Patents

Literature

111results about How to "Solve the problem of hydrolysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

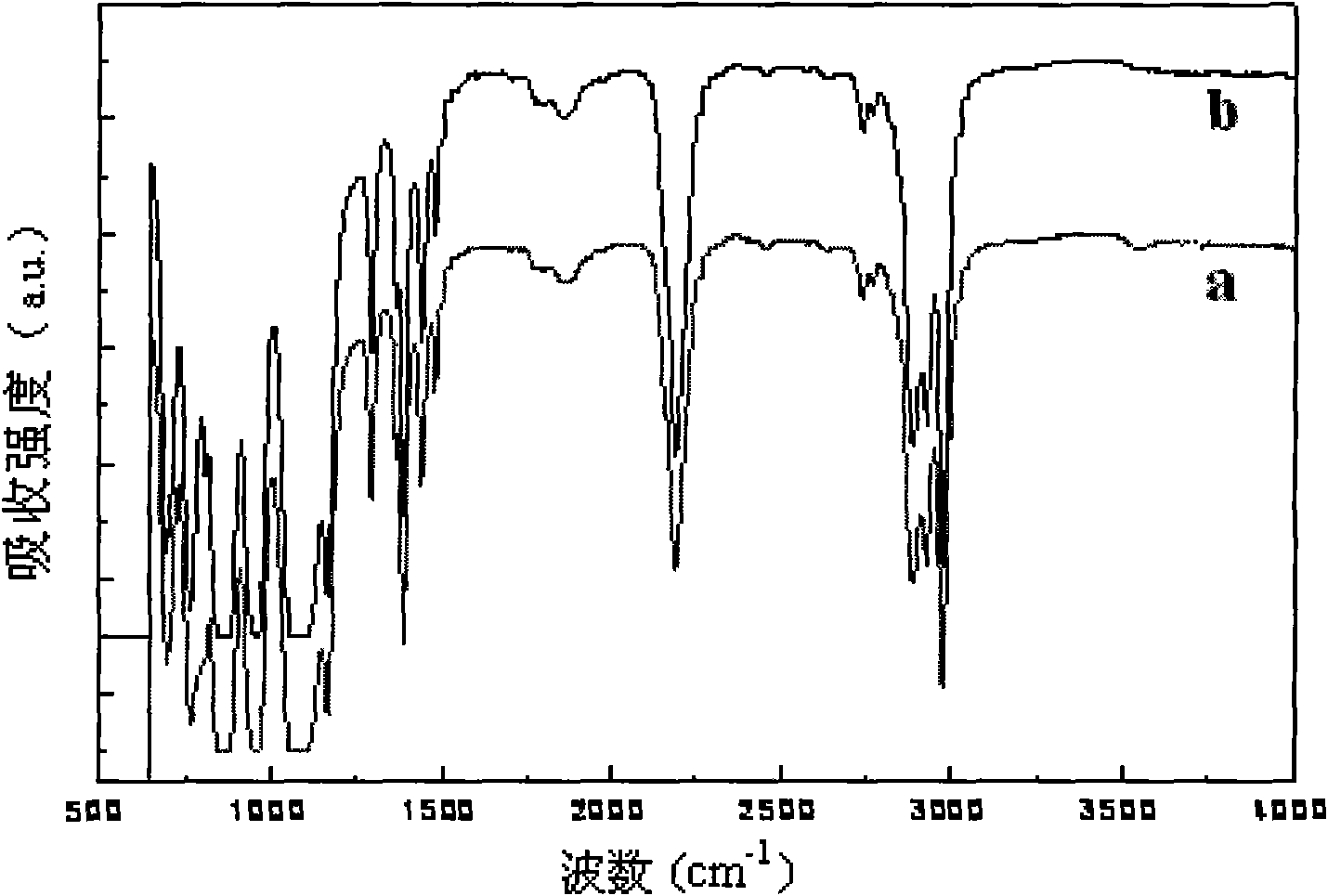

Silicone modified acrylic ester emulsion and preparation method thereof

The invention discloses a silicone modified acrylic ester emulsion and a preparation method thereof. The emulsion is prepared from the following raw materials in parts by weight: 6.5-9 parts of acrylic ester mixed monomers, 1-3.5 parts of an organosilicone monomer, 0.4-0.6 part of an emulsifier, 0.2-0.3 part of an initiating agent, 0.01-0.03 part of a pH conditioning agent, 28-32 parts of deionized water, wherein the acrylic ester mixed monomers are methyl methacrylate and butyl acrylate with the mass ratio of (5.5-6.5):(3.5-4.5); the organosilicone monomer is gamma- 3-[Tris(trimethylsiloxy)silyl]propyl methacrylate. According to the emulsion, the reactive emulsifier is adopted for polymerization reaction, the prepared emulsion is stable, and the latex film of the emulsion has lower surface energy and better water resistance, and can be used as the main film forming matter of a metal anti-corrosion coating.

Owner:INST OF IND TECH GUANGZHOU & CHINESE ACADEMY OF SCI

Organic bentonite pesticide sustained-release granular formulation and preparation method thereof

InactiveCN102578081AGood compatibilityDoes not constitute pollutionBiocideFungicidesChemical structureControl release

The invention relates to a sustained-release granular formulation for preventing and treating crop diseases and insect pests and a preparation method thereof. The pesticide sustained-release granular formulation comprises bentonite, an organic modifier, pesticide active ingredients, an inert filler and a binding agent, and is prepared by the preparation method comprising the steps of: (1) with the bentonite as a basic material, modifying the bentonite by the organic modifier to obtain organic bentonite; (2) loading the pesticide active ingredients on the organic bentonite to prepare medicine-carrying organic bentonite; and (3) mixing the medicine-carrying organic bentonite, the inert filler and the binding agent proportionally, and pelleting to obtain the sustained-release granular formulation. The preparation method of the sustained-release granular formulation, provided by the invention, not only overcomes the defect of low pesticide loading rate of the natural bentonite, but also realizes the controlled release of the pesticide by adjusting a chemical structure and the amount of the modifier, so that the sustained-release granular formulation is coincident with an occurrence rule of the plant diseases and insect pests, and the pesticide sustained-release granular formulation is used safely, reasonably, economically and effectively.

Owner:GAUNGXI TIANYUAN BIOCHEM +1

Core/shell type organosilicone-modified acrylate emulsion and preparation method and application thereof

InactiveCN105601799AUniform appearanceImprove stabilityLiquid repellent fibresEmulsionEmulsion polymerization

The invention relates to a core / shell type organosilicone-modified acrylate emulsion and a preparation method and application thereof. The core / shell type emulsion is prepared through polymerization based on the core / shell emulsion polymerization technology and is prepared from, by weight, 500-850 parts of acrylate mixed monomers, 150-500 parts of organosilicone monomers, 10-50 parts of an emulsifying agent, 5-12 parts of an initiating agent, 5-50 parts of a crosslinking agent and 1000-4000 parts of water, wherein acrylate mixed monomers are composed of methyl methacrylate, butyl acrylate and acrylic acid at the mass ratio of (1.0-3.5):(6.5-9.0):(0.15-0.75), and a seed emulsion in the core / shell emulsion polymerization technology is obtained through polymerization of the acrylate mixed monomers. The core / shell type emulsion is good in stability, the mean grain size is 170 nm or so, and an emulsion film has an excellent film-forming property, an excellent bonding property, low surface energy and good waterproofness.

Owner:INST OF IND TECH GUANGZHOU & CHINESE ACADEMY OF SCI

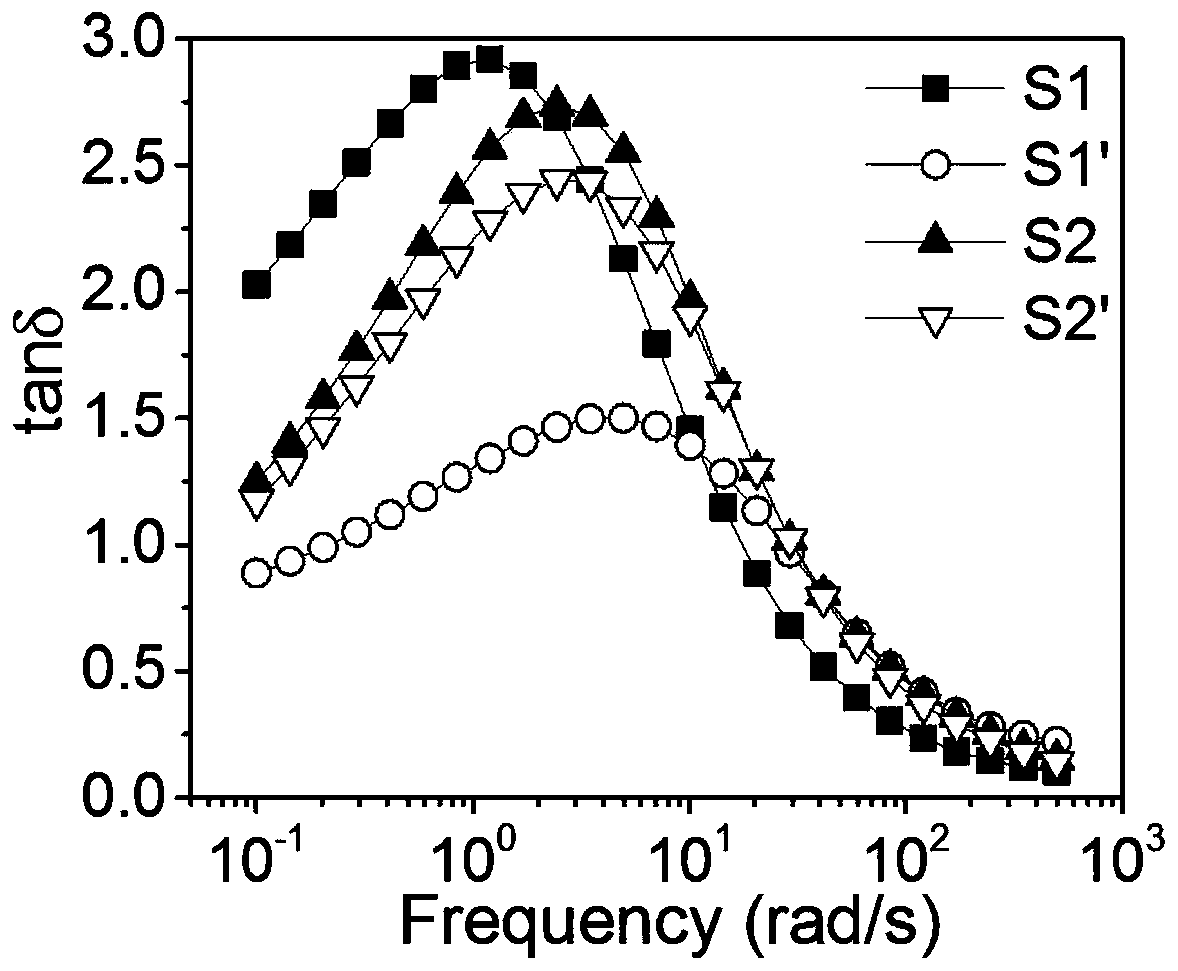

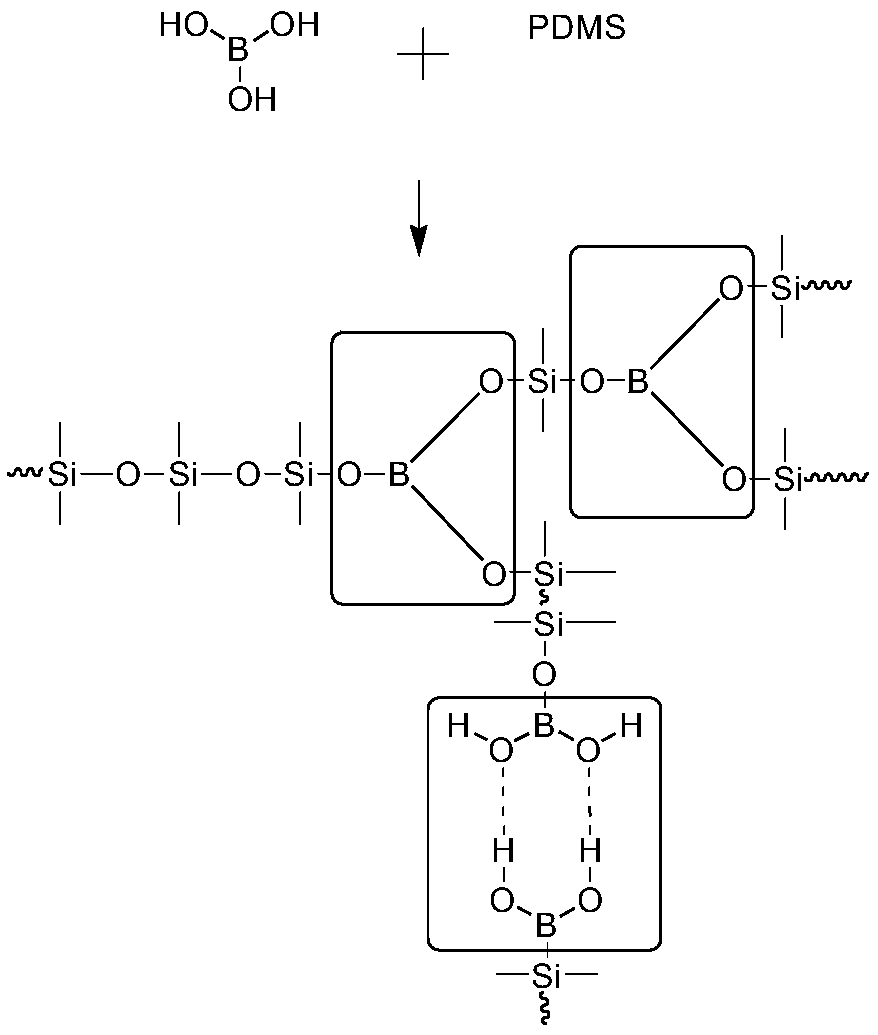

Waterproof polyborosiloxane impact-resistant damping material and preparation method thereof

