Patents

Literature

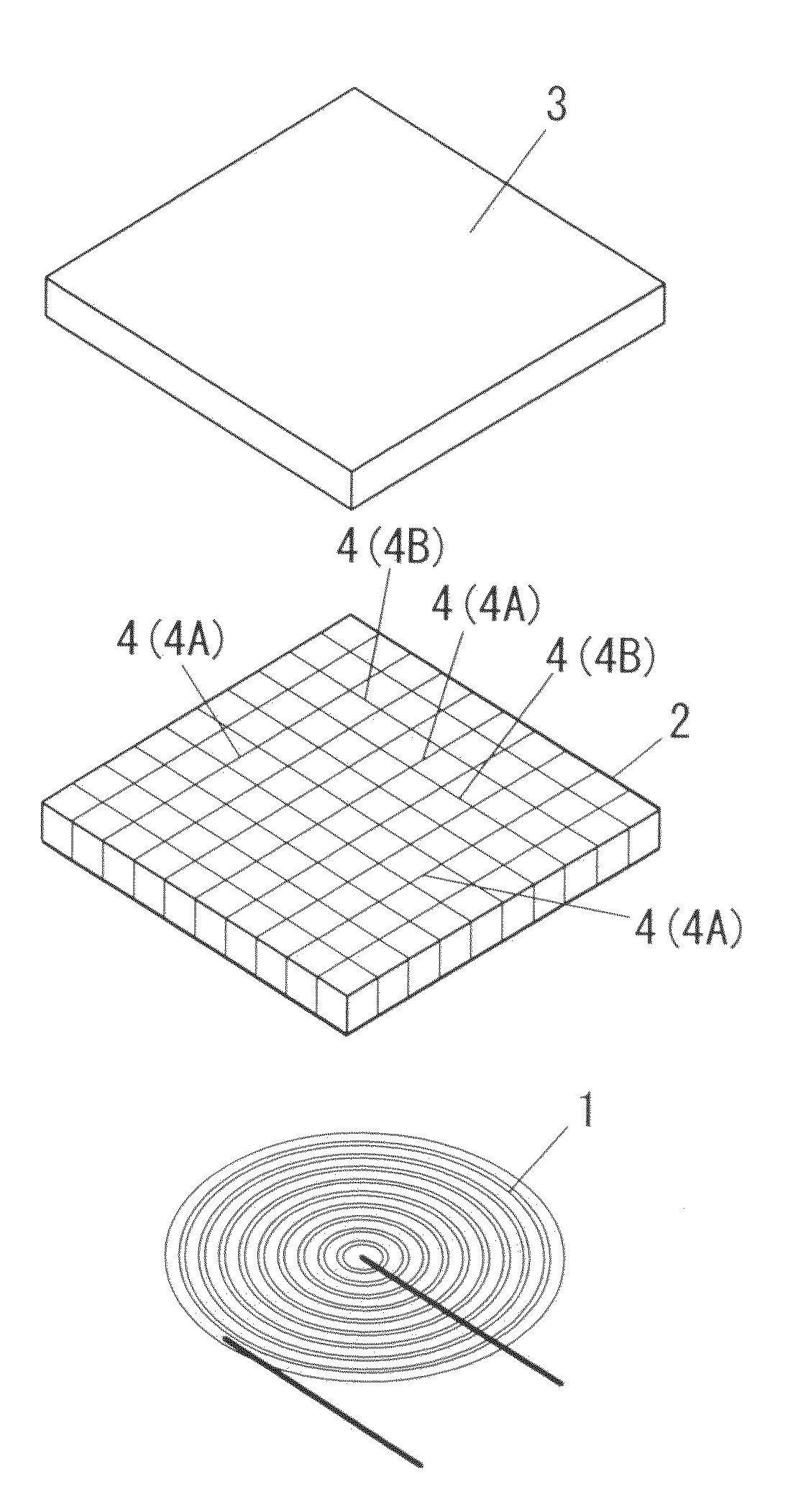

505 results about "Planar coil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

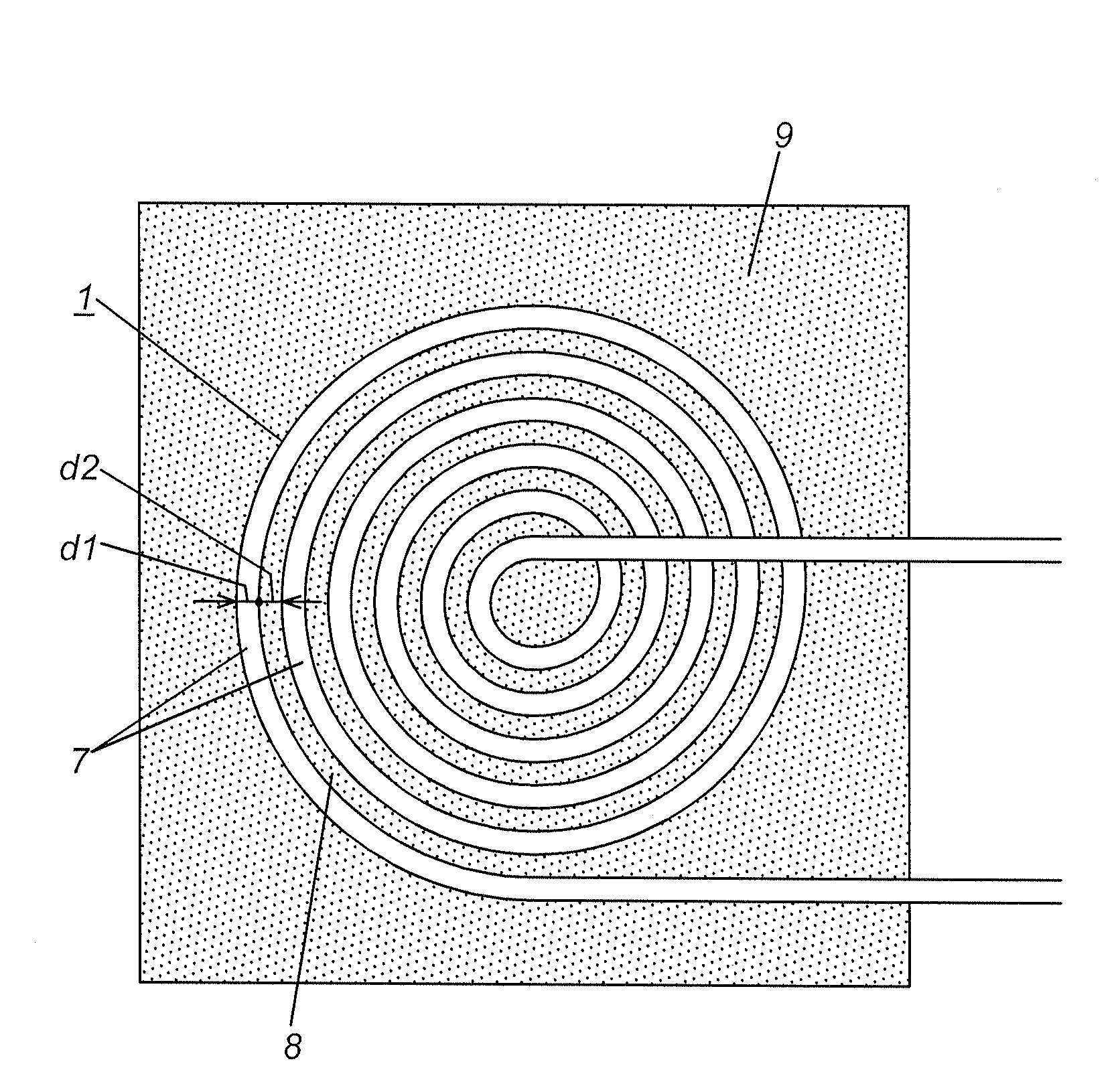

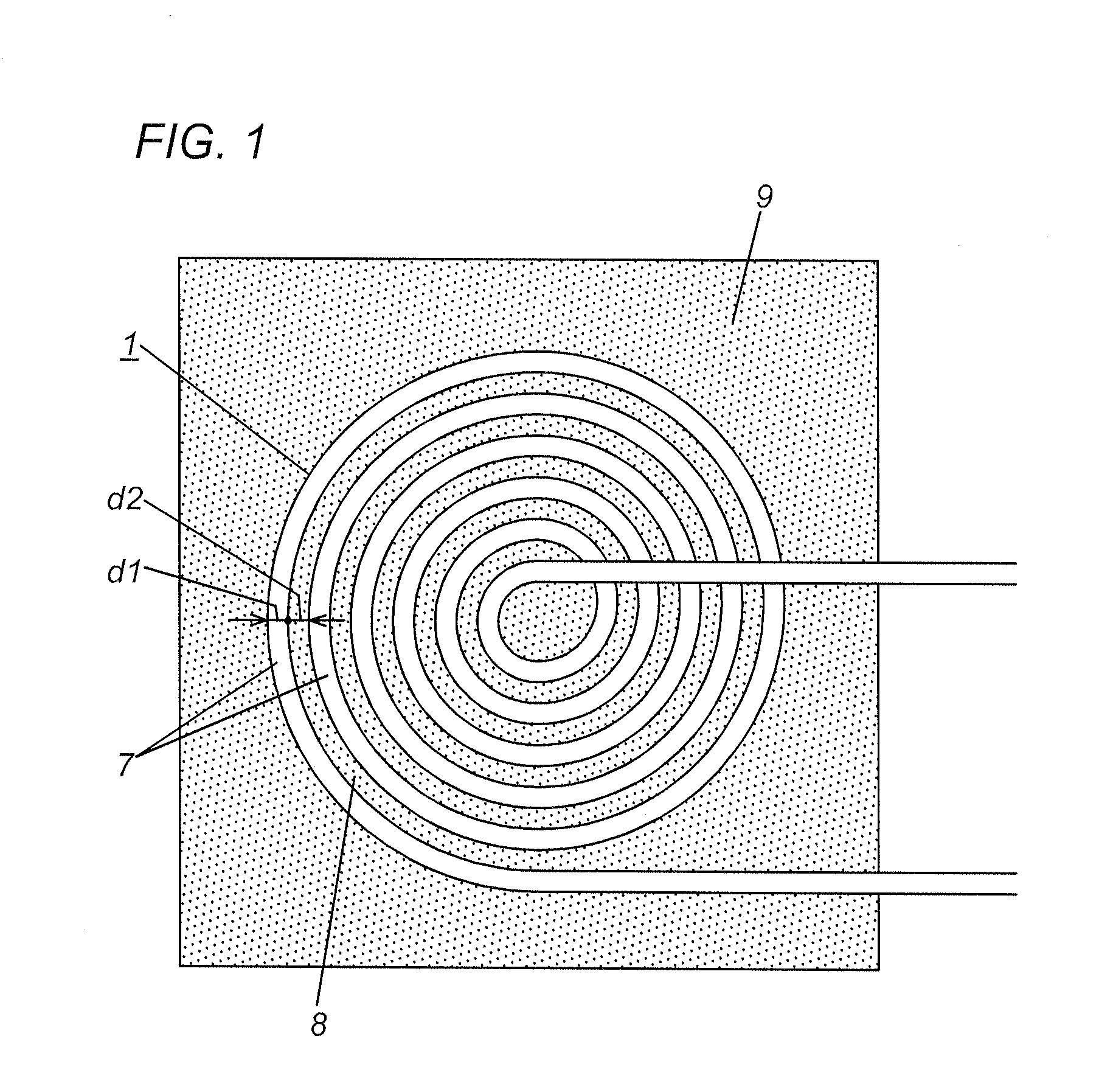

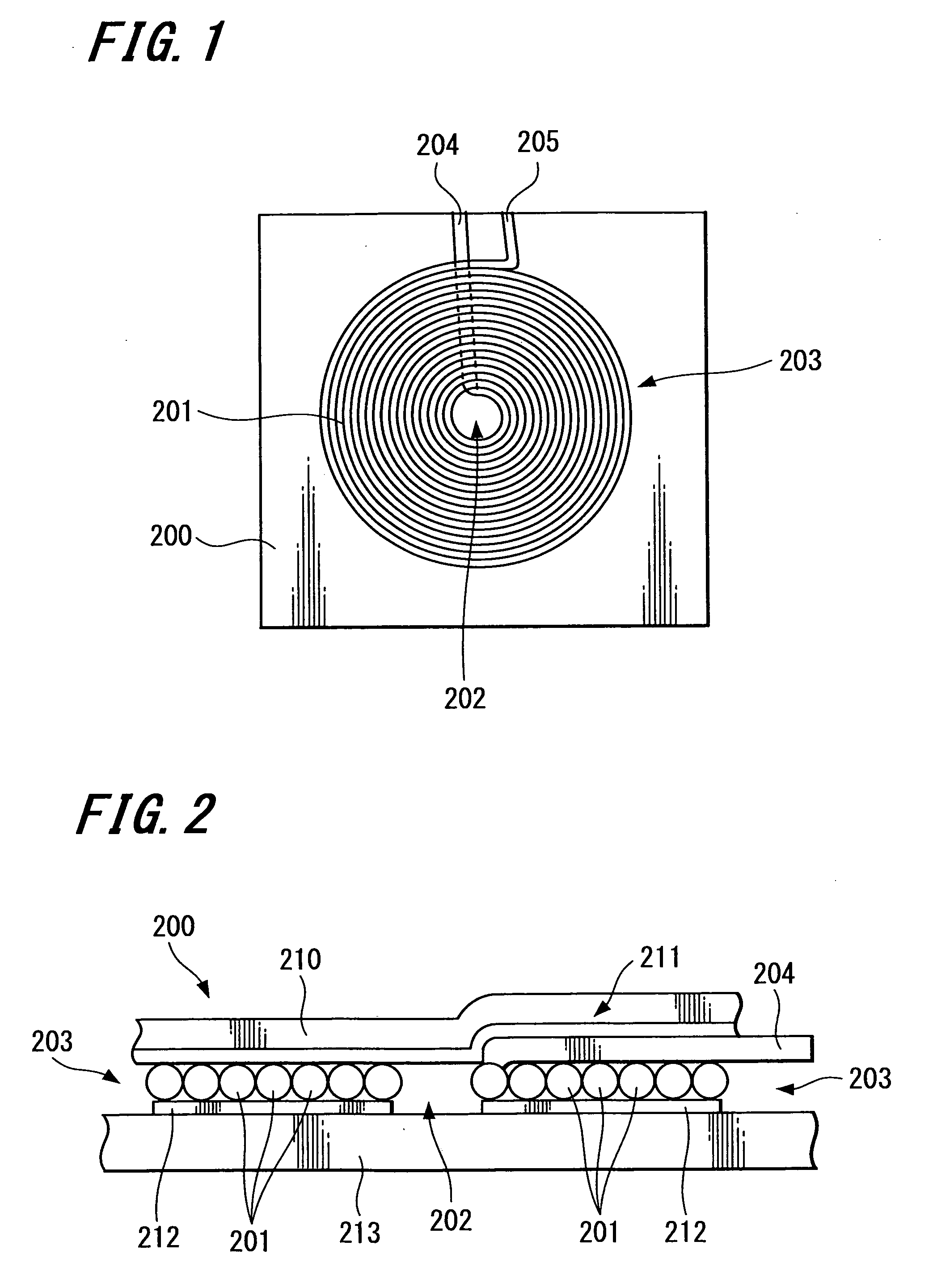

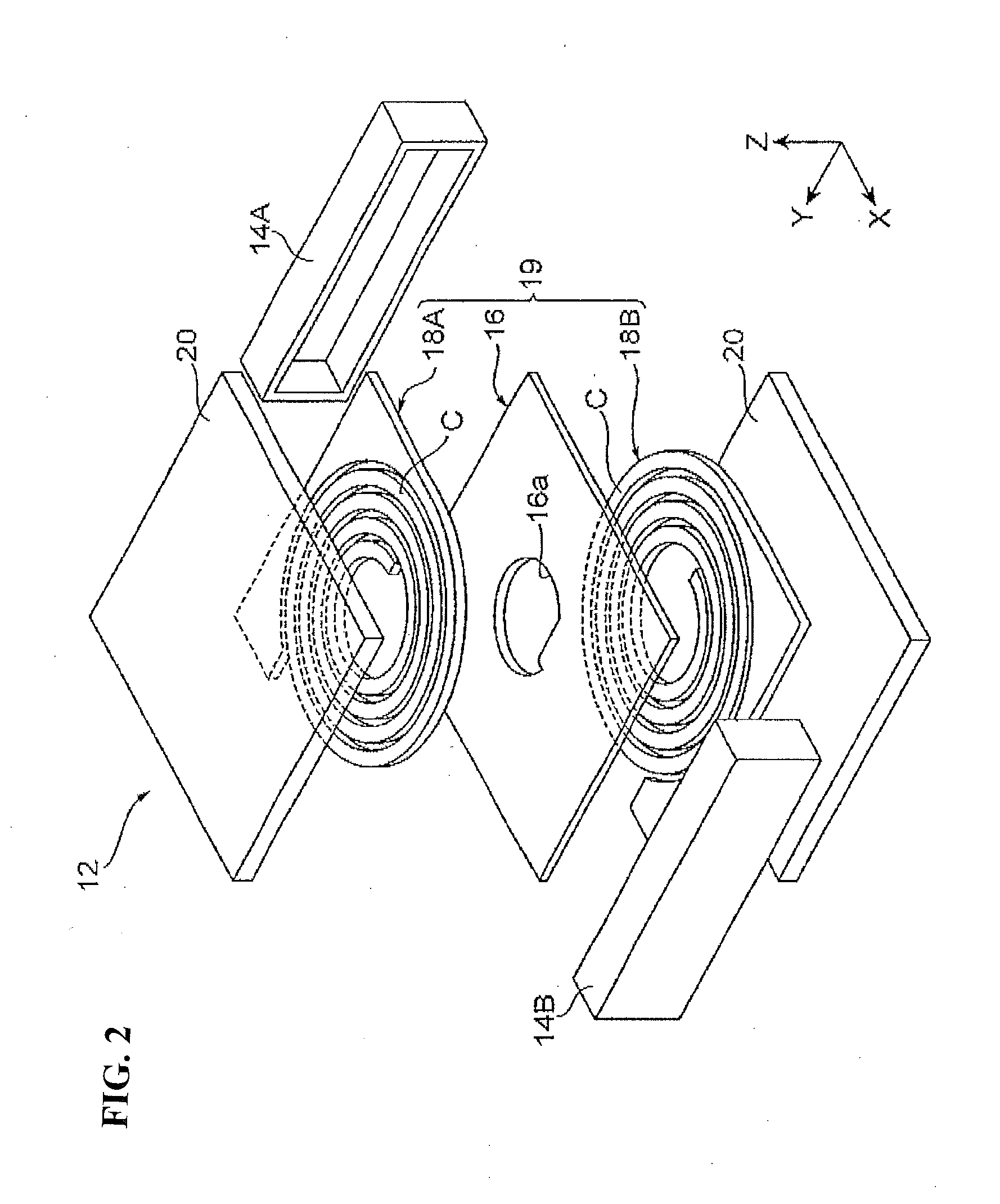

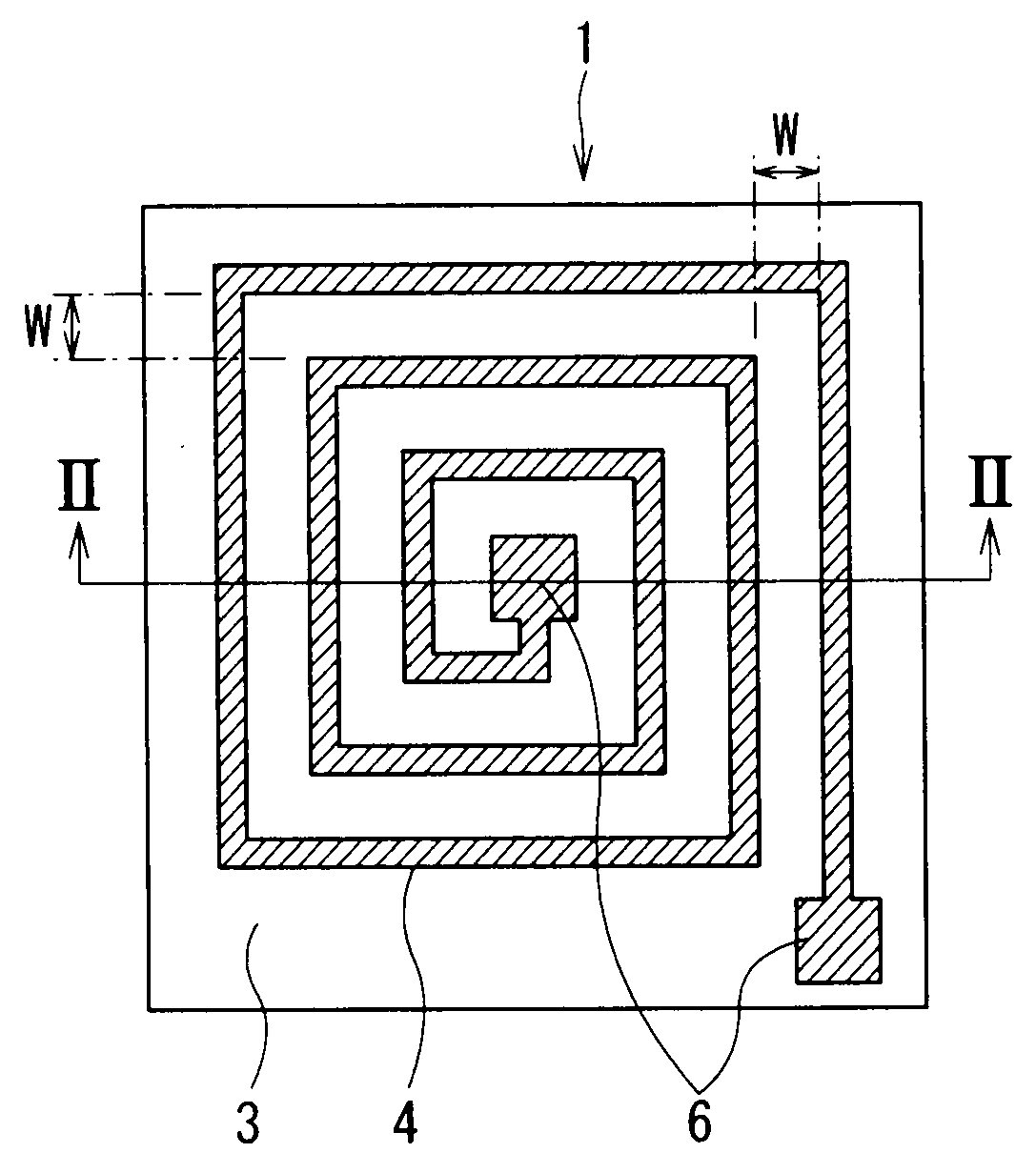

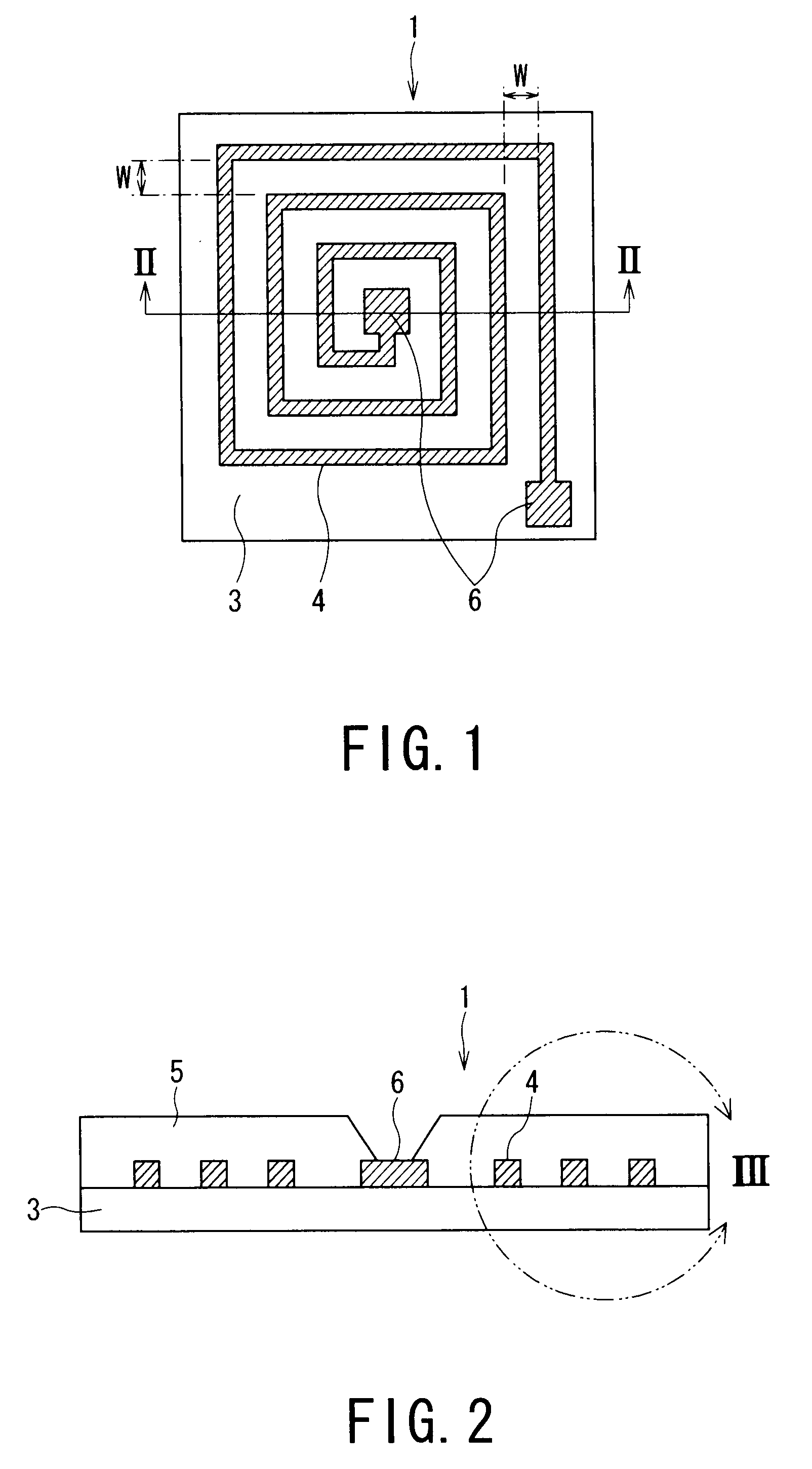

Planar coil and contactless electric power transmission device using the same

InactiveUS20100277004A1Avoid it happening againImprove productivityBatteries circuit arrangementsElectromagnetic wave systemElectric power transmissionEddy current

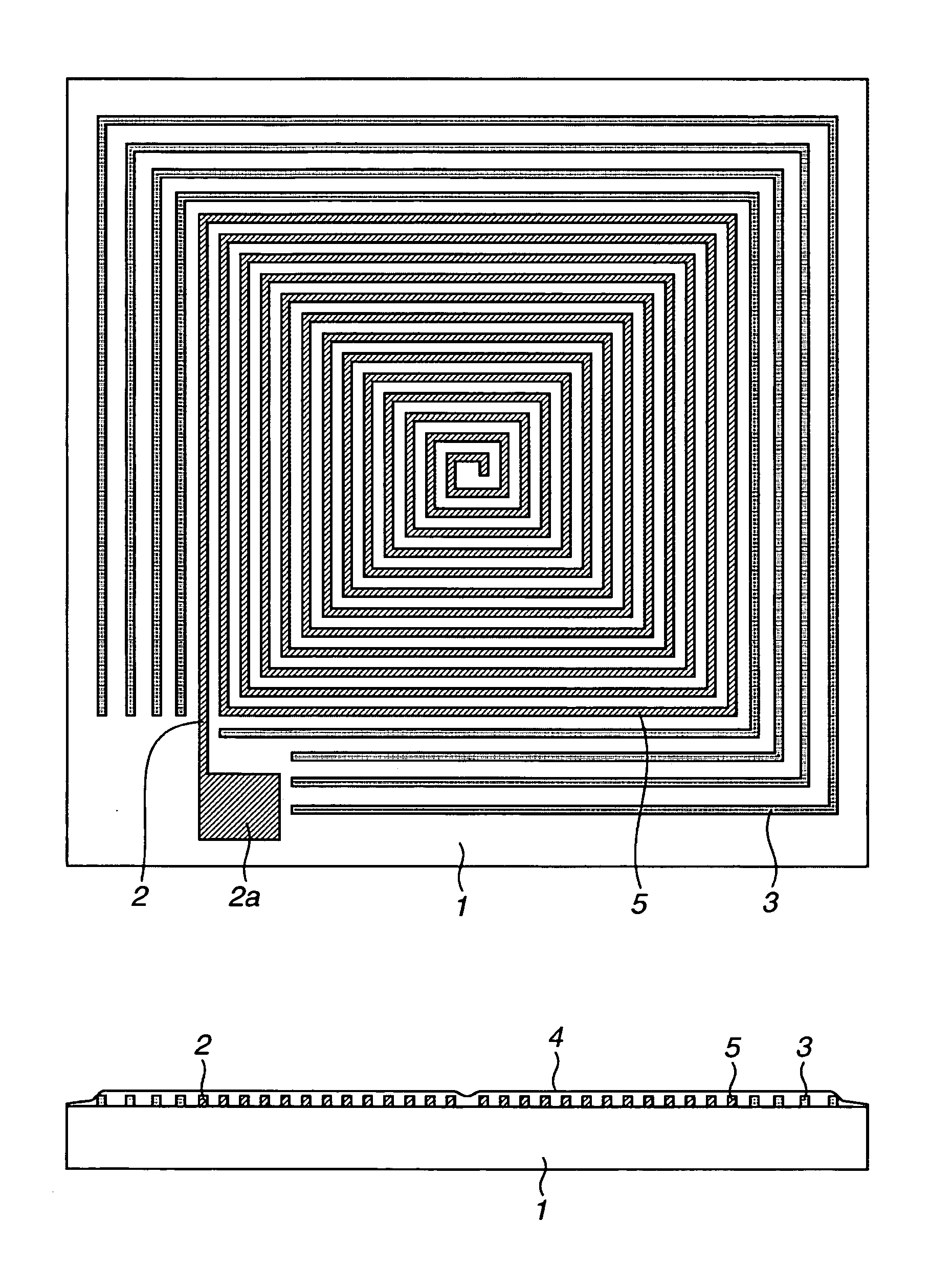

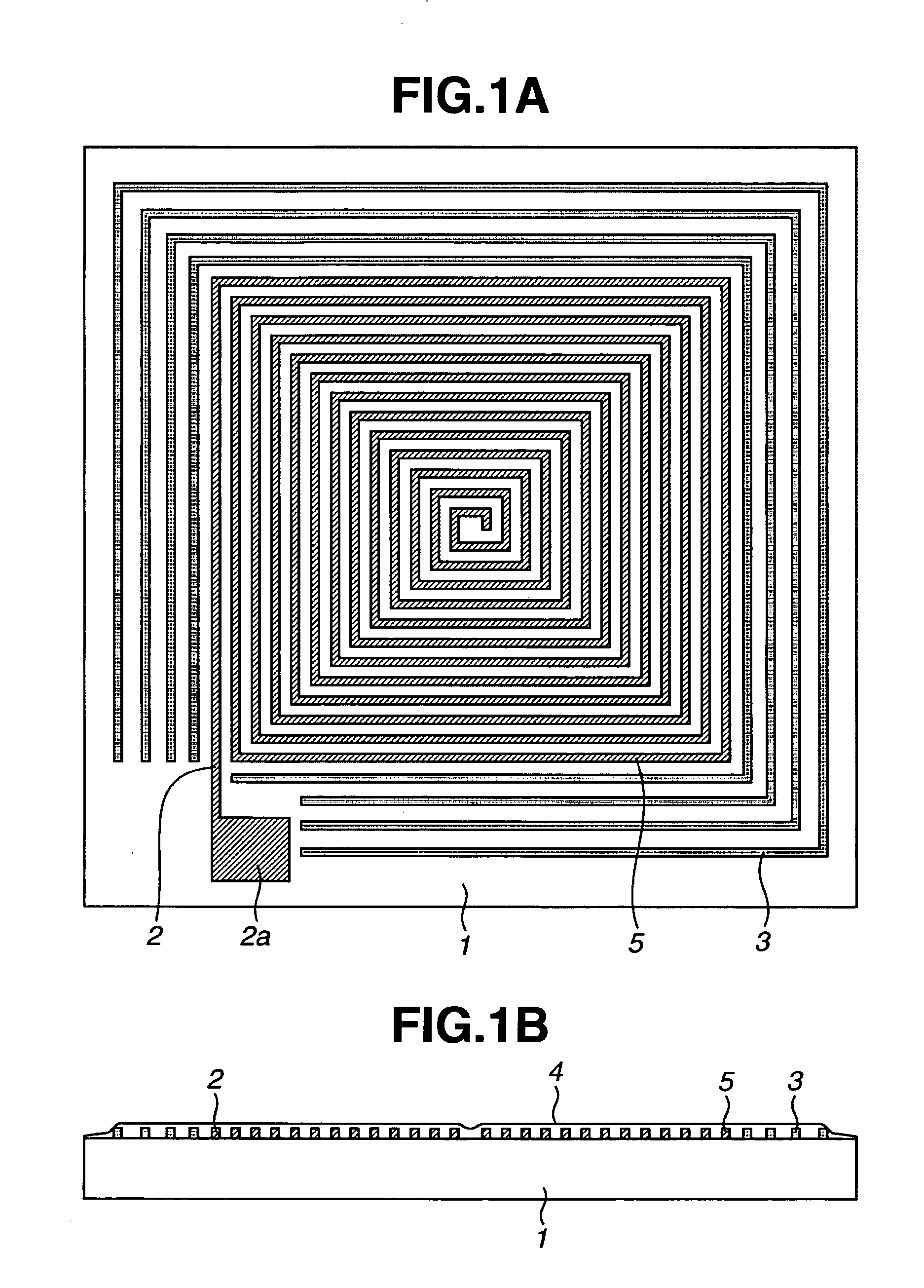

This invention has an object to a planar coil, a contactless electric power transmission device using the same. This planar coil is configured to suppress an eddy current developed between adjacent turns of wire for minimizing adverse effects on ambient electrical appliances resulting from heat generation. The planar coil 1 in the present invention is formed of spiral shaped wire 7 coated with thinned insulative film, in which adjacent turns of the wire 7 are spaced in radial direction at such a predetermined interval to suppress an eddy current. This planar coil 1 is preferably employed as a power transmission coil or power receiving coil.

