Patents

Literature

8945results about "Transformers/inductances magnetic cores" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

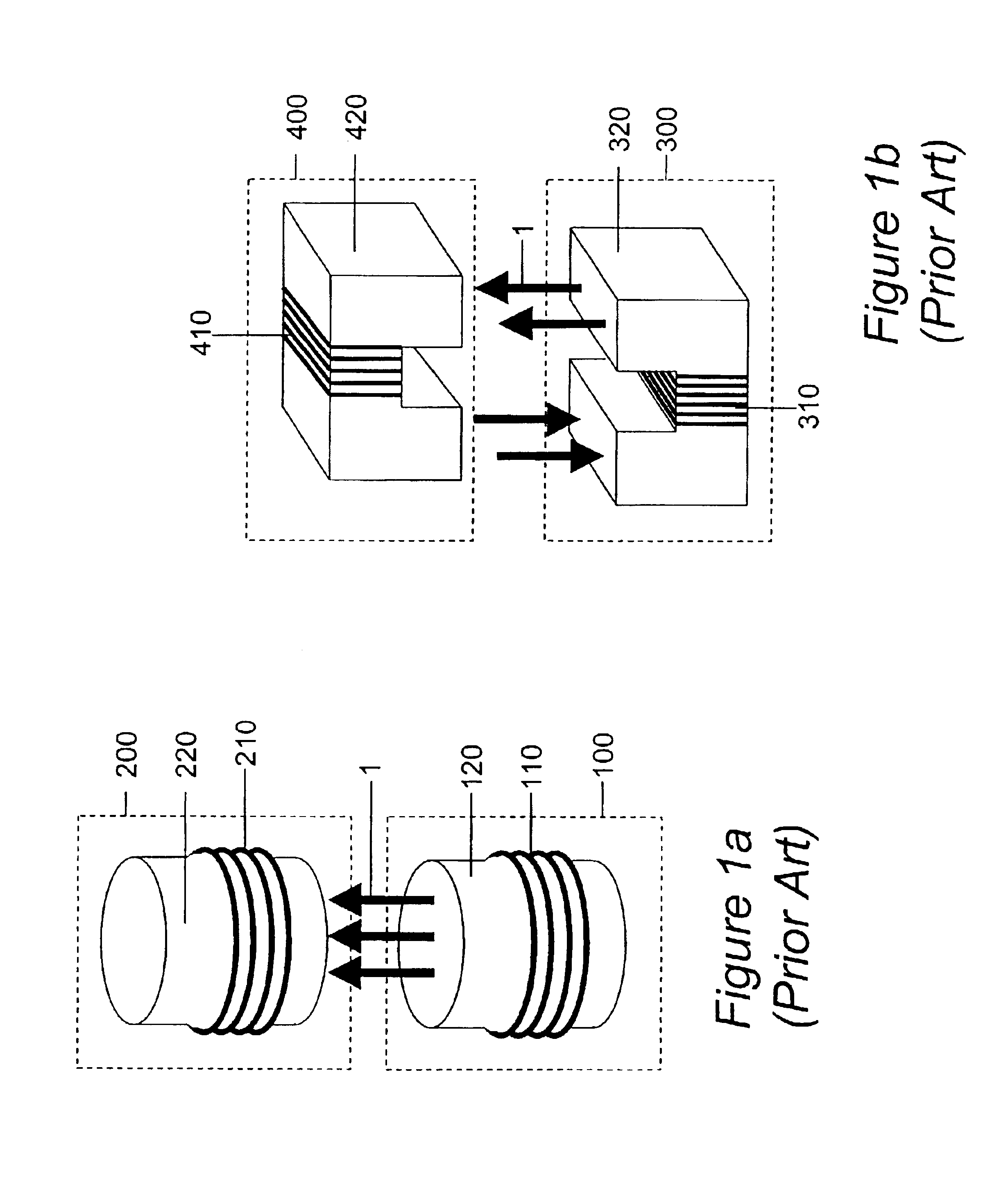

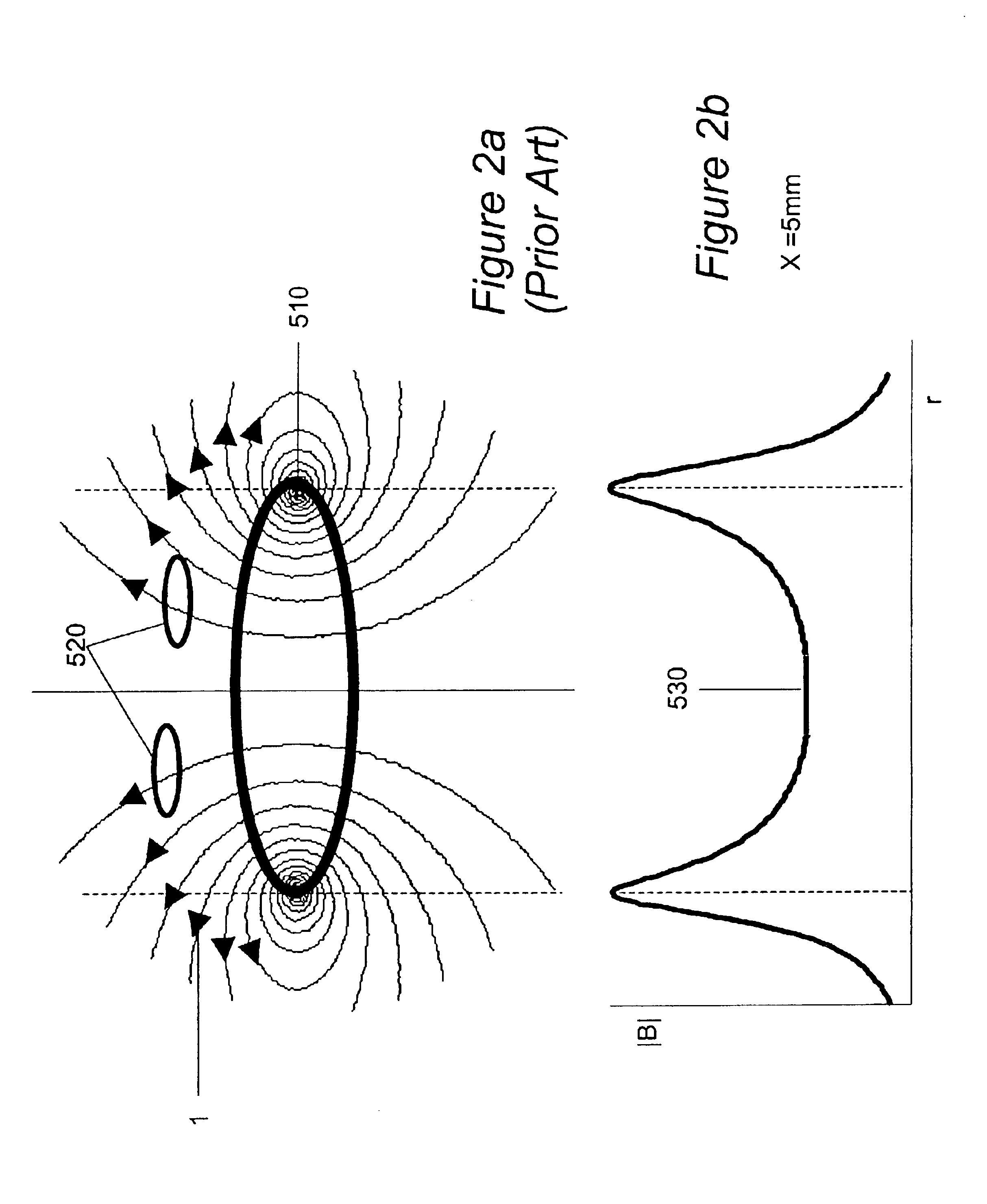

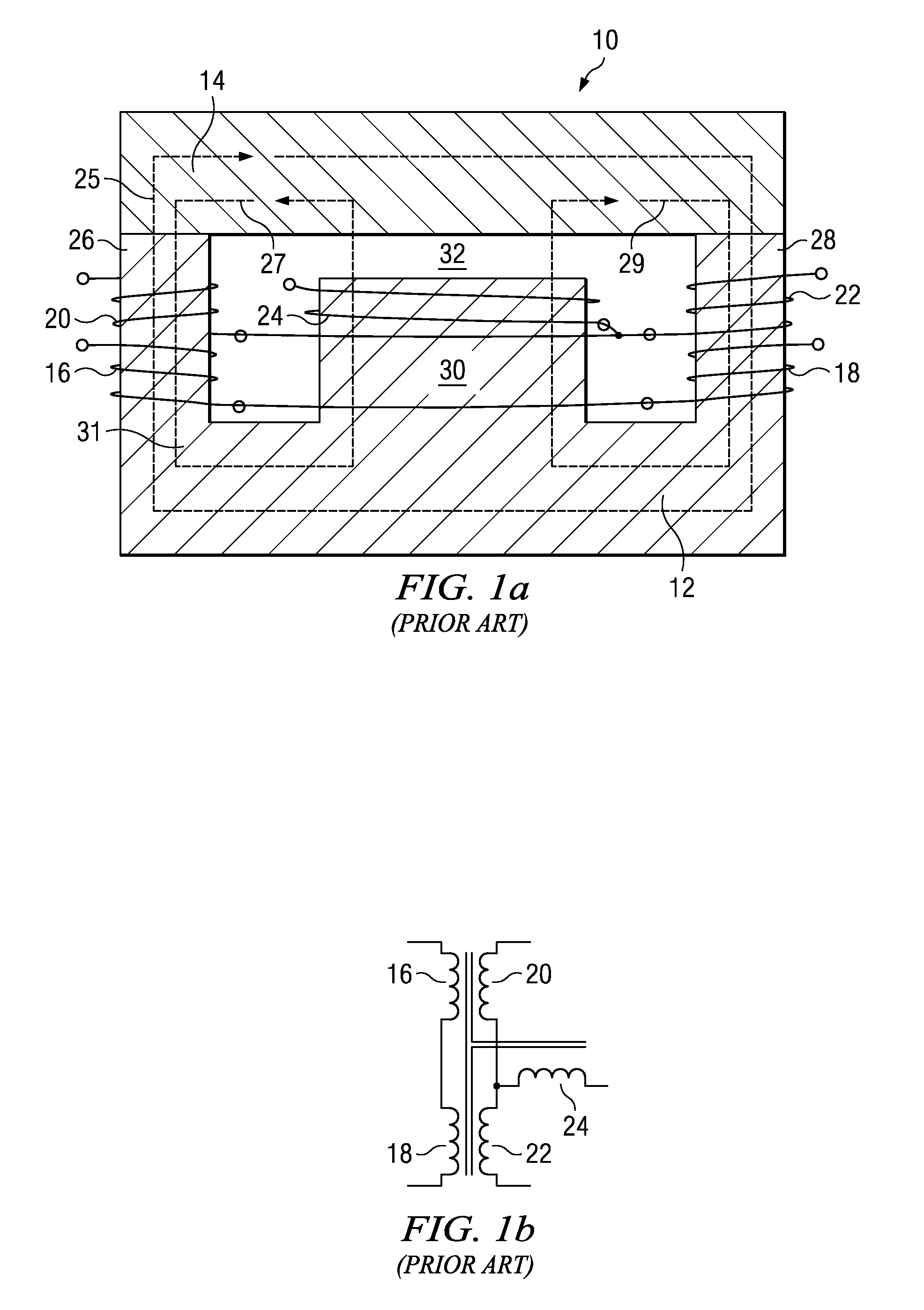

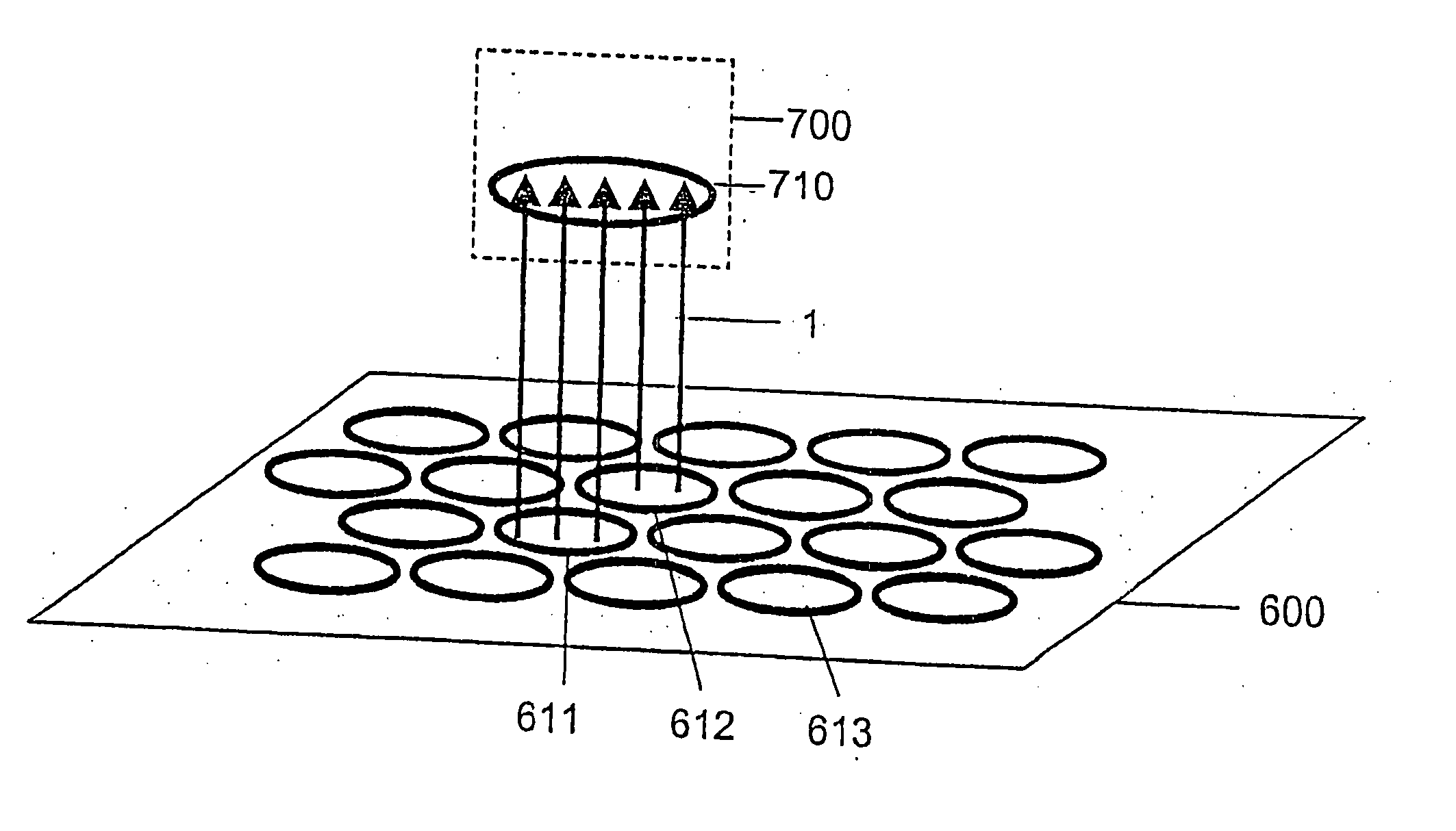

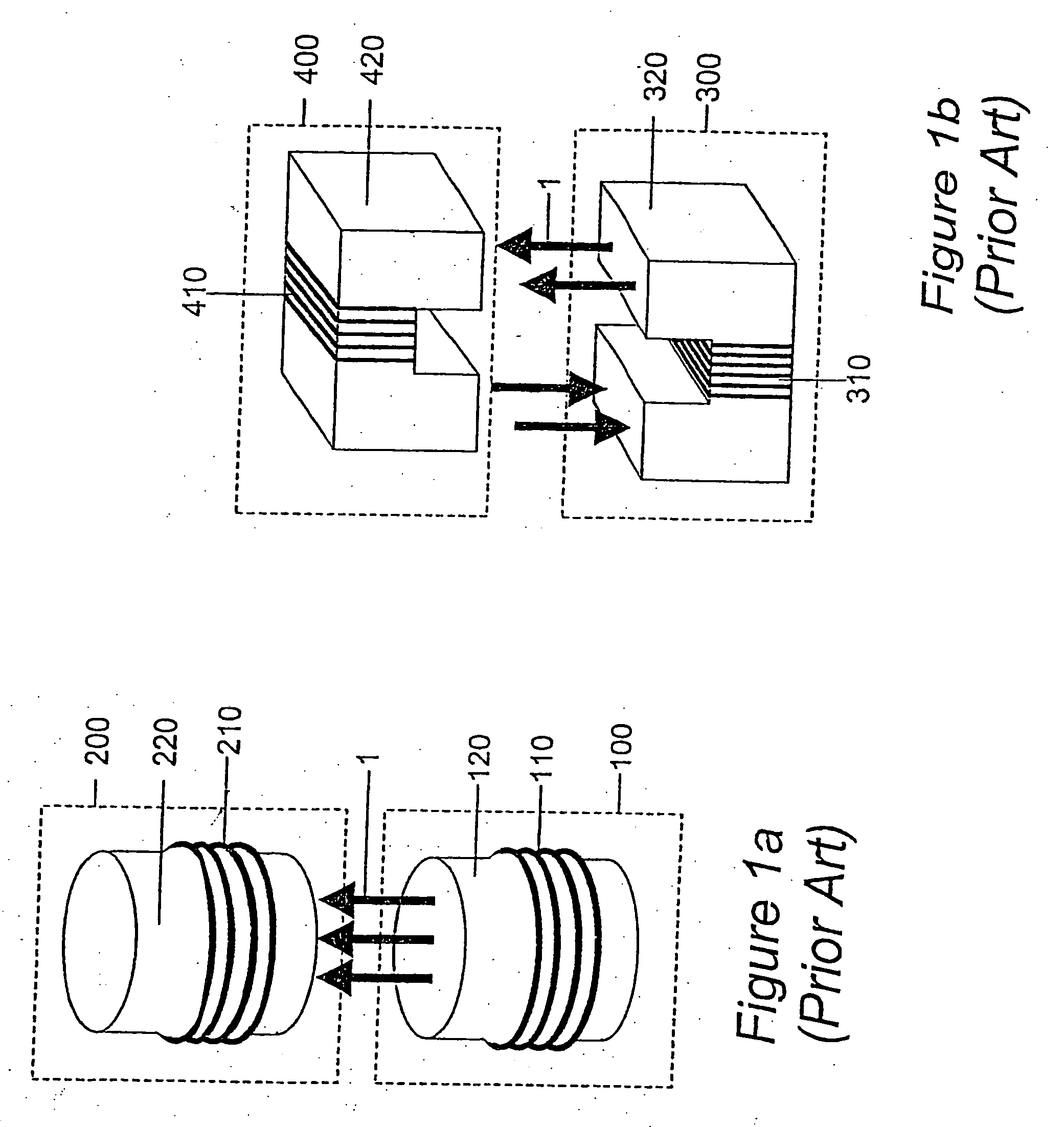

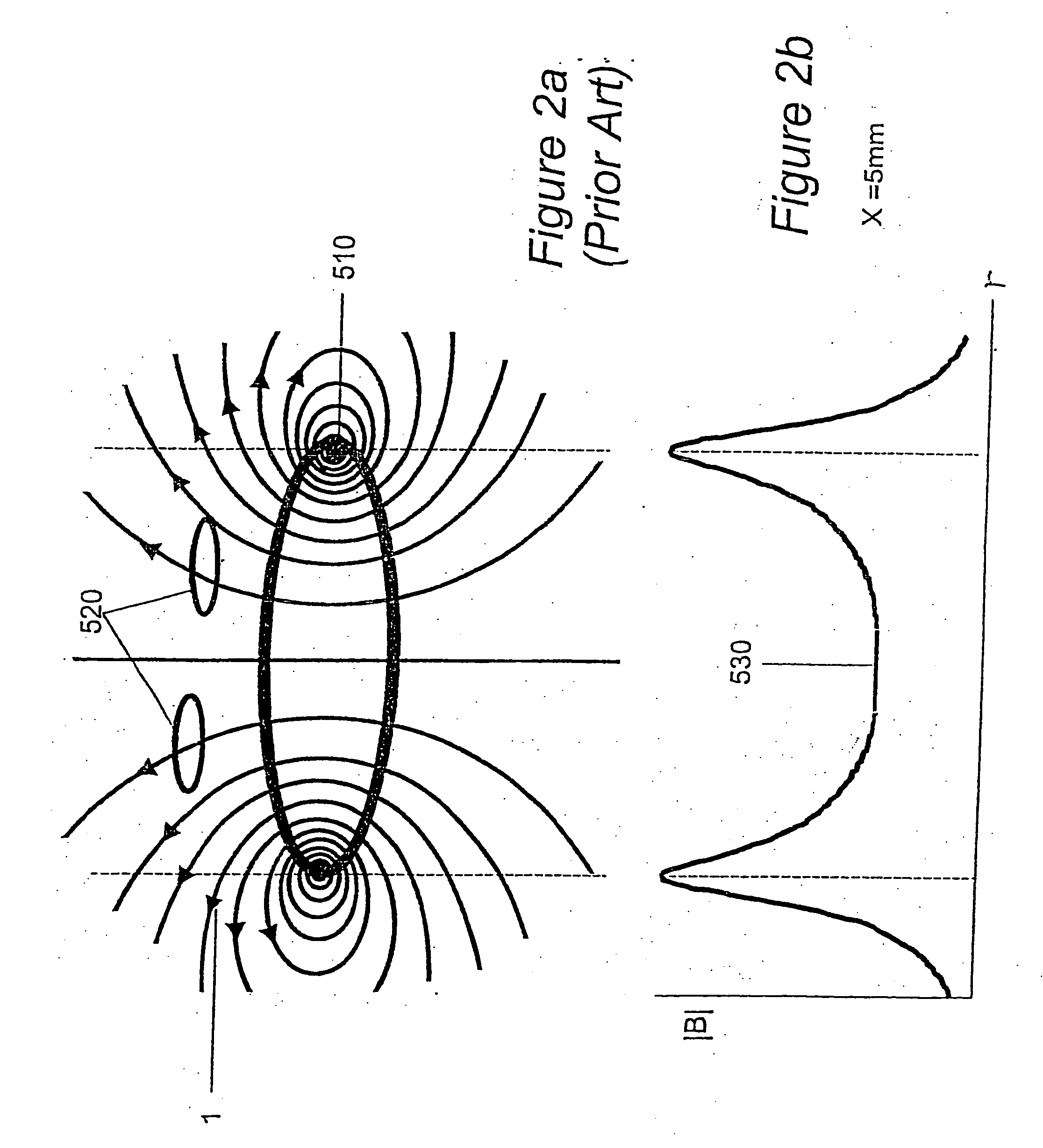

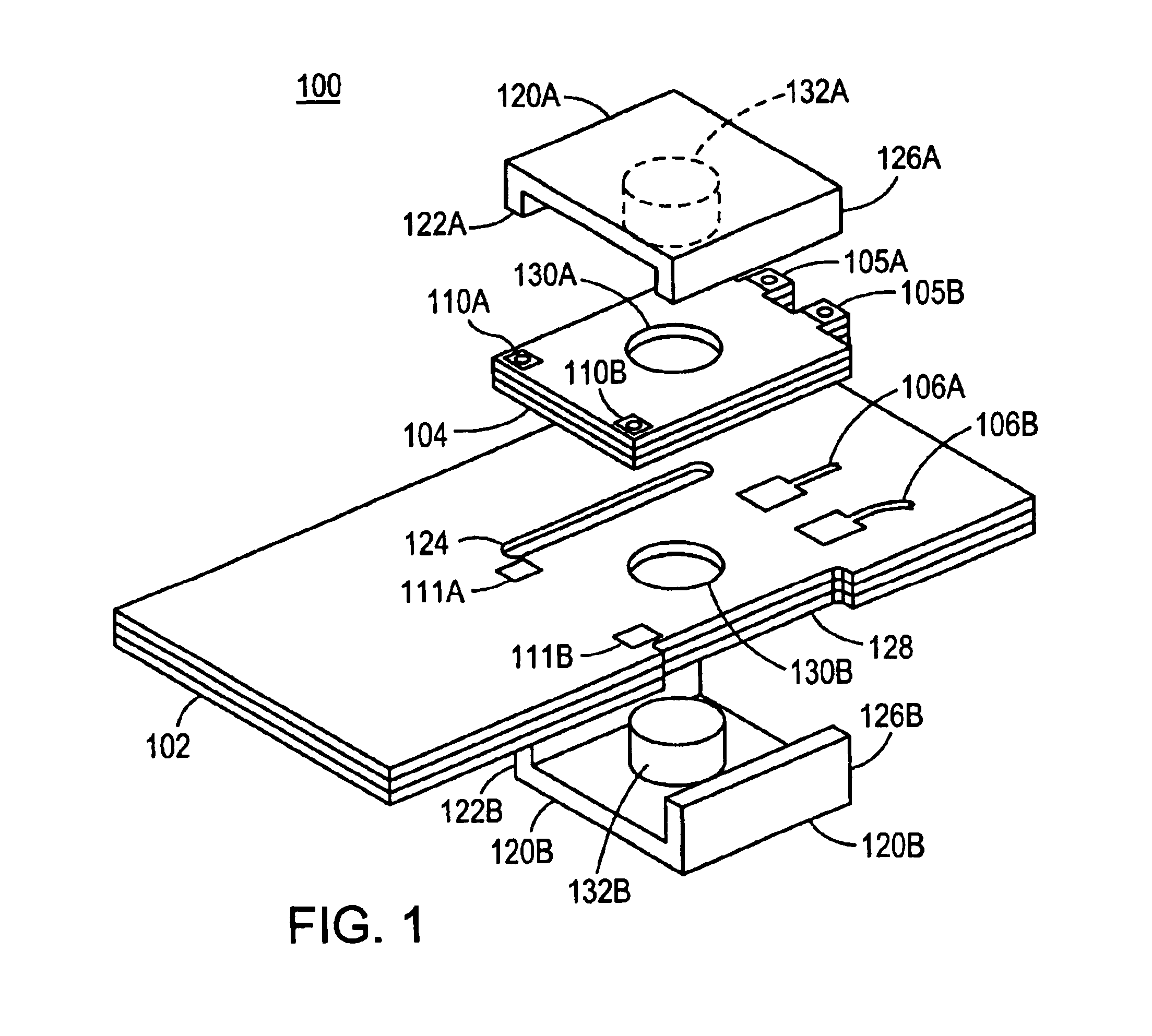

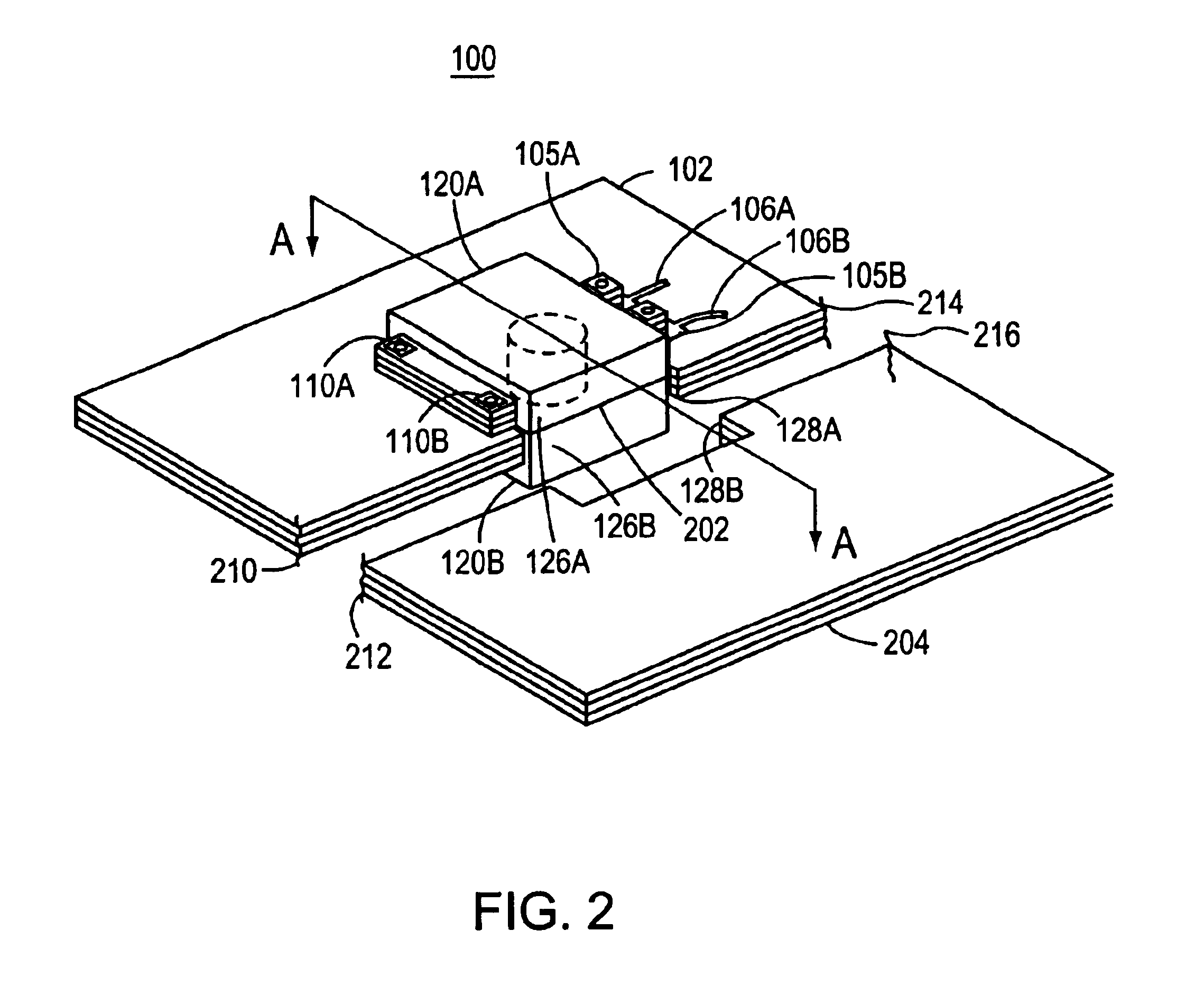

Contact-less power transfer

A system and method for transferring power does not require direct electrical conductive contacts. There is provided a primary unit having a power supply and a substantially laminar surface having at least one conductor that generates an electromagnetic field when a current flows therethrough and having an active area defined within a perimeter of the surface, the at least one conductor being arranged such that electromagnetic field lines generated by the at least one conductor are substantially parallel to the plane of the surface within the active area; and at least one secondary device including at least one conductor that may be wound about a core; wherein the active area has a perimeter large enough to surround the conductor or core of the at least one secondary device in any orientation thereof substantially parallel to the surface of the primary unit in the active area, such that when the at least one secondary device is placed on or in proximity to the active area in a predetermined orientation, the electromagnetic field induces a current in the at least one conductor of the at least one secondary device.

Owner:PHILIPS IP VENTURES BV

Portable contact-less power transfer devices and rechargeable batteries

InactiveUS7248017B2Maximise currentMaximise voltageTransformersTransformers/inductances coils/windings/connectionsElectric power transmissionElectrical conductor

There is disclosed a system and method for transferring power without requiring direct electrical conductive contacts. There is provided a primary unit having a power supply and a substantially laminar charging surface having at least one conductor that generates an electromagnetic field when a current flows therethrough and having an charging area defined within a perimeter of the surface, the at least one conductor being arranged such that electromagnetic field lines generated by the at least one conductor are substantially parallel to the plane of the surface or at least subtend an angle of 45° or less to the surface within the charging area; and at least one secondary device including at least one conductor that may be wound about a core. Because the electromagnetic field is spread over the charging area and is generally parallel or near-parallel thereto, coupling with flat secondary devices such as mobile telephones and the like is significantly improved in various orientations thereof.

Owner:PHILIPS IP VENTURES BV

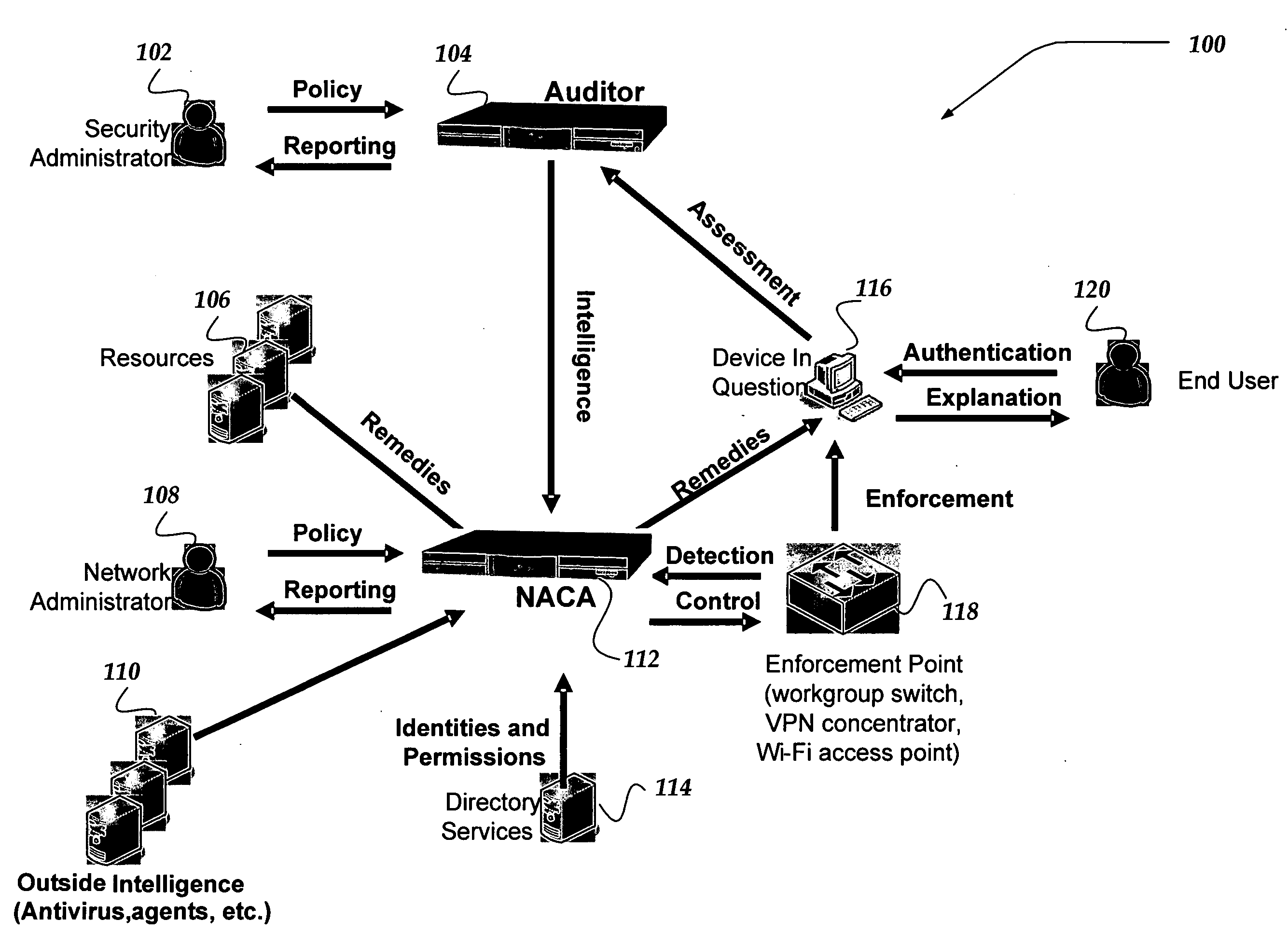

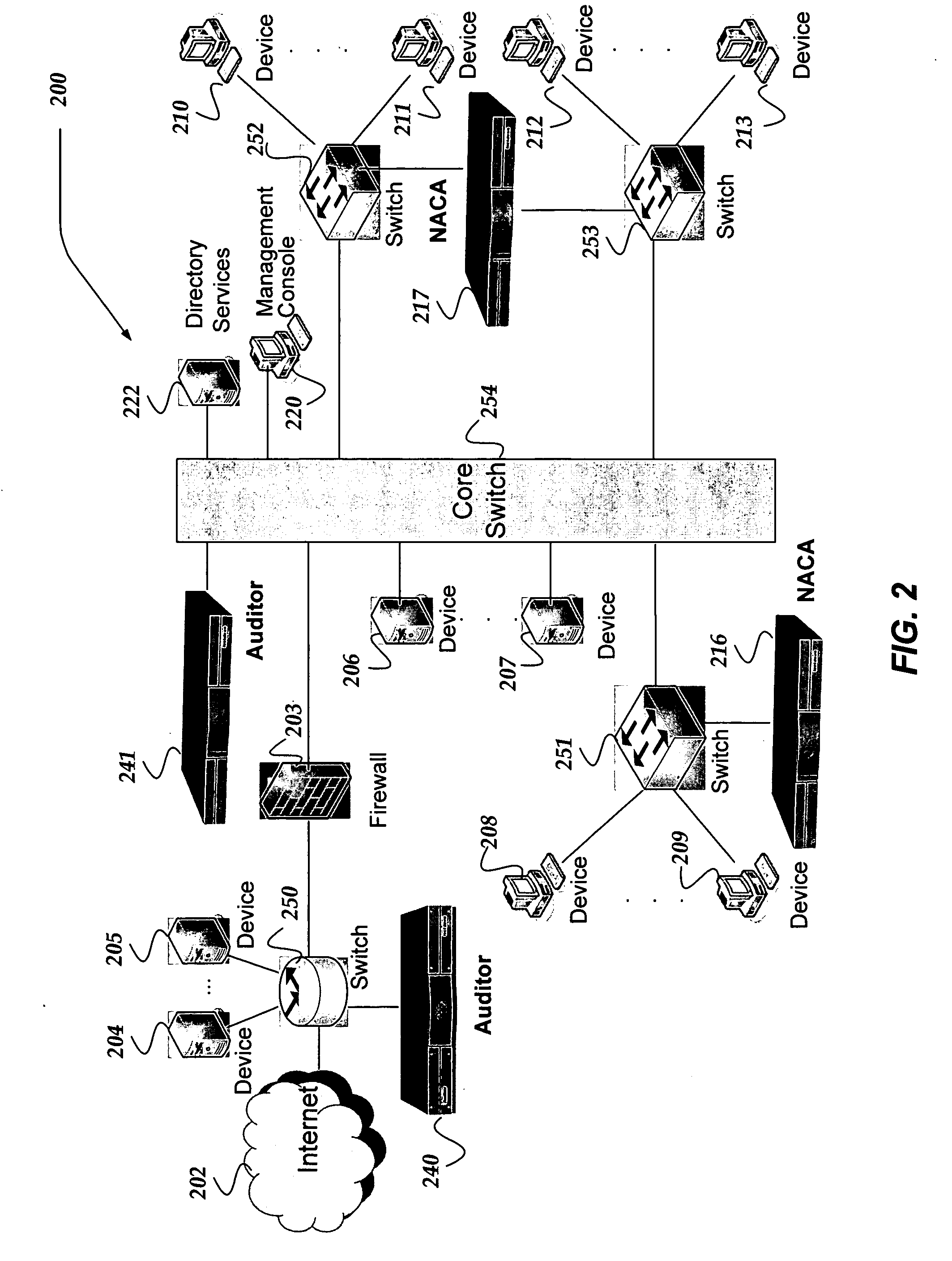

Network appliance for securely quarantining a node on a network

InactiveUS20060164199A1Transformers/inductances magnetic coresData switching networksNetwork Access ControlSecurity policy

An apparatus, system, and method for managing dynamic network access control. The invention provides services and controlled network access that includes quarantining nodes so that they may be identified, audited, and provided an opportunity to be brought into compliance with a security policy. The invention is configured to detect a device seeking to join the network, and determine if the device is allowed to join the network. If the invention determines that the device is not to be allowed, the device may be quarantined using a VLAN. The suspect device may then be audited for vulnerabilities. If vulnerabilities are identified, remediation may be employed to guide the suspect device, a user, and / or administrator of the suspect device towards a resolution of the vulnerabilities, such that the device may be reconfigured for acceptance onto the network.

