Patents

Literature

918 results about "Vapor generator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

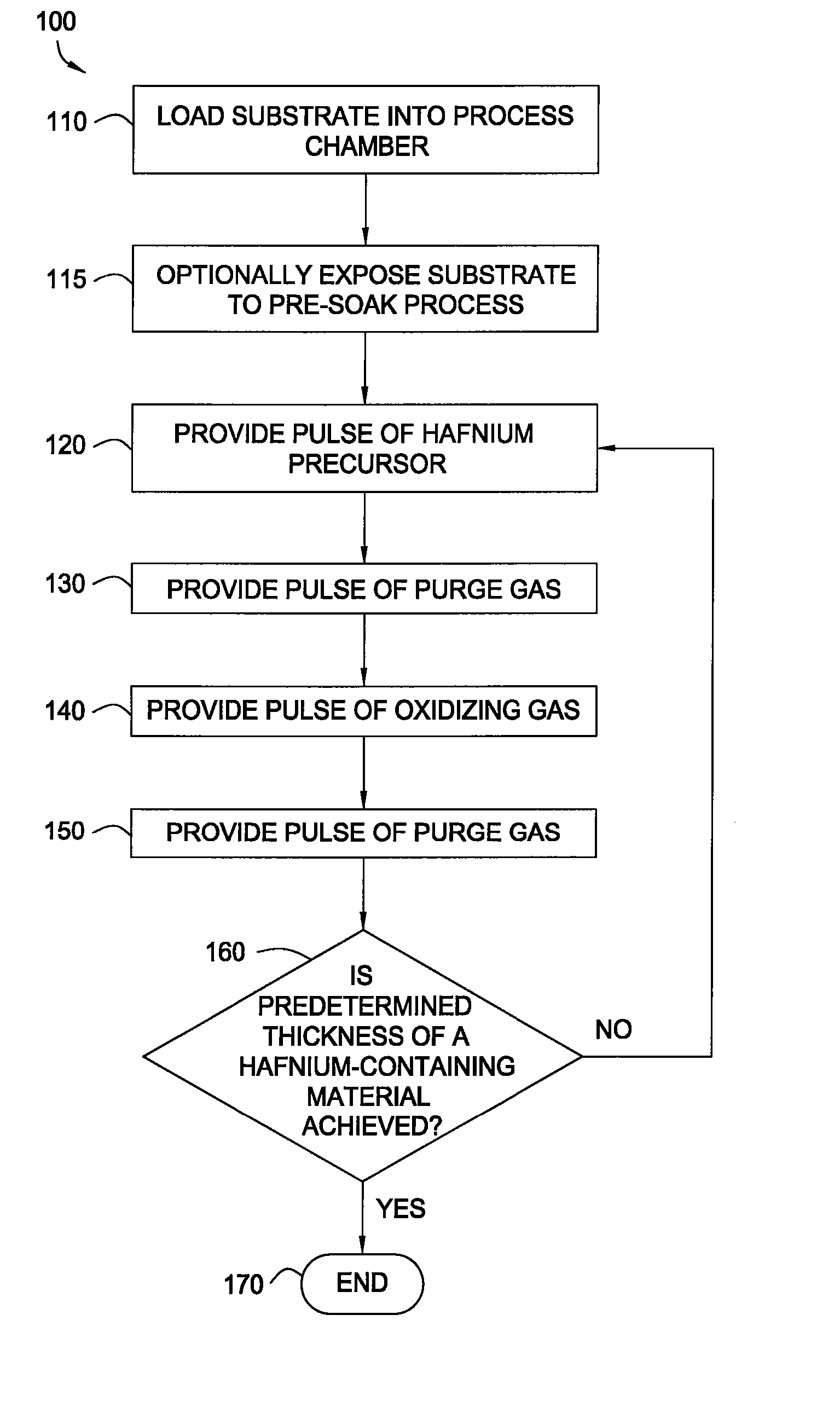

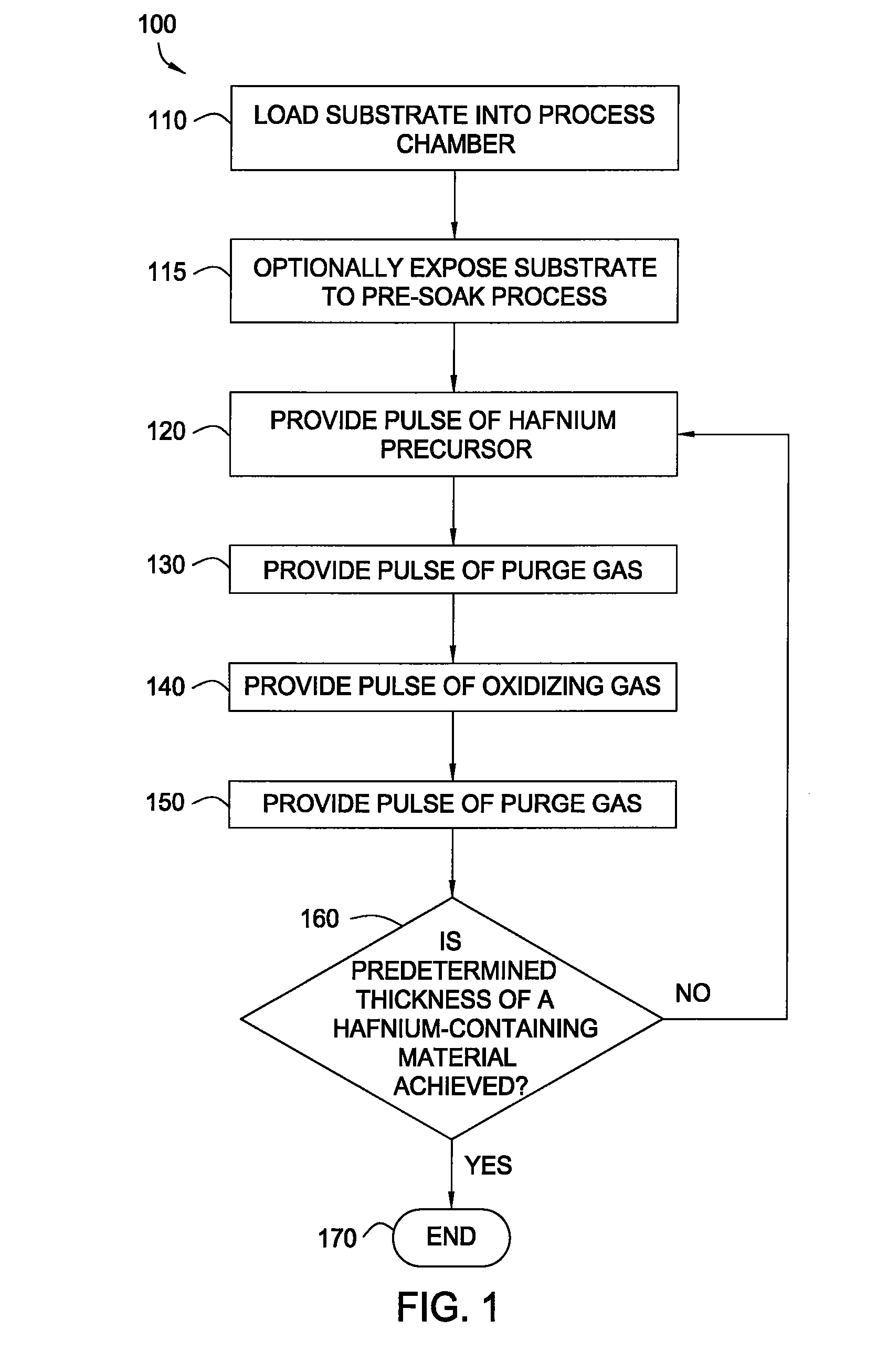

Apparatuses and methods for atomic layer deposition of hafnium-containing high-k dielectric materials

ActiveUS20050271812A1Steam generation heating methodsEfficient propulsion technologiesWater vaporGas phase

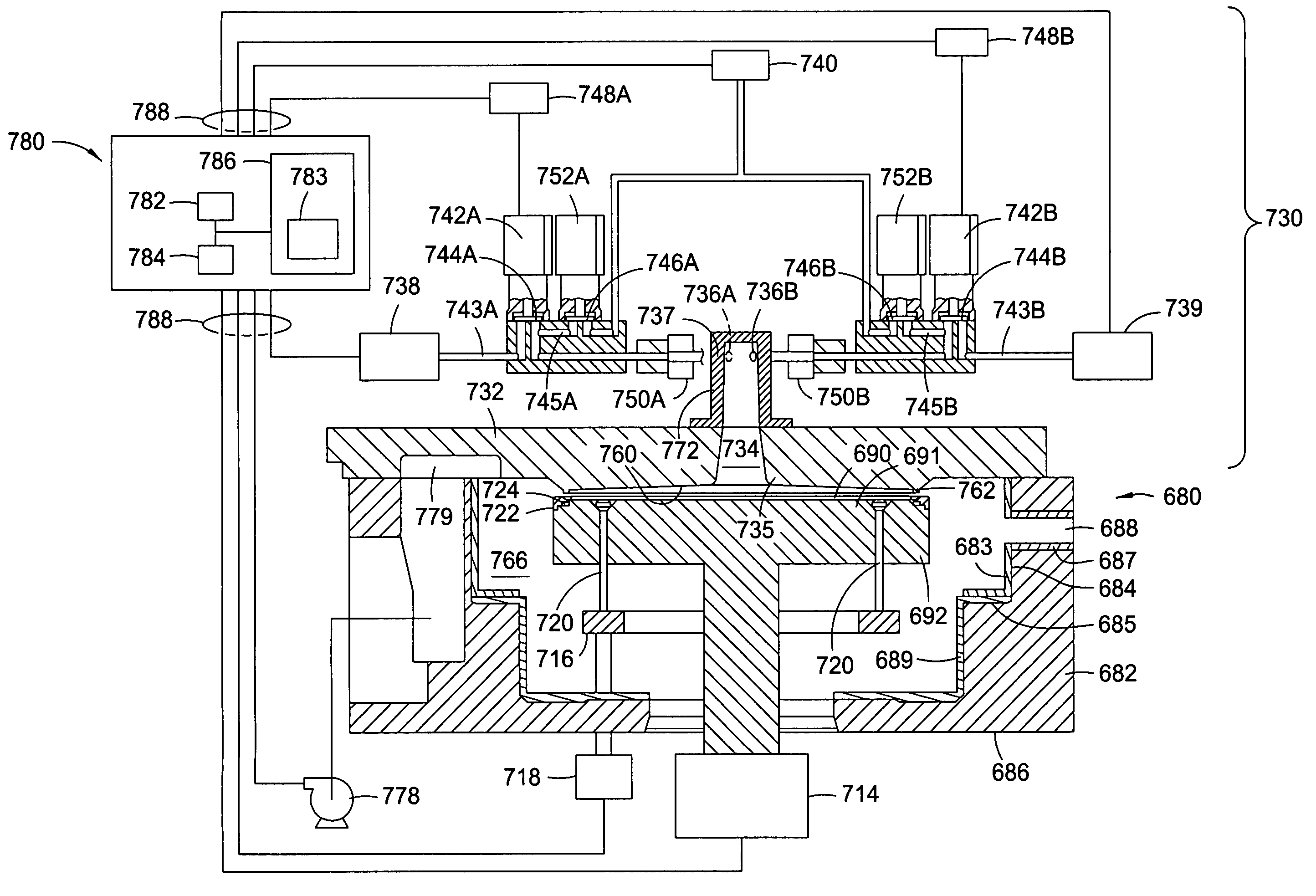

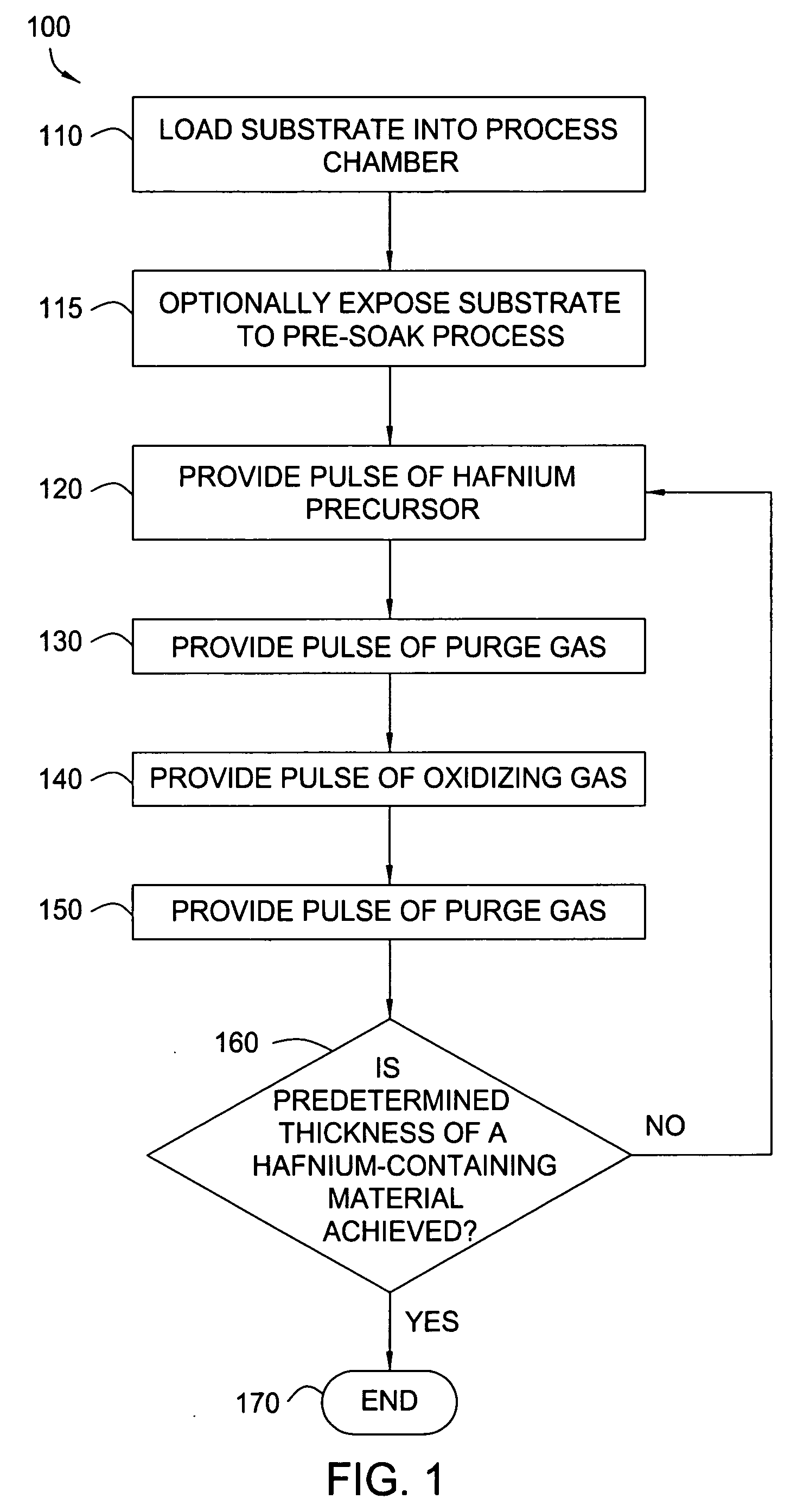

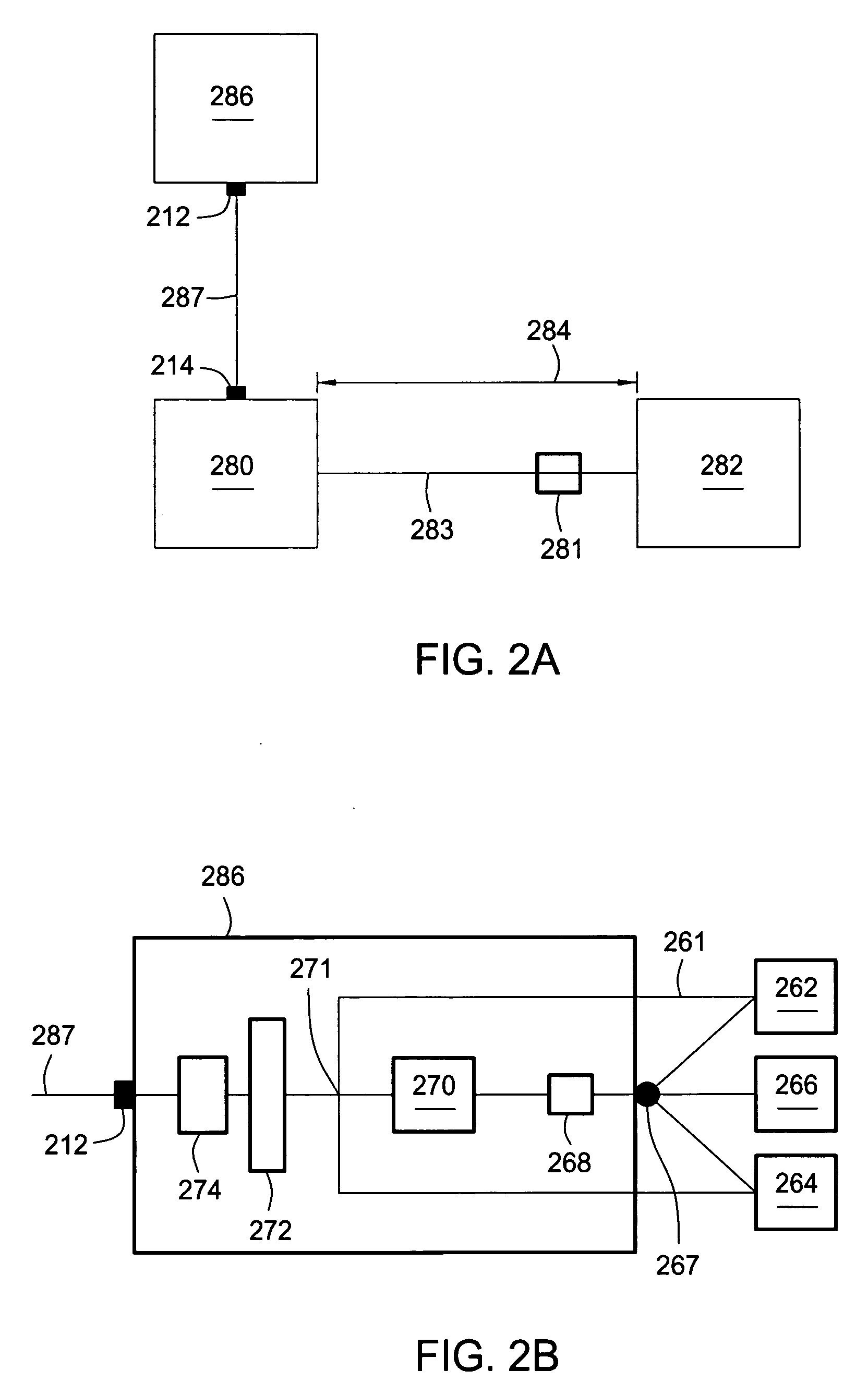

Embodiments of the invention provide apparatuses and methods for depositing materials on substrates during vapor deposition processes, such as atomic layer deposition (ALD). In one embodiment, a chamber contains a substrate support with a receiving surface and a chamber lid containing an expanding channel formed within a thermally insulating material. The chamber further includes at least one conduit coupled to a gas inlet within the expanding channel and positioned to provide a gas flow through the expanding channel in a circular direction, such as a vortex, a helix, a spiral or derivatives thereof. The expanding channel may be formed directly within the chamber lid or formed within a funnel liner attached thereon. The chamber may contain a retaining ring, an upper process liner, a lower process liner or a slip valve liner. Liners usually have a polished surface finish and contain a thermally insulating material such as fused quartz or ceramic. In an alternative embodiment, a deposition system contains a catalytic water vapor generator connected to an ALD chamber.

Owner:APPLIED MATERIALS INC

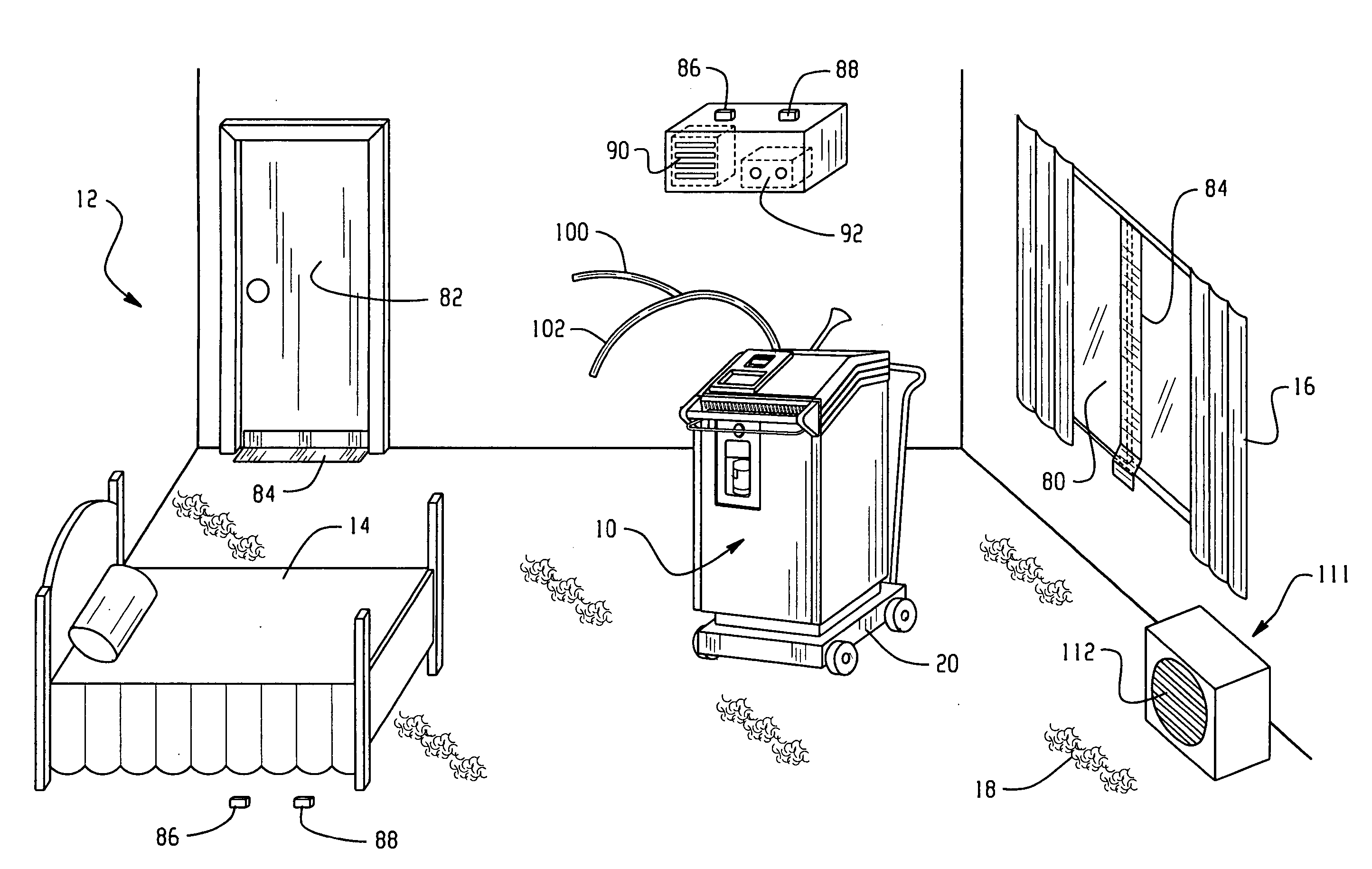

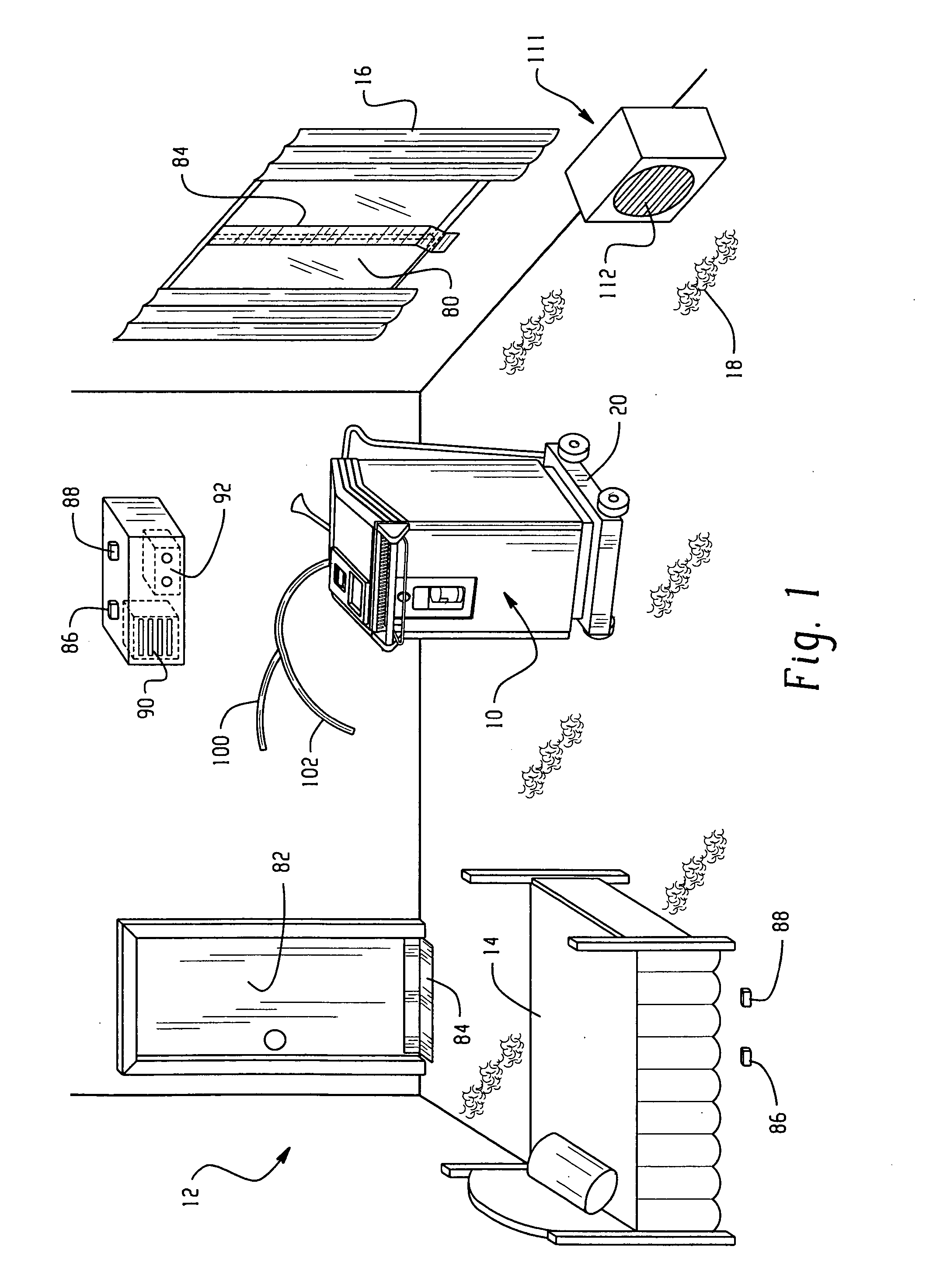

Room decontamination with hydrogen peroxide vapor

ActiveUS20060008379A1Reduce or even removeMinimize residual amountGaseous substancesDeodrantsHotel roomVapor generator

A system for microbially and / or chemically decontaminating a room such as a hotel room includes a vapor generator which supplies a decontaminant vapor, such as hydrogen peroxide vapor to the room. The room is then aerated to a level at which it is safe for normal occupants to enter. By using a two step aeration, with a second step at lower humidity than the first, the concentration of residual hydrogen peroxide is reduced rapidly to safe levels of 1 ppm or less, typically about 0.5 ppm, in under four hours. The room is rendered substantially free of contaminants, such as those responsible for Severe Acute Respiratory Syndrome (SARS), Norwalk virus, and unpleasant odors.

Owner:STERIS CORP

Ventilation device

InactiveCN102095236APromote absorptionImprove cooling effectLighting and heating apparatusJet pumpsWater vaporEngineering

The invention discloses a ventilation device, which aims to solve the problem that the conventional ventilation device does not have an air adjusting function. The device comprises a pedestal, a high-speed air blower and an annular ejector, wherein the high-speed air blower is arranged at the bottom of the pedestal; the annular ejector is arranged at an air outlet of the high-speed air blower and is fixed on the pedestal; and the air inlet or the air outlet of the high-speed air blower is provided with a vapor generator which is fixed on the pedestal for producing water vapor. In the ventilation device, the water vapor is produced through the vapor generator and is ejected through an atomization nozzle at a high speed to produce fog of smaller granularity, so that a hot air flow can more easily absorb the latent heat of vaporization, and the ventilation device has a humidification effect and a heat absorption and temperature reduction effect on a large amount of hot air sucked by the annular nozzle, and brings comfortable cool air similar to air on the shore of a lake or a sea to the surrounding environment. In the ventilation device, an external circulating device is not required to be mounted, so the cost is low; the space is not required to be closed, so that air convection is guaranteed; and the ventilation device is more energy-saving in the same temperature reduction range compared with a fan and an air conditioner, and can be used conveniently and safely.