Owner:PANASONIC CORP

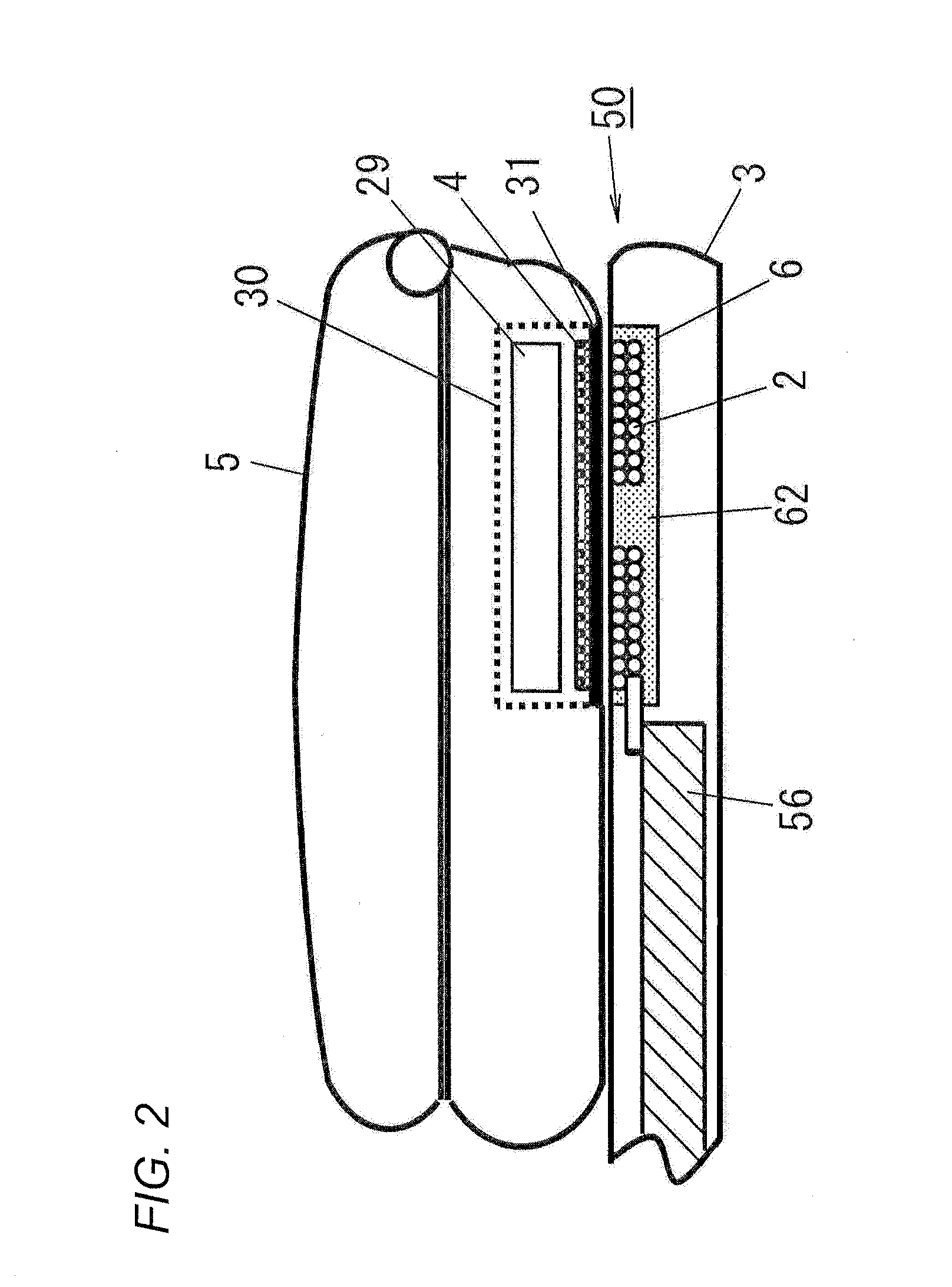

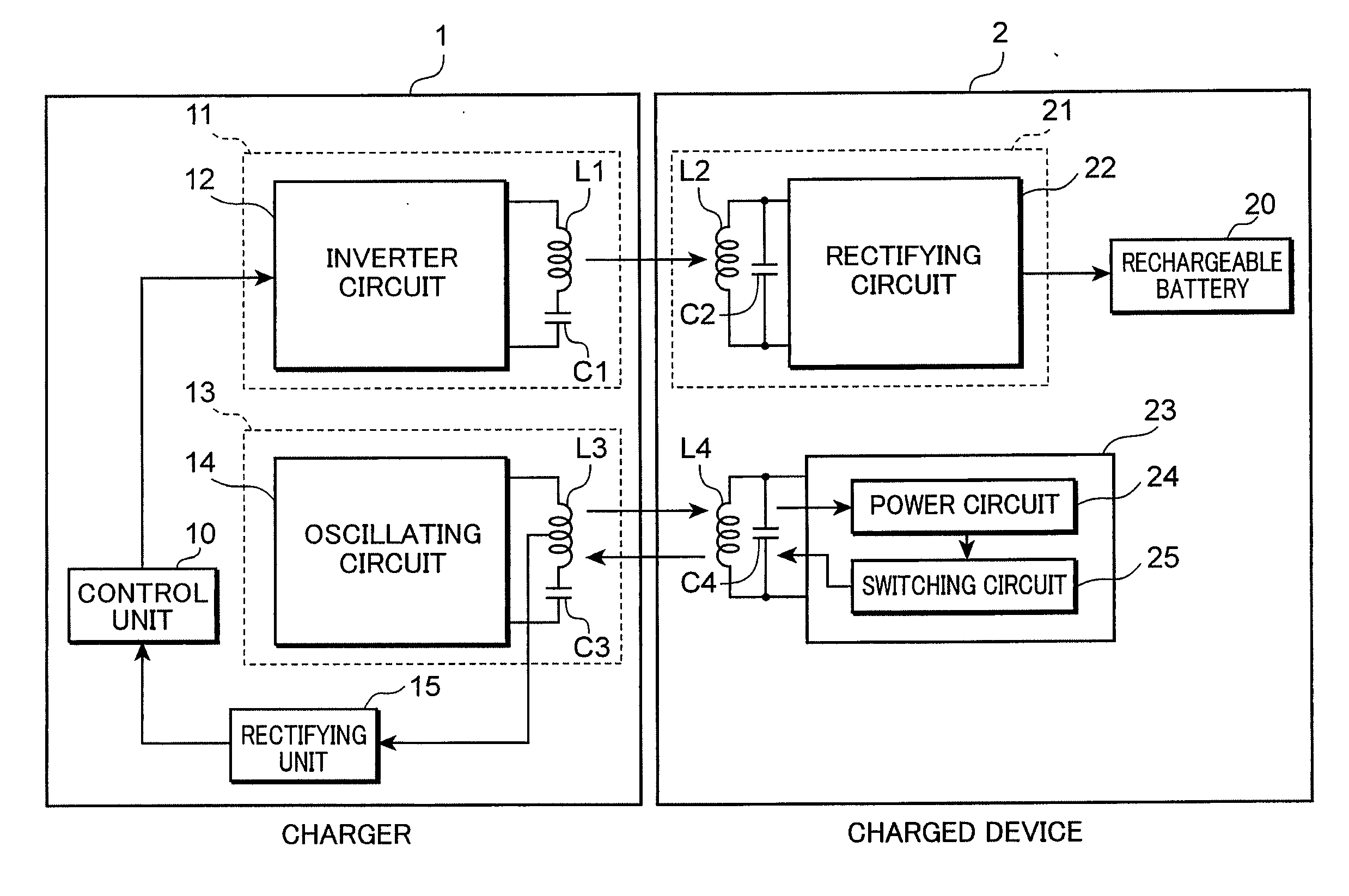

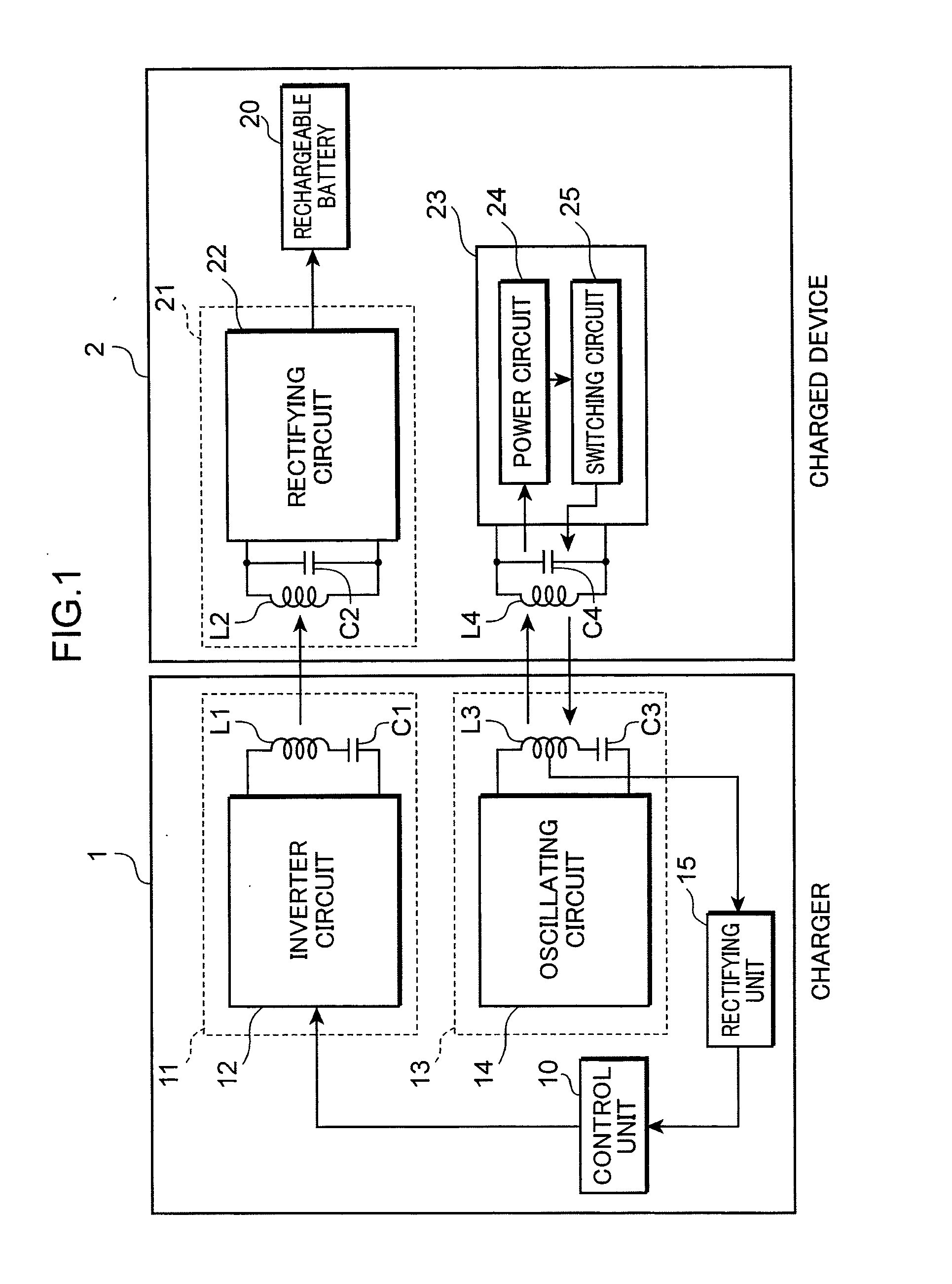

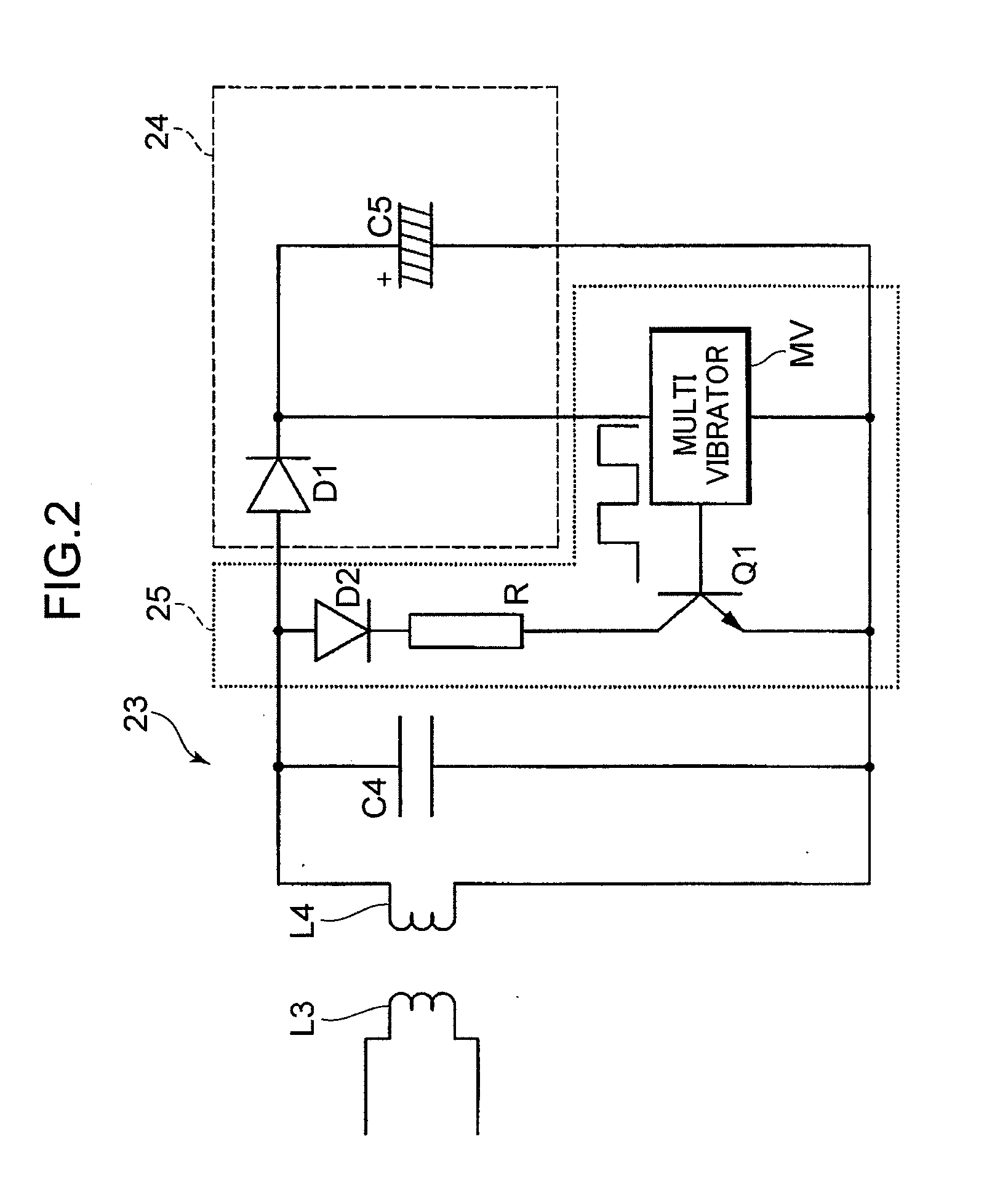

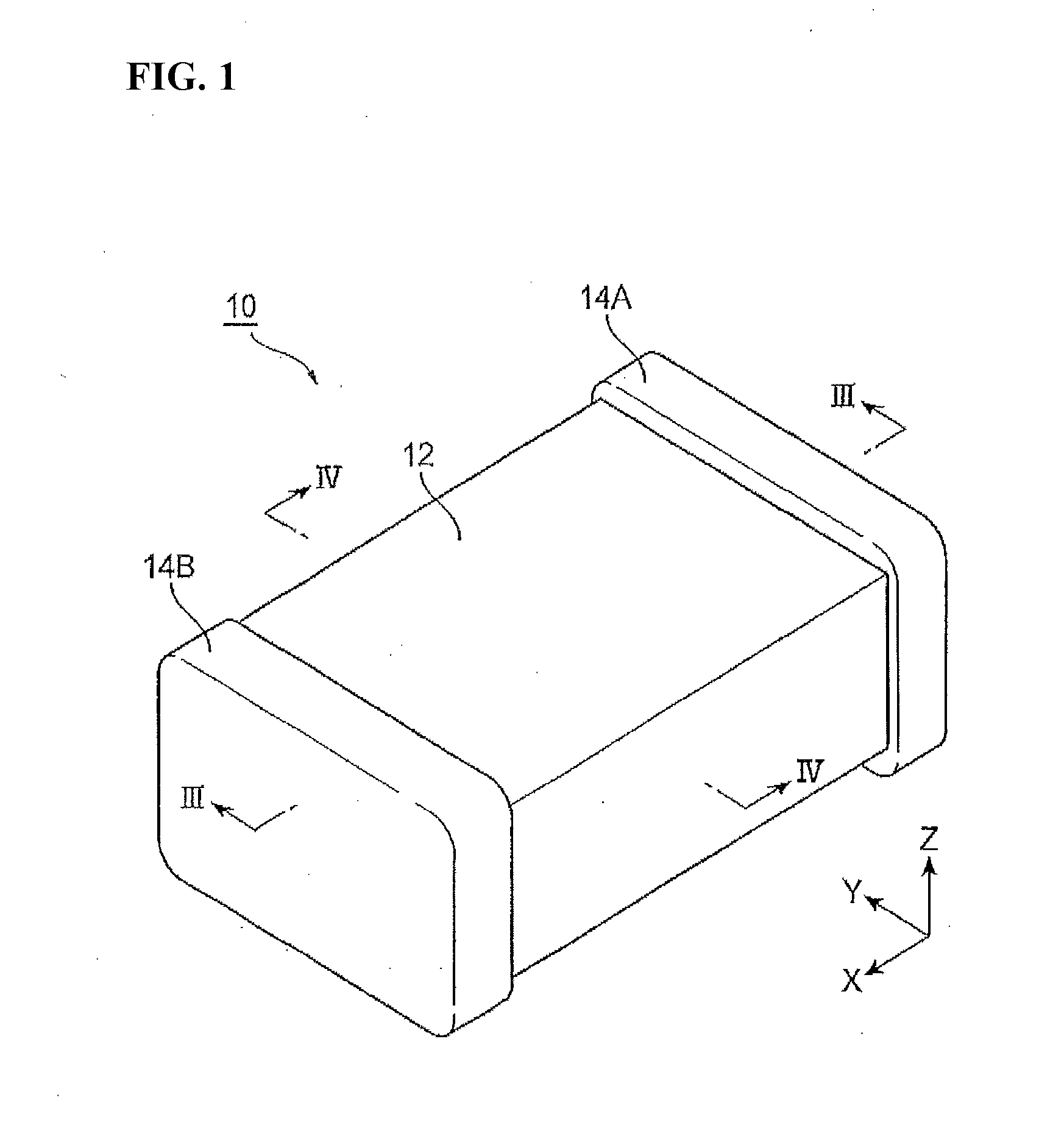

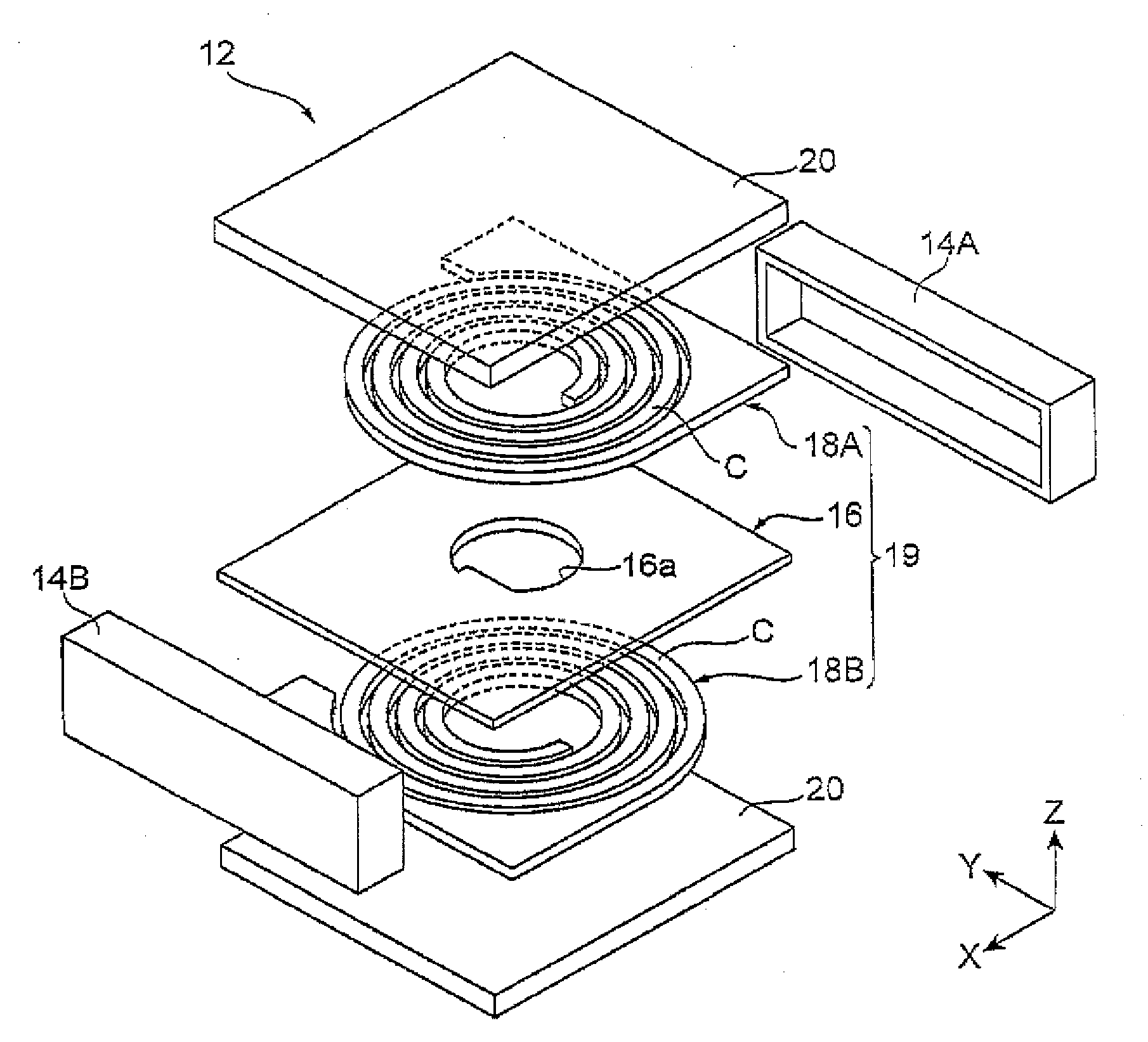

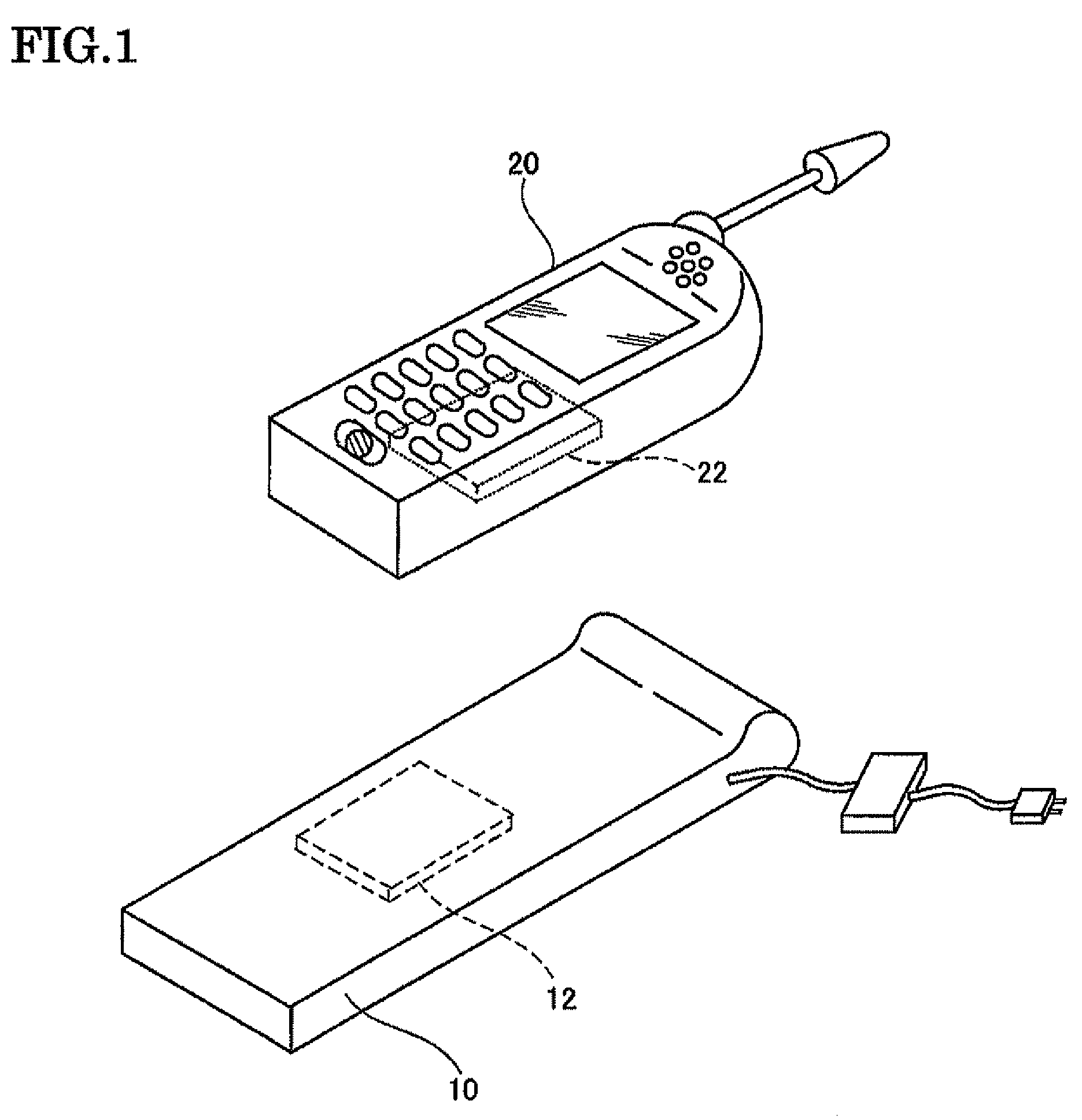

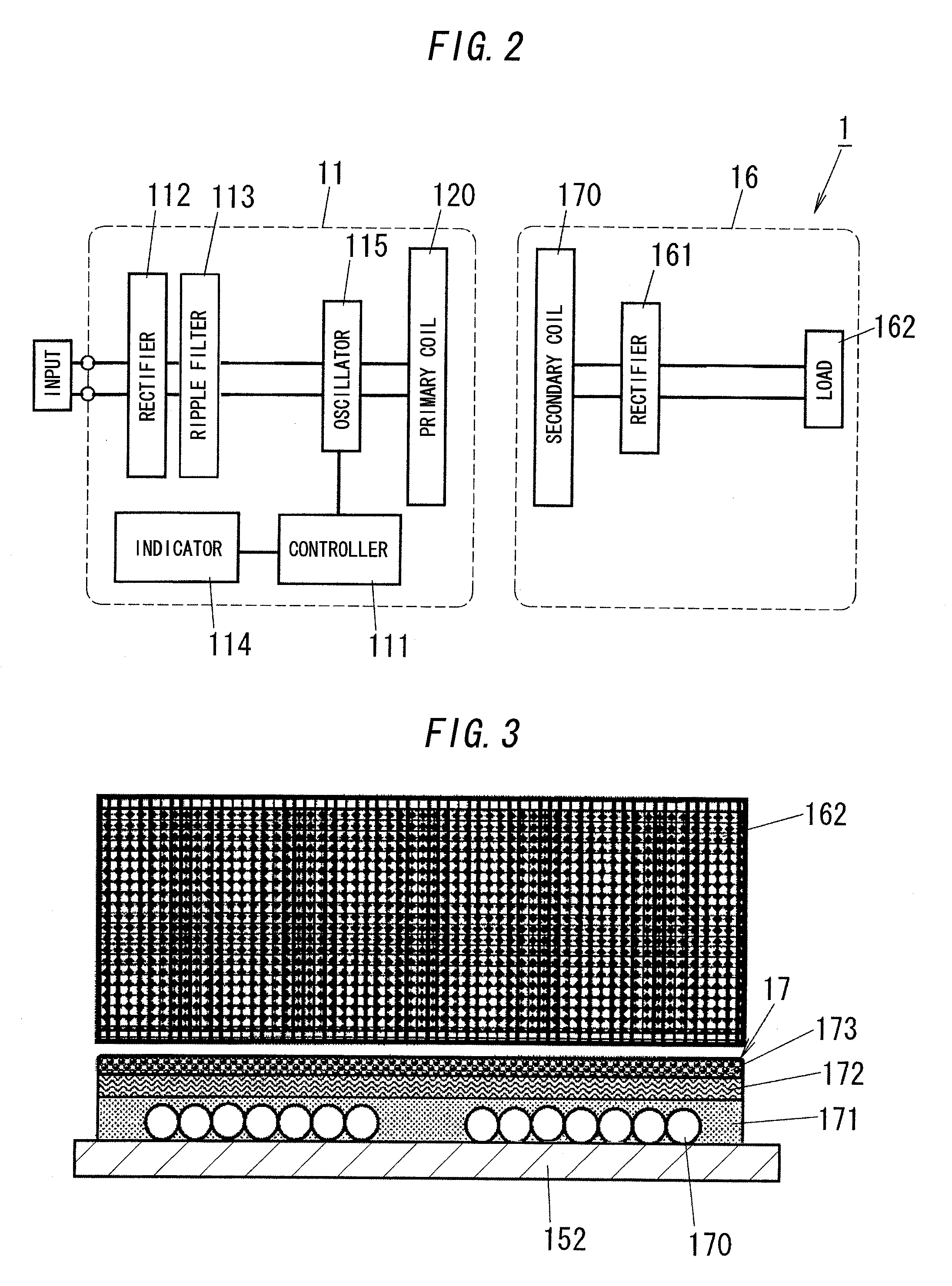

Noncontact charger system

InactiveUS20120146580A1Low costCircuit authenticationTransformersElectric power transmissionEngineering

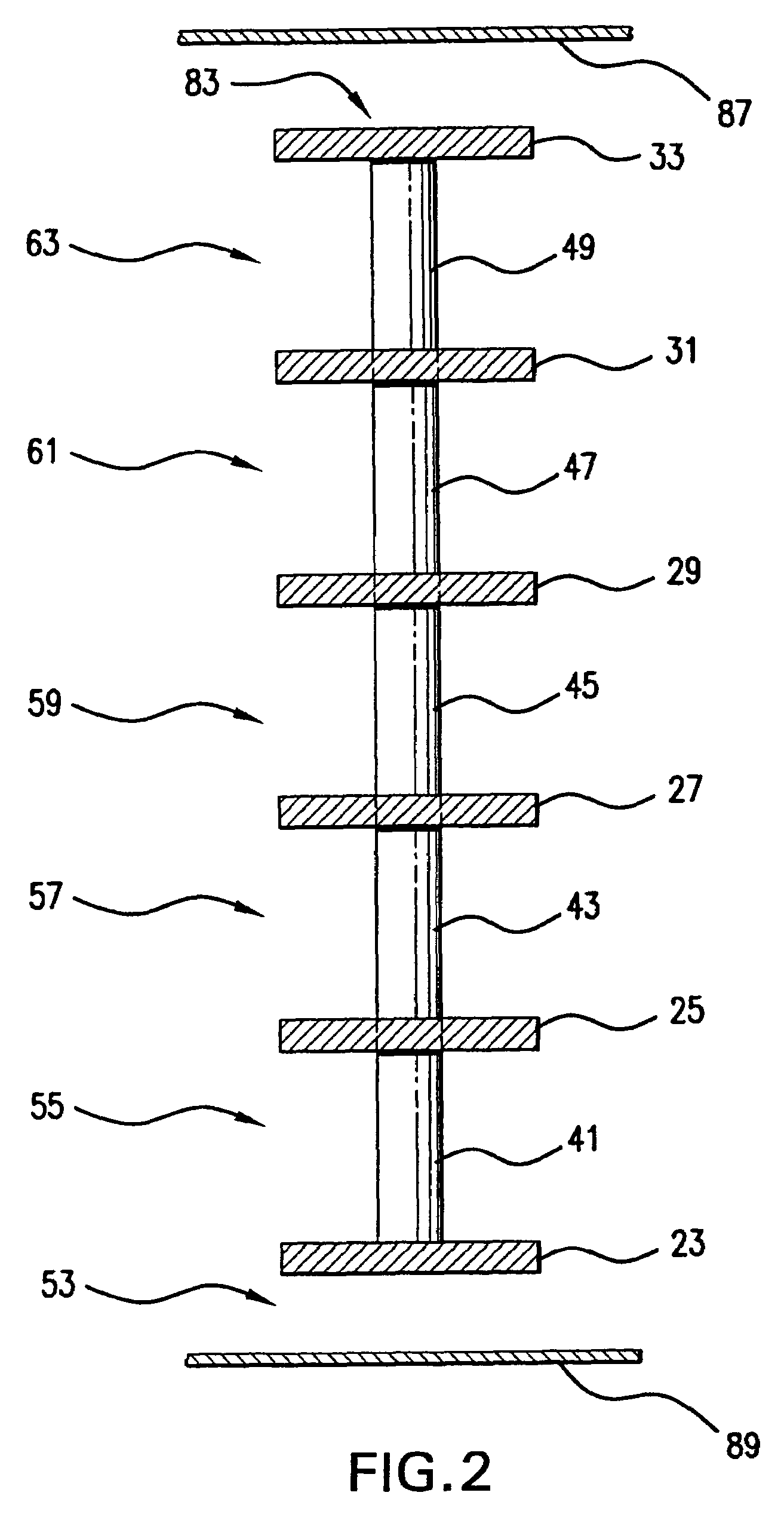

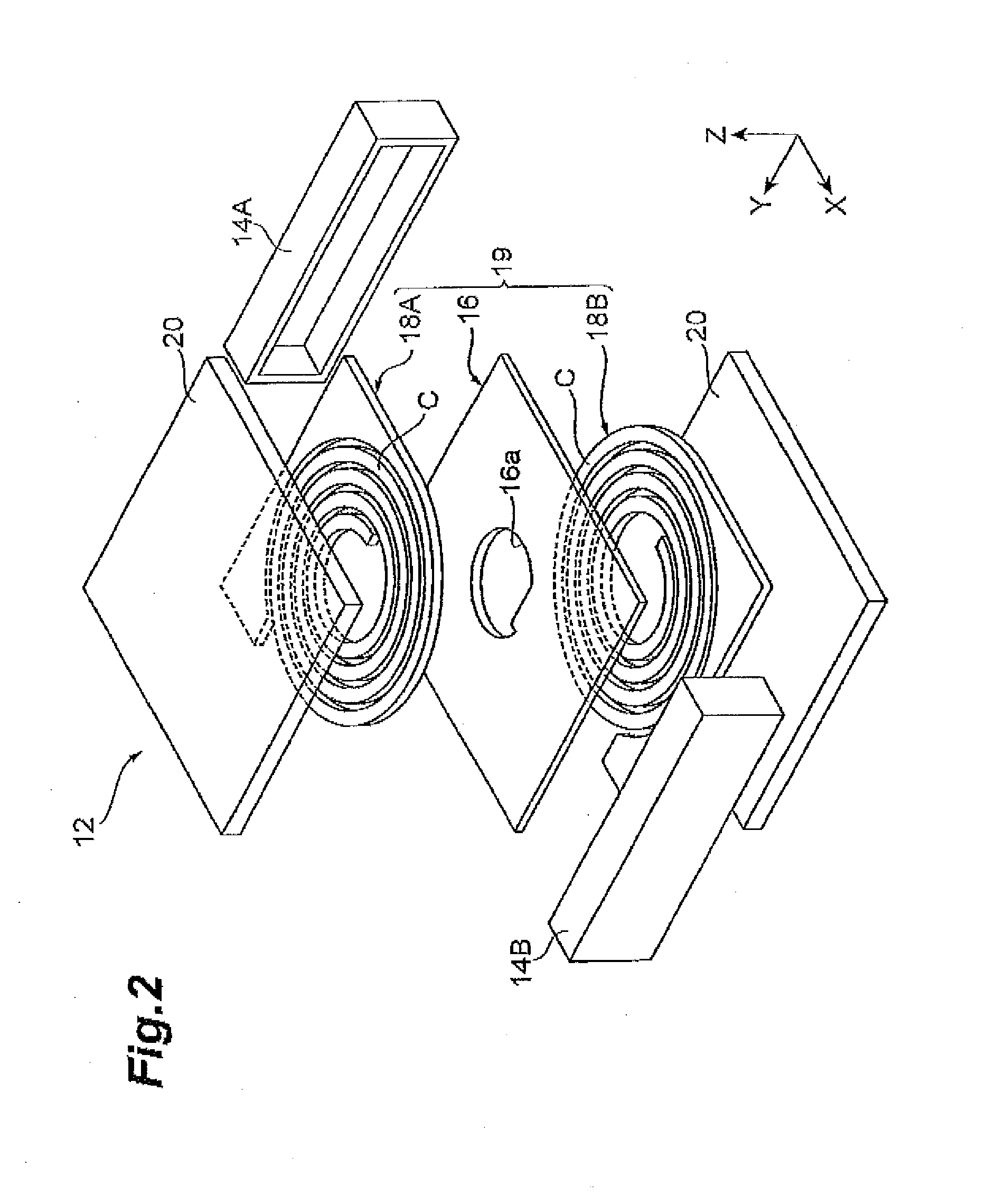

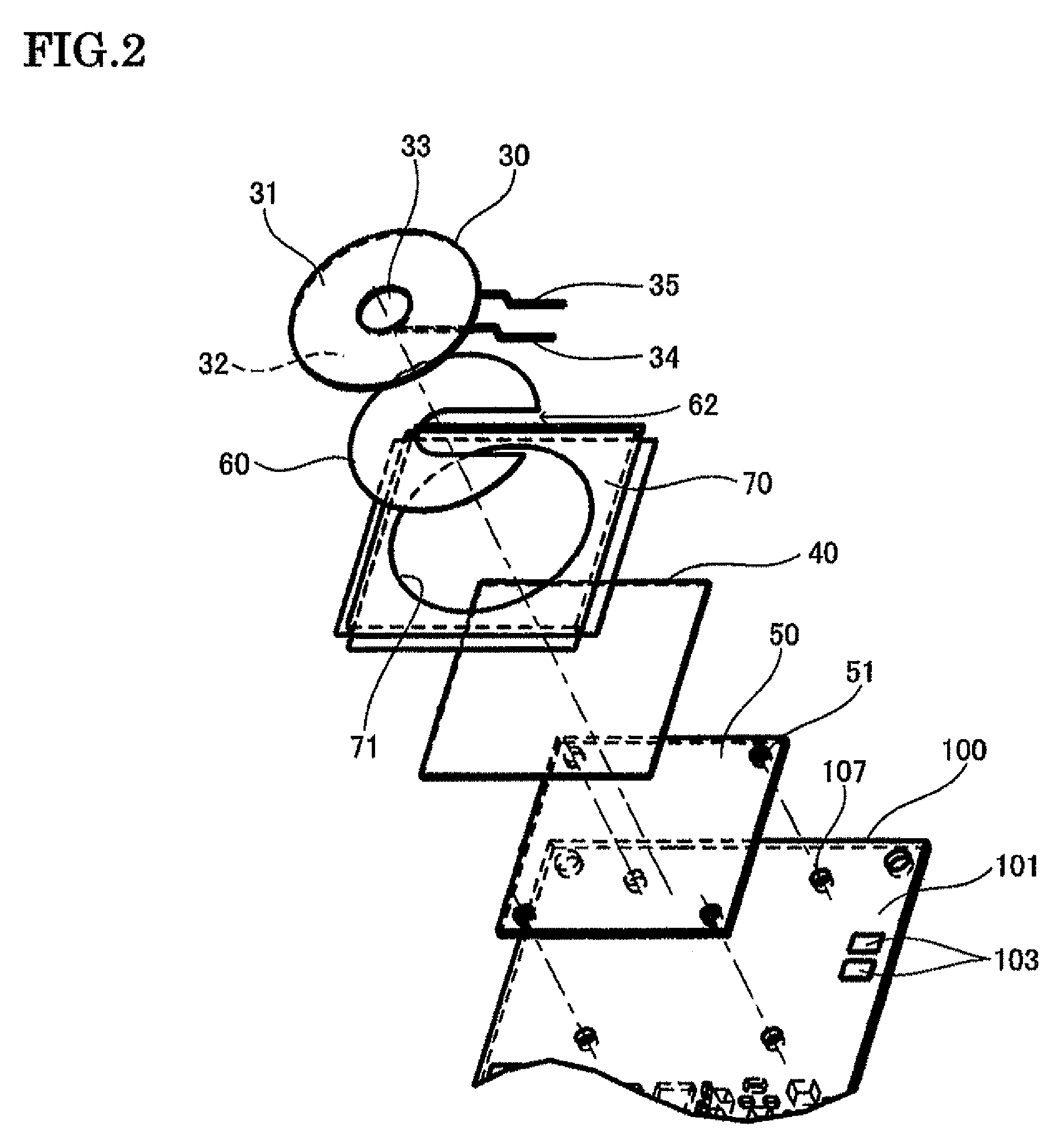

A noncontact charger includes a charger having a power transmitting planar coil that transmits high-frequency charging power and a charged device including a power receiving planar coil magnetically coupled to the power transmitting planar coil to receive the charging power, wherein the charger includes a primary authentication planar coil which transmits high-frequency authenticating power for authenticating the charged device and receives a high-frequency authenticating signal for authenticating the charged device, a secondary authentication planar coil is magnetically coupled to the primary authentication planar coil to receive the authenticating power and output the authenticating signal generated from the authenticating power to the primary authentication planar coil, and a space between the power transmitting planar coil and the power receiving planar coil overlaps with a space between the primary authentication planar coil and the secondary authentication planar coil.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Noncontact power-transmission coil, portable terminal and terminal charging device, planar coil magnetic layer formation device, and magnetic layer formation method

ActiveUS20080164844A1Efficiently formedImprove efficiencyCircuit authenticationTransformers/inductances coils/windings/connectionsElectric power transmissionElectrical conductor

Owner:SONY MOBILE COMM INC +1

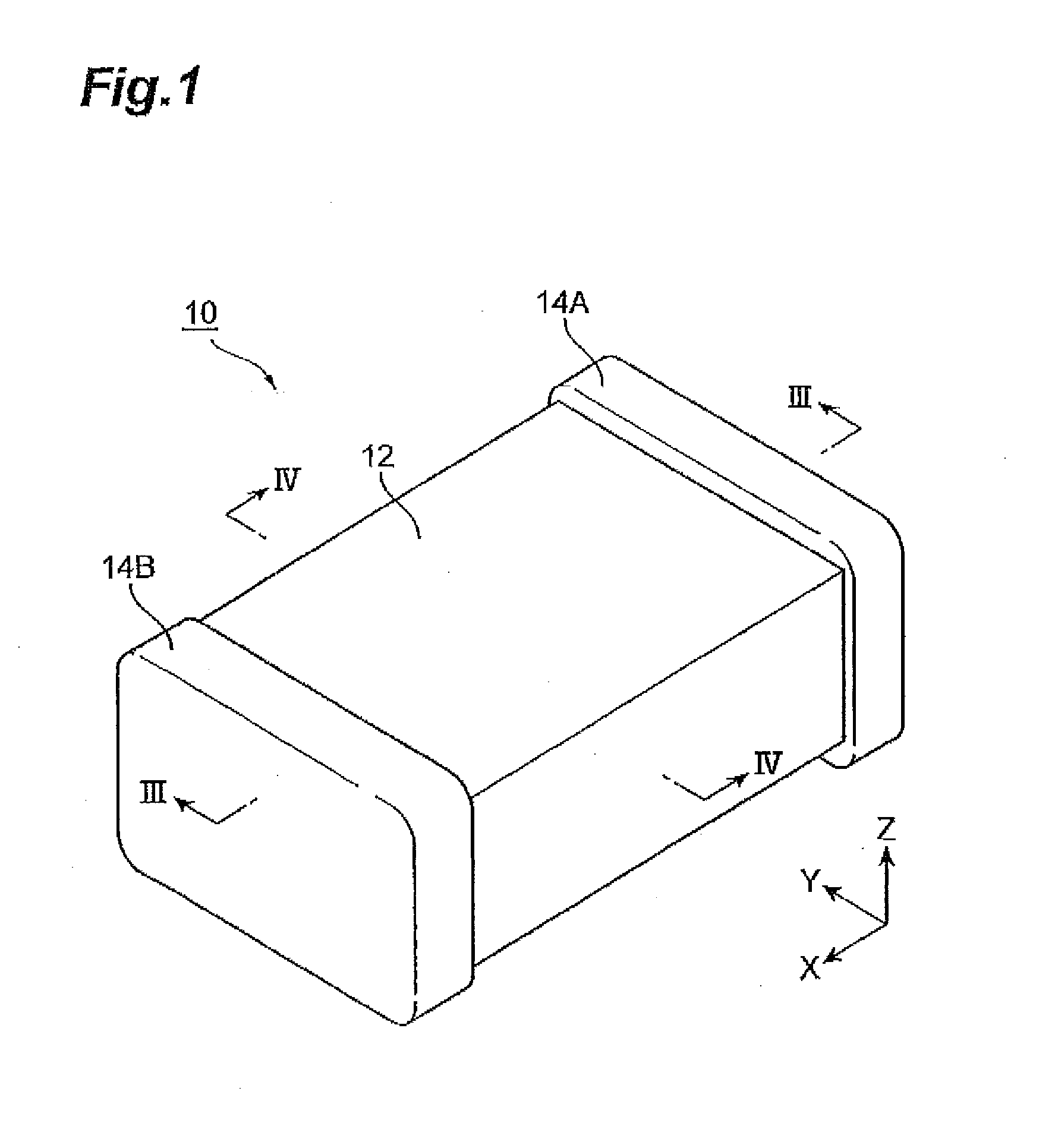

Planar coil element and method for producing the same

ActiveUS20130249664A1Easy to produceLow viscosityInorganic material magnetismTransformers/inductances detailsViscositySpherical form

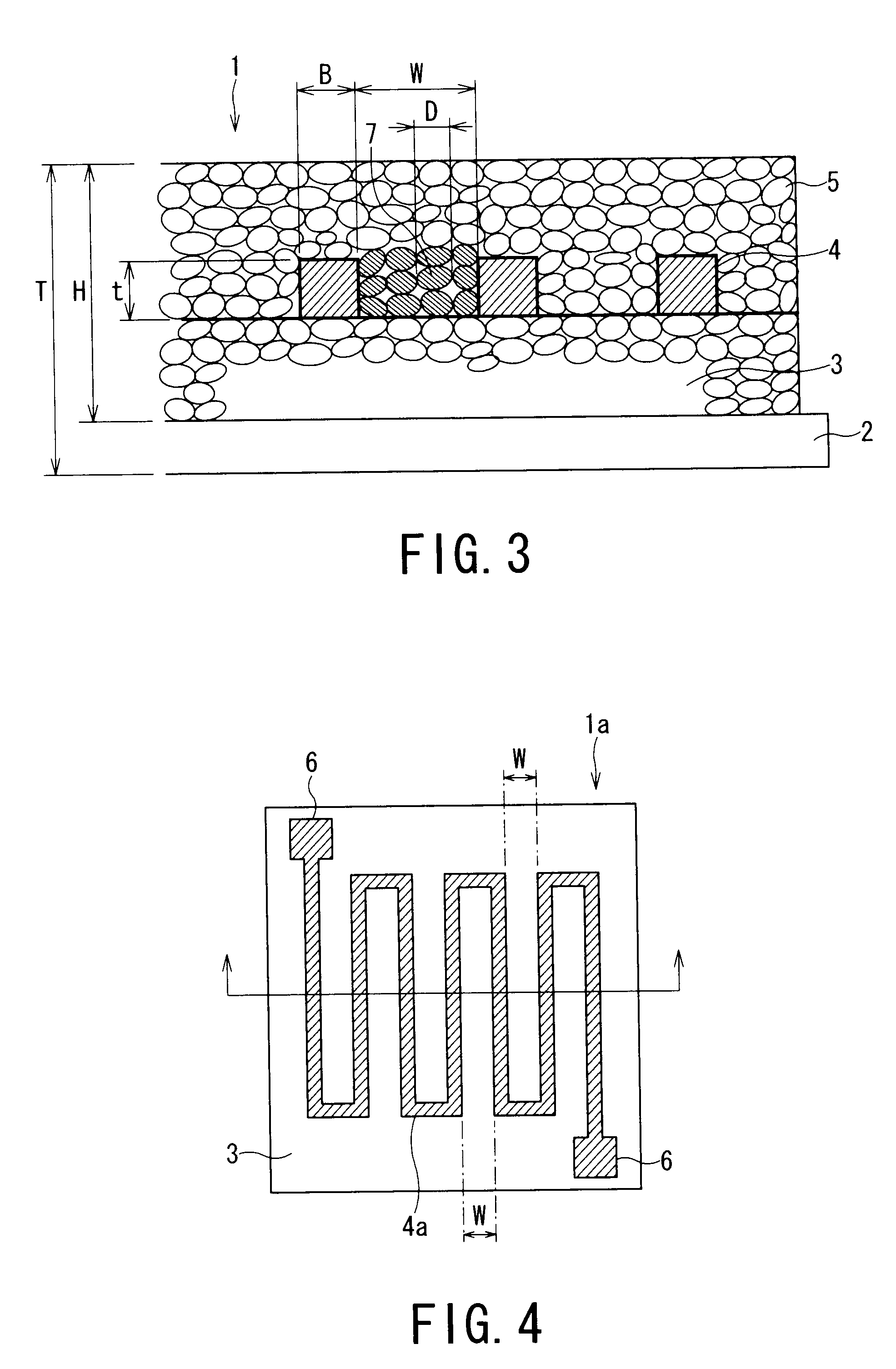

In a planar coil element and a method for producing the same, a metal magnetic powder-containing resin containing an oblate or needle-like first metal magnetic powder contains a second metal magnetic powder having an average particle size (1 μm) smaller than that (32 μm) of the first metal magnetic powder, which significantly reduces the viscosity of the metal magnetic powder-containing resin. Therefore, the metal magnetic powder-containing resin is easy to handle when applied to enclose a coil unit, which makes it easy to produce the planar coil element.

