Patents

Literature

137results about How to "Stable reaction temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

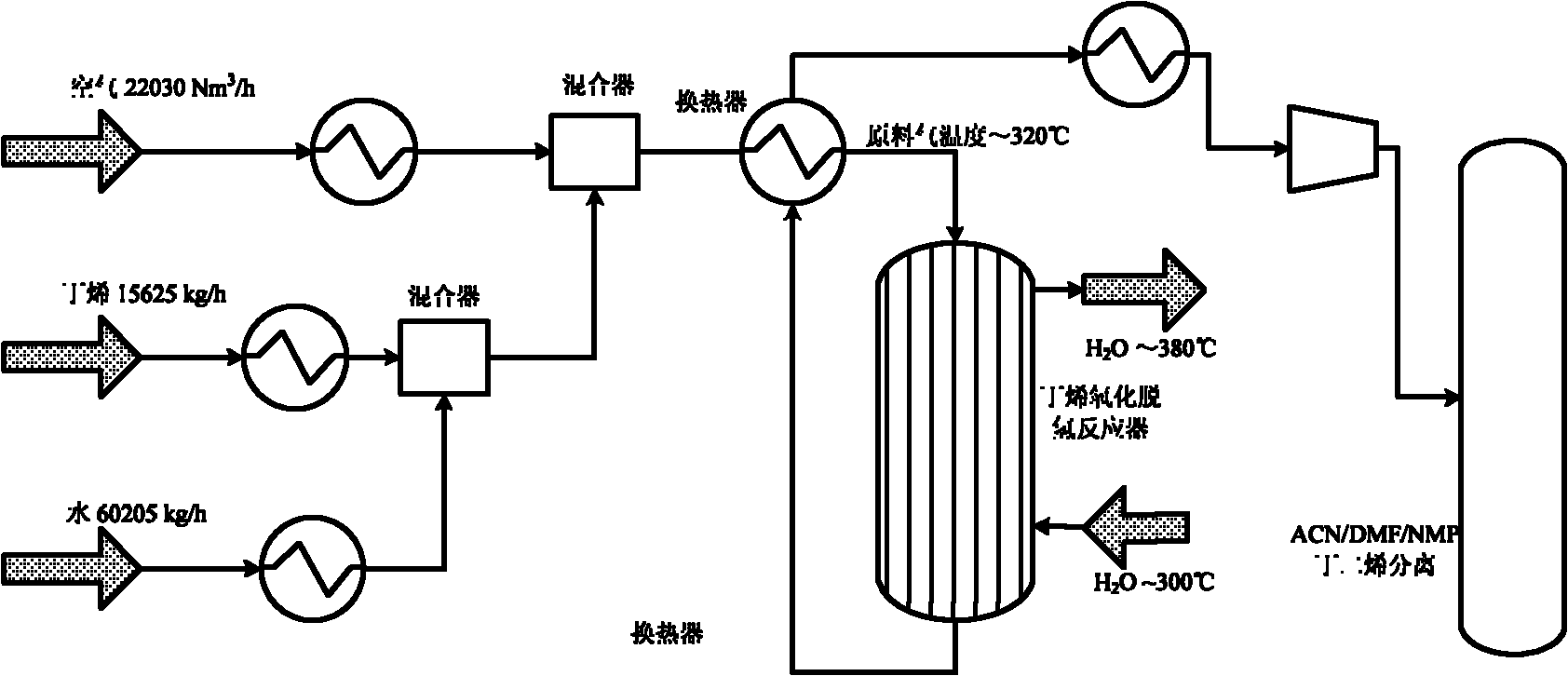

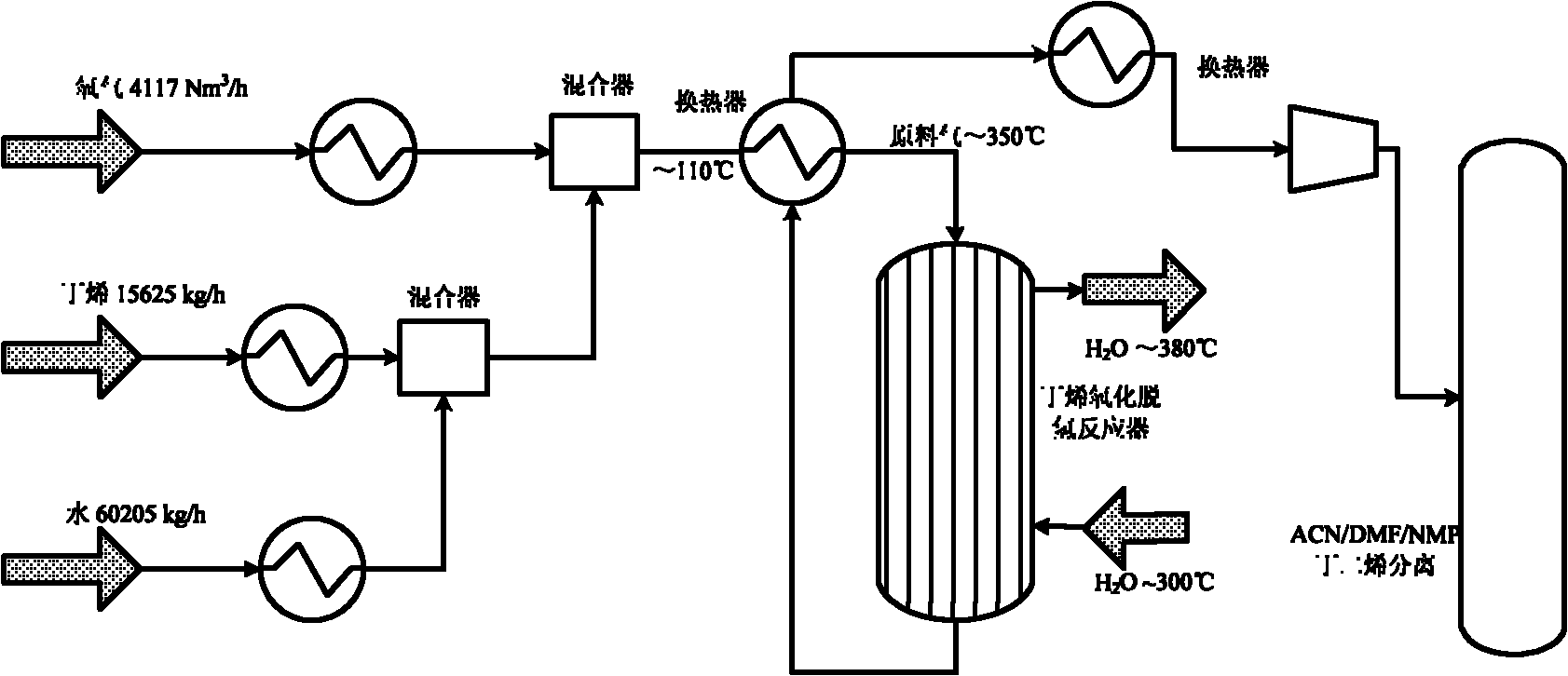

Method for producing butadiene by oxidatively dehydrogenating butene and used catalyst

ActiveCN103102238AHigh yieldHigh selectivityHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsExtractive distillationLattice oxygen

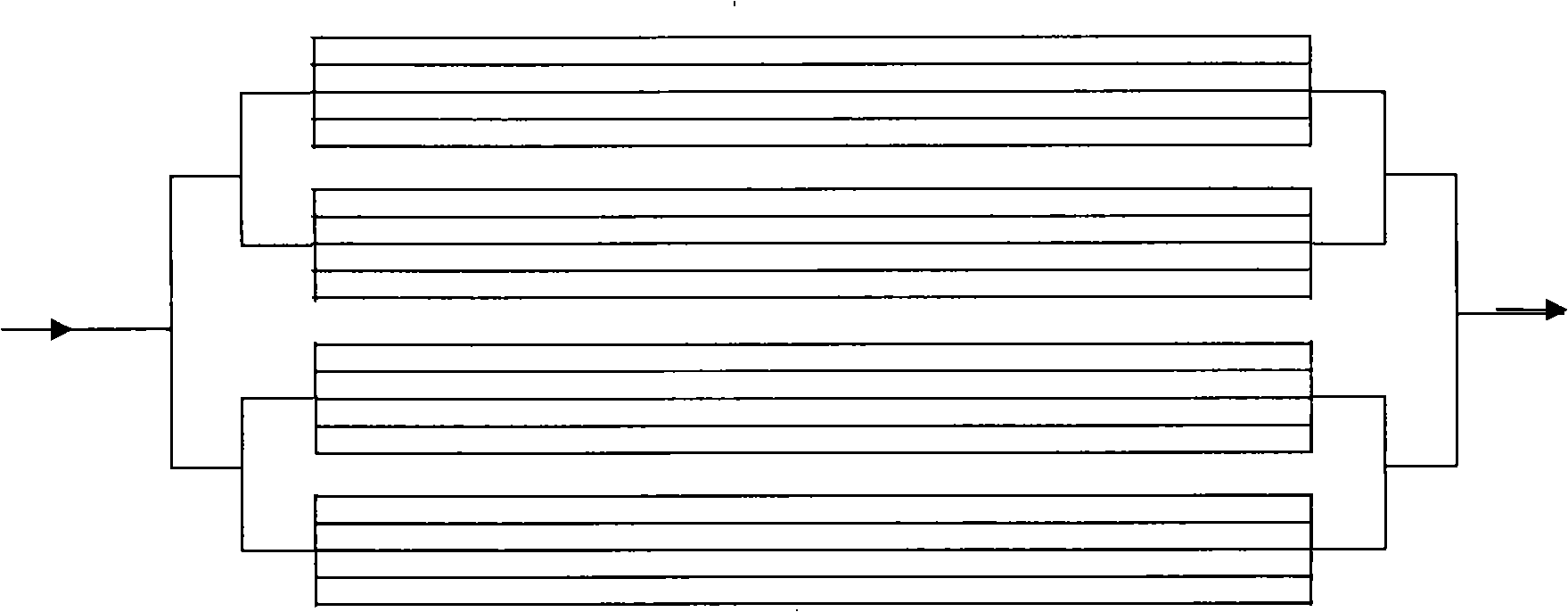

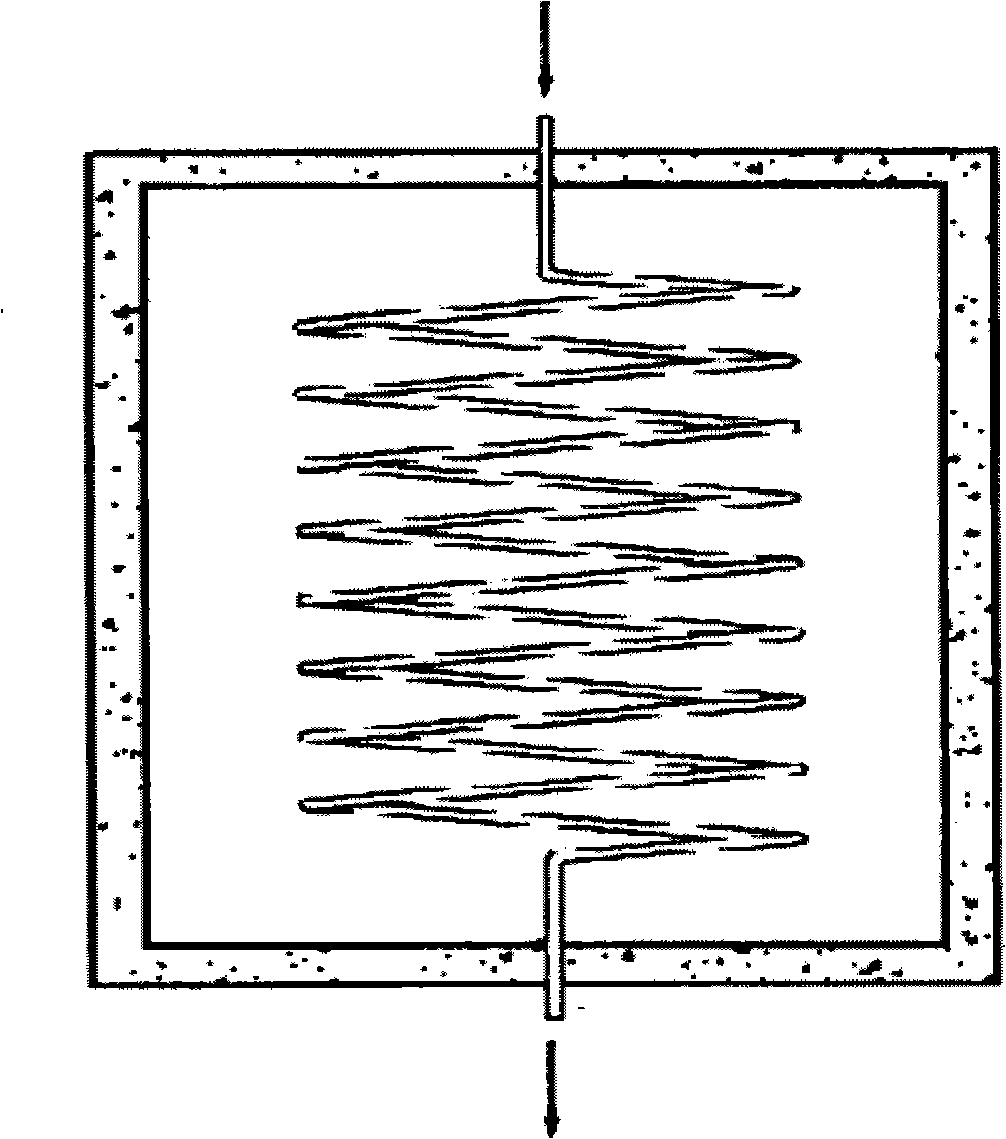

The invention discloses a method for producing butadiene by oxidatively dehydrogenating butane and a used catalyst. The method comprises the following steps of using product gas heat and reaction heat to exchange heat with raw material butene, water, oxygen or air, and then catalytically converting on a fixed bed to effectively prepare butadiene. The invention in particular relates to an alpha-Fe2O3, ZnFe2O4 composite oxide lattice oxygen catalyst. The raw material gas preheated to a certain temperature is heated to the temperature for reaction by adopting the sensible heat of the reaction product gas, the temperature of the reactor is controlled by steam heat-exchange, the raw material gas is heated by the sensible heat of the product gas and the stable operation of the reactor is realized, the oxidatively dehydrogenated rough butadiene logistics generated gas is separated through the processes of compression, oil-absorption and de-absorption, and extractive distillation of a butadiene solvent so as to efficiently, continuously and stably prepare the butadiene product, the once through yield of the butadiene is more than 80%.

Owner:CHINA PETROLEUM & CHEM CORP

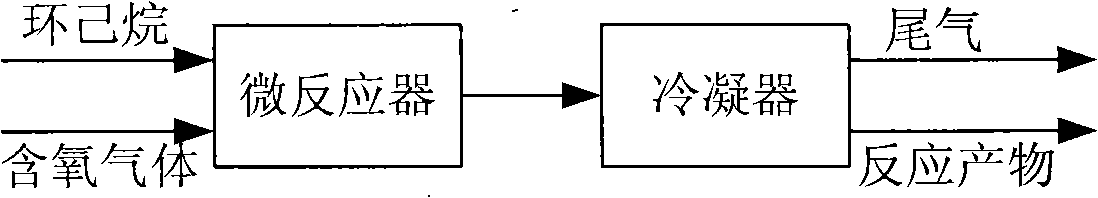

Liquid-phase oxidation method for cyclohexane

ActiveCN101293810AIncreased reaction rate and heat transfer rateIncrease speedOrganic compound preparationPreparation by hydrogenationCyclohexanoneCyclohexanol

A liquid-phase oxidation method of cyclohexane is provided. The oxidation method is characterized in that the method comprises carrying out reaction of molecular oxygen-containing gas and cyclohexane at a mole ratio of (0.1-10):1 in a micro-reactor under 0.8-2.5MPa at 145-200 DEG C for 0.5-30min. The micro-reactor is a micro-channel reactor or a micro-tube reactor. The method ensures safety and enhances heat transfer, and can remarkably improve the oxidizing reaction speed of cyclohexane and the total selectivity of cyclohexanone, cyclohexanol and cyclohexyl hydrogen peroxide.

