Patents

Literature

1139results about How to "Control concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

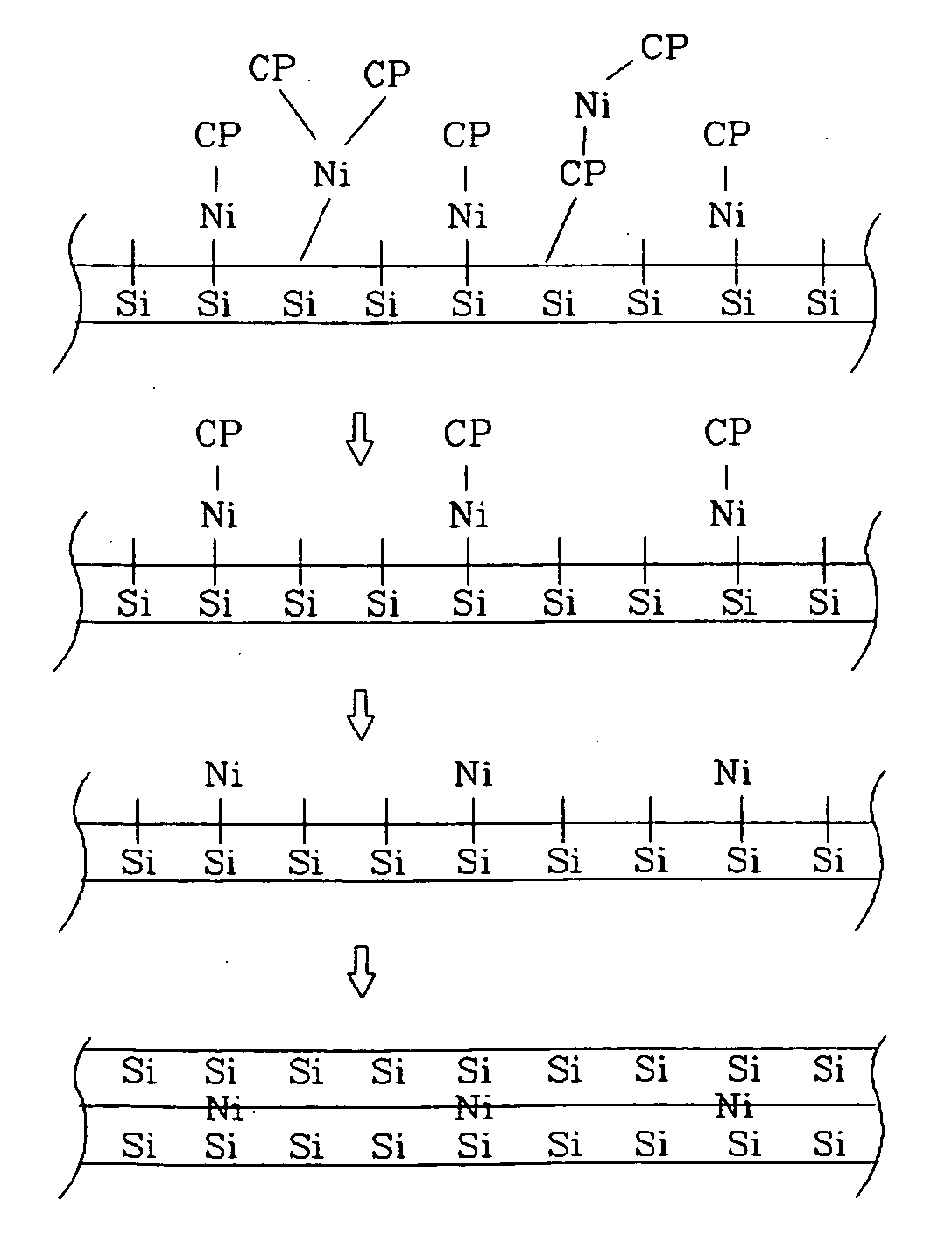

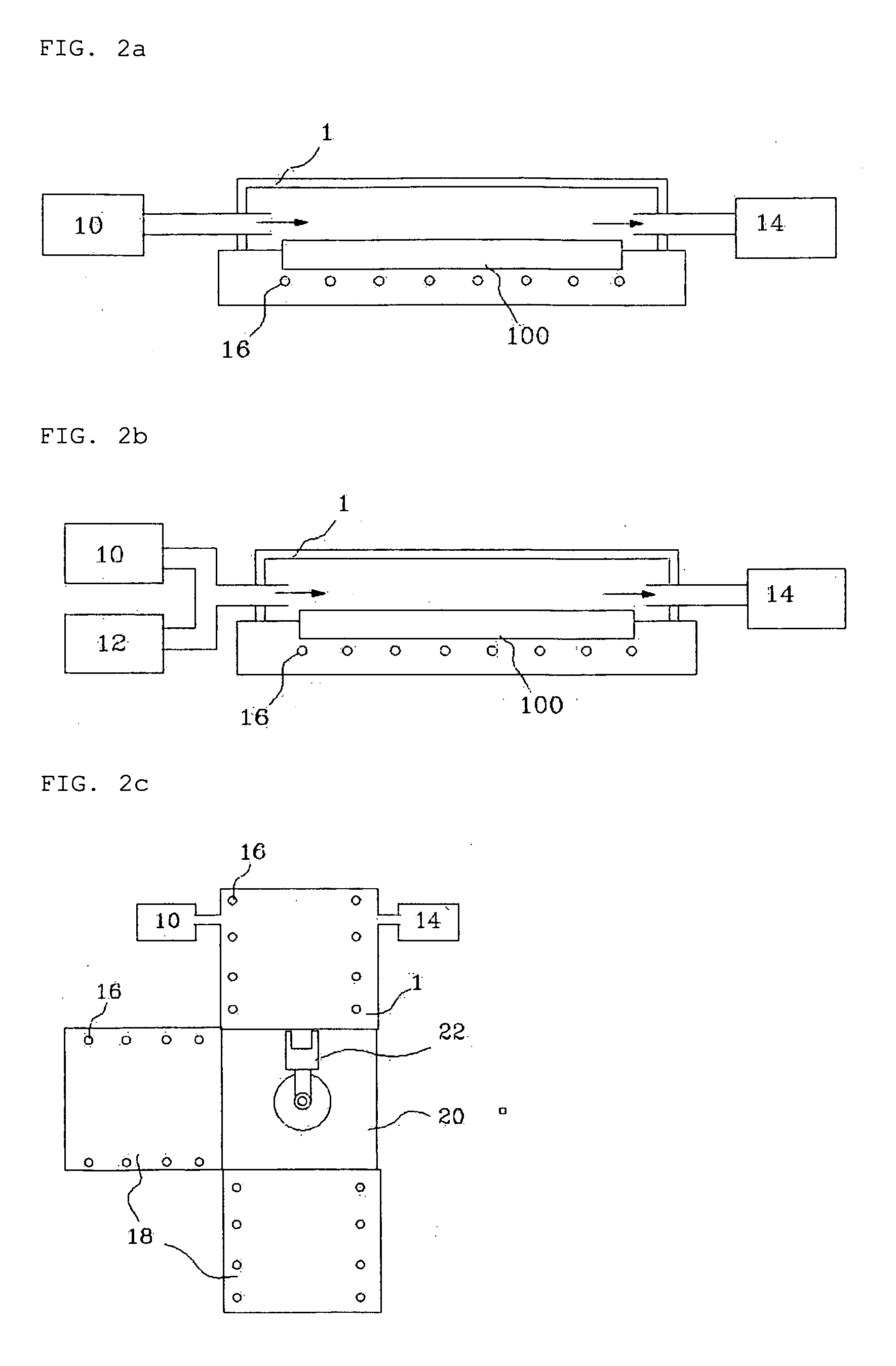

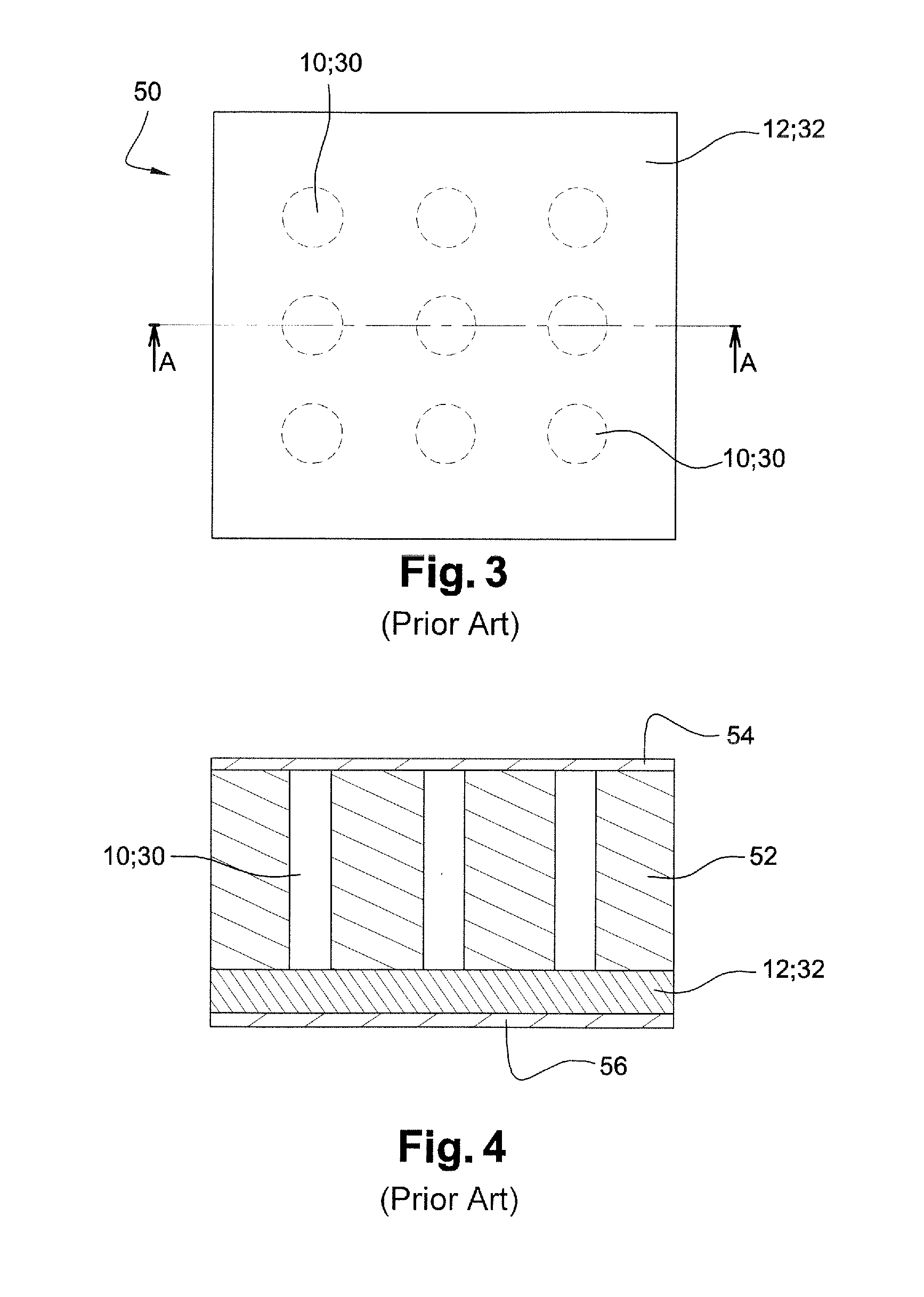

Apparatus and method for forming polycrystalline silicon thin film

ActiveUS20070054499A1Increase the rate of crystallizationDecrease in crystallization temperatureAfter-treatment apparatusSemiconductor/solid-state device manufacturingGas phaseAmorphous silicon

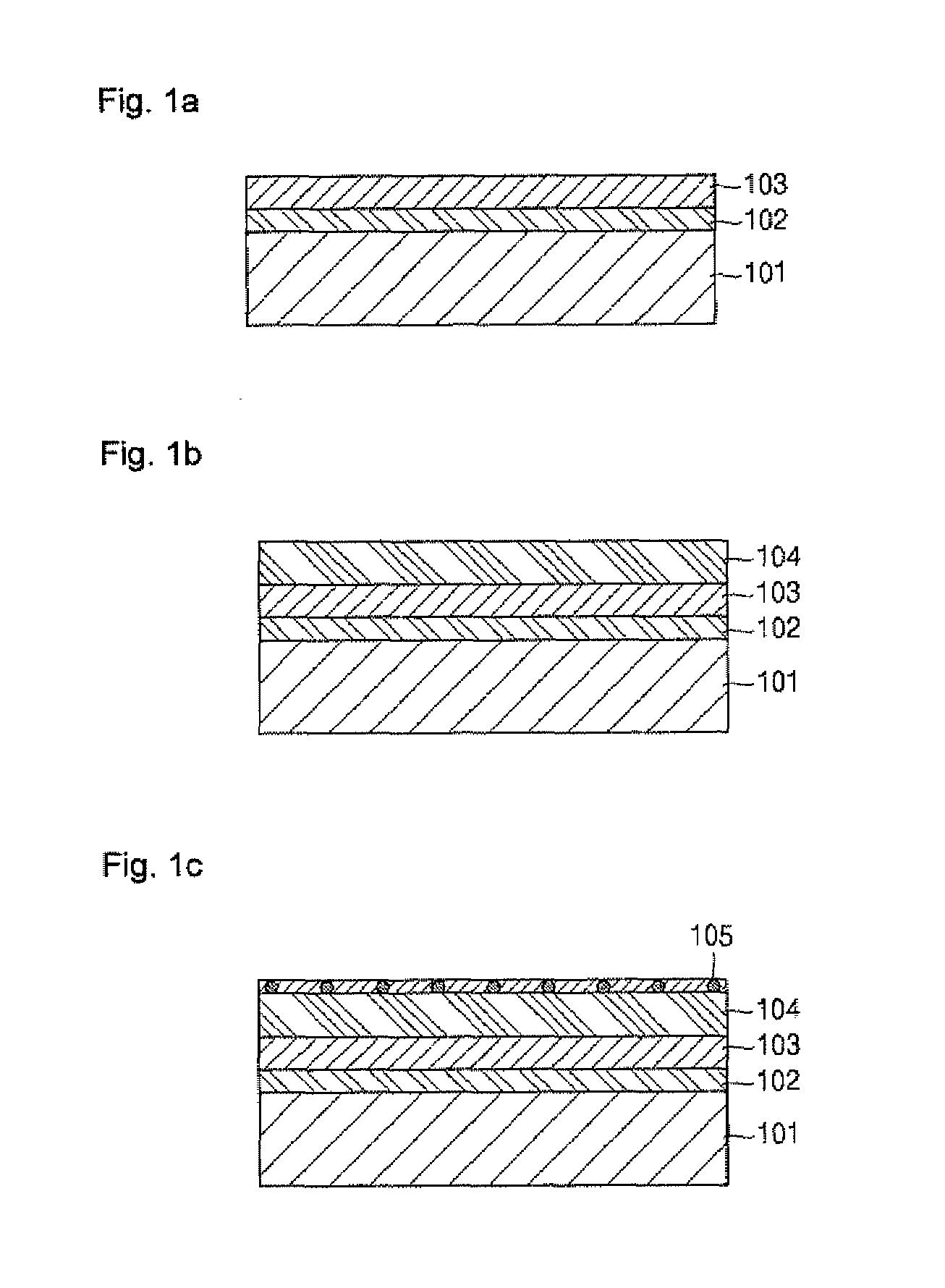

Apparatus and method for forming a polycrystalline silicon thin film by converting an amorphous silicon thin film into the polycrystalline silicon thin film using a metal are provided. The method includes: a metal nucleus adsorbing step of introducing a vapor phase metal compound into a process space where the glass substrate having the amorphous silicon formed thereon is disposed, to adsorb a metal nucleus contained in the metal compound into the amorphous silicon layer; a metal nucleus distribution region-forming step of forming a community region including a plurality of silicon particles every metal nucleus in a plane boundary region occupied by the metal compound by a self-limited mechanism due to the adsorption of the metal nucleus; and an excess gas removing step of purging and removing an excess gas which is not adsorbed in the metal nucleus distribution region-forming step.

Owner:WONIK IPS CO LTD

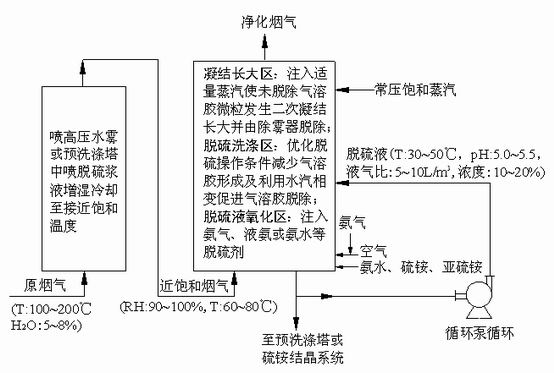

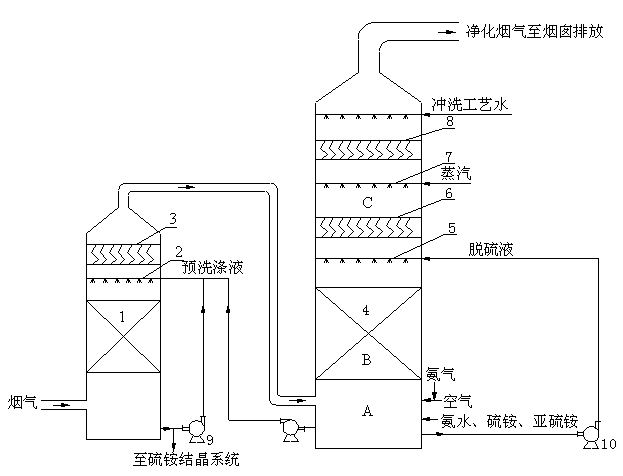

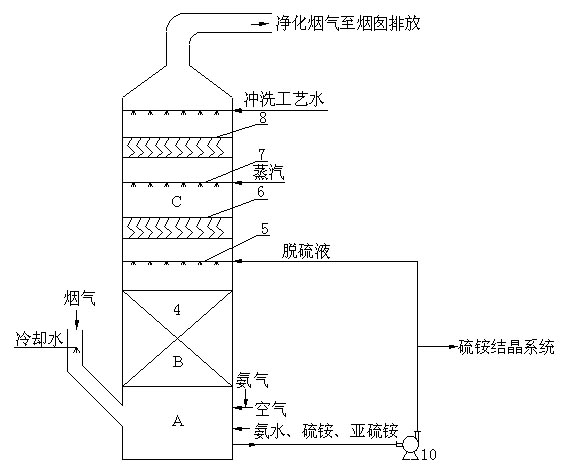

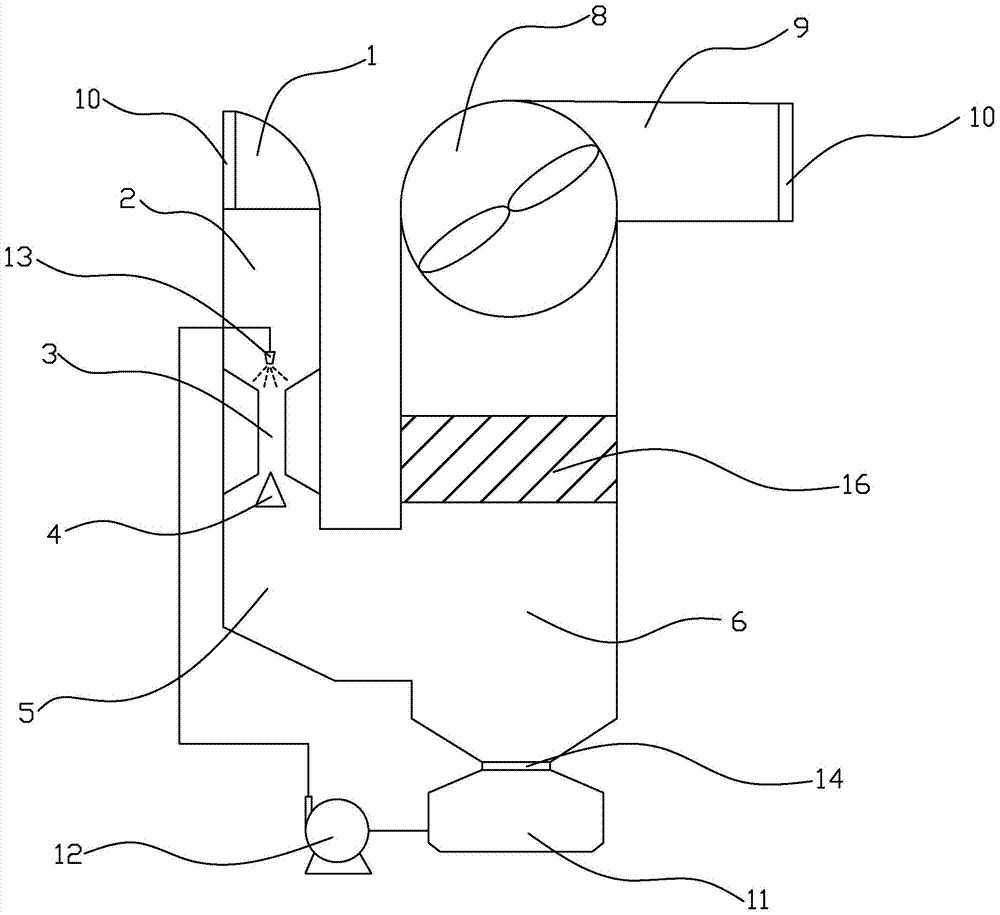

Control method for aerosol in flue gas desulfurization by utilizing ammonia method and master desulfurizing tower

InactiveCN102000490ASolve the emission problemSimple processDispersed particle separationThermodynamicsWater vapor

The invention discloses a control method for aerosol in flue gas desulfurization by utilizing an ammonia method and a master desulfurizing tower, and the control method is characterized in that flue gas enters the master desulfurizing tower after being cooled to the relative humidity of 90 to 100% and the temperature of 60 to 80 DEG C through high-pressure waster mist or prewashing temperature reduction; the generation of the aerosol particles in the desulfurization by utilizing the ammonia method is reduced by optimizing desulfurization operating conditions, and the formed aerosol particles are condensed to grow big and are partially washed to be eliminated through a desulfurizing solution; an appropriate amount of steam is injected into the saturated flue gas through desulfurizing and eliminating the partial aerosol particles; the oversaturated water vapor environment required by the secondary condensation and the growth of the aerosol particles is established on the top of the master desulfurizing tower; and the condensed and the grown aerosol particles are eliminated through a high-efficiency demister. The invention combines the formation mechanism of the aerosol in the flue gas desulfurization by utilizing the ammonia method; and the formation of the aerosol is reduced by optimizing the process conditions of the desulfurization operation and the elimination of the formed aerosol is promoted by utilizing a steam phase change principle at the same time so that the exhaust problem of the aerosol in the flue gas desulfurization by utilizing the ammonia method can be effectively solved.

Owner:SOUTHEAST UNIV

Medical anti-sticking membrane and preparation method thereof

The invention provides a medical anti-sticking membrane and a preparation method thereof. The anti-sticking membrane comprises a nanometer frame and hydrosol attached thereon. The hydrosol is internally packed with one or several kinds of styptic medicament or / and anti-sticking medicament. The invention also provides a preparation method of the anti-sticking membrane, comprising the following steps of: preparing electro-spinning solution, styptic medicament and / or anti-sticking medicament-containing hydrosol solution and crosslinker solution; receiving static spinning with the crosslinker solution to obtain the nanometer frame; printing the styptic medicament and / or anti-sticking medicament-containing hydrosol solution onto the nanometer frame by an ink-jet printer, and solidifying the hydrosol solution to obtain the anti-sticking membrane. The anti-sticking membrane has good capability and biological compatibility, and nontoxicity as well as nonirritant, can be completely degraded and absorbed, is compounded with controllably released styptic medicament or / and anti-sticking medicament, has controllable degrading time and speed, and conquers defects of the prior art.

Owner:MEDPRIN REGENERATIVE MEDICAL TECH

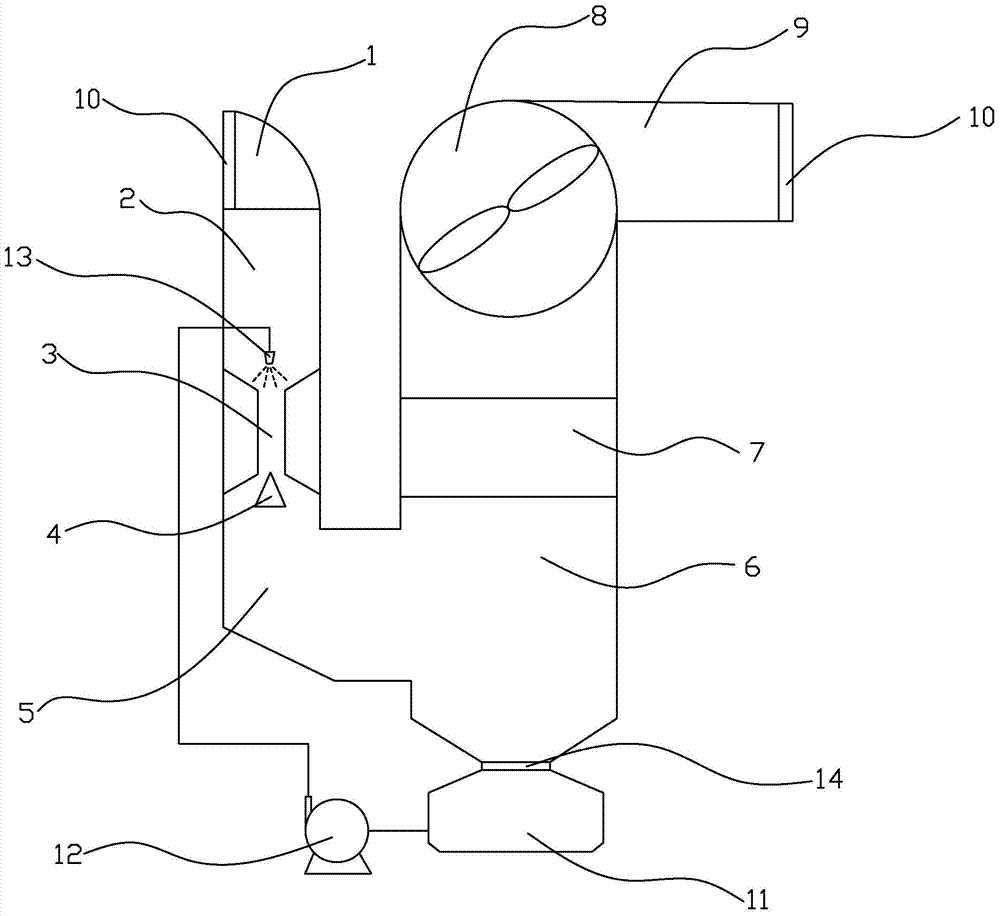

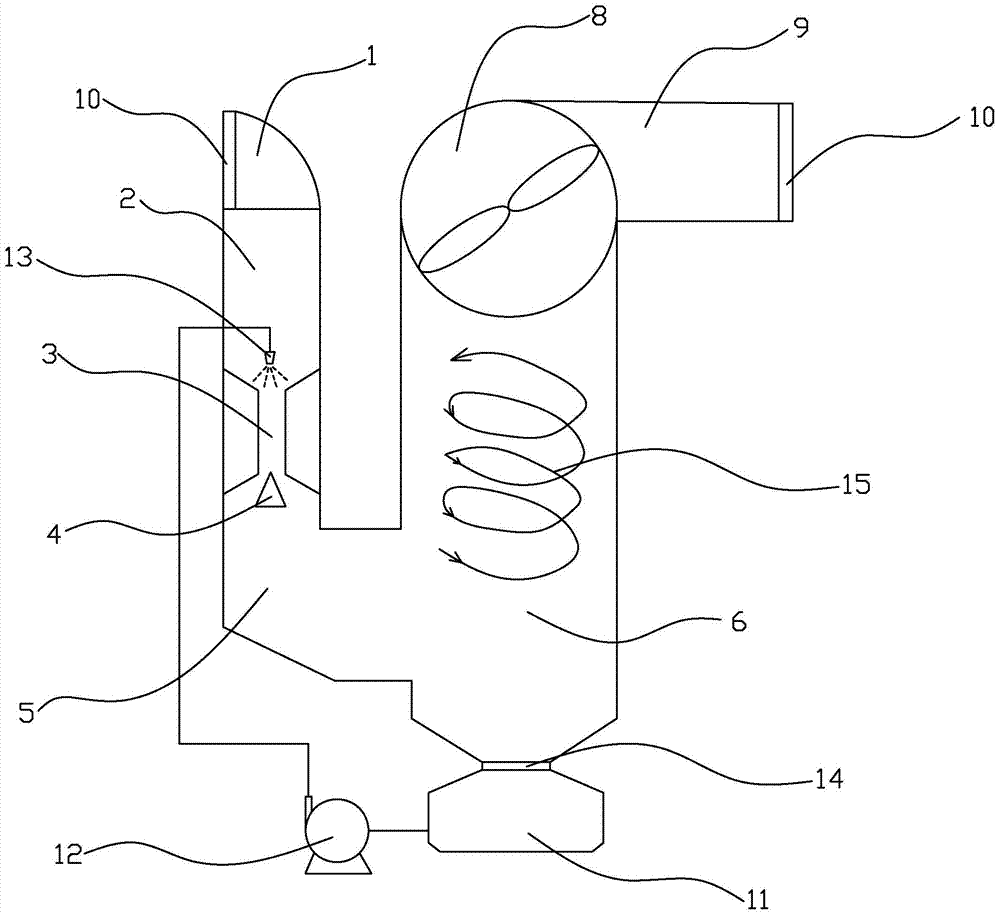

Novel indoor air purification device

InactiveCN103785265AEfficient removalNo need to replaceCombination devicesUsing liquid separation agentParticulatesGas passing

The invention provides a novel indoor air purification device. Water or an aqueous solution is used for absorbing various types of gas and granular pollution components in air, so that the aim of purifying the air is fulfilled; a Venturi throat opening is formed in an air channel; when the gas passes through the throat opening, the speed of gas flow is obviously increased, and high shearing force is formed in the gas flow, so that liquid entering the Venturi throat opening is sheared into extremely thin fog drops; after leaving the Venturi throat opening, the gas flow is slowed down and forms strong turbulent fluctuation, so that particles in the air and the extremely thin water drops can be in full contact and collision, and the particles in the air are transferred into liquid; the water drops in a turbulent fluctuation region also collide, and the water drops are re-enlarged, so that the water drops can be removed from a gas-liquid separation chamber, and the gas pollution components in the air are dissolved in the liquid so as to be absorbed and removed.

