Preparation method of superfine cadmium sulfide particles-sensitized titanium dioxide nanotube array

A nanotube array and titanium dioxide technology, applied in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve problems such as poor repeatability, large CdS particles, and reduced contact area, so as to increase the effective contact area and photoelectric conversion High efficiency, increase the effect of charge transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) The base material is a titanium sheet with a thickness of 0.3 mm, which is ultrasonically cleaned in acetone, ethanol and deionized water, and dried in the air for use. Prepare 0.2M NH 4 F and 0.1M H 3 PO 4 solution, using Ti sheet as the working electrode and Pt sheet as the counter electrode, anodizing at a control voltage of 20V for 7h, ultrasonic cleaning for 1min, drying, and roasting in a muffle furnace at 500°C for 2h to obtain anatase TiO 2 -NTs films.

[0021] (2) TiO2 nanotube arrays sensitized by ultrafine cadmium sulfide particles were prepared by electrodeposition combined with ion exchange. Place the sample obtained in step (1) in CdCl 2 Ultrasound in the solution for 6min, with 0.2M CdCl 2 For the electrolyte, TiO 2 -NTs is the working electrode, the Pt sheet is the counter electrode, the saturated calomel electrode (SCE) is the reference electrode, and the Cd / TiO 2 -NTs, then calcined in a muffle furnace at 500 °C for 1 h, and finally at 140 °...

Embodiment 2

[0023] (1) TiO 2 - The preparation of the NTs film is the same as in Example 1.

[0024] (2) Place the sample obtained in step (1) in CdCl 2 Ultrasound in the solution for 6min, with 0.2M CdCl 2 For the electrolyte, TiO 2 -NTs is the working electrode, the Pt sheet is the counter electrode, and the saturated calomel electrode (SCE) is the reference electrode. Cd / TiO is obtained by electrodeposition for 60s by controlling the potential (0.9V vs. 2 -NTs, then calcined in a muffle furnace at 500 °C for 1 h, and finally at 140 °C in 0.2 M Na 2 Perform ion exchange in S solution for 10h to obtain CdS / TiO 2 -NTs.

Embodiment 3

[0026] (1) TiO 2 - The preparation of the NTs film is the same as in Example 1.

[0027] (2) Place the sample obtained in step (1) in CdCl 2 Ultrasound in the solution for 6min, with 0.2M CdCl 2 For the electrolyte, TiO 2 -NTs is the working electrode, the Pt sheet is the counter electrode, the saturated calomel electrode (SCE) is the reference electrode, and the Cd / TiO 2 -NTs, then calcined in a muffle furnace at 500 °C for 1 h, and finally at 140 °C in 0.2 M Na 2 Perform ion exchange in S solution for 15h to obtain CdS / TiO 2 -NTs.