Owner:曾小颖 +1

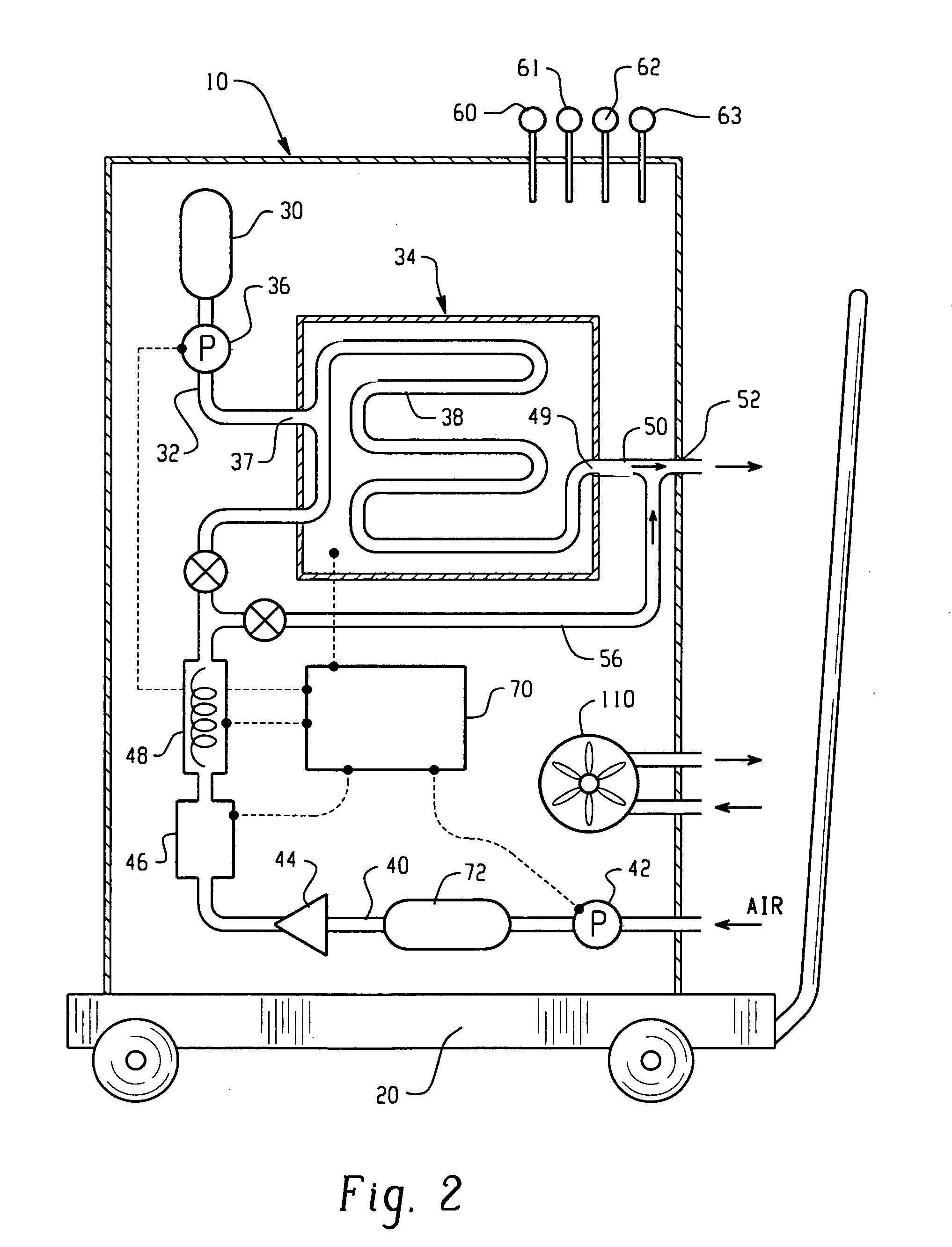

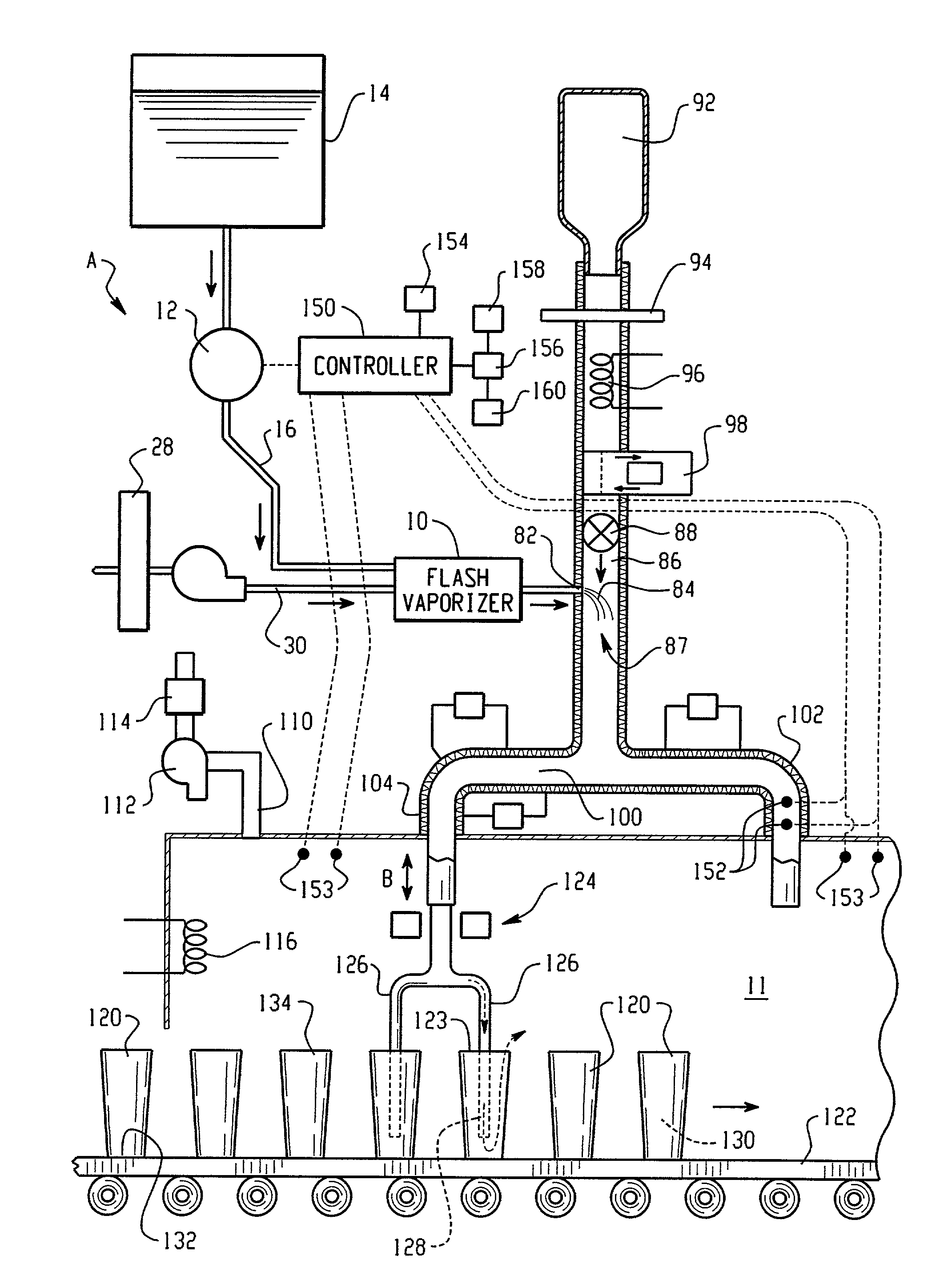

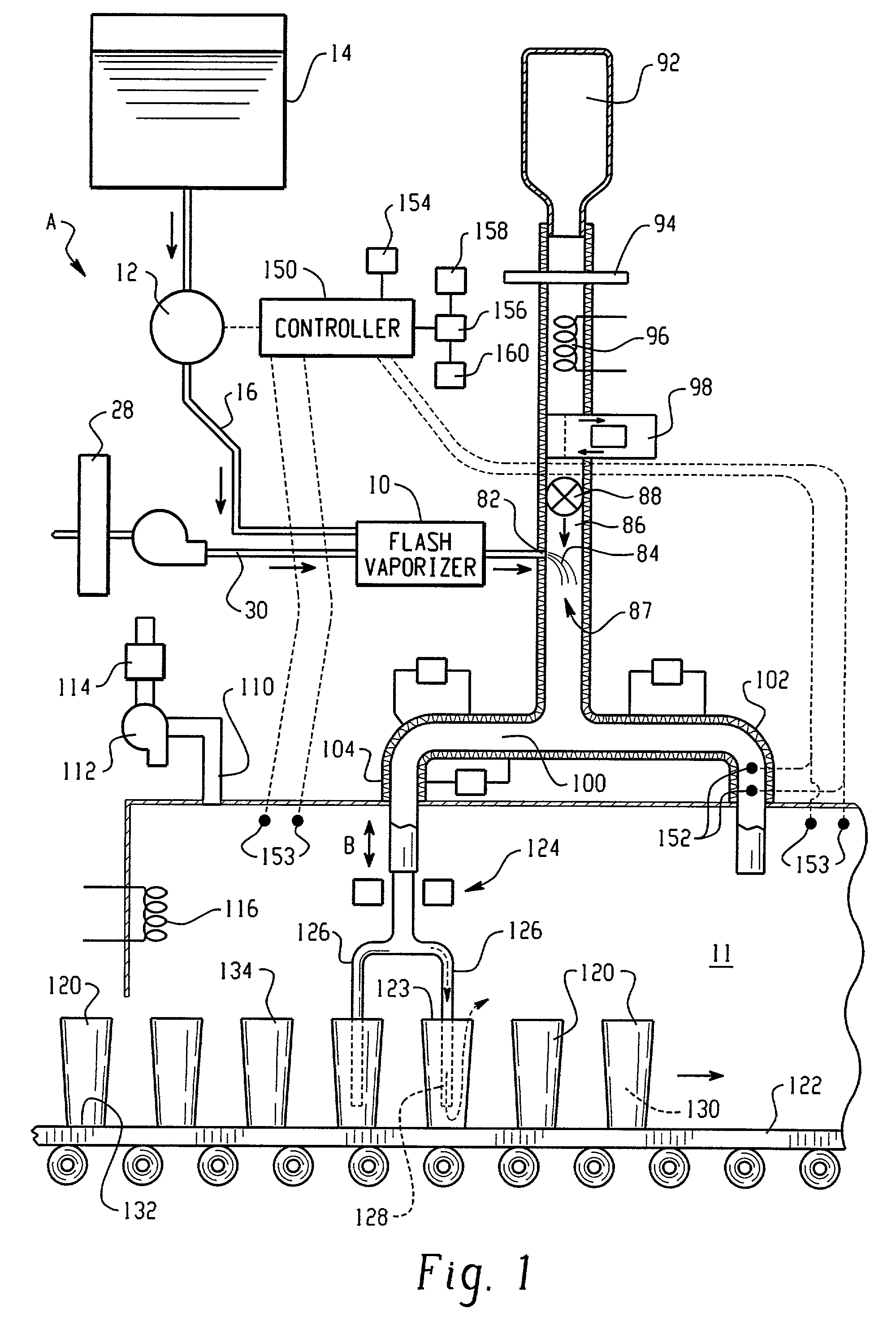

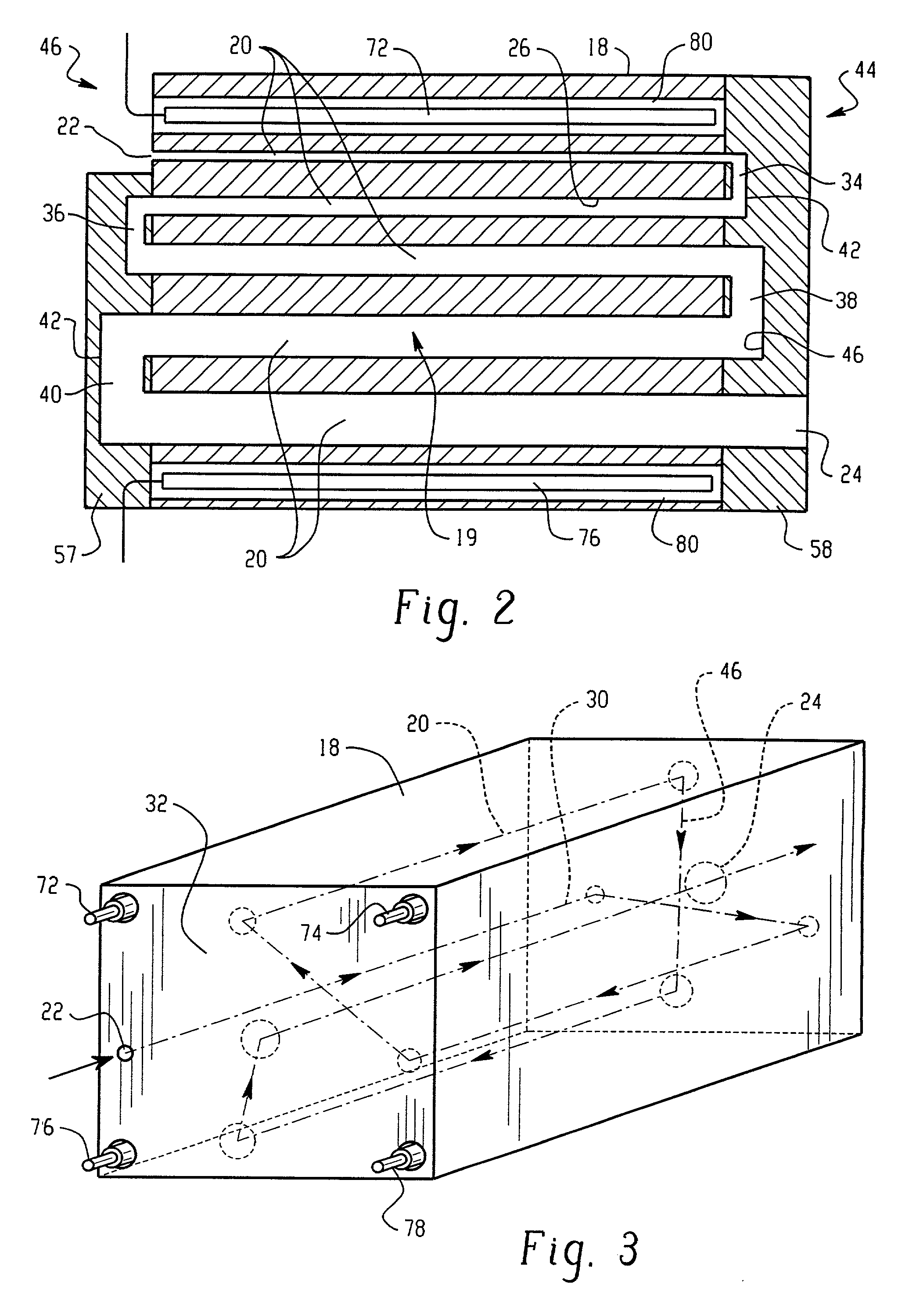

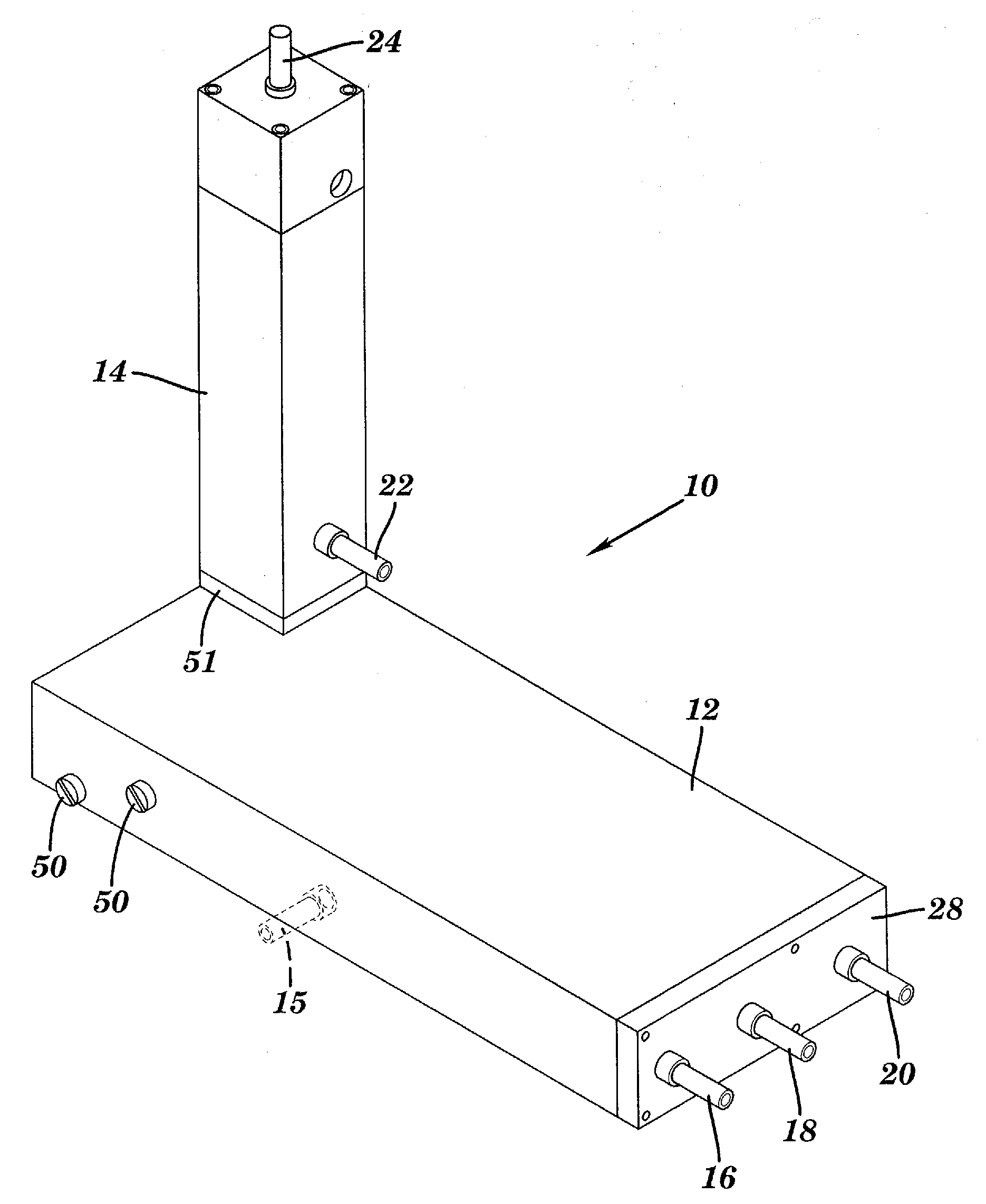

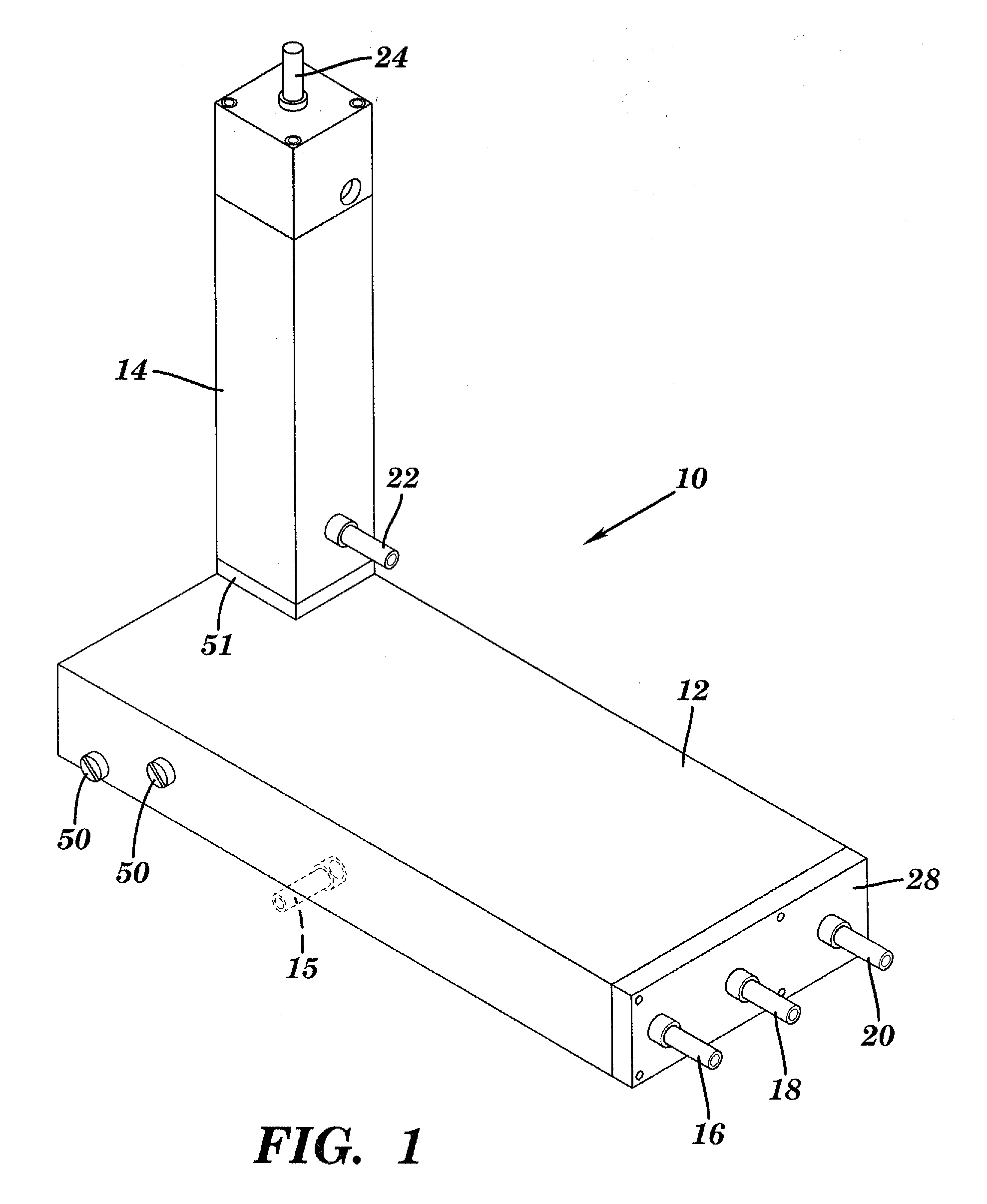

Vapor phase decontamination of containers

ActiveUS7186374B2Increase productionLarge throughputPackage sterilisationLavatory sanitoryVapor phaseVapor generator

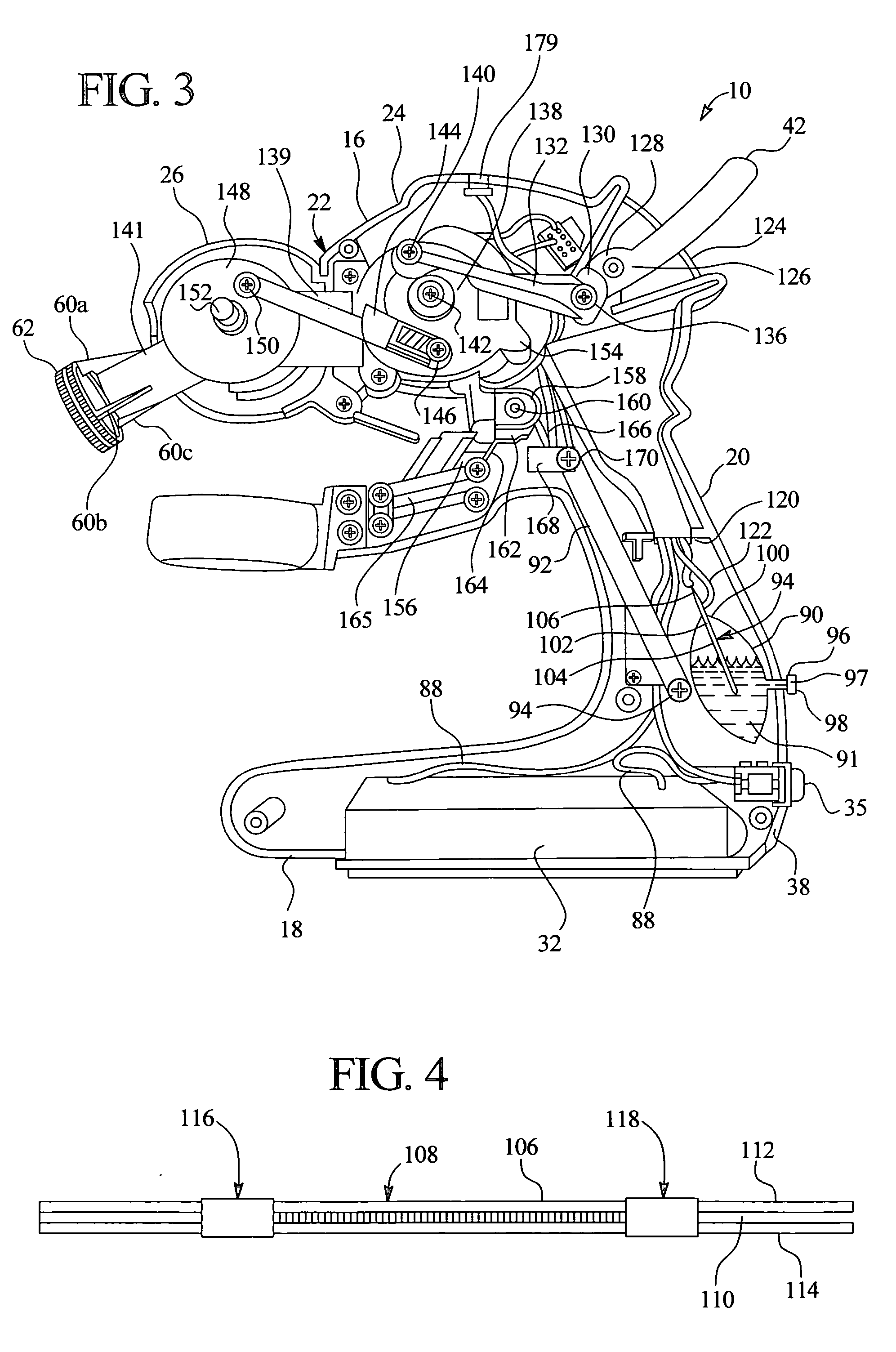

A flash vapor generator (10) provides a constant flow of vaporized hydrogen peroxide for rapidly sterilizing a large decontamination tunnel (11) with a high container throughput. The vaporizer includes a heated block which defines an interior bore or bores. The conditions within the decontamination tunnel are carefully monitored to avoid condensation of the vapor while maintaining the vapor as close as possible to the saturation limit.

Owner:AMERICAN STERILIZER CO

Methods for atomic layer deposition of hafnium-containing high-k dielectric materials

InactiveUS20080044569A1Steam generation heating methodsEfficient propulsion technologiesWater vaporGas phase

Embodiments of the invention provide methods for depositing materials on substrates during vapor deposition processes, such as atomic layer deposition (ALD). In one embodiment, a chamber contains a substrate support with a receiving surface and a chamber lid containing an expanding channel formed within a thermally insulating material. The chamber further includes at least one conduit coupled to a gas inlet within the expanding channel and positioned to provide a gas flow through the expanding channel in a circular direction, such as a vortex, a helix, a spiral, or derivatives thereof. The expanding channel may be formed directly within the chamber lid or formed within a funnel liner attached thereon. The chamber may contain a retaining ring, an upper process liner, a lower process liner or a slip valve liner. Liners usually have a polished surface finish and contain a thermally insulating material such as fused quartz or ceramic. In an alternative embodiment, a deposition system contains a catalytic water vapor generator connected to an ALD chamber.

Owner:APPLIED MATERIALS INC

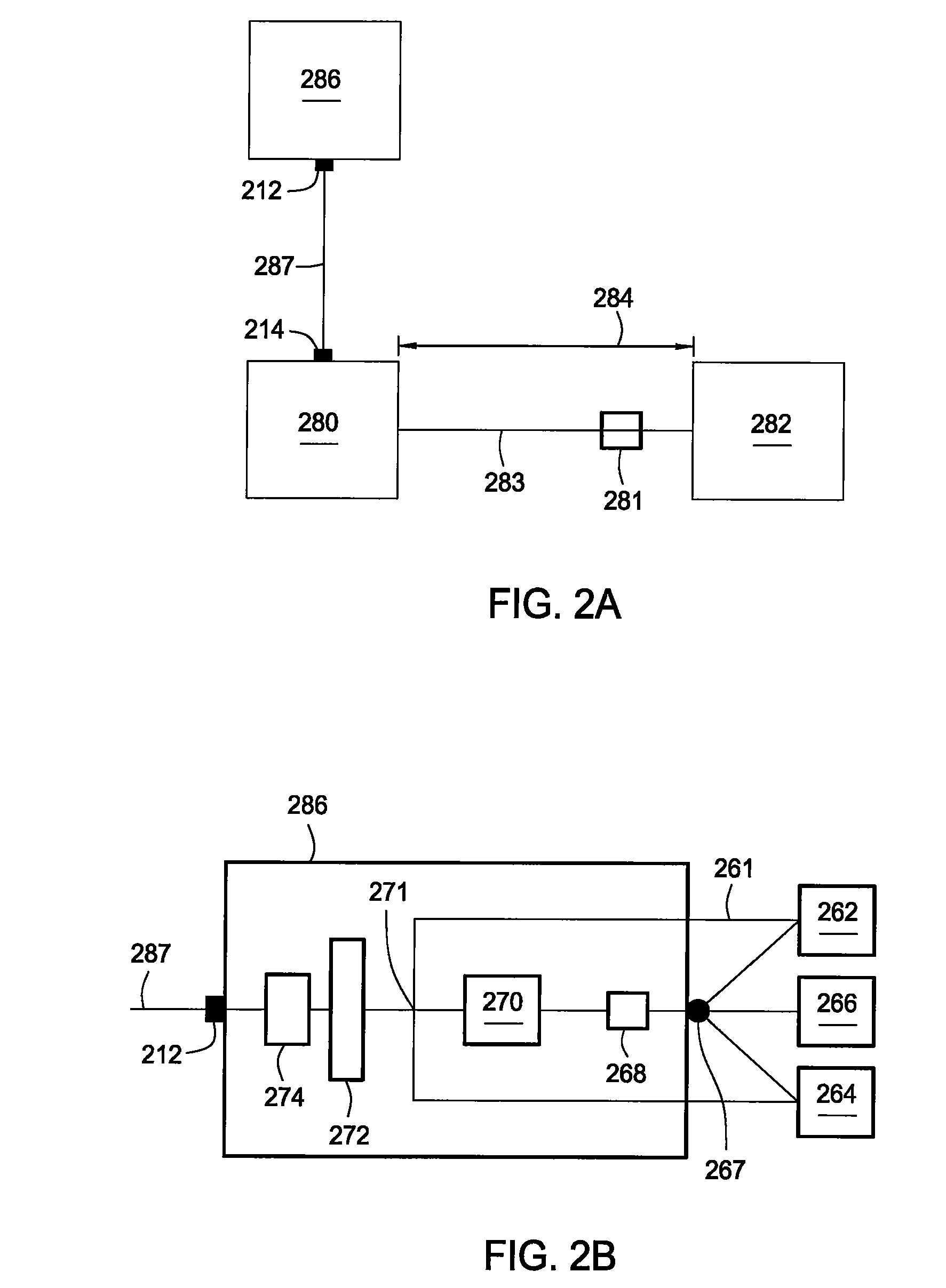

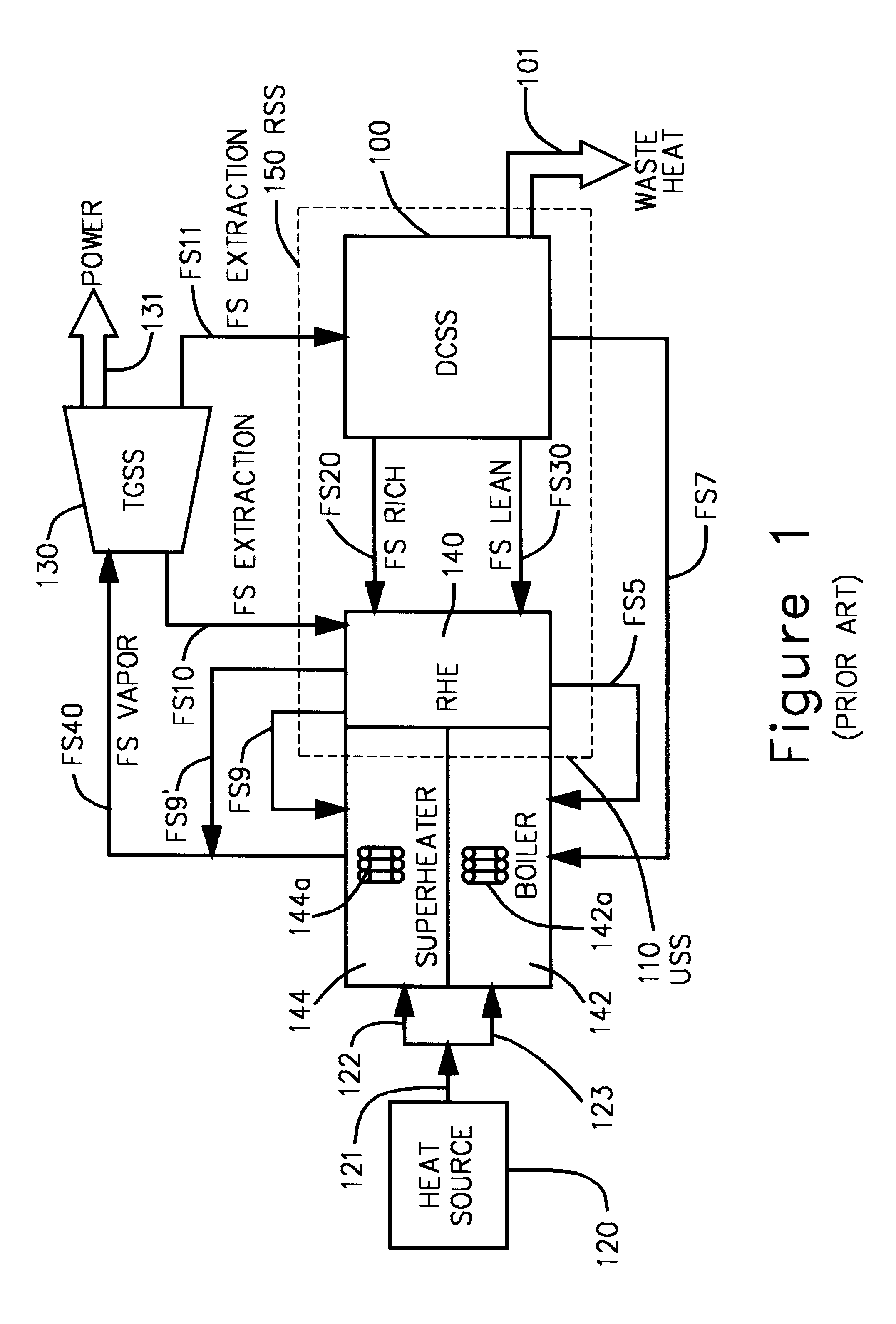

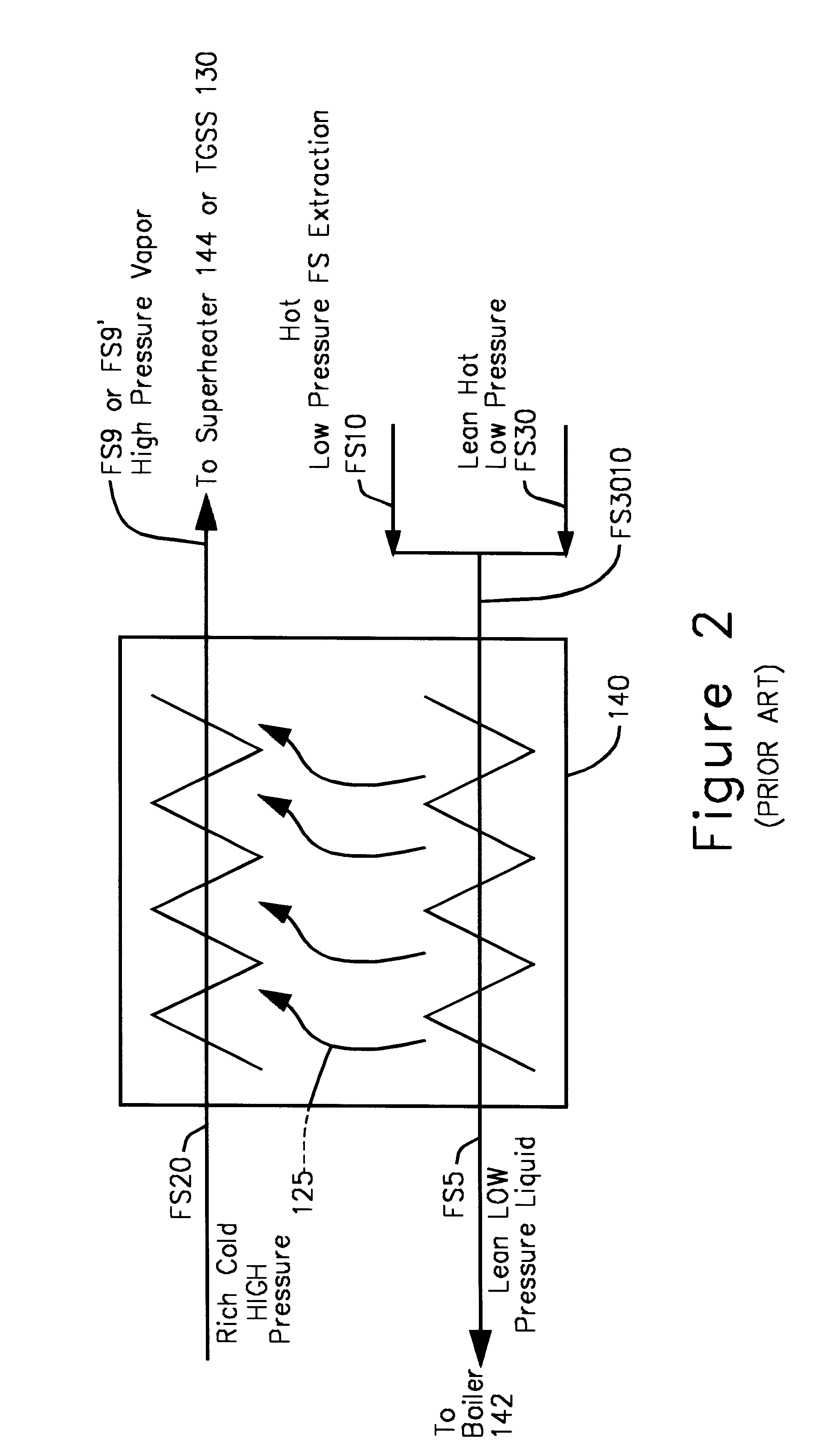

System and apparatus for power system utilizing wide temperature range heat sources