ActiveCN110564164ASolve the problem of hydrolysisHigh anti-damping characteristicsMolecular sieveBoric acid

The invention provides a waterproof polyborosiloxane impact-resistant damping material and a preparation method thereof. The waterproof polyborosiloxane impact-resistant damping material provided by the invention comprises the following components in parts by mass: 75-97 parts of a polyborosiloxane-based material and 3-25 parts of a water-absorbing material, wherein polyborosiloxane in the polyborosiloxane-based material is prepared from boric acid and polydimethylsiloxane through a condensation reaction; the polydimethylsiloxane is terminated by a hydroxyl group; the water-absorbing materialis one or more selected from the group consisting of organic polymer water-absorbent resin and an inorganic water-absorbing agent; and the inorganic water-absorbing agent is one or more selected fromthe group consisting of a molecular sieve and mineral soil. According to the invention, the specific polyborosiloxane-based material and the specific water-absorbing material are matched according toa certain ratio, so that the defect that the polyborosiloxane is easy to hydrolyze can be overcome, and the hydrolysis stability of the polyborosiloxane impact-resistant damping material is improved.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

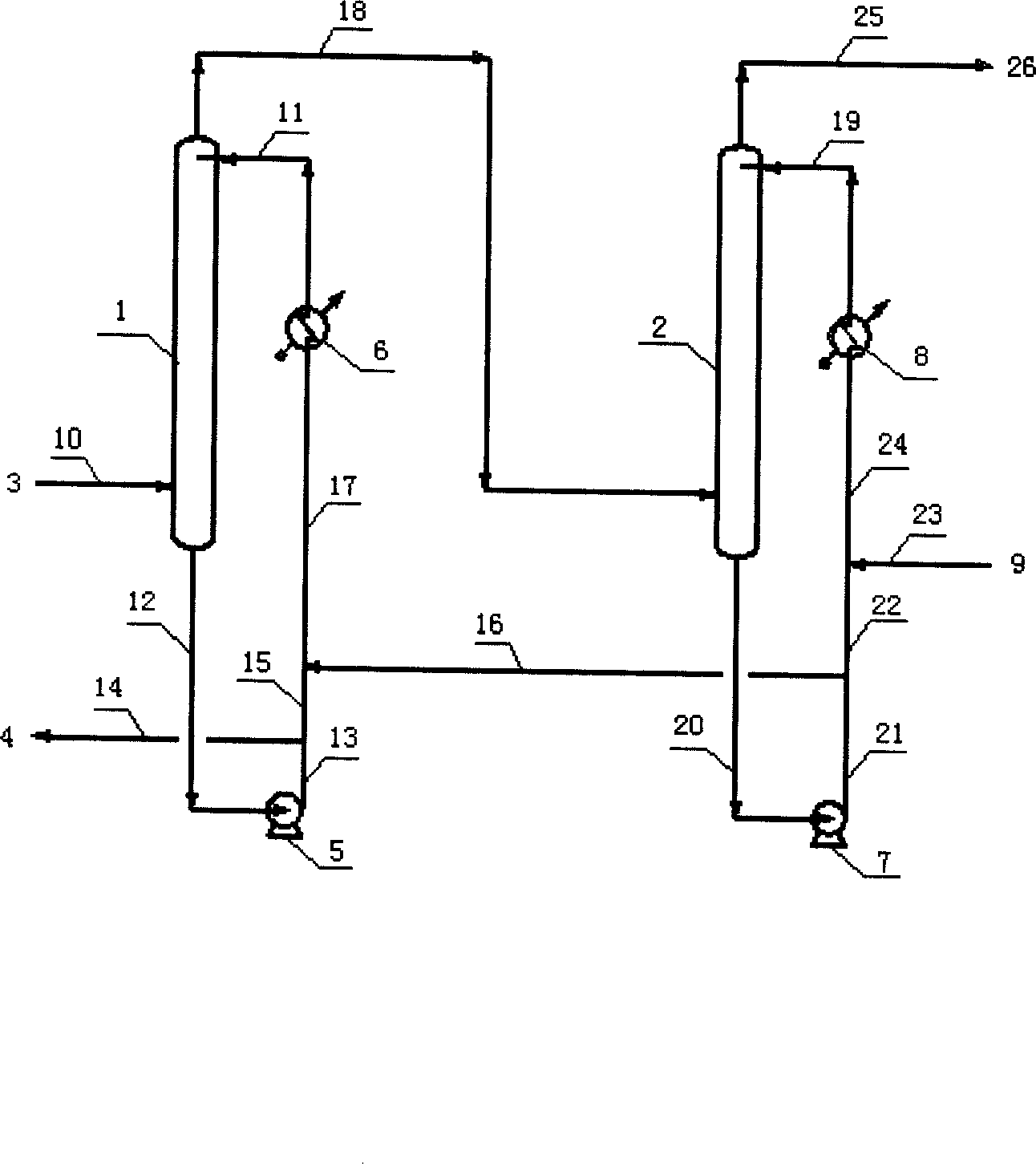

3-cyanopyridine absorption method

ActiveCN101045706AControl concentrationReduce lossesOrganic chemistryTheoretical plateLiquid temperature

This invention relates to a absorption approach of 3 - cyan pyridine, mainly solve the problem that while using circulating water solution to assimilate 3 - cyan pyridine in anciently literature, not involved with theoretical plate number of absorption column, weight proportion of liquid and air, as well as 3 - cyan pyridine easily hydrolyzing. This invention adopts two tandem circulation absorption columns. Control the concentration of 3 - cyan pyridine in first absorption column bottom at 3 to 10 percent of weight, the liquid temperature while circulating to overhead is 5 to 50 deg, theoretical plate number of absorption column is 2 to 20 pieces, weight proportion of liquid and air is 2 to 15. The weight ratio between liquid circulating to second absorption column overhead and circulating to first absorption column overhead is 0.25 to 0.8.

