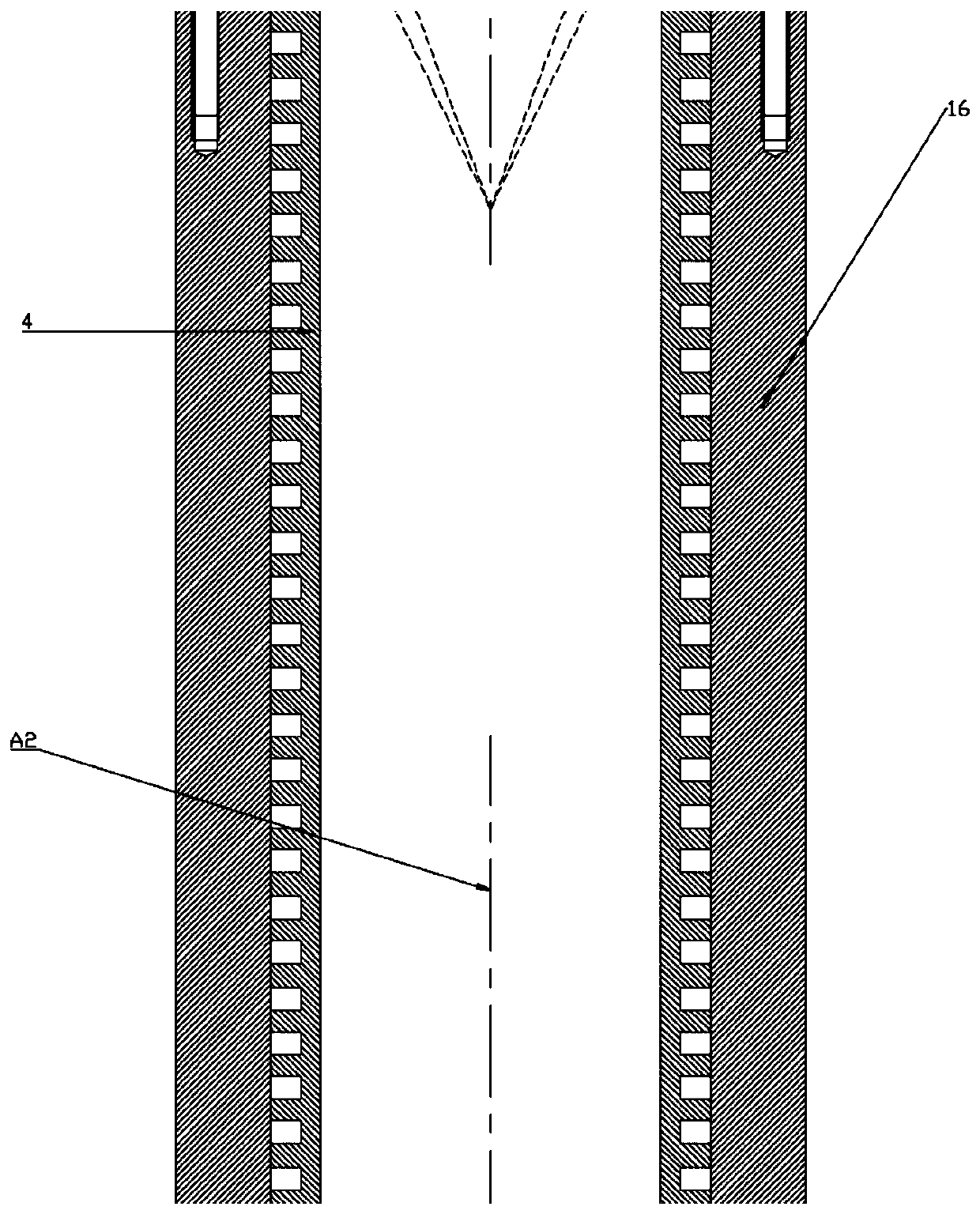

The invention discloses a method and device for controlling NOx concentration in smoke gas of a cement kiln; the device comprises a decomposing kiln, a preheater and a reducing agent supply device, wherein the bottom of the decomposing kiln is communicated with a kiln tail chimney of the cement kiln by an inlet smoke flue; the top of the decomposing kiln is communicated with the preheater by an outlet smoke flue; a plurality of spray guns communicated with the reducing agent supply devices are arranged at or / or in the middle upper part of the decomposing kiln or / and the outlet smoke flue in a layered way; and the device further comprises a central controller and a smoke gas automatic monitoring system, wherein the central controller is connected to the reducing agent supply devices; and the smoke gas automatic monitoring system is used for monitoring NOx concentration and smoke gas flow information in the kiln tail chimney and transmitting the NOx concentration and smoke gas flow information to the central controller. According to the invention, as a reducing agent is sprayed into the decomposing kiln through multi-site combined control, high removal rate of the NOx can be achieved without an SNCR (Selective Non Catalytic Reduction) and SCR (Selective Catalytic Reduction) combined technology.

Owner:ENVIRONMENTAL SCI RES & DESIGN INST OF ZHEJIANG PROVINCE

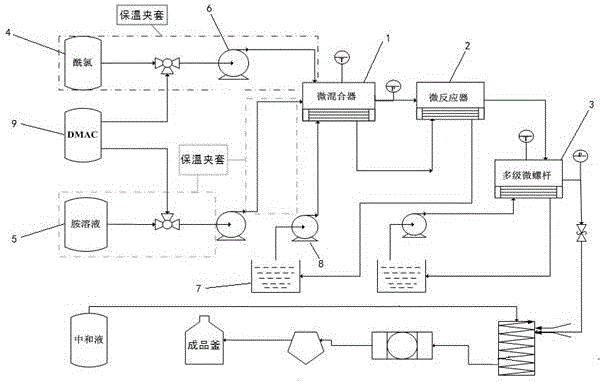

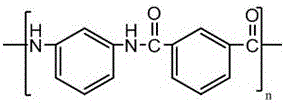

Continuous micro-reaction device and method for preparing meta-aramid resin and product

ActiveCN106478940AEasy transferReduce polydispersityChemical/physical/physico-chemical microreactorsMonocomponent polyamides artificial filamentAfter treatmentEngineering

A continuous micro-reaction device for preparing meta-aramid resin comprises a prepolymerization system, a polycondensation system, an after-treatment system and a heat exchange system, wherein the prepolymerization system, the polycondensation system and the after-treatment system are connected in sequence, and the heat exchange system is connected with the prepolymerization system and the polycondensation system to control temperatures of the prepolymerization system and the polycondensation system. The continuous micro-reaction device is characterized in that the prepolymerisation system comprises a raw material storage device, a micro-mixer and a micro-reactor which are connected in sequence; the polycondensation system comprises a multistage micro-screw device, and the micro-reactor is connected with multistage micro-screw device. The continuous micro-reaction device for preparing the meta-aramid resin improves the heat transfer effect at the polycondensation stage and the mass transfer effect at the polycondensation stage during preparation of the meta-aramid resin, and achieves the purpose of improving the performance of a meta-aramid resin product. The invention further provides a continuous micro-reaction method for preparing the meta-aramid resin and the product.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

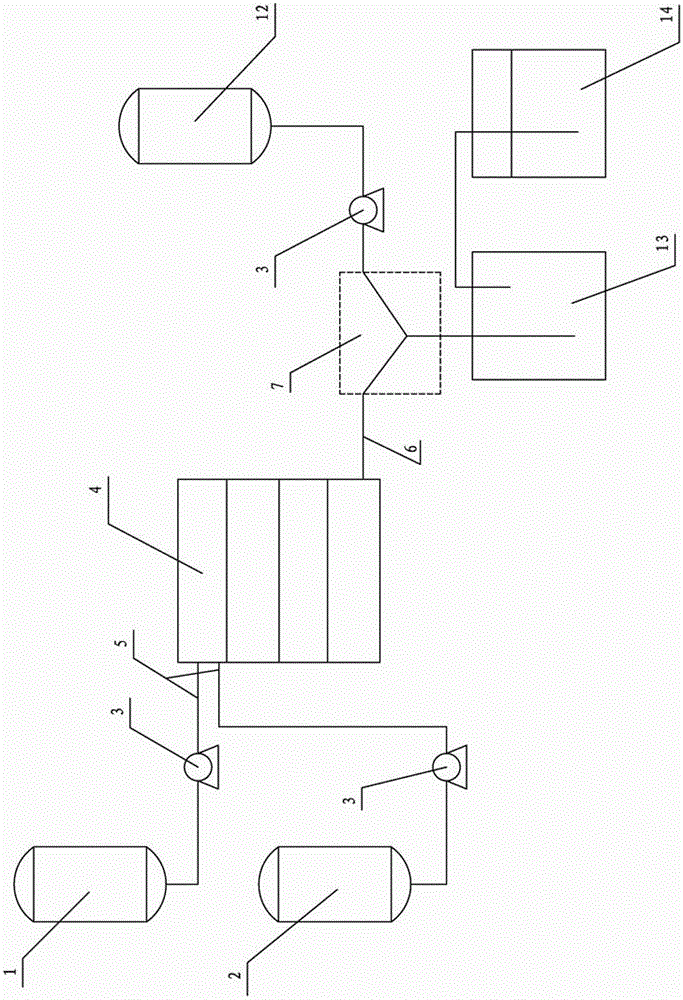

Continuous synthesis system and method of ethyl 4-chloroacetoacetate

InactiveCN106748764AHigh selectivityReduce manufacturing costPreparation from carboxylic acid halidesCarboxylic acid halides preparationEthyl acetateDiketene

The invention relates to a continuous synthesis system and method of ethyl 4-chloroacetoacetate. The method comprises the steps of adopting diketene, chlorine and ethyl alcohol as raw materials and inputting the raw materials into a micro-channel reactor through a metering pump; and carrying out chlorination and esterification and then synthesizing the ethyl 4-chloroacetoacetate. The reaction time is greatly shortened, and the produced product is high in content, low in cost, small in pollution and high in security and meets the requirements of industrial production.

