Air vortex spinning method of multi-component full-colored spun yarns

A vortex spinning and multi-component technology, which is applied in the direction of continuous winding spinning machine, spinning machine, open-end spinning machine, etc., can solve the problem of no color spinning success, multi-component yarn dyeing difficulty, etc. problems, to achieve the effect of improving the performance of yarn and clothing, avoiding hydrolysis problems, and expanding the color spinning space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] After the pretreated loose fibers are dyed separately, the colored fibers are mixed according to a certain ratio, and the spinning is carried out according to the following steps:

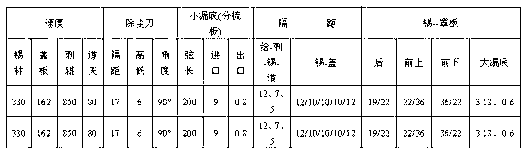

[0027]

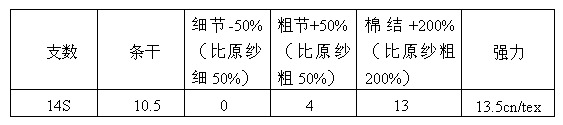

[0028] Among them, the raw materials used for bulk fiber are 1.2D*38mm viscose fiber, 1.2D*38mm tencel, 7000 public count wool and first-class spun silk, and all the above-mentioned fibers are dyed brilliant blue. , its blending mass percentage is: 50% viscose fiber, 20% tencel, 10% wool, 10% spun silk, yarn for spinning 14 sweaters.

[0029] Before mixing and loading, the loading moisture regain of viscose fiber and tencel fiber shall not exceed 13%, the loading moisture regain of wool shall be controlled at 22%±2, and the loading moisture regain of spun silk shall be controlled at 17%±2. Among them, tencel and viscose fibers are processed by ordinary loose fiber dyeing before they are put on the car. Antistatic testing is required before wool and spun silk are mixed. When ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com