Owner:CESTOIL ENVIRO CO LTD

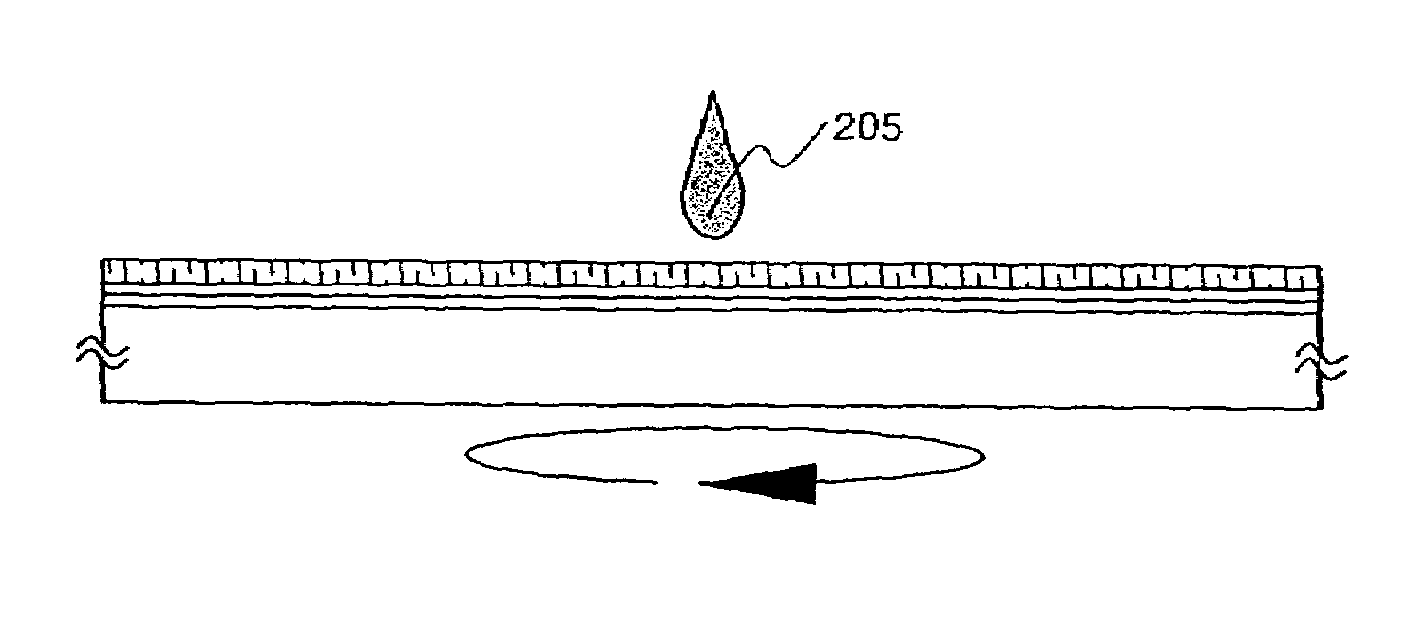

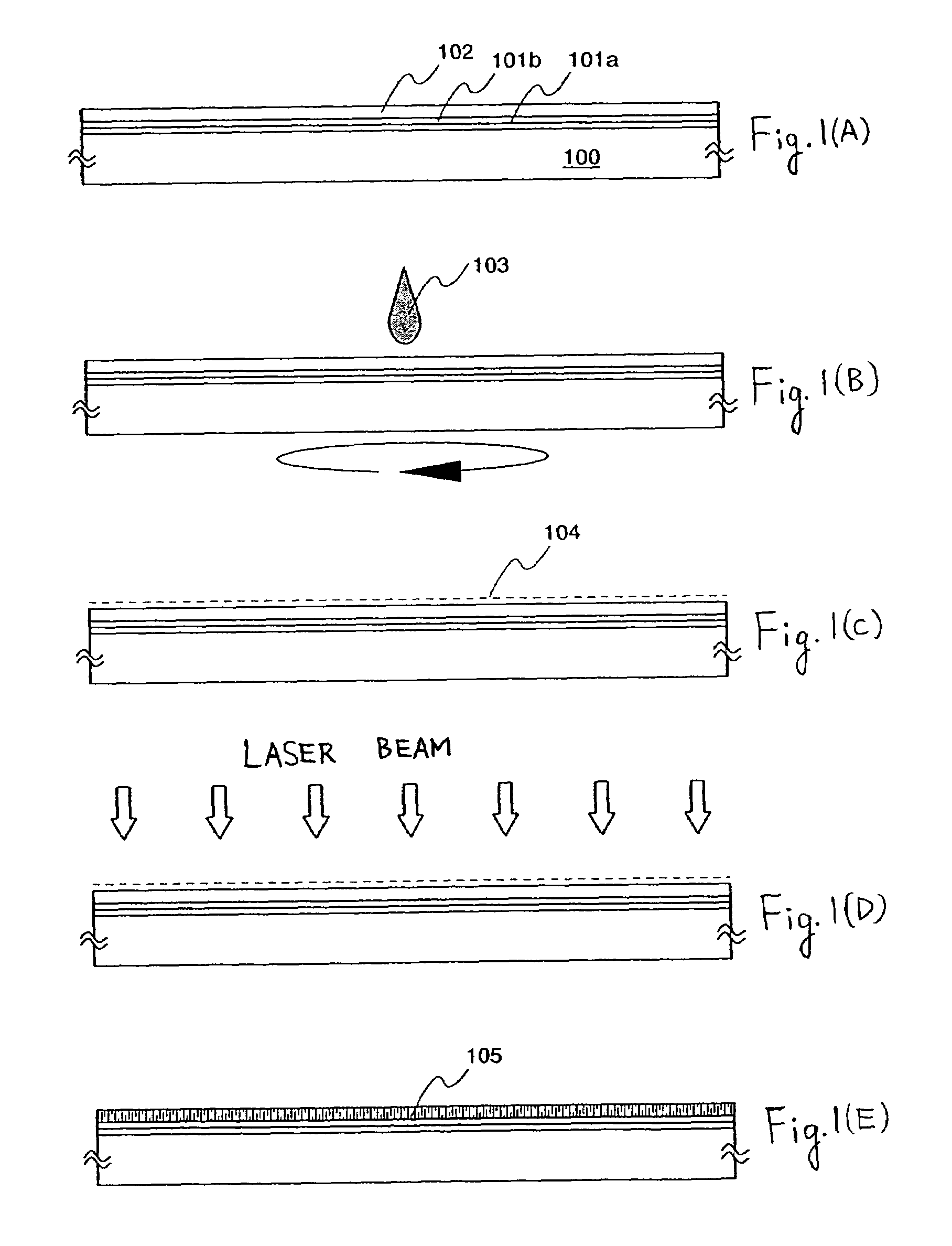

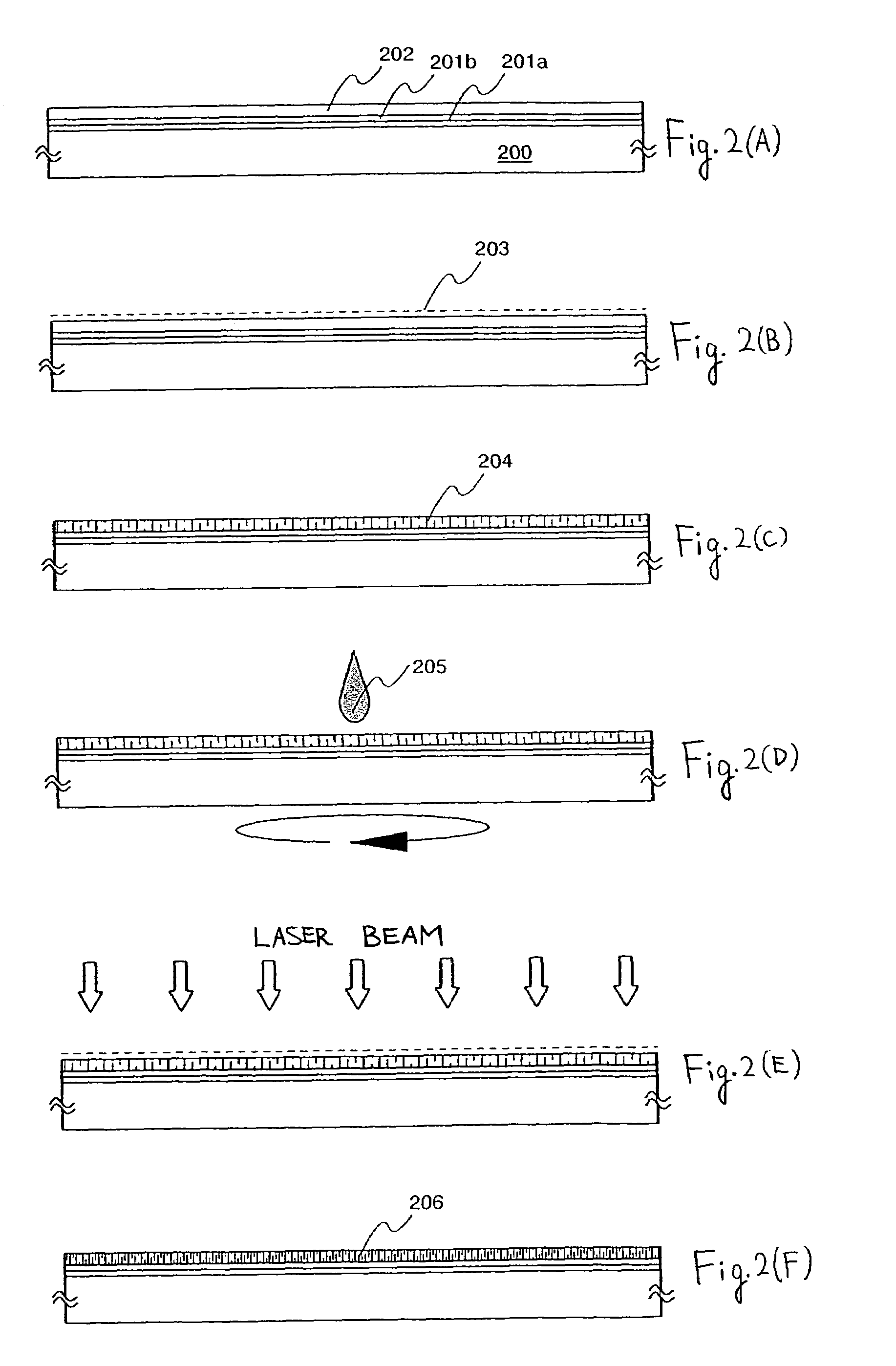

Laser doping processing method and method for manufacturing semiconductor device

It is an object of the present invention to provide an easy doping method where concentration control is easy, where doping with respect to a large area can be practically conducted and which does not require a special device. The present invention provides a laser doping method where a liquid including a dopant is applied to the surface of a semiconductor that is to be doped and the surface of the semiconductor is irradiated with laser light to add the dopant to the semiconductor. It is also possible to conduct crystallization at the same time.

Owner:SEMICON ENERGY LAB CO LTD

Taste Making Formulation Comprising The Drug In A Dissolution-Retarded Form And/Or Cyclodextrin In A Dissolution-Enhanced Form

InactiveUS20080075784A1Great tasteBetter taste maskingBiocideOrganic active ingredientsCyclodextrinDissolution

Improved taste masking of pharmaceutical compositions of unpleasant-tasting drugs and cyclodextrin is achieved by forming a mixture of drug and cyclodextrin wherein the drug's dissolution rate has been retarded, or the the cyclodextrin's dissolution rate has been enhanced, or by both.

Owner:BEND RES

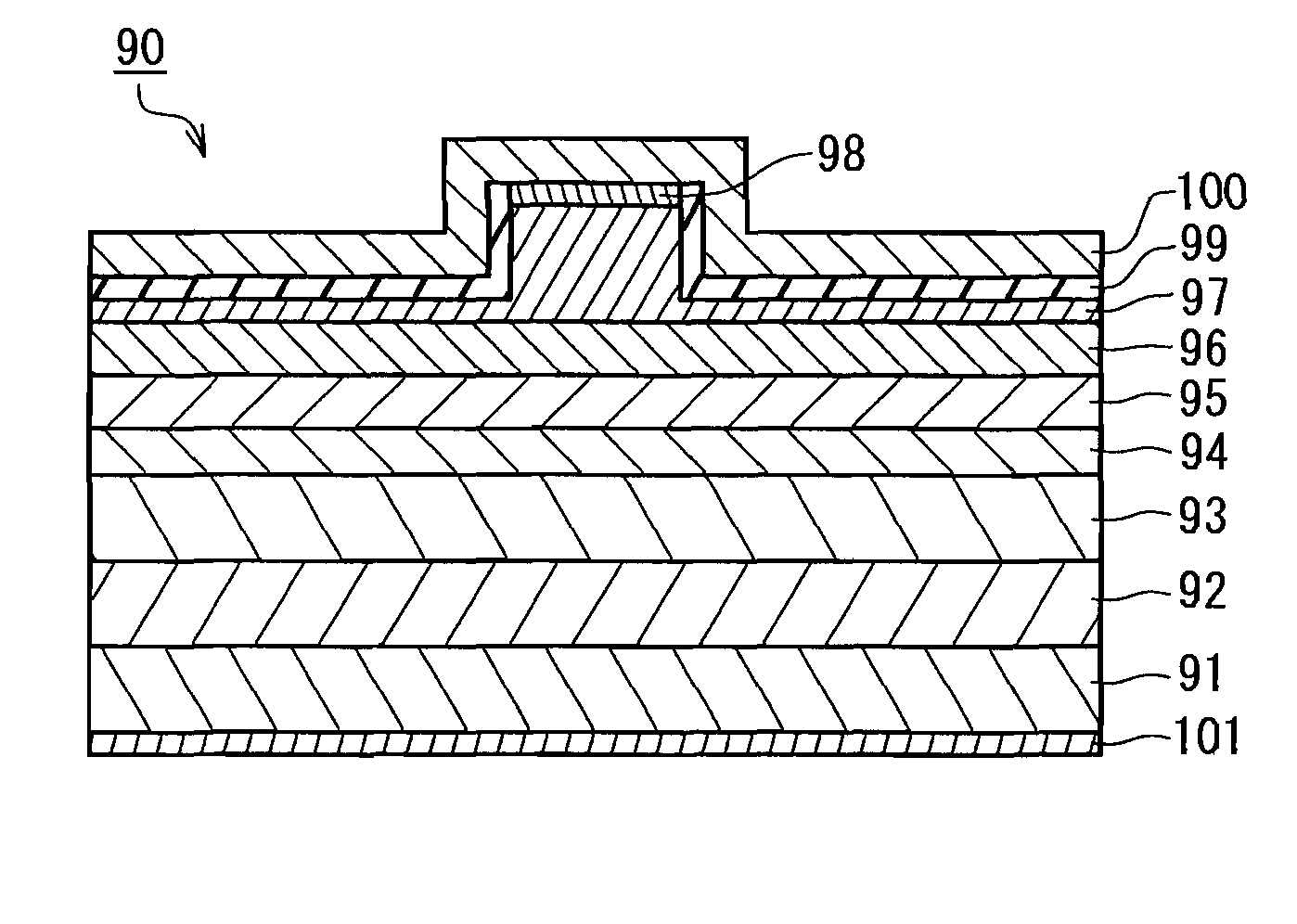

Organic luminescent materials, coating solution using same for organic emitting layer, organic light emitting device using coating solution and light source device using organic light emitting device

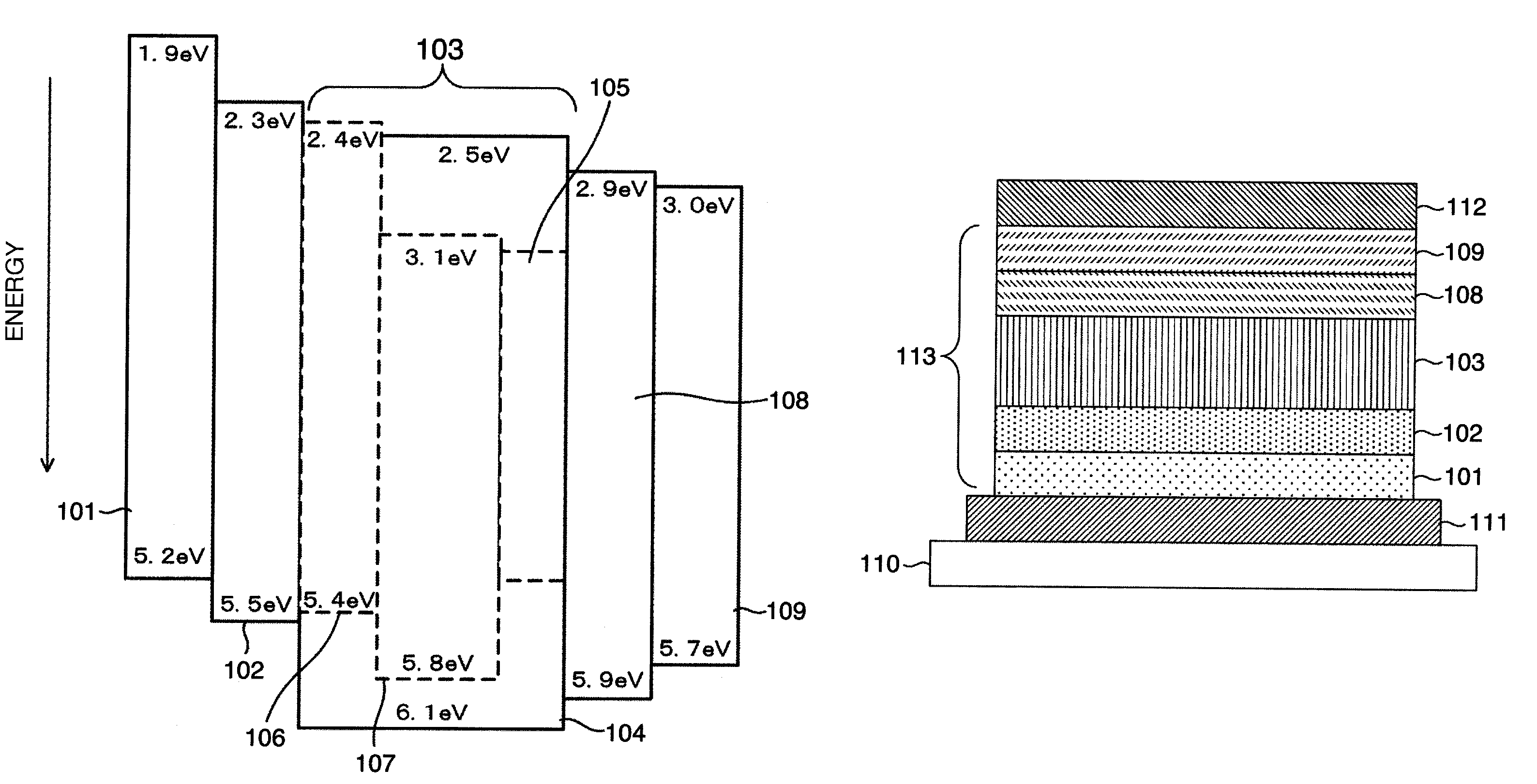

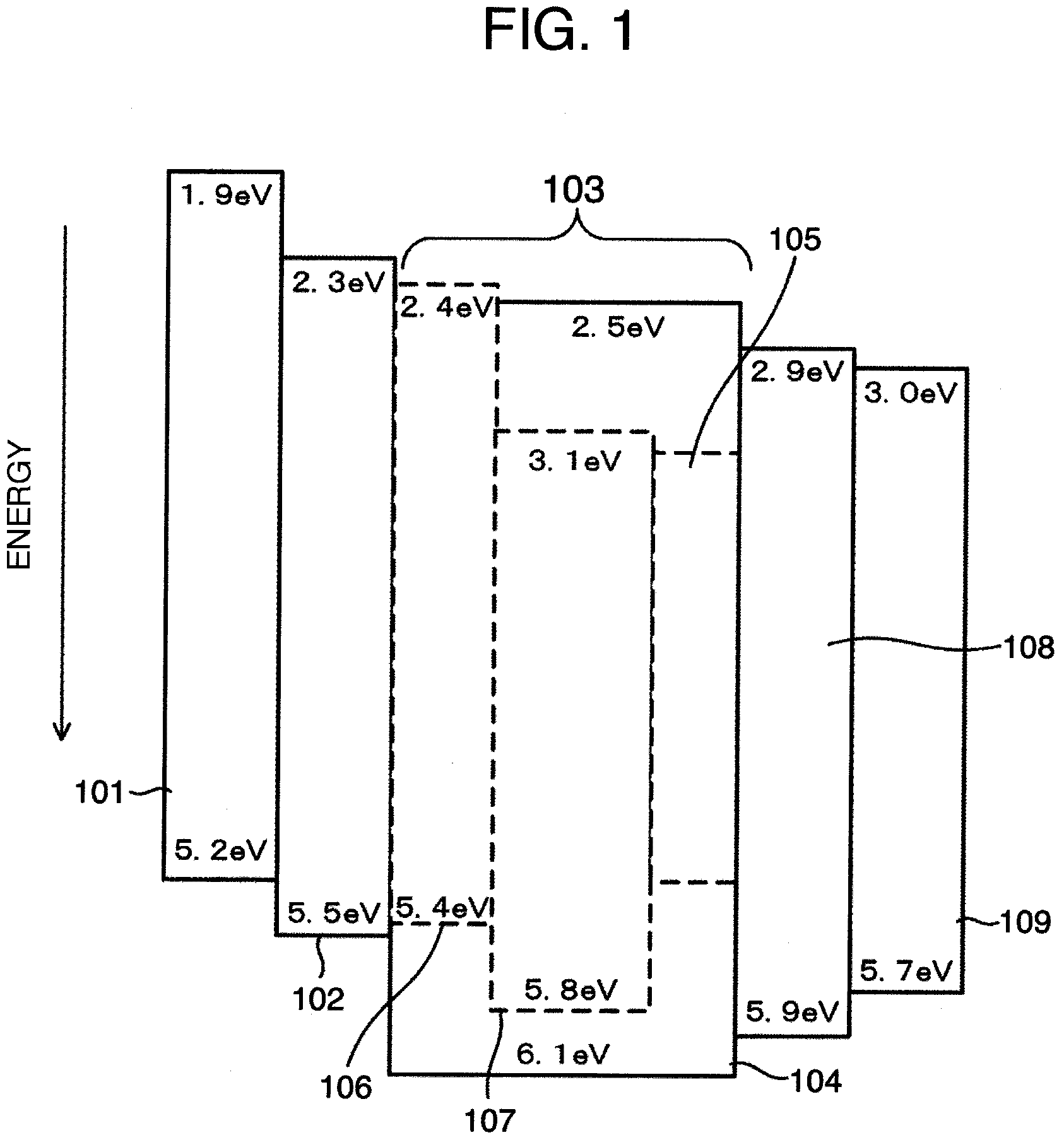

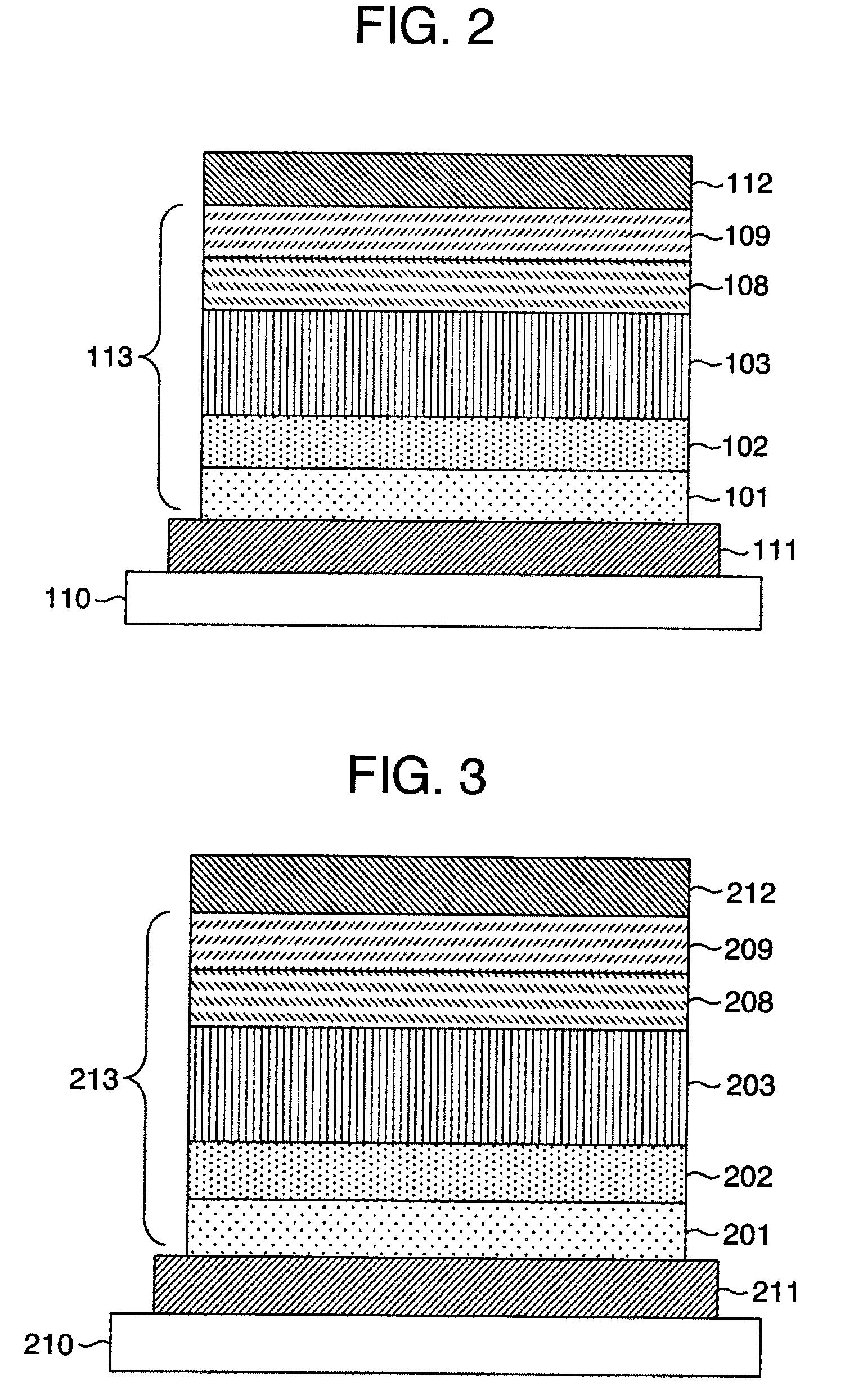

InactiveUS8319211B2Control concentrationImprove distributionElectroluminescent light sourcesSolid-state devicesDopantOrganic light emitting device

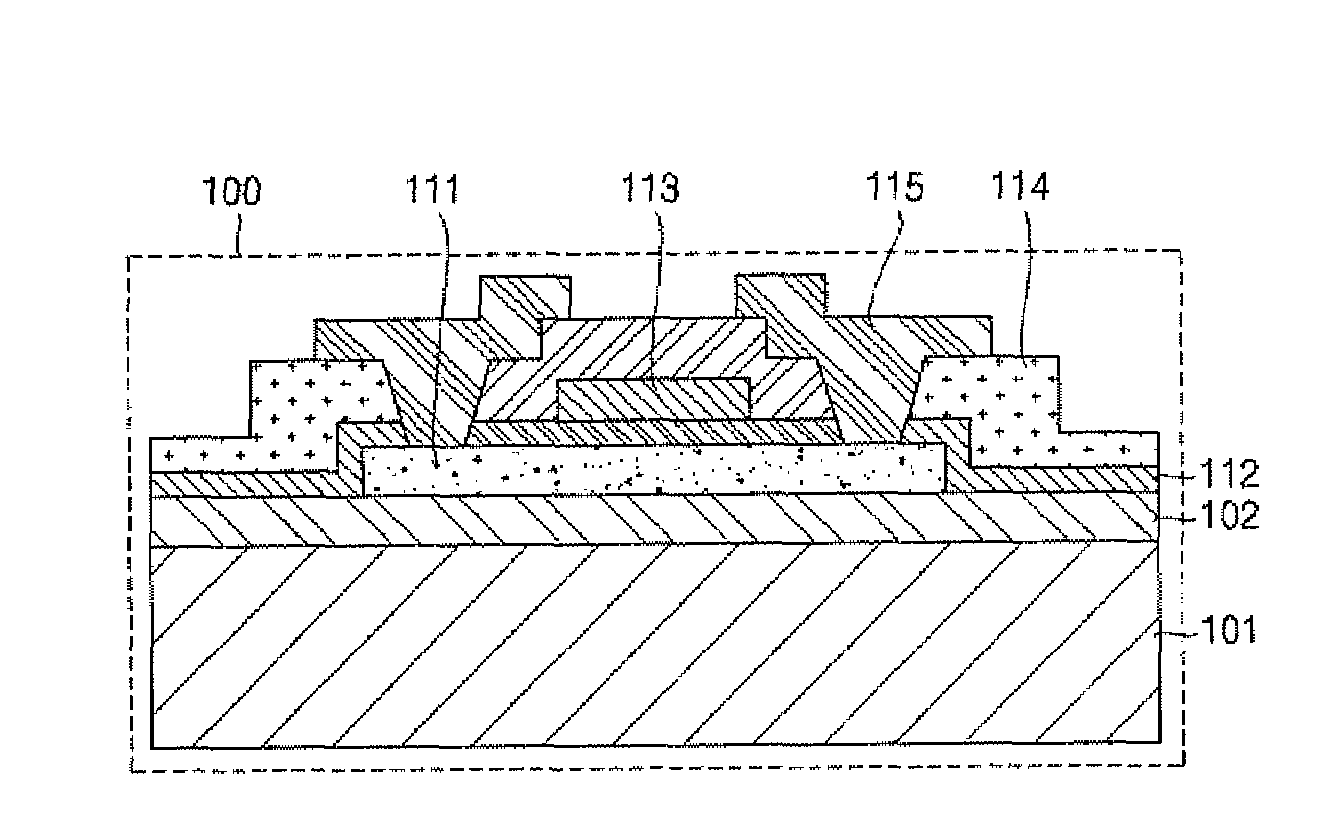

It is an object of the present invention to provide an organic light-emitting device which can emit white light by easily controlling dopant concentrations. The organic light-emitting device has a first electrode (112) and second electrode (111) which hold a light-emitting layer (113) in-between, wherein the light-emitting layer contains a host material (104), red-light-emitting dopant (105), green-light-emitting dopant (106) and blue-light-emitting dopant (107), the red-light-emitting dopant containing a first functional group for transferring the dopant toward the first electrode and the green-light-emitting dopant containing a second functional group for transferring the dopant toward the second electrode.

