Oxygen ion conductor and preparation method and application thereof

A technology of oxygen ion conductor and molecular formula, which is applied in the field of oxygen ion conductor and its preparation, can solve the problems of poor chemical stability and increased impedance of solid fuel cells, improve adsorption performance and charge transfer process, increase conductivity, and achieve huge The effect of capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

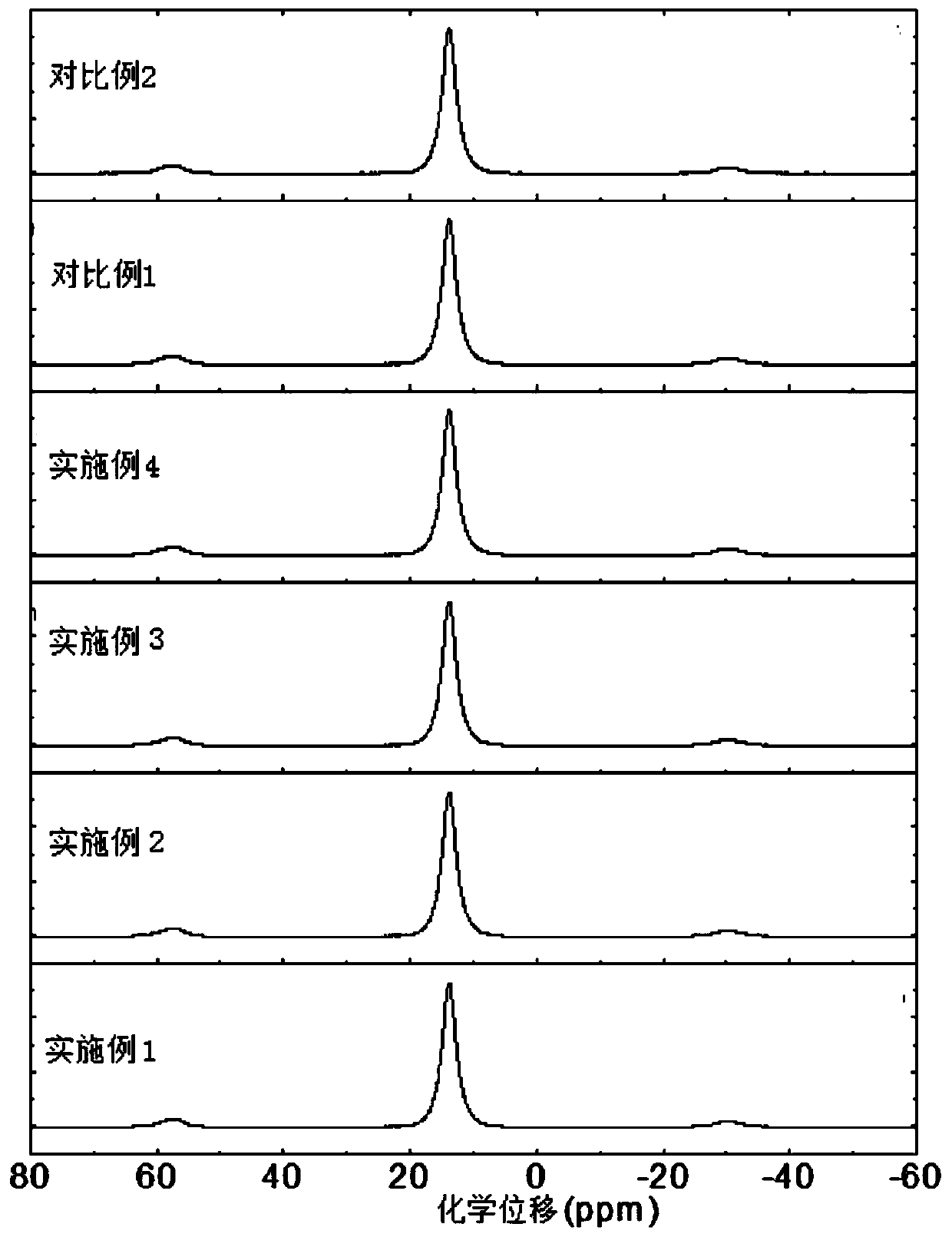

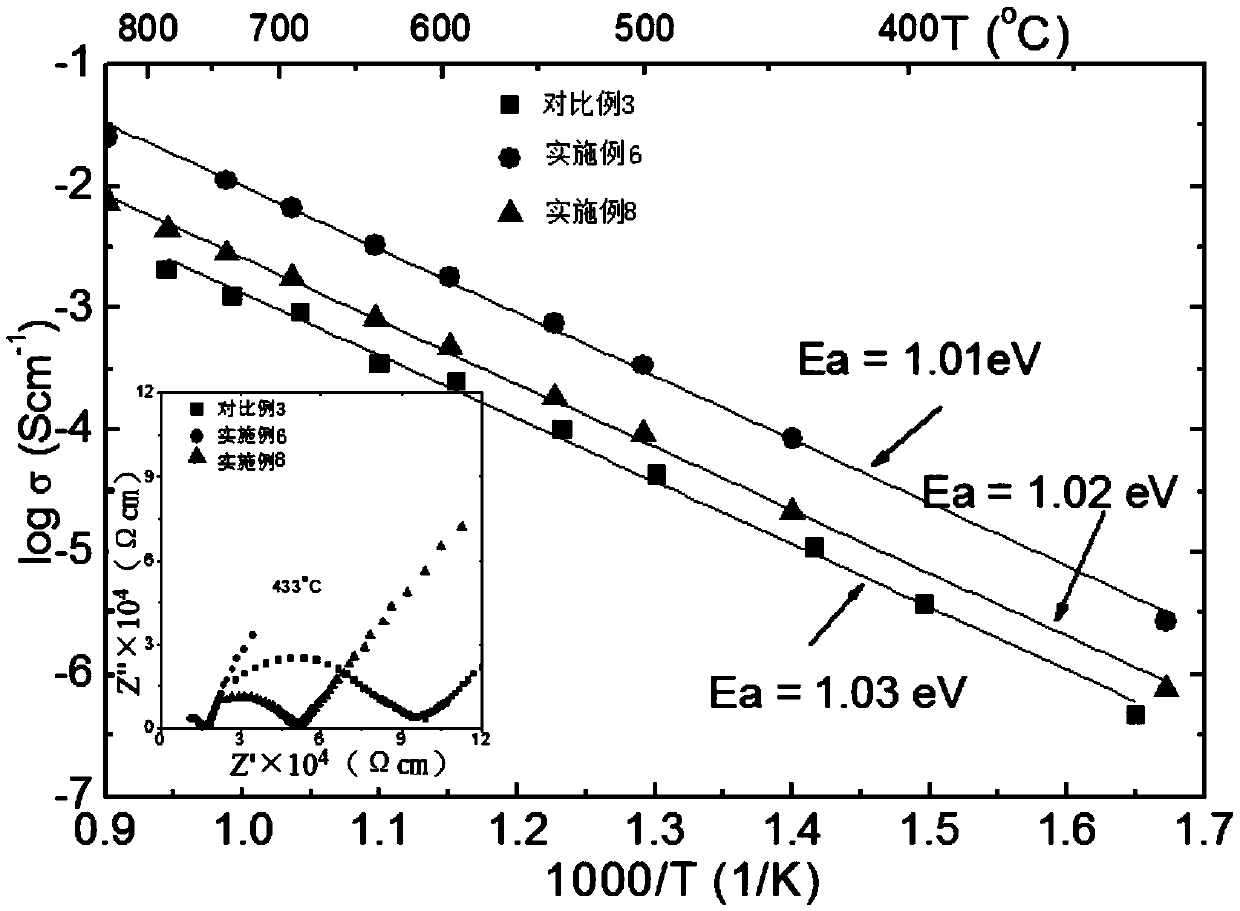

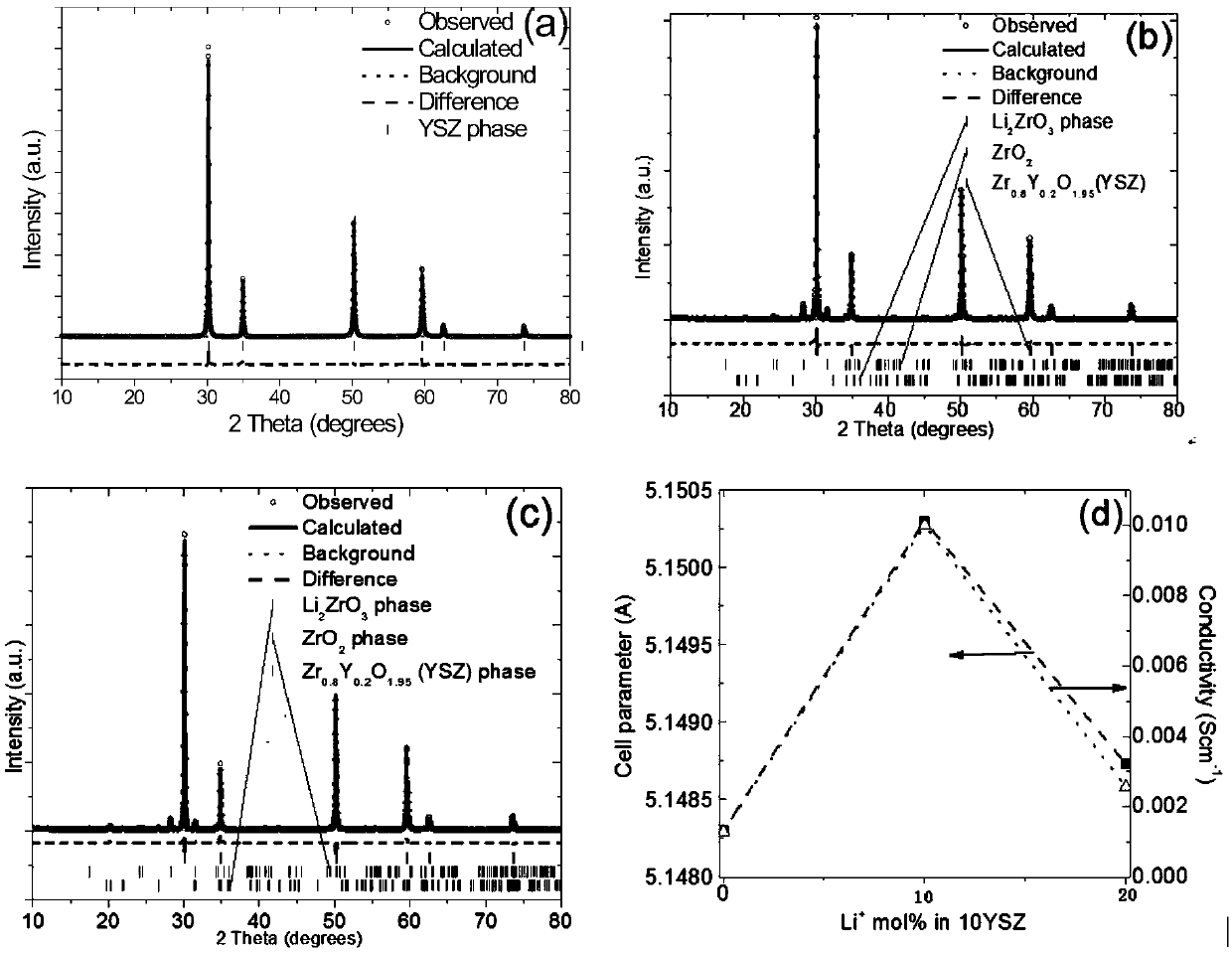

[0038] Will Zr 0.8 Y 0.2 o 1.9 with LiOH·H 2 O ball milling is evenly mixed, the ball milling speed is 200rpm, and the ball milling time is 12h to obtain a granular mixture, wherein the molar ratio of Li in the dopant to the YSZ electrolyte raw material is 10mol.