Owner:KALINA POWER LTD

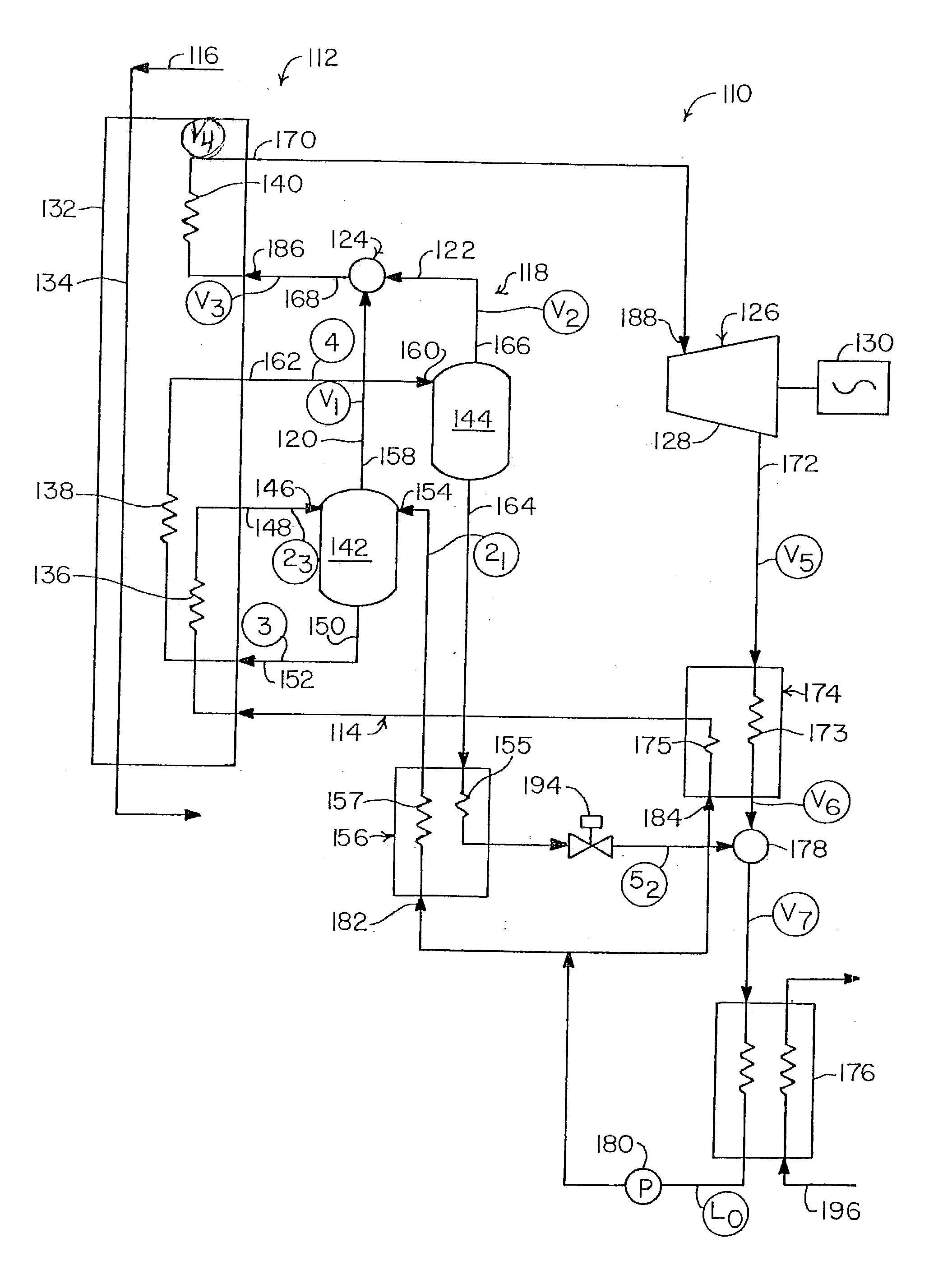

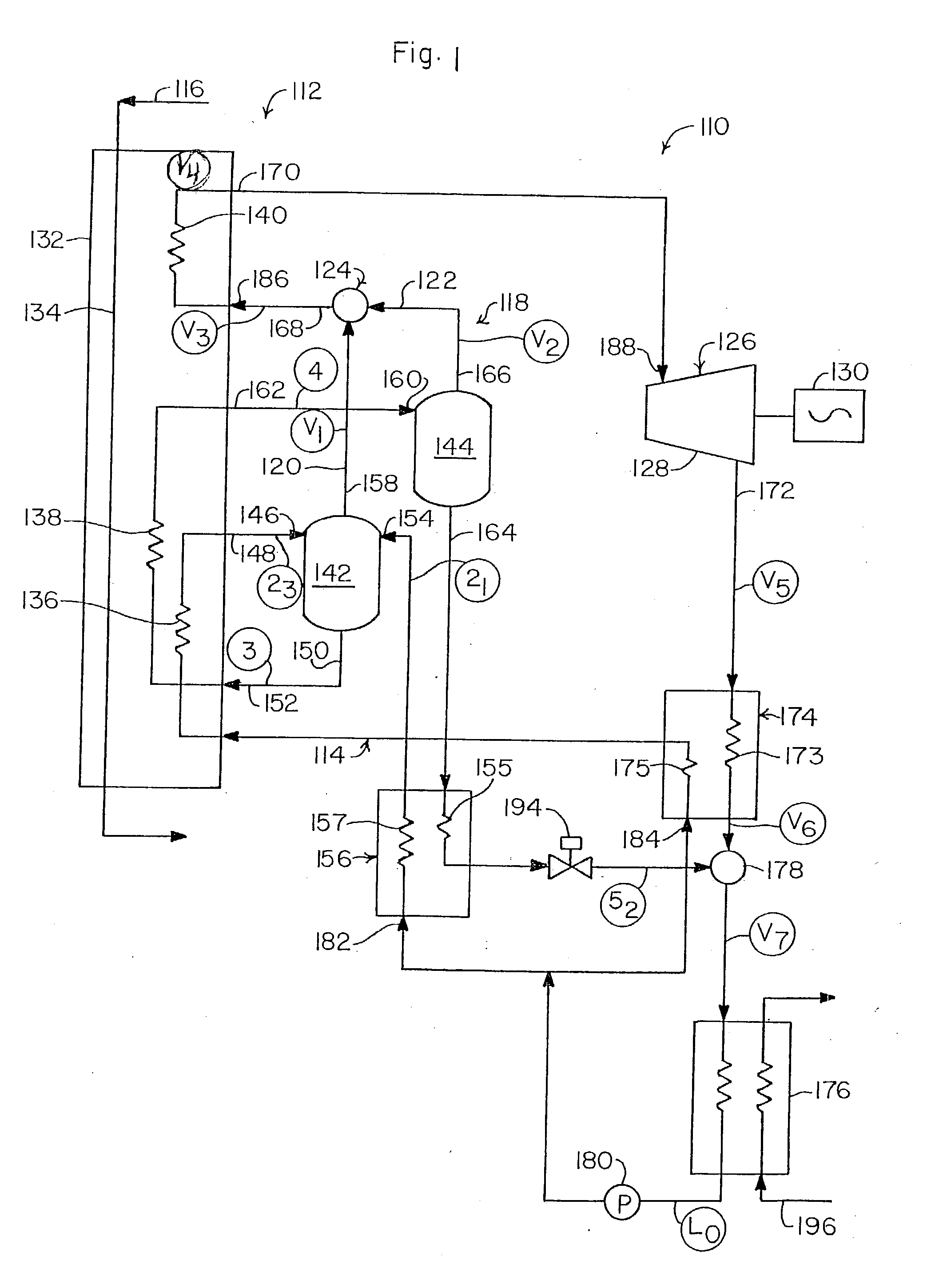

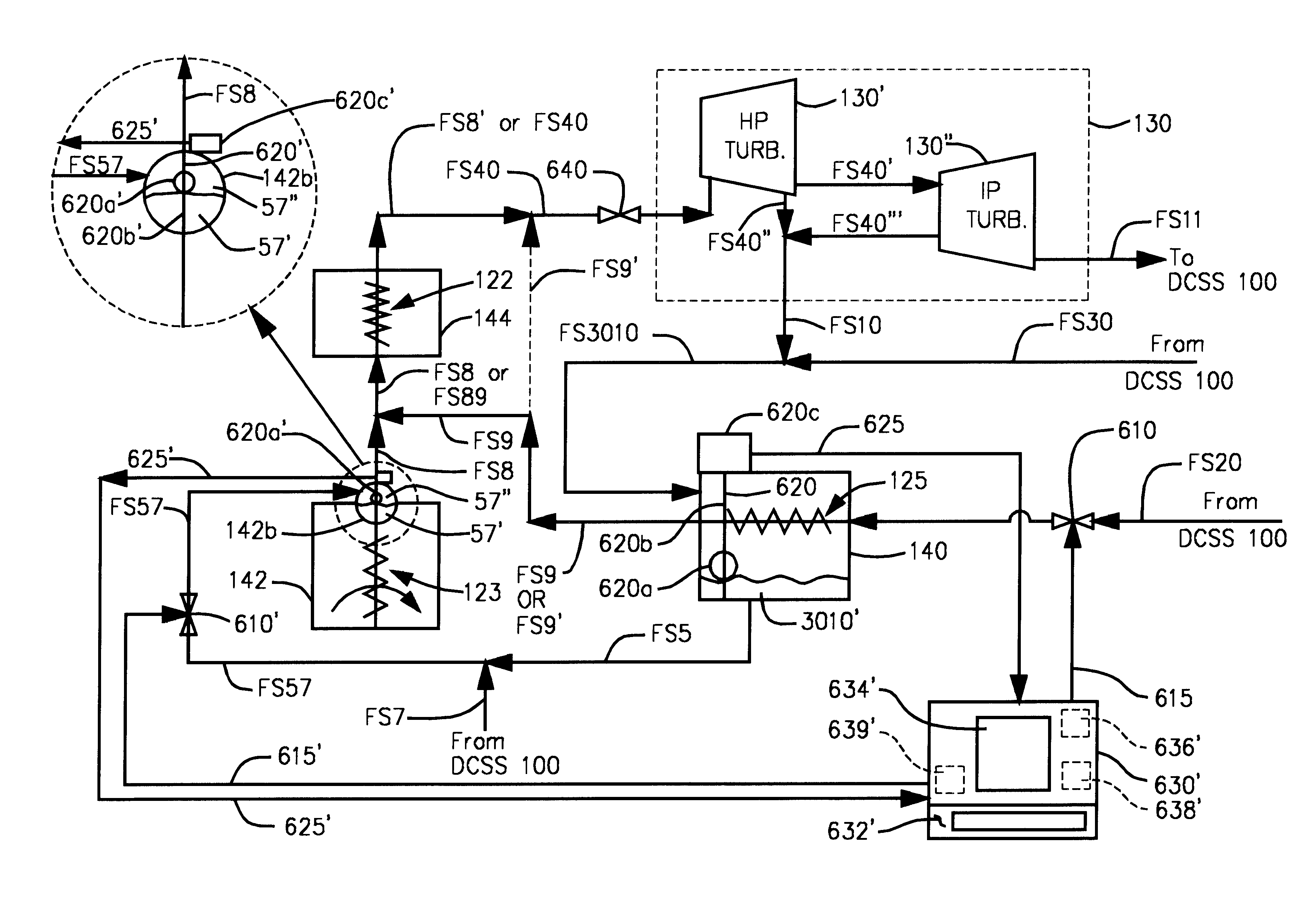

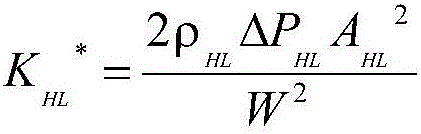

Mixed working fluid power system with incremental vapor generation

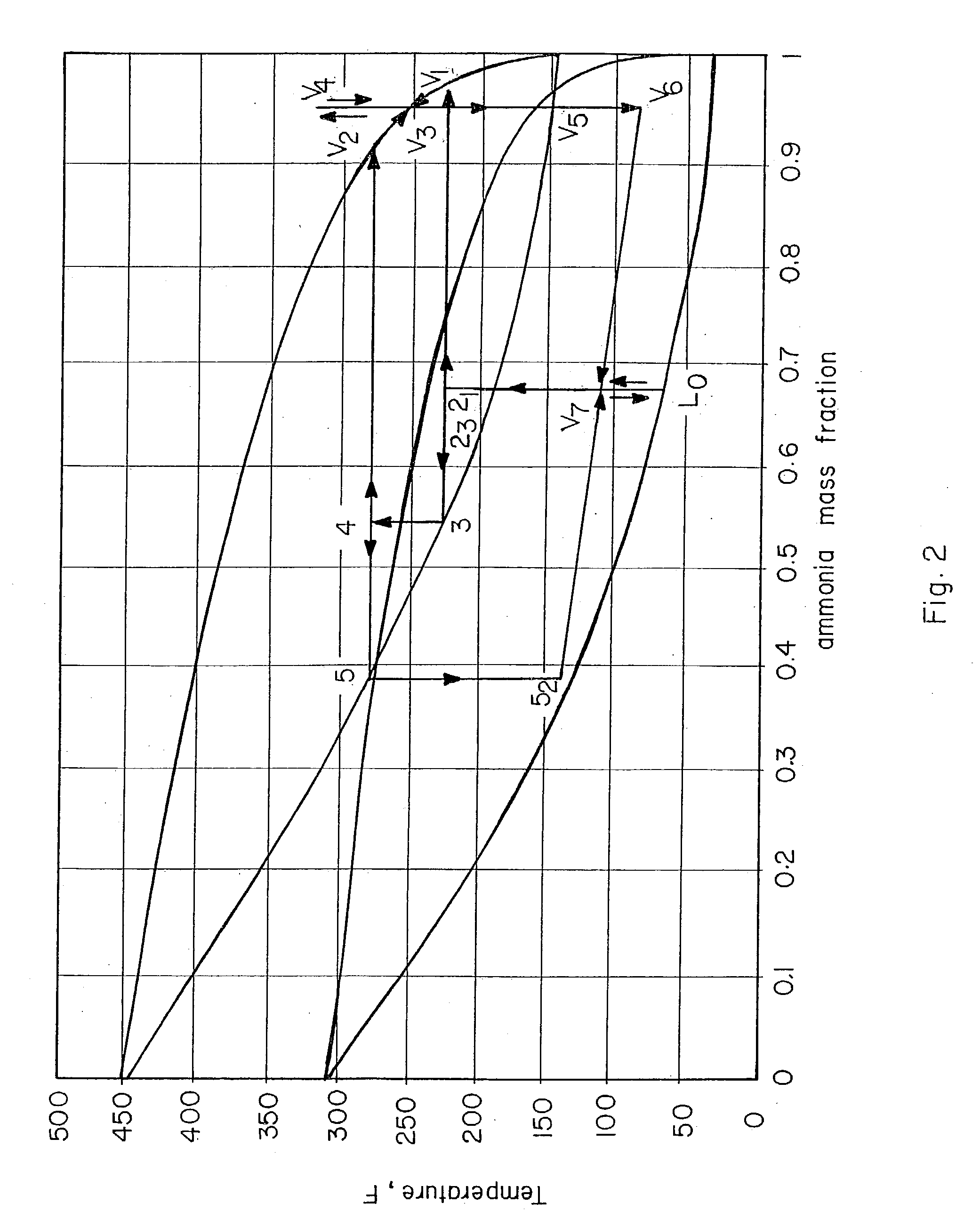

A power generating system (110) comprising a heat source (116) and an incremental vapor generator system (112) operatively associated with the heat source (116). The incremental vapor generator system (112) includes a first heating section (136) and a second heating section (138). The first heating section (136) receives a mixed working fluid (114) and generates a first heated working fluid stream comprising a vapor portion (120) and a liquid portion. The second heating section (138) is operatively associated with the first heating section (136) and receives the liquid portion from the first heated working fluid stream. The second heating section (138) generates a second heated working fluid stream comprising a vapor portion (122). An energy conversion device (126) operatively associated with the incremental vapor generator system (112) converts into useful work heat energy contained in the vapor portions (120, 122) of the first and second heated working fluid streams.