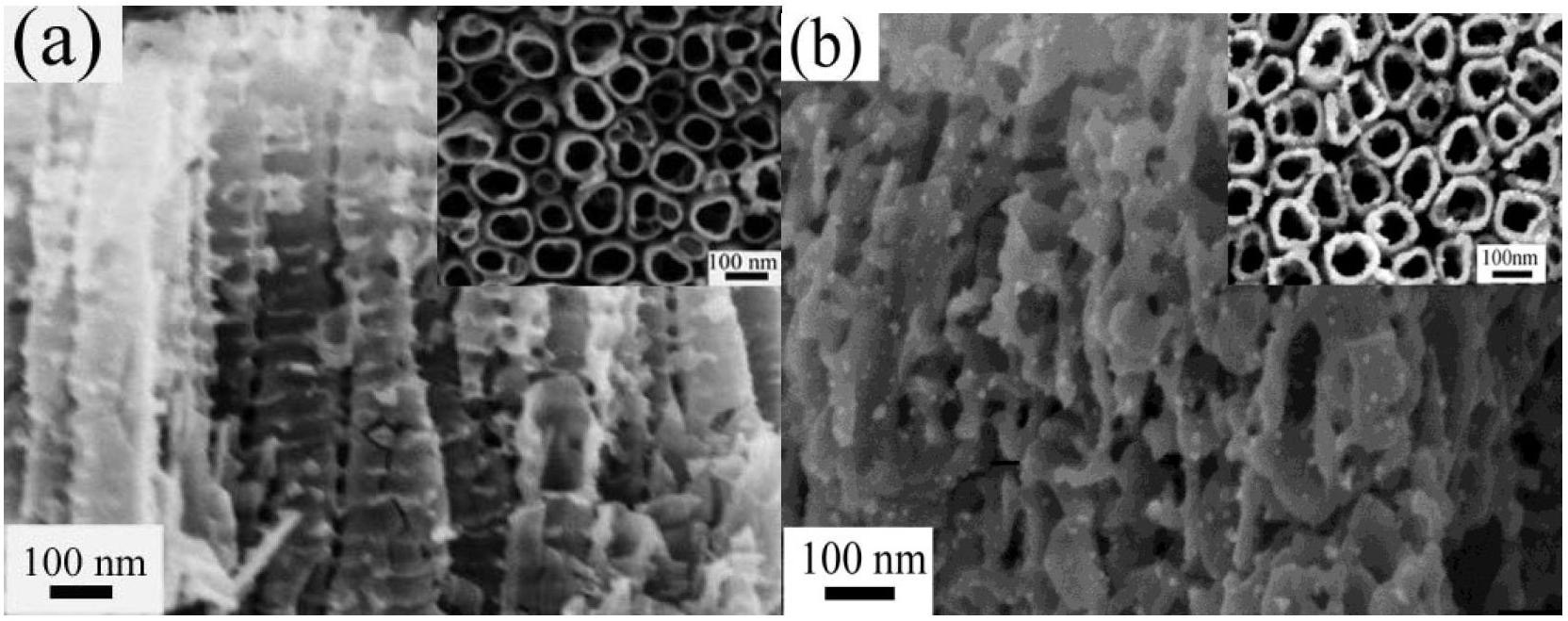

[0028] from figure 1 It can be seen that the ultrafine CdS particles obtained in the experiment are not only highly dispersed in TiO 2 The nozzles of the nanotube array are distributed in the nanotubes.