Owner:SHANGHAI RES INST OF PETROCHEMICAL TECH SINOPEC

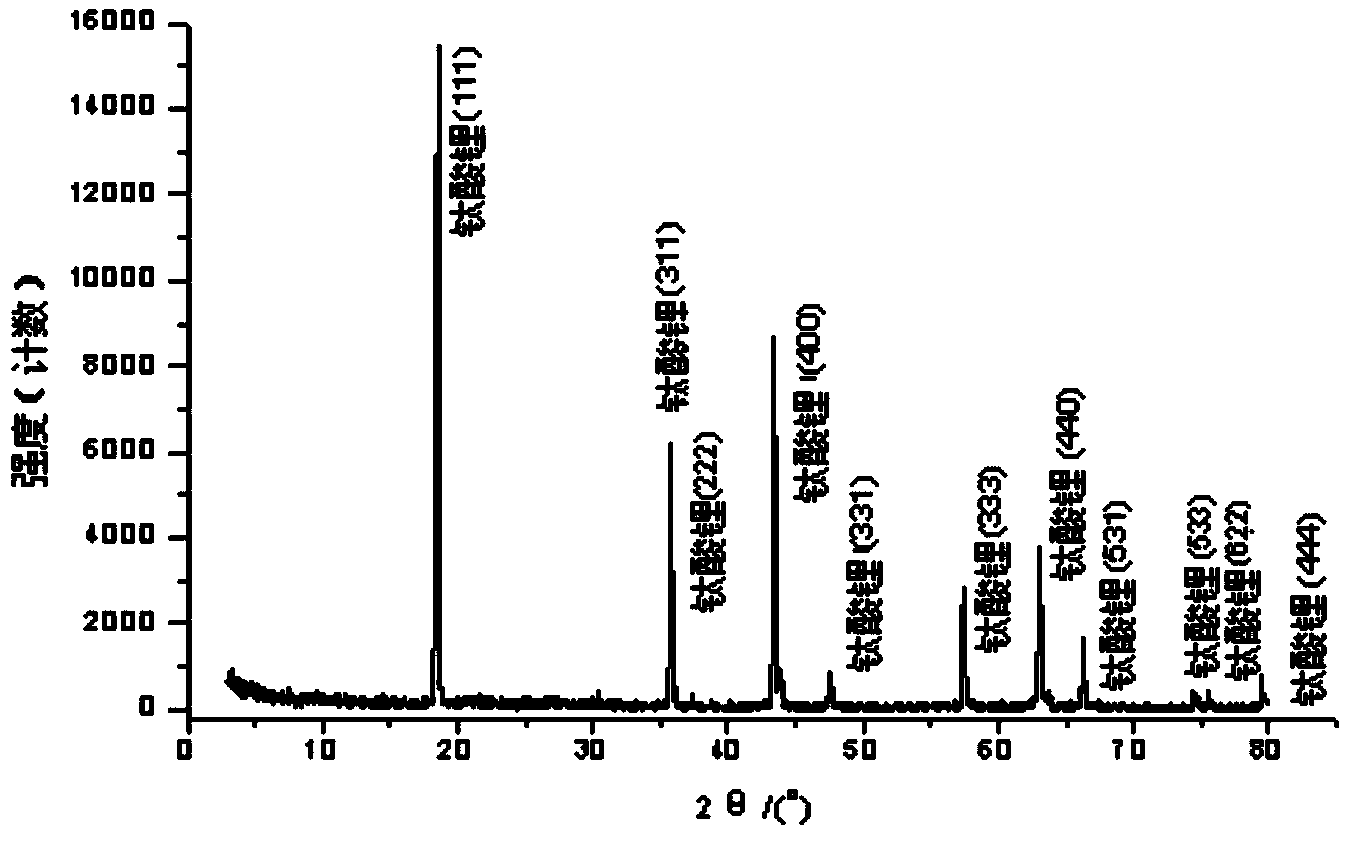

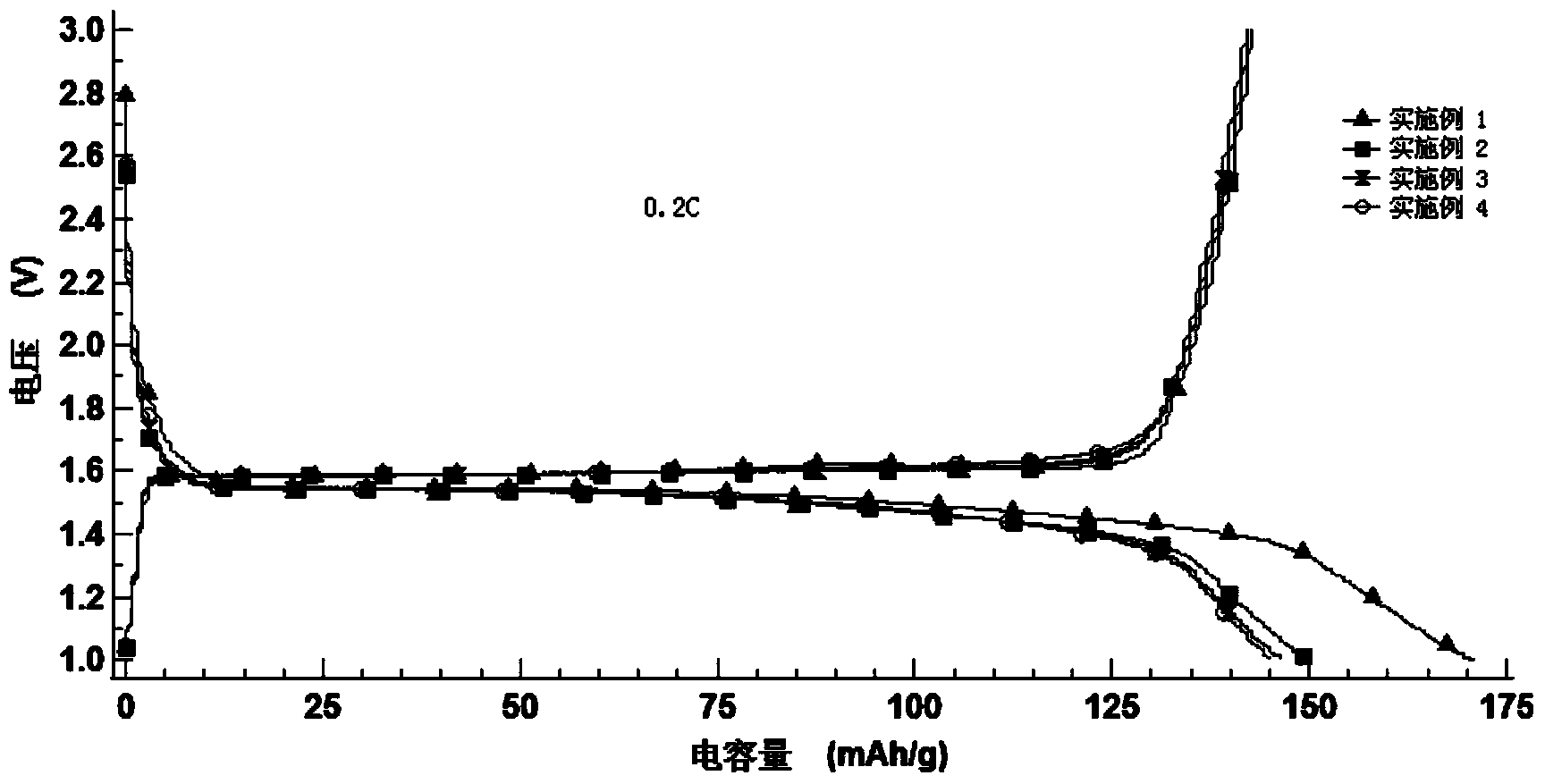

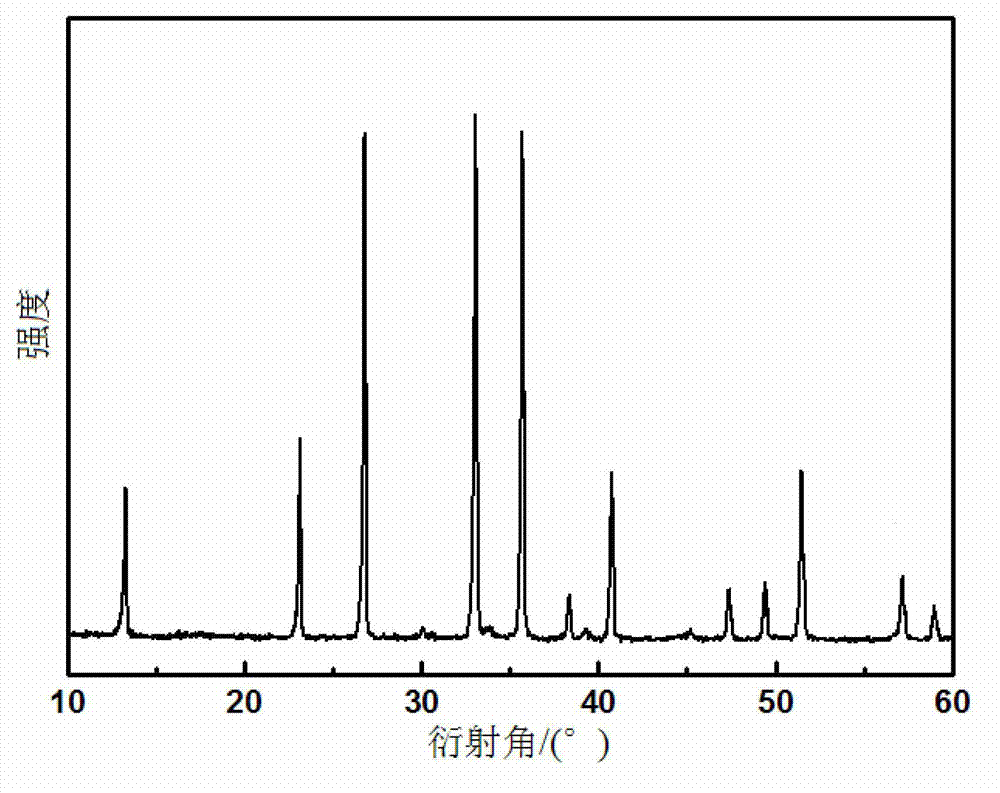

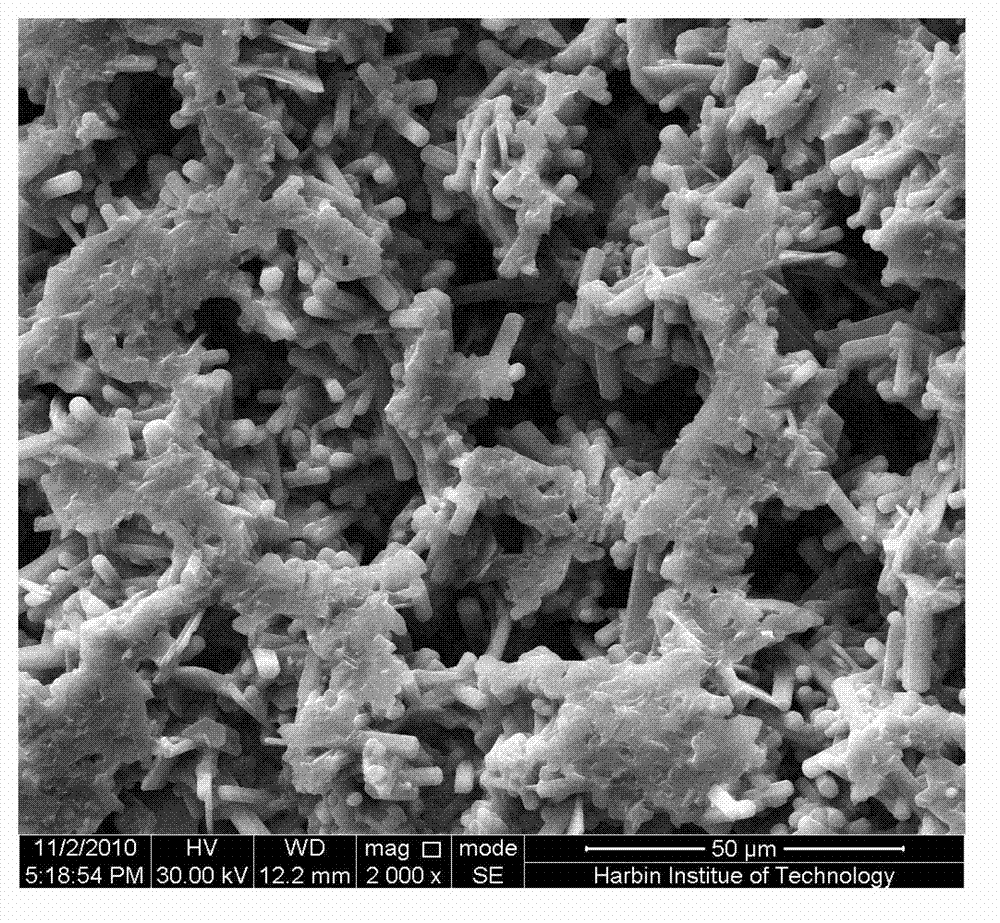

Sol-gel method for preparing lithium titanate

The invention belongs to the technology field of lithium battery, and especially relates to a sol-gel method for preparing lithium titanate. The invention aims to solve the technology problem of uneasy operation control, which causes the instability of gel, in the conventional sol-gel method. In order to solve the technology problem mentioned above, the invention provides a sol-gel method for preparing lithium titanate. The method comprises following steps: step a, dissolving butyl titanate in glycol to prepare a solution; step b, mixing dihydrate lithium acetate, citric acid, absolute ethanol and deionized water together to prepared a solution; step c, dropwise adding the solution obtained in the step b into the solution obtained in the step a, adding ammonia liquor at the same time, then stirring to obtain transparent sol, then ageing to obtain the gel; step d, drying the gel under constant temperature to obtain dry gel, then fully grinding the dry gel to obtain precursors; step e, and finally sintering the precursors in sections to obtain lithium titanate. The preparation method has the advantages of convenient operation, excellent product properties and preferably good application prospect.

Owner:PANZHIHUA UNIV

Dye liquor preparation method capable of improving first-time success rate of cold pad-batch dyeing

InactiveCN101864674ASolve the problem of hydrolysisIncrease profitDyeing processSodium silicateHydrolysis

The invention provides a dye liquor preparation method capable of improving the first-time success rate of cold pad-batch dyeing, which belongs to a dye liquor preparation method for use in printing and dyeing production. The method comprises: a, preparing mixed alkaline solution and dye solution respectively, wherein the mixed alkaline solution is prepared by adding water into a material mixing tank, then adding aqueous solution of sodium silicate and sodium hydroxide are added into the water, stirring the mixture uniformly and the dye solution is prepared by adding water in the dye solution mixing tank, then adding penetrant and urea into the water, adding a reactive dye and stirring the mixture uniformly; and b, delivering the mixed alkaline solution and the dye solution to a chassis by using a proportioning pump to mix the mixed alkaline solution and the dye solution to obtain the dye liquor, wherein in mixing, the volume ratio of the dye solution to the mixed alkaline solution is 4:1. The dye liquor preparation method solves the dye hydrolysis problem of pre-mixing by preparing and mixing the mixed alkaline solution and the dye solution separately, improves the success rate of first-time samples and dye utilization rate and saves production cost.

Owner:HUAFANG

Method for producing high-purity inulin

InactiveCN101955553AHigh degree of polymerizationSolve the problem of hydrolysisFiltrationStrong acids

The invention provides a method for producing high-purity inulin, which comprises the following steps of: a, performing cleaning, shredding, countercurrent leaching, flocculation and impurity removal, and filtration on jerusalem artichoke or chicory serving as a raw material to obtain inulin feed solution; b, making the inulin feed solution obtained in the step a pass through macroporous decolorization resin, strong acid resin, and strong base resin for decoloration in turn at a linear speed of 2-3 meters / second, and performing ion exchange to obtain inulin solution, wherein the macroporous decolorization resin, the strong acid resin, and the strong base resin are respectively added with 8 to 12 weight percent sodium chloride solution in an amount which is 2 to 4 times volume thereof for regeneration; and c, performing nanofiltration on the inulin solution by using a nanofiltration membrane, eluting monosaccharide and sodium chloride by using purified water, concentrating, and performing spray drying to obtain the product. The method has the advantages of avoiding hydrolysis caused by reduced pH value of the inulin solution, regenerating and recycling ion exchange resin, and realizing comprehensive utilization, clean production and pollution-free emission in the whole production process.