Owner:MIDWEST RES INST

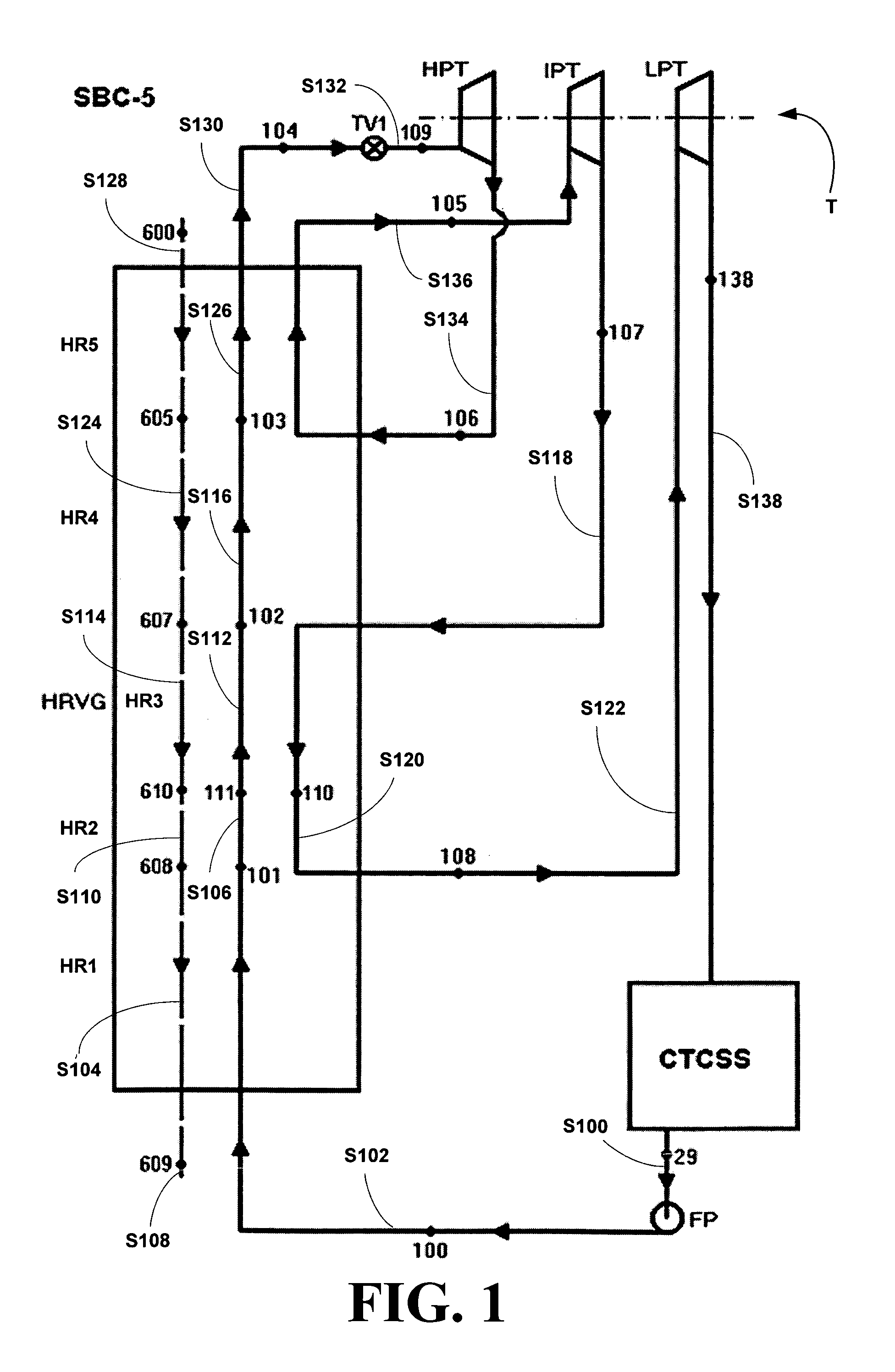

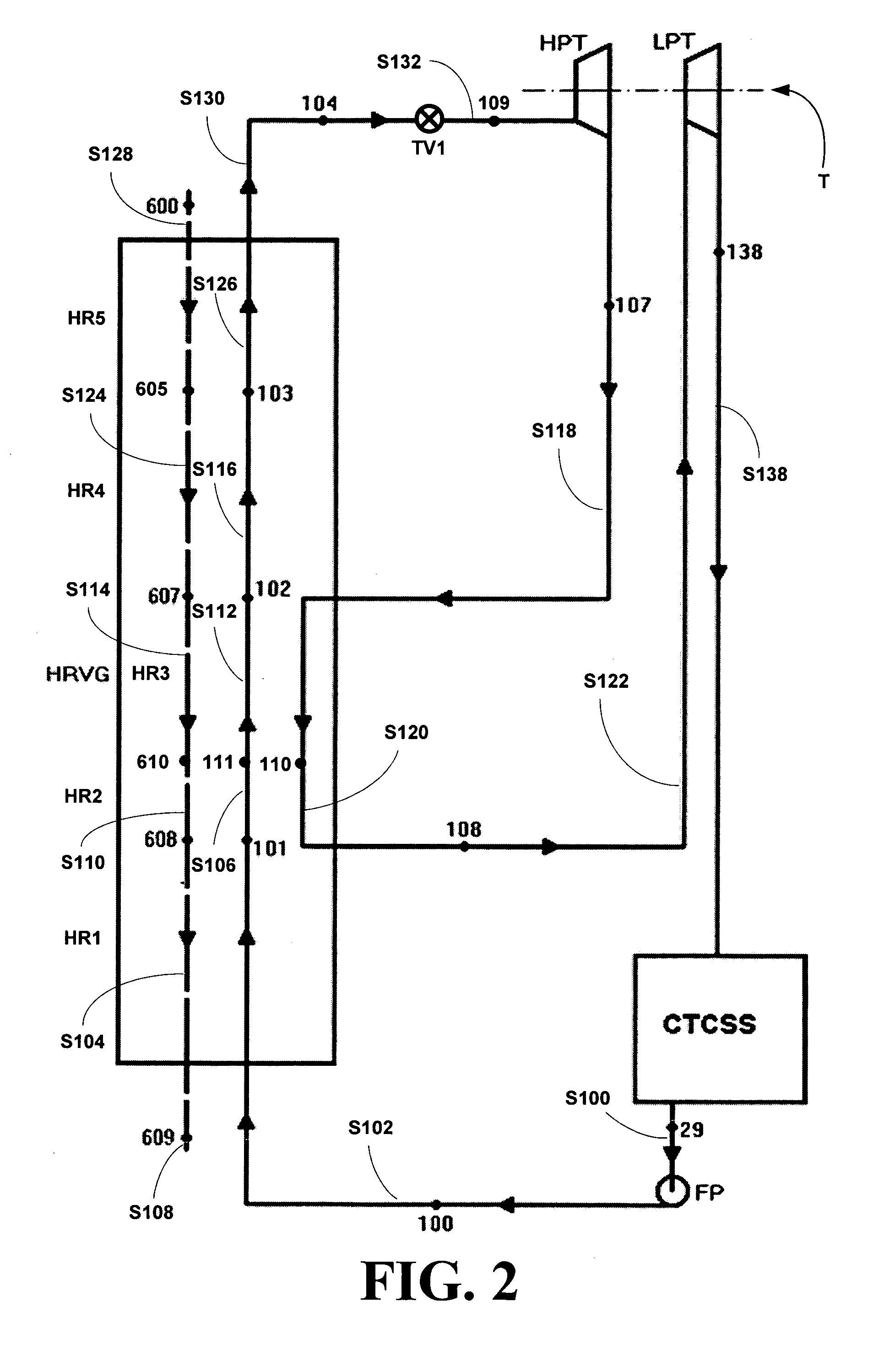

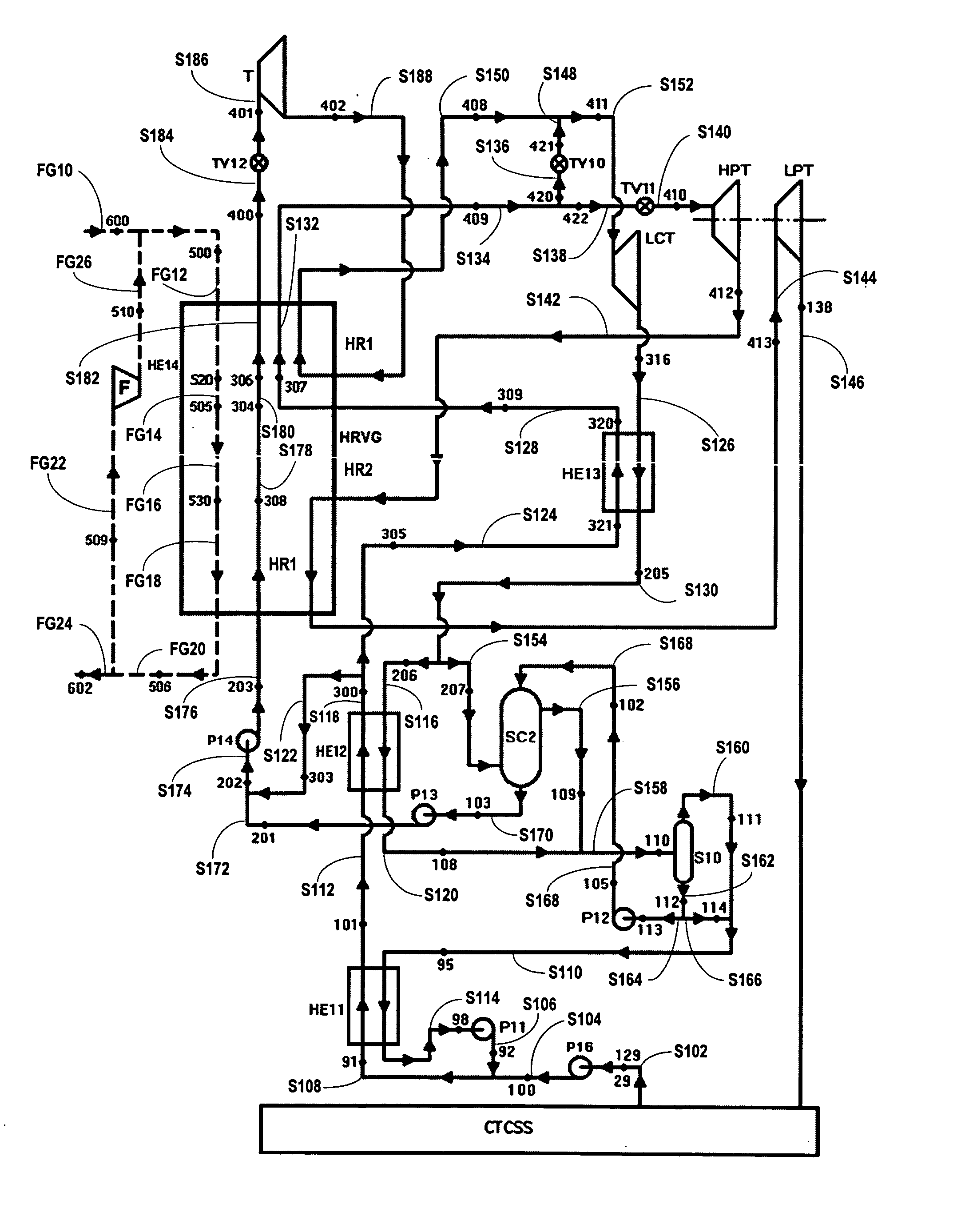

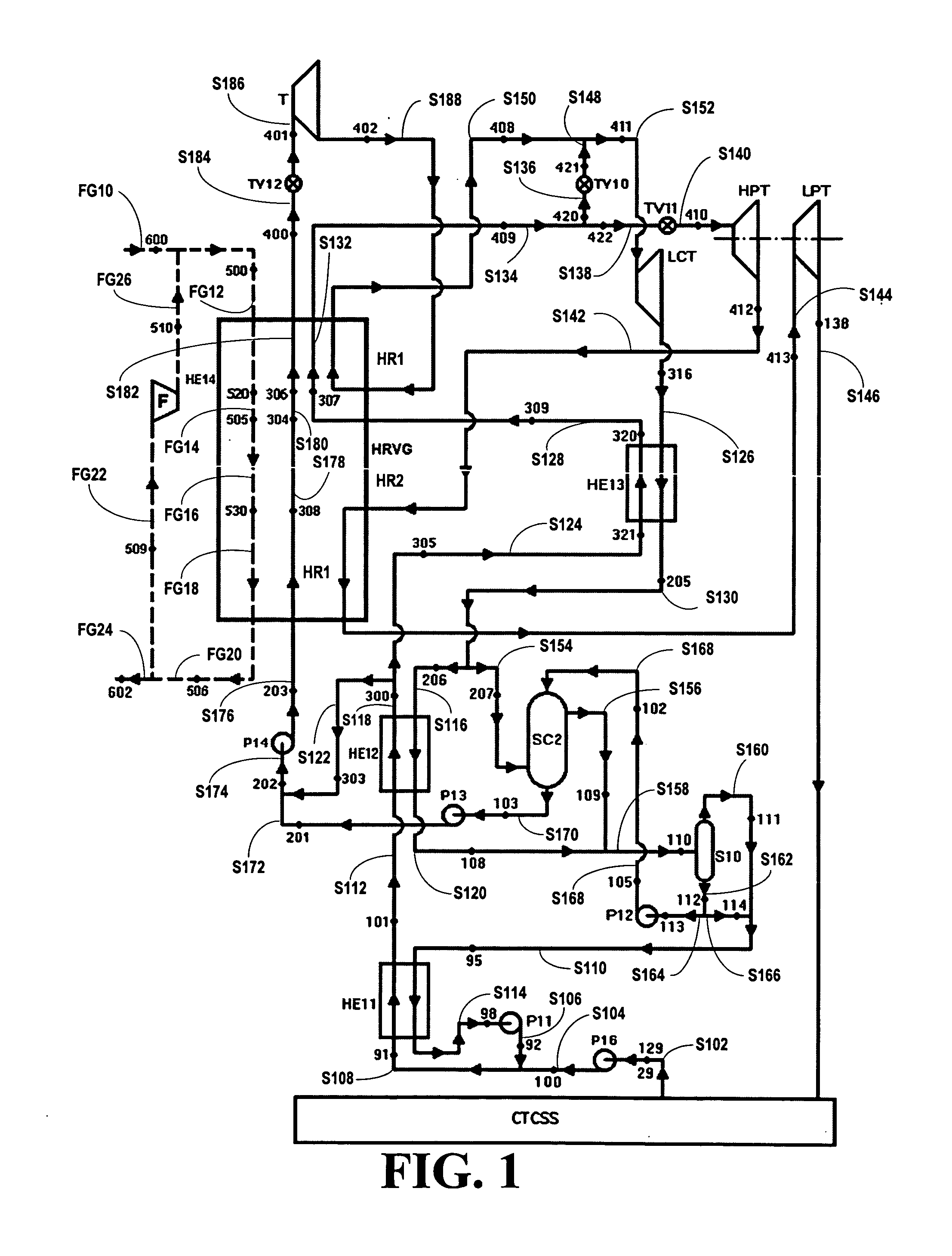

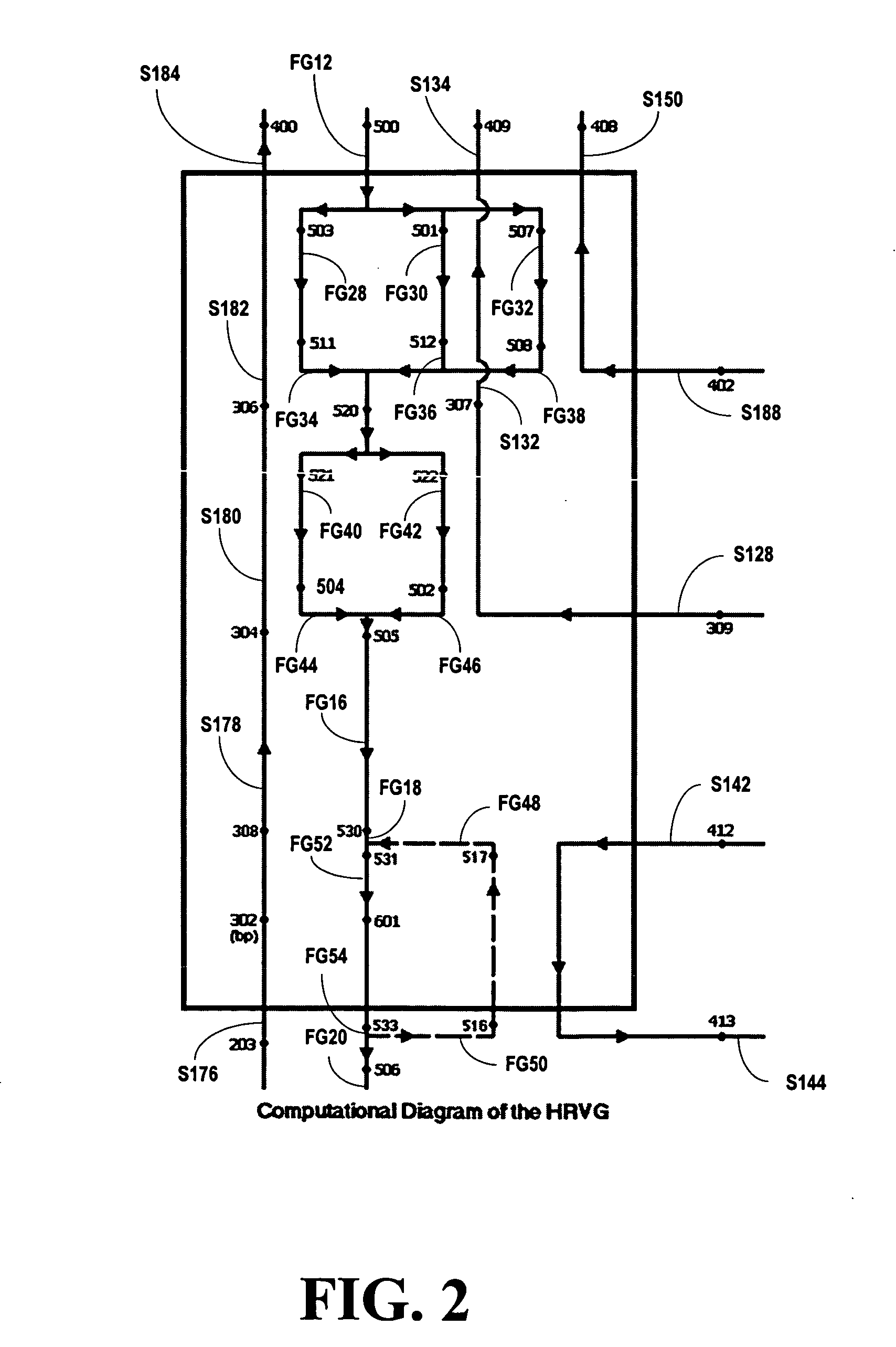

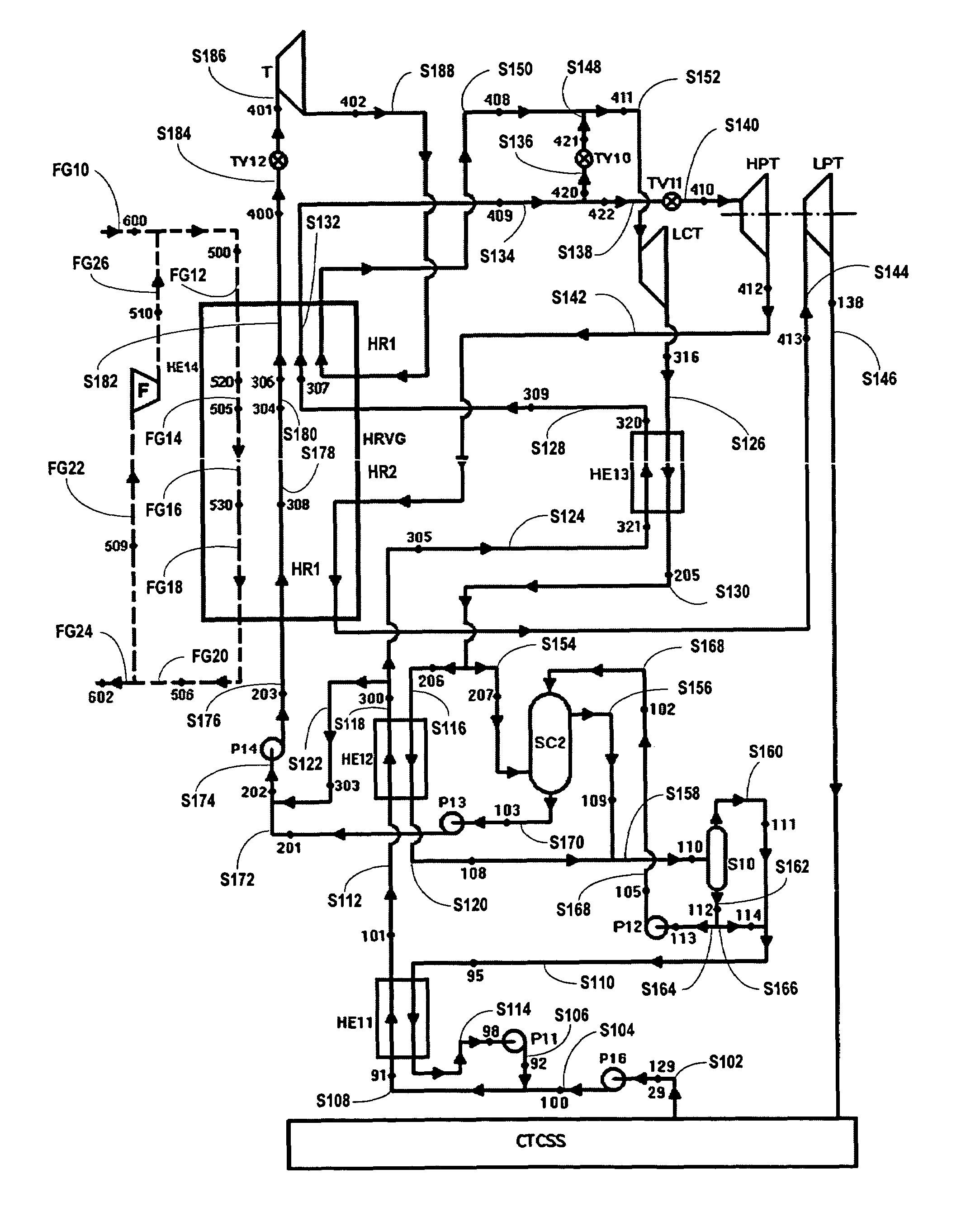

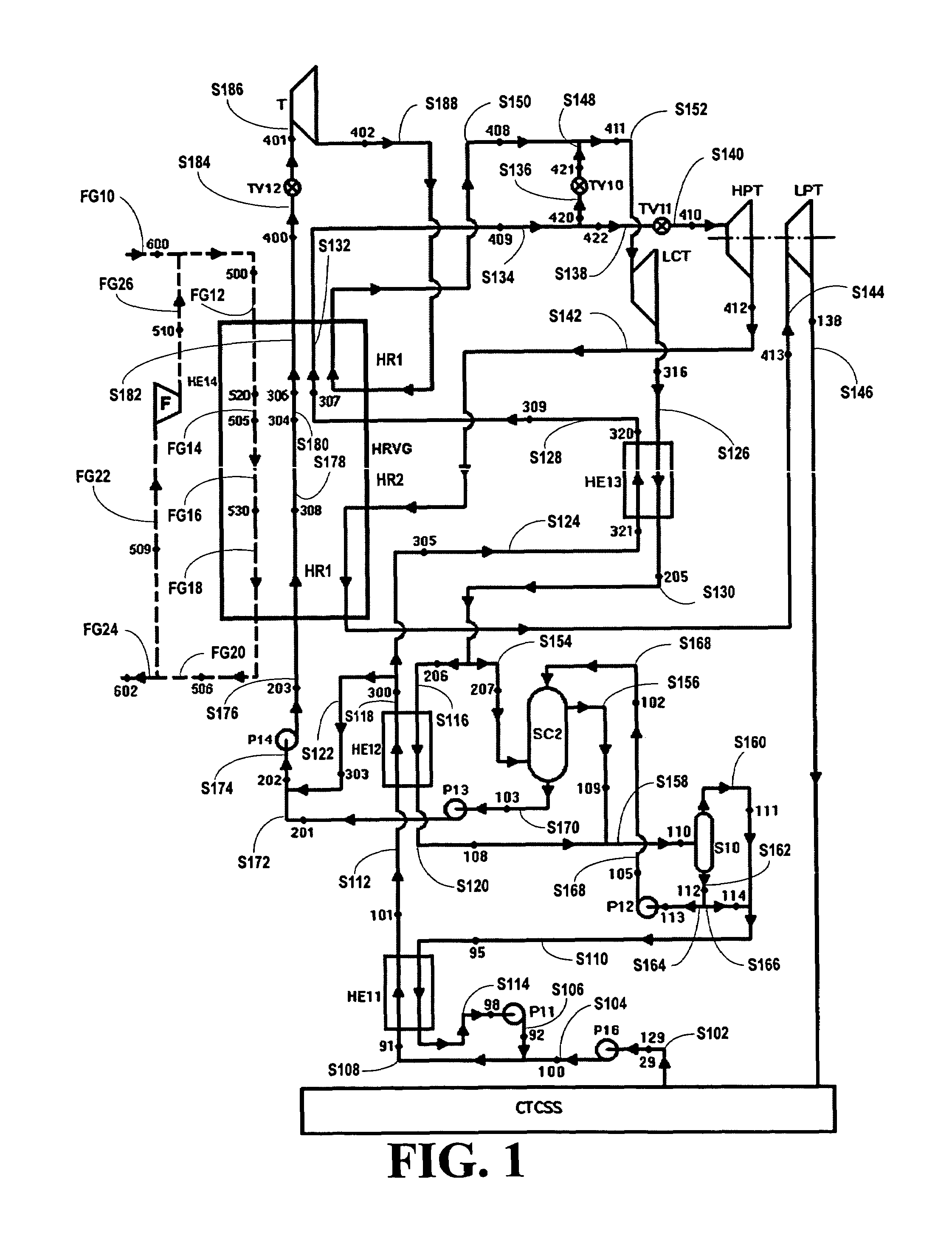

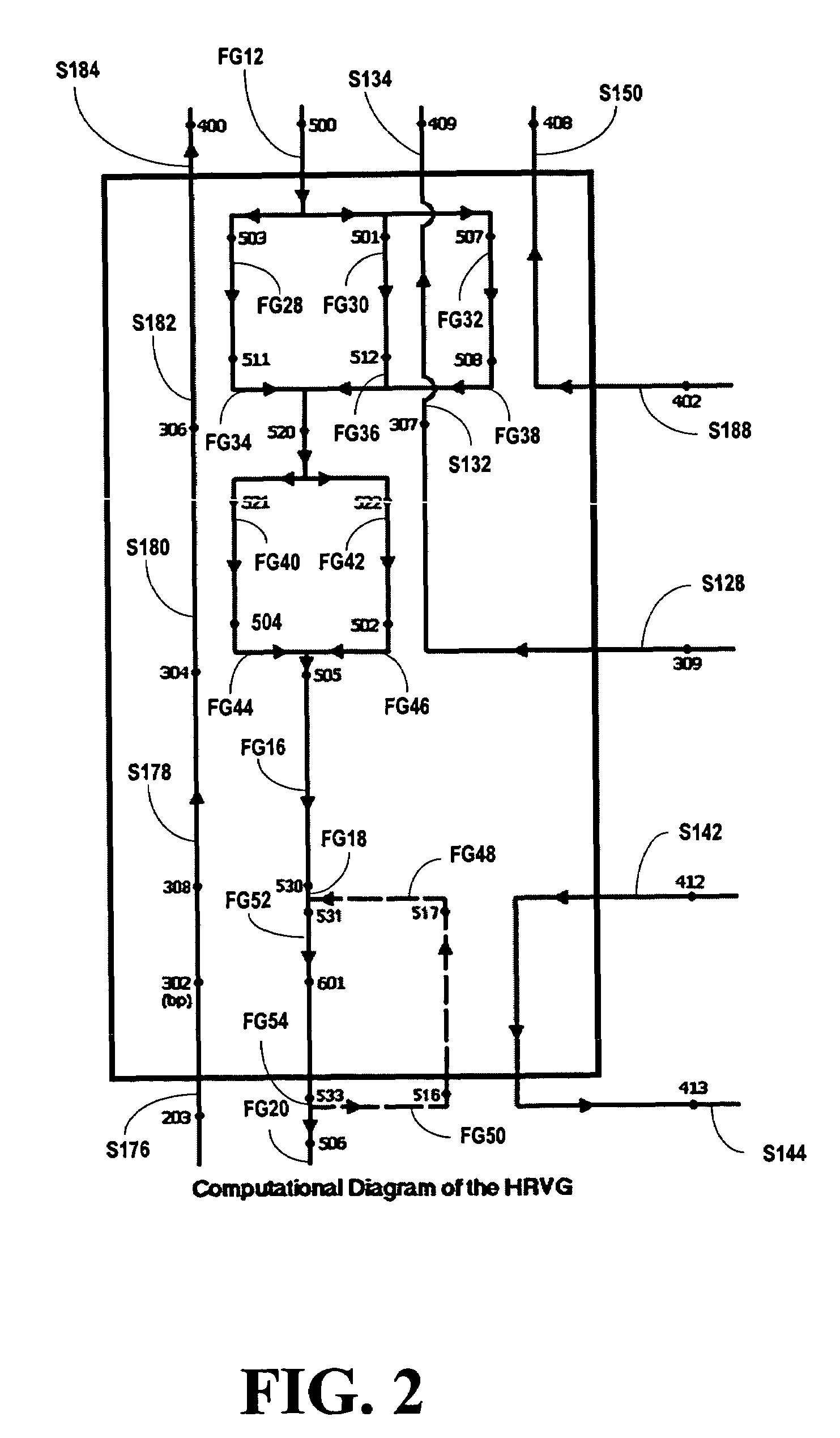

System and process for base load power generation

A system and process are disclosed for converting thermal energy into power from three different compositional streams of a multi-component working fluid, one of the streams being a lean working fluid stream pressurized into its super-critical state before being vaporized in a heat recovery vapor generator, another stream is a rich working fluid steam and the third stream is an intermediate working fluid stream, where the system and process has increased overall efficiency.

Owner:KALINA POWER LTD

Multiple mode vapor generator

InactiveUS20160360788A1Easy to installReduce the amount of solutionTobacco devicesElectronic cigaretteEngineering

The electronic cigarette device releasably houses a plurality of electronic cigarettes around a central shaft and between an upper bracket and a lower bracket, a cigarette holder, and the first frame. The first cigarette holder, the holder, the central shaft, the holder and lower bracket are sequentially connected. The central shaft ends are provided in a sleeve on the stand and holder, and a plurality of electronic cigarettes are disposed between the upper bracket and the bracket, and on display around the central shaft of circumferentially distributed. The first cigarette holder end surface has a cigarette jack, cigarette jack first communicating hole. In the second end of the central shaft, the connector sleeve is provided.

Owner:SHANGHAI GREEN VAPER TECH CO LTD

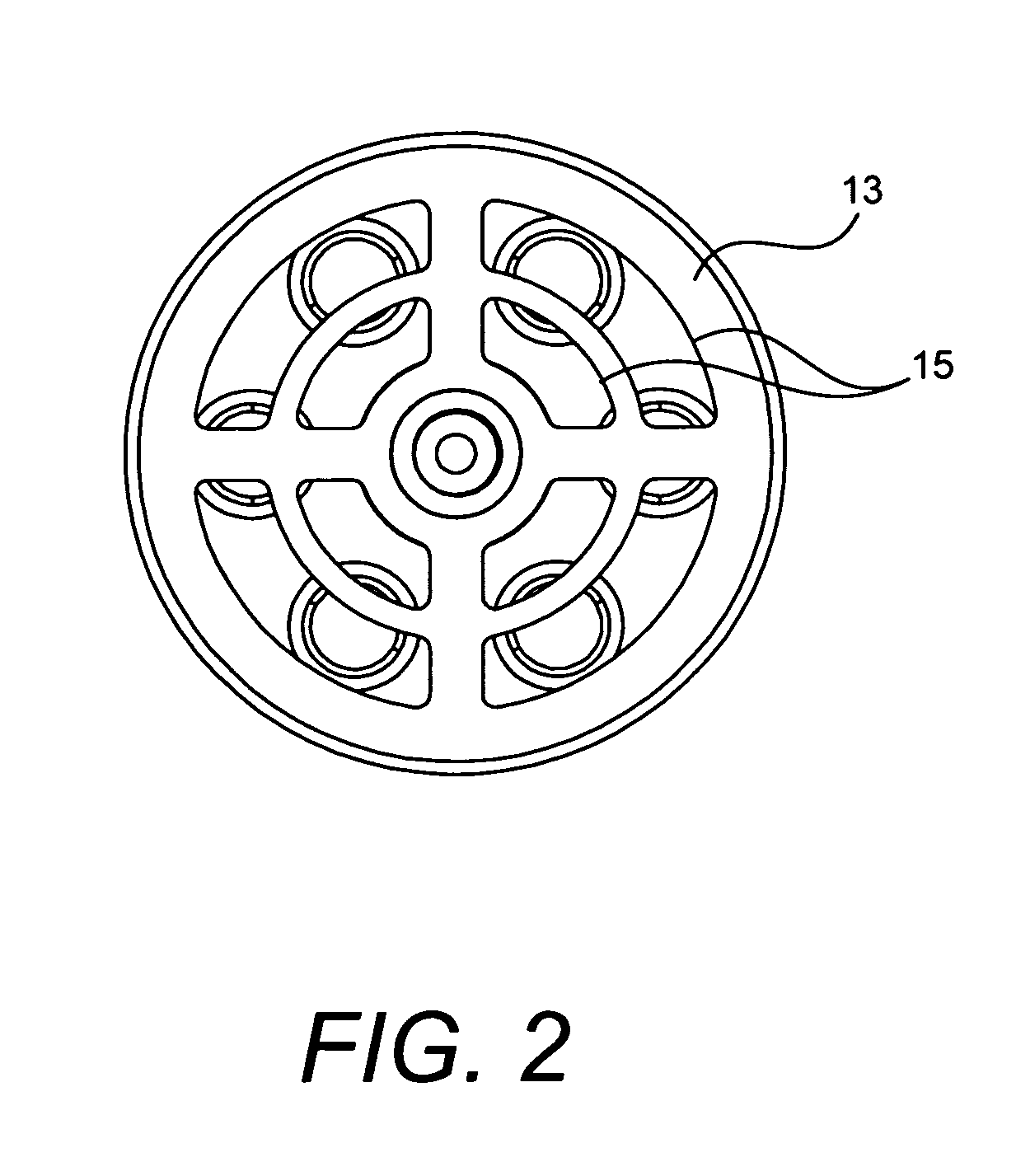

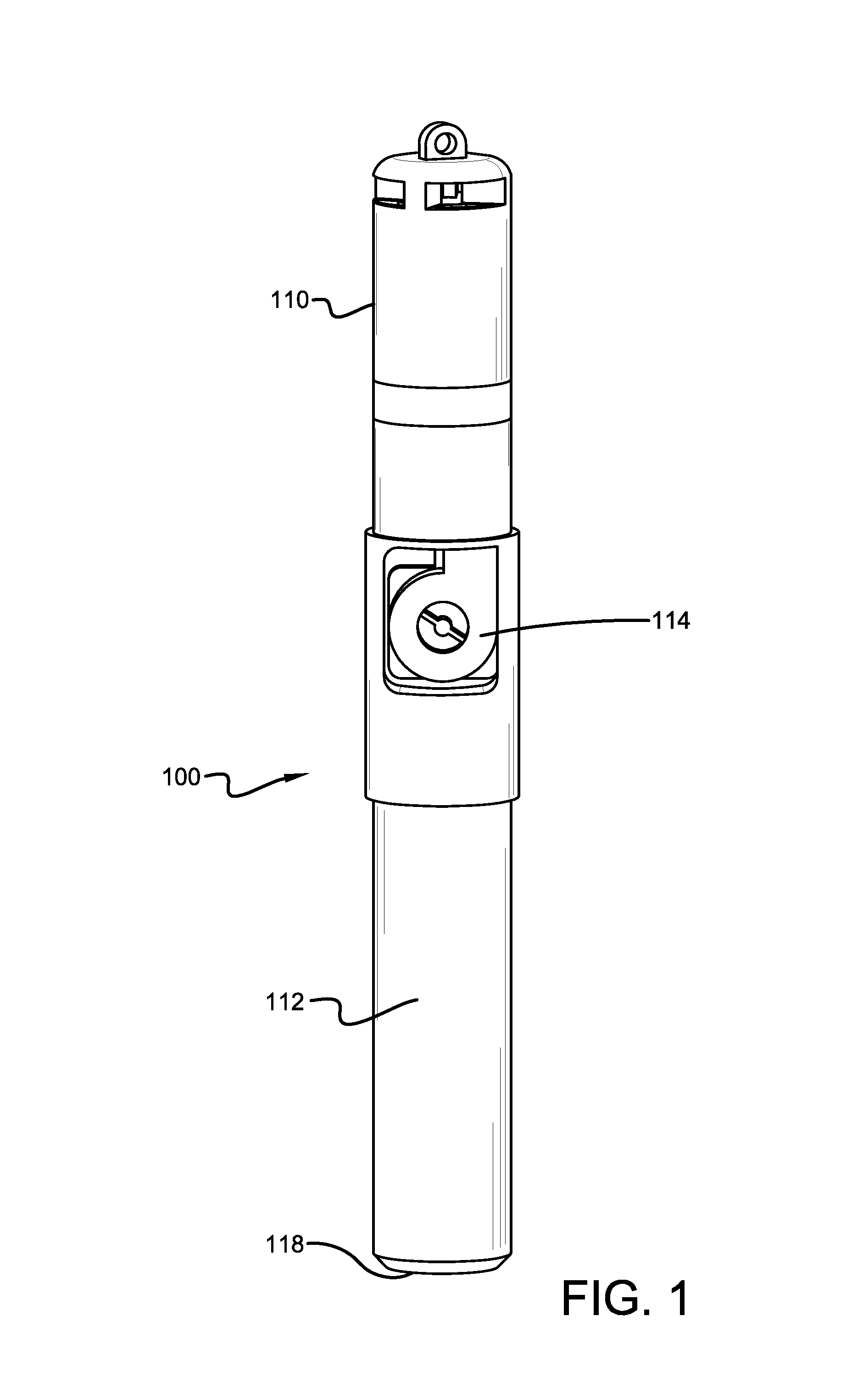

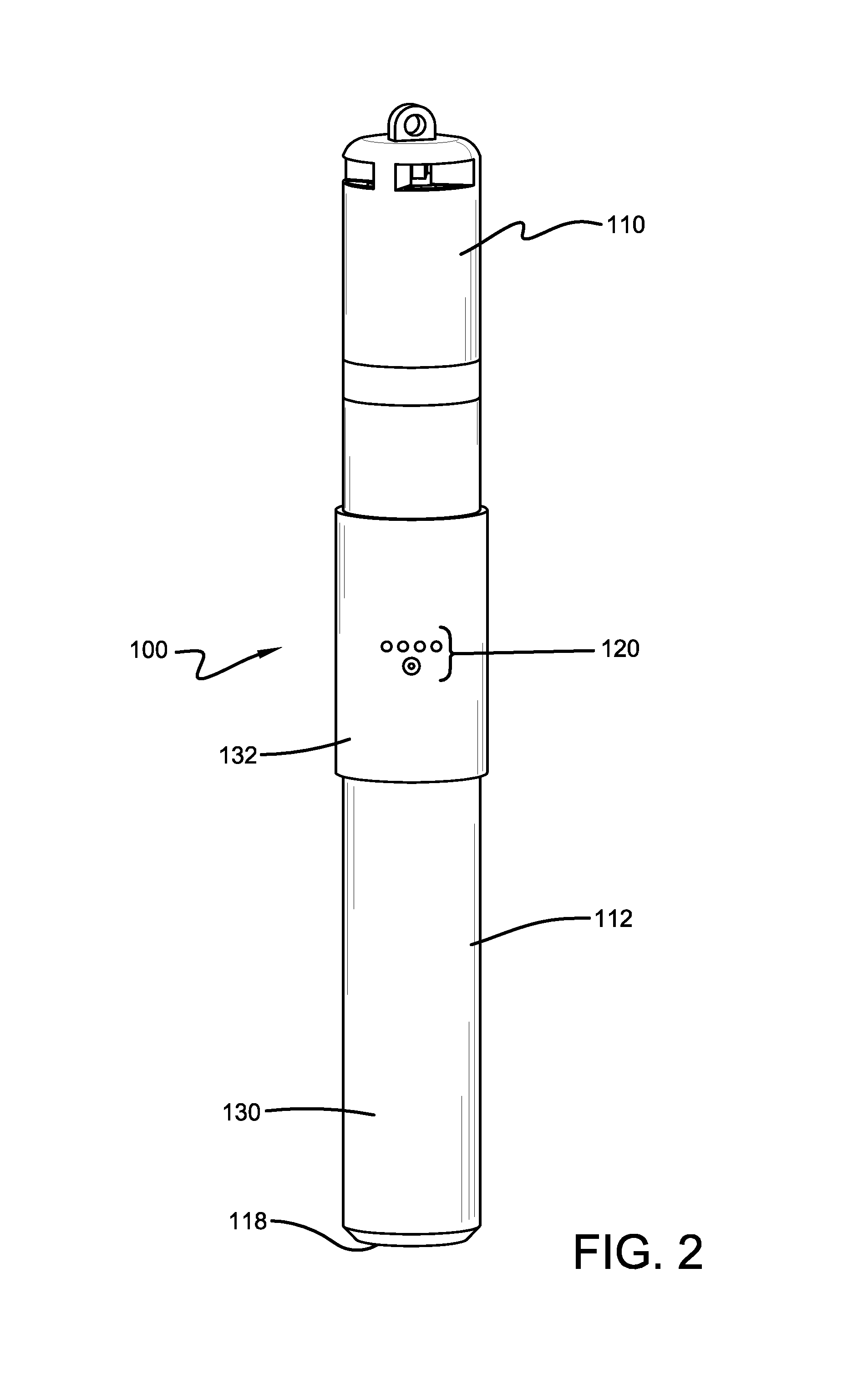

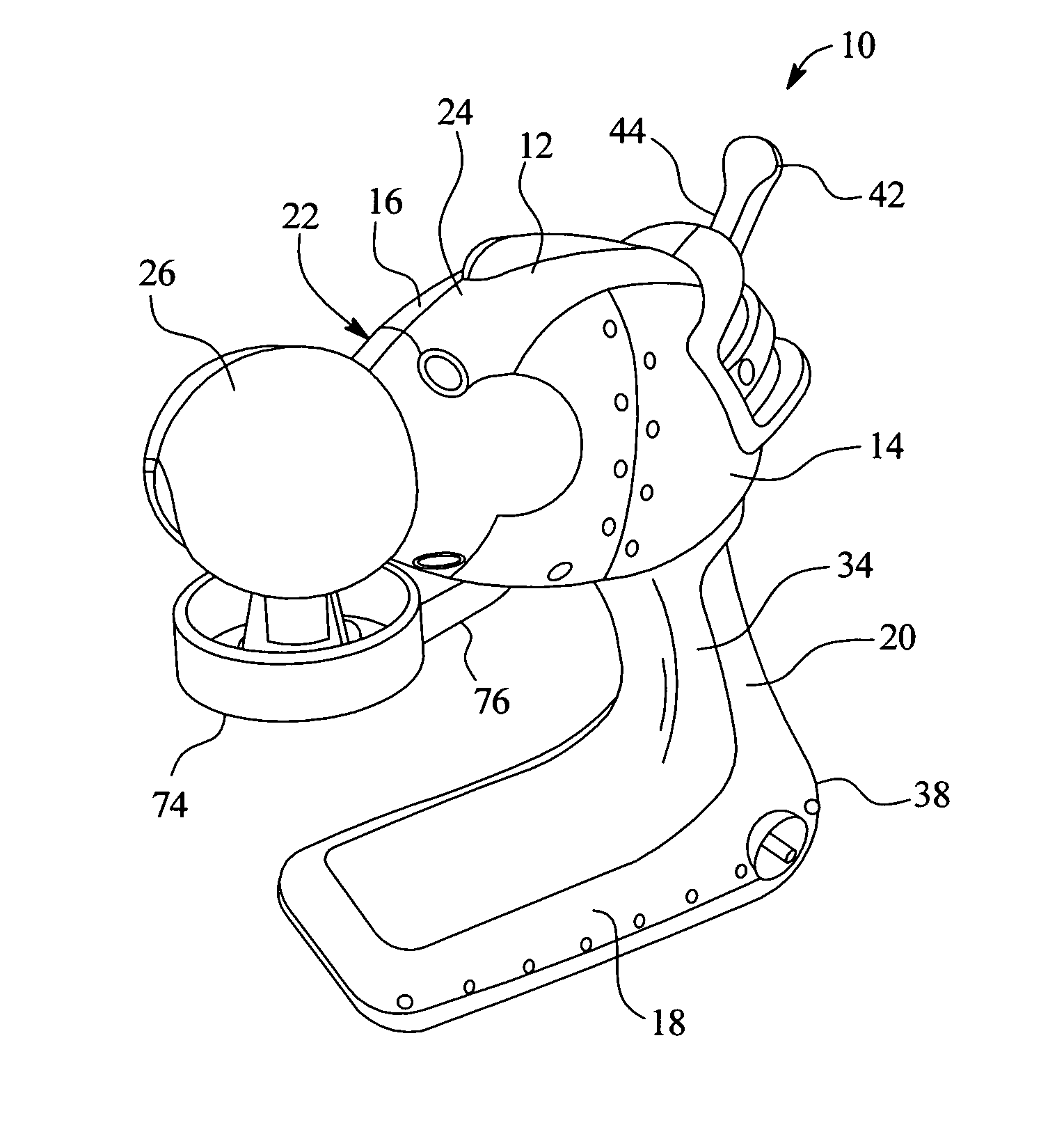

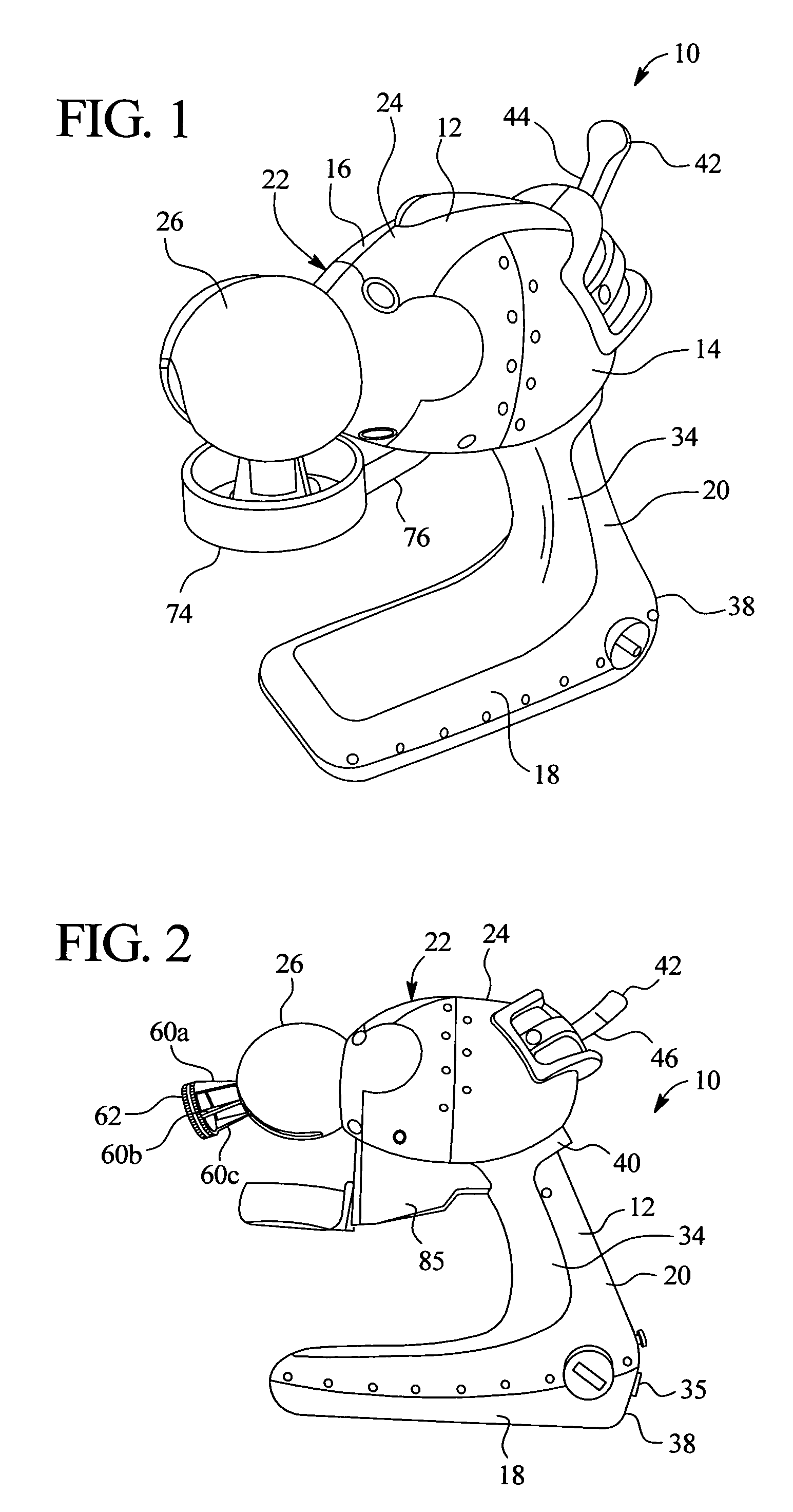

Device for creating and distributing vaporized scent

ActiveUS9585981B2Vaporization fastEliminates or substantially reduces the user's scentAnimal huntingSteam generation heating methodsEngineeringVapor generator

A scent vaporizing and distribution device uses an electric heating element to rapidly vaporize a liquid scent material. An airflow generator is used to create a distribution airflow that distributes the vapor from the device. The airflow generator can be an electric-powered fan or a manually-powered pump or squeezable bladder. The liquid scent material can include a glycol or a water-glycol mixture. A scent material such as liquid or powdered deer urine or a pleasant scent that can be used as a room or automobile or room freshener is mixed with the liquid. The vapor generator can be removable and replaceable such that different scents can be used with a single airflow generator or an empty generator can be replaced.

Owner:WYNDSCENT LLC

Devices, methods, and systems for detecting particles in aerosol gas streams

Turbulent mixing condensation devices, methods, and systems adapted to condense a working fluid on particles from a sample gas to enlarge the particles for subsequent detection are provided. The device includes a vapor generator adapted to produce a working-fluid saturated carrier gas and a condensation chamber. The working-fluid saturated carrier gas is mixed with a sample gas containing particles to be detected and is then introduced to the condensation chamber. The operating conditions are controlled to enhance the condensation of the working fluid on the particles. The particles are typically forwarded to a particle detection device to detect at least one characteristic, for example, the size, of the particles. The flow of carrier gas to the vapor generator may be regulated to vary the degree of saturation of the carrier gas with working fluid.

Owner:THERMO FISHER SCIENTIFIC INC

Apparatus, methods, and compositions for adding fragrance to laundry

The invention provides an apparatus, methods, and compositions for dispensing a fragrance onto laundry in a dryer without substantial loss of that fragrance during the drying process. The apparatus includes an electrostatic vapor generator capable of dispensing a fragrance composition into a dryer. The invention also provides electrostatically dispensable fragrance compositions containing glycols, vegetable oils, and perfumes. The invention further provides a kit and method for enhancing residual fragrance on laundry by adding a fabric conditioning composition and a fragrance composition in separate steps during the laundering process. The invention includes embodiments wherein the dispensation of the fragrance compositions is computer controlled.