Owner:CHINA PETROLEUM & CHEM CORP +1

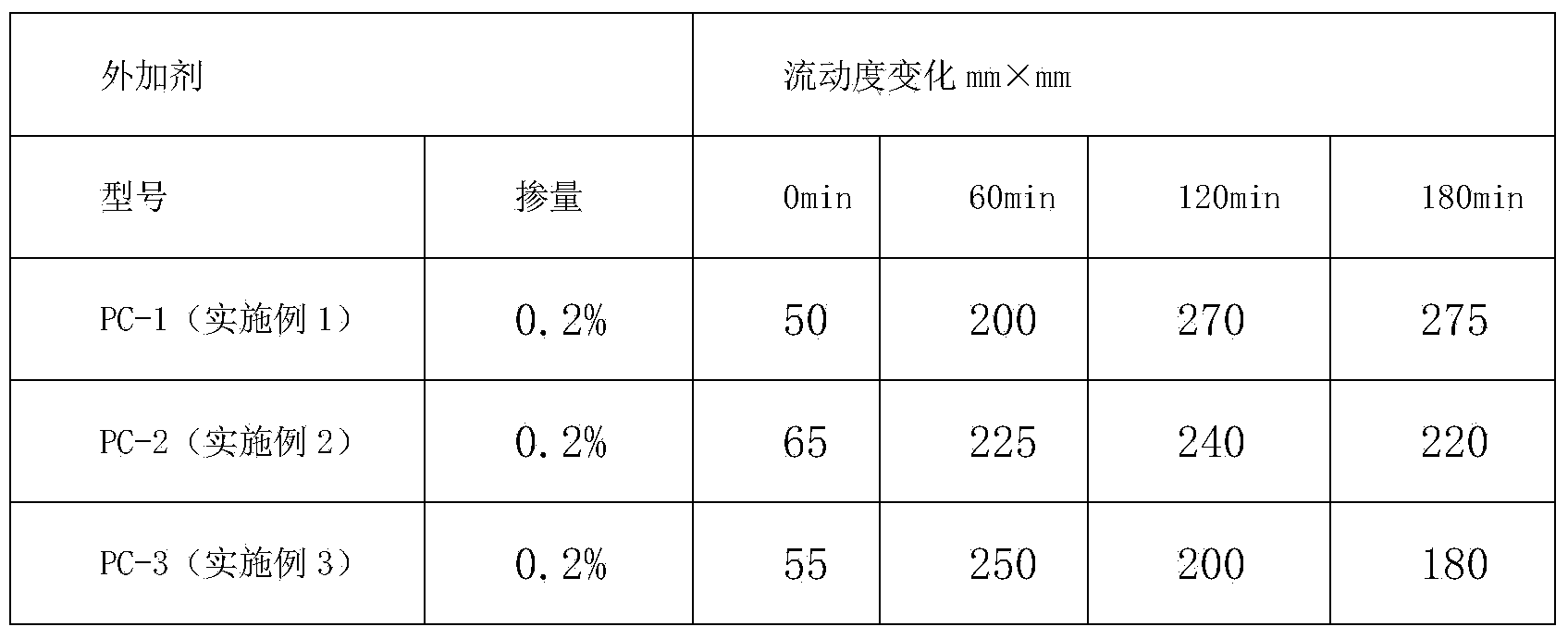

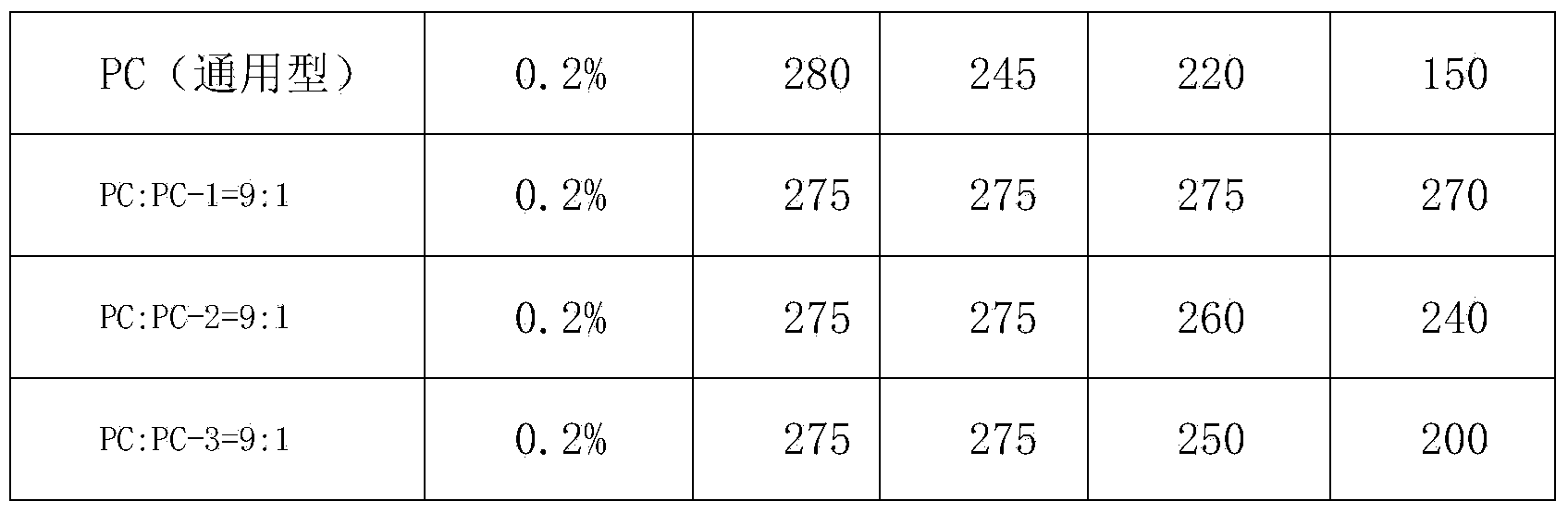

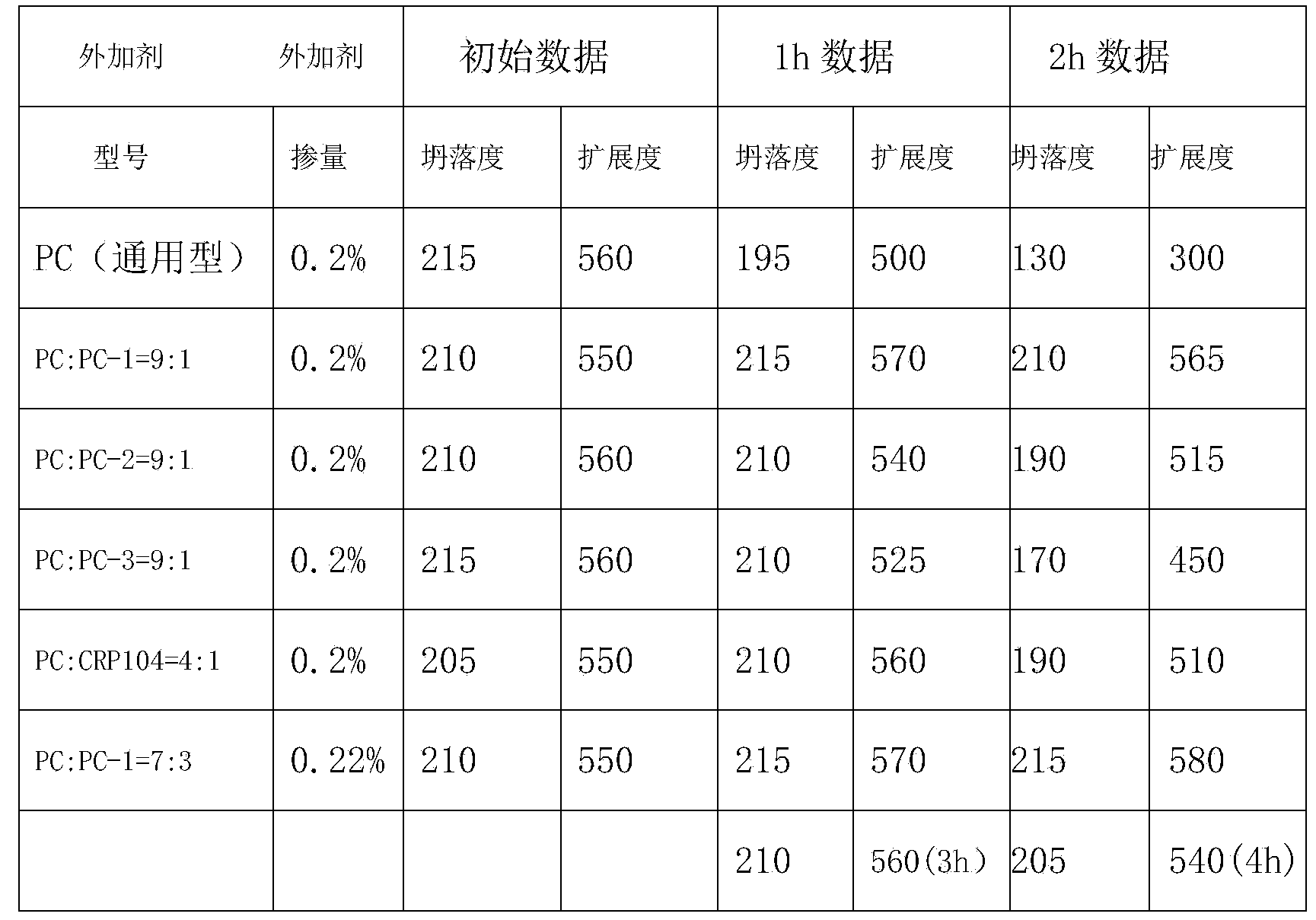

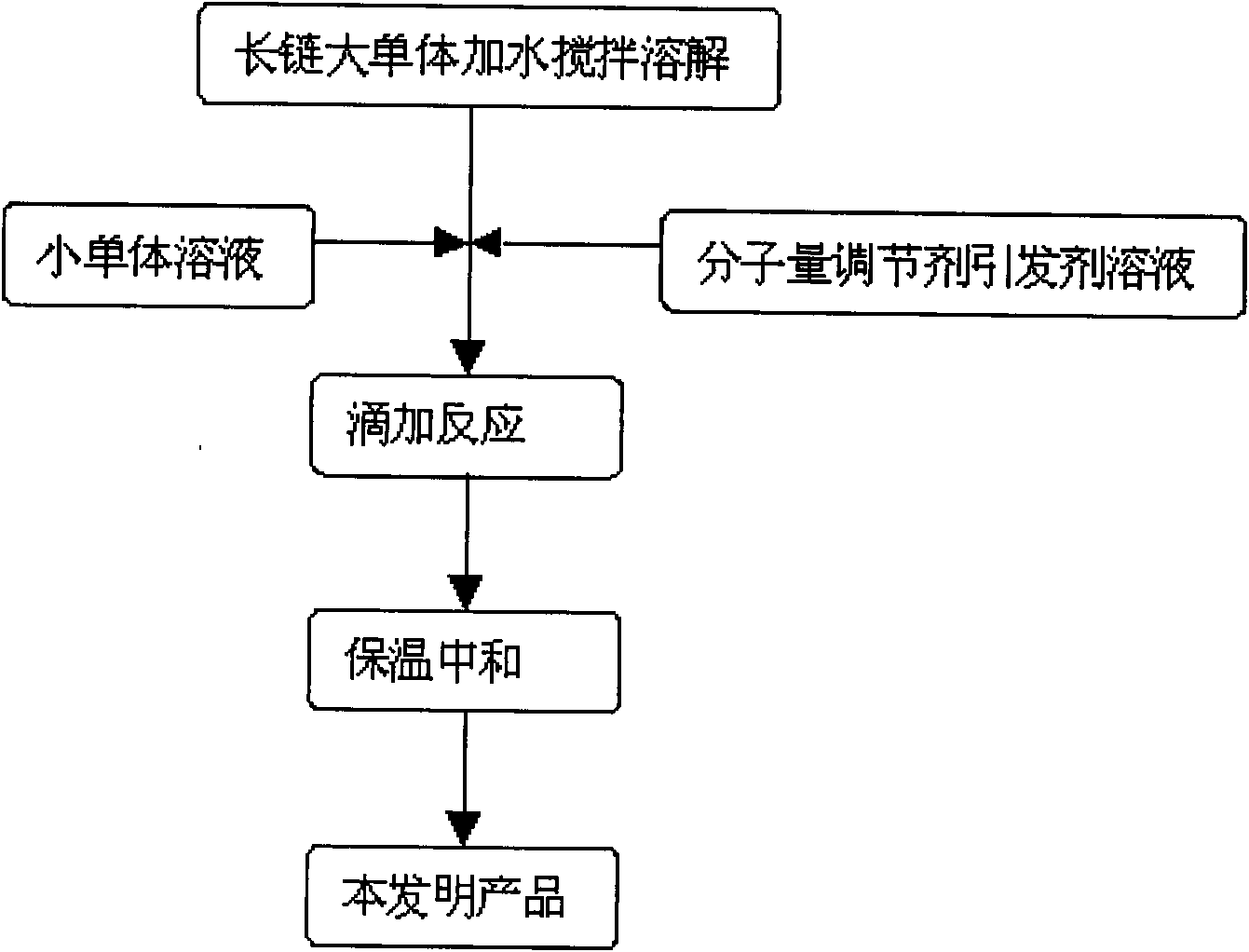

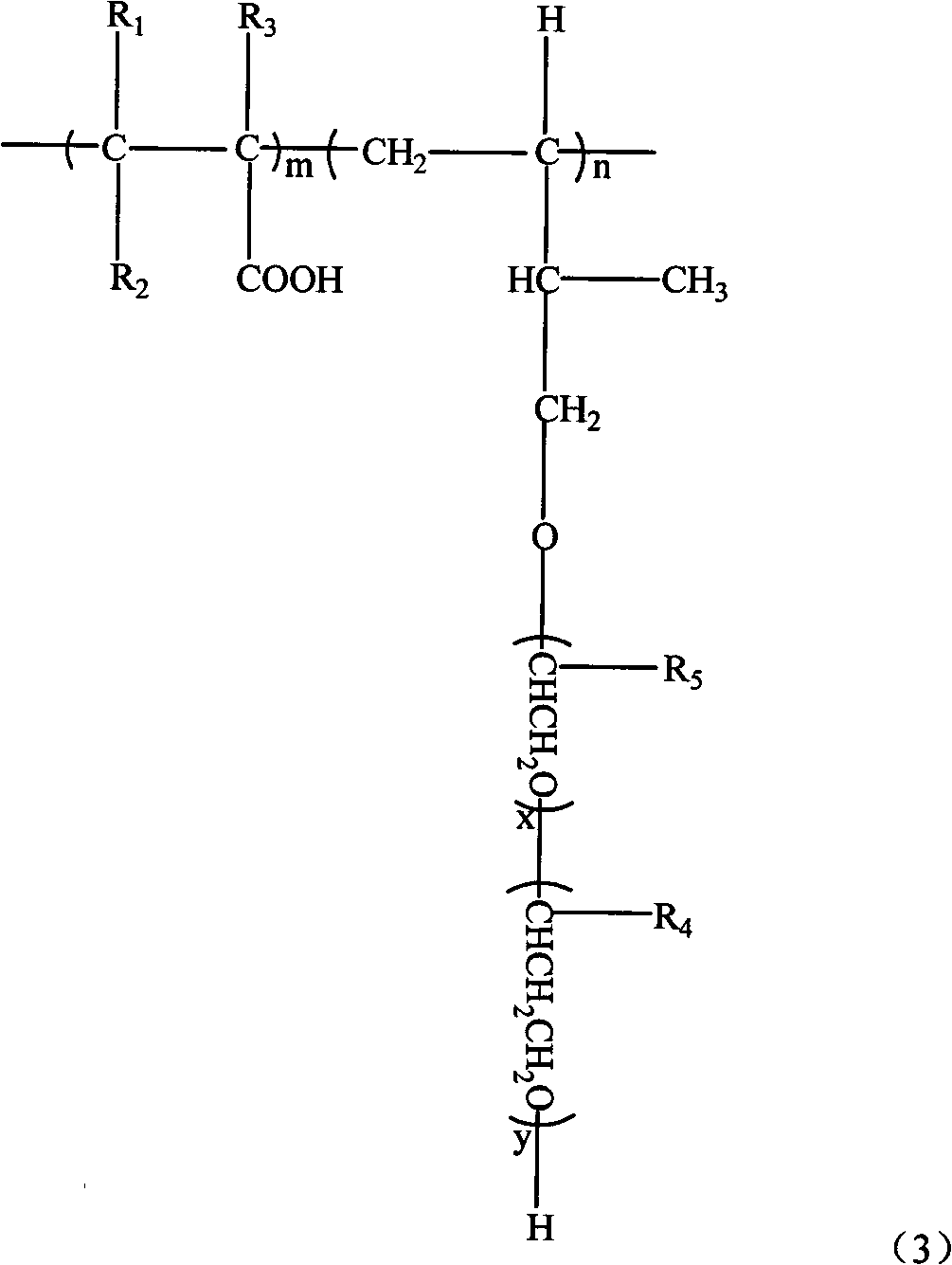

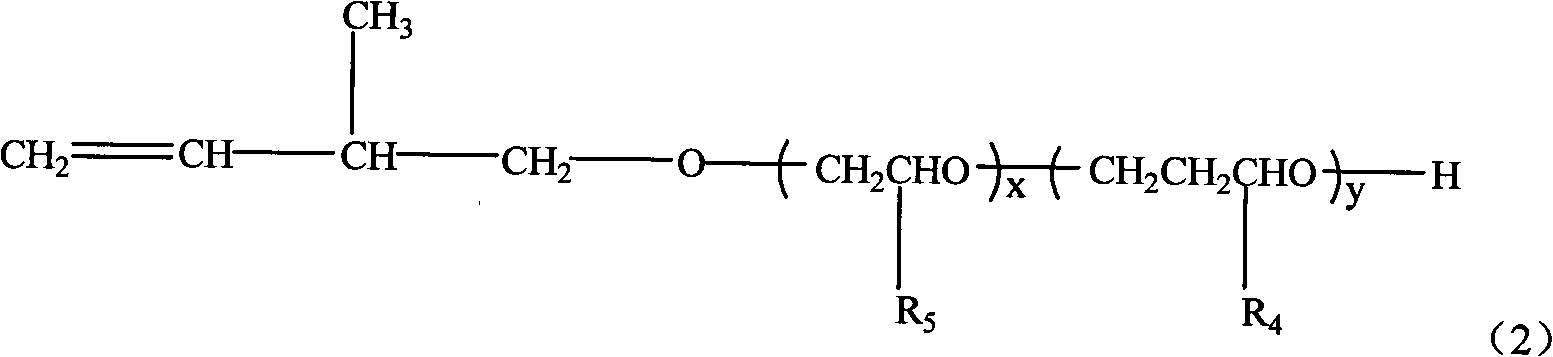

Super controlled release type polycarboxylate slump retention agent and preparation method thereof

The invention discloses a super controlled release type polycarboxylate slump retention agent and a preparation method thereof. The preparation method of the polycarboxylate slump retention agent comprises the following steps: carrying out free radical polymerization on a monomer A, namely polyoxyethylene ether (TPEG), a monomer B, namely maleic anhydride or polyethylene glycol maleic acid esters, a monomer C, namely acrylic acid, a monomer D, namely hydroxyalkyl acrylate or vinyl acetate, an initiator, a chain transfer agent and water, adding an alkaline liquor to neutralize the mixture, wherein a molar ratio of the monomer A to the monomer B to the monomer C to the monomer D is 1 to (1.0-2.5) to (1.0-2.5) to (2.0-4); the dosage of the initiator accounts for 1%-8% of the total mole number of the monomer A, the monomer B, the monomer C and the monomer D; the dosage of the chain transfer agent is 1%-3% of the total mole number of the monomer A, the monomer B, the monomer C and the monomer D. The super controlled release type polycarboxylate slump retention agent disclosed by the invention is in a liquid state, has solid content of 50%, and has performances of low alkaline content, a low water-reducing rate and excellent slump retention performance. Besides, the production process is simple, the reaction conditions are easy to control, and the environmental pollution is avoided.