Owner:TDK CORPARATION

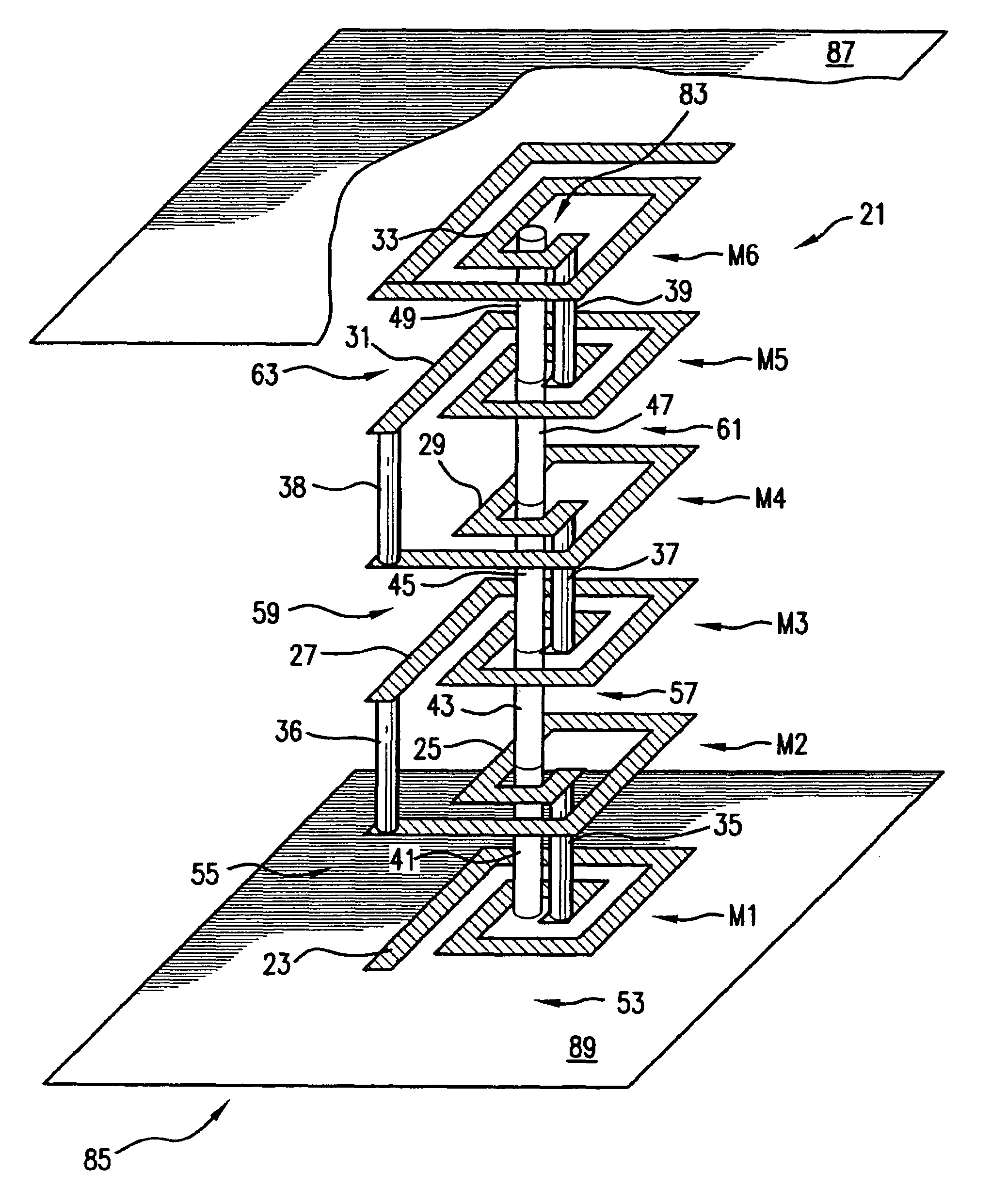

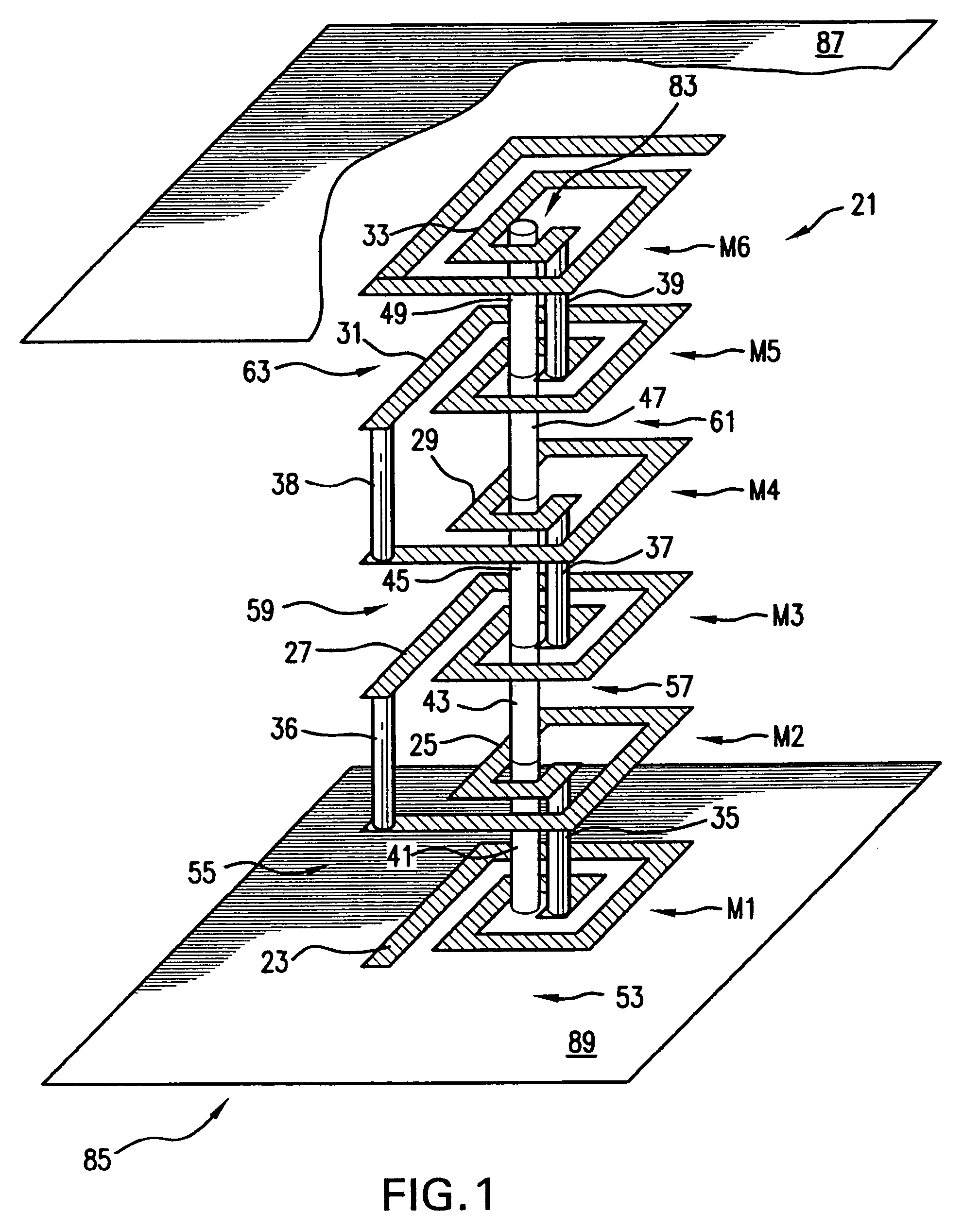

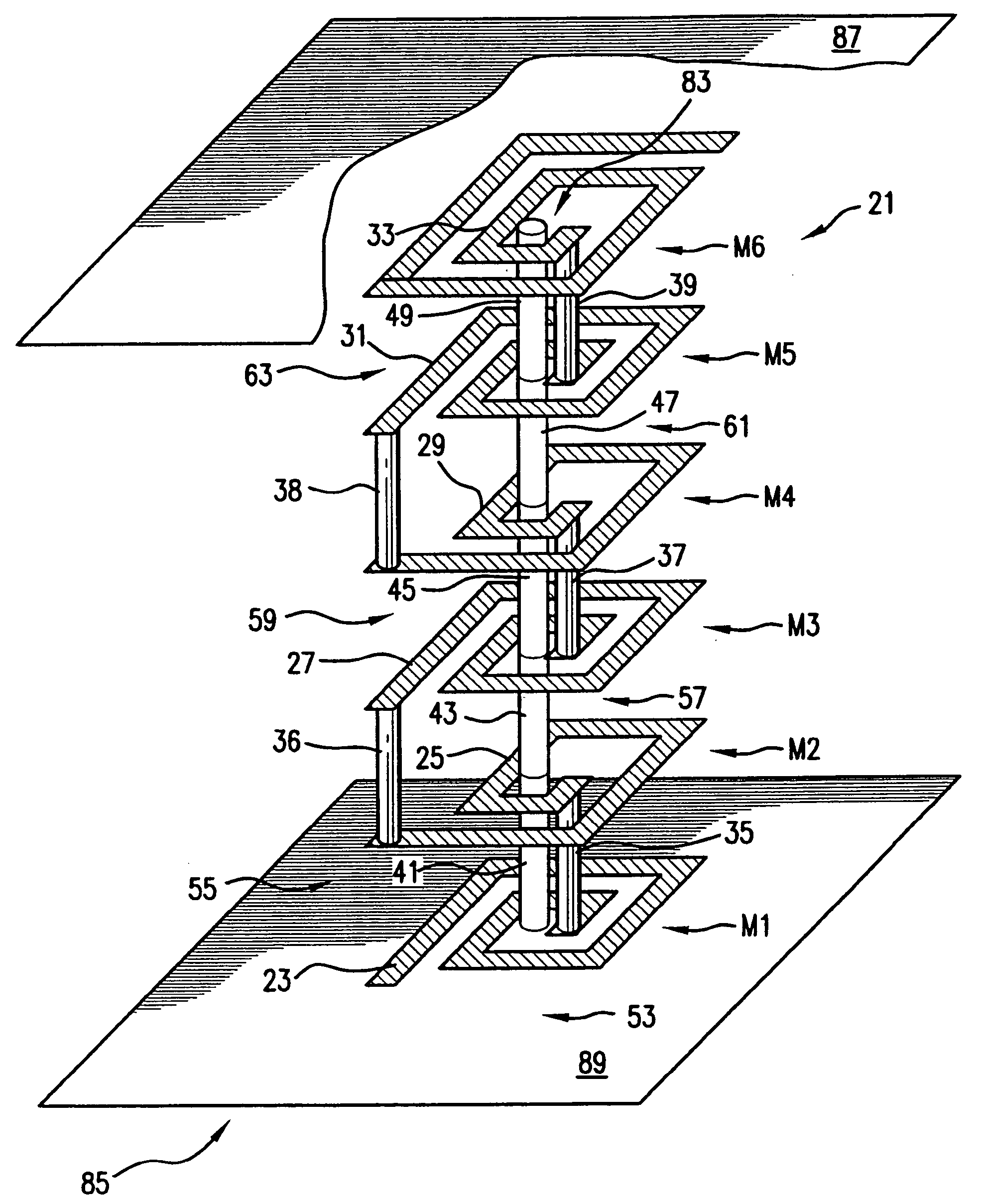

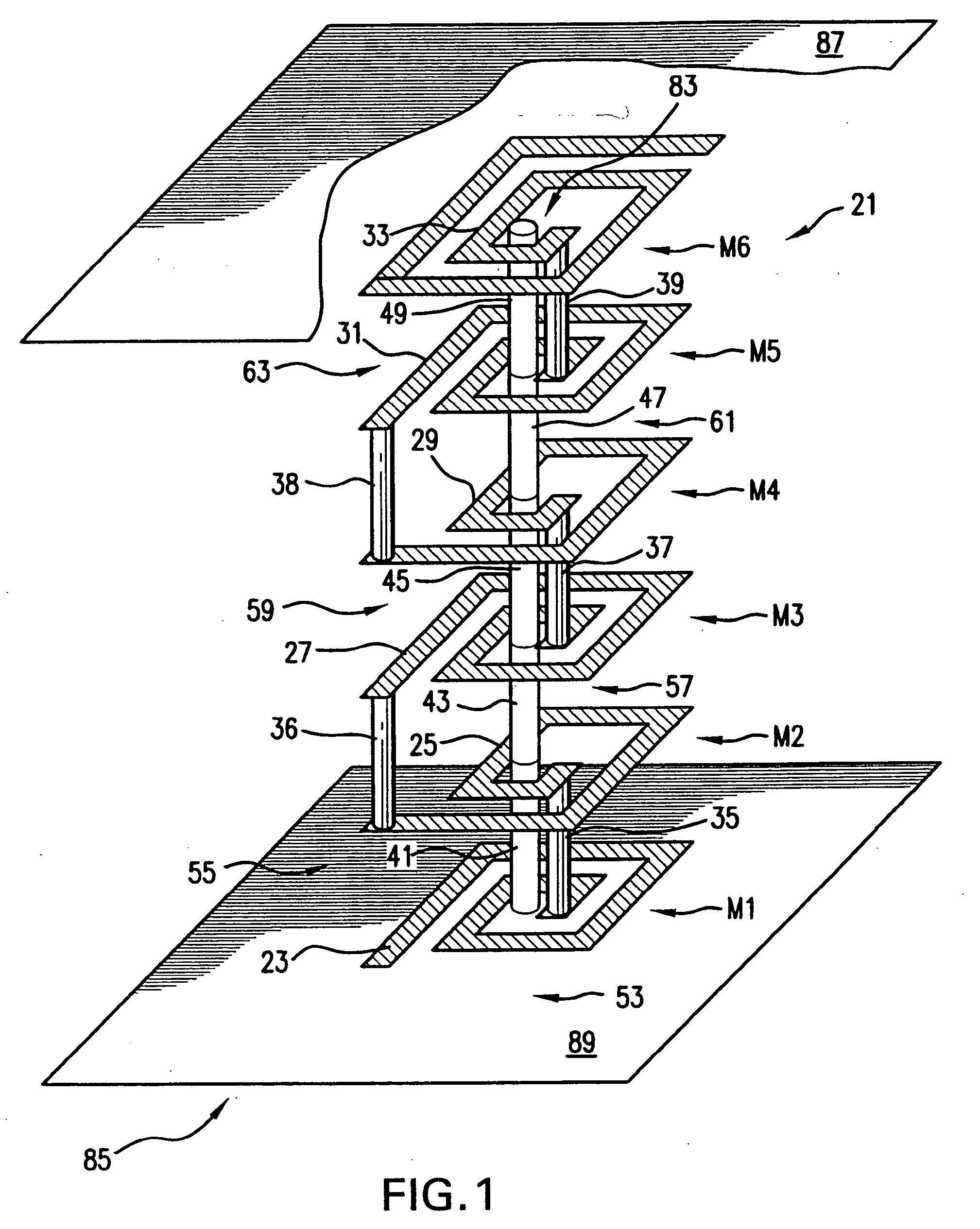

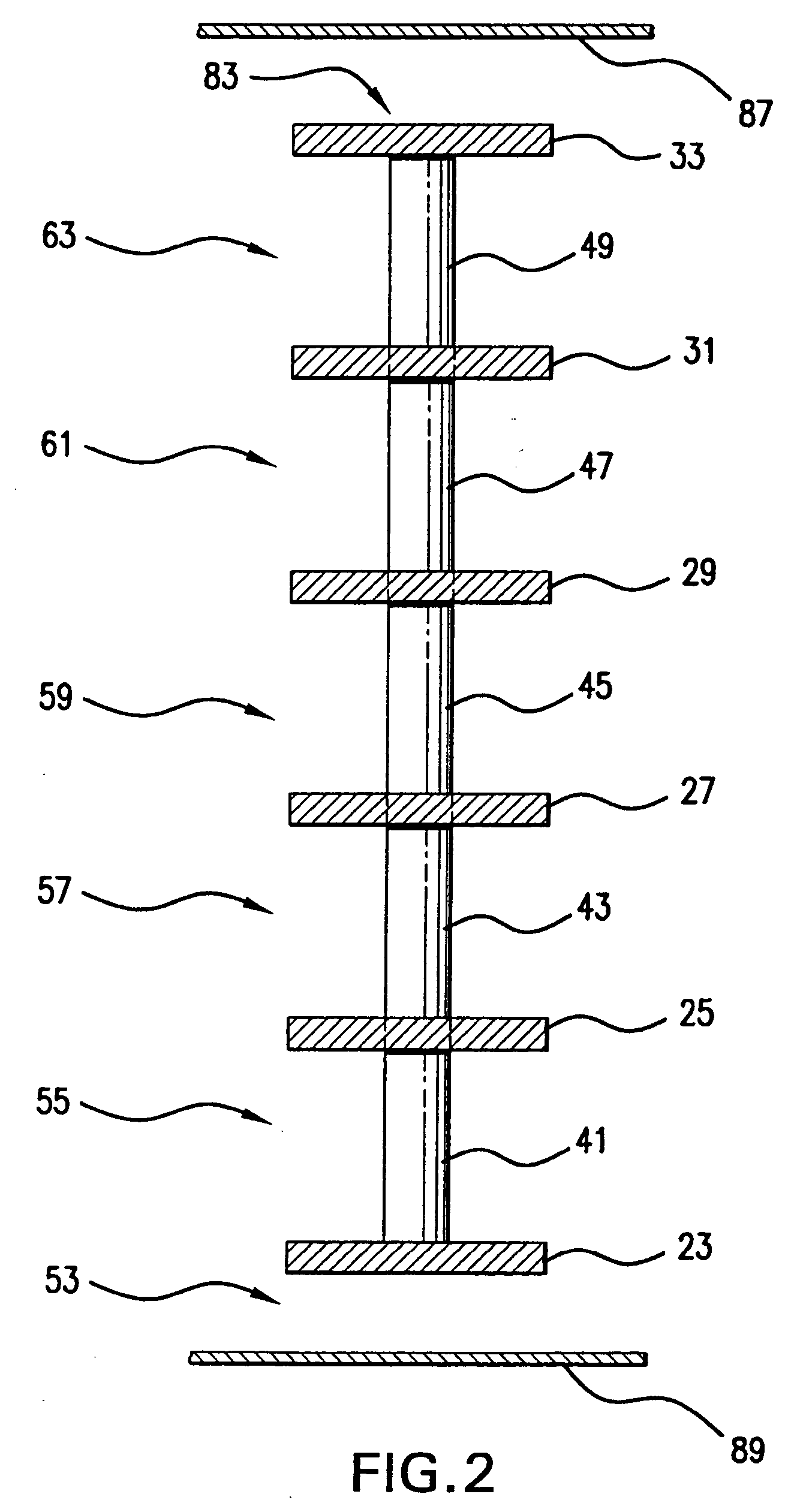

Compact inductor with stacked via magnetic cores for integrated circuits

InactiveUS7262680B2Small sizeReduce manufacturing costSemiconductor/solid-state device detailsSolid-state devicesIntegrated circuit designIntegrated circuit

An on-chip inductor device for Integrated Circuits utilizes coils on a plurality of metal layers of the IC with electrical connectors between the coils and a magnetic core for the inductor of stacked vias running between the coils. The magnetic core is made from a series of stacked vias which are deposited between each metal layer of the IC having a coil. The magnetic core desirably includes an array of magnetic bars comprising the magnetic core. The via material of the magnetic core may be both magnetic and electrically conductive. The magnetic and electrically conductive via material may also be used for the planar coil electrical connectors or other electrically conductive parts of the IC, or both, thereby lessening fabrication steps. Films of magnetic material may be formed at the ends of the inductor to provide a closed magnetic circuit for the inductor. A high Q factor inductor of small (e.g., transistor) size is thus obtained. The materials and processes which enable the on-chip inductor device are compatible with ordinary IC fabrication methods.

Owner:ILLINOIS INSTITUTE OF TECHNOLOGY

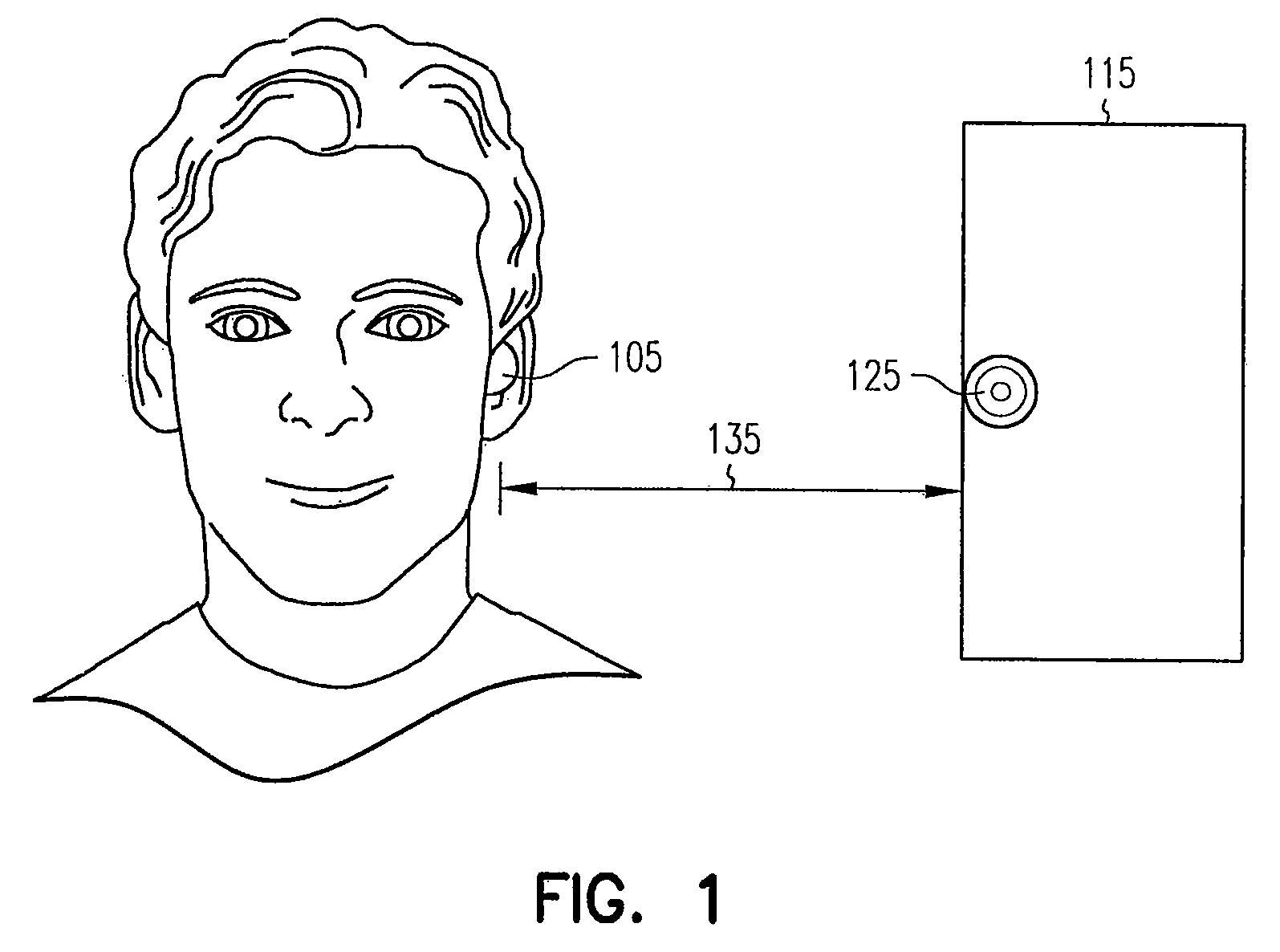

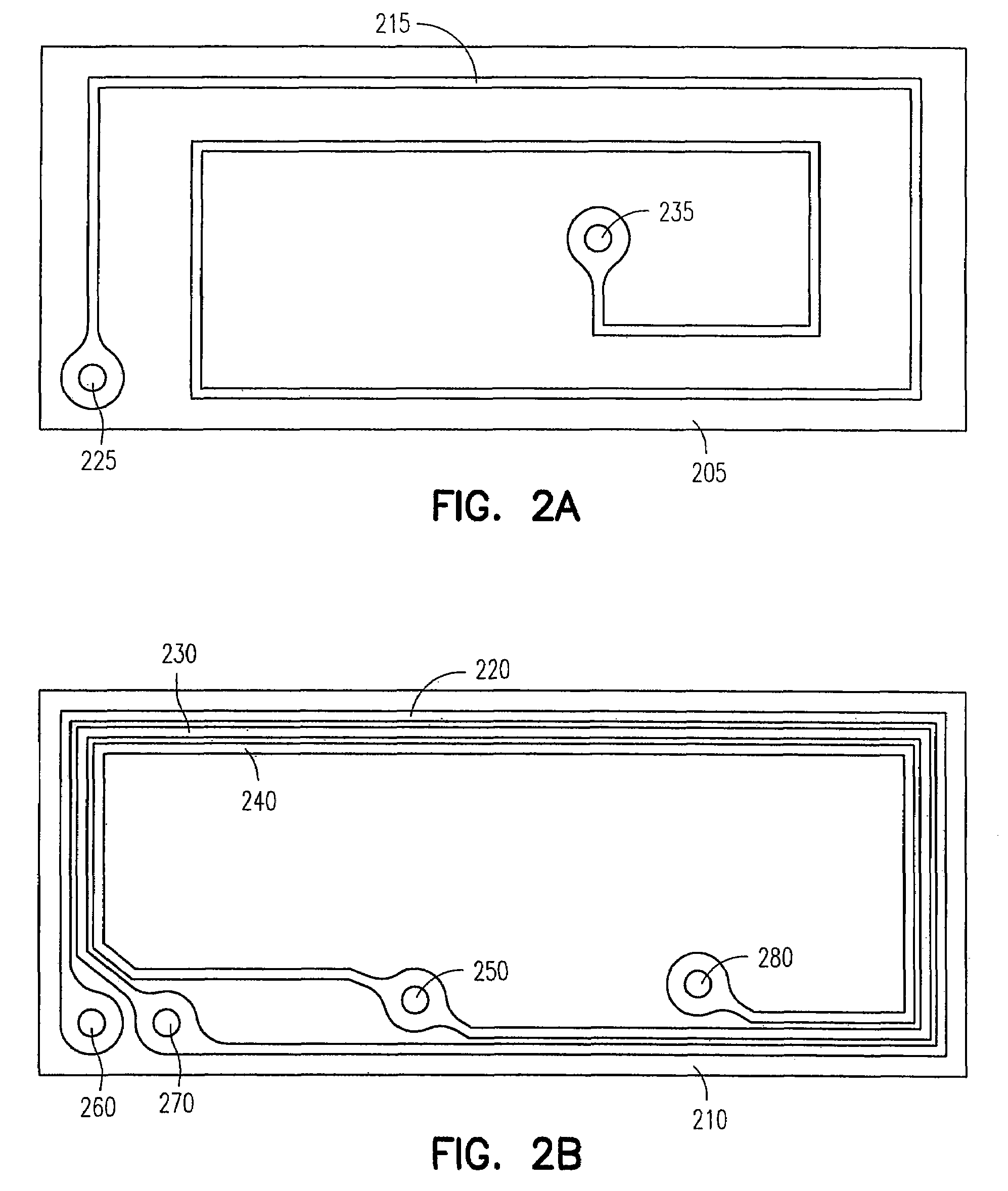

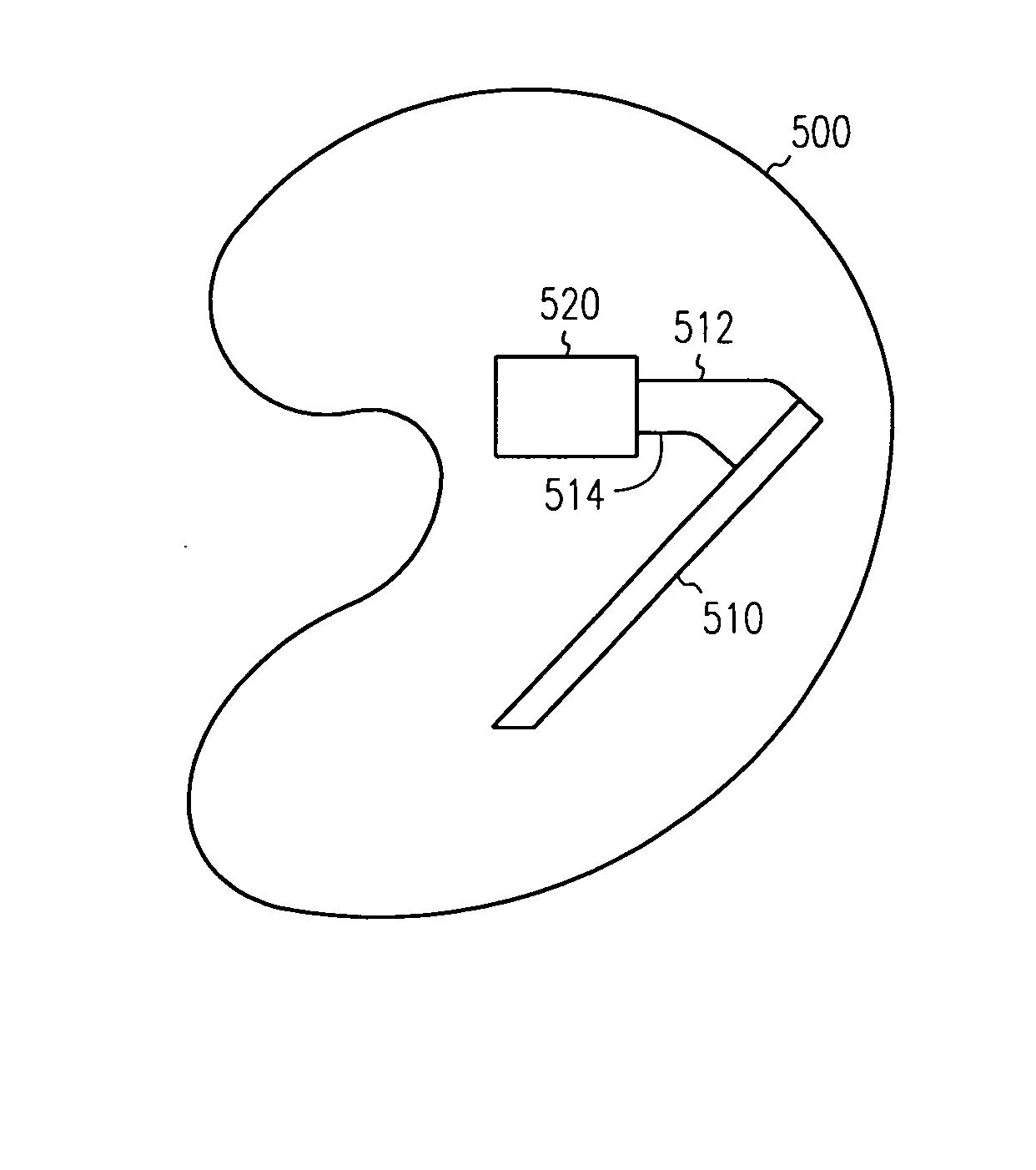

Antennas for hearing aids

ActiveUS7593538B2Completely in canal hearing aidsAntenna supports/mountingsEngineeringFit hearing aid

Owner:STARKEY LAB INC

Planar coil element

ActiveUS20130249662A1Improve permeabilitySmall particle sizeInorganic material magnetismTransformers/inductances detailsMetalMaterials science

In a planar coil element, the quantitative ratio of inclined particles to total particles of a first metal magnetic powder contained in a metal magnetic powder-containing resin provided in a through hole of a coil unit is higher than the quantitative ratio of inclined particles to total particles of the first metal magnetic powder contained in the metal magnetic powder-containing resin provided in other than the through hole, and many of particles of the first metal magnetic powder in the magnetic core are inclined particles whose major axes are inclined with respect to the thickness direction and the planar direction of a substrate. Therefore, the planar coil element has improved strength as compared to a planar coil element shown in FIG. 9A and has improved magnetic permeability as compared to a planar coil element shown in FIG. 9B.