Owner:MCAFEE INC

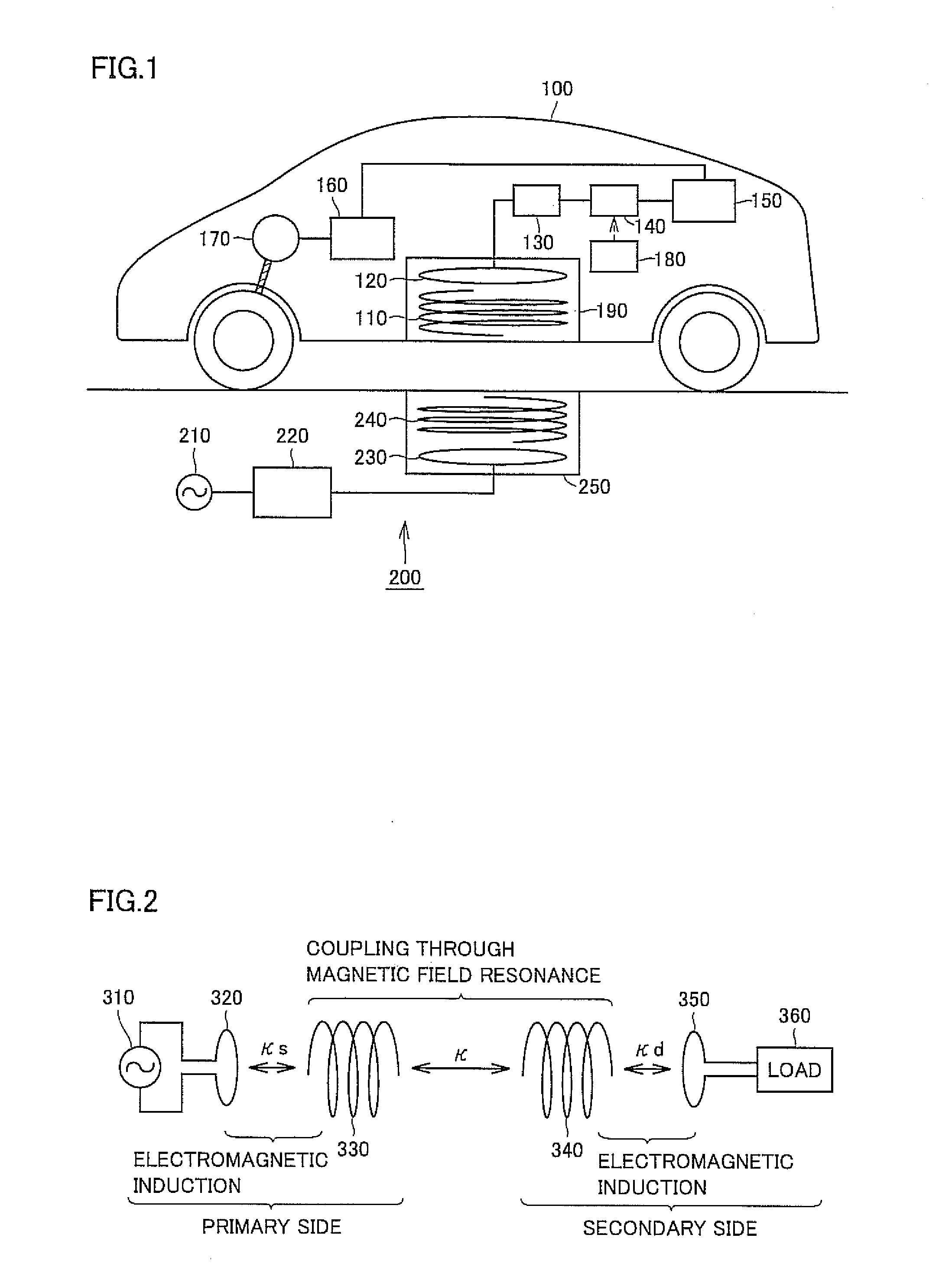

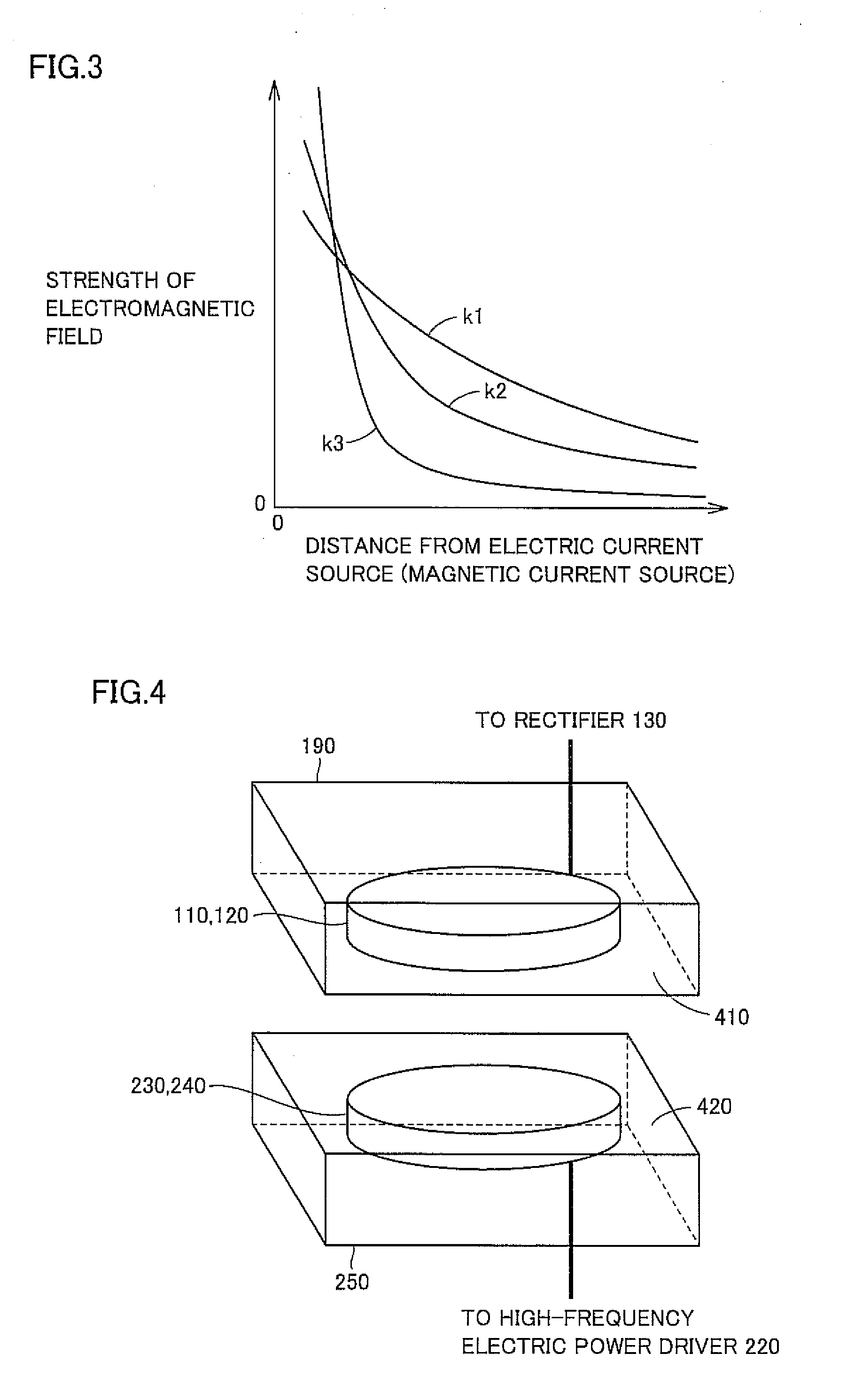

Noncontact electric power receiving device, noncontact electric power transmitting device, noncontact electric power feeding system, and electrically powered vehicle

A first shielding box is disposed so that its first surface can be opposite to an electric power feeding unit. The first surface has an opening and remaining five surfaces thereof reflect, during reception of electric power from the electric power feeding unit, a resonant electromagnetic field (near field) generated in the surroundings of the electric power receiving unit. The electric power receiving unit is provided in the first shielding box to receive the electric power from the electric power feeding unit via the opening (first surface) of the first shielding box. A second shielding box has a similar configuration, i.e., has a second surface with an opening and remaining five surfaces thereof reflect the resonant electromagnetic field (near field) generated in the surroundings of the electric power feeding unit.

Owner:TOYOTA JIDOSHA KK

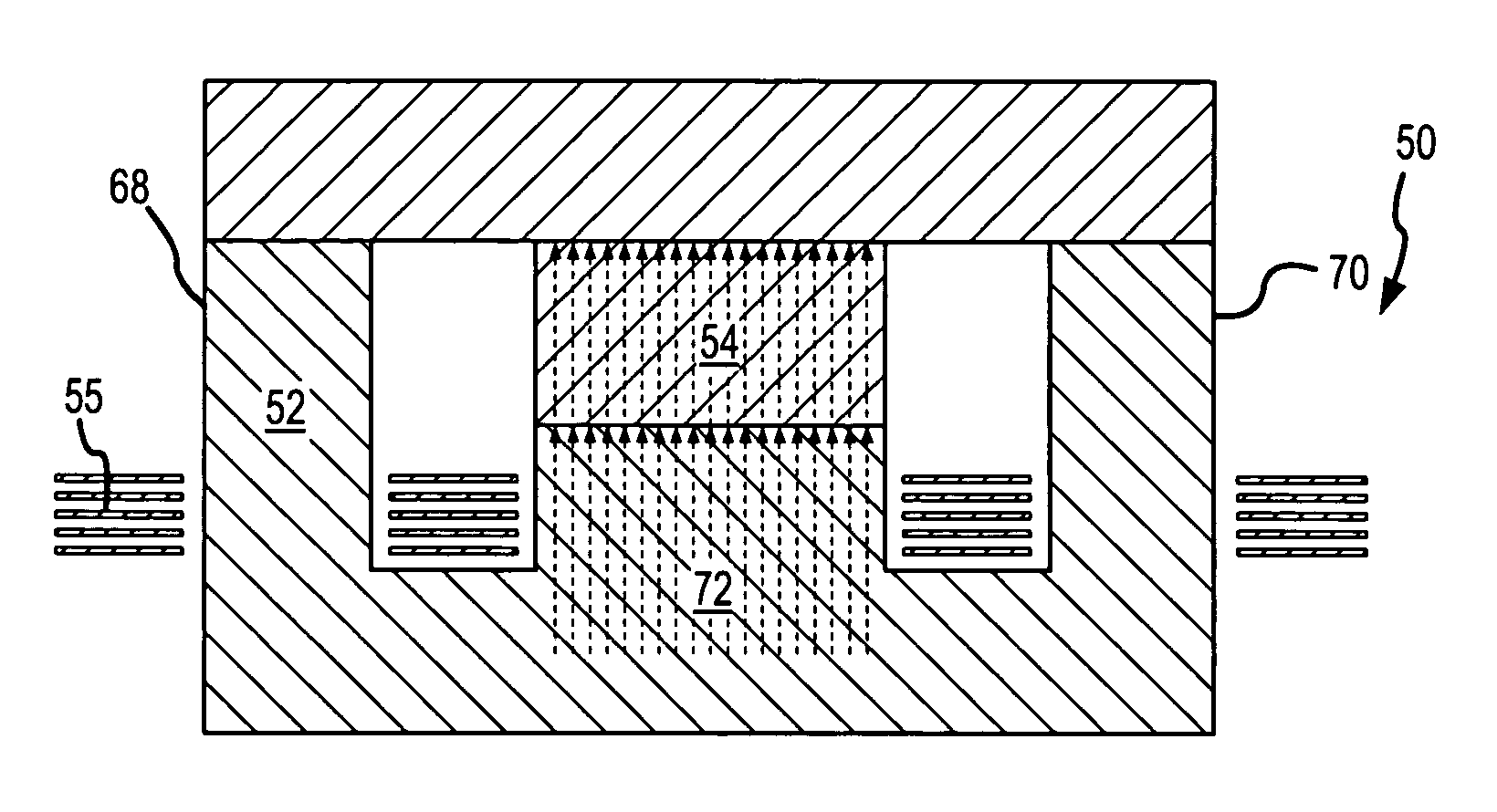

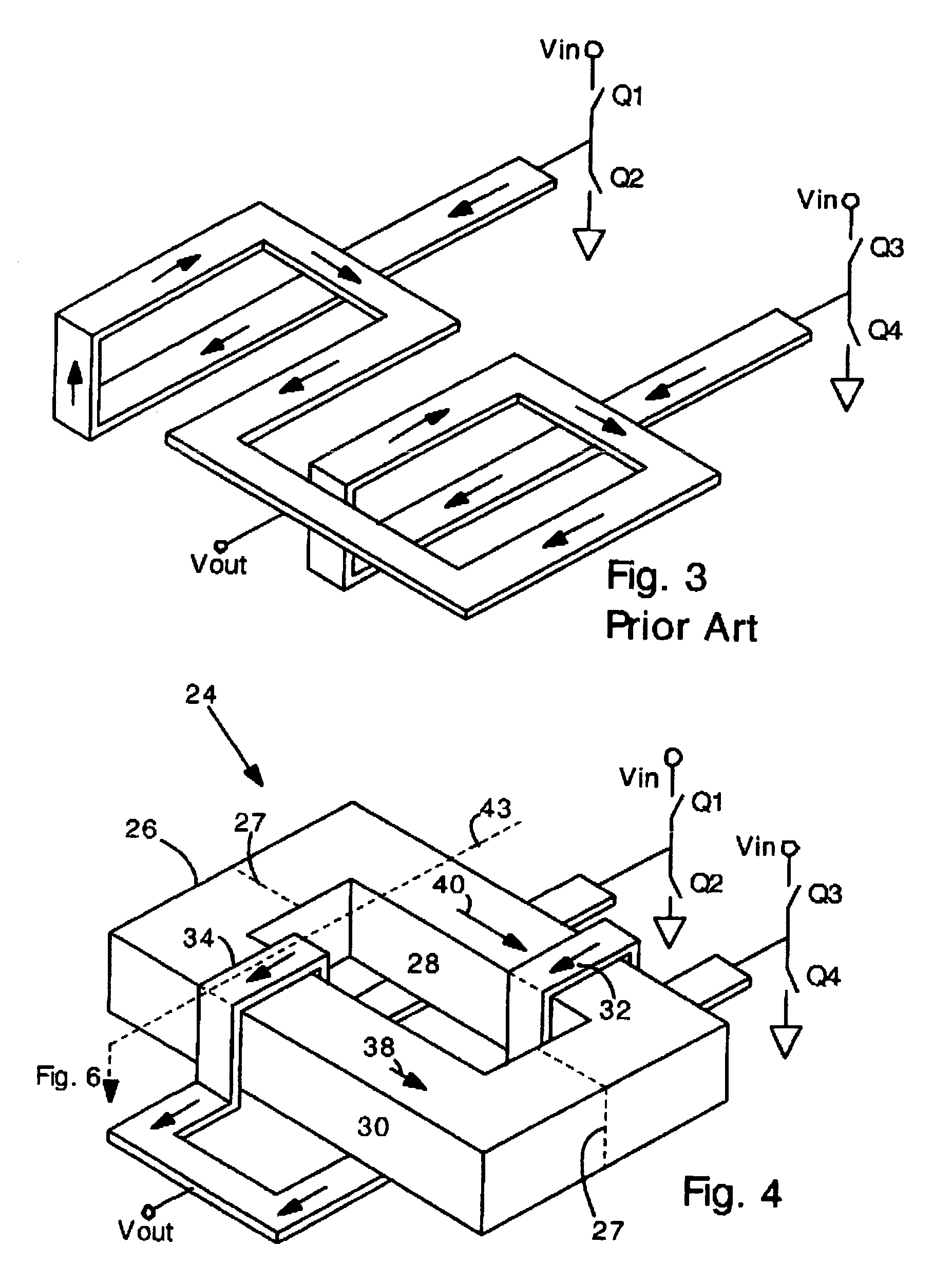

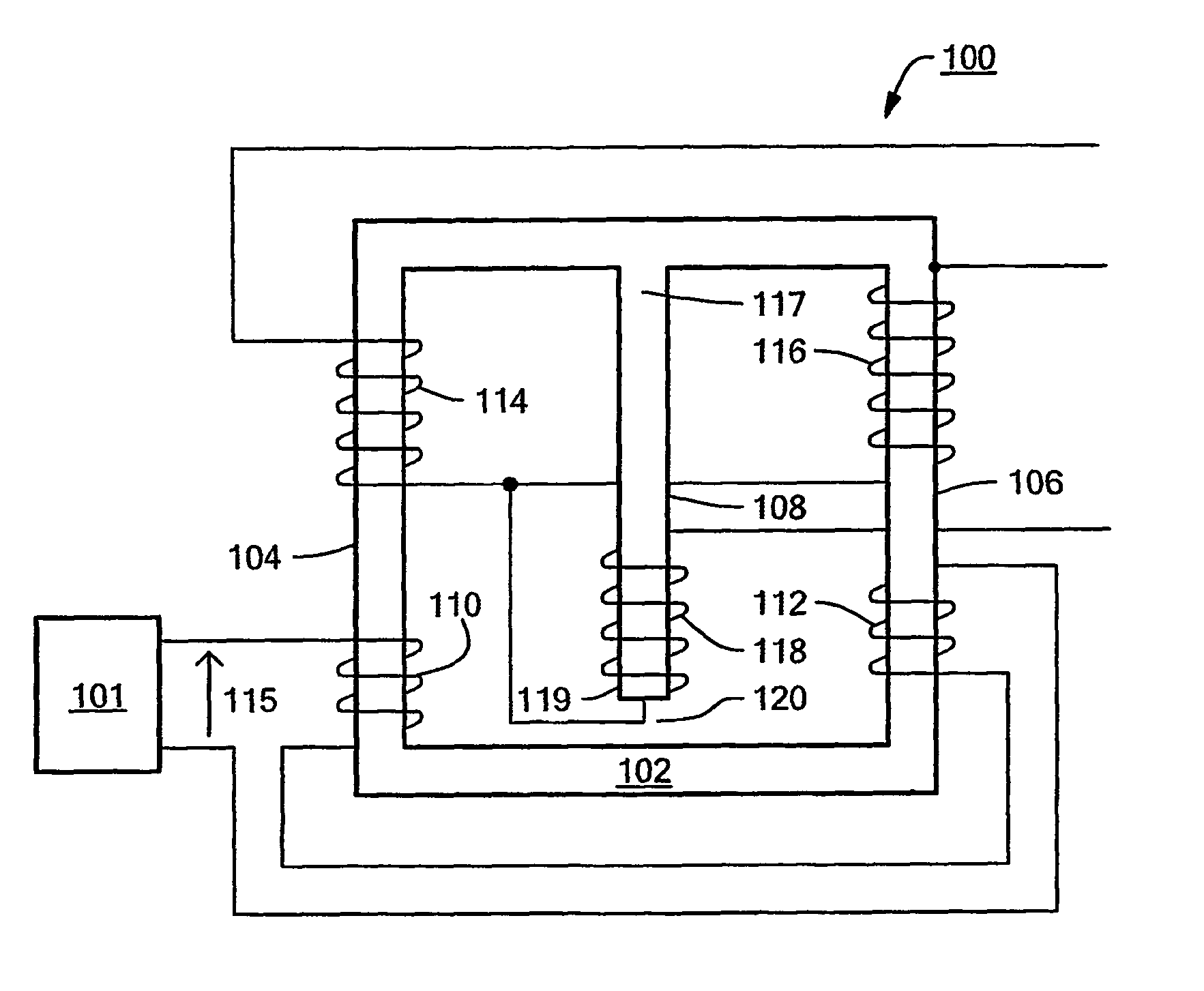

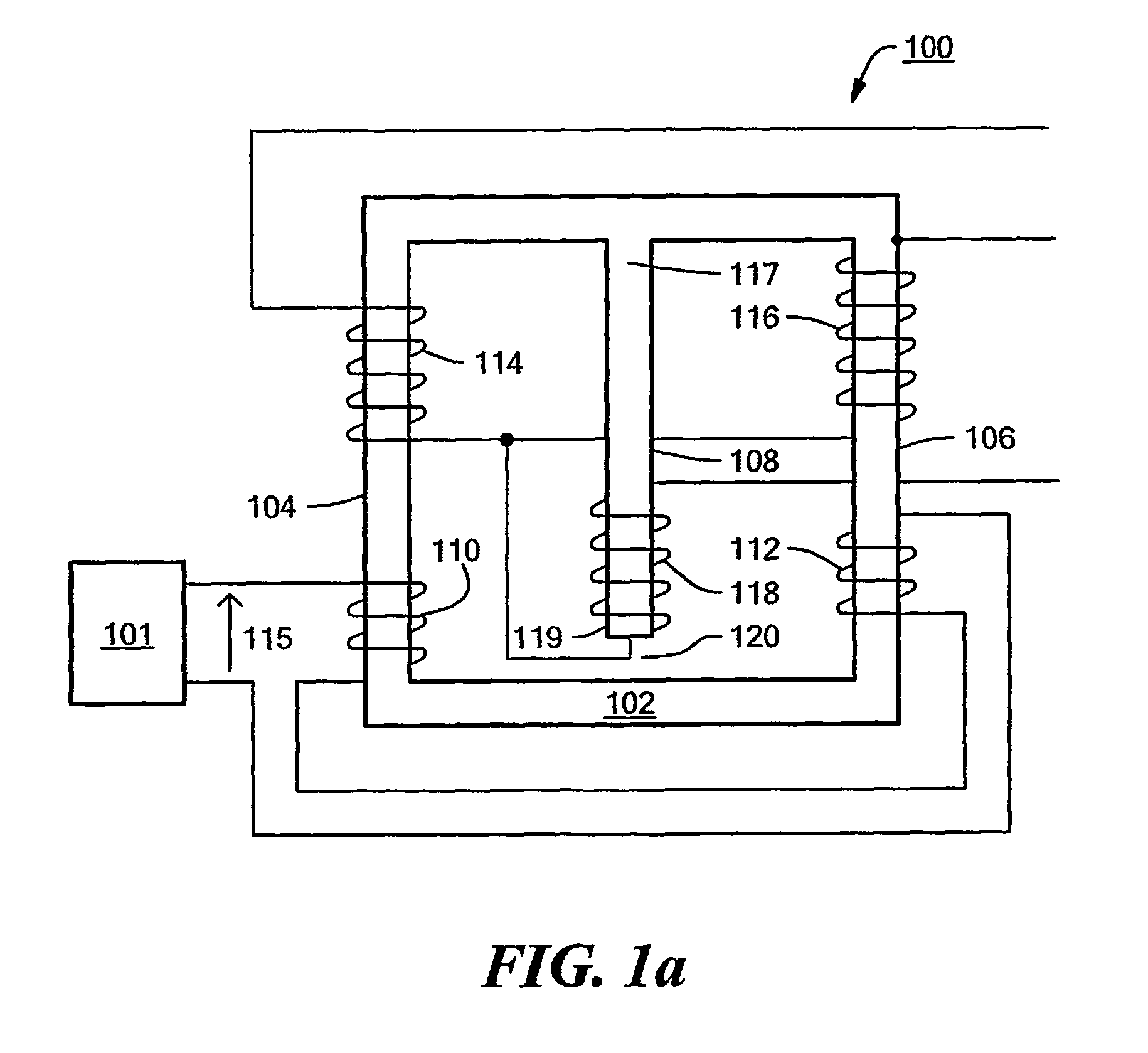

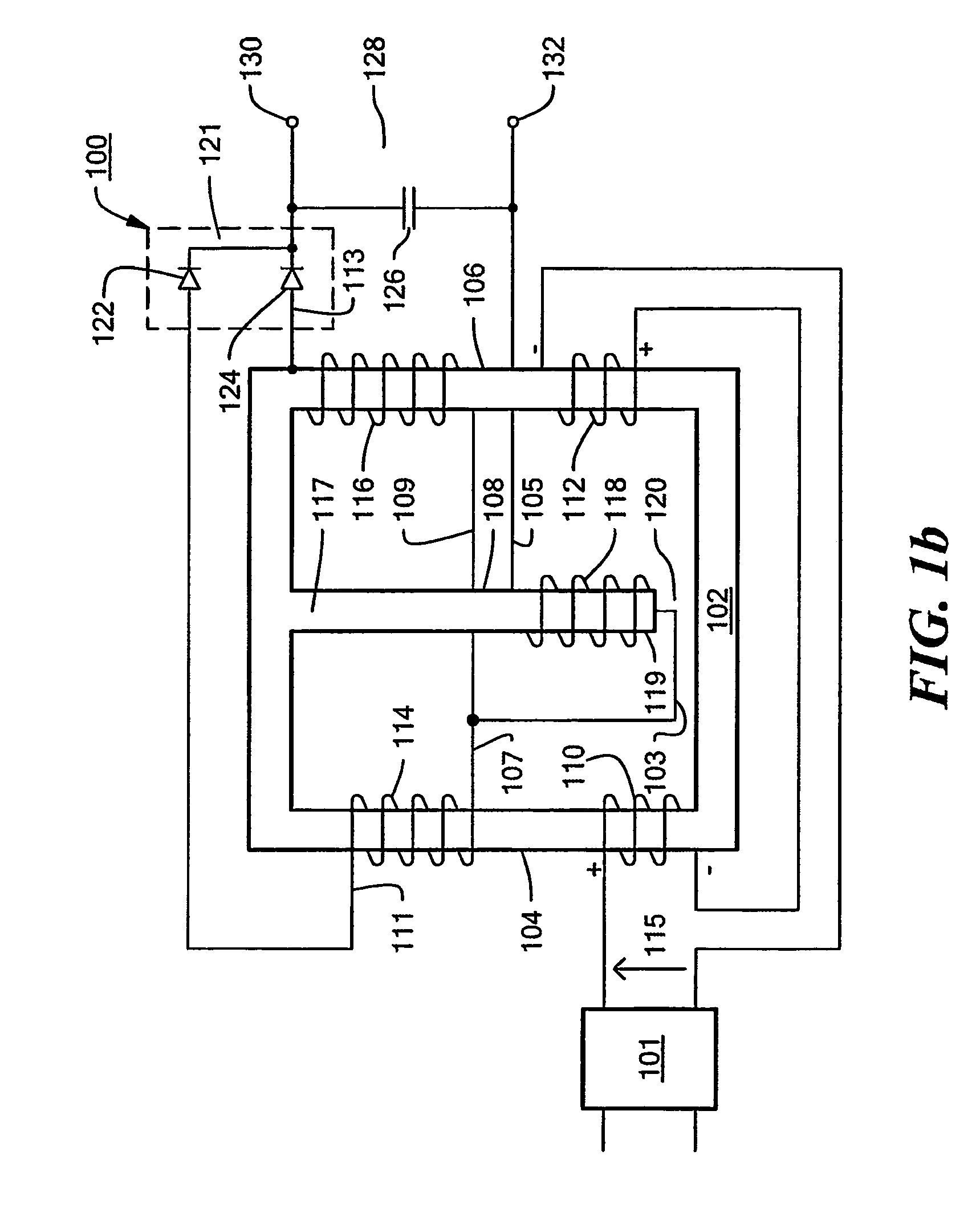

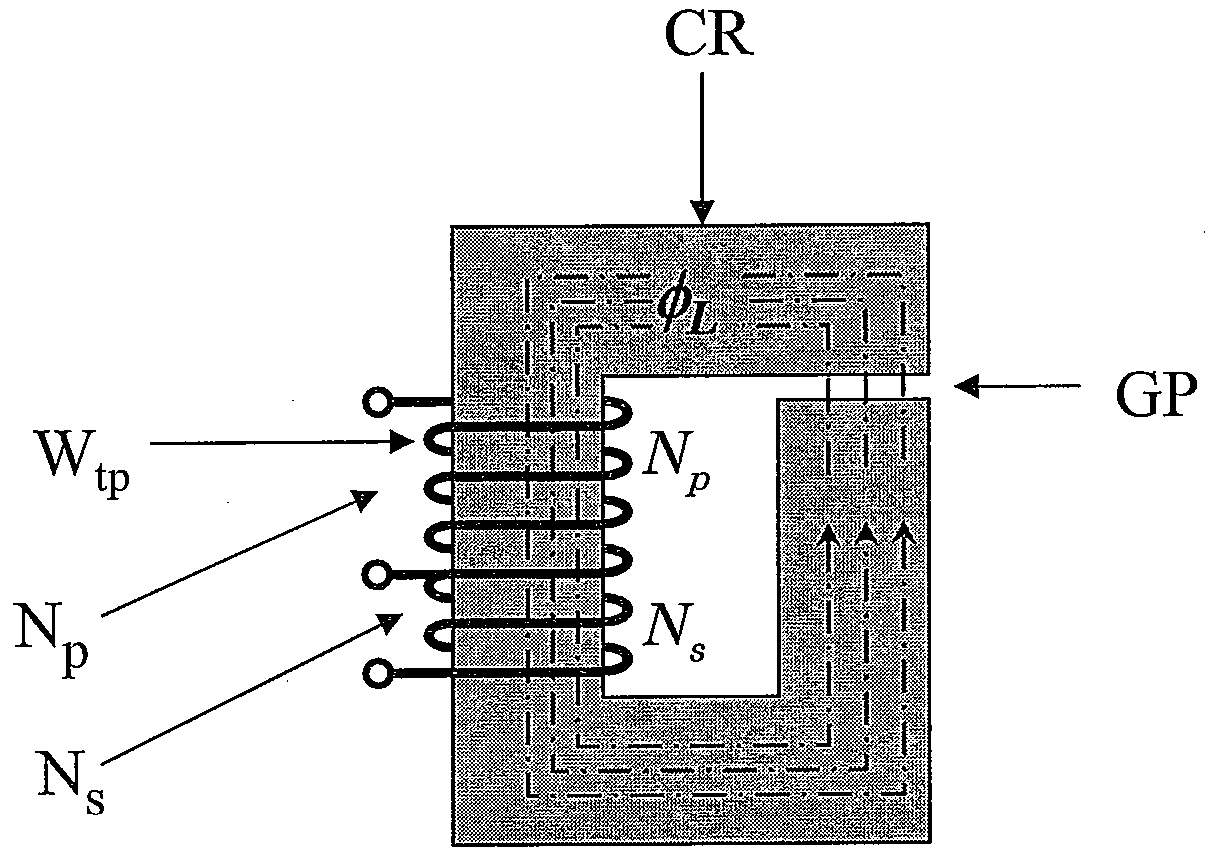

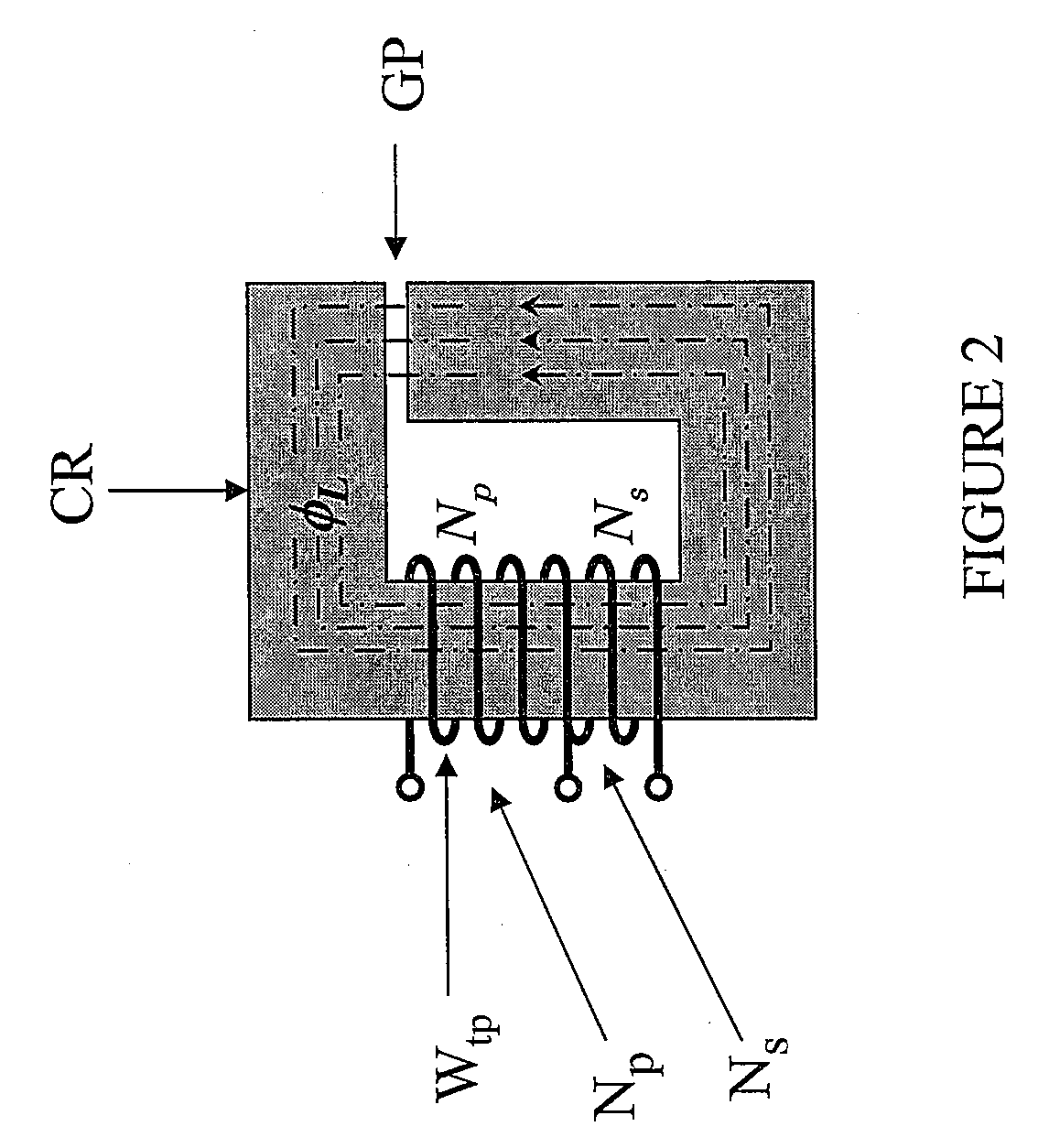

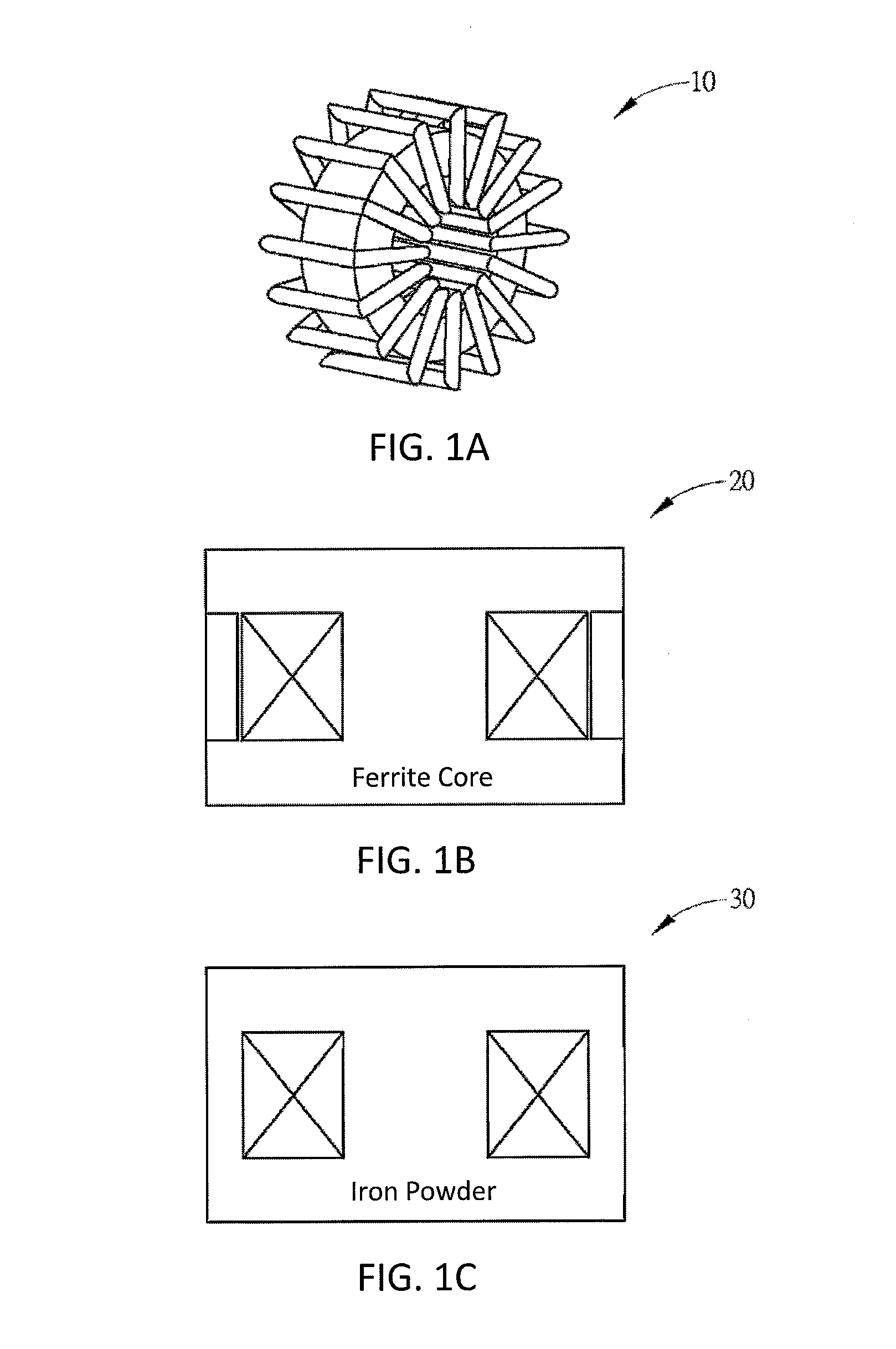

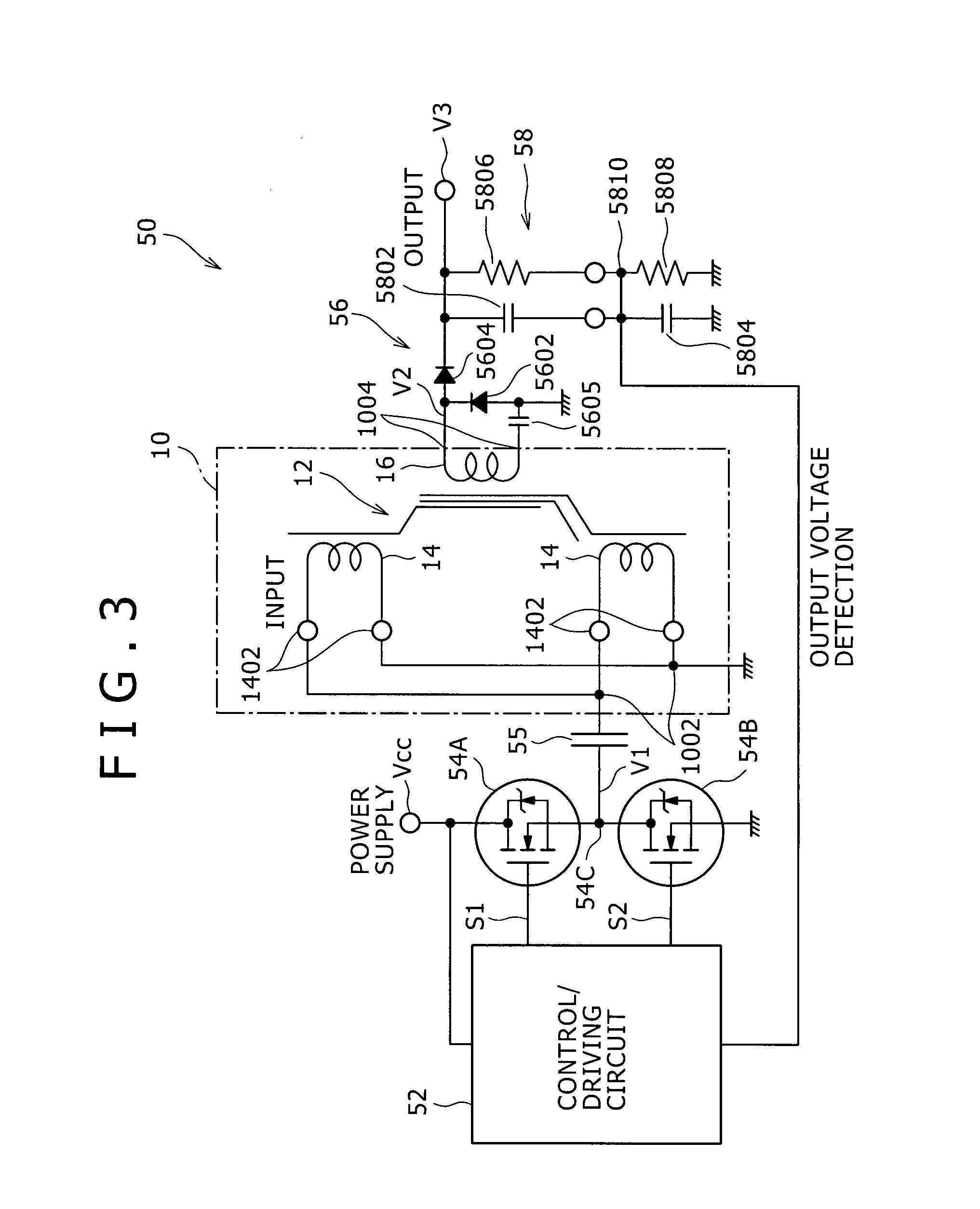

Composite magnetic core for switch-mode power converters

ActiveUS6980077B1Avoid Core SaturationLower average currentTransformers/inductances magnetic coresCores/yokesEddy currentConductor Coil

A composite magnetic core formed of a high permeability material and a lower permeability, high saturation flux density material prevents core saturation without an air gap and reduces eddy current losses and loss of inductance. The composite core is configured such that the low permeability, high saturation material is located where the flux accumulates from the high permeability sections. The presence of magnetic material having a relatively high permeability keeps the flux confined within the core thereby preventing fringing flux from spilling out into the winding arrangement. This composite core configuration balances the requirements of preventing core saturation and minimizing eddy current losses without increasing either the height or width of the core or the number of windings.