Owner:SHANDONG NINE RING GASOLINEEUM MACHINERY

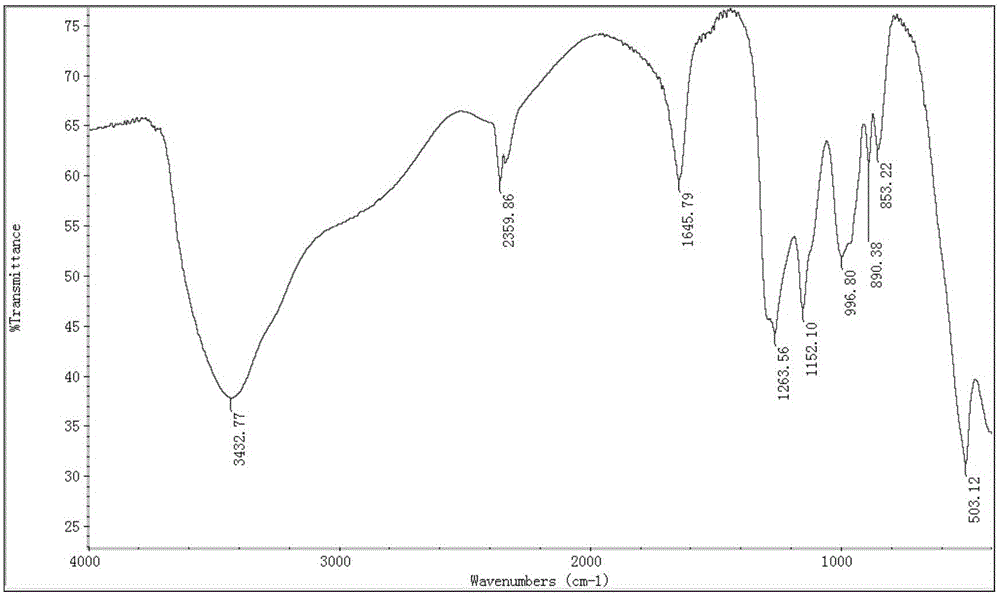

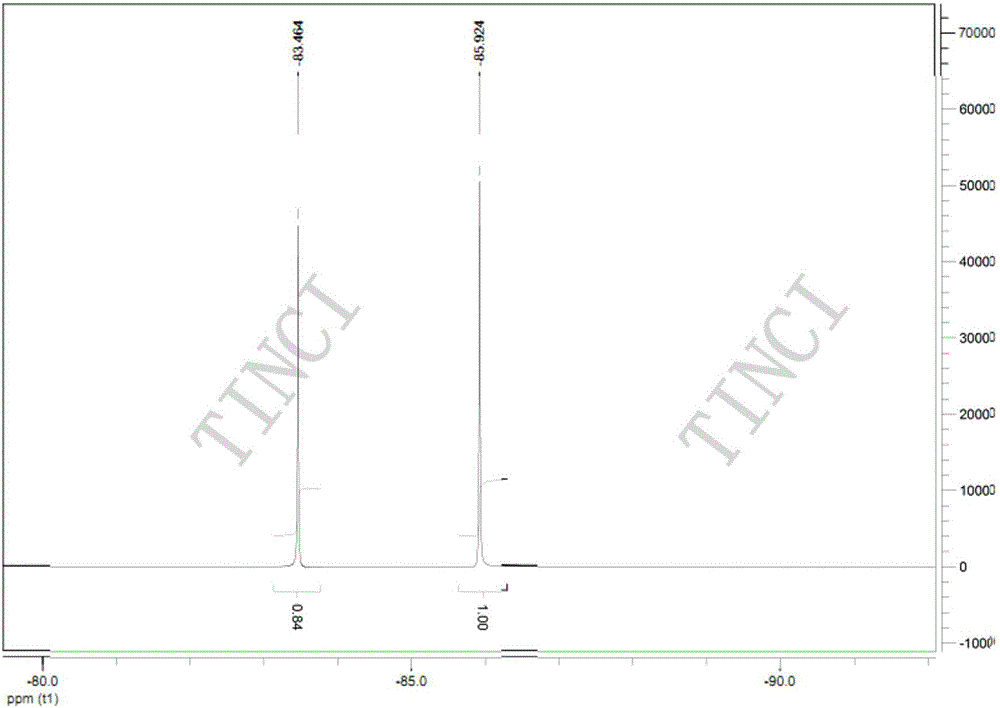

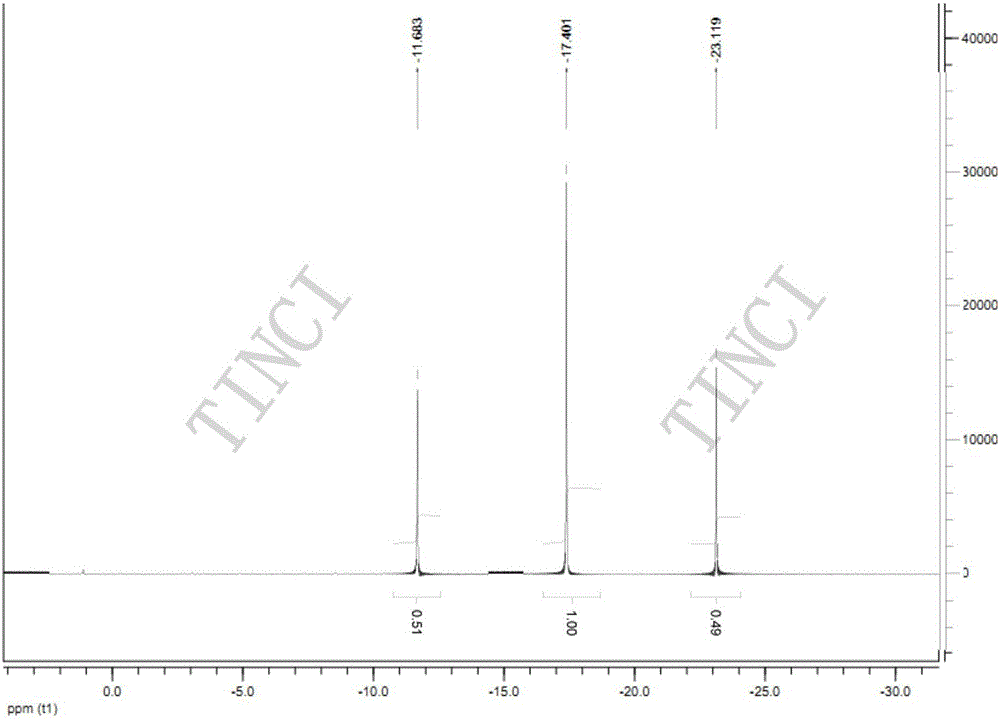

Method for preparing difluorophosphates

The invention belongs to the technical field of lithium-ion batteries and particularly relates to an efficient method for preparing difluorophosphates. The method comprises the following steps: metering a hexafluorophosphate solution with the concentration being 5wt% to 50wt% and a cyclosiloxane or an acetal, then, introducing the metered materials to a microchannel reactor, carrying out a reaction for 60 to 900 seconds at the temperature of 20 DEG C to 150 DEG C, carrying out membrane filtration on an obtained reaction solution, and then, carrying out concentrating and drying, thereby obtaining a corresponding difluorophosphate product. The method disclosed by the invention has the advantages that the process route is simple, the raw materials are readily available, the reaction efficiency is high, the energy consumption is low, the product purity is high, and the like.

Owner:JIUJIANG TINCI ADVANCED MATERIALS CO LTD

Method for preparing porous beta-SiAlON ceramic

InactiveCN102807373ASolve the problem of hydrolysisMeet the requirements of dielectric propertiesSlurrySialon

A method for preparing porous beta-SiAlON ceramic relates to a method for preparing porous ceramic. The method aims to solve the problem that the porous beta-SiAlON ceramic prepared by an existing partially sintering method is not uniform in distribution of pore structures and uncontrollable in poriness. The method includes the steps of firstly, preparing materials according to the chemical formula Si6-zAlzOzN8-z; secondly, mixing by ball milling to obtain mixed powder; thirdly, subjecting camphene, dispersing agent and the mixed powder to ball-milling to obtain uniform and stable camphene-beta-SiAlON slurry; fourth, condensing to obtain concretionary camphene-beta-SiAlON; fifthly, drying to obtain dried camphene-beta-SiAlON; and sixthly, pressurelessly sintering to obtain the porous beta-SiAlON ceramic. The method is mainly used for preparing porous beta-SiAlON ceramic.

Owner:HARBIN INST OF TECH

Preparation method of hydrated titanium dioxide double-effect seed crystal

ActiveCN102153136ARaw materials are easy to getQuality improvementTitanium dioxideSlurryHydrolytic Process

The invention belongs to the technical field of the production of titanium dioxide and in particular relates to a preparation method of hydrated titanium dioxide double-effect seed crystal. The preparation method comprises the following steps: adding sulfuric acid in metatitanic acid slurry to prepare titanium sulfate solution, using titanium sulfate solution and sodium carbonate to react and generate titanic acid, and using monoprotic acid to neutralize titanic acid and obtain the finished product. The hydrated titanium dioxide double-effect seed crystal can be a solid object with a certain water content or slurry of which concentration is less than 220g / L (calculated by TiO2). The rutile-type TiO2 content of the seed crystal is 5-95% of the total weight of TiO2 and the seed crystal also contains anatase TiO2 and amorphous TiO2. The seed crystal is added in the hydrolysis process of titanium-containing solution, wherein the weight percentage is 1-3% which is calculated by TiO2; and after hydrolysis, new rutile-type seed crystal is not required to be added in the calcining link.