Owner:TDK CORPARATION

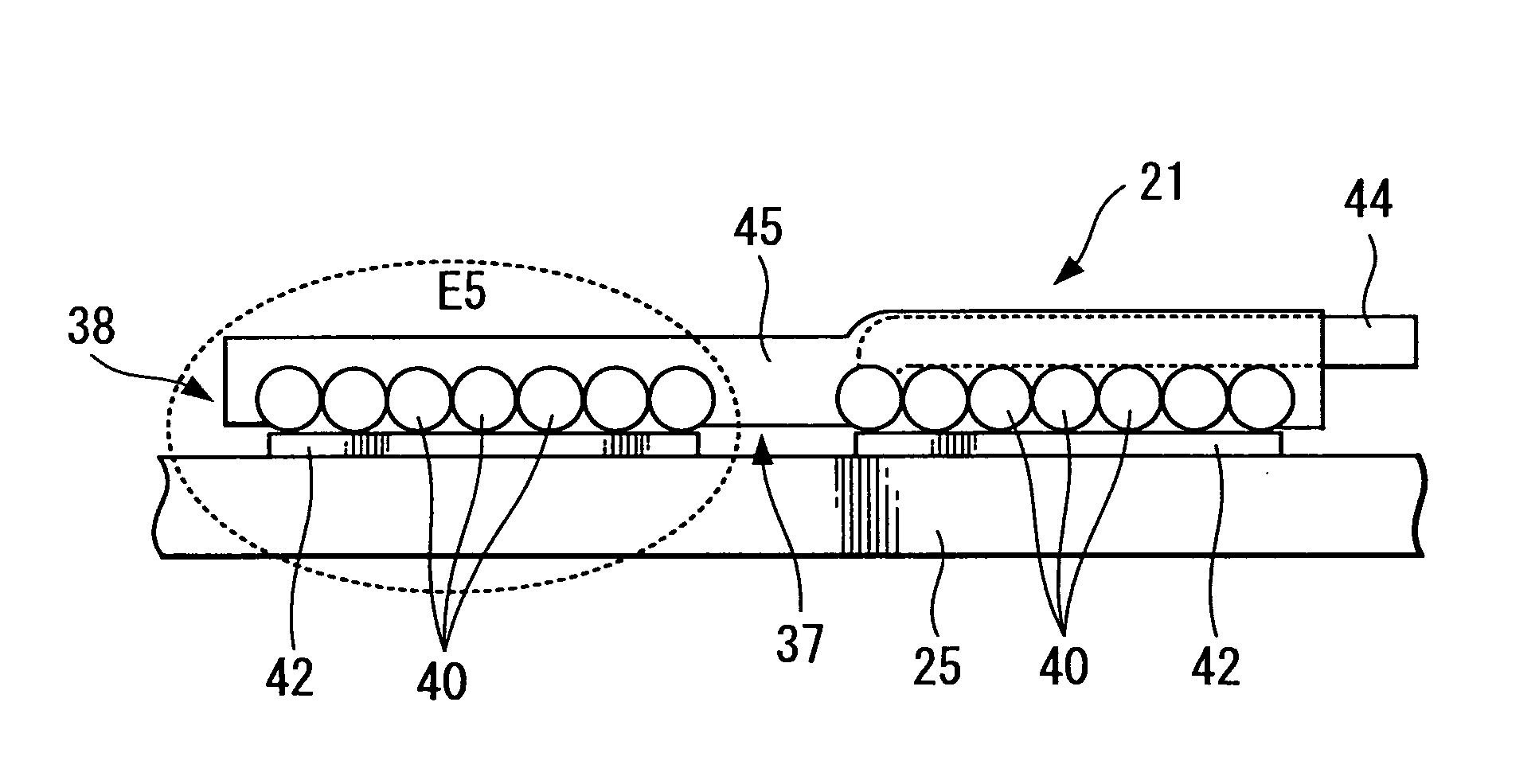

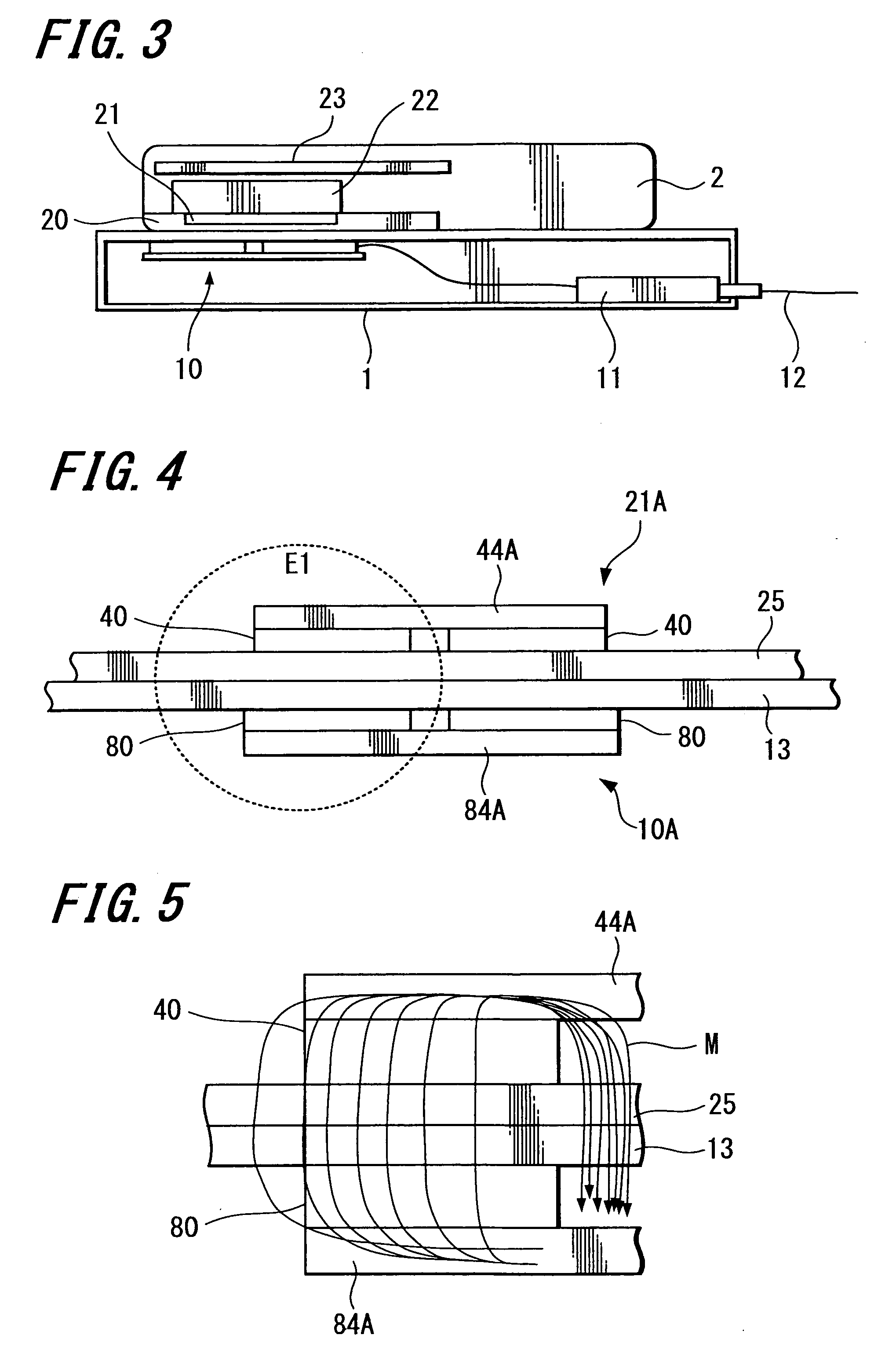

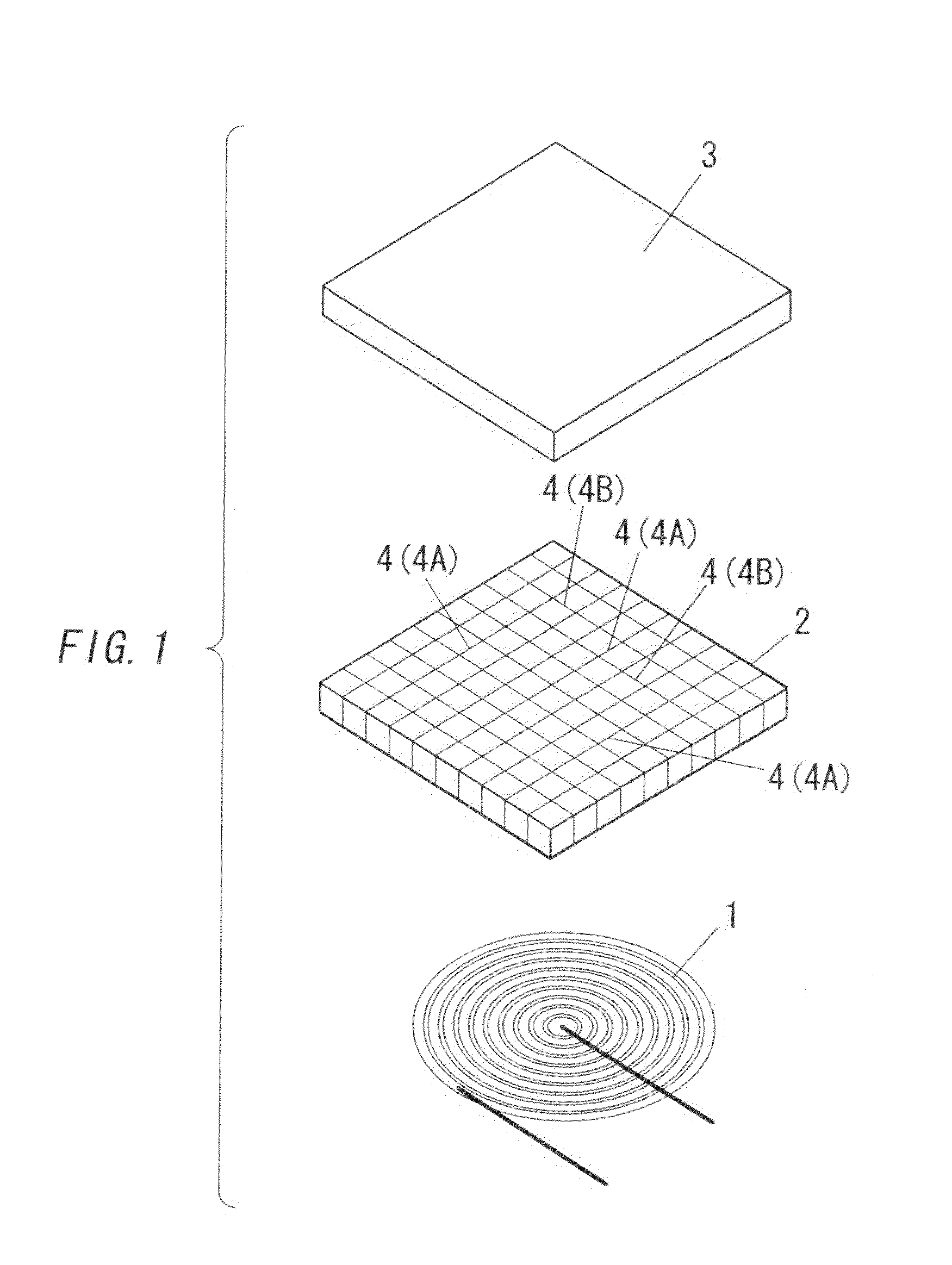

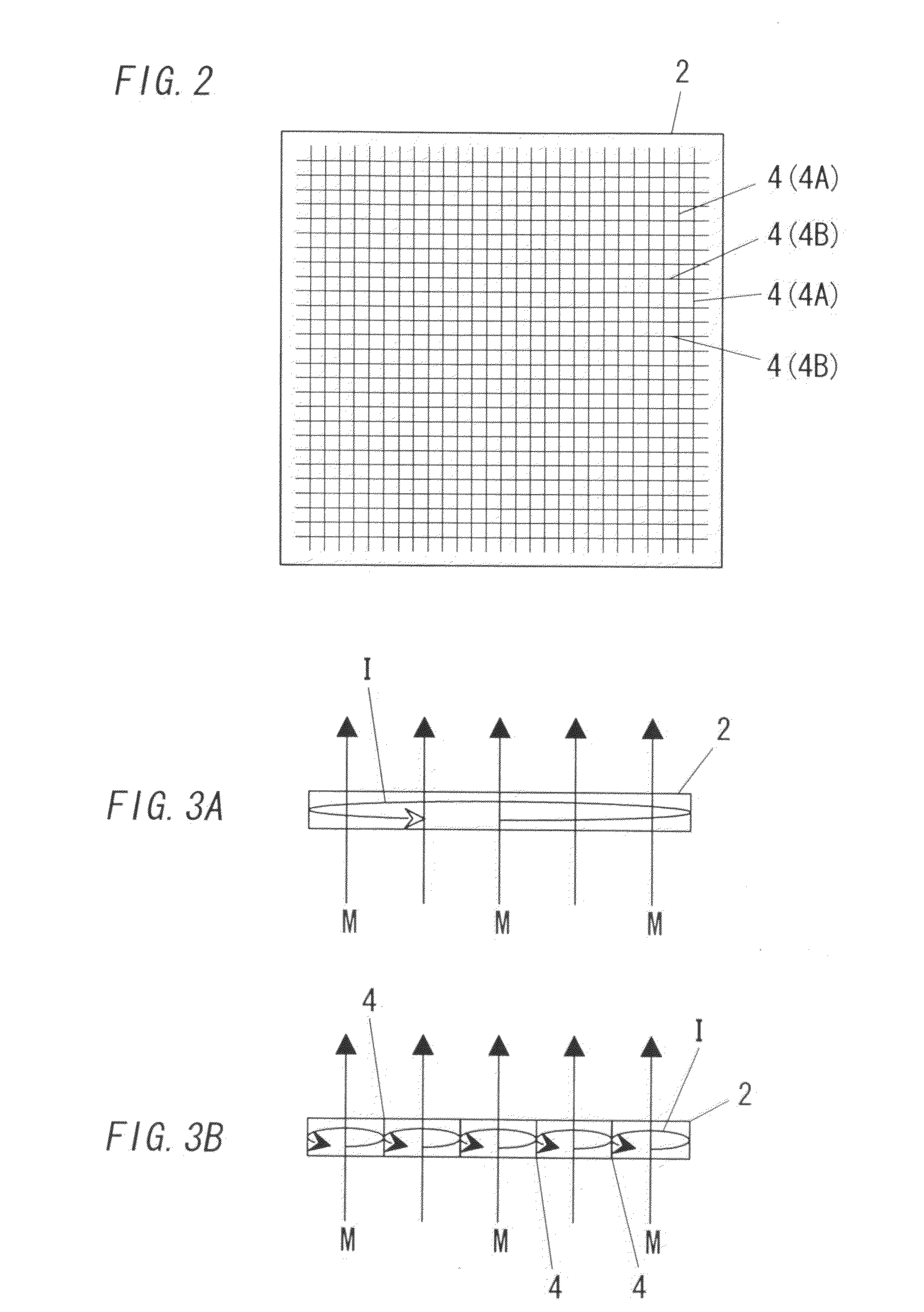

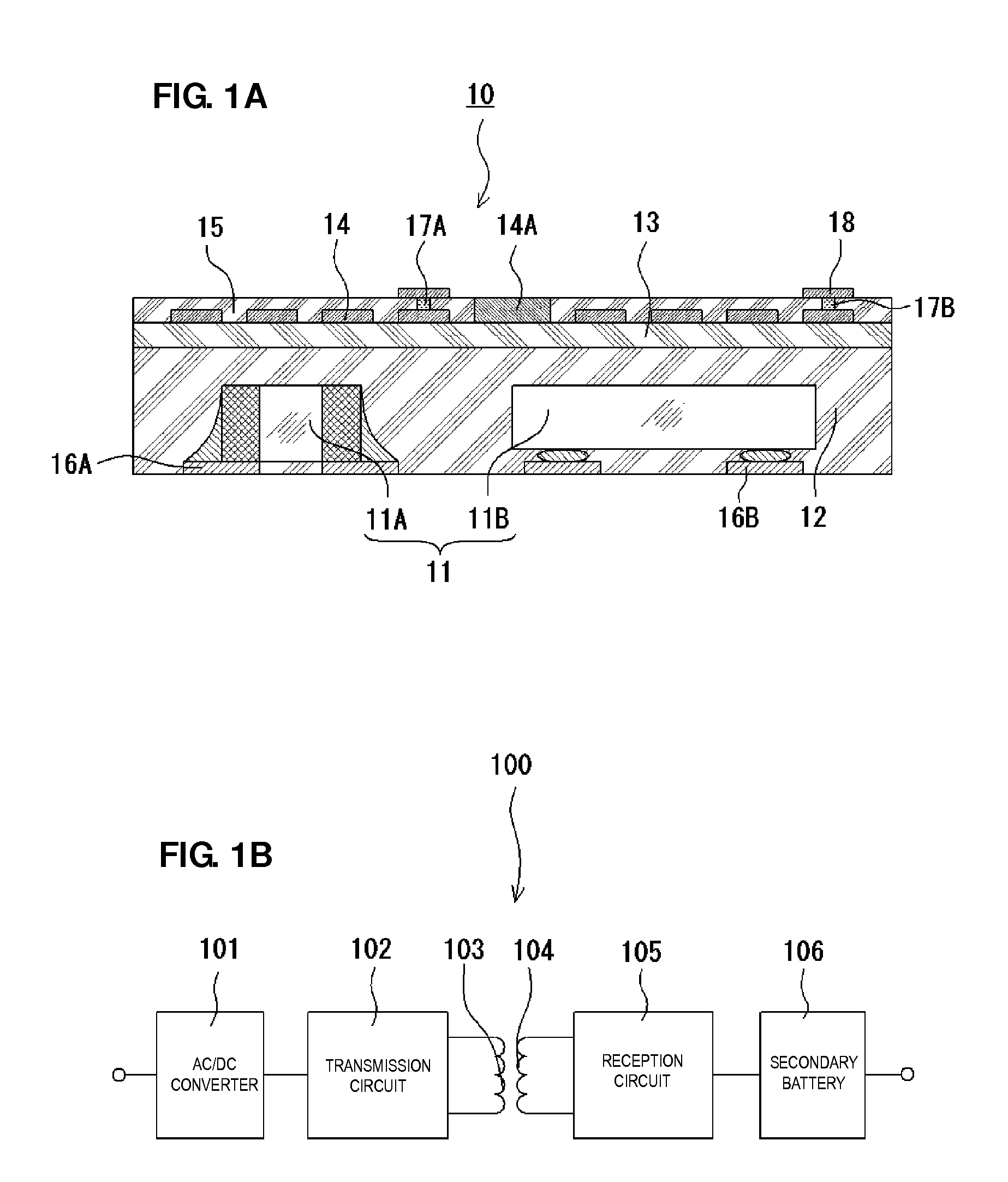

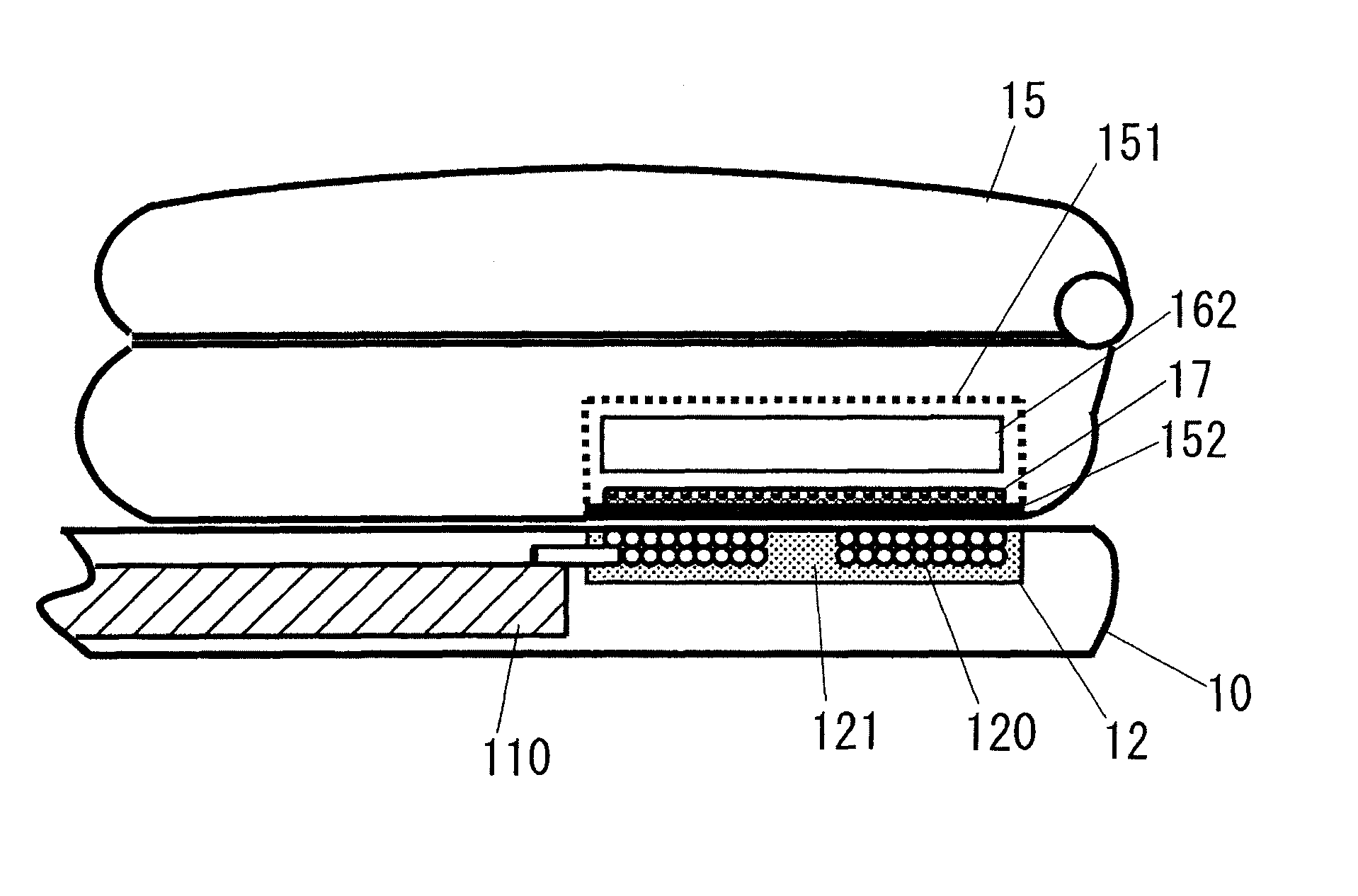

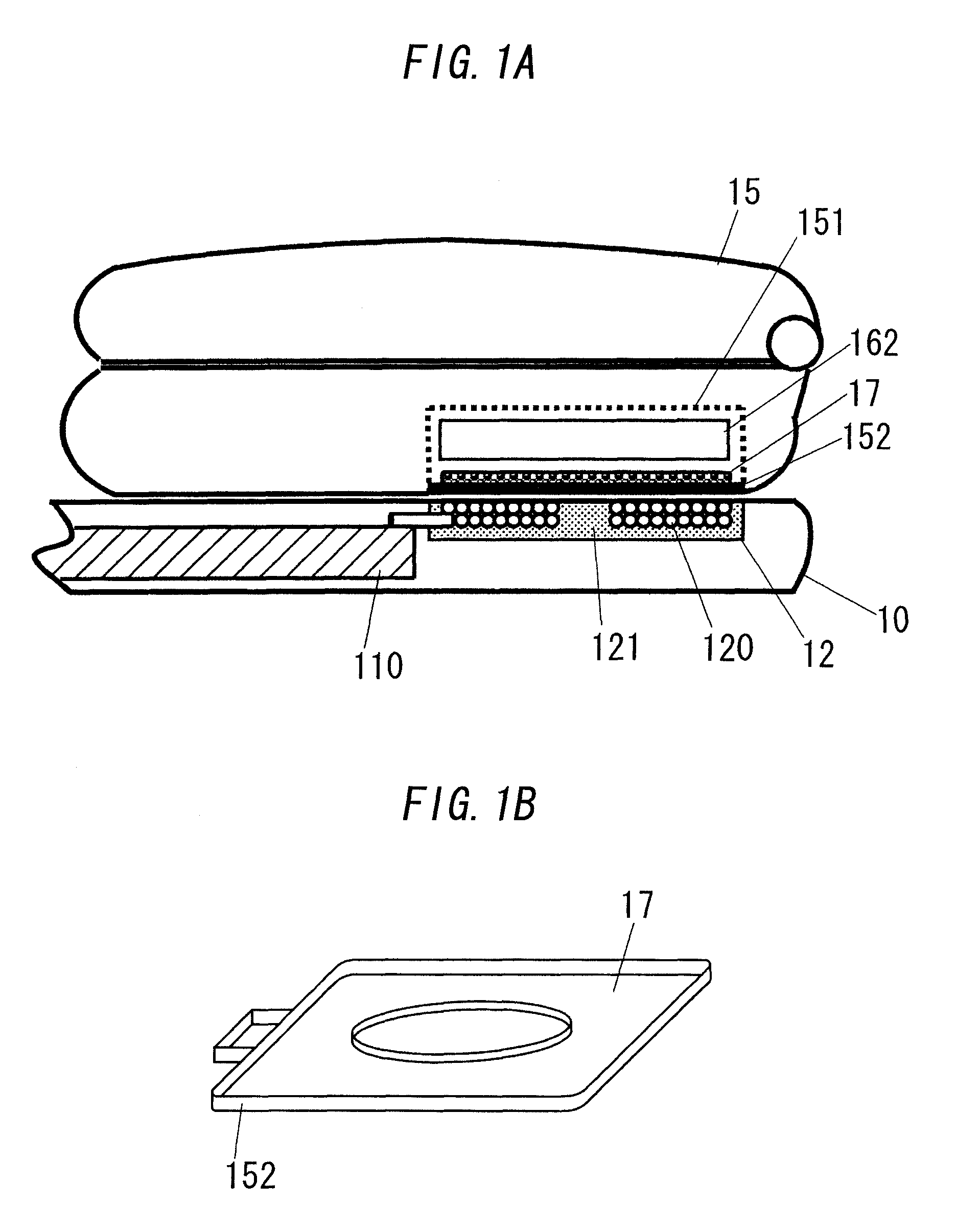

Contactless power transmission apparatus and a method of manufacturing a secondary side thereof

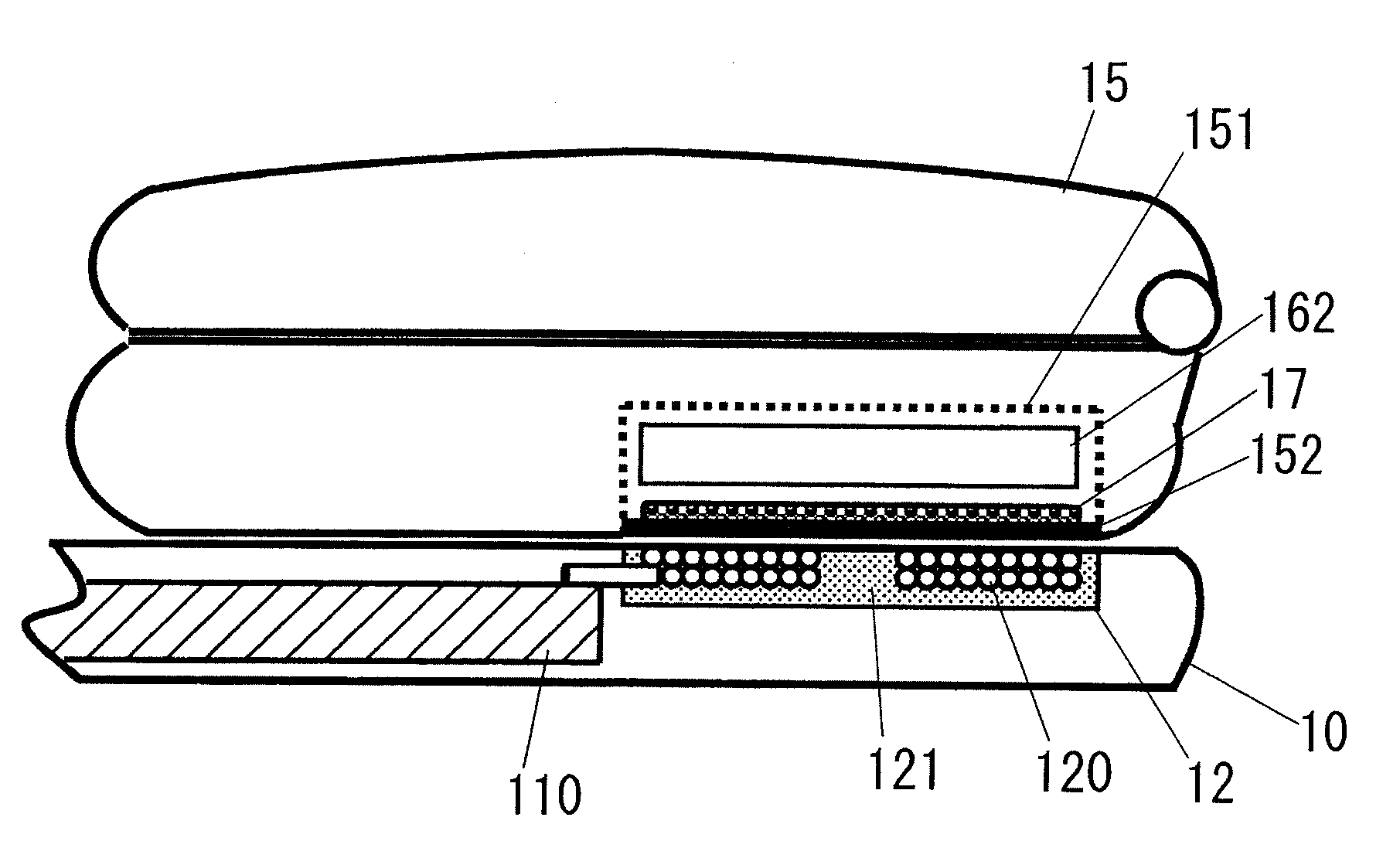

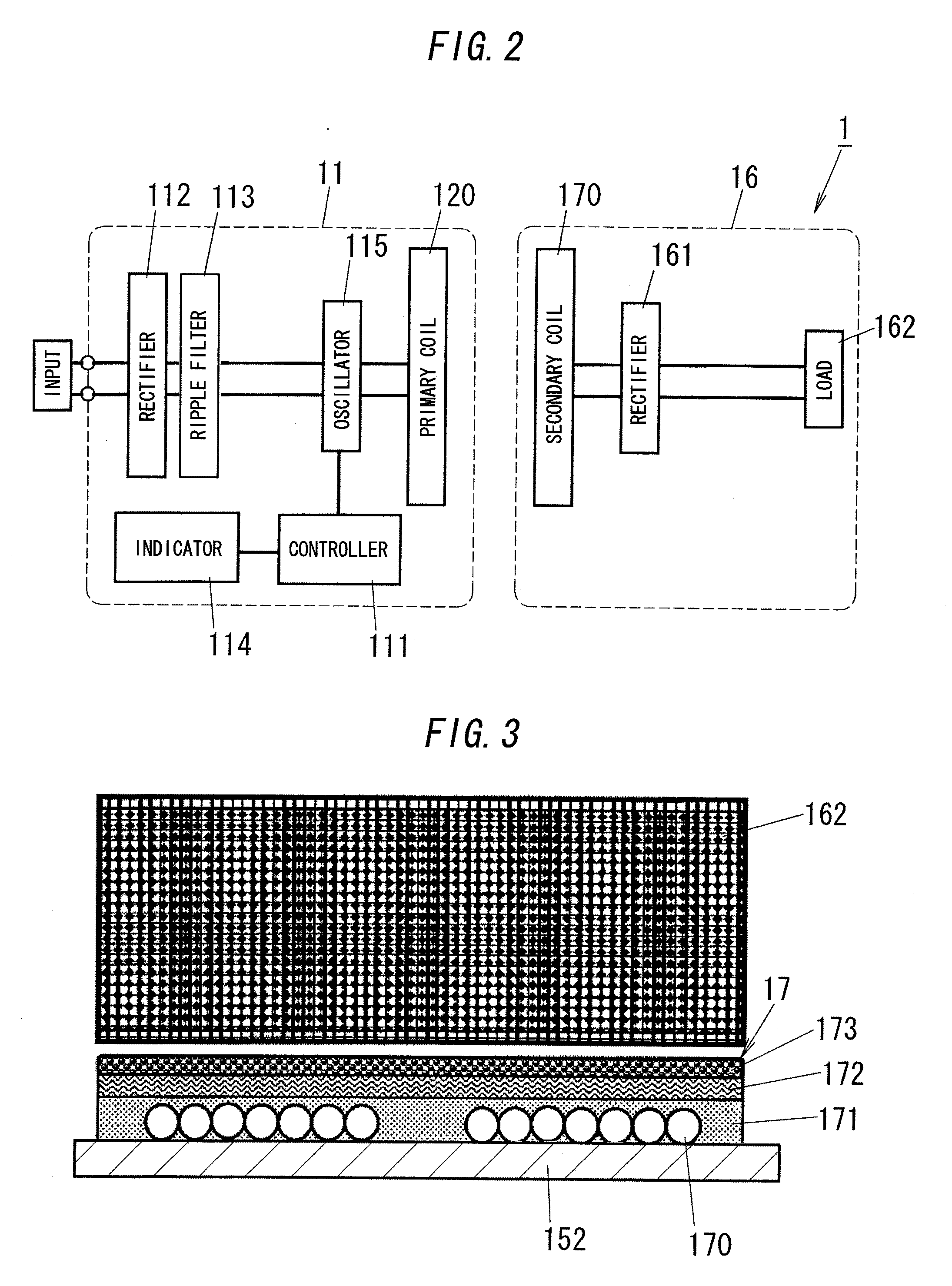

InactiveUS20100181842A1High power transmission efficiencyReduce the impact of noiseBatteries circuit arrangementsElectromagnetic wave systemElectric power transmissionInsulation layer

According to a first aspect, a secondary side of contactless power transmission apparatus includes: a holding member which is physically separated from a primary side; a magnetic layer; a shield layer for shielding electromagnetic noise; and a heat insulation layer. The secondary coil is a planar coil and supported by the holding member, and at least the magnetic layer is laminated on one side of the planar coil and unified with the planar coil. According to a second aspect, the secondary side of the apparatus includes a plurality of magnetic layers. Each permeability of the magnetic layers is different from each other, and each of the magnetic layers forms a magnetic path with the primary side.

Owner:PANASONIC CORP

Planar coil and planar transformer, and process of fabricating a high-aspect conductive device

InactiveUS6600404B1Improve electrical performanceIncreases conductor thicknessTransformers/inductances coils/windings/connectionsPrinted circuit aspectsPlanar transformersPhysics

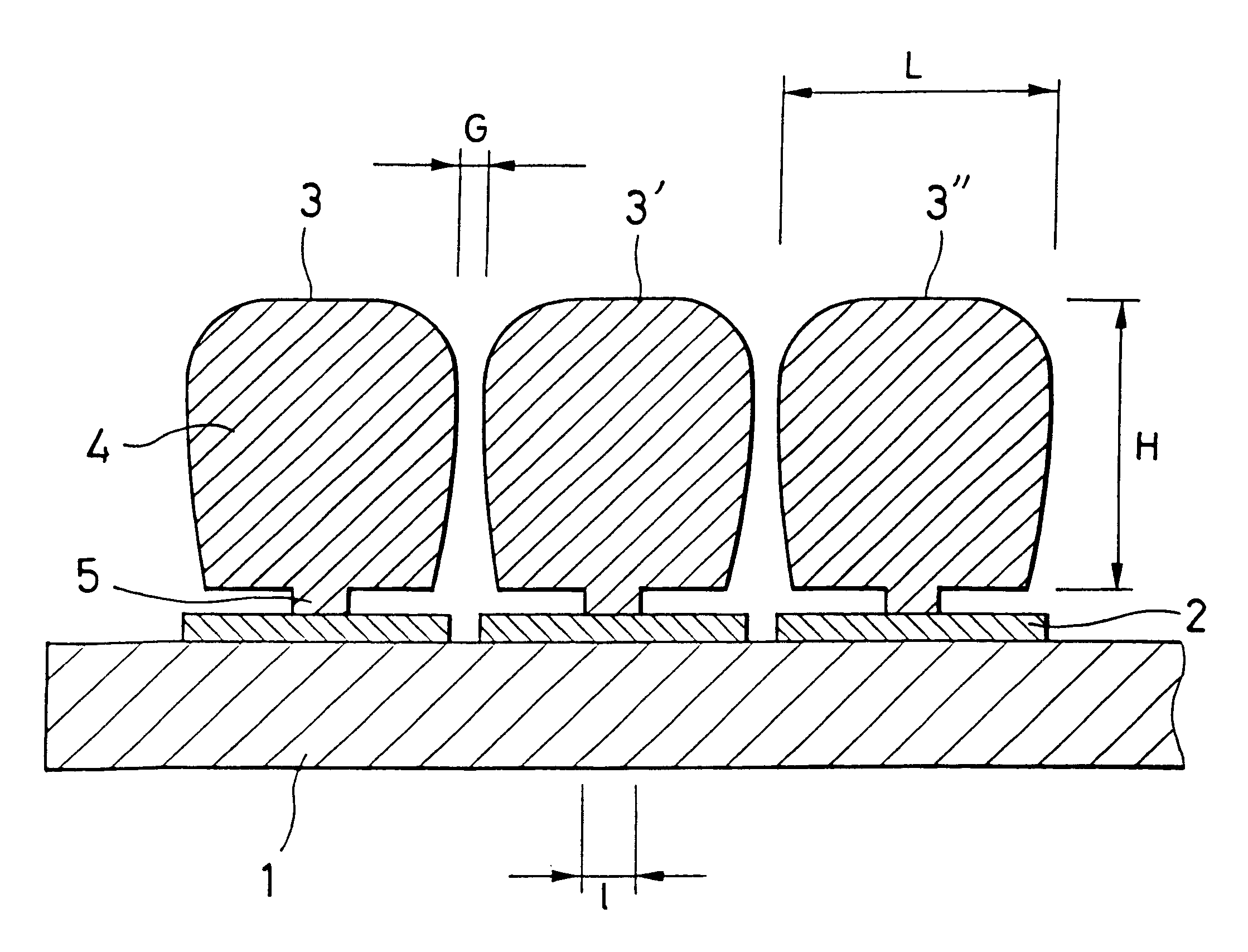

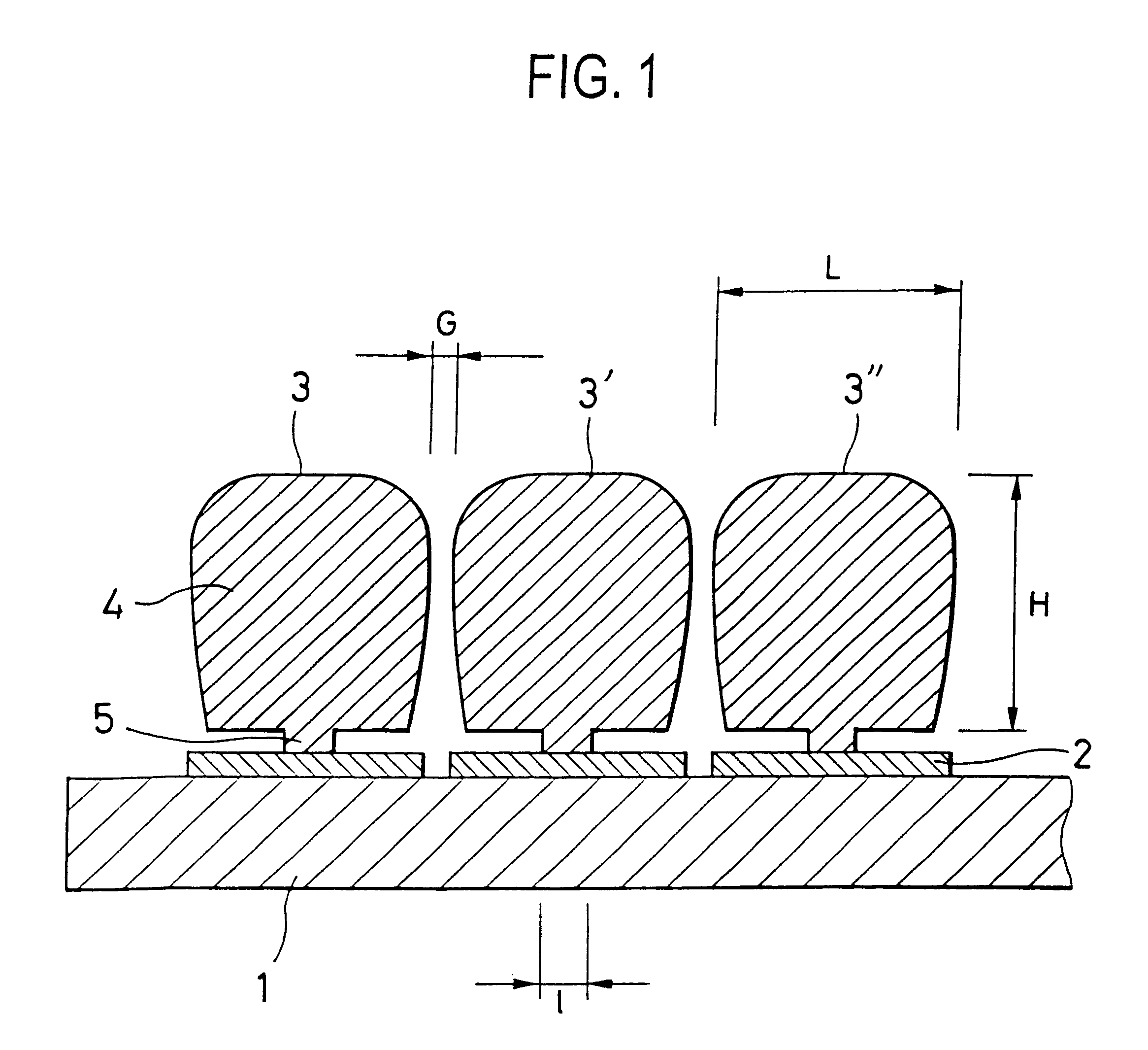

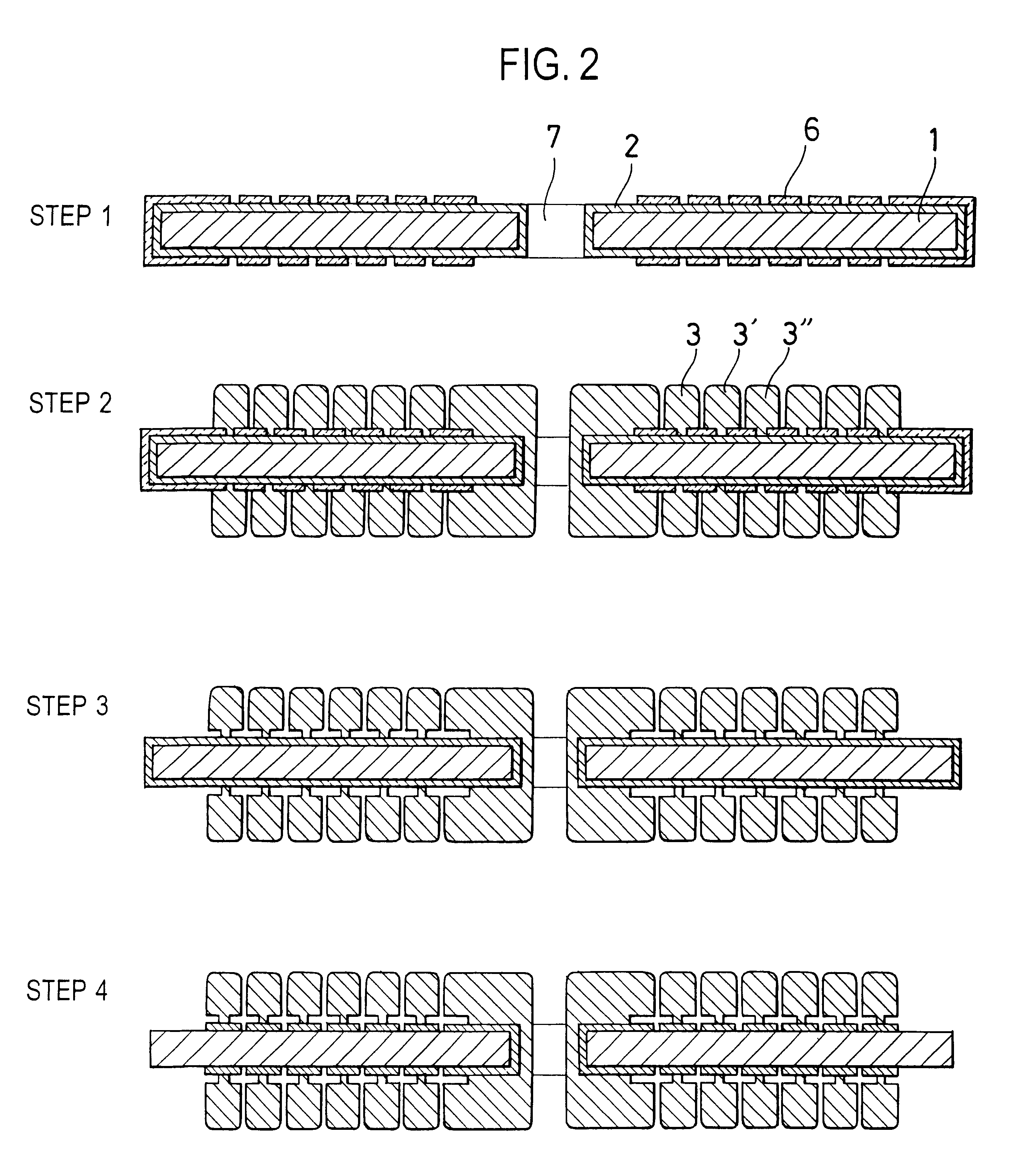

A planar coil including and insulating substrate, and a coil conductive filament having a thickness of 20 to 400 mum and formed on at least one surface of the insulating substrate, the coil conductive filament having a gap whose aspect ratio (H / G) is at least 1. The coil conductive filament has a cross-section in a substantially mushroom shape having a head and a neck, the head has a width (L) which is a least twice as large as a width (l) of the neck thereof, at most 1.5 times as large as a height of the head, and at least twice as large as a minimum spacing (G) between adjacent coil conductive filaments.