Owner:MYPAQ HLDG LTD

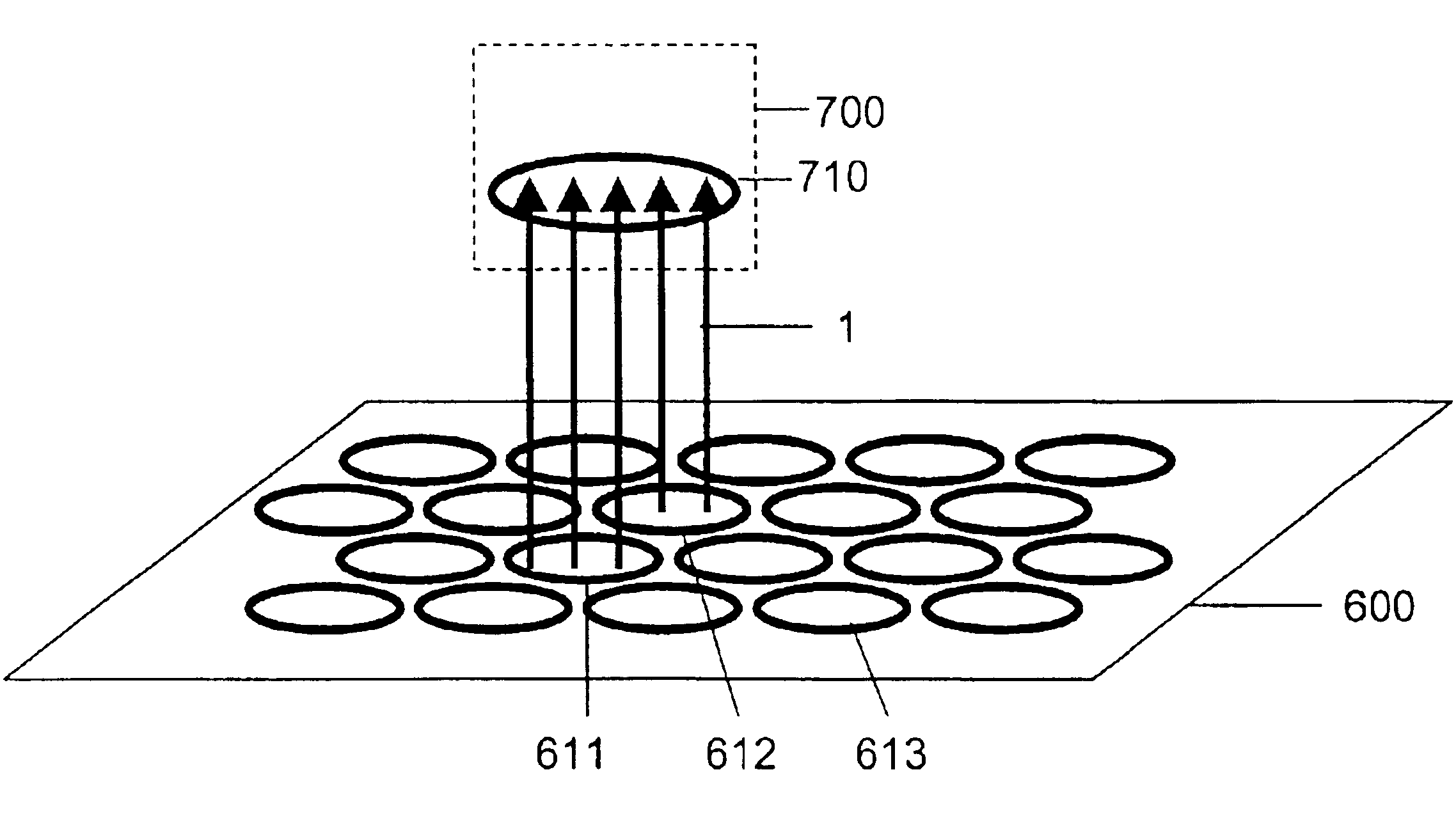

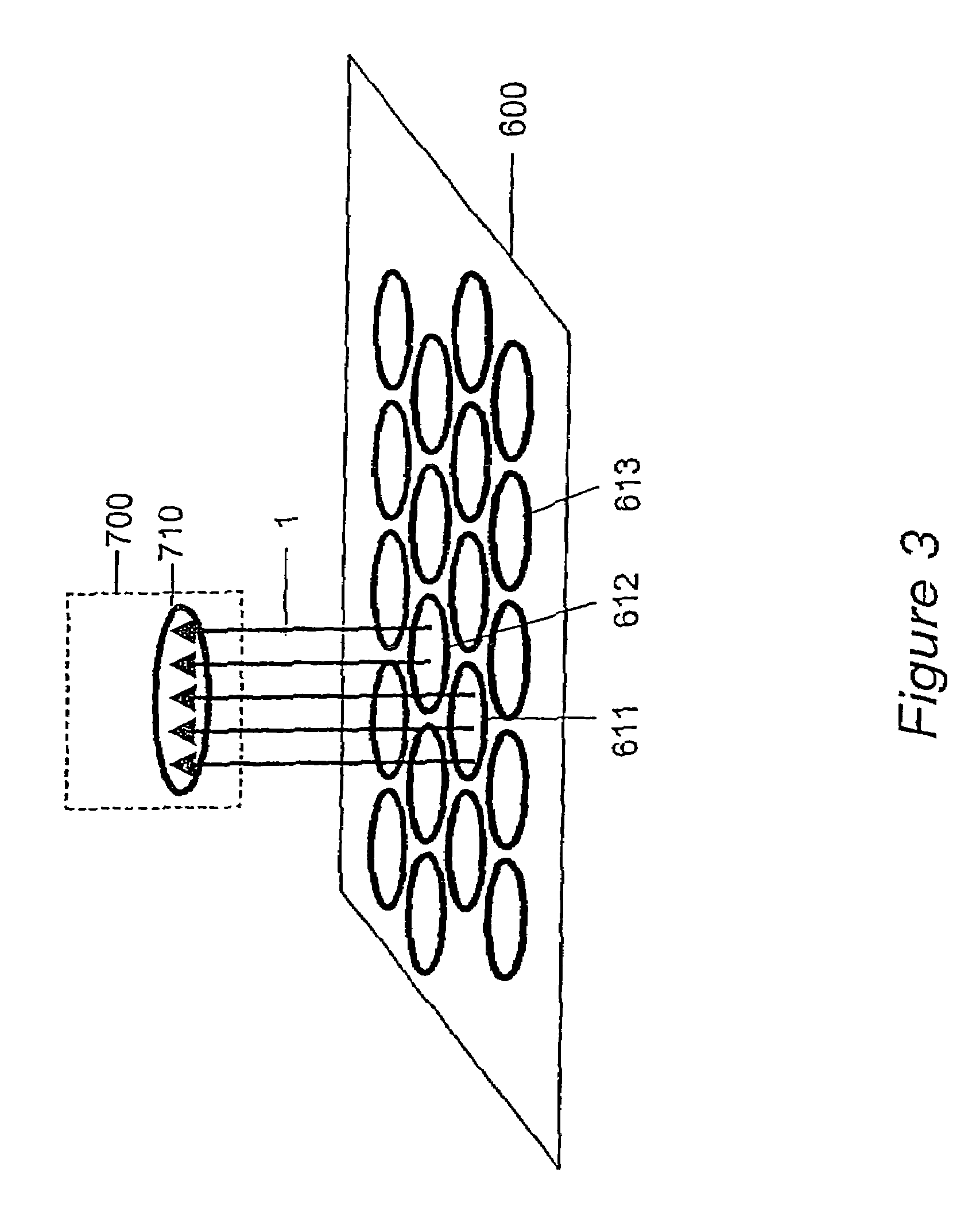

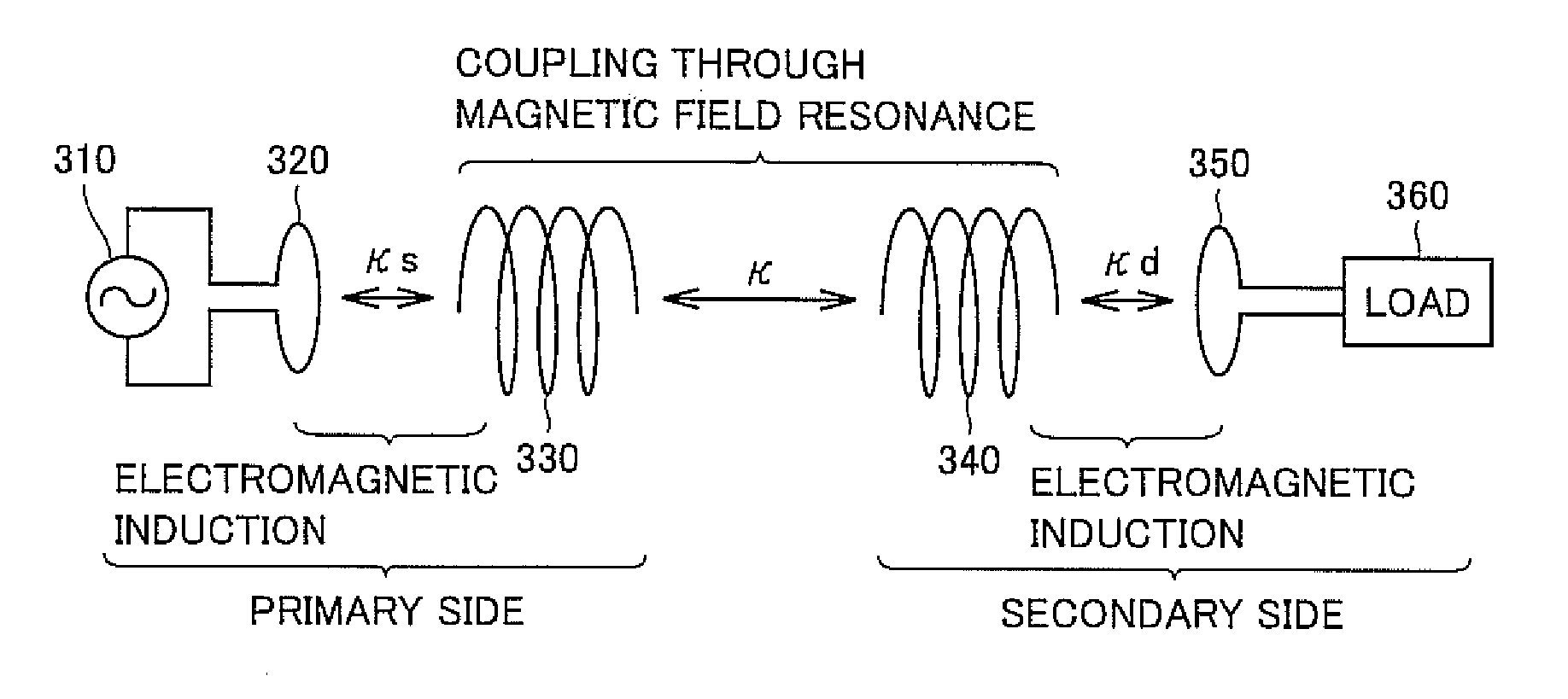

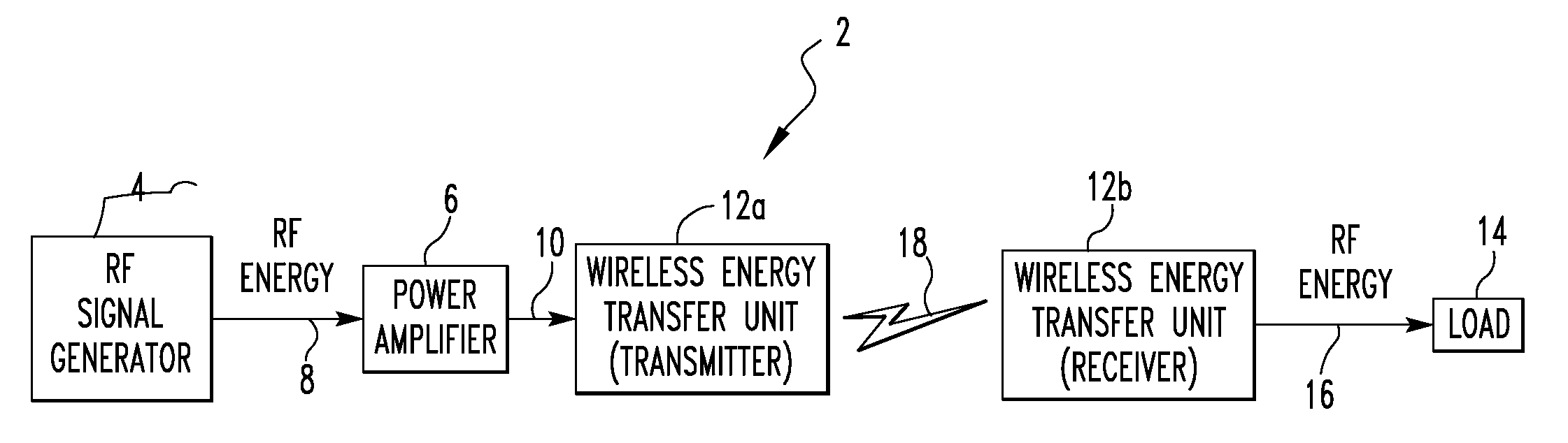

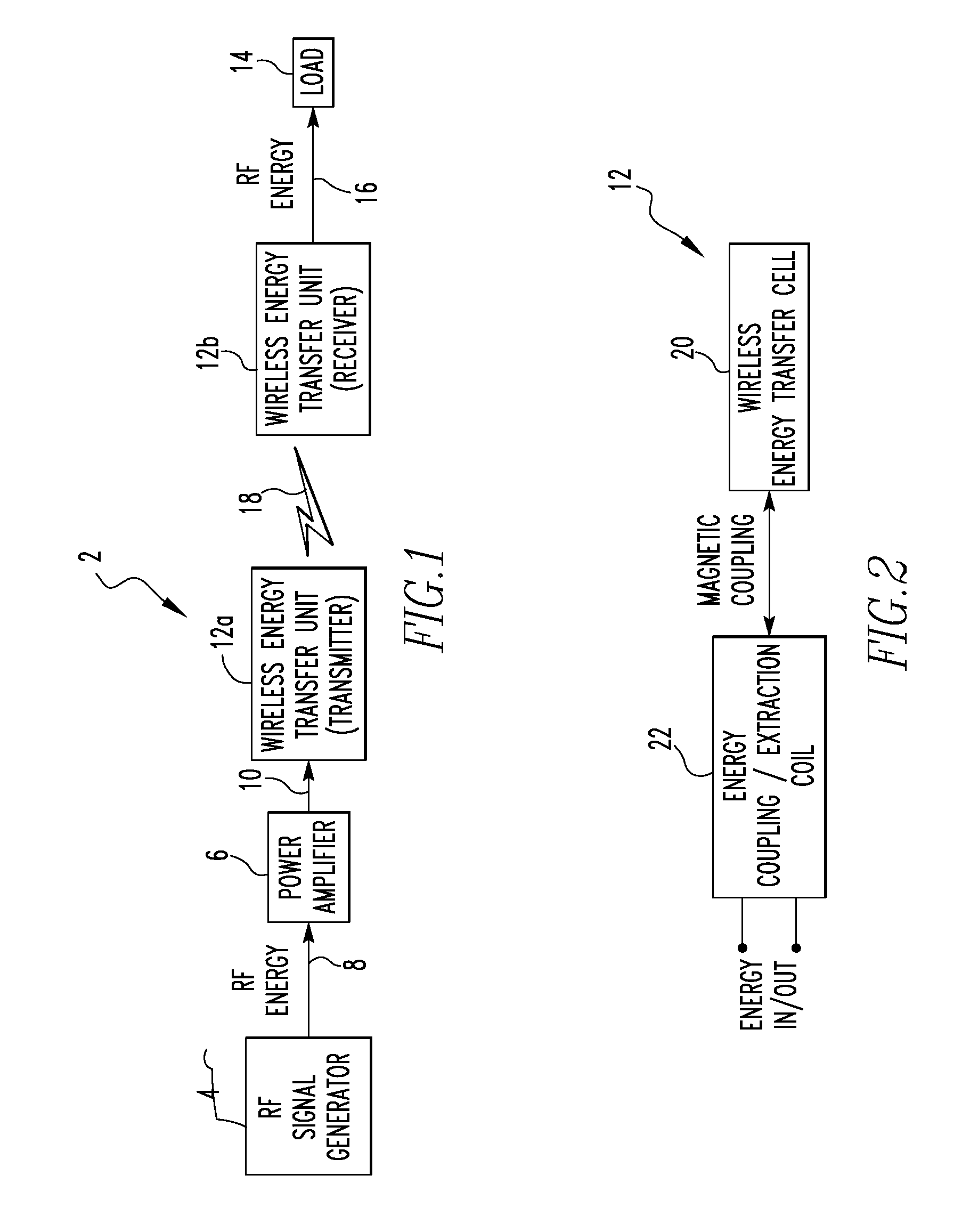

Wireless Energy Transfer System

ActiveUS20110101788A1Significant variabilityCapacitance varyNear-field transmissionTransformersEnergy transferCoupling

A wireless energy transfer system includes a first energy transfer unit having at least one resonant frequency, a second energy transfer unit having the at least one resonant frequency, and a load. The first wireless energy transfer unit includes a first coil magnetically coupled to a first wireless energy transfer cell, and the second wireless energy transfer unit includes a second coil magnetically coupled to a second wireless energy transfer cell. The first coil receives first energy and through the magnetic coupling between the first coil and the first wireless energy transfer cell, the first wireless energy transfer cell is caused to generate second energy, wherein the second wireless energy transfer cell receives the second energy and through the magnetic coupling between the second wireless energy transfer cell and the second coil, the second coil is caused to provide third electromagnetic wave energy to the load.

Owner:UNIVERSITY OF PITTSBURGH

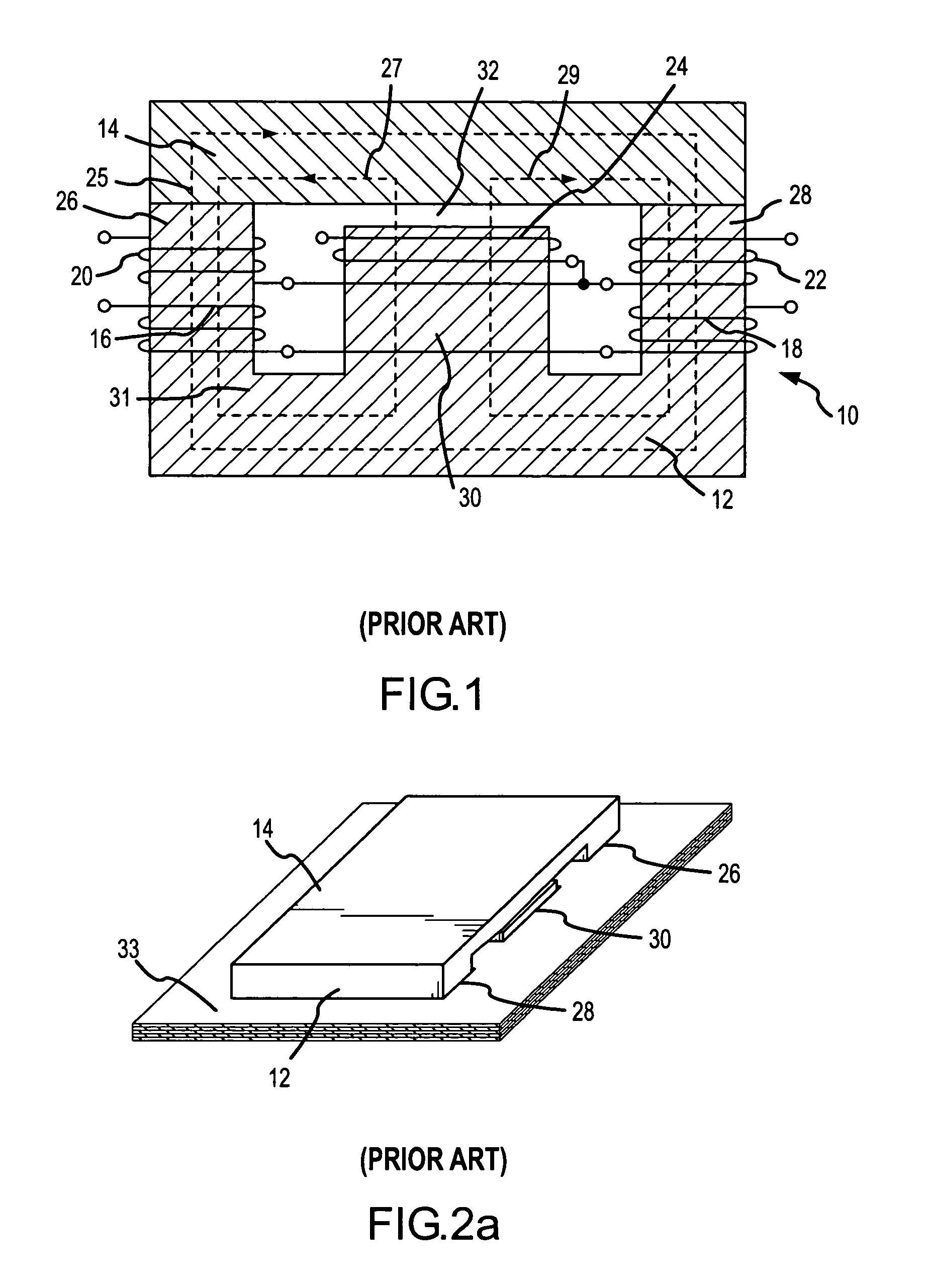

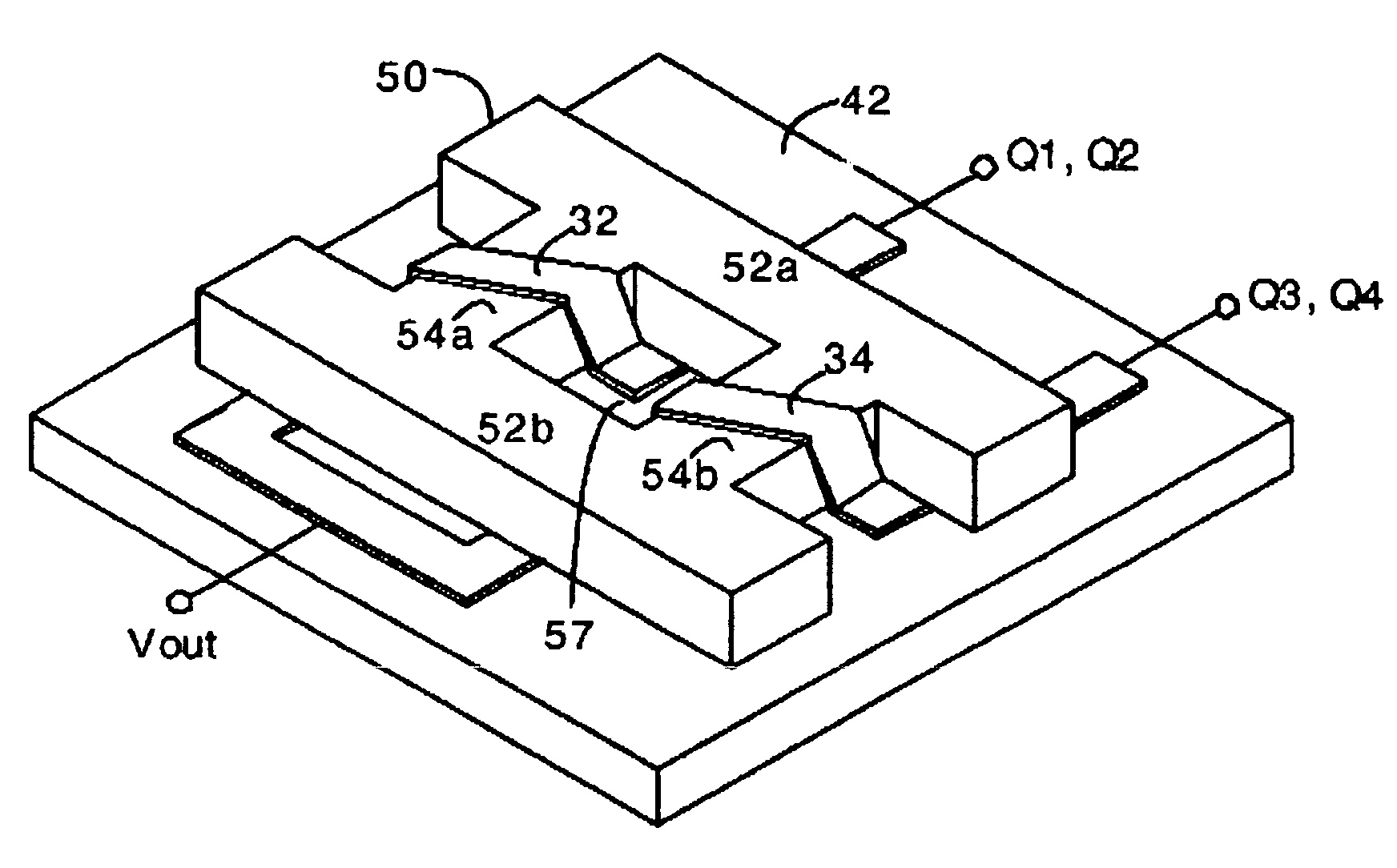

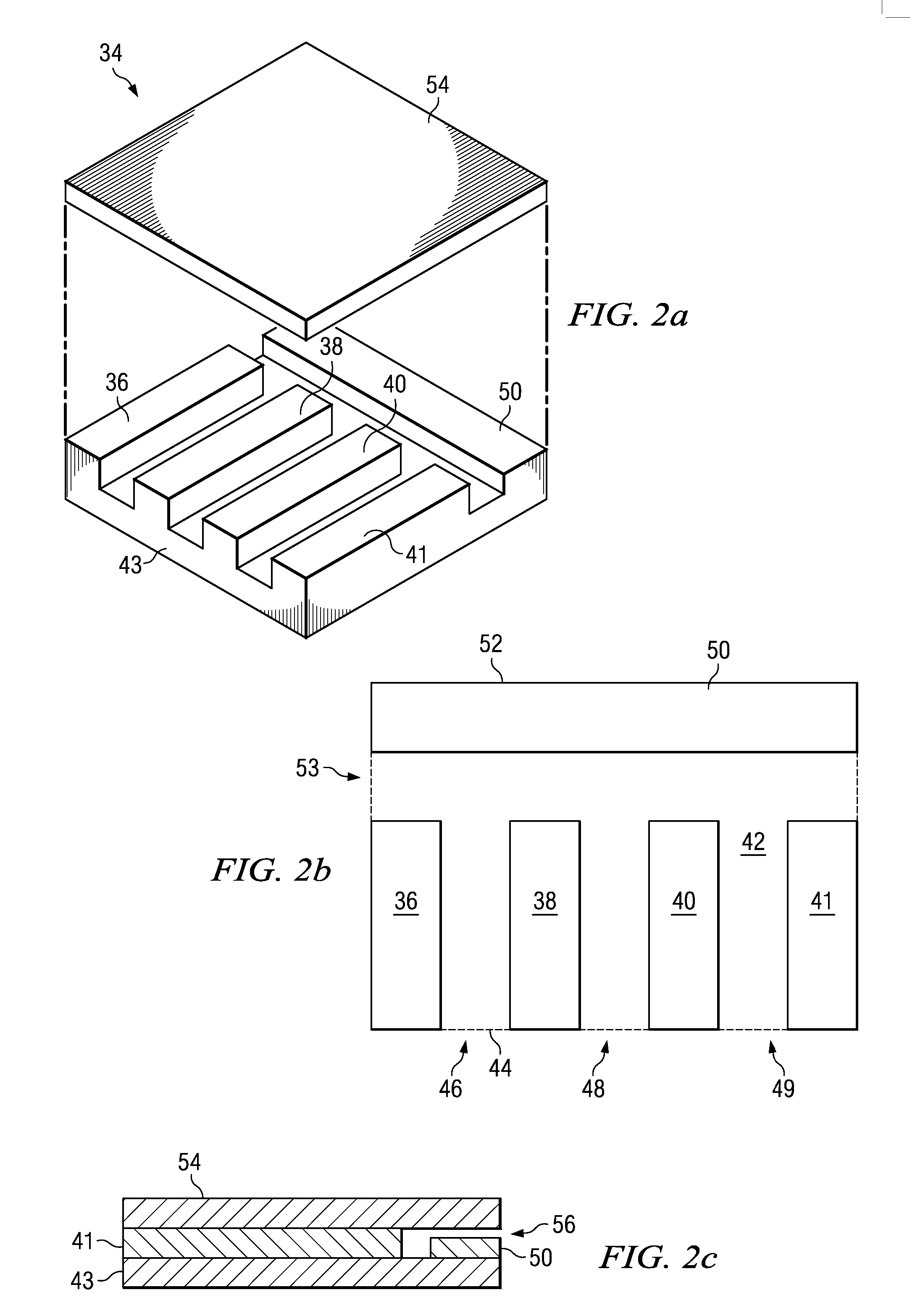

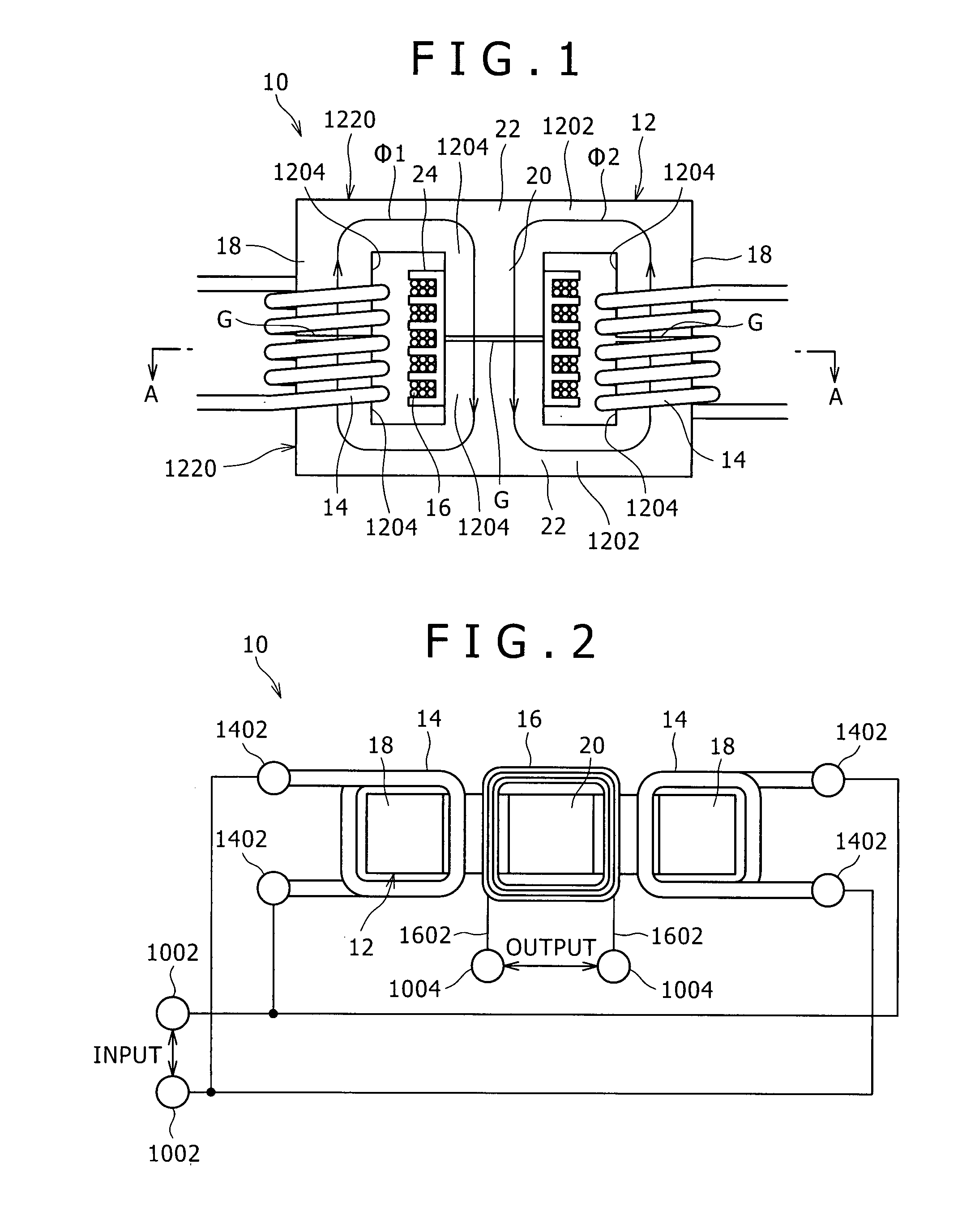

Extended E matrix integrated magnetics (MIM) core

InactiveUS20050024179A1Easy and less-expensive to fabricateLow profileAc-dc conversion without reversalTransformers/inductances magnetic coresEngineeringMechanical engineering

Owner:MYPAQ HLDG LTD

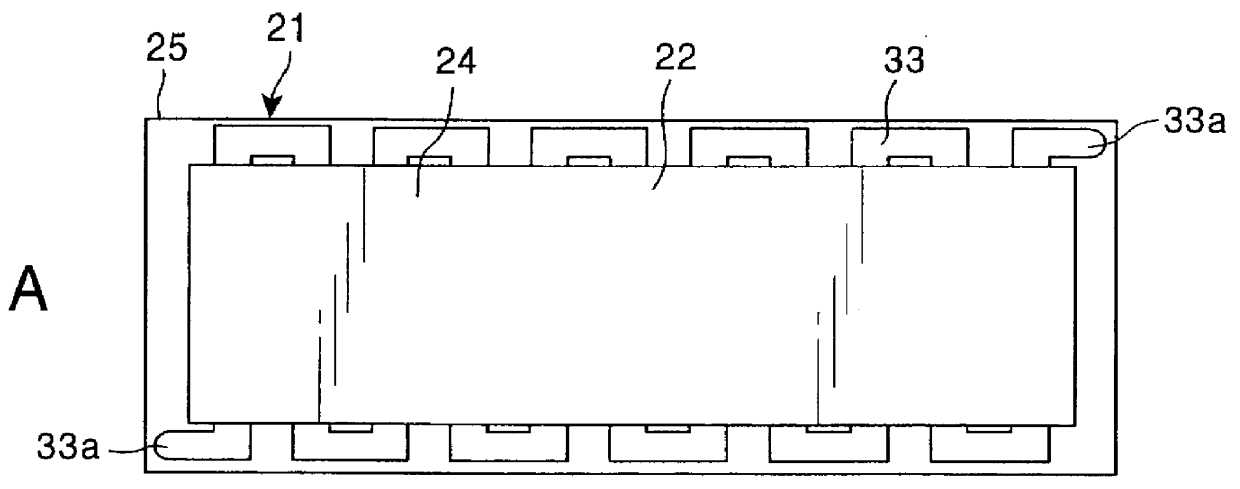

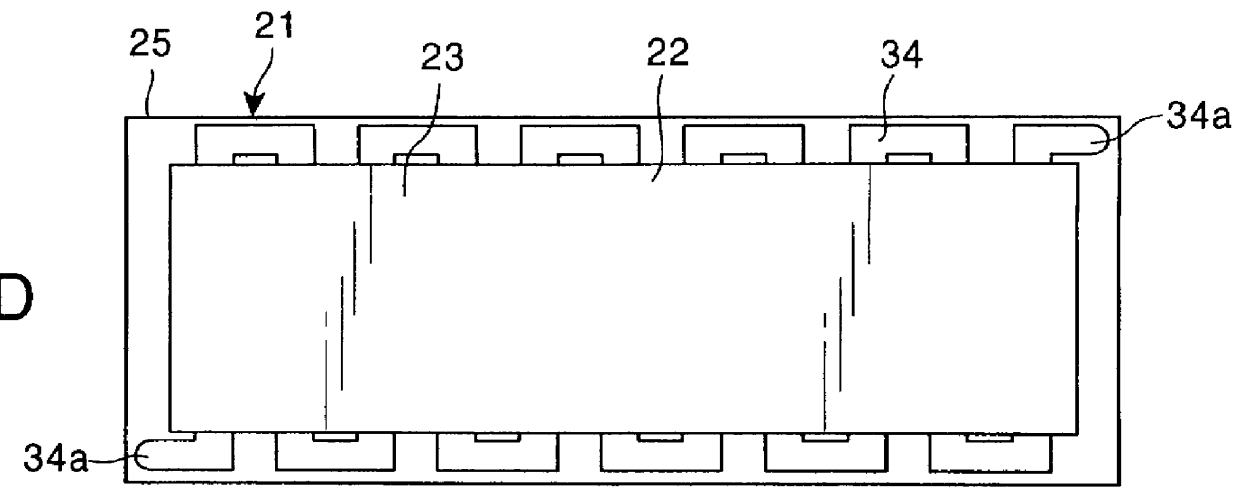

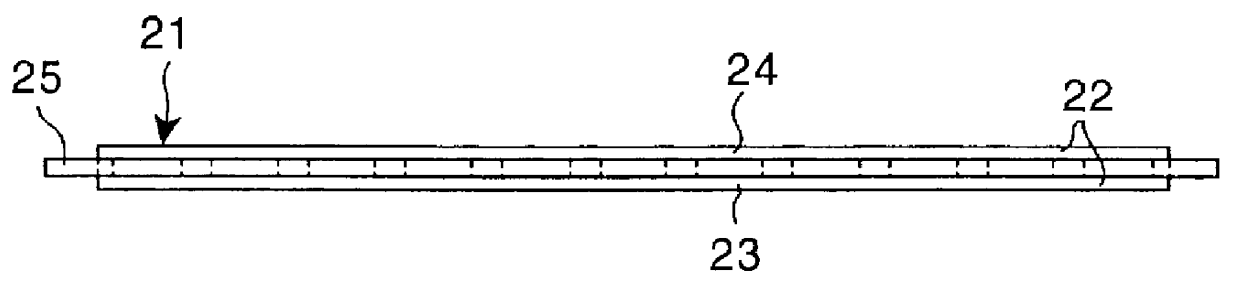

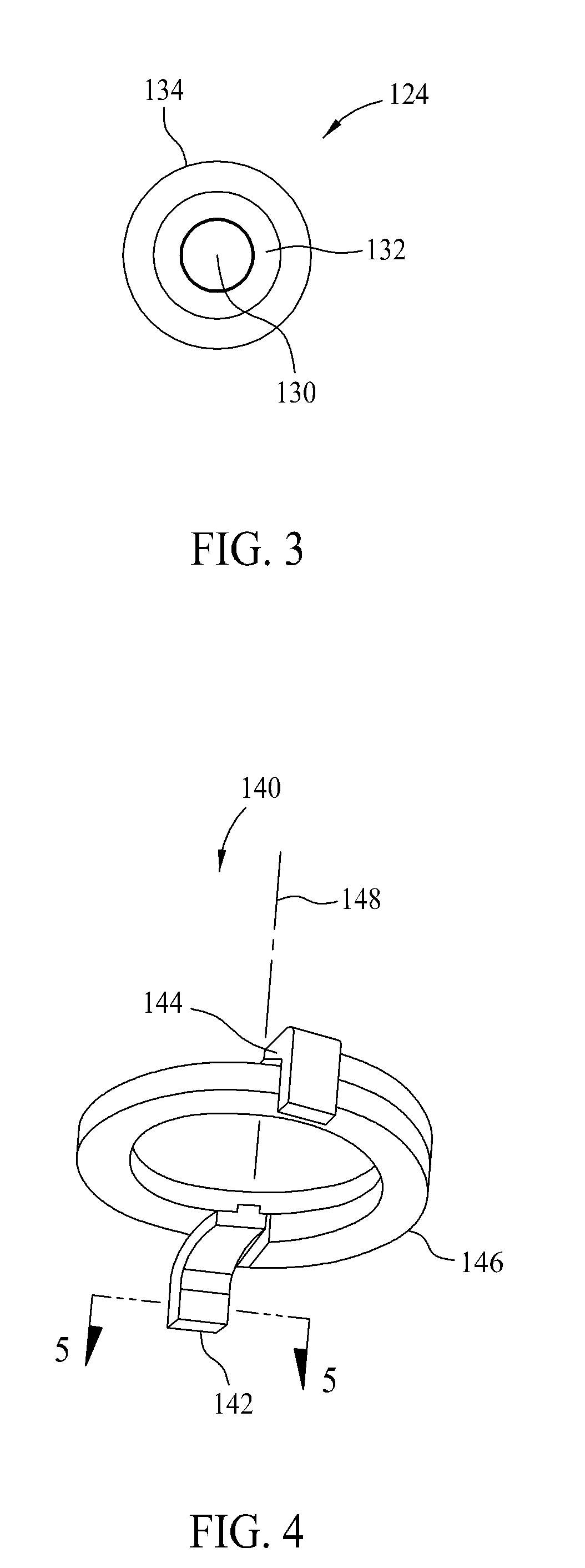

Multiphase voltage regulator having coupled inductors with reduced winding resistance

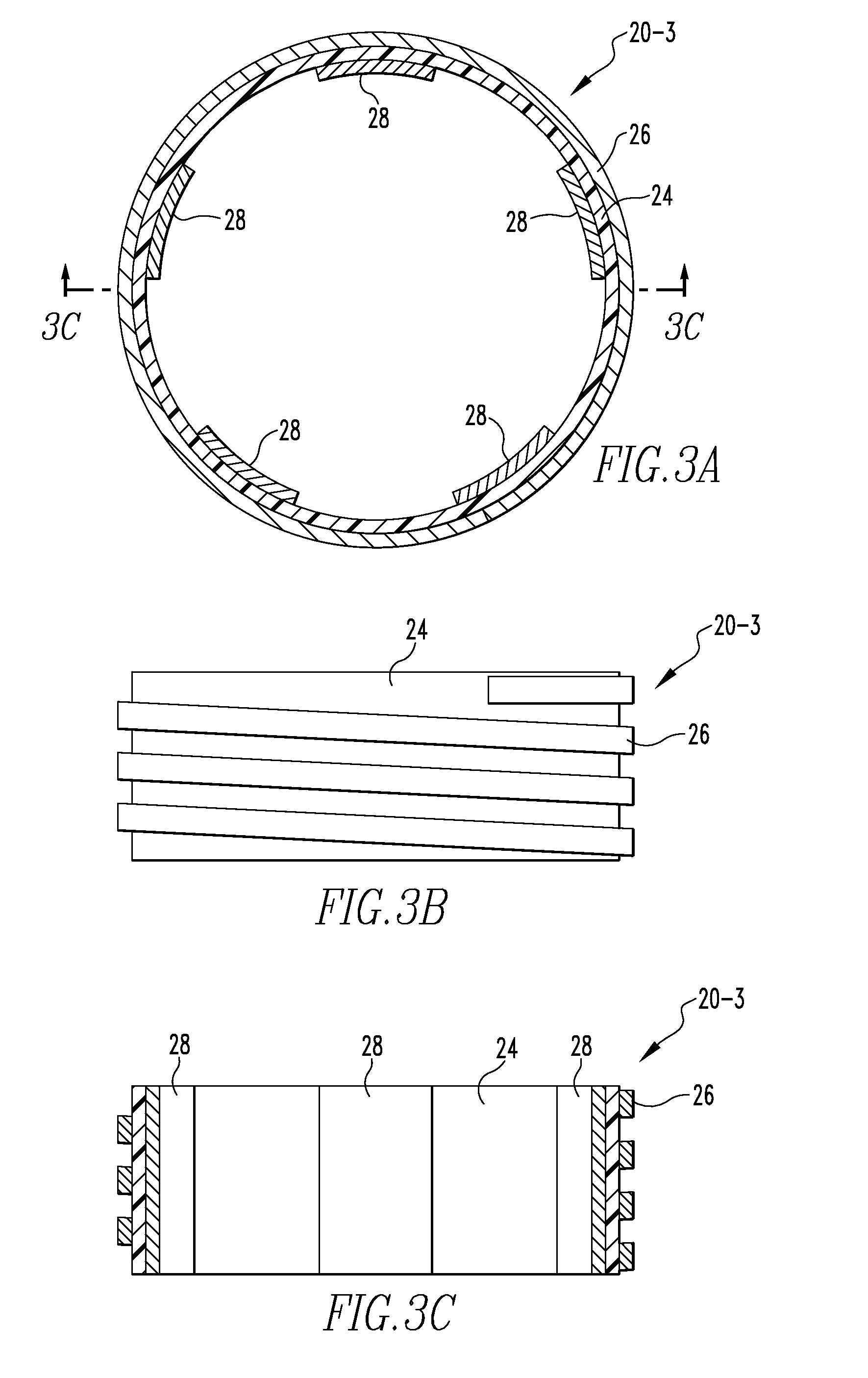

InactiveUS7649434B2Transformers/inductances coils/windings/connectionsDc-dc conversionBuck converterCoupling

A multiple phase buck converter or boost converter, or buck-boost converter has an inductor in each phase. The inductors are inversely coupled. In a first embodiment, the converter includes a toroidal magnetic core with inductors extending under and over opposite sides of the toroidal magnetic core. The coupled inductors are thereby inversely coupled and have a relatively low ohmic resistance. In a second embodiment, the converter comprises a ladder-shaped magnetic core (i.e. having parallel sides, and connecting rungs). In this case, the inductors extend under the sides, and over the rungs. Each inductor is disposed over a separate rung. The ladder-shaped magnetic core is preferably disposed flat on a circuit board. Inverse coupling and low ohmic resistance are also provided in the second embodiment having the ladder structure.