Owner:JOHNSONDIVERSEY INC

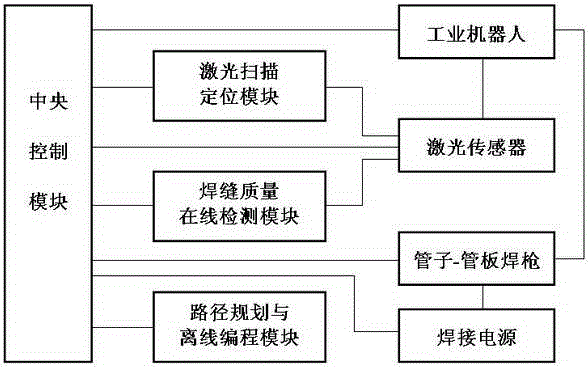

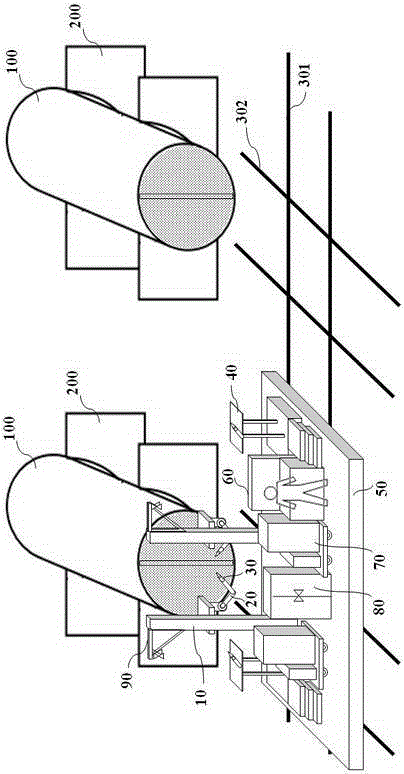

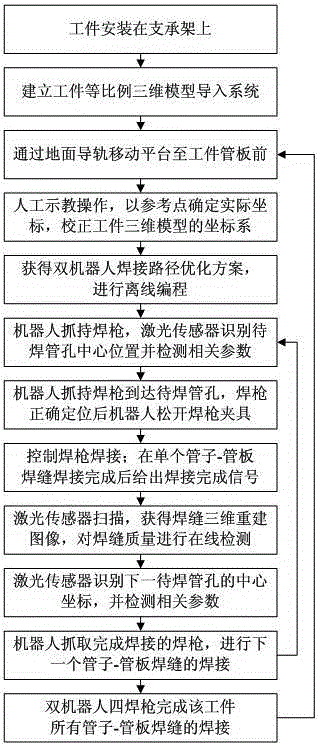

Robot welding system and welding method thereof

ActiveCN105195868AImprove work efficiencyHigh repeatabilityProgramme-controlled manipulatorHeat exchange apparatusLaser scanningVapor generator

The invention provides a robot welding system and a welding method thereof and suitable for pipe-pipe plate welding for a vapor generator of a main device in a nuclear island. According to the invention, a path planning and off-line programming module is used for planning an anti-collision welding path for an industrial robot and performing off-line programming on a planned scheme; a laser scanning positioning module obtains the circle centre coordinate of a pipe hole according to scanning results and performing initial welding position identification and autonomous guiding; the two industrial robots controlled by a central control module are matched with four pipe-pipe plate welding guns to perform welding on all pipe-pipe plate welding lines on a pipe plate; and an on-line welding line quality detection module obtains a three-dimensional reconstruction image according to welding line laser scanning results and performing on-line detection on welding line quality according to morphologies of the welding lines. Due to adoption of the system and the method disclosed by the invention, the pipe-pipe plate welding efficiency is improved, and the stability of the welding line quality is ensured.

Owner:SHANGHAI ELECTRIC NUCLEAR POWER EQUIP CO LTD

Regenerative subsystem control in a kalina cycle power generation system

A method of operating a Kalina cycle power generation system includes directing a stream of vaporized binary working fluid to a turbine where it is expanded to produce power. At least a portion of the expanded binary working fluid is directed to a regenerative heat exchanger where it is transformed into a feed binary working fluid. The feed binary working fluid is directed to a vapor generator where it is vaporized. The binary working fluid flow within the regenerative heat exchanger is actively regulated to balance the expanded binary working fluid and the feed working fluid.

Owner:ABB ALSTOM POWER INC

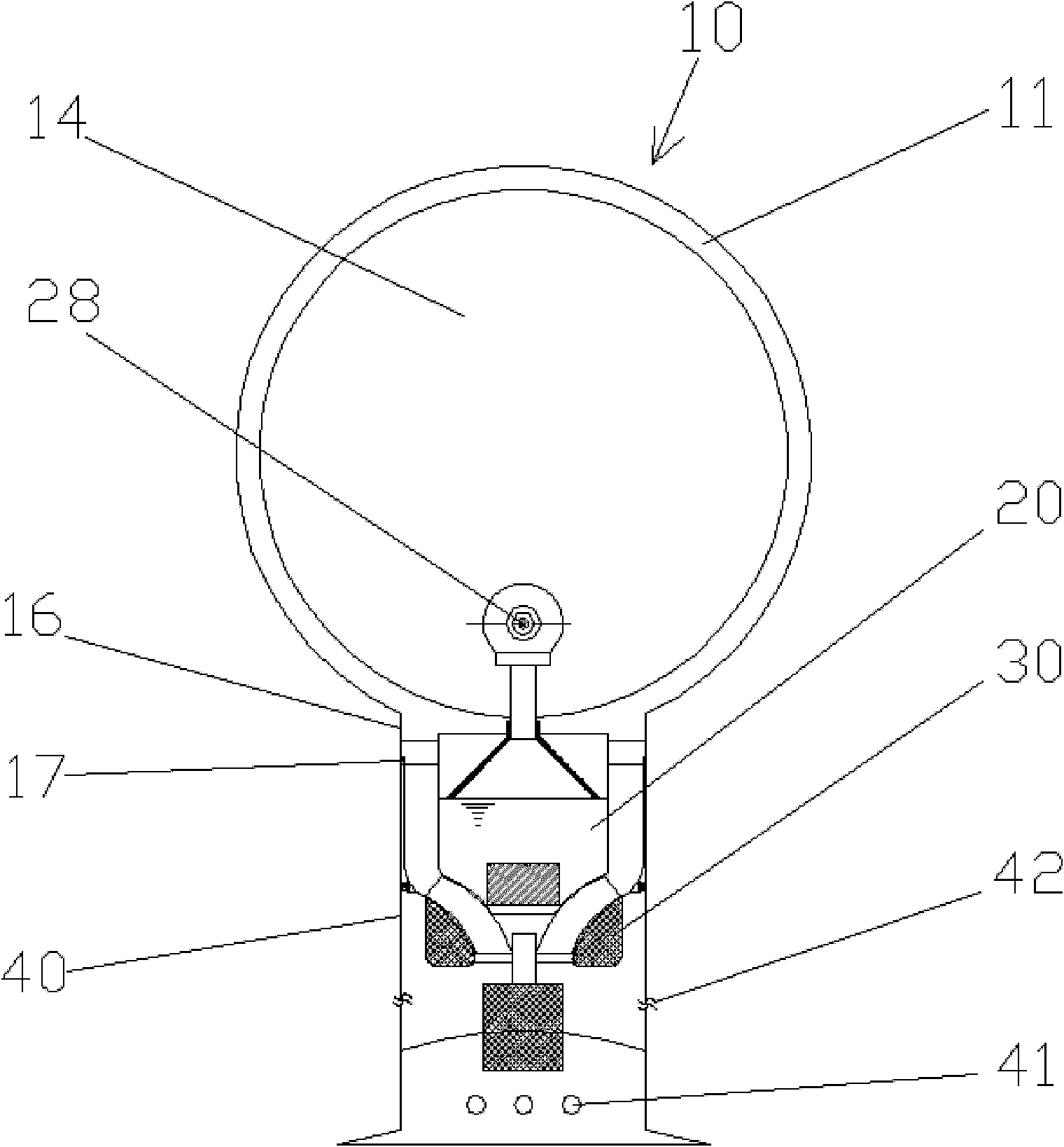

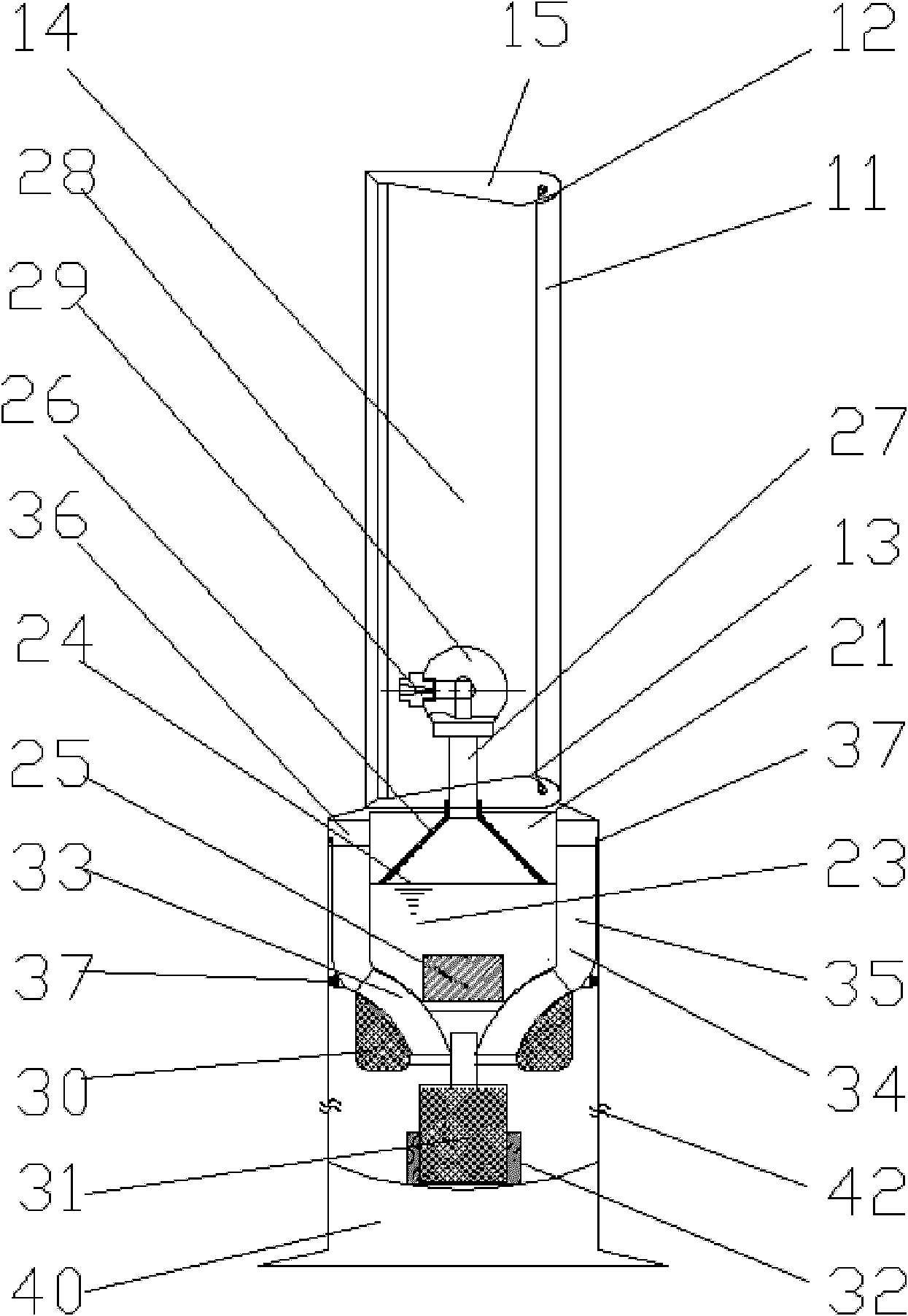

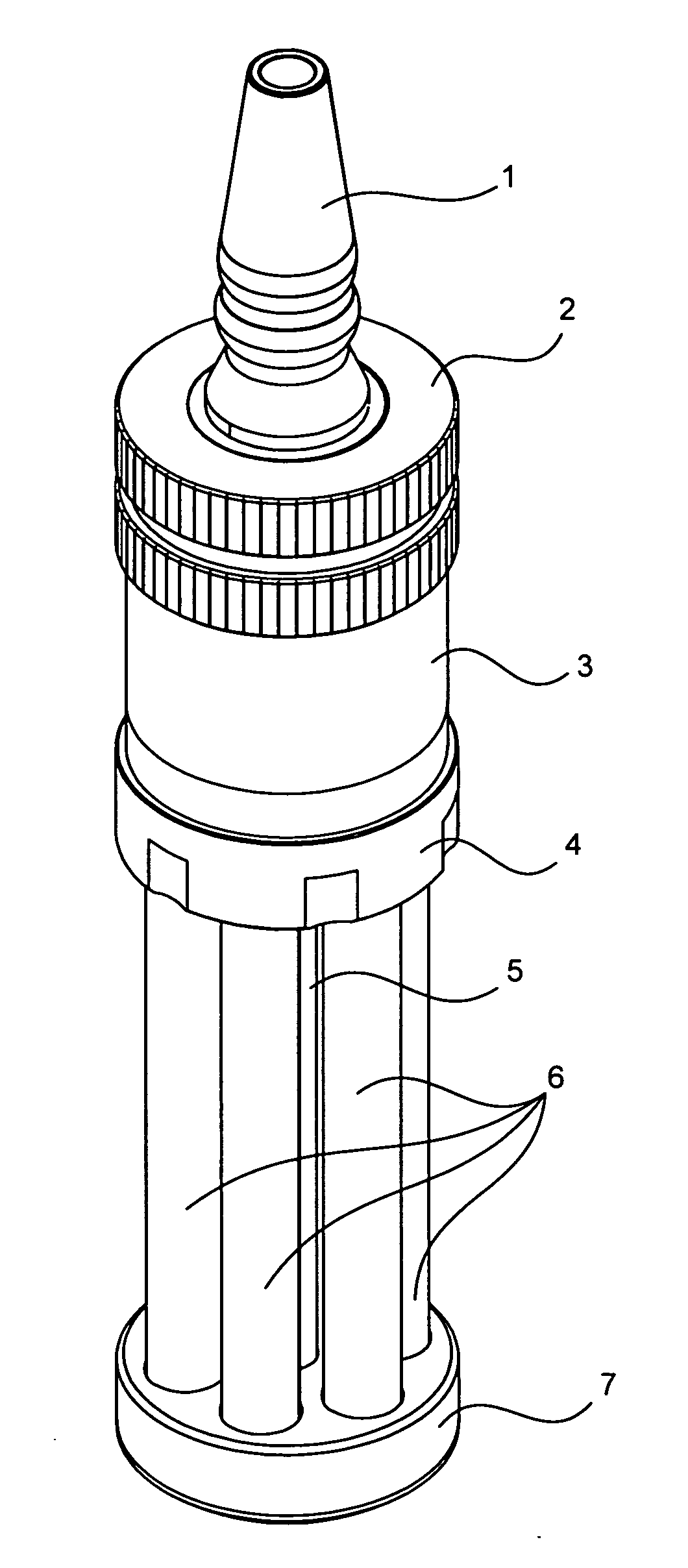

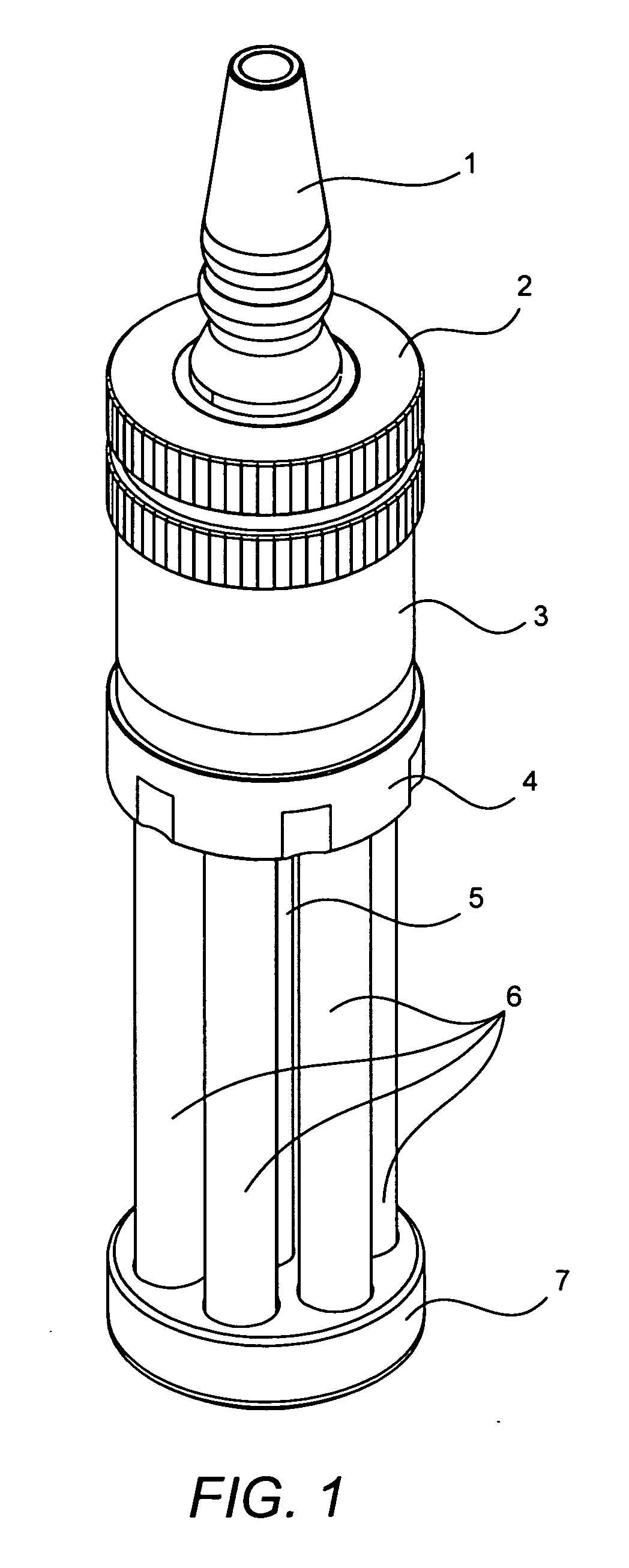

Toy for producing fog filled bubbles

A toy for producing bubbles including a nozzle connected to the housing. The nozzle is adapted to receive and at least temporarily hold a bubble solution. The toy also includes a vapor generator mounted in the housing, where the vapor generator is positioned adjacent to the nozzle and an air mover mounted in the housing, where the air mover is positioned adjacent to the vapor generator. The toy further includes at least one activator movably connected to the housing. The activator being in communication with the vapor generator and the air mover. Upon the activation of the activator by a user, the activator causes the vapor generator to generate vapor and causes the air mover to move an amount of air through the vapor generator and the bubble solution on the nozzle to produce at least one vapor-filled bubble.

Owner:LAFATA JOHN E +1

System and process for base load power generation

A system and process are disclosed for converting thermal energy into power from three different compositional streams of a multi-component working fluid, one of the streams being a lean working fluid stream pressurized into its super-critical state before being vaporized in a heat recovery vapor generator, another stream is a rich working fluid steam and the third stream is an intermediate working fluid stream, where the system and process has increased overall efficiency.

Owner:KALINA POWER LTD

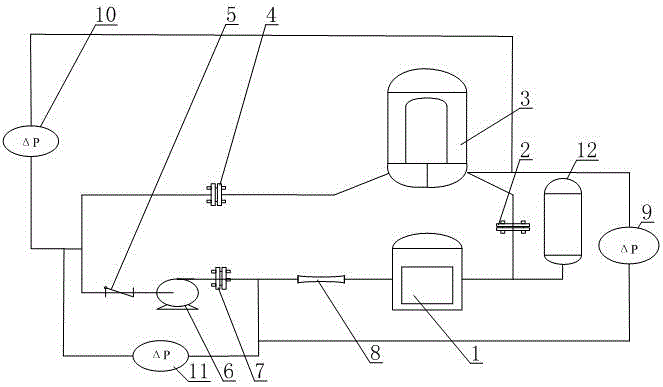

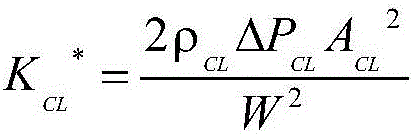

Reactor thermal-hydraulic simulation testing apparatus and fluid dynamics characteristic simulation method

ActiveCN106340329ASimulation is accurateConsistent Kinetic PropertiesNuclear energy generationNuclear monitoringEngineeringCheck valve

The invention discloses a reactor thermal-hydraulic simulation testing apparatus which comprises a reactorsimulation body, a vapor generator simulation body and a main circulating pump. The inlet and the outlet of the vapor generator simulation body are communicated with the outlet of the reactorsimulation body and the inlet of the main circulating pump, and the outlet of the main circulating pump is communicated with the inlet of the reactorsimulation body. A heat-section resistance adjusting part is arranged on the pipeline between the inlet of the vapor generator simulation body and the outlet of the reactorsimulation body, a cold-section resistance adjusting part and a stop valve are arranged on the pipeline between the outlet of the vapor generator simulation body and the inlet of the main circulating pump, and a pump way resistance adjusting part and a Venturi flowmeter are arranged on the pipeline between the outlet of the main circulating pump and the inlet of the reactorsimulation body. The invention further discloses a fluid dynamics characteristic simulation method based on the reactor thermal-hydraulic simulation testing apparatus. During application, fluid dynamics characteristics are adjusted to be consistent to a reactor prototype for implementation, and the testing efficiency of a simulation test can be improved.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