Owner:YUEYANG ORIENTAL YUHONG WATERPROOF TECH +1

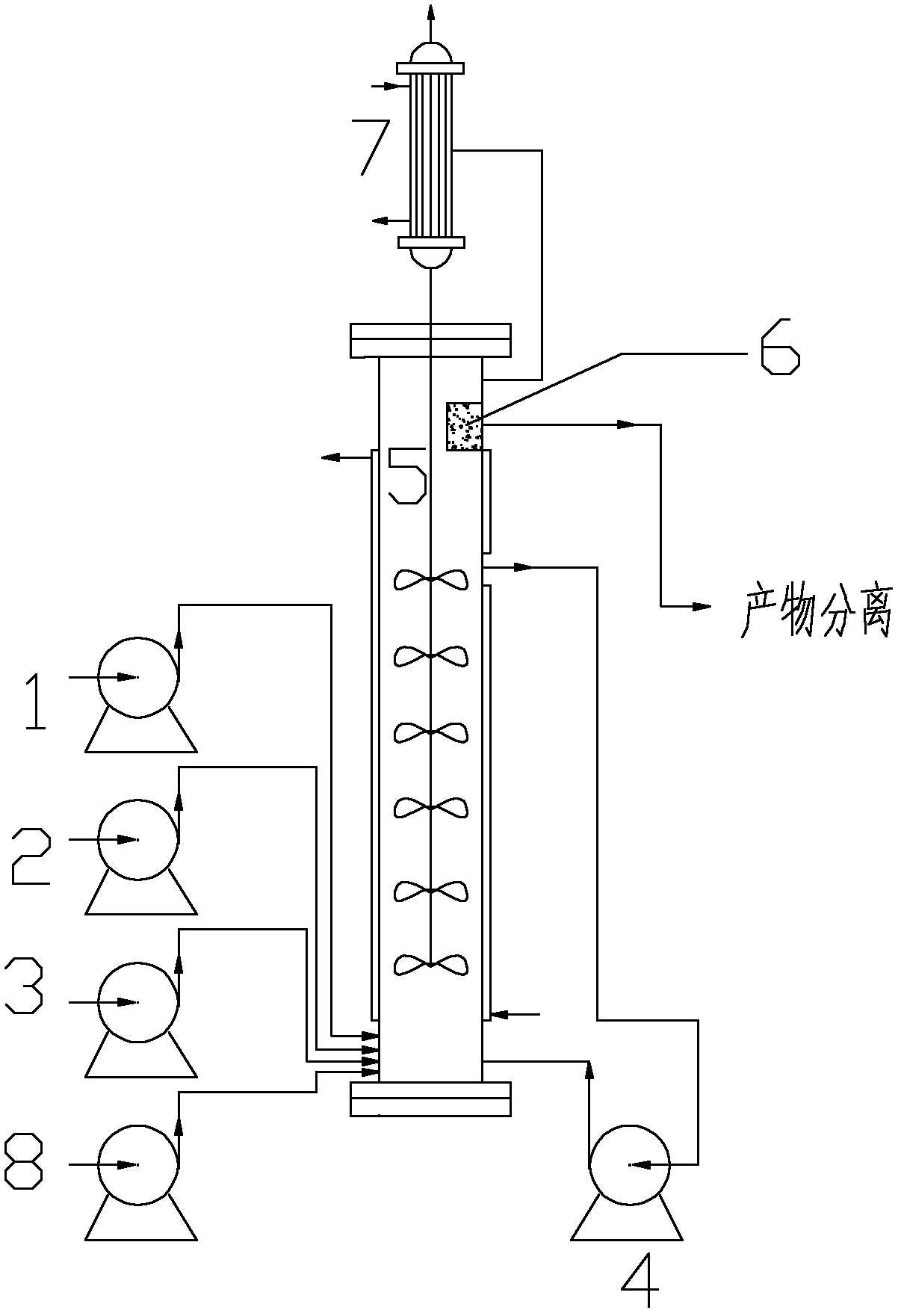

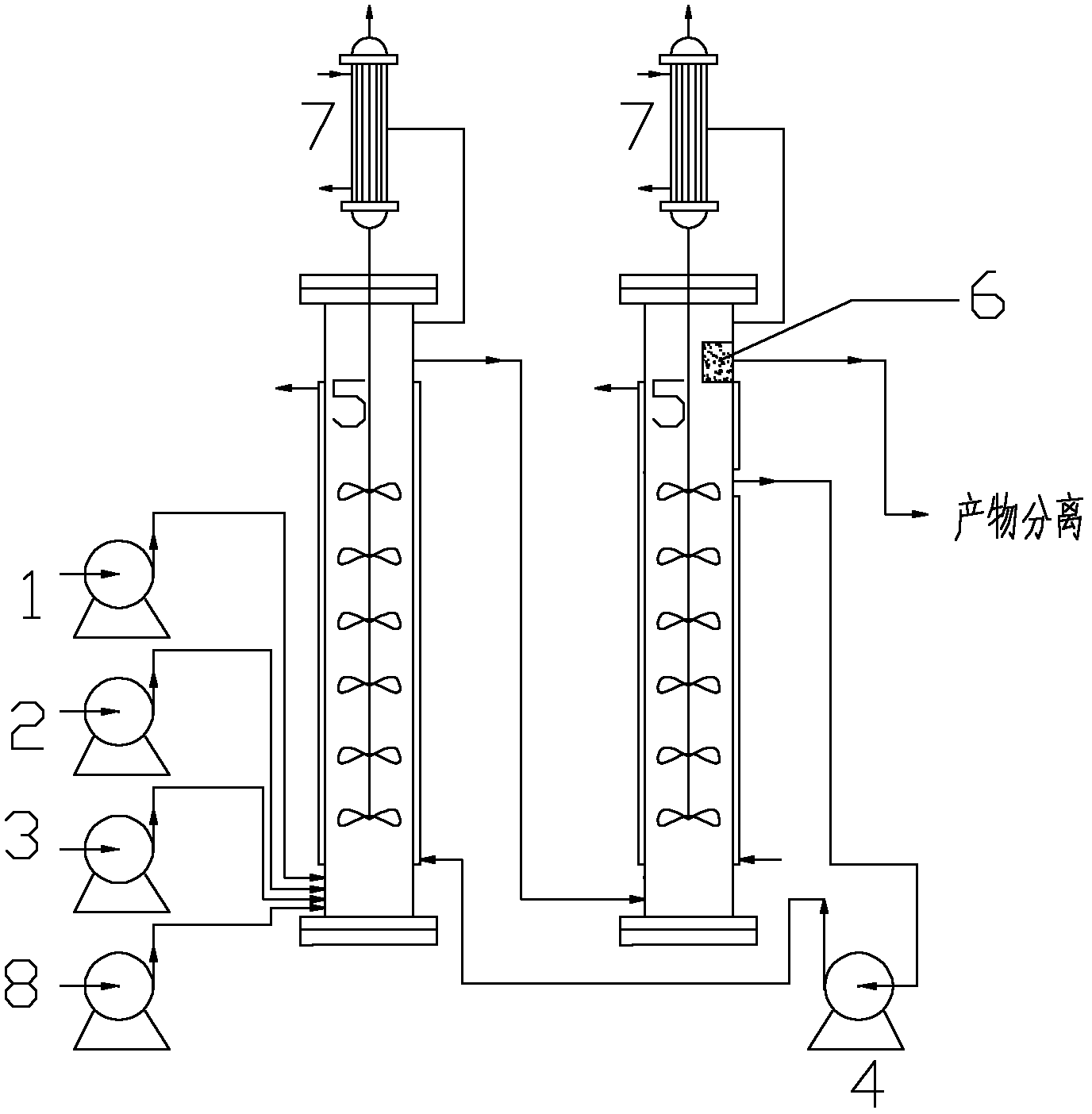

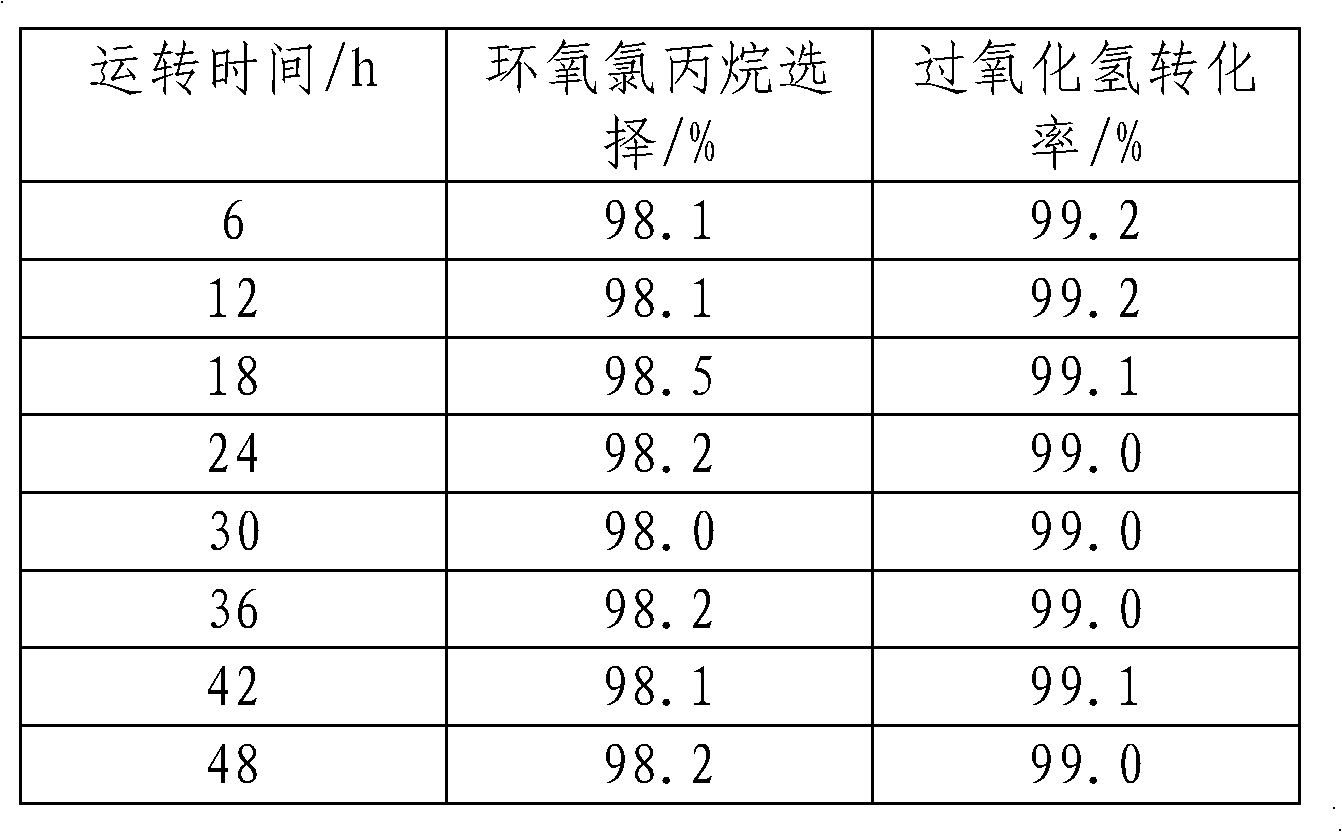

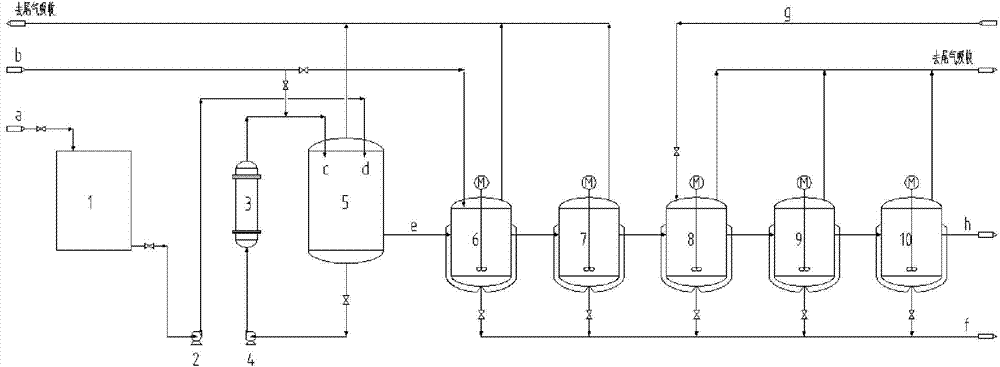

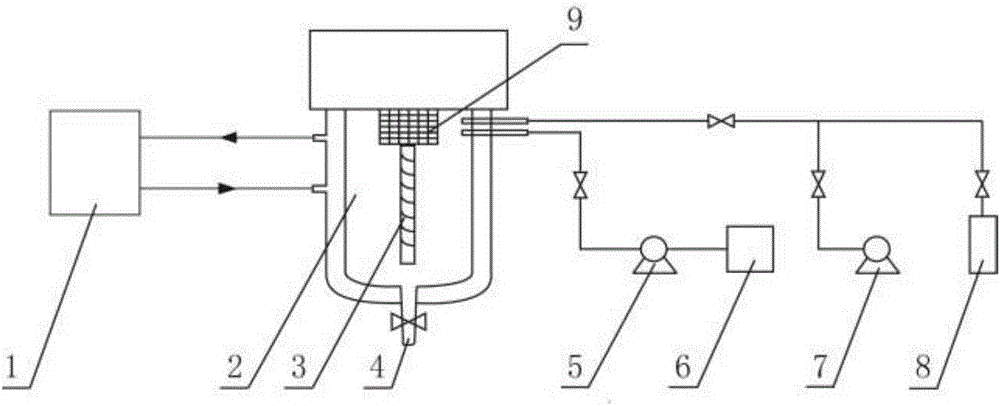

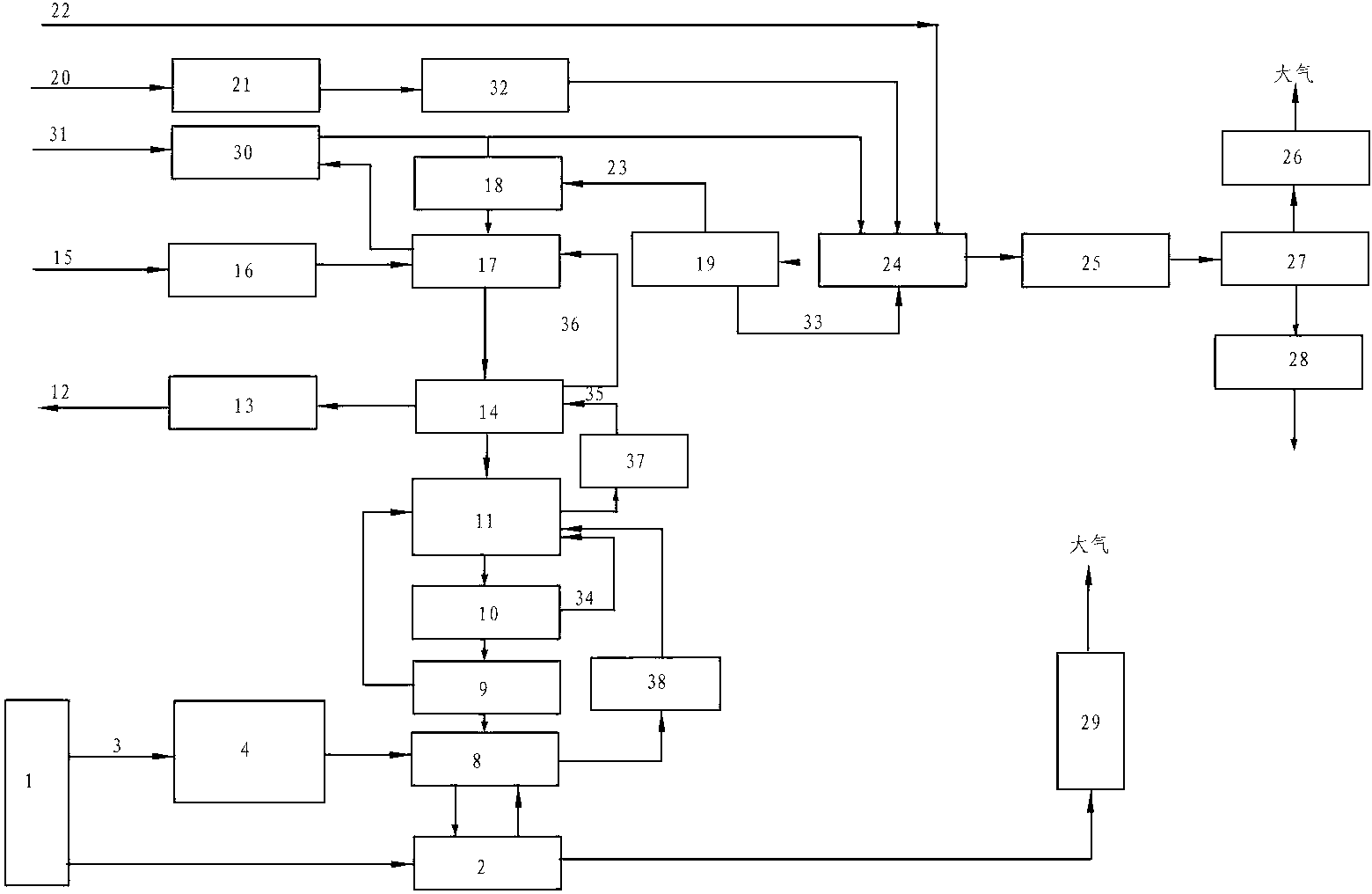

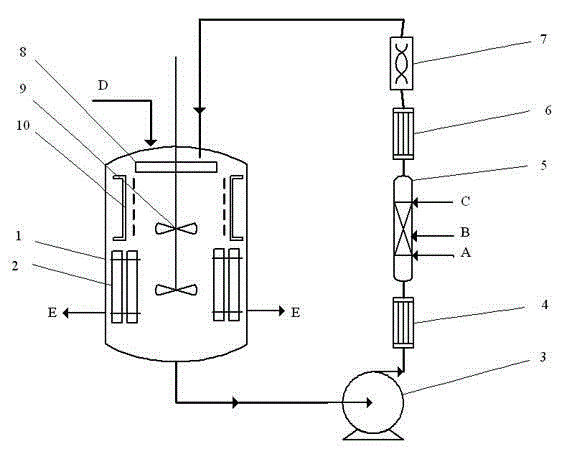

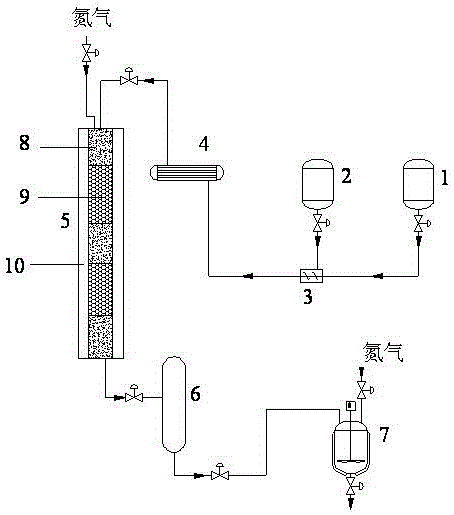

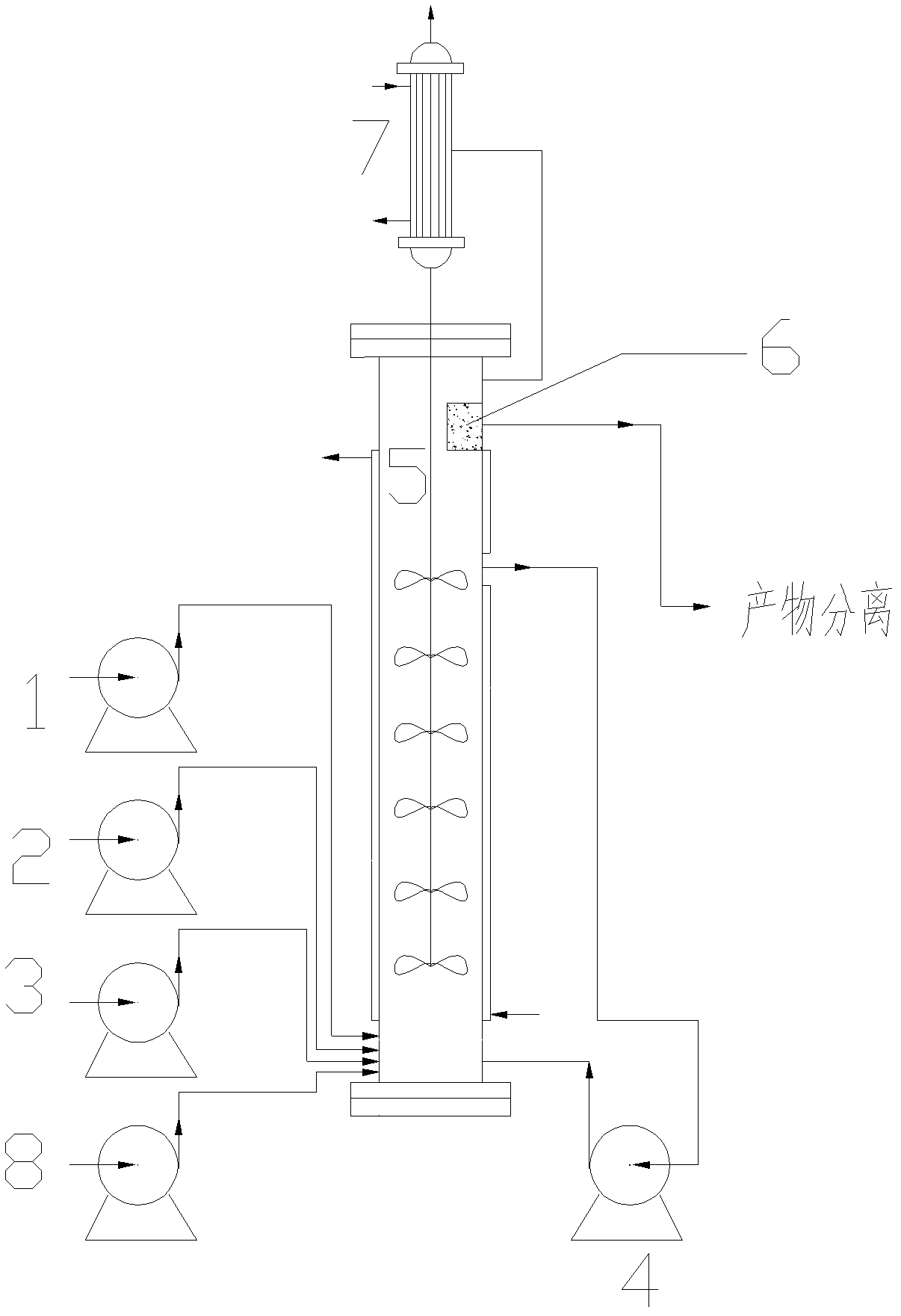

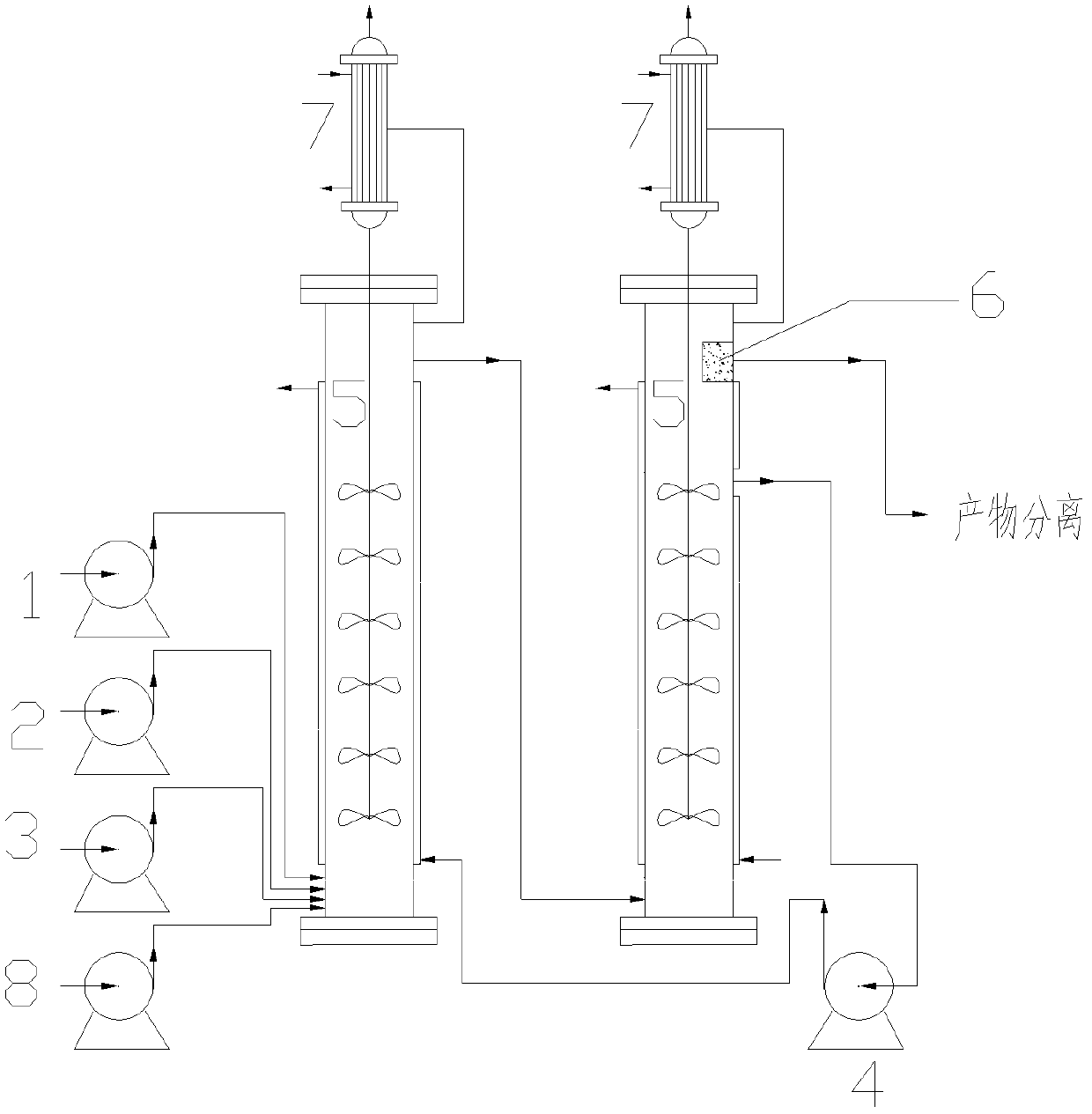

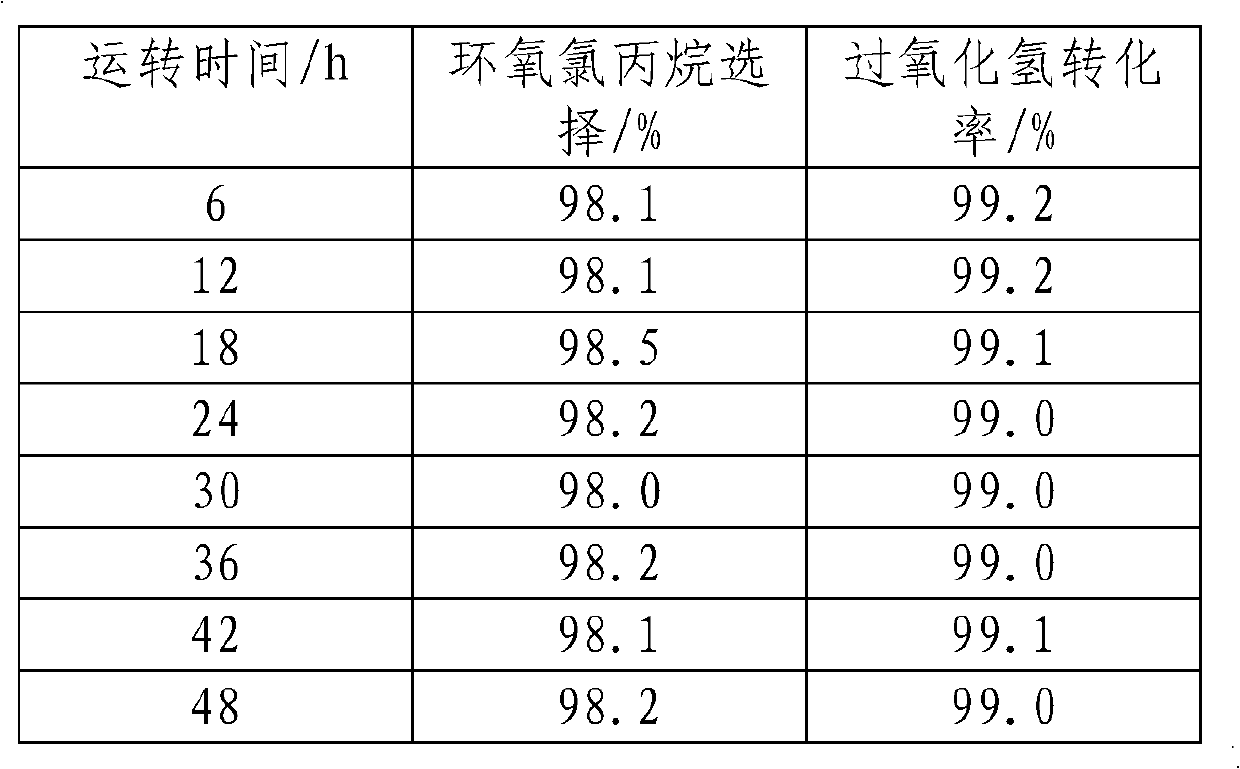

Method of continuously producing epichlorohydrin by directly epoxidizing chloropropene