Owner:VIRGINIA TECH INTPROP INC

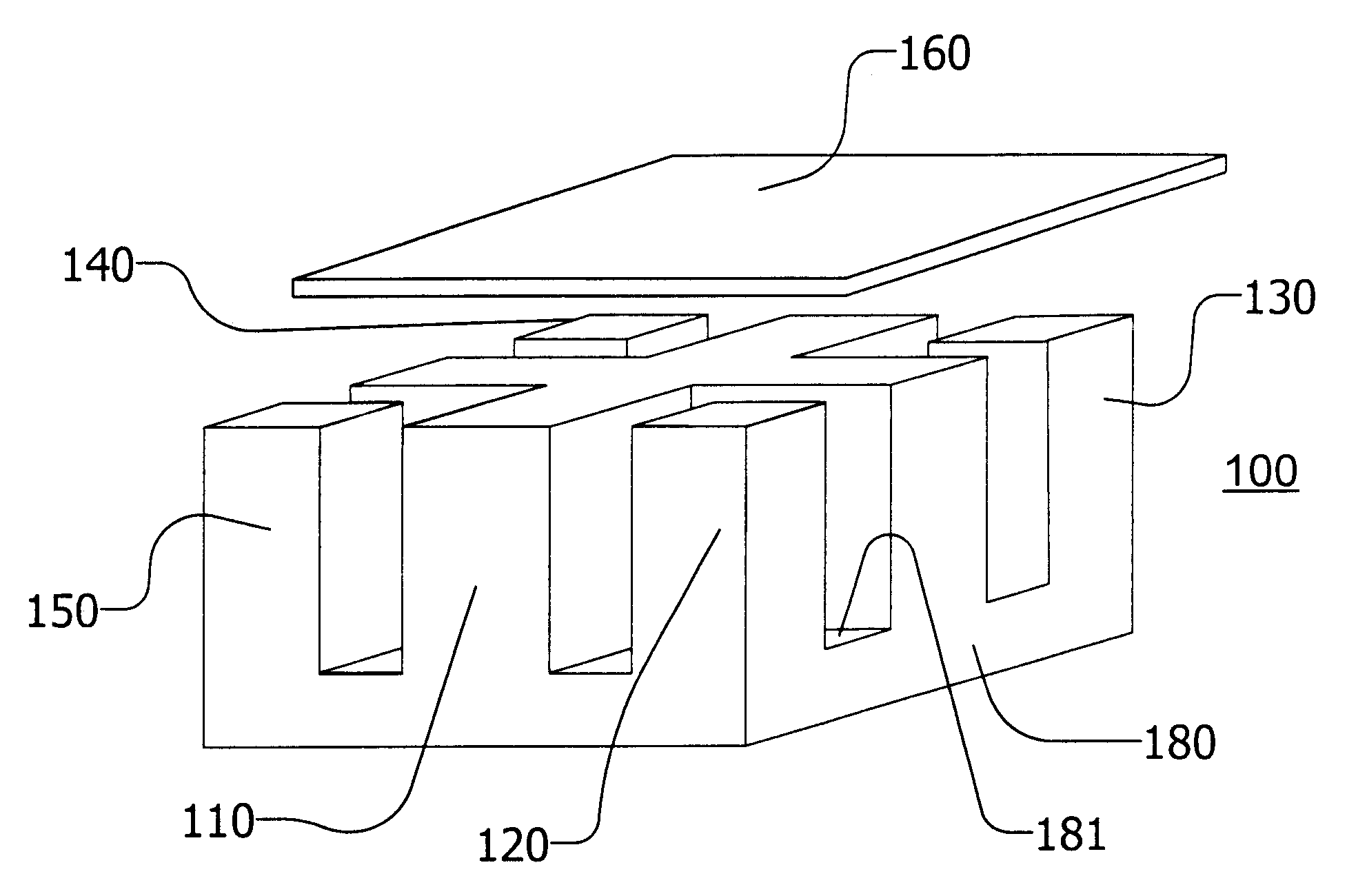

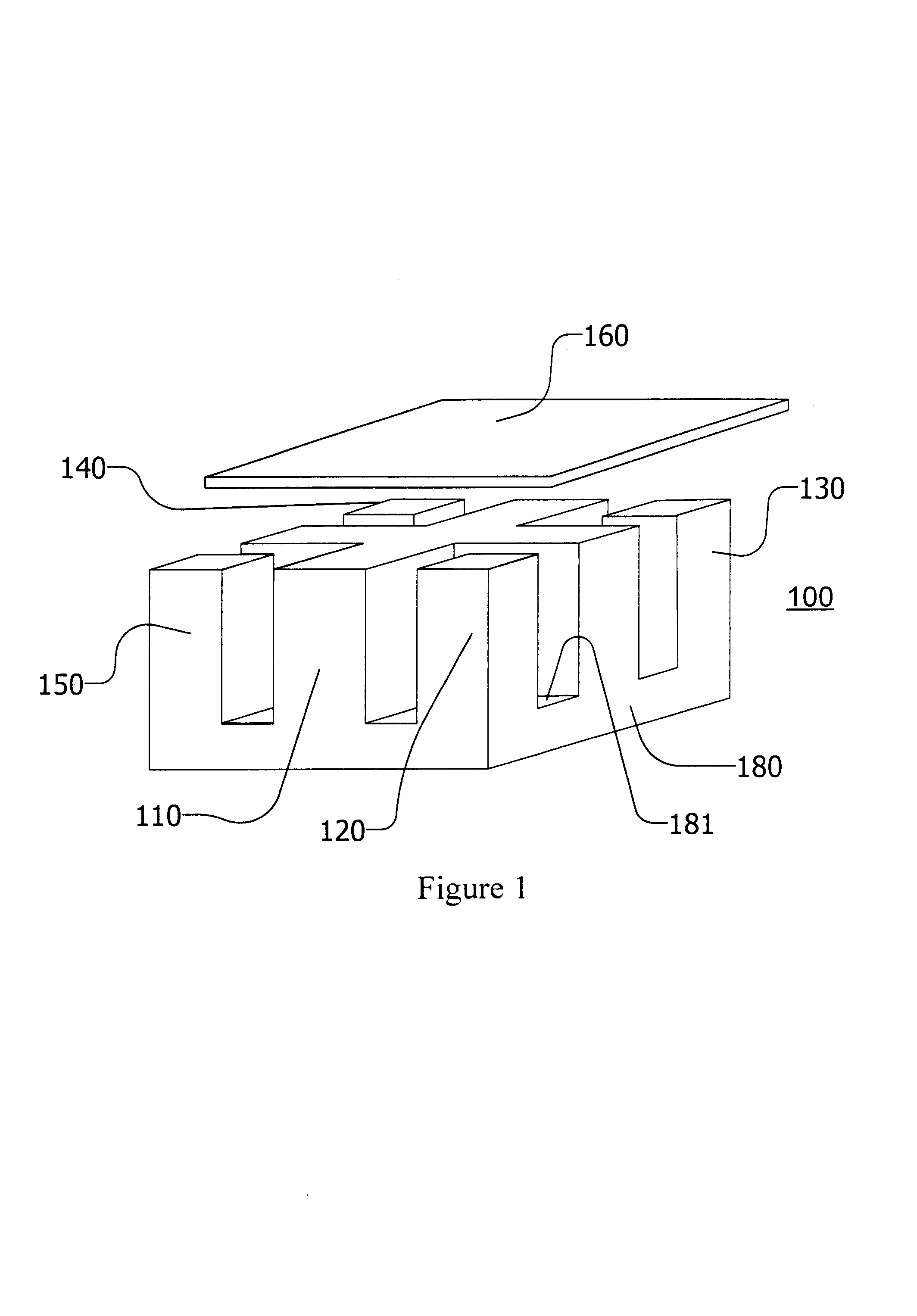

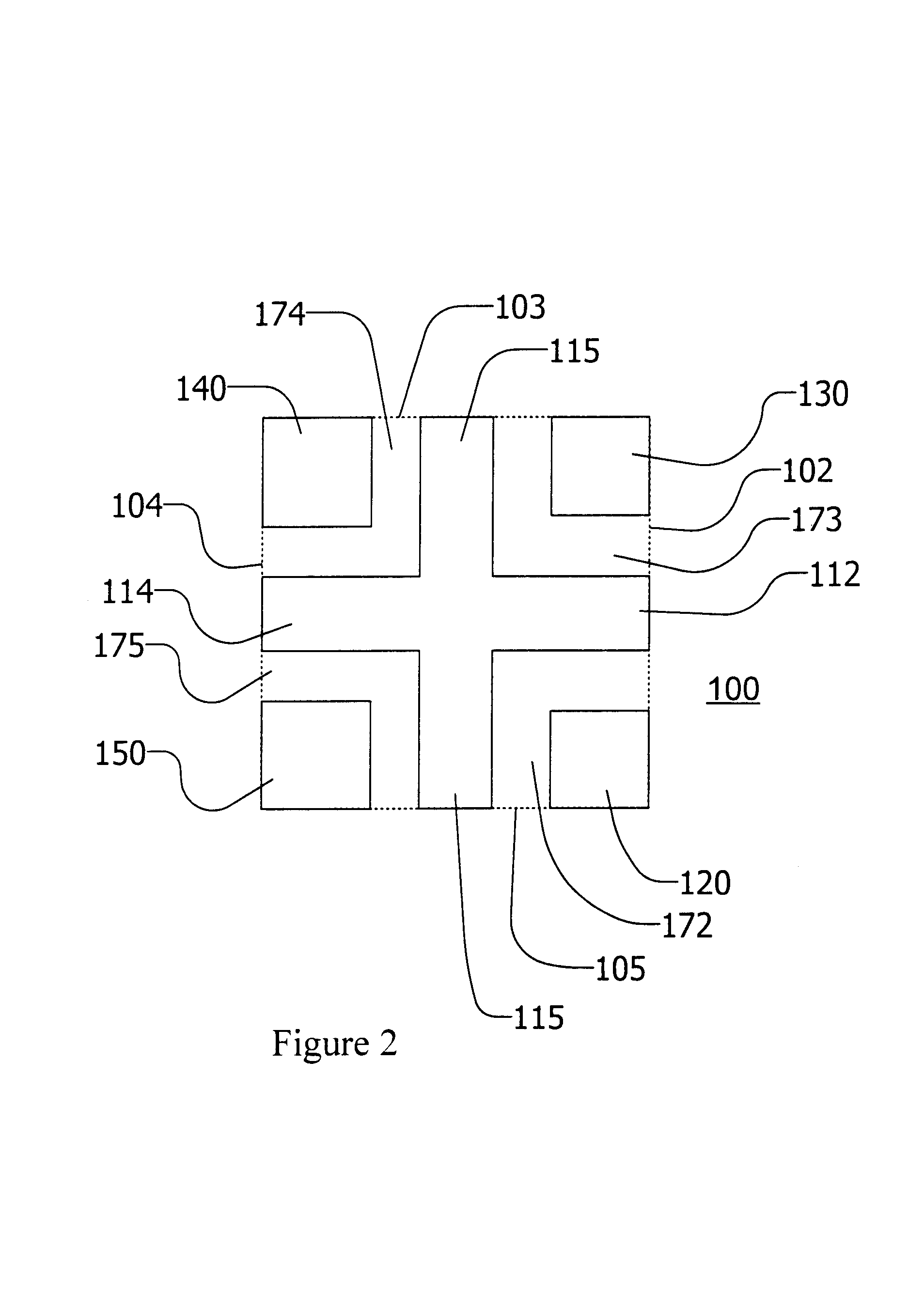

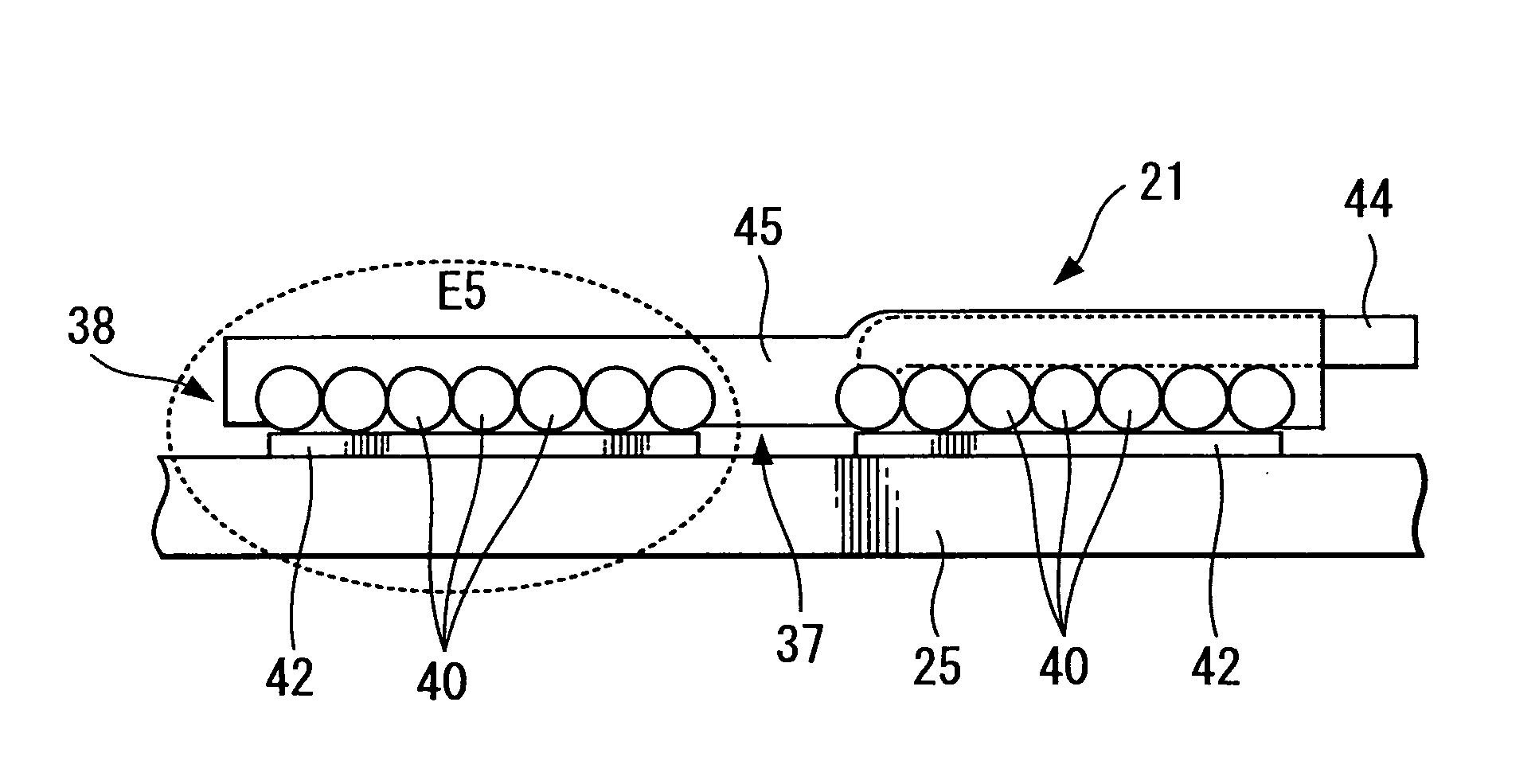

Core structure

InactiveUS6873237B2Ac-dc conversion without reversalTransformers/inductances casingsHigh power densityLarge core

There is disclosed a core structure with a very low profile, high power density and lower losses. Higher core surface area and improved core utilization in terms of flux density are other desirable feature in the disclosed design. The disclosed design also allowed for a larger core area where the DC fluxes are added, thereby reducing the air-gap requirements in the cores derived from low saturation density materials such as ferrites. The cellular nature of the design can also be effectively employed in vertically packaged power converters and modules.

Owner:MYPAQ HLDG LTD

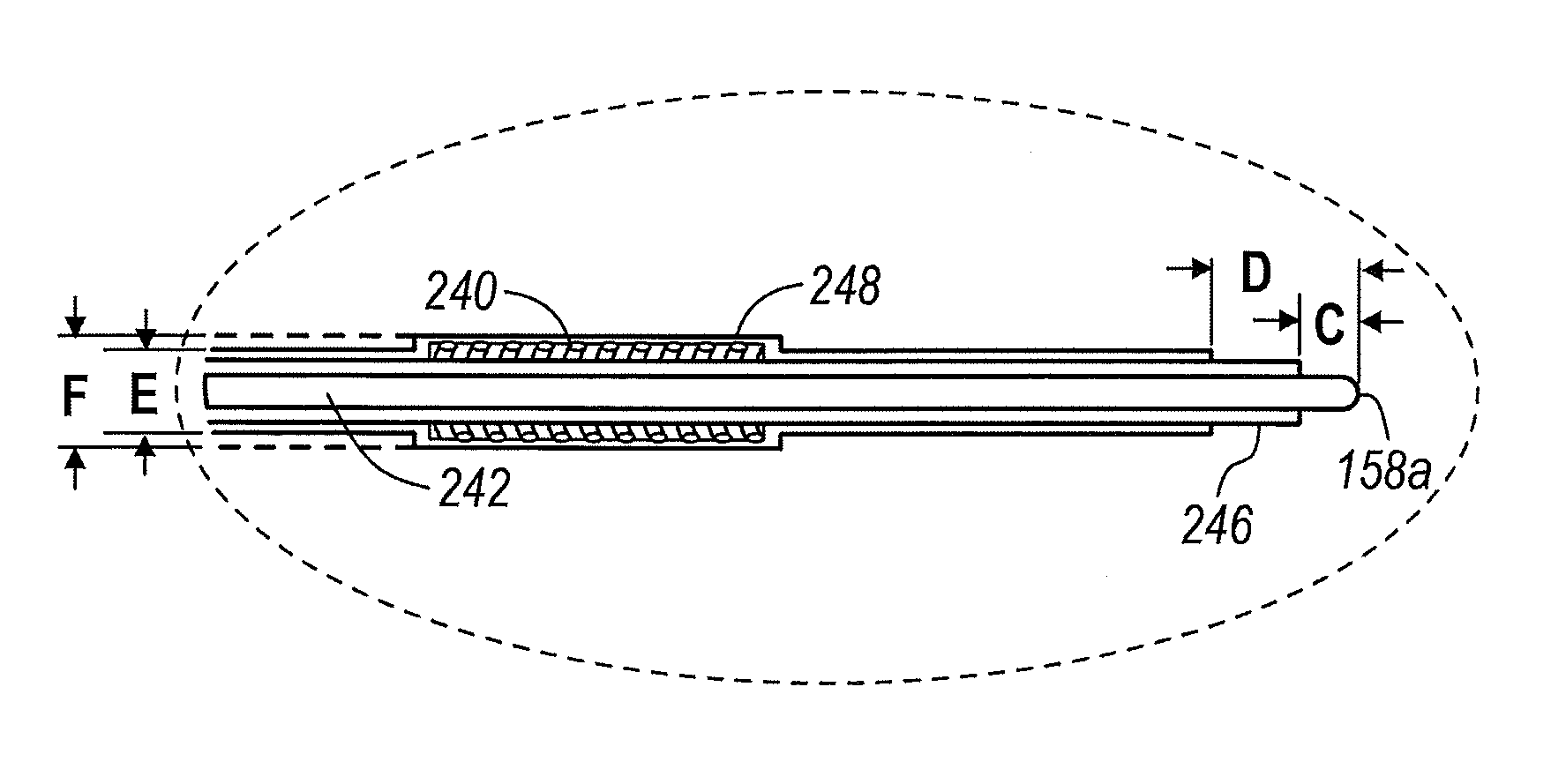

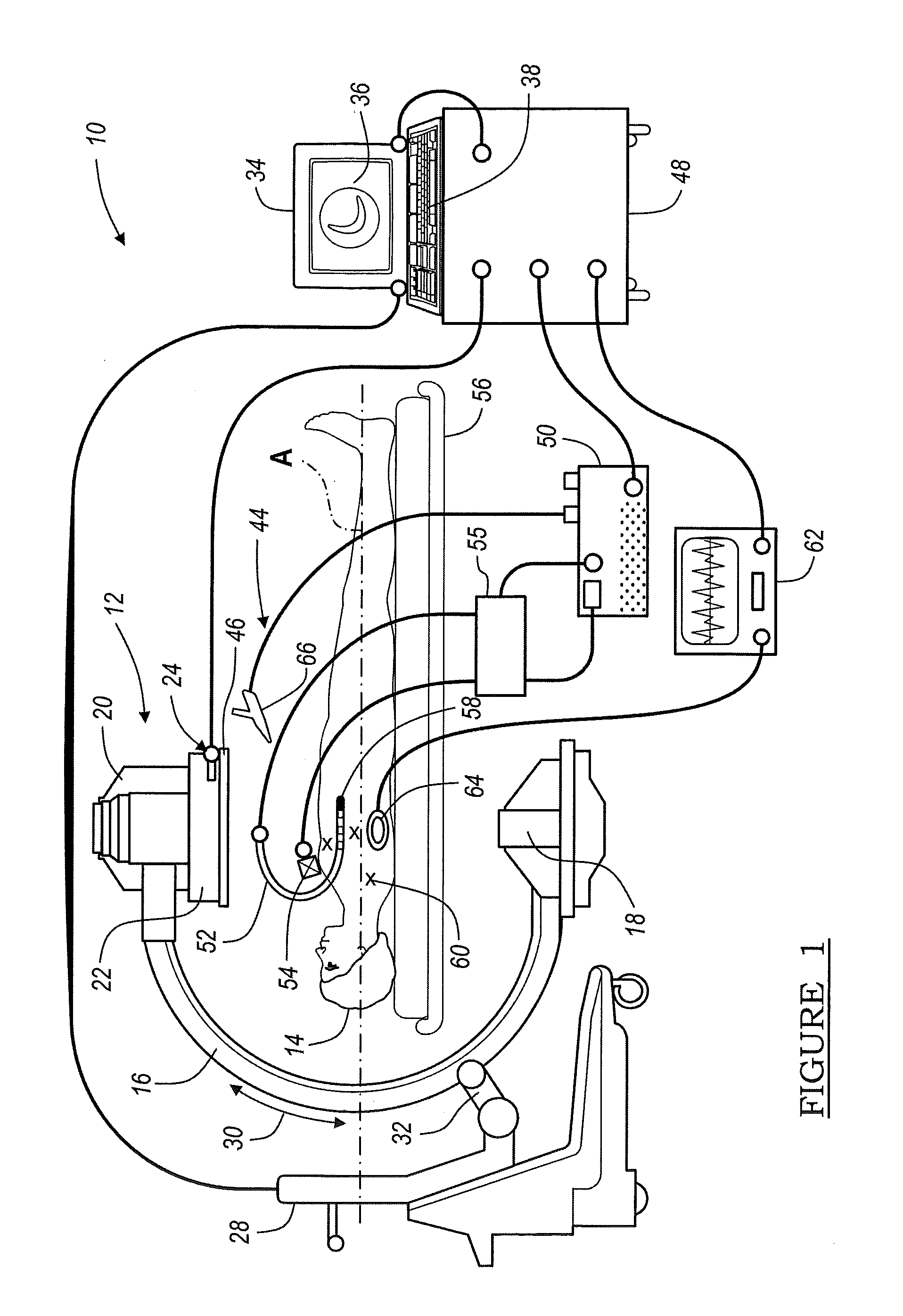

Method of forming an electromagnetic sensing coil in a medical instrument

ActiveUS8549732B2Accurate guideUltrasonic/sonic/infrasonic diagnosticsTransformers/inductances coils/windings/connectionsElectricityEngineering

A surgical navigation system for navigating a region of a patient includes a non-invasive dynamic reference frame and / or fiducial marker, sensor tipped instruments, and isolator circuits. The dynamic reference frame may be repeatably placed on the patient in a precise location for guiding the instruments. The instruments may be precisely guided by positioning sensors near moveable portions of the instruments. Electrical sources may be electrically isolated from the patient.

Owner:MEDTRONIC NAVIGATION

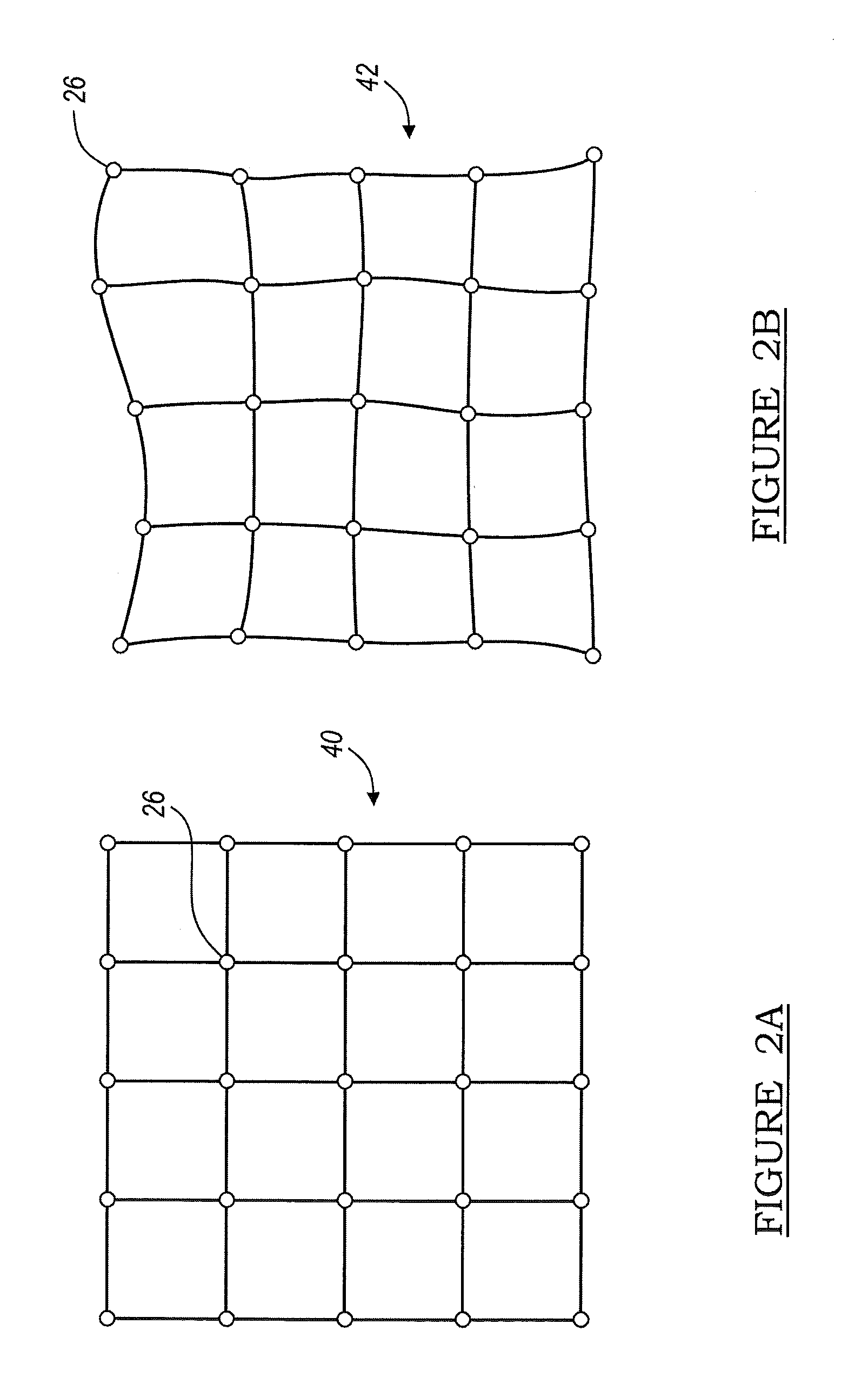

Extended E Matrix Integrated Magnetics (MIM) Core

InactiveUS20080024259A1Easy and less-expensive to fabricateLow profileAc-dc conversion without reversalTransformers/inductances magnetic coresMechanical engineeringMagnetic core