Owner:JIANGSU CHENGXIN PHARMA

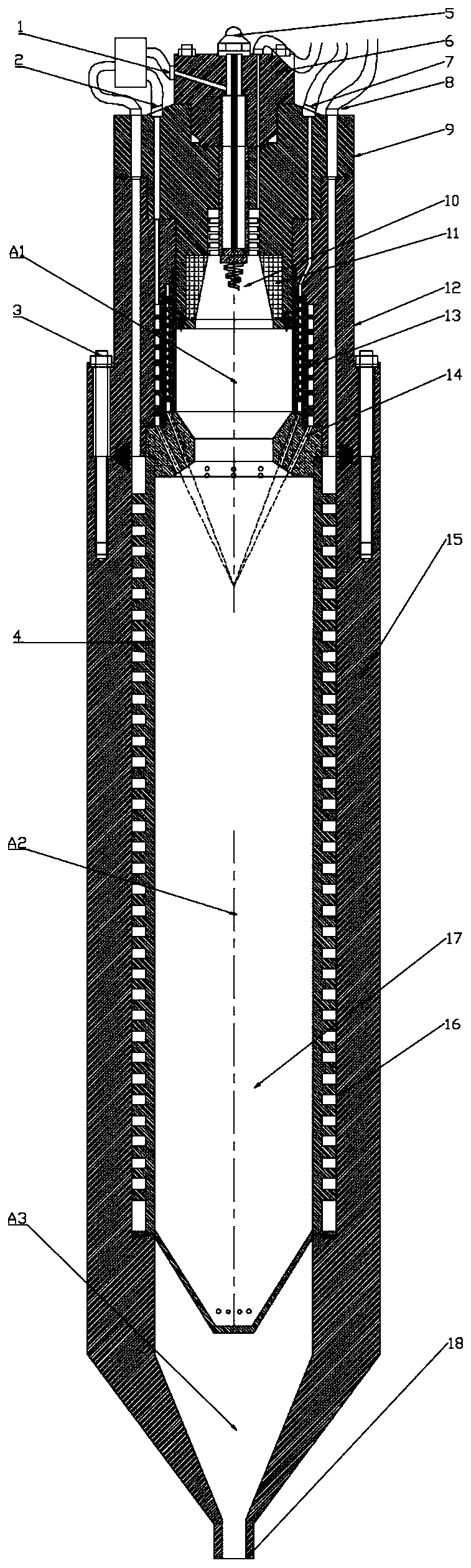

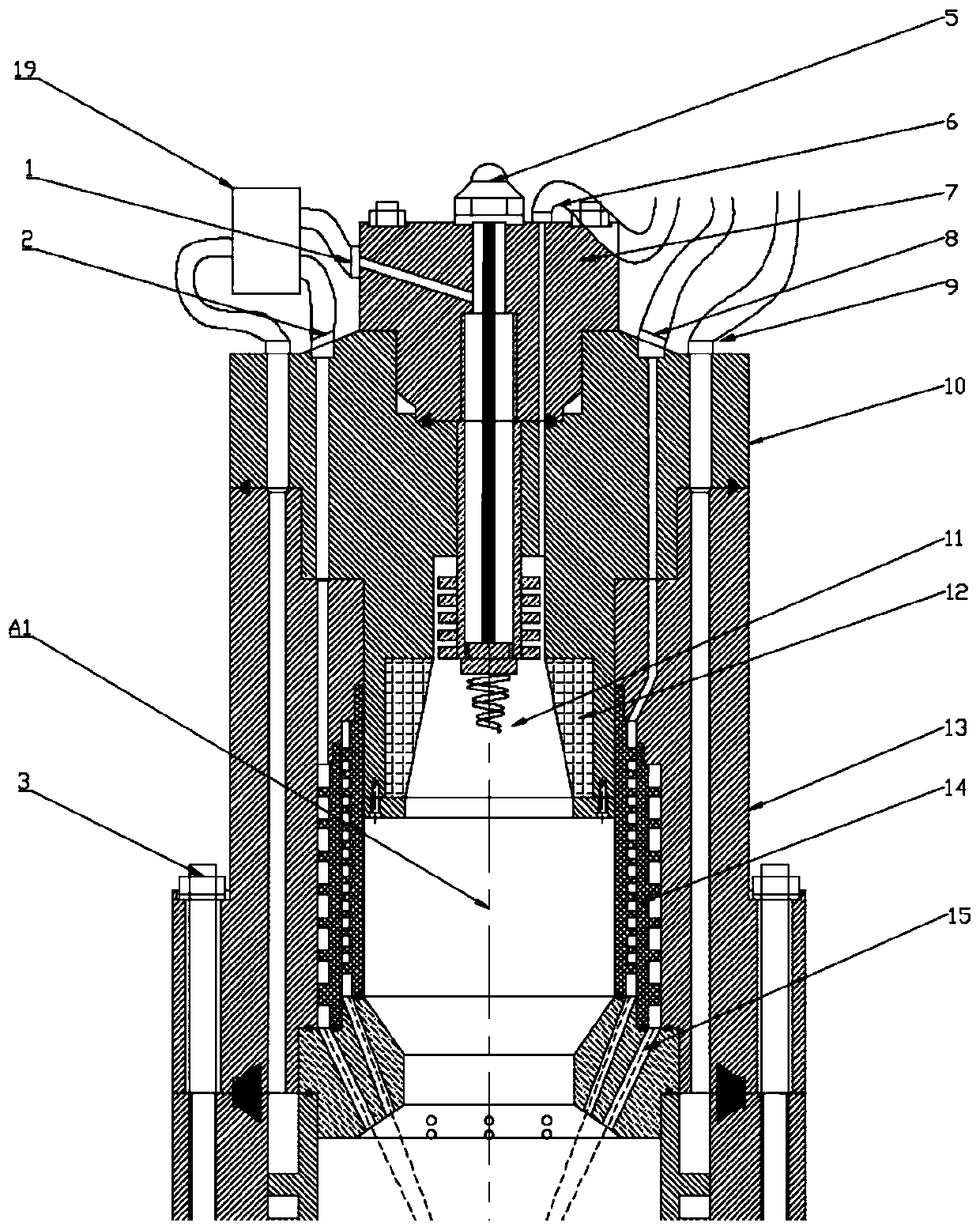

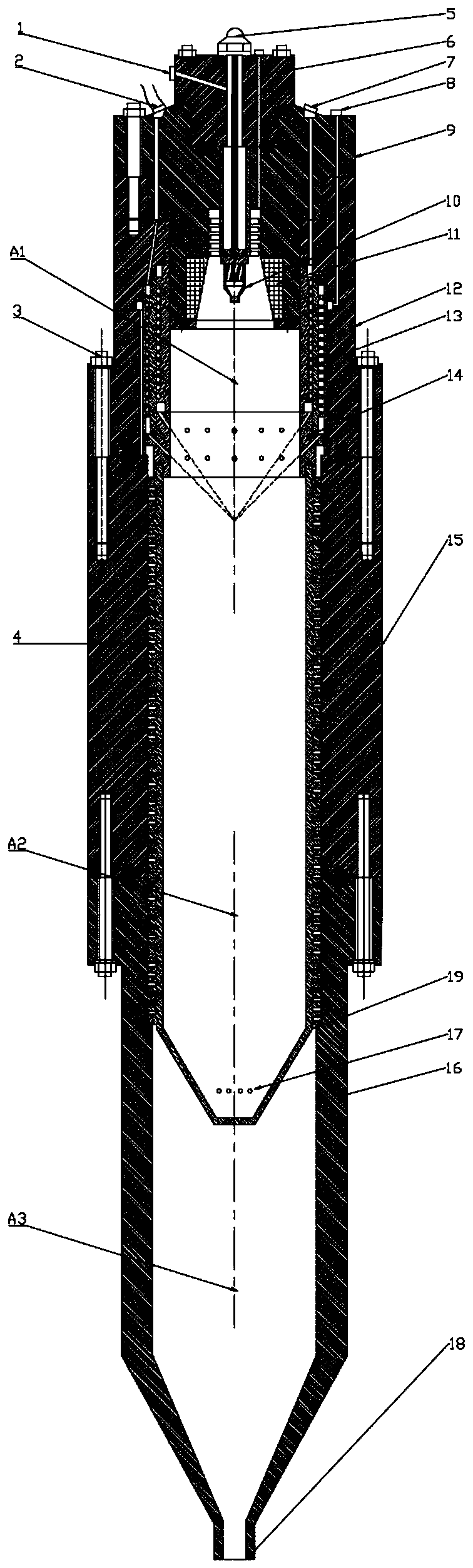

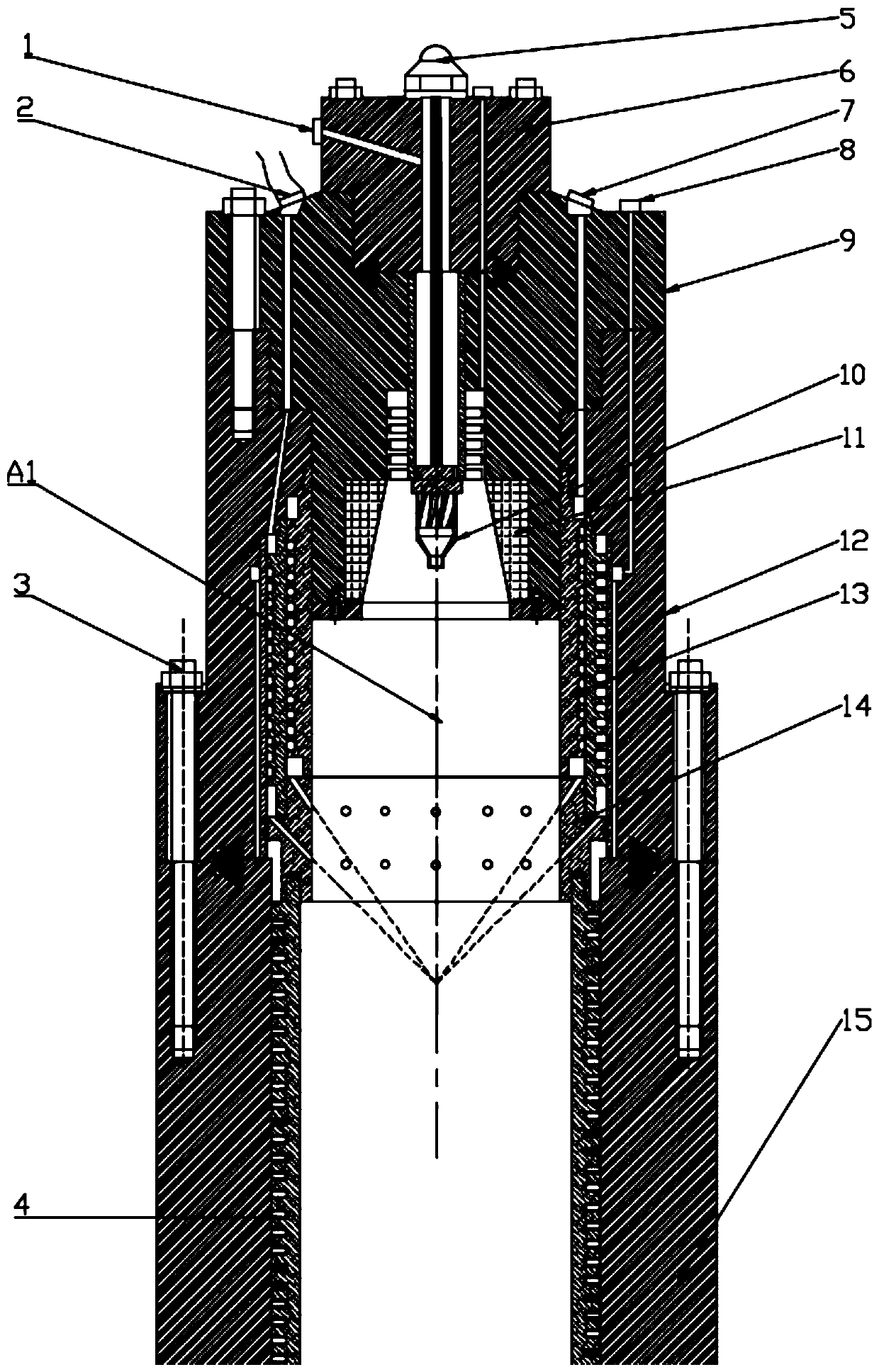

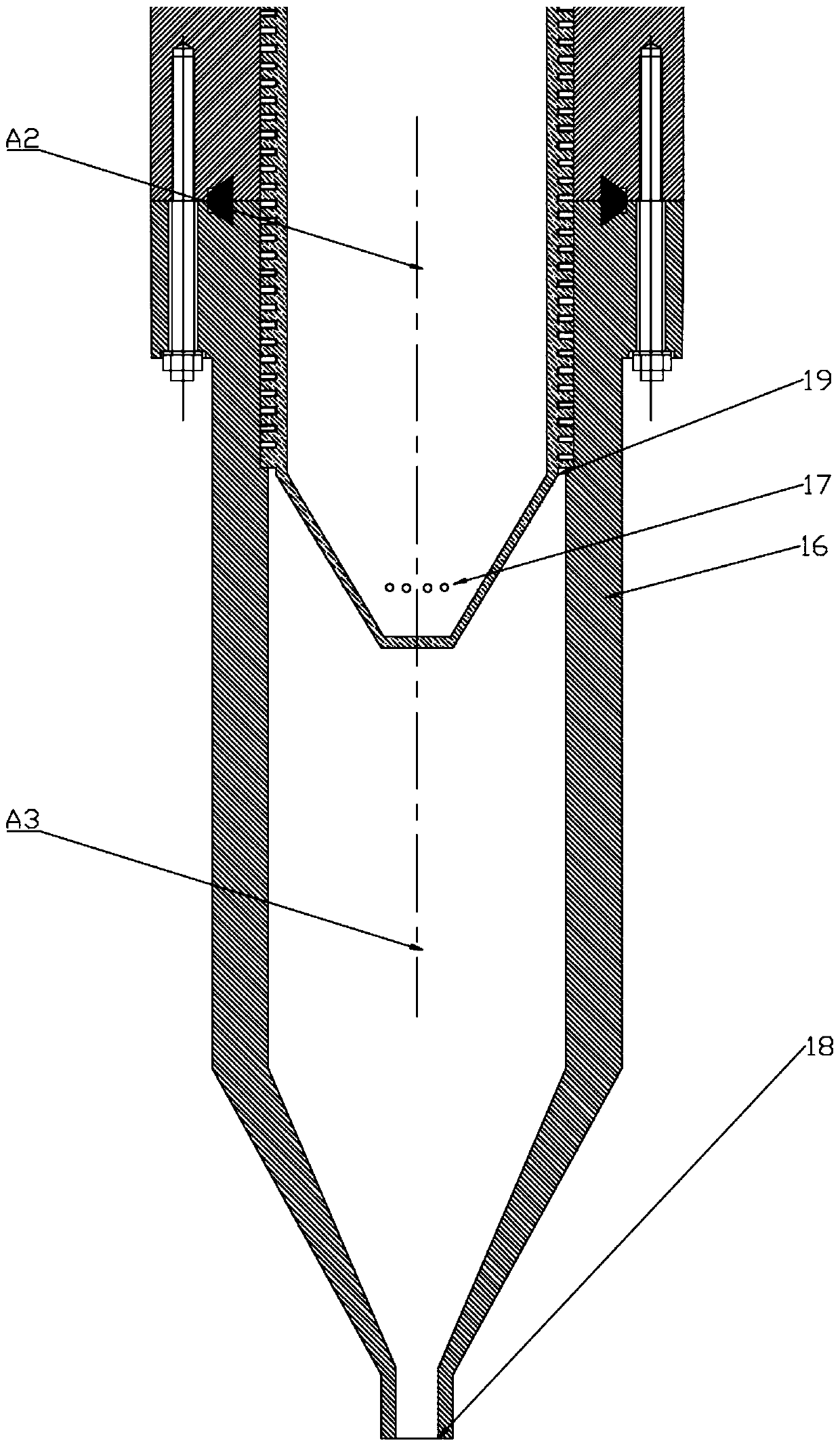

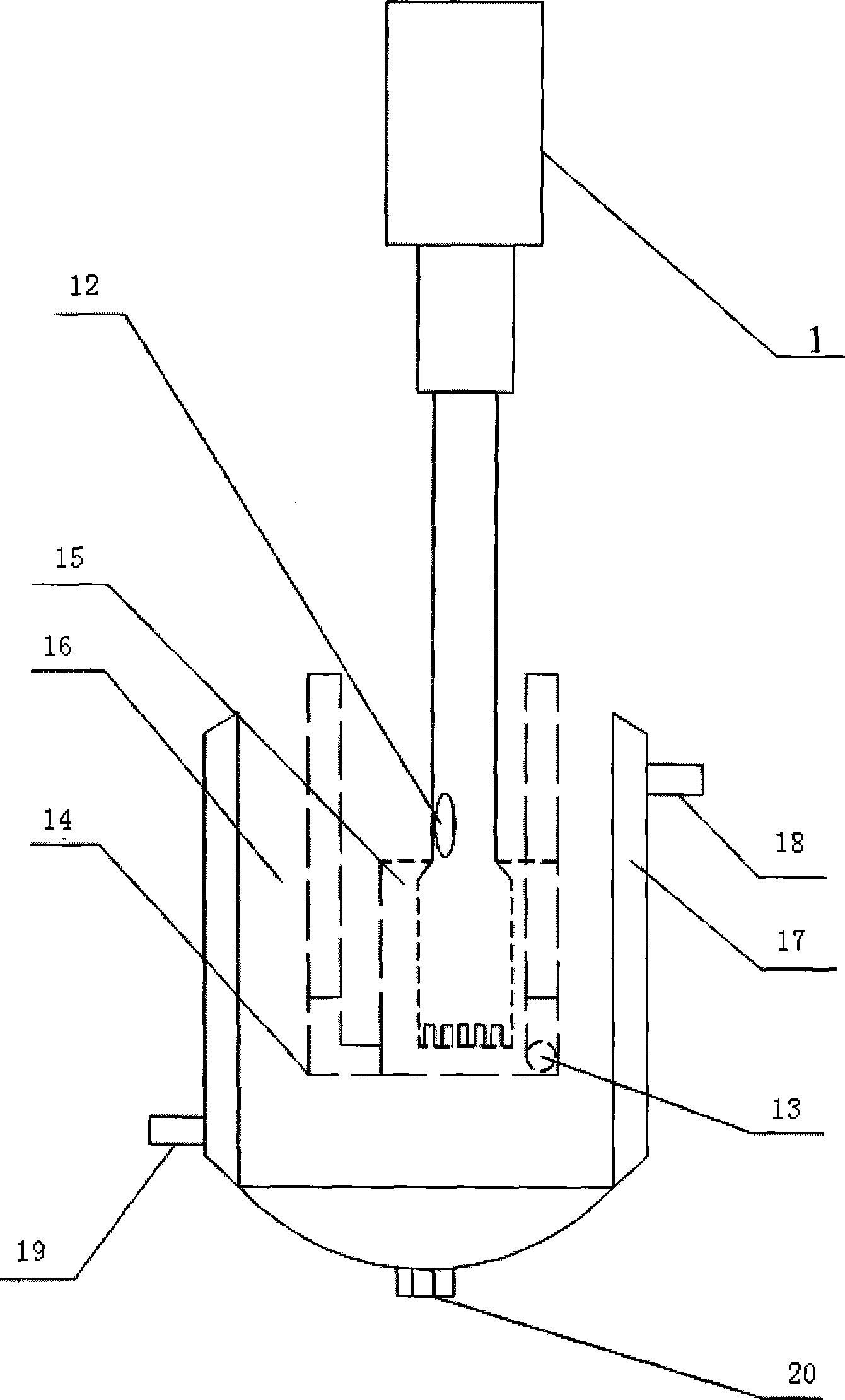

Supercritical hydrothermal combustion device suitable for high-viscosity fuel

PendingCN110645555AAvoid lostImprove heat utilizationFluid removalSteam generationThermodynamicsCombustion chamber

The invention provides a supercritical hydrothermal combustion device suitable for high-viscosity fuel. The supercritical hydrothermal combustion device suitable for the high-viscosity fuel is mainlycomposed of an upper end cover, a middle end cover, a first combustion stabilization chamber body and a second combustion chamber body which are sequentially connected and assembled. The upper end cover is provided with a first-grade fuel inlet, a high-energy heating rod and a first-grade oxidizing agent inlet. The middle end cover is provided with a second-grade fuel inlet, a second-grade oxidizing agent inlet and a reactant first-grade spray nozzle. The reactant first-grade spray nozzle communicates with the first-grade fuel inlet. The inner wall of the first combustion stabilization chamberbody is a double-layer-spiral wall, the bottom end of the first combustion stabilization chamber body is provided with a second-grade spray nozzle communicating with the second-grade fuel inlet and the second-grade oxidizing agent inlet. The inner wall of the second combustion chamber main body is a double-spiral cooling wall, and the bottom end of the second combustion chamber main body is provided with an outlet hole group. Finally, a combustion stabilization chamber is formed between the first-grade spray nozzle and the second-grade spray nozzle. A combustion chamber is formed between thesecond-grade spray nozzle and the outlet hole group. A mixing chamber is formed between the outlet hole group and a bottom outlet of a reactor. The supercritical hydrothermal combustion device suitable for the high-viscosity fuel directly generates steam in an oil layer, so that the problems of high energy consumption and heavy pollution caused in the steam injection process of a heavy oil thermalrecovery ground boiler are solved.

Owner:XI AN JIAOTONG UNIV

Multi-channel harmful gas detection device and method based on micro-fluidic chip

InactiveCN105717107AEasy to operateFully automatedMaterial analysis by observing effect on chemical indicatorLiquid storage tankData transmission

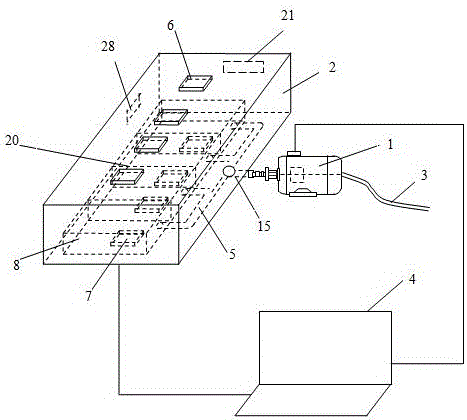

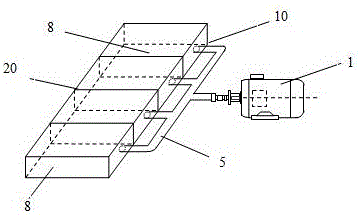

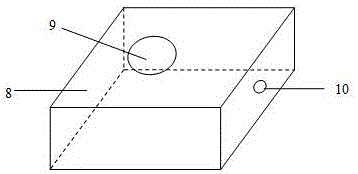

The invention discloses a multi-channel harmful gas detection device and method based on a micro-fluidic chip. The micro-fluidic chip is composed of two or more same single chips bound together into a column. The interior of each single chip is provided with a liquid storage tank, a barrier liquid mixing channel and a wheel-disc-shaped gas-liquid mixing channel, wherein the liquid storage tank is connected with the wheel-disc-shaped gas-liquid mixing channel through the barrier liquid mixing channel, and the wheel-disc-shaped gas-liquid mixing channel is connected with a gas-liquid outlet through a rising channel. Multiple light-emitting diodes, multiple light-sensitive diodes and a circuit chip are further arranged. The light-sensitive diodes transmit collected data to a computer, the volume of reaction harmful gas is obtained, a flow meter transmits the volume of gas pumped by a miniature gas pump to the computer, and the percentage of the harmful gas in air is obtained by dividing the volume of the harmful gas by the volume of the gas pumped by the miniature gas pump. The micro-fluidic chip technology and the optical detection technology are combined, the automatic sample pretreatment function is achieved, and the whole detection process is fully automatic.

Owner:JIANGSU UNIV

Supercritical hydrothermal combustion type downhole steam generator for heavy oil thermal recovery

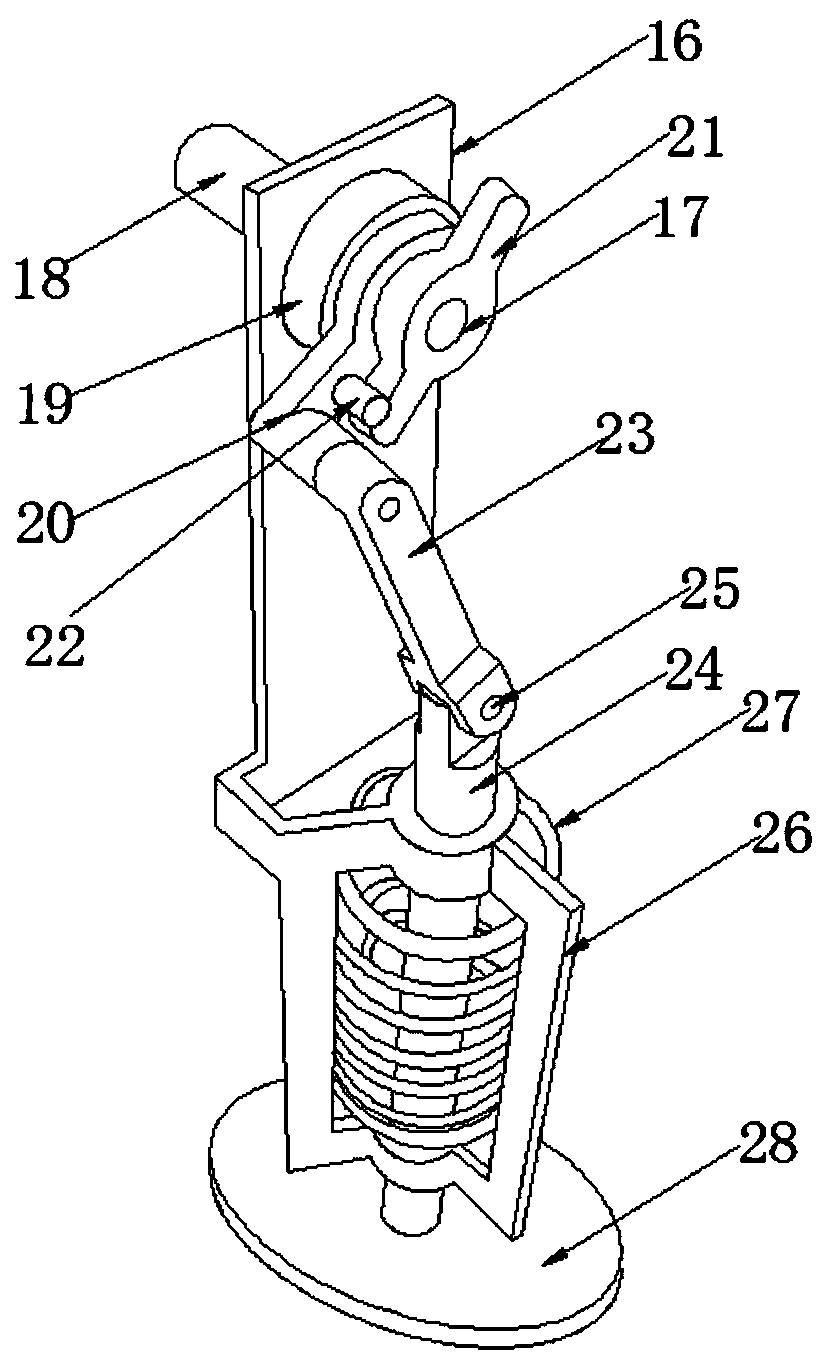

PendingCN110644962AGuaranteed mixPrevent high temperature burning or even explosionFluid removalCombustionHeater Rod

A supercritical hydrothermal combustion type downhole steam generator for heavy oil thermal recovery mainly comprises a top end cover, a middle end cover, a reflux stable combustion area shell, a mainreaction area shell and a blending area shell which are connected and assembled sequentially; a cyclone fuel inlet and a heating rod are arranged on the top end cover; a heating rod inserting hole runs through the center of the middle end cover; the middle end cover is provided with a main combustion hole jet fuel inlet, a main combustion hole jet oxidizing agent inlet, a cooling water inlet anda swirl nozzle; the swirl nozzle communicates with the cyclone fuel inlet; the inner side of the reflux stable combustion area shell is wrapped with a composite spiral wall circumferentially; a main combustion nozzle structure is arranged at the bottom end of the reflux stable combustion area shell; the inner wall of the main reaction area shell is a spiral cooling wall; the main combustion hole jet oxidizing agent inlet, the main combustion hole jet fuel inlet and the cooling water inlet communicate with the main combustion nozzle structure and the spiral cooling wall correspondingly throughinner, middle and outer channels of the composite spiral wall; and steam can be efficiently generated in the stratum directly and heat loss in the steam conveying process is avoided.

Owner:XI AN JIAOTONG UNIV

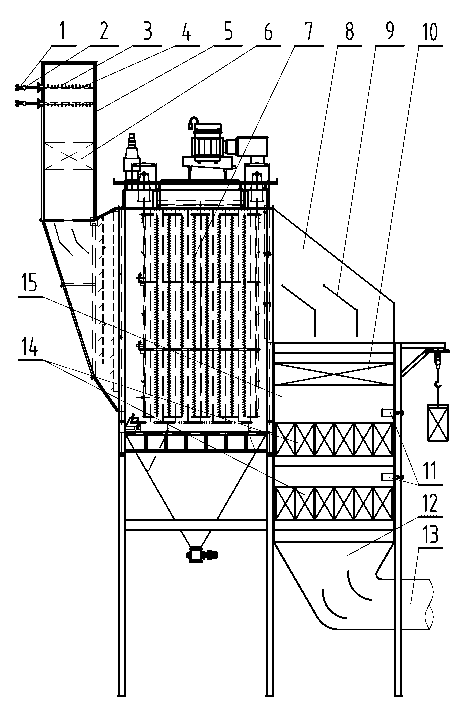

SCR (silicon controlled rectifier) denitration system of cement kiln gas

InactiveCN103120899AReduce dust concentrationPromote denitrification reactionCombination devicesElectricitySilicon-controlled rectifier

The invention discloses an SCR (silicon controlled rectifier) denitration system of cement kiln gas. The SCR denitration system comprise an ammonia spraying device, a reactor box body, a wind evening rectifying device, catalysts and sound wave soot blowers, wherein the wind evening rectifying device and the catalysts are respectively arranged on the upper part and the lower part in the reactor box body; and the sound wave soot blowers are arranged in the reactor box body. The SCR denitration system also comprises an electrofilter and a mixing device, wherein the electrofilter comprises a gas inlet and a gas outlet; and the gas inlet of the electrofilter is provided with a gas inlet pipeline. The ammonia spraying device and the mixing device are respectively arranged on the gas inlet pipeline, the mixing device is positioned on the down stream of the ammonia spraying device, an exit of the electrofilter is connected with the upper end of the reactor box body by a gas collection cover, the lower end of the reactor box body is provided with a lower cone bucket, and the lower cone bucket is connected with a gas outlet channel. The SCR denitration system of the cement kiln gas is long in service life and low in use cost.

Owner:YANCHENG LANFENG ENVIRONMENTAL ENG TECH

Flame-retardant high-temperature modified nylon material for automobile plastic

The invention relates to the field of automobile plastic and discloses a flame-retardant high-temperature modified nylon material for automobile plastic. The material is prepared from 100-120 parts of nylon resin, 4-6 parts of inorganic filler A, 4-6 parts of inorganic filler B, 10-12 parts of polyurethane-graphene composite light foam filler, 1-2 parts of coupling agent, 1-3 parts of polyethylene wax, 0.5-1.5 parts of antioxidant, 2-4 parts of nano bamboo fiber and 1-2 parts of calcium sulfate whiskers. The inorganic filler A is selected from at least one of mullite powder, spinel powder, white corundum powder and magnesite powder. The inorganic filler B is selected from at least one of hollow glass microspheres, sepiolite powder, halloysite powder, shell powder and vermiculite powder. The prepared modified nylon material has excellent flame retardancy, high temperate resistance and physical properties, density is not obviously increased, and the nylon material has excellent denoising and heat-isolation effects and antistatic performance.

Owner:宁波英格塑料制品有限公司

Novel nucleic acid test micro-fluidic chip device

ActiveCN107723210AIncrease the number ofQuality improvementBioreactor/fermenter combinationsBiological substance pretreatmentsNucleic acid detectionNucleic acid test

The invention relates to a novel nucleic acid test micro-fluidic chip device for automatic extraction and purification detection of nucleic acid. The novel nucleic acid test micro-fluidic chip deviceis of a sealed cavity type structure and comprises a waste liquid chamber, a sample reagent chamber, a mixing chamber, a pre-amplifying chamber, an amplifying chamber, a biosensor and a signal outputport, wherein the waste liquid chamber, the sample reagent chamber, the mixing chamber, the pre-amplifying chamber and the amplifying chamber are connected through fluid microchannels, the biosensor and the signal output port are connected through electrical signals, and the fluid microchannels are distributed in the novel nucleic acid test micro-fluidic chip device in a three-dimensional and tubular mode; micropumps are respectively arranged in the waste liquid chamber, the sample reagent chamber, the mixing chamber and the pre-amplifying chamber, or flow dividing holes which are respectivelyconnected with external micropumps are formed in the waste liquid chamber, the sample reagent chamber, the mixing chamber and the pre-amplifying chamber. According to the novel nucleic acid test micro-fluidic chip device disclosed by the invention, pipelines can be cleaned by the micropumps, circular, repeated and discontinuous detection can be achieved, one item or a plurality of items of detection of one sample or a plurality of samples is achieved, and use cost is reduced.

Owner:湖南宏雅基因技术有限公司

Low-concentration viscose wastewater and waste gas treatment system

ActiveCN110449002AReduce dust concentrationReduce the risk of explosionGas treatmentDispersed particle filtrationPollutionDisposal Technique

The invention discloses a low-concentration viscose wastewater and waste gas treatment system and belongs to the technical field of waste gas treatment. aiming at solving the problems that a single treatment technique is poor in effect, carbon disulfide is liable to combust and explode, and the like since a low-concentration waste gas which is generated in a viscose wastewater treatment process iscomplex in constitution (within carbon disulfide, hydrogen sulfide, volatile organic compounds and the like), the invention provides a novel treatment system which consists of plasma deodorization equipment and biological deodorization equipment in serial connection. A waste gas is fed into the plasma deodorization equipment, and a plasma generation chamber and a plasma reaction chamber are indirectly connected through a butt joint component, so that the problem that explosion is caused as a plasma pipeline group is in direct contact with flammable and combustible waste gases such as the carbon disulfide can be avoided; meanwhile, pollutants such as the carbon disulfide can be rapidly degraded and are fed into a biological deodorization system for secondary removal, so that the pollutantremoval efficiency, the removal rate and the operation security can be greatly improved; and in addition, the system has the advantages of being low in investment cost, free of secondary pollution, and the like.

Owner:恩宜瑞(江苏)环境发展有限公司

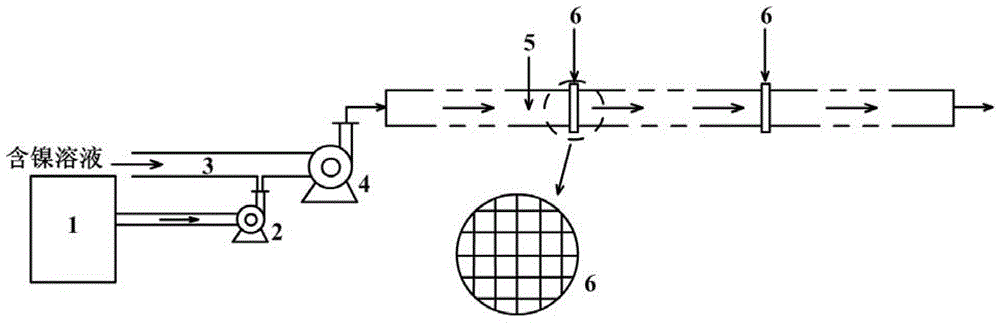

Method and device for deeply removing copper of nickel thiocarbonate from nickel-containing solution

InactiveCN102719671AFully mixed reactionEliminates unwanted effects of lower densityProcess efficiency improvementSlagCopper

The invention discloses a method and device for deeply removing copper of nickel thiocarbonate from a nickel-containing solution. Substantially, the nickel thiocarbonate after pulping is used as a copper removal agent; and the copper removal agent is automatically added through a mechanical mixing pump and is uniformly mixed with the nickel-containing solution in a pipeline reactor to remove copper. The method can realize continuous copper removal in the closed environment, the copper removal efficiency is high, and the concentration of the liquid cooper after copper removal is lower than 3mg / l. The copper-nickel ratio in the copper removal slag is greater than 15, thereby completely meeting the production requirements.