Owner:四川安宁铁钛股份有限公司

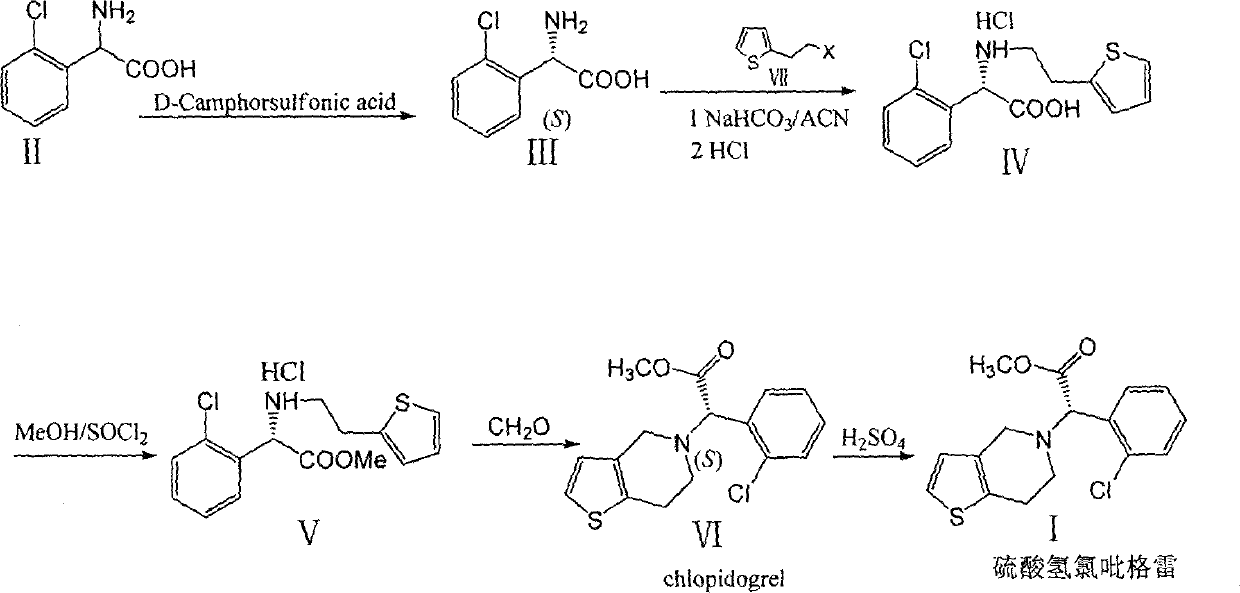

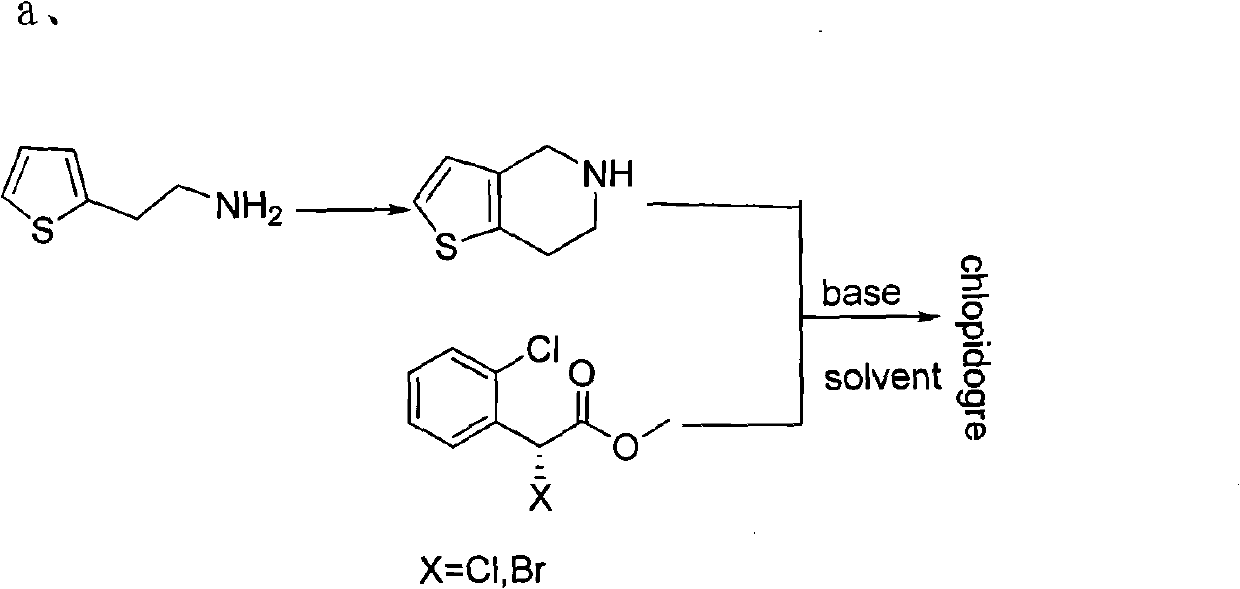

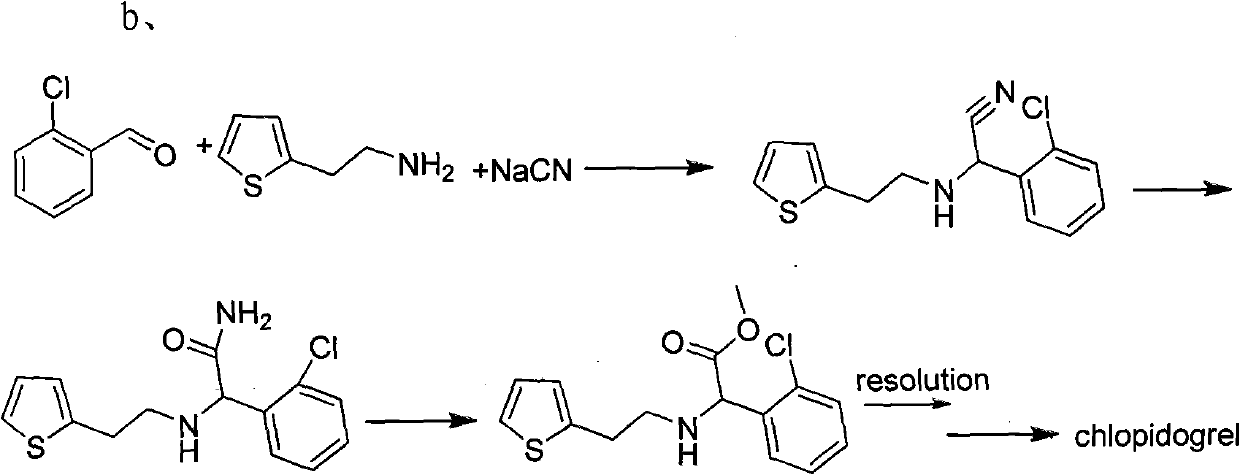

Novel method for preparing clopidogrel and slat thereof

The invention discloses a novel method for preparing a clopidogrel compound, which comprises the following steps: taking a compound shown in Formula (II) as a raw material, obtaining a compound shown in Formula (III) through optical resolution, obtaining a compound shown in Formula (IV) through substitution reaction of the compound shown in Formula (III), further obtaining a compound shown in Formula (V) by acetifying the compound shown in Formula (IV) to be salt, obtaining the final product, i.e. the lopidogrel compound shown in Formula (VI), through Mannich cyclization, and then generating salt by mixing the compound shown in Formula (VI) and sulfuric acid for reaction to obtain the target product (I). The method of the invention for preparing the clopidogrel compound has the advantages of readily available raw materials, low price, mild reaction condition, simple operation and high total yield, and is a novel integrated synthesis method applicable for industrial production of clopidogrel.

Owner:无锡好芳德药业有限公司

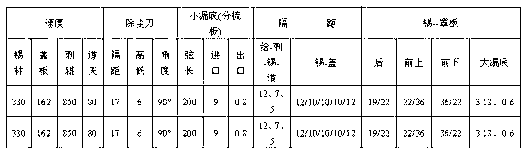

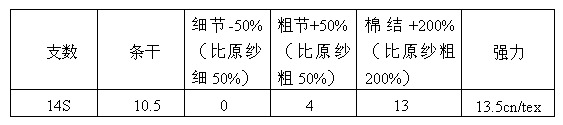

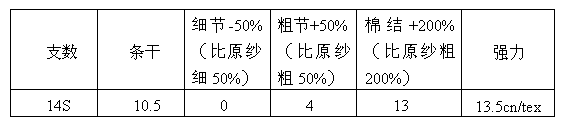

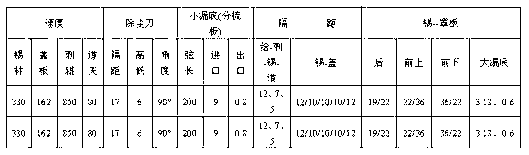

Air vortex spinning method of multi-component full-colored spun yarns

ActiveCN102995176AExpand the color spinning spaceAvoid craft difficultyContinuous wound-up machinesOpen-end spinning machinesYarnCarding

The invention discloses an air vortex spinning method of multi-component full-colored spun yarns, belonging to the technical field of novel spinning. The air vortex spinning method comprises the steps of: blending preprocessed dyed loose yarns according to a certain proportion, obtaining card slivers by cotton blending, blowing and cotton carding, obtaining drawn slivers by drawing and blending the card slivers for three times, and obtaining finished products by vortex spinning of the drawn slivers. The loose yarns comprise viscose, tencels, wools and spun silks at the mass percent ratio of 50:20:10:10; and 14 yarns for sweaters are spun. The air vortex spinning method of the multi-component full-colored spun yarns can meet multi-component full-colored spinning technical requirements and has the advantages of low cost, uniform coloring, no color difference and the like; and vortex spinning is applied to the color spinning field.

Owner:SHAOXING GUOZHOU TEXTILE NEW MATERIAL

Preparation method of multi-component full-color spinning fabrics

The invention discloses a preparation method of multi-component full-color spinning fabrics, and belongs to the technical field of spinning fabrics. The fabrics are made of air vortex spinning yarn. The process of the air vortex spinning yarn includes: entering start-clearing process after the mixture of disperse fiber colored respectively, obtaining card slivers after cotton clearing and cotton carding, obtaining drawn slivers after the card slivers are mixed through three ways of drawing and doubling, and obtaining finished products after the drawn slivers pass through vortex spinning. The disperse fiber comprises viscose, gossamer, wool and spun silk. In the cotton clearing process, the disc heater speed is 740 r / min, the beater stretches out 1-1.5 mm of a rib strip, the cotton opening machine beater speed is 450 r / min, and full-close is formed below a grid bar. In the vortex spinning process, the spinning speed is 340 m / min, first break draft is three times, dominant draft is fifteen times, traverse angle is 14 deg and feeding rate is 0.98. The preparation method of the multi-component full-color spinning fabrics can meet the technical requirements of multi-component full-color spinning, and the vortex spinning is applied to the color spinning field, and thus the preparation method of the multi-component full-color spinning fabrics has the advantages of being low in cost, uniform in coloring, and free from color aberration and the like.

Owner:SHAOXING GUOZHOU TEXTILE NEW MATERIAL

Organosilicon acrylate compound waterproof finishing agent emulsion

The invention discloses an organosilicon acrylate compound waterproof finishing agent emulsion. The organosilicon acrylate compound waterproof finishing agent emulsion is prepared from in percentage by mass: 52-68% of an organosilicon emulsion and 32-48% of a silicon-contained acrylate emulsion in a blending mode; the organosilicon emulsion is mainly prepared from vinyl nano SiO2 sol, polymerizable organosilicon monomers, and a vinyl siloxane emulsion in a polymerized mode; and the silicon-contained acrylate emulsion is mainly prepared from acrylate monomers and vinyl siloxane monomers in a polymerized mode through an emulsion. The acrylate emulsion has good film formation, adhesion and weather resistance, and has the compatibility with polar polymers and non-polar polymers, and the acrylate emulsion is in composition with the organosilicon emulsion, the defects that a single-composition organosilicon emulsion has poor film formation fastness and poor washing resistance on the surfacesof fabrics can be overcome. The emulsion can form the organosilicon film with low surface energy, can also change the surface roughness, and enhance the water repellency of the surface synergistically.

Owner:浙江东进新材料有限公司

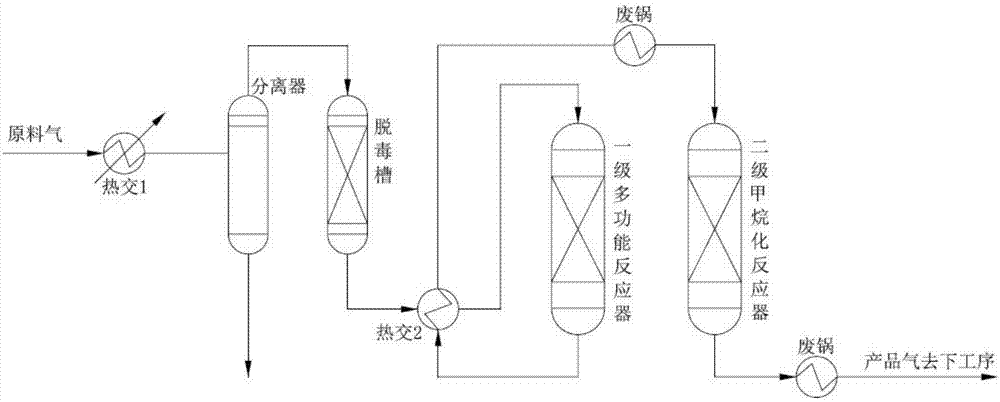

Multifunctional sulfur-resistant methanation transformation process adapting to coal gas

ActiveCN104119972ASatisfy the self-heating balanceReduce manufacturing costGaseous fuelsMethanationHeat balance

The invention provides a multifunctional sulfur-resistant methanation and transformation process adapting to coal gas. The process at least comprises two stages of multifunctional catalytic reactions. The process comprises the following steps: in a reactor, by adopting a multifunctional composite catalyst with integrated transformation, hydrolysis and methanation functions, performing reactions such as partial methanation, transformation and organic sulfur hydrolysis and hydrogenolysis to meet the self-heat balance of a system and regulate a reasonable ratio of hydrogen to carbon, wherein (H2-CO2) / (CO+CO2) is approximately equal to 3:1; enabling the transformation rate of organic sulfur to reach 99% so as to provide qualified raw material gas for a methanation synthesis section which is used for preparing natural gas or liquefied natural gas. The multifunctional sulfur-resistant methanation and transformation process provided by the invention has the advantages of steam conservation, low energy consumption, low equipment investment and low operation cost, can be used for solving the problems of raw material gas pre-treatment, difficultly-controllable transformation depth and unstable organic sulfur hydrolysis and operation before methanation synthesis at present, and has relatively good economic and environment-friendly benefits.

Owner:青岛联信催化材料有限公司 +1

Preparation method of polyurethane fireproof glue used for building

ActiveCN107722908AImprove high temperature resistanceImprove flame retardant performanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyolPolymer science

The invention relates to a preparation method of polyurethane fireproof glue used for a building. The polyurethane fireproof glue used for the building is prepared by mixing a prepolymer component anda polyol component, wherein the prepolymer component is prepared from diisocyanate, antimony trioxide, asbestos fiber, polypropylene carbonate polyol and a catalyst, and the polyol component is prepared from polypropylene carbonate polyol, a chain extender, a crosslinking agent and bromine-containing polyol; and antimony trioxide, asbestos fiber, bromine-containing polyol have a synergistic flameretardant effect, and the obtained fireproof glue can give consideration to flame retardant property, flame retardant durability and mechanical properties at the same time.

Owner:骏能化工(龙南)有限公司

Novel method for synthesizing bromo-triazine

InactiveCN102838554ASolve the problem of hydrolysisProcess stabilityOrganic chemistrySolubilityOrganic solvent

The invention discloses a novel method for synthesizing bromo-triazine, which belongs to the field of flame retardant synthesis; the novel method for synthesizing the bromo-triazine is characterized by comprising the following steps of: adding tribromophenol and cyanuric chloride to an organic solvent containing no water in sequence; dripping an organic base into the organic solvent; after finishing the dripping, heating the organic solvent to 40 DEG C to backflow temperature; taking reaction for 1-3 hour by heat preservation; separating out organic base hydrochloride or adding sodium hydroxide aqueous solution to a reaction product, so that the pH value of the solution is 7-10; by using distilling or other separating methods, separating the organic solvent and the organic base from the water; and then centrifuging, washing and drying an obtained product so as to obtain a bromo-triazine finished product, wherein the quantity ratio of substances of the cyanuric chloride and the tribromophenol is 1:3-3.3, the quantity ratio of substances of the cyanuric chloride and the organic base is 1:2-3.3, the selected organic solvent obtains good dissolubility for the tribromophenol, the cyanuric chloride and the bromo-triazine; and the tribromophenol, the cyanuric chloride and the bromo-triazine can be completely dissolved by the selected organic solvent. As no water is available in the whole reaction system, the hydrolysis possibility of the cyanuric chloride is prevented.