Owner:MYPAQ HLDG LTD

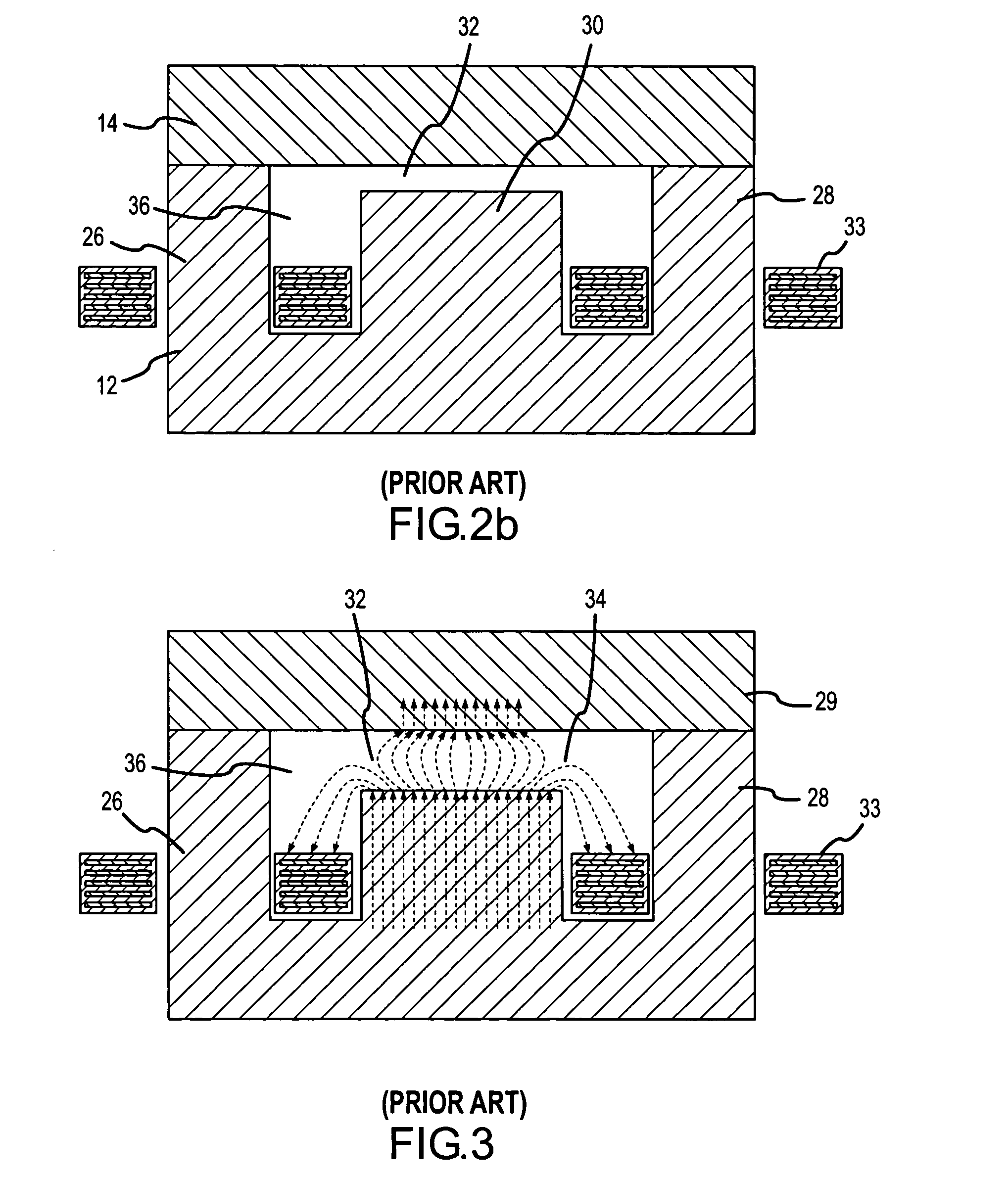

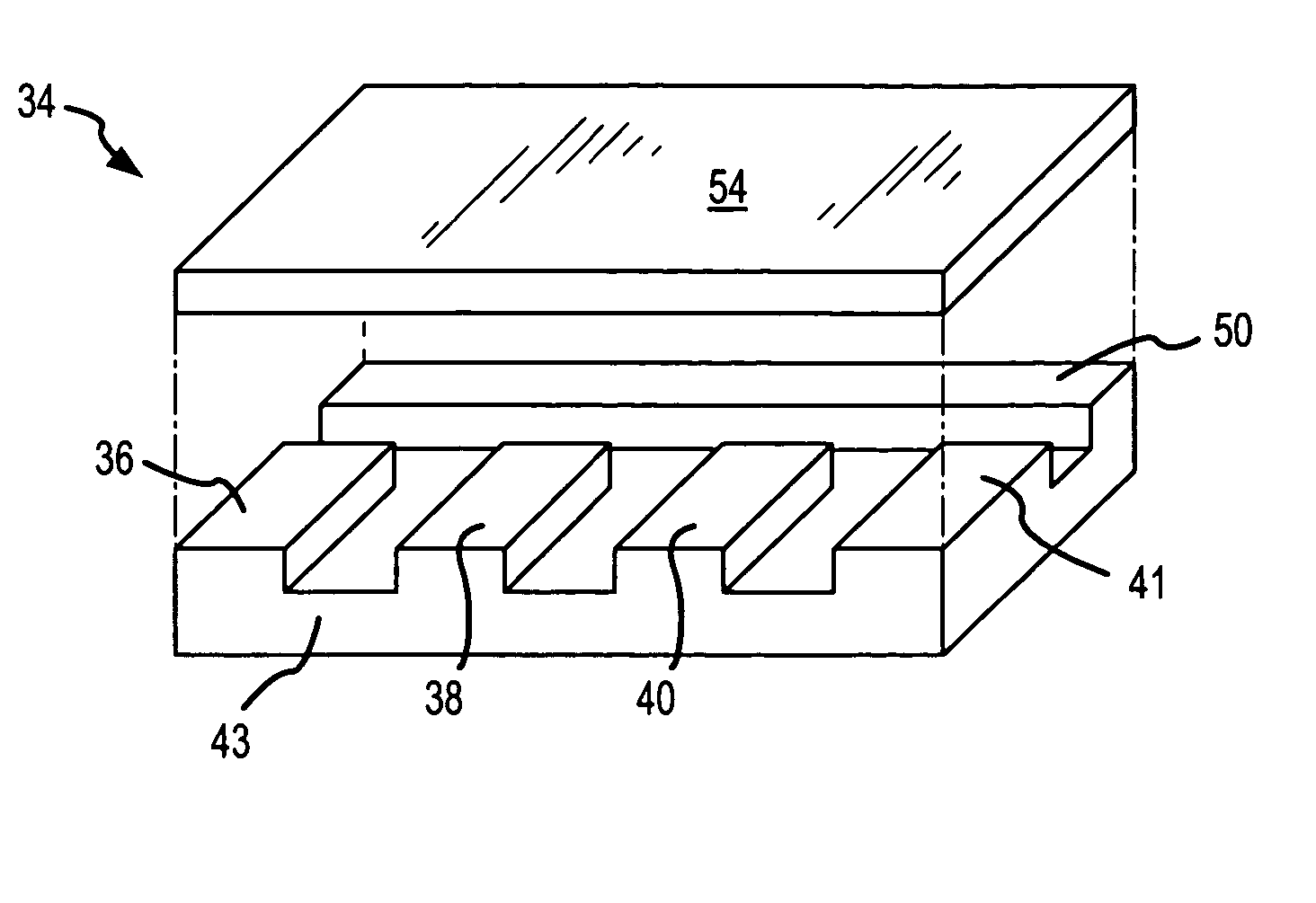

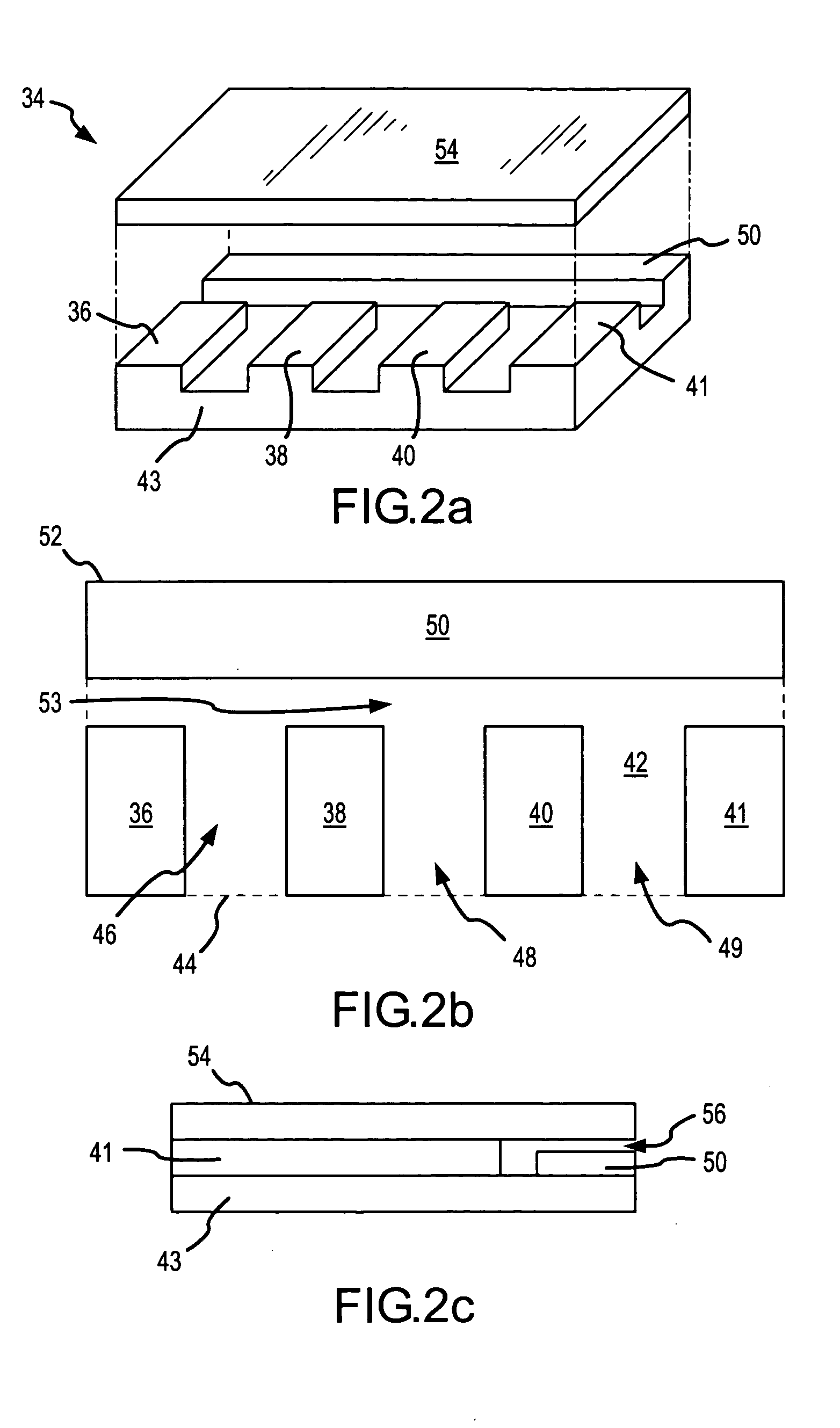

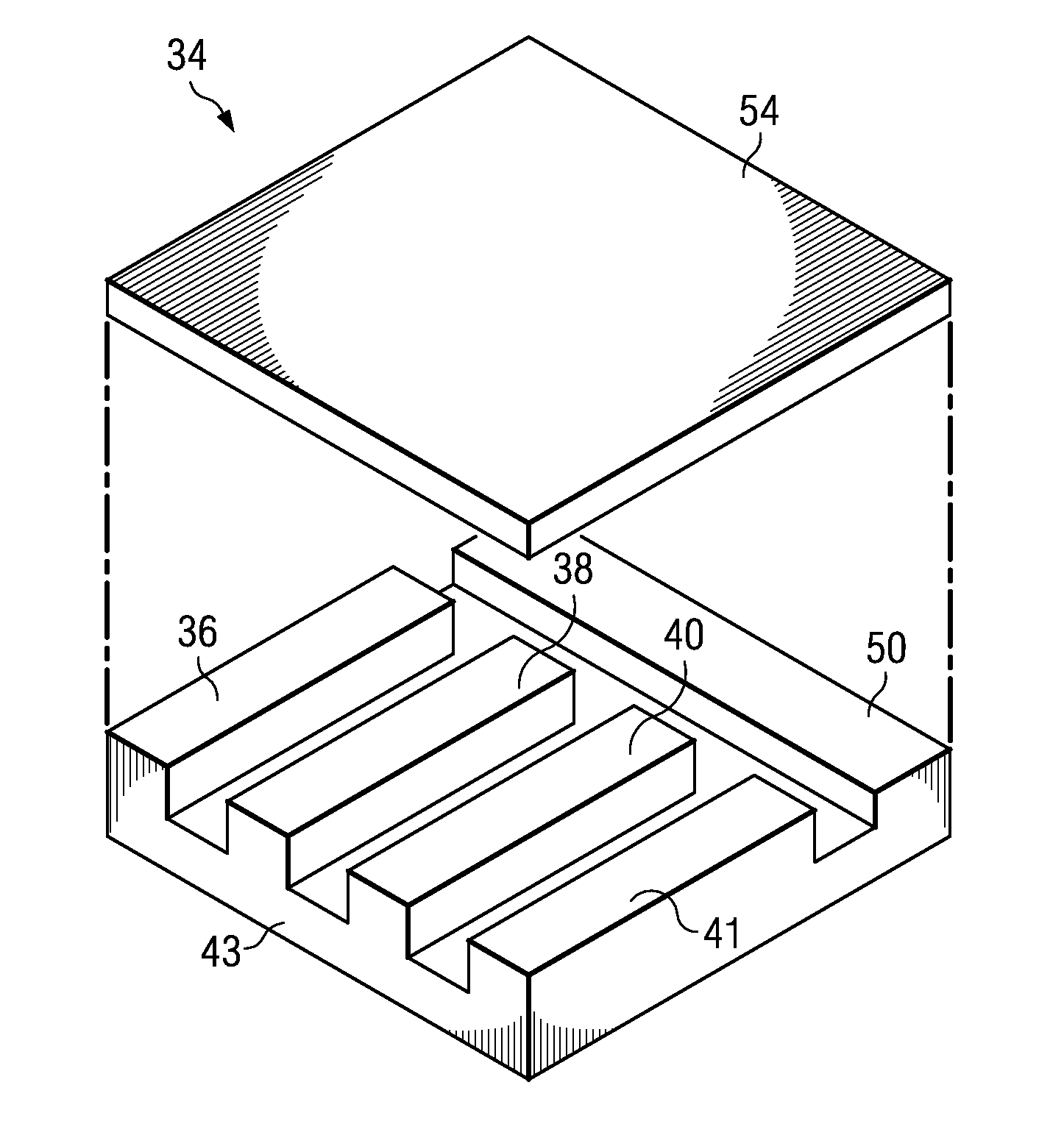

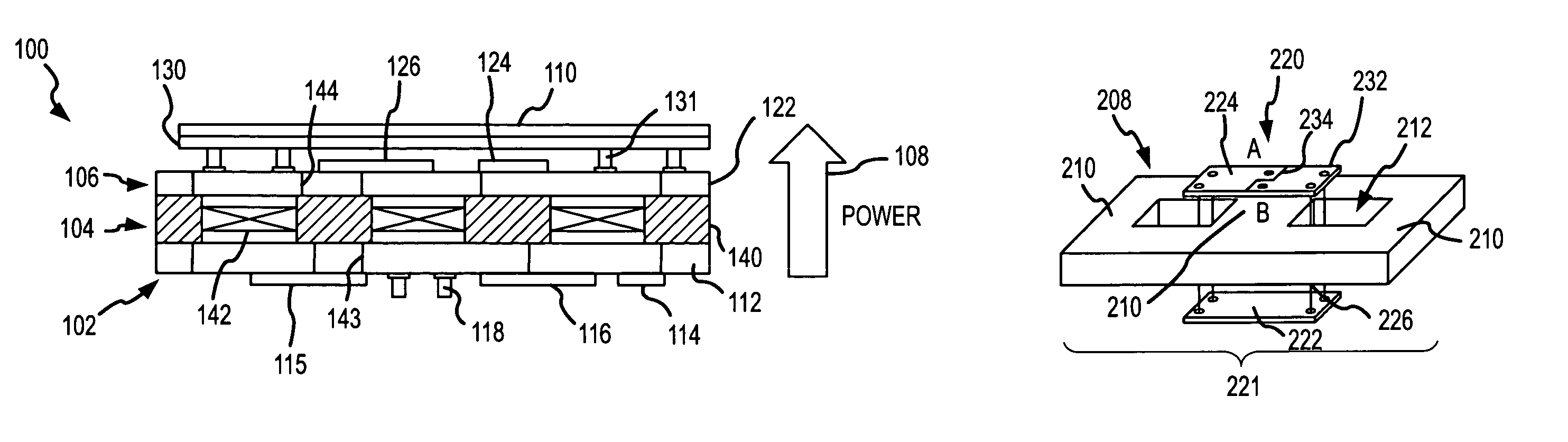

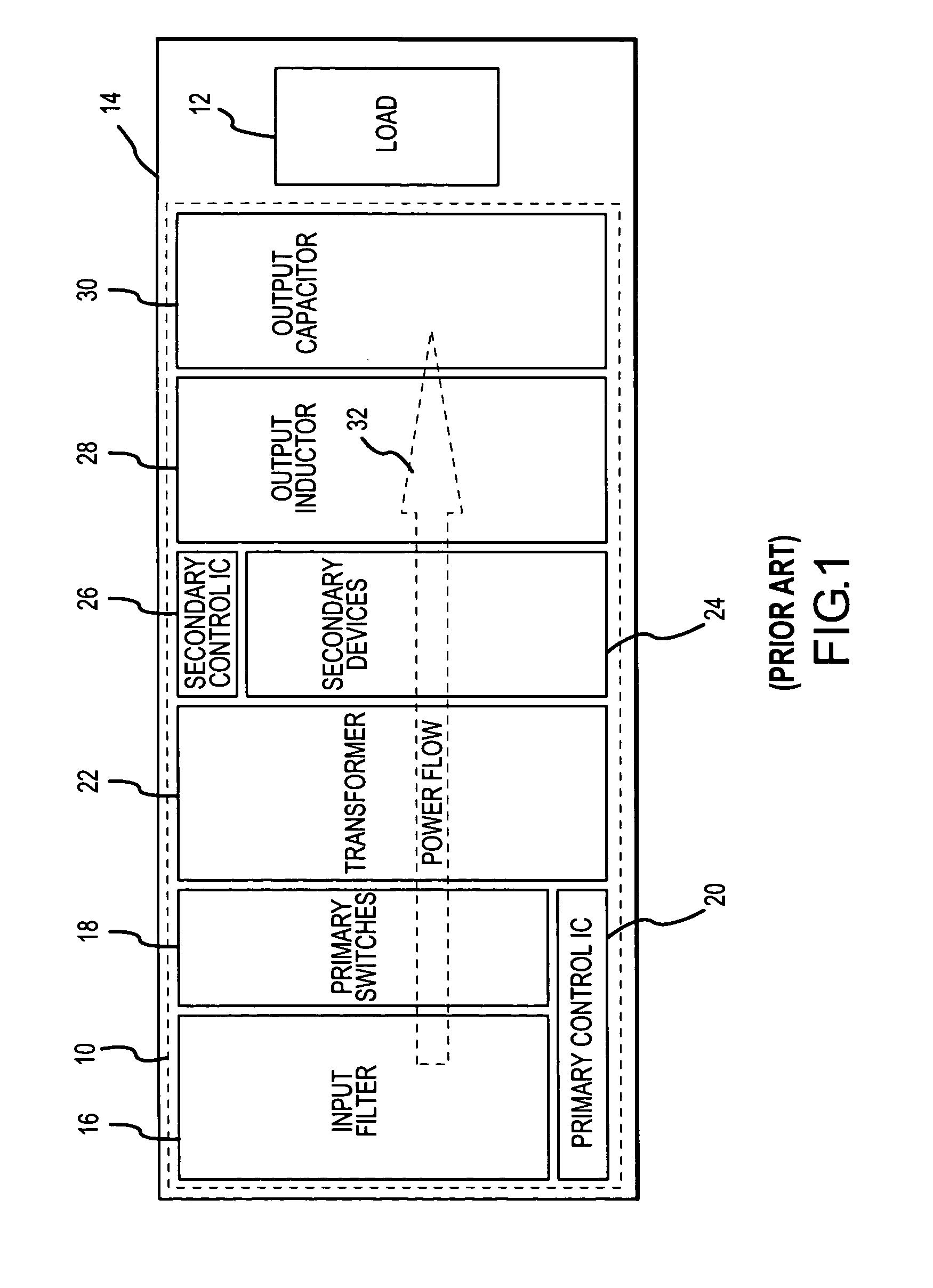

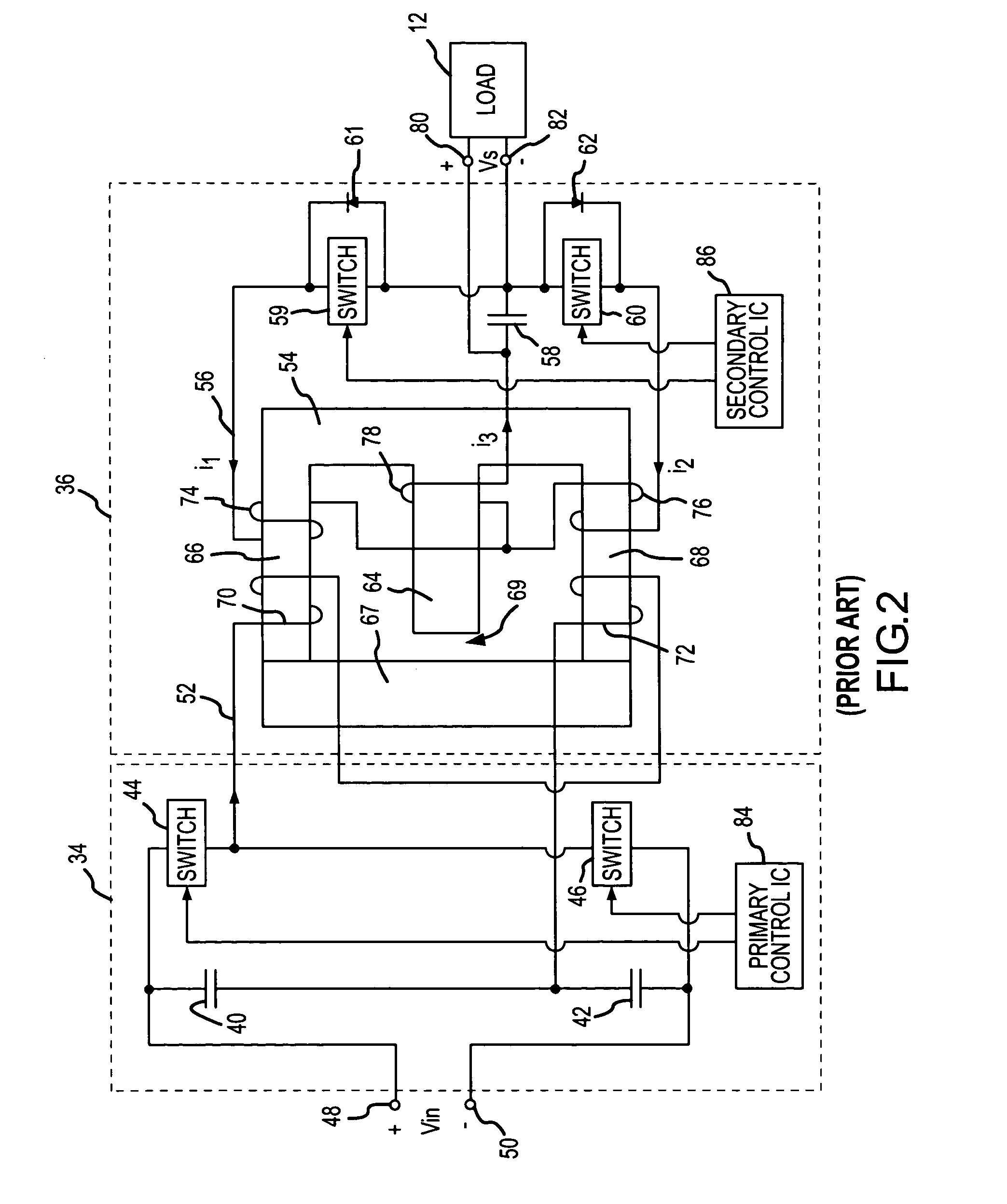

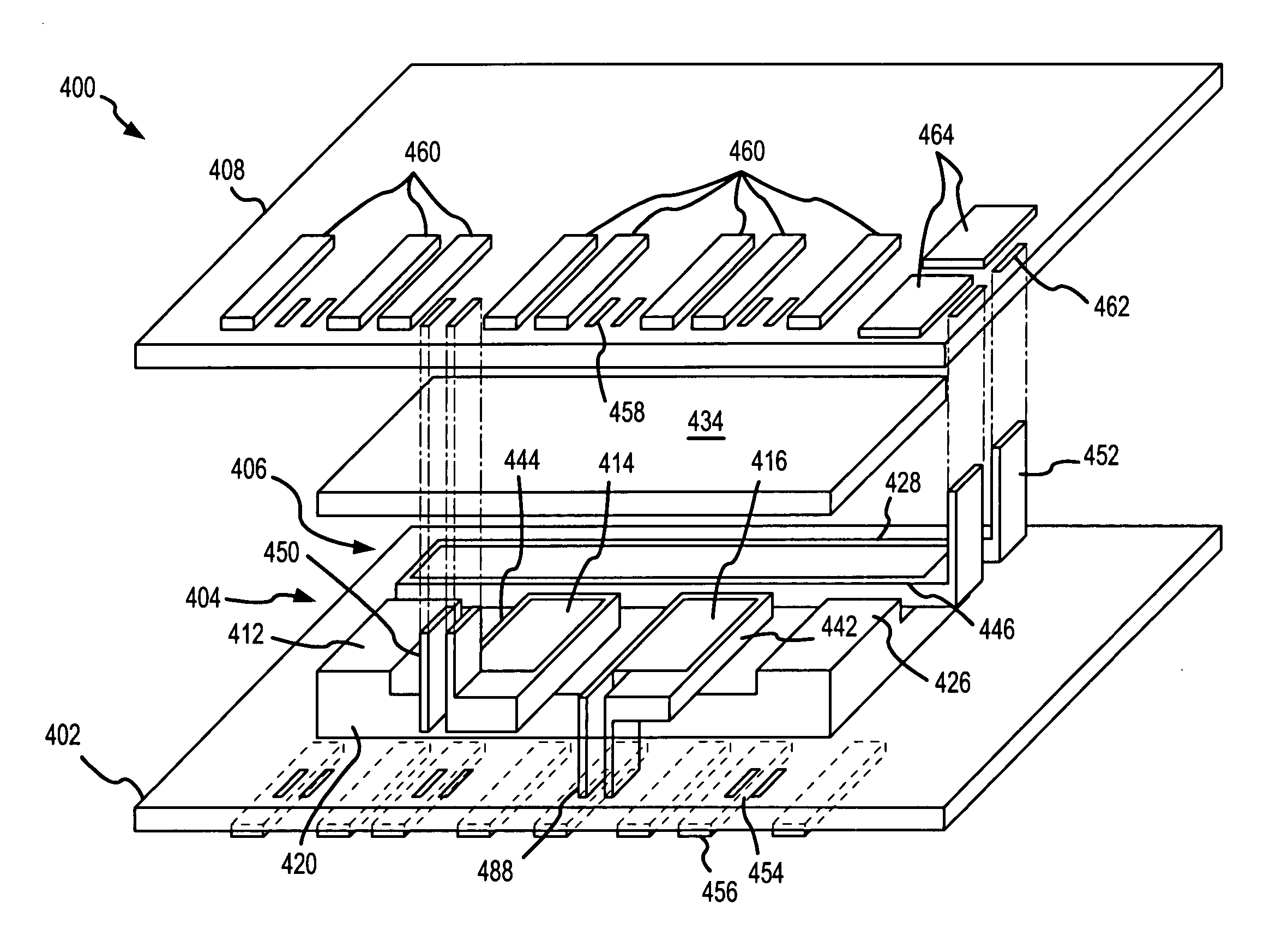

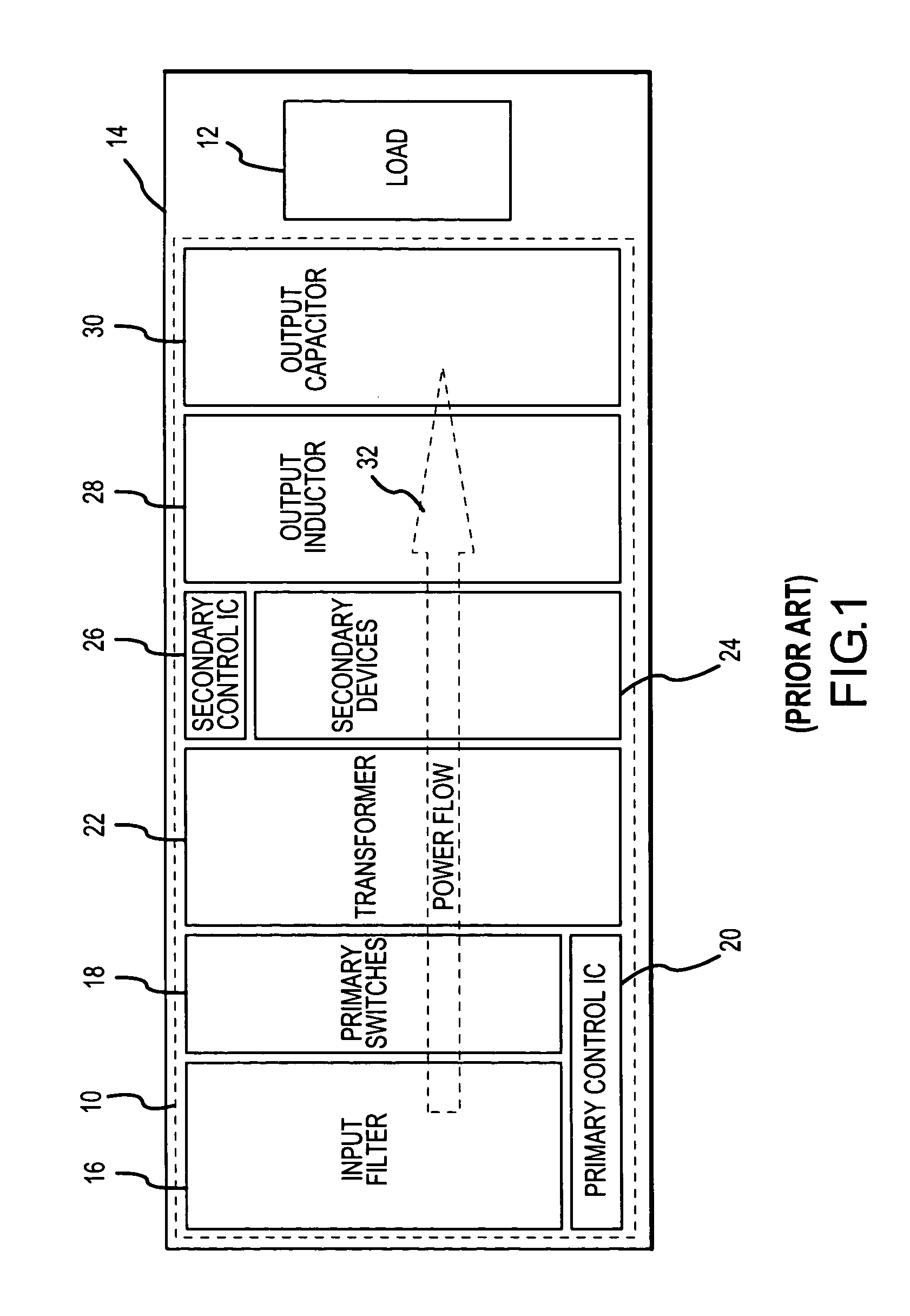

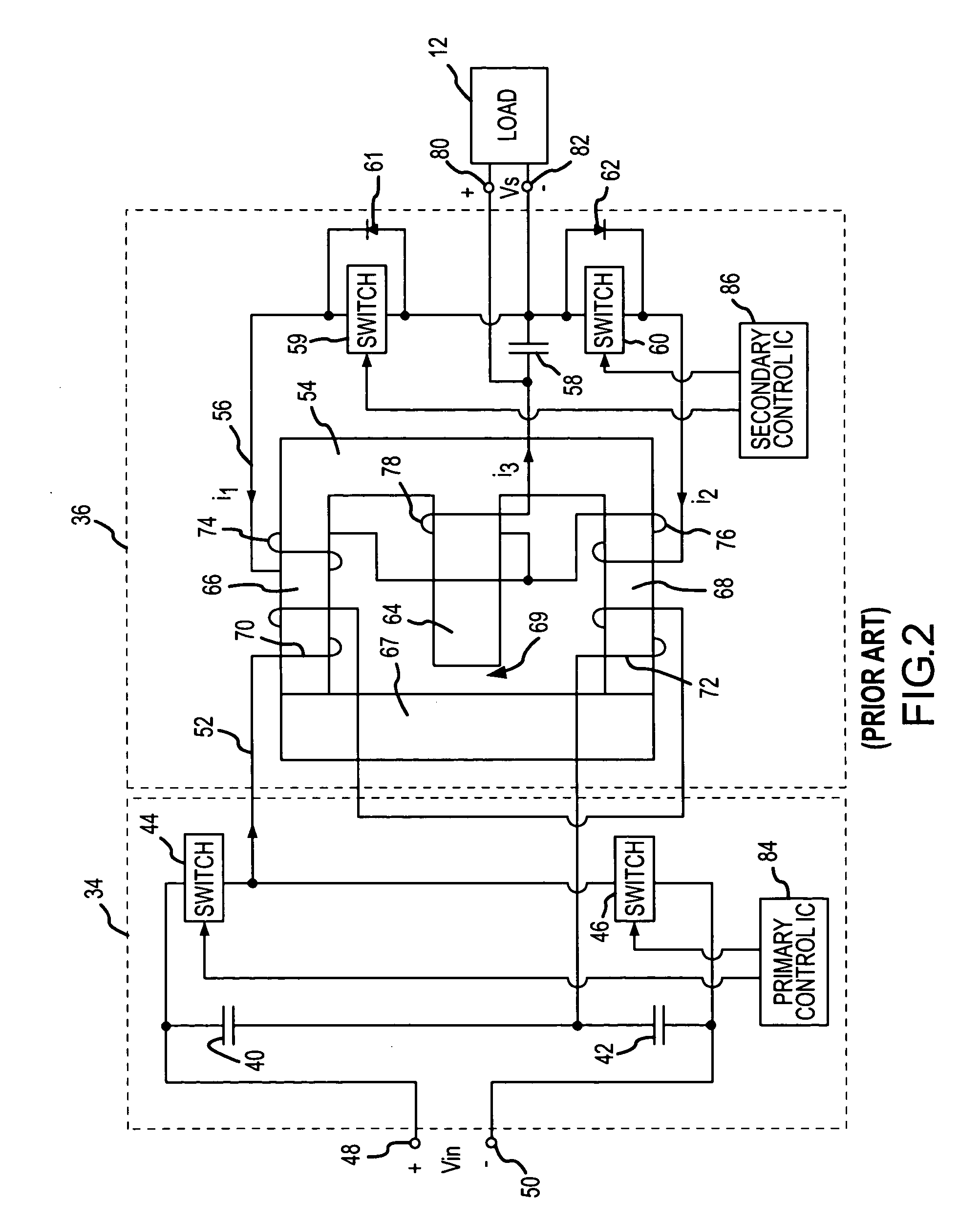

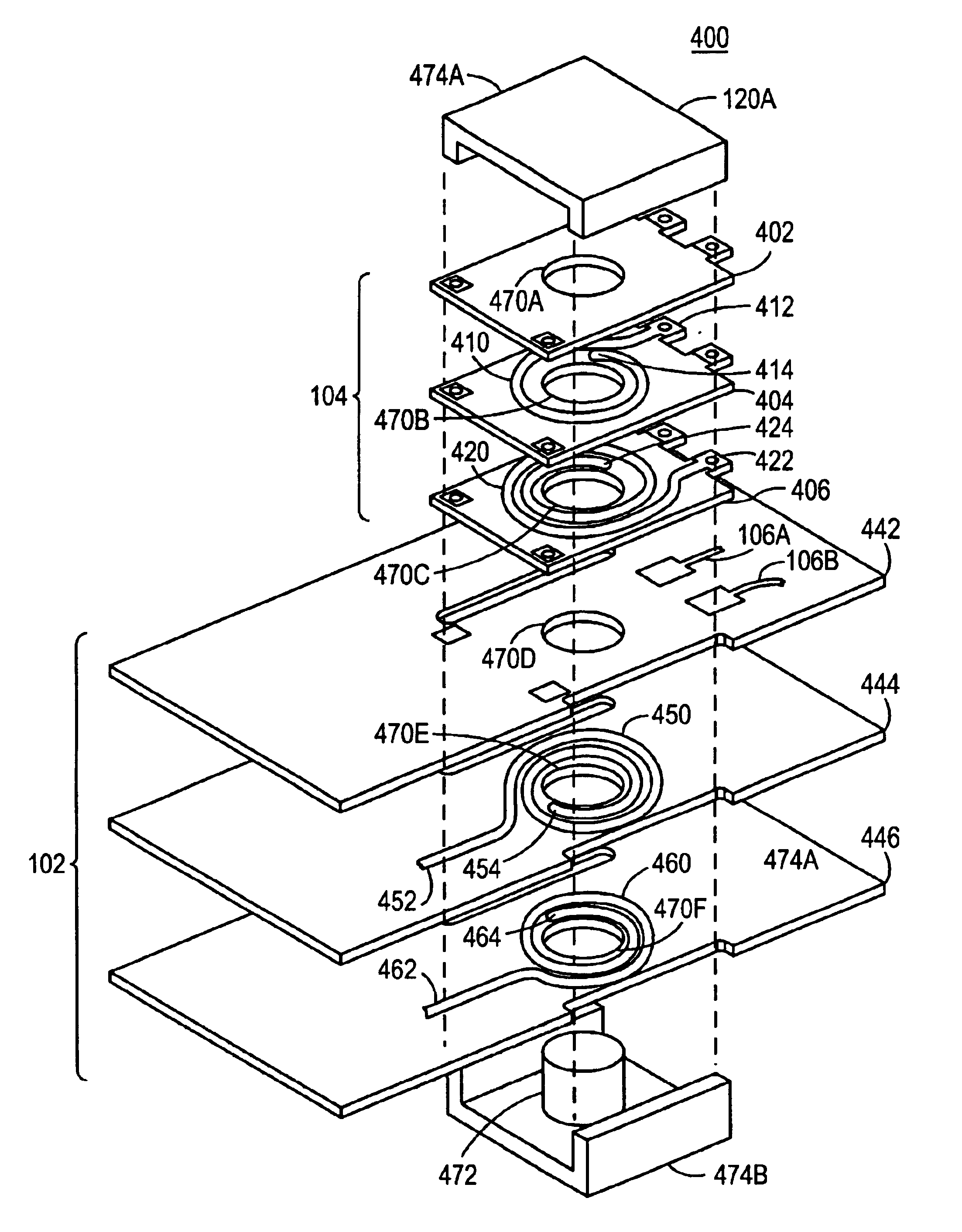

Vertically packaged switched-mode power converter

ActiveUS7012414B1Tight regulationFast transient responseTransformersConversion constructional detailsElectrical resistance and conductanceCellular architecture

A vertically packaged cellular power converter solves the problems associated with conventional designs and paves the way for a cellular circuit architecture with ultra-low interconnect resistance and inductance. The vertical packaging results in a power flow in the vertical direction (from the bottom to the top) with very short internal interconnects, thereby minimizing the associated conduction losses and permitting high conversion efficiency at high currents. The cellular architecture is ideally suited for generating multiple supply voltages.

Owner:MYPAQ HLDG LTD

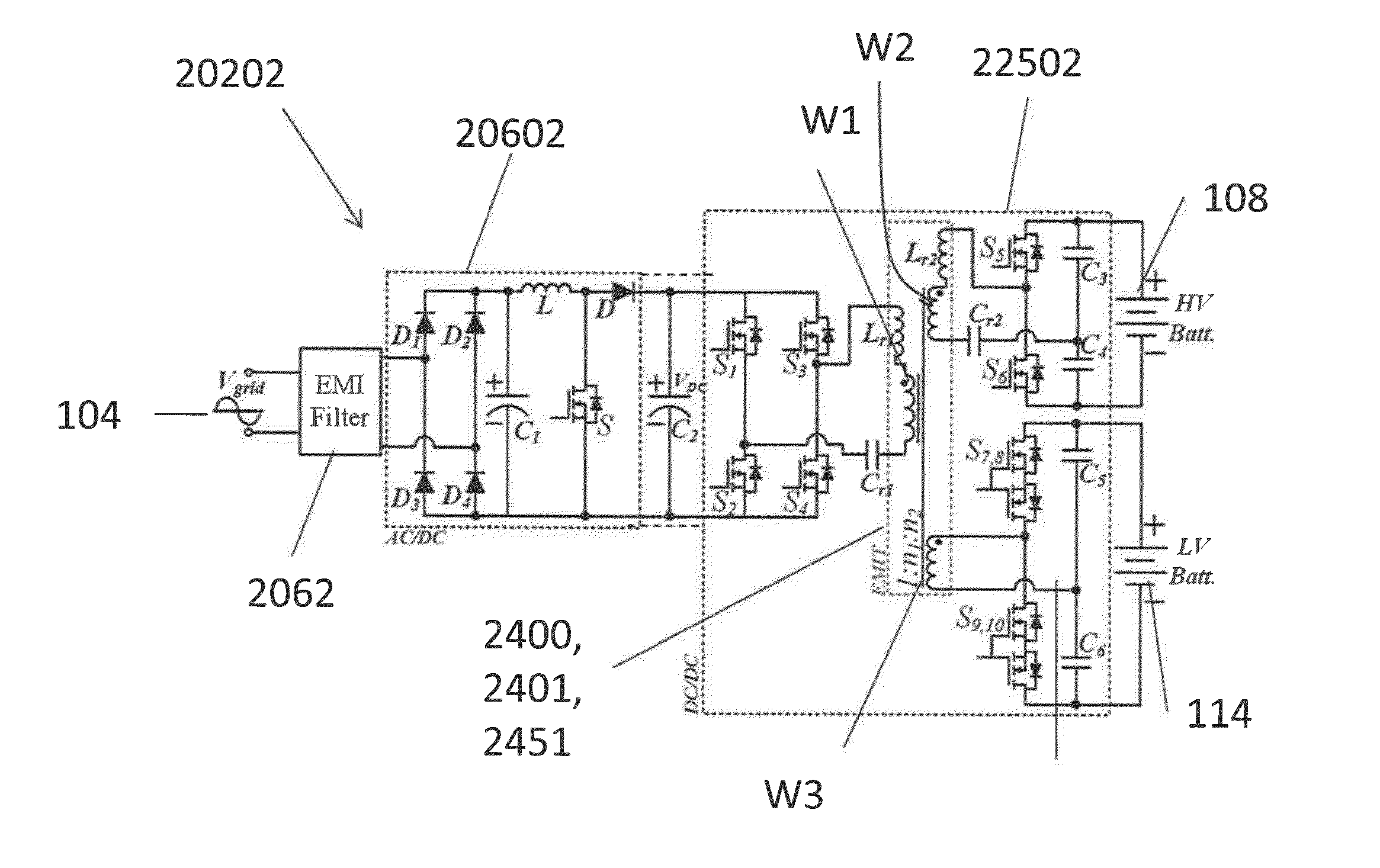

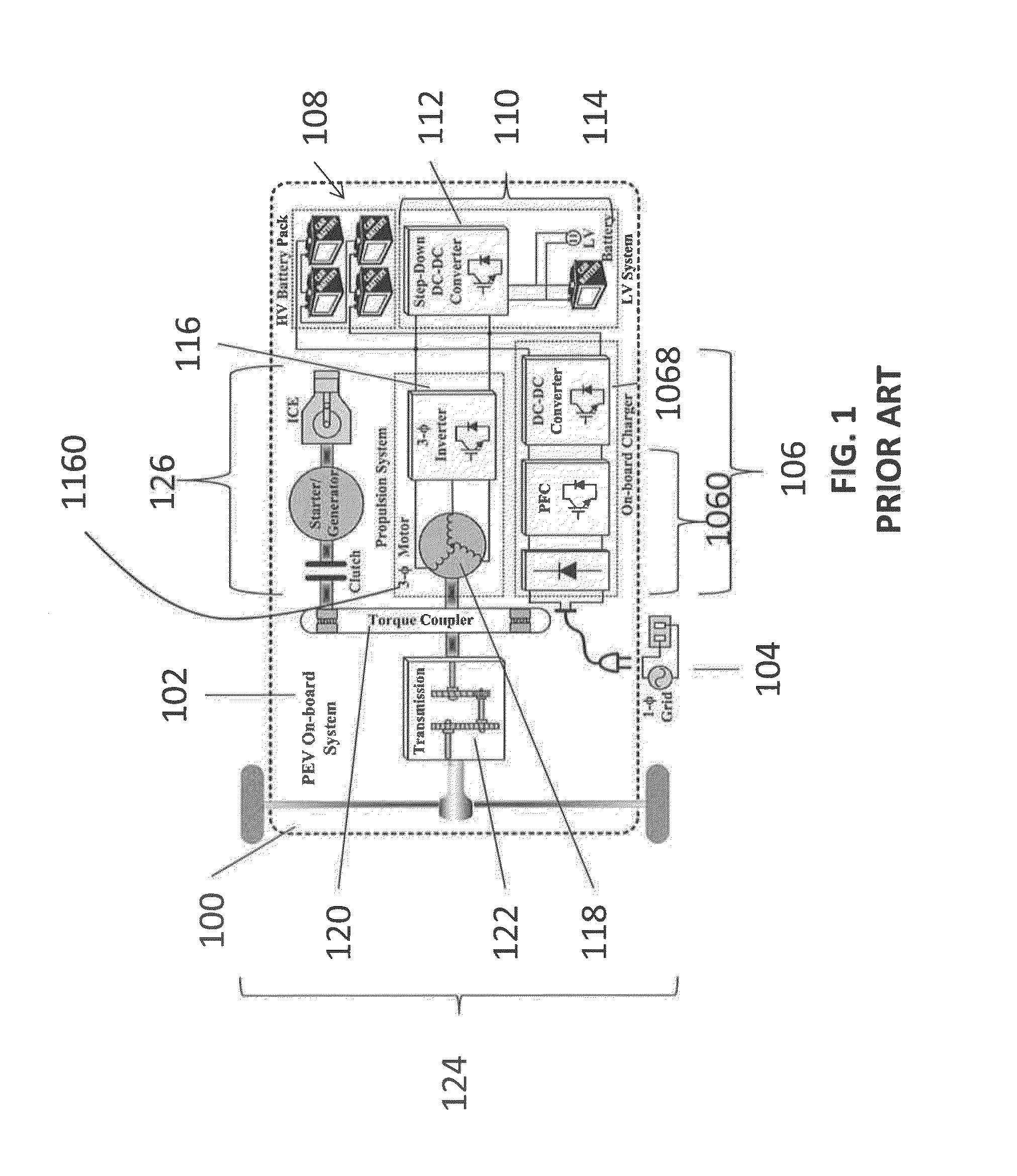

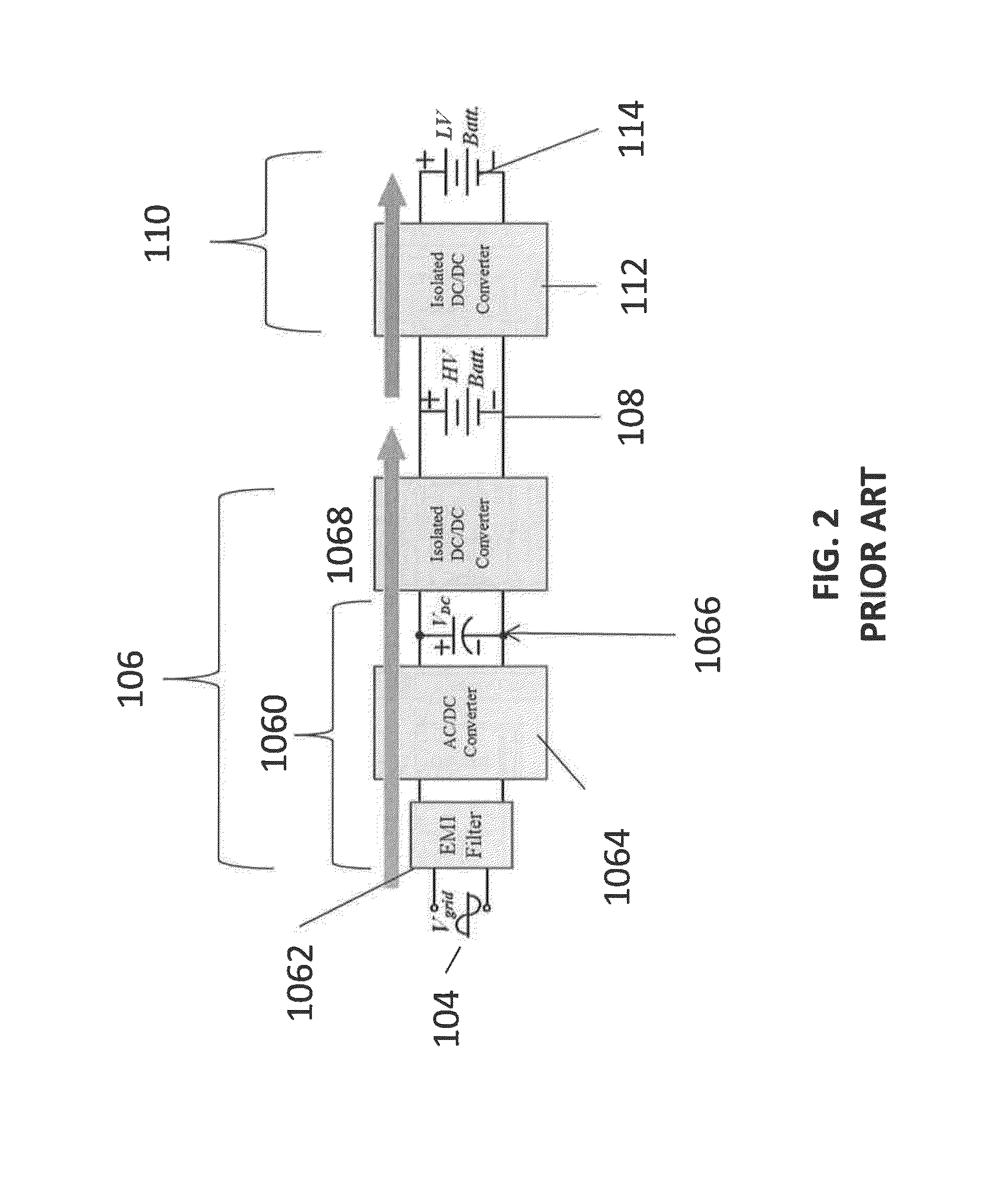

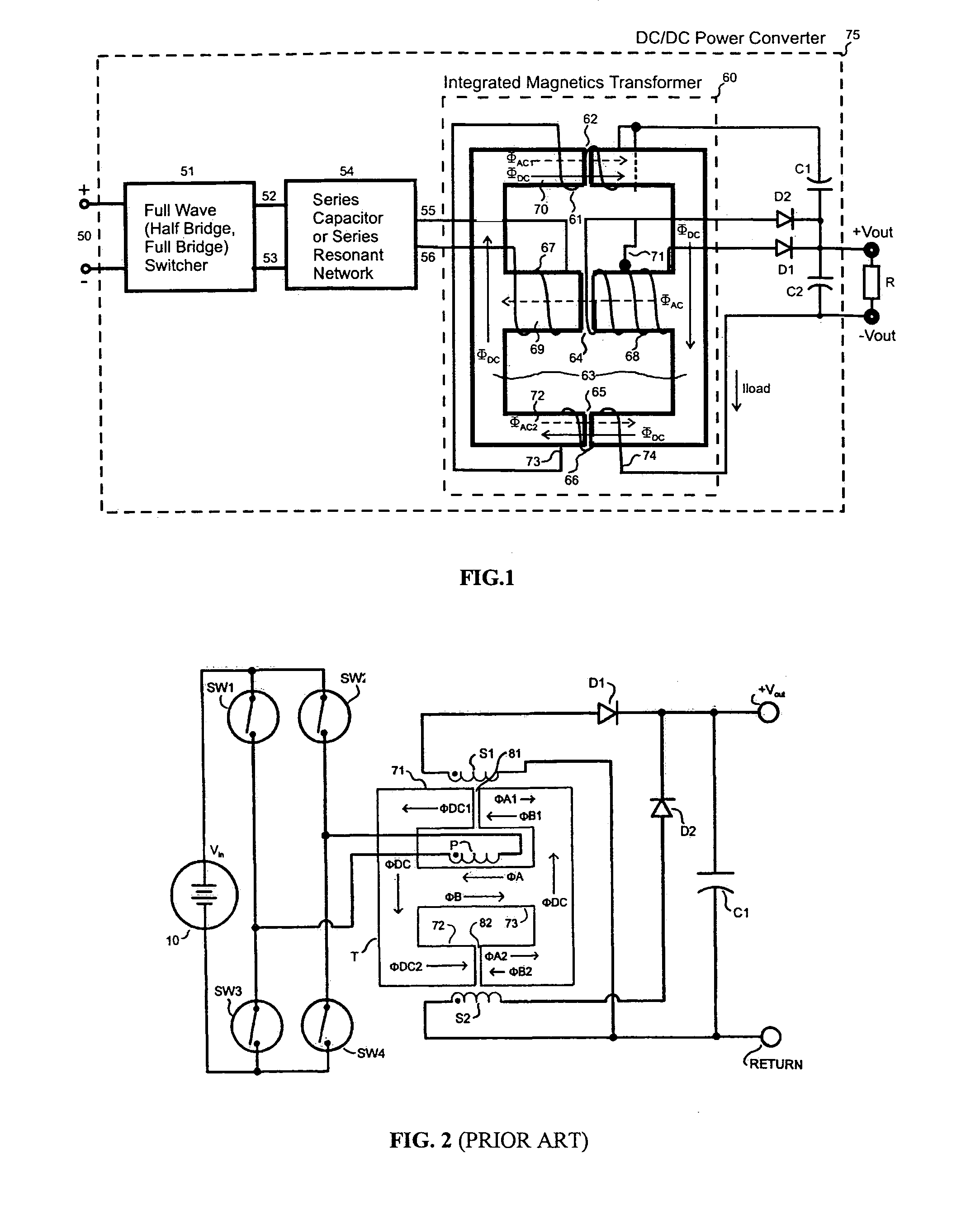

An integrated dual-output grid-to-vehicle (G2V) and vehicle-to-grid (V2G) onboard charger for plug-in electric vehicles

ActiveUS20160016479A1Improve power densitySmall sizeTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresElectrical batteryLow voltage

An integrated and isolated onboard charger for plug-in electric vehicles, includes an ac-dc converter and a dual-output dc-dc resonant converter, for both HV traction batteries and LV loads. In addition, the integrated and isolated onboard charger may be configured as unidirectional or bidirectional, and is capable of delivering power from HV traction batteries to the grid for vehicle-to-grid (V2G) applications. To increase the power density of the converter, the dual-output DC-DC resonant converter may combine magnetic components of resonant networks into a single three-winding electromagnetically integrated transformer (EMIT). The resonant converter may be configured as a half-bridge topology with split capacitors as the resonant network components to further reduce the size of converter. The integrated charger may be configured for various operating modes, including grid to vehicle (G2V), vehicle to grid (V2G) and high voltage to low voltage, HV-to-LV (H2L) charging.