Owner:CENT SOUTH UNIV

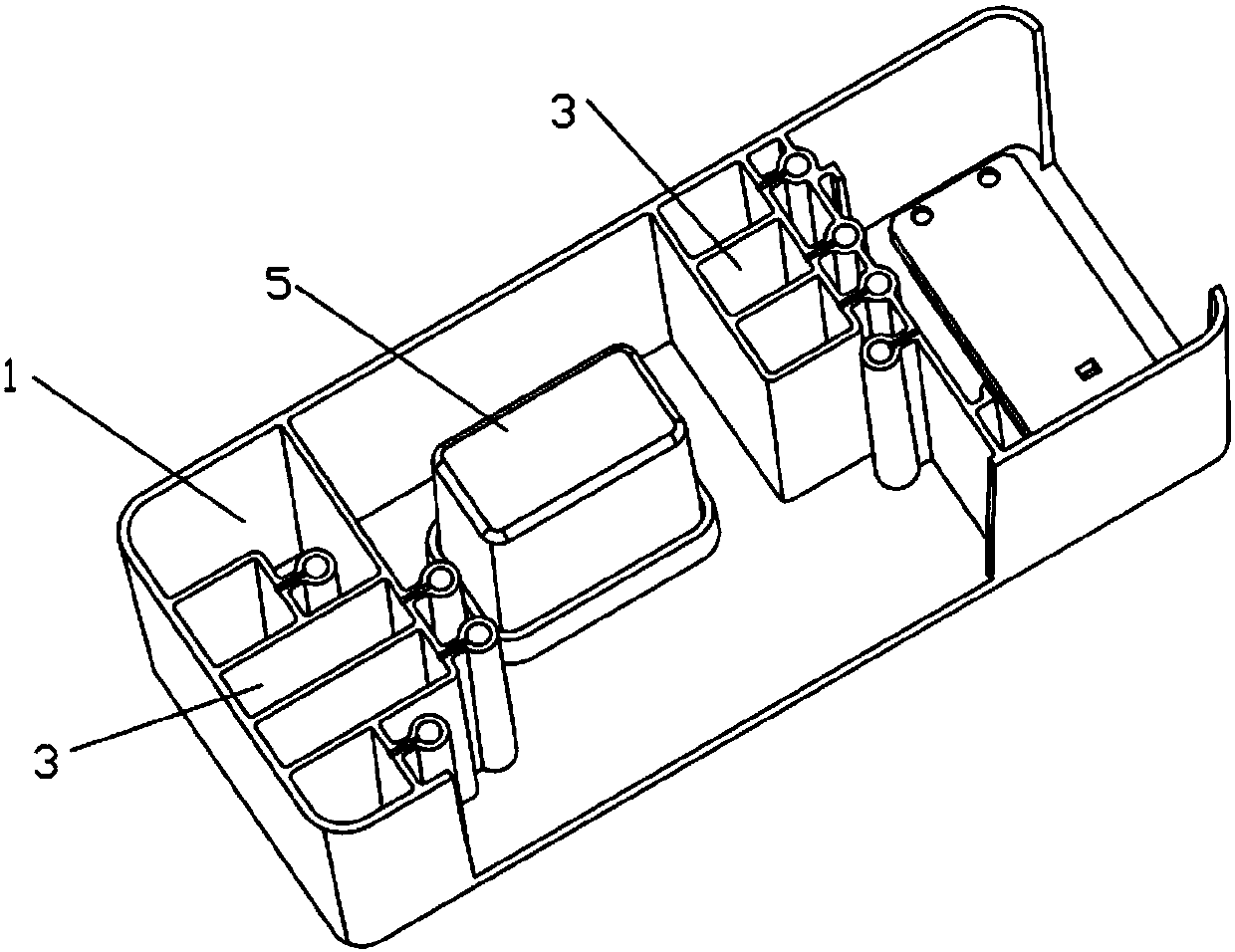

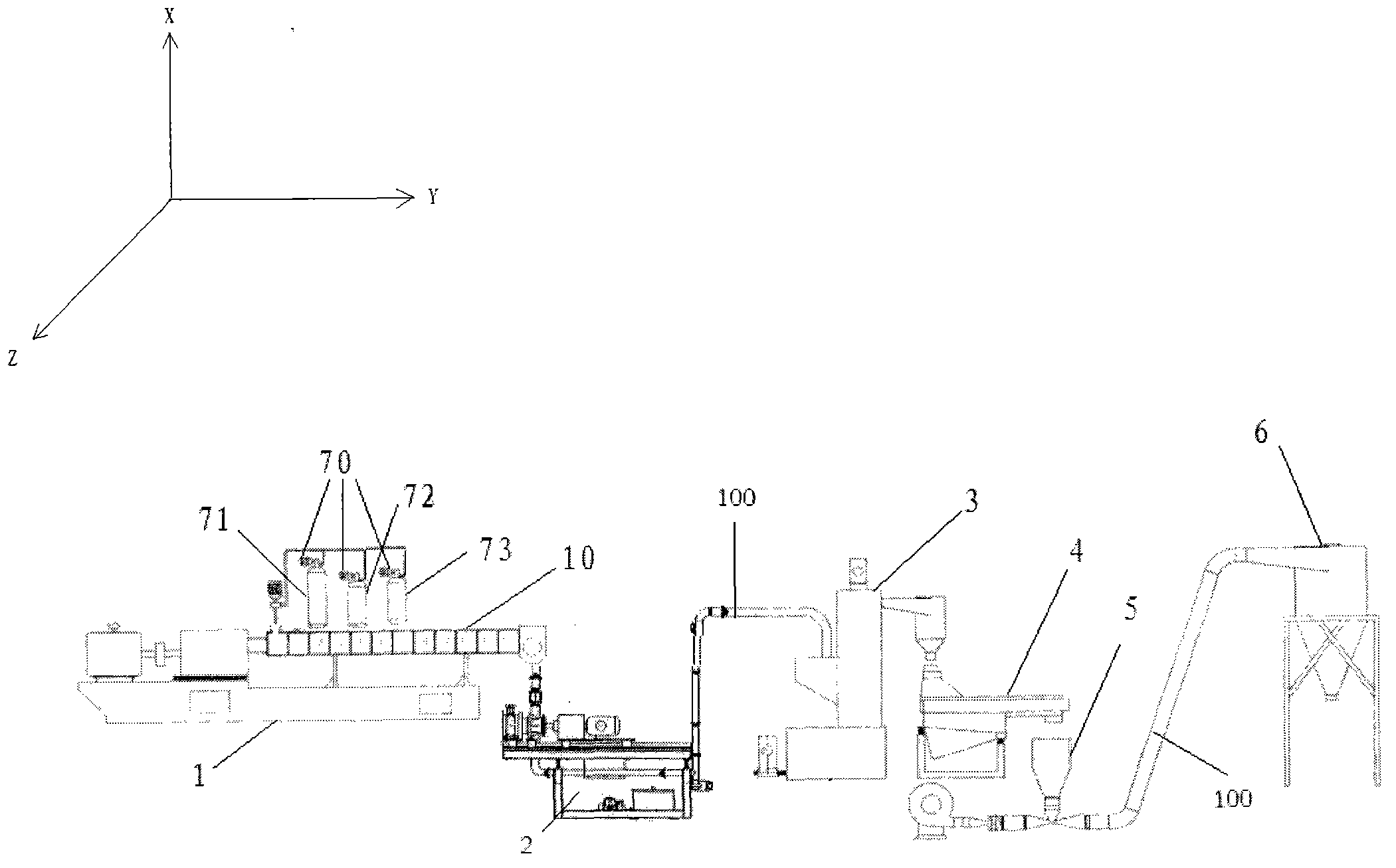

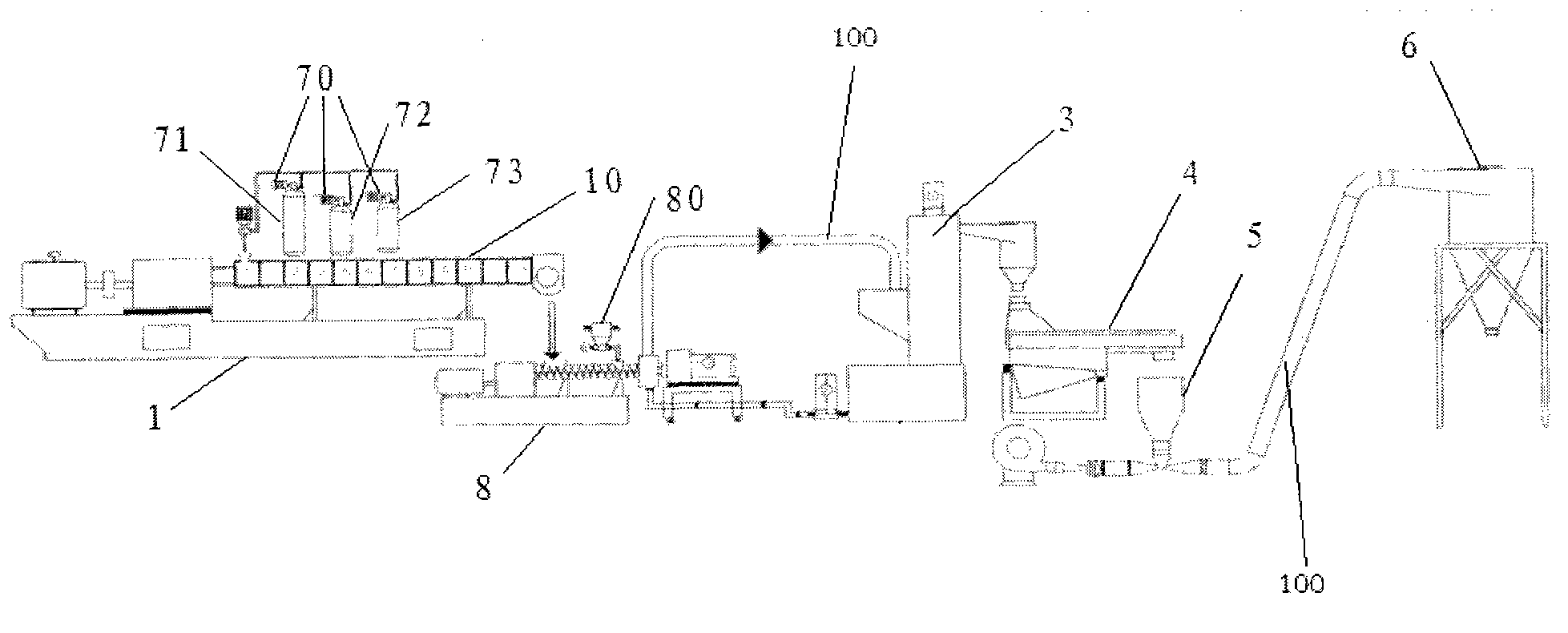

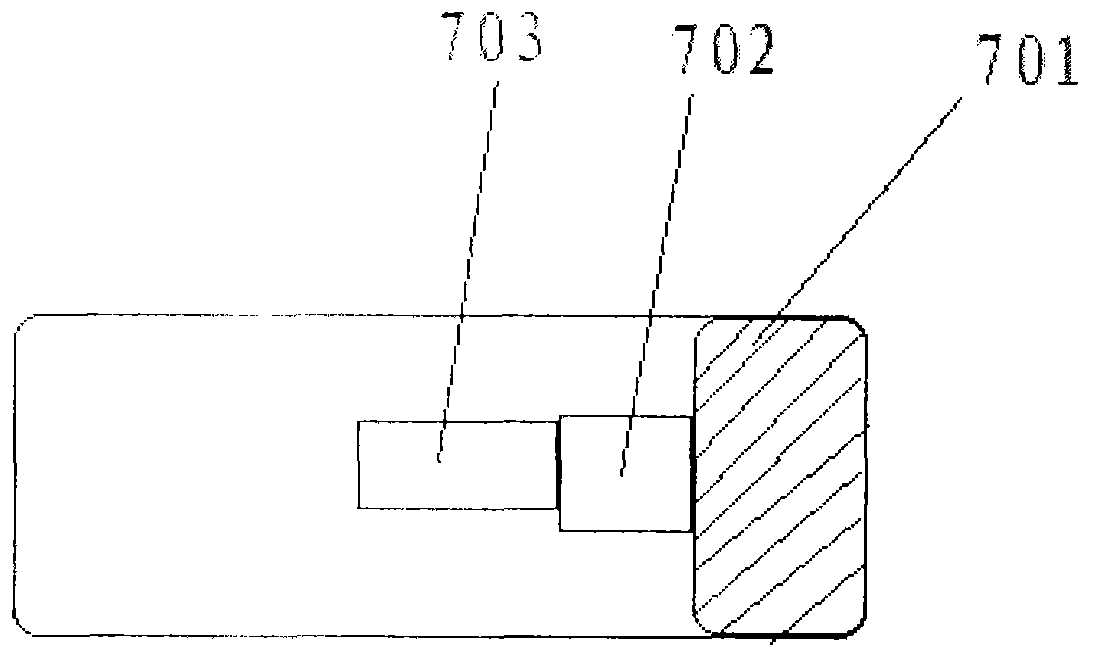

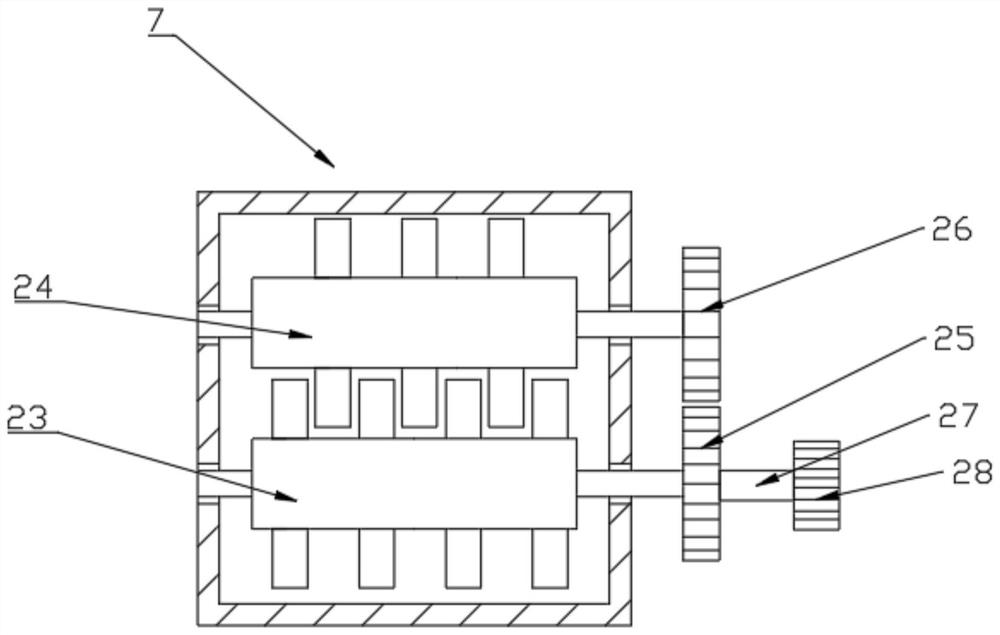

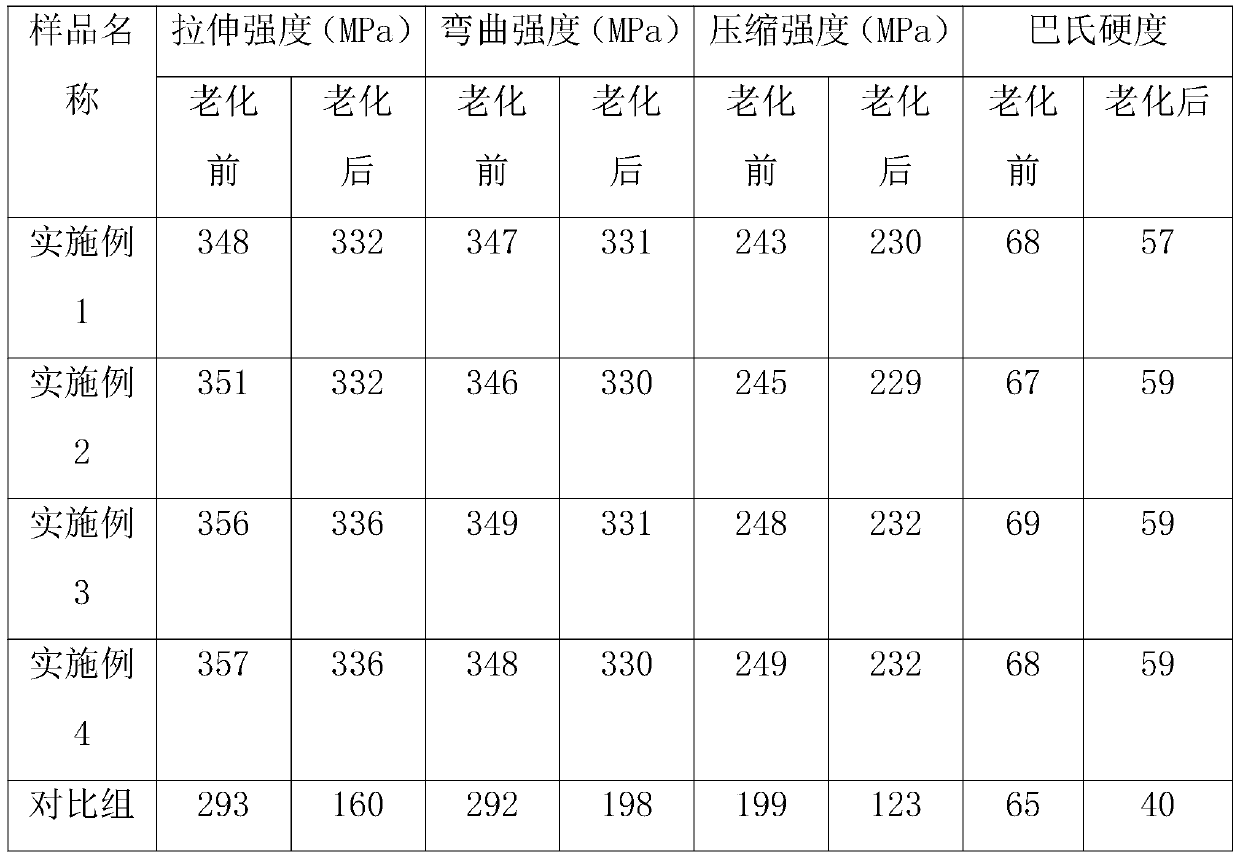

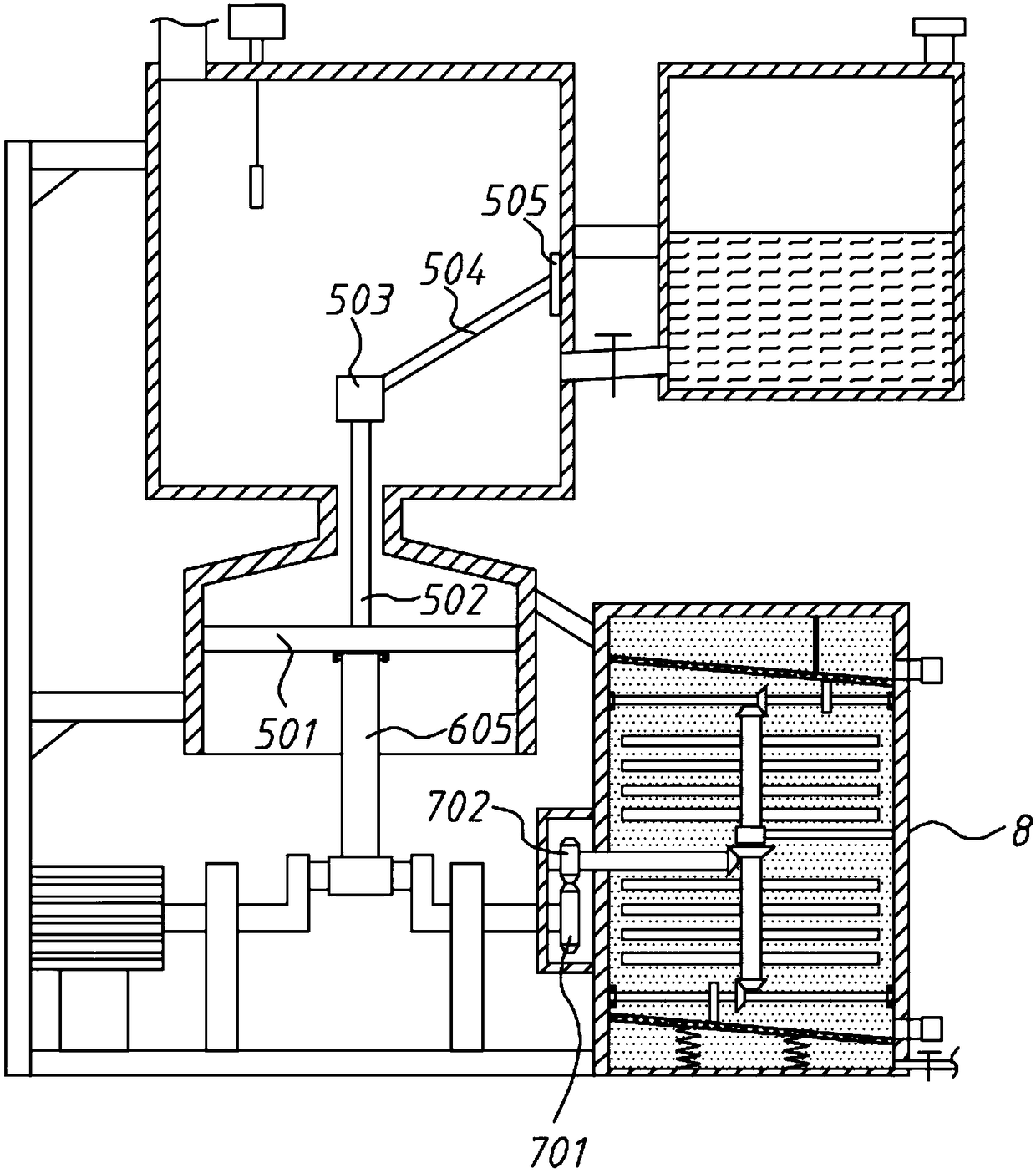

Thermoplastic polyurethane elastomer production device and method

The invention discloses a thermoplastic polyurethane elastomer production device which comprises a twin-screw extruder, an in-water pelletizer, a dehydrator, a vibration screen, a packing machine and a material cabin, wherein the in-water pelletizer is connected to the rear end of the twin-screw extruder; the dehydrator is connected with the in-water pelletizer; the vibration screen is connected with the dehydrator; a discharging port is arranged at the lower part of the vibration screen; the packing machine is connected with the vibration screen; and the material cabin is connected with the packing machine. The thermoplastic polyurethane elastomer production device is characterized in that three liquid material tanks are directly connected to the front end of the twin-screw extruder; raw material measuring members are arranged at the upper parts of the liquid material tanks; and at least twelve raw material continuous reaction stations on which the liquid materials are sufficiently reacted are arranged at the front part of the twin-screw extruder. The ratio of raw materials of the device is controllable, the raw materials are sufficiently reacted, the working efficiency is high, the occupied space is small, and the environmental pollution is greatly reduced.

