Chip type micro reaction channel and micro reactor

A micro-reaction channel and chip-type technology, applied in chemical/physical/physical chemical reactors, chemical instruments and methods, chemical/physical/physical chemical processes, etc., can solve the problem of low yield of reaction products, general mixing effect, Inability to fully mix the reaction and other issues to achieve the effects of reducing the possibility of safety accidents and quality accidents, ensuring the reaction temperature, and improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the application according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. . In the following description, different "one embodiment" or "embodiment" do not necessarily refer to the same embodiment. Furthermore, the particular features, structures, or characteristics of one or more embodiments may be combined in any suitable manner.

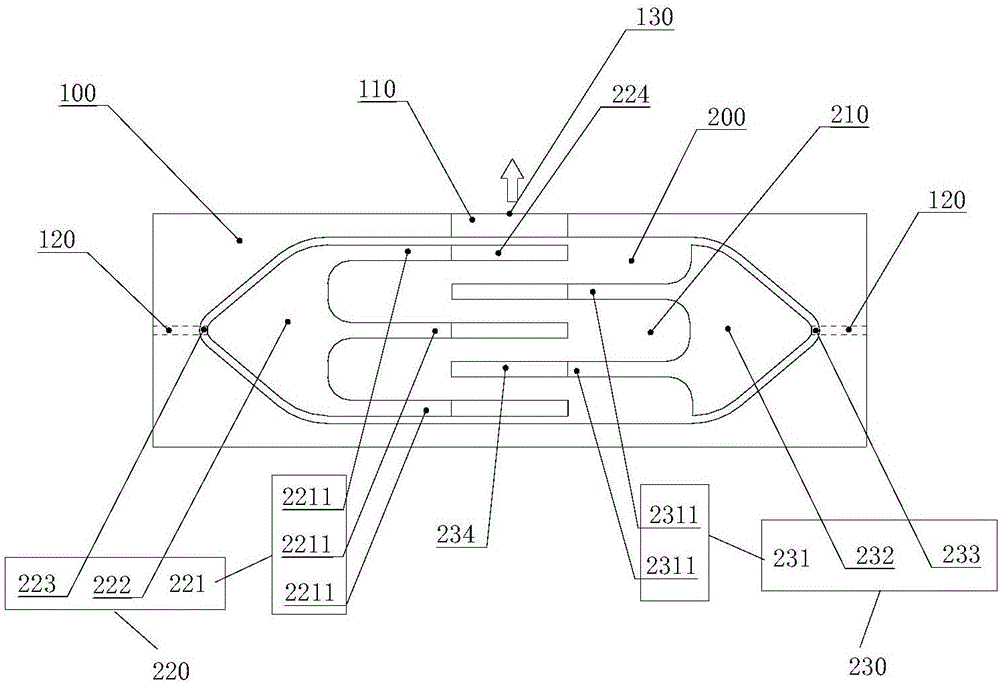

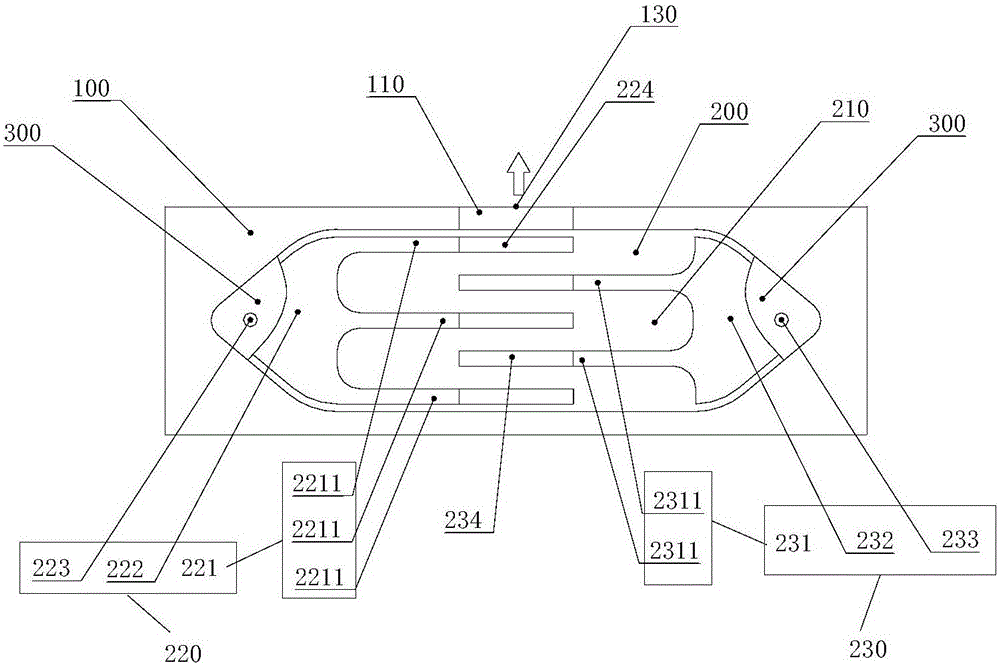

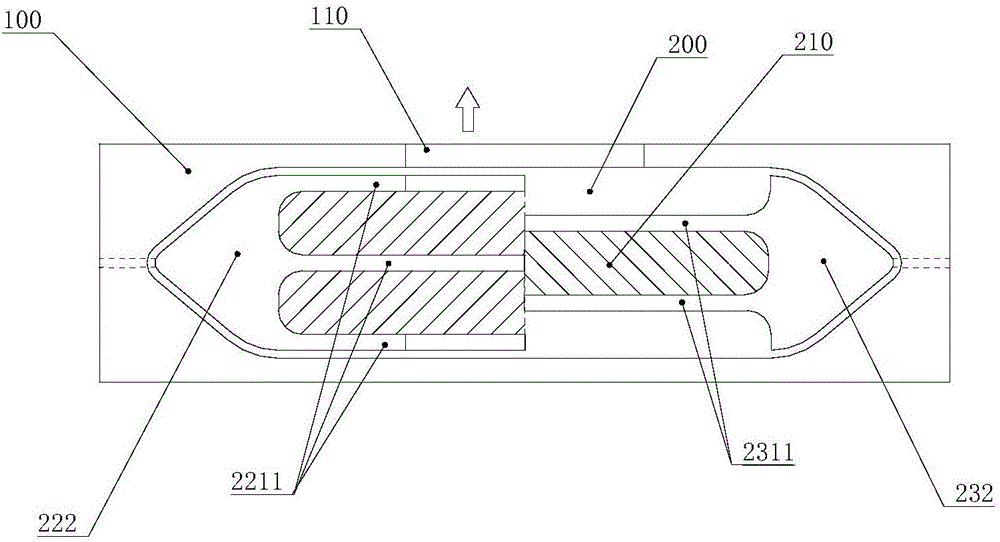

[0034] Such as figure 1 and figure 2 As shown, a chip-type micro-reaction channel proposed by an embodiment of the present invention includes a substrate 100 and a chip 200 on it. A fluid part 220 and a second fluid part 230 , and the first fluid part 220 includes a first inlet 223 , and the second fluid part 230 includes a second inlet 233 .

[0035] Meanwh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com