Owner:UNIV OF MARYLAND

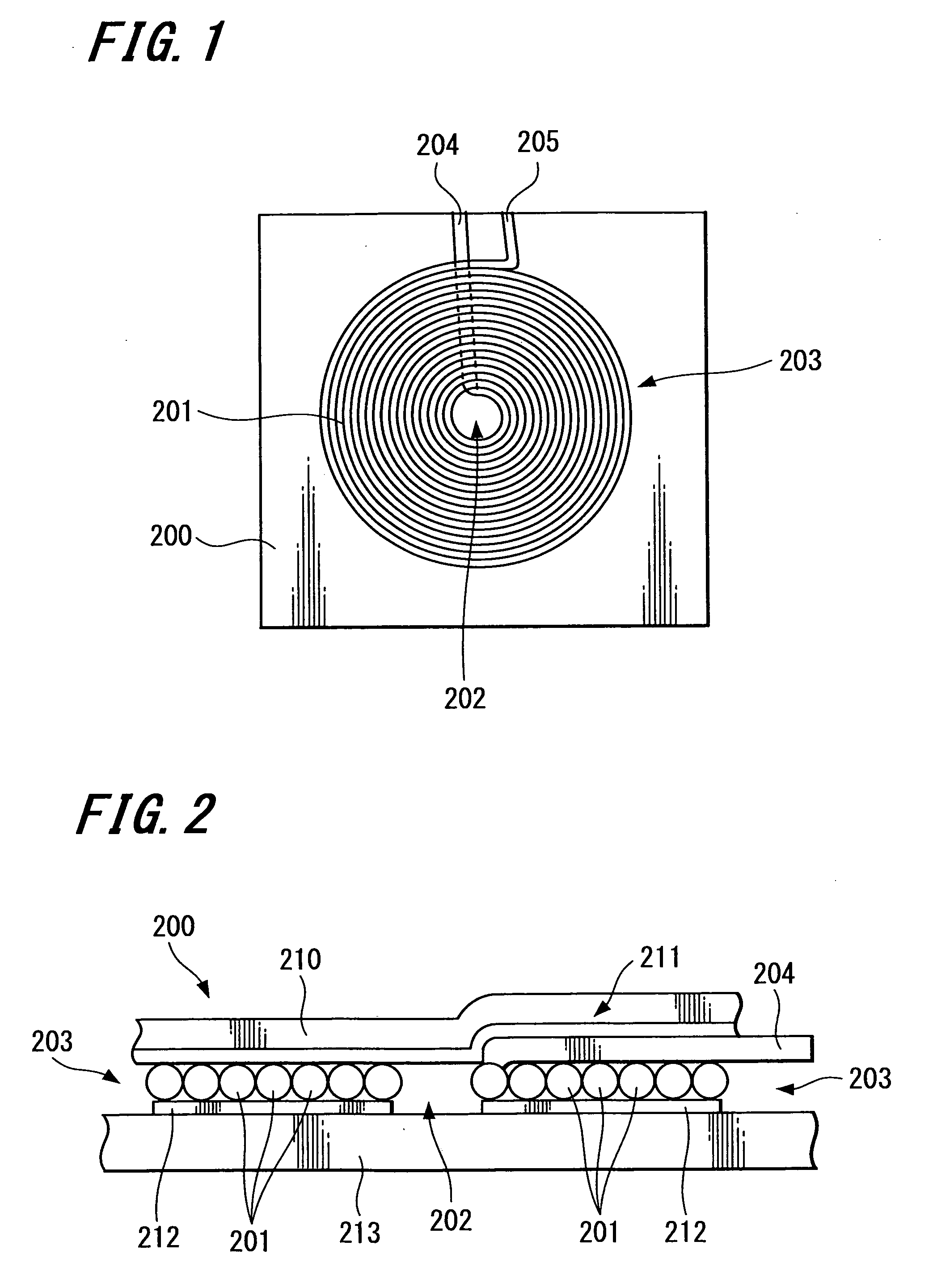

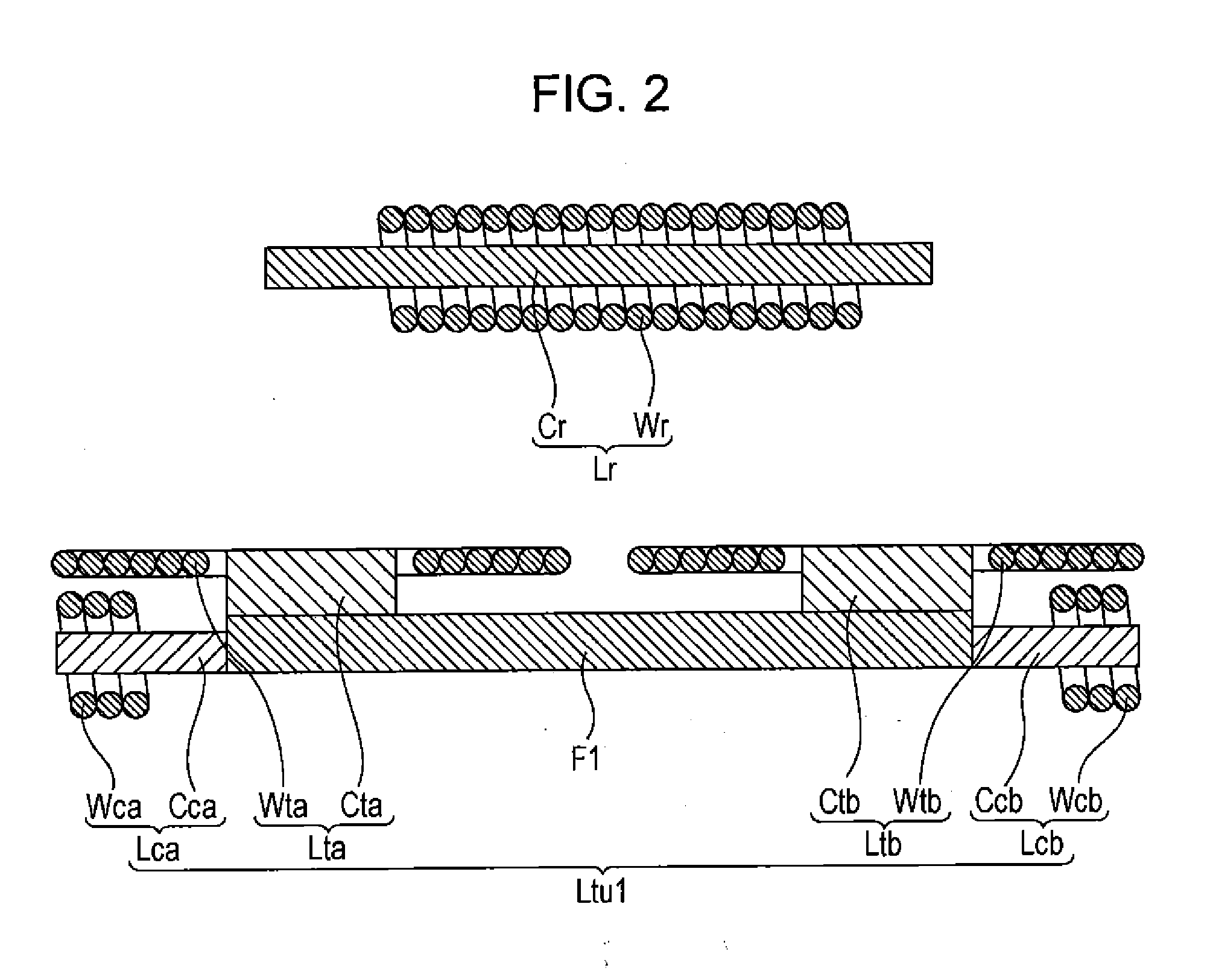

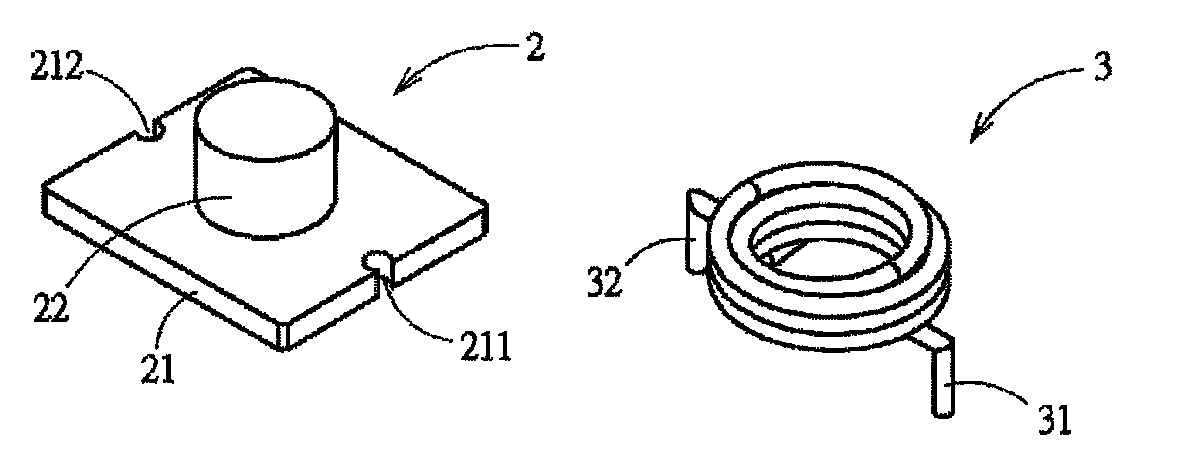

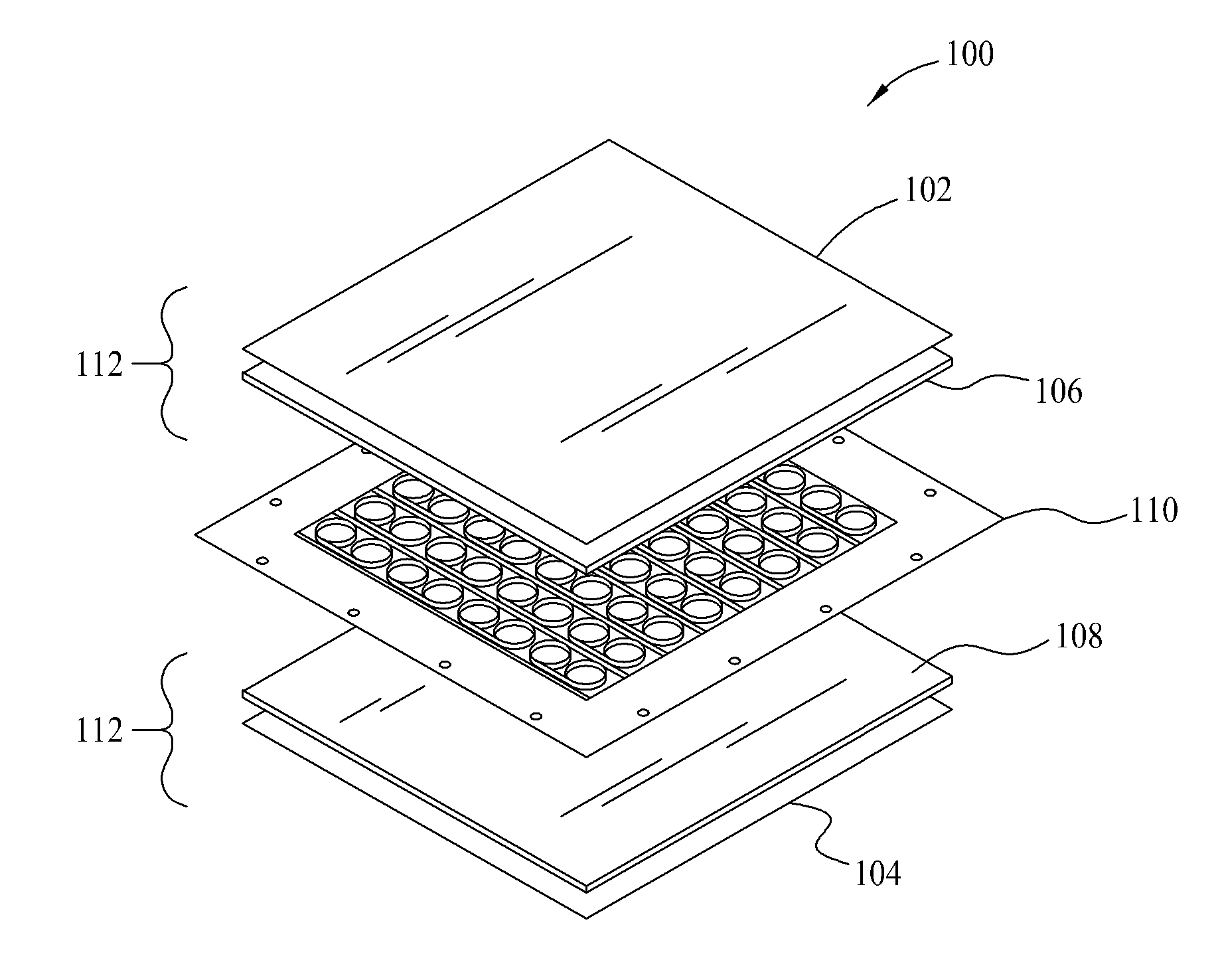

Noncontact power-transmission coil, portable terminal and terminal charging device, planar coil magnetic layer formation device, and magnetic layer formation method

ActiveUS20080164844A1Efficiently formedImprove efficiencyCircuit authenticationTransformers/inductances coils/windings/connectionsElectric power transmissionElectrical conductor

Owner:SONY MOBILE COMM INC +1

Integrated magnetics for a DC-DC converter with flexible output inductor

InactiveUS7034647B2Simple designTransformers/inductances coils/windings/connectionsDc-dc conversionInductor windingsDc dc converter

An integrated magnetic assembly that allows the primary and secondary windings of a transformer and a separate inductor winding to be integrated on a unitary magnetic structure is disclosed. The unitary magnetic structure includes first, second, and third legs that are physically connected and magnetically coupled. The primary and secondary windings of the transformer can be formed on the third leg of the unitary magnetic structure. Alternatively, the primary and secondary windings can be split between the first and second legs. Thus, the primary winding includes first and second primary windings disposed on the first and second legs and the secondary winding includes first and second secondary windings disposed on the first and second legs. The inductor winding may also be formed either on the third leg or it may split into first and second inductor windings and disposed on the first and second legs. In addition, one or more legs may include an energy storage component such as an air gap. This integration of the primary and secondary windings and the inductor winding on the unitary magnetic structure advantageously decouples the inductor function from the transformer function and allows the more optimal design of both the inductor and the transformer. The unitary magnetic structure may be coupled to a full bridge, a half bridge, or a push pull voltage input source to form a DC—DC converter.

Owner:NORTHEASTERN UNIV

Vertically packaged switched-mode power converter

ActiveUS20060038549A1Tight regulationFast transient responseTransformersConversion constructional detailsCellular architectureElectrical resistance and conductance

A vertically packaged cellular power converter solves the problems associated with conventional designs and paves the way for a cellular circuit architecture with ultra-low interconnect resistance and inductance. The vertical packaging results in a power flow in the vertical direction (from the bottom to the top) with very short internal interconnects, thereby minimizing the associated conduction losses and permitting high conversion efficiency at high currents. The cellular architecture is ideally suited for generating multiple supply voltages.

Owner:MYPAQ HLDG LTD

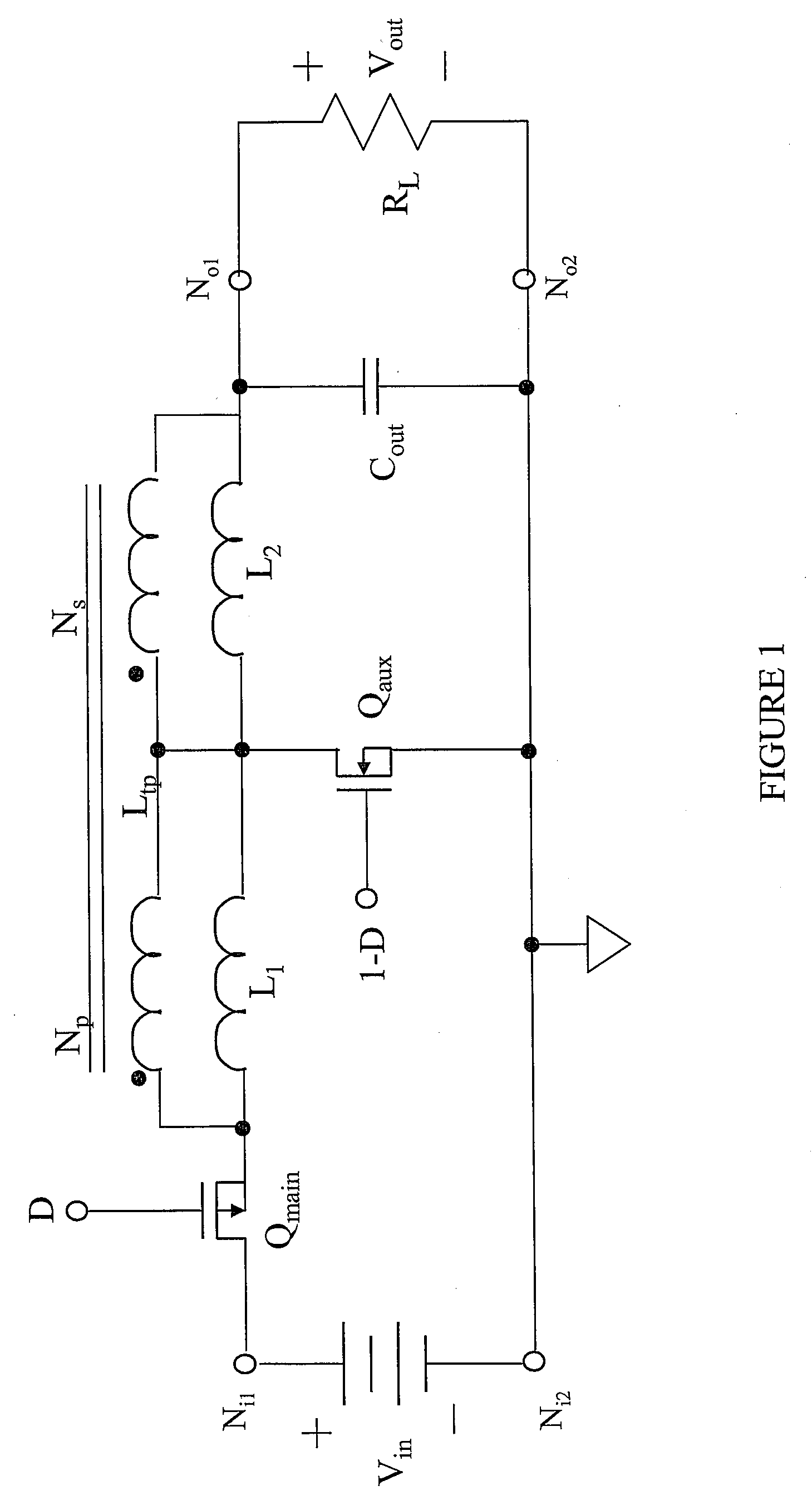

Power Converter Employing a Tapped Inductor and Integrated Magnetics and Method of Operating the Same

ActiveUS20080150666A1Ac-dc conversionTransformers/inductances coils/windings/connectionsSurface mountingInductor

A power converter employing a magnetic device including a magnetic core and first and second tapped windings. Each winding of the magnetic device has first and second winding sections, respectively, coupled to the magnetic core, wherein the first and second winding sections are formed from a formed and folded planar conductive sheet. The magnetic core includes a common leg, a plurality of outer legs, and a top plate. The first and second winding sections are constructed with a formed and folded planar conductive sheet formed with structures usable as pins in a through-hole, surface-mount, or combined printed wiring board assembly process. The outer legs at either end of the magnetic core are positioned back from magnetic core ends, and the magnetic core is formed with a stepped structure to accommodate winding pins in a surface-mount printed wiring board assembly process.

Owner:MYPAQ HLDG LTD

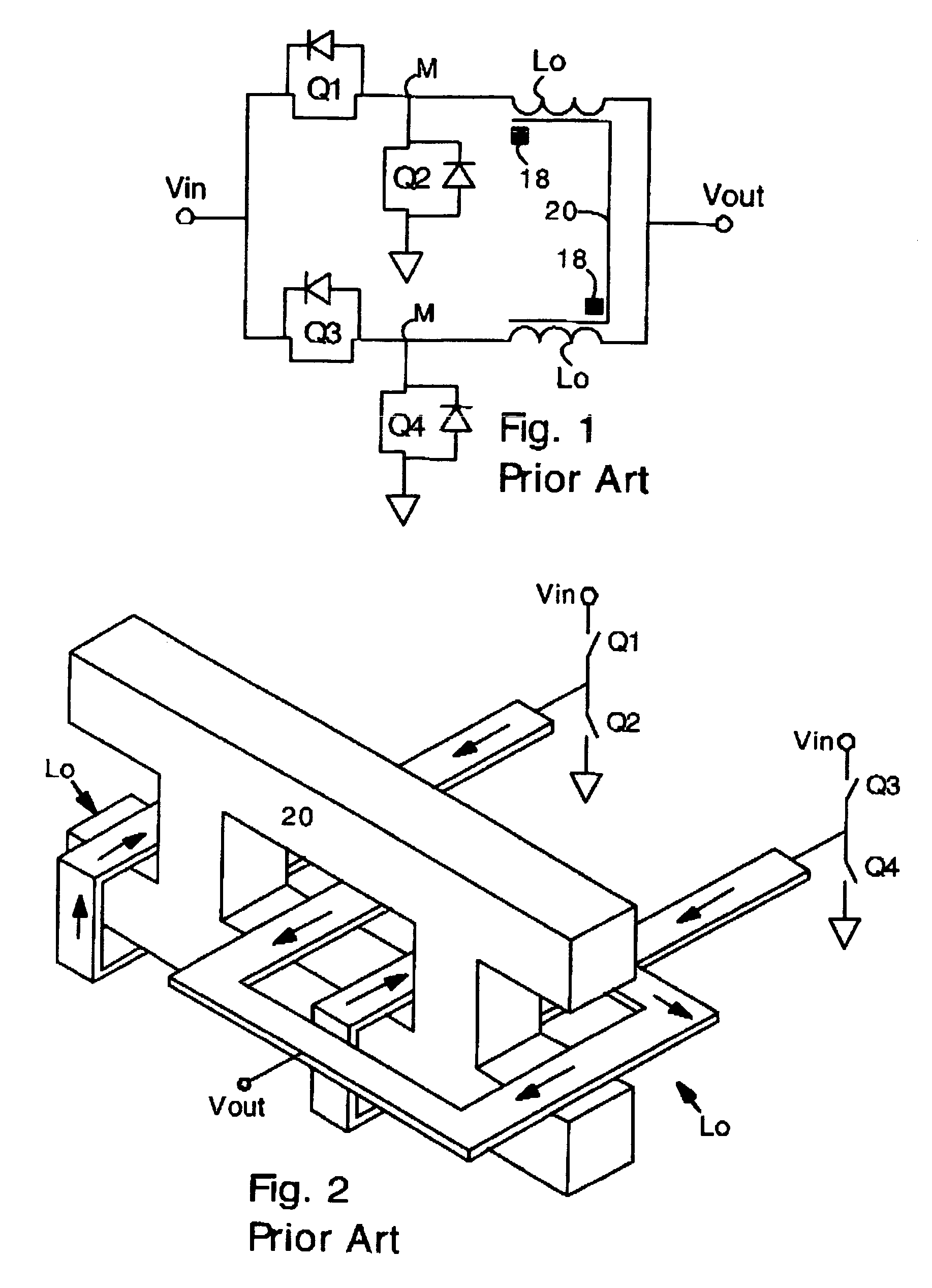

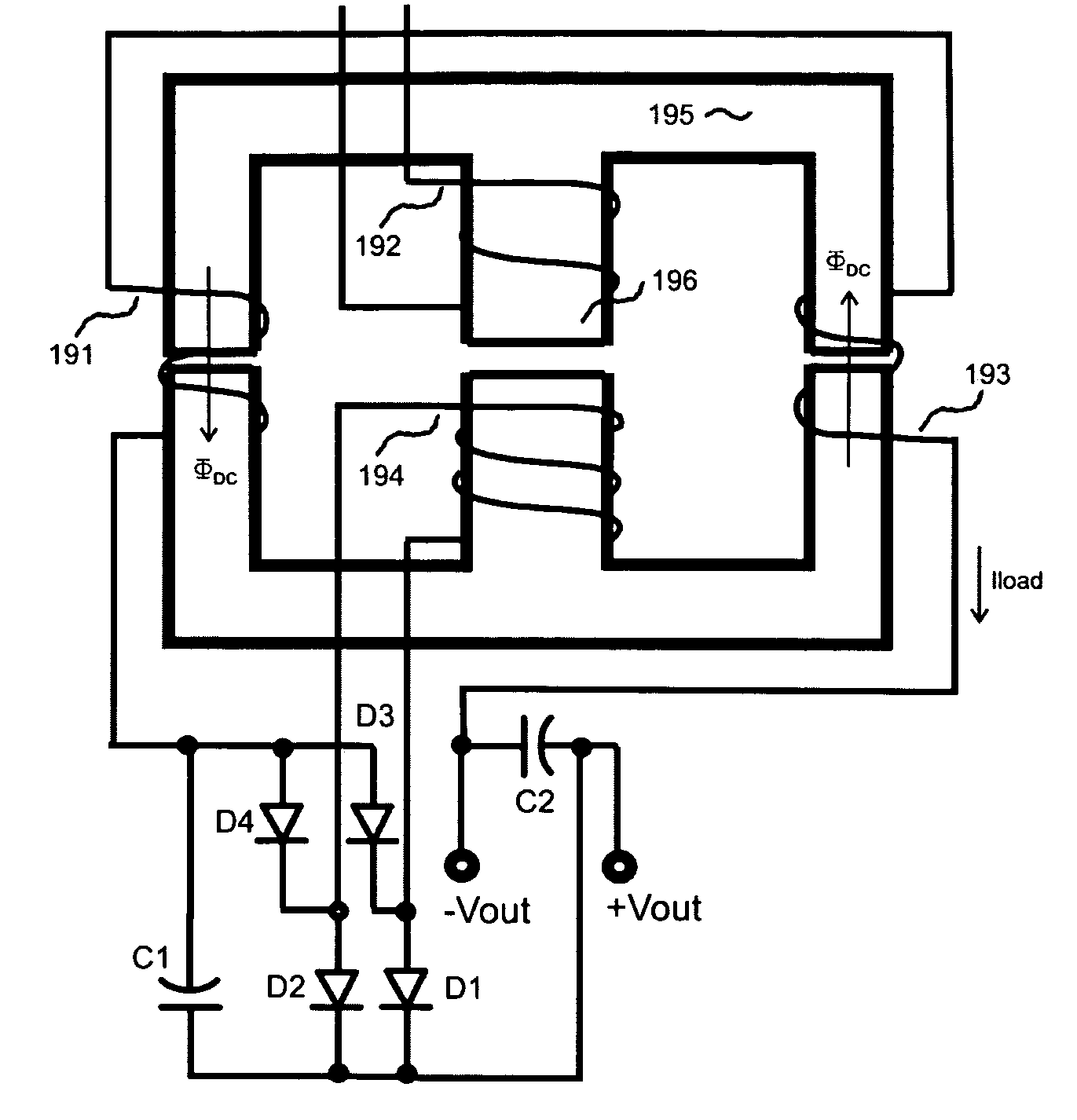

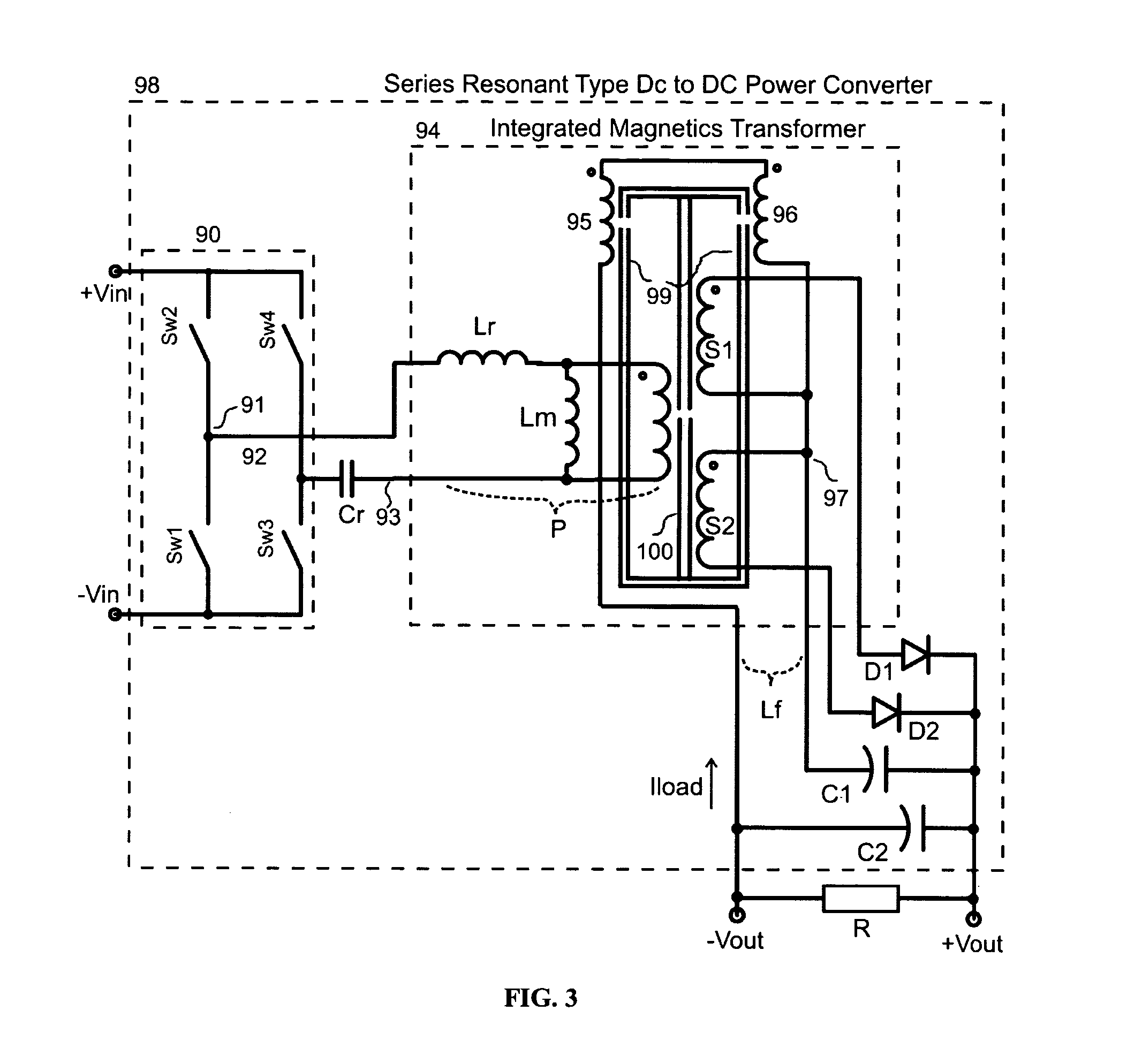

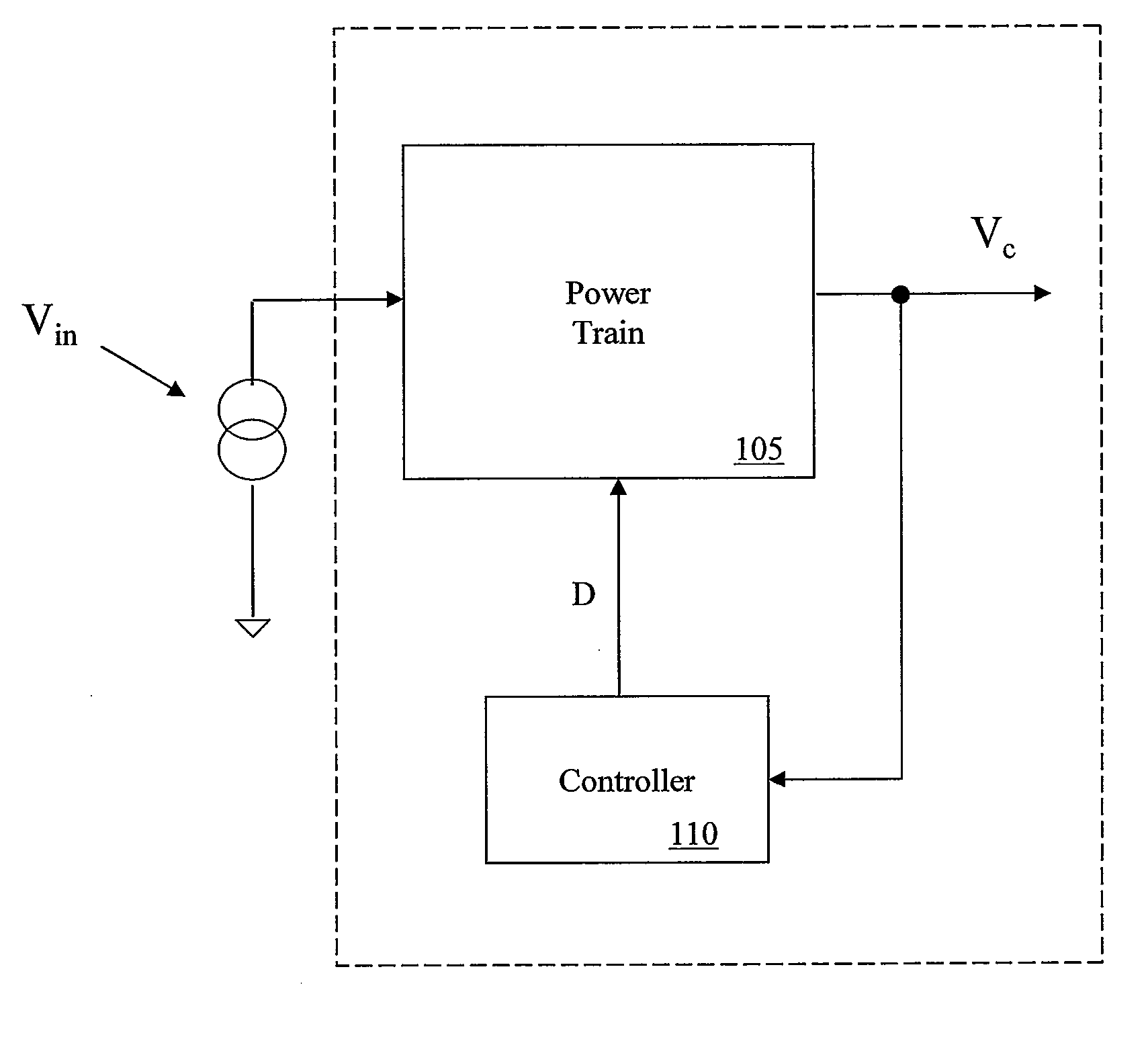

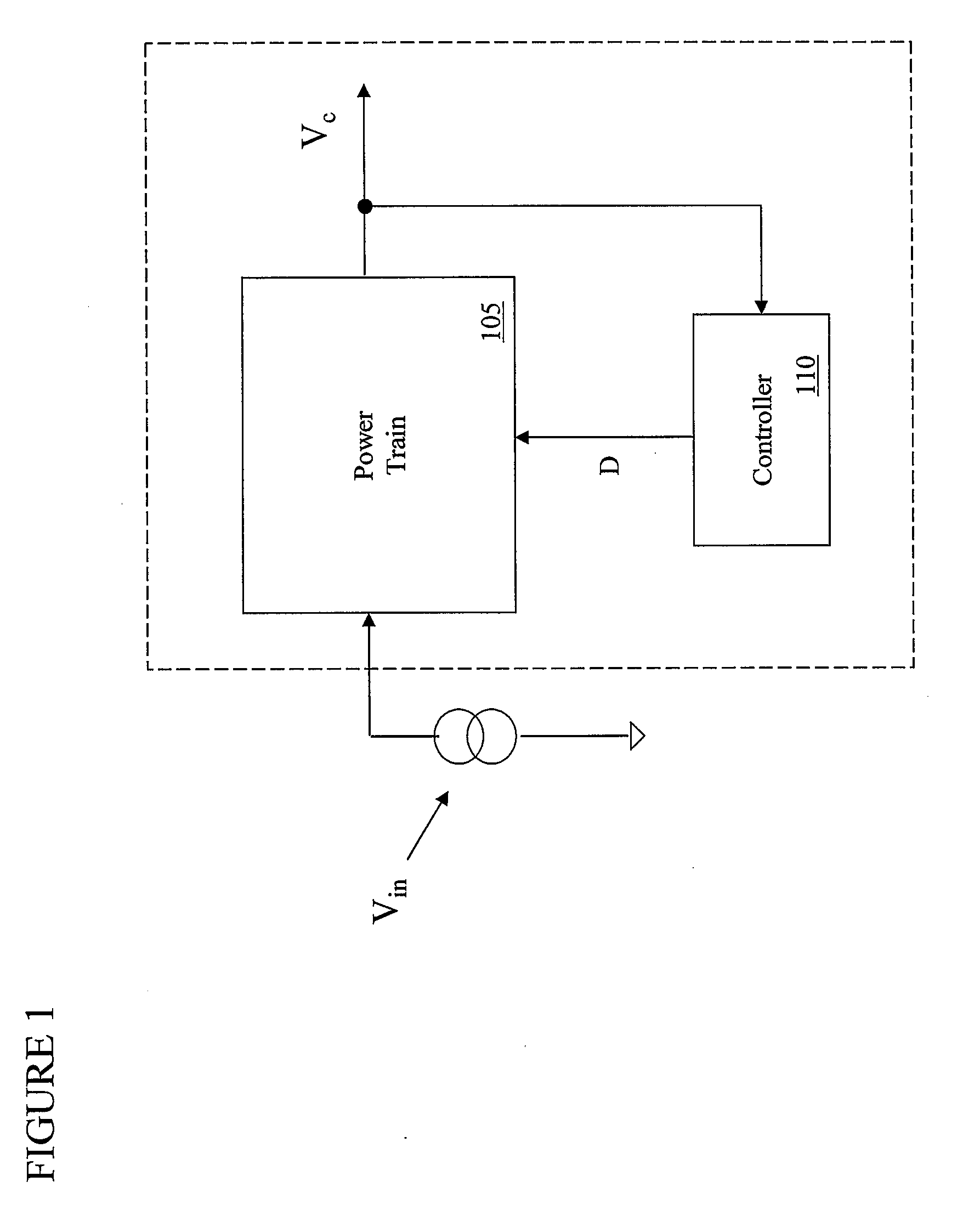

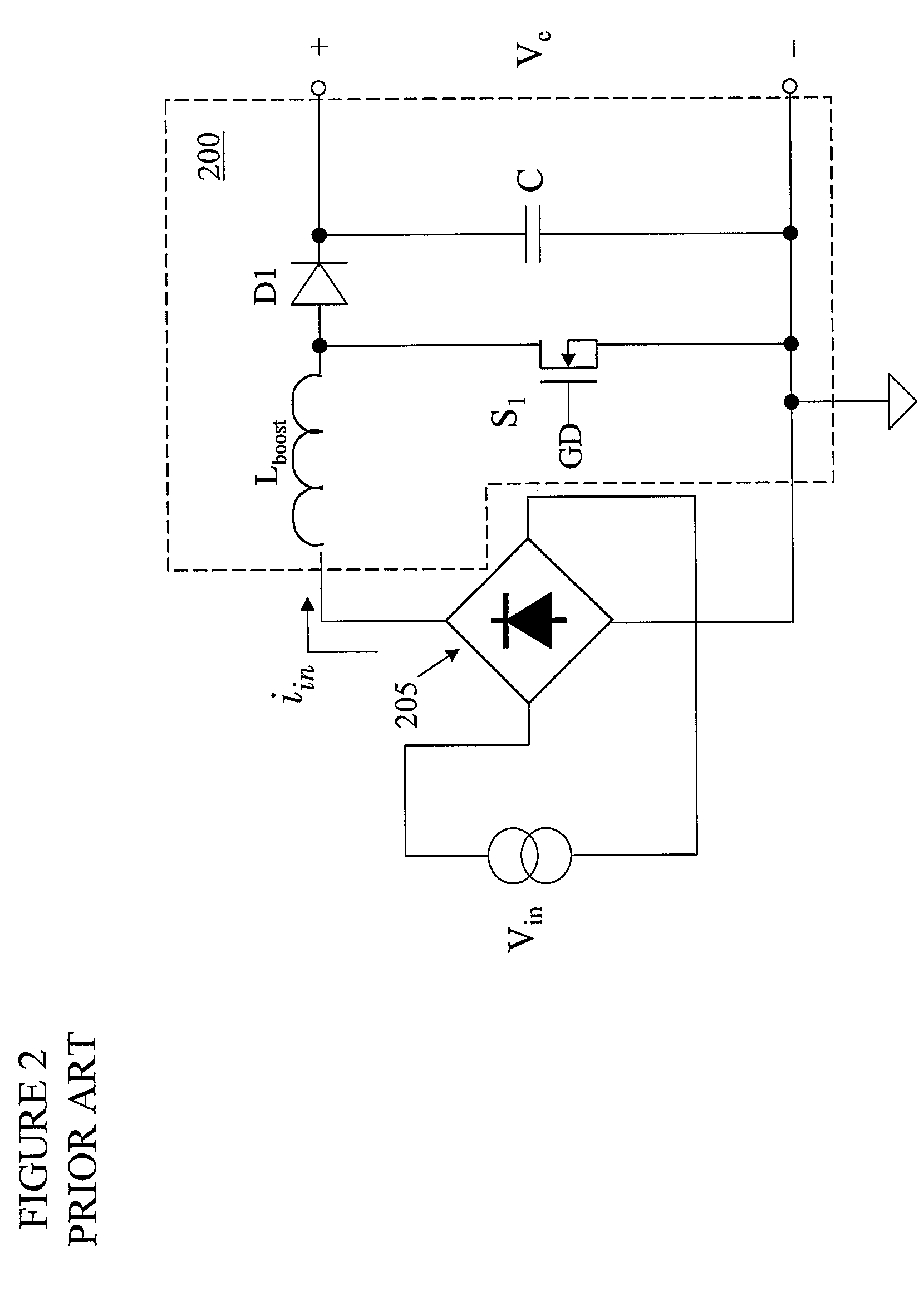

Full wave series resonant type DC to DC power converter with integrated magnetics

ActiveUS7136293B2Reduce current rippleThick currentAc-dc conversion without reversalTransformersTransformerFull wave

A full wave DC / DC converter magnetically integrates into the transformer assembly the functions of the resonant inductor, magnetizing inductor and the output filter inductor. The primary and the secondary windings are assembled on a gapped center leg of an E-core, while two output filter windings with an equal number of turns are assembled on gapped left and gapped opposed side legs of the E-core. The length of the gaps in the side legs is selected so that the DC current does not saturate the side legs. The two filter windings are connected in series and are oppositely polarized so that the voltages induced in these windings by the primary winding flux cancel each other.