Owner:翰泰科技(深圳)有限公司

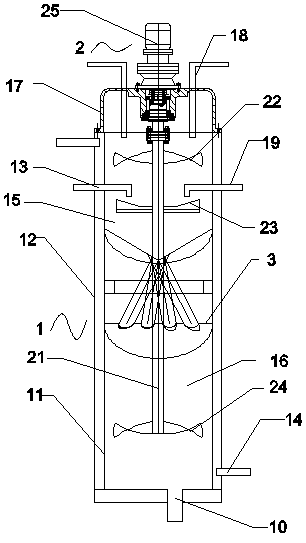

Tube type precipitation reactor

InactiveCN101422718ANarrow particle size distributionUniform shapeLiquid-liquid reaction processesImpellerDistribution control

The invention discloses a pipeline-typed precipitation reactor which belongs to the technical field of pipeline reaction devices. The wall of the pipeline-typed precipitation reactor is provided with a jacket, an upper medium inlet and a lower medium outlet, and heating and cooling operations can be realized through heating or cooling the medium according to reaction needs. The interior of the pipeline-typed precipitation reactor is provided with a high-speed agitating impeller which is fixed respectively by an upper end enclosure and a bearing in a lower bracket, and connected with an electric motor at the upper part of the reactor. Two material inlets are arranged along a tangential direction on a top lateral surface of the reactor, and are respectively connected with the pipelines of two constant-voltage material feeders or pumps. Two types of materials are respectively fed into the pipeline-typed precipitation reactor through the two material inlets and carry out instantaneous hybrid reaction under high-speed rotation of the agitating impellers. The bottom of the reactor is open, and precipitation products are discharged through the bottom. The pipeline-typed precipitation reactor is convenient for realizing the size and distribution control of the precipitation reaction particles, reduces manual factors, and obtains narrow distribution and precipitation particle products with good batch stability.

Owner:JIANGNAN UNIV

Reaction kettle for chemical production

InactiveCN111804264AFully mixed reactionReduce in quantityTransportation and packagingHollow article cleaningMetallurgyReagent

The invention discloses a reaction kettle for chemical production. The reaction kettle comprises a main kettle body, secondary kettle bodies and a mixing kettle body, a plurality of secondary kettle bodies are arranged, the plurality of secondary kettle bodies are communicated with the mixing kettle body through material conveying pipes, a feeding channel and a driving mechanism are arranged at the top of the main kettle body, a crushing device is arranged in the feeding channel, a cleaning plate is arranged in each of the plurality of secondary kettle bodies, by arranging the driving mechanism and the plurality of secondary kettle bodies, different reaction raw materials are premixed in the secondary kettle bodies at the same time and do not interfere with each other, the premixed reaction raw materials enter the mixing kettle body through the material conveying pipe and pass through the stirring blades on the first rotating shaft to finally obtain a reaction finished product, so thatthe reaction container is reduced, and the reaction time is shortened, the crushing device is arranged to crush and refine large reaction materials, so that premixing of the reaction materials is facilitated, and the premixing time is shortened. By arranging a high-pressure spray head and a cleaning plate, the inner wall of the kettle body is convenient to clean, so that the influence on subsequent products is reduced.

Owner:尧治康

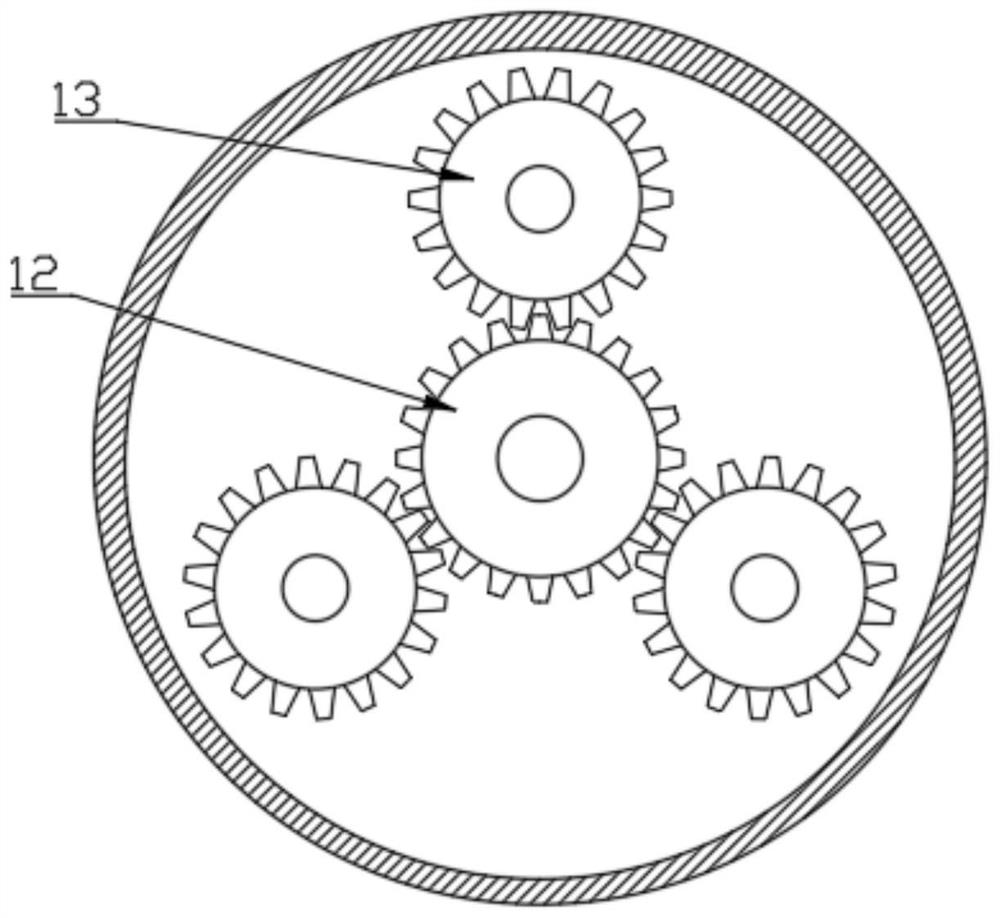

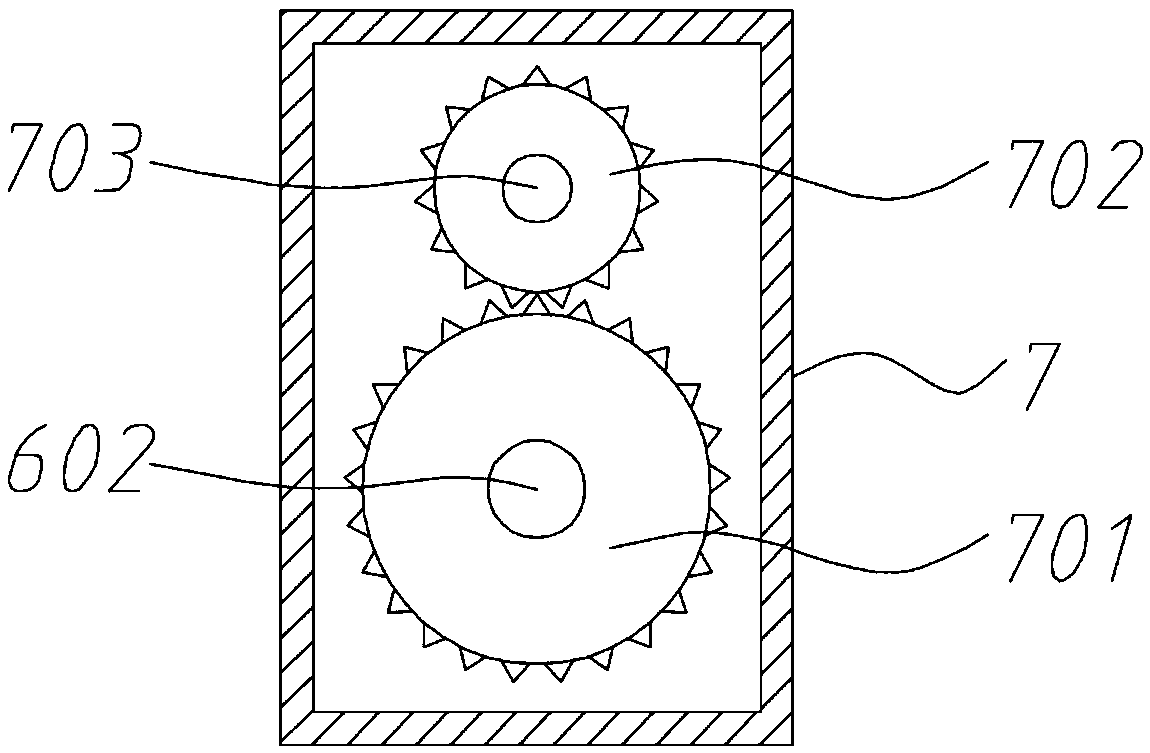

Treating device for sewage in sludge

InactiveCN109293201AImprove purification efficiencyFully mixed reactionSludge treatmentRotary stirring mixersBiochemical engineeringSludge

The invention discloses a treating device for sewage in sludge. The treating device comprises a shell, sewage inlet pipes are penetratingly arranged on two sides of an inner upper end of the shell, asqueezing device is arranged on an inner wall of the shell and is positioned between the two sewage inlet pipes, a filtering plate is fixedly mounted below the squeezing device and is positioned in the inner middle of shell, telescopic cylinders are respectively arranged on two sides of an upper end of the filtering plate and are also positioned on two sides of the shell, output ends of the telescopic cylinders are connected with one sides of scrapping plates, a drain outlet is formed in one side of the filtering plate and is positioned between the two scrapping plates, a sewage purifier is arranged at a lower end of the filtering plate and is positioned inside the shell, a handle is arranged on one side, outside the shell, of the sewage purifier, a feeding pipe is arranged at a lower endof the handle and is positioned outside the shell, a gearbox is arranged at the lower end of the feeding pipe and is positioned outside the shell, a movable shaft is arranged on one side of the gearbox and is positioned inside the shell, a sleeve is arranged on one side of the movable shaft in a sleeved manner, a second stirring rod is arranged at one end of the movable shaft, and a second stirring rod is arranged at one end of the sleeve.

Owner:贺昭华

Efficient dispersed venturi ejection reactor

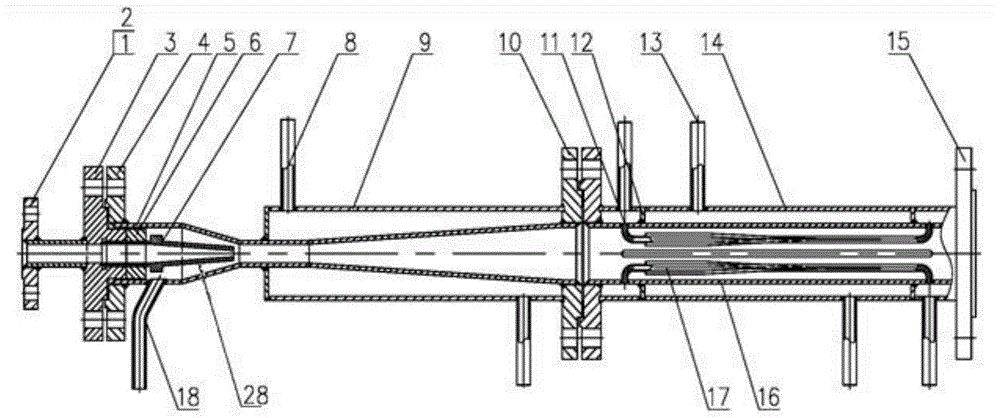

InactiveCN104549056AAchieve structural optimizationSimple structureChemical/physical/physico-chemical nozzle-type rreactorsPhosphorus compoundsWorking temperatureEngineering

The invention relates to an efficient dispersed venturi ejection reactor, which comprises a high-speed jet nozzle, venturi equipment and a heat insulation jacket, wherein the connecting end of the high-speed jet nozzle and the venturi equipment is connected and sealed by a non-standard flange and a venturi flange, and a venturi section hot steam inlet and outlet pipe is arranged on a venturi heat insulation jacket; a drainage tube section hot steam inlet and outlet pipe is arranged on a drainage tube heat insulation jacket, and a finned tube is arranged in the drainage tube heat insulation jacket. Hydrogen peroxide is ejected out by the nozzle at high speed, and a negative pressure area is formed in a suction chamber, so that a yellow phosphorus liquid containing an arsenic impurity flows through a suction tube into the suction chamber, the yellow phosphorus is efficiently dispersed under the action of jet turbulence, and then the yellow phosphorus and the hydrogen peroxide are subjected to a sufficient contact and mixing reaction in a throat tube and are drained along a diffusion tube and a drainage tube; an outer-layer heat insulation jacket allows the reactor to be at appropriate work temperature. Through the driving of a circulating pump, the uninterrupted contact and mixing reaction of the hydrogen peroxide and the yellow phosphorus is realized, and the ultimate purpose of arsenic removal of the yellow phosphorus is achieved.

Owner:TIANJIN UNIV

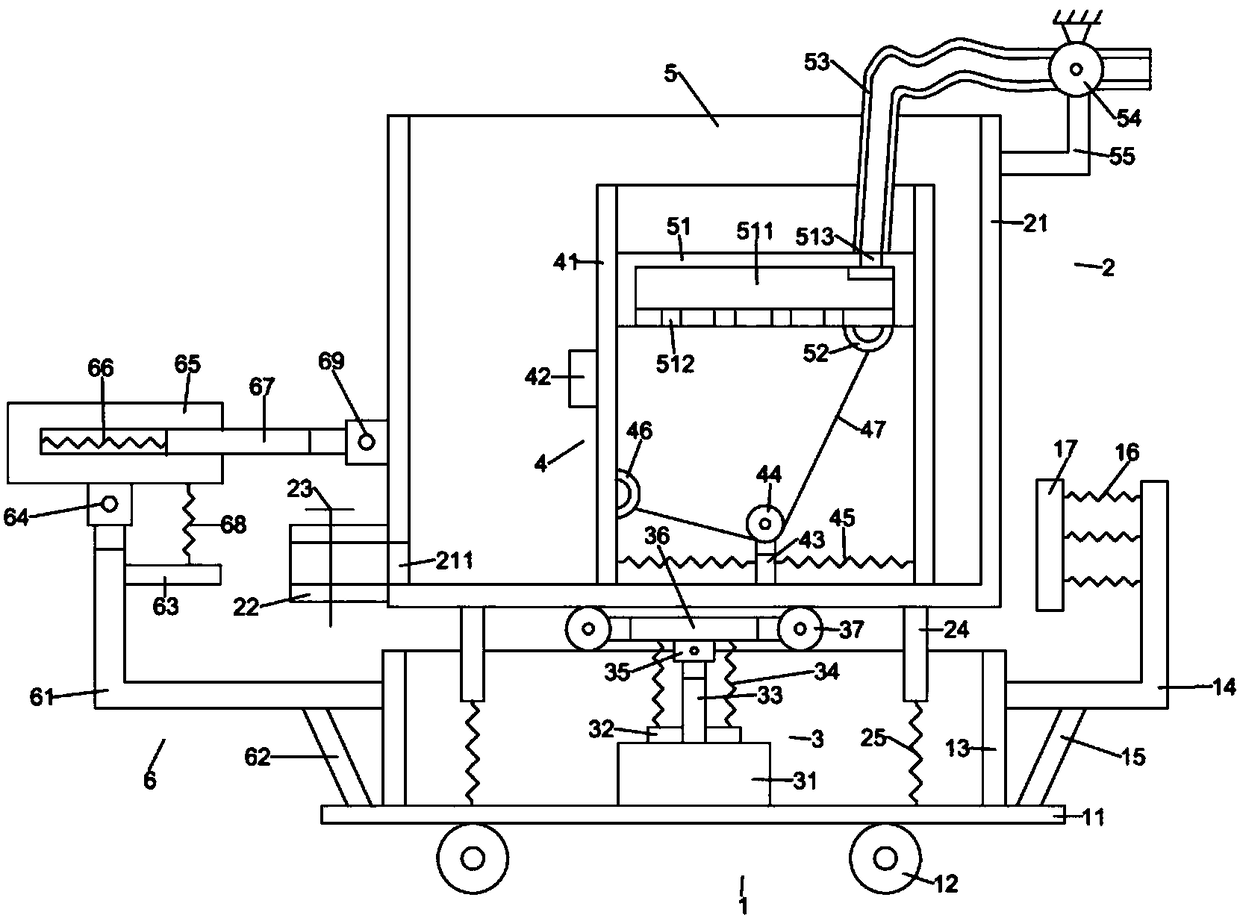

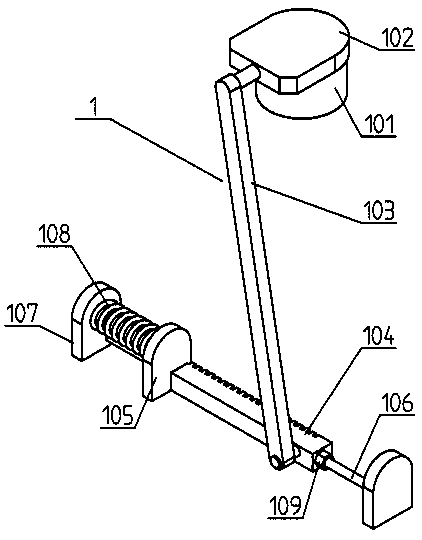

Mixing processing device for biological agents in field of bioengineering

InactiveCN108543481AWell mixedMixed comprehensiveShaking/oscillating/vibrating mixersTransportation and packagingBiochemical engineeringBiological agent

Provided is a mixing processing device for biological agents in the field of bioengineering. The mixing processing device comprises a bottom plate device, a frame device which is arranged on the bottom plate device, an electric cylinder device which is disposed on the bottom plate device, a filter frame device which is accommodated in the frame device, a blowing device which is disposed on the filter frame device and a positioning device which is arranged on the left side of the frame device. Through the mixing processing device, the biological agents can be mixed fully, the mixing processingdevice has comprehensive mixing, diversified stirring modes and an ideal stirring effect, and full mixing for a reaction can be realized between the agents, so that needs of bioengineering are met.

Owner:张雪媚

Two-step isolation type full non-chlorine full cotton stalk bleaching pulp cleaning production process

ActiveCN101435165AControl concentrationAccurate measurementPulp bleachingCellulose material pulpingMaterials preparationPulp and paper industry

The invention discloses a clean production technology of two-step isolation type totally chlorine-free and whole cotton stalk bleaching pulp, which has the advantages of simplifying the process, saving cost, reducing pollution, saving energy and the like. The clean production technology comprises the following steps of: 1) material preparation: the whole cotton stalk plant material is treated with cotton-shell removal, leave removal and cutting-off; 2) steaming and water washing; 3) discongesting: the whole cotton stalk material is sent to a compressing and discongesting machine for compression and discongesting; 4) first-step dipping: a one-step bleaching solution is used for dipping the whole cotton stalk material released from the compressing and discongesting machine, and the dipping is maintained; 5) first-step bleaching: the dipped whole cotton stalk material is heated and bleached; 6) jordaning of a first stage: the bleached whole cotton stalk material is ground into unscreened stock by a pulping machine; 7) second-step dipping: the unscreened stock ground by the pulping machine is dipped by using a second-step bleaching solution; 8) second-step bleaching: the unscreened stock treated with second-step dipping is heated and bleached; 9) jordaning of a second stage: the unscreened stock treated with second-step bleaching is ground and dissolved into water pulp; 10) pulp washing and pulp shoving; and 11) stock screening and pulp forming.

Owner:山东凯隆材料科技有限公司

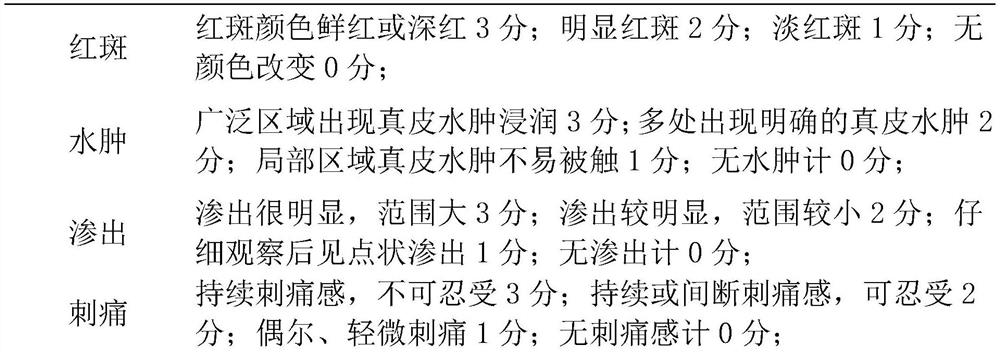

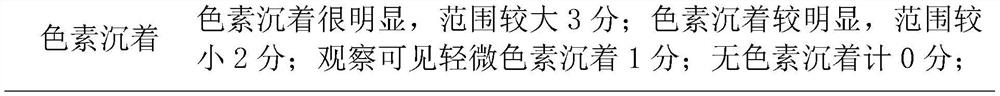

Liquid trehalose dressing for skin barrier wound repair and preparation method thereof

ActiveCN111956860AReduce hyperpigmentationEnhance soothing and caring functionsClimate change adaptationBandagesSodium hyaluronateAnti-inflammatory

The invention provides a liquid trehalose dressing for skin barrier wound repair and a preparation method thereof. The liquid trehalose dressing comprisese 8 to 10 parts of trehalose, 1 to 5 parts ofcompound polysaccharide, 1 to 3 parts of epsilon-polylysine, 0.5 to 1.5 parts of an ethanol extract of bamboo leaf flavonoid, 0.03 to 0.06 part of a lactic acid bacillus / soybean milk fermentation product filtrate, 12 to 15 parts of sodium hyaluronate, 5 to 6 parts of collagen, 1.5 to 2.5 parts of a polyol humectant and 1000 to 1100 parts of water. According to the invention, a more stable and moist microenvironment with good air permeability is provided for wound healing; good antibacterial, anti-inflammatory and anti-oxidation effects and a wound surface nursing function are achieved; pigmentation is reduced; stimulation effect on the skin of a wound surface is reduced; the ability of the skin in adapting to the environment is improved; wound surface healing time is shortened; and the dressing can be widely applied to auxiliary repair of wound surfaces produced in laser and tartaric acid skin replacement, microcrystal grinding, hydro lifting and microacupunoture.

