Method for preparing epoxypropane

A technology of propylene oxide and propylene, which is applied in the field of organic matter preparation, can solve the problems of high reaction risk, small effective contact area, and non-replaceable catalyst, and achieve the effects of improving conversion rate, simplifying internal structure, and increasing effective contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

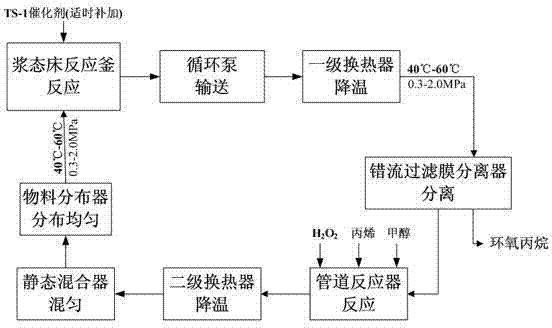

[0025] see figure 1 The technological process schematic diagram of the present invention that provides, technological process of the present invention comprises the steps:

[0026] (1) Add raw material propylene, hydrogen peroxide, solvent methanol and an appropriate amount of catalyst titanium silicon molecular sieve to the reactor at a molar ratio (1.2~2):1:1:(2~4), adjust the temperature in the reactor to 40~60°C, The pressure is 0.3 ~ 2.0Mpa, and the cycle is established;

[0027] (2) Control the temperature and pressure in the reactor to meet the above conditions. According to the unit consumption of the catalyst, add catalyst titanium silicon molecular sieve to the reactor every shift, and the materials will react. Turn on the circulation pump and agitator, and on the external pipeline of the reactor, the raw materials propylene, hydrogen peroxide and solvent methanol are respectively continuously added into the pipeline reactor, and the propylene and hydrogen peroxide ...

Embodiment 2

[0034] The separation of the product propylene oxide and the catalyst in this example is carried out in a metal membrane separator outside the reactor, and the filtration method is also cross-flow filtration, and other process conditions are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com