Owner:TDK CORPARATION

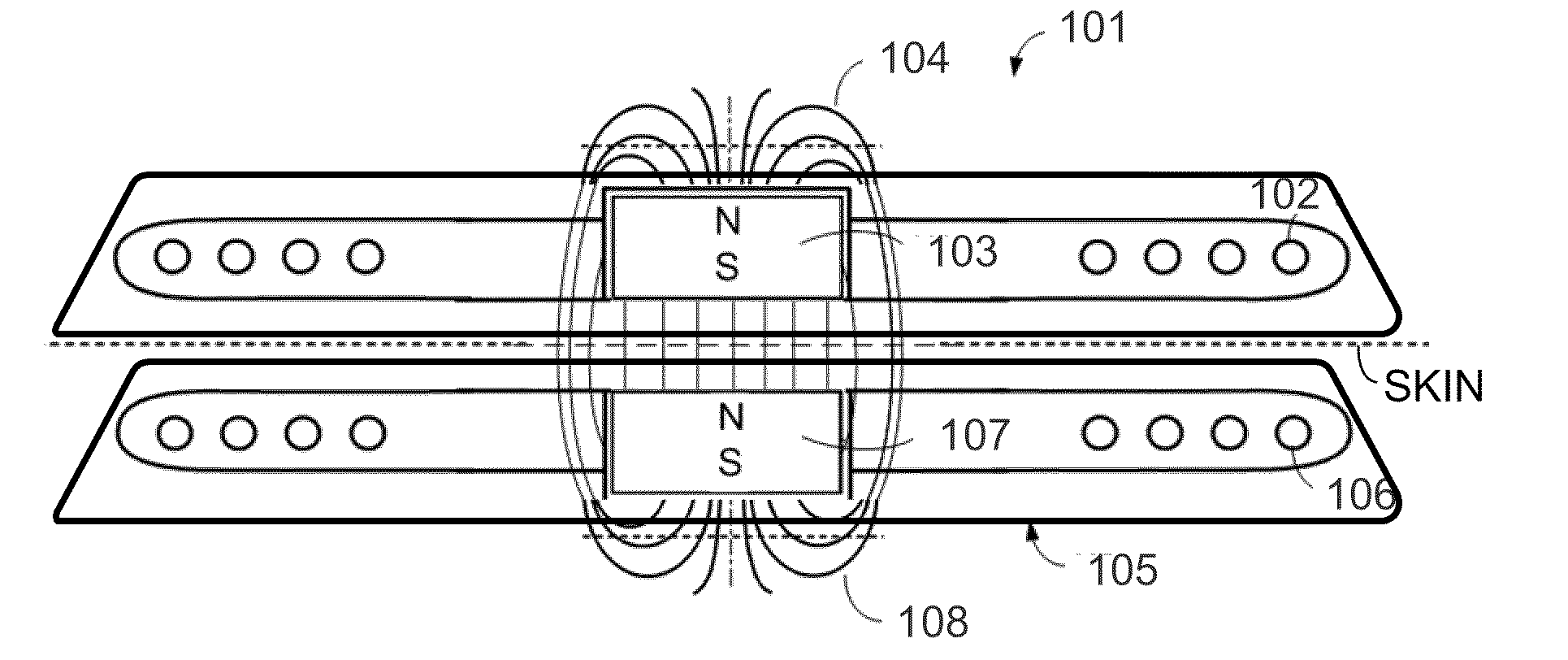

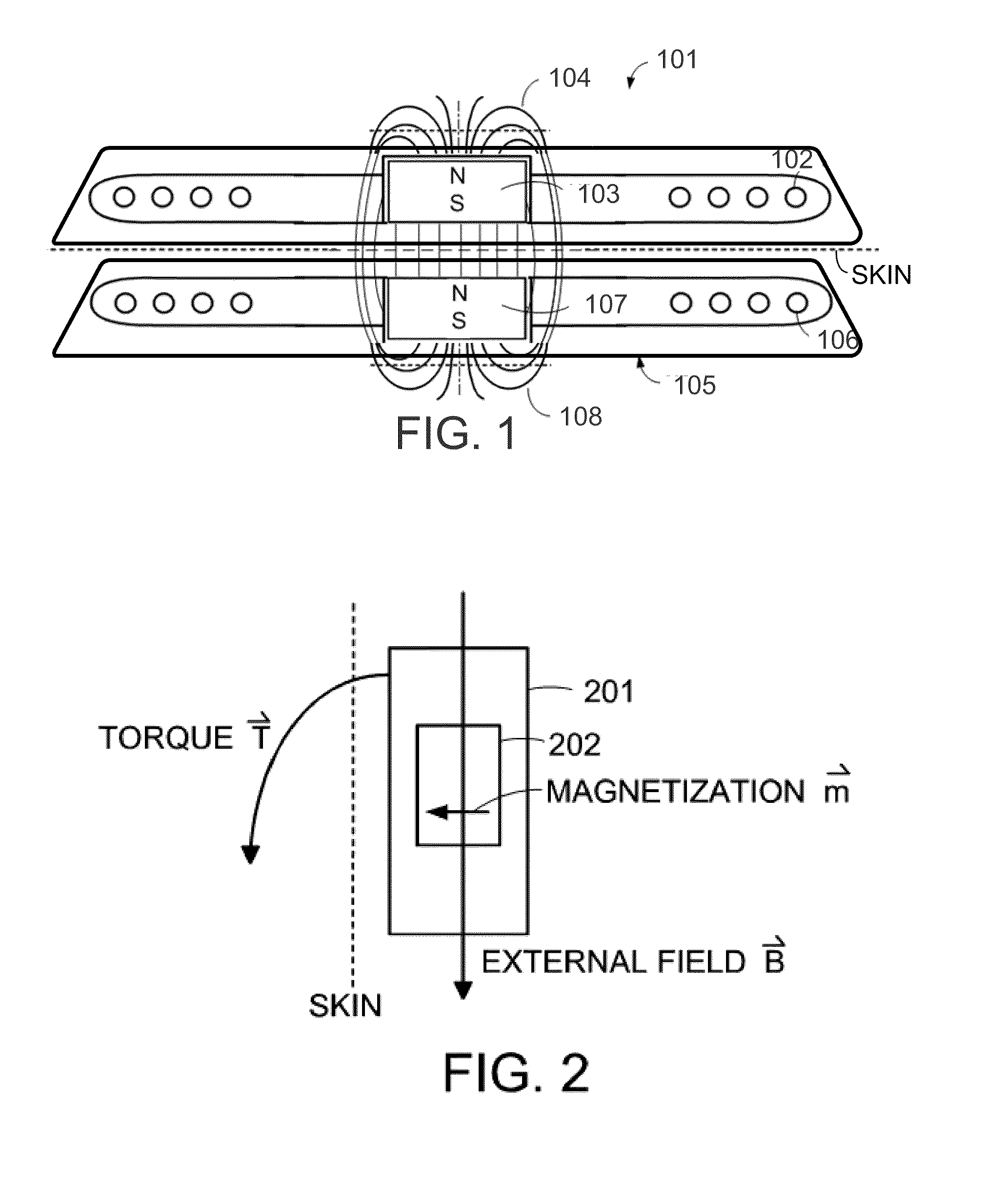

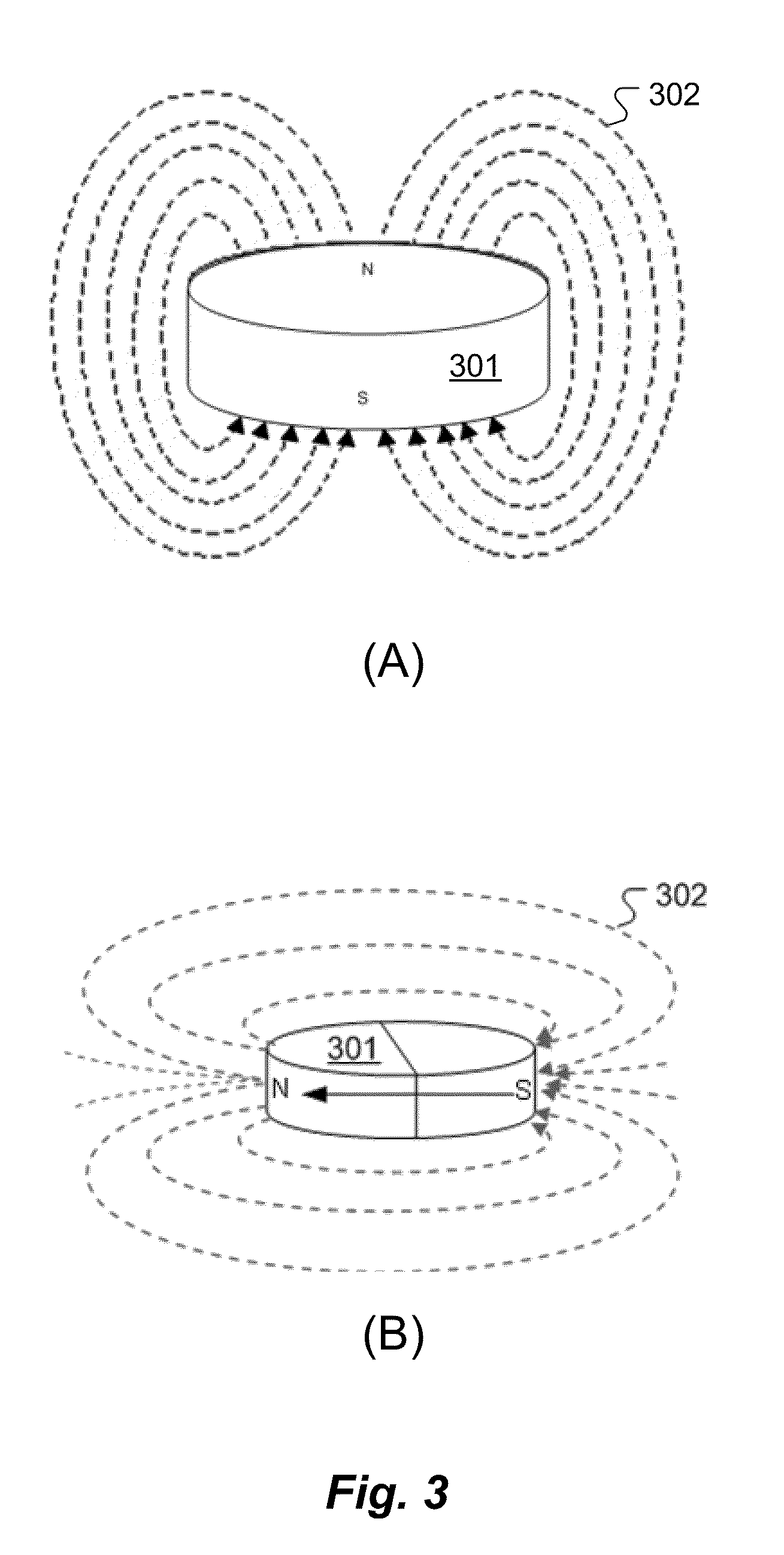

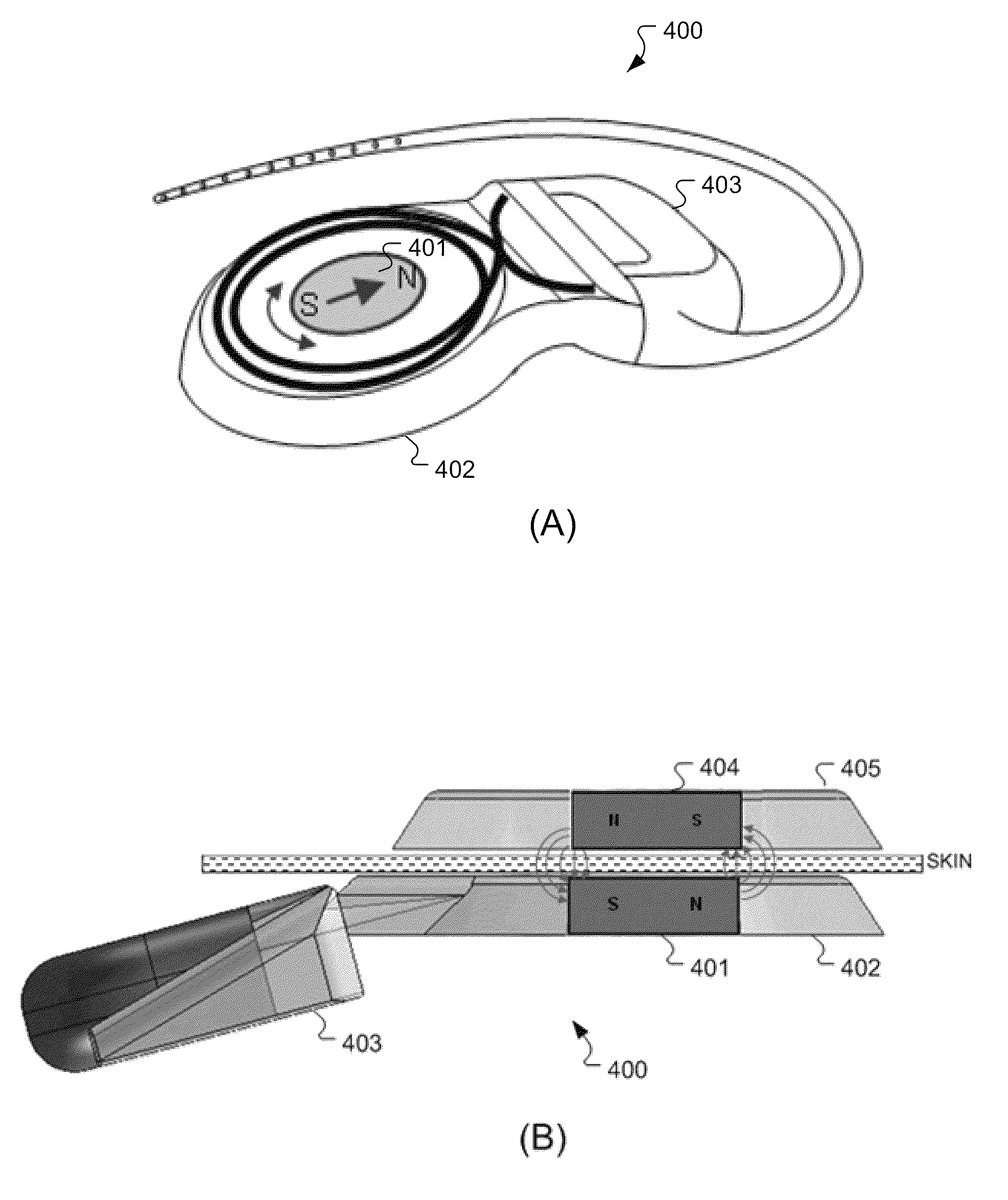

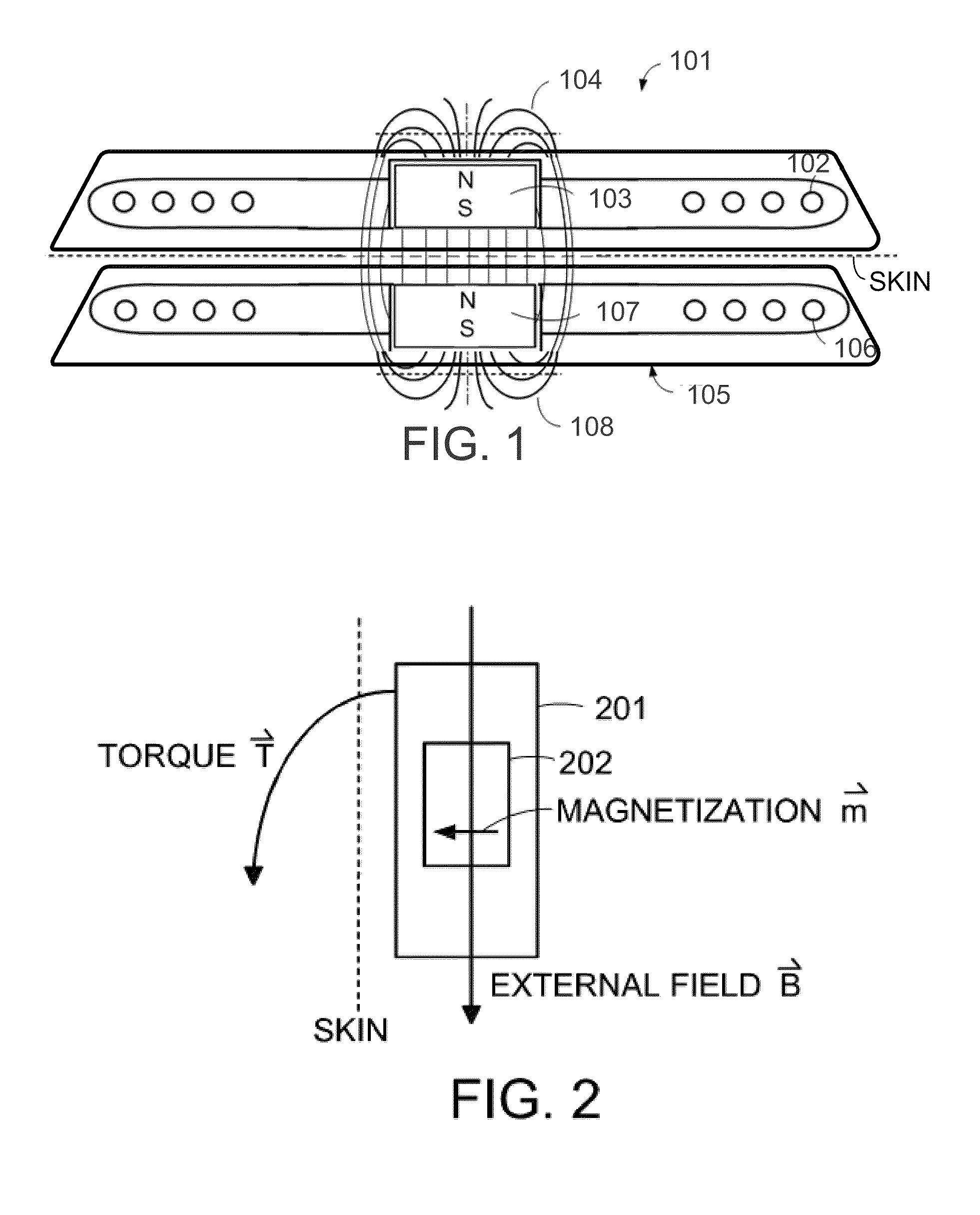

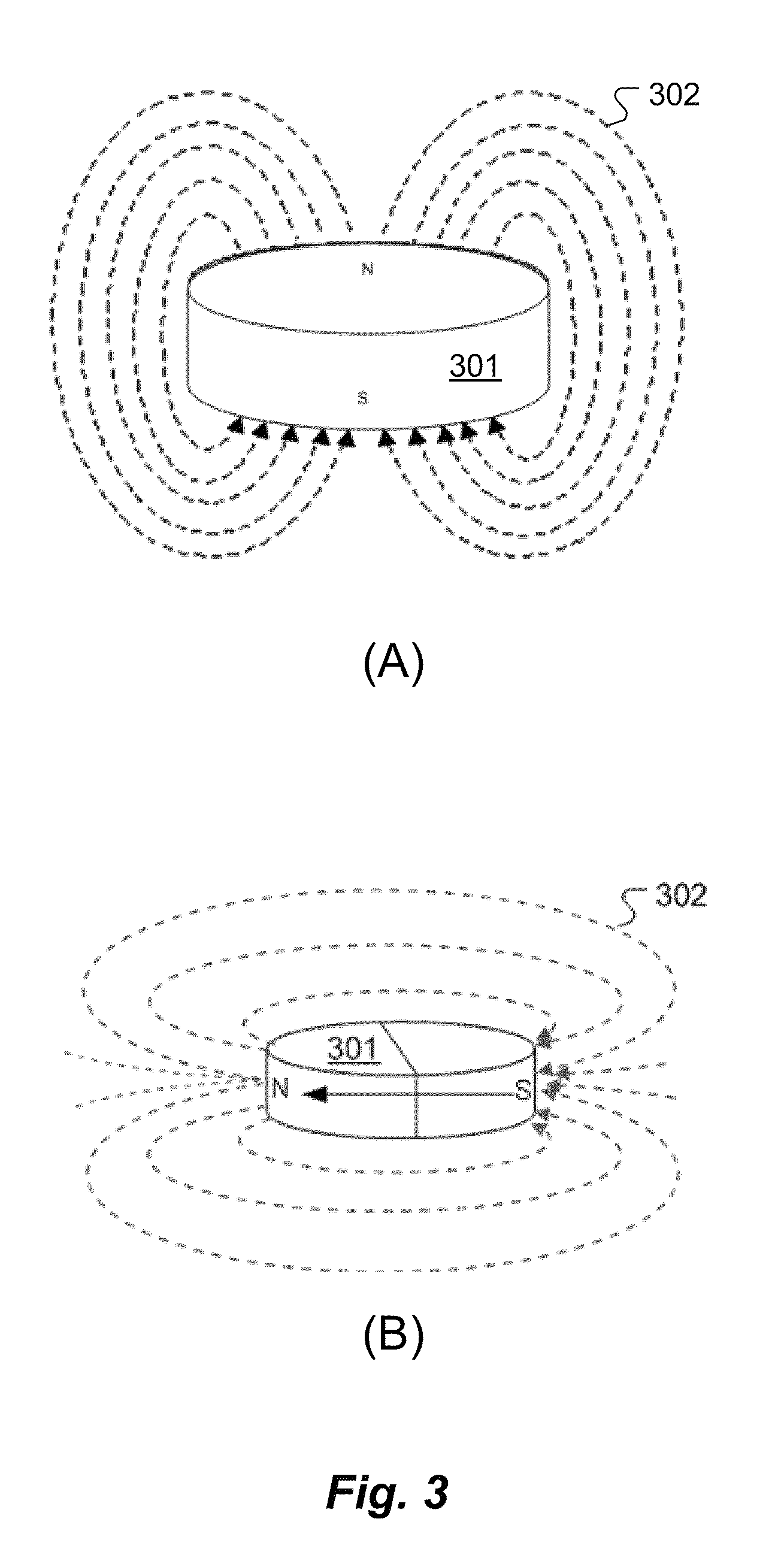

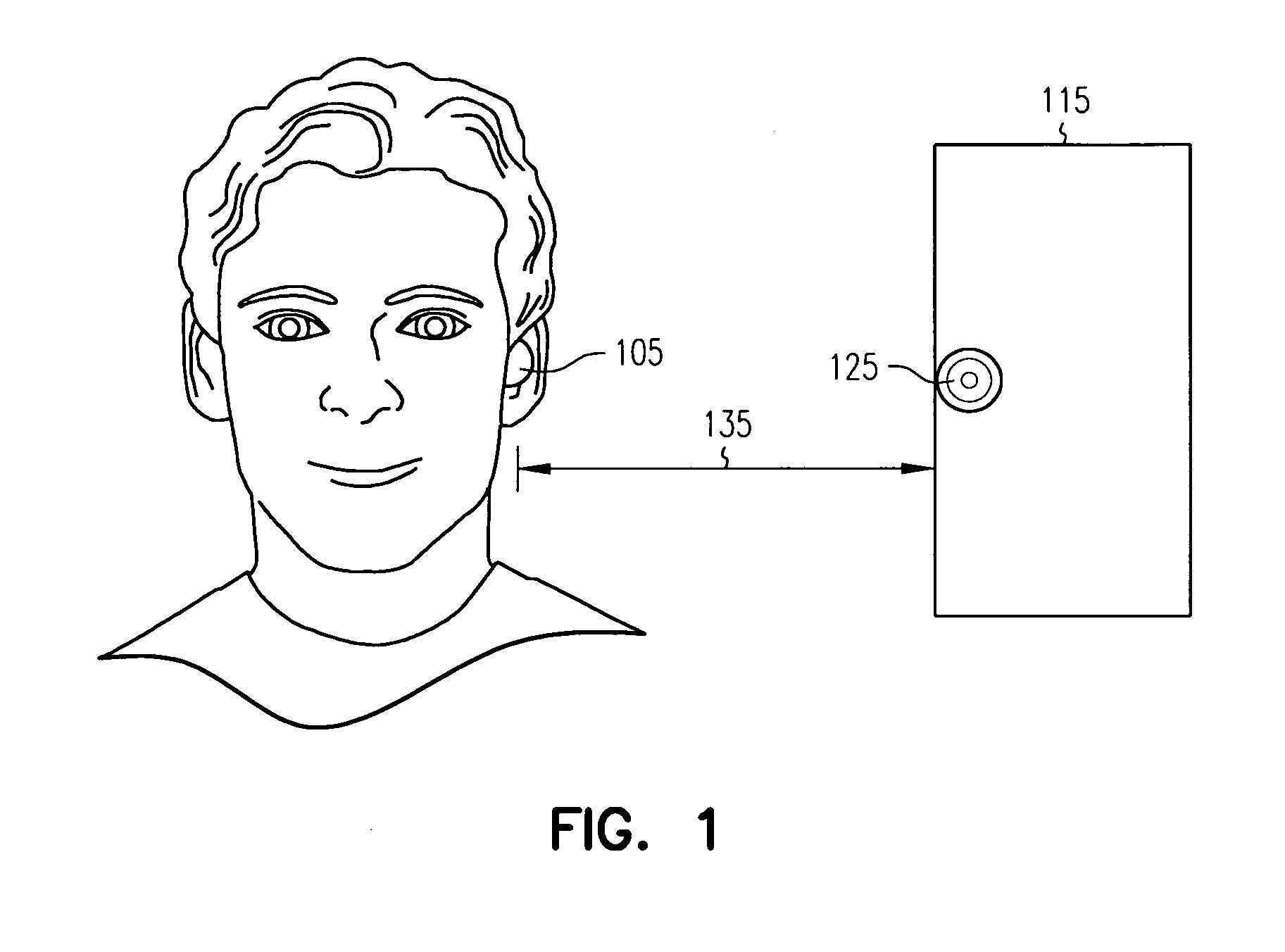

MRI-Safe Disc Magnet for Implants

ActiveUS20110264172A1Smooth rotationReduce frictionElectrotherapyTracheaeMagnetic interactionMagnetic dipole

A magnetic arrangement is described for an implantable system for a recipient patient. A planar coil housing contains a signal coil for transcutaneous communication of an implant communication signal. A first attachment magnet is located within the plane of the coil housing and rotatable therein, and has a magnetic dipole parallel to the plane of the coil housing for transcutaneous magnetic interaction with a corresponding second attachment magnet.

Owner:MED EL ELEKTROMEDIZINISCHE GERAETE GMBH

MRI-safe disc magnet for implants

A magnetic arrangement is described for an implantable system for a recipient patient. A planar coil housing contains a signal coil for transcutaneous communication of an implant communication signal. A first attachment magnet is located within the plane of the coil housing and rotatable therein, and has a magnetic dipole parallel to the plane of the coil housing for transcutaneous magnetic interaction with a corresponding second attachment magnet.

Owner:MED EL ELEKTROMEDIZINISCHE GERAETE GMBH

Compact inductor with stacked via magnetic cores for integrated circuits

InactiveUS20050190035A1Small sizeReduce manufacturing costSemiconductor/solid-state device detailsSolid-state devicesQ factorPlanar coil

An on-chip inductor device for Integrated Circuits utilizes coils on a plurality of metal layers of the IC with electrical connectors between the coils and a magnetic core for the inductor of stacked vias running between the coils. The magnetic core is made from a series of stacked vias which are deposited between each metal layer of the IC having a coil. The magnetic core desirably includes an array of magnetic bars comprising the magnetic core. The via material of the magnetic core may be both magnetic and electrically conductive. The magnetic and electrically conductive via material may also be used for the planar coil electrical connectors or other electrically conductive parts of the IC, or both, thereby lessening fabrication steps. Films of magnetic material may be formed at the ends of the inductor to provide a closed magnetic circuit for the inductor. A high Q factor inductor of small (e.g., transistor) size is thus obtained. The materials and processes which enable the on-chip inductor device are compatible with ordinary IC fabrication methods.

Owner:ILLINOIS INSTITUTE OF TECHNOLOGY

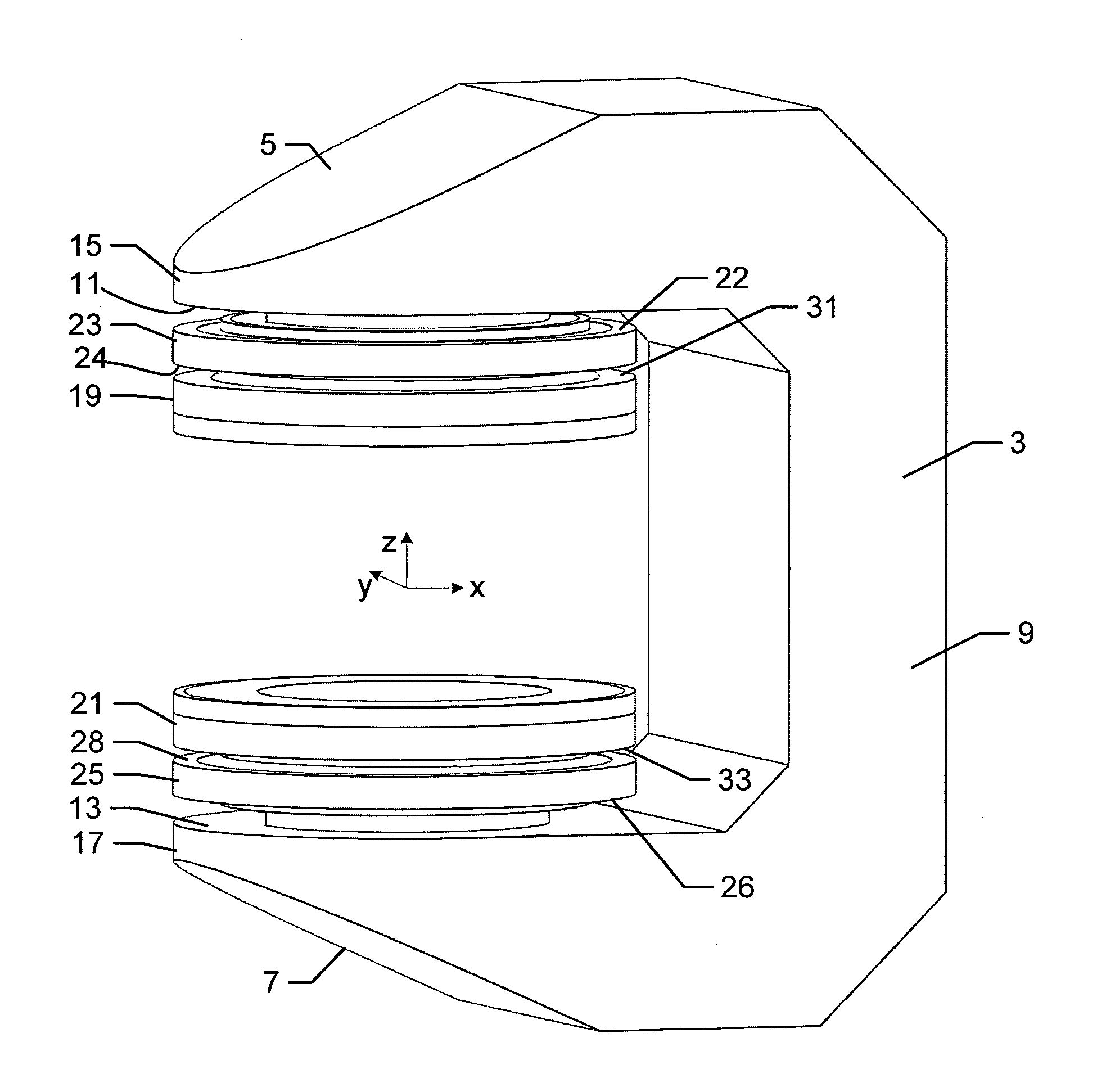

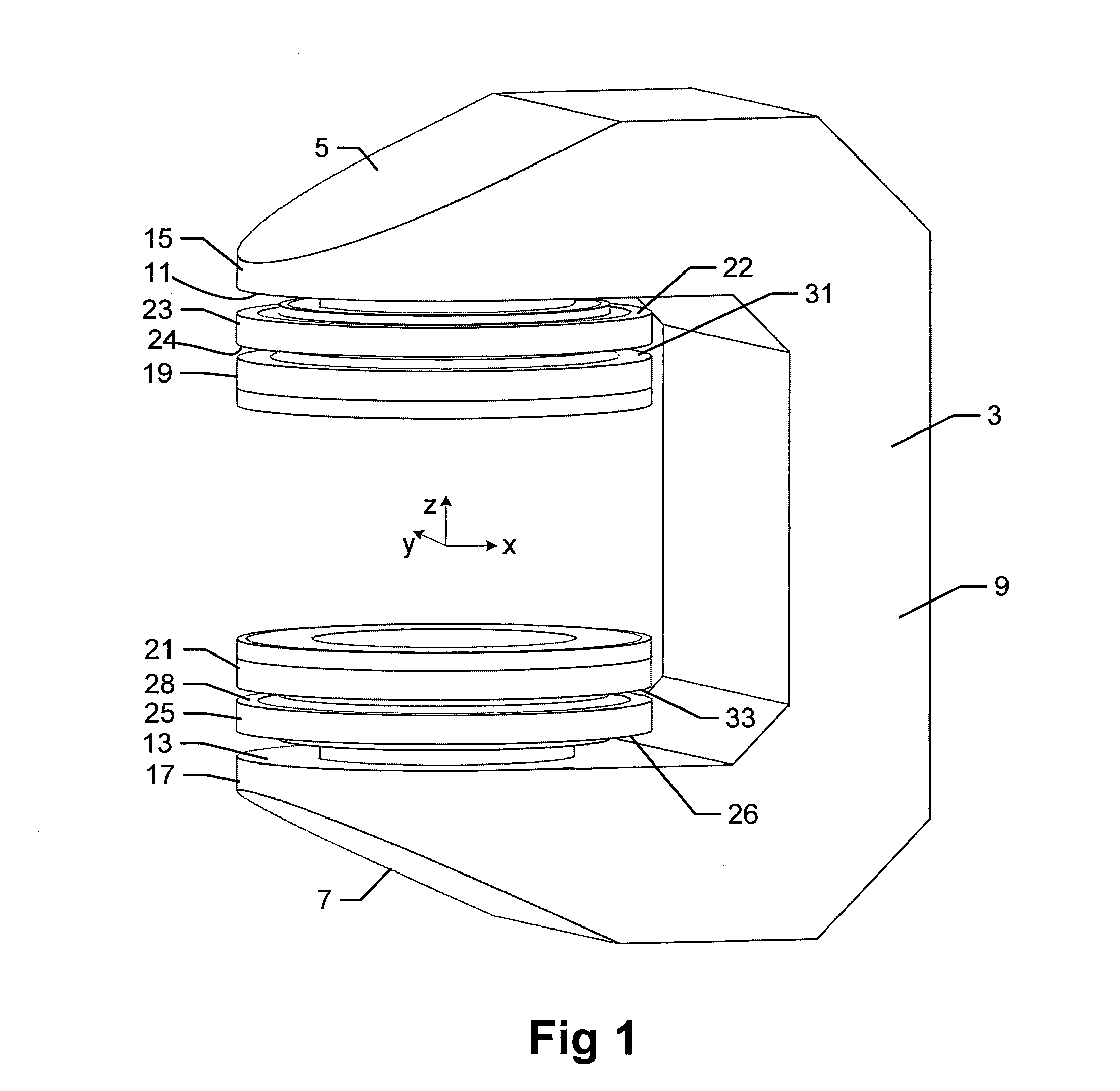

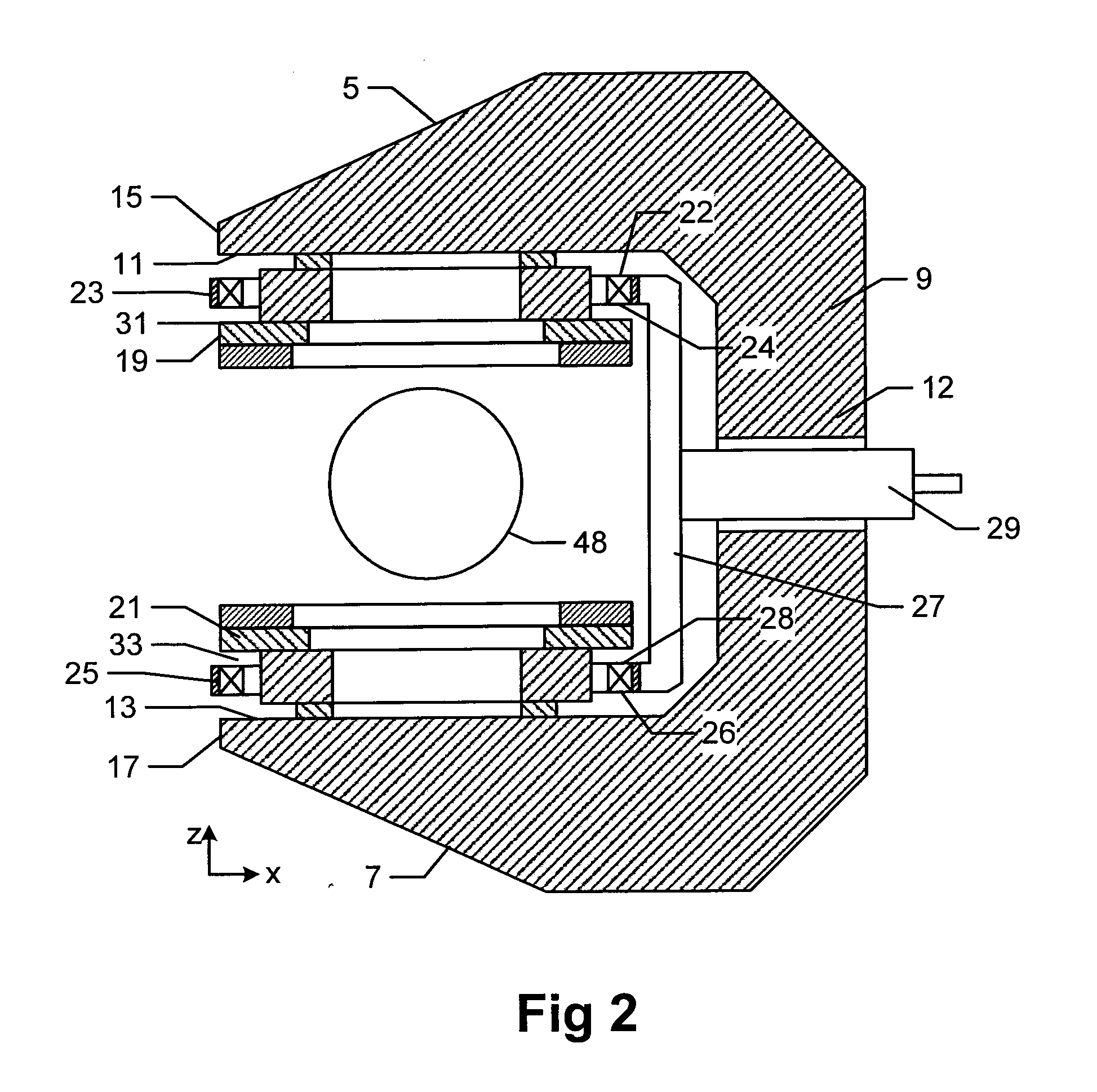

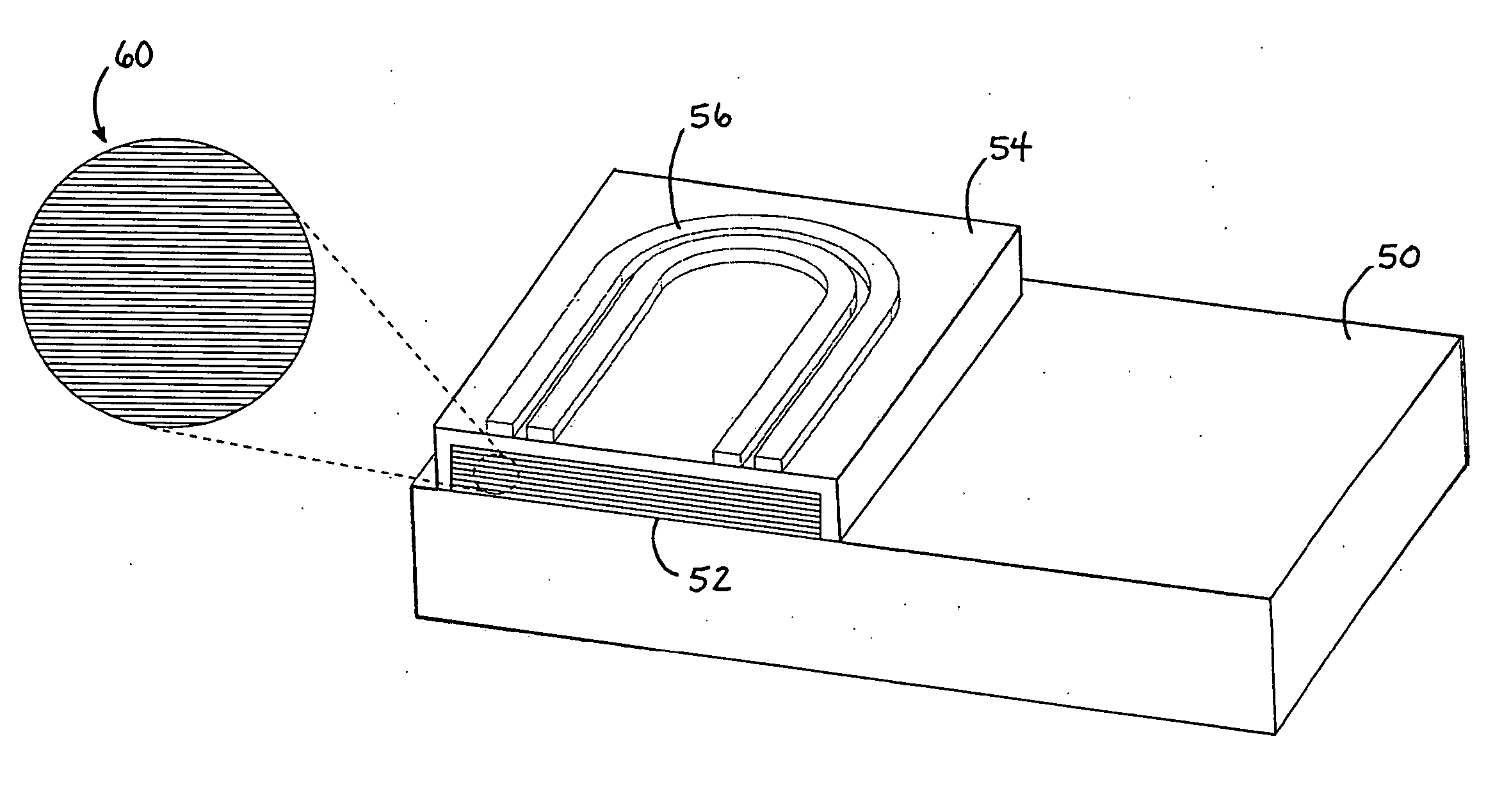

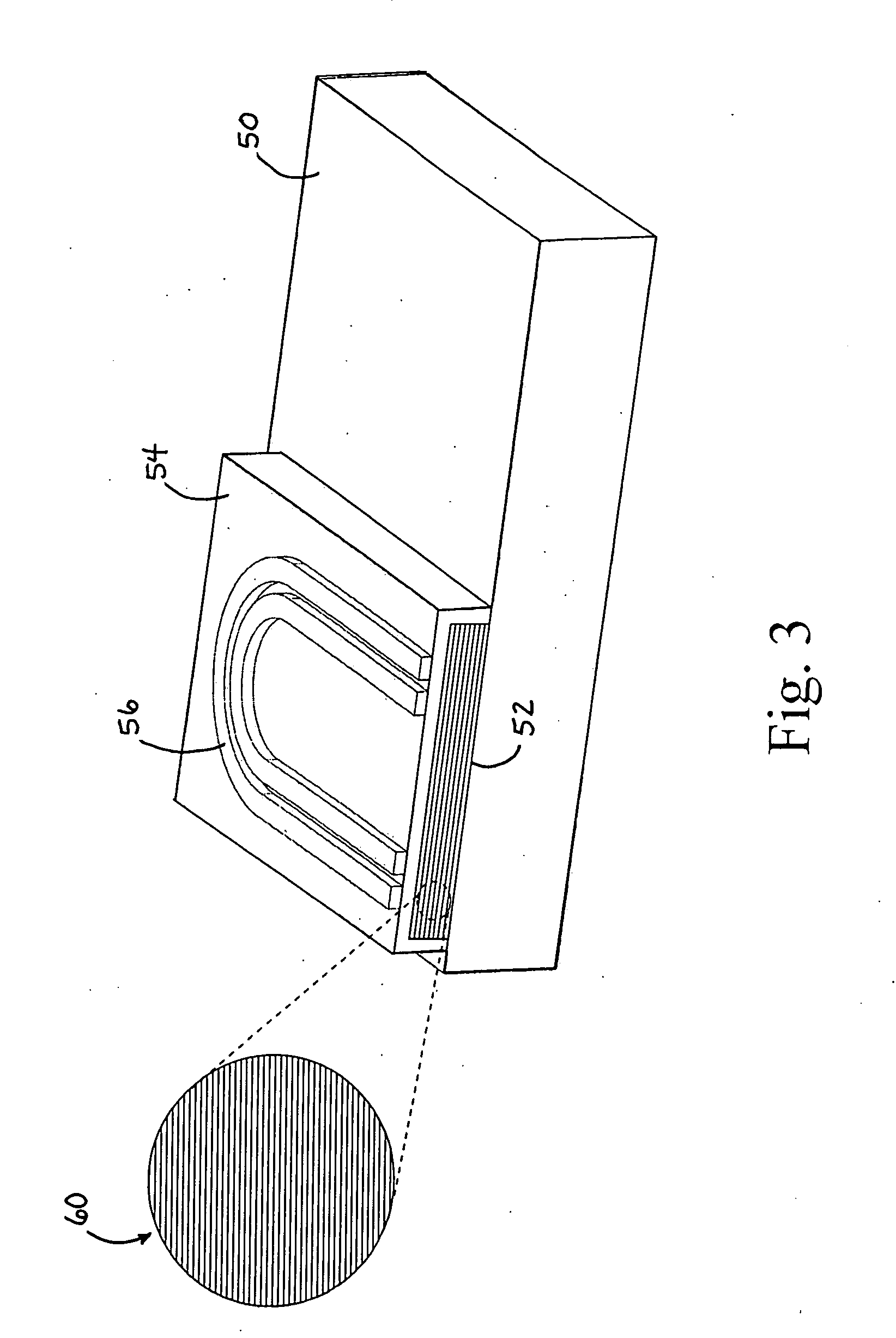

Magnet assembly

InactiveUS20100219833A1Maintain good propertiesPrecise positioningMagnetic materialsSuperconducting magnets/coilsEngineeringPole piece

An electromagnet comprising a ferromagnetic yoke which comprises a yoke. Mutually opposing first and second pole pieces are provided. The first pole piece is provided with a planar coil having a first side facing the yoke and a second side facing the yoke. A balancing member is arranged on the second side of the planar coil to counterbalance the attractive force between the planar coil and the yoke. The other pole piece may also be provided with a corresponding balancing member.