Owner:海南鸿翼医疗器械有限公司

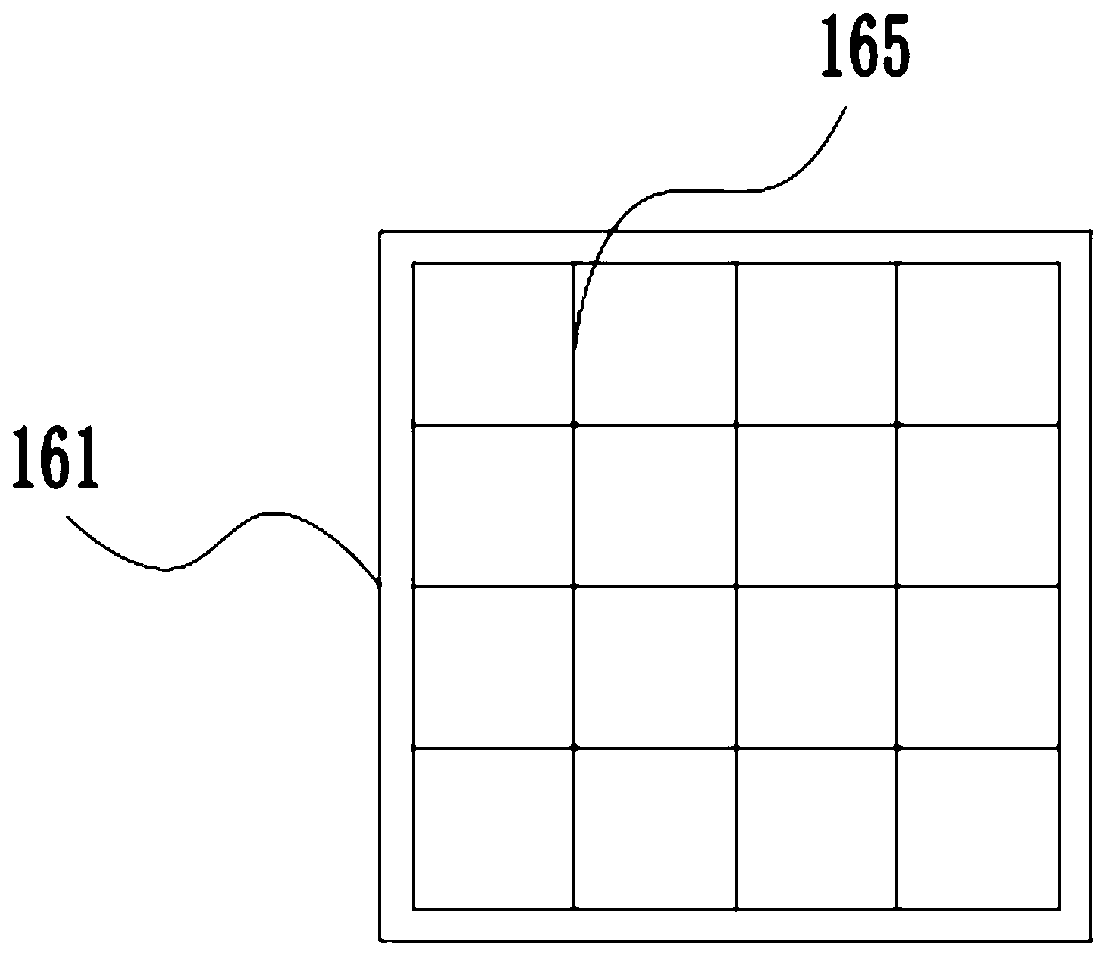

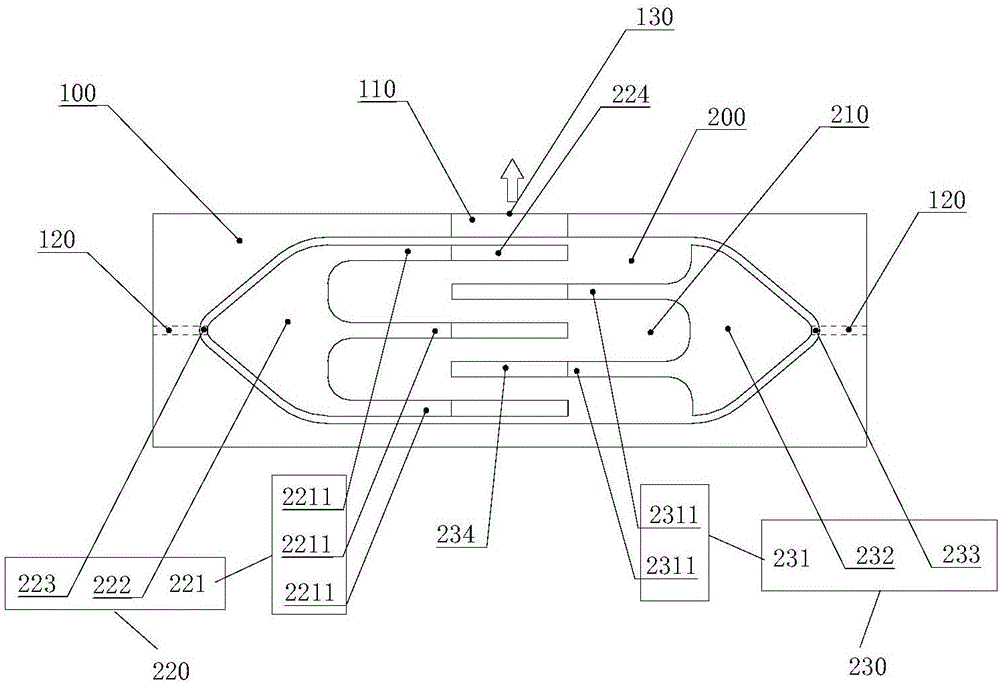

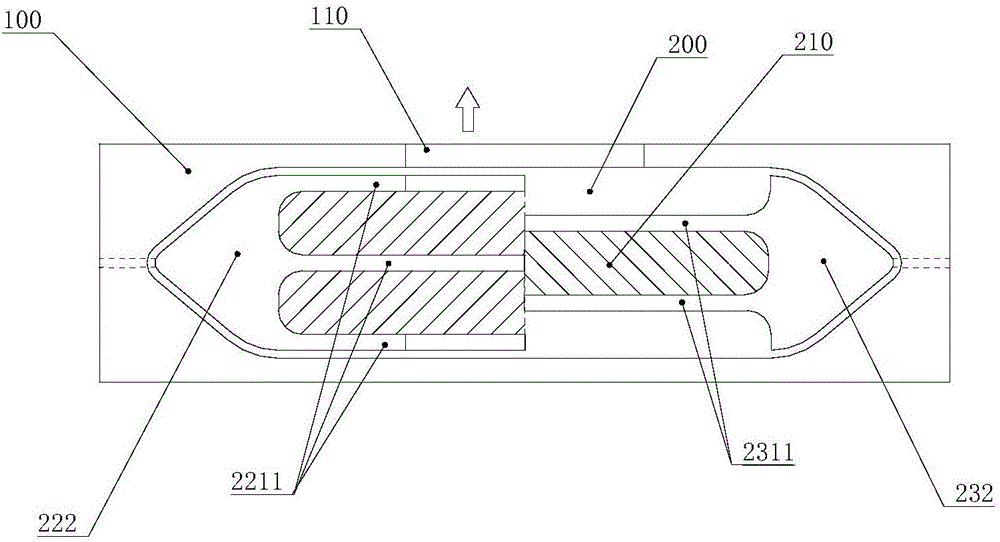

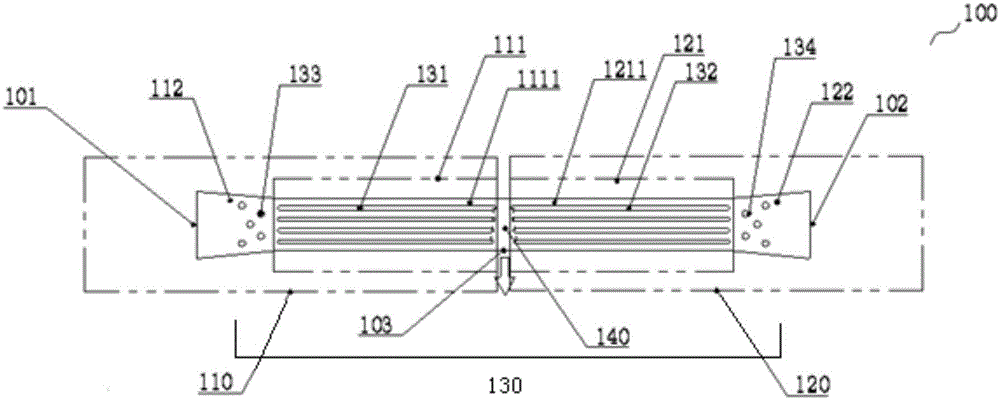

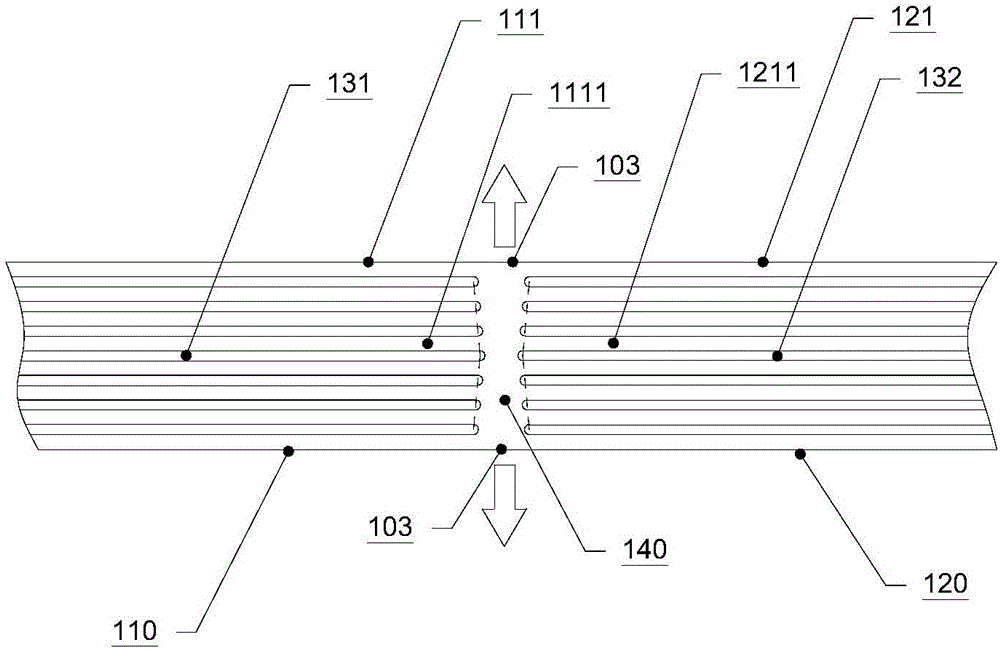

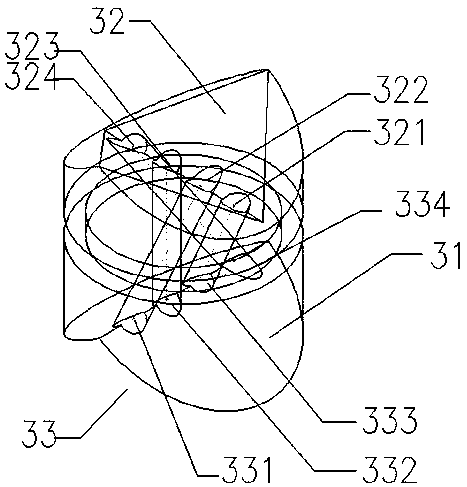

Chip type micro reaction channel and micro reactor

ActiveCN106492718AImprove production efficiencyIncrease the reaction contact areaChemical/physical/physico-chemical microreactorsMicroreactorEngineering

The invention discloses a chip type micro reaction channel and a micro reactor. The chip type micro reaction channel comprises a substrate and a chip, wherein the chip is positioned on the substrate and comprises a diversion structure and a first fluid part and a second fluid part which are partitioned by the diversion structure; the first fluid part comprises a first inlet; the second fluid part comprises a second inlet; meanwhile the first fluid part is partitioned into at least first diversion channels by the diversion structure; the second fluid part is partitioned into at least two second diversion channels by the diversion structure; moreover mixing channels are formed in a connected manner in corresponding positions of the first diversion channels and the second diversion channels on the substrate; the mixing channels are respectively connected with the first diversion channels and the second diversion channels. The micro reactor comprises a first chip type micro reaction channel. By adopting the chip type micro reaction channel and the micro reactor, different reactants in two types of fluid can be sufficiently mixed and reacted, the reaction speed can be increased, the reactant generation efficiency can be improved, and meanwhile the reaction security and reliability can be improved.

Owner:SHANDONG HIMILE CHEM TECH

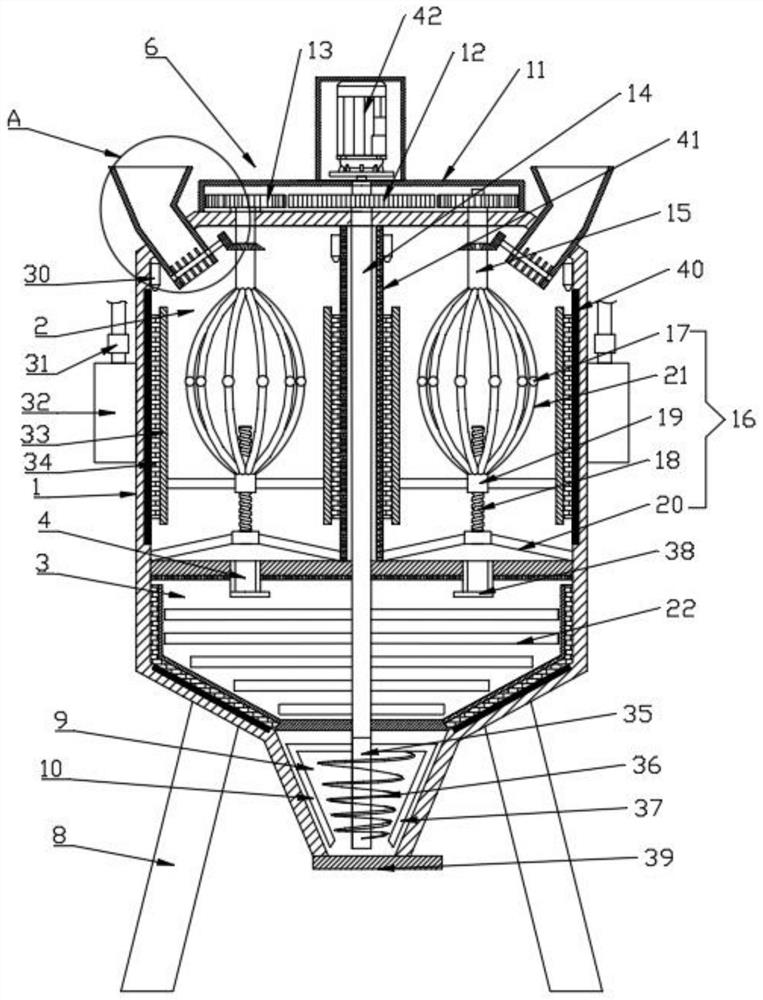

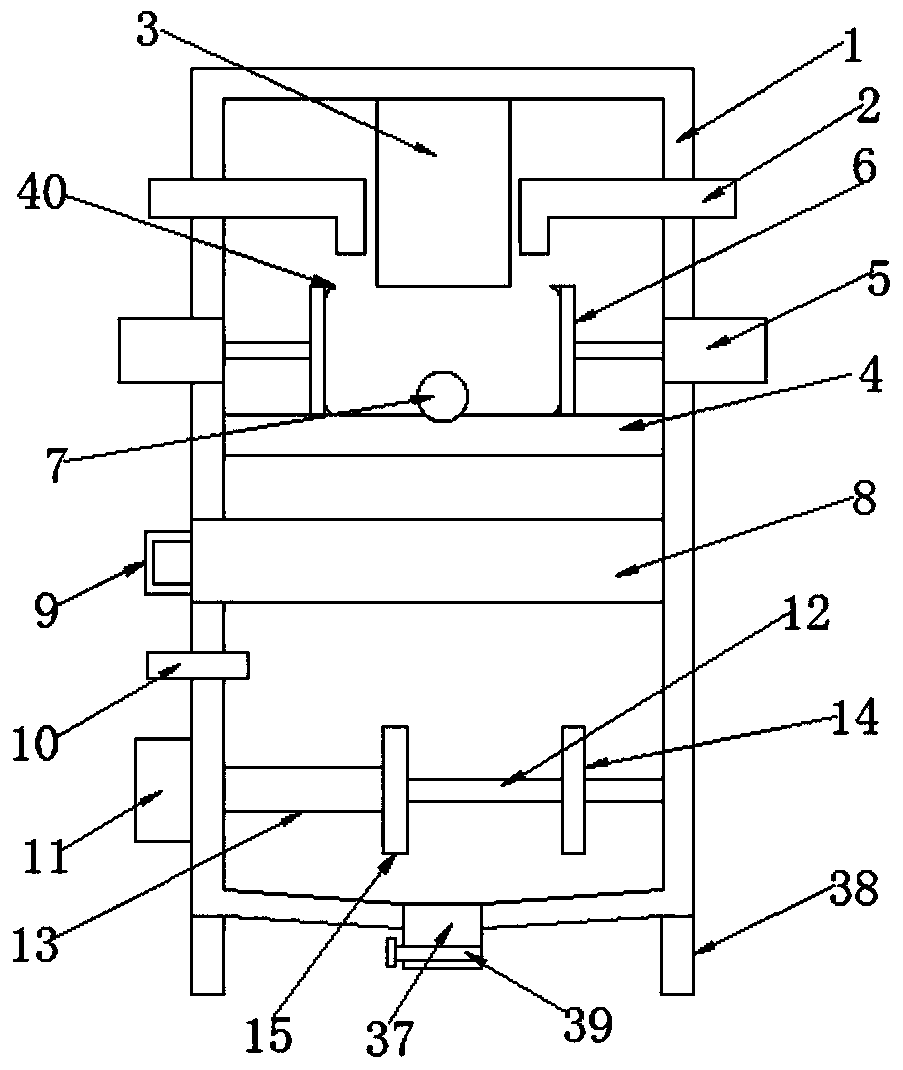

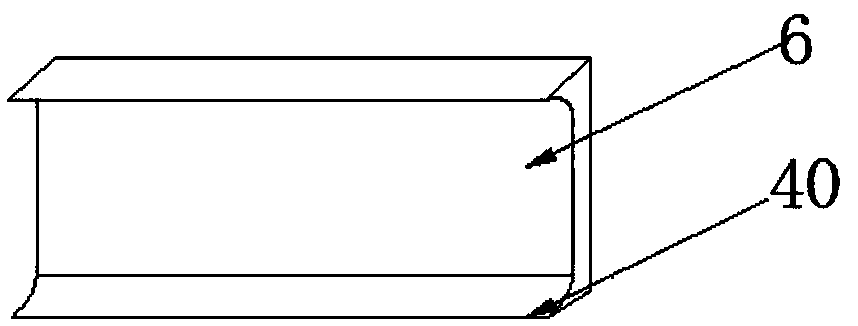

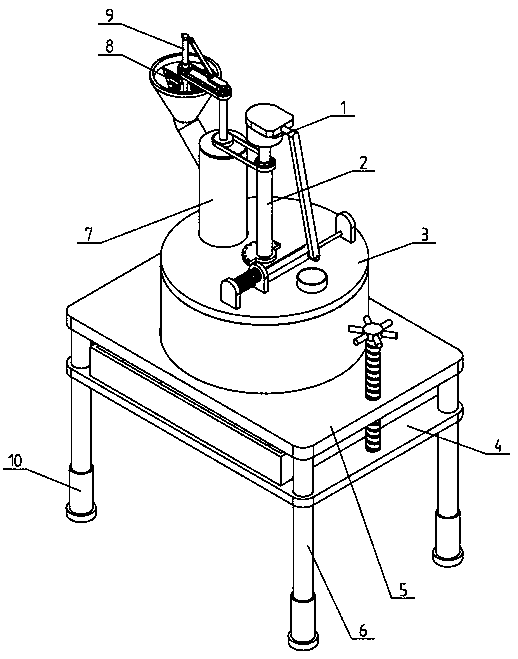

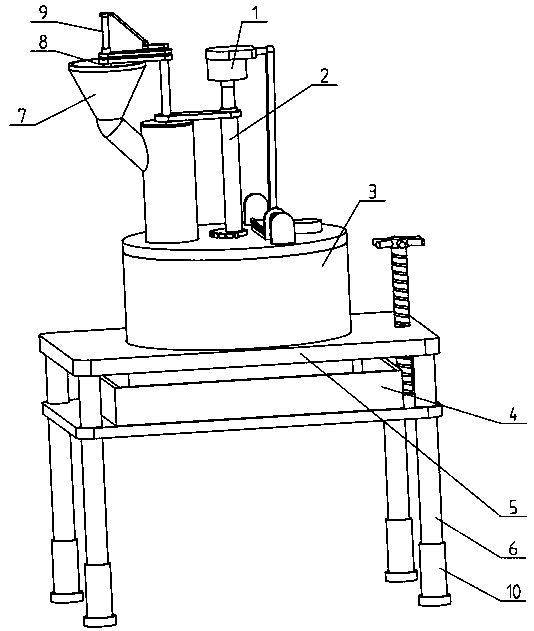

Compound microbial organic fertilizer production device

ActiveCN111039704AImprove mixing processing effectFully mixed reactionBio-organic fraction processingOrganic fertiliser preparationAgricultural engineeringEnvironmental engineering

The invention relates to the field of microbial organic fertilizer production, particularly to a composite microbial organic fertilizer production device, which comprises a driving mechanism, a stirring mechanism, a mixing box, a box cover mechanism, a box body bracket and supporting legs, wherein the driving mechanism is connected to the mixing box, the driving mechanism is in transmission connection with the stirring mechanism, the stirring mechanism is arranged in the mixing box in a running fit manner, a feeding hole and a discharge hole are respectively formed in the top and the bottom ofthe mixing box, the mixing box is connected to the box body bracket, and the four corners of the box body bracket are respectively connected with one supporting leg. According to the invention, the blocking cover plate capable of being adjusted to be opened and closed in a lifting mode is adopted, so that discharging and unloading can be conveniently conducted after organic fertilizer productionand processing are completed, and materials adhering to the interior of the mixing box can be conveniently cleaned from the lower portion.

