Organic bentonite pesticide sustained-release granular formulation and preparation method thereof

A slow-release granule, bentonite technology, applied in the fields of botanical equipment and methods, insecticides, biocides, etc., can solve problems such as complex processes, achieve the effects of good environmental compatibility, reduce contact, and improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1: Preparation of 10% phoxim granules by dodecyltrimethylammonium chloride modified bentonite with an amount of 0.5CEC

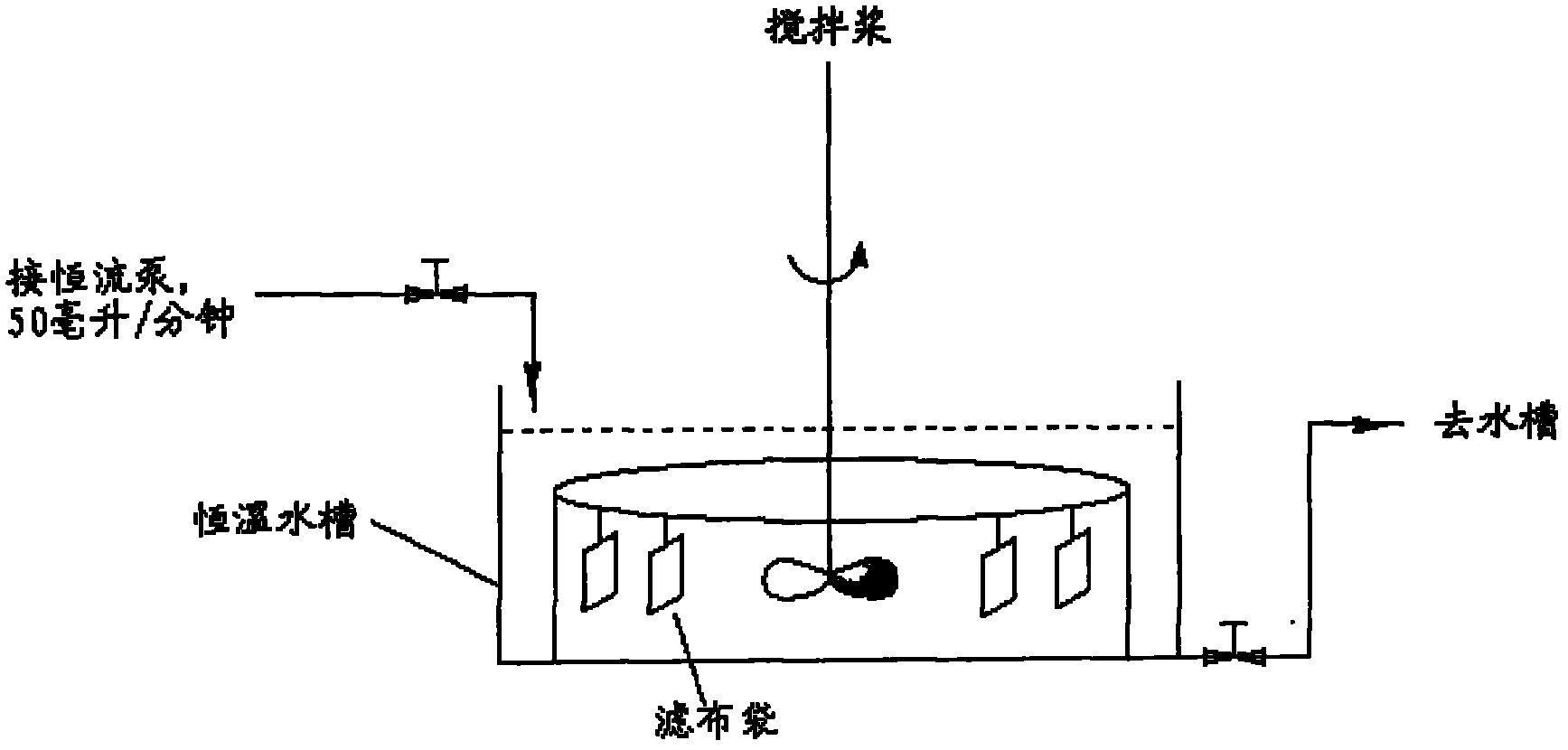

[0040] Step 1: Add 1 part of bentonite with a cation exchange capacity of 82mmol / 100g to 50 parts of water, fully disperse to make a bentonite suspension, add 0.108 parts of dodecyltrimethylammonium chloride (0.5CEC), and heat up to 60°C Continue to stir for 4 hours, add 50 parts of water to the organic bentonite obtained after suction filtration, and stir at 30° C. to prepare an organic bentonite suspension.

[0041] Step 2: 1 part of phoxim was dissolved in 1 part of methanol, and added dropwise to the above organobentonite suspension, stirred at 30°C for 4 hours, suction filtered and washed with water to obtain drug-loaded organobentonite. Gained drug-loaded organobentonite was sampled, dried, and its moisture content was measured by weighing method to be 23.9%; another drug-loaded organobentonite sample was extracted by methanol and its ph...

Embodiment 2

[0043] Embodiment 2: 10% phoxim granules are prepared by modifying bentonite with 1.0CEC dosage of dodecyltrimethylammonium chloride

[0044] Step 1: Add 1 part of bentonite with a cation exchange capacity of 82mmol / 100g to 50 parts of water, fully disperse to form a bentonite suspension, add 0.216 parts of dodecyltrimethylammonium chloride (1.0CEC), and heat up to 60°C Continue to stir for 4 hours, add 50 parts of water to the organic bentonite obtained after suction filtration, and stir at 30° C. to prepare an organic bentonite suspension.

[0045] Step 2: 1 part of phoxim was dissolved in 1 part of methanol, and added dropwise to the above organobentonite suspension, stirred at 30°C for 4 hours, suction filtered and washed with water to obtain drug-loaded organobentonite. Gained drug-loaded organobentonite was sampled, dried, and its moisture content was determined by weighing method to be 17.1%; another drug-loaded organobentonite sample was extracted with methanol and its...

Embodiment 3

[0047] Embodiment 3: 10% phoxim granule prepared by dodecyltrimethylammonium chloride modified bentonite with 1.5CEC dosage

[0048] Step 1: Add 1 part of bentonite with a cation exchange capacity of 82mmol / 100g to 50 parts of water, fully disperse to make a bentonite suspension, add 0.324 parts of dodecyltrimethylammonium chloride (1.5CEC), and heat up to 60°C Continue to stir for 4 hours, add 50 parts of water to the organic bentonite obtained after suction filtration, and stir at 30° C. to prepare an organic bentonite suspension.

[0049] Step 2: 1 part of phoxim was dissolved in 1 part of methanol, and added dropwise to the above organobentonite suspension, stirred at 30°C for 4 hours, suction filtered and washed with water to obtain drug-loaded organobentonite. Gained drug-loaded organobentonite was sampled, dried, and its moisture content was determined by weighing method to be 15.6%; another drug-loaded organobentonite sample was extracted by methanol and its phoxim con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com