Owner:孔庆池

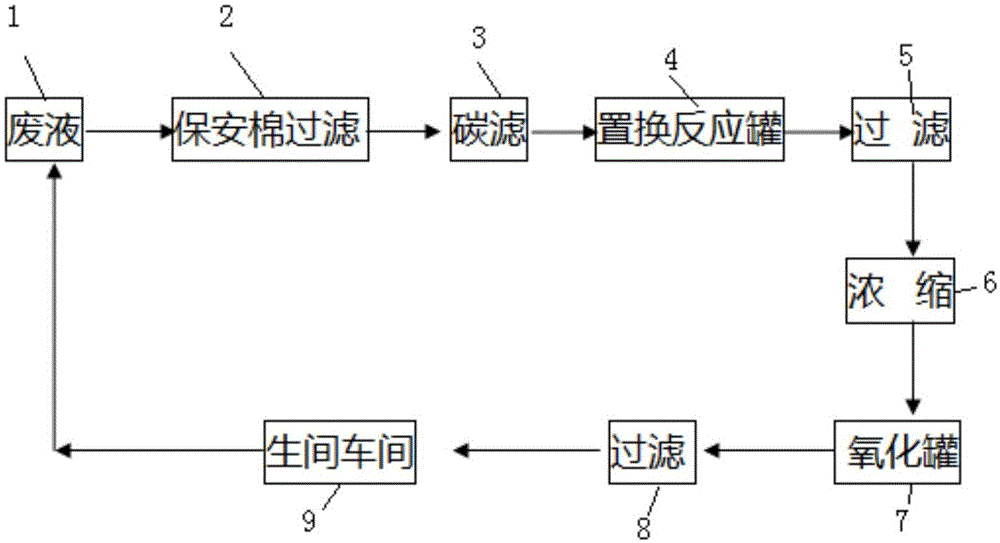

Method for reusing ferric trichloride corrosive liquid in gravure plate making

ActiveCN106348509ASolve the problem of instability and easy precipitationSolve the problem of hydrolysisMultistage water/sewage treatmentFiltrationActivated carbon filtration

The invention relates to a method for reusing a ferric trichloride corrosive liquid in gravure plate making. The method comprises the following steps: (1) performing primary filtration: removing impurities and granules of a waste liquid by using security cotton; (2) performing carbon filtration: filtering filtrate after primary filtration through activated carbon; (3) performing an replacement reaction: adding reduced iron powder into the filtrate after carbon filtration with stirring, enabling the components to react for 15-30 minutes, stopping stirring, and leaving to deposit naturally, wherein the addition amount of the reduced iron powder is 3-5 times of copper ions in the waste liquid; (4) concentrating: in a depressurized or high-temperature evaporation mode, concentrating till the baume degree meets a production control standard; (5) oxidizing: adding hydrogen peroxide and concentrated hydrochloric acid into a concentrated liquid; (6) filtering: filtering an oxidized liquid again to obtain the ferric trichloride corrosive liquid which can be reused. Compared with the prior art, the method is capable of completely solving the problem of waste liquid discharge, saving resources and protecting the environment, and has the advantages of being simple in method, easy to implement and the like.

Owner:SHANXI YUNCHENG PLATE MAKING GRP SHANGHAI ENTERPRISE DEV CO LTD

Synthesis method of N, N-dimethyl-2-chloro nicotinamide

InactiveCN102329265ASolve the problem of hydrolysisReduce hydrolysisOrganic chemistrySynthesis methods2-chloronicotinamide

The invention relates to a synthesis method of an intermediate of agricultural herbicide nicosulfuron, which comprises rapid reaction of dichloroethane solution and dimethylamine agueous solution of acyl chloride under conditions with a phase transfer catalyst. The problem of fumigachlorin hydrolysis is solved, and the dimethylamine agueous solution can be successfully applied in production of the intermediate of N, N-dimethyl-2-chloro nicotinamide.

Owner:JIANGSU CHANGQING AGROCHEMICAL CO LTD

Hydrophobic calcium-based magnesium synthetic clinker

The invention relates to a hydrophobic calcium-based magnesium synthetic clinker and belongs to the technical field of fire-retarding materials. The synthetic clinker is prepared by mixing lightly calcined dolomite, lightly calcined magnesium oxide and additives, rolling the mixture for forming, and drying and sintering the formed product, and comprises the following ingredients in percentage by weight: 55 to 65 percent of lightly calcined dolomite, 35 to 45 percent of lightly calcined magnesium oxide, 0.5 to 1 percent of ferricoxide, 0.5 to 1 percent of rare earth oxide and 6 to 7 percent of forming bonder. By adjusting the ingredients and a preparation process, the protection with high density and a covering layer is obtained; and the high volume density of the clinker blocks the permeation passage of water and vapor and the covering layer reduces the contact between lime and water, so the waterproof effect is good and the hydrolysis problem of the CaO is solved. The synthetic clinker has high thermal shock stability, corrosion resistance, erosion resistance and high temperature strength and is applicable to brick making by using various bonders. Particularly, the magnesia-calcium bricks produced by using the material can be used in burnt belts in cement kilns in place of magnesia-chrome brick stones. The synthetic clinker is an environmentally-friendly pollution-free refractory material.

Owner:淄博鑫耐达耐火材料股份有限公司

Injection containing meclofenoxate hydrochloride and its preparing method

InactiveCN100998585ASolve the problem of hydrolysisImprove stabilityOrganic active ingredientsNervous disorderPEG 400Alcohol

An injection of meclofenoxate hydrochloride and its preparing process which features use of non-water solvent chosen from alcohol, propanediol, glycerin, polyethanediol-300 and polyethanediol-400, and use of filter sterilizing method or wet-heat sterilizing method for high stability are disclosed.

Owner:ZHENDI MEDICINE CONSULTATION NANJING

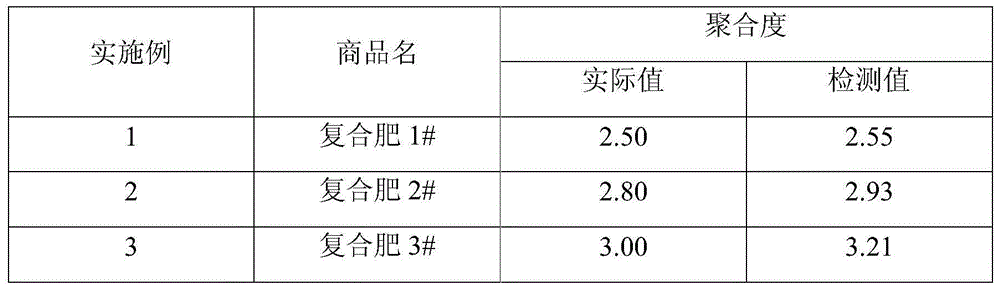

Method for detecting ammonium polyphosphate polymerization degree of fertilizer

InactiveCN104792929ASolve the problem of hydrolysisEasy to operateChemical analysis using titrationEnd-groupIon exchange

The invention discloses a method for detecting the ammonium polyphosphate polymerization degree of a fertilizer. The method comprises the following steps: (1) dissolving fertilizer samples, adjusting the pH value to be alkaline, defining the volume of a solution subjected to ion exchange, and uniformly dividing the solution into two liquids to be detected; (2) adding acid in one liquid to be detected to adjust the pH value to 2-4, titrating with alkali, recording the volume of alkali consumed in the process of titrating when the pH value ranges from 4.5 to 9.5, and marking A; (3) adding acid in the other liquid to be detected for digestion, adding acid to adjust the pH value to 2-4, titrating with alkali, recording the volume of alkali consumed in the process of titrating when the pH value ranges from 4.5 to 9.5, and marking Ah; calculating the polymerization degree of the fertilizer containing ammonium polyphosphate according to the content of end group weak acid and the total phosphorus content in the solution. The method has the advantages of being small in error, and high in precision.

Owner:SHENZHEN BATIAN ECOTYPIC ENG

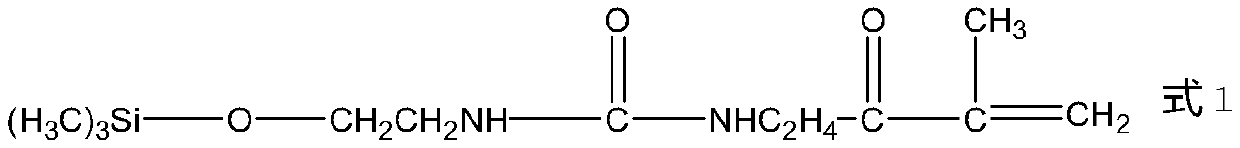

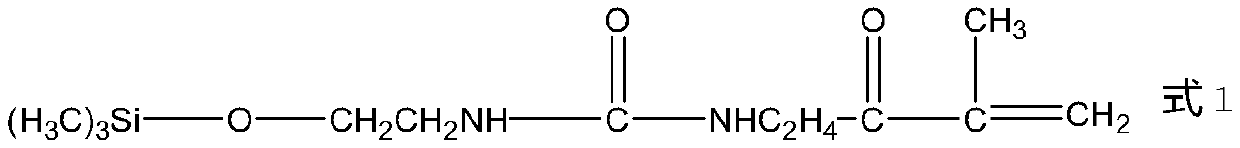

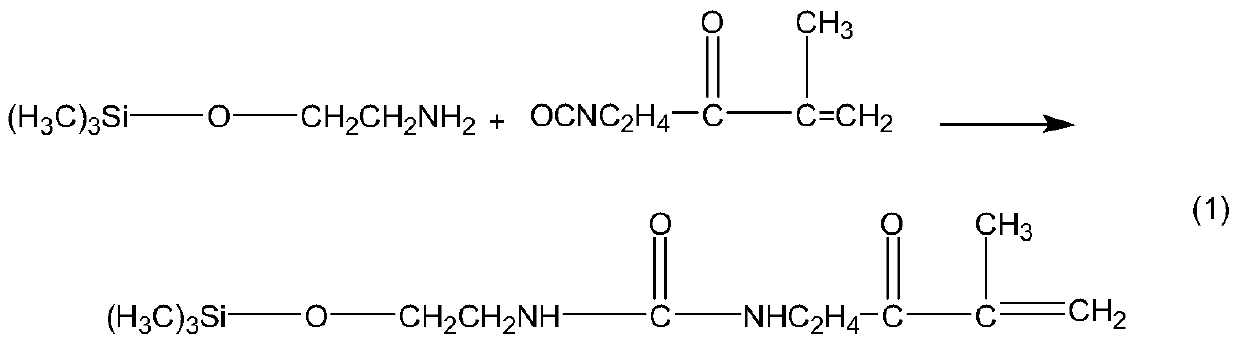

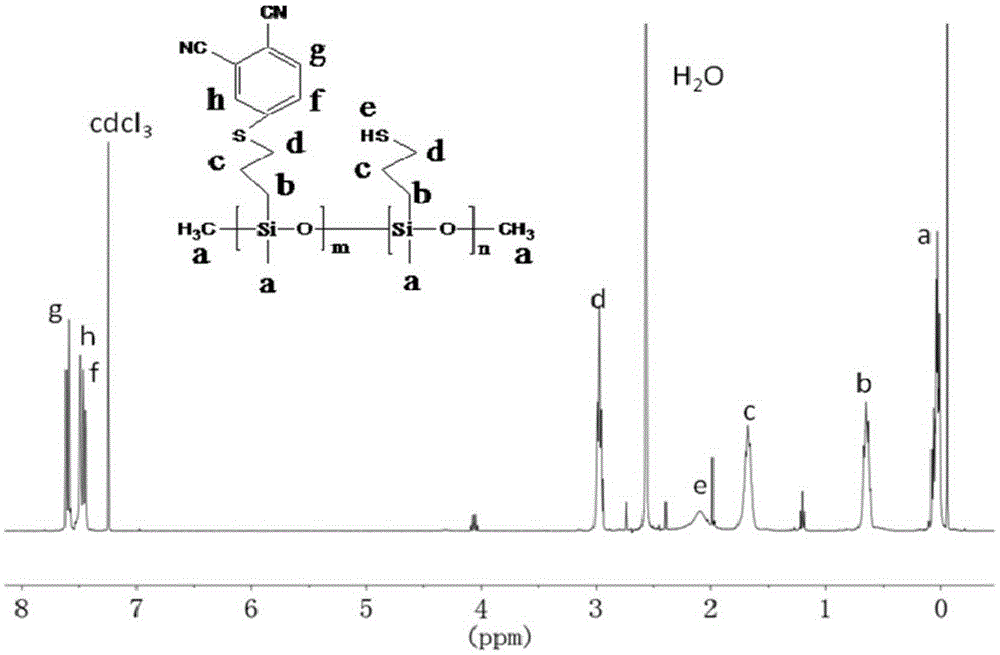

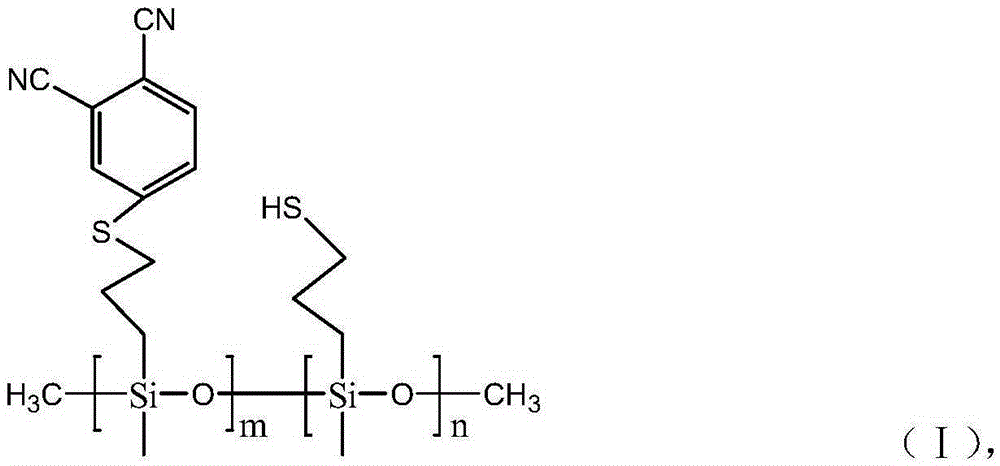

Silicon-nitrile-based hybrid resin and synthesizing method thereof

ActiveCN105315469AImprove thermal stabilityImprove mechanical propertiesSynthesis methodsReaction temperature

The invention discloses silicon-nitrile-based hybrid resin and a synthesizing method thereof. The molecular structural formula of the silicon-nitrile-based hybrid resin is shown as a formula (I). The synthesizing method comprises the following steps that reacting is performed by taking sulfydryl propyl methylsiloxane and 4-nitrophthalonitrile as main raw materials, and then the silicon-nitrile-based hybrid resin is obtained. The silicon-nitrile-based hybrid resin has the advantages of being low in melting point, capable of resisting high temperature, not prone to hydrolysis, excellent in heat stability and curing performance and the like; the synthesizing method is simple and easy to control, lower in reaction temperature, shorter in time and suitable for industrialized production.