Owner:EMSCAN

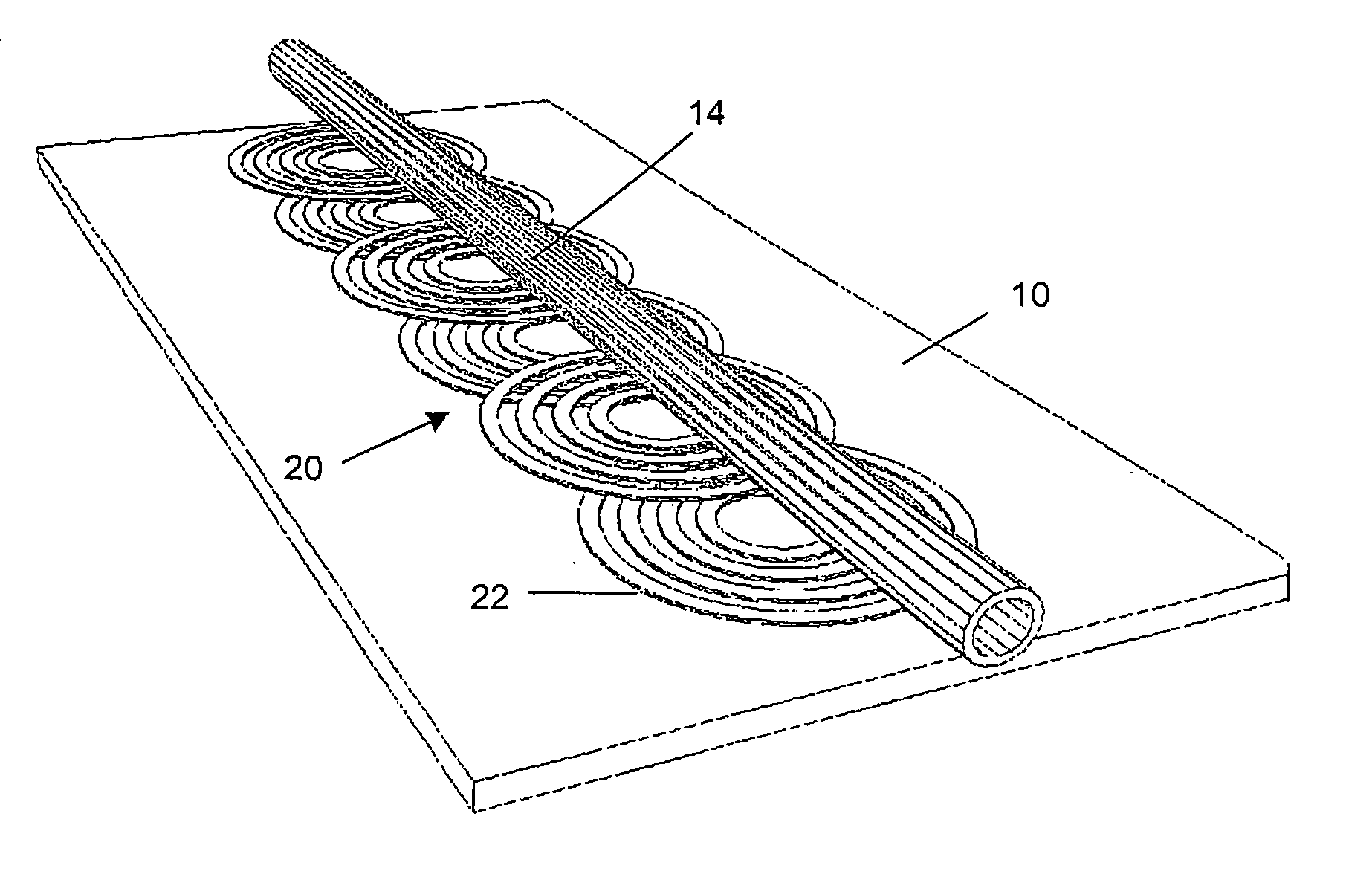

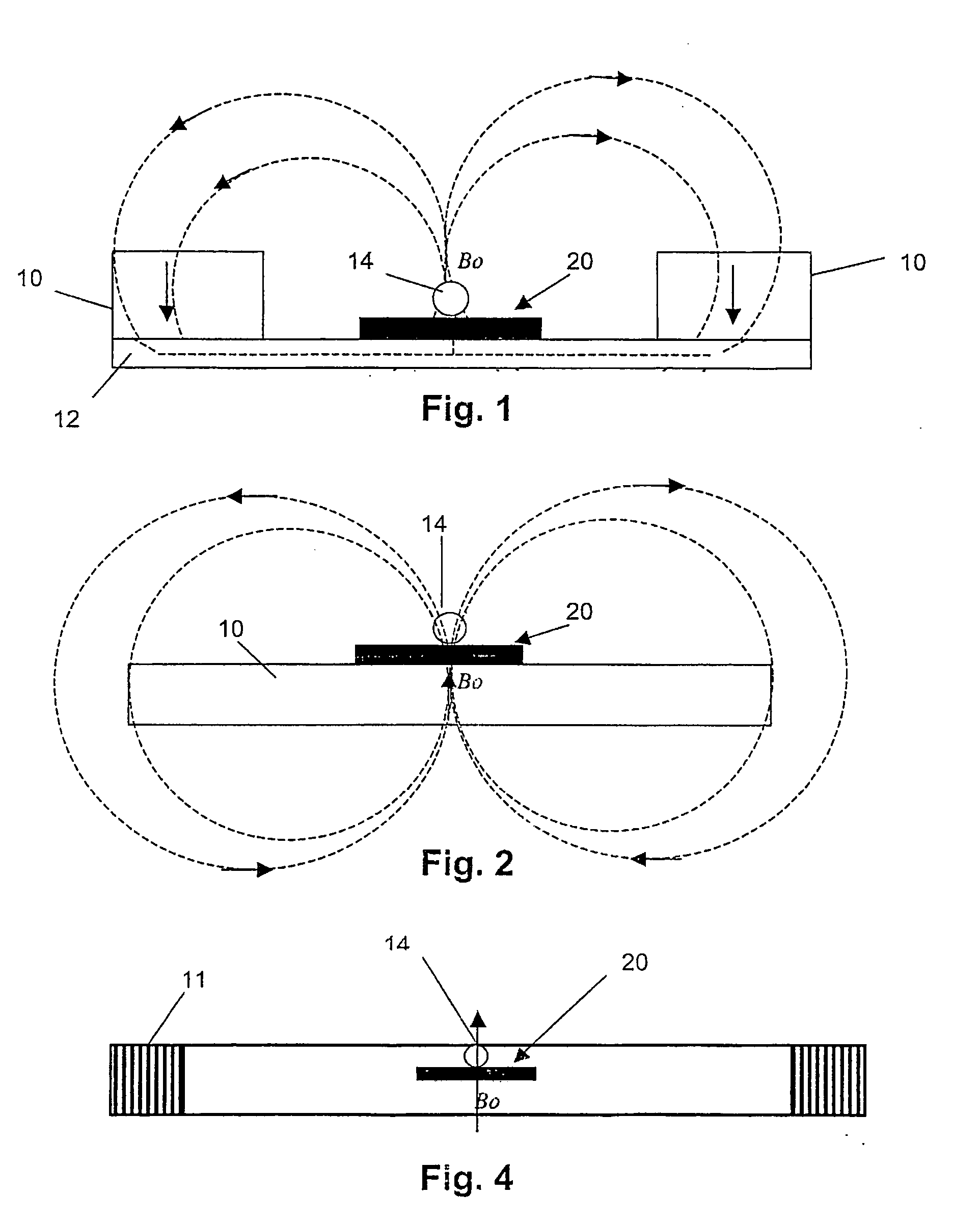

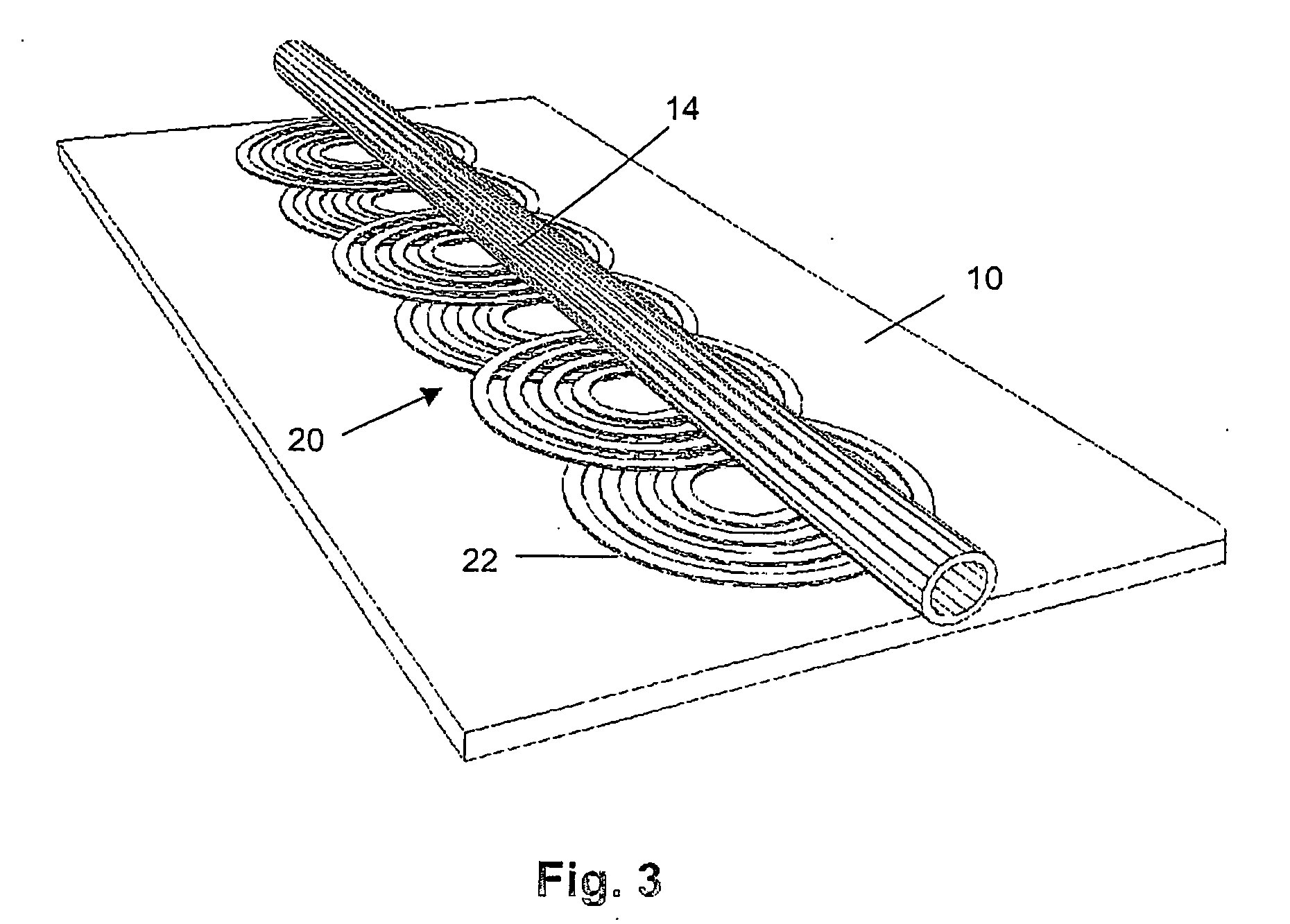

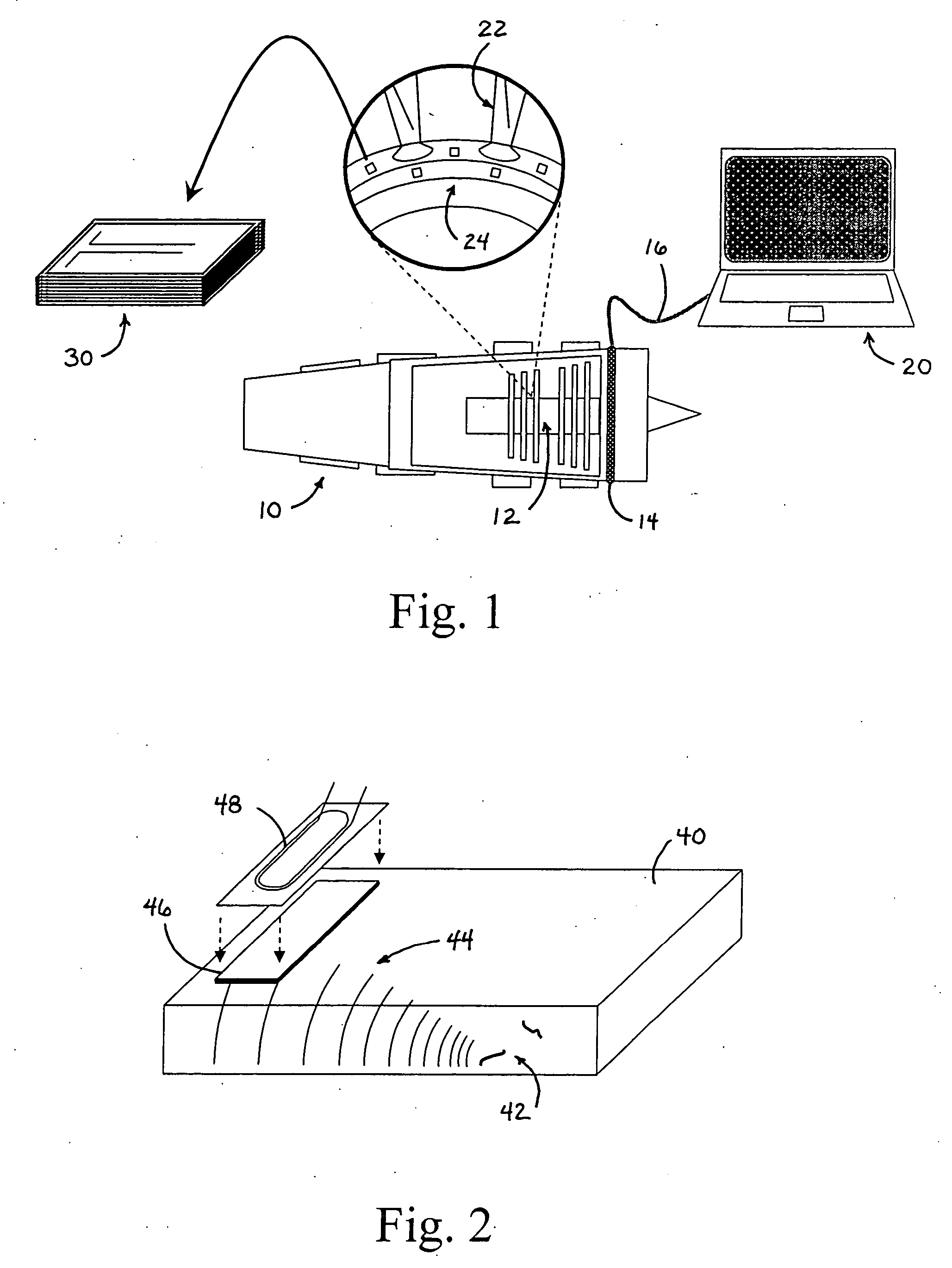

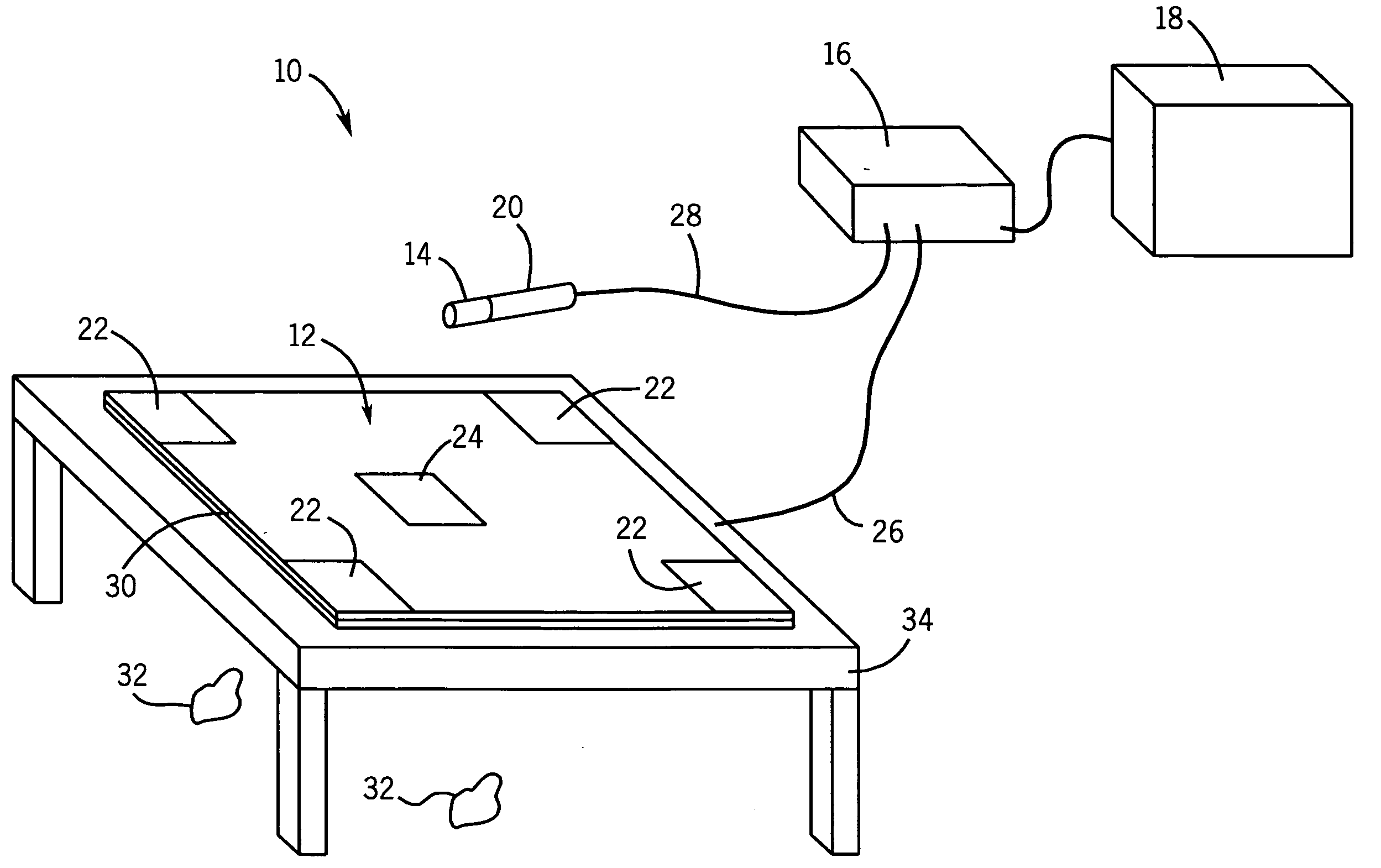

Magnetic bead manipulation and transport device

InactiveUS20050284817A1Increase speedLow magnetic fieldsElectrostatic separationTransportation and packagingClinical chemistryMagnetic bead

A device for transporting magnetic or magnetisable microbeads (25) in a capillary chamber (14) comprises a permanent magnet (10) or an electromagnet (11) for subjecting the capillary chamber to a substantially uniform magnetic field, to apply a permanent magnetic moment to the microbeads (25). At least one planar coil (22) and preferably an array of overlapping coils are located adjacent to the capillary chamber (14) for applying a complementary magnetic field on the microbeads parallel or antiparallel to said substantially uniform magnetic field, to drive the microbeads. An arrangement is provided for switching the current applied to the coil(s) (22) to invert the field produced thereby, to selectively apply an attractive or repulsive driving force on the microbeads (25). The device is usable to transport microbeads for performing chemical and biochemical reactions or assay, as is done for instance in clinical chemistry assays for medical diagnostic purposes.

Owner:ECOLE POLYTECHNIQUE FEDERALE DE LAUSANNE (EPFL)

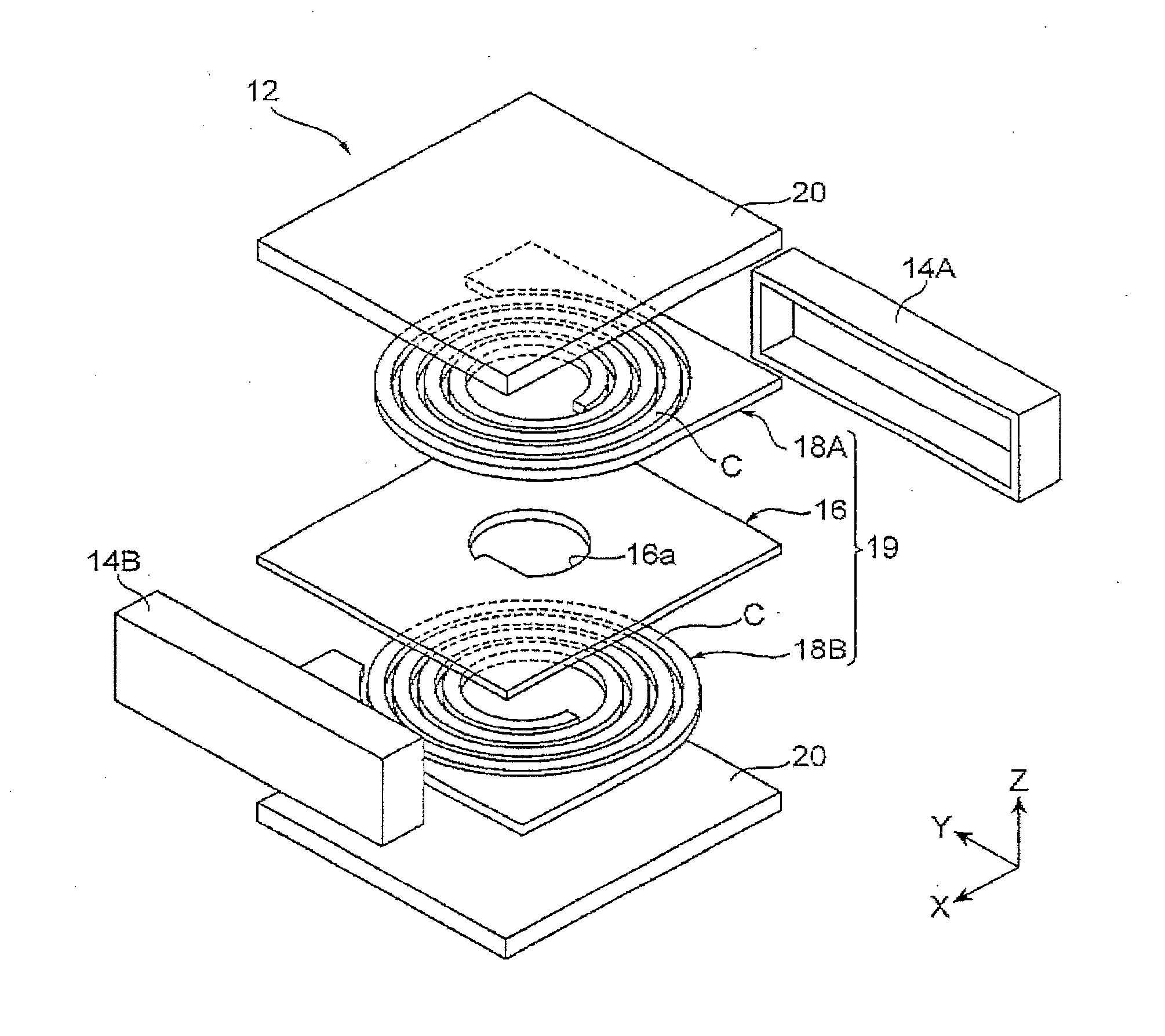

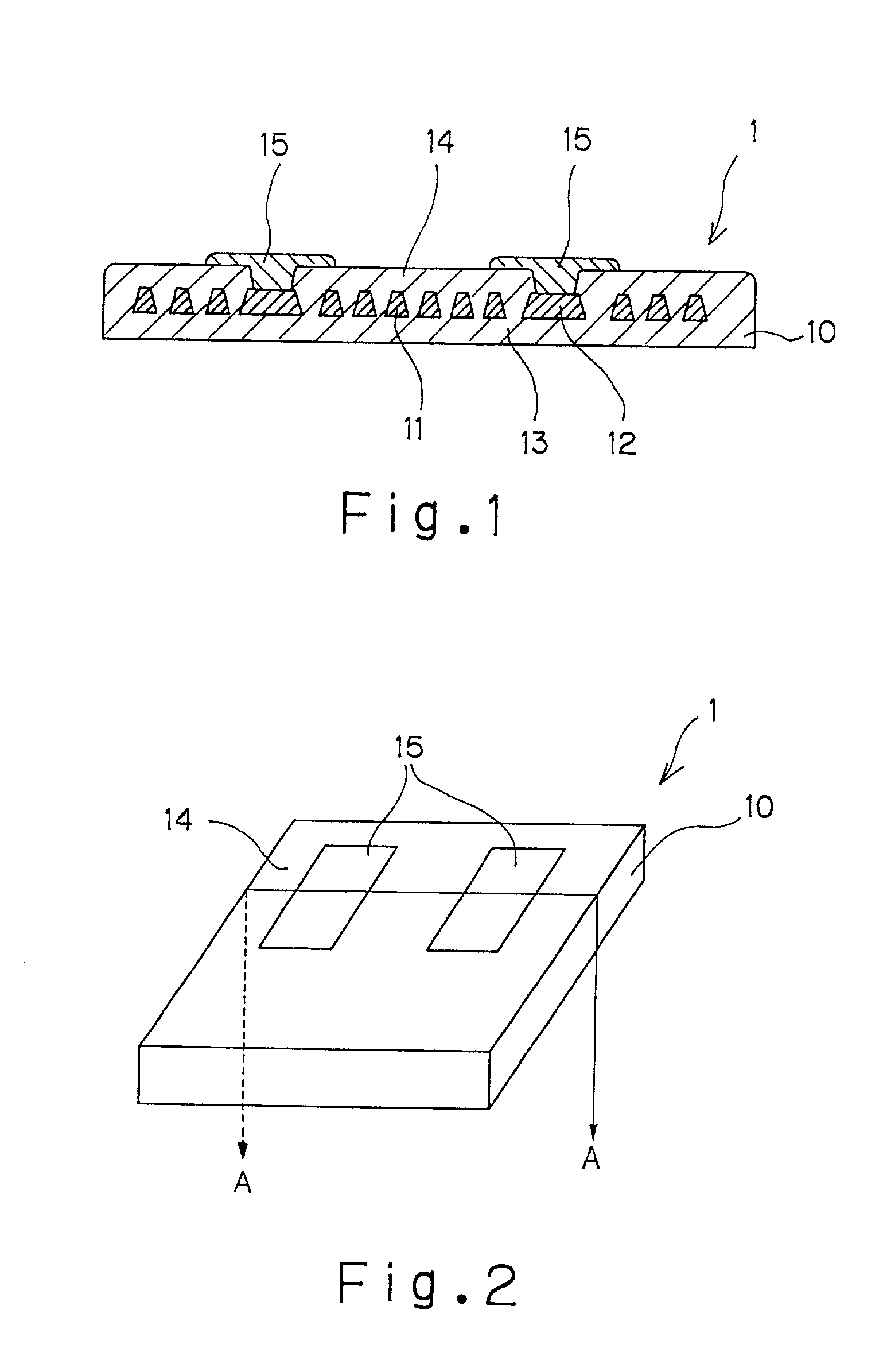

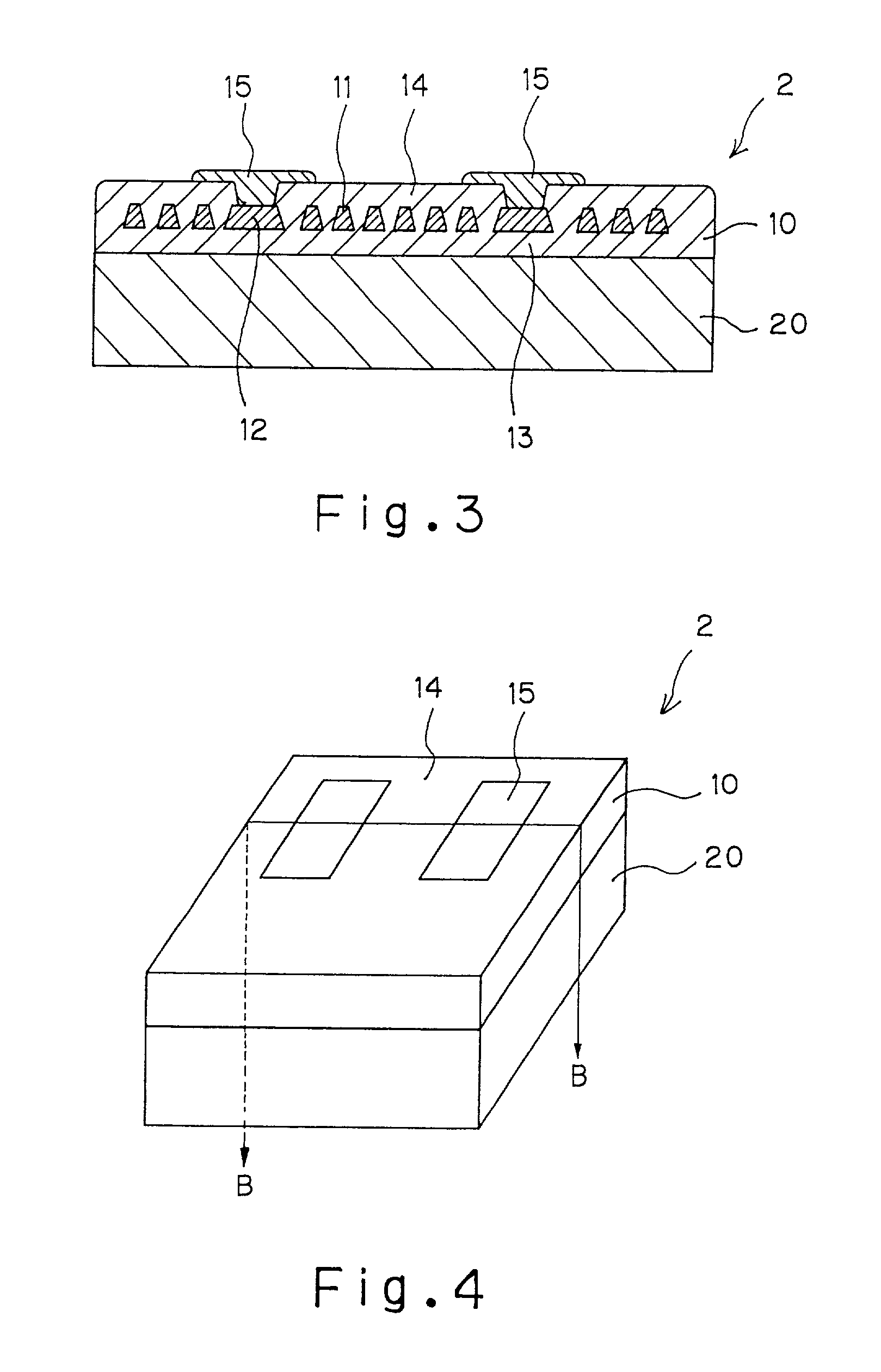

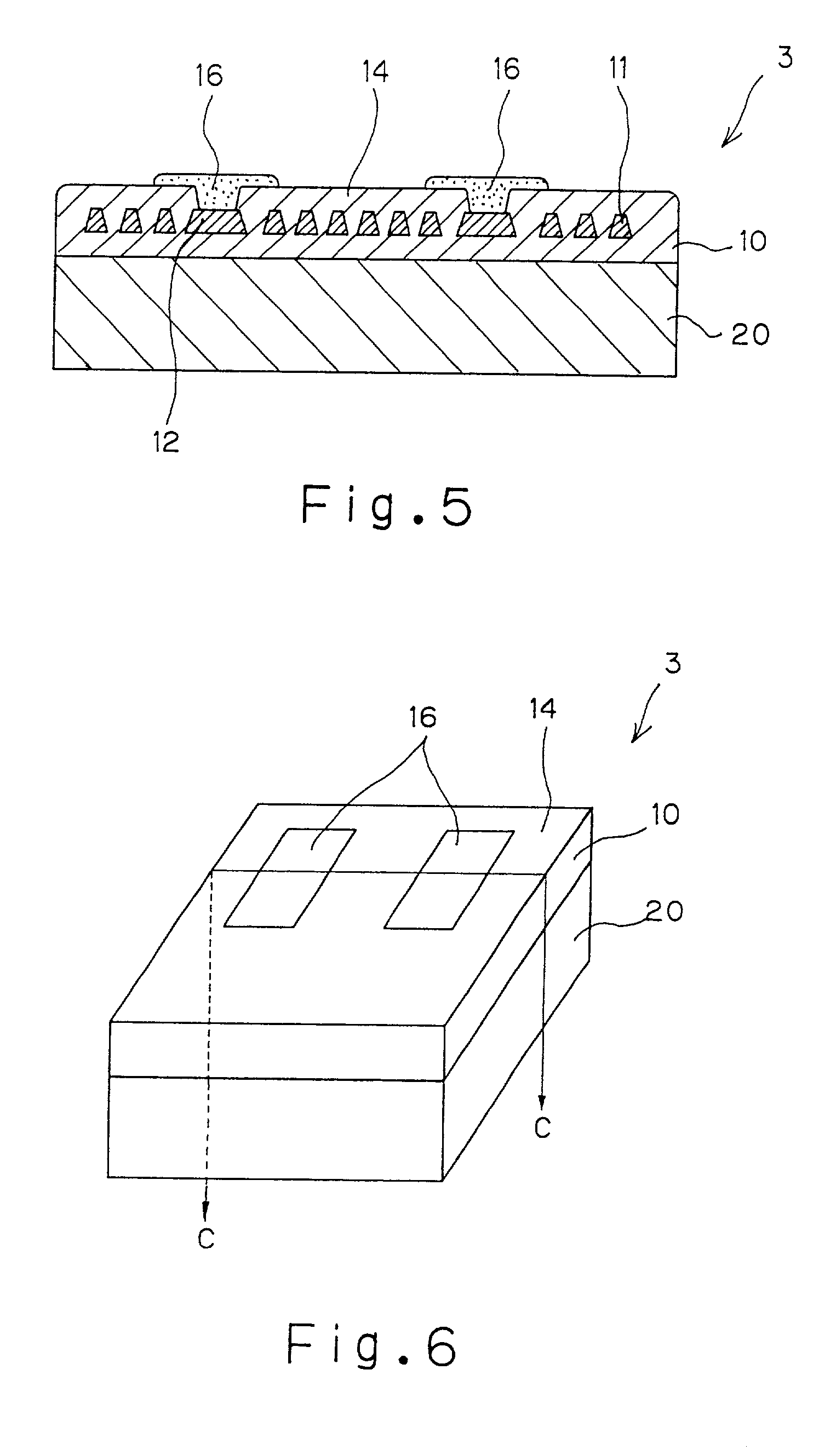

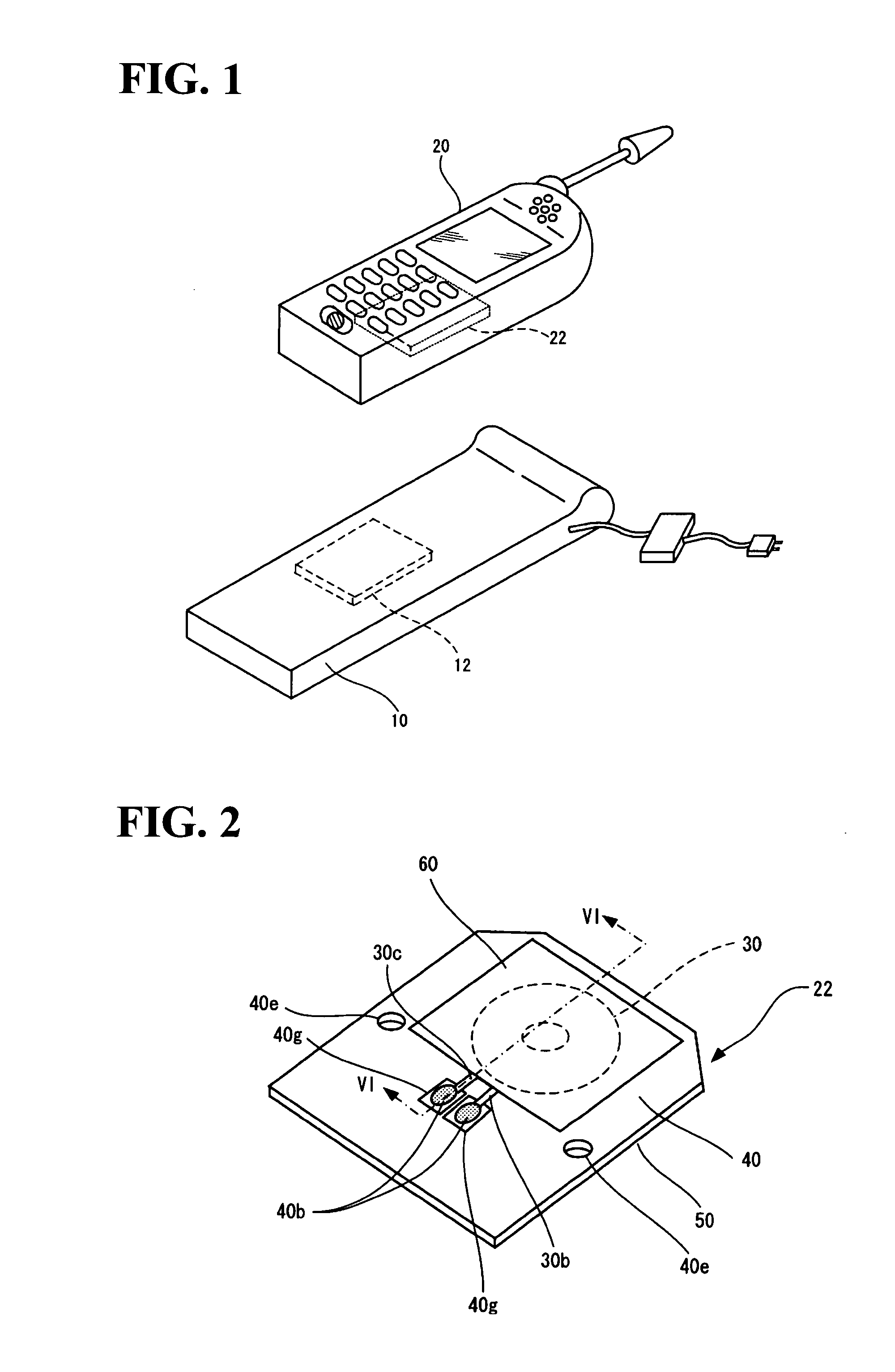

Coil unit and electronic instrument

A coil unit includes a planar coil that has a transmission side and a non-transmission side, a magnetic sheet provided over the non-transmission side of the planar coil, and a heat sink / magnetic shield plate stacked on a side of the magnetic sheet opposite to a side that faces the planar coil, the heat sink / magnetic shield plate dissipating heat generated by the planar coil and shielding magnetism by absorbing a magnetic flux that has not been absorbed by the magnetic sheet. The heat sink / magnetic shield plate has a thickness larger than that of the magnetic sheet.

Owner:SAMSUNG ELECTRONICS CO LTD

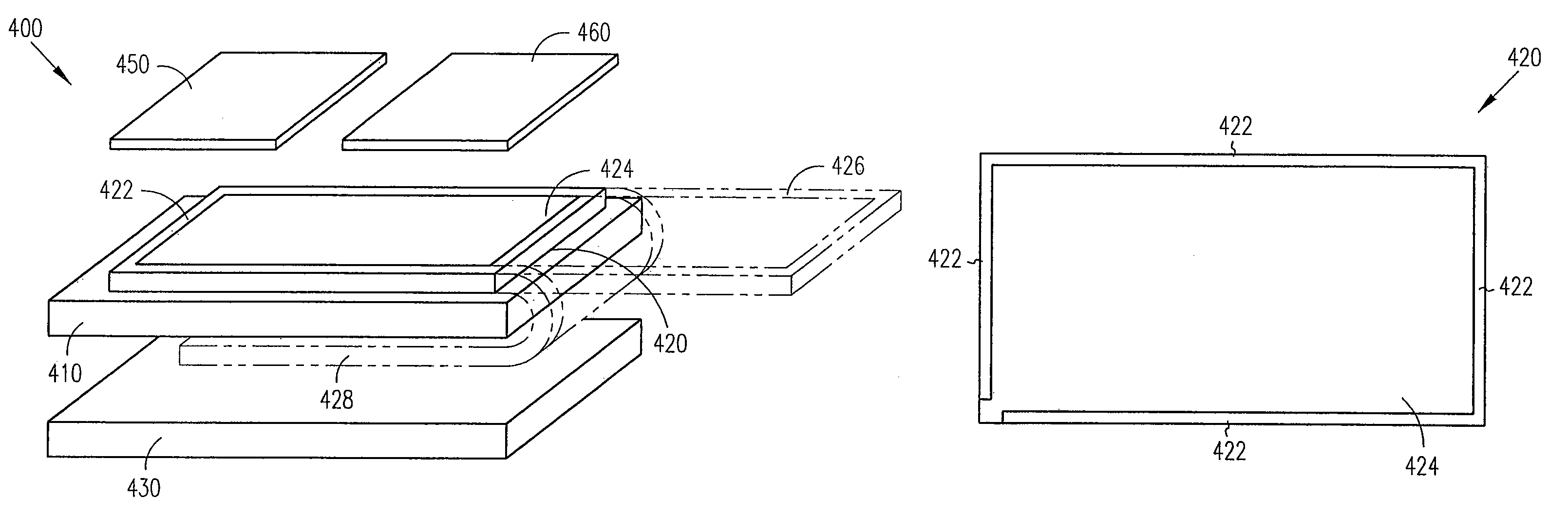

Antennas for hearing aids

ActiveUS20060227989A1Completely in canal hearing aidsAntenna supports/mountingsEngineeringFit hearing aid

An antenna configured in a hybrid circuit provides a compact design for a hearing aid to communicate wirelessly with a system external to the hearing aid. In an embodiment, an antenna includes metallic traces in a hybrid circuit that is configured for use in a hearing aid. The antenna includes contacts in the hybrid circuit to couple the metallic traces to electronic devices in the hybrid circuit. In an embodiment, the metallic traces form a planar coil design having a number of turns of the coil in a substrate in the hybrid circuit. In another embodiment, the metallic traces are included in a flex circuit on a substrate in the hybrid circuit. An antenna configured in a hybrid circuit allows for use in a completely-in-the-canal hearing aid.

Owner:STARKEY LAB INC

Flat magnetic element and power IC package using the same

ActiveUS20090243780A1Improve permeabilityIncrease inductanceSemiconductor/solid-state device detailsSolid-state devicesInductorInductance

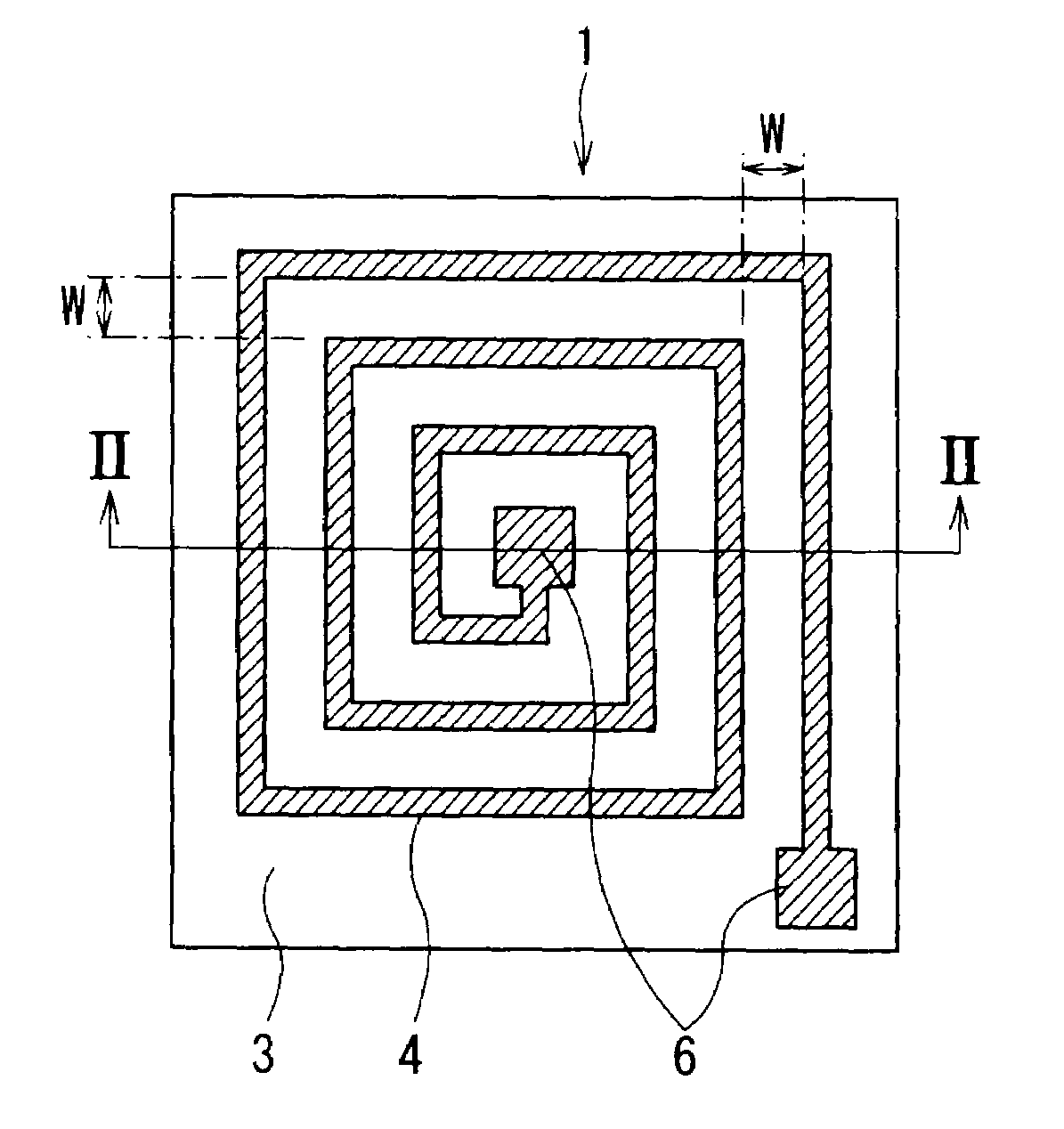

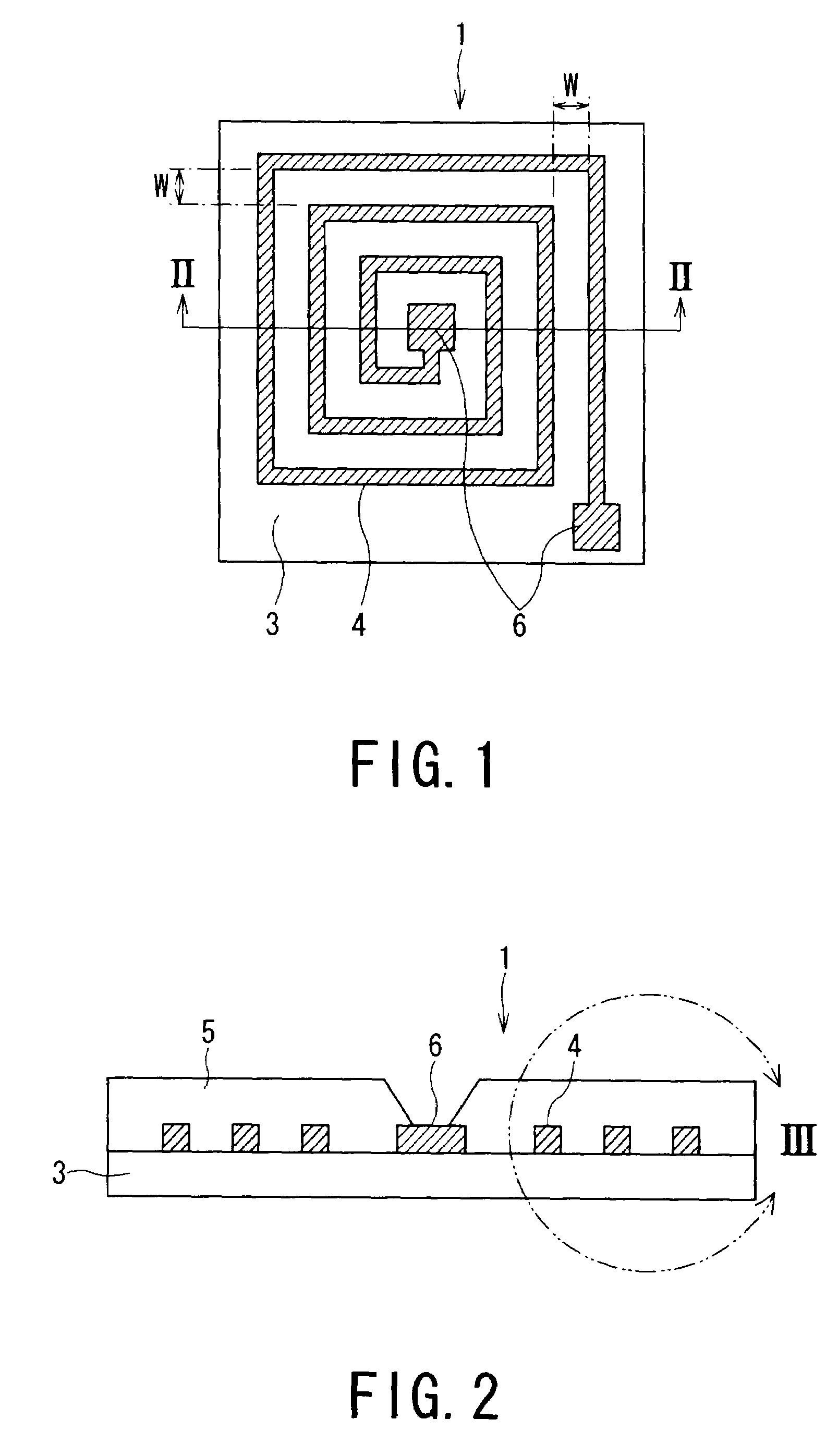

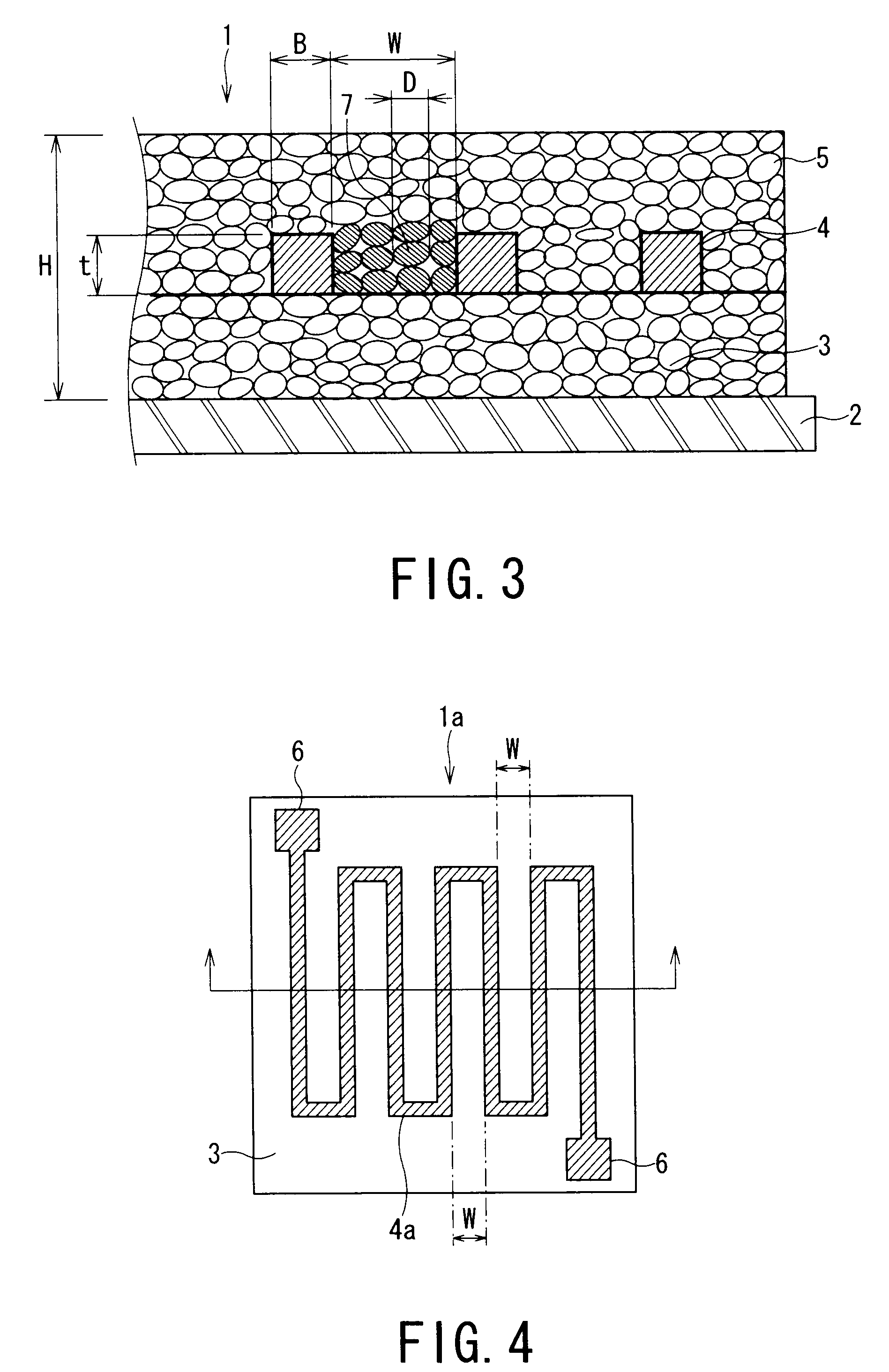

A planar magnetic device 1 including a first magnetic layer 3, a second magnetic layer 5, and a planar coil 4 disposed between the first magnetic layer 3 and the second magnetic layer 5, wherein magnetic particles 7 having a shape ratio S / L of 0.7 to 1 when a length of a long axis is L and a length of a short axis orthogonal to the long axis is L are filled in a gap W between coil wirings of the planar coil 4. According to the planar magnetic device 1, it is possible to realize a planar magnetic device such as an inductor reduced in height by using fine particles that enable to effectively obtain a large inductance value.