Owner:HITACHI LTD

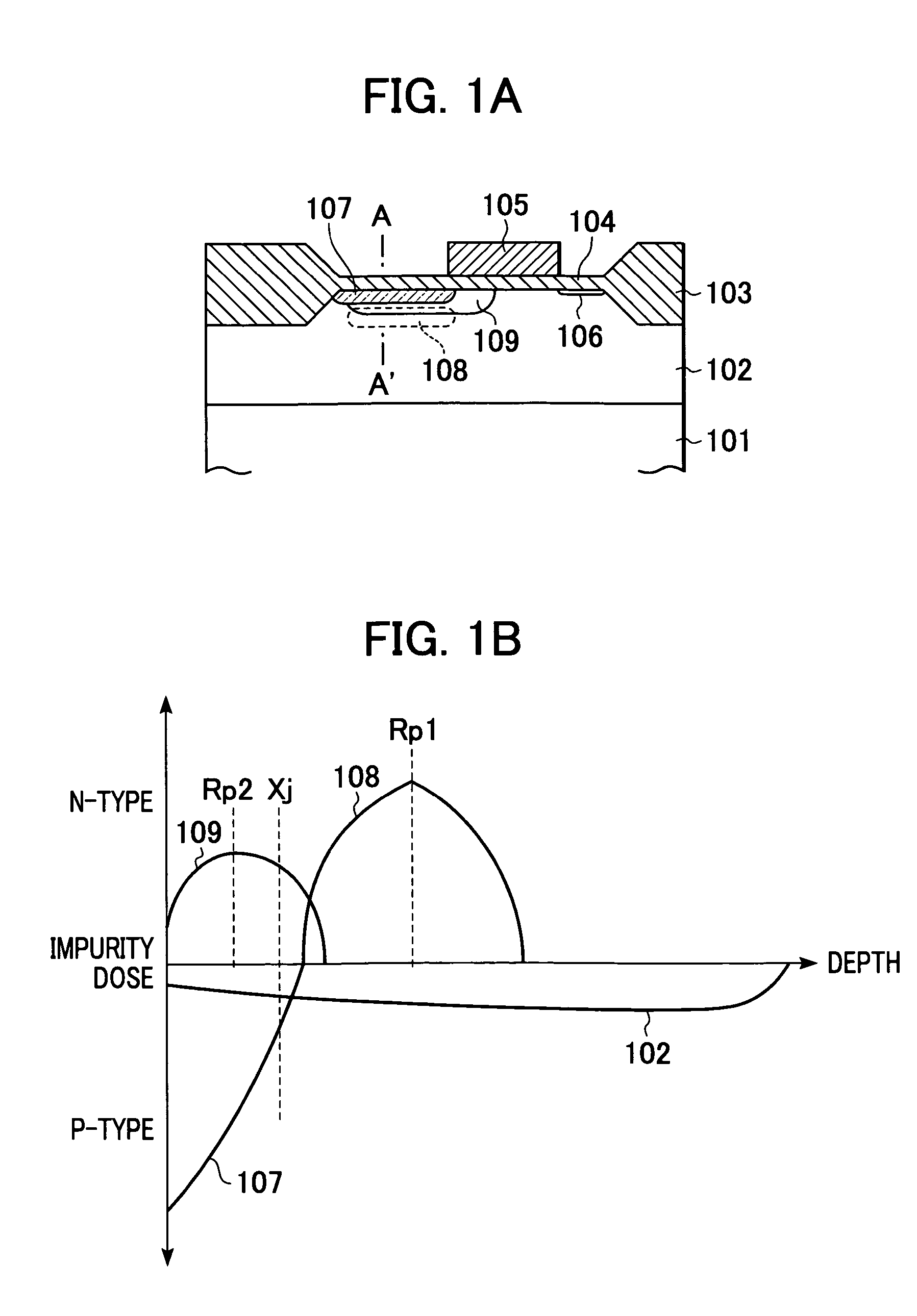

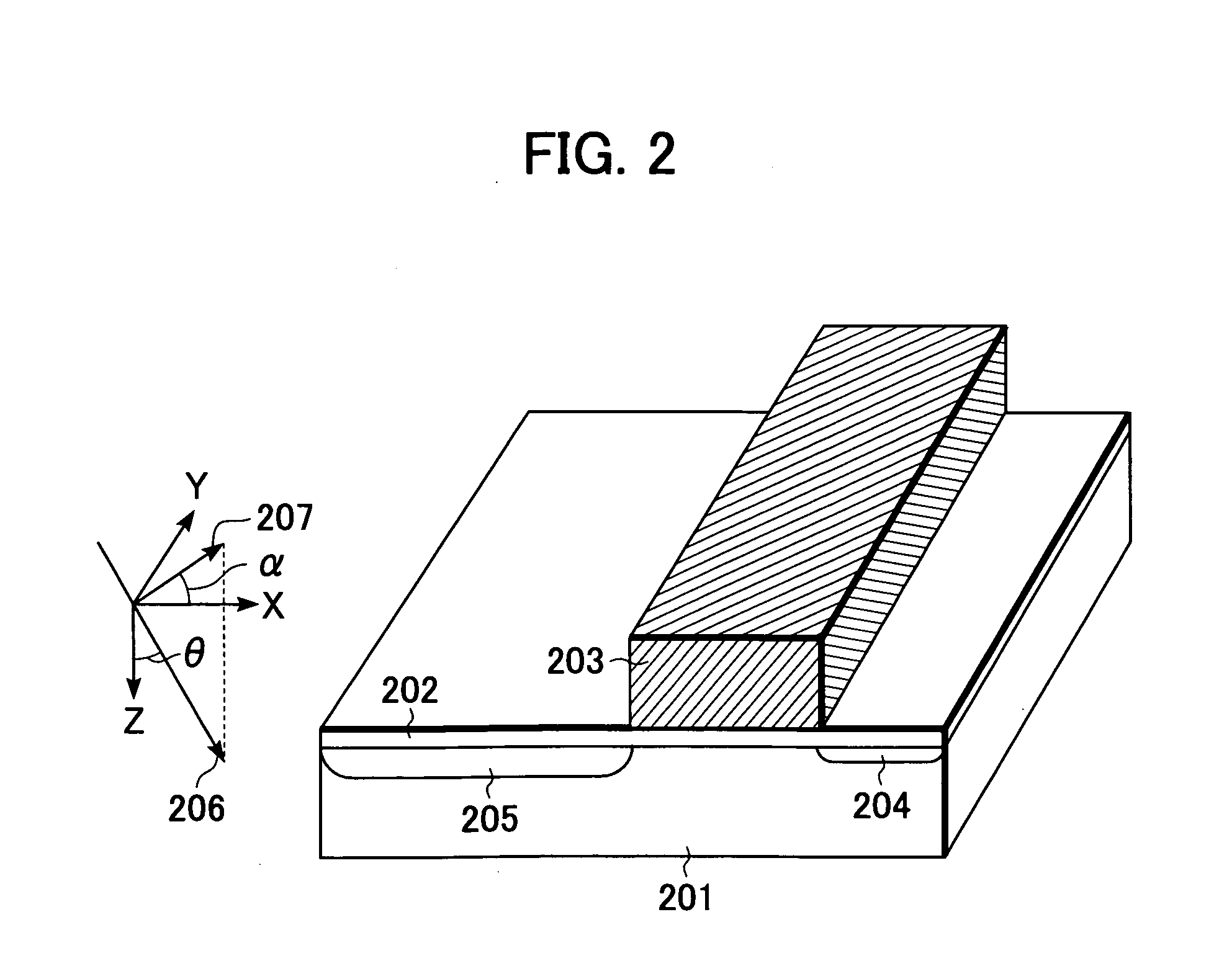

Solid-state image sensor, production method for solid-state image sensor, and camera using solid-state image sensor

InactiveUS20050006676A1Reduces power voltage and power consumptionHigh SIN ratioTelevision system detailsSolid-state devicesSolid-stateImage sensor

A solid-state image sensor includes, in each pixel, a p-type well provided on a semiconductor substrate, a photodiode provided in the p-type well, a transfer gate for transferring photocharges accumulated in the photodiode, and an n-type diffusion region for receiving the transferred photocharges. The photodiode includes a first n-type accumulation region, and a second n-type accumulation region having a concentration higher than that of the first accumulation region and provided at a position deeper than the first accumulation region. The first accumulation region extends toward an end of the transfer gate, and the second accumulation region is separate from the transfer gate.

Owner:CANON KK

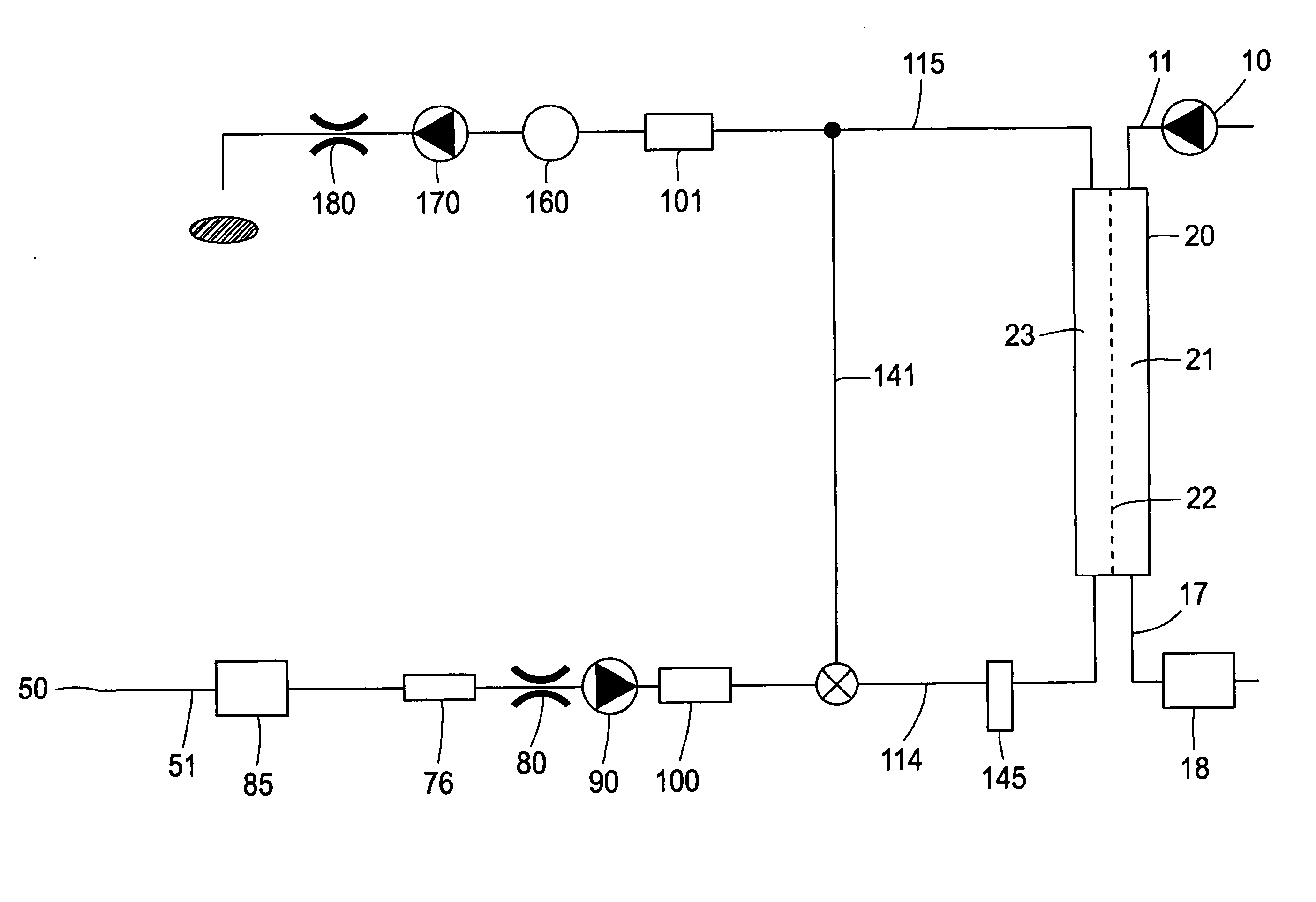

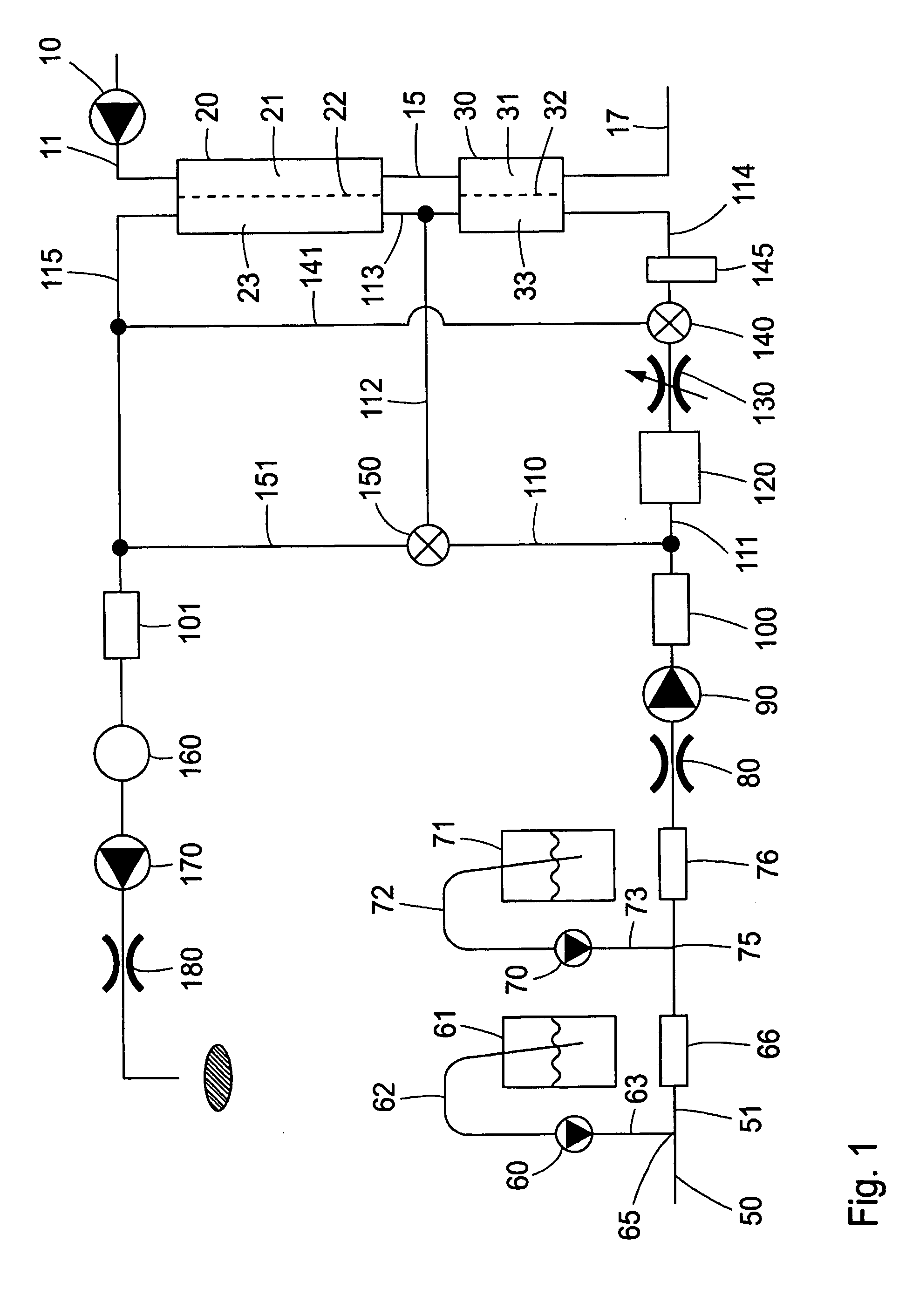

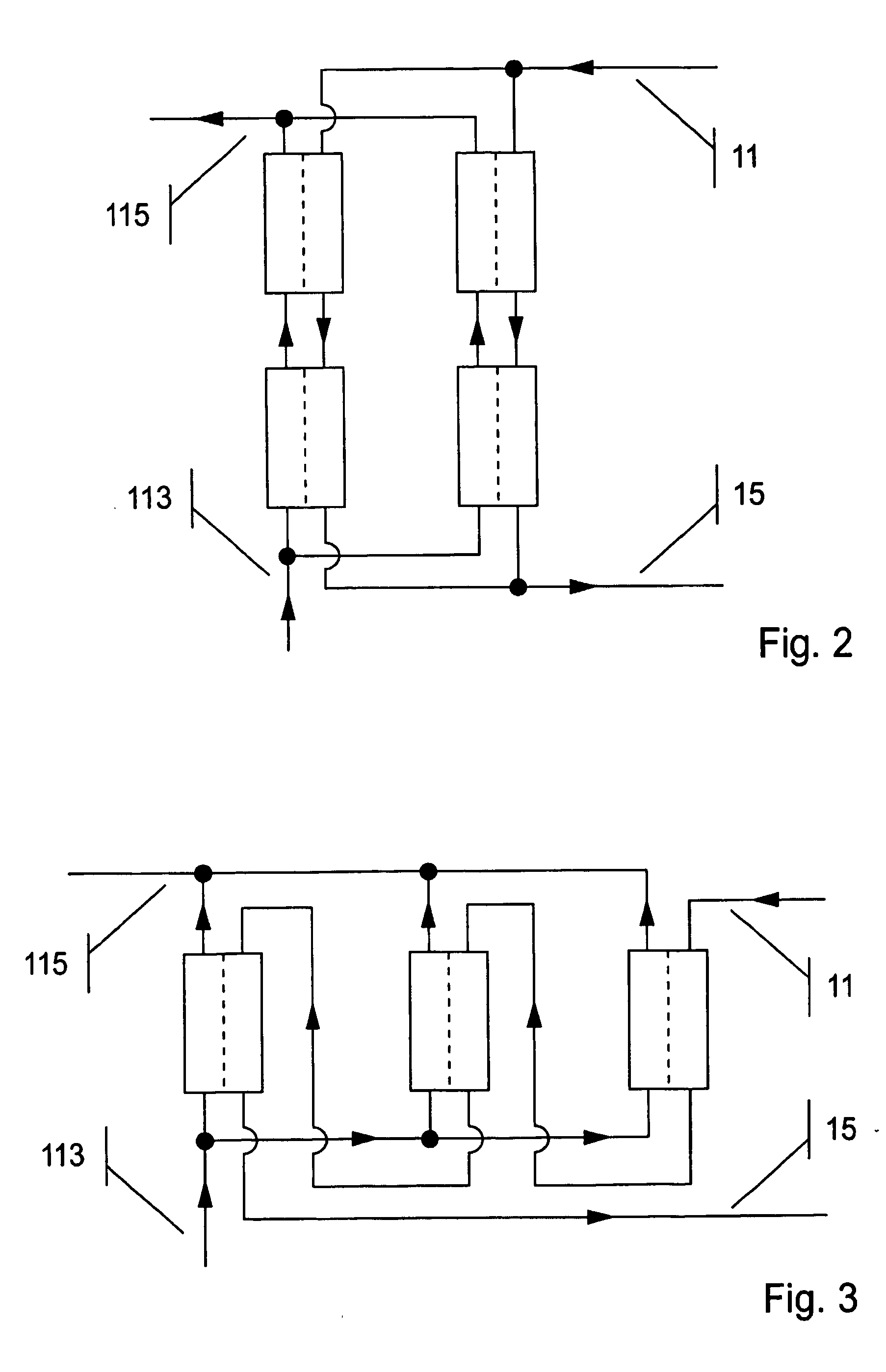

Method and device for the removal of partially protein bound substances

ActiveUS20050115898A1Large clearanceHigh ratioLiquid separation auxillary apparatusOther blood circulation devicesDialysis fluidMembrane configuration

A method and a device to increase the efficiency of dialysis for the removal from blood of substances that are more or less tightly bound to carriers such as albumin. According to the invention this is accomplished by a simultaneous significant increase of the flow rate of the dialysis fluid and of the area of the membrane that separates the blood from the dialysis fluid, compared to conventional dialysis.

Owner:GAMBRO LUNDIA AB

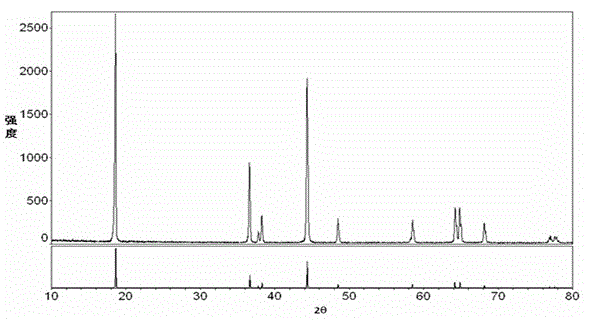

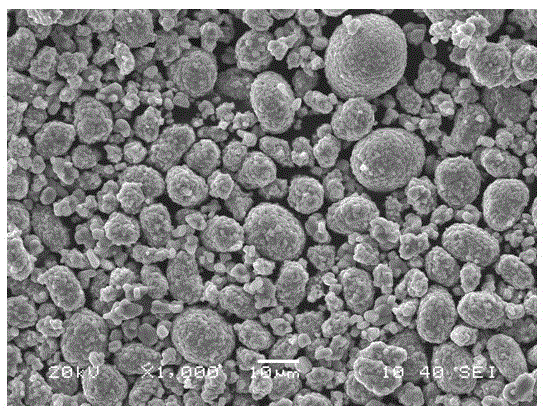

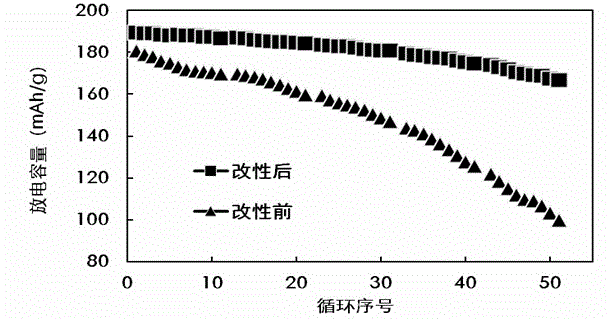

Positive electrode material of high-capacity dynamic-type nickel-rich lithium ion battery and preparation method thereof

ActiveCN103606671AStable structureImprove cycle performanceCell electrodesMaterials processingLithium-ion battery

The invention relates to a positive electrode material of a high-capacity dynamic-type nickel-rich lithium ion battery and a preparation method. The molecular formula of the positive electrode material of the high-capacity dynamic-type nickel-rich lithium ion battery is LiaNi1-x(MM')xO2.M''O, wherein a is equal to 0.9-1.2, x is more than or equal to 0 and less than or equal to 0.7, and M is at least one of Co, Mn and Al; M' is at least one of Co, Al, V, Mn, Zr, Mg, Ti, Cr, Zr, La, Ce, Pr, Nd, Nb, Mo, Y, Sr, Ba, B, Sr, Sn and Ta; M''O is a cladding layer, and M'' is Co and Al. The invention also relates to a preparation method for the positive electrode material of the high-capacity dynamic-type nickel-rich lithium ion battery. The material machining performance is excellent, the battery prepared by utilizing the material, the cycling performance and the high-voltage performance are excellent, the safety and stability in use can be realized, not only can the application performance requirement of a portable electronic device on the battery be met, but also the positive electrode material is applicable to the power battery.

Owner:HUNAN SHANSHAN ENERGY TECH CO LTD

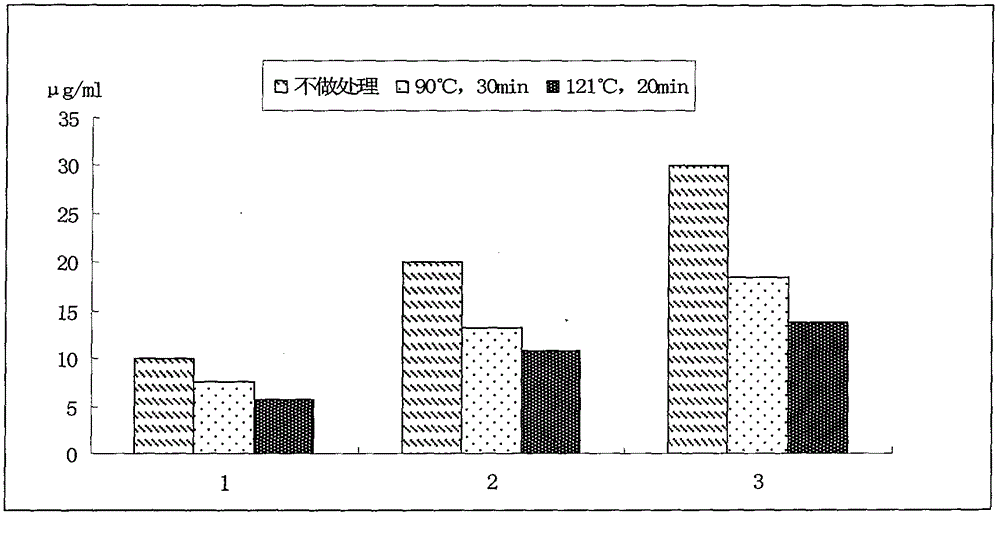

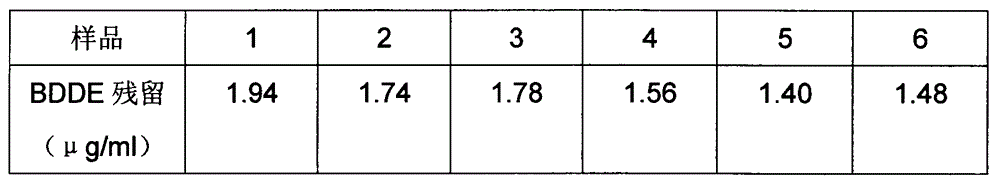

Preparation method of low-temperature secondary cross-linked sodium hyaluronate gel

InactiveCN103146003AImprove cross-linking efficiencyAvoid the disadvantages of yellowingProsthesisHigh concentrationCross linker

The invention relates to a preparation method of 1,4-butanediol diglycidyl ether cross-linked sodium hyaluronate gel. The method comprises the steps of: by taking high-concentration sodium hyaluronate solution as reaction matrix, performing first cross-linking for a longer time under the low-temperature condition by adding less cross-linking agent, then performing secondary deep cross-linking under high-temperature condition, and finally processing and pelleting through short-time dialysis technique, thereby obtaining the sodium hyaluronate gel product. With the method, the cross-linking condition of the high-concentration cross-linking agent under the traditional high-temperature condition can be eliminated, milder secondary depth cross-linking condition is adopted, the reaction efficiency of the less cross-linking agent can be greatly improved, the residual cross-linking agent is more easily removed, and the excellent biocompatibility of the cross-linked sodium hyaluronate gel can be ensured. The method is simple in preparation technique, excellent in controllability and easier to practically produce on large scale.