Owner:NAT UNIV OF DEFENSE TECH

Nanometer aluminum carbide particle reinforced aluminum matrix composite material and manufacturing method thereof

ActiveCN109680188ASolve the problem of hydrolysisFix stability issuesArgon atmosphereMetallic materials

The invention belongs to the field of metal materials, and particularly relates to an aluminum oxide layer cladding type nanometer aluminum carbide particle reinforced aluminum matrix composite material and a manufacturing method of the aluminum oxide layer cladding type nanometer aluminum carbide particle reinforced aluminum matrix composite material. The aluminum oxide layer cladding type nanometer aluminum carbide particle reinforced aluminum matrix composite material is characterized in that according to the mass percentage of various chemical components, the mass percentage of aluminum ranges from 65% to 99.5%, the mass percentage of carbon ranges from 0.5% to 15.0%, and the balance is at least one of the magnesium element, the copper element, the silicon element, the zinc element, the ferrum element, the manganese element, the chromium element and the titanium element. Aluminum oxide cladding type nanometer aluminum carbide particles which are formed in an in-situ synthesis modeare distributed on an aluminum or aluminum alloy matrix. The manufacturing method of the aluminum oxide layer cladding type nanometer aluminum carbide particle reinforced aluminum matrix composite material comprises the steps that raw materials are prepared in proportion, and graphite powder and activated carbon are subjected to vacuum drying, and then are mixed and reserved; and commercial purityaluminum and at least one of magnesium, copper, silicon, zinc, ferrum, manganese, chromium and titanium are molten in a smelting furnace, after the temperature is stabilized, the mixed powder of thegraphite powder and the activated carbon are uniformly blown to the molten body in the argon atmosphere by a rotary blowing device, then the temperature is rapidly reduced until solidification is achieved, the materials are transferred to a resistance furnace to conduct a liquid-solid reaction, and therefore the nanometer aluminum carbide particle reinforced aluminum matrix composite material is obtained. The manufacturing method is low in cost, is green and environmentally friendly, and has the good industrial production prospect.

Owner:SHANDONG UNIV +1

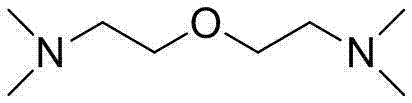

Synthetic method of bis-(2-dimethylaminoethyl)ether

InactiveCN102786427AFewer extraction stepsShort reaction timeOrganic compound preparationAmino-hyroxy compound preparationChemistryEther

The invention discloses a synthetic method of bis-(2-dimethylaminoethyl)ether. The method comprises the following steps: (1) chlorination is carried out by using 2-dimethylethanolamine as raw material and thionyl chloride as a chlorinating agent to obtain chloride hydrochloride; (2) 2-dimethylethanolamine and sodium are used as the raw material and reacted to obtain a sodium alkoxide solution; (3) etherification: chloride hydrochloride is added into the sodium alkoxide solution, then a catalyst is added for etherification to obtain a reaction solution; the reaction solution is filtered to obtain filtrate; (4) separation and purification: vacuum rectification of the filtrate is carried out to obtain bis-(2-dimethylaminoethyl)ether.

Owner:ZHEJIANG UNIV

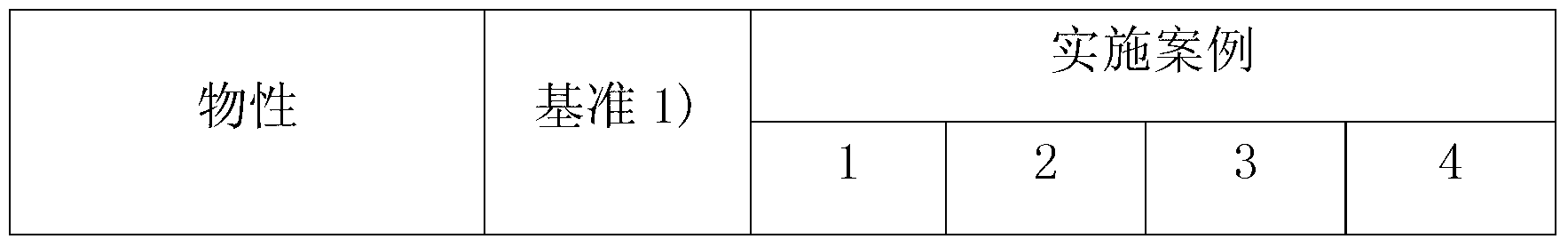

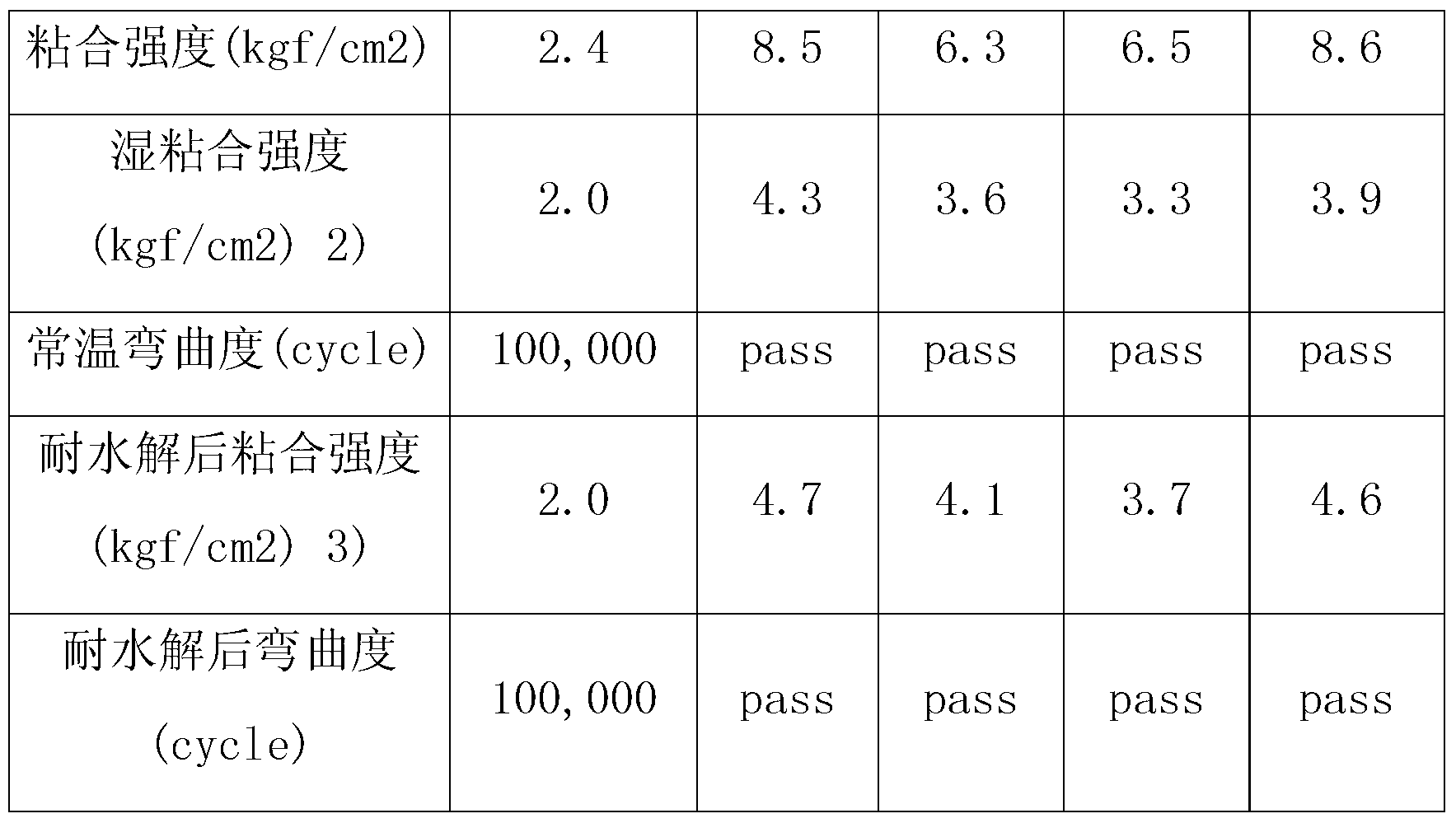

Production method of waterborne polyurethane used for artificial leather bonding resin

InactiveCN103320084AHigh solid contentGood hydrolysis resistancePolyureas/polyurethane adhesivesChemistryPolyresin

The invention discloses an artificial leather bonding resin, and especially relates to a production method of a waterborne polyurethane. The object of the invention is to make up the defect existing in a previous method, and provide the production method of the waterborne polyurethane used for the artificial leather bonding resin, and the waterborne polyurethane has the advantages of good storage stability, high solid content, stable physical properties, regular resin chains, good initial adhesion and good durability. The waterborne polyurethane is prepared by preparing a waterborne polyurethane A, preparing a waterborne polyurethane B, and mixing the waterborne polyurethane A and the waterborne polyurethane B by weight ratio; and the waterborne polyurethane A accounts for 40-70%. The production method of the waterborne polyurethane is characterized by simple process, convenient operation, low labor intensity and the like.