Owner:PETKOV ROUMEN D +1

Power Converter Employing Regulators with a Coupled Inductor

A power converter includes a power train with a coupled inductor and a plurality of regulators, and method of forming and operating the same. In one embodiment, the power train includes a coupled inductor including a magnetic core with a common leg, a first leg and a second leg. The coupled inductor also includes a common winding formed around the common leg, and first and second windings. The first winding is formed around the first leg, and is electrically and magnetically coupled to the common winding. The second winding is formed around the second leg, and is electrically and magnetically coupled to the common winding. The power train also includes a first regulator including a first main switch coupled to the first winding and a second regulator including a second main switch coupled to the second winding.

Owner:MYPAQ HLDG LTD

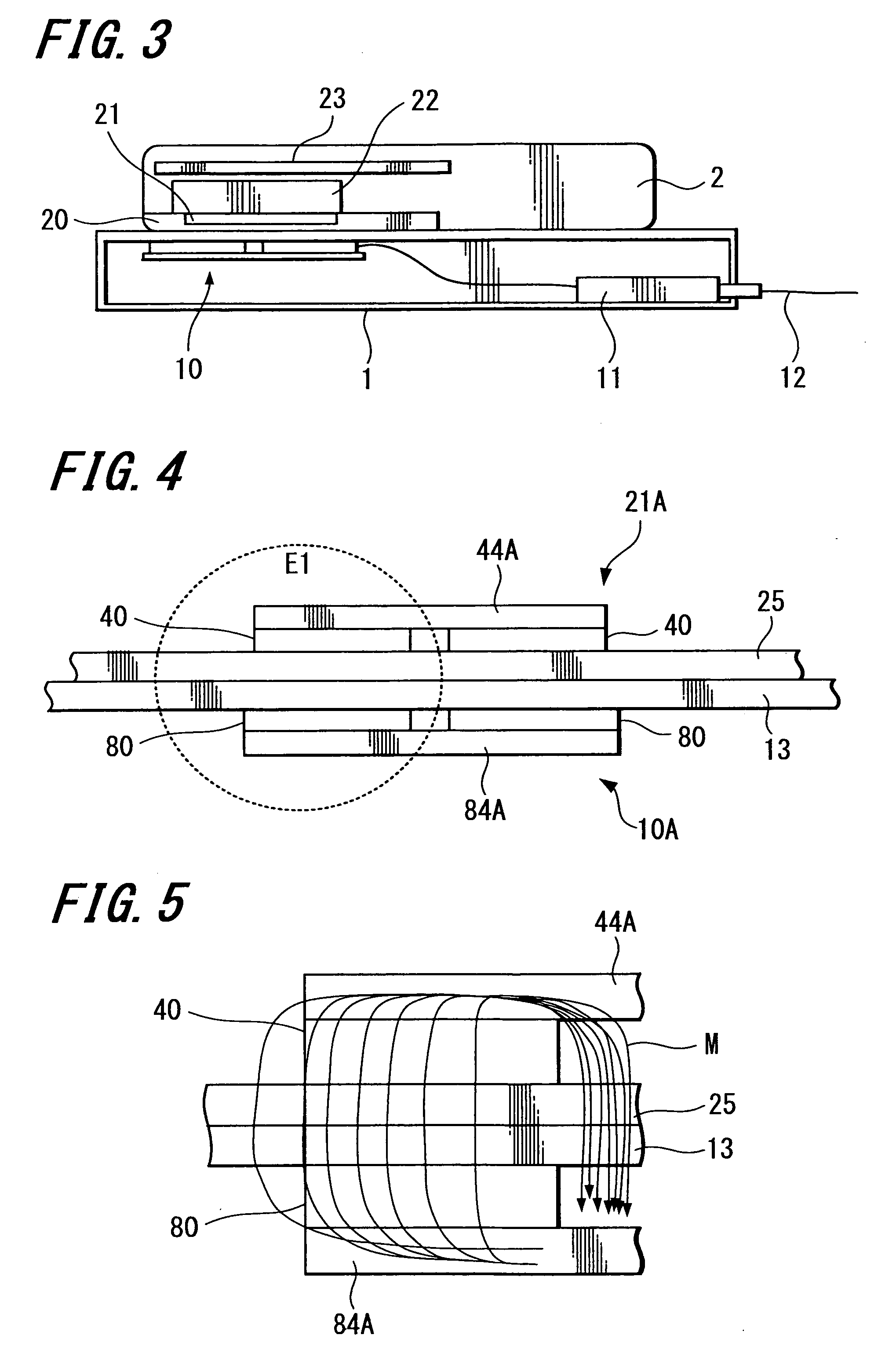

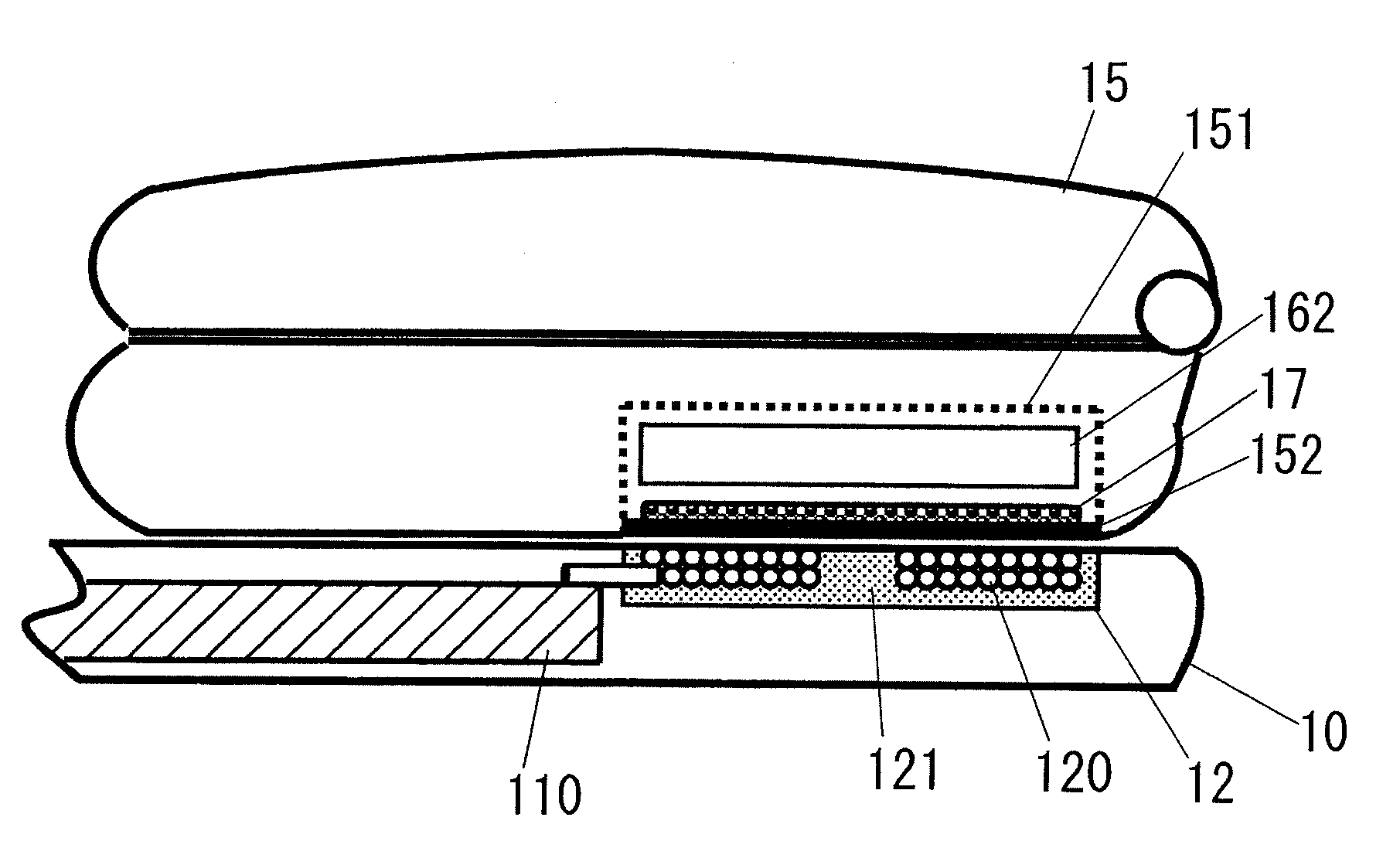

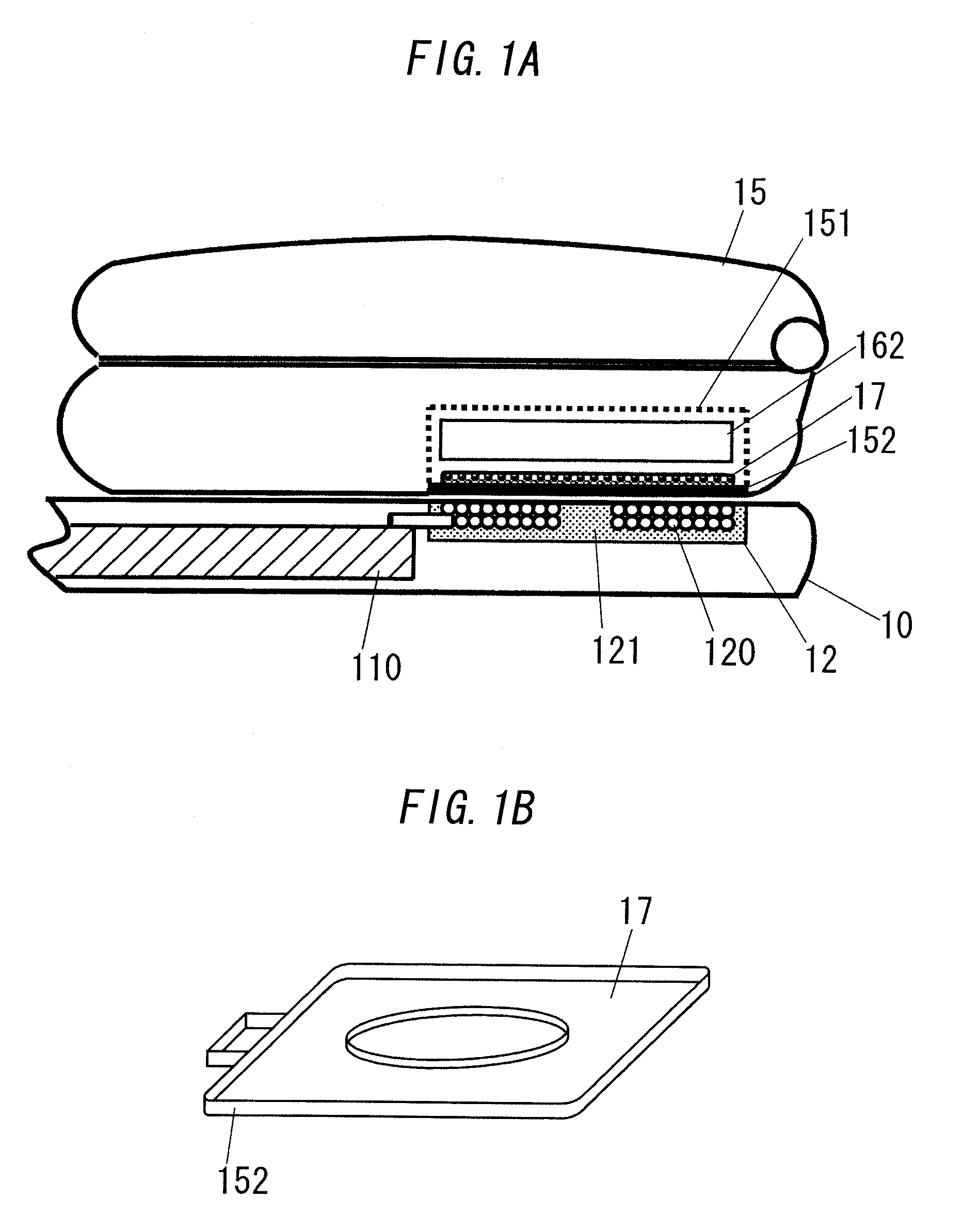

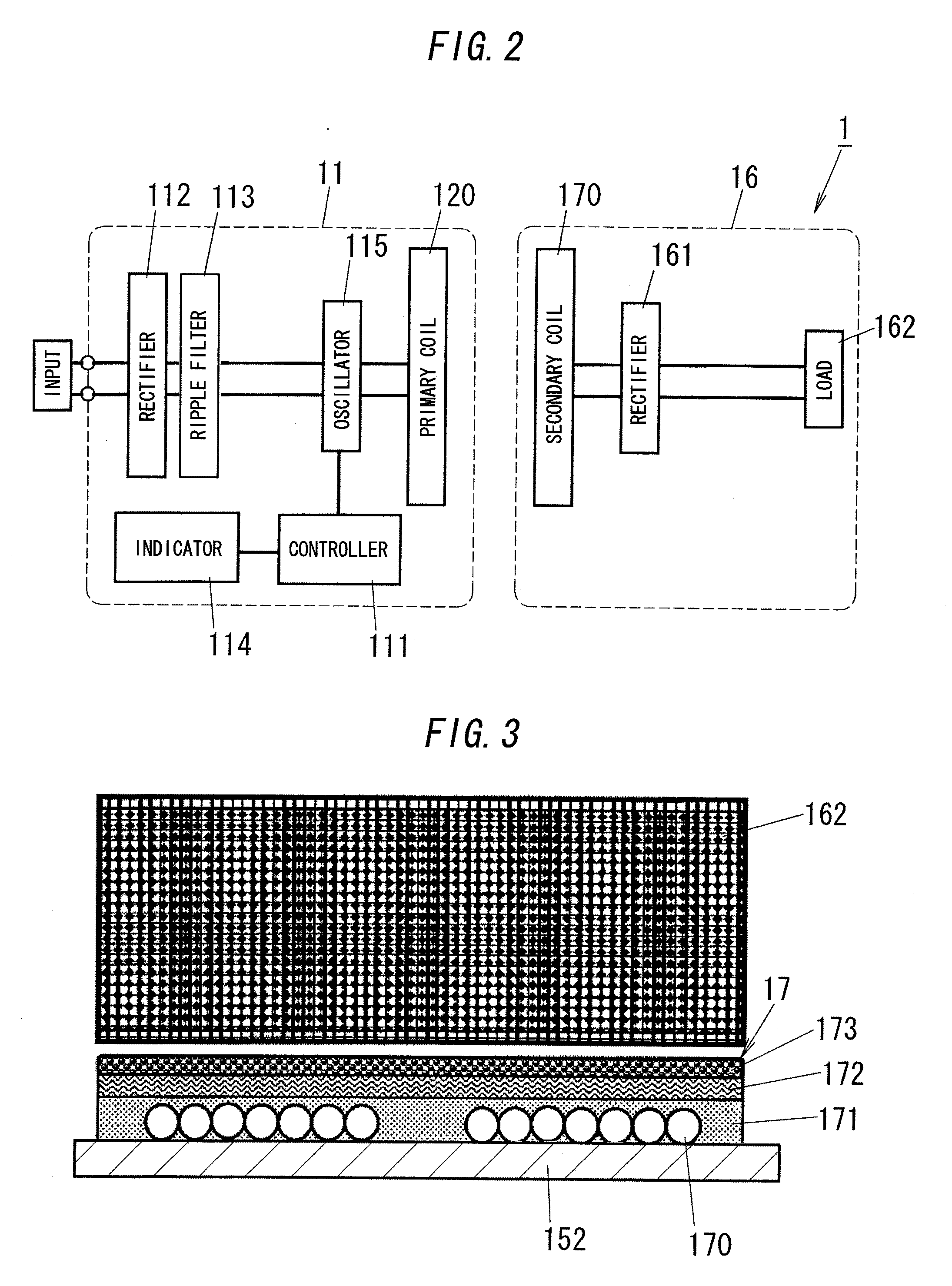

Contactless power transmission apparatus and a method of manufacturing a secondary side thereof

InactiveUS20100181842A1High power transmission efficiencyReduce the impact of noiseBatteries circuit arrangementsElectromagnetic wave systemElectric power transmissionInsulation layer

According to a first aspect, a secondary side of contactless power transmission apparatus includes: a holding member which is physically separated from a primary side; a magnetic layer; a shield layer for shielding electromagnetic noise; and a heat insulation layer. The secondary coil is a planar coil and supported by the holding member, and at least the magnetic layer is laminated on one side of the planar coil and unified with the planar coil. According to a second aspect, the secondary side of the apparatus includes a plurality of magnetic layers. Each permeability of the magnetic layers is different from each other, and each of the magnetic layers forms a magnetic path with the primary side.

Owner:PANASONIC CORP

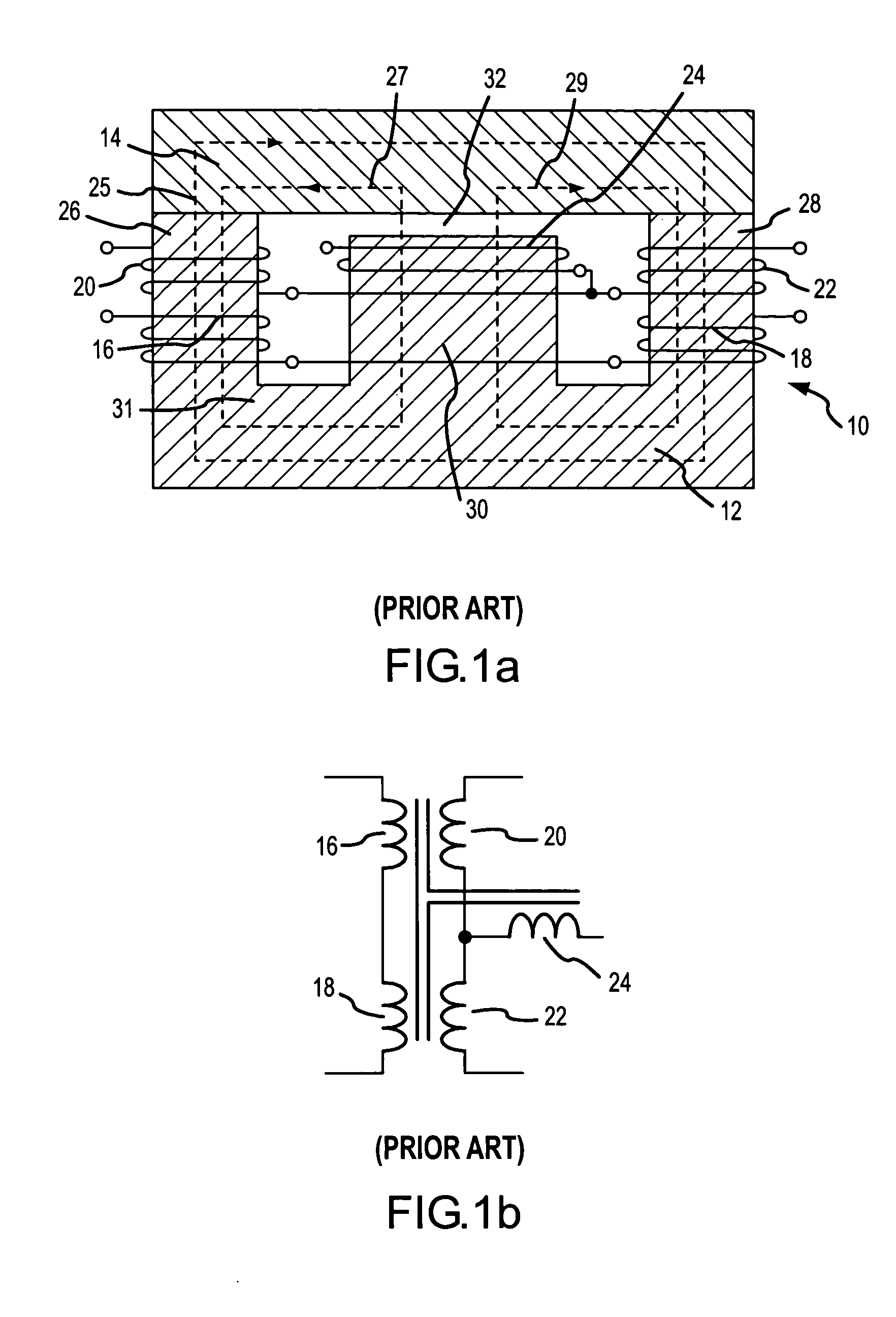

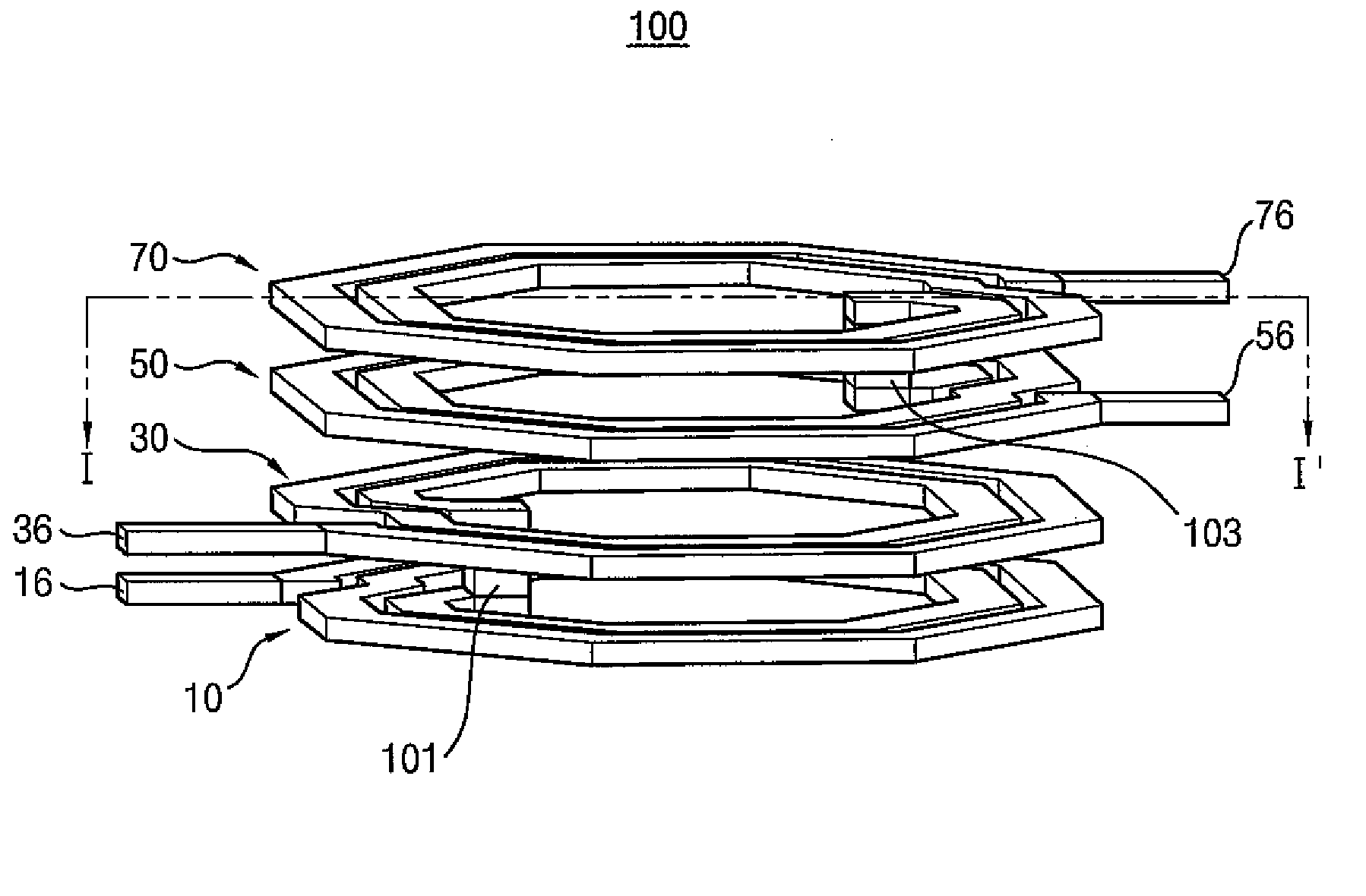

Transformers and baluns

InactiveUS20080174396A1High electromagnetic inductanceGood symmetrySemiconductor/solid-state device detailsTransformers/inductances coils/windings/connectionsInsulation layerTransformer

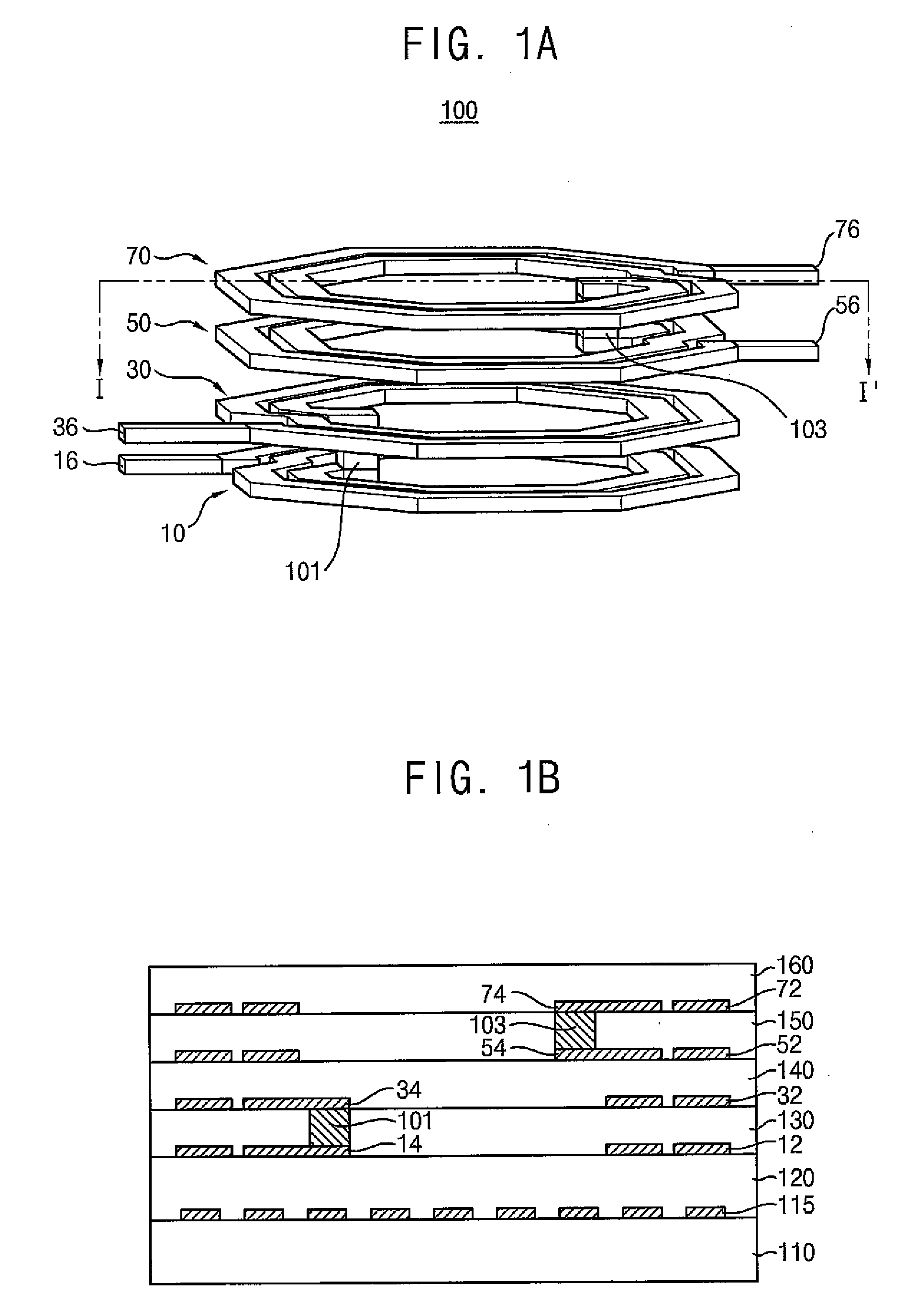

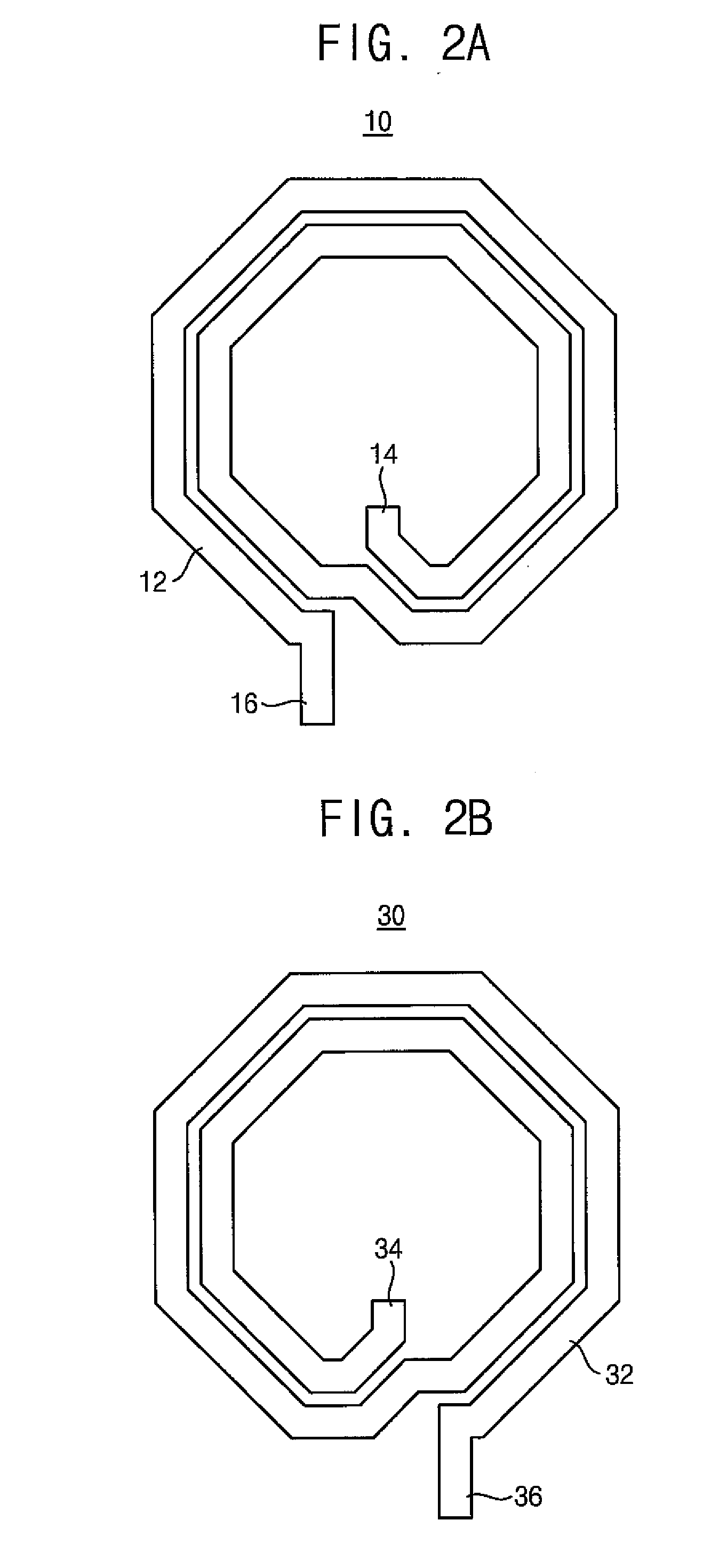

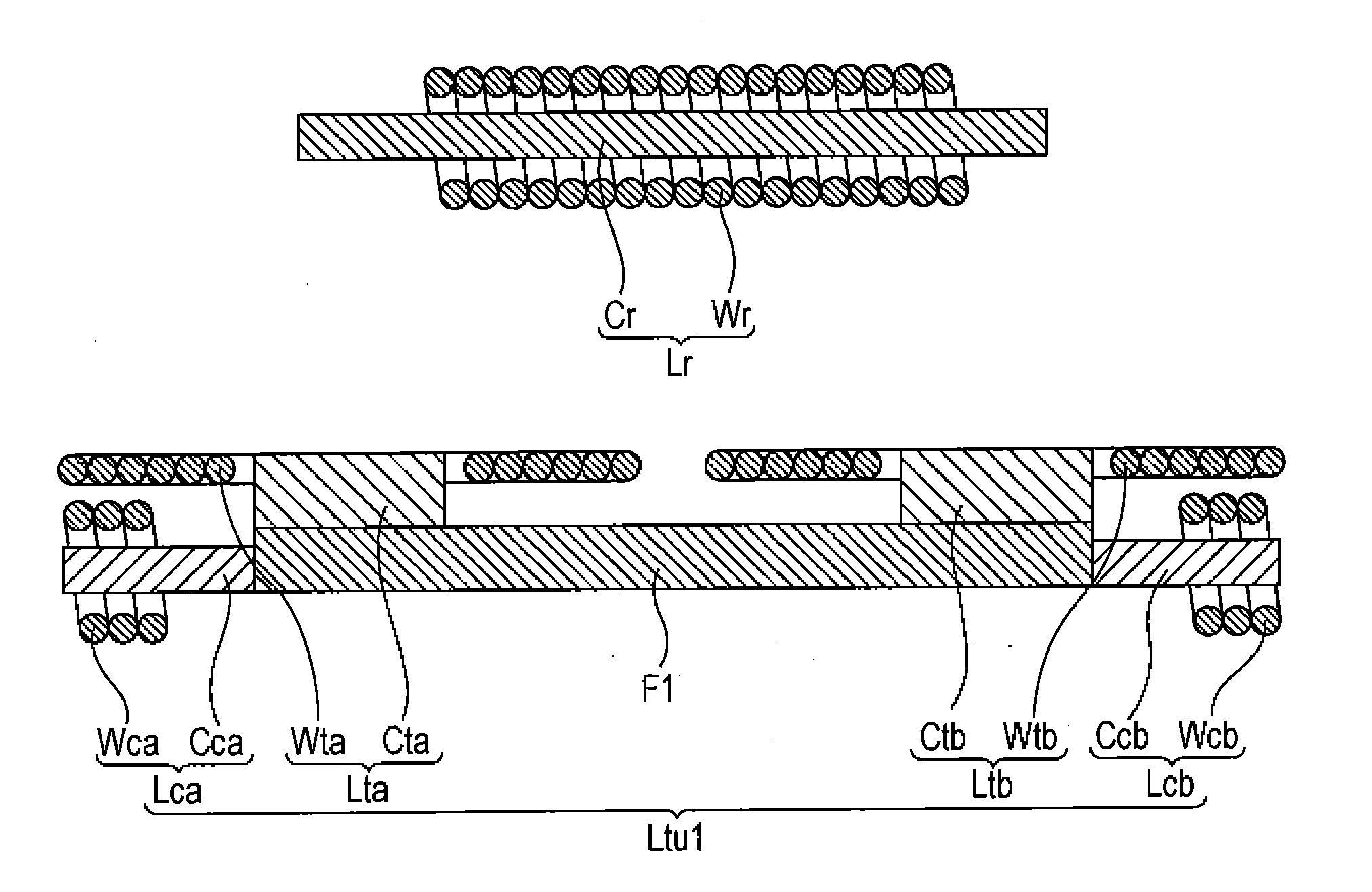

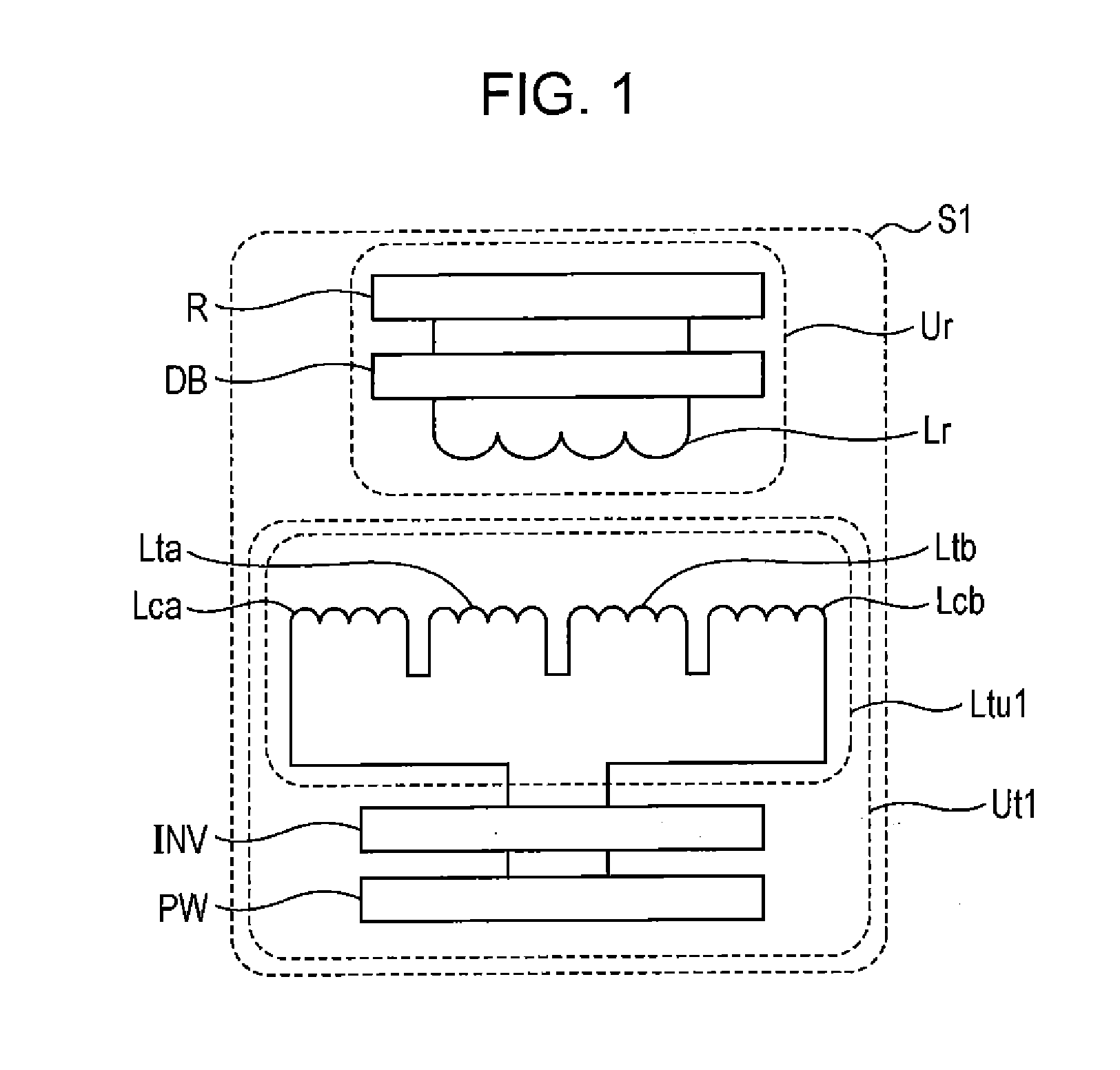

A transformer includes a primary coil assembly and a secondary coil assembly juxtaposed in a stack and which are electromagnetically inductively coupled and substantially symmetrical to one another. The primary coil assembly includes a plurality of primary coils coplanar with first insulation layers, respectively, and symmetrical to each other, and a first via unit connecting adjacent ones of the primary coils to each other. The secondary coil assembly includes a plurality of secondary coils coplanar with a plurality of second insulation layers, respectively, and symmetrical to each other, and a second via unit connecting adjacent ones of the secondary coils to each other.