Owner:SHANGHAI QISHENG BIOLOGICAL PREPARATION CO LTD

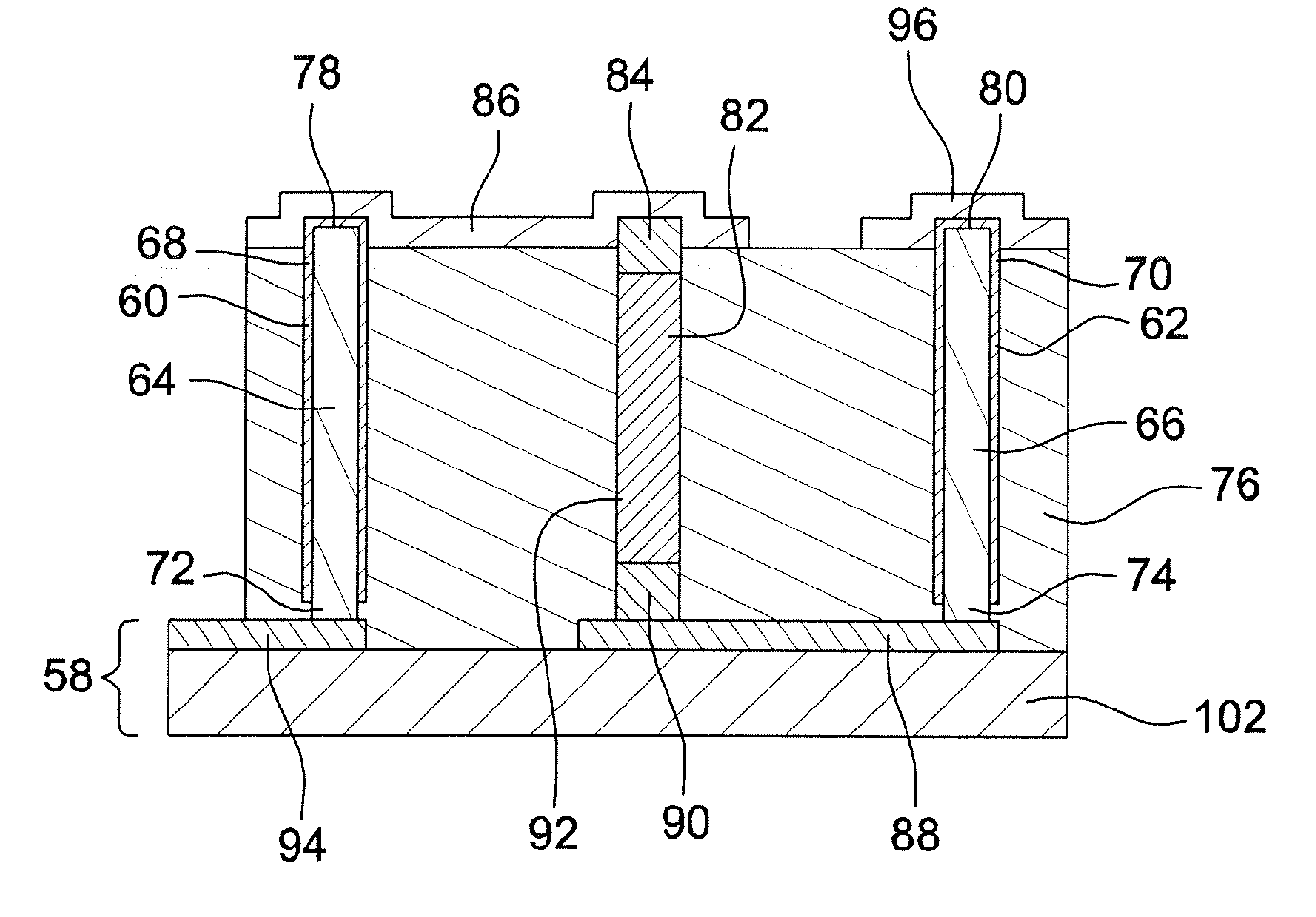

In-series electrical connection of light-emitting nanowires

ActiveUS20140077156A1Easy to limitControl concentrationSolid-state devicesSemiconductor/solid-state device manufacturingElectron injectionNanowire

An optoelectronic device includes at least first and second light-emitting nanowires on a support, each comprising an area for the injection of holes and an area for the injection of electrons, a series electric connection including a connection nanowire on the support, which includes a first region forming an electric path with the hole injection area of the first nanowire, a second region forming an electric path with the electron injection area of the second nanowire, and a third region enabling a current to flow between first and second regions. Also included are a first conductive area connecting the hole injection area of the first nanowire and the first region of the connection nanowire and electrically insulated from the second nanowire, and a second conductive area connecting the second region of the connection nanowire and electron injection area of the second nanowire and electrically insulated from the first nanowire.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

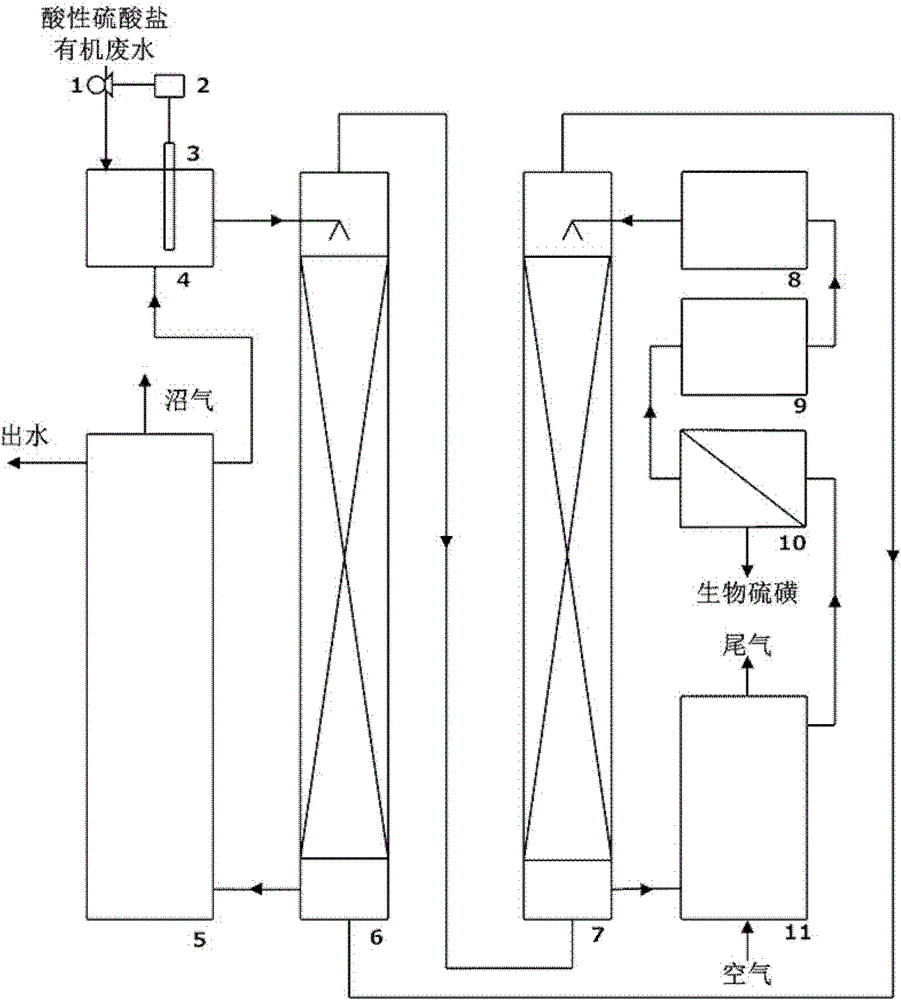

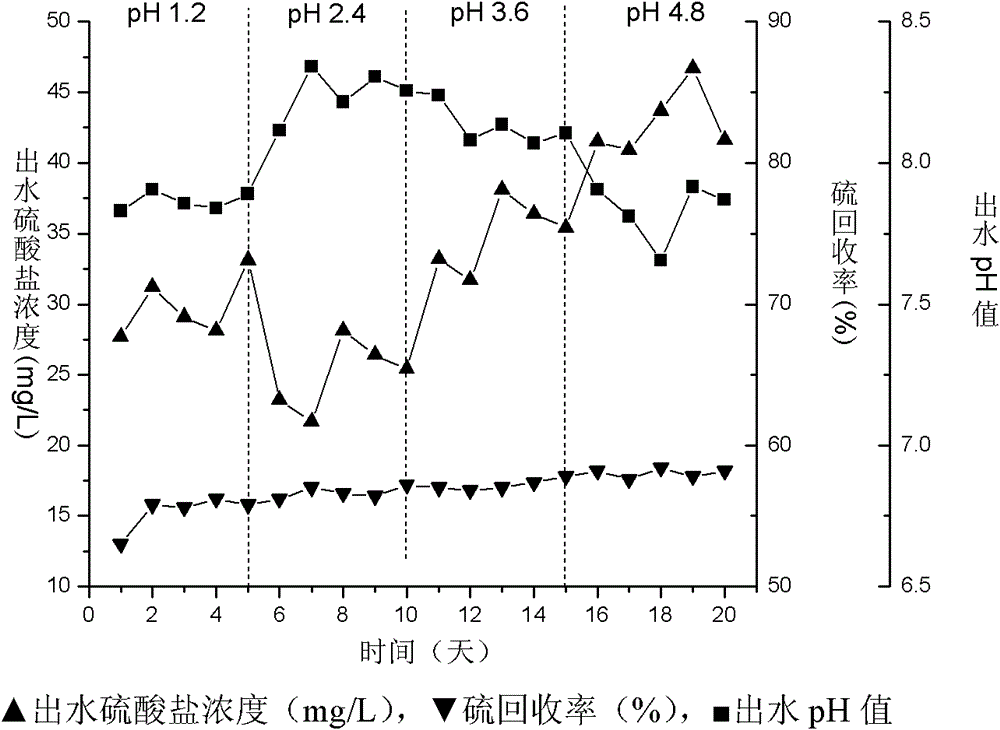

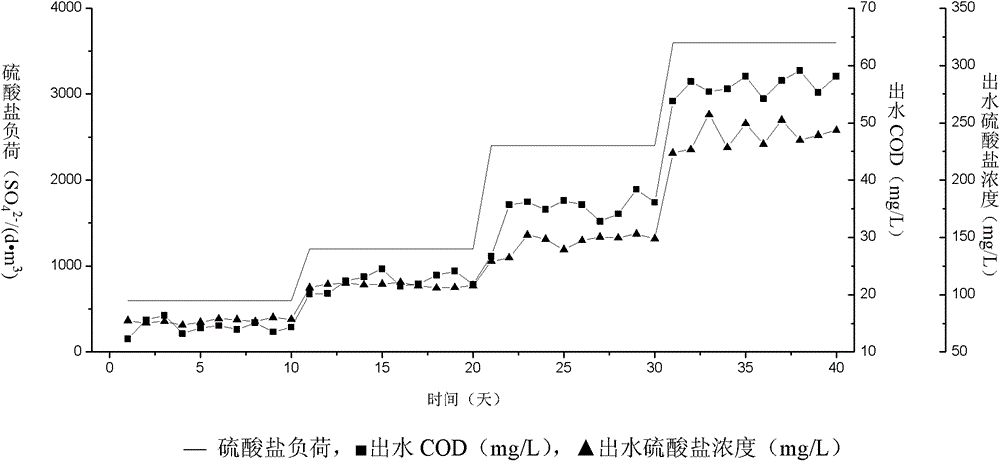

Device and method for comprehensively treating acidic sulfate organic waste water based on biological desulfurization

InactiveCN102795739AAchieving processing powerFacilitate conversion and strippingMultistage water/sewage treatmentWater basedSulfate-reducing bacteria

The invention belongs to the field of environmental engineering, and in particular relates to a device and a method for comprehensively treating acidic sulfate organic waste water based on biological desulfurization. The method comprises the following steps of: 1, reducing sulfate in the organic waste water, blowing hydrogen sulfide off, namely (1-1) mixing the acidic sulfate organic waste water and sulfide-containing recirculation water in an anaerobic digestion reactor, controlling the pH of the mixture to be 5.0 to 6.0, and thus obtaining a hydrogen sulfide-containing acidic mixed solution, and (1-2) introducing inert gas, blowing the hydrogen sulfide off, adding sulfate reducing bacteria, reducing the sulfate to form sulfide, obtaining the sulfide-containing recirculation water and returning to the step (1-1); and 2, absorbing, oxidizing and recycling the hydrogen sulfide, namely (2-1) absorbing the hydrogen sulfide blown off in the step (1-2) by using a weak alkaline solution, adding sulfur-oxidizing bacteria, oxidizing the hydrogen sulfide to form elemental sulfur, separating to obtain the elemental sulfur and effluent, and (2-2) treating the effluent for recycling. By the device and the method, sulfate innocent treatment and resource recovery treatment are realized.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

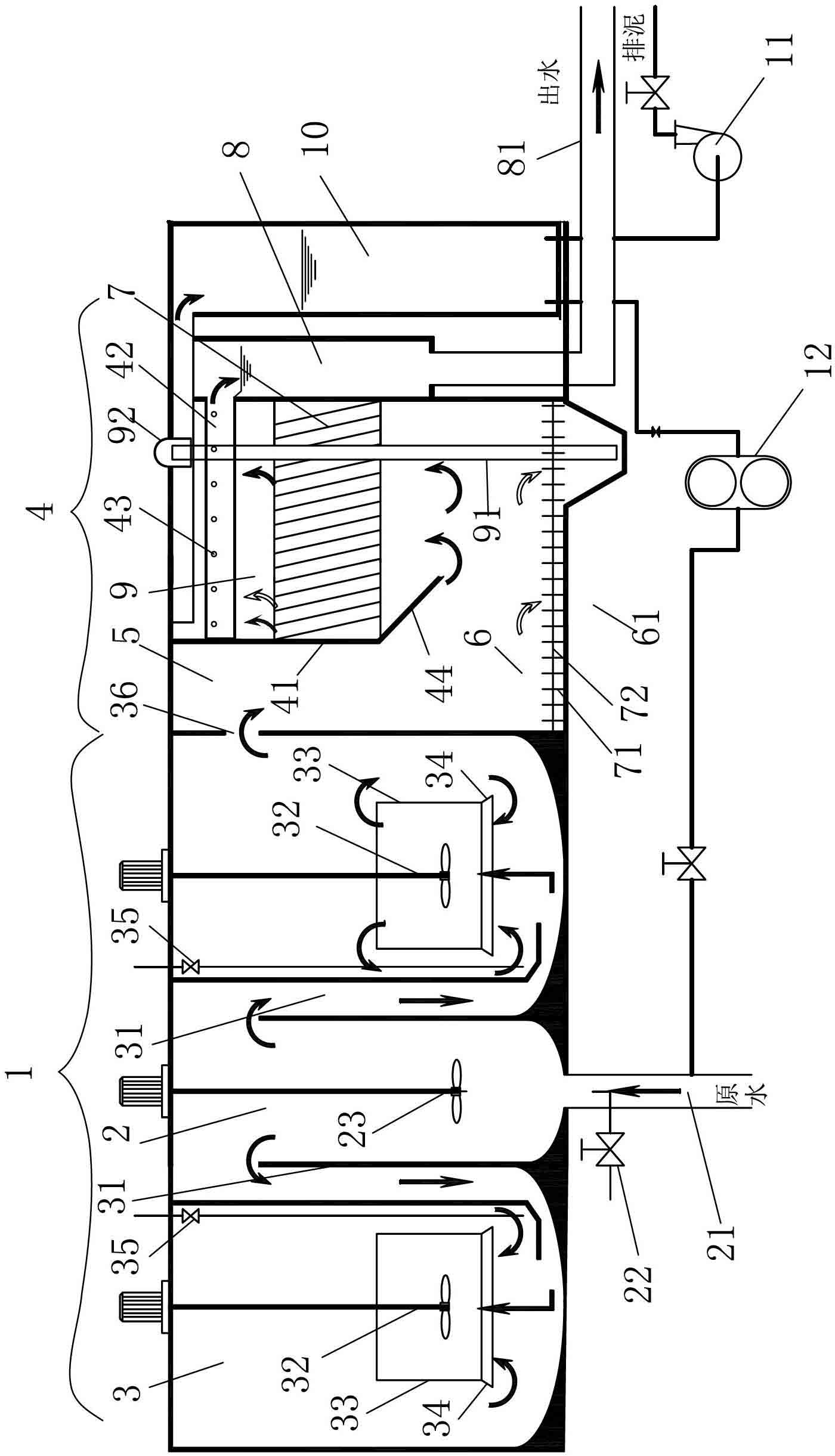

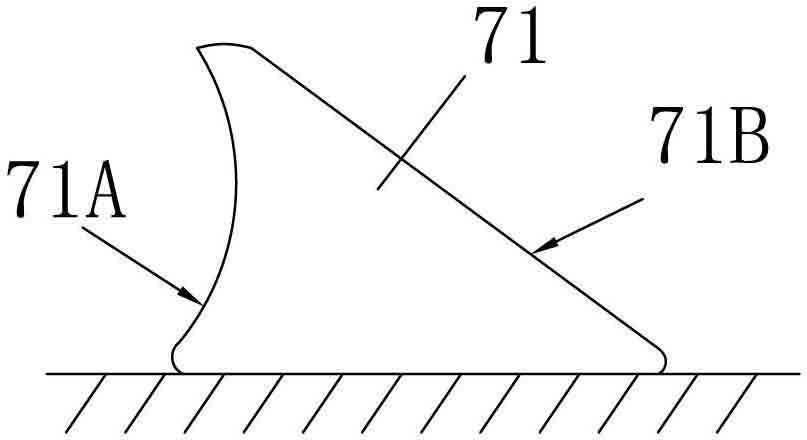

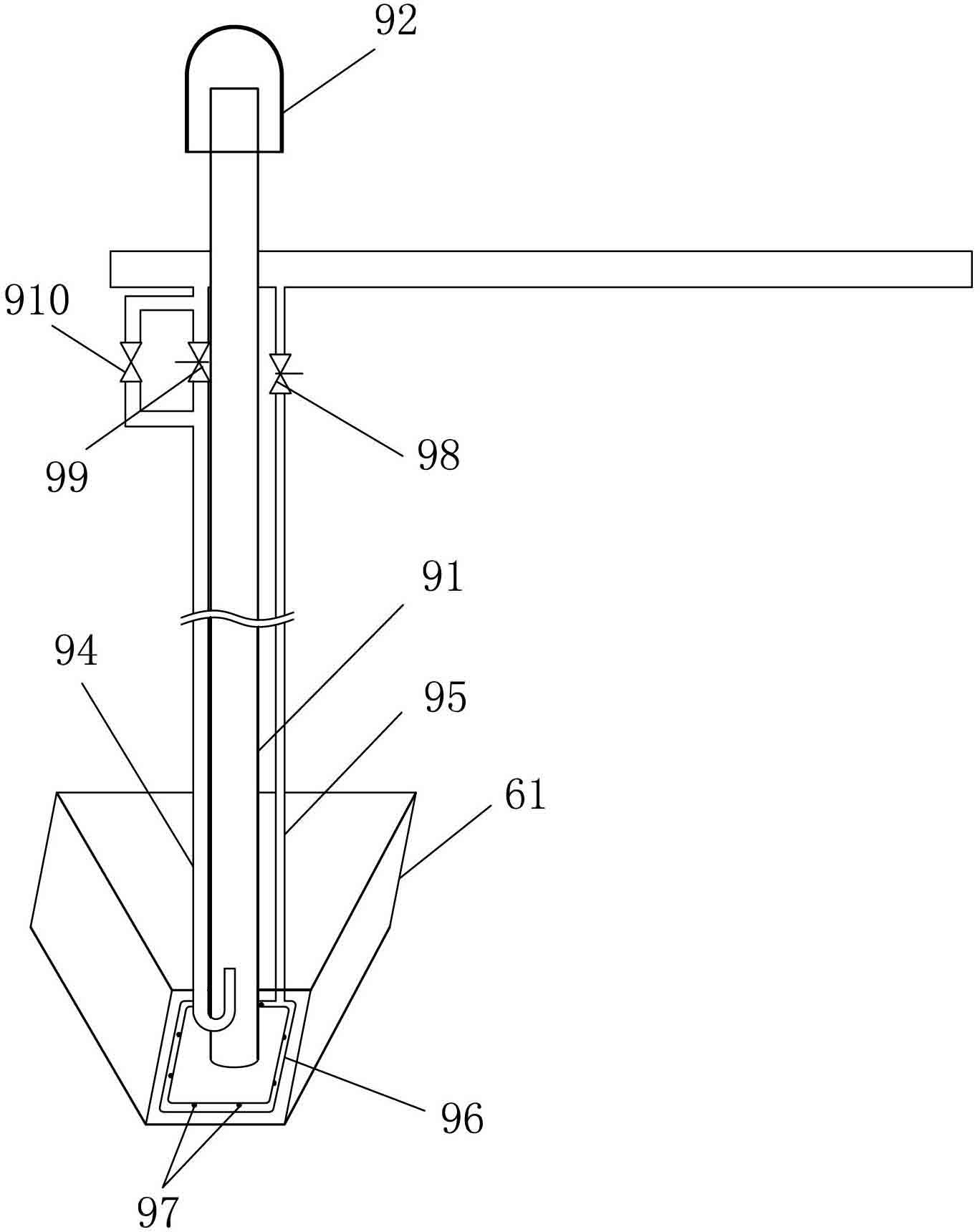

Middle-set type high density sediment water purification tank and purification technology thereof

ActiveCN102659227AControl concentrationControl quantityEnergy based wastewater treatmentWater/sewage treatment by flocculation/precipitationFlocculationReflux

The invention mainly discloses a middle-set type high density sediment water purification tank and a purification technology thereof. The middle-set type high density sediment water purification tank comprises a reaction region, a clarification region and a sludge transfer tank. The reaction region comprises a mixing tank and a flocculation tank; the clarification region comprises a pre-sedimentation region, a sludge concentration region, an inclined pipe sedimentation region and a clear water canal, wherein the sludge concentration region is arranged at the bottom of the clarification region, the inclined pipe sedimentation region is arranged above the clarification region, and the clear water canal is connected with a water outlet pipe through a finger type water collecting tank positioned above the inclined pipe sedimentation region. A plurality of conical sludge collecting pits are arranged at one side of the bottom surface of the clarification region, and a sludge scraper is arranged on the bottom surface of the clarification region; a gas stripping device which lifts sludge in the sludge collecting pit to a sludge discharging groove at the upper part of the clarification region is arranged in each sludge collecting pit; the gas stripping sludge discharging groove is connected to the sludge transfer tank; the sludge transfer tank is connected with a water inlet pipe through a reflux pump; and simultaneously, the sludge transfer tank is connected with a sludge pump. The middle-set type high density sediment water purification tank has the advantages of having simple tank shape, compact structure and water outlet quality, being beneficial to the control on a sedimentation tank and the concentration and number of returned sludge, ensuring the stability of operation conditions and being low in operating cost.

Owner:SHAOXING WATER MAKING

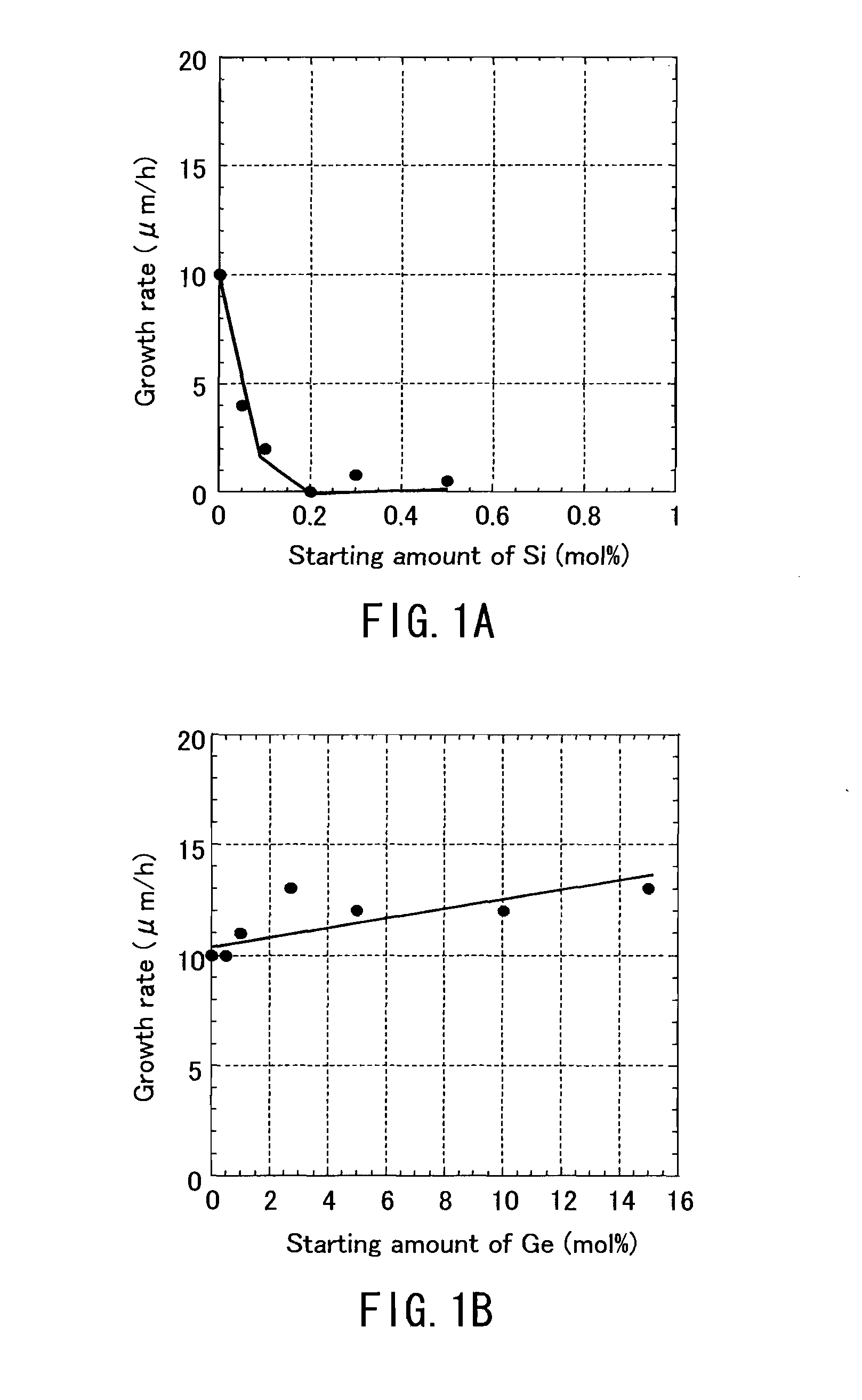

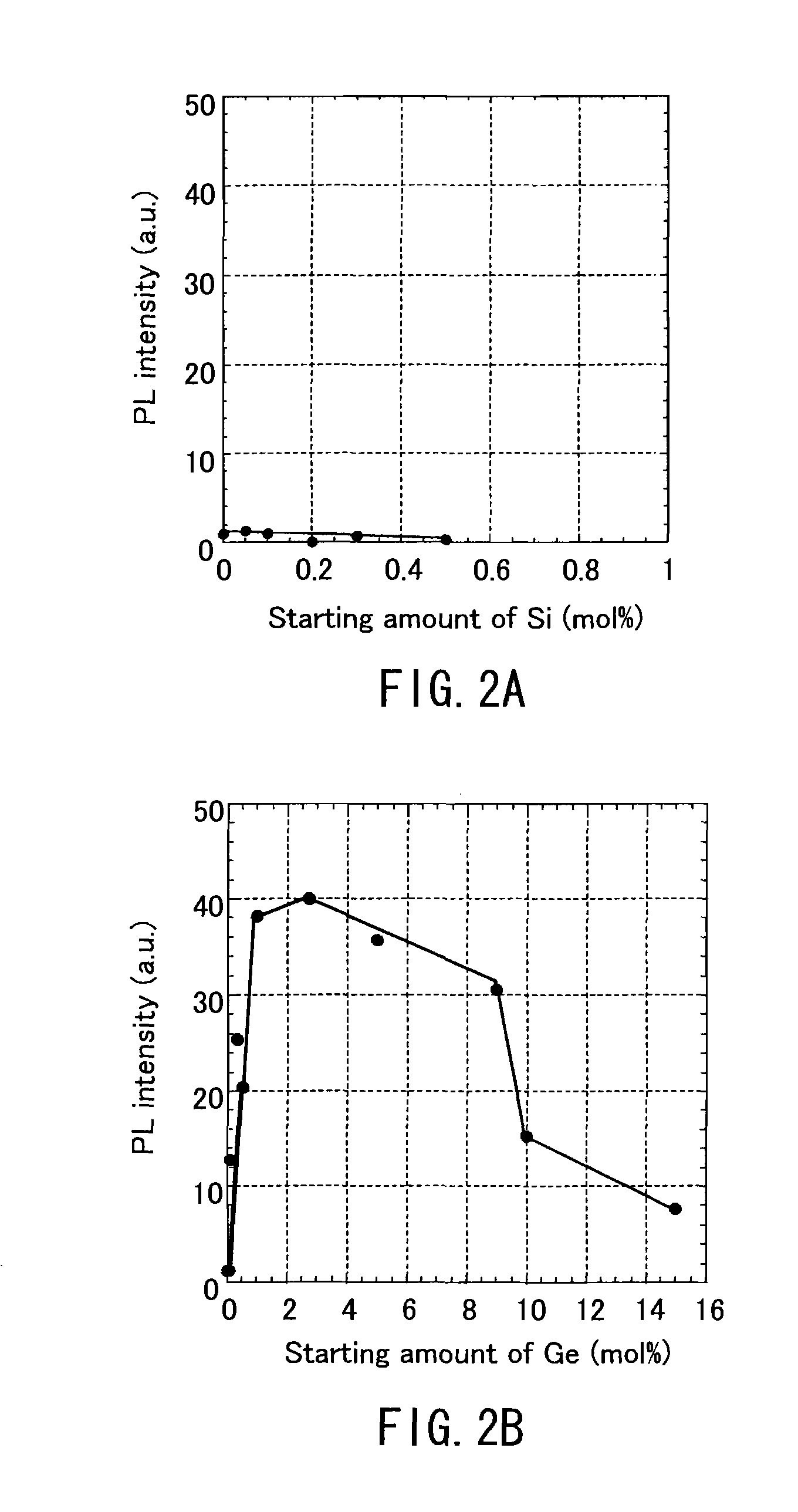

Semiconductor light emitting element, group iii nitride semiconductor substrate and method for manufacturing such group iii nitride semiconductor substrate

InactiveUS20100230713A1Excellent light extraction propertyDopant concentration is therefore limitedOptical wave guidancePolycrystalline material growthDopantAlkaline earth metal

An object of the present invention is to obtain, with respect to a semiconductor light-emitting element using a group III nitride semiconductor substrate, a semiconductor light-emitting element having an excellent light extraction property by selecting a specific substrate dopant and controlling the concentration thereof. The semiconductor light-emitting element comprises a substrate composed of a group III nitride semiconductor comprising germanium (Ge) as a dopant, an n-type semiconductor layer composed of a group III nitride semiconductor formed on the substrate, an active layer composed of a group III nitride semiconductor formed on the n-type semiconductor layer, and a p-type semiconductor layer composed of a group III nitride semiconductor formed on the active layer in which the substrate has a germanium (Ge) concentration of 2×1017 to 2×1019 cm−3. The substrate is produced in a nitrogen-containing atmosphere using a melt comprising at least a group III element, an alkali or alkaline earth metal, and germanium (Ge) and nitrogen.