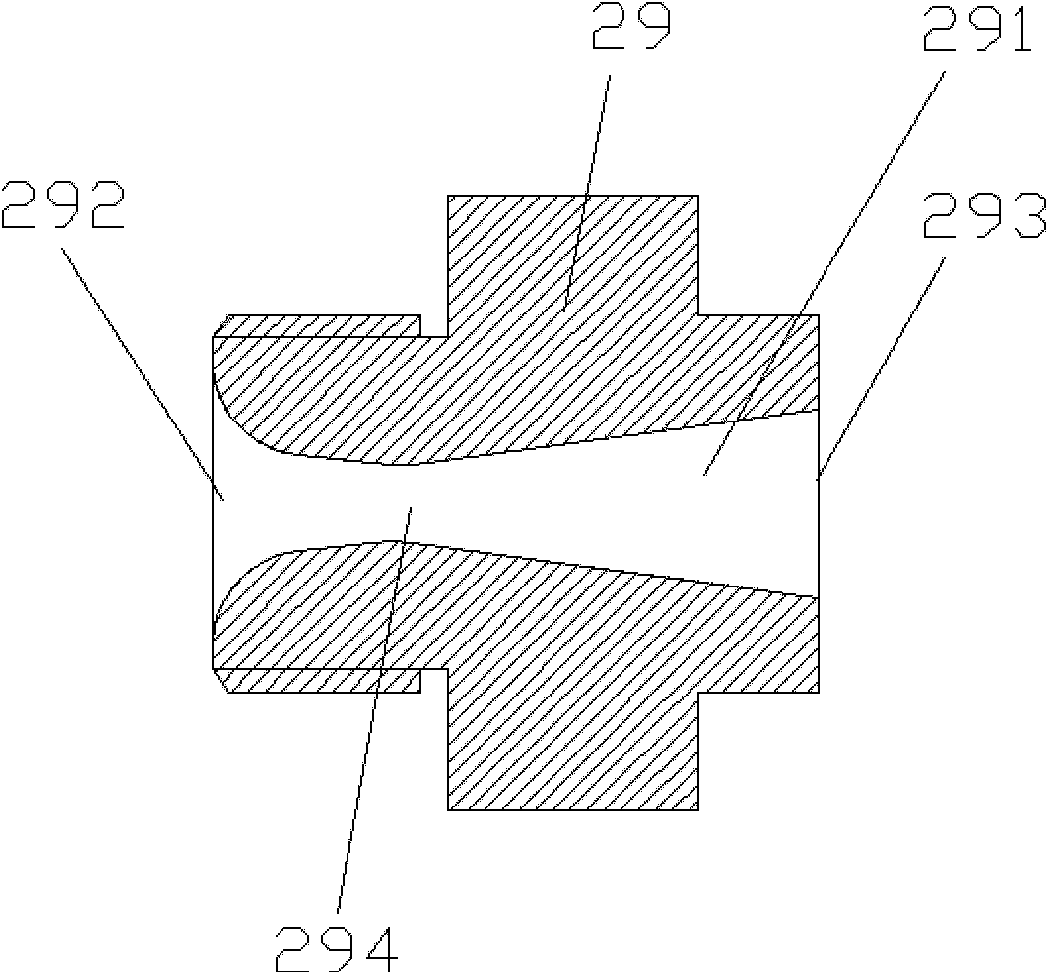

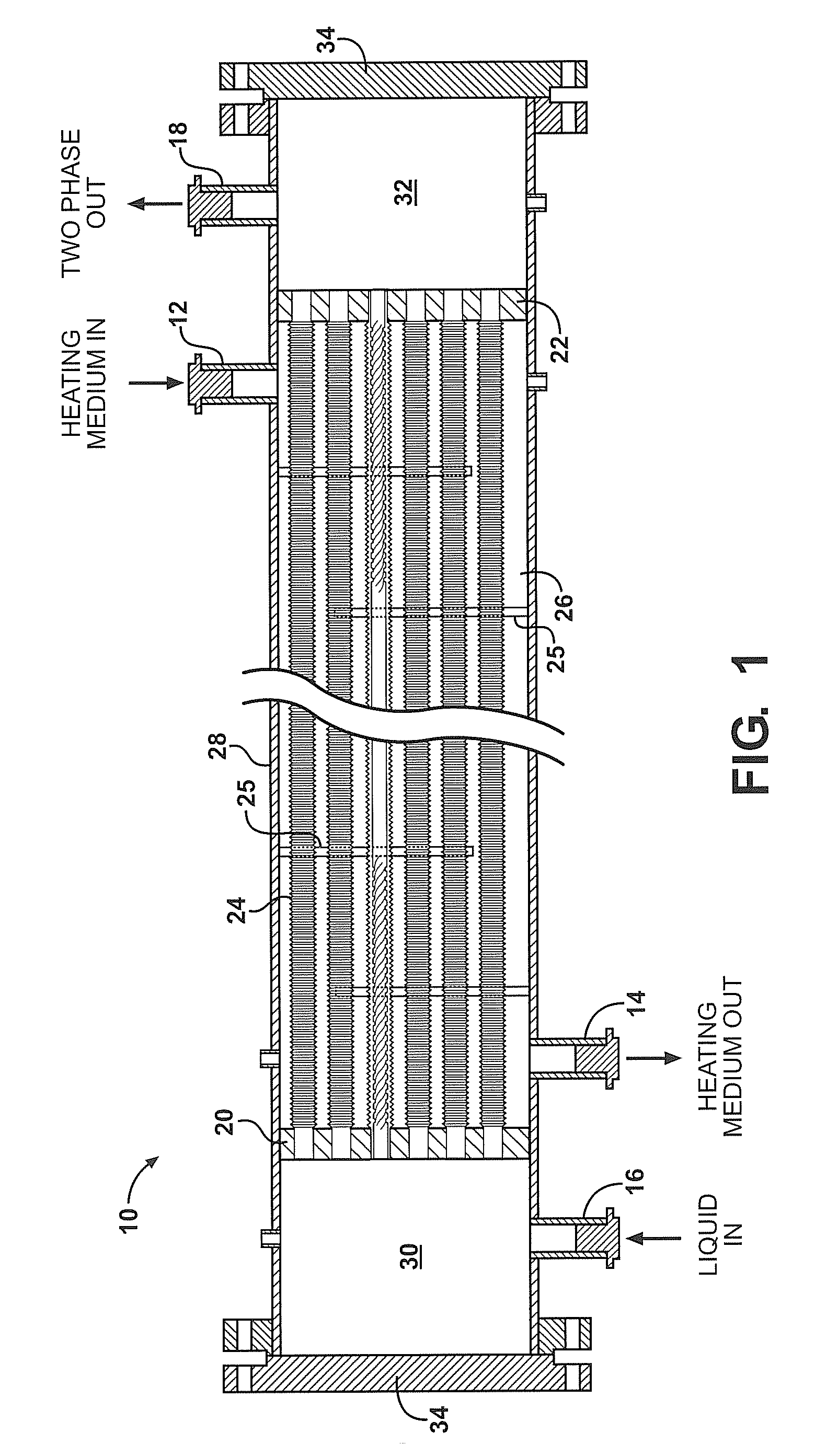

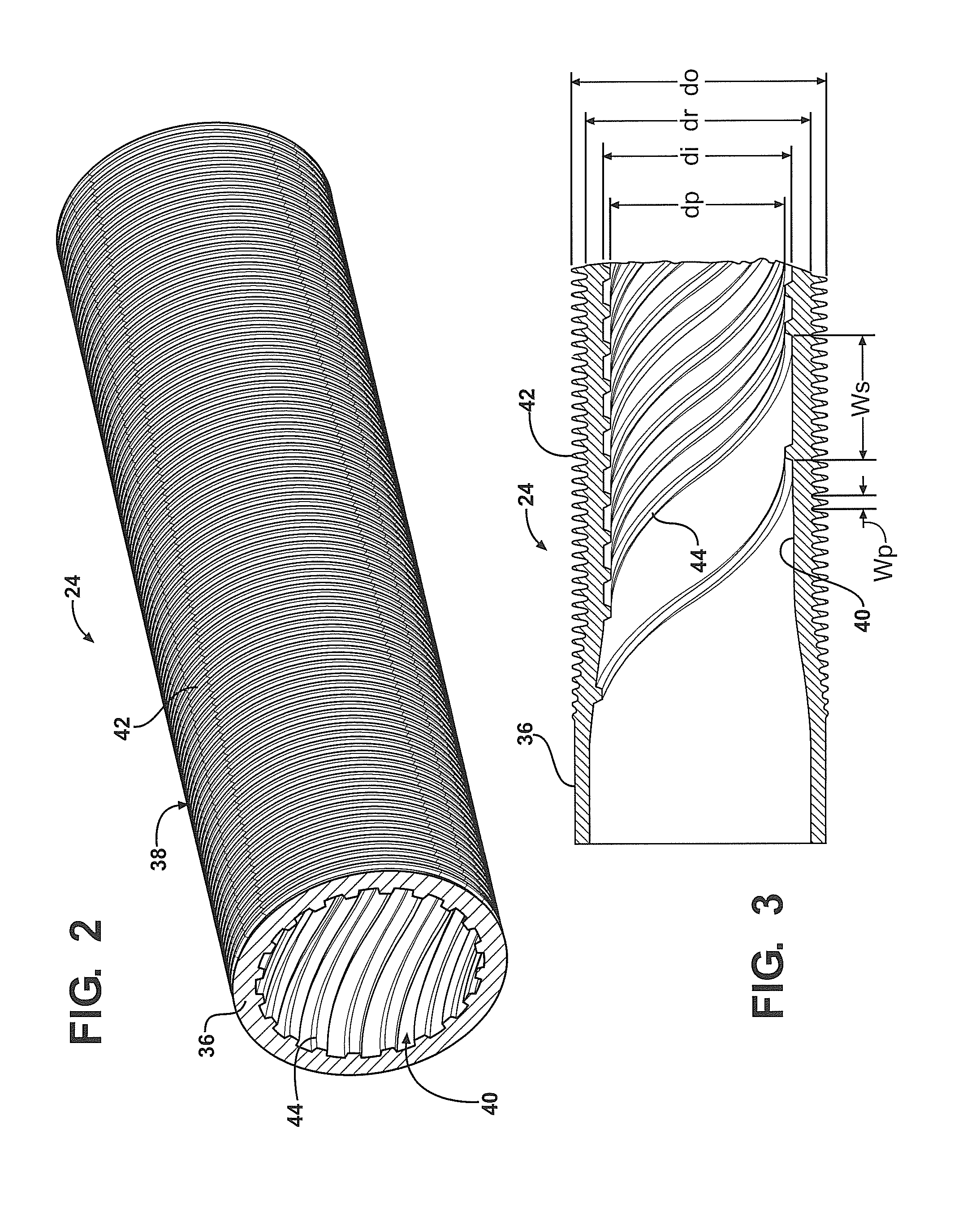

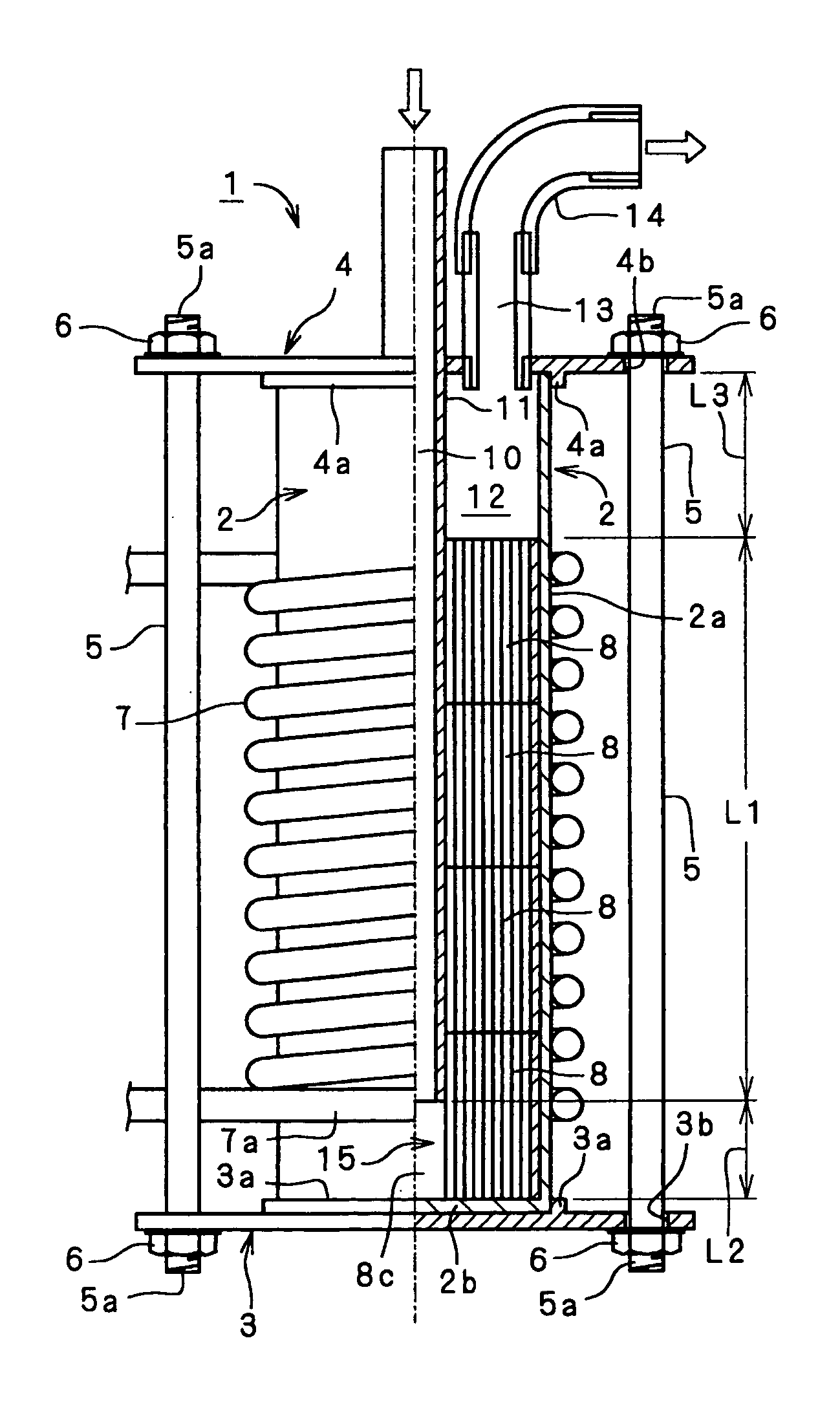

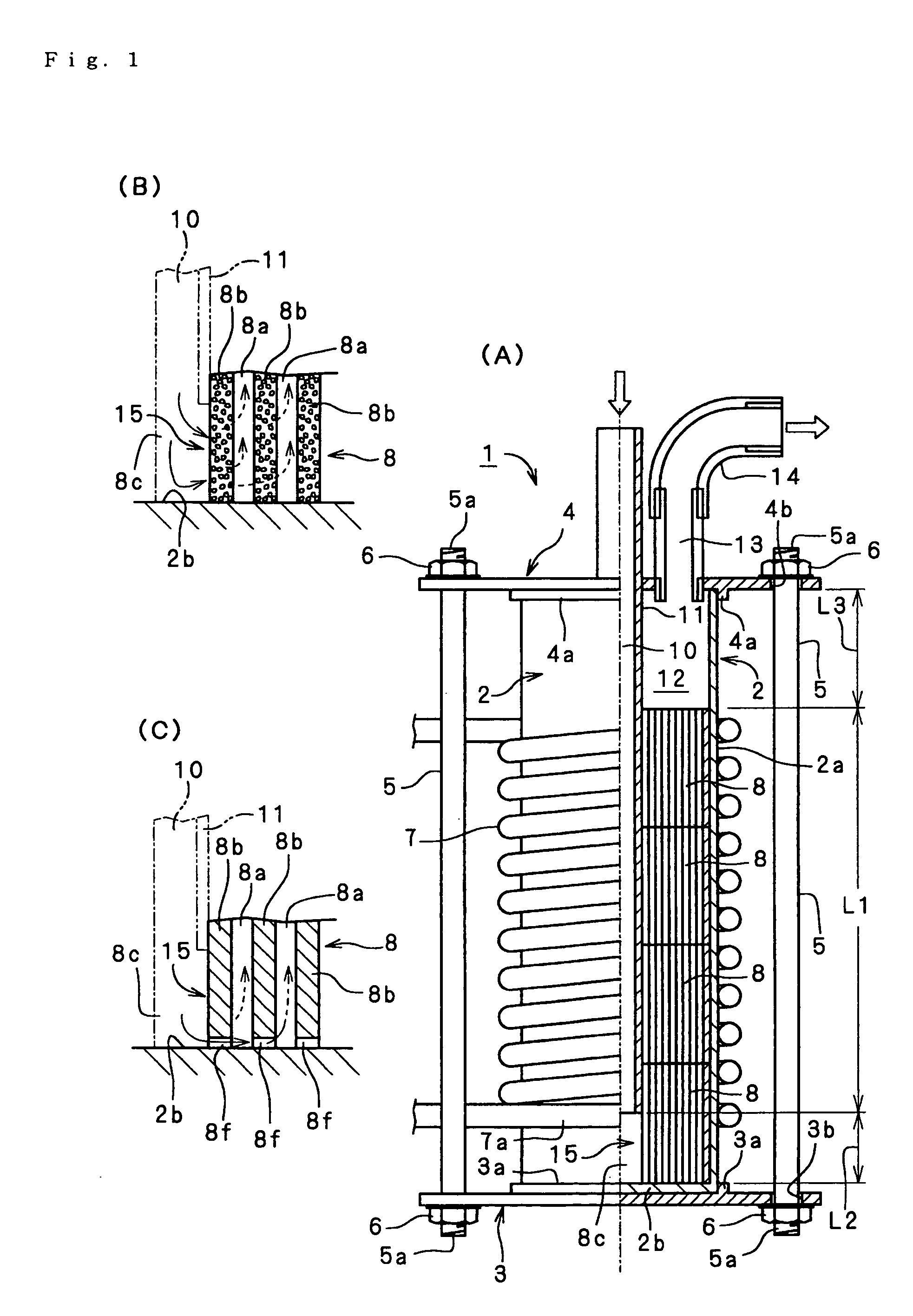

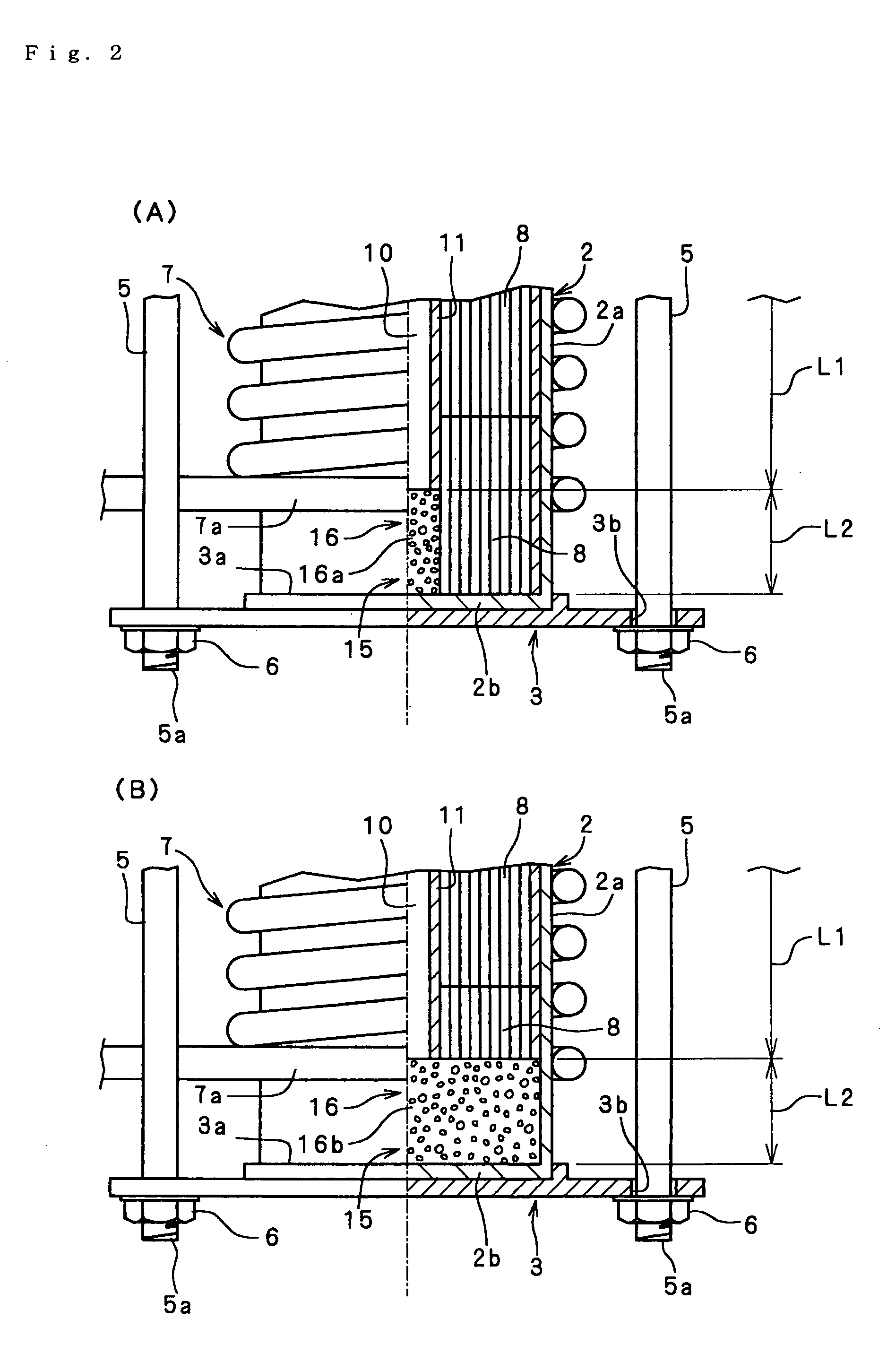

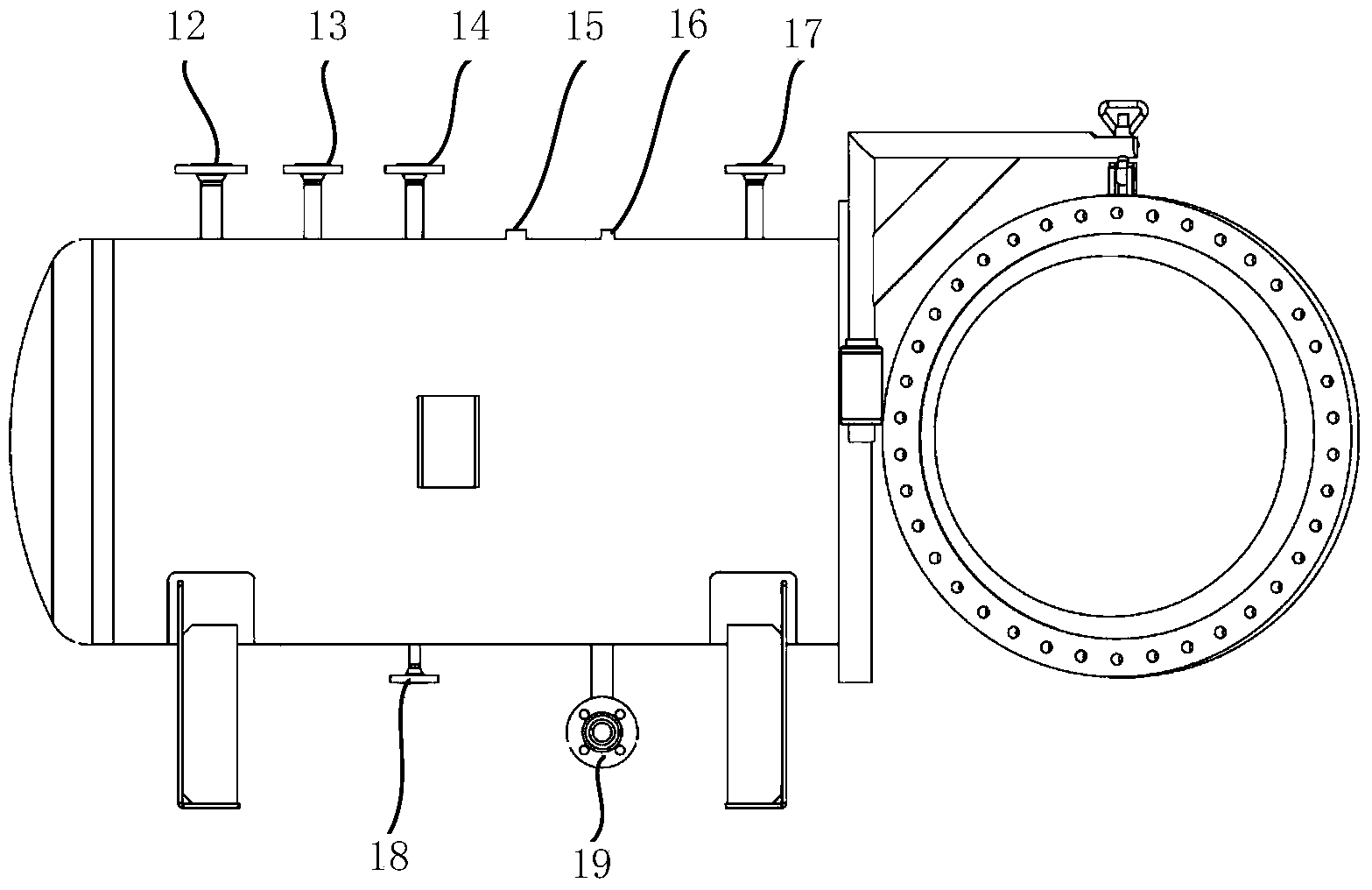

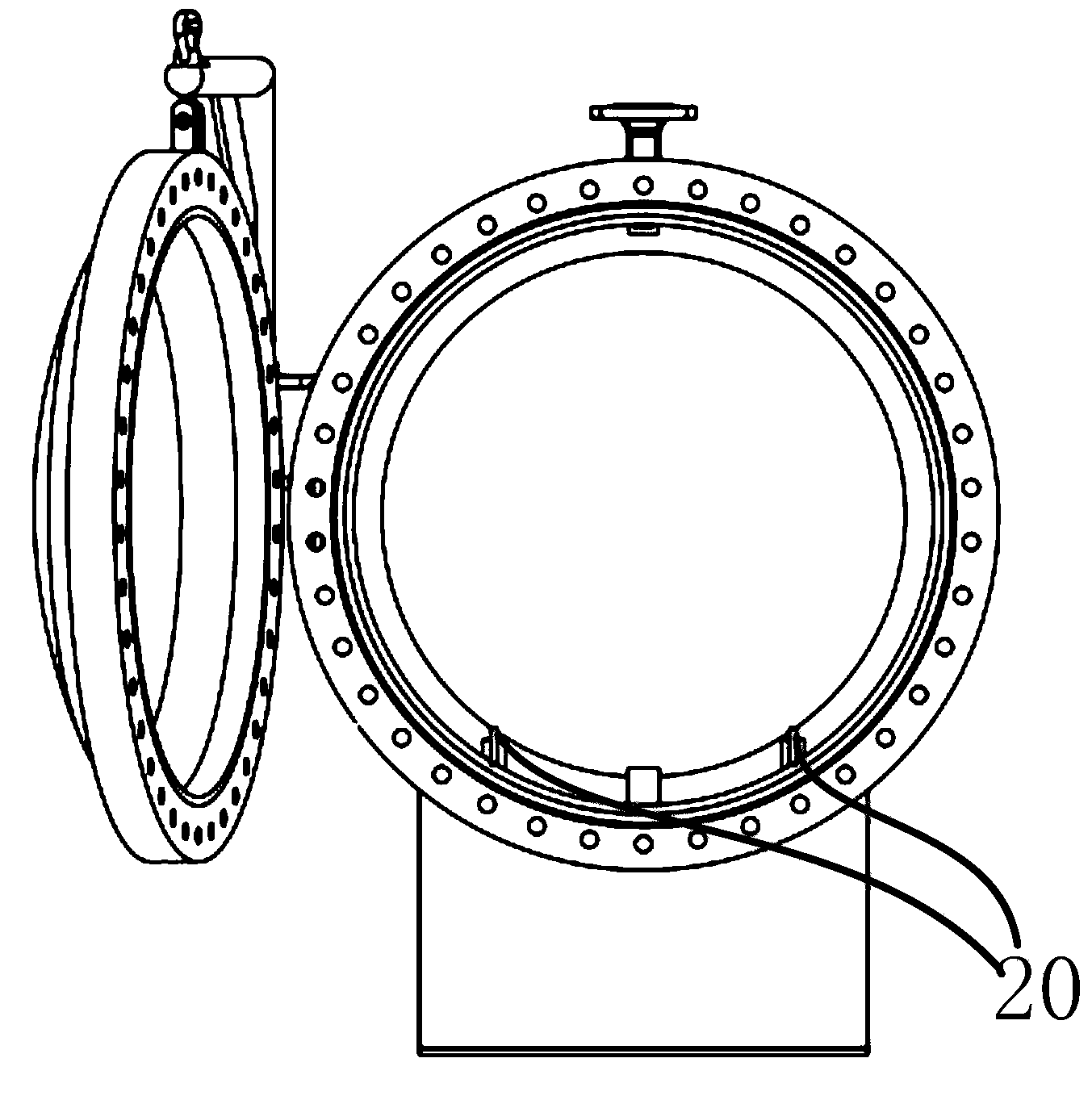

Dual enhanced tube for vapor generator

InactiveUS20110083619A1Increase the heat transfer surface areaImprove heat transfer efficiencyHeat exhanger finsWater-tube boilersElectricityEngineering

A heat exchange assembly for generating steam from a second medium to be used to drive a steam turbine for generating electricity or for other process, includes a tube having a longitudinal axis and an inner wall and an outer wall. The outer wall includes a plurality of spaced fins oriented generally perpendicular to the longitudinal axis. The inner wall defines a preheat zone and a dual phase zone. The preheat zone defines a helical rib configured to provide swirling motion and increase heat transfer surface area to liquid entering the tube increasing heat transfer from the tube to the liquid. The dual phase zone is spaced from the preheat zone and defines a helical rib configured to provide swirling motion to steam and liquid passing through the dual phase zone increasing heat transfer from the tube to the steam and liquid while preventing vapor stagnation and film boiling.

Owner:HAMON RES COTTRELL

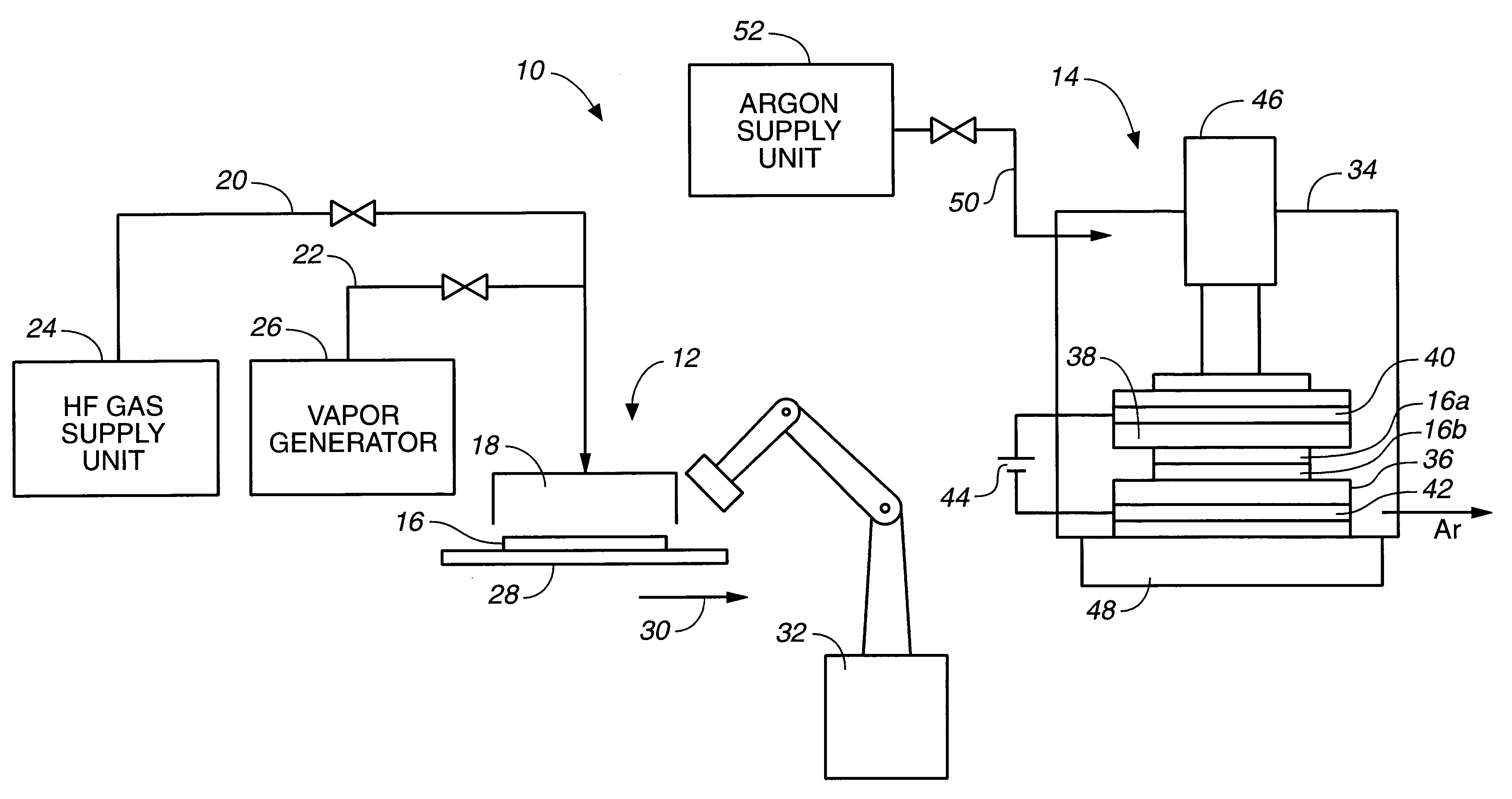

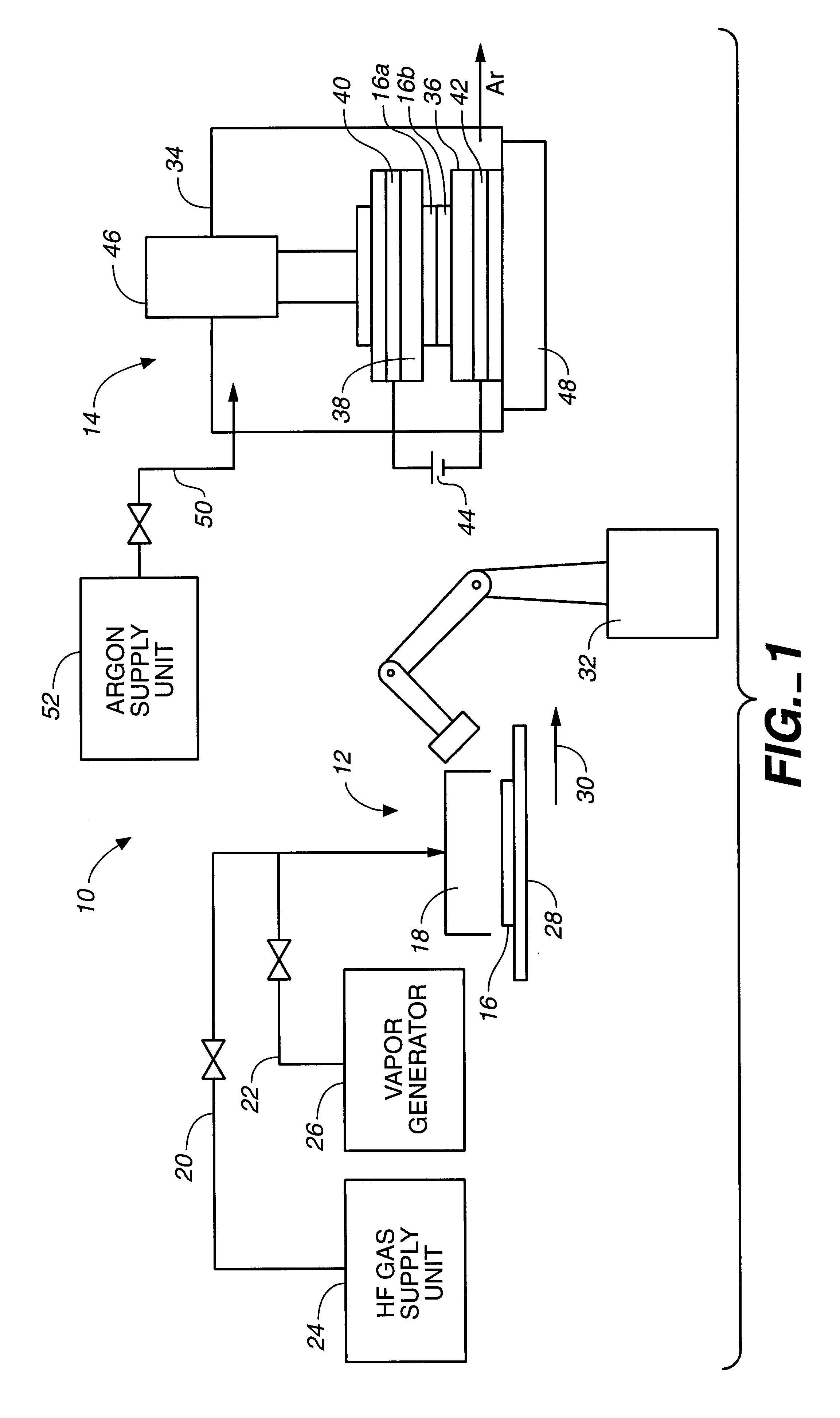

Method and apparatus for solid bonding, a conductor bonding method, a packaging method, and a bonding agent and a method for manufacturing a bonding agent

InactiveUS6221197B1Increase temperatureRequired bonding timeMechanical working/deformationLamination ancillary operationsElectrical conductorWater vapor

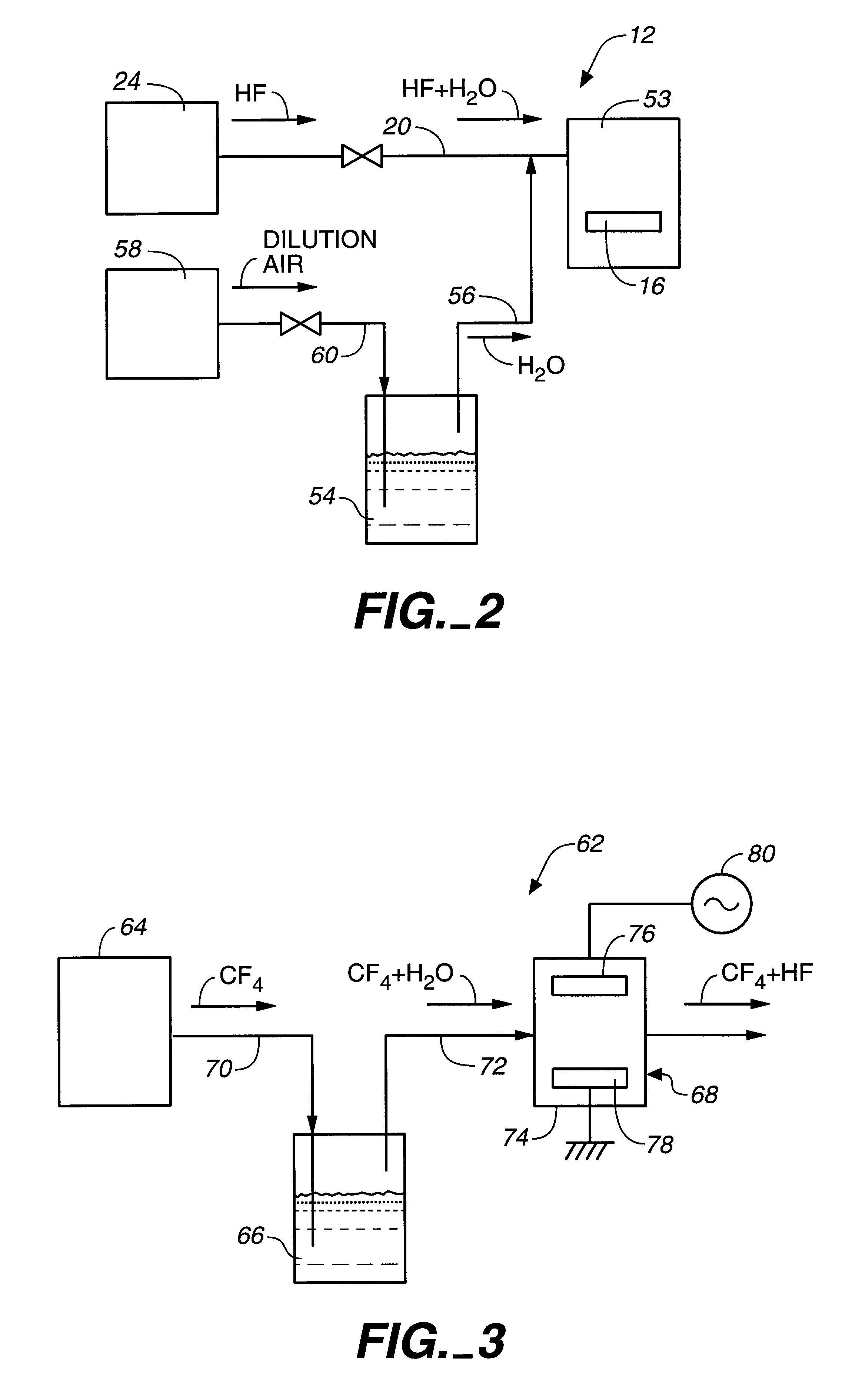

A method and apparatus for solid bonding without using a bonding agent are provided. A surface of metal, glass, or other bond members 16a and 16b is fluorinated by exposure to a mixture of HF gas from a HF gas supply unit 24 and water vapor from a vapor generator 26 in a fluorination process section 12. The bond members 16a and 16b are then placed in contact at the fluorinated surface on table 36 in bonding process section 14. Argon is then introduced to bonding chamber 34. Pressure is then applied to the first bond member 16a and second bond member 16b by a cylinder 46, and heated to below the melting point by a heater 48, to bond the first and second bond members together.

Owner:SEIKO EPSON CORP

Superheated vapor generator

InactiveUS20050178761A1Well formedReduce channel resistanceSteam generation heating methodsDomestic cooling apparatusMaterial supplySuperheated steam

A superheated vapor generator has a tubular, vertically extending container with closed ends. A high frequency induction heating coil is wound around the container. A heating medium is placed in the container and is made from material heatable by electromagnetic conduction. A number of vapor passages extend through the heating medium longitudinally of the tubular container. The tubular container has a heating section with the heating coil and a non-heating section under the heating section. Material for superheated vapor is supplied through a supply passage from a position above the heating medium to the non-heating section. A passage structure is provided in the non-heating section for flow of material supplied through the supply passage therethrough into the vapor passages of the heating medium. A discharge passage is formed above the heating medium. A discharge passage is formed above the heating medium for discharging superheated vapor.

Owner:NEPUREE CORP

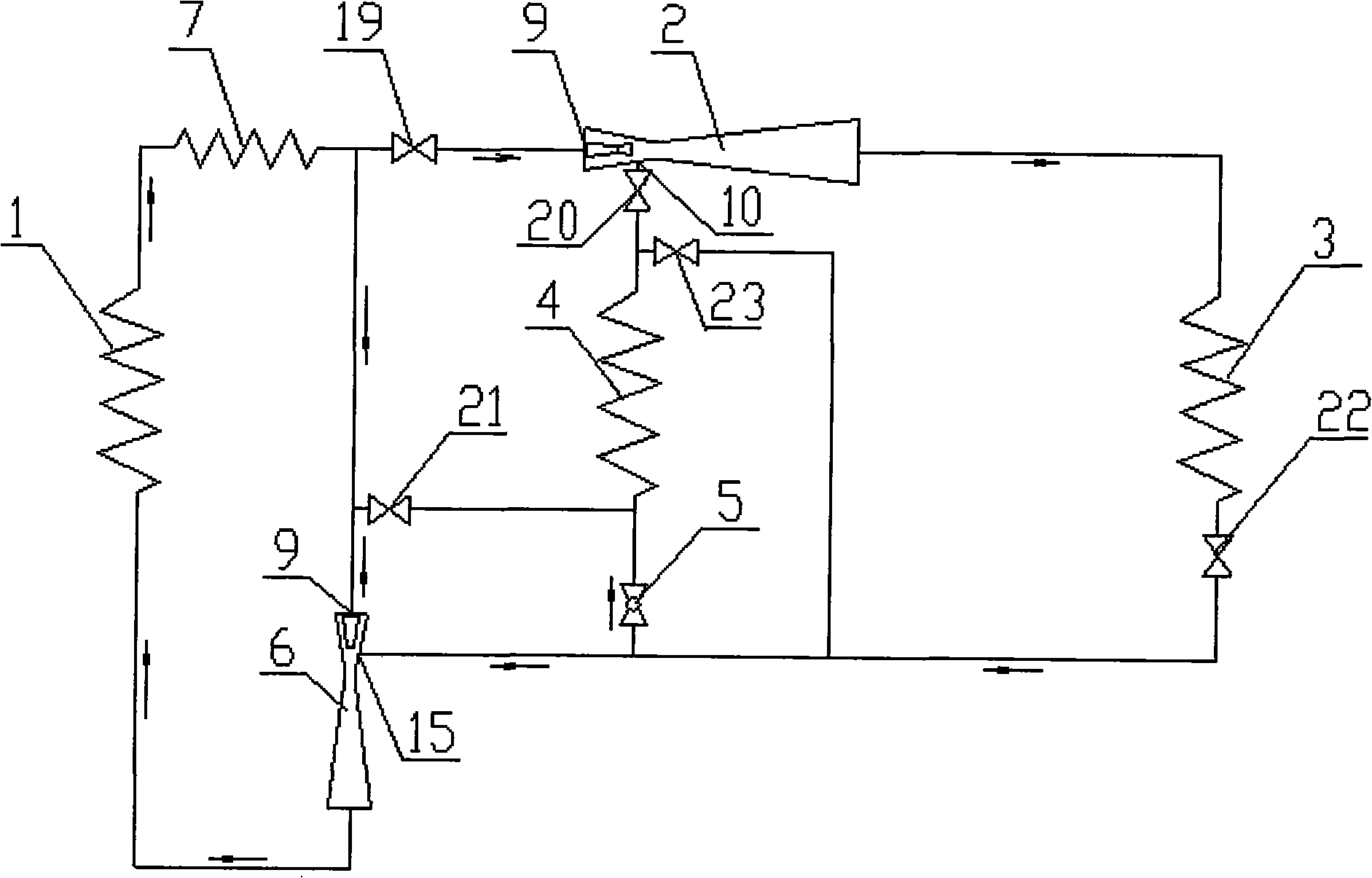

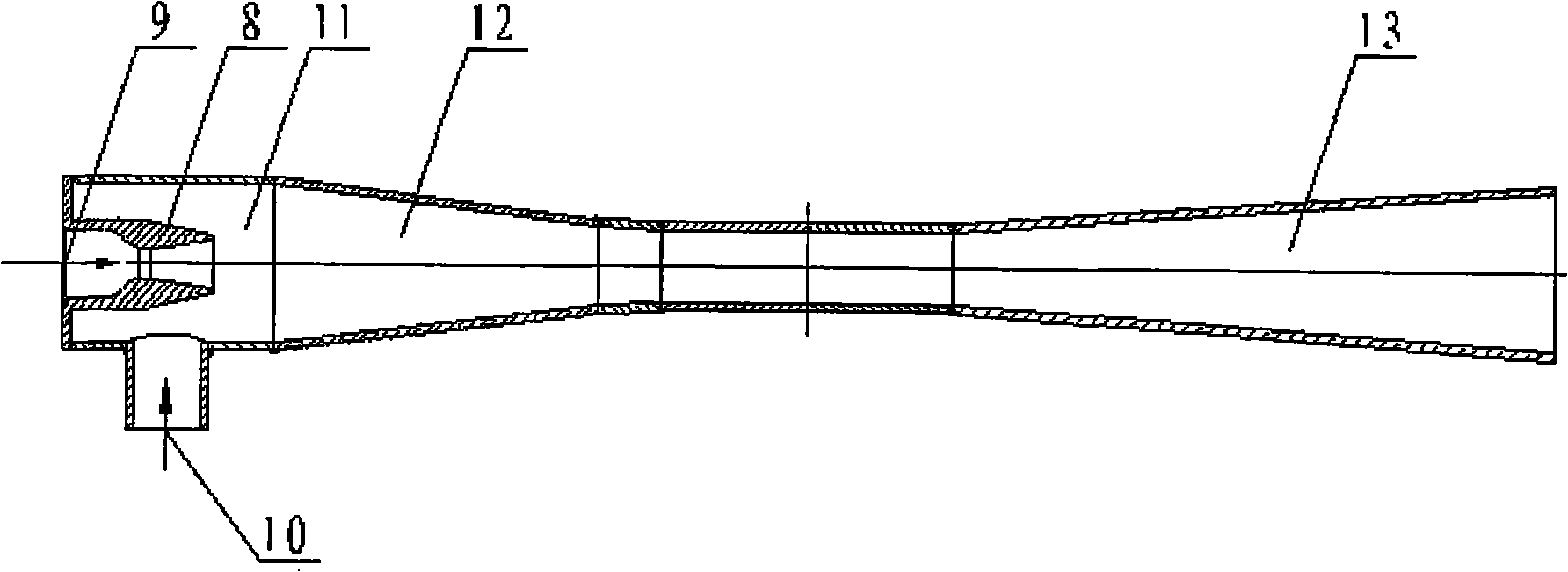

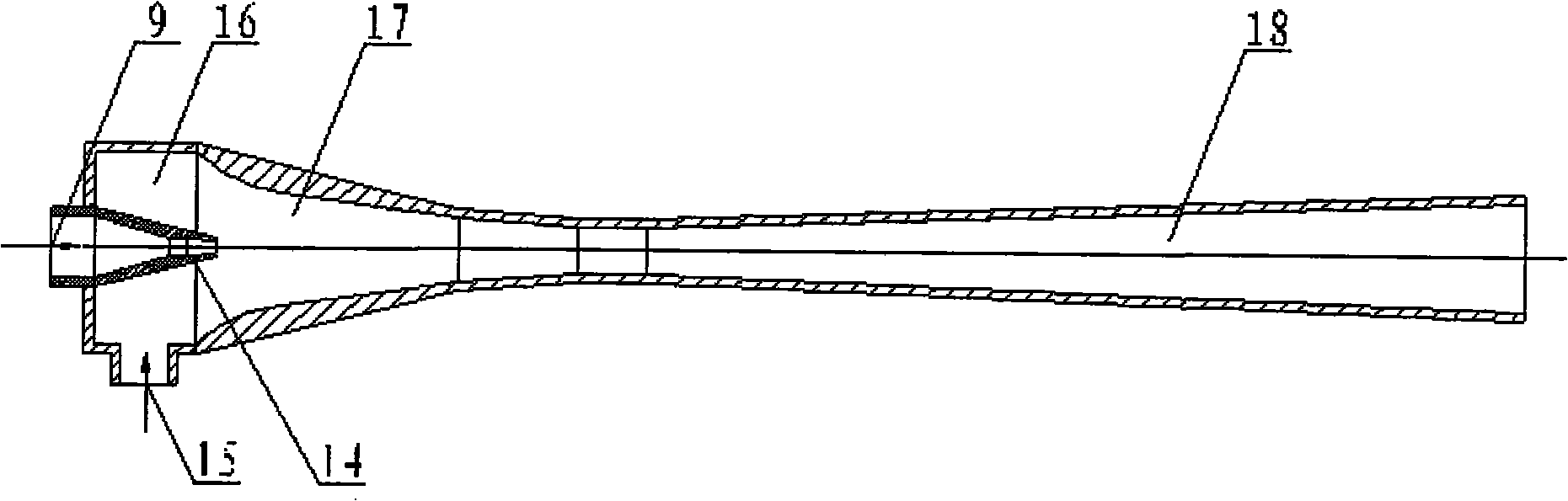

Jet-type automobile air conditioner

InactiveCN101566407AReduce loadIncrease profitClimate change adaptationCompression machinesAutomobile air conditioningInlet valve

The invention discloses a jet-type automobile air conditioner, which comprises a steam generator, a condenser and an evaporator, and is characterized in that the inlet of the steam generator is connected with the outlet of a gas-liquid injector, and one path of the outlet of the steam generator is connected with a working steam inlet of the gas-liquid injector through an auxiliary heater, while the other path of the outlet is connected with the working steam inlet of a gas-gas injector through an inlet valve of the gas-gas injector; the outlet of the gas-gas injector is connected with the inlet of the condenser; and through an outlet valve of the condenser, a first path of the outlet of the condenser is connected with the inlet of the evaporator through a throttle valve, a second path is connected with the liquid inlet of the gas-liquid injector, and a third path is connected with the outlet of the evaporator through a second bypass pipe valve; the inlet of the evaporator is connected with the working steam inlet of the gas-liquid injector through a first bypass pipe valve; and the outlet of the evaporator is connected with the refrigerant steam inlet of the gas-gas injector through an evaporator outlet valve to form a closed system.