ActiveCN103159703AStable reaction temperatureSimple processOrganic chemistryChemical recyclingRefluxReaction temperature

The invention discloses a method of continuously producing epichlorohydrin by directly epoxidizing chloropropene. The method of continuously producing epichlorohydrin by directly epoxidizing chloropropene includes: respectively transporting chloropropene, hydrogen peroxide, catalyst slurry or / and solvent to a reactor through a metering pump, the reactor is a single reactor or multistage reactors which are connected in series, reaction pressure is 0.1 to 1.0 MPa, and reaction liquid is in a homogeneous phrase state or a non-homogeneous phrase state. A filter is arranged at the upper end of a discharge port in the reactor to extract liquor with products, materials which are arranged at the lower end of the filter, are not filtered, contain catalyst and are not completely reacted is transported to the reactor through the metering pump which is arranged at the lower end of the reactor, the catalyst is free from recycling the catalyst in the continuous production process, and gaseous phrase portion conducts condensation reflux through a condenser which is arranged at the top of the reactor. The method of continuously producing epichlorohydrin by directly epoxidizing chloropropene has the advantages of being stable in reaction temperature and simple in process flow, the catalyst is free from being separated, beaten and configured again after reaction, the hydrogen peroxide is high in effective utilization and epichlorohydrin is high in yield, and method of continuously producing epichlorohydrin by directly epoxidizing chloropropene can be used in industry production.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

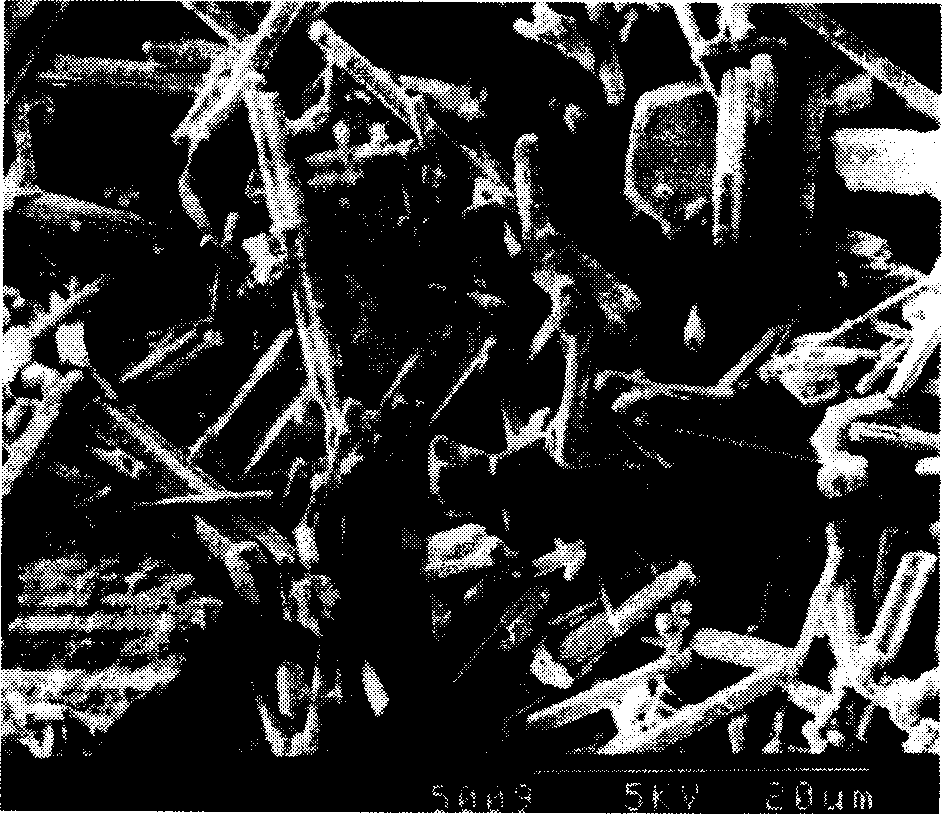

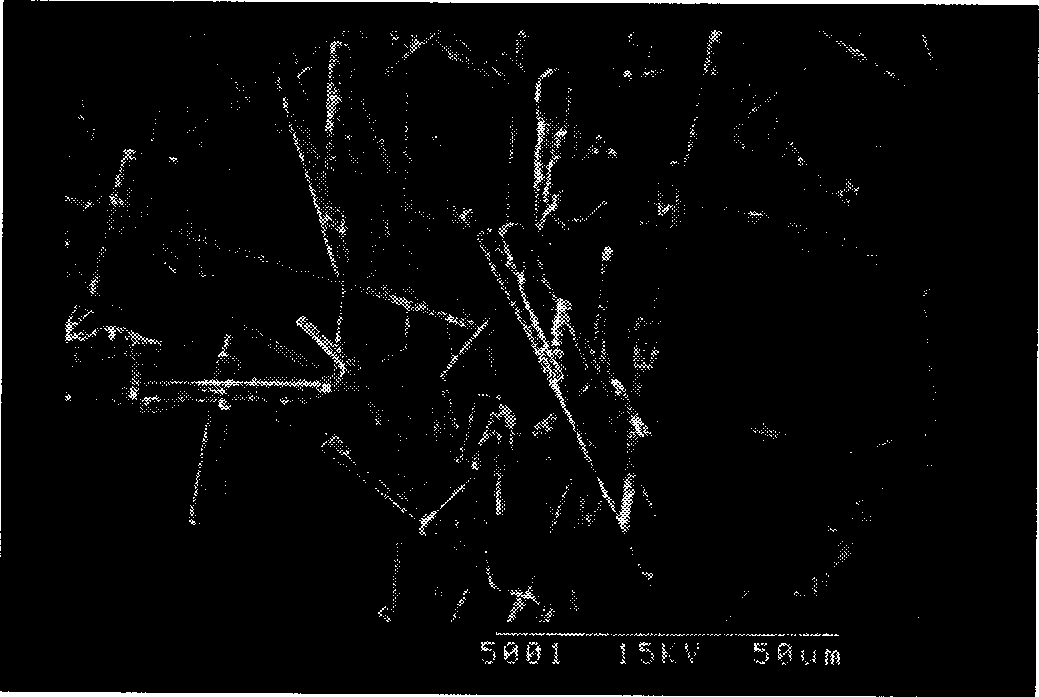

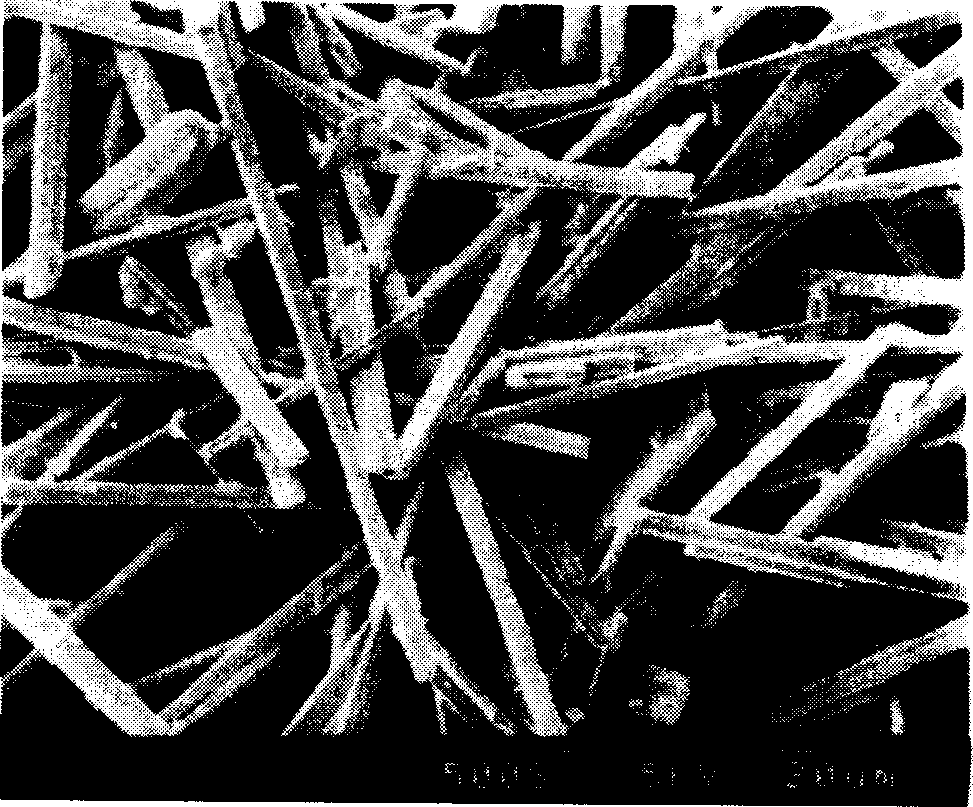

High length-diameter ratio antifungin whisker synthesis method

ActiveCN1807242AImprove qualityAvoid pollutionPolycrystalline material growthBoratesSynthesis methodsHigh-temperature corrosion

The invention relates to a process for synthesizing magnesium borate crystal whisker with high length-diameter ratio, which consists of reacting boric acid, magnesium chloride and caustic soda in water solution by right proportion to obtain boracic magnesium compound precipitate, filtering to obtain precursor for magnesium borate crystal whisker production, then mixing fluxing agent comprising NaCl or NaCl and KCl with the precursor, charging menthol, ethanol, water or their mixed solution, immersing, agitating and mixing, subjecting the mixture to high temperature reaction at 500-900 deg C for 5-10 hours, cooling down, washing with water, and finally drying.

Owner:青海中信国安科技发展有限公司 +1

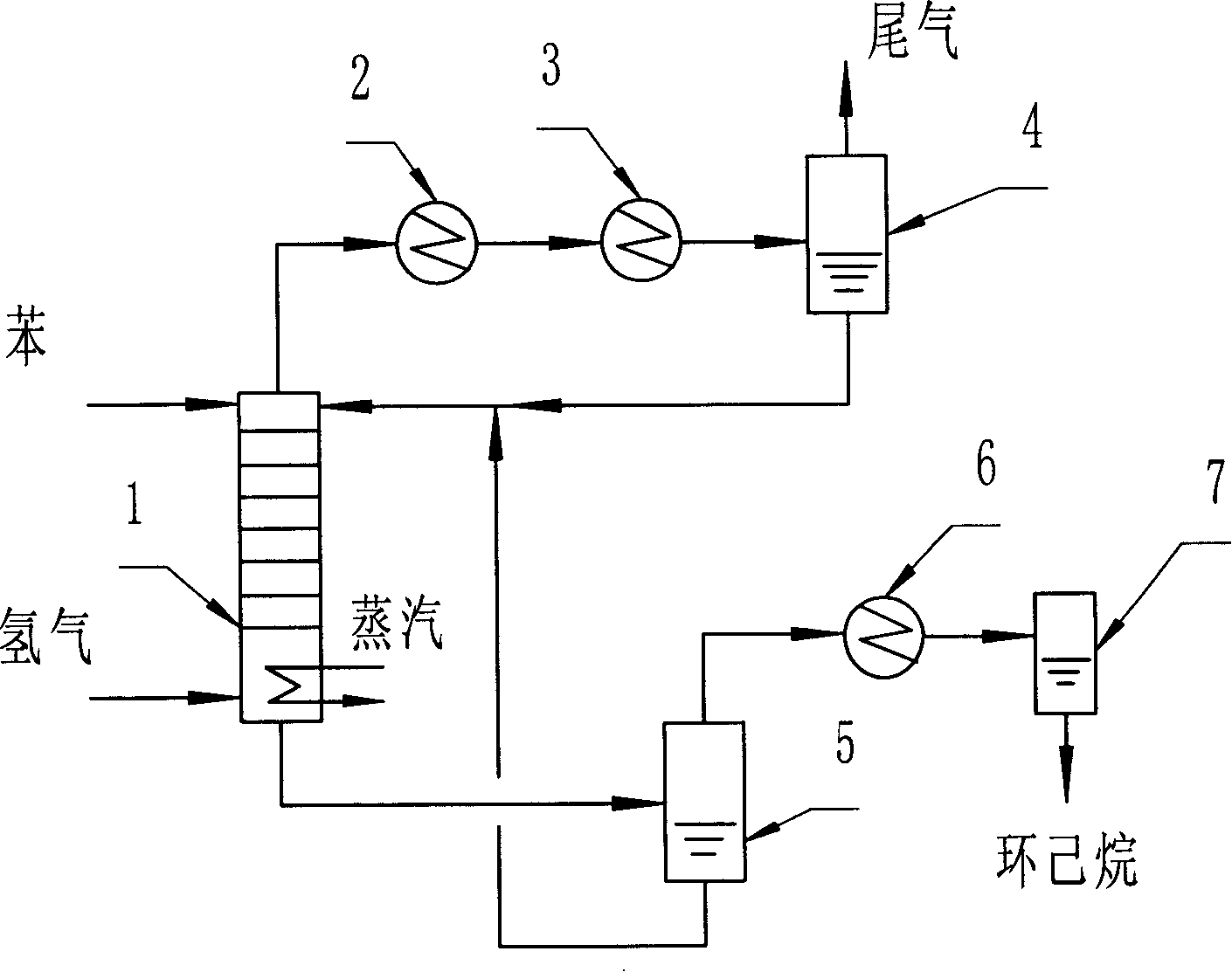

Preparation method of cyclohexane

ActiveCN101205163ASolve the problem of heat transferStable reaction temperatureHydrocarbon by hydrogenationBenzeneHydrogen

A method for preparing a cyclohexane comprises the following steps: a benzene and a hydrogenation catalyst are driven to enter a distillation tower from the tower top and the hydrogen goes into the distillation tower from the tower bottom; the tower bottom is heated by the steam and a reaction in which the benzene hydrogenation is used for generating the cyclohexane is conducted in the tower; the condensate at the tower top refluxes and the discharged materials from the tower bottom are subject to the flash separation so as to obtain the cyclohexane. The method of the invention can lower the content of the methyl cyclopentane in the products and is beneficial to the stabilized operation and the enhancement of the hydrogen utilization ratio and the effective reaction volume of the tower.

Owner:CHINA PETROLEUM & CHEM CORP +1

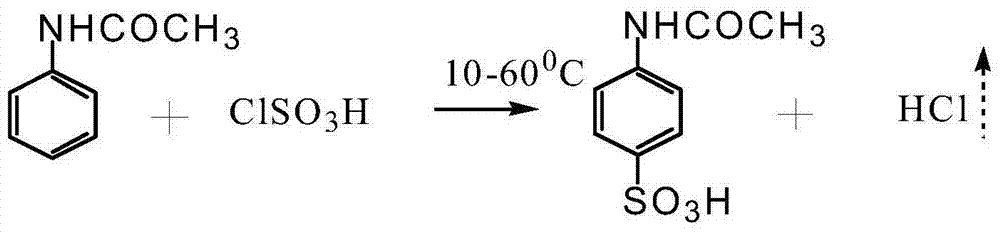

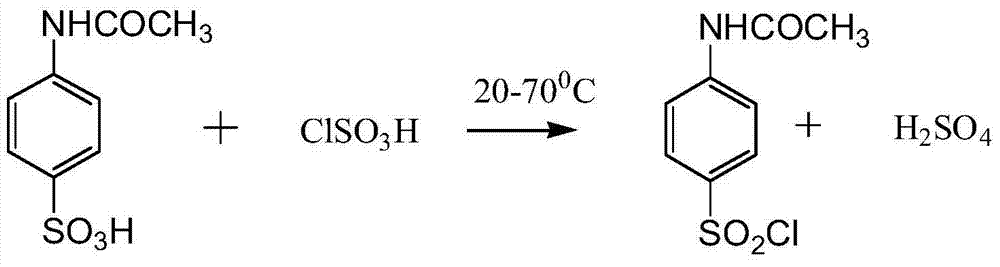

Continuous sulfonating process for synthesizing p-aminophenyl-beta-hydroxyethyl sulfone sulphate

ActiveCN104496866AImprove conversion rateThe reaction temperature is easy to controlSulfonic acid preparationMolten stateChlorosulfuric acid

The invention discloses a continuous sulfonating process for synthesizing p-aminophenyl-beta-hydroxyethyl sulfone sulphate. The process comprises the steps: performing reaction on chlorosulfonic acid and acetanilide which serve as raw materials; respectively atomizing chlorosulfonic acid and molten-state acetanilide and contacting with each other during feeding to perform reaction. According to the continuous sulfonating process for synthesizing p-aminophenyl-beta-hydroxyethyl sulfone sulphate, the molten-state acetanilide is used as a raw material, and the reaction on the acetanilide in an atomizing state and chlorosulfonic acid which is also in an atomizing state are carried out and the reaction temperature is easily controlled, so that the production of byproducts such as parachloroaniline is avoided, and the conversion rate of acetanilide serving as a raw material is high. The process is convenient to operate, short in production period, controllable in reaction process, less in labor demands, low in cost and easy for industrial production.

