Boost transformer for arc striking of argon arc welding machine

A technology for step-up transformers and argon arc welding machines, which is applied to transformers, transformer/inductor magnetic cores, transformer/inductor components, etc. It can solve the problems of difficult winding process, difficult to master, and unsuitable for mass production. , to achieve the effect of simple and easy processing technology and solving difficulties that are not easy to master

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to clearly illustrate the technical characteristics of this solution, the following describes this solution through a specific implementation and in conjunction with the accompanying drawings.

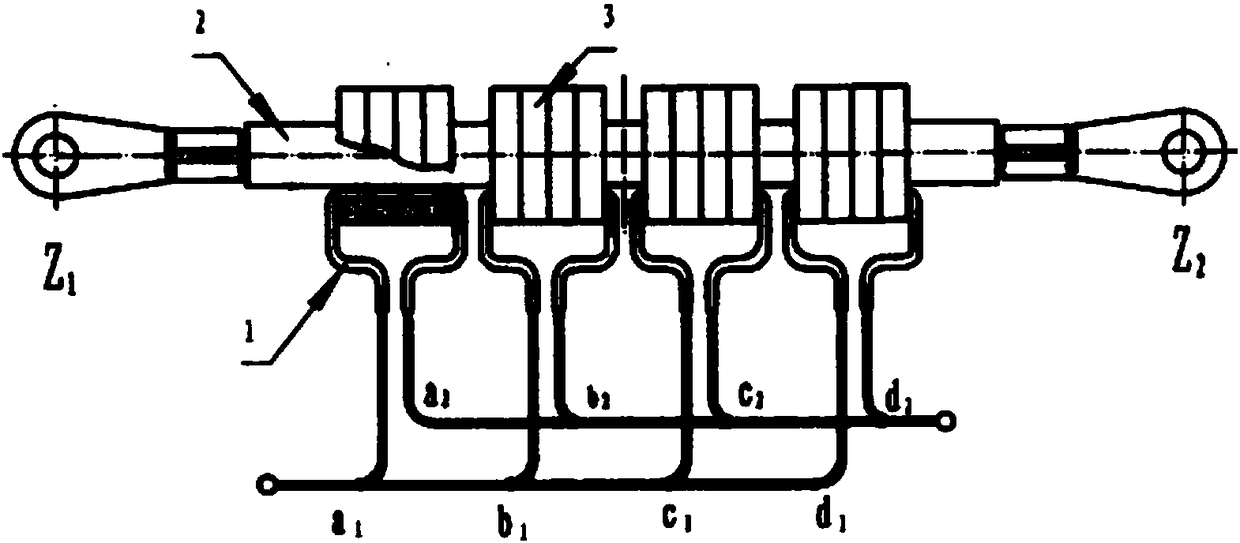

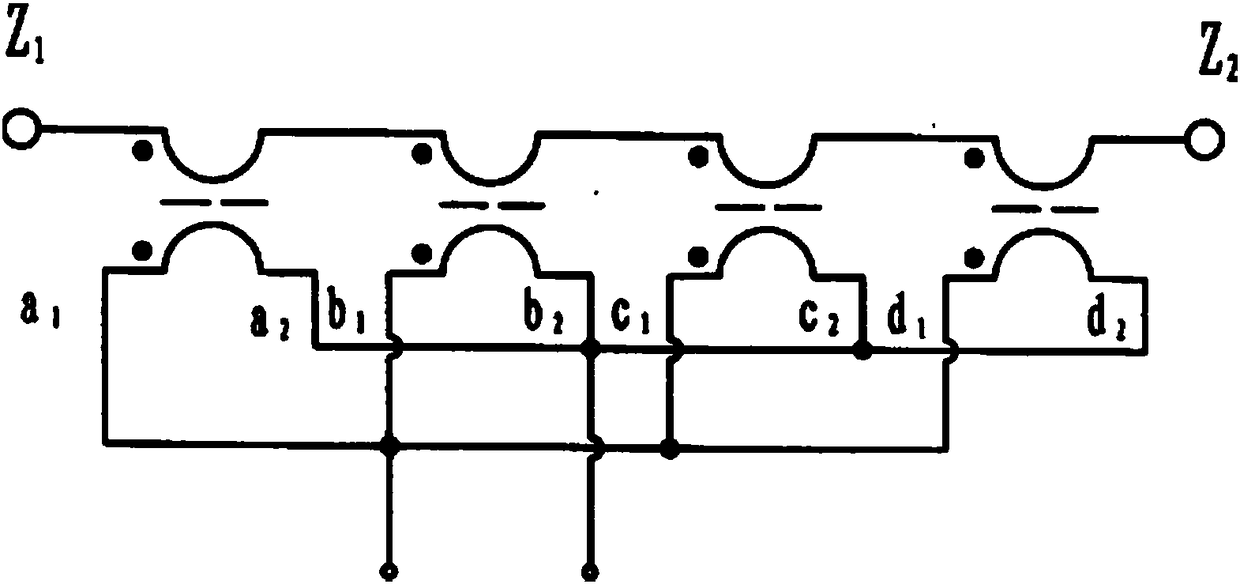

[0010] By attaching figure 1 It can be seen that the step-up transformer for arc welding of the argon arc welding machine of this scheme is mainly equipped with a contact Z1 and Z2 at both ends of a multi-core cable (2) as the secondary coil of the transformer. On the multi-core cable (2) between Z2, there are 2-5 sets of magnetic rings (3) composed of 2-5 identical magnetic rings (3). This specific embodiment consists of four identical magnetic rings (3). The ring (3) constitutes a set of four sets of magnetic rings (3), and each set of magnetic rings (3) is also wound with a single-core thin wire (1) a1a2, b1b2, c1c2 and d1d2, and each turn is thin The starting ends a1, b1, c1, and d1 of the wire (1) are connected, and the ends a2, b2, c2, and d2 of each turn of the thin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com