Owner:CHANGAN UNIV

Cooking device

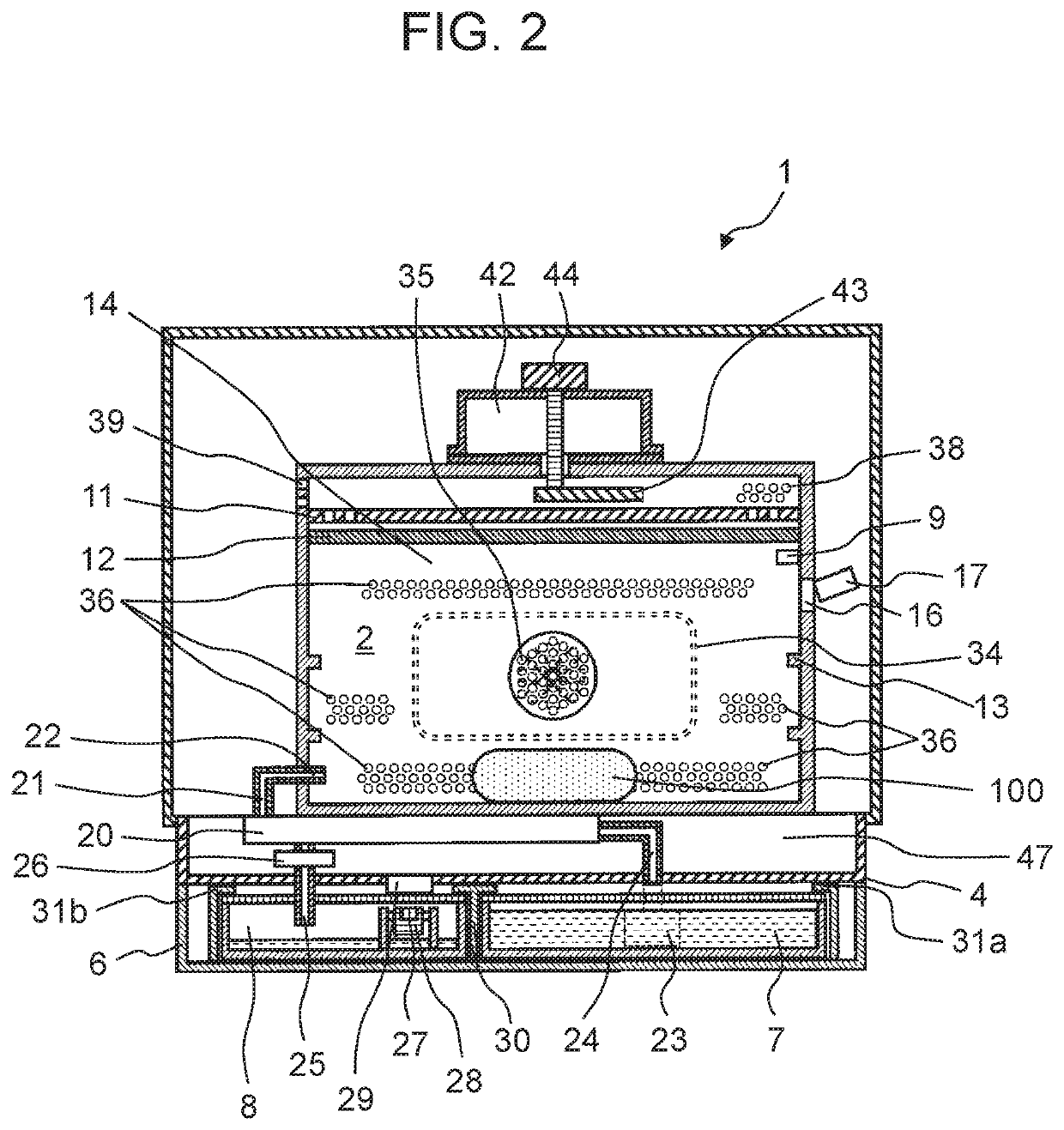

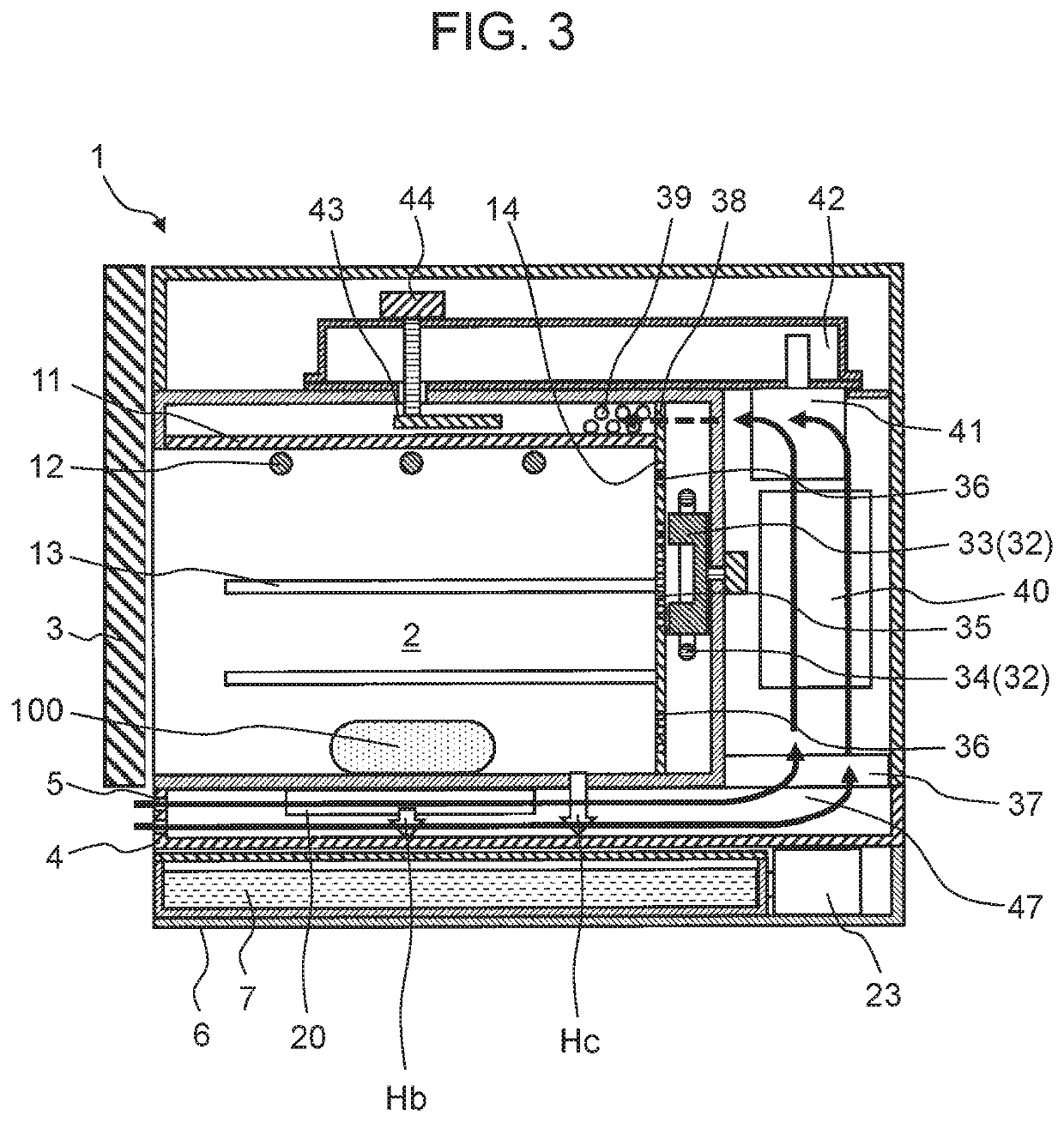

ActiveUS10645765B2Increased pressure lossReduce cooling efficiencyCooking-vessel materialsDomestic stoves or rangesThermodynamicsWater storage tank

Cooking device includes heating chamber with door for housing object to be heated, vapor generator for supplying vapor into heating chamber, and water storage tank. Cooking device further includes cooling air passage provided between heating chamber and water storage tank and allowing cooling air to pass therethrough, and air inlet provided to the side of door and introducing cooling air into cooling air passage. This enables cooling, using a smaller and more inexpensive cooling fan. As a result, cooking device is made shorter in overall height.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

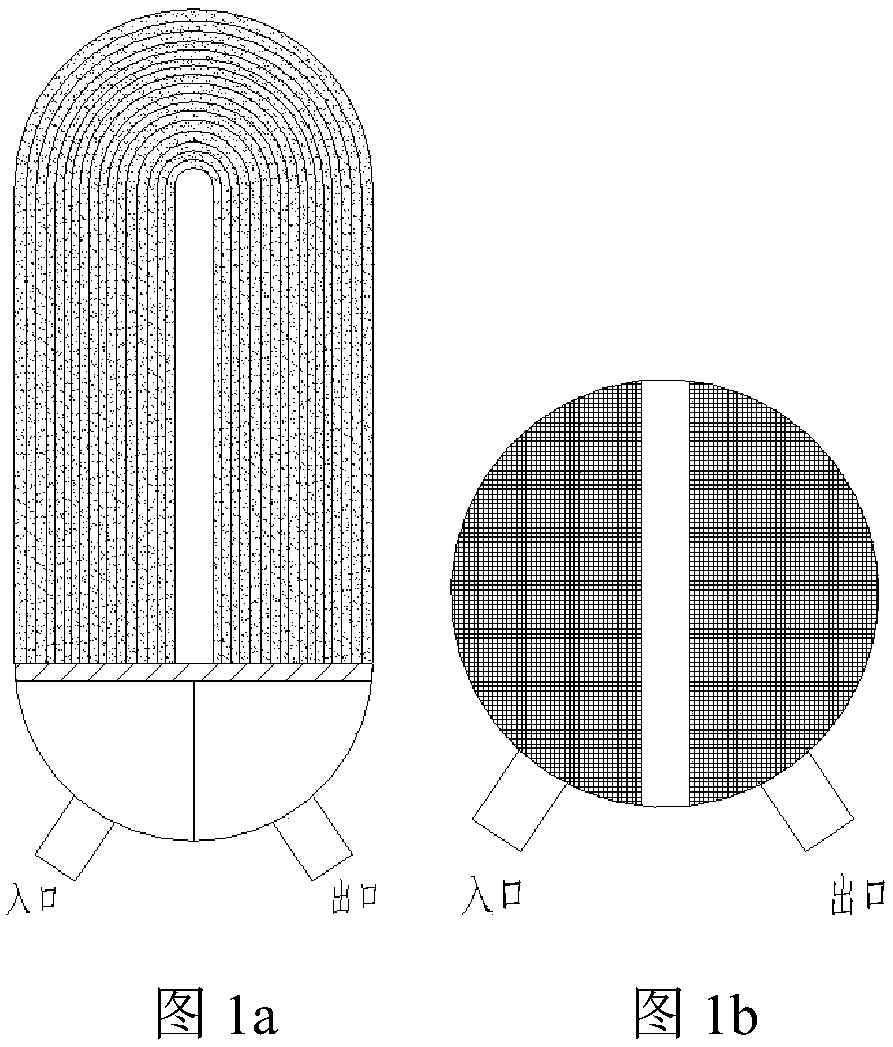

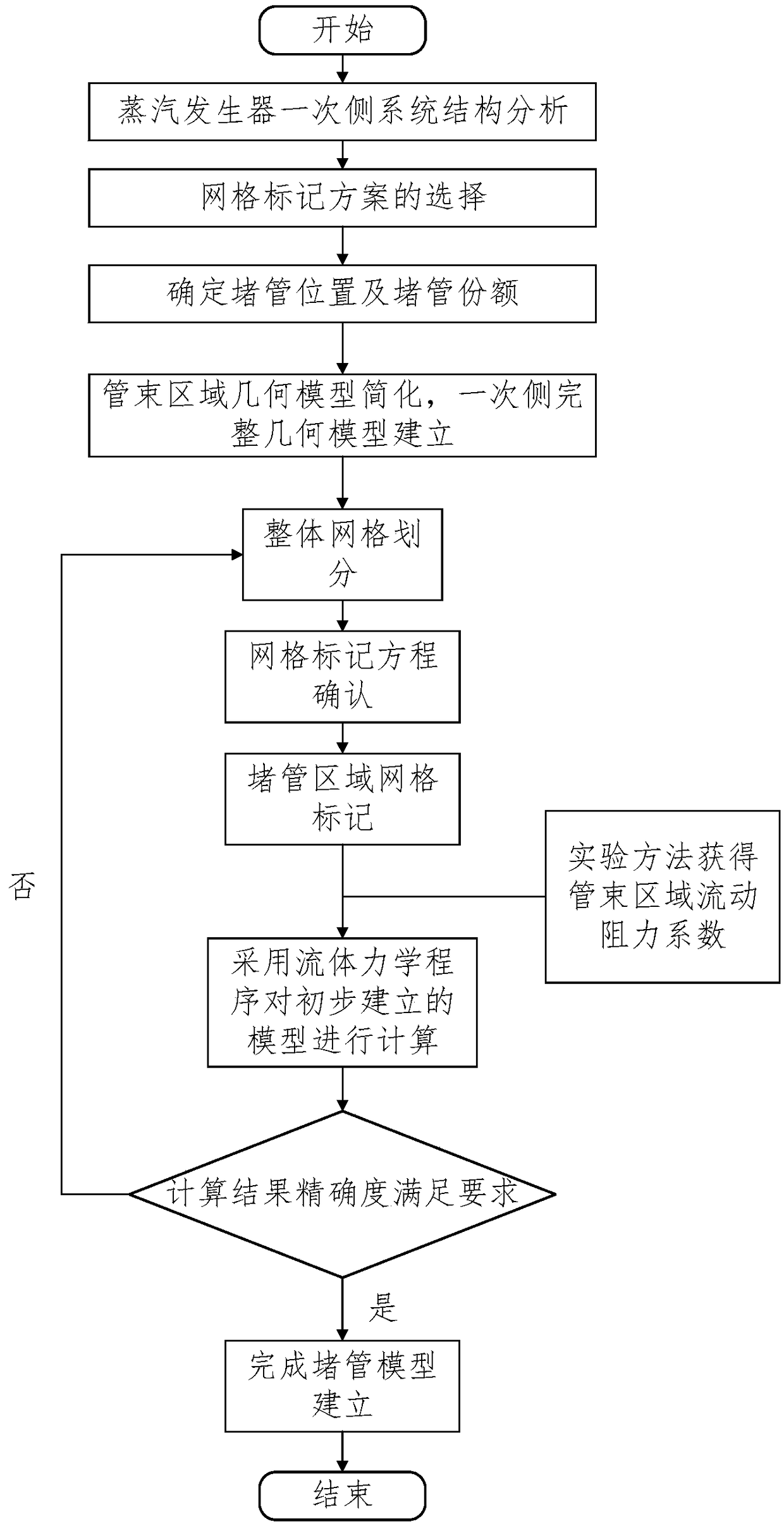

Method for establishing blocking condition models of heat transfer tubes of vapor generators in nuclear power plants

ActiveCN108170924AChange changeChange heat transferGeometric CADSpecial data processing applicationsNODALNuclear power

The invention discloses a method for rapidly establishing three-dimensional fine thermos-hydraulic calculation models for primary side systems of large-scale natural circulation vapor generators in nuclear power plants under certain heat transfer tube blocking accident conditions. The method comprises the following steps of: 1, carrying out complete primary side hydraulic analysis on a vapor generator so as to analyze a flow distribution law at a tube plate; 2, selecting a tube blocking scheme according to a result of the last step; 3, determining a tube blocking share and a tube blocking position; 4, carrying out geometric simplification and overall geometric modeling on a plurality of heat transfer tubes in the real vapor generator; 5, dividing preliminary calculation nodes; 6, establishing a tube blocking equation to tracing marked control areas, and carrying out calculation domain grid marking on the control areas by adoption of a network marking method so as to realize a tube blocking function; and 7, carrying out blocking condition calculation by adoption of a preliminarily established model and analyzing the precision of the result, and if a requirement is satisfied, considering that the modeling is completed, and otherwise, returning to the step 5 to encrypt the calculation nodes until the model satisfies the calculation precision requirement.

Owner:XI AN JIAOTONG UNIV

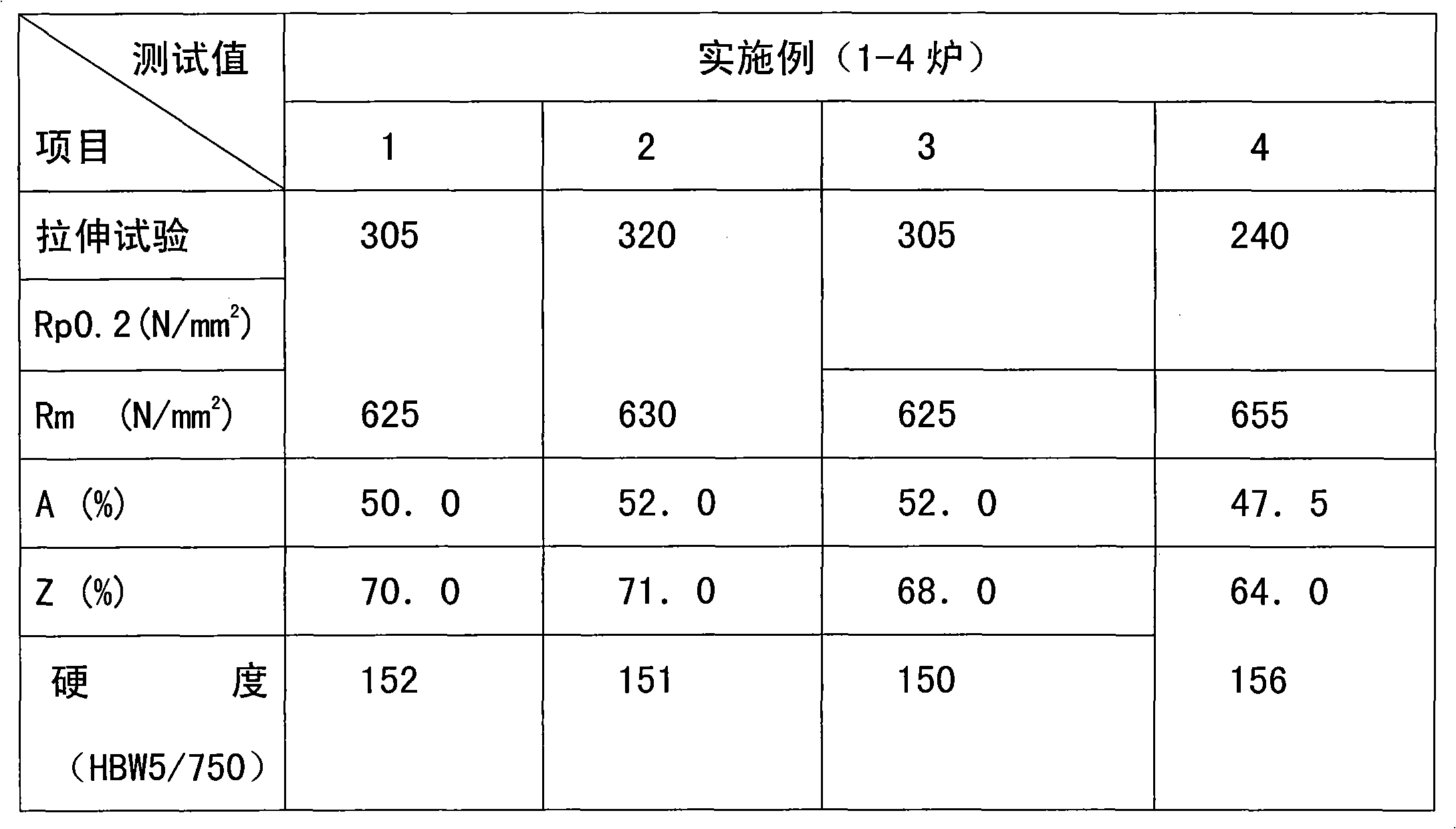

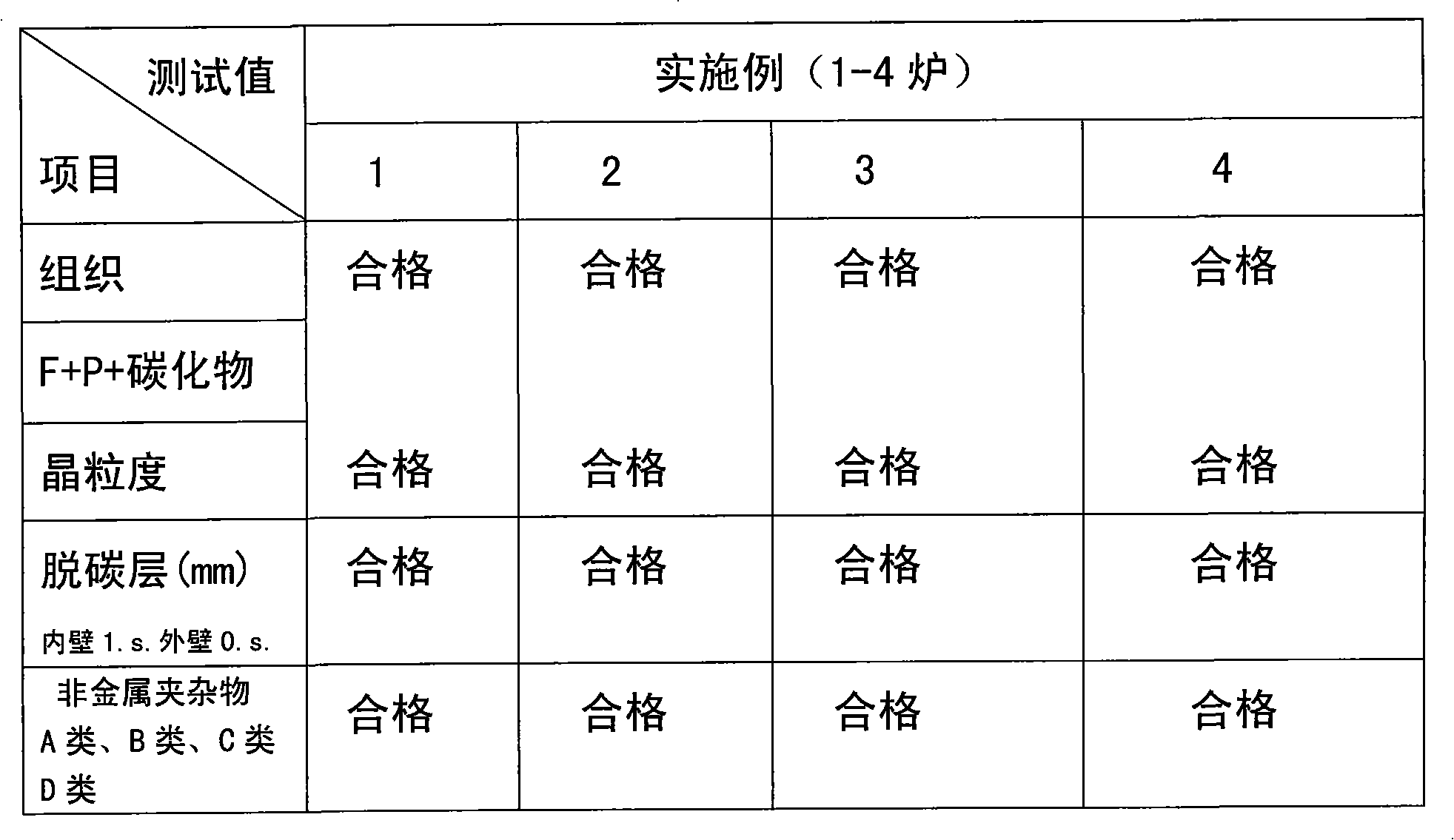

Shockproof strip end-plate material of vapor generator of nuclear power plant and preparation method thereof

InactiveCN101851714AReasonable design of ingredientsLow costPressurized water reactorVapor generator

The invention discloses a shockproof strip end-plate material of a vapor generator of a nuclear power plant and a preparation method thereof, relating to a shockproof strip end-plate material of a vapor generator of a pressurized water reactor nuclear island CPR1000. The shockproof strip end-plate material is prepared from the following components in percentage by weight: 0.003-0.08 percent of C, 0.1-0.4 percent of Si, 0.3-0.8 percent of Mn, not more than 0.015 percent of P, not more than 0.01% of S, 14-17 percent of Cr, 72-78 percent of Ni, 0.05-0.5 percent of Cu, 0.05-0.5 percent of Ti, 0.05-0.5 percent of Al, 6-10 percent of Fe, 0.01-1.0 percent of Xt and the balance of inevitable impurities. The preparation method of the shockproof strip end-plate material comprises the following steps of: preparing raw materials; smelting in a vacuum refining furnace; refining electroslag; forging; thermally rolling; normalizing; and repeating the process of drawing-annealing- drawing) many times to obtain a finished product of shockproof strip end-plate material. The designed shockproof strip end-plate material of the vapor generator of the nuclear power plant has reasonable content design, excellent resistance of corrosion, fatigue and creep properties and processing performance and has very important economic meaning to improve the production efficiency, effectively prolong the service life of the vapor generator of a nuclear power plant and decrease the production cost.

Owner:JIANGSU XINHUA ALLOY ELECTRIC

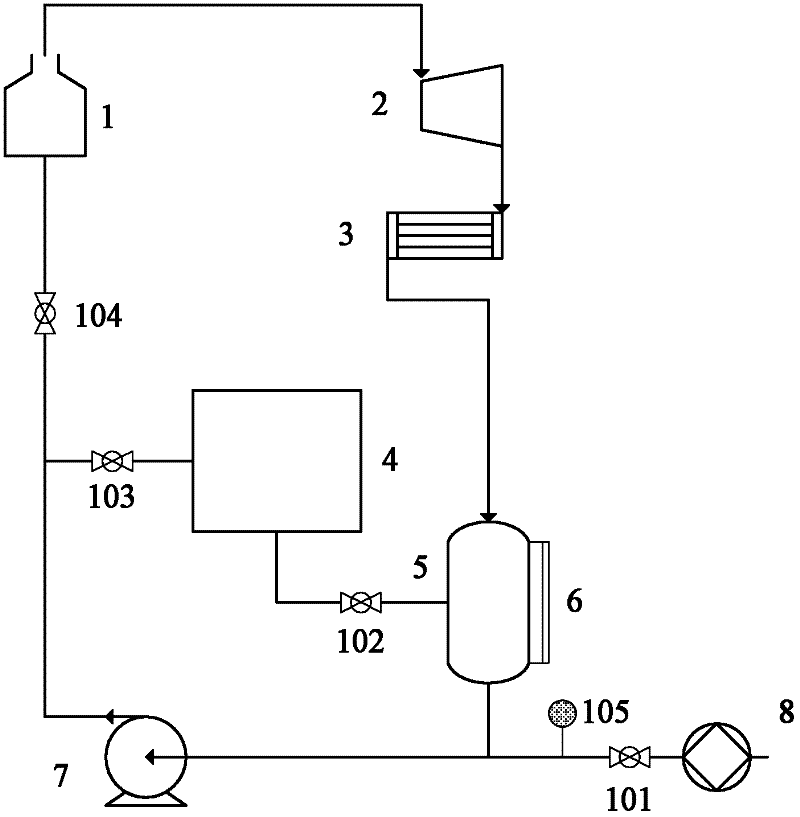

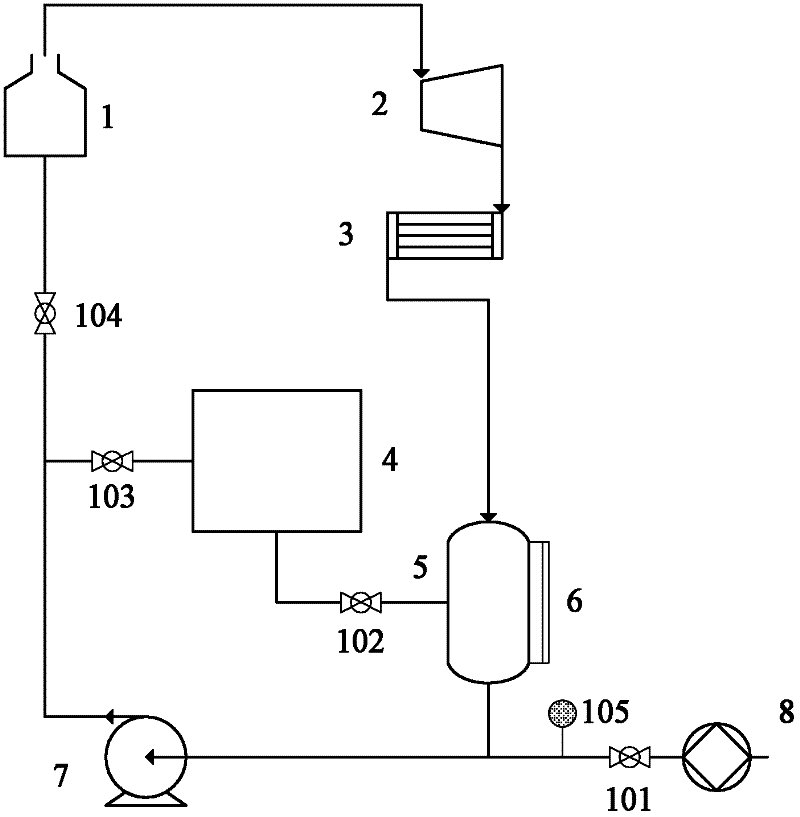

Replacement system of organic Rankine cycle low-temperature power generation working medium and replacement method thereof

ActiveCN102230401AGuaranteed operational safetyEliminate the effects ofSteam engine plantsVapor generatorOrganic Rankine cycle

The invention provides a replacement system of an organic Rankine cycle low-temperature power generation working medium and a replacement method thereof. The replacement system of an organic Rankine cycle low-temperature power generation working medium comprises a vacuum pump, a booster pump, a working medium hold-up vessel and a fluid reservoir, wherein the output end of the vacuum pump is connected to the input end of the booster pump by a first valve; the output end of the booster pump is connected to the steam generator of a circulating system by a fourth valve; the booster pump is connected to the working medium hold-up vessel by a third valve; the other end of the working medium hold-up vessel is connected to the fluid reservoir by a second valve; and meanwhile, the fluid reservoir is also respectively connected with the vacuum pump and the condenser of the circulating system. When working medium needs to be injected into the low-temperature power generation system of the organic working medium, air is extracted from the circulating system by the vacuum pump to cause the system to generate vacuum degree; the working medium is injected into the fluid reservoir by differential pressure to inject the working medium; and when the low-temperature power generation system halts and needs to recover the working medium, and the working medium in the fluid reservoir is injected back to the working medium hold-up vessel by the booster pump, thereby recovering the working medium.

