Cobalt phosphide molybdenum particle modified nitrogen-phosphorus co-doped carbon composite material and preparation method and application thereof

A carbon composite material, cobalt molybdenum phosphide technology, applied in the direction of nanotechnology for materials and surface science, electrochemical generators, active material electrodes, etc., can solve the problem of high synthesis cost, unfavorable commercial production, and complex synthesis process problems such as low production cost, good practical application value, and ease of volume change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] In yet another specific embodiment of the present invention, a method for preparing the nitrogen-phosphorus co-doped carbon composite material modified by the above cobalt-molybdenum phosphide particles is provided, the preparation method comprising:

[0034] Disperse cobalt salt, molybdenum salt, organic matrix and phosphorus-containing inorganic acid in water evenly, and dry to obtain the precursor;

[0035] The nitrogen-phosphorus-loaded carbon composite material modified by cobalt-molybdenum-phosphide particles is obtained by heat-treating the prepared precursor.

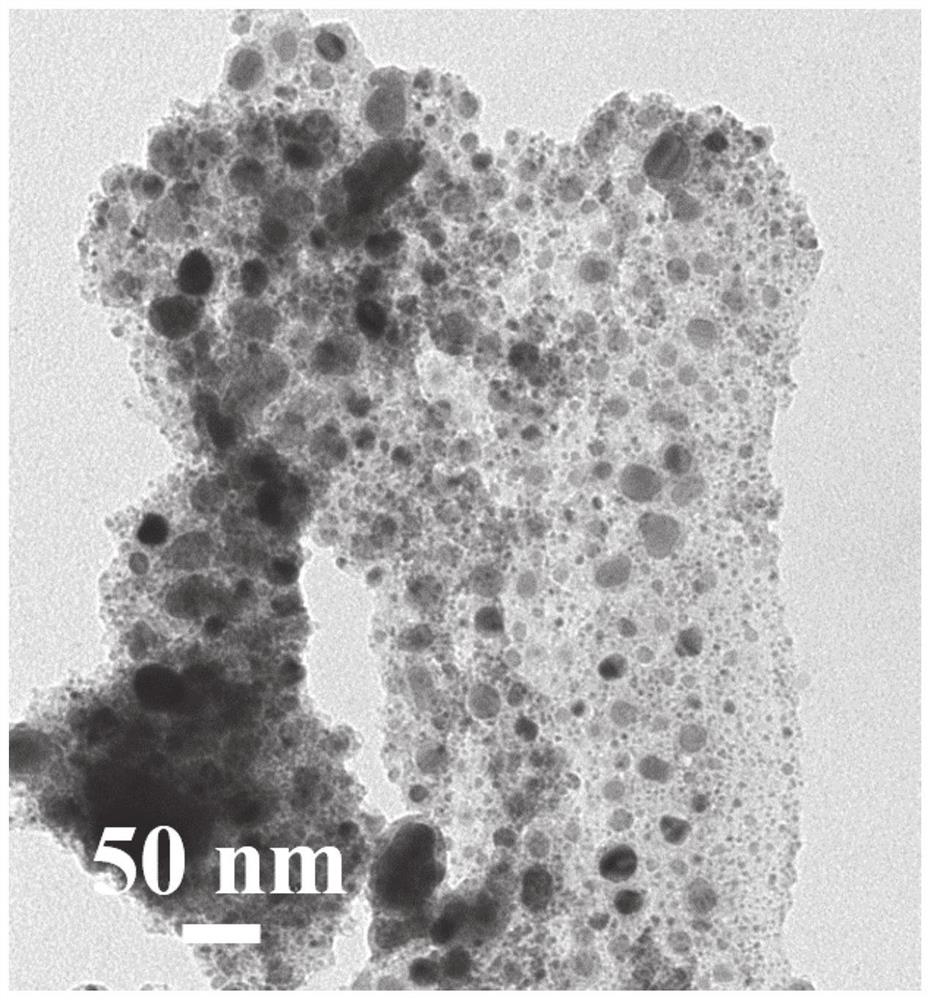

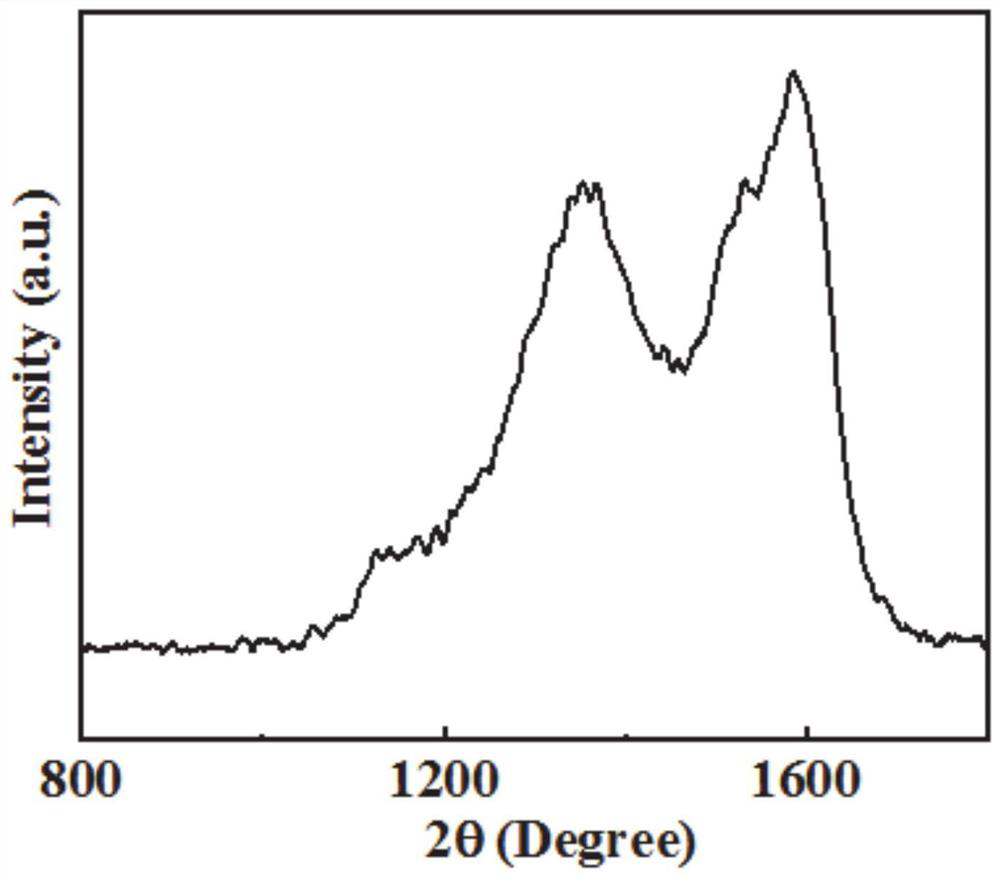

[0036] The above method has simple preparation process, less pollution, no additional phosphorus source and nitrogen source, and large yield, which can provide effective benefits for the large-scale production and practical application of bimetallic phosphide materials. And the prepared cobalt-molybdenum-phosphide particle-modified nitrogen-phosphorus co-doped carbon composite material can show better spe...

Embodiment 1

[0052] The nitrogen-phosphorus co-doped carbon composite material modified by cobalt and molybdenum phosphide particles is prepared by the following steps:

[0053] (1) Preparation of precursor:

[0054] Mix 1 mmol of cobalt nitrate hexahydrate, 0.13 mmol of ammonium molybdate, 4 g of urea, 200 mg of glucose and 2 mmol of phosphoric acid, dissolve in 40 mL of deionized water, and stir until clear and transparent without solids. The mixed liquid was dried in a blast oven at 80°C until no liquid existed, and finally dried in a vacuum oven at 60°C for 12 hours.