Owner:韩小荣

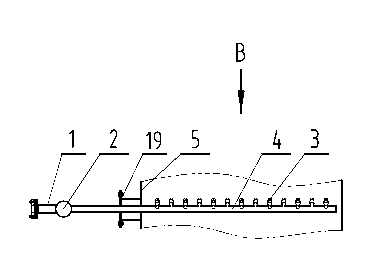

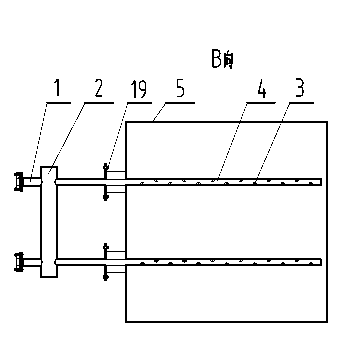

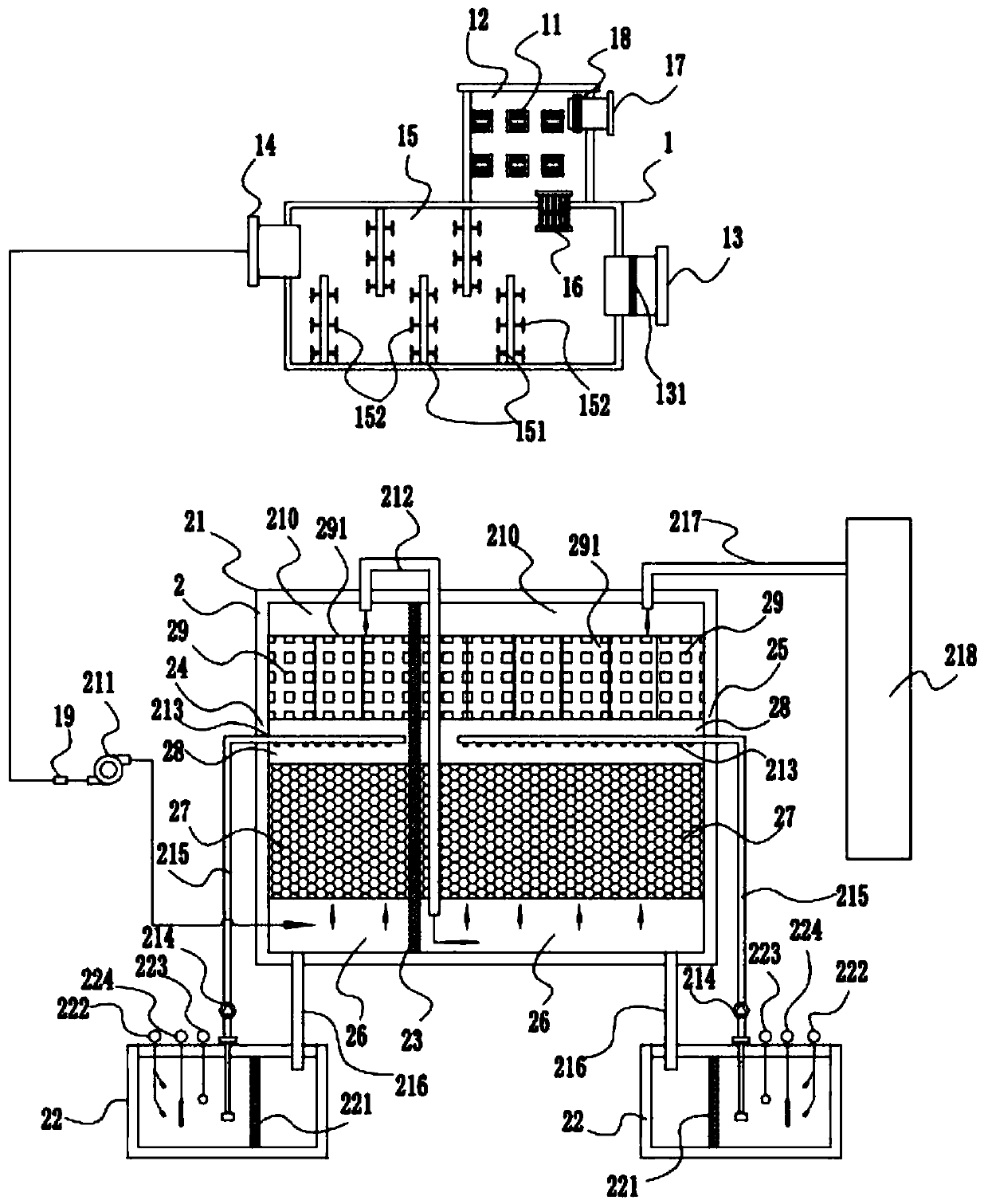

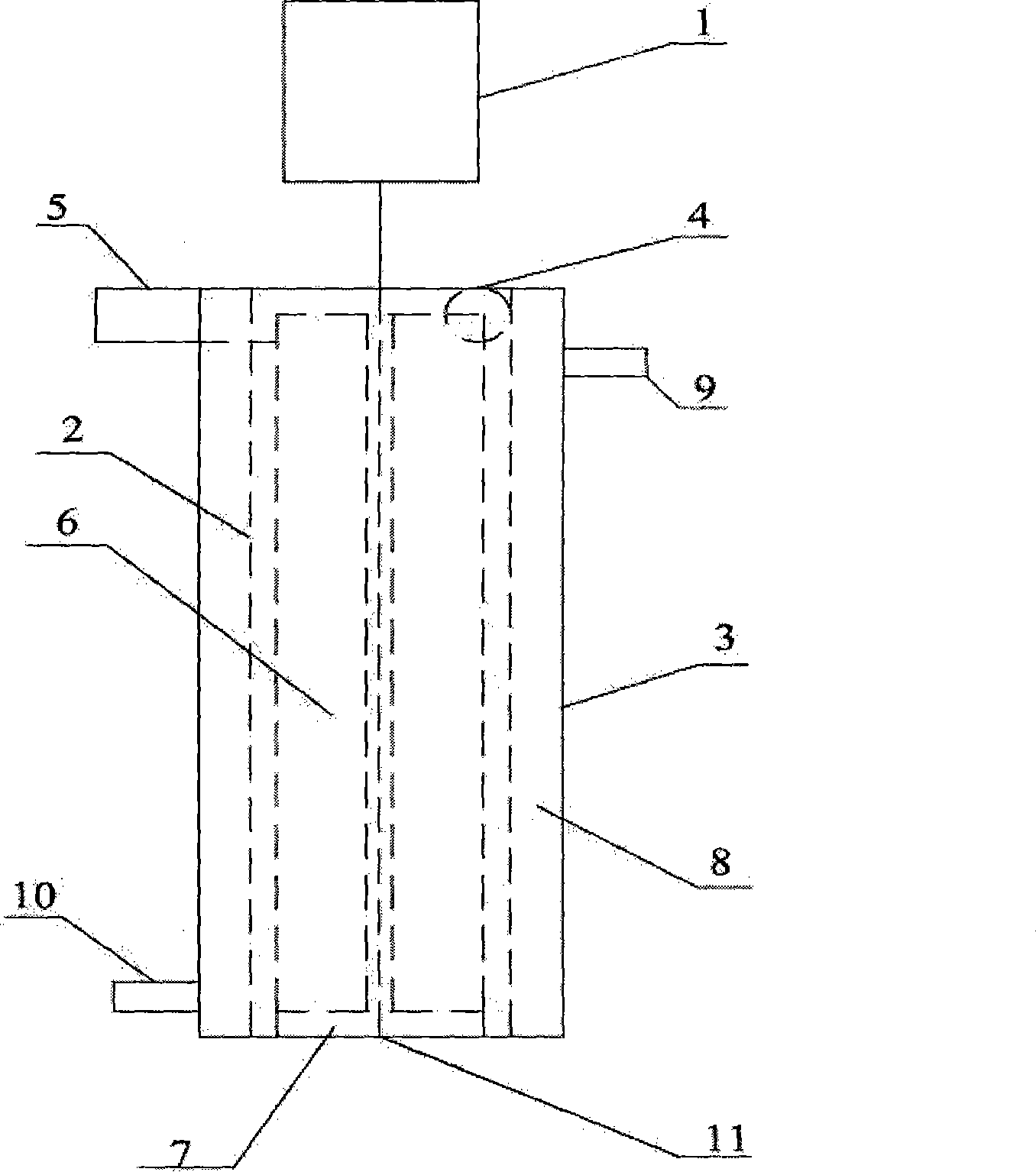

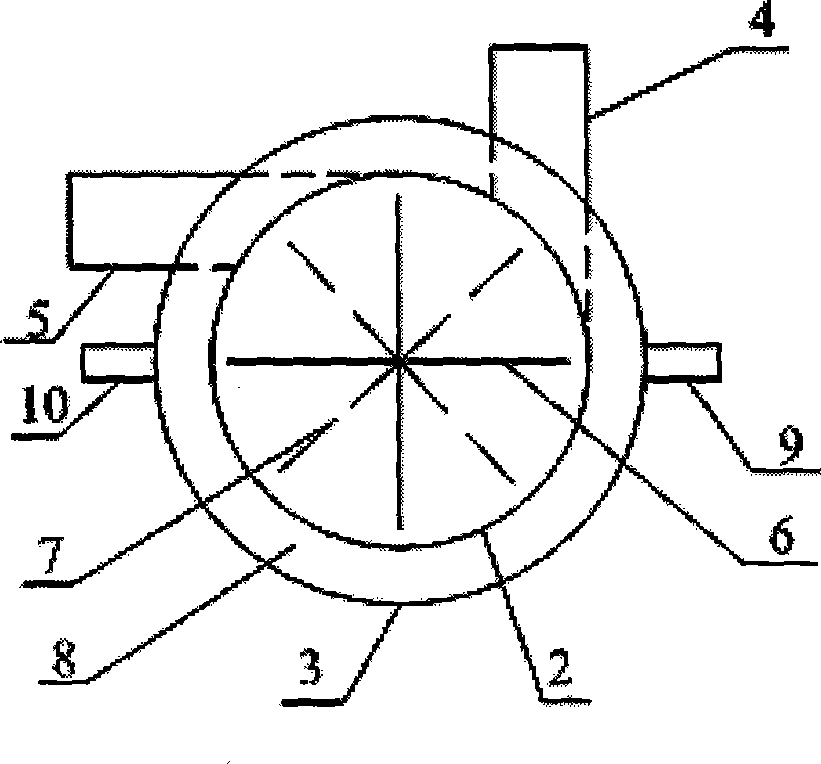

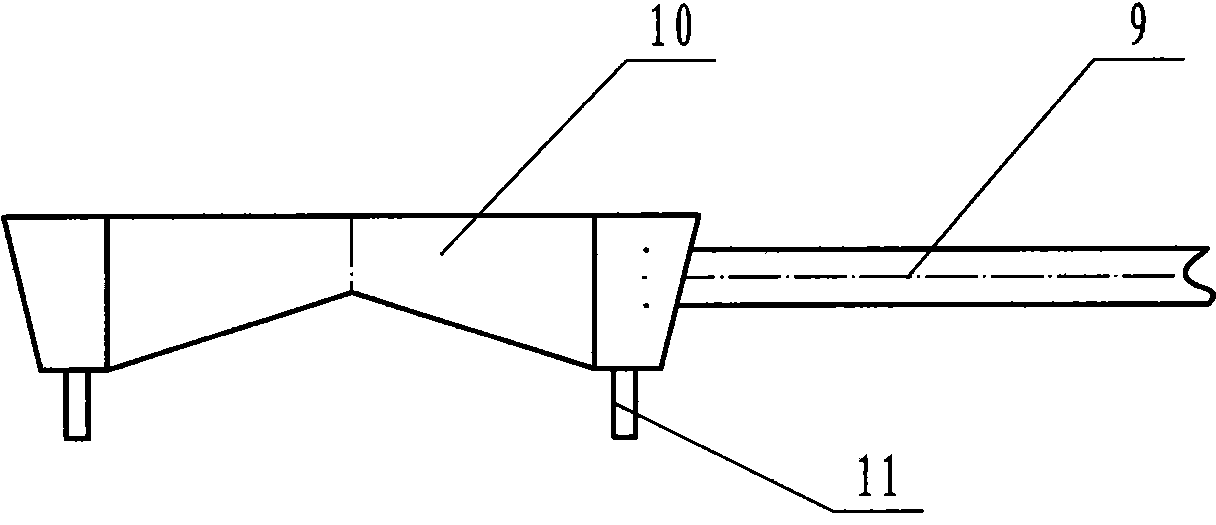

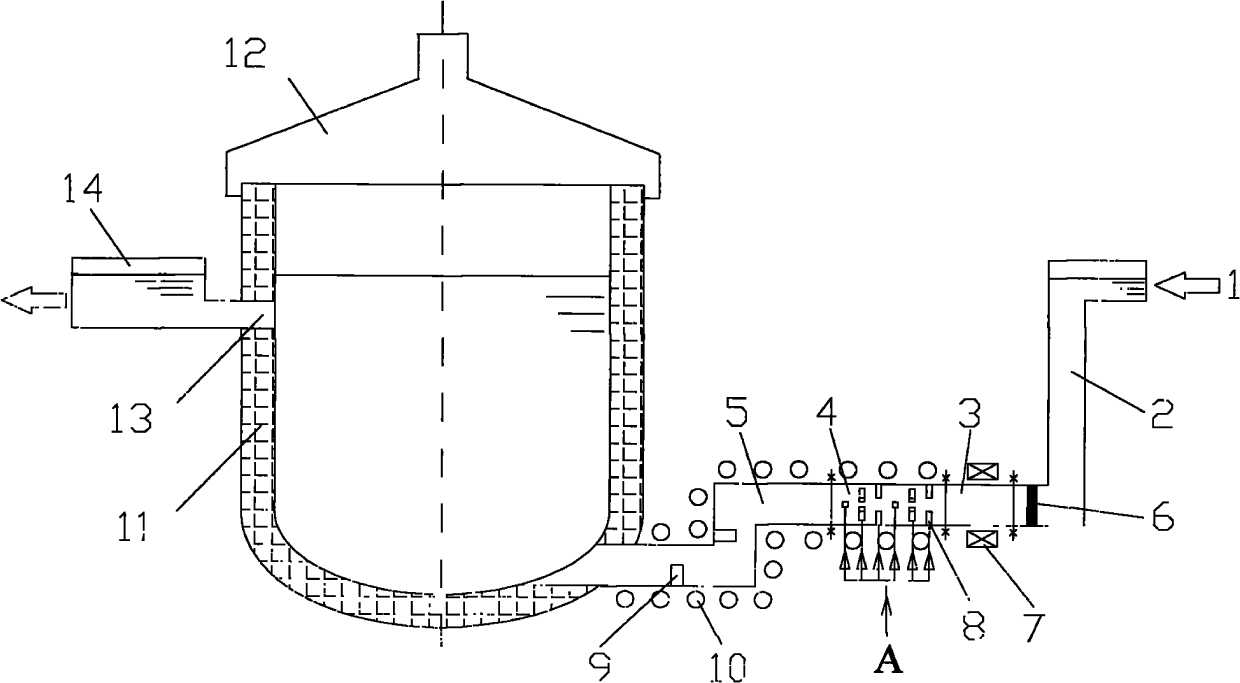

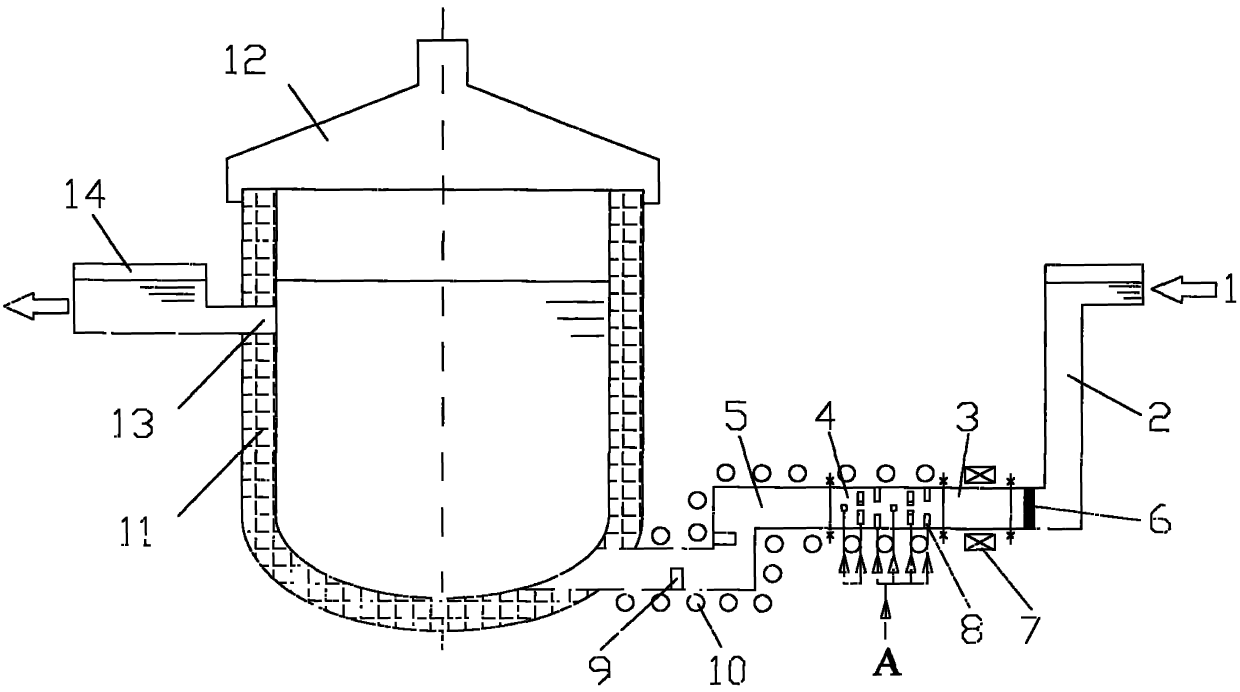

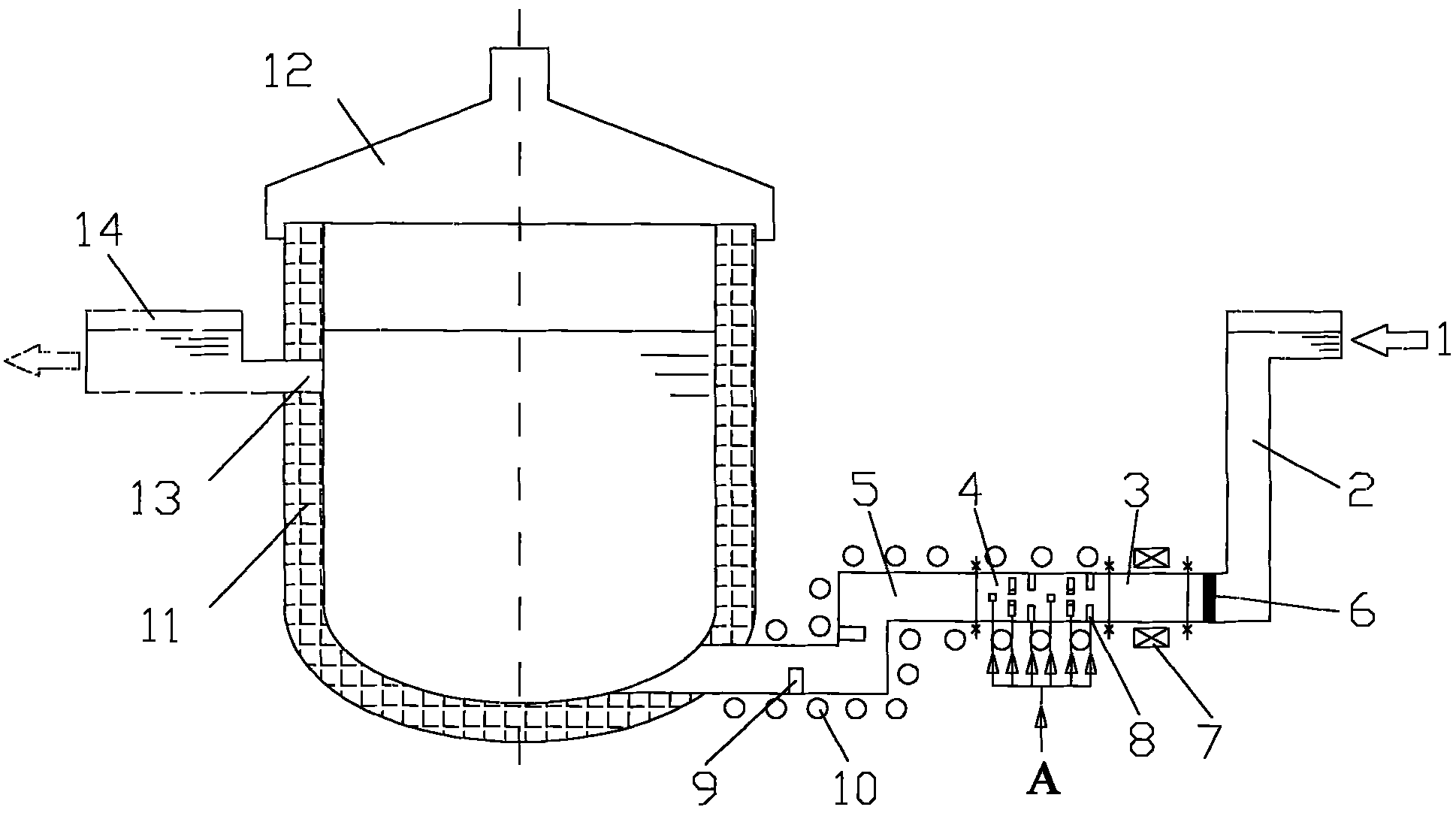

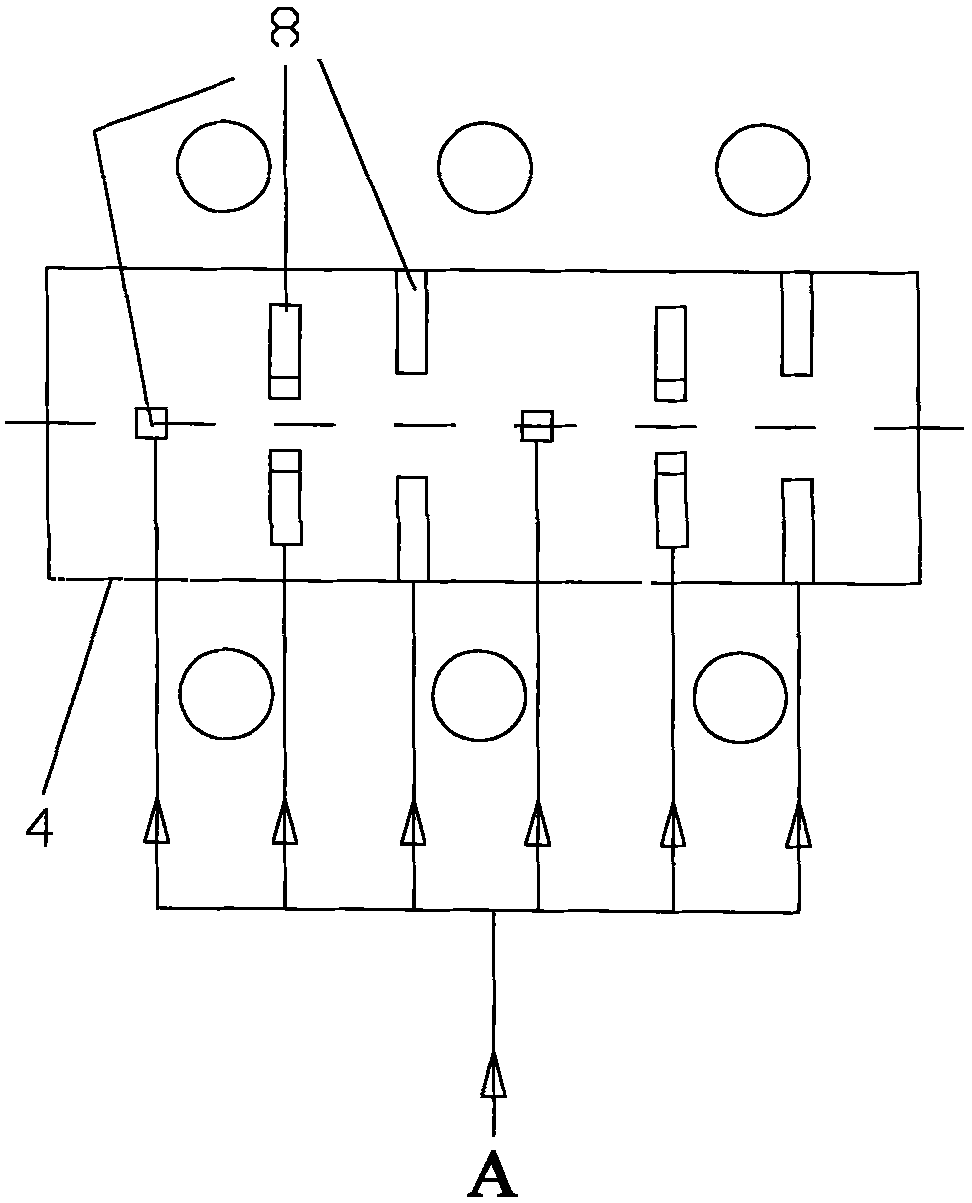

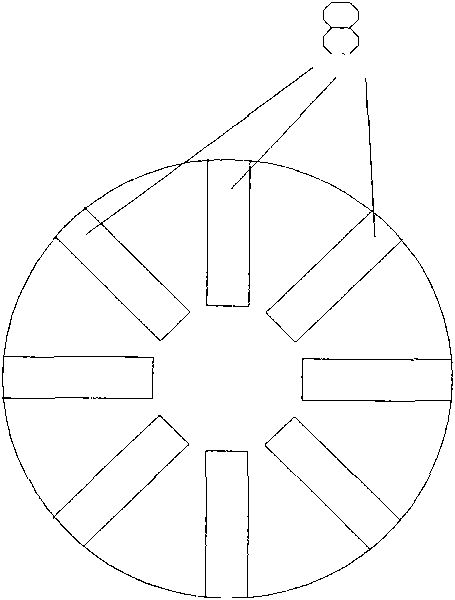

On-line degassing method for aluminium melt

The invention discloses an on-line degassing method of an aluminium melt, comprising the following steps: 1) leading an aluminium melt to be purified to enter into a runner 2 with a ceramic filter plate 6 via a melt inlet to remove large-sized slag in the molten aluminum; 2) designing a small-diameter channel consisting of an acceleration pipeline 3 and a gas mixed pipe 4 between the melt inlet and a melt outlet; 3) further mixing the aluminium melt with mixed gas evenly via a secondary mixed pipe 5 with a stop dog; 4) discharging the mixture of the molten aluminum and the mixed gas in a standing chamber 11, and forming an argon protective layer above the liquid level of an escaped gas while bubbles disperse and float upwards evenly; and 5) collecting the processed gas via a tail gas collector 12, and discharging the molten aluminum from the melt outlet of the standing chamber. The method in the invention can effectively ensure fully mixed reaction of the molten aluminum with sufficient cleaned gas in a sealed space, shortens the dispersion course of hydrogen in the aluminium melt and achieves the aim of hydrogen removal efficiently.

Owner:SHANGHAI DIANJI UNIV

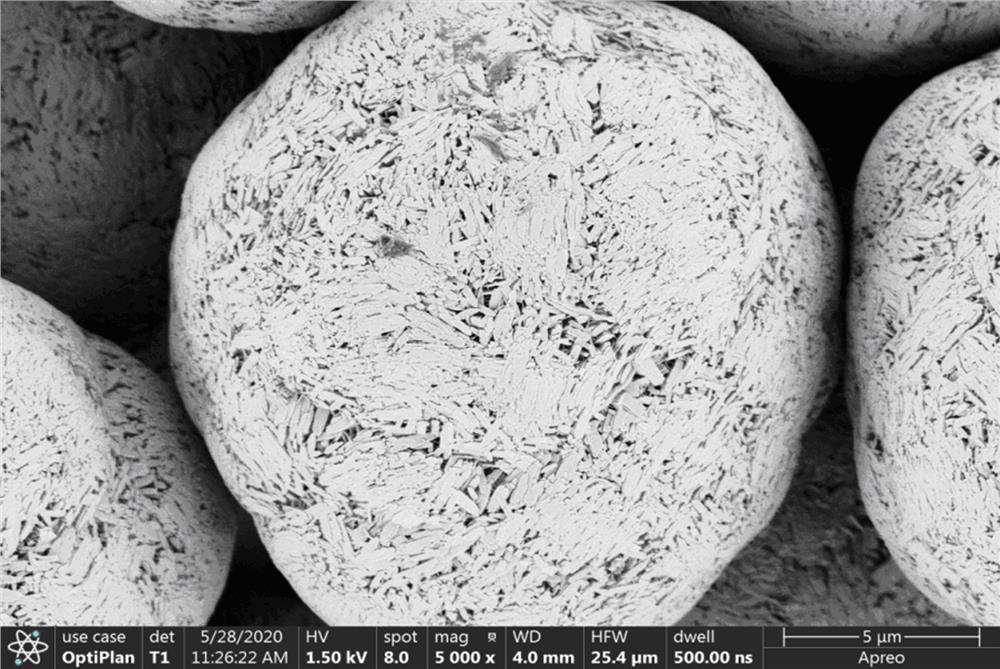

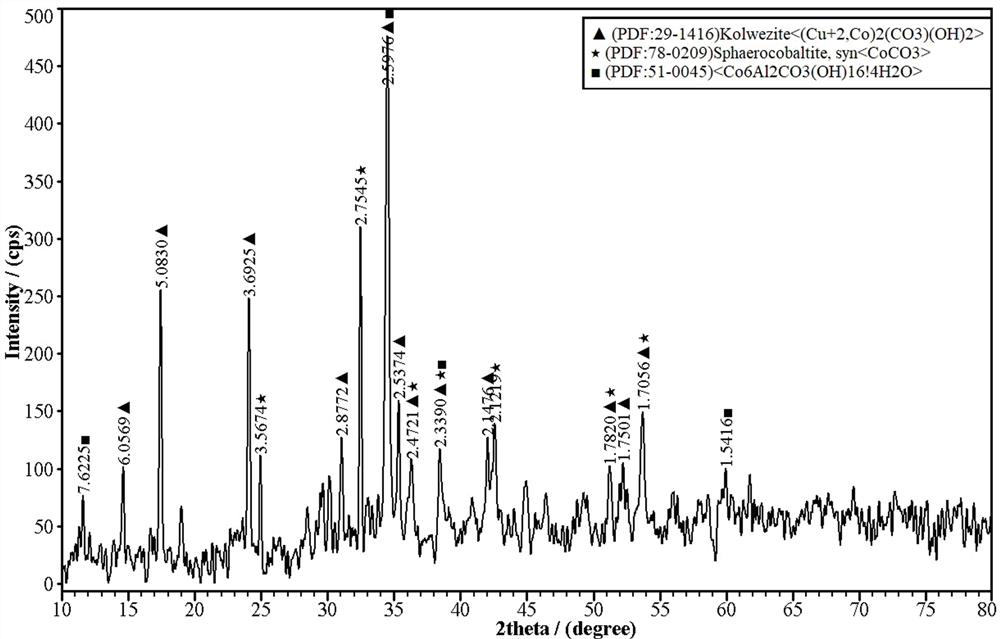

Doped basic cobalt carbonate/cobalt carbonate composite precursor and preparation method and application thereof

ActiveCN111825125AHigh tap densityAppropriate particle size increaseCell electrodesSecondary cellsPhysical chemistryBattery cell