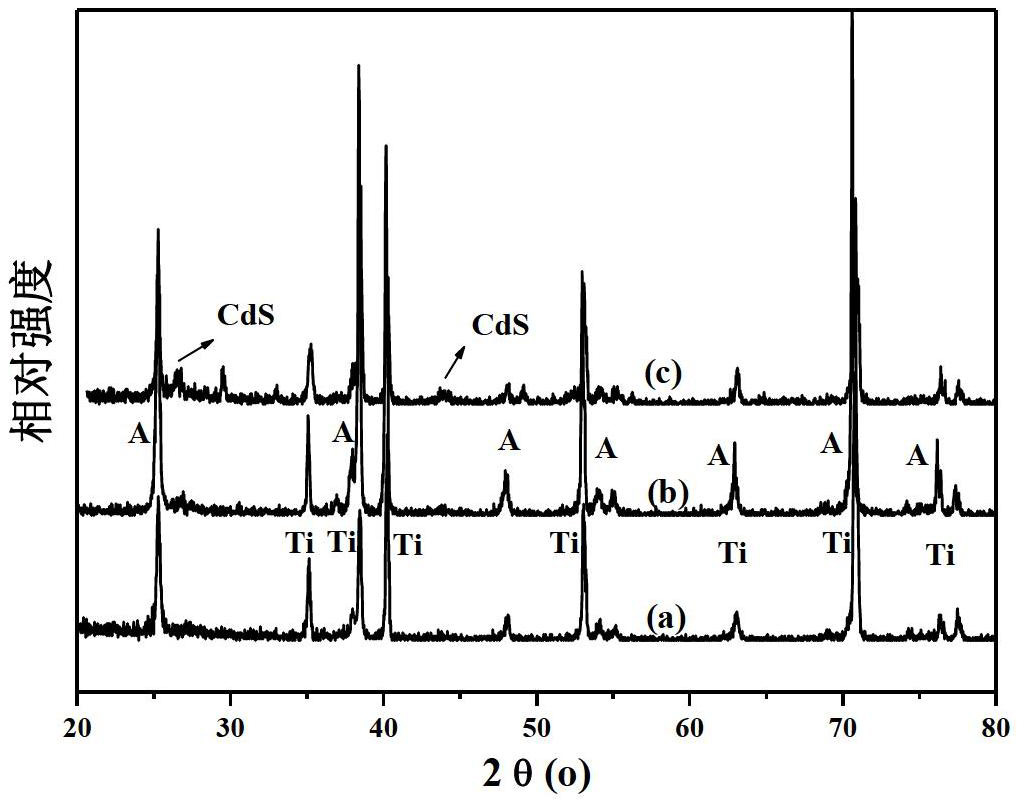

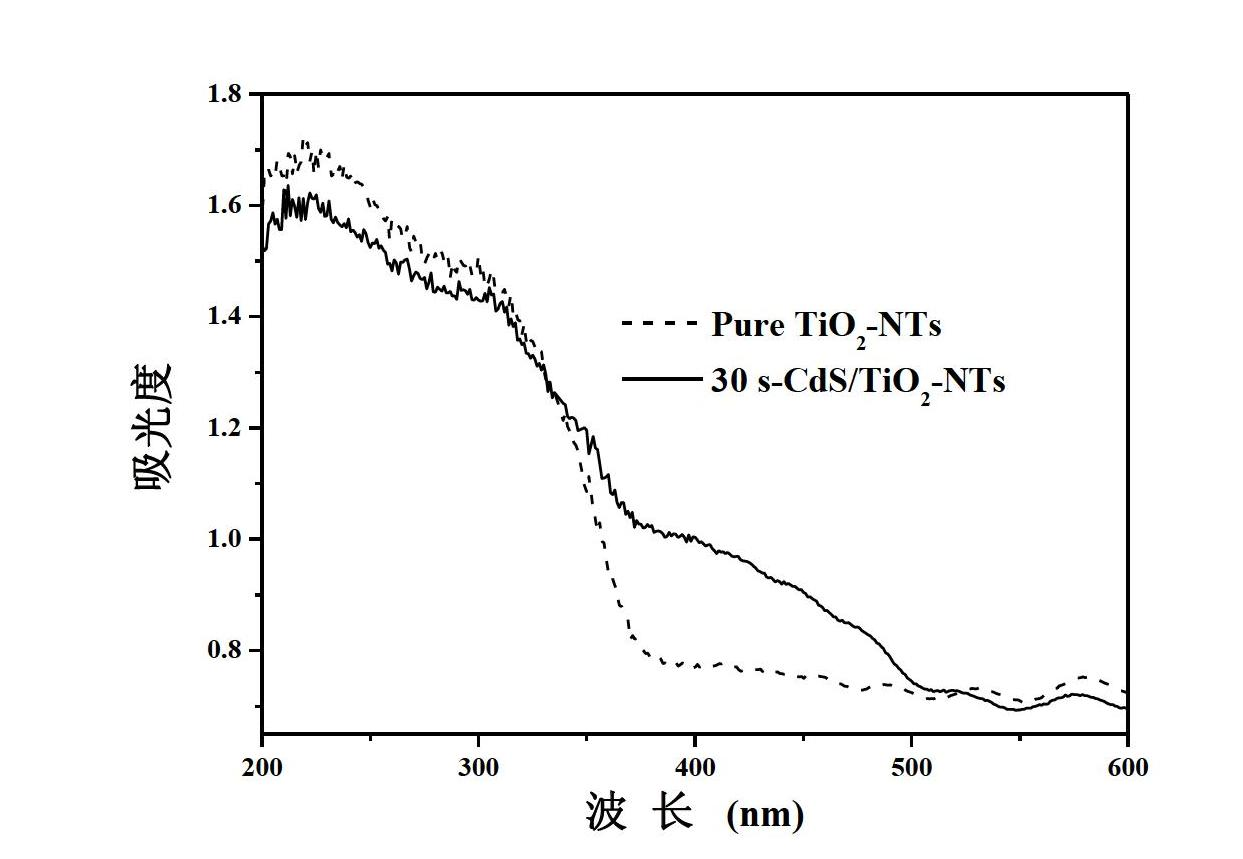

[0029] Such as figure 2 shown, from TiO 2 -NTs and 30s-CdS / TiO 2 - The XRD pattern of NTs samples can only see only Ti substrate and anatase TiO 2 The diffraction peaks of CdS appear when the electrodeposition time is increased to 60s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com