[0055] (2) Preparation of nitrogen and phosphorus co-doped carbon composites modified with cobalt and molybdenum phosphide particles

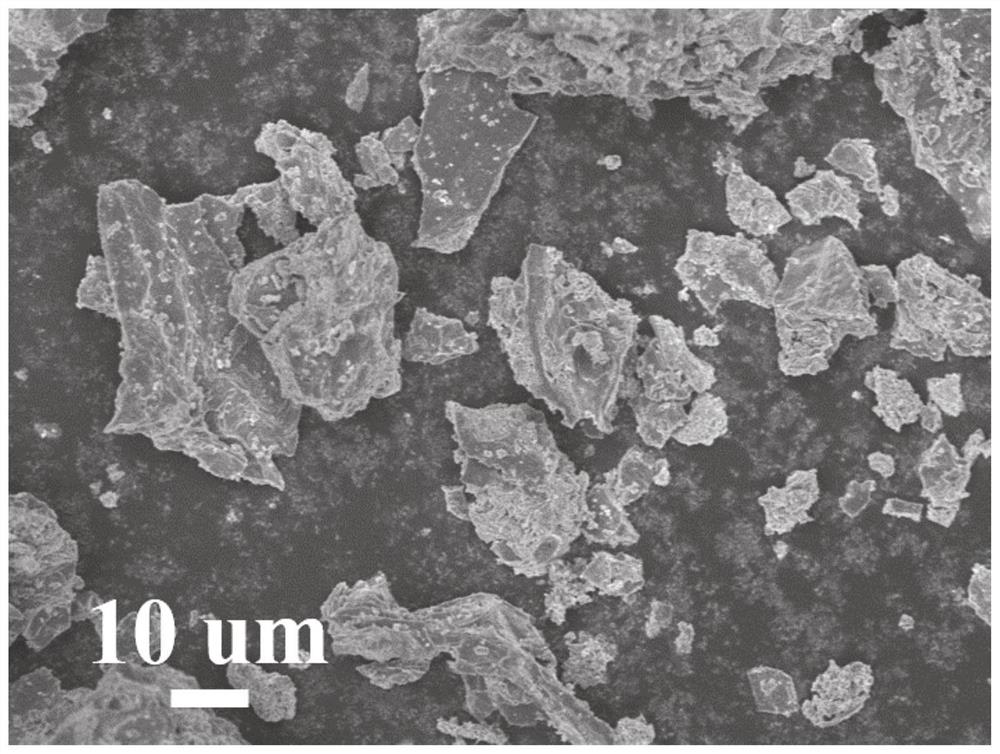

[0056] Place the precursor prepared in step 1 in a tube furnace in a nitrogen atmosphere at 3 °C min -1 The heating rate is increased from room temperature to 900°C, and the temperature is maintained for 2 hours, and the nitrogen-phosphorus co-doped carbon composite material modified by...

Embodiment 2

[0061] The nitrogen-phosphorus co-doped carbon composite material modified by cobalt and molybdenum phosphide particles is prepared by the following steps:

[0062] (1) Preparation of precursor:

[0063] Mix 0.5mmol of cobalt nitrate hexahydrate, 0.1mmol of ammonium molybdate, 4g of urea, 200mg of glucose and 2mmol of phosphoric acid, dissolve in 40mL of deionized water, and stir until clear and transparent without solids. The mixed liquid was dried in a blast oven at 80°C until no liquid existed, and finally dried in a vacuum oven at 60°C for 12 hours.

[0064] (2) Preparation of nitrogen and phosphorus co-doped carbon composites modified with cobalt and molybdenum phosphide particles

[0065] Place the precursor prepared in step 1 in a tube furnace in a nitrogen atmosphere at 3 °C min -1 The heating rate is raised from room temperature to 900°C, and the temperature is kept at 900°C for 2 hours to obtain a nitrogen-phosphorus co-doped carbon composite material modified by c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com