The invention belongs to the field of lithium ion battery materials, and particularly relates to a doped basic cobalt carbonate / cobalt carbonate composite precursor and a preparation method and application thereof. According to the doped basic cobalt carbonate / cobalt carbonate composite precursor, primary particles are in a sheet shape, the length of the primary particles ranges from 500 nm to 2 [mu] m, and the width of the primary particles ranges from 100 nm to 500 nm; secondary particles are formed by tightly stacking the lamellar primary particles, so that the degree of sphericity is perfect. The composite precursor has very high tap density, and lays a certain foundation for a high-tap-density lithium ion battery anode material precursor. In the process of synthesizing the composite precursor by a wet method, the stirring linear speed of a reaction system is stably reduced, the particle size increase of the reaction system is appropriate, and the lamellar primary particles are closely stacked to form the secondary spherical particles.

Owner:JINCHI ENERGY MATERIALS CO LTD +1

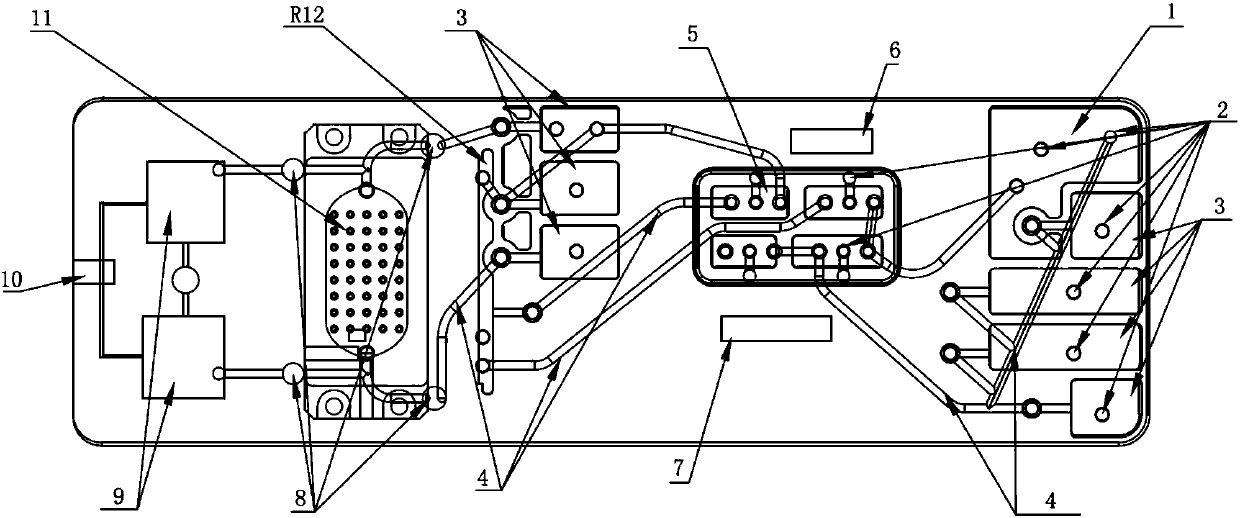

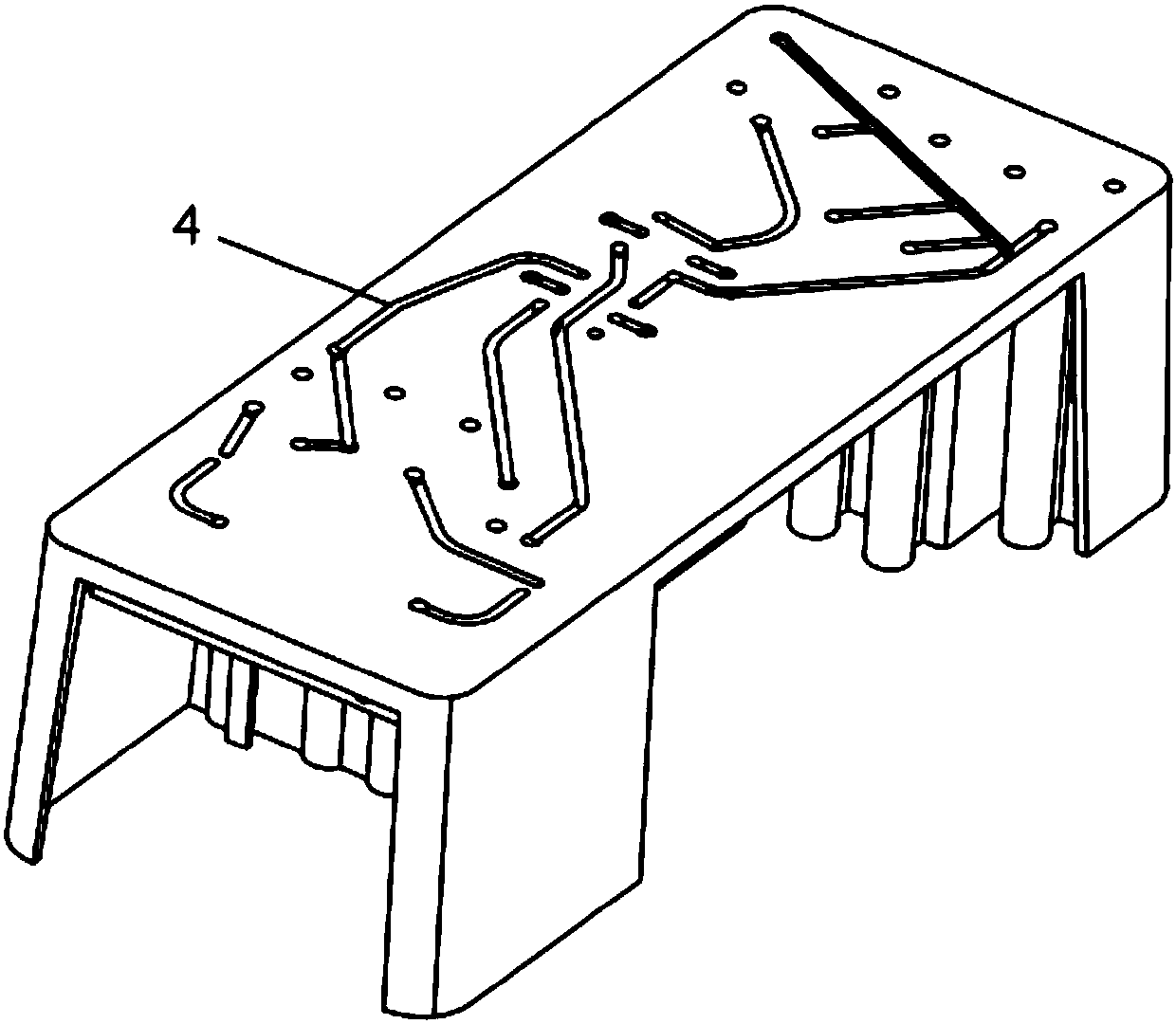

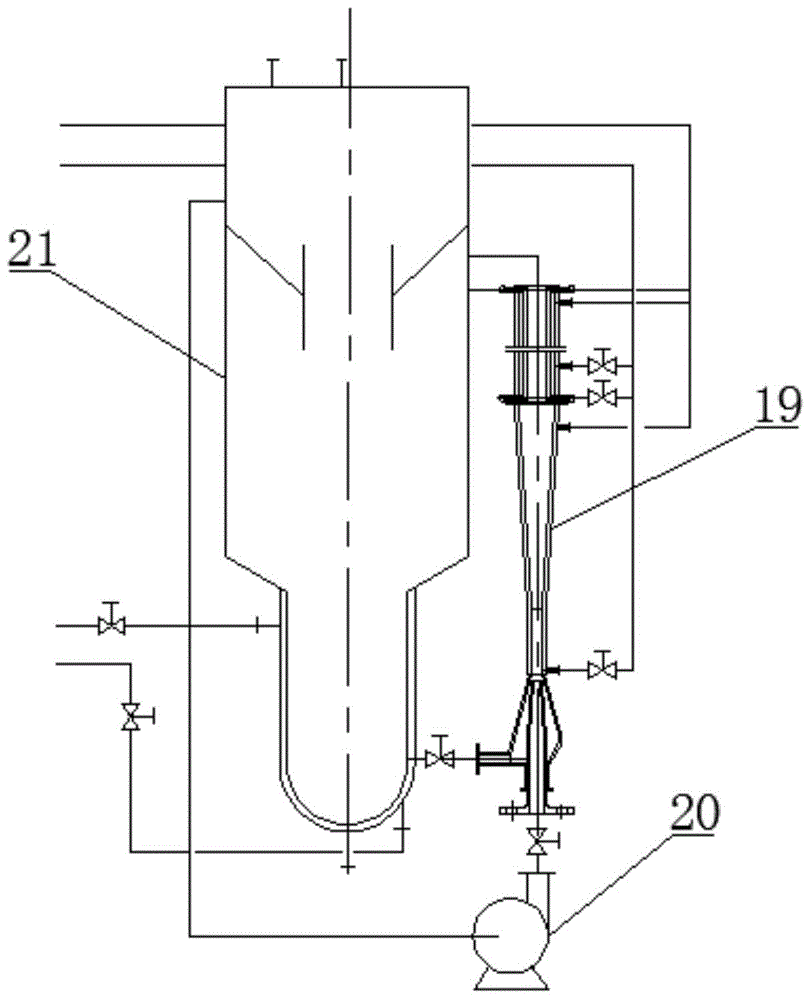

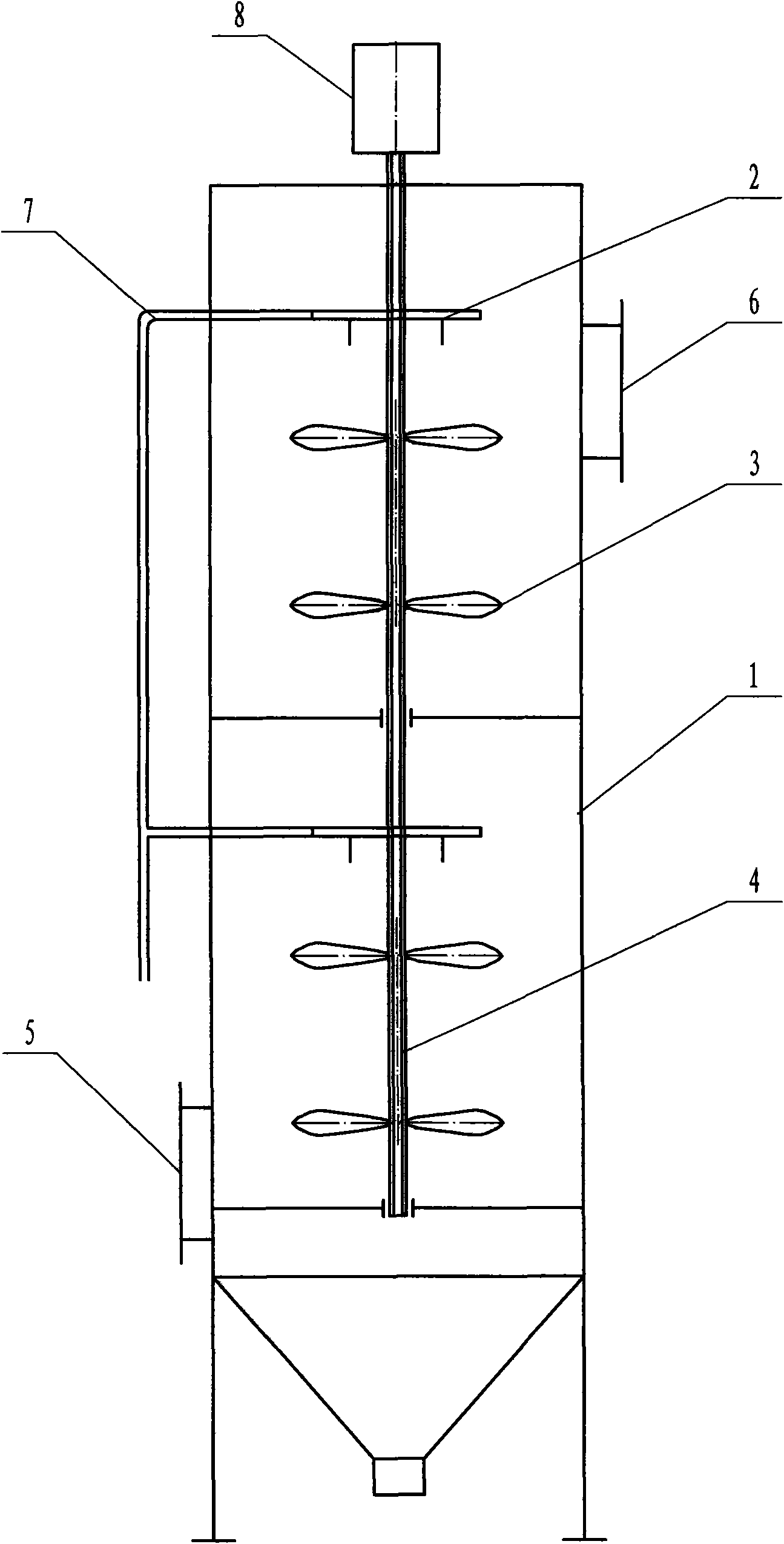

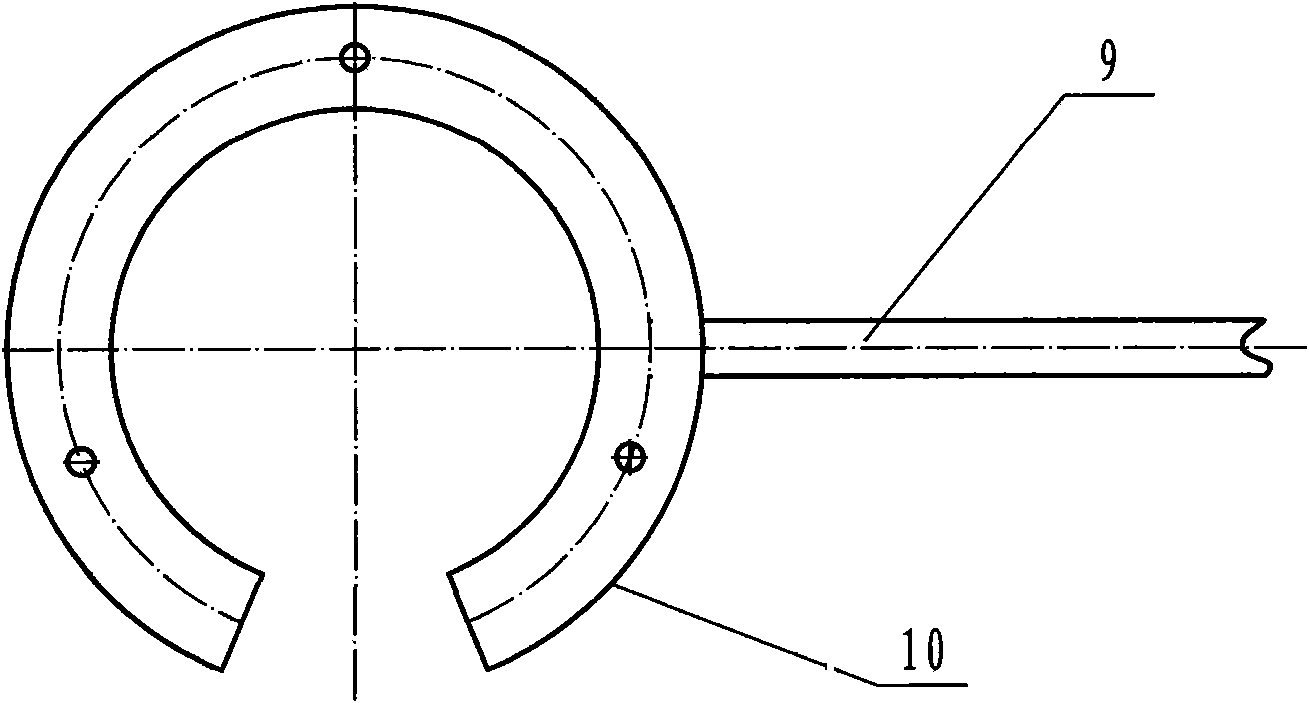

On-line degassing device for aluminium melt

InactiveCN101984099AFully mixed reactionIncrease contactProcess efficiency improvementHydrogenGas mixing

The invention discloses an on-line degassing device of aluminium melt, which can effectively ensure fully mixed reaction between all aluminum melts and sufficient cleaned gas in a sealed space, enhances gas-liquid contact, shortens the dispersion course of hydrogen in the aluminium melt and achieves the aim of hydrogen removal efficiently. The device comprises a melt inlet, a runner, an acceleration pipeline, a gas mixed pipe, a secondary mixed pipe and a standing chamber which are successively connected with each other along the melt flow direction, wherein the secondary mixed pipe and the bottom part of the standing chamber are communicated; the melt inlet is arranged below the melt liquid level of the standing chamber; a tail gas collector is arranged above the standing chamber; and the inner wall of the gas mixing pipe is provided with multiple gas ejectors, the tail end of each gas ejector is connected with a device for inputting cleaned gas, and each gas ejector is provided with multiple orifices.

