Preparation method of multi-component full-color spinning fabrics

A multi-component and fabric technology, applied in the field of textile fabrics, can solve the problems of multi-component yarn dyeing difficulty and no color spinning success, so as to improve the performance of yarn and clothing, expand the color spinning space, and improve the application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

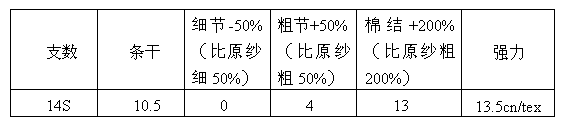

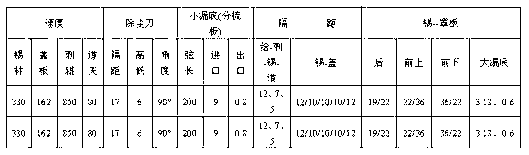

[0027] A method for preparing a multi-component full-color yarn fabric. The fabric is woven by yarns prepared by a vortex spinning method.

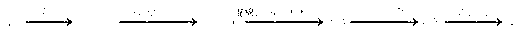

[0028] Firstly, the yarn is prepared. After the pretreated loose fibers are dyed separately, the colored fibers are mixed according to a certain ratio, and the spinning is performed according to the following steps:

[0029]

[0030] Among them, the raw materials used for bulk fiber are 1.2D*38mm viscose fiber, 1.2D*38mm tencel, 7000 metric stretch-cut wool and first-class spun yarn. All the above-mentioned fibers are dyed brilliant blue. , The mixed mass percentage is: viscose fiber 50%, tencel 20%, wool 10%, spun silk 10%, and spinning 14 sweater yarns.

[0031] Before mixing and boarding, the boarding moisture regain rate of viscose fiber and tencel fiber does not exceed 13%, the boarding moisture regain rate of wool is controlled at 22%±2, and the boarding moisture regain rate of spun silk is controlled at 17%±2. Among them, Tencel and visc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com