Owner:ZHEJIANG QICAI ECO TECH CO LTD

Technology of transforming common magnesium hydrexide into hexagonal sheel shaped magnesium hydroxide by hydrothermal method

ActiveCN1830788AImprove conversion rateImprove product qualityMagnesium hydroxideLithium hydroxidePotassium hydroxide

A process for preparing hexagonal flake type magnesium hydroxide from ordinary one by dydrothermal method includes such steps as proportionally mixing ordinary magnesium hydroxide with lithium hydroxide and / or potassium hydroxide, or their mixture with sodium hydroxide, stirring, hydrothermal reaction at 140-200 deg.C for 2-6 hr, cooling, filtering, washing, drying, and pulverizing.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

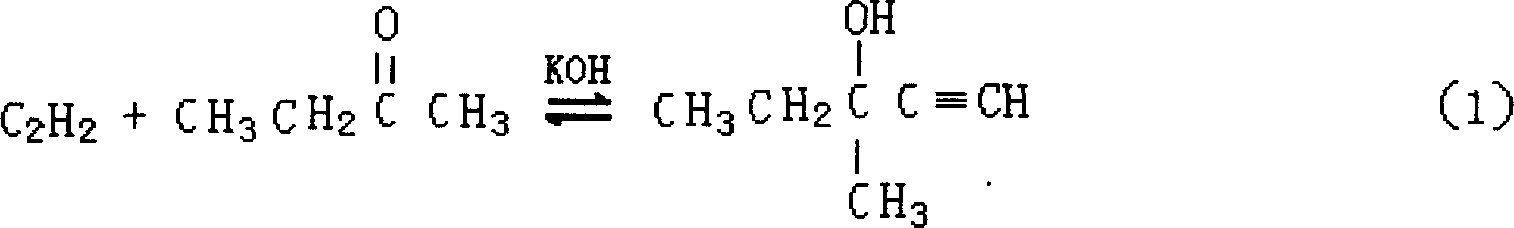

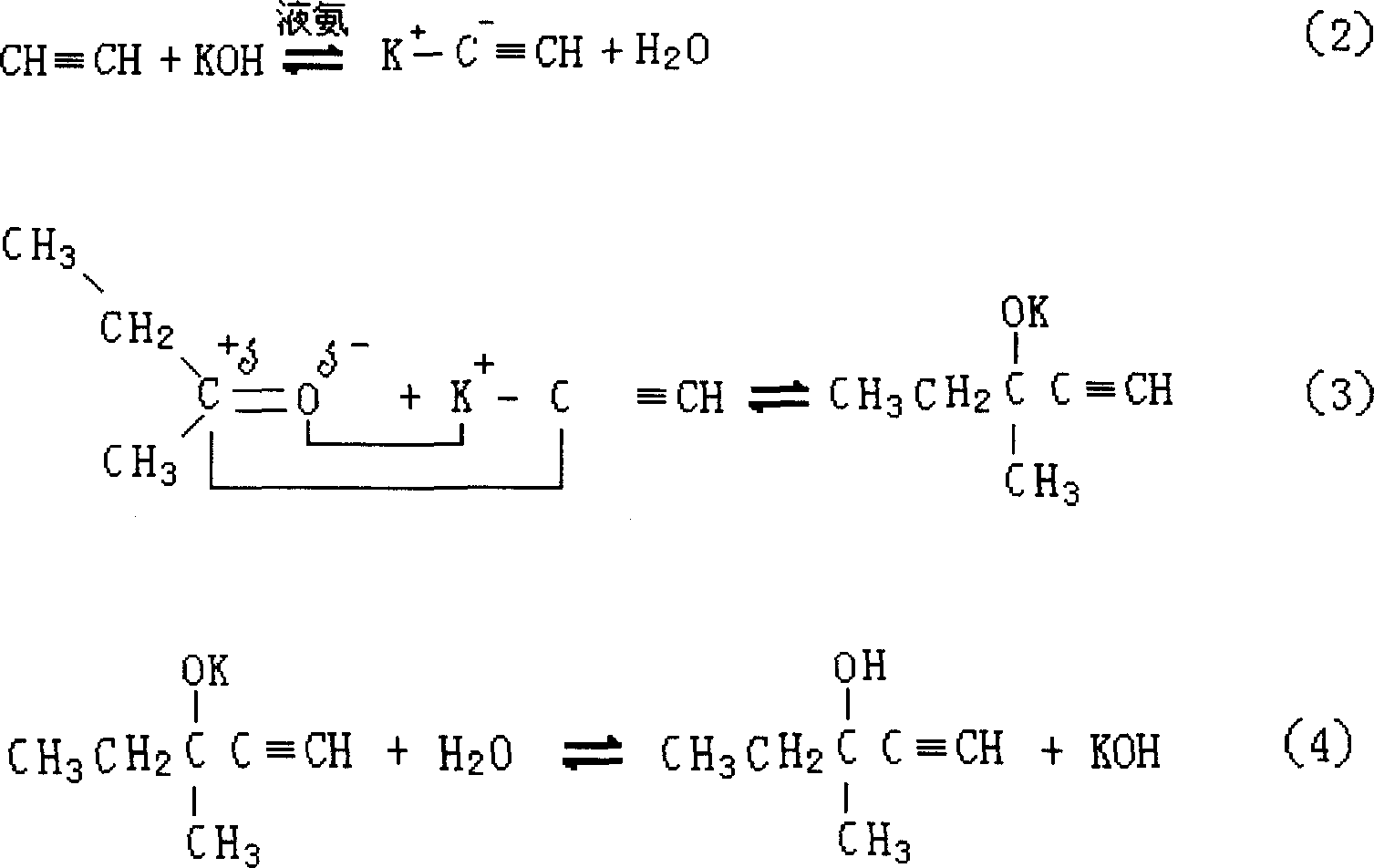

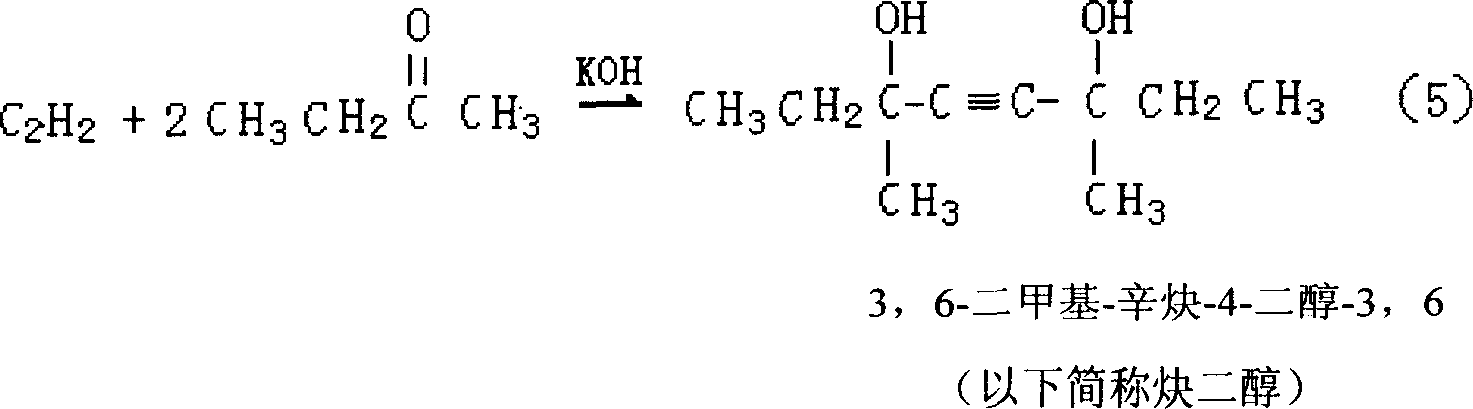

Method for synthesizing alkynol by ketone and acetylene

ActiveCN1765862AGood dispersionImprove efficiencyOrganic compound preparationHydroxy compound preparationDispersityPotassium hydroxide

The invention relates to a method to compose alkynol by ketone and acetylene, which comprises: adding the ketone and catalyst of caustic potash solution into reaction system with mole ratio as 0.15~0.30. The catalyst has well dispersity and high efficient as well as recycle to reduce cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

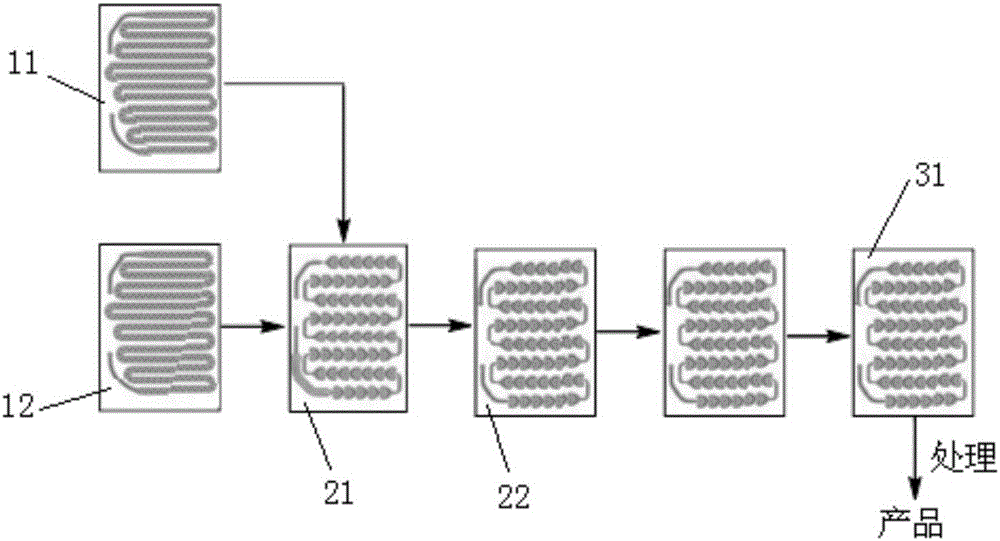

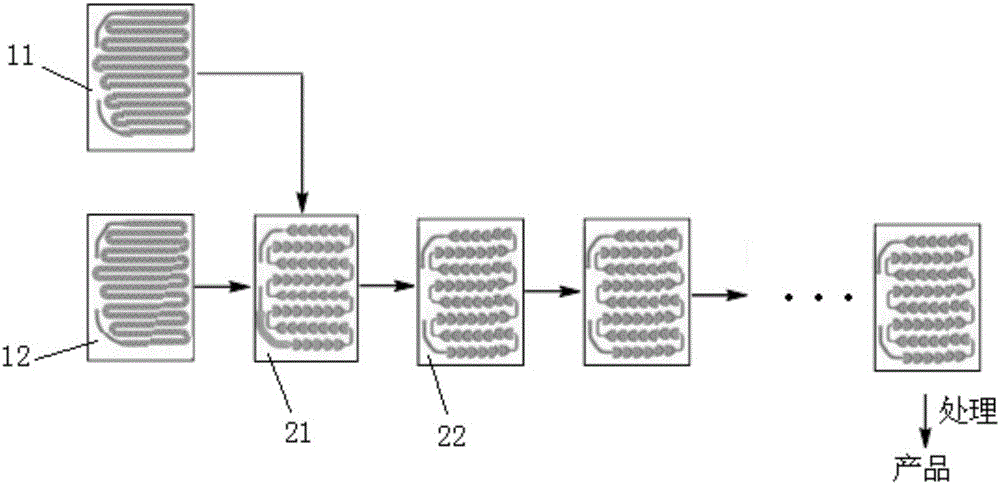

Narrow-distribution middle-low-molecular-weight sodium polyacrylate preparation method

InactiveCN103497267AGood cooling effectStable reaction temperature and reaction timeSodium polyacrylateChemistry

The invention discloses a narrow-distribution middle-low-molecular-weight sodium polyacrylate preparation method. According to the method, materials are uniformly mixed under normal temperature, and the mixture is subjected to polymerization in a tubular reactor. Through the adjustments upon material formula, reaction time, temperature, and the like, relative molecular mass and relative molecular mass distribution of the polymer are controlled, such that a product satisfies the following performance indicators: (1) product solid content is higher than 45%; (2) product relative molecular mass distribution coefficient is lower than 2.0; and (3) product relative molecular mass is precisely controllable. With the technology, a series of water-soluble dispersing agent products with precise grading and with relative molecular mass of hundreds to tens of thousands can be produced according to the requirements of different industries. According to the technology, water solution polymerization is adopted, cost is low, and the method is environment-friendly. The method has wide application prospect in the fields such as industrial cooling water, sewage treatment, textile printing and dyeing, papermaking, and the like.

Owner:NANJING UNIV OF SCI & TECH

Method for preparing porous covalent organic material by using ultra-gravity method

The invention discloses a method for preparing a porous covalent organic material by using the ultra-gravity method, and belongs to the technical field of preparation of porous covalent organic materials. The method comprises the following steps: under a high gravity field, the micromixing and mass transferring process is strengthened, materials in a cavity of a preferable over-gravity rotary bed are sucked into a rotor of the rotary bed through a rotating inner spiral pipe, and the materials are sheared by, mixed and reacted with a filler rotating at a high speed in the rotor. Compared with reaction under a normal gravity filed, the method is greatly increased in reaction rate, and shortened in reaction time; besides, as for reaction systems sensitive to air, the water-free and oxygen-free reaction condition can also be achieved without a glove box, and compared with low-dosage preparation in the glove box, the method is greater in preparation amount and higher in production efficiency.

Owner:BEIJING UNIV OF CHEM TECH

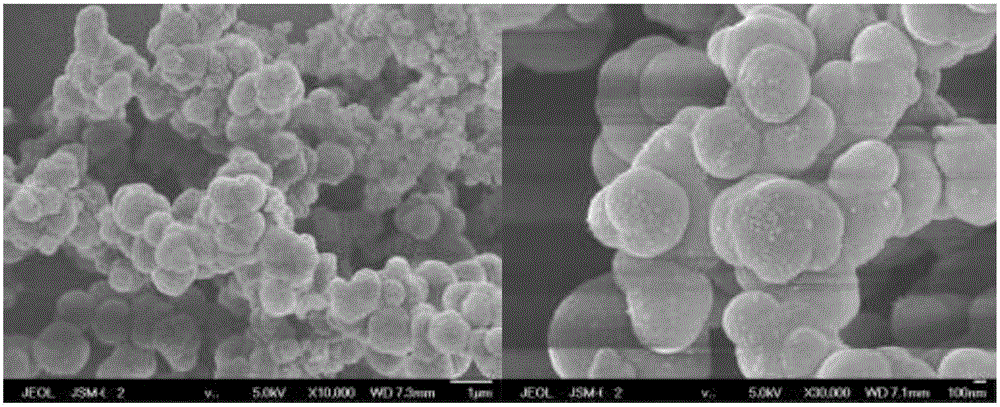

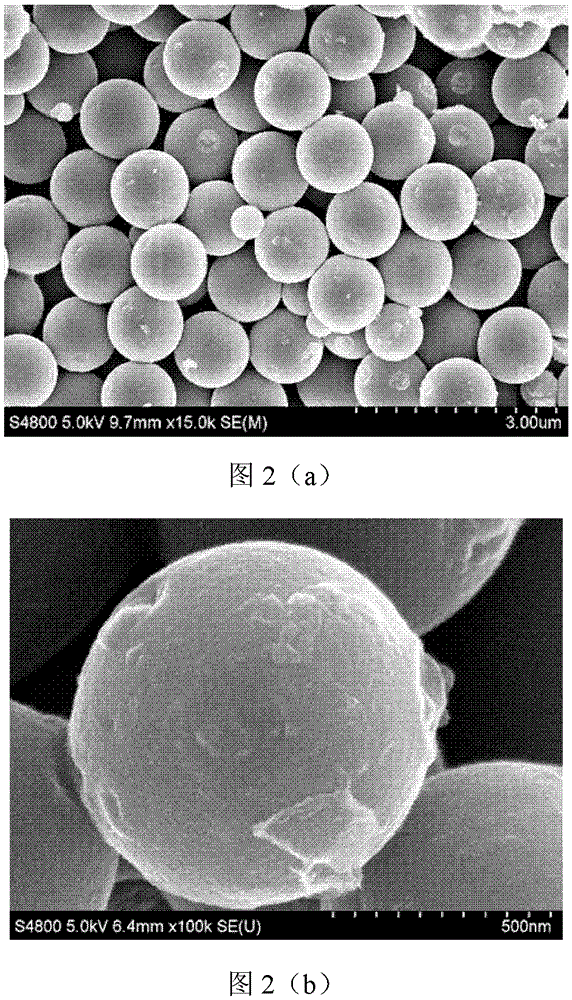

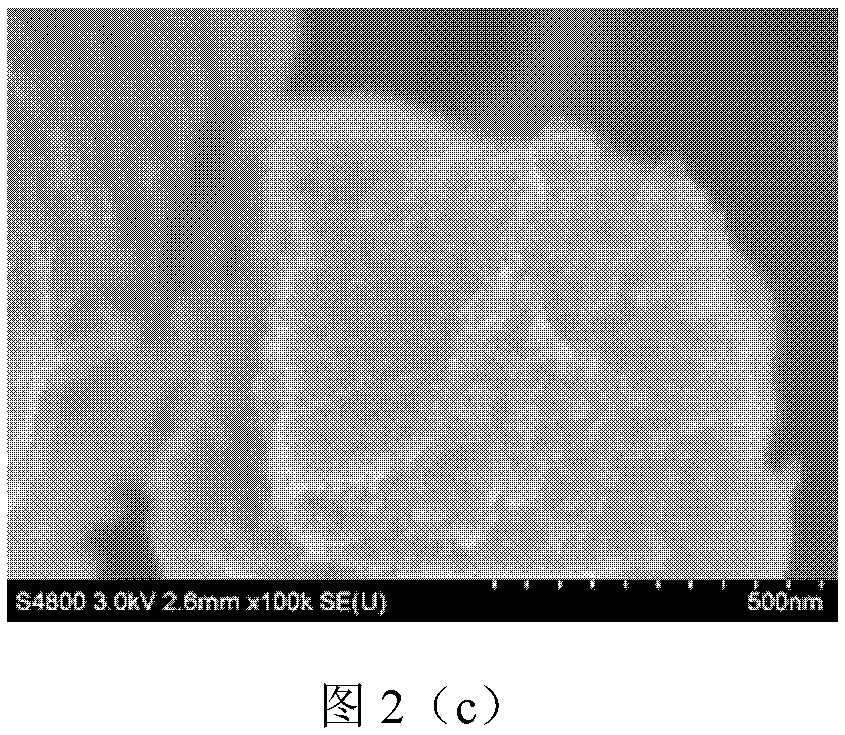

Mesopore-micropore carbon micro sphere of high specific surface area for super capacitor and preparation method of carbon micro sphere

InactiveCN105355464AHigh specific surface areaSimple preparation processHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceMicrosphere

The invention relates to a mesopore-micropore carbon micro sphere of high specific surface area for a super capacitor and a preparation method of the carbon micro sphere. A polystyrene micro sphere is prepared by using styrene as a monomer, SBA-15 as a mesopore template and ammonium polyphosphate as a multifunctional auxiliary agent; and the polystyrene micro sphere is crosslinked, carbonized and etched to obtain the polystyrene-based mesopore-micropore carbon micro sphere of the high specific surface area. The preparation method is characterized in that the ammonium polyphosphate serves as the multifunctional auxiliary agent, acid and alkali activation is not needed, and the N and P codoped mesopore-micropore carbon micro sphere of the high high specific surface area for the super capacitor can be obtained; the specific surface area of the material is 1168-1476m2 / g, the pore volume is 1.069-1.341m3 / g, and when the mesopore-micropore carbon micro sphere is used as the electrode material of the super capacitor, the specific capacitance in a water system electrolyte is 132.5-175F / g; and the mesopore-micropore carbon micro sphere is very suitable for serving as the electrode material of the super capacitor.

Owner:XIAN UNIV OF SCI & TECH

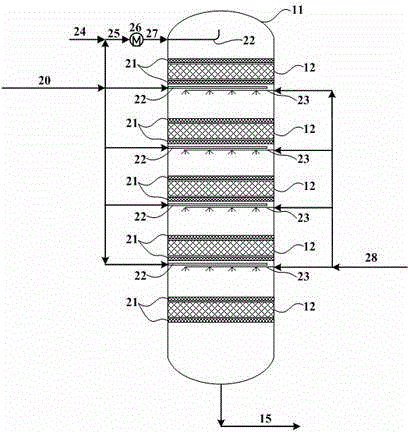

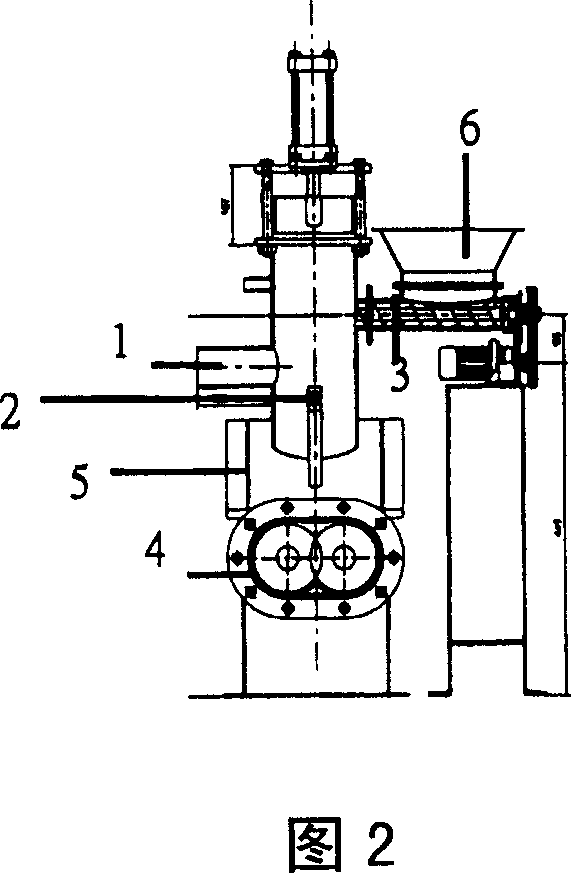

Device for preparing olefin with oxygen compounds and application of device for preparing olefin with oxygen compounds

ActiveCN104437267AEasy to controlReduce dirtHydrocarbon from oxygen organic compoundsChemical/physical/physico-chemical nozzle-type rreactorsFixed bedReaction temperature

The invention relates to a device for preparing olefin with oxygen compounds and application of device for preparing olefin with oxygen compounds, mainly solving the technical problems that a chilling liquid phase spray head device of a multistage fixed bed reactor for preparing olefin with oxygen compounds has high requirements and is easily blocked, the reaction temperature and the reaction air speed of the fixed bed reactor interact, and the utilization rate of the chilling liquid phase vaporization space is not high in the prior art. The device for preparing olefin with oxygen compounds mainly comprises catalyst bed layers (16-21), distributors (27-31) and packing layers (22-26), wherein the top layer in the device is the catalyst bed layer (16), the distributors are arranged below the catalyst bed layer (16), the packing layer (22) is arranged below the distributor (27), the catalyst bed layer (17) is arranged below the packing layer (22), and according to the arrangement way, the bottom layer in the device is the catalyst bed layer (21); and feeding holes are formed between bed layers, and the distributors are of ring-shaped pipe structures of distribution pipes. According to the technical scheme, the device for preparing olefin with oxygen compounds can well solve the problems, and can be used for industrial production of olefin with oxygen compounds.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for fabricating high water absorption resin

ActiveCN101050251AImprove uniformityStable reaction temperatureAbsorbent padsBandagesWater soluble polymersChemistry

This invention discloses a method for producing powdery and water-insoluble high-water-absorbent resin with low soluble content. The high-water-absorbent resin can absorb water, urine and blood. The method comprises: (1) adding crosslinking agent to acid-containing monomer aqueous solution with a neutralization rate higher than 50 mol.%, and performing free radical polymerization; (2) standing monomer solution, catalyst and water-absorbent resin (less than 100 mu.m) in a mixer with at least one screw for 3-600 s; (3) drying with 100-250 deg.C hot wind, pulverizing, and screening; (4) coating with surface crosslinking agent; (5) performing surface thermal treatment at 80-230 deg.C; (6) adding inert organic salt powder. The acid-containing monomer is selected from acrylic acid, methacrylic acid and 2-allylamine-2-methylpropane sulfonic acid, and the monomer aqueous solution contains 0-5 wt. % of water-soluble polymer.