Owner:SAMSUNG ELECTRONICS CO LTD

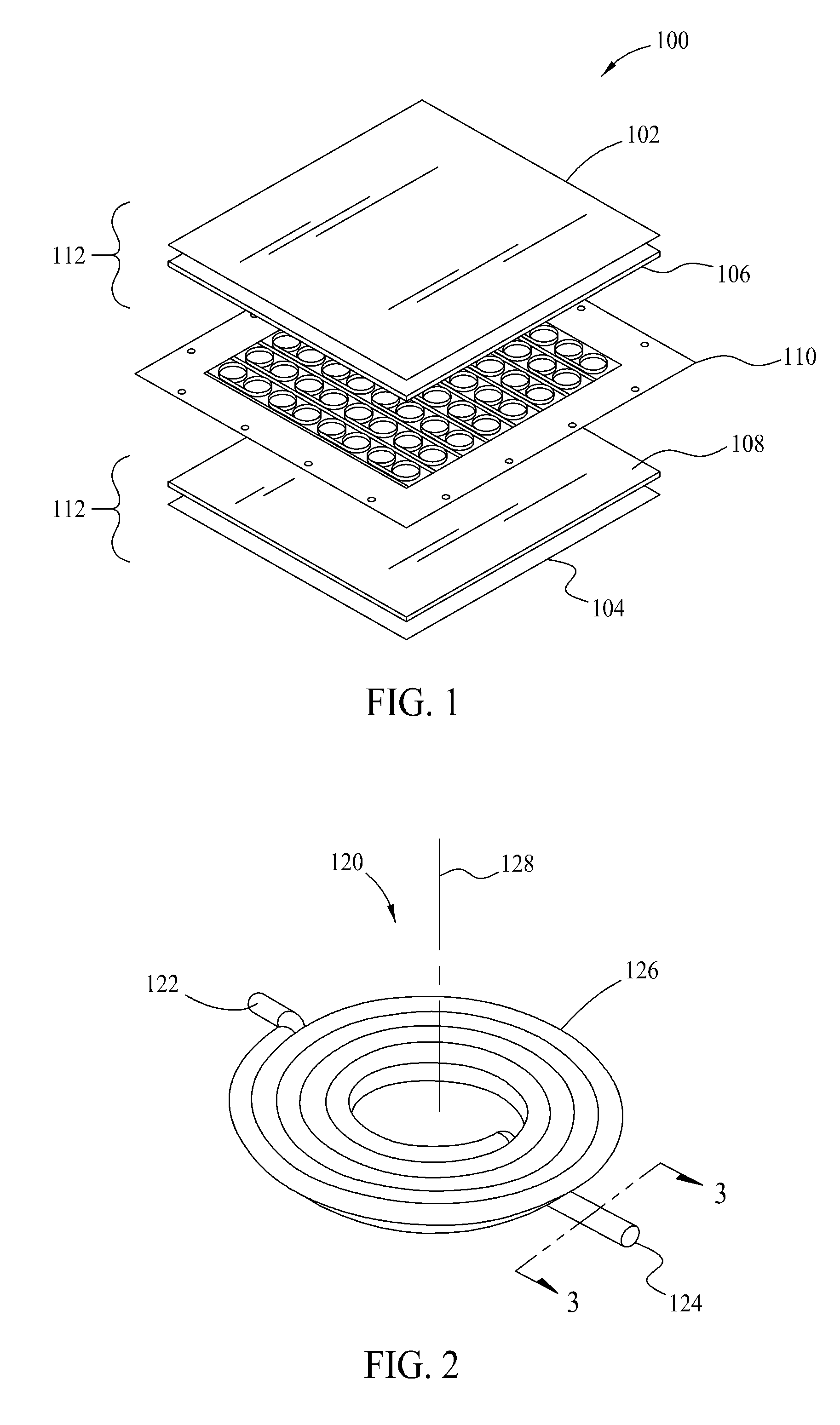

Power feeding coil unit and wireless power transmission device

ActiveUS20150145339A1Improve transmission efficiencyPromote generationBatteries circuit arrangementsCharging stationsElectricityElectric power transmission

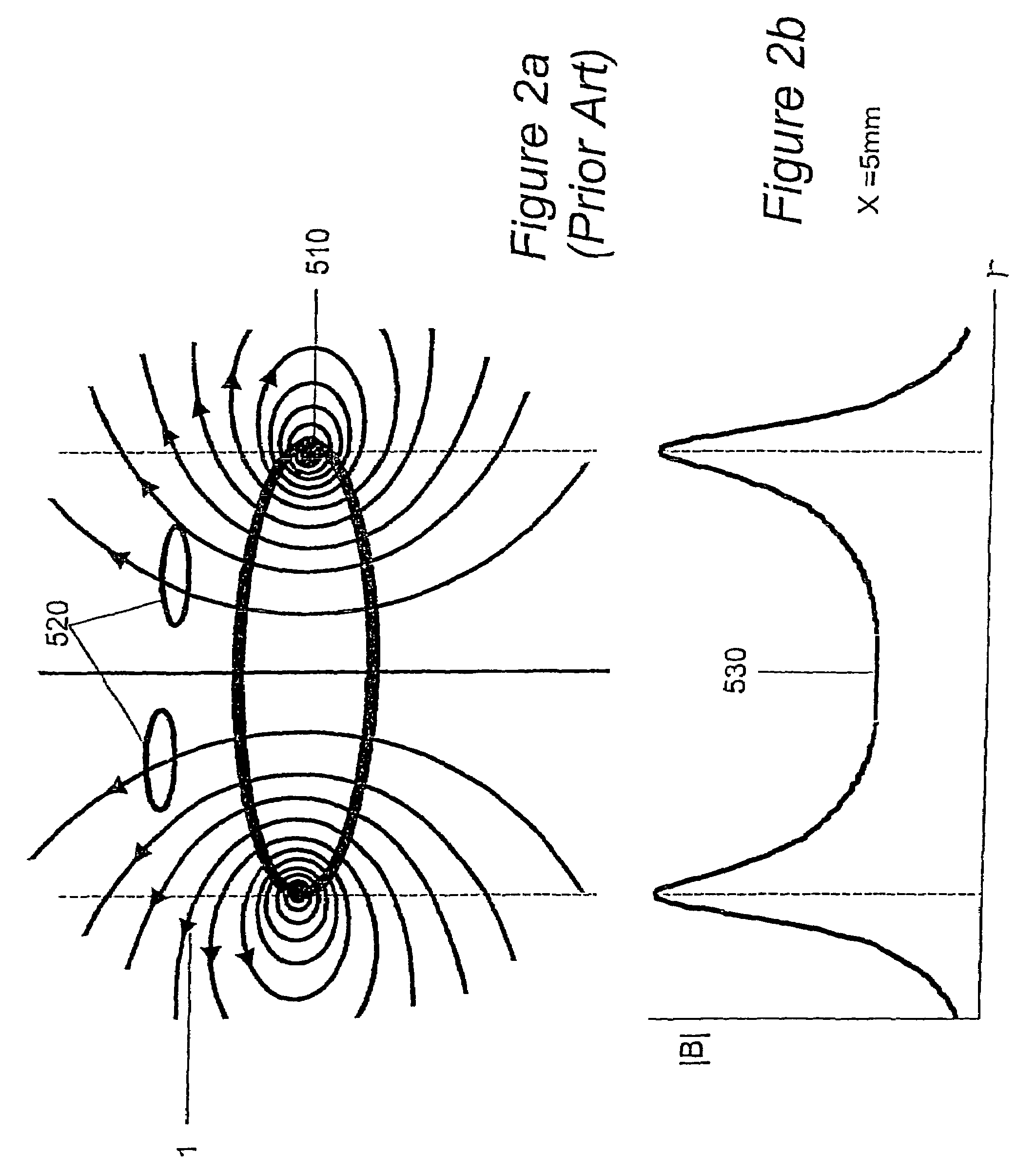

A power feeding coil unit includes a power feeding coil, and an auxiliary coil. The auxiliary coil is arranged not to interlink with a magnetic flux that interlinks with a power receiving coil that is arranged to face the power feeding coil during power feeding. An axial direction of the auxiliary coil is nonparallel to an opposing direction of the power feeding coil and the power receiving coil. A direction of circulation of a magnetic flux generated by the auxiliary coil is opposite to a direction of circulation of a magnetic flux generated by the power feeding coil.

Owner:TDT

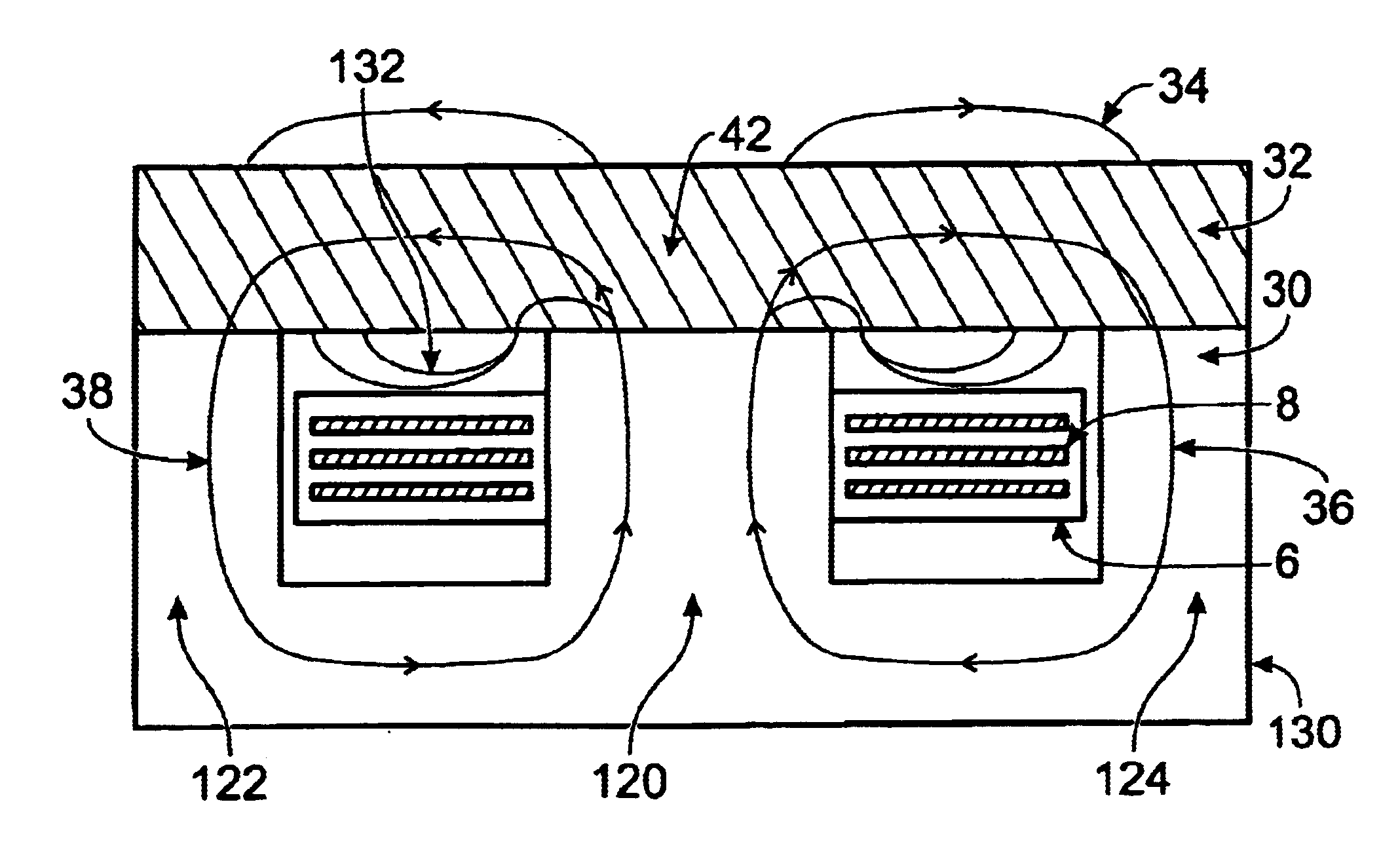

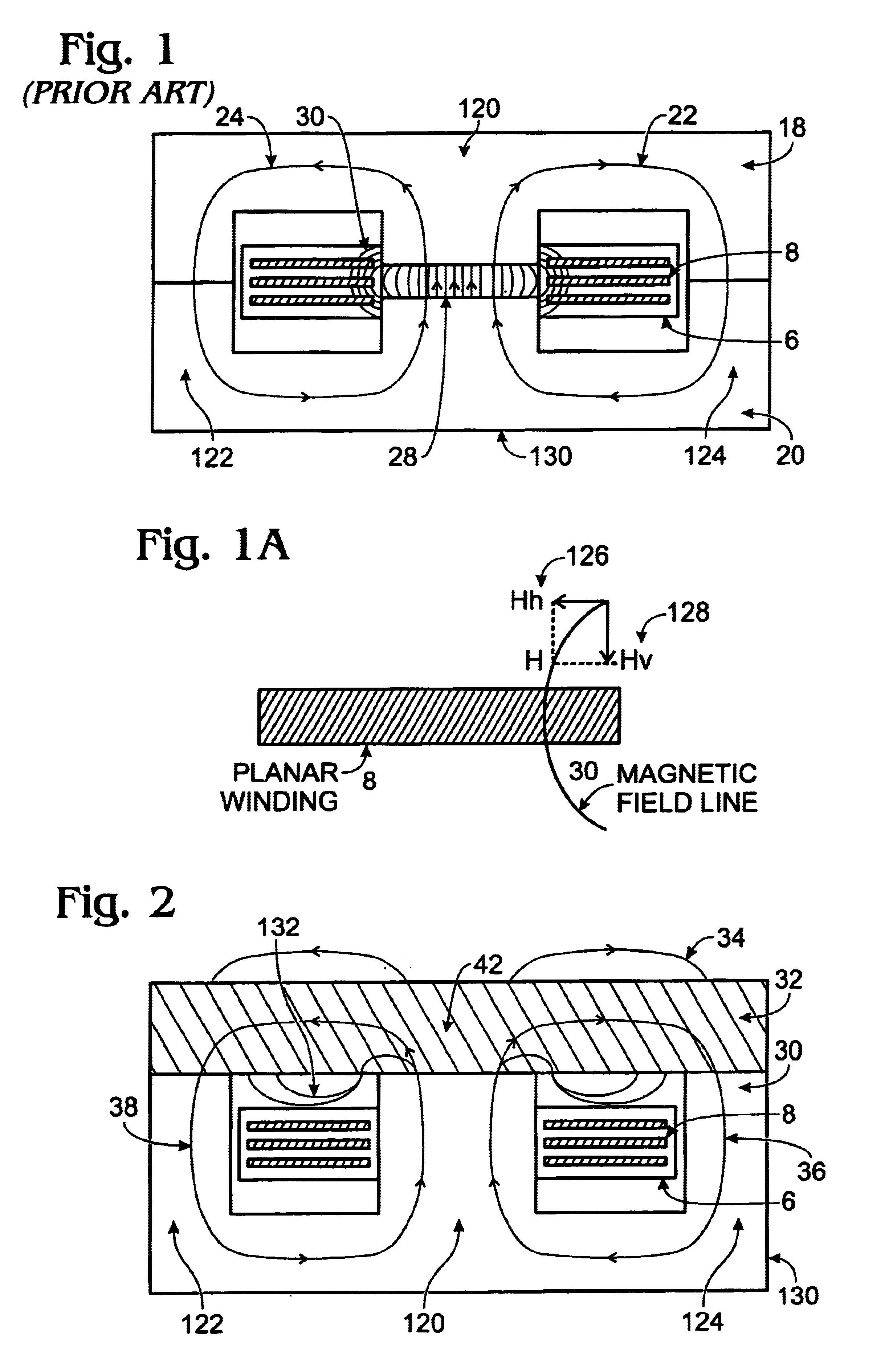

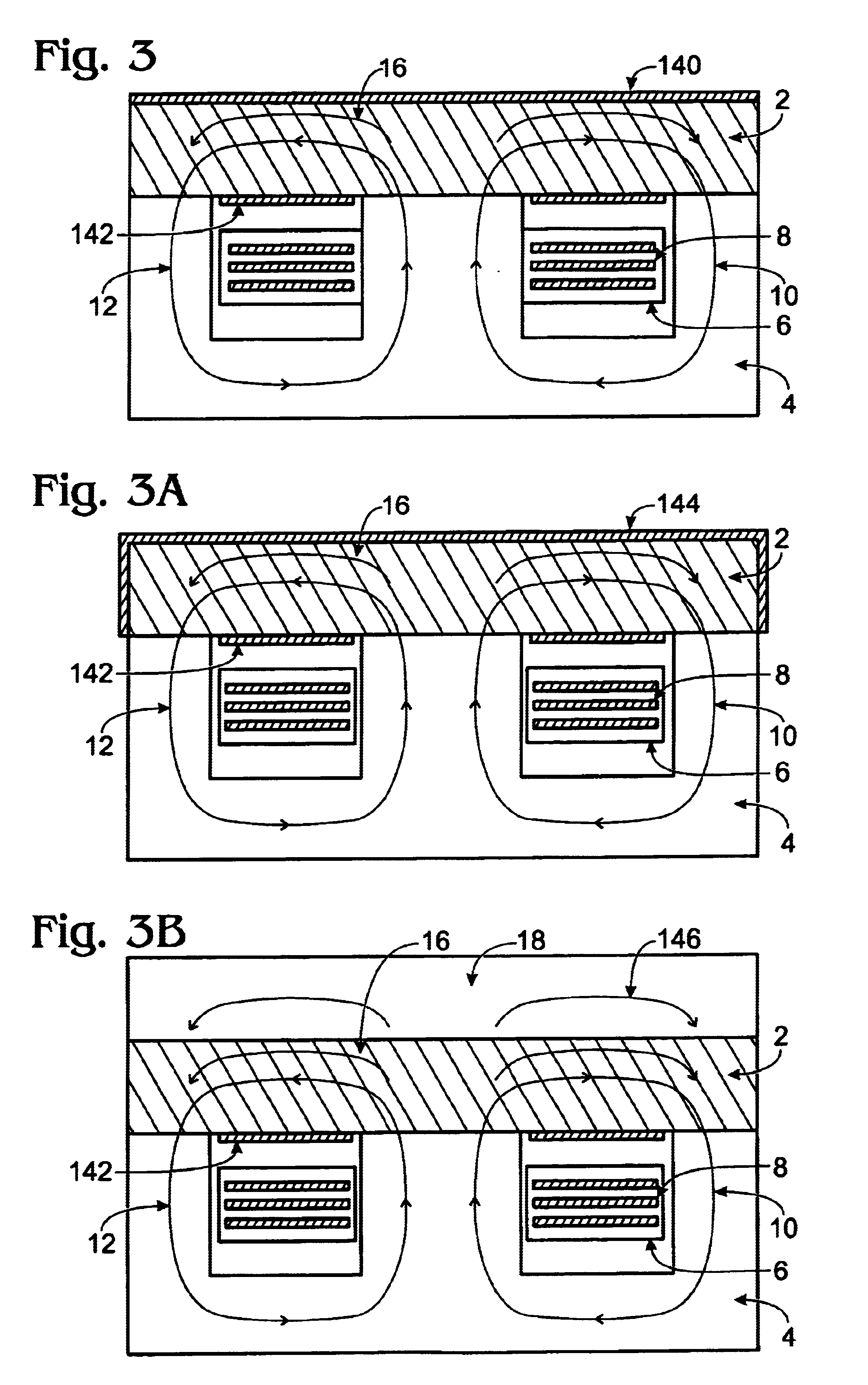

Planar inductive element

InactiveUS6967553B2Reduce the impactReduce impactTransformers/inductances casingsTransformers/inductances magnetic coresEddy currentPlanar inductor

A storage magnetic element, which minimizes the power loss in the planar winding due to the fringe magnetic field associated with a discrete air gap, is presented. The invention describes a construction technique wherein the magnetic core is formed by an E section made of high permeability magnetic material and an I section made by a material capable to store energy due to its distributed gap structure. The I section of the magnetic core in one of the embodiments is covered by an electrically conductive shied to force the magnetic flux into the I section and to minimize the component of the fringe magnetic field perpendicular on the planar winding. In another embodiment of this invention the electrically conductive shield is replaced by a high magnetic permeability material to accomplished the same goal of reducing the magnetic field component perpendicular on the planar winding. In a prefer embodiment of this invention the I section of the magnetic core has a cavity which will accommodate the middle leg of the E section. This construction will force the fringe magnetic field at the edge of the gap to be parallel with the planar winding of the storage magnetic element. In another embodiment of this invention a flat I section is used with the addition of another high permeability magnetic material placed on the I section on top of the winding. This construction will force the fringe magnetic field around the edge of the gap to be parallel with the planar winding. The embodiments of this invention are aimed at reducing the fringe magnetic field perpendicular on the planar winding, lowering the eddy current induced by this field.

Owner:DELTA ENERGY SYST SWITZERLAND

Contact-less power transfer

InactiveUS20060076922A1Maximise currentMaximise voltageTransformersTransformers/inductances coils/windings/connectionsElectrical conductorEngineering

There is disclosed a system and method for transferring power without requiring direct electrical conductive contacts. There is provided a primary unit having a power supply and a substantially laminar charging surface having at least one conductor that generates an electromagnetic field when a current flows therethrough and having an charging area defined within a perimeter of the surface, the at least one conductor being arranged such that electromagnetic field lines generated by the at least one conductor are substantially parallel to the plane of the surface or at least subtend an angle of 45° or less to the surface within the charging area; and at least one secondary device including at least one conductor that may be wound about a core. Because the electromagnetic field is spread over the charging area and is generally parallel or near-parallel thereto, coupling with flat secondary devices such as mobile telephones and the like is significantly improved in various orientations thereof.

Owner:PHILIPS IP VENTURES BV

Simplified transformer design for a switching power supply

InactiveUS6914508B2High currentTransformers/inductances coils/windings/connectionsPrinted circuit aspectsHelical lineTransformer

A transformer has a primary winding made from a first conducting trace formed on a first multilayer printed circuit board, and a secondary winding made from a second conducting trace formed on a second multilayer printed circuit board. The primary winding is magnetically coupled to the secondary winding. The windings are etched as traces in copper layers of the PC boards as spirals. The spiral of one copper layer is connected to the spiral of a different copper layer by a via, or vias, formed through the insulating layer of the PC board. The vias are drilled, cleaned, and plated with conducting material, for example copper. By using multiple layers, and by connecting spiral windings of each layer to the windings of the next layer by use of vias, any number of turns can be built into a primary winding, or into a secondary winding.

Owner:GALAXY POWER

Magnetic device with high saturation current and low core loss

ActiveUS8723629B1Low costHigh saturation currentTransformers/inductances casingsTransformers/inductances coils/windings/connectionsPower flowMagnetic flux

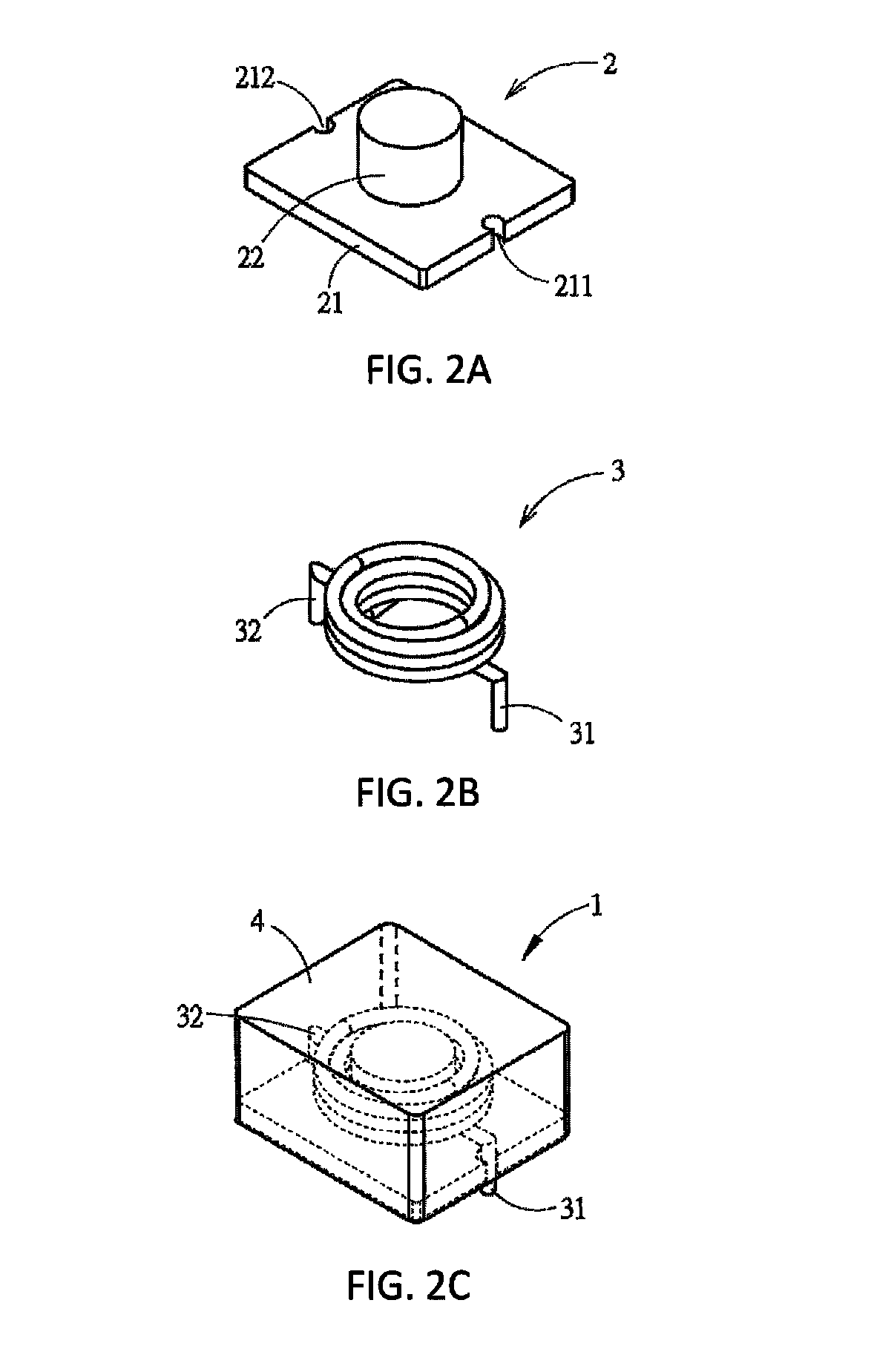

A magnetic device includes a T-shaped magnetic core, a wire coil and a magnetic body. The T-shaped magnetic core includes a base and a pillar, and is made of an annealed soft magnetic metal material, a core loss PCL (mW / cm3) of the T-shaped magnetic core satisfying: 0.64×f0.95×Bm2.20≦PCL≦7.26×f1.41×Bm1.08, where f (kHz) represents a frequency of a magnetic field applied to the T-shaped magnetic core, and Bm (kGauss) represents the operating magnetic flux density of the magnetic field at the frequency. The magnetic body fully covers the pillar, any part of the base that is located above the bottom surface of the base, and any part of the wire coil that is located directly above the top surface of the base.

Owner:CYNTEC

Core for use in inductive element, transformer and inductor

InactiveUS6060977ATransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresElectric power transmissionTransformer

Owner:ALPS ALPINE CO LTD +1

Coil component and fabricaiton method of the same

ActiveUS20050012581A1Suppress whineTransformers/inductances casingsInorganic material magnetismEngineeringElectrical and Electronics engineering

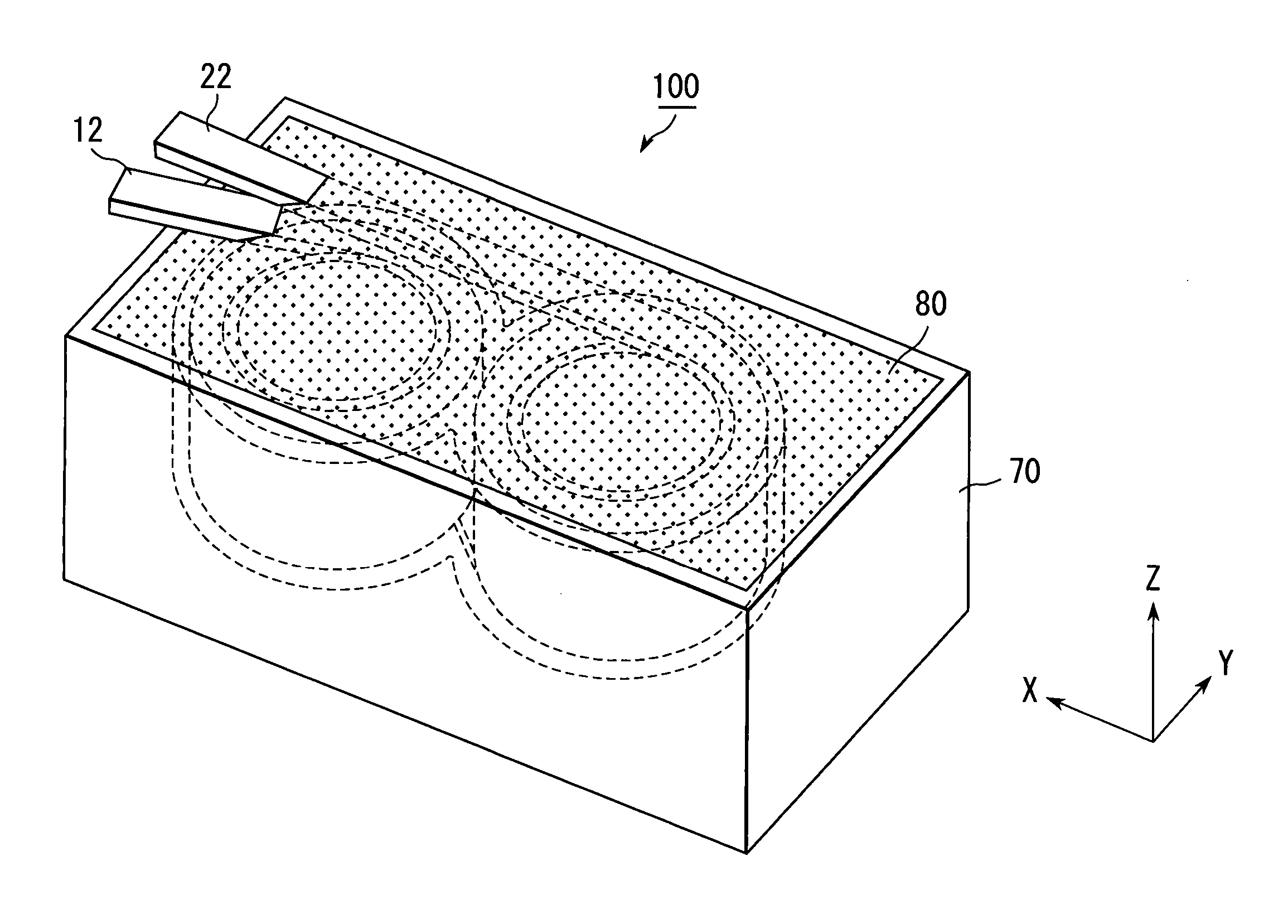

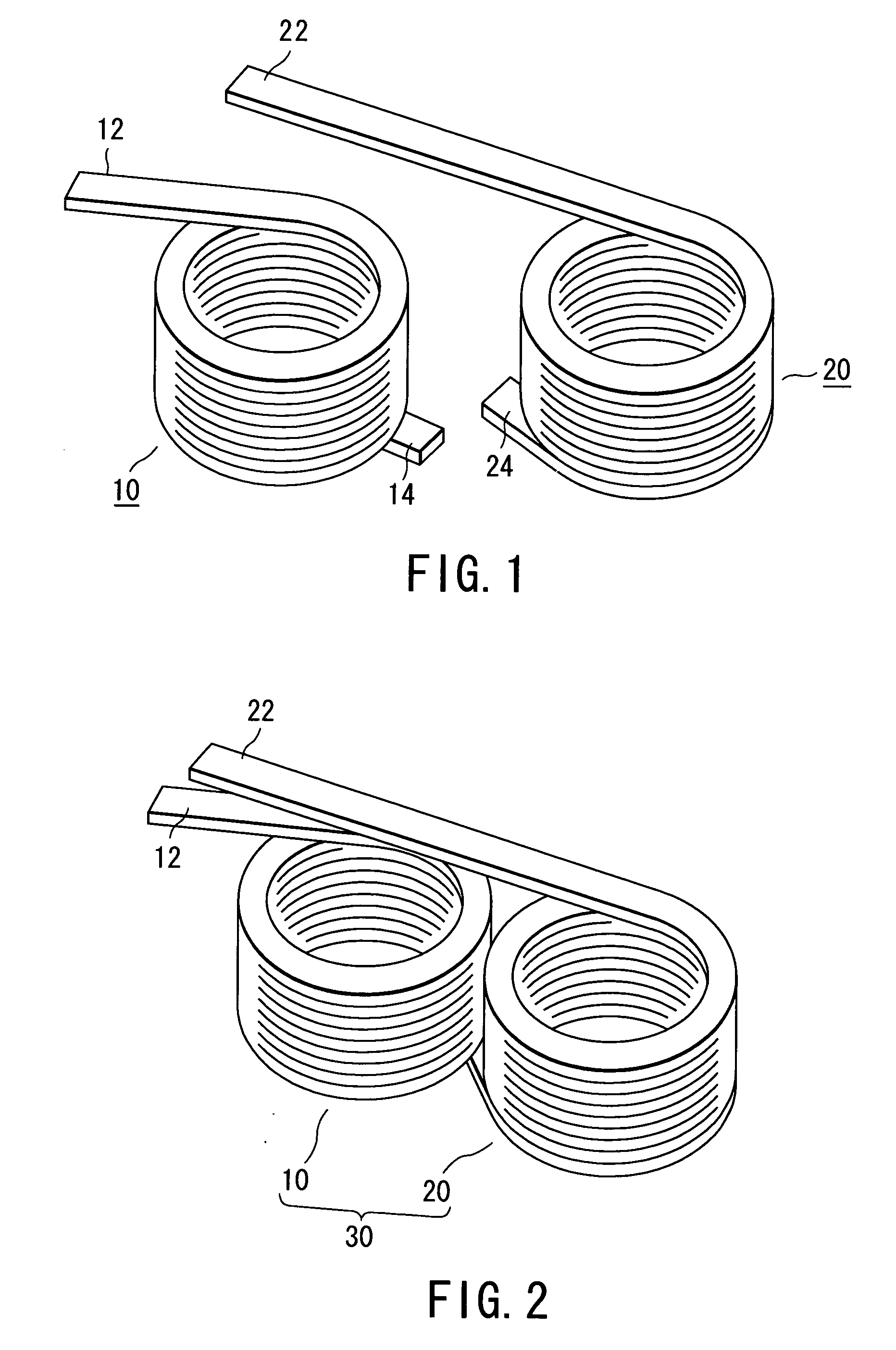

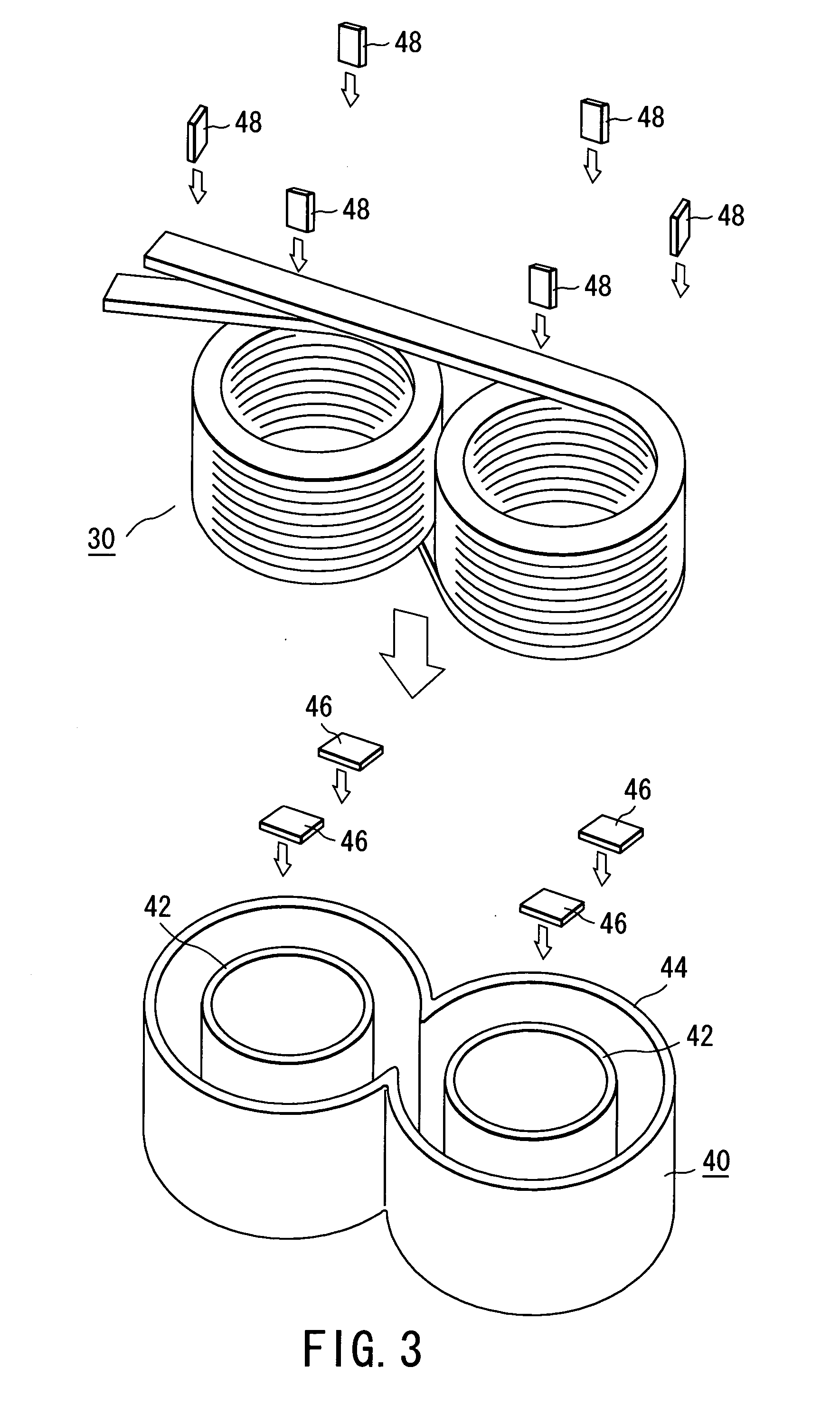

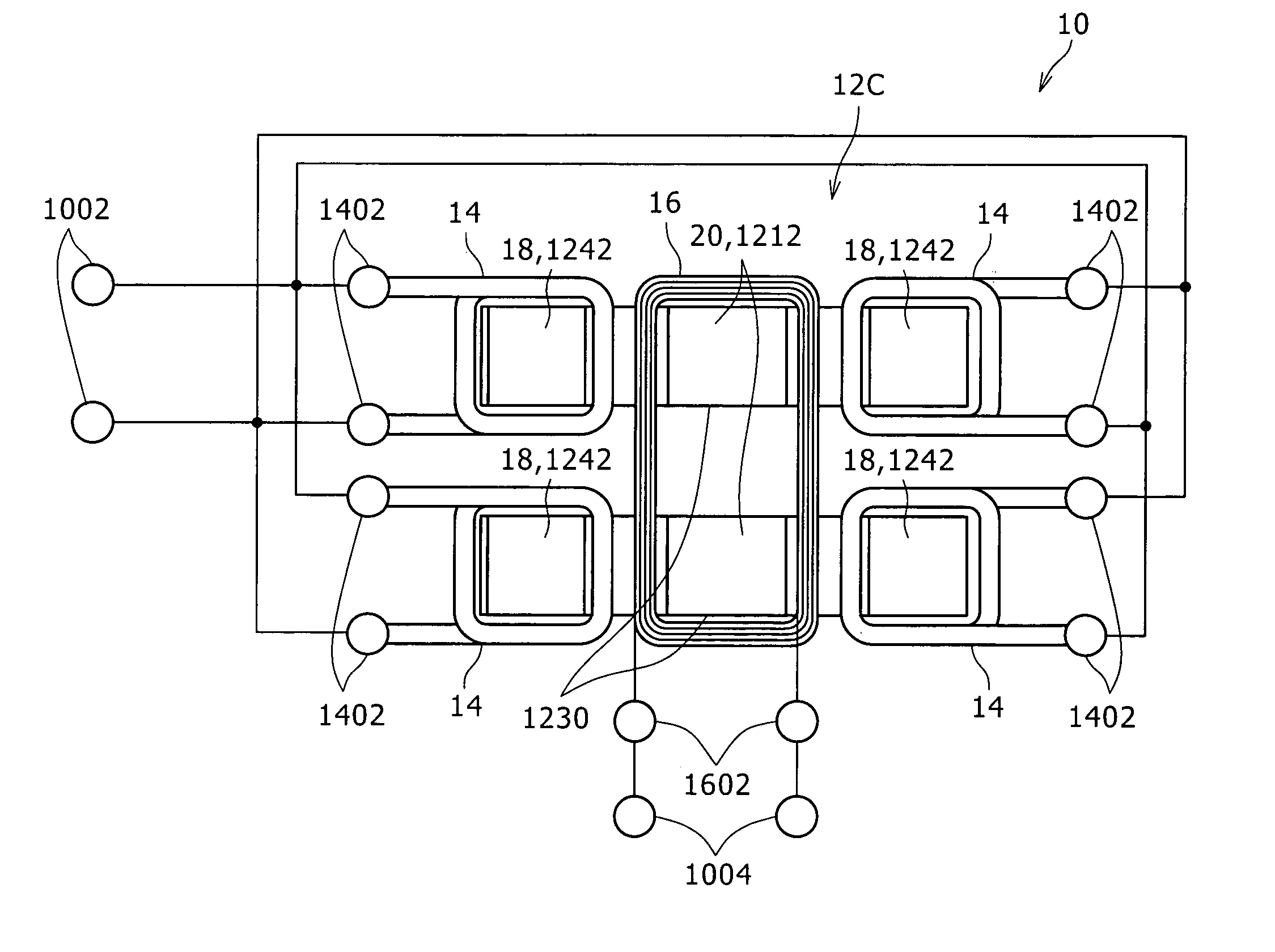

A coil component (100) comprises a coil-containing insulator enclosure and a magnetic core (80). The coil-containing insulator enclosure can be obtained by enclosing a coil (30), except for end portions (12, 22) of the coil (30), with an insulator (50), wherein the insulator (50) comprises at least first resin. The magnetic core (80) is made of a mixture of a second resin (82) and powder, which comprises at least magnetic powder (84). The coil-containing insulator enclosure is embedded in the magnetic core (80).

Owner:DENSO CORP 50 INTEREST +2

Transformer

InactiveUS7332992B2High voltageLow costTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresTransformerConductor Coil

Disclosed herein is a transformer including: an iron core; and a winding wound around the iron core; wherein the iron core includes a column-shaped output side iron core part, a plurality of column-shaped input side iron core parts, and a connecting iron core part, the winding includes a plurality of primary windings, a secondary winding, and generated magnetic fluxes.

Owner:SONY CORP

Magnetic components and methods of manufacturing the same

InactiveUS20100271161A1Small sizeExpensive manufacturing processTransformers/inductances casingsTransformers/inductances coils/windings/connectionsTransformerSurface mounting

Magnetic component assemblies including moldable magnetic materials formed into magnetic bodies, at least one conductive coil, and termination features are disclosed that are advantageously utilized in providing surface mount magnetic components such as inductors and transformers.

Owner:EATON INTELLIGENT POWER LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com