An improved alignment method for efd assembly

A substrate and cover technology, applied in the field of EFD display, can solve the problems of misalignment, low yield, and inability to correct unaligned defects, so as to improve yield, reduce errors and deformation, and improve reversibility and reliability. The effect of modifiability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

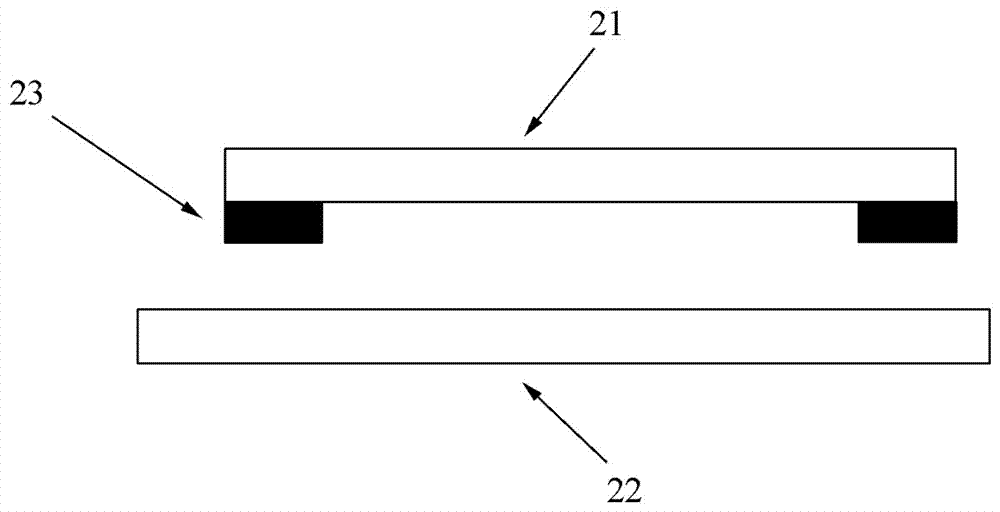

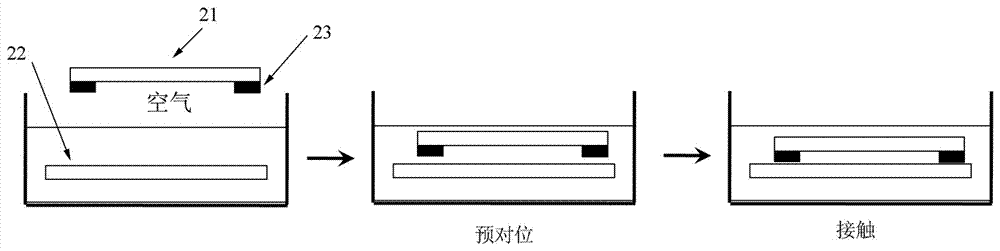

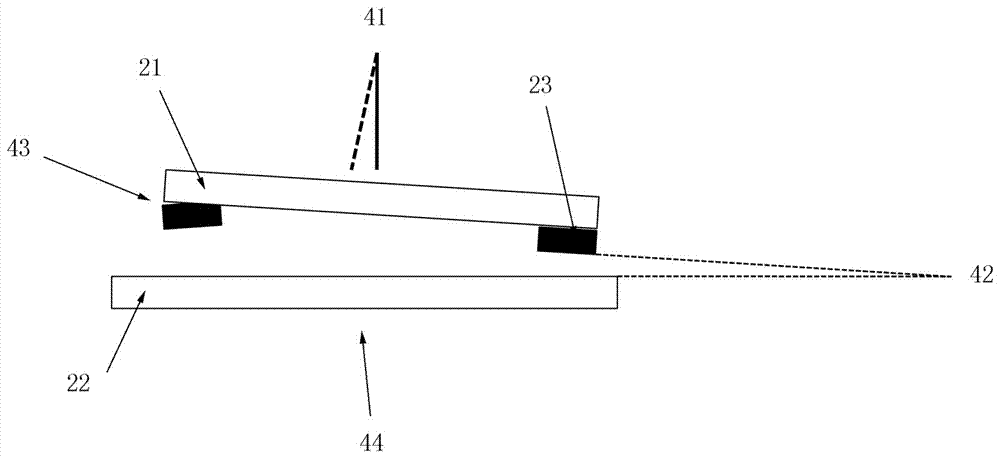

[0030] Regarding the application of the electrowetting display principle, its schematic structure diagram is as follows Figure 1a , 1b As shown, the EFD display unit includes a pixel wall 13, a substrate 14, a transparent electrode 15, and a cover plate (not shown) containing a sealing material. Figure 1a It is shown that when no voltage V is applied, the colored oil layer 11 completely covers the hydrophobic coating 12; Figure 1b It is shown that after the voltage V is applied, the colored oil layer 11 is pushed to one side. When a voltage V is applied to the electrodes, charges accumulate on the lower surface of the polarized liquid layer 10, and then its electrostatic force F el Overcome the capacitive force F cap The colored oil layer 11 is broken down to cover the hydrophobic coating 12 on the substrate, so that the polarized liquid layer 10 is in contact with the original hydrophobic coating under the action of the voltage V. By further increasing the voltage V, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com