Owner:KK TOSHIBA +1

Power reception coil unit

InactiveUS20100320843A1Inhibit temperature riseImprove transmission efficiencyElectromagnetic wave systemTransformersElectricityElectric power transmission

A power reception coil unit includes a power reception coil configured to be magnetically coupled to a power supply coil during a power transmission and a magnetic plate made of a magnetic material having electrical conductivity. The power reception coil is a planar coil. The magnetic plate has its surface opposed to the power reception coil and is parallel to the power reception coil. The magnetic plate is provided with a plurality of slits in the surface.

Owner:PANASONIC CORP

Planar magnetic device and power supply IC package using same

ActiveUS20090045905A1Increase inductanceImprove permeabilitySemiconductor/solid-state device detailsTransformers/inductances coils/windings/connectionsInductorConductor Coil

A planar magnetic device 1 includes a first magnetic layer 3 and a second magnetic layer 5 that are made of a mixture of a magnetic powder 7 and a resin, and a planar coil 4 disposed between the magnetic layers. When the planar coil 4 has an adjacent winding interval W between the potions 4c of the coil and the magnetic powder 7 has a maximum particle size L, planar magnetic device 1 satisfies the relationship W>L. In the planar magnetic device 1 having the above structure, fine magnetic powder that can produce a high inductance fills the spaces between the adjacent windings. Thus, the invention can achieve a high-performance planar magnetic device, such as a thin inductor.

Owner:KK TOSHIBA +1

Surface mounting type planar magnetic device and production method thereof

InactiveUS20010024739A1Reduce loss by DC resistance of the coilIncrease the sectionTransformers/inductances coils/windings/connectionsRecord information storageSurface mountingEngineering

This invention provides a surface mounting type planar magnetic device comprised of upper ferrite magnetic film, lower ferrite magnetic film and a planar coil interposed therebetween. For applying surface mount technology, an opening is formed in the upper ferrite magnetic film above a coil terminal portion and then, an external electrode conductive with the coil terminal portion through the opening is formed on the upper ferrite magnetic film. Further, this surface mounting type planar magnetic device is of a thin structure and can be mounted on the surface of a printed board. Its power loss is small, its inductance is large, its frequency characteristic is excellent, the disparity of the characteristic is small and its reliability is excellent.

Owner:KK TOSHIBA +1

Battery pack rechargeable by magnetic induction effect

InactiveUS20080061735A1Fast chargingLarge widthBatteries circuit arrangementsSecondary cells charging/dischargingElectromagnetic couplingElectric power

A battery pack rechargeable by a magnetic induction effect incorporates a secondary coil electromagnetically coupled to a primary coil of a battery charger and a secondary battery rechargeable by electric power induced to the secondary coil. The secondary battery is in a form of a thin battery having a larger width than a thickness, and two opposing surfaces of the secondary battery are composed of a first flat surface and a second flat surface. The secondary coil is in a form of a planar coil with a wire material being spirally coiled in the plane. In the battery pack, the secondary coil in the form of the planar coil is fixedly layered on the first flat surface of the thin battery.

Owner:SANYO ELECTRIC CO LTD

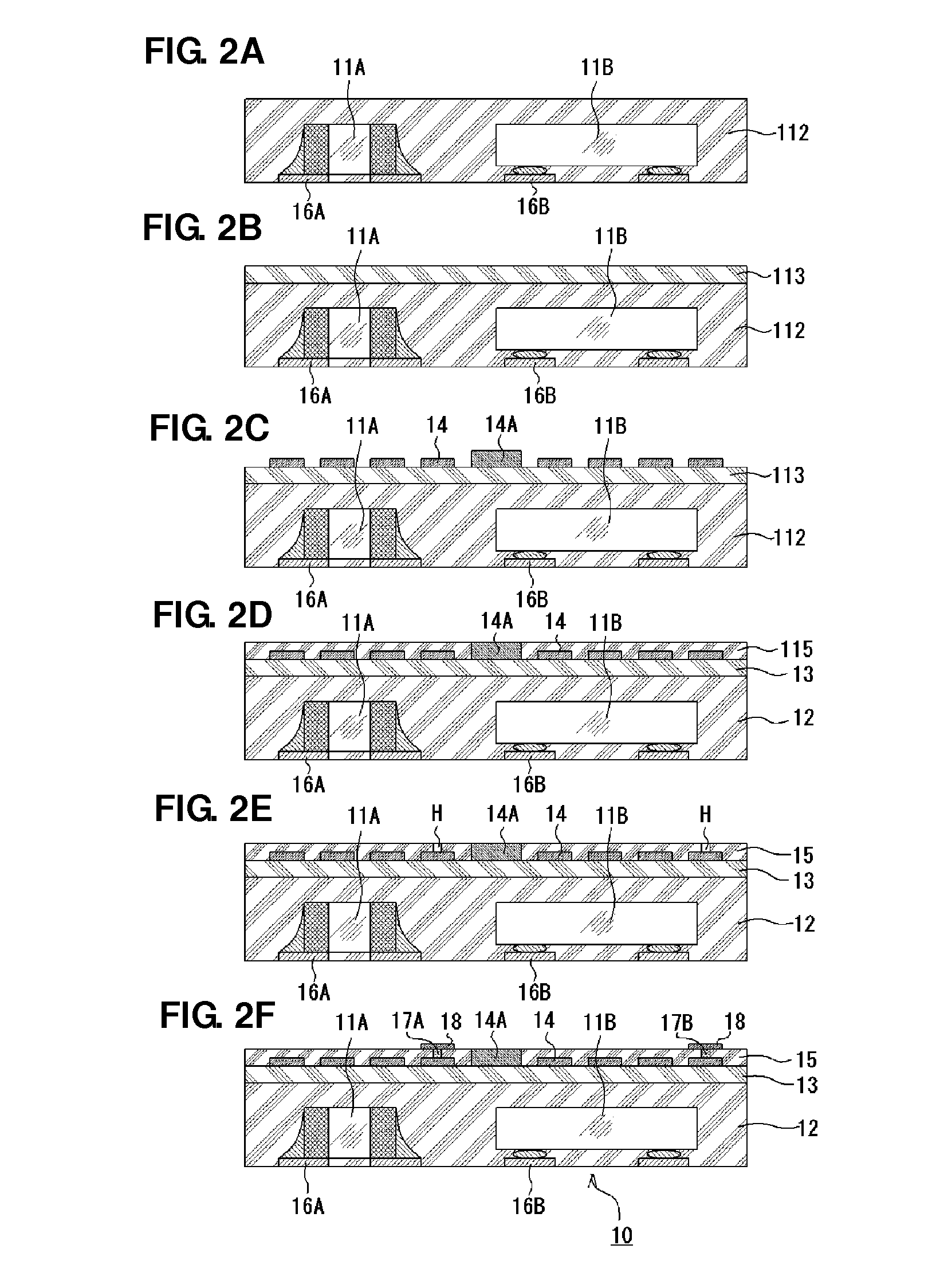

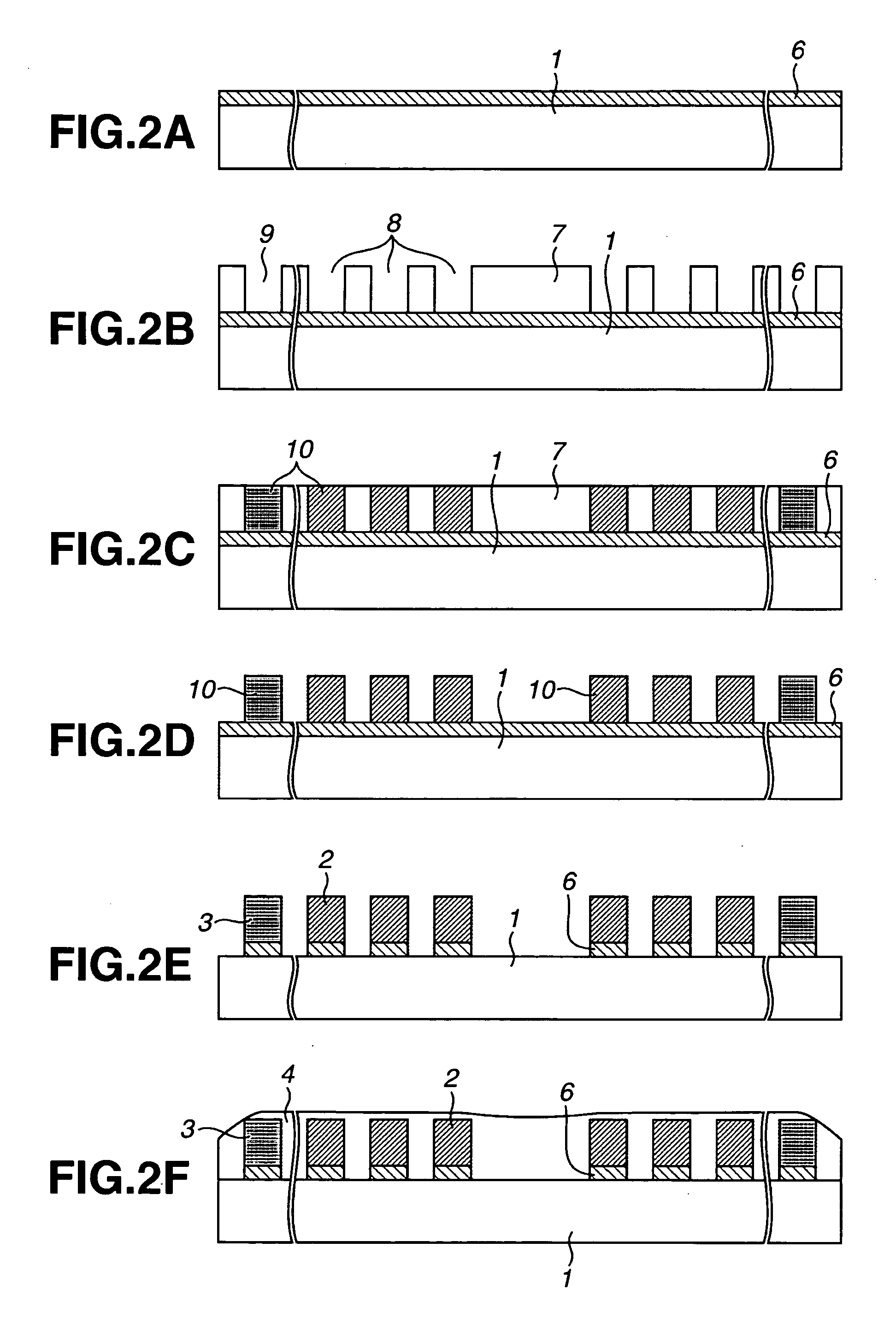

Method for manufacturing module with planar coil, and module with planar coil

ActiveUS20110285215A1Reduce manufacturing costHigh currentMultiple-port networksTransformersComputer moduleEngineering

A method for manufacturing a module including a planar coil, and a module including a planar coil, reduce manufacturing cost and also are able to handle a large current. The method for manufacturing the module including the planar coil includes the steps of providing a second resin layer including a magnetic filler on a first resin layer with a built-in chip-type electronic component; providing a planar coil on the second resin layer; and providing a third resin layer including a non-magnetic property so as to coat the planar coil.

Owner:MURATA MFG CO LTD

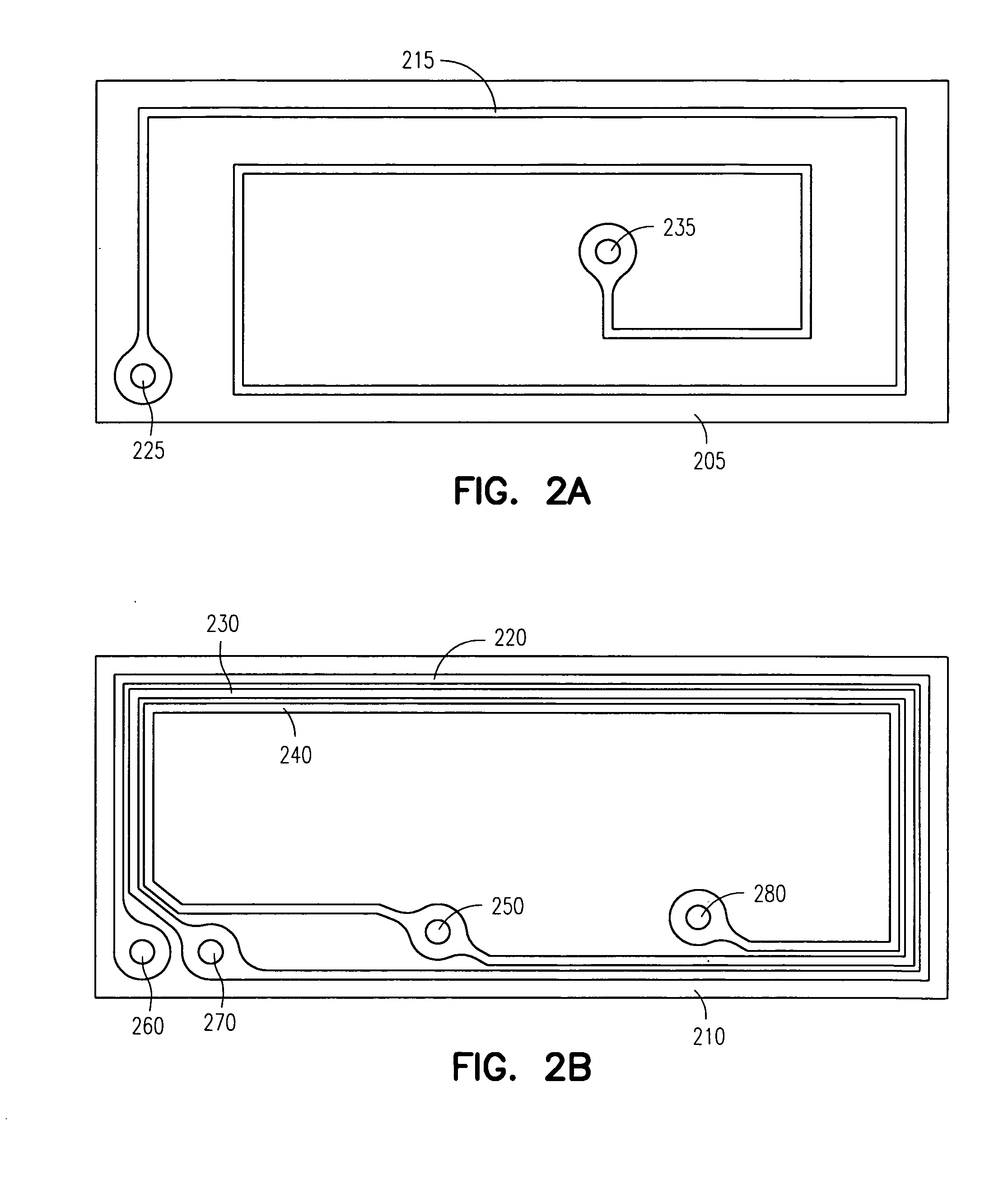

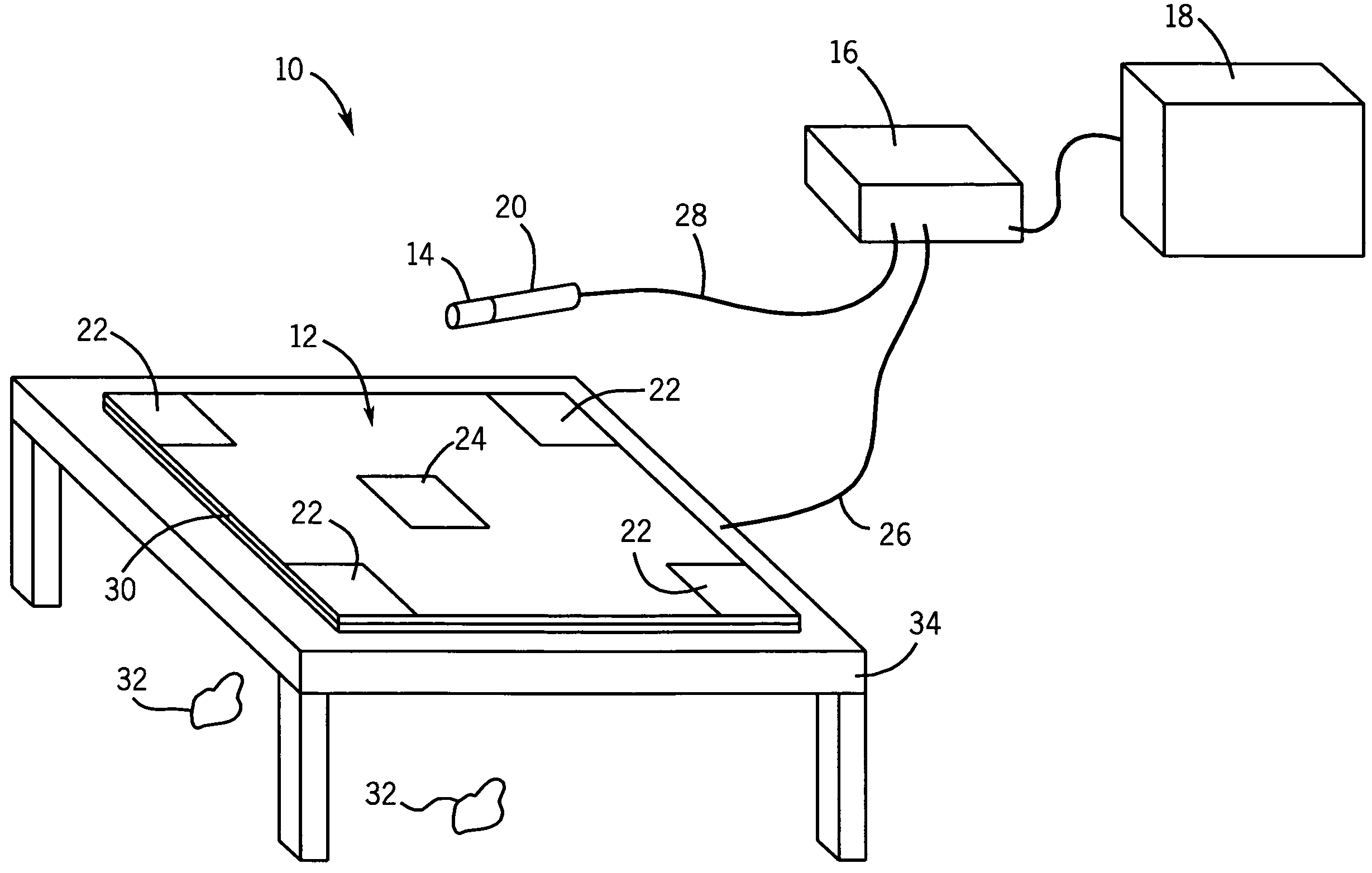

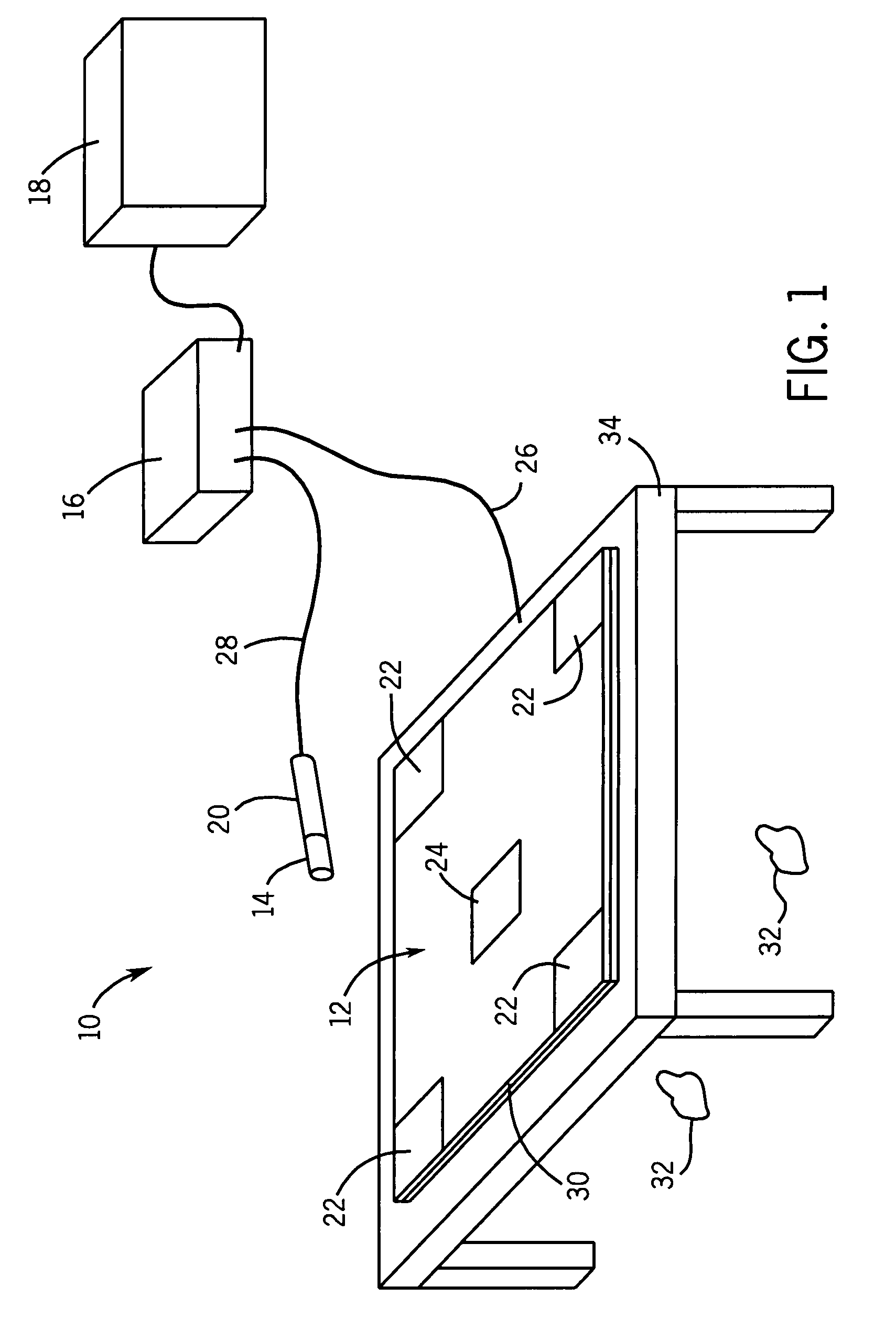

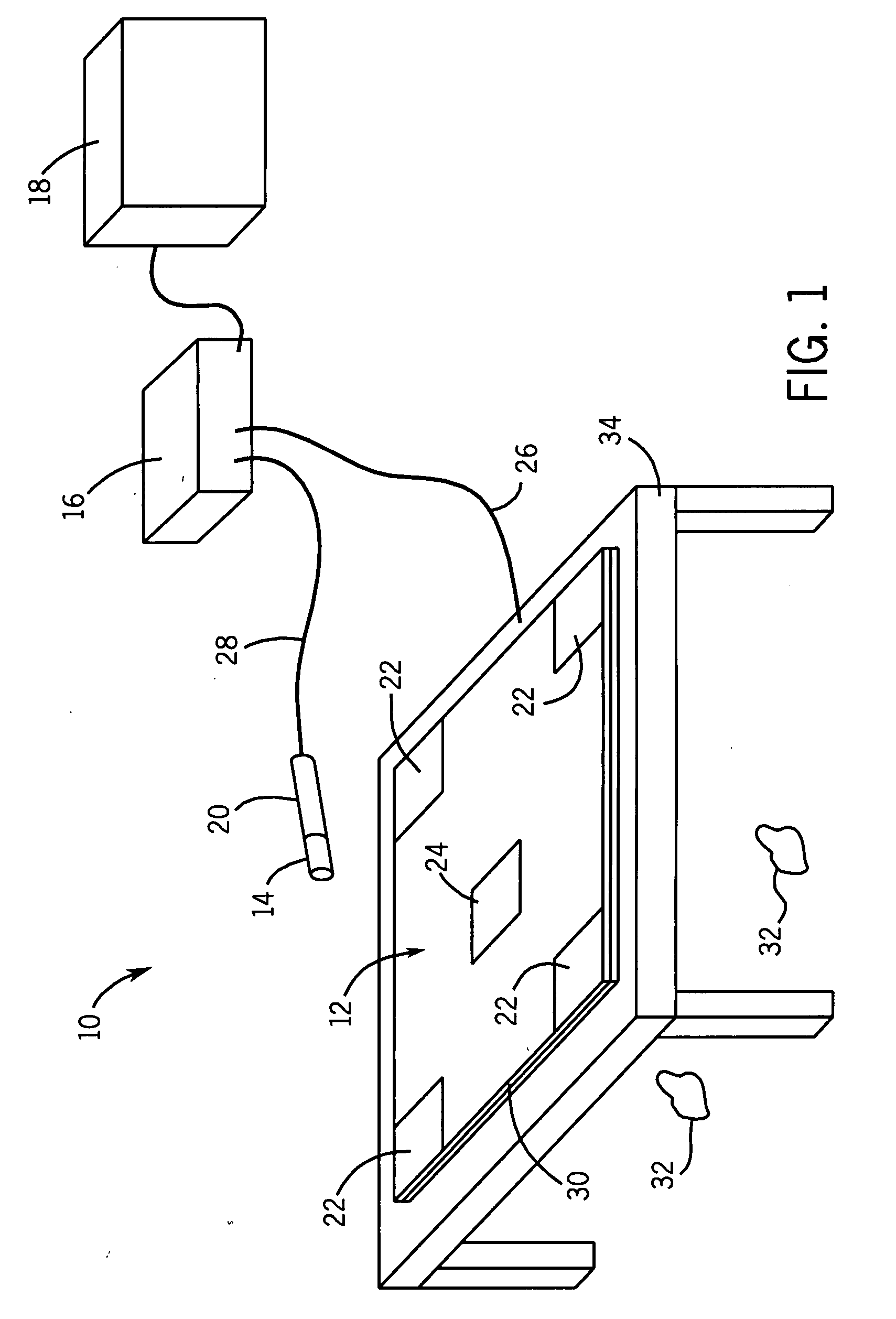

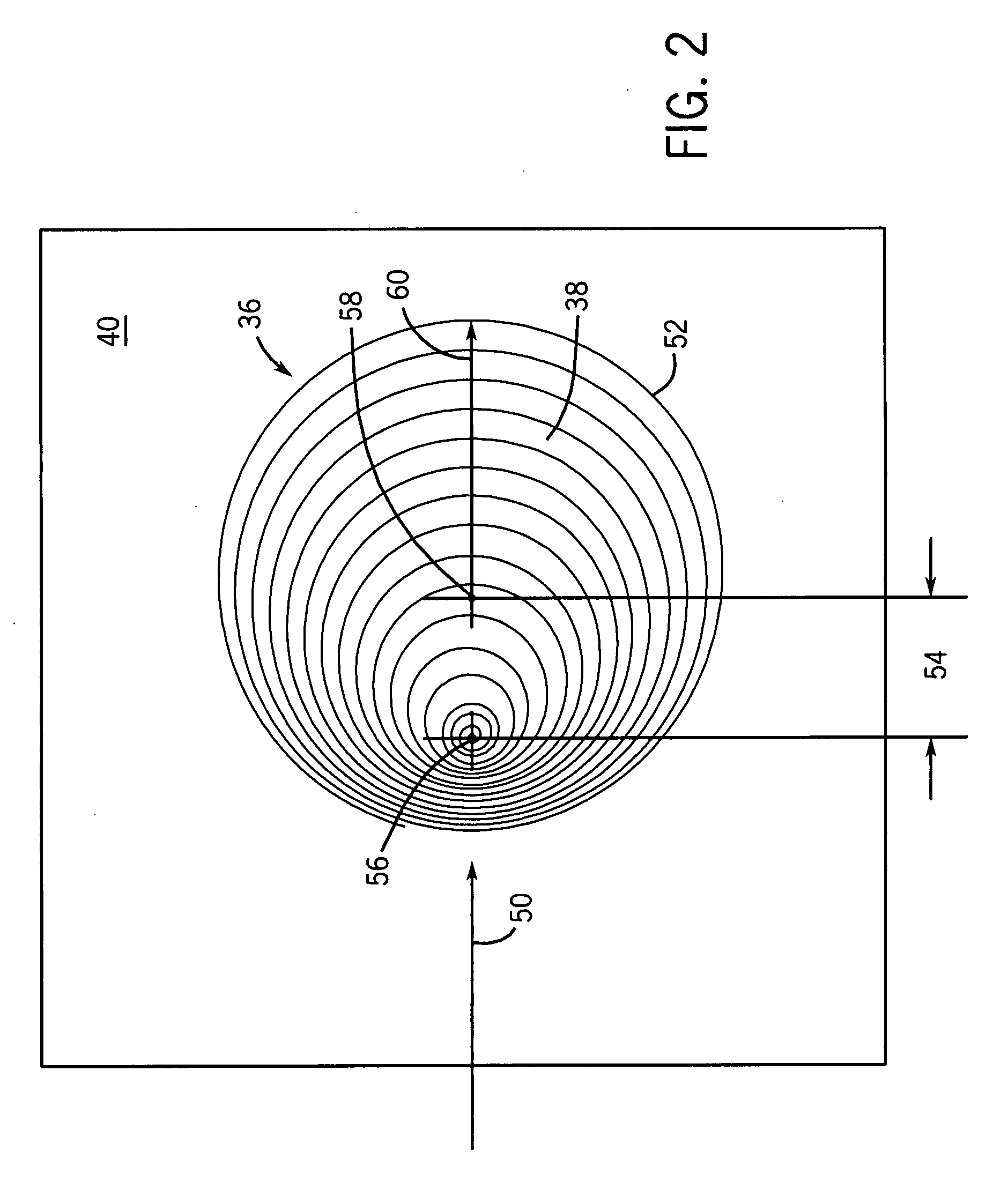

Electromagnetic tracking method and system

ActiveUS7782046B2Electromagnets without armaturesTransformers/inductances coils/windings/connectionsClassical mechanicsElectromagnetic shielding

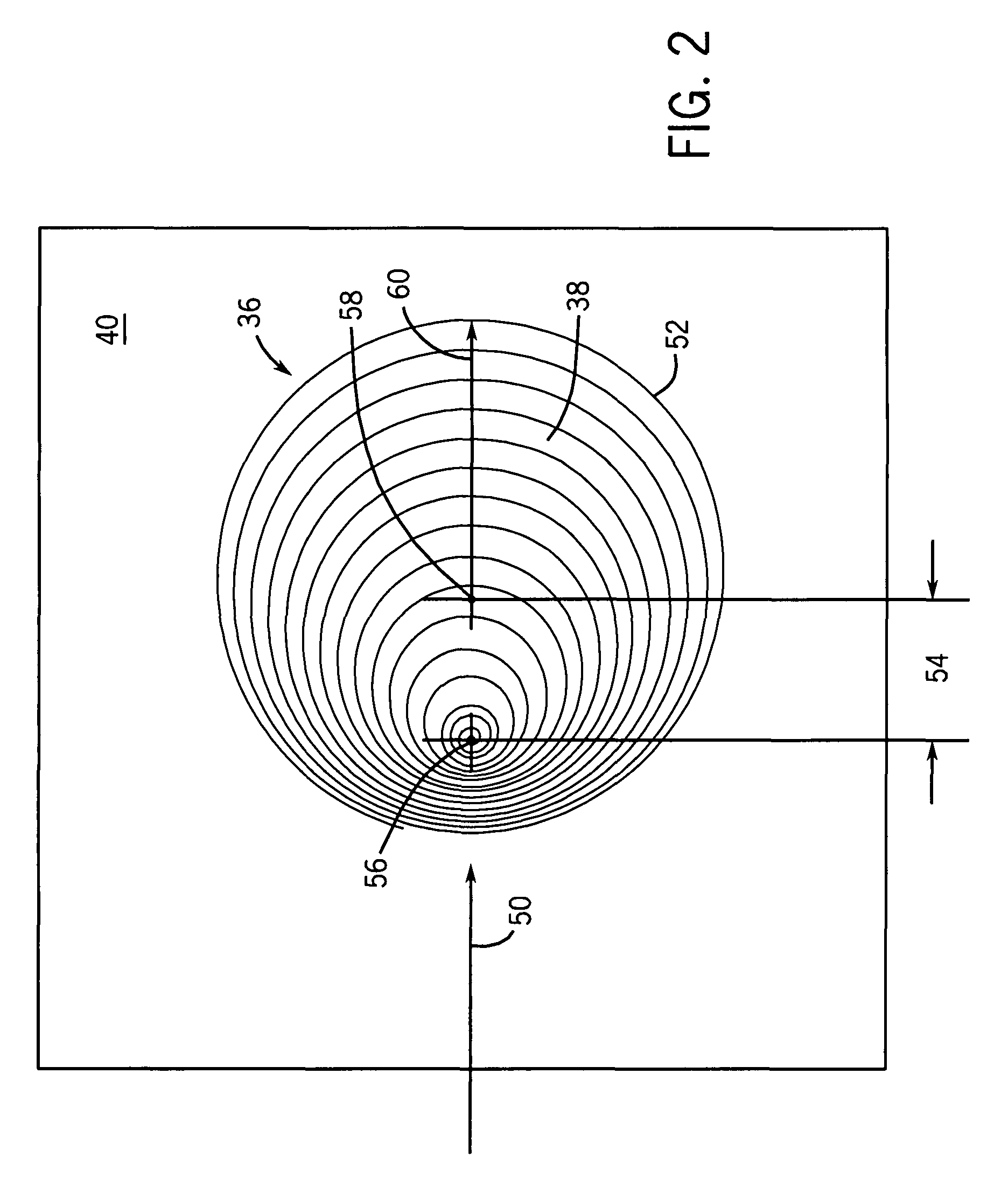

Provided is an electromagnetic coil arrangement comprising a set of electromagnetic sensors at fixed locations with respect to each other, each of the electromagnetic sensors comprising a planar coil coupled to a conductive layer, the planar coil comprising non-concentric rings. Further, provided is an electromagnetic tracking system, comprising an electromagnetic coil arrangement, at least one complementary electromagnetic sensor and a processor configured to process a signal comprising data indicative of a mutual inductance between the at least one complementary electromagnetic sensor and each of the set of the electromagnetic sensors of the electromagnetic coil arrangement. Also, provided are a method of tracking and a method of manufacturing an electromagnetic coil arrangement.

Owner:STRYKER EURO OPERATIONS HLDG LLC

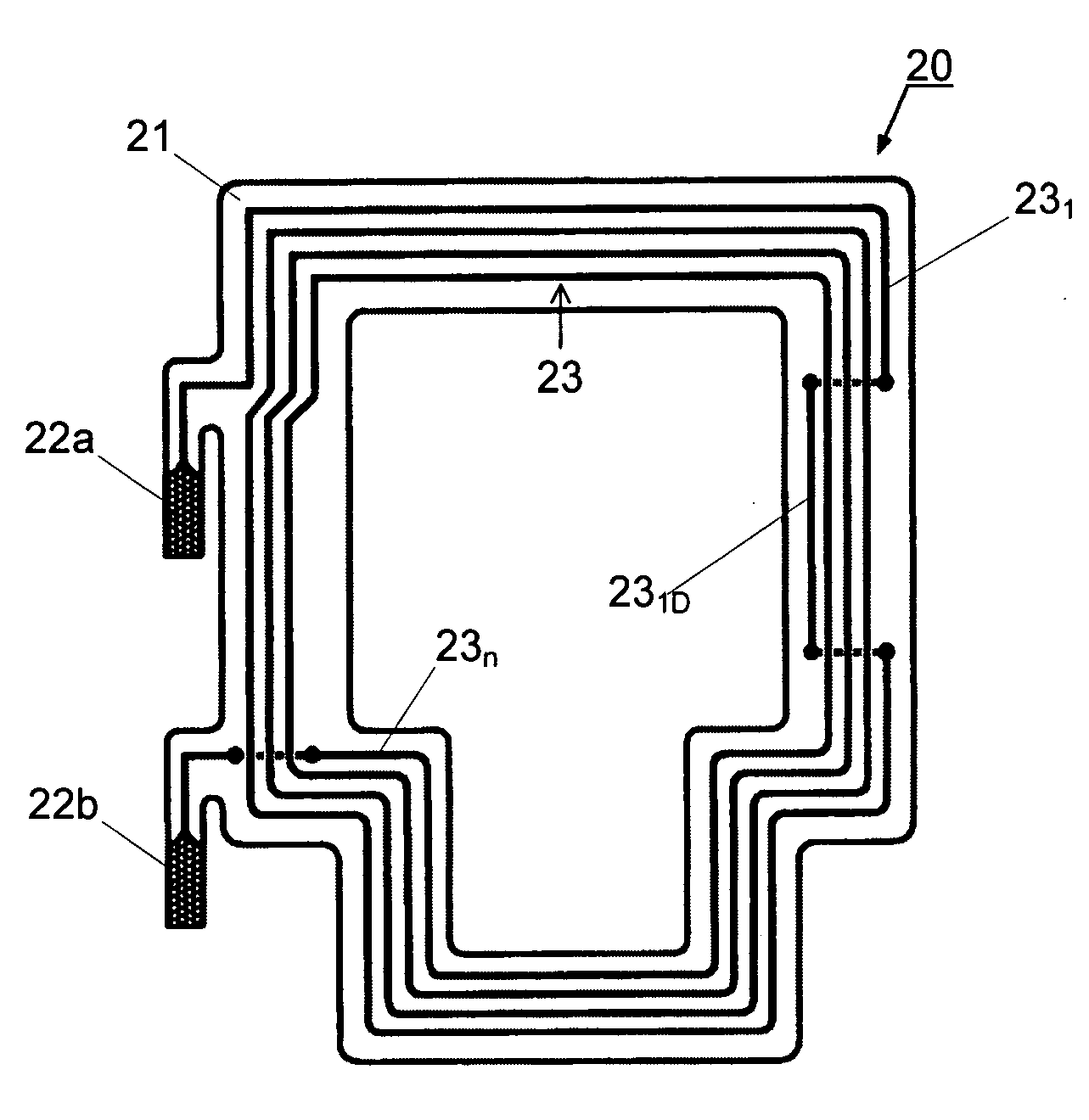

Antenna and portable electronic device

ActiveUS20080055046A1Reliable communicationResonant long antennasAntenna supports/mountingsElectrical conductorElectromagnetic field

A portable electronic device having an RFID function has an RFID antenna having a planar coil formed by winding a conductor. The RFID antenna is a loop antenna having a loop diameter corresponding to RFID with a strong electromagnetic field characteristic, and has an antenna pattern where a part of its coil turn which is other than an innermost coil turn is placed inward of the innermost coil turn. The antenna pattern can be provided by bending or branching a part of a coil turn of the conductor which is other than the innermost coil turn in such a way that the part of the coil turn is laced inward of the innermost coil turn, thereby ensuring compensation for the magnetic field strength at the center portion of the antenna and achieving excellent communications without a non-communicatable area even with the RFID having a slight electromagnetic field characteristic.

Owner:LENOVO INNOVATIONS LTD HONG KONG

Systems & methods for flaw detection and monitoring at elevated temperatures with wireless communication using surface embedded, monolithically integrated, thin-film, magnetically actuated sensors, and methods for fabricating the sensors

ActiveUS20070108973A1Effective structural health managementEffective prognosisNanomagnetismVacuum evaporation coatingThin film sensorElectricity

Systems and methods for flaw detection and monitoring at elevated temperatures with wireless communication using surface embedded, monolithically integrated, thin-film, magnetically actuated sensors, and methods for fabricating the sensors. The sensor is a monolithically integrated, multi-layered (nano-composite), thin-film sensor structure that incorporates a thin-film, multi-layer magnetostrictive element, a thin-film electrically insulating or dielectric layer, and a thin-film activating layer such as a planar coil. The method for manufacturing the multi-layered, thin-film sensor structure as described above, utilizes a variety of factors that allow for optimization of sensor characteristics for application to specific structures and in specific environments. The system and method integrating the multi-layered, thin-film sensor structure as described above, further utilizes wireless connectivity to the sensor to allow the sensor to be mounted on moving components within the monitored assembly.

