Low cobalt positive electrode active material, method for preparing same, electrochemical device, and electronic apparatus

A cathode active material, electrochemical technology, applied in the field of batteries, can solve the problems of excellent kinetic performance, narrow particle size distribution, low capacity, etc., to achieve the effects of excellent performance, narrow particle size distribution, and uniform particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

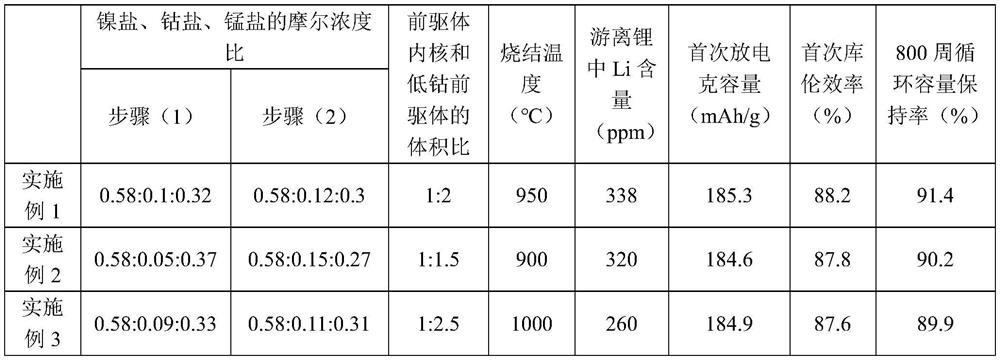

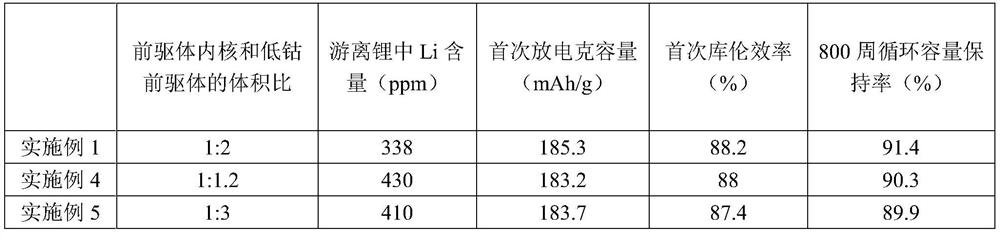

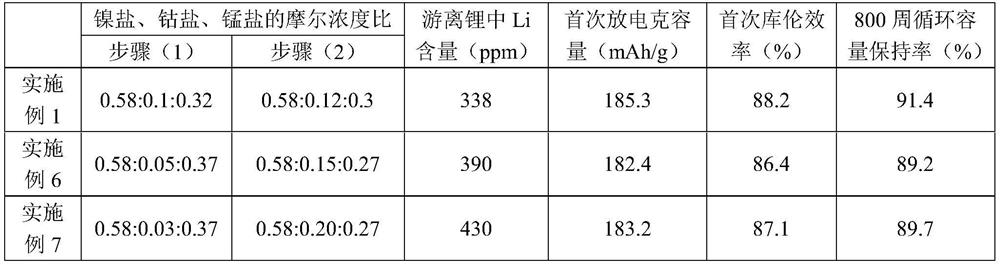

Examples

Embodiment 1

[0065] The present embodiment provides a method for preparing a low-cobalt positive electrode active material, including:

[0066] (1) nickel sulfate, cobalt sulfate, manganese sulfate, ammoniacal liquor and sodium hydroxide are added in reactor, carry out co-precipitation reaction, when the volume of the product of co-precipitation reaction is half the volume of target product, stop reaction, obtain precursor In vivo core Ni 58 Co 10 Mn 32 (OH) 2 ;

[0067] (2) the core of the precursor described in step (1) is taken out, placed in another reaction kettle with nickel sulfate, cobalt sulfate, manganese sulfate, ammonia water and sodium hydroxide to mix, again carry out coprecipitation reaction, in Ni 58 Co 10 Mn 32 (OH) 2 Ni generated on the surface 58 Co 12 Mn 30 (OH) 2 , the low-cobalt precursor is obtained, and the volume of the low-cobalt precursor is twice the volume of the core of the precursor;

[0068] (3) mixing the low-cobalt precursor and lithium hydroxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com