Owner:FORMOSA PLASTICS CORP

Process and equipment for preparing nickel oxide product and recovering hydrochloric acid through nickel chloride solution

InactiveCN103058288ANo emissionsReduce consumptionNickel oxides/hydroxidesPreparation from chloridesCooking & bakingReaction temperature

The invention relates to the technical field of preparing nickel oxide and recovering hydrochloric acid, and in particular relates to a process and equipment for preparing nickel oxide and recovering hydrochloric acid. The equipment comprises a nickel oxide solution tank for recovering waste acid, a waste acid filter, a pre-concentrator, a baking furnace, a furnace top spraying device, burners in tangent distribution, a rotary horizontal mixer, a breaker, a rotary valve, a nickel oxide powder pneumatic conveying and collecting system, a first-stage absorption tower, a second-stage absorption tower, a smoke exhaust fan, a washing tower, a feeding pump sealing as well as cooling water circulating and supplying device, a pyrolysis acid storage tank, a conveying pipeline, a gas and liquid separator, a chimney, a dust extractor, a pneumatic feeding device, a feeding pipeline online cleaning device, a combustion supporting and heating device, a back-flushing flow aiding device, a chlorine removal device and an air purifier. The process and the equipment for preparing nickel oxide and recovering hydrochloric acid have the following advantages that reaction temperature regulating range of the baking furnace is widened, waste gas reaches the discharge standard, equipment utilization rate of the baking furnace is improved, and environmental pollution is avoided.

Owner:赫东波

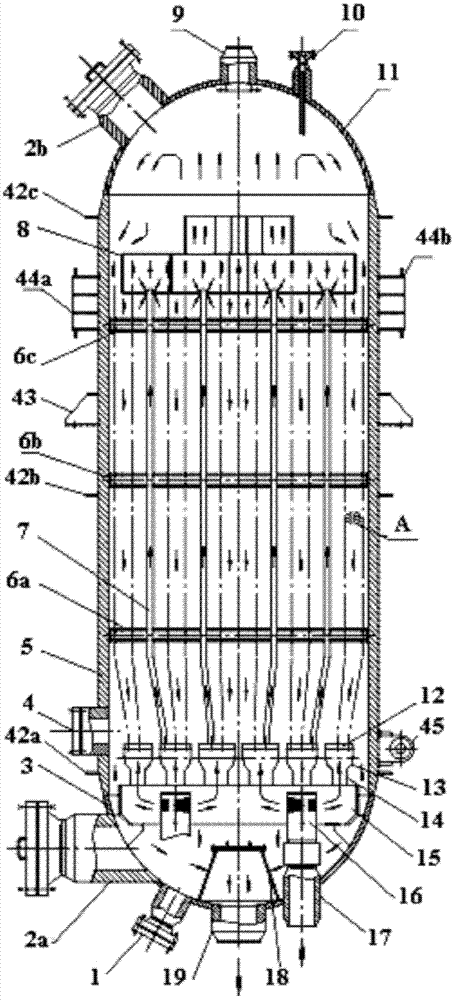

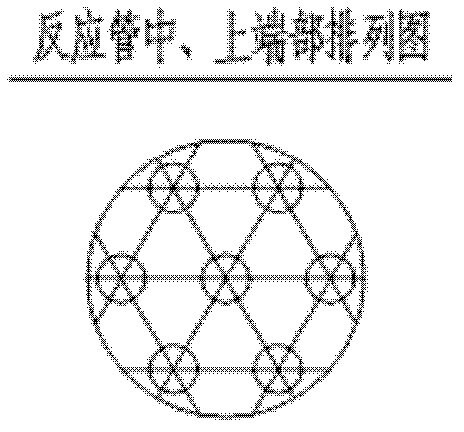

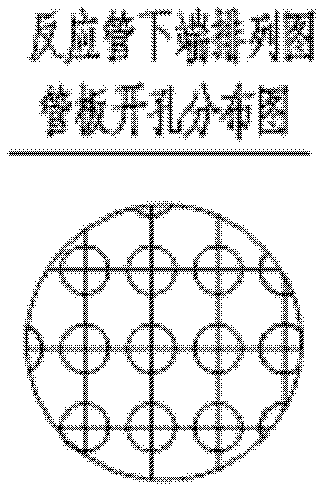

Gas-cooled methanol reactor

ActiveCN103111239AImprove production efficiencyImprove energy efficiencyOrganic compound preparationHydroxy compound preparationArchitectural engineeringMixed gas

The invention belongs to the coal-to-methanol field, and concretely discloses a gas-cooled methanol reactor. The reactor comprises a cylinder, an upper seal head packaged at the top of the cylinder and a lower seal head packaged at the bottom of the cylinder, the cylinder, the upper seal head and the lower seal head form a closed cavity, reaction tubes are arranged in the cavity, the top of each of the reaction tubes is inserted to a mixed gas tank, the middle of each of the reaction tubes is inserted to a tube support, and the bottom of each of the reaction tubes is inserted to a tube plate; tube supports are fixed on the reaction tubes, the bottom of the tube plate is fixed at the top of a U-shaped cylinder, the bottom of the U-shaped cylinder is fixed on a branch tube, the bottom of the branch tube is inserted to a manifold trunk, the top of a distribution tube is inserted to the manifold trunk, the bottom of the distribution is positioned outside the manifold trunk, and the bottom of an adaptor penetrates through the lower seal head; the top of the upper seal head is provided with a work starting gas inlet; and the bottom of the lower seal head is provided with an outlet collector, and the bottom of the outlet collector is provided with a generated gas outlet. The reactor has the advantages of methanol output improvement, cost reduction, energy saving and energy consumption reduction.

Owner:西安核设备有限公司

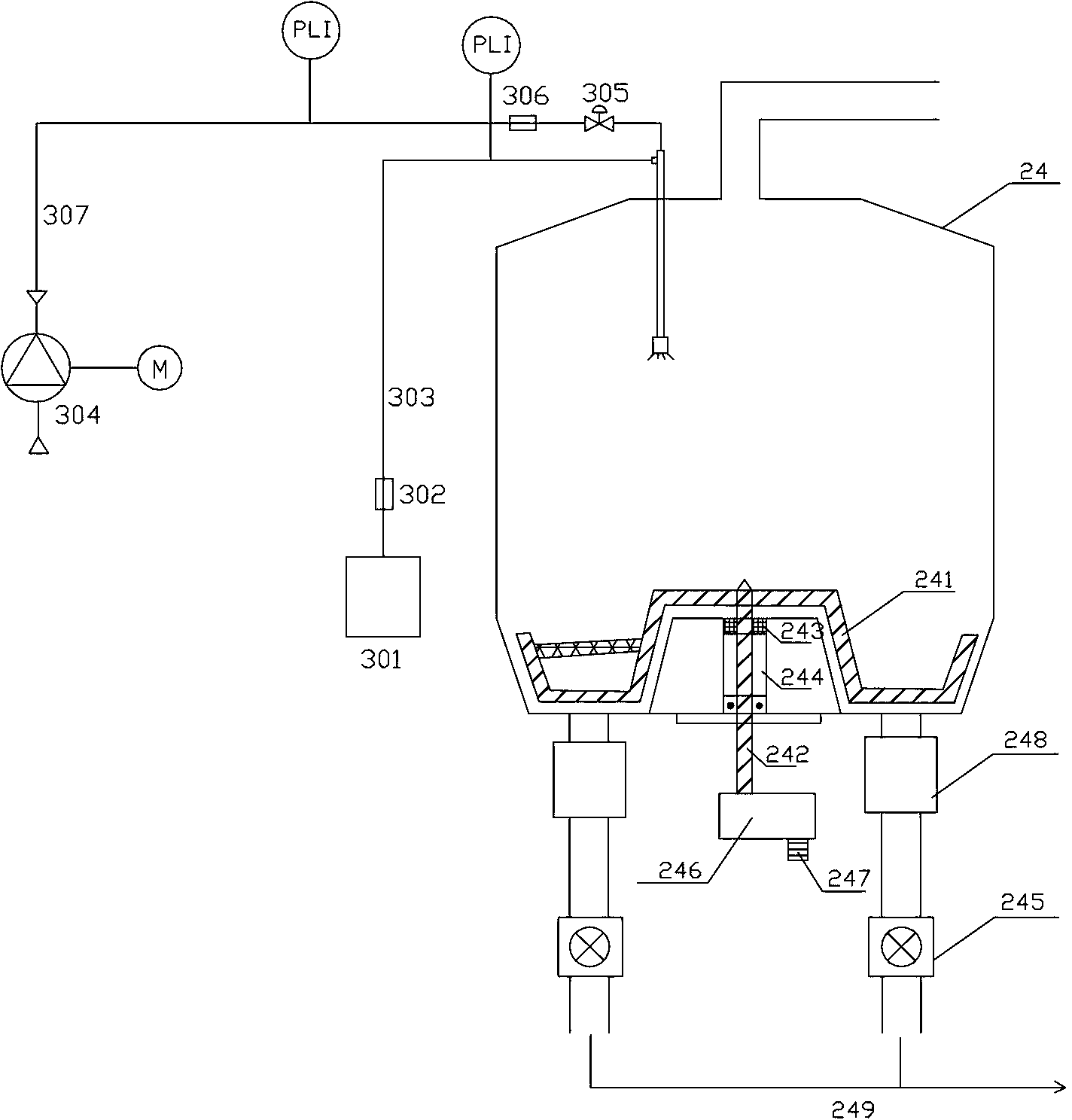

Method of preparing propylene epoxide

ActiveCN104311513AIncrease the effective contact areaImprove conversion rateOrganic chemistryMolecular sieveMixed materials

The invention discloses a method of preparing propylene epoxide. The method comprises the following steps: adding raw materials propylene, hydrogen peroxide, a solvent methanol and a titanium silicalite molecular sieve catalyst into a reaction kettle in proportion, regulating the temperature and the pressure in the reaction kettle, and establishing a cycle; continuously adding the reaction raw materials and the solvent into a pipeline reactor to react from the outside of the reaction kettle, mixing the reaction raw materials and the solvent in a static mixer and then feeding the mixed materials and the solvent into a reaction kettle to react sufficiently to obtain the propylene epoxide. On the lower part of the reaction kettle, the reaction product propylene epoxide and the catalyst are separated under a certain pressure, so that the separated propylene epoxide enters a follow-up process, and the catalyst is fed into the equipment such as the pipeline reactor by virtue of a circulating pump outside the reaction kettle to return to the reaction kettle to continuously react. In the reaction kettle, backwashing is performed once every 10-300s to guarantee the continuity of the separation of the reaction. According to the method disclosed by the invention, the raw materials sufficiently contact with the catalyst, so that the conversion ratio of the hydrogen peroxide is not lower than 96%, and the selectivity of the propylene epoxide is not lower than 95%. The reaction separating device is reasonable in structural arrangement and stable in reaction.

Owner:河北美邦工程科技股份有限公司

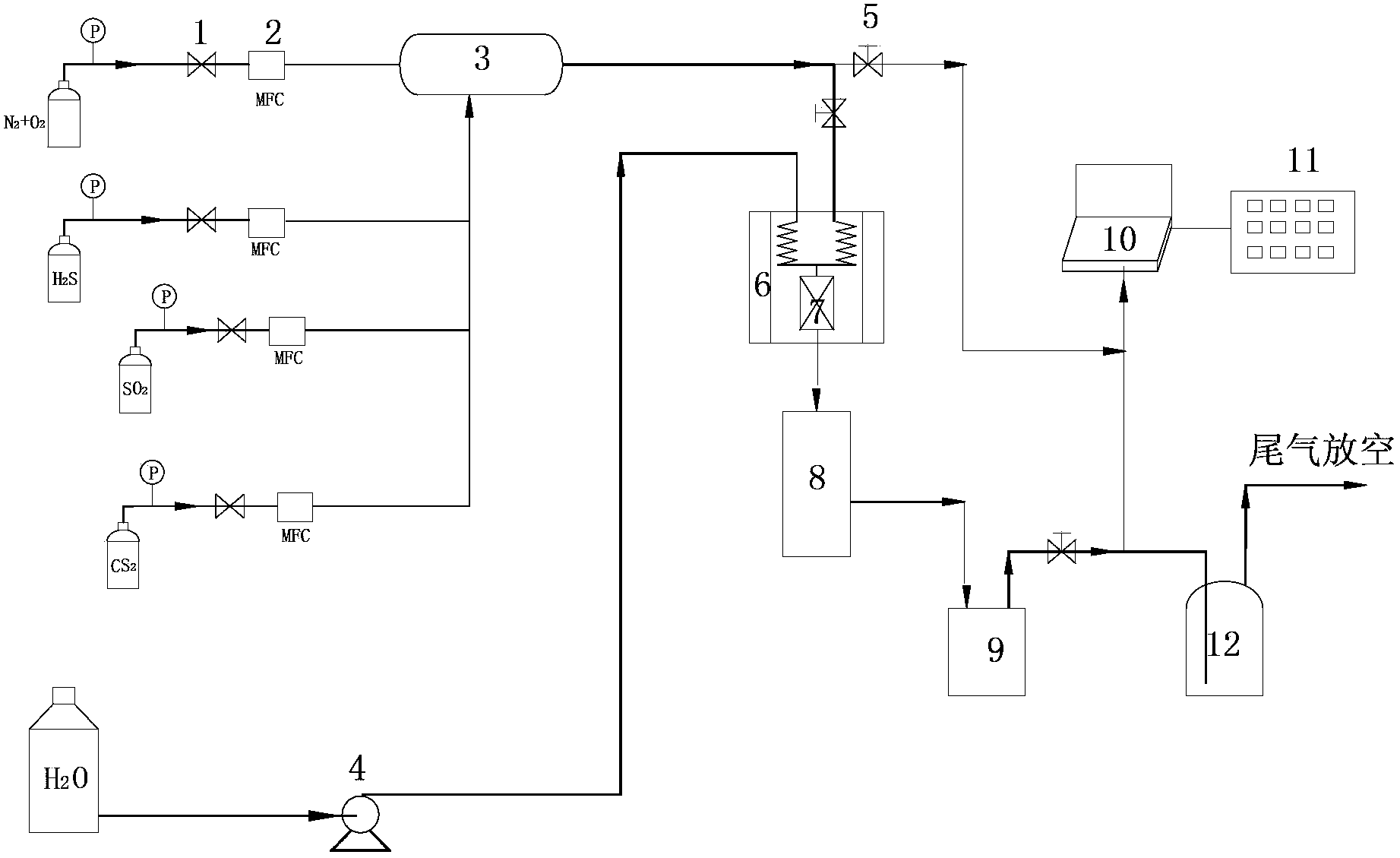

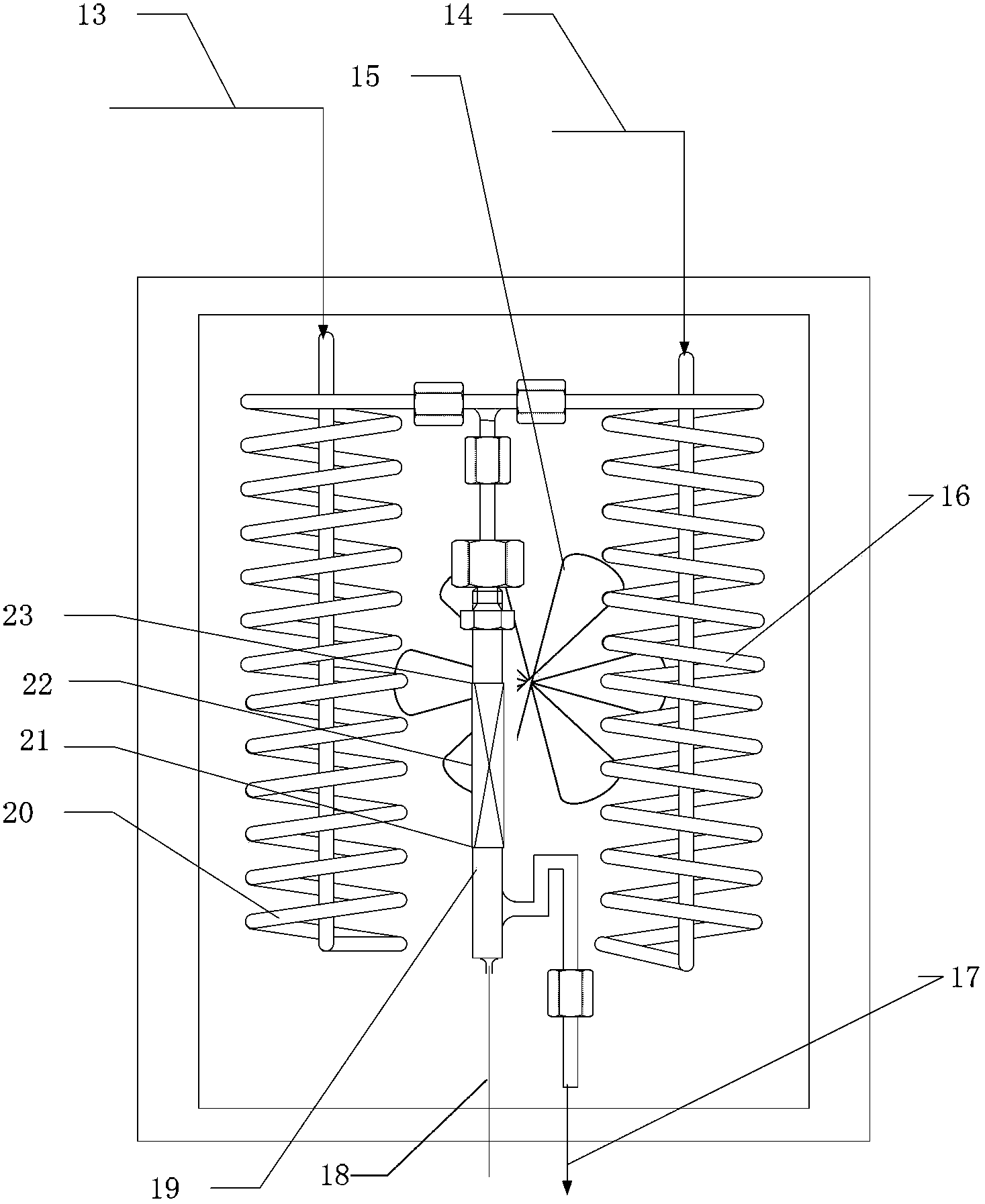

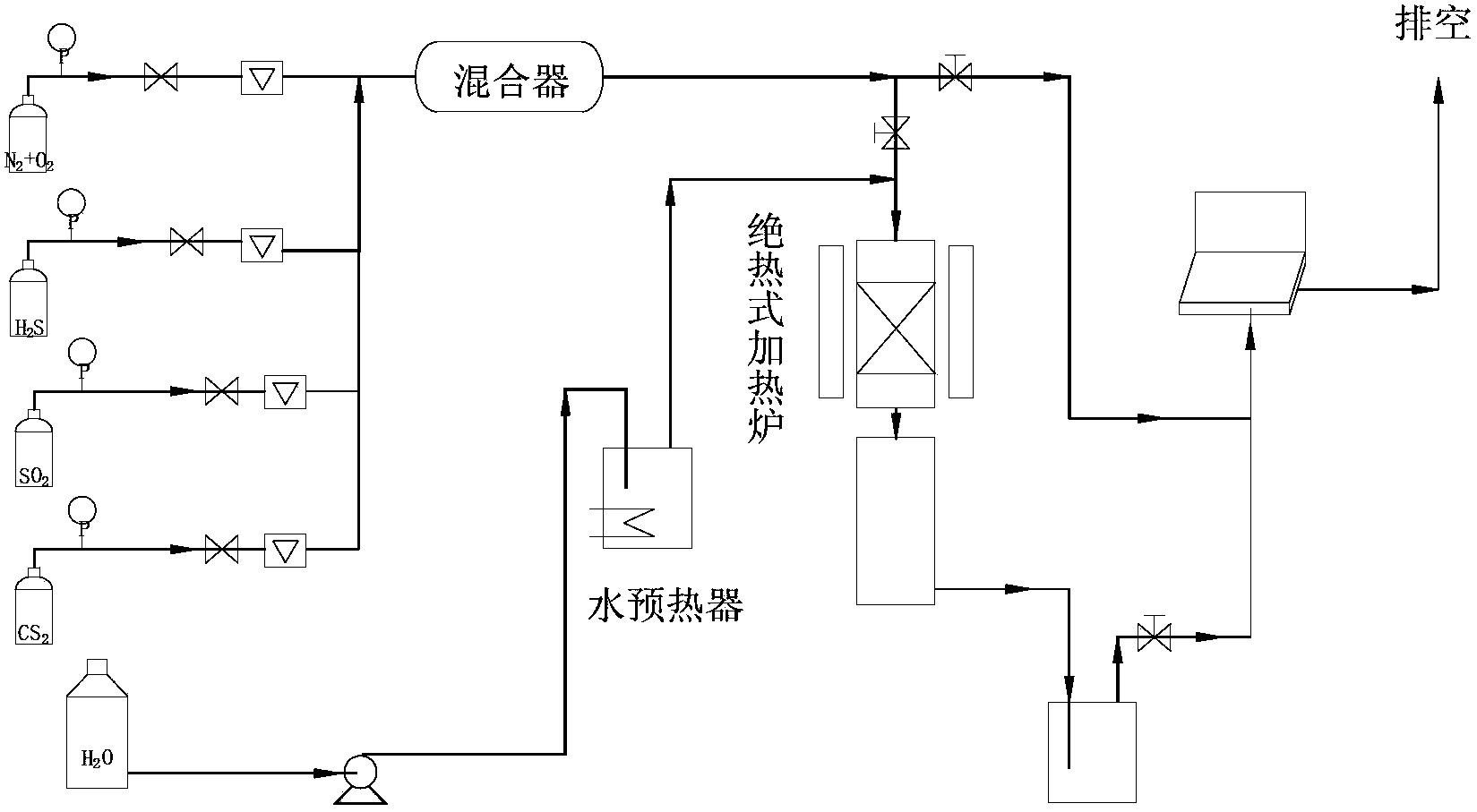

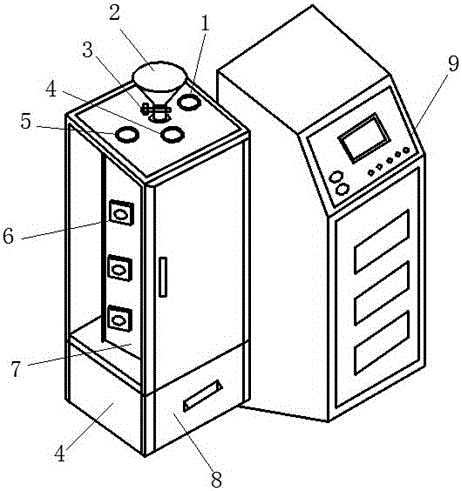

Sulfur recovery catalyst activity evaluating device and test method

ActiveCN103512966AGuaranteed uptimeSmall temperature differenceComponent separationElectricityComputer control system

The invention provides a sulfur recovery catalyst activity evaluating device and a test method, and belongs to the field of testing or analyzing a material by testing the chemical or physical property of the material. The device is characterized in that 1, a heat insulation type electric heating furnace is replaced by a blowing-type constant-temperature electric heating case (6), a reactor (7) is arranged in the blowing-type constant-temperature electric heating case (6); 2, a water pre-heater is saved, the distilled water after being measured is directly gasified in a water gasifying electric heating pre-heating coil (16) arranged in the blowing-type constant-temperature electric heating case (6); 3, an alkali liquor absorbing tank (12) is added; and 4, a computer control system (11) is provided. The sulfur recovery catalyst activity evaluating device and the test method provided by the invention have the characteristics of safety and stability in running, low temperature difference of a catalyst bed layer of the reactor, constant reaction temperature, exact and reliable test data, good repeatability, safety and environmental protection and convenience in use.