Owner:SHANGHAI DIANJI UNIV

High-strength coal gangue sintered porous brick and preparation method thereof

The invention discloses a high-strength coal gangue sintered porous brick. The high-strength coal gangue sintered porous brick is prepared from the following raw materials (by weight): 30-50 parts ofcoal gangue particles, 20-30 parts of river bottom silt, 10-20 parts of quartz sand, 10-20 parts of waste ceramic particles, 3-8 parts of glass powder, 5-10 parts of bentonite, 8-15 parts of mixed auxiliaries, 3-6 parts of asbestos fibers and 2-5 parts of sulfate. The mixed auxiliaries comprise the following components in percentage by mass: 5-15% of a flame retardant, 20-30% of an anti-freezing agent, 50-70% of a reinforcing agent and 3-5% of a binder. The preparation method comprises the following steps of: (1) pretreating raw materials; (2) weighing the raw materials; (3) conducting primarymixing; (4) aging; (5) secondary mixing; (6) preparing a blank; (7) drying; (8) sintering; and (9) conducting steam curing. The preparation process is scientific and reasonable, the adopted raw materials are easy to obtain, the production cost is controllable, and the raw material components are reasonably matched, so that the prepared porous brick is easy to form, has few cracks, good compactness and good strength, and has a heat preservation effect.

Owner:师宗县泰宇新型建材有限公司

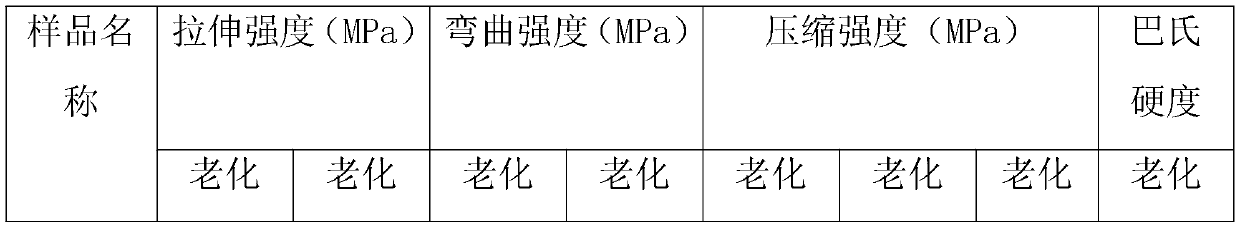

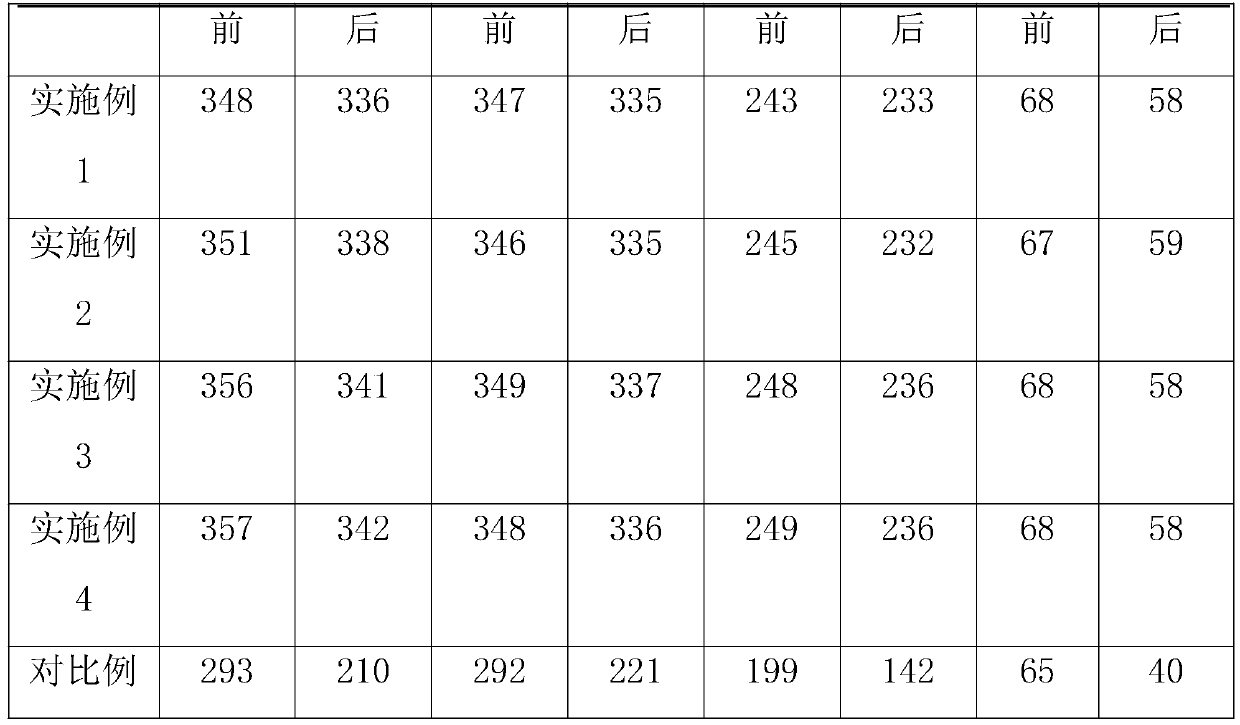

Anti-aging glass fiber reinforced plastic material and preparation method thereof

The invention provides an anti-aging glass fiber reinforced plastic material. The anti-aging glass fiber reinforced plastic material is prepared from the following raw materials in parts by weight: 100 parts of unsaturated polyester resin, 2-8 parts of styrene, 1-3 parts of a curing agent, 1-3 parts of an accelerant, 80-120 parts of glass fibers, 10-40 parts of an illite functional powder material, 1-3 parts of a coupling agent I, 1-2 parts of zinc oxide and 5-6 parts of graphene. The preparation method comprises the following steps: pickling illite powder, washing with water to be neutral, drying, and modifying with a coupling agent II to obtain the illite functional powder material. The illite functional powder material is added and compounded with other raw materials, so that the crosslinking degree between macromolecular chains can be increased; the anti-aging glass fiber reinforced plastic material is particularly suitable for marine environments such as ships, and the salt fog resistance, the aging resistance and the strength of the anti-aging glass fiber reinforced plastic material are remarkably improved compared with those of a common glass fiber reinforced plastic material.

Owner:CHENGDE RENHE MINING CO LTD

Multilayer-filtering purifying equipment suitable for sewage treatment

ActiveCN109354266AAvoid cloggingEasy to cleanRotary stirring mixersSpecific water treatment objectivesPistonDrive motor

The invention relates to the technical field of sewage treatment, in particular to multilayer-filtering purifying equipment suitable for sewage treatment. A sewage tank receives domestic sewage, and an agent liquid tank is filled with a chemical agent which flows into the sewage tank for water purifying; when sewage in the sewage tank reaches certain volume, a driving motor drives a first rotatingshaft to rotate so as to drive a piston plate to move up and down through action of a crank, a sleeve and a number 6 connection rod and to drive a blocking end head to move up and down through a number 4 connection rod to open or block a downcomer inlet to guide the sewage into a piston cavity one stream by one stream, so that using of a valve is avoided; when the piston cavity is full of the sewage, the piston plate works to squeeze the sewage into a purifying tank from a liquid guide pipe; the sewage can be discharged from a liquid discharging pipe after being filtered through a bilayer filter net.

Owner:哈尔滨海纳众创科技有限公司

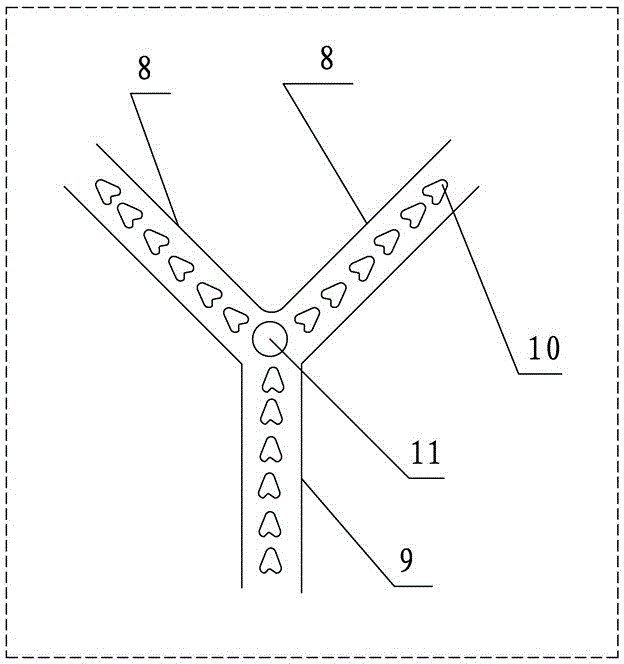

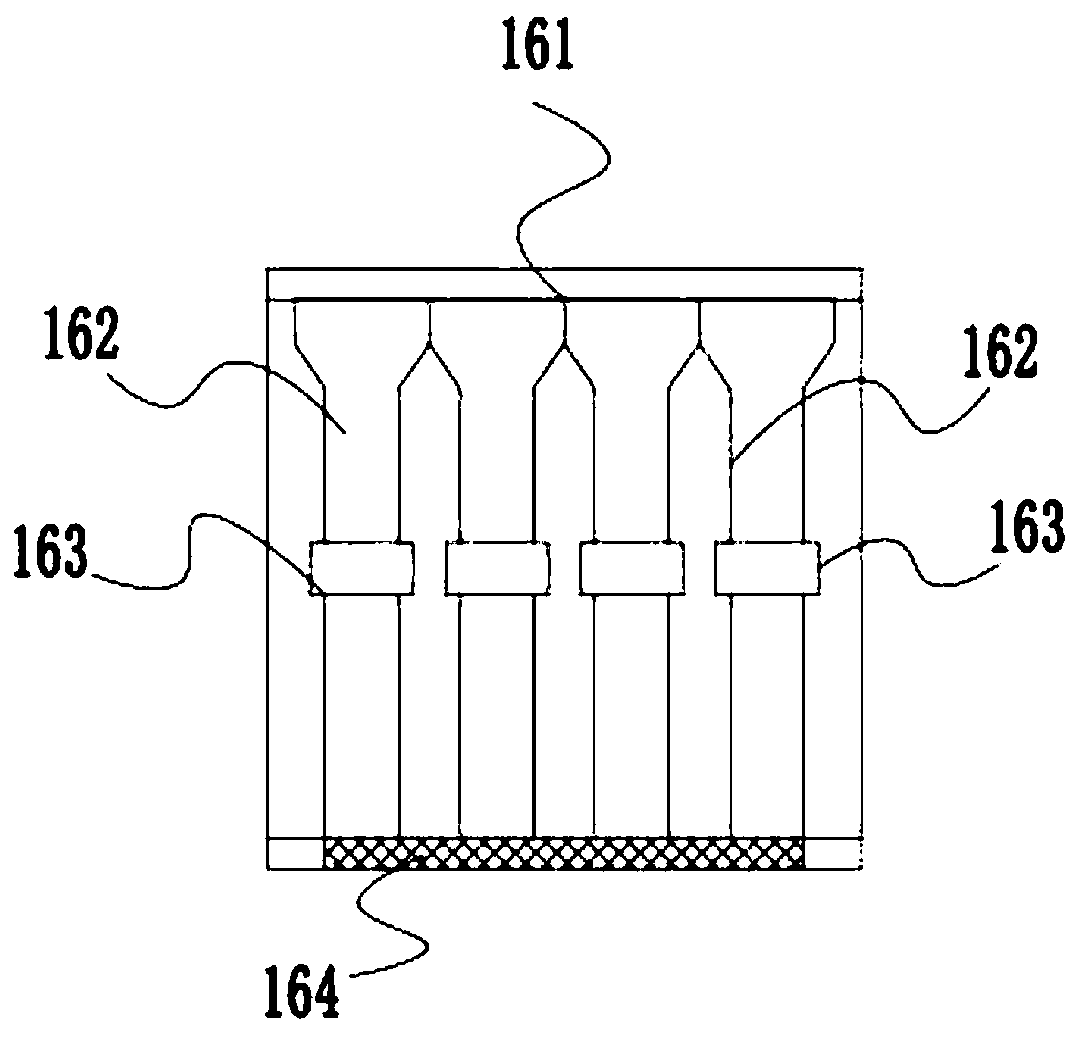

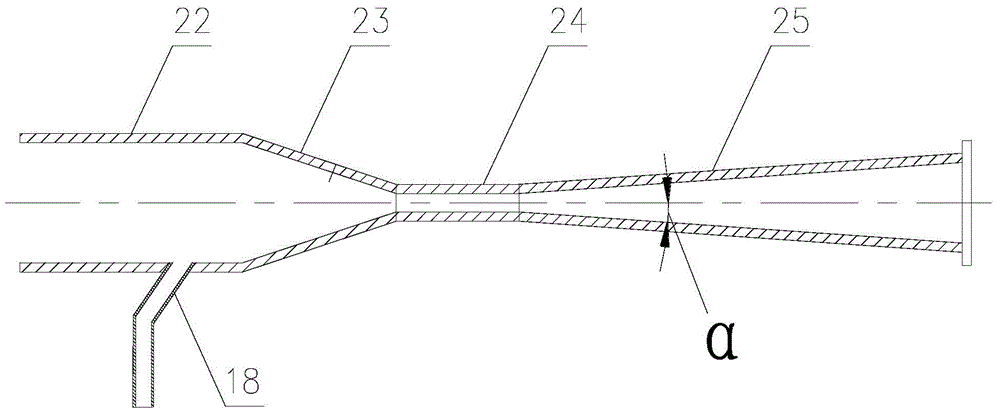

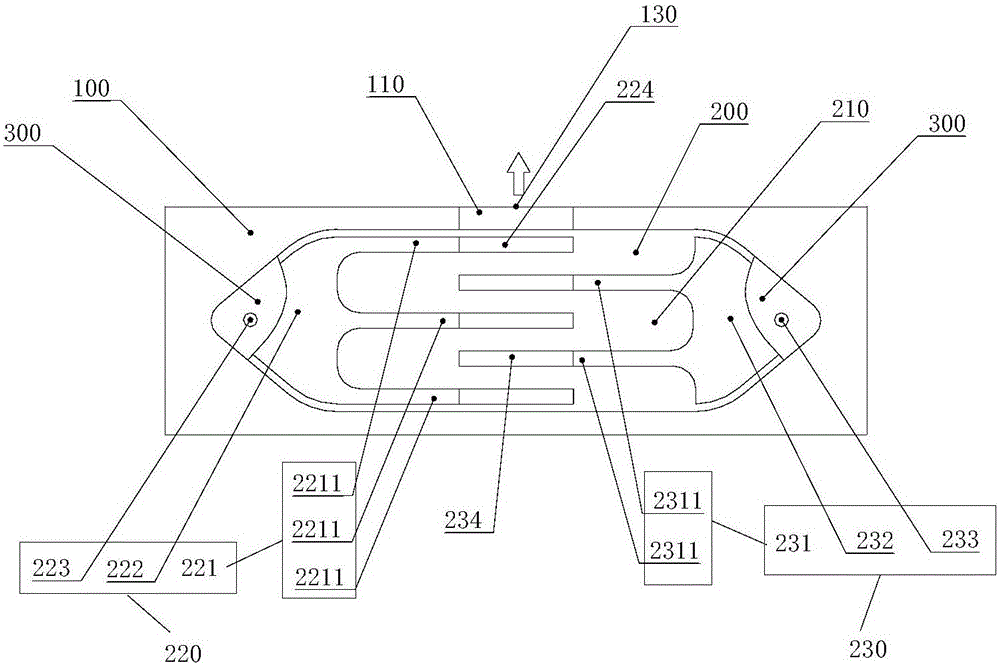

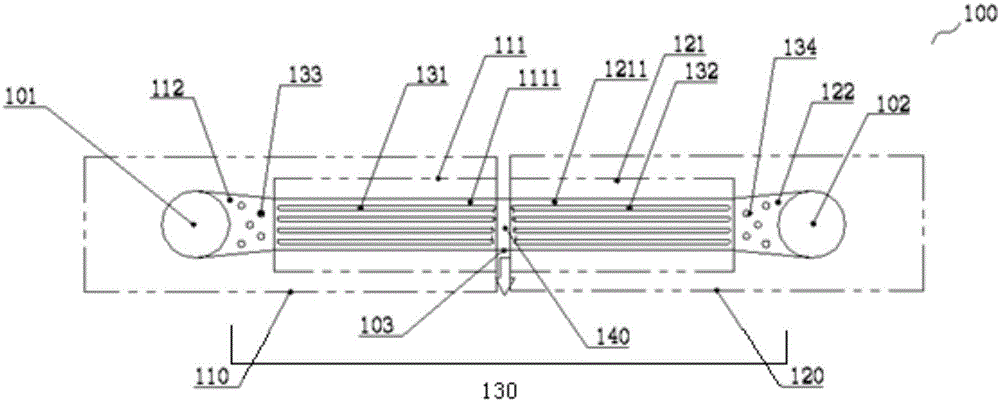

Flow dividing opposite impact microreaction passage and microreactor

InactiveCN106378081AGuaranteed reaction temperatureEnsure stabilityChemical/physical/physico-chemical microreactorsChemical/physical/physico-chemical reactor detailsEngineeringReaction speed

The invention relates to a flow dividing opposite impact microreaction passage and a microreactor. The flow dividing opposite impact microreaction passage comprises a reaction body, wherein one end of the reaction body is provided with a first inlet; the other end of the reaction body is provided with a second inlet; the reaction body is also provided with a fluid outlet positioned between the first inlet and the second inlet; a first fluid section is arranged between the first inlet and the outlet; a second fluid section is arranged between the second inlet and the outlet; a flow dividing structure for performing flow dividing on fluid is also arranged in the first fluid section and / or the second fluid section; the first fluid section and / or the second fluid section are / is separated into at least two flow dividing passages through which reaction fluid is allowed to pass by the flow dividing structure; the reaction body also comprises a mixing region which is positioned between the first fluid section and the second fluid section and communicates with the outlet; the mixing region is used for mixing the fluid of the first fluid section and the second fluid section. The microreactor comprises the flow dividing opposite impact microreaction passage. Two kinds of fluid can realize full mixed reaction; the reaction speed is accelerated; the reactant generation efficiency is improved.

Owner:SHANDONG HIMILE CHEM TECH

Preparation method of layered functional material calcium sulphoaluminate

ActiveCN109455749ASimple preparation processEasy to operateChemical/physical/physico-chemical stationary reactorsAluminium sulfur compoundsAluminium hydroxideSulfate

The invention relates to a preparation method of layered functional material calcium sulphoaluminate. The preparation method comprises the following steps of: (1) mixing a certain proportion of calcium sulfate, aluminum hydroxide and calcium oxide in a full backmixing explosive nucleation reactor, and adding water more than the materials to mix; and (2) synthesizing calcium sulphoaluminate gel under the conditions that the revolving speed of a rotor is 4,000-6,000 rpm, the voltage is 220-330 V and the nucleating time is 8-16 min by adopting the full backmixing explosive nucleation reactor, then enabling the calcium sulphoaluminate gel to be crystallized for 12-16 h at 90-150 DEG C, cooling to 30-50 DEG C, stirring for 12-16 h, then heating to 90-150 DEG C, and circulating 3-5 times to prepare the layered functional material calcium sulphoaluminate. The preparation method of the layered functional material calcium sulphoaluminate has the advantages that the calcium sulfate, the aluminumhydroxide and the calcium oxide can nucleate and grow in the full backmixing explosive nucleation reactor through a 'one-pot method', the preparation process of the calcium sulphoaluminate is effectively simplified, the preparation time is shortened, the reaction operation is simplified, and the production efficiency is improved.

Owner:JIANGSU LONGCHANG CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com