Humic acid-containing compound fertilizer and preparation method thereof

A humic acid and compound fertilizer technology, which is applied in urea compound fertilizer, ammonium orthophosphate fertilizer, alkaline orthophosphate fertilizer and other directions, can solve the problems of inability to increase the content of humic acid, reducing the difficulty of the process, and troughing, etc. Achieve the effect of solving the difficulty of granulation, reducing the difficulty of the process and improving the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A compound fertilizer containing humic acid, prepared from the following raw materials in parts by weight: 50 parts of urea, 1 part of ammonium phosphate, 10 parts of potassium chloride, 55 parts of humic acid, 5 parts of organic matter, 5 parts of phosphorus and potassium fertilizer, Effect agent 1 part; Among them, the organic matter is the mixture of potassium humate, cellulose and decomposed animal and plant residues.

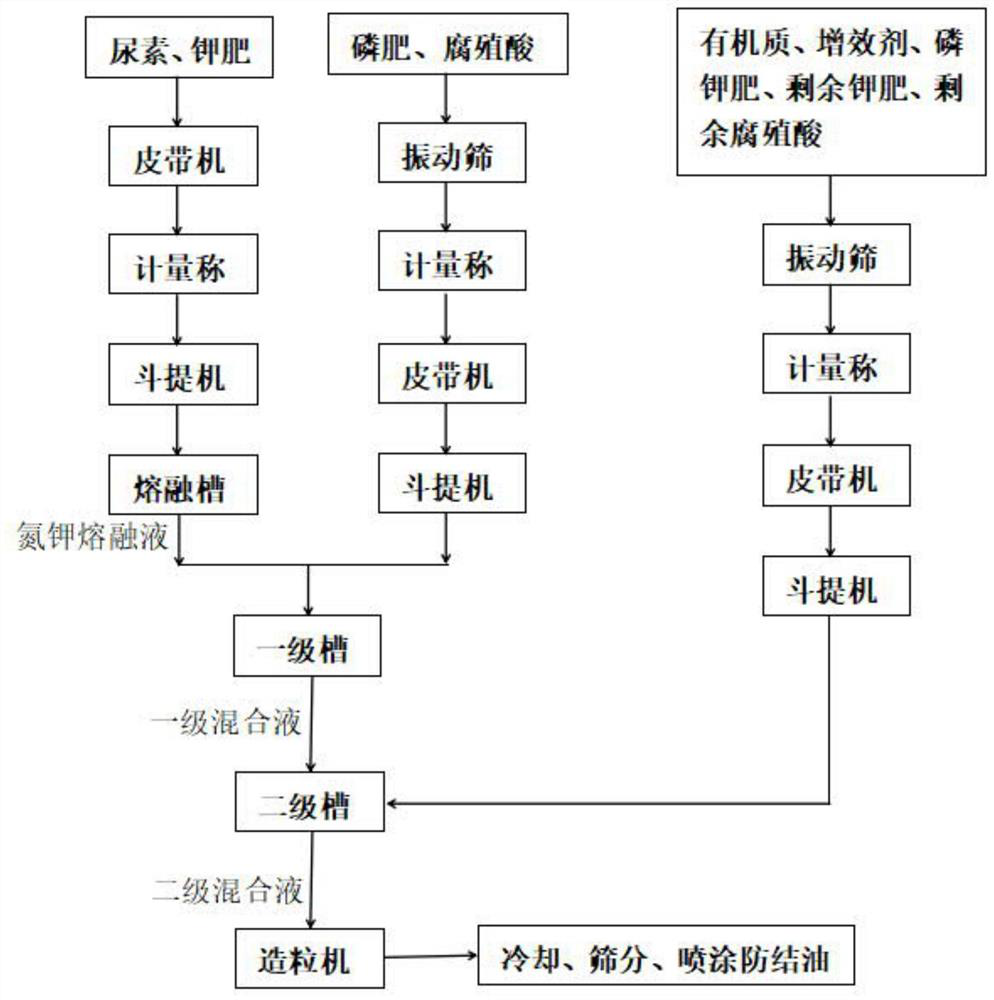

[0056] The preparation method of the above-mentioned compound fertilizer containing humic acid, such as figure 1 As shown, it specifically includes the following steps:

[0057] (1) 50 parts of urea and 5 parts of potassium chloride are dropped into a melting tank with a temperature of 120° C. through a belt conveyor, weighing scale and bucket elevator to obtain nitrogen and potassium molten liquid;

[0058] (2) When the nitrogen and potassium molten liquid overflowed from the melting tank to the first-level tank, the temperature of ammonium phospha...

Embodiment 2

[0063] A compound fertilizer containing humic acid, prepared from the following raw materials in parts by weight: 30 parts of urea, 20 parts of ammonium phosphate, 5 parts of potassium sulfate, 10 parts of humic acid, 0 part of organic matter, 15 parts of phosphorus and potassium fertilizer, synergistic Agent 0 parts; Among them, the organic matter is the mixture of potassium humate, cellulose and decomposed animal and plant residues.

[0064] The preparation method of the above-mentioned compound fertilizer containing humic acid, such as figure 1 As shown, it specifically includes the following steps:

[0065] (1) 30 parts of urea and 3 parts of potassium sulfate are dropped into a melting tank with a temperature of 125°C through a belt conveyor, a metering scale and a bucket elevator to obtain nitrogen and potassium molten liquid;

[0066] (2) When the nitrogen and potassium molten liquid overflows from the melting tank to the first-level tank, the temperature of ammonium p...

Embodiment 3

[0071] A compound fertilizer containing humic acid, prepared from the following raw materials in parts by weight: 45 parts of urea, 10 parts of ammonium phosphate, 20 parts of potassium chloride, 40 parts of humic acid, 10 parts of organic matter, 10 parts of phosphorus and potassium fertilizer, Effect agent 1 part; Among them, the organic matter is the mixture of potassium humate, cellulose and decomposed animal and plant residues.

[0072] The preparation method of the above-mentioned compound fertilizer containing humic acid, such as figure 1 As shown, it specifically includes the following steps:

[0073] (1) 45 parts of urea and 3 parts of potassium chloride are dropped into the melting tank that temperature is 122 ℃ through belt conveyor, metering scale and bucket elevator, to obtain nitrogen and potassium molten liquid;

[0074] (2) When the nitrogen and potassium molten liquid overflows from the melting tank to the first-level tank, the temperature of ammonium phospha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com