Owner:CHINA PETROLEUM & CHEM CORP

Super-efficient carboxylic acid water reducer without thermal energy consumption

The invention relates to a super-efficient carboxylic acid water reducer without thermal energy consumption, which belongs to concrete admixtures. The super-efficient carboxylic acid water reducer is prepared by polymerizing small polymerizable organic acid monomers, with carboxyl groups, with large polymerizable polyether monomers, with long chains, under the normal temperature of 20 DEG C to 35 DEG C. The super-efficient carboxylic acid water reducer has advantages of simple reaction, no thermal energy consumption, short reaction time, safety in the production process and no pollution. The water reduction ratio is up to between 45% and 50%. By adopting the super-efficient carboxylic acid water reducer, the blended quantity of mineral blending materials in the concrete can be increased properly, the cost of construction materials is lowered, the performance of the concrete is enhanced, and the comprehensive cost performance is enhanced. The super-efficient carboxylic acid water reducer is widely applied in the preparation of ultra-durable concrete.

Owner:NANJING RUIDI HIGH TECH

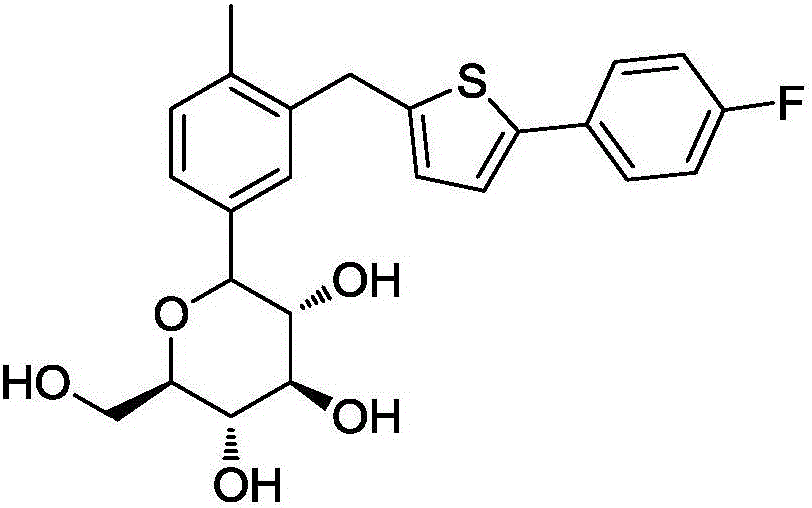

Method for synthesizing 2-(4-fluorophenyl) thiophene

The invention discloses a method for synthesizing 2-(4-fluorophenyl) thiophene. The method comprises the following steps: 1) preparing 4-fluorophenylboronic acid: separately preserving heat for a 4-fluorophenylmagnesium bromide solution which is taken as a material 1 and a boric acid ester solution which is taken as a material 2 to the reaction temperature, carrying out mixing reaction, and carrying quenching and post-treatment to obtain 4-fluorophenylboronic acid; and 2) preparing 2-(4-fluorophenyl) thiophene): adding the 4-fluorophenylboronic acid, 2-bromo thiophene and a Pd catalyst into an organic solvent to dissolve to obtain a material 3, separately preserving the heat for the material 3 and an inorganic alkali aqueous solution which is taken as a material 4 to the reaction temperature, carrying out mixing reaction, and carrying out post-treatment to obtain 2-(4-fluorophenyl) thiophene. The method is simple in operation process, is short in production period, is gentle in condition, is fewer in side reactions and is high in yield; and the obtained product is high in purity.

Owner:HEILONGJIANG XINCHUANG BIOLOGICAL TECH DEV CO LTD

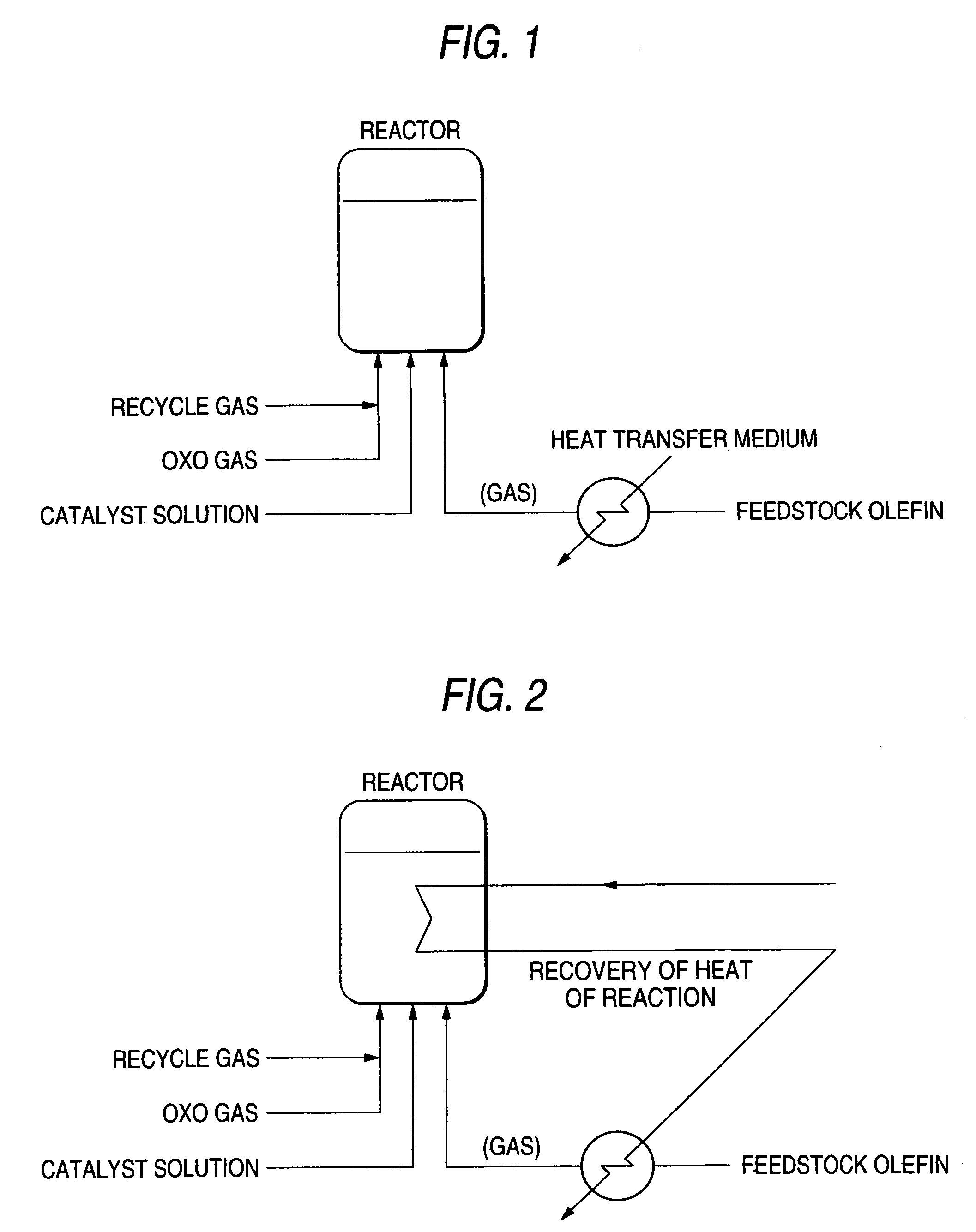

Process for producing aldehyde

ActiveUS7420092B2Constant reaction temperatureAvoid poor resultsOrganic compound preparationOrganic chemistry methodsHydrogenAlkene

A process by which a hydroformylation reaction can be efficiently conducted without lowering the yield of an aldehyde in the reaction is provided. A process for producing an aldehyde which includes subjecting an olefin to a hydroformylation reaction with carbon monoxide and hydrogen in the presence of a catalyst, characterized in that the olefin is fed as a gas to a reactor. In feeding the olefin as a gas to the reactor, it is preferred to gasify the olefin with the heat of the hydroformylation reaction.

Owner:MITSUBISHI CHEM CORP

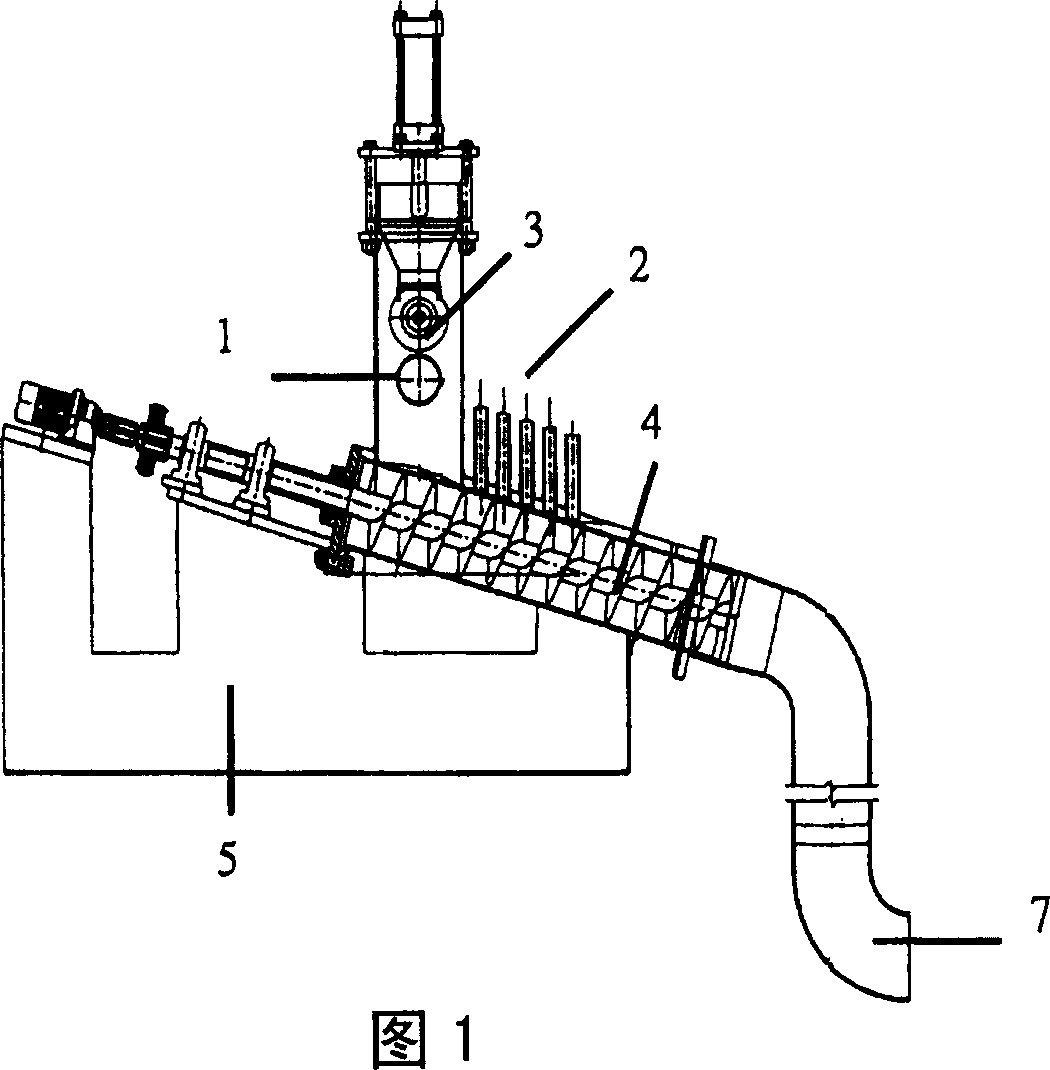

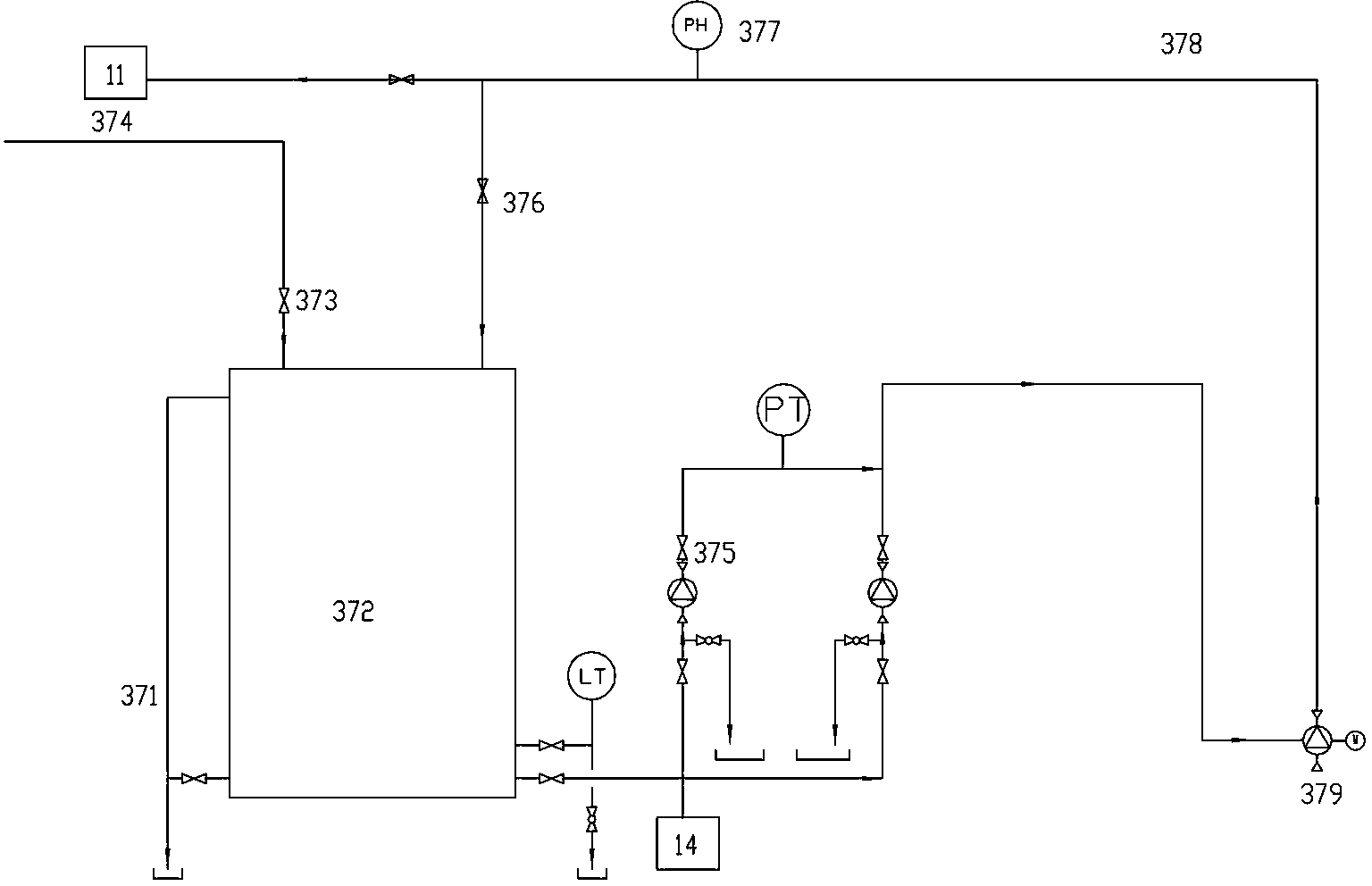

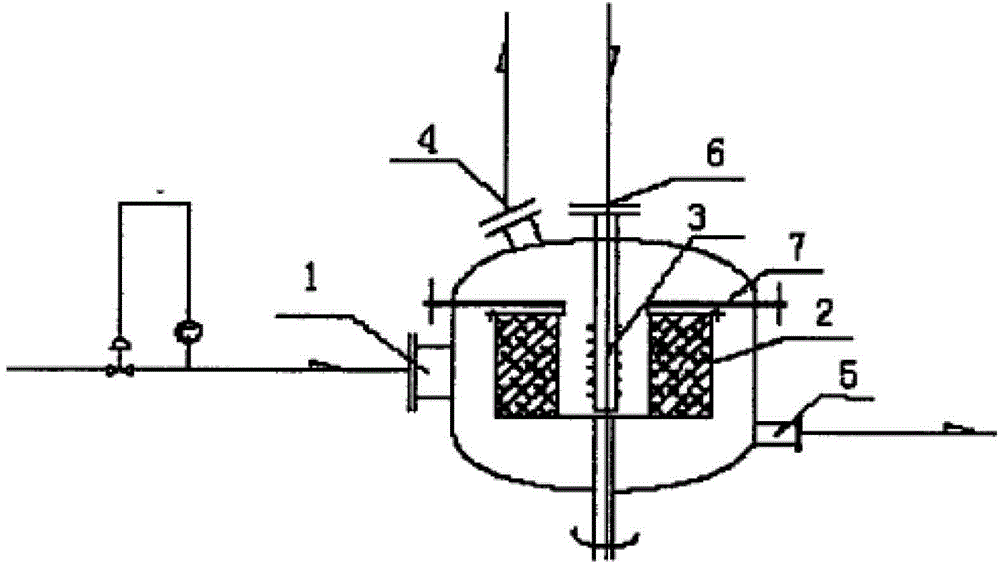

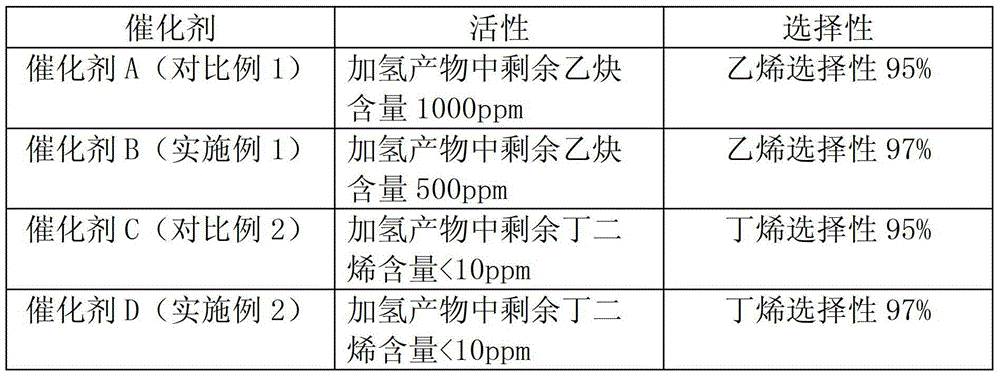

Method for selective hydrogenation of unsaturated polyhydrocarbon

ActiveCN104419453ALarge amount of processingImprove processing efficiencyRefining by selective hydrogenationUnsaturated hydrocarbonHydrogenation reaction

The invention discloses a method for selective hydrogenation of unsaturated polyhydrocarbon. The method is characterized in that a high-molecular compound carrier catalyst as an inner part is fixed on a rotor of a super-gravity rotary bed reactor so as to form a rotating catalyst bed layer; a hydrocarbon material and hydrogen pass through the rotating catalyst bed layer in a reverse flow manner or a parallel flow manner so that a selective hydrogenation reaction of the unsaturated polyhydrocarbon can be implemented in a super-gravity field. The method is good in heat and mass transfer effect, high in catalyst selectivity and high in yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

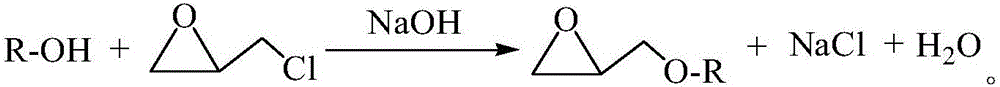

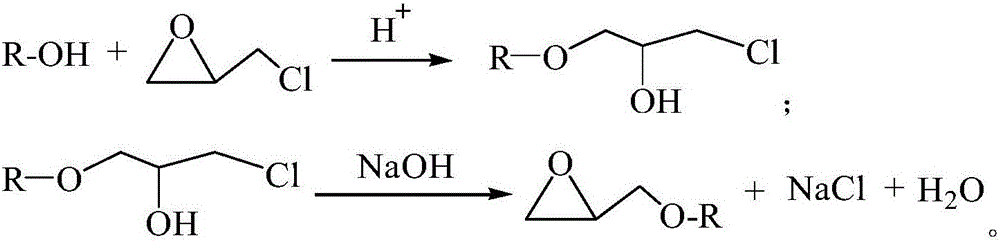

A continuous ring-opening production process for epoxy-terminated polyether

The invention relates to a continuous ring-opening production process for epoxy-terminated polyether and belongs to the technical field of organic polymer compounds. Allyl alcohol polyoxyethylene ether and epichlorohydrin are adopted as raw materials. The process includes mixing the allyl alcohol polyoxyethylene ether and the epichlorohydrin, heating, continuously feeding the mixture to a two-stage fixed bed reactor, performing a ring-opening reaction under catalysis of a solid superacid, adding a product collected by a collecting tank at the lower end of the reactor to a reaction kettle through a metering pump every 2-4 h, adding an alkali and a quaternary ammonium salt catalyst, stirring for 1-4 h while maintaining the temperature, filtering to obtain a crude product, performing vacuum distillation to recover the epichlorohydrin, and purifying to obtain a qualified product. The process is applied for producing the epoxy-terminated polyether, and has advantages of a high equipment utilization rate, a high production efficiency, and the like.

