Evaluation device for coal-fired flue gas pollutant sorbent and application thereof

An adsorbent and pollutant technology, which is applied in the field of devices for evaluating flue gas pollutant adsorbents, can solve problems such as being unsuitable for flue gas pollutant control and complex structure, and achieve the effects of increasing implementation benefits and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

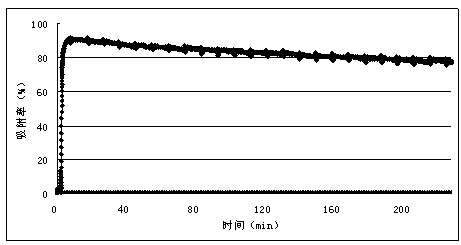

Examples

Embodiment 1

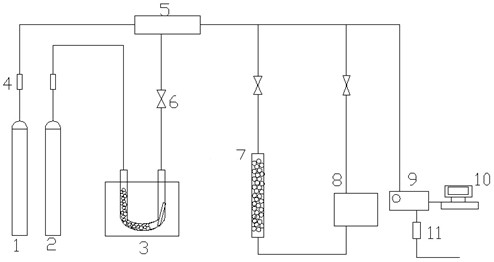

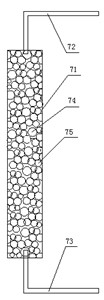

[0068] A device for evaluating smoke pollutant adsorbents, the schematic diagram of which is shown in figure 1 As shown, 1 is the simulated flue gas cylinder carrying pollutants, 2 is the mercury-carrying gas cylinder, 3 is the mercury vapor generator, 41 is the mass flow meter A, 42 is the mass flow meter B, 5 is the gas mixing tank, 6 is a two-way valve, 7 is a fixed bed, 8 is a mercury form conversion device, 9 is a mercury analyzer, 10 is a computer, and 11 is a tail gas treatment device;

[0069] The mercury-carrying gas cylinder 2 is connected to the inlet of the mixing tank 5 after compressed air passes through the mass flow meter A41, the mercury vapor generator 3, and the two-way valve 6;

[0070] The simulated flue gas cylinder 1 carrying pollutants is connected to the inlet of the gas mixing tank 5 after passing through the mass flow meter B42;

[0071] The pipeline at the outlet of the gas mixing tank 5 is divided into two paths. One pipeline enters the fixed bed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com