%, that is, Zr 0.8 Y 0.2 o 1.9 with LiOH·H 2 The molar ratio of O was 1:0.1; then, the mixture was heated to 1000 °C in air atmosphere, kept at this temperature for 24 h, and then cooled to room temperature to obtain the oxygen ion conductor Li 0.1 Zr 0.8 Y 0.2 o 1.95 , in this embodiment, x=0.05.

[0039] Using LiOH·H 2 The general reaction formula of O as a dopant is:

[0040] Zr 0.8 Y 0.2 o 1.9 (YSZ)+2xLiOH·H 2 O = Li 2x Zr 0.8 Y 0.2 o 1.9+x +3xH 2 o

Embodiment 2

[0042] Will Zr 0.8 Y 0.2 o 1.9 with LiOH·H 2 O ball milling is evenly mixed, the ball milling speed is 200rpm, and the ball milling time is 12h to obtain a granular mixture, wherein the molar ratio of Li in the dopant to the YSZ electrolyte raw material is 10mol.%, that is, Zr 0.8 Y 0.2 o 1.9 with LiOH·H 2 The molar ratio of O was 1:0.1; then, the mixture was heated to 1400 °C in air atmosphere and kept for 12 h, and then cooled to room temperature to obtain the oxygen ion conductor Li 0.1 Zr 0.8 Y 0.2 o 1.95 , in this embodiment, x=0.05.

Embodiment 3

[0044] Will Zr 0.8 Y 0.2 o 1.9 with LiOH·H 2 O ball milling is evenly mixed, the ball milling speed is 200rpm, and the ball milling time is 12h to obtain a granular mixture, wherein the molar ratio of Li in the dopant to the YSZ electrolyte raw material is 20mol.%, that is, Zr 0.8 Y 0.2 o 1.9 with LiOH·H 2 The molar ratio of O was 1:0.2; then, the mixture was heated to 1000°C in air atmosphere and kept for 18h, and then cooled to room temperature to obtain the oxygen ion conductor Li 0.2 Zr 0.8 Y 0.2 o 2 , in this embodiment, x=0.1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com