Owner:ZHEJIANG HUANGMA TECH

Iron cobalt composite carbon copper catalyst for continuous production of 4,4-diaminodiphenyl ether as well as method

InactiveCN110639553ASimple compositionLow costOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsDiaminodiphenyl etherPtru catalyst

The invention discloses an iron cobalt composite carbon copper catalyst for continuous production of 4,4-diaminodiphenyl ether as well as a method. The catalyst takes carbon coated foam copper as a carrier and loads Fe, Co and noble metal; and the mass contents of the Fe, the Co and the noble metal in the catalyst are sequentially 0.1 to 1.0 percent, 0.1 to 0.8 percent and 0.1 to 0.9 percent. The4,4-diaminodiphenyl ether is continuously produced by adopting the iron cobalt composite carbon copper catalyst, by taking 4,4-dinitrodiphenyl ether as a raw material and by performing nitro hydrogenation reaction on a catalyst bed by a trickle bed, the catalytic reaction efficiency is high, the reaction heat is concentrated, the carbon coated foam copper carrier can disperse the active componentsof the catalyst well, also can rapidly remove reaction heat and guarantees that the reaction is conducted within the proper temperature range rapidly and stably, the raw material conversion rate is 100 percent, the selectivity of target products is more than 99.9 percent, the catalyst property is stable, the catalytic reaction is too simple the catalytic reaction heat is recoverable, the heat energy utilization efficiency is high, and environmental friendliness is realized.

Owner:XIAN CATALYST NEW MATERIALS CO LTD

Semi-continuous microwave catalytic thermal cracking reactor

InactiveCN105771809ATake advantage ofIncrease distanceChemical/physical/physico-chemical reactor detailsEnergy based chemical/physical/physico-chemical processesChemical industryThermodynamics

The invention discloses a semi-continuous microwave catalytic thermal cracking reactor. The semi-continuous microwave catalytic thermal cracking reactor of a vertical structure comprises a heating chamber, a microwave heating source and a catalytic static bed device. The cross section of the heating chamber is orthohexagonal. An inner quartz reaction cavity is formed in the heating chamber. Materials react in the inner quartz reaction cavity. Two groups of umbrella-shaped partition boards are arranged in the inner quartz reaction cavity. The upper umbrella-shaped structure is smaller than the lower umbrella-shaped structure in each group so as to enable the materials to slide down from top to bottom, and accordingly, motion paths of the materials are increased. The umbrella-shaped partition boards can be rotated according to needs. Three groups of microwave heating sources extending to the heating chamber are provided. The axes of each group of microwave heating sources do not coincide so as to reduce mutual interference. The catalytic static bed device can be mounted in the reactor, the reactor is provided with two temperature measurement openings, and one of the temperature measurement openings is used according to needs. The semi-continuous microwave catalytic thermal cracking reactor has the advantages that biomass conversion rate can be increased, heating stability can be improved and heating and catalyzing are integrated, and can be applied to the fields such as energy and chemical industry.

Owner:JIANGSU UNIV

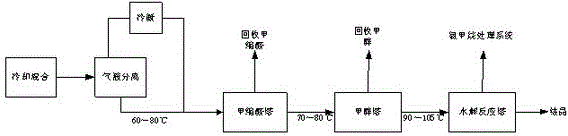

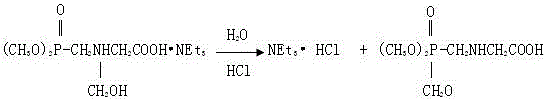

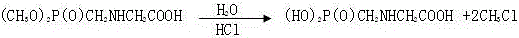

Continuous hydrolysis process for preparing glyphosate by glycine method

ActiveCN103739625BGuaranteed hydrolysis effectLess side effectsGroup 5/15 element organic compoundsGlycineHydrolysis

The invention provides a continuous hydrolysis process for preparing glyphosate by a glycine method. The process comprises following specific steps: (A) conveying a condensation reaction synthetic solution into a mixing reactor by a pump and controlling a material temperature to be lower than 55 DEG C to finish an acid adding and neutralizing process; (B) carrying out gas-liquid separation on materials discharged by a heat exchanger and enabling condensed gas and liquid to respectively enter a methylal recycling tower to recycle methylal; (C) enabling kettle bottom liquid discharged from the methylal recycling tower to enter a methanol recycling tower to recycle methanol; enabling kettle bottom liquid discharged from the methanol recycling tower to enter a hydrolysis tower to finish a hydrolysis reaction; and (D) carrying out flash evaporation on kettle bottom liquid discharged from hydrolysis tower; removing water and acid and enabling the kettle bottom liquid enter a crystallization kettle; and cooling and crystallizing under agitation to obtain the glyphosate.

Owner:SICHUAN LESHAN FUHUA TONGDA AGRO-CHEM TECH CO LTD

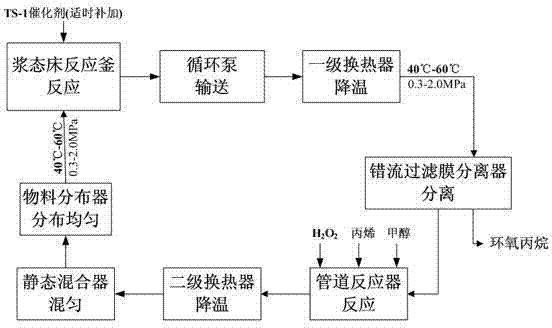

Method for preparing epoxypropane

ActiveCN104327016AIncrease the effective contact areaImprove conversion rateOrganic chemistryMolecular sieveCross-flow filtration

The invention relates to a method for preparing epoxypropane. The method comprises the following steps: adding raw materials propylene and oxydol, a solvent methanol and a titanium silicon molecular sieve catalyst into a reaction kettle according to the mole ratio, and regulating the temperature and pressure in the reaction kettle to establish circulation; continuously adding the raw materials and solvent into the pipeline reactor from the outside of the reaction kettle to react, mixing with a static mixer, and sending into the reaction kettle; discharging the reaction mixture from the bottom of the reaction kettle, delivering to a primary heat exchanger through a circulating pump to perform cooling, separating the product epoxypropane and catalyst in a cross-flow filter membrane separator to obtain the product epoxypropane, and returning the trapped catalyst into the reaction kettle via the pipeline reactor, heat exchanger, static mixer and other apparatuses to form the circulation and continue entering into the reaction; and carrying out backflush every other 3-5 hours. The raw materials sufficiently contact the catalyst, the conversion rate of oxydol is at least 96%, and the epoxypropane selectivity is at least 95%. The epoxypropane has stable membrane flux, thereby lowering the membrane pollution, enhancing the product purity and lowering the production cost.

Owner:河北美邦工程科技股份有限公司

Method of continuously producing epichlorohydrin by directly epoxidizing chloropropene

ActiveCN103159703BStable reaction temperatureSimple processOrganic chemistryChemical recyclingRefluxReaction temperature

The invention discloses a method of continuously producing epichlorohydrin by directly epoxidizing chloropropene. The method of continuously producing epichlorohydrin by directly epoxidizing chloropropene includes: respectively transporting chloropropene, hydrogen peroxide, catalyst slurry or / and solvent to a reactor through a metering pump, the reactor is a single reactor or multistage reactors which are connected in series, reaction pressure is 0.1 to 1.0 MPa, and reaction liquid is in a homogeneous phrase state or a non-homogeneous phrase state. A filter is arranged at the upper end of a discharge port in the reactor to extract liquor with products, materials which are arranged at the lower end of the filter, are not filtered, contain catalyst and are not completely reacted is transported to the reactor through the metering pump which is arranged at the lower end of the reactor, the catalyst is free from recycling the catalyst in the continuous production process, and gaseous phrase portion conducts condensation reflux through a condenser which is arranged at the top of the reactor. The method of continuously producing epichlorohydrin by directly epoxidizing chloropropene has the advantages of being stable in reaction temperature and simple in process flow, the catalyst is free from being separated, beaten and configured again after reaction, the hydrogen peroxide is high in effective utilization and epichlorohydrin is high in yield, and method of continuously producing epichlorohydrin by directly epoxidizing chloropropene can be used in industry production.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

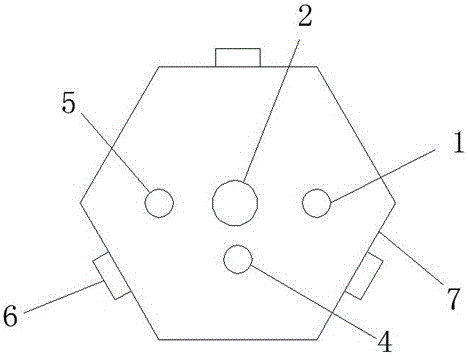

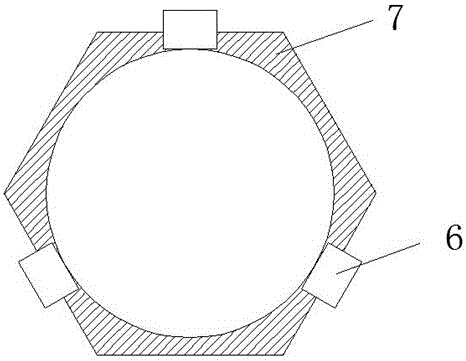

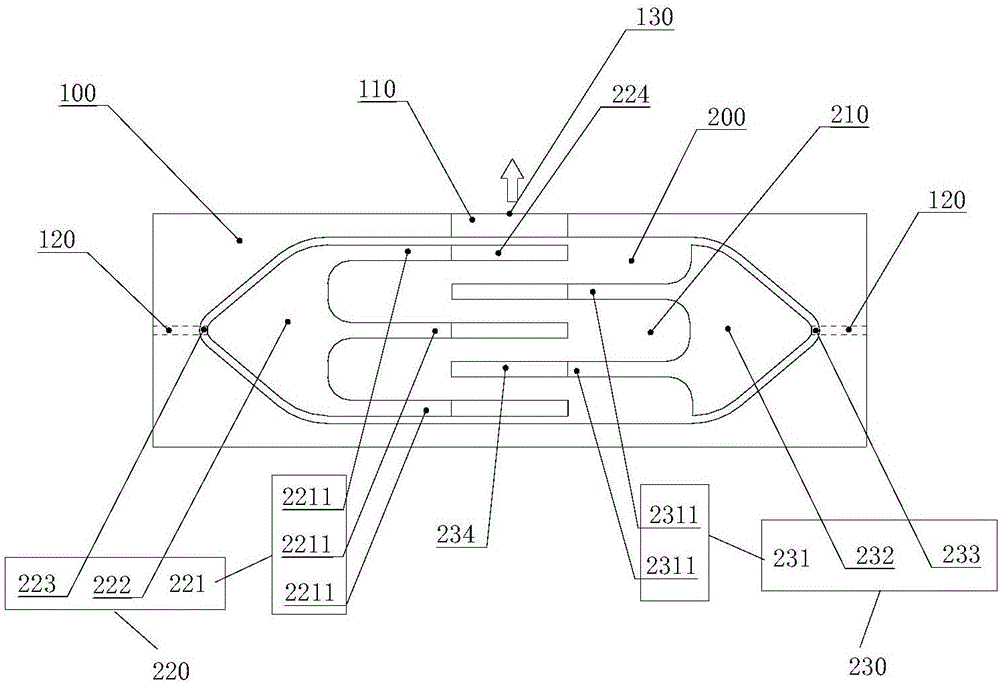

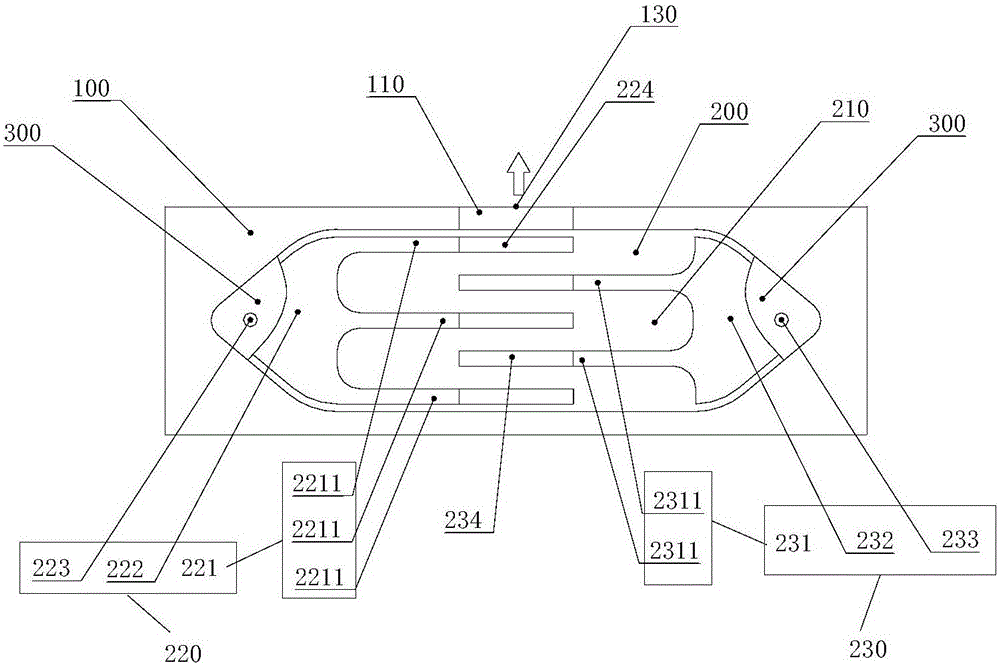

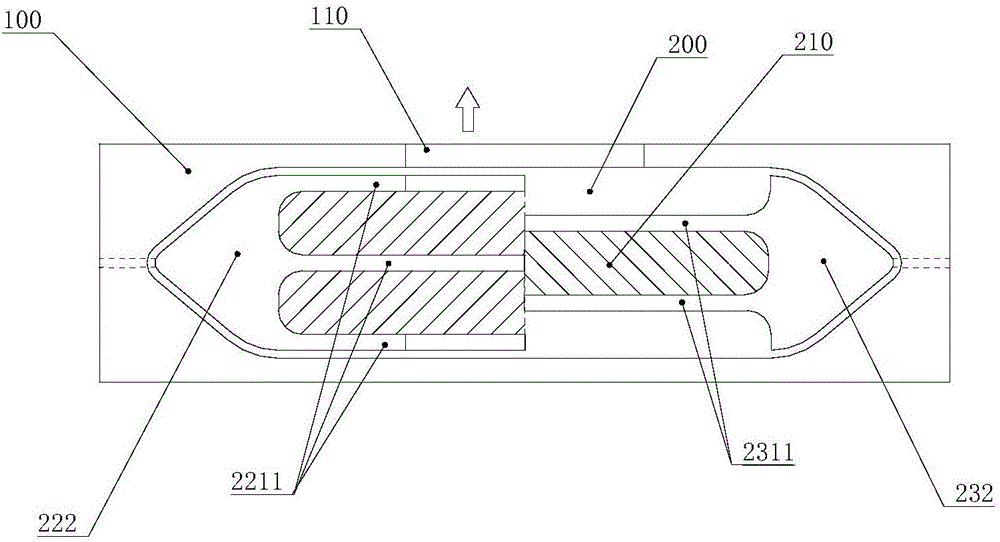

Chip type micro reaction channel and micro reactor

ActiveCN106492718AImprove production efficiencyIncrease the reaction contact areaChemical/physical/physico-chemical microreactorsMicroreactorEngineering

The invention discloses a chip type micro reaction channel and a micro reactor. The chip type micro reaction channel comprises a substrate and a chip, wherein the chip is positioned on the substrate and comprises a diversion structure and a first fluid part and a second fluid part which are partitioned by the diversion structure; the first fluid part comprises a first inlet; the second fluid part comprises a second inlet; meanwhile the first fluid part is partitioned into at least first diversion channels by the diversion structure; the second fluid part is partitioned into at least two second diversion channels by the diversion structure; moreover mixing channels are formed in a connected manner in corresponding positions of the first diversion channels and the second diversion channels on the substrate; the mixing channels are respectively connected with the first diversion channels and the second diversion channels. The micro reactor comprises a first chip type micro reaction channel. By adopting the chip type micro reaction channel and the micro reactor, different reactants in two types of fluid can be sufficiently mixed and reacted, the reaction speed can be increased, the reactant generation efficiency can be improved, and meanwhile the reaction security and reliability can be improved.

Owner:SHANDONG HIMILE CHEM TECH

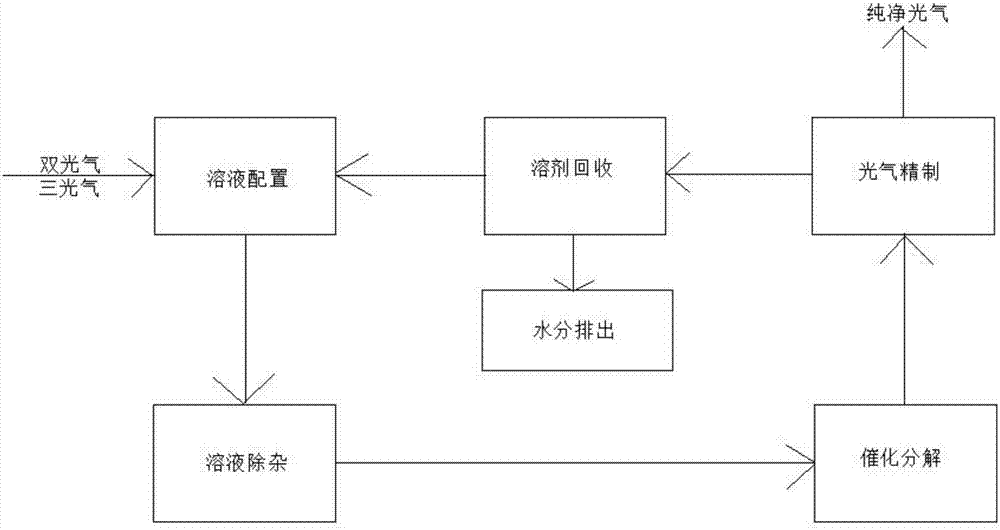

Method for producing diphosgene or triphosgene from phosgene

ActiveCN107324334AFlexible control of reaction speedAvoid poisoningPhosgeneCatalytic decompositionSide reaction

The invention provides a method for producing diphosgene or triphosgene from phosgene. The method comprises the following steps: preparing a solution, performing solution decontamination, performing catalytic decomposition, performing phosgene refining and recycling a solvent. A diphosgene or triphosgene solution is adopted to contact and react with a catalyst, and the reaction velocity can be flexibility controlled by controlling the concentration of the solution. Before contacting the catalyst, the diphosgene or triphosgene solution is firstly purified, catalyst poisoning is avoided, the service life of the catalyst is prolonged, and the cost is lowered. Moisture and the solvent mixed with phosgene are removed by using a phosgene decomposition refining tower, so that the situations that side reactions and equipment erosion are increased as moisture carried in the solvent and raw materials is fed into a phosgene use unit along with the phosgene can be avoided.

Owner:MOJIA (SHANGHAI) BIOTECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com