Owner:PANASONIC CORP

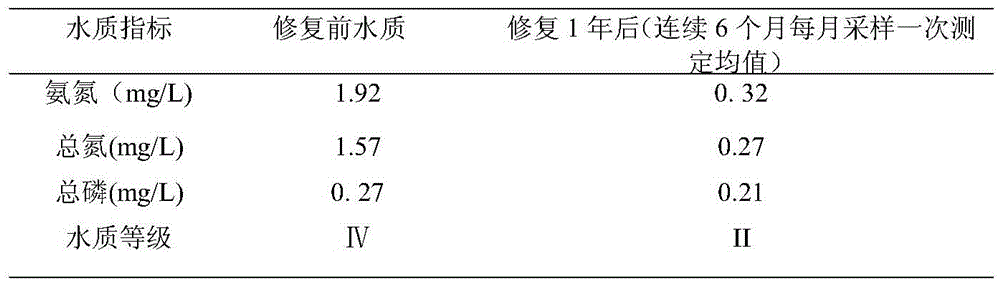

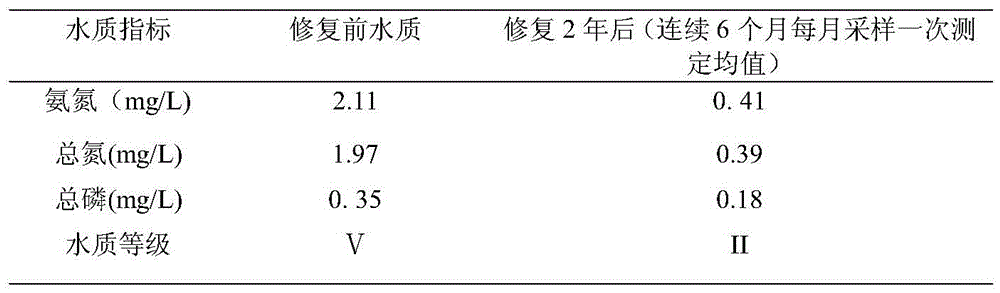

A benthonic animal-algae-aquatic plant-fish based river water ecological environment self-remediation method

ActiveCN105523637AControl quantityControl concentrationSustainable biological treatmentBiological water/sewage treatmentEcological environmentIndividual animal

The invention relates to a benthonic animal-algae-aquatic plant-fish based river water ecological environment self-remediation method. The method is to overcome problems of river water ecological environment remediation methods at present, namely short effect duration, high costs and easy generation of secondary pollution. The method includes 1) evaluating the degree of pollution of a river, 2) planting reed and seeding algae, 3) throwing in plankton and benthic mollusks, 4) planting submerged plants, 5) throwing in shrimps, herbivorous fishes, omnivore fishes and filter-feeding fishes, 6) throwing in carnivorous fishes, and 7) harvesting the reed and the submerged plants before the reed and the submerged plants die, catching the benthic mollusks and the shrimps, and catching the fishes after two years. The method is long in effect duration, low in cost and free of secondary pollution and is applied for the field of river water pollution remediation.

Owner:JIAYING UNIV

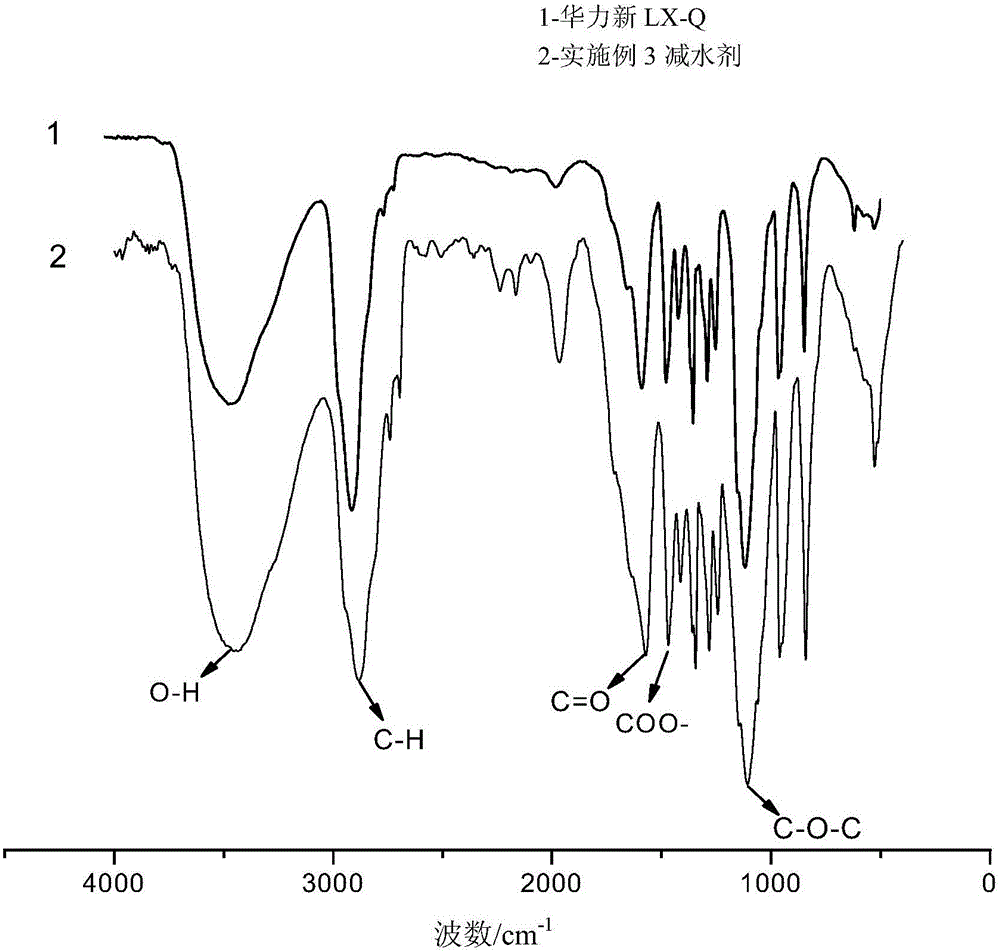

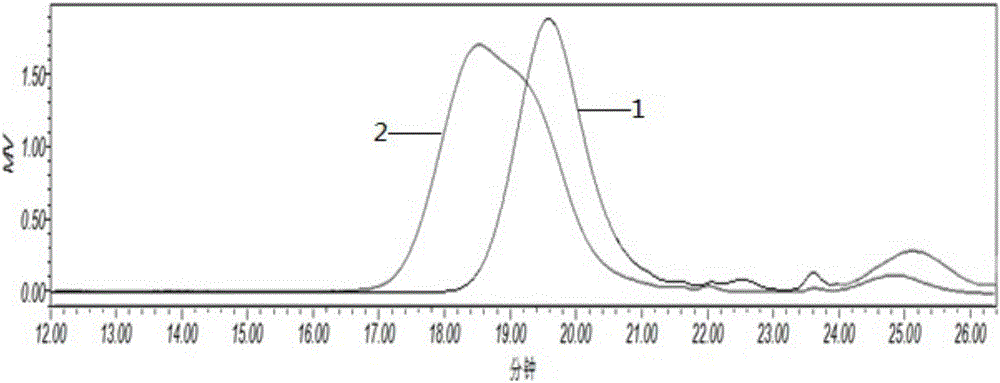

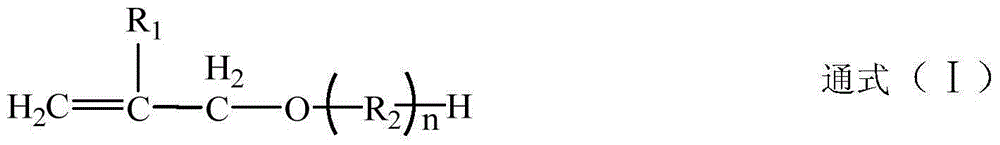

Method for synthesizing polycarboxylate superplasticizer through RAFT method

The invention discloses a method for synthesizing polycarboxylate superplasticizer through a RAFT method. According to the method, firstly, macro-monomers A are added into a reaction kettle, water is added, water bath heating is performed till the temperature is 65-85 DEG C, and constant-temperature stirring is performed; then, a trithio ester chain transferring agent is dissolved in a mixed solution of micro-monomers B and water, the mixture is dropwise added into the reaction kettle at constant speed, and meanwhile an initiator aqueous solution is dropwise added; after all the needed matter is dropwise added, a stirring reaction lasts for 3-5 h under the continuous constant-temperature stirring condition of 65-85 DEG C; after the reaction ends, an alkali solution and water are added to adjust PH to 6-7, and the polycarboxylate superplasticizer is obtained after reaction products are cooled to room temperature. By means of the method, the molecular-structure-controllable polycarboxylate superplasticizer can be prepared, the molecular weight is controllable, the molecular weight distribution range is narrow, polymer molecule design can also be performed, and the method has great significance in research and development of the polycarboxylate superplasticizer synthetic technology.

Owner:SOUTH CHINA UNIV OF TECH +1

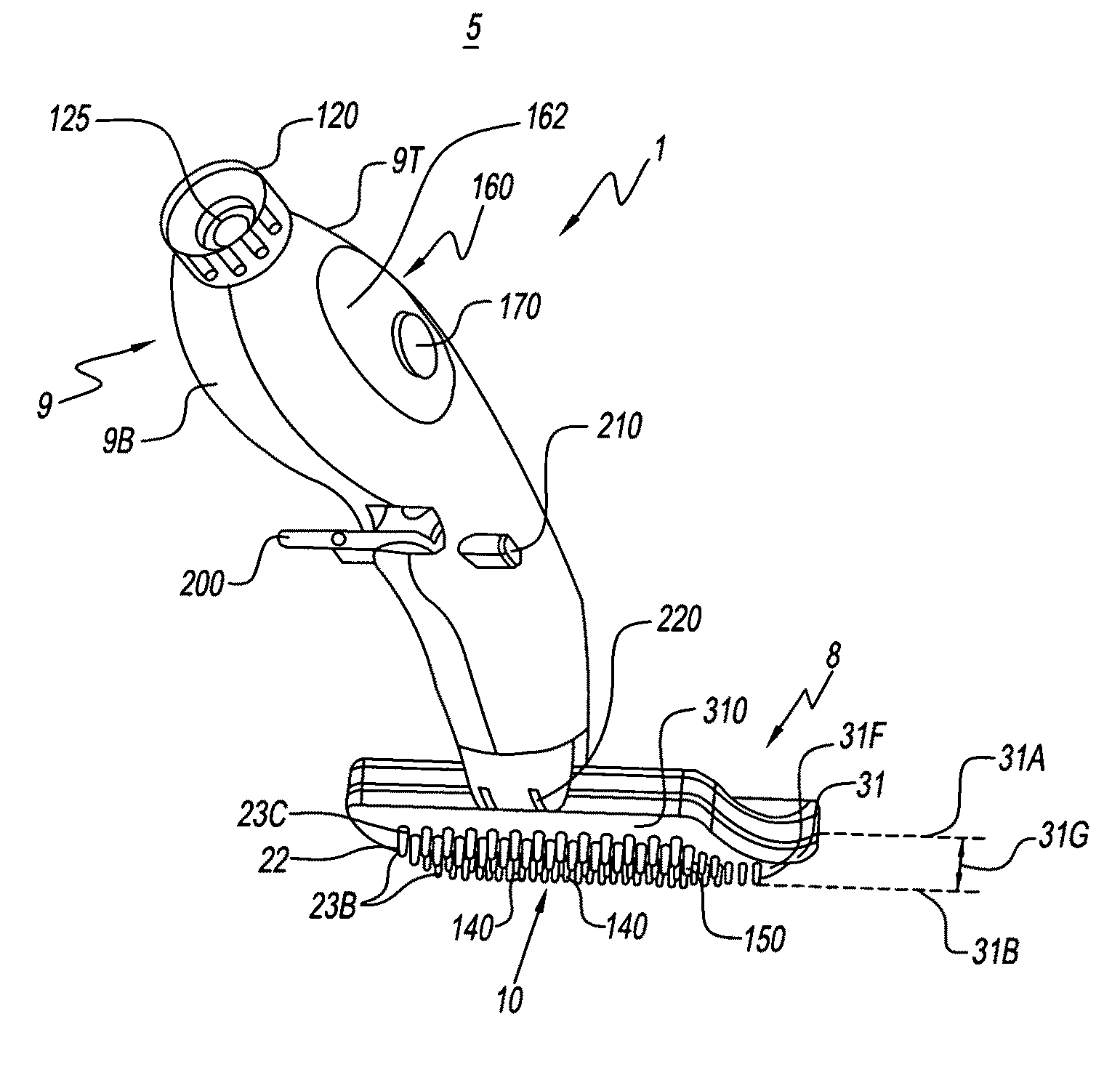

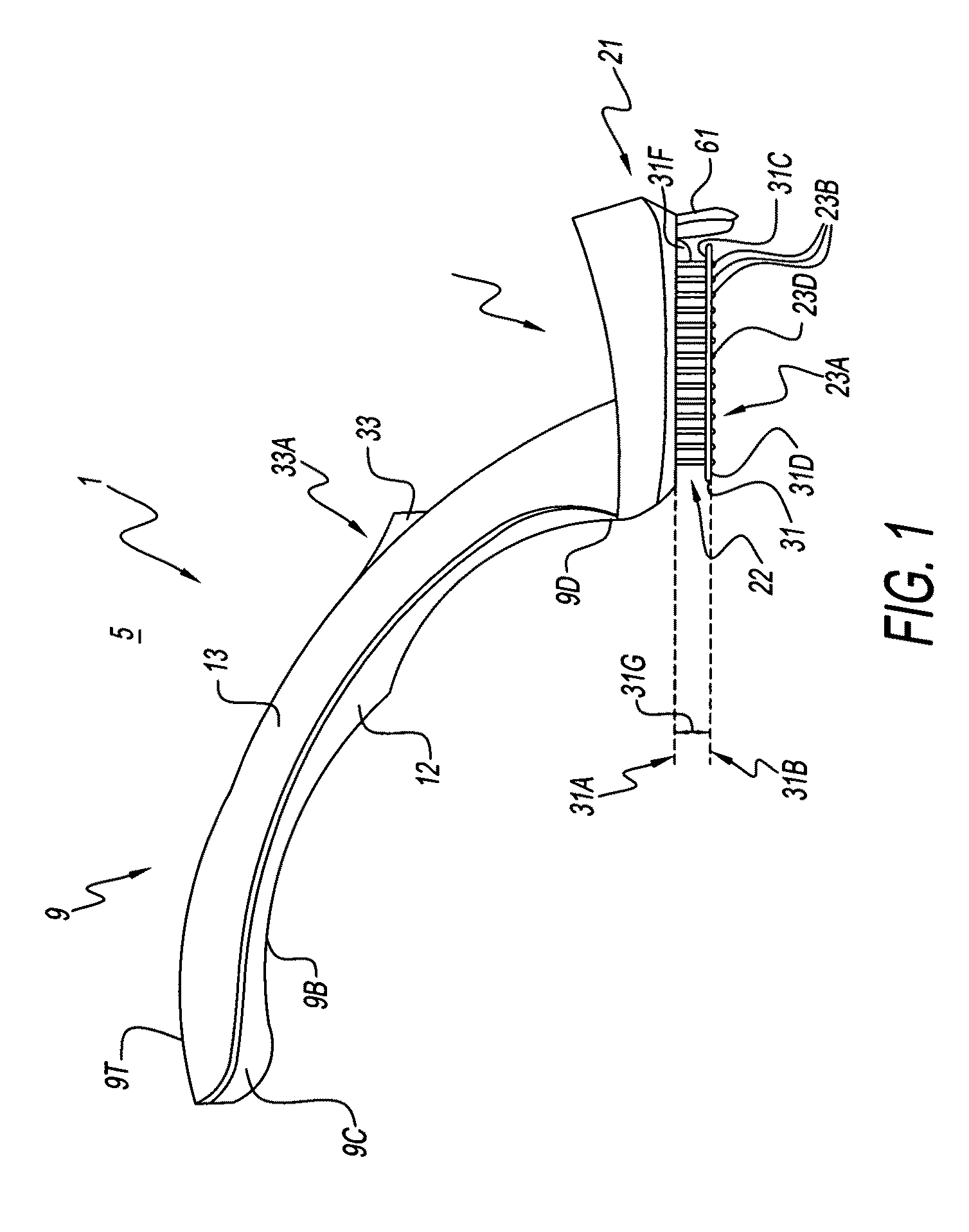

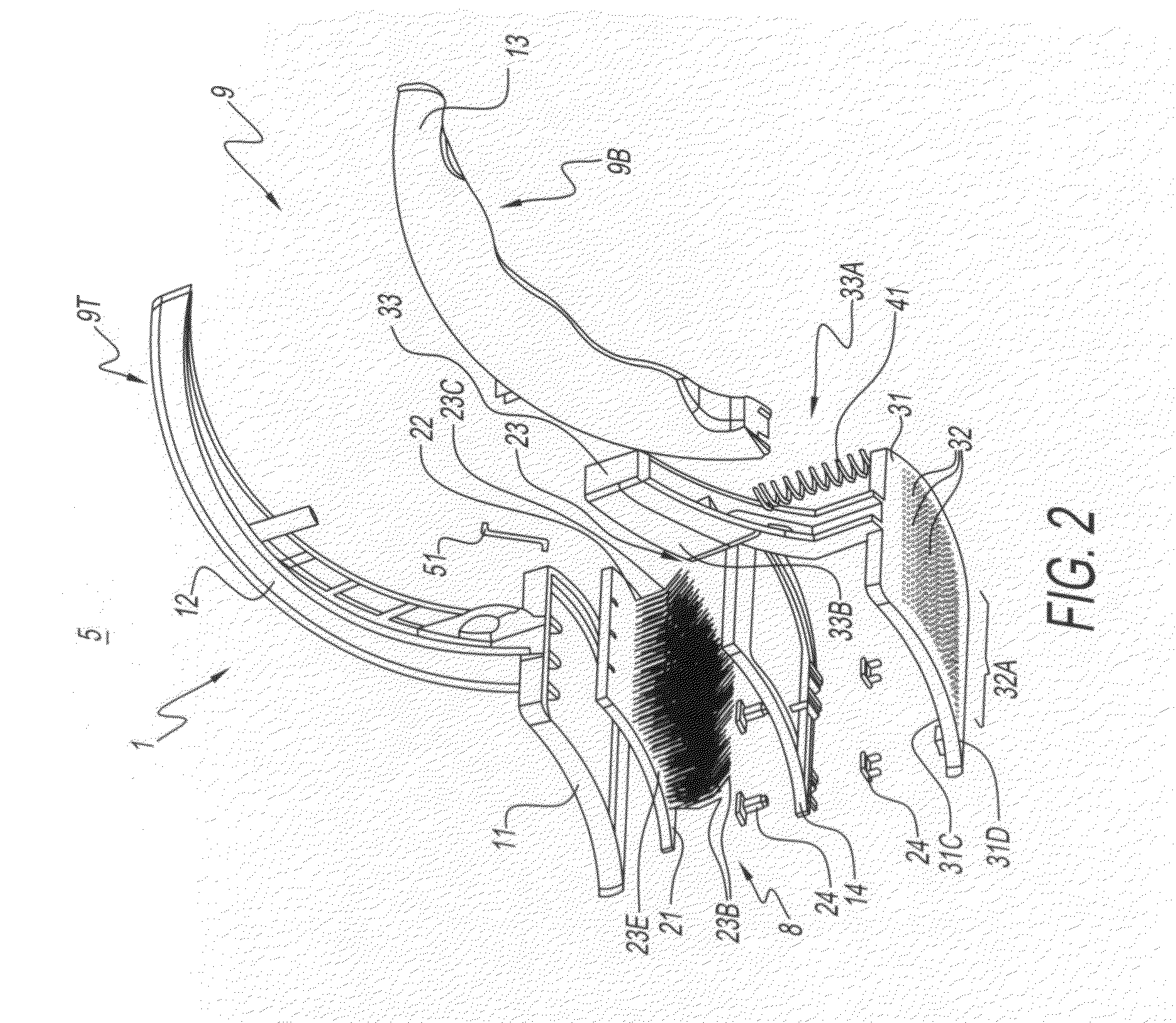

Grooming device

InactiveUS8082887B2Increase the lengthControl concentrationOther apparatusGrooming devicesBristleEngineering

The invention is an apparatus for grooming an animal having a brush head, the brush head having a plurality of bristles, each bristle having a midpoint and an endpoint, where the bristles are in general perpendicular orientation to the brush head, a cleaning plate, in general parallel orientation to the brush head, the cleaning plate able to move from a contracted to an extended position, the cleaning plate further having material removed to allow the bristles to protrude through the cleaning plate when it is in the retracted position; and a mechanism for extending and contracting the cleaning plate, wherein the cleaning plate has a bottom surface and the bottom surface does not extend past the bristle endpoint when the cleaning plate is in the extended position. In one embodiment, at least some bristles are wire, and in further embodiments the wire bristles have round coated tips. The brush head may further have a water outlet and a hose coupling for intake and dispensing of liquids. Furthermore, the present invention may have means for conducting water through the handle and out the water outlet, which may be a plurality of hollow bristles.

Owner:PRODS OF TOMORROW

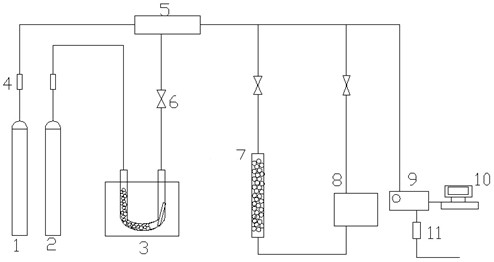

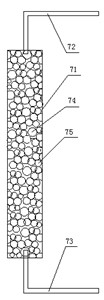

Evaluation device for coal-fired flue gas pollutant sorbent and application thereof

InactiveCN102565287ALow costIncrease implementation benefitsDispersed particle separationMaterial analysisVapor generatorFlue gas

The invention discloses an evaluation device for coal-fired flue gas pollutant sorbent, which includes a simulation flue gas steel bottle carrying pollutant, a gas steel bottle carrying mercury, a mercury vapor generator, mass flowmeters A and B, a gas mixing tank, a two-way valve, a mercury state converting device, a mercury analyzer, a computer, a tail gas processing device and a fixed bed, wherein in the bed body of the fixed bed, glass beads with the particle size of 0.5 to 2mm or hard polyester material can be adopted as bed material, sorbent with the particle size of 0.5 to 1.5mm is dispersed in the bed material, and the mass ratio of the bed material to the sorbent in the fixed bed is 50-70:1. Through the adoption of the evaluation device for the coal-fired flue gas pollutant sorbent, provided by the invention, related pollutant entering the fixed bed such as SO2, NOx and HgO can be absorbed by the sorbent in the fixed bed at a certain temperature, so as to control the pollutant; meanwhile, the adsorption effect of the sorbent can be evaluated conveniently and quickly.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

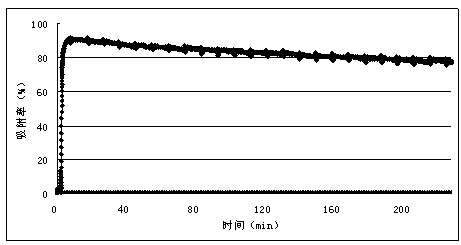

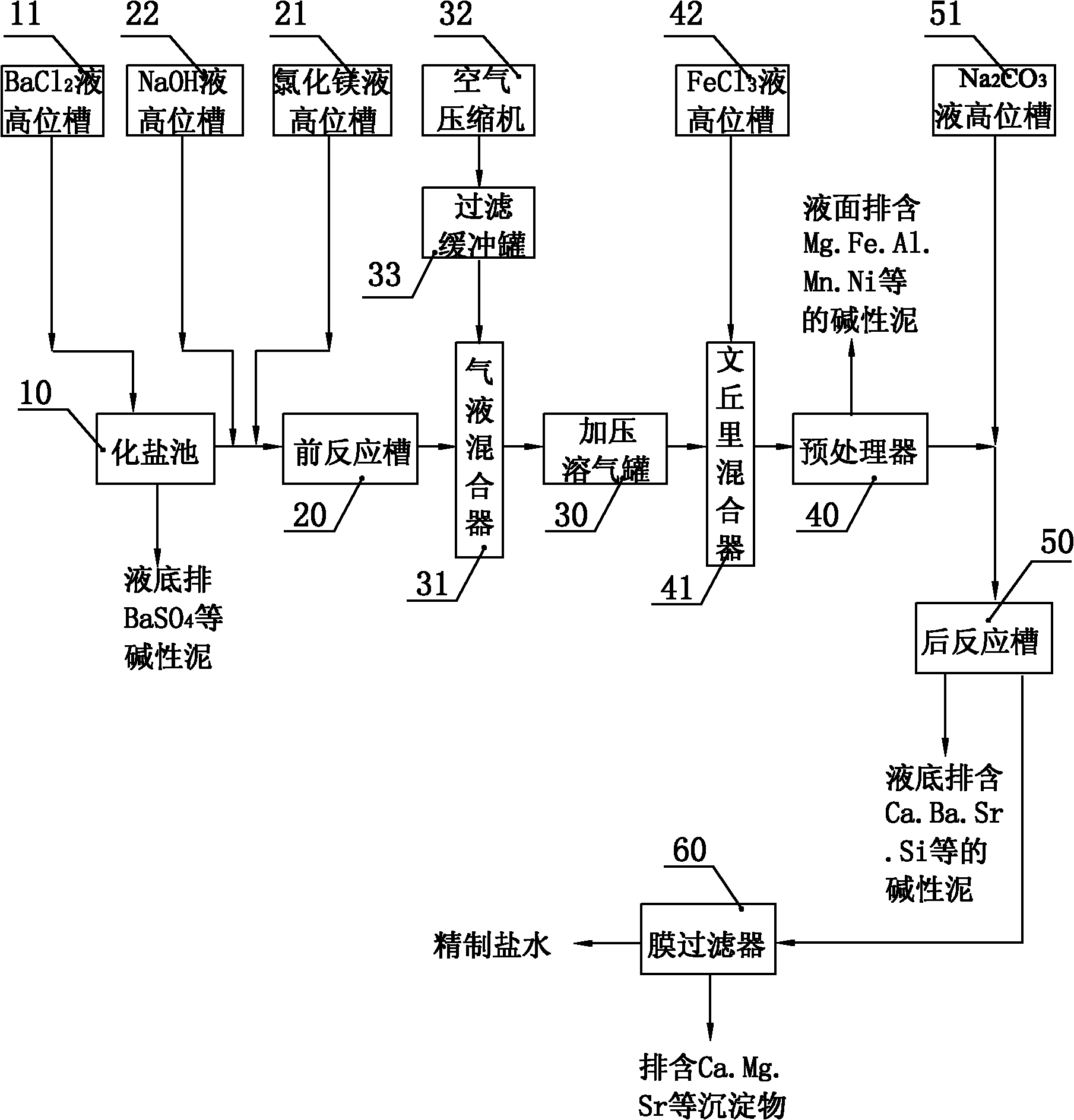

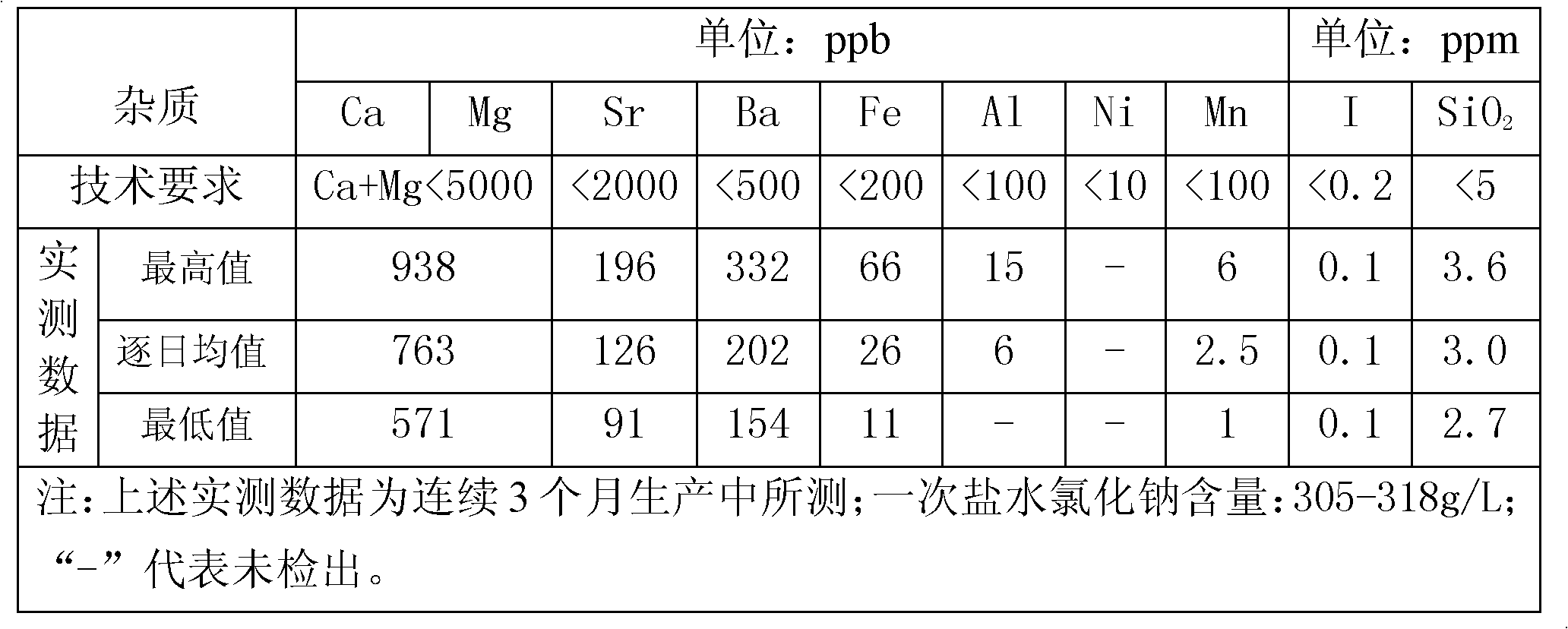

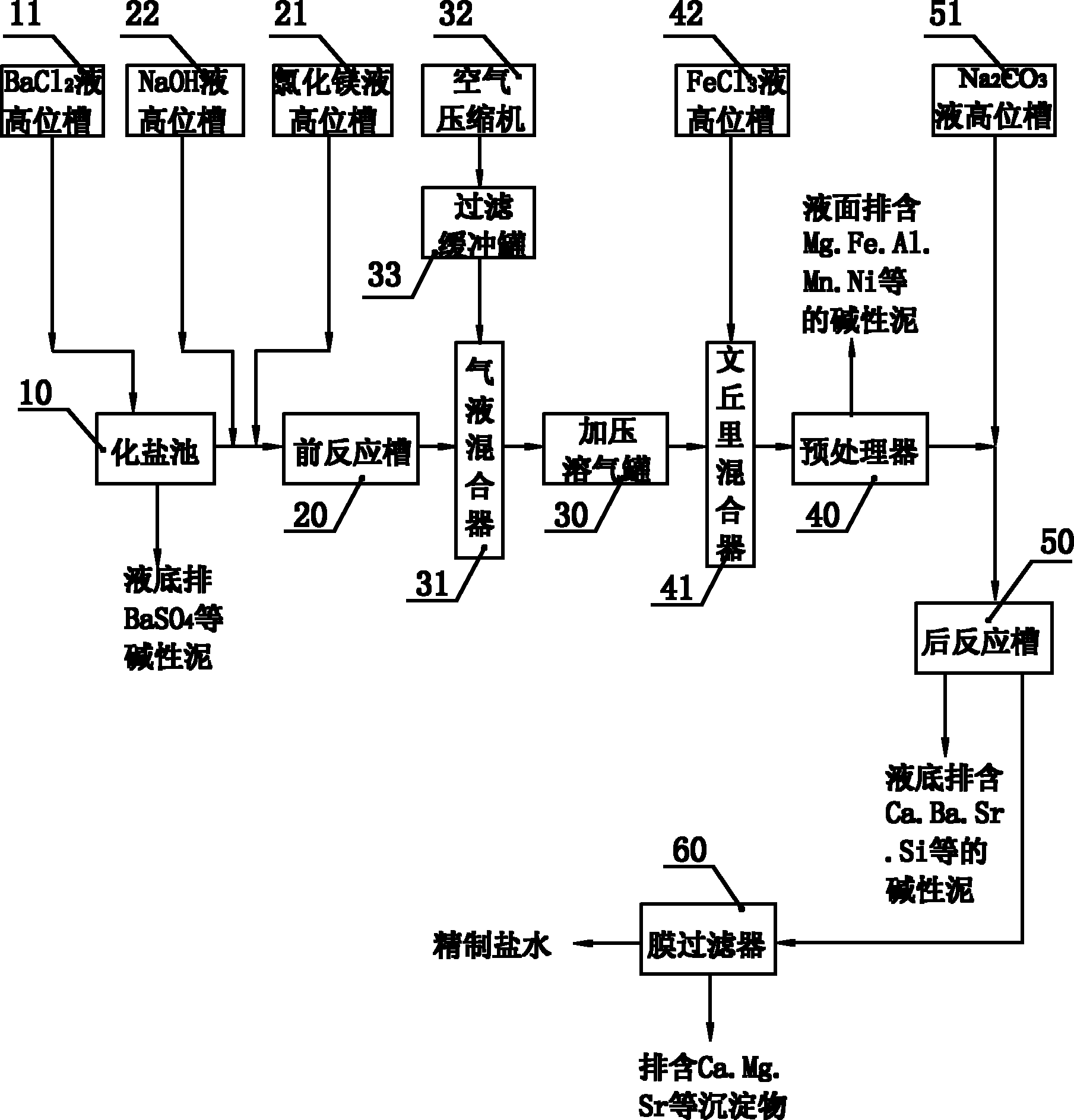

Method and system for refining crude brine

InactiveCN102120590AGood technical effectExcellent and unique refining effectAlkali metal halide purificationIon-exchange membranesSea salt