Owner:ZHEJIANG JOYA POLYMER TECH

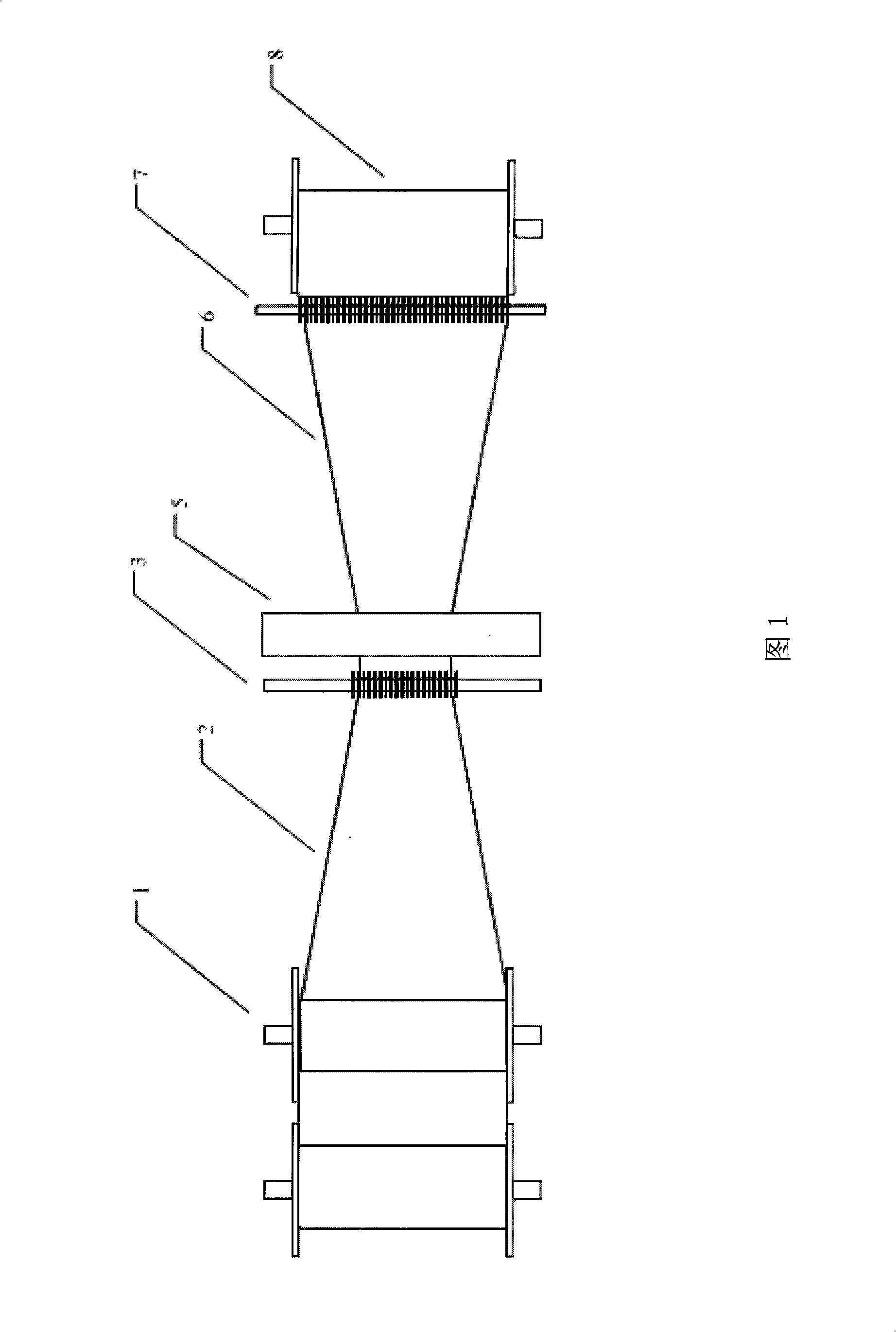

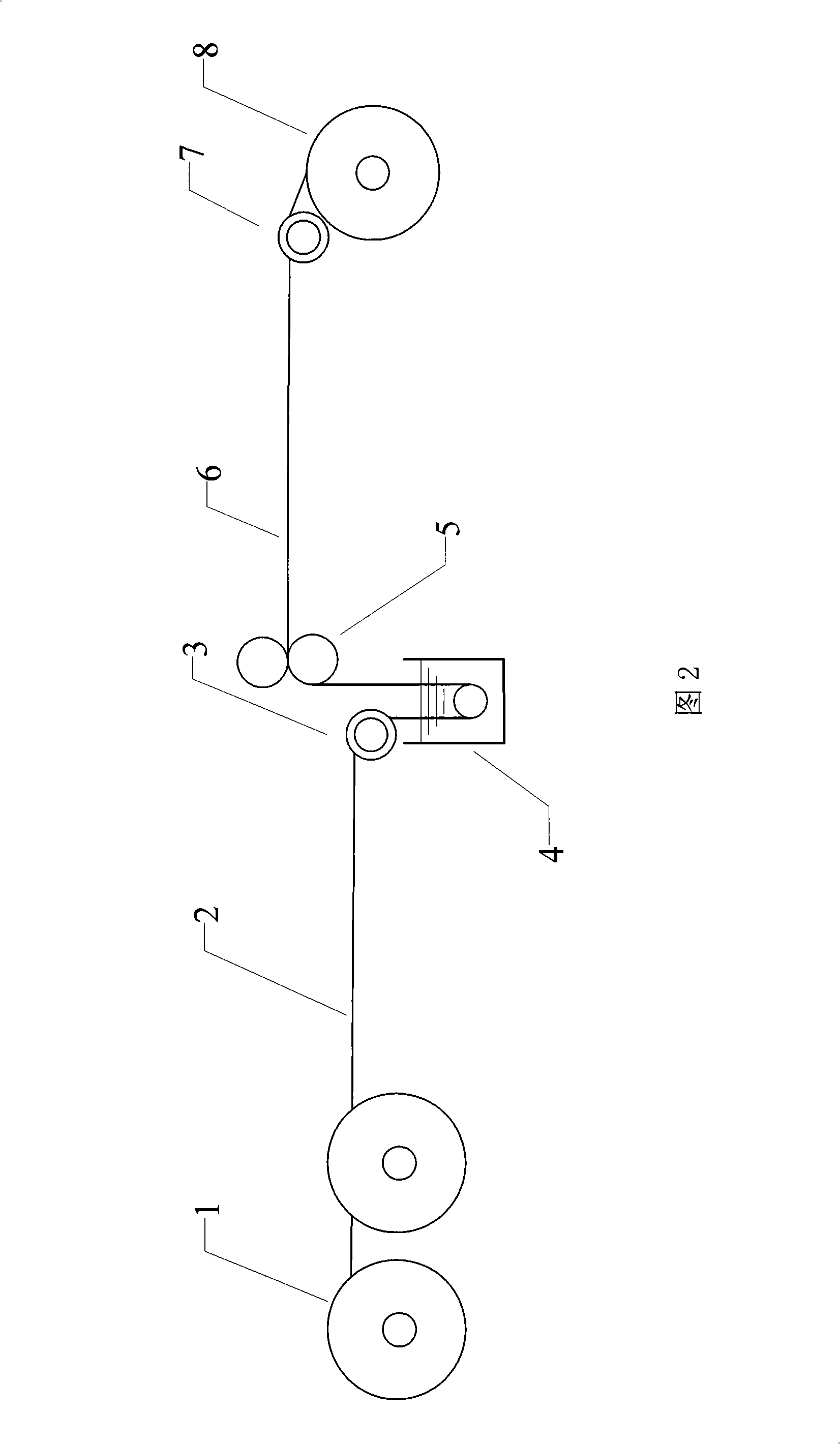

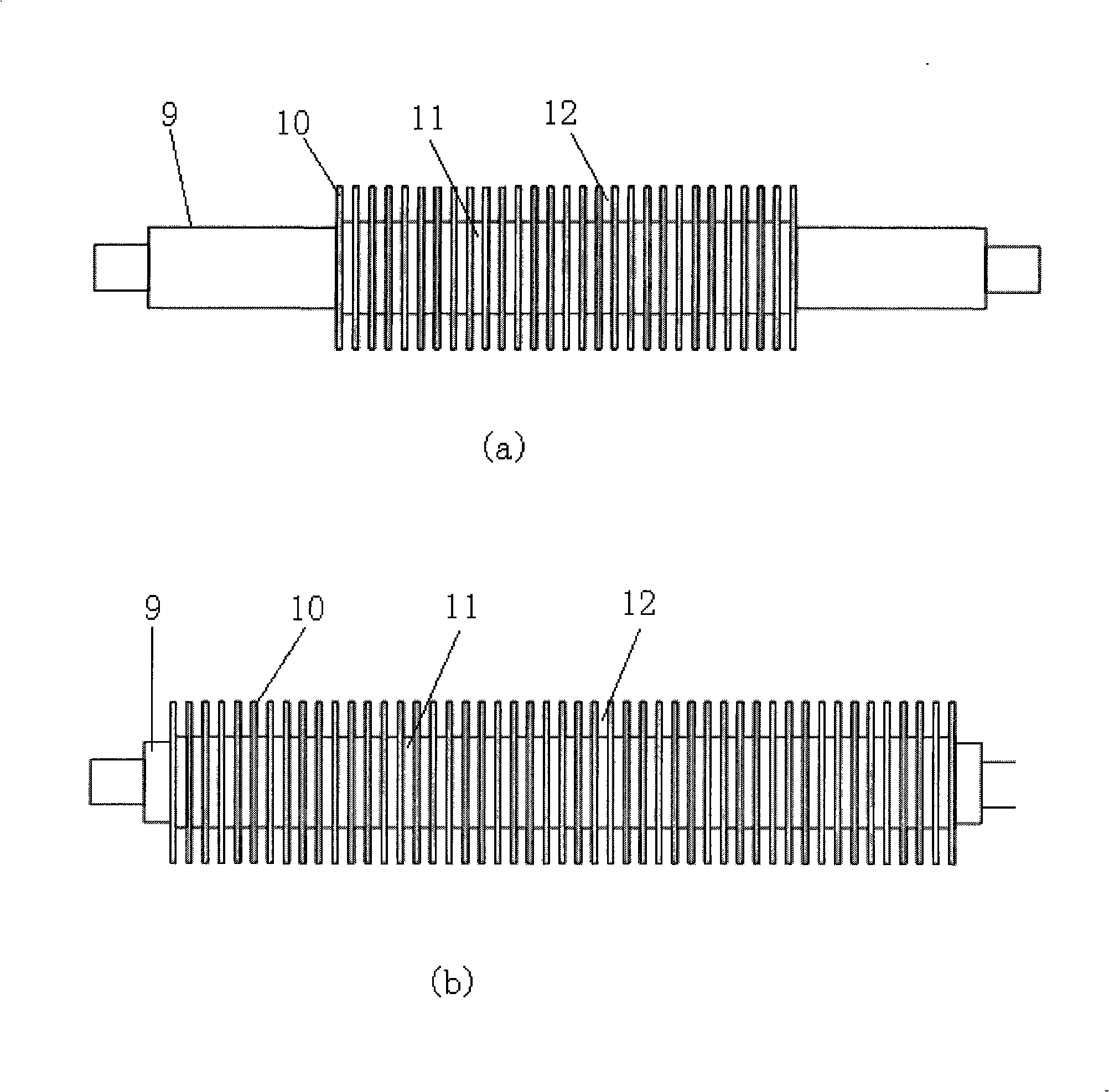

Sheet shaped yarn pinches slop padding method and apparatus

InactiveCN101270540AReduce wearReduce end break rateTextile treatment machine partsLiquid/gas/vapor yarns/filaments treatmentYarnEngineering

The invention relates to a yarn processing method. A flake yarn amplitude shrinking padding method is processed according to the following two steps of: the first steps of amplitude shrinking padding: dipping the flake yarn unreeled from a warp beam after shrinking amplitude by an amplitude shrinking roller into a dipping slot, putting the yarn after dipped into a padder to remove redundant dipping liquid; the second step of amplitude expanding rolling; carrying out rolling on the flake yarn out of a roller after amplitude expanding by an amplitude expanding roller. The invention is mainly characterized in that the amplitude shrinking padding of the yarn integrates the advantages of bunchiness padding and flake padding and overcomes the defects of the two. The colorizing uniformity is improved remarkably; the left and right color difference and the front and back color difference are reduced remarkably; wherein, the left and right color difference reaches grade 4.5; the front and back color difference reaches grade 4.0, thus meeting the technical requirements. The device adopted by the invention has simple structure and reduces the broken end rate to a large extent.

Owner:营口中基纺织有限公司

Method for compositing trialkoxysilanes by adopting multistage fluidized bed

ActiveCN101671355AEasy to recycleEasy to separateGroup 4/14 element organic compoundsMetal/metal-oxides/metal-hydroxide catalystsProduction rateAlcohol

A method for compositing trialkoxysilanesby adopting a multistage fluidized bed relates to a composite method of trialkoxysilanesby. The composite method solves the problems that in the existing composite technology of trialkoxysilanesby, catalytic agent is difficult to be recycled, reactive efficiency is low, products are difficult to be separated, silica powder and copper-based catalytic agent have poor contact, copper silicon contacts have slow productivity and low reactive activity, the catalytic agent loses effectiveness easily after meeting water, and the products are easily hydrolyzed after meeting water. The composite method of trialkoxysilanesby comprises the following steps: 1. preparing copper silicon contacts containing different cuprous chloride mass percents; 2. charging copper silicon contacts obtained in the step one to a reactor of the multistage fluidized bed in stages; and 3. introducing alcohol gas dried by ethyl orthosilicate into the reactor of the multistage fluidized bed to obtain trialkoxysilanesby after reaction and composition. By adopting the method for compositing trialkoxysilanes by adopting the multistage fluidized bed, the selectivity of trialkoxysilanesby reaches 95% and reactive transformation ratio reaches 95%.

Owner:WUXI HAITE NEW MATERIAL RES INST

Water-repellent polyolefin elastic fabric

ActiveCN109706746AHigh water repellencySolve the problem of hydrolysisTextiles and paperPolyesterPolyolefin

The invention discloses a water-repellent polyolefin polyester fabric. The fabric comprises a polyolefin polyester fabric substrate and an organosilicon water-repellent finishing agent latex film arranged on the surface of the substrate; by mass, 10 parts of a water-repellent finishing agent, 4 parts of a thickener and 86 parts of water are mixed and fully stirred to form a coating agent, the viscosity reaches 35,000-40,000 CPS, the coating agent coats the polyolefin polyester fabric substrate with the application amount of 70-90 parts / m<2>, drying is conducted at 70 DEG C for 5 min, baking isconducted at 160 DEG C for 2 min, and the water-repellent polyolefin polyester fabric is prepared; the organosilicon water-repellent finishing agent is formed by blending an organosilicon modified acrylate emulsion and an organosilicon modified polyurethane emulsion according to the mass ratio of 1:1.2-1:2. Through the modification of organosilicon, the polyolefin polyester fabric has good waterproof performance and breathability.

Owner:浙江东进新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com