Owner:XI AN JIAOTONG UNIV

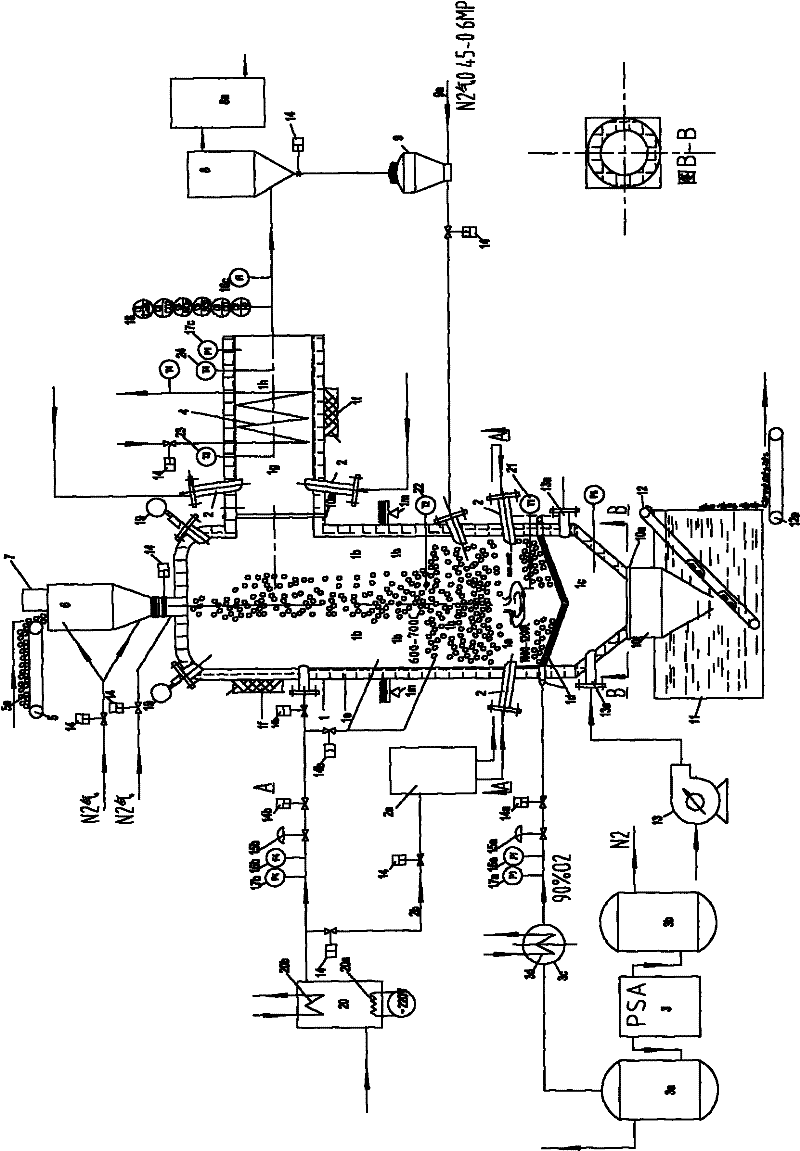

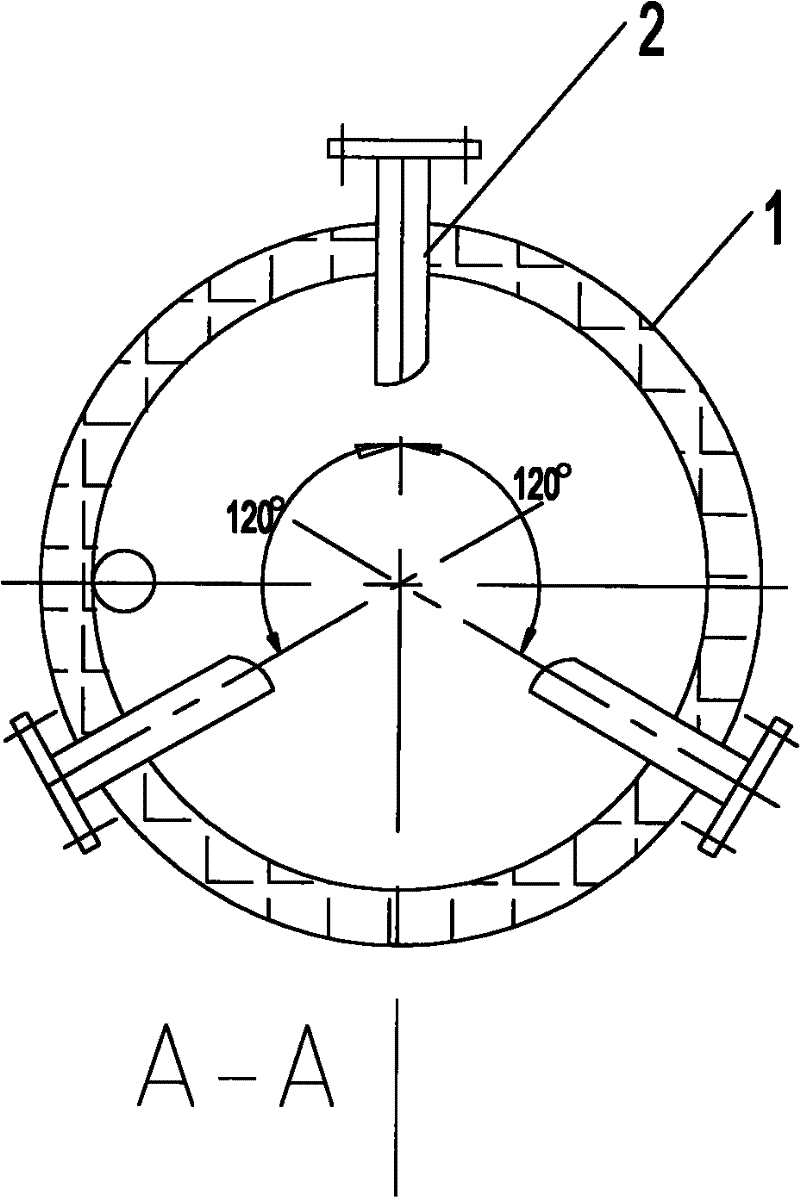

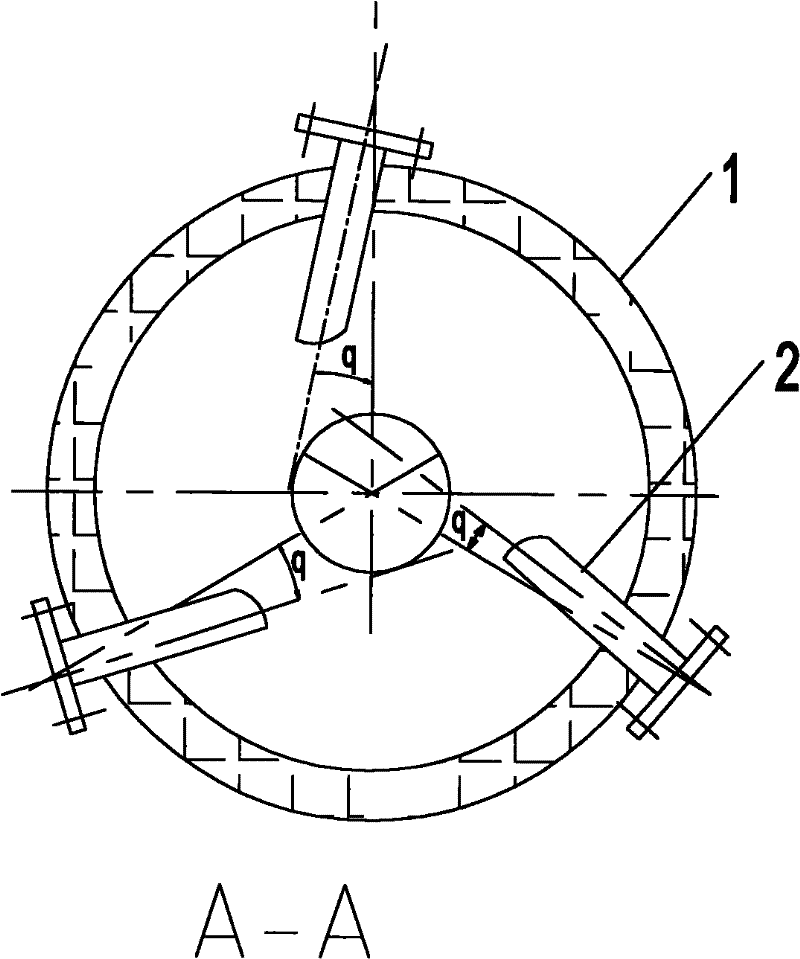

A device for producing combustible gas by plasma pyrolysis and oxygen-enriched combustion-supporting materials

ActiveCN102260537AControl furnace temperatureImprove gas production efficiencyGranular/pulverulent flues gasificationFurnace temperatureSlag

The invention relates to the technical field of combustible gas preparation by virtue of biomass pyrolysis and gasification and further relates to the clean energy field of combustible gas preparation by virtue of pyrolysis and gasification of waste polymer compounds. The device consists of a gasification furnace, a plasma generation device, an oxygen-enriched combustion-supporting device, a biomass transporting device, a cyclone separation conveying device, a steam generation device, an air blower and a slag processing device, wherein the plasma generation device, an oxygen-enriched combustion-supporting pyrolysis region, a steam-adding thermalization reaction region and a second cracking region are arranged in a gasifying hearth; and multiple operation and control means are set, thereby conveniently regulating and controlling the furnace temperatures of various functional regions in the furnace to the optimal temperatures for gasifying the biomass or polymer compounds. By using the device, the generation of tar and K and Na metal salt gases can be avoided, thus the device provided by the invention is a combustible gas preparing device capable of improving the gasifying efficiency and the product quality, reducing the energy consumption and prolonging the service life of equipment.

Owner:SUNSHINE KAIDI NEW ENERGY GROUP CO LTD

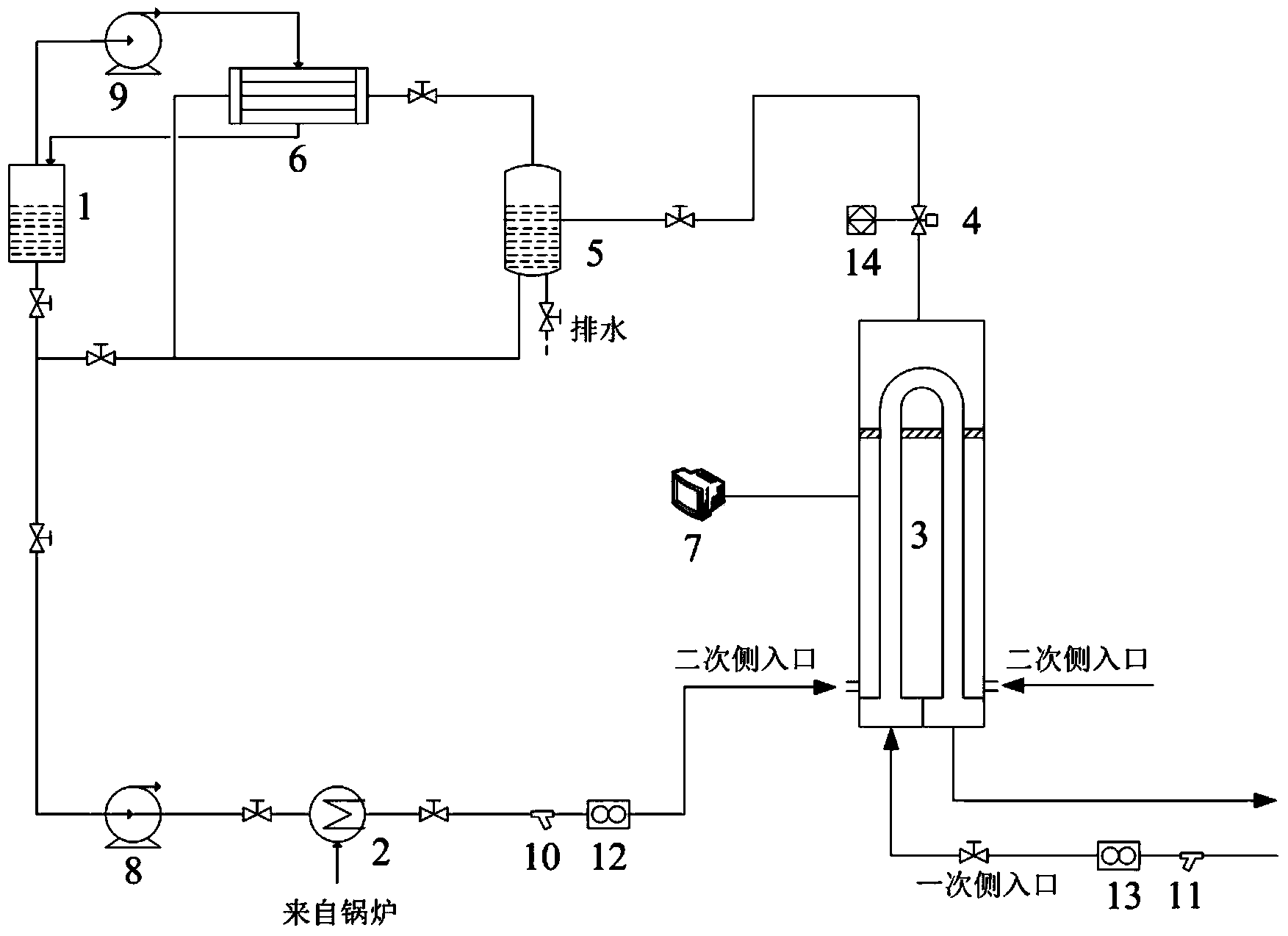

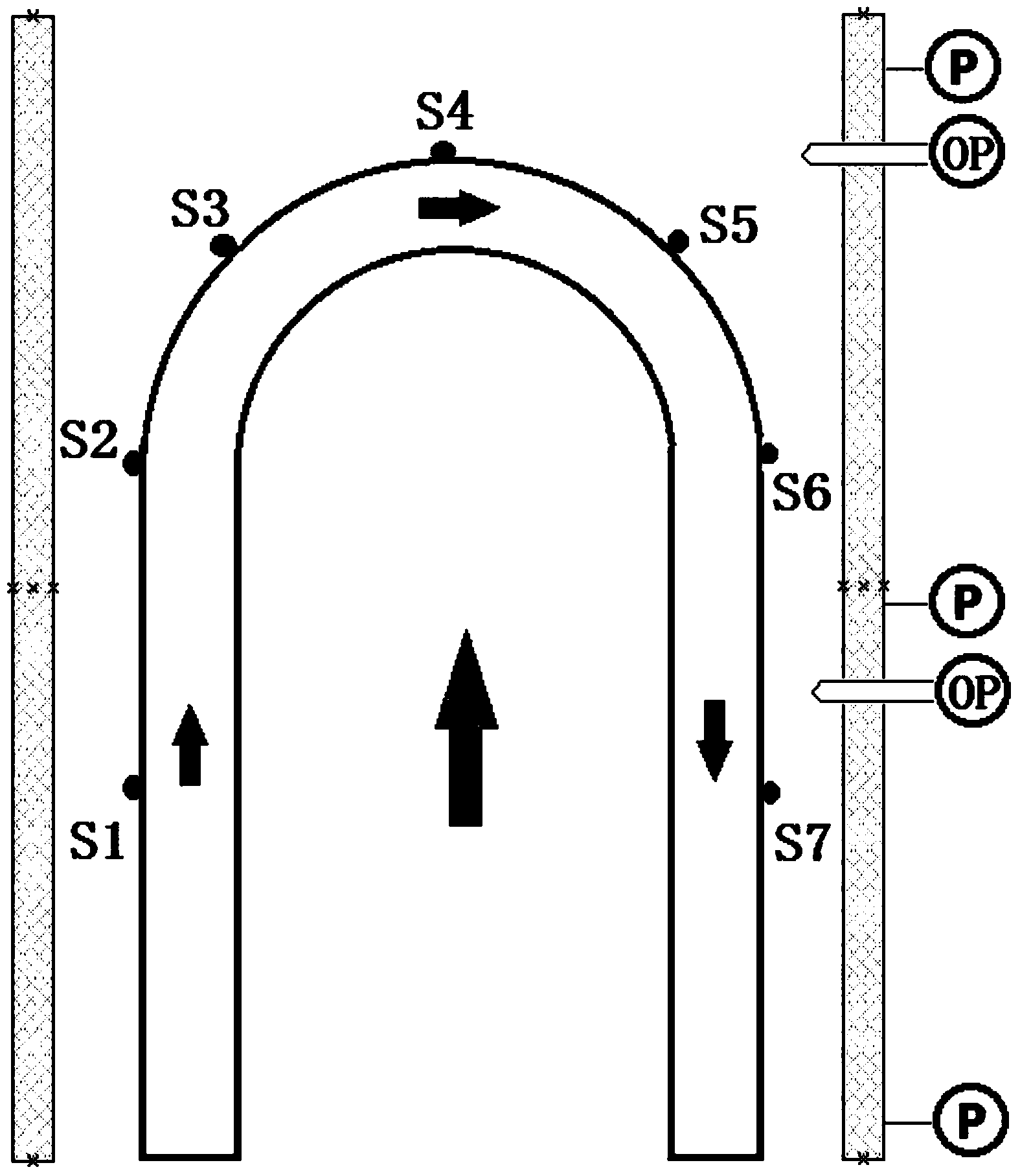

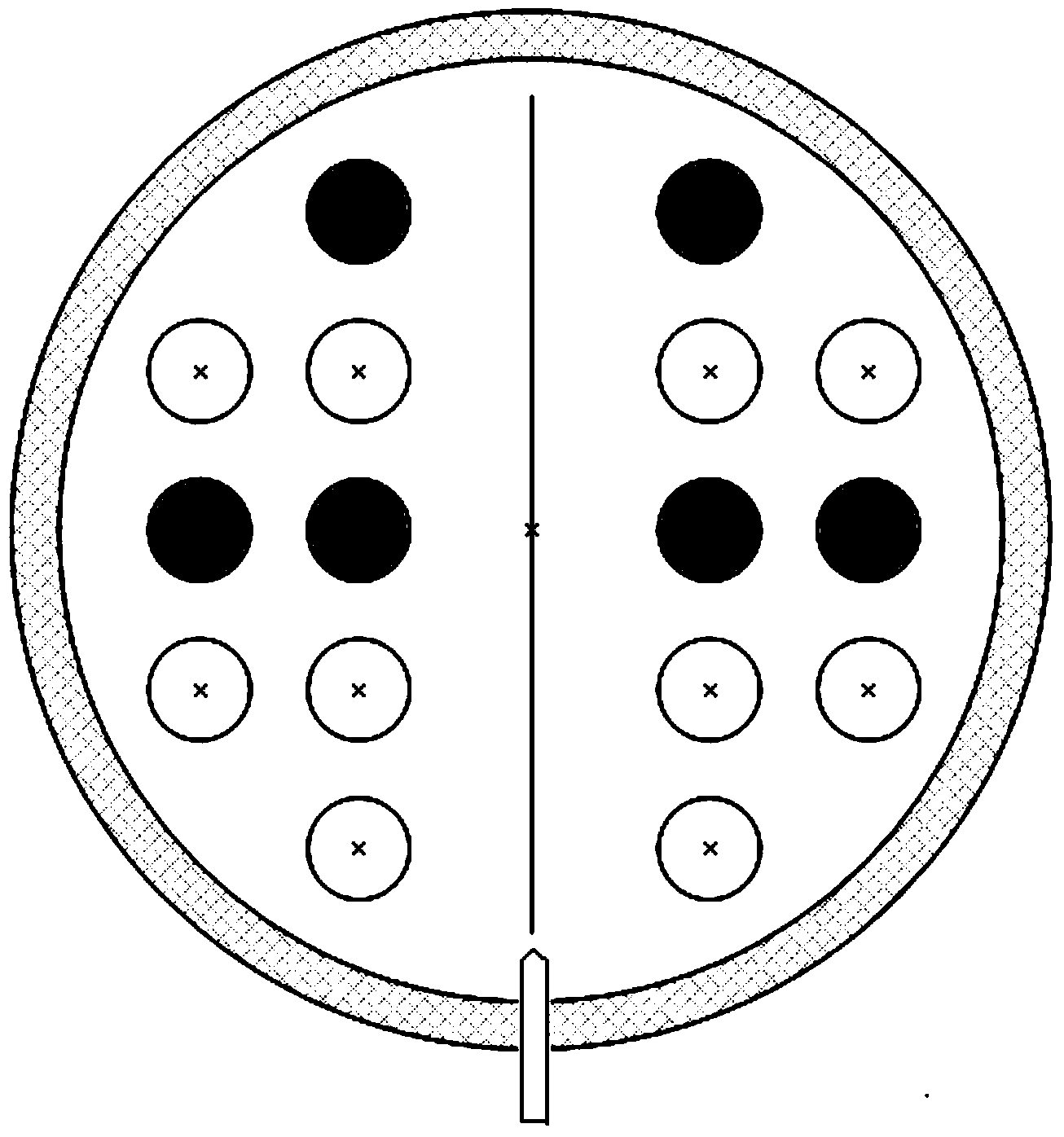

Interbank two-phase flow instability and alternating heat stress research testing device under load shedding disturbance

ActiveCN103471810AAdjustment of operating characteristicsIncrease reflectionHydrodynamic testingMaterial strength using tensile/compressive forcesVapor liquidWater storage tank

The invention aims at providing an interbank two-phase flow instability and alternating heat stress research testing device under load shedding disturbance. A preheater and a vapor-water separator are installed at the two ends of an experimental section respectively, a water storage tank is respectively connected with a condenser and the preheater through pipes, the preheater is connected with the experimental section through a high-pressure pump, and a self-reliance type pressure flow combination valve is installed at an outlet of the experimental section. A double-end conducting probe, a pressure sensor, an orifice plate flowmeter, a stress strain gage and a sheathed thermocouple are installed on the experimental section. According to the interbank two-phase flow instability and alternating heat stress research testing device under load shedding disturbance, the method that primary side high-temperature high-pressure fluid is used for heating secondary side fluid is used, a U-type bank of the experimental section is arranged in a square mode, the characteristics of actual vapor-liquid two-phase flow of a vapor generator can be well reflected, the temperature and stress of the same position are measured, change rules of stress strain of a heat transmitting pipe are researched under the joint effect of the external force and the temperature, and a damage mechanism of the heat transmitting pipe of the vapor generator under specific disturbance caused by load shedding is disclosed.

Owner:HARBIN ENG UNIV

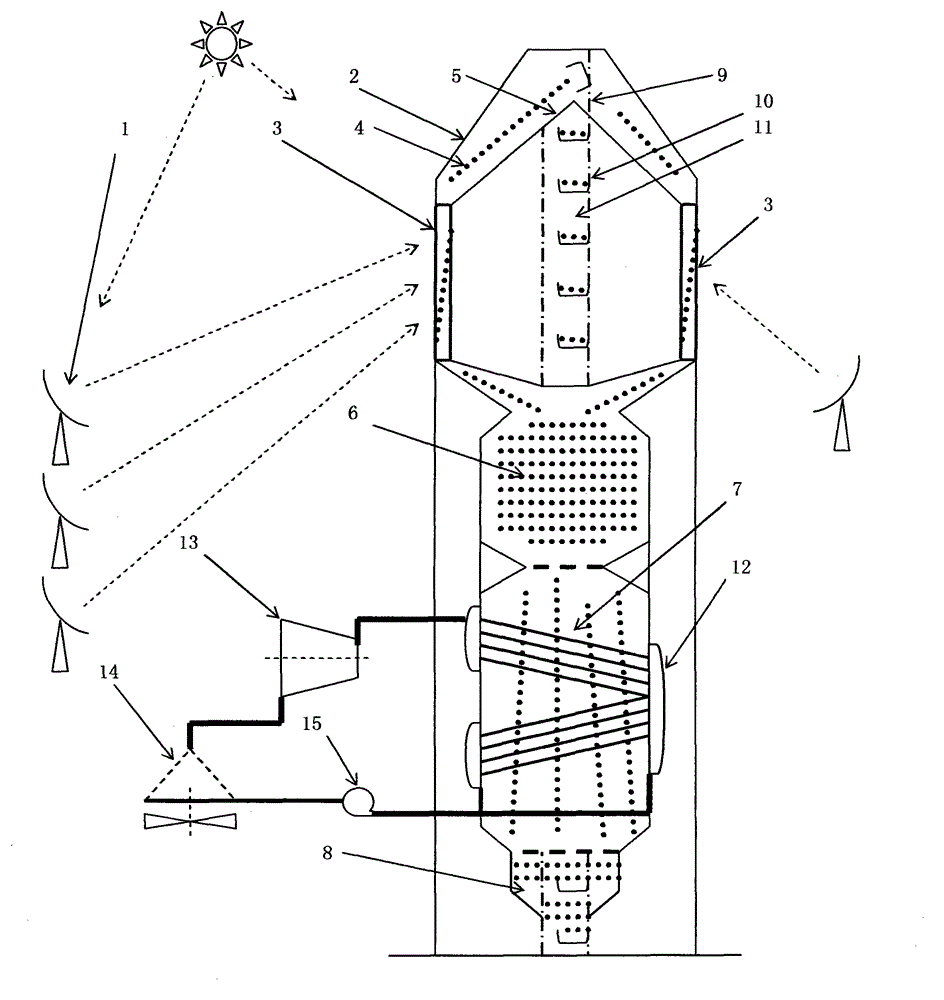

Integrated tower solar thermal power generation unit employing quicksand to store and transfer heat

InactiveCN102913405AWide variety of sourcesHigh heat storage temperatureSolar heating energySteam generation heating methodsEngineeringSuperheated steam

The invention discloses an integrated tower solar thermal power generation unit employing quicksand to store and transfer heat, and a tower solar thermal power generation unit built by 'quicksand' instead of conduction oil, fused salt or gas and the like to transfer and store heat. The device adopts fluid characteristics of the 'quicksand', and has the characteristics of thermostability, zero pressure, small thermal resistance and low cost of the 'quicksand'; and superheated steam is generated by sensibile heat and high-temperature air carried by the quicksand when flowing through a vapor generator to push a steam turbine generator to generate electricity, therefore, the construction cost of a tower solar thermal power generation unit is reduced by integral design, and a technological base is established for final implementation of parity power generation. The device belongs to the technical field of solar thermal electric power generation.

Owner:张建城

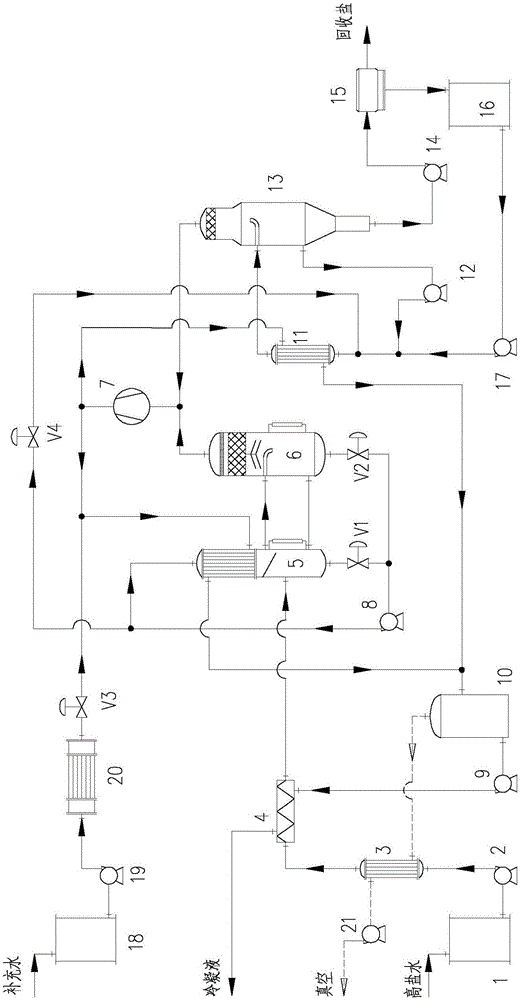

MVR (mechanical vapor recompression) evaporation crystallization system and method for high-salinity wastewater

PendingCN106669207ATake advantage ofAchieve recyclingEvaporator accessoriesEvaporators with forced circulationVapor–liquid separatorEvaporation

The invention discloses an MVR (mechanical vapor recompression) evaporation crystallization system and method for high-salinity wastewater[0]. The system comprises a raw material tank, a first preheater, a second preheater, an MVR evaporator, a gas-liquid separator, a compressor, a first circulating pump, a condensate tank, a forced circulation evaporator, a second circulating pump, a crystallizer, a centrifuge and a vapor generator. The full utilization of secondary vapor is realized after high-salinity wastewater is treated with the system, and the system has the advantages that the cost is low, the continuity and the energy saving effect are good, and the crystal salt quality is high.

Owner:JIANGSU PROVINCIAL ACAD OF ENVIRONMENTAL SCI

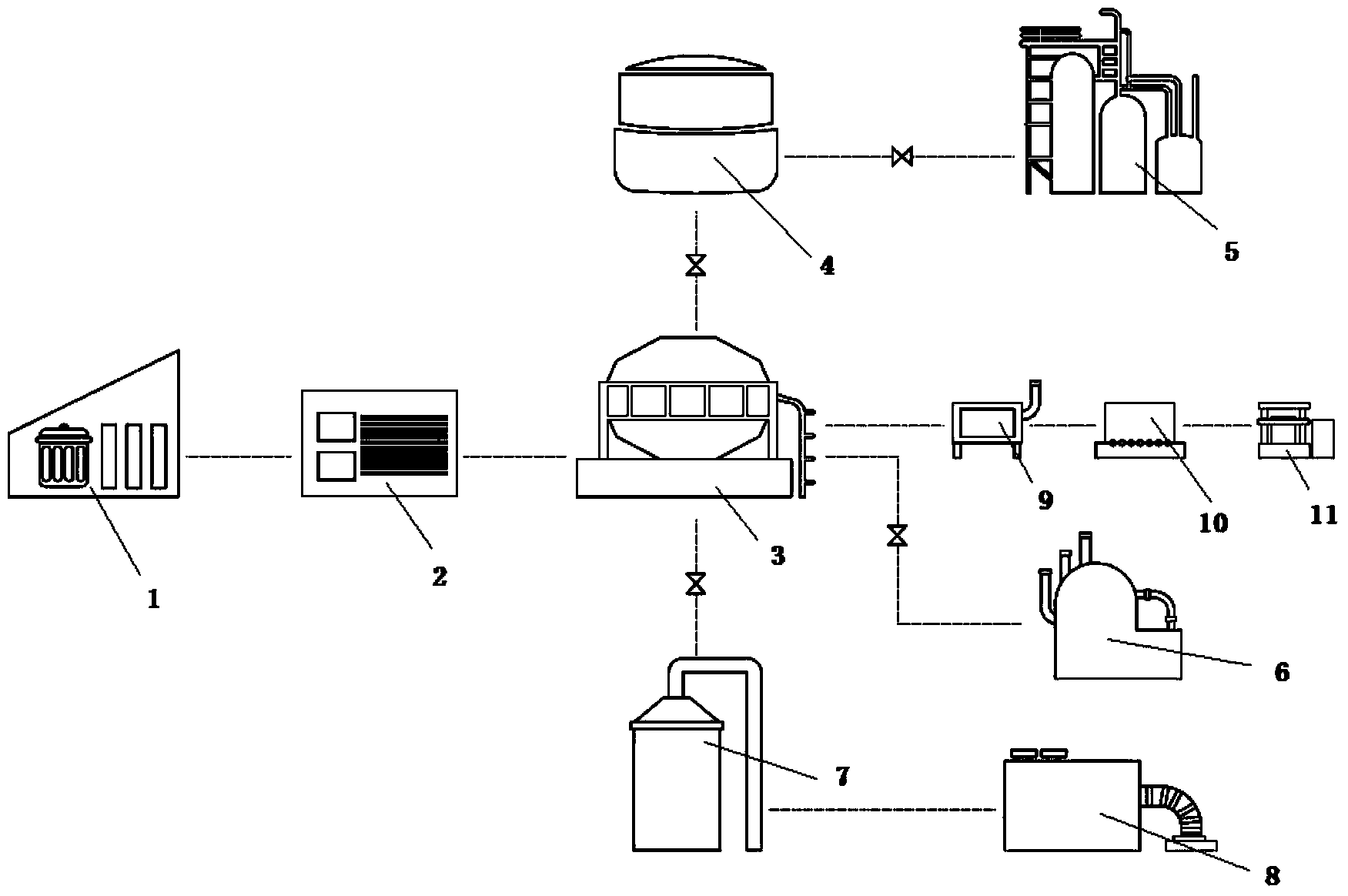

Garbage carbonization reacting system

ActiveCN104263388AClassification requirements are lowHarmlessSolid waste disposalDirect heating destructive distillationLitterCarbonization

The invention provides a garbage carbonization reacting system. The system comprises a reaction still, a reaction tank, a vapor generator and a control device, wherein the vapor generator is connected with the reaction still, and the vapor generator is used for supplying vapor to the reaction still; the reaction tank is used for placing garbage. When a reaction is carried out, the reaction tank is pushed into the reaction still to react to generate a carbonization mixture; after the reaction is completed, the reaction tank is pulled out of the reaction still. The reaction still comprises a still body and a still cover, wherein the still body is connected with the still cover in a sealing manner; the control device is connected with the reaction still, and the control device is used for controlling the change of the pressure and the temperature in the reaction still and the reaction time; a first guide rail which extends in the length direction of the still body is arranged in the still body. The system disclosed by the invention has the advantages that the structural scheme is reasonable, the device is advanced, the degree of automation is high, the investment cost of equipment is low, the occupation area of a required plant is small, and burning value of prepared biomass fuel is high, and the discharge is low.

Owner:NANTONG QIANGSHENG SAFETY PROTECTION TECHNOLOGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com