The invention relates to a method and a system for refining crude brine. The method comprises the following steps of: performing pre-reaction; pressurizing and dissolving gas; pretreating; performing post reaction; filtering by using a membrane; and filtering off residual slag particles by using a membrane filter to obtain the refined brine. By the method and the system for refining crude brine, under the condition of not introducing new impurities, various metal impurity ions are efficiently flocculated and precipitated, so that problems of great mineral salt impurity fluctuation and overproof Fe and Al ions are solved, the high quality of the finished brine product and the high-efficiency and normal operation of subsequent ion-exchange membrane electrolysis can be ensured, and the aim that mineral salt replaces sea salt to serve as chlor-alkali electrolysis raw salt is fulfilled; moreover, brine sludge emission and treatment cost can be obviously reduced, and the method and the system have good emission reduction effect and good environment-friendly property.

Owner:RUYUAN DONGYANGGUANG ELECTROCHEM FACTORY

Manufacturing method of R-Fe-B sintered magnet

ActiveCN103646773ALow priceReduce spacingInorganic material magnetismInductances/transformers/magnets manufactureRare-earth elementEvaporation

The invention discloses a manufacturing method of an R-Fe-B sintered magnet. The manufacturing method of the R-Fe-B sintered magnet comprises the main steps of preparing a R1-Fe-B-M sintered magnet as a matrix; arranging an RLO particle layer of light rare earth element on the surface of the matrix and arranging a heavy rare earth RHX which comprises either dysprosium metal, or dysprosium hydride or both the dysprosium metal and the dysprosium hydride on the RLO particle layer; performing heating treatment inside a sintering furnace to enable the heavy rare earth RHX to evaporate to the surface of matrix by penetrating through the RLO particle layer and to diffuse from the surface to the inside of the magnet, wherein during the whole process, the RLO particle layer serves as transmission media and does not react with heavy rare earth elements. According to the manufacturing method of the R-Fe-B sintered magnet, the RLO particle layer of oxide and fluoride of light rare earth element is arranged between the magnet and the heavy rare earth RHX, so that on the one hand, non-direct contact of the magnet and the heavy rare earth RHX is achieved, on the other hand, the diffusion process of heavy rare earth RHX steam can be inhibited and slowed down, and excessive evaporation of the heavy rare earth RHX steam to the surface of the magnet can be prevented.

Owner:YANTAI ZHENGHAI MAGNETIC MATERIAL CO LTD

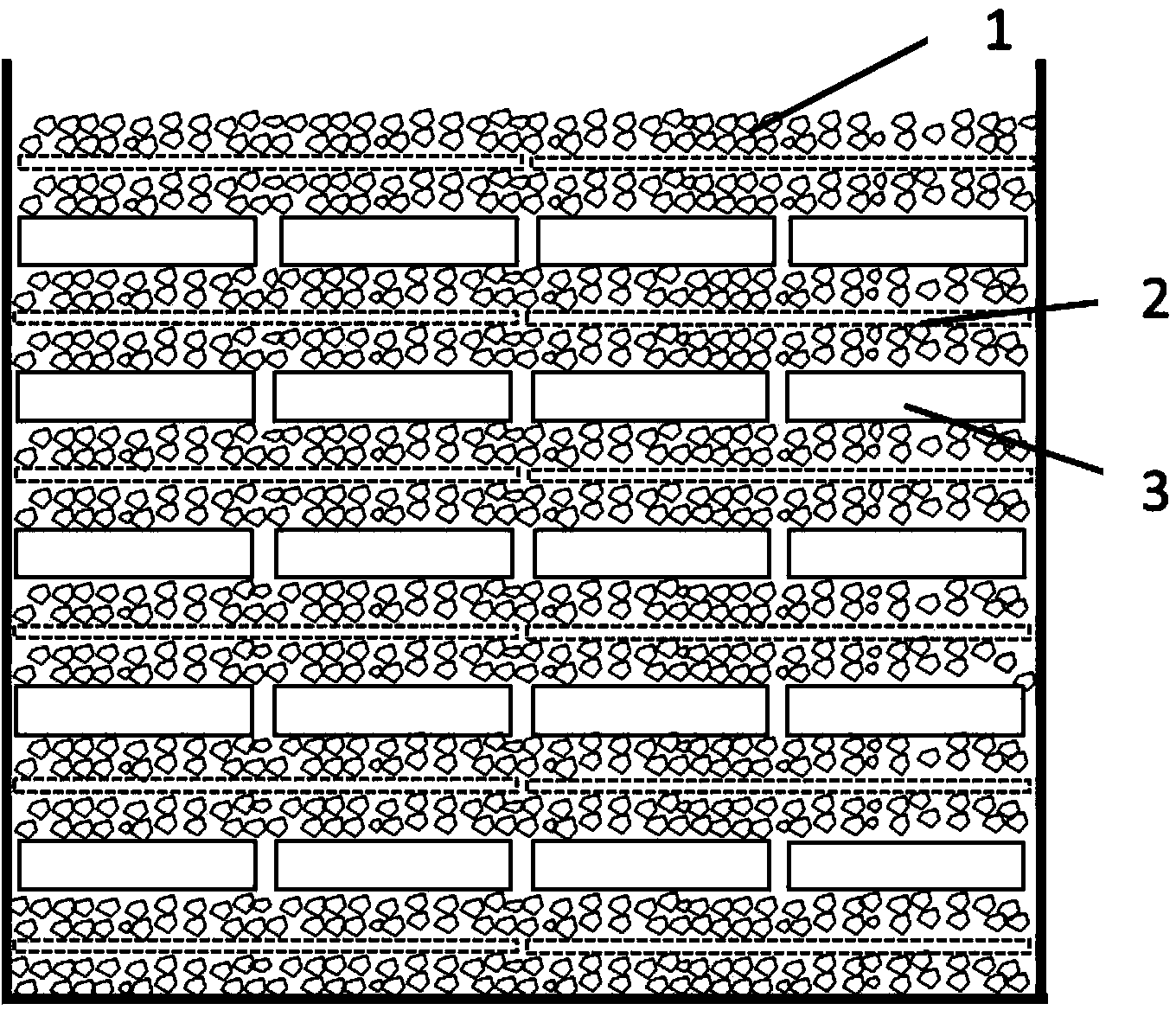

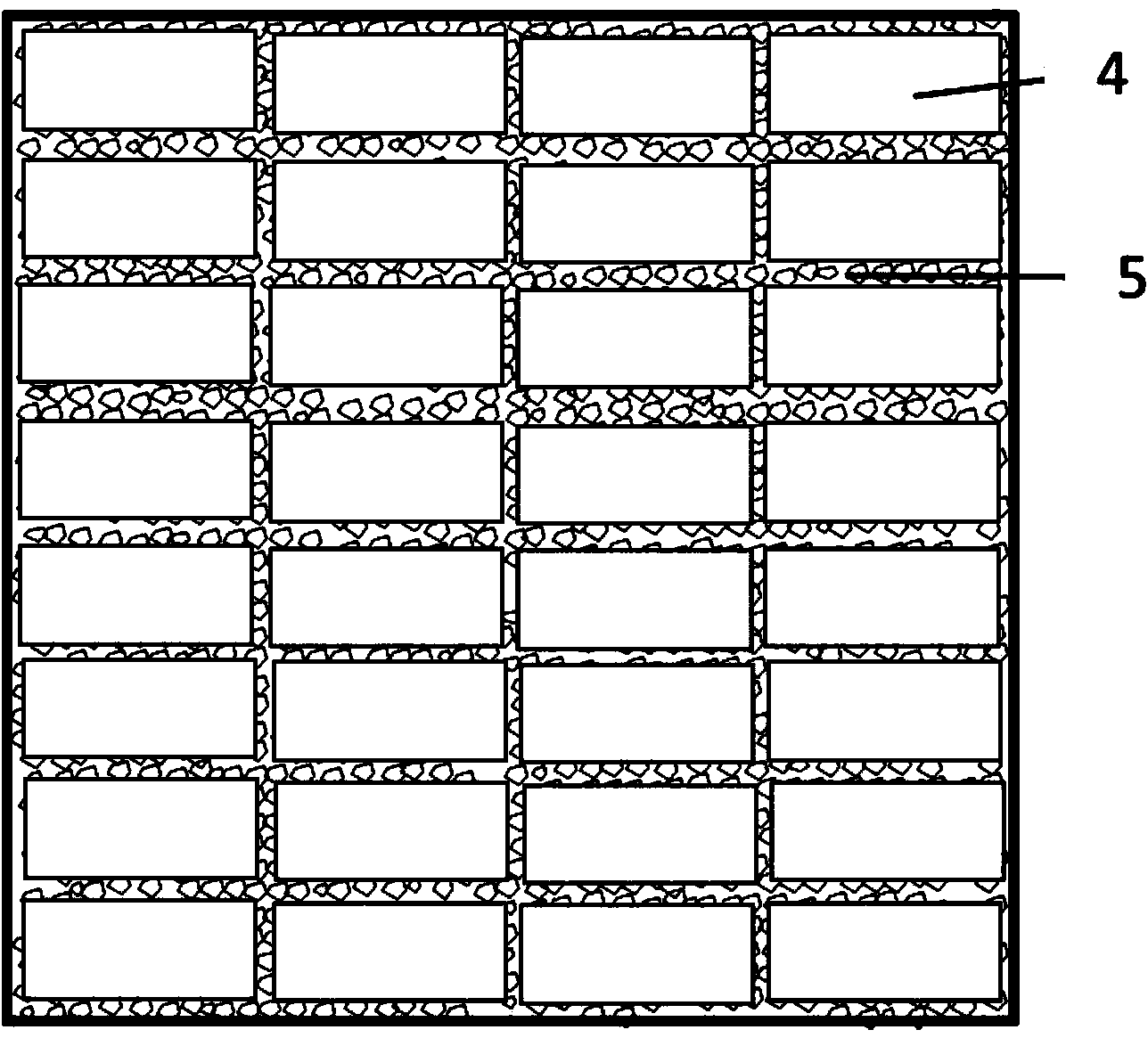

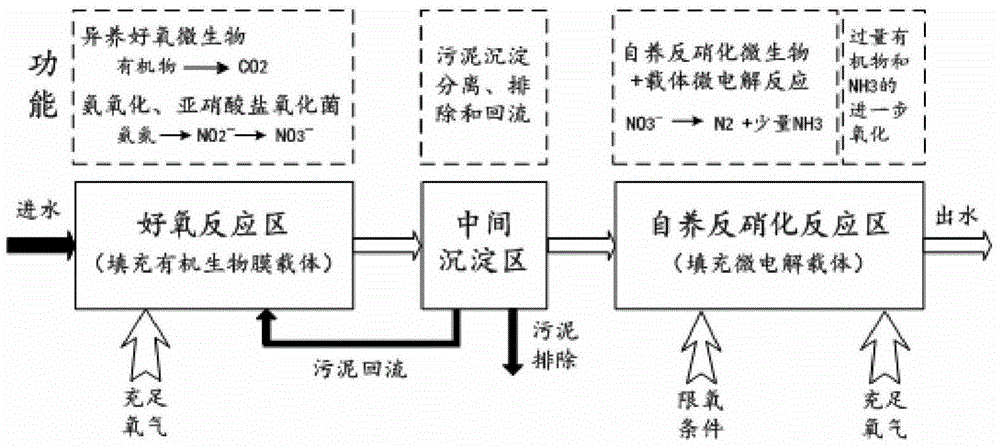

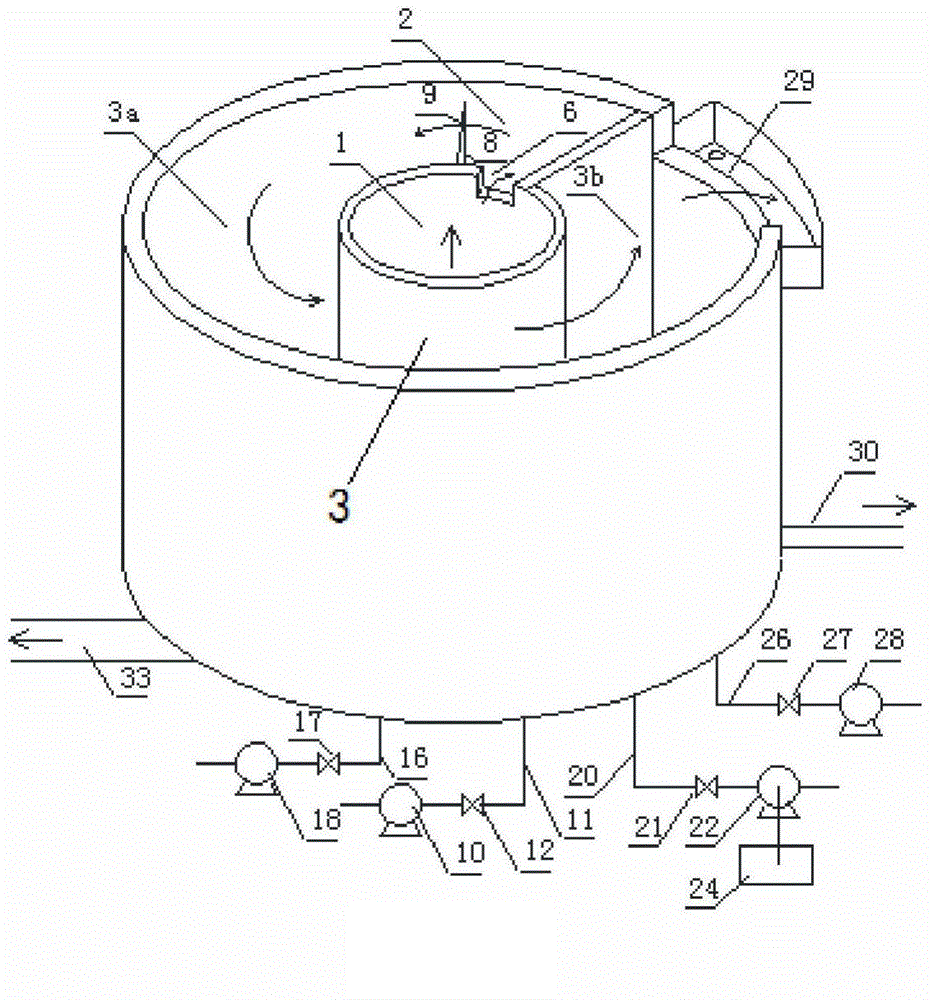

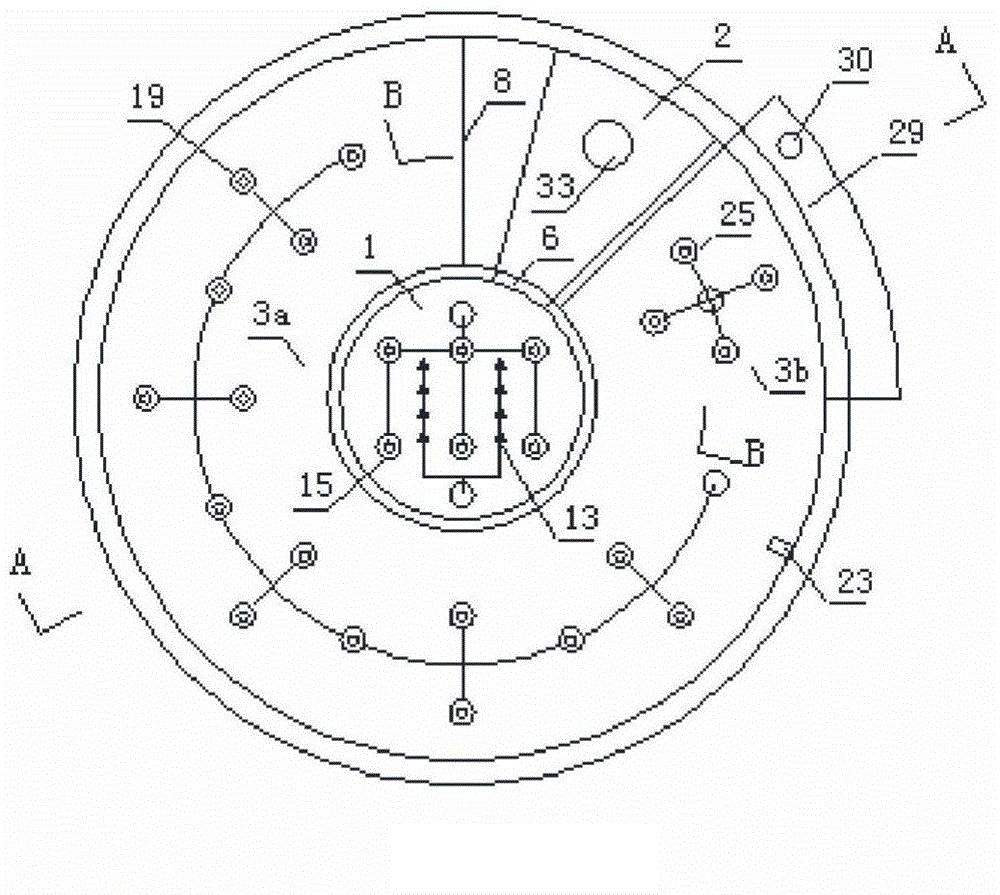

Autotrophic denitrification based integrated novel denitrification reaction device and technological process thereof

ActiveCN104628132AGuarantee water qualityReduce land costWater contaminantsTreatment with aerobic and anaerobic processesElectrolysisOxygen

The invention discloses an autotrophic denitrification based integrated novel denitrification reaction device and a technological process thereof, belonging to the technical field of water pollution control. The device comprises a reactor main body, a water feeding system, a water draining system, a sludge removal system, and an aeration and oxygen-limiting system, wherein the reactor main body is concentric cylinder-shaped, an inner ring is an aerobic reaction area, an outer ring is a middle precipitation area and an autotrophic denitrification area, and the inner side walls of the middle precipitation area and the autotrophic denitrification area of the outer ring are the outer side wall of the aerobic reaction area of the inner ring; a porous carrier bearing plate is arranged in the aerobic reaction area, and an organic biofilm carrier is filled in the porous carrier bearing plate; and a porous carrier bearing plate is arranged in the autotrophic denitrification area, and a micro-electrolysis carrier is filled in the porous carrier bearing plate. According to the invention, when the carbon nitrogen ratio of sewage is relatively low, an organic carbon source is not required to be additionally added, so that compared with traditional autotrophic denitrification based denitrification processes, the device disclosed by the invention can control the concentration of organic matters in drained water better, and can be used for saving the operating cost produced by the addition of the organic carbon source.

Owner:BEIJING JIAOTONG UNIV

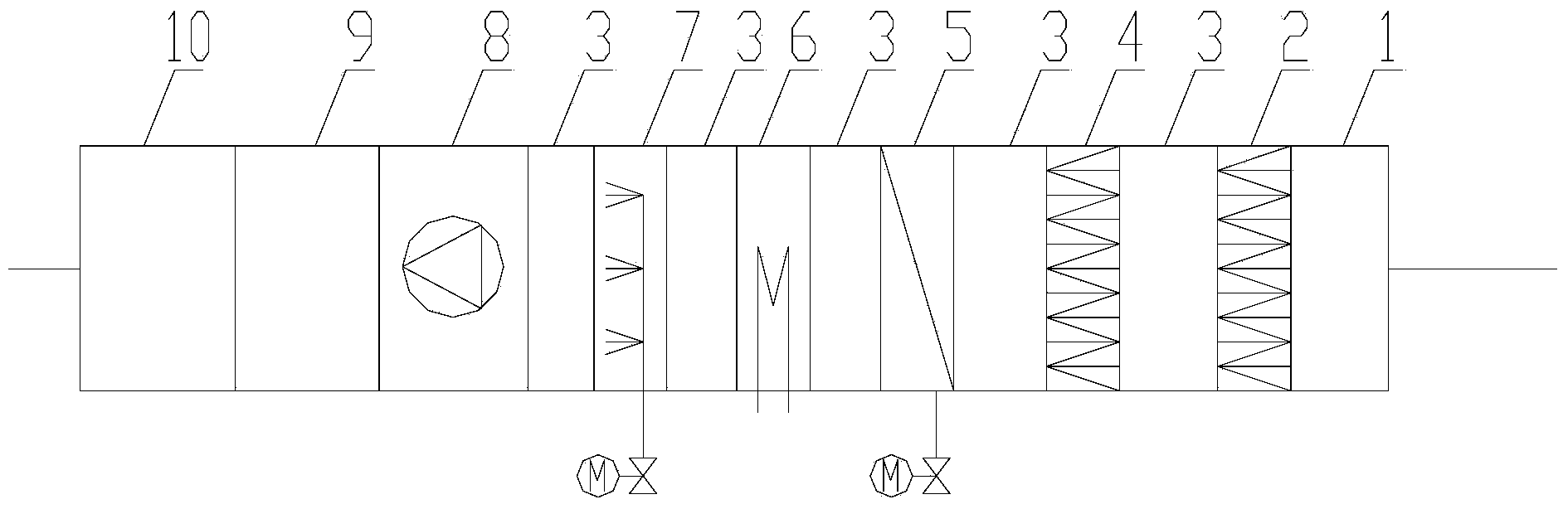

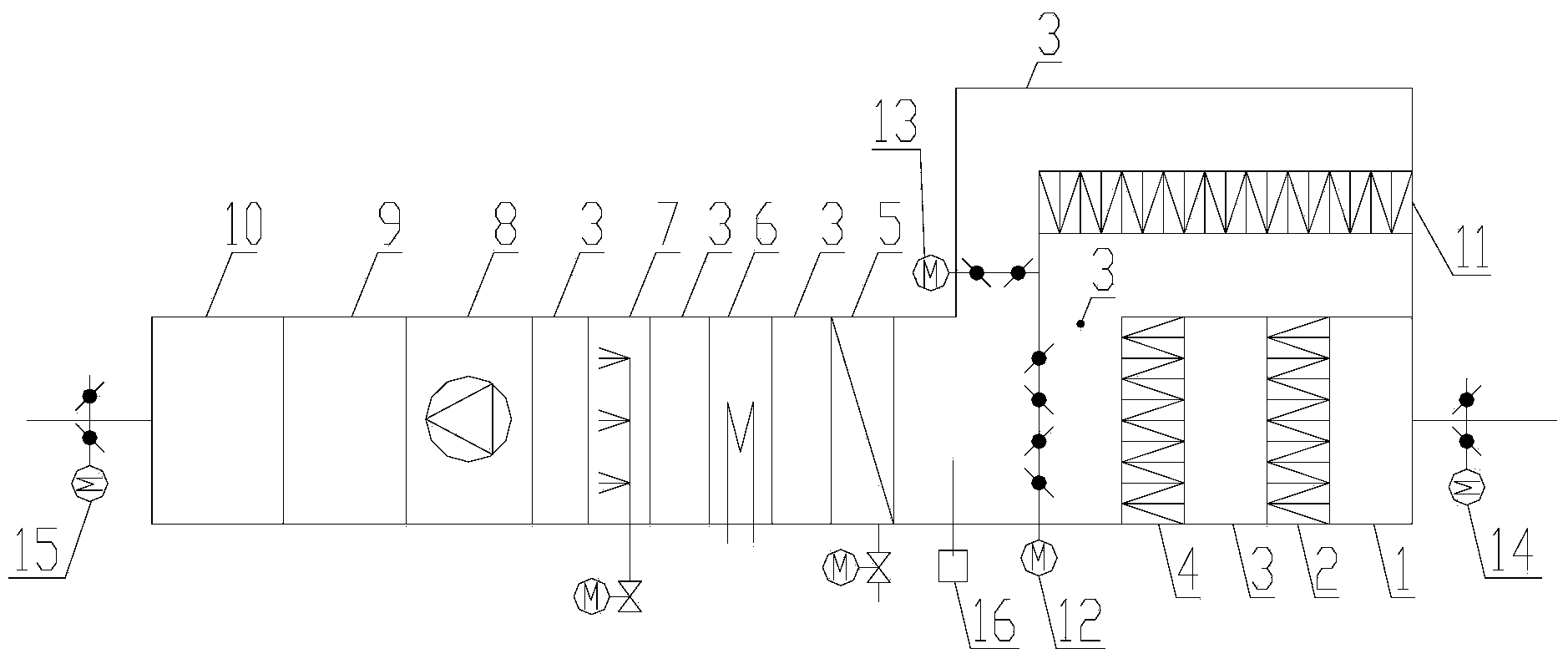

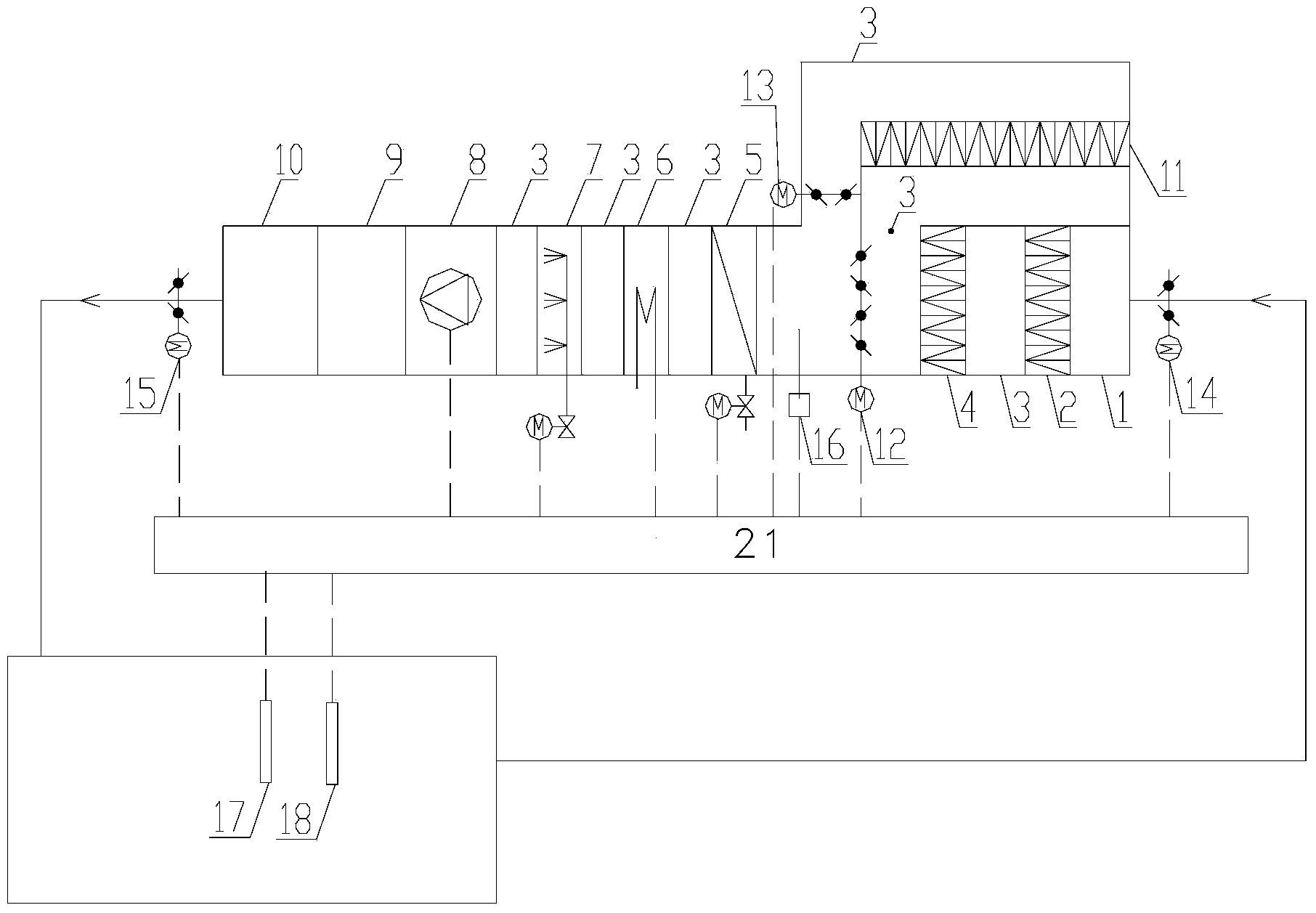

Intelligent purifying and bacterium resisting air processing machine set

ActiveCN103644600AControl concentrationGrowth inhibitionSpace heating and ventilation safety systemsLighting and heating apparatusAir filtrationSurface cooling

The invention provides an intelligent purifying and bacterium resisting air processing machine set. The intelligent purifying and bacterium resisting air processing machine set comprises a high-medium or sub-high efficiency air filtering section. The high-medium or sub-high efficiency air filtering section is in parallel connection between an air inlet section and a surface cooling / heating section of the machine set. A first-mode starting and stopping valve is arranged between a primary-medium efficiency filtering section and the surface cooling / heating section of the machine set, a second-mode starting and stopping valve is arranged between the high-medium or sub-high efficiency air filtering section and the surface cooling / heating section, and either the first-mode starting and stopping valve or the second-mode starting and stopping valve is opened. In this way, the working modes can be automatically switched according to the concentration of PM2.5 of indoor air and the concentration of PM2.5 of outdoor air, the concentration of PM2.5 pollutants of the indoor air is effectively controlled on the premise that energy resources are saved, and accordingly a clean indoor environment is built.