Owner:SOUTHWEST RES INST

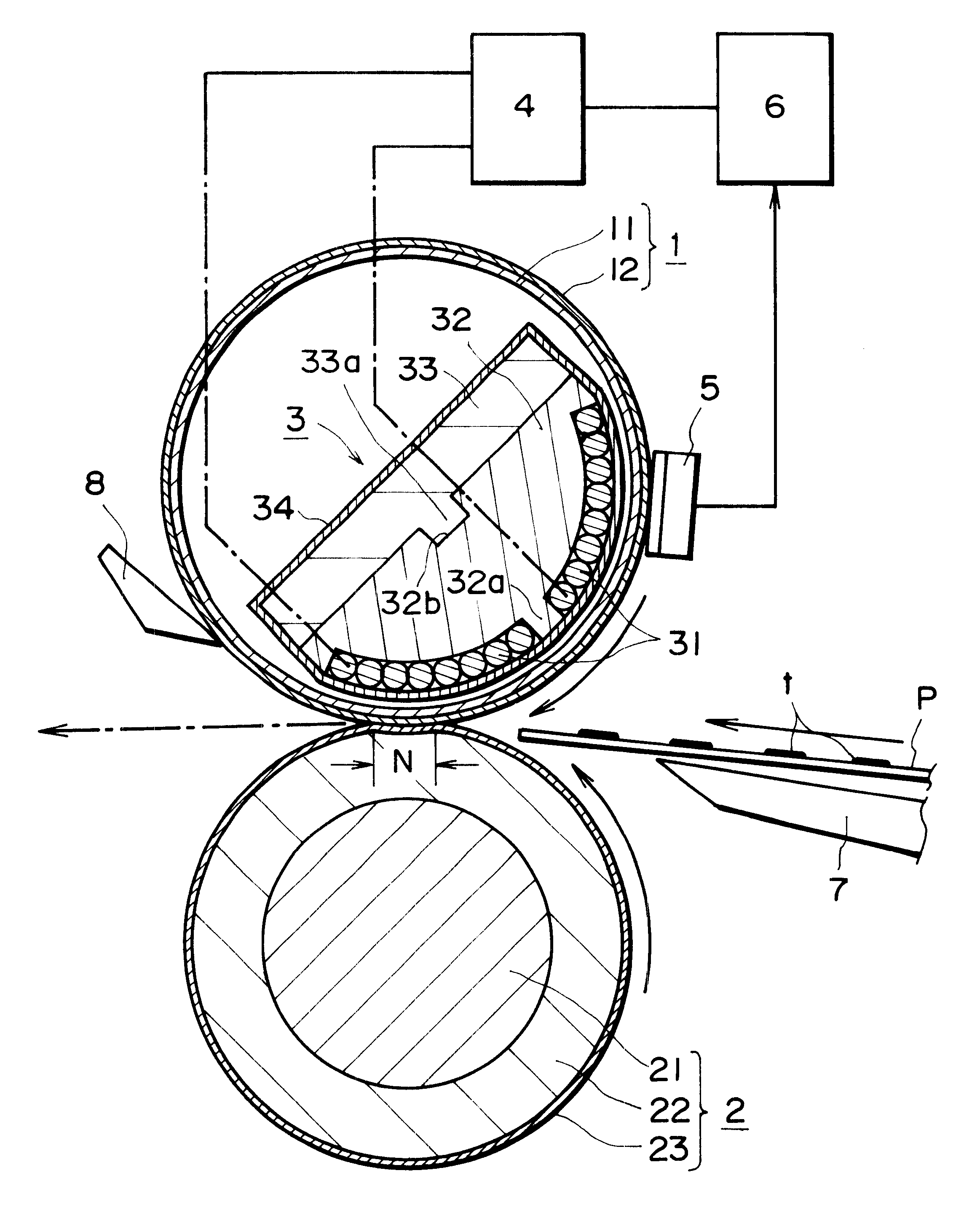

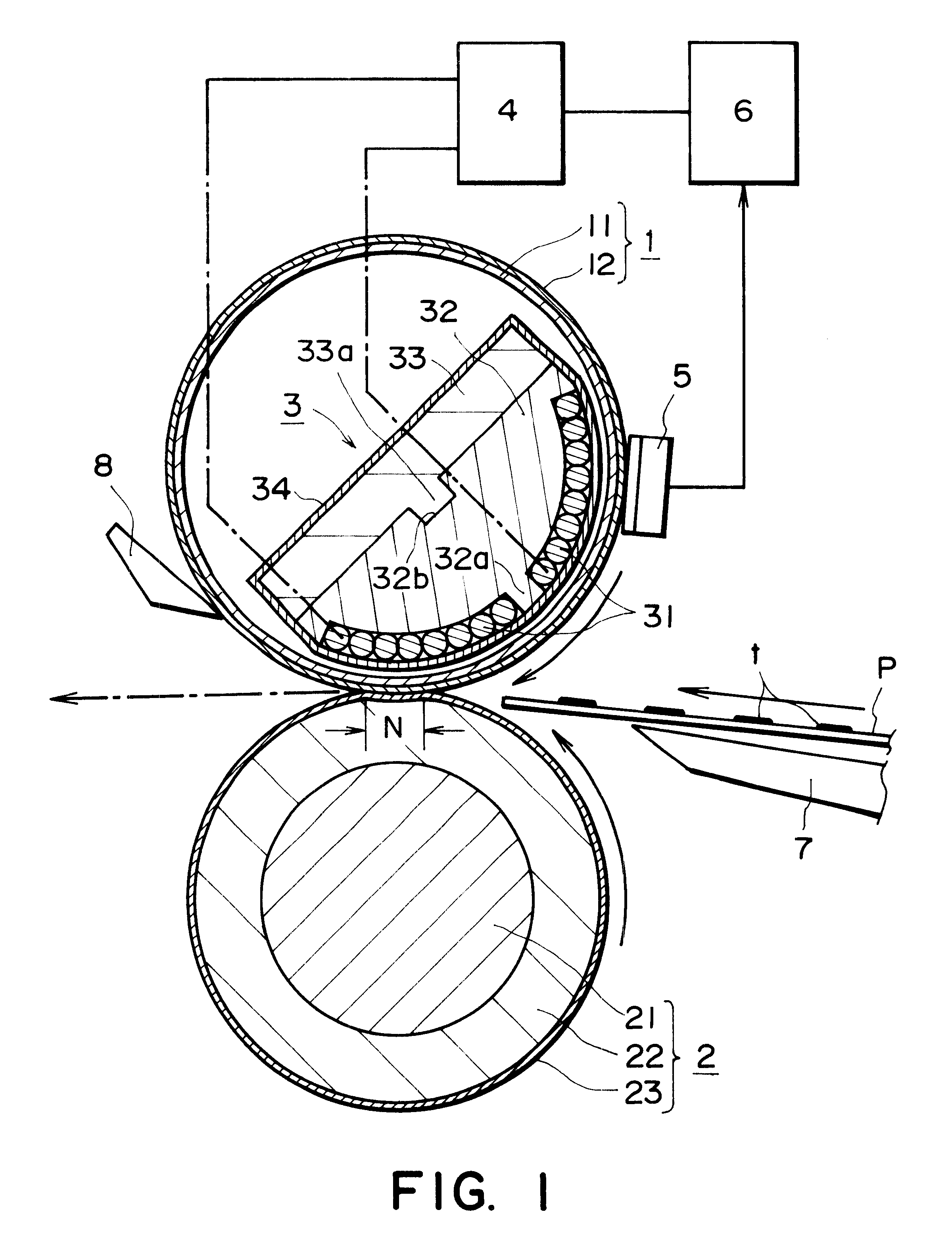

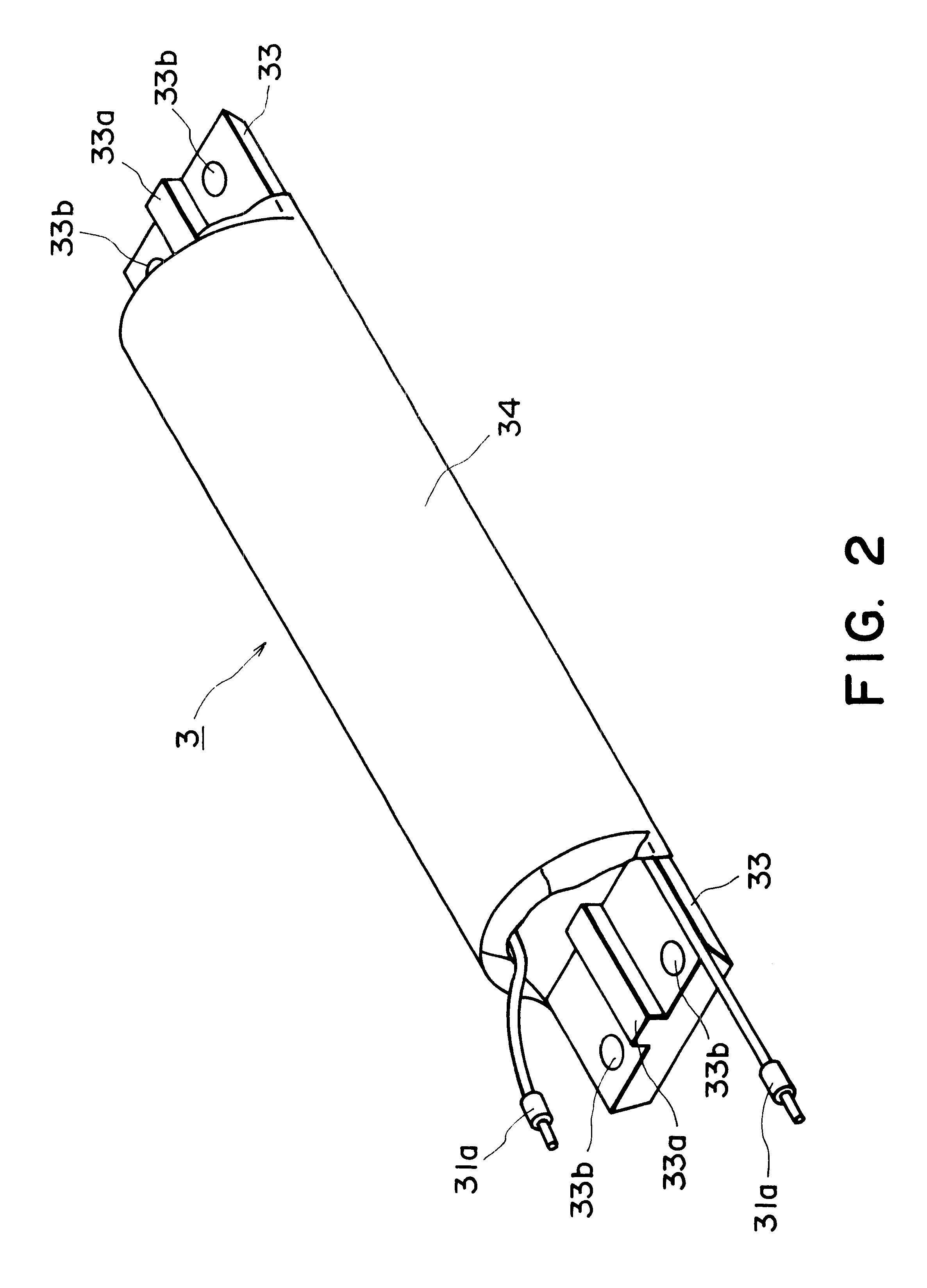

Method of mounting a coil unit for use as an image heating apparatus

InactiveUS6691399B1Line/current collector detailsElectrographic process apparatusConductor CoilElectrical and Electronics engineering

Owner:CANON KK

Wiring structure, and fabrication method of the same

InactiveUS20050174209A1Transformers/inductances coils/windings/connectionsPrinted circuit aspectsElectrical conductorEngineering

An electrical wiring structure, such as a planar coil, includes a set of wiring formed of an electrical conductor and formed on an insulating surface of a substrate. A dam-up wall structure is provided around an outermost peripheral portion of the set of wiring on the substrate. The dam-up wall structure is electrically disconnected from the set of wiring. An insulating layer is formed over an area from the set of wiring to the dam-up wall structure on the substrate, wherein the dam-up wall structure dams up the insulating layer.

Owner:CANON KK

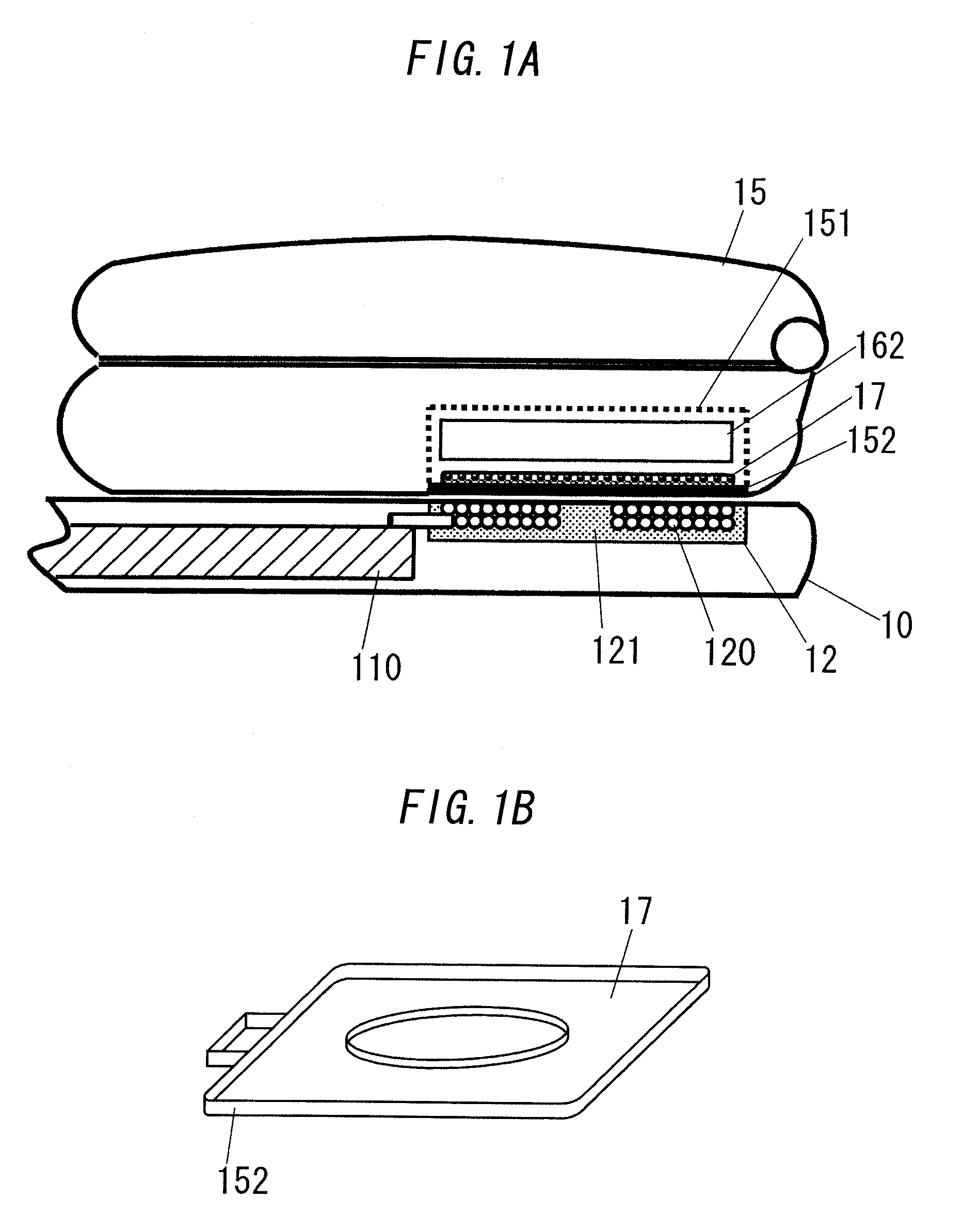

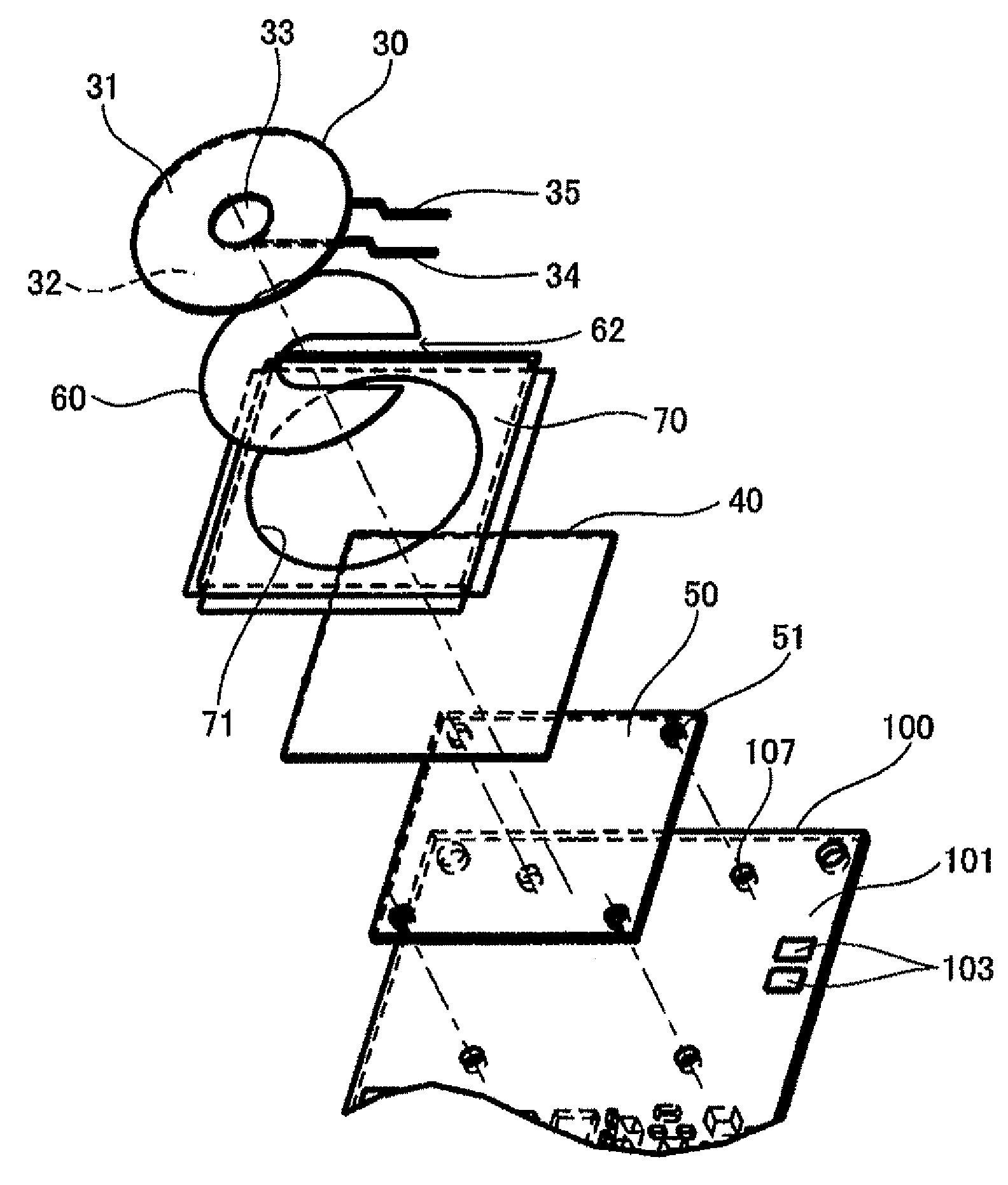

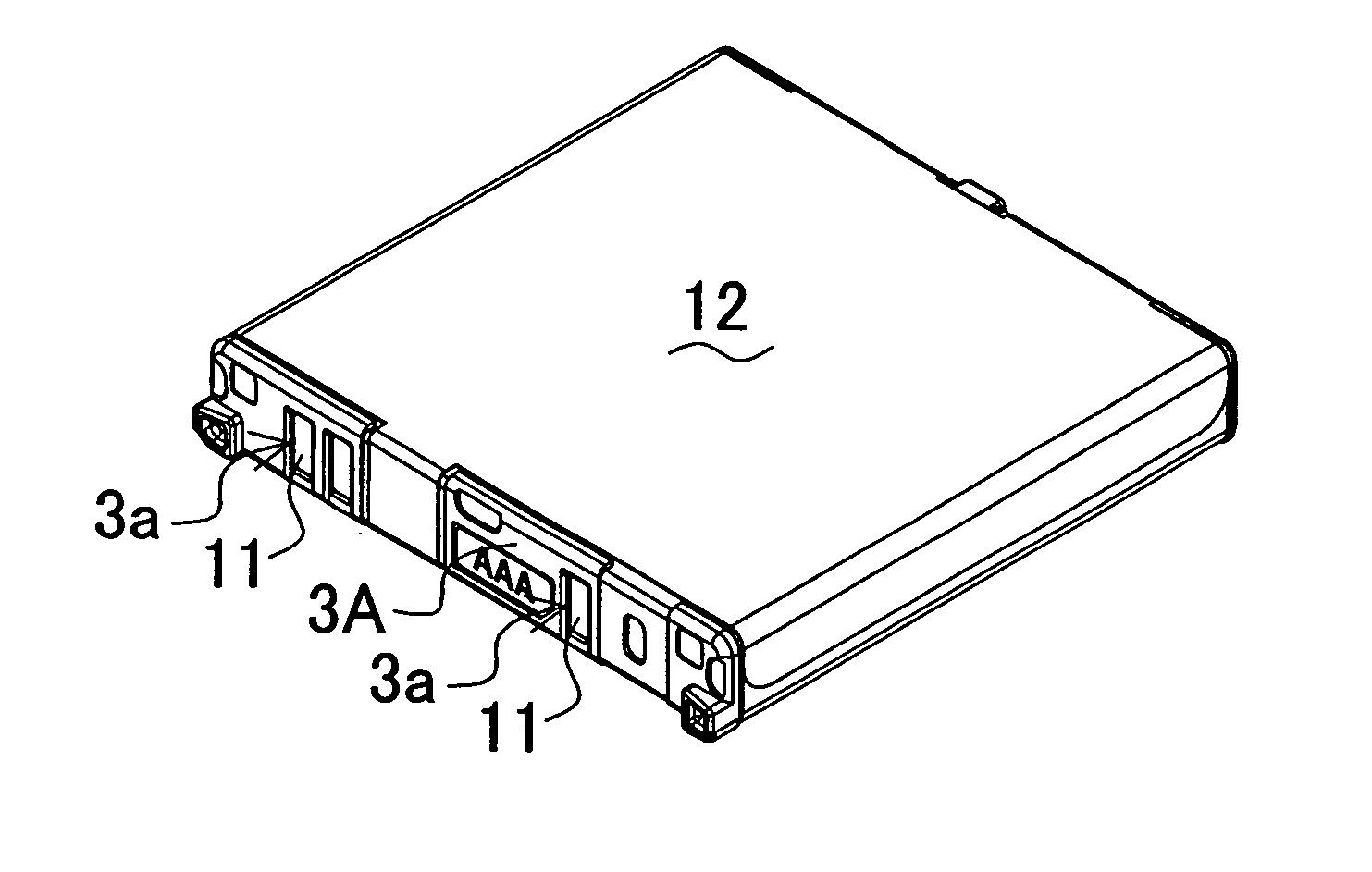

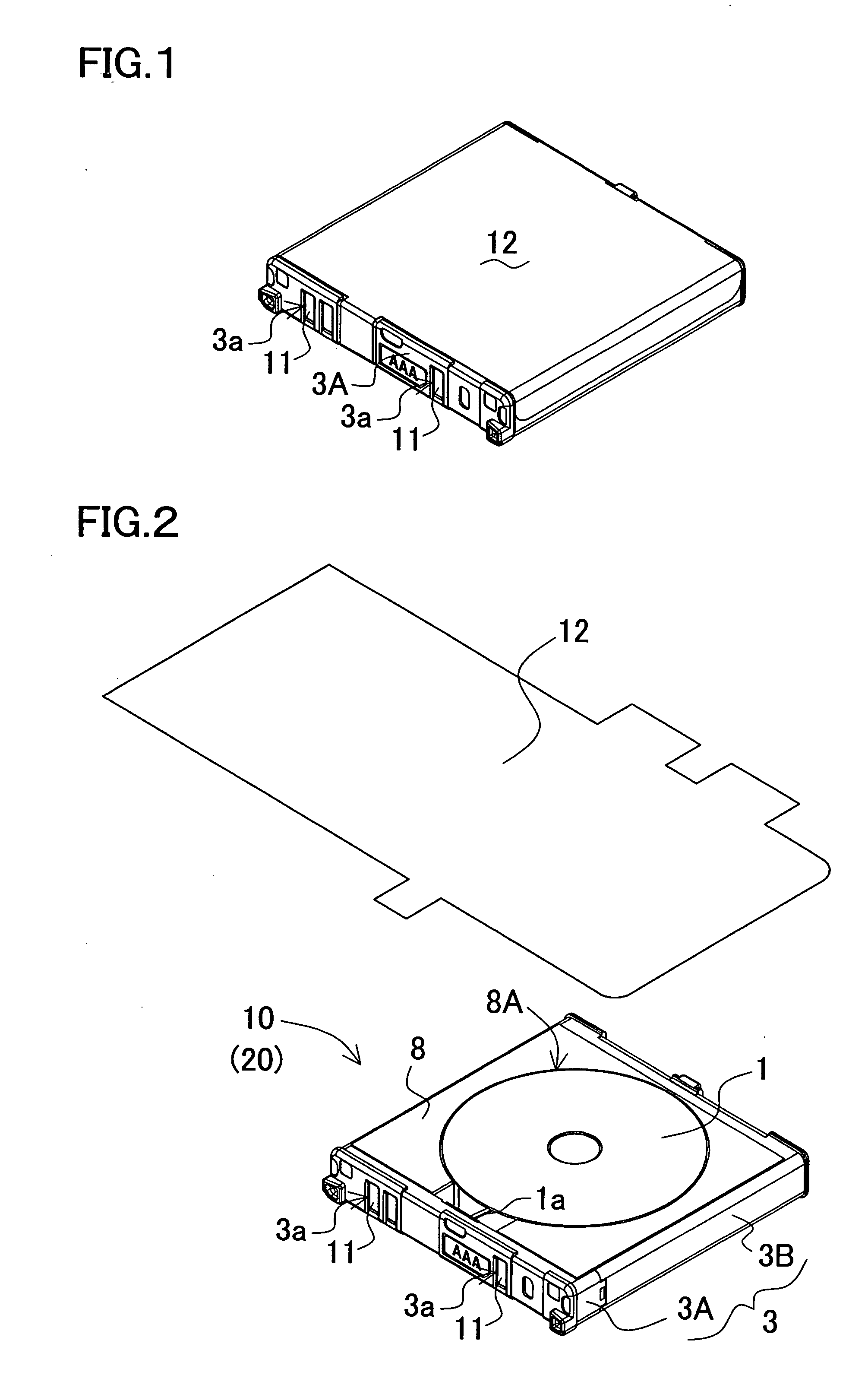

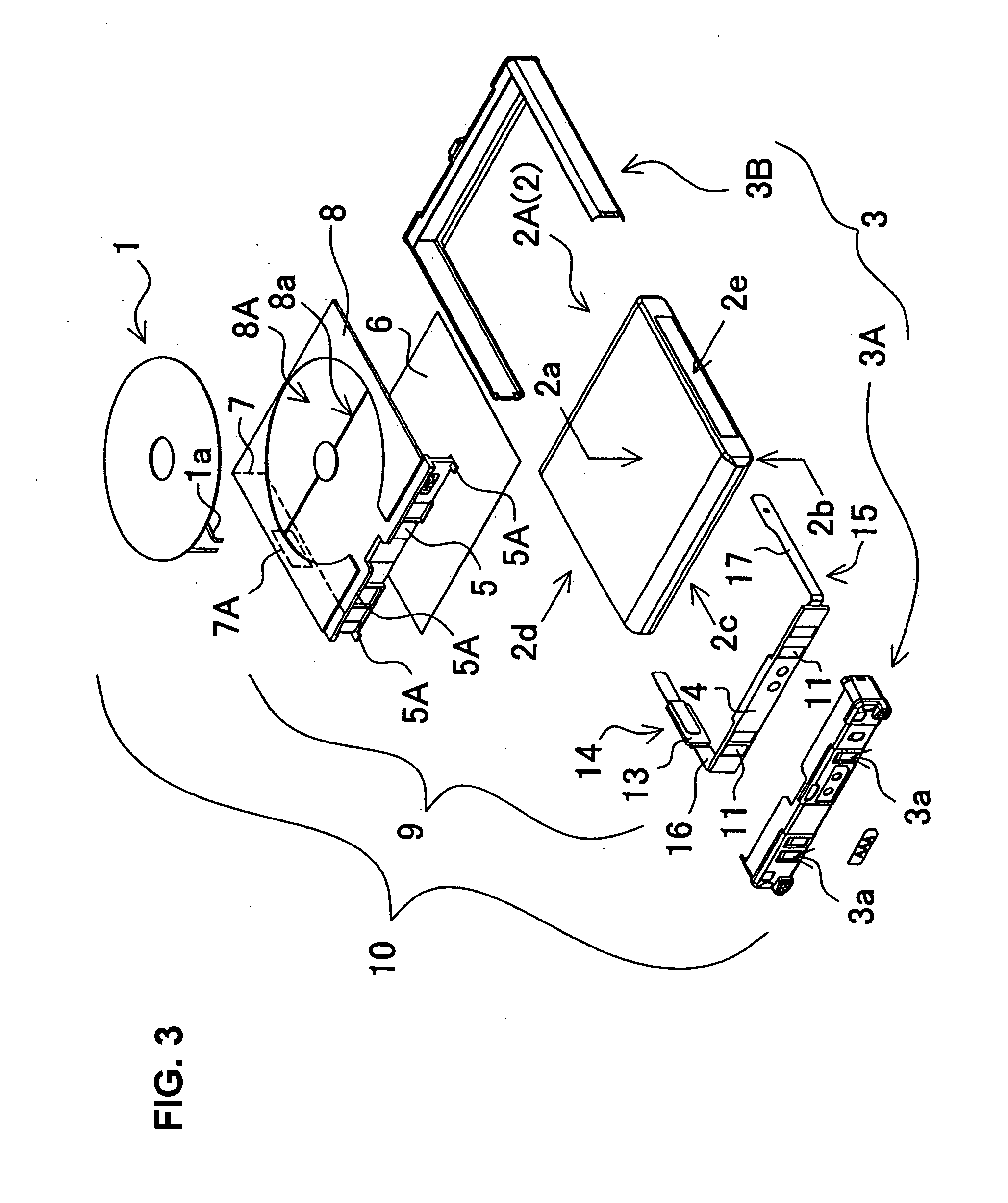

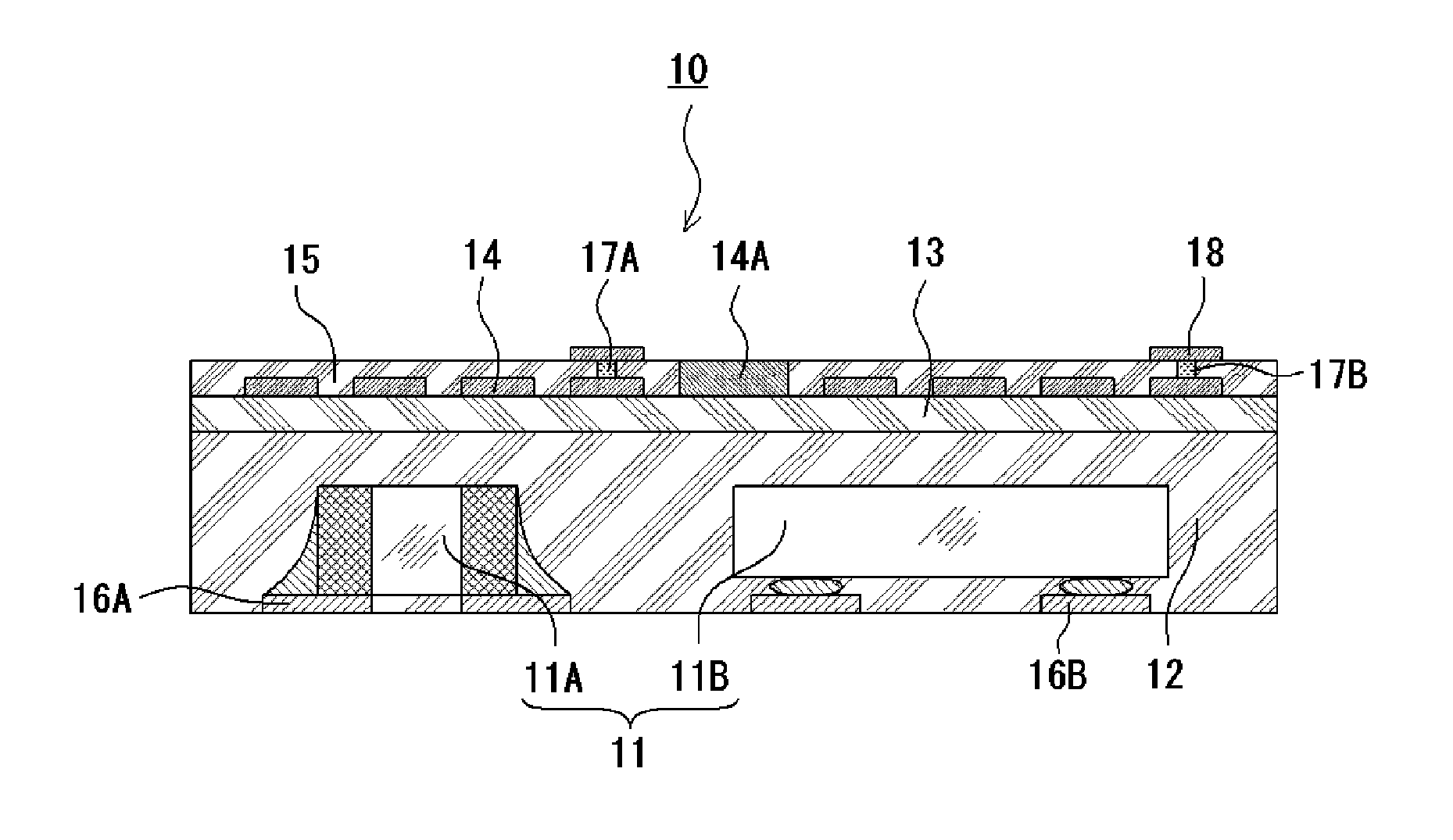

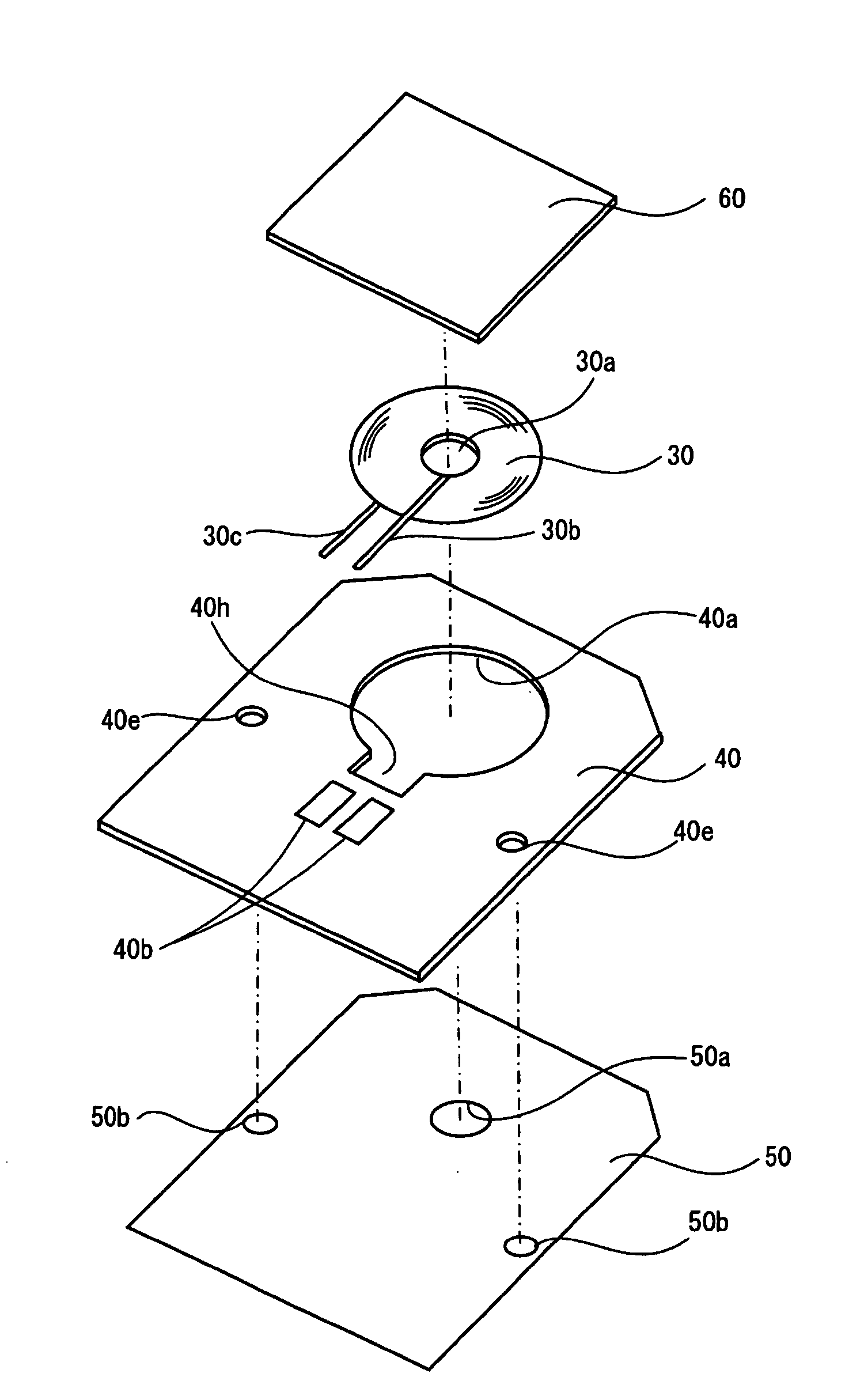

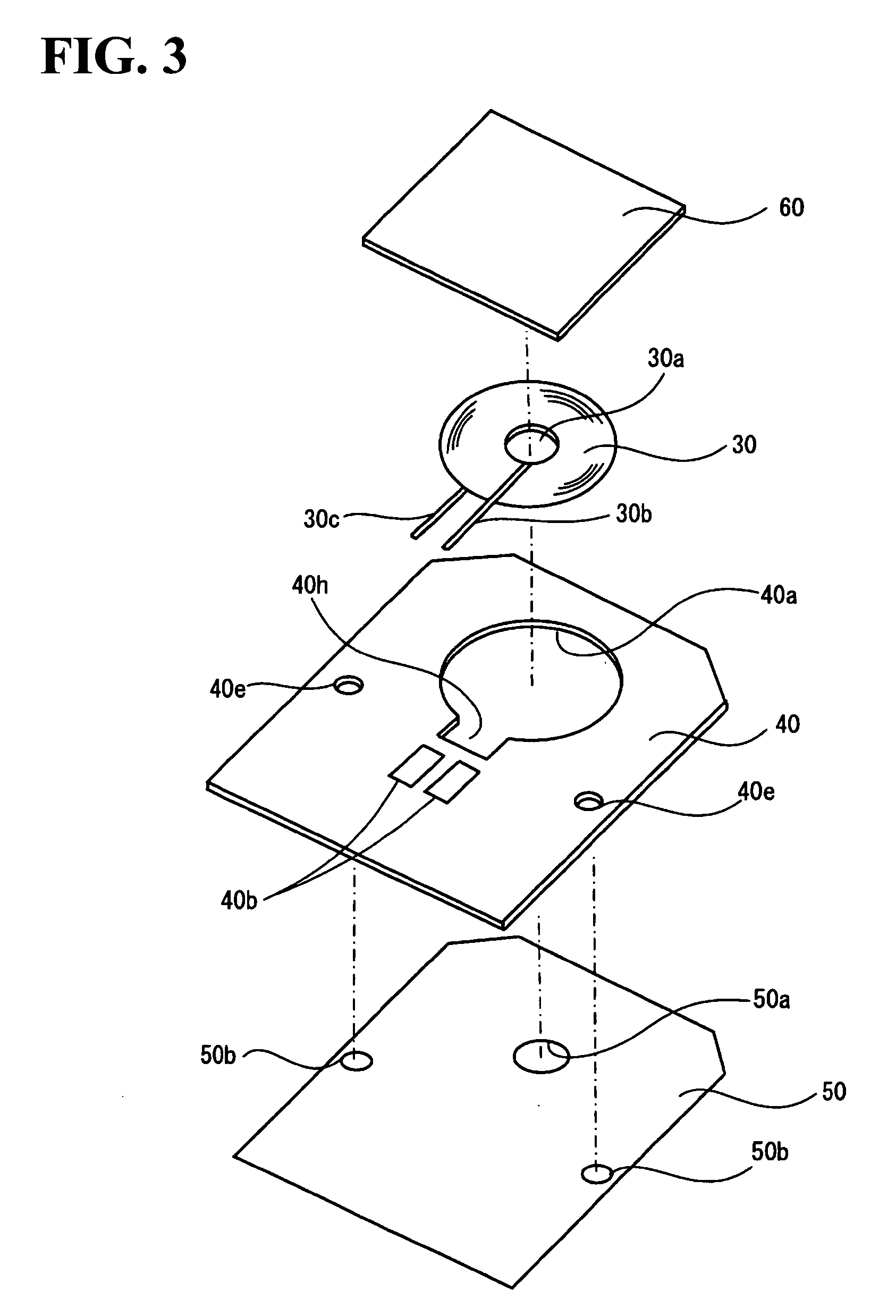

Coil unit, method of manufacturing the same, and electronic instrument

ActiveUS20080197960A1Transformers/reacts mounting/support/suspensionTransformers/inductances coolingElectronic instrumentPrinted circuit board

A coil unit includes a planar coil, a printed circuit board that includes a planar coil placement section that receives the planar coil, a protective sheet that is provided on a transmission side of the planar coil and protects the planar coil, and a magnetic sheet that is provided on a non-transmission side of the planar coil. The planar coil is placed in the planar coil placement section and is electrically connected to the printed circuit board. The planar coil placement section has a shape that corresponds to an external shape of the planar coil.

Owner:138 EAST LCD ADVANCEMENTS LTD

Contactless power transmission apparatus and a method of manufacturing a secondary side thereof

InactiveUS8421574B2High power transmission efficiencyReduce the impact of noiseBatteries circuit arrangementsTransformersElectric power transmissionInsulation layer

According to a first aspect, a secondary side of contactless power transmission apparatus includes: a holding member which is physically separated from a primary side; a magnetic layer; a shield layer for shielding electromagnetic noise; and a heat insulation layer. The secondary coil is a planar coil and supported by the holding member, and at least the magnetic layer is laminated on one side of the planar coil and unified with the planar coil. According to a second aspect, the secondary side of the apparatus includes a plurality of magnetic layers. Each permeability of the magnetic layers is different from each other, and each of the magnetic layers forms a magnetic path with the primary side.

Owner:PANASONIC CORP

Electromagnetic tracking method and system

ActiveUS20080186018A1Electromagnets without armaturesTransformers/inductances coils/windings/connectionsClassical mechanicsElectromagnetic shielding

Provided is an electromagnetic coil arrangement comprising a set of electromagnetic sensors at fixed locations with respect to each other, each of the electromagnetic sensors comprising a planar coil coupled to a conductive layer, the planar coil comprising non-concentric rings. Further, provided is an electromagnetic tracking system, comprising an electromagnetic coil arrangement, at least one complementary electromagnetic sensor and a processor configured to process a signal comprising data indicative of a mutual inductance between the at least one complementary electromagnetic sensor and each of the set of the electromagnetic sensors of the electromagnetic coil arrangement. Also, provided are a method of tracking and a method of manufacturing an electromagnetic coil arrangement.

Owner:STRYKER EURO OPERATIONS HLDG LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com