Ternary positive-electrode material prepared by solvothermal method and preparation method thereof

A positive electrode material and a solvothermal technology are applied in the field of ternary positive electrode materials for lithium ion batteries and their preparation, which can solve the problems of complex preparation process and expensive raw materials, and achieve controllable morphology, uniform particles, and improved electrochemical performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

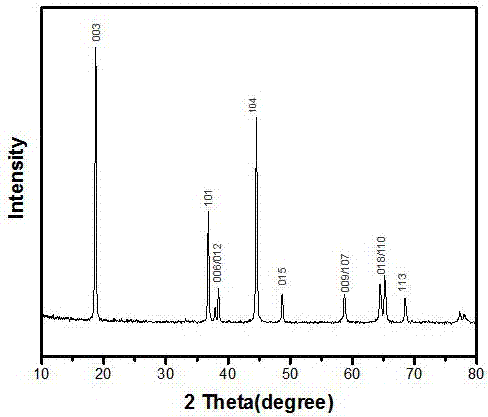

Image

Examples

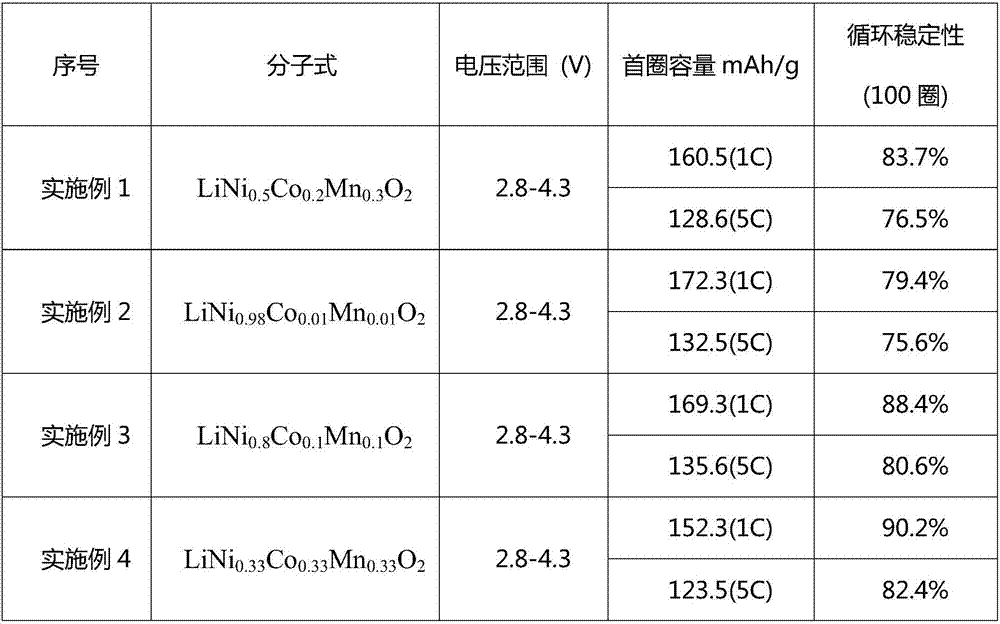

Embodiment 1

[0024] Dissolve nickel nitrate, cobalt nitrate, and manganese sulfate in a molar ratio of 0.5:0.2:0.3 in a certain amount of deionized water and isopropanol mixed solution to prepare solution A. Dissolve a certain amount of urea and polyvinylpyrrolidone in a mixed solution of deionized water and isopropanol to prepare solution B. Mix solution A and solution B, stir for 0.5h, and configure solution C, in which the total concentration of metal ions is 0.2mol / L, the amount of polyvinylpyrrolidone added is 1g / L, and the amount of hydrolysis aid added is the total amount of metal ions The amount of 20 times, deionized water accounts for 10% of the total volume of the mixed solution C. The solution C was transferred to a 50ml stainless steel reaction kettle with polytetrafluoroethylene lining, and the temperature was raised from room temperature to 200°C, and the temperature was kept for 10h. The obtained product was filtered, washed, dried at 80°C for 10h, placed in a muffle furna...

Embodiment 2

[0027] Dissolve nickel acetate, cobalt acetate, and manganese acetate in a molar ratio of 0.98:0.01:0.01 in a certain amount of deionized water and a mixed solution of triethanolamine to prepare solution A. Dissolve a certain amount of urotropine and cetyltrimethylammonium bromide in a mixed solution of deionized water and triethanolamine to prepare solution B. Mix solution A and solution B, stir for 20 hours, and configure solution C, wherein the total concentration of metal ions is 0.002mol / L, the amount of cetyltrimethylammonium bromide is 15g / L, and urotropine The added amount is 0.5 times of the total amount of metal ions, and the deionized water accounts for 80% of the total volume of the mixed solution C. The solution C was transferred to a 100ml stainless steel reaction kettle with polytetrafluoroethylene lining, raised from room temperature to 160°C, and kept at this temperature for 20h. The obtained product was filtered, washed, dried at 80°C for 15h, placed in a mu...

Embodiment 3

[0030]Dissolve nickel chloride, cobalt chloride, and manganese acetate in a molar ratio of 0.8:0.1:0.1 in a deionized aqueous solution to form solution A. Solution B was prepared by dissolving sodium bicarbonate and hydroxyethylcellulose in deionized water. Mix solution A and solution B, stir for 5 hours, and configure solution C, wherein the total concentration of metal ions is 0.02mol / L, the amount of hydroxyethyl cellulose added is 10g / L, and the amount of sodium bicarbonate added is the total amount of metal ions 5 times the amount of substance. The solution C was transferred to a 100ml stainless steel reactor with polytetrafluoroethylene lining, and the temperature was raised from room temperature to 90°C for 2h. The obtained product was filtered, washed, dried at 80°C for 24h, placed in a muffle furnace, and calcined at 600°C for 4h in an air atmosphere (calcination heating rate was 5°C / min) to obtain a nickel-cobalt-manganese ternary oxide precursor . The ternary oxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com