Owner:CHINA ACAD OF BUILDING RES +1

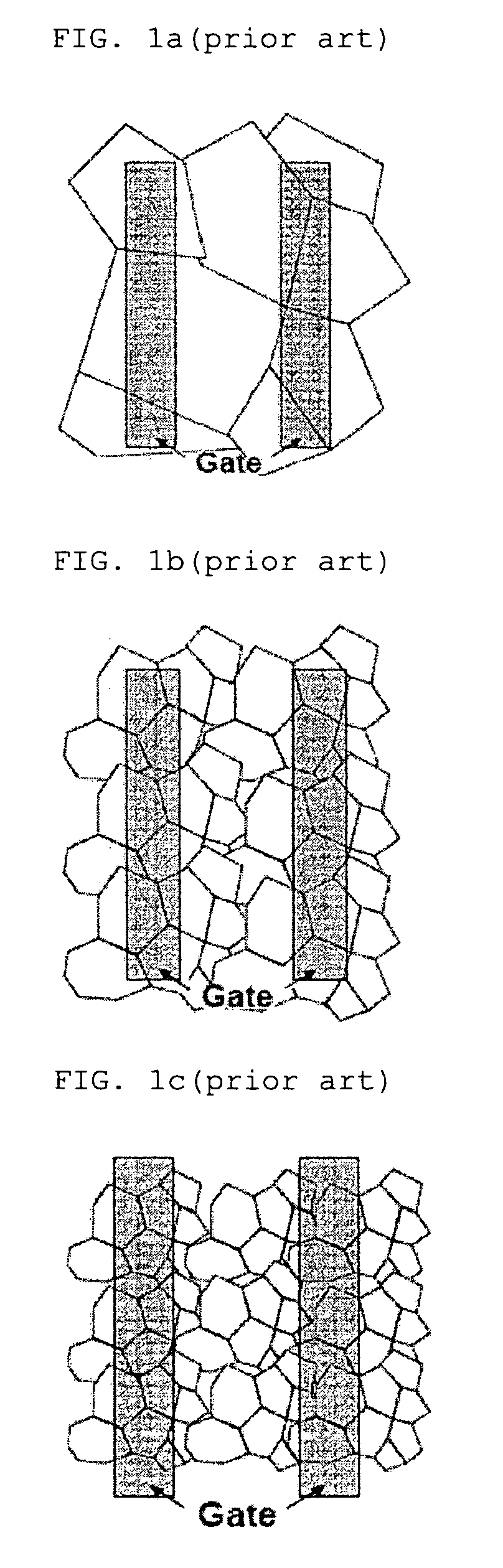

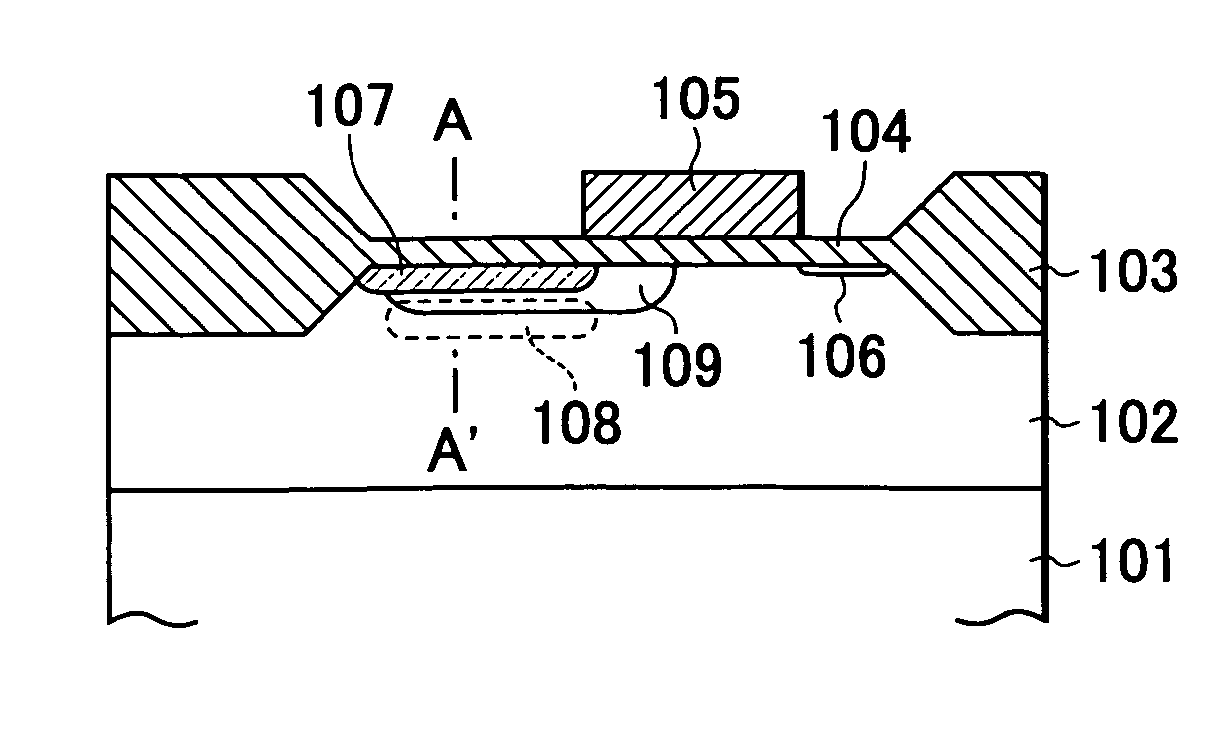

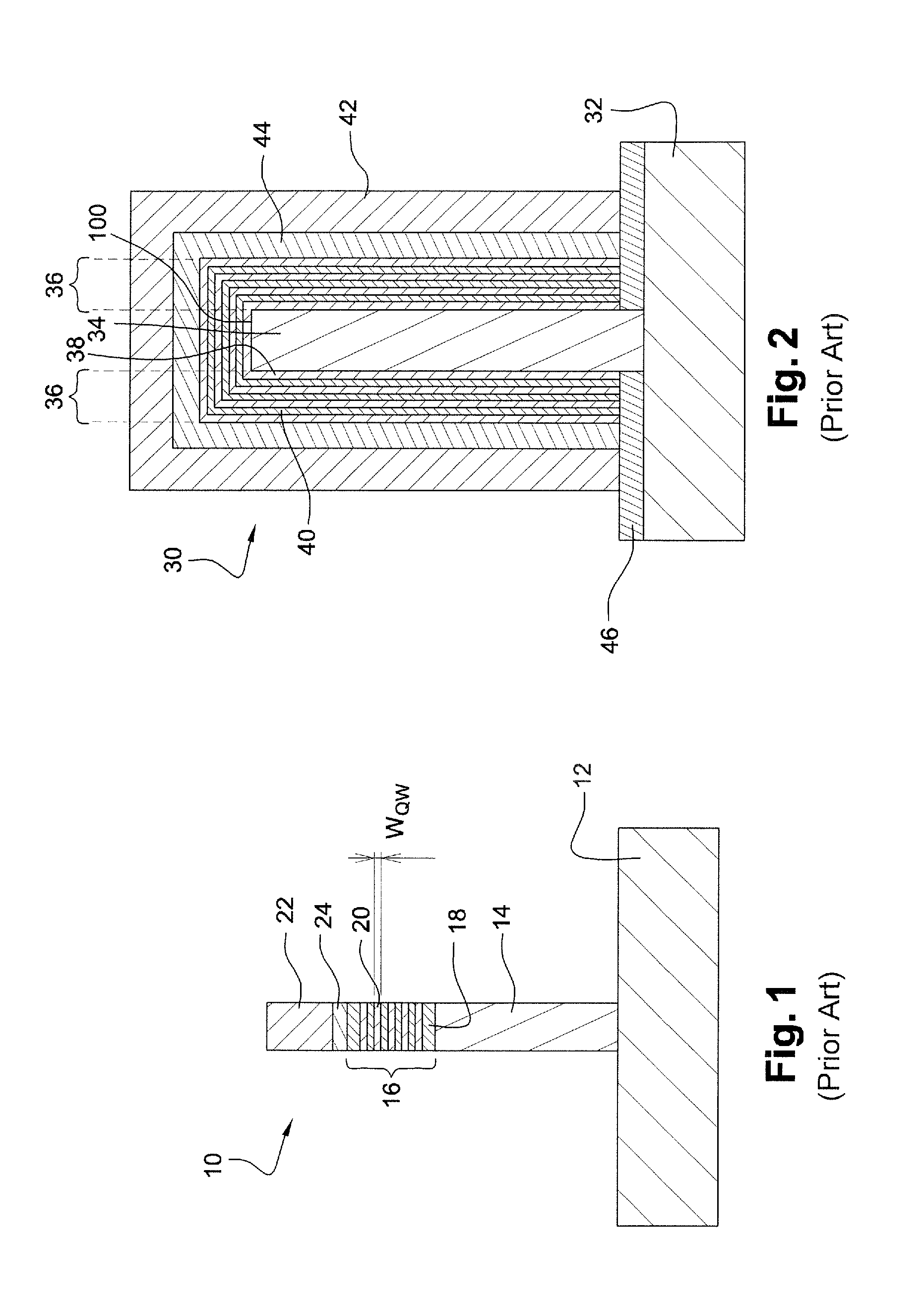

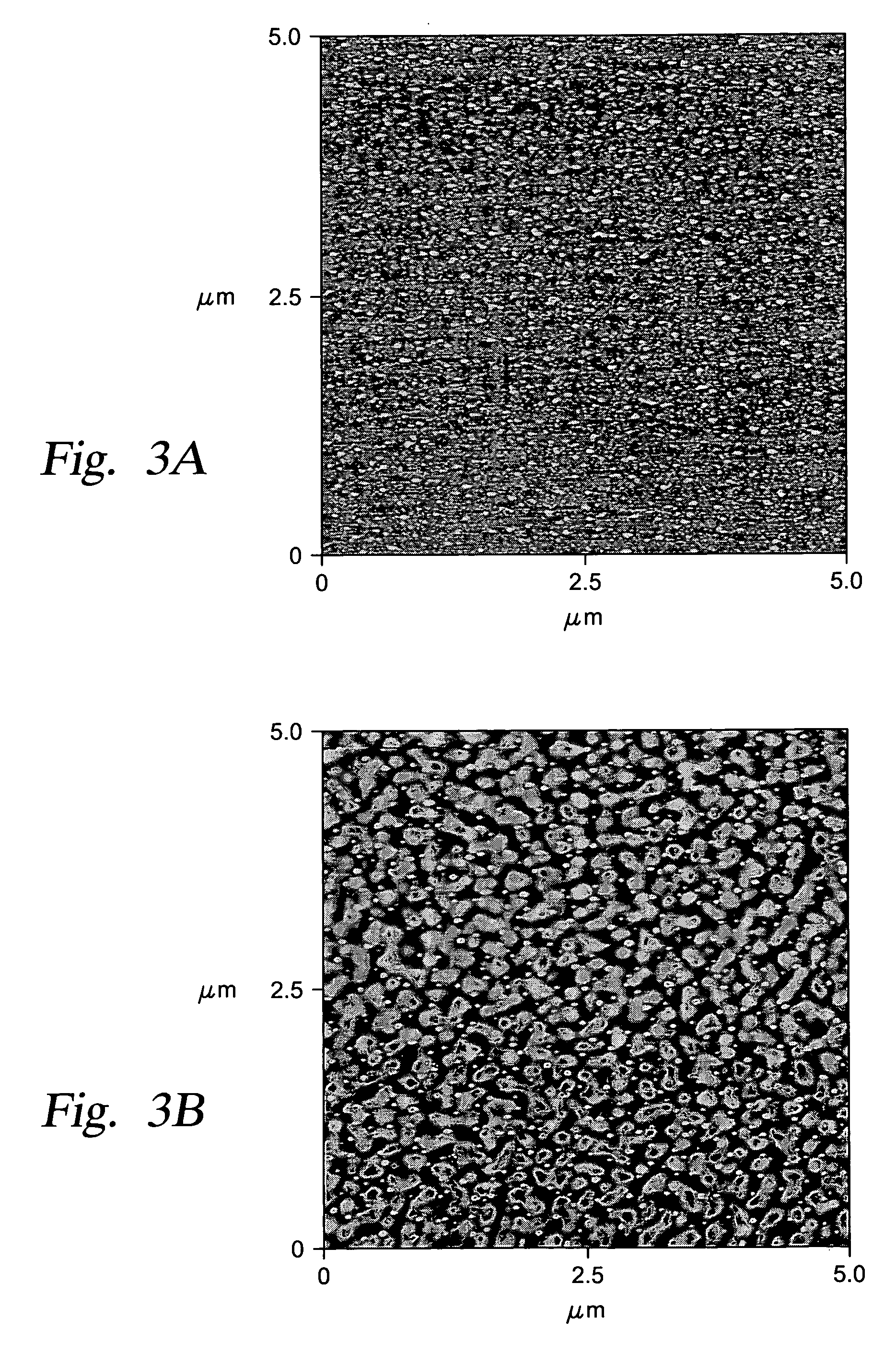

Transistor, fabricating method thereof and flat panel display therewith

InactiveUS20080157083A1Control concentrationMinimise currentSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceFlat panel display

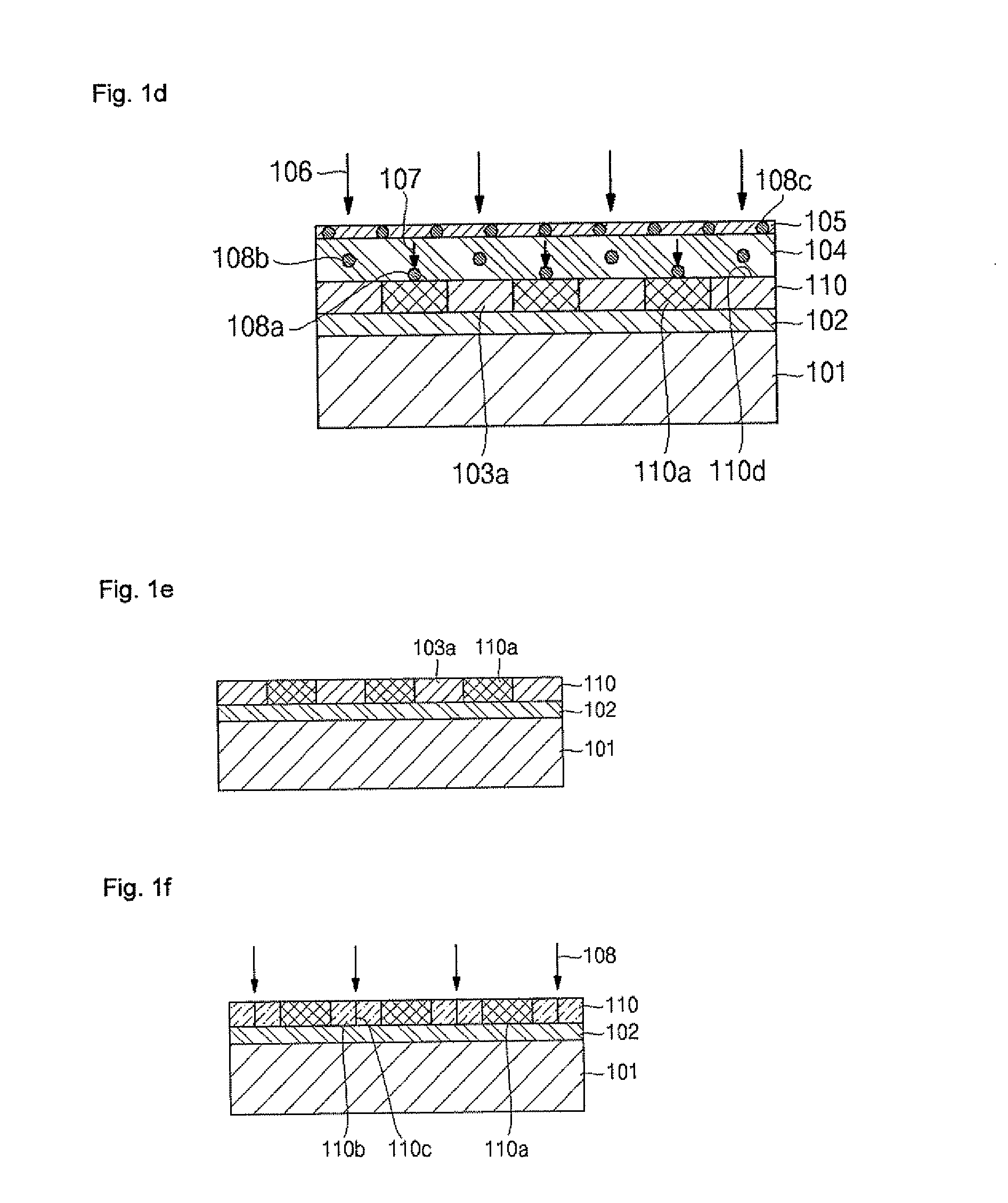

A transistor includes a substrate, an active region including a source region, a channel region, and a drain region which are crystallized using an SGS crystallization method and are formed on the substrate so that a grain size of a first annealed portion and a second annealed portion are different from each other, a gate insulating layer formed on the active region, and a gate electrode formed on the gate insulating layer.

Owner:SAMSUNG MOBILE DISPLAY CO LTD

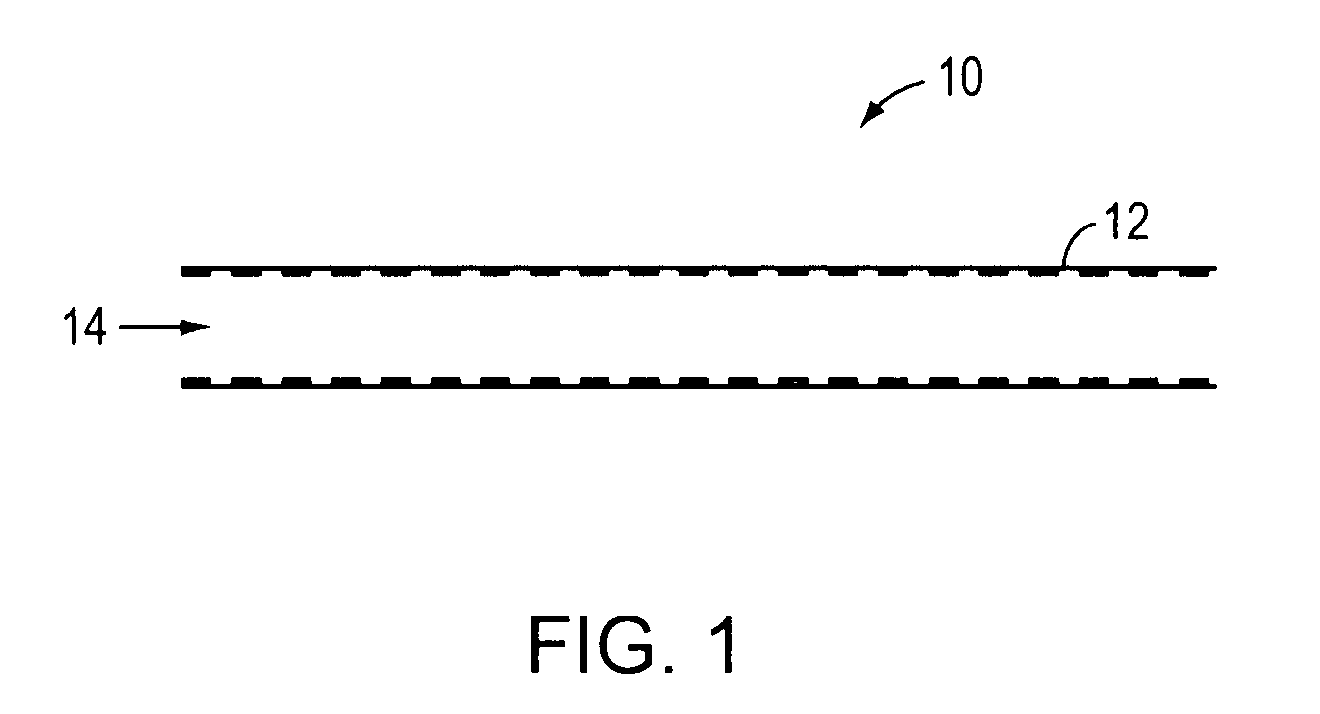

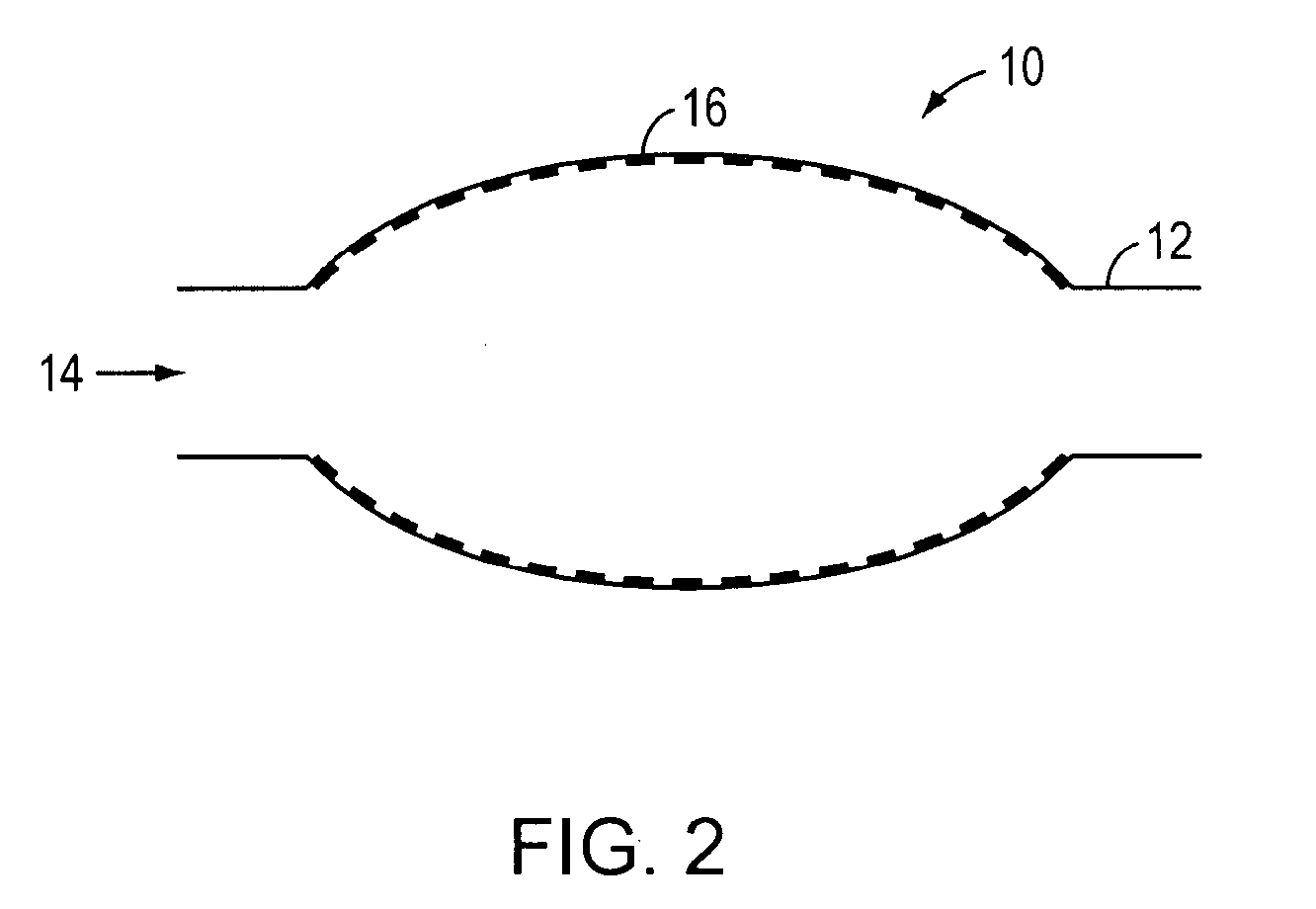

Endovascular devices with axial perturbations

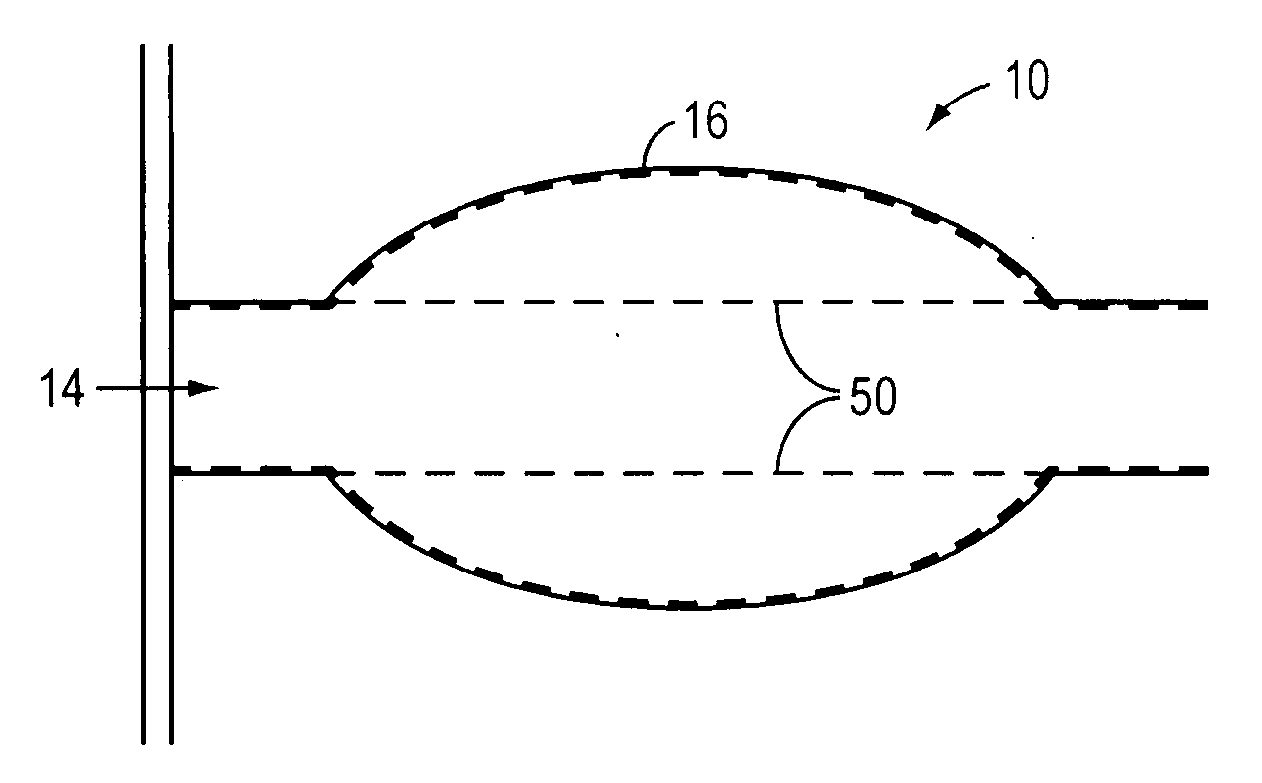

Endovascular devices are provided. The endovascular devices include a conformable scaffold with one or more outpocketings. The outpocketing in the endovascular device creates a corresponding outpocketing of a vessel wall, thereby altering local fluid dynamics.

Owner:MASSACHUSETTS INST OF TECH

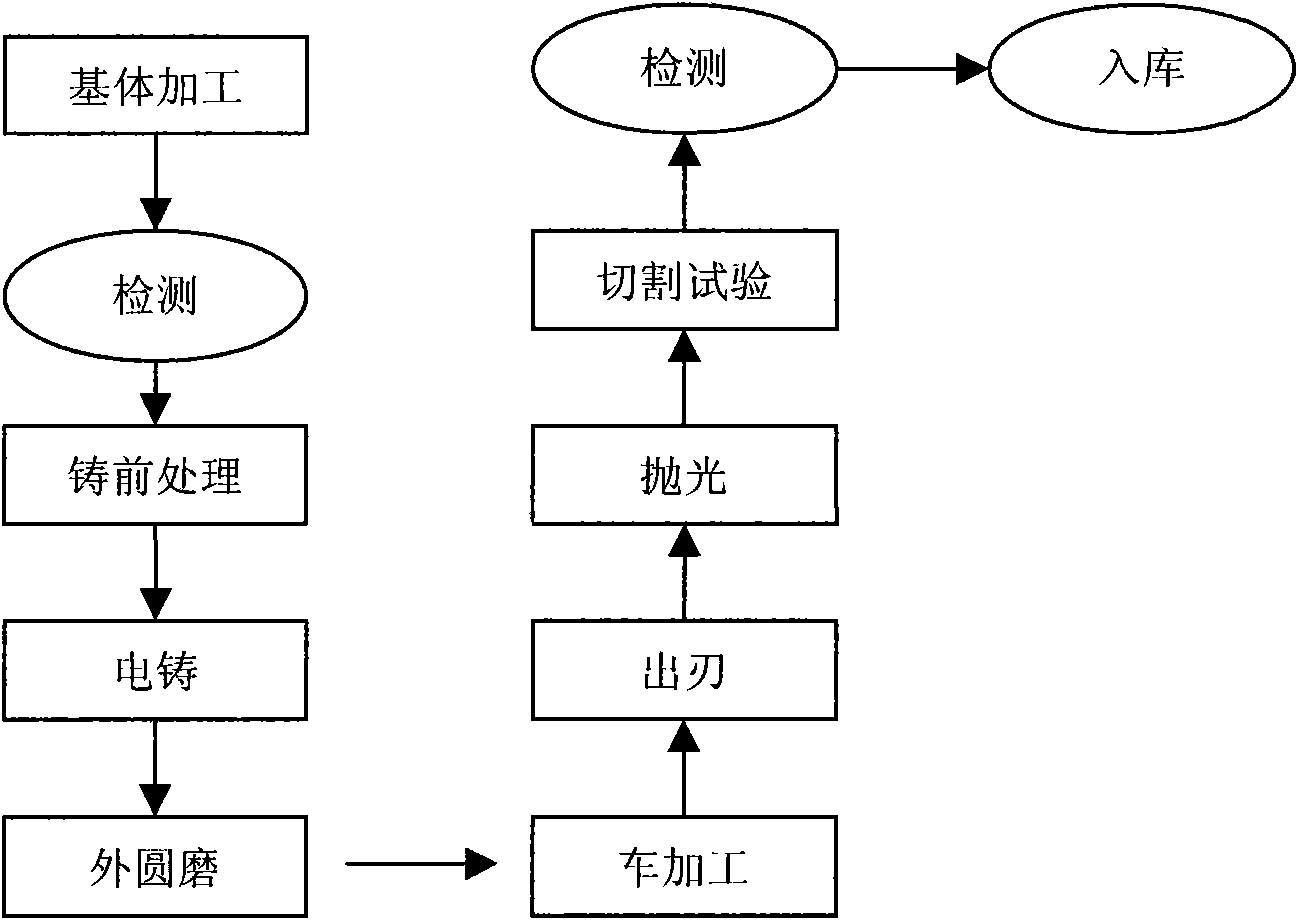

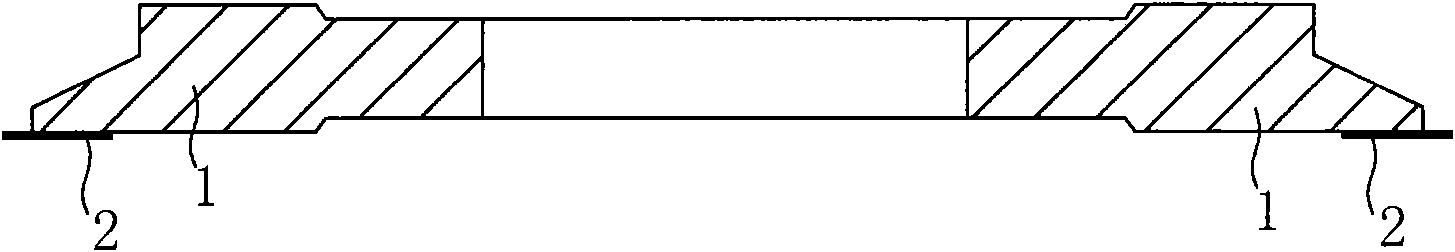

Diamond grinding wheel for cutting silicon crystal circle and preparation method thereof

ActiveCN101633158AHigh strengthImprove rigidityGrinding devicesGrinding machinesNumerical controlCobalt sulphate

The invention discloses a diamond grinding wheel for cutting a silicon crystal circle and a preparation method thereof. The method comprises the following steps: (1) preprocessing an aluminum alloy basal body; (2) configuring electroforming liquid: configuring the electroforming liquid according to the weight ratio of (38-43):(15-20):(43-57):(50-180):(4-8) of nickel sulphate, cobalt sulphate, deionized water, a diamond grinding material and a suspending agent; fully stirring evenly and obtaining the electroforming liquid; (3) carrying out insulation processing on the aluminum alloy basal body obtained in the step (1), putting the aluminum alloy basal body into the electroforming liquid, electroforming in an ultrasonic field, evenly precipitating the diamond grinding material in the electroforming liquid and metal on the basal body together and obtaining a grinding wheel blank body with a compound electroforming layer; and (4) taking out the grinding wheel blank body completing electroforming, and carrying out accurate processing on the grinding wheel blank body on a numerical control grinder and a numerical control lathe respectively according to the accuracy requirements of the required basal body and the required cutting edge. The diamond grinding wheel obtained by the invention meets the ultrathin and superfine technical conditions and also has favorable strength and rigidity.

Owner:赛尔科技(如东)有限公司

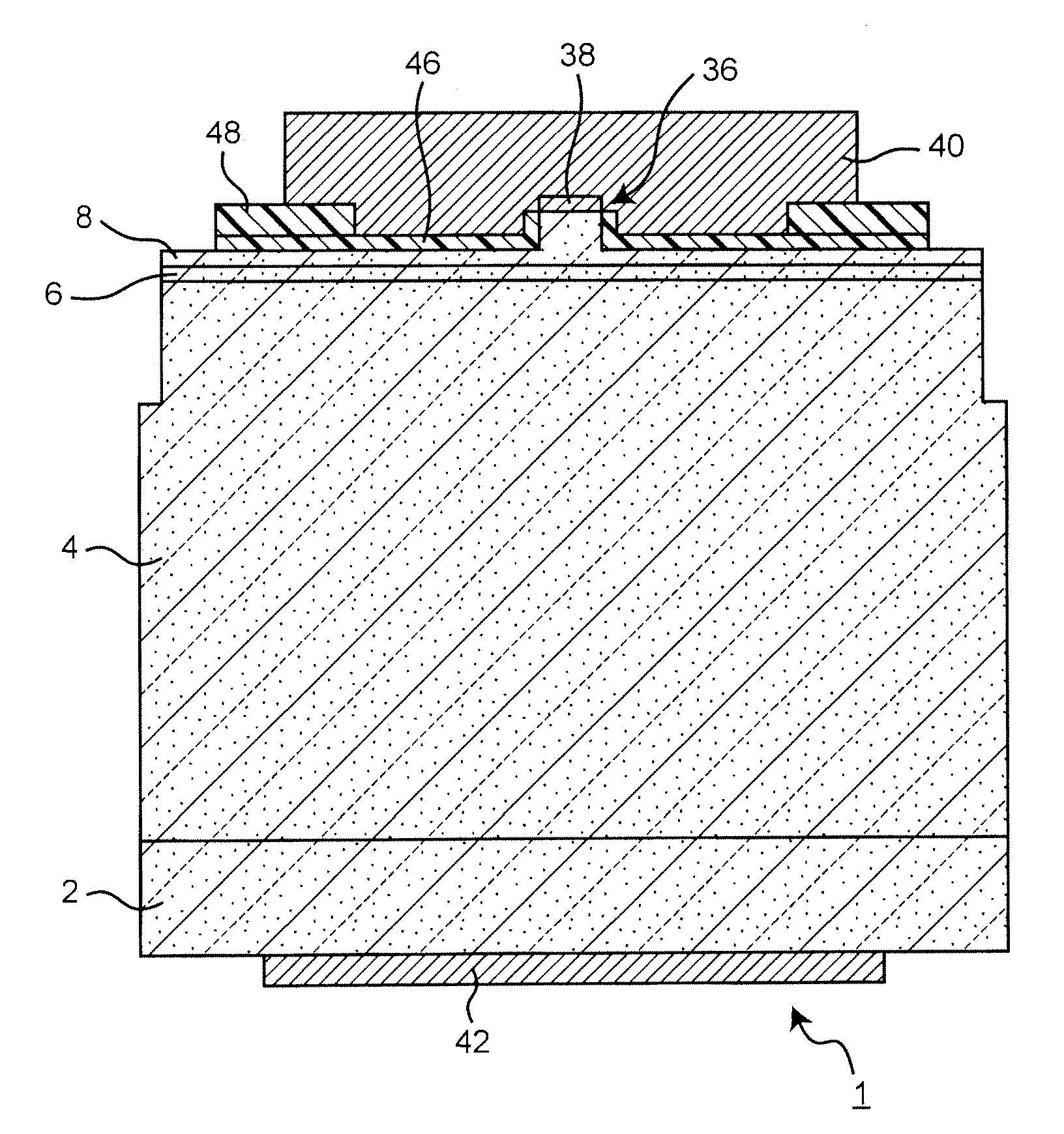

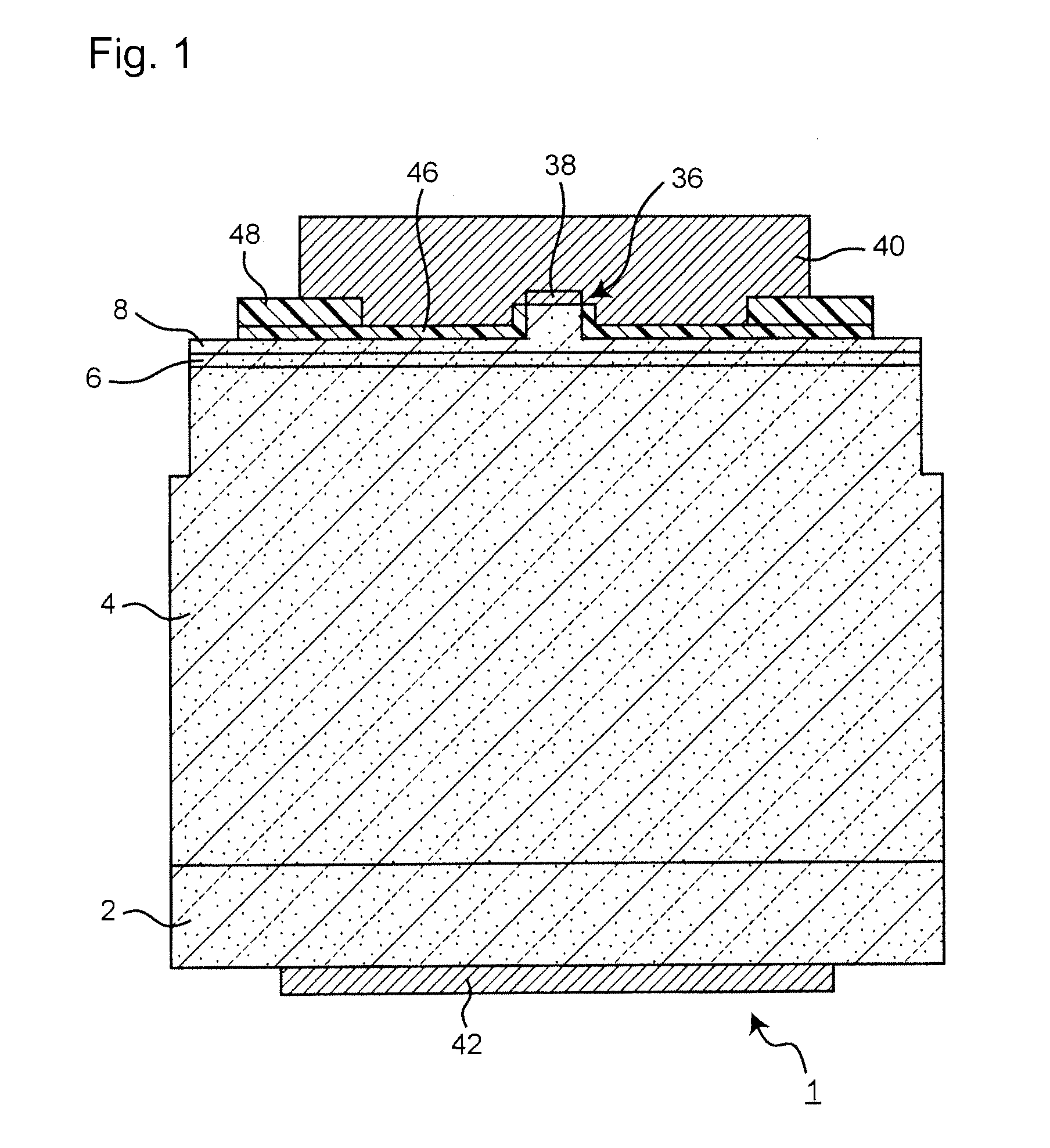

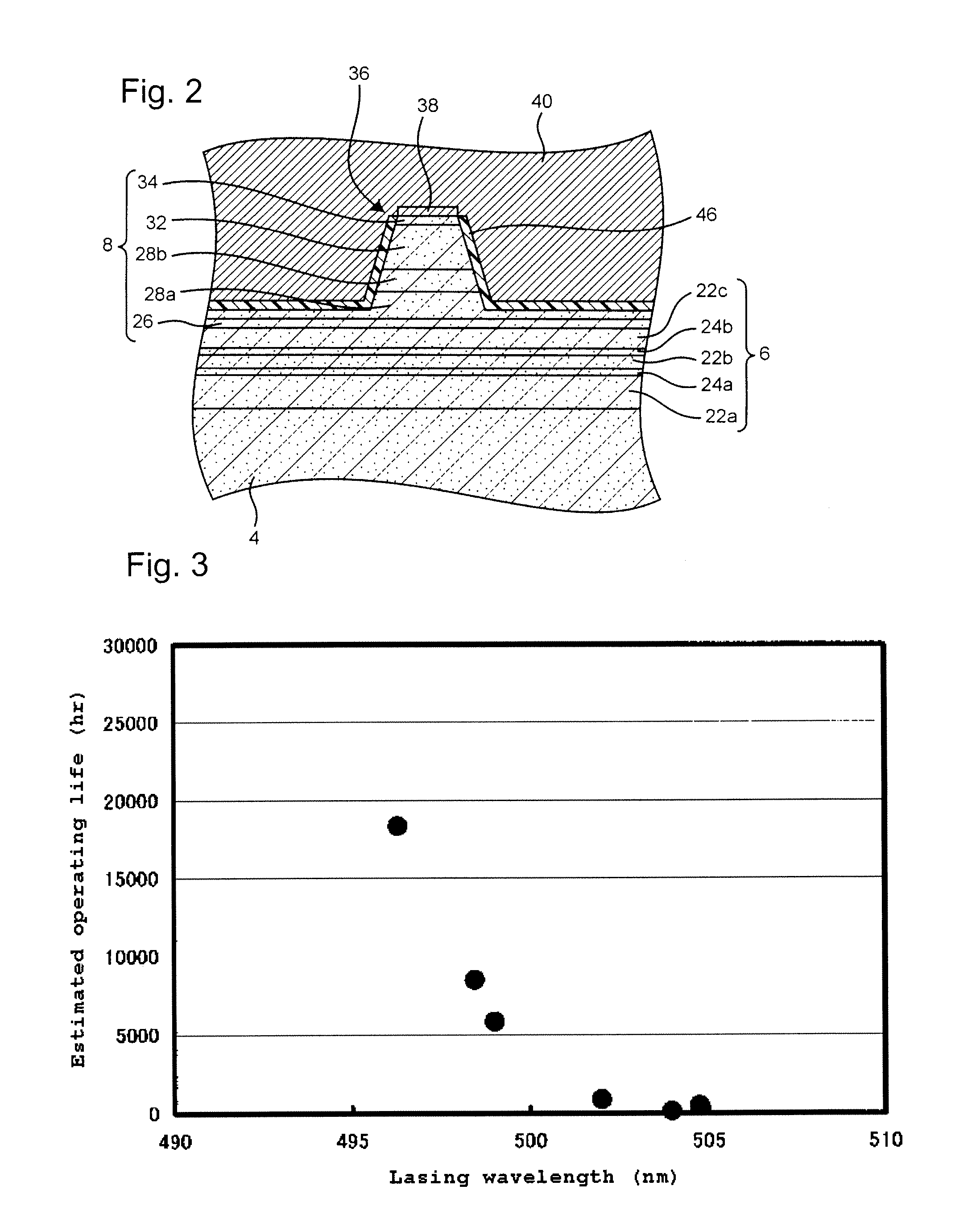

Nitride semiconductor laser diode

ActiveUS20120189030A1Improve life characteristicsControl concentrationOptical wave guidanceLaser detailsLasing wavelengthWavelength

A nitride semiconductor laser diode includes a substrate, an n-side nitride semiconductor layer formed on the substrate, an active layer formed on the n-side nitride semiconductor layer and having a light emitting layer including InxAlyGa1−x−yN (0<x<1, 0 y<1, 0<x+y<1), and a p-side nitride semiconductor layer formed on the active layer. In the nitride semiconductor laser diode, the lasing wavelength of the nitride semiconductor laser diode is 500 nm or greater, dislocations originated in the active layer penetrate through the p-side nitride semiconductor layer, with the dislocation density in the p-side nitride semiconductor layer being 1×106 cm−2 or greater, and the concentration distribution of p-type impuritys in the depth direction is such that, from the light emitting layer toward the surface of the p-side nitride semiconductor layer, the concentration of the p-type impurity reaches a maximum value of 5×1018 cm−3 or greater within a range of 300 nm from the top portion of the light emitting layer which is closest to the p-side nitride semiconductor layer, and after reaching the maximum value, the concentration remains at 6×1017 cm−3 or greater in the above-described range of 300 nm.

Owner:NICHIA CORP

Hepatic targeted temperature sensitive microsphere and preparation method therefor

InactiveCN103709323AControlled release rateControl concentrationPowder deliveryPharmaceutical non-active ingredientsCross-linkTemperature response

The invention discloses a hepatic targeted temperature sensitive microsphere and a preparation method therefor, and belongs to the functional polymer material field, and especially relates to a drug sustained release and targeted drug delivery material and a preparation method therefor. The temperature response range of the material is 25 DEG C-37 DEG C, and the particle size of the microsphere is about 500nm. The microsphere can be prepared through the following method: glycyrrhetinic acid (GA) is modified by ethylene diamine and acrylic acid (AAc) and vinyl monomers are generated; ammonium persulfate (APS) is employed as an initiator, N,N-methylene bisacrylamide (MBA) is employed as a cross-linking agent, hepatic targeted temperature sensitive microspheres are prepared through a semicontinuous soap-free emulsion polymerization method. The preparation method has simple technological processes, and mild experiment conditions, needs no special devices, has a low investment cost, and has good operability. The reagents are all common reagents. The reaction residues are easy to remove. The preparation method is convenient for industrial implementation.

Owner:TIANJIN POLYTECHNIC UNIV

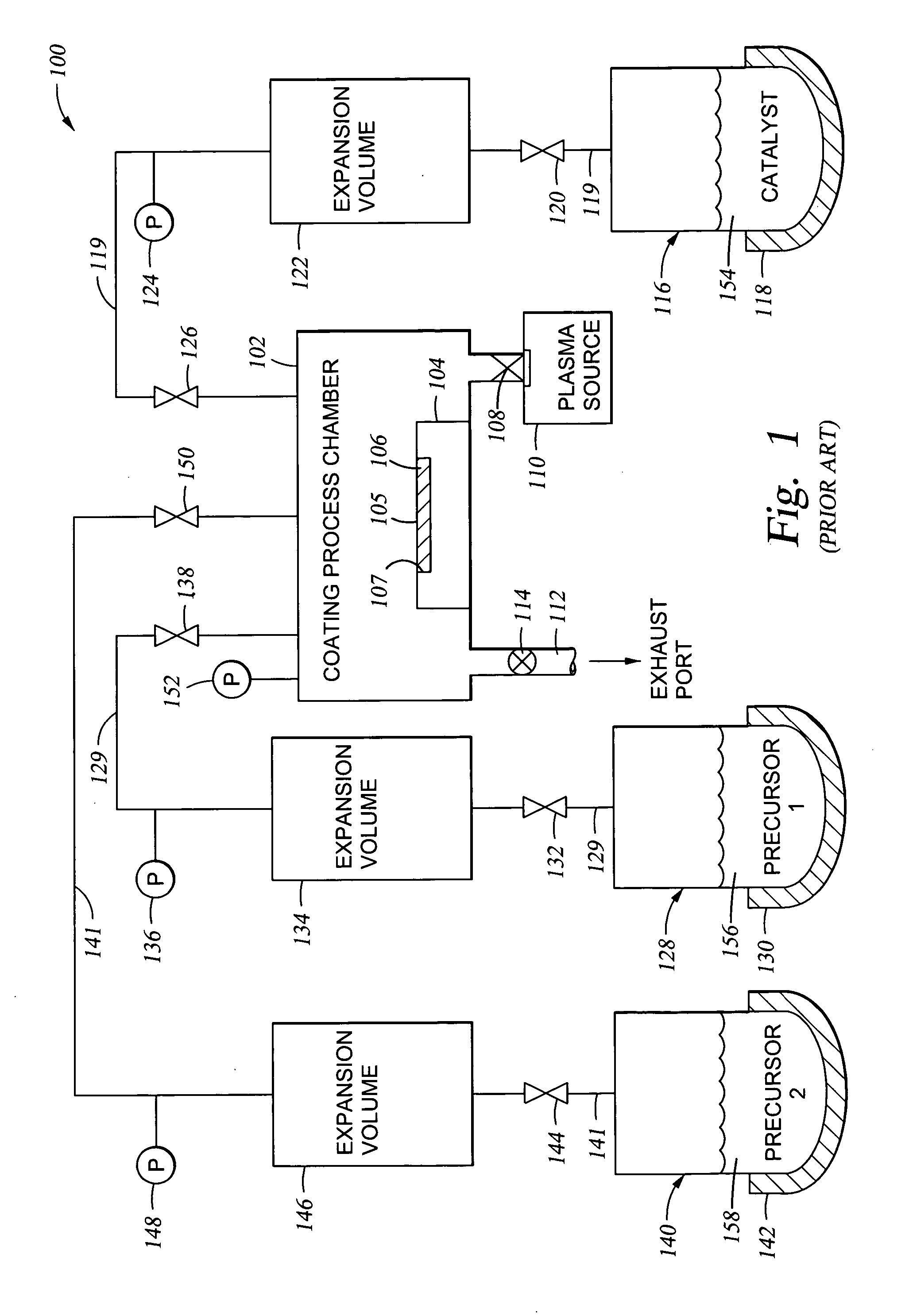

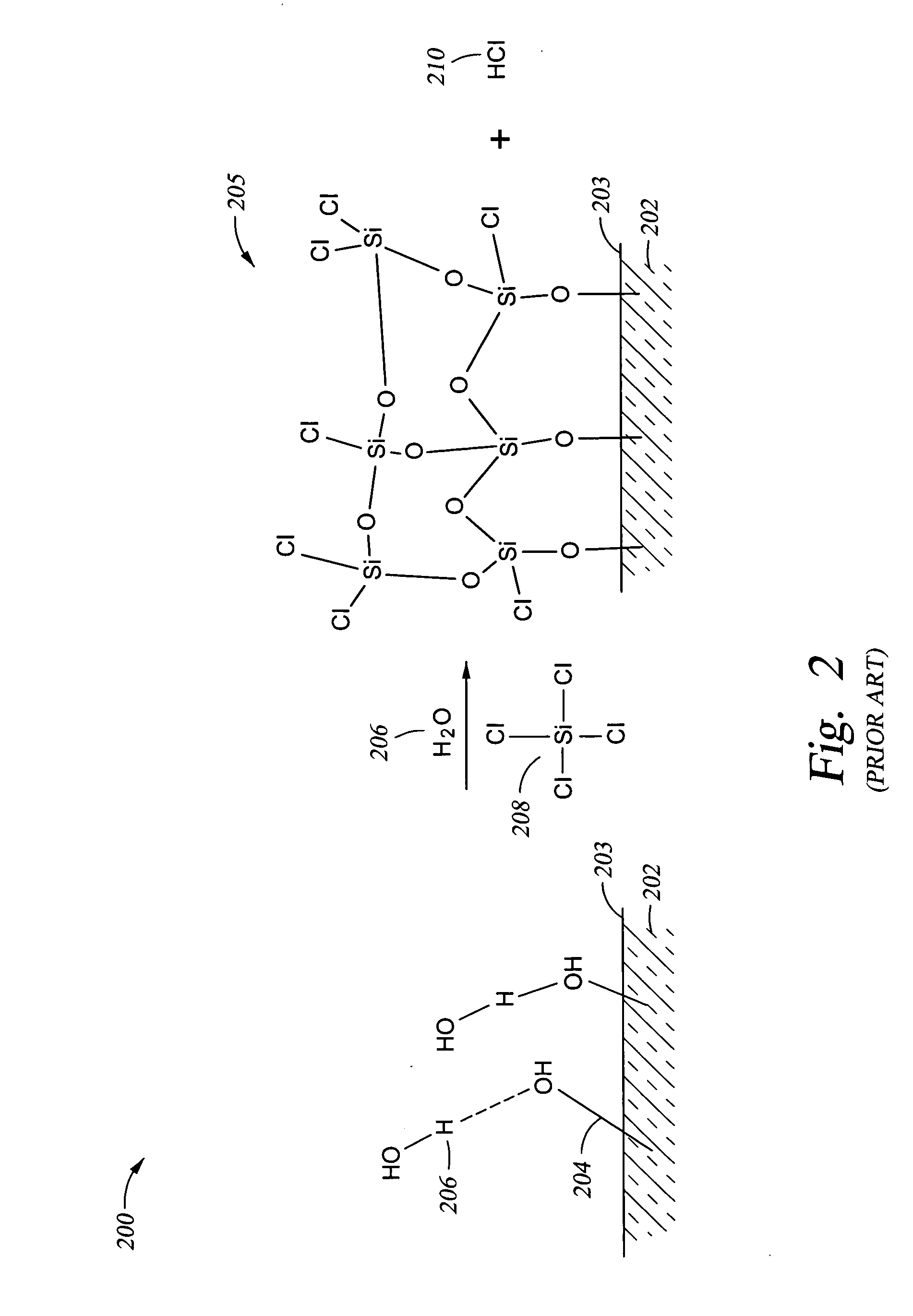

Controlled deposition of silicon-containing coatings adhered by an oxide layer

ActiveUS20050271809A1Smoother filmPrevent wrong additionMaterial nanotechnologyVacuum evaporation coatingGas phaseAtmospheric pressure

We have developed an improved vapor-phase deposition method and apparatus for the application of films / coatings on substrates. The method provides for the addition of a precise amount of each of the reactants to be consumed in a single reaction step of the coating formation process. In addition to the control over the amount of reactants added to the process chamber, the present invention requires precise control over the total pressure (which is less than atmospheric pressure) in the process chamber, the partial vapor pressure of each vaporous component present in the process chamber, the substrate temperature, and typically the temperature of a major processing surface within said process chamber. Control over this combination of variables determines a number of the characteristics of a film / coating or multi-layered film / coating formed using the method. By varying these process parameters, the roughness and the thickness of the films / coatings produced can be controlled.

Owner:SPTS TECH LTD

Pressure synthesis and refining process of methane chloride

InactiveCN1515528AAvoid quenchingAvoid sudden heatHalogenated hydrocarbon preparationCatalytic methodLiquid methane

The present invention relates to a new process for producing methane chloride by using liquid-phase catalytic method and pressurization process. The hydrogen chloride and methyl alcohol are mixed according to a certain ratio, then placed in a tank reactor with catalyst, and under the condition of a certain temp. and pressure the invented methane chloride can be synthesized. It adopts acid / water washing and alkali-washing processes to remove unreacted methyl alcohol and hydrogen chloride, and adopts concentrated sulfuric acid washing process to remove residual water content and reaction by-product dimethyl ether, then the purified and dried methane chloride gas is undergone the processes of compression and condensation so as to obtain high-purity liquid methane chloride product